Page 1

V

V

A

A

A

A

S

S

S

R

E

E

E

R

R

V

I

I

I

COLOUR TELEVISION

C

C

C

E

E

E

M

M

M

A

N

N

N

PF-68T31

PF-68V21

U

U

U

A

L

L

L

TV/AV

P+

V- MENU V+

CALL P-

SLEEP LOCK

QV

1 2 3

4 5 6

ZOOM

7 8 9

0 - / --

♪ Æ| ♪|Å

RE-001

Æ|

SCAN

|Å

CONTENTS

z SPECIFICATIONS …………………………………………………………………….. 2

z SAFETY PRECAUTIONS …………………………………………………………….. 3

z SERVICE ADJUSTMENTS …………………………………………………………… 7

z PARTS LIST …………………………………………………………………………… 19

z STANDARD CIRCUIT DIAGRAM

Page 2

SPECIFICATIONS

Item Specifications

.

Dimensions(W x H x D)

Weight

TV RF System

Colour System

TV Mode

Video Mode

Receiving

Frequency

VHF (VL)

VHF (VH)

UHF

CATV None

Intermediate

Frequency

VIF Carrier

SIF Carrier

Colour Sub Carrier Frequency

Aerial Input Terminal

Power Input Rated Voltage

730 mm x 590 mm x 520 mm

49.5 kg

B/G

PAL

PAL/ NTSC 3.58/ NTSC 4.43

46.25 MHz to 168.25 MHz

175.25 MHz to 463.25 MHz

471.25 MHz to 863.25 MHz

38.9 MHz

33.4 MHz

PAL (4.43 MHz)

75 Ohm Unbalanced DIN

240 V AC, 50/60 Hz

Power Consumption

Picture Tube

High Voltage

Speaker

Audio Output

Input

Video

Audio

Output

Video

Audio

Headphone jack

Remote Control Unit

Design & specifications are subject to change without notice.

145 W (Max.)

Visible Size: 68 cm measured diagonally

30 kV ±1.5 kV (at Zero beam current)

8 cm x 13 cm Oval x 2

8 W + 8 W

1 Vpp, 75 Ohm, RCA x 2

S-Video Input Y, C

Components Input Y, Cb, Cr (PF-68T31)

500 mVrms (-4dBs), High impedance, RCA x 4

1 Vpp, 75 Ohm, RCA x1

500mVrms (-4dBs), Low impedance, RCA x 2

Stereo Mini jack (φ3.5mm)

RE-002 (PF-68V21), RE-003 (PF-68T31)

(Battery size: AAA/R03/UM-4 x 2)

2

Page 3

SAFETY PRECAUTIONS

1. The design of this product contains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the

original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to those

used in the original circuits. Service should be performed by

qualified personnel only.

2. Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer’s warranty and will further relieve the

manufacturer of responsibility for personal injury or property

damage resulting therefrom.

3. Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics

are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by

using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these special

safety characteristics are identified in the parts list of

Service manual. Electrical components having such

features are identified by shading on the schematics

and by (

of a substitute replacement which does not have the same

safety characteristics as the recommended replacement

part shown in the parts list of Service manual may cause

shock, fire, or other hazards

4. Don’t short between the LIVE side ground and

ISOLATED (NEUTRAL) side ground or EARTH side

ground when repairing. Some model’s power circuit is

partly different in the GND. The difference of the GND is

shown by the LIVE: ( ) side GND, ISOLATED (NEUTRAL) :

( ) side GND and EARTH : ( ) side GND. Don’t short

between the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND and never measure with a

measuring apparatus (oscilloscope etc.) the LIVE side GND

and ISOLATED (NEUTRAL) side GND or EARTH side GND

at the same time. If above note will not be kept, a fuse or

any parts will be broken.

5. If any repair has been made to the chassis, it is

recommended that the B1 setting should be checked or

adjusted (See ADJUSTMENT OF B1 POWER SUPPLY).

6. The high voltage applied to the picture tube must conform

with that specified in Service manual. Excessive high

voltage can cause an increase in X-Ray emission, arcing

and possible component damage, therefore operation under

excessive high voltage conditions should be kept to a

minimum, or should be prevented. If severe arcing occurs,

remove the AC power immediately and determine the cause

by visual inspection (incorrect installation, cracked or melted

high voltage harness, poor soldering, etc.). To maintain the

proper minimum level of soft X-Ray emission, components

in the high voltage circuitry including the picture tube must

be the exact replacements or alternatives approved by the

manufacturer of the complete product.

7. Do not check high voltage by drawing an arc. Use a high

voltage meter or a high voltage probe with a VTVM.

Discharge the picture tube before attempting meter

connection, by connecting a clip lead to the ground frame

and connecting the other end of the lead through a 10kΩ

2W resitor to the anode button.

8. When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the

manufacturer’s replacement components.

) on the parts list in Service manual. The use

.

9. Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the exposed metal parts of the cabinet (antenna

terminals, video/audio input and output terminals, Control

knobs, metal cabinet, screwheads, earphone jack, control

shafts, etc.) to be sure the product is safe to operate without

danger of electrical shock.

(1) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand a

voltage of 3000V AC (r.m.s.) for a period of one second.

(…Withstand a voltage of 1100V AC (r.m.s.) to an appliance

rated up to 120V, and 3000V AC (r.m.s.) to an appliance

rated 200V or more, for a periode of one second.)

This method of test requires a test equipment not generally

found in the service trade.

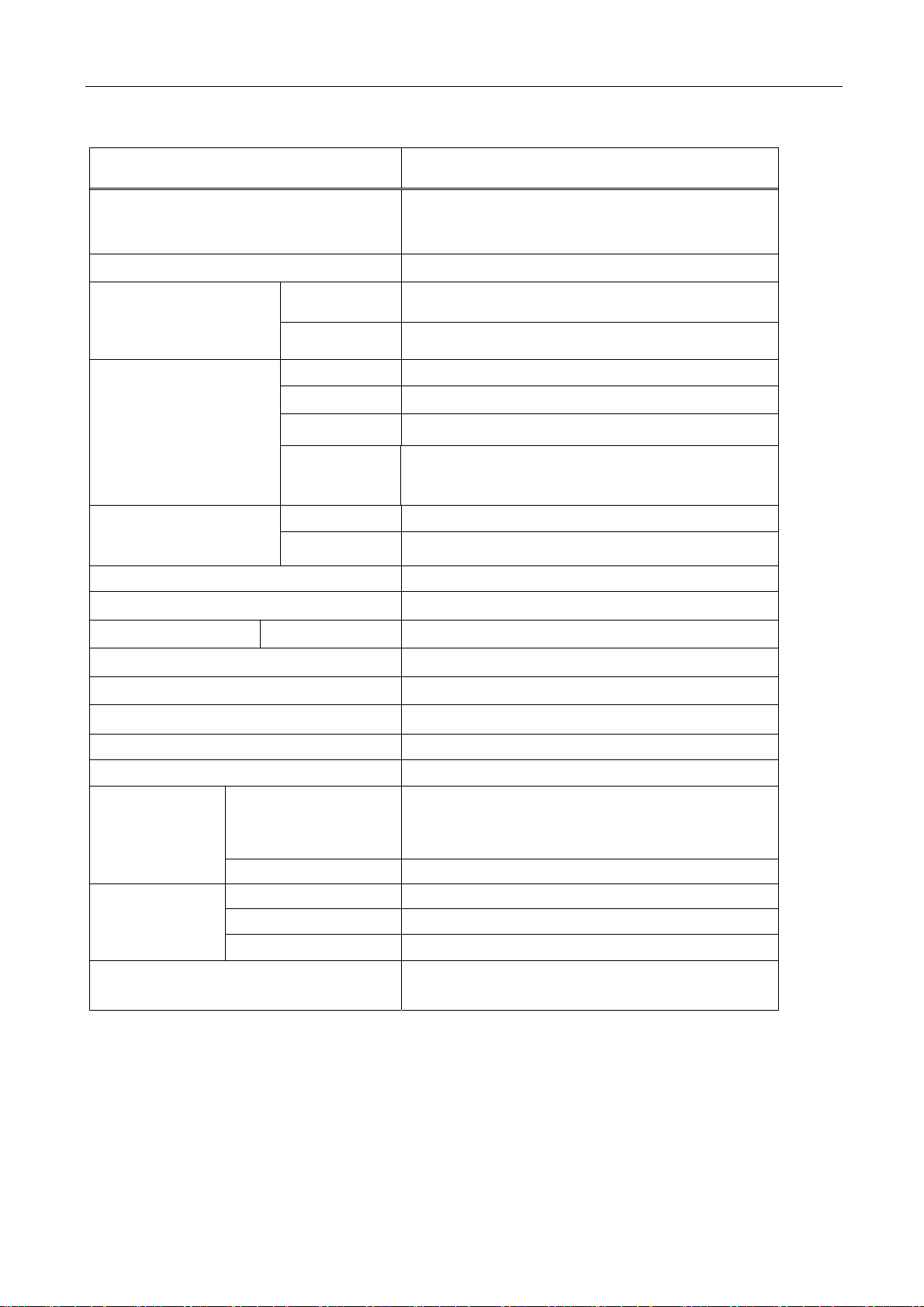

(2) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

“Leakage Current Tester”, measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any

leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

●Alternate Check Method

Plug the AC line cord directly into the AC outlet ( do not use

a line isolation transformer during this check.). Use an AC

voltmeter having 1000 ohms per volt or more sensitivity in

the following manner. Connect a 1500 Ω 10W resistor

paralleled by a 0.15 μ F AC-type capacitor between an

exposed metal part and a known good earth ground (water

pipe, etc.). Measure the AC voltage across the resistor with

the AC voltmeter. Move the resistor connection to each

exposed metal part, particularly any exposed metal part

having a return path to the chassis, and measure the AC

voltage across the resistor. Now, reverse the plug in the AC

outlet and repeat each measurement. Any voltage

measured must not exceed 0.75V AC (r.m.s.). This

corresponds to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.).

This corresponds to 0.2mA AC (r.m.s.)

3

Page 4

.

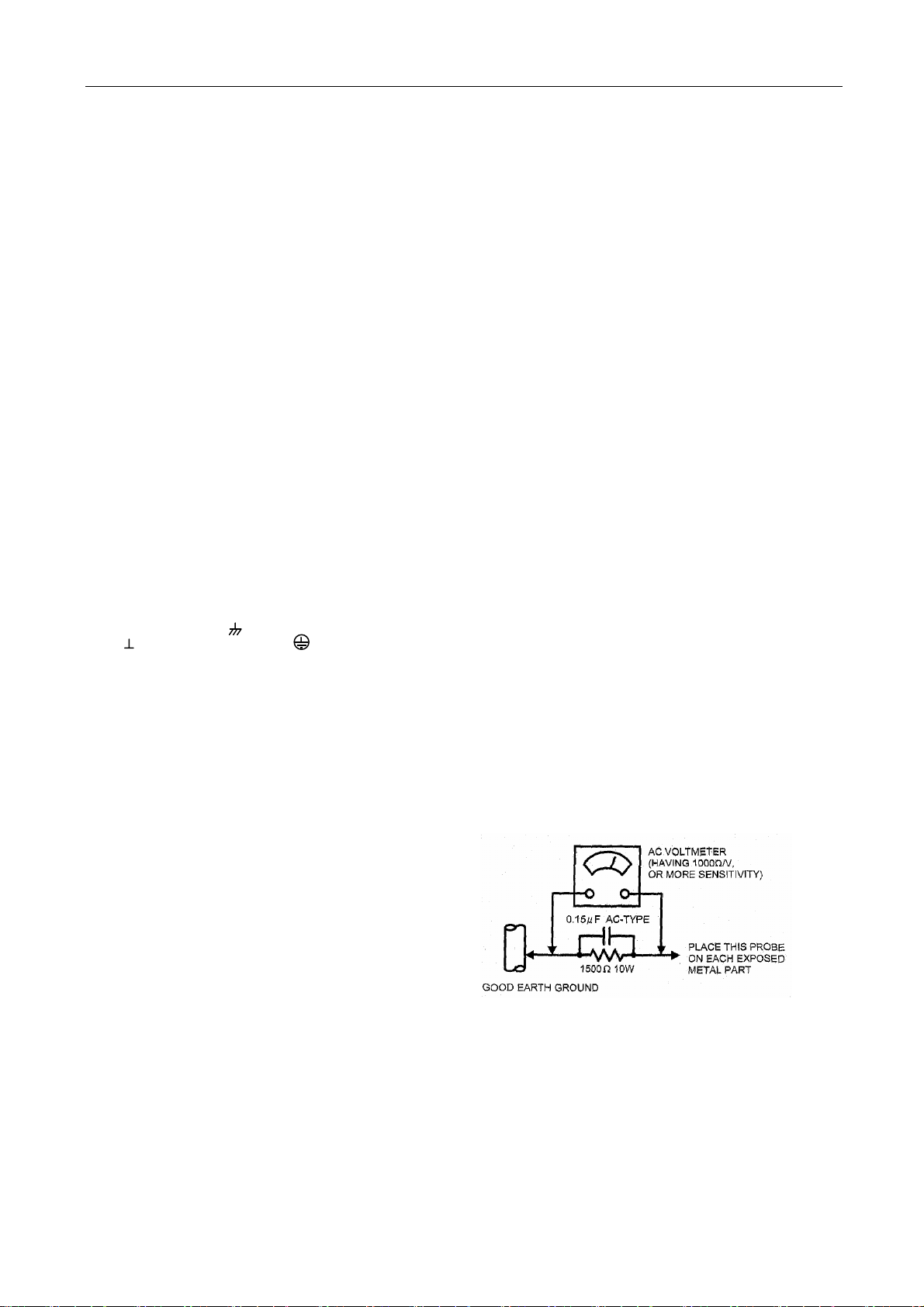

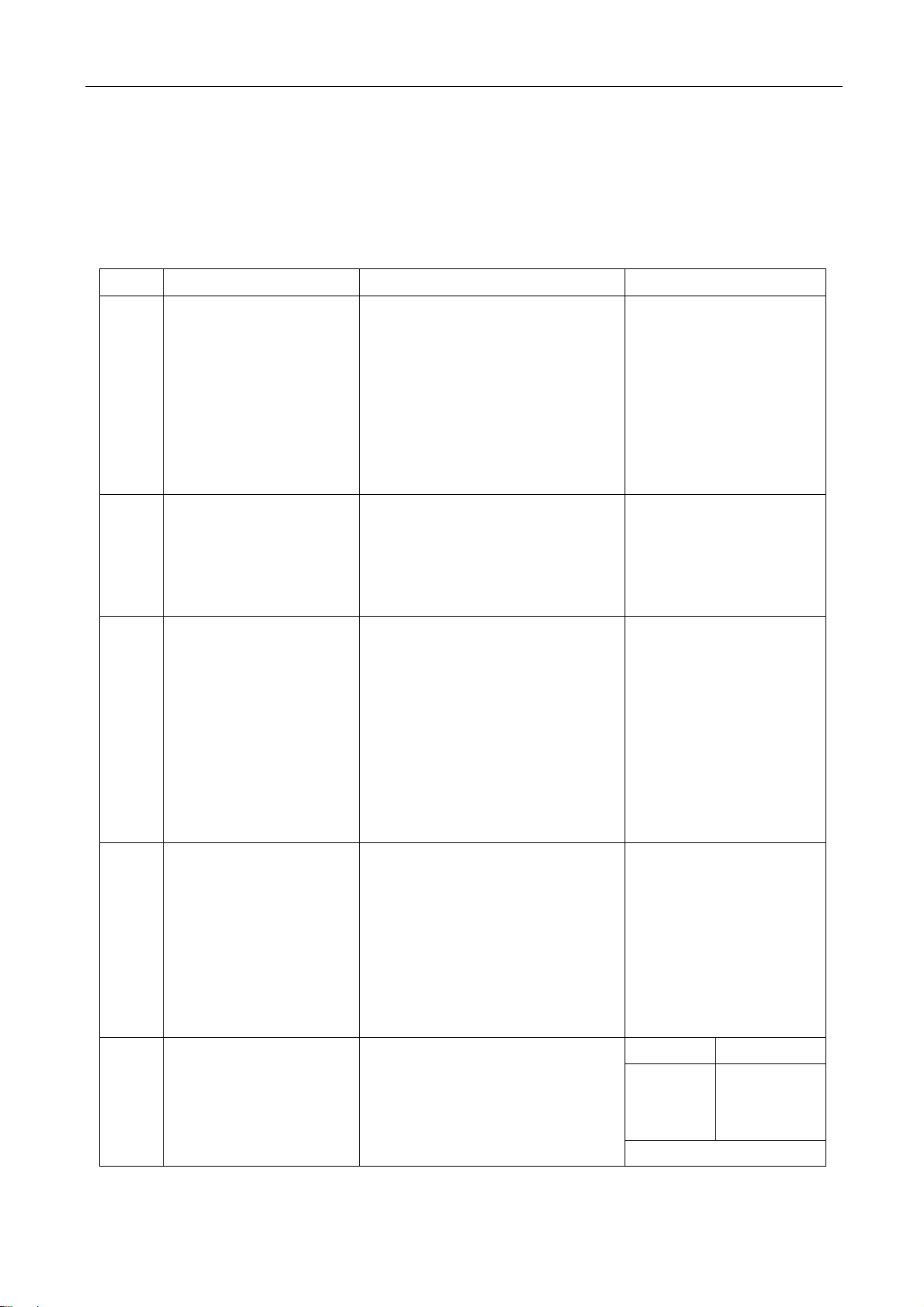

EXPLODED VIEW PF-68T31/PF-68V21

FRONT CABINET

CRT PWB

CONTROL PWB

SPEAKER &

SPEAKER BOX

-

STEREO PWB PF-68T31

REAR TERMINAL

BOARD

POWER PWB

MAIN PWB

REAR CABINET

AC POWER CORD

4

Page 5

.

REPLACEMENT OF MEMORY IC

1. MEMORY IC.

This TV uses memory IC. In the memory IC are memorized data for correctly operating the video

and deflection circuits.

When replacing memory IC, be sure to use IC written with the initial value of data.

2. PROCEDURE FOR REPLACING MEMORY IC

(1) Power off

Switch the power off and unplug the power cord from AC outlet.

(2) Replace IC

Be sure to use memory IC written with the initial data values.

(3) Power On

Plug the power cord into the AC outlet and switch the power On.

(4) Check and set SYSTEM default value:

1) Press “TEST” key on the special service use Remote control unit.

2) The “TEST” will be displayed on the screen.

3) Press “0” to “8“ key, (Mkey) and corresponding on-screen display will be appeared.

4) In this section, except “3”, “4” and “5” key function would be confirmed.

5) Check the setting value of the SYSTEM default value of Table 1. If the value is different,

select items by [CH+]/[CH-] keys and set value by [VOL+]/[VOL-] keys.

6) Press “TEST” key again and return to the normal screen.

SERVICE ADJUSTMENT

B1 POWER SUPPLY

1. Receive normal colour bar signal.

2. Connect DC voltmeter to TP91 and isolated ground.

3. Adjust VR651 to get the voltage as 130V ±1.0V.

FOCUS ADJUSTMENT

1. Receive a crosshatch signal.

2. While watching the screen, adjust the FOCUS VR to make the vertical and horizontal lines as

fine and sharp as possible.

STEREO ADJUSTMENT (PF-68T31)

1. Receive A2 stereo signal.

2. Adjust L3101 to get the voltage at TP1 (N3101 Pin #3) as 2.5V ±0.1V

3. Adjust VR3101 to get same amplitude at TP3 and TP4.

BUS CONTROL ADJUSTMENT

To enter BUS control mode, use special remote control with “TEST” key, and push “TEST” key.

On TV screen “TEST” will be indicated, this means entered bus control mode.

5

Page 6

.

And press following key, each function will be available.

Remote Hand Unit keys

[M1] [M2] [M3] [M4]

1 2 3 4

[M5] [M6] [M7]

5 6 7 8

[M0]

9 0

[M4] menu

MENU4 Geometrical adjustment

Receive PAL standard Complete pattern signal.

Adjustment steps:

a) Adjust V. SLOPE, to the center horizontal line just appeare from half bottom shadow.

b) Adjust V-SHIFT, the center horizontal line correspond to CRT vertical center.

c) Adjust V-AMPL, to get 90% of vertical picture contents would be displayed on CRT.

[M5] menu

a) Adjust H-SHIFT, to get the picture horizontal center correspond to CRT horizontal center.

b) Adjust H-AMP, to get 90% of horizontal picture contentswould be displayed on CRT.

c) Adjust H-PARABORA, to get minimum side pincushion distortion.

d) Adjust CORNER, to get minimum distortion of 4-corners.

e) Adjust TRAPEZ, to get minimum trapezoid distortion.

Receive NTSC signal and repeat above [M4] and [M5] adjustment.

[M2] Menu

RF AGC Adjustment.

Receive 60dBμ(1mV)V

noise reduce gradually and just disappeared point.

[M3] Menu

CRTcut off and white balance adjustment.

Receive white signal.

a) CRT cut off adjustment.

1. Select “SC”, then automatically vertical scan will be stopped.

2. Adjust SCREEN control on Flyback transformer to get the darkest single horizontal line

(red, green, or blue, sometimes shows more yellow, more purple or more white).

3. Using (above) 1、2,5、6, 9, 0 keys, to get one white horizontal bar. Then re-adjust

SCREEN control to get horizontal bar would be just visible.

b) White balance adjustment.

1. Select WR/WB menu.

2. Adjust WR/WB to get colour temperature as x=281, y=311

colour bar pattern signal,adjust AGC value(voltage from high to low),to

H

6

Page 7

.

c) Sub-Brightness adjustment. (Use stair case signal)

1. Select SB menu.

2. Adjust SB to get the darkest step being cutoff.

Default Settings

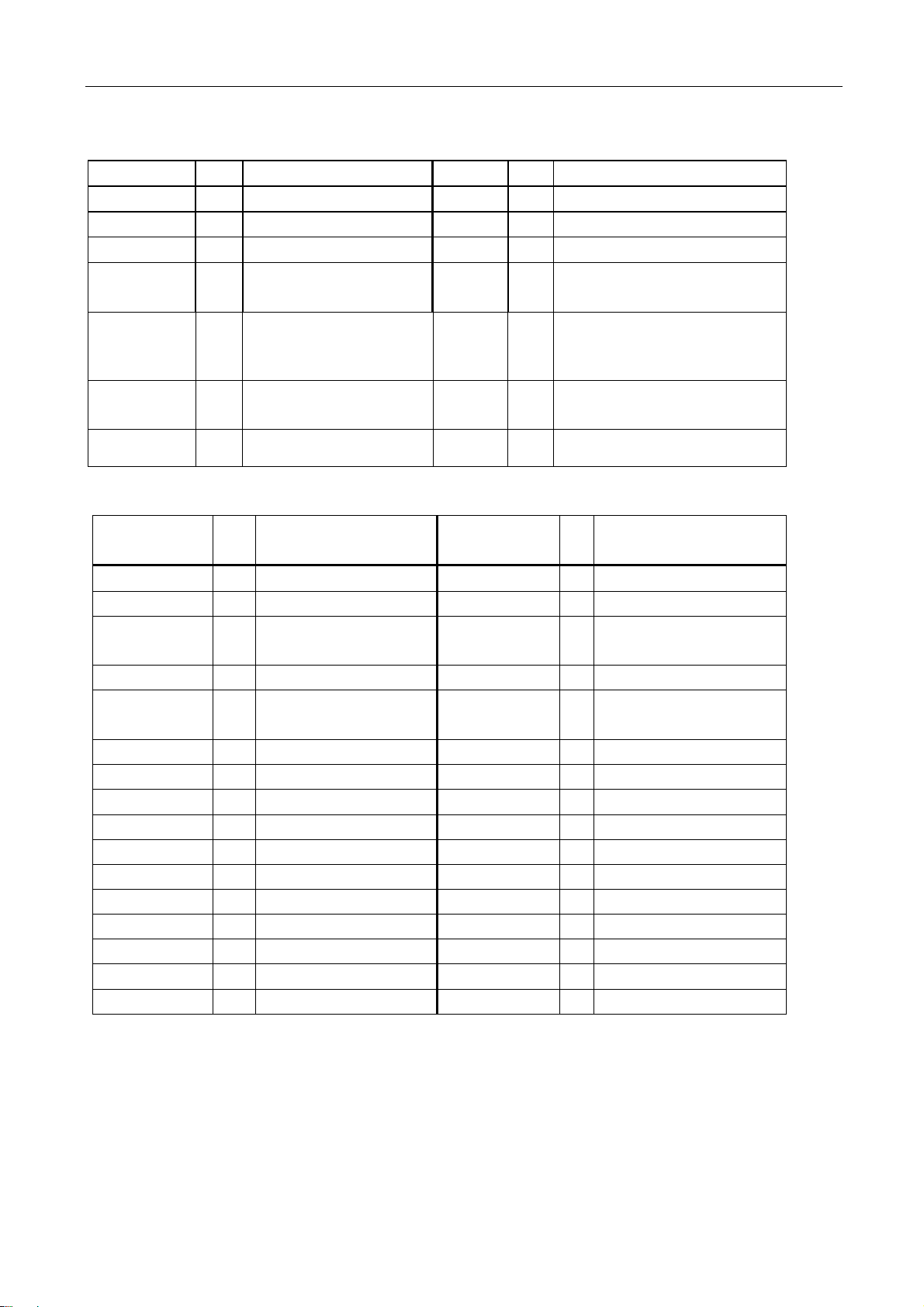

Mkey ITEMS VARIABLE RANGE DEFAULT

M0

M1

M2

M3 C

M4

PAL

NTSC 3.58

NTSC 4.43

SECAM

D/K

I

B/G

M

Headphone

CPU Vol

Band Mode

Search Speed

Power ON

BUS Stop(Open)

Shipping

RF AGC Delay

Y-Delay

Sound Volume

Sub-Sharpness

Sub-Colour

IF Freq.

AV Mode

BR

CT

SC

WR

WG

WB

SB

V.SLOPE

V.SHIFT

V.AMPL

S.CORR

0 →1

0 →1

0 → 1

0 → 1

0 → 1

0 → 1

0 → 1

0 → 1

0 → 1

0 →1

0 → 1

0 → 1

0 → 1

0 → 1

0 → 63

0 → 15

0 → 63

0 → 63

0 → 63

0 → 5

0 → 7

0 → 100

0 → 100

0 → 63

0 → 63

0 → 63

0 → 63

0 → 63

0 → 63

0 → 63

0 → 63

1

1

1

0

0

0

1

0

1

0

1

0

0

0

0

6

7

46 (PF-68V21)

47 (PF-68T31

50

50

38.9

4 (PF-68V21)

5 (PF-68T31)

6

20

75

45

45

45

50

PAL NTSC

32

29

30

21

32

28

31

7

Page 8

.

H-SHIFT

H-AMPL

H-PARABORA

CORNER

TRAPEZ

M6 OSD-H

OSD-V

M7

V. AMPL1

V. AMPL2

0 → 63

0 → 63

0 → 63

0 → 63

0 → 63

0 → 29

0 → 29

0 → 38

0 → 38

PAL NTSC M5

39

53

23

30

32

2

1

9

0

ICs functional description

3.1 N701 KS88P8432N-XXX function:Microcomputer

NAME PI

N

VT 1 Tuning Voltage Output TTX RST 42

RELAY 2 Relay control output STAND BY 41 Stand-by output

Y Cb Cr 3 Component input

control

AV1 4 Input select output SCL 39 IIC clock

AV2 5 Input select output SERVICE 38

6 Not used VSS 37 GND

7 Not used IR IN 36 Remote signal input

8 Not used 35 Not used

KEY IN 9 Local key input VDD 34 Vdd 5V

10 Not used RESET 33 Reset input

LV PROTECT 11 Low Voltage protect X’TAL OUT 32 X’tal output

MUTE 12 Mute output X’TAL IN 31 X’tal input

VSS 13 GND VSS 30 GND

14 Not used OSD OUT 29

15 Not used OSD IN 28

LED1 16 Stand by LED output V SYNC 27 V. Sync input

BAND1 17 Band select output H SYNC 26 H. Sync input

BAND2 18 Band select output FAST BLANK 25 OSD Fast blank output

LED2 19 On-Timer LED output R OUT 24 OSD Red output

20 Not used G OUT 23 OSD Green output

21 Not used B OUT 22 OSD Blue output

NOTE:· · Pin No. 9: Control key input (Analog to Digital Convertor)

(Max. Limit voltage)

FUNCTION MENU TV/AV POWER V+ V- P+ P-

VOLTAGE 0 0.625 1.25 1.875 2.5 3.125 3.75

FUNCTION NAME PIN FUNCTION

SDA 40 IIC data

43

53

31

30

30

8

Page 9

.

N301 TDA8843 Function: I

2

C bus controled PAL/NTSC one chip processor

Symbol PIN Function Symbol PIN Function

SIF IN 1 B-Y OUT 29

EXT AUDIO IN 2 R-Y OUT 30

3 B-Y IN 31

4 R-Y IN 32

PLL LOOP FILT 5 CHROMA 33

VIDEO OUT 6 X’tal 3.58 34

SCL 7 X’tal 4.43 35

SDA 8 COLOR PLL 36

BANDGAP 9 +B SUPPLY 37

S Video C IN 10 CVBS SW OUT 38

S Video Y IN 11 DIGIDEC 39

VDD 12 H OUT 40

INT CVBS IN 13 FBT PULSE 41

GND 14 PH-2 42

AUDIO OUT 15 PH-1 43

16 GND 44

EXT CVBS IN 17 E/W OUT 45

BLACK

18 Y OUT- 46

CURRENT

B-OUT 19 Y OUT+ 47

G-OUT 20 IF IN 48

R-OUT 21 IF IN 49

BEAM 22 EHT 50

R-IN 23 VSAW 51

G-IN 24 V-REF 52

B-IN 25

IF AGC 53

F BLANK 26 TUNER AGC 54

Y-IN 27 DE EMPH 55

Y OUT 28 SOUND 56

N802 TDA2009A Function : audio output

Symbol PIN Function

description

NON INV IN(1) 1 LEFT IN(NON INV) N.C.+ 7 N.C.

INV IN(1) 2 LEFT IN(INV) OUT(2) 8 RIGHT OUT

SVRR 3 SVRR +Vs- 9 POWER SUPPLY-

INV IN(2) 4 RIGHT IN(INV) OUT(1) 10 LEFT OUT

NON INV IN(2) 5 RIGHT IN(NON INV) N.C. 11 N.C.

GND 6 GND

Symbol PIN Function

description

9

Page 10

.

N801 TDA8354Q Function : vertical output

Symbol PIN Function description Symbol PIN Function description

Vo(guard) 1 Guard output voltage GNDA 8 Ground A

Vi(M) 2 Input measuring resistor Vo(A) 9 Output voltage A

Vi(con) 3 Input conversion resistor Vp(A) 10 Supply voltage A

Vp(B) 4 Supply voltage B Ii(neg) 11 Input power stage(negative);

includes Ii(sb) signal bias

Vo(B) 5 Output voltage B Ii(pos) 12

Input power stage (positive;

includes Ii(sb) signal bias

GNDB 6 Ground B Ii(comp) 13 Input for damping resistor

compensation current

Vflb 7 Flyback supply voltage

N503 TDA9860 Universal Sound processor

Symbol Pin Function Symbol Pi

Function

n

AV1L 1 AV1 Audio Left input AV1R 32 AV1 Audio input Right

P1 2 Not used P2 31 Not used

MAINL 3 Main Audio Left

AV2R 30 AV2 Audio input Right

input

CSMO 4 Smoothing Capacitor CPS1 29 Pseudo stereo Cap. 1

MAINR 5 Main Audio Right

AV2L 28 AV2 Audio input Left

input

VP 6 Power Supply CPS2 27 Pseudo stereo Cap. 2

OUT R 7 Right Output OUT L 26 Left Output

GND 8 Ground MAD 25 Not used (GND)

LINOR 9 Line Output Right LINOL 24 Line Output Left

LINIR 10 Line Input Right LINIL 23 Line Input Left

CBR1 11 Bass Cap. Right 1 CBL1 22 Bass Cap. Left 1

CBR2 12 Bass Cap. Right 2 CBL2 21 Bass Cap. Left 2

Headphone R 13 Headphone-R output Headphone L 20 Headphone-L output

CTR 14 Treble Cap. Right CTL 19 Treble Cap. Left

MAINOR 15 Main Audio out Right MAINOL 18 Main Audio out Left

SCL 16 I2C Bus clock SDA 17 I2C Bus data

10

Page 11

. Wave forms

.

4.6Vpp 4.2Vpp

N701 PIN27 N701 PIN26

2.5Vpp 2.5Vpp

N301 PIN20 N301 PIN19

1.3Vpp 1Vpp

N301 PIN15 N301 PIN47

95Vpp 95Vpp

N1701 PIN8 N1701 PIN7

1Vpp

N301 PIN17

2.5Vpp

N301 PIN21

2.7Vpp

V902 B

95Vpp

N1701 PIN9

0.6Vpp

2.2Vpp 1.2Vpp

N301 PIN38 N301 PIN13

5Vpp

N301 PIN41 N301 PIN40

1000Vpp

V902 C

300Vpp 22Vpp

T611 PIN10 HEATER

All IC/Transistors voltages

N301 TDA8843

PIN 1 2 3 4 5 6 7 8 9 10 11 12 13 14

V 0.2 3.6 0 0 2.5 3.0 4.5 4.6 6.7 1.1 3.4 7.8 3.9 0

PIN 15 16 17 18 19 20 21 22 23 24 25 26 27 28

V 3.0 0 3.4 5.6 2.5 2.5 2.4 2.0 2.6 2.6 2.6 0.1 2.8 2.8

PIN 29 30 31 32 33 34 35 36 37 38 39 40 41 42

V 2.3 2.3 2.3 2.3 0.3 2.5 2.5 5.0 7.1 2.5 5.0 0.4 0.7 3.4

PIN 43 44 45 46 47 48 49 50 51 52 53 54 55 56

V 4.0 0 4.0 1.3 2.8 4.6 4.6 1.9 3.8 3.9 4.5 2.6 2.9 3.4

N202 LA7910

PIN 1 2 3 4 5 6 7 8 9

VHF-L 8.5 0 0 0 0 10.3 0 0 8.5

VHF-H 0 8.5 1.6 0 0 10.3 0 0 8.5

UHF 0 0 0 1.6 0 10.2 8.5 6.4 8.5

11

Page 12

.

N802 TDA2009A

PIN 1 2 3 4 5 6 7 8 9

V 1.3 0.7 12.6 0 1.3 0 0 11.4 20.1

N503 TDA9860

PIN 1 2 3 4 5 6 7 8 9 10 11 12 13 14

V 4.0 0 4.0 8.0 4.0 8.0 4.0 0 4.0 4.0 4.0 4.0 4.0 4.0

PIN 15 16 17 18 19 20 21 22 23 24 25 26 27 28

V 4.0 4.5 4.6 4.0 4.0 4.0 4.0 4.0 4.0 4.0 0 4.0 4.0 4.0

PIN 29 30 31 32

V 4.0 4.0 0 4.0

10 11

11.4 0

Transistors voltages

V201 V301 V302

B C E B C E B C E

1.0 8.5 0.2 2.2 0 2.9 2.9 7.2 2.2

V303 V304 V480

B C E B C E B C E

1.8 5.8 1.3 3.8 7.8 3.2 2.5 8.1 1.8

V560 V561 V611

B C E B C E B C E

1.3 2.0 2.0 1.3 2.0 2.0 5.4 3.6 5.8

V612 V615

B C E B C E

3.6 2.1 0

V651 V681 V702

B C E B C E B C E

7.0 36.8 6.4 0 0 0 0 5 0.1

V703 V704 V705

1.7 2.1 0

B C E B C E B C E

0 5.0 2.5 0 5.0 2.5 4.4 5.1 5.1

V706 V707 V801

B C E B C E B C E

0 5.1 0 5.1 0 5.1 0 0 0

V802 V804 V806

B C E B C E B C E

0 0 0

8.16 0.1 8.22

12

5.6 20.1 5.0

Page 13

.

V901 V902 V905

B C E B C E S D G

0.5 44.1 0 -0.1 128.6 0 0 16.0 4.0

V906 V908

B C E B C E

5.5 0 5.6

*********************** Special Function ************************************

Special Setup for limited purpose.

This TV has special setup for TV locking function. From normal operation select “CHILD

LOCK” and…

Receiving [LOCK] key command, CHILD-LOCK menu

will be appeared.

On this situation, received [LOCK] key again, over

3 seconds,

i) All front panel keys will be disabled.

ii) Only by remote control, TV can be operated.

By receiving over 3 seconds [LOCK] key command, lock situation will be changed as ON or

OFF.

If {PANEL LOCK} system, describe later, set to ON, even with above command can not turn

to OFF.

In this mode, if receiving numeric command “9999”, CHILD LOCK mode will be changed to

“LOCK FUNCTION” mode. “9999” will not be displayed on screen.

In this mode, cursor can be moved up/down

by [CH+]/[CH-] keys.

Setting status can be changed by

[VOL+]/[VOL-] keys.

After setting to “ON”, the program can not be

accessed by [CH+]/[CH-] keys.

By [LOCK] key command, mode can be exit.

0.7 1.4 0

CHILD LOCK

ON

LOCK FUNCTION

CH PRESET LOCK OFF

VOLUME LIMIT 33

AV LOCK OFF

PANNEL LOCK ON

CH PRESET LOCK

If this item were set to “ON”;

i) Automatic Search and Memory function were disabled.

ii) Manual Search function were disabled.

iii) Fine Tuning function were disabled.

13

Page 14

.

VOLUME LIMIT

Maximum Volume control value by customer would be limited with this figure.

AV LOCK

If this item were set to “ON”, after exit from this LOCK mode;

i) Only with AV input are available to use.

ii) RF (Tuner) input function will be disabled.

PANNEL LOCK

If this item were set to “ON”;

iii) All front panel keys will be disabled.

iv) Only by remote control, TV can be operated.

**************************** End Special **********************************

14

Page 15

.

PURITY / CONVERGENCE ADJUSTMENT

PURITY ADJUSTMENT

1. Demagnetize CRT with the demagnetizer.

2. Loosen the retainer screw of the deflection yoke.

3.

Remove the wedges.

4.

Input a green raster signal from the signal

generator, and turn the screen to green raster.

5.

Move the deflection yoke backward.

6.

Bring the long lug of the purity magnets on the short

lug and position them horizontally. (Fig2)

7.

Adjust the gap between two lugs so that the GREEN

RASTER will come into the center of the screen.

(Fig. 3)

8.

Move the deflection yoke forward, and fix the

position of the deflection yoke so that the whole

screen will become green.

9.

Insert the wedge to the top side of the deflection

yoke so that it will not move.

10.

Imput a crosshatch signal.

11.

Verify that the screen is horizontal.

12.

Input red and blue raster signals, and make sure

that purity is properly adjusted.

Long lug

Short lug

WEDGE

DEFLECTION YOKE

P

CRT

P: PURITY MAGNET

4: 4-POLES

6: 6-POLES (convergence magnets)

4 6

P/C MAGNETS

(convergence magnets)

Fig. 1

PURITY MAGNETS

Bring the long lug over the short lug

and position them horizontally.

Fig. 2

(FRONT VIEW)

GREEN RASTER

CENTER

Fig. 3

15

Page 16

.

3

STATIC CONVERGENCE ADJUSTMENT

1. Input a crosshatch signal.

2. Using 4-pole convergence magnets, overlap the red

and blue lines in the center of the screen (Fig. 1) and

turn them to magenta (red/blue).

3. Using 6-pole convergence magnets, overlap the

magenta (red/blue) and green lines in the center of

the screen and turn them to white.

4. Repeat 2 and 3 above, and make the best

convergence.

DYNAMIC CONVERGENCE ADJUSTMENT

1. Move the deflection yoke up and down and overlap

lines in the periphery. (Fig. 2)

2. Move the deflection yoke left to right and overlap the

lines in the periphery. (Fig. 3)

3. Repeat 1 and 2 above, and make the best

convergence.

After adjustment, fix the wedge at the original position.

Fasten the retainer screw of the deflection yoke.

Fix the 6 magnets with glue.

(FRONT VIEW)

Fig. 1

(FRONT VIEW)

RED GREEN BLUE

BLUE

RED

GREEN GREEN

RED BLUE

BLUE GREEN RED

Fig.2

(FRONT VIEW)

RED GREEN BLUE BLUE GREEN RED

RED

GREEN

BLUE

BLUE

GREEN

RED

Fig.

16

Page 17

.

PARTS LIST

CAUTION

z The parts identified by the symbol are important for the safety. Whenever replacing these parts, be sure to use

specified ones to secure the safety.

z The parts not indicated in this Parts List and those which are filled with lines ------ in the Part No. columns will not be

supplied.

ABBREVIATIONS OF RESISTORS, CAPACITORS AND TOLERANCES

RESISTORS CAPACITORS

C R

F R

P R

V R

HV R

MF R

MG R

MP R

OM R

CMF R

UNF R

CH V R

CH MG R

COMP R

LPTC R

F G J K M N R H Z P

±1%

Carbon Resistor

Fusible Resistor

Plate Resistor

Variable Resistor

High Voltage Resistor

Metal Film Resistor

Metal Glazed Resistor

Metal Plate Resistor

Metal Oxide Resitor

Coating Metal Film Resistor

Non-Flammable Resistor

Chip Variable Resistor

Chip Metal Glazed Resistor

Composition Resistor

Linear Positive Temperature Coefficent

Resistor

±

2%

±

5%

±

10%

C CAP

E CAP

M CAP

HV CAP

MF CAP

MM CAP

MP CAP

PP CAP

PS CAP

TF CAP

MPP CAP

TAN CAP

CH C CAP

BP E CAP

CH AL E CAP

CH AL BP CAP

CH TAN E CAP

CH AL BP E CAP

TOLERANCES

±

20%

±

30%

+30%

-10%

Ceramic Capacitor

Electrolytic Capacitor

Mylar Capacitor

High Voltage Capacitor

Metalized Film Capacitor

Metalized Mylar Capacitor

Metalized Polystyrol Capacitor

Polypropylene Capacitor

Polystyrol Capacitor

Thin Film Capacitor

Metalized Polypropylene Capacitor

Tantalum Capacitor

Chip Ceramic Capacitor

Bi-Polar Electrolytic Capacitor

Chip Alminum Electrolytic Capacitor

Chip Alminum Bi-Polar Capacitor

Chip Tantalum Electrolytic Capacitor

Chip Alminum Bi-Polar Electrolytic

Capacitor

+50%

-10%

+80%

-20%

+100%

-0%

17

Page 18

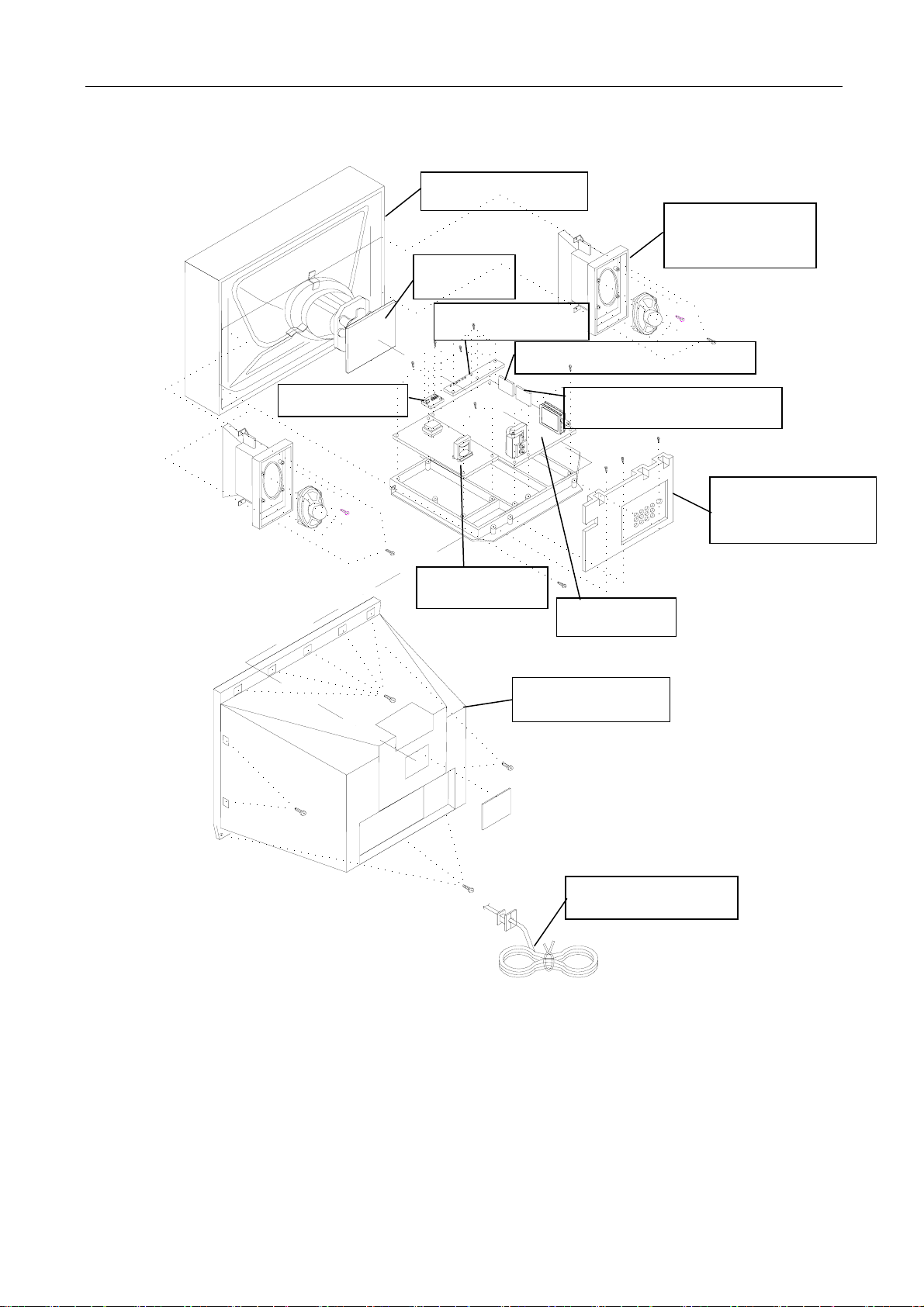

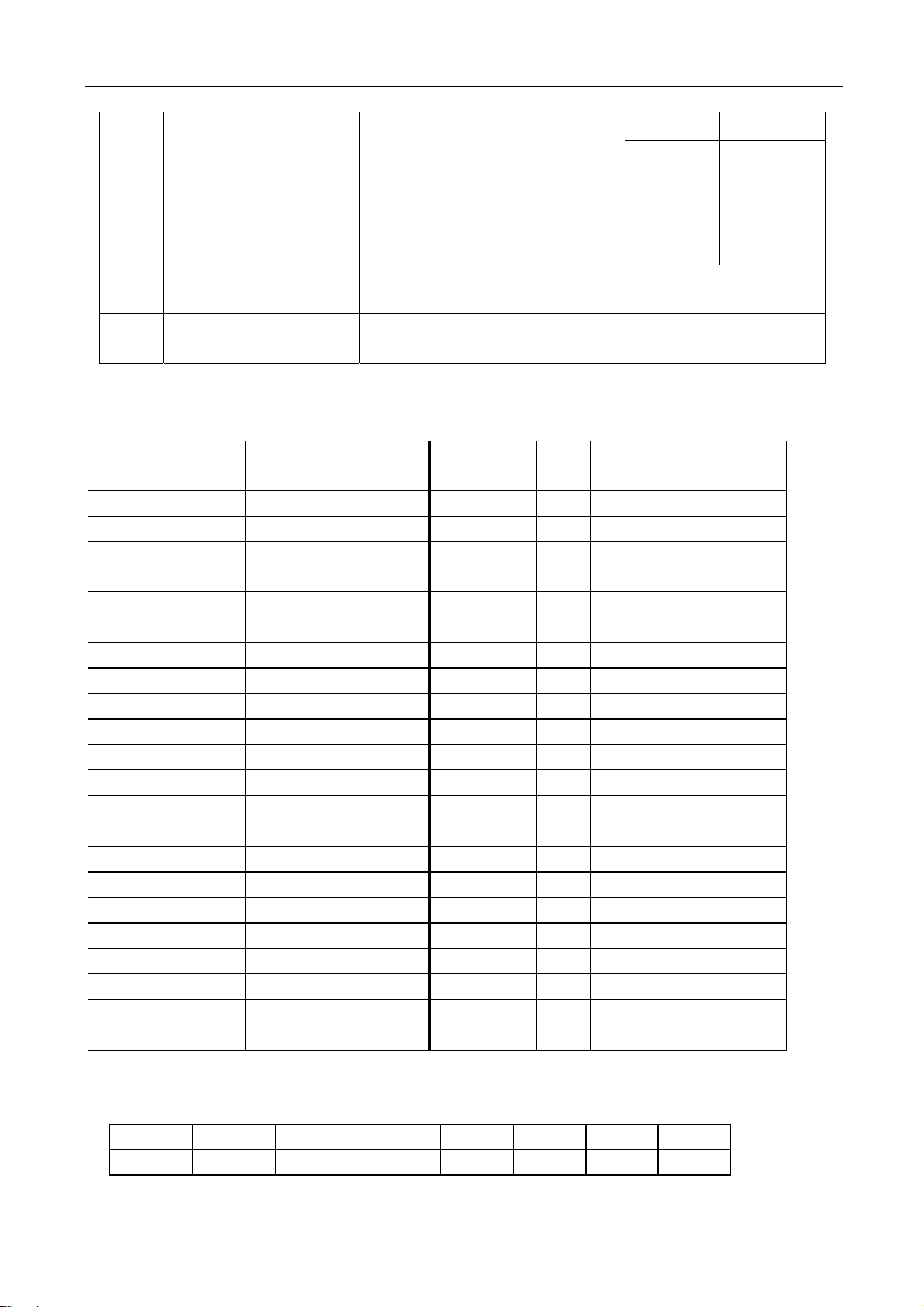

EXPLODED PARTS LIST

.

⑥

⑮

⑰

⑱

①

②

④⑤

⑳

⑨

①

②

⑧

⑫⑬

⑦

18

Page 19

.

Ref. No. Part Name. Part No. Model Q’ty

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

SWMAIN POWER SWITCH(KDC-A04-11) KPW12HL057--B C 1

0

2

1

2

CRT

2

SPEAKER BOX RSR7.013.0136

SPEAKER BOX BRACKET RSR8.078.0331

IRON BRACKET FOR CRT RSR8.038.0233

DAMPER GEAR DP-1

DAMPER GEAR BRACKET RSR8.078.0161

FRONT CABINIT

BACK CABINIT

BACK TERMINAL BOARD

MAIN PWB FRAME

POWER SWITCH KNOB

KEY KNOB

RSR8.074.0288

RSR8.074.0297

E/RSR8.078.007

RSAG8.078.116

RSR8.337.0309

RSR8.337.0310

BACK TERMINAL PVC SHEET E/RSR8.808.132

BACK TERMINAL PVC SHEET E/RSR8.808.133

DOOR LID RSR8.632.0163

HANDLE BRACKET RSR8.634.0123

LED LENS

RSR8.640.0182

HANDLE (R ) RSR8.671.0103

HANDLE (L) RSR8.671.0104

FRONT CONTROL PVC SHEET E/RSR8.808.131

AC SWITCH BRACKET

A68QCP893X300

RSR8.038.0181

A68QCP893X300

C 2

C 2

C 4

C 1

C

C 1

C 1

C 1

C 1

C 1

C 1

T31 1

V21

C 1

C 2

C 1

C 1

C 1

C 1

C 1

C 1

19

Page 20

.

PRINTED CIRCUIT BOARD PARTS

LIST

Model C: Common usage T31: PF-68T31 V21: PF-68V21

Symbol Name Part No Model

A 201 TUNER(9V 470M

AS 8S SOCKET GACV8001----C C

AZ 2S SOCKET GAAV2001----C C

BC2 3S SOCKET GACV3001----C C

BM 3S SOCKET GABV3001----C C

BM1 3S SOCKET GABV3001----C C

BM-BM

BS 3S SOCKET GABV3001----C C

BS1 3S SOCKET GABV3001----C C

BS-BS

BX 8S SOCKET GACV8001----C C

C 1102 50V 0.01u CKF103Z1FA-FC T31 Z

C 1103 50V 0.01u CKF103Z1FA-FC T31 Z

C 1104 100v 10u CEC100MYACANP T31 M

C 1106 50V 56P CCF560J1CA-FC T31 J

C 1107 50V 56P CCF560J1CA-FC T31 J

C 1108 50V 0.01u CKF103Z1FA-FC T31 Z

C 1109 50v 2.2u CEF2R2MYACANP T31 M

C 1110 10v 100u CEB101MYACBNP T31 M

C 1112 100V 0.012u CFG123J1-H-NW T31 J

C 1701 250V 10u CEK100M1ACHNP C M

C 1702 500V 1000P CKP102K1BA-FC C K

C 1703 2KV 1000P CKX102P2EJ-ND C P

C 1706 50V 0.01u CKF103Z1FA-FC C Z

C 201 50V 27P CCF270J1CA-FC C J

C 203 50V 1000P CKF102K1BA-FC C K

C 206 50V 0.01u CKF103Z1FA-FC C Z

C 208 50V 4700P CKF472K1BA-FC C K

C 210 50V 1000P CKF102K1BA-FC C K

C 220 50V 1000P CKF102K1BA-FC C K

C 251 100v 10u CEC100MYACANP C M

C 252 100V 0.015u CFG153J1-H-NW C J

C 253 100v 10u CEC100MYACANP C M

C 255 100v 10u CEC100MYACANP C M

C 256 100v 10u CEC100MYACANP C M

C 257 50V 0.01u CKF103Z1FA-FC C Z

C 258 16v 100u CEC101MYACBNP C M

C 259 50V 100u CEF101M2ACENP C M

C 268 100v 10u CEC100MYACANP C M

C 301 50V 0.01u CKF103Z1FA-FC C Z

C 302 50V 1000P CKF102K1BA-FC C K

C 303 63V 0.1u CAY104K1-H-FC C K

C 304 50v 2.2u CEF2R2MYACANP C M

C 305 100V 0.022u CFG223J1-H-NW C J

C 306 50v 4.7u CEF4R7MYACANP C M

C 307 16v 100u CEC101MYACBNP C M

C 308 100V 0.022u CFG223J1-H-NW C J

C 309 63V 0.22u CAY224K1-H-FC C K

C 310 16v 47u CEC470MYACANP C M

C 3101 50V 1000P CKF102K1BA-FC T31 K

C 3102 50V 1000P CKF102K1BA-FC T31 K

C 3103 63V 0.22u CAY224K1-H-FC T31 K

C 3104 63V 0.1u CAY104K1-H-FC T31 K

C 3105 50v 2.2u CEF2R2MYACANP T31 M

C 3106 50v 2.2u CEF2R2MYACANP T31 M

C 3107 50V 47P CCF470J1CA-FC T31 J

C 3108 50V 0.01u CKF103Z1FA-FC T31 Z

C 3109 63V 0.22u CAY224K1-H-FC T31 K

38.9 B/G)

2P

Connector(230mm)

2P

Connector(230mm)

BXATB026----S C

JS2231-B002-C C

JS2231-B002-C C

C 3110 50V 47P CCF470J1CA-FC T31 J

C 3113 50V 0.01u CKF103Z1FA-FC T31 Z

C 3114 50v 2.2u CEF2R2MYACANP T31 M

C 3115 50v 2.2u CEF2R2MYACANP T31 M

C 3116 50V 1000P CKF102K1BA-FC T31 K

C 3117 50V 1000P CKF102K1BA-FC T31 K

C 3118 50V 0.01u CKF103Z1FA-FC T31 Z

C 3119 50V 0.01u CKF103Z1FA-FC T31 Z

C 3120 63V 0.47u CAY474K1-H-FC T31 K

C 3121 100V 6800P CFG682K1-H-NW T31 K

C 3122 50V 680P CKF681K1BA-FC T31 K

C 3123 100V 6800P CFG682K1-H-NW T31 K

C 3124 50V 680P CKF681K1BA-FC T31 K

C 3125 63V 0.47u CAY474K1-H-FC T31 K

C 3126 50V 47P CCF470J1CA-FC T31 J

C 3127 63V 0.47u CAY474K1-H-FC T31 K

C 3128 63V 0.47u CAY474K1-H-FC T31 K

C 3129 63V 0.47u CAY474K1-H-FC T31 K

C 3130 63V 0.47u CAY474K1-H-FC T31 K

C 3131 63V 0.47u CAY474K1-H-FC T31 K

C 3132 100V 4700P CFG472J1-H-NW T31 J

C 3133 63V 0.47u CAY474K1-H-FC T31 K

C 3134 16v 47u CEC470MYACANP T31 M

C 3135 16v 47u CEC470MYACANP T31 M

C 3136 16v 47u CEC470MYACANP T31 M

C 3137 50V 0.01u CKF103Z1FA-FC T31 Z

C 3138 50V 1000P CKF102K1BA-FC T31 K

C 3139 50V 1000P CKF102K1BA-FC T31 K

C 316 50v 1.0u CEF1R0MYACANP C M

C 317 50V 3300P CKF332K1BA-FC C K

C 318 100v 10u CEC100MYACANP C M

C 321 50v 4.7u CEF4R7MYACANP C M

C 322 100V 0.022u CFG223J1-H-NW C J

C 324 63V 0.1u CAY104K1-H-FC C K

C 326 63V 0.1u CAY104J1-H-FC C J

C 327 100v 10u CEC100MYACANP T31 M

C 330 16v 47u CEC470MYACANP C M

C 336 50V 680P CKF681K1BA-FC C K

C 337 50V 680P CKF681K1BA-FC C K

C 351 50v 1.0u CEF1R0MYACANP C M

C 352 50v 1.0u CEF1R0MYACANP C M

C 353 50V 0.01u CKF103Z1FA-FC C Z

C 354 50V 68P CCF680J1CA-FC C J

C 355 50V 47P CCF470J1CA-FC C J

C 3710 16v 100u CEC101MYACBNP C M

C 3711 50V 0.01u CKF103Z1FA-FC C Z

C 3725 50V 1000P CKF102K1BA-FC C K

C 3726 50V 1000P CKF102K1BA-FC C K

C 395 16v 100u CEC101MYACBNP C M

C 396 16v 220u CEC221MYACCNP C M

C 397 16v 330u CEC331MYACCNP C M

C 398 16v 330u CEC331MYACCNP C M

C 401 50V 220P CKF221K1BA-FC C K

C 402 50V 220P CKF221K1BA-FC C K

C 405 63V 0.1u CAY104K1-H-FC C K

C 406 50V 3300P CKF332K1BA-FC C K

C 407 50v 1.0u CEF1R0MYACANP C M

C 408 50V 2200P CKF222K1BA-FC C K

C 409 50V 1000P CKF102K1BA-FC C K

C 410 50V 4700P CKF472K1BA-FC C K

C 411 63V 0.1u CAY104K1-H-FC T31 K

C 412 63V 0.1u CAY104K1-H-FC T31 K

C 413 63V 0.1u CAY104K1-H-FC T31 K

C 414 100V 0.015u CFG153J1-H-NW C J

C 420 16v 470u CEB471MYACCNP C M

C 421 100v 10u CEC100MYACANP T31 M

20

Page 21

.

C 422 100V 0.022u CFG223J1-H-NW C J

C 484 16v 330u CEC331MYACCNP C M

C 485 16v 100u CEC101MYACBNP T31 M

C 501 50v 1.0u CEF1R0MYACANP C M

C 503 50v 0.47u CEFR47MYACANP C M

C 504 50v 0.47u CEFR47MYACANP C M

C 506 16v 100u CEC101MYACBNP C M

C 507 16v 47u CEC470MYACANP C M

C 509 50v 1.0u CEF1R0MYACANP C M

C 510 50V 1000P CKF102K1BA-FC C K

C 511 100V 0.068u CFG683K1-H-NW C K

C 512 63V 0.15u CAY154K1-H-FC C K

C 513 50v 1.0u CEF1R0MYACANP C M

C 514 100V 6800P CFG682K1-H-NW C K

C 515 50v 1.0u CEF1R0MYACANP C M

C 516 50v 1.0u CEF1R0MYACANP C M

C 517 100V 6800P CFG682K1-H-NW C K

C 518 50v 1.0u CEF1R0MYACANP C M

C 519 63V 0.15u CAY154K1-H-FC C K

C 520 100V 0.068u CFG683K1-H-NW C K

C 521 50v 1.0u CEF1R0MYACANP C M

C 522 50V 1000P CKF102K1BA-FC C K

C 523 100V 0.015u CFG153J1-H-NW C J

C 524 50v 1.0u CEF1R0MYACANP C M

C 527 50v 1.0u CEF1R0MYACANP C M

C 529 50v 1.0u CEF1R0MYACANP C M

C 532 50v 1.0u CEF1R0MYACANP C M

C 533 100v 10u CEC100MYACANP C M

C 541 50V 1000P CKF102K1BA-FC C K

C 542 50v 1.0u CEF1R0MYACANP C M

C 544 63V 0.1u CAY104K1-H-FC T31 K

C 545 63V 0.1u CAY104K1-H-FC T31 K

C 547 16v 47u CEC470MYACANP T31 M

C 548 16v 47u CEC470MYACANP T31 M

C 549 63V 0.1u CAY104K1-H-FC T31 K

C 550 63V 0.1u CAY104K1-H-FC T31 K

C 553 16v 330u CEC331MYACCNP C M

C 559 50V 0.01u CKF103Z1FA-FC C Z

C 560 16v 330u CEC331MYACCNP C M

C 580 16v 100u CEC101MYACBNP C M

C 581 100V 4700P CFG472J1-H-NW C J

C 582 100V 4700P CFG472J1-H-NW C J

C 587 16v 330u CEC331MYACCNP C M

C 592 50V 1000P CKF102K1BA-FC C K

C 593 50V 1000P CKF102K1BA-FC C K

C 594 50V 1000P CKF102K1BA-FC C K

C 595 50V 1000P CKF102K1BA-FC C K

C 601 AC 300v 0.1u CMLX104M901NE C M

C 602 AC 300v 0.1u CMLX104M901NE C M

C 603 1KV 1000P CKW102K2BJ-ND C K

C 604 1KV 1000P CKW102K2BJ-ND C K

C 605 1KV 1000P CKW102K2BJ-ND C K

C 606 1KV 1000P CKW102K2BJ-ND C K

C 607 400V 270u CEM271M3AECNB C M

C 608 2KV 680P CKX681K2RJ-ND C K

C 611 100V 4700P CFG472J1-H-NW C J

C 612 100V 1000P CFG102J1-H-NW C J

C 614 63V 0.1u CAY104K1-H-FC C K

C 615 100V 0.022u CFG223J1-H-NW C J

C 616 2KV 680P CKX681K2RJ-ND C K

C 617 100V 0.015u CFG153J1-H-NW C J

C 628 AC 400V 470P CKMX471K301ND C K

C 629 AC 400V 470P CKMX471K301ND C K

C 652 2KV 220P CKX221K2RJ-ND C K

C 653 2KV 220P CKX221K2RJ-ND C K

C 654 2KV 220P CKX221K2RJ-ND C K

C 656 160V 470u CEH471M3AEBNK C M

C 657 25v 1000u CED102M1ACHNP C M

C 658 25v 2200u CED222M2ACKNP C M

C 659 16v 470u CEC471MYACCNP C M

C 661 16v 470u CEC471MYACCNP T31 M

C 665 50V 0.01u CKF103Z1FA-FC C Z

C 666 50V 0.01u CKF103Z1FA-FC T31 Z

C 669 50V 0.01u CKF103Z1FA-FC C Z

C 680 25v 470u CED471M1ACENP C M

C 681 16v 470u CEC471MYACCNP C M

C 682 50V 0.01u CKF103Z1FA-FC C Z

C 684 63V 0.1u CAY104K1-H-FC C K

C 685 50V 0.01u CKF103Z1FA-FC C Z

C 686 50V 0.01u CKF103Z1FA-FC C Z

C 702 50V 0.01u CKF103Z1FA-FC C Z

C 704 50V 0.01u CKF103Z1FA-FC C Z

C 706 50V 0.01u CKF103Z1FA-FC C Z

C 708 50V 0.01u CKF103Z1FA-FC C Z

C 709 50V 0.01u CKF103Z1FA-FC T31 Z

C 712 50V 22P CCF220J1CA-FC C J

C 713 50V 22P CCF220J1CA-FC C J

C 714 50V 22P CCF220J1CA-FC C J

C 715 50V 390P CKF391K1BA-FC C K

C 716 50V 100P CCF101J1CA-FC C J

C 717 16v 22u CEC220MYACANP C M

C 718 50V 100P CCF101J1CA-FC C J

C 719 50V 1000P CKF102K1BA-FC C K

C 720 50V 0.01u CKF103Z1FA-FC C Z

C 721 50V 56P CCF560J1CA-FC C J

C 722 50V 56P CCF560J1CA-FC C J

C 723 16v 100u CEC101MYACBNP C M

C 724 50V 0.01u CKF103Z1FA-FC C Z

C 725 16v 47u CEC470MYACANP C M

C 726 50V 0.01u CKF103Z1FA-FC C Z

C 727 50V 0.01u CKF103Z1FA-FC C Z

C 728 50V 0.01u CKF103Z1FA-FC C Z

C 729 50V 0.01u CKF103Z1FA-FC C Z

C 732 50V 0.01u CKF103Z1FA-FC C Z

C 740 50V 100P CCF101J1CA-FC C J

C 741 50V 100P CCF101J1CA-FC C J

C 742 63V 0.33u CAY334K1-H-FC C K

C 743 63V 0.33u CAY334K1-H-FC C K

C 744 63V 0.33u CAY334K1-H-FC C K

C 770 50V 0.01u CKF103Z1FA-FC C Z

C 791 50V 15P CCF150J1CA-FC C J

C 792 50V 15P CCF150J1CA-FC C J

C 793 50V 22P CCF220J1CA-FC C J

C 794 50V 22P CCF220J1CA-FC C J

C 801 50V 1000P CKF102K1BA-FC C K

C 802 50V 1000P CKF102K1BA-FC C K

C 803 25v 100u CED101MYACBNP C M

C 804 50V 0.01u CKF103Z1FA-FC C Z

C 805 63V 100u CEY101M1ACFNP C M

C 806 50V 1000P CKF102K1BA-FC C K

C 822 16v 100u CEC101MYACBNP C M

C 855 16v 100u CEC101MYACBNP C M

C 875 25V 330u CED331M1ACFNP C M

C 876 16v 22u CEC220MYACANP C M

C 877 16v 100u CEC101MYACBNP C M

C 878 63V 0.1u CAY104K1-H-FC C K

C 879 63V 0.1u CAY104K1-H-FC C K

C 881 16v 220u CEC221MYACCNP C M

C 882 16v 220u CEC221MYACCNP C M

C 883 16v 100u CEC101MYACBNP C M

C 885 16v 100u CEC101MYACBNP C M

C 887 63V 0.1u CAY104K1-H-FC C K

21

Page 22

.

C 888 63V 0.1u CAY104K1-H-FC C K

C 889 25v 1000u CED102M1ACHNP C M

C 890 25v 1000u CED102M1ACHNP C M

C 891 100V 0.012u CFG123J1-H-NW C J

C 892 100V 0.012u CFG123J1-H-NW C J

C 893 16v 220u CEC221MYACCNP C M

C 894 16v 220u CEC221MYACCNP C M

C 895 50v 2.2u CEF2R2MYACANP C M

C 896 50v 2.2u CEF2R2MYACANP C M

C 897 100v 10u CEC100MYACANP C M

C 899 25v 2200u CED222M2ACKNP C M

C 901 160v 4.7u CEH4R7MYBCCNP C M

C 902 500V 470P CKP471K1BA-FC C K

C 905 2KV 7500P CMX752J8-H-NE C J

C 905A 2KV 9100P J CMX912J8-H-NE C J

C 906 400V 0.033u CNM333J7-H-NE C J

C 908 50V 6.8u CPFX6R8MY01NP C M

C 909 400V 0.39u MKP478 CMM394J8-K-NS C J

C 910 63V 0.1u CAY104K1-H-FC C K

C 911 63V 0.33u CAY334K1-H-FC C K

C 913 63V 0.22u CAY224K1-H-FC C K

C 915 100v 10u CEC100MYACANP C M

C 916 160v 10u CEH100M1ACENP C M

C 922 25V 330u CED331M1ACFNP C M

C 923 63V 22u CEY220MYACCNP C M

C 924 250v 22u CEK220M1ECHNP C M

C 931 50V 100P CCF101J1CA-FC C J

C 952 50V 0.01u CKF103Z1FA-FC C Z

C 953 50V 2200P CKF222K1BA-FC C K

C 954 50v 10u CEF100MYACANP C M

C 955 100v 10u CEC100MYACANP C M

C 970 160v 4.7u CEH4R7MYBCCNP C M

CN-AS1

CN-AZ

CN-BC

CN-BX

CN-CZ DEGAUSS COIL LM-025-----NB C

CN-DY

CN-EK1

CN-HE1

CN-HE2

CN-HE3

CN-HP1

CN-KE2

CN-KP

CN-KQ

CN-SL

CN-SR

CORD AC CORD JP2282-A001-Y C

CRTPW

B

CZ 2S SOCKET GABV2001----C C

8P LINE(160mm XHD2)

CONNECT WIRE

400mm

3P Connector(60mm

XH-D2)

8P

Connector(230mm

XH-D2)

DY

Connector(500mm)

2P Connector(80mm

XHCOATING Ground

WIRE(1280m

Connector for

coating

Connector for

coating

3P

Connector(100mm

XH)

5P

Connector(170mm

XH

4P

Connector(430mm

XH-D2)

6P

Connector(450mm

EH-D2)

2P

Connector(600mm)

2P

Connecor(600mm

EX)

CRT PCB PB40042----1H C

JB8161-E001-C C

JD2401-A012-A C

JW3600-E001-C C

JW8231-E002-A C

JS4501-B001-C C

JW2800-E001-C C

JE1----B033-C C

JE1-----009-C C

JE1-----009-C C

JW3101-C001-C C

JW5171-E001-C C

JW4431-E001-C C

JW6451-F001-C C

JS2601-D002-C C

JS2601-D001-C C

F 601 FUSE 4A 250V FBA4004S02--W C

F601A FUSE HOLDER MB0X0011---G8 C

F601B FUSE HOLDER MB0X0011---G8 C

FB652A

FB652B

FL3101

H-A2 HEAT SINK MB0X0016---BF T31

HE 2S SOCKET GABV2001----C C

HN1701 HEAT SINK MB1X0070---BC C

H-N801 HEAT SINK MB1X0045---BC C

H-N802 HEAT SINK MB1X0080---BC C

HP 3S SOCKET GACV3001----C C

H-V613 HEAT SINK MB1X0152---BG C

H-V902 HEAT SINK MB1X0044---BC C

H-V905 HEAT SINK MB1X0108---BG C

KE 5S SOCKET GACV5001----A C

KE1 2S SOCKET GACV2001----C C

KP 4S SOCKET GACV4001----C C

KQ 6S SOCKET GADV6001----C C

L 210 1uH-K LBB1R0K----TG C K

L 301 10uH-K LBB100K----TG C K

L 305 10uH-K LBB100K----TG C K

L 306 10uH-K LBB100K----TG C K

L 3101 AFT 76M LTC007-C---NV T31

L 3102 10uH-K LBB100K----TG T31 K

L 3103 39uH-K LBB390K----TG T31 K

L 404 10uH-K LBB100K----TG T31 K

L 601 LINE FILTER LG-006-----NL C

L 602 LINE FILTER LG-006-----NL C

L 701 10uH-K LBB100K----TG C K

L 702 10uH-K LBB100K----TG C K

L 791 27uH-K LBB270K----TG C K

L 901 LGB-600uH(1.5A) LAD601K2---NJ C K

L 902 LINE COIL LF-019-3---NJ C

L 911 M-COIL LEA001-5---NJ C

M 3705 SOCKET GBBB3-04----Y C

M 3708

M 501 AV RCA JACK (9) GBBA9-01----Y C

M 506 AV RCA JACK (3) GBBH3-03----Y T31

M 507 S-Video JACK GBCH5001----R C

M-PWB

N 1101 SAA5261PS/110 NSAA5261PS-N- T31

N 1701 TDA6108 NTDA6108---N- C

N 201 KA33V NKA33V-----N- C

N 202 LA7910 NLA7910----N- C

N 301 TDA8843 NTDA8843---N- C

N 3101 TDA9808 NTDA9808---N- T31

N 3102 TDA9873H NTDA9873H--N- T31

N 3701 HS0038B NHS0038B---N- C

N 450 HEF4053B NHEF4053B--N- T31

N 503 TDA9860 NTDA9860---N- C

N 504 CD2822 NCD2822CS--N- C

N 652 BA17805T NBA17805T--N- T31

N 653 KA7809 NKA7809----N- C

N 655 uPC78L05J NUPC78L05J-N- C

N 701 KS88P8432N NKS88P8432NNA C

N 702 AT24C08 NAT24C08---N- C

N 801 TDA8354 NTDA8354---N- C

N 802 TDA2009 NTDA2009---N- C

N-PWB NICAM PCB(A2) PE20006----1H T31

PA

PB

Ferrite

Bead(5*10*1.8)

Ferrite

Bead(5*10*1.8)

SAW

FILTER(G9251M)

EARPHONE

SOCKET (3.5mm)

MAIN PCB(PF68T31)

SOCKET 2.5mm

3P(JL)

SOCKET 2.5mm

8P(JL)

LEF001-----NJ C

LEF001-----NJ C

XFS018-----NR T31

GBDH5002----Y C

PA-0061----1H C

GAMV3001----Y T31

GAMV8001----Y T31

22

Page 23

.

PC

PR 602 2S SOCKET GAAV2001----C C

PS 601 Positive Thermister DH1120M001-NC C M

PT 2S SOCKET GADV2001----C C

R 1101 1/6W 27K RDB273J-NAATD T31 J

R 1102 1/6W 4.7K RDB472J-NAATD T31 J

R 1103 1/6W 4.7K RDB472J-NAATD T31 J

R 1104 1/6W 4.7K RDB472J-NAATD T31 J

R 1105 1/6W 4.7K RDB472J-NAATD T31 J

R 1106 1/6W 220 RDB221J-NAATD T31 J

R 1107 1/6W 220 RDB221J-NAATD T31 J

R 1108 1/6W 4.7K RDB472J-NAATD T31 J

R 1109 1/6W 560 RDB561J-NAATD T31 J

R 1110 1/6W 2.7K RDB272J-NAATD T31 J

R 1111 1/6W 10K RDB103J-NAATD T31 J

R 1112 1/6W 10K RDB103J-NAATD T31 J

R 1701 1/4W 100 RDC101J-NABTD C J

R 1702 1/4W 100 RDC101J-NABTD C J

R 1703 1/4W 100 RDC101J-NABTD C J

R 1704 1/2W 1.5K RCD152K-NACNH C K

R 1705 1/2W 1.5K RCD152K-NACNH C K

R 1706 1/2W 1.5K RCD152K-NACNH C K

R 1711 2W 4.7 RSF4R7J5ACDND C J

R 1712 1/4W 1.5K RDC152J-NABTD C J

R 1713 1/4W 1.5K RDC152J-NABTD C J

R 206 1/6W 68 RDB680J-NAATD C J

R 207 1/6W 1.8K RDB182J-NAATD C J

R 208 1/6W 82 RDB820J-NAATD C J

R 210 1/6W 8.2K RDB822J-NAATD C J

R 211 1/6W 1.2K RDB122J-NAATD C J

R 212 1/6W 470 RDB471J-NAATD C J

R 214 1/6W 33K RDB333J-NAATD C J

R 215 1/6W 8.2K RDB822J-NAATD C J

R 218 1/6W 22 RDB220J-NAATD C J

R 220 1/6W 10 RDB100J-NAATD C J

R 251 1W 1K RSE102J4ACCND C J

R 256 1/6W 10K RDB103J-NAATD C J

R 257 1/6W 1.2K RDB122J-NAATD C J

R 258 1/6W 15K RDB153J-NAATD C J

R 259 1/6W 15K RDB153J-NAATD C J

R 268 1W 1.0 RSE1R0J4ACCND C J

R 301 1/6W 390 RDB391J-NAATD C J

R 302 1/6W 470 RDB471J-NAATD C J

R 303 1/6W 1K RDB102J-NAATD C J

R 304 1/6W 220 RDB221J-NAATD C J

R 305 1/6W 220 RDB221J-NAATD C J

R 306 1/6W 47 RDB470J-NAATD C J

R 308 1/6W 180 RDB181J-NAATD C J

R 310 1/6W 100 RDB101J-NAATD C J

R 3101 1/6W 22K RDB223J-NAATD T31 J

R 3102 1/6W 22K RDB223J-NAATD T31 J

R 3103 1/6W 1K RDB102J-NAATD T31 J

R 3104 1/6W 180 RDB181J-NAATD T31 J

R 3105 1/6W 470 RDB471J-NAATD T31 J

R 3106 1/6W 390 RDB391J-NAATD T31 J

R 3107 1/6W 22K RDB223J-NAATD T31 J

R 3108 1/6W 22K RDB223J-NAATD T31 J

R 3109 1/6W 22K RDB223J-NAATD T31 J

R 311 1/6W 1K RDB102J-NAATD C J

R 3110 1/6W 22K RDB223J-NAATD T31 J

R 3111 1/6W 220 RDB221J-NAATD T31 J

R 3112 1/6W 1.5K RDB152J-NAATD T31 J

R 3113 1/6W 1K RDB102J-NAATD T31 J

R 3115 1/6W 1K RDB102J-NAATD T31 J

R 3116 1/6W 5.6K RDB562J-NAATD T31 J

SOCKET 2.5mm

12P

GANVL007----- T31

R 3117 1/6W 5.6K RDB562J-NAATD T31 J

R 3118 1/6W 4.7K RDB472J-NAATD T31 J

R 3119 1/6W 100 RDB101J-NAATD T31 J

R 3120 1/6W 100 RDB101J-NAATD T31 J

R 3121 1/6W 3.3K RDB332J-NAATD T31 J

R 3122 1/6W 10K RDB103J-NAATD T31 J

R 3123 1/6W 10K RDB103J-NAATD T31 J

R 3125 1/6W 4.7K RDB472J-NAATD T31 J

R 3126 1/6W 4.7K RDB472J-NAATD T31 J

R 3128 1/6W 100 RDB101J-NAATD T31 J

R 315 1/6W 390 RDB391J-NAATD C J

R 319 1/6W 1K RDB102J-NAATD C J

R 320 1/6W 1K RDB102J-NAATD C J

R 323 1/6W 39K RDB393J-NAATD C J

R 324 1/6W 100K RDB104J-NAATD V21 J

R 324 1/6W 39K RDB393J-NAATD T31 J

R 325 1/6W 27K RDB273J-NAATD C J

R 326 1/6W 1K RDB102J-NAATD C J

R 351 1/6W 33K RDB333J-NAATD C J

R 352 1/6W 10K RDB103J-NAATD C J

R 353 1/6W 2.2K RDB222J-NAATD C J

R 354 1/6W 3.3K RDB332J-NAATD C J

R 356 1/6W 10K RDB103J-NAATD C J

R 357 1/6W 10K RDB103J-NAATD C J

R 358 1/6W 1K RDB102J-NAATD C J

R 359 1/6W 56K RDB563J-NAATD C J

R 3701 1/6W 2.2K RDB222J-NAATD C J

R 3702 1/6W 3.3K RDB332J-NAATD C J

R 3704 1/6W 5.1K RDB512J-NAATD C J

R 3705 1/6W 9.1K RDB912J-NAATD C J

R 3710 1/6W 2.2K RDB222J-NAATD C J

R 3711 1/6W 180 RDB181J-NAATD C J

R 3718 1/6W 220K RDB224J-NAATD C J

R 3719 1/6W 1K RDB102J-NAATD C J

R 3720 1/6W 220K RDB224J-NAATD C J

R 3721 1/6W 1K RDB102J-NAATD C J

R 3757 1/6W 82 RDB820J-NAATD C J

R 3774 1/6W 680 RDB681J-NAATD C J

R 3777 1/6W 100 RDB101J-NAATD C J

R 401 1/6W 100K RDB104J-NAATD C J

R 402 1/6W 15K RDB153J-NAATD C J

R 403 1/6W 12K RDB123J-NAATD C J

R 404 1/6W 100 RDB101J-NAATD C J

R 405 1/6W 100 RDB101J-NAATD C J

R 406 1/6W 100 RDB101J-NAATD C J

R 407 1/6W 27K RDB273J-NAATD C J

R 408 1/6W 2.7K RDB272J-NAATD C J

R 420 1W 1.0 RSE1R0J4ACCND C J

R 431 1/6W 1K RDB102J-NAATD T31 J

R 432 1/6W 150 RDB151J-NAATD T31 J

R 433 1/6W 150 RDB151J-NAATD T31 J

R 434 1/6W 47 RDB470J-NAATD T31 J

R 458 1/6W 100K RDB104J-NAATD V21 J

R 458 1/6W 47K RDB473J-NAATD T31 J

R 459 1/6W 47K RDB473J-NAATD C J

R 480 1/6W 100 RDB101J-NAATD C J

R 481 1/6W 33 RDB330J-NAATD T31 J

R 481 1/6W 82 RDB820J-NAATD V21 J

R 502 1/6W 4.7K RDB472J-NAATD T31 J

R 503 1/6W 4.7K RDB472J-NAATD T31 J

R 504 1/6W 100 RDB101J-NAATD V21 J

R 504 1/6W 1K RDB102J-NAATD T31 J

R 505 1/6W 100 RDB101J-NAATD V21 J

R 505 1/6W 1K RDB102J-NAATD T31 J

R 506 1/6W 12K RDB123J-NAATD C J

R 507 1/6W 100 RDB101J-NAATD C J

23

Page 24

.

R 508 1/6W 220K RDB224J-NAATD C J

R 509 1/6W 1K RDB102J-NAATD C J

R 511 1/6W 100 RDB101J-NAATD C J

R 512 1/6W 100 RDB101J-NAATD C J

R 514 1/6W 1K RDB102J-NAATD C J

R 515 1/6W 12K RDB123J-NAATD C J

R 516 1/6W 220K RDB224J-NAATD C J

R 517 1/6W 100 RDB101J-NAATD C J

R 524 1/6W 68 RDB680J-NAATD C J

R 530 1/6W 470K RDB474J-NAATD C J

R 541 1/6W 150 RDB151J-NAATD C J

R 542 1/6W 150 RDB151J-NAATD C J

R 543 1/6W 82 RDB820J-NAATD C J

R 544 1/6W 82 RDB820J-NAATD C J

R 545 1/6W 82 RDB820J-NAATD T31 J

R 546 1/6W 82 RDB820J-NAATD T31 J

R 549 1/6W 6.8K RDB682J-NAATD T31 J

R 551 1/6W 180 RDB181J-NAATD T31 J

R 552 1/6W 220 RDB221J-NAATD T31 J

R 553 1/6W 82 RDB820J-NAATD C J

R 554 1/6W 10K RDB103J-NAATD C J

R 555 1/6W 4.7K RDB472J-NAATD C J

R 556 1/6W 1.5K RDB152J-NAATD C J

R 558 1/6W 10K RDB103J-NAATD C J

R 559 1/6W 150 RDB151J-NAATD C J

R 560 1/6W 2.2K RDB222J-NAATD T31 J

R 561 1/6W 1.5K RDB152J-NAATD C J

R 562 1/6W 4.7K RDB472J-NAATD C J

R 563 1/6W 100 RDB101J-NAATD T31 J

R 564 1/6W 220 RDB221J-NAATD T31 J

R 565 1/6W 100 RDB101J-NAATD T31 J

R 567 1/6W 10K RDB103J-NAATD T31 J

R 568 1/6W 3.3K RDB332J-NAATD T31 J

R 569 1/6W 180 RDB181J-NAATD T31 J

R 570 1/6W 470 RDB471J-NAATD T31 J

R 571 1/6W 10K RDB103J-NAATD T31 J

R 572 1/6W 3.3K RDB332J-NAATD T31 J

R 573 1/6W 220 RDB221J-NAATD T31 J

R 574 1/6W 470 RDB471J-NAATD T31 J

R 575 1/6W 22K RDB223J-NAATD T31 J

R 578 1/6W 470 RDB471J-NAATD T31 J

R 580 1/6W 1K RDB102J-NAATD C J

R 581 1/6W 1K RDB102J-NAATD C J

R 592 1/6W 1K RDB102J-NAATD C J

R 593 1/6W 220K RDB224J-NAATD C J

R 594 1/6W 1K RDB102J-NAATD C J

R 595 1/6W 220K RDB224J-NAATD C J

R 596 1/6W 100 RDB101J-NAATD C J

R 597 1/6W 220K RDB224J-NAATD C J

R 598 1/6W 100 RDB101J-NAATD C J

R 599 1/6W 220K RDB224J-NAATD C J

R 601 1/2W 1M RDD105J-NACTD C J

R 602 NTC 4.7ohm DN14R7M001-NY C

R 610 1/6W 5.6K RDB562J-NAATD C J

R 612 1/6W 10K RDB103J-NAATD C J

R 613 1/6W 100 RDB101J-NAATD C J

R 614 1/6W 1.2K RDB122J-NAATD C J

R 615 1/6W 2.2K RDB222J-NAATD C J

R 616 1/6W 22 RDB220J-NAATD C J

R 617 1/4W 1.8K RDC182J-NABTD C J

R 618 5W 15(RF-5ZX-15) RWH150K5AF-NR C K

R 619 1/4W 22 RDC220J-NABTD C J

R 620 1/2W 120K RDD124J-NACTD C J

R 621 1/2W 120K RDD124J-NACTD C J

R 622 1/4W 15K RDC153J-NABTR C J

R 625 2W 56 RSF560J7ACDND C J

R 625A 2W 56 RSF560J7ACDND C J

R 628 1/2W 12M RCD126K-NACNH C K

R 629 1/2W 12M RCD126K-NACNH C K

R 652 1/4W 100K RDC104J-NABTR C J

R 653 1/6W 4.7K RDB472J-NAATD C J

R 654 1/4W 150K RDC154J-NABTR C J

R 655 1/2W 47K RDD473J-NACTD C J

R 656 1/6W 22K RDB223J-NAATD C J

R 662 2W 0.47 RFFR47J7ACDNF C J

R 664 2W 1K RSF102J5ACDND C J

R 665 3W 5.6 RSG5R6J7ACENM T31 J

R 666 2W 56 RSF560J7ACDND C J

R 669 2W 56 RSF560J7ACDND T31 J

R 681 1/6W 1K RDB102J-NAATD C J

R 683 1W 4.7 RFE4R7J5ACDNF C J

R 684 1/2W 4.7 RDD4R7J-NACTN C J

R 707 1/6W 10K RDB103J-NAATD C J

R 708 1/6W 100 RDB101J-NAATD C J

R 709 1/6W 10K RDB103J-NAATD C J

R 716 1/6W 1K RDB102J-NAATD C J

R 717 1/6W 4.7K RDB472J-NAATD C J

R 720 1/6W 4.7K RDB472J-NAATD C J

R 721 1/6W 4.7K RDB472J-NAATD T31 J

R 722 1/6W 4.7K RDB472J-NAATD C J

R 723 1/6W 100 RDB101J-NAATD C J

R 725 1/6W 100 RDB101J-NAATD C J

R 726 1/6W 100 RDB101J-NAATD C J

R 727 1/6W 100 RDB101J-NAATD C J

R 728 1/6W 68 RDB680J-NAATD C J

R 729 1/6W 100 RDB101J-NAATD C J

R 730 1/6W 100 RDB101J-NAATD C J

R 731 1/6W 10K RDB103J-NAATD C J

R 732 1/6W 4.7K RDB472J-NAATD C J

R 733 1/6W 10K RDB103J-NAATD C J

R 734 1/6W 220K RDB224J-NAATD C J

R 738 1/6W 100 RDB101J-NAATD C J

R 739 1/6W 4.7K RDB472J-NAATD C J

R 740 1/6W 1K RDB102J-NAATD C J

R 741 1/6W 180 RDB181J-NAATD C J

R 743 1/6W 100 RDB101J-NAATD C J

R 745 1/6W 180 RDB181J-NAATD C J

R 747 1/6W 100 RDB101J-NAATD C J

R 748 1/6W 3.3K RDB332J-NAATD C J

R 749 1/6W 10K RDB103J-NAATD C J

R 750 1/6W 100 RDB101J-NAATD C J

R 751 1/6W 4.7K RDB472J-NAATD C J

R 752 1/6W 10K RDB103J-NAATD C J

R 753 1/6W 4.7K RDB472J-NAATD C J

R 756 1/6W 10K RDB103J-NAATD C J

R 760 1/6W 1K RDB102J-NAATD C J

R 770 1/6W 4.7K RDB472J-NAATD C J

R 773 1/6W 3.3K RDB332J-NAATD C J

R 781 1/6W 1.5K RDB152J-NAATD C J

R 782 1/6W 1.5K RDB152J-NAATD C J

R 783 1/6W 1.5K RDB152J-NAATD C J

R 790 1/6W 4.7K RDB472J-NAATD C J

R 792 1/6W 100K RDB104J-NAATD C J

R 793 1/6W 100K RDB104J-NAATD C J

R 794 1/6W 10K RDB103J-NAATD C J

R 795 1/6W 10K RDB103J-NAATD C J

R 796 1/6W 10K RDB103J-NAATD C J

R 797 1/6W 10K RDB103J-NAATD C J

R 798 1/4W 3.9K RDC392J-NABTD C J

R 801 1/6W 3.3K RDB332J-NAATD C J

R 802 1/6W 390K RDB394J-NAATD C J

R 803 1W 1.0 RSE1R0J4ACCND C J

24

Page 25

.

R 804 1/2W 2.2 RDD2R2J-NACTD C J

R 805 1W 220 RSE221J4ACCND C J

R 806 1/2W 1.0 RSD1R0J3ASBNM C J

R 807 1/4W 3.3 RDC3R3J-NABTD C J

R 809 1/6W 10K RDB103J-NAATD C J

R 810 1/6W 100 RDB101J-NAATD C J

R 812 1/6W 100 RDB101J-NAATD C J

R 816 1/6W 1.5K RDB152J-NAATD C J

R 864 1/6W 39K RDB393J-NAATD C J

R 865 1/6W 39K RDB393J-NAATD C J

R 867 1/6W 10K RDB103J-NAATD C J

R 872 1/6W 10K RDB103J-NAATD C J

R 882 1/6W 1.2K RDB122J-NAATD C J

R 885 1/4W 1.0 RDC1R0J-NABTD C J

R 886 1/4W 1.0 RDC1R0J-NABTD C J

R 887 1/4W 1.0 RDC1R0J-NABTD C J

R 888 1/4W 1.0 RDC1R0J-NABTD C J

R 889 1/4W 18 RDC180J-NABTD C J

R 890 1/4W 18 RDC180J-NABTD C J

R 891 1/4W 1.2K RDC122J-NABTD C J

R 892 1/4W 1.2K RDC122J-NABTD C J

R 893 1/6W 2K RDB202J-NAATD C J

R 894 1/6W 2K RDB202J-NAATD C J

R 895 1/6W 1K RDB102J-NAATD C J

R 896 1/6W 1K RDB102J-NAATD C J

R 897 1/6W 22K RDB223J-NAATD C J

R 898 1W 10 RSE100J5ACCND C J

R 899 2W 0.47 RFFR47J7ACDNF V21 J

R 899 3W 0.82 RSGR82J7ACENM T31 J

R 902

R 903 1/2W 2.7K RDD272J-NACTD C J

R 904 1/6W 75 RDB750J-NAATD C J

R 906 1/6W 82 RDB820J-NAATD C J

R 907 1/4W 10K RDC103J-NABTD C J

R 909 1W 4.7 RSE4R7J4ACCND C J

R 910 1W 1K RSE102J4ACCND C J

R 916 1/6W 1.8K RDB182J-NAATD T31 J

R 916 1/6W 3.9K RDB392J-NAATD V21 J

R 917 1/6W 1K RDB102J-NAATD C J

R 918 1/6W 10K RDB103J-NAATD C J

R 920 1/6W 560K RDB564J-NAATD C J

R 921 1/6W 100K RDB104J-NAATD C J

R 925 1/6W 3.9K RDB392J-NAATD C J

R 925A 1/6W 1K RDB102J-NAATD C J

R 926 5W 3.9 RWH3R9K3AK-NR C K

R 929 1/6W 2.2K RDB222J-NAATD C J

R 933 2W 3.9 RSF3R9J5ACDND C J

R 941 1/6W 100K RDB104J-NAATD T31 J

R 944 1/6W 10K RDB103J-NAATD T31 J

R 951 1/6W 100K RDB104J-NAATD C J

R 952 1/6W 220 RDB221J-NAATD C J

R 955 1/6W 82K RDB823J-NAATD C J

R 956 1/6W 3.3K RDB332J-NAATD C J

R 957 1/6W 270 RDB271J-NAATD C J

R 958 1/6W 2.7K RDB272J-NAATD C J

R 959 1/6W 47K RDB473J-NAATD C J

R 962 2W 0.47 RSFR47J5ACDND C J

R 963 1W 1.0 RSE1R0J4ACCND C J

R 964 1W 1.5 RSE1R5J4ACCND C J

R 965 1/6W 5.6K RDB562J-NAATD C J

R 966 1/6W 68K RDB683J-NAATD C J

R 967 1/6W 5.6K RDB562J-NAATD C J

R 968 1/6W 22K RDB223J-NAATD C J

R 970 2W 10K RSF103J5ACDND C J

R 976 1/6W 47K RDB473J-NAATD C J

7W 2.2K(RS7ZK222)

RWK222K8AG-NU C K

RL 601

SKN701

SL 3S SOCKET GADV3001----C C

SN652 HEAT SINK MB1X0114---BF T31

SN653 HEAT SINK MB1X0040---BF T31

S-PWB

SR 2S SOCKET GADV2001----C C

ST 4S SOCKET GACV4001----C C

SW3701

SW3702

SW3703

SW3704

SW3706

SW3707

T 611 CON.TRANS TM-0053----0L C

T 612 CON.TRANS TB-0003----0L C

T 901 H-DRIVER TD-0045----0L C

T 902 F.B.T TF-0065----0D C

TEXPWB

TX PLUG 2.5mm 12P GANVL008----- T31

V 1102 2PC1815 G Q2PC1815-GNF- T31

V 1103 2PC1815 G Q2PC1815-GNF- T31

V 201 KSC1674C QKSC1674C-NN- C

V 301 KSA1015 G QKSA1015-GNF- C

V 302 2PC1815 G Q2PC1815-GNF- C

V 303 2PC1815 G Q2PC1815-GNF- C

V 304 2PC1815 G Q2PC1815-GNF- C

V 3101 2SC2216 Q2SC2216--NN- T31

V 3102 2PC1815 G Q2PC1815-GNF- T31

V 3103 2PC1815 G Q2PC1815-GNF- T31

V 405 2PC1815 G Q2PC1815-GNF- T31

V 480 2PC1815 G Q2PC1815-GNF- C

V 541 2PC1815 G Q2PC1815-GNF- T31

V 542 KSA1015 G QKSA1015-GNF- T31

V 543 2PC1815 G Q2PC1815-GNF- T31

V 544 2PC1815 G Q2PC1815-GNF- T31

V 555 2PC1815 G Q2PC1815-GNF- T31

V 556 2PC1815 G Q2PC1815-GNF- T31

V 560 KSA1015 G QKSA1015-GNF- C

V 561 KSA1015 G QKSA1015-GNF- C

V 611 2SB892 Q2SB892---NN- C

V 612 2SC3807 Q2SC3807-CBN- C

V 613 2SC4430 Q2SC4430--NN- C

V 615 2SD1246 Q2SD1246--NN- C

V 651 2PC1815 G Q2PC1815-GNF- C

V 681 2PC1815 G Q2PC1815-GNF- C

V 702 2PC1815 G Q2PC1815-GNF- C

V 703 2PC1815 G Q2PC1815-GNF- C

V 704 2PC1815 G Q2PC1815-GNF- C

V 705 KSA1015 G QKSA1015-GNF- C

V 706 2PC1815 G Q2PC1815-GNF- C

V 707 KSA1015 G QKSA1015-GNF- C

V 801 2PC1815 G Q2PC1815-GNF- C

V 802 2PC1815 G Q2PC1815-GNF- C

V 804 KSA1015 G QKSA1015-GNF- C

V 805 2PC1815 G Q2PC1815-GNF- V21

V 806 2SC2271 Q2SC2271--NN- C

V 901 2SC2271 Q2SC2271--NN- C

V 902 2SD1886 Q2SD1886--NN- C

SMIT-SS112DM(27ohm)

IC SOCKET 1.78mm

42P

POWER PCB(PF68T31)

PUSH

SWITCH(3.85mm)

PUSH

SWITCH(3.85mm)

PUSH

SWITCH(3.85mm)

PUSH

SWITCH(3.85mm)

PUSH

SWITCH(3.85mm)

PUSH

SWITCH(3.85mm)

TELETEXT

PCB(PF68T31)

HAA0004-----G C

GAGBE001----- C

PC20001----1H C

KTA11HA010--Y C

KTA11HA010--Y C

KTA11HA010--Y C

KTA11HA010--Y C

KTA11HA010--Y C

KTA11HA010--Y C

PYA0005----1H T31

25

Page 26

.

V 905 IRFS630A QIRFS630A-NN- C

V 906 KSA1015 G QKSA1015-GNF- C

V 908 PH2369 QPH2369---NN- C

VD 201 1N4148 DR1N4148---TR C

VD 215 1N4148 DR1N4148---TR C

VD 303 MTZJ3.6A DZMTZJ3R6A-TR C

VD 401 MTZJ8.2C DZMTZJ8R2C-TR C

VD 402 MTZJ8.2C DZMTZJ8R2C-TR C

VD 403 MTZJ8.2C DZMTZJ8R2C-TR C

VD 404 MTZJ8.2C DZMTZJ8R2C-TR C

VD 480 BYD33G-T DRBYD33G---BP C

VD 502 MTZJ8.2C DZMTZJ8R2C-TR C

VD 503 1N4148 DR1N4148---TR C

VD 580 BYD33G-T DRBYD33G---BP C

VD 603 TTVR4J DRTTVR4J---NZ C

VD 604 TTVR4J DRTTVR4J---NZ C

VD 605 TTVR4J DRTTVR4J---NZ C

VD 606 TTVR4J DRTTVR4J---NZ C

VD 611 1N4148 DR1N4148---TR C

VD 612 MTZJ6.8A DZMTZJ6R8A-TR C

VD 614 1N4148 DR1N4148---TR C

VD 616 1N4148 DR1N4148---TR C

VD 617 RGP10D DRRGP10D---TD C

VD 618 1N4148 DR1N4148---TR C

VD 621 PC817X2 NPC817X2---N- C

VD 622 PC817X2 NPC817X2---N- C

VD 652 RU3AM DRRU3AM----NS C

VD 653 RGP15J DRRGP15J---ND V21

VD 653 RGP30D DRRGP30D---ND T31

VD 654 RGP30D DRRGP30D---ND C

VD 655 MTZJ6.8A DZMTZJ6R8A-TR C

VD 661 1N4148 DR1N4148---TR T31

VD 662 1N4148 DR1N4148---TR C

VD 663 1N4148 DR1N4148---TR C

VD 680 RGP10D DRRGP10D---TD C

VD 683 1N4148 DR1N4148---TR C

VD 701 MTZJ5.1B DZMTZJ5R1B-TR C

VD 703 MTZJ3.6A DZMTZJ3R6A-TR C

VD 801 1N4148 DR1N4148---TR C

VD 803 MTZJ15A DZMTZJ15A--TR C

VD 804 1N4148 DR1N4148---TR C

VD 805 RGP10D(GI) DRRGP10D---NG C

VD 806 ZPY56 DZZPY56----BG C

VD 807 BAV21 DRBAV21----BP C

VD 808 MTZJ5.1B DZMTZJ5R1B-TR C

VD 809 MTZJ5.6B DZMTZJ5R6B-TR C

VD 901 MTZJ8.2C DZMTZJ8R2C-TR C

VD 903 TRU4DS DRTRU4DS---NZ C

VD 904 TRU4C DRTRU4C----NZ C

VD 906 1N4148 DR1N4148---TR C

VD 908 RGP15J DRRGP15J---ND C

VD 909 RGP10D(GI) DRRGP10D---NG C

VD 910 RGP10J DRRGP10J---TD C

VD 911 1N4148 DR1N4148---TR C

VD 912 MTZJ5.6B DZMTZJ5R6B-TR C

VD 913 1N4148 DR1N4148---TR C

VD 914 BYD33G-T DRBYD33G---BP C

VD 916 MTZJ5.1B DZMTZJ5R1B-TR C

VD 920 1N4148 DR1N4148---TR C

VD 970 RGP15J DRRGP15J---ND C

VD1701 BAV21 DRBAV21----BP C

VD1702 BAV21 DRBAV21----BP C

VD1703 BAV21 DRBAV21----BP C

VD1704 BYD33M DRBYD33M---BP C

VD1711 MTZJ22D DZMTZJ22D--TR C

VD3701 LED (RED) DLC42001---NA C

VD3702 LED (GREEN) DLC45003---NA C

VD808A MTZJ18C DZMTZJ18C--TR C

VR 651 2KB VCAAA202A001B C

VR3101 10KB VDAAA103A001F T31

X 1101 OR.OSC 12M(16P) XX-008-----NJ T31

X 3101

X 401 CR.OSC 4.43 XX-001-----NL C

X 402 CR.OSC 3.58 XX-002-----NL C

X 701 CR.OSC 8.000 XX-006-----NJ C

XD3701 LED HOLDER MG3X0013---D7 C

XD3702 LED HOLDER MG3X0013---D7 C

XN3701 LED HOLDER MG3X0013---D7 C

XS1701 CRT SOCKET GBAVL005----E C

XS3101 PLUG 2.5mm 3P(JL) GALH3001----Y T31

XS3102 PLUG 2.5mm 8P(JL) GALH8001----Y T31

Z 201

Z 304 F 5.5M XFC013-----ND C

Z 308 T 5.5M XTC008-----ND C

CR.OSC (4.00M

16P)

SAW

FILTER(38.9MHZ)

XX-022-----NC T31

XFS019-----NB C

26

Page 27

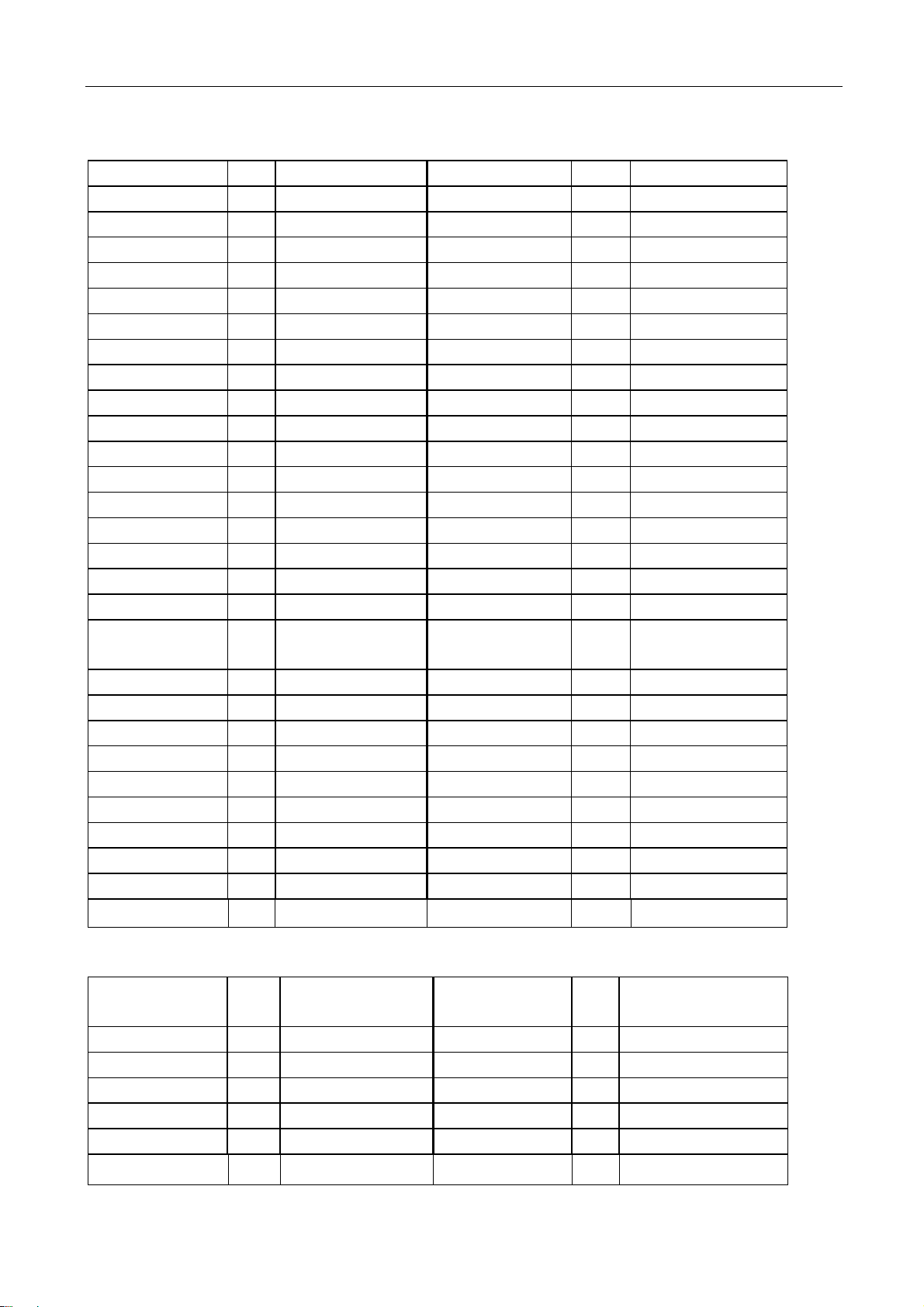

PACKING

⑥⑦

③

⑤⑧

①

②

④

PACKING PARTS LIST

Ref. No. Part No. Part Name Description

1

CATON BOX

2 CATON BOX

3 FOAM SPACER (TOP)

4 FOAM SPACER (BOTTOM)

5 USER MANUAL

6 zz030 Remote Handunit(RE-003) BT-0074A---CX T31 1

7 zz030 Remote Handunit(RE-002) BT-0075A---CX V21 1

8 zz147 BATTERY DRY(UM4 1.5V 7#) MT1X0001---T2 C 2

E/RSR8.865.281

E/RSR8.865.282

E/RSR8.870.039

E/RSR8..870.039

PF-68V21/T31

V21 1

T31 1

C 2

C 2

C 1

27

Page 28

Page 29

Page 30

Page 31

Page 32

Loading...

Loading...