NEC NEFAX 671, NEFAX 691 Service Manual

SERVICE MANUAL

FIELD SERVICE

NEC Unified Solutions, Inc.

NEFAX 671/691

SAFETY AND IMPORTANT WARNING ITEMS

Read carefully the Safety and Important Warning Items described below to understand

them before doing service work.

IMPORTANT NOTICE

Because of possible hazards to an inexperienced person servicing this product as well as

the risk of damage to the product, NEC Unified Solutions, INC. (hereafter called the NEC )

strongly recommends that all servicing be performed only by NEC-trained service technicians.

Changes may have been made to this product to improve its performance after this Service

Manual was printed. Accordingly, NEC does not warrant, either explicitly or implicitly, that

the information contained in this Service Manual is complete and accurate.

The user of this Service Manual must assume all risks of personal injury and/or damage to

the product while servicing the product for which this Service Manual is intended.

Therefore, this Service Manual must be carefully read before doing service work both in the

course of technical training and even after that, for performing maintenance and control of

the product properly.

Keep this Service Manual also for future service.

DESCRIPTION ITEMS FOR DANGER,

WARNING AND CAUTION

In this Service Manual, each of three expressions “ DANGER”, “ WARNING”, and

“ CAUTION” is defined as follows together with a symbol mark to be used in a limited

meaning.

When servicing the product, the relevant works (disassembling, reassembling, adjustment,

repair, maintenance, etc.) need to be conducted with utmost care.

DANGER : Action having a high possibility of suffering death or serious injury

WARNING : Action having a possibility of suffering death or serious injury

CAUTION : Action having a possibility of suffering a slight wound, medium

trouble, and property damage

Symbols used for safety and important warning items are defined as follows:

:Precaution when servicing the product.

:Prohibition when servicing the product.

:Direction when servicing the product.

General precaution

General prohibition

General instruction Unplug Ground/ Earth

Electric hazard

Do not touch

with wet hand

High temperature

Do not disassemble

P-1

SAFETY WARNINGS

1. MODIFICATIONS NOT AUTHORIZED BY

NEC UNIFIED SOLUTIONS, INC.

NEC brand products are renowned for their high reliability. This reliability is achieved

through high-quality design and a solid service network.

Product design is a highly complicated and delicate process where numerous mechanical,

physical, and electrical aspects have to be taken into consideration, with the aim of arriving

at proper tolerances and safety factors. For this reason, unauthorized modifications involve

a high risk of degradation in performance and safety. Such modifications are therefore

strictly prohibited. the points listed below are not exhaustive, but they illustrate the reasoning behind this policy.

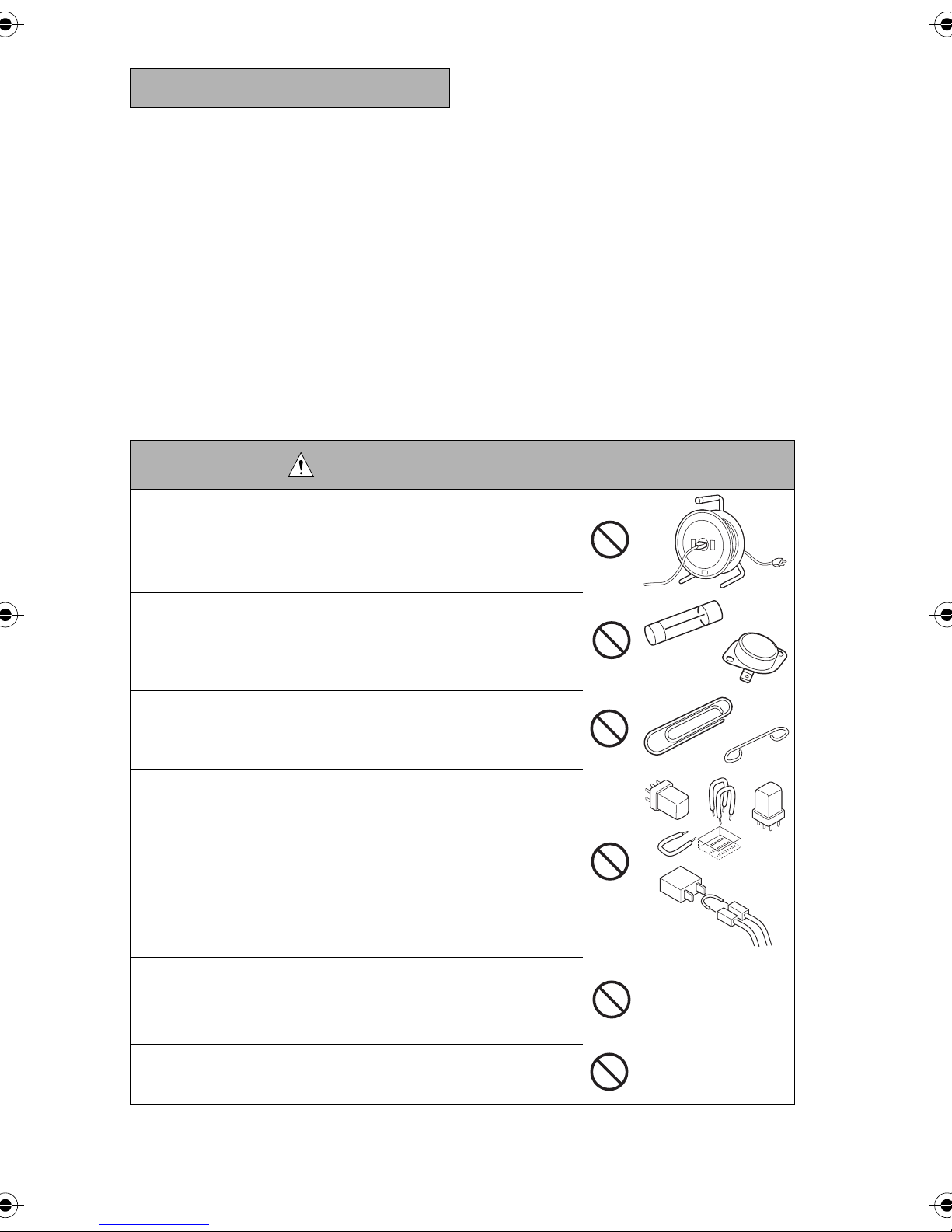

DANGER: PROHIBITED ACTIONS

• Using any cables or power cord not specified by NEC.

• Using any fuse or thermostat not specified by NEC. Safety

will not be assured, leading to a risk of fire and injury.

• Disabling fuse functions or bridging fuse terminals with

wire, metal clips, solder or similar object.

• Disabling relay functions (such as wedging paper between

relay contacts)

• Disabling safety functions (interlocks, safety circuits, etc.)

Safety will not be assured, leading to a risk of fire and

injury.

• Making any modification to the product unless instructed

by NEC.

P-2

DANGER: PROHIBITED ACTIONS

• Using parts not specified by NEC.

2. CHECKPOINTS WHEN PERFORMING ON-SITE SER-

VICE

NEC brand products are extensively tested before shipping, to ensure that all applicable

safety standards are met, in order to protect the customer and customer engineer (hereafter called the CE) from the risk of injury. However, in daily use, any electrical equipment

may be subject to parts wear and eventual failure. In order to maintain safety and reliability,

the CE must perform regular safety checks.

1. Power Supply

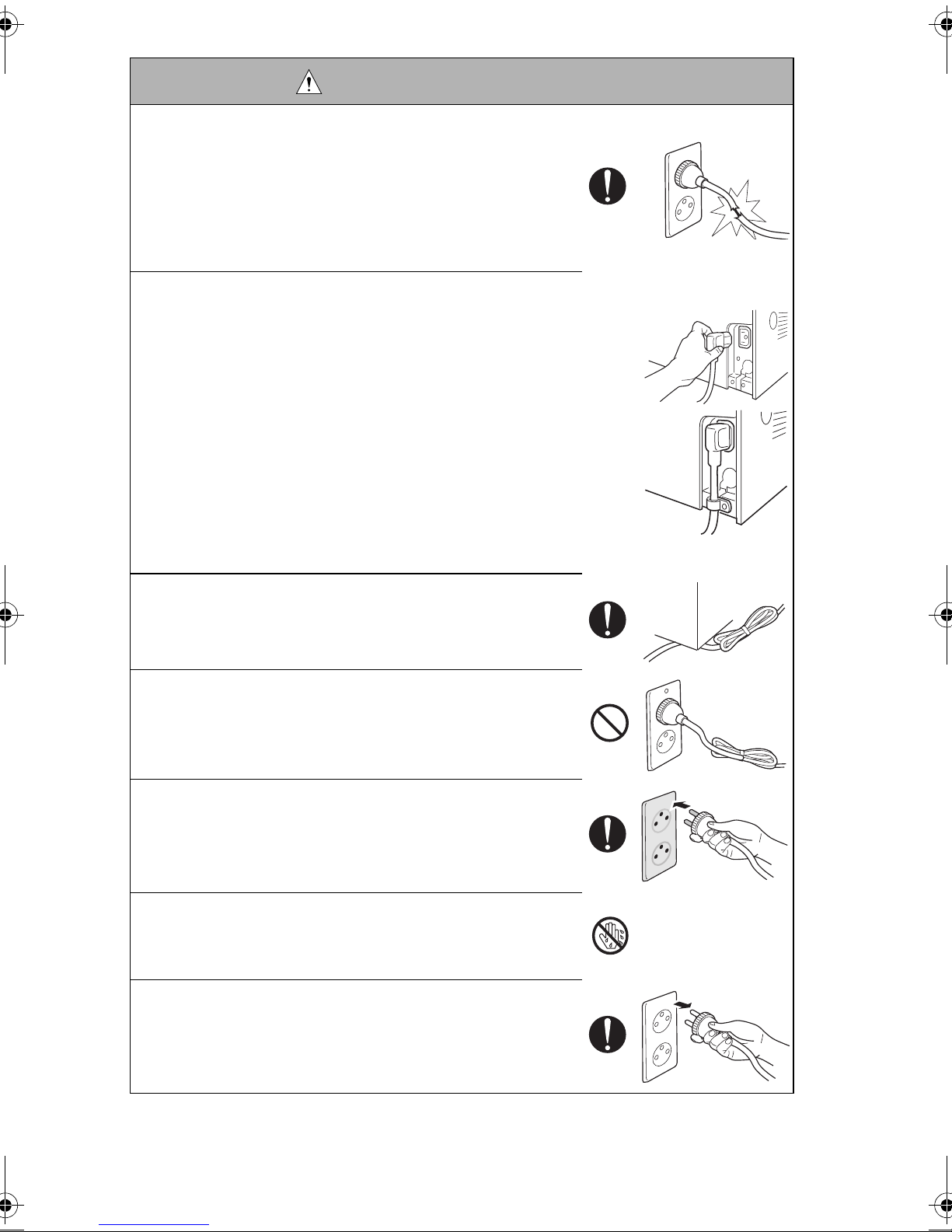

WARNING: Wall Outlet

• Check that mains voltage is as specified. Plug the power

cord into the dedicated wall outlet with a capacity greater

than the maximum power consumption.

If excessive current flows in the wall outlet, fire may

result.

• If two or more power cords can be plugged into the wall

outlet, the total load must not exceed the rating of the wall

outlet.

If excessive current flows in the wall outlet, fire may

result.

WARNING: Power Plug and Cord

• Make sure the power cord is plugged in the wall outlet

securely.

Contact problems may lead to increased resistance,

overheating, and the risk of fire.

P-3

WARNING: Power Plug and Cord

• Check whether the power cord is damaged. Check

whether the sheath is damaged.

If the power plug, cord, or sheath is damaged, replace

with a new power cord (with plug and connector on each

end) specified by NEC. Using the damaged power cord

may result in fire or electric shock.

• When using the power cord (inlet type) that came with this

product, be sure to observe the following precautions:

a. Make sure the connector is securely inserted in the inlet

on the rear panel of the product.

Secure the cord with a fixture properly.

b. If the power cord or sheath is damaged, replace with a

new power cord (with plugs on both ends) specified by

NEC.

If the power cord (inlet type) is not connected to the

product securely, a contact problem may lead to

increased resistance, overheating, and risk of fire.

• Check whether the power cord is not stepped on or

pinched by a table and so on.

Overheating may occur there, leading to a risk of fire.

• Do not bundle or tie the power cord.

Overheating may occur there, leading to a risk of fire.

• Check whether dust is collected around the power plug

and wall outlet.

Using the power plug and wall outlet without removing

dust may result in fire.

• Do not insert the power plug into the wall outlet with a wet

hand.

The risk of electric shock exists.

• When unplugging the power cord, grasp the plug, not the

cable.

The cable may be broken, leading to a risk of fire and

electric shock.

P-4

WARNING: Wiring

• Never use multi-plug adapters to plug multiple power

cords in the same outlet.

If used, the risk of fire exists.

• When an extension cord is required, use a specified one.

Current that can flow in the extension cord is limited, so

using a too long extension cord may result in fire.

Do not use an extension cable reel with the cable taken

up. Fire may result.

WARNING: Ground connection

• Check whether the product is grounded properly.

If current leakage occurs in an ungrounded product, you

may suffer electric shock while operating the product.

Connect power plug to grounded wall outlet.

2. Installation Requirements

WARNING: Prohibited Installation Place

• Do not place the product near flammable materials or volatile materials that may catch fire.

A risk of fire exists.

• Do not place the product in a place exposed to water such

as rain.

A risk of fire and electric shock exists.

WARNING: When not using product for a long time

• When the product is not used over an extended period of

time (holidays, etc.), switch it off and unplug the power

cord.

Dust collected around the power plug and outlet may

cause fire.

P-5

CAUTION: Ventilation

• The product generates ozone gas during operation, but it

will not be harmful to the human body.

If a bad smell of ozone is present in the following cases,

ventilate the room.

a. When the product is used in a poorly ventilated room

b. When taking a lot of copies

c. When using multiple products at the same time

CAUTION: Fixing

• Be sure to lock the caster stoppers.

In the case of an earthquake and so on, the product may

slide, leading to a injury.

CAUTION: Inspection before Servicing

• Before conducting an inspection, read all relevant docu-

mentation (service manual, technical notices, etc.) and

proceed with the inspection following the prescribed procedure, using only the prescribed tools. Do not make any

adjustment not described in the documentation.

If the prescribed procedure or tool is not used, the product may break and a risk of injury or fire exists.

• Before conducting an inspection, be sure to disconnect the

power plugs from the product and options.

When the power plug is inserted in the wall outlet, some

units are still powered even if the POWER switch is

turned OFF. A risk of electric shock exists.

• The area around the fixing unit is hot.

You may get burnt.

P-6

WARNING: Work Performed with the product Powered

• Take every care when making adjustments or performing

an operation check with the product powered.

If you make adjustments or perform an operation check

with the external cover detached, you may touch live or

high-voltage parts or you may be caught in moving gears

or the timing belt, leading to a risk of injury.

• Take every care when servicing with the external cover

detached.

High-voltage exists around the drum unit. A risk of electric shock exists.

WARNING: Safety Checkpoints

• Check the exterior and frame for edges, burrs, and other

damages.

The user or CE may be injured.

• Do not allow any metal parts such as clips, staples, and

screws to fall into the product.

They can short internal circuits and cause electric shock

or fire.

• Check wiring for squeezing and any other damage.

Current can leak, leading to a risk of electric shock or

fire.

• Carefully remove all toner remnants and dust from electrical parts and electrode units such as a charging corona

unit.

Current can leak, leading to a risk of product trouble or

fire.

• Check high-voltage cables and sheaths for any damage.

Current can leak, leading to a risk of electric shock or

fire.

• Check electrode units such as a charging corona unit for

deterioration and sign of leakage.

Current can leak, leading to a risk of trouble or fire.

P-7

WARNING: Safety Checkpoints

• Before disassembling or adjusting the write unit (P/H unit)

incorporating a laser, make sure that the power cord has

been disconnected.

The laser light can enter your eye, leading to a risk of

loss of eyesight.

• Do not remove the cover of the write unit. Do not supply

power with the write unit shifted from the specified mounting position.

The laser light can enter your eye, leading to a risk of

loss of eyesight.

• When replacing a lithium battery, replace it with a new lithium battery specified in the Parts Guide Manual. Dispose

of the used lithium battery using the method specified by

local authority.

Improper replacement can cause explosion.

• After replacing a part to which AC voltage is applied (e.g.,

optical lamp and fixing lamp), be sure to check the installation state.

A risk of fire exists.

• Check the interlock switch and actuator for loosening and

check whether the interlock functions properly.

If the interlock does not function, you may receive an

electric shock or be injured when you insert your hand in

the product (e.g., for clearing paper jam).

• Make sure the wiring cannot come into contact with sharp

edges, burrs, or other pointed parts.

Current can leak, leading to a risk of electric shock or

fire.

• Make sure that all screws, components, wiring, connectors, etc. that were removed for safety check and maintenance have been reinstalled in the original location. (Pay

special attention to forgotten connectors, pinched cables,

forgotten screws, etc.)

A risk of product trouble, electric shock, and fire exists.

P-8

WARNING: HANDLING OF CONSUMABLE

• Toner and developer are not harmful substances, but care

must be taken not to breathe excessive amounts or let the

substances come into contact with eyes, etc. It may be

stimulative.

If the substances get in the eye, rinse with plenty of water

immediately. When symptoms are noticeable, consult a

physician.

• Never throw the used cartridge and toner into fire.

You may be burned due to dust explosion.

CAUTION: HANDLING OF SERVICE MATERIALS

• Unplug the power cord from the wall outlet.

Drum cleaner (isopropyl alcohol) and roller cleaner (acetone-based) are highly flammable and must be handled

with care. A risk of fire exists.

• Do not replace the cover or turn the product ON before

any solvent remnants on the cleaned parts have fully

evaporated.

A risk of fire exists.

• Use only a small amount of cleaner at a time and take care

not to spill any liquid. If this happens, immediately wipe it

off.

A risk of fire exists.

• When using any solvent, ventilate the room well.

Breathing large quantities of organic solvents can lead to

discomfort.

P-9

3. MEASURES TO TAKE IN CASE OF AN ACCIDENT

1. If an accident has occurred, the distributor who has been notified first must immediately

take emergency measures to provide relief to affected persons and to prevent further

damage.

2. If a report of a serious accident has been received from a customer, an on-site evaluation must be carried out quickly and NEC must be notified.

3. To determine the cause of the accident, conditions and materials must be recorded

through direct on-site checks, in accordance with instructions issued by NEC.

4. CONCLUSION

1. Safety of users and customer engineers depends highly on accurate maintenance and

administration. Therefore, safety can be maintained by the appropriate daily service

work conducted by the customer engineer.

2. When performing service, each product on the site must be tested for safety. The customer engineer must verify the safety of parts and ensure appropriate management of

the equipment.

P-10

5. Used Batteries Precautions

ALL Areas

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

Germany

VORSICHT!

Explosionsgefahr bei unsachgemäßem Austausch der Batterie.

Ersatz nur durch denselben oder einen vom Hersteller empfohlenen gleichwertigen Typ.

Entsorgung gebrauchter Batterien nach Angaben des Herstellers.

France

ATTENTION

Il y a danger d’explosion s’il y a remplacement incorrect de la batterie.

Remplacer uniquement avec une batterie du même type ou d’un type équivalent recommandé par le constructeur. Mettre au rebut les batteries usagées conformément aux

instructions du fabricant.

Denmark

ADVARSEL!

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri af samme fabrikat og type. Levér det brugte batteri tilbage til leverandøren.

Finland, Sweden

VAROlTUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin. Hävitä käytetty paristo

valmistajan ohjeiden mukaisesti.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent typ som rekommenderas av apparattillverkaren. Kassera använt batteri enligt fabrikantens instruktion.

Norway

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type anbefalt av apparatfabrikanten. Brukte

batterier kasseres i henhold til fabrikantens instruksjoner.

ADVARSEL

P-11

INDEX (Field Service)

GENERAL

MAINTENANCE

DIS/REASSEMBLY,

ADJUSTMENT

CONTROL PANEL/SERVICE

MODE DESCRIPTIONS

TROUBLESHOOTING

i

CONTENTS

GENERAL

1. SPECIFICATIONS ........................................................................................... G-1

1-1. Main Uint .................................................................................................. G-1

1-2. GDI Printer Function ................................................................................ G-3

1-3. FAX Function ............................................................................................ G-3

1-4. Network Function (NEFAX 691 only) ....................................................... G-5

2. PRECAUTIONS FOR INSTALLATION ............................................................ G-6

2-1. To Ensure THIS MACHINE is Used in an Optimum Condition ................ G-6

2-2. To Ensure the printer is Used in an Optimum Condition .......................... G-6

3. PRECAUTIONS FOR USE .............................................................................. G-7

3-1. To Ensure the Printer is Used in an Optimum Condition ......................... G-7

3-2. Operating Environment ............................................................................ G-7

3-3. Power Requirements ................................................................................ G-7

4. HANDLING OF THE CONSUMABLES ............................................................ G-8

5. MISCELLANEOUS PRECAUTIONS ................................................................ G-8

6. PARTS IDENTIFICATION ................................................................................ G-9

MAINTENANCE

1. MAINTENANCE SCHEDULE .......................................................................... E-1

1-1. Guidelines for Life Specifications Values by Unit ..................................... E-2

(1) Life Specifications Values ................................................................ E-2

2. REPLACEMENT/CLEANING OF PARTS ........................................................ E-3

(1) Cleaning of the Paper Take-Up Roller ............................................. E-3

(2) Replacement of the Paper Take-Up Roller ...................................... E-3

(3) Replacement of the Image Transfer Roller ...................................... E-4

3. REPLACEMENT OF UNITS ............................................................................ E-5

(1) Replacement of the Toner Cartridge ................................................ E-5

(2) Replacement of the Drum Cartridge ................................................ E-7

(3) Replacement of the Fusing Unit ....................................................... E-7

4. REPLACEMENT OF DOCUMENT FEEDER ................................................... E-10

(1) Cleaning of the Paper Take-Up Roller .............................................. E-10

(2) Replacement of the Paper Take-Up Roller....................................... E-10

(3) Cleaning of the Pick-Up Roller.......................................................... E-11

(4) Removal of the Pick-Up Roller.......................................................... E-12

(5) Cleaning of the Registration Rollers ................................................. E-12

(6) Cleaning of the Transport Roller....................................................... E-12

(7) Cleaning of the Exit Roller ................................................................ E-12

(8) Cleaning of the Paper Separator Pad............................................... E-13

(9) Removal of the Paper Separator Pad............................................... E-13

(10) Cleaning of the CIS and Shading roller............................................. E-14

(11) Removal of the CIS........................................................................... E-15

DIS/REASSEMBLY,ADJUSTMENT

1. SAFETY INFORMATION ................................................................................. D-1

1-1. Laser Safety ............................................................................................. D-1

1-2. Internal Laser Radiation ........................................................................... D-1

1-3. Laser Safety Label ................................................................................... D-4

ii

1-4. Laser Safety Label .................................................................................. D-4

1-5. Precautions for Handling the Laser Equipment ....................................... D-5

2. PRECAUTIONS FOR DISASSEMBLY/ADJUSTMENTS ................................ D-6

2-1. Parts That Must Not be Touched ............................................................ D-6

(1) Red Painted Screws ........................................................................ D-6

(2) Variable resistors on board ............................................................. D-6

(3) Other Screws not Marked with Red Paint ....................................... D-6

3. DISASSEMBLY/REASSEMBLY ...................................................................... D-7

3-1. Identification of Exterior Parts and Removal Procedures for Them ........ D-8

3-2. Name/Removal of External Parts ............................................................ D-8

3-3. Removal of the Circuit Boards and Other Eletrical Components...................D-9

3-4. Removal of Ciruit Boards ........................................................................ D-10

(1) Removal of the Network Interface Card Board................................. D-11

(2) Removal of the Network Control Unit Board D-11

(3) Removal of the Controller/Mechanical Control Board ..................... D-12

(4) Removal of the Control Panel ......................................................... D-12

(5) Removal of the Interface Board ....................................................... D-13

(6) Removal of the Plate NIC Board .................................................... D-14

(7) Removal of the Power Unit ............................................................. D-15

(8) Removal of the High Voltage Unit ................................................... D-16

3-5. Removal of Units ..................................................................................... D-17

(1) Removal of the ADF Unit ................................................................ D-17

(2) Removal of the PH Unit ................................................................... D-17

(3) Removal of the Automatic Document Feeder unit............................ D-21

(4) Removal of the Automatic Document Feeder Control...................... D-22

(5) Removal of the AFEIF Board ........................................................... D-22

(6) Removal of the Automatic Document Feeder Main Motor ............... D-23

3-6. Disassembly of the Main Drive Section ................................................... D-24

(1) Removal of the Main Motor ............................................................. D-24

(2) Removal of the Paper Empty Sensors ............................................ D-24

(3) Removal of the Paper Take-Up Solenoid ........................................ D-25

(4) Removal of the Paper Take-Up Clutch Gear ................................... D-27

(5) Removal of the Torque Limiter ........................................................ D-28

(6) Disassembly of the Fusing Unit ....................................................... D-29

4. ADJUSTMENTS .............................................................................................. D-31

4-1. Electrical/Image Adjustment .................................................................... D-31

(1) Accessing the Service Mode ........................................................... D-31

(2) Accessing the “ADJUST” Menu ....................................................... D-31

(3) Printing a Test Pattern .................................................................... D-31

(4) Margin Adjustment (Leading Edge/Trailing Edge/Both Sides) ........ D-32

(5) Printer’s Main Scanning Registration Adjustment ........................... D-33

(6) Printer’s Sub-Scanning Registration Adjustment ............................ D-34

(7) Leading Edge Tilt Adjustment .......................................................... D-35

(8) Automatic Document Feeder Sub-Scanning Zoom Ratio

Adjustment ..................................................................................... D-36

(9) Automatic Document Feeder Main-Scanning Registration

Adjustment ..................................................................................... D-37

iii

(10) Automatic Document Feeder Sub-Scanning Registration

Adjustment ....................................................................................... D-38

4-2. ADJUSTMENT OF JUMPER SWITCHES ON NCU BOARD ................... D-39

5. MISCELLANEOUS ........................................................................................... D-40

5-1. Updating the Firmware ............................................................................. D-40

(1) Installing the GDI Printer Driver/

TWAIN Driver Using Plug and Play ..................................................D-40

(2) Procedure for Upgrading the Firmware

(Engine firmware/ FAX firmware) ..................................................... D-42

5-2. Procedure for Upgrading the Firmware

(NIC Firmware NEFAX 691 only) ............................................................. D-45

5-3. Remedy for a Failed Updating of the Firmware ....................................... D-47

5-4. Moving the EEPROM ............................................................................... D-49

CONTROL PANEL/SERVICE MODE DESCRIPTIONS

1. CONTROL PANEL DESCRIPTIONS ............................................................... S-1

1-1. Names of Control Panel Parts and Their Functions ................................ S-1

2. FUNCTIONS OF SWITCHES AND PARTS ON PWBs ................................... S-4

2-1.. Circuit Board Locations NEFAX 671......................................................... S-4

2-2.. Circuit Board Locations NEFAX 691......................................................... S-4

2-3. PWB-P (Controller/Mechanical Control Board) ........................................ S-5

2-4. PWB-IF (Interface Board) ......................................................................... S-5

2-5. NCU (Network Control Unit Board) ......................................................... S-6

2-6. NIC (Network Interface Card Board) ........................................................ S-6

2-7. NIC-IF (Plate NIC Board) ........................................................................ S-6

(1)LED status display list ......................................................................... S-7

2-8. PWB-A ADF Board) ................................................................................ S-7

3. STATUS MODE ............................................................................................... S-8

3-1. Status Mode Function Tree ...................................................................... S-8

3-2. Status Mode Setting Procedure ............................................................... S-9

(1) Total Page ........................................................................................ S-10

(2) TX/ RX Result ................................................................................. S-10

(3) Print Report ..................................................................................... S-11

4. UTILITY MODE ) .............................................................................................. S-18

4-1. Utility Mode Function Tree (Outline) ........................................................ S-18

4-2. Utility Mode Function Tree (Details) ......................................................... S-19

4-3. Utility Mode Setting Procedure ................................................................. S-22

(1) Machine Setting ............................................................................... S-22

(2) Paper source setting ........................................................................ S-24

(3) Admin. management ........................................................................ S-25

(4) Copy setting ..................................................................................... S-27

(5) FAX registration ............................................................................... S-27

(6) TX operation .................................................................................... S-30

(7) RX operation .................................................................................... S-33

(8) Comm. setting .................................................................................. S-41

(9) Reporting ......................................................................................... S-44

(10) Initial user data ................................................................................. S-45

iv

(11) Network setting ................................................................................ S-46

(12) E-mail setting 1 ................................................................................ S-48

(13) E-mail setting 2 ................................................................................ S-50

(14) Scan setting ..................................................................................... S-52

5. SERVICE MODE ............................................................................................. S-54

5-1. Service Mode Function Tree(Outline) ...................................................... S-54

5-2. Service Mode Function Tree(Details) ...................................................... S-55

5-3. Service Mode Setting Procedure ............................................................. S-58

(1) <Procedure> .................................................................................... S-58

(2) <Exiting Procedure> ........................................................................ S-58

(3) <Changing the Settings for Service Mode Functions> .................... S-58

5-4. Service’s Choice Functions ..................................................................... S-59

(1) Marketing Area ................................................................................ S-60

(2) Shipment Destination ...................................................................... S-61

(3) Leading Edge Erase ........................................................................ S-62

(4) Trailing Edge Erase ......................................................................... S-62

(5) Vertical Edge Erase ......................................................................... S-63

(6) FLS Paper Size ............................................................................... S-63

(7) TX Speed ........................................................................................ S-63

(8) RX Speed ........................................................................................ S-63

(9) TX Level .......................................................................................... S-64

(10) RX Level .......................................................................................... S-64

(11) DTMF Level ..................................................................................... S-64

(12) CNG Level ....................................................................................... S-64

(13) CED Level ....................................................................................... S-65

(14) ECM Mode ...................................................................................... S-65

(15) Coding Scheme ............................................................................... S-65

(16) Toner Empty Report ........................................................................ S-66

(17) Protocol Report ............................................................................... S-67

(18) GDI Time out ................................................................................... S-67

(19) Toner Empty Stop ........................................................................... S-68

(20) Pre-rotation ...................................................................................... S-68

(21) Fuser Temp Ad. ............................................................................... S-68

5-5. Adjust Function ........................................................................................ S-69

(1) Adjust ............................................................................................ S-69

5-6. Counter Function ..................................................................................... S-70

(1) Counter ............................................................................................ S-70

5-7. Display Function ...................................................................................... S-73

(1) Display ............................................................................................ S-73

5-8. Soft Switch Function ................................................................................ S-74

5-9. Reporting ................................................................................................. S-75

(1) Service Data List ............................................................................. S-75

(2) Error Code List ................................................................................ S-78

(3) T.30 Protocol List ............................................................................ S-79

5-10.Admin. Registration (Administrator number registration) ........................ S-80

5-11.Fixed zoom change ................................................................................. S-81

(1) <Metric> .......................................................................................... S-81

v

(2) <Inch> ............................................................................................. S-81

5-12.Clear Data ................................................................................................ S-82

(1) DRAM clear ...................................................................................... S-82

(2) SRAM clear ...................................................................................... S-83

(3) Memory clear ................................................................................... S-85

(4) Total clear ........................................................................................ S-87

(5) Total counter..................................................................................... S-87

(6) PM counter (clear) ........................................................................... S-87

(7) I/C counter (clear) ............................................................................ S-87

(8) Application counter (clear) ............................................................... S-87

(9) Scan counter (clear) ......................................................................... S-87

6. Soft Switch Set ................................................................................................ S-88

6-1. Description ............................................................................................... S-88

6-2. Default setting .......................................................................................... S-89

(1) Country for each Marketing area ..................................................... S-89

6-3. Default soft switch setting for each market area 1 ................................... S-90

6-4. Default soft switch setting for each market area 2 ................................... S-92

6-5. Default soft switch setting for each market area 3 ................................... S-94

6-6. Default soft switch setting for each market area 4 ................................... S-96

6-7. Default soft switch setting for each market area 5 ................................... S-98

6-8. Default soft switch setting for each market area 6 ................................... S-100

6-9. Default soft switch setting for each market area 7 ................................... S-102

6-10.Default soft switch setting for each market area 8 ................................... S-104

6-11.Soft Switch List ........................................................................................ S-106

6-12.Soft Switch definition ................................................................................ S-110

(1) SOFT SWITCH: #01 ........................................................................ S-110

(2) SOFT SWITCH: #02 ........................................................................ S-111

(3) SOFT SWITCH: #03 ........................................................................ S-112

(4) SOFT SWITCH: #04 ........................................................................ S-113

(5) SOFT SWITCH: #05 ........................................................................ S-114

(6) SOFT SWITCH: #06 ........................................................................ S-115

(7) SOFT SWITCH: #07 ........................................................................ S-115

(8) SOFT SWITCH: #08 ........................................................................ S-116

(9) SOFT SWITCH: #09 ........................................................................ S-117

(10) SOFT SWITCH: #10 ........................................................................ S-118

(11) SOFT SWITCH: #11 ........................................................................ S-119

(12) SOFT SWITCH: #12 ........................................................................ S-119

(13) SOFT SWITCH: #13 ........................................................................ S-120

(14) SOFT SWITCH: #14 ........................................................................ S-121

(15) SOFT SWITCH: #15 ........................................................................ S-121

(16) SOFT SWITCH: #16 ........................................................................ S-122

(17) SOFT SWITCH: #17 ........................................................................ S-122

(18) SOFT SWITCH: #18 ........................................................................ S-123

(19) SOFT SWITCH: #19 ........................................................................ S-124

(20) SOFT SWITCH: #20 ........................................................................ S-125

(21) SOFT SWITCH: #21 ........................................................................ S-126

(22) SOFT SWITCH: #22 ........................................................................ S-127

vi

(23) SOFT SWITCH: #23 ........................................................................ S-127

(24) SOFT SWITCH: #24 ........................................................................ S-128

(25) SOFT SWITCH: #25 ........................................................................ S-128

(26) SOFT SWITCH: #26 ........................................................................ S-129

(27) SOFT SWITCH: #27 ........................................................................ S-130

(28) SOFT SWITCH: #28 ........................................................................ S-131

(29) SOFT SWITCH: #29 ........................................................................ S-132

(30) SOFT SWITCH: #30 ........................................................................ S-133

(31) SOFT SWITCH: #31 ........................................................................ S-134

(32) SOFT SWITCH: #32 ........................................................................ S-134

(33) SOFT SWITCH: #33 ........................................................................ S-135

(34) SOFT SWITCH: #34 ........................................................................ S-135

(35) SOFT SWITCH: #35 ........................................................................ S-136

(36) SOFT SWITCH: #36 ........................................................................ S-137

(37) SOFT SWITCH: #37 ........................................................................ S-138

(38) SOFT SWITCH: #38 ........................................................................ S-139

(39) SOFT SWITCH: #39 ........................................................................ S-139

(40) SOFT SWITCH: #40 ........................................................................ S-140

(41) SOFT SWITCH: #41 ........................................................................ S-141

(42) SOFT SWITCH: #42 ........................................................................ S-142

(43) SOFT SWITCH: #43 ........................................................................ S-142

(44) SOFT SWITCH: #44 ........................................................................ S-142

(45) SOFT SWITCH: #45 ........................................................................ S-143

(46) SOFT SWITCH: #46 ........................................................................ S-144

(47) SOFT SWITCH: #47 ........................................................................ S-144

(48) SOFT SWITCH: #48 ........................................................................ S-145

(49) SOFT SWITCH: #49 ........................................................................ S-146

(50) SOFT SWITCH: #50 ........................................................................ S-146

(51) SOFT SWITCH: #51 ........................................................................ S-147

(52) SOFT SWITCH: #52 ........................................................................ S-147

(53) SOFT SWITCH: #53 ........................................................................ S-148

(54) SOFT SWITCH: #54 ........................................................................ S-148

(55) SOFT SWITCH: #55 ........................................................................ S-149

(56) SOFT SWITCH: #56 ........................................................................ S-149

(57) SOFT SWITCH: #57 ........................................................................ S-149

(58) SOFT SWITCH: #58 ........................................................................ S-150

(59) SOFT SWITCH: #59 Part 1 ............................................................. S-151

(60) SOFT SWITCH: #59 Part 2 ............................................................. S-152

(61) SOFT SWITCH: #59 Part 3 ............................................................. S-153

(62) SOFT SWITCH: #60 ........................................................................ S-154

(63) SOFT SWITCH: #61 ........................................................................ S-154

(64) SOFT SWITCH: #62 ........................................................................ S-155

(65) SOFT SWITCH: #63 ........................................................................ S-155

(66) SOFT SWITCH: #64 ........................................................................ S-156

7. Fax Protocols ................................................................................................... S-157

7-1. G3 ECM (G3 Error Correction Mode) ...................................................... S-157

7-2. Line Control ............................................................................................. S-158

vii

(1) Procedure of G3 mode communication ........................................... S-158

7-3. Table of reference code ........................................................................... S-159

7-4. How to analyze the T30 protocol monitor ................................................. S-160

TROUBLESHOOTING

1. INTRODUCTION .............................................................................................. T-1

1-1. Electric Components Check Procedures ................................................. T-1

(1) Sensors ............................................................................................ T-1

(2) Switches ........................................................................................... T-2

(3) Solenoids ......................................................................................... T-2

(4) Motors ............................................................................................. T-3

(5) Clutches ........................................................................................... T-4

1-2. Overall Control Configuration ................................................................... T-5

2. PAPER MISFEED ............................................................................................ T-6

2-1. Initial Check Items .................................................................................... T-6

2-2. ADF Unit Initial Check Items .................................................................... T-6

2-3. Paper Misfeed Displays ........................................................................... T-7

2-4. ADF Unit Paper Misfeed Displays ............................................................ T-8

2-5. Locations of Misfeed Detection Sensors .................................................. T-9

2-6. ADF Unit Locations of Misfeed Detection Sensors .................................. T-10

2-7. Misfeed Detection Timing and Troubleshooting Procedures ................... T-11

(1) Paper Take-Up/Transport Misfeed ................................................... T-11

(2) Fusing/Exit Misfeed .......................................................................... T-12

3. PAPER MISFEED(Document Feeder Section)................................................. T-13

(1) The Original Timing ................................................................................... T-13

4. MALFUNCTIONS/WARNING .......................................................................... T-14

4-1. List of Malfunctions .................................................................................. T-14

4-2. Malfunction Detection Timing and Troubleshooting Procedures .............. T-16

(1) C0045: Fuser fan motor error .......................................................... T-16

(2) C0210: H.V. abnormal ..................................................................... T-17

(3) C0500: Fuser warm up error ............................................................ T-18

(4) C0510: Fuser temperature low ........................................................ T-19

(5) C0520: Fuser overheat .................................................................... T-20

(6) C1200: ASIC memory abnormal ...................................................... T-21

(7) C1300: Polygon mirror motor error .................................................. T-21

(8) C133B: Communication with option error ........................................ T-22

(9) C133C: Modem error ....................................................................... T-22

(10) C133D: ROM checksum error .......................................................... T-22

(11) C13F0: Laser error ........................................................................... T-23

(12) C1468: EEPROM error .................................................................... T-23

(13) C14A3: CIS LED malfunction ........................................................... T-24

5. MALFUNCTIONS RELATED TO POWER SUPPLY ....................................... T-25

5-1. Power is not Turned ON. .......................................................................... T-25

6. IMAGE QUALITY PROBLEMS ........................................................................ T-26

6-1. Troubleshooting Image Quality Problems ................................................ T-26

6-2. Initial Checks ............................................................................................ T-26

viii

6-3. Troubleshooting for Specific Image Quality Problems ............................. T-27

(1) Image reading system: Blank or black prints ................................... T-28

(2) Image reading system: Low image density ...................................... T-29

(3) Image reading system: Foggy background or rough image ............. T-30

(4) Image reading system: Black streaks or bands ............................... T-31

(5) Image reading system: Black spots ................................................. T-31

(6) Image reading system: Blank streaks or bands ............................... T-32

(7) Printer system: Blank or black prints ................................................ T-33

(8) Printer system: Blank spots ............................................................. T-34

(9) Printer system: Smears on back ...................................................... T-34

(10) Printer system: Low image density .................................................. T-35

(11) Printer system: Foggy background .................................................. T-36

(12) Printer system: Blank streaks or bands ........................................... T-36

(13) Printer system: Black streaks or bands ............................................ T-37

(14) Printer system: Offset image ............................................................ T-37

7. FAX Error ) ....................................................................................................... T-38

7-1. Communication Error ............................................................................... T-38

(1) Outline ............................................................................................. T-38

(2) Error occurring during transmission ................................................. T-38

(3) Error occurring during reception ...................................................... T-38

7-2. Error Code ................................................................................................ T-39

(1) Reception ......................................................................................... T-39

(2) Transmission .................................................................................... T-41

8. TROUBLESHOOTING ) ................................................................................... T-45

8-1. Troubleshooting Procedure Overview ...................................................... T-45

8-2. Troubleshooting Procedure Chart ............................................................. T-45

8-3. Main Error Messages and Their Remedies .............................................. T-46

8-4. Troubleshooting Functions ....................................................................... T-47

8-5. List Communication Error Codes .............................................................. T-51

G-1

1. SPECIFICATIONS

1-1. Main Unit

Copy Medium

NOTE

The dimension for Tray2 is fixed at A4L or Letter L.

Type

Original scanning system

Photo conductor type

Copying system

Resolution

Paper feed-in system

Exposure system

Developing system

Drum-charging system

Image transfer system

Paper separation system

Fusing system

Max. Original size

Memory Capacity

:

:

:

:

:

:

:

:

:

:

:

:

:

:

Desktop

Scanning in main scanning direction with a CIS (Contact

Image System) sensor.

OPC (Organic Photo conductor)

Electrostatic dry Powdered image transfer to plain paper with

laser

600 dpi × 600 dpi, 600 dpi × 300 dpi

2-Way system (Tray1 and Bypass Tray)

*3-Way system is possible if optional PF-125 (Tray2) is

installed.

Unit scanning slit exposure

FMT (Fine Micro Toning) single component developing

Rotating brush with pre-charge film

Roller transfer

Curvature separation + Charge Neutralizing needle

Heat roller

Up to Legal size

STD: 16 MB (48 MB Maximum with 32 MB Option Memory:

NEFAX 691 only)

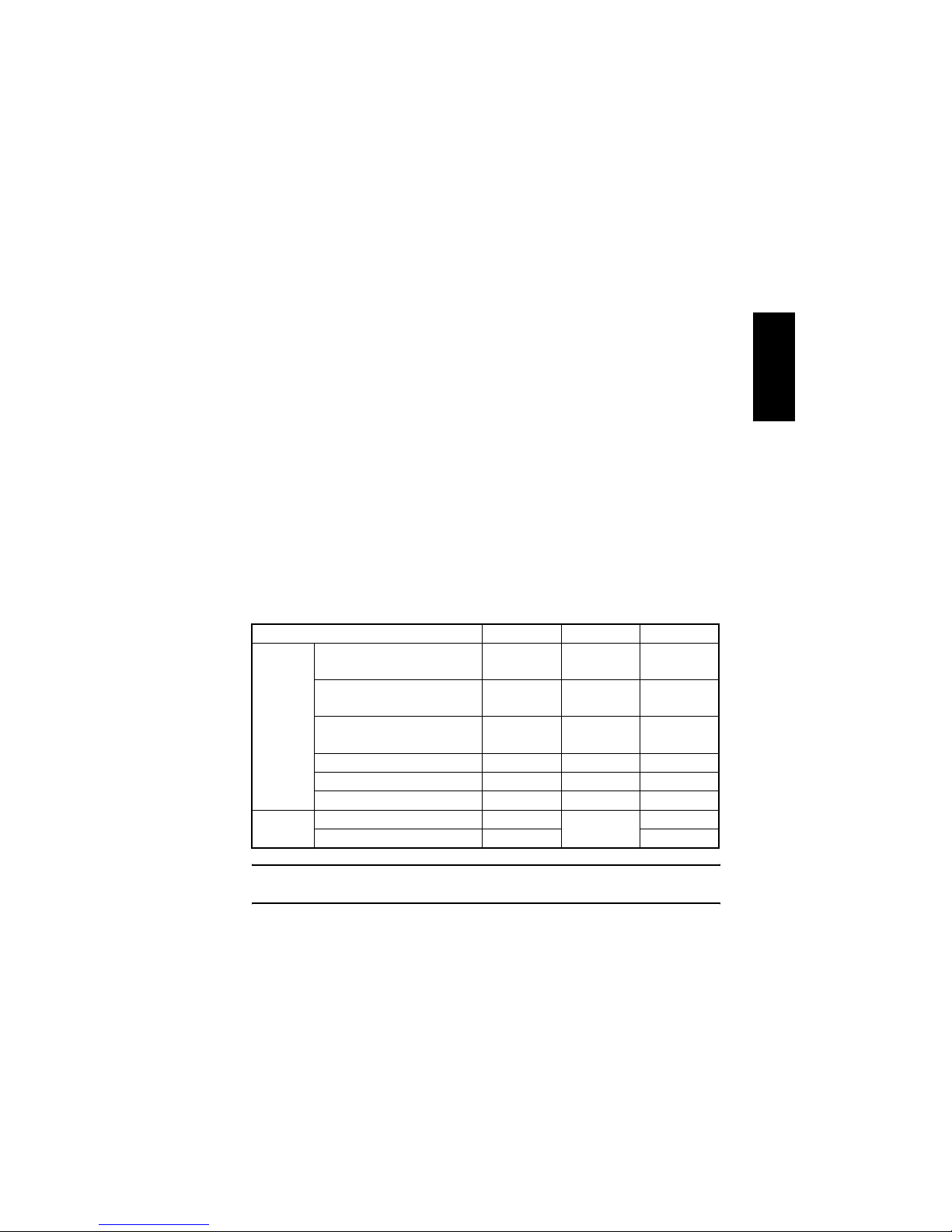

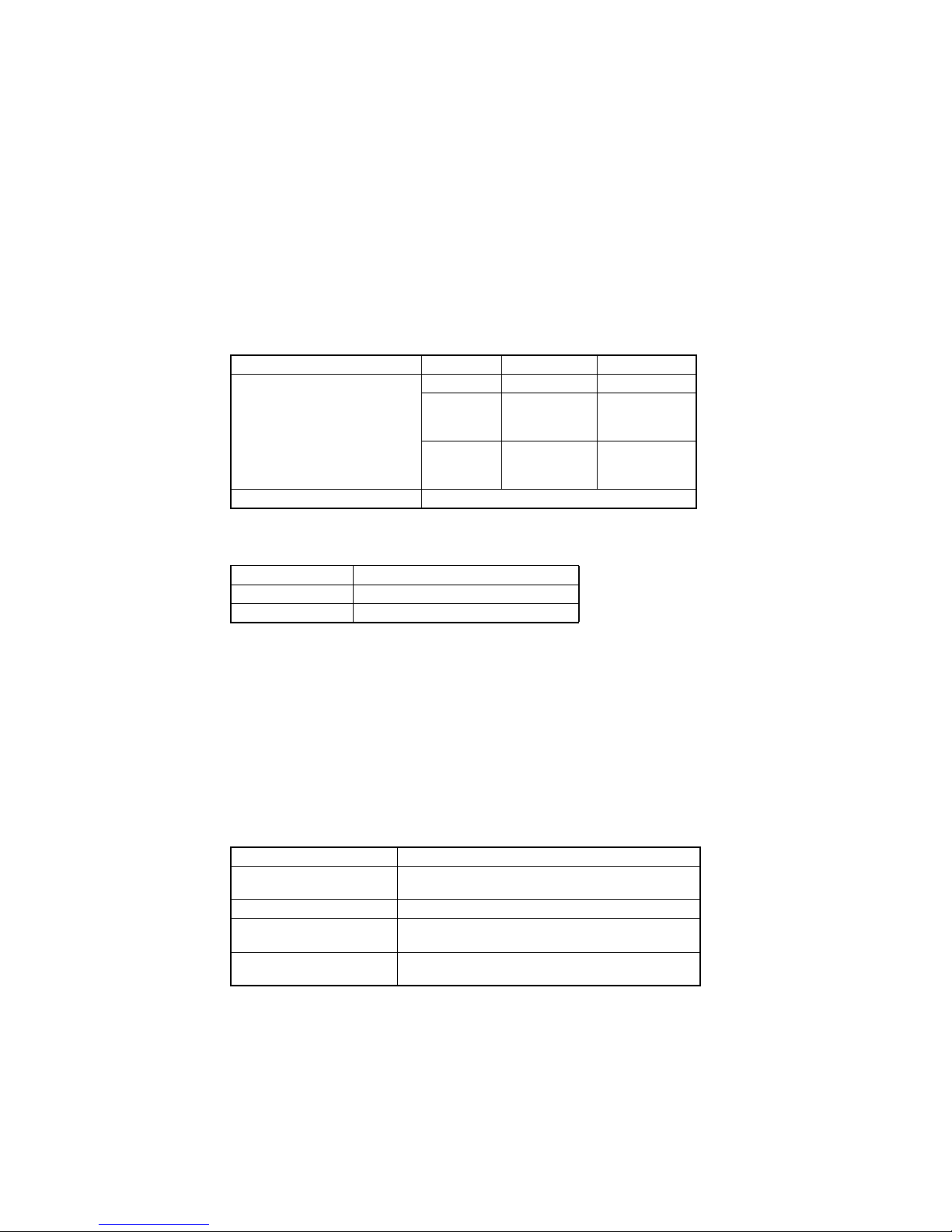

Paper source Tray1 Tray2 Bypass Tray

Type

Plain paper (60 to 90 g/m

2

)

(16 to 24 lb.)

❍❍❍

Recycled paper (60 to 90 g/m

2

)

(16 to 24 lb.)

❍❍❍

Special paper (91 to 163 g/m

2

)

(24 to 43 lb.)

❍ – ❍

Transparencies ❍ – ❍

Label sheets ❍ – ❍

Envelopes ❍ – ❍

Dimension

Maximum (width × length) 216×356 mm

A4 L, Letter L

216×356 mm

Minimum (width × length) 105×148 mm 105×148 mm

G-2

Zoom Ratios

Power /Current Consumption (main unit only)

copy speed (copies/min.)

Continuous print speed

(sheets/min.)

Warm-up time

:

:

:

:

16 copies/minute (at full size and 600 dpi × 300 dpi, with

ADF)

More than 16 sheets/minute (with plain A4 L or Letter L

paper)

Less than 25 seconds (at a room temperature of 23 °C and

at the rated voltage)

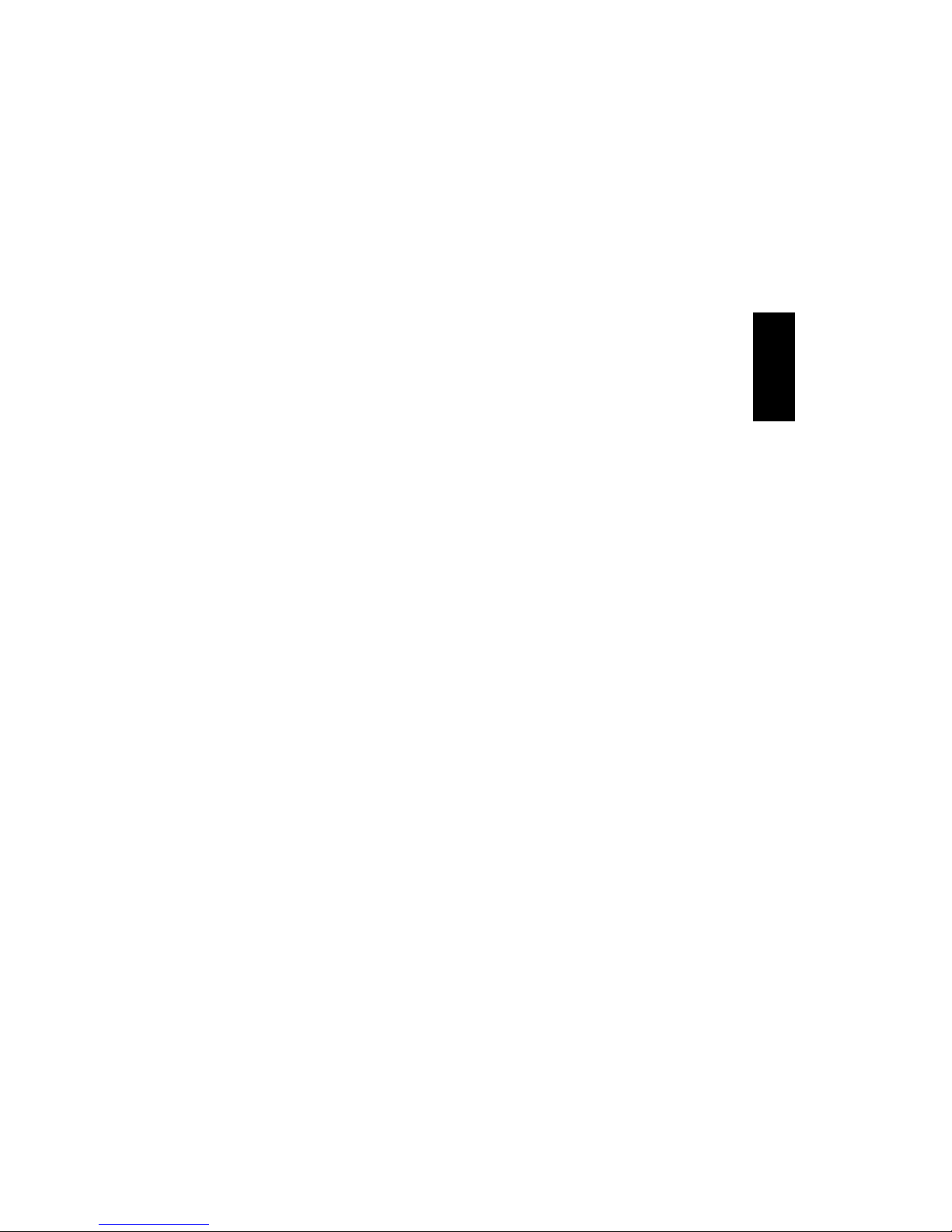

Metric Size (Inch Size)

Fixed

Full size ×1.00 ×1.00

Enlargement

×1.15

×1.41

×2.00

×1.29

×1.54

×2.00

Reduction

×0.81

×0.70

×0.50

×0.78

×0.64

×0.50

Var iabl e ×0.50 to ×2.00 (in ×0.01 increments)

Fusing temperature : 200 °C

Voltage Maximum power consumption

110 V, 120-127 V 770-890 W

220-240 V 740-850 W

Power source : 110 V, 120V-127 V, 220-240 V 50/60 Hz

Main unit dimensions

(including Automatic document feeder)

weight

Original type

Orignal capacity

Registration

Original loading orientation

Scan speed

:

:

:

Width....416 mm

Depth....419 mm

Height...408 mm

12kg

Plain paper: 35 to 128 g/m

2

(9 to 34 lb.)

width: 148 to 216 mm; length: 140 to 1000 mm

Maximum 50 sheets (80 g/m

2

)

Center

Face up

2.5sec(plain A4L,with standard mode of orginal feeding

Original types Possible problems

Originals bound with staples or

paper clips

Incorrect paper take-up, damaged originals or drive malfunctions due to jammed paper clips

Originals bound with glue Incorrect paper take-up or damaged originals

Folded, torn or extremely wrinkled originals

Incorrect paper take-up or damaged originals

Curled originals (more than 10

mm from front edge)

Paper misfeeds due to folded or skewed originals

G-3

1-2. GDI Printer Function

1-3. FAX Function

RAM

Interfaces

Printer Language

Fonts

Supported Operating

Systems

Web Browser

:

:

:

:

:

:

Share with main unit.

USB Revision 1.1

(except for Windows 95 and Windows NT)

GDI

Windows

Windows XP (SP1 or later)/Windows 2000 (SP3 or later)/

Windows Me/Windows 98 Second Edition/

Internet Explorer 4.0 or later

General

Compatibility : Super G3/ G3/ ECM (Error correction mode)

Scanning Resolution : STD: 204x98( 3.85 lines/mm)

Fine: 204x196(7.7 lines/mm)

Super Fine: 204x392(15.4 lines/mm)

Line : PSTN/ PBX

Data Transmission Rate : 33.6 kbps(4 Second : NEFAX 671)

33.6 kbps(3 Second : NEFAX 691)

*ITU-T No.1, A4 size, Normal resolution without header.

Coding Method : MH/ MR/ MMR/ JBIG (NEFAX 691 only)

Scanning Area : Sheet through scanning

Maximum 208mm

Internet fax : Enable (NEFAX 691 only)

Dialing

Direct dialing : Entering the fax number directly using the 10-Key Pad.

One touch dial : 32keys: NEFAX 671

64keys: NEFAX 691

Speed dial : 100 fax numbers: NEFAX 671

200 fax numbers: NEFAX 691

Group dial : 32 groups: NEFAX 671

64 groups: NEFAX 691

Program dial : NO/4 keys (No. 61,62,63,64)

Other dialing : Pause insert, Phone Book dial, On-hook dial,

Automatic redial, Redial, Chain dial, Combination dial

G-4

Transmission

Transmission mode : ADF TX, Memory TX, Batch TX, Broadcast TX,

Confidential Mailbox TX,

F code TX (SubAddress TX, SID TX), Forward TX

Manual TX, Polling TX, Quick Memory TX, Book TX,

Relay initiate TX, Reservation TX, Timer TX,

TX resolution mode/ TX

image mode

: Standard (204 dpi x 98 dpi),

Fine (204 dpi x 196 dpi),

Super fine (204 dpi x 392 dpi),

Standard + halftone (204 dpi x 98 dpi),

Fine + halftone (204 dpi x 196 dpi),

Super fine + halftone (204 dpi x 392 dpi)

Receiving

Receiving mode : Auto RX, Closed network RX, Confidential Mailbox RX,

Inward Polling RX, Manual RX, Memory RX, Substitute RX,

RX resolution : 204 dpi x 98 dpi, 204 dpi x 196 dpi, 204 dpi x 392 dpi,406 dpi

x 392 dpi

Max. recording paper

size

: A4/ Legal

Report : Activity report, Back up RAM error report,

G3 protocol monitor report, Memory image print,

Power failure report, Reservation report, RX result report,

Service report, TX result report,

List : Key setting list, Machine status list, Memory data list,

One-touch dial list, Service data list, Speed dial list,

Other Features : Automatic paper selection, Backup of memory,

Confirmation of communication result, Daylight saving time,

Date/Time setting, Display of destination station, Footer,

Header, Package reception printing, Pause insert,

Quick memory printing, Remote monitor, RX print cancel,

RX printing mode (100 %reception/ Reception print mode/

Cut mode), Separate print, Smoothing, Speaker, Time zone,

Tone signal transmission, TX cancel, RX cancel

G-5

1-4. Network Function (NEFAX 691 only)

Interface

Data format

Content Type

I-FAX Communication Protocol

I-FAX Data Format

I-FAX Cording method

I-FAX TX resolution

I-FAX RX resolution

Scan to E-Mail / Scan to FTP

Communication Protocol

Scan to E-Mail / Scan to FTP

Data Format

Scan to E-Mail / Scan to FTP

Cording method

Scan to E-Mail / Scan to FTP

resolution

:

:

:

:

:

:

:

:

:

:

:

:

Ethernet 10/100Base T /TX (RJ-45)

MIME, Base64

Multi-part/Mixed (text/plain, image/tiff)

TX: SMTP

RX: POP3

E-Mail Format: MIME

Attached File format: TIFF-F

Transmission: MH

Reception: MH, MR, MMR, JBIG

204 dpi × 98 dpi

204 dpi × 196 dpi

204 dpi × 98 dpi

204 dpi × 196 dpi

204 dpi × 392 dpi

200 dpi × 100 dpi

200 dpi × 200 dpi

E-Mail TX: SMTP

FTP TX: FTP

E-Mail Format: MIME

Attached File format: TIFF, PDF

MH, MR, MMR, JPEG (For Color and Gray mode, fixed

at JPEG)

150 dpi × 150 dpi

300 dpi × 300 dpi

600 dpi × 600 dpi

G-6

2. PRECAUTIONS FOR INSTALLATION

2-1. Installation Site

To ensure utmost safety and avoid breakdown, this machine should NOT be used in a

place:

• Where it will be subjected to extremely high or low temperature or humidity.

• Where it will be subjected to sudden fluctuations in either temperature or humidity.

• Which is exposed to direct sunlight.

• Which is in the direct air stream of an air conditioner, heater, or ventilator.

• Which has poor ventilation or is dusty.

• Which does not have a stable, level floor or where it will receive undue vibration.

• Which is near any kind of heating device.

• Which is near volatile flammables (thinner, gasoline, etc.).

• Where it may be splashed with water and electric leakage is likely to occur.

• Which puts the operator in the direct stream of exhaust from this machine.

• Where ammonia gas might be generated.

2-2. Power Source

• If any other electrical equipment is sourced from the same power outlet, make sure that

the capacity of the outlet is not exceeded.

• Use a power source with little voltage fluctuation.

• Never connect by means of a multiple socket any other appliances or machines to the

outlet being used for this machina.

• Ensure that this machine does not ride on the power cord or communications cable of

other electric equipment, and that it does not become wedged into or underneath the

mechanism.

• Make the following checks at frequent intervals:

✽ Is the power plug abnormally hot?

✽ Are there any cracks or scrapes in the cord?

✽ Has the power plug been inserted fully into the outlet?

✽ Does something, including this machine itself, ride on the power cord?

Use an outlet with a capacity of 110/120/127 V, or 220-240 V.

G-7

3. PRECAUTIONS FOR USE

3-1. To Ensure this Machine is Used in an Optimum Condition

• Never place a heavy object on this machine or subject this machine to shocks.

• Insert the power plug all the way into the outlet.

• Do not attempt to remove any panel or cover that is secured while this machine is in a

print cycle.

• Do not turn OFF this machine while it is in a print cycle.

• Provide good ventilation if this machine is to be used for a long time in a narrow room.

• Never use flammable sprays near this machine.

• If this machine becomes inordinately hot or produces abnormal noise, immediately turn it

OFF and unplug it.

• Do not turn ON the power switch at the same time that you plug the power cord into the

outlet.

• When unplugging the power cord, do not pull on the cord; hold the plug and pull it out.

• Do not bring any magnetized object near this machine.

• Do not place a vase or vessel containing water on this machine.

• Be sure to turn OFF the power switch at the end of the workday or upon power failure.

• Use care not to drop paper clips, staples, or other small pieces of metal into this

machine.

3-2. Operating Environment

The operating environmental requirements of this machine are as follows.

• Temperature: 10 to 30 °C

• Humidity: 15 to 85 %

• Rate of temperature change: 10 °C/h

• Rate of humidity change: 20 % Rh/h

3-3. Power Requirements

The power source voltage requirements are as follows.

• Voltage fluctuation: AC110 V - AC127 V -10 %, +6 % (Copying performance assured)

AC 220 V - AC 240 V ±10 % (Copying performance assured)

AC 110 V - AC 127 V -10 %, +6 % (Paper feeding performance

assured)

AC 220 V - AC 240 V ±10 % (Paper feeding performance assured)

• Frequency fluctuation: 50/60 Hz ± 3 Hz

G-8

4. HANDLING OF THE CONSUMABLES

Before using any consumables, always read the label on its container carefully.

• Paper can easily damp. To prevent absorption of moisture, store paper in a place with lit-

tle moisture.

• Keep consumables out of the reach of children.

• Do not touch the PC Drum with bare hands.

• The same sized paper is of two kinds, short grain and long grain. Short grain paper

should only be fed through this machine crosswise, while long grain paper should only be

fed lengthwise. The wrapper of the paper is properly marked.

• If your hands become soiled with toner, wash them with soap and water.

• Do not throw away any used consumables. They are to be collected.

• Do not burn, bury in the ground, or throw into the water any consumables.

• Do not store consumables in a place which:

✽ Is hot and humid.

✽ Is subject to direct sunlight.

✽ Has an open flame nearby.

5. MISCELLANEOUS PRECAUTIONS

Use the following precautions when performing service jobs for the machine that uses a

laser.

• When a service job needs to be performed in the laser beam path, such as when working

around the Print Head Unit or PC Drum, be sure first to unplug the power cord of the

machine from the outlet.

• If the service job requires that the power cord be left plugged in, observe the following

precautions:

1. Take off your watch, ring, and any other reflective object and wear laser protective gog-

gles.

2. Keep users away from the job site.

3. Do not bring a highly reflective tool into the laser beam path during the service job.

G-9

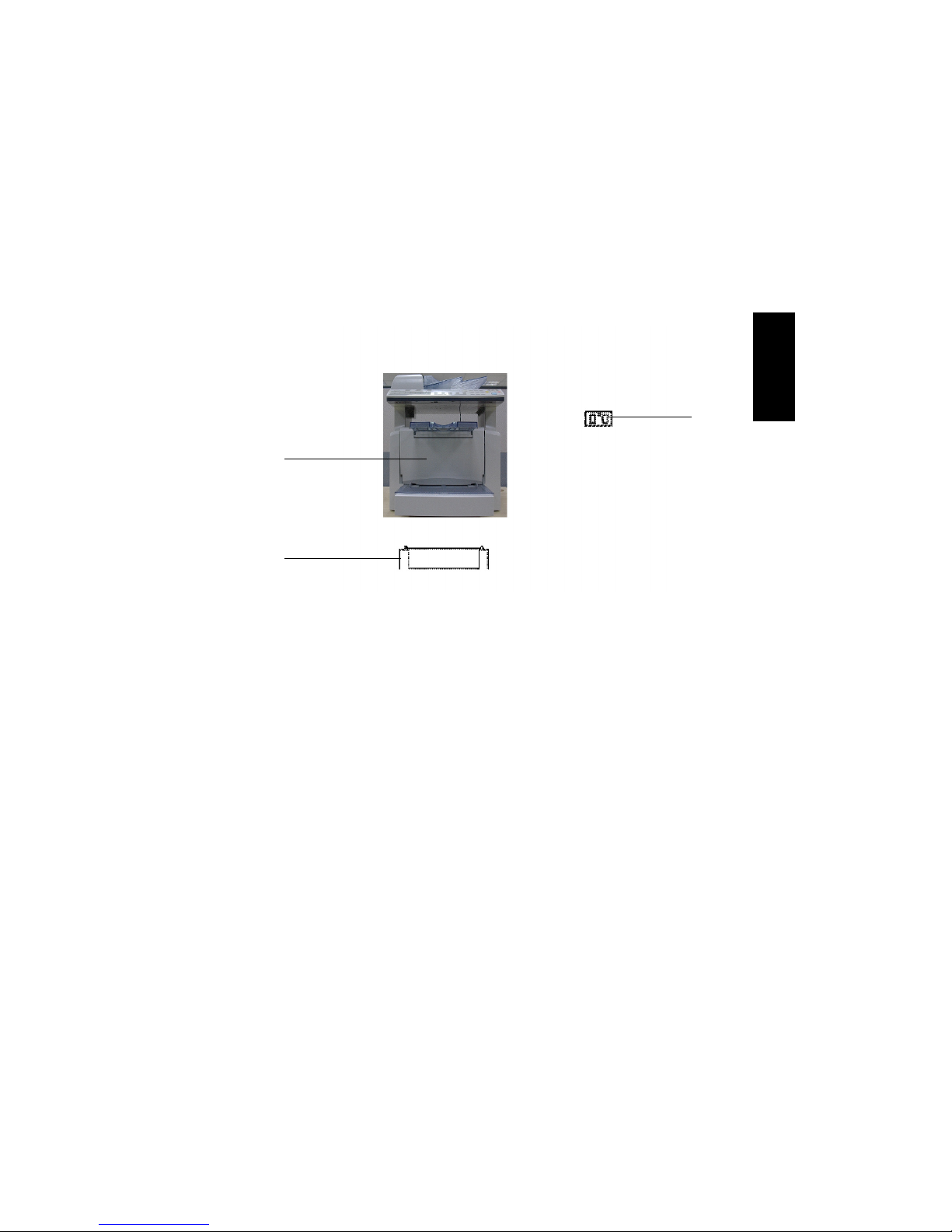

6. PARTS IDENTIFICATION

1

2

3

1. Main Unit NEFAX 671/

NEFAX 691

2. Paper Feed Cassette PF-

125

3. Expansion memory 32-5 (32

MB): NEFAX 691 only

Loading...

Loading...