Page 1

()

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

Server HX4500

User's Guide

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

Page 2

xxx

Page 3

Server HX4500

()

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

User's Guide

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

Page 4

Proprietary Notice and Liability Disclaimer

The information disclosed in this document, including all designs and related materials, is

the valuable property of NEC Computer Systems Division, Packar d Bell NEC, Inc.

(hereinafter “NEC CSD”) and/or its licensor s. NEC CSD and/or its licensors, as

appropriate, reserve all patent, copyright and other proprietary rights to this document,

including all design, manufacturing, reproduction, use, and sales rights thereto, except to

the extent said rights are expressly granted t o others.

The NEC CSD product(s) discussed in this document are warranted in accordance with the

terms of the Warranty Statement accompa nying each product. However, actual

performance of each such product is dependent upon factors such as system configuration,

customer data, and oper ator control. Since imple ment ation by customers of each product

may vary, the suitability of specific pro duct configurat ions and applications must be

determined by the customer and is not warrant ed by NEC CSD.

To allow for design and specification improve ment s, the information in this document is

subject to change at any time, without notice. Reproduction of this document or portions

thereof without prior written approval of NEC CSD is prohibited.

Trademarks

INTEL is a registered t r ademark of Inte l Corpo r at ion.

MS-DOS is a registered tr ademark of Microsoft Corporation.

Pentium is a registered trademark of Inte l Corpor ation.

All other product, brand, or trade names used in this publication are t he trademarks o r

registered trademarks of their respective trademark owners.

PN: 456-00005-000nnnnnnnnnnnnnnnnnn12/98

Copyright 1998

NEC Computer Systems Division

Packar d Bell NEC, Inc.

1 Packar d Bell Way

Sacramento, CA 95828-0903

All Rights Reserved

Page 5

Contents

Proprietary Notice and Liability Disclaimer

Regulatory Information

Using This Guide...................................................vii

Text Conventions............................................................................ viii

Related Documents.............................................................................ix

Safety Notices.....................................................................................x

Safety Notices for Users Outside of the U.S.A. and Canada...........xi

Care and Handling.............................................................................xii

System Overview.................................................. 1-1

Overview......................................................................................... 1-2

System Feature Summary........................................................... 1-3

Expanding the Server as Needs Grow......................................... 1-4

Configuration Constraints........................................................... 1-4

Chassis............................................................................................ 1-5

Status LED Indicator Descriptions.............................................. 1-6

Opening the Front Doors............................................................ 1-7

Chassis Features and Controls.....................................................1-9

System Board Features.................................................................. 1-11

Processor.................................................................................. 1-16

Memory.................................................................................... 1-16

Bus Master I/O Expansion Slots............................................... 1-16

Real-Time Clock/Calendar ....................................................... 1-16

BIOS........................................................................................ 1-16

Video....................................................................................... 1-17

SCSI Controller........................................................................ 1-17

Peripheral Controller................................................................ 1-17

External Device Connectors...................................................... 1-17

Keyboard and Mouse ................................................................ 1-17

Fans......................................................................................... 1-18

Peripheral Devices......................................................................... 1-18

Ultra2 Wide SCSI-2 Hard Drive Bays....................................... 1-18

Removable Media Drive Bays .................................................. 1-19

System Power................................................................................ 1-20

Software Locks via the BIOS Setup............................................... 1-20

Setting Up Your System ....................................... 2-1

Selecting a Site................................................................................ 2-2

Unpacking the System..................................................................... 2-3

Moving the System to the Site......................................................... 2-3

Getting Familiar With the System.................................................... 2-4

Making Connections........................................................................ 2-4

Connecting the Power Cords............................................................ 2-6

Powering On Your System.............................................................. 2-7

Contents iii

Page 6

Configuring Your System......................................3-1

Configuring Your System................................................................ 3-2

Resource Configuration Utility (RCU)............................................. 3-2

Using the RCU ........................................................................... 3-3

RCU Command Line Parameters................................................ 3-5

RCU Configuration Settings....................................................... 3-5

ISA Board Configuration............................................................ 3-6

BIOS Setup Utility .......................................................................... 3-8

Using the BIOS Setup Utility...................................................... 3-8

BIOS Setup Configuration Settings............................................. 3-9

Exiting BIOS Setup.................................................................... 3-9

SCSISelect Utility......................................................................... 3-14

Using the SCSISelect Utility..................................................... 3-14

SCSISelect Configuration Settings............................................ 3-15

Exiting SCSISelect................................................................... 3-15

Configuring the RAID Controller .................................................. 3-17

Configuring System Jumpers and Switches.................................... 3-18

Before You Begin..................................................................... 3-18

Configuring I/O Riser Board Function Select Switches............. 3-18

Configuring CPU Base Board Function Select Switches........... 3-20

Configuring Memory Board Function Jumpers......................... 3-21

Configuring System I/O Board Switches and Jumpers............... 3-21

Setting Switches and Jumpers................................................... 3-24

BIOS........................................................................................ 3-25

Updating the BIOS .............................................................. 3-25

Changing the BIOS Setup Language.................................... 3-26

Resetting the CMOS NVRAM.................................................. 3-27

Clearing and Changing the Password........................................ 3-28

Upgrading Your System ........................................4-1

Precautions...................................................................................... 4-4

Preparing Your System for Upgrade................................................ 4-6

Equipment Log........................................................................... 4-6

Removing the Front Doors..........................................................4-7

Installing the Front Doors........................................................... 4-7

Removing the Top Cover and Side Panels................................... 4-8

Installing the Top Cover and Side Panels.................................. 4-10

Modifying the System I/O Board................................................... 4-11

Installing Video Memory.......................................................... 4-11

Replacing the Non-Volatile Memory ........................................ 4-12

Replacing the Real-time Clock Battery..................................... 4-13

DIMMs......................................................................................... 4-15

Installing DIMMs..................................................................... 4-15

Removing DIMMs ................................................................... 4-17

Processors..................................................................................... 4-18

Installing a Processor Cartridge ................................................ 4-19

Removing a Processor Cartridge or Termination Board............. 4-22

Option Boards............................................................................... 4-23

Installation Considerations........................................................ 4-23

Controller/Adapter Hardware Configurations............................ 4-25

Installing an Option Board........................................................ 4-26

Removing an Option Board...................................................... 4-28

Power Supply................................................................................ 4-29

iv Contents

Page 7

Installing a Power Supply......................................................... 4-29

Removing a Power Supply........................................................ 4-30

Hot-Swapping a Power Supply ................................................. 4-30

Removable Media Devices ............................................................ 4-31

Installing a 5 1/4-Inch Device or 3 1/2-Inch Diskette Drive....... 4-33

Removing a 5 1/4-Inch Device or 3 1/2-Inch Diskette Drive ..... 4-37

Hard Disk Drives........................................................................... 4-38

Installing a Hard Drive............................................................. 4-39

Removing a Hard Drive............................................................ 4-42

Hot-Swapping a Hard Drive...................................................... 4-43

Problem Solving ...................................................5-1

Resetting the System........................................................................ 5-2

Troubleshooting Checklists.............................................................. 5-2

Initial System Startup................................................................. 5-2

Running New Application Software............................................ 5-3

After System Has Been Running Correctly................................. 5-4

Additional Troubleshooting Procedures ........................................... 5-5

Error Checking........................................................................... 5-5

Troubleshooting Guide............................................................... 5-5

Preparing the System for Diagnostic Testing.......................... 5-5

Monitoring POST While Running..........................................5-6

Verifying Proper Operation of Key System Indicators............5-6

Confirming Loading of the Operating System ........................ 5-7

Specific Problems and Corrective Actions ....................................... 5-7

Power LED Does Not Light........................................................ 5-7

System Cooling Fans Do Not Rotate........................................... 5-7

No Characters Appear On Screen................................................ 5-8

Characters are Distorted or Incorrect........................................... 5-9

Floppy Disk Drive Activity LED Does Not Light ....................... 5-9

Hard Disk Drive Activity LED Does Not Light........................... 5-9

Problems with Application Software......................................... 5-10

Error Messages.............................................................................. 5-10

Alarm Indication during POST................................................. 5-10

Alarm Indication during Operation........................................... 5-13

CPU Error Messages ........................................................... 5-14

Memory Error Messages...................................................... 5-14

Status LED.................................................................................... 5-15

System Cabling ....................................................A-1

Before You Begin............................................................................A-2

Static Precautions............................................................................A-2

RAID Configuration........................................................................A-3

Memory Configurations........................................B-1

Memory DIMM Configurations .......................................................B-2

Glossary

Equipment Log

Contents v

Page 8

vi Contents

Page 9

Contents vii

Page 10

Page 11

Using This Guide

This User’s Guide provides a quick reference to information about your

system. Its goal is to familiarize you with your system and the tasks

necessary for system configuring and upgrading.

This guide contains the following information:

Chapter 1, “System Overview” provides an overview of your

syste m and describes your system’s major system co mpo ne nts.

See this chapter to familiarize yourself with your system.

Chapte r 2, “Setting Up Your System” tells yo u how to select a

site, unpack the system, make cable connect ions, and power on

your system.

Chapt er 3, “Configuring Your System” tells you how to configure

the system and provides instructions for running the Resource

Configuration Utility, BIOS Setup Utility, and SCSISelect Utility.

It also provides information on system board jumper settings.

Chapter 4, “Upgrading Your System” provides you with

instructions for upgrading your system with additional processors,

optional memory, option cards, and peripheral devices.

Chap ter 5, “Pro blem Solving ” cont a ins helpful informa tion for

solv ing pr oblems that might oc cur with your syst e m.

Appendix A, “System Cabling” includes cabling information for

the onbo a rd SCSI co ntroller.

Appendix B, “Memory Configurat ions” defines the allowable

memory configurations for your system.

“Glossary” defines t he st andard acr onyms and technical ter ms

used in th is ma nu a l.

“Equipment Log” provides you with a sample equipment log for

documenting the system configuration and future updates you

may make to your system.

Using This Guide vii

Page 12

Text Conventions

This guide uses the following text c onventions.

War n ings, cautions, and not es have the following me anings:

Warnings alert you to situations that could result i n

serious personal injury or loss of life.

Cautions indi c ate situations that can damage the

system hardware or software.

Note:

Notes give important inf ormation about the

material being described.

Names of keyboard keys are printed as they appear on the

keyboard. For example, Ctrl, Alt, or Enter.

!

WARNING

!

CAUTION

T ext o r keystrok es that you enter appear as bo ldface type. For

example, type abc123 and press ENTER.

File names are pr inted in uppercase lett ers. For example,

AUTOEXEC.BAT.

viii Using This Guide

Page 13

Related Documents

In addition to this guide, the following system documentation is included

with your server either as electronic files on E

paper copy shipped with your server.

System Release Notes

Release Not es pro vide you with t he latest information about your

system. This infor mat ion was not avai lable at the time your user’s

guide was developed.

Getting Started Sheet

The Getting Started S heet prov ides several easy-to-follow steps to

become familiar with your server do cumentation and to complete

your inst a lla tion suc c es s fu l ly.

Net work Operating System Configuration Guide

This guide contains supp leme nt al instructions needed to insta ll

and configure your server Windows NT v4.0, Novell NetWare

v4.11, Santa Cruz Operation (SCO) OpenServer Re lease 5. 04, and

SCO UNIXWARE 7.0 Network Operating Systems. This

document is intended to complement the more detailed procedural

documents available from the vendor of the network operating

system.

XPRESSBUILDER

or as

Using This Guide ix

Page 14

Safety Notices

Caution: To reduce the risk of electric shock which co uld cause

per s onal injury, follow all safe ty no tices. The symbols shown are

used in your documentation and on your equipment to indicate

safety hazards.

Warning: Lith ium ba tte ries can be dangerous. Improper ha ndling

of lit h iu m bat t e r ies ma y re su lt in a n exp lo s io n. Dis pose o f lit hium

batteries as required by loca l ordinance or as normal waste if no

local ordinance exists.

Warning: The detachable power supply cord is intended to serve

as the disconnect device.

Warning: This equipment has two 3-wire, grounded power cords.

To prevent electrical hazards, do not remove or defeat t he ground

prong on the power cord. Replace the power cord if it gets

damaged. Contact your dealer for an exact replacement.

!

Warning: The DC push-button on/off switch on the front panel

does not turn off the syste m AC power. Also , +5vdc is present o n

the system board whenever the AC power cord is connected

between the system and an AC out let. Befor e doing the

procedures in this manual, make sure that your system is powered

off and unplug the AC power cord from the back of the chassis.

Failure to disconnect power before opening your system can result

in personal injury and equipment damage.

In the U.S.A. and Canada, each power cord must be a UL-listed

detachable power cord (in Canada, CSA-certified), type ST or SJT, 16

AWG, 3-conductor, provided with a molded-on NEMA type 5-15 P plug

cap at one end and a molded-on cord connector body at the other end.

The cord length must not exceed 9 feet ( 2.7 meter s).

x Using This Guide

Page 15

Outside the U.S.A. and Canada, the plug must be rated for 250 Vac, 10

amp minimum, and must display an international agency approval

marking. The cord must be suitab le for use in the end-user country.

Consult your dealer or the local electrical author it ies if you are unsure o f

the type of power cord to use in your country. The voltage change occurs

via a switch in the power supply.

Warning: Under no circumstances should the user attempt to

disassemble the power supply. The power supply has no userreplaceable parts. Inside the power supply are hazardous voltages

that can cause serious personal injury. A defective power supply

must be returned to your dealer.

Safety Notices for Users Outside of the U.S.A. and Canada

PELV (Protected Ext ra-Low Voltage) Integrity: To ensure the

extra-low voltage integrit y of the equipment, co nnect only

equipment with mains-protected electrically-compatible circuits to

the external port s.

Remote Earths: To pr event electr ica l shock, connect all loca l

(individual office) computers and computer support equipment to

the same electrical circuit of the building wiring. If you are

unsure, check the building wiring to avoid remote earth

conditions.

Earth Bo ndi n g : Fo r safe op er ation, only connect the equipment

to a building supply that is in accordance with current wiring

regulations in your countr y. In the U.K., those regu lations are t he

IEE.

Using This Guide xi

Page 16

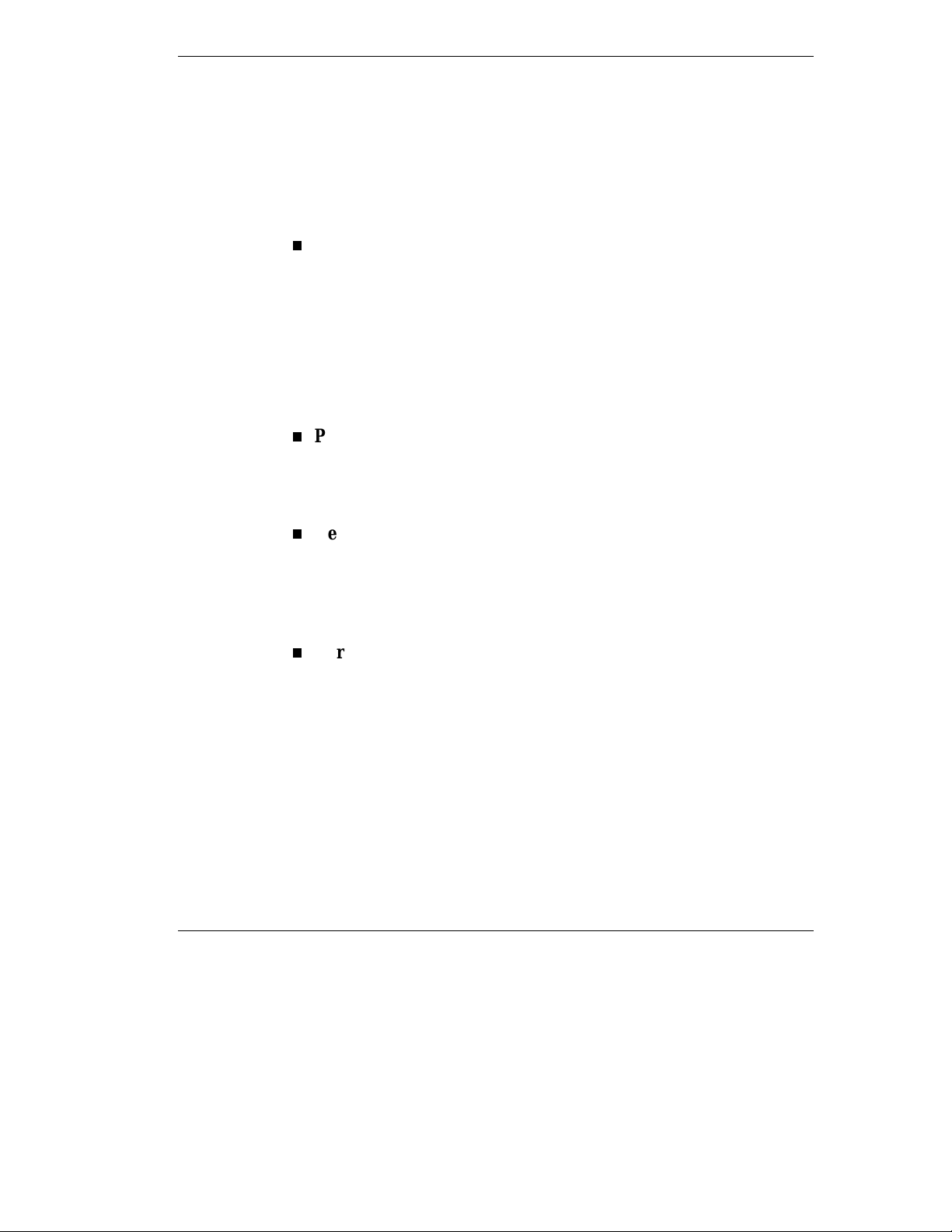

Care and Handling

Use the following guidelines to pro p er ly handle and care for your

system.

Protect the system from extremely low or h igh

temperatures. Let the system warm (or cool)

to room temperature before using it.

Keep the system away from magnetic forces.

Keep th e system dry. Do n ot wash the

system with a wet cloth or pour fluid

into it.

Prot ect t he s ystem from bein g bum ped or

dropped.

xii Using This Guide

Check the system for con densa tion . If

condensation exists, allow it to evaporate

before powering on the system.

Keep th e system away fr om dust , sand,

and dirt.

Page 17

System Overview

Overview

Chassis

System Board Features

Peripheral Devic es

System Power

Software Locks via the BIOS Set up

1

Page 18

Overview

The server is a modular, multiprocessing server based on the Int el Pentium®

II Xeon chip set. The chip set incor po r ates a modular sca lea ble arc h itect ure that

integrates a 64-bit bus interface with three Peripheral Co mponent I nt er co nnect

(PCI) buses and an Indust r y Standard Arc h itect ure (ISA) bus. The architecture

supports Symmetrical Multiprocessing (SMP) and a variety of operating

systems. The chassis and system boards ar e designed to meet the needs of the

server marketplace.

The combination of comput ing performance, memory capacity, and integrated

I/O provides a high performance environment for many applications including

network servers and multi-user systems. The server is designed for use in

applications where downtime must be minimized. To this end, the server

includes or has the option to include the following.

Power system redundancy; in a system configured with redundant power

Self-c ontained power sup ply units tha t can b e easily insta lle d or removed

Hot-swap SCSI hard drive bays accessible from the front of the chassis; a

supplies, the system will continue to operate with a single power supply

failure.

from the back of the chassis.

failed drive can be removed, and a new drive installed without system

power being turned off.

High degree of SCSI hard disk fault tolerance and advanced disk array

management features through the use of RAID (Redundant Array of

Independent Disks) technology.

Hardware monitors (temperature and voltage) and software monitors to

indicate failure s.

E asy access to all parts for ser v ice.

1-2 System Overview

Page 19

System Feature Summary

A summary of the system features is included in Table 1-1.

Table 1-1. System Features

Feature Description

Modular board set System is intended for use with a modular board set based on Pentium II

Xeon processor technology; from one to four processors and up to 4 GB

of memo ry .

Add-in board support Rail and back panel slots support up to 11 add-in boards (two ISA and

nine PCI).

3 1/2-inch diskette drive 3 1/2-inch diskette drive is externally accessible.

One location for a 3 1/2-inch

removable media device

5 1/4-inch SCSI CD-ROM 5 1/4-inch CD-ROM drive is externally accessible.

Three locations f or 5 1/4 -

inch removable media

devices

12 locat ions f or 3 1/2-inc h

Ultra2 Wide SCSI-2 hard

drives

Hot swap-capable

backplane

Power supply From two to three 420 Watt autoranging power supplies are easily

Software: utilities, setup BIOS Setup, Resource Configuration Utility, and SCSISelect Utility. The

Security Mechanical: Key lock at the front door. One intrus ion se nsor for front door

One extern ally accessi ble 3 1/2-inch ha lf-heigh t bay is available for server

expansion.

Three externally accessible 5 1/4-inch half-height bays are available for

server expansion (diskette, CD-ROM, and/or tape drives).

Three hard disk drive cages; each holding up to four 3 1/2-inch hot-

swappable Ultra2 wide SCSI-2 hard drives. Each cage is secured behind

a metal EMI door; drives can be swapped in or out of the system without

powering it down. T he arr ay of drives allows eas y setup of RAID

applications.

A hot swap-capable backplane is part of each drive cage assembly for

SCSI hard drives. The backplane is designed for Ultra2 wide SCSI-2

devices that use the industry standard 80-pin Single Connector Attach

(SCA) connector. The backplane consists of a row of four drive

connectors.

removed/installed for service. In a three-supply system, the third supply is

redundant.

XPRESSBUILDER

E

CD-ROM contains the serve r management software.

to secure disk ette, hard disk, removabl e media devic e, pow er on/o f f

switch, reset switch, top cover, and left/right panel access. Three power

inter-lock sensors one on each side of the chassis and one on top of the

chassis. BIOS: Password enable.

CD-ROM contains the setup ut ilities a nd th e E SMPRO

System Overview 1-3

Page 20

Expanding the Server as Needs Grow

A typ ical mini mum sys te m config uration may includ e the following:

boa rd set co nsist i ng of sys te m I /O bo ard, CPU base bo ard w ith a

Pentium II Xeon processor, and a memory board

diskette drive and SCSI CD-ROM drive

three SCSI hard drive cages with one hard drive and a RAID contro ller

installed

ne t w o r k add - in bo a r ds

two 420 watt power supplies (an opt ional third power supply provides

redundant power)

onboard 2 MB video memory

system I/O board has two ISA slots and nine PCI slots for add-in boards.

The system I/O board also has a riser board for external I/O (serial,

parallel, video) interfaces.

chassis can hold six removable media drives: four 5 1/4-inch half-height

bays with a CD-R OM drive in s ta lle d in o ne bay; a nd t wo 3 1/ 2-inc h halfheight bays w ith a dis ket te dr ive installed.

As server/client needs grow, you can expand system processor capacity,

memory, drives, option boards, and the number of power supplies.

C PU base board ha s four slo ts fo r C PUs, for a configura ble ra nge of one,

two, three, or four processors.

Memory board supports 16 DIMM devices for up to a maximum memory

size of 4 GB.

System I/O board has eleven option board slots (two ISA and nine PCI).

C hassis can hold six re mova ble media drive s .

Three SCSI hard drive cages support up to 12 hot-swap bays for 3 1/2-

inch ultra wide SCSI-2 hard drives.

Confi gur a tion Cons tr ai nt s

The system has four 5 1/4-inch half-he ig ht ba ys access ib le fro m the front . These

bays are convenient for diskette, tape, and CD-ROM drives (removable media).

Because of the EMI generated by hard drives, the increased susceptibility to

ESD, and cooling requirements, hard drives should not be insta lled in the 5 1/4inch half- he ig ht bays.

1-4 System Overview

Page 21

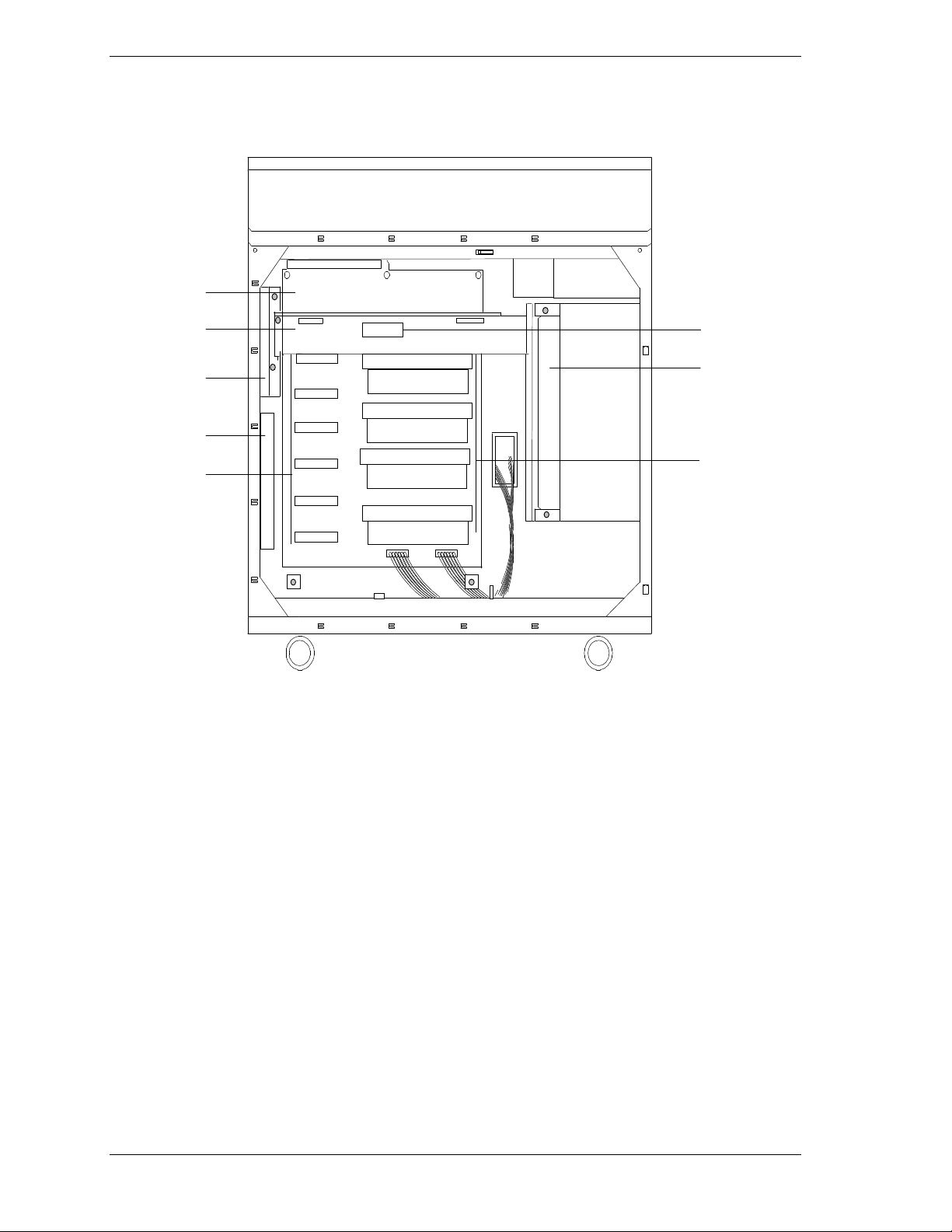

Chassis

Figure 1-1 shows the server fro nt chassis features and controls.

A

B

C

FGH

3

POWER

STATUS

DISK

D

E

I

A

Power LED When green, power i s present in syst em . When off, power is

turned of f or power s ourc e is disrupt ed. See Table 1-1 f or a

list and description of the system LEDs.

B

Status LED

C

Disk LED

D

Key lock

E

LCD panel

F

Drive pr esent /pow er on

G

Drive acti v e

H

Drive faulty.

I

Casters (4) Used when moving the server. Fixed by the caster hol ders.

When green the syst em is OK. S ee Table 1-1 f or a li st and

description of the system LEDs.

When green, in ternal disk drives are being accessed. See

Table 1-1 for a list and description of the system LEDs.

Secures both front external doors.

Displays information about BIOS and system failures (error

and diagnostic information).

Each drive has three LEDs visible above the bay from the

front. See Table 1-2 for a list of SCSI disk drive status LED

indicators.

Figure 1-1. Front Chassis Features and Controls

System Overview 1-5

Page 22

Status LED In dicator Descr iptions

Table 1-2 lists the system status LED indicators along with a description of each

LED indicator. Table 1-3 lists the disk drive status LED panel indicators along

with a description of each LED indicator. Table 1-4 lists system status abnormal

conditions.

Table 1-2. System Status LED Indicators

LED Status Description Response

Power Off Power OFF None required (normal)

Green Power ON None required (normal)

Amber System power supply

failure

Status Off Power OFF None required (normal)

Green No alarms None required (normal)

Amber Abnormal condition

(see Table 1- 4)

Disk Off Not accessing disk drives None required (normal)

Amber Internal disk drive failure Check disk drive status LEDs

Green Accessing disk drives None required (normal)

Replace failed power supply module.

Check condition

Table 1-3. Disk Drive Status LED Panel Indicators

LED Status Description Response

Disk Drive

Present

Disk Drive

Activity

Off Disk drive not present None required (normal)

Green Disk drive present None required (normal)

Off Not accessing disk drive None required (normal)

Disk Drive

Status

1-6 System Overview

On Accessing disk drive None required (normal)

Off No alarms None required (normal)

Amb er Disk dr ive failure Replace d isk drive.

Page 23

Table 1-4. System Status Abnormal Conditions

LED (Amber) Conditions

System Status Chassis intrusion (front cover)

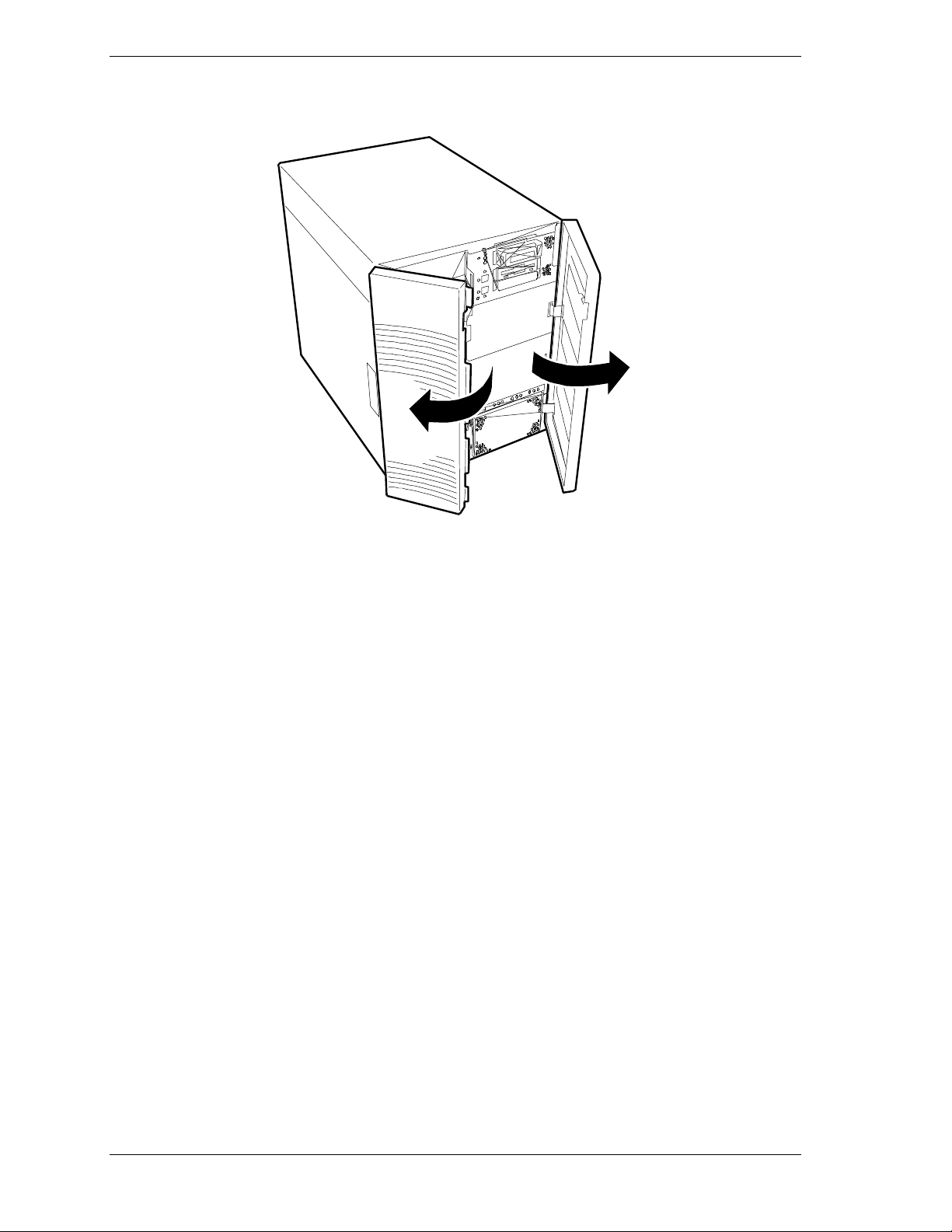

Opening the Front Doors

You must open the right front door to turn the server power on or off, reset the

server, mount or dismount a floppy disk, or mount or dismount a hard disk

drive. Open the left front door to mount or dismount 5 1/4-inch removable

media devices.

Open the front doo rs as follows.

Unit fan alarm

Memory multi-bit error (SERR)

P6 bus error (SERR)

Thermal sensor

Temperatur e

Voltage

CPU thermal trip

PCI PERR# (OPB/ESC detect)

PCI SERR#

CPU internal error

WDT

IOCHK

To open the front doors, you need to use the securit y key provided with the

1.

server. Insert the secur it y key into t he key slot and turn the key to the right

(see the following figure).

LOCK

UNLOCK

System Overview 1-7

Page 24

2. First open the right front door, then open the left door (see the following

figure).

1-8 System Overview

Page 25

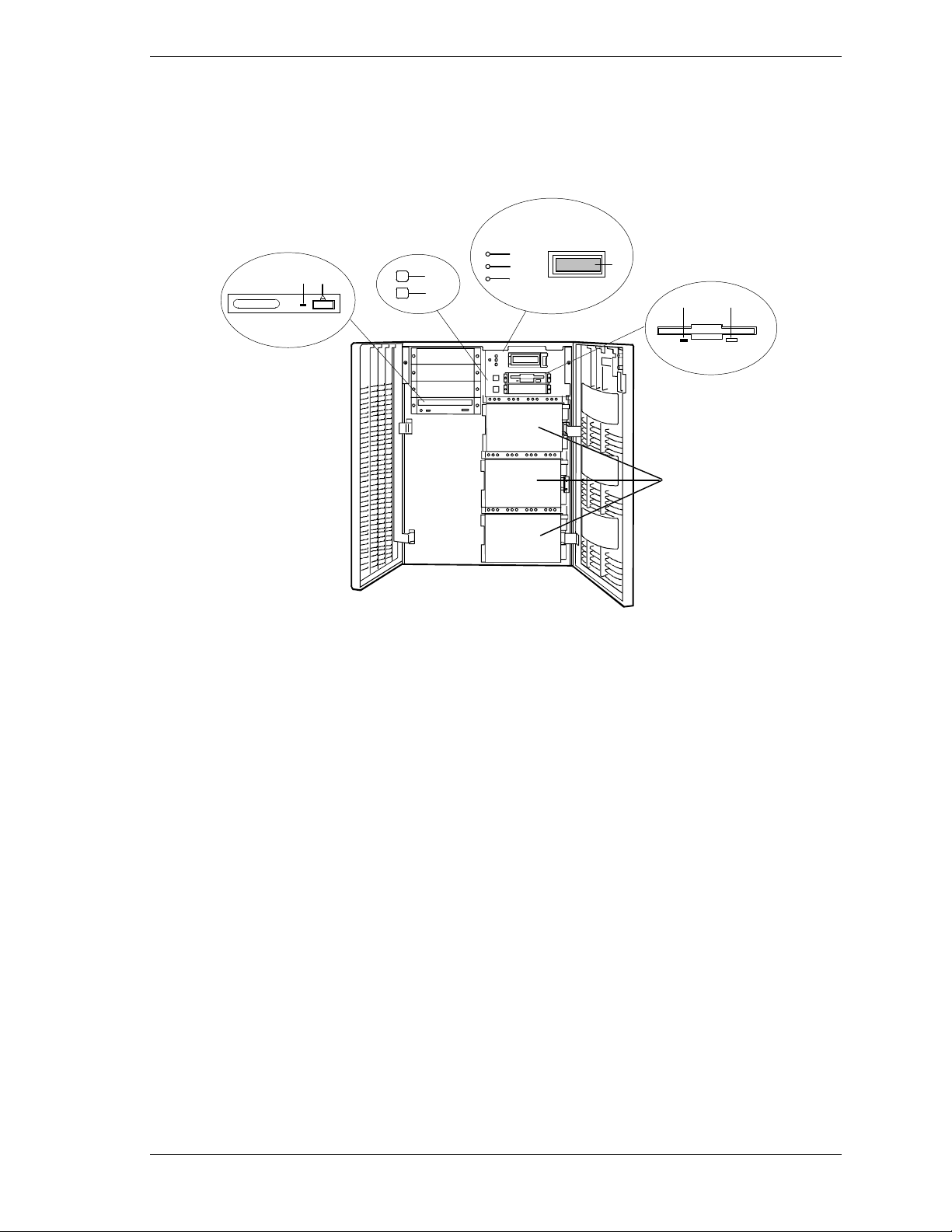

Chassis Fea tures and Con tr ol s

Figure 1-2 shows the server fro nt chassis features and controls. Figure 1-3

shows the server rear chassis features and co nt rols.

E

J

K

H

F

G

I

D

CB

A

A

SCSI hard drive cages Used to mount the hard disks. Each cage contains four disks with

their three status LEDs mounted above.

B

Ejector button, 3 1/2-inch

diskette drive

Press to eject diskette.

C

Activity light, 3 1/2-inch

diskette drive

D

LCD panel Displays information about BIOS and system failures (error and

E

Power LED When green, power i s present in syst em . When off, power is

F

Status LED When green the system is O K. See Ta ble 1 - 2 for a l ist and

G

Disk LED When green, internal disk drives are being accessed. See Table

H

DC power switch Press to turn system DC power on or off.

I

Reset switch Press to cause a hard reset to the system; the power-on self test

J

Load/eject button, CD-ROM

drive

K

Activity light, CD-ROM drive When lit, drive is in use.

When lit, dri ve is i n use.

diagnostic information).

turned of f or power s ourc e is disrupt ed. See Table 1-2 f or a li st

and description of the system LED indicators.

description of the system LED indicators.

1-2 for a list and description of the system LED indicators.

(POST) will run.

Press to load CD and eject CD.

Figure 1-2. Front Chassis Features and Controls (front doors opened)

System Overview 1-9

Page 26

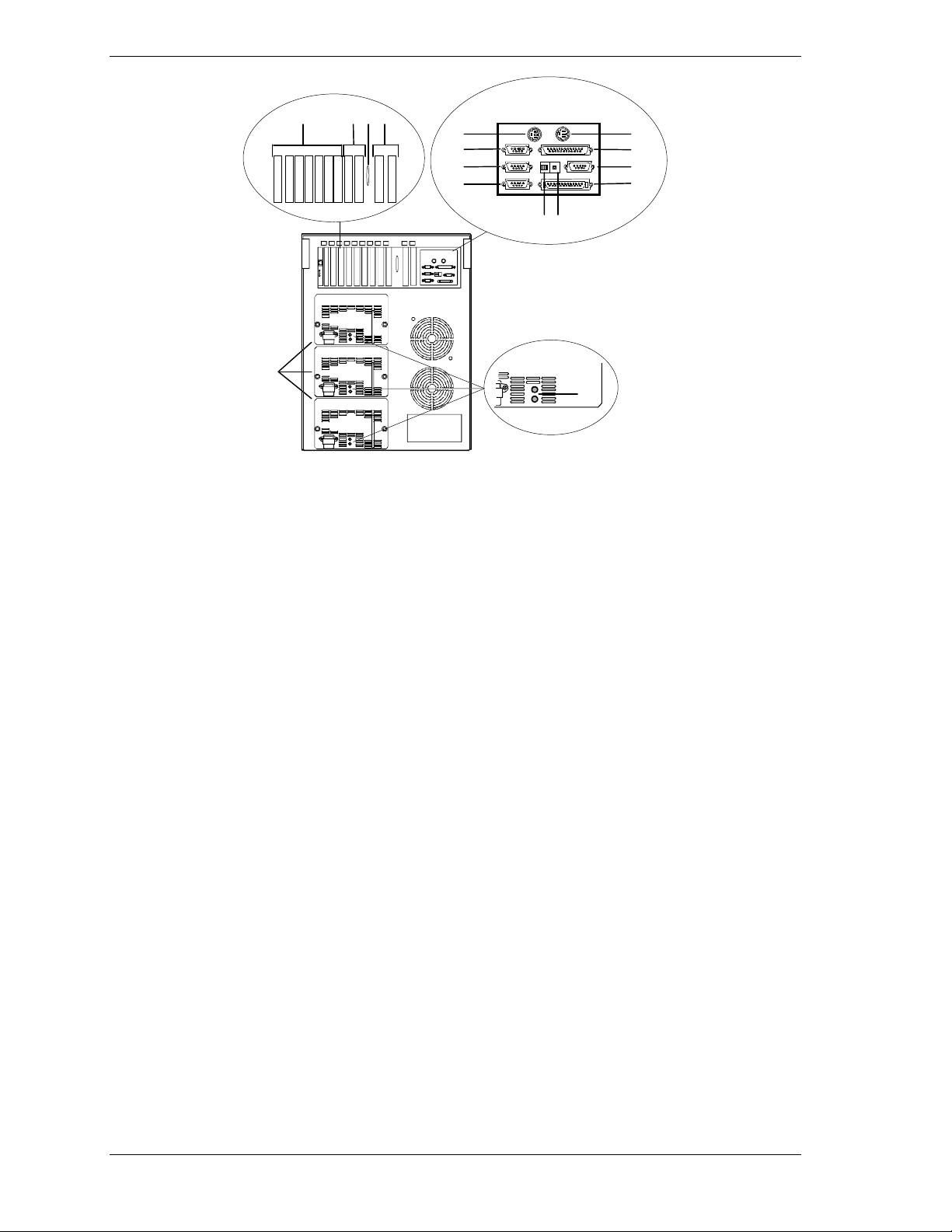

LONM

G

H

I

J

P

A Keyboard PS/2-c om p ati bl e 6- pi n mi ni- D I N c onnector.

B Printer LPT1 25-pin parallel port connector.

C VGA VGA mon it or 15-pin conn ec tor.

A

B

C

D

EF

K

D External-SCSI Narrow-SCSI 50-pin connector

See

E Dump button

F Function select

switches

G Mouse PS/2-compatible 6-pi n mini-DIN connect or.

H COM1 COM1 serial port 9-pin connector.

I COM2 COM2 serial port 9-pin connector.

J — Reserved.

K Power sta tus

LEDs

L PCI slots Two PCI add-in board slot locations (PCI #11 and PCI #12).

M Knocko ut Available to route SCSI signals to peripheral boxes.

N ISA slots Two ISA add-in board slot locations (ISA #1 and ISA #2).

O PCI slots Seven PCI add-in board slot locations (PCI #21, PCI #22, PCI #23, PCI #31, PCI #32, PCI

P Power supplies

(three shown)

Configuring Switch and Jumper Settings

See

Configuring Switch and Jumper Settings

Both indicators are gr een during normal op eration. Either or both indic ators go off when

power supply fails. See Table 1-1 for status descriptions.

#33, and PCI #34).

Possible configurations, installed from bottom most bay:

2 supp lies (nonredundant ), 3 supplies (one redundant).

Each power supply has a separate AC input power connector .

in Chapter 4 of this User’s Guide.

in Chapter 4 of this User’s Guide.

Figure 1-3. Rear Chassis Features and Controls

1-10 System Overview

Page 27

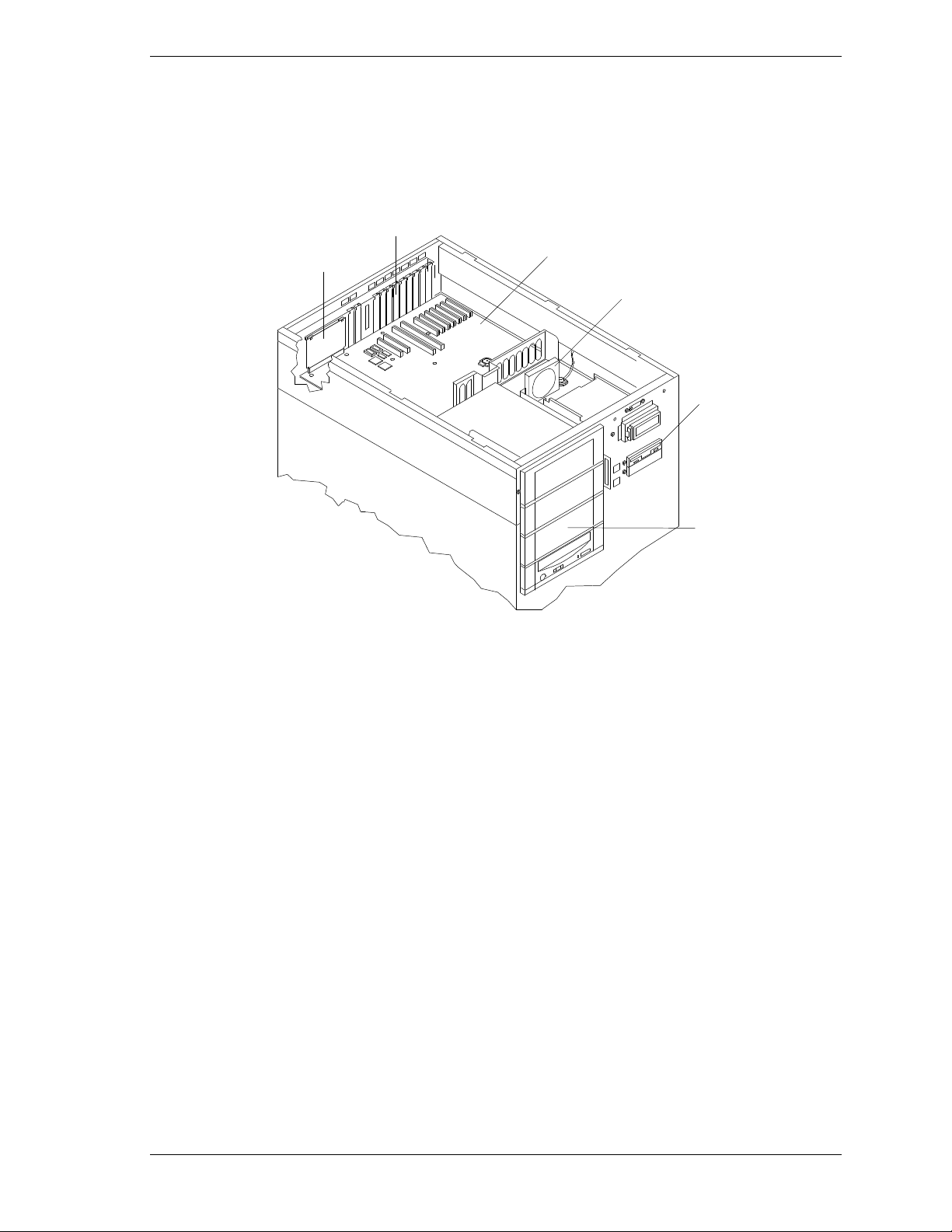

System Board Features

The board set includes the system I/O board, CPU base board, and a memory

board. The system I/O board is mou nted at the top of the system. Figure 1-4

shows the system with the top co ver removed.

F

E

A

System I/O Board

B

Option board Fan

C

Diskette drive

A

B

C

D

D

Four 5 1/4-inch half-height bays with a CD-ROM

drive installed in bottom bay

E

I/O ris er boa rd

F

Expansion slot covers

Figure 1-4. System I/O Board Location

System Overview 1-11

Page 28

The CPU base board plugs into the underside of the system I/O board and the

memory board plugs into the CPU base board. Figure 1-5 shows the system with

the left side cover removed.

A

B

C

D

E

H

F

G

A CPU base board

B Memory b oa rd

C Rear CPU fan

Figure 1-5. CPU Base Board and CPU Board Location

1-12 System Overview

D Rear CPU fan

E Voltage Regulator Module socket

(VRM1 - VRM6)

F Front CPU fan (2)

G Pentium II Xeon processors (1 - 4)

H Voltage Module Socket (memory)

Page 29

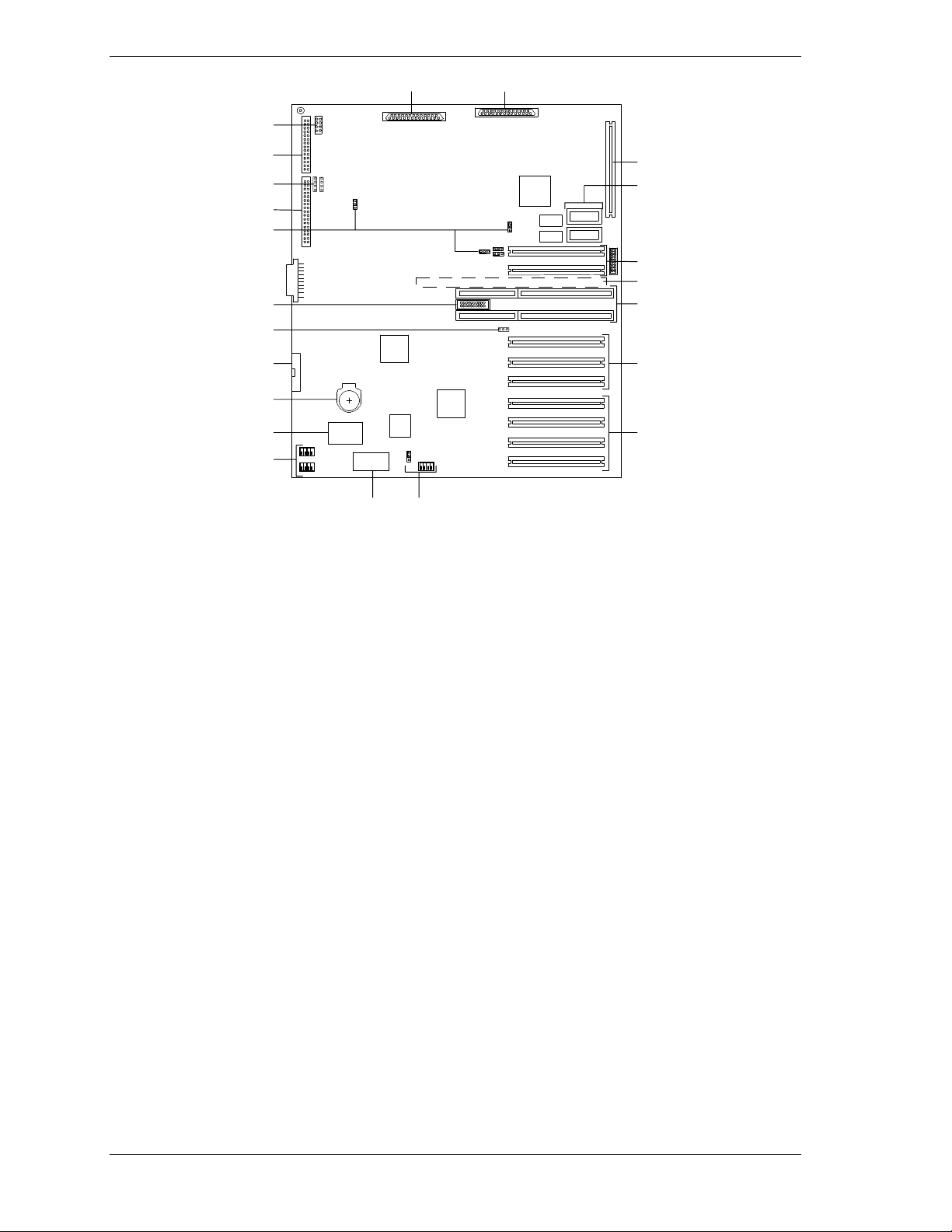

Figures 1-6, 1-7, and 1-8 show the major components on the system I/O board,

CPU base board, and Memory board. Table 1-5 summarizes t he featur es of the

boa rd set.

Table 1-5. Features of the Board Set

Feature Description

Multiple processor

slots

Upgradable

memory

Add-in board

support

SCSI controller Dual onboard SCSI-2 controller (PCI-based).

BIOS Flash memory-based BIOS (Basic Input/Output System ) and Setup

Video Integrated super VGA controller ships with either 1 MB or 2 MB of video

External device

connectors

Clock Real-time clock/calendar (RTC).

System hardware

monitoring

Configuration

utilities

Four processor sockets on the CPU base board, for a total of four

processors.

Sixteen DIMM sockets on the memory board, supporting up to 4 GB

memory us ing 256 MB DIMMs.

Two dedicated ISA bus slots and nine dedicated 32-bit PCI slots on the

system I/O board.

utilities.

memory. Upgrade socket (1 MB) is available for 1 MB system to

increase total video memory size to 2 MB.

Onboard connectors for two serial ports, parallel port, narrow SCSI port,

PS/2-compatible keyboard and mouse, and VGA monitor.

Detects chassis intrusion and contains sensors for temperature,

voltage, and fan failure.

Resource Config u ration Utility (RCU) and SCSISelect Utility.

System Overview 1-13

Page 30

HI

J

SM

T

K

L

M

N

O

P

Q

R

M

G

F

E

D

C

B

A

A

PCI expansion slots (#31, #32, #33, and #34)

B

PCI expansion slots (#21, #22, and #23)

C

ISA expansion slots (#1 and #2)

D

CPU base board connector (underside of board)

E

PCI expansion slots (#11 and #12)

F

Optional Video DRAM sockets

G

I/O riser board connector

H

SCSI channel B connector

I

SCSI channel A connector

J

SCSI status cable connector

K

Option board fan connector

L

Front panel connector

M

Configuration jumpers

N

Reserved

O

Reserved

P

Diskette connector

Q

Real time clock battery

R

Flash board

S

Non-v olati le memo ry

T

Figure 1-6. System I/O Board Connector and Component Locations

1-14 System Overview

Power st atus c able c onnector

Page 31

F

A

I

B

G

H

C

D

E

A CPU front fan connector

B Memo r y board connector

C Pentium II Xeon processor (1 - 4)

D CPU front fan connector

E Configuration switch

F CPU rear fan connector

G Voltage module socket (VRM1 - VRM6)

H CPU rear fan connector

I Voltage Module Socket (memory)

Figure 1-7. CPU Base Board Component Locations

C

A DI MM sockets

B Configuration jumper

C DI MM sockets

Figure 1-8. Memory Board Component Locations

System Overview 1-15

A

B

Page 32

Processor

Each Pentium II Xeo n processor is packaged in a single edge contact (S.E.C.)

cartridge. The cartridge includes the processor core with an integrated 16 KB

primary (L1) cache; the secondar y (L2) cache; a thermal plate; and a back cover.

The cartridge is secured by a retention module attached to t he baseboard.

Depending on configuration, your system has one to four processors (see

Figure 1-7). Additional Pentium processors enhance performance and enable

symmetric multiprocessing (SMP). All processors access the same me mory and

I/O space and tasks can run on either CPU if your op er ating system (OS)

supports SMP.

Memory

The Memory board contains sixteen 168-pin DIMM sockets (see Figure 1-8,

A and C). A minimum system configuration includes 128 MB (using four 32

MB DIMMs) o f syst em memory. Sixteen DIMM sockets allow for system

memory expansion up to 4 GB (using sixteen 256 MB DIMMs). ECC

generation/checking is provided for detection and correction of memory errors.

Note:

Only use DIMMs approved for use in this server

system. Call your custom er service representative f or

information.

Bus Master I/O Expansion Slots

The server's expansio n capab il it ies meet t he needs o f high performance I/O

servers by providing a combination of PCI local bus and ISA connectors. The

system I/O board offers nine dedicated PCI slots and two dedicated ISA slots.

The system I/O board contains two ISA bus master I/O (input/output) expansion

slots (see Figure 1-6, C). The ISA architectur e suppo rt s 32-bit memory

addressing and 16-bit data transfers for the CPU, DMA, and bus masters.

The system I/O board also contains nine PCI bus master I / O expansion slots

(Figure 1-6, A, B, and E).

Real-Time Clock/Calendar

The real-time clock provides syste m clock/calendar information stored in a nonvolatile memory (NVRAM). The real-time clock battery (see Figure 1-6, Q)

provides power backup for the real-time clock.

BIOS

A BIOS and Setup Utility are located in the Flash memory (see Figure 1-6, R)

on the system I/O board and include support for system setup and PCI/ISA

Plug-and-Play auto-configurat ion. A number of security, reliability, and

management features ar e also incor porated to meet vital server needs.

1-16 System Overview

Page 33

Video

The onboard super VGA controller (PCI ) is a high-perfor mance SVGA

subsystem that supports:

BIOS compatibility with VGA, EGA, CGA, Hercules Graphics, and

MDA

1 MB of Video Memory expandable to 2 MB (Figure 1-6, F)

16-bit bus for high-speed displa y memor y access

hardware accelerated bit block transfers ( BITBLT)

72Hz refresh, non-interlaced at: 640x480, 800x600, or 1280x1024

resolutions

up to 16M colors at 640x480 and 800x600 resolutions, 64K colors at

1024x768 resolutions and 256 colors at 1280x1024 resolutions with the

optional 2 MB video memory.

SVGA drivers may be required to use the hi gh-

Note:

performance video modes.

SCSI Controller

The system I/O board includes a dual Ultra2 w ide SCSI-2 controller (Adaptec

AIC-7895) integrated as a PCI bus master. This controller supports data paths of

8-bit (fast/narrow SCSI) at a data transfer rate of 10 MB/sec and 16-bit

(fast/wide or ultra /wide SCSI) at a data transfer rat e of 20 MB/sec or 40

MB/sec. As a PCI bus master, this controller supports burst data transfer rates

up to the maximum of 133 MB/sec.

On this server, channel B is cabled to the four SCSI devices in the removable

media dr ive bays . Channe l A is available for optio nal SCS I dev ices.

Peripher al C o ntroller

The advanced integrated peripheral contro ller support s two serial ports and one

parallel port through the I/O riser board (see Figure 1-6, G). The advanced

integrated peripheral controller also supports the connection of two diskette

drives (see Figure 1-6, P).

External Device Connectors

The I/O panel provides connector s for a PS/2 compatible mouse and a keyboard,

connectors for VGA monitor, two serial port connectors, and a parallel port

connector. It also provides a narrow SCSI external connector .

®

Keybo ar d an d Mo us e

The keyboard/mouse cont ro ller is PS/2-co mpat ible.

System Overview 1-17

Page 34

Fans

In addition to the power supply fans, the system has an option board fan (see

Figure 1-4, B) cabled to the I/O board (see Figure 1-6, K) and three CPU fans

(see Figure 1-5, C, D and F) cabled to the CPU base board (see Figure 1-7, A,

D, F and H). The three CPU fans (front and rear) are redundant in configuration.

If one fan fails, its associated fan changes its rotating speed to high.

Peripheral Devices

The following paragraphs describe the Ultra2 wide SCSI-2 hard drive bays and

5 1/4-inch removable media drive bays.

Ultra2 Wide SCSI-2 Hard Drive Bays

The right side of the system contains up to three Ultra2 wide SCSI hard drive

cages for 3 1/2-inch SCSI-2 hard drives (see Figure 1-9). Each hard drive cage

has a hot-swap backplane that supports four drives. The backplanes require an

80-pin single connector att achment (S CA) co nnector o n the drives you install.

A drive carrier is required as part of the hot swap implementation. A 3 1/2-inch

peripheral between 1.0 and 1.6 inches high can be accommodated in each

carrier. A drive is mounted in the carr ier with four fasteners, and the carrier is

retained in the chassis by a locking handle.

A fault light on the front panel board g ives a genera l indication that there has

been a fault on a hot-swap drive. Each drive has a set of three lights to indicate

the fault or other status: power-o n (green LED), activity (green LED), or fault

(yellow LED).

Three hard drive cages

(EMI panel and exterior door

shown open)

Figure 1-9. Ultra2 Wide SCSI-2 Hard Drive Bays

1-18 System Overview

Page 35

The backplane has two main functions: SCSI drive control and system dat a

logging. Drive status is monitored to detect failing drives and to control LED

indicator s. T he backplane features include the following:

insertion and removal of hard drives while power is on (referred to as

“hot swap”)

simplified cable management

SCA connectors to simplify inserting and removing hard drives

SCSI management of fault LEDs.

Each backplane supports SCSI drives with SCA connectors.

Removable Media Drive Bays

On the upper left side of the system, four 5 1/4-inch half-height bays (see

Figure 1-10) are designed for peripherals with removable media (diskette, CDROM, tape). Two available adjacent 5 1/4-inch bays can be converted to a

single full-height bay. The 5 1/4- inch drives can be removed directly from the

front of the chassis. Remova l o f the syst em top cover may be required to

install/remove the device cables. Cosmet ic filler panel are inst alled over all

unused 5 1/4-inch bays.

Factory-installed CD-ROM reader plus

three bays for removable media

drives.

Factory-installed 3 1/2-inch diskette

drive plus second bay for removable

3 1/2-inch drive.

(Exterior doors shown open)

Figure 1-10. Removable Media Drive Bays

On the upper right side of the system, below t he LCD panel, are two built-in

3 1/2-inch bays. One contains a 3 1/2-inch diskett e drive that supports both 720

KB and 1.44 MB media (see Figure 1-10).

The SCSI terminati on r esi stor s must be installed in

Note:

the last SCSI drive of the dai sy chain cabling (bottom media

bay). All other dev ic es must have terminators removed.

System Overview 1-19

Page 36

System Power

The system may be configured with up to three 420 Watt power supplies. Each

supply automatically switche s between these input voltage ranges:

100-120 VAC at 50/60 Hz; 7 A maximum current

200-240 VAC at 50/60 Hz; 3.5 A maximum current

Each power supply provides DC outputs of +5 V, +12 V, +3.3 V, -5 V, and

-12 V. All output grounds connect to the power supply chassis and to earth

ground through the AC line cord. Each supply has:

individual AC input line cord that plugs into the external side of the

power supply

isolating device on each DC output so that the failure of one supply does

not affect the operation of the others

cooling fan integra l with each power supply enclosure. The fan circuit

implements fan failure detection.

In a system, power is drawn equally from all supplies installed. A system with

two power supplies can be fully loaded (all drive bays and add-in board slots

filled). The supp lies use a forced cur r ent - shar ing technique t hat ensures the

supplies share within 10 percent at full load. In a high-access system with three

power supplies, the third supply gives redunda ncy, becau se the load is

redistributed if one supply fails.

Software Locks via the BIOS Setup

The BIOS Setup has software feat ur es t hat let you cont rol access to one or more

parts o f the s ystem:

set and enable an administrative password

set and enable a user password

enable password on boot

disable writing to the diskette drive when secure mode is set.

If only a supervisor password is set and enabled, enter this password to boot the

server and run the SCU.

If both the user and administrative passwords are set and enabled, enter either

one to boot the server. Enter t he ad ministrative password to access t he SCU or

BIOS Setup to change the system configuration.

1-20 System Overview

Page 37

Setting Up Your System

Selecting a Site

Unpacking the System

Moving the System to the Site

Getting Familiar With the System

Making Connections

Connecting the Power Cords

Powering On Your System

2

Page 38

Selecting a Site

The system operates r eliably in a t ypical o ffice en vironme nt . Choo se a site that

meets the following requirements.

Site the system near grounded, three-pronged power o utlets.

Note:

NEMA 5-15R outlets for 100-120 Vac or NEMA 6-15R

outlets for 200-240 Vac. For other international sites, this

means three-pronged power outlets applicable for the

electrical c ode of t he r egion.

Be sure the power service connec tion is through a properly

grounded outlet.

For the United States and Canada, this means

!

CAUTION

Each power cord can be plugged into a separate phase of a main AC

supply, assuming the circuit is rated for that load.

Note:

For Denmark, the system must be c onnec ted to an

AC power source rated at 16 amps.

Select a site that is clean, dust-free, and well vent ilated. Keep front and

rear ventilating op enings free o f obstr u ctions. Locate the system away

from sources of heat, vibration, or physical shock

I solate the system from stro ng e lectr omagnetic fields and electrical noise

produced by electrical devices (such as air cond it ioners, large fans, large

electric motors, radio and TV transmitters, and high-frequency security

devices)

T he site shou ld be spacious enough to pro vide at least five inches (13

centimeters) behind the system and three inches (eight centimeters) on

each side of the system for proper cooling, airflow, and cable clearance.

Allow at least 11 inches (27 centimeter s) in front of the system for proper

front door clearance.

P osition the syste m for easy access for system maintenance and

installation of system upgrades.

2-2 Setting Up Your System

Page 39

Unpacking the System

!

CAUTION

Your system weighs approximately 207 pounds (94 kg). To

avoid personal i njur y , mak e sure you hav e someone help

you lift or move the system.

When you receive your system, inspect the shipping co ntainers prior to

unpacking. If the shipping boxes are damaged, note the damage, and if possible,

photograph it for reference. After re moving the cont ent s of the containers, keep

the cartons and the packing materials. If the cont ent s appear damaged when you

unpack the boxes, file a damage claim with the carrier immediately. To unpack

your system, see the unpacking instr uctions on the shipping carton.

Moving the System to the Site

Once you have selected t he system installation site, move it as follows.

1.

Casters are pro v ided on the botto m of the server. S low ly push the server t o

the selected installation locat ion.

!

CAUTION

For safety reasons, be sure to attach the caster holders on

the casters when the system is at the selected site.

2.

To stabilize the syst em, attach the caster holders o n t he cast er s as sho wn

below.

Setting Up Your System 2 -3

Page 40

Getting Familiar With the System

Before sett ing up your system, see Chapter 1, “System Overview,” to become

familiar with syst em features, such as the location of your system's securit y

keylocks and front and rear panel switc hes, indicators and connectors, etc.

Making Connections

Connect your keyboard, monitor, and mouse (see Figure 2-1). Connect any

external peripheral devices such as a printer or modem by following the

instruct ions included with t hese devices. To connect external SCSI cables, refer

to Cabling in Appendix A.

Note:

cable is inserted or rem ov ed when power i s appl ied to the

system.

Inserting a telephone line connector into a LAN board RJ- 45

port may result in personal injury and equipment damage.

Damage to the system may result if the keyboar d

!

CAUTION

2-4 Setting Up Your System

Page 41

IIKJ

E

F

G

H

A

B

C

D

A. Keyboard, PS/2-compatible 6-pin connector

B. Printer, parallel port 25-pin connector

C. VGA monit or, 15-pi n connector

D. External-narrow SCSI, 50-pin high density connector

E. Mouse, PS/2-compatibl e 6-pin conn ector

F. COM1, serial port 9-pin connector

G. COM2, serial port 9-pin connector

H. Res erved, 9-p in co nnect or

I. PCI slots, nine PCI add-in board slots

J. Reserved, connector knockout

K. ISA slots, two ISA add-in board slots

Figure 2-1. Making Connections

Setting Up Your System 2 -5

Page 42

Connecting the Power Cords

Plug the female end of each AC power cord into the input receptacles on the

rear of the power supplies (see Figure 2-2). Plug the male end of each power

cord into NEMA 5-15R outlet for 100-120 Vac or NEMA 6-15R outlet for 200240 Vac. If the power cords supplied with the system are not compatible with

the AC wall outlet in your region, o bt ain a suitable power cor d that meets t he

following cr iter ia.

The power cord must be rated for the available AC voltage and have a

current rating that is at least 125% of the current rat ing of the system.

T he power cord connecto r t hat plugs into the wall outlet must be

terminated in a grounding-type male plug designed for use in your region.

It must have certification marks showing certification by an agency

acceptable in your region.

T he po wer cord connector that plugs into the system must be an IEC-

type CEE-22 female connector.

The power cord must be less than 1.8 meters (6.0 feet) long.

!

WARNING

Your system shipped with two AC power cords. Do not

attempt to modif y or use the supplied AC power cords if it

not the exact type requi r ed.

Figure 2-2. Connecting the AC Power Cord

2-6 Setting Up Your System

Page 43

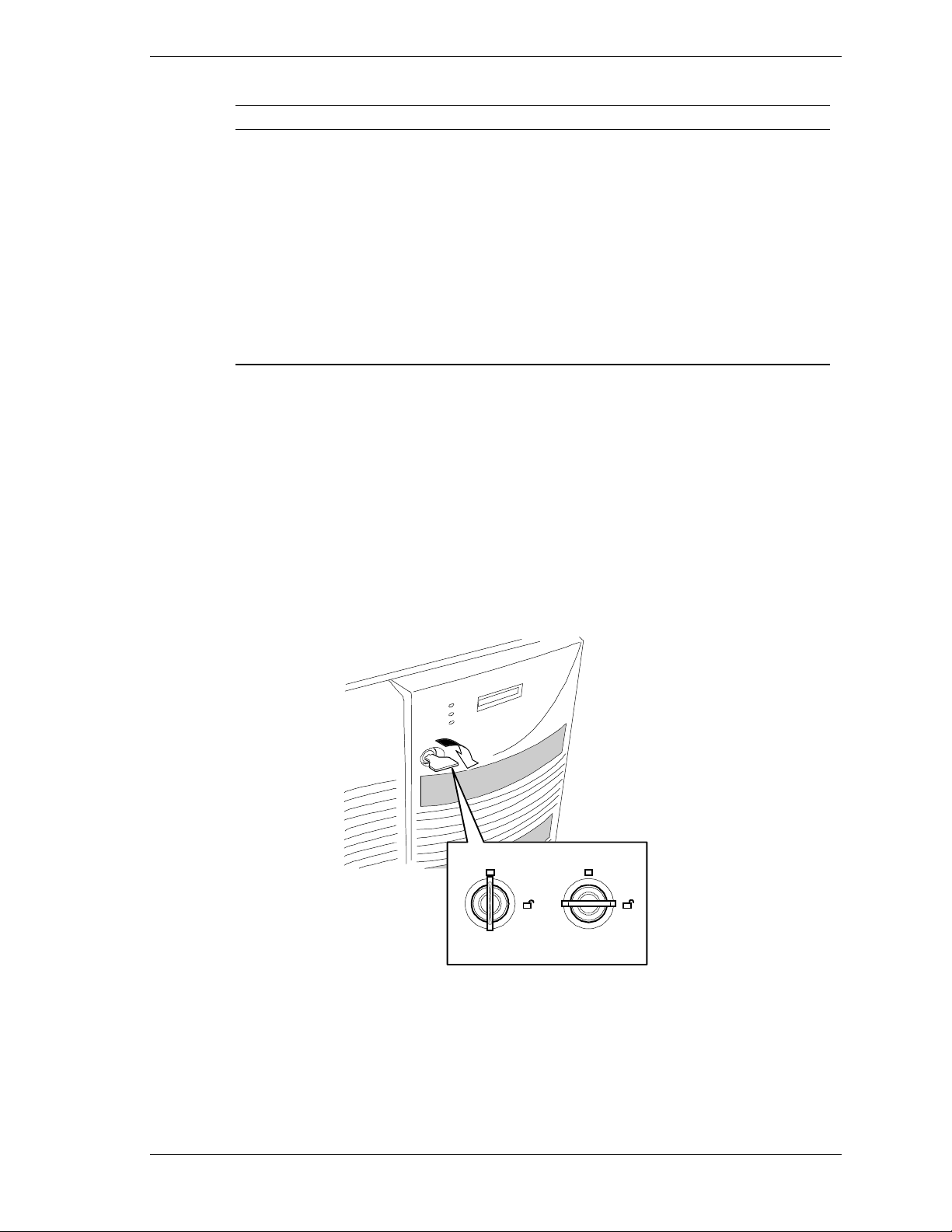

Powering On Your System

Power o n you r system as follows.

1. Make sure all external devices, such as a video display, keyboard, and

mouse (optional) have been connected, and t he power cor ds are connected.

2. Power on the video d isplay and any other external devices.

3. Open the right front door and press the power on/off switch on the front

panel (see Figure 2-3).

4. Verify that the Power LED is lit. If it is not lit, ensure the AC power cords

are connected to functional AC power sour ces.

After a few seconds your s yst em begins the internal Power-O n Se lf Tests

(POST). POST automatically checks the system, CPU module, memory,

keyboard, and most installed peripheral devices. If you have problems powering

on your system, refer to Problem Solving in Chap ter 6.

After you have successful l y powered on your system, verify that the system

boo ts to a DOS p r ompt . You can now run the E

XPRESSBUILDER

CD-ROM.

Power LED

Power On/Off Switch

Figure 2-3. Powering On Your System

Setting Up Your System 2 -7

Page 44

Page 45

Configuring Your System

Configuring Your System

Resource Configurat i on Utility (RCU)

BIOS Setup Utility

SCSISelect Utility

Viewing the Event Log

Configuring the RAID Controller

Configuring Syst em Jumpers and Switches

3

Page 46

Configuring Your System

Configuration and setup utilit ies are used to change your system configuration.

You can configure your system, as well as any option boards you may add to

your system, using the Resource Configuration Utility (RCU) diskette. Also,

several unique system parameters are configured using BIOS Setup (stored in

the system FLASH memory). A diskette is not needed to run BIOS Setup.

The SCSISelect Utility, also stored in the system FLASH memor y, is used if

you need to configure the SCSI controller in your system or to perform a SCSI

disk format or verify disk operation of these dr ives. A diskette is not needed to

run SCSISelect.

A Ut ilities d iskette contains the Event Log Utility. The Event Lo g Utility is used

to read stored syste m event information.

If your system has been factory configured, the RCU, BIOS Setup, or

SCSISelect utilities do not need to be run unless you want to change the

password or security features, add option boards or devices, or upgrade the

boards in your system.

There are some system configuration parameters that ar e set by jumpers.

However, these parameter s do not usua lly require change. F inally, the EZ-SCSI

utility is included with your s yste m. This program performs MS-DOS driver

installation for SCSI devices in your system a nd also inst alls ba sic utilities that

format a nd ma na ge SCSI hard disk drives . Refe r to the documentation supp lied

with the EZ-SCSI utility for more information.

The following provide procedures for running the RCU, BIOS Setup, and the

Utilities diskette. Also, a section describing t he syst em jumper configurations is

presented. Several configurat ion tables are a lso pro v ided to recor d changes you

make to the default system configuration.

You use the E

diskett e s.

XPRESSBUILDER

CD-ROM to create the RCU and Utilities

Resource Configuration Utility (RCU)

The Resource Configuration Utility is used to configure your system. The RCU

can be used to configure the memory subsystem, peripheral device subsystems,

and interface adapters. RCU recognizes ISA Plug-and-Play boards and PCI

boards and displays their configuration. ISA (non-Plug and Play) adapter boards

must be added to the RCU configuration to reserve the resources required by the

ISA boards.

After you add options using the RCU, the system automatically configures and

initializes them during system initialization at boot up.

3-2 Configuring Your System

Page 47

The RCU stores t he configuration information in the non-volat ile memory on

your system. When you exit the RCU, the configurat ion information is written

to non-volatile memory. The R C U also mainta ins the Set up co nfigura tio n,

which is stored in the batter y-backed me mory. This means that when you exit

the RCU, the Setup and RCU configurat ion agree with each ot her.

Using the RCU

If you are adding a non-Plug and Play ISA option board, run the RCU before

installing the board using procedures found in the Upgrades and Options

chapter of this guide. If you are upgrading system memory, do so before running

the RCU using procedures found in the Upgrades and Options chapter of this

guide. Use the RCU as fo llows.

Note:

configurati on. Always save the current settings before

reconfiguring the system.

The system can fail following improper

1. Power on the system.

2. If the diskette drive is disabled, enable it using the BIOS Setu p utility,

explained later (see BIOS Setup Utility). Specify the correct t ype of diskette

drive.

3. Using the E

XPRESSBUILDER

CD-ROM, create the RCU diskette. Note that the

CD-ROM refers to the RCU as the SCU.

4. Start the RCU by rebooting the system, with the RCU diskette in Drive A.

When the RCU banner is displayed, pr ess

and the Resource

Enter

Configuration Utility Main Menu shown in Table 3-1 displays.

5. Select Learn about configuring your computer from the RCU Main Menu

and press

through the information and press t he

6. Using the up and

. The Resource Configuration Utility Menu shown in Table 3-2

Enter

if you need information on system configuration. Read

Enter

key when you are done.

F10

down

arrows, highlight Configure Computer and press

displays. The keys that ar e active while viewing a screen are displayed on

the bottom of the screen.

Note:

additional information on each option. To retur n from help,

press

Press the F1 key at any time for help and

.

ESC

7. Select Step 1: Important System Configurat ion information and press

to learn more about the Resour ce Configurat ion Utility.

Configuring Your System 3-3

Enter

Page 48

8. Select Step 2 to add an ISA board to your system (see “ISA Board

Configuration”).

9. Select Step 3 to view your systems configurat ion settings. The normal

(default) RCU sett ings are sho wn in table 3-3.

Table 3-1. Resource Configuration Utility Main Menu

Menu Options Description

1. Learn about configuring your computer Provides basic instructions on system configuration and

using th e Help program.

2. Configure computer Lists automatically detected boards, and enables manually

adding, moving and removing boards. Plug-and-Play boards

don’t require configuration files. If the ISA board requires

configuration files, use “Add or remove boards” for a menu

to enter or change ISA board configurations. (See ISA

Board Configuration.)

INSERT adds a board not detected or has not been

installed.

DEL removes a selected board.

F7 moves a selected board to a different slot.

3. Set date Enables viewing and changing the date that the computer

uses.

4. Set time Enables viewing and changing the time that the computer

uses.

5. Maintain system configuration diskette Enables viewing and changing Configuration (.CFG) files

and System Configuration Infor ma tion (SCI ) files.

6. Exit from this utility Exits from the RCU.

Table 3-2. Resource Configuration Utility Menu

Menu Options Description

Step 1. Important System configuration

information.

Step 2. Add and remove boards Lists automatically detected boards, and enables manually

Step 3. View and Edit Details Enables viewing and changing your system configuration

Step 4. Examine Switches or Print Report Enables viewing the required switch and jumper settings

Step 5. Save and Exit Allows you to save your configuration and exits to the

Provides information on the Resource Configuration

program and how it differs from ISA board configuration.

adding, moving and removing boards. Plug-and-Play boards

don’t require configuration files. This list shows all the

boards and options that will be installed in your system.

settings including embedded features, functionality, IRQs,

and port selections. Perform Step 3 only if you need to

change the system default settings.

and allows printing of a configuration report.

operating system. You can also exit without saving.

3-4 Configuring Your System

Page 49

RCU Command Line Parameters

There are RCU options that can be enabled by star ting the RCU from the

command line with the appropr iate sw itch listed below. To enable an option,

insert the RCU diskette in drive A and type

followed by one of these command line parameters:

/HHigh resolution display. Sets the display mode to 43 lines for an EGA

add-in video controller board or to 50 lines for a VGA board. T he default is

25 lines for all add-in video controller boards.

/M Mono chr ome display. The d isplay screens are s ho w n us ing

monochro me attr ibutes, even o n a co lor display. The de fault is to display

color, unless a monochro me video display is detected. Use this parameter

when you have redirected the conso le to one of the onboard ser ial ports.

RCU Configuration Settings

Table 3-3 sho ws the recommended RCU settings for a sample system and

provides a place for you to record any changes you make to the settings. To

display the configuration settings, select St ep 3 under the Resour ce

Configuration Utility Menu. To edit any of the configurat ion parameters, use the

up and down arrows to highlight the desired configuration parameter and press

. Press ing F6 at this point allows you to edit any of the parameters

Enter

resources (IRQs, DMAs, I/O ports or memory).

at the MS-DOS prompt,

A:SD

Table 3-3. RCU Configurations

Main Menu Normal Setting Your Configuration

System - Express 5800 HX4500 System Board

RS - 232 COM Port 1 PORT 3F8h - 3FFh IRQ 4

RS - 232 COM Port 2 PORT 2F8h - 2FFh IRQ 3

Parallel Port PORT 378h - 37Fh IRQ 7

Floppy Controller Enabled

Mouse Controller Enabled

PCI -2 - PCI Ether net Contr oller

PCI Function 1 Enabled

PCI -3 - PCI Ether net Contr oller

PCI Function 1 Enabled

Embedded - PCI PCI Bridge - Bus 2

PCI Function 1 Enabled

Embedded - PCI SCSI Controller

PCI Function 1

PCI Function 2

Embedded - PCI VGA Controller

PCI Function 1

Standard VGA Resources

Enabled

Enabled

Enabled

Enabled

Configuring Your System 3-5

Page 50

ISA Board Configuration

If adding a non-Plug and Play ISA board to your system, use the following

procedures to define and add the option board. It’s necessary to define an ISA

board to prevent other boards in the system from using the same IRQ levels,

DMA channels, I/O port addresses, or memory addresses, that your I S A board

uses.

You must run the RCU and add the ISA board to the configurat ion before

installing the ISA board in the system. Otherwise, the reso urces on the ISA

board may conflict with a Plug-and-Plug board in the system.

BIOS automatically assigns ISA P lug-and-P lug boards t o the next availa ble slot .

If the slot displayed in Step 2: “Add or Remove Boards” is not the actual slot, it

can be moved by using the F7 function key.

IRQ levels, DMA channels, I/O port addr esses,

Note:

and memory addresses defined using this procedure should

reflect the same setti ngs defined by supplied jumpers and/or

configurati on doc um ents.

1.

Insert the RCU diskett e into dr ive A: and power o n t he system. The syst em

boots-up using the RCU diskette.

2.

The RCU Main Menu shown in Table 3-1 is displayed. At the Startup Menu,

enter choice 2, Configure Computer.

3.

The Resource Configuration Utility Menu shown in Table 3-2 is displayed.

Select Step 2 Add or Remove Boards and press

4.

The Step 2: Add or remove boards screen is disp layed. At this scree n s elect

Add by pressing

5.

The Add screen is displayed telling you to locate t he diskette that contains

Insert

the .cfg file for the board. Press

6.

The Select a Configuration (CFG) file to add screen is displayed. At this

.

Enter

at this screen.

Enter

.

screen select No t L i st ed by pressing F5.

7.

The Add a board without a .cfg file screen is displayed. Read through the

information and press

. The Add a board without a .cfg file screen

Enter

reappears. When t he screen reappears select Create .cfg file and press

8.

The Create A Board CFG File screen is displayed. At this screen ente r t he

board description and manufacturer and press

9.

The New Board Setup scr een is displayed. Using t he s c rollable lis t se lect the

Enter

.

resources used by the new ISA board. Table 3-4 pro vides a place for you to

record the configuration you assign to the board.

Enter

.

10.

Press

when you are finished selecting the resources used by the new

F10

ISA board.

3-6 Configuring Your System

Page 51

11. The View Current Settings screen is d isplayed. Pr ess

Enter

to save the

current settings.

12. The Add confirmation screen is displayed. Review the manufacturer’ s

comments and press

Table 3-4. ISA Board Configurations

ISA Board Definitions Your Configuration

Board Description:

Manufacturer:

Interrupts (Select from scrollable list)

DMA Channels (Select fro m scrollable list )

Port address (Select from scrollable list)

Start

End

Mem ory addres s (Sel ect fr om scrollable l ist)

Start

Length

Enter

.

Slot (Select from scrollable list)

13. The Add screen is displayed. Select the slot in w hich you want to install the

board and press

Note:

configurati on, a Caution message is displayed. Pr ess

at the message. This l eads you t o screens that allow you to

resolve the conflic t.

If the board you add causes a conflict in the

Enter

.

Enter

14. The Step 2: Add or remove boards screen is displayed . At this screen se lect

Done by pressing

F10

.

15. The Steps in configuring your computer screen is displayed. At this screen

select “Step 4: Examine switches or print report” and press

Enter

.

16. The Step 4: Examine switches or print report screen is displayed. T he

boards marked with an arrow indicate that the boards in your system may

have jumpers and switc hes t hat you must physica lly verify or that a software

statement with additional information about the board is provided. Select

Done by pressing

F10

.

Note:

configurati on does not have switches, jumpers, software

statements, or connection information, an Information

message appears on the screen. Pres s

to the next step.

If the ISA board you are adding to the

Enter

and proceed

Configuring Your System 3-7

Page 52

17. The Steps in configuring your computer screen is displayed. At this screen

select “Step 5: Save and exit” and press

Enter

.

18. The Save and exit screen is displayed. At this screen se lect “Save the

configuration and restart t he co mputer” and press

Enter

.

19. The Reboot screen is displayed. At t h is screen press

20. Now that you have reserved the syst em resources, you can insta ll the ISA

board.

BIOS Setup Utility

The BIOS Setup Utility, like the RCU, is used to change system configuration

parameters. This utility has several unique parameters and many parameters that

are also configurable w ith the RCU. The utility is reside nt in the syst em FLASH

memory and does not require a diskette or an oper ating syste m present to run.

However, some parameters set with the BIOS Setup Utility that can also be set

with the RCU, are overwritten by the RCU the next time the RCU is run.

Using the BIOS Setup Utility

You access the BIOS S et up Utility when you tu r n o n or reboot your system. To

run the BIOS Setup Utility, perform the following pro cedur e.

1. Power on or reboot the system. BIOS displays the following:

Press <F2> to enter SETUP

Enter

.

2. Press F2. After BIOS POST completes, the BIOS Setup Utility starts and the

Main Menu is displayed. The menu bar at the top o f the Main Me nu lists t he

following selections.

Menu Use

Main Use this menu for basic system configuration.

Adv anced Use thi s men u f or settin g the Advanced Fea tures availabl e on your

system.

Security Use this menu to set User and Supervisor Passwords and the Backup

and Virus-Check reminders.

Server Use this menu for confi guring Server Features.

Exit Exits the current menu.

Use the arrow keys to select a menu or an ite m on a displayed menu. Press

the value keys (listed in the table below) to cycle through the allowable

values for the selected field. Use the Exit menu’s “Save Values” select ion to

save the c urrent values on a ll the menus.

To display a submenu, posit ion the curso r on a selection that has a submenu

and press

. Selections with submenus are preceded by an arrow.

Enter

3-8 Configuring Your System

Page 53

See the following table for information on the keys you use with Setup.

These keys are also listed at the bottom of the Setup menu.

Key Function in Setup Menu

F1 or Alt-H General Help window.

ESC Exit the curr ent m enu.

← or → arrow keys

↑ or ↓ arrow keys

TAB or SHIFT-TAB Cycle cursor up and down.

HOME or EN D Move cursor to top or bottom of wi ndow.

PAGE UP or PAGE DOWN Move cursor to next or previous page.

F5 o r - Select the previous val ue for the field.

F6 or + or SPACE Select the next value for the field.

F9 Load default configuration values for this menu.

F10 Load previous configuration values for this menu.

ENTER

ALT-R Refresh the s creen.

Select a different menu.

Move cur sor up and dow n. The cursor moves only to the

settings that you can change.

Exec ute c omma nd or Select

BIOS Setup Configuration Settings

Table 3-5 shows the normal settings for the BIOS Setup Utility and provides a

place for you to record any changes you make to these settings.

➨

submenu.

Exiting BIOS Setup

To exit Se tup, select Ex it from the me n u bar to dis pl ay th e Exit Setup me nu.

The following describes the options on this menu. Note that ESC does not exit

t his me n u. You must select one of the items from the menu or me nu bar to exit

this menu.

Selection Description

Save changes and Exit Stores the selections displayed in the menus in CMOS and exits

Exit without Saving

Changes

Get Default Values Displays default values for all Setup menus. Useful if BIOS

Load Previous Values Reverts to previously saved values if the new values have not

Save Changes Stores the current selections without exiting the Setup program.

the Setup program.

Exits the program without saving any changes you have made in

this session. Previous selections remain in effect.

detects a problem with the values stored in CMOS.

been saved to CMOS.

Configuring Your System 3-9

Page 54

Table 3-5. BIOS Setup Configurations, Main Menu

Menu Parameter Name Normal Setting or

Display Only

MAIN MENU

System Time

Enter current time (hour, minutes, seconds on

24 hour clock).

System Date

Enter current date.

*Diskette A:

Use +/- to change values; indicates the type of

diskette drive installed.

*Diskette B:

Use +/- to change values; indicates the type of

diskette dri ve ins tall ed (Not Inst alled in your

system).

Memory Cache

Press Enter for menu.

Memory Cache Enabled

Cac he Sys tem BIOS Area Write Protec ted

Cac he Video BIOS Area Write Protec ted

Cache Base 0 - 512K Write Back

Current Time