Page 1

Express5800/320Ma:

Operation and Maintenance Guide

NEC Solutions (America), Inc.

NR574

Page 2

Notice

The information contained in this document is subject to change without notice.

UNLESS EXPRESSLY SET FORTH IN A WRITTEN AGREEMENT SIGNED BY AN AUTHORIZED REPRESENTATIVE

OF NEC, NEC MAKES NO WARRANTY OR REPRESENTATION OF ANY KIND WITH RESPECT TO THE

INFORMATION CONTAINED HEREIN, INCLUDING WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PURPOSE. NEC assumes no responsibility or obligation of any kind for any errors contained herein or in connection with

the furnishing, performance, or use of this document.

Software described in NEC (a) is the property of NEC and/or its licensees, (b) is furnished only under license, and (c) may

be copied or used only as expressly permitted under the terms of the license.

NEC documentation describes all supported features of the user interfaces and the application programming interfaces

(API) developed by NEC and/or its licensees. Any undocumented features of these interfaces are intended solely for use

by NEC personnel and are subject to change without warning.

This document is protected by copyright. All rights are reserved. No part of this document may be copied, reproduced, or

translated, either mechanically or electronically, without the prior written consent of NEC Solutions (America), Inc.

The NEC Solutions (America), Inc. logo, Express5800/320Ma, and the Express5800/320Ma logo, are trademarks of NEC

Solutions (America), Inc. ActiveService Network is a trademark of Stratus Technologies Bermuda, Ltd. All other

trademarks and trade names are the property of their respective owners.

Manual Name: Express5800/320Ma: Operation and Maintenance Guide

Part Number: NR574

Express5800/320Ma Software Release Number: 4.1.0

Publication Date: January 2006

NEC Solutions (America), Inc.

10850 Gold Center Drive, Suite 200

Rancho Cordova, CA 95670

© 2006 NEC Solutions (America), Inc. All rights reserved.

Page 3

Contents

Preface ix

1. Overview of Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core

Systems 1-1

System Design 1-1

System Features 1-2

System Components and CRUs 1-3

2. Hardware Operation 2-1

Standby Power 2-1

System Power 2-1

Starting Up the System 2-2

Shutting Down the System 2-2

Fan Speed 2-3

3. Troubleshooting the Hardware 3-1

System LEDs 3-1

CPU-I/O Enclosure Status LEDs 3-3

SATA Disk-Drive LED 3-5

PCI Slot Status LEDs 3-7

Ethernet Port and VTM Port LEDs 3-8

Modem Assembly LEDs 3-10

General Disk Drive Problems and Solutions 3-12

CD- or DVD-Drive Problems and Solutions 3-13

Using the Dump Button to Create a Dump File 3-15

4. General Servicing Information 4-1

Unpacking CRUs 4-1

Storing CRUs 4-2

Repacking CRUs 4-3

Contents iii

Page 4

Contents

Replacing a CRU 4-3

General Safety Precautions 4-4

5. CRU Replacement Procedures 5-1

Before Replacing CRUs 5-1

Using ESD Precautions 5-2

Tools 5-3

Removing and Replacing the Bezel 5-3

Removing and Replacing a CPU-I/O Enclosure 5-4

Removing a CPU-I/O Enclosure 5-5

Replacing a CPU-I/O Enclosure 5-8

Replacing the System Backplane Assembly 5-10

Removing the System Backplane Assembly 5-10

Replacing the System Backplane Assembly 5-12

Resetting the Ethernet Address of an Ethernet Team 5-14

Removing and Replacing a CPU-I/O Enclosure Cover 5-15

Removing an Enclosure Cover 5-17

Replacing an Enclosure Cover 5-18

Replacing or Installing a PCI Adapter 5-19

Removing a PCI Adapter 5-20

Installing a PCI Adapter 5-23

Removing and Replacing the PCI Riser Assembly 5-27

Removing the PCI Riser Assembly 5-27

Replacing the PCI Riser Assembly 5-31

Removing and Inserting a SATA Disk Drive 5-32

Replacing a SATA Backplane Assembly 5-34

Removing and Replacing a CD or DVD Drive 5-36

Removing a CD or DVD Drive 5-36

Replacing a CD or DVD Drive 5-37

Replacing an IDE Backplane Assembly 5-38

Replacing a CPU Fan 5-42

Replacing a Power Supply Unit Fan 5-45

Replacing or Installing a VTM 5-48

Removing a VTM 5-48

Installing a VTM 5-49

Replacing or Installing a Modem Assembly 5-49

Removing a Modem Assembly 5-50

Installing the Modem Assembly 5-51

iv Express5800/320Ma: Operation and Maintenance Guide

Page 5

Appendix A. Installing the AK533 Kit in an

Express5800/320Ma 3.2 GHz System A-1

Index Index-1

Contents

Contents v

Page 6

Figures

Figure 1-1. Main Enclosures of Express5800/320Ma 3.2 GHz, 3.6 GHz, and

Dual-Core Systems 1-3

Figure 1-2. CPU-I/O Enclosure: Front Panel 1-5

Figure 1-3. CPU-I/O Enclosure: Rear Panel 1-5

Figure 1-4. CPU-I/O Enclosure: Interior Components 1-6

Figure 1-5. System Backplane Assembly 1-7

Figure 3-1. CPU-I/O Enclosure Status LEDs 3-3

Figure 3-2. SATA Disk-Drive LED 3-5

Figure 3-3. PCI Slot LEDs 3-7

Figure 3-4. Ethernet Port and VTM Port LEDs 3-9

Figure 3-5. Modem Assembly LEDs 3-10

Figure 3-6. Pressing the Dump Button 3-15

Figure 4-1. Shipping Impact Indicators 4-2

Figure 5-1. Removing the Bezel 5-4

Figure 5-2. Unlocking the Rear Interlock on an Enclosure 5-6

Figure 5-3. Unlocking the Front Release Levers on an Enclosure 5-7

Figure 5-4. Removing a CPU-I/O Enclosure 5-7

Figure 5-5. Removing the System Backplane Assembly 5-12

Figure 5-6. Changing the Mode of an Ethernet Team 5-15

Figure 5-7. Removing an Enclosure Cover 5-17

Figure 5-8. Replacing an Enclosure Cover 5-18

Figure 5-9. PCI Slot Locations 5-19

Figure 5-10. Stabilizing the PCI Riser Assembly 5-21

Figure 5-11. Removing the PCI Adapter Support Clip 5-21

Figure 5-12. Removing a PCI Adapter from PCI Slot 1 5-22

Figure 5-13. Removing a PCI Adapter from the PCI Riser Assembly 5-23

Figure 5-14. Removing the Blank PCI Slot Faceplate from Slot 1 5-24

Figure 5-15. Storing a Blank PCI Faceplate 5-25

Figure 5-16. Removing the Blank PCI Faceplate from Slot 2 or 3 5-26

Figure 5-17. Releasing the PCI Adapter Supports 5-28

Figure 5-18. Unlocking the Dual PCI Cover 5-29

Figure 5-19. Removing the PCI Riser Assembly 5-30

Figure 5-20. Removing a SATA Disk Drive 5-33

Figure 5-21. Removing the SATA Backplane Assembly 5-35

Figure 5-22. Removing a CD or DVD Drive 5-37

Figure 5-23. Removing the IDE Ribbon Cable from the IDE Backplane

Assembly 5-39

Figure 5-24. Removing the Screws from the IDE Backplane 5-40

vi Express5800/320Ma: Operation and Maintenance Guide

Page 7

Figure 5-25. Routing Power Cables Through the Chassis Divider 5-41

Figure 5-26. Disconnecting a CPU-Fan Power Connector 5-43

Figure 5-27. Removing a CPU Fan 5-44

Figure 5-28. Disconnecting the PSU-Fan Power Connector 5-46

Figure 5-29. Removing the PSU Fan 5-47

Figure 5-30. Removing the VTM 5-48

Figure 5-31. Removing the Modem Module 5-51

Figure A-1. Stabilizing the PCI Riser Assembly A-2

Figure A-2. Installing the PCI Adapter Support Clip A-3

Figure A-3. Installing the PCI Support Bracket A-4

Figure A-4. Removing the Blank PCI Filler Panel A-4

Figure A-5. Installing the Dual-PCI Cover A-5

Figure A-6. Installing the Blank PCI Faceplate in Slot 2 or 3 A-6

Figure A-7. Storing a Blank PCI Faceplate A-6

Figure A-8. Releasing the PCI Adapter Supports A-7

Figure A-9. Installing the PCI Riser Assembly A-8

Figures

Figures vii

Page 8

Tables

Table 1-1. Standard CRUs of Express5800/320Ma 3.2 GHz, 3.6 GHz, and

Dual-Core systems 1-4

Table 1-2. Optional CRUs and Components 1-4

Table 3-1. General Status LED Meanings 3-2

Table 3-2. CPU-I/O Enclosure Status LEDs 3-4

Table 3-3. SATA Disk Drive LED 3-6

Table 3-4. PCI Slot Status LEDs 3-8

Table 3-5. Ethernet Port LED States 3-9

Table 3-6. VTM Port LED States 3-10

Table 3-7. Modem Assembly LEDs 3-11

Table 3-8. Troubleshooting Disk Drives 3-12

Table 3-9. Troubleshooting the CD or DVD Drive 3-14

viii Express5800/320Ma: Operation and Maintenance Guide

Page 9

Purpose of This Manual

The Express5800/320Ma: Operation and Maintenance Guide documents how to

operate and maintain Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems.

It explains how to start up and shut down the system, how to interpret system

operational status based on the state of the light-emitting diodes (LEDs), and how to

remove and replace the customer-replaceable units (CRUs).

Audience

This manual is intended for anyone who monitors and maintains Express5800/320Ma

3.2 GHz, 3.6 GHz, and Dual-Core system hardware.

Notation Conventions

This document uses the notation conventions described in this section.

Warnings, Cautions, and Notes

Warnings, cautions, and notes provide special information and have the following

meanings:

Preface

WARNING

!

A warning indicates a situation where failure to take

or avoid a specified action could cause bodily harm or

loss of life.

CAUTION

!

A caution indicates a situation where failure to take or

avoid a specified action could damage a hardware device,

program, system, or data.

NOTE

A note provides important information about the operation

of a system.

Preface ix

Page 10

Preface

Typographical Conventions

The following typographical conventions are used in Express5800/320Ma system

documents:

• The bold font emphasizes words in text or indicates text that you type, the name of

a screen object, or the name of a programming element. For example:

Before handling or replacing system components, make sure that you are

properly grounded by using a grounded wrist strap.

In the System Properties dialog box, click the Hardware tab.

Call the RegisterDeviceNotification function.

• The italic font introduces new terms and indicates programming and command-line

arguments that the user defines. For example:

Many hardware components are customer-replaceable units (CRUs), which

can be replaced on-site by system administrators with minimal training or tools.

copy filename1 filename2

Pass a pointer for the NotificationFilter parameter

• The monospace font indicates sample program code and output, including

message text. For example:

Getting Help

If you have a technical question about Express5800/320Ma hardware or software, try

these online resources first:

• Online support from NEC Technical Support. You can find the latest technical

information about an Express5800/320Ma through online product support at the

NEC Technical Support Web site:

• Online product support for Microsoft

support is the computer manufacturer who provided your software, or an

authorized Microsoft Support Provider. You can also find the latest technical

information about Microsoft Windows

product support at the Microsoft Help and Support Web site:

#include <iostream.h>

The operation completed successfully.

http://support.necsam.com/servers/

®

products. Your primary source for

®

and other Microsoft products through online

http://support.microsoft.com/

x Express5800/320Ma: Operation and Maintenance Guide

Page 11

Notices

Preface

If you are unable to resolve your questions with the help available at these online sites,

and the Express5800/320Ma system is covered by a service agreement, please

contact NEC Technical Support (866-269-1239).

• All regulatory notices are provided in the site planning guide for your system.

• Although this guide documents modem functionality, modems are not available for

all systems. Ask your sales representative about modem availability.

• ActiveService Network (ASN) is not currently available, but may be ordered in the

future.

Preface xi

Page 12

Preface

xii Express5800/320Ma: Operation and Maintenance Guide

Page 13

Chapter 1

Overview of Express5800/320Ma 3.2

The following sections provide an overview of Express5800/320Ma 3.2 GHz, 3.6 GHz,

and Dual-Core systems:

• “System Design” on page 1-1

• “System Features” on page 1-2

• “System Components and CRUs” on page 1-3

System Design

The design of Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems

includes the following:

• Fault-tolerant architecture

Critical components are redundant (duplexed). If one duplexed component fails,

the system continues to operate with the redundant component in simplex mode

until you can remove an enclosure or the system from service to replace the failed

component.

GHz, 3.6 GHz, and Dual-Core Systems

1-

• Customer-replaceable units (CRUs), parts that you can replace on-site with

minimal training or tools

Some CRUs are hot-pluggable. You can replace them without interrupting system

operation.

• Fault-hardened drivers that enhance application reliability and availability

• Optional support by the ActiveService Network (ASN)

This support provides remote service and incident management of the system by

NEC Technical Support, or your authorized service representative. Connectivity to

the ASN is through a pair of remote management adapters — Virtual Technician

Modules (VTMs) — and a modem, only through a modem, or over the Internet.

Overview of Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core Systems 1-1

Page 14

System Features

System Features

Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems include the following:

• Two CPU- I ⁄O enclosures for dual-modular redundancy (DMR)—Each enclosure

contains independent CPU and I/O elements. The CPU and I/O elements can

operate with each other, or, if necessary, with elements in the second enclosure to

emulate a single logical system.

A CPU- I ⁄ O enclosure fits into any slot in the system, and it locks into a system

backplane assembly when fully inserted. Ejector levers on the enclosure facilitate

insertion or removal.

• Intel

®

Xeon™ processor technology:

– Express5800/320Ma 3.2 GHz systems: one processor in each enclosure

(second processor is optional)

– Express5800/320Ma 3.6 GHz systems: two processors in each enclosure

– Express5800/320Ma Dual-Core systems: two dual-core processors in each

enclosure

Two-way symmetric multiprocessing (SMP) is available on dual-processor

systems.

• Eight dual-inline memory module (DIMM) slots in each enclosure.

• Online-upgradeable basic input/output system (BIOS).

• One Baseboard Management Controller (BMC) in each enclosure to monitor

system operation and report faults to the system management software.

• One VTM in each enclosure and a single backplane modem assembly for the

system:

– Express5800/320Ma 3.2 GHz systems: VTMs optional, modem optional

– Express5800/320Ma 3.6 GHz and Dual-Core: VTMs standard, modem

optional

VTMs provide redundant access points to the system even when the system is not

operational. Access to the VTMs is through the modem assembly or over a local

area network (LAN).

• One slimline CD-ROM or DVD±RW drive in each enclosure.

• Two embedded Ethernet ports on each enclosure that you can configure to operate

at 10, 100, or 1000 megabits per second (Mbps).

1-2 Express5800/320Ma: Operation and Maintenance Guide

Page 15

System Components and CRUs

• Two to six 64-bit, 100-MHz user-configurable PCI-X adapter slots:

– –Express5800/320Ma 3.2 GHz systems: one low-profile slot per enclosure

standard, install optional AK533 attachment kit to add two full-height slots.

– Express5800/320Ma 3.6 GHz, and Dual-Core systems: one low-profile slot

and two full-height slots per enclosure standard

• Two serial ports, three USB 2.0 ports, and a video port on the system backplane

assembly.

• Support for up to six internal Serial Advanced Technology Attachment (SATA) disk

drives, three in each enclosure. The disks in one enclosure can mirror the disks in

the other for fault-tolerance.

• Support for EMC

®

CLARiiON® or Symmetrix® external storage systems with

installation of appropriate HBAs.

• Support for the Windows Server 2003 operating system:

– Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems: Enterprise

Edition with SP1

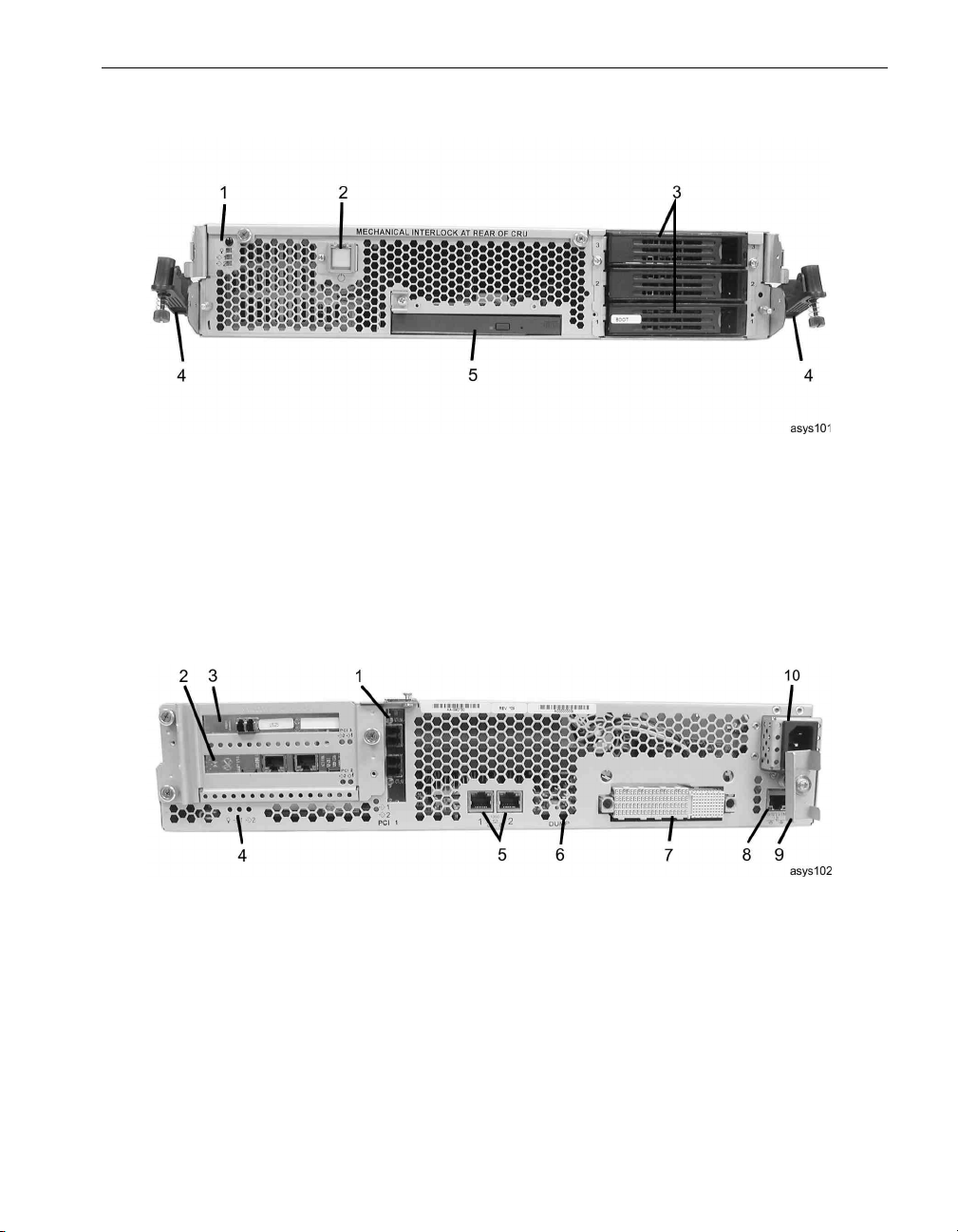

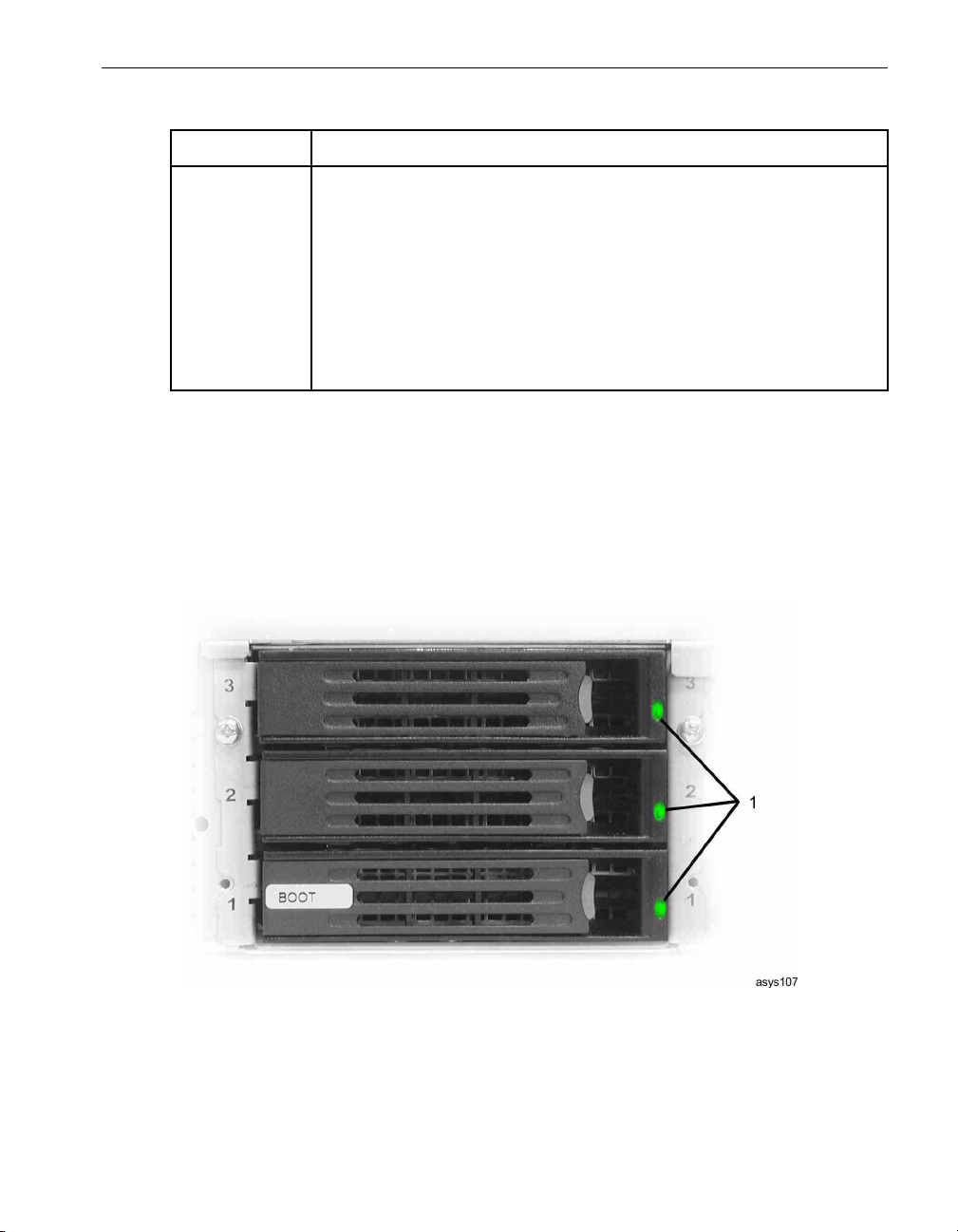

Figure 1-1 shows a system, with its bezel detached.

System Components and CRUs

Each system includes two CPU- I ⁄ O enclosures, as shown in Figure 1-1.

Figure 1-1. Main Enclosures of Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core Systems

1CPU-I⁄ O enclosure, CPU 0, I/O 10

Overview of Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core Systems 1-3

Page 16

System Components and CRUs

2CPU-I⁄ O enclosure, CPU 1, I/O 11

Ta bl e 1- 1 lists the systems’ standard CRUs.

Table 1-1. Standard CRUs of Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems

Standard CRUs

Bezel

CPU-I/O enclosures

System backplane assembly

PCI adapters and PCI riser assembly

Internal SATA disk drives

SATA backplane assembly

IDE backplane assembly

CD or DVD drives

CPU fans and PSU fan

VTMs

Modem assembly

Ta bl e 1- 2 lists the systems’ optional CRUs and components.

Table 1-2. Optional CRUs and Components

Optional CRUs and Components Documentation

External USB floppy drive Vendor documentation

EMC CLARiiON and Symmetrix storage

systems

Keyboard-video-mouse (KVM) switch NEC 4-Port KVM Switch: Installation and User’s

Power distribution unit (PDU) Vendor documentation

Vendor documentation and, for the

AX100 storage system, Attaching an EMC

CLARiiON AX100 Storage System to an

Express5800/320Ma System.

Guide

Figure 1-2 shows the front panel of a CPU-I ⁄ Oenclosure.

1-4 Express5800/320Ma: Operation and Maintenance Guide

Page 17

System Components and CRUs

Figure 1-2. CPU-I/O Enclosure: Front Panel

1CPU-I⁄ O enclosure status LEDs (front) 4 Release levers

2 Power button 5 CD or DVD drive

3 SATA disk drives

Figure 1-3 shows the rear panel of a CPU-I ⁄ Oenclosure.

Figure 1-3. CPU-I/O Enclosure: Rear Panel

1 Slot 1, low profile (PCI Slot Info - 9 in ftSMC) 6 Dump button

2 Slot 2, full height† (PCI Slot Info - 10)

3 Slot 3, full height† (PCI Slot Info - 11) 8 10/100-Mbps VTM Ethernet port

4CPU-I⁄ O enclosure status LEDs (rear) 9 Mechanical interlock

5 10/100/1000-Mbps Ethernet ports 10 Power receptacle

† Slots 2 and 3 are located on the PCI riser assembly, which is standard in

Express5800/320Ma 3.6 GHz and Dual-Core, is optional for Express5800/320Ma 3.2 GHz

systems. To add slots 2 and 3 to an Express5800/320Ma 3.2 GHz system, install the

optional AK533 PCI riser assembly kit. See Appendix A.

Overview of Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core Systems 1-5

7 Backplane connector

Page 18

System Components and CRUs

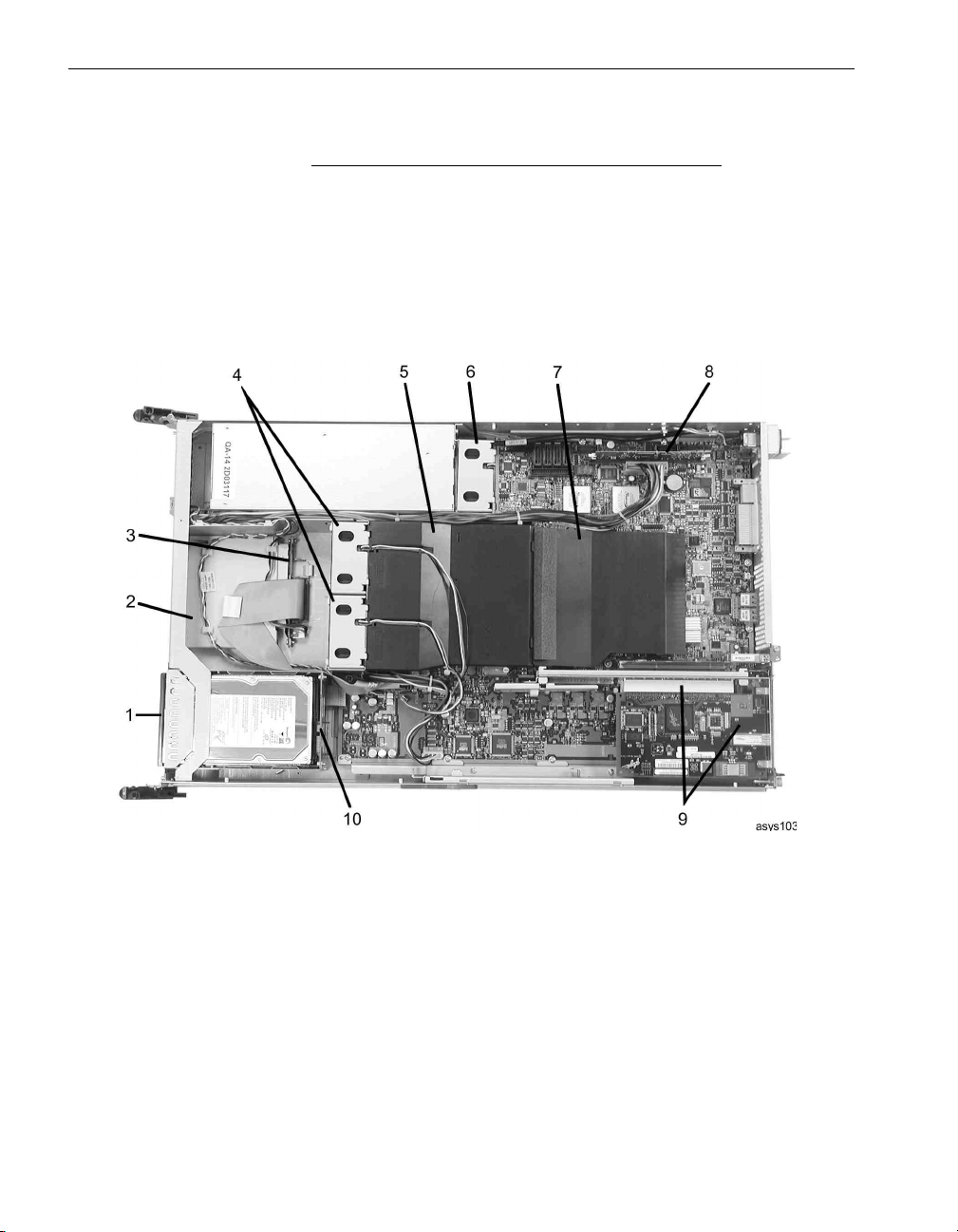

Figure 1-4 shows the internal components of a CPU-I ⁄ Oenclosure.

NOTE

Also see the inside of each CPU- I ⁄ O enclosure cover for

a quick-reference diagram that labels the internal

components of the enclosure.

Figure 1-4. CPU-I/O Enclosure: Interior Components

1 SATA disk drives 6 PSU fan

2 CD/DVD drive bay 7 DIMM baffle

3 IDE backplane assembly 8 VTM

4 CPU fans 9 PCI riser assembly and PCI adapters

5 CPU plenum 10 SATA backplane assembly

Figure 1-5 shows the system backplane assembly, which is located at the rear of the

system. When you insert CPU- I ⁄ O enclosures into the system enclosure, they are

connected to each other by the system backplane assembly.

1-6 Express5800/320Ma: Operation and Maintenance Guide

Page 19

System Components and CRUs

The assembly contains the serial, USB, and VGA ports, as well as a socket for the

detachable modem assembly.

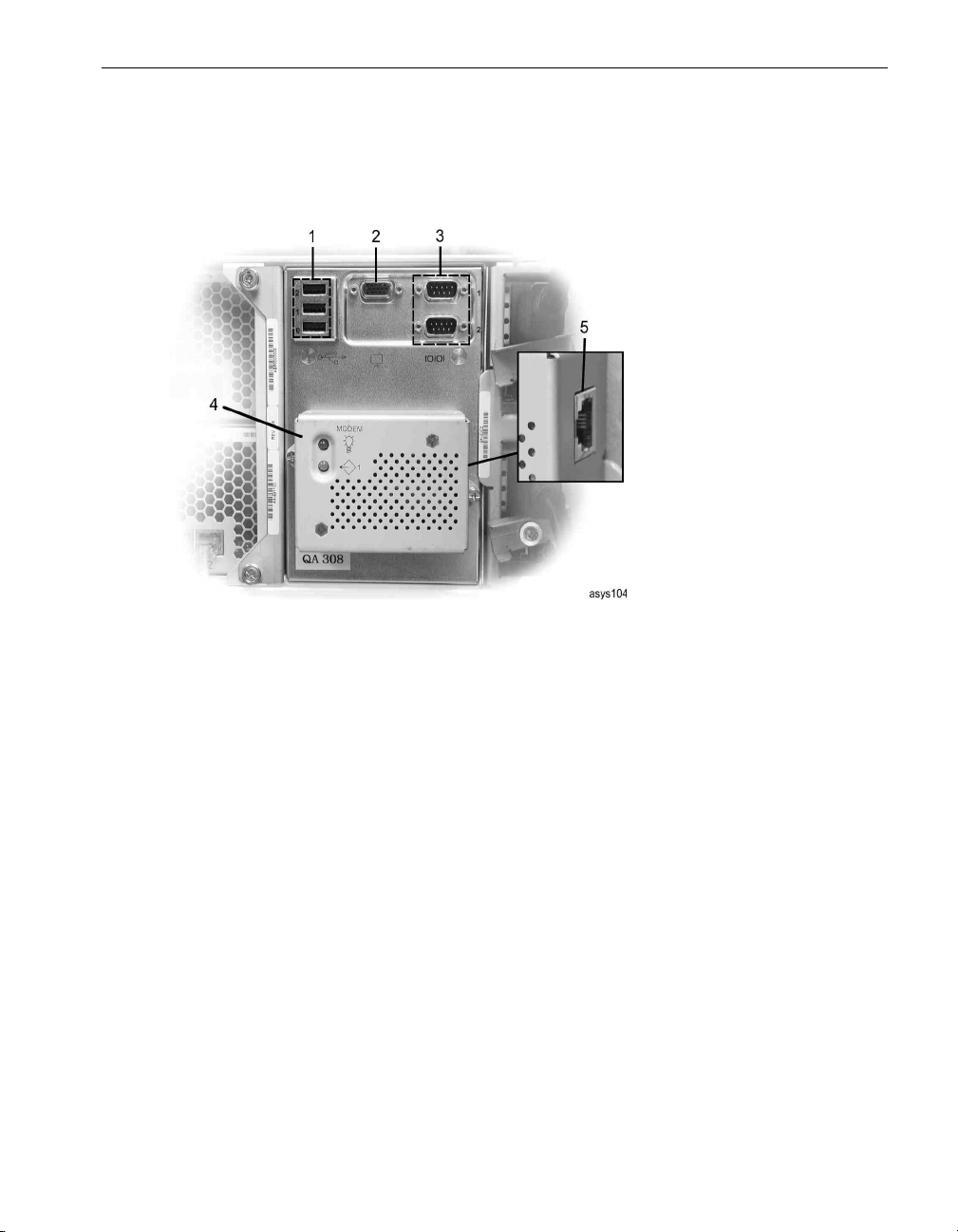

Figure 1-5. System Backplane Assembly

1 USB ports

2 VGA (monitor) port

3 Serial ports

4 Modem assembly

5 Phone line connector

Overview of Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core Systems 1-7

Page 20

System Components and CRUs

1-8 Express5800/320Ma: Operation and Maintenance Guide

Page 21

Chapter 2

See the following for information about the basic operation of Express5800/320Ma 3.2

GHz, 3.6 GHz, and Dual-Core systems:

• “Standby Power” on page 2-1

• “System Power” on page 2-1

• “Starting Up the System” on page 2-2

• “Shutting Down the System” on page 2-2

• “Fan Speed” on page 2-3

See the vendor documentation for information about operating optional equipment.

Standby Power

When one or both of the system power cords are connected to live AC power outlets,

low-level standby power is present in the system. Standby power enables the primary

BMC controller to monitor the status of system components, even when the system

power is off.

Hardware Operation

2-

Standby power also allows for continuous operation of the VTMs and the modem

assembly; therefore, while the system power is off, administrators can still connect to

the system through the VTMs or the modem assembly to diagnose problems, or to turn

system power on and off from a remote location.

Standby power remains present even after the system has been powered down. To

remove power to the standby devices, remove the power cords.

System Power

Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems have two power

buttons, one on each CPU- I ⁄ O enclosure. Because only one enclosure is the primary

or active enclosure, only one power button is the active button: the one whose LED is

lit (assuming the system has standby power). This button, which you press to start the

system, indicates the primary CPU- I⁄ Oenclosure.

Hardware Operation 2-1

Page 22

Starting Up the System

The system power button is located on the front of the system and functions as follows:

• If the system power is off and standby power is on, pressing the power button turns

the system on and boots the operating system.

• If the system power is on and the operating system or BIOS is starting, stopping,

or running, pressing the power button for several seconds shuts down the system

in the same way as the shut down option from Windows. (Standby power remains

on.)

• If the operating system hangs or a hardware failure occurs, pressing the power

button for several seconds shuts down the system power. (Standby power remains

on.)

NOTE

If you do not want to risk loss of data that might occur from

this action, and if the system contains VTM adapters, you

can attempt less severe actions to restart the system. See

the Express5800/320Ma Virtual Technician Module

User’s Guide for more information.

Starting Up the System

Make sure the system power cords are plugged into live AC outlets.

To boot a system and start the operating system

1. Turn on the monitor and any other peripheral devices.

2. On the CPU- I⁄ O enclosure whose power-button LED is lit, lift the plastic cover that

shields the system power button (number 2 in Figure 1-2) and press the button.

Shutting Down the System

Exit from all applications before shutting down a system.

To shut down a system

1. Click the Start button on the Windows desktop, and then click Shut Down.

2. In the Shut Down Windows dialog box, select Shut Down in the drop-down list,

and then click OK.

3. Turn off power to the monitor and any peripheral devices.

2-2 Express5800/320Ma: Operation and Maintenance Guide

Page 23

Fan Speed

You might notice fan-speed increases in high-temperature environments, during high

system activity periods, or while performing an IPL (loading the operating system

software), shutting down the system, or restarting Windows. The increase in fan speed

ensures adequate cooling under these conditions and is normal behavior.

Fan Speed

NOTE

The system’s standby devices have power even after the

system has been powered down. To remove power to the

standby devices, you must remove the power cords.

Hardware Operation 2-3

Page 24

Fan Speed

2-4 Express5800/320Ma: Operation and Maintenance Guide

Page 25

Chapter 3

See the following sections for information about troubleshooting Express5800/320Ma

3.2 GHz, 3.6 GHz, and Dual-Core systems:

• “System LEDs” on page 3-1

• “General Disk Drive Problems and Solutions” on page 3-12

• “CD- or DVD-Drive Problems and Solutions” on page 3-13

• “Using the Dump Button to Create a Dump File” on page 3-15

System LEDs

System LEDs are located on the front and rear of each CPU-I ⁄ O enclosure.

The LEDs can be single-color or bicolor:

• Single-color LEDs are green, amber, or white.

• Bicolor LEDs can be green or amber.

Troubleshooting the Hardware

3-

At any time, the LEDs can also have one of three different states:

• Unlit, or OFF

• Steady on, or ON

• Blinking

You can determine the state of a particular component by interpreting the combinations

of LED colors and states. For example, you can determine if system components are

operating in duplex or simplex mode. Duplex mode means that the components are

partnered and the partner is operating properly. Simplex mode means that the partner

failed or was removed.

Ta bl e 3- 1 describes the general meaning of the LED colors and states.

Troubleshooting the Hardware 3-1

Page 26

System LEDs

Table 3-1. General Status LED Meanings

LED Color

(Purpose) LED State CRU State

Green

(Power indicator)

Amber

(Fault/Identify

indicator)

White

(Simplex/Duplex

indicator)

Unlit Offline or unpowered

Blinking Green Offline with standby power (enclosure)

Duplexed and active (disk drive)

Steady Green Online and functioning normally

Duplexed and inactive (disk drive)

Unlit Offline or functioning normally

Steady Amber Broken or partially broken

Blinking Amber Simplexed and unsafe to remove (disk drive)

Component is being identified

Unlit or steady white Duplexed and safe to remove

Blinking white Simplexed and unsafe to remove

For more specific information about each status LED and actions you can take

depending on the state of the system, see one of the following sections:

• “CPU-I/O Enclosure Status LEDs” on page 3-3

• “SATA Disk-Drive LED” on page 3-5

• “PCI Slot Status LEDs” on page 3-7

• “Ethernet Port and VTM Port LEDs” on page 3-8

• “Modem Assembly LEDs” on page 3-10

See Chapter 2, “Hardware Operation” for information about the LED in the system

power button.

For information about LEDs in optional components, see the vendor documentation.

3-2 Express5800/320Ma: Operation and Maintenance Guide

Page 27

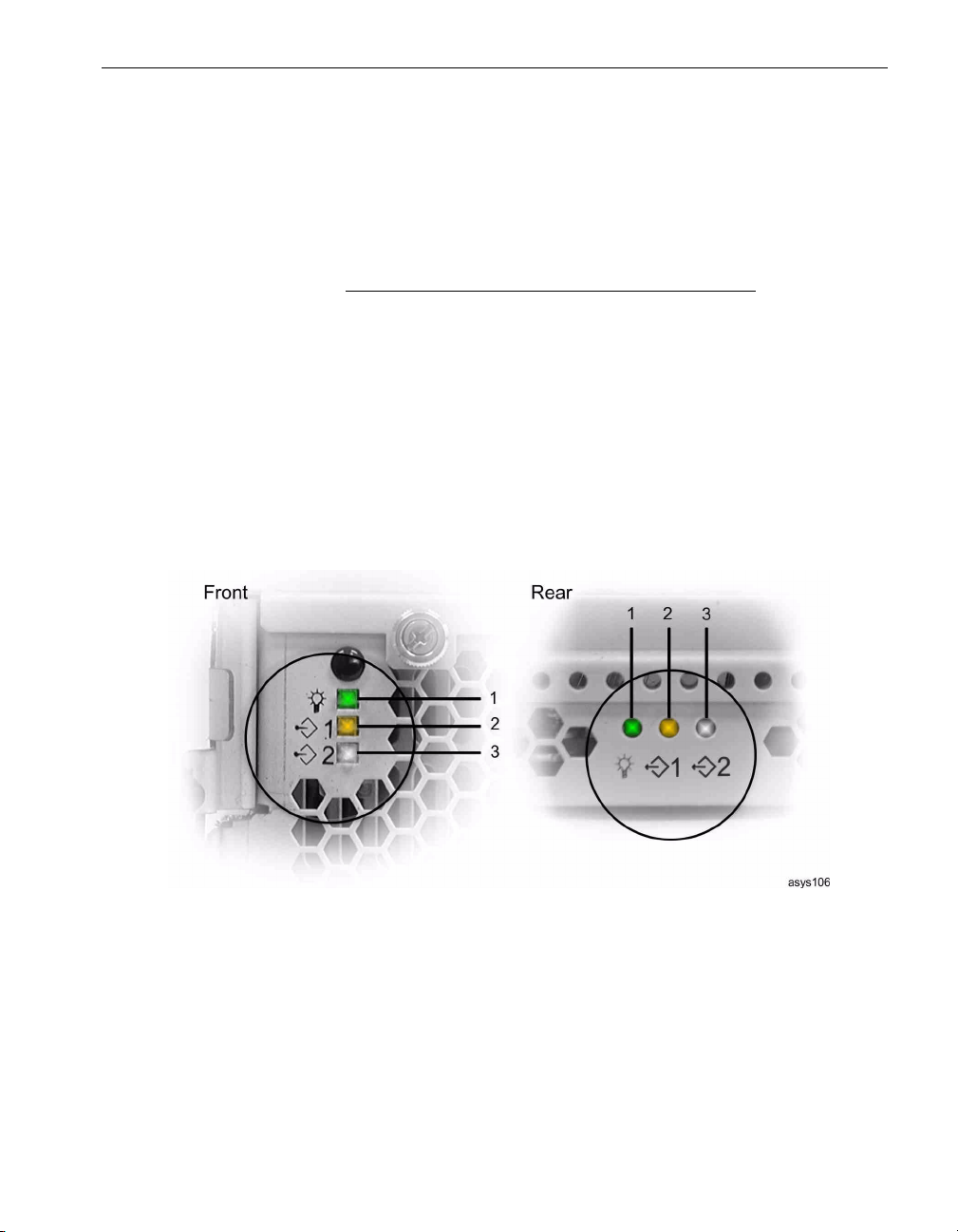

CPU-I/O Enclosure Status LEDs

Each CPU- I ⁄ O enclosure contains three LEDs that describe the status of the

components in the enclosure, including the CPU, BMC, VTM, PCI adapters, and SATA

disk drives. These LEDs, which are located on the front and rear of each enclosure, are

green, amber, and white. The CPU-I ⁄ O enclosure status LEDs are shown in

Figure 3-1 and described in Tab le 3- 2.

NOTE

During the boot process, the BMC verifies that all devices

in the CPU- I ⁄ O enclosures are present and performing

normally before the BMC activates that enclosure. If a

component has failed, the BMC removes power from that

enclosure. As a result, the LEDs on an enclosure might

turn on briefly and then turn off, or the LEDs might not turn

on at all, indicating a failed component of the enclosure.

Figure 3-1. CPU-I/O Enclosure Status LEDs

System LEDs

1 Green LED (power indicator)

2 Amber LED (fault/identify indicator)

3 White LED (simplex/duplex indicator)

Troubleshooting the Hardware 3-3

Page 28

System LEDs

Table 3-2. CPU-I/O Enclosure Status LEDs

LED and State Description/Action

Green, unlit Power off or no standby power.

Green, blinking Standby power.

Green, steady Online or booting.

Amber, unlit Offline or functioning normally.

Amber, steady Broken or partially broken components (CPU, BMC, VTM, PCI adapter, or

Action: If necessary, verify that the AC power cords are connected at

both ends. Verify that the system power connections are seated properly.

Action: Press the power button to boot the system.

SATA disk drive) in the enclosure.

Action: Refer to ftSMC for information about the failure, then attempt to

correct the failure within the operating system. For help in interpreting the

information displayed in ftSMC, see the Help for ftSMC and

Express5800/320Ma: System Administrator’s Guide. If you need to

remove an enclosure for troubleshooting, first determine if it is safe to pull

by verifying the state of the white status LED.

the

If you are unable to fix the condition, contact NEC Technical Support or

your authorized service representative.

Amber, blinking Either the CPU element or the I/O element is being identified from a

command in ftSMC.

For more information about locating a component by flashing an LED, see

the Help for ftSMC or the Express5800/320Ma: System Administrator’s

Guide.

White, unlit Safe to remove, offline or power off.

White, steady Operating in duplex mode. If system power is off (green blinking LED), the

BMC and VTM are operating in duplex mode.

It is safe to remove the enclosure, because its partner keeps the system

operational.

3-4 Express5800/320Ma: Operation and Maintenance Guide

Page 29

Table 3-2. CPU-I/O Enclosure Status LEDs (Continued)

LED and State Description/Action

White, blinking Operating in simplex mode.

SATA Disk-Drive LED

Each CPU- I ⁄ O enclosure can support up to three internal SATA disk drives. Each

SATA disk drive has a single green-amber LED (number 1 in Figure 3-2) on its bezel.

Ta bl e 3- 3 describes the SATA disk drive LED states.

Figure 3-2. SATA Disk-Drive LED

System LEDs

If system is on (steady green LEDs), removing the enclosure will crash

the system because no partner is available.

If system power is off (green blinking LED), either the BMC or the VTM is

operating in simplex mode. If you remove the enclosure, you cannot

power the system on, or access the system remotely.

Action: Return the offline partner component to service.

1 SATA Disk Drive LEDs

Troubleshooting the Hardware 3-5

Page 30

System LEDs

Table 3-3. SATA Disk Drive LED

State Description/Action

Unlit Not powered, safe to pull.

Green, steady Duplexed and inactive, safe to pull.

Green, blinking Duplexed and active, safe to pull.

Amber, steady Broken and safe to pull.

Amber, blinking Simplexed and unsafe to pull for one of the following reasons:

Action: Verify that the drive is properly installed. Verify the connection

by removing and replacing the drive.

Refer to ftSMC for information about the failure and attempt to correct

the failure in the operating system. For help in interpreting the

information displayed in ftSMC, see the Help for ftSMC and

Express5800/320Ma: System Administrator’s Guide. If necessary,

replace the drive with a new one.

If you are unable to fix the condition, contact NEC Technical Support or

your authorized service representative.

the

– If the drive is part of a Rapid Disk Resync (RDR) drive pair, the

partner drive is unavailable.

Action: Reinsert the partner drive to restore duplex operation.

Verify that the partner drive is functioning normally.

– If the drive is not part of an RDR pair, a non-mirrored volume

exists on the drive. Or, a mirrored volume exists on the drive, but its

partner volume is unavailable.

Action: If the drive contains a mirrored volume, reinsert the drive

that contains its partner volume to restore duplex operation. If the

drive is not mirrored, consider creating an RDR drive pair or

another type of mirrored set to increase fault tolerance.

– If the drive is part of an RDR drive pair or it contains part of a

mirrored volume pair, the drive or volume is resynchronizing.

Action: Wait for the process to complete.

For information about RDR and mirrored volumes, see the

Express5800/320Ma: System Administrator’s Guide.

See “General Disk Drive Problems and Solutions” on page 3-12 for additional

troubleshooting information.

3-6 Express5800/320Ma: Operation and Maintenance Guide

Page 31

PCI Slot Status LEDs

Each PCI slot has two LEDs, one amber LED and one white LED, that indicate the

status of the PCI slot. The PCI slot status LEDs are adjacent to each PCI slot at the

rear of the enclosure, as shown in Figure 3-3.

NOTE

Figure 3-3 shows a system that contains PCI slots 2

and 3.

Figure 3-3. PCI Slot LEDs

System LEDs

1 Amber LED (fault/identify indicator)

2 White LED (simplex/duplex indicator)

Ta bl e 3- 4 describes the PCI slot status LED states.

Troubleshooting the Hardware 3-7

Page 32

System LEDs

Table 3-4. PCI Slot Status LEDs

LED and State Description/Action

Amber, unlit Operating normally, or slot is empty.

Amber, steady PCI adapter or slot has failed.

Amber, blinking PCI slot is being identified from a command in ftSMC.

White, unlit Offline.

Action: Refer to ftSMC for information about the failure and attempt to

correct the failure in the operating system. For help in interpreting the

information displayed in ftSMC, see the Help for ftSMC and

Express5800/320Ma: System Administrator’s Guide. If necessary,

replace the PCI adapter.

If you are unable to fix the condition, contact NEC Technical Support or

your authorized service representative.

For more information about locating a component by flashing an LED, see

the Help for ftSMC or the Express5800/320Ma: System Administrator’s

Guide.

the

White, steady Operating in duplex mode.

White, blinking Operating in simplex mode and unsafe to remove. Taking it offline will

result in lost connectivity.

Action: If necessary, insert an identical adapter in the corresponding slot

in the other enclosure to enable duplex mode.

Ethernet Port and VTM Port LEDs

Each CPU- I ⁄ O enclosure contains up to three Ethernet ports. Two ports, which

operate at 10, 100, or 1000 Mbps, are connected to the embedded Ethernet controller.

Another port, which operates at 10 or 100 Mbps, is dedicated to the VTM (if installed).

Each port has two integrated LEDs that indicate Ethernet activity and connection

speed.

The Ethernet ports and the VTM port are shown in Figure 3-4. Tab le 3 - 5 and Ta b le 3 -6

describe the system Ethernet port LED states and VTM port LED states, respectively.

3-8 Express5800/320Ma: Operation and Maintenance Guide

Page 33

Figure 3-4. Ethernet Port and VTM Port LEDs

1 Ethernet port ACT/LINK LED 3 VTM port 10/100-Mbps LED

2 Ethernet port 10/100/1000-Mbps LED 4 VTM port ACT/LINK LED

Table 3-5. Ethernet Port LED States

System LEDs

Function (Location) Color and State Description

ACT/LINK (Left) Unlit Link not present

Green, steady Link present

Green, flashing Ethernet activity

10/100/1000 (Right) Unlit 10-Mbps connection

Green, steady 100-Mbps connection

Amber, steady 1000-Mbps connection

Amber, flashing Identifies the PCI adapter when you click on

Identify Adapter on the General tab in the

PROSet utility.

Troubleshooting the Hardware 3-9

Page 34

System LEDs

Table 3-6. VTM Port LED States

Function (Location) Color and State Description

10/100 (Left) Unlit 10-Mbps connection

ACT/LINK (Right) Unlit Link not present

Modem Assembly LEDs

When present, a single modem assembly is attached to the system backplane

assembly at the rear of the system. The modem assembly has two LEDs: a green

power LED and an amber fault LED (Figure 3-5).

Figure 3-5. Modem Assembly LEDs

Green, steady 100-Mbps connection

Green, steady Link present

Green, flashing Ethernet activity

1 Green LED (power indicator)

2 Amber LED (fault/identify indicator)

Ta bl e 3- 7 describes the modem assembly LED states.

3-10 Express5800/320Ma: Operation and Maintenance Guide

Page 35

CAUTION

!

Do not remove the modem assembly when it is powered

on (steady green LED). For information about removing

and replacing a modem assembly, see “Replacing or

Installing a Modem Assembly” on page 5-49.

Table 3-7. Modem Assembly LEDs

LED and State Description/Action

Green, unlit Powered off and safe to pull.

Green, steady Powered on and unsafe to pull.

Action: If you need to replace the modem, either turn the modem power

off or shut down the system and unplug the power cords. For information

about removing and replacing a modem assembly, see “Replacing or

Installing a Modem Assembly” on page 5-49.

Amber, off Operating normally.

Amber, steady Broken or hung.

System LEDs

Action: Refer to ftSMC for information about the failure and attempt to

correct the failure in the operating system. For help in interpreting the

information displayed in ftSMC and, if necessary, resetting the modem,

see the Help for ftSMC and the

Administrator’s Guide. If necessary, replace the modem assembly.

If you are unable to fix the condition, contact NEC Technical Support or

your authorized service representative.

Amber, blinking Modem is being identified.

See the Express5800/320Ma: System Administrator’s Guide for the

procedure to identify a modem.

Express5800/320Ma: System

Troubleshooting the Hardware 3-11

Page 36

General Disk Drive Problems and Solutions

General Disk Drive Problems and Solutions

Ta bl e 3- 8 lists some possible problems that the internal SATA disk drives may

encounter, as well as some corrective actions.

Table 3-8. Troubleshooting Disk Drives

Problem Action

System will not boot

from system disk

Cannot access data Some files might contain viruses. Run a virus-scan utility on the disk drive.

Disk drive fails, or disk

status LED is steady

amber

System does not

recognize disk drive

Ensure that the disk-drive boot is enabled through the BIOS setup

program.

Try to boot from the system disk’s mirrored partner. To do so, unlatch the

suspected faulty system disk.

Some files might be corrupted. If possible, restore the files from a backup.

If there is a problem with the system files, and you have an Automated

System Recovery (ASR) backup, use the ASR backup to repair the system

files. See the Help for Windows for more information.

Use the System event log and ftSMC to try to determine what might have

caused the disk drive to fail. For more information about the System event

log and ftSMC, see the Help for Windows and the Express5800/320Ma:

System Administrator’s Guide. If you cannot resolve the problem, contact

NEC Technical Support or your authorized service representative.

Ensure that the disk drive was installed correctly. See “Removing and

Inserting a SATA Disk Drive” on page 5-32 and “Removing and Replacing

a CD or DVD Drive” on page 5-36 for information about installing a disk

drive. For external floppy disk drives, ensure that the USB cable is plugged

into the USB connectors on the system backplane assembly. Note that you

cannot connect the floppy drive through the USB connectors on the

keyboard.

3-12 Express5800/320Ma: Operation and Maintenance Guide

Page 37

CD- or DVD-Drive Problems and Solutions

Table 3-8. Troubleshooting Disk Drives (Continued)

Problem Action

Slow response time The disk drive might be full. Ideally, at least 15 percent of the disk drive

should be free for system activity. Delete unnecessary files, or move files

to another disk drive.

You might need to defragment the disk drive.

Mirror regeneration might be occurring. Try to schedule mirror

regeneration for a time when the system is not heavily used. However, if

the disk contains business-critical data, you should regenerate the mirrors

as soon as possible.

The disk drive might be reading a compressed file. In the future, avoid

compressing files that are heavily used.

Many read or write operations might be queued to the disk drive. If the

Express5800/320Ma Software Availability Manager indicates an unusually

high number of disk requests outstanding, you should examine how your

applications are using the disks. For more information about the

Express5800/320Ma Software Availability Manager, see the

Express5800/320Ma Software Availability Manager User’s Guide.

Errors might be occurring on the drive. Check the system event log.

CD- or DVD-Drive Problems and Solutions

The CD or DVD drive has a single LED that indicates whether the drive is busy. It does

not have an LED that indicates whether a fault has occurred.

Ta bl e 3- 9 lists some possible problems that the CD-ROM drive could encounter, as well

as some corrective actions.

Troubleshooting the Hardware 3-13

Page 38

CD- or DVD-Drive Problems and Solutions

Table 3-9. Troubleshooting the CD or DVD Drive

Problem Action

CD-ROM drive is not

working properly

System cannot read CD

or DVD

CD or DVD drawer will

not open

Ensure that the CD or DVD has been inserted correctly.

Ensure that the CD or DVD has been inserted into the correct

drive, and that you are accessing the correct drive on the

Windows desktop.

Check for environmental problems that can damage CD or DVD

media and drive heads. Environmental problems can result from

airborne contaminants (smoke, steam, dust, and ashes) or

radiated interference (hand-held receivers, communications and

radar installations, and radio/television broadcast transmitters).

Check that no paper or plastic label, or any residue, is attached to

the surface of the CD or DVD that is in use.

Ensure that the correct drivers are installed.

Ensure that the CD or DVD drive was installed correctly. See

“Removing and Replacing a CD or DVD Drive” on page 5-36 for

more information.

Ensure that the CD or DVD is clean and does not contain any

scratches. Attempt to read a known good CD or DVD.

If you are attempting to load a DVD, verify that the drive is a DVD

drive by checking the logo on the front panel of the drive.

Insert a straightened paper clip into the emergency eject hole.

System will not boot

from CD or DVD drive

Busy Indicator stays on Ensure that the CD or DVD has been inserted correctly.

3-14 Express5800/320Ma: Operation and Maintenance Guide

Ensure that CD boot is enabled through the BIOS Setup

program.

Ensure that the CD or DVD drive is operating properly by

attempting the same operation with a different CD or DVD. If the

second CD or DVD works, the first one might be damaged.

Page 39

Using the Dump Button to Create a Dump File

Using the Dump Button to Create a Dump File

To enable NEC Technical Support or your authorized service representative to

diagnose problems with your system, you might need to create a snapshot, or dump

file, of the system’s memory while the system is running.

One method for creating a dump file on a system is to press the dump button on its

primary CPU- I ⁄ O enclosure (the enclosure with a lit power button). The dump button

is located inside a pin-hole opening (Figure 3-6) at the rear of each enclosure. You

need a fine-tipped object, such as an unfolded paper clip or pushpin, to reach the

button.

Figure 3-6. Pressing the Dump Button

NOTE

Because the dump button reboots the entire system, you

need to schedule downtime for this procedure. If your

CPU- I ⁄ O enclosures are duplexed, you might prefer to

use the Dump and Go command in ftSMC, which can

dump system memory while keeping the system online.

For more information, see the Express5800/320Ma:

System Administrator’s Guide or the Help for ftSMC.

To create a dump file, press and hold the dump button for at least three seconds, but

no longer than eight seconds, then release it. In response, the system:

Troubleshooting the Hardware 3-15

Page 40

Using the Dump Button to Create a Dump File

• Goes offline with its memory intact

• Dumps a snapshot of the memory to C:\sradumps\Memoryn.dmp

• Reboots and returns to online status

To ensure that the system generates a dump file, verify that you have not changed the

following default settings in ftSMC under Drivers, Board Instance Driver - srabid:

• DumpQuickEnabled = True

• DumpNumberOfFilesToSave = 2 (must be greater than 0)

If you use the dump button incorrectly, or if the button is pressed by mistake, the system

ignores the dump signal and, ultimately, deactivates the button to prevent the system

from crashing, as follows:

• If you tap the button, hold it for less three seconds, or hold it for longer than eight

seconds, the system counts this as a spurious signal and ignores it.

• If you press the button more than once within a five-second period, the system also

counts this as a spurious signal and ignores it.

• If seven spurious activations occur within a 24-hour period, the system disables the

dump button (only on the enclosure where it was activated) and sends an alert to

NEC Technical Support or your authorized service provider.

All spurious signals from the dump button and the deactivation alert are logged in the

Application event log for the operating system.

The system resets the spurious signal count and re-enables the dump button only if you

reset the Base Management Controller (BMC) for the enclosure. To reset the BMC,

take the affected enclosure offline, remove and replace it, then bring it online again.

NOTE

If you intend to generate a dump file for an enclosure

where the dump button has been disabled, you should

use another method to save the dump file before resetting

the BMC, because you might lose valuable

troubleshooting data by doing so.

3-16 Express5800/320Ma: Operation and Maintenance Guide

Page 41

Using the Dump Button to Create a Dump File

To generate a dump file when the dump button on the primary enclosure is disabled,

do one of the following:

• In ftSMC, select the CPU node for the primary enclosure, then select Dump and

Go from its Action Menu. For more information, see the Express5800/320Ma:

System Administrator’s Guide and the online help for ftSMC.

• On a system that contains VTMs, open a VTM session to the primary enclosure

and click NMI (non-maskable interrupt) on the Troubleshoot Server tab. For more

information, see the Express5800/320Ma Virtual Technician Module User’s Guide.

Troubleshooting the Hardware 3-17

Page 42

Using the Dump Button to Create a Dump File

3-18 Express5800/320Ma: Operation and Maintenance Guide

Page 43

Chapter 4

General servicing information is discussed in the following sections:

• “Unpacking CRUs” on page 4-1

• “Storing CRUs” on page 4-2

• “Repacking CRUs” on page 4-3

• “Replacing a CRU” on page 4-3

• “General Safety Precautions” on page 4-4

See Chapter 5, “CRU Replacement Procedures” for detailed information.

Unpacking CRUs

Upon receiving a CRU, perform the following:

• Inspect the packing slip to ensure that the correct CRU was received.

• Inspect the packing container for damage.

General Servicing Information

4-

• Check the shipping impact indicators to ensure that they have not been activated

(see Figure 4-1).

If any of the following conditions apply to your shipment, see “Using the Dump Button

to Create a Dump File” on page 3-15:

• The package is damaged.

• An impact indicator has been activated.

• You received the wrong shipment.

If there are no problems, unpack the CRU.

General Servicing Information 4-1

Page 44

Storing CRUs

Figure 4-1. Shipping Impact Indicators

To unpack the CRU

1. While observing any printed directions or warnings, carefully open the package.

2. Carefully remove the protective packaging and save it for possible reuse in storing

3. Verify that you received the correct CRU by checking the packing slip and the bar

4. Inspect the CRU for shipping damage.

HANDLE

WITH CARE

WARNING

or returning a CRU.

code label on the CRU.

TIP-N-TELL

UP

msys034

5. If the CRU is wrapped in an antistatic bag, keep it in the bag until it is installed. If

you are not going to install the CRU immediately, protect it from damage by

repacking it in its shipping package.

Storing CRUs

If you need to store a CRU, keep it in the protective packaging and take the following

precautions:

• Ensure that the CRU is right-side up by following the directions on the carton.

• Comply with all warning labels.

• Avoid placing the CRU in a location where heavier items might be placed on it.

• Protect the CRU from exposure to dust, electromagnetic fields, vibrations, extreme

heat, or any other environmental conditions that might damage the CRU.

• Avoid prolonged storage that could reduce the useful life of the CRU.

If you are uncertain about the proper storage conditions for a specific CRU, see “Using

the Dump Button to Create a Dump File” on page 3-15.

4-2 Express5800/320Ma: Operation and Maintenance Guide

Page 45

Repacking CRUs

When returning a defective or incorrect CRU, package the CRU using the original

packing materials or the replacement-CRU packing materials. Ensure that the CRU is

adequately protected from the following:

• Dents, scratches, and impact damage

• Magnetic fields and static electricity

• Accidental opening of the package in transit

• Detachment of the address label

If you are uncertain that the CRU will be adequately protected during shipment, see

“Using the Dump Button to Create a Dump File” on page 3-15. Also, see “Using ESD

Precautions” on page 5-2 for information about how to protect components from

exposure to static electricity.

Replacing a CRU

Before replacing a CRU, do the following:

• Confirm that the CRU has failed and needs to be replaced. You can view failure

information from the status LEDs on each hardware component and from your

system’s event or error logs.

• Determine if a component needs to be taken out of service. Refer to your system

administration or analysis documentation to remove the component from service

via software before removing it physically.

• Take proper grounding precautions. When handling components, especially those

with exposed integrated circuits, use proper grounding procedures to avoid

electrostatic discharge (ESD) damage to the component. See “Using ESD

Precautions” on page 5-2.

• Observe the proper safety precautions. Follow the precautions listed in “General

Safety Precautions” on page 4-4.

Repacking CRUs

After replacing a CRU, do the following:

• Replace the bezels, if applicable, and close the cabinet doors.

• Place the component in service if it is out of service.

• Verify system operation.

• Package and ship the failed component. See “Repacking CRUs” on page 4-3.

General Servicing Information 4-3

Page 46

General Safety Precautions

General Safety Precautions

• To help identify problems that might occur during the CRU removal and

replacement, read the entire procedure before performing it.

• Provide the space and illumination necessary to safely perform the procedure.

• Conduct all activities in compliance with all applicable industry safety standards

and practices.

• When performing maintenance procedures, do not wear conductive articles or

material such as rings, bracelets, keys, chains, garments with metallic thread, and

so forth.

4-4 Express5800/320Ma: Operation and Maintenance Guide

Page 47

Chapter 5

CRU Replacement Procedures

Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems accommodate safe

and easy removal, replacement, and addition of customer-replaceable units (CRUs).

CRU replacement procedures are discussed in the following sections:

• “Before Replacing CRUs” on page 5-1

• “Removing and Replacing the Bezel” on page 5-3

• “Removing and Replacing a CPU-I/O Enclosure” on page 5-4

• “Replacing the System Backplane Assembly” on page 5-10

• “Removing and Replacing a CPU-I/O Enclosure Cover” on page 5-15

• “Replacing or Installing a PCI Adapter” on page 5-18

• “Removing and Replacing the PCI Riser Assembly” on page 5-26

• “Removing and Inserting a SATA Disk Drive” on page 5-31

• “Replacing a SATA Backplane Assembly” on page 5-33

• “Removing and Replacing a CD or DVD Drive” on page 5-35

• “Replacing an IDE Backplane Assembly” on page 5-37

5-

• “Replacing a CPU Fan” on page 5-41

• “Replacing a Power Supply Unit Fan” on page 5-44

• “Replacing or Installing a VTM” on page 5-47

• “Replacing or Installing a Modem Assembly” on page 5-48

Before Replacing CRUs

Observe the following warnings, cautions, and notes when replacing or adding CRUs.

WARNING

!

If a component is not a CRU, do not attempt to remove

or replace it. Doing so may result in serious personal

injury and/or damage to the system.

CRU Replacement Procedures 5-1

Page 48

Before Replacing CRUs

!

!

WARNING

RISK OF EXPLOSION IF BATTERY IS REPLACED BY

AN INCORRECT TYPE. DISPOSE OF USED

BATTERIES ACCORDING TO THE INSTRUCTIONS

PROVIDED WITH THE BATTERY.

CAUTION

When replacing a CRU, always observe the following

guidelines.

• Do not remove a CRU when its white LED is blinking. This indicates

that the CRU is operating in simplex mode (its duplex partner is not

functional). Removing the CRU would cause the system to fail.

• Observe ESD handling precautions if they are indicated for the

procedure.

• Read the entire procedure so that you fully understand it. If any part

of the procedure is not clear, see “Using the Dump Button to Create a

Dump File” on page 3-15.

• When necessary, refer to your system administration documentation

for instructions in how to identify a failed component and take it offline

before servicing it.

NOTE

A quick-reference diagram on the inside of each

CPU- I ⁄ O enclosure cover labels the internal components

of the enclosures. Refer to the diagram when replacing a

CRU to determine the route of cables from the CRU to the

connectors on the main board of the enclosure. On this

diagram, connectors are identified by circuit board

junction, for example, J16 is the power connector for a

CPU fan.

Using ESD Precautions

Doing work inside an uncovered CPU- I ⁄ O enclosure exposes electronic components

to potential damage from ESD.

5-2 Express5800/320Ma: Operation and Maintenance Guide

Page 49

Tools

Removing and Replacing the Bezel

CAUTION

!

To avoid damaging ESD-sensitive components during

handling, always take the following precautions.

1. Ground yourself before working inside an enclosure. Put a grounding strap on your

wrist and attach its other end to some suitable grounding point, such as a

computer-system cabinet.

2. Discharge static electricity by touching an unpainted portion of the enclosure or

system just before handling ESD-sensitive parts.

3. Store PCI adapters in their static-protective envelope until you are ready to install

them in the system.

4. Hold a PCI adapter by its edges.

Although you can replace some CRUs without the use of tools, others require use of

the following tools:

• An ESD strap

• A #2 or #1 Phillips head screwdriver

Removing and Replacing the Bezel

The systems have a single removable bezel that attaches to the face of both

CPU- I ⁄ O enclosures.

Estimated time: One minute.

Tools: None.

To remove the bezel

1. Grasp the bezel on its right and left sides if the system is in a rack, or on its top and

bottom sides if the system is in a pedestal case.

2. Pull the bezel straight toward you (Figure 5-1) until it snaps free from the ball studs.

3. If you are replacing a defective bezel, set it aside for repacking. See “Repacking

CRUs” on page 4-3.

CRU Replacement Procedures 5-3

Page 50

Removing and Replacing a CPU-I/O Enclosure

Figure 5-1. Removing the Bezel

To attach the bezel

1. At the front of the system, align the bezel with its location on the system frame.

Align the LED light pipes inside the bezel with the left side of the system if it is in a

rack, or with the bottom of the system if it is in a pedestal case.

2. Press the U-shaped openings on the inside of the bezel into the ball studs on the

mounting rails until the bezel snaps into place.

Removing and Replacing a CPU-I/O Enclosure

Remove a CPU- I ⁄ O enclosure to replace it or to access its internal components for

other procedures.

See the following sections:

• “Removing a CPU-I/O Enclosure” on page 5-5

• “Replacing a CPU-I/O Enclosure” on page 5-8

Estimated time: Five minutes, not including the time for other CRU replacement

procedures.

Tools: None.

5-4 Express5800/320Ma: Operation and Maintenance Guide

Page 51

Removing a CPU-I/O Enclosure

WARNING

!

To avoid personal injury or damage to the system, two

persons are required to replace an enclosure.

1. If necessary, use ftServer Management Console (ftSMC) to take the enclosure

offline. See the Help for ftSMC for detailed instructions.

Verify that the enclosure is offline before proceeding.

2. Remove the bezel, as described in “Removing and Replacing the Bezel” on

page 5-3.

3. Disconnect all of the data cables from the rear of the enclosure. Then, disconnect

the power cord.

CAUTION

!

You must disconnect the VTM network cable before you

disconnect the power cord. When you remove the power

cord, the mechanical interlock at the rear of the system

springs into the unlocked position and could damage the

VTM connector or cable (Figure 5-2, inset).

Removing and Replacing a CPU-I/O Enclosure

4. Ensure that the mechanical interlock on the rear of the enclosure is in the unlocked

position (number 1 in Figure 5-2). If the system is in a rack, the unlocked position

is the vertical position. If the system is in a pedestal case, the unlocked position is

the horizontal position.

CRU Replacement Procedures 5-5

Page 52

Removing and Replacing a CPU-I/O Enclosure

Figure 5-2. Unlocking the Rear Interlock on an Enclosure

1 Mechanical interlock (unlocked position)

2 Mechanical interlock (locked position)

3 VTM Ethernet cable

5. Loosen the two thumbscrews (number 1 in Figure 5-3) on the release levers at the

front of the enclosure.

6. Pull on the two release levers to loosen the enclosure from the rails (number 2 in

Figure 5-3). Pull the enclosure a few inches out of the slot.

5-6 Express5800/320Ma: Operation and Maintenance Guide

Page 53

Removing and Replacing a CPU-I/O Enclosure

Figure 5-3. Unlocking the Front Release Levers on an Enclosure

1 Thumbscrew

2 Release lever (unlocked)

7. With one person supporting the enclosure on each side, pull it straight out until it is

stopped by the safety lever (Figure 5-4) on its right side. Push down the front end

of the lever to disengage it.

Figure 5-4. Removing a CPU-I/O Enclosure

1 Safety lever

8. With each person holding a side of the enclosure, pull the enclosure straight out

and place it on a flat, stable surface.

CRU Replacement Procedures 5-7

Page 54

Removing and Replacing a CPU-I/O Enclosure

If you are replacing the CPU- I ⁄ O enclosure with a new enclosure, transfer the SATA

drives, the CD or DVD drive, the VTM (if applicable), the PCI riser assembly (if

applicable), and the PCI adapters from the old enclosure to the new enclosure.

NOTES

1. Before you remove the SATA disk drives from the old

enclosure, label the drives on the bezel of each drive

to ensure that you can replace them in the proper

order. The numerical slot designation for each disk is

noted on the front of the SATA drive bay.

2. When you remove the PCI riser assembly from the old

enclosure, you do not need to remove the PCI

adapters from it. Transfer the entire PCI riser

assembly, with adapters, to the replacement system.

3. The replacement enclosure will contain the same

CPU and memory configuration as the enclosure you

are replacing. Do not remove processors or memory

modules from the enclosure when you return it to

NEC Solutions (America), Inc.

Refer to the following sections for more information:

• “Replacing or Installing a PCI Adapter” on page 5-18

• “Removing and Replacing the PCI Riser Assembly” on page 5-26

• “Replacing or Installing a VTM” on page 5-47

• “Removing and Inserting a SATA Disk Drive” on page 5-31

• “Removing and Replacing a CD or DVD Drive” on page 5-35

When you are finished removing components from the old CPU- I⁄ O enclosure, set

it aside for repacking. See “Repacking CRUs” on page 4-3.

Replacing a CPU-I/O Enclosure

NOTES

1. The first CPU- I ⁄ O enclosure to complete power up is

the primary (boot) enclosure: the LED in its power

switch will be lit.

2. Each CPU- I⁄ O enclosure is identical (aside from

installed options) and may occupy either of the two

enclosure slots.

5-8 Express5800/320Ma: Operation and Maintenance Guide

Page 55

Removing and Replacing a CPU-I/O Enclosure

WARNING

!

To avoid personal injury or damage to the system, two

persons are required to replace an enclosure.

1. Ensure that the mechanical interlock on the rear of the enclosure is in the unlocked

position (number 1 in Figure 5-2).

2. With one person supporting the enclosure on each side, align the rear end of the

enclosure with the appropriate rails on both sides (Figure 5-4). The enclosure

should be perfectly level.

3. With the release levers in the open position (number 2 in Figure 5-3), slide the

enclosure almost all the way into its opening.

4. Position the lower ends of the release levers over the inside edge of the positioning

pins, then push the release levers into their fully-closed position to push the

enclosure into place.

5. Tighten the two thumbscrews (number 1 in Figure 5-3) to lock the enclosure

securely into the backplane.

6. Turn the mechanical interlock on the rear of the system into the locked position

(number 2 in Figure 5-2), and plug in the power cord.

7. Plug in all of the data cables.

8. Restore the enclosure to service in ftSMC.

CAUTION

!

When you plug the power cord into the

CPU- I ⁄ Oenclosure, its white LED will blink for about 30

seconds while its BMC is synchronizing. Do not remove

the enclosure during this process! If the white LED

continues to blink for several minutes, contact NEC

Technical Support or your authorized service

representative.

9. Ensure that the enclosure and any CRUs you replaced are functioning properly.

• Verify that all installed options appear in ftSMC, and, if applicable, that they are

operating in Duplex mode. (Note that it could take the system several minutes

to update the status of all the devices in ftSMC, particularly for mirrored disk

drives.)

• In the Intel PROset utility, click each Ethernet PCI adapter and then click the

General tab to verify that the adapters have a link and are actively passing

packets. For information about PROSet and troubleshooting PCI adapters, see

the Express5800/320Ma: PCI Adapter Guide.

CRU Replacement Procedures 5-9

Page 56

Replacing the System Backplane Assembly

If any devices are not functioning properly, verify that you properly installed all of

the data cables. If the cabling is correct, try removing and replacing the enclosure

again to resolve the problem, starting with “Removing a CPU-I/O Enclosure” on

page 5-5.

10. Install the bezel, as described in “Removing and Replacing the Bezel” on page 5-3.

Replacing the System Backplane Assembly

To replace a system backplane assembly, you must disconnect both

CPU- I ⁄ O enclosures from it. Also, you must remove the modem assembly from the old

backplane assembly to install it on the new system backplane assembly.

NOTES

1. Because you remove both enclosures from operation

to replace a system backplane assembly, you must

schedule downtime to shut down the system.

2. When you replace a system backplane assembly with

a new assembly, you need to reset the Ethernet

address (also known as the MAC address) of any

Ethernet team that includes embedded Ethernet PCI

adapters. In addition, your network administrator must

update any network filtering or security settings that

might be based on the Ethernet (MAC) addresses of

any embedded Ethernet adapter, teamed or

non-teamed.

Estimated time: Fifteen minutes.

Tools: None.

See the following sections:

• “Removing the System Backplane Assembly”

• “Replacing the System Backplane Assembly” on page 5-12

• “Resetting the Ethernet Address of an Ethernet Team” on page 5-14

Removing the System Backplane Assembly

1. Shut down the system.

2. Remove the bezel, as described in “Removing and Replacing the Bezel” on

page 5-3.

5-10 Express5800/320Ma: Operation and Maintenance Guide

Page 57

Replacing the System Backplane Assembly

3. Release each CPU- I ⁄ O enclosure from the system chassis, as follows:

a. Disconnect all of the data cables from the rear of the enclosure. Then,

disconnect the power cord.

CAUTION

!

You must disconnect a VTM network cable before you

disconnect the power cord. When you remove the power

cord, the mechanical interlock at the rear of the system

springs into the unlocked position and could damage the

VTM connector or cable (Figure 5-2, inset).

b. Ensure that the mechanical interlock on the rear of the enclosure is in the

unlocked position (number 1 in Figure 5-2). If the system is in a rack, the

unlocked position is the vertical position. If the system is in a pedestal case, the

unlocked position is the horizontal position.

c. Loosen the two thumbscrews (number 1 in Figure 5-3) on the release levers at

the front of the enclosure.

d. Pull on the two release levers to loosen the enclosure from the rails (number 2

in Figure 5-3). Pull the enclosure out only 3 or 4 inches to separate it from the

backplane. You do not need to remove the enclosures from the rails.

4. Disconnect all of the cables from the system backplane assembly, if you have not

done so already.

5. Remove the modem assembly from the system backplane assembly, as follows:

a. Disconnect the phone line from the modem assembly.

b. Loosen the two captive screws (number 2 in Figure 5-31) that fasten the

modem assembly to the system backplane assembly.

c. Disconnect and remove the modem assembly by pulling it gently off of the

system backplane assembly.

6. Loosen the two thumbscrews (number 1 in Figure 5-5) on the system backplane

assembly.

7. Slide the system backplane assembly to the left if the system is in a rack, or toward

the top of the enclosure if the system is in a pedestal case. Pull the assembly out

of the system (Figure 5-5).

CRU Replacement Procedures 5-11

Page 58

Replacing the System Backplane Assembly

Figure 5-5. Removing the System Backplane Assembly

1 Thumbscrew

2 Modem connector

NOTE

If the system backplane assembly does not slide, pull the

enclosures a little further out of the system chassis.

If the system backplane assembly is defective, set it aside for repacking. See

“Repacking CRUs” on page 4-3.

Replacing the System Backplane Assembly

1. Line up the new system backplane assembly with the system chassis, as shown in

Figure 5-5. (The USB connectors are located on the side of the assembly that is

closest to the PCI adapters.)

5-12 Express5800/320Ma: Operation and Maintenance Guide

Page 59

Replacing the System Backplane Assembly

2. Insert the system backplane assembly into the enclosure, then slide it to the right

if the system is in a rack (Figure 5-5). Slide the assembly toward the bottom of the

enclosure if the system is in a pedestal case.

The thumbscrews on the assembly should line up with the screw holes on the rear

of the enclosure.

3. Tighten the two thumbscrews on the system backplane assembly to fasten it to the

system chassis.

4. Attach the modem assembly to the new system backplane assembly, as follows:

a. Press the modem assembly firmly into the connector (number 2 in Figure 5-5).

The modem connector is keyed to fit only the correct way.

b. Tighten the two captive screws on the modem assembly to fasten it to the

system backplane assembly.

c. Connect the phone line to the connector on the modem assembly.

5. Connect all of the cables to the system backplane assembly.

6. Replace each CPU- I ⁄ O enclosure, as follows:

a. Ensure that the mechanical interlock on the rear of the enclosure is in the

unlocked position (number 1 in Figure 5-2).

b. With the release levers on the front of the enclosure in the open position

(number 2 in Figure 5-3), slide the enclosure almost all the way into its

opening.

c. Position the lower ends of the release levers over the inside edge of the

positioning pins, then push the release levers into their fully-closed position to

push the enclosure into place.

d. Tighten the two thumbscrews (number 1 in Figure 5-3) to lock the enclosure

securely into the backplane.

e. Turn the mechanical interlock on the rear of the system into the locked position

(number 2 in Figure 5-2), and plug in the power cord.

f. Plug in all of the data cables.

NOTE

If you need to reset the Ethernet address of any Ethernet

team that includes embedded Ethernet PCI adapters, as

discussed in the following section, do not reconnect the

network cables to the embedded Ethernet PCI adapter

ports until after you reset the address(es).

7. Start the system and ensure that it is functioning properly. If necessary, reset the

Ethernet address of any Ethernet teams, as discussed in the following section.

8. Replace the bezel, as described in “Removing and Replacing the Bezel” on

page 5-3.

CRU Replacement Procedures 5-13

Page 60

Replacing the System Backplane Assembly

Resetting the Ethernet Address of an Ethernet Team

When you replace a system backplane assembly, you must reset the Ethernet address

of any Ethernet teams that include embedded Ethernet PCI adapters.

NOTE

This section applies only to teams with embedded PCI

Ethernet adapters. Teams with other types of Ethernet

PCI adapters are not affected by replacing the system

backplane assembly.

Typically, the Ethernet address of a team is the permanent MAC address of the primary

(active) adapter for the team. The MAC addresses for embedded Ethernet PCI

adapters in Express5800/320Ma 3.2 GHz and 3.6 GHz systems are stored in the

system backplane assembly. If you replace the assembly with a new one, the MAC

addresses of all the embedded Ethernet PCI adapters in the system change. If the

embedded Ethernet PCI adapters were in teams before you replaced the system

backplane assembly, those teams continue to use Ethernet addresses from the old

assembly.

Continuing to use these old addresses might cause network problems in the future,

especially if the old system backplane assembly is repaired and redeployed in another

Express5800/320Ma system on your network. Therefore, when you replace the system

backplane assembly, you should change the Ethernet addresses of any teams with

embedded Ethernet PCI adapters before you bring your system back into service.

You can change the Ethernet address of a team in the Intel

®

PROSet utility. For more

information about PROset and teaming Ethernet adapters, see the

Express5800/320Ma: PCI Adapter Guide.

To update the Ethernet Address for a team

NOTE

You can accomplish the same goal by deleting teams with

embedded adapters and creating them again; however,

you will lose any customized settings for the teams by

doing so.

1. Start PROSet in one of the following ways:

• Double-click PROSet in the system tray:

• Double-click PROSet in the Control Panel:

5-14 Express5800/320Ma: Operation and Maintenance Guide

Page 61

Removing and Replacing a CPU-I/O Enclosure Cover

2. In the left pane of the Intel(R) PROSet for Wired Connections dialog box,

right-click the appropriate team. In the menu that appears, click Change Team

Mode (see Figure 5-6). Click a mode different from the one with the check mark.

NOTE

Changing the team mode forces PROSet to update the

Ethernet address of the team.

Figure 5-6. Changing the Mode of an Ethernet Team

3. Again, right-click the team in the device tree in the left pane, and, on the menu that

appears, click Change Team Mode. Verify that the mode has been changed.

4. Click OK to allow PROSet to process the procedure and to close. Allow PROSet

time to process the update, approximately 30 seconds.

5. Restart PROSet and restore the team to its previous mode.

6. Click Apply to process and save the changes. Again, allow PROSet processing

time.

7. Reconnect the network cables to the embedded Ethernet PCI adapter ports and

verify network connectivity.

Removing and Replacing a CPU-I/O Enclosure Cover

Remove the cover of a CPU- I ⁄ O enclosure to access the CRUs located within it.

Estimated time: One minute.

Tools: ESD strap and #2 Phillips head screwdriver.

CRU Replacement Procedures 5-15

Page 62

Removing and Replacing a CPU-I/O Enclosure Cover

See the following sections:

• “Removing an Enclosure Cover” on page 5-16

• “Replacing an Enclosure Cover” on page 5-17

Removing an Enclosure Cover

1. Remove the CPU-I/O enclosure.

2. Loosen the thumbscrews (number 2 in Figure 5-7) at the front of the cover and the

screw at the rear of the enclosure (number 1).

NOTE

You do not need to fully remove the screw at the rear of

the enclosure to remove the cover unless you intend to