Page 1

Express5800/320Ma:

Site Planning Guide

NEC Solutions (America), Inc.

NR573

Page 2

Notice

The information contained in this document is subject to change without notice.

UNLESS EXPRESSLY SET FORTH IN A WRITTEN AGREEMENT SIGNED BY AN AUTHORIZED REPRESENTATIVE

OF NEC, NEC MAKES NO WARRANTY OR REPRESENTATION OF ANY KIND WITH RESPECT TO THE

INFORMATION CONTAINED HEREIN, INCLUDING WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PURPOSE. NEC assumes no responsibility or obligation of any kind for an y errors contained herein or in connection with

the furnishing, performance, or use of this document.

Software described in NEC (a) is the property of NEC and/or its licensees, (b) is furnished only under license, and (c) may

be copied or used only as expressly permitted under the terms of the license.

NEC documentation describes all supported features of the user interfaces and the application programming interfaces

(API) developed by NEC and/or its licensees. Any undocumented f eatures of these interfaces are intended solely for use

by NEC personnel and are subject to change without warning.

This document is protected by copyright. All rights are reserved. No part of this document may be copied, reproduced, or

translated, either mechanically or electronically, without the prior written consent of NEC Solutions (America), Inc.

The NEC Solutions (America), Inc. logo, Express5800/320Ma, and the Express5800/320Ma logo, are trademarks of NEC

Solutions (America), Inc. ActiveService Network is a trademark of Stratus Technologies Bermuda, Ltd. All other

trademarks and trade names are the property of their respective owners.

Manual Name: Express5800/320Ma: Site Planning Guide

Part Number: NR573

Express5800/320Ma Software Release Number: 4.1.0

Publication Date: January 2006

NEC Solutions (America), Inc.

10850 Gold Center Drive, Suite 200

Rancho Cordova, CA 95670

© 2006 NEC Solutions (America), Inc. All rights reserved.

Page 3

Contents

Preface vii

1. Welcome to Site Planning for Express5800/320Ma 3.2 GHz, 3.6 GHz,

and Dual-Core systems 1-1

Site Planning Overview 1-1

Site Planning for Fault-Tolerant Systems 1-2

Site Planning Checklist 1-3

System Documentation 1-5

2. Cabinet and Monitor Requirements 2-1

Cabinet Requirements 2-1

Monitor Requirements 2-4

3. Space Planning 3-1

Room Requirements 3-1

Planning for Cables 3-2

4. Electrical (AC) Power Planning 4-1

Redundant Power Sources 4-1

AC Power Service Requirements 4-2

Power Outlet Requirements 4-4

Connecting a System Directly to Two Separate Power Sources 4-5

NEC-Supplied Power Cords 4-6

System Power Cords 4-7

PDU Power Cords 4-8

Power Cords for Optional Components 4-9

5. UPS Planning 5-1

Contents iii

Page 4

Contents

Qualified APC UPS Models 5-1

Communicating with a UPS over a Network 5-2

Connecting Power to Systems, PDUs, and a UPS 5-3

Connecting a System Directly to a UPS 5-4

6. Network and Telephone Line Planning 6-1

Network Cable Requirements 6-1

Telephone Line Requirements 6-2

Site Planning for Systems in an ftGateway Group 6-3

7. Rack Configuration Planning 7-1

Using PDUs 7-1

Determining PDU Requirements 7-2

Sample PDU Usage Calculation 7-4

Appendix A. System Specifications A-1

System Specifications A-1

Rack-Mountable System Specifications A-7

Appendix B. Electrical Circuit and Wiring Information B-1

Fault Protection Requirements B-1

Grounding Considerations B-1

Circuit Wiring Diagrams B-3

Electrical Power Connectors B-9

Appendix C. Standards Compliance C-1

Index Index-1

iv Express5800/320Ma: Site Planning Guide

Page 5

Figures

Figure 2-1. Rail Clearance 2-3

Figure 4-1. Rack-Mounted System Connected Directly to AC Power 4-6

Figure 4-2. Pedestal System Connected Directly to AC Powe r 4-6

Figure 5-1. Power Cord Connections for Systems, PDUs, and a UPS 5-3

Figure 5-2. Rack-Mountable Systems: A-Side Power Connected

Directly to a UPS 5-4

Figure 5-3. Pedestal Systems: A-Side Power Connected Directly to

a UPS 5-5

Figure A-1. Pedestal System - Front View A-2

Figure A-2. Pedestal Express5800/320Ma 3.2 GHz systems -

Rear View A-3

Figure A-3. Pedestal Express5800/320Ma 3.6 GHz systems-

Rear View A-4

Figure A-4. Rack-Mountable System - Front View A-7

Figure A-5. Rack-Mountable Express5800/320Ma 3.2 GHz system -

Rear View A-8

Figure A-6. Rack-Mountable Express5800/320Ma 3.6 GHz or Dual-Core

System - Rear View A-9

Figure B-1. Star Ground Example B-2

Figure B-2. Power Input Labeling B-3

Figure B-3. Single-Phase 120-Volts AC Circuit Connection B-4

Figure B-4. Single-Phase 240-Volts AC Circuit Connection B-5

Figure B-5. Split-Phase 120/240 Volts AC Circuit Connection B-6

Figure B-6. Three-Phase 208-Volts AC, Y-, or

Connection, Phase-to-Neutral B-7

Figure B-7. Three-Phase 208-Volts AC, Y-, or

Connection, Phase-to-Phase B-8

Figure B-8. Three-Phase 380V AC, Y-, or

Phase-to-Neutral B-9

∆-Source Circuit

∆-Source Circuit

∆-Source Circuit Connection,

Figures v

Page 6

Tables

Table 1-1. Ethernet PCI Adapters 1-4

Table 1-2. Optical Fibre Channel PCI Adapters 1-4

Table 1-3. Express5800/320Ma Documentation 1-6

Table 4-1. AC Power Service Requirements 4-2

Table 4-2. Worksheet for Determining A-Side Power Requirements 4-3

Table 4-3. Worksheet for Determining B-Side Power Requirements 4-3

Table 4-4. Worksheet for Determining External Power Requirements 4-3

Table 4-5. Worksheet: A-Side External Power Outlet Requirements -

PDUs Used 4-4

Table 4-6. Worksheet: B-Side External Power Outlet Requirements -

PDUs Used 4-4

Table 4-7. Worksheet: A-Side External Power Outlet Requirements -

No PDUs 4-5

Table 4-8. Worksheet: B-Side External Power Outlet Requirements -

No PDUs 4-5

Table 4-9. System Power Cords to AC Power 4-7

Table 4-10. Systems: Power Cords to a UPS 4-8

Table 4-11. PDU Power Cords to AC Power 4-9

Table 4-12. System Power (Jumper) Cables to a PDU 4-9

Table 4-13. Po wer Cords for Optional Components 4-9

Table 5-1. APC Symmetra Models for PDUs or for Multiple Systems 5-1

Table 5-2. APC UPS Models for a Single Rack-Mountable System 5-2

Table 5-3. APC UPS Models for a Single Pedestal System 5-2

Table 6-1. Customer-Supplied Ethernet Cables 6-2

Table 7-1. Current and Rack-Space Requirements 7-2

Table 7-2. Calculating A-Side PDU and Rack-Space Requirements 7-3

Table 7-3. Sample: Current and Rack-Space Requirements 7-4

Table 7-4. Sample: Calculating A-Side PDU and Rack-Space

Requirements 7-4

Table A-1. Pedestal System Specifications A-5

Table A-2. Cabinet Dimensions A-10

Table A-3. Rack-Mountable System Specifications A-11

Table B-1. Connectors for AC Power Outlets B-10

Table C-1. EMI Standards C-2

Table C-2. Immunity Standards C-2

Table C-3. Safety Standards C-2

Table C-4. Noise Standards C-2

vi Express5800/320Ma: Site Planning Guide

Page 7

Purpose of This Manual

The Express5800/320Ma: Site Planning Guide documents the site requirements and

customer responsibilities related to preparing a site for the installation of

Express5800/320Ma 3.2 GHz, 3.6 GHz, or Dual-Core systems.

Audience

This manual is intended for those responsible for pr eparing a site for the installatio n of

an Express5800/320Ma 3.2 GHz, 3.6 GHz, or Dual-Core system.

Notation Conventions

This document uses the notation conventions described in this section.

Warnings, Cautions, and Notes

Warnings, cautions, and notes provide special information and have t he following

meanings:

WARNING

!

A warning indicates a situation where failure to take

or avoid a specified action could ca use bodily harm or

loss of life.

Preface

CAUTION

!

A caution indicates a situation where failure to t ake or

avoid a specified action could damage a hardwar e device,

program, system, or data.

NOTE

A note provides important information about the opera tion

of an Express5800/320Ma system.

Preface vii

Page 8

Preface

Typographical Conventions

The following typographical conventions are used in Express5800/320Ma document s:

• The bold font emphasiz es w ords in t e xt or indicates text that you type or the name

of a screen object. For example:

Before handling or replacing a PCI adapter, make sure that you are properly

grounded by using a grounded wrist strap.

In the System Properties dialog box, click the Hardware tab.

• The italic font introduces new terms. For example:

Many hardware components are custom er -r ep la cea b le un its (CRUs), which

can be replaced on-site by system adm inistrators with minimal tr aining or tools.

copy filename1 filename2

• The monospace font indicates message text. For example:

The operation completed successfully.

Getting Help

If you have a technical question about Express5800/320Ma hardware or software, try

these online resources first:

• Online support from NEC Technical Support. You can find the latest technical

information about an Express5800/320Ma through online product support at the

NEC Technical Support Web site:

http://support.necsam.com/servers/

• Online product support for Microsoft

®

products. Your primary source for

support is the computer manufacturer wh o provided your software, or an

authorized Microsoft Support Provider . You can also find the latest technical

information about Microsoft Windows

®

and other Microsoft products through online

product support at the Microsoft Help and Support Web site:

http://support.microsoft.com/

If you are unable to resolve your questions with t he help available at these online sites,

and the Express5800/320Ma system is covere d by a service agreement, please

contact NEC Technical Support (866-269-1239).

viii Express5800/320Ma: Site Planning Guide

Page 9

Notices

Preface

• All regulatory notices are provided in Appendix C, “Standards Com pliance” of this

site planning guide.

• Although this guide documents modem functionality, modems are not a v ailab le f or

all systems. Ask your sales representative about modem availability.

• ActiveService Network (ASN) is not currently availa ble, but may be ordered in the

future.

Preface ix

Page 10

Preface

x Express5800/320Ma: Site Planning Guide

Page 11

Chapter 1

Welcome to Site Planning for

Express5800/320Ma 3.2 GHz, 3.6 GHz,

For an overview of the information you need to know and of the tasks you need to

perform to prepare a site for a n Expr ess5800/ 32 0Ma 3.2 GHz, 3. 6 GH z, or Du al- Core

system, see:

• “Site Planning Overview” on page 1-1

• “Site Planning for Fault-Tolerant Systems” on page 1-2

• “Site Planning Checklist” on page 1-3

• “System Documentation” on page 1-5

Site Planning Overview

Site planning for fault-tolerant systems includes:

• Space planning

Provide adequate space for the system or cabinet and for a desk or table to

accommodate components outside a cabinet. Also provide enough space for

servicing the systems and components.

and Dual-Core systems

1-

• Purchasing an appropriate cabinet and monitor

If you do not purchase a monitor from NEC Solutions (Amer ica) , Inc., provide a

monitor that meets the system’s requirements.

If you do not purchase the cabinet that NEC Solutions (America), Inc. references,

provide a cabinet that meets the system’s requirements.

• Electrical (AC) power planning

Provide electrical power sources that meet the system’s requirements, optionally

including the purchase of a qualified uninterruptible power supply (UPS).

• Network and telephone line planning

Provide sufficient network and analog telephone lines.

Welcome to Site Planning for Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems 1-1

Page 12

Site Planning for Fault-Tolerant Systems

Use the “Site Planning Checklist” on page 1-3 to track your site preparation progress.

For a list of other documents related to your Express5800/320Ma system, see “System

Documentation” on page 1-5.

During the site planning and preparation processes, work closely with your facilities

group or contractor to determine space, power, and environmental requirements. Enlist

their help to provide a suitable location with sufficient alternating current (AC) power,

heating, ventilation and air conditioning (HVAC) capabilities, and network and

telephone connections.

If your system is covered by a service agreem ent and you need help with site planning,

contact the NEC Technical Support. If you have a contract with the NEC Technical

Support to install the system, contact them after you have pre pared the installation site

and moved the system to the site. For more information about NEC Technical Support,

visit http://support.necsam.com/servers.

See Appendix A, “System Specifications” for Express5800/320Ma 3.2 GHz, 3.6 GHz,

or Dual-Core system specifications and the Express5800/320Ma: Peripherals Site

Planning Guide for specifications of other components.

Site Planning for Fault-Tolerant Systems

Consider the following specific fault-tolerant features of Express5800/320Ma 3.2 GHz,

3.6 GHz, and Dual-Core systems for site planning:

• Lockstep technology means that the Express5800/320Ma 3.2 GHz and 3.6 GHz

systems contain redundant hardwa re. The Express5800/320Ma 3.2 GHz and 3.6

GHz systemssystems contain two enclosures, each cont aining a full computing

environment that consists of a CPU element and an I/O element.

If a component in a CPU element malf unctions, the correspon ding CPU element in

the other enclosure, which is processing the same information in lockstep,

continues processing without interruption. If a component in the I/O element

malfunctions, the system fails operation over to the corresponding element in the

other enclosure and continues to operate normally. Th e only consequences are

that the system is less fault tolerant, and any I/O throughput distributed between

the enclosures may be reduced. To restore full fault tolerance , an enclosure can

be replaced without taking the system offline.

• Express5800/320Ma 3.2 GHz and 3.6 GHz systems can connect to the

ActiveService Network (ASN).

Connecting a system to the ASN allows the NEC Technical Support to remotely

diagnose, troubleshoot, and resolve problems online.

1-2 Express5800/320Ma: Site Planning Guide

Page 13

T o e nable connectivity to th e ASN, a modem can be attached directly to the system

and managed by Windows Server software or two partnered Virtual Technician

Modules (VTMs) in the system. The VTMs can also connect to the ASN through

their Ethernet ports, if the network to which they are attached has Internet access.

Systems that connect to the ASN using partnered VTMs provide the highest level

of availability. VTMs provide ASN connectivity even when the operating system is

not operational. VTMs also allow internal adminis trators to re mo te ly se rvice the

system over a t elephone line or IP netw ork, regardless of the state of the operating

system.

Without VTMs, ASN connectivity is only possible if the operating system is

operational.

Site Planning Checklist

Referring to the information in this document, answer t he following questions:

Planning for ASN Connectivity

❏ Will your system use VTMs to connect to the ASN?

❏ If your system uses VTMs, will you connect them to a network so that you can

manage the server from a remote system? Are there mainten ance network

connections to which you can connect the VTMs?

Site Planning Checklist

❏ If your VTMs are connected to a netw ork, does the network have Internet

connectivity so that the system can connect to the ASN without a modem?

❏ If your system uses an ASN modem, do you have an external analog telephone line

available for the modem?

NOTE

A dedicated phone line provides the most reliable service.

ASN calls routed through a PBX may be slo w due to load

on the PBX, or may not complete successfu lly due to

disconnections. If you must use a PBX, do not route the

telephone extension through a switchboard; instead,

provide a direct-dial analog number.

❏ Do you hav e an additional telephone line and telephon e near the operator’ s station

for voice communications when calling for support?

Planning for Optional Components

❏ The system contains four 10/100/1000 megabits-per-second (Mbps) Ethernet

ports. Will your system additionally include any of the following PCI adapters for

network communications? If so, indicate how many of each and plan network

connections for all Ethernet ports you will use.

Welcome to Site Planning for Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems 1-3

Page 14

Site Planning Checklist

Table 1-1. Ethernet PCI Adapters

Adapter Number of Ports

U575 Dual-Port Copper Gigabit Ethernet Adapter

❏ Will your system connect to an EMC® CLARiiON® AX100 ® storage system? If so,

the system requires one pair of U531 Optical Fibre Channel PCI Adapter s, which

are provided when you order the storage system.

❏ Will your system connect to EMC CLARiiON CX or to EMC Symmetrix

systems? If so, the syst em requires one pair of opt ical fibre channel PCI ad apters,

as described in Table 1-2.

Table 1-2. Optical Fibre Channel PCI Adapters

Attachment Method PCI Adapter

®

storage

Through a Storage Area

Network (SAN) or switch

Directly attached U526 Optical Fibre Channel PCI Adapter, two of which are

U525 Optical Fibre Channel PCI Adapter, two of which are

provided in the AK415 Attachment Kit

provided in the AK419 Attachment Kit

❏ Will you supply your own monitor or will NEC Solutions (America), Inc. supply the

monitor?

NOTE

Use the USB keyboard and mouse supplied by NEC

Solutions (America), Inc..

❏ Will the components in a cabinet include a keyboard-video-mouse (KVM) switch?

Planning AC Power

❏ Will you provide power through a power distribution unit (PDU)?

❏ Will you provide power from a UPS?

❏ What are the AC power requirements of your system, including all optional

components?

❏ Is the AC power service wired properly?

❏ What are the lengths and types of the power cords that are provided with your

system? What type of receptacles do you need to provide?

Planning Space for Your System

❏ Will your system and its external components fit where you plan to place them?

1-4 Express5800/320Ma: Site Planning Guide

Page 15

System Documentation

❏ If you are rack-mounting the system, what is the height of the cabinet you will use

and what is the total height of the systems and components that will be installed in

the cabinet? Will the items fit into the cabinet? What components will be located

outside the cabinet?

❏ What are the lengths and types of the cables that will connect to your system?

❏ Have you creat ed a sketch of how y ou plan to arrange the system at th e installation

site? Consider the av ailab le ca b le lengths , t he placement of e xt ernal devices , an d

the location of network and voice communication connections.

On the sketch, sho w the following:

• Location of the system and its external components

• Power cords, and telephone and interface cables

• Locations of AC pow er receptacles, phone jacks, Ethernet jacks, switches,

and/or hubs

NOTE

Make sure that all cords and ca bles are long enough to

reach between their respectiv e components and

connectors. Route all cables out of the way of foot traffic.

Working with Other Groups

❏ Have you pr ovided y our f acilities gr oup and contractors with the sketch and cop ies

of the following?

• Tables 4-2, 4-3, and 4-4, worksheets for determining AC power requirements

• Tables 4-5 and 4-6 or Tables 4-7 and 4-8, worksheets for determining the

number of external power outlets required

• Appendix B, “Electrical Circuit and Wiring Information”

• Any notes you have about site planning

❏ Have you reviewed and discussed the requirements with the facilities personnel

and contractors to ensure that all site modifications are understood and

implemented?

If you have any questions about the number and types of components, contact your

Express5800/320Ma account executive or distributor.

System Documentation

When you receive your system, you receive a printed copy of the Express5800/320Ma:

Installation Guide. The software installation program lets you install an online copy of

Welcome to Site Planning for Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems 1-5

Page 16

System Documentation

this document, along with other Express5800/320Ma system documentation, on your

system. You also have the option to install documentation on a remote system. The

Express5800/320Ma Help and Manuals folder on the Windows desktop, contains

these documents.

To order additional documentation, visit the NEC Technical Support Web site:

http://support.necsam.com/servers/

Express5800/320Ma Express5800/320MaExpress5800/320MaTable 1-3 lists

Express5800/320Ma 3.2 GHz, 3.6 GHz, or Dual-Core system documents and the tasks

described in each document.

Table 1-3. Express5800/320Ma Documentation

Document Task

Express5800/320Ma: Site Planning

Guide

Express5800/320Ma: Installation Guide Install your system, including mounting the

Express5800/320Ma: Operation and

Maintenance Guide

Release Notes: Express5800/320Ma Learn the contents of the latest

Prepare a site for installation of your

Express5800/320Ma 3.2 GHz, 3.6 GHz, or

Dual-Core system.

system in a cabinet

Find the part number of a customer-rep lac eab l e

unit (CRU)

Respond to Mini-Setup questions on your new

Express5800/320Ma system

Install Express5800/320Ma System software

and Windows Server on your new system

Start up, shut down, and operate your system

Troubleshoot system hardware

Remove and replace CRUs

Express5800/320Ma software release

Learn the latest information about the product

Learn about significant known problems and

how to work around or avoid the problems

1-6 Express5800/320Ma: Site Planning Guide

Page 17

Table 1-3. Express5800/320Ma Documentation (Continued)

Document Task

System Documentation

Express5800/320Ma: Software

Installation and Configuration Guide

Express5800/320Ma ActiveService

Network Configuration Guide

Express5800/320Ma Virtual Technician

Module User’s Guide

Express5800/320Ma: System

Administrator’s Guide

Respond to Mini-Setup questions

Install or reinstall Express5800/320Ma System

software and Windows Server software

Upgrade software and BIOS, BMC, and VTM

firmware

Configure Express5800/320Ma System

software

Connect a UPS to your system

Configure your system for support by the NEC

ActiveService Network (ASN)

†

Configure the VTMs

Configure and use VTMs to remotely control,

monitor, and troubleshoot your system

Use tools that are provided by Windows Server

software or Express5800/320Ma System

Software and by other vendors to manage the

system

Use ftServer Management Console (ftSMC) to

administer or troubleshoot Express5800/320Ma

systems

Express5800/320Ma Software

Availability Manager User’s Guide

Express5800/320Ma: PCI Adapter

Guide

Express5800/320Ma: Technical

Reference Guide

Monitor the performance of critical system

components and the status of user applications

Install, configure, replace, or troubleshoot PCI

adapters

Consult technical reference information for

Express5800/320Ma systems

Change BIOS settings

† ActiveService Network (ASN) is not currently available, but may be ordered in the future.

Welcome to Site Planning for Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems 1-7

Page 18

System Documentation

1-8 Express5800/320Ma: Site Planning Guide

Page 19

Chapter 2

For requirements related to supplying your own cabinet and monitor, see:

• “Cabinet Requirements” on page 2-1

• “Monitor Requirements” on page 2-4

Cabinet Requirements

If you are providing your own cabinet for an Express5800/320Ma 3.2 GHz, 3.6 GHz, or

Dual-Core systems, make sure the cabinet contains a rack that is 19-in. wide and that

meets the Electronic Industries Association (EIA) 310-D standard.

Make sure that:

• The cabinet contains two front and two rear v ertical EIA rails, one in each corner of

the cabinet, that have the EIA universal square-hole pattern as defined in the EIA

310-D specification.

• The front vertical rails extend at least 0.5 in. (1.27 cm) beyond the inside edge of

the accessory leg, if present, to allow the mounting rails to be fit ted. See Figure 2-1.

Cabinet and Monitor Requirements

2-

• The distance between the front and r ear vertical rails is between 24 .5 in. and 30 in.

(62.23 cm and 76.20 cm).

• The vertical mounting rails accept 10-32 cage nuts and mounting hardware.

• The distance between the front vertical rails and the inside of the front door is at

least 3.0 in. (7.62 cm).

• The distance between the rear of t he system chassis and the inside of the rear do or

is at least 6.0 in. (15.24 cm).

• The vertical mounting rails are plated or some other method is used to ensure

continuity for g rounding between installed equipment.

• Cable management brac kets are pro vided to support and constrain data and power

cords so that the cables do not interfere with air flow out of the rear of the

enclosures, and so that the connectors do not disconnect or break.

• The cabinet provides enough stability so that system components pass T elcordia

®

GR-63-CORE Section 5.4.2 regulations for operational vibration.

Cabinet and Monitor Requirements 2-1

Page 20

Cabinet Requirements

• To prevent stray voltages, all components are grounded together through the

vertical mounting rails to the cabinet frame, and then to local building ground. To

ensure signal quality , us e a grounding cable pr ovided by NEC Solutions (America),

Inc. for local building ground.

• There is a plan for maintaining cables and wires to the cabinet by either running

them under the floor or placing them overhead in an overhead cable tray.

• Air flows through the cabinet from f ront to back.

• Filler panels cover any unused rack space to prevent air recirculation.

• V ents are evenly distributed on the front and rear doors and comprise at least 63%

of the surface area.

Figure 2-1 shows the required rail clearance between the front vertical rails and the

inside edge of an accessory leg.

NOTE

If your cabinet does not ha v e ve nted front and rear doors,

you can remove the doors from the cabinet while your

Express5800/320Ma 3.2 GHz or 3.6 GHz system is

operating.

2-2 Express5800/320Ma: Site Planning Guide

Page 21

Figure 2-1. Rail Clearance

0.5-inch

(1.27-cm)

minimum

1 2

Cabinet Requirements

0.5-inch minimum

3

msys182

1 Front vertical EIA rail

2 Accessor y leg

3 Front of cabinet

Cabinet and Monitor Requirements 2-3

Page 22

Monitor Requirements

Monitor Requirements

If you are using a monitor that is not supplied by NEC Solutions (America), Inc., make

sure that:

• The monitor accepts universal 100–240 VAC, 50/60 Hz power.

• The VGA cable has a 15-pin D-sub connector.

• The power cord for the monitor is long enough to reach the power source.

• The plug type on the power cord is compatible with the external power source at

the site.

Use the keyboard and mouse provided by NEC Solutions (America), Inc..

2-4 Express5800/320Ma: Site Planning Guide

Page 23

Chapter 3

For information about planning sufficient space for your Exp ress5800/320Ma 3.2 GHz,

3.6 GHz, or Dual-Core system, see:

• “Room Requirements” on page 3-1

• “Planning for Cables” on page 3-2

Room Requirements

To ensure that the installation site provides a properly equipped, cooled, and sized

environment, make sure that the site:

• Provides clearances for air circulation and servicing the system

Locate the front and rear of the system at least 2.5 ft (0.76m) a w a y from w alls an d

other obstructions.

• Maintains reasonable temperat ure and humidity lev els and has a thermometer and

humidistat to monitor room temperature and humidity

Space Planning

3-

• Is as free of dust as possible

Dust buildup in the system can impede air circulation and heat transfer, causing

components to become less reliable as the ambient t emperature rises.

• Provides a table or desktop for external devices such as a telephone, keyboard,

and mouse

• Provides cutouts in the floor for routing cables, if the site has an elevated floor

CAUTION

!

Do not place the system in an area of high electrostatic

discharge. Static electricity may damage components.

Do not locate components near transformers or other

electromagnetic devices.

See Appendix A, “System Specifications” for the dimensions of system components.

Space Planning 3-1

Page 24

Planning for Cables

Planning for Cables

To accommodate cables from your Express5800/320Ma 3.2 GHz o r 3.6 G Hz system,

make sure to provide:

• Two telephone lines:

– One telephone line for use when calling for service

– One telephone line for the ASN modem

• Ethernet jacks, switches, or hubs, as needed

• Two electrically separate grounded AC wall outlets, or a UPS and a wall outlet,

within reach of the power cords f rom the system or PDUs and addition al outlets f or

any components that do not connect to a PDU

Make sure that cables you plan to connect to the system are long enough to reach

between the system and external comp on e nt s or co nn ections. S

3-2 Express5800/320Ma: Site Planning Guide

Page 25

Chapter 4

For information about planning appropriate AC electrical power for your

Express5800/320Ma 3.2 GHz, 3.6 GHz, oe Dual-Core system, see:

• “Redundant Power Sources” on page 4-1

• “AC Power Service Requirements” on page 4-2

• “Power Outlet Requirements” on page 4-4

• “Connecting a System Directly to Two Separate Power Sources” on page 4-5

• “NEC-Supplied Power Cords” on page 4-6

Related Topics

• Chapter 5, “UPS Planning”

• Chapter 7, “Rack Configuration Planning”

Redundant Power Sources

Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems require at least two

separate and independent AC power sources–an A-side power source and a B-side

power source–that provide power to the system’s power receptacles, labeled,

respectively, A and B. Either source must be capable of continuing to provide power if

power to the other source is lost.

Electrical (AC) Power Planning

4-

The A-side power source provides power to components th at do not require two

sources of power: a KVM switch. If you use an uninterruptible power supply (UPS), the

UPS is the A-side power source.

The B-side power source provides power to the oth e r side of ea ch syste m .

The wattage required from the A-side power source will always be equal to or greater

than the wattage required from the B-side power source.

Electrical (AC) Power Planning 4-1

Page 26

AC Power Service Requirements

AC Power Service Requirements

Table 4-1 describes the nominal input line voltage (volts AC) and frequency (Hz)

required for your system and opt ional components. The table al so provides a reference

to a table that lists the receptacles to provide for each component.

Table 4-1. AC Power Service Requirements

Nominal Input Voltage;

Component

Nominal Frequency Range Receptacle

Express5800/320Ma 3.2 GHz, 3.6

GHz, or Dual-Core system

PDU 200–240V; 50/60 Hz See Table 4-11.

KVM switch 100–240V; 50/60 Hz See Table 4-13.

100–240V; 50/60 Hz See Table 4-9.

The power service must be properly wired and grounded a ccording to local standar ds

and regulations. See Appendix B for electrical circuit and wiring information.

NOTE

Circuit breakers must provide a protective earth ground

current at a maximum of 3.5 milliamperes for each AC

power cord.

Use the following worksheets to determine AC power requirements for the site.

• In Table 4-2, determine the power requirements at the A-side power source.

• In Table 4-3, determine the power requirements at the B-side power source.

• In Table 4-4, determine the power requirements for components outside of the

cabinet. These components can share a power source with the A-side or B-side

components.

To determine power requirements

Provide information in Tables 4-2, 4-3, and 4-4 as follows:

1. In the Quantity column, write the number of each type of component.

2. Multiply the entry in the Qua nt ity colu m n by the number in the @ Power (Watts)

column, and enter the result in the AC Power (Extended) column.

3. Add the values in the AC Power (Extended) column, and enter the sum on the

bottom line. This value indicates the maximum power requirement for each power

source.

4-2 Express5800/320Ma: Site Planning Guide

Page 27

AC Power Service Requirements

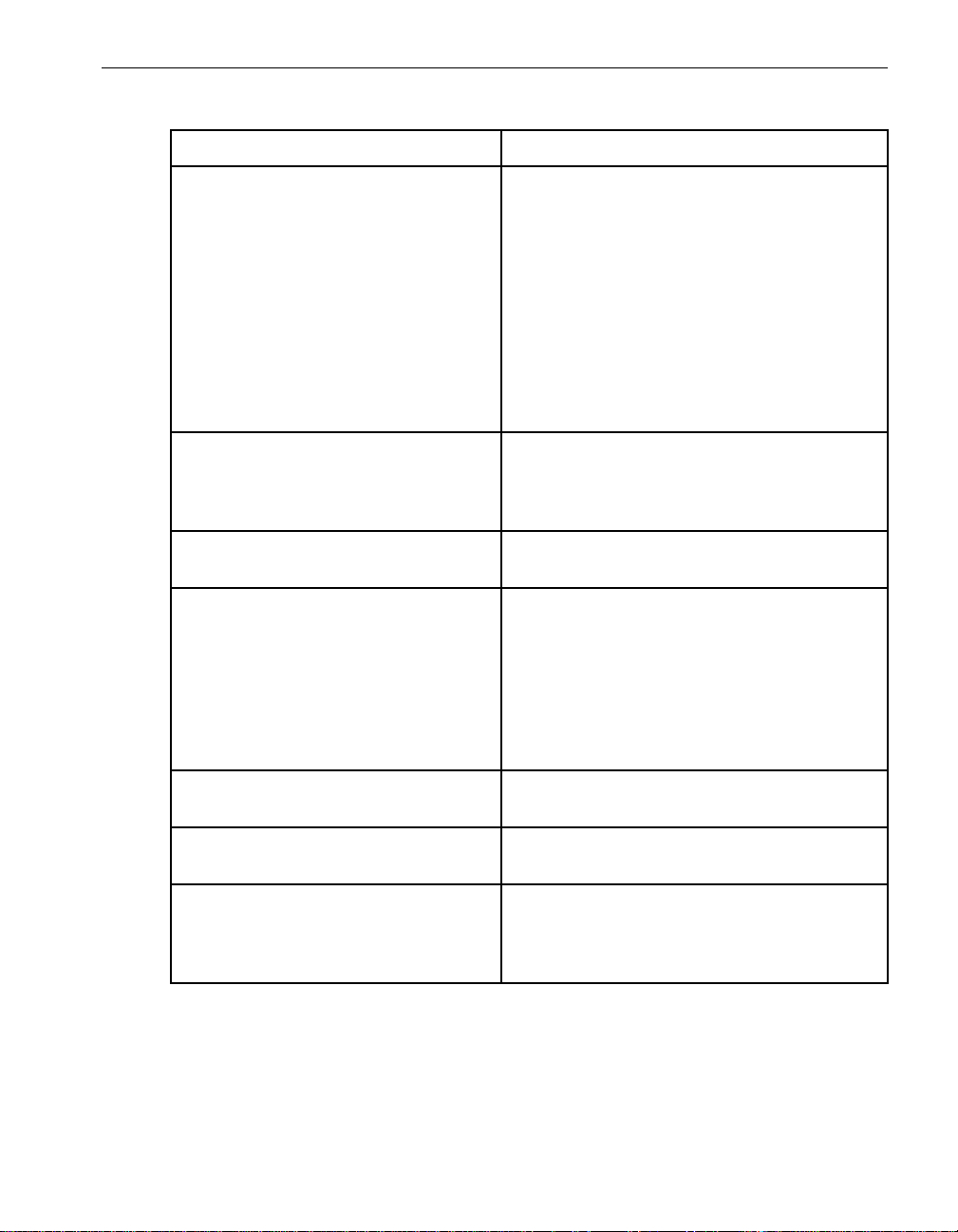

Table 4-2. Workshee t for Determining A-Side Pow e r R eq uirements

@ Power

System Component Quantity

Express5800/320Ma 3.2 GHz, 3.6

(Watts)

x 650 =

GHz, or Dual-Core system

KVM switch x 20 =

TOTAL A-SIDE POWER REQUIREMENTS

Table 4-3. Workshee t for Determining B-Side Pow e r R eq uirements

@ Power

System Component Quantity

Express5800/320Ma 3.2 GHz, 3.6

GHz, or Dual-Core system

TOTAL B-SIDE POWER REQUIREMENTS

Table 4-4. Worksheet for Determining External Power Requirements

System Component Quantity

Other external components

(Watts)

x 650 =

@ Power

(Watts)

AC Power

(Extended)

AC Power

(Extended)

AC Power

(Extended)

TOTAL EXTERNAL POWER REQUIREMENTS

Electrical (AC) Power Planning 4-3

Page 28

Power Outlet Requirements

Power Outlet Requirements

If you do use a pair of PDUs in the cabinet, use Tables 4-5 and 4-6 to determine the

total number of power outlets required outside the cabinet.

1. In the Quantity column, write the number of each type of component.

2. Multiply the value in the Quantity column by the value in the Outlets column, and

enter the total in the Subtotal column.

3. Add the values in the Subtotal column and enter the sum next to TOTAL NUMBER

OF A-SIDE POWER OUTLETS and TOTAL NUMBER OF B-SIDE POWER

OUTLETS.

Table 4-5. Workshee t: A -Sid e External Power Outlet Requiremen ts - PDUs Use d

Component Quantity Outlets Subtotal

PDUs x 1

Other external components

TOTAL NUMBER OF A-SIDE PO WER OUTLETS

Table 4-6. Workshee t: B -Sid e External Power Outlet Requiremen ts - PDUs Use d

Component Quantity Outlets Subtotal

PDUs x 1

Other external components

TOTAL NUMBER OF B-SIDE PO WER OUTLETS

If you do not use PDUs in the cabinet, use Tabl es 4-7 and 4-8 to determine the number

of power outlets required outside the cabinet.

1. In the Quantity column, write the number of each type of component.

2. Multiply the value in the Quantity column by the value in the Outlets column, and

enter the total in the Subtotal column.

3. Add the values in the Subtotal column and enter the sum next to TOTAL NUMBER

OF A-SIDE POWER OUTLETS and TOTAL NUMBER OF B-SIDE POWER

OUTLETS.

4-4 Express5800/320Ma: Site Planning Guide

Page 29

Connecting a System Directly to Two Separate Power Sources

Table 4-7. Workshee t: A -Side External Power Outlet Requirem ents - No PDUs

Component Quantity Outlets Subtotal

Express5800/320Ma 3.2 GHz, 3.6

GHz, or Dual-Core systems+

TOTAL NUMBER OF A-SIDE POWER OUTLETS

Table 4-8. Workshee t: B -Side External Power Outlet Requirem ents - No PDUs

Component Quantity Outlets Subtotal

Express5800/320Ma 3.2 GHz, 3.6

GHz, or Dual-Core systems

TOTAL NUMBER OF B-SIDE POWER OUTLETS

x 1

x 1

Connecting a System Directly to Two Separate Po wer Sources

If you do not connect your Express5800/320Ma 3.2 GHz or 3.6 GHz system or PDUs

to a UPS, provide two AC power sources that are as electrically independent of each

other as the installation site allows. At a minimum, the two pow er sou rce s mu st be

powered by separate circuit breakers (maximum of 2 0A) to AC power and, if po ssible,

be independent of each other beyond that level. The more electrical separation

between the two power sources, the less likely they will both fail at the same time. Due

to redundancy in Express5800/320Ma 3.2 GHz and 3.6 GHz syste ms, power to eit her

side of the system keeps the system in operation, although the system is no longer

fault-tolerant with regard to power.

Figure 4-1 shows how to connect a rack-mounted Express5800/320Ma 3.2 GHz,

3.6GHz, or Dual-Core system directly to two separate AC power sources, and

Figure 4-2 shows how to connect a pedestal system directly to two separate power

sources.

Electrical (AC) Power Planning 4-5

Page 30

NEC-Supplied Power Cords

Figure 4-1. Rack-Mounted System Connected Directly to AC Power

1

Figure 4-2. Pedesta l Sy ste m Co nn ec te d D ir ec tly to AC Power

4

4

4

3

3

asys001

3

4

3

1

2

asys002

1 A-side system power cord

2 B-side system power cord

3 AC power outlets

4 Circuit breakers (maximum of 20A)

NEC-Supplied Po wer Cords

NEC Solutions (America), Inc. supplies power cords for:

4-6 Express5800/320Ma: Site Planning Guide

Page 31

• Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems

• PDUs

• KVM switches

WARNING

!

Place all power cords out of the way of foot traffic.

Power cords described as Domestic are made with American Wire Gauge (AWG)

cordage and are intended for use in North America. Refer to UL 62 and CSA C22.2,

No. 49.

Power cords described as International are made with International Harmonized

cordage and are intended for use outside of North America.

System Power Cords

Table 4-9 lists the available power cords for Express5800/320Ma 3.2 GHz, 3.6 GHz,

and Dual-Core systems that connect directly to an AC power source (not to a PDU or

to a UPS).

Table 4-10 lists the available power cords that connect Express5800/320Ma 3.2 GHz,

3.6 GHz, and Dual-Core systems to qualified UPS models from American Power

Conversion (APC).

NEC-Supplied Power Cords

Table 4-9. System Power Cords to AC Power

Marketing

Locale Plug Type Rating Length

North America and Japan

locking power cord

International, locking power

cord

North America (Chicago) NEMA 5-15 15A/127V 7 ft B50101

North America (domestic) NEMA 5-15 15A/127V 15 ft B50104

Australia AS/NZS 3112:1993 10A/250V 4.5m B50124

China GB1002-1996 10A/250V 4.5m B50162

Europe (Continental) CEE 7 VII 16A/250V 4.5m B50112

Israel SI 32:1971 16A/250V 4.5m B50132

Italy CEI23-16 10A/250V 4.5m B50136

Electrical (AC) Power Planning 4-7

NEMA L6-20 20A/250V 15 ft

(4.5m)

IEC 60309

(formerly IEC 309)

16A/250V 4.5m B50153

ID

B50161

Page 32

NEC-Supplied Power Cords

Table 4-9. System Power Cords to AC Power (Continued)

Locale Plug Type Rating Length

Marketing

ID

Japan NEMA 5-15 15A/127V 15 ft

South Africa/India SABS164-1:1992

Switzerland SEV 1011-S24507 10A/250V 4.5m B50140

United Kingdom BS 1363/A, 13A/250V 4.5m B50116

Table 4-10. Systems: Power Cords to a UPS

Locale

North America

(Chicago) and Japan

North America

(Domestic) and

Japan

International 250V IEC 320 C14 to

PDU Power Cords

B50160

(4.5m)

13A/250V 4.5m B50152

ZA/3

Voltage

Rating Plug Types Length Marketing ID

120V NEMA 5-15 to IEC 60320

(formerly 320) C13

250V NEMA L6-20 to

IEC 60320 C13

IEC 60320 C13

15 ft

(4.5m)

15 ft

(4.5m)

3.5m B50301

B50104

B50161

The AA-P41104 PDU supplies power to Express5800/320Ma 3.2 GHz, 3.6 GHz, and

Dual-Core systems. Table 4-11 lists the available power cords to connect PDUs directly

to an AC power source or to the APC

®

Smart-UPS® and APC Symmetra® UPS models.

Table 4-12 describes the gray and black power (jumper) cables that are provided to

connect Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems to PDUs.

4-8 Express5800/320Ma: Site Planning Guide

Page 33

NEC-Supplied Power Cords

Table 4-11. PDU Power Cords to AC Pow er

Locale Plug Type Rating Length Marketing ID

North America

and Japan

North America IEC 60320 C19 to

International

† Use this power cord to connect the PDU directly to the AC power mains or to a UPS.

Table 4-12. System Power (Jumper) Cables to a PDU

Length Rating Plug Type to System Plug Type to PDU Marketing ID

2.0m 10A/250V IEC 320 C13 IEC 60320 (formerly

†

IEC 60320 (formerly 320)

C19 to NEMA L6-20P

NEMA L6-30P

(Receptacle must be fused

at no more than 20A)

†

IEC 60320 C19 to

IEC 60309

Power Cords for Optional Components

Table 4-13 lists the available power cords to connect to KVM switches directly to

external AC power sources.

Table 4-13. Power Cords for Optional Components

20A/250V

50–60 Hz

30A/250V

50–60 Hz

20A/250V

50–60 Hz

IEC 320) C14

15 ft

(4.5m)

15 ft B50156

15 ft

(4.5m)

B50155

B50154

B50502

Locale Rating Plug Type Length Marketing ID

North America and Japan 15A/120V NEMA 5-15 7 ft B501-01

North America and Japan 15A/120V NEMA 5-15 10 ft B501-02

United States (Domestic) 15A/127V NEMA 5-15 10 ft B501-06

Australia 10A/250V AS/NZS 3112:1993 2.5m B501-21

China (CCC) 10A/250V GB1002-1996 2.5m B50162-8F

Europe (Continental) 16A/250V CEE 7 VII 2.5m B501-09

India 13A/250V SABS164-1:1992;

ZA/3

Israel 16A/250V SI 32:1971 2.5m B501-29

Italy 16A/250V CEI23-16; 2.5m B501-33

Electrical (AC) Power Planning 4-9

2.5m B501-49

Page 34

NEC-Supplied Power Cords

Table 4-13. Power Cords for Optional Components (Continued)

Locale Rating Plug Type Length Marketing ID

New Zealand 10A/250V AS/NZS 3112:1993 2.5m B501-21

South Africa 13A/250V SABS164-1:1992;

ZA/3

Switzerland 10A/250V SEV 1011-S24507 2.5m B501-37

United Kingdom 13A/250V BS1363/A 2.5m B501-13

2.5m B501-49

4-10 Express5800/320Ma: Site Planning Guide

Page 35

Chapter 5

For information about planning for an uninterruptible power supply (UPS) to use with

your Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core system, see:

• “Qualified APC UPS Models” on page 5-1

• “Communicating with a UPS over a Network” on page 5-2

• “Connecting Power to Systems, PDUs, and a UPS” on page 5-3

• “Connecting a System Directly to a UPS” on page 5-4

Qualified APC UPS Models

NEC Solutions (America), Inc. has qualified certain UPS models from American Power

Conversion Corporation (APC) for use with Express5800/320Ma 3.2 GHz, 3.6 GHz,

and Dual-Core systems. The qualified APC Symmetra and APC Smart-UPS models

are listed in Tables 5-1, 5-2, and 5-3.

NOTE

Site planning information for the UPS, which you must

supply , is of a general nature only. Do not rely exclusively

on the UPS information in this document. Contact APC at

http://www.apcc.com for detailed UPS specifications,

documentation, and ordering information.

UPS Planning

5-

Table 5-1. APC Symmetra Models for PDUs or for Multiple Systems

AC Power

Locale APC Symmetra Model

North America SYH2K6RMT-P1, SYH4K6RMT-P1,

SYH6K6RMT-P1, SYA8K16RMP, or

SYA12K16RMP

With SYA8K16RMP and SYA12K16RMP, also

order AP7582, a rack PDU extender.

UPS Planning 5-1

Input

120V 120V or 208V

AC Power

Output

Page 36

Communicating with a UPS over a Network

Table 5-1. APC Symmetra Models for PDUs or for Multiple Systems

AC Power

Locale APC Symmetra Model

Japan SYH2K6RMJ-P1, SYH4K6RMJ-P1, or

SYH6K6RMJ-P1

Rest of the world SYK2K6RMI, SYK4K6RMI, SYK6K6RMI,

SYA8K16RMI, or SYA12K16RMI

Table 5-2. APC UPS Models for a Single Rack-Mountable System

Locale Smart-UPS AC Power Input A C Power Output

North America Model SUA1500RM2U 120V 120V

Japan Model SUA1500RMJ2U 80V to 123V 100V

Rest of the world Model SUA1500RMI2U 160V to 286V 120V or 208V

Table 5-3. APC UPS Models for a Single Pedestal System

Locale Smart-UPS AC Power Input AC Power Output

North America Model SUA1500 120V 120V or 208V

Japan Model SUA1500J 80V to 123V 100V

Input

100V 100V or 200V

230V 230V or 240V

AC Power

Output

Rest of the world Model SUA1500I 160V to 286V 230V or 240V

Communicating with a UPS over a Network

Use the following additional tools to enable an Expres s5800/320Ma system and a UPS

to communicate over the network:

• APC Network Management Card EX (APC part number AP9617)

An APC Network Management Card EX is a standar d component of the Symmet ra

UPS, but you must purchase the network card for the APC Smart-UPS.

• APC PowerChute

When you install your Express5800/320Ma system, download PowerChute

Network Shutdown from APC, and install and configure the tool on the system, as

described in the Express5800/320Ma: Software Installation and Configuration

Guide. PowerChute Network Shutdown monitors the UPS for an imminent power

loss, and initiates a shutdo wn of the system before power is lost.

5-2 Express5800/320Ma: Site Planning Guide

®

Network Shutdown for the Exp ress5800/320Ma system

Page 37

Connecting Power to Systems, PDUs, and a UPS

Connecting Power to Systems, PDUs, and a UPS

When you plan for PDUs, note the following:

• Only the top PDU is connected to the UPS.

• The bottom PDU is connected directly to an AC power main.

• The UPS can be connected to the same AC power main that the bottom PDU is

connected to, or the UPS can be connected to another AC power main.

Figure 5-1 shows how to connect systems to PDUs and a UPS to the top PDU.

Figure 5-1. Power Cord Connections for Systems, PDUs, and a UPS

9 9

8 8

7

3

3

1

2

1 A-side PDU

2 B-side PDU

3 B-side system power cables (black)

4 A-side system power cables (gray)

5 PDU power cords

6UPS

7 UPS power cord

8 AC power outlets

UPS Planning 5-3

4

4

5

6

5

asys003

Page 38

Connecting a System Directly to a UPS

9 AC power (mains) distribution circuit breaker (maximum of 20A)

Connecting a System Directly to a UPS

You can connect the A-side power connectors of your system directly to a UPS, as

shown in Figure 5-3.

Figure 5-2. Rack-Mountable Systems: A-Side Power Connected Directly to a UPS

1 B-side system power cord

2 A-side system power cord

3UPS

4 UPS power cord

5 AC power outlets

6 Circuit breakers (maximum of 20A)

6

5

1

2

3

6

5

4

asys004

5-4 Express5800/320Ma: Site Planning Guide

Page 39

Connecting a System Directly to a UPS

Figure 5-3 shows how to connect a UPS to pedestal Express5800/320Ma 3.2 GHz and

3.6 GHz systems.

Figure 5-3. Pedestal Sy ste m s : A-Side Power Connected Directly to a UPS

6

5

6

5

4

3

1 B-side system power cord

2 A-side system power cord

3UPS

4 UPS power cord

5 AC power outlets

6 Circuit breakers (maximum of 20A)

1

2

asys005

UPS Planning 5-5

Page 40

Connecting a System Directly to a UPS

5-6 Express5800/320Ma: Site Planning Guide

Page 41

Chapter 6

Network and Telephone Line Planning

For information about planning network and telephone lines for your

Express5800/320Ma 3.2 GHz, 3.6 GHz, or Dual-Core system, see:

• “Network Cable Requirements” on page 6-1

• “Telephone Line Requirements” on page 6-2

• “Site Planning for Systems in an ftGateway Group” on page 6-3

Network Cable Requirements

Ethernet PCI adapters are typically supplied in pairs and teamed in software for fault

tolerance. Each member of the pair requires a ca ble .

WARNING

!

Make sure Ethernet cables can be route d out of the

way of foot traffic.

Table 6-1 describes the Ethernet cables you must supply. Be sure to provide a cable of

sufficient length for the distance between the system and a wall jack or hub.

6-

NOTE

See the Express5800/320Ma: PCI Adapter Guide for

more information about the adapters NEC Solutions

(America), Inc. supplies for your Express5800/320Ma

system.

Network and Telephone Line Planning 6-1

Page 42

Telephone Line Requirements

Table 6-1. Customer-Supplied Ethernet Ca bles

Component Quantity Cable

†

VTM Ethernet port

10/100/1000-Mbps

system Ethernet port

Dual-port

10/100/1000Base-T

Ethernet PCI Adapter

(gigabit copper adapter for

servers)

2 24 AWG Unshielded Twisted Pair (UTP)

2 or 4

2 for each pair of

10/100/1000Base-T

Ethernet ports

EIA/TIA-V erified, Category-3 or Category-5

wire, with RJ-45 modular connectors

terminated with pair-wiring adhering to the

EIA/TIA 568-A or EIA/TIA 568-B standard.

For connections to an Ethernet hub or switch,

provide a straight-through cable.

For 100- or 1000-Mbps (fast Ethernet)

operation, provide full-duplex, or Category-5

Ethernet cables.

The maximum allowable distance from an

Ethernet port to a switch or a hub is 100

meters (328 ft).

Dual-port 1000Base-SX

Ethernet PCI Adapter

(gigabit fiber-optic adapter

for servers)

† Some systems may not contain Virtual Technician Modules (VTMs), a system management module

that provides remote access to and management of the system.

2 for each pair of

1000Base-SX

Ethernet ports

Multimode, 62.5- or 50-micron, DUAL fiber

cable with LC-type connectors to the PCI

adapter, and connectors on the other end that

are compatible with the network switch. The

maximum distance between the U574 PCI

adapter and a switch is 902 ft (275m).

Telephone Line Requirements

Generally, two telephone lines are required to ensure technical support for your

Express5800/320Ma 3.2 GHz or 3.6 GHz system:

• One telephone line for use when calling for service

• One analog telephone connection point for the modem

A 7-ft (2.13m) telephone cable, part number AW-B202 45, is shipped with the

modem assembly.

NOTES

1. If you implement ftGateway groups, you do not need

to supply telephone connection points for each

system. See “Site Planning for Systems in an

ftGateway Group” for more information.

6-2 Express5800/320Ma: Site Planning Guide

Page 43

Site Planning for Systems in an ftGateway Group

2. If your system will be configured with VTMs whose

network ports are connected to a network with

Internet access, your system will not have a modem

installed for ASN support, and the second telephone

line will not be necessary.

3. A dedicated phone line provides the most reliable

service. ASN calls routed through a PBX might be

slow due to the load on the PBX, or might not

complete successfully because the calls can become

disconnected. If you must use a PBX, do not route the

telephone extension through a switchboard; instead,

provide a direct-dial analog number.

Site Planning for Systems in an ftGateway Group

Multiple Express5800/320Ma systems at a site can share a single telephone

connection to the ASN by implementing an ftGateway group. Unless VTMs are

installed in each system, the systems in the group must be connected to a single

physical Ethernet subnetwork. One system acts as a gateway for ASN connectivity.

This gateway system requires an analog telephone line that connects to the modem.

Other systems in the gateway group, called gateway slaves, connect to the gateway

system over the network. In this case, Ethernet connections are required for each

system, but only two analog telephone lines for each site are required.

Members of an ftGateway group:

• Are limited to a maximum of 20 Express5800/320Ma systems.

• Must connect to the same subnetwork through system Ethernet ports, ports of

Ethernet adapters, or VTMs. An ftGateway group that contains

Express5800/320Ma 3.2 GHz, 3.6 GHz, or Dual- Core systems can con sist of one

of the following:

– Slave systems with no remote management adapter in a group with an

ftGateway system that has VTMs

– Slave systems that have VTMs in a group with an ftGateway system that has

VTMs

Using VTMs provides the highest level of manageability b y allo wing the system to

be serviced even when the operating system is not operational.

NOTE

You cannot mix VTMs and ftServer Access Adapters in

the same ftGateway group. ftServer Access Adapters are

Network and Telephone Line Planning 6-3

Page 44

Site Planning for Systems in an ftGateway Group

system management adapters used in earlier models of

Express5800/320Ma systems.

Make sure that only layer 1 and layer 2 devices separate the gateway and slave

systems. During a connection, the gateway system assign s the slave system a

temporary IP address from an IP addr ess range reserved by NEC Solutions (America),

Inc. and uses that address for all traffic.

6-4 Express5800/320Ma: Site Planning Guide

Page 45

Chapter 7

For information about planning a rack configuration, see:

• “Using PDUs” on page 7-1

• “Determining PDU Requirements” on page 7-2

• “Sample PDU Usage Calculation” on page 7-4

Using PDUs

Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems have tw o power

receptacles. Correspondingly, two power distribu tion units (PDUs) provide power to the

receptacles.

Use of PDUs is optional unless you have a support agreement with NEC Solutions

(America), Inc. If you do have a support agreement with NEC Solutions (America), Inc.,

use pairs of PDUs to provide AC power to systems and components in a cabinet if six

or more power cords would otherwise exit from the cabinet.

The A-side (top) PDU provides power to:

Rack Configuration Planning

7-

• The A-side of each system

• A KVM switch

The B-side (bottom) PDU provides power to the other side of each system.

Because the A-side PDU always uses at least as many power cords an d consumes at

least as much power as the B-side PDU, plan the cabinet configuration so that the

A-side PDU can support the configuration.

Rack Configuration Planning 7-1

Page 46

Determining PDU Requirements

NOTES

1. Connect each PDU to a separate AC power source.

2. Install a maximum of two pairs of PDUs in a rack.

Use the information in “Determining PDU Requirements” on page 7-2 to plan the rack

configuration for your Express5800/320Ma system. “Sample PDU Usage Calculation”

on page 7-4 shows how to use the information you gather for planning the rack

configuration.

Determining PDU Requirements

Using the nominal voltage rating of the power receptacle at your site and the total

wattage of the components that will draw power from the A-side PDU, complete the

information in Tables 7-1 and 7-2. This information will help you determine the current

that the Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems and

rack-mounted components will draw and whether you need a second pair of PDUs.

To complete Table 7-1

1. Obtain the voltage available at your location. Consult a facilities manager at your

site to make sure you know the correct voltage.

2. For each type of component you plan to place in the rack, calculate the required

current, as follows: Divide the wattage of the element, listed in th e W atts column of

Table 7-1, by the voltage a vailab le at yo ur site. Multiply the result by 1.25 and enter

the value in the Current column.

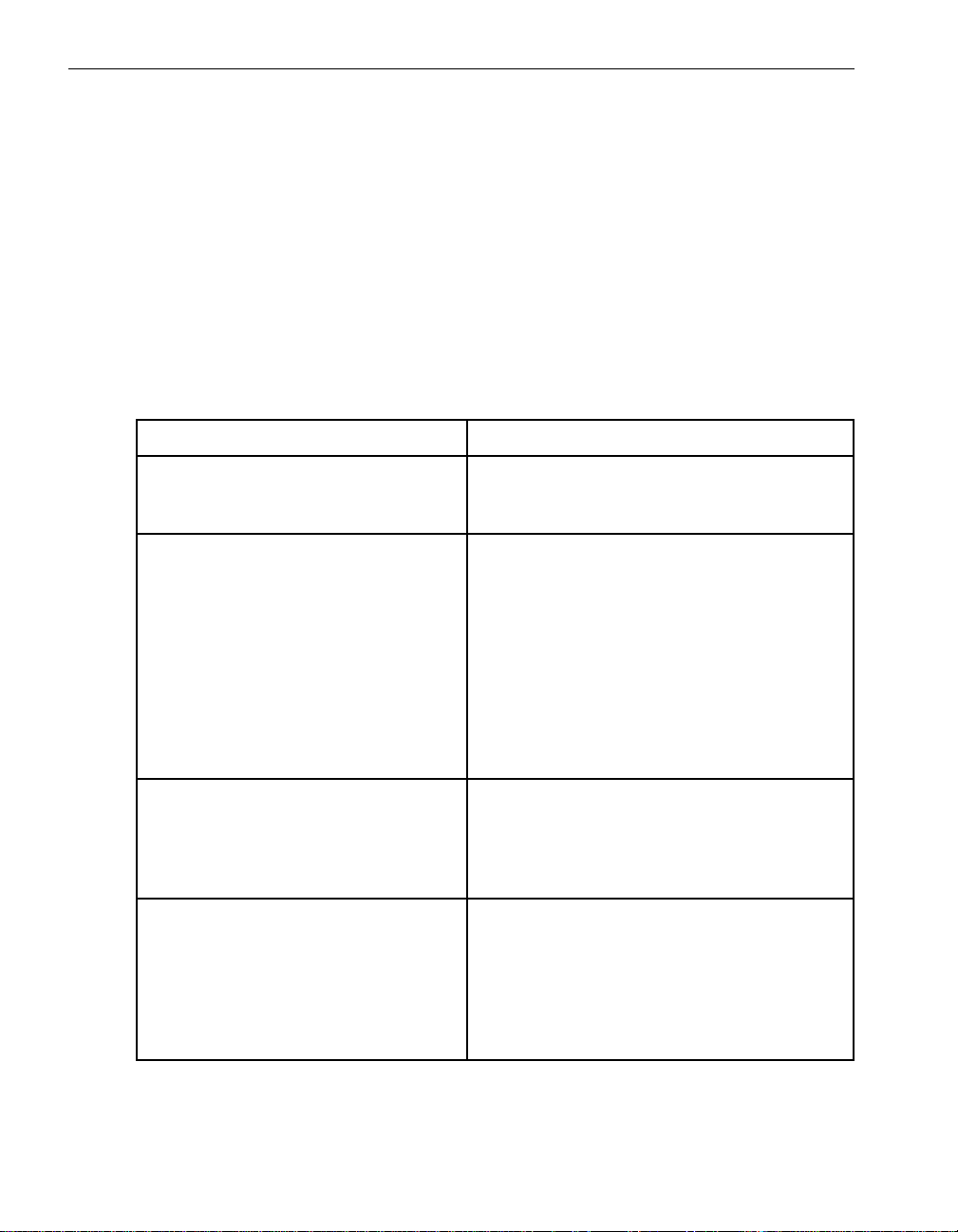

Table 7-1. Current and Rack-Space Requirements

Component Watts Current Rack Space

Express5800/320Ma 3.2 GHz, 3.6

650 4U

GHz, and Dual-Core

KVM switch 20 1U

7-2 Express5800/320Ma: Site Planning Guide

Page 47

To complete Table 7-2

1. In column 1, write the names of each system or component in the rac k. If you ha ve

more than one system, use a row for each system.

2. In column 2, write the cumulative number of rac k units (Us): Add t he number of Us

(see Table 7-1) for the component to the value in the space above and write the

result.

3. In column 3, write the cumulative n umber of outlets required. F or each component,

add 1 to the value in the space above and write the result.

4. In column 4, write the cumulative current required. For each component, add the

current for the compon ent, which you entered in Table 7-1, to the value in the space

above and write the result.

You need another pair of PDUs if the cumulative number of outlet s exceeds 8 or if the

cumulative current exceeds 15A. Use the informa tion in column 2 to plan the size and

number of racks required.

Table 7-2. Calculating A-Side PDU and Rack-Space Requirements

Determining PDU Requirements

2. Cumulative

1. Component

PDU Pair 2U 0 0.00

Space Used

3. Cumulative

Number of Outlets

4. Cumulative

Current (A)

Rack Configuration Planning 7-3

Page 48

Sample PDU Usage Calculation

Sample PDU Usage Calculation

Table 7-3 shows how to use the information from Table 7-1 to calculate the current

when the PDU is connected to a NEMA L6-20R receptacle in the United States, with a

power voltage of 208V.

Table 7-3. Sample: Current and Rack-Space Requirements

Component Watts Current Rack Space

Express5800/320Ma Dual-Core

system

KVM switch 20 0.12 1U

650 3.91A 4U

Table 7-4 and the explanation which follows show how to use the information from

Table 7-3 to determine when you need to buy an additional pair of PDUs or calculate

the size and number of cabinets you need.

Table 7-4. Sample: Calculating A-Side PDU and Rack-Space Requirements

3. Cumulative

2. Cumulative

1. Component

PDU pair 2 0 0.00

Express5800/320Ma 3.2 GHz, 3.6

GHz, or Dual-Core system

KVM switch 8 3 4.15

Express5800/320Ma 3.2 GHz, 3.6

GHz, or Dual-Core system

PDU pair 19 0 0

Express5800/320Ma 3.2 GHz, 3.6

GHz, or Dual-Core system

Space Used (U)

6 1 3.91

15 5 11.06

23 1 3.91

Number of

A-Side Outlets

4. Cumulative

Current (A)

Express5800/320Ma 3.2 GHz, 3.6

GHz, or Dual-Core system

29 3 9.62

In this calculation, components were added one by one, calculating:

• The total current demanded by the components

• The total space used in the rack

• The total number of outlets required

7-4 Express5800/320Ma: Site Planning Guide

Page 49

Sample PDU Usage Calculation

In this example, two PDUs can provide enough current for the KVM switch, and two

Express5800/320Ma 3.2 GHz, 3.6 GHz, or Dual-Core system systems. This set of

components occupies six outlets in the PDU and 17U of rack space.

To add any more components, you require another pair of PDUs.

Rack Configuration Planning 7-5

Page 50

Sample PDU Usage Calculation

7-6 Express5800/320Ma: Site Planning Guide

Page 51

Appendix A

NOTE

The system temperature and humidity requirements,

defined in Table A-1 and Table A-3 are the minimum

requirements the site must provide.

System Specifications

Figure A-1 shows the front of a pedestal Express5800/320Ma 3.2 GHz or 3.6 GHz

systems system, its bezel pulled forward. Figure A-2 shows the rear of a typical

pedestal Express5800/320Ma 3.2 GHz system, and Figure A-3 shows the rear of a

pedestal Express5800/320Ma 3.6 GHz systems, specifying the locations of the

connectors at the back of the system. Table A-1 lists specifications for the pedestal

Express5800/320Ma 3.2 GHz, 3.6 GHz, and Dual-Core systems system.

System Specifications

A-

System Specifications A-1

Page 52

System Specifications

Figure A-1. Pedestal System - Front View

asys006a

A-2 Express5800/320Ma: Site Planning Guide

Page 53

System Specifications

Figure A-2. Pedestal Express5800/320Ma 3.2 GHz systems - Rear View

1

2

3

4

5

6

7

asys007

1 Ports on a PCI adapter in slot 1

2 System 10/100/1000-Mbps Ethernet ports (4)

3 USB ports (3)

4 VGA (monitor) port

5 Serial (COM) ports (2)

6 Power receptacles (2)

7 VTM 10/100-Mbps Ethernet port (2)

System Specifications A-3

Page 54

System Specifications

Figure A-3. Pedestal Express5800/320Ma 3.6 GHz systems- Rear View

1

2

3

4

5

6

7

8

9

asys008

1 PCI slot 3

2 PCI slot 2

3 PCI slot 1

4 System 10/100/1000-Mbps Ethernet ports (4)

5 USB ports (3)

6 VGA (monitor) port

7 Serial (COM) ports (2)

8 Power receptacles (2)

9 VTM 10/100-Mbps Ethernet ports (2)

A-4 Express5800/320Ma: Site Planning Guide

Page 55

System Specifications

Table A-1. Pedestal System Specifications

Power

Input power A-side enclosure: 650W

B-side enclosure: 650W

Nominal input voltage (AC) 100-230 volts +/- 10% 240V + 6%/-10%; 50/60 Hz

Protective earth ground current 3.5 milliamperes maximum for each AC power cord

Physical Dimensions of System in a Pedestal Case

Height 23.25 in. (59.05 cm.)

Width 8.62 in. (21.89 cm); 12.88 in. (32.72 cm)

Depth 31.38 in. (79.71 cm)

Weight, including 8 DIMMS, 4

processors, and 6 disks

Environmental

Operating temperature 41

Storage temperature -38

Operating altitude 0 ft to 10,000 ft (0m to 3,048m)

Maximum rate of temperature

change during operation

Relative humidity during

operation

Relative humidity during storage 8% to 80%

Heat dissipation 4432 BTUs per hour

Two enclosures: 110 lb (49.9 kg), fully loaded

Case: 68 lb (30.84 kg)

°F to 95°F (5°C to 35°C)

For every 800 ft (243.8m) above 2,000 ft (609.6m),

lower the maximum operating temperature (35°C) by

°C.

1

° F to 140° F (-40° C to 60° C)

18°F/hr (10

0.30°F/min (0.17°C/min)

20% to 80% (noncondensing)

°C/hr) or

System Specifications A-5

Page 56

System Specifications

Table A-1. Pedestal System Specifications (Continued)

Features

Processors

Memory Eight physical dual data rate (DDR) inline memory

Ports Four 10/100/1000-Mbps Ethernet ports

Express5800/320Ma 3.2 GHz systems: One or two

Intel Xeon 3.2 GHz processors with Hyper-Threading

Technology in each CPU-I⁄ O enclosure

Express5800/320Ma 3.6 GHz systems: Two Intel

Xeon 3.6 GHz processors with Hyper-Th rea d i ng

Technology in each CPU-I⁄ O enclosure

Express5800/320Ma Dual-Core systems: Two

Dual-Core Intel Xeon 2.8 GHz processors with

Hyper-Threading Technology in each

CPU-I ⁄ O enclosure

module (DIMM) slots in each CPU-I⁄ O enclosure

Two AC power connectors, one VGA port, two serial

ports, and three USB ports

PCI slots

Express5800/320Ma 3.2 GHz systems: One

user-configurable, low-profile PCI adapter slot operating

at 64-bits and 100 MHz in each CPU-I⁄ O enclosure

(you can add two full-height PCI adapter slots in each

CPU-I/O enclosure with the optional AK533 riser

assembly kit)

Express5800/320Ma 3.6 GHz and Dual-Core

systems

full-height PCI adapter slots operating at 64-bits and

100 MHz, all user-configurable, in each

CPU-I ⁄ O enclosure

VTM Virtual Technician Module (VTM)

The VTM is a system management module.

When VTMs are installed, two 10/100-Mbps Ethernet

ports dedicated to the VTMs are present.

Disk drives Six Serial ATA (SATA) disk drives

A-6 Express5800/320Ma: Site Planning Guide

: One low-profile PCI adapter slot and two

Page 57

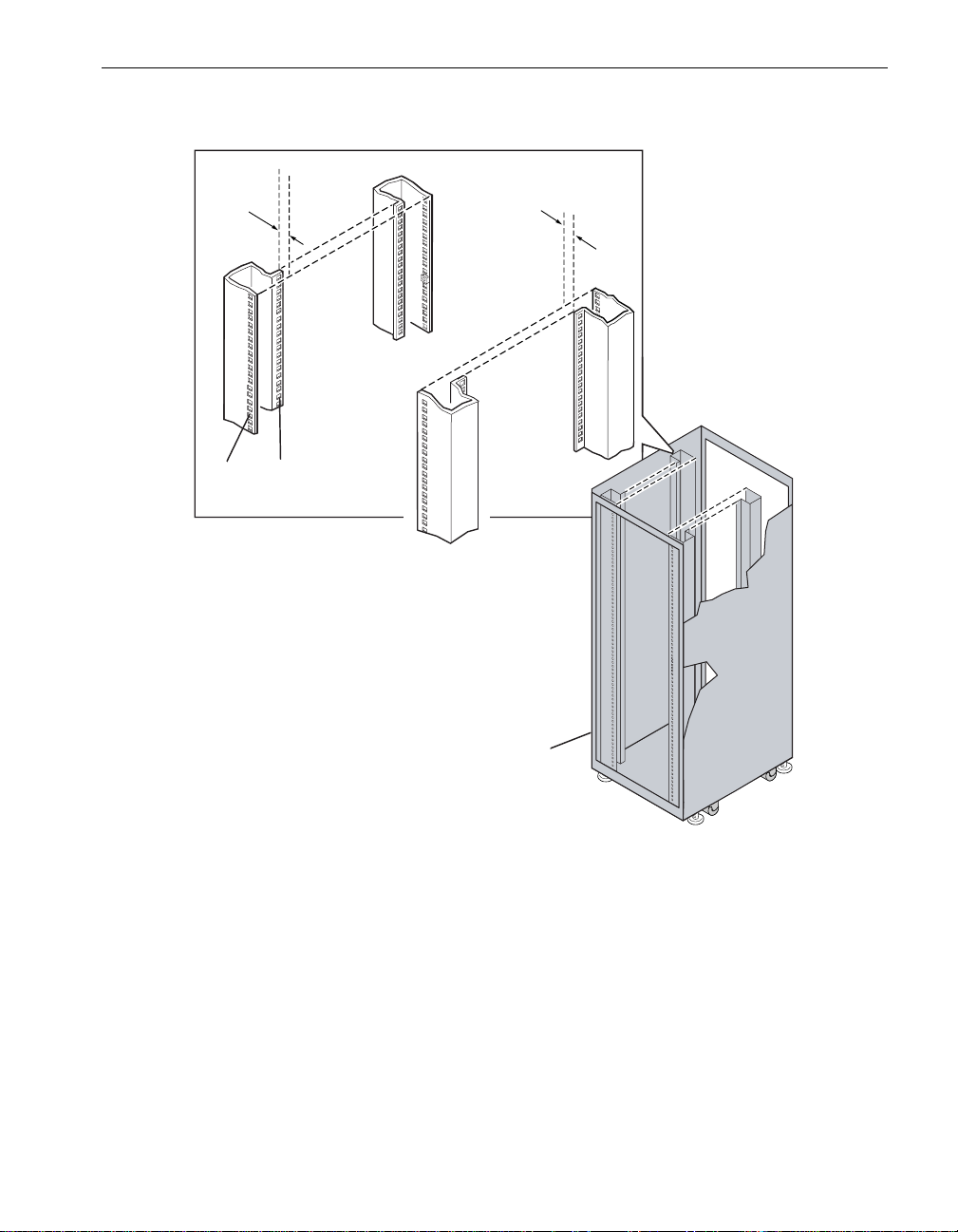

Rack-Mountable System Specifications

Figure A-4 shows the front of a rack-mountable Express5800/320Ma 3.2 GHz, 3.6 GHz

and Dual-Core system, mounted in a rack with its bezel pulled forward. The fr ont views

of the systems are identical. Figure A-5 shows the rear of a rack-mountable

Express5800/320Ma 3.2 GHz system, and Figure A-6 shows the rear of a

rack-mountable Express5800/320Ma 3.6 GHz or Dual-Core system, specifying the

locations of the connectors at the back of the system. Table A-3 lists the specifications

for the rack-mountable Express5800/320Ma 3. 2 GHz, 3.6 G Hz and Dual-Core syst em

systems.

Figure A-4. Rack-Mountable System - Front View

Rack-Mountable System Specifications

asys009

System Specifications A-7

Page 58

Rack-Mountable System Specifications

Figure A-5. Rack-Mountable Express5800/320Ma 3.2 GHz system - Rear View

1

1 PCI slot 1

2 System 10/100/1000-Mbps Ethernet

ports (4)

3 USB ports (3)

4 VGA (monitor) port

5 Serial (COM) ports (2)

6 Power receptacles (2)

7 VTM 10/100-Mbps Ethernet ports (2)

8 Telephone cord port

32

45

67

asys010

A-8 Express5800/320Ma: Site Planning Guide

Page 59

Rack-Mountable System Specifications

Figure A-6. Rack-Mountable Express5800/320Ma 3.6 GHz or Dual-Core System - Rear View

2

1

3

1 PCI slot 3

2 PCI slot 2

3 PCI slot 1

4 System 10/100/1000-Mbps Ethernet ports (4)

5 USB ports (3)

6 VGA (monitor) port

7 Serial (COM) ports (2)

8 Power receptacles (2)

9 VTM 10/100-Mbps Ethernet ports (2)

10 Telephone cord port

54

67

9

8

asys011

System Specifications A-9

Page 60

Rack-Mountable System Specifications

Table A-2. Cabinet Dimensions

24U Shipping Container

Height (including pallet) 56 in. (1.42m)

Width 41 in. (1.04m)

Depth 53 in. (1.35m)

38U Shipping Container

Height (including pallet) 79.75 in. (2.03m)

Width 41 in. (1.04m)

Depth 53 in. (1.35m)

24U Cabinet

Height (including casters) 50 in. (1.27m)

Width 27.5 in. (70 cm)

Depth 41 in. (1.04m)

Weight, empty 275 lb (125 kg)

Weight, empty with pallet and shipping container 436 lb (197.8 kg)

38U Cabinet

Height (including casters) 74 in. (1.9m)

Width 27.5 in. (70 cm)

Depth 41 in. (1.04m)

Weight, empty 344 lb (156 kg)

Weight, empty with pallet and shipping container 512 lb (232.2 kg)

A-10 Express5800/320Ma: Site Planning Guide

Page 61

Rack-Mountable System Specifications

Table A-3. Rack-Mountable System Specifications

Power

Input power A-side enclosure: 650W

B-side enclosure: 650W

Nominal input voltage (AC) 100-230 volts +/- 10% 240V + 6%/-10%; 50/60 Hz

Protective earth ground current 3.5 milliamperes maximum for each AC power cord

Physical Dimensions

Height 7.0 in. (17.78 cm; 4U)

Width 17.50 in. (44.45 cm)

Depth 30 in. (76.2 cm), excluding screws and bezel

Weight, including 8 DIMMS, 4

processors, and 6 disks

Environmental

Operating temperature 41

Storage temperature -38

Operating altitude 0 ft to 10,000 ft (0m to 3,048m)

Maximum rate of temperature

change during operation

Relative humidity during

operation

Relative humidity during storage 8% to 80%

Heat dissipation 4432 BTUs per hour

Two enclosures: 110 lb (49.9 kg), fully loaded

Rails and shelf unit: 13.8 lb (6.26 kg)

° F to 95° F (5° C to 35° C)

For every 800 ft (243.8 m) above 2000 ft (609.6 m),

lower the maximum operating temperature (35°C) by

°C.

1

° F to 140° F (-40° C to 60° C)

18

° F/hr (10° C/hr) or 0.30° F/min (0.17° C/min)

20% to 80% (noncondensing)

System Specifications A-11

Page 62

Rack-Mountable System Specifications

Table A-3. Rack-Mountable System Specifications (Continued)

Features

Processors

Express5800/320Ma 3.2 GHz: One or two Intel Xeon

3.2 GHz processors with Hyper-Threading Technology

in each CPU-I⁄ Oenclosure

Express5800/320Ma 3.6 GHz: Two Intel Xeon 3.6

GHz processors with Hyper-Threading Technology in

each CPU-I⁄ O enclosure

Express5800/320Ma Dual-Core: Two Dual-Core

Intel Xeon 2.8 GHz processors with Hyper-Threading

Technology in each CPU-I⁄ O enclosure

Memory Eight physical dual data rate (DDR) inline memory

module (DIMM) slots in each CPU-I⁄ O enclosure

Ports Two 10/100/1000-Mbps Ethernet ports in each

CPU-I ⁄ O enclosure

Two AC power connectors, one VGA port, two serial

ports, and three USB ports

PCI slots

Express5800/320Ma 3.2 GHz systems: One

user-configurable, low-profile PCI adapter slot operating

at 64-bits and 100 MHz in each CPU-I⁄ O enclosure

(you can add two full-height PCI adapter slots in each

CPU-I/O enclosure with the optional AK533 riser

assembly kit)

Express5800/320Ma 3.6 GHz and Dual-Core

systems: One low-profile PCI adapter slot and two

full-height PCI adapter slots operating at 64-bits and

100 MHz, all user-configurable, in each

CPU-I ⁄ O enclosure

VTM A Virtual Technician Module (VTM), a system

management module CPU-I⁄ O enclosure

When VTMs are installed, a 10/100-Mbps Ethernet

ports dedicated to the VTM is present for each VTM.

Disk Drives Three Serial ATA (SATA) disk drives in each

CPU-I ⁄ O enclosure

A-12 Express5800/320Ma: Site Planning Guide

Page 63

Appendix B

Electrical Circuit and Wiring Information

For electrical circuit and wiring information that you need to provide to the contractor

and/or facilities personnel responsible for wiring the power at the system installation

site, see:

• “Fault Protection Requirements” on page B-1

• “Grounding Considerations” on page B-1

• “Circuit Wiring Diagrams” on page B-3

• “Electrical Power Connectors” on page B-9

Fault Protection Requirements

Each enclosure in Express5800/320Ma 3.2 GHz, 3.6 GHz, or Dual-Core systems

contains internal fault/overload current pr otection. However, the system relies on the

power distribution system at your site for protect ion against potential faults in the p ower

cords and the wiring in the system base.

• If you are using a pair of PDUs in the cabinet, use 30A or less circuit breakers in

each power distribution br anch that feeds the PDUs.

B-

• T o connect a single system t o power , use 20A or less circuit breakers in each powe r

distribution branch that feeds the systems.

Grounding Considerations

The system obtains an earth reference ground thr ough the power cords attached to the

system. Similarly, each peripheral device connected to the system obtains ground

through its power cord. For each peripheral device, you must ensure that a

high-integrity safety-ground conductor is installed as part of the wiring system (in

accordance with U.S. national electric code NFPA 70 or the equivalent). The

international safety standard (EN60950) for electronic data processing (EDP)

equipment also requires a ground conducto r, but calls it a protective earth (PE) ground.

Depending upon local conditions, ground potentials may differ between the system

base and any peripheral devices connected to the system base . All grounds in the

system must return to the same reference point in the power distribution system, as

close as possible to zero (0) volt potential relative to earth reference ground. Ear th

Electrical Circuit and Wiring Information B-1

Page 64

Grounding Considerations

reference ground is typically a metal stake in the ground to which the ground

conductors from one or more buildings are attached.

As shown in Figure B-1, a star ground is often used to obtain the same earth reference

ground. Each earth reference ground, such as the system base ground, is returned

separately to a common point where a zero-volt (0V) earth ground exists. The star

ground ensures that all equipment is at the same potent ial and that no noise or sa fety

problems associated with an unpredictable or uncharacterized grounding system will

occur.

Figure B-1. Star Ground Example

1

2

3

1 To monitor

2 T o Express5800/320Ma 3.2 GHz, 3.6 GHz, or

Dual-Core system

3 Earth reference ground (0V)

B-2 Express5800/320Ma: Site Planning Guide

Page 65

Circuit Wiring Diagrams

The following circuit wiring diagrams show how the hot, ground, and/or neutral AC

signals should be connected to the system’s power input plug:

• Figure B-3 illustrates a single-phase 120-volts AC circuit connection.

• Figure B-4 illustrates a single-phase 240-volts AC circuit connection.

• Figure B-5 illustrates a split-phase 120/240-volts AC circuit connection.

• Figure B-6 illustrates a three-phase 208-volts AC, Y-, or ∆-source circuit

connection, phase-to-neutral.

• Figure B-7 illustrates a three-phase 208-volts AC, Y-, or ∆-source circuit

connection, phase-to-phase.

• Figure B-8 illustrates a three-phase 380V AC, Y-, or ∆-sourc e circ uit conn e ctio n,

phase-to-neutral.

In the diagrams in this appendix, the power inputs for Express5800/320Ma 3.2 GHz,

3.6 GHz, or Dual-Core system are labeled X and Y, as shown in Figure B-2, to

eliminate any ambiguities in the nomenclature. For single-phase applications, the X

input is connected to the L (Line) hot input, and the Y input is connected to the N

(Neutral) input. However, for split-phase or thre e-phase applications, the X and Y