查询ED2-1.5供应商查询ED2-1.5供应商

DATA SHEET

MINIATURE SIGNAL RELAY

ED2/EF2 SERIES

Ultra-low power, compact and lightweight, High breakdown voltage,

Surface mounting type

DESCRIPTION

NEC's new miniature signal relays, ED2/EF2 series, achieved 50 mW of ultra low power consumption.

FEATURES

™ Low power consumption (50 mW)

™ Applicable for the surge voltage standard of FCC (1500 V, 10 × 160

™ Two types for through-hole mounting (ED2 series) and surface mounting (EF2 series)

™ Variation of dense mounting type and/or long-joint-life type for latest SMT

• Compatible configuration and terminal allocation with dense mounting type of EE2 series

• Upgraded soldering joint reliability between the relay terminal and PCB by optimization of the terminal

configuration;

20-year-joint-life under 35˚C-per -day-temperature-difference specified in IPC-SM-785 for telecommuication

equipment

µ

s) and BELLCORE (2500 V, 2 × 10 µs)

APPLICA TIONS

Electronic switching systems, PBX, terminal equipment, telephone system, instrumental equipment.

For Right Use of Miniature Relays

DO NOT EXCEED MAXIMUM RATINGS.

Do not use relays under exceeding conditions such as over ambient temperature, over voltage

and over current. Incorrect use could result in abnormal heating, damage to related parts or

cause burning.

READ CAUTIONS IN THE SELECTION GUIDE.

Read the cautions described in NEC's "Miniature Relays" (ER0046EJ∗) when you choose relays

for your application.

The information in this document is subject to change without notice.

Document No. ER0304EJ2V0DS00 (2nd edition)

Date Published February 1999 M

Printed in Japan

©

1997

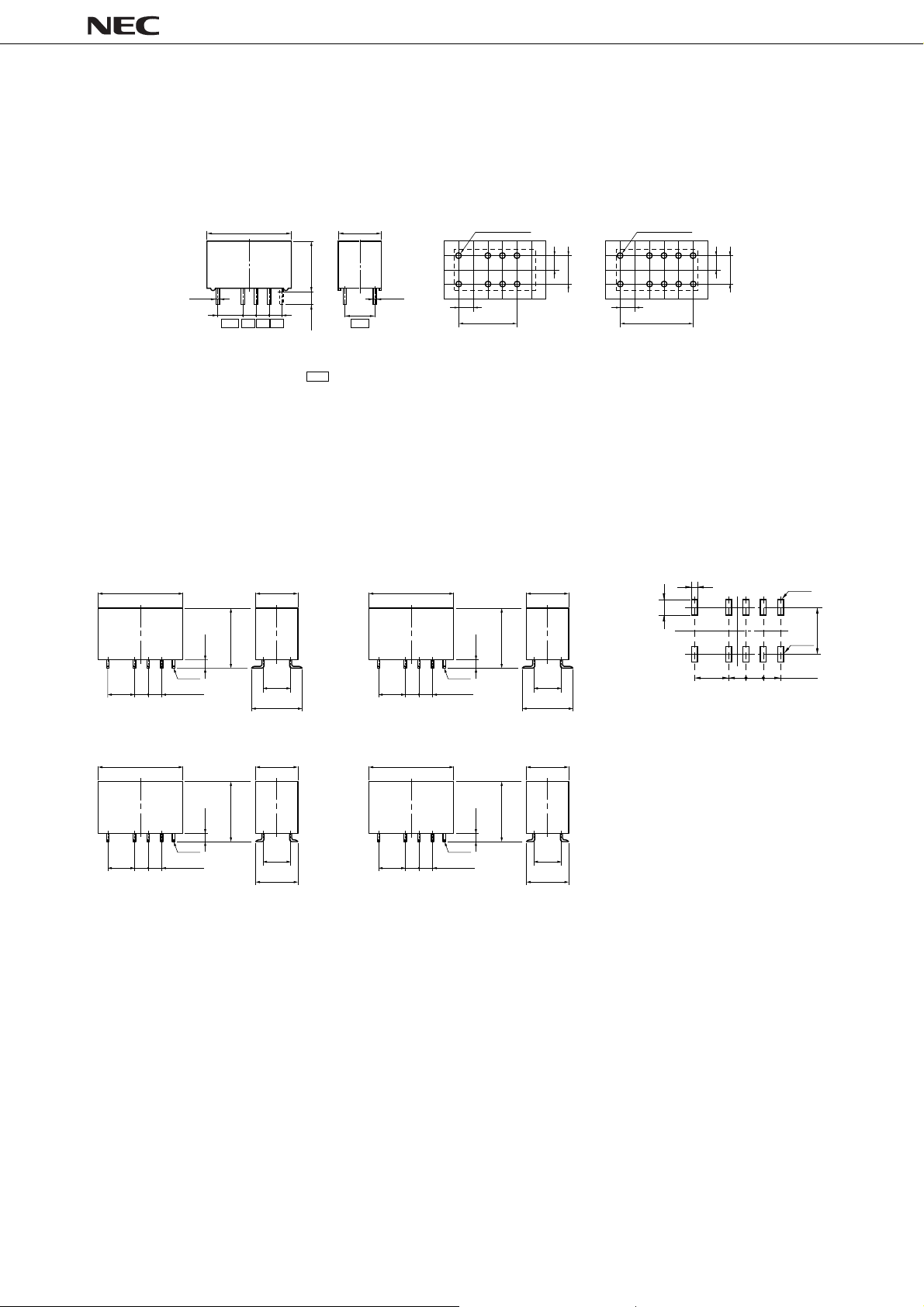

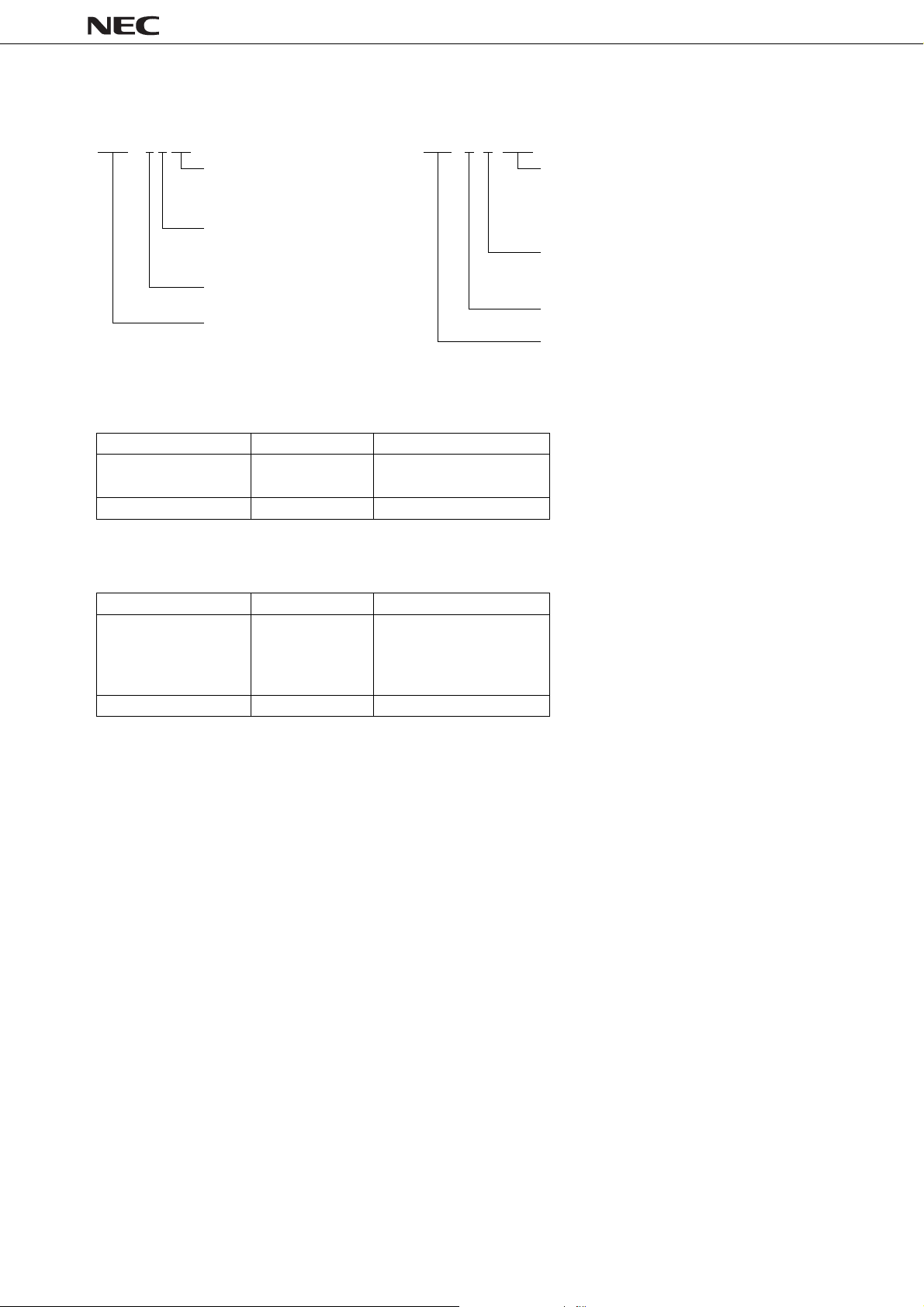

DIMENSIONS AND PAD LAYOUTS (Unit : mm (inch))

ED2 SERIES

Non-latch and Single coil latch Double coil latch

ED2/EF2 SERIES

EF2-..

EF2-..NU

(0.200)

EF2-..NUH

EF2 SERIES

15.0 MAX.

(0.591)

(0.591)

2-2.54

(2-0.100)

5.08

15.0 MAX.

7.5 (0.30) MAX.

9.4(0.37) MAX.

3.2

(0.13)

5.08

(0.20)

0.5

(0.02)

15.0 (0.59) MAX.

5.08

2.54 2.54 2.54

(0.20)

(0.10)(0.10)(0.10)

Note. General tolerance : ±0.2 (±0.008)

Dimensions in show basic size.

NJ type : Leads-2.8 mm (0.110)

EF2-..NUX

7.5 MAX.

(0.296)

1.0

(0.394)

(0.039)

10.0 MAX.

note2

5.08

(0.200)

9.5

(0.374)

7.5 MAX.

(0.296)

EF2-..NUN

0.25

(0.01)

5.08

(0.200)

15.0 MAX.

(0.591)

15.0 MAX.

(0.591)

φφ

2.54

(0.100)

8- 0.8 (0.031)

4 × 2.54 (0.100)

2.54(0.1)

×

2

2.54(0.1)

(Bottom fiew)

(0.100)

Note. General tolerance : ±0.1 (±0.004)

7.5 MAX.

(0.296)

(0.408)

1.35

(0.053)

10.35 MAX.

note2

2-2.54

(2-0.100)

5.08

(0.2)

9.0

(0.354)

7.5 MAX.

(0.296)

2.54

10- 0.8 (0.031)

5 × 2.54 (0.100)

A

2.54(0.100)

1.0(0.039)

5.08

(0.200)

(Bottom view)

2.54(0.100)

×

2

note2

note2

3-2.54

(0.100)

B

5.08

(0.200)

1.0

(0.394)

(0.039)

10.0 MAX.

note2 note2

2-2.54

(2-0.100)

5.08

(0.200)

7.5

(0.295)

5.08

(0.200)

2-2.54

(2-0.100)

Note 1. General torelance : ±0.2 (±0.008)

Note 2. This pair of pins at the right end applies

to double coil latch type only.

1.6

(0.063)

10.6 MAX.

(0.418)

5.08

(0.200)

7.5

(0.295)

Type A B

EF2-.. 3.0 (0.118) 7.29 (0.287)

EF2-..NU 3.0 (0.118) 7.29 (0.287)

EF2-..NUX 2.73 (0.107) 7.02 (0.276)

EF2-..NUH 2.0 (0.079) 6.29 (0.248)

EF2-..NUN 2.0 (0.079) 6.29 (0.248)

Note 1. General torelance : ±0.1 (± 0.004)

Note 2. This pair of pads at the right end

applies to double coil latch type only.

DATA SHEET ER0304EJ2V0DS002

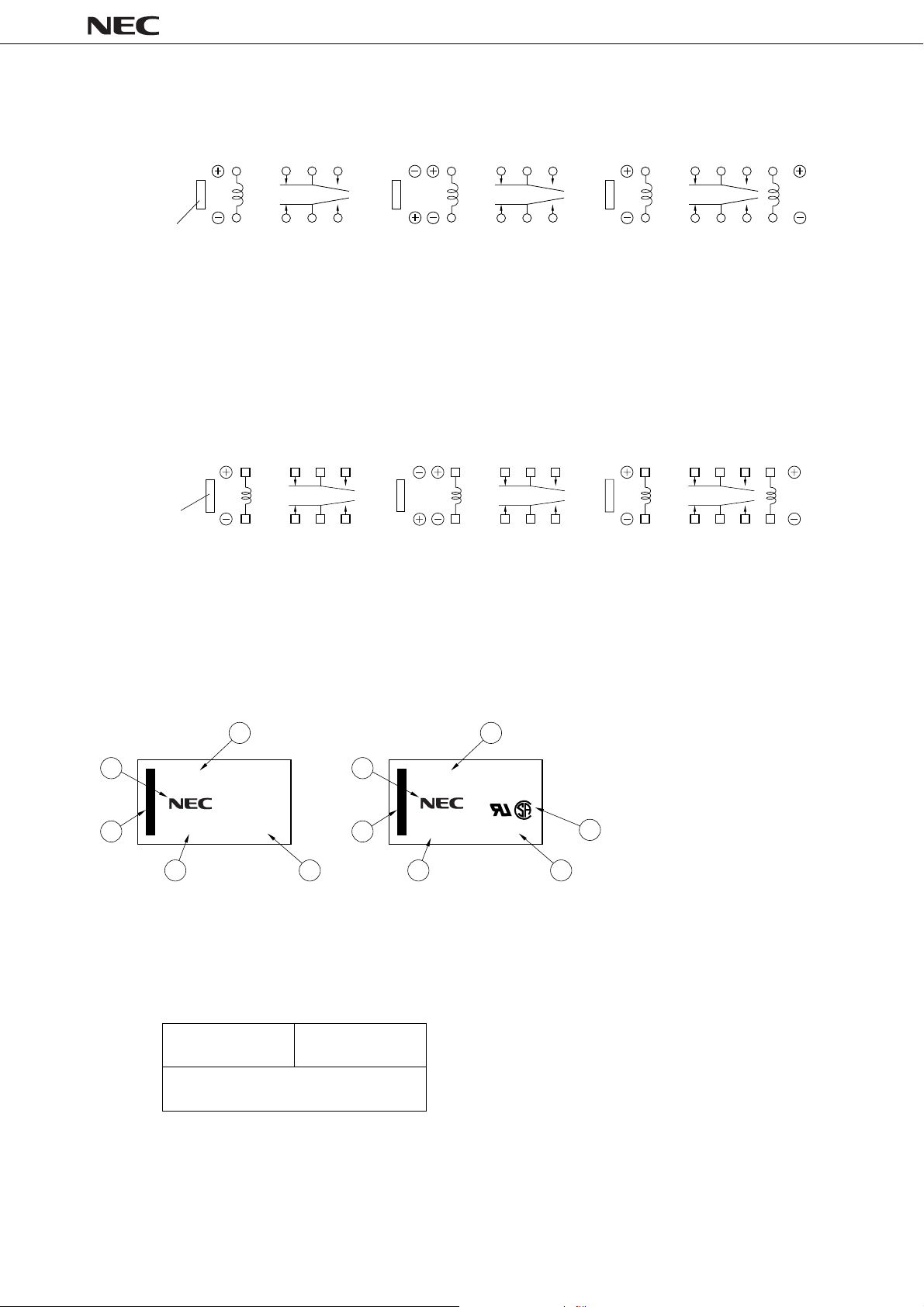

PIN CONFIGURATIONS (bottom view)

ED2 SERIES

ED2/EF2 SERIES

Index mark of

relay direction

EF2 SERIES

Index mark of

relay direction

1345

12 10 9 8

Non-latch type

(not energized position)

1345

12 10 9 8

Non-latch type

(not energized position)

1345

SRSR

12 10 9

Single coil latch type

(reset position)

S : Coil polarity of set (operate)

R : Coil polarity of reset (release)

1345

R

S

12 10 9 8

Single coil latch type

(reset position)

8

13456

12 10 9 8 7

Double coil latch type

(reset position)

1345

RS

12 10 9 867

Double coil latch type

(reset position)

MARKINGS (top view)

1

2

5

ED2-5

JAPAN

Standard type UL recognized,

9717

43

SAFETY STANDARD AND RATING

UL Recognized CSA Certificated

(UL508)* (CSA C22.2 No14)

File No E73266 File No LR46266

30 Vdc, 1 A (Resistive)

110 Vdc, 0.3 A (Resistive)

125 Vac, 0.5 A (Resistive)

* Spacing : UL114, UL478

S : Coil polarity of set (operate)

R : Coil polarity of reset (release)

1

q Part number

2

5

ED2-5NU

JAPAN

CSA certified type (Under application for latch type)

9717

6

43

w Manufacturer

e Country of origin

r Date code

t Index mark of relay direction

(pin No. 1, 12)

y UL, CSA Marking

3DATA SHEET ER0304EJ2V0DS00

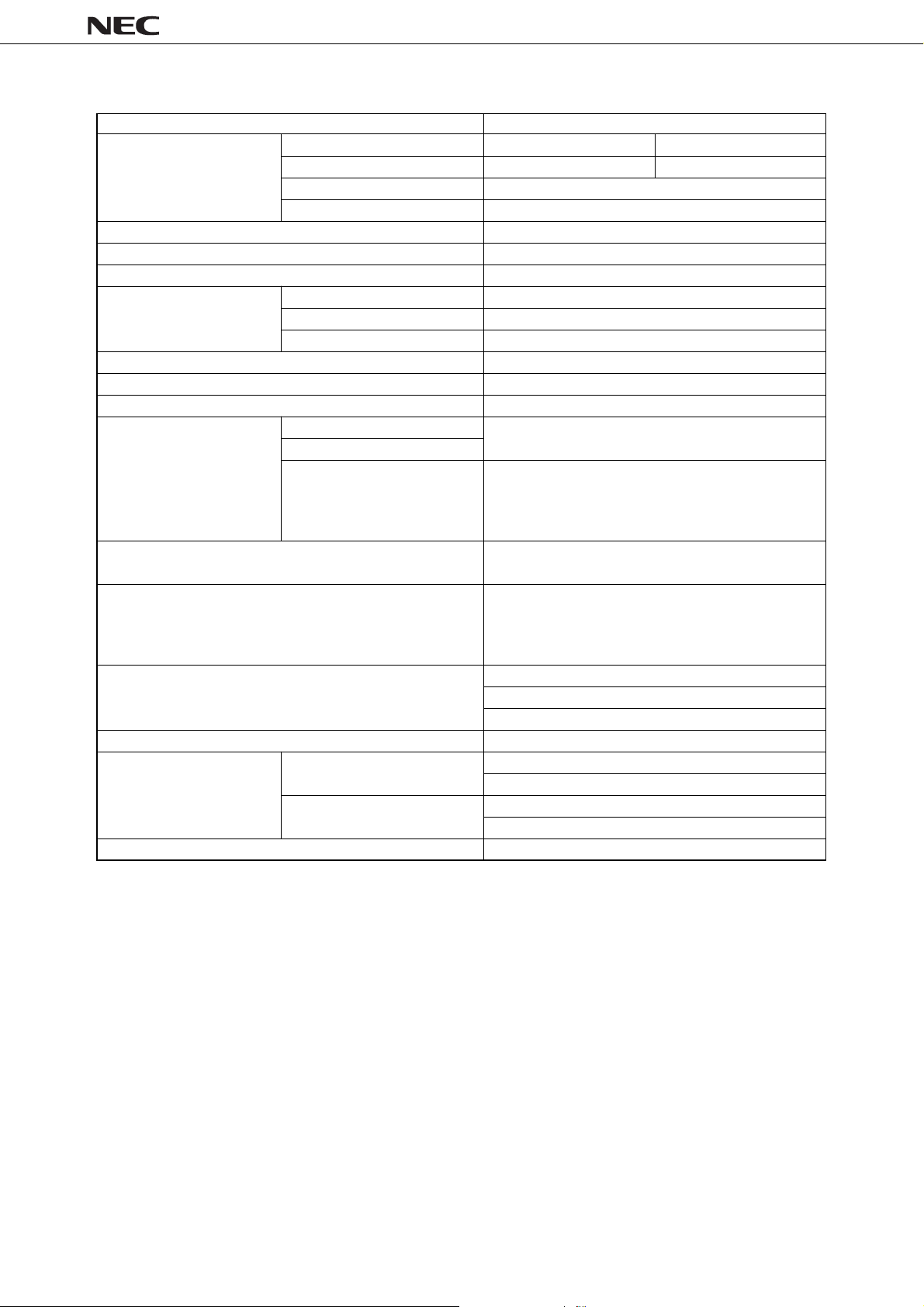

PERFORMANCE CHARACTERISTICS (Community)

ED2/EF2 SERIES

Contact Form

Contact Ratings

Minimum Contact Ratings

Initial Contact Resistance

Contact Material

Nominal Operating Power

Operate Time (Excluding Bounce)

Release Time (Excluding Bounce)

Insulation Resistance

Maximum Switching Power

Maximum Switching Voltage

Maximum Switching Current

Maximum Carrying Current

Non-Latch Type

Single Coil Latch Type

Double Latch Type

Between Open Contacts

2 Form c

30 W (resistive) 62.5 VA (resistive)

220 Vdc 250 Vac

1 A

2 A

10 mV.dc, 10 µA *

4

50 mΩ typ. (Initial)

Silver alloy with gold alloy overlay

50 to 70 mW

30 to 80 mW

50 to 80 mW

Approximately 3 ms

Approximately 2 ms without diode

1000 MΩ at 500 Vdc

1000 Vac for one minute (1500 V surge, 10 × 160 µs

Breakdown Voltage Between Adjacent Contacts

Non-latch type and single-coil latch type

Between Coil and Contact

1500 Vac for one minute (2500 V surge, 2 × 10 µs *2)

Double-coil latch type

1000 Vac for one minute (1500 V surge, 10 × 160 µs *1)

735 m / s2 (75 G) (misoperating)

Shock Resistance

980 m / s2 (100 G) (destructive failure)

10 to 55 Hz at double amplitude of 3 mm (20 G)

Vibration Resistance

(misoperating)

10 to 55 Hz, double amplitude of 5 mm (30 G)

(Destructive failure)

Non-latch type (Additional “N”): –40 to +85˚C

Ambient Temperature

Non-latch type (Standard): –40 to +70˚C

Latch type : –40 to +70˚C

Coil Temperature Rise

No-load

Running specifications

Load

Weight

1

∗

rise time : 10 µs, fall time : 160 µs

2

∗

rise time : 2 µs, fall time : 10 µs

3

∗

This shows a number of operation where it can be running by which a fatal is not caused, and number of operation by wich

a stesdy characteristic is maintained is 1 × 107 times.

4

∗

This value is a reference value in the resistive load.

7 degrees at nominal coil voltage (50 mW)

1 × 108 *3 operations (Non-latch type)

1 × 107 operations (Latch type)

50 Vdc 0.1 A (resistive), 1 × 106 operations at 70˚C

10 Vdc 10 mA (resistive), 1 × 106 operations at 70˚C

Approximately 2.2 grams

Minimum capacity changes depending on seitching frequency and enviroment temperature and the load.

1

∗

)

DATA SHEET ER0304EJ2V0DS004

PART NUMBER SYSTEM

ED2/EF2 SERIES

ED2 – 9 S NU

Nil : Standard type

NU : UL recognized, CSA certified type

NJ : Trimed leads

(UL recognized, CSA certified type)

Latch type

Nil : Non-latch type (Note 1)

S : Single coil latch type

T : Double coil latch type

Nominal coil voltage

1.5, 3, 4.5, 5, 6, 9, 12, 24 V

ED2 series

(UL, CSA : Under application for latch type)

EF2 - 5 S NUH

Note 1. There are two specification in operate voltage of Non-latch type relay.

Additional “N” type

Standard type

Part Number

ED2-*NU

-*NJ

ED2-∗

Must Operate Voltage

75%

80%

∗ : Nominal coil voltage

Note 2. There are two specification in operate voltage of Non-latch type relay.

Part Number

Must Operate Voltage

ED2-*NU

Additional “N” type

-*NUX

-*NUH

75%

-*NUN

Standard type

EF2-∗

80%

∗ : Nominal coil voltage

Feature

Nil : Standard type

NU : UL recognized, CSA certified type

NUX : High solder joint reliability (20 years)

NUH : Minimum footprint (7.5 × 15)

NUN : High solder joint reliability with minimum footprint

Latch type

Nil : Non-latch type (Note 2)

S : Single coil latch type

T : Double coil latch type

Nominal coil voltage

1.5, 3, 4.5, 5, 6, 9, 12, 24 volts

EF2 series

5DATA SHEET ER0304EJ2V0DS00

NOMINAL LINEUP (Community)

Non-latch Type (Standard)

Nominal Coil

Voltage

(Vdc)

1.5

3

4.5

5

6

9

12

24

Coil

Resistance

(Ω) ±10 %

45

180

405

500

720

1473

2400

8229

Must Operate

Voltage

(Vdc)

1.2

2.4

3.6

4

4.8

7.2

9.6

19.2

ED2/EF2 SERIES

Must Release

Voltage

(Vdc)

0.15

0.3

0.45

0.5

0.6

0.9

1.2

2.4

at 20˚C

Nominal

operate power

(mW)

50

50

50

50

50

55

60

70

Non-latch Type (Additional “N”)

Nominal Coil

Voltage

(Vdc)

1.5

3

4.5

5

6

9

12

24

Coil

Resistance

(Ω) ±10 %

45

180

405

500

720

1473

2400

8229

Single-Coil Latch Type

Nominal Coil

Voltage

(Vdc)

1.5

3

4.5

5

6

9

12

24

Coil

Resistance

(Ω) ±10 %

75

300

675

833

1200

2700

4800

7200

Must Operate

Voltage

(Vdc)

1.13

2.25

3.38

3.75

4.5

6.75

9

18

Must Operate

Voltage

(Vdc)

1.2

2.4

3.6

4

4.8

7.2

9.6

19.2

Must Release

Voltage

(Vdc)

0.15

0.3

0.45

0.5

0.6

0.9

1.2

2.4

Must Release

Voltage

(Vdc)

1.2

2.4

3.6

4

4.8

7.2

9.6

19.2

at 20˚C

Nominal

operate power

(mW)

50

50

50

50

50

55

60

70

at 20˚C

Nominal

operate power

(mW)

30

30

30

30

30

30

30

80

DATA SHEET ER0304EJ2V0DS006

ED2/EF2 SERIES

Double-Coil Latch Type

Nominal Coil

Voltage

(Vdc)

1.5

3

4.5

5

6

9

12

24

Coil

Must Operate

Resistance

(Ω) ±10 %

S45

R45

S 180

R 180

S 405

R 405

S 500

R 500

S 720

R 720

S 1620

R 1620

S 2880

R 2880

S 7200

R 7200

Voltage

(Vdc)

1.2

–

2.4

–

3.6

–

4

–

4.8

–

7.2

–

9.6

–

19.2

–

Must Release

Voltage

(Vdc)

–

1.2

–

2.4

–

3.6

–

4

–

4.8

–

7.2

–

9.6

–

19.2

at 20˚C

Nominal

operate power

(mW)

50

50

50

50

50

50

50

80

Recommended coil voltage with ambient temperature

Non latch typ (Additional “N”)

150

–40% / 45 deg

100

90

80

70

A ratio of nominal coil voltage (%)

60

50

–40 –40

+20% / 65 deg

75%

57%

0 20406080

Ambient temperature (˚C)

110%

95%

Latch typ

150

100

90

80

70

A ratio of nominal coil voltage (%)

60

50

–40 –40

+10% / 50 deg

73%

0 20406080

Ambient temperature (˚C)

–40% / 30 deg

85%

110%

95%

7DATA SHEET ER0304EJ2V0DS00

TYPICAL PERFORMANCE DATA

ED2/EF2 SERIES

● Coil Temperature Rise

20

15

10

5

Coil Temperature Rise(deg)

0

50 100 150 200

Applied Power(mW) at 20˚C

● Operate Time

Operate Time

4

2

Operate Time or

Bounce Time at Operate(ms)

0

50 100 150 200 250

Applied Power(mW)

Bounce Time at Operate

● Breakdown Voltage

99.99

99.9

99

95

90

80

60

40

20

10

5

1

0.1

Cumulative Distribution(%)

0.01

12 345

Breakdown Voltage(KV,AC)

● Release Time without diode

2

1

Release Time or

Bounce Time at Release(ms)

0 50 100 150 200

Applied Power(mW)

Between

adjacent

contacts

Between coil

and contacts

Between open

contacts

Release Time

Bounce Time at Release

● Contact Resistance

99.99

99.9

99

95

90

80

60

40

20

10

5

1

0.1

Cumulative Distribution(%)

0.01

0 102030405060708090100

Contact Resistance(mΩ)

● Switching Capacity

2.0

1.0

0.5

0.4

0.3

Switching Capacity(A)

0.2

Switching Voltage(V)

Make contact

Break contact

DC Load

(resistive)

AC Load

(resistive)

30 100 200

● Release Time with diode

4

2

Release Time or

Bounce Time at Release(ms)

0 50 100 150 200

Applied power(mW)

● Transfer Time

99.99

99.9

99

95

90

80

60

40

20

10

5

1

0.1

Cumulative Distribution(%)

0.01

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

Transfer Time(ms)

Release Time

Bounce Time at Release

At operate

At release

DATA SHEET ER0304EJ2V0DS008

● Magnetic Interference (ED2 Relay)

ED2/EF2 SERIES

40

30

20

10

0

-10

-20

-30

-40

Drift of Operate Voltage(%)

ON ON

Layout

II III IV V VI

I

I

ON

ON

ON

OFF OFF

Layout

Layout V

II

Layout

OFF

OFF

OFF

Max.

Min.

ON

ON

Layout

Layout VI

40

30

20

10

0

-10

-20

-30

-40

Drift of Release Voltage(%)

OFF

OFF

III

Layout

IV

Sample

II III IV V VI

I

Layout

Mounting Layout mm(inch)

Max.

Min.

2.54 (0.1)

● Mechanical Life

5

Operate Voltage

Release Voltage

4

3

2

1

Operate Voltage or

Release Voltage(V)

0

123410

Number of Operations(x105operations)

at 70˚C, 50 operation/sec

1000

500

Make contact

Break contact

at 70˚C, 50 operations/sec

300

200

100

50

30

20

Contact Resistance(mΩ)

10

0

1

Number of Operations(x105operations)

23 5 10

9DATA SHEET ER0304EJ2V0DS00

TUBE PACKAGE (ED2, EF2)

Dimension of Package (Unit : mm) 35 pieces / Tube

ED2/EF2 SERIES

Material : Polyvinyl chloride

(anti-static treated)

11.9 ±0.3

(0.5 t)

(2.4)

(4.8)

15.5 ±0.3

543 ±1

( ) Reference

Outline of Package

Rubber stopper (Red) Rubber stopper (Green)

Index Mark

TAPE PACKAGE (EF2)

APPEARANCE TAPE DIMENSION mm (inch)

Reel

Top cover tape

Embossed carrying tape

φ

1.5

(0.054)

φ

2.2

(0.087)

16.0(0.63)

2.0(0.079)

4.0(0.157)

B

A

0.4

(0.016)

1.75(0.069)

11.5

(0.453)

15.5

(0.610)

24.0(0.945)

EF2-∗∗ Max.10.9 10.0

EF2-∗∗NU (0.429) (0.394)

EF2-∗∗NUX

EF2-∗∗NUH Max.11.1 8.0

EF2-∗∗NUN (0.437) (0.315)

AB

Relay orientation mark and tape carrying direction.

Orientation mark Orientation mark

Tape carrying direction

Carrying tape type

Part number

L

EF2-

***

-L

DATA SHEET ER0304EJ2V0DS0010

R

EF2-

****

-R

SOLDERING TEMPERATURE CONDITION

Through–hole mounting type (ED2)

q Automatic soldering

* Preheating : 100°C max. 1 minute max.

* Solder temperature : 250°C max.

* Solder time : 10 seconds max.

w Manual soldering

* Solder temperature : 350°C max.

* Solder time : 3 seconds max.

Surface mounting type (EF2)

IRS Method

T max.; 235

200

175

150

ED2/EF2 SERIES

30 sec.

VPS Method

Temperature (˚C)

T max.; 215

200 max.

165 max.

100 max.

Temperature (˚C)

80 sec.

200 sec.

Time

Time

60 sec . max.

90 sec. max.60 sec.

Note:

1. Temperature profile shows printed circuit board surface temperature on the relay terminal portion.

2. Check the actual soldering condition to use other method except above mentioned temperature profiles.

11DATA SHEET ER0304EJ2V0DS00

ED2/EF2 SERIES

GUIDE TO APPLICATIONS

1. When connecting coils, refer to the pin configuration to prevent misoperation or malfunction.

2. The latch type relay should be initialized at the appointed position (set or reset position) when using, and should

be energized or deenergized to the specified polarity to avoid wrong operations by reversed contact state.

3. Ultrasonic cleaning is not recommended to keep contact performance reliable. Alcohol based solvents are

available as proper solvents.

4. Pressurized stress on the relay cover may affect reliable operation.

µ

5. Minimum contact load of the relay is 10 mVdc, 10

This value is a reference value in the resistance load.

Minimum capacity changes depending on switching frequency and environment temperature and the load.

A.

DATA SHEET ER0304EJ2V0DS0012

ED2/EF2 SERIES

13DATA SHEET ER0304EJ2V0DS00

ED2/EF2 SERIES

DATA SHEET ER0304EJ2V0DS0014

ED2/EF2 SERIES

15DATA SHEET ER0304EJ2V0DS00

ED2/EF2 SERIES

No part of this document may be copied or reproduced in any form or by any means without the prior

written consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which

may appear in this document.

NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property rights of third parties by or arising from use of a device described herein or any other

liability arising from use of such device. No license, either express, implied or otherwise, is granted

under any patents, copyrights or other intellectual property rights of NEC Corporation or others.

While NEC Corporation has been making continuous effort to enhance the reliability of its electronic

components, the possibility of defects cannot be eliminated entirely. To minimize risks of damage or

injury to persons or property arising from a defect in an NEC electronic component, customers must

incorporate sufficient safety measures in its design, such as redundancy, fire-containment, and antifailure features.

NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based

on a customer designated "quality assurance program" for a specific application. The recommended

applications of a device depend on its quality grade, as indicated below. Customers must check the

quality grade of each device before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment, au-

dio and visual equipment, home electronic appliances, machine tools, personal electronic equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed for life support)

Specific: Aircrafts, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

Anti-radioactive design is not implemented in this product.

Loading...

Loading...