Page 1

User’s Manual

EB-V850ES/HG2-EE

Demonstration Kit for the H_Line Family

Document No. EBV850ESHG2EE_V100

Date Published November 2005

NEC Electronics (Europe) GmbH

Page 2

EB-V850ES/HG2-EE

・

The information in this document is current as of date of its publication. The information is subject to

change without notice. For actual design-in, refer to the latest publications of NEC Electronics data

sheets or data books, etc., for the most up-to-date specifications of NEC Electronics products. Not all

products and/or types are available in every country. Please check with an NEC sales representative

for availability and additional information.

・

No part of this document may be copied or reproduced in any form or by any means without prior

written consent of NEC Electronics. NEC Electronics assumes no responsibility for any errors that

may appear in this document.

・

NEC Electronics does not assume any liability for infringement of patents, copyrights or other

intellectual property rights of third parties by or arising from the use of NEC Electronics products listed

in this document or any other liability arising from the use of such NEC Electronics products. No

license, express, implied or otherwise, is granted under any patents, copyrights or other intellectual

property rights of NEC Electronics or others.

・

Descriptions of circuits, software and other related information in this document are provided for

illustrative purposes in semiconductor product operation and application examples. The incorporation

of these circuits, software and information in the design of customer's equipment shall be done under

the ful l responsibility of customer. NEC Electronics no responsibility for any losses incurred by

customers or third parties arising from the use of these circuits, software and information.

・

While NEC Electronics endeavors to enhance the quality, reliability and safety of NEC Electronics

products, customers agree and acknowledge that the possibility of defects thereof cannot be

eliminated entirely. To minimize risks of damage to property or injury (including death) to persons

arising from defects in NEC Electronics products, customers must incorporate sufficient safety

measures in their design, such as redundancy, fire-containment and anti-failure features.

・

NEC Electronics products are classified into the following three quality grades: “Standard”, “Special”

and “Specific”.

The "Specific" quality grade applies only to NEC Electronics products developed based on a customerdesignated “quality assurance program” for a specific application. The recommended applications of NEC

Electronics product depend on its quality grade, as indicated below. Customers must check the quality

grade of each NEC Electronics product before using it in a particular application.

"Standard": Computers, office equipment, communications equipment, test and measurement

equipment, audio and visual equipment, home electronic appliances, machine tools,

personal electronic equipment and industrial robots.

"Special": Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti disaster systems, anti-crime systems, safety equipment and medical equipment (not

specifically designed for life support).

"Specific": Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control syste ms,

life support systems and medical equipment for li fe support, etc.

The quality grade of NEC Electronics products is “Standard” unless otherwise expressly specified in NEC

Electronics data sheets or data books, etc. If customers wish to use NEC Electronics products in

applications not intended by NEC Electronics, they must contact NEC Electronics sales representative in

advance to determine NEC Electronics 's willingness to support a given application.

Notes: 1." NEC Electronics" as used in this statement means NEC Electronics Corporation and also

includes its majority-owned subsidiaries.

2. " NEC Electronics products" means any product developed or manufactured by or for NEC

Electronics (as defined above).

M8E 02.10

2

Page 3

EB-V850ES/HG2-EE

CAUTION

This is a Test- and Measurement equipment with possibility to be significantly

altered by user through hardware enhancements/modifications and/or test or

application software. Thus, with respect to Council Directive 89/336/EEC

(Directive on compliance with the EMC protection requirements), this

equipment has no autonomous function. Consequently this equipment is not

marked by the CE-symbol.

Redemption of Waste Electrical and Electronic Equipment

(WEEE) in accordance with legal regulations applicable in the

European Union only: This equipment (including all

accessories) is not intended for household use. After use the

equipment cannot be disposed of as household waste. NEC

Electronics (Europe) GmbH offers to take back the equipment.

All you need to do is register at www.eu.necel.com/weee.

EEDT-ST-0005-10

3

Page 4

EB-V850ES/HG2-EE

Revision History

Date Revision Chapter Description

16-11-2005 V1.00 --- First release

4

Page 5

EB-V850ES/HG2-EE

Table of Contents

1. Introduction .....................................................................................................................10

1.1 Main features of EB-V850ES/HG2-EE........................................................................................10

1.2 System requirements.................................................................................................................11

1.3 Package contents.......................................................................................................................11

1.4 Trademarks.................................................................................................................................11

2. EB-V850ES/HG2-EE system configuration....................................................................12

2.1 EB-V850ES/HG2-EE....................................................................................................................12

2.2 Host computer.. .... ... .... ... .... .... ... .... ... .... .... ... .... ... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... ...........12

2.3 Power supply via USB interface...... .... .... ... .... ... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... ....... ....12

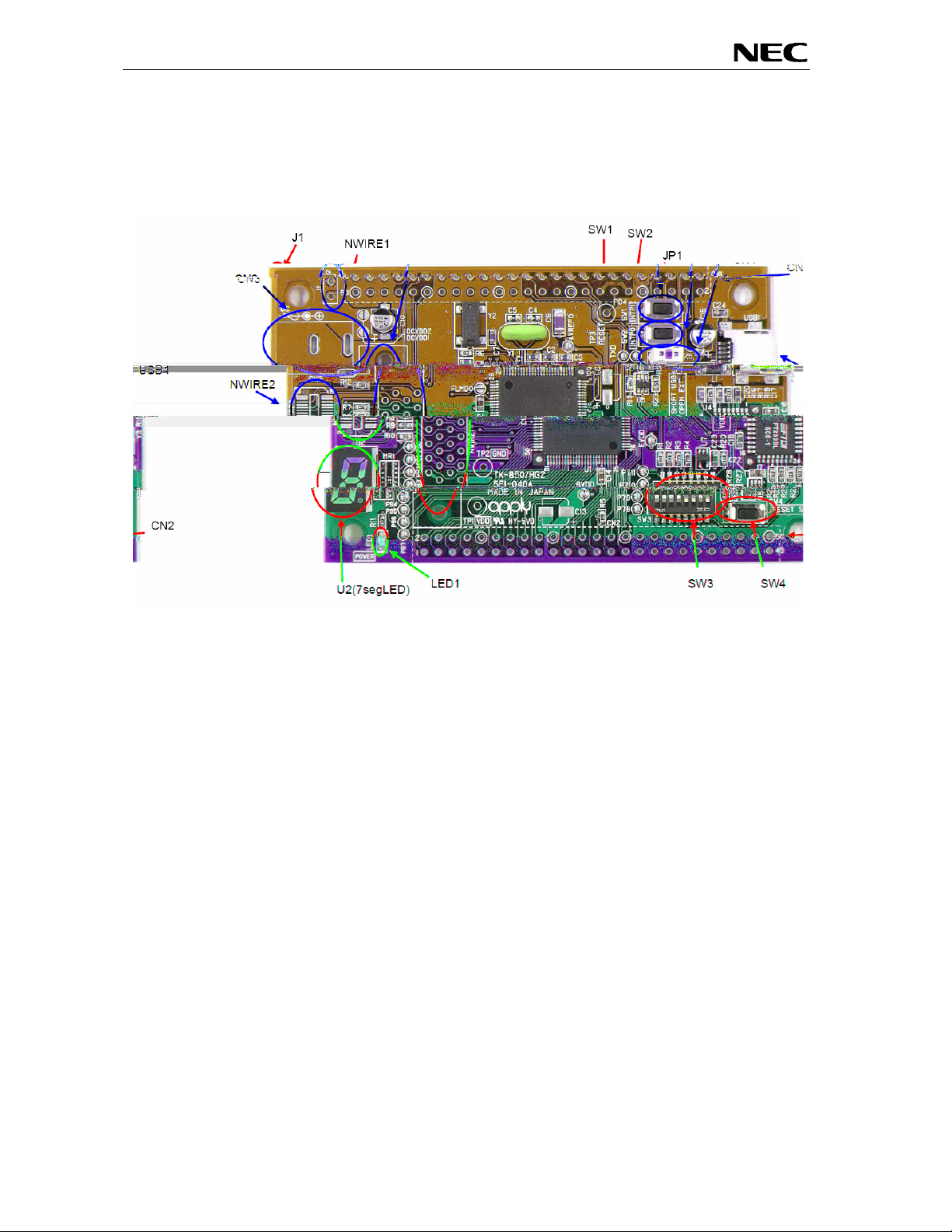

3. EB-V850ES/HG2-EE board components........................................................................13

3.1 User button SW1 ........................................................................................................................14

3.2 User button SW2 ........................................................................................................................14

3.3 Configuration switch SW3. .... ... .... ... .... ... .... .... ... .... ... .... .... ... .... ... .... ... .... ... .... .... ... .... ... .... .... ... ....14

3.3.1 Normal operation mode.............................................................................................................14

3.3.2 On-Board debug mode..............................................................................................................14

3.3.3 FLASH programming mode.......................................................................................................15

3.3.4 N-Wire debugging mode............................................................................................................15

3.3.5 General-purpose switches......... .... ... .... ... .... .... ... .... ... .... ... .... .... ... ....... .... .... ... .... ... .... ... .... ... .... ....15

3.4 RESET button SW4....................................................................................................................15

3.5 Power LED LED1..... .... ... .... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... ... .... ... .... .... ... .... ... .... ... ........15

3.6 Power supply selector JP1....... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... .... ... .... ... .... ... .... ... .... ....16

3.7 External power supply...............................................................................................................16

3.8 USB interface connector USB1..................................................................................................17

3.9 N-Wire connectors NWIRE1, NWIRE2........................................................................................18

3.10 External LED U2....................... .................................................................................................20

3.11 External connectors CN1 and CN2..........................................................................................21

3.12 Soldering Bridges ....................................................................................................................24

3.13 V850ES/HG2 memory map............................................................................................ ...........25

4. EB-V850ES/HG2-EE installation and operation.............................................................26

4.1 Getting started............................................................................................................................26

4.1.1 CD-ROM contents.....................................................................................................................26

5. Hardware installation ......................................................................................................27

6. Software installation........................................................................................................27

6.1 IAR Systems Embedded Workbench for V850 installation ......................................................27

6.2 FPL FLASH programming GUI installation...............................................................................27

6.3 Sample program installation ................................................... ..................................................27

6.4 USB Driver Installation...............................................................................................................28

6.4.1 Installation on Windows 98SE/Me..............................................................................................28

6.4.2 Installation on Windows 2000 ....................................................................................................30

6.4.3 Installation on Windows XP .......................................................................................................36

6.5 Confirmation of USB Driver Installation ...................................................................................41

5

Page 6

EB-V850ES/HG2-EE

6.6

Driver Uninstallation ..................................................................................................................42

7. FPL FLASH programming software................................................................................ 44

7.1 Introduction................................................................................................................................44

7.2 Starting up the GUI Software.....................................................................................................44

7.3 Toolbar........................................................................................................................................45

7.4 Menu Bar........... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... .... ... ....... .... ... .... ... .... .... ... .... ... . ..............46

7.4.1 [Fil e] menu ... ... .... ... .... ... .... .... ... .... ... .... .... ... ....... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... ...........46

7.4.2 [Device] menu...........................................................................................................................47

7.4.3 [View] menu ..............................................................................................................................54

7.4.4 [Help] menu .. ... .... ... .... ... .... ....... .... ... .... ... .... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... ... .... ...........55

7.5 Programmer Parameter Window ......................................................................... ......................56

8. How to use FPL FLASH programming software............................................................ 57

(1) Installing the FPL GUI software.....................................................................................................57

(2) Installing the driver........................................................................................................................57

(3) Installing the parameter file...........................................................................................................57

(4) Connecting and starting................................................................................................................58

(5) Setting the programming environment ..........................................................................................59

(6) Selecting a user program..............................................................................................................62

(7) [Autoprocedure(EPV)] command execution...................................................................................63

(8) Terminating the GUI .....................................................................................................................63

(9) Execute “CountDownTimer” application ............. ... .... ... .... .... ... .... ... .... ... .... ... .... .... ... .... ... .... ... .... ....63

(10) Restarting the GUI......................................................................................................................63

9. TROUBLESHOOTING......................................................................................................64

10. On-Board debugging..................................................................................................... 66

10.1 Monitor resources............ .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... ... .... ... .... .... ... .... ... .... ... ........67

10.1.1 UARTA0..................................................................................................................................67

10.1.2 Interrupt vectors ... .... ... .... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... ....... .... ... .... .... ... .... ... .... ... ........67

10.1.3 Reset vector ............................................................................................................................68

10.1.4 Memory area..... ... .... .... ... .... ... .... ... .... ... .... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... ... .... ... ........68

10.1.5 Clock oper ation..... .... ... .... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... ... .... ... .... .... ... .... ... .... ... ........68

10.1.6 Other limitations ... .... ... .... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... ... .... ... .... .... ... .... ... .... ... ........68

10.2 IAR sample session... ... .... .... ... .... ... .... ....... .... ... .... ... .... ... .... .... ... .... ... .... ... .... ... .... .... ... .... ... ........69

11. Sample programs..........................................................................................................75

11.1 General Introduction........ .... ... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... .... ... .... ... .... ... .... ... ........75

11.2 Count Down Timer ............... ... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... .... ... ....76

11.3 Electronic Dice .........................................................................................................................76

11.4 Entrance code checker.............................................................................................................77

11.5 Lightshow .................................................................................................................................77

11.6 Melody maker ....................................................................................... ....................................78

11.7 Reaction time measurement....................................................................................................78

12. Cables ............................................................................................................................79

12.1 USB interface cable (Mini-B type).......... ... .... ... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... ... .... ....79

6

Page 7

EB-V850ES/HG2-EE

13. Schematics ....................................................................................................................80

7

Page 8

EB-V850ES/HG2-EE

List of Figures

Fig u re 1: EB-V850ES/HG2-EE system configuration.............................................................................12

Fig u re 2: EB-V850ES/HG2-EE board connectors, switches and LED’s....... ... .... ... .... ... .... .... ... .... ... .... .... 13

Figure 3: Connector USB1, USB Mini-B Type Host Connector Pin Configuration.. .... .... ... .... ... .... ... .... .... 17

Figure 4: On-chip debugging system configuration ................................................................................18

Figure 5: External connectors CN1 and CN2.............. ...........................................................................21

Figure 6: Placement of soldering bridges............................................................................................... 24

Figure 7: Add New Hardware Wizard (Windows 98SE).........................................................................28

Figure 8: Search Method (Windows 98SE)............................................................................................28

Figure 9: Search Location Specification (Windows 98SE)......................................................................29

Figure 10: Checking Driver to Be Installed (Windows 98SE)..................................................................29

Figure 11: Installation Completion (Windows 98SE) ........................................................ ...................... 30

Figure 12: Found New Hardwar e W izard 1 (Wi ndows 2000). .... ... .... .... ... .... ... .... .... ... ....... .... ... .... .... ... .... 30

Figure 13: Search Method 1 (Windows 2000)............. ... .... ... .... .... ... .... ... .... ... .... ... .... .... ... .... ... .... ... .... .... 31

Figure 14: Driver File Location 1 (Windows 2000) .................................................................................31

Figure 15: Address Specification 1 (Wi ndows 2000)............. .... ... .... .... ... .... ... .... .... ... .... ... .... ... .... ... .... .... 32

Figure 16: Driver File Search 1 (Windows 2000) ...................................................................................32

Figure 17: USB Driver Installation Completion 1 (Windows 2000)........... .... ... .... ... .... .... ... .... ....... ... .... .... 33

Figure 18: Found New Hardwar e W izard 2 (Wi ndows 2000). .... ... .... .... ... .... ... .... .... ... ....... .... ... .... .... ... .... 33

Figure 19: Search Method 2 (Windows 2000)............. ... .... ... .... .... ... .... ... .... ... .... ... .... .... ... .... ... .... ... .... .... 34

Figure 20: Driver File Location 2 (Windows 2000) .................................................................................34

Figure 21: Address Specification 2 (Windows 2000).......... ... .... ... .... .... ... .... ... .... .... ... .... ... .... ... .... ... .... .... 35

Figure 22: Driver File Search 2 (Windows 2000) ...................................................................................35

Figure 23: USB Driver Installation Completion 2 (Windows 2000)........... .... ... .... ... .... .... ... .... ....... ... .... .... 36

Figure 24: Found New Hardwar e W izard 1 (Wi ndows XP ).... .... .... ... .... ... .... ... .... ... .... .... ... .... ... .... ... .... .... 36

Figure 25: Search Location Specification 3 (Windows XP).....................................................................37

Figure 26: Windows XP Logo Testing 3 (Windows XP).......................................................................... 37

Figure 27: USB Driver Installation Completion 1 (Windows XP ) .... ... .... ... .... ... .... .... ... .... ... .... ... .... ....... .... 38

Figure 28: Found New Hardware Wizard 2 (Windows XP)........ .... ... .... ... .... ... .... ... .... .... ... .... ... .... ... .... .... 38

Figure 29: Search Location Spec ification 2 (Windows XP)........ .... ... .... ... .... ... .... ... .... .... ... .... ... .... ... .... .... 39

Figure 30: Windows XP Logo Testing 2 (Windows XP).......................................................................... 39

Figure 31: USB Serial Port2 Driver Installation Completion (Windows XP) ............................................ 40

Figure 32: Device Manager ................................................................................................................... 41

Figure 33: Driver Uninstallation ............................................................................................................. 42

Figure 34: Driver Uninstaller................................................................................. ................................. 42

Figure 35: Completion of Driver Uninstallation....................................................................................... 43

Figure 36: GUI Software Main Window.................................................................................................. 44

Figure 37: Toolbar Buttons....................................................................................................................45

Fig u re 38 : [ F ile] Menu ....................................................................................................................... .... 46

Figure 39: HEX Fil e Selection Window . .... ... .... .... ... .... ... .... ... .... ... .... .... ... .... ... .... .... ... .... ... .... ... .... .... .......46

Fig u re 40 : [ D evice] Menu ......................................................................................................................47

Figure 41: Device Setup Window - Standard.........................................................................................49

Figure 42: Setup Window - Parameter File Selection............................................................................. 50

Figure 43: Parameter File Selection Window.........................................................................................50

Figure 44: Setup Window - Communication interface to device.............................................................51

Figure 45: Setup Window - Supply Oscillator Selection ....................................................... ..................51

Figure 46: Setup Window - Operation Mode..........................................................................................52

Figure 47: Device Setup Window - Advance................................................................. .........................53

Figure 48: Setup Window - Command options.......................................................................................53

Fig u re 49 : [ V iew] Menu.......................................................................................................................... 54

Fig u re 50 : [ H elp] Menu.......................................................................................................................... 55

Figure 51: About FPL Window............................................................................................................... 55

Figure 52: Programmer Parameter W indow ........... .... ... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... ... .... ....56

Figure 53: GUI Software Startup Screen.......... .... ... .... ... .... ... .... ... .... .... ... .... ... .... ... .... .... ... .... ... .... ... .... .... 59

Figure 54: <Standard Device Setup> Dialog Box...................................................................................59

Figure 55: Parameter File Selection ......................................................................................................60

Figure 56: Port Selection...................................................................................................... .................60

Figure 57: <Standard Device Setup> Dialog Box after Setting............................................................... 61

Figure 58: <Advance Device Setup> Dialog Box...................................................................................61

8

Page 9

EB-V850ES/HG2-EE

Page 10

EB-V850ES/HG2-EE

1. Introduction

EB-V850ES/HG2-EE is a demonstration kit for the NEC’s H_Line V850ES microcontroller family. It

supports On-Board debugging, FLASH programming and real time execution of application programs.

The board is prepared to be connected to user hardware parts such as digital I/O or analogue signals.

1.1 Main features of EB-V850ES/HG2-EE

• Easy to use device demonstration capabilities

EB-V850ES/HG2-EE contains elements to easily demonstrate simple I/O-functions, i.e. push buttons,

7 segment LED output, AD reference voltage, I/O lines, UART serial interface.

• Power supply via USB interface

EB-V850ES/HG2-EE is powered via USB interfac e, no separate power supply is needed.

• On-Board debug function

The EB-V850ES/HG2-EE supports an On-Board debug function by using the IAR C-SPY debugger,

without a need of additional debug hardware. It allows FLASH programming and supports standard

debug functions i.e. code execution, single stepping, software breakpoints, memory manipulation etc.

• N-Wire debugging

The EB-V850ES/HG2-EE is prepared to be equipped with a KEL adapter in order to connect the QBV850MINI-EE or IE-V850E1-CD-NW On-Chip debug emulator to use On-Chip debug function of the

V850ES/HG2 device. Please note, the QB-V850MINI-EE and IE-V850E1-CD-NW are separate

products from NEC and there are not included in this starterkit package.

• FPL, FLASH programming software

A windows based FLASH programming software allows to select and download application programs

to the EB-V850ES/HG2-EE board for evaluation purposes.

• Analogue to digital signal conversion is supported

• Vari ous input / out put signals available, such as

° All I/O ports prepared to be connected to user hardware

° Timer input / output signals

° Two or three wire serial I/O

° UART interface, via USB UART chip FT232

° 16 analogue input lines

° 7 segment LED

° 2 push buttons prepared for external interrupt generation

• The IAR Embedded Workbench for V850 and the IAR C-SPY debugger / simulator are included.

These packages are restricted in such that maximum program code size is limited to 16 kByte.

• Full documentation is included for the NEC V850ES/HG2 device, the IA R Systems Embedded

Workbench, IAR Systems C-SPY debugger / simulator and the NEC FPL FLASH programming

software.

EB-V850ES/HG2-EE is not intended for code development. NEC does not allow and does not

support in any way any attempt to use EB-V850ES/HG2-EE in a commercial or technical product.

10

Page 11

EB-V850ES/HG2-EE

1.2 System requirements

HOST PC

Host interface

1.3 Package contents

Please verify that you have received all parts listed in the package contents list attached to the

EB-V850ES/HG2-EE p a c k a ge . I f any pa rt is mi ssing or see ms to be da maged , plea se co ntact t h e de aler

fro m whom yo u r ec e i ved yo ur EB-V850ES/HG2-EE starterkit.

Note:

Updates to this User Manual, additional documentation and/or utilities for EB-V850ES/HG2-EE

starterkit, if available, may be downloaded from the NEC WEB page(s) at

http://www.eu.necel.com/updates.

A PC supporting Windows 98SE, Windows ME, Windows 2000 or

Windows XP is required for the IAR Systems Embedded Workbench

demo-version and the FPL FLASH programming software.

Pentium 166 MHz (at least), 128 MB of RAM, 256-color display (1024 *

768), mouse, CD-ROM drive and 200 Mbytes of free hard disk space are

required to install the tool packages.

Above listed requirements are valid for the IAR Systems Embedded

Workbench and the FPL FLASH programming software.

USB interface that enables communication based on USB (Ver1.1 or

later)

1.4 Trademarks

IAR Embedded Workbench, visualSTATE, IAR MakeApp and C-SPY are registered trademarks of IAR

Systems AB. Microsoft and Windows are registered trademarks of Microsoft Corporation. Adobe and

Acrobat Reader are registered trademarks of Adobe Systems Incorporated.

All other product names are trademarks or registered trademarks of their respective owners.

11

Page 12

EB-V850ES/HG2-EE

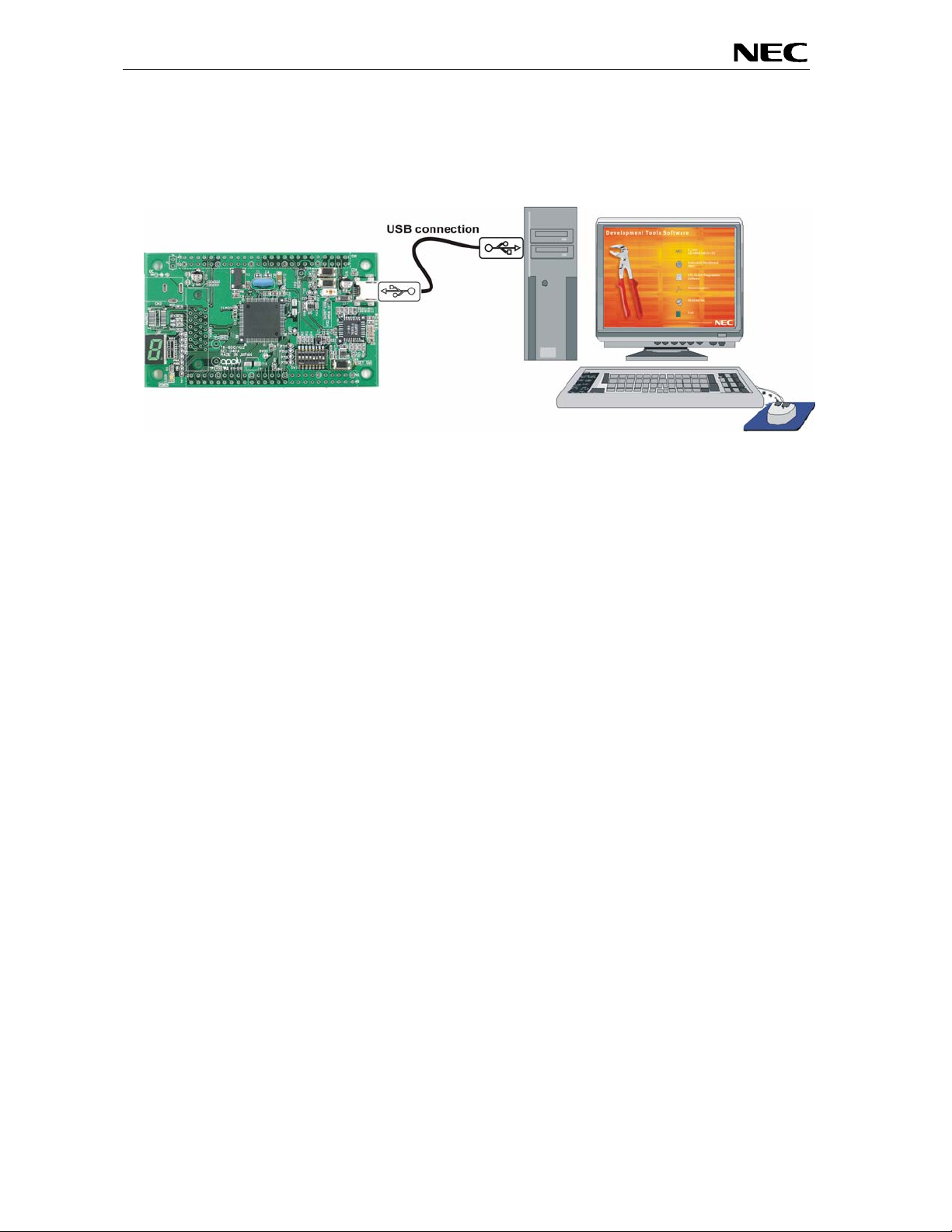

2. EB-V850ES/HG2-EE system configuration

The EB-V850ES/HG2-EE system configuration is given in the diagram below:

Figure 1: EB-V850ES/HG2-EE system configuration

2.1 EB-V850ES/HG2-EE

EB-V850ES/HG2-EE is a demonstration kit for the NEC H_Line V850ES family devices. As a typical

microcontroller from H_Line family the V850ES/HG2 device (µPD70F3707) is used. The board is

connected to the host system via a USB interface cable. The host system may be used for On-Boa rd

debugging or FLASH programming and to allow execution of application programs on the V850ES/HG2

device.

The EB-V850ES/HG2-EE board is equipped with an 5.0000 MHz oscillator, allows running the

V850ES/HG2 microcontroller at 20MHz. Sub-clock is provided with 32.768 kHz.

2.2 Host computer

The USB host interface enables communication to the EB-V850ES/HG2-EE board. Th e USB UART chi p

FT232 allows application software to access the USB device in the same way as it would access a

standard RS232 interface. The FTDI's Virtual COM Port (VCP) driver appears to the windows system as

an extra Com Port, in additi on to any existing hardware Com Ports.

2.3 Power supply via USB interface

EB-V850ES/HG2-EE is powered by USB interface, no separate power supply is needed. The USB

interface provides the EB-V850ES/HG 2-EE board with 5V supply voltage.

12

Page 13

EB-V850ES/HG2-EE

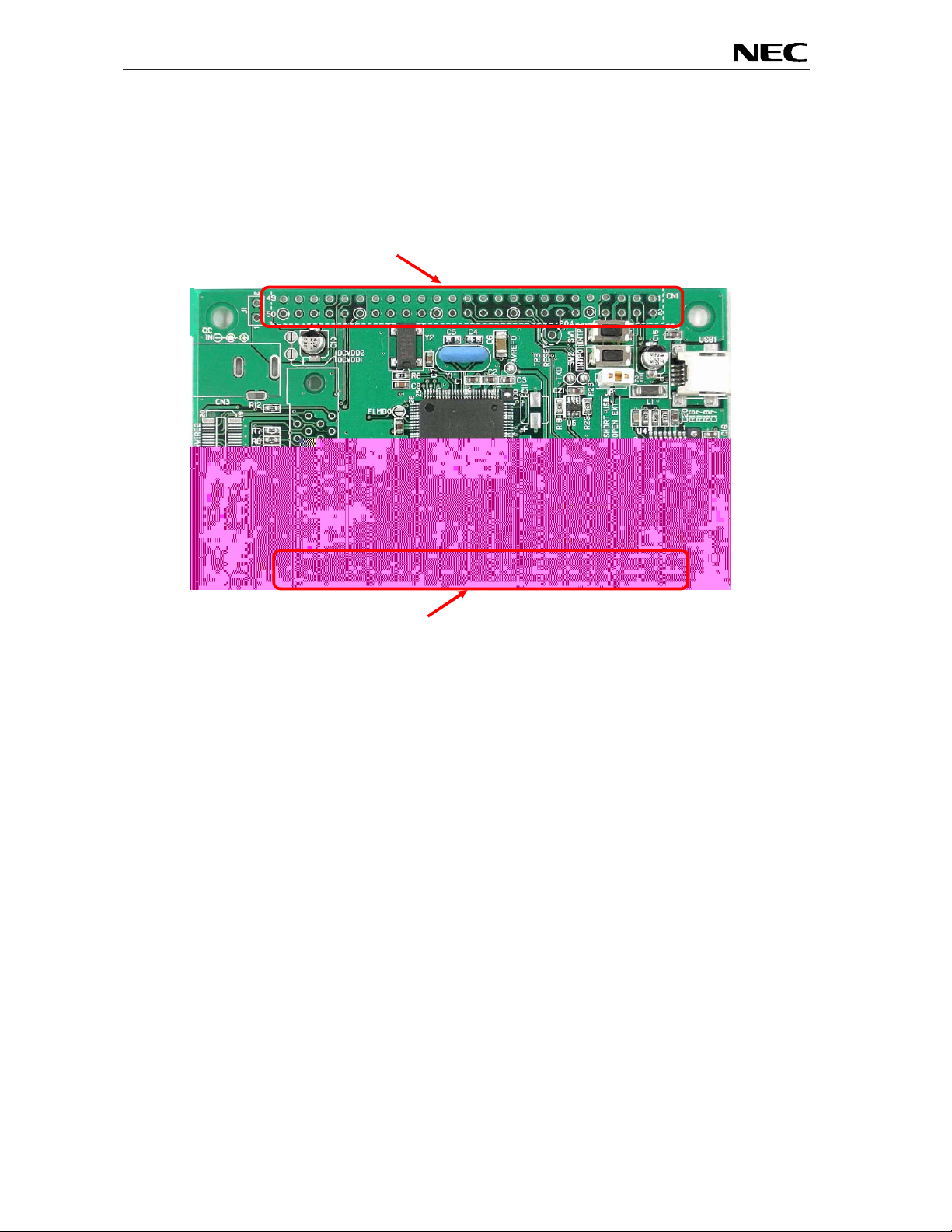

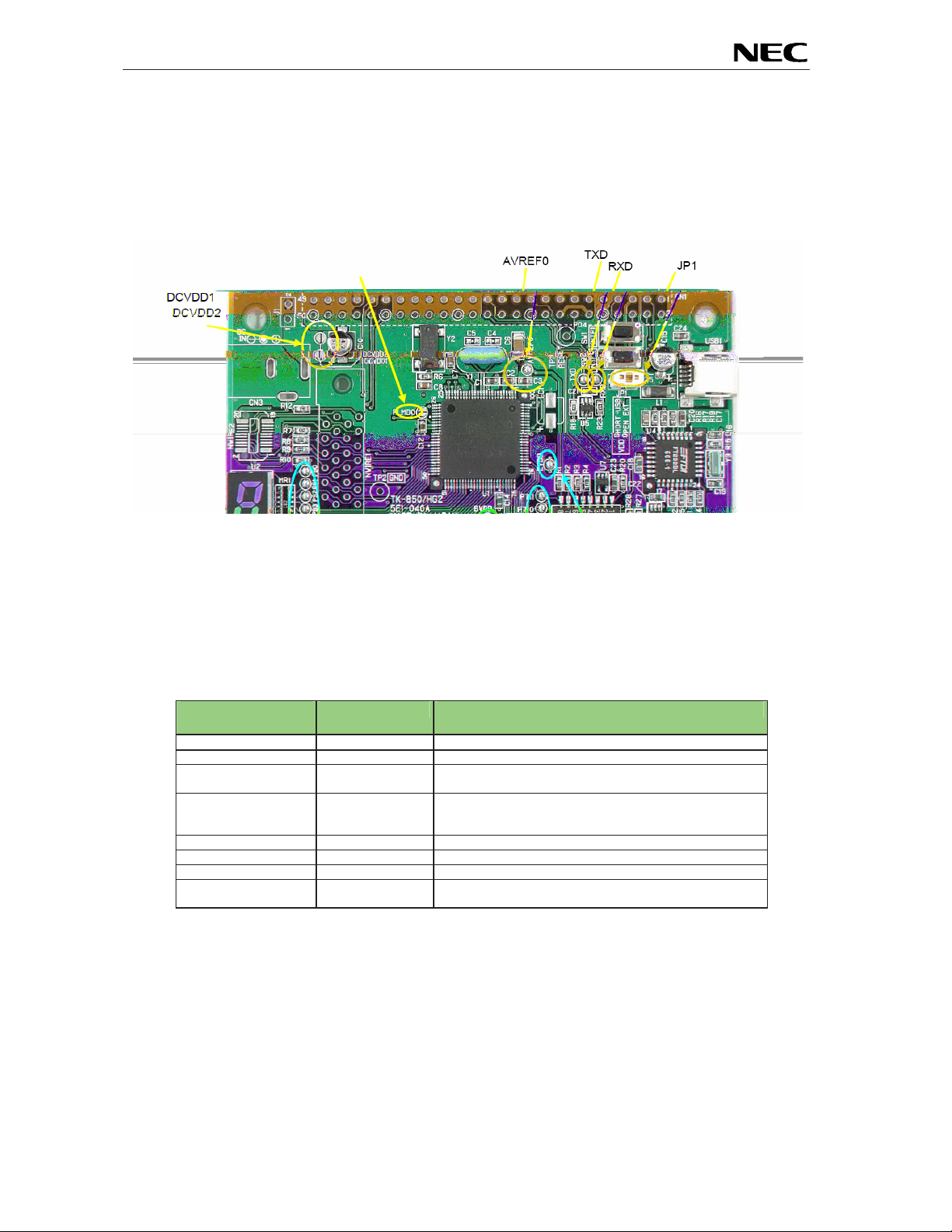

3. EB-V850ES/HG2-EE board components

The EB-V850ES/HG2-EE board is equipped with push buttons, a 7 segment LED and several connectors

in order to be connected to user hardware or host computers.

Figure 2: EB-V850ES/HG2-EE board connectors, switches and LED’s

Some of the EB-V850ES/HG2-EE components are free for user application hardware and software.

Please read the user’s manual of the V850ES/HG2 device carefully to get information about the

electrical specification of the available I/O ports before you connect any external signal to the EB-

V850ES/HG2-EE board.

13

Page 14

EB-V850ES/HG2-EE

3.1 User button SW1

SW 1 i s a pus h bu tt o n c on necting VS S to ext e rna l inte r r u pt i n pu t I NT P1 of the m icr oc o ntrolle r . Th i s is

equal to port P04 of the V850ES/HG2 device. The port may be programmed to generate interrupt INTP1.

The necessary initialisation for this purpose is described in the user’s m anual of the V850ES/HG2 device.

Please note, when using SW1 turn ON the built-in pull-up resistor of V850ES/HG2 device, register PU0.

3.2 User button SW2

SW 2 i s a pus h bu tt o n c on necting VS S to ext e rna l inte r r u pt i n pu t I NT P0 of the m icr oc o ntrolle r . Th i s i s

equal to port P03 of the V850ES/HG2 device. The port may be programmed to generate interrupt INTP0.

The necessary initialisation for this purpose is described in the user’s m anual of the V850ES/HG2 device.

Please note, when using SW2 turn ON the built-in pull-up resistor of V850ES/HG2 device, register PU0.

3.3 Configuration switch SW3

The dip-switch SW3 (Bits 1-4) controls the different operating modes of the EB-V850ES/HG2-EE board.

The Bits 5-8 of dip-switch SW3 are for general-purpose input and are connected to the ports P78~P711

of t h e m icr oc o nt rol l e r .

14

Page 15

EB-V850ES/HG2-EE

3.3.3 FLASH programming mode

For programming of the built-in FLASH memory of the V850ES/HG2 device by using the FPL FLASH

programming GUI please configure switch SW 3 as following:

SW3 Configuration

Bit 1 ON

Bit 2 OFF

Bit 3 ON

Bit 4 ON

Table 3: SW3, FLASH program m ing m ode

3.3.4 N-Wire debugging mode

To enable N-Wire On-Chip debugging by using the QB-V850MINI-EE or IE-V850E1-CD-NW On-Chip

debug emulators please configure switch SW3 of the EB-V850ES/HG2-EE board as following:

SW3 Configuration

Bit 1 OFF

Bit 2 OFF

Bit 3 OFF

Bit 4 OFF

Table 4: SW3, N-Wire debugging mode

Please refer also to CHAPTER 3.9 N-WIRE CONNECTORS NWIRE1, NWIRE2 of this document.

3.3.5 General-purpose switches

The Bits 5-8 of dip-switch SW3 are for general-purpose inputs and are c onnected to the ports P78~P711

of the microcontroller. Switching Bits 5-8 to ON applies VSS to the corresponding port of the

microcontroller. Switching Bits 5-8 to OFF applies VDD to the corresponding port.

SW3 V850ES/HG2

Bit 5 P78

Bit 6 P79

Bit 7 P710

Bit 8 P711

Table 5: SW3, general-purpose switches

3.4 RESET button SW4

SW4 is a reset button. It activates the power on reset. It is connected to the reset circuit of the

EB-V850ES/HG2-EE board.

3.5 Power LED LED1

LED1 is the Powe r LED. LED1 is activated if power is supplied to the EB-V850ES/HG2-EE board.

15

Page 16

EB-V850ES/HG2-EE

3.6 Power supply selector JP1

Jumper JP1 selects the power supply of the EB-V850ES/HG2-EE board. Closing jumper JP1 (default

setting) supplies power (VCC = 5V) from the USB interface line. When opening JP1, external power can

be supplied by using connectors CN3 or J1.

JP1 Mode

closed (default) Power supplied by USB interface

open External power supply

Table 6: Power supply selector, JP1

Note: When choosing external power supply, please open jumper JP1!

3.7 External power supply

External power can be supply by connecting a 5V AC adapter to connector CN3 (not assem bled). Per

def ault, the ex ternal power is s uppli ed to th e connect or CN1 only ( pins 10, 12 a nd 16) . To power th e

com plet e bo ard v i a exte r na l po wer supp ly, t he sol d erin g br idge s DCVDD1 and D CV D D2 m us t be cl o sed .

CN3 Function

Center (1) Vcc = 5V

Ring (2,3) Gnd

Table 7: External power supply, connector CN3

Additionally a stabilizing 5V power supply can be connected directly to the connector J1 i nstead of using

a 5V AC adapter. Also in this case the soldering bridges DCVDD1 and DCVDD2 must be closed.

Note: When using an external power supply, please open jumper JP1!

J1 Function

1 Vcc = 5V

2 Gnd

Table 8: External power supply, connector J1

16

Page 17

EB-V850ES/HG2-EE

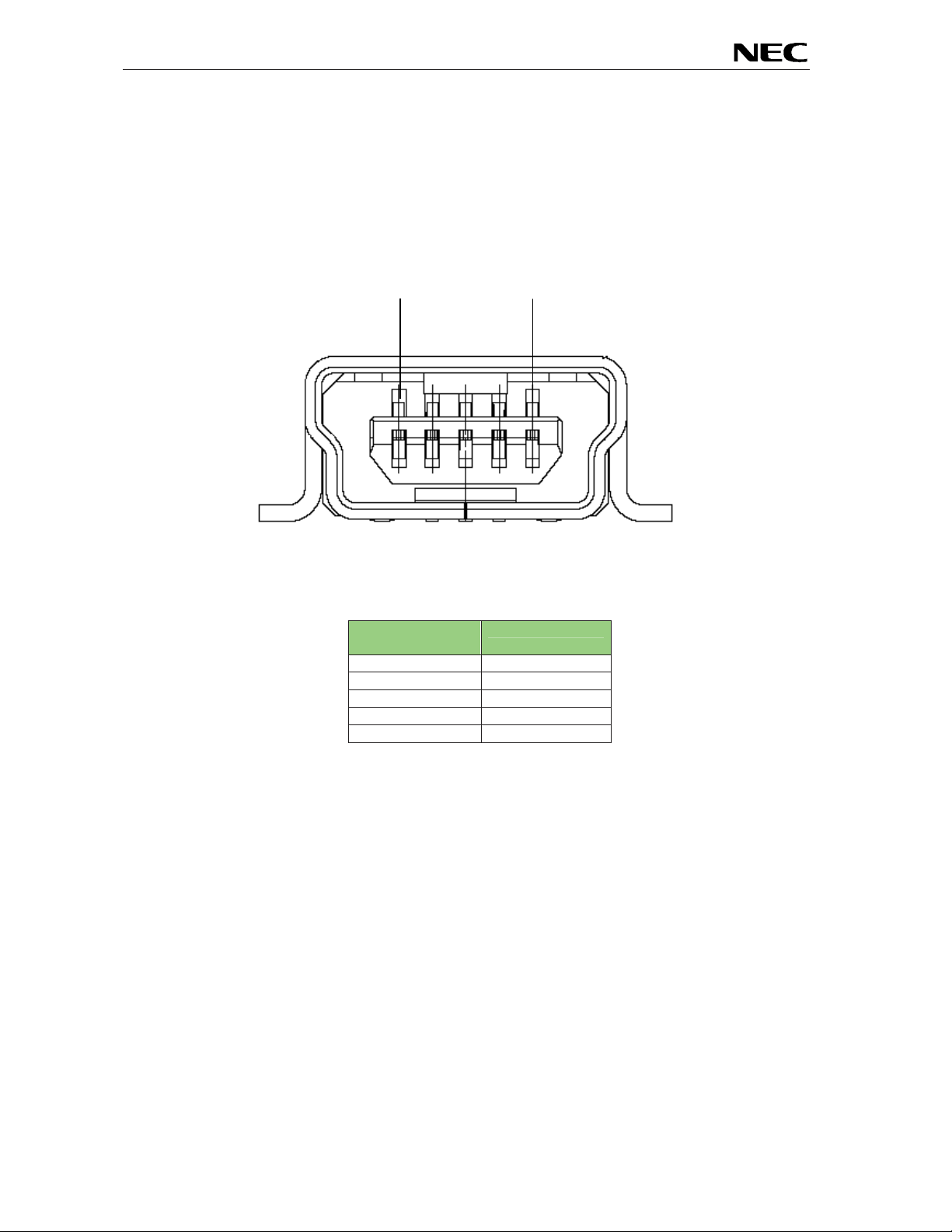

3.8 USB interface connector USB1

USB1 connector allows connecting the IAR C-SPY debugger or the F PL FLASH programming software

to the EB-V850ES/HG2-EE board in order to debug or program application software to the V850ES/HG2

device. The board power supply of 5V is also provided by this connector.

Additionally connector US B1 connects UARTA0 of the V850ES/HG2 device to the host system.

1

Figure 3: Connector USB1, USB Mini-B Type Host Connector P in Configurati on

USB Co nn ec t o r

USB1

1 VBUS

2 D3 D+

4 N.C.

5 GND

Table 9: Pin Configuration of USB Connector USB1

For connection with the host machine, use a USB cable (Mini-B type). For confirmation, NEC Electronics

used only the USB cable delivered with the EB-V850ES/HG2-EE board.

5

Signal Name

17

Page 18

EB-V850ES/HG2-EE

3.9 N-Wire connectors NWIRE1, NWIRE2

The NWIRE1 and NWIRE2 connectors (not assembled) do allow the connection of the QB-V850MINI-EE

or alternative the IE-V850E1-CD-NW On-Chip debug emulators to the EB-V850ES/HG2-EE board in

orde r to use On-Chip debug function (N-Wire) of the V850ES/HG2 device.

IE-V850E1-CD-NW Laptop/Desktop PC

alternative

USB cable

QB-V850MINI-EE

Figure 4: On-chip debugging system configurati on

N-Wire I/F

cable

EB-V850ES/HG2-EE

Please note that the QB-V850MINI-EE and IE-V850E1-CD-NW are separate products from NEC and are

not included in this starterkit package.

To enable On-Chip debugging via N-Wire please configure switch SW3 of the EB-V850ES/HG2-EE

boar d as following:

SW3 Configuration

Bit 1 OFF

Bit 2 OFF

Bit 3 OFF

Bit 4 OFF

18

Page 19

EB-V850ES/HG2-EE

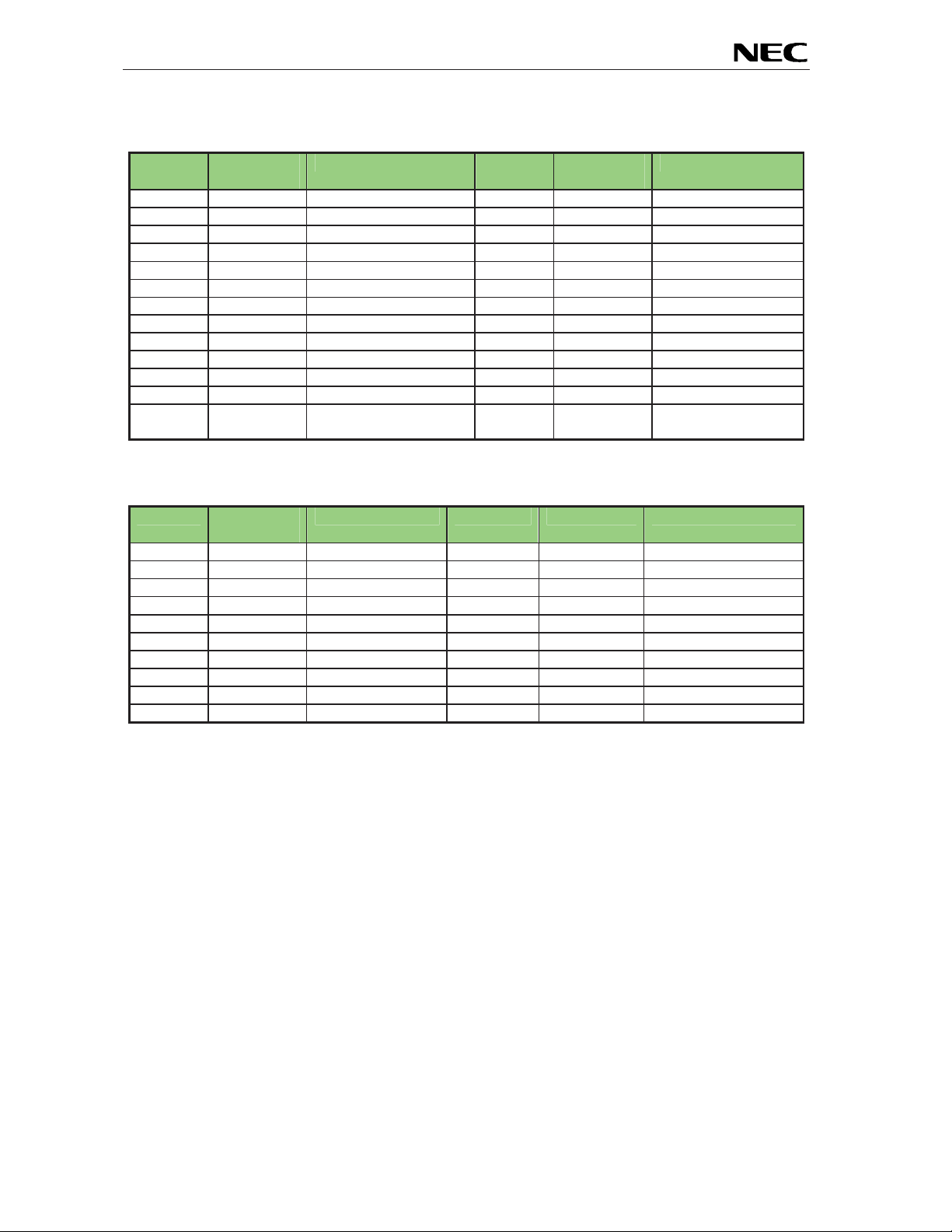

NWIRE1 Signal

Name

A1 TRCCLK not connected B1 GND_0 connected to VSS

A2 TRCDATA0 not connected B2 GND_1 connected to VSS

A3 TRCDATA1 not connected B3 GND_2 connected to VSS

A4 TRCDATA2 not connected B4 GND_3 connected to VSS

A5 TRCDATA3 not connected B5 GND_4 connected to VSS

A6 TRCEND not connected B6 GND_5 connected to VSS

A7 DDI connected to P52 B7 GND_6 connected to VSS

A8 DCK connected to P54 B8 GND_7 connected to VSS

A9 DMS connected to P55 B9 GND_8 connected to VSS

A10 DDO connected to P53 B10 GND_9 connected to VSS

A11 DRST_ connected to P05 B11 GPIO2 connected to VSS

A12 GPIO0 connected to RESET0 B12 GPIO3 connected to VSS

A13 GPIO1 connected to FLMD0

NWIRE2 Signal

Name

1 -- VSS 11 -- VSS

2 DCK Connected to P54 12 RESET0 connected to RESET

3 -- VSS 13 -- VSS

4 DMS connected to P55 14 FLMD0 connected to FLMD0

5 -- VSS 15 -- VSS

6 DDI connected to P52 16 -- not connected

7 -- VSS 17 -- VSS

8 DRST Connected to P05 18 DDO connected to P53

9 -- VSS 19 -- VSS

10 -- not connected 20 EVDD connected to VDD

description NWIRE1 Signal

Name

B13 TRGT_VDD connected to EVDD

logic

Table 10: N-Wire connector NWIRE1

description NWIRE2 Signal Name

Table 11: N-Wire connector NWIRE2

description

description

19

Page 20

EB-V850ES/HG2-EE

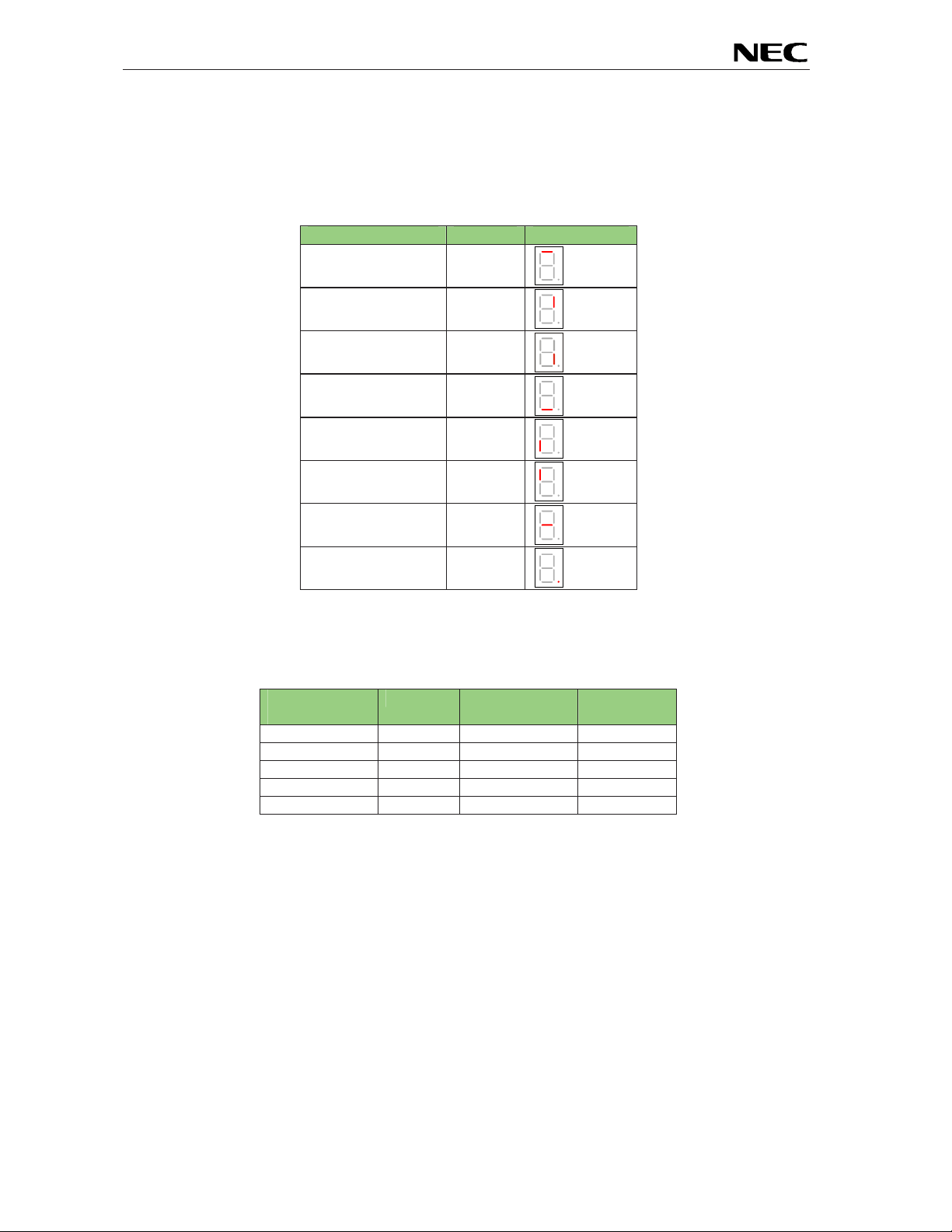

3.10 External LED U2

The 7 segment LED U2 is connected to port P90-P97 of the V850ES/HG2 device. A low signal output at

each port switches the corresponding LED on.

Port V850ES/HG2 Segment LED U2

P90 A

P91 B

P92 C

P93 D

P94 E

P95 F

P96 G

P97 DP

Table 12: External LED U2

Example: The figures of 0 to 9 can be displayed by writing the following values to the port register P9.

P9, register

value

0xC0

0xF9

0xA4

0xB0

0x99

LED U2 P9, register

value

0

1

2

3

4

0x92

0x83

0xF8

0x80

0x98

LED U2

5

6

7

8

9

20

Page 21

EB-V850ES/HG2-EE

CN2

CN1

3.11 External connectors CN1 and CN2

CN1 and CN2 are connectors for external user hardware. Please read the user’s manual of the

V850ES/HG2 devic e carefully to get information about the electrical specification of the available I/O

ports.

Figure 5: External connectors CN1 and CN2

21

Page 22

EB-V850ES/HG2-EE

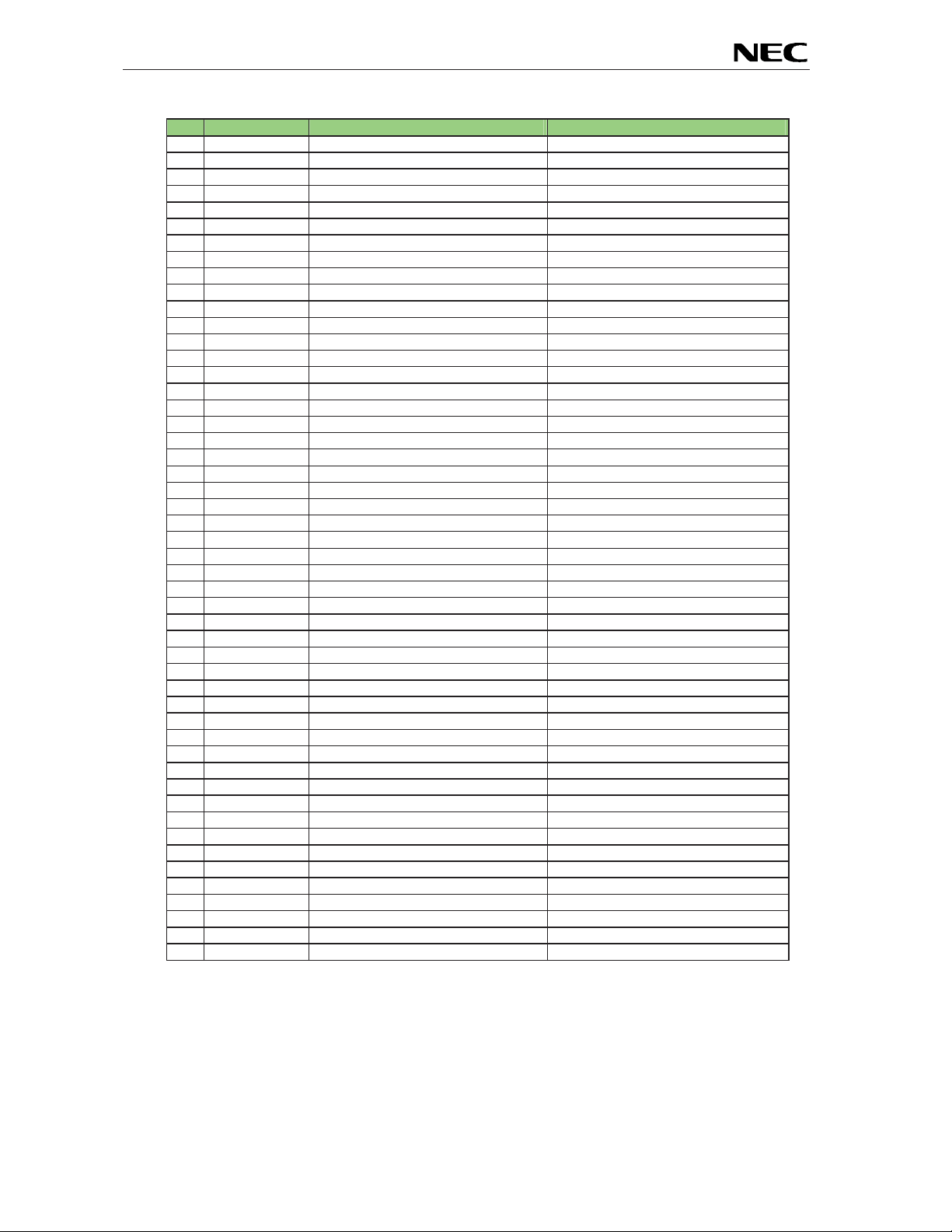

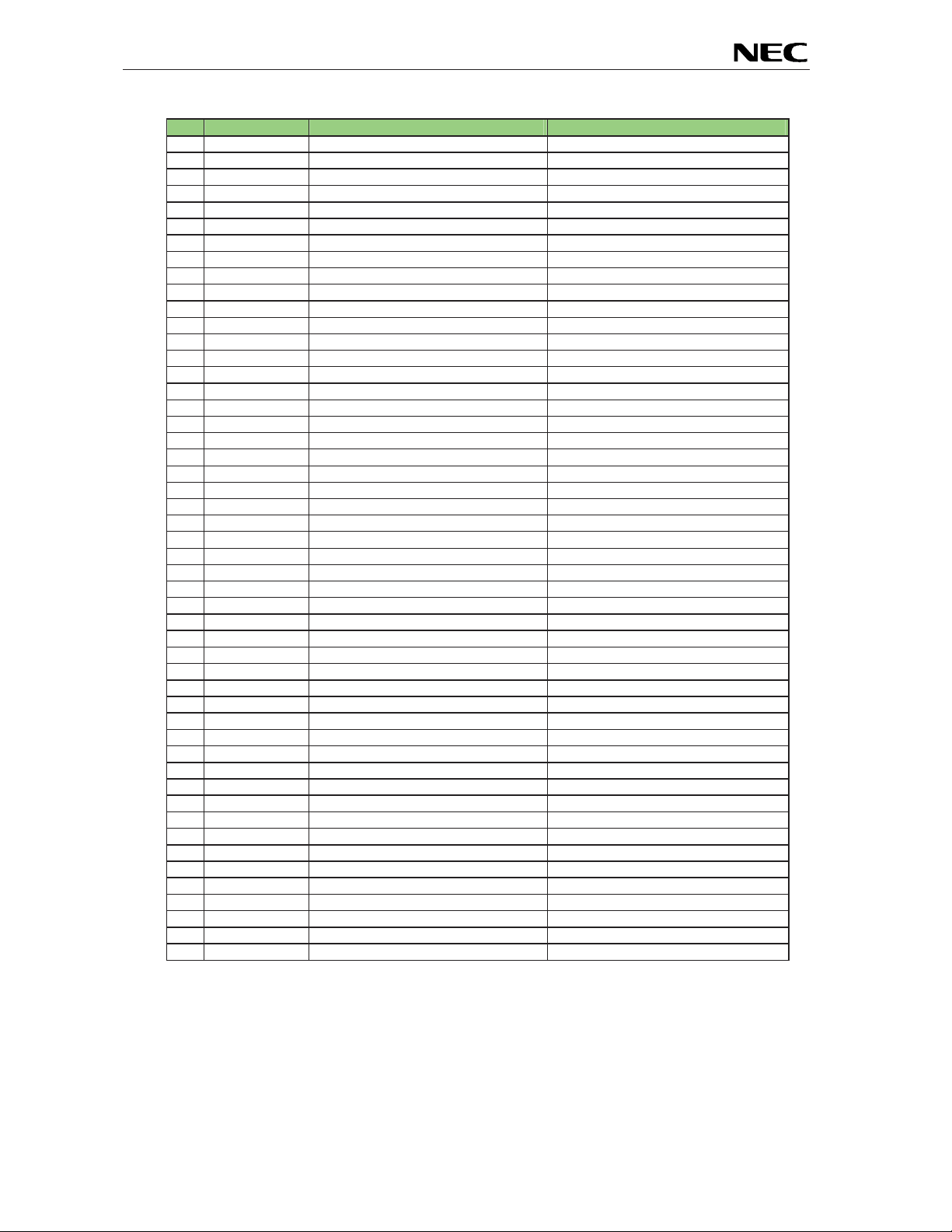

CN1 Signal name V850ES/HG2 Pin name Comment

AVREF0 AVREF0 Connected to VDD by soldering bridge

1

VSS AVSS, VSS, EVSS, BVSS

2

P10 P10/INTP9

3

P11 P11/INTP10

4

EVDD EVDD Connected to VDD by soldering bridge

5

P78 P78/ANI8 Connected to SW3-5 by soldering bridge

6

P79 P79/ANI9 Connected to SW3-6 by soldering bridge

7

FLMD0 FLMD0 Connected to FLMD0 control logic

8

VDD VDD

9

+12V Connected to CN3, J1

10

VSS AVSS, VSS, EVSS, BVSS

11

+12V Connecte d to CN3, J1

12

VDD VDD

13

RESET0 RESET Connected to reset cir c uit

14

VDD VDD

15

+12V Connecte d to CN3, J1

16

P02 P02 / NMI

17

P03 P03 / INTP0 / ADTRG C onnected to SW2

18

P04 P04 / INTP1 Connected to SW1

19

P05 P05 / INTP2 / DRST

20

P06 P06 / INTP3

21

P40 P40 / SIB0

22

P41 P41 / SOB0

23

P42 P42 / SCKB0

24

P30 P30 / TXDA0 Connected to RXD by soldering bridge

25

P31 P31 / RXDA0 / INTP7 Connected to TXD by soldering bridge

26

P32 P32 / ASCKA0 / TOP01 / TIP00 / TOP00

27

P33 P33 / TIP01 / TOP01

28

P34 P34 / TIP10 / TOP10

29

P35 P35 / TIP11 / TOP11

30

P36 P36

31

P37 P37

32

VSS AVSS, VSS, EVSS, BVSS

33

EVDD EVDD Connected to VDD by soldering bridge

34

P38 P38 / TXDA2

35

P39 P39 / RXDA2 / INTP8

36

P50 P50 / KR0 / TIQ01 / TOQ01

37

P51 P51 / KR1 / TIQ02 / TOQ02

38

P52 P52 / KR2 / TIQ03 / TOQ03 / DDI

39

P53 P53 / KR3 / TIQ00 / TOQ00 / DDO

40

P54 P54 / KR4 / DCK

41

P55 P55 / KR5 / DMS

42

P90 P90 / KR6 / TXDA1 Connected to 7seg LED by soldering bridge

43

P91 P91 / KR7 / RXDA1 Connected to 7seg LED by s oldering bridge

44

P92 P92 / TIQ11 / TOQ11 Connected to 7seg LED by solde ring bridge

45

P93 P93 / TIQ12 / TOQ12 Connected to 7seg LED by solde ring bridge

46

P94 P94 / TIQ13 / TOQ13 Connected to 7seg LED by solde ring bridge

47

P95 P95 / TIQ10 / TOQ10 Connected to 7seg LED by solde ring bridge

48

P96 P96 / TIP21 / TOP20 Connected to 7seg LED by solde ring bridge

49

P97 P97 / SIB1 / TIP20 / TOP20 Connected to 7seg LED by solde ring bridge

50

Table 13: Connector CN1

Connected to 4.7 kΩ pull-up resistor

Connected to 4.7 kΩ pull-up resistor

Connected to 4.7 kΩ pull-up resistor

Connected to 4.7 kΩ pull-up resistor

22

Page 23

EB-V850ES/HG2-EE

CN2 Signal name V850ES/HG2 Pin name Comment

P98 P98 / SOB1

1

P99 P99 / SCKB1

2

P910 P910

3

P911 P911

4

P912 P912

5

P913 P913 / INTP4 / PCL

6

P914 P914 / INTP5

7

P915 P915 / INTP6

8

P710 P710 / ANI10 Connected to SW3-7 by soldering bridge

9

P711 P711 / ANI11 Connected to SW3-8 by soldering bridge

10

PCM0 PCM0

11

PCM1 PCM1

12

PCM2 PCM2

13

PCM3 PCM3

14

PCT0 PCT0

15

PCT1 PCT1

16

PCT4 PCT4

17

PCT6 PCT6

18

VSS AVSS, VSS, EVSS, BVSS

19

BVDD BVDD Connected to VDD by soldering bridge

20

PDL0 PDL0

21

PDL1 PDL1

22

PDL2 PDL2

23

PDL3 PDL3

24

PDL4 PDL4

25

PDL5 PDL5 / FLMD1

26

PDL6 PDL6

27

PDL7 PDL7

28

PDL8 PDL8

29

PDL9 PDL9

30

PDL10 PDL10

31

PDL11 PDL11

32

PDL12 PDL12

33

PDL13 PDL13

34

P715 P715 / ANI15

35

P714 P714 / ANI14

36

P713 P713 / ANI13

37

P712 P712 / ANI12

38

PCS0 PCS0

39

PCS1 PCS1

40

P00 P00 / TIP31 / TOP31

41

P01 P01 / TIP30 / TOP30

42

P77 P77 / ANI7

43

P76 P76 / ANI6

44

P75 P75 / ANI5

45

P74 P74 / ANI4

46

P73 P73 / ANI3

47

P72 P72 / ANI2

48

P71 P71 / ANI1

49

P70 P70 / ANI0

50

Table 14: Connector CN2

Connected to 10 kΩ pull-down resistor

23

Page 24

EB-V850ES/HG2-EE

3.12 Soldering Bridges

Some terminals of the V850ES/HG2 device can be customized by opening respectively closing the

corresponding soldering bridge. By opening the soldering bridge the connection to the onboard circuit is

cut. Accordingly, the corresponding signals can be used for external user hardware using the connectors

CN1 and CN2. F o r m o r e de t a i ls plea se r efer t o t h e bo ard schemat i c s, pa ge s 80- 8 1 .

FLMD0

Figure 6: Placement of soldering bridges

Sold e ri n g br idge

name

P90 – P97 Closed

P78 ~ P711 Closed Co nne cted to switch SW3, Bits 5-8

RXD, TXD Closed Connection of ports RXDA0 / P31 and TXDA0 / P30 to the

FLMD0 Open By closing the so lde ring bridge the FLMD0 pin is connected to

AVREF0 Closed Connected to VDD

BVDD Closed Connected to VDD

EVDD Closed Connected to VDD

DCVDD1, DCVDD2 Open When using external power supply, via connector CN3 or J1, the

Factory setting Comment

Connected to 7seg LED via 1 KΩ resistor

FT232 UART/USB circuit.

port pin P37. This allows by using FLASH self-programming to

enable or disable FLASH write operations via port pin P37.

soldering bridges must be closed.

Table 15: Soldering brigdes

24

Page 25

EB-V850ES/HG2-EE

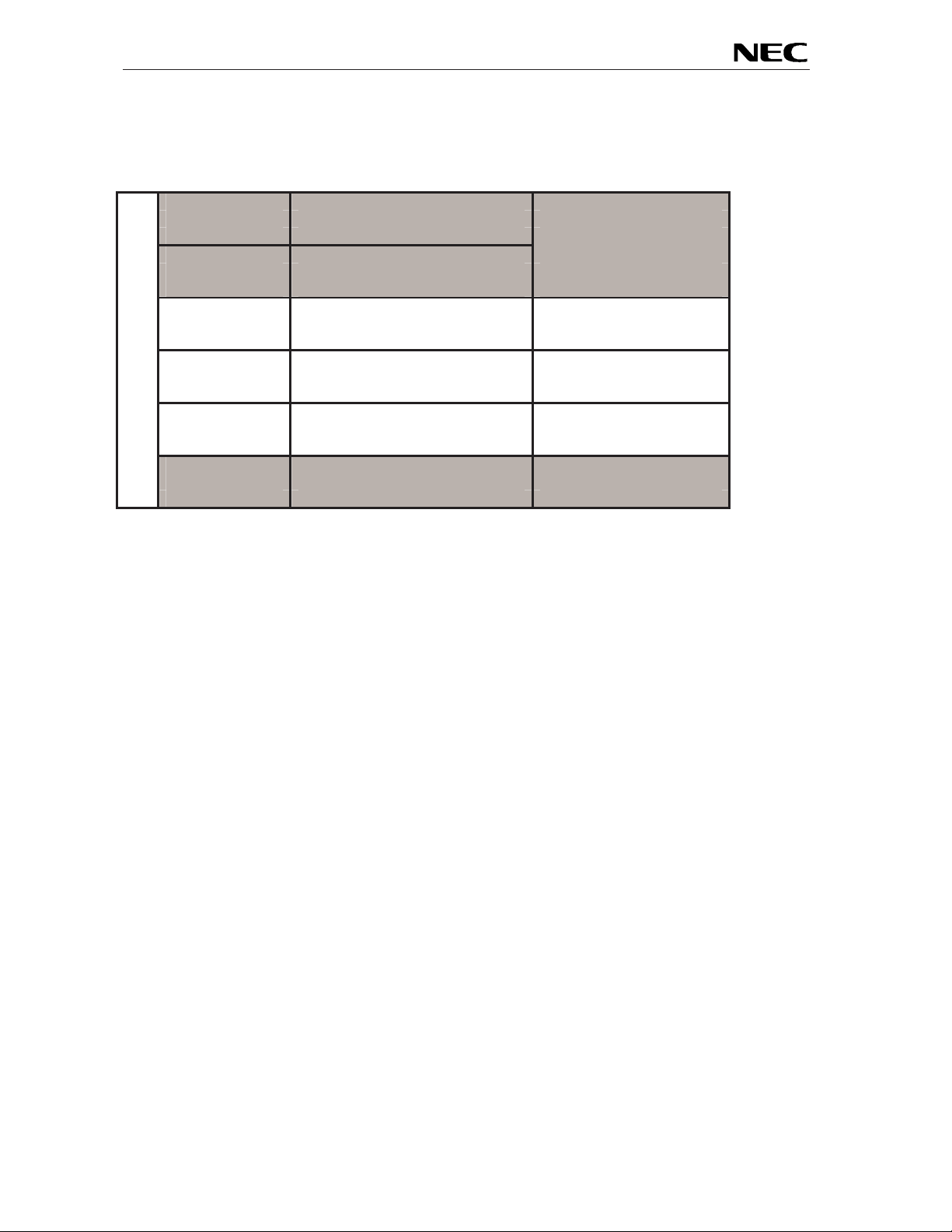

3.13 V850ES/HG2 memory map

The V850ES/HG2 memory layout is shown in the table below.

0x3FFFFFF

SFR Area

0x3FFF000 Free for user application

0x3FFEFFF software

12 KB Internal RAM

0x3FFC000

0x3FFBFFF

Acce ss pro h ibi t e d ar ea

0x3FF0000

0x3FEFFFF Programmable peripheral

I/O area or use prohibited area

Address area

0x0100000 (program fetch prohibited area)

0x00FFFFF

Acce ss pro h ibi t e d ar ea

0x0040000

0x003FFFF

256 KB Flash memory Free for user application

0x0000000 Software

Table 16: V850ES/HG2 memory map

25

Page 26

EB-V850ES/HG2-EE

4. EB-V850ES/HG2-EE installation and operation

4.1 Getting started

The IAR C-SPY debugger allows to download and debug application software on the EB-V850ES/HG2EE starterkit hardware. Additionally the FPL FLASH programming software can be used for simple

FLASH programming of the V850ES/HG2 internal FLASH memory. As communication interface between

the host computer and the EB-V850ES/HG2-EE board a USB interface line is needed. Before you can

download, debug or execute an application programs, hardware and software must be installed properly.

4.1.1 CD-ROM contents

The CD-ROM shows following directory structure:

EB_V850ESHG2_EE (F:)

Acrobat

Doc

FPL

Drivers

FPL

PRM

IAR Embedded Workbench V850

SamplePrograms

Table 17: EB-V850ES/HG2-EE CD-ROM directory structu re

CD-ROM ROO T

- Acrobat Reader for 32Bit Windows OS

- Documentation

- FPL FLASH programming software

… USB driv er

… FPL setup directory

… PRM parameter file

- IAR Embedded Workbench for V850

- Sample program for EB-V850ES/HG2-EE

26

Page 27

EB-V850ES/HG2-EE

5. Hardware installation

After unpacking EB-V850ES/HG2-EE, connect the board to your host computer by using the provided USB

interface cable. When EB-V850ES/HG2-EE is connected, the USB driver needs to be installed on the host

machine. Please refer to the following CHAPTER 6 SOFTWARE INSTALL AT IO N.

6. Software installation

The EB-V850ES/HG2-EE package comes with several software demo packages:

• IAR Systems Embedded Workbench for V850, including C compiler, assembler, linker, librarian

and IAR C-SPY debugger / simulator

• FPL FLASH programming software

• Sample programs

The IAR Systems Embedded Workbench and the FPL FLASH programming GUI must be installed on your

PC. For detailed installation hints, refer to the following chapters and to the corresponding documentation of

the IAR Embedded Workbench.

6.1 IAR Systems Embedded Workbench for V850 installation

To install the IAR Systems Embedded Workbench for V850 including the C-SPY debugger / simulator,

select the SETUP program in the dir ectory \IAR Embedde d Workbench V850\ewv850\ of the CDROM.

The setup dialogues will guide you through the installation process.

6.2 FPL FLASH programming GUI installation

To install the FPL FLASH programming GUI select the SETUP program in the directory \FPL\ of the

CDROM. The setup dialogues will guide you through the installation process.

6.3 Sample program installation

To install the demonstration programs for the EB-V850ES/HG2-EE board select the SETUP pr o g ram i n th e

directory \SampleProgram\ of the CDROM. The setup d ialogues will guide you through the installation

process.

27

Page 28

EB-V850ES/HG2-EE

6.4 USB Driver Installation

When the EB-V850ES/HG2-EE board and FPL is used, the driver needs to be i nstalled on the

host machine. Install the driver according to the following procedure:

Installation on Windows 98SE/Me ......... Page 28

Installation on Windows 2000 ............... Page 30

Installation on Windows XP ............... .... Page 36

6.4.1 Installation on Windows 98SE/Me

1. When the EB-V850ES/HG2-EE board is connected with the host machine, the board is

recognized by Plug and Play, and t he wizard for adding new hardware is started. Cli ck

Next>.

Figure 7: Add New Hardware Wizard (Windows 98SE)

Click.

2. The window below is displayed. So, check that "Search for a suitable driver ..." is selected,

then click Next>.

Figure 8: Search Method (Windows 98 SE)

Check that "Search for a

suitable driver ..." is selected.

Click.

28

Page 29

EB-V850ES/HG2-EE

3. Check the "Specify a location" check box only and enter "C:\Program

Files\NECTools32\FPL\DRIVER" in the address bar, then click Next>.

Figure 9: Search Location Specification (Windows 98SE)

<1> Check "Specify

a l

ocation" only.

備考

<2> Enter "C:\Program Files\NECTools32\FP L\DRIVER".

3.1

ソフトウエアのインスト ール先の フォルダを変更した場合は,

<3> Click.

Remark If the installation destination f older is changed at the time of GUI software installation,

enter "new-folder\DRIVER".

4. The window below is displayed. Click Next>.

Figure 10: Checking Driver to Be Installed (Windows 98SE)

Click.

29

Page 30

EB-V850ES/HG2-EE

5. When the window below is displayed, the installation of the USB driver is completed. Click

Finish. The installation of the USB Serial Port driver is then automatically performed.

Figure 11: Installation Completion (Windows 98SE)

Click.

6.4.2 Installation on Windows 2000

1. When the EB-V850ES/HG2-EE board is connected with the host machine, the board is

recognized by Plug and Play, and t he wizard for finding new hardware is started. Click

Next>.

Figure 12: Found New Hardware Wizard 1 (Windows 2000)

Click.

30

Page 31

EB-V850ES/HG2-EE

that "Search for a

..." is

a

2. The window below is displayed. So, check that "Search for a suitable driver ..." is selected,

then click Next>.

Figure 13: Search Method 1 (Windows 2000)

Check

suitable driver

selected.

Click.

3. Check the "Specify a location" check box only, then click Next>.

Check that "Specify

location" only is checked.

ed.hed.

Figure 14: Driver File Location 1 (Windows 2000)

Click.

31

Page 32

EB-V850ES/HG2-EE

4. Enter "C:\Program Files\NECTools32\FPL\DRIVER" in the address bar, then click OK.

Figure 15: Address Specification 1 (Windows 2000)

Click.

Enter "C:\Program Files\NECTools32\FPL\DRIVER".

Remark If the installation destination folder is changed at the time of GUI software installation,

enter "new-folder\FPL\DRIVER".

5. Click Next>.

Figure 16: Driver File Search 1 (Windows 2000)

Click.

32

Page 33

EB-V850ES/HG2-EE

Click.

6. Click Finish to complete the installation of the USB driver.

Figure 17: USB Driver Installation Completion 1 (Windows 2000)

7. Proceed to the installation of the USB Serial Port driver. Click Next>.

Figure 18: Found New Hardware Wizard 2 (Windows 2000)

Click.

33

Page 34

EB-V850ES/HG2-EE

Check

that "Search for a

..." is

a

suitable driver

selected.

8. The window below is displayed. So, check that "Search for a suitable driver ..." is selected,

then click Next>.

Figure 19: Search Method 2 (Windows 2000)

Click.

9. Check the "Specify a location" check box only, then click Next>.

Check that "Specify

location" only is checked.

Figure 20: Driver File Location 2 (Windows 2000)

Click.

34

Page 35

EB-V850ES/HG2-EE

10. Enter "C:\Program Files\NECTools32\FPL\DRIVER" in the address bar, then click OK.

Figure 21: Address Specification 2 (Windows 2000)

Click.

Enter "C: \Program Files\NECTools32\FPL\DRIVER".

Remark If the installation destination folder is changed at the time of GUI software installation,

enter "new-folder\DRIVER".

11. Click Next>.

Figure 22: Driver File Search 2 (Windows 2000)

Click.

35

Page 36

EB-V850ES/HG2-EE

that "Install from a list

12. Click Finish to complete the installation of the USB driver.

Figure 23: USB Driver Installation Completion 2 (Windows 2000)

Click.

6.4.3 Installation on Windows XP

1. When the EB-V850ES/HG2-EE board is connected with the host machine, the board is

recognized by Plug and Play, and the wizard for f inding new hardware is started. Check

that "Install from a list or specific ..." is selected, then click Next>.

Figure 24: Found New Hardware Wizard 1 (Windows XP)

Check

or specific ..." is selected.

Click.

36

Page 37

EB-V850ES/HG2-EE

best driver in these locations."

2. Check that "Search for the best driver in these locations." is selected. Check t he "Include

this location in the search:" check box and enter "C:\Program

Files\NECTools32\FPL\DRIVER" in the address bar, then click Next>.

Figure 25: Search Location Specification 3 (Windows XP)

<1> Check that "Search for the

is selected.

<2> Check "Include this

location in the search:"

only.

<4> Click. <3> Enter "C:\Program Files\NECTools32\FPL\DRIVER".

3. As shown below, "has not passed Windows Logo testing to v erify its compatibility with

Windows XP." is displayed. Click Continue Anyway.

Figure 26: Window s XP Logo Testi ng 3 (Wind ows XP)

Click.

37

Page 38

EB-V850ES/HG2-EE

that "Install from a list

4. When the window below is displayed, the installation of the USB driver is completed. Click

Finish .

Figure 27: USB Driver Installation Completion 1 (Windows XP)

Click.

5. Proceed to the installation of the USB Serial Port driver. Click Next>.

Figure 28: Found New Hardware Wizard 2 (Windows XP)

Check

or specific ..." is selected.

Click.

38

Page 39

EB-V850ES/HG2-EE

that "Search for the best

<2> Check

"Include this location

6. Check that "Search for the best driver in these locations." is select ed. Check the "Include

this location in the search:" check box and enter "C:\Program

Files\NECTools32\FPL\DRIVER", then click Next>.

Figure 29: Search Location Specification 2 (Windows XP)

<1> Check

driver in these locations." is

selected.

in the search:" only.

<3> Enter "C:\Program Files\NECTools32\FPL\DRIVER".

<4> Click.

7. As shown below, "has not passed Windows Logo testing to v erify its compatibility with

Windows XP." is displayed. Click Continue Anyway.

Figure 30: Window s XP Logo Testi ng 2 (Wind ows XP)

Click.

39

Page 40

EB-V850ES/HG2-EE

8. When the window below is displayed, the installation of the USB driver is completed. Click

Finish .

Figure 31: USB Serial Port2 Driver Installation Completion (Windows XP)

Click.

40

Page 41

EB-V850ES/HG2-EE

Check

that "USB Serial Port

6.5 Conf i rm ati on of USB Dri ver In sta ll at io n

After installing the two types of drivers, check that the drivers have been instal led normally,

according to the pr ocedure below. W hen using the EB-V850ES/HG2-EE board i n co m bi nat i on

with FPL GUI, the information to be checked here is needed.

By clicking the "Device Manager" tab, check that the drivers are installed normally.

Figure 32: Device Manager

(COM?)" is present.

Check that "USB High Speed

Serial Converter" is present.

For Windows 98SE/Me

Caution Do not select Update and Erase when communicating with the target

device.

For Windows 2000/XP

Caution Do not perform "Hardware Modification Scan" when communicating with the

target device.

Remark In the GUI port l ist box, the same communication port as COM? of USB Serial Port

(COM?) needs to be selected.

If the drivers above are not displayed, or the mark "×" or "!" is prefix ed, refer to

CHAPTER 9 TROU BLESHOOTING.

41

Page 42

EB-V850ES/HG2-EE

6.6 Driver Uninstallation

The driv er uninstallati on program is installed on the host machine when the F PL software is

instal l e d. U se t h e pr o c ed ur e be low f or driver uninst alla t ion.

1. When using Windows XP, log on as the computer administrator. When using Windows

2000, l o g on as th e A dmi nistr a t or .

2. Double-click in the order from "My Computer" to "(C:)" to "Program Fi les" to "NECTools32"

to "FPL" t o " DR IVER" . "Ftd i u nin. exe" is displa y ed . Do ub l e - c l ick "Ftdi u n i n . exe" .

Figure 33: Driver Uninstallation

Double-click.

3. Click Continue.

Figure 34: Driver Uninstaller

Click.

42

Page 43

EB-V850ES/HG2-EE

Click.

4. Click Finish to complete driver uninstallation.

Figure 35: Completion of Driver Uninstallation

Caution If the GUI software is uninstalled earlier, "Ftdiunin.exe" is also deleted. At this time,

delet e "USB Serial Port (COM?)" and "USB High Speed Serial Converter" from Device

Manager manually.

43

Page 44

EB-V850ES/HG2-EE

Programm er

window

7. FPL FLASH programming software

7.1 Introduction

The parameter file of t he V850ES/HG2 device is installed automatically during installation of FPL

GUI, folder <FPL install-path>\PRM. Nevertheless, newest version of parameter file for the

µPD70F3707 device can by download from the NEC Electronics Web site.

Download the parameter file for the PG-FP4 from the following NEC Electronics Web site:

Copy the parameter file downloaded from the NEC Electronics Web site into sub-directory

<FPL.EXE-install-path>\PRM created during GUI software setup (refer to CHAPTER 6

SOFTWARE INSTALLATION).

7.2 Starting up the GUI Software

• GUI software startup

Select FPL.EXE from the start menu to start the FPL GUI software.

When the GUI software is started normally, the following screen appears.

Menu bar

http://www.eu.necel.com/updates

Figure 36: GUI Software Main Window

Toolbar

Status bar

parameter

Action log window

44

Page 45

EB-V850ES/HG2-EE

Thi s wi nd ow co nsi s ts of t h e fol l o win g i t ems:

Name Display Information

Menu bar

(displayed at the top)

Toolbar

(displayed under the menu bar)

Action log window

(displayed under the toolbar)

Programmer parameter window

(displayed to the right of the action log

window)

Status bar Displays status.

7.3 Toolbar

The toolbar contains buttons for starting the important procedures of the FPL.

Figure 37: Toolbar Buttons

Displays menu items executable by the

FPL.

Displays frequently used commands as

icons.

Displays an FPL action log.

Displays programming parameter

settings.

evice] → [Setup] button

[D

ile] → [Load] button

[F

evice] → [Bla nk Ch eck ] but to n

[D

evice] → [Erase] button

[D

evice] → [Program] button

[D

evice] → [Verify] button

[D

evice] → [Autoprocedure(EPV)] button

[D

45

Page 46

EB-V850ES/HG2-EE

7.4 Menu Bar

Depending on the actual device status and dev i ce type, some menu items may be enabled or

disabled.

7.4.1 [File] menu

Clicking the [F

This menu mainly contains commands related to file operation.

ile] menu displays the pull-down menu as shown below.

Figure 38: [File] Menu

(1) [L

oad] command

The [L

oad] comm a nd al lows you t o sel ec t a pr o g r am f i le.

The selected program file is programmed into the flash memory of the dev ice by

executing the [P

rogram] command or [Autoprocedure(EPV)] command.

Figure 39: HEX File Sel e ct ion Window

T he f il e sel ect ion wind ow fo r pr ogram l oadi ng di spla ys t he m ost rece ntl y u sed di re ctor y t o

which a user program has been loaded. After a user program is loaded, a checksum

calculation is made and the result is displayed in the programmer parameter window.

[ O

pen button]

Selects a user program as a program to be written to the target device.

[ Cancel button]

Closes the window without selecting a program.

46

Page 47

EB-V850ES/HG2-EE

(2) [Q

The [Q

User settings are sav ed in the F PL.INI

uit] command

uit] menu is the command for terminating the FPL GUI software. Clicking × on the

right side of the task bar also terminates the FPL GUI software.

Note

file, so that the GUI software starts up next time

with the same settings.

Note FPL.INI is created in the Windows folder when Windows 98SE, Windows Me, or

Windows XP is used.

When Windows 2000 is used, FPL.INI is created in the Winnt folder.

7.4.2 [D

evice] menu

Clicking the [D

evice] menu displays the pull-down menu as shown below.

This menu mainly contains commands for programming operations such as deletion,

programming, and verification on the target device.

(1) [B

lank Check] command

The [Blank Check] comm and allows you to make a blank check on the target device

connected to the F PL. If the flash memory of t he target device is erased, a blank

check is terminated normally. If the flash memory is not completely erased, the

indication "not blank" is provided. Before starting programming, erase the flash

memory of the target device.

(2) [E

rase] command

The [E

rase] command erases the f lash mem ory of the target device c onnected to the

FPL. W hi l e the fl ash me mo ry i s bein g era sed, th e pr ogre ss st at us i s di spl ay ed i n the

action log window to indicate programmer operation.

The execution on the [B

executed follows the setti ng of 'Command options' of the Advance tab displayed by

selecting [D

evice] → [Setup].

Upon completion of [E

of executing the command on the target device.

Figure 40: [Device] Menu

lank Check] command before the [Erase] command is

rase] command execution, the GUI software displays the result

47

Page 48

EB-V850ES/HG2-EE

(3) [Program] command

The [P

rogram] command sends a specified user program to the target device and

writes the program to the fl ash memory.

The execution of Verify operation for detecting an error in user program

communication from the FPL to the target device after the execution of t he [P

command follows the setting of the 'Comm and options' on the Advance tab displayed

by selecting [D

During programming, the progress status is displayed in the action log window to

indicate programmer operation. This progress status display window displays the

progress status on target device programming by percentage.

Upon completion of [P

result of executing the command on the target device.

(4) [V

(5) [S

This command is not supported.

(6) [Checksum

The [Checksum

This value differs from the value displayed in the parameter window of the main window.

(7) [A

(8) [Sig

The [Sig

erify] command

The [V

erify] command sends a speci f ied user program to the target device connected

with the FPL, and perf orms verifi cation agai nst the data written to the flash memory

of the target device.

During verification, the progress status is displayed in the action log window to

indicate programmer operation. This progress status display window displays the

progress status of target device verification by percentage.

Upon completion of [V

of executing the command on the target device.

ecurity] command

] command

the FPL.

utoprocedure(EPV)] command

The [A

command and [V

When a user program is to be resent to the target device for comparison with the data

written to the flash memory of the target device because of a user program

communication error, execute the [P

[S

execution of the [V

During EPV execution, the progress status is displ ayed in the action log window to

indicate programmer operation. For a selected command, its execution operation,

and messages, refer to CHAPTER 8 HOW TO USE FPL.

Upon completion of [A

displays the result of executing the command on the target device.

nature read] command

memor y i n for m a t ion, an d so fort h) of th e t a r ge t .

utoprocedure(EPV)] command executes the [Erase] command, [Program]

etup] and specifying 'Command options' on the Advance tab, then set the automatic

nature read] command reads the signature information (device name, flash

evice] → [Setup].

rogram] command execution, the GUI software displays the

erify] command execution, the GUI software displays the result

] command reads the checksum value of the target devi ce connected with

erify] command in succession.

rogram] command by selecting [Device] →

erify] command.

utoprocedure(EPV)] command execution, the GUI software

rogram]

48

Page 49

EB-V850ES/HG2-EE

(9) [Setup] command

The [S

according to the user environment and to set command options. Each time the GUI

software is started, the most recently used parameter file (.PRM) is read and the

settings are di splayed. The [S

other than those items consisting of shadowed characters according to the user

environment.

(a) Standard setup

This menu is used to set the environment for rewriting the flash memory of the target

device.

The mode of communication with the target, the operating clock, and so forth differ

depending on the device used. For details, refer t o the manual of the device used,

when making settings.

The window shown below is opened.

etup] menu allows you to make settings related to flash memory rewriting

etup] menu allows you to modify the settings of items

Figure 41: Device Setup Window - Standard

This window shows all basic options that can be set in accordance with the user

environment and target device.

[ OK button]

Clicking the OK button saves the settings on the Standard and Advance menus and

closes the window.

[ Cancel button]

Clicking the Cancel button closes the window without saving the settings on the

Standard and Advance menus.

49

Page 50

EB-V850ES/HG2-EE

<1> Parameter file

This file holds parameters and timing data required to rewrite the flash memory of

the target device. Do not modify the data in the param eter fil e because the data is

related to the guarantee of rewrite data.

The parameter file is protected by the checksum function. If the checksum result

indicates an error, the FPL does not accept the parameter file.

Figure 42: Setup Window - Pa ram e ter File Sel ec tion

Figure 43: Parameter File Selection Window

[ PRM File Read button]

A window for specifying a parameter file is displayed. Specify a desired file then

pen.

click O

50

Page 51

EB-V850ES/HG2-EE

<2> Communication interface to device

"Com m uni cat ion inte rf ace t o dev i ce" i s use d to se lec t a ch anne l f or c om mu nic ati on

between the EB-V850ES/HG2-EE board and host machine.

Figure 44: Setup Window - Communication interface to device

[Port list box]

Select a channel for communication between the EB-V850ES/HG2-EE board and

host machine.

• COM1 to COM16

Remark Selectable ports can be checked using Device Manager. For details,

refer to CHAPTER 6.5 Confirmation of USB Driver Installation.

[Speed list box]

Select a communication rate for the selected communication channel from the

following:

• 9600 bps

• 19200 bps

• 38400 bps

Remark For selectable communication rates, refer to the user's manual of the

device used.

<3> Supply oscillator

"Supply oscillator" is used to select a clock that determines programming, data

transfer, and a transfer rate.

51

Page 52

EB-V850ES/HG2-EE

<4> Operation Mode

The setting of "Operation Mode" may divide the flash memory of some target

devices into blocks or areas.

This menu is used to select an operation mode of the flash memory. Som e dev ices

do not have the block and area divi sion modes, and some devi ces have only one of

the modes. In these cases, a nonexisting mode is unchoosable.

Figure 46: Setup Window - Operation Mode

[When Chip is selected]

The entire flash memory area of the target device is subject to rewrite processing.

[When Block is selected]

Specify the Block number range subject to rewrite processing by using Start/End.

The Start/End list box es display the Block numbers where the flash memory of the

target device is configured.

[When Area is selected]

Specify the Area number range subject to rewrite processing by using Start/End.

The Start/End list boxes display the Area numbers where the flash memory of the

target device is configured.

[Show Address check box]

Specify whether numbers or addresses are displayed in the Start/End list boxes.

If this check box is checked, addresses are displayed.

If this check box is not checked, numbers are displayed.

52

Page 53

EB-V850ES/HG2-EE

(b) Advance setup

The Advance setup menu is used to specify the command options and security flag

settings.

When "Advance" is clicked, the following window is displayed:

Figure 47: Device Setup Window - Advance

<1> Command options

This dialog box is used to specify the FPL flash processing command options.

Figure 48: Setup Window - Command options

[Blank check before Erase check box]

If this check box is checked, blank check is made before the Erase command or

EPV command is executed.

If the result of a blank check indicates OK, erase processing is not executed.

[Read verify after Program check box]

If this check box is checked, write data is sent from the programmer after execution

of the Program command and EPV command, then the data is v erif ied against the

data written to the fl ash memory.

[Security flag after Program check box] Not usable

[Checksum after Program check box]

If this check box is checked, the flash memory checksum v alue of the target devi ce

is read from the target device after execution of the Program command and EPV

command.

This v alue dif fers from the val ue displayed i n the parameter window of the main

window.

<2> Security flag settings Not usable

53

Page 54

EB-V850ES/HG2-EE

7.4.3 [V

iew] menu

Clicking the [V

iew] menu displays the pull-down menu shown below.

This menu contains commands for setting whether to display the toolbar and status bar.

Figure 49: [View] Menu

(1) [Toolbar] command

Checking the [T

oolbar] command displays the toolbar. Unchecking the command hides

the toolbar.

(2) [S

Checking the [S

tatus Bar] command

tatus Bar] command displays the status bar. Unchecking the command

hides the status bar.

54

Page 55

EB-V850ES/HG2-EE

7.4.4 [H

elp] menu

Clicking the [H

elp] menu displays the following pull-down menu:

Figure 50: [Help] Menu

(1) [About FPL] command

The [A

bout FPL] command opens the program entry window as shown bel ow and indicates

the version.

Clicking OK terminates the display.

Figure 51: About FP L Wind ow

55

Page 56

EB-V850ES/HG2-EE

7.5 Programm er Parameter Wind ow

This window displays the settings of the programming parameters.

Figure 52: Programmer P ara m eter Window

[Device]

Updated after communication with the target device to display information about the target

device.

[Parameter file]

Updated af t er [S

etup] command execution to display information about a read parameter file.

[Loa d file]

Updated af t er [L

oad] command execution to select information about a selected program file.

[Connection to device]

Updated af t er [S

etup] command execution to display information about the connection with the

target device.

56

Page 57

EB-V850ES/HG2-EE

8. How to use FPL FLASH programming software

This chapter explains the basic operations of the FPL GUI for programming the EB-V850ES/HG2-EE

board. This chapter covers how to start the system, execute the EPV command, and program the target

V850ES/HG2 device.

The conditions of the series of operations described in this chapter are as follows:

Hardware configuration of EB-V850ES/HG2-EE:

Board : EB-V850ES/HG2-EE

CPU : V850ES/HG2

Target device : µPD70F3707

Clock : 5 MHz

Voltage level : 5 V

Software configuration of FPL:

Parameter fil e: 70F3707.PRM

Clock setting : 5 MHz Multiplied by 4

Port : COM3 (38400 bps)

Operation mode: Chip

Write HEX : CountDownTimer.hex

Option setting : Blank check before Erase

(1) Installing the FPL GUI software

Install the FPL GUI software on the host machine you are using, by referring to CHAPTER 6

SOFTWARE INSTALLATION (if the software has not been installed yet).

(2) Installing the driver

Install the USB driver on the host machine you are using, by referring to CHAPTER 6

SOFTWARE INSTALLATION (if the driver has not been installed yet).

(3) Installing the parameter file

The parameter file f or the V850ES/HG2 device is installed automatically during installation of FPL

GUI, folder <FPL install-path>\PRM. Nevertheless, newest version of parameter file for the

µPD70F3707 device can by download from the NEC Electronics Web site.

Download the parameter file for the PG-FP4 from the following NEC Electronics Web site:

Copy the parameter file downloaded from the NEC Electronics Web site into sub-directory

<FPL.EXE-install-path>\PRM created during GUI software setup (refer to CHAPTER 6

SOFTWARE INSTALLATION)..

http://www.eu.necel.com/updates

57

Page 58

EB-V850ES/HG2-EE

(4) Connecting and starting