Page 1

D2246

8-INCH

WINCHESTER

DISK

DRIVE

MAINTENANCE

GUIDE

NEe

NEe

Information

Systems,

Inc.

819-000080-5001

Rev.

00

12-83

Page 2

LIABILITY

DISCLAIMER

NEC

Information Systems, Inc. (NECIS) products are warranted in accordance with the

terms

of

the applicable NEC Information Systems, Inc.

product

specification. Product

performance

is

affected by system configuration, software, the application, customer

data,

and

operator control

of

the system among other factors. While NECIS products are

considered to be compatible with most systems, the

product

functional implementation

by customers

of

the product may vary.

Therefore, the suitability

of a product

for a specific application must be determined by

the customer and

is

not

warranted by NECIS.

This manual

is

as complete

and

factual as possible

at

the time

of

printing; however, the

information in this manual may have been updated since

that

time. NEC Information

Systems, Inc. reserves the right

to

change the functions, features,

or

specifications

of

its

products

at

any time, without notice.

NEC

Information Systems, Inc. has prepared this document for use by NECIS

employees

and

customers. The information contained herein

is

the property

of

NECIS

and

shall not be reproduced without prior written approval from

NEelS.

First Printing - December

1983

Copyright

1983

NEC Information Systems, Inc.

5 Militia Drive

Lexington, MA

02173

Printed in U.S.A.

Page 3

Contents

Chapter 1 System Overview

1.1

D2246 System

1.2 Disk Circuitry

1.3

Power

1.4 Features

1.5

Related

1.6 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7

Options...........................................................

Chapter 2 Installation Procedures

2.1

Unpacking/Repacking

2.2 Terminating

2.3

Jumper

2.4 Switch

Cabinet/Rack

2.5

2.6 Cable Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Lock

Requirements.

1.4.1 Enhanced Seek Time

1.4.2 Rapid

Compact

1.4.3

1.4.4 Simplified

1.4.5 Design Reliability. . . . . . . . . . . . . . . . . . . . .

1.4.6

Standard

1.4.7

Safety.......................................................

1.4.8 System Configuration Flexibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Document.

Requirements.

Settings.

2.4.1 Installation Switch Assembly

Control

2.4.2

2.4.3 Sector Select Switch

2.6.1 Interface Cables

2.6.2 System

Power Cable

2.6.3

Control

Design.

.....................................................

..........................................................

Data

Mounting

Interfaces

Resistors.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Switch

Installation

Ground

Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..........................................

Transfer

Maintenance.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.................................................

Rate.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...........................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...........................................

..............................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...................................

Assembly.

Assembly.

...........................................

..............................................

Cable

.........................................

....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

. . . . . . . . . . . . . . . . . . . .

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

Page

1-1

1-4

1-4

1-4

1-4

1-4

1-4

1-6

1-6

1-6

1-6

1-6

1-7

1-7

1-7

2-1

2-2

2-4

2-4

2-5

2-6

2-7

2-16

2-16

2-16

2-18

2-18

2-18

Chapter 3

3.1

General Maintenance

3.2 Maintenance Tools

3.3 Preventive

Troubleshooting...........

3.4

3.5 Servo System Signals

3.6 Seek

Preventive Maintenance and Troubleshooting

Maintenance.

Operations Testing

3.6.1 Repeat Seek

3.6.2

One-Cylinder Seek Operation

Rules.

.................................................

................................................

Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.............................................

........................................

...................................

III

..

..

..

3-1

3-1

3-2

3-2

3-13

3-18

3-18

3-18

Page 4

Contents (cont'd)

Chapter 4 Removal and Replacement Procedures

4.1

G9QST (Logic

4.2 G9QSN (Read/Write) PCB

4.3

Earth

Pad Assembly

4.4 G9QSQ (Power Amplifier) PCB

4.5

Motor

Chapter 5 Adjustments

5.1

Required

Stator

and

Servo) PCB Removal

Removal.

Assembly Removal

Tools... . ........

..............................

Removal.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

.....................................

.... . ............. .............

.

..

.......

5.2 Servo Offset Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Seek Speed Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 Illustrated Parts Breakdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7

7.1

General

DKUOOO-H3PM

Description.......

3-Input

DC

Regulator Option

.

....

....... . .....

.. . ...

....

.... . ... ...

7.2 Interface Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1

DC

Power Connector (P4)

7.2.2 Signal

7.2.3

DC

7.3 Installing the 3-Input

Chapter 8

8.1

General Description

DKU-HDPI

Ground

Terminal.

Power Input Requirements

DC

Dual-Port Interface Option

................................................

8.2 Switches and Indicators

8.2.1 Port A (Route

8.2.2 Port B (Route

8.2.3 Release

Timer.

0) Switches and Indicators. . . . . . . . . . . . . . . . . . . . . . .

1)

Power

.............................................

Switches

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.....................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.................................

Regulator.

and

Indicators.

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

8.3 Drive Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Interface

..........................................................

8.5 Status Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.1 Release

8.5.2 Priority

8.6 Installing the Dual-Port

Command

Select.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

............................................

Interface.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

Page

4-1

4-3

4-3

4-4

4-6

5-1

5-1

5-3

5-1

7-1

7-2

7-2

7-3

7-3

7-4

8-1

8-2

8-3

8-3

8-3

8-3

8-4

8-4

8-4

8-4

8-7

Appendix A Schematic Diagrams

A.1 Signal Tracing Scheme

A.2

Drawings.........................................................

Appendix B Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..............................................

IV

..

A-I

A-I

B-1

Page 5

Contents (cont'

d)

Page

Appendix C DKUOOO-HLOG

Diagnostic Panel

C.I

Control Panel

..

0 0

000 0 000

000

0 0 0 0 0 0 0 0 0 0 0 • 0 0 0 0

000

0 • 0 0 0 0 0 0 • 0 0 0

•• 0 000

0 0 C-I

Col.1

Keypad 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 C-4

C.I.2

LED

Status Indicators 0 0 0 0 0 0 0 0 0 • 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 C-6

C.I.3

LCD

Display Window 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 C-6

C.1.4

Diagnostic Panel Summary Charts 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 C-6

C.2

Status Mode 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 • 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 C-6

C.2.1

Starting Status Mode 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 C-6

C.2.1.1

Drive Status 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 C-7

C.2.1.2 Cylinder

and

Head

Addresses 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

C-ll

C.2.2 Using Status Mode 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

••••

0

••••••••••••

C-II

C.2.3 Ending Status Mode 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

C-II

C.3 Test Mode 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

C-II

C.3.1 Starting Test Mode

00000.0000000000000000000000000000000000000

C-II

C.3.1.1

Input

Parameters 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

C-II

C.3.1.2 Seek Modes

00000000000000000000000000000000000000000000

C-13

C.3.2

Using Test Mode

000000000000000000000000000000000000000000000

C-14

C.3.3

Ending Test Mode

..

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

000000000000

C-14

C.4

Log Read Mode

0000000000000000000000000000

o.

0000000000000000000000

C-14

C.4.1

Error/Count

Log

000000000000000000000000000000000000000000000

C-14

C.4.2

Sequential Operations Log 0 0 0 0 0

0000

0 0 0 0 0 0 0 0 0 0 0 0

00000

0 0 0 0 0 0 0 0 0 0 0 C-16

C.4.3

Ending Log Read Mode 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 C-17

v

Page 6

Illustrations

Figure Title Page

1-1

D2246

Major

Components.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-1

1-2

D2246 Disk

and

Read/Write

Head

Arrangement.

. . . . . . . . . . . . . . . . .

..

1-2

1-3

D2246 Servo Disk

Surface.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-3

1-4

D2246

Functional

Block

Diagram

................................

1-4

1-5

Daisy-Chain System Configuration

...............................

1-6

1-6

Radial System

Configuration.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-7

2-1

D2246

Packaging.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-1

2-2

G9QST

Terminating Resistor

and

Jumper

Locations

................

2-2

2-3 Terminating Resistors in Radial

System.

. . . . . . . . . . . . . . . . . . . . . . . . .

..

2-2

2-4 Individual Drive

Termination/Daisy-Chain

System. . . . . . . . . . . . . . . .

..

2-3

2-5 Last Drive

Termination/Daisy-Chain

System.

. . . . . . . . . . . . . . . . . . . .

..

2-3

2-6

DIP

Switch Assembly

Locations.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-4

2-7 Installation

DIP

Switch

.........................................

2-5

2-8

Control

Mode

DIP

Switch.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-6

2-9 Sector Select Switch

............................................

2-7

2-10 Sector

Allocation.

. .

..

. . . . . .

.. . ... . ..

. . .

.. . ..

...

. .

..

. .

..

..

... . ..

2-7

2-11

Mounting

Bracket

..............................................

2-16

2-12 Horizontal

and

Vertical Installation

...............................

2-16

2-13 Interface Cable Connections

.....................................

2-17

2-14 Cable

A/Daisy-Chain

System

....................................

2-17

2-15 Signal

Ground

and

Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . .

..

2-18

2-16 Lock

Control

Assembly

.........................................

2-18

3-1

Troubleshooting Flowcharts

.....................................

3-2

3-2

G9QST

Test

Point

Locations

.....................................

3-13

3-3 Repeat Seek Using

TPI

..........................................

3-18

3-4 One-Cylinder Seek Using

TPI

....................................

3-18

4-1

D2246

Board

Cover.

. . . . . . . . .

.. . ..

. . . . . . .

..

. . .

..

. . .

..

..

..

. .

.. ..

4-2

4-2

G9QST

Cable Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4-2

4-3 D2246 Air

Separators.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4-3

4-4

G9QSN

Cable

Connectors.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4-4

4-5 G9QSQ Cable

Connectors.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

4-5

4-6 D2246

Fan.

. . .

..

. . . .

..

. . . . . . . . . . . . . . . . . .

..

. . .

..

. . . . .

..

. . . . . .

..

4-5

4-7 D2246

Stator

Assembly

.........................................

4-6

5-1

Servo Offset

and

Seek Speed Adjustment Test Points

................

5-2

5-2 Servo

Offset Waveform

.........................................

5-2

5-3 Seek Speed Waveform

..........................................

5-2

5-4 Transient Response Waveform

...................................

5-3

5-5 Increment Seek (Cylinder

000

to

Cylinder 691)

Waveform.

. . . . . . . . .

..

5-4

6-1

D2246

Standard

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

6-2

6-2 D2246

Head/Disk

Enclosure (External Parts)

......................

6-4

VI

Page 7

Illustrations (cont'

d)

Figure

Title

Page

7-1

3-Input

DC

Regulator Block

Diagram.

. . . . . . . . . . . . . . . . . . . . . . . . . .

..

7-1

7-2 3-Input

DC

Regulator Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7-2

7-3

P4

Connector.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7-2

7-4 Installing the 3-Input

DC

Regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7-4

8-1

Dual-Port System

Cabling.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8-2

8-2 Dual-Port Control Switches and Indicators. . . . . . . . . . . . . . . . . . . . . . .

..

8-2

8-3

Unit Select Timing for Dual-Port Option

..........................

8-5

8-4 Sample Priority Select

Timing.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8-6

8-5

Installing the Dual-Port Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

8-7

A-I Schematic

Format

..............................................

A-2

B-1

D2246 Basic Assembly Dimensions

...............................

B-7

B-2

D2246 Standard Assembly

Dimensions.

. . . . . . . . . . . . . . . . . . . . . . . . .

..

B-7

B-3

Cable A

Signals.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

B-8

B-4 Cable B Signals

................................................

B-9

C-l

Diagnostic

Panel.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

C-2

C-2 Attaching the Diagnostic Panel to the

Drive.

. . . . . . . . . . . . . . . . . . . . .

..

C-3

C-3 Diagnostic Panel Cable and

Connector.

. . . . . . . . . . . . . . . . . . . . . . . . .

..

C-3

C-4 Status Mode Display

Format.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

C-6

C-5 Status Mode

Error

Display Format

...............................

C-ll

C-6 Low Cylinder Parameter Display

.................................

C-12

C-7 High Cylinder Parameter Display

.................................

C-12

C-8 Interval Timing Parameter Display

................................

C-12

C-9 Seek Mode Display

.............................................

C-13

C-I0

Error/Count

Log Display

Format

................................

C-15

C-ll

Error/Count

Log Power-On Count

...............................

C-16

C-12

Error/Count

Log

Error

Display

Format

...........................

C-16

C-13 Sequential Operations Log Display

Format

........................

C-17

C-14 Sequential Operations Log Entries

................................

C-17

Vll

Page 8

Tables

Table

Title

Page

1-1

DC

Power

Requirements.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-5

1-2

Available Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

1-7

2-1

Sector Select Switch Settings (Segment 1 =

0)

. . . . . . . . . . . . . . . . . . . . .

..

2-8

2-2 Sector Select Switch Settings (Segment 1 =

1)

.......................

2-12

3-1

Test Point Signal Outputs

.......................................

3-14

3-2 G9QST Servo Signals

...........................................

3-15

4-1

D2246 Field Replaceable

Components.

. . . . . . . . . . . . . . . . . . . . . . . . . .

..

4-1

6-1

D2246

Standard

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

6-1

6-2

Head/Disk

Enclosure External

Parts.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

..

6-3

7-1

P4 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7-3

7-2

DC

Power Requirements

........................................

7-3

A-I Schematic Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-I

B-1

Operating Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

B-1

B-2

Design Specifications

...........................................

B-3

B-3

Physical

Dimensions.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

B-3

B-4 Interface Cable Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

B-4

B-5

Power Cable Descriptions

.......................................

B-4

B-6

Option Cable Description

.......................................

B-4

B-7

Interface Connector

Descriptions.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

B-5

B-8

DC

Power Cable Connector Description. . . . . . . . . . . . . . . . . . . . . . . . .

..

B-5

B-9

AC Power Cable Connector

Description.

. . . . . . . . . . . . . . . . . . . . . . . .

..

B-5

B-I0 3-DC Option Cable Connector Descriptions. . . . . . . . . . . . . . . . . . . . . .

..

B-6

B-ll

Operator

Panel Cable Connector

Descriptions.

. . . . . . . . . . . . . . . . . . .

..

B-6

C-l

Mode Selection Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

C-4

C-2 Diagnostic Panel

Functions.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

C-5

C-3 Disk Drive

Operational

States.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

C-7

C-4 Drive Status

Reports.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

C-7

C-5 Seek Modes

...................................................

C-13

viii

Page 9

Page 10

Abbreviations

A

Ampere

ac alternating current

AM

Address Mark

AWG

American Wire Gauge

CA Cylinder Address

CRC Cyclic Redundancy Check

dc direct current

DE

Disk Enclosure

DIP

Dual-inline-packaged

DKC

Disk Controller

DKU

Disk Unit

ECC

Error

Correction Code

EOR

End

of

Record

GND

Ground

HA

Head

Address

HEX

Hexadecimal

1GB

Inner

Guard

Band

I/O

Input/Output

LED

Light emitting diode

m meter

MB Megabyte

MFM

Modified Frequency Modulation

MHz

Megahertz

mm

Millimeter

ms

Millisecond

mV

Millivolt

MTBF

Mean Time Between Failures

MTTR

Mean Time to Repair

NRZ

N on-Return-to-Zero

ns

Nanosecond

OGB

Outer

Guard

Band

PCB

Printed Circuit Board

PLO

Phase Locked Oscillator

RMS Root-Mean-Square

ROM

Read only memory

RPM

Revolutions per Minute

R/W

Read/Write

SA

Sector Address

TTL

Transistor/Transistor Logic

V

Volt

f.ls

microsecond

Page 11

Chapter

1

System Overview

The D2246

is

a new addition to the

NEe

D2200 series

of

disk drives. It

is

a compact,

highly reliable, low-cost unit

and

is

fully compatible with earlier D2200 models.

It

offers

85

megabytes (MB)

of

unformatted

data

storage on four 8-inch platters. Actual storage

capacity depends upon the formatting method used.

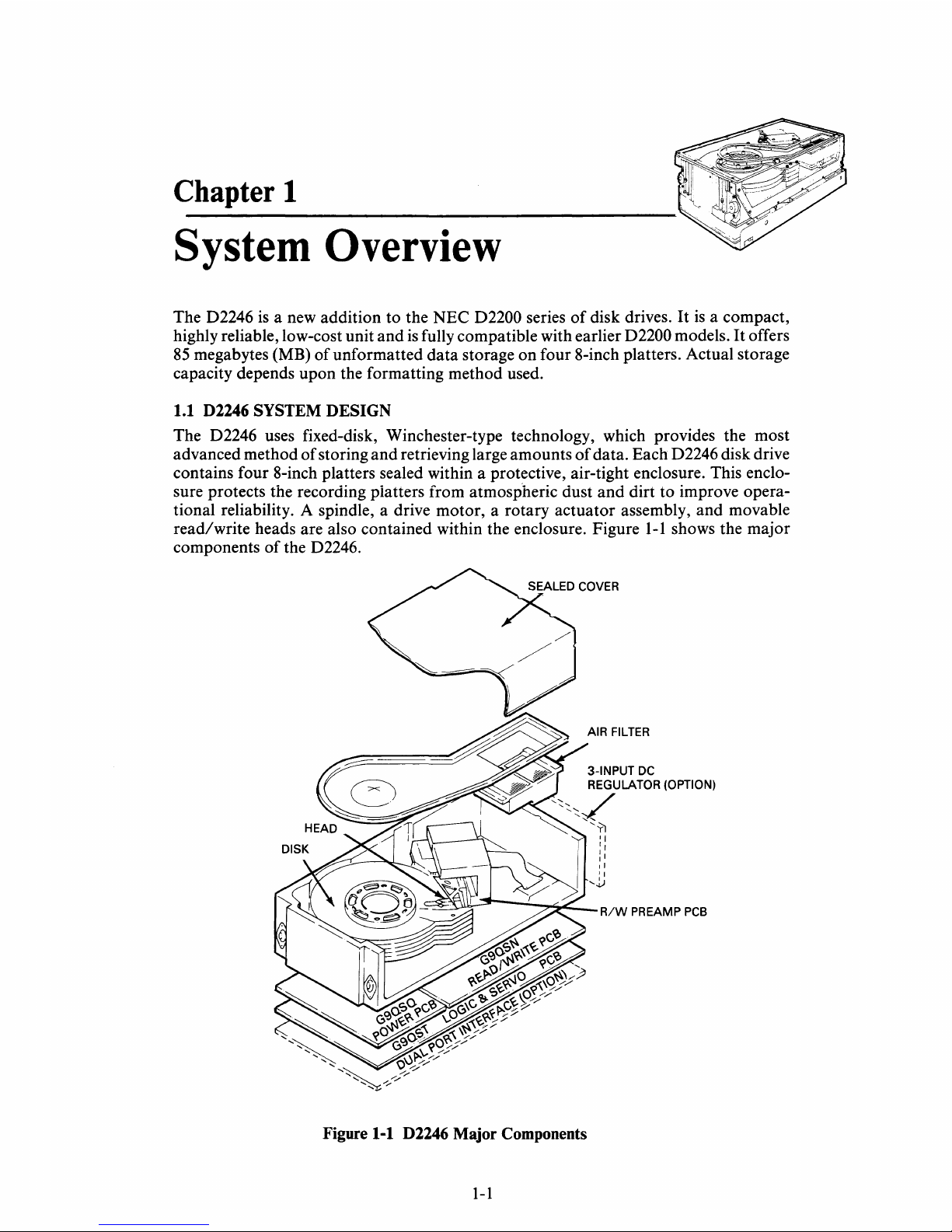

1.1 D2246

SYSTEM DESIGN

The D2246 uses fixed-disk, Winchester-type technology, which provides the most

advanced method

of

storing

and

retrieving large amounts

of

data. Each D2246 disk drive

contains four 8-inch platters sealed within a protective, air-tight enclosure. This enclosure protects the recording piatters from atmospheric dust

and

dirt to improve operational reliability. A spindle, a drive motor, a rotary actuator assembly, and movable

read/write heads are also contained within the enclosure. Figure

1-1

shows the major

components

of

the D2246.

Figure

1-1

D2246 Major Components

1-1

3-INPUT

DC

'I

I,

:1

,I

'I

....

.1.;

R/W

PREAMP

PCB

Page 12

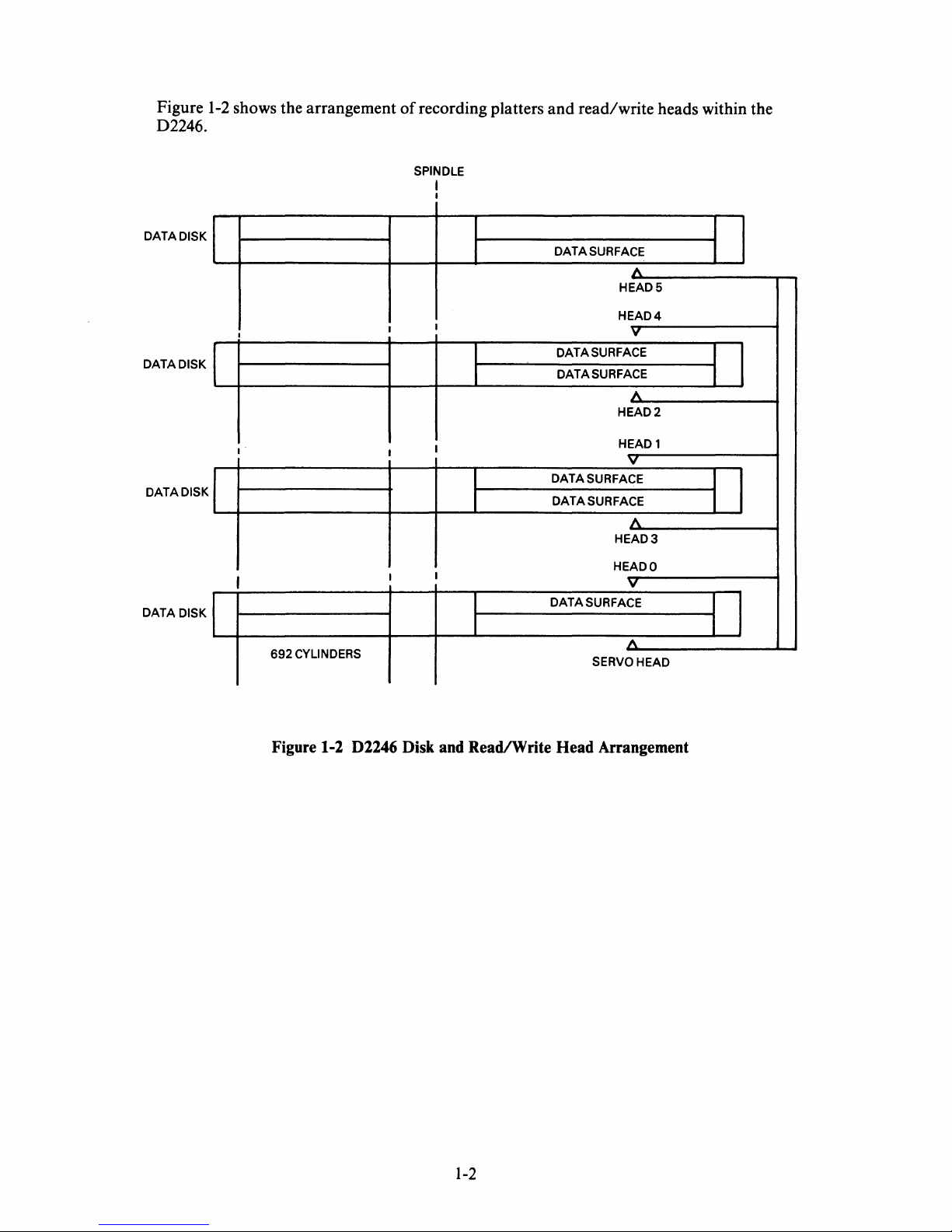

Figure

1-2

shows the arrangement

of

recording platters

and

read/write heads within the

D2246.

DATA DISK

I

DATA DISK

I

DATA DISK

I

DATA DISK

I

I

I

692

CYLINDERS

SPINDLE

I

I

I

I

I

DATA SURFACE

A

HEADS

HEAD4

V

DATA SURFACE

DATA SURFACE

A

HEAD2

HEAD 1

v

DATA

SURFACE

DATA

SURFACE

A

HEAD3

HEADO

V

DATA

SURFACE

A

SERVO HEAD

Figure

1-2

D2246

Disk

and

Read/Write

Head

Arrangement

1-2

Page 13

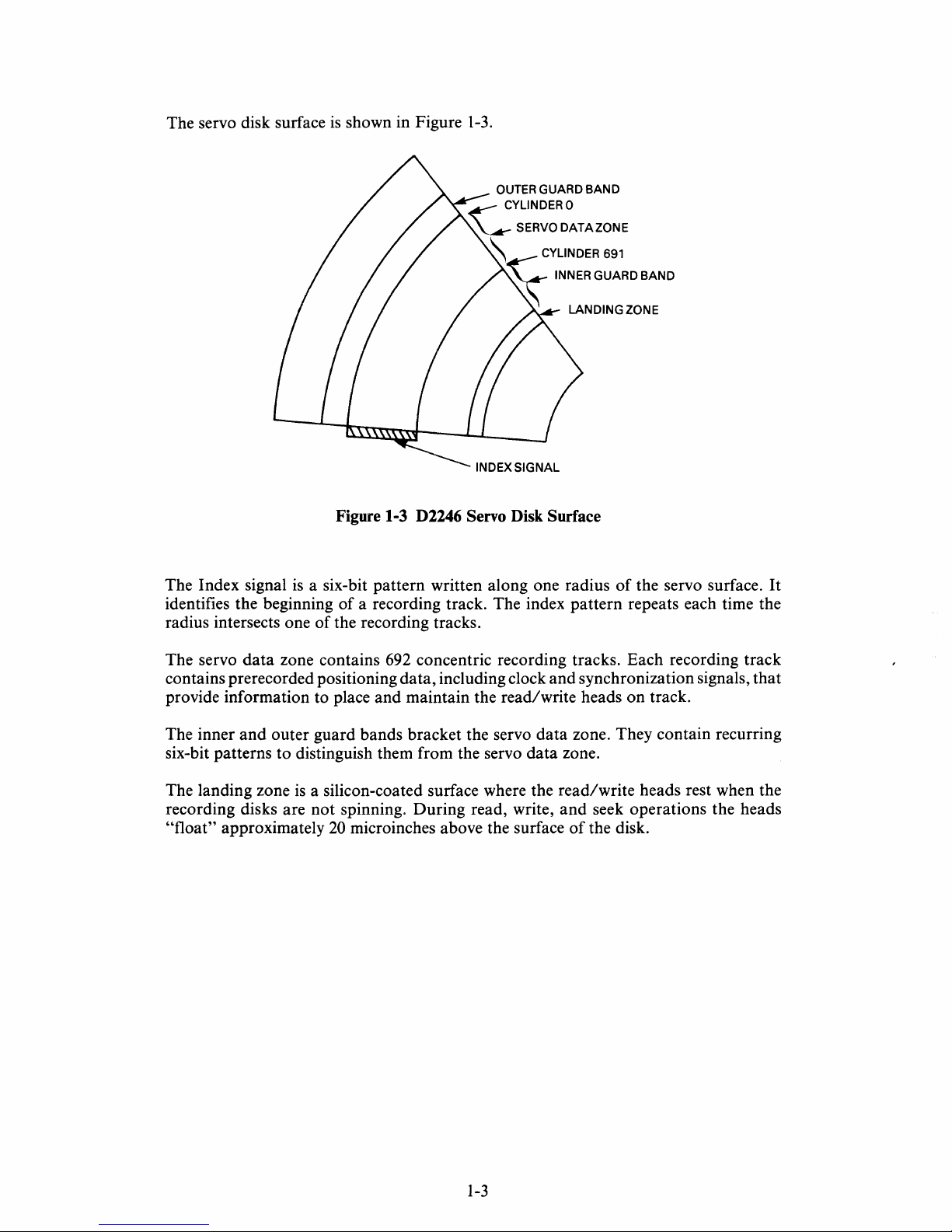

The servo disk surface

is

shown in Figure

1-3.

Figure 1-3 D2246 Servo Disk Surface

The Index signal

is

a six-bit pattern written along one radius

of

the servo surface.

It

identifies the beginning

of

a recording track. The index pattern repeats each time the

radius intersects one

of

the recording tracks.

The servo

data

zone contains 692 concentric recording tracks. Each recording track

contains prerecorded positioning data, including clock and synchronization signals, that

provide information to place and maintain the read/write heads on track.

The inner

and

outer guard bands bracket the servo data zone. They contain recurring

six-bit patterns to distinguish them from the servo data zone.

The landing zone

is

a silicon-coated surface where the read/write heads rest when the

recording disks are not spinning. During read, write,

and

seek operations the heads

"float"

approximately

20

microinches above the surface

of

the disk.

1-3

Page 14

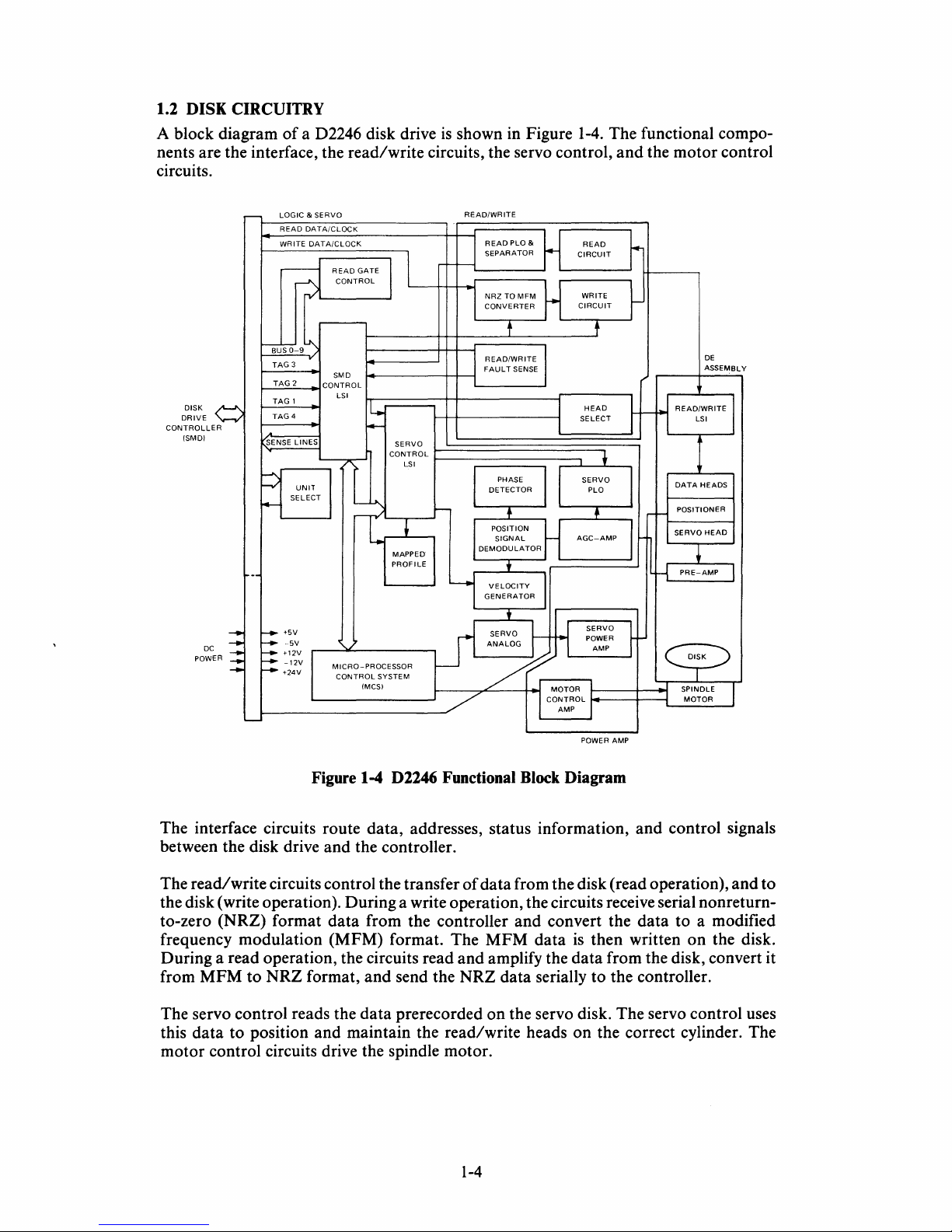

1.2 DISK

CIRCUITRY

A block diagram

of

a D2246 disk drive

is

shown

in

Figure 1-4. The functional components are the interface, the read/write circuits, the servo control, and the motor control

circuits.

~

DISK

DRIVE

CONTROLLE

(SMDI

DC

POWE

-

-

R:::::

-

r--

-

--

LOGIC & SERVO

READ/WRITE

READ

DATA/CLOCK

WRITE

DATA/CLOCK

J

READPLO&

READ

I

_

SEPARATOR

CIRCUIT

I

-a

"eA,GA"

CONTROL

I

NRZ

TO

MFM

WRITE

CONVERTER

CIRCUIT

f

j

~SO-9~

I

"eA","m

I

TAG

3

FAUL

T SENSE

SMD

I

TAG

2

CONTROL

TAG

1

LSI

!L.

I

HEAD

TAG

4

l

SELECT

-

A

SENSE

LINES

SERVO

~

CONTROL

,

l~

LSI

~

I

/I

PHASE

SERVO

UNIT

DETECTOR

PLO

t-

SELECT

It

r-

+

~

t

I

",m,o,

SIGNAL

AGC-AMP

MAPPED

DEMODULATOR

PROFILE

t

VELOCITY

j

GENERATOR

t

__

t5V

r H

SERVO

~

SERVO

POWER

__

-5V

ANALOG

AMP

f-+-

t12V

AMOTO"

I

r--

-12V

MICRO-PROCESSOR

r--

t24V

CONTROL

SYSTEM

(MCSI

/

-,

CONTROL

l

AMP

I

POWER AMP

Figure

1-4 D2246

Functional

Block

Diagram

r

~

DE

ASSEMBLY

"

r

-

H

"eA"WR'"

LSI

I

DATA

HEADS

r-

POSITIONER

I

SERVO

HEAD

lH

PRE-AMP

r

-

DISK

--,-

SPINDLE

I

MOTOR

L

The interface circuits route data, addresses, status information, and control signals

between the disk drive and the controller.

The read/write circuits control the transfer

of

data from the disk (read operation), and to

the disk (write operation). During a write operation, the circuits receive serial nonreturnto-zero

(NRZ) format data from the controller and convert the data to a modified

frequency modulation (MFM) format. The MFM data is then written

on

the disk.

During a read operation, the circuits read and amplify the data from the disk, convert it

from MFM to

NRZ format, and send the NRZ data serially to the controller.

The servo control reads the data prerecorded on the servo disk. The servo control uses

this data to position and maintain the read/write heads on the correct cylinder. The

motor control circuits drive the spindle motor.

1-4

Page 15

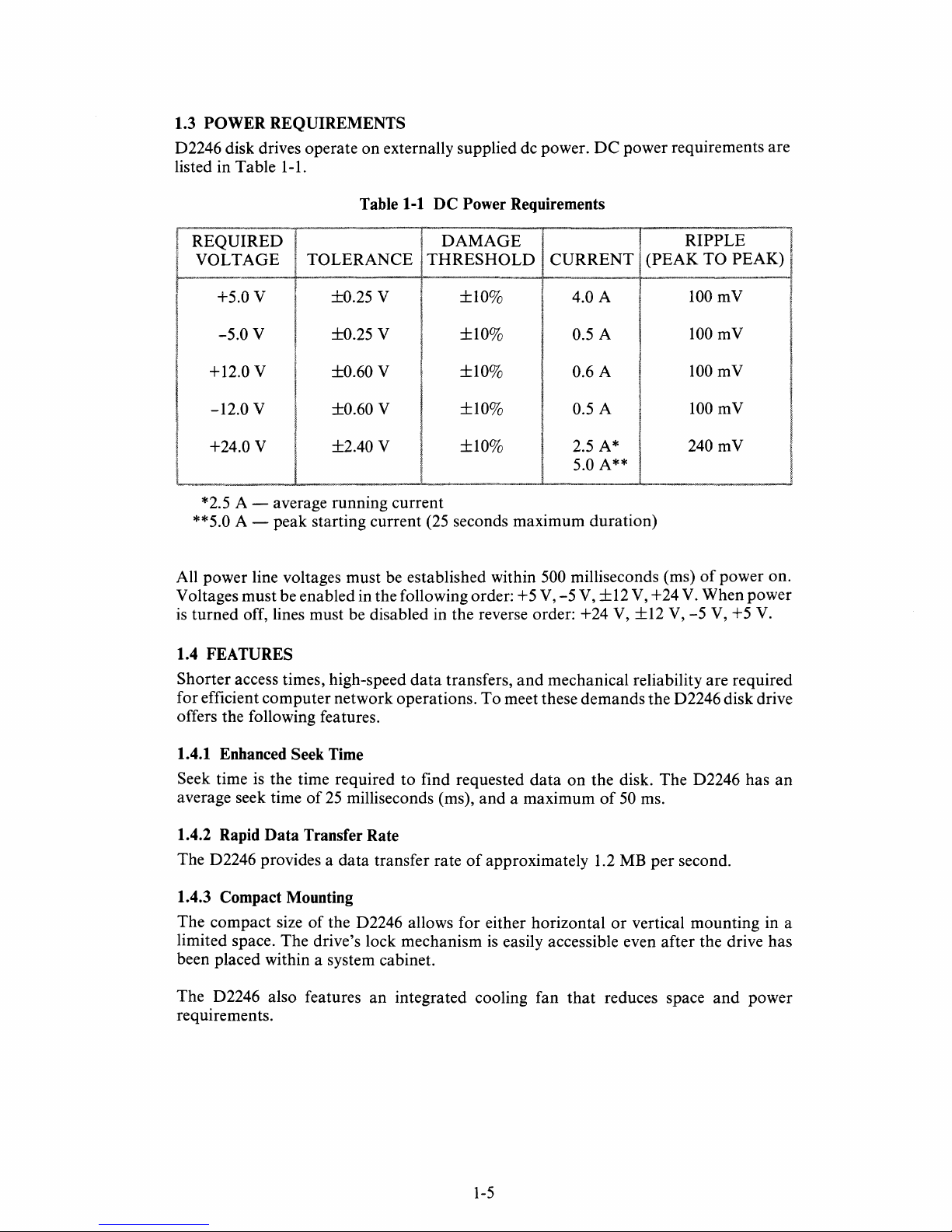

1.3 POWER REQUIREMENTS

D2246 disk drives operate on externally supplied dc power.

DC

power requirements are

listed in Table

1-1.

Table 1-1 DC Power Requirements

REQUIRED

DAMAGE

RIPPLE

VOLTAGE

TOLERANCE

THRESHOLD

CURRENT

(PEAK TO PEAK)

+5.0V

±0.25 V

±10%

4.0A

100mV

-5.0V

±0.25 V ±10%

0.5

A

100mV

+12.0V

±0.60 V ±10%

0.6

A

100mV

-12.0 V

±0.60 V

±10%

0.5

A

100

mV

+24.0 V

±2.40 V ±10%

2.5

A*

240mV

5.0 A**

*2.5 A - average running current

**5.0 A - peak starting current (25 seconds maximum duration)

All power line voltages must be established within

500 milliseconds (ms)

of

power on.

Voltages must be enabled in the following order: +5

V,

-5

V,

±12

V,

+24

V.

When power

is

turned off, lines must be disabled in the reverse order: +24

V,

±12

V,

-5

V,

+5

V.

1.4 FEATURES

Shorter access times, high-speed

data

transfers,

and

mechanical reliability are required

for efficient computer network operations. To meet these demands the D2246 disk drive

offers the following features.

1.4.1 Enhanced

Seek Time

Seek time

is

the time required to find requested

data

on the disk. The D2246 has

an

average seek time

of

25

milliseconds (ms), and a maximum

of

50

ms.

1.4.2 Rapid

Data

Transfer Rate

The D2246 provides a data transfer rate

of

approximately 1.2

MB

per second.

1.4.3 Compact Mounting

The compact size

of

the D2246 allows for either horizontal

or

vertical mounting in a

limited space. The drive's lock mechanism

is

easily accessible even after the drive has

been placed within a system cabinet.

The D2246 also features an integrated cooling fan

that

reduces space

and

power

requirements.

1-5

Page 16

1.4.4 Simplified Maintenance

The air-tight, sealed

disk/head

assembly

and

the D2246's simplified design produce a

disk drive

that

requires no periodic maintenance. Neither installation

nor

field service

requires special tools.

Motor

electronics are placed outside the

head/disk

assembly

and

do

not need "clean

room"

repair facilities.

An

optional diagnostic panel

is

available for test

and

maintenance purposes (see Appen-

dix C).

1.4.5 Design Reliability

Lightweight, contact-type

start/stop

heads

that

reduce damage

to

the heads

and

disks

are used within the D2246 disk drive. A simplified rotary actuator, a directly coupled,

brushless dc motor,

and

a closed-loop air circulation system are the drive's major

mechanical components. The control logic

is

microprocessor controlled

and

designed

to

minimize electronic components. This design strategy ensures high reliability

and

low

cost.

1.4.6 Standard Interfaces

The D2246 uses standard original equipment manufacturer interfaces for connection to a

disk controller and

to

a power supply.

1.4.7 Safety

The D2246 conforms to Underwriter's Laboratories Safety Regulation UL478.

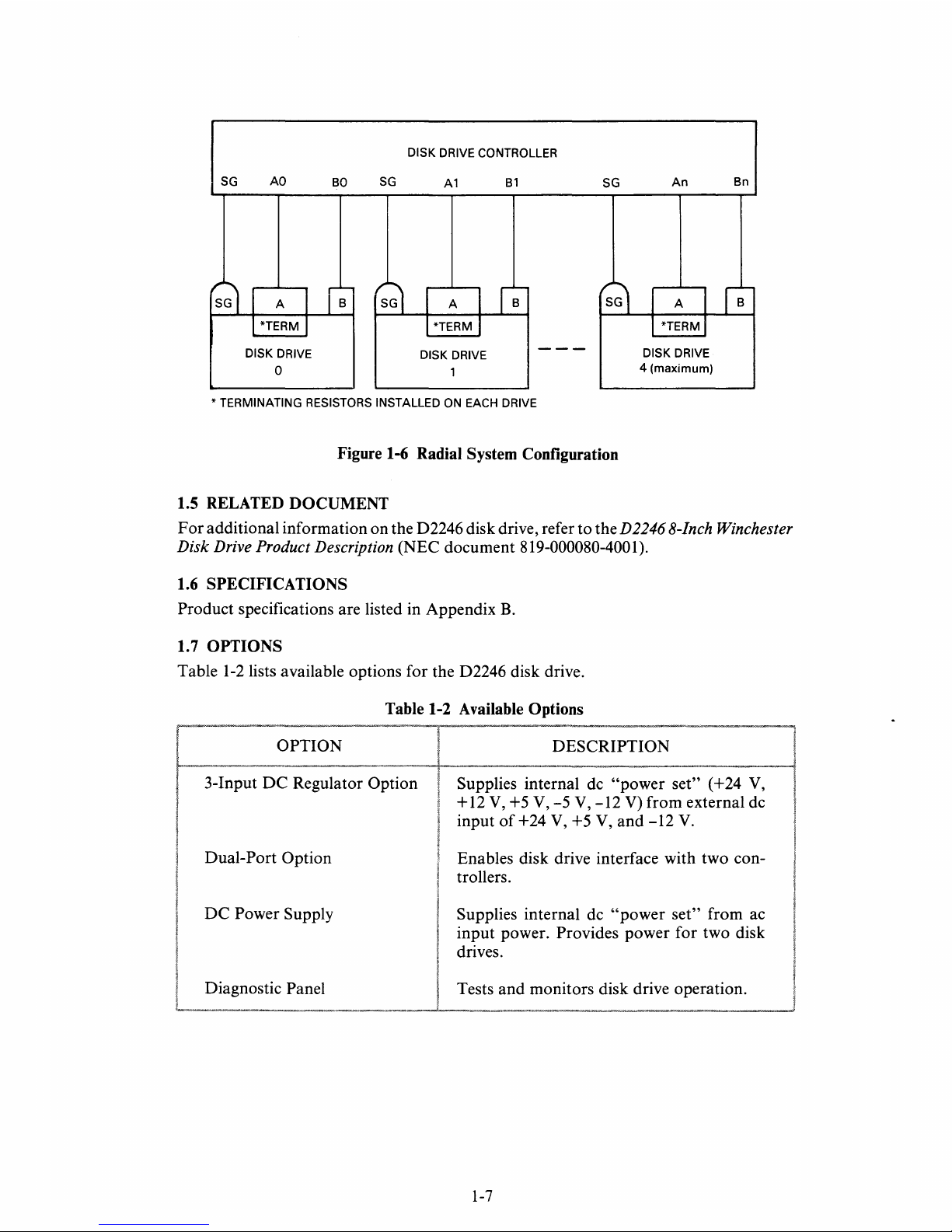

1.4.8 System Configuration Flexibility

A maximum

of

four D2246 disk drives can be connected

to

a single controller in either a

daisy-chain

or

radial system (see Figures

1-5

and

1-6).

DISK DRIVE CONTROLLER

SG

AO

BO

B1

Bn

r

CABLEA

CABLE B

/

-

\

/

-

\

V

V

-

~

V

-

~

si)

A

IB~

A

IB-

A

Is~

*TERM

*TERM

*TERM

DISK DRIVE

DISK DRIVE

---

DISK DRIVE

0

1

4 (maximum)

* TERMINATING RESISTORS INSTALLED ON EACH DRIVE

Figure 1-5 Daisy-Chain System Configuration

1-6

Page 17

DISK DRIVE CONTROLLER

SG

AO

BO

SG

A1

B1

SG

An

Bn

S~

A

1;-

~~

A

1;-

S~

A

IB

....

*TERM

*TERM

*TERM

DISK DRIVE

DISK DRIVE

---

DISK DRIVE

a

1

4

(maximum)

* TERMINATING RESISTORS INSTALLED

ON

EACH DRIVE

Figure 1-6 Radial System Configuration

1.5 RELATED

DOCUMENT

For

additional information on the D2246 disk drive, refer to the D2246 8-Inch Winchester

Disk

Drive Product Description (NEC document 819-000080-4001).

1.6 SPECIFICATIONS

Product

specifications are listed in Appendix

B.

1.7 OPTIONS

Table

1-2

lists available options for the D2246 disk drive.

Table 1-2 Available

Options

OPTION

DESCRIPTION

3-Input

DC

Regulator Option

Supplies internal dc

"power

set" (+24

V,

+

12

V,

+5

V,

-5

V,

-12

V)

from external dc

input

of

+24

V,

+5 V,

and

-12

V.

Dual-Port Option

!

Enables disk drive interface with two con-

I

trollers.

!

\.

DC

Power Supply

I

Supplies internal dc

"power

set"

from ac

input power. Provides power for two disk

drives.

Diagnostic Panel

I

Tests and monitors disk drive operation.

1-7

Page 18

Chapter

2

Installation

Procedures

This chapter provides procedures for installing a D2246 disk drive. When preparing the

installation site, refer to the environmental specifications listed in Appendix

B.

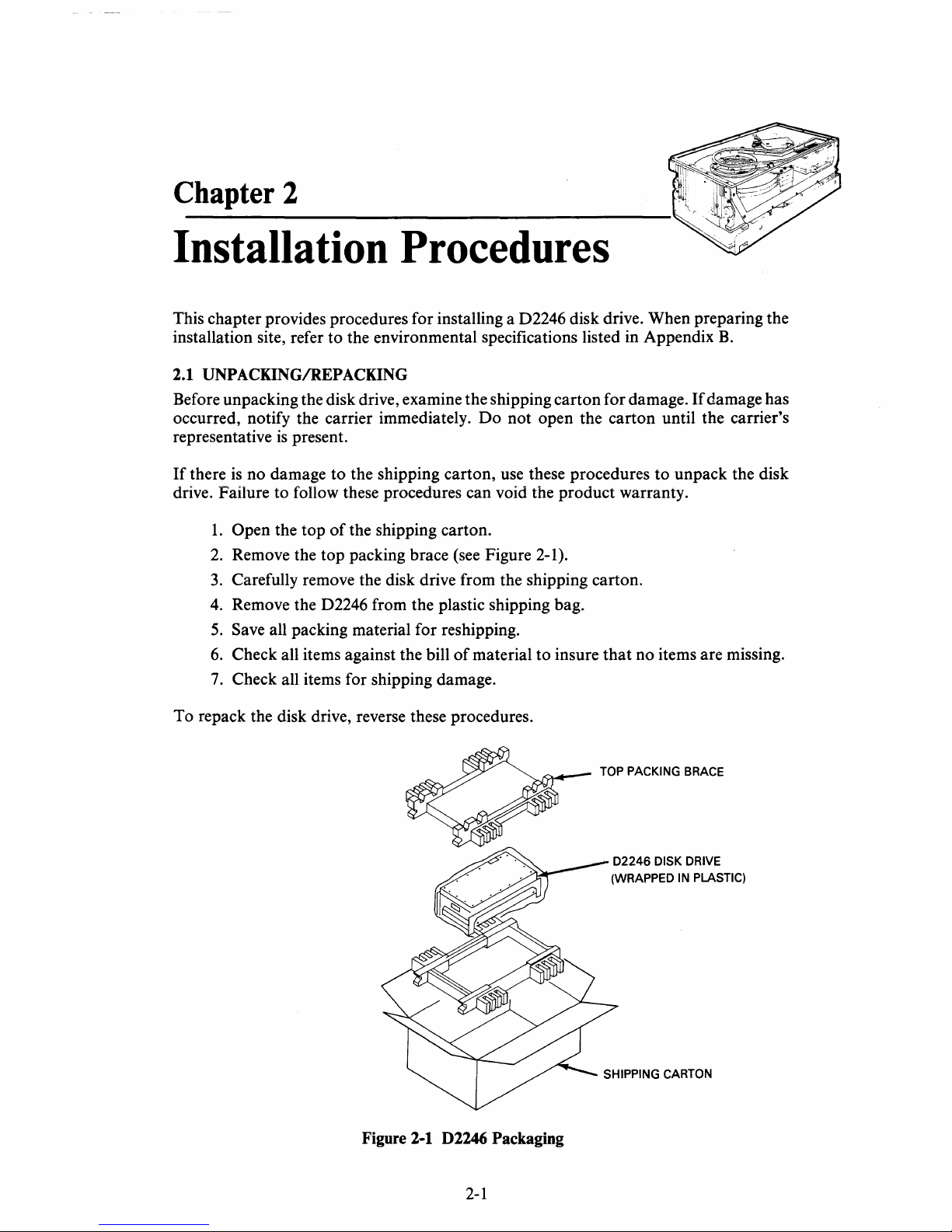

2.1

UNPACKINGIREPACKING

Before unpacking the disk drive, examine the shipping carton for damage.

If

damage has

occurred, notify the carrier immediately.

Do

not open the carton until the carrier's

representative

is

present.

If

there

is

no damage to the shipping carton, use these procedures to unpack the disk

drive. Failure to follow these procedures can void the product warranty.

1.

Open the top

of

the shipping carton.

2.

Remove the top packing brace (see Figure 2-1).

3.

Carefully remove the disk drive from the shipping carton.

4.

Remove the D2246 from the plastic shipping bag.

5.

Save all packing material for reshipping.

6.

Check all items against the bill

of

material to insure

that

no items are missing.

7.

Check all items for shipping damage.

To repack the disk drive, reverse these procedures.

TOP PACKING BRACE

02246

DISK DRIVE

SHIPPING

CARTON

Figure

2-1

D2246

Packaging

2-1

Page 19

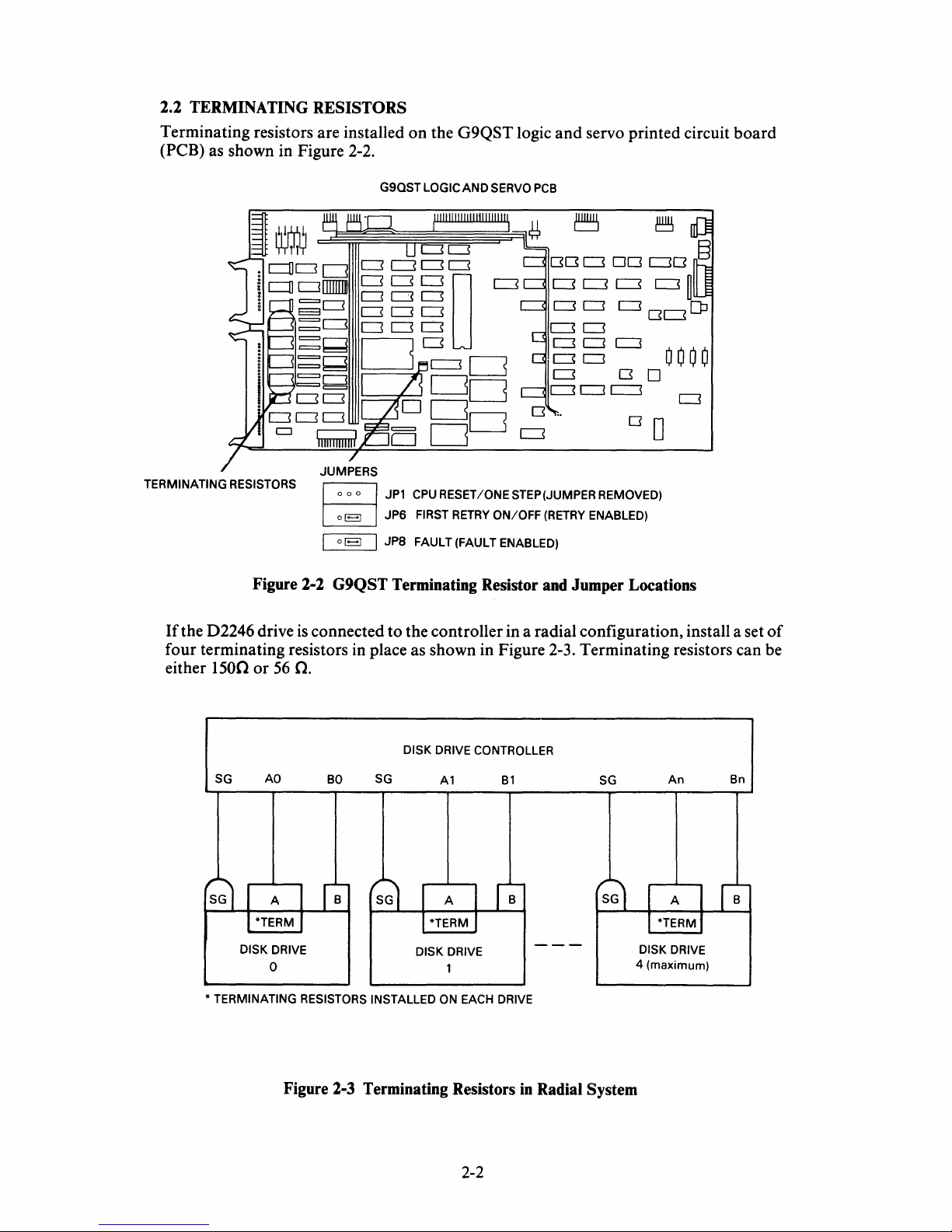

2.2 TERMINATING RESISTORS

Terminating resistors are installed on the G9QST logic and servo printed circuit board

(PCB) as shown in Figure

2-2.

G9QST LOGIC

AND

SERVO

PCB

DCJC3

c:::::3.c]

CJD

~~

c:::::3

CJ

c:::J

c::J

CJ

0 0

c:::J

CJ~

[]

0 [JJ

0000

o 0

TERMINATING RESISTORS

Figure 2-2 G9QST Terminating Resistor and Jumper Locations

If

the D2246 drive

four terminating resistors in place as shown in Figure 2-3. Terminating resistors can be

either 150a

or

56

JUMPERS

EJ

~

lOB

is

connected to the controller in a radial configuration, install a set

JPl

CPU

RESET

JP6

FIRST

RETRY

I

JP8

FAULT (FAULT ENABLED)

lONE

STEP (JUMPER REMOVED)

ONIOFF

(RETRY

ENABLED)

n.

of

DISK DRIVE CONTROLLER

SG

~~

TERMINATING RESISTORS INSTALLED ON EACH DRIVE

*

AO

A

*TERM

DISK DRIVE

0

BO

r;-

SG

S~

A1

A

*TERM *TERM

DISK DRIVE

1

B1

r;-

Figure 2-3 Terminating Resistors

2-2

---

in

Radial System

SG

S~

An

A

DISK DRIVE

4 (maximum)

Bn

,;-

Page 20

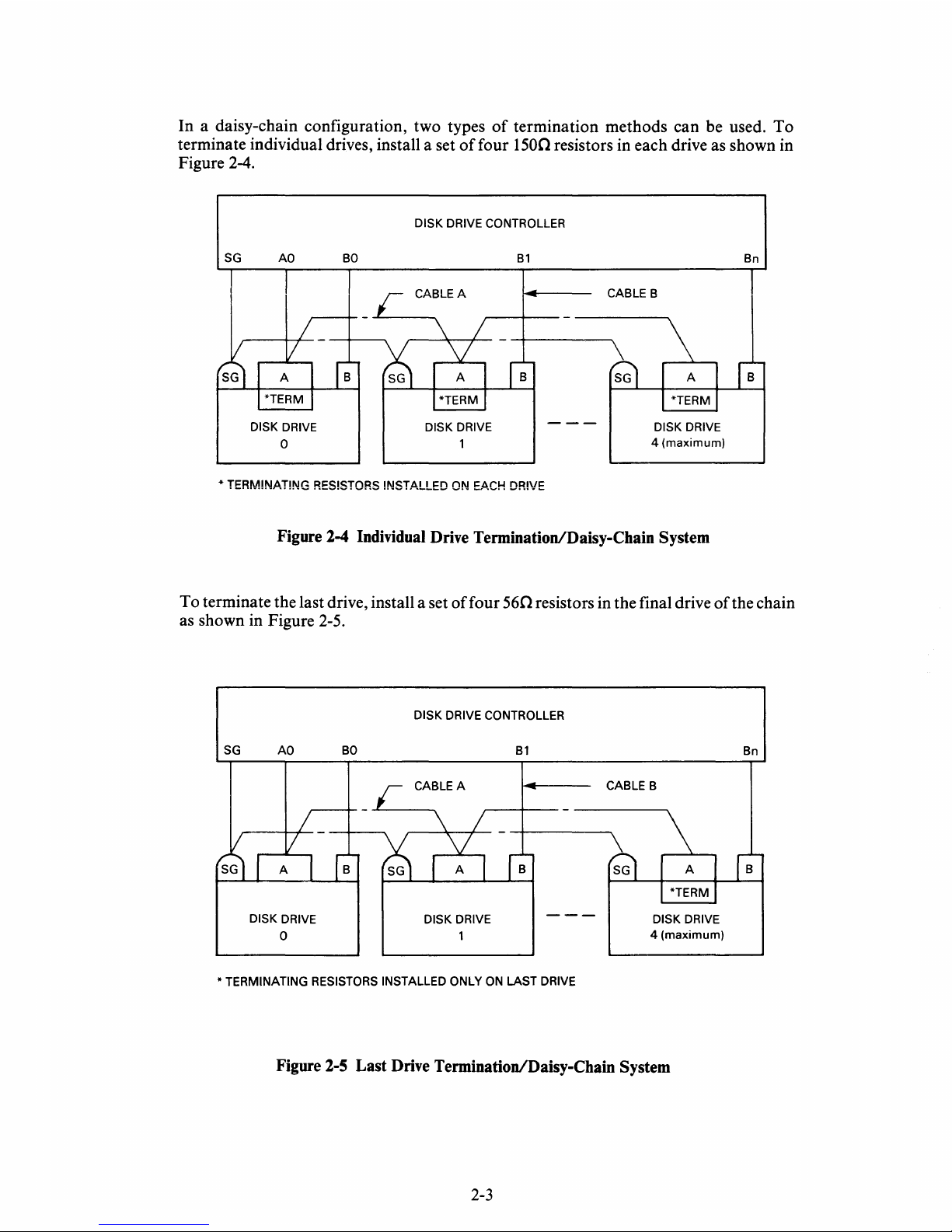

In

a daisy-chain

configuration,

two

types

of

termination

methods

can

be

used.

To

terminate

individual drives, install a set

of

four

150n resistors in

each

drive as

shown

in

Figure 2-4.

DISK DRIVE CONTROLLER

SG

AO

BO

B1

Bn

r

CABLEA

CABLE B

- -

/

-

\ /

-

\

V

V

~

V

~

~~

A

IB~

A

I;

A

IB~

*TERM

*TERM *TERM

DISK DRIVE DISK DRIVE

---

DISK DRIVE

0

1

4

(maximum)

* TERMINATING RESISTORS INSTALLED ON EACH DRIVE

Figure 2-4 Individual Drive Termination/Daisy-Chain System

To

terminate

the last drive, install a set

of

four

56n

resistors in

the

final drive

of

the chain

as shown in Figure 2-5.

DISK DRIVE CONTROLLER

SG

AO

BO

B1

Bn

r

CABLEA

-

CABLE B

/

-

\ /

-

\

V

V

-

~

V

-

~

S~

I

A

I

ls-

I

A I

[B-

A

IB~

*TERM

DISK DRIVE

DISK DRIVE

---

DISK DRIVE

0

1

4

(maximum)

* TERMINATING RESISTORS INSTALLED ONLY ON LAST DRIVE

Figure 2-5

Last

Drive Termination/Daisy-Chain System

2-3

Page 21

2.3

JUMPER

Three

location

jumper

Figure 2-2. Insure

REQUIREMENTS

settings

of

these three

must

be verified before power is applied

jumpers

that

settings

Do not alter these

for factory adjustments only.

(JPl,

match

jumper

JP6,

and

those shown in Figure 2-2.

CAUTION

settings. They are intended

JP8)

on

the

to

the disk drive. The

G9QST

PCB

is

shown in

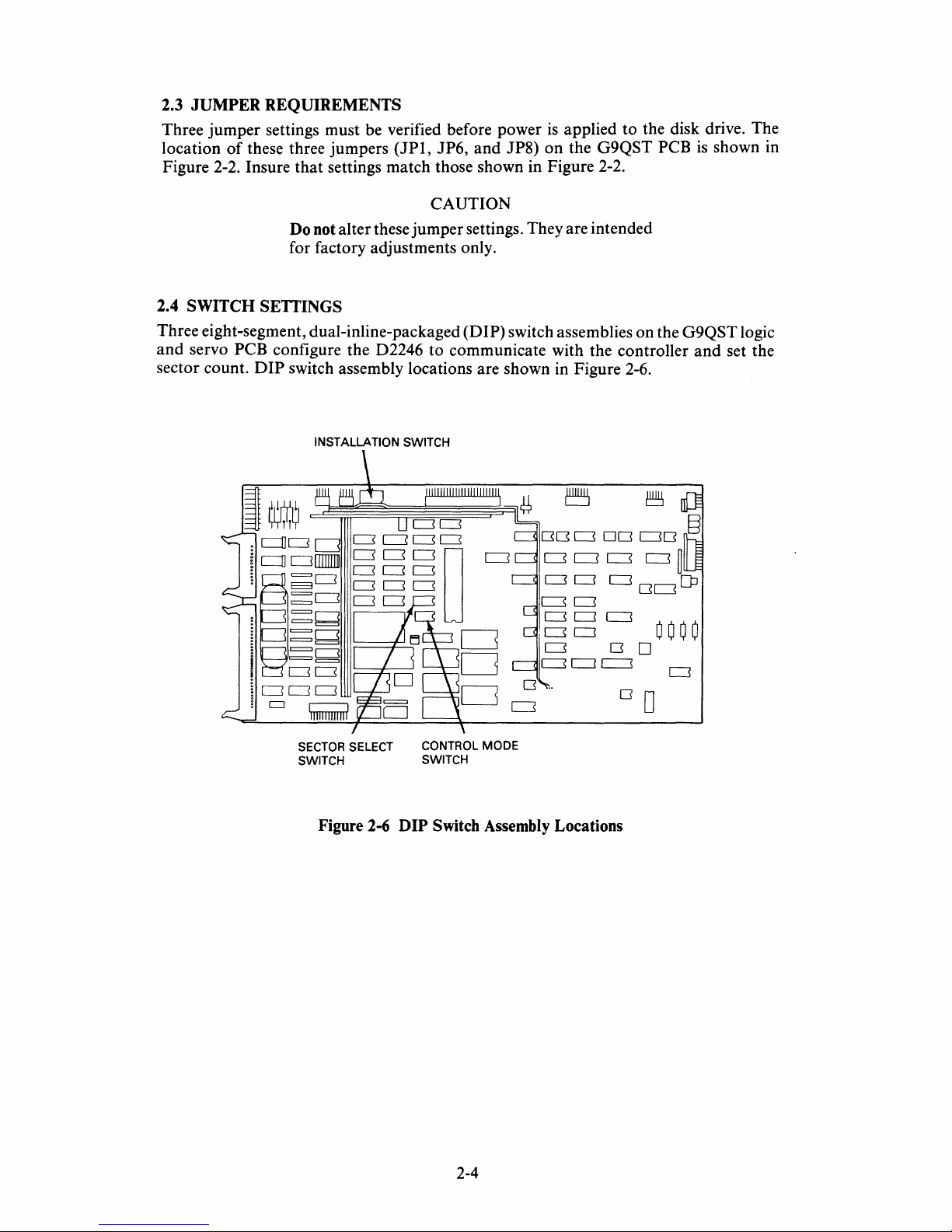

SWITCH

2.4

Three eight-segment, dual-inline-packaged

and

servo PCB configure

sector count.

SETTINGS

the

D2246 to communicate with the controller

DIP

switch assembly locations are shown in Figure 2-6.

INSTALLATION SWITCH

;\®i

CjJcsD

o

ornIIIIlJ

~C1

~CJ

SECTOR

SWITCH SWITCH

C1

DDO[]

C1

C]

DO

SELECT CONTROL MODE

C1C3

CJC3CJ

C]

C]

C]

C]

(DIP)

D

D

D

switch assemblies on the

0000000

o

C5

c:::::s

CJ

C3

C]

c:::J 0

C]

c::::::3

C]

~~CJ

DOD

~CJc=J

0000

o 0

G9QST

and

~

[]::J

logic

set the

Figure 2-6

DIP

Switch Assembly Locations

2-4

Page 22

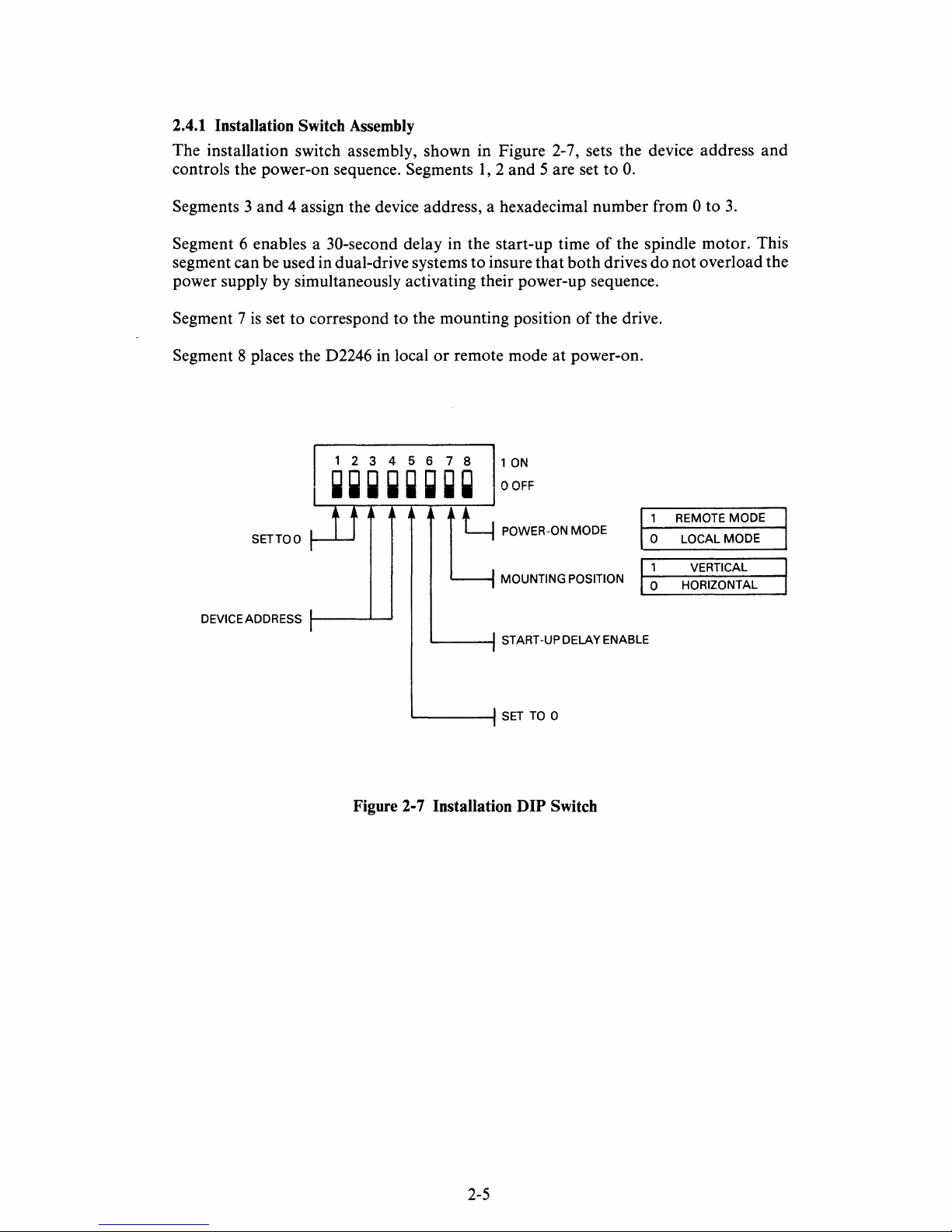

2.4.1 Installation Switch Assembly

The installation switch assembly, shown in Figure 2-7, sets the device address

and

controls the power-on sequence. Segments

1, 2 and

5 are set to

O.

Segments 3

and

4 assign the device address, a hexadecimal number from 0 to

3.

Segment 6 enables a 30-second delay in the start-up time

of

the spindle motor. This

segment can be used in dual-drive systems to insure

that

both

drives

do

not

overload the

power supply by simultaneously activating their power-up sequence.

Segment 7

is

set to correspond to the mounting position

of

the drive.

Segment 8 places the D2246 in local

or

remote mode

at

power-on.

SETTOO

DEVICEADDRESS

t----....L-...J

I'

ON

o

OFF

~---f

START -up DELAY ENABLE

~----f

SET

TO

0

Figure 2-7 Installation DIP Switch

2-5

1 REMOTE MODE

o LOCAL MODE

1 VERTICAL

o HORIZONTAL

Page 23

2.4.2 Control Mode Switch Assembly

The

control

mode

switch assembly (shown in Figure 2-8) configures the D2246

to

communicate

with the disk controller

and

enables certain

optional

drive features.

Segment 1

is

set

to

1.

Segments 2

and

3 are set

to

O.

Segment 4 enables the Address

Mark

function.

Segment 5 enables the

Read

Sector

function.

When

segments 5

and 7 of

the

control

mode

switch assembly

are

set

to

1,

Tag 4 can

be used with

bus

bits 8

and 9 to

request the

current

sector address.

The

D2246 issues the

current

sector address across the sense lines.

Segment 6 enables the

Format

Write Release

Option

used with some controllers.

Segment 7 enables the

Tag

4 line.

Segment 8 enables the controller interface.

SETTO

1

SET TO 0

1--_.1..-1

1 ON

OOFF

INTERFACE ENABLE

TAG 4 ENABLE

ON LINE

OFF LINE

L..-

__

.....

FORMAT

WRITE RELEASE ENABLE

ADDRESS

MARK

ENABLE

1-----

......

~----f

READ SECTOR ENABLE

Figure 2-8 Control Mode

DIP

Switch

2-6

Page 24

2.4.3 Sector Select Switch Assembly

The

sector select switch assembly (see Figure 2-9) sets the

number

of

sectors

per

track.

Any

number

of

sectors

up

to

128

can

be selected.

1 2 3 4 5 6 7 8 1

ON

~ ~

~

~

~

~ ~

~

0

OFF

SECTOR

COUNT

DISPOSITION SWITCH

Figure 2-9 Sector Select Switch

Segment 1

of

this assembly determines

the

disposition

of

odd

or

remainder

bytes. These

are

extra bytes

that

must

be allocated when the available bytes

per

track

are

not

evenly

divisible by the

number

of

sectors

per

track.

With

segment 1 in the 0 position,

odd

bytes

are

grouped

together

in

an

extra

sector

at

the

end

of

the

track.

With

this segment in the 1

position, the last sector

is

reduced

to

account

for

odd

bytes.

INDEX

Jl

n

If

PULSE

I

I

I

"SA"

"SA"

"SA"

"SA"

I

"SA"

I

SECTOR

0

n

1

~S

31

n

32

n(33)

I

0

rL

PULSE

F

"0"

(620

(620)

(620)

(620)

f-20~

(620)

BYTES

BYTE

I

(EXTRA

SECTOR)

I

"SA"

"SA"

"SA"

"SA"

I

"SA"

I

SECTOR

0

n

~$

31

n

32

I

0

rL

PULSE

(621)

(621 )

(621 )

608

BYTE

I

(621 )

F"1"

I

(LAST SECTOR)

Figure 2-10

Sector Allocation

Figure

2-10 illustrates the allocation

of

33

sectors with segment 1

of

the sector select

switch assembly in

both

the 0

and

1 positions.

2-7

Page 25

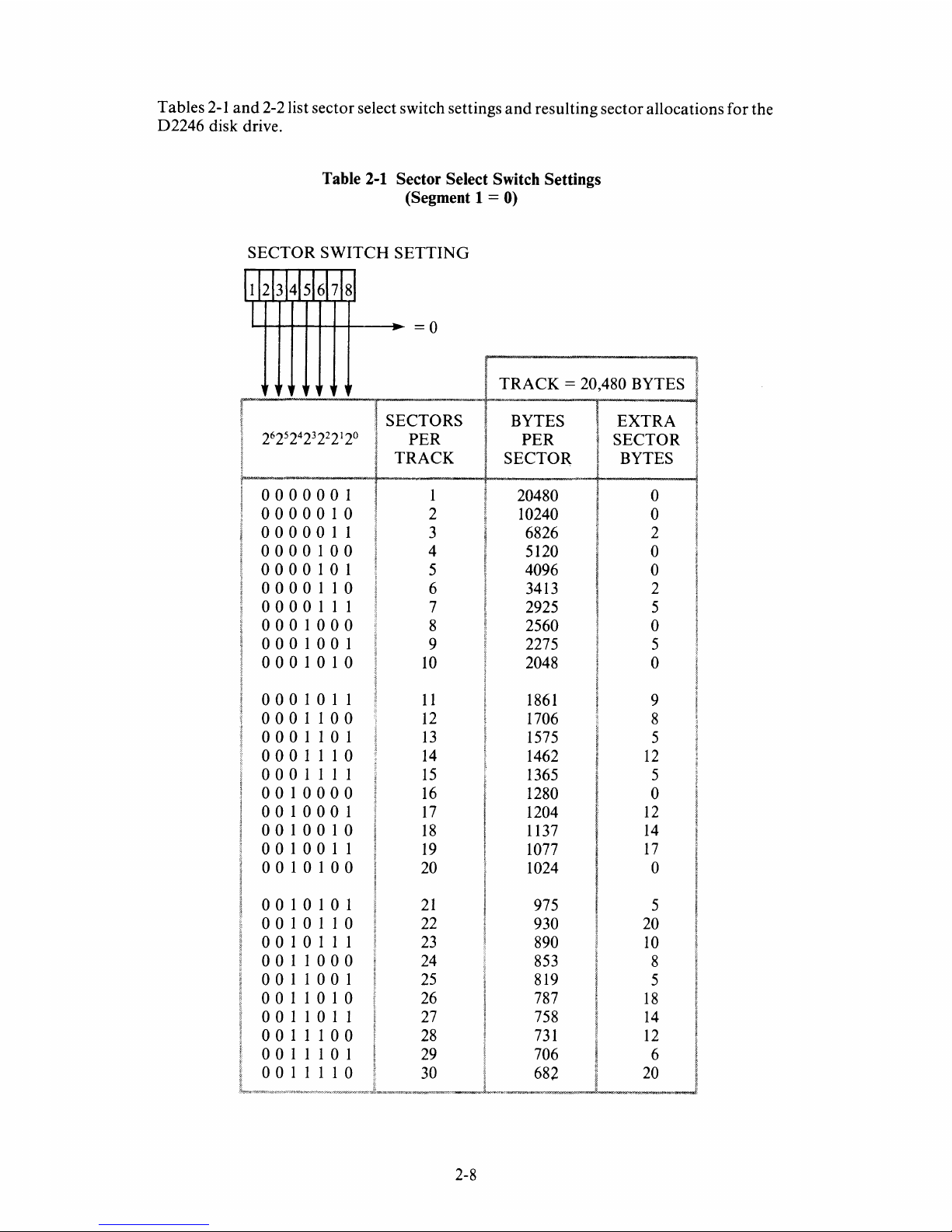

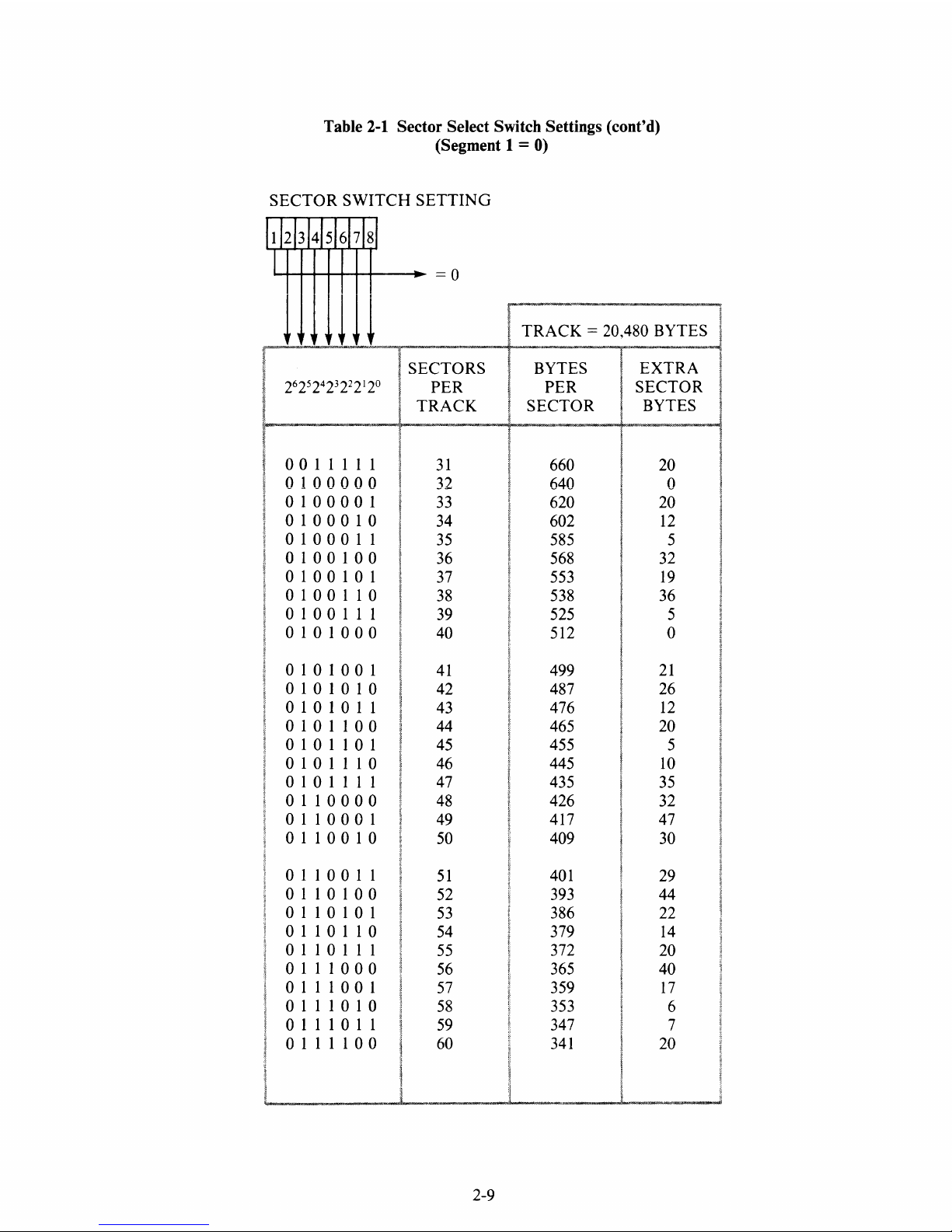

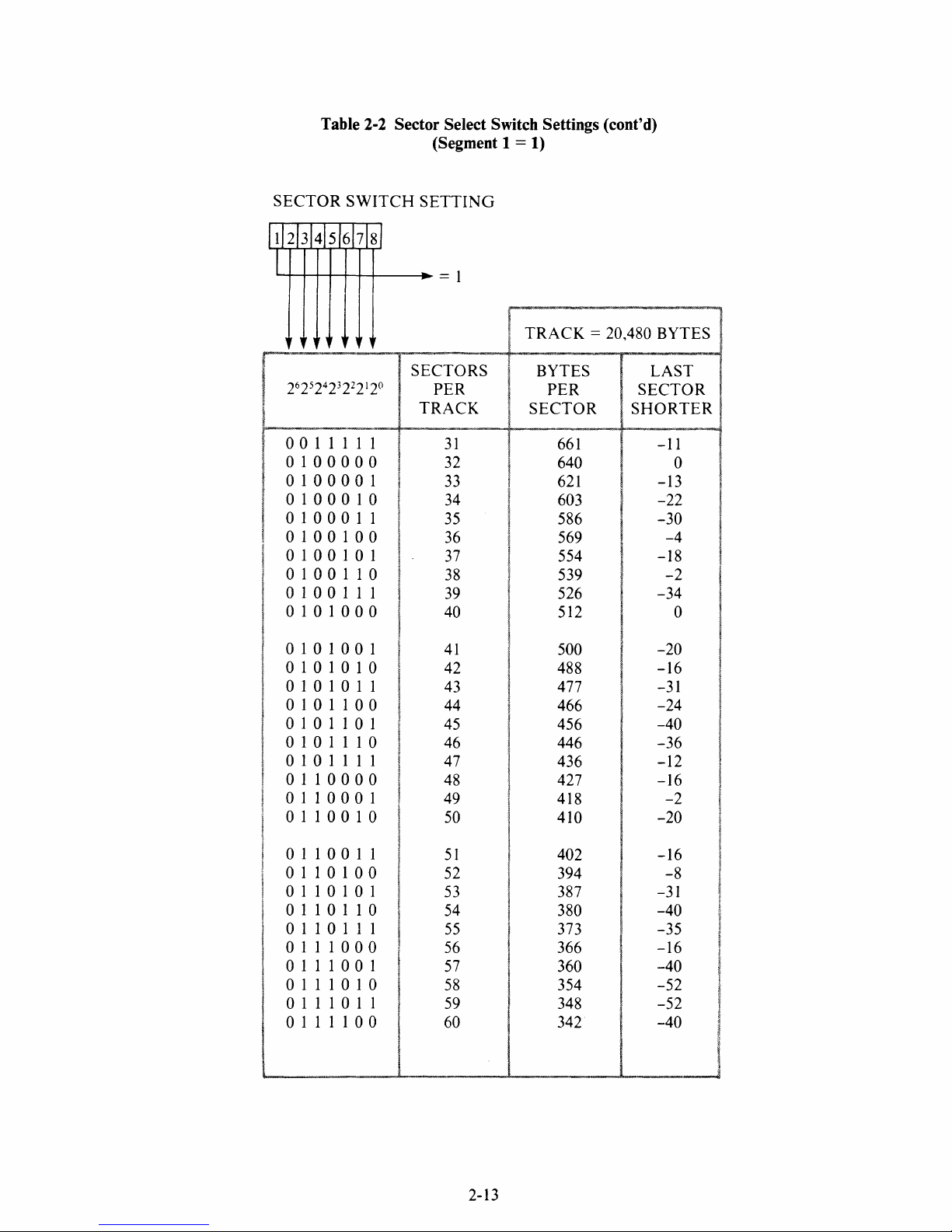

Tables

2-1

and

2-2

list sector select switch settings

and

resulting sector allocations for the

D2246

disk drive.

Table 2-1 Sector Select Switch Settings

(Segment 1

= 0)

SECTOR

SWITCH

SETTING

Id2bl41516bl81

,-+-I~~I-+-_.

= 0

, , , 1 1

If

TRACK

=

20,480

BYTES

SECTORS

2625242322212°

PER

TRACK

o 0 0 0 0 0 1 1

0000010

2

0000011

3

0000100

4

o 0 0 0

101

5

0000110

6

o 0 0 0 1 1 1 7

0001000

8

000

100

1 9

o 0 0 1 0 1 0

10

000

1 0 1 1

11

o 0 0 1 1 0 0

12

o 0 0 1 1 0 1

13

o 0 0 1 1 1 0

14

o 0 0 1 1 1 1

15

o 0 1 0 0 0 0

16

0010001

17

o 0 1 0 0 1 0

18

o 0 1 0 0 1 1

19

o 0 1 0 1 0 0

20

o 0 1 0 1 0 1

21

o 0 1 0 1 1 0

22

o 0 1 0 1 1 1

23

o 0 1 1

000

24

o 0 1 1 0 0 1

25

o 0 1 1 0 1 0

26

o 0 1 1 0 1 1

27

o 0 1 1 1 0 0

28

o 0 1 1 1 0 1

29

o 0 1 1 1 1 0

30

2-8

BYTES

PER

SECTOR

20480

10240

6826

5120

4096

3413

2925

2560

2275

2048

1861

1706

1575

1462

1365

1280

1204

1137

1077

1024

975

930

890

853

819

787

758

731

706

682

EXTRA

SECTOR

BYTES

o

o

2

o

o

2

5

o

5

o

9

8

5

12

5

o

12

14

17

o

5

20

10

8

5

18

14

12

6

20

Page 26

Table 2-1 Sector Select Switch Settings (cont'd)

(Segment 1

= 0)

SECTOR SWITCH

SETTING

112bI415/617/81

I-+I-+-+-+-+-+-+---

.....

~

= 0

I

!"

!

SECTORS

2625242322212°

PER

TRACK

0011111

31

o 1 0 0

000

32

o 1 0

000

1

33

o 1 0 0 0 1 0 34

o 1

000

1 1

35

o 1 0 0 1 0 0 36

o 1 0 0 1 0 1 37

o 1 0 0 1 1 0

38

o 1 0 0 1 1 1

39

o 1 0 1 0 0 0 40

o 1 0 1 0 0 1

41

o 1 0 1 0 1 0 42

o 1 0 1 0 1 1 43

0101100

44

o 1 0 1 1 0 1 45

o 1 0 1 1 1 0 46

o 1 0 1 1 1 1 47

o 1 1 0 0 0 0

48

o 1 1

000

1 49

o 1 1 0 0 1 0 50

o 1 1 0 0 1 1

51

o 1 1 0 1 0 0 52

o 1 1 0 1 0 1

53

o 1 1 0 1 1 0 54

o 1 1 0 1 1 1

55

o 1 1 1

000

56

o 1 1 1 0 0 1

57

o 1 1 1 0 1 0

58

o 1 1 1 0 1 1

59

o 1 1 1 1 0 0 60

2-9

TRACK

= 20,480 BYTES

BYTES

PER

SECTOR

660

640

620

602

585

568

553

538

525

512

499

487

476

465

455

445

435

426

417

409

401

393

386

379

372

365

359

353

347

341

EXTRA

SECTOR

BYTES

20

o

20

12

5

32

19

36

5

o

21

26

12

20

5

10

35

32

47

30

29

44

22

14

20

40

17

6

7

20

Page 27

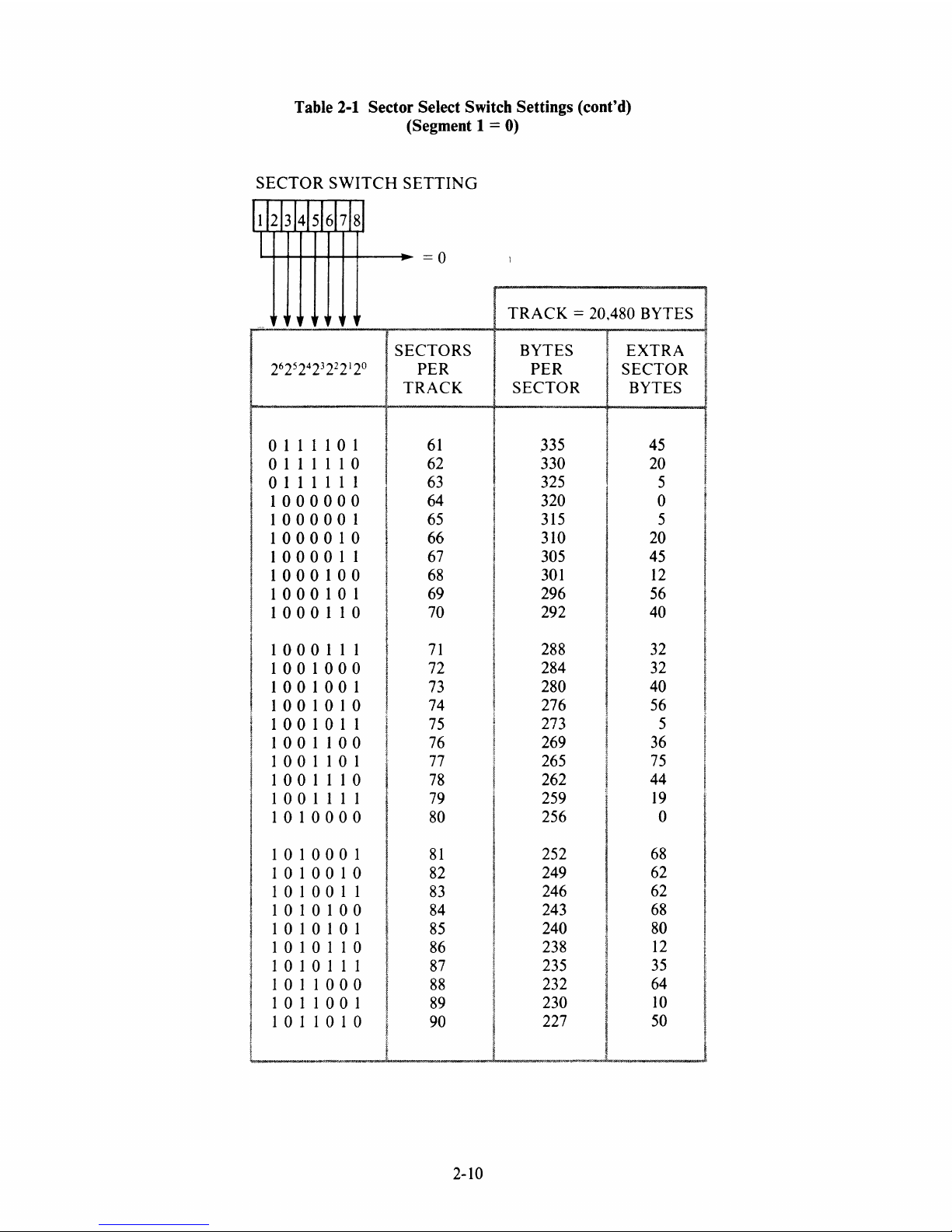

Table 2-1 Sector Select Switch Settings (cont'd)

(Segment 1

= 0)

SECTOR

SWITCH

SETTING

112b14[sf6b181

I~+-+-+--+-+----.

= 0

,

, , ,

SECTORS

2625242322212°

PER

o 1 1 1

101

0111110

0111111

1000000

1000001

1

000

0 1 0

1000011

1000100

1

000

101

1000110

1000111

1001000

100

100

1

1001010

1001011

!

1001100

I

1001101

'

1001110

1001111

1 0 1

000

0

1 0 1

000

1

1 0

100

1 0

1010011

1 0 1 0

100

1 0 1 0

101

1010110

1010111

1011000

1011001

1011010

TRACK

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

2-10

TRACK

= 20,480 BYTES

BYTES

PER

SECTOR

,335

330

325

320

315

310

305

301

296

292

288

284

280

276

273

269

265

262

259

256

252

249

246

243

240

238

235

232

230

227

EXTRA

SECTOR

BYTES

45

20

5

o

5

20

45

12

56

40

32

32

40

56

5

36

75

44

19

o

68

62

62

68

80

12

35

64

10

50

Page 28

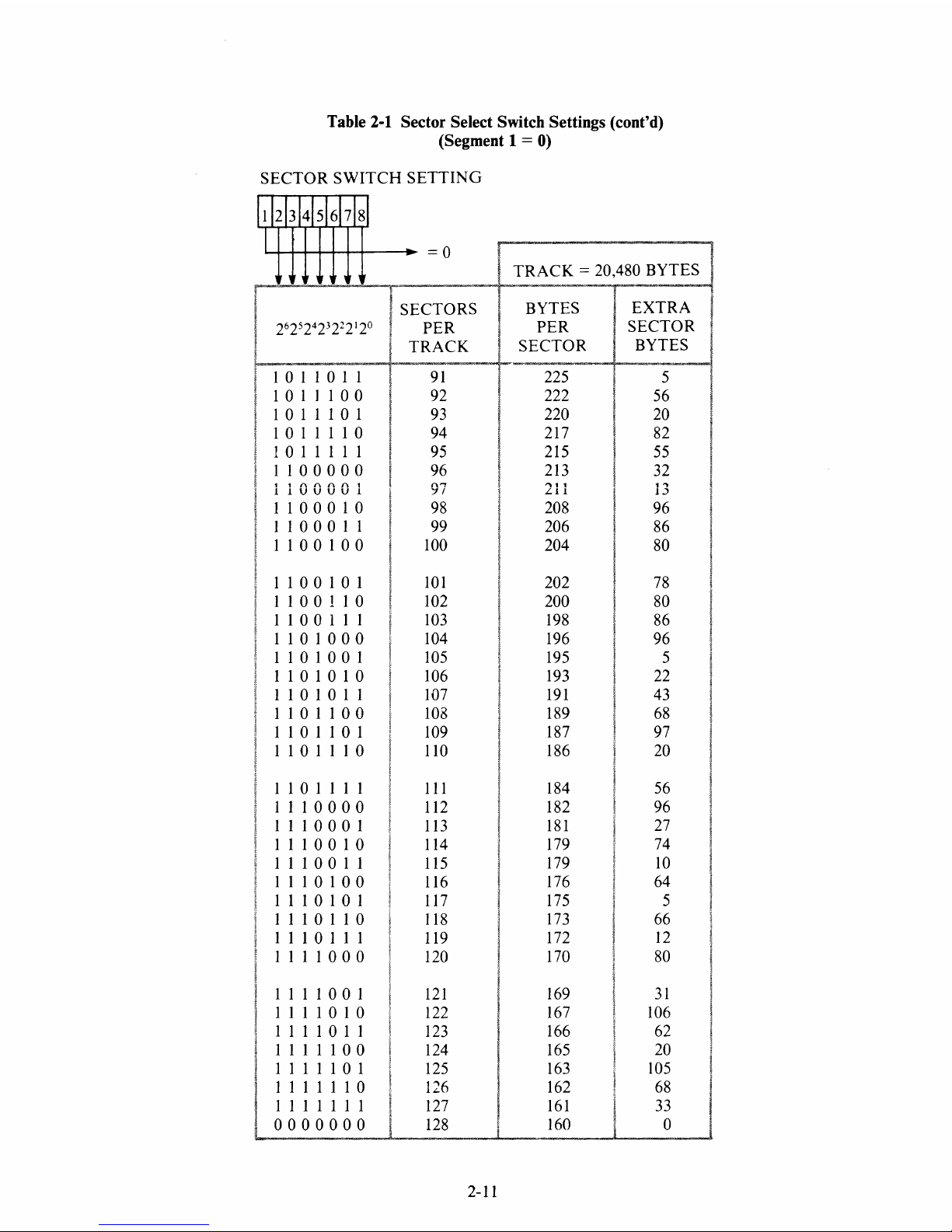

Table 2-1 Sector Select Switch Settings (cont'd)

(Segment 1

= 0)

SECTOR

SWITCH

SETTING

I d2bl41s1617181

L....+--41-+-+-+--+--+-----...

= 0

SECTORS

26252423222'2°

PER

TRACK

1 0 1 1 0 1 1

91

1 0 1 ] 1 0 0 92

1

0 1 1 1 0 1 93

1

0 1 1 1 1 0 94

1 0 1 1 1 1 1 95

1 1

0 0 0 0 0 96

1 1 0 0 0 0 1 97

1 1 0 0 0 1 0 98

1

1 0 0 0 1 1 99

1 1

0 0 1 0 0 100

1

100

101

1100110

1100111

1101000

110 1 001

1101010

1101011

1101100

1101101

1101110

1101111

1110000

1110001

1110010

1110011

1110100

1 1 1 0

101

1110110

1110111

1111000

1111001

1 1 1 1 0 1 0

1111011

1 1 1 1

100

1111101

1111110

1111111

0000000

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

2-11

TRACK

= 20,480

BYTES

BYTES

PER

SECTOR

225

222

220

217

215

213

"'11

L.l

1

208

206

204

202

200

198

196

195

193

191

189

187

186

184

182

181

179

179

176

175

173

172

170

169

167

166

165

163

162

161

160

EXTRA

SECTOR

BYTES

5

56

20

82

55

32

13

96

86

80

78

80

86

96

5

22

43

68

97

20

56

96

27

74

10

64

5

66

12

80

31

106

62

20

105

68

33

o

Page 29

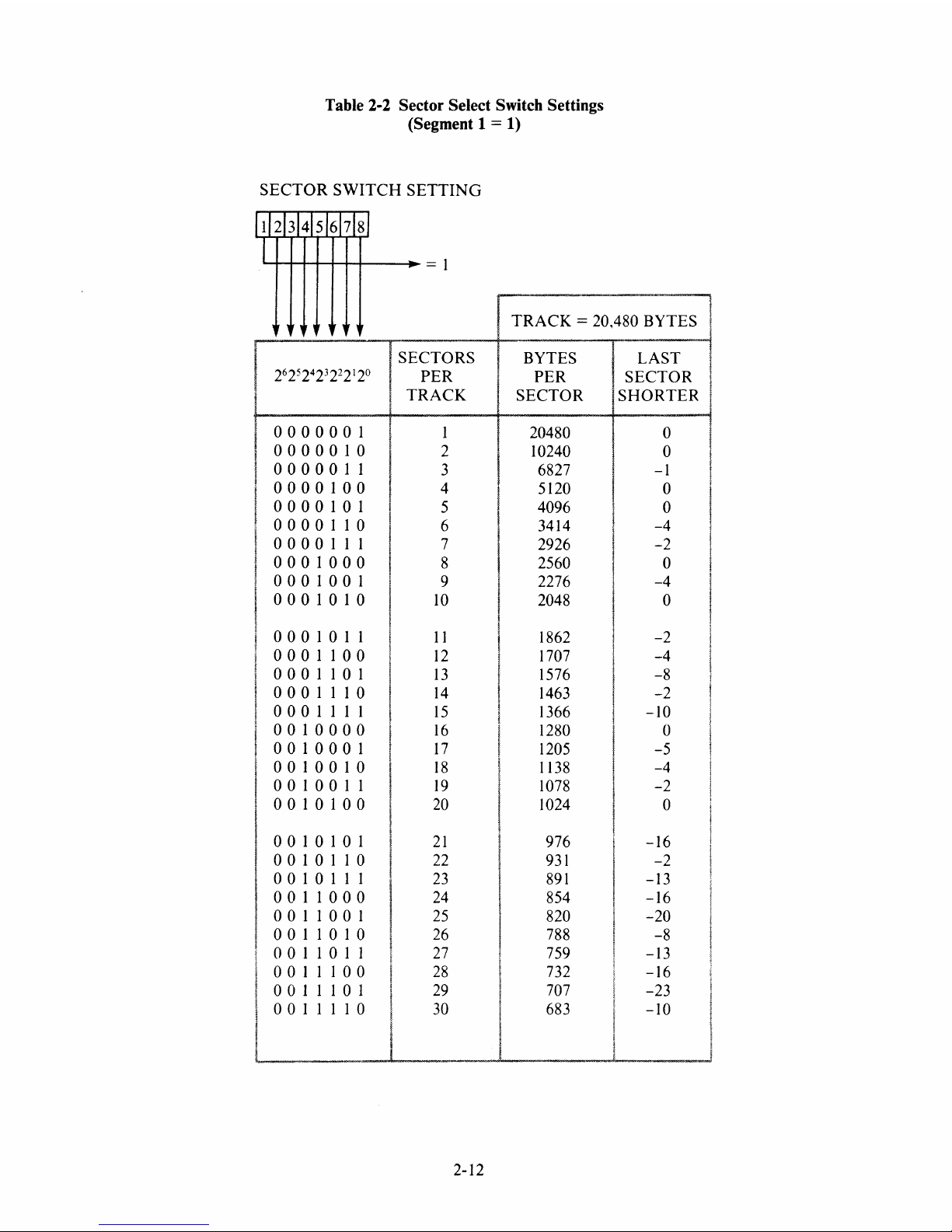

Table 2-2 Sector Select Switch Settings

(Segment 1

= 1)

SECTOR SWITCH SETTING

112/314151617181

'L+-H-+--+--4--+--

.... = 1

, , , •

1~

I TRACK =

20,480

BYTES

SECTORS

2625242322212°

PER

TRACK

o 0 0 0 0 0 1 1

0000010

2

0000011

3

0000100

4

o 0 0 0

101

5

0000110

6

0000111

7

0001000

8

0001001

9

o 0 0 1 0 1 0

10

0001011

0001100

0001101

0001110

0001111

0010000

o 0

100

0 1

o 0

100

1 0

0010011

o 0 1 0

100

o 0 1 0

101

0010110

0010111

0011000

0011001

0011010

0011011

0011100

0011101

0011110

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

2-12

BYTES

PER

SECTOR

20480

10240

6827

5120

4096

3414

2926

2560

2276

2048

1862

1707

1576

1463

1366

1280

1205

1138

1078

1024

976

931

891

854

820

788

759

732

707

683

LAST

SECTOR

SHORTER

o

o

-1

o

o

-4

-2

o

-4

o

-2

-4

-8

-2

-10

o

-5

-4

-2

o

-16

-2

-13

-16

-20

-8

-13

-16

-23

-10

Page 30

Table 2-2 Sector Select Switch Settings (cont'd)

(Segment 1

= 1)

SECTOR

SWITCH

SETTING

/1/213141516/718/

I~+-+-+-+-+-~

= 1

,

SECTORS

26252423222'2°

PER

TRACK

0011111

31

o 1 0

000

0 32

o 1 0 0 0 0 1

33

o 1

000

1 0 34

o 1 0 0 0 1 1

35

o 1 0 0 1 0 0

36

o 1 0 0 1 0 1

37

o 1 0 0 1 1 0

38

o 1 0 0 1 1 1

39

o 1 0 1

000

40

010

100

1

0101010

0101011

0101100

0101101

I"

0101110

j

010 1 111

I

0110000

II',

0110001

0110010

0110011

0110100

0110101

I

0110110

I,

0110111

0111000

0111001

0111010

0111011

0111100

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

2-13

TRJ-\CK = 20,480 BYTES

BYTES

PER

SECTOR

661

640

621

603

586

569

554

539

526

512

500

488

477

466

456

446

436

427

418

410

402

394

387

380

373

366

360

354

348

342

LAST

SECTOR

SHORTER

-11

o

-13

-22

-30

-4

-18

-2

-34

o

-20

-16

-31

-24

-40

-36

-12

-16

-2

-20

-16

-8

-31

-40

-35

-16

-40

-52

-52

-40

I

I

I

I

i

I

I

I

,

t

i

~

i

Page 31

Table 2-2 Sector Select Switch Settings (cont'd)

(Segment 1

= 1)

SECTOR SWITCH

SETTING

1/2/3/4/5/6/7181

l............-+-t-t---1r--t-+--

... = 1

, , , ,

SECTORS

2625242322212°

PER

0111101

0111110

0111111

1000000

100

000

1

1

0 0 0 0 1 0

1000011

1

000

100

1

000

101

1000110

1000111

100

100

0

100 1 001

100

1 0 1 0

1001011

1001100

1001101

1001110

100

1 1 1 1

1

0 1

000

0

1 0 1

000

1

1

0

100

1 0

1010011

1 0 1 0

100

1 0 1 0

101

1010110

1 0

101

1 1

1011000

1011001

1011010

TRACK

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

2-14

i

TR/\CK

= 20,480

BY

!

t:~

BYTES

PER

SECTOR

336

331

326

320

316

311

306

302

297

293

289

285

281

277

274

270

266

263

260

256

253

250

247

244

241

239

236

233

231

228

LAST

SECTOR

SHORTER

-16

-42

-58

o

-60

-46

-22

-56

-13

-30

-39

-40

-33

-18

-70

-40

-2

-34

-60

o

-13

-20

-21

-16

-5

-74

-52

-24

-79

-40

Page 32

I

Table 2-2 Sector Select Switch Settings (cont'd)

(Segment 1

= 1)

SECTOR SWITCH SETTING

~

= 1

TRACK

=

20,480

BYTES

11121314151617181

'HHH!

SECTORS

BYTES

LAST

2625242322212°

PER

PER

SECTOR

TRACK

SECTOR

SHORTER

1011011

91

226

-86

1011100

92

223

-36

1011101

93

221

-73

1011110

94

218

-12

1011111

95

216

-40

1100000

96

214

-64

1100001

97

212

-84

1100010

98

209

-2

1100011

99

207

-13

1100100

100

205

-20

1100101

101

203

-23

1100110

102

201

-22

1

100

1 1 1

103

199

-17

1101000

104

197

-8

1101001

105

196

-100

1101010

106

194

-84

1101011

107

192

-64

1101100

108

190

-40

1101101

109 188

-12

1101110

110

187

-90

1101111

111

185

-55

1110000

112

183

-16

1110001

113

182

-86

1 1

100

1 0

114 180

-40

1 1

100

1 1

115

179

-105

1 1 1

0

100

116 177

-52

1

110

101

117

176

-112

1110110

118

174

-52

1110111

119

173

-107

111 1 000

120

!

171

-40

1 1 1

100

1

121

170

-90

1 1 1 1 0 1 0

122

168

-16

1111011

123

167

-61

111 1 100

124

166

-104

1111101

125

164

-20

1111110

126

163

-58

1111111

127

162

-94

0000000

128

160

0

2-15

Page 33

2.5

CABINETIRACK

INSTALLATION

The mounting bracket (see Figure 2-11) shipped with the D2246 secures the disk drive

when it

is

installed in a cabinet

or

rack.

Figure

2-11

Mounting

Bracket

The drive can be installed in either a horizontal

or

vertical position as shown in Figure

2-12. Figure 2-12 also shows the required ventilation for each mounting position. An air

flow

of

1.1

cubic yards per minute

(1.1

yd3/min)

is

required on a O.4-inch surface.

NOTE

Be

certain

that

the segment 7

of

the installation

switch assembly

is

set according to the mounting

position (see Section 2.4.1).

HORIZONTAL INSTALLATION

Figure

2-12

Horizontal

and

Vertical

Installation

When installing the disk drive, first verify that the mounting holes in the rack

or

cabinet

align with the holes in the mounting bracket. Refer to Appendix B for information on

unit dimensions.

2-16

Page 34

2.6 CABLE

CONNECTIONS

This section describes the different connectors for the interface signal cables (cables A

and

B),

for

the system

ground

cable,

and

for the

power

cable.

2.6.1 Interface Cables

Interface cables

A

and

B are connected

to

the

G9QST

PCB

as

shown

in Figure 2-13.

~

PIN 1 MARK

02246

~

POWER

CABLE------.

B CABLE

-

I

-k~_®u

G9QST

PCB

P1:

] A CABLE

{

:1

r---

j

.

:~----~

L---.l:~===:E=t:~~~

Figure 2-13

Interface

Cable Connections

Cable B should

not

exceed 49.2

ft

(15 m) in length. Cable A should

not

exceed 98.4 ft (30 m)

in length.

In

a daisy-chain system, the

total

length

of

cable A

(from

the controller

to

the

last drive) should

not

exceed 98.4

ft

(see Figure· 2-14).

DISK DRIVE CONTROLLER

SG

AO

BO

B1

Bn

r

CABLEA

CABLE B

-

-

/ \ /

\

/

I

-

~

V

-

~

~~

A

fa-

A

r

B

-

A

rs-

*TERM

*TERM

*TERM

DISK DRIVE DISK DRIVE

---

DISK DRIVE

0

1

4 (maximum)

'-

98.4'

MAXIMUM

j

* TERMINATING RESISTORS INSTALLED

ON

EACH DRIVE

Figure 2-14 Cable AlDaisy-Chain System

2-17

Page 35

2.6.2 System Ground Cable

Connect

a system

ground

cable

to

the signal

ground

(SG) terminal

at

the

rear

of

the disk

drive (see Figure 2-15).

SG (SIGNAL GROUND) TERMINAL

POWER CONNECTOR

(P3)

Figure 2-15 Signal Ground and Power Connections

2.6.3 Power Cable

Connect

the

power

cable

to

connector

P3

at

the rear

of

the disk drive (see Figure 2-15).

2.7

LOCK

CONTROL

ASSEMBLY

When

the disk drive

is

shipped, the spindle

and

actuator

positioner are secured with a

lock device

to

prevent movement. This lock must be released

prior

to

operating the drive.

To

unlock the spindle

and

actuator,

slide the lock

control

lever

to

the

FREE

position (see

Figure 2-16).

I

IliD

LOCK LEVER

Figure 2-16 Lock Control Assembly

2-18

Page 36

Chapter

3

Preventive

Maintenance

and

Troubleshooting

This

chapter

outlines maintenance

and

troubleshooting

procedures

for

the D2246 disk

drive.

It

describes preventive

maintenance,

test

operations

and

test points,

and

asso-

ciated waveforms. Refer

to

Appendix C for

information

on

how

to

use the

optional

diagnostic panel.

3.1 GENERAL MAINTENANCE

RULES

Always observe the following general rules when replacing

parts

or

servicing the disk

drive.

•

Turn

off

the disk drive

and

disconnect all ac

power

to

the

drive

power

supply

before performing

any

maintenance procedure

on

the drive.

• Never remove

or

install

any

PCB,

or

disconnect

any

connector,

plug,

or

wire

while

power

is

on.

•

When

removing

any

connector,

grasp

it firmly

by

its sides

and

pull it

out.

Do

not

remove any connector by pulling

on

the wire bundle.

•

Do

not

remove

any

parts

that

are

not

specified in the replacement procedures.

• Package PCBs in

an

electrostatic-free envelope when they

are

transported.

3.2 MAINTENANCE

TOOLS

Standard

maintenance procedures require the following

common

hand

tools.

•

No.1

Phillips screwdriver

•

No.2

Phillips screwdriver

• Small straight-tip screwdriver

The following instruments are also required.

• High impedance voltmeter

• Oscilloscope (Tektronics 465

or

equivalent)

A

rotor

handler

(NEC

part

number

134-233280)

and

a diagnostic panel

(NEC

part

number

134-200267) are recommended.

3-1

Page 37

3.3 PREVENTIVE MAINTENANCE

Preventive maintenance

is

limited to periodic dusting

of

the surface

of

the drive. No

lubrication

or

further cleaning

is

required

or

recommended. D2246 disk drives contain

no parts

that

require scheduled adjustment

or

replacement.

NOTE

The air filter in the sealed

head/disk

assembly can-

not be replaced

or

cleaned.

As

part

of

a periodic preventive maintenance routine,

run

system-specific (software)

diagnostic programs

or

use the diagnostic panel to

run

offline test procedures (see

Appendix C).

3.4

TROUBLESHOOTING

If

a fault occurs, attempt

to

isolate the fault

to

the host, to the host controller,

to

the disk

drive,

or

to another connecting component.

For

faults isolated to the disk drive, use the

troubleshooting procedures outlined in the following flowcharts. These procedures

localize the fault to a specific drive component.

Figure 3-1 Troubleshooting Flowcharts

3-2

Page 38

W

I

W

-

~

READJUST

INSTALLATION

CH

ECK/REPLACF

DC

POWER

SUPPLY

UNIT

CHECK FOR

SHORT

IN CABLE

OR DRIVE

CONTINUE

T&D

REPLACE

DRIVE

CONTINUE

1 & D

HEPLACE

LOGIC

& SERVO

PCB

CONTINUE

T&D

REPLACE

FAILED

COMPONENTS

REPLACE

DRIVE

CHECK/REPLACE

CONTROLLER

PCB

CONTINUE

T&D

Figure 3-1 Troubleshooting Flowcharts (cont'd)

CONTINUE

T&D

CONTINUE

T & D

Page 39

W

I

VI

0\

9

CHECK

MOTOR

START

REPLACE

LOGIC

& SERVO

PCB

REPLACE

DRIVE

CHECK

LOCK

ASSEMBLY

REPLACE

POWER

AMP

PCB

REPLACE

DRIVE

CONTINUE

T&D

CONTINUE

T&D

REPLACE

DRIVE

CONTINUE

T&D

CONTINUE

T&D

CONTINUE

T&D

<

CONTINUE

T&D

REPLACE

POWER

AMP

PCB

REPLACE

LOGIC

& SERVO

PCB

[

REPLACE

DRIVE

-

Figure 3-1 Troubleshooting Flowcharts (cont'd)

CONTINUE

T&D

CONTINUE

T&D

Page 40

N

REPLACE

LOGIC

& SERVO

PCB

REPLACE

DRIVE

RUN DIAG-

NOSTICS

REPLACE

DRIVE

CONTINUE

T&D

REPLACE

FAILED

COMPONENTS

REPLACE

DRIVE

Figure

3-1

Troubleshooting

Flowcharts

(cont'd)

3-7

CONTINUE

T

r.

D

Page 41

N

REPLACE

LOGIC

& SERVO

PCB

CHECK

SE~UENCE

HOLD

REPLACE

DRIVE

RUN

DIAG-

NOSTICS

REPLACE

DRIVE

CONTINUE

T&D

CONTINUE

T & D

REPLACE

FAILED

COMPONENTS

N

REPLACE

DRIVE

Figure

3-1

Troubleshooting

Flowcharts

(cont'd)

3-8

CONTINUE

T&D

Page 42

REPLACE

FAILED

COMPONENTS

REPLACE

LOGIC

PCB

CHECK

SOFTWARE

& SERVO

REPLACE

DRIVE

CONTINUE

1&D

REPLACE

DRIVE

CONTINUE

T&D

REPLACE

DRIVE

Figure

CONTINUE

T&D

3-1

Troubleshooting Flowcharts (cont'd)

3-9

Page 43

9

CHECK

STATUS

TAG 1

CHECK CYLINDER

ADDRESS(ES)

CAUSING

ERROR

REPLACE

DRIVE

CHECK/REPLACE

INTERFACE

CABLES

N

REPLACE

& SERVO

LOGIC

PCB

CONTINUE

T&D

CONTINUE

T & 0

CONTINUE

T&D

Figure

3-1

Troubleshooting

REPLACE

CONTROLLER

PCB

REPLACE

DRIVE

3-10

Flowcharts

CONTINUE

T&D

(cont'd)

Page 44

Figure 3-1 Troubleshooting Flowcharts (cont'd)

3-11

Page 45

CHECK

HEAD

ADDRESSIESI

CAUSING ERROR

CHECK

SERVO

CLOCK

REPLACE

LOGIC

& SERVO

PCB

REPLACE

DRIVE

CONTINUE

T&D

REPLACE

CONTROLLER

PCB

REPLACE

DRIVE

REPLACE

LOGIC

& SERVO

PCB

REPLACE

READ/WRITE

PCB

REPLACE

DRIVE

CONTINUE

T&D

Figure

3-1

Troubleshooting

Flowcharts

(cont'd)

3-12

CONTINUE

T&D

CONTINUE

T&D

Page 46

3.5 SERVO SYSTEM SIGNALS

on

Test point locations

3-1

lists the signal

the G9QST logic

output

and

TP1