Page 1

Nautilus® U624/U626 (Model Year 2014)

Upright Bikes Service Manual

Table of Contents

Important Safety Instructions 2

Safety Warning Labels and Serial Number 3

Reading the Product Specication Label 3

Specications 3

Maintenance 4

Leveling the Machne 5

Moving the Machine 5

Troubleshooting 6

Console Service Mode 8

Maintenance Parts Exploded View 10

Replacement Procedure Skill Level 12

Mechanical Procedures 13

Belt Tension Adjustment 13

Set the Brake Tension (Calibration) 16

Service Manual

8008323.040115.A

Part Replacement 19

Console 19

Pedals 21

Crank Arms – U626 23

Transport Wheels, Front Endcaps and Footpads 27

Shrouds 29

Handlebar Assembly 34

Console Mast 37

Data Cable in the Mast 41

Brake Assembly 44

Servo Motor 46

Drive Belt and Flywheel Assembly 50

Belt Tensioner Assembly (Idler Assembly) 53

Drive Pulley Assembly (Crank Assembly) – U624 55

RPM Sensor (Speed Sensor) 58

Power Inlet 60

Nautilus, Inc., www.NautilusInc.com - Customer Service: technics@nautilus.com | 18225 NE Riverside Parkway, Portland, OR 97230 USA | © 2014 Nautilus, Inc. | ® indicates trademarks

registered in the United States. These marks may be registered in other nations or otherwise protected by common law. Polar® and Bluetooth® are registered trademarks of their

respective owners.

ORIGINAL DOCUMENT - ENGLISH VERSION ONLY

1

Page 2

Important Safety Instructions and General Troubleshooting

Information for the Nautilus

NOTICE: This document provides important safety instructions, adjustments, and general troubleshooting information for the maintenance of the Nautilus® U624 and

U626 Upright Bikes.

If you need assistance, please contact your local distributor. To find your local distributor, go to: www.nautilusinternational.com

®

U624/U626 Bikes

Service Procedures

8008329.040115.A

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings

on this machine.

Nautilus, Inc., , www.NautilusInc.com - Customer Service: technics@nautilus.com | © 2014 Nautilus, Inc. | ® indicates trademarks registered in the United States. These marks may be registered in other nations or otherwise protected by common law. Polar® and Bluetooth® are registered trademarks of their respective owners. | ORIGINAL DOCUMENT - ENGLISH VERSION ONLY

Important Safety Instructions

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all

Warnings on this machine.

Before servicing or using this equipment, obey the following warnings:

Read and understand the Service Manual before working on the machine. Failure to obey the instructions and safety warnings could

cause injury to the service technician or bystanders.

• Keep bystanders and children away from the product being serviced at all times.

• Make sure that the repair is done in an appropriate work space away from foot trafc and exposure to bystanders.

• Some components of the equipment can be heavy or awkward. Enlist the service of a second person when you do maintenance steps involving

these components. Do not try to do heavy or awkward steps on your own.

• If replacement parts are necessary, use only genuine replacement parts and hardware supplied by Nautilus. Failure to use genuine replacement

parts can cause a risk to users, keep the machine from operating correctly and void the warranty.

• Be sure that all warning stickers and instructional placards applied to the product stay present and in good condition when doing maintenance or

replacing components. If necessary, request replacement warning stickers or placards from your local distributor.

• Do not try to change the design or functionality of the machine being serviced as this can adversely affect user safety.

• Do not put the machine back in service until all shrouds, instructions, warning labels and correct functionality have been veried and tested for

correct performance.

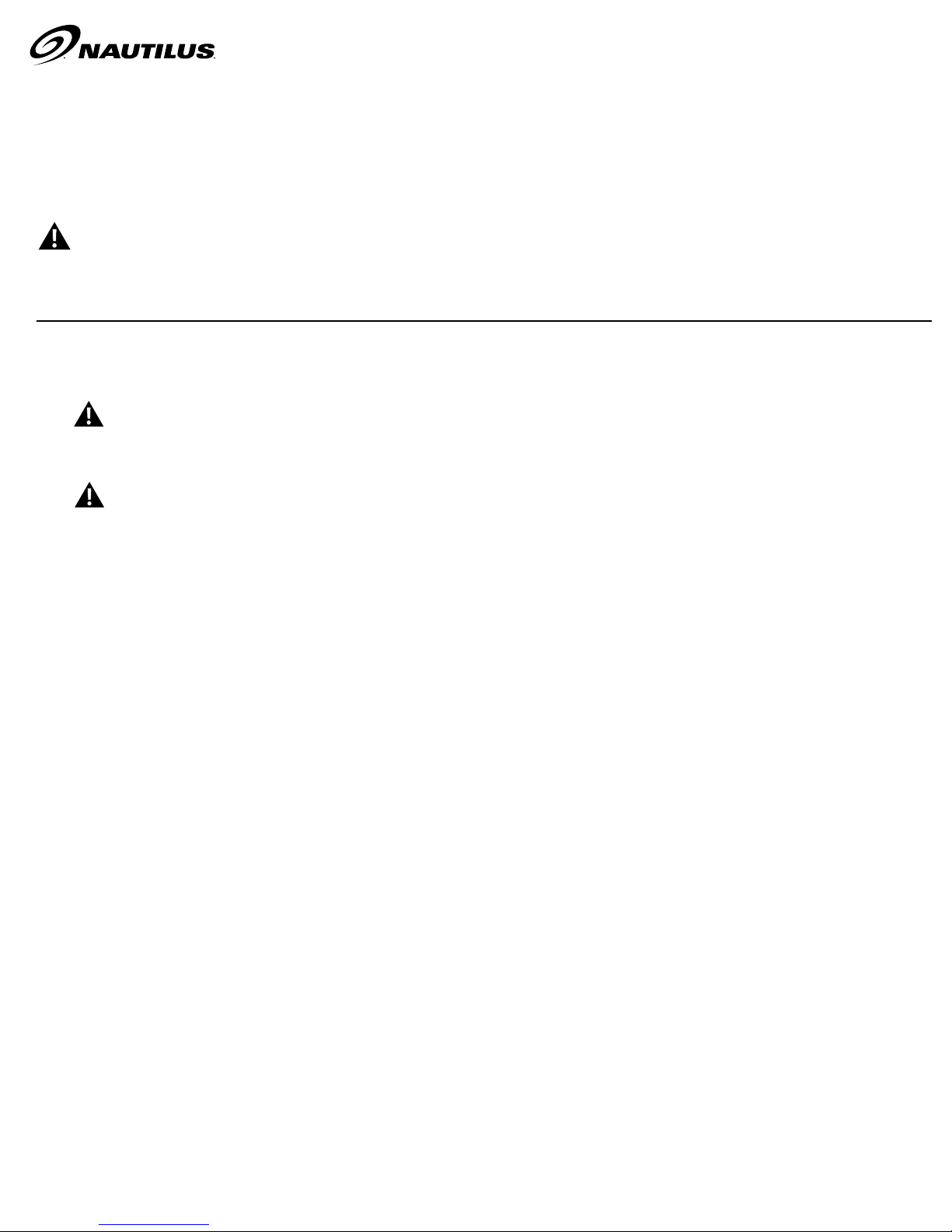

• This product contains magnets. Magnetic elds can interfere with the normal use of certain medical devices at a close range. Users may come

into proximity of the magnets in the assembly, maintenance, and/or use of the product. Given the obvious importance of these devices, such as

a pacemaker, it is important that you consult with your medical provider in connection with the use of this equipment. Please consult the “Safety

Warning Labels and Serial Number” section to determine the location of the magnets on this product.

2

Page 3

Safety Warning Labels and Serial Numbers

REVISIONS

ECO

REVISION

REV DESCRIPTION

A RELEASE TO PRODUCTION

001060 LSEVIER

58mm

30mm

REVISIONS

ECO

REVISION

REV DESCRIPTION

A RELEASE TO PRODUCTION

001060 LSEVIER

58mm

30mm

Serial number

Reading the Product Specification Decal

The Manufacture Date on the Product Specication Decal is a date code: YY/WW (year/week).

Product

specification

Manufacture Date Code:

ISO

20957

compliant

Brand: NAUTILUS Model: U624

Electrical Rating: 9V DC, 1.5A

Accuracy Class: C

Usage Class: H / Consumer use only.

Maximum User Weight: 136kg (300lb)

Equipment Type: Fitness

Made in: China

Patent: www.nautilusinc.com/IP

YYWW

Specifications

Maximum User Weight: 136 kg (300 lb)

Total Surface Area (footprint) of equipment: 5720 cm2 (902.9 in2)

Machine Weight: U624: 30.9 kg (68.1 lb)

U626: 31.1 kg (68.6 lb)

Power Requirements:

Operational Voltage: 9 VDC

Operating Current: 1.5A

AC Power Adapter: 220V - 240V AC, 50Hz

Complies with the following:

ISO 20957 compliant.

Connectivity:

U626 only:

Nautilus, Inc.

18225 NE Riverside Parkway,

Portland, Or. 97230

www.nautilusinternational.com

Phone:1-800-NAUTILUS

8004288_A

Manufacture Date Code:

Brand: NAUTILUS Model: U626

Electrical Rating: 9V DC, 1.5A

Accuracy Class: C

Usage Class: H /Consumer use only.

Max User Weight:136kg (300lb)

Equipment Type: Fitness

Made in: China

Patent: www.nautilusinc.com/IP

104cm (41.8”)

ISO

20957

compliant

YYWW

Nautilus, Inc.

18225 NE Riverside Pkwy,

Portland, Or. 97230

www.nautilusinternational.com

Phone:1-800-NAUTILUS

®

146cm (57.6”)

55cm (21.6”)

8004287_A

DO NOT dispose of this product as refuse. This product is to be recycled. For proper disposal of this product,

please follow the prescribed methods at an approved waste center.

3

Page 4

Maintenance

WARNING

DANGER

Read all maintenance instructions fully before you start any repair work. In some conditions, an assistant is necessary to

do the necessary tasks.

Equipment must be regularly examined for damage and repairs. The owner is responsible to make sure that regular

!

maintenance is done. Worn, damaged or loose components must be repaired or replaced immediately. Only

manufacturer supplied components can be used to maintain and repair the equipment.

If at any time the Warning labels become loose, unreadable or dislodged, contact from your local distributor for

replacement labels.

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the

power cord from the wall outlet and wait 5 minutes before cleaning, maintaining or repairing this

machine. Place the power cord in a secure location.

When disposing of old parts, obey the applicable local and provincial requirements.

!

Daily:

Weekly:

Monthly

or after 20 hours:

NOTICE: Do not clean with a petroleum based solvent or an automotive cleaner. Be sure to keep the Console free

Before each use, examine the exercise machine for loose, broken, damaged, or worn parts.

Do not use if found in this condition. Repair or replace all parts at the first sign of wear or damage.

After each workout, use a damp cloth to wipe your machine and Console free of moisture.

Note: Avoid excessive moisture on the Console.

Clean the machine to remove any dust, dirt, or grime from the surfaces. Check for smooth seat

slider operation. If needed, apply a very thin coating of silicone lube to ease operation.

Note: Do not use petroleum based products.

Check pedals and crank arms and tighten as necessary. Make sure all bolts and screws are tight.

Tighten as necessary.

of moisture.

4

Page 5

Leveling Your Bike

Levelers are found on each side of the Rear Stabilizer. Turn the stabilizer foot to adjust. Make sure the bike is level

and stable before you exercise.

Moving the Bike

To move the upright bike, carefully tilt the Handlebars toward you while pushing the front of the bike downward. Push the

bike to the desired location.

NOTICE: Be careful when you move the bike. Abrupt motions can affect the computer operation.

5

Page 6

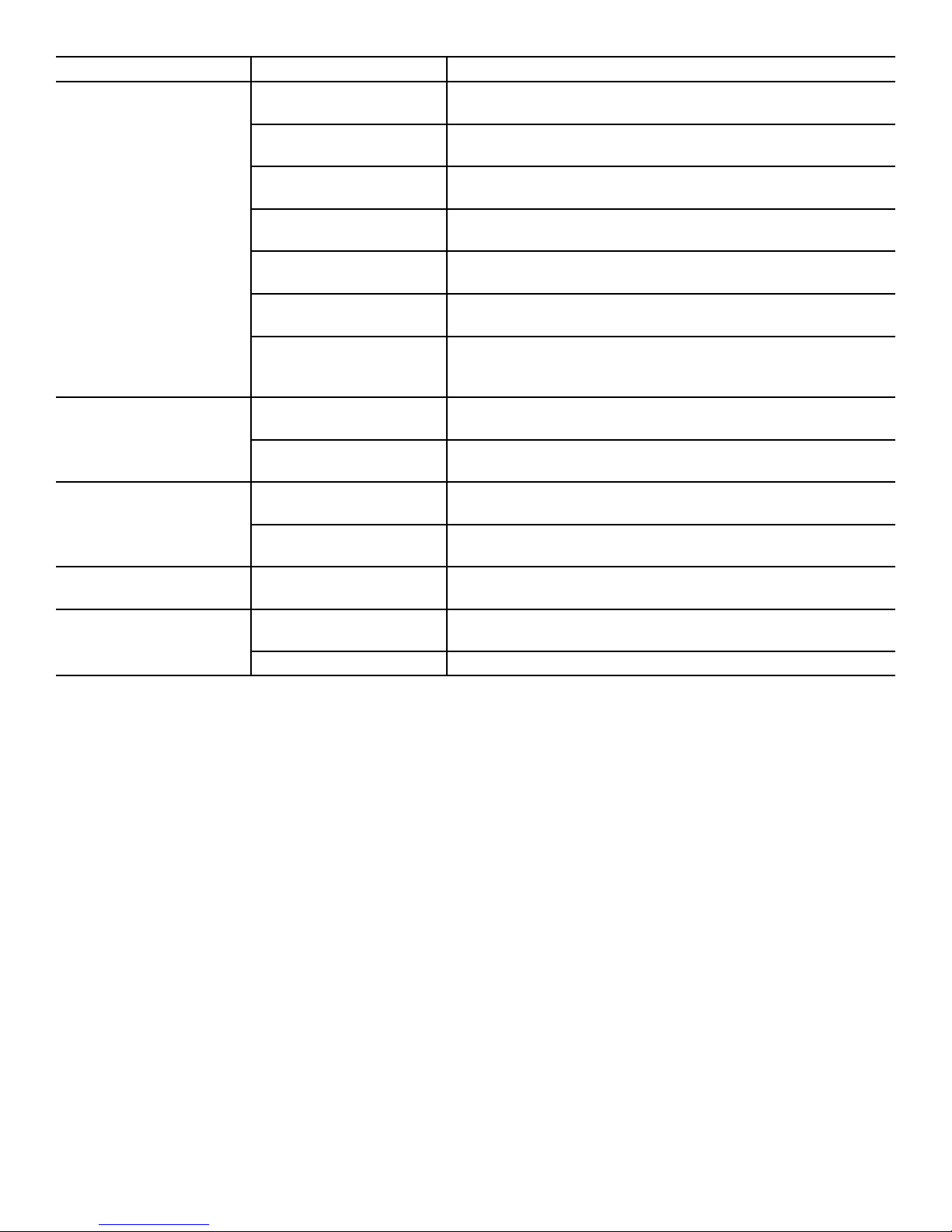

Troubleshooting

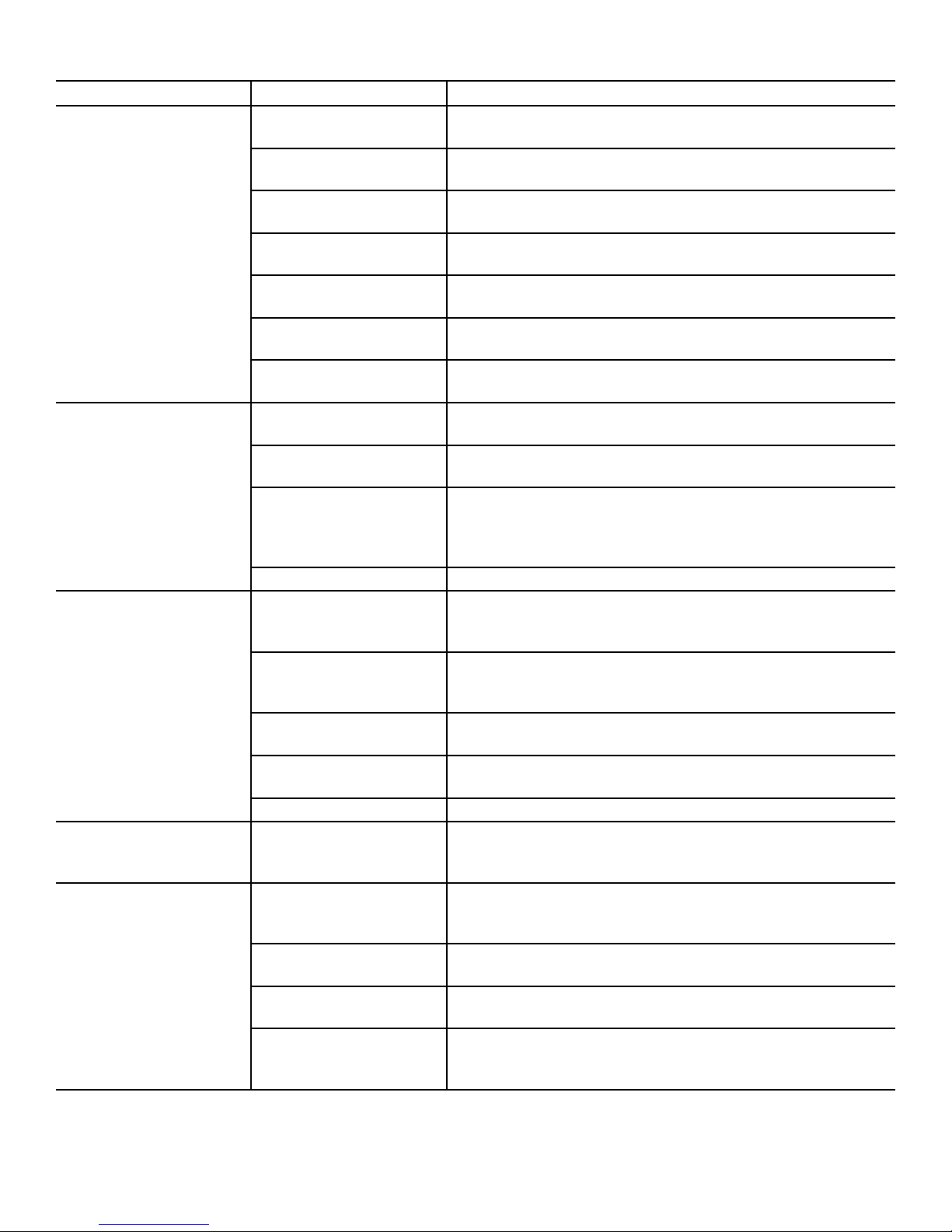

Condition/Problem Things to Check Solution

No display/partial display/

unit will not turn on

Unit operates but Contact

HR not displayed

Unit operates but

Telemetric HR not

displayed (U626 only)

Unit operates but

Telemetric HR displayed

incorrectly (U626 only)

No speed/RPM reading,

Console displays “Please

Pedal” error code

Check electrical (wall)

outlet

Check connection on

console

Check data cable integrity All wires in cable should be intact. If any are visibly crimped or

Check data cable

connections/orientation

Check console display for

damage

Console Display If Console only has partial display and all connections are ne,

HR cable connection at

Console

Sensor grip Be sure hands are centered on HR sensors. Hands must be

Dry or calloused hands Sensors may have difculty with dried out or calloused hands.

Handlebar If tests reveal no other issues, Handlebars should be replaced.

Chest Strap (optional) Strap should be “POLAR®” compatible and uncoded. Make

Check User Prole Select the Edit User Prole option for the User Prole. Go to

Interference Try moving unit away from sources of interference (TV, Micro-

Replace Chest Strap If interference is eliminated and HR does not function, replace

Replace Console If HR still does not function, replace Console.

Interference Make sure that the HR receiver is not blocked by a personal

Check data cable integrity All wires in cable should be intact. If any are cut or crimped,

Check data cable

connections/orientation

Check magnet position

(requires shroud removal)

Check Speed Sensor

(requires shroud removal)

Make sure unit is plugged into a functioning wall outlet.

Connection should be secure and undamaged. Replace

adapter or connection at unit if either are damaged.

cut, replace cable.

Be sure cable is connected securely and oriented properly.

Small latch on connector should line up and snap into place.

Check for visual sign that console display is cracked or otherwise damaged. Replace Console if damaged.

replace the Console.

If the above steps do not resolve the problem, contact your

local distributor for further assistance.

Be sure cable is connected securely to Console.

kept still with relatively equal pressure applied to each side.

A conductive electrode cream (heart rate cream) can help

make better conduct. These are available on the web or at

medical or some larger tness stores.

sure strap is directly against skin and contact area is wet.

the WIRELESS HR setting and make sure that the current

value is set to ON.

wave, etc).

strap.

electronic device in the left side of the media tray.

replace cable.

Be sure cable is connected securely and oriented properly.

Small latch on connector should line up and snap into place.

Magnet should be in place on pulley.

Speed sensor should be aligned with magnet and connected to

data cable. Realign sensor if necessary. Replace if there is any

damage to the sensor or the connecting wire.

6

Page 7

Condition/Problem Things to Check Solution

Console shuts off (enters

sleep mode) while in use

Check electrical (wall)

outlet

Check connection on

console

Make sure unit is plugged into a functioning wall outlet.

Connection should be secure and undamaged. Replace

adapter or connection at unit if either are damaged.

Check data cable integrity All wires in the cable should be intact. If any are cut or crimped,

replace cable.

Check data cable

connections/orientation

Be sure cable is connected securely and oriented properly.

Small latch on connector should line up and snap into place.

Reset Machine Unplug unit from electrical outlet for 3 minutes. Reconnect to

outlet.

Check magnet position

Magnet should be in place on pulley.

(requires shroud removal)

Check Speed Sensor

(requires shroud removal)

Speed sensor should be aligned with magnet and connected to

data cable. Realign sensor if necessary. Replace if there is any

damage to the sensor or the connecting wire.

Unit rocks/does not sit

Check leveler adjustment Adjust levelers until bike is level.

level

Check surface under unit Adjustment may not be able to compensate for extremely un-

even surfaces. Move bike to level area.

Pedals loose/unit difcult

to pedal

Clicking sound when

pedaling

Check pedal to crank arm

connection

Check crank arm to axle

connection

Check pedal to crank arm

connection

Pedal should be tightened securely to crank. Insure connection

is not cross-threaded.

Crank should be tightened securely to axle. Be sure cranks are

connected at 180 degrees from each other.

Remove pedals. Make sure there is no debris on threads, and

reinstall the pedals.

Seat post movement Check locking pin Be sure adjustment pin is locked into one of the seat post

adjustment holes.

Check adjustment knob Be sure knob is securely tightened.

7

Page 8

Console Service Mode – x624 / x626 series (MY14) Consoles

The Console Setup Mode lets you input the date and time, set the units of measurement to either English or Metric, change

the machine type, control the sound settings ( on/ off), or see maintenance statistics (Total Run Hours – for service technician

use only).

1. Hold down the PAUSE/END button and Right button together for 3 seconds while in the Power-Up Mode to go into the

Console Setup Mode.

Note: Push PAUSE/END to exit the Console Setup Mode and return to the Power-Up Mode screen.

2. The Console display shows the Date prompt with the current setting. To change, push the Increase/Decrease buttons to

adjust the currently active value (flashing). Push the Left/Right buttons to change which segment is the currently active

value (month / day / year).

3. Push OK to set.

4. The Console display shows the Time prompt with the current setting. Push the Increase/Decrease buttons to adjust the

currently active value (flashing). Push the Left/Right buttons to change which segment is the currently active value (hour /

minute / AM or PM).

5. Push OK to set.

6. The Console display shows the Units prompt with the current setting. To change, push OK to start the Units option. Push

the Increase/Decrease buttons to change between “MILES” (Imperial English units) and “KM” (metric units).

Note: If the units change when there is data in User Statistics, the statistics convert to the new units.

7. Push OK to set.

8. The Console display shows the Machine Type prompt with the current setting. This menu option appears in the x624

series console only (not the x626 series consoles). Push the Increase/Decrease buttons to change between “BIKE” and

Elliptical (“ELIP”).

9. Push OK to set.

10. The Console display shows the Sound Settings prompt with the current setting. Push the Increase/Decrease buttons to

change between “ON” and “OFF”.

11. Push OK to set.

12. The Console display shows the TOTAL RUN HOURS for the machine.

To go to the next Console Setup Mode prompt, push the OK button.

To enter the Manufacturing Menu (MFG Menu), hold down the PAUSE/END button and Down button together for 3

seconds. The Console display shows the Firmware Version string. Push the Up/Down buttons to move through the MFG

Menu options. Push OK to make a selection.

a. ENTER MFG TEST – This option is intended for use on the manufacturing production line only. It is a chained series

of tests similar to the tests listed below, but optimized to be run on the production line. This chained test should not

be used anywhere but on the production line.

b. DEBUG TERMINAL – Not used.

c. MOVE LIFT – (E626 elliptical only) Used to adjust a new lift motor. The Console displays “UP MX DN MN RT CAL”: Up

arrow will move the lift motor to the maximum position; Down arrow will move the lift motor to the minimum position;

Right arrow will perform a lift motor calibration by moving the lift motor to its minimum and maximum position. Note:

Lift motor calibration is no longer required, so calibration is not needed.

d. RESET MFG NVM – Resets MFG NVM (non volatile memory). Must be run before lift motor calibration if a valid lift

table exists in NVM (lift motor has been calibrated before).

e. RUN BEEP TEST – Sounds each system beep / tone / sequence in order. Press any key to exit

f. RUN BUTTON TEST – The Console display shows the function of each button as buttons are pressed. If the display

shows an incorrect function, the overlay on the Console may be incorrect for that model. If the display does not show

a function, the firmware version may be incorrect. No beeps are sounded during this test.

To exit the test, push and hold one of the long key sequences (i.e. long Pause / End + Right or long Pause / End +

Down).

g. RUN LED TEST – Drives LEDs to the following states:

1. All LEDs On 1 second

8

Page 9

2. All LEDs Off 1 second

3. Sequence Segments 1 at a time – on 1 second, off 1 second

Press any key to exit test

h. RUN LCD TEST – Drives 3x5 and 1x5 LCD displays with the following patterns:

1. All segments on

2. All segments off

3. Set individual segments one at a time until all segments are illuminated.

Press any key to exit.

i. RESET CONSOLE – Resets the data from user inputs. The Console setup, user records and workout records will be

reset to defaults. This option does not reset MFG NVM (non volatile memory).

13. The Console display shows the Software Version prompt.

14. For the next prompt, push the OK button.

15 . The Console will display the Power-Up Mode screen.

9

Page 10

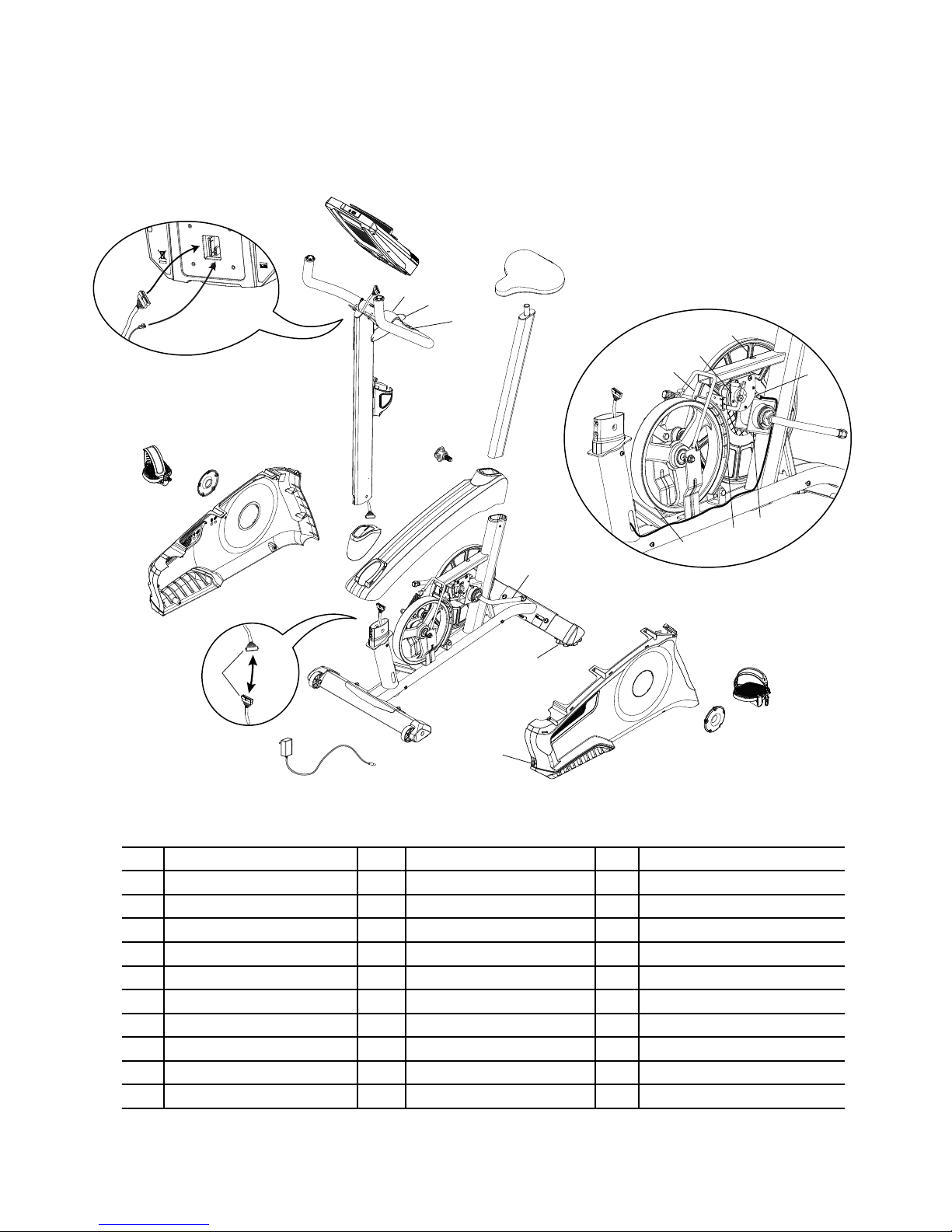

Maintenance Parts Exploded View

Your machine may differ. Use only as a guide.

U624

A

A

J

L

C

FF

G

J

K

DD

EE

M

R

B

I

U

P

H

N

O

BB

J

D

S

T

E

AA

W

CC

Y

D

Z

X

C

Q

V

F

FF

A Console L HR Cable W Flywheel

B Console Mast M CHR Sensors X Brake Assembly

C Pedals N Seat Y RPM Sensor

D Crank Arms O Seat Post w/ Slider Z Speed Sensor Magnet

E Left Shroud P Adjustment Knob AA Servo Motor

F Power Inlet Q AC Adapter BB Drive Belt

G Right Shroud R Water Bottle Holder CC Drive Pulley

H Top Shroud S Rear Stabilizer DD Handlebar Mount Cover

I Mast Gasket T Levelers EE T-handle

J Data Cable U Front Stabilizer FF Cover, Crank Disc

K Handlebars V Transport Wheels

10

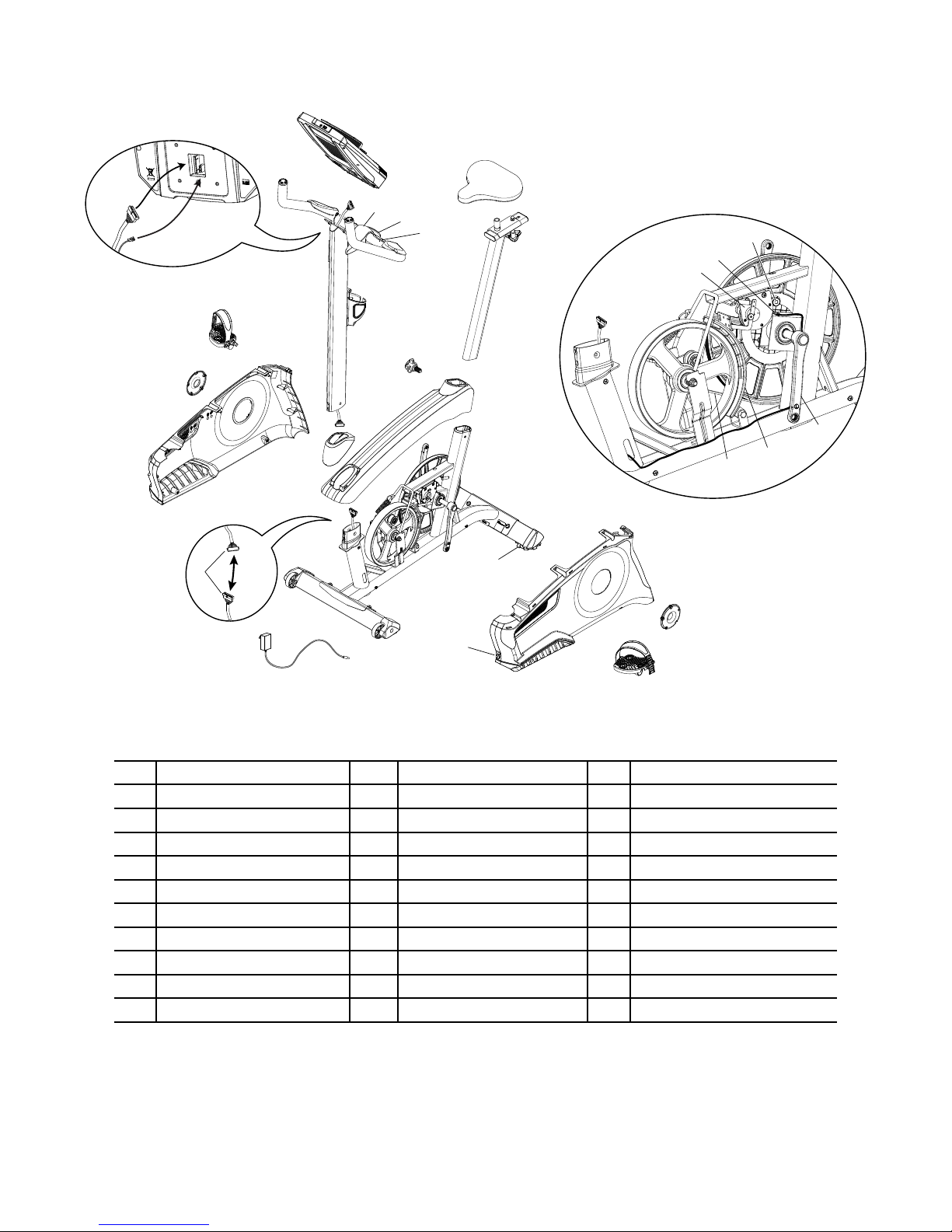

Page 11

U626

A

A

J

L

C

FF

G

J

K

DD

EE

M

R

B

I

U

P

H

D

N

Z

Y

O

J

S

T

E

AA

W

CC

D

X

BB

FF

Q

V

F

C

A Console L HR Cable W Flywheel

B Console Mast M CHR Sensors X Brake Assembly

C Pedals N Seat Y RPM Sensor

D Crank Arms O Seat Post w/ Slider Z Speed Sensor Magnet

E Left Shroud P Adjustment Knob AA Servo Motor

F Power Inlet Q AC Adapter BB Drive Belt

G Right Shroud R Water Bottle Holder CC Drive Pulley

H Top Shroud S Rear Stabilizer DD Handlebar Mount Cover

I Mast Gasket T Levelers EE T-handle

J Data Cable U Front Stabilizer FF Cover, Crank Disc

K Handlebars V Transport Wheels

11

Page 12

REPLACEMENT PROCEDURE SKILL LEVEL

WARNING

DANGER

Level I : Low - very little mechanical knowledge or exposure.

Level II : Intermediate - some experience with mechanical procedures

Level III : Advanced - knowledgeable about mechanical procedures

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power

cord from the wall outlet and wait 5 minutes before cleaning, maintaining or repairing this machine. Place

the power cord in a secure location.

When disposing of old parts, obey the applicable local and provincial requirements.

!

For instructions to replace the following parts, please refer to the Assembly Manual for your bike:

• AC Adapter

• Seat

• Seat Post

• Front Stabilizer

• Rear Stabilizer

• Water Bottle Holder

12

Page 13

Adjust the Belt Tension on the Nautilus® U624/U626 and

WARNING

DANGER

R624/R626 (Model Year 2014) Bikes

NOTICE: This document provides instructions for the adjustment of the Drive Belt tension on the Nautilus® U624 and U626 Upright Bikes, and

R624 and R626 Recumbent Bikes.

If you need assistance, please contact your local distributor. To find your local distributor, go to: www.nautilusinternational.com

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings

on this machine.

Nautilus, Inc., , www.NautilusInc.com - Customer Service: technics@nautilus.com | © 2014 Nautilus, Inc. | ® indicates trademarks registered in the United States. These marks may be registered in other nations or otherwise

protected by common law. | ORIGINAL DOCUMENT - ENGLISH VERSION ONLY

Replacement Procedure

Skill Level: II

8008330.040115.A

Important Safety Instructions - Before servicing or using this equipment, obey the following warnings:

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings on

this machine.

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and

wait 5 minutes before cleaning, maintaining or repairing this machine. Place the power cord in a secure location.

• Read and understand the Part Replacement Procedure before working on the machine. Failure to obey the instructions and safety warnings

could cause injury to the service technician or bystanders.

• Keep bystanders and children away from the product being serviced at all times.

• Make sure that the repair is done in an appropriate work space away from foot trafc and exposure to bystanders.

• Some components of the equipment can be heavy or awkward. Enlist the service of a second person when you do maintenance steps

involving these components. Do not try to do heavy or awkward steps on your own.

• If replacement parts are necessary, use only genuine Nautilus replacement parts and hardware. Failure to use genuine replacement parts

can cause a risk to users, keep the machine from operating correctly and void the warranty.

• Be sure that all warning stickers and instructional placards applied to the product stay present and in good condition when doing

maintenance or replacing components. If necessary request replacement warning stickers or placards from from your local distributor.

• Do not try to change the design or functionality of the machine being serviced as this can adversely affect user safety.

• Do not use the machine until all shrouds, instructions, warning labels and correct functionality have been verified and tested for correct

performance.

• This product contains magnets. Magnetic elds can interfere with the normal use of certain medical devices at a close range. Users may

come into proximity of the magnets in the assembly, maintenance, and/or use of the product. Given the obvious importance of these devices,

such as a pacemaker, it is important that you consult with your medical provider in connection with the use of this equipment. Please consult

the “Safety Warning Labels and Serial Number” section in the Owner’s Manual to determine the location of the magnets on this product.

Tools Required (not included)

#2 Phillips screwdriver 15mm open end wrench

Small athead screwdriver 15mm socket and wrench

Pedal wrench (U624/R624)

or crank puller (U626/R626)

13

Page 14

NOTICE: It is necessary to remove the Shrouds for this procedure. Refer to the “Replace the Shrouds” procedure.

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and wait 5

!

minutes before cleaning, maintaining or repairing this machine. Place the power cord in a secure location.

Note: Your machine may not match the image. For reference only.

1. Remove the Top Shroud, Left Shroud and Right Shroud from the

Main Unit. Refer to the “Replace the Shrouds” procedure.

2. To test the Drive Belt tension:

• Push the Drive Belt downward at the midpoint (M) between the

pulleys and measure the distance. The Drive Belt should have

only 0.25” (0.64 cm) of give. See Figure 1.

Or:

• Hold the edges of the Drive Belt at the midpoint (M) and twist it

(see Figure 2). It should turn only 90 degrees

(1/4 turn, to vertical).

If the tension is correct, go to Step 6.

If the tension is too loose or too tight, adjust the position of the

Flywheel. Continue to Step 3.

3. To loosen the Flywheel hardware (A), use a 15 mm open end

wrench to hold the nut on one side steady and loosen the nut on the

opposite side with a 15 mm socket and wrench.

Figure 1

0.64 cm

0.25”

}

M

A

4. Move the Flywheel in the Main Frame bracket as necessary to

adjust the tension. Hold it in position and tighten the hardware.

Note: This step may require two people.

To tighten the Flywheel hardware, use a 15 mm open end

wrench to hold the nut on one side steady and tighten the nut on

the opposite side with a 15 mm socket and wrench.

5. Carefully turn the crank arms and check the movement of the drive

belt. The Crank Arms and Flywheel should move as one.

Be sure to keep ngers clear of all pinch hazards when you turn

!

the Drive Pulley.

Adjust the belt tension again if necessary.

M

(Main Frame bracket not shown for clarity)

Figure 2

14

Page 15

6. Reassembly is the reverse procedure.

NOTICE: Be sure not to crimp any cables.

U624/R624 bikes—To reinstall the Pedals, carefully align the threads

and hand tighten to prevent cross-threading. Then tighten fully with pedal

wrench.

Note: The Left Pedal is reverse-threaded. Orientation is based

from a seated position on the bike. The Left Pedal has an “L”,

the Right Pedal an “R”.

16. Final Inspection

Inspect your machine to ensure that all hardware is tight and components

are properly assembled.

Do not use until the machine has been fully assembled and

!

inspected for correct performance in accordance with the Owner’s

Manual.

15

Page 16

Set the Brake Tension (Calibration)

WARNING

DANGER

®

on the Nautilus

NOTICE: This document provides instructions for the calibration of the Brake tension on the Nautilus® U624 and U626 Upright Bikes.

If you need assistance, please contact your local distributor. To find your local distributor, go to: www.nautilusinternational.com

U624/U626 (Model Year 2014) Bikes

Replacement Procedure

Skill Level: III

8008331.040115.A

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings

on this machine.

Nautilus, Inc., , www.NautilusInc.com - Customer Service: technics@nautilus.com | © 2014 Nautilus, Inc. | ® indicates trademarks registered in the United States. These marks may be registered in other nations or

otherwise protected by common law. | ORIGINAL DOCUMENT - ENGLISH VERSION ONLY

Important Safety Instructions - Before servicing or using this equipment, obey the following warnings:

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings on

this machine.

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and

wait 5 minutes before cleaning, maintaining or repairing this machine. Place the power cord in a secure location.

• Read and understand the Part Replacement Procedure before working on the machine. Failure to obey the instructions and safety warnings could cause

injury to the service technician or bystanders.

• Keep bystanders and children away from the product being serviced at all times.

• Make sure that the repair is done in an appropriate work space away from foot trafc and exposure to bystanders.

• Some components of the equipment can be heavy or awkward. Enlist the service of a second person when you do maintenance steps involving these

components. Do not try to do heavy or awkward steps on your own.

• If replacement parts are necessary, use only genuine replacement parts and hardware supplied by Nautilus. Failure to use genuine replacement parts can

cause a risk to users, keep the machine from operating correctly and void the warranty.

• Be sure that all warning stickers and instructional placards applied to the product stay present and in good condition when doing maintenance or replacing

components. If necessary request replacement warning stickers or placards from from your local distributor.

• Do not try to change the design or functionality of the machine being serviced as this can adversely affect user safety.

• Do not use the machine until all shrouds, instructions, warning labels and correct functionality have been verified and tested for correct performance.

• This product contains magnets. Magnetic elds can interfere with the normal use of certain medical devices at a close range. Users may come into

proximity of the magnets in the assembly, maintenance, and/or use of the product. Given the obvious importance of these devices, such as a pacemaker, it

is important that you consult with your medical provider in connection with the use of this equipment. Please consult the “Safety Warning Labels and Serial

Number” section in the Owner’s Manual to determine the location of the magnets on this product.

Tools Required (not included)

#2 Phillips screwdriver 7mm open end wrench

Small athead screwdriver

Pedal wrench (U624)

or crank puller (U626)

2.5” x 10” cardboard (3mm / 1/8” thick)

and tape

16

Page 17

NOTICE: It is necessary to remove the shrouds for this procedure. Refer to the “Replace the Shrouds” procedure.

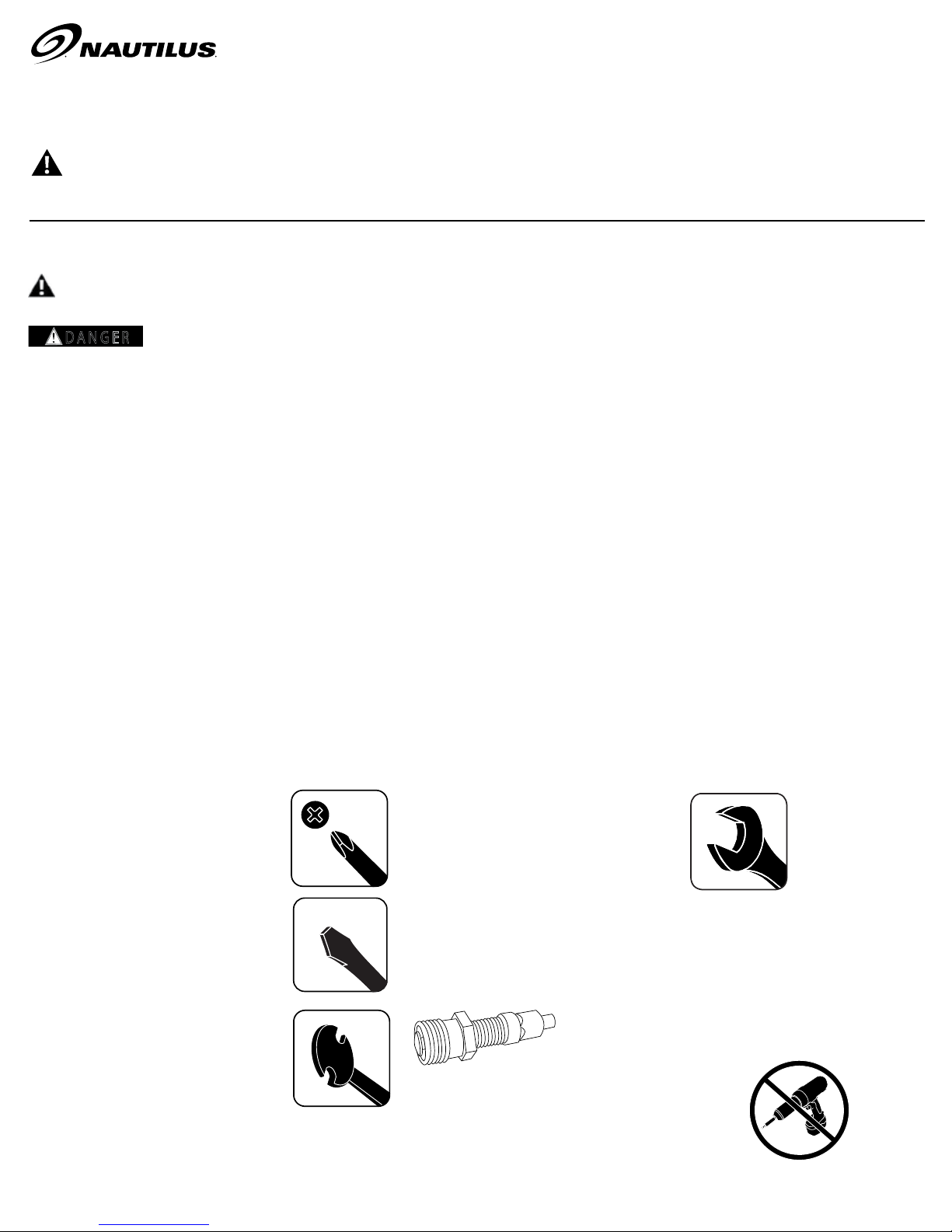

Note: Your machine may not match the image. For reference only.

1. Disconnect and reconnect the AC Adapter from the wall outlet to turn

the power off and on.

2. Push QuickStart and verify that the console shows that the default

resistance level is 4.

Disconnect all power and allow to sit for 5 minutes.

3. Carefully remove the Seat Post, Left Shroud and Right Shroud.

(Refer to the “Replace the Shrouds” procedure.) Do not remove the

Console and Mast, and keep the Power Inlet cable (P) in the Shroud

connected to the wiring harness on the motor (D). Slide the Mast Gasket

and Top Shroud up the Mast. Lean the Top Shroud against the Seat Post

mount to keep it clear of the pulley assembly.

Note: It may be necessary to remove the Water Bottle Holder.

4. Insert 2.5” x 10” cardboard between the Brake Magnet (A) and the

Flywheel (B), and tape the cardboard to the Brake Magnet.

Note: Be sure the cardboard covers all of the Brake Magnet.

5. Turn the power on again.

Machine is on. Current is active. There is risk of electrical shock.

6. Use the console to set the resistance to the highest level. This moves

the Brake Magnet Arm (A1) forward. After the Brake Magnet Arm stops at

the highest resistance level, turn power off.

Disconnect all power and allow to sit for 5 minutes.

D

B

A1

A

P

17

Page 18

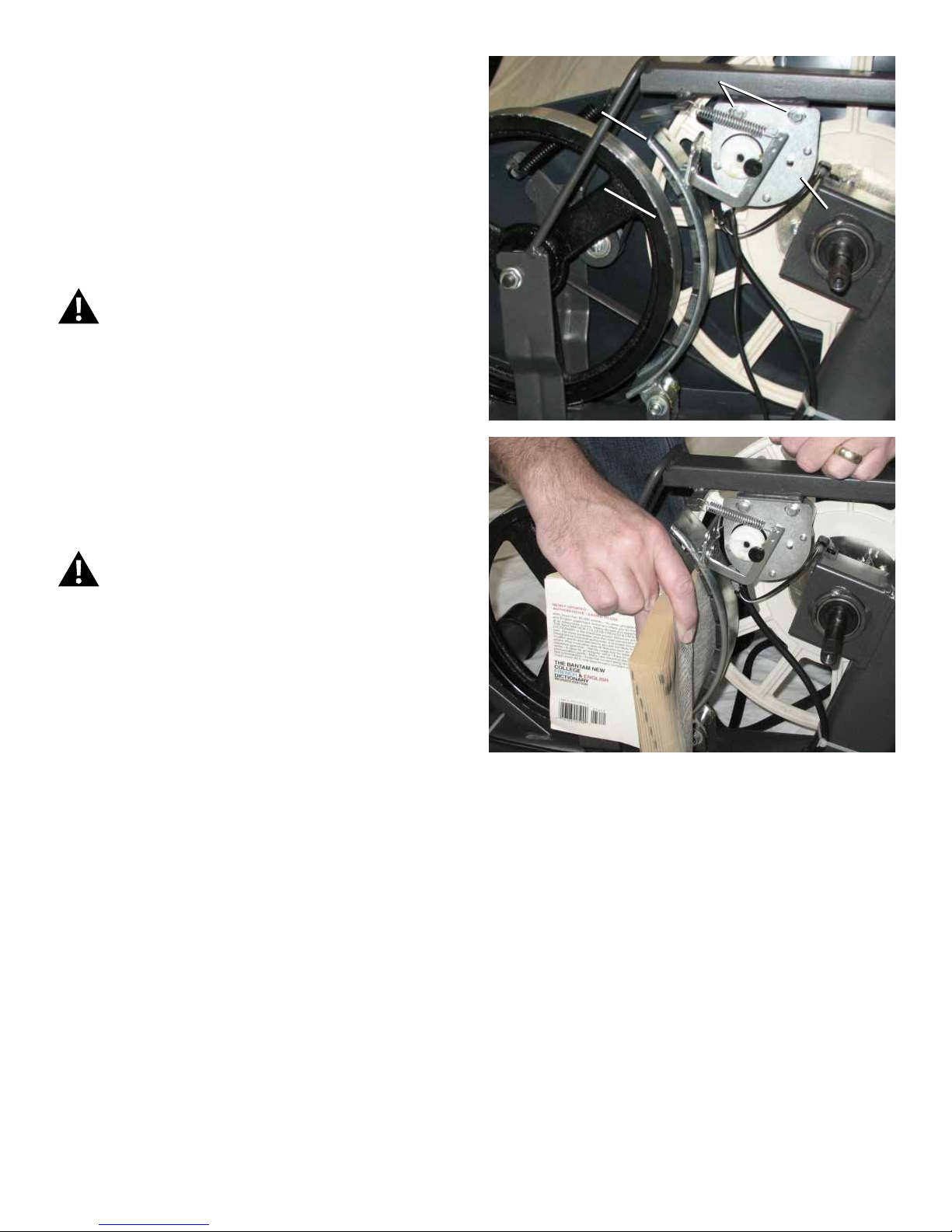

7. To adjust the Brake tension, loosen the 2 hex head bolts (C) and

move the Servo Motor assembly (D) until the closest point on the Brake

Magnet (A) is within 3.0 mm (1/8”) of the Flywheel (B). Tighten the bolts.

Note: If the cardboard is not 3mm (1/8”) thick, you can use

the pages of a paperback book to measure the gap.

Approximately 36 pages (sheets) = 3mm.

8. Turn the power on again. Use the console to check the resistance

adjustment.

Machine is on. Current is active. There is risk of electrical shock.

Note: Before fully attaching the Shrouds, remove the cardboard

from between the Brake Magnet (A) and the Flywheel (B).

Power up the machine to verify that the Magnet Arm can

move freely, and that the Brake Magnet and Flywheel do not

touch.

9. Final Inspection

Inspect your machine to ensure that all hardware is tight and components

are properly assembled.

C

A

B

D

Do not use until the machine has been fully assembled and

inspected for correct performance in accordance with the

Owner’s Manual.

18

Page 19

Replace the Console on the Nautilus®

WARNING

DANGER

U624/U626 and R624/R626 (Model Year 2014) Bikes

NOTICE: This document provides instructions for the replacement of the Console on the Nautilus® U624 and U626 Upright Bikes, and R624 and R626 Recumbent Bikes.

If you need assistance, please contact your local distributor. To find your local distributor, go to: www.nautilusinternational.com

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings

on this machine.

Nautilus, Inc., , www.NautilusInc.com - Customer Service: technics@nautilus.com | © 2014 Nautilus, Inc. | ® indicates trademarks registered in the United States. These marks may be registered in other nations or otherwise

protected by common law. | ORIGINAL DOCUMENT - ENGLISH VERSION ONLY

Replacement Procedure

Skill Level: I

8008332.040115.A

Important Safety Instructions - Before servicing or using this equipment, obey the following warnings:

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings on

this machine.

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and

wait 5 minutes before cleaning, maintaining or repairing this machine. Place the power cord in a secure location.

• Read and understand the Part Replacement Procedure before working on the machine. Failure to obey the instructions and safety warnings

could cause injury to the service technician or bystanders.

• Keep bystanders and children away from the product being serviced at all times.

• Make sure that the repair is done in an appropriate work space away from foot trafc and exposure to bystanders.

• Some components of the equipment can be heavy or awkward. Enlist the service of a second person when you do maintenance steps

involving these components. Do not try to do heavy or awkward steps on your own.

• If replacement parts are necessary, use only genuine Nautilus replacement parts and hardware. Failure to use genuine replacement parts

can cause a risk to users, keep the machine from operating correctly and void the warranty.

• Be sure that all warning stickers and instructional placards applied to the product stay present and in good condition when doing

maintenance or replacing components. If necessary request replacement warning stickers or placards from from your local distributor.

• Do not try to change the design or functionality of the machine being serviced as this can adversely affect user safety.

• Do not use the machine until all shrouds, instructions, warning labels and correct functionality have been verified and tested for correct

performance.

• This product contains magnets. Magnetic elds can interfere with the normal use of certain medical devices at a close range. Users may

come into proximity of the magnets in the assembly, maintenance, and/or use of the product. Given the obvious importance of these devices,

such as a pacemaker, it is important that you consult with your medical provider in connection with the use of this equipment. Please consult

the “Safety Warning Labels and Serial Number” section in the Owner’s Manual to determine the location of the magnets on this product..

Tools Required (not included)

#2 Phillips screwdriver

19

Page 20

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and the

machine and wait 5 minutes before cleaning, maintaining or repairing the machine. Place the power cord in a secure location.

Note: Your machine may not match the image. For reference only.

1. Remove screws that attach Console to the Mast. Carefully lift the

Console off the Mast.

2. Disconnect the Data Cable and Heart Rate Cable from the back of

the Console. Discard the Console and screws.

Note: Do not let the cables fall down inside the Mast. This step may

require two people.

3. Installation is the reverse procedure.

4. Inspect your machine to ensure that all hardware is tight and compo-

nents are properly assembled.

Do not use until the machine has been fully assembled and

inspected for correct performance in accordance with the Owner’s

Manual.

Initial Setup

During the rst power-up, the Console should be set up with the date,

time, your preferred measurement units and machine type.

1. Date: Push the Increase/Decrease buttons to adjust the currently active

value (ashing). Push the Left/Right buttons to change which segment is

the currently active value (month / day / year).

2. Push OK to set.

3. Time: Push the Increase/Decrease buttons to adjust the currently active

value (ashing). Push the Left/Right buttons to change which segment is

the currently active value (hour / minute / AM or PM).

4. Push OK to set.

5. Units of Measurement: Push the Increase/Decrease buttons to adjust

between “MILES” (Imperial English) or “KM” (metric).

6. Push OK to set.

7. The Console display shows the Machine Type prompt with the current

setting. This menu option appears in the x624 series console only (not the

x626 series consoles). Push the Increase/Decrease buttons to change

between “BIKE” and Elliptical (“ELIP”).

8. Push OK to set. The Console goes back to the Power-Up / Idle Mode

screen.

Note: To adjust these selections, consult the “Console Service

Mode” section.

20

Page 21

Replace the Pedals on the Nautilus®

WARNING

DANGER

U624/U626 and R624/R626 (Model Year 2014) Bikes

NOTICE: This document provides instructions for the replacement of the Pedals on the Nautilus® U624 and U626 Upright Bikes, and R624 and R626

Recumbent Bikes.

If you need assistance, please contact your local distributor. To find your local distributor, go to: www.nautilusinternational.com

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings

on this machine.

Nautilus, Inc., , www.NautilusInc.com - Customer Service: technics@nautilus.com | © 2014 Nautilus, Inc. | ® indicates trademarks registered in the United States. These marks may be registered in other nations or otherwise

protected by common law. | ORIGINAL DOCUMENT - ENGLISH VERSION ONLY

Replacement Procedure

Skill Level: I

8008333.040115.A

Important Safety Instructions - Before servicing or using this equipment, obey the following warnings:

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings on

this machine.

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and

wait 5 minutes before cleaning, maintaining or repairing this machine. Place the power cord in a secure location.

• Read and understand the Part Replacement Procedure before working on the machine. Failure to obey the instructions and safety warnings

could cause injury to the service technician or bystanders.

• Keep bystanders and children away from the product being serviced at all times.

• Make sure that the repair is done in an appropriate work space away from foot trafc and exposure to bystanders.

• Some components of the equipment can be heavy or awkward. Enlist the service of a second person when you do maintenance steps

involving these components. Do not try to do heavy or awkward steps on your own.

• If replacement parts are necessary, use only genuine replacement parts and hardware supplied by Nautilus. Failure to use genuine replacement parts can cause a risk to users, keep the machine from operating correctly and void the warranty.

• Be sure that all warning stickers and instructional placards applied to the product stay present and in good condition when doing

maintenance or replacing components. If necessary request replacement warning stickers or placards from from your local distributor.

• Do not try to change the design or functionality of the machine being serviced as this can adversely affect user safety.

• Do not use the machine until all shrouds, instructions, warning labels and correct functionality have been verified and tested for correct

performance.

• This product contains magnets. Magnetic elds can interfere with the normal use of certain medical devices at a close range. Users may

come into proximity of the magnets in the assembly, maintenance, and/or use of the product. Given the obvious importance of these devices,

such as a pacemaker, it is important that you consult with your medical provider in connection with the use of this equipment. Please consult

the “Safety Warning Labels and Serial Number” section in the Owner’s Manual to determine the location of the magnets on this product.

Tools Required (not included)

Pedal wrench

21

Page 22

Note: Your machine may not match the image. For reference only.

1. Loosen and remove the old Pedals. Discard the old Pedals.

Note: The Left Pedal is reverse-threaded. Orientation is based

from a seated position on the bike. The Left Pedal has an “L”,

the Right Pedal an “R”.

(R)

(L)

2. Install the new Pedals. Carefully align the threads and hand tighten

to prevent cross-threading. Then tighten fully with pedal wrench.

Note: The Left Pedal is reverse-threaded. Be sure to attach

Pedals on the correct side of the Bike. Orientation is based

from a seated position on the bike. The Left Pedal has an “L”,

the Right Pedal an “R”.

(R)

3. Final Inspection

Inspect your machine to ensure that all hardware is tight and components

are properly assembled.

(L)

Do not use until the machine has been fully assembled and

inspected for correct performance in accordance with the

Owner’s Manual.

22

Page 23

Replace the Crank Arms

WARNING

DANGER

®

on the Nautilus

NOTICE: This document provides instructions for the replacement of the Crank Arms on the Nautilus® U626 Upright Bike and R626 Recumbent Bike.

If you need assistance, please contact your local distributor. To find your local distributor, go to: www.nautilusinternational.com

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings

on this machine.

Nautilus, Inc., , www.NautilusInc.com - Customer Service: technics@nautilus.com | © 2014 Nautilus, Inc. | ® indicates trademarks registered in the United States. These marks may be registered in other nations or otherwise

protected by common law. | ORIGINAL DOCUMENT - ENGLISH VERSION ONLY

U626/R626 (Model Year 2014) Bikes

Replacement Procedure

Skill Level: II

8008334.040115.A

Important Safety Instructions - Before servicing or using this equipment, obey the following warnings:

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings on

this machine.

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and

wait 5 minutes before cleaning, maintaining or repairing this machine. Place the power cord in a secure location.

• Read and understand the Part Replacement Procedure before working on the machine. Failure to obey the instructions and safety warnings

could cause injury to the service technician or bystanders.

• Keep bystanders and children away from the product being serviced at all times.

• Make sure that the repair is done in an appropriate work space away from foot trafc and exposure to bystanders.

• Some components of the equipment can be heavy or awkward. Enlist the service of a second person when you do maintenance steps

involving these components. Do not try to do heavy or awkward steps on your own.

• If replacement parts are necessary, use only genuine replacement parts and hardware supplied by Nautilus. Failure to use genuine replacement parts can cause a risk to users, keep the machine from operating correctly and void the warranty.

• Be sure that all warning stickers and instructional placards applied to the product stay present and in good condition when doing

maintenance or replacing components. If necessary request replacement warning stickers or placards from from your local distributor.

• Do not try to change the design or functionality of the machine being serviced as this can adversely affect user safety.

• Do not use the machine until all shrouds, instructions, warning labels and correct functionality have been verified and tested for correct

performance.

• This product contains magnets. Magnetic elds can interfere with the normal use of certain medical devices at a close range. Users may

come into proximity of the magnets in the assembly, maintenance, and/or use of the product. Given the obvious importance of these devices,

such as a pacemaker, it is important that you consult with your medical provider in connection with the use of this equipment. Please consult

the “Safety Warning Labels and Serial Number” section in the Owner’s Manual to determine the location of the magnets on this product.

Tools Required (not included)

#2 Phillips screwdriver 13mm wrench and socket

Flathead screwdriver Crank puller

Adjustable wrench

Pedal wrench

23

Page 24

Note: Your machine may not match the image. For reference only.

1. Loosen and remove the old Pedals. Set them safely aside for

reassembly.

Note: The Left Pedal is reverse-threaded. Orientation is based

from a seated position on the bike. The Left Pedal has an “L”,

the Right Pedal an “R”.

(R)

(L)

2. Using a athead screwdriver, remove the threaded Cap (A) from the

Crank Arm (B) to expose the Hex Head Bolt (C).

Crank arm shown is on a Schwinn® 170 bike.

3. Using a wrench and socket, remove the Hex Head Bolt (C).

A

B

B

C

24

Page 25

4. Thread the Crank Puller into the Crank Arm (B). When the Crank

Puller is in the correct position, only 1-2 threads on the outer portion (CP2)

of the Crank Puller should show.

Note: Be sure the end of the Bolt (CP1) of the Crank Puller is ush

with the Nut (CP2) as shown, before use.

5. Using a wrench, turn the inner portion (CP3) of the Crank Puller

clockwise. The Crank Arm (B) will slide off as it is tightened.

CP1 CP2 CP3

CP2

B

CP3

25

Page 26

6. Installation is the reverse procedure. Installation does not require the

use of the crank puller. Be sure the Crank Arms are connected at 180°

from each other.

To reinstall the Pedals, carefully align the threads and hand tighten to

prevent cross-threading. Then tighten fully with pedal wrench.

Note: The Left Pedal is reverse-threaded. Be sure to attach

Pedals on the correct side of the Bike. Orientation is based

from a seated position on the bike. The Left Pedal has an “L”,

the Right Pedal an “R”.

(R)

7. Final Inspection

Inspect your machine to ensure that all hardware is tight and components

are properly assembled.

Do not use until the machine has been fully assembled and

inspected for correct performance in accordance with the

Owner’s Manual.

(L)

26

Page 27

Replace the Transport Wheels, Endcaps and Footpads on the

WARNING

DANGER

®

Nautilus

NOTICE: This document provides instructions for the replacement of the Transport Wheels, Front Endcaps and Footpads on the Nautilus® U624

and U626 Upright Bikes, R624 and R626 Recumbent Bikes, and E624 and E626 Elliptical Fitness Machines.

If you need assistance, please contact your local distributor. To find your local distributor, go to: www.nautilusinternational.com

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings

on this machine.

Nautilus, Inc., , www.NautilusInc.com - Customer Service: technics@nautilus.com | © 2014 Nautilus, Inc. | ® indicates trademarks registered in the United States. These marks may be registered in other nations or

otherwise protected by common law. | ORIGINAL DOCUMENT - ENGLISH VERSION ONLY

U/R/E 624/626 (Model Year 2014) Bikes and Elllipticals

Replacement Procedure

Skill Level: II

8008335.040115.A

Important Safety Instructions - Before servicing or using this equipment, obey the following warnings:

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings on

this machine.

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and

wait 5 minutes before cleaning, maintaining or repairing this machine. Place the power cord in a secure location.

• Read and understand the Part Replacement Procedure before working on the machine. Failure to obey the instructions and safety warnings

could cause injury to the service technician or bystanders.

• Keep bystanders and children away from the product being serviced at all times.

• Make sure that the repair is done in an appropriate work space away from foot trafc and exposure to bystanders.

• Some components of the equipment can be heavy or awkward. Enlist the service of a second person when you do maintenance steps

involving these components. Do not try to do heavy or awkward steps on your own.

• If replacement parts are necessary, use only genuine replacement parts and hardware supplied by Nautilus. Failure to use genuine replacement parts can cause a risk to users, keep the machine from operating correctly and void the warranty.

• Be sure that all warning stickers and instructional placards applied to the product stay present and in good condition when doing

maintenance or replacing components. If necessary request replacement warning stickers or placards from from your local distributor.

• Do not try to change the design or functionality of the machine being serviced as this can adversely affect user safety.

• Do not use the machine until all shrouds, instructions, warning labels and correct functionality have been verified and tested for correct

performance.

• This product contains magnets. Magnetic elds can interfere with the normal use of certain medical devices at a close range. Users may

come into proximity of the magnets in the assembly, maintenance, and/or use of the product. Given the obvious importance of these devices,

such as a pacemaker, it is important that you consult with your medical provider in connection with the use of this equipment. Please consult

the “Safety Warning Labels and Serial Number” section in the Owner’s Manual to determine the location of the magnets on this product.

Tools Required (not included)

6mm hex key Static solid object (like a book or box)

#2 Phillips screwdriver (short)

13mm open end wrench

27

Page 28

Note: Your machine may not match the image. For reference only.

1. Place a static object (like a book or box) under the front stabilizer (C).

The static object should not be compressible.

D

2. Using a short #2 Phillips screwdriver, loosen and remove the screws

(A1) from the Footpad (A), and set them safely aside. Remove the

Footpad from the front stabilizer (D). Set the Footpad and screws safely

aside.

3. Loosen and remove the screw (B1) from the Endcap assembly (B)

and set it safely aside. Remove the Endcap from the front stabilizer (D).

Set the Endcap and screw safely aside.

A

A1

D

B1

B

4. Using the 6mm hex key and 13mm wrench, loosen and remove

the hardware (C1) from the old Transport Wheel assembly (C). Remove

the old Transport Wheel from the front stabilizer bracket (D1). Set the

Transport Wheel and hardware safely aside.

5. Installation is the reverse procedure.

NOTICE: Before fully attaching the Endcap, be sure that the Trans-

port Wheel can turn freely.

6. Dispose of the old parts.

7. Final Inspection

Inspect your machine to ensure that all hardware is tight and components

are properly assembled.

Do not use until the machine has been fully assembled and

inspected for correct performance in accordance with the

Owner’s Manual.

C1

D1

C

28

Page 29

Replace the Shrouds

WARNING

DANGER

®

on the Nautilus

NOTICE: This document provides instructions for the replacement of the Shrouds on the Nautilus® U624 and U626 Upright Bikes.

If you need assistance, please contact your local distributor. To find your local distributor, go to: www.nautilusinternational.com

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings

on this machine.

Nautilus, Inc., , www.NautilusInc.com - Customer Service: technics@nautilus.com | © 2014 Nautilus, Inc. | ® indicates trademarks registered in the United States. These marks may be registered in other nations or

otherwise protected by common law. | ORIGINAL DOCUMENT - ENGLISH VERSION ONLY

U624/U626 (Model Year 2014) Bikes

Replacement Procedure

Skill Level: II

8008336.040115.A

Important Safety Instructions - Before servicing or using this equipment, obey the following warnings:

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings on

this machine.

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and

wait 5 minutes before cleaning, maintaining or repairing this machine. Place the power cord in a secure location.

• Read and understand the Part Replacement Procedure before working on the machine. Failure to obey the instructions and safety warnings

could cause injury to the service technician or bystanders.

• Keep bystanders and children away from the product being serviced at all times.

• Make sure that the repair is done in an appropriate work space away from foot trafc and exposure to bystanders.

• Some components of the equipment can be heavy or awkward. Enlist the service of a second person when you do maintenance steps

involving these components. Do not try to do heavy or awkward steps on your own.

• If replacement parts are necessary, use only genuine replacement parts and hardware supplied by Nautilus. Failure to use genuine replacement parts can cause a risk to users, keep the machine from operating correctly and void the warranty.

• Be sure that all warning stickers and instructional placards applied to the product stay present and in good condition when doing

maintenance or replacing components. If necessary request replacement warning stickers or placards from from your local distributor.

• Do not try to change the design or functionality of the machine being serviced as this can adversely affect user safety.

• Do not use the machine until all shrouds, instructions, warning labels and correct functionality have been verified and tested for correct

performance.

• This product contains magnets. Magnetic elds can interfere with the normal use of certain medical devices at a close range. Users may

come into proximity of the magnets in the assembly, maintenance, and/or use of the product. Given the obvious importance of these devices,

such as a pacemaker, it is important that you consult with your medical provider in connection with the use of this equipment. Please consult

the “Safety Warning Labels and Serial Number” section in the Owner’s Manual to determine the location of the magnets on this product.

Tools Required (not included)

#2 Phillips screwdriver 6mm hex key

Flathead screwdriver 13mm wrench and socket (U626)

Pedal wrench (U624)

or crank puller (U626)

29

Page 30

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and wait 5

minutes before cleaning, maintaining or repairing this machine. Place the power cord in a secure location.

Note: Your machine may not match the image. For reference only.

1. Remove the Seat Post and the Seat Adjustment Knob (A). Set them safely

aside for reassembly.

A

2. Your machine has one of these Crank congurations. Please use the im-

ages to select your conguration:

1-Piece Crank:

Go to Step 6.

3. Using a wrench and socket, remove the Hex Head Bolt (D) .

4. Thread the Crank Puller into the Crank Arm (C). When the Crank Puller is

in the correct position, only 1-2 threads on the outer portion (CP2) of the Crank

Puller should show.

Note: Be sure the end of the Bolt (CP1) of the Crank Puller is ush with

the Nut (CP2) as shown, before use.

5. Using a wrench, turn the inner portion (CP3) of the Crank Puller clockwise.

The Crank Arm (C) will slide off as it is tightened.

Go to Step 8.

B

C

3-Piece Crank:

Using a athead screwdriver, remove the threaded Cap (B)

from the Crank Arm (C) to expose the Hex Head Bolt (D).

Continue to Step 3.

D

C

CP1 CP2 CP3

30

Page 31

6. Loosen and remove the Pedals. Set them safely aside for

reassembly.

Note: The Left Pedal is reverse-threaded.

Orientation is based from a seated position on the bike. The

Left Pedal has an “L”, the Right Pedal an “R”.

(R)

7. Twist the Crank Cover (P) toward the front of the machine to

disengage the inner tabs. Carefully remove the Crank Covers and set

them safely aside.

P

(L)

8. Slide the Mast Gasket up the Mast.

9. Remove the hardware (indicated) from the Mast. Gently pull the Mast

out and disconnect the cables. Set the hardware, Mast and Mast Gasket

safely aside.

NOTICE: Do not crimp the cables. This step may require two people.

Note: Do not let the cable fall down inside the Frame.

10. Bend the edges of the Top Shroud to disengage the inside tabs from

the Main Assembly, and remove the Top Shroud.

X2

Cable connectors

31

Page 32

11. Using a #2 Phillips Screwdriver, remove the 6 screws (indicated) that

secure the Left Shroud. Remove the bottom screws rst, and then the top

screws. Slowly remove the Left Shroud.

Note: Find the Power Inlet (E) in the Left Shroud. Disconnect the

Power Inlet cable (E1) from the wiring harness (F).

NOTICE: Be sure not to crimp any cables.

E

E

Power Inlet cable connection

E1

E1

F

32

Page 33

12. Using a #2 Phillips Screwdriver, remove the 3 screws that secure the

Right Shroud. Remove the bottom screws rst, and then the top screw.

Slowly remove the Right Shroud.

13. Installation is the reverse procedure. Put the Left Shroud in postion

rst to align the screws for the Right Shroud. Install the top screws rst.

NOTICE: Be sure not to crimp any cables. Be sure the tabs in the

Top Shroud snap into the Main Assembly.

U624 bike—To reinstall the Pedals, carefully align the threads and hand

tighten to prevent cross-threading. Then tighten fully with pedal wrench.

Note: The Left Pedal is reverse-threaded. Orientation is based

from a seated position on the bike. The Left Pedal has an “L”,

the Right Pedal an “R”.

U626 bike—Be sure the Crank Arms are connected at 180° from each

other.

14. Final Inspection

Inspect your machine to ensure that all hardware is tight and components

are properly assembled.

Do not use until the machine has been fully assembled and

inspected for correct performance in accordance with the

Owner’s Manual.

33

Page 34

Replace the Handlebar Assembly

WARNING

DANGER

®

on the Nautilus

NOTICE: This document provides instructions for the replacement of the Handlebar Assembly on the Nautilus® U624 and U626 Upright Bikes.

If you need assistance, please contact your local distributor. To find your local distributor, go to: www.nautilusinternational.com

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings

on this machine.

Nautilus, Inc., , www.NautilusInc.com - Customer Service: technics@nautilus.com | © 2014 Nautilus, Inc. | ® indicates trademarks registered in the United States. These marks may be registered in other nations or

otherwise protected by common law. | ORIGINAL DOCUMENT - ENGLISH VERSION ONLY

U624/U626 (Model Year 2014) Bikes

Replacement Procedure

Skill Level: II

8008337.040115.A

Important Safety Instructions - Before servicing or using this equipment, obey the following warnings:

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings on

this machine.

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and

wait 5 minutes before cleaning, maintaining or repairing this machine. Place the power cord in a secure location.

• Read and understand the Part Replacement Procedure before working on the machine. Failure to obey the instructions and safety warnings

could cause injury to the service technician or bystanders.

• Keep bystanders and children away from the product being serviced at all times.

• Make sure that the repair is done in an appropriate work space away from foot trafc and exposure to bystanders.

• Some components of the equipment can be heavy or awkward. Enlist the service of a second person when you do maintenance steps

involving these components. Do not try to do heavy or awkward steps on your own.

• If replacement parts are necessary, use only genuine replacement parts and hardware supplied by Nautilus. Failure to use genuine replacement parts can cause a risk to users, keep the machine from operating correctly and void the warranty.

• Be sure that all warning stickers and instructional placards applied to the product stay present and in good condition when doing

maintenance or replacing components. If necessary request replacement warning stickers or placards from from your local distributor.

• Do not try to change the design or functionality of the machine being serviced as this can adversely affect user safety.

• Do not use the machine until all shrouds, instructions, warning labels and correct functionality have been verified and tested for correct

performance.

• This product contains magnets. Magnetic elds can interfere with the normal use of certain medical devices at a close range. Users may

come into proximity of the magnets in the assembly, maintenance, and/or use of the product. Given the obvious importance of these devices,

such as a pacemaker, it is important that you consult with your medical provider in connection with the use of this equipment. Please consult

the “Safety Warning Labels and Serial Number” section in the Owner’s Manual to determine the location of the magnets on this product.

Tools Required (not included)

#2 Phillips screwdriver 3’ (91 cm) length of string

Small athead screwdriver

6mm hex key

34

Page 35

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and wait 5

minutes before cleaning, maintaining or repairing this machine. Place the power cord in a secure location.

Note: Your machine may not match the image. For reference only.

1. Remove screws that attach Console to the Mast. Carefully lift the

Console off the Mast.

2. Disconnect the Data Cable and Heart Rate Cable from the back of

the Console. Set the Console and screws safely aside for reassembly.

Note: Do not let the cables fall down inside the Mast. This step may

require two people.

3. Remove the Handlebar Bracket Cover and set it safely aside for

reassembly.

4. Tie the length of string to the end of the Heart Rate Cable at the top

of the Mast. Grasp the section of HR Cable under the Handlebar Bracket

and carefully pull the cable and string down through the Mast and out

of the hole so that the string extends through the Mast and Handlebar

Bracket.

Note: Do not let the Data Cable fall down inside the Mast.

35

Page 36

5. Remove the T-handle and washers that attach the Handlebar to the

Mast. Set them safely aside for reassembly.

NOTICE: Hold the Handlebar so that it does not fall.

6. Untie the string from the HR Cable. Remove the old Handlebar and

discard it.

7. Put the replacement Handlebar in the bracket, adjust the Handlebar to

the desired angle, and install the T-handle through the holes.

NOTI CE: Do not crimp the cables.

8. Tie the end of the string under the Handlebar Bracket to the end of

the HR cable. Carefully pull the cable through the slot under the Handlebar

Bracket to the top of the mast. Fully tighten the T-handle to keep the

Handlebar in position. Push the cover into position on the Handlebar

Bracket.

NOTIC E : Do not crimp the cables. Do not let the cables fall down in

the Mast.

9. Connect the cables to the back of the Console and attach the

Console to the Mast.

NOTICE: Do not crimp the cables.

10. Final Inspection

Inspect your machine to ensure that all hardware is tight and components

are properly assembled.

Do not use until the machine has been fully assembled and

inspected for correct performance in accordance with the

Owner’s Manual.

36

Page 37

Replace the Console Mast

WARNING

DANGER

®

on the Nautilus

NOTICE: This document provides instructions for the replacement of the Console Mast on the Nautilus® U624 and U626 Upright Bikes.

If you need assistance, please contact your local distributor. To find your local distributor, go to: www.nautilusinternational.com

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings

on this machine.

Nautilus, Inc., , www.NautilusInc.com - Customer Service: technics@nautilus.com | © 2014 Nautilus, Inc. | ® indicates trademarks registered in the United States. These marks may be registered in other nations or

otherwise protected by common law. | ORIGINAL DOCUMENT - ENGLISH VERSION ONLY

U624/U626 (Model Year 2014) Bikes

Replacement Procedure

Skill Level: II

8008338.0401115.A

Important Safety Instructions - Before servicing or using this equipment, obey the following warnings:

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings on

this machine.

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and

wait 5 minutes before cleaning, maintaining or repairing this machine. Place the power cord in a secure location.

• Read and understand the Part Replacement Procedure before working on the machine. Failure to obey the instructions and safety warnings

could cause injury to the service technician or bystanders.

• Keep bystanders and children away from the product being serviced at all times.

• Make sure that the repair is done in an appropriate work space away from foot trafc and exposure to bystanders.

• Some components of the equipment can be heavy or awkward. Enlist the service of a second person when you do maintenance steps

involving these components. Do not try to do heavy or awkward steps on your own.

• If replacement parts are necessary, use only genuine replacement parts and hardware supplied by Nautilus. Failure to use genuine replacement parts can cause a risk to users, keep the machine from operating correctly and void the warranty.

• Be sure that all warning stickers and instructional placards applied to the product stay present and in good condition when doing

maintenance or replacing components. If necessary request replacement warning stickers or placards from from your local distributor.

• Do not try to change the design or functionality of the machine being serviced as this can adversely affect user safety.

• Do not use the machine until all shrouds, instructions, warning labels and correct functionality have been verified and tested for correct

performance.

• This product contains magnets. Magnetic elds can interfere with the normal use of certain medical devices at a close range. Users may

come into proximity of the magnets in the assembly, maintenance, and/or use of the product. Given the obvious importance of these devices,

such as a pacemaker, it is important that you consult with your medical provider in connection with the use of this equipment. Please consult

the “Safety Warning Labels and Serial Number” section in the Owner’s Manual to determine the location of the magnets on this product.

Tools Required (not included)

#2 Phillips screwdriver 5’ (152 cm) length of string

Small athead screwdriver

6mm hex key

37

Page 38

To reduce the risk of electrical shock or unsupervised usage of the equipment, always unplug the power cord from the wall outlet and wait 5

minutes before cleaning, maintaining or repairing this machine. Place the power cord in a secure location.

Note: Your machine may not match the image. For reference only.

1. Remove screws that attach Console to the Mast. Carefully lift the

Console off the Mast.

2. Disconnect the Data Cable and Heart Rate Cable from the back of

the Console. Set the Console and screws safely aside for reassembly.

Note: Do not let the cables fall down inside the Mast. This step may

require two people.

3. Remove the Handlebar Bracket Cover and set it safely aside for

reassembly.

4. Grasp the section of HR Cable under the Handlebar Bracket and

carefully pull the cable down through the Mast and out of the hole in the

Handlebar Bracket.

Note: Do not let the Data Cable fall down inside the Mast.

38

Page 39

5. Remove the T-handle and washers that attach the Handlebar to the

Mast. Set them safely aside for reassembly.

NOTICE: Hold the Handlebar so that it does not fall.

6. Remove the Handlebar and set it safely aside for reassembly.

7. Remove the Mast Gasket.

8. Remove the hardware (indicated) from the Mast. Gently pull the Mast

out and disconnect the cables. Set the hardware, Mast Gasket and Top

Shroud safely aside for reassembly. Discard the old Mast.

NOTICE: Do not crimp the cables. This step may require two people.

Note: Do not let the cables fall down inside the Frame.

X2

9. Install the replacement Console Mast and the Mast Gasket on Main

Assembly.

NOTIC E : Make sure the Console Cable connector does not fall into

the Console Mast. Align the clips on the cable connectors and make sure the connectors lock. Do not crimp

Console Cable.

Cable connectors

39

Page 40

10. Put the Handlebar in the bracket, adjust the Handlebar to the desired

angle, and install the T-handle through the holes and washers.

NOTICE : Do not crimp the cables.

11. Use the pull cable in the Handlebar Bracket to route the HR cable

through the slot under the Handlebar Bracket to the top of the mast. Fully

tighten the T-handle to keep the Handlebar in position. Push the cover into

position on the Handlebar Bracket.

NOTIC E : Do not crimp the cables. Do not let the cables fall down in

the Mast.

12. Connect the cables to the back of the Console and attach the

Console to the Mast.

NOTICE: Do not crimp the cables.

13. Final Inspection

Inspect your machine to ensure that all hardware is tight and components

are properly assembled.

Do not use until the machine has been fully assembled and

inspected for correct performance in accordance with the

Owner’s Manual.

40

Page 41

Replace the Data Cable in Console Mast

WARNING

DANGER

®

on the Nautilus

NOTICE: This document provides instructions for the replacement of the Data Cable in the Console Mast on the Nautilus® U624 and U626 Upright Bikes.

If you need assistance, please contact your local distributor. To find your local distributor, go to: www.nautilusinternational.com

This icon means a potentially hazardous situation which, if not avoided, could result in death or serious injury. Read and understand all Warnings

on this machine.

Nautilus, Inc., , www.NautilusInc.com - Customer Service: technics@nautilus.com | © 2014 Nautilus, Inc. | ® indicates trademarks registered in the United States. These marks may be registered in other nations or

otherwise protected by common law. | ORIGINAL DOCUMENT - ENGLISH VERSION ONLY

U624/U626 (Model Year 2014) Bikes

Replacement Procedure

Skill Level: II

8008339.040115.A

Important Safety Instructions - Before servicing or using this equipment, obey the following warnings: