Page 1

Model U916

Be Strong.

™

Commercial Series Bike

PN 001-6884 Rev B (03/27/2007)

Model R916

Service Manual

Model: U916 & R916

Page 2

Important—Please Read

This manual is intended for authorized Nautilus or Nautilus certied service personnel and not for the consumer.

There are no user serviceable parts. Servicing of the Nautilus® Commercial Series Bike by other than authorized

Nautilus or Nautilus certied service personnel may result in voiding of the warranty.

If you are a consumer and require technical support to resolve a problem with your Nautilus® Commercial

Series Bike, please call Nautilus® Customer Service at 800-628-8458 (North America) or +41-26-460-77-77

(outside North America).

2

Page 3

Table of Contents

Product Specifications ................................5

Important Safety Information ...............6

Safety Warning Labels ...........................................7

Maintenance .......................................................9

Maintenance Records .......................................... 11

Resetting the Maintenance Hour Timer ...............11

Routine Maintenance

Checking the Battery Charge................................ 11

Recharging the Battery Back-up .......................... 12

Battery Disposal ...................................................12

........................................... 11

Console Codes ................................................13

Overview................................................................15

Defaults .................................................................15

Cable Connections - U916

Cable Connections - R916 .....................................56

.....................................53

Appendixes ........................................................59

Required Tools .......................................................60

Using a Multimeter ...............................................61

International Power Plug Configurations ..............64

Warranty Information

Contact Numbers .........................................................67

...................................................65

Customize ..............................................................15

Machine Status .....................................................16

Diagnostics ............................................................17

Maintenance Logs .................................................18

Machine Configuration ..........................................20

Electrical Troubleshooting ......................21

U916/R916 Main Wiring Diagram .......................23

U916 Console Heart Rate Wiring Diagram ...........24

R916 Console Heart Rate Wiring Diagram ...........25

General Bike Electronics Troubleshooting ............26

Mechanical Troubleshooting ................35

Removing/Replacing Parts -

U916 and R916 Common Parts..............................37

Removing/Replacing Parts -

U916 Parts .............................................................48

Removing/Replacing Parts -

R916 Parts .............................................................51

Nautilus® Commerical Series Bike Service Manual

3

Page 4

Contents

4

Page 5

PRODUCT SPECIFICATIONS

U916 Upright Bike R916 Recumbent Bike

Length 45 in. (114.3 cm) 67 in (170.18 cm)

Width 24 in. (60.96 cm) 24 in. (60.96 cm)

Height 57 in. (144.78 cm) 46 in. (116.84 cm)

Workout Area 50” W x 81” L (127 cm x 205.74 cm) 50” W x 103” L (127 cm x 261.62 cm)

Unit Weight 150 lb. (68 kg) 180 lbs (82 kg)

Physical

Shipping Package Weight 178 lb. (81 kg) 231 lbs (105 kg)

Max User Weight Supported 400 lb. (182 kg) 400 lb. (182 kg)

Belt(s) Two: Poly-V (6V) self-tensioning belt and timing belt

Power

Cordless; or 108-132VAC 60 Hz, or 220-240VAC 50 Hz, 20 watts maximum

(operation with charger connected)

Battery Type 6VDC sealed lead-acid

Battery Charge Time 8 hours to full charge, starting with discharged battery

Electrical

Display C51 blue/white LCD with backlight. Tactile membrane keypanel

Number of Functions

Heart Rate Monitoring

Eleven: Heart rate, elapsed time, calories burned, calories burned per hour,

watts, METS, resistance level, rpm, speed, distance, and workout profile

Integrated heat rate monitoring system with polar-compatible wireless and

contact HR

Eleven: Quick Start, Manual, Fat Burner, Calorie Burner, Intervals, HR Zone

Workout Programs

Trainer, multi-stage Fit Test. Calorie Goal, HR Intervals, Random Play, Custom

Intervals

Functionality

Resistance Range Twenty: 20 watts (level 1, 20 rpm) to 500 watts (level 20, 80 rpm)

Language Options English, German, French, Spanish, Italian, Dutch, Portuguese

C-Safe Compatible Level 2 compatible. Owner/manager will be able to customize console.

Operating Temperature 50–90 oF (10–32 oC)

Storage Temperature -25–50 oC

Operating Humidity (noncondensing)

Environmental

Storage Humidty (noncondensing)

3–95% relative humidity

3–95% relative humidity

Nautilus® Commerical Series Bike Service Manual

5

Page 6

SAFETY REQUIREMENTS

7 ! 2 . ) . '

7 ! 2 . ) . '

IMPORTANT SAFETY INFORMATION: SAVE THESE INSTRUCTIONS

The following definition applies to the word “Warning” found throughout this guide:

- Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

This symbol appearing ThroughouT This manual means

pay aTTenTion! be alerT! your safeTy is involved!

1. Read, understand and carefully follow all warnings,

instructions and procedures in this manual. Failure to do

so can produce a serious electrical shock hazard or other

serious injury.

2. The external power supply should always be unplugged from the

AC wall outlet before removing or installing parts. Never make

adjustments or repairs while an exercise program is in progress.

3. Close supervision is necessary whenever the machine is being

used or serviced whenever children, invalids, or disabled persons

are in the vicinity.

4. Keep hands away from all moving parts. Keep feet on the pedals

while exercising or testing the machine.

5. Do not operate the machine with the side covers removed, or

outdoors.

6. Use this machine only for its intended use as described in this

Manual. Do not use parts, attachments, or accessories other than

those provided by Nautilus, Inc.

7. Do not use the ex ternal power supply if it has a damaged cord or

plug, it is not working properly, if it has been dropped or damaged,

or dropped in water. Contact our Technical Service Department to

arrange for the return of damaged parts.

8. To avoid potential safety and electrical problems, replace with

manufacturer’s specified par ts only.

9. Connect the external power supply to a properly grounded AC wall

outlet.

10. Keep all cords away from heated surfaces.

14. Keep the area underneath and around the machine clear.

15. Do not operate where aerosol (spray) products are being used.

16. Always wear insulated gloves when handling batteries.

17. Do not crush, incinerate, or dismantle the battery.

THE ELECTROLY TE CONTAINS SUL FURIC ACID, WHICH CAN

CAUSE SERIOUS DAMAGE TO EYES AND SKIN. SHOULD

THIS OCCUR, FLUSH PROFUSELY WITH WATER

AND SEEK MEDICAL ATTENTION.

18. The safety level provided by the design of this equipment can

only be maintained when the equipment is regularly examined for

damage and wear. Inoperable components should be replaced

immediately or the equipment be put out of use until it is repaired.

19. Failure to follow the guidelines may compromise the effectiveness

of the exercise experience, expose you (and possibly others) to

injury, and reduce the longevit y of the machine. Follow all training

instructions listed in the manual and/or on the machine.

Failure to follow the conditions set forth below shall limit, to the extent

allowed by law, Nautilus, Inc. responsibility for the safety, reliability,

and performance of this equipment.

• The operator manual must be read in full by each owner and trainer

before the product is first used. Each user must be instructed in the

proper use of the bike and its accessories.

• The equipment must be used in accordance with the instructions

for use.

11. To disconnect the external power supply, remove the plug from the

AC wall outlet.

12. Do not let liquid enter the console. If liquid does enter the console,

the console must be inspected and tested for safety by an approved

technician before it can be used again.

13. Never drop or insert any object into any opening on the machine.

6

• Only Nautilus-trained or Nautilus-authorized personnel should

carry out assembly operations, extensions, readjustments,

modifications, or repairs.

• For further information or instruction on use, maintenance or

specifications, please contact your Authorized Nautilus Fitness

Dealer or Service Technician.

Page 7

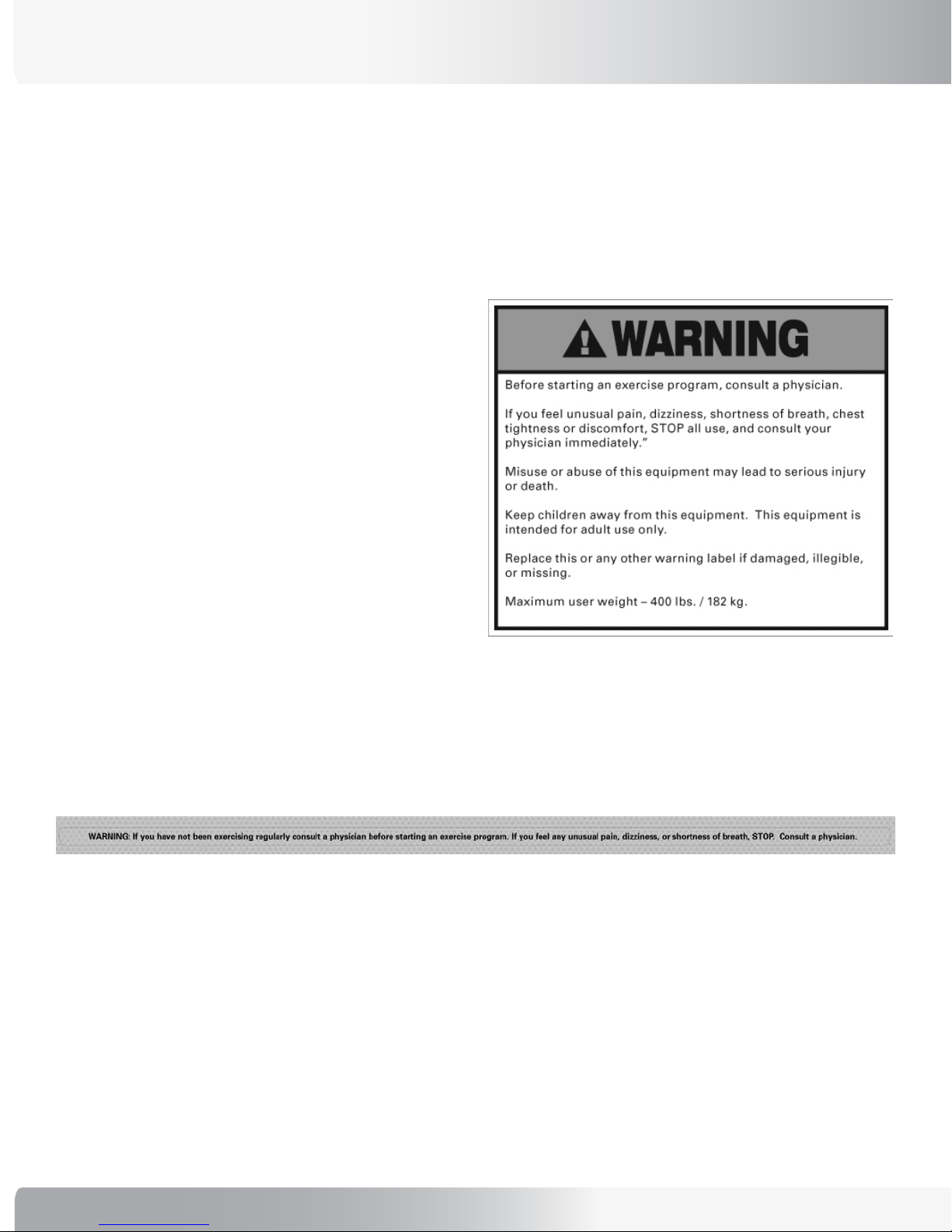

SAFETY WARNING LABELS

The following safety warnings are located on the Nautilus® Commercial Series Bike. Please read all safety precautions and

warning information prior to using your product. Be sure to replace any warning label if damaged, illegible, or missing. If

you need replacement labels, please call a Nautilus Representative at (800) 628-8458 (North America) or +41-26-460-77-77

(International office).

Label 2

Label 1

Label 1

Label 2

Nautilus® Commerical Series Bike Service Manual

7

Page 8

SAFETY WARNING LABELS

The following safety warnings are located on the unit. Please review and understand the safety warning labels and their

locations on the unit prior to use.

If you do not have, or cannot find, or need to replace a warning label please call 1-800-628-8458 (North America) or

+41-26-460-77-77 (International office) to obtain a new label.

Label 1: See Figure 1 for general warning label.

Location: The warning label in Figure 1 is located on the

side of the console mast.

Label 2: See Figure 2 for general exercise warning label.

Figure 2

Location: Affixed to the console face below the keypanel.

Figure 1

8

Page 9

1

Maintenance

Contents

Maintenance Records .................................................................................11

Resetting the Maintenance Hour Timer ..................................................... 11

Routine Maintenance.................................................................................. 11

Checking the Battery Charge ...................................................................... 11

Recharging the Battery Back-up ................................................................. 12

Battery Disposal .......................................................................................... 12

Nautilus® Commerical Series Bike Service Manual

9

Page 10

10

Page 11

Maintenance

Maintenance Records

For ease of maintenance the U916 and R916 console will keep track of hours, number of workouts, time between last

servicing, etc. You can quickly access any of the custom menus by pressing [LEVEL: UP], [4], [ENTER]. The console will

then display “MACHINE STATUS.” Use the [Level: UP] and [Level: DOWN] keys to scroll through the options. For details,

refer to the Machine Status Console Codes.

Resetting the Maintenance Hour Timer

After each maintenance period reset the counter. Press [LEVEL: UP], [7], [ENTER]. Then use the Level keys to scroll

through the options. When “MAINT HOURS” is displayed, press [ENTER]. Press the [0] key, then press [ENTER]. Press

[CLEAR] to return to the opening screen.

Routine Maintenance

Upon receiving your machine, use a soft, clean towel to wipe off the dust, which may have accumulated during shipping.

Your new machine will require minor assembly. Refer to the “Installation Instructions” section for details.

Cleaning

1. DO NOT USE GLASS CLEANERS OR ANY OTHER HOUSEHOLD CLEANERS ON THE CONSOLE. Clean the console daily

with a water-dampened cloth and wipe dry after cleaning.

2. Clean the exterior of the machine daily using soap and water or a diluted, non-mineral based household cleaner such

as Fantastic®.

Inspection

1. Frame:

Inspect the frame for any rust, bubbling, or paint chips during the weekly cleaning. The salt in perspiration

can damage the unpainted surfaces. Repair the damaged area with a touch-up paint kit purchased from Nautilus (call

Customer Service for order information).

Checking the Battery Charge

1. Using your multimeter, touch the red lead to the positive terminal of the battery and the black lead to the negative

terminal.

2. If the voltage level is less than 6.1 VDC, charge the battery.

Nautilus® Commerical Series Bike Service Manual

11

Page 12

Maintenance

Recharging the Battery Back-Up

The Commercial Series U916 and R916 bikes are both self-powered (cordless) with a rechargeable battery back-up.

Typically, the bike can be operated without plugging in the battery charger. If, however, the console flickers during

operation or the console display does not light up while using the machine, then use the battery charger to recharge the

battery back-up.

The battery charger is supplied with the unit and plugs into a standard 115 volt, 15 amp outlet, or a 220 volt, 15 amp outlet.

(All major voltage plugs are available.) The plug-in for the battery charger is located

in the front of the machine at the base.

NOTE: If installing the optional LCD Monitor, refer to the NV915 installation manual at

this time.

Plug the wall pack battery charger into the connector and charge the battery for

approximately 24 hours and then recheck it. It is okay to use the machine while the

battery charger is connected.

When the bike is not connected to an external power source, the console will power

on as the user starts to pedal machine, and will stay lit for up to 60 seconds in pause

mode. The console will power off after 60 seconds of stopping exercise.

If the bike is connected to an external power source, the console will power on automatically and stay on until power is

disconnected.

Battery charger plug-in

Battery Disposal

When ordering new batteries, you will need to properly dispose of (recycle) your old lead-acid batteries. Most federal

and state regulations require lead-acid batteries to be recycled. Do not throw away old batteries. Lead is a toxic heavy

metal, hazardous to living organisms. Disposal instructions and a list of recycling centers are tabulated in the Appendix.

If you have questions, contact the Customer Service Department at 800-628-8458 (North America) or +41-26-460-77-77

(International office).

12

Page 13

2

Console Codes

Contents

Overview ..................................................................................................... 15

Defaults ....................................................................................................... 15

Customize .................................................................................................... 15

Machine Status ........................................................................................... 16

Diagnostics.................................................................................................. 17

Maintenance Logs....................................................................................... 18

Reset Maintenance Hours ...................................................................... 19

Error Log.................................................................................................. 19

Machine Configuration................................................................................ 20

Nautilus® Commerical Series Bike Service Manual

13

Page 14

14

Page 15

Customization

Overview

To enter a Service Mode, the unit must be in IDLE DISPLAY state or an ERROR. The service screens cannot be entered during

a workout, paused or in a WARNING state. (If the unit is in a Warning state, you must press [CLEAR] before entering the

Service Modes.) To access the console codes, press the Level Up button (

▲), the group number code, and [ENTER]. Then use

the arrow buttons to scroll through the menu options for each group. The procedures are outlined in the tables below.

There are six groups of Service Mode console codes: Defaults (codes starting with 2), Customize (codes starting with 3),

Machine Status (codes starting with 4), Diagnostics (codes starting with 6), Maintenance Logs (codes starting with 7), and

Change Machine (codes starting with 8). Each group of codes is defined below.

Defaults

You can customize several workout parameters on the R916/U916 Bike with default values to conform to your individual

requirements, including:

• % target heartrate (10-90%)

• age (10-99)

• workout time (5-99 min)

• workout level (1-20)

• weight (50-400 lbs. or 25-180 kg)

Refer to the following table to scan through and customize the settings:

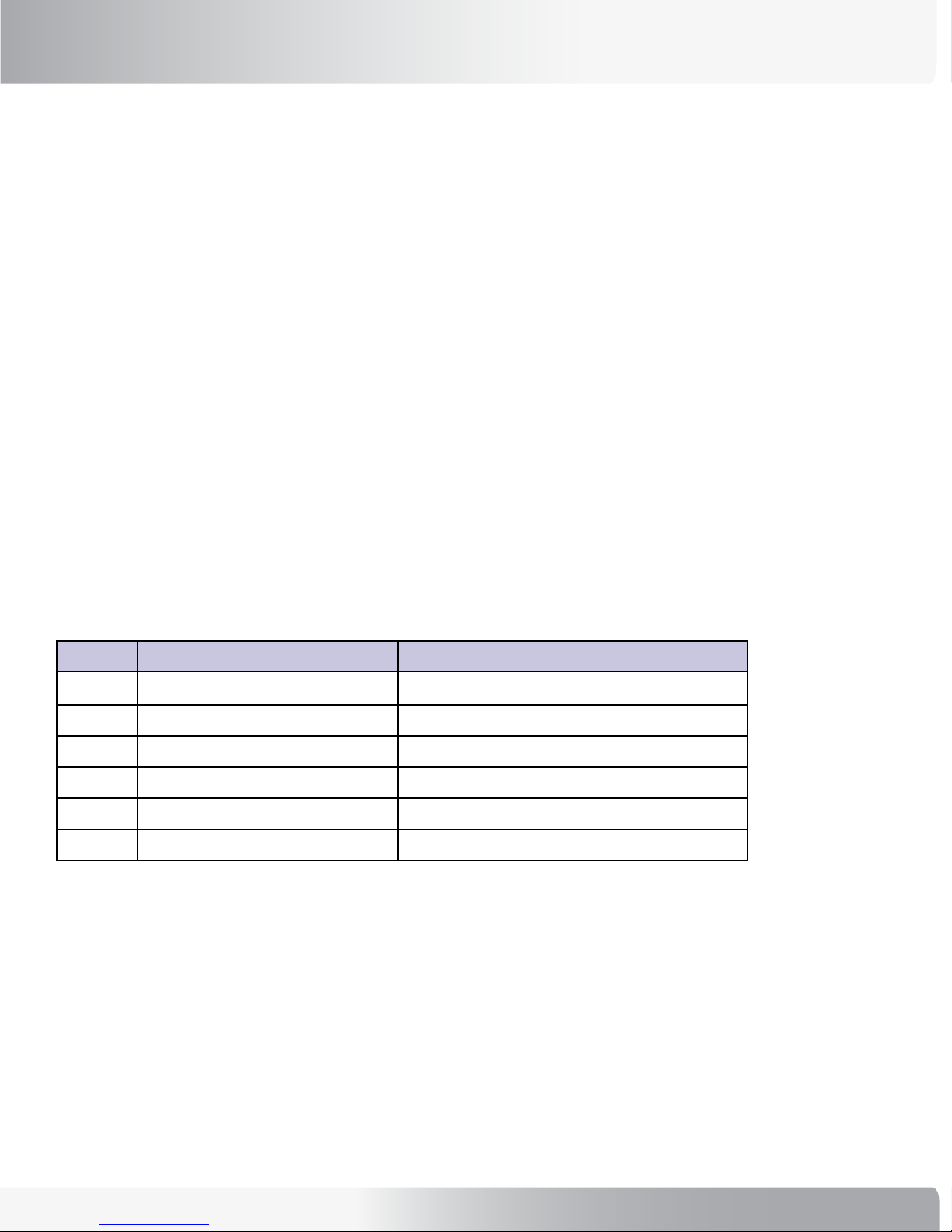

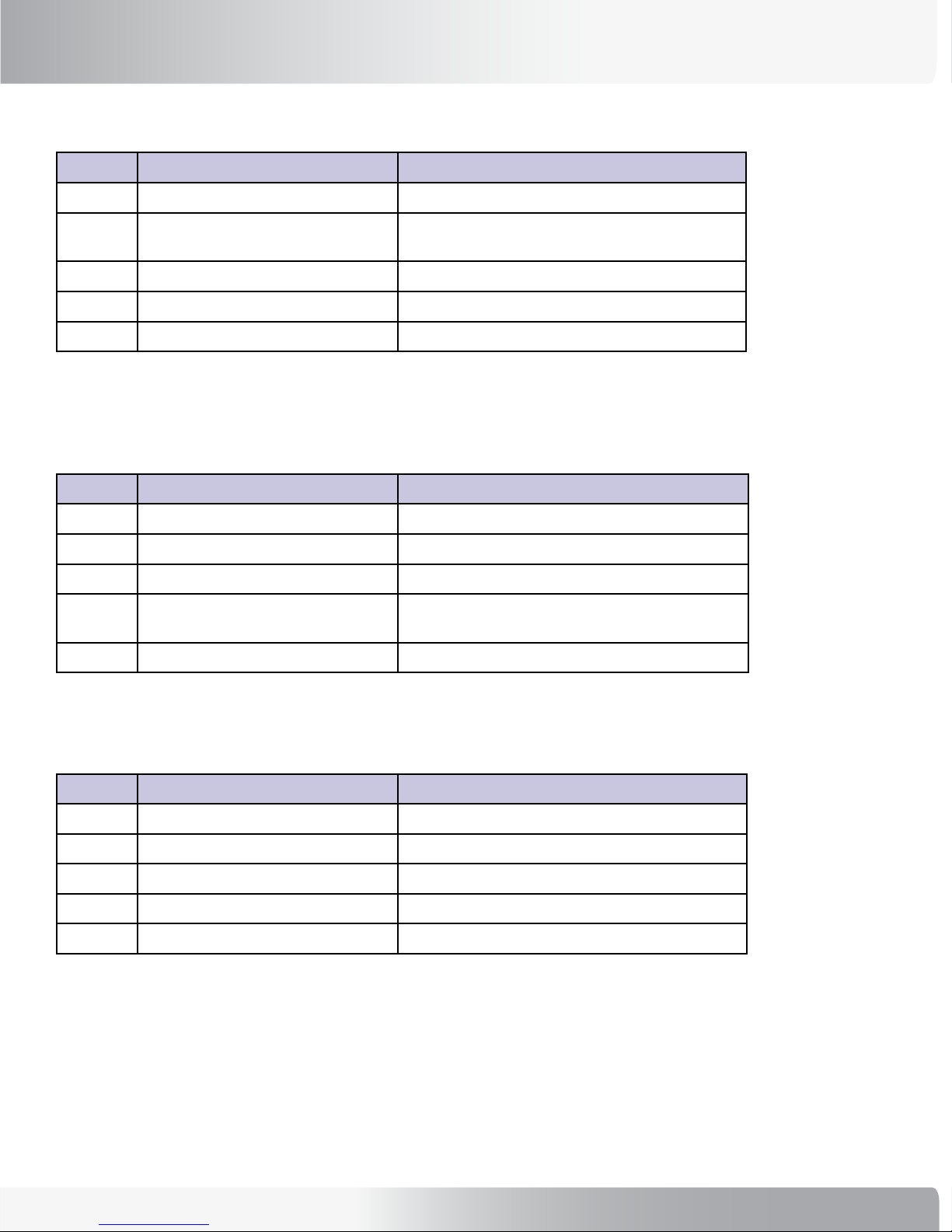

Table 2–1. Defaults

Step No. Press Keys Display (What you will see)

1

2 ▼ or ▲

3

4 ▼ or ▲ (or numeric keypad)

5

6

▲, 2, ENTER

ENTER

ENTER

CLEAR

DEFAULTS

CHR PERCENT, AGE, TIME, LEVEL, WEIGHT

Selected choice

Default value changes

DEFAULTS

SELECT WORKOUT

Customize

You can customize several console settings on the R916/U916 Bike with default values to conform to your individual

requirements, including:

• resetting all configurable settings to factory defaults (see below)

• adjusting lower screen contrast (0-15)

• adjusting upper screen contrast (0-15)

• console language

• choosing type of heartrate inputs (description below)

Nautilus® Commerical Series Bike Service Manual

15

Page 16

Machine Status

• change units (USA units or metric units)

• cooldown time (1-10 min)

• maximum time limit (10-99 min or OFF)

Refer to the following table to scan through and customize the settings:

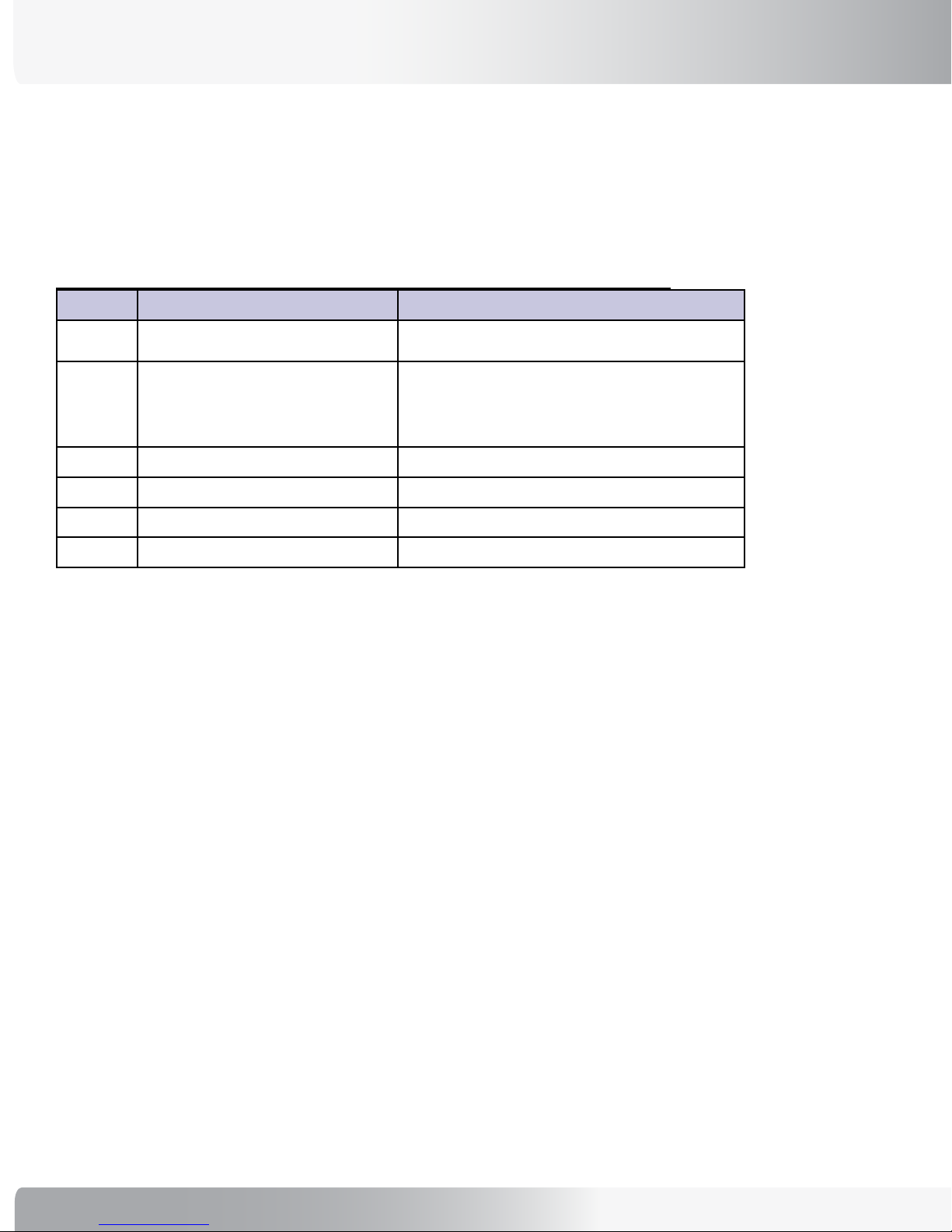

Table 2–2. Customize

Step No. Press Keys Display (What you will see)

1 ▲, 3, ENTER CUSTOMIZE

2 ▼ or ▲ SET DEFAULTS, CONTRAST ADJ LOWER,

CONTRAST ADJ UPPER, LANGUAGE,

SELECT STATS*, HR INPUTS, CHANGE

UNITS, COOL DOWN, MAX TIME LIMIT

3 ENTER Selected choice

4 ▼ or ▲ (or numeeric keypad) Default value changes

5 ENTER CUSTOMIZE

6 CLEAR SELECT WORKOUT

*The SELECT STATS menu display option is not active for the R916 and U916.

Set Defaults – resets the machine to the factory defaults for all configurable values. Please note that selecting this option

will require the machine to be reconfigured (see Change Machine section).

NOTE: All error and history counter data (Maint Hours, Distance, Workouts, Run Hours, Error Log, and QA ID Number) will

be lost if Set Defaults is selected.

HR Inputs – enables the various heart rate inputs that can be used. Heart rate configurations include: Locked Inputs (both

heart rate monitors are read until it detects a valid signal to lock on, at which point the other HR inputs are ignored), HAND

HR PRGM OFF, Both HR OFF, Hand Only, Telemetry Only, and Either Input (if one input is lost, then the other input may

become active).

Change Units - changes all displayed data (service information and user data) to the selected units. Units are: Miles or

Kilometers, MilesPerHour or KilometersPerHour, Pounds (LB) or Kilograms (KG), MinutesPerMile or MinutesPerKM.

Machine Status

Use the machine status codes to view maintenance information such as:

• maintenance hours

• machine type (U/R916)

• console software version

• distance traveled

• number of workouts

• machine run-time hours

16

Page 17

Refer to the following table to scan through and customize the settings:

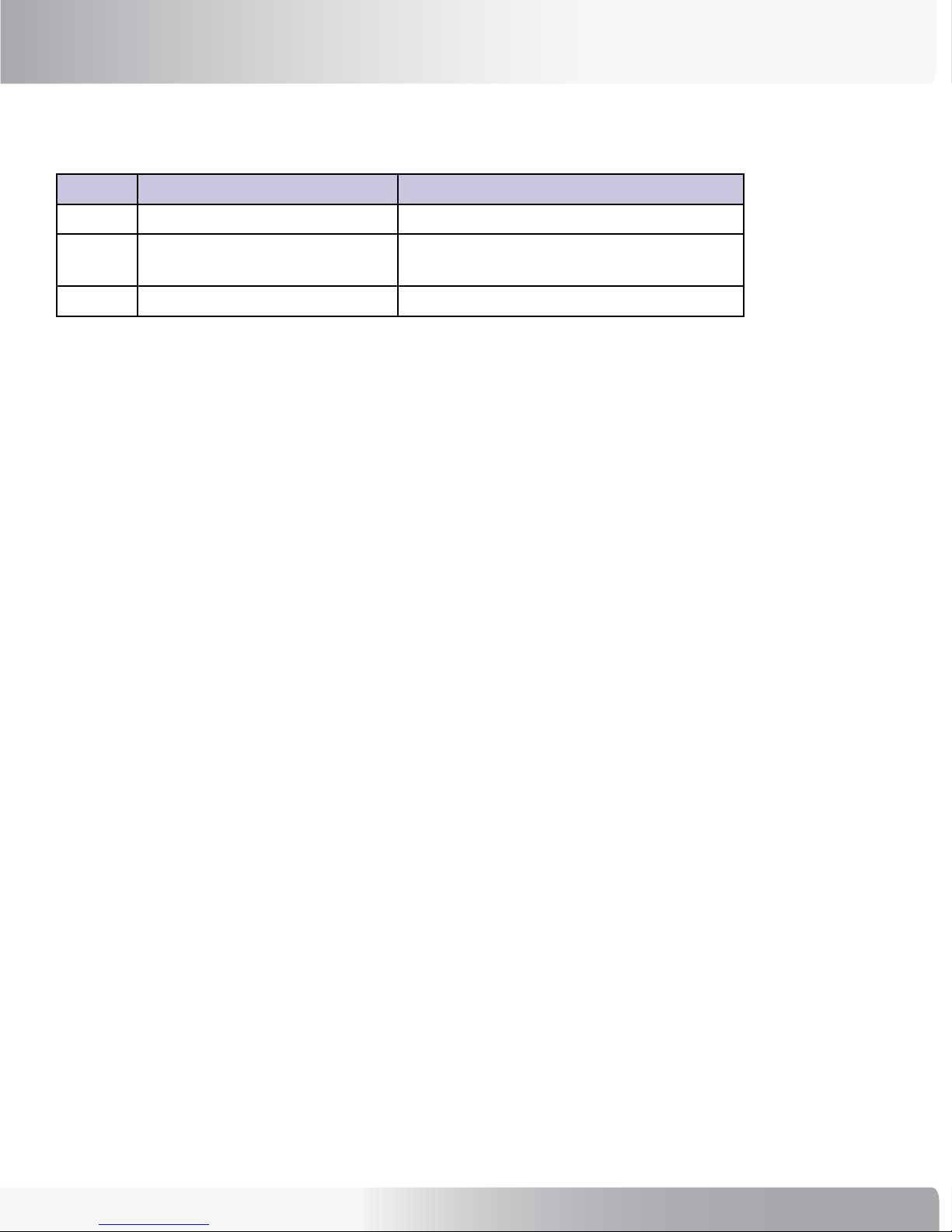

Table 2–3. Machine Status

Step No. Press Keys Display (What you will see)

1 ▲, 4, ENTER MACHINE STATUS

Diagnostics

2 ▼ or ▲

3 CLEAR SELECT WORKOUT

MAINT HOURS, U/R916 [or other], CONS,

DISTANCE, WORKOUTS, RUN HOURS

Maint Hours – displays the number of hours (incremented every hour) the machine has been running. The start value is set

under the Maintenance Logs service screen. (The start value can be set to any value—e.g. if the service tech had entered

100 in the Maintenance Logs service screen and there was 1 hour of running time on the machine, the value under this

Maint Hours screen would read 101).

Machine Type – should display U/R916. “NTM Config REQD” appears on the console if the software has been updated on

the machine or the machine froze up and the power had to be cycled. The message also appears when the console assembly

has been replaced and no configuration established. Configuring the machine will eliminate this message (see the table

“Machine Configuration”).

Distance – displays the total distance in miles (or kilometers) of machine operation. This value is auto-incremented every

1/100th or 1/10th unit, depending on how many miles/km have accrued.

Workouts – displays the total number of workouts performed on the machine. This value is auto-incremented only if the

user enters a workout and either completes the workout or presses the [STOP] key twice.

Run Hours – displays the total number of hours on the machine.

NOTE: The R&D options (codes starting with 5) are not used for servicing machines. Do not change these settings. If an

R&D setting is inadvertently changed, it will reset when the machine is powered off and then back on.

Diagnostics

Use diagnostic codes to test various components of the machine such as the:

tachometer

•

• alternator

• I/O

• sensor (for EV9.16 only)

• serial ports

• keypad

• display

Nautilus® Commerical Series Bike Service Manual

17

Page 18

Maintenance Logs

Refer to the following table to scan through the diagnostic tests and view diagnostic information:

Table 2–4. Diagnostics

Step No. Press Keys Display (What you will see)

1 ▲, 6, ENTER DIAGNOSTICS

2 ▼ or ▲ TACH TEST, ALT TEST, I/O TEST,

A SENSOR B, SERIAL PORTS, KEY TEST,

DISPLAY TEST

3 ENTER Selected choice

4 CLEAR DIAGNOSTICS

5 CLEAR SELECT WORKOUT

Tach Test – performs a tachometer test. On the left hand side of the display the target rate of 2000 rpm is displayed. On

the right hand side of the display the actual rpm is displayed. If the actual rpm is above the target rate, then the alternator

field turns on (the level increases). If the actual rpm is below the target rate, then the alternator field shuts off (the level

decreases).

Alt Test – performs an alternator test. By pressing the level up key, the alternator field will turn on and the steps will

become harder to rotate. By pressing the level down key, the alternator field will turn off and the steps will become easier to

rotate.

I/O Test – The AUX and B+ values represent the current and voltage delivered from the alternator respectively. AUX is

scaled by 1000 and B+ is scaled by 300. These values will increase with the speed of the alternator (note that both values

will reach 0 if the alternator is left at rest). The “---” string is displayed at all times since the bikes do not require a magnetic

key.

A Sensor B – is used only on the ellipticals. The A Sensor B diagnostic screen ensures the optical detector is functional.

The A value is displayed on the left hand side of the upper display (B is not used on the EV9.16). Under normal conditions,

the A value should toggle between the “0” and “1”.

Serial Ports - tests the serial ports (UARTS) for proper functionality. The tech can choose from either the CSAFE-1

Loopback or TM Loopback tests. Both of these tests result in PASS or FAIL. Please note that a null modem must be used to

perform these tests.

Key Test - tests all of the user interface keys. Once a key is pressed, its value will show up on the display screen. After all

keys have been pressed and are functional, a PASS message appears on the display.

Display Test - will test all segments on both the top and bottom displays.

Maintenance Logs

The MAINTENANCE LOGS settings allow you to view the quality assurance data, the machine’s error log, and reset the time

between service and maintenance calls.

18

Page 19

Refer to the following table to scan through the Maintenance Logs tests and view diagnostic information:

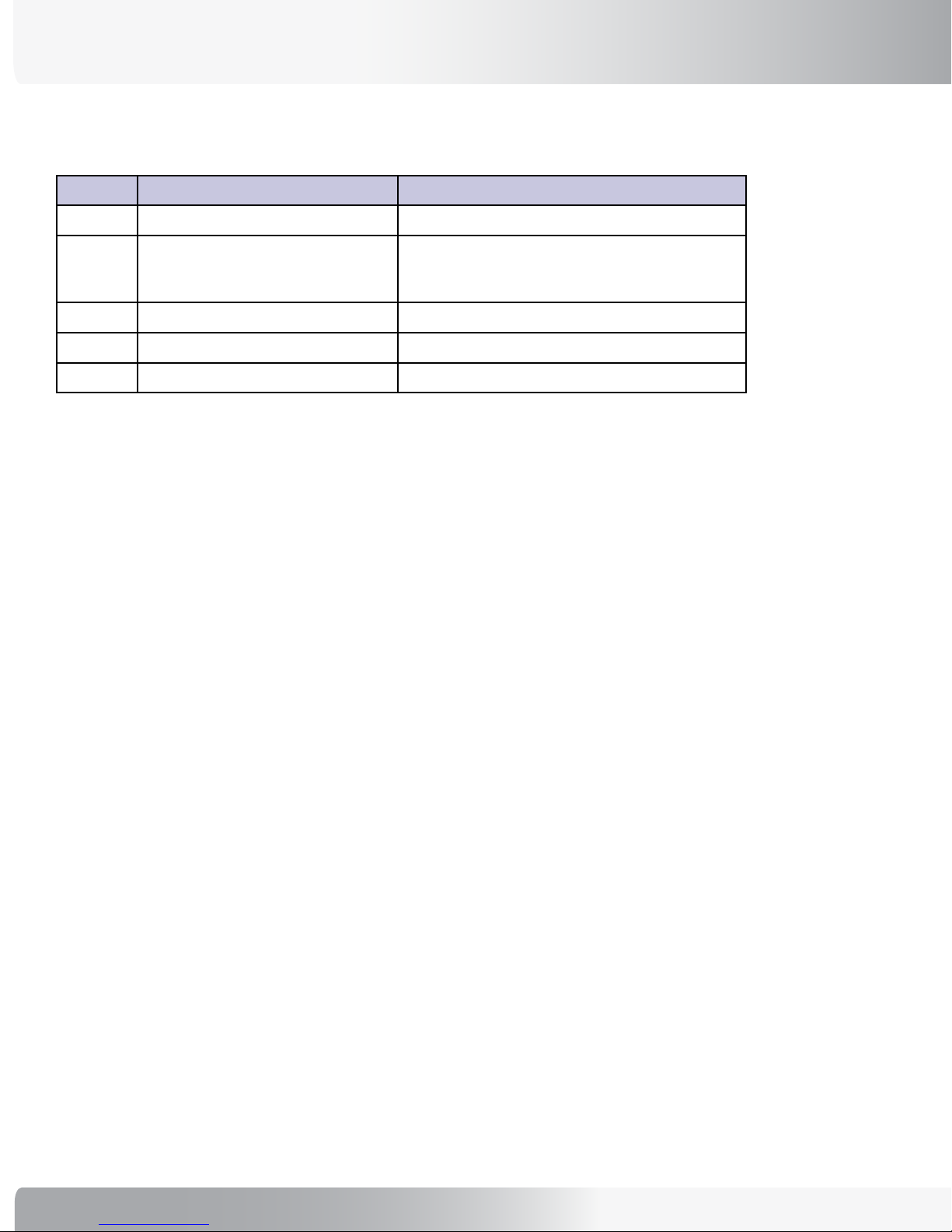

Table 2–5. Maintenance Logs

Step No. Press Keys Display (What you will see)

Maintenance Logs

1

2 ▼ or ▲ QA ID NUMBER*, MAINT HOURS, ERROR

3 ENTER Selected choice

4 CLEAR after viewing (or reset) MAINTENANCE LOGS

5 CLEAR SELECT WORKOUT

* The QA ID NUMBER option is not used for servicing machines in the field.

▲, 7, ENTER

MAINTENANCE LOGS

LOG

The following tables provide the steps for resetting the time between service or maintenance calls, and for viewing the error

log:

Table 2–6. Reset Maintenance Hours

Step No. Press Keys Display (What you will see)

1 ▲, 7, ENTER MAINTENANCE LOGS

2 ▼, ▼ MAINT HOURS

3 ENTER MAINT HOURS ####

4 CLEAR to exit after viewing, or

0, ENTER to reset

MAINTENANCE LOGS

5 CLEAR SELECT WORKOUT

Maint Hours – lets the service technician enter a value representing the maintenance hours.

Table 2–7. Error Log

Step No. Press Keys Display (What you will see)

1 ▲, 7, ENTER MAINTENANCE LOGS

2 ▼, ▼, ▼ ERROR LOG

3 ENTER NO ERROR or the highest priority error

4 ▼ or ▲ Scrolls through the error log list

5 CLEAR SELECT WORKOUT

Error Log – displays fatal errors accrued on the system. The log holds up to 8 error entries. Errors are handled in two ways:

n First, as a non-fatal Warning, which will display the error response text but continue system operation until you

press the [CLEAR] key. Warnings are not logged in the Error Log.

n The second way is a fatal Error, which will stop the exercise and return the system to an idle intensity state. The

console will display the error response and a number showing how many errors were logged during the specific

event. (Some errors trigger multiple responses). To view the non-displayed errors, access the Error Log. The unit will

not let you restart the program unless power has been turned off and then back on.

Nautilus® Commerical Series Bike Service Manual

19

Page 20

Machine Status

Once you access the Error Log, you can cycle the display through 8 entries by using the up/down keys. Each entry displays

the error label, its position in the log (1-8), and the time (hours) the error occurred. Note that the most recent error might

not be in log position 1—as the number of errors exceeds 8, the newest error will overwrite the oldest. In addition, if a new

error is identical to the log’s previous entry, the system checks the time. If the time is the same (within minutes), the error is

not logged, to help prevent redundant errors.

The only way to reset the Error Log is to reconfigure the machine.

Machine Configuration

Use Machine Configuration to change the machine type. The choices are:

• Stepper

• StepMill

• U/R916

• Elliptical

In general, only the U/R916 machine type is used for the U916 or R916.

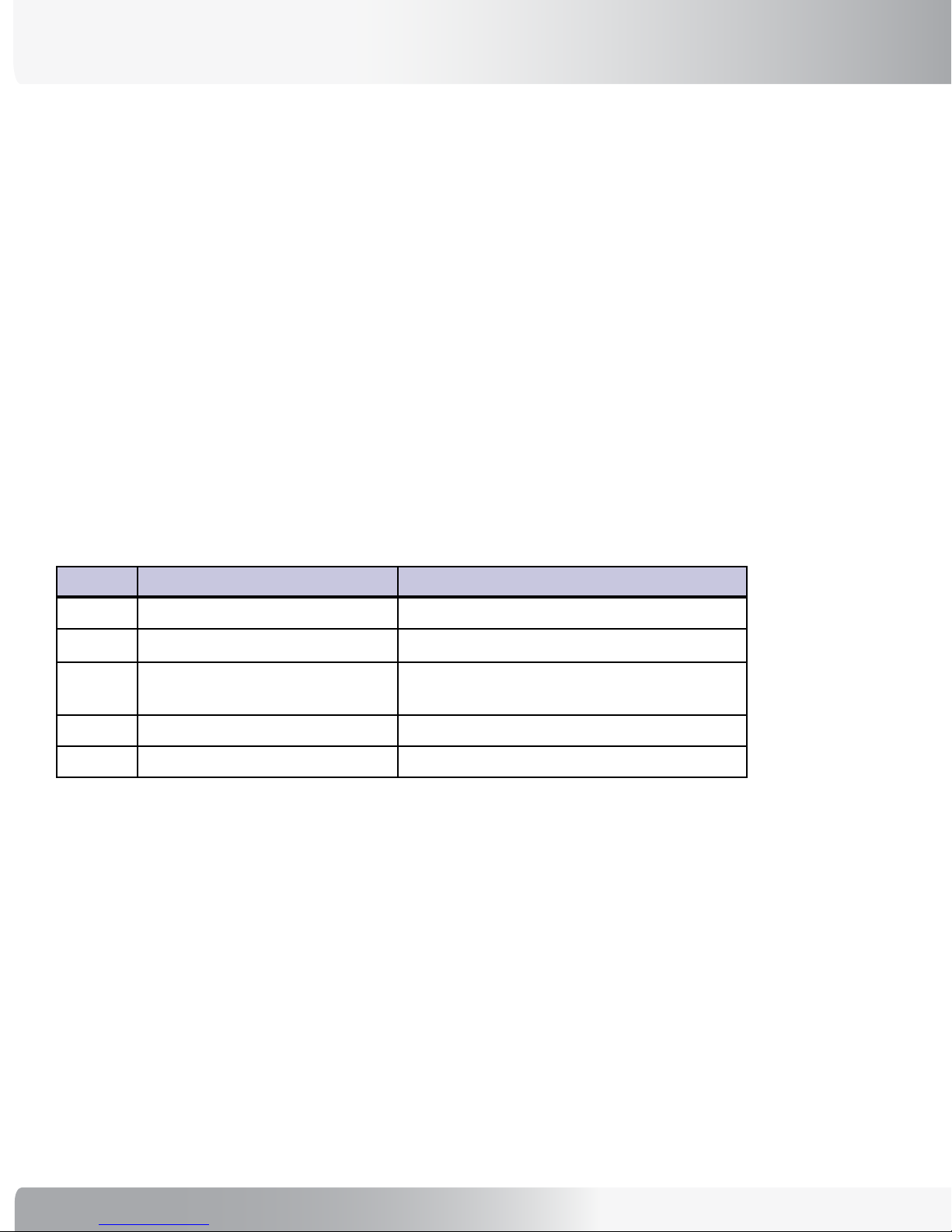

Refer to the following table to scan through and customize the settings:

Table 2–8. Machine Configuration

Step No. Press Keys Display (What you will see)

1

2

3

4

5

▲, 8, ENTER

ENTER

▼ or ▲

ENTER

CLEAR

CHANGE MACHINE

U/R916

NTM CONFIG RQD, STEPPER CL, STEPMILL,

ELLIPTICAL, U/R916

Selects your choice

SELECT WORKOUT

NTM Config RQD – resets the machine to a “blank” configuration. The configuration must be set to Elliptical (or other

machine type) for the workout functions to operate.

Stepper CL – configures the machine as a cordless Stepper. Please note that there is a sense line to let the software

know if the system is a Stepper PT (corded); if the system is indeed a Stepper PT, then Stepper PT will appear in the screen

instead of Stepper CL.

20

Page 21

3

Electrical Troubleshooting

Contents

U916 and R916 Main Power Wiring Diagram ........................................ 23

U916 Console Heart Rate Wiring Diagram ............................................ 24

R916 Console Heart Rate Wiring Diagram ............................................ 25

General Bike Electronics Troubleshooting .............................................. 26

Contact Heart Rate Testing ....................................................................28

Battery Charge Testing ........................................................................... 29

Alternator Testing ................................................................................... 30

Start-Up Circuit Testing .......................................................................... 31

Load Resistor Testing .............................................................................32

Shut-Down Testing ................................................................................. 33

Nautilus® Commerical Series Bike Service Manual

21

Page 22

Electrical Troubleshooting

22

Page 23

"2/7.

",!#+

'2/5.$

7()4%"

30%%$

3%.3/2

%840/7%2

",!#+

7()4%

"!44%29

2%3)34/2

!,4%2.!4/2

467)2%

7()4%

U916/R916 Main Power Wiring Diagram

U916 and R916 Main Power Wiring Diagram

Nautilus® Commerical Series Bike Service Manual

23

Page 24

U916 Console Heart Rate Wiring Diagram

"LEVEL (UP) - (DOWN)"

"DISPLAY LOCK

QUICKSTART"

GREEN

BLACK

RED

WHITE

RED

FRONT

GRIP

BLACK

REAR

GRIP

RED

FRONT

GRIP

BLACK

REAR

GRIP

41700 (CONSOLE)

40679

001-5378

001-5378

FIXED "T-BAR" CONTACT

HEART RATE GRIPS

41702

RIGHT

LEFT

TO BIKE

POWER ELECTRONICS

AND ALTERNATOR

25473

41187

(TELEMETRY SENSOR)

40466

RIGHT HANDGRIP

40465

LEFT HANDGRIP

001-6349

(PCBA)

001-6349

(PCBA)

U916 Console Heart Rate Wiring Diagram

24

Page 25

40466

RIGHT HANDGRIP

40465

LEFT HANDGRIP

001-6349

(PCBA)

"LEVEL (UP) - (DOWN)"

"DISPLAY LOCK

QUICKSTART"

RED

FRONT

GRIP

BLACK

REAR

GRIP

RED

FRONT

GRIP

BLACK

REAR

GRIP

41703 (CONSOLE)

TO BIKE

POWER ELECTRONICS

AND ALTERNATOR

001-5100

41187

(TELEMETRY SENSOR)

41702

RIGHT

LEFT

001-6349

(PCBA)

25473

001-5110

R916 Console Heart Rate Wiring Diagram

R916 Console Heart Rate Wiring Diagram

Nautilus® Commerical Series Bike Service Manual

25

Page 26

General Bike Electronics Troubleshooting

With external

power removed,

pedal the bike at

25RPM or greater

Does

the console

turn on?

Yes

No

Is

battery in a

charged state?

Yes

No

Using external

power supply,

charge battery for

8 hours

Remove plastic

shrouds so

electronics can be

observed

Hold both Contact

Heart Rate grips

firmly

On the 27451

PCB, measure the

voltage on J1 pins

2 and 3

Is

battery voltage 6V

or greater?

Yes

No

Perform

general bike

electrical

testing

Have a helper

pedal bike at 25

RPM or greater

Perform Battery

Charge Testing

On the 27451

PCB, measure the

voltage on J5 pins

1 and 10

Is

voltage here 6V

or greater?

Yes

No

Perform Start-Up

Circuit Testing

2

Does a

heart symbol

appear

Yes

No

In 10S

or less, does the

heart beat?

Yes

No

Perform Contact

Heart Rate Testing

This section applies to both

Contact Heart Rate and

Telemetry sensing

On the console,

press "Quick Start"

to enter a manual

workout

Is an

increase in

resistance felt?

Yes

No

Perform Alternator

Testing

3

26

Page 27

2

Does

the resistance feel

smooth?

Yes

No

Perform Alternator

Testing

Increase RPM and

levels until firm

resistance is felt

Is

firm resistance

felt?

Yes

No

Perform Load

Resistor Testing

Stop pedaling, and

press stop twice if

workout results

are desired

Approximately 1

minute after

pedaling stops, the

console should

shut off

Did

the console shut

off?

Yes

No

Bike Is Operating

Properly!

Perform ShutDown Testing

3

Remove 4 screws

holding console to

mast

While noting

locations, carefully

unplug all

connections to

console coming

from mast

Using OHM Meter,

perform continuity

check on main

interface cable,

using wire colors

as a guide

Is

continuity OK?

Yes

No

Replace console

Replace main

interface cable

General bike

electrical testing

General Bike Electronics Troubleshooting

Continuation of General Bike Electronics Troubleshooting

Nautilus® Commerical Series Bike Service Manual

27

Page 28

Contact Heart Rate Testing

Contact Heart

Rate Testing

Turn on console,

by either pedaling

bike, or installing

external power

supply

Using volt meter,

measure voltage

potential on ALL

Contact Heart

Rate plates

When performing

measurement,

confirm positive

lead is on top plate

(users' palm)

Is a

voltage of about 2V

measured?

Yes

No

Is

the voltage

positive?

Yes

Remove the

screws securing

the Contact Heart

Rate plates

Remove 4 screws

holding console to

mast

While noting

locations, carefully

unplug the suspect

Contact Heart

Rate cable

Using OHM Meter,

perform continuity

check on cable,

using wire colors

as a guide

Is

continuity OK?

Yes

No

Replace Contact

Heart Rate cable

Replace console

Remove the

screws securing

the Contact Heart

Rate plates

Reverse the

polarity of the

plates' wires. Red

should be on top,

black on bottom

Have you had

success previously with

Contact Heart Rate

Systems?

*

Yes

No

Perform Contact

Heart Rate Testing

* Contact Heart Systems perform properly on roughly 87% of the population, according to latest data from Salutron. Many factors affect the

pulse strength at the user's palms.

No

General bike

electrical testing

28

Page 29

Battery Charge Testing

Battery

Charge

Testing

Due to requiring many pieces of test equipment, this procedure does not test the complete functionality of the charger but rather its final "float" state.

If the battery voltage is less than 3V, no more than 50mA is applied. From 3V to 6.8V current control applies nearly .4A until voltage control or float

state is entered.

Batteries can only be tested under load. Even if it measures 6V or more unloaded, it can still produce little or no voltage under load as a defective

battery's internal impedance increases.

Apply power to the

bike from the

external power

supply, first

confirming AC

voltage is present

Remove the

battery connector

from the 27451

PCB at location J1

Is

the voltage 6.8V

+/- 3%

Yes

Measure the

voltage on the

27451's J1 pins 2

and 3

Replace the

battery

No

Replace the 27451

PCB

Measure the

voltage on test

points 1 and 3 of

the 27451

Is

the voltage 9V

+/- 10%

Yes

No

General bike

electrical testing

Unplug the

external power

supply cable at

location J3

Is

the voltage 9V

+/- 10%

Yes

Replace the 27451

PCB

Measure the

voltage of the

contacts of this

connector on pins

1 and 2

No

Unplug the power

supply and

measure its

voltage on pins 1

and 2

Is

the voltage 9V

+/- 10%

Yes

No

Replace the

external power

cable

Replace the power

supply

General bike

electrical testing

Charge the battery

for 8 hours, or until

6.8V is achieved

Charge the battery

for 8 hours, or until

6.8V is achieved

Nautilus® Commerical Series Bike Service Manual

29

Page 30

Alternator Testing

To minimize the complexity of the flowchart, this section will best be described in terms of system theory.

The colored connections to the alternator are as follows:

White-B+ — Alternator output voltage

Brown-Field — Alternator Control Current

Black-Ground — Alternator return

Prior to proceeding with tests below, perform continuity checks on the alternator cable, and confirm cable is securely

fastened to the alternator and the 27451 PCB.

For workouts that require levels of less than 50W resistance to the user, clinical mode must be used. In this condition,

the console is powered by an external power supply, and the alternator is not powered unless the user decides to

achieve levels of 50W or more.

If the bike’s speed is 40 RPM or greater, and assuming clinical mode is not desired, the system can subject the user

to a workout that is self-generating. Under self-generating conditions, the alternator is on; it is powering itself, the

console, and providing charge to the battery.

Prior to entering workout information, it is desired to have the user subjected to minimal resistance, and the console

is powered by the battery. Once the console knows all the user’s desired information, it turns on the alternator. The

alternator is turned on by a logic low on pin 2 of J5 of the 27451 PCB. This signal is also accessible on the 27451’s TP11.

Once the alternator is powered, the user sees an increase in resistance due to the alternator’s internal magnetic fields.

The 27451 PCB maintains a regulated voltage on the alternator’s B+ by varying the amount of current sourced into the

alternator’s field. B+ is sensed by the 27451, and the field current is altered until the alternator is at the desired voltage.

As the RPM increases, the alternator’s efficiency increases, and less field current is required.

Depending on the desired resistance level, the console can control the alternator’s output voltage by controlling the

logic level of pin 7 of J5 on the 27451 PCB. A logic low on pin 7 tells the 27451 to control at 7.8V or a logic high sets

9.8V.

If the alternator is not powering on, first confirm the bike is cranked at ~50 RPM, and that pin 2 of J5 (TP 11) is NOT

high. If it is, and a workout has been entered, suspect the console. If pin 2 of J5 is low, measure the alternator’s field

voltage. Without B+ the 27451 will attempt to force full current into the field, and in this condition it will be limited by

its input voltage, or the battery in this case. Therefore, if 5V or more is measured on the field with no B+, either B+ is

shorted or the alternator is defective. Before replacing the alternator, disconnect the B+ wires from the alternator’s

B+ terminal and see if an output voltage exists. If voltage is now present, which could easily exceed 30V in an uncontrolled state, the 27451 PCB is probably defective. With no load on B+, 5V or more field current, adequate RPM and no

B+, replace the alternator.

If no field voltage is detected, disconnect the B+ connections on the alternator, along with the field wire. Measure

the field resistance to alternator ground, which should be approximately 4 ohms which is a typical value of Prestolite

units. If the field resistance is way less than this or shorted, replace the alternator. If the field measures ~4 ohms, take

a jumper wire, and make a connection from the positive battery terminal to the alternator’s field tab. If the voltage now

jumps up to a level of 20 to 30V the alternator is good, and the 27451 needs replacing.

If the B+ voltage is sporadic first look for loose connections. This type of problem could be caused by a defective

alternator or 27451. If a known-good 27451 unit is available it will be the easiest component to replace. If the problem

goes away, confirm the other PCB still causes sporadic behavior, and the problem was not in fact a loose connection.

30

Page 31

Start-Up

Circuit

Testing

Connect external

power supply

Does

Console turn

on?

Yes

No

Unplug external

power supply

Confirm the

magnetic pick-up

on the alternator is

mounted such that

its face is parallel

and within 1mm of

every fin on the

speed disk

Adjustment

required?

Yes

No

Tighten magnetic

pick-up securely,

and confirm the

sensor is free of

contact from the

sensor

Using the Battery

Charge Testing

section as a

reference, confirm

operation of

external power

supply and

external power

cable

9V +/- 10%

measured on TP1?

Yes

No

~8V

measured on J5

#1?

Yes

No

Replace 27451

PCB

General bike

electrical testing

Perform continuity

check on main

interface cable,

pins 1 and 10

Continuity

OK?

Yes

No

Replace console

Replace or repair

main interface

cable

General bike

electrical testing

Unplug the speed

sensor from the

27451 at J2

Have a helper

pedal bike at 25

RPM or greater

while measuring

the AC voltage on

J2 pins 1 and 2

Voltage

measure 4VAC

or more?

Yes

No

Replace 27451

PCB

Replace the

magnetic pick-up

Start-Up Circuit Testing

Nautilus® Commerical Series Bike Service Manual

31

Page 32

Load Resistor Testing

Load Resistor

Testing

Remove plastic

shrouds so

electronics can be

observed

Measure

resistance from

the 27451's J6 pin

3 to the

alternator's B+

terminal

Have a helper

pedal the bike in

elevated

resistance workout

levels

Is the

resistance .33

+/- 3%?

Yes

No

Is

voltage present?

Yes

Measure the

voltage potential

on the resistor

terminals

General bike

electrical testing

Resolve any loose

connections, and

replace the

resistor cable or

the resistor is

opened

Is the

resistance high?

Yes

No

Is the

resistance low?

Yes

Resolve any

shorted

connections in the

resistor cable or

resistor

Replace the

console

No

Measure the

voltage potential

on J5 pin 4

Is

voltage less than

5V?

Yes

No

Replace the 27451

PCB

General bike

electrical testing

32

Page 33

Perform Shut-

Down testing

One minute after a

workout ends, the

console should

turn off

Does

the console shut

off?

No

Is

external power

supplied?

Yes

No

General bike

electrical testing

It is normal for the

27451 PCB to

keep the console

powered if

externally powered

Measure the

voltage potential of

J5 pin 9 and 10

Yes

Is

this close to 0V?

Yes

No

Replace the 27451

PCB

Replace the

console

General bike

electrical testing

Shut-Down Testing

Nautilus® Commerical Series Bike Service Manual

33

Page 34

Electrical Troubleshooting

34

Page 35

4

Mechanical Troubleshooting

Contents

Removing/Replacing Parts - U916 and R916 Common Parts ..................... 37

Removing the Console ................................................................... 37

Removing the Mast ........................................................................ 38

Removing the Right and Left Pedals .............................................. 39

Removing the Load Resistor .......................................................... 40

Removing the Battery ....................................................................41

Removing the Power Board ...........................................................41

Removing the Power Inlet Connector ............................................ 42

Removing the Speed Sensor .......................................................... 43

Removing the Alternator ................................................................ 44

Removing the HTD Belt .................................................................. 46

Removing the Poly-V Wheel .......................................................... 47

Removing/Replacing Parts - U916 Parts ..................................................... 48

Removing the Upper Handle Bar ...................................................48

Replacing the Upper Right or Left CHR Plates ..............................48

Nautilus® Commerical Series Bike Service Manual

35

Page 36

Mechanical Troubleshooting

Replacing the Lower T-Bar Right or Left CHR Plates ..................... 49

Removing the Seat Assembly

Removing the Side Covers

........................................................ 50

............................................................. 50

Removing/Replacing Parts - R916 Parts ..................................................... 51

Removing the Side Covers ............................................................. 51

Removing the Left and Right Rear Covers ..................................... 52

Cable Connections - U916........................................................................... 53

Cable Connections - R916 ........................................................................... 56

36

Page 37

Mechanical Procedures

This section of the Service Manual provides instructions for removing and replacing parts of the U916 and R916

bikes. The first segment contains procedures that apply to both bike models. The second segment contains

instructions specific to the U916 bike, and the third contains instructions specific to the R916 bike. The fourth

segment focuses on the cable connections for the U916 and R916 bikes. For part number information, please

refer to the separate documents for warranty parts lists and exploded drawings.

U916 and R916 Procedures

REMOVING THE CONSOLE:

Tools needed:

• Phillips screwdriver or Cordless drill with Phillips tip

Step 1: Remove the four Phillips screws attaching the Console

to the Mast. See Figure 1a and 1b.

Set the screws aside for Step 5.

Step 2: Tilt the console forward and disconnect all the cables

from the Mast to the PC board connectors (Figure 2).

Note: Make note of each cable and the location of its

connector on the PC board.

Figure 1a - U916 console

Figure 1b - R916 console

Step 3: Remove the Console.

Step 4: To replace the Console, position the Console at the top

of the Mast so that you can connect the cables to the

PC board (Figure 2). For specific connector locations,

refer to the CABLE CONNECTIONS segment later in

this section.

Figure 2 - Cable connections in back of

Console (R916 console shown)

Nautilus® Commerical Series Bike Service Manual

37

Page 38

Mechanical Procedures

Step 5: Install the Console to the Mast using the four Phil-

lips screws that you removed in Step 1. See Figure

1a and 1b.

REMOVING THE MAST:

Tools needed:

Phillips screwdriver or Cordless drill with Phillips tip

6 mm Allen wrench

8 mm Allen wrench

Step 1: Remove the console according to the REMOVING

THE CONSOLE procedure.

Step 2: For the U916 only – Remove the Upright Handlebar

according to REMOVING THE UPPER HANDLE BAR

procedure.

Figure 3a - Remove right mast cover

Step 3: Remove the right and left Mast covers with a phil-

lips screw driver. See Figure 3a and 3b.

Step 4: For the U916 only – Remove the Cupholder from the

Mast with a phillips screwdriver (see Figure 4).

Step 5: Using a 8mm Allen wrench, remove the four bolts

securing the Mast to the bottom half frame. See

Figure 5a and 5b.

Figure 3b - Remove left mast cover

Figure 4 - Remove cupholder (U916 only)

38

Figure 5a - Unbolt mast from frame (U916)

Page 39

Step 6: Carefully lift and remove the Mast, allowing clear-

ance so that the wires coming out the bottom are

not pinched or scraped. See Figure 6a and 6b.

Mechanical Procedures

Figure 5b - Unbolt mast from frame (R916)

REMOVING THE RIGHT AND LEFT PEDALS:

Tools needed:

15mm Wrench

Step 1: Position yourself on the left side of the bike and

place your left hand on the left pedal to stabilize it.

Step 2: Using a 15mm Wrench, turn the pedal nut clockwise

to loosen and remove the left pedal (Figure 7).

Step 3: Position yourself on the right side of the bike and

place your right hand on the right pedal to stabilize.

Step 4: Using a 15mm Wrench, turn the pedal nut counter-

clockwise to loosen and remove the pedal (Figure

8).

Figure 6a - Lift mast

off frame (U916)

Figure 7 - Loosen left pedal nut

Figure 6b - Lift mast off

frame (R916)

Figure 8 - Loosen right pedal nut

Nautilus® Commerical Series Bike Service Manual

39

Page 40

Mechanical Procedures

REMOVING THE LOAD RESISTOR:

Tools needed:

Phillips screwdriver or Cordless drill with Phillips tip

5/16 Nut driver

Step 1: Remove the right and left side covers according

to the appropriate REMOVING THE SIDE COVERS

procedure (U916 or R916).

Step 2: Using a 5/16 Nutdriver and Phillips screwdriver,

remove the hardware attaching the black and white

wires of the Load Resistor cable from the tabs of

the resistor. See Figure 9a and 9b.

Step 3: Using a Phillips screwdriver, remove the two

mounting screws attaching the Load Resistor to the

frame (Figure 10a) and remove the resistor (Figure

10b).

Figure 9a - Detach resistor wires (U916)

Figure 9b - Resistor wires (R916)

40

Figure 10a - Unscrew resistor (U916 shown)

Figure 10b - Remove resistor (U916 shown)

Page 41

REMOVING THE BATTERY:

Tools needed:

Phillips screwdriver or Cordless drill with Phillips tip

Wire cutters

Step 1: Remove the right and left side covers according

to the appropriate REMOVING THE SIDE COVERS

procedure (U916 and R916).

Step 2: Cut the cable tie holding the Battery in place (Figure

11).

Step 3: Disconnect the black and white Battery cable from

the Battery. See Figure 12.

Mechanical Procedures

Cable tie

Figure 11 - Cut cable tie

Step 4: Lift and remove the Battery (Figure 13).

REMOVING THE POWER BOARD:

Tools needed:

Phillips screwdriver or Cordless drill with Phillips tip

Step 1: Remove the right and left side covers according

to the appropriate REMOVING THE SIDE COVERS

procedure (U916 and R916).”

Figure 12 - Disconnect battery cable

Figure 13 - Remove battery

Step 2: Disconnect the attaching cables from Power board.

See Figure 14a and 14b.

Figure 14a - Disconnect power board cables

(U916 shown)

Nautilus® Commerical Series Bike Service Manual

41

Page 42

Mechanical Procedures

Step 3: Remove the four mounting screws at the corners

of the Power board. See Figure 15 (U916 shown).

Figure 14b - Power board cables disconnected

(R916 shown)

REMOVING THE POWER INLET CONNECTOR:

Tools needed:

#0 Phillips screwdriver

Wire cutters

Step 1: Remove the right and left side covers according

to the appropriate REMOVING THE SIDE COVERS

procedure (U916 or R916).

Step 2: Disconnect the cable end of the Inlet connector

from J3 on the Power board. See Figure 16.

Step 3: Cut the cable tie from the wire bundle to remove

the cable. See Figure 17.

Figure 15 - Power board mounting screws

Figure 16 - Disconnect inlet connector cable

42

Figure 17 - Cut cable tie

Page 43

Step 4: Remove the screw attaching the ground wire to the

frame. See Figure 18.

Step 5: Using a #0 Phillips screwdriver, remove the four

screws attaching the Power Inlet Connector to the

frame and remove the connector. See Figure 19a and

19b.

Mechanical Procedures

Figure 18 - Remove ground wire screw

Power Inlet

Connector

REMOVING THE SPEED SENSOR:

Tools needed:

Phillips screwdriver or Cordless drill with Phillips tip

Wire cutters

Step 1: Remove the right and left side covers according to

the appropriate REMOVING THE SIDE COVERS procedure (U916 or R916).

Figure 19a - Remove mounting screws

Figure 19b - Remove power inlet connector

Step 2: Cut the cable tie from the wire bundle. See Figure 20.

Figure 20 - Cut cable tie

Nautilus® Commerical Series Bike Service Manual

43

Page 44

Mechanical Procedures

Step 3: Disconnect the cable end of the Speed Sensor from

J2 on the Power board and remove the wire from the

bundle. See Figure 21.

Step 4: Loosen the adjustment screw and remove the Speed

Sensor from the Alternator (Figure 22).

Note: Early model Speed Sensors are tightened with

a screw adjustment. Later models are tightened

with a nut and bolt.

When you (re)place the sensor on the Alternator, be sure the gap between the fan blade and

the Sensor is .020 - .040.

Figure 21 - Disconnect speed sensor cable

REMOVING THE ALTERNATOR:

Tools needed:

Phillips screwdriver or Cordless drill with Phillips tip

Wire cutters

Impact cordless wrench

15/16” socket and ratchet

6mm Allen wrench

8mm Allen wrench

9/16” socket

Step 1: Remove the right and left side covers according to the

appropriate REMOVING THE SIDE COVERS procedure

(U916 or R916).

Step 2: Remove all the attached cables from the Alternator,

then detach the Speed Sensor from the Power board.

See Figure 23.

Figure 22 - Loosen adjustment screw

Figure 23 - Detach all cables from alternator

Note: Make note of where and how the cables are

attached to the Alternator.

44

Figure 24 - Remove flywheel

Page 45

Step 3: Using the 15/16 socket, remove the Flywheel nut with

an Impact wrench or similar tool. See Figure 24.

Step 4: Remove the Alternator Poly-V belt by slowly “walking

off” the belt in a clockwise motion (Figure 25).

Step 5: Remove the Flywheel and Fan disk (Figure 26).

Mechanical Procedures

Figure 25 -

Step 6: Using a 6mm Allen wrench, 8mm Allen wrench, and

9/16 socket with ratchet, remove the two bolts that

attach the Alternator to the frame. See Figure 27a and

27b.

Figure 26 -

Figure 27a - Remove alternator mounting bolts

Figure 27b -

Nautilus® Commerical Series Bike Service Manual

45

Page 46

Mechanical Procedures

Step 7: Remove the Speed Sensor from the old Alternator ac-

cording to the REMOVING THE SPEED SENSOR procedure, and install the Speed Sensor on the new Alternator. See Figure 28.

Note: When placing the sensor on the Alternator, be

sure the spacing between fan blade and the Sensor is .020 - .040

REMOVING THE HTD BELT:

Figure 28 -

Tools needed:

Phillips screwdriver or Cordless drill with Phillips tip

17mm Wrench

19mm Wrench

Step 1: Remove the Side covers according to the appropriate

REMOVING THE SIDE COVER procedure (U916 or R916).

Step 2: Using a 17mm wrench and 19mm wrench, loosen the belt

tensioner and slide upward along the slotted cut-out.

Note: Do not completely remove the screw. See Figure

29a and 29b.

Figure 29a - Loosen belt tensioner

Belt tensioner

Slotted

cutout

Figure 29b - Belt tensioner

Step 3: Remove the belt and place a new one on (Figure 30).

46

Figure 30 - Replace HTD Belt

Page 47

REMOVING THE POLY-V WHEEL:

Tools needed:

Phillips screwdriver or Cordless drill with Phillips tip

3/16 Allen wrench

Snap ring pliers

Step 1: Remove the Side covers according to REMOVING THE

SIDE COVER procedure for the U916 or R916.

Step 2: Remove the Alternator Poly-V belt by slowly “walking”

the belt off the Poly-V wheel in a clockwise motion.

See Figure 31.

Mechanical Procedures

Figure 31 -

Step 3: Using a 3/16 Allen wrench, loosen and remove the

four mounting screws. See Figure 32.

Step 4: Remove the Snap ring (Figure 33) and pull off the Poly-

V wheel.

Figure 32 -

Snap ring

Figure 33 -

Nautilus® Commerical Series Bike Service Manual

47

Page 48

Mechanical Procedures

U916 Procedures

REMOVING THE UPPER HANDLEBAR:

Tools needed:

Phillips screwdriver or Cordless drill with Phillips tip

6 mm Allen wrench

Step 1: Remove the console according to REMOVING THE

CONSOLE procedure.

Step 2: Remove the four Allen screws attaching the Handlebar

to the frame with a 6mm Allen wrench. See Figure 34.

Step 3: Carefully pull the cables out from the Mast (Figure 35).

Figure 34 -

Step 4: Reverse the steps to install a new Handlebar assembly

on the machine.

REPLACING THE UPPER RIGHT OR LEFT CHR PLATES:

Tools needed:

#0 Phillips screwdriver

Step 1: Carefully remove the two screws from the rear CHR

plate and separate the plates. See Figure 36.

Step 2: Disconnect the black CHR wire from the rear plate and

place to the side. See Figure 37.

Figure 35 -

Figure 36 -

48

Figure 37 -

Page 49

Step 3: Disconnect the cable wire connected to the PC board

from the front plate. See Figure 38.

Step 4: Disconnect the red CHR wire from the front plate and

place to the side. See Figure 39.

Step 5: Reverse the steps when reinstalling the plates.

Note: Be careful not to pinch the cable wires when

reattaching the Front and Rear housings.

Mechanical Procedures

Figure 38 -

REPLACING THE LOWER T-BAR RIGHT OR LEFT CHR PLATES:

Tools needed:

#0 Phillips screwdriver

Step 1: Carefully remove the two screws from the rear CHR

plate and separate the plates. See Figure 40.

Step 2: Disconnect the black CHR wire from the rear plate and

place to the side.

Step 3: Disconnect the red CHR wire from the top plate and

place to the side.

Step 4: Reverse the steps when reinstalling the plates.

Note: Be careful not to pinch the cable wires when

reattaching the Front and Rear housings.

Figure 39 -

Figure 40 -

Nautilus® Commerical Series Bike Service Manual

49

Page 50

Mechanical Procedures

REMOVING THE SEAT ASSEMBLY:

Step 1: Press and hold the adjustment seat lever, then pull

seat upward, straight out of the frame. See Figure 41a

and 41b.

Figure 41a -

REMOVING THE SIDE COVERS:

Tools needed:

Phillips screwdriver or Cordless drill with Phillips tip

Step 1: Position yourself on the left side of the bike, and

remove the 13 phillips screws from the left side cover.

See Figure 42.

Step 2: Position the left pedal so the cover may be carefully

lifted and removed. See Figure 43.

Step 3: Position yourself on the right side of the bike and

remove the two phillips screws from the bottom of the

right side cover.

Figure 41b -

Figure 42 -

Step 4: Position the right pedal so the cover may be carefully

lifted and removed.

50

Figure 43 -

Page 51

R916 Procedures

REMOVING THE SIDE COVERS

REMOVING THE LEFT AND RIGHT FRONT COVERS:

Tools needed:

Phillips screwdriver or Cordless drill with Phillips tip

Step 1: Remove the six screws attaching the right and left

Mast covers (Figure 44). Place the covers to the

side.

Step 2: Position yourself on the left side of the bike, and

remove the eight phillips screws from the left side

cover. See Figure 45.

Mechanical Procedures

Figure 44 -

Step 3: Move the Seat Assembly back to the top position

on the seat rail. Position the left pedal so the cover

may be carefully lifted and removed. See Figure 46.

Step 4: Position yourself on the right side of the bike, and

remove the one phillips screw located near the

Mast from the right side cover. See Figure 47.

Figure 45 -

Figure 46 -

Figure 47 -

Nautilus® Commerical Series Bike Service Manual

51

Page 52

Mechanical Procedures

Step 5: Position the right pedal so the cover may be carefully

lifted and removed. See Figure 48.

REMOVING THE LEFT AND RIGHT REAR COVERS:

Tools needed:

Phillips screwdriver or Cordless drill with Phillips tip

Step 1: Remove the left and right Front covers according to

the REMOVING THE LEFT AND RIGHT FRONT COVERS

procedure.

Figure 48 -

Step 2: Position yourself on the left side and remove the 13

Phillips screws from the side cover, then carefully lift

and remove. See Figure 49a and 49b.

Step 3: Position yourself on the right side and remove the

three Phillips screws from the side cover, then carefully lift and remove. See Figure 50.

Figure 49a -

Figure 49b -

52

Figure 50 -

Page 53

Cable Connections - U916

Cable Connections - U916

Routing and connector points for the main U916 cable connections are shown below. Wiring diagrams for the U916

console, handles and main power are provided in Section 2.

Main and TV Cables - Frame to Front Mast:

Cables exit from Mast

WIRE TIE

CABLES

MAST

Connect the attached long Wire Tie to the

main and TV cables and use it to pull the

cables up through the Mast . Discard the

Wire Tie after use.

NOTE: TAKE CARE NOT TO PINCH CABLES

WHEN ASSEMBLING.

Cables enter Mast

MAIN FRAME

Nautilus® Commerical Series Bike Service Manual

53

Page 54

Cable Connections - U916

HR Cables - Handlebars to Front Mast:

Connect the attached long Wire Tie to the

handlebar cables and use it to pull the

cables out through the Mast . Discard the

Wire Tie after use. (The main and TV cables

are not shown, for clarity.)

CABLES

Cables exit

from Mast

MAST

HANDLEBARS

NOTE: TAKE CARE NOT TO PINCH CABLES

WHEN ASSEMBLING.

WIRE TIE

Cables enter Mast

through handlebar

support arm

54

Page 55

Main and HR Cables - Front Mast to Console:

Cable Connections - U916

Figure A - Heart Rate Wires Not Bound

Ferrite Bead

Housing

Figure B - Ferrite Bead Housing Reconnected

Ferrite Bead Housing

If the Ferrite Bead Housing is not bound around

the Main Console Wire and all three Heart Rate

Wires (Figure A), open the bead and reconnect it

around those wires (Figure B). Confirm that all

four wires are the same length before closing

the bead.

Do not include the TV wires.

Plug the Main Console Wire into the large

connector labeled J5 on the back of the Console.

The Right Heart Rate Wire is labeled with an

“R”. Plug the Right Heart Rate Wire into the

connector labeled P1 on the back of the console.

Plug the Left Heart Rate Wire into the P2

connector.

Plug the Center Heart Rate Wire into the P3

connector.

Gently push the excess wires back down into

the mast.

TV Cables

Main Console Wire

Ferrite Bead Housing

TV Cables

CONSOLE

Right Heart Rate Wire

Left Heart Rate Wire

Center Heart Rate Wire

NOTE: If installing the optional LCD Monitor

refer to the NV915 installation manual at this

time. If not installing the LCD Monitor, wrap the

end of the TV Cables with electrical tape and

tuck them into the Mast.

Back of Console:

P1

P3

J5

P2

MAST

Nautilus® Commerical Series Bike Service Manual

55

Page 56

Cable Connections - R916

Cable Connections - R916

Routing and connector points for the main R916 cable connections are shown below. Wiring diagrams for the R916

console, handles and main power are provided in Section 2.

Main and TV Cables - Frame to Front Mast:

Connect the attached long Wire Tie to the

main and TV cables and use it to pull the

Cables exit from Mast

MAST

cables up through the Mast. Discard the

Wire Tie after use.

NOTE: TAKE CARE NOT TO PINCH CABLES

WHEN ASSEMBLING.

WIRE TIE

CABLES

MAIN FRAME

Mast attached to Main Frame:

Cables exit

from Mast

Cables enter Mast

56

Page 57

Main and HR Cables - Front Mast to Console:

Cable Connections - R916

CONSOLE

MAIN CONSOLE WIRE

TV CABLES

RIGHT HEART

RATE WIRE

LEFT HEART

RATE WIRE

Plug the Main Console Wire into the large

connector labeled J5 on the back of the

Console.

The Right Heart Rate Wire is labeled with

an “R”. Plug the Right Heart Rate Wire into

the connector labeled P1 on the back of the

console.

Plug the Left Heart Rate Wire into the P2

connector.

NOTE: If installing the optional LCD Monitor

refer to the NV915 installation manual at this

time. If not installing the LCD Monitor, wrap

the end of the TV Cables with electrical tape

and tuck them into the Mast.

MAST

Back of Console:

P1

J5

P2

Nautilus® Commerical Series Bike Service Manual

57

Page 58

Cable Connections - R916

HR Cables - Handlebars to Main Frame:

Carefully Align the Seat Assembly with the

Seat Carriage. Connect the Heart Rate

Cables from the Handlebars to the corresponding connectors exiting the Seat

Carriage.

NOTE: Use caution as the Seat Assembly

is not secured to the Seat Carriage. It is

easier to connect the cables if the Carriage

is positioned toward the bottom of the the

range.

To avoid damage to the Heart Rate Cables,

do not apply excessive force.

SEAT ASSEMBLY

SEAT CARRIAGE

CABLE CONNECTORS

HEART RATE

CABLES

MAIN FRAME

58

Page 59

Appendixes

Contents

Appendix A—Required Tools .....................................................................60

Appendix B—Using a Multimeter .............................................................. 61

Appendix C—International Power Plug Configurations

............................. 64

Nautilus® Commerical Series Bike Service Manual

59

Page 60

Appendix

Required Tools

This is a list of the most common tools you will need to service the R916 and U916 Bikes.

Table A–1. Required Tools and Uses

Tool Purposes

Socket wrench General

#0 Phillips screwdriver General

#2 Phillips screwdriver General

Cordless drill w/bit General

Rachet General

Wire cutters General

15mm Pedal Wrench Removing Pedals

8mm Allen Wrench Removing/Installing crank bolts

ISIS Crank puller Removing Crank Arms

17mm and 19mm open end wrench Adjusting timing belt tension

Impact cordless drill Flywheel

3/16 Allen Poly-V wheel

5/16 Nut driver Resistor cable

9/16 socket Alternator

Snap Ring Pliers Intermediate Hub

5mm Allen Wrench Intermediate Pulley

6mm Allen Wrench Removing/Installing Handlebars

Multimeter Electrical troubleshooting

60

Page 61

Using a Multimeter

How to Use a Multimeter

This is a basic overview of mutlimeters. For in depth directions, please use the manual provided

with your multimeter.

What Does a Multimeter Do?

A multimeter combines the functions of three instruments: ammeter (measures current),

voltmeter (measures voltage), and ohmmeter (measures resistance).

Electronic signals are usually thought of in terms of voltage. For that reason, and because it is an

easier measurement to take, we will use the volts setting. We will not want to use the ammeter

setting to troubleshoot fitness equipment.

The ohmmeter setting is used to determine whether there is an open circuit (a bad connection

or break in the wires) or a short circuit (two wires that normally would not come in contact with

each other have been pinched together or crossed in some way).

Appendix

Ohmmeters work by passing a small current through the wire or component and measuring the

voltage produced.

Type of Multimeters

Multimeters are available in digital and analog models. Digital meters give an output in numbers

usually on a LCD. Analog meters move a needle along a scale.

We recommend using a digital meter. While analog meters can be very cheap, they are difficult

for beginner to read accurately, especially on resistance scales. Also, the components are

delicate and easily damaged.

Settings

For the beginner the multimeter can be intimidating because of the range of settings available.

The diagrams on the next page show what settings to use when checking voltage and resistance

on the fitness equipment. Perhaps more importantly, it shows which settings are not needed.

There are two types of digital multimeters commonly available:

• switched range and

• autoranging.

Switched range meters require you to choose the appropriate position from the many choices

available on the dial. For example, if the dial is switched to 20VDC, 20 volts is the maximum

voltage that can be measured. This is important when you want to read small increments in

voltage accurately. For example, if the required voltage is 13.5 volts and the meter is set too high,

you may only see 13 volts on the readout. Setting the meter to a lower maximum will show 13.5

volts.

Nautilus® Commerical Series Bike Service Manual

61

Page 62

Appendix

Autoranging meters automatically adjust the range to give an accurate reading. This type of

meter is more expensive but much easier to use.

Switched Range Meter

Set here to check DC

voltage

20 will be the most used

setting for measuring

DC voltage output

Set here to check

resistance (ohms)

Or here to listen for

an audible response

(useful when testing a

sensor)

Autoranging Meter

Set here to check AC

voltage

These are for

checking amps and

are not needed for

our purposes

Black (negative) lead

always goes here

Set here to check AC

or DC voltage

Set here to check

resistance (ohms)

Set here for an

audible response

The remaining three

are for amps settings

Black (negative) lead

always goes here

62

Page 63

Checking Resistance

Use this procedure to check for broken wires:

1 Set the multimeter to the lowest OHMs (resistance) range.

2 Attach the test leads on both ends of the wire being tested.

3 Observe the reading.

short circuit will read less than approximately 3 ohms. This is the correct reading for an

• A

undamaged wire.

Appendix

• An

open circuit will usually read infinite; on a digital meter it will have an error code. This signals

a broken or cut wire.

Use this procedure to test for crossed wires. In most circumstances all indivudual wires in a

cable will be insulated from each other. When a wire is pinched, it becomes short circuited to an

adjacent wire. This can cause problems resulting in blown fuses or fried components.

1 Set the multimeter to the lowest OHMs (resistance) range.

2 Attach one test lead of the multimeter to one wire and check all adjacent wires. This can all

be done at one end of the cable. However, the other end of the cable must be disconnected

from the circuit board. All wires should be insulated from each other and therefore test open.

3 Observe the reading.

Checking Voltage

Use this procedure to check voltage output:

1 Determine whether the voltage is AC or DC voltage, and choose the appropriate setting on the

multimeter.

2 Set the multitmeter to the lowest setting that is still higher than the highest output of the

component being tested.

3 Place the black and red leads or probes on the appropriate corresponding wires, pins, or

connectors.

4 Observe the reading, and proceed according to the troubleshooting sections in this manual.

Nautilus® Commerical Series Bike Service Manual

63

Page 64

Appendix

International Power Plug Configurations

Table B–1. International Power Plugs

Power Cords System Country

G UK

C, E, F Europe

J Swiss

K Australia

L

64

Page 65

Limited Warranty

Commercial Market Warranty Information

All Nautilus® exercise products are warranted to the

commercial market purchaser to be free from defects in

materials and workmanship. Warranty coverage valid to

the original purchaser only and proof of the purchase will

be required. Any product sold or placed in an application

not recommended by Nautilus will void any warranty

coverage set forth by Nautilus warranty policies and

procedures.

Time Period

15 Years - Frame

3 Years- Mechanical and electrical parts

1 Year- Labor

1 Year - Wear items

Warranty terms may differ outside the USA.

amount of the purchase price of the exercise product

in question. Some states do not permit the exclusion

or limitation of implied warranties or incidental or