Page 1

Evaluation Board User’s Guide for

ADC12V170: 12-Bit, 170 MSPS Analog to Digital Converter

with LVDS Outputs

N www.national.com

Rev 0.0

October 2007

Page 2

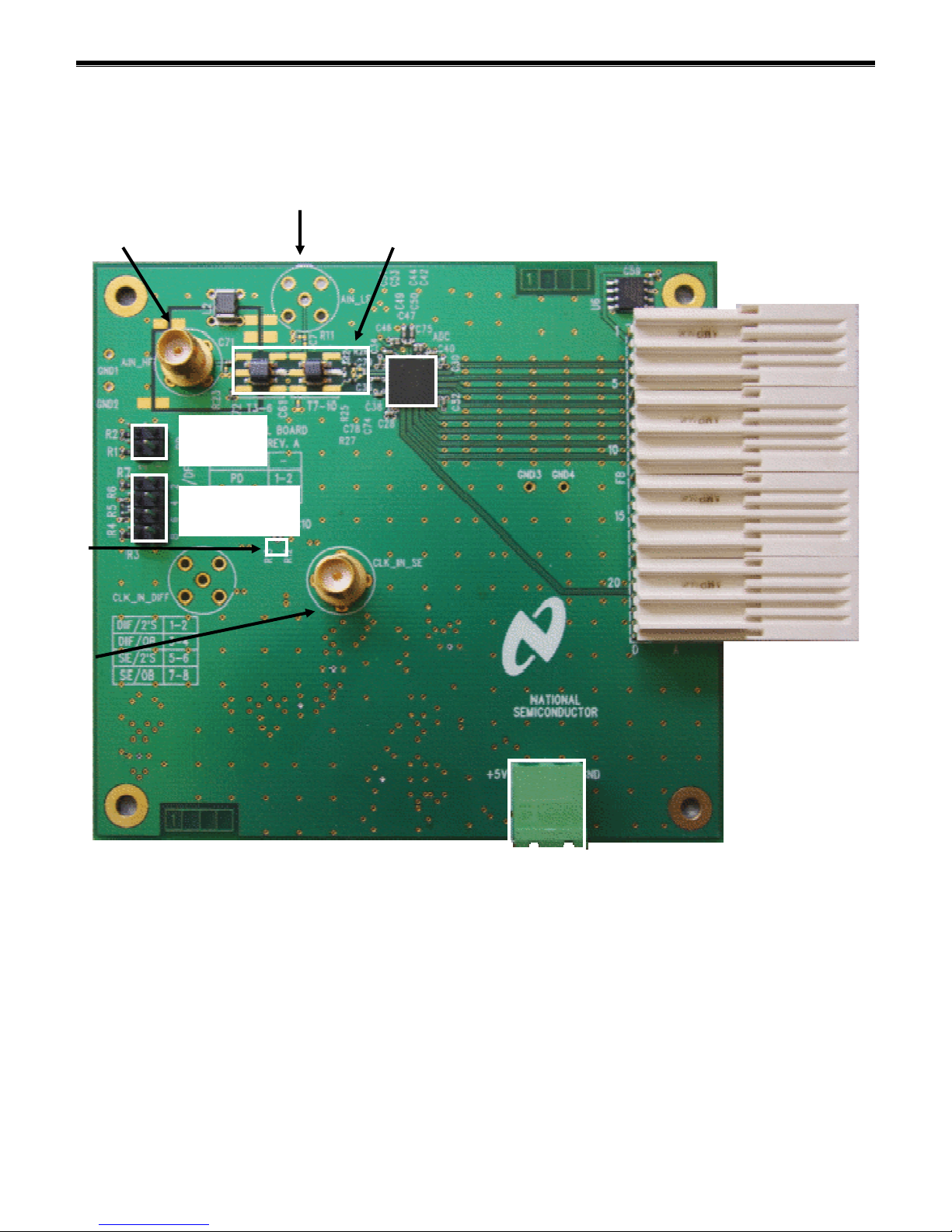

ADC12V170 Evaluation Board User’s Guide

FIN < 1

5

0 MHz

Connector

ADC

Network

FIN > 1

5

0 MHz

Connector

Analog Input

Clock

Buffer

(Reverse

Side)

Analog Input

PD

Jumper

CLK_SEL/DF

Jumper

Analog Input

Single-

Ended

Clock

Input

5.0V Power

Figure 1. ADC12V170 Evaluation Board Connector and Jumper Locations

FutureBus

N - 2 - www.national.com

Rev 0.0

Page 3

ADC12V170 Evaluation Board User’s Guide

1.0 Introduction

The ADC12V170 Evaluation Board is designed to

support the ADC12V170 12-bit 170 Mega Sample Per

Second (MSPS) Analog to Digital Converter with LVDS

Outputs.

The ADC12V170 Evaluation Board comes in two

versions:

1. ADC12V170HFEB (high frequency version)

for input frequencies greater than 150 MHz.

2. ADC12V170LFEB (low frequency version) for

input frequencies less than 150 MHz.

The digital data from the ADC12V170 evaluation board

can be captured with a suitable instrument, such as a

logic analyzer, or with National Semiconductor’s

WaveVision signal path data acquisition hardware and

software platform. The ADC12V170 evaluation board

can be connected to the data acquisition hardware

through the FutureBus connector (schematic reference

designator FB).

The ADC12V170 is compatible with National

Semiconductor’s WaveVision 5.1 and higher Signal

Path Digital Interface Board and associated

WaveVision software. Please note that the

ADC12V170 board is not compatible with previous

versions of the WaveVision hardware (WaveVision 4.x

Digital Interface Boards).

The WaveVision hardware and software package

allows fast and easy data acquisition and analysis. The

WaveVision hardware connects to a host PC via a USB

cable and is fully configured and controlled by the latest

WaveVision software. The latest version of the

WaveVision software is included in this evaluation kit

on a CD-ROM. The WaveVision 5.1 Signal Path Digital

Interface hardware is available through the National

Semiconductor website (part number: WAVEVSN 5.1).

2.0 Board Assembly

Each evaluation board from the factory is configured for

single-ended clock operation and is populated with an

analog input network which has been optimized for one

of two analog input frequencies ranges:

1. ADC12V170HFEB (high frequency version)

for input frequencies greater than 150 MHz.

2. ADC12V170LFEB (low frequency version) for

input frequencies less than 150 MHz.

Please refer to the input circuit configurations

described in the Analog Input Section (4.2) of this

guide.

The location and description of the components on the

ADC12V170 evaluation board can be found in Figure 1

as well as Section 5.0 (Schematic) and Section 7.0 (Bill

of Materials) of this user’s guide.

3.0 Quick Start

The ADC12V170 evaluation board enables easy set up

for evaluating the performance of the ADC12V170.

If the WaveVision data acquisition and data analysis

system is to be used for capturing data, please follow

the Quick Start Guide in the WaveVision User’s Guide

to install the required software and to connect the

WaveVision Digital Interface Board to the PC and to

the ADC12V170 evaluation board. Please note that the

ADC12V170 evaluation board is only compatible with

National Semiconductor’s WaveVision 5.1 and higher

Signal Path Digital Interface boards.

3.1 Evaluation Board Jumper Positions

The ADC12V170 evaluation board jumpers should be

configured as follows. Please refer to Figure 1 for the

exact jumper locations.

1. J1 on the reverse of the board should be shorted.

2. The PD jumper places the ADC12V170 into either

powerdown or sleep mode. Table 1 below shows

how to select between the power modes.

PD Jumper

Setting

Open Normal Operation

1-2 Power-down

3-4 Sleep

Table 1. CLK_SEL/DF Selection Table

3. CLK_SEL/DF pin jumpers select the output data

format (2’s complement or offset binary) and clock

mode (single-ended or differential). Table 2 below

shows how to select between the clock modes and

output data formats. Please note that the

ADC12V170 evaluation board is delivered with the

ADC12V170 clock input configured for singleended operation and Offset Binary output data

format (Jumper 7-8).

CLK_SEL/DF

Jumper

Setting

1-2 Differential 2’s Complement

3-4 Differential Offset Binary

5-6 Single-Ended 2’s Complement

7-8* Single-Ended Offset Binary

* As assembled from factory.

Table 2. CLK_SEL/DF Selection Table

Mode

Clock Mode Output Data

Format

N - 3 - www.national.com

Rev 0.0

Page 4

ADC12V170 Evaluation Board User’s Guide

3.2 Connecting Power and Signal Sources

1. To power the ADC12V170 evaluation board,

connect a 5.0V power supply capable of supplying

up to 500mA to the green power connector labeled

“+5V” which is located along the bottom edge of

the ADC12V170 evaluation board.

2. Use the FutureBus connector (FB) to connect the

ADC12V170 evaluation board to the instrument

being used to capture the data from the evaluation

board. If the WaveVision Digital Interface Board is

being used for data capture, please consult the

WaveVision User’s Guide for details on installing

and operating the WaveVision hardware and

software system.

3. Connect the clock and signal inputs to the

CLK_IN_SE and AIN_XX (where XX = HF or LF)

SMA connectors.

4.0 Functional Description

4.1 Clock Input

The clock used to sample the analog input should be

applied to the CLK_IN_SE SMA connector (if using the

single-ended clock mode).

To achieve the best noise performance (best SNR), a

low jitter clock source with total additive jitter less than

150 fs should be used. A low jitter crystal oscillator is

recommended, but a sinusoidal signal generator with

low phase noise, such as the SMA100A from Rohde &

Schwarz or the HP8644B (discontinued) from Agilent /

Hewlett Packard, can also be used with a slight

degradation in the noise performance. When using a

low phase noise clock source, the SNR is primarily

degraded by the broadband noise of the signal

generator. The clock signal generator amplitude is

typically set to +19.9 dBm to produce the highest

possible slew rate, but the SNR performance will be

impacted minimally by lowering the signal generator

amplitude slightly. Placing a bandpass filter between

the clock source and the CLK_IN_SE SMA connector

will further improve the noise performance of the ADC

by filtering out the broadband noise of the clock source.

All results in the ADC12V170 datasheet are obtained

with a tunable bandpass filter made by Trilithic, Inc. in

the clock signal path.

The noise performance of the ADC12V170 can be

improved further by making the edge transitions of the

clock signal entering the ADC clock input (pin 11,

CLK+) very sharp. The ADC12V170 evaluation board

is assembled with a high speed buffer gate

(NC7WV125K8X, schematic reference designator U2)

in the clock input path to provide a sharp clock edge to

the clock inputs and improve the noise performance of

the ADC. The amplitude of the clock signal from the

NC7WV125K8X high speed buffer is 3.3V.

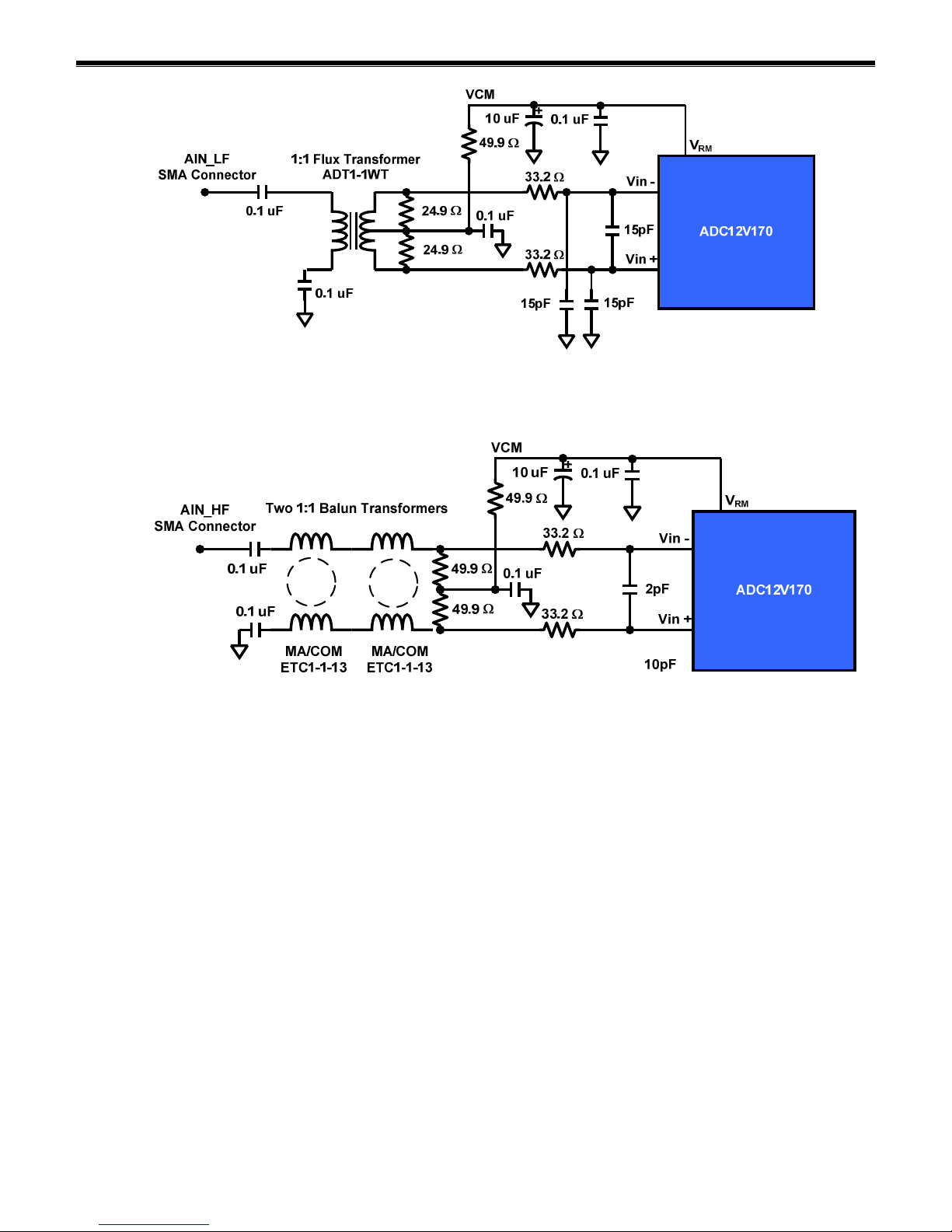

4.2 Analog Input

To obtain the best distortion results (best SFDR), the

analog input network on the evaluation board must be

optimized for the signal frequency being applied.

For analog input frequencies up to 150 MHz, the circuit

in Figure 2 is recommended. This is the configuration

of the assembled ADC12V170LFEB as it is delivered

from the factory. For input frequencies above 150

MHz, the circuit in Figure 3 is recommended. This is

the configuration of the assembled ADC12V170HFEB

as it is delivered from the factory.

A low noise signal generator such as the HP8644B is

recommended to drive the signal input of the

ADC12V170 evaluation board. The output of the signal

generator must be filtered to suppress the harmonic

distortion produced by the signal generator and to allow

accurate measurement of the ADC12V170 distortion

performance. A low pass or a bandpass filter is

recommended to filter the analog input signal. In some

cases, a second low pass filter may be necessary. The

bandpass filter on the analog input will further improve

the noise performance of the ADC by filtering the

broadband noise of the signal generator. Data shown

in the ADC12V170 datasheet was taken with a tunable

bandpass filter made by Trilithic in the analog signal

path.

N - 4 - www.national.com

Rev 0.0

Page 5

ADC12V170 Evaluation Board User’s Guide

Figure 2. Analog Input Network of ADC12V170LFEB: FIN < 150 MHz

Figure 3. Analog Input Network of ADC12V170HFEB: FIN > 150 MHz

4.3 ADC Reference and Input Common Mode

The internal 1.0V reference on the ADC12V170 is used

to acquire all of the results in the ADC12V170

datasheet. It is recommended to use the internal

reference on the ADC12V170. However, if an external

reference is required, the ADC12V170 is capable of

accepting an external reference voltage between 0.9V

and 1.1V (1.0V recommended). The input impedance

of the ADC12V170 V

Therefore, to overdrive this pin, the output impedance

of the exernal reference source should be << 9 kΩ.

It is recommended to use the voltage at the VRM pin

(pin 45) of the ADC12V170 to provide the 1.5V

common mode voltage required for the differential

analog inputs V

evaluation board is factory-assembled with VRM

connected to the transformer center-tap through a

and V

IN+

pin (pin 46) is 9 kΩ.

REF

. The ADC12V170

IN-

49.9Ω resistor to provide the necessary common mode

voltage to the differential analog input.

4.4 Board Outputs

The digitized 12-bit output word from the ADC12V170

evaluation board is presented in interleaved double

data rate (DDR) format. The digital output lines from

the ADC12V170 evaluation board consist of 16 lines

which are arranged into 8 LVDS pairs. These 8 pairs

of lines carry the 12-bit output data (6 pairs), the DRDY

signal which should be used to capture the output data

(1 pair) and the over-range bit (OVR) which indicates

that the digital output has exceeded the maximum

digitizable signal (1 pair).

Since the data is presented in interleaved double data

rate (DDR) format, the 12-bit word is output on 6 data

pair lines with half of the data (odd bits: D1+/-, D3+/-,

N - 5 - www.national.com

Rev 0.0

Page 6

ADC12V170 Evaluation Board User’s Guide

…, D11+/-) being emitted with one clock edge during

the first half of the clock period and the other half of the

data (even bits: D0+/-, D2+/-, …, D10+/-) being emitted

with the opposite clock edge during the second half of

the clock period. The odd data bits should be captured

with the falling edge of DRDY and the rising edge of

DRDY should be used to capture the even bits of the

data.

The data is available on the evaluation board at pins

A5/B5 (MSB +/-) through A10/B10 (LSB +/-) of the

FutureBus connector (schematic reference designator

FB). Please keep in mind that because the data is in

DDR format, pins A5/B5 will carry data bit D11+/during the first half of the clock period and these lines

will carry bit D10+/- during the second half of the clock

period. Similarly, pins A10/B10 will carry D1+/- during

the first half of the clock period and these pins will carry

D0+/- during the second half of the clock period. The

DRDY signal which is used to capture the data is also

in LVDS format and it is available at pins A4/D4

(DRDY+/-) on the FutureBus connector. The overrange bit (OVR) LVDS signal is available on pins

D22/D21 (OVR+/-) on the FutureBus connector.

Please see the Evaluation Board schematic in Section

5.0 and the ADC12V170 datasheet for further details.

4.5 Power requirements.

Power to the ADC12V170 evaluation board is supplied

through the green power connector labeled “+5V”

which is located along the bottom edge of the board.

Voltage and current requirements are:

• +5V capable of providing up to 500mA (ADC12V170

evaluation board only)

N - 6 - www.national.com

Rev 0.0

Page 7

5.0 Evaluation Board Schematic

ADC12V170 Evaluation Board User’s Guide

N - 7 - www.national.com

Figure 4. Signals

Rev 0.0

Page 8

5.0 Schematic (cont.)

ADC12V170 Evaluation Board User’s Guide

N - 8 - www.national.com

Figure 5. Power Distribution

Rev 0.0

Page 9

6.0 Evaluation Board Layout

ADC12V170 Evaluation Board User’s Guide

N - 9 - www.national.com

Figure 6. Layer 1 - Signal

Rev 0.0

Page 10

6.0 Evaluation Board Layout (cont.)

ADC12V170 Evaluation Board User’s Guide

N - 10 - www.national.com

Figure 7. Layer 2 - Ground

Rev 0.0

Page 11

6.0 Evaluation Board Layout (cont.)

ADC12V170 Evaluation Board User’s Guide

N - 11 - www.national.com

Figure 8. Layer 3 - Power

Rev 0.0

Page 12

6.0 Evaluation Board Layout (cont.)

ADC12V170 Evaluation Board User’s Guide

N - 12 - www.national.com

Figure 9. Layer 4 - Signal

Rev 0.0

Page 13

ADC12V170 Evaluation Board User’s Guide

N - 13 - www.national.com

Rev 0.0

7.0 Evaluation Board Bill of Materials

7.1 ADC12V170HFEB (For Fin > 150 MHz)

Item

Quantity

Schematic Reference

Part Name

Description

PCB Footprint

Manufacturer

1 1 U6 24C02 2K SERIAL EEPROM 1.8V SOIC-8

Atmel

2 1 ADC ADC12V170 12-Bit, 170 MSPS Analog/Digital Converter with LVDS Outputs 48-LLP

National Semiconductor

3 2 T6, T10 ETC1-1-13 BALUN TRANSFORMER

MA/COM

4

4

FB

AMP_5223514-1

Z-PACK 2mm FB (Futurebus+) RIGHT ANGLE HEADER CONNECTOR

-

AMP

5 1 C75 0.1uF 0.1uF SMD CAP CERAMIC 6.3V X5R 10% sm/c_0201

Panasonic - ECG

6 6 C2, C14, C20, C22, 0.1uF 0.1uF SMD CAP CERAMIC 25V X7R 10% sm/c_1206

Panasonic - ECG

C24, C66

7 21 C9, C15 0.1uF 0.1uF SMD CAP CERAMIC 10V X5R 10% sm/c_0402

Panasonic - ECG

C26, C27, C29, C31, C33,

C35, C37, C39, C41,

C43, C45, C47, C49-51,

C53, C59, C71, C72

8 12 C10, C12, C28, C30, C32, 0.01uF 0.01uF SMD CAP CERAMIC 16V X7R 10% sm/c_0402

AVX Corporation

C34, C36, C38, C40, C42

C44, C46

9 1 C13 10uF 10uF SMD CAP CERAMIC 10V X5R 20% sm/c_1206

Panasonic - ECG

10 1 C74 2pF 2pF SMD CAP CERAMIC 50v +/-0.25pF sm/c_0402

Murata Electronics

11 2 C4, C6 1uF 1uF SMD CAP CERAMIC 25V X7R 10% sm/c_1206

Panasonic - ECG

12 9 C1, C3, C8, C19, C21, C23, 10uF 10uF SMD CAP TANTALUM 6.3V 20% sm/c_3216

Kemet

C48, C52, C54

13 1 C11 2.2uF 2.2uF SMD CAP TANTALUM 16V 10% sm/c_3216

Kemet

14 1 C5 68uF 68uF SMD CAP TANTALUM 6.3V 10% sm/c_7343

Kemet

15 2 L1, L2 Ferrite Bead Core SMD FERRITE BEAD CORE 4.5X3.2X1.8 -

Panasonic -ECG

16 1 JTAG Jumper 1x8 JUMPER BLO CK USING 8 PIN SIP HEADER -

Samtec

17 1 PD Jumper 2X2 2X2 JUMPER BLOCK HEADER CUT TO SIZE FROM 2X6 HEADER -

Samtec

18 1 CLK_SEL/DF Jumper 2X4 2X4 JUMPER BLOCK HEADER CUT TO SIZE FROM 2X6 HEADER -

Samtec

19 1 - Shunt PLACE SHUNT ACROSS PINS 7-8 ON CLK_SEL/DF JUMPER -

FCI Electronic

20 1 U1 3.3V Regulator 1A LOW DROPO UT REGULATOR FOR 5V TO 3.3 V CONVERSION SOT-223

National Semiconductor

21 1 U3 1.8V Regulator

MICROPOWER/LOW NO ISE, 500 mA ULTRA LOW-DROPOUT REGULATOR

SOIC NARROW -8

National Semiconductor

22 1 +5V Power Connector Terminal Block TERMINAL BLOCK 2POS 5.08mm -

Phoenix Contact

23 1 - Power Connector Plug TERMINAL BLOCK PLUG 2POS 5.08mm -

Phoenix Contact

24 4 MT1-4 Bump-on Rubber Feet PLACE BUMP ONS AT TH E 4 CORNERS, ON BOTTOM OF BOARD -

3M

25 1 U2 Tinylogic Buffer TINYLOGIC ULP-A BUFFER WITH 3-STATE OUTPUT -

Fairchild Semiconductor

8-LEAD US8, JED EC MO-187, CA 3.1 mm WIDE

26 4 Z1-3, Z6 Noise Suppression Filter FILTER LC HIGH FREQ .2UF 1806

Murata Electronics

27 2 R17, R19 0 ohms 0 OHM SMD RESISTOR sm/r_0402

Vishay Dale

28 9 R1-7, R12-13 1 kOHM 1 kOHM SMD RESISTOR 1/16W 1% sm/r_0402

Panasonic - ECG

29 2 R14-15 24.9 ohms 24.9 OHM SMD RESISTOR 1/16W 1% sm/r_0402

Yageo Corporation

30 2 R26-27 33.2 ohms 33.2 OHM SMD RESISTOR 1/16W 1% sm/r_0402

Vishay Dale

31 3 R10, R24-25 49.9 ohms 49.9 OHM SMD RESISTOR 1/16W 1% sm/r_0402

Yageo Corporation

32 2 AIN_HF, SMA Input PCB MOUNTABLE SMA CONNECTOR -

Emerson Network Power Connectivity

CLK_IN_SE

Page 14

ADC12V170 Evaluation Board User’s Guide

N - 14 - www.national.com

Rev 0.0

7.0 Evaluation Board Bill of Materials (cont.)

7.2 ADC12V170LFEB (For Fin < 150 MHz)

Item

Quantity

Schematic Reference

Part Name

Description

PCB Footprint

Manufacturer

1 1 U6 24C02 2K SERIAL EEPROM 1.8V SOIC-8

Atmel

2 1 ADC ADC12V170 12-Bit, 170 MSPS Analog/Digital Converter with LVDS Outputs 48-LLP

National Semiconductor

3 1 T7 ADT1-1W T+ WIDEBAND RF TRANSFORMER 0.4MHz - 800 MHz CD542

MINI CIRCUITS

4

4

FB

AMP_5223514-1

Z-PACK 2mm FB (Futurebus+) RIGHT ANGLE HEADER CONNECTOR

-

AMP

5 1 C75 0.1uF 0.1uF SMD CAP CERAMIC 6.3V X5R 10% sm /c_0201

Panasonic - ECG

6 6 C2, C14, C20, C22, 0.1uF 0.1uF SMD CAP CERAMIC 25V X7R 10% sm/c_1206

Panasonic - ECG

C24, C66

7 21 C9, C15 0.1uF 0.1uF SMD CAP CERAMIC 10V X5R 10% sm/c_0402

Panasonic - ECG

C26, C27, C29, C31, C33,

C35, C37, C39, C41,

C43, C45, C47, C49-51,

C53, C59, C71, C72

8 12 C10, C12, C28, C30, C32, 0.01uF 0.01uF SMD CAP CERAMIC 16V X7R 10% sm/c_0402

AVX Corporation

C34, C36, C38, C40, C42

C44, C46

9 1 C13 10uF 10uF SMD CAP CERAMIC 10V X5R 20% sm /c_1206

Panasonic - ECG

10 3 C74, C78-79 15pF 15pF SMD CAP CERAMIC 50v NP0 5% sm/c_0402

Panasonic - ECG

11 2 C4, C 6 1uF 1uF SMD CAP CERAMIC 25V X7R 10% s m/c_1206

Panasonic - ECG

12 9 C1, C 3, C8, C19, C21, C23, 10uF 10uF SMD CAP TANT ALUM 6.3V 20% sm/c_3216

Kemet

C48, C52, C54

13 1 C11 2.2uF 2.2uF SMD CAP TANTALUM 16V 10% sm/c_3216

Kemet

14 1 C5 68uF 68uF SMD CAP TANTALUM 6.3V 10% sm/c_7343

Kemet

15 2 L1, L2 Ferrite Bead Core SMD FERRITE BEAD CORE 4.5X3.2X1.8 -

Panasonic -ECG

16 1 J TAG Jump er 1x8 JU MPER BLOCK USING 8 PIN SIP HEADER -

Samtec

17 1 PD Jump er 2X2 2X2 JUMPER BLOCK HEADER CUT TO SIZE FROM 2X6 HEADER -

Samtec

18 1 CLK_SEL/DF Jum per 2X4 2X4 JUMPER BLOCK HEADER CUT TO SIZE FROM 2X6 HEADER -

Samtec

19 1 - Shunt PLACE SHUNT ACROSS PINS 7-8 ON CLK_SEL/DF JUMPER -

FCI Electronic

20 1 U1 3.3 V Regulator 1A LOW DROPOUT REGULATOR FOR 5V TO 3.3 V CONVERSION SOT-223

National Semiconductor

21 1 U3 1.8V Regulator

MICROPOWER/LOW NO ISE, 500 mA ULTRA LOW-DROPOUT REGULATOR

SOIC NARROW -8

National Semiconductor

22 1 +5V Power Connector Terminal Block TERMINAL BLOCK 2POS 5.08mm -

Phoenix Contact

23 1 - Power Connector Plug TERMINAL BLOCK PLUG 2POS 5.08mm -

Phoenix Contact

24 4 MT 1-4 Bump-on Rubber Feet PLACE BUMP ONS AT THE 4 CORNERS, ON BOTTOM OF BOARD -

3M

25 1 U2 Tinylogic Buffer TINYLOGIC ULP-A BUFFER WITH 3-STATE O UTPUT -

Fairchild Semiconductor

8-LEAD US8, JEDEC MO-187, CA 3.1 mm WIDE

26 4 Z1-3 , Z6 Noise Suppression Filter FILTER LC HIGH FREQ .2UF 1806

Murata Electronics

27 2 R17, R19 0 o hms 0 OHM SMD RESISTOR sm/r_0402

Vishay Dale

28 9 R1-7, R 12-13 1 kOHM 1 kOHM SMD RESISTOR 1/16W 1% sm/r_0402

Panasonic - ECG

29 4 R14-15, R24-2 5 24.9 ohms 24.9 OHM SMD RESISTOR 1/16W 1% sm/r_0402

Yageo Corporation

30 2 R26-27 33.2 ohms 33.2 OHM SMD RESIST OR 1/16W 1% sm/r_0402

Vishay Dale

31 1 R10 49.9 ohms 49.9 OHM SMD RESISTOR 1/1 6W 1% sm/r_0402

Yageo Corporation

32 2 AIN_LF, SMA Input PCB MOUNT ABLE SMA CONNECTOR -

Emerson Network Power Connectivity

CLK_IN_SE

Page 15

ADC12V170 Evaluation Board User’s Guide

The ADC12V170 Evaluation Board is intended for product evaluation purposes only and is not intended for resale to end

consumers, is not authorized for such use and is not designed for compliance with European EMC Directive 89/336/EEC.

WaveVision is a trademark of National Semiconductor Corporation. National does not assume any responsibility for use of any

circuitry or software supplied or described. No circuit patent licenses are implied.

LIFE SUPPORT POLICY

NATIONAL'S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into the body, or (b) support or sustain life, and whose failure to

perform, when properly used in accordance with instructions for use provided in the labeling, can be reasonably expected to result in a significant injury to the user.

2. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the failure of the life

support device or system, or to affect its safety or effectiveness.

National Semiconductor

N

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

National does not assume any responsibility for any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change

said circuitry and specifications.

Email: support@nsc.com

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80 532 78 32

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

N - 15 - www.national.com

Rev 0.0

Loading...

Loading...