MYDATA MY500 JetPrinter Service Manual

MY500 JetPrinter™

P-030-0014-EN

Service Manual

English

®

For a fast changing world

MYDATA MY500 JetPrinter Preface

MY500 JetPrinter™

Service Manual

English

P-030-0014-EN – Service Manual Rev. 0003 2008-06 i

Preface MY500 JetPrinter MYDATA

This document is intended for the MY500 JetPrinter running any version of the software.

A standard system and available optionals are covered by this document. Depending on your system configuration you may lack

some of the features mentioned in the document.

Disclaimer

Hardware and software mentioned in this document are subjected to continuous development and improvement. Consequently,

there may be minor discrepancies between the information in the document and the performance or design of the product.

Specifications, dimensions and other statements mentioned in this document are subject to changes without prior notice.

Federal Communications Commission (FCC)

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection agains t harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if no t installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be required to correct the inte rference at his own

expense.

Do not start, operate or service the

machine until you have read and

understood the safety chapter.

MYDATA and its suppliers shall not be liable for any damages related to this software or hardware, or for any other damages whatsoever caused by the use of or inability

to use any MYDATA product. This is applicable even if MYDATA has been advised of the damage risk. Under any circumstances, MYDATA’s entire liability shall be

JetPrint, MYPlan, SYS2.9, TEX, TMFlex, TRAYWagon Magazine, TUBEFork, and YWagon are trademarks of MYDATA automation AB. TPSys, Agilis, HYDRA

SpeedMount, MYLink, and TM8 are registered trademarks of MYDATA automation AB. The MY... and TP... machine names are either trademarks or registered

trademarks of MYDATA automation AB. DOS is a trademark of Microsoft Corporation. Microsoft, Microsoft Windows and Microsoft Access are registered trademarks

of Microsoft Corporation. Other trademarks mentioned in this document are trademarks or registered trademarks of their respective owners.

limited to replace such defective software or hardware that was originally purchased from MYDATA.

MYDATA automation AB, Box 20155, S-161 02 Bromma, Sweden.

Phone +46 8 475 55 00 – Fax +46 8 475 55 01 – Internet www.mydata.com

This document or parts of it may not be reproduced without a written permission of MYDATA automation AB.

Infringements will be prosecuted. All rights reserved.

Copyright © MYDATA automation AB, Sweden, 1990–2008.

ii Rev. 0003 2008-06 P-030-0014-EN – Service Manual

MYDATA MY500 JetPrinter Preface

Table of Contents

Text Conventions ......................................................................................................... vi

Danger, Warning, Caution, and Note ................................................................ vi

Italic Font ......................................................................................................... vii

Bold Font ......................................................................................................... vii

Menu Selections ............................................................................................... vii

Lists .................................................................................................................. vii

1. Safety ........................................................................................................................ 1-1

Emergency Stop Buttons .................................................................................... 1-2

Emergency Movement of Machine Elements .................................................... 1-3

Safety Hoods and Devices ................................................................................. 1-3

Warning Signs .................................................................................................... 1-4

Fast Moving Machinery ................................................................................ 1-4

Dangerous Voltage ....................................................................................... 1-6

Laser Classification ...................................................................................... 1-7

Magnetic Fields ............................................................................................ 1-8

Type Plate .......................................................................................................... 1-9

Noise .................................................................................................................. 1-9

Equipment Precautions ...................................................................................... 1-10

Magnetic Fields ............................................................................................ 1-10

Compressed Air ............................................................................ ..................... 1-11

Solder Paste, Glue and Conditioner ................................................................... 1-11

Waste Disposal ............................................................................................. 1-11

Material Safety Data Sheets .......................................................... ..................... 1-12

Greases .......................................................................................................... 1-12

Solder Paste .................................................................................................. 1-12

Glue ............................................................................................................... 1-12

Conditioner ................................................................................................... 1-12

In Case of Fire .................................................................................................... 1-13

ESD .................................................................................................................... 1-13

How To Help Prevent ESD ........................................................................... 1-13

2. Installation ................................................................................................................. 2-1

Site Preparation .................................................................................................. 2-2

Required Working Area ................................................................................ 2-2

Environmental Requirements ....................................................... .... ............ 2-5

Electrical Requirements ................................................................................ 2-6

Compressed Air ............................................................................................ 2-6

Transporting the Machine .................................................................................. 2-6

Installation .......................................................................................................... 2-7

Equipment ..................................................................................................... 2-7

Installation Summary .................................................................................... 2-8

Unpacking ..................................................................................................... 2-9

Lifting the Machine ...................................................................................... 2-10

Moving and Placing the Machine ................................................................. 2-12

Leveling ........................................................................................................ 2-12

Main Machine Connections ............................................................................... 2-13

Powering ............................................................................................................ 2-14

Electrical Configuration ................................................................................ 2-14

Electrical Connection .................................................................................... 2-15

Power Plug Connection ................................................................................ 2-15

Pneumatic Connection ....................................................................................... 2-16

Optional Air Cooling Unit ............................................................................ 2-17

Optional Micro Mist Separator Unit ............................................................. 2-18

Network Connection .......................................................................................... 2-19

SMEMA Connection ......................................................................................... 2-19

P-030-0014-EN – Service Manual Rev. 0003 2008-06 iii

Preface MY500 JetPrinter MYDATA

Transport Lock ................................................................................................... 2-20

Software Installation ................................................................... ..... .... ............... 2-22

Optional Equipment ........................................................................................... 2-22

3. Machine Systems ....................................................................................................... 3-1

MY500 JetPrinter ............................................................................................... 3-1

Jet Printing .................................................................................................... 3-1

MY500 JetPrinter Main Parts ............................................................................. 3-2

Inputs and Controls ............................................................................................ 3-4

Touch Screen ................................................................................................. 3-4

Keyboard ....................................................................................................... 3-5

Trackball ........................................................................................................ 3-5

Barcode Scanner .................................................................................. .......... 3-5

Framework .......................................................................................................... 3-6

Movement Systems ............................................................................................ 3-7

The Y Beam .................................................................................................. 3-8

The X Wagon ................................................................................................ 3-9

The Cassette .................................................................................................. 3-13

Conveyor ............................................................................................................ 3-18

Manual Load Table ............................................................................................ 3-19

Machine Electronics ........................................................................................... 3-20

Block Diagrams ............................................................................................. 3-22

4. Adjustments .......................................................................... .... ................................. 4-1

System Overview ............................................................................................... 4-2

Screen Examples ................................................................................................ 4-3

5. Routine Maintenance ................................................................ ..... .... ..... ................... 5-1

Daily Maintenance ............................................................................................. 5-3

Equipment ..................................................................................................... 5-3

Cassette .......................................................................................................... 5-3

Machine ......................................................................................................... 5-4

Calibration Units ........................................................................................... 5-5

Filters ............................................................................................................. 5-6

Weekly Maintenance .......................................................................................... 5-7

Equipment ..................................................................................................... 5-7

Machine ......................................................................................................... 5-7

Others ............................................................................................................ 5-8

Monthly Maintenance ......................................................................................... 5-9

Equipment ..................................................................................................... 5-9

Machine ......................................................................................................... 5-9

Optional Refrigerated Air Dryer ................................................................... 5-9

Yearly Maintenance ........................................................................................... 5-10

Changing Calibration Paper ................................................................ ............... 5-11

Changing Waste Container ................................................................................. 5-14

Waste Disposal .............................................................................................. 5-14

Changing Cassette Ejector .................................................................................. 5-15

Lubricating X wagon Rail – 720 Operating Hours ............................................ 5-19

Testing the Safety System ............................................................... ................... 5-20

Testing the Safety Circuits ............................................................................ 5-20

Maintenance Tables ............................................................................................ 5-21

Daily Maintenance ........................................................................................ 5-21

Weekly Maintenance ..................................................................................... 5-21

Monthly Maintenance ................................................................................... 5-22

720 Operating Hours ..................................................................................... 5-22

iv Rev. 0003 2008-06 P-030-0014-EN – Service Manual

MYDATA MY500 JetPrinter Preface

Appendix A – Specifications ...................................................... .... .............................. A-1

Appendix B – About the Documentation ..................................................................... B-1

Operator's Manual .............................................................................................. B-2

Programming Manual ........................................................................................ B-2

MYCamJP .......................................................................................................... B-2

Service Manual .................................................................................................. B-3

Spare Parts Catalog ............................................................................................ B-3

Index ............................................................................................................................... I-1

P-030-0014-EN – Service Manual Rev. 0003 2008-06 v

Preface MY500 JetPrinter MYDATA

Text Conventions

This document uses text conventions to present information in various

situations. This is explained below.

Danger, Warning, Caution, and Note

In this document a particular text layout is used to make danger, warning, and

caution information evident. A triangular icon identifies the type of risk and

the text describes the risk.

Danger, warning, and caution information must be followed.

Assisting information, notes, have the same layout but never triangular icons.

Danger

DANGER! Danger means a potentially dangerous situation that can cause

death or severe bodily injury. The icon identifies the type of risk.

Warning

WARNING! Warning means a potentially dangerous situation that can cause

bodily injury or considerable damage to the system or equipment. The icon

identifies the type of risk.

Caution

CAUTION! Caution means that the system or equipment can be damaged or

data be lost. To distinguish caution information from warning and danger

information, this icon is always an empty triangle.

Note, example 1

A note contains any type of assisting information.

Note, example 2

One type of assisting information is tips, which normally have this icon.

vi Rev. 0003 2008-06 P-030-0014-EN – Service Manual

MYDATA MY500 JetPrinter Preface

Italic Font

Italic font is used for software screen text (for example Parameter 1), names

(for example Spare Parts Catalog), and for warning text (described in the

previous section).

Bold Font

Bold font is used for particular important words (for example This must not

be done in reverse order).

Menu Selections

When describing software handling, menu selections are described in the

following format:

File > Page Setup > Paper Size > Portrait > OK

Lists

This example describes to open the File menu and select the Page Setup,

Paper Size, and Portrait options, and finally click the OK button.

Lists of items, points to consider, or procedures that have no relative order

appear in bulleted or hyphenated format like this:

• Item 1.

• Item 2.

or

–Item1.

–Item2.

Procedures that must be performed in a specific order appear in numbered lists

like this:

1. Perform this step first.

2. Perform this step second.

P-030-0014-EN – Service Manual Rev. 0003 2008-06 vii

Preface MY500 JetPrinter MYDATA

viii Rev. 0003 2008-06 P-030-0014-EN – Service Manual

MYDATA MY500 JetPrinter Safety

1. Safety

Before starting the machine, personnel involved in the machine operation,

maintenance or service must understand and follow these points:

• This machine is designed to apply solder paste and glue onto printed wiring

boards. The machine must be used excl usively for this purpose and nothing

else.

• The machine must be operated by qualified personnel only. Qualified

personnel should meet the following qualifications:

– Be above 18 years of age.

– Have no rmal depth percep tion, field of vi sion, reaction time, manual

dexterity, coordination, and no tendency to dizziness.

– Completed operators training.

• All personnel involved in machine operation must understand the use of the

emergency stop buttons. See the Emergency Stop Buttons section.

• Anyone operating this machine must obey the warning signs.

• At least one manual describing the warning signs of the particular machine

type must always be kept. For instance if the machine is upgraded to a later

version.

• An emergency stop button must be pressed down when a solder paste

cassette is manually inserted or removed.

• If there is a risk that any unauthorized personnel may alter the system

settings and thus the behavior of the machine, the logon facility for

individual access rights must be used.

• Ensure that all covers and shields are intact, mounted, and closed while the

machine is in operation.

• Do not disable or disengage any safety switch or sensor.

• Do not configure or modify MYDATA machines or devices without

consulting MYDATA. The machines, devices or the interfaces between

them might become unsafe.

• Do not use chemicals or other substances which may have any influence on

the operator or other personnel involved in the machine operation.

P-030-0014-EN – Service Manual Rev. 0003 2008-06 1 - 1

Safety MY500 JetPrinter MYDATA

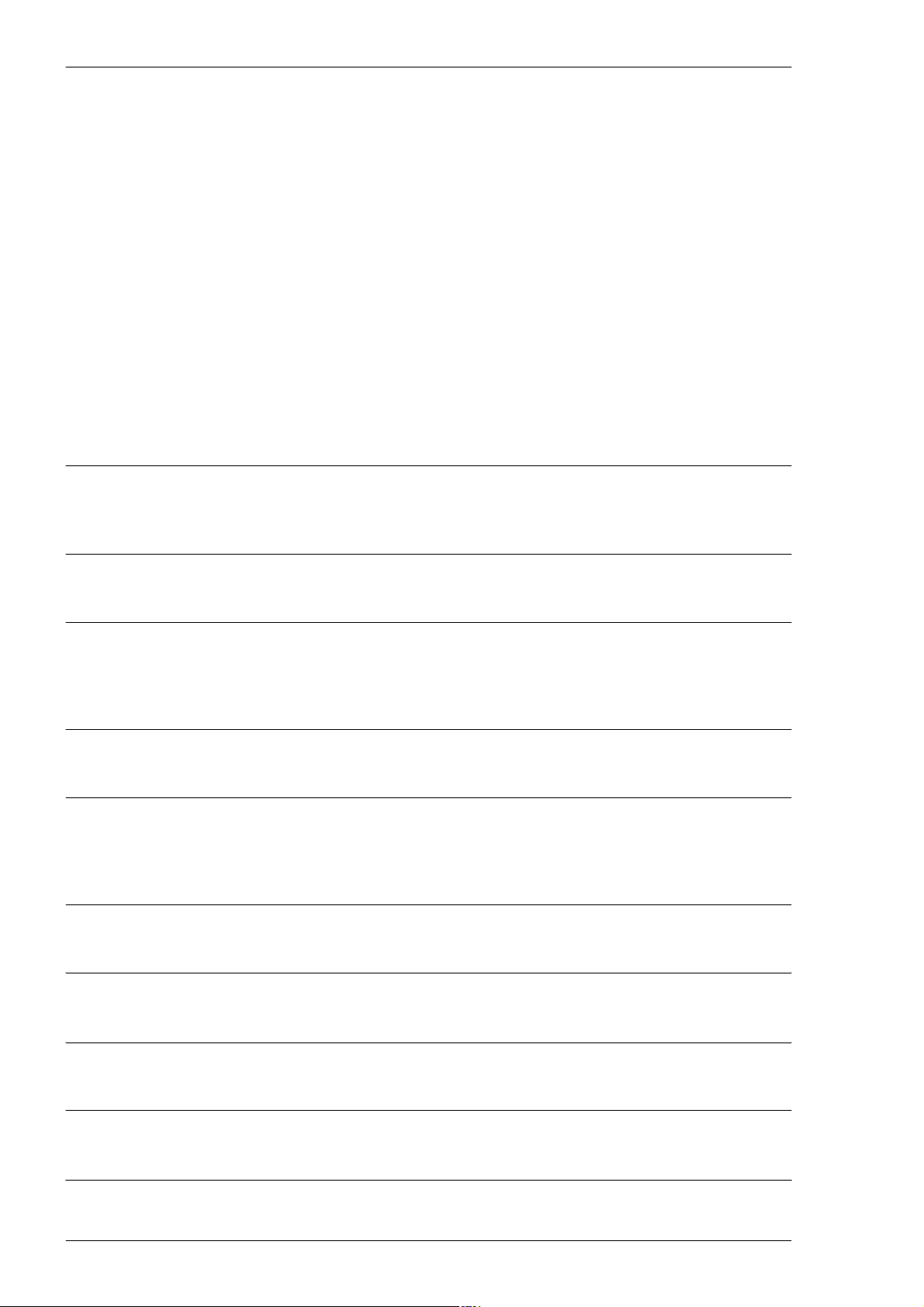

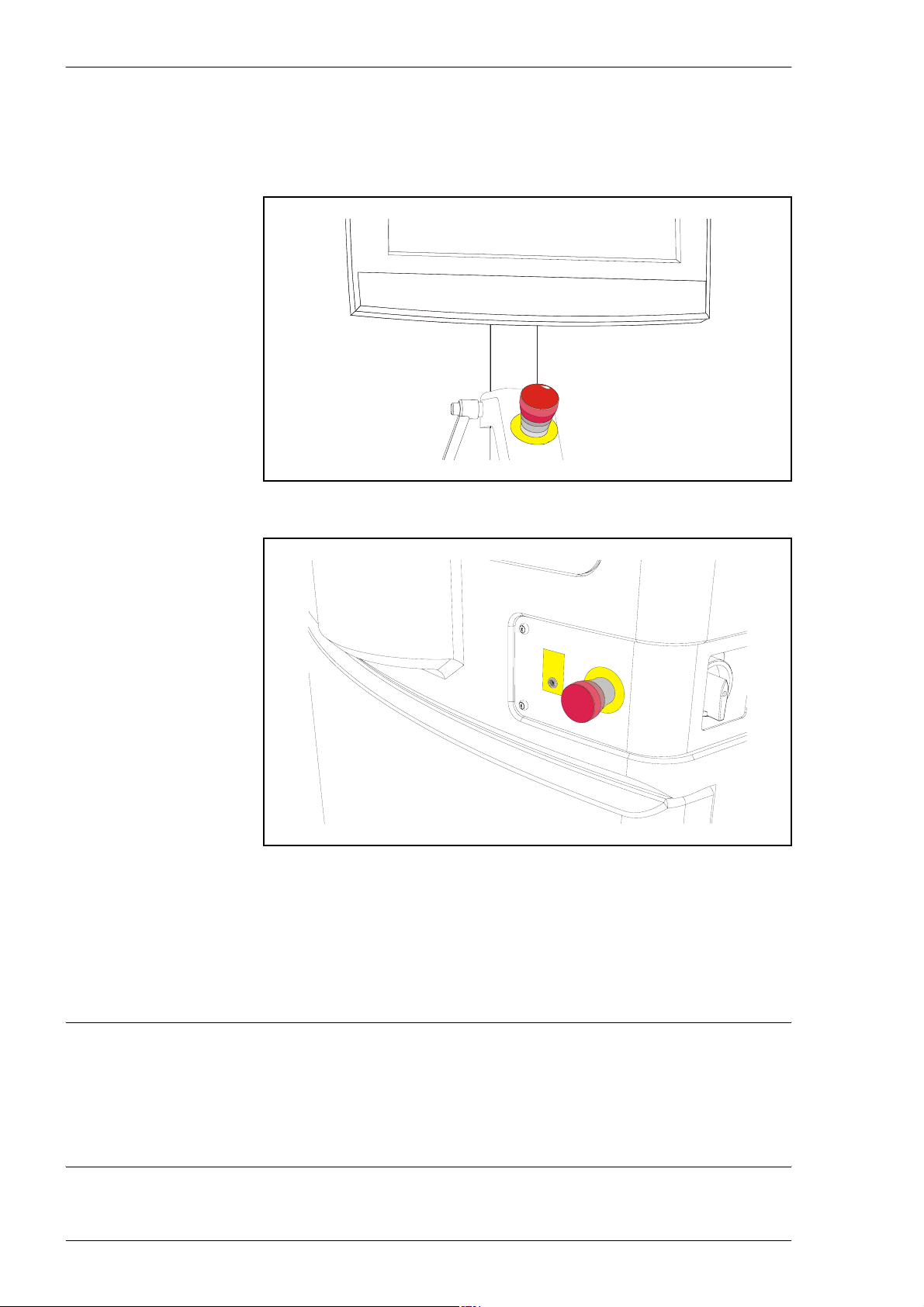

Emergency Stop Buttons

There are two red emergency stop buttons on the machine. When an

emergency stop button is pressed down, the machine will stop immediately.

Figure 1-1. Emergency stop button above the keyboard.

Figure 1-2. Emergency stop button on the machine front.

Emergency stop buttons are released by being turned clockwise.

When the front hood is lifted, a safety switch is activated and all movements

in the MY500 JetPrinter are stopped immediately.

Extra, auxiliary safety buttons can be connected at the rear of the machine.

WARNING! Always press down an emergency stop button before hands,

1 - 2 Rev. 0003 2008-06 P-030-0014-EN – Service Manual

fingers, tools, or other objects are entered within a shielded area, or if any

hoods are opened.

Test the function of emergency stop buttons at regular intervals.

MYDATA MY500 JetPrinter Safety

Emergency Movement of Machine Elements

If an accident has occurred and an emergency movement of a machine element

is required, use the following procedure:

1. Press down an emergency stop button.

This will disconnect the motors used to position the machine elements.

2. Move the machine element away by hand.

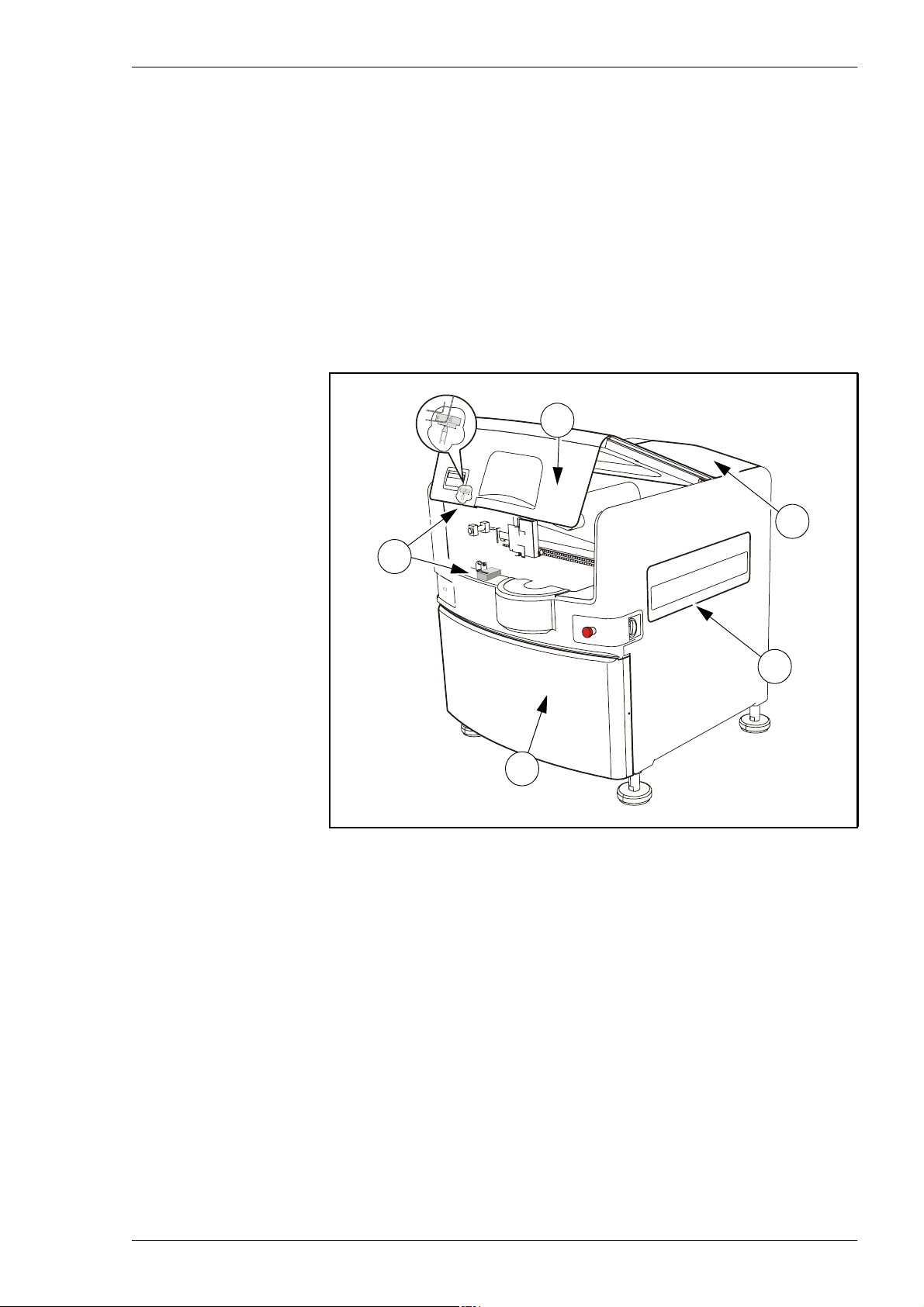

Safety Hoods and Devices

1

2

4

3

Figure 1-3. Safety hoods and switch on a MY500.

The following safety hoods and devices are found on the machine:

1. Hood front.

2. Hood front safety switch.

5

3. Front cover.

4. Side hood (one on each side of the machine).

5. Hood back.

P-030-0014-EN – Service Manual Rev. 0003 2008-06 1 - 3

Safety MY500 JetPrinter MYDATA

Warning Signs

The warning signs on the machine must be observed as this machine contains

fast moving parts, magnetic fields, and high voltage. The machine has warning

signs placed as shown on the following pages.

At least one manual that describes the warning signs of the particular machine

type must always be kept, for instance if the machine is upgraded with a later

TPSys version.

Optional devices have the warning signs shown in their documents.

Number and position of each sign type is described in the following text. If a

sign is missing, it must be replaced immediately. Part numbers are printed on

the signs, and can also be read from this description.

All signs must be kept clean and readable.

Fast Moving Machinery

Sign 1 warns of the fast machine movement. No hands, fingers, or other

objects are allowed beyond the shield. Ensure that all covers and shields are

intact, mounted and closed while the machine is in operation. Do not disable

or disengage any safety switch or sensor.

1

European and

Canadian

standards

These signs are applied as follows:

– One sign on the left side protective shield, see Figure 1-4.

– One sign on the right side protective shield, see Figure 1-5.

US standards

1 - 4 Rev. 0003 2008-06 P-030-0014-EN – Service Manual

MYDATA MY500 JetPrinter Safety

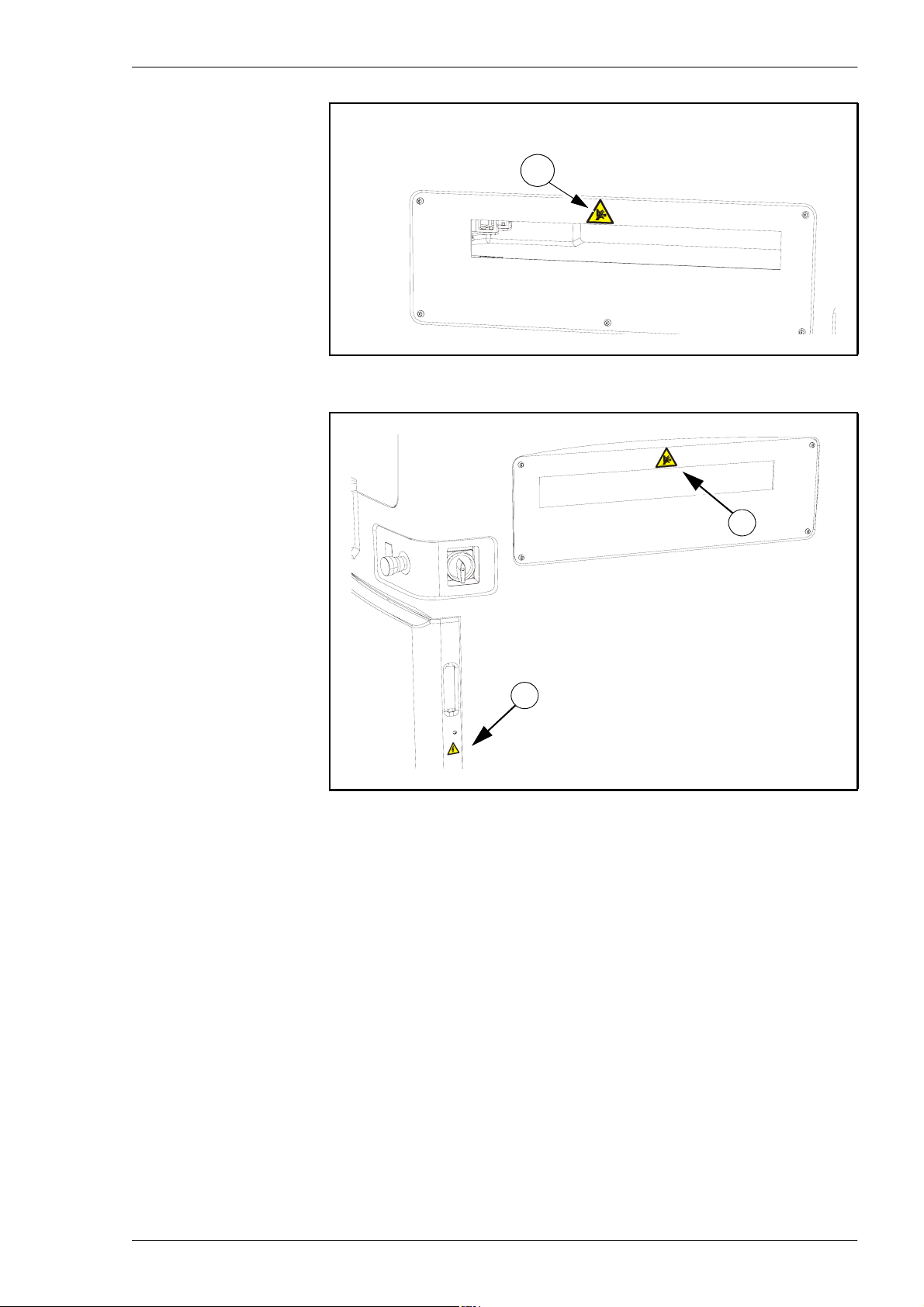

1

Figure 1-4. Warning sign on the machine’s left side hood.

1

2

Figure 1-5. Warning signs on the machine’s right side hood.

P-030-0014-EN – Service Manual Rev. 0003 2008-06 1 - 5

Safety MY500 JetPrinter MYDATA

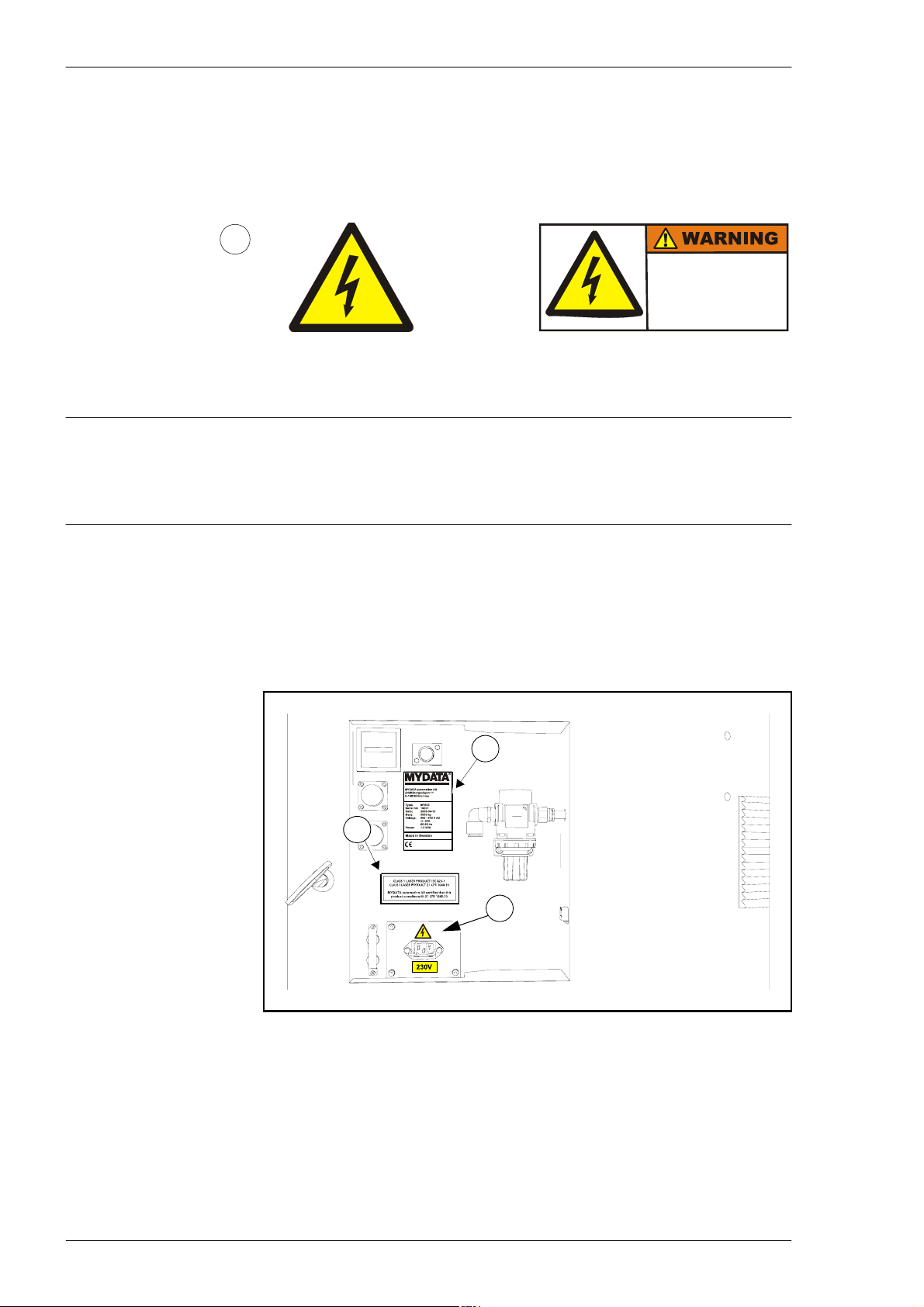

Dangerous Voltage

These signs warns of electric shock. Units on which this sign is placed contain

dangerous voltage levels. Power must be switched off before opening the unit.

Only authorized service personnel are allowed to operate the machine when

such a unit is open.

2

HAZARDOUS

VOLTAGE.

Disconnect power

before servicing.

European and

Canadian

standards

DANGER! Always lock out and tag the main switch before opening the hoods

and commencing any servicing within the machine. Always use the main

switch to restart the machine or any of its components.

This sign is applied as follows:

– One sign on the front cover, see Figure 1-5.

– One sign by the power supply unit on the connection plate at the rear

of the machine, see Figure 1-6.

– One sign on the inside of the connection plate, see Figure 1-7.

5

US standards

3

2

Figure 1-6. Warning signs at the rear of the machine.

1 - 6 Rev. 0003 2008-06 P-030-0014-EN – Service Manual

MYDATA MY500 JetPrinter Safety

2

Figure 1-7. Warning sign at the connection plate inside.

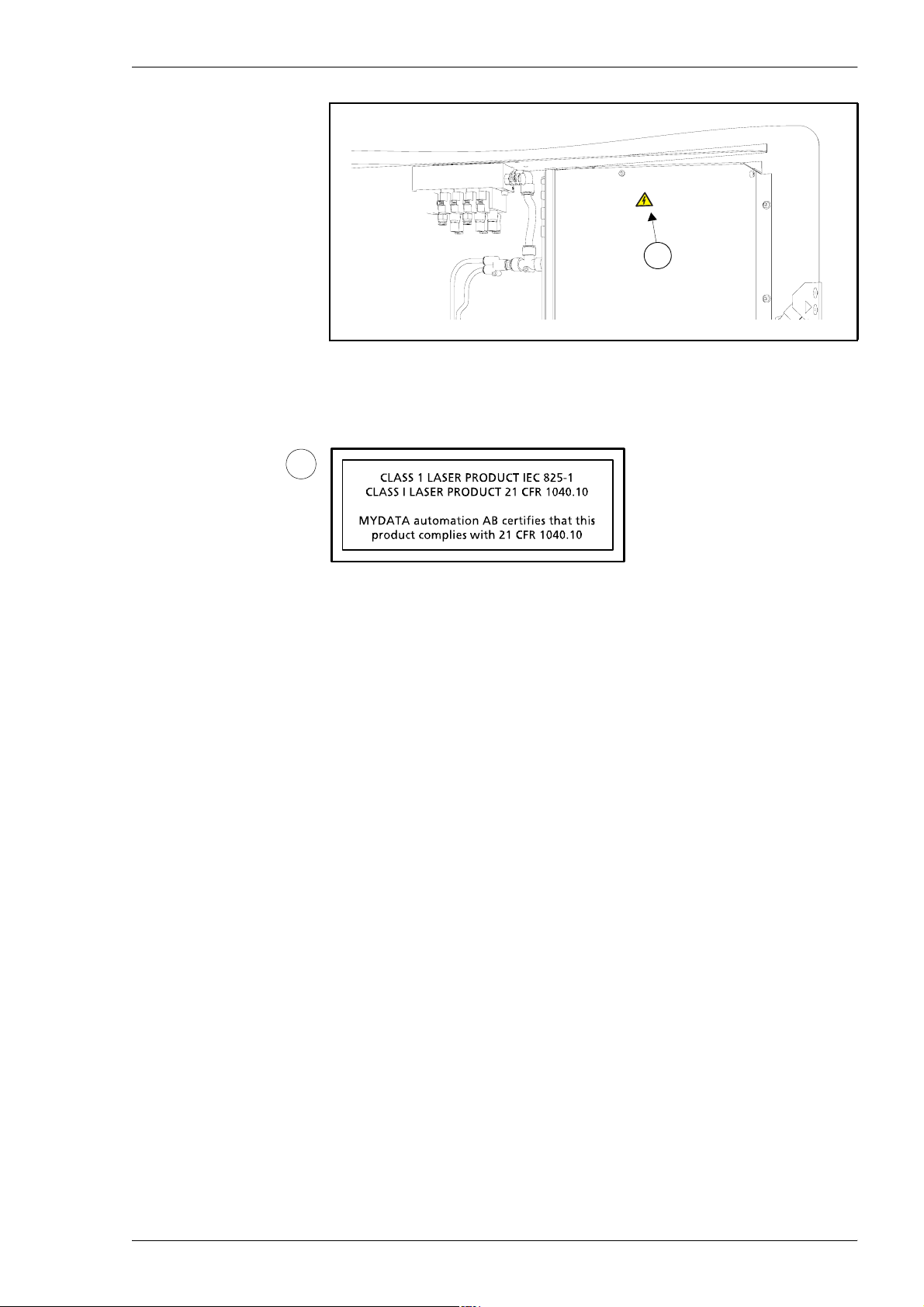

Laser Classification

3

Sign 3 states the laser classification for the MY500 JetPrinter. One

certification sign is applied as shown in Figure 1-6.

P-030-0014-EN – Service Manual Rev. 0003 2008-06 1 - 7

Safety MY500 JetPrinter MYDATA

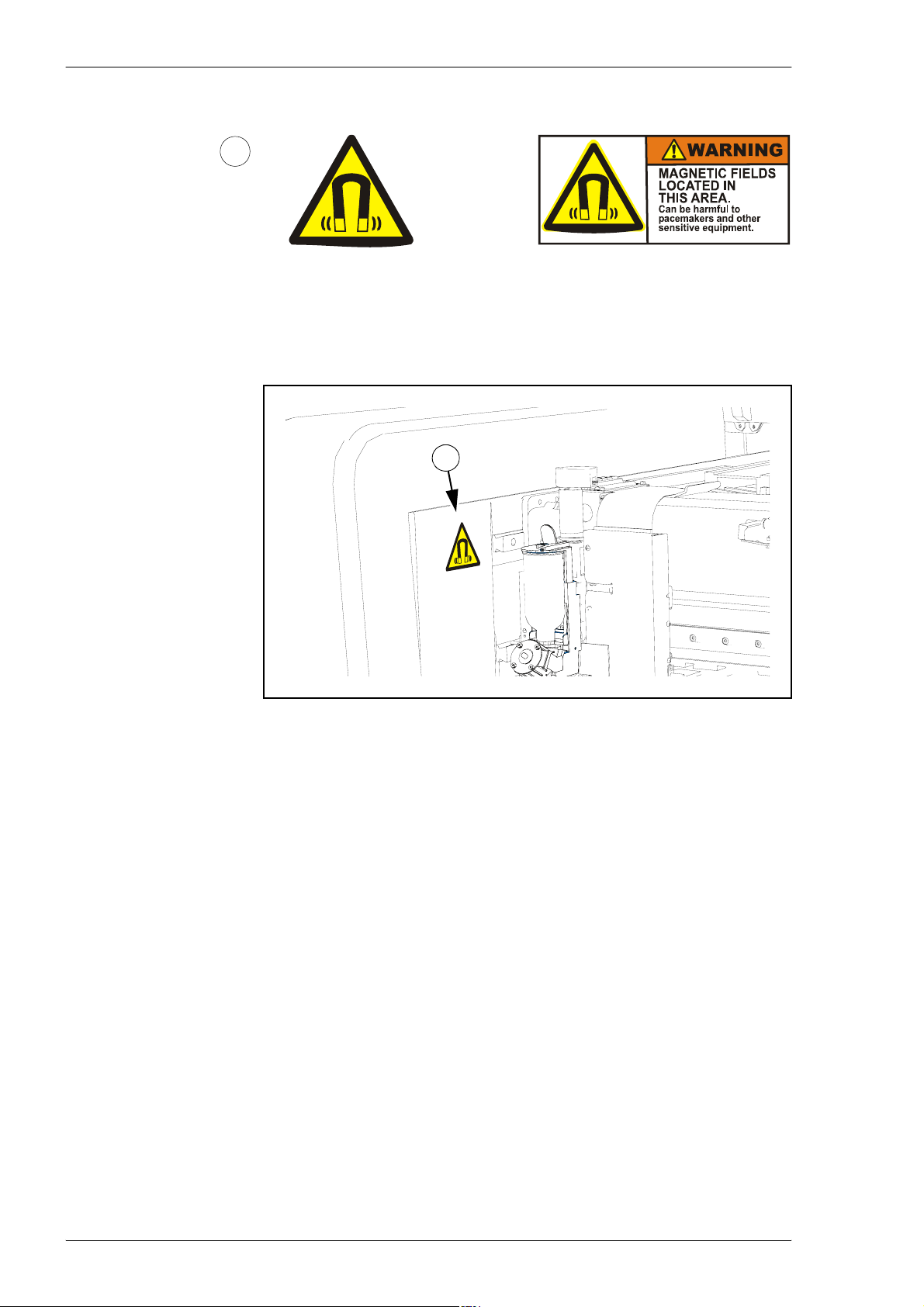

Magnetic Fields

4

European and

Canadian

standards

US standards

Sign 4 warns for magnetic fields. One warning sign is applied as shown in

Figure 1-8.

4

Figure 1-8. Warning signs inside the machine.

1 - 8 Rev. 0003 2008-06 P-030-0014-EN – Service Manual

MYDATA MY500 JetPrinter Safety

Type Plate

The type plate shows the name and address of the manufacturer, the machine

type and serial number, and manufacturing date and country. An exampl e of a

type plate is shown below.

Noise

Figure 1-9. Machine type plate.

The type plate is found at the back of the machine, see '5' in Figure 1-6.

For the MY500 JetPrinter, the equivalent continuous sound pressure level is

measured to be 68 dB(A).

P-030-0014-EN – Service Manual Rev. 0003 2008-06 1 - 9

Safety MY500 JetPrinter MYDATA

Equipment Precautions

This section has to be read before handling the machine.

CAUTION! Always ensure that there are no foreign objects on the conveyor

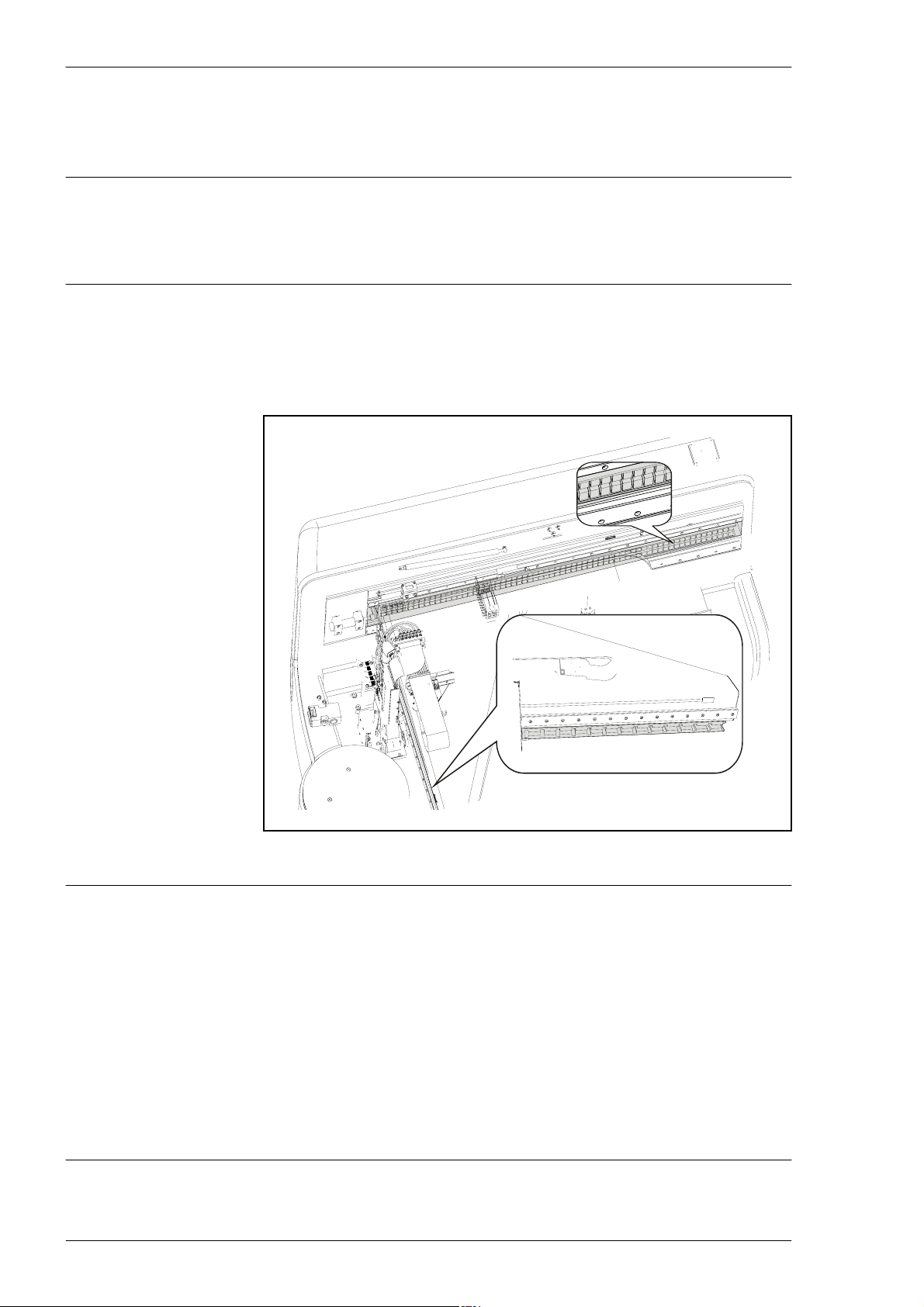

Magnetic Fields

or within the X wagon and Y beam moving areas before operating the

machine.

There are permanent magnets on the Y beam and in the stone frame. They

have extremely powerful magnetic fields.

Figure 1-10. Permanent magnets.

DANGER! Personnel wearing pace-makers must be careful in the vicinity of

1 - 10 Rev. 0003 2008-06 P-030-0014-EN – Service Manual

permanent magnets.

CAUTION! Do not approach permanent magnets when carrying objects made

of iron, steel or nickel. The force of attraction may cause fingers to be bruised.

CAUTION! Do not wear watches in the vicinity of permanent magnets since

they can be damaged.

CAUTION! Do not bring magnetic data media, check or credit cards near

permanent magnets. The data on the data media may be erased by the

magnetic field.

MYDATA MY500 JetPrinter Safety

Compressed Air

This machine uses compressed air for its operation.

WARNING! Compressed air can be dangerous if handled incorrectly.

Assembly, handling, or repair of pneumatic systems must be performed by

trained and experienced personnel.

Solder Paste, Glue and Conditioner

Cassettes for the machine contain solder paste, which is a mixture of powder

and flux. They can also contain glue. Ejectors are filled with conditioner at

delivery.

WARNING! During handling and use, solder paste, glue and conditioner may

be hazardous to health and to the environment. Read the Material Safety Data

Sheet and warning label before usage.

Waste Disposal

Always remember that care should be taken to avoid the ingestion of

chemicals. They may contain lead and other toxic materials, so gloves, safety

goggles and gowns should be worn during handling, and hands should be

washed afterwards.

– Observe normal standards for handling chemicals.Avoid breathing

vapour. Avoid contact with skin and eyes. Wash hands before breaks

and after work. Wear personal protective equipment appropriate to the

task.

– Avoid breathing vapour. Avoid contact with skin and eyes. Wash

hands before breaks and after work. Wear personal protective

equipment appropriate to the task

Solder paste and any material with remnants of solder paste must be treated as

hazardous waste. This also applies to glue.

Do not allow to get into waste water or waterways. If this occurs, inform the

relevant water authority at once.

Empty containers may contain product residue.

Observe all label precautions.

P-030-0014-EN – Service Manual Rev. 0003 2008-06 1 - 11

Safety MY500 JetPrinter MYDATA

Material Safety Data Sheets

The machine is shipped with various types of grease and oil. Below are

references to descriptions of chemical composition and toxicity (Material

Safety Data Sheets, shortened to MSDS) of these products.

If you have problems accessing the web sites referenced below, contact

MYDATA support.

Greases

GREASE PASTE OKS 270, part number K-013-0014

MSDS is found at http://www.mydata.com, document number P-0400137-EN. A logon user name and password may be required.

GREASE AFA+70 THK, part number K-035-0095

MSDS is found at http://www.mydata.com, document number P-0350095-EN. A logon user name and password may be required.

Solder Paste

Glue

Conditioner

SENJU SPARKLE PASTE OZ 2062-AC19 F13, part number L-038-0185

MSDS is found at http://www.mydata.com, document number P-0380010-EN. A logon user name and password may be required.

SENJU ECOSOLDER PASTE M705-LFAC19, part number L-038-0186

MSDS is found at http://www.mydata.com, document number P-0380012-EN. A logon user name and password may be required.

ALMIT SRC SN62U SS4M, part number L-038-0187

MSDS is found at http://www.mydata.com, document number P-0380014-EN. A logon user name and password may be required.

ALMIT LFM-48U MDA-5, part number L-038-0188

MSDS is found at http://www.mydata.com, document number P-0380016-EN. A logon user name and password may be required.

HERAEUS PD 205 A-JET

Request MSDS from your local distributor, or the manufacturer

W.C. Heraeus GmbH (http://www.4cmd.com).

INDIUM C-1

Request MSDS from your local distributor, or the manufacturer Indium

Corporation of America (http://www.indium.com).

1 - 12 Rev. 0003 2008-06 P-030-0014-EN – Service Manual

MYDATA MY500 JetPrinter Safety

In Case of Fire

Only use carbon dioxide (CO2) extinguishers or dry chemical extinguishers in

case of fire. Under no circumstances use water, as the machine contains

electronic equipment.

ESD

ESD, ElectroStatic Discharge, is one of the few things an individual can

unwittingly do to damage or destroy components. Much like the shock you

receive when rubbing your feet on a carpet and then touching some metal. ESD

can occur when working and will cause components you touch to no longer

work properly.

How To Help Prevent ESD

The following steps help reducing the chances of ESD:

– Do not touch components unless you are constantly earthed by an

– Always ensure that people, the workplace and packaging are safely

– If the packaging is not conductive, place the modules in a conductive

– Make sure not to wear any clothing that conducts a lot of electrical

– Most plastics can easily become charged and must therefore be kept

– Do not touch electronic modules unless it is absolutely necessary to

All MYDATA machines have jacks for wrist straps. They are marked with an

ESD sign.

ESD wrist strap or you are wearing ESD shoes or ESD shoe earthing

strips on an ESD floor.

earthed when handling electrostatic sensitive components.

envelope before packaging. Use ESD bags, domestic aluminum foil

or paper, for example. Never use plastic bags or film.

charge, such as a wool sweater or synthetic fibers.

away from components.

do so in order to carry out other work. If it is necessary, make sure that

you do not touch pins or printed conductors .

P-030-0014-EN – Service Manual Rev. 0003 2008-06 1 - 13

Safety MY500 JetPrinter MYDATA

1 - 14 Rev. 0003 2008-06 P-030-0014-EN – Service Manual

MYDATA MY500 JetPrinter Installation

2. Installation

In this chapter you will find the following information:

– Site Preparation on page 2-2.

Describes what is required of the site for a successful installation.

– Installation on page 2-7.

Describes how to install the machine at the site. There is also site

preparation check list on page 2-22.

P-030-0014-EN – Service Manual Rev. 0003 2008-06 2 - 1

Installation MY500 JetPrinter MYDATA

Site Preparation

In this section you will find prerequisites of what is required of the site for a

successful installation of a MYDATA MY500 JetPrinter. Details about the

working area, environmental and electrical requirements, and regulatory

compliance are given. Follow these directions to ensure a safe and proper

installation, as well as ongoing operating efficiency.

Site preparation check list

1. Identify the desired location for the machine. Verify that enough space

is available.

2. Verify that all environmental requirements are met, for example:

– Temperature

– Humidity

– Cleanliness/airborne contaminants.

3. Verify that the floor is level and can take the weight.

4. Plan the transportation route to the installation site.

5. Verify that means for transportation and lifting are available (for

6. Obtain required, stable input power.

7. Obtain pneumatic air connection.

8. Arrange for electrostatic avoidance equipment.

9. Table (and chair) for offline station.

10. Network connection.

Required Working Area

Space around the machine is necessary for maintenance of the machine and

optional equipment, if any. Prepare a suitable working area according to the

dimensions shown in Figure 2-1, Figure 2-3 and Figure 2-4. The dimensions

shown are the minimum space required for the machine with no extra options

or external conveyors. To achieve a more efficient working area, add space for

operating personnel and storage area for solder paste and boards.

Check that the transportation route can take the weight of the machine.

instance fork lift or crane).

Machine weight

The floor, on which the machine is transported and finally positioned, must

support the machine weight, which is 2 000 kg net weight.

2 - 2 Rev. 0003 2008-06 P-030-0014-EN – Service Manual

MYDATA MY500 JetPrinter Installation

Shipping gross weight

The shipping gross weight depends on the quantity of delivered options. An

usual gross weight is the machine weight plus roughly 100 kg.

The site

The floor at the machine site must be level.

It is recommended that the area at the machine site is ESD (Electrostatic

Discharge) protected.

Cable for mains, tube for pneumatic air, and cable for computer network are

connected to the machine at the rear (shown in Figure 2-3). The machine is

delivered with two network cables. One cable, 1 m of length, for the

connection of the offline station to a gateway. One cable, 30 m of length, for

the connection of the MY500 JetPrinter.

CAUTION! Always make sure that the way cables and tubes are placed do not

present a hazard. Always use cable ties or such to bundle them together, or

place in cable channels.

The machine noise is maximum 68 dB (A).

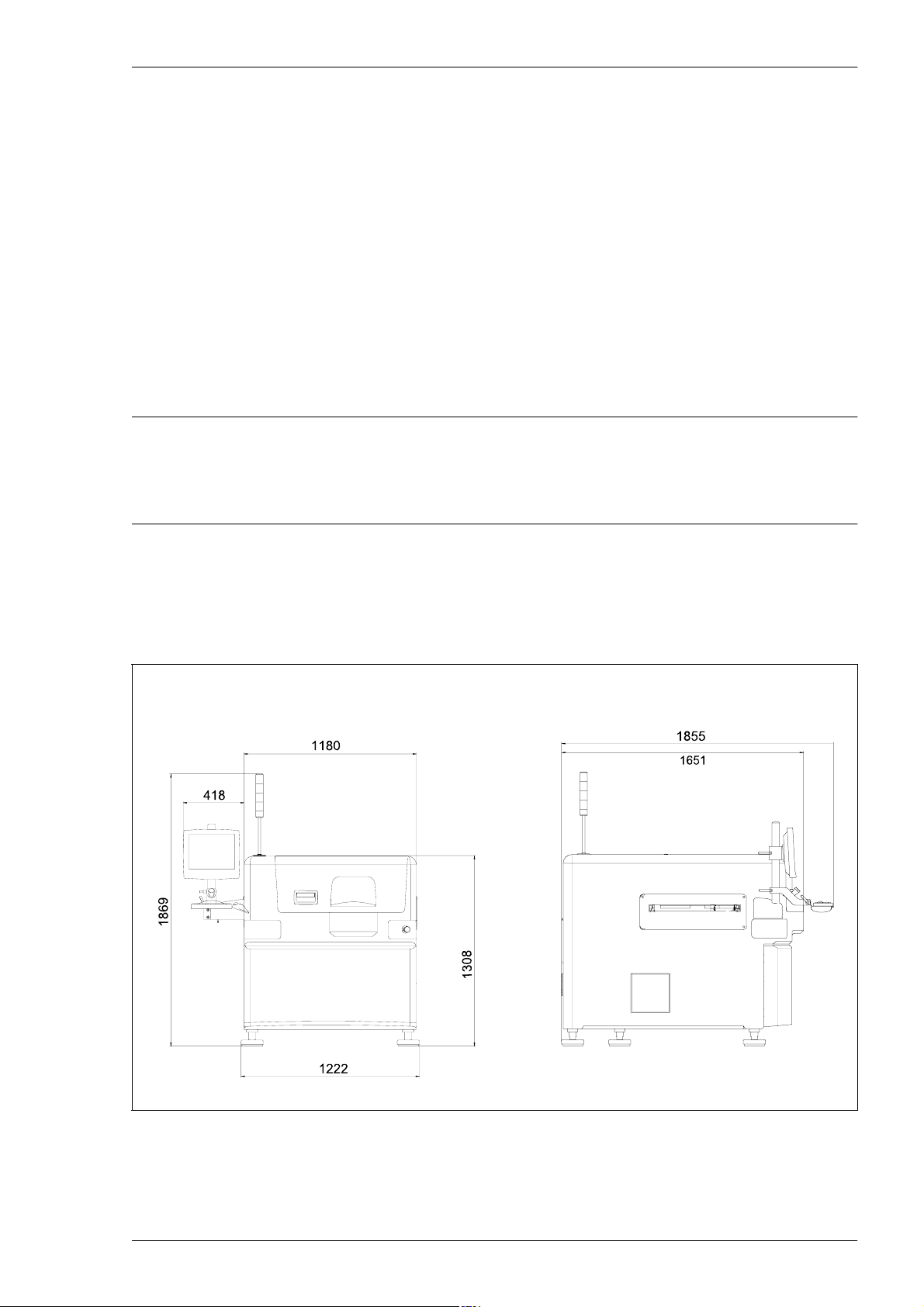

Machine dimensions

All dimensions shown in Figure 2-1 are in mm.

Figure 2-1. Main dimensions.

P-030-0014-EN – Service Manual Rev. 0003 2008-06 2 - 3

Installation MY500 JetPrinter MYDATA

1070

75

386

75

769

919

75 75

Bottom view

75

55

75

65

1090

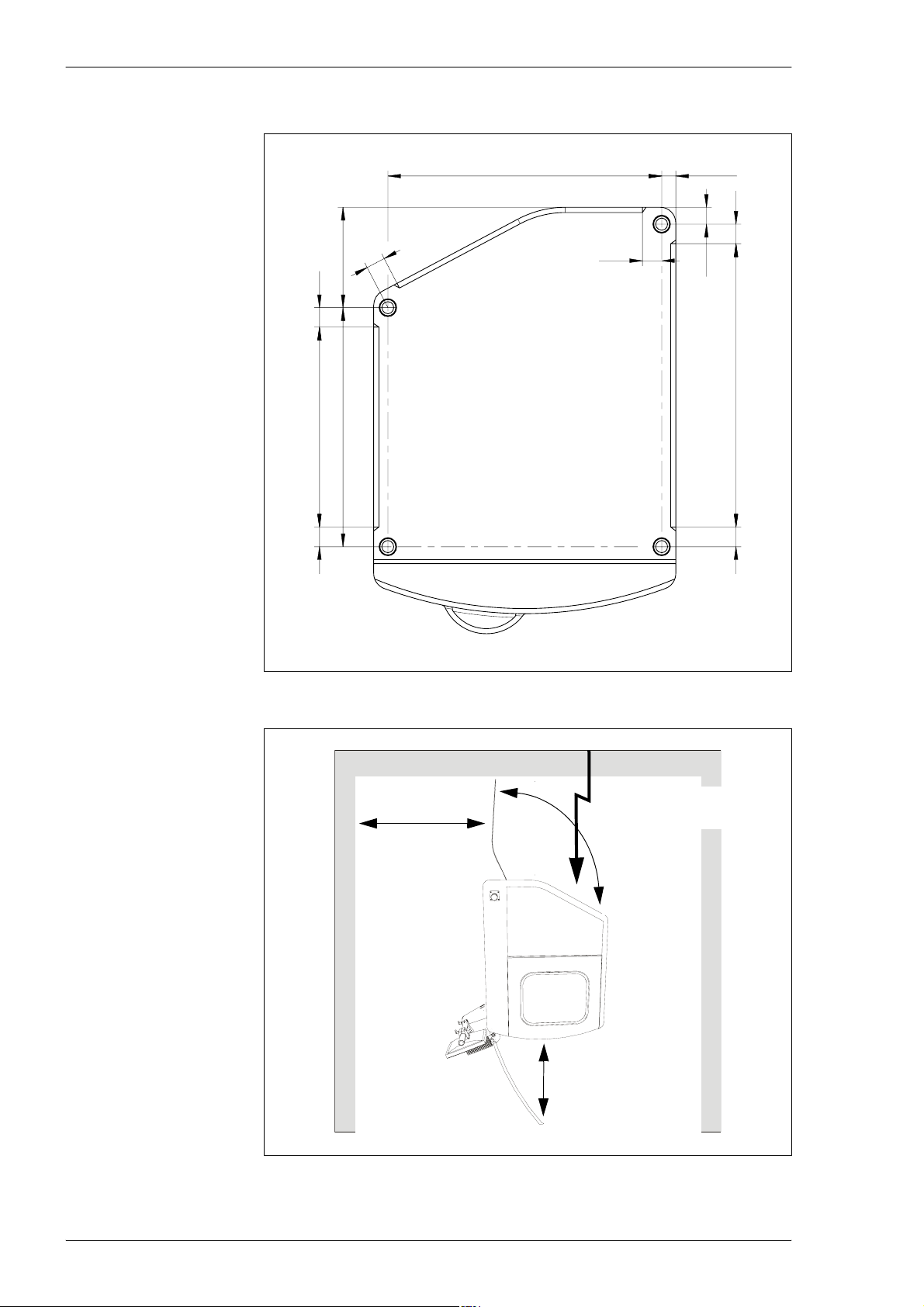

Figure 2-2. Machine footprint.

1 000 mm

1 000 mm

1000mm

Power, network and

compressed air in.

Figure 2-3. Clear space required around the machine.

2 - 4 Rev. 0003 2008-06 P-030-0014-EN – Service Manual

MYDATA MY500 JetPrinter Installation

Figure 2-3 shows a top view over the required service area around the machine

(measurements in mm). Also the position of the network and power inlets are

shown in the figure. Note that there is no specific area required on the sides of

the machine. It is sufficient to be able to pass around to the backside.

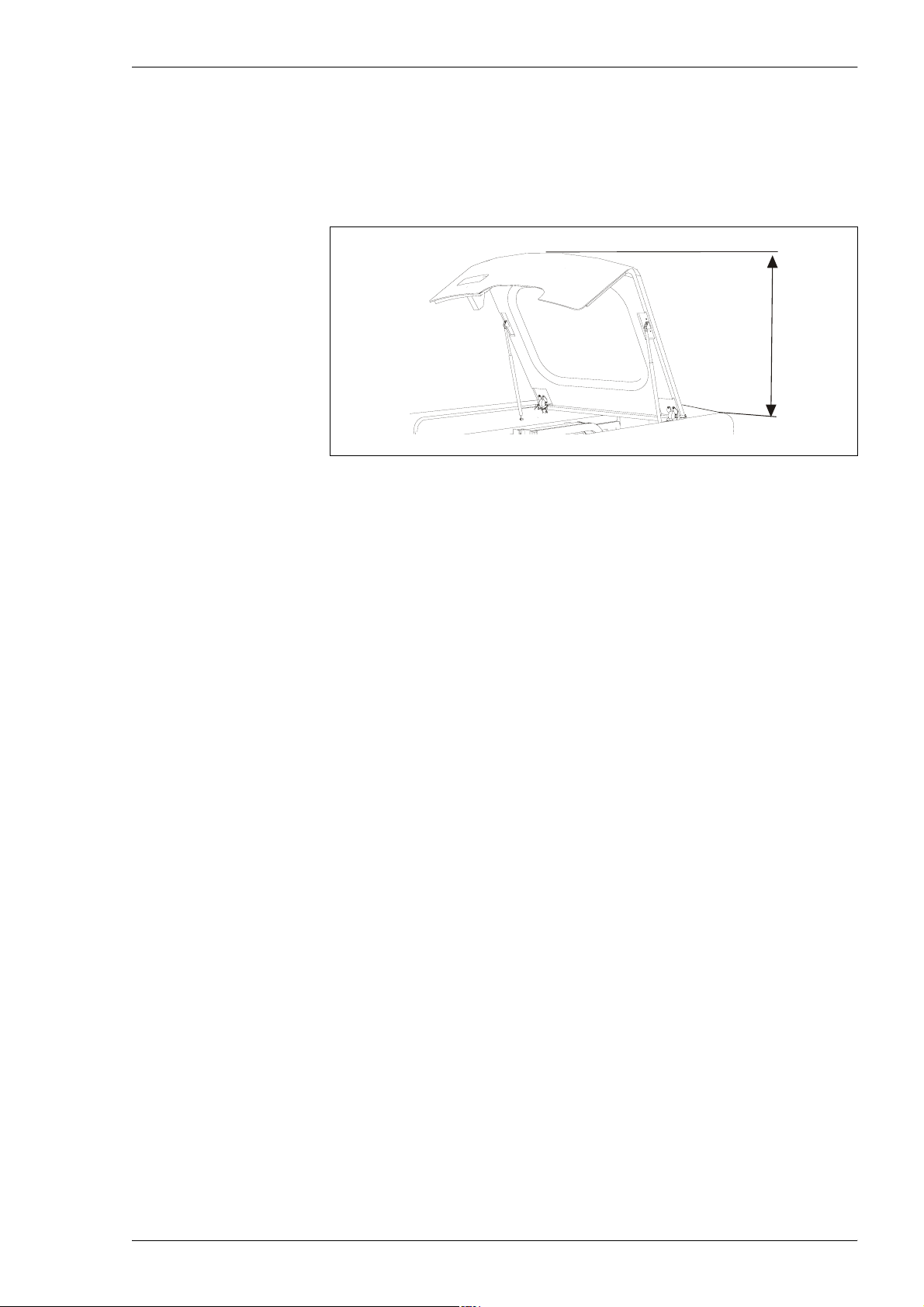

Figure 2-4 shows the space required above the machine.

750 mm

Figure 2-4. Clear space above the machine.

If you have the optional Air Cooling unit, this will require a minimum distance

of 400 mm to the nearest wall or machine.

Environmental Requirements

Temperature

Operating: +18 to +30 °C with full performance.

Storage: –30 to +65 °C

Relative humidity

Operating: <95 %, non-condensing

Storage: 100 %

Altitude

The MY500 JetPrinter is capable to operate correctly at altitudes up to 1 000 m

above mean sea level.

+5 to +18 °C and +30 to +40 °C with no guarantee of the

accuracy.

Dust and dirt

The machine does not require a clean-room environment but dust and dirt must

be kept as low as possible. The maintenance intervals are shortened by high

temperature and dusty or dirty environment.

P-030-0014-EN – Service Manual Rev. 0003 2008-06 2 - 5

Installation MY500 JetPrinter MYDATA

Electrical Requirements

Always follow the existing local, national or international regulations when

installing this equipment.

Acceptable voltages (±10 %): 230/115 VAC.

Compressed Air

The pneumatic system in the machine requires compressed air. Minimum

pressure required is 7 bar, maximum allowed is 10 bar.

Transporting the Machine

Whenever the machine has to be transported, avoid vibrations and impacts in

order to prevent damage to the machine. It must be ensured that the machine

is stable while it is being transported.

Truck transport

Remove the optional equipment and the MMI-module (i.e. the arm and tube

holding the screen and keyboard) and by-pack it in a separate box.

Secure the Y beam with the transport lock, see page 2-20 for details on the

lock. Fix the X wagon in position secured to the cassette exchange plate using

cable ties, see Figure 2-17. To secure the X wagon do as follows:

– Position the X wagon above the cassette exchange plate.

– Draw the cable ties through the holes in the plate.

– Tighten them around the end stops of the x-wagon. The cable ties

must be tight enough to ensure that the X wagon does not move.

CAUTION! Ensure that the left cable tie does not touch the camera.

To prevent dust and dirt to enter the machine you should wrap it in plastic.

Please refer to page 2-10 for details on how to lift and move the machine.

Use strong straps to secure the machine and equipment to the truck bed. The

machine should be tied down to the truck bed with straps attached to the

machine’s leveling feet.

Air and sea transport

For air and sea transport there is a special crate, and special locking brackets

available from MYDATA.

2 - 6 Rev. 0003 2008-06 P-030-0014-EN – Service Manual

Loading...

Loading...