Page 1

❒ Wrenches (two 9/16 inch)

❒ Screwdriver (medium-sized)

❒ Soft Rubber Mallet

❒ Penetrating Oil

❒ Metal File (needed only if

tine holders are also

removed)

How To Reach Us

If you have any questions about removing or installing tines, please

refer to the “Customer Assistance” information on the back cover.

These instructions apply only

to owners of the following

tillers:

❒ HORSETMModel

❒ ECONO HORSE

TM

Model

❒ PONY

®

Model

First, read the general

information given for all model

tillers on Pages 1 through 4. You

will then be directed to installation instructions for your

particular model tiller. Carefully

look at the adjacent figures while

following the step-by-step

instructions. Finally, see the

Bolo Tines Maintenance Section

on Page 16.

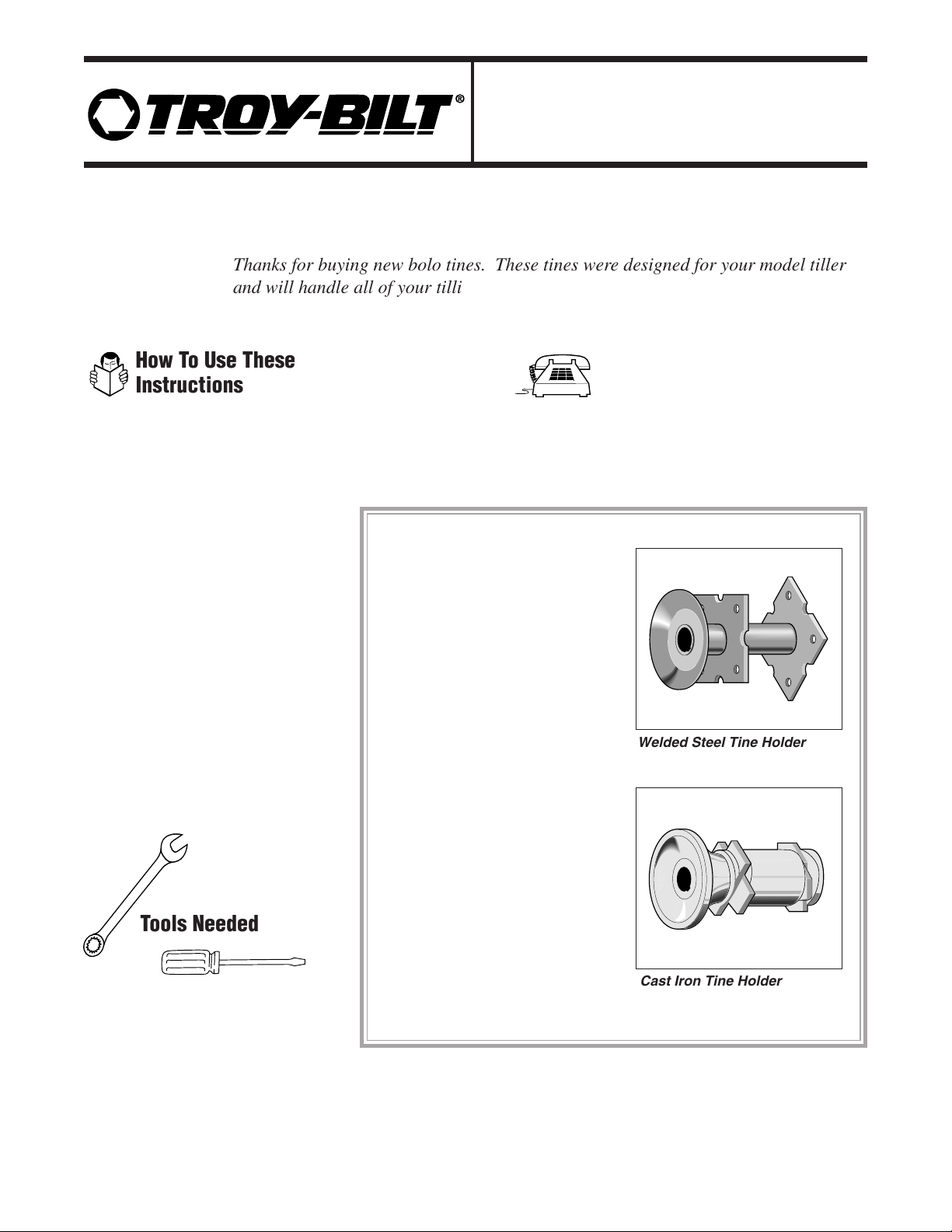

Attention!

HORSE Model Owners

Horse Model tillers have two

different style tine holders as

shown in figures to the right:

❒ Welded steel

Note: Welded steel holders may

be secured to tine shaft either

with two bolts and nuts or with

single mounting bolt (illustrated

in these instructions).

❒ Cast iron

Owners of HORSE Model

tillers with

cast iron tine holders

should keep the cardboard box in

which this kit was shipped to use

with the template (pattern) on the

inside back cover of these

instructions. You will use both

the template and the box when

assembling tines.

Owners of all other models can

ignore the template and discard

the box.

Welded Steel Tine Holder

Cast Iron Tine Holder

How To Use These

Instructions

Tools Needed

Thanks for buying new bolo tines. These tines were designed for your model tiller

and will handle all of your tilling needs including sod busting, seedbed preparation,

cultivating, and turning under crop residue.

THANK

YOU!

Bolo Tine Kit

OEM-290-253 / 290-253-081

for HORSETM, ECONO HORSETM,and PONY®Tillers

Installation Instructions

Page 2

C. Use two 9/16-inch wrenches

to remove the bolts which attach

the tines to the holders. (Tines

are not attached to cast iron

holders with bolts. In the case

of cast iron holders, remove

each gang [set of four tines]

from a holder by removing

only one bolt, and then

loosening the other three bolts

on the same gang.)

D. Always discard old hardware

and tines. Use only the

hardware which came with your

new tines.

Bolt Removal Tips

❑ Loosen all four nuts on a holder plate or tine gang before trying to remove any of the nuts and bolts.

❑ If necessary, use penetrating oil to loosen stubborn nuts.

❑ If necessary, place the closed (boxed) end of a wrench on the nut and sharply tap the wrench with the

rubber mallet until the nut is loose.

Item Qty Part # Description

Horse, Econo Horse, 8 GW-1270-1 Left-curved Tines

and Pony Standard Tines 8 GW-1270-2 Right-curved Tines

Hardware for Standard 16 1100043 3/8"-16 x 1-1/4" Hex Head Bolts (Grade 5)

Tines (All Models) 16 1733398 3/8"-16 Hex Locknuts

Custom Tines 8 GW-2475-1 Left-curved Custom Tines

(All Models) 8 GW-2475-2 Right-curved Custom Tines

16 710-0514 3/8"-16 x 1-1/4" Hex Head Bolts (Grade 5)

16 712-0798 3/8"-16 Hex Nuts

16 736-0169 3/8" Lock Washers

If You Ordered Custom

Tines...

Custom tines (special, hardfaced tines which last up to 21/2 times longer than standard tines) are perfect for

tilling sandy, gritty soil, or for

custom tilling or market gardening.

If you received Custom

tines, read this General

Information and then follow

the standard tine installation

instructions which apply to

your particular model tiller.

If you have any difficulty

installing your Custom tines,

contact our Service

Department (Refer to the

back cover of this manual.)

2

Step 1: Check Your Parts

Remove the tines and hardware package and check that you received all of the parts listed below for your

model tiller. If any parts are missing or damaged, contact our Technical Service Department and we will arrange

for replacements.

To prevent serious personal

injury when removing or

installing your bolo tines:

• Stop the engine, and

remove the electric start

key (if your tiller features

electric start).

• Let the engine and

muffler area cool.

• Disconnect the spark

plug wire, and position the

wire away from the plug to

prevent accidental starting.

WARNING

Tine edges can be sharp

and can have slivers that

could cause personal

injury. Use care at all

times when handling tines.

The tine hood edges may

also be sharp. To prevent

personal injury, wear thick

gloves when touching the

edges of the hood.

CAUTION

Step 2: Tine Removal

A. Carefully tilt the tiller

forward until the engine is

resting on the ground. (On some

models it may be necessary to

prop up the rear of the tiller or to

add additional weight to the

engine to stabilize the tiller in

this position.)

B. Raise the tiller hood flap and

secure it out of the way with a

rubber band, string or, in the case

of the PONY tiller, with the

depth regulator adjustment bar

knob.

PRE-INSTALLATION STEPS

Page 3

3

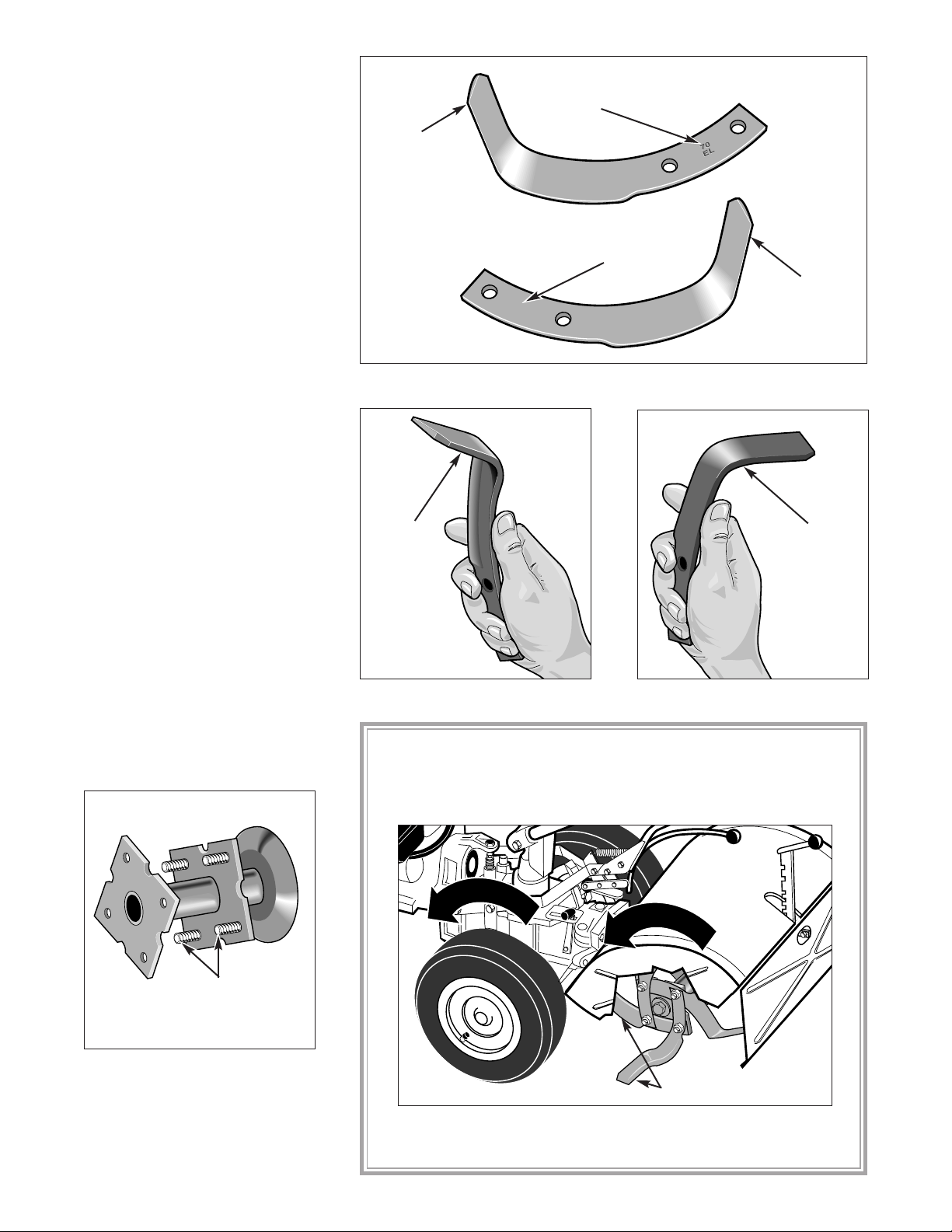

Step 3: Tine Identification

Separate the sixteen new tines

into two groups: eight left-

curved tines and eight rightcurved tines. Tines can be

identified as either left-curved or

right-curved tines in two ways:

Figure 1: Look for "L" or "R" stamped on the tines.

Figure 4: Insertion of bolts.

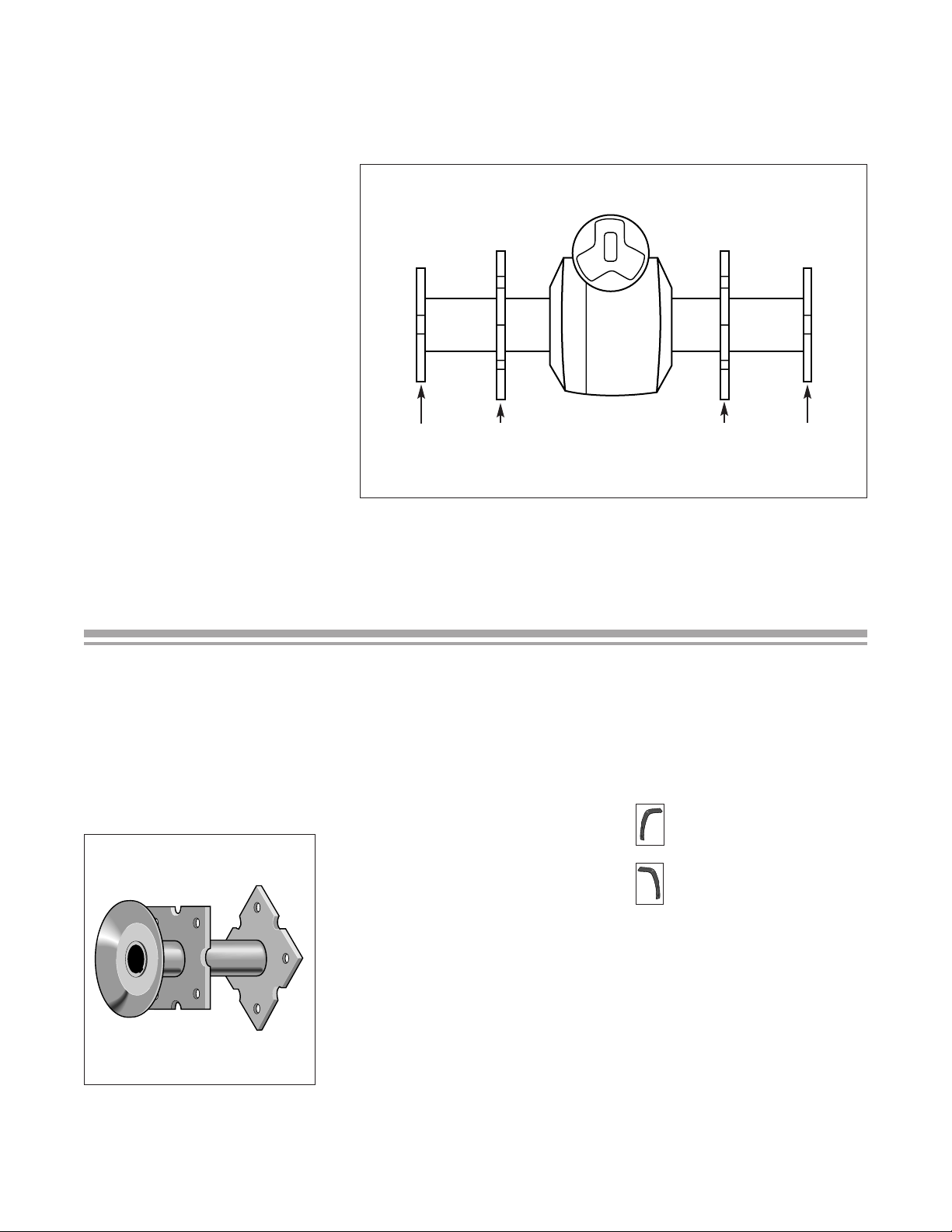

Step 4: Bolt Installation

NOTE: Skip this step if you

have a HORSE Model tiller with

cast iron tine holders.

A. On all other models, place

the sixteen bolts through the

holes in the tine holders with the

threaded ends of the bolts

pointing outward toward each

side of the tiller as shown below

in Figure 4.

(The installation of

tines on holders is described

later in these instructions.)

Figure 3: Right-curved tine.

Figure 2: Left-curved tine.

B. Or, hold the tine with the

blunt edge toward you. If the tip

curves toward the left, the tine is

a left-curved tine. If the

tip

curves toward the right, the tine

is a right-curved tine. See

Figures 2 and 3 which show the

two types of tines.

A. The letters and numbers

stamped on the side of each tine

are factory code marks which

contain either an "L" (on leftcurved tines) or an "R" (on rightcurved tines). See Figure 1.

Blunt

Edge

Blunt

Edge

B. Sort lock washers and nuts

into four groups of four each.

Figure 5: Cutting edges of tines must enter the soil first when the

tiller moves forward.

I

MPORTANT: Tines rotate in the same direction as the

wheels. During the installation steps, place tines on holders

so cutting edges (not the blunt, wider edges) will enter the soil

first when the tiller moves forward. See Figure 5.

Threaded

Ends

Cutting Edges

Tip Pointing

Up

Tip Pointing

Up

Look for "L" on

Left-curved Tine

Look for "R" on

Right-curved Tine

70

70

ER

ER

R

l

o

e

t

e

a

W

h

t

i

o

n

R

o

e

t

n

i

a

T

t

i

o

n

Page 4

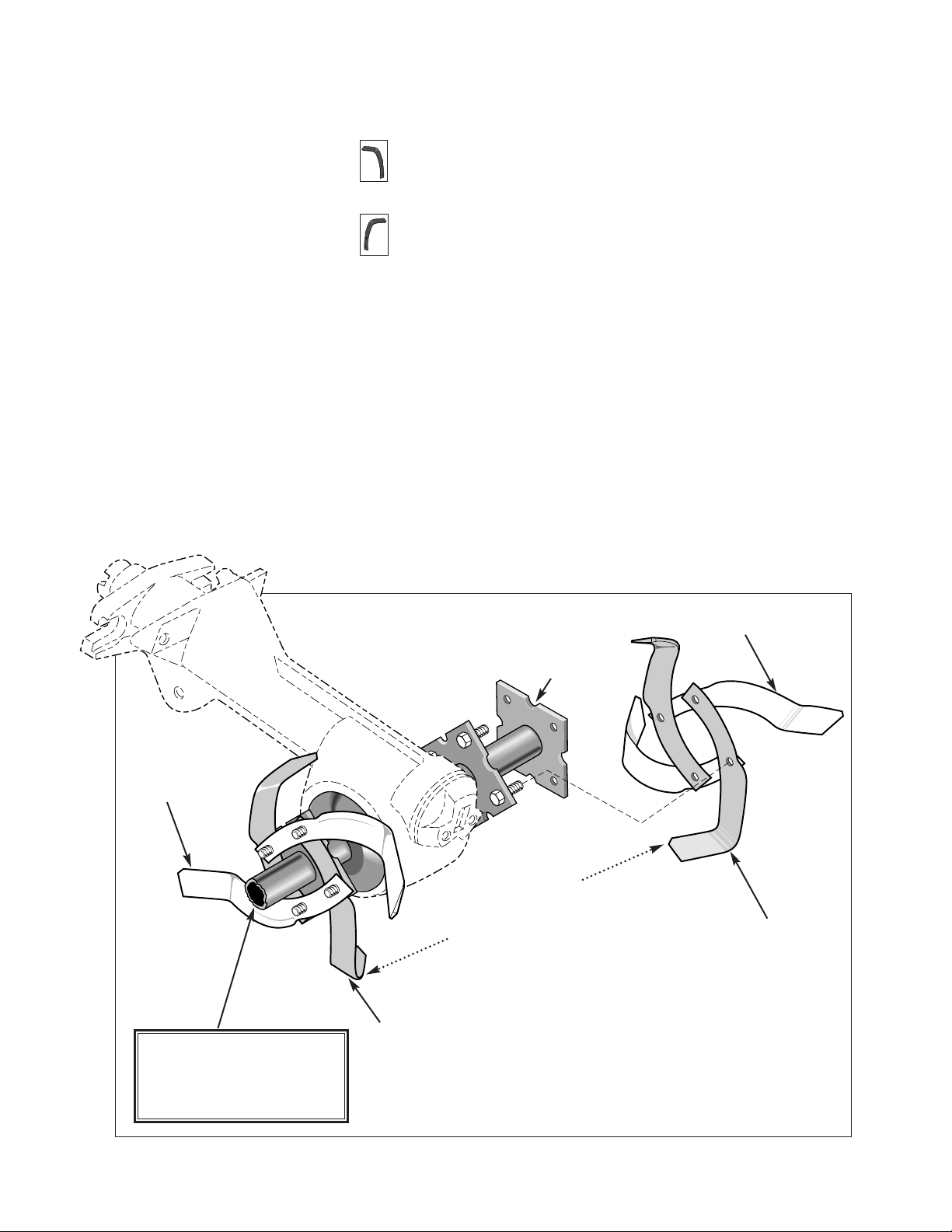

Use this procedure to install

tines only if your tine holders are

shaped as shown below in

Figure 7.

NOTE: Be sure to use the

specific tines (left or right

curved) called for in each

installation step.

HORSE MODEL TINE INSTALLATION

(WELDED STEEL HOLDERS)

Figure 7: Welded steel tine holder.

Step 1: Position Holders

Before Starting Tine

Installation

On PTO Models, disengage the

PTO Lever. On non-PTO

Models, place the Forward/

Reverse Lever in Neutral.

Rotate the tine holders and

shaft (by hand) until any one of

the semi-circles on the

outer

mounting plates of the holders is

at the 12 o'clock position in

relation to the ground. See

Figure 8 on Page 5.

Step 2: Install Tines on Left

Inner Holder

Tines used in this step:

two right-curved tines

followed by

two

left-curved tines

A. Place two right-curved tines

(shown shaded in Figure 8)

opposite each other on the

previously installed bolts. Make

sure that the tines are positioned

as follows:

✔ Tines are across from each

other.

✔ Tines are against the outer

surface of the left inner holder

plate.

NOTE: When installing the

tines you will be directed to

perform a two step procedure

and then check to ensure that the

installation is correct before

going on to the next step.

4

Step 5: Find the Installation Instructions for Your Model

Each tiller's distinctive tine pattern provides the optimum in tilling performance for that model. Be sure to

install tines in the pattern described for your tiller.

Find your tiller in the following list and go to the indicated

page to continue with tine installation.

❑ HORSE (Welded Steel Tine

Holders), see the instructions

at the bottom of this page.

❑ HORSE (Cast Iron Tine

Holders), see

Page 8.

❑

PONY, see Page 12.

❑ ECONO HORSE, see Page 14.

Figure 6: Order of installation on holders (welded steel holders shown).

On all models, tines will be

installed in the following order

(see Figure 6):

A Left Inner Holder

B. Right Inner Holder

C. Left Outer Holder

D. Right Outer Holder

Order of Installation

C A B D

Page 5

Step 3: Install Tines on Right

Inner Holder

Tines used in this step:

two left-curved tines

followed by

two right-curved tines

A. Place two left-curved tines

(shown shaded in Figure 8)

opposite each other on the

previously installed bolts. Make

sure that the tines are positioned

as follows:

✔ The tips of these two tines

should be directly opposite the

tips of the two right-curved tines

installed on the left inner holder

in Step 2-A (see Figure 8).

5

✔ Tips point inward toward

the transmission housing.

✔ The cutting edges will enter

the soil first when the tiller

moves forward.

B. Place two left-curved tines

(unshaded in Figure 8) opposite

each other on the bolts, overlapping the tines installed in Step

2-A. Make sure that the tines are

positioned as follows:

✔ These tines are also across

from each other.

✔ Tips point outward toward

the sides of the tiller.

✔ The cutting edges will enter

the soil first when the tiller

moves forward.

C. Add lock washers and nuts to

all four bolts and tighten

securely.

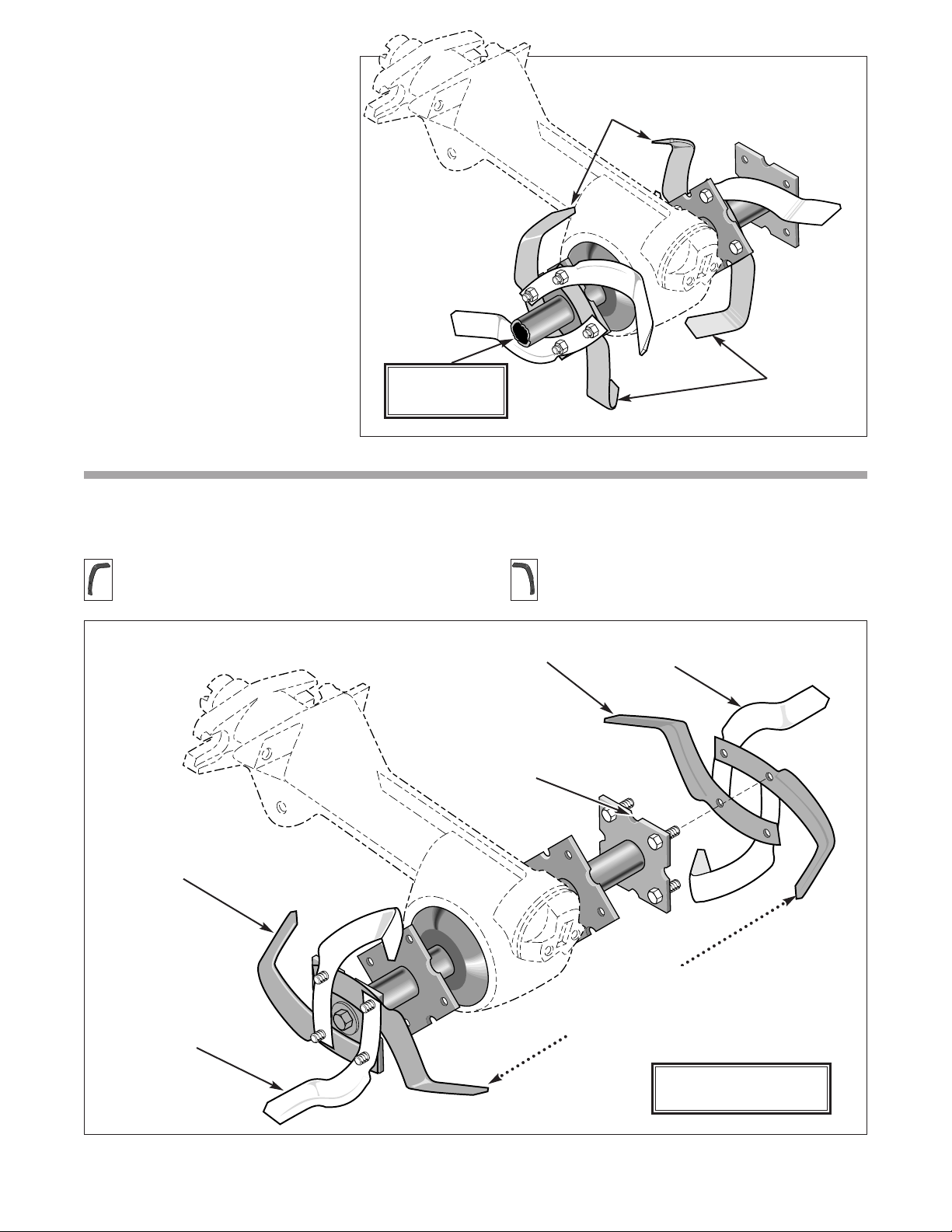

Figure 8: Installing tines on inner holders.

✔ Tines are against the outer

surface of the right inner holder

plate.

✔ Tips point inward toward

the transmission housing.

✔ The cutting edges will enter

the soil first when the tiller

moves forward.

B. Place two right-curved tines

(unshaded in Figure 8) opposite

each other on the bolts, overlapping the tines installed in Step

3-A. Make sure that the tines are

positioned as follows:

✔ These tines are also across

from each other.

✔ Tips point outward toward

the sides of the tiller.

✔ The cutting edges will enter

the soil first when the tiller

moves forward.

C. Add lock washers and nuts to

all four bolts and tighten

securely.

Right-curved

Tine

Left -curved

Tine

Left-curved

Tine

Right-curved

Tine

To allow an unobstructed view

of the left inner tine holder,

the left outer tine holder is not

shown in this drawing.

Position SemiCircle at 12

o'clock

Tips of innermost tines

are directly opposite

from and point toward

each other.

Page 6

Figure 9: Innermost tines on inner holders.

Step 5: Install Tines on Left Outer Holder

Tines used in this step:

Two right-curved tines followed two left-curved tines

Figure 10: Installing tines on outer holders.

6

Step 4: Check the Installation

This completes the installation

of the tines on the two inner

holders. To ensure that the

installation is correct, check for

the following:

A. Make sure that the tips of the

four innermost tines (those

nearest the transmission

housing) are directly opposite

each other, pointing toward each

other and toward the transmission housing. See Figure 9.

B. Make sure that the cutting

edges of all tines will enter the

soil first when the tiller moves

forward.

Left-curved

Tine

Right-curved

Tine

Left-curved

Tine

Right-curved

Tine

Innermost

Tines

Position SemiCircle at 12 o'clock

Tips of innermost tines

are directly opposite from

and point toward each

other.

Innermost

Tines

Left outer holder

not shown.

Tines on inner holders

not shown.

Page 7

7

✔ Tips point inward toward

the transmission housing.

✔ The cutting edges will enter

the soil first when the tiller

moves forward.

B. Place two left-curved tines

(unshaded in Figure 10) opposite

each other on the bolts,

overlapping the tines installed in

Step 5-A. Make sure that the

tines are positioned as follows:

✔ Tines are across from each

other.

✔ Tips point outward toward

the sides of the tiller.

✔ The cutting edges will enter

the soil first when the tiller

moves forward.

C. Add lock washers and nuts to

all four bolts and tighten

securely

A. Place two right-curved tines

(shown shaded in Figure 10)

opposite each other on the

previously installed bolts. Make

sure that the tines are positioned

as follows:

✔ Tines are across from each

other.

✔ Tines are against the outer

surface of the left holder outer

plate.

Step 6: Install Tines on Right

Outer Holder

Tines used in this step:

two left-curved tines

followed by

two right-curved tines

A. Place two left-curved tines

(shown shaded in Figure 10)

opposite each other on the

previously installed bolts. Make

sure that the tines are positioned

as follows:

✔ The tips of these tines are

directly opposite the tips of the

two tines installed in Step 5-A.

✔ Tines are against the outer

surface of the right holder outer

plate.

✔ Tips point inward toward

the transmission housing.

✔ The cutting edges will enter

the soil first when the tiller

moves forward.

B. Place two right-curved tines

(shown unshaded in Figure 10)

opposite each other on the bolts,

overlapping the tines positioned

in Step 6-A. Make sure that the

tines are positioned as follows:

✔ Tines are across from each

other.

✔ Tips point outward toward

the sides of the tiller.

✔ The cutting edges will enter

the soil when the tiller moves

forward.

C. Add lock washers and nuts to

all four bolts and tighten

securely

Step 7: Check the Installation

This completes the installation

of the tines on the two outer

holders. To ensure that the

installation is correct, check for

the following:

A. Make sure that the tips of the

four innermost tines on the

outer holder (those nearest the

transmission) are directly

opposite each other and pointing

inward, toward each other. See

Figure 11.

This completes the installation

steps for HORSE Models with

welded steel tine holders. Also

read and follow the instructions

given in the Bolo Tines Maintenance Section on Page 16.

B. Make sure that the cutting

edges of all tines will enter the

soil first when the tiller is

moving forward.

Figure 11: Outermost tines on outer holders.

Innermost

Tines

Innermost Tines

Page 8

8

HORSE MODEL TINE ASSEMBLY AND INSTALLATION

(CAST IRON HOLDERS)

Use these instructions only if

your tiller is equipped with tine

holders shaped as shown below

in Figure 12.

Figure 12: Cast iron tine holder.

;;

@@

ÀÀ

;;

@@

ÀÀ

;;

@@

ÀÀ

;

;

;

;;

@

@

@

@@

À

À

À

ÀÀ

;

;

;

;;

@

@

@

@@

À

À

À

ÀÀ

;

;

;

;;

@

@

@

@@

À

À

À

ÀÀ

Figure 13: Template taped on box.

Figure 14: Three "A" gangs and one "B" gang.

Step 1: Assemble Tines Into

Gangs

Before starting this procedure,

tape the tine pattern template

(from the inside back cover),

onto the bottom of the shipping

box as shown in Figure 13.

Position the box with the taped

template in front of you.

In this assembly procedure,

you will be assembling leftcurved and right-curved tines

into gangs (sets of four tines

assembled according to a

specific pattern). When the

assembly is complete, you will

have three (3) "A" gangs and one

(1) "B" gang (see Figure 14).

All "A" gangs have have an

identical tine pattern. The "B"

gang has a slightly different

pattern.

A A A

B

#3

#3 TINE

UP

POINTS

E

L

or

A

#4 TINE

POINTS

or

BOLT

A

L

E

R

or

A

R

BOLT

#2

POINTS

DOWN

TINE

E

L

L

UP

#1

POINTS

DOWN

BOLT

TINE

E

R

or

A

R

#4

Page 9

9

A. Place two left-curved tines

onto the template so that the

tines cover the outlines of tines

#1 and #2 as shown in Figure 15.

The tips of the tines point

Figure 15: Assembly of an "A" gang. Figure 16: Insert bolts.

Step 3. Assemble One "B" Gang

Tines used in this step:

two right-curved tines

followed by

two left-curved tines

downward (overhanging the

sides of the box).

B. Place three bolts through the

holes as shown in Figure 16.

C. Place two right-curved tines

(shown in Figure 16) onto the

bolts so that the tines cover the

outlines of tines #3 and #4.

These tines are opposite each

other on top of the tines already

in place. The tips of these tines

face upward as shown.

NOTE: Do not insert a bolt

through the fourth hole.

D. Add lockwashers (not used

with Custom tines) and nuts to

the three bolts and barely tighten

the nuts (just so they do not fall

off the bolts).

E. For future identification

when installing the gangs on the

holders, use chalk or crayon to

mark each gang with an "A."

F. Repeat Steps A through E to

construct two more "A" gangs.

Set these gangs aside until you

install them in Step 4 on

Page 10.

A. Position the box (with the

attached template) in front of

you as was done when

assembling the "A" gangs.

B. Place two right-curved tines

(shown in Figure 17 on Page 10)

onto the template so that the

tines cover outlines of tines #3

and #4. The tips of these tines

point upward.

C. Place three bolts through the

holes shown in Figure 18 on

Page 10.

D. Place two left-curved tines

(shown in Figure 18) onto the

bolts so that the tines cover the

outlines of tines #1 and #2.

These tines are opposite each

other on top of the tines already

in place. The tips of these tines

point downward (overhanging

the sides of the box).

two left-curved tines

followed by

two right-curved tines

Step 2: Assemble Three "A"

Gangs

Tines used in this step:

;;

@@

ÀÀ

;;

@@

ÀÀ

;;

@@

ÀÀ

;;;

;;;

@@@

@@@

ÀÀÀ

ÀÀÀ

;;;

;;;

@@@

@@@

ÀÀÀ

ÀÀÀ

;;;

;;;

@@@

@@@

ÀÀÀ

ÀÀÀ

;@À;@À;@

À

;;

;

;

;

@@

@

@

@

ÀÀ

À

À

À

;;

;

;

;

@@

@

@

@

ÀÀ

À

À

À

;;

;

;

;

@@

@

@

@

ÀÀ

À

À

À

Cutting

Edge

Cutting

Edge

Cutting

Edge

Cutting

Edge

#3

#3 TINE

UP

#1

POINTS

DOWN

TINE

#4

POINTS

E

L

or

BOLT

E

R

or

A

R

E

L

or

A

L

#4 TINE

POINTS

UP

BOLT

A

L

E

R

or

A

R

#2

TINE

BOLT

POINTS

DOWN

#1

TINE

POINTS

DOWN

E

or

A

R

#4

#3

#3 TINE

UP

POINTS

E

L

or

BOLT

R

E

L

or

A

L

#4 TINE

POINTS

UP

BOLT

A

L

E

R

or

A

R

#2

TINE

BOLT

POINTS

DOWN

Page 10

C. Insert a new bolt (of the four

set aside for this set) through the

remaining set of holes in the

tines. (See "Installation Tips" on

Page 11.) Add lockwashers (not

used with Custom tines) and

nuts. Tighten all four bolts

securely.

;@À;@À;@

À

;

;

;

;

@

@

@

@

À

À

À

À

;

;

;

;

@

@

@

@

À

À

À

À

;

;

;

;

@

@

@

@

À

À

À

À

10

;;@@ÀÀ;;@@ÀÀ;;@@À

À

;

;

;

;

@

@

@

@

À

À

À

À

;

;

;

;

@

@

@

@

À

À

À

À

;

;

;

;

@

@

@

@

À

À

À

À

Figure 18: Add lockwashers and nuts to "B" gang.

Figure 19: Position of tine gangs on cast iron holders as viewed from rear

of tiller.

E. Add locknuts to the three

bolts and barely tighten the nuts

(just so they do not fall off the

bolts).

F. For future identification when

installing this gang on the

holder, use chalk or crayon to

mark the gang with a "B."

B. Rotate the gang so that the

the two innermost tines are

around one lug on the tine holder

and the other two tines are

around the other lug.

In the gangs just assembled, all

cutting edges are facing in one

direction. When installed on the

holders, these cutting edges must

enter the soil first when the tiller

is moving forward. Figure 19

shows the correct position on the

tine holders for the three "A"

gangs and the "B" gang.

Note that each holder shows a

letter which corresponds to the

"A" and "B" markings on the

tine gangs just assembled, and a

number which represents the

order in which the tine gangs are

installed on the holders.

A. Make sure that the tine bolts

are loose. Take one "A" gang

and wrap it around the tine

holder at position #1. Check that

the cutting edges are positioned

so that they will enter the soil

first when the tiller moves

forward.

Figure 17: Assembly of a "B" gang.

NOTE: Do not insert a bolt

through the fourth hole.

Step 4: Install Gangs on Holders

B

3

A

A A

421

Cutting

Edge

Cutting

Edge

Cutting

Edge

Cutting

Edge

#3

#3 TINE

UP

POINTS

E

L

#1

TINE

POINTS

DOWN

or

A

#4

or

BOLT

A

E

R

L

R

E

L

BOLT

or

A

L

#4 TINE

POINTS

UP

#3

#4

#3 TINE

UP

POINTS

E

L

or

BOLT

E

R

or

A

R

E

L

or

A

L

#4 TINE

POINTS

UP

BOLT

A

L

E

R

or

A

R

#2

TINE

BOLT

POINTS

DOWN

BOLT

E

R

or

A

R

#2

TINE

POINTS

DOWN

#1

POINTS

DOWN

TINE

Page 11

11

D. Follow the procedure

described in Steps A through C

to install the other two "A"

gangs at positions #2 and #4.

E. Install the "B" gang on the

left outer holder at position #3 as

shown in Figure 20, after

following Steps A through C

above.

Step 5: Check the Installation

This completes the installation of the tines. To ensure that the installation is correct, check for the following:

❑ Make sure that the tips of the four innermost tines (on the left and right sides) are directly opposite each

other and pointing toward each other. See Figure 20.

❑ Make sure that the cutting edges of all tines will enter the soil first when the tiller is moving forward.

❑ Also read and follow the instructions provided in the Bolo Tines Maintenance Section on Page 16.

Figure 20: Tines installed on cast iron holders.

Installation Tips

If you encounter difficulty in aligning the two holes when

inserting the fourth bolt, check the following:

❑ Make sure that the bolts in the other three sets of holes are as

loose as possible.

❑ Use a screwdriver inserted through the two empty holes to pry

the tines together.

❑ Use a mallet to lightly tap the tines into the proper position.

❑ If the holes still cannot be aligned, remove the tine gangs from

the holder, remove the holder from the tine shaft and examine

the holder for rough spots in the groove between the lugs.

Smooth any rough spots with a metal file and repeat Steps A

through C. Refer to your Owner/Operator Manual for holder

removal and replacement instructions.

A Gang

A Gang

A Gang

B Gang

Innermost

Tines

Page 12

PONY MODEL BOLO TINE INSTALLATION

12

Follow these installation steps

if you own a PONY Tiller.

ECONO HORSE owners

follow only Steps 1 and 2

below.

Step 1: Install Tines on Left

Inner Holder

Tines used in this step:

four right-curved tines

A. Begin installing new tines on

the left inner holder. See

Figure 21.

B. Carefully place two right-

curved tines (shown shaded in

Figure 21) opposite each other

on the previously installed bolts.

Make sure that tines are positioned as follows:

✔ Tines are across from each

other.

✔ Tines are against the outer

surface of the left holder inner

plate.

✔ The tips point inward

toward the transmission housing.

✔ The cutting edges will enter

the soil first when the tiller

moves forward.

C. Place two more right-curved

tines (shown partially shaded in

Figure 21) opposite each other

on the bolts, overlapping the

tines installed above in Step 1-B.

Make sure that the tines are

positioned as follows:

✔ Tines are across from each

other.

✔ The tips point inward

toward the transmission housing.

✔ The cutting edges will enter

the soil first when the tiller

moves forward.

D. Add lock washers and nuts to

all four bolts and tighten

securely.

Step 2: Install Tines on Right

Inner Holder

Tines used in this step:

four left-curved tines

ECONO HORSE owners should now go to the instructions for

the Left Outer Holder on Page 14 to complete tine installation.

Figure 21: Installing tines on left inner tine holder.

Figure 22: Installing tines on right inner tine holder.

in Step 1 for the left inner holder.

(The tips of the first two tines

installed in this step should be

directly opposite and point

toward the tips of the first two

tines installed in Step 1-B.)

Make sure that the tips of all

tines point inward, and that all

cutting edges face forward.

Right-curved

Tines

Right-curved

Tines

Left-curved

Tine

Install the four left-curved

tines on the outer surface of the

right inner holder (see Figure

22) using the procedure given

NOTE: To allow an

unobstructed view of the left

inner holder, the left outer

holder is not shown.

Page 13

Step 3. Install Tines on Left

Outer Holder

Tines used in this step:

four right-curved tines

Follow Steps 1-A through 1-D

on Page 12 to install right-

curved tines on the left outer

holder. Make sure that the tines

are installed against the outer

surface of the holder. Make sure

that all tips point inward, and all

cutting edges face forward. See

Figure 23.

Step 4: Install Tines on Right

Outer Holder

Tines used in this step:

four left-curved tines

Follow Step 2 on Page 12 to

install left-curved tines on the

right outer holder. Make sure

that the tines are installed against

the outer surface of the holder.

All tips point inward. See Figure

23 which shows PONY tines

completely installed.

Step 5: Check the Installation

This completes the installation

of the tines on your PONY

Tiller. To ensure that the

installation is correct, check for

the following:

❑ Make sure that the tips of all

tines are pointing inward

(toward the transmission

housing).

❑ Make sure that the cutting

edges of all tines will enter

the soil first when the

tiller is moving forward.

Also read and follow the

instructions provided in the Bolo

Tines Maintenance Section on

Page 16.

13

Figure 23: PONY tines installed.

Eight Rightcurved Tines

Eight Leftcurved Tines

NOTE: Shaded tines

are installed first.

Innermost Tines

Innermost Tines

Page 14

ECONO HORSE MODEL BOLO TINE INSTALLATION

Follow these installation steps only if you own an ECONO HORSE Tiller.

NOTE: Tines on inner holders

are installed the same for both

PONY and ECONO HORSE

Tillers. However, tines on the

outer holders of the ECONO

HORSE have a different

installation pattern as explained

in the following instructions.

ECONO HORSE Tiller owners should first follow Steps 1

and 2 of the instructions given on Page 12 for installing

tines on the PONY Model. Then, return to Step 1 below to

continue tine installation on your ECONO HORSE Model.

Step 1: Install Tines on Left

Outer Holder

Tines used in this step:

two right-curved tines

followed by

two left-curved tines

A. Place two right-curved tines

(shown shaded in Figure 24)

opposite each other on the

previously installed bolts. Make

sure that the tines are positioned

as follows:

✔ Tines are across from each

other.

✔ Tines are against the outer

surface of the left holder outer

plate.

✔ Tips point inward toward

the transmission housing.

✔ The cutting edges will enter

the soil first when the tiller

moves forward.

Figure 24: Installing tines on ECONO HORSE outer holders.

B. Place two left-curved tines

(unshaded in Figure 24) opposite

each other, overlapping the tines

positioned in Step 1-A. Make

sure that these tines are

positioned as follows:

✔ Tines are across from each

other.

✔ Tips point outward toward

the sides of the tiller.

✔ The cutting edges will enter

the soil first when the tiller

moves forward.

C. Add lock washers and nuts to

all four bolts and tighten

securely.

14

Right-curved

Tine

All Bolt Threads

Face Outward

Left-curved

Tine

Left-curved

Tine

NOTE: To allow an unobstructed view of

the outer tines, the inner tines (which

were previously installed) are not shown

in this drawing.

Right-curved

Tine

Page 15

✔ Tines are against the outer

surface of the right holder outer

plate.

✔ Tips point inward toward

the transmission housing.

✔ The cutting edges will enter

the soil first when the tiller

moves forward.

B. Place two right-curved tines

(shown unshaded in Figure 24)

opposite each other, overlapping

the tines positioned in Step 2-A.

Make sure that the tines are

positioned as follows:

✔ Tines are across from each

other.

✔ Tips point outward toward

the sides of the tiller.

✔ The cutting edges will enter

the soil first when the tiller

moves forward.

C. Add lock washers and nuts to

all four bolts and tighten

securely.

15

A. Place two left-curved tines

(shown shaded in Figure 24)

opposite each other on the bolts

which were previously installed.

Make sure that the tines are

positioned as follows:

✔ The tips of these two tines

should be directly opposite and

point toward the tips of the two

tines installed in Step 1-A. See

Figure 25.

✔ Tines are across from each

other.

Step 2: Install Tines on Right

Outer Holder

Tines used in this step:

two left-curved tines

followed by

two right-curved tines.

Check the Installation

This completes the tine installation of tines on the ECONO

HORSE Model. To ensure that

the installation is correct, check

for the following:

❑ Make sure that the tips of the

four innermost tines on the

outer holders are pointing

toward each other and

inward (toward the transmission housing). See

Figure 25.

❑ Make sure that the cutting

edges of all tines will enter

the soil first when the

tiller is moving forward.

Also read and follow the

instructions provided in the Bolo

Tines Maintenance Section on

Page 16.

Figure 25: ECONO HORSE tines installed.

Innermost Tines

Innermost Tines

Page 16

BOLO TINES MAINTENANCE

Check Bolts and Nuts

Check all tine attachment bolts

and nuts for tightness every 10

hours of tiller operation.

Inspect Tines for Wear

Inspect tines after the first 10

to 15 hours of tiller operation

and then after every 10 hours.

See Figure 26.

Compare your tines to those

shown in Figure 26 to decide

whether your tines need

replacement. Your tines should

be replaced when the following

conditions occur:

❑ Tines are worn beyond the

line shown in Figure 26.

❑ Tines do not dig more than 3

to 5 inches and do not perform well for burying crop

residue and for sod busting.

❑ Tines leave a wide, untilled

gap in the middle of a tilled

row, so that overlapping

becomes very timeconsuming.

Rotate HORSE and ECONO HORSE Tines for Longer Tine Life

HORSE and ECONO HORSE bolo tines can be rotated to obtain a

longer life. PONY tines are subject to equal wear because the tine

pattern is the same for all tines on a holder. Therefore, rotating tines

is not effective for that model.

❑ Rotate tines once during their life cycle to increase tine life up to

40%.

❑ Rotate tines to equalize wear among the tines.

❑ Rotate tines before they wear beyond the line shown in Figure 26.

16

Figure 26: New and worn tines.

Horse Model Tine Rotation (Welded Steel Holders)

Tines shown shaded in Figure 27 are in high wear positions.

When rotating tines, these tines are moved from high wear to low

wear positions.

Figure 27: Shaded tines are in high wear positions.

Wear Line

Page 17

17

Step 1: Move the two left-

curved tines (labelled "A" in

Figure 28) from the left outer

holder to the "B" position on the

right outer holder. Move the two

left-curved tines which were at

the "B" position to "A."

Figure 28: Exchanging position of tines at "A" and "B."

Figure 29: Exchanging position of tines at "C" and "D."

Figure 30: Exchanging position of tines at "E" and "F."

Figure 31: Exchanging position of tines at "G" and "H."

Step 2: Move the two right-

curved tines

from position "C"

on the left inner holder to the

"

D" position on the right inner

holder. Move the two rightcurved tines which were at the

"

D" position to "C." See Figure

29.

Step 3: Move the two left-

curved

tines from the "E"

position on the left inner holder

to the "

F" position on the right

inner holder. Move the two

left-

curved

tines which were at the

"

F" position to "E." See Figure

30.

Step 4: Move the two right-

curved

tines from position "G"

on the left outer holder to the

"

H" position on the right outer

holder. Move the two

right-

curved

tines which were at the

"

H" position to "G." See Figure

31.

I

MPORTANT: Make sure

that the cutting edges on all

tines will enter the soil first

when the tiller is moving

forward.

A

B

C

D

E

F

G

H

Page 18

Horse Model Tine Rotation

(Cast Iron Holders)

Step 1: Move the entire tine

gang labelled "1" in Figure 32

(from the left outer holder) to the

"4" position on the right outer

holder. Move the entire tine

gang labelled "4" in Figure 32

(on the right outer holder) to the

"1" position (on the left outer

holder).

Note: The shaded tines in

Figures 32 are the tines which

receive the most wear.

Step 2: Move the entire tine

gang labelled "2" in Figure 32

(on the left inner holder) to the

"3" position (on the right inner

holder). Move the entire tine

gang labelled "3" in Figure 32

(on the right inner holder) to the

"2" position (on the left inner

holder). Now, see Figure 33

which show the positions of the

tine gangs after rotation.

Econo Horse Model Tine

Rotation

Rotate only the four tines on

the outer holders as indicated

below.

Step 1: Move the tines labelled

"A" in Figure 34 (on the left

outer holder) to the "B" position

(on the right outer holder). Move

the tines which were at the "B"

position to "A."

18

Figure 32: BEFORE rotating gangs on cast iron holders.

Figure 33: AFTER rotating gangs on cast iron holders.

Figure 34: Rotating tines on ECONO HORSE outer holders.

I

MPORTANT: Make sure

that the cutting edges on all

tines will enter the soil first

when the tiller is moving

forward.

I

MPORTANT: Make sure

that the cutting edges on all

tines will enter the soil first

when the tiller is moving

forward.

A B

1

12

2 3

3

4

4

Before

After

Shaded tines

are now in low

wear positions.

Shaded tines are

in high wear

positions.

Page 19

;;;

;;;

@@@

@@@

ÀÀÀ

ÀÀÀ

;;;

;;;

@@@

@@@

ÀÀÀ

ÀÀÀ

;;;

;;;

@@@

@@@

ÀÀÀ

ÀÀÀ

CUT ON THIS LINE

CUT ON THIS LINE

✄

DO NOT

INSERT

BOLT

IN THIS

HOLE

THIS TEMPLATE IS USED

TO ASSEMBLE TINES

ONLY FOR HORSE

MODEL TILLERS WITH

CAST IRON HOLDERS.

#3 TINE

POINTS

E

#3

UP

L

#1

TINE

POINTS

DOWN

BOLT BOLT

or

AL

ER

or

AR

ER

or

AR

EL

or

BOLT

AL

#4 TINE

POINTS

UP

#2

TINE

POINTS

DOWN

#4

Page 20

For customer assistance, visit www.troybilt.com, contact your nearest authorized dealer or:

TROY-BILT LLC, P.O. BOX 361131, CLEVELAND, OHIO 44136-0019, 1-866-840-6483

Printed in U.S.A. Form 769-00080 (01/02)

Loading...

Loading...