Page 1

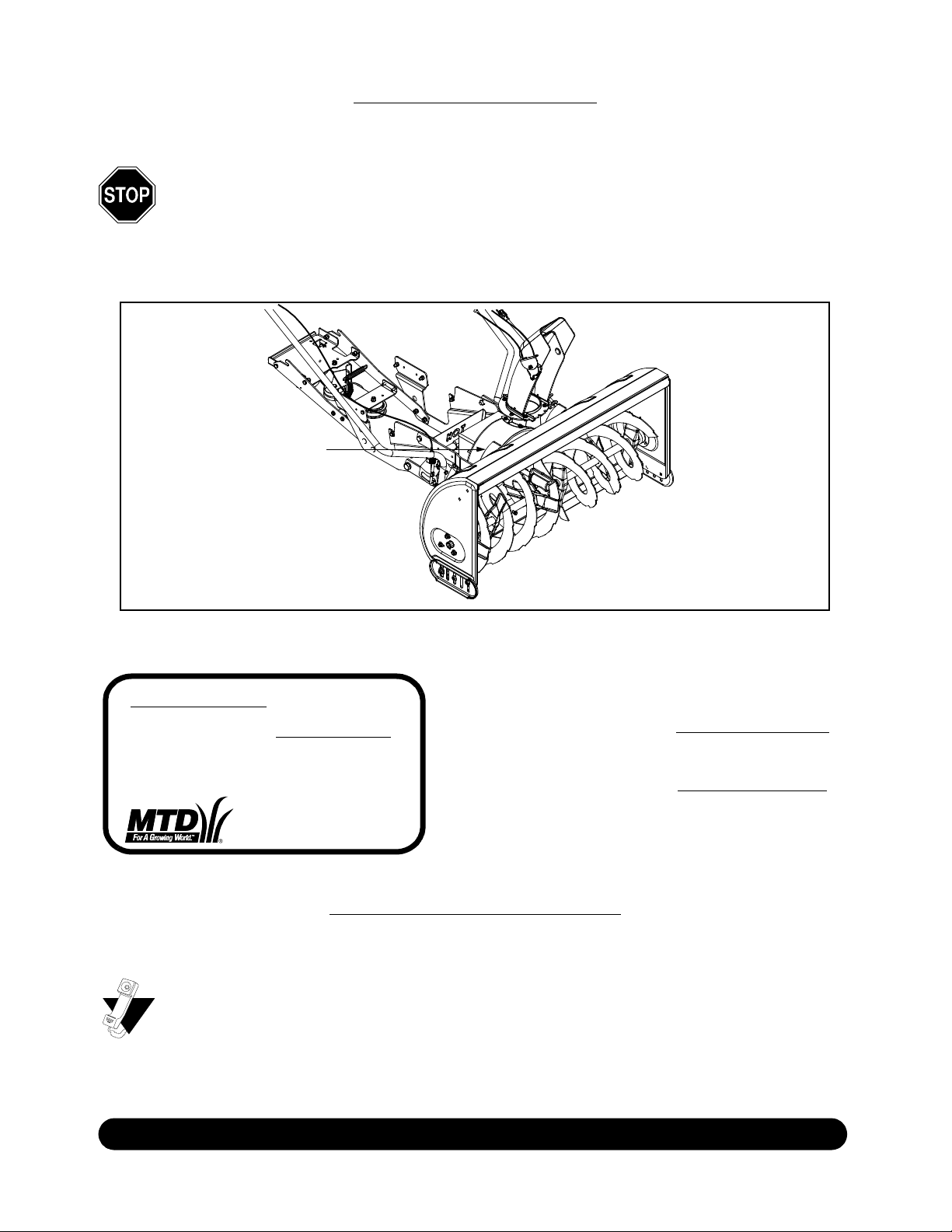

Operator’s Manual

42-inch Snow Thrower Attachment

For 600-ser ies Lawn Tractors

Model

OEM-190-627

NOTE: This snow thrower attachme nt will NOT fit on all 600-s eries lawn tr actors. It is NOT designed for

and will NOT operate safely or properly on FastAttach™ compatible tractors. Check your tractor’s right fender for the

FastAttach™ label before attempting to mount this attachment.

NOTE: This snow thrower attachme nt will NOT fit on ANY 800-ser ies garden tracto rs, regardless of the tractor’s

FastAttach™ compat ibility.

MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A.

FORM NO. 770-10056A

(05/00)

Page 2

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new snow thrower attachment. It will help you assemble,

prepare and maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the

equipment and copy the information from it in the space provided below. The information on the

model plate is very important if you need help from our Customer Support Department or an

authorized dealer.

You can locate the model number by looking on the rear, right portion of the snow thrower impeller housing. A

sample model plate is explained below. For future reference, please copy the model number and the serial number

of the equipment in the space below.

Model Plate

Figure 1

• An example of what the model plate will look like is shown below.

(Model Number)

CLEVELAND, OHIO 44136

(Serial Number)

MTD PRODUCTS INC

Copy the model number here:

Copy the serial number here:

CALLING CUSTOMER SUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, please call the Customer Support Department.

Call 1- (330) 220-4MTD (4683) or 1- (800)-800-7310 to reach a Customer Support representative.

Please have your unit’s model number and serial number ready when you call. See previous section

to locate this information. You will be asked to enter the serial number in order to process your call.

• Although both numbers are important, you will be asked to enter only your serial number before your call can

be processe d.

For more details about your unit, visit our website at www.mtdproducts.com

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

W ARNING: This symbol points out important safety instructions which, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with these instructions may result in personal injury. When you see this symbol—heed its warning.

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components contain or

emit chemicals known to State of California to cause cancer and birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this man-

ual. As with any type of power equipment, carelessness or error on the part of the operator can result in

serious injury. This machine is capable of amputating hands and feet and throwing objects. Failure to

observe the following safety instructions could result in serious injury or death.

TRAINING

1. Read, understand, a nd follow all in struction s on the

machine and in the manual(s ) before a ttempting to

assemble and o perate. Keep this ma nual in a safe pl ace

for future and regular re ference a nd for orde ring

replacement parts.

2. Be familiar with all controls and their prope r operation.

Know how to stop the mach ine and d isengage them

quickly.

3. Never allow childre n under 14 y ears old to operate this

machine. Children 14 years old and over shou ld read and

understand the op eration in struction s and sa fety rules i n

this manual and should be trained and sup ervised b y a

parent.

4. Never allow adults to op erate this machine withou t proper

instruction.

5. Thrown objects can cause seriou s personal injury . Plan

your snow throwing patte rn to avoid discha rge of material

toward roads, bystanders and the like.

6. Keep bystanders, hel pers, pets and chi ldren at l east 75

feet from the machin e while it is in operatio n. Stop

machine if anyo ne enters the area.

7. Exercise caution while operati ng tractor with this

attachment, especi ally wh en traveling in revers e.

PREPARATION

1. Thoroughly inspec t the area where the equipm ent is to be

used. Remove all door ma ts, newspap ers, sleds, bo ards,

wires and other fore ign objec ts which could be thrown by

the auger/impeller.

2. Always wear safet y glasses or eye s hields d uring

operation and while performi ng an adjustment or repair to

protect your eyes. T hrown ob jects whi ch ricochet can

cause serious inj ury to the eyes.

3. Do not operate wit hout wearing adequate winter outer

garments. Do not wear jewelry, long scarves or other

loose clothing which cou ld becom e entang led in m oving

parts. Wear footwear w hich wi ll improve footing on

slippery surfaces.

4. Adjust collector housing hei ght to clear gravel or crush ed

rock surfaces.

5. Disengage all cl utches a nd shift into neutra l before

starting the engine.

6. Never attempt to ma ke any adjustme nts whi le engin e is

running, except where speci fically recom mended in the

operator’s manual(s).

7. Let tractor engine and attachm ent adjust to outdoor

temperature before sta rting to c lear snow.

8. To avoid personal injury or propert y damage use extreme

care in handling gasolin e. Gasoline is extremely

flammable and the v apors are explosive . Serious

personal injury c an occu r when gas oline is spilled on

yourself or your c lothes w hich can ignite . Wash y our skin

and change cloth es imm ediately.

a. Use only an approved gasol ine container.

b. Extinguish all ci garettes, c igars, pipe s and oth er

sources of ignition .

c. Never fuel machine indoo rs.

d. Never remove gas c ap or add fuel wh ile the

engine is hot or running.

e. Allow engine to c ool at le ast two mi nutes be fore

refueling.

f. Never over fill fuel tank. F ill tank to no more than ½

inch below bot tom of fil ler neck to provi de space

for fuel expansion.

g. Replace gasolin e cap and tigh ten secu rely.

h. If gasoline is spilled, wipe i t off the e ngine and

equipment. Move machine to another area . Wait 5

minutes before starti ng the en gine.

i. Never store the machine or fue l cont ainer insid e

where there is an o pen flam e, spark or pilot l ight

(e.g. furnace, water h eater, spa ce heate r, clothes

dryer etc.).

j. Allow machine to cool at lea st 5 min utes befo re

storing.

OPERATION

1. Do not put hands or fee t near rota ting parts, in the auge r/

impeller housing or disc harge chut e. Contact with th e

rotating parts can am putate ha nds and feet.

2. Never operate with a missing or damag ed discharge

chute. Keep all s afety dev ices in pl ace and working .

3. Never run an engine indoors or in a po orly ventil ated

area. Engine exhaust contains carbon monoxide, an

odorless and dea dly gas.

4. Do not operate mach ine wh ile under the influ ence of

alcohol or drugs.

3

Page 4

5. Muffler and engine become hot an d can cause a bu rn. Do

not touch.

6. Exercise extreme ca ution when operating on or cro ssing

gravel surfaces. Stay alert for hidden hazards or traffic.

Do not carry passengers.

7. Exercise caution w hen changi ng directi on and w hile

operating on slop es.

8. Plan your snow throwi ng pat tern to av oid discha rge

towards windows, wa lls, cars e tc. To avoid prope rty

damage or personal injury caus ed by a ricochet.

9. Never direct disc harge at c hildren, b ystander s and pet s

or allow anyone in front of t he machi ne.

10. Do not overload machine capa city by attemptin g to clear

snow at too fast of a rate.

11. Never operate this ma chine with out good visi bility or light.

12. Disengage power to t he auger/i mpeller w hen

transporting or not in use.

13. Never operate mach ine at hi gh transp ort speeds on

slippery surfaces. Look down and b ehind an d use ca re

when in reverse.

14. If the machine should s tart to vibrate abno rmally, stop the

engine, disengage the power take-o ff, lower the

attachment and set the parking brake. I nspect thorough ly

for damage. Repair any damage bef ore starting and

operating.

15. Disengage the power take-off, lower attachme nt, se t the

parking brake and stop en gine befo re you leave the

operating position . Wait until the au ger/impeller comes to

a complete stop before un clogging the disc harge ch ute,

making any adj ustme nts, or in spect ions.

16. Never put your hand in the d ischarge or colle ctor

openings. Always use a cl earing to ol to unc log the

discharge opening.

17. Use only attachm ents a nd acce ssories approved by the

manufacturer (e.g. wheel weigh ts, tire c hains, cabs etc.) .

18. If situations occur which are not covered in this manua l,

use care and good judgment. Cont act your dealer or

telephone 1-800-800-73 10 for assistance and the name

of your nearest s ervicing dealer.

MAINTENANCE AND STORAG E

1. Never tamper with sa fety dev ices. Chec k their p roper

operation regularly .

2. Disengage power take-off, lower the attach ment, set the

parking brake, st op engine and remo ve key to preven t

unintended startin g. Wait un til the a uger/impe ller com es

to a complete stop before cleaning , repairing , or

inspecting.

3. Check bolts, and sc rews for pro per tightne ss at fre quent

intervals to keep the machi ne in sa fe worki ng condi tion.

Also, visually inspect ma chine for any damage .

4. Do not change the engi ne governor setti ng or over-speed

the engine. The go vernor co ntrols the maximum safe

operating speed o f the engi ne.

5. Snow thrower shave plates an d skid shoes are subject to

wear and damage. Fo r your sa fety prote ction, frequen tly

check all compon ents and replace w ith orig inal

equipment manufacturer’ s (O.E.M.) parts onl y. “Use of

parts which do not meet the original equ ipment

specifications may lead to improper performance and

compromise safety!”

6. Check clutch con trols peri odicall y to veri fy they e ngage

and disengage prope rly and adjust, if n ecessary. Refer to

the PTO and safety inter lock sy stem in your t ractor’s

operator’s manual for instru ctions.

7. Maintain or replac e safety and ins truction l abels, a s

necessary.

8. Observe proper dispos al laws and regulation s for gas, oil,

etc. to protect the environment.

9. Prior to storing, run machine a few min utes to c lear sno w

from machine and prevent freeze up of auger/i mpeller.

10. Never store the mac hine or f uel conta iner inside where

there is an open flame, sp ark or pilot light such as a water

heater, furnace, clothes dryer etc .

11. Always refer to the Ope rator’s M anual for proper

instructions on off-season storage.

WARNING — YOUR RESPONSIBILITY:

Restrict the use o f this po wer machine to person s who re ad, unders tand and follow the warnings and instru ctions i n

this manual and on the mac hine.

AND CLOTHING AWAY.

KEEP HANDS, FEET

ROTATING AUGER AVOID INJURY FROM

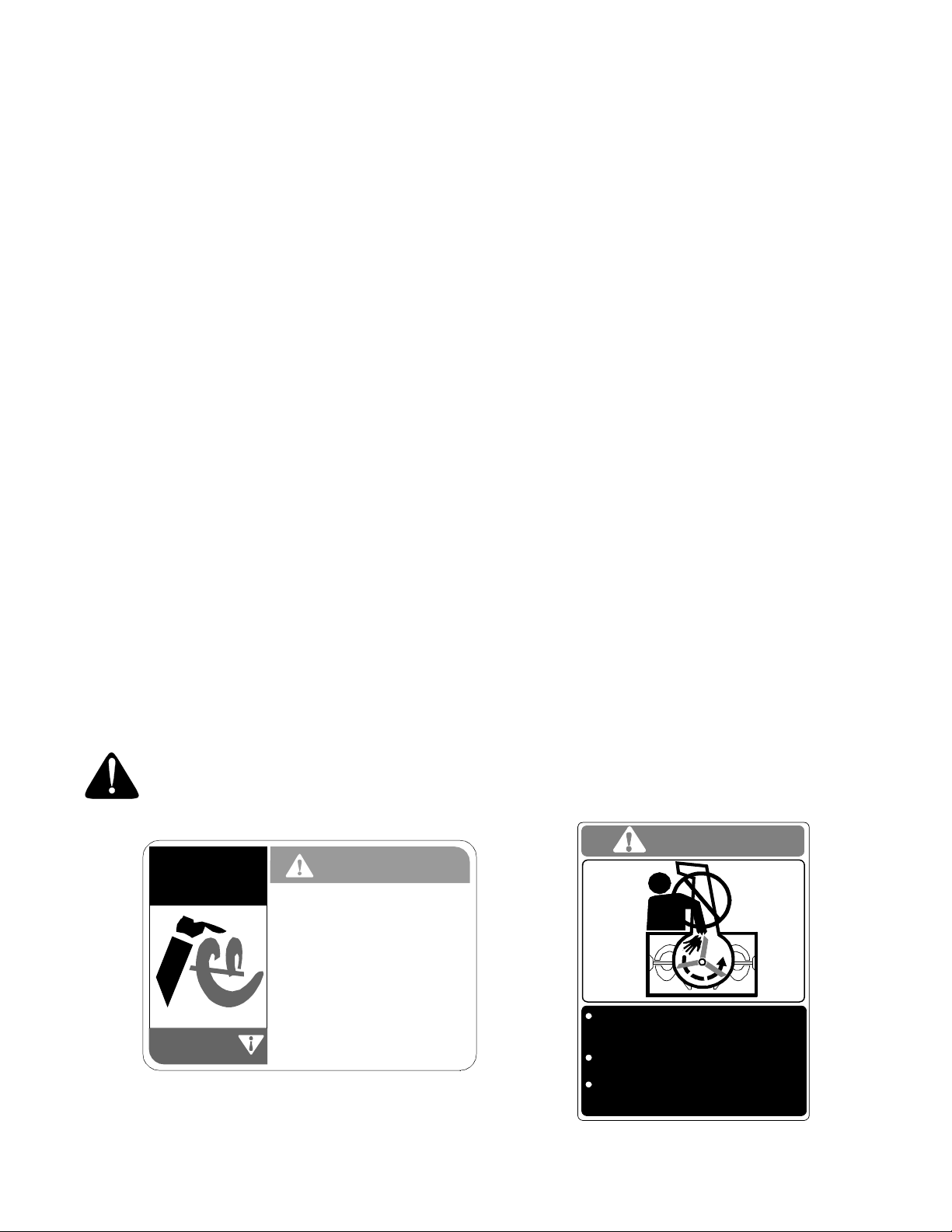

DANGER

DANGER

1.

KEEP AWAY FROM ROTATING IMPELLER

AND AUGER. CONTACT WITH IMPELLER

OR AUGER CAN AMPUTATE HANDS AND FEET.

2.

DISENGAGE PTO, STOP ENGINE, SET PARK

BRAKE, AND REMAIN ONMACHINE UNTIL

ALL MOVING PARTS HAVE STOPPED BEFORE

UNCLOGGING OR SERVICING.

3.

TO AVOID THROWN OBJECTS INJURIES,

NEVER DIRECT DISCHARGE AT BYSTANDERS.

USE EXTRA CAUTION WHEN OPERATING ON

GRAVEL SURFACES.

READ OPERATOR’S MANUAL.

4.

FOR BALLAST INFORMATION REFER TO

5.

YOUR ATTACHMENT MANUAL.

NEVER PUT HAND IN CHUTE. CONTACT WITH

ROTATING PARTS CAN AMPUTATE FINGERS

AND HANDS.

DO NOT UNCLOG DISCHARGE CHUTE WHILE

ENGINE IS RUNNING.

SHUT OFF ENGINE AND REMAIN BEHIND

HANDLES UNTIL ALL MOVING PARTS HAVE

STOPPED BEFORE UNCLOGGING.

Figure 2 Safety Labels Found on Snow Thrower

4

DANGER

Page 5

SECTION 2: TO THE OWNER

Model 627 42-inch two-stage snow thrower is designed for use on 600-series lawn tractors manufactured in

1996 or later ONLY. It will NOT fit nor operate properly or safely on ANY other tractor. It will NOT fit on any

FastAttach™ compatible tractor.

NOTE: If your 600-series lawn tractor was manufactured prior to 1996, model 627 snow thrower attachment can be

mounted on the tractor with special instructions and minor modifications to the tractor. Phone our Customer Support

Department as instructed on page 2 for details.

NOTE: Referenc es to LEFT and RI GHT indicate the left and right sides o f the tractor when fa cing forward in th e

operator’s position. Reference to the FRONT indicates the grille end; to the REAR the drawbar end.

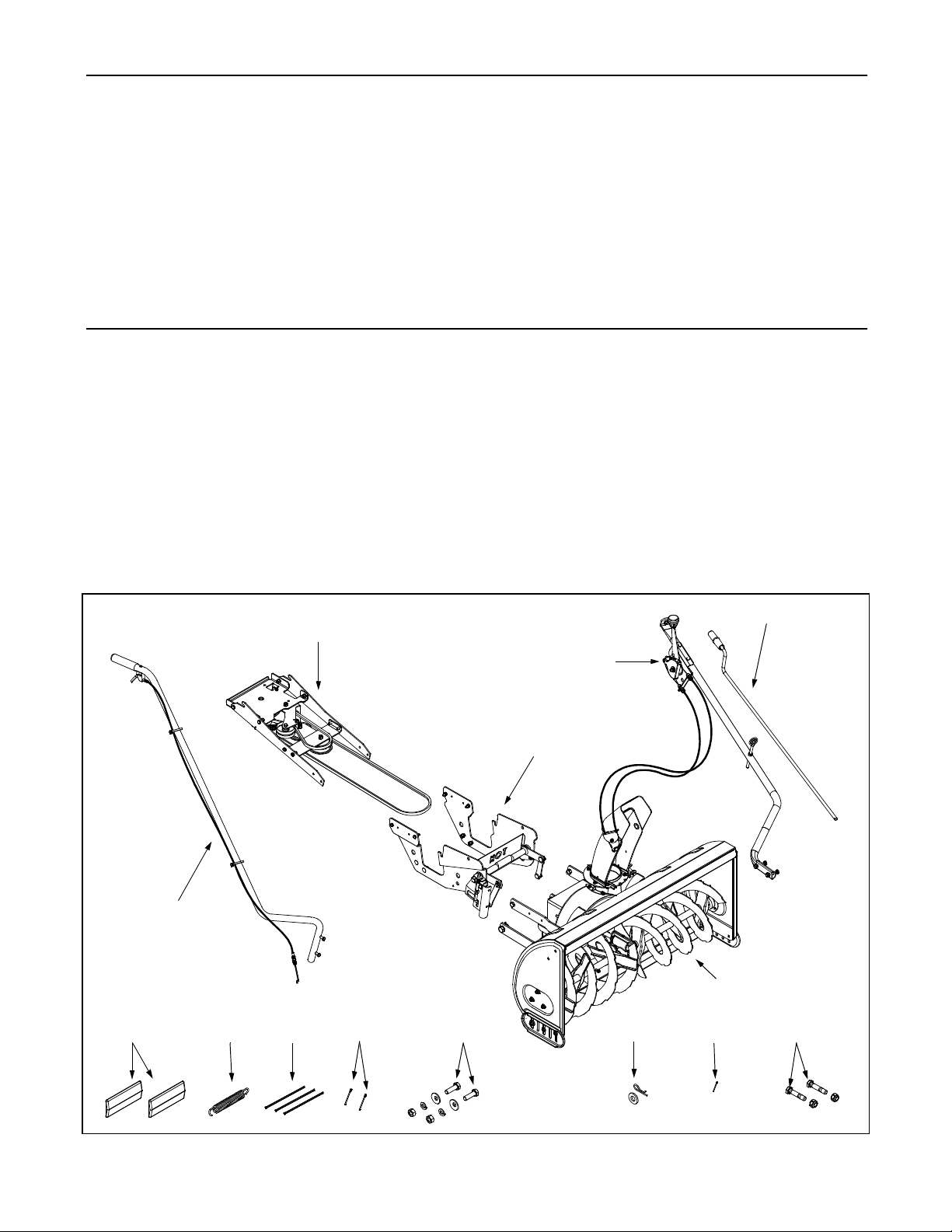

SECTION 3: CONTENTS OF CARTON

Before beginning installation, remove all parts from the carton to make sure everything is present. Carton contents

are listed below and shown in Figure 3. Part numbers are shown in parentheses.

• One Auger Housing Assembly

• One Undercarriage Assembly with

Upper V-belt (754-0449) & Lower V-belt (754-0330)

• One Support Carriage Assembly

• One Chute Directional Control with Tilt Lever

• One Lift Handle Assembly with Cable

• One Upper Chute Crank Rod

• Two Self-adhesive Reflectors (730-3000)

• Three Cable Ties (725-0157)

• One Extension Spring (732-0626)

• Two Spare Shear Bolts (710-0890A)

& Hex Lock Nuts (712-0429)

• One Flat Washer (736-3019)

• One Hairpin Clip (714-0145)

• Two Hex Screws (710-0376)

• Two Belleville Washers (736-0242)

• Two Lock Washers (736-0119)

• Two Hex Nuts (712-3010)

• Two 1¼-inch Cotter Pins (714-0470)

• One ¾-inch Cotter Pin (714-0507)

with Upper V-belt & Lower V-belt

Lift Handle Assembly

With Cable

Self-adhesive

Reflectors Spring

Extension

Undercarriage Assembly

Cable

Ties

1¼ Cotter Pins

Chute Directional Control

with Tilt Le v er

Support Carriage Assembly

Hex Screws,

Belleville Washers,

Lock Wash ers

and Hex Nuts

Flat Washer

& Hairpin Clip

Upper Chute Crank Rod

Auger Housing Assembly

¾-inch

Cotter Pin

Spare Shear Bolts

& Hex Lock Nuts

Figure 3

5

Page 6

SECTION 4: ASSEMBLY

WARNING: Before installing attachment,

place tractor on a firm and level surface. Place

the PTO in the disengaged (OFF) position, set

the parking brake, shut engine off and remove

key to prevent unintended starting.

NOTE: Your tractor’s cu tting deck and PTO belt must

be removed prior to mounting the snow thrower

attachment. Refer to your tractor’s Operator’s Manual

for detailed instru ctions. Retain all the deck hardware

and store it in a safe pla ce. If your tractor is eq uipped

with any front-end acc essory such as a front bumper

kit, it must also be removed.

NOTE: It is strongly recommended that a second

person act as an assistant through out the assembly of

the snow thrower atta chm ent . Ha vi ng a sec ond pe rson

present eases the completion of many of the steps.

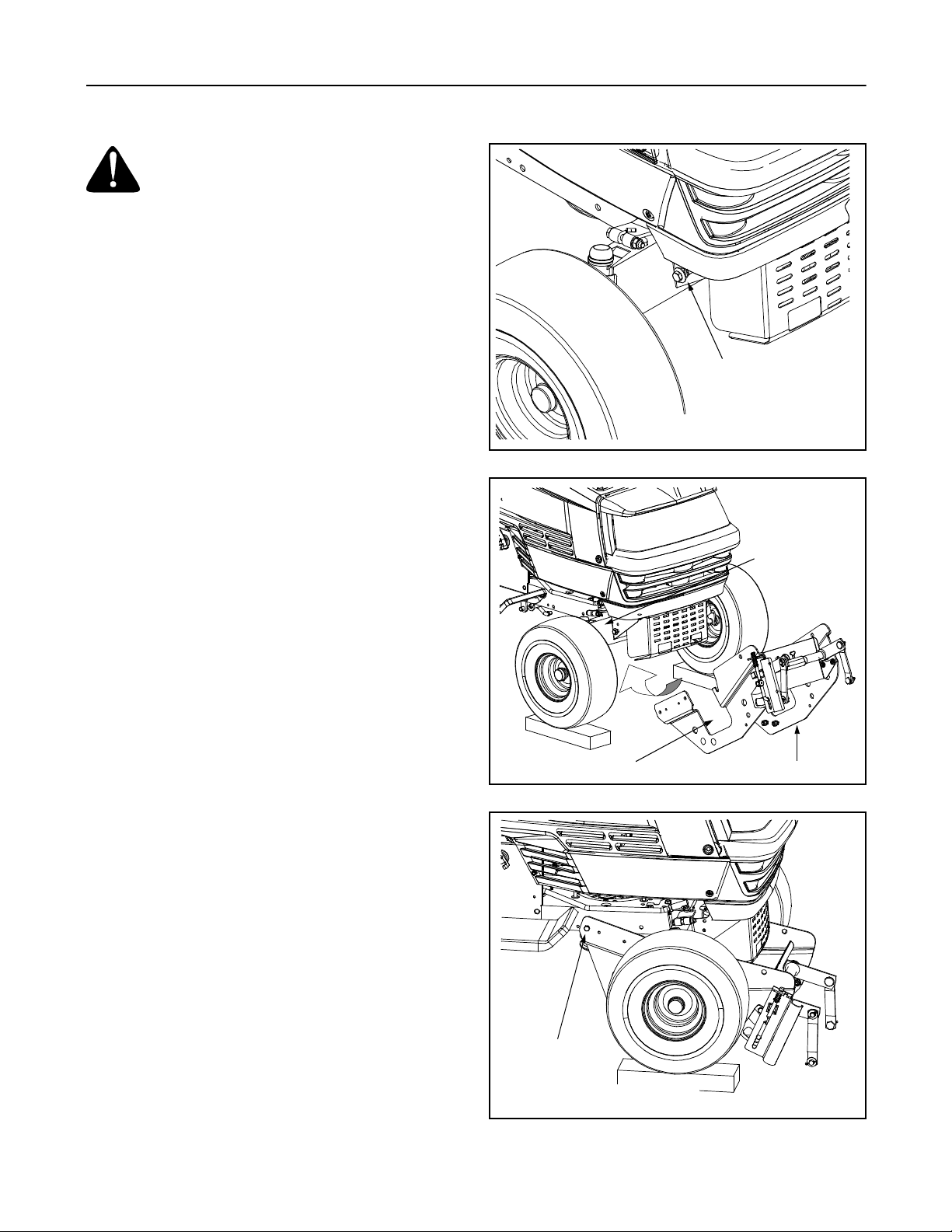

Mounting the Support Carriage Assembly

1. Fasten the provided hex screws, belleville washers,

lock washers and lock nuts to the tractor’s front

pivot bracket as illustrated in Figure 4 on both the

left side and the right side. Do NOT tighten the

hardware at this point in the assembly.

2. Place the tractors front tires on 2x4s to bring the

tractor’s front end up a few inches and allow

clearance for positioning the support carriage.

3. Remove the hex scr ews, lo ck wa shers an d hex

nuts from the both sides of the rear of the support

carriage asse mbly.

4. Place the support carriage assembly between the

tractor’s front tires so that the large notch on both

sides of the support carriage straddles the tractor’s

front pivot bar. See Figure 5.

5. Position the rear of the support carriage so that the

holes where the hardware was just removed align

with the holes in the tractor’s frame rail.

Large Notch

Hex Screw,

Belleville Washer

NOTE: The lock washer and hex nut

are on the INSIDE of the pivot bracket.

Figure 4

Front Pivot Bar

Support Carriage

Figure 5

NOTE: Make certain that the support carriage is to the

OUTSIDE of the frame rail on both sides of the tractor.

6. Reinsert the rearmost hex screw removed in Step 3

through the aligning holes in both the support

carriage assembly and the tractor’s frame rail.

Fasten with the lock washer and hex nut but do not

tighten the hardware at this time. See Figure 6.

7. Pivot the front of the support carriage upward until

the small grooves found in the front portion of

support carriage slide between the belleville

washers ins erted in ste p 1 an d the tract or’s f ront

pivot bracket. See Figure 7.

Hex Screw

NOTE: The lock washer and hex nut are

on the INSIDE of the tractor’s frame rail.

Figure 6

6

Page 7

8. Reinsert the remaining hex screws removed in

Step 4 through the remaining aligning holes in both

the support carriage assembly and the tractor’s

frame rail (just behind the tractor’s front pivot

bracket). Securely fasten with the remaining lock

washers and hex nuts. See Figure 7.

9. Securely ti ghten al l the othe r hardwa re used to

mount the support carriage assembly.

Mounting the Undercarriage Assembly

1. Remove the carriage bolts, lock washers and hex

nuts from both sides of the front of the undercarriage asse mbly.

2. Carefully position the undercarriage assembly

right-side up beneath the tractor and stretch both

belts out toward the front of the tractor to keep them

from getting in the way of completing the following

steps.

NOTE: The zin c-plated double p ulley is loca ted in the

REAR of the undercarriage assembly.

3. Position the slot found on both the left, rear and the

right, rear sides of the undercarriage onto the

tractor’s running board rod. See Figure 8.

4. Pivot the undercarriage upward allowing the

tractor’s front lift links to suspend between the

undercarriage’s left side plates and the tractor’s

frame rails. The tractor’s adjustable lift link (an ‘L’shaped rod found on the front, right) will suspend

through the opening in the right side of the

undercarriage.

Hex

Screw

Support Carriage Groove

Figure 7

NOTE: The rear lift links (See Figure 8) are unaffected

by this assembly and not used in any regard by the

snow thrower attachment. Both can be ignored.

5. With the undercarriage’s side plates positioned to

the inside of the support carriage mounted earlier,

reinsert the carriage bolts removed in step 1

through aligning holes in both the undercarriage

assembly and support carriage assembly. See

Figure 9.

6. Secure the undercarriage to the support carriage

by refastening the lock washers and hex nuts

removed in Step 1 to the carriage bolts just

inserted.

NOTE: Disregard both the upper drive belt and the

lower drive belt at this point in the assembly of the snow

thrower. They will both be routed in later steps.

Attaching the Reflectors

1. Peel off the backing from each of the reflectors to

expose the adhesive surface.

2. Adhere the reflectors to the rear of the tractor’s

fender (one on the left and one on the right) so that

the reflectors simulate taillights.

Rear Lift Links

Front Lift Link

Side Plate

Running Board Rod

NOTE: The tractor’s frame and running

board are ‘cut away’ for clarity in this figure.

Figure 8

Carriage Bolts

NOTE: The lock washer and hex nut are on

the INSIDE of the support carriage assembly.

Figure 9

7

Page 8

Attaching The Lift Handle

1. Remove the hex screws and flange nuts from the

lower portion of the lift handle.

2. Attach the lift handle to the lift bracket found on the

right side of the support carriage a ssembly with the

two hex screws and two flange lock nuts just

removed. See Figure 10.

Mounting the Auger Housing Assembly

1. Carefully remove the 2x4s placed under the

tractor’s front tires in Step 2 of Mounting the Support

Carriage Assembly.

2. Position the auger housing assembly closely in

front of the tractor’s front-end.

IMPORT ANT :

significantly ease the following steps.

Having a second pe rson ass ist you wil l

Vertical

Links

Hex Screws

Lift Handle

3. Place the 2x4s removed in Step 1 beneath the

auger housing assembly’s lower lift links, just

behind the skid plate. This will cause the housing to

tilt slightly forward and ease in completing the

following s teps.

4. Remove the clevis pin, flat washer and hairpin clip

from the lower portion of each vertical link on the

front of the support carriage assembly. See Figure

10.

5. Align the hol e in the lower portion of each vertical

link with the hole found near the center of each of

the auger assembly’s lower lift links and reinsert

the clevis pins just removed through these aligned

holes.

6. Secure the vertical lift links to the lower lift links by

fastening with the flat washers and hairpin clips

also removed in Step 4. See Figure 11.

7. Remove the hex scr ews, f lat wa shers a nd crow n

nuts from the rear portion of each lower lift link.

8. Grasp the auger housing support bar, refer to

Figure 11, on the left rear (have a second person

grasp the support bar on the right rear) portion of

the auger housing and lift upward until the holes

found on the rear of the lower lift links are aligned

with the holes found on both (left & right) sides of

the support carriage.

9. Reinsert the hex screws (with one flat washer each)

removed in Step 7 through the aligning holes.

10. Secure the lower lift links to the support carriage by

fastening with the crown nuts and remaining two flat

washers removed in Step 8 in addition to the two

1¼-inch cotter pins provided.

IMPORT ANT :

After inserting, bend the tips of the cotter

pins outward to prevent them from backing out of the

hex screws.

Figure 10

Vertical Link Secured

to Lower Lift Link

Figure 11

Lower Lift Link Secured

to Support Carriage

Auger Housing

Support Bar

Figure 12

8

Page 9

11. Remove the hex screws and hex nuts from the rear

portion of each upper lift link.

12. Have an assistant grasp the upper portion of the

auger housing and pivot the assembly upward until

the holes of the upper links align with holes in the

front of the support carriage.

13. Reinsert the hex screw s removed in St ep 11

through the aligning holes and secure the upper lift

links to the support carriage by fastening with the

hex nuts also removed in Step 12. See Figure 13.

IMPORT ANT :

Make certain that the hex nut securing the

left upper lift link is positioned to the INSIDE of link. This

will avoid any interference when attaching the chute

directional control in following steps.

Attaching the Chute Directional Control

1. Remove the hex screws and flange nuts from the

lower portion of the chute directional control.

2. Attach the chute directional control to the upper lift

link on the left side of the auger housing assembly

with two hex screws and two flange nuts just

removed. See Figure 14.

3. Slide the upper chute crank rod through the eyelet

in the top of the chute directional control and the

eyebolt found midway down.

4. Pivot the lower chute crank rod upward and secure

it to the upper chute crank rod with the

¾-inch cotter

pin provided. See Figure 14.

5. Fasten the chute tilt cables to the chute directional

control with the three cable ties provided. Pull the

cable ties until they’re snug and trim off any excess.

Routing the Upper Drive Belt

1. Make sure that the “V” side of the upper drive belt is

seated firmly in the upper portion of the double

pulley found in the rear of the undercarriage

assembly.

2. Route the opposite end of the upper drive belt

around the engine pulley, to the INSIDE of the belt

keeper pins found on either side of the engine

pulley.

3. Place the tractor’s lift lever in the lowest reachable

engagement notch.

4. Hook one end of the extension spring provided into

the hole on the left side of the undercarriage idler

bracket’s surface, just to the rear of the belt keeper.

See Figure 15

5. Using a pair of vise grips, hook the other end of the

extension spring to a hole in the tractor’s left fram e

rail. See Figure 15.

Upper Lift Link Secured

to Support Carriage

Figure 13

Upper

Rod

Lower

Rod

Hex Screws

Chute Directional Control

Figure 14

Hook Extension Spring Here

WARNING: Always wear safety glasses or

eye shields during operation and while

performing an adjustm ent or repair to protec t

your eyes.

Double Pulley

Belt Keeper on Idler Bracket

Figure 15

9

Page 10

Routing the Lower Drive Belt

1. Loosen, but do NOT remove the flange nut which

secures the belt keeper to the drive mounting

bracket. See Figure 16.

2. Make sure that the “V” side of the lower drive belt is

seated firmly in the lower portion of the double

pulley found in the rear of the undercarriage

assembly.

3. Route the opposite end of the lower drive belt

around the snow thrower’s drive pulley, to the

INSIDE of the belt keeper loosened in Step 1.

NOTE: Having a second person carefully pivot the

double-idler pulley mounted beneath the undercarriage

toward the left side of the trac tor will relieve tension on

the lower drive belt and ease in routing it around the

drive pulley.

4. Retighten the flange nut loosened in Step 1 to

secure the belt keeper.

Attaching the Adjustable Lift Link

Power to the snow thrower attachment is engaged and

disengaged through the tractor’s adjustable lift link

found suspending through the front left area of the

undercarriage assembly mounted earlier. To properly

attach the adjustable lift link to the undercarriage

assembly, proceed as follows:

1. Place the tractor’s lift lever in the lowest reachable

engagement notch.

2. Locate the adjustable lift link and thread it upward

as far as possible.

3. Insert the end of the tractor’s adjustable lift link

through the hole found in the undercarriage’s

engagement bracket. See Figure 17 .

4. Secure the adjustable lift link to the engagement

bracket with the flat washer and hairpin clip

provided.

Flange Nut

Drive Mounting

Bracket

NOTE: View shown is from above the tractor.

Figure 16

Adjustable Lift Link Secured

to Engagement Bracket

Figure 17

Attaching the Lift Cable

1. Insert the “Z” end of the lift cable into the hole in the

lift index rod found on the right side of the support

carriage assembly. See Figure 18 .

2. Position the threaded portion of the cable end into

the slot found on the lift bracket making certain that

one hex nut is above the lip of the bracket and the

flat washer and second hex nut are below the lip.

3. Tighten both hex nuts to securely fasten the

threaded portion of the lift cable to the lip of the lift

bracket.

IMPORT ANT :

to the Lift Adjustment in SECTION 7: ADJUSTMENTS to assure

your snow thrower’s lift cable is properly adjusted.

Before operating your snow thrower, refer

Hex Nuts

Lift Cable

‘Z’ End

Lift Index Rod

Figure 18

10

Page 11

SECTION 5: CONTROLS

Engaging the Augers and Impeller

Power to the snow thrower attachment is activated by

lowering the tractor’s lift lever and placing it into the

lowest notch possible.

• Move the tractor’s throttle lever into the FAST

(rabbit) position and allow it to remain there for the

most efficient use of the snow thrower attachment.

• Move the tractor’s lift lever to the right before

lowering it and placing it in any of the notches on

the index bracket. This will engage the augers and

impeller.

NOTE: The tractor’s lift lever cannot be in the engaged

(lowered) position when the tractor is driving in the

reverse direction. T he tractor’s lift leve r must be in the

disengaged (BLADES STOP) position when the shift

lever is placed in REVE RSE or the tractor ’s engi ne wi ll

automatically shut off.

Refer to your tractor’s Operator’s Manual for more

information regarding your tractor’s safety interlock

system.

Lift Handle

The lift handle is located on the right side of the tractor

and is used to raise and lower the snow thrower

attachment.

• To raise the snow thrower attachment off of the

ground, pull rearward and down on the lift handle

until you feel the lift latch on the right side of the

snow thrower engage, locking the snow thrower in

a raised position.

• To lower the snow thrower, push downward on the

lift handle until there is enough slack in the lift cable

so that you may squeeze the trigger control. With

the trigger control squeezed, gently allow the snow

thrower to lower until it reaches the ground.

Chute Directional Control

The chute directional control assembly is found on the

left side of the tractor and includes both the chute tilt

lever as well as the chute crank. Both affect the

direction that the discharged snow is thrown.

• To pivot the upper section of discharge chute,

affecting the distance and angle which the snow is

thrown, move the chute tilt lever forward or

rearward into a desired position.

• The direction which snow is thrown can be changed

by rotating the discharge chute with the chute

crank. Turn the chute crank

chute and discharge snow to the left. Crank it

counterclockwise to rotate the chute and discharge

snow to the right.

clockwise to rotate the

SECTION 6: OPERATION

This snow thrower attachment is capable of displacing snow and clearing a path a width of 42 inches.

Observe the following operating instructions for both effective and efficient snow removal.

• Become familiar with and comfortable using all of

your tractor’s controls as instructe d in your tr actor’s

Operator’s Manual before operating it with the snow

thrower attachment.

• Make certain the correct weight and volume of

motor oil in is you r tractor ’s engine as instructed in

the engine Owner’s Guide packed with the tractor’s

Operator’s Manual.

• Always operate the snow thrower with the tractor’s

engine at maximum RPM (full throttle).

• NEVER override any safety features on either your

tractor or the snow thrower attachment.

• Make certain that all nuts, bolts, and hardware are

fastened securely and tight on both the tractor and

the snow thrower attachment prior to use.

• Make certain the snow thrower is assembled

properly and mounted to the tractor as instructed

earlier in this manual.

• Test all th e contr ols ( tract or li ft lev er, sn ow th rower

lift handle, chute tilt lever & chute crank) for smooth

operation prior to operating the snow thrower in the

snow.

• Make all adjustments (i.e. skid shoes, lift latch)

before operating your snow thrower attachment.

Follow instructions in SECTION 7: ADJUSTMENTS when

doing so.

• Engage power to the augers and impeller BEFORE

driving the tractor forward and into the snow.

• Keep your tractor’s ground speed slow. The slower

your tractor is traveling, the more effectively the

snow thrower attachment can displace snow.

• Adjust ground speed for snow conditions and

become familiar with different snow applications.

Your snow thrower attachment will operate

differently in wet heavy snow than it will it light, fluffy

snow.

11

Page 12

• Overlap a previously cleared path when necessary

(deep snow) so as not to overload the auger

housing with snow.

• NEVER drive the tractor into a snow bank. The

snow thrower attachment is NOT a dozer plow. The

lift linkage and/or the snow thrower drive system

can be damaged as a result of “plowing” with the

snow thrower attachment.

• Whenever possible, discharge snow downwind.

• When the tractor (with the snow thrower

attachment mounted) is not in use, use the lift lever

to lower the auger housing assembly to the ground

to relieve strain on the tractor’s front end between

uses.

• Do NOT attempt to remove ice or hard-packed

frozen snow.

• If the augers become jammed with a chunk of ice or

a foreign object, move the tractor’s lift lever into the

disengaged (BLADES STOP) position immediately

and turn off the tractor’s engine and remove the

ignition key. Examine the auger area thoroughly for

damage and do NOT operate the snow thrower

attachment until any damage is repaired.

IMPORT ANT :

with two shear bolts and hex lock nuts. If you hit a hard

foreign object or an ice jam, the snow thrower is

designed so that the bolts may shear. Two replacement

shear bolts and hex lock nuts are provided for your

convenience. Store in a safe place until needed.

NEVER replace the auger shear bolts with standard

hex bolts. Any damage to the auger gearbox or other

components as a result of doing so will NOT be covered

by your snow thrower attachment’s warranty.

The augers are secured to the spiral shaft

• Always use tire chains and rear wheel weights on

your tractor where extra traction is needed. Refer to

the table to the right to determine which kits will fit

your tractor (tire dimensions are stamped into the

sidewalls of your tractor’s tires).

• Use drift cutters to aid in displacing snow through

deep, drifted areas.

NOTE: None of the kits in the table are included as

standard equipment with snow thrower attachment

OEM-190-627. Call our Custo mer Supp ort Depa rtment

as instructed on page 2 of th is manual for availability

and information regarding these kits.

Tire Size Tire Chain Kit Number

20” x 10.0” OEM-190-916

20” x 8.0” OEM-190-658

18” x 9.5” OEM-190-657

18” x 8.5” OEM-190-754

18” x 6.5” OEM-190-664

Wheel Weight Kit Numb er

All Tire Sizes OEM-190-215

Drift Cutter Kit Number

OEM-390-679

SECTION 7: ADJUSTMENTS

WARNING: Never attempt to make any

adjustments while the engine is running,

except where specified in the Operator’s

Manual. Place tractor on a firm and level

surface. Place the PTO in the disengaged

(OFF) position, set the parking brake, shut

engine off, and remove key to prevent

unintended starting

Lift Adjustment

If the lift index rod doesn’t latch securely or the pivot

release has too much slack in it, an adjustment can be

made as follows:

1. Loosen the upper hex nut a few turns, then tighten

the lower hex nut to shorten the cable length. Refer

to Figure 18.

2. Loosen the lower hex nut a few turns, then tighten

the upper hex n ut to leng then the cable . Ref er to

Figure 18.

Skid Shoe Adjustment

The space between the shave plate and the ground can

be adjusted by repositioning the skid shoes found on

either side of the snow throwers auger housing. For

close snow removal, place skid shoes in the low

position. Use middle or high position when area to be

cleared is uneven. See Figure 19.

IMPORT ANT :

thrower be operated on a gravel surface, as loose

stones can be easily picked up and thrown by the

machine. If you must operate on a gravel surface,

ALWAYS adjust the skid shoes into the HIGH position

to allow the shave plate maximum clearance.

12

It is NOT recommended that this snow

Page 13

Adjust skid shoes as follows:

1. Loosen, but do NOT remove, the three hex nuts

which fasten the skid shoe to the auger housing.

2. Raise or lower the skid shoe to desired position.

NOTE: Make certai n t he en t ir e ba s e of bo th skid s hoe s

are against the ground to avoid uneven wear on the

skid shoes. When one side does wear out, the skid

shoes are reversible.

3. Retighten the hex nuts loosened earlier.

4. Repeat this adjustment on the skid shoe found on

the opposite side of the snow thrower.

Engagement/Disengagement Adjustment

If the snow thrower’s auger and impeller:

a. Fail to engage when lowering the tractor’s lift

lever and placing it into the lowest notch

possible, or

b. Fail to disengage when raising the tractor’s

lift lever and placing it into the Blades Stop

notch, perform the following adjustment.

1. Place the tractor’s lift lever in the second

engagement notch (third notch down).

2. Locate the control rod found to the inside of the

engagement plate on the undercarriage assembly.

See Figure 20 .

3. Remove the hairpin clip and flat washer from the

ferrule found at the rear of the control rod. See

Figure 20 .

4. Remove the ferrule from the hole in the

engagement plate and slide the control rod as far

forward as it will go in the slot in the idler bracket.

See Figure 21 .

IMPORT ANT :

beyond the end of the slot in the idler bracket. The idler

bracket is under tension from the spring which secures

it to the tractor’s frame rail.

5. While holding the control rod forwardmost end of

the slot, thread the ferrule inward or outward

(whichever is applicable) until it is realigned with

the hole.

6. Reinsert the ferrule into the hole and secure it to the

engagement plate by fastening with the flat washer

and hairpin clip removed in Step 3.

Do not attempt to force the control rod

Skid Shoe

Idler Bracket

Slot

Figure 19

Control Rod

Figure 20

Hex Nuts

Engagement Plate

Ferrule

Engagement Plate

13

Control Rod

Ferrule

Figure 21

Page 14

Lower Chute Crank

Support Bracket Adjustment

If the spir al at the base of the lo wer ch ute cr ank i sn’t

fully engaging with the notches in the lower chute

assembly, the support bracket can be adjusted inward

or outward as follows:

1. Loosen, but do NOT remove the two hex nuts

which secure the support bracket to the snow

thrower housing. See Figure 22.

2. Adjust the support bracket inward or outward so

that the spiral is fully engaged in the notches on the

chute before retightening the hex nuts.

SECTION 8: LUBRICATION

Spiral

Support Bracket

Hex Nuts

Figure 22

Auger Shaft

• At least onc e a season, re move the shear bolt s on

the auger shaft. Oil or spray lubricant inside and on

the plastic bearings on the shaft and near the holes

where the shear bolts were removed before

reattaching them. See Figure 23.

Shear Bolts

Plastic Bearings

Figure 23

Chute Directional Control

• The spiral on the end of the lower chute crank, the

base of the discharge chute itself and the joint

blocks which connect the lower and upper chute

cranks should be lubed with multi-purpose

automotive grease once a season. See Figure 24.

Lube Spiral

and Chute Base

Joint Block

Figure 24

14

Page 15

NOTES

15

Page 16

Model 627

52

60

59

75

44

71

61

82

103

55

52

66

29

104

46

58

35

37

38

37

27

47

105

102

30

31

34

42

21

20

17

48

33

77

64

63

42

91

103

42

40

114

93

117

118

5

73

17

20

5

116

36

20

43

111

41

13

40

20

36

20

26

108

39

25

21

19

45

17

77

8687

89

115

112

33

15

62

32

33

113

61

88

53

58

50

84

65

52

12

56

15

49

48

57

56

11

95

100

89

33

51

101

54

94

90

92

85

98

85

83

96

61

9

22

8

54

97

99

54

61

32

19

1

72

78

81

106

Hook Spring

Ref. 13 Here

110

74

32

76

67

109

2

33

14

9

8

10

7

32

70

79

68

23

24

6

8

3

16

4

14

107

77

69

15

9

28

16

Page 17

Model 627

REF.

NO. PART NO. DESCRIPTION

1 611-0132 Rod Assembly

2 710-3131 Hex Cap Screw, 1/2-13 x 1.0

3 710-0151 Hex Cap Screw, 3/8-24 x 2.0

4 710-0964A Hex Cap Screw, 5/8-18 x 1.31

5 710-0514 Hex Cap Screw, 3/8-16 x 1.0

6 711-0332 Clevis Pin, .5 x .78

7 712-0386A Slotted Hex Nut, 5/8-18

8 712-3022 Hex Lock Nut, 1/2-13

9 714-0474 Cotter Pin, .125 x .75

10 714-0470 Cotter Pin, 1/8 x 1.25

11 714-0507 Cotter Pin

12 716-0102 Snap Ring

13 732-0262 Extension Spring

14 736-0366 Flat Washer, .64 x 1.12 x .125

15 736-0272 Flat Washe r, .51 x 1.0 x .060

16 710-0331 Hex Cap Screw, 3/8-24 x 2.25

17 756-0300 Flat Washer, .406 x .875 x .059

18 738-0234 Shoulder Screw, .5 x .29, 3/8-16

19 741-0170 Flange Bearing w/ Flats

20 736-0169 Lock Washer, 3/8

21 738-0347 Shoulder Spacer, .625 x .169

22 783-0382 Link, 4.88

23 783-0878 Link, 13.25

24 783-1263 Link, 17.30

25 784-5727 Idler Pivot Arm

26 784-5728 Idler Support Bracket

27 756-3080 Double Pulley, 7.0 x 3.5

28 710-3180 Hex Cap Screw, 5/16-18 x 1.75

29 716-3020 Internal Snap Ring

30 750-3164 Spacer, .635 x 2.0

31 736-0290 Flat Washe r, 5/8 x 1.0 x .063

32 712-3004A Flange Lock Nut, 5/16-18

33 712-3010 Hex Nut, 5/16-18

34 710-3151 Hex Cap Screw, 5/8-18 x 4.25

35 736-0329 Lock Washer, 1/4

36 714-0145 Click Pin, .092 x 1.64

37 712-3006 Hex Nut, 1/4-20

38 747-3250 Belt Guard Rod

39 711-0242 Spacer

40 712-0241 Hex Nut, 3/8-24

41 712-0116 Nylon Jam Lock Nut, 3/8-24

42 712-3017 Hex Nut, 3/8-16

43 747-0871 Belt Keeper Rod

44 754-0449 Upper V-belt

45 756-0627 Idler Pulley, 3.5” Diameter

46 741-0524 Sealed Ball Bearing, .625 x 1.574 x .470

47 603-0302 Chute Tilt Bracket Assembly

48 710-0262 Carraige Bolt, 5/16-18 x 1.5

49 710-0451 Carraige Bolt, 5/16-18 x .75

50 710-0896 Hex Index Washer Screw, 1/4-14 x .625

51 710-3015 Hex Cap Screw, 1/4-20 x .75

52 712-0429 Nylon Hex Lock Nut, 5/16-18

53 710-0376 Hex Cap Screw, 5/16-18 x 1.0

54 712-3027 Hex Flange Lock Nut, 1/4-20

55 720-0232 Knob

56 731-0851A Chute Flange Keeper

57 731-1300A Lower Chute

58 731-1313C Chute Tilt Cable Guide

59 731-1320 Upper Chute

REF.

NO. PART NO. DESCRIPTION

60 736-0231 Flat Washer, .344 x 1.125 x .125

61 736-0242 Bell Washer, .34 x .872

62 736-0451 Saddle Washer, .32 x .93

63 746-0929 Chute Cable w/ Clip, 54.5”

64 746-0928 Chute Cable, 54.5”

65 784-5594 Cable Bracket

66 784-5604 Chute Tilt Handle

67 683-0298 Lift Bracket Assembly

68 703-2728A Snow Thrower Lift Bracket

69 710-3008 Hex Cap Screw, 5/16-18 x .75

70 710-1268 Hex Index Washer Screw #10-16 x .375

71 710-3143 Pan Phillips Screw, #10-24 x .75

72 712-0127 Flat Weld Nut, #10-24

73 756-0218 Flat Idler Pulley, 3.25

74 715-0114 Heavy Duty Spirol Pin, 1/4 x 1.5

75 720-0274 Handle Grip

76 732-0306 Compression Spring, .406 x .531 x 1.75

77 736-0119 Lock Washer, 5/16

78 736-0140 Flat Washer, .385 x .62 x .063

79 736-0400 Flat Washer, .194 x .62 x .063

80 746-3060A Lift Cable, 42” w/ Trigger Control

81 747-1203 Lift Index Rod

82 750-1028A Lift Handle Tube

83 710-0805 Hex Cap Screw, 5/16-18 x 1.5

84 715-0138 Rolled Pin, 1/8 x .63

85 715-0129 Spirol Pin, .125 x .82

86 720-0201A Crank Knob

87 726-0100 Push Cap, 3/8 ID

88 735-0234 Rubber Grommet , .44 x .94 x .5

89 741-0475 Plastic Bushing

90 747-0697 Eye Bolt

91 747-0931 Chute Crank Rod, .38 x 28

92 747-0932 Rod, .375 x 11.375

93 750-1054 Support Chute Tube

94 784-5149 Joint Block Assembly

95 684-0061 Chute Crank Assembly

96 703-2735A Chute Crank Bracket

97 705-5226 Chute Reinforcer

98 710-0276 Splined Carriage Screw, 5/16-18 x 1.0

99 710-0167 Carriage Screw, 1/4-20 x .5

100 731-1379A Adapter Chute

101 784-5647 Chute Crank Bracket

102 710-3144 Hex Cap Screw, 3/8-16 x 2.0

103 725-0157 Cable Tie

104 683-0133 Pulley Mounting Bracket Assembly

105 783-0358A Idler Bracket

106 783-0362A Mounting Strap Hanger Bracket

107 783-0372 RH Side Pla te

108 783-0373 LH Side Plate

109 710-3168 Carr i age Bolt, 3/8-16 x 1.0

110 710-0650 Self-tapping Screw, 5/16-18 x .875

111 783-1274 Heat Shield

112 736-0101 Flat Washer, .406 x 1.0 x .030

113 747-0533 Clutch Adjustment C ontrol Rod

114 732-0626 Extension Spring, .75 x 5.06

115 714-0101 Internal Cotter Pin

116 736-3019 Flat Washer, .531 x 1.062 x .134

117 783-0359 Idler Engagement Bracket

118 711-0198 Ferrule, 3/8-24 x .375

17

Page 18

Model 627

63

26

69

65

64

68

8

26

62

5

29

20

28

17

59

66

29

29

61

35

38

19

60

31

12

3

23

67

33

14

26

22

15

4

6

29

2

34

29

12

18

33

27

22

69

18

69

27

19

27

33

37

30

10

36

11

43

49

47

55

54

45

39

50

58

43

48

57

18

41

56

46

57

51

58

42

40

42

19

36

33

27

30

37

Page 19

Model 627

REF.

NO. PART NO. DESCRIPTION

1 05931 Bearing Housing, 1.85 ID

2 618-0407 Auger Gear Case (Incl. Ref. 39-58)

3 747-1257 Belt Keeper Rod

4 684-0065 Impeller Assembly, 12”

5 684-0148 Housing Assembly

6 703-2734 Housing Brace Bracket

7 703-2735A Chute Crank Bracket

8 703-2736 Belt Cover

9 705-5226 Chute Reinforcer

10 705-5269 LH Spiral Auger, 40”

11 705-5270 RH Spiral Auger, 40”

12 710-0157 Hex Cap Screw, 5/16-24 x .75

13 710-0167 Carriage Screw, 1/4-20 x .5

14 710-0260A Carriage Bolt, 5/16-18 x .62

15 710-0276 Splined Carriage Screw, 5/16-18 x 1.0

16 710-0451 Carriage Bolt, 5/16-18 x .75

17 710-0604A Self Tapping Screw, 5/16-18 x .625

18 710-0890A Shear Bolt, 5/16-18 x 1.5

19 712-0429 Hex Lock Nut, 5/16-18

20 712-3010 Hex Nut, 5/16-18

21 712-3027 Hex Flange Lock Nut, 1/4-20

22 712-3057 Hex Nut, 5/16-24

23 715-0114 Spirol Pin, 1/4 x 1-1/2

24 715-0129 Spirol Pin, .125 x .812

25 731-1379 Adapter Chute

26 712-3004A Flange Lock Nut, 5/16-18

27 736-0188 Flat Washer, .76 x 1.49 x .06

28 736-0231 Flat Washer, .344 x 1.125 x .12

29 736-0242 Bell Washer, .340 x .872

30 741-0245 Hex Flange Bearing, .75 ID

31 741-0309 Flange Ball Bearing, .75 x 1.85

32 741-0475 Plastic Bushing, .38

33 741-0493A Flange Bushing, .80 x .91

34 784-0396 Skid Plate Bracket, 42”

35 784-5038B Slide Shoe

REF.

NO. PART NO. DESCRIPTION

36 711-0469 Spacer, .75 x .125 x .5

37 784-5618 Hex Bearing Housing, 1.0

38 784-0402 Skid Plate

39 618-0123 RH Reducer Housing (Incl. Ref. 57, 58)

40 618-0124 LH Reducer Housing (Incl. Ref. 57, 58)

41 703-2733 Housing Brace Plate

42 710-0642 Self Tapping Screw, 1/4-20 x .75

43 711-1395 Spiral Axle, 41.5”

44 714-0161 Hi-Pro Key, 3/16 x 5/8

45 715-0143 Spring Spirol Pin, .25 x 1.25

46 717-0528 Worm Gear, 20-tooth

47 717-3320 Worm Shaft

48 718-0513 Thrust Collar

49 721-0325 Grease Plug

50 721-0327 Grease Seal

51 736-0351 Flat Washer, .76 x 1.5 x .030

52 736-0369 Flat Washer, .508 x 1.0 x .020

53 736-0617 Thrust Washer, .75 x 1.25 x .0615

54 741-0150 Thrust Bearing, .75 x 1.25 x .078

55 741-0700 Flange Bearing, .75 x 1.0 x .59

56 748-0108 Flange Bearing, .503 x .75

57 741-0661 Flange Bearing, .754 x 1.0 x .925

58 721-0179 Grease Seal

59 754-0330 Lower V-belt

60 756-1181 Drive Pulley, 7”

61 783-1014 Drive Mounting Bracket

62 710-0216 Hex Cap Screw, 3/8-16 x .75

63 717-1714 Right Angle Drive

64 710-0514 Hex Cap Screw, 3/8-16 x 1.0

65 718-0691 Coupling

66 710-3251 Socket Head Cap Screw, 5/16-18 x 1.75

67 712-0431 Flange Lock Nut, 3/8-16

68 714-0122 Square Key, 3/16 x .75

69 714-0126 Hi-pro Key, 3/16 x .75

70 783-1264 Bearing Housing, 1.85 ID

IMPORTANT:

For a proper working machine, use

Factory Approved Parts.

V-belts are especially designed to engage and

disengage safely. A substitute (non-OEM) V-belt can

be dangerous by not disengaging completely.

19

Page 20

MANUFACTURER’S

LIMITED WARRANTY

The limited warranty set forth below is given by MTD

PRODUCTS INC (“MTD”) with res pect to new merchandise

purchased and used in the United States, its possessions

and territories.

MTD warrants this product against defects in material and

workmanship for a per iod of two (2) years commencing on

the date of original purchase and wil l, at its option, rep air or

replace, free of charge, any par t found to be defective in

material or workmanship. This limited warranty shall only

apply if this product has been operated and maintained in

accordance with the Operator’s Manual furnished with the

product, and has not been subject to misuse, abuse, commercial use, neglect, accident, improper maintenance,

alteration, vandalism, theft, fire, water or damage because

of other peril or nat ur al dis as ter. Damage resulting from th e

installation or use of any accessory or attachment not

approved by MTD Products Inc. for use with the product(s)

covered by this manual wil l void your warranty as to any

resulting damages.

Normal wear parts or components thereof are subject to

separate terms as follows: All normal wear part or component failures will be covered on the product for a period of

90 days regardless of cause. After 90 days, but within the

two year period, nor mal wear part failures will be covered

ONLY IF caus ed by defects in mat erial or workmans hip of

OTHER component parts. Normal wear parts and components include, but are not limited to, belts, blades, blade

adapters, grass bags, rider deck wheels, seats, snow

thrower skid shoes, shave plates and tires. Batteries are

covered by a 90-day limited replacement warranty.

HOW T O OBTAIN SERVICE: W arranty service is available,

WITH PROOF OF PURCHASE THROUGH YOUR LOCAL

AUTHORIZED SERVICE DEALER. To locate the dealer in

your area, please check for a listing in the Yellow Pages or

contact the Customer Service Department of MTD PRODUCTS INC by calling 1-800-800-7310 or writing to P.O. Box

368022, Cleveland, Ohio 44136-9722. No product returned

directly to the factory wil l be accepted unless pri or writt en

permission has been extended by the Customer Service

Department of MTD PRODUCTS INC.

b.Routine maintenance items such as lubricants, filters,

blade sharpening and tune-ups, or adjustments such

as brake adjustments, clutch adjustments or deck

adjustments; and normal deterioration of the exterior

finish due to use or exposure.

c. Log splitter pumps, valves and cylinders have a sepa-

rate one year warranty.

d. MTD does not extend any warranty for products sold

or exported outside of the United States of Amer ica,

its possessions and territories, except those sold

through MTD’s au thor ized chan nels of expor t dist ribu-

tion.

No implied warranty, including any implied warranty of

merchantability or fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty or guaranty, whether written or oral,

except as mentioned above, given by any person or

entity, including a dealer or retailer, with respect to any

product shall bind MTD. During the period of the Warranty, the exclusive r em edy i s re p a ir or rep l a ce me n t o f

the product as set forth above. (Some states do not

allow limitations on how long an implied warranty lasts, so

the above limitation may not apply to yo u.)

The provis ions as s et forth in this Warranty provide the

sole and exclusive remedy arising from the sales. MTD

shall not be liable for incidental or consequential loss

or damages including, without limitation, expenses

incurred for substitute or replacement lawn care services, for transportation or for related expenses, or for

rental expenses to temporarily replace a warranted

product. (Some states do not allow the ex clusion or limita-

tion of incidental or consequential damages, so the above

exclusion or limitation may not apply to you.)

In no event shall recovery of any kind be greater than the

amount of the purch ase price of t he p roduct sold. Altera tio n

of the safety features of the product shall void this Warranty. Yo u as s um e th e risk and li ab il i ty for loss, da ma ge, or

injury to you and your property and/or to others and their

property arising out of the use or misuse or inability to use

the product.

This limited warranty does not provide coverage in the

following cases:

a. The engine or component parts thereof. These items

carry a separate manufa cturer’s warranty. Please refer

to the applicable manufacturer’s warranty on these

items.

This limite d warrant y shal l not extend to anyone othe r th an

the original purchaser, original lessee or the person for

whom it was purchased as a gift.

How State Law Relates to this Warranty: This limited

warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Loading...

Loading...