Page 1

OWNER'S GUIDE

ASSEMBLY • OPERATION • MAINTENANCE • PARTS

$1.00

16"

Model Number

ROTARY

110-017R000

MOWER

Important: Read Safety Rules and Instructions Carefully

PRINTED IN U.S.A.

FORM NO. 770-7247E

Page 2

INDEX

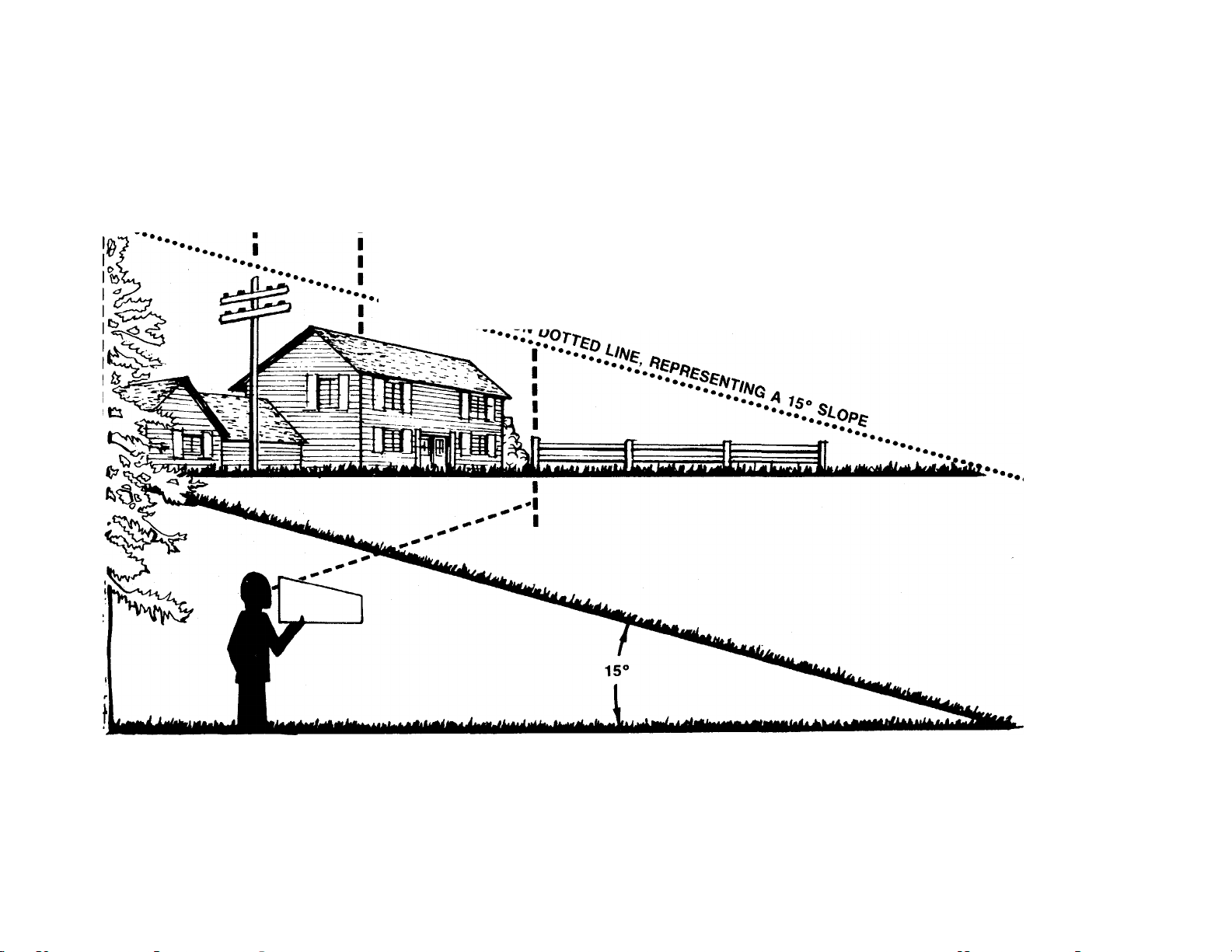

Slope Gauge

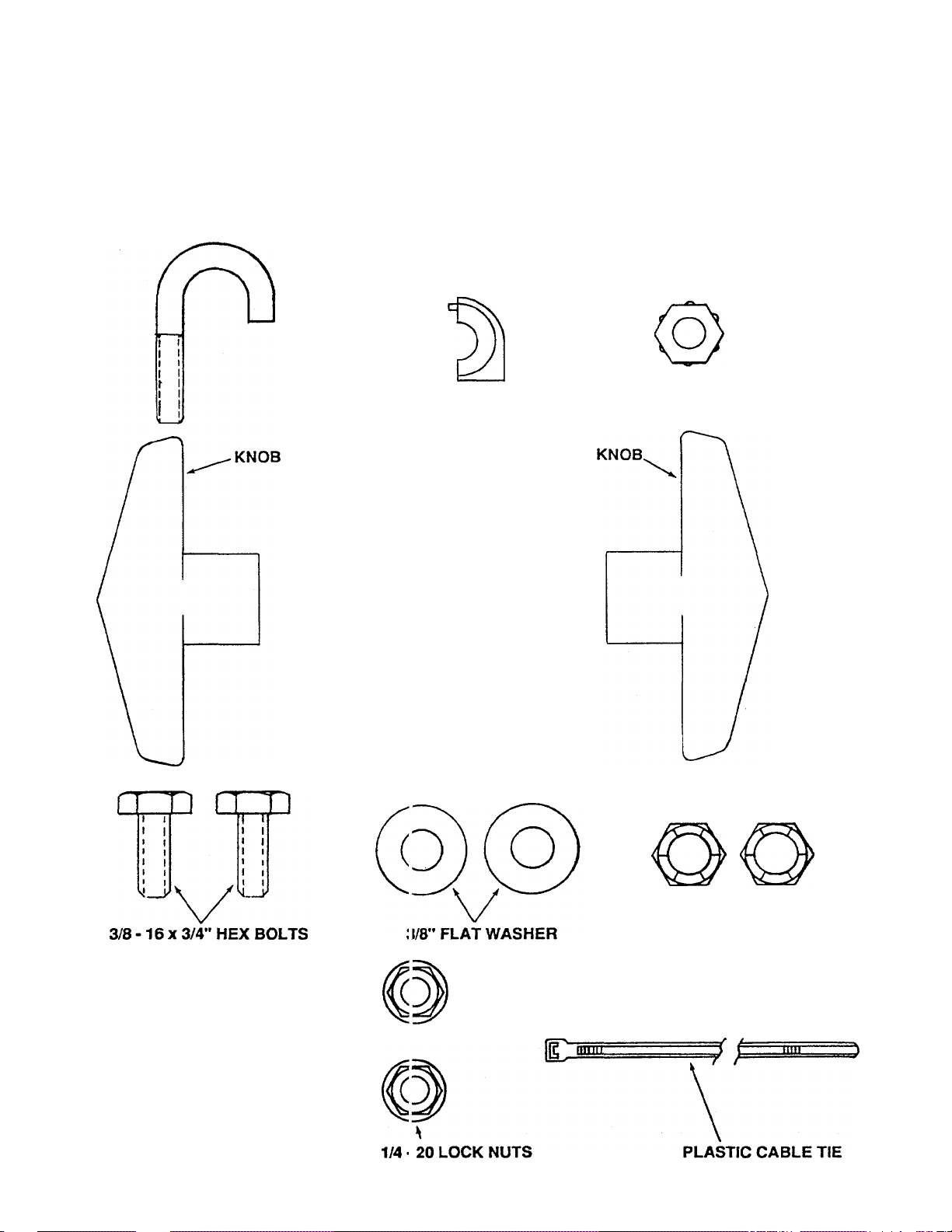

Contents of Hardware Pack

Safety Rules...................................................................5

Assembly........................................................................6

Operation........................................................................7

Maintenance...................................................................9

Service and Adjustments

Storage

Service Recommendations

Trouble Shooting..........................................................13

Replacement Parts

Parts Information

The use of any accessory on this Rotary Mcwer other than those manufactured by the mower manufacturer

is not recommended.

A

..................................................................

...........................................

.............................................

........................................................................

..........................................

..............................................

..........................................

WARNING: To reduce the risk of injury, do not operate mower unless rear trailing shield and guard are in their proper places.

Back Cover

3

4

10

11

12

14, 15

Dear Customer,

So often throughout the year we are all in a

rush to meet our daily obligations.

However, we at MTD Products Inc are tak

ing a quick moment out to say...

“Thank you for your business.”

Sincerely,

MTD PRODUCTS INC

INSTRUCTIONS GIVEN WITH THIS SYM

BOL ARE FOR PERSONAL SAFETY. BE

A

SURE TO FOLLOW THEM.

WARNING: This unit is equipped with an internal combustion engine and should not be used on or near any unim

proved forest-covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with

a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal la\i/s apply on federal lands. A spark arrester for the muffler is available

through your nearest engine authorized serv ce dealer.

Page 3

---------

/

------------------------------------------------------------------------------------

cut Aior Line---------------------------------------------------------------------------------------- ^ —-

USE THIS SHEET AS A GUIDE TO DETERMINE SLOPES WHERE YOU MAY NOT OPERATE SAFELY.

SIGHT AND HOLD THIS LEVEL WITH A VERTICAL TREE

----------------

^

--------------------------------

..................

w

A POWER POLE

A CORNER OF A BUILDING

..

OR A FENCE POST

WARNING

7;

(D

O

•D

in

(n

3T

o

o

5‘

0)

0>

D>

(D

■D

0)

O

<D

O

■i4i

c

f¥

c

<D

•T

<D

<D

-t

O

3

o

<b

CO

"D

O

O

Ac

Do not mow on inclines with a slope in excess of 15 degrees (a rise of approximately 2V2 feet every 10 feet). A

riding mower could overturn and cause serious injury. If operating a walk-behind mower on such a slope, it is

extremely difficult to maintain your footing and you could slip, resulting in serious injury.

Operate RIDING mowers up and down slopes, never across the face of slopes.

Operate WALK-B^HIND mowers across the face of slopes, never up and down slopes.

Page 4

I I

Remove this sheet from your owner’s manual and lay the hardware on the illustration for identification purposes.

After assembly, keep the Slope Gauge which is on the reverse side of this sheet for future use.

HARDWARE PACK CONTENTS

J - BOLT

I

ROPE (iUIDE HALVES 1/4 - 20 HEX NUT

/ \

1

3

CURVED WASHERS

-----

-----Tf

h

\ /

5/16 - 18 X 2" SADDLE BOLTS

V

3/8-16 LOCK NUTS

o

c

>

—I

3"

at

3

<0

(to

1/4 - 20 X 3/4" CARRIAGE BOLTS

Page 5

SAFETY RULES

CAUTION: ALWAYS DISCONNECTSPARK PLUG WIREAND PLACE WIRE WHERE IT CANNOT

CONTACT SPARK PLUG TO PREVENT ACCIDENTAL STARTING WHEN SETTING-UP, TRANS

A

PORTING, ADJUSTING OR MAKING REPAIRS TO YOUR MOWER.

A

IMPORTANT

FEDERAL REGULATIONS REQUIRE OPERATOR PRESENCE BLADE STOP CONTROLS TO MINIMIZE THE RISK

OF CONTACT INJURY. YOUR MOWER IS EQUIPPED WITH SUCH CONTROLS. DO NOT ATTEMPT TO DEFEAT

THE FUNCTION OF THE OPERATOR PRESENCE CONTROL UNDER ANY CIRCUMSTANCES.

TRAINING:

• Read the owner's manual carefully. Becxime familiar with

the controls and know how to operate this mower prop

erly. Learn how to stop the mower quickly.

• DO NOT allow children to use this mower. Never allow

adults to use the mower without proper instructions.

• Keep the area of operation clear of all persons, especially

small children and pets.

• Use the moweronly as the manufacturer intended and as

described in this manual.

• When not using your mower, store it indoors in a dry, high

or locked-up place - out of reach of children.

• DO NOT operate mower if it has been dropped or dam

aged in any manner. Always have damage repaired

before using the mower.

• DO NOT use accessory attachments not recommended

by the manufacturer - it may be hazardous.

PREPARATION:

• Objects struck by the lawn mower will be thrown and can

cause severe injury to persons. Always check the area to

be mowed and clear it of all stones, sticks, wires, bones,

etc.

• Dress properly - Wear only solid shoes when mowing.

Never mow when barefoot or wearing open sandals.

• Always wear safety glasses or eye shields when starting

and while using your lawn mower.

• DO NOT fill gas tank when the engine is running, indoors

or when engine is hot. Allow the engine to cool for several

minutes before filling the gas tank. Clean off any spilled

gasoline before starting the engine.

• Never make wheel height adjustments while the engine is

running.

• Mow only in daylight or good artificial light.

• DO NOT operate mower in wet grass. Always be sure of

your footing - keep a firm hold on the handles and walknever run.

OPERATION:

• DO NOT change the governor settings or overspeed the

engine.

• DO NOT put hands or feet near or under rotating parts.

Keep clear of the discharge opening at all times.

• Stop the engine whenever you leave the mower, before

crossing drives, walks or roads.

• DO NOT continue to run your mower if you hit a foreign

object. Stop the engine, make absolutely sure the blade

and all moving parts have stopped, disconnect the spark

plug wire from the spark plug to prevent accidental

starting, then inspect the mower for damage and repair

before restarting and operating the mower.

• If mower should start to vibrate heavily, stop the engine,

check for the cause and repair. Remember, heavy

vibration is generally a sign of trouble.

• Stop the engine, wait for blade and all moving parts to

stop, before cleaning, unclogging chute, removing grass

catcher, repairing or inspecting the mower. Always

disconnect the spark plug wire and keep away from plug

to prevent accidental starting.

• DO NOT run engine indoors - exhaust fumes are danger

ous.

• Never cut grass by pulling the mower towards you. Mow

grass across the face of slopes, never up and down or you

could lose your footing. DO NOT mow excessively steep

slopes. Use caution when operating the mower on

uneven terrain or when changing direction - maintain

good footing.

• Never operate the mower without proper guards, plates

or other safety devices in place.

MAINTENANCE AND STORAGE:

Check the blade and the engine mounting bolts often to

be sure they are tightened properly.

Check all bolts, nuts and screws at frequent intervals for

proper tightness to be sure mower is in safe working

condition.

Never store mower with fuel in the tank inside a building

where ignition sources are present such as hot water

heater and space heaters, clothes dryers, and the like.

Allow engine to cool before storing in any enclosure.

To reduce fire hazard, keep the engine free of grass,

leaves or excessive grease and oil.

If grass catcher is used with your mower, check it often for

deterioration and wear and replace worn bags. Use only

replacement bags that are recommended by and comply

with specifications of the manufacturer of your mower.

Keep a sharp blade on your mower.

A

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANTSAFETY PRECAUTIONS. IT MEANSATTENTION!!! BECOME ALERT!!! YOUR

SAFETY IS INVOLVED.

Page 6

ASSEMBLY

Your lawn mower has been completely assembled i it the

factory except for the handles and safety chute gu ard.

TO REMOVE MOWER FROM CARTON

• Remove loose parts if included with mower, (i.e.

handles, chute guard, hardware pack, etc.).

• Cut down corners on one end of carton and la^ end

down flat.

• Remove packing material.

• Roll mower out of carton and check carton thor

oughly for loose parts.

HOW TO SET-UP YOUR LAWN MOWER

ATTACH LOWER HANDLE (See Fig. 1)

Your mower handle can be raised or lowered for your

mowing comfort by assembling the lower handle ii i the

desired position. This must be done before yoi as

semble the upper handle.

• Lay upper handle on work surface behind mowe ■ and

position engine cable so it is on the outside of jeck

mounting bracket as shown.

• We recommend attaching the handles in the "H GH"

position. This will put the upper handle approxi

mately 37 inches up from the ground with the wt leels

adjusted in the mid-position. The "LOW" pos ition

measurement is approximately 34 inches.

• Position lower handle in desired position by turning

handle over so desired "HIGH" or "LOW" readi ig is

upwards.

• Attach loosely one leg of lower handle to handle

bracket with 3/8-16 x 3/4" hex bolt, 3/8" flat washer

and 3/8-16 lock nut as shown. Do not tighten.

NOTE: Be sure hex bolt is assembled from outside of

bracket as shown.

• Repeat assembly for opposite side of lower ha idle.

• Now tighten all bolts and nuts securely on both t ides

of lower handle.

Tighten knobs securely.

Secure engine cable to lower handle with plastic tie

(See Fig. 5).

ATTACH STARTER ROPE TO HANDLE (See Fig. 3)

Assemble starter rope to lower handle cross bar, from

eithertop or bottom side as desired, with "J" bolt, two (2)

rope guide halves and 1/4-20 hex nut. Tighten nut

securely with 7/16" wrench.

ATTACH SAFETY CHUTE GUARD (See Fig. 4)

Assemble safety chute guard to mower with two (2) each

carriage bolts and 1/4" locknuts as shown. Tighten nuts

securely with 7/16" wrench.

Position upper handle so operator presence control

bar is on top and assemble to lower handle with

saddle bolts, curved washers and knobs as shown.

A

CAUTION: DO NOT RUN YOUR LAWN MOWER

WITHOUTCHUTEGUARDORAPPROVEDGRASS

CATCHER IN PLACE.

Page 7

OPERATION

KNOW YOUR LAWN MOWER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR ROTARY

MOWER. Compare the illustrations with your Rotary Mower to familiarize yourself with the location

of various controls and adjustments. Save this manual for future reference.

OPERATOR PRESENCE CONTROL BAR

MEETS CPSC SAFETY REQUIREMENTS

Our Rotary Walk-Behind Power Mowers conform to the safety standards of the American National Standards Institute, and

the U.S. Consumer Product Safety Commission. The blade turns when the engine is running.

OPERATOR PRESENCE CONTROL BAR - must be

held down to the handle to start and run the engine.

Release to stop the engine.

STARTER ROPE - used for starting the engine.

PRIMER - pumps additional fuel from the carburetor to

the cylinder for use when starting a cold engine.

Page 8

OPERATION

BEFORE USING YOUR LAWN MOWER, AGi\IN REFER TO THE “SAFETY RULES” AS SHOWN ON PAGE

5 OF THIS MANUAL. ALWAYS BE CAREFUI..

The operation of any Liiwn Mower can result in foreign objects being thrown into the eyes, which can

result in severe eye danage. Always wear safety glasses or eye shields before starting power tool

operation or while perfo rming any adjustments or repairs. We recommend wide vision safety mask for

over spectacles or stardard glasses available at your nearest distributor.

HOWTO USE YOUR MOWER

OPERATOR PRESENCE CONTROL BAR

Your mower has a control barwhich requires the op srator

to be behind the handle to start and run the mower. When

the operator releases the control bar the engine will stop

and an internal brake helps the blade to stop quickly.

When the operator leaves the operating positiDn to

remove the grass catcher, change the cutting heigh t, pick

up sticks or other objects in the way, the engine will stop

automatically when the control bar is released.

ADJUST CUTTING HEIGHT (See Flg.6)

Raise wheels for low cut and lower wheels fo'

cut.

Adjust cutting height to suit your requirements.

Medium position is best for most lawns.

To change cutting height, squeeze adjuster lever

toward wheel. Move wheel up or down to sui: your

requirements. Be sure all wheels are in the same

setting.

high

WARNING: Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attract moisture which leads to separation and formation

of acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before

storage for 30 days or longer. Drain the gas tank, start the

engine and let it run until the fuel lines and carburetor are

empty. Use fresh fuel next season. See Storage Instruc

tions for additional information. Never use engine or

carburetor cleaner products in the fuel tank or permanent

damage may occur.

• TO MIX OIL & GASOLINE - To assure thorough

mixing of oil and gasoline, fill an approved, clean

container with recommended gasoline to one quar

ter full. Add recommended oil per 24:1 mix ratio.

(One gallon of gasoline requires 5 ounces of oil).

• Screw cap tightly on container and shake vigorously.

Then unscrew cap and fill container with gasoline

until fu II. Once oil and gasoline are mixed they will not

separate.

• DO NOT MIX OIL AND GASOLINE DIRECTLY IN'

THE ENGINE FUELTANK. This will allow oil to enter

the carburetor which will cause engine to be inopera

tive.

BEFORE STARTING ENGINE

OIL & GAS MIXING

• Use a clean, high quality 2 cycle oil. DO NOT use

multi-viscosity oils. Such oils may not provide ade

quate lubrication and additives in the oil may cause

fouling of the spark plug resulting in difficult oi non

starting of the engine. DISREGARD THE Ml KING

INSTRUCTIONS ON THE OIL CONTAINER. Follow

the instructions below.

• Use fresh, clean, unleaded automotive gasDiine.

(Leaded gasoline and oil mix can be used). DO NOT

USE PREMIUM OR HIGH OCTANE GASOLNE.

TO START ENGINE

• Connect spark plug wire to spark plug.

• PRIME ENGINE (See Fig. 5 on page 7) A. To start a new engine, or one that has run out of

fuel, push primer 12 to 15 times to fill fuel lines and

carburetor. Use firm full pushes.

B. To start a cold engine which has been run

previously, but not emptied of fuel, push primer 1 time

using a full push.

C. To start a warm engine, priming is not usually

necessary. (If engine does not start after three pulls

of the starter, push primer 1 time using a full push).

• Hold operator presence control bar down to the

handle and pull starter handle quickly. Do not allow

starter rope to snap back.

• To "STOP" engine, release operator presence con

trol bar.

NOTE: In cooler weather it may be necessary to use 2

pushes and repeat priming steps between pulls. In

warmer weather over priming may cause flooding and

engine will not start. If you do flood engine wait a few

minutes before attempting to start and DO NOT repeat

priming steps.

Page 9

OPERATION

MOWING TIPS

• Under certain conditions, such as very tall grass, it

may be necessary to raise the height of cut to reduce

pushing effort and to keep from overloading the

engine and leaving clumps of grass clippings.

• For extremely heavy cutting, reduce the width of cut.

MAINTENANCE

CAUTION: DISCONNECT SPARK PLUG WIRE

FROM SPARK PLUG AND PLACE Wl RE WH ERE IT

A

GENERAL RECOMMENDATION

• Once a year you should replace the spark plug, air

• Follow the Service Recommendation Schedule on

CANNOT COME IN CONTACT WITH THE SPARK

PLUG BEFORE PERFORMING ANY MAINTE

NANCE OR ADJUSTMENTS.

filter, and check blade for wear. A new spark plug

and air filter assures proper air-fuel mixture and

helps your engine run better and last longer.

page 12.

Cutting in a counterclockwise direction, starting at

the outside of the area to be cut, spreads grass

dippings more evenly and puts less load on the

engine. To keep clippings off of walkways, flower

beds, etc., make the first cuts in a clockwise direc

tion.

Pores in cloth grass catchers (optional accessory)

can become filled with dirt and dust with use and

catchers wilt collect less grass. To prevent this,

regularly hose catcher off with water and let dry

before using.

• Use block of wood to hold blade and tighten bolt

clockwise. The recommended torque is 35 - 40 ft.

lbs.

NOTE: The bolt used to secure the blade to engine is

specially heat treated. Do not substitute (See Repair

Parts).

CAUTION: A LOOSE BLADE CAN BE DANGER

A

Use only an original manufacturer's replacement blade to

get the best cutting results.

OUS AND MAY MAKE THE ENGINE HARD TO

START.

MOWER

BLADE CARE

Your mower will work better with a sharp blade.

TO REMOVE BLADE (SEE FIG. 7):

• Turn mower on its side. Make sure air filter and

carburetor are up.

• Use a block of wood between blade and mower

housing to prevent blade from turning when bolt is

removed. Protect your hands with gloves and/or

wrap Wade with heavy cloth.

• Remove blade bolt by turning counterclockwise.

Use a 9/16" box or open-end wrench.

NOTE: Check the blade bolt lock washer at each

removal for damage and replace if necessary. The lock

washer should be replaced after every three (3) blade

removals to insure proper tightness.

TO REPLACE BLADE (SEE FIG. 7):

• Make sure key is in slot in crankshaft.

> Put blade adaptor on engine crankshaft.

Fit blade in adaptor. Be sure trailing edge of blade is

up towards engine.

• Assemble retainer plate, lock washer (undamaged)

and blade bolt.

NOTE: We do not recommend sharpening the blade - but

if you do, be sure blade is balanced.

TO SHARPEN BLADE:

• The blade can be sharpened with a file or on a

grinding wheel. Do not attempt to sharpen while on

the mower.

Page 10

MAINTENANCE

• Careshouldbetakentokeepthebladebalanced. An

unbalanced blade will cause excessive vib ation

when running and eventual damage to mower and

engine.

• To check blade balance, drive a nail into a beam or

wall. Leave about one inch of the straight nail

exposed. Place center hole of blade over the head

of the nail. If blade is balanced, it should rema n in a

horizontal position. If either end of the blade moves

downward, blade is not balanced. Sharpen the

heavy end until the blade is balanced.

ENGINE

SPARK PLUG

Change your spark plug each year to make your engine

start easier and run better. Set spark plug gap a .025

inch.

AIR FILTER

Your engine will not run properly and may be damaj led by

using a dirty air filter.

Replace the air filter every year, more often if you n low in

very dusty, dirty conditions. Do not wash air filter, -liters

are available at your nearest Tecumseh Dealer.

CLEANING

CAUTION: DISCONNECT SPARK PLUG WIRE

FROM SPARK PLUG AND PLACE WIRE WH ERE IT

A

• Clean your mower and engine often to keep build-up

• Turn mower on its side with carburetor up.

• Clean the underside of your mower by scraping to

NOTE: We recommend that you clean the underside of

your mower after each use. We DO NOT recommend

using a garden hose to clean mower unlessthe electrical

system, muffler, air filter and carburetor are covered to

keep water out. Water in engine can result in shortening

engine life.

CANNOT COME IN CONTACT WITH THE SPARK

PLUG.

of trash from accumulating around engine. A

clogged engine runs hotter and shortens engine life.

remove build-up of grass and trash.

SERVICE AND ADJUSTMENTS

TO ADJUST HANDLE HEIGHT

See "ATTACH LOWER HANDLE" in assembly sec (ion of

manual.

TO ADJUST CUniNG HEIGHT

See "ADJUST CUTTING HEIGHT' in operation section

of manual.

CARBURETOR

Your carburetor has a non-adjustable fixed main jet for

mixture control. If your engine does not operate properly

due to suspected carburetor problems, take your mower

to a authorized Service Center for repair and adjus tment .

ENGINE SPEED

Your engine speed has been factory set. Do not attempt

to increase engine speed or it may result in personal

injury. If you believe that the engine is running too fast or

too slow, take your mower to an authorized Service

Center for repair and adjustment.

REAR TRAIL SHIELD

The reartrail shield, attached between the rear wheels of

your mower, is provided to minimize the possibility that

objects will be thrown out the rear of the mower into the

operator mowing position.

If the shield becomes damaged, it should be replaced.

10

Page 11

STORAGE

"^our mower and engine should be prepared for off-

jeason storage as follows:

MOWER

• Clean underside of mower housing (See "CLEAN

ING" in maintenance section of manual).

• Inspect and replace/sharpen blade, if required (See

"BLADE CARE" in maintenance section of manual).

• Lubricate as shown in Service Recommendation

chart on page 12 of manual.

HANDLE (See Fig. 8)

You can fold your mower handle for storage as shown.

• Loosen the two (2) hand knobs on sides of the handle

and fold upper handle as shown.

CAUTION: When folding handle for storage or transpor

tation, be careful not bend or kink the engine control

cable.

ENGINE

Drain fuel and run engine until fuel system is empty.

IMPORTANT: IT IS IMPORTANT TO PREVENT GUM

DEPOSITS FROM FORMING IN ES

SENTIAL FUEL SYSTEM PARTS

SUCH AS CARBURETOR, FUEL FIL

TER, FUEL HOSE, OR TANK DURING

STORAGE. ALSO, EXPERIENCE

INDICATES THAT ALCOHOL

BLENDED FUELS (CALLED GASOHOL OR USING ETHANOL OR

METHANOL) CAN ATTRACT MOIS

TURE WHICH LEADS TO SEPARA

TION AND FORMATION OF ACIDS

DURING STORAGE. ACIDIC GAS

CAN DAMAGE THE FUEL SYSTEM OF

AN ENGINE WHILE IN STORAGE.

OTHER

• Do not store gasoline from one season to another.

• Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline can cause prob

lems.

• Do not store your mower under any plastic cover.

Plastic cannot breathe which allows condensation to

form and cause your mower to rust.

A

CAUTION: NEVER STORE THE LAWN

MOWER WITH GASOLINE IN THE TANK

INSIDE A BUILDING WHERE FUMES MAY

REACH AN OPEN FLAME OR SPARK.

ALLOW THE ENGINE TO COOL BEFORE

STORING IN ANY ENCLOSURE.

11

Page 12

SERVICE FIECOMMENDATIONS

SERVICE RECORD

Fill in Dates as you complete regu

lar service

Blade Replaced

Blade Lock Washer Checked/

Replaced (See "BLADE CARE")

Air Cleaner Replaced

Spark Plug Replaced

Lubricate Mower

Cleaning

Grass Catcher (if applicable)

Muffler

SCHEDULE

Every

25

Hours

v/

v/

v/

v/

Every

SERVICE DATES

Use

v/

- CHECK

LUBRICATION

ENGINE

Your mower has a 2-cycle engine. The engine is II bricaled

by the oil you mix with the gasoline.

WHEEL ADJUSTERS

Use a spray lubricant on the wheel adjuster pivoi bolt.

SPRAY LUBRICANT HERE

WHEELS

DO NOT oil or grease the wheel bearings. Viscous lubri

cants will attract dust and dirt that will shorten the ife of the

self-lubricating wheel bearings. If youfeelthewhoels must

be lubricated, use only a dry, silicon type lubricant spar

ingly.

12

Page 13

TROUBLE SHOOTING POINTS

PROBLEM

Does not start 1. Dirty Air Filter.

Loss of Power

Poor cut ■ Uneven

CAUSE

Out of fuel.

2.

3. Stale fuel.

4. Spark plug wire is disconnected. 4.

5. Bad spark plug. 5.

6. Water in fuel. 6.

Improper mixture of gasoline and oil.

7.

8. Loose blade.

Operator Presence Control Bar in released

9.

position.

Operator Presence Control Bar defective.

10.

1. Cutting too much grass. 1.

2. Dirty Air Filter. 2.

Build-up of grass, leaves and trash under

3.

mower.

Worn, bent or loose blade. 1.

1.

Wheel heights uneven. 2.

2.

Build-up of grass, leaves and trash under

3.

mower.

CORRECTION

1.

Replace Air Filter

2.

Fill fuel tank.

3.

Drain fuel tank and refill with mixture

of fresh gasoline and oil.

Connect wire to spark plug.

Replace spark plug.

Drain fuel tank and refill with mixture

of fresh gasoline and oil.

7.

Drain fuel tank and refill with proper

mixture of gasoline and oil.

8.

Tighten blade bolt (Check lock washer).

9.

Depress Operator Presence Control

Bar.

10.

Replace Control Bar.

Set in "Higher Cut" position.

Replace Air Filter.

3.

Disconnect spark plug wire and clean

underside of mower housing.

Replace blade. Tighten blade bolt.

Set all wheels at same height.

3.

Disconnect spark plug wire and clean

underside of mower housing.

Too much Vibration

Starter Rope

Hard to Pull

Hard to Push

1. Worn, bent or loose blade. 1.

Bent engine crankshaft. 2.

2.

Engine brake is on when Operator

1.

Presence Control Bar is released.

2. Bent engine crankshaft. 2.

3. Blade dragging in grass. 3.

1. High grass or cutting height too low.

Rear of mower housing/blade dragging

2.

in heavy grass.

Handle height position not right for you. 3.

3.

2.

Replace blade. Tighten blade bolt.

Contact authorized Service Department.

1.

Depress Operator Presence Control

Bar to upper handle before pulling

on starter rope.

Contact authorized Service Department.

Get over low grass and/or hard surface

to start engine.

1.

Raise cutting height.

Raise cutting height.

Adjust handle height to suit.

13

Page 14

Model 017R

14

Page 15

Model 017R

PARTS LIST FOR MODEL 017R ROTARY MOWER

.EF.

NO.

1

706-13897-28

PART

NO.

CODE DESCRIPTION

N Hex Bolt 3/8-16 X 1-3/4" 30 747-0779

REF.

NO.

Lg-

2

706-14499-00-90

3 706-11872-01 N

4

710-0258

Plate Assembly 32 17098

N

Int. L-Wash. 1/4" I.D.

Hex Bolt 1/4-20 X 5/8" 34

Lg*

5

706-11785-06

6

706-13863-01

7

706-13815-01 N Housing—Brake Spring 38 706-13831-01-91 N

706-13865-02

8

N Screw #6-20 X 3/8 Tapping 36

N Contact—Brake Arm 37 706-10488 N

Spring—Brake Arm

N

9 706-13806-02 N Brake Arm & Pad 40

Assembly

10

706-15829

11

712-0430

12

706-10778-01 N

13

706-10777-01

14

706-13915

N FI-Wash. 3/8" I.D. 42

L-Nut 3/8-16 Thd. 43

Spacer Ring 44

Spacer

N

N

Wire Assembly—Brake

Arm

15

706-10005

16

712-0429 L-Nut 5/16-18 Thd. 49 738-0102

17

706-14487-00-14 N

18

706-13988

19

706-13856

20

706-16118

21

706-10004 N Key—Woodruff #6 53 720-0190

706-13807-01-05

.3

706-13813-00-08 N Blade—16" Gas 55

24

706-10110-00-05

25

736-0217 L-Wash. 3/8" I.D.

26

710-0152 Blade Bolt (Special)

27

706-13840-00-90 N

28

706-10007-20-09 N

N FI-Wash. 5/16" I.D. 48 706-15581-00-90 N

Deck Assembly—16" Steel

N Key—Square 5/32 x 1/2"

N Pulley—Brake 51

N Set Screw 5/16-18 x 3/8" 52 732-0404

N

Adapter Blade Mtg.

N Plate—Blade Retainer 56

Control—Handle

Hex Bolt 1/4-20 x 1-1/4"

Lg.

29

712-0324 L-Nut 1/4-20 Thd. 60

PART

NO.

31

706-10786

33 706-13816

706-10065-01

35

706-10072-32-09

706-10057-01

39

706-14486-01-91

706-10067-01

41

706-10007-10-09 N

706-10685-02-90

706-10684-02-90

710-0216

45 706-15491-01-90

46 731-1027

47

710-0134

50 706-15533-09 N

—

706-15533-10 N

738-0507B

54 15262B

15261A

736-0105

57

736-0356

58 712-0798

59

706-11909 N

706-10003-01

CODE

N

N

N

N

N

N

N

N

N

N

N

DESCRIPTION

J-Bolt (Rope Guide)

Rope Guide Half (2 Req’d.)

Clip—Trail Shield

Control Cable—Brake

Plastic Tie

Saddle Bolt 5/16-18 x 2"

Saddle Washer

Knob Assembly

Upper Handle

Lower Handle

Fl-Wash. 3/8" I.D.

Hex Bolt 1/4-20 x 1/2" Lg.

R.H. Handle Bracket

L.H. Handle Bracket

Hex Bolt 3/8-16 X 3/4" Lg.*

Safety Chute Guard

Safety Trail Shield

Carriage Bolt 1/4-20 x 3/4"

Hub Cap

Wheel Bolt

Front Wheel—6"

Rear Wheel—7"

Pivot Bolt—Adjuster

Lever—Adjuster

Knob—Adjuster Lever

Pivot Arm—Adjuster

Plate—Height Adjuster

Bell-Wash. 3/8" I.D. x 7/8"

O.D.

Bell-Wash. 3/8" I.D. x

1.13" O.D.

Hex Nut 3/8-16 Thd.*

Flange Lock Nut 1/4-20

Keps Nut 1/4-20

*For faster service obtain standard nuts, bolts and washers locally.

If these items cannot be obtained locally, order by part number and

size as shown on parts list.

NOTE

Specifications subject to change without notice or

obligation.

15

NOTE: The engine is not under warranty by

the mower manufacturer. . .If repairs or

service is needed on the engine, please

contact your nearest author

ized engine service outlet.

Check the “Yellow Pages” of

your telephone book under

"Engines—Gasoline.”

Find It Fast

In The

Yellow Pages

Page 16

PARTS INFORMATION

POWER EQUIPMENT PARTS AND SERVICE

Parts and service are available through the authorized service firm s listed

below. All orders should specify the model number of your urit, part

numbers, description of parts and the quantity of each part re :|uired.

BRIGGS AND STRATTON, TECUMSEH AND PEERLESS PARTS AN'

SERVICE

Briggs & Stratton, Tecumseh and Peerless parts and service should b.,

handled by your nearest authorized engine sen/ice firm. Check the yellow

pages of your telephone directory under the listing Engines—Gasoline,

Briggs & Stratton or Tecumseh Lauson.

NOTE: If any parts are found to be missing or de ective upon assembly of this unit, write to advise the factory so that

immediate replacement can be made.

ARKANSAS NORTH LITTLE ROCK

Sutton’s Lawn Mower Shop............ 5301 Roundtop Drive

CALIFORNIA PORTERVILLE

Billious ............................................. 75 North D Street

COLORADO DENVER

Spitzer Industrial Products Co. .. 6601 N.

FLORIDA JACKSONVILLE

Radco Distributors

Small Eng. Dist................................. 7995 W. 26th Court. . . 33016

ILLINOIS LYONS

Keen Edge Co

INDIANA ELKHART

Parts & Sales Inc.............................. 2101 Industrial Pkwy.

IOWA DUBUQUE

Power Lawn & Garden Equip.. . . 2551 J.F. Kennedy

MARYLAND BELTSVILLE

Center Supply Co

MASSACHUSETTS SPRINGFIELD

Morton B. Collins Co

MICHIGAN MOUNT CLEMENS

Power Equipment Dist

MINNESOTA PLYMOUTH

Hance Distributing Inc

MISSOURI EARTH CITY

Oscar Wilson Engine & Parts ... 4159 Shoreline Dr

Automotive Equip. Service

NEW YORK CARTHAGE

Gamble Dist., Inc

..........................

.......................................

..............................

.......................

....................

.............

...............

..................................

Box 368, Rt. 4

Washington St

4909 Victor St.

Box 5459 ......................... 32207

HIALEAH

8615 Ogden Ave

Box 277

6802 Industrial Dr.

#208

..................................

300 Birnie Ave.....................01107

340 Hubbard .......................48043

12795 16th Ave. North .55441

KANSAS CITY

3117 Holmes St

West End Ave.

Box 389

.................

_______

................

...........

...........................

..................

..........

...........

............................

72117

93257

80229

60534

46516

52001

20705

63045

..64109

13619

NORTH CAROLINA

Dixie Sales Company

OHIO

Stebe’s Mid-State Mower Supply

Bleckrie, Inc

National Central...............................

Burton Supply Co............................

PENNSYLVANIA

EECO Inc

Bluemont Co

Frank Roberts & Sons

Scranton Auto Ignition Co

TENNESSEE

Ace Distributors...............................

Chilton Air Cooled Engine

TEXAS

Marr Brothers, Inc

UTAH

Powered Products...........................

VIRGINIA

RBI Corp

WASHINGTON

Equip. Northwest.............................

WISCONSIN

Wisconsin Magneto Inc

PUERTO RICO

Island Distribution Center

.....................................

..........................................

.........................................

......................

....................................

....................

..............

..............

...........................

................

............

BROWNS SUMMIT

5920 Summit Ave.............27214

CARROLL

Box 366, 71 High St

CLEVELAND

7900 Lorain Ave

WADSWORTH

687 Seville Rd..................44281

YOUNGSTOWN

1301 Logan Ave.

Box 929

HARRISBURG

4021 N. 6th St

PITTSBURGH

11101 Frankstown Rd. .15235

PUNXSUTAWNEY

R.D. 2

SCRANTON

1133-35 Wyoming Ave. . 18509

KNOXVILLE

2103 Magnolia

NASHVILLE

319 4th Ave. S

DALLAS

423 E. Jefferson

SALT LAKE CITY

1661 N. Beck St

ASHLAND

101 Cedar Ridge Dr. . . .23005

SEATTLE

1410 14th Ave

MILWAUKEE

4727 N. Teutonia St. . . .53209

RAMEY

102 N. St

...........................

...................

................................

..................

..................

..................

..........................

____

...............

...............

...............

43112

44102

44501

17110

15767

37917

3721'^

7520.

84116

98122

00604

WARRAN Y PARTS AND SERVICE POLICY

The purpose of warranty is to protect the customer from defects in workmanship and materials, defects which are NOT detected at the time

of manufacture. It does not provide for the unlimited and i nrestricted replacement of parts. Use and maintenance are the responsibility of the

customer. The martufacturer cannot assume responsibility ior conditions over which it has no control. Simply put, if it’s the manufacturer’s fault,

it’s the manufacturer’s responsibility; if it’s the customer’ i fault, it’s the customer’s responsibility.

CLAIMS AGAINST THE MANUFACTURER’S WARRANTY

INCLUDES:

1. Replacement of Missing Parts on new equipment.

2. Replacement of Defective Parts within the warranty period.

3. Repair of Defects within the warranty period.

MTD PRODUCTS INC

P.O. BOX 360900

All claims MUST be substantiated with the following

information:

1. Model Number, Serial Number and/or Date Code of unit in

volved.

2. Date unit was purchased.

3. Date of Failure.

4. Nature of Failure.

CLEVELAND, OHIO 44136

(0689)

Loading...

Loading...