Page 1

OPERATING MANUAL

and PARTS LIST

i -- 7/

MODEL 10710-0

21 INCH

REEL MOWER

0611-704

Page 2

IMPORTANT

RULES FOR SAFE OPERATION

Your Mower is a precision piece of power equipment. Engineering skill and experience have

been combined to provide the ultimate in safety and efficiency. As with any type of power

equipment, carelessness or error on the part of the operator can result in injury. Exercise

extreme caution at all times.

1.

KNOW YOUR MACHINE — Read the Owner's Manual carefully — learn how

to operate your mower properly.

2.

MAKE SURE THE LAWN IS CLEAR of sticks, stones, wire and other hazardous

items before mowing. Such items are dangerous to both the mower and

individuals in the vicinity of the mower.

3.

ADD FUEL BEFORE STARTING ENGINE—never when engine is hot or running.

4.

KEEP AREA OF OPERATION CLEAR of all persons, particularly small children

and pets.

5.

DISENGAGE ALL BLADE AND DRIVE CLUTCHES so equipped before starting

engine.

6.

ALWAYS STOP ENGINE and disconnect sparkplug wire before making cut

ting height adjustments.

7.

CHECK ALL NUTS, BOLTS, AND SCREWS occasionally to be sure mower is

in good operating condition.

8.

NEVER OPERATE EQUIPMENT IN WET GRASS. Always be sure of your

footing; keep a firm hold on the handle and walk, never run.

9.

ALWAYS CHECK FOR DAMAGE if you should strike some foreign object

with the blade while moving, stop your mower. Inspect for and repair

any damage before restarting and operating the mower.

1 0 .

STOP THE ENGINE when you leave the equipment. Make certain the blades

and all moving parts have stopped.

11.

WHEN MOWING A TERRACE, slope or incline, mow lengthwise. DO NOT

mow up or down. Be careful when turning to avoid slipping.

Page 3

PREPARING YOUR MOWER FOR USE

UPPER HANDLE

HANDLE COVER

LOWER HANDLE

SET-UP

To assemble the handle to the chassis — place the lower handle through the opening in the left hand end plate

and slip it over the 1/2 in. dia. trunnion. While holding the stand-up handle latch open — press the right hand

side of the lower handle toward the center of the mower until it will fit into the opening in the end plate —

place handle through the opening and slip it over the 1/2 dia. trunnion.

With the lower handle section in operating position the upper handle can now be loose assembled to the lower

section with the nuts and bolts provided. Fit handle cover in place as shown and tighten bolts securely.

Page 4

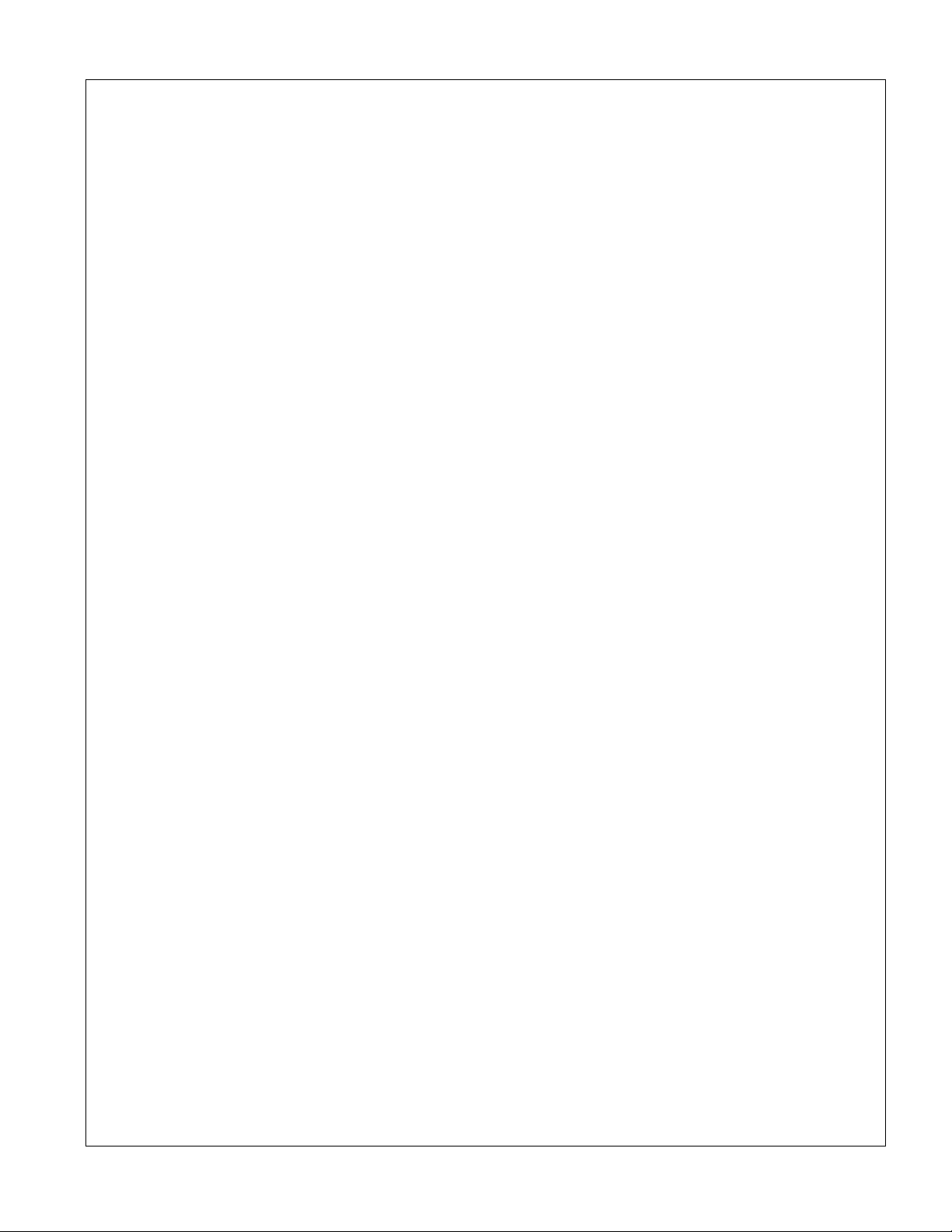

BEFORE STARTING ENGINE

1. Remove oil fill plug (Fig. 2). Place mov/er level

and fill engine crankcase to top of oil plug with

S.A.E. No. 30 oil. Tilt mower to make sure oil

flows completely into crankcase. Replace fill plug

and tighten.

2. The air cleaner protects the engine against grit

and dirt. CAUTION, an extremely dirty air cleaner

element may cause engine to stall.

SEE ENGINE INSTRUCTION MANUAL FOR PROPER

AIR CLEANER MAINTENANCE.

3. Fill tank with good grade regular, clean fresh gas

oline. DO NOT MIX OIL with gasoline.

FOR COMPLETE ENGINE INFORMATION READ ENGINE

INSTRUCTION BOOKLET FURNISHED WITH YOUR

MOWER BEFORE STARTING OR OPERATING.

TO ADJUST HEIGHT OF CUT

TO START ENGINE

1. Place handle in neutral position with handle down.

2. Set throttle control in start position.

3. Pull starter rope with a smooth, quick full stroke

once. Move throttle lever to run positipn. Pull

starter rope again.

4. When engine starts move throttle lever to an idle

position until the engine warms up.

BREAK-IN PERIOD

1. During first 10 hours of operation check frequently

the following:

* Oil level in engine crankcase.

* Belt adjustment on engine to jackshaft drive.

(Page 6)

* Check all bolts, nuts and screws for tightness.

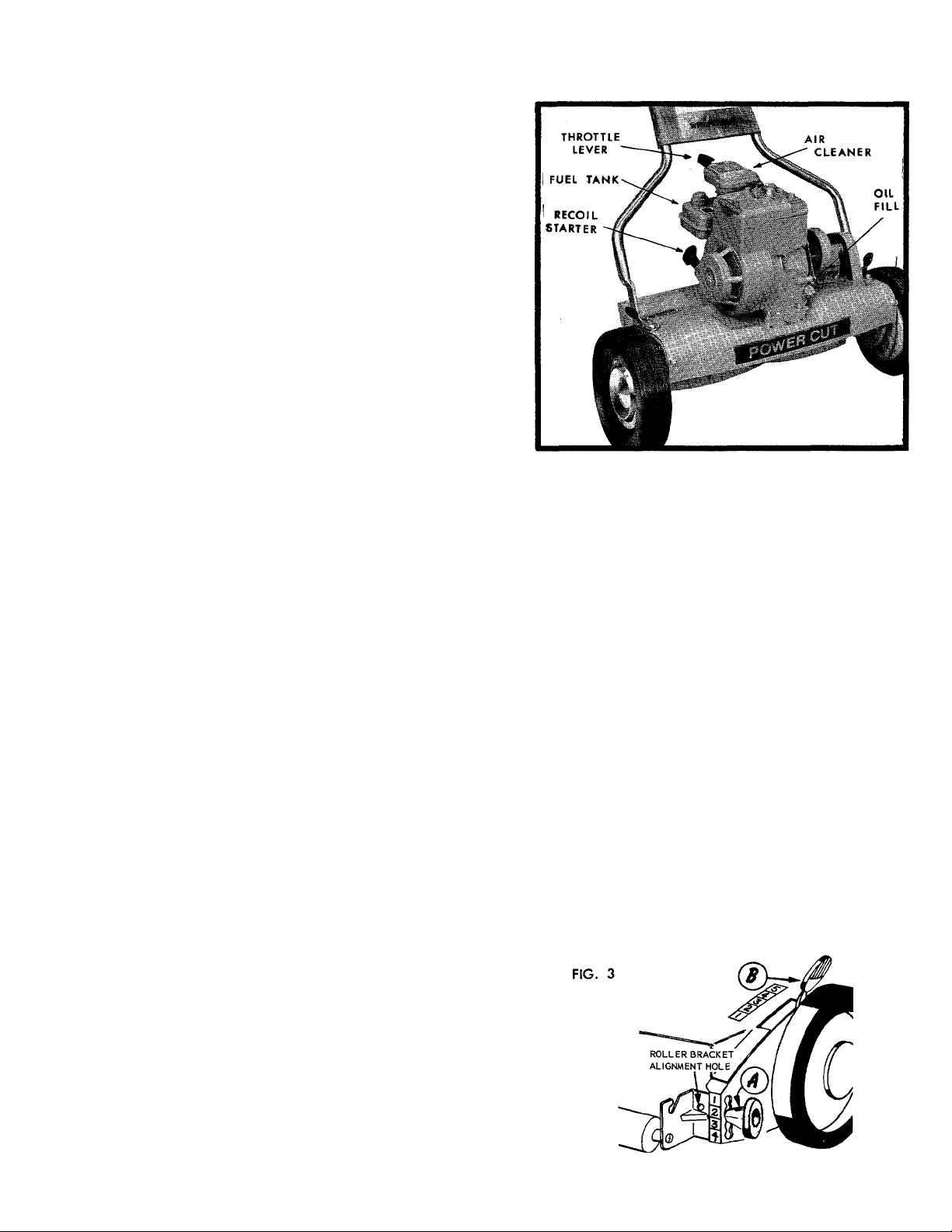

1. Consult the chart located on Page 5, (Fig. 3A) and

Fig. 3 shown below. The roller adjusting knobs (A)

and wheel adjusting levers (B) must be in positiotrs

shown for desired cutting height. EXAMPLE: for

1 '/2" cutting height roller knob must be in No. 2

position, and wheel lever must be in No. 4 position.

(Fig. 3 and Fig. 3A)

2. Place mower on hard, flat surface and tilt machine

back on roller until wheels are off the ground. Move

right hand wheel lever outward to disengage locat

ing pin, then move lever forward or back until it is

aligned with proper number on deck label. Release

outward pressure on lever and be sure that locating

pin seats properly in hole in end plate. Repeat this

procedure on left hand side, position lever so that

mower is level.

3. Tilt mower forward until roller is off the ground.

Turn right hand roller knob counter clockwise 2 full

turns and move knob up or down until alignment

hole in roller bracket is in line with proper number

on label at rear of end plate, (see illustration)

Turn knob clockwise until tightened securely. Repeat

this procedure for other side.

OPERATING INSTRUCTIONS

TO PROPEL MOWER FORWARD, simply raise the han

dle .. . TO STOP MOWER, lower the handle.

Page 5

”f/lsr-S£r"mim

H E I G H T C O N T R O L *

ROLLER BRACKET»'

ALIGNMENT HOLE

7)1

CUTTING

HEIGHT

IN INCHES

2> /4

--- -------

2

------------

® (D

13 /4 ---- ------

1 ’/ 2

----------

iVi

------

1

-------

j/ 4----------

*Reg. T.M. Pat. opplied for.

QUALITY OF CUT

Since a reel type mower does not create a lifting action

like a rotary mower, it CANNOT lift up and cut tall

blades of grass that are bent over. If cutting height

is set too high, grass of this nature will not be in posi

tion to be drawn between the reel blades and cutter

bar and in many cases will be pushed away by the

revolving reel. Therefore, to obtain the utmost in per

formance and laWn appearance, cutting height ABOVE

W2" IS NOT RECOMMENDED except where grass is up

right and dense.

FIG. 3A

CUTTER BAR ADJUSTMENT

(Fig. 4) Cutter Bar bolts (2 & 3) are tapered and extend

beyond the side plate slightly. When these tapered

bolts are tight any end play or looseness is eliminated.

Be sure these bolts are tight before making adjust

ments.

TO TIGHTEN CUTTER BAR

Turn hex adjusting nut counterclockwise.

TO LOOSEN CUTTER BAR

Turn hex adjusting nut clockwise.

SERVICE INSTRUCTIONS

ALWAYS REMOVE SPARK PLUG WIRE BEFORE MAKING

ADJUSTMENTS

WITH ENGINE RUNNING.

Check your mower frequently to make sure all parts

are operating smoothly. Your mower left the factory

properly adjusted and properly lubricated to assure

you of a smooth clean cutting job. Keep it clean. The

mower should be thoroughly cleaned and lubricated at

the start of each mowing season for better operation

and longer service life.

DO NOT use water to clean the mower—use a broom

or brush to remove grass and dirt. When storing mow

er for any length of time, follow storage instructions in

engine instruction booklet.

CHECKING AND ADJUSTING CUTTER BAR

CLEARANCE

When properly set, the cutter bar should almost contact

the reel blades. Only on very fine grass should the reel

blades touch the cutter bar, and then very lightly so

that only a slight scraping noise is heard.

It's easy to check proper cutter bar clearance — just

place a piece of newspaper about 2" wide and 6"

long, between reel blades and cutter bar — See Step

2. Correct cutter bar clearance should pinch but not

cut, the paper at both ends and the middle of the

cutter bar. If it doesn't adjust as follows;

-------

NEVER MAKE ANY ADJUSTMENTS

REEL AND CUTTER BAR PAPER TEST

1. Insert strip of newspaper between cutter bar and

reel blades.

2. Torn reel slowly backwards. If the paper is held

snugly by each blade then adjustment is correct.

3. Adjust cutter bar so that reel blades pinch paper

without cutting it.

SERVICE

1. Sharpening is required when the mower will not

cut satisfactorily without the reel blades wiping on

the cutter bar.

SEE PAGE 12 ON HOW TO OBTAIN SERVICE AND

REPLACEMENT PARTS.

NOTE:

When cutter bar is removed for sharpening, left hand

pivot bolt (Item 2 fig. 5) must be turned counter clock

wise to be removed. Right hand pivot bolt on right

hand side of mower must be turned clock-wise.

Page 6

IMPORTANT

Your mower has been designed with a stand-up han

dle (See instructions on Pg. 7). Make sure the mower

handle is in the stand-up position before attempting

the following adujstments.

TO ADJUST CHAIN DRIVE

1. Loosen 4 engine mounting bolts and pull engine

back.

2. Loosen 4 jackshaft mounting bolts and pull jack

shaft assembly back to tighten chain. Allow Vs

inch of slack in the chain, tighten mounting bolts

and nuts securely.

3. Pull engine forward until the belt is tight then

tighten the 4 engine mounting bolts securely.

TO ADJUST RELT DRIVE

1. Check chain — if necessary adjust as described

above (To Adjust Chain Drive).

2. If the chain does not need adjusting — loosen the

4 engine mounting bolts and with the handle in

the stand-up position pull the engine forward until

the belt is tight, then retjghten the 4 engine mount

ing bolts securely.

3. Lower handle to neutral position. Disconnect spark

plug wire and fasten to the engine approx. 1-1/2

inches from the sparkplug. With a slow smooth

motion pull the starter rope a few times — watching

closely to see if the belt moves with the engine pul

ley. If the belt does move then a slight adjustment

of one or two turns (counterclockwise) of the ad

justment screw at the back of the jackshaft assem

bly must be made. CAUTION: Remember the han

dle must be in the stand-up position before making

the adjustment.

4. Repeat Step 3 if necessary until a good disengage

ment of the belt (neutral position) is obtained, then

while holding the adjustment screw — tighten the

adjustment screw locknut.

fir

JACKSHAFT ASS'Y\ ^^TG BOLTS

OPERATING^;//

POSITION

NEUTRAL

POSITION

LUBRICATION

1. Change engine oil (crankcase) after first 5 hours of

operating. See engine operating instructions.

2. Check air cleaner frequently.

3. Reel bearings require no attention until mower is

serviced.

4. Check jockshaft oiler cup frequently, oil at begin

ning or mowing season and as needed. Oil roller

shaft once or twice a year or as needed.

5. Lightly lubricate with engine oil, points indicated

on roller and between end plates and wheel dust

covers. Periodic lubrication at these points, will

insure smooth mechanical operation.(Fig. 8)

Page 7

STAND-UP HANDLE

1. There's no storage problemi with the stand-up

handle.

2. Move handle latch on the end plate in and move

handle to upright position. To transport mower in

car, remove handle from chassis for more conven

ient handling. CAUTION^ Always remove spark

plug wire before attempting to lift the mower.

STORAGE

Store your mower in a clean, dry place and keep clean

to serve you well. If stored for a length of time, the en

gine should be drained of fuel. This will prevent the

forming of gum deposits on essential parts in the car

buretor fuel line and tank, which might affect the effi

cient operation of your engine when again used.

»N

DATE

DESCRIPTION

Page 8

ALL UN-NUMBERED PARTS

INTER-CHANGEABLE WITH

OPPOSITE SIDE.

Page 9

PARTS LIST

MODEL 10710-0

When ordering parts listed as L.H. or R.H.—determine the left or right

hand side of your mower by standing behind the unit as you mow.

Do not use Reference Numbers when ordering Repair Parts, always use Part Numbers.

REF.

NO. PART NO.

1511-18

1

2 1540-59

1112-19-69

3

4

1530-6

2135-21-69

5

1548-5

6

7 2121-2-69

8 1530-20

9 1629-28

10 104

11 106

12 3

2674-26

13

1509-86

14

15 142

16 141

17 1108-95-40

1110-30-40

18

2619-34

19

1652-52

20

425

21

22 109

23 323

24

1118-9-69

1631-26

25

1540-55

26

1629-41

27

1657-19

28

2643-18

29

41-028

30

NAME OF PART

Screw (10-32 X % Phillips)

Washer—Roller

Spacer Tube Assembly —

* Rivet (3/16 X %)

Reel Assembly

Rollpin

Sprocket, Anti-Wind Cup &

Hub Ass'y

*Rivet (3/16 X 13/32)

Retainer

Felt Washer

Felt Retainer

Bearing

Hub Cap______________________

Screw Cutter Bar L. H. Thd.

*Cotter Pin (Vs X %)

Washer

Wheel and Tire Assembly

Drive Wheel & Bearings Less Tire

Tire ______________________________

Bearing___________________________

Pinion Gear—L.H.

Felt Washer

Pawl _____________________________

Gear Housing—L.H.

Axle

_____________________________

Washer

Retainer

Bushing

Knob-Wheel Adjust

Nut ______________________________

______________

_____________

______________

____________________

__________________

_____________

_____________________

___________________

------------------------------

______________________

_____________

______________________

____________

-------------------------------

---------------------------------------

----------------------------

__________________________

_________________________

__________________________

-----------------------------

REF.

NO. PART NO.

31 1117

1129-207-69

32

33 1723-1

1129-208-69

34

1624-138

35

1118-8-55

36

1657-23

37

38 428

1539-31

39

40 1156-6

1513-40

41

42

453

455

43

3134-23-69

44

1622-50

45

1643-23

46

2132-44-69

47

1529-25

48

49 1548-7

1632-58

50

1645-37

51

52 2658-13

2132-45-69

53

1540-43

54

1650-21

55

1509-38

56

1155-14

57

1616-119

58

59 1534-8

2624-112-69

60

NAME OF PART

*Screw (10-32 X % Sems)------------------------

End Plate with Trunnions—L.H. _—

Scraper ----------------------------------------------

End Plate with Trunnions—R.H. ___

Spacer

_______

Gear Housing—R.H. ------------------------------

Nylon Bushing -------------------------------------

Pinion Gear—R.H.

Trunnion

Bolt ________________________

Screw _____________

Screw Cutter Bar—R.H. Thd.

Cutter Bar Assembly __ _ ^

Dust Cover

Roller Adjust Knob

Roller Bracket Assembly—L.H. —

*Bolt (5/16-18 X %)

Rollpin

----------------------Roller Shaft

Trunnion _ Roller

_____________________________

Roller Bracket Assembly—R.H. ^—

Washer—Special

Retaining Ring

*Screw (#10-32- X % Hex Hd.) —

Spring & Trunnion Assembly

Roller Adjust Label

*Nut (10-32 Gripco)

Spacer—End Plate _

-

-------------------------------

-----------------------------

___________ _________

___

____

___________

-------------------

--------- -------------------------------

-------------- -----------

___________________

-----------------------

________________________

_____________ -...................

----------------------------------

-----------

-------------------------

-------------------

__________________

___________________

------------- -----------

.......

____

___

—

-

-

*Standard Hardware Item—Purchase Locally.

Page 10

Page 11

PRICE LIST

MODEL 10710-0

When ordering parts listed as L.H. or R.H.—determine the left or right

hand side of your mower by standing behind the unit as you mow.

Do not use Reference Numbers when ordering Repair Parts, always use Part Numbers.

REF.

PART NO.

NO.

1

2 70

3 1025

1529-11

4

5 1724-8

1509-69

6

1651-20

7

1508-13

8

9 1626-40-69

10 1548-11

2120-34-69

11

1540-17

12

1511-9

13

1540-55

14

3639-51-69

15

2102-144-69

16

3601-122-69

17

1652-1

18

19 1691-2

20 1632-26

1546-2

21

1654-2

22

1638-16

23

1036

24

1538-16

25

1113-13

26

1650-10

27

1547-3

28

29 1624-122

1642-82-69

30

2609-322-69

31

2624-164

32

1511-36

33

1616-114

34

1650-37

35

2610-14

36

2705-25-69

37

NAME OF PART

Engine—Briggs & Stratton

Model 60102-Type 0136-01

*Nut (5/16-18 Hex)

*Lock Washer (5/16) —

*Bolt (5/16-18 X 1% Carriage)

Keeper—Belt Upper — ----------------------------

*Screw (14-20 x 1% Fillister Hd.) —

"V" Belt (4L X 18")

*Set Screw (5/16-24 x 7/32)

Pulley

_________________ __________

Rollpin -------------

Pulley Assembly —_

*Washer (% x 15/16)

Screw (10-32 x ’/2 Sems) ------------------------Washer ____________________________

Belt Guard . _ - — — — -

Jackshaft Housing, Bearings

& Oiler Assembly

Jackshaft Housing

Bearing

_____

Oiler

________

Jackshaft

Pin

______:_____________

Chain

____ ___

Sprocket

Washer

_________ __________________

Nut (7/16-20 Hex Jam)

Connector Link

Retaining Ring ______________________

Pin________________________________

Spacer

___

Spring

-----------

Bracket—Striker

Spacer—Adjust --------Screw—Adjust

Label—Wheel Adjust

Retaining Ring ______________________

Adaptor .

Lever—Throttle Control

____________________

-------------------- -------

......................

_____________

---------------------

------

---------------------------

-----------------------------

------------------------------

_________________

.............. ....

—

--------------------

-

------------------------------

------------------------- -----------------

____________________

______ -------------------- -----------

------------

_____________________

_________________________

------

-----------------------------

_____________________

--------- ----------------

-------------------—---------

-----------------------------

_______ ___

— —

--------------- ---------

___

............

— —

___

_______

-----

--------

--------

----------------

REF.

NO. PART NO.

2643-41

38

1652-12

39

1534-8

40

1650-36

41

1625-24

42

1616-280

43

67

44

1018

-

- -

-

-

45

2616-493

46

3609-82-69

47

41-028

48

1513-18

49

1513-41

50

2705-26

51

52 3639-48-69

1513-8

53

117

54

55 1020

1605-563

56

57 1545-23

1547-4

58

2627-21

59

2642-51

60

1097

61

5690-10-69

62

1529-15

63

4117-95-01

64

3712-18-01

65

1509-22

66

3622-126-69

67

1538-8

68

1710-8

69

2616-492

70

1624-69

71

1724-10

72

1606-48

73

1616-449

74

1616-441

75

1616-442

76

NAME OF PART

Knob—Throttle Control

Wave Washer

*Nut (10-32 Hex Lock)

Retaining Ring

Link—Throttle Control ----------------------- —

Label—Throttle Control

*Nut (’/4-20 Hex)

*Lockwasher (’/4) ------------------------------ -

Label—Deck

Bracket

*Nut (5/16-24 Hex Lock Gripco) —

Bolt (5/16-24 Hex Shoulder Bolt) -

Bolt (5/16-24 X ¥4 Hex Hd.)

Lever — __________________________ -

Guard......................... —

*Bolt (5/16-24 X '/2 Hex Hd.)

*Screw (10-32 X % Phillips Hd.) —

*Screw (6 X V4 Rd. Hd.) _

Name Plate Clevis Pin

Cotter Pin

Latch

Spring - -------------- -------------------------- —

*Washer (3/16)

Deck

Bolt ('/4-10 X %)

Handle—Upper Section _ ----------------- -

Handle—Lower

Bolt (’/4-20 X 1% Hex Hd.)

Cover—Handle

Nut (14-20 Hex Lock)

Grip—Handle

Label—Handle Cover

Spacer

Lower Belt Keeper

Belt Keeper Bracket

Label—(Neutral-Caution)

Label—(Drive-Neutral)

Label—Lower Handle

____________________

----

________________ _________

--------------- ----------------------

______

______

------ ----------

---------

-----

_____________ ______

--------- ----- -------------------------------

--------------------------

_________________

---------------------------------

---------------------

______________________

---------------

-

-

-

--------------------------------------

-----------------------------------

_____________________

_______________ ______

______________________

--------------------

____________

-------------_____________

-----------------------

--------- ---------------

--------------------------

-----------------------------

_____________

________________

_________________

-------------- --------------

-------------------------

------------------------

---------------------------

-----------------------

----------

—

-

—

-

-

.

—

*Standard Hardware Item—Purchase Locally.

n

Loading...

Loading...