Page 1

Page 2

Page 3

THE OWNER

DELIVERY SERVICE

SERVICE MANUAL INFORMATION

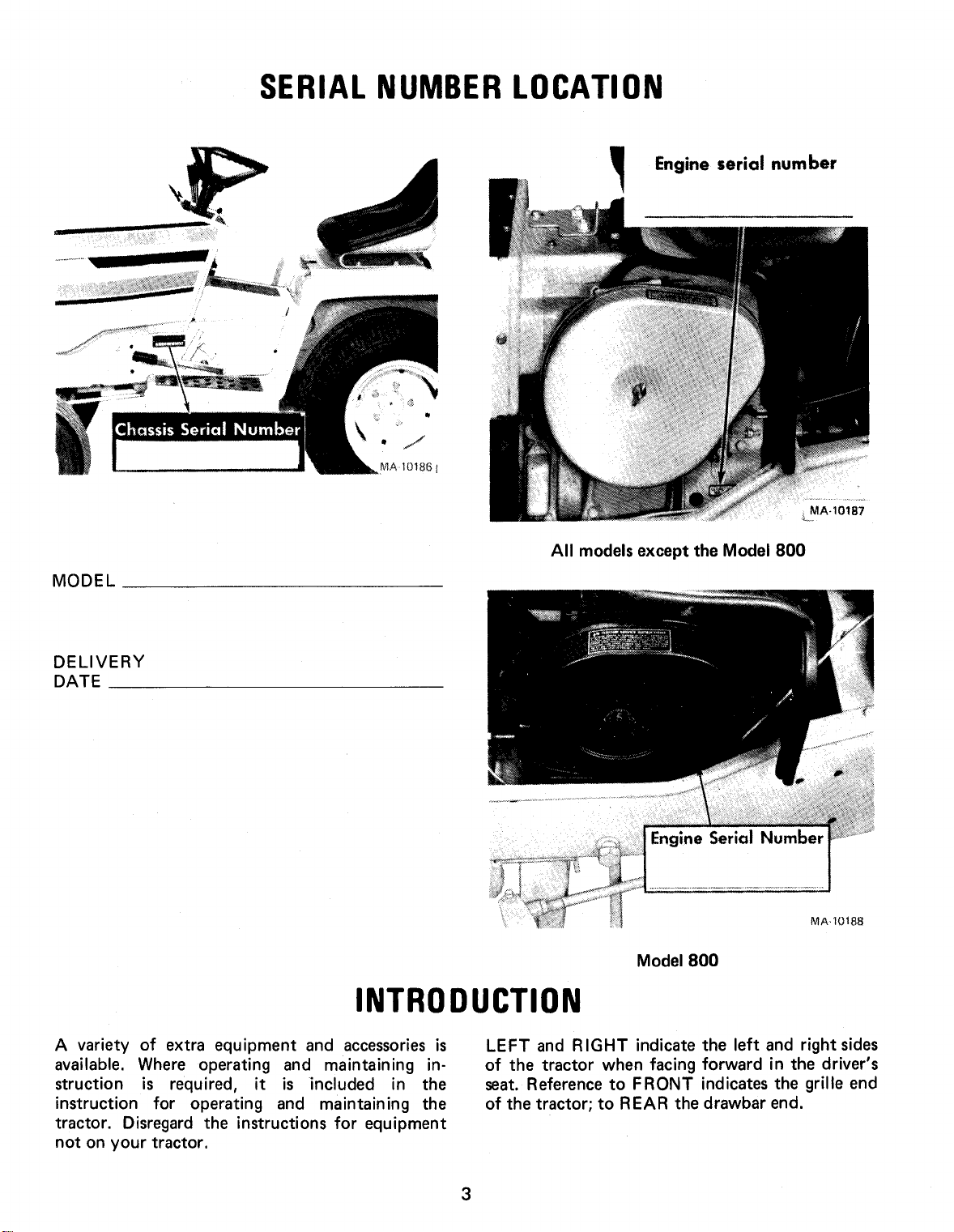

SER1AL NUMBER LOCATION

nside Cover

1,2

3

I nternational Cub Cadet 1250, 1450,

and 1650 Tractors

Brake pedal

Speed control lever

Starting the tractor

Release lever

Stopping,the tractor

EGUIPME'NT LIFT HANDLE

14

INTRODUCTION

WO'RK SAFELY-FOllOW THESE

RULES

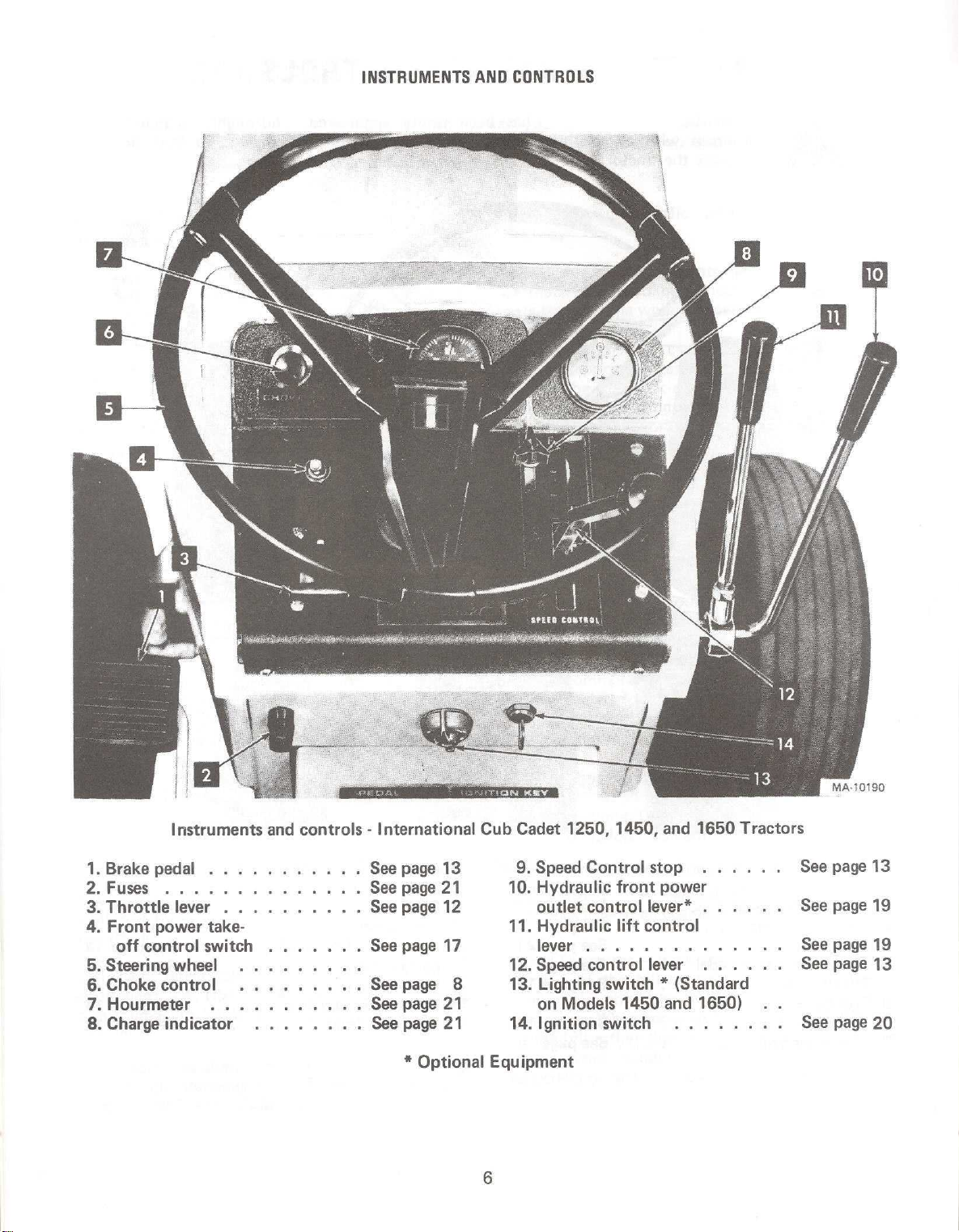

INSTRUMENTS AND CONTROLS

aEFOREOPERATING YOUR NEW

TRACTQ,R:

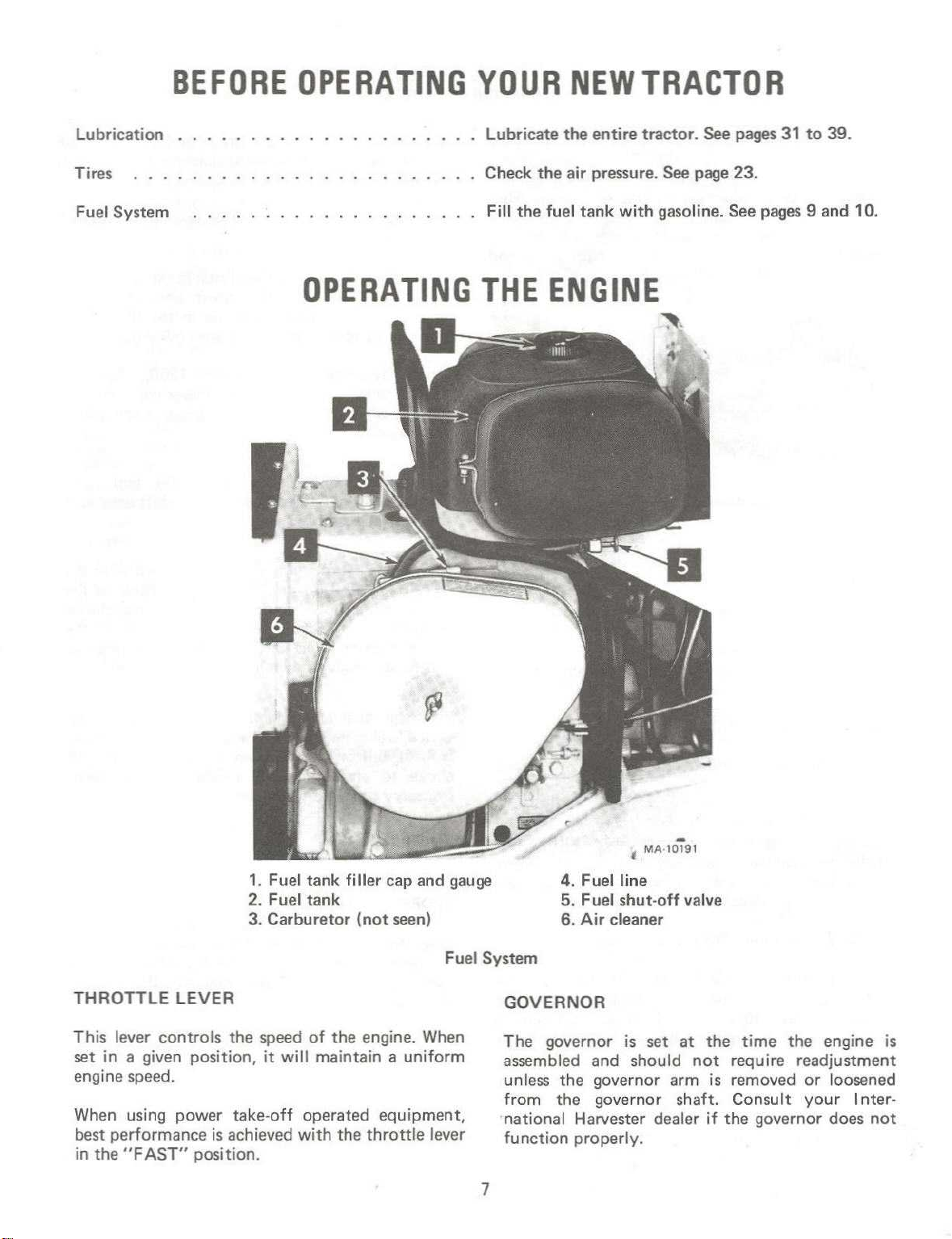

OPERATING THE ENGINE

Throttle lever

Governor

Lifting, the hood

Starting the engine

Stopping the engine

FUEL SYSTEM

Fuel shut-c.ff valve

Carburetor adjustments

4

5,6

7

7,8:

9 10

,

Height adjustment

HITCHING EOU1PMENT TO THE

TRACTO'R

0 raw bar

Three-point hitch

REAR POWER TAKE-OFF

0 peratrng the rear power

take-off wrth the tractor

standing sti II

Operating the rear power

take-off with the tractor

in motion

FRONT POWER TAKE-OFF

Operating the front power

take-off clutch

Adjusting the power take-off

clutch

15

17

THE TRACTOR

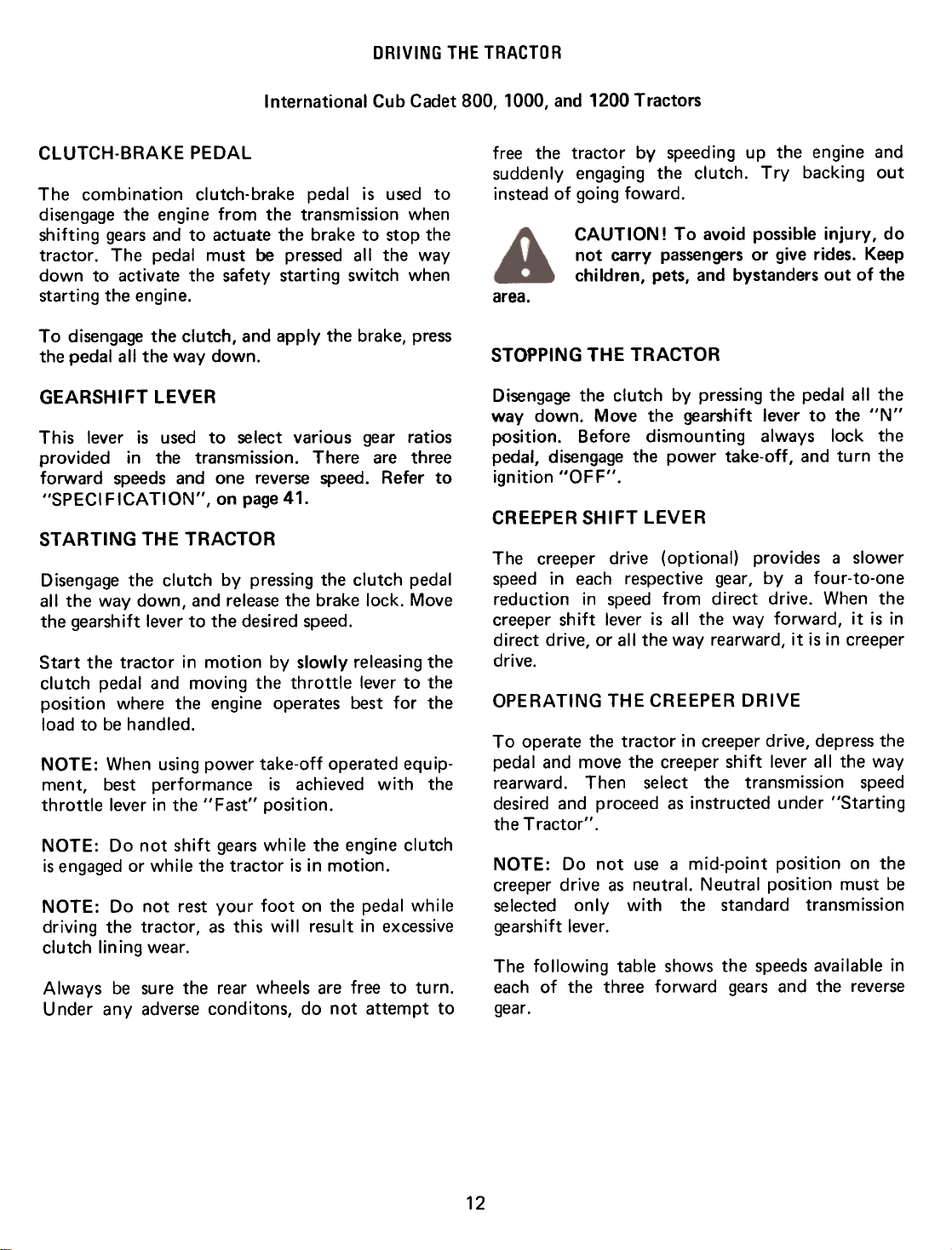

Adjusting the seat

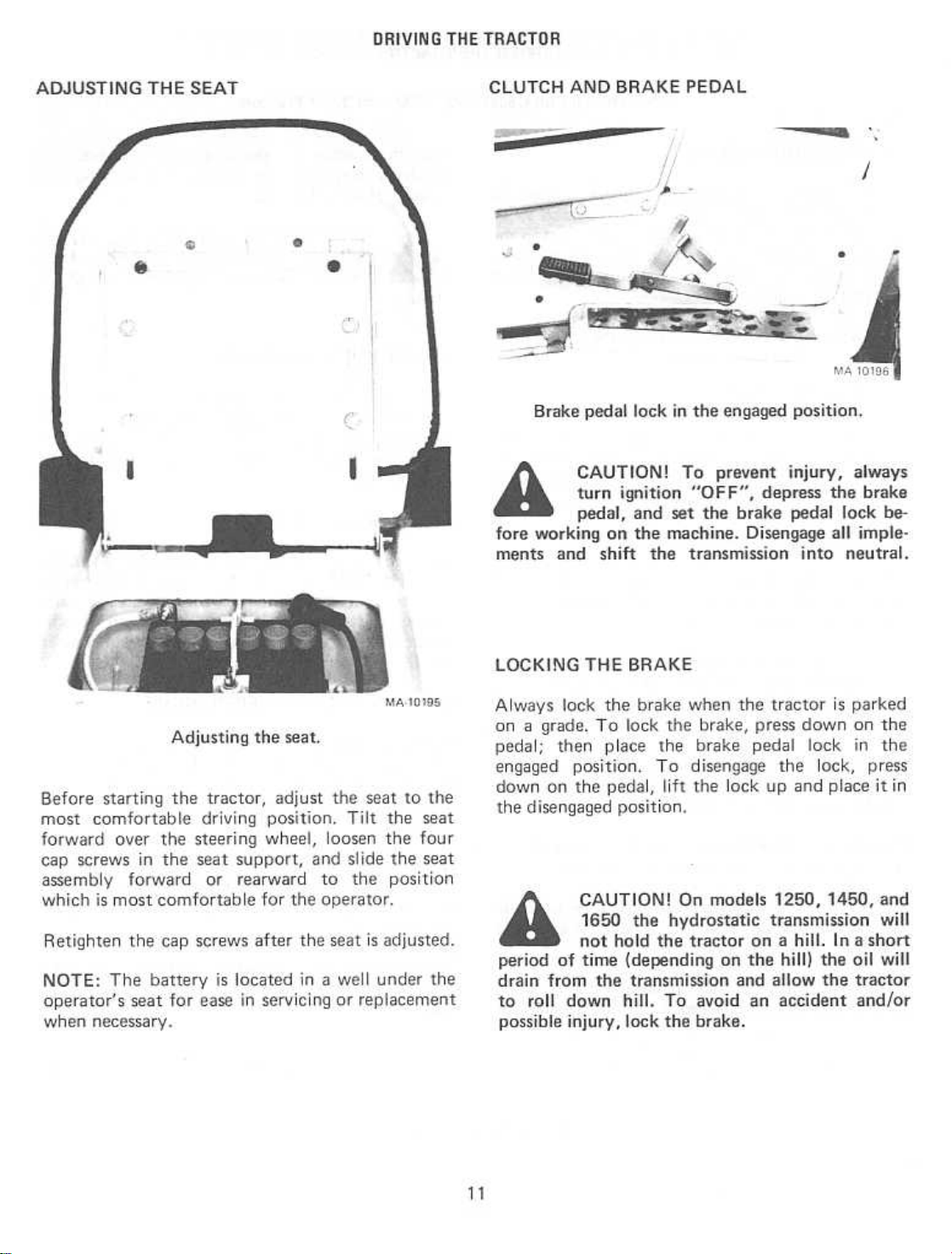

Clutch and brake pedal

Locking the brake

International Cub Cadet ROO, 1000,

and 1200 Tractors

Clutch-brake pedal

Gearshift lever

Starting the tractor

Stopping the tractor

Creeper shift lever

Operating the creeper drive

TO

I

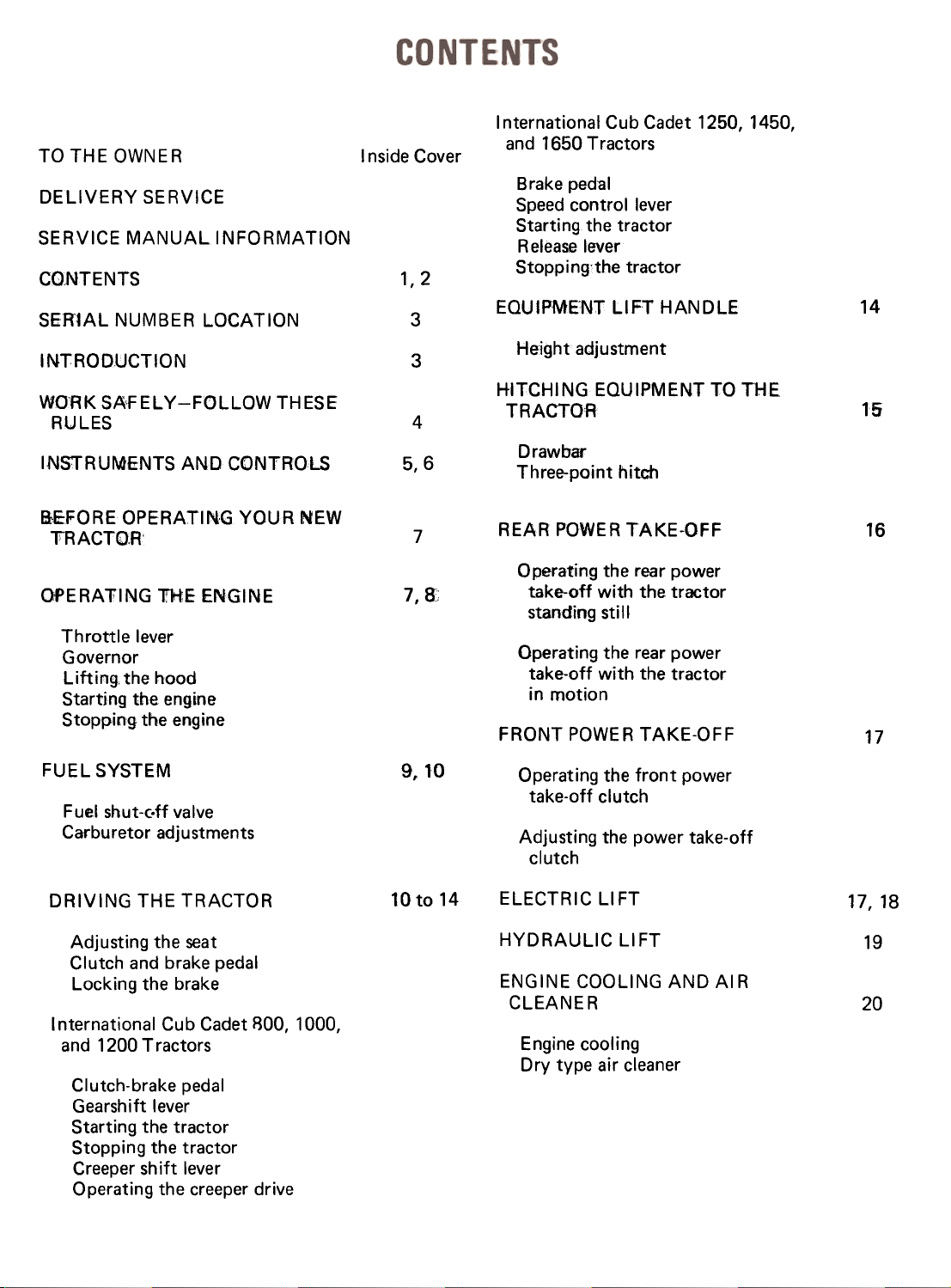

CONTENTS

3

16

DRIVING

10 to 14

ELECTRIC LIFT

HYDRAULIC LIFT

ENGINE COOLING AND AI R

CLEANER

Engine cooling

Dry type air cleaner

17, 18

19

20

Page 4

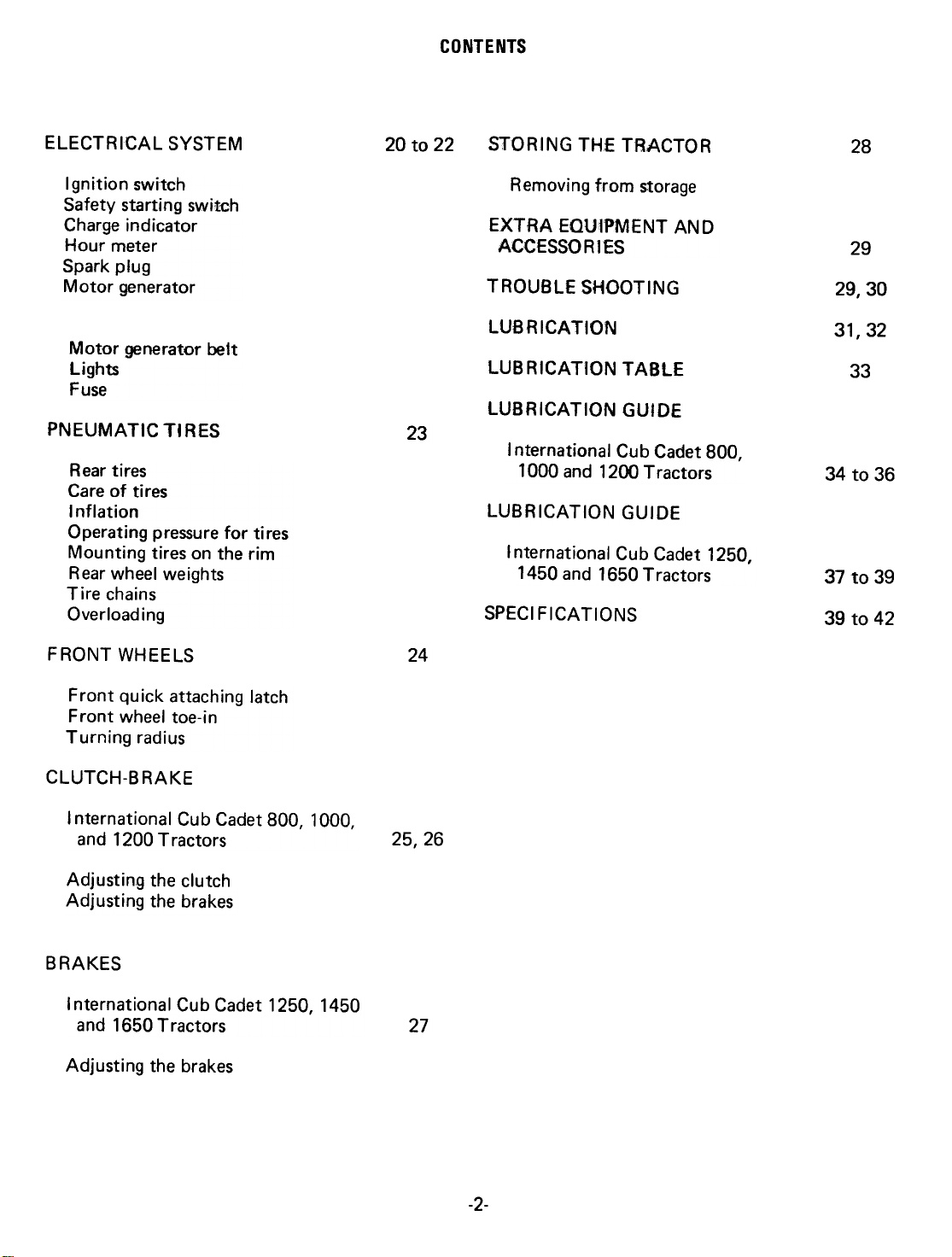

CONTENTS

ELECTRICAL SYSTEM

Ignition swrtch

Safety starting switch

Charge indicator

Hour meter

Spark plug

Motor generator

Motor generator belt

lights

Fuse

TIRES

Rear tires

Care of tires

Inflation

Operating pressure for tires

Mounting tires on the rim

Rear wheel weights

Tire chains

Overloading

23

STORING THE TRACTOR20 to 22

Removing from storage

EXTRA EOU1PMENT AN D

ACCESSO R 1 ES

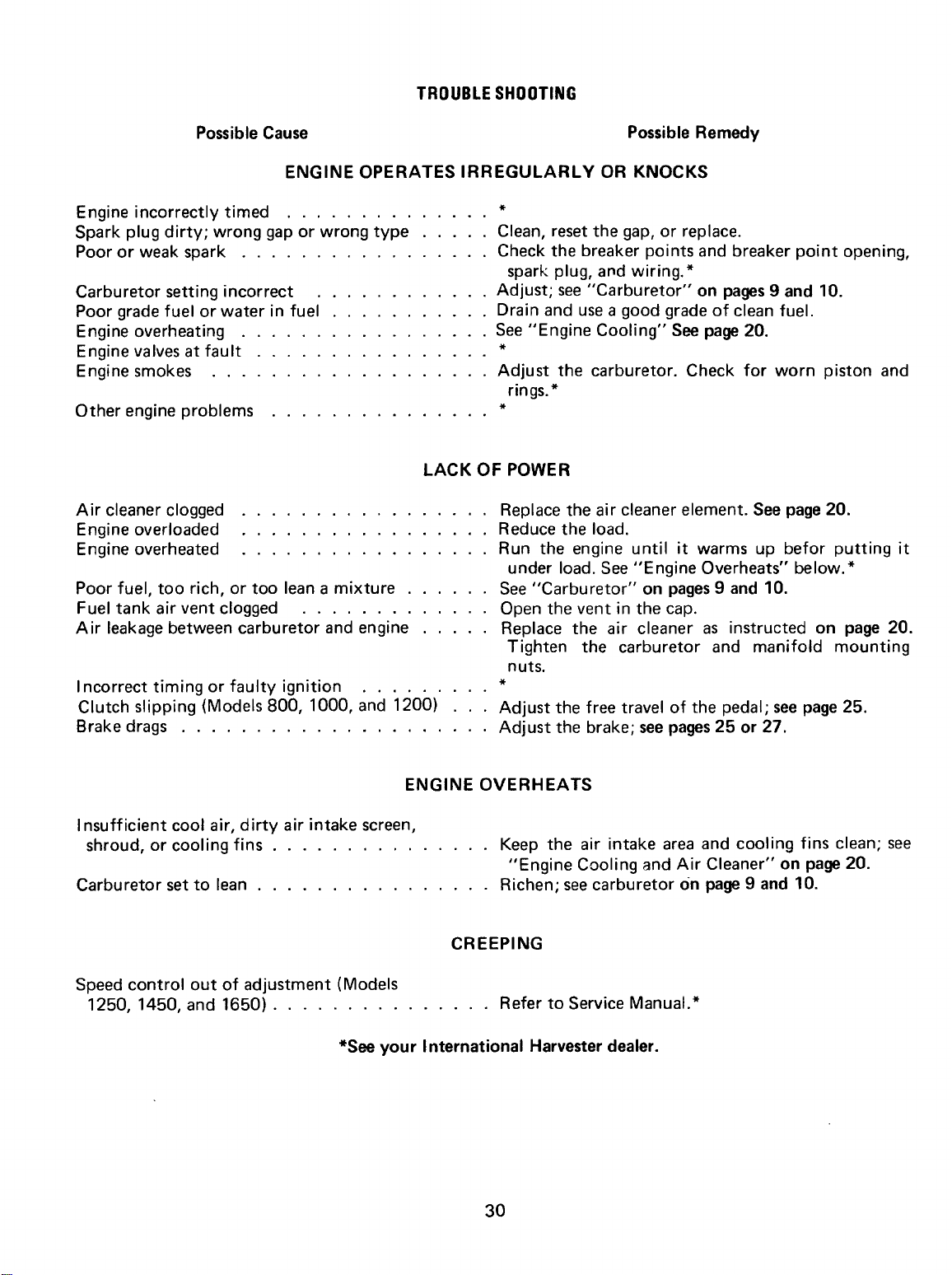

TROUBLE SHOOTING

LUBRICATION

LUBRICATION TABLE

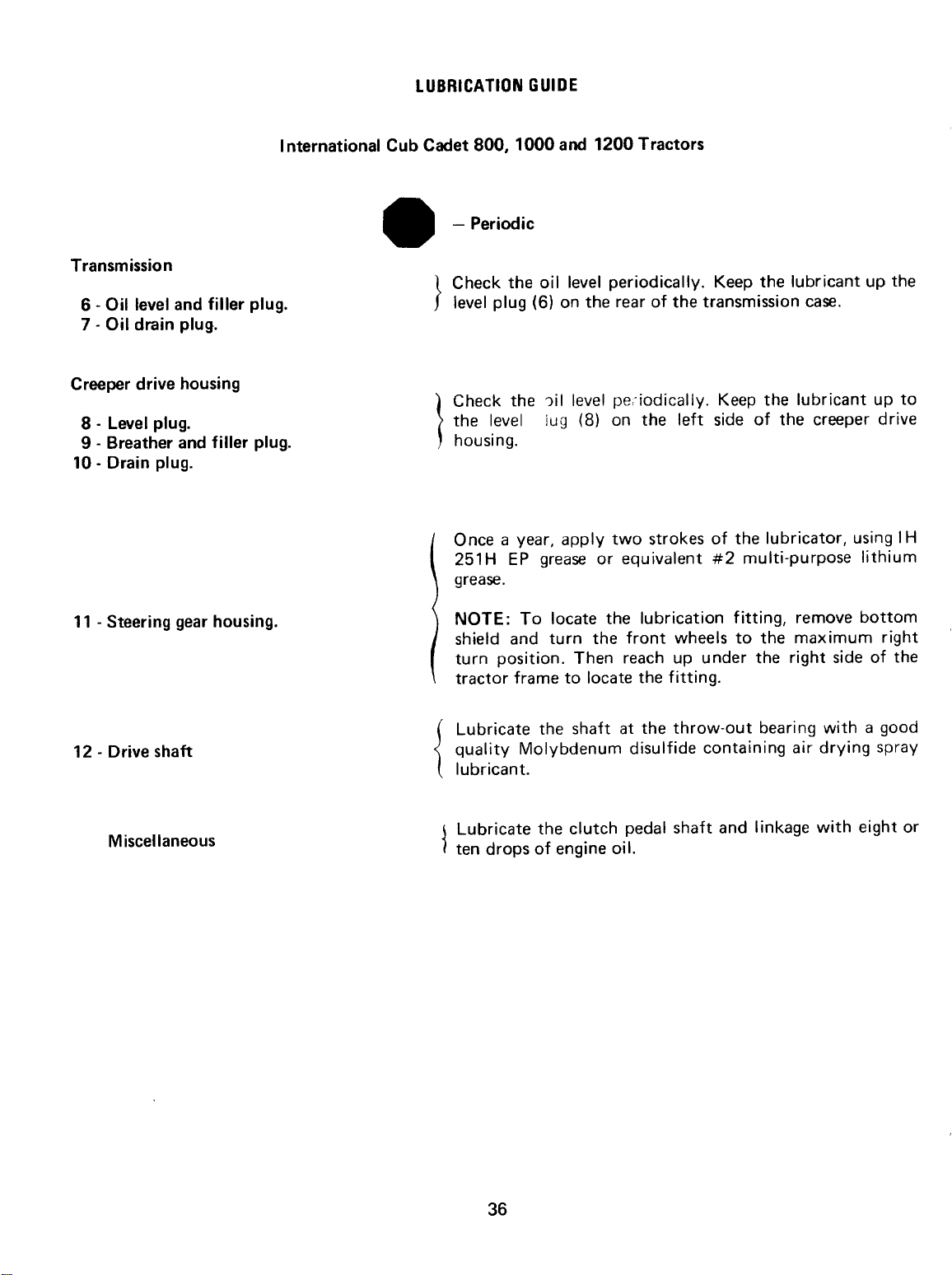

LUBRICATION GUIDE

I nternational Cub Cadet 800,

1000 and 1200 Tractors

LUBRICATION GUIDE

I nternational Cub Cadet 1250,

1450 and 1650 Tractors

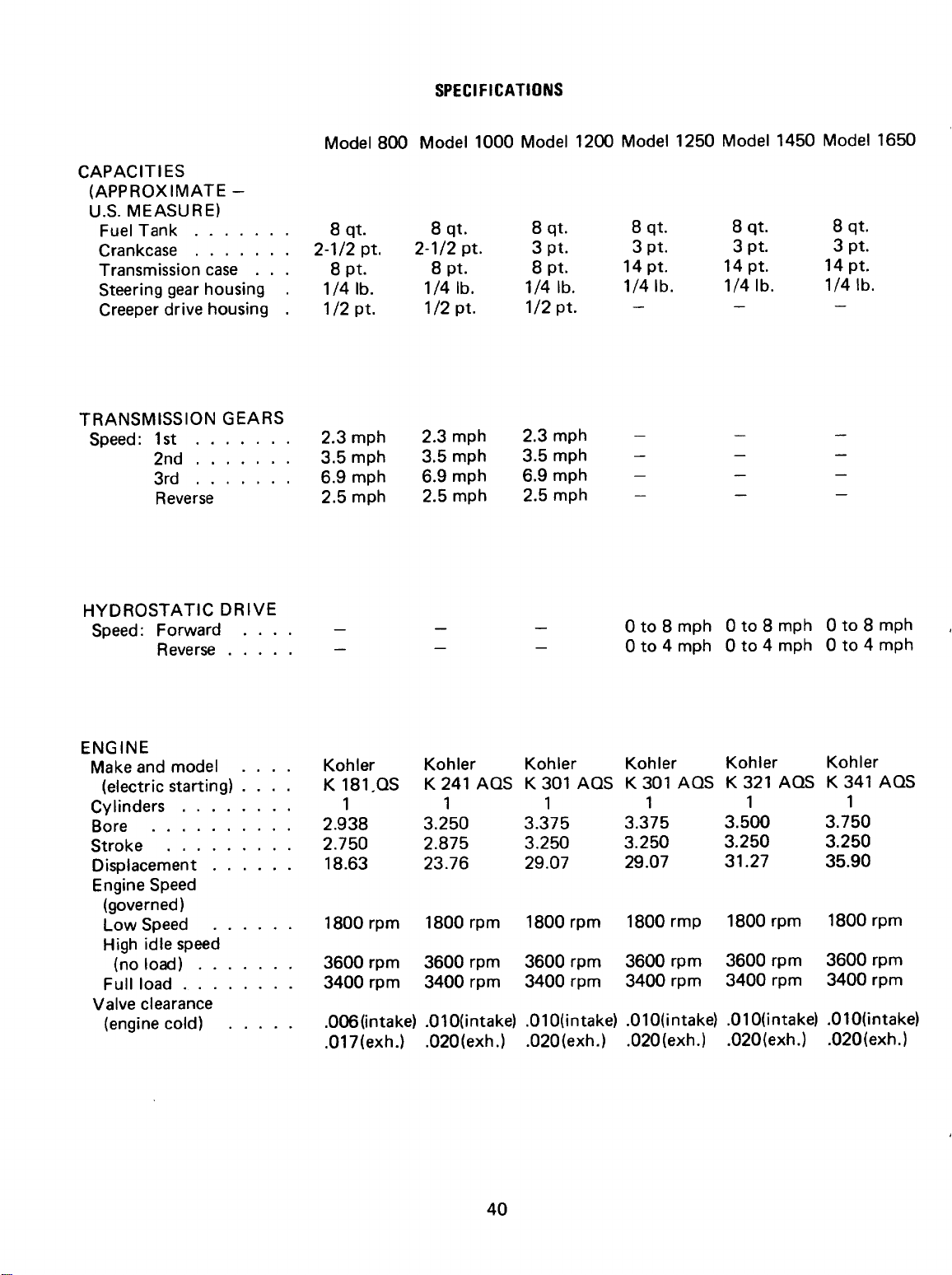

SPECIFICATIONS

28

29

29,30

31,32

33

34 to 36

37 to 39

39 to 42

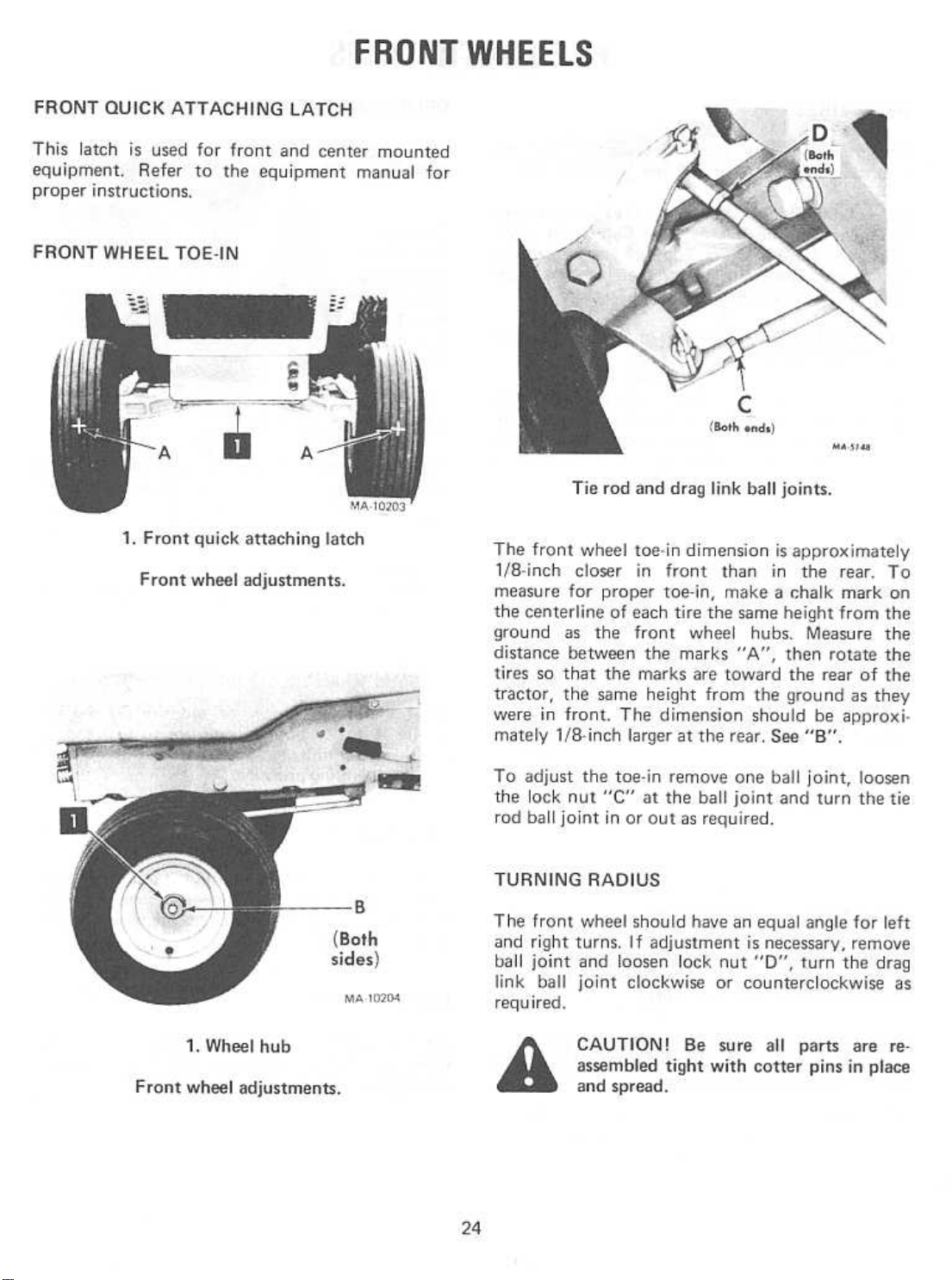

FRONT WHEELS

Front quick attaching latch

Front wheel toe-in

Turning radius

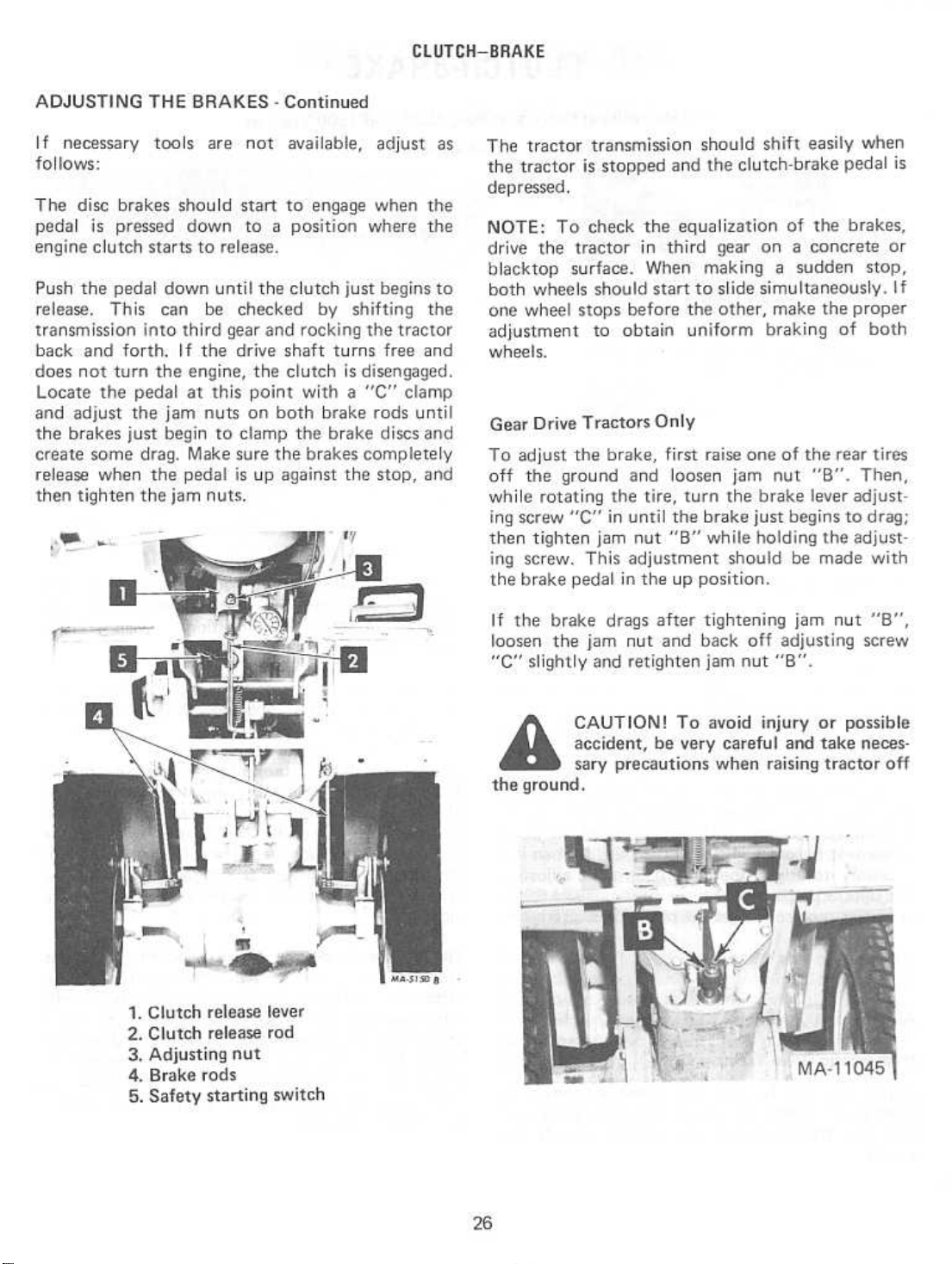

CLUTCH-BRAKE

I nternational Cub Cadet 800, 1000,

and 1200 Tractors

Adjusting the clutch

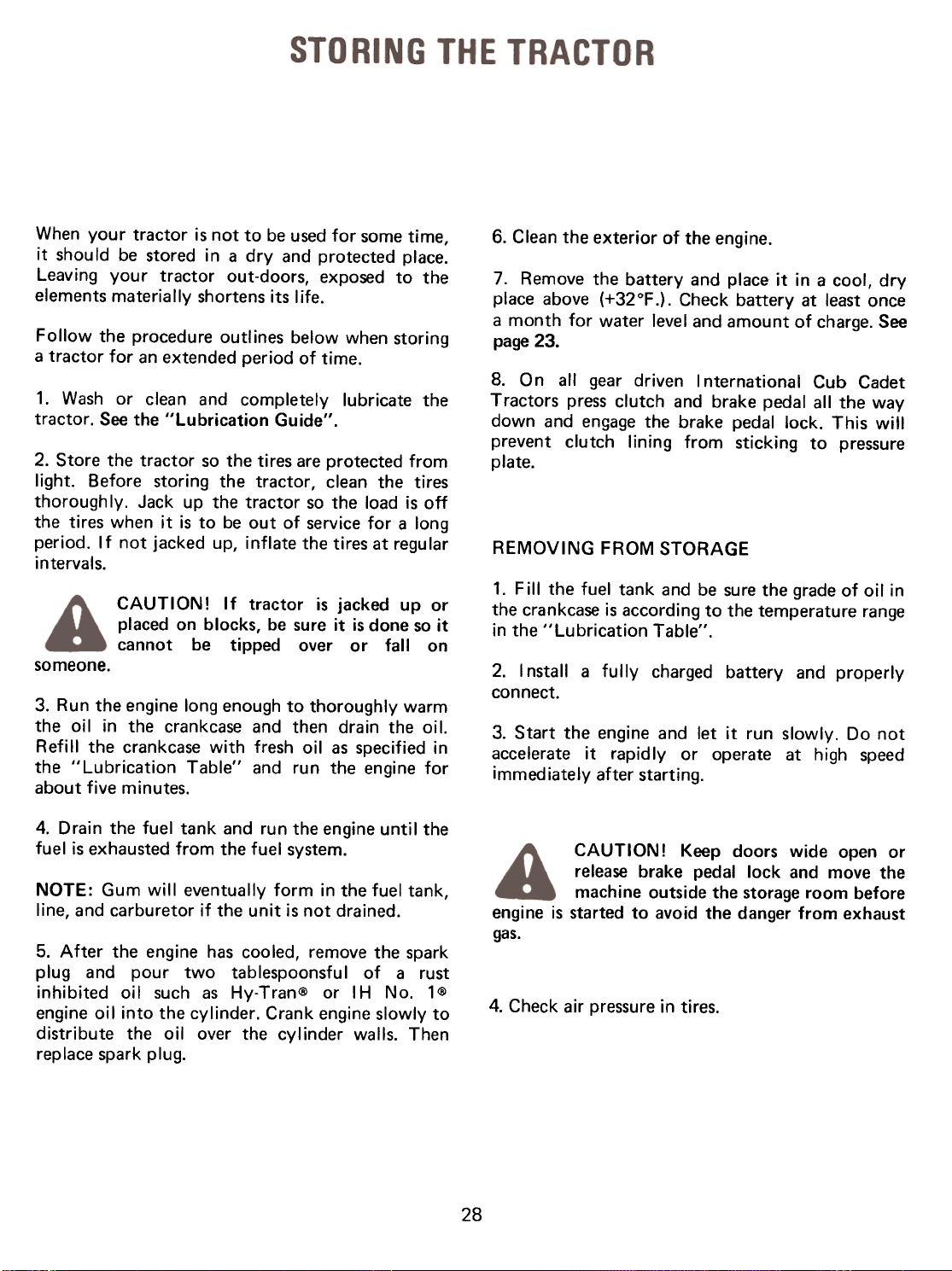

Adjusting the brakes

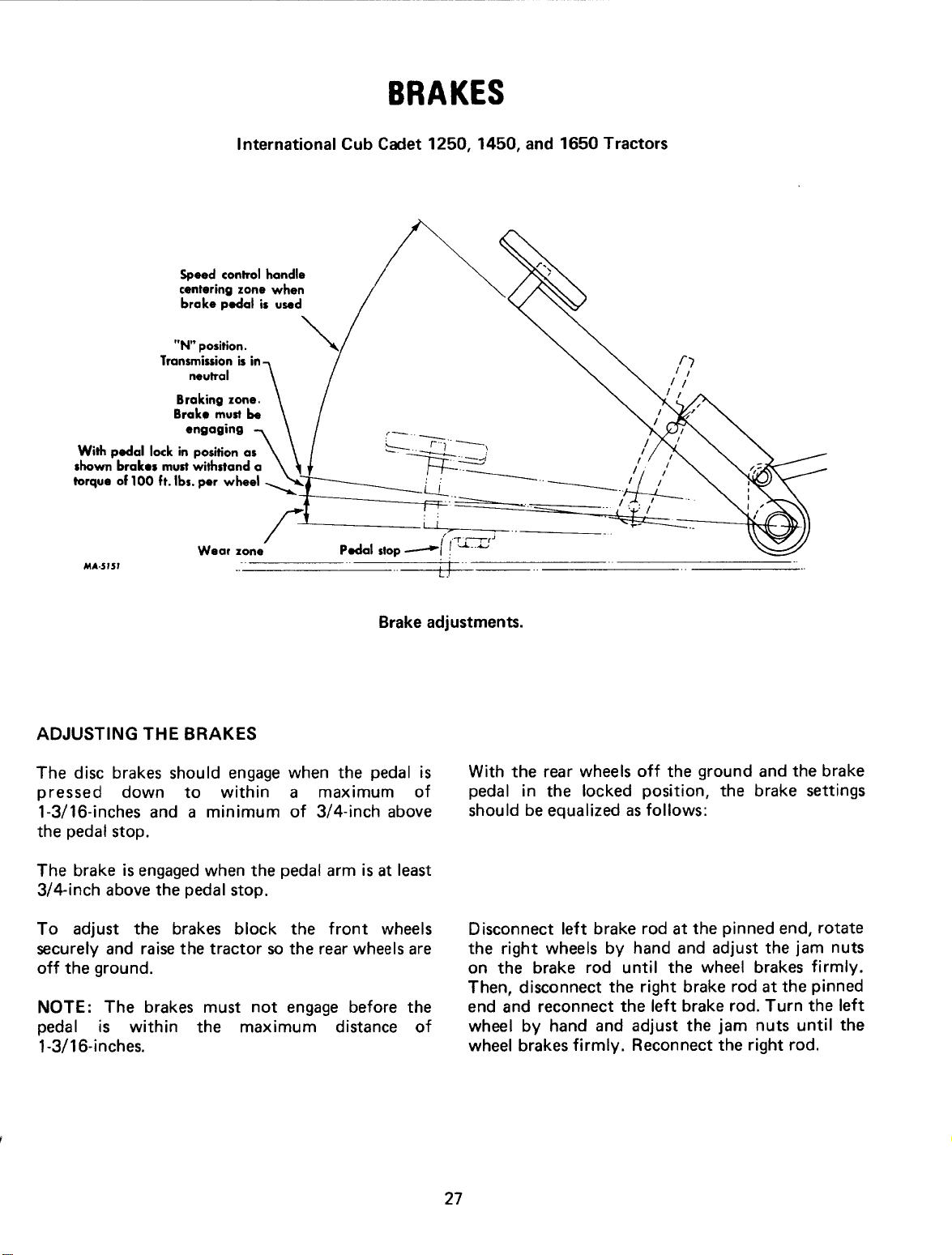

BRAKES

nternational Cub Cadet 1250, 1450

and 1650 Tractors

Adjusting the brakes

24

25,26

27

PNEUMATIC

I

-2-

Page 5

Page 6

This symbol is used to call your attention to instructions

concerning your personal safety. Be sure to observe and

following these instructions.

Disengage all clutches and shift into neutral beforestarting

the engine.

To avoid injury, disengage power to any attachments and stop engine before leaving operator',s

seat or making any repairs or adjustments.

Know the controls and how m stop quickly.

READ THE OPERATOR'S MANUAL.

To avoid an accident or injury, do not allow

children or adults to operate the equipment

without proper instruction.

Clear work area of objects which might be p.icked

up and thrown.

Disengage power to any attachment when transporting or not in use.

To prevent injury, do not carry passengers or give

rides. Keep children, pets, and by-standers a safe

distance away.

To prevent an accident, always disengage the

power take-off, shift transmission into neutral, set

the parking brake, stop the engine, and remove

ignition key when leaving the machine unattended.

Watch out for traffic when crossing or near

roadways.

When using any attachments, never direct discharge

of material toward by-standers nor allow anyone

near the machine while in operation.

Handle gasoline wfth care -it is highly flammable: -

A. Use approved gaso1ine container. B. Never

remove the fuel tank cap or fiJ1 the fuel tank when

the engine is running, is hot, or indoors. Also, do

not smoke when working around inflammable fuel.

Wipe up spilled gasoline. C. Replace gasoline cap

securely.

During operation do not run the engine in confined

area such as storage building any longer than is

necessary for immediate moving of the tractor'outside

into the air.

Keep machine in good operating condition and

keep safety devices in place. Use guards or shields

as instructed in Operator's Manual

1t is recommended that the machine be stopped

and inspected for damage after striking a foreign

object and that any damage be repaired before

restarting and operating the machine.

Reduce speed on slopes and in sharp turns to

prevent tipping or loss of control.

Stay alert for holes in terrain and other hidden

hazards.

Before backing the tractor, always look for obstacles or bystanders in the area where the tractor

will move.

Use care when pulling loads or using heavy

equipment: -A. Use only approved hitch points. B.

Limit loads to those you can safely control. C.

Don't turn too sharp, and use care when backing.

D. Use counterweight or wheel weights when

suggested in Operator's Manual.

Always turn ignition "OFF", depress the brake

pedal, and set the brake pedal lock before working

on the machine. Disengage all implements and shift

the transmission into neutral.

REMEMBER -A careful operator is the best

insurance against an accident.

Avoid Overturns -Back the tractor up the steepest

portion of the hill to be mowed! If the tractor

cannot do this, the hill is too steep for safe

operation. When mowing hills, cut down the face

of the hill rather than across to avoid side tipping.

Also, avoid sudden starts, stops, and turns,

especially on steep slopes to avoid an upset.

4

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

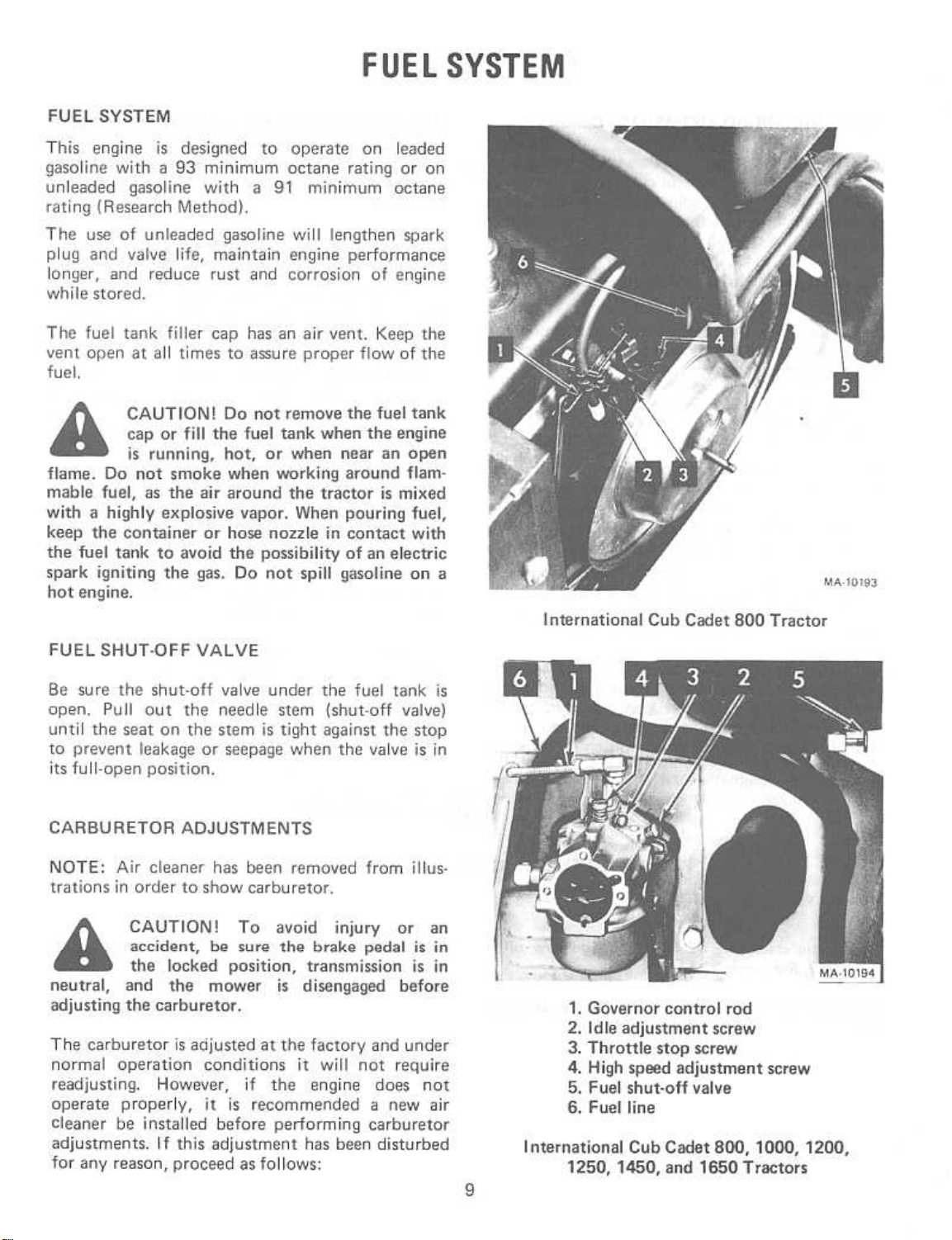

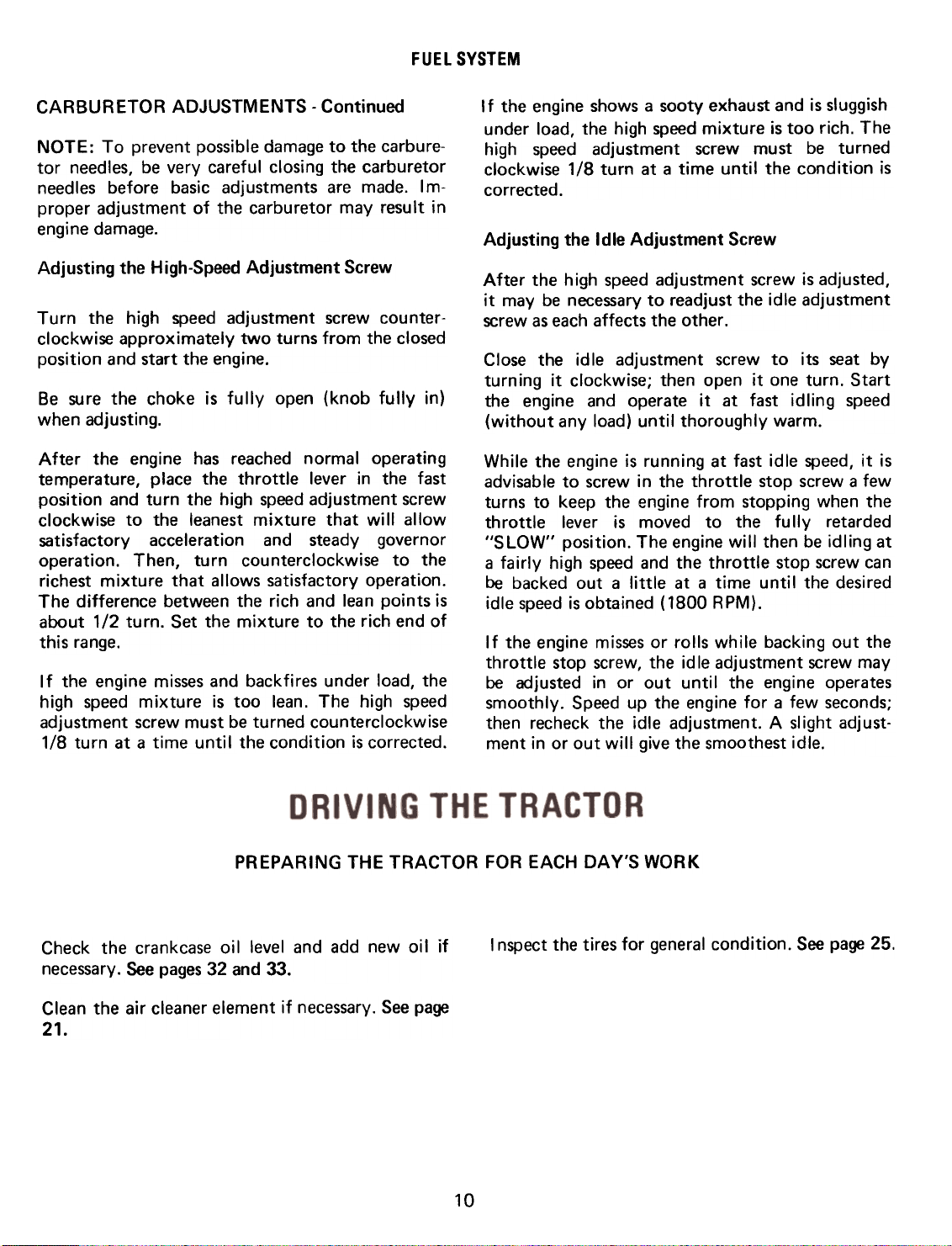

FUEL SYSTEM

CARBURETOR ADJUSTMENTS -Continued

NOTE: To prevent possible damage to the carburetor needles, be very careful closing the carburetor

needles before basic adjustments are made. Im-

proper adjustment of the carburetor may result in

engine damage.

Adjusting the High-Speed Adjustment Screw

Turn the high speed adjustment screw counterclockwise approximately two turns from the closed

position and start the engine.

Be sure the choke is fully open (knob fully in)

when adjusting.

After the engine has reached normal operating

temperature, place the throttle lever in the fast

position and turn the high speed adjustment screw

clockwise to the leanest mixture that will allow

satisfactory acceleration and steady governor

operation. Then, turn counterclockwise to the

richest mixture that allows satisfactory operation.

The difference between the rich and lean points is

about 1/2 turn. Set the mixture to the rich end of

this range.

If the engine misses and backfires under load, the

high speed mixture is too lean. The high speed

adjustment screw must be turned counterclockwise

1/8 turn at a time until the condition is corrected.

I f the engine shows a sooty exhaust and is sluggish

under load, the high speed mixture is too rich. The

high speed adjustment screw must be turned

clockwise 1/8 turn at a time until the condition is

corrected.

Adjusting the Idle Adjustment Screw

After the high speed adjustment screw is adjusted,

it may be necessary to readjust the idle adjustment

screw as each affects the other.

Close the idle adjustment screw to its seat by

turning it clockwise; then open it one turn. Start

the engine and operate it at fast idling speed

(without any load) until thoroughly warm.

While the engine is running at fast idle speed, it is

advisable to screw in the throttle stop screw a few

turns to keep the engine from stopping when the

throttle lever is moved to the fully retarded

"SLOW" position. The engine will then be idling at

a fairly high speed and the throttle stop screw can

be backed out a little at a time until the desired

idle speed is obtained (1800 RPM).

If the engine misses or rolls while backing out the

throttle stop screw, the idle adjustment screw may

be adjusted in or out until the engine operates

smoothly. Speed up the engine for a few seconds;

then recheck the idle adjustment. A slight adjust-

ment in or out will give the smoothest idle.

PREPARING THE TRACTOR FOR EACH DAY'S WORK

Check the crankcase oil level and add new oil if

necessary. See pages 32 and 33.

Clean the air cleaner element if necessary. See page

21.

I nspect the tires for general condition. See pa~ 25.

10

Page 13

Page 14

DRIVING THE TRACTOR

International Cub Cadet 800, 1000, and 1200 Tractors

CLUTCH-BRAKE PEDAL

The combination clutch-brake pedal is used to

disengage the engine from the transmission when

shifting gears and to actuate the brake to stop the

tractor. The pedal must be pressed all the way

down to activate the safety starting switch when

starting the engine.

To disengage the clutch, and apply the brake, press

the pedal all the way down.

GEARSHIFT LEVER

This lever is used to select various gear ratios

provided in the transmission. There are three

forward speeds and one reverse speed. Refer to

"SPECIFICATION", on page 41.

STARTING THE TRACTOR

Disengage the clutch by pressing the clutch pedal

all the way down, and release the brake lock. Move

the gearshift lever to the desired speed.

Start the tractor in motion by slowly releasing the

clutch pedal and moving the throttle lever to the

position where the engine operates best for the

load to be handled.

NOTE: When using power take-off operated equip-

ment, best performance is achieved with the

throttle lever in the "Fast" position.

NOTE: Do not shift gears while the engine clutch

is engaged or while the tractor is in motion.

NOTE: Do not rest your foot on the pedal while

driving the tractor, as this will result in excessive

clutch lining wear.

Always be sure the rear wheels are free to turn.

Under any adverse conditons, do not attempt to

free the tractor by speeding up the engine and

suddenly engaging the clutch. Try backing out

instead of going foward.

CAUTION! To avoid possible injury, do

not carry passengers or give rides. Keep

children, pets, and bystanders out of the

STOPPING THE TRACTOR

Disengage the clutch by pressing the pedal all the

way down. Move the gearshift lever to the "N"

position. Before dismounting always lock the

pedal, disengage the power take-off, and turn the

ignition "OFF".

CREEPER SHIFT LEVER

The creeper drive (optional) provides a slower

speed in each respective gear, by a four-to-one

reduction in speed from direct drive. When the

creeper shift lever is all the way forward, it is in

direct drive, or all the way rearward, it is in creeper

drive.

OPERATING THE CREEPER DRIVE

To operate the tractor in creeper drive, depress the

pedal and move the creeper shift lever all the way

rearward. Then select the transmission speed

desired and proceed as instructed under "Starting

the Tractor".

NOTE: Do not use a mid-point position on the

creeper drive as neutral. Neutral position must be

selected only with the standard transmission

gearshift lever.

The following table shows the speeds available in

each of the three forward gears and the reverse

gear.

area.

12

Page 15

Page 16

DRIVING THE TRACTOR

1nternational Cub Cadet 1250, 1450, and 1650 Tractors

STARTING THE TRACTOR NOTE: Never operate engine with release lever in

(UP) position. Towing or pushing the tractor for

1. Depress the brake pedal and release the brake

lock. Move the throttle lever to the position where

the engine operates best for the load to be handled.

more than a few feet may result in transmission

damage.

2. Start the tractor in motion by moving the speed

control lever slowly forward or rearward as

described above.

RELEASE lEVER

To push or move the tractor for a short distance,

the release lever, located on the right side of the

frame near the cam stop, must be held in the (up)

position and the speed control lever must be in the

"N" position.

The lift handle is used to lift or lower equipment

used with the tractor. The equipment can be set in

multiple positions by depressing the button on the

top of the handle and releasing it when the desired

position is reached.

HEIGHT ADJUSTMENT

THE TRACTOR

Move the speed control lever to the "N" position

or use the brake. Before dismounting always lock

the brake pedal and turn the ignition "OFF". Also,

disengage the power take-off clutch lever.

CAUTION! To prevent injury or an

accident, do not carry passengers or give

rides. Keep children, pets, and by-

standers out of the area.

Lock cam into this position by turning knobclockwise.

If free handle travel between cam stop and fully

raised position is desired (Float Position), depress

the release button on top of the handle, press in

the lock button located at the front of the handle

and release the top button.

If a single implement height is normally used, the

handle may be adjusted to locate the desired

position by use of the cam stop.

With lift handle in desired implement height

position, release cam by turning locking knobcounterclockwise.

Turn cam until it contacts tang.

STOPPING

NOTE: To disengage the lift handle from the float

position, pull lift handle back slightly and depress

top button.

NOTE: Refer to the equipment manual for proper

hitching instructions.

14

Page 17

Page 18

Page 19

OPERATING THE FRONT POWER TAKE-OFF

CLUTCH

The front power take-off clutch is an electric

clutch operated by a toggle switch on the left side

of the instrument panel.

The clutch is factory adjusted and should not

require further adjustment under normal operating

conditions. However, if the clutch fails to operate

properly check as follows:

Check fuse on pedestal.

1. Move the throttle lever back to the medium or

"slow" position.

2. Flip the toggle switch on to the "ON" position.

Advance throttle to operating speed (full speed).

ADJUSTING THE POWER TAKE-OFF CLUTCH

Using a feeler gauge check the clearance. If the

clearance is not .015/.010 inches tighten the four

(4) self-locking nuts to obtain the proper clearance.

If the above procedure does not work, see your

I nternational Harvester dealer.

CAUTION! To avoid an accident or

possible injury, always disengage all

clutches and shift into neutral before

starting the engine.

CAUTION! To avoid possible injury,

always disengage all clutches, shift the

transmission into neutral, depress the

brake, set the brake pedal lock and turn the ignition "OFF" before working on the machine.

1. Self-locking nuts (4)

2. Feeler gauge openings (4)

The electric lift is a self-contained unit designed to

provide power with fingertip control for raising the

lowering mounted equipment.

3.

The ~Iectric lift is available on all Cub Cadet

Tractors except the Models 1450 and 1650 which

is equipped with a hydraulic lift as standard.

17

Page 20

Page 21

Page 22

Page 23

ELECTRICAL SYSTEM

CHARGE INDICATOR

This instrument indicates whether the alternator is

charging or the battery is discharging. If it shows

discharge continuously, investigate the cause to

avoid completely discharging the battery and

possible damage to the charging circuit.

HOUR METER

The I nternational Cub Cadet Tractors are equipped

with an hour meter which is located on the

instrument panel. It indicates the actual hours of

engine operation, enabling the operator to deter-

mine without guesswork, when lubrication, change

of oil or periodic inspections are necessary. It also

provides a means of computing cost of specific

!obs. The hour meter operates whenever the engine

is running or the ignition key is in the "ON"

position.

SPARK PLUG

Remove the spark plug, always using a spark plugwrench,

after every 100 hours of operation to

check the gap.

CAUTION! To avoid possible injury, be

sure engine is off and cool before making

any adjustments or repairs.

Be sure the gasket is in good condition. Tighten the

plug 1/2 to 3/4 turns past finger tight.

Replace a defective plug with a new plug. See your

I nternational Harvester dealer for the correct

replacement plug.

LIGHTS

Checking the spark plug gap.

Set gap at .O25-inch.

NOTE: Remove all dirt from around the spark plug

before removing.

Lights are optional on all models except the

Models 1450 and 1650.

The headlights are sealed-beam units. Refer to

"SPECIFICATIONS" when replacement is

necessary.

To replace the taillight lamp, remove the lens from

the taillight and replace. Refer to

"SPECIFICATIONS".

FUSES (Electric lighting and Electric Power

Take-Off Clutch)

Always use the same capacity fuse for replacement.

Refer to "Specifications". If the lights fail or the

clutch does not engage, check the appropriate fuse.

21

Page 24

ELECTRICAL SYSTEM

FUSE -Continued

NOTE: There are two fuses adjacent to the lighting

switch on the tractor pedestal (left side), The lower

fuse is for the lights; the upper fuse is for the

electric clutch.

To install a new fuse, press in on the fuse housing

cap and turn counterclockwise to remove it from

the fuse housing. Remove the old fuse and replace

it with a new one. Then reassemble the cap to the

housing.

Before working on any part of the electrical

system, disconnect the battery ground cable at the

battery negative (-) terminal. Do not reconnect this

cable until all work has been completed. This will

prevent shorting and damage to any of the elec-

trical units. Examine the electrcial cables occa-

sionally to be sure they are not being frayed by

contact with adjacent parts.

When replacing a battery, make certain the ground

cable is connected to the negative (-) terminal on

the battery. Be su re the rubber boot is properly

positioned over the positive (+) terminal on the

battery. NOTE: Both cables must be assembled

with the nuts to the inside of the terminals to

prevent shorting against fender well.

Cleaning and Servicing the Battery

The electrolyte (acid and water) in each cell should

be at ring level at all times to prevent batteryfailure.

When the electrolyte is below this level,

add pure, distilled water.

Acid or electrolyte should never be added except

by a skilled battery man. Under no circumstances

add any special battery "dopes", solutions or

powders.

CAUTION! If the tractor is to be tipped

up or on its side remove the batteries to

avoid spilling the electroyte. Battery

electrolyte is poisonous and can be injurious to

eyes, skin, and clothing. If electrolyte is spilled,

flush immediately with water, followed by a

solution of one part baking soda to four parts

water.

Connecting Booster Batteries

When required, a booster 12-volt battery may be

connected in parallel with the 12-volt system on

I nternational Cub Cadet Tractors.

CAUTION! Gas discharged by batteries

is explosive. Avoid sparks near the

batteries.

Occasionally remove the battery cables and

brighten the terminal contact surfaces with wire

wool, and reassemble them. Apply a light coat of

vaseline or chassis lubricant. Be sure the terminals

are clamped tightely and that the battery is

fastened securely in the battery box. Replace

unserviceable cable. Keep the vent holes in the

battery filler caps open.

Keeping the battery fully charged not only adds to

its life but makes it available for instant use when

needed.

Liquid Level

Check the battery at least once a month for water

level.

NOTE: All circuits must be turned "off/. Electrical system is NEGATIVE (-) grounded only.

Reversed polarity will result in permanent damageto

components of the electrical system.

The first jumper cable must connect the positive

(+) terminal of the booster battery and the positive

terminal of the battery on the tractor.

The second jumper cable must first be connected

to the negative (-) terminal of the booster battery;

and then to a point on the frame of the tractor,

away from the battery, having a good ground, so

no spark occurs near the battery.

For dependable battery service, see your I nternational Harvester dealer.

22

Page 25

OPERATING PRESSURE FOR TIRESREAR TIRES

6-12 rear tires are standard equ ipment on the

I nternational Cub Cadet 800 and 1000 Tractors.

23 x 8.50-12 high floatation tires are standard

equipment on the I nternational Cub Cadet 1200,

1250, and 1450 Tractors. They are also available as

optional equipment when ordered for the I nter-

national Cub Cadet 800 and 1000 Tractors.

23 x 10.5-12 tires are standard on the International

Cub Cadet 1650 Tractor.

The high floatation tires provide maximum

mobility in sand, snow, and soft soil conditions.

The reduced ground pressure and low inflation

provides maximum protection for turf, soil and

crops.

CARE OF TIRES

Avoid stumps, stones, deep ruts, curbs, and other

hazards. Cuts in tires should be repaired imme-

diately as neglect decreases the tire lift.

I nflate the front and rear tires for normal or heavy

load operations as shown in the following table.

Tire Size

Front Tires

4.80/4.00-8

16 x 6.50-8

Rear Tires 6-12

23 x 8.50-12

23 x 10.50-12

REAR WHEEL WEIGHTS

Pounds per square inch

12

12

12

12

12

Rear wheel weights increase traction and reduce

wheel slippage. The weights weight approximately

26 pounds each. They are attached to each rear

wheel with two bolts, lock washers, and hex nuts.

I f additional weight is desired, a second set of

weights can be attached to each first weight by

using two longer bolts.

MOUNTING TIRES ON THE RIM

Keep tires free from oil and grease as both destroy

rubber.

After using the tractor for spraying use water to

remove any chemicals that may be on the tires.

INFLATION

Keep the pneumatic tires properly inflated. Overinflation will cause operator discomfort. Underinflation will cause short tire life.

Always see that the tire valve caps are in place and

tightened securely to prevent loss of air and

protect the valve core and stem.

After mounting a new or old tire on the rim,

inflate it to 20 pounds pressure to seat the tire

bead on the rim flange. Then deflate the tire to the

correct operating pressure.

TIRE CHAINS

Tire chains will provide additional traction for wet

ground conditions, when plowing snow, or pulling

heavy loads. Rear wheel weights are recommended

when using chains.

OVERLOADING

Do not overload the tractor tires by mounting

equipment on the tractor which exceed the load

capacity of the size of the tires on the tractor.

23

Page 26

Page 27

Page 28

Page 29

Page 30

When your tractor is not to be used for some time,

6. Clean the exterior of the engine.

it should be stored in a dry and protected place.

Leaving your tractor out-doors, exposed to the

elements materially shortens its life.

7. Remove the battery and place it in a cool, dry

place above (+32°F.). Check battery at least once

a month for water level and amount of charge. See

Follow the procedure outlines below when storing

page 23.

a tractor for an extended period of time.

8. On all gear driven I nternational Cub Cadet

1. Wash or clean and completely lubricate the

tractor. See the "lubrication Guide".

Tractors press clutch and brake pedal all the way

down and engage the brake pedal lock. This will

prevent clutch lining from sticking to pressure

2. Store the tractor so the tires are protected from

plate.

light. Before storing the tractor, clean the tiresthoroughly.

Jack up the tractor so the load is off

the tires when it is to be out of service for a long

period. If not jacked up, inflate the tires at regular

REMOVING FROM STORAGE

intervals.

1. Fill the fuel tank and be sure the grade of oil in

If tractor is jacked up or

placed on blocks, be sure it is done so it

the crankcase is according to the temperature range

in the "lubrication Table".

cannot be tipped over or fall on

someone.

3. Run the engine long enough to thoroughly warm

the oil in the crankcase and then drain the oil.

Refill the crankcase with fresh oil as specified in

the "lubrication Table" and run the engine for

about five minutes.

2. I nstall a fully charged battery and properly

connect.

3. Start the engine and let it run slowly. Do not

accelerate it rapidly or operate at high speed

immediately after starting.

Drain the fuel tank and run the engine until the

fuel is exhausted from the fuel system.

NOTE: Gum will eventually form in the fuel tank,

line, and carburetor if the unit is not drained.

After the engine has cooled, remove the spark

plug and pour two tablespoonsful of a rust

inhibited oil such as Hy-Tran@ or IH No. 1@

engine oil into the cylinder. Crank engine slowly to

distribute the oil over the cylinder walls. Then

replace spark plug.

CAUTION!

4.

5.

4.

CAUTION! Keep doors wide open or

release brake pedal lock and move the

machine outside the storage room before

engine is started to avoid the danger from exhaust

gas.

Check air pressure in tires.

28

Page 31

Page 32

Page 33

ENGINE OIL

The engine crankcase is filled with ship-away oil.This

oil may be used for the first 30 hours of

engine operation at temperatures between +90

degrees F. and 0 degrees F. If temperatu res are not

within this range, drain the oil from the crankcase

and replace with new oil as specified in the

"lubrication Table". The engine oil must be

drained and replaced with new oil every 30 hours

of engine operation.

We recommend I.H. No. 1@ Engine Oil. If other

than I.H. No. 1@ Engine Oil is used, it must be

designated as meeting either SO or SE re-

quirements.

To aid starting, the selection of crankcase lubri-

cating oils should be based on the lowest anticipated temperature until the next drain period. See

page 33.

lubricate the entire tractor, using only high

quality lubricating oils and grease as specified in

the "lubrication Table", For your own protection,

select only oils and greases of recognized manu-

facture.

Regularly check the oil levels of the engine

crankcase and transmission to see that they are

filled to the correct levels. NOTE: Check the oil

level only while the engine is stopped.

Always keep the oil level between the "FULL" and

the "LOW" marks on the gauge. When checking

the oil level the gauge must be withdrawn and

wiped clean, then inserted all the way and withdrawn for a true reading.

NOTE: Never overfill the engine crankcase. Engine

damage may result if the crankcase is below the

"LOW" mar!< or over the "FULL" mark.

31

Page 34

ENGINE OIL -Continued

1. Oil filler cap and oil level gauge Cub Cadet 800 Tractor

LUBRICATION

Keep your supply of lubricating oil absolutely

clean and free from dust. Always use clean

containers. Keep the lubricator clean and wipe dirtfrom

the lubrication fittings before applying thelubricator.

TRANSMISSION OIL FILTER

(International Cub Cadet 1250, 1450, and 1650

Tractors)

Remove the throw-away can-type filter and replacewith

a new filter after the first 10 hours and after

50 hours of operation, and every 100 hou rs of

operation thereafter.

Oil filler cap and oil level gauge -All

models except the Cub Cadet 800 Tractor

NOTE: Right hand side panel removed to show

location.

Clean the outside area before removing thefilter

to keep dirt from getting into the trans-

mission case. I f a mower is mounted on the tractor,the

mower must be lowered to facilitate removal ofthe

filter.

remove the filter, turn the filter counter-clockwise

using an automotive type filter wrenchor

an open end wrench.

Before installing the new filter, apply a coating of

oil on the filter gasket. Thread the filter on by

hand until tight enough to seat the gasket. Loosen

the filter. Then turn it until the gasket contacts the

base. Tighten the filter an additional one half turn.

Check for leaks and check oil level of transmission

case.

NOTE:

To

1.

32

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Loading...

Loading...