Page 1

Atomic LS EFI

DANGER

Master Kit LS2/LS3, PN 2950

Thank you for selecting the Atomic LS EFI System! MSD’s Atomic EFI systems are designed with

two major goals; to simplify EFI and deliver better overall performance from your engine. Simplicity

is achieved through wired-less technology

with no PC required! Performance is delivered through advanced control of the fuel and ignition, just

as you’d expect from MSD.

to ease installation plus the Atomic is simple to program

Parts Included:

2 – Integrated Fuel/ECU Rail Assemblies

1 - Power Module

1 - Handheld Monitor

1 - Wideband O2 Sensor, Bung and Plug

2 - MAP Sensor Adapter Harnesses

2 - Camshaft Sensor Harnesses, 1x and 4x

2 - Crankshaft Harnesses, 24x and 58x

4 - Injector Harnesses

1 - IAT Sensor and Grommet

Parts Required, Not Included:

• Injector O-Rings

• Fuel System: Fuel Pump, Regulator, Line

• LS1 and LS6 Installation Kit - PN 2955

For use with Master Kit PN 2950. Provides the

correct brackets and EV-1 injector connectors

for the early car intake manifolds identified by

a 3-bolt throttle body.

• Thread Sealer for Intake Bolts

Not legal for use on pollution controlled vehicles: The MSD Atomic LS EFI system is not CARB

approved for use on emission controlled vehicles. This system is designed to control the EFI and

ignition on LS based engines being retro-fit into older vehicles that do not require emission controls.

1 - TPS Sensor Harness

2 - 90° -6 AN fittings

4 - -6 AN fittings

1 - 15" High Pressure Fuel Hose

2 - Fuel Hose Clamps

4 - Installation Brackets

4 - Intake Manifold Bolts

8 - Injector Retainers

8 - 8/32" Socket Head Cap Screws

1 - 4G Micro SD Card

4 - Grommet, Sleeves and Mounting Screws

WARNING

modifications must be carried out by a qualified automotive technician. Installation of fuel system

parts requires handling of gasoline. Ensure that work is performed in a well ventilated area with an

approved fire extinguisher nearby. Extinguish all open flames, prohibit smoking and eliminate all

sources of ignition in the area of the vehicle before beginning the installation.

When working with fuel systems, eye goggles and other safety apparel should be worn to protect

against debris and sprayed gasoline. The finished work must be thoroughly checked to ensure

there are no fuel leaks.

Installation of this product requires detailed knowledge of automotive systems

and repair procedures. Installation of fuel system parts and any fuel tank

Page 2

2 INSTALLATION INSTRUCTIONS

CAPABILITIES

The Atomic LS EFI system is designed to fit OE intake manifolds, as well as some aftermarket intakes.

The Atomic EFI is a self-tuning fuel system that continuously adjusts after the basic configuration is

complete. There is no laptop programming. Based on the engine descriptors you input, the Atomic

will automatically create a base fuel map to get the engine running. Once running, the self learning

system will optimize those maps resulting in the best performance possible. If you change altitude,

outside temperature, or other factors the Atomic will adjust accordingly, on the fly. This ensures that

your engine will produce excellent driveability at all times, even if you drive from the sunny coast to

the cold mountains.

The Atomic LS fuel injection system is capable of running the fuel and ignition system of most LS engines.

The system incorporates OE style connectors to use with the factory sensors on the engine. The only

external sensor required to add is the supplied Wide-Band Oxygen sensor.

There are four main components of the Atomic LS system; the driver’s side and passenger side integrated

fuel rails, the Power Module and the Handheld Monitor. The ECU of the system is divided onto the fuel

rail assemblies and communicate to each other, as well as the Power Module, through MSD’s proprietary

CAN-Bus technology.

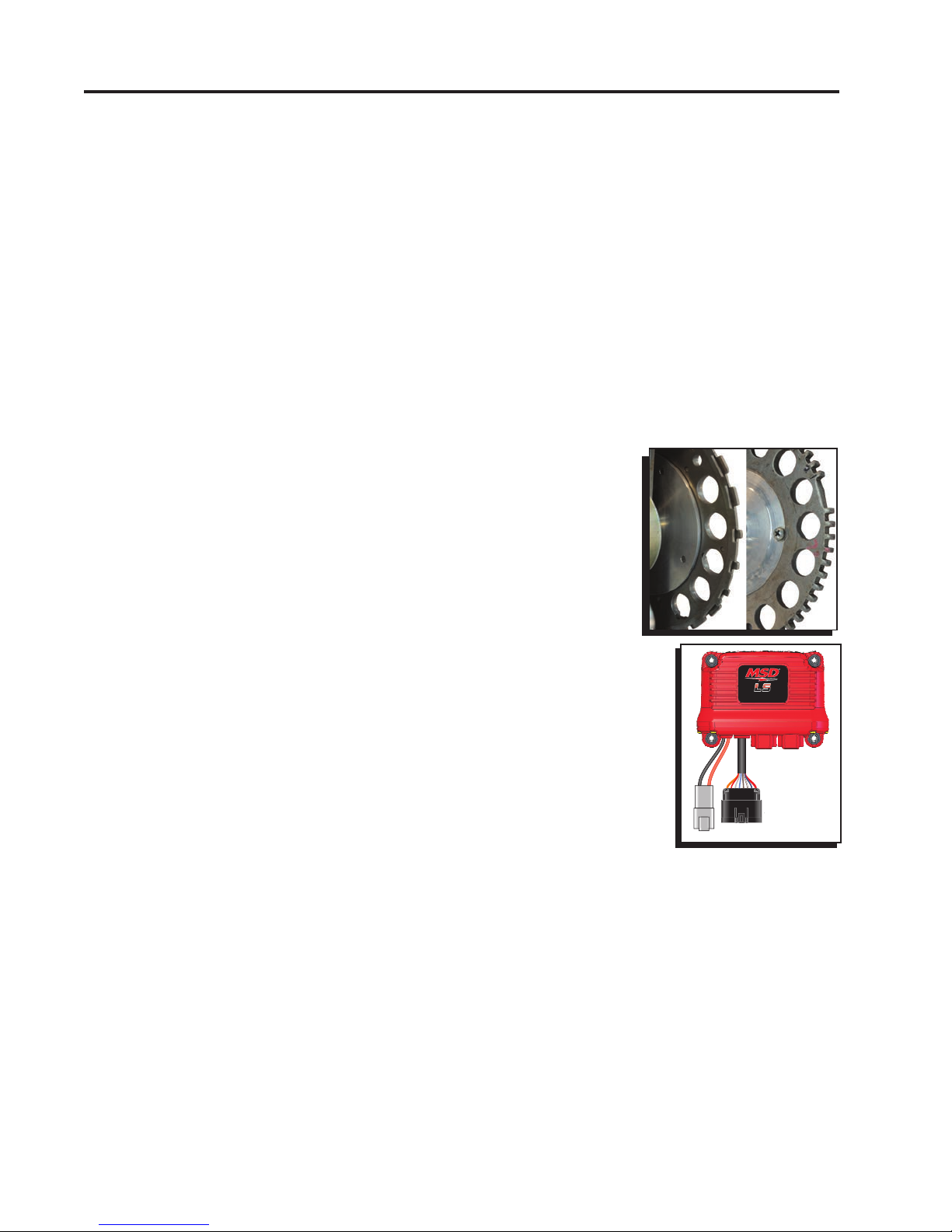

Crankshaft Trigger Wheel ID: It is important to know what crankshaft

trigger wheel your engine is fit with. There are two; early engines used a

24-tooth wheel and later model engines use a 58-tooth wheel. These can

be identified by removing the crank sensor (located behind the starter)

and looking inside the engine (see photo at the right).

Fuel/ECU Rails: The unique fuel rails of the Atomic LS EFI system also

incorporate the ECU of the system. The two banks receive power from the

Power Module and communicate to the system through MSD’s CAN-Bus

network. To install the rails to the intake manifold, the covers will need to be

24x 58x

removed (which is outlined in the instructions).

®

Each bank has OEM connectors that plug into the injectors, coils and specific

sensors of the engine. Each bank has a ground wire that must be connected to the

LS

CONTROLLER

block. The fuel line inlets of the rail accept -6 AN and -8 AN fittings and internally

are equivalent to a -8 line (-6 AN fittings are supplied.)

Power Module: The Power Module of the Atomic LS is the communication hub of

the system and provides the high current fuel pump circuit and other input/outputs

for optional features. The unit has two ports for the MSD CAN system as well as

a wiring harness. There are connections for the WB02, the Handheld Monitor as

POWER MODULE

well as power and communication to the integrated fuel rails.

Programming: The Atomic EFI is a self-tuning fuel system that continuously adjusts after the basic

configuration is complete. There is no laptop programming. Based on the engine descriptors you input, the

Atomic will automatically create a base fuel map to get the engine running. Once running, the self- learning

system will continuously adjust those maps to obtain the desired air/fuel ratio. This feature ensures that

your engine will have the right fuel mixture at all times, no matter where you are driving.

Intake Manifolds: The Atomic LS EFI system is designed to fit most OE intake manifolds, as well as some

aftermarket intakes. There are different mounting brackets available for several of the key intake manifolds.

MSD offers two Installation Kits that are supplied with different injector connects and fuel rail brackets for

manifolds such as the LS1 or truck. They are described in the ‘Not Included’ list of parts above.

Fuel System: The Atomic LS system can be used with return or returnless EFI system. Review the Fuel

System Information section starting on page 3 for detailed information.

Page 3

INSTALLATION INSTRUCTIONS 3

Wide-Band 02 Sensor: A Wide-Band 02 sensor is supplied in the Atomic LS Master Kit. This sensor is

responsible for constantly monitoring the exhaust gases and relaying that information to the ECU where

adjustments are constantly made to the fuel delivery in order to meet the air/fuel targets. Only one sensor

is required. Page 5 outlines the sensor installation.

Crank Sensor: The LS engine platform has used two different crank position sensors through the years.

There is a 24-tooth wheel or a 58-tooth wheel on the crankshaft. The sensor has always been located

behind the starter. The 24-tooth sensor has a black connector whereas the 58-tooth sensor has a gray

connector. The Master Kits are supplied with connectors for both the 24x and 58x trigger sensors.

Cam Sensor: The Cam Sensor of LS engines has changed throughout the years. Not only it’s location,

but its wiring as well. Early models have the cam sensor located at the back of the block near the deck

surface. During 2005, as a running change, the location changed to the front of the block between the cam

and crankshaft. The Atomic LS system can function with both designs.

Throttle Body and Sensors: The Atomic LS requires a mechanically operated throttle body. In the future

Throttle by Wire applications will be covered. The Atomic has all of the OE connections for the throttle

body including Throttle Position (TPS) and Idle Air Control Solenoid (IAC).

Intake Air Temperature (IAT) Sensor: This sensor is supplied and it is recommended to install it in the

air intake duct before the throttle body. A 3/4" hole is required for the sensor.

Rev Limiter: There are two settings for a rev limiter; one through fuel, one through ignition. There is an

optional 2-Step Rev Limiter that can be used on the starting line for a low rpm limit. This is temporarily

activated through the Dark Blue wire of the Power Module to produce consistent launch rpm.

Aftermarket Auxiliary Settings: The Atomic LS system can support aftermarket performance parts or

power adders that carry a CARB Executive Order number. There are accessory controls to properly adjust

the timing and fuel delivery to meet the requirements of these auxiliary components. See the advanced

settings on pages 15-16.

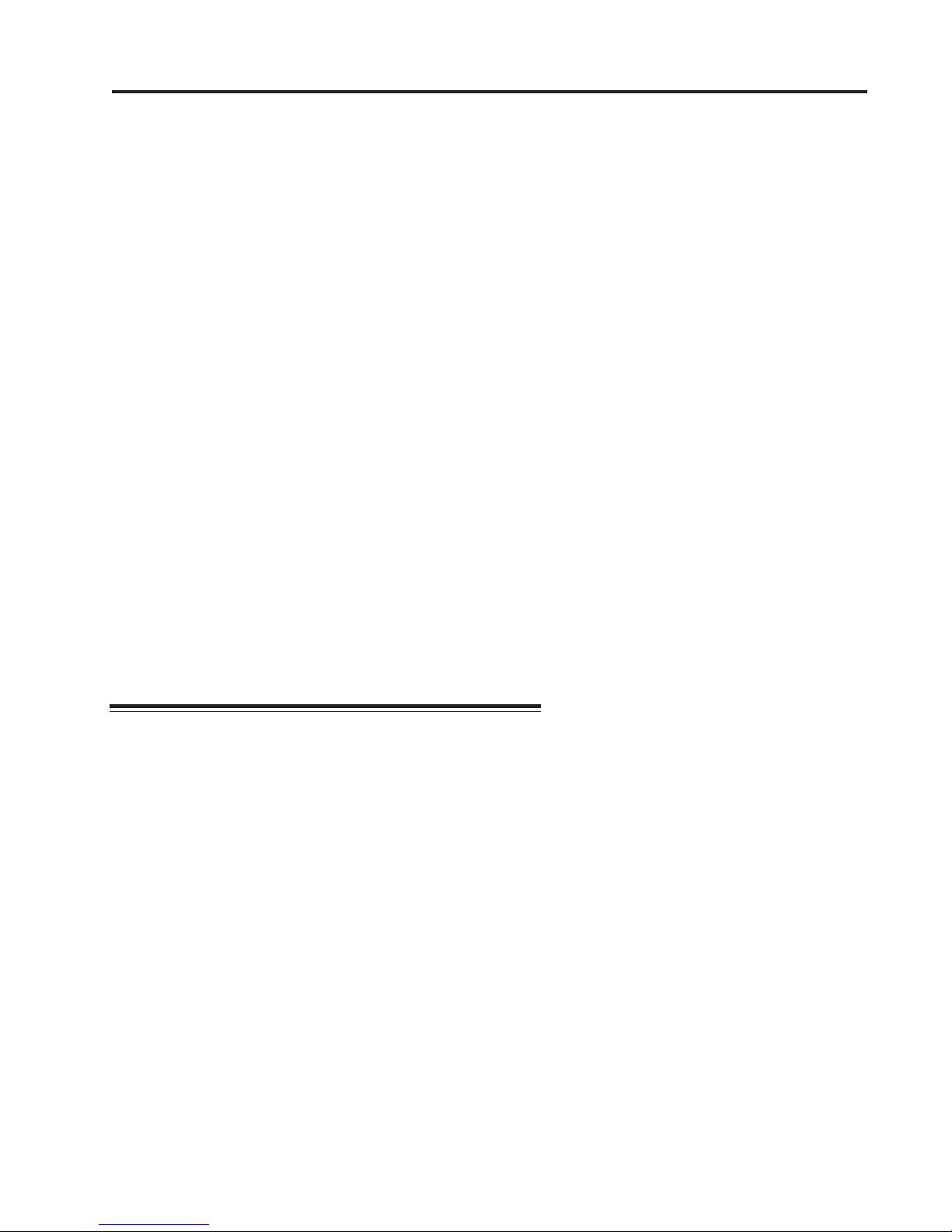

FUEL SYSTEM REQUIREMENTS

The Atomic LS fuel injection system requires a high pressure fuel pump system. The fuel system is

not supplied due the large variety of applications incorporating the LS engine platform. Depending on

your engine combination, the Atomic LS requires a minimum of 58-62 psi to operate. When selecting

a pump, regulator and lines, be sure each component is designed to perform at high pressure. MSD

offers fuel pumps, hose and accessories to complete your installation. Following are some guidelines

in helping set up a fuel system for your Atomic as well as components available separately from MSD.

• The Atomic is capable of operating with a return or returnless style system. For best results with

either system, MSD strongly recommends an in-tank pump. Installing the fuel pump in the tank

results in quieter operation, less chance of cavitation and a reduction in pump temperature.

• When running a returnless fuel system (Pulse Width Modulated) the fuel pump must be mounted

in the tank. It is recommended to use an MSD Atomic Fuel Pump, PN 2925 or PN 2926.

• MSD supplies -6 AN clamp-style ttings for the fuel rails. These ttings must be used with MSD's

high pressure EFI hose. Refer to page 9 for installation.

• If mounting the pump in the tank is not an option, install the pump as close as possible to the tank.

Within 2-feet of sending unit is recommended.

• Do not use hard line when plumbing the fuel system. When using a PWM fuel system, pulsations

and harmonics could cause unstable fuel pressure resulting in pump cavitation or poor engine

performance.

Page 4

4 INSTALLATION INSTRUCTIONS

, MOUNT

FUEL RAIL

(UNDER COVER)

-6 90° FITTING SUPPLIED

FUEL RAIL

FUEL RAIL

(UNDER COVER)

(UNDER COVER)

NOTE: IF RUNNING A RETURNLESS

FUEL SYSTEM, THE PUMP MUST

BE MOUNTED IN THE TANK.

MSD ADJUSTABLE

REGULATOR

FUEL

FILTER

FUEL TANK

FUEL

PUMP

IT IS RECOMMENDED TO MOUNT

THE FUEL PUMP IN THE TANK

WHENEVER POSSIBLE. IF IT MUST

BE MOUNTED EXTERNALLY

THE PUMP WITHIN 2-FEET OF THE

FUEL TANK SENDING UNIT.

Figure 1 Atomic LS Return Fuel System.

In-Tank Pumps

The MSD Atomic Fuel Pump (not supplied) can be used in the tank however it would require a sock, or

filter element, on the pickup side. It is important to note that the wiring used to run the pump will need

to meet requirements to be submersed in fuel. When wiring an in-tank pump, it is recommended to

use a wire that conforms to SAE specifications J1128 and J378. This wiring features a Thermoplastic

insulated wiring with polyvinyl chloride insulation for protection against gasoline, oil, and more.

In addition, different fuel line will be required internally if the pump is to be mounted in the tank. Fuel

line that meets SAE 30R10 specifications MUST be used. Failure to do so will cause severe damage

to your engine and/or fuel system.

WARNING: Improper installation or use of fuel system components can cause severe damage your

engine and/or fuel system that will not be covered by the manufacturer’s warranty.

Atomic Fuel Pump, PN 2925: This pump features 3/8” inlet and outlet. The pump will support

approximately 525 hp and is approved for in-tank use (no wiring or in-tank mounting hardware/

pickup element are supplied).

Fuel Pump Kit, PN 2920: This Kit is supplied with MSD’s PWM Fuel Pump, a pre and post-filter, 15-ft

of 3/8 fuel injection line and mounting hardware.

Fuel System Return Kit, PN 2922: If you plan on running a return line with your Atomic LS, this kit

provides another 15-ft of 3/8” injection line, an MSD Regulator and -6AN-to-hose fittings.

High Horsepower Fuel Kit, PN 2921: This pump will support the power demands of engines up to 650

horsepower. The pump features 3/8” inlet and outlet. The pump will support approximately 650

hp and is approved for in-tank use (no wiring or in-tank mounting hardware/sock are supplied).

WARNING: MSD's hose ttings are designed for use with MSD fuel hose only. Do not use the MSD

fuel hose with other fittings. Do not use MSD fittings with other fuel hose. Compatibility

issues may cause fuel leaks.

Page 5

INSTALLATION INSTRUCTIONS 5

WIDE BAND OXYGEN SENSOR INSTALLATION

The MSD Atomic EFI system requires a single Wide Band

02 SENSOR

Oxygen Sensor (WBO2) for operation. MSD suggests that

the bung for this sensor be installed prior to starting any

other part of the conversion process. By having the WBO2

in place first, there is a reduced chance of the vehicle

being immobilized for an extended time. The bung for

the WBO2 provided by MSD has a plug included so that

POSITION

AT LEAST

10°

the vehicle can be driven between the time of exhaust

modification and installing the rest of the Atomic system,

if needed.

The WBO2 can be installed in downstream of either

EXHAUST

COLLECTOR

Figure 2 WBO2 Sensor Location.

exhaust bank. The sensor connects to the Power Module,

so install the sensor on the bank closest to where you

plan to mount the Module. The bung should be installed by a qualified exhaust technician and pressure

tested. Proper installation of the oxygen sensor is critical to the performance of the Atomic EFI. Improper

installation could lead to engine damage.

1. Locate the ideal spot to install the WBO2.

a. This location should be 2-4 inches after the exhaust collector. The sensor must be more than

18 inches forward of the exhaust tip. For applications where short or open headers are used,

install the WBO2 in the primary tube of the rear cylinder at least 8 inches away from the exhaust

port. The Atomic will not work on “Zoomie” style headers.

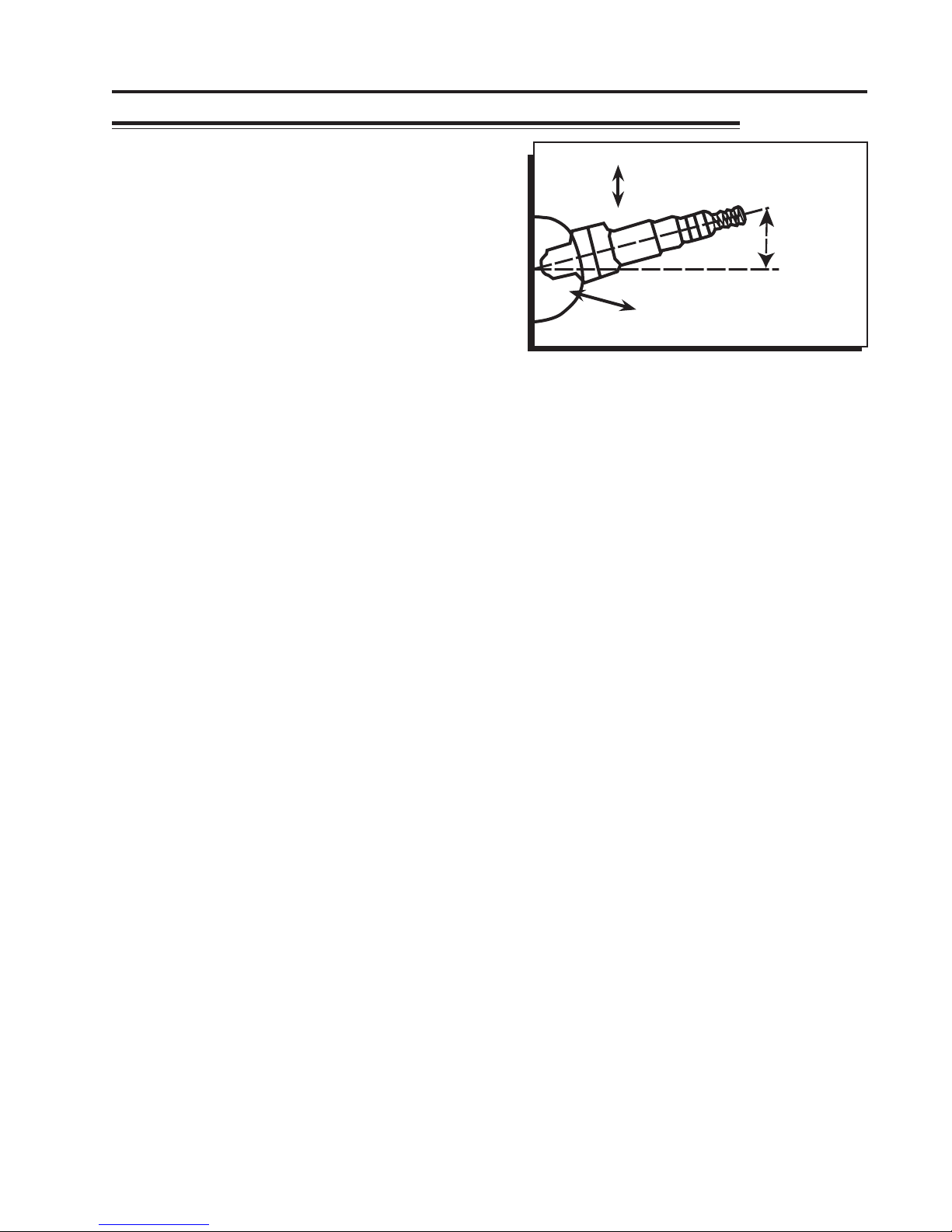

b. The WBO2 sensor should be at least 10˚ above horizontal to allow condensation runoff. Without

this angle the sensor is significantly more likely to sustain water damage (Figure 2).

c. Never place a WBO2 on the outside of a bend.

d. The WBO2 must be mounted in the exhaust prior to any catalytic converter, if applicable.

2. Drill a 7/8” hole in the exhaust where the WBO2 will go.

3. Weld in the supplied bung. Ensure the weld goes completely around the bung and is air tight.

4. Insert supplied plug in bung. Never run the vehicle with a WBO2 installed but not powered; it will

damage the sensor.

5. When completing the Atomic EFI installation, remove the plug and insert the WBO2 for use. MSD

suggests using a small amount of anti-seize on the threads.

Note: The Atomic EFI is extremely sensitive to air leaks in the exhaust system. Any air leak between

the engine and the WBO2 will cause the Atomic to have false readings, which can lead to poor

engine performance, misfires, and an inability to properly auto-tune. Extended running of the

Atomic EFI with an exhaust leak can result in detonation and severe engine damage. Improper

installation of the oxygen sensor, and any damage that may result from such an installation, is

not covered by the manufacturer’s warranty.

Page 6

6 INSTALLATION INSTRUCTIONS

INSTALLING THE INTEGRATED FUEL/ECU RAILS

The integrated fuel/ECU rails are supplied with the covers installed. The rails are designed to install to OEM

intake manifolds and many aftermarket designs. To prepare the rails for installation, locate the four intake

manifold bolts supplied with the Atomic LS Master Kit, as well as the four mounting brackets.

It is important to note at this point, that you have the correct injectors for your application as well as O-ring

seals and the injector retainers. These components are not supplied in the master kit.

WARNING: Care must be used when installing the fuel injectors and rail assemblies.

COVER

COVER

FUEL RAILFUEL RAIL

LIFT THIS SIDE OF

COVER ENOUGH TO

CLEAR FUEL RAIL

The following steps will guide you

through the installation of the two fuel

rail assemblies.

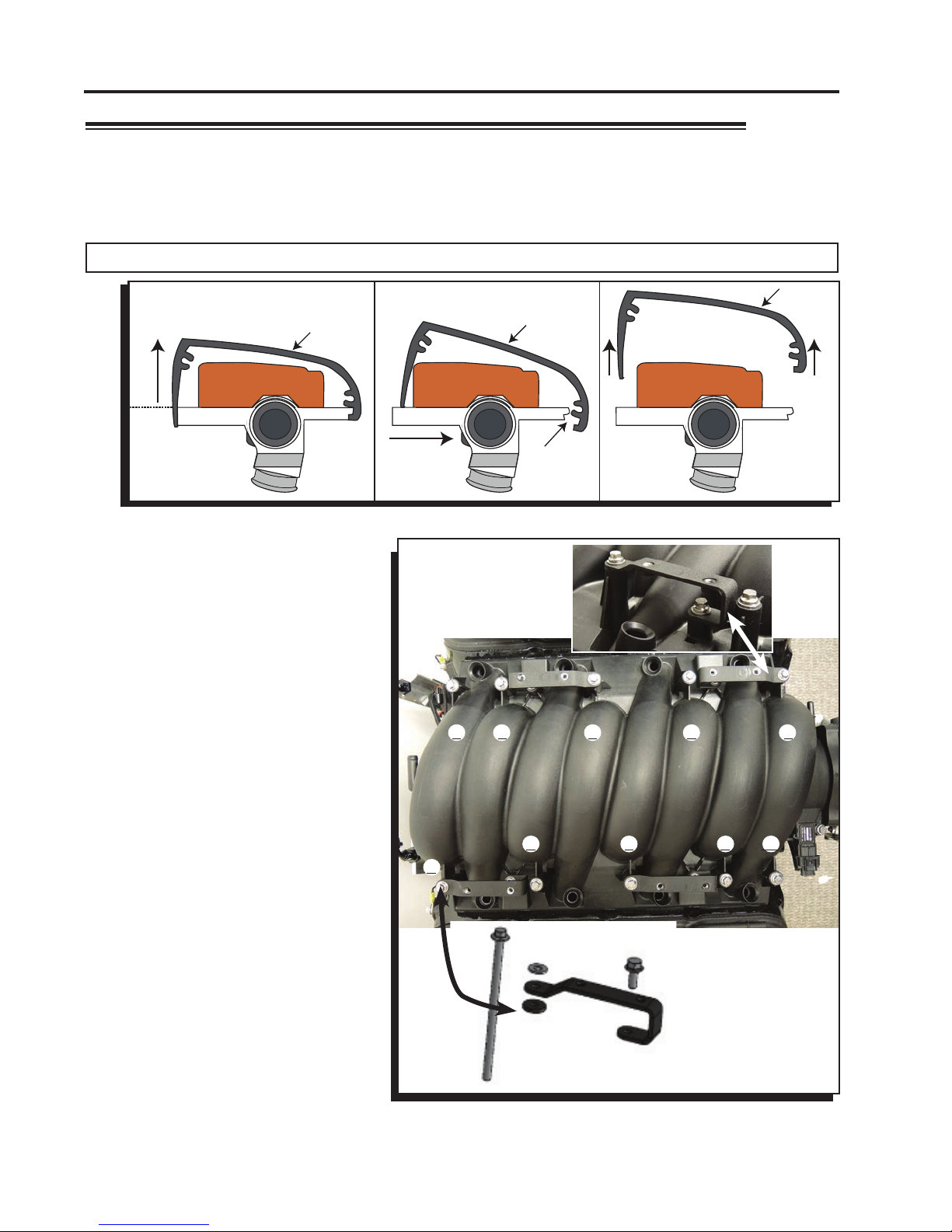

1. The fuel rails are supplied with

the covers in place. Remove the

covers to prepare and install the

rail assemblies (Figure 3). Also,

determine which rail is which by

reviewing the sensor connectors

and location as shown in Figure 9

on page 8.

2. Figure 4 shows the location for the fuel

rail brackets. Remove the hardware

from the intake manifold and install

the brackets as shown using the

supplied longer intake bolts. Use

GM 1245383 thread sealant or

equivalent on the intake manifold

bolts. Note that the passenger rear

bracket requires a spacer (supplied)

as shown in Figure 4. Torque the new

intake bolts to 89 in-lbs.

NOTE:

If installing the intake manifold

for the first time follow the

torque sequence in Figure

4. Torque in steps; 44 in-lbs

first, followed by 89 in-lbs.

It is recommended to hold

a straight edge against the

brackets to ensure alignment

while torquing.

COVER

FUEL RAILFUEL RAIL

PUSH COVER

DISENGAGE

FROM FUEL

RAIL

Figure 3 Removing Fuel Rail Covers.

REAR

9 3 2 6 7

REAR FRONT

5 1 4 10

8

Figure 4 Fuel Rail Bracket Locations.

LIFT COVER UP

FUEL RAILFUEL RAIL

BRACKET

NOTE: THE PASSENGER

SIDE REAR MOUNT

REQUIRES THE

SUPPLIED SPACER.

TORQUE SEQUENCE

STEP 1 - 44 LBS/INCH

STEP 2 - 89 LBS/INCH

MUST USE THREAD SEALANT

Page 7

INSTALLATION INSTRUCTIONS 7

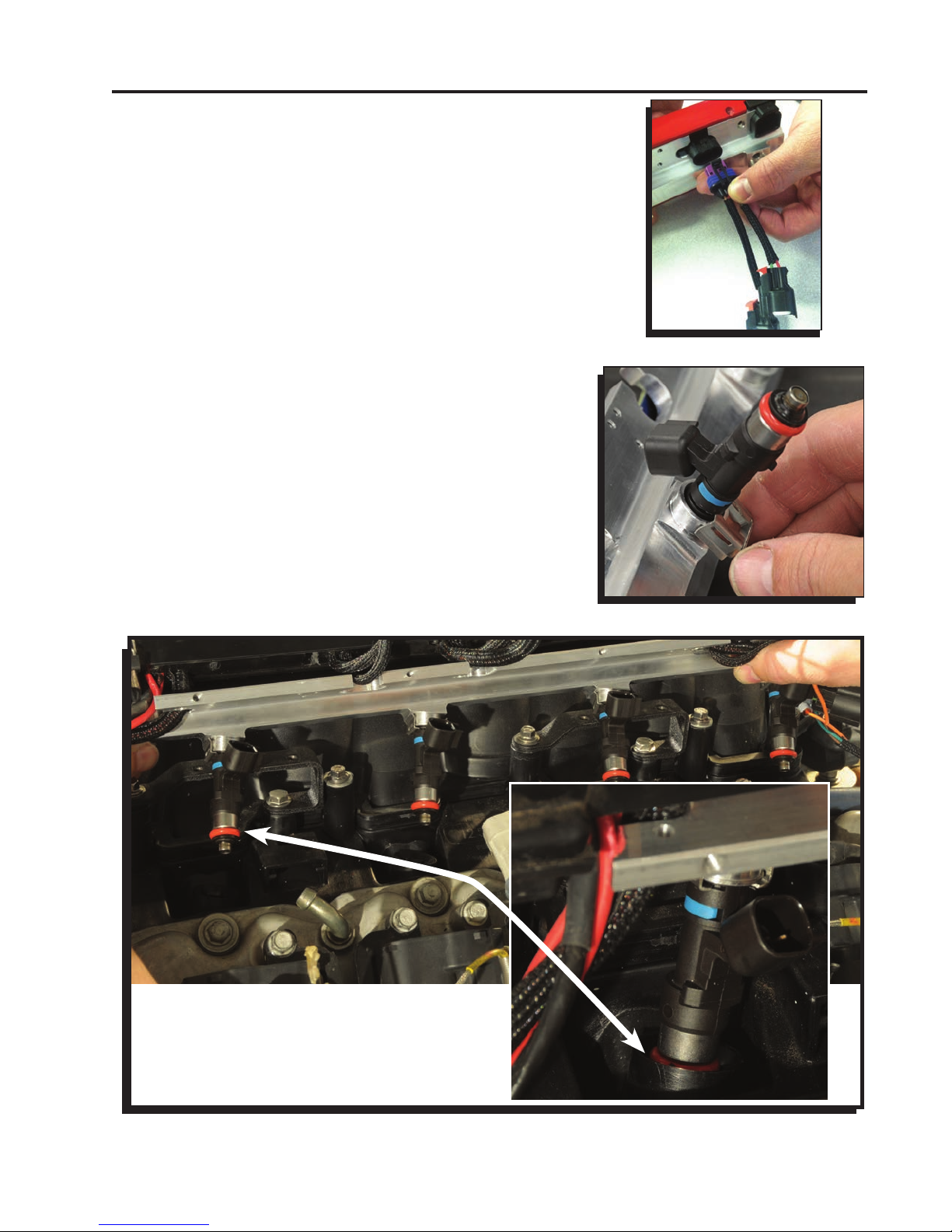

3. Locate the four injector harness pigtails. These need

to be connected to the fuel rails (Figure 5).

4. With the brackets and injector pigtails installed on the

intake manifold, it is time to install the injectors to the

fuel rails. Apply a dab of engine oil to the o-ring seals

of the injectors. Insert the injector with its connector

facing towards the outside of engine into the fuel rail.

Install the injector retainer securely and check that it

is properly installed and sealed to the rail (Figure 6).

Continue with the other three injectors.

5. With the injectors installed, it is time to install the fuel

rail assembly to the engine. Position the rail assembly

over the intake manifold with the injectors aligning

Figure 5 Connecting Injector Pigtail.

with their mounting pockets on the intake (Figure 7).

6. With the injectors lined up, lightly press down on the

fuel rail using caution not to bind any of the injectors

or connectors. The fuel rail assembly should come

close to contacting the manifold brackets with very

little pressure. Use caution not to bind or tear any

injector O-rings.

ENSURE THAT THE

INJECTORS AND O-RINGS

SETTLE INTO THE POCKETS

WITH NO BINDING.

Figure 6 Installing the Injectors.

Figure 7 Installing the Rail Assemblies.

Page 8

8 INSTALLATION INSTRUCTIONS

7. Install the retaining bolts and washers to secure

the fuel/ECU rails to the mounting brackets. Move

between the retainers as they are tightened to ensure

even pressure (Figure 8).

8. Connect the injector wiring, coil packs and other

wiring.

9. Repeat (Figure 9) the procedure for the opposite

engine bank.

Figure 8 Tighten the Fuel Rail Bolts.

TO

POWER

MODULE

PASSENGER

SIDE

CAN

PWR

PWR

CRANK

GND

FGH

MAP

INJ8

INJ6

COILS

2468

CAN

OIL

INJ5

COILS

1357

INJ7

FPS

CAM

GND

PWR

DRIVER

F

G

H

SIDE

**FOR DUAL THROTTLE

BODIES

**FOR ENGINES WITH

V V T OPTIONS

INJ3

INJ4

INJ1

INJ2

AC

IAT

D LPHI

D LPHI

IAC2*

ETC2/

V V T**

(NOT USED)

ECT

IAC

ETC1/

TPS

ALT

NOTE: PAGE 18 SHOWS PINOUTS FOR THE COIL CONNECTORS AND IAC.

Figure 9 Fuel Rails and Connections.

Page 9

INSTALLATION INSTRUCTIONS 9

Fuel Inlet Fittings and Cross-Over Line: LS

engines require a cross-over fuel line to route

the fuel from one bank to the other. This is

typically done at the front of the engine. (Figure

10) Due to the variety of intake manifolds and

accessories, a cross-over line must be made

for each application

Figure 10 Installing Fuel Hose to AN Fittings.

CORRECT CLEAN,

SQUARE CUT

MSD supplies a length of fuel hose and two 90°

-6AN fittings to prepare a fuel crossover line. The fittings

are designed for use with the supplied hose and clamps.

Proper installation begins with a clean, square cut of

the hose. A hose cutting tool or a new razor blade are

INCORRECT

JAGGED, ROUGH

CUT

recommended. When installing the hose, it is important

that the hose is pushed all the way to the backstop. The

clamp must be centered between the fitting rib and the

backstop before it is tightened.

Figure 11 Severing the Hose Properly.

1. Determine the length of hose needed. Mark the hose

and cut it using a hose cutter or new razor blade.

There should be minimal disturbance of the jacket and

braids. The cut plane should be perpendicular to the

hose axis (Figure 11).

CLAMP

2. Before installing the hose to the fitting, it is important to

anchor the fitting (Figure 12). Proper installation may

be difficult when holding the hose and fitting with your

hands. For best results, the hose should be installed

with minimal twisting or pausing.

3. Apply a light coating of oil to the rib on the fitting. Use

care not to get oil on the outside of the hose as it will

be impossible to maintain a grip on the hose.

4. With the fitting anchored securely, push the hose

over the fitting until it bottoms against the backstop.

Center the clamp between the rib and backstop before

tightening (Figure 13).

WARNING: The supplied MSD AN Fittings are

designed only for use with the supplied

fuel hose. We do not recommend

mixing fittings and hoses from different

manufacturers. Doing so may result in

fuel leaks and expose other dangerous

incompatibilities.

CLAMP

Figure 12 Installing Fuel Hose to the Push-Lock Fittings.

Properly Installed Clamp and Fitting

END OF HOSE IS FLUSH

WITH BACKSTOP

CLAMP IS CENTERED

BETWEEN RIB AND

BACKSTOP

Figure 13 Installed Fitting and Clamp.

Page 10

10 INSTALLATION INSTRUCTIONS

POWER MODULE INSTALLATION

The Power Module of the Atomic EFI system handles

high current circuits such as the fuel pump and WBO2.

The unit has two ports for the MSD CAN system as

well as a wiring harness. The CAN ports will provide

LS

CONTROLLER

®

communication between the Power Module, the

passenger side fuel/ECU rail and the Handheld Monitor.

It is important to select a proper mounting location for the

Power Module. The unit can be mounted in the interior

or the engine compartment as long as it is away from

direct heat sources. It is not recommended to mount the

unit in an enclosed area, such as the glovebox. When

a suitable location is found, make sure all wires reach

their connections. Also be sure that the CAN port can

be accessed for use with the Handheld Monitor.

Figure 14 Power Module Wiring Diagram.

Use the Power Module as a template and mark the location of the holes. Use a size #20 drill bit to

prepare for the supplied self tapping screws. Install the supplied rubber grommets (Figure 14).

POWER MODULE

WIRING

There are a number of

electrical connections on

the Power Module that

are required for proper

operation (Figure 15). Other

wires, such as the nitrous

input, 2-step rev control or

electric fan controls, only

need to be connected if

their optional functions are

being used. In the chart

below, wires marked “REQ”

must be connected for the

system to operate while

those marked “OPT” are

optional depending on

the features being used.

For the installation it is

recommended to connect

only the required wires.

FUEL PUMP

GROUND

BATTERY 1*

BATTERY 2*

* BATTERY 1 AND 2

MUST BOTH BE

CONNECTED

ORANGE

BLACK

HEAVY RED

HEAVY RED

CONTROLLER

®

LS

CAN

ONLY

RED SLED POWER

RED FAN 1

DARK BLUE LAUNCH

BROWN/WHITE NITROUS

BROWN SPEED REF (-)

LT BLUE SPEED (+)

GRAY TACH

RED SW 12V

ORANGE FAN 2

LT GREEN MIL GROUND

IP

RED

VM

YELLOW

H-

BLK/WHT

H+

BLK/RED

IA

GREEN

UN

BLACK

MONITOR

CONNECTOR

ONLY

HANDHELD

MONITOR

CAN TO

PASSENGER

FUEL RAIL

TO PASSENGER

FUEL RAIL

Figure 15 Power Module Wiring Diagram.

Page 11

INSTALLATION INSTRUCTIONS 11

Power Module

Pin

1

2

4-Way

Deutsch

CONNECTOR

3

4

A

B

C

Color

Red

Black

Orange

Red

Red

Blue

Bro/Wht

Use

REQ

REQ

REQ

REQ

OPT

OPT

OPT

Function

Battery 1, Connect to Positive Battery terminal.

Ground, Connect to solid, clean engine ground.

Pump, Connect to Fuel Pump Positive terminal.

Battery 2, Connect to Battery Positive terminal.

Fan 1, Supplies ground to activate Fan 1

Launch, Connect to 12 volts to activate 2-step RPM limit.

Auxiliary Timing and Fuel, When supplied with 12 volts, timing

will be retarded and the air/fuel ratio will be corrected to the

target auxiliary setting.

D

Brown

E

Lt Blue

F

Gray

G

Red

H

Orange

J

Red

CONNECTOR

GT Series 16 Way

K

L

M

N

P

R

S

Red

Yellow

Blk/Wht

Blk/Red

Green

Black

Lt Green

OPT

OPT

OPT

REQ

OPT

REQ

REQ

REQ

REQ

REQ

REQ

REQ

OPT

Speed Ref.

Speed Signal

Tach, Supplies 12V square wave signal

Switched 12V, Connect to ignition switch

Fan 2, Supplies ground to activate Fan 2 at desired temperature.

Supplies power to the Fuel Rail

IP

VM

H-

WBO2

H+

IA

UN

MIL Ground

It is recommended to connect a Malfunction

Indicator Lamp (MIL) to your dash. A simple

bulb is required with switched 12 volts on

one side and this Light Green wire on the

ground side. If there is a malfunction in the

system, ground will be supplied through this

wire to illuminate the lamp.

Wire

(2)

Black wires w/ring lugs

(1)

Orange flying Lead

REVIEW YOUR INSTALLATION

It is recommended to review your installation at this point. The 02 Sensor should be installed and connected as

well as the Power Module and corresponding wiring. Confirm that all of the rail wiring connections are complete

including the injectors and sensors. Ensure all fuel lines and fittings are tight and secure from any heat sources or

sharp edges. The next section will require powering the Atomic LS to go through the Initial Setup menus and the

fuel pump will run. DO NOT START THE ENGINE AT THIS TIME!

Sleds

Function

Coil ground wires that should be attached to the cylinder

heads.

A/C kick up wire. This should be wired to a source that

gets 12V then the A/C compressor clutch is engaged. This

will open the IAC up slightly and will also kick on fan #1

regardless of coolant temperature.

STOP HERE

Page 12

12 INSTALLATION INSTRUCTIONS

ENGINE IDENTIFICATION INFORMATION

has produced a number of different LS based engine

GM

platforms. When setting up your Atomic LS system, it is helpful

to know the model engine you have. If you don’t know what

engine you have, locate the casting number on the back of the

block, below the driver's side cylinder head (Figure 16). That

number will assist in determining what engine you have. If

you still have no idea of your engine’s origin, you can select

a base calibration from the menu to get the engine started.

Figure 16 Casting

WARNING: DO NOT ATTEMPT TO START THE ENGINE. Before turning the ignition key to the

ON position, confirm all fuel line connections are tight and all electrical connections

are correct. After confirming all electrical connections and fuel lines, turn the ignition

key to the ON position. Check every hose and fitting connection for any signs of fuel

leaks. The Handheld screen should illuminate and display the Main Menu.

PROGRAMMING

The Handheld Monitor plugs into the Power Module via the

CAN connection. It can be removed once the initial setup is

complete, or can remain connected for use of features such

as the dash or digital gauge displays. The Handheld Monitor

features a joystick to scroll through the settings. Scroll up and

down to the setting and push the joy stick to the right to select

the options. When the selection is made, either push in, or

go back (push to the left) to save/confirm settings changes.

MAIN MENU

Six selections will come up the Monitor under the Main Menu.

If this is the first time powering up the Atomic LS, select Initial

Setup (Figure 17).

Atomic LS Dash: This selection allows you to view a variety

of engine functions in real time when the engine is

running. Refer to page 19 for a complete description

of each parameter in the Atomic Dash.

Atomic LS Gauges: This setting puts five important values

in gauge form to ease viewing the data. This includes

engine rpm, oil pressure, engine coolant temperature,

speed (when connected), battery voltage, and air/fuel

ratio.

Initial Setup: These are values that are required to start the

engine.

Advanced Setup: Optional settings for features and optimized

drivability settings.

Diagnostics: This screen will help you troubleshoot and

identify potential issues.

Display Setup: Provides adjustments for the appearance of

the monitor screen. See page 18 for more information.

Main Menu

Atomic LS Dash

Atomic LS Gauges

Figure 17 Monitor Main Menu

Page 13

INSTALLATION INSTRUCTIONS 13

INITIAL SETUP PROGRAMMING

Scroll down to Initial Setup and push the joystick to the right.

The following parameters must be programmed.

Engine Type: This value determines the engine platform (Figure

18). There are over 26 engine combinations to select

from. This setting is important as once an engine type

is programmed, other settings will default to the OEM

components that were supplied on that engine.For

example, if LS1 is selected, the coil, injector and MAP

sensor will automatically set to the OEM components.

Engine Size: Once the engine type has been selected, the

stock cubic inches will automatically be set. If the engine

has been modified with a different stroke or bore, select

and input the size. The range is from 100-800 cubic

inches (Figure 18).

Camshaft Type: There are three cam selections to choose;

Street/Stock, Mild and Performance. Note that if the

lobe separation angle (LSA) is less than 108°, it is

recommended to input the next larger cam. Cams with

over 250° are not recommended for use with the Atomic

LS system (Figure 18).

Handheld Main Menu

Engine Type

CAM

DURATION AT .050"

Street Stock Less than 210°

Mild 211° - 230°

Performance 231° - 250°

Coils: Once the engine type is selected, the OEM coil pack

will be automatically loaded in the default calibration

file. If a different coil or an MSD LS Coil pack is used,

change the setting to the correct coil type (Figure 18).

Note: There is a setting in Display Setup labeled User Mode.

When User Mode is changed from Basic to Advanced,

the coil selection menu will open up to all the coil

combinations preprogrammed into the Atomic LS

system.

Engine Size

Camshaft Type

Coils

Figure 18

Page 14

14 INSTALLATION INSTRUCTIONS

Fuel Injector: Once the engine type is selected above, the

OEM style injector will be automatically loaded in the

default calibration file. If a different injector is used,

change the setting to the correct injector. Most LS

based injectors have the part number stamped on

them (Figure 19).

Note: There is a setting in Display Setup labeled User

Mode. When User Mode is changed from Basic

to Advanced, the fuel injector selection menu

Fuel Injector Type

will open up to all the fuel injector combinations

preprogrammed into the Atomic LS system.

This setting will also unlock a setting called

User Defined. User Defined allows the injector

flow rate to manually be entered by selecting

Set Calibration (Figure 19).

MAP Sensor: Once the engine type is selected above, the

OEM MAP Sensor will be automatically selected.

(Figure 19).

Fuel Injector

Note: There is a setting in Display Setup labeled User

Mode. When User Mode is changed from Basic

to Advanced, the MAP sensor selection menu

will open up to all the MAP Sensor combinations

preprogrammed into the Atomic LS system.

This setting will also unlock a setting called

User Defined. User Defined allows the Slope

and offset to manually be entered by selecting

Set Calibration.

Injector Lbs/Hr

Fuel Pump Type: There are three selections for the fuel pump

system. Select the system in use with the Atomic LS

system (Figure 19).

• Pulse Width Modulated: This selection is used

only when running a returnless fuel system with NO

regulator.

• Non-PWM with Regulator: This selection is used

when running a return style system with a regulator.

• PWM with Regulator: This selection is used when

running a return style system with a regulator. It will

run the pump at 50% duty cycle at idle producing

quieter pump operation and will increase the duty

cycle to 100% as the throttle and injector load

increase.

Note: It is recommended to use Non-PWM with a regulator

when setting fuel pressure as the PWM setting may

decrease fuel pressure slightly at idle.

Map Sensor

Fuel Pump Type

Figure 19

Page 15

INSTALLATION INSTRUCTIONS 15

Idle RPM Target: Select the rpm that the engine should idle

at. The rpm range is adjustable in 25 rpm increments

(Figure 20).

Note: Running too high of an idle speed in an automatic

transmission equipped vehicle with a stock torque

converter can cause idle issues in gear. The IAC counts

should be set at approximately 10-30 in neutral with the

engine warmed up, running and the A/C off. This is

done by opening or closing the throttle blade. It must

be set after the commanded idle is entered here.

Idle RPM Target

Rev Limit: The rev limiter can be set as a fuel cut-off or ignition

cut-off limiter. The default setting is as a fuel cut-off

limiter set at 6500 RPM. The programming range for

both rev-limiters is 3000 RPM-10,000 RPM (Figure 20).

The ignition cut should only be used on race vehicles

with a very free flowing exhaust. DO NOT use with

catalytic converters or severe damage may result!

Rev Limit

Once all of the settings in the Initial Setup menu are selected,

the Atomic has enough information to start and run the engine.

It is recommended to scroll through the advanced settings to

program selections that may be useful after the initial start up

(such as the cooling fan activation temperatures).

ADVANCED SETUP

The Advanced Setup features are optional as the Initial Setup

menu provides the Atomic EFI with the values needed to run

the engine. Features in the Advanced Menu are designed to

deliver additional features and advanced tuning functions to

further enhance the drivability and overall performance of the

engine.

Fans: This setting sets the temperatures to activate two electric

fans. Each circuit will be activated by supplying ground

through the Red (Pin A) and Orange (Pin H) wires of

the GT-Series 16 pin harness from the Power Module. A

relay is required for both circuits since those wires are a

low current ground. The fans will activate at the desired

temperature and will remain on until the temperature

falls below 10° of the setting. Settings are 100°-300°F

(Figure 20).

Advanced Setup

Fans

Figure 20

Page 16

16 INSTALLATION INSTRUCTIONS

A/F Targets: The Atomic LS provides an option to set an air/fuel

target for Idle, Part Throttle, Wide Open (WOT), Boost and

an Auxiliary setting. The Atomic will use its self-learning

technology to adjust the fuel delivery to meet the target air/

fuel ratio. The values are adjusted in 0.1 increments and

range from rich at 10:1 to dead lean at 16:1. The ideal air/fuel

ratio for cruising is called stoichiometric and is commonly

referred as a 14.7:1 air/fuel ratio.

Boost: The Atomic will switch to the commanded boost

A/F ratio once the manifold pressure reaches

A/F Targets

110Kpa (approximately 16 psia - 32.5in/Hg)

(Figure 21).

Ignition Timing: The Atomic provides a base timing table for each

engine application. These values can also be modified to

compensate for CARB approved accessories. Each setting

is adjustable +/-10°. Note that the values programmed

are set for stock engines using 91 octane fuel. For lower

octane fuels it is recommended to retard the timing 5° as

a starting point. Timing can be retarded up to 20° in 0.1°

increments. Note that in order to alter the timing for auxiliary

Igniton Timing

use, the Auxiliary Selection in the Advanced menu MUST be

programmed to ENABLE. When 12 volts are applied to the

Brown/White wire (Pin C), the timing will retard (Figure 21).

TPS Enrichment: To assist in throttle transitions the Atomic EFI has

a feature to increase fuel delivery by a prescribed percentage

any time there is an increase in throttle position. If needed,

make small changes in no more than 5% increments without

further testing. Most engines will find 25% sufficient. Most

applications will accept 15%-35% enrichment. Adjustable

from 0-100% in 1% increments (Figure 21).

MAP Enrichment: To assist in manifold pressure transitions the

TPS Enrichment

Atomic EFI offers a MAP enrichment feature. This function

adds fuel based on MAP transitions while moving the throttle.

Large cam vehicles with low vacuum generally required a

slightly smaller number while stock/small camshaft vehicles

with a high vacuum may require more. If needed make small

changes of no more than 5% increments without further

testing, 25% is sufficient for most engines but between 1535% is normal. Typically, the higher the vacuum the higher

the percentage needed. Adjustable from 0-100% in 1%

MAP Enrichment Setting

increments (Figure 21).

2-Step: This setting will rev-limit the engine at the programmed RPM

when the Blue wire is activated with 12V. The 2-Step setting

is used in drag racing applications to help launch the car at

a consistant RPM. The blue wire is normally connected to a

clutch switch or a brake switch. The default setting is 10,000

RPM and can be adjusted from 1000 RPM to 7500 RPM in

25 RPM increments (Figure 21). The ignition cut should only

be used on race vehicles with a very free flowing exhaust.

DO NOT use with catalytic converters or severe damage

2-Step RPM Limit

may result!

Figure 21

Page 17

INSTALLATION INSTRUCTIONS 17

Auxiliary: When switched to Enabled, this setting will ready

the Auxiliary timing retard and Air/Fuel Ratio settings

to compensate for approved accessories when the

Brown/White wire is connected to 12v. The default

setting is DISABLED (Figure 22).

Calibrate Speed: If there is speed output on the transmission,

a reference signal can be delivered to the Atomic

LS. On manual transmission equipped vehicles, the

Calibrate Speed option improves drivability when

transitioning from high RPM conditions to an idle

Advanced Setup

(such as comming off of a hill / between moving and

coming to a complete stop). The Power Module has

a Brown (Pin D) wire and a Light Blue (Pin E) wire.

These wires connect to a magnetic pickup monitoring

driveshaft speed with a collar mounted on a yoke. To

program the calibration, drive to 40mph on an open

road to maintain speed. Once at 40mph, select YES

on the handheld. This will calibrate the speed input.

This option will also enable a speedometer reading in

the handheld Atomic LS Dash (Figure 22).

Enable or Disable Nitrous

Note: Use of a minimum four magnet collar is

recommended with this option.

Racepak Dash: This setting allows the Atomic LS kit to

interface with a Racepak dash such an IQ3. Disable

is the default setting. Racepak offers an optional V-net

sensor to connect their dash to the MSD Can-Bus

connector (Figure 22).

Speed Reference Setting

Racepak Dash Option

Figure 22

Page 18

18 INSTALLATION INSTRUCTIONS

PRE-START CHECK LIST

Before attempting to start the motor, run through the pre-start check list to ensure a safe and successful

start.

• Double-check all wiring

• Power and ground leads are connected directly to the battery.

• Red (Pin G) should be connected to a 12v ignition source that is hot in the RUN and START positions

of the key cycle.

• All wiring, modules, and fuel components are mounted away from heat sources such as exhaust

and pinch points.

• Wideband O2 sensor is installed and plugged into the Power Module

• There are no exhaust leaks.

• The throttle linkage is connected and moves freely with no binding.

• The initial programming has been set in the handheld menu.

• Key on the ignition a few times to prime the fuel pump. The fuel pressure may need to be adjusted

to 58-60psi. Fuel pressure can be monitored in the Atomic Dash section of the handheld menu.

• With the fuel system under pressure from priming the system, check for leaks or fuel spraying. Do

not attempt to start the engine if fuel leaks are present.

• Monitor Engine RPM in the Atomic Dash in the handheld unit as the engine is cranked over to

ensure the crank sensor is providing an RPM signal.

HANDHELD DISPLAY OPTIONS

Display Setup: The display Setup controls the look of the

handheld unit and the Firmware version. The Atomic

LS can be reset to factory default in this section as well

(Figure 23).

LCD Contrast: Adjust the contrast on the LCD screen if it is

hard to see the display. Contrast is adjusted using the

joystick to go up or down in five percentage increments.

Backlight Level: The brightness of the screen is determined

by this setting. The Backlight Level may need to be

adjusted depending on outside light levels. Brightness

is adjusted using the joystick to go up or down in five

percentage increments (Figure 23).

Display Units: The Atomic can display items in either English (cubic inches, Fahrenheit) or Metric

(liters, Celsius). Set Atomic Defaults: Use this feature to reset the Atomic EFI. Selecting “YES”

on this screen will take all setting, including fuel maps, back to the factory defaults. This can

be done when installing the Atomic on a different engine, or for troubleshooting reasons

(Figure 23).

User Mode: This setting can be changed from Basic to Advanced. When the User Mode setting is

changed to Advance the fuel injector selection menu, coil selection menu, and the MAP sensor

menu will open up to all the combinations preprogrammed into the Atomic LS system. The

fuel injector flow rate and MAP sensor Slope and Offset can be manually entered by selecting

user defined in the selection menu (Figure 23).

Set Atomic Defaults: This setting resets all the programming parameters to the default settings out

of the box (Figure 23).

Firmware Versions: The Atomic Firmware version can be found in this section (Figure 23).

Figure 23 Monitor Display Selections.

Page 19

INSTALLATION INSTRUCTIONS 19

The Atomic LS Dash is a live display when the engine is running.

This is a brief description of each parameter in the Atomic LS Dash.

ATOMIC LS DASH:

Tach Displays engine RPM.

Speed Displays Speed if speed if speed sensor is equipped and calibrated.

ECT Displays coolant temperature.

IAT Displays intake air temperature.

TPS Displays throttle position sensor percentage.

BARO Displays barometric pressure

MAP Displays manifold absolute pressure

FUEL PRESS Displays fuel pressure.

OIL PRESS Displays oil pressure.

BAT VOLTS Displays battery voltage.

A/F RATIO Displays air/fuel ratio.

INJ DUTY Displays injector duty cycle.

IGN TIMING Displays ignition timing.

IAC POS Displays idle air control motor position.

THROTTLE Displays throttle condition closed/part/WOT (Wide Open Throttle)

CLOSED LOOP Displays closed loop on or off.

LEARNING Displays Atomic LS learning on or off.

FAN 1 Displays Fan 1 on or off.

FAN 2 Displays Fan 2 on or off.

DECEL FUEL Displays if decel fuel is active

IDLE COND Displays if engine is in an idle condition

FLOOD CLEAR Displays if throttle is in a flood clear condition (no fuel will go in)

REV LIMIT Displays if the rev limiter is active

TWO STEP Displays if the two step is active.

AUXILIARY Displays if the Auxiliary timing/AFR is active.

Page 20

20 INSTALLATION INSTRUCTIONS

DIAGNOSTICS

There is a self-diagnosing system built into the Atomic EFI. Each

covered parameter can show a status in one of three ways

(Figure 24).

• “OK”: the parameter is functioning normally.

• “Error C”: there is currently an error occurring.

• “Error H”: A previous error that has been reset since it did

not reoccur within the last ten ignition cycles.

The following chart gives the most likely solution(s) to each

possible error.

Figure 24

CLEARING HISTORY ERRORS

CODE NAME

TPS

MAP

IAT

ECT

BATT

INJ DC

FUEL

PRESSURE

WBO2

WHAT IT MEANS

There is no reading for the Throttle Position Sensor.

There is no reading for the Manifold Absolute Pressure Sensor.

There is no reading for the Inlet Air Temperature Sensor. The ECU will default

to 275°F when shorted or -40°F when

open.

There is no reading for the Engine Coolant Temperature Sensor. The ECU will

default to 275°F when shorted or -40°F

when open.

The Atomic is receiving the wrong voltage. The unit is measuring either less

than 9 volts or greater than 16 volts.

Excessive Injector Duty Cycle

There is no reading for the Fuel Pressure

Sensor.

A. "NOT CONNECTED" indicates that no

sensor is detected.

B. "ERROR" indicates that the sensor

has failed.

PROBABLE CORRECTION(S)

The sensor may be at fault. Check wiring and/or replace sensor.

The sensor maybe at fault. Check wiring and/or replace sensor.

Faulty sensor; loose or no connection. Check wiring and/or replace sensor.

Faulty sensor; loose or no connection. Check wiring and/or replace sensor.

Check the battery connection from the Power Module to the

battery. Ensure that the battery and alternator are working correctly.

If you are running a returnless fuel system, your engine's needs

may exceed the Atomic's maximum capabilities. If you are run-

ning a return system check to see that you are maintaining the

recommended fuel pressure. If you have adequate fuel pressure the engine's needs may exceed the Atomic's system capabilities.

Faulty sensor; loose or no connection. Check wiring and/or replace sensor.

A. Check to see that the sensor is securely plugged into the

system. Inspect wiring if it is plugged into the system.

B. The sensor will need to be replaced.

Note that 'warming up' is normal during start-up for the rst 20

seconds.

FP CAV

MAP SELECT

BARO

This code will set if there is an issue with

Fuel Pump Cavitation (similar to vapor

lock). It can only set when running a

returnless fuel system. This may occur

when the commanded fuel pressure

(from the ECU) is different than the fuel

pressure (at the sending unit).

ECU compares the MAP reading with

the Baro reading on key up. If these are

different by more than 5kPa, the code

is activated.

The Baro sensor voltage is out of range,

and the ECU has defaulted to the last

known good Baro value.

Check the fuel system and etermine that it meets the requirements

to run a returnless (PWM) system. Check the filters, the sock in

the tank, and inspect the lines for any kinks or pinches that

would affect the fuel flow and pressure of the system. If the code

continues, the fuel system may need to be converted to an in-tank

fuel pump and/or regulated (return) fuel system.

Double check your MAP selection and make sure that you

selected the correct P/N of sensor. It could also mean a problem

with the Baro or MAP sensor itself (see above codes).

Turn the ignition off. Wait 10 seconds, and turn the ignition

back on. If the code remains, call customer service. Unless the

vehicle has been through a large change in altitude since the

last ignition on/off cycle (towed somewhere), everything will

function normally.

Page 21

INSTALLATION INSTRUCTIONS 21

CLEAR FLOOD

If a flood condition occurs, turn the key on then press the accelerator to wide-open throttle. This tells

the ECU to turn off the injectors. Crank the engine to clear the flood condition until the engine starts

(release the throttle).

Note: The TPS is self calibrating so the key must be in the ON position prior to pressing the accelerator.

INSTRUCTIONS FOR UPDATING THE ATOMIC EFI

In

order to update the Atomic EFI you will first need to download the updated files. (Right click and

choose "Save Target As" if it doesnt download automatically)

UPDATED: 05-31-13 Version numbers below.

ALL THREE UPDATES MUST BE DONE SIMULTANEOUSLY

1. The update will reset all settings in the Atomic EFI.

a. Be sure that you make note of all settings in the Initial and Advanced Set-ups prior to performing

the update.

Download the update files.

2.

a. Be sure they are saved in a place that you will find them (the desktop is often the best place to

save them).

b. DO NOT rename the files, the Atomic EFI will only recognize files with the names assigned by

MSD.

3. Transfer the files to the Micro-SD Card that came with the Atomic.

You will need an SD Card reader for

this – if you do already not have a reader, they can be found

at most electronics stores.

a. Open the Micro-SD card’s window on your computer.

b. Drag and drop the MSD files into the folder.

c. The files must remain in the main folder do NOT put them in a sub-folder.

4. Move the Micro-SD card to the Atomic EFI’s Handheld

5. Ensure the Handheld is plugged in to the Power Module

6. Turn the vehicle’s ignition switch to Key-On

a. Do not start the engine

7. At this time the Atomic will automatically update the Handheld.

a. This process will take approximately 30 seconds, do not remove power.

8. When the handheld update is complete you will be prompted to update the Atomic ECU as well.

a. Use the Handheld joystick see “YES” by pushing the joystick up.

b. Push the joystick in to accept.

9. At this time the Atomic ECU will be updated.

a. This process will take approximately 30 seconds.

b. The beginning of this process will display “Erasing” – this is normal, do not remove power.

c. The handheld’s screen will notify you when the update is complete.

10. Use the handheld’s joystick to go back (left) to the main menu.

11. Input all previous settings for the Initial and Advanced setups.

12. Enjoy your updated Atomic EFI.

You can check to see that the Atomic update is successful by looking at the version numbers on the

Handheld. To do so go to:

- Display setup

- Firmware versions

- Dash – 2.0.3

- EFI – 1.1.1

- P.M. – 1.0.7

Loading...

Loading...