Page 1

Atomic EFI

DANGER

DANGER

CAUTION

WARNING

NOTICE

DANGER

PN 2920 - Fuel Pump Kit, 525 HP

WARNING

modifications must be carried out by a qualified automotive technician. Installation of fuel system

parts requires handling of gasoline. Ensure that work is performed in a well ventilated area with an

approved fire extinguisher nearby. Extinguish all open flames, prohibit smoking and eliminate all

sources of ignition in the area of the vehicle before beginning the installation.

When working with fuel systems, eye goggles and other safety apparel should be worn to protect

against debris and sprayed gasoline. The finished work must be thoroughly checked to ensure

there are no fuel leaks.

Parts Included:

1 - Fuel Pump

1 - Small Parts Bag (screws, nuts & washers)

2 - Fuel Pump Clamps

1 - Pre Filter (pre pump)

1 - Post Filter (post pump)

15 ft 3/8" Fuel Line

WARNING

The Fuel Pump Kit, PN 2920, contains all the components necessary to set up a returnless fuel system

for the Atomic EFI. This means that a return line to the fuel tank is not required, which simplifies the

fuel system installation. This kit can also be used with the MSD PN 2922 return kit, if a return line to the

tank is needed.

A Returnless fuel system does have limitations depending on your application and a few other

variables. Please see the included addendum for determining whether a returnless system is right for you.

Installation of this product requires detailed knowledge of automotive systems

and repair procedures. Installation of fuel system parts and any fuel tank

Parts Bag:

1 - Clamp, Pre-filter

1 - Clamp, Post-filter

7 - Clamps, Fuel Line

2 - Self Tapping Screws

2 - Fitting, 6AN, 90°

2 ft. Black Wire

1 - 14g Ring Lug

The fuel system is under pressure. Do not open the fuel system until the pressure

has been relieved. Refer to the appropriate vehicle service manual for the

procedure and precautions for relieving the fuel system pressure.

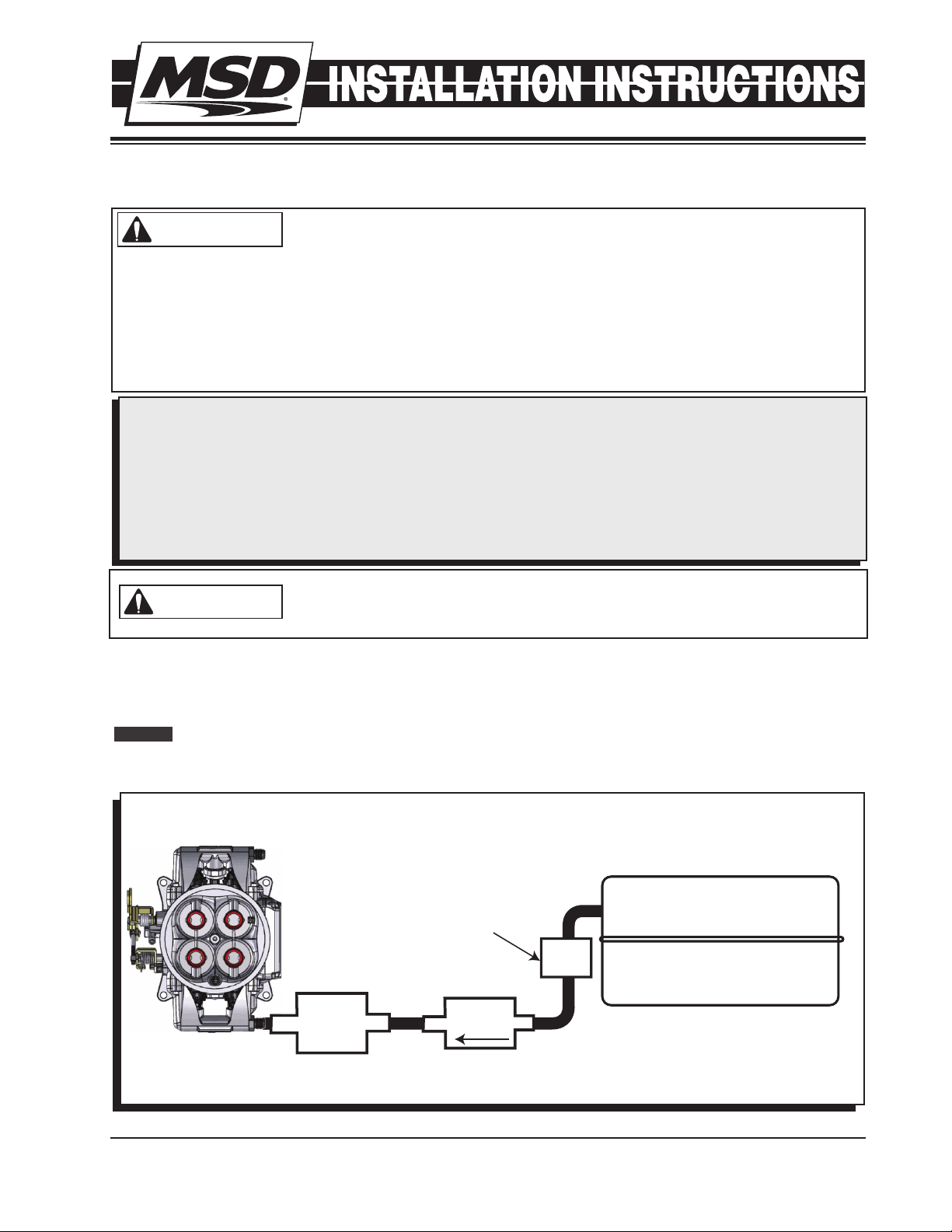

INSTALLING THE RETURNLESS FUEL SYSTEM

CORRECT RETURNLESS (PWM) INSTALLATION

PRE FUEL

FILTER

FUEL TANK

POST

FUEL

FILTER

Figure 1 Atomic Returnless Fuel System.

MSD • WWW.ATOMICEFI.COM • (915) 855-7123 • FAX (915) 857-3344

FUEL

PUMP

NOTE: Hard fuel lines are NOT recommended

for use with the returnless fuel system.

Page 2

2 INSTALLATION INSTRUCTIONS

DANGER

INSTALLING THE FUEL PUMP

The Fuel Pump, PN 2920, is designed to support engines up to 525hp. The pump specifications will

support the volume and pressure required when being used with a returnless or return style fuel system.

1. It is recommended to mount the pump close to the gas tank and in a position that is below the lowest

point of the tank.

2. Before mounting the pump, it is recommended to install the ground wire to the negative terminal and

the orange wire from the Atomic to the positive terminal with the hardware supplied in the small parts

bag. Connect the ground wire to a clean, bare metal ground source.

3. Connect the fuel line to the pump and secure with a small fuel line clamps, and then mount the pump

with the supplied clamps and self drilling screws.

4. Install the fuel filters. Find a suitable location for the supplied fuel filters and use the supplied clamps and

self drilling screws to secure them to their mounting locations. The small filter is the pre-filter and needs

to be mounted between the fuel tank and the fuel pump. The large filter is the post filter and needs to

be mounted between the fuel pump and the throttle body. Both filters and the pump incorporate 3/8"

beaded inlet/outlets. Note: Many carbureted fuel tanks have a 5/16" diameter supply line. The Atomic

EFI requires a 3/8" diameter supply line. Fuel line size mismatching will cause fuel vapor lock, even if the

vehicle qualifies for returnless using the points system(described (described in PN 2910 instructions.

5. Connect the supplied fuel hose from the pump to the filter using the supplied clamps.

6. Determine if the fuel line is going to be routed to the front or rear port on the throttle body. Route the

hose to the inlet port making sure to secure it to the frame and away from heat sources and suspension components.

7. Install the 3/8" hose to the inlet of the Atomic throttle body using the -6 fitting supplied in the kit. It is

recommended to use dish soap to push the hose over the fitting. Make sure the line is pushed all the

way to the end of the fitting. DO NOT use a clamp on the push lock fitting.

WARNING

leak(s) before proceeding!

8. Turn the ignition to ON without starting the engine, allow the pump to run for several seconds and

check the fuel pressure. If there is no pressure, turn the ignition to OFF, wait one minute, then turn the

ignition to ON and recheck the pressure. Repeat this ignition OFF and ON procedure until the gauge

registers pressure or you detect a fuel leak. If no pressure is registered on the gauge after running the

pump for several seconds and you have found no leaks, check all fuel and electrical connections to

determine the cause.

Failure to follow the above may result in fuel leakage, bursting of the fuel lines, poor vehicle

performance and/or decreased fuel pump life! Improper installation will void all warranties for

this product!

While performing the following steps, if any fuel leaks are detected,

immediately turn the ignition to OFF, remove any spilled fuel and repair the

IN TANK MOUNT

The MSD pump can be used in the tank however it would require a sock, or filter element, on the pickup

side. It is important to note that the wiring used to run the pump will need to meet requirements to be

submersed in fuel. When wiring an in-tank pump, it is recommended to use a wire that conforms to

SAE specifications J1128 and J378. This wiring features a Thermoplastic insulated wiring with polyvinyl

chloride insulation for protection against gasoline, oil, and more.

In addition, different fuel line will be required internally if the pump is to be mounted in the tank. Fuel

line that meets SAE30R10 specifications MUST be used. DO NOT use the included fuel line inside

the fuel tank. Failure to do so will cause severe damage to the engine and/or fuel system.

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

Page 3

INSTALLATION INSTRUCTIONS 3

DANGER

CAUTION

WARNING

NOTICE

FUEL TANK

FUEL

PUMP

MSD ADJUSTABLE

REGULATOR

POST

FUEL

FILTER

PRE FUEL

FILTER

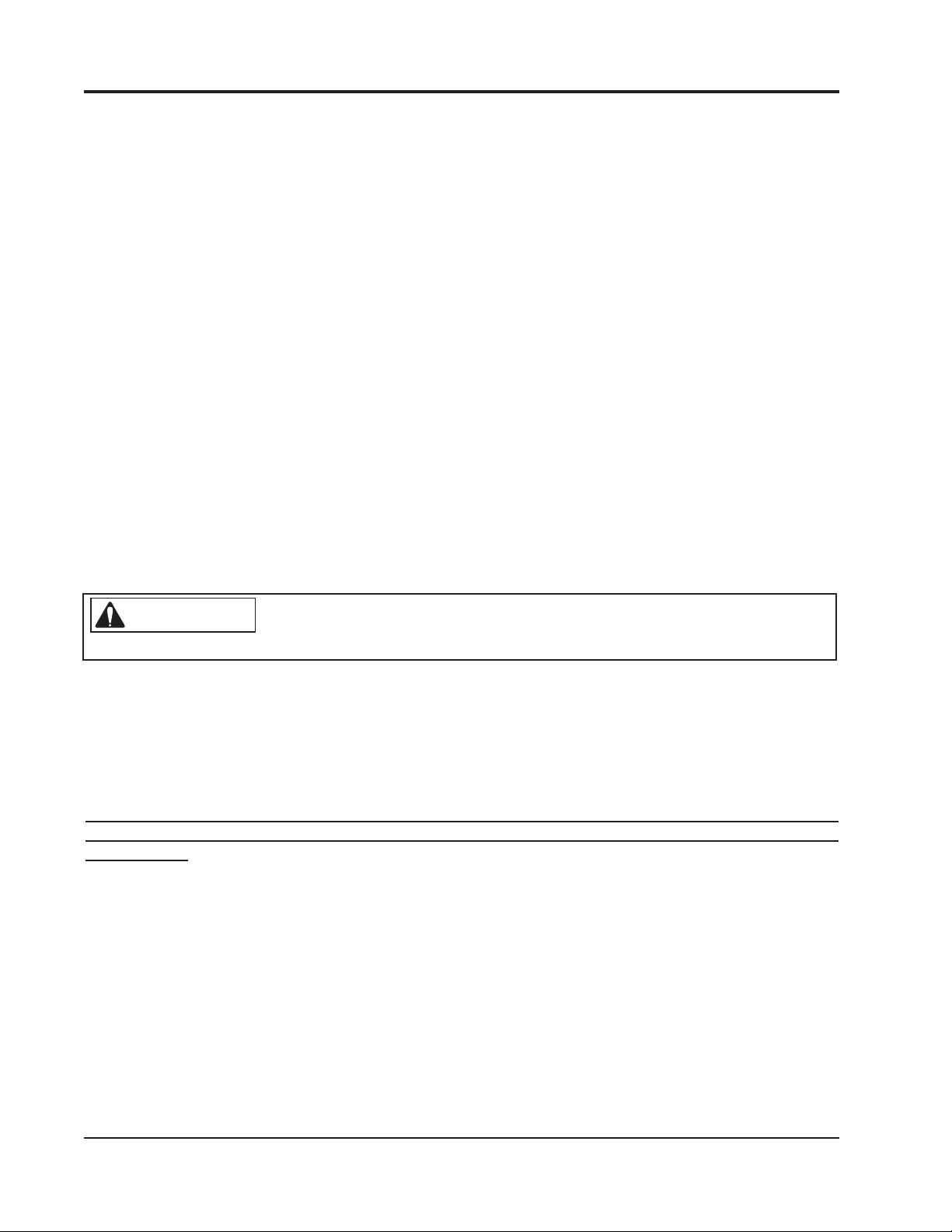

RETURN STYLE FUEL SYSTEM

If you have decided that a returnless fuel system will not produce the best performance for your

application, you will need to route a return line in the fuel system. There are many aftermarket fuel

regulators available. The fuel can then be routed to the sending unit of the gas tank, or even the filling

port of the tank. This will take modification. Figure 2 shows an example of a return style fuel system.

The most efficient system is to return the fuel from the opposite outlet of the throttle body.

The fuel pressure required for a return fuel system is approximately 45psi. If the pressure is not enough

the injectors will be over-worked and an “INJ DC” code will appear in the Diagnostics on the Handheld.

If this happens increase the fuel pressure by 5 PSI increment and test again. A rule of thumb is to start

at approximately 60 psi for engines over 400 horsepower.

With a return style system you must connect the fuel lines as pictured below. Connecting them

like in the lower picture can cause fluid hammer inside of the throttle body on transient operations. This

will cause hesitatons and possibly dead zones at certain RPM ranges.

CORRECT FOR RETURN STYLE FUEL SYSTEM.

POST

FUEL

FILTER

MSD ADJUSTABLE

REGULATOR

NOTE: Do not use tubing (hard fuel lines) with the Atomic EFI system.

INCORRECT

AFTERMARKET

ADJUSTABLE

REGULATOR

FUEL

PUMP

FUEL

PUMP

PRE FUEL

FILTER

PRE FUEL

FILTER

FUEL TANK

FUEL TANK

Figure 2 Atomic Return Style Fuel System.

MSD • WWW.ATOMICEFI.COM • (915) 855-7123 • FAX (915) 857-3344

Page 4

4 INSTALLATION INSTRUCTIONS

The MSD Customer Support phone lines are available 7am-5pm Mountain Standard Time Monday

through Friday to answer any technical questions you may have in regards to installing the Atomic

EFI or other MSD parts (915) 855-7123.

TECH NOTES

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

Service

In case of malfunction, this MSD component will be repaired free of charge according to the terms of the warranty.

When returning MSD components for warranty service, Proof of Purchase must be supplied for verification. After

the warranty period has expired, repair service is based on a minimum and maximum fee.

All returns must have a Return Material Authorization (RMA) number issued to them before

being returned. To obtain an RMA number please contact MSD Customer Service at 1 (888) MSD-7859 or visit

our website at www.msdperformance.com/rma to automatically obtain a number and shipping information.

When returning the unit for repair, leave all wires at the length in which you have them installed. Be sure to include

a detailed account of any problems experienced, and what components and accessories are installed on the vehicle.

The repaired unit will be returned as soon as possible using Ground shipping methods (ground shipping is covered

by warranty). For more information, call MSD at (915) 855-7123. MSD technicians are available from 7:00 a.m. to

5:00 p.m. Monday - Friday (mountain time).

Limited Warranty

M

SD warrants this product to be free from defects in material and workmanship under its intended normal use*,

when properly installed and purchased from an authorized MSD dealer, for a period of one year from the date of

the original purchase. This warranty is void for any products purchased through auction websites. If found to be

defective as mentioned above, it will be repaired or replaced at the option of MSD. Any item that is covered under

this warranty will be returned free of charge using Ground shipping methods.

This shall constitute the sole remedy of the purchaser and the sole liability of MSD. To the extent permitted by

law, the foregoing is exclusive and in lieu of all other warranties or representation whether expressed or implied,

including any implied warranty of merchantability or fitness. In no event shall MSD or its suppliers be liable for special

or consequential damages.

*Intended normal use means that this item is being used as was originally intended and for the original application

as sold by MSD. Any modifications to this item or if it is used on an application other than what MSD markets the

product, the warranty will be void. It is the sole responsibility of the customer to determine that this item will work for

the application they are intending. MSD will accept no liability for custom applications.

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

© 2013 MSD LLC

FRM 31396 Revised 12/13 Printed in U.S.A.

Loading...

Loading...