Page 1

MSD Cap and Rotor

for Early, Non-vented GM LT-1 Engines

PN 8481

Parts Included:

1 - Cap

1 - Rotor

1 - Isolator

2 - Rotor Screws

IMPORTANT: Due to the number of applications and years that the LT-1 Cap and Rotor are used on, it is

highly recommended to have the Service Manual for your vehicle during this installation.

This Cap and Rotor Kit is supplied with a vacuum line assembly to vent the cap. This helps prevent ozone

and moisture build-up within the distributor cap.

DISASSEMBLY

1. Disconnect the negative battery cable.

2. Locate the radiator petcock and drain the coolant from the system.

3. Disconnect the MAF and IAC sensors. Remove the air intake ductwork and the MAF sensor.

4. Once the coolant is drained, remove the upper radiator hose from the thermostat housing.

5. Loosen the three bolts that secure the crankshaft pulley/hub assembly. Do not remove them entirely

at this time.

6. Remove the accessory drive belt by moving the spring loaded idler pulley. Use caution as this pulley is

spring loaded! The belt will slide off the pulley system and the idler pulley will settle beyond its installed

position.

7. Once the belt is removed, proceed with removing the pulley from the crankshaft hub by pulling the

three retaining bolts.

8. It may be necessary to remove the cooling fan. This is done by removing the four bolts and disconnecting

the wiring connection.

9. Disconnect the air pump power wires and remove the air pump from its mounting brackets.

10. Disconnect the coolant temperature wiring sensor located on the water pump.

11. Loosen the lower radiator hose clamp and the two heater hose clamps at the water pump. Coolant

will generally still pour out of the hoses and water pump.

12. To remove the water pump, the power steering pump may need to be removed. With a shorter extension,

the water pump bolt should be able to be accessed. There

are five water pump bolts. Once again, more coolant may

spill out.

13. At this point, you should be able to access the distributor cap.

Mark the location of each spark plug wire before removing

them.

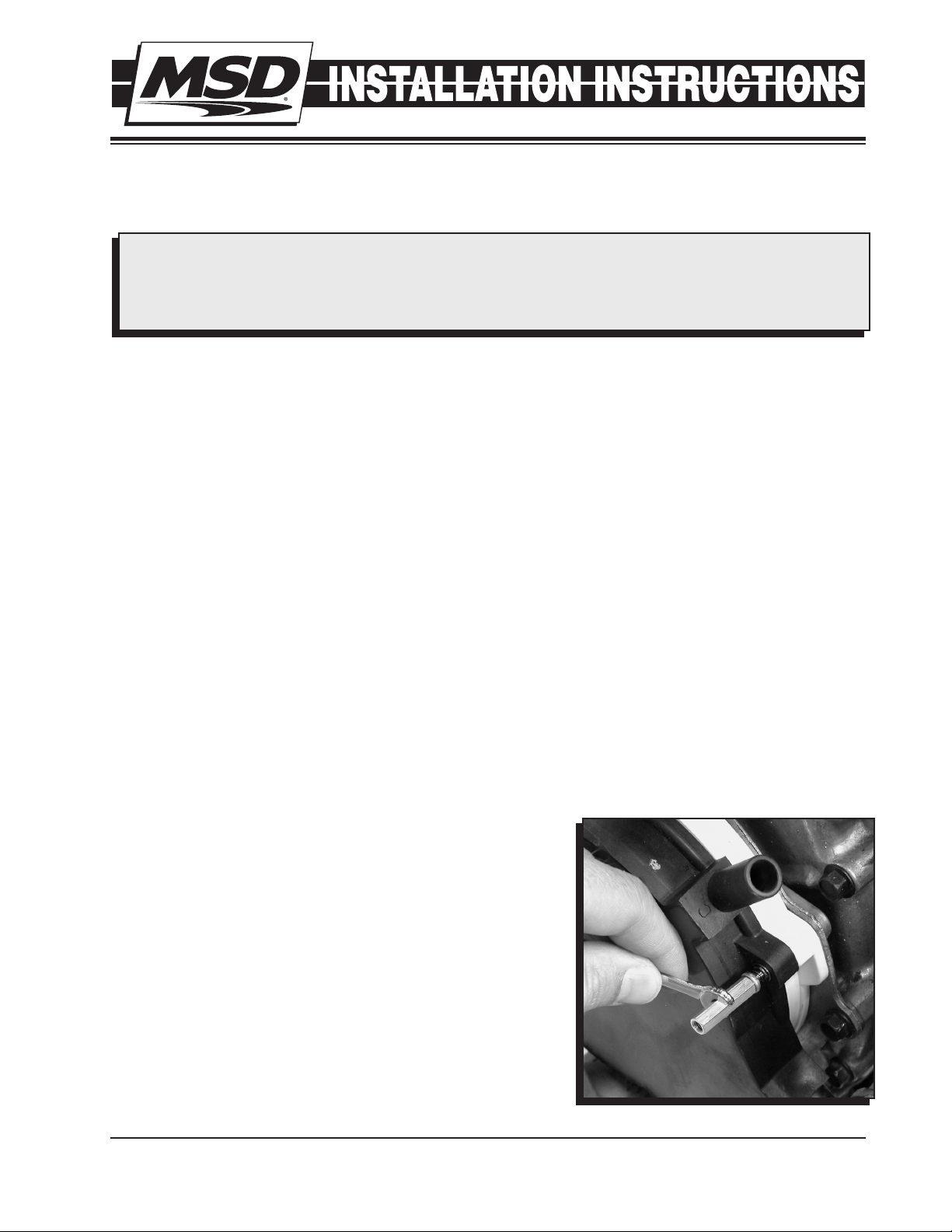

14. Using the supplied special tool and a 1/4" wrench, remove

the four screws that hold the distributor cap to the engine

and pull the cap off (Figure 1).

15. Note the position of the rotor, optical disk and shims. These

must be installed in the same position with the new rotor.

Remove the two rotor screws and pull the rotor off. At this

time, the isolator assembly will slide off the housing.

16. Now is a good time to visually inspect and clean the

distributor for excessive wear.

2 - Seals

1 - Vacuum Line Assembly

4 - 3.5mm x 6mm Phillips Screws

1 - 8-32 x 1.125 Phillips Screw

1 - Clamp-Block

1 - Removal Tool

Figure 1 Removing the Original Cap.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 2

2 INSTALLATION INSTRUCTIONS

INSTALLATION

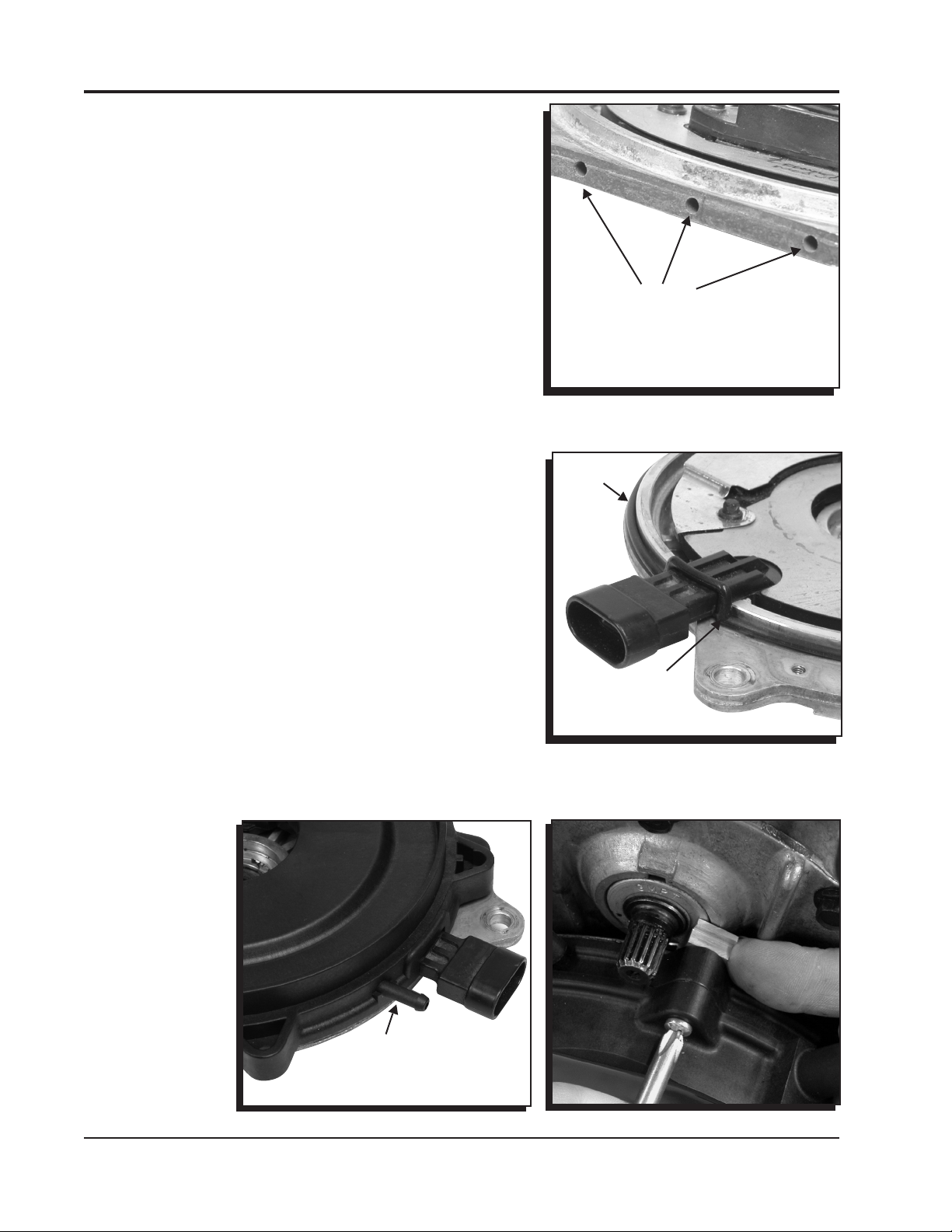

Before proceeding, you will need to seal the distributor

housing's original vent holes. These are located at the bottom

of the distributor housing (Figure 2). Use a silicone gasket

sealer or equivalent.

1. Locate and install the distributor-to-isolator seal then

position the isolator in place on the distributor (Figure

3). Note the fresh air inlet port on the isolator (Figure 4).

2. Make sure the optical disk and shims are installed in the

right position, then install the new rotor with the supplied

hardware. The rotor only installs one way. Make sure it

sits squarely on the shaft.

Note: It is recommended to use a threadlocker like Loctite

Blue on the two rotor screws.

3. Make sure that the Isolator-to-Cap seal is installed on the

Isolator, then install the cap using the supplied Phillips

head screws.

4. Locate four metric Phillips screws that retain the cap

assembly. There is also a standard, slightly larger and

longer Phillips screw. This screw is used with the ClampBlock that goes in the cap tab located between the wiring

harness and the coil wire tower (Figure 5).

5. Note that the Clamp-Block has two different thicknesses

(Figure 6). Some distributor housings have a machined

surface while others are cast. Determine which side works

best in your application to secure the top mount of the

cap. Once the direction is achieved, slide the Clamp-Block

into position and screw the standard Phillips screw into

position (Figure 6).

6. Connect the distributor connector followed by the coil

wire and spark plug wires. Ensure that each wire is in the

correct location (Figure 10).

7. Install Vacuum hoses as shown on page 3 (Figures 7 - 9).

8. The distributor is assembled. Reinstall all of the components in the reverse order. It is recommended to follow

along with your

vehicle’s service manual.

SEAL THREE HOLES

WITH SILICONE

SEALER OR

EQUIVALENT.

Figure 2 Sealing the Vent Holes.

SEAL

ADD SILICONE

SEALER BENEATH

CONNECTOR

Figure 3 Installing the

Distributor-to-Isolator Seal.

FRESH AIR INLET

Figure 4 Isolator Inlet.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Figure 5 Clamp-Block Mounting Boss.

Page 3

INSTALLATION INSTRUCTIONS 3

VACUUM LINE ROUTING

This kit is supplied with a vacuum

line kit that will aid in venting the

distributor cap. One hose assembly

connects to a vacuum port on the

intake manifold while the other line

connects to the air inlet going into

the throttle body. In order to take

NOTE

DIFFERENT

THICKNESSES

advantage of this venting technique,

you will need to seal the three small

holes on the bottom of the distributor

(Figure 2).

1. Connect the long hose assembly

to the lower vacuum inlet of the

MSD distributor cap (Figure 7).

Use the supplied clamp to secure

the hose.

2. Route the vacuum line around the

side of the engine and up to the

Figure 6 Installing the Clamp-Block.

intake manifold. Splice into the

hose that connects just over the

PCV valve (Figure 8). Also note the check valve that is

in-line. The black side of the valve must face towards the

vacuum source.

3. Connect the smaller vacuum line to the fresh air inlet port

of the isolator (see Figure 4).

4. Locate the supplied 90° vacuum nipple. Using a 3/16" drill

bit, drill a hole in the air intake duct and install the nipple

(Figure 9). Make sure the barb goes through and into the

duct. Connect the line from the distributor cap to this inlet.

This line completes the fresh air circulation through the

distributor cap (Figure 11).

5. Install the spark plug wires ensuring they are routed to the

correct terminal (Figure 10).

EDGE MUST

SIT FLUSH

WITH

HOUSING

LOWER VACUUM

INLET

Figure 7 Install the Lower Vacuum Line.

VACUUM

SOURCE

CHECK

VALVE

Figure 8 Connecting the Vacuum Source.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Figure 9 Installing the Fresh Air Line.

FRESH AIR

SOURCE

Page 4

COIL WIRE

4

6

8

2

5

3

7

1

FRESH AIR INLET

VACUUM LINE: Route behind

plug wires and pump up to intake

manifold connection.

Figure 10 Spark Plug Wire Location.

Figure 11 Fresh Air Hose Routing.

TECH NOTES

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

Service

In case of malfunction, this MSD component will be repaired free of charge according to the terms of the warranty.

When returning MSD components for warranty service, Proof of Purchase must be supplied for verification. After

the warranty period has expired, repair service is based on a minimum and maximum fee.

All returns must have a Return Material Authorization (RMA) number issued to them before

being returned. To obtain an RMA number please contact MSD Customer Service at 1 (888) MSD-7859 or visit

our website at www.msdperformance.com/rma to automatically obtain a number and shipping information.

When returning the unit for repair, leave all wires at the length in which you have them installed. Be sure to include

a detailed account of any problems experienced, and what components and accessories are installed on the vehicle.

The repaired unit will be returned as soon as possible using Ground shipping methods (ground shipping is covered

by warranty). For more information, call MSD at (915) 855-7123. MSD technicians are available from 7:00 a.m. to

5:00 p.m. Monday - Friday (mountain time).

Limited Warranty

M

SD warrants this product to be free from defects in material and workmanship under its intended normal use*,

when properly installed and purchased from an authorized MSD dealer, for a period of one year from the date of

the original purchase. This warranty is void for any products purchased through auction websites. If found to be

defective as mentioned above, it will be repaired or replaced at the option of MSD. Any item that is covered under

this warranty will be returned free of charge using Ground shipping methods.

This shall constitute the sole remedy of the purchaser and the sole liability of MSD. To the extent permitted by

law, the foregoing is exclusive and in lieu of all other warranties or representation whether expressed or implied,

including any implied warranty of merchantability or fitness. In no event shall MSD or its suppliers be liable for special

or consequential damages.

*Intended normal use means that this item is being used as was originally intended and for the original application

as sold by MSD. Any modifications to this item or if it is used on an application other than what MSD markets the

product, the warranty will be void. It is the sole responsibility of the customer to determine that this item will work for

the application they are intending. MSD will accept no liability for custom applications.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

© 2012 Autotr onic Co ntrol s Corpo ratio n

FRM30087 Revised 01/12 Printed in U.S.A.

Loading...

Loading...