MSD Pro-Billet Small Diameter

Ready-to-Run Ford V8 Distributor

PN 8350; 351C-460, PN 8354; 351W

PN 8352; 289/302

ONLINE PRODUCT REGISTRATION: Register your MSD product online and you’ll be entered

in our monthly 8.5mm Super Conductor Spark Plug Wire give-away! Registering your product

will help if there is ever a warranty issue with your product and helps the MSD R&D team create

new products that you ask for! Go to www.msdperformance.com/registration.

Important: Read these instructions before attempting the installation.

Parts Included:

1 - Pro-Billet Distributor

1 - Rotor, PN 8467

1 - Distributor Cap, PN 8431

1 - Advance Kit

Note: The terminals of the Ready-to-Run Ford Distributors require spark plug style terminals. You may

need to change the terminals and boots of your wires. MSD offers two kits, PN 8849 or PN 8848 that

are supplied with nine boots and terminals.

1 - O-ring Seal

1 - Vacuum Advance Lock-Out Kit

1 - Tube of Gear Lubricant

1 - Wiring Harness

1 - Gray Tach Jumper

TIMING FUNCTIONS

Before continuing with the installation, here are a few definitions you should be aware of:

Initial Timing: This is the base timing (also referred to as idle timing) of the engine before the

centrifugal advance begins.

Centrifugal Advance: The centrifugal (or mechanical) advance mechanism is made up of weights,

springs, advance cams, and an advance stop bushing. The amount and rate of advance that your

distributor is capable of is determined by the centrifugal timing. If you ever wish to lock out the

centrifugal advance, refer to the centrifugal advance section.

Total Timing: This is the total of the initial timing plus the centrifugal advance added together. Example:

10° Initial + 25° centrifugal = 35° Total Timing. (When checking Total timing, disconnect and cap

the vacuum canister and plug the vacuum line.)

Vacuum Advance: The vacuum advance will advance the timing up to 10° during partial throttle

driving (with 15 lbs of vacuum). The vacuum line should be routed to a ported vacuum outlet above

the throttle plates.

Note: MSD Distributors are supplied with the heavy (slow) advance springs and the 21° stop bushing

installed. This is to prevent detonation in certain applications. Review the information on pages

2-3 to determine the best advance curve for your application.

RPM LIMIT AND TACHOMETER INFORMATION

Tach Signal: The Ready-to-Run Distributor features a Gray Tach Output wire which provides a clean signal

for most tachometers and even some aftermarket fuel injection systems. The signal output

is a 12 volt square wave, 20° duty cycle. This wire is also responsible for programming the

built-in rev limiter.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

2 INSTALLATION INSTRUCTIONS

Rev Limiter: The Ready-to-Run Distributor has a built-in rev limit that can easily be adjusted from 2,000

rpm to over 10,000 rpm. The default is 10,000 rpm. To set the rev limiter, run the engine to half

the desired rpm then ground the Gray Tach wire (a jumper is supplied) for approximately one

second. Every time the key is turned to the On position, the tach will display the programmed

rpm limit. See page 8 for the programming procedure.

CHOOSING AN ADVANCE CURVE

The function of the advance curve is to match the ignition timing to the burning rate of the fuel and speed

(rpm) of the engine. Any factor that changes the burning rate of the fuel or the engine speed can cause a

need for an ignition timing change. Figure 1 shows some of the factors that will affect engine timing.

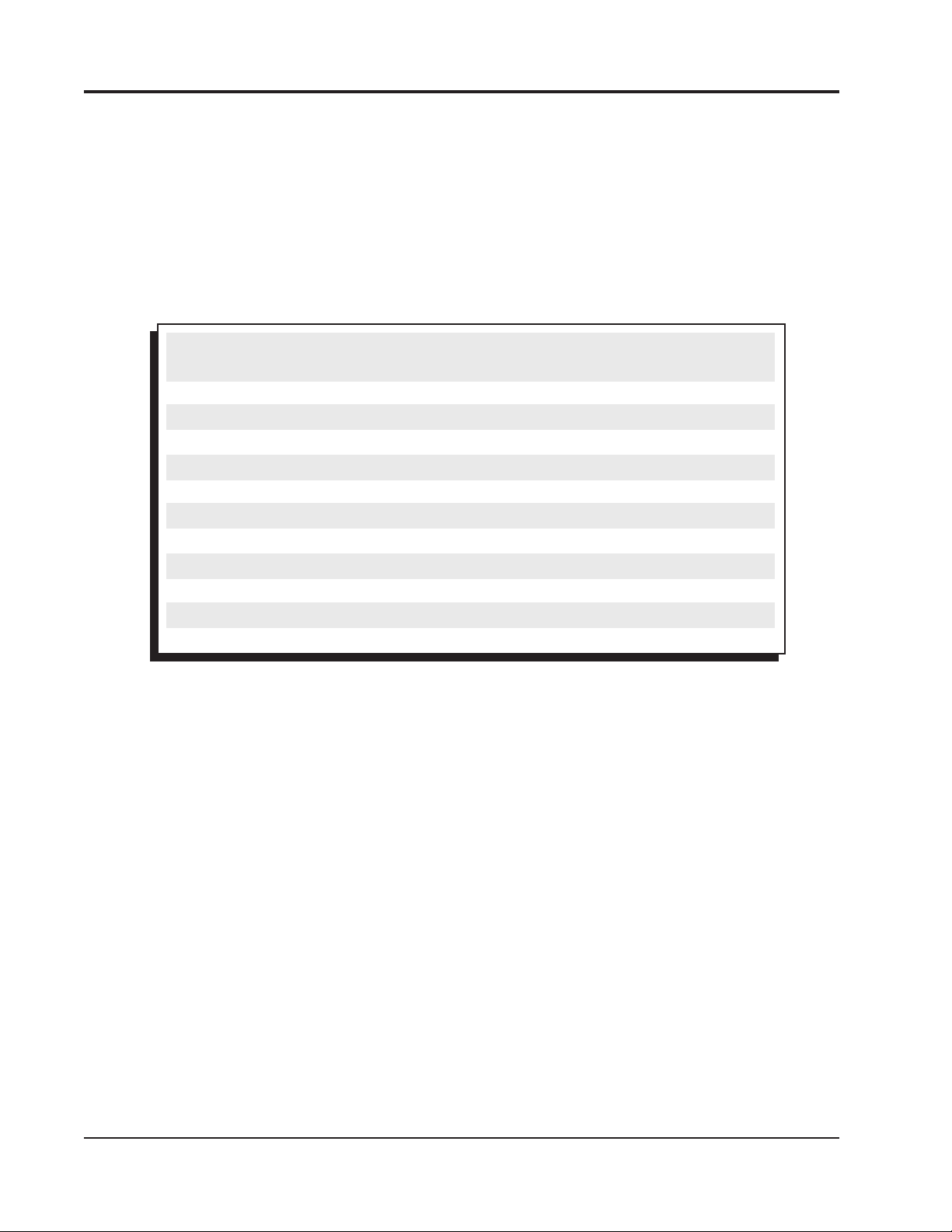

FACTOR Advance Timing Retard Timing

For For

Cylinder Pressure Low High

RPM Low High

Vacuum High Low

Energy of Ignition Low High

Fuel Octane High Low

Mixture (Air/Fuel) Rich Lean

Temperature Cool Hot

Combustion Chamber Shape Open Compact

Spark Plug Location Offset Center

Combustion Turbulence Low High

Load Light Heavy

Figure 1 Ignition Timing Factors.

As you can see from the chart, most factors will change throughout the range of the engine operation.

The timing mechanism of the distributor must make timing changes based on these factors.

Example: An engine has 11:1 compression, a high energy ignition and turns 5,500 rpm. With the

specifications given, you will have to retard the timing for the high compression, low rpm and high energy

ignition. By comparing the engine’s specifications against the chart, a usable timing guideline can be found.

Engines with a combination of items from both columns will require a timing that is set in the mid range.

Obviously a full technical explanation of correct ignition timing would be very complicated. The best

way to arrive at a suitable ignition curve for your engine is to use the Ignition Timing Factors Chart

as a guide and compare it to the Advance Graphs in Figure 4 until a suitable curve is found. When

selecting your advance curve, use detonation (engine ping) as an indicator of too much advance,

and a decrease in power as an indicator of too little advance.

TIPS ON SELECTING AN ADVANCE CURVE

• Use as much initial advance as possible without encountering excessive starter load.

• Start the centrifugal advance just above the idle rpm.

• The starting point of the c entrifugal advance curve is controlled b y the installed length and

tension of the spring.

• How quickly the centrifugal advance (slope) comes in is controlled by the spring stiffness. The

stiffer the spring, the slower the advance curve.

• The amount of advance is controlled by the advance bushing. The bigger the bushing, the

smaller the amount of advance.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

INSTALLATION INSTRUCTIONS 3

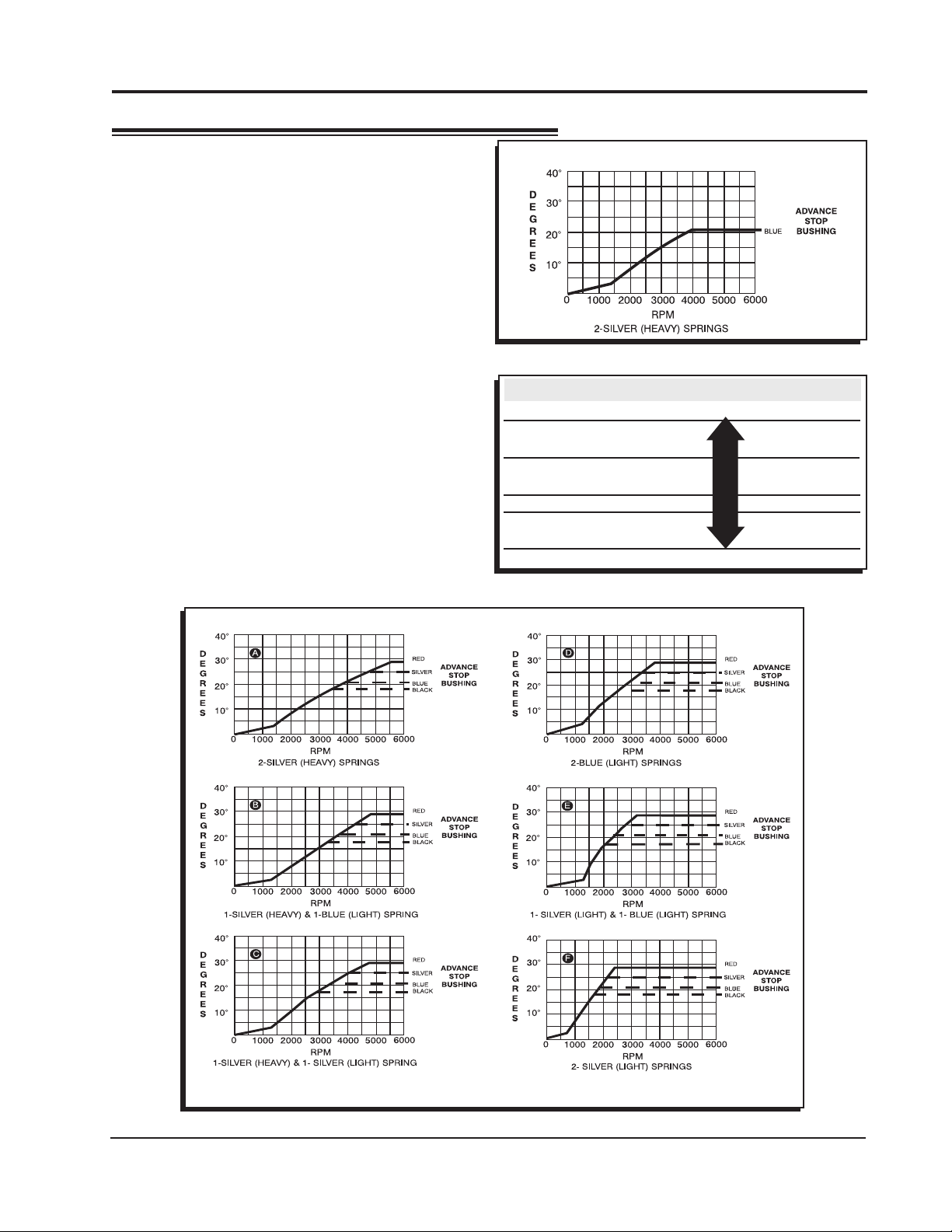

CENTRIFUGAL ADVANCE CURVE

SELECTING THE ADVANCE SPRINGS

The rate, or how quick the adva nce comes in

is determined by the ty pe of springs which are

installed on the distributor. The MSD distributors

are equipped with two Heavy Silver spr ings

ins talle d. These will give you the slowest

advance curve possible (Figure 2). The parts

kit contains two additional sets of springs which

can be u sed to match the advance curve to

your particular application. Refer to the Spring

Combination Chart (Figure 3) for combinations

that can be achieved.

To change the springs, remove the cap and rotor

and use needlenose pliers to remove the springs.

Be sure the new springs seat in the groove on

the pin.

Timing Curve From Factory

Figure 2 The Factory Equipped Curve.

SPRING COMBINATION RATE OF ADVANCE FIGURE 4

2- Heavy Silver SLOWEST A

1- Heavy Silver B

1- Light Blue

1-Heavy Silver C

1-Light Silver

2- Light Blue D

1- Light Silver E

1- Light Blue

2- Light Silver FASTEST F

Figure 3 Spring Combination Chart.

Figure 4 Advance Curves.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Loading...

Loading...