Page 1

MSD Modified Honda Distributor Cap

PN 82901, PN 82902, PN 82921 and PN 82922

Parts Included In This Kit:

1 - Distributor Cap

1 - Coil Wire

WARNING: During installation, disconnect the battery cables. When disconnecting the battery

cables, always remove the Negative cable first and install it last.

Note: The Modified Cap is designed so that you can remove the stock internal coil, and use a higher

output external coil. The stock internal coil MUST be removed before the installation of this

cap. Failure to do so will cause damage

to the MSD cap.

Note: The supplied spark plug style terminals

are required with the PN 82902 and PN

82922 caps.

1 - Parts Bag

1 - Mini-Stripper-Crimper

INSTALLATION:

1. Mark the location of each plug wire, then

remove the wires. Remove the stock distributor

cap, rotor and dust cover.

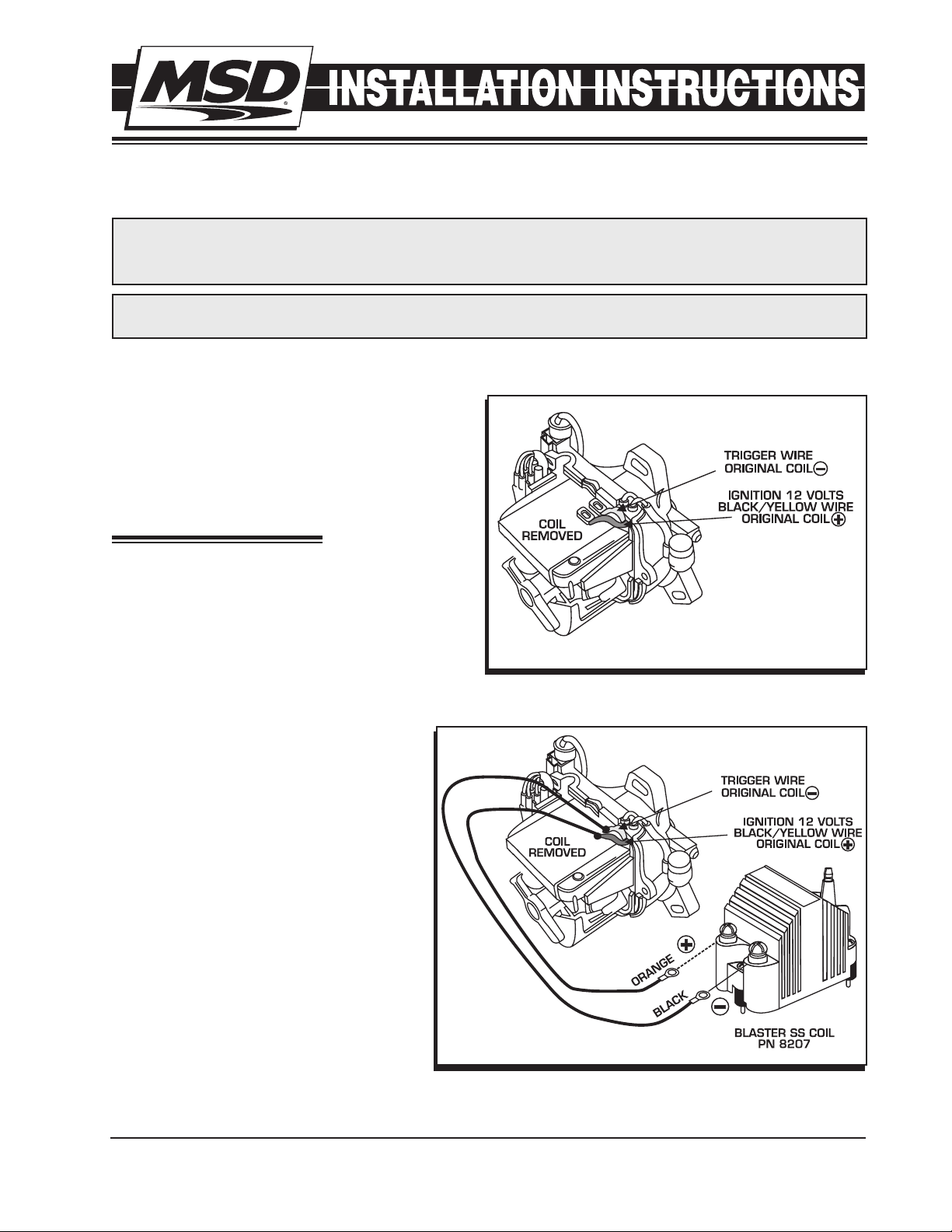

2. Locate the coil wires and note their color and

location. On the majority of Honda or Acura

engines, the Black/Yellow wire is positive. The

coil negative wire is generally White/Blue, Blue,

Green/Yellow or Green. In some cases, the coil

itself is marked negative (-) and positive (+).

Figure 1 Primary Wiring with the Coil Removed.

1 - Retainer and Screw

(Extreme Caps only)

Note: If you have a question as to the

wires’ polarity, use a volt-meter and

probe each wire with the ignition

key turned to the On position. Coil

positive will show 10-12 volts.

3. Once you determine the polarity of the

coil wires you will need to extend the

wires to reach the MSD coil. Cut the

factory terminals off and solder to a 14

gauge wire. Seal the soldered joint with

shrink sleeve or electrical tape.

4. Depending on the model of distributor

you have, you may need to drill a hole

in the new cap to route the wires out.

In some applications the factory rubber

seal is thick enough to cut and slide the

new wires out.

5. Install the rotor, the new cap and then

the wires. For Extreme model caps, install the wire retainer with the supplied screw.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Figure 2 Wiring with a Blaster SS Coil.

Page 2

2 INSTALLATION INSTRUCTIONS

DUAL CRIMP

TERMINAL

STANDARD

TERMINAL

CONDUCTOR

CRIMP TABS

WIRE SLEEVE

CRIMP TABS

STANDARD

DUAL CRIMP

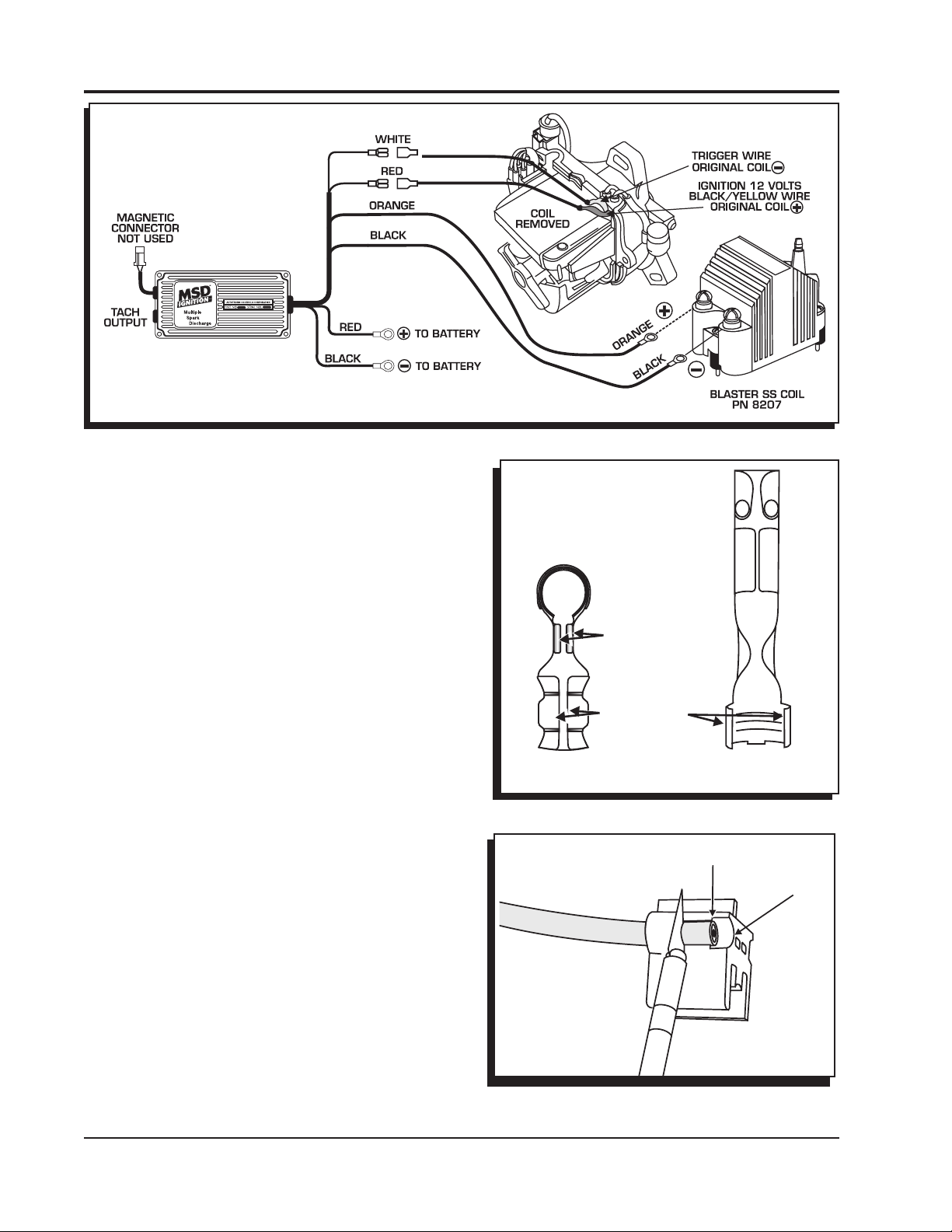

Figure 3 Wiring an MSD SCI Ignition with a Blaster SS Coil.

ASSEMBLING THE COIL WIRE

Once the cap is installed and the coil is wired, you

will need to assemble a coil wire. You will need a

razor blade and a 4-inch vice.

The Mini-Stripper-Crimper is an all in one spark plug

wire stripper and crimp tool. It will work with both

MSD 8.5mm Super Conductor and 8mm Heli-Core

wires to produce a strong, professional crimp.

TERMINALS

MSD offers several different terminals with our

Universal wire sets. There are two terminal styles

used, either a standard style or the Dual Crimp

Terminal (Figure 4). The standard design requires

stripping more of the wire sleeve because the

conductor will be bent under the terminal. The Dual

Crimp has specific crimp tabs for the conductor

which require needle nose pliers.

STRIPPING THE WIRE

1. Once you’ve determined which terminals you are

working with, position the wire in the corresponding

strip guide. There are two holes; one for the 8mm

wire and another for the 8.5mm wire.

2. There are two stripping positions indicated on the

stripping slot, depending on the terminal being

used. Slide the wire to the correct position and

strip the sleeve by holding a razor blade flush with

the strip guide and rotate the wire 360° (Figure

5).

3. Remove the wire and twist the cut end of the sleeve

off in a counterclockwise direction.

Figure 4 Identifying the Different Style Terminals.

Figure 5 Stripping the Sleeve.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 3

INSTALLATION INSTRUCTIONS 3

TERMINAL

CRIMPING

To achieve the strongest crimp possible, it is required

to bend the crimp tabs over about 90° using needle

nose pliers (Figure 6). Follow the instructions for the

terminal you are using.

STANDARD TERMINALS

1. After stripping the sleeve, fold the conductor back

along the wire insulation (Figure 7).

2. Do not allow the conductor to pull tightly against

the insulation. A small gap around the conductor

should be present before crimping. Slide the wire

into the terminal with the conductor positioned

so it is in contact with the bottom of the terminal.

Position the wire through until the insulation

protrudes about 1/8" beyond the crimp tabs.

3. Position the wire and terminal into the "W" groove

of the Mini-Stripper Crimper and crimp.

Figure 6 Preparing the Terminals.

STANDARD

DUAL CRIMP TERMINALS

1. After stripping the sleeve, position the wire in

the terminal so the insulation protrudes about

1/8" beyond the insulation crimp tabs and the

conductor extends about 1/8" past the conductor

crimp tabs (Figure 8).

2. Position the wire and terminal into the "W" groove

of the Mini-Stripper Crimper and follow Steps 4 - 6

to crimp the terminal to the sleeve.

Note: It is normal for the conductor to retract into

the insulation slightly as the sleeve crimp is

made.

3. After the sleeve is crimped, push the conductor

between the crimp tabs and use a set of

needlenose pliers to crimp them together. DO

NOT OVER CRIMP.

4. Slide the other part of the Mini-Stripper-Crimper

over the wire terminal and lightly press them

together (Figure 9).

5. Put the assembly into a vise making sure the

alignment tabs are on the outside edge of the

vise jaws (Figure 9).

SMALL GAP

PLUG WIRE

BEND CONDUCTOR BACK

CRIMPING TABS 1/8”

PLUG WIRE

INSERT WIRE

Figure 7 Positioning the Wire in the Terminal.

DUAL CRIMP TERMINAL

POSITION WIRE

PLUG WIRE

CRIMP FIRST

1/8”

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

PLUG WIRE

CRIMP SECOND

PLUG WIRE

Figure 8 Crimping a Dual Crimp Terminal

Page 4

ALIGNMENT TABS

6. Slowly close the vise making sure the tool and terminal stay properly positioned and aligned. Stop

applying pressure when the terminal ends have wrapped securely around the sleeve and grip the

wire.

Note: DO NOT OVER CRIMP! It is possible to tear the sleeve of the wire by excessive pressure on

the vise. This will cause a weaker crimp.

7. Back off the vise and remove the wire from the Crimper. Gently tug the terminal and inspect the

position of the conductor to make sure the crimp is solid and firm.

Figure 9 Crimping the Terminal.

Service

In case of malfunction, this MSD component will be repaired free of charge according to the terms of the warranty.

When returning MSD components for warranty service, Proof of Purchase must be supplied for verification. After

the warranty period has expired, repair service is based on a minimum and maximum fee.

All returns must have a Return Material Authorization (RMA) number issued to them before

being returned. To obtain an RMA number please contact MSD Customer Service at 1 (888) MSD-7859 or visit

our website at www.msdperformance.com/rma to automatically obtain a number and shipping information.

When returning the unit for repair, leave all wires at the length in which you have them installed. Be sure to include

a detailed account of any problems experienced, and what components and accessories are installed on the vehicle.

The repaired unit will be returned as soon as possible using Ground shipping methods (ground shipping is covered

by warranty). For more information, call MSD at (915) 855-7123. MSD technicians are available from 7:00 a.m. to

5:00 p.m. Monday - Friday (mountain time).

Limited Warranty

M

SD warrants this product to be free from defects in material and workmanship under its intended normal use*,

when properly installed and purchased from an authorized MSD dealer, for a period of one year from the date of

the original purchase. This warranty is void for any products purchased through auction websites. If found to be

defective as mentioned above, it will be repaired or replaced at the option of MSD. Any item that is covered under

this warranty will be returned free of charge using Ground shipping methods.

This shall constitute the sole remedy of the purchaser and the sole liability of MSD. To the extent permitted by

law, the foregoing is exclusive and in lieu of all other warranties or representation whether expressed or implied,

including any implied warranty of merchantability or fitness. In no event shall MSD or its suppliers be liable for special

or consequential damages.

*Intended normal use means that this item is being used as was originally intended and for the original application

as sold by MSD. Any modifications to this item or if it is used on an application other than what MSD markets the

product, the warranty will be void. It is the sole responsibility of the customer to determine that this item will work for

the application they are intending. MSD will accept no liability for custom applications.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

© 2012 Autotr onic Contro ls Corp orati on

FRM28974 Revised 01/12 Printed in U.S.A.

Loading...

Loading...