Page 1

Programmable Digital-7

PN 7530T

ONLINE PRODUCT REGISTRATION: Register your MSD product online and you’ll be entered

in our monthly 8.5mm Super Conductor Spark Plug Wire give-away! Registering your product

will help if there is ever a warranty issue with your product and helps the MSD R&D team create

new products that you ask for! Go to www.msdperformance.com/registration.

Parts Included:

1 - Ignition Control, PN 7530T

1 - MSD Pro-Data+ CD

4 - Vibration Mounts & Screws

1 - Shielded Cam Sync Harness

Accessories (Not Supplied):

Hand Held Monitor, PN 7550

Inductive Cam Sync Pickup Kit, PN 7555

Non-Magnetic Cam Sync Pickup Kit,

PN 2346

Manual Launch RPM Control, PN 7551

WARNING: During installation, disconnect the battery cables. When disconnecting, always remove

the Negative cable first and install it last.

1 - 9-Pin Computer Harness

1 - Shielded Mag Pickup Harness, PN 8862

1 - 12-Pin Harness

1 - Coil Harness

1 - Power Lead Harness

LED Shift Light, PN 7552

Manual Launch Control w/Shift Light,

PN 8736

Single Pole/Single Throw Relay, PN 8961

Double Pole/Double Throw Relay,

PN 8960

OPERATION

DIGITAL OPERATION

The MSD Programmable Digital-7 uses a high speed RISC microcontroller to control the ignition’s output while

constantly analyzing the various inputs such as supply voltage, trigger signals and rpm. The high speed controller

can make extremely quick compensations to the output voltage, multiple spark series, timing and rpm limits while

maintaining accurate timing signals to better than 0.1° total accuracy and +/- 2 rpm. The circuits and controller

of the ignition have been thoroughly debounced and suppressed to create protection against Electro Magnetic

Interference (EMI).

CAPACITIVE DISCHARGE

The MSD features a capacitive discharge ignition design. The majority of stock ignition systems are inductive ignitions.

In an inductive ignition, the coil must store energy and step up the supplied voltage to maximum strength between

each firing. At higher rpm, since there is less time to charge the coil to full capacity, the secondary voltage falls short

of reaching its maximum energy level which results in a loss of power or top end miss.

The MSD Ignition features a capacitor which is quickly charged to 520 - 535 volts and stores its energy until the

ignition is triggered. With the CD design, the energy sent to the coil is always at maximum power even at high rpm.

MULTIPLE SPARKS

The MSD produces full power multiple sparks for each firing of a plug. The number of multiple sparks that occur

decreases as rpm increases, however the spark series always lasts for 21° of crankshaft rotation. Above 3,300 rpm

there is simply not enough “time” to fire the spark plug more than once, so there is only one powerful spark.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 2

2 INSTALLATION INSTRUCTIONS

PROTECTION

The MSD Digital-7 Programmable has a built in reverse polarity protection circuit. This will protect the ignition

in the event of wrong connections. It will also shut off for protection from a surge in power. The ignition will still

operate once the surge or polarity is corrected.

LED INDICATOR

There is an LED that monitors the status of the Ignition. The LED will verify trigger inputs and will flash trouble

codes such as a Code 2 for No Cam Sync, Code 3 for Low Battery supply voltage or Code 4 for Traction Control

Detection.

CAMSHAFT SYNCHRONIZATION

This is used only in applications where the individual cylinder timing is going to be used. The 2-pin connector

with a Light Blue and Light Green wire connects to a sensor that is used to synchronize or alert the Ignition as to

when the number one cylinder is going to be triggered. With this information, the Ignition knows which cylinder

is being fired allowing for the individual cylinder timing capabilities. A Universal Cam Sensor is available from

MSD as PN 2346. MSD offers two kits to use for sync signals: Universal Cam Sensor, PN 2346 and Fiber Optic

Inductive Pickup Kit, PN 7555.

WIRING

Heavy

Ignition supply wire. Connects to battery positive (+) terminal or battery junction.

Red

Note: Do not connect to the alternator.

Heavy

Ignition supply Ground wire. Connect to battery negative (-) terminal or engine block.

Black

Red On/Off switch wiring. Connects to a switched 12 volt source.

Primary Coil Leads

Orange Connects to the coil positive (+) terminal. This is the only wire that makes contact to

the coil positive terminal.

Black Connects to the coil negative (-) terminal. This is the only wire that makes contact to

the coil negative terminal.

WARNING: High voltage is present at the coil primary terminals. Do not touch the coil or connect

test equipment to the terminals while the engine is running or cranking.

Trigger Wires

Violet/ Magnetic pickup, 2-pin connector. Plugs into an MSD Distributor or Crank Trigger

pickup. Violet is positive, Green is negative. Note: When this connector is used, the

Green

White wire is not connected.

2-Pin

White Trigger input for electronic ignition amplifiers, an ECU’s trigger or points.

Note: When this wire is used, the magnetic pickup wire is not connected.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 3

INSTALLATION INSTRUCTIONS 3

Accessories

Dark Blue This wire activates the Launch Rev Limit and is the main reset wire for several features of the

Ignition. When 12 volts are applied to this wire it will activate the Launch Rev Limit. It also

resets the shift light and gear indicator to first gear. It also will select the Launch Retard value

and Gear 1 curve.

Note: When this wire is activated it will override all other Rev Limits except the TCD Limit.

Light Blue Burnout Rev Limit. When 12 volts are applied the Burnout Rev Limit is active.

Gray Tach output. This wire will provide the same 12 volt square wave tach signal as the tach

terminal on the side of the unit.

Retard Stage Wires or Gear Select

These three wires can be used as Retard Stage Activation and/or as a gear select wire.

Pink Step1 retard enabled with +12 volt input and above Step1 Rpm value and Gear 2 Select.

Violet Step2 retard enabled with +12 volt input and above Step2 Rpm value and Gear 3 Select.

Tan Step3 retard enabled with +12 volt input and above Step3 Rpm value and Gear 4 Select.

Note: When activated at the same time, these retard stages are added together. They are also

added with any Gear Retard Curve or Boost Retard values as well. Maximum retard is 30°.

Yellow Shift Light output wire. It can handle up to 3 amps continuous to ground when enabled.

Brown/White RPM/Time switch output wire. It can switch up to 3 amps continuous to ground when enabled.

Yellow/Yellow

Output for data acquisition or fuel controls. Note, only two wires are used.

Cam Synchronization

Fiber Optic This input requires the PN 7555 Inductive Sync Pickup. When this input is used, the 2-pin

connector is not. Note: If this input is not used, the plug or a cover should be installed.

2-Pin Connector

Light Blue/ This 2-pin plug connects to Cam Sync Sensor, PN 2346, to indicate when cylinder number

Light Green

one is firing. Note: When used, the fiber optic connector is not used and must be covered.

Light Blue is cam (+) and Light Green (-).

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 4

4 INSTALLATION INSTRUCTIONS

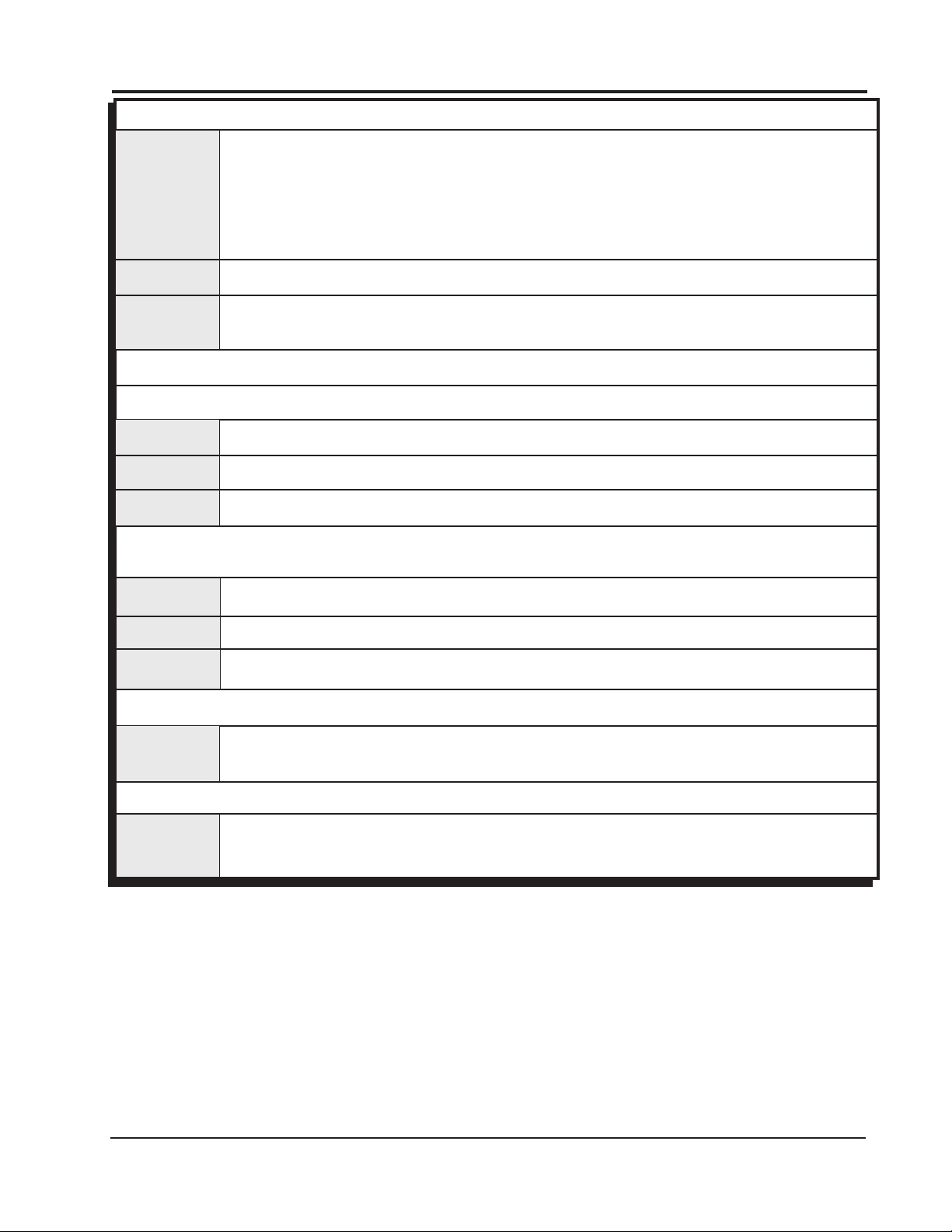

Figure 1 Wiring the Programmable Digital-7 Ignition.

PRO-DATA+

INSTALLATION OF THE PRO-DATA+ SOFTWARE

1. Insert the installation CD into your CD drive.

2. In Windows, click on Start then select Run.

3. In the box type, “A:Setup” and press Enter (or whatever disk drive you are using).

4. The screen will walk you through several steps.

5. Once loaded, your monitor will have an MSD Graph View logo. Click on it to open the software.

6. A program will open. Go to the upper left corner of the screen and click on File, then Open.

7. This will open a menu of part numbers. Select “7530T”.

8. This will open another menu of versions. Highlight and open the “7530Tvxx.IGN” (xx determines

the versions, such as 22). This will open the Pro-Data+ software for the Programmable Digital-7

Ignition.

SAVES AND TRANSFERS

Whenever a change is made to a program, it either must be saved to a file in your PC or it needs to

be transferred to the ignition. You will notice that whenever you make a change to a program, the

bullet next to the modified value will turn red. It will remain red until you save it to a file or to the MSD.

There are two ways to save your files.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 5

INSTALLATION INSTRUCTIONS 5

Save to MSD: This step will save any changes directly into the ignition. If you are only making

one or just a couple modifications this works well.

Save to PC: This will save your changes to only show on the PC screen (indicated by a red

bullet point next to any altered values). These modifications will not be active or saved until

you save the file or transfer the information to the MSD.

You can create numerous files on your PC and download them for testing purposes or by saving

programs you used at different races or events.

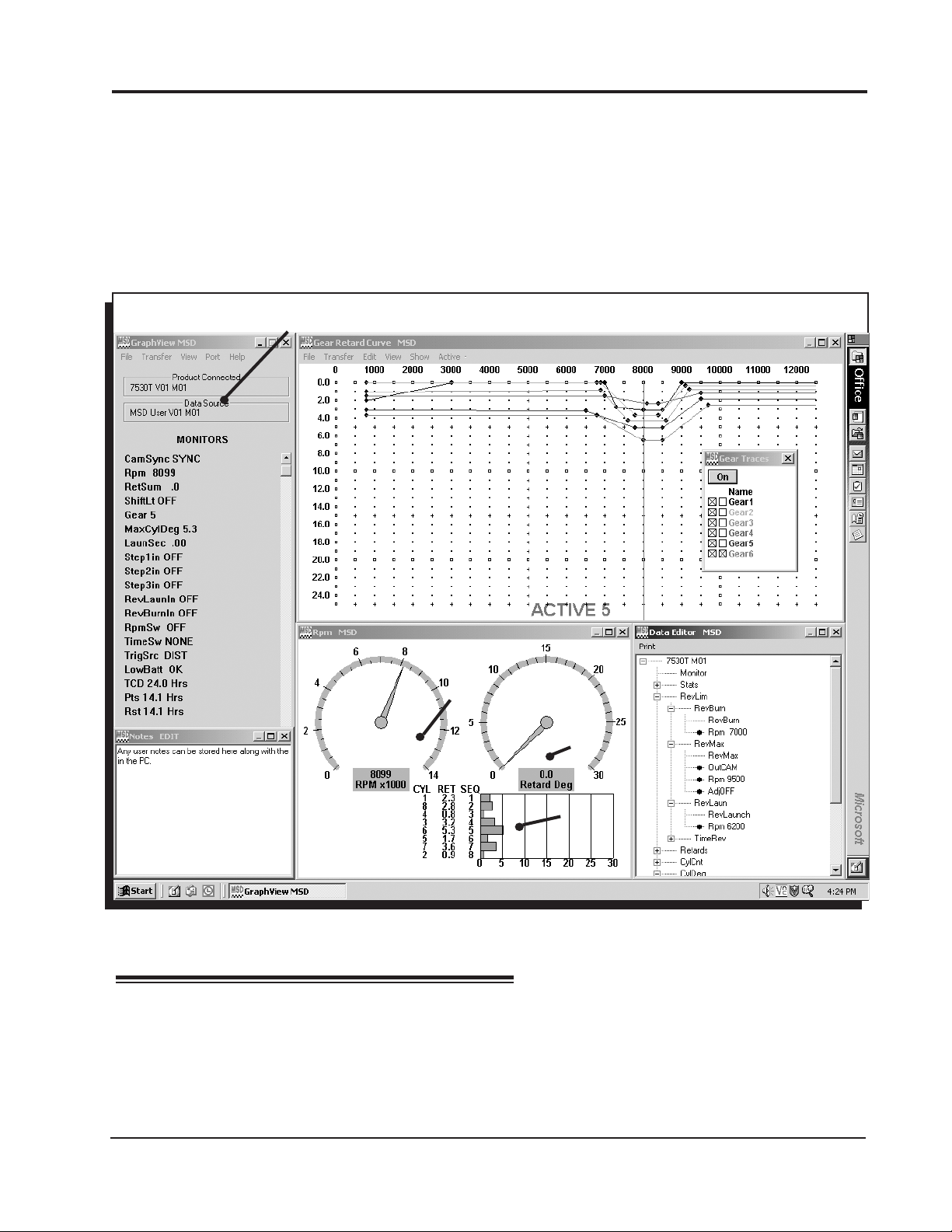

MONITOR

PROGRAM

STATUS

SOFTWARE

VERSION

GEAR RETARD CURVES

TACH

MENU

TREE

TIMING

USER

ICM

NOTES

Figure 2 Pro-Data+ Screen and Program Windows.

PROGRAMMABLE FEATURES

The following explains the programmable features of the PN 7530T Ignition. The features are listed

in the same order that they show on the Data Editor list in the software. Note that all of the retard

amounts are cumulative and the maximum amount of retard is 30°.

STATS

Stat 1: This is only used with the Hand Held Monitors, PN 7550, PN 7553.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 6

6 INSTALLATION INSTRUCTIONS

REV LIMITS

Up to three different rev limits can be programmed in 100 rpm increments.

RevBurn: Burnout Rev Limit. This limit is activated when 12 volts are applied to the Light Blue

wire. It is adjustable from 2,000 to 12,500 rpm.

RevLaunch: Launch Rev Limit. This limit is activated when 12 volts are applied to the Dark

Blue wire. It is adjustable from 2,000 to 12,500 rpm. This Limit has priority over all the other

rev limits.

RevMax: Max Speed Rev Limit. This is the overrev limit and is active whenever the Launch

and Holeshot limits are off.

OutCam: Select either a Cam Sync output or a Rev Limiting output that can be used with

MSD components that use rpm modules for the rev limit.

AdjOff: This program enables an automatic compensating rev limiter that will correct trigger

input offsets and variables. It can be turned On or Off.

RPM: Adjustable in 100 rpm increments from 2,000 – 12,500.

TIMED SAFETY REV LIMIT

This provides a time activated rpm limit ramp that is designed to work as a safe shutdown. The ramp

will lower the rpm to an adjustable amount, within two seconds after it is activated. The activation point

ranges from 1-12.5 seconds after the burnout and the shutdown rpm value can be set from 100012,500 rpm. The time before the safety RPM Limit ramp is activated begins when the Dark Blue wire

is released from 12 volts, and only if the programmed Launch Rev Limit rpm has been acheived

on the starting line.

START RETARD

Program an amount of retard that will occur while the engine is cranking. This helps reduce the load

on the starter for easier cranking. It is adjustable from 0° - 25° in 1° increments. This is an automatic

feature and will enable below 500 rpm and will deactivate when the engine reaches above 800 rpm.

Default is 10°.

LAUNCH RETARD

This is the time based retard ramp. It can be programmed from 0°-15° in 0.1° increments and from

0-2.5 seconds. When the Dark Blue Launch/Reset wire is connected to 12 volts, the retard value is

activated and is added to the retard sum. When 12 volts are removed from the Dark Blue wire, the

retard value begins to ramp up to 0° over the programmed time. Once the time is over, the retard will

not be activated again.

TCD

The PN 7530T Ignition incorporates a unique Traction Control Detection (TCD) circuit. This software

code monitors the magnetic pickup circuit for changes that would only come from an installed traction

control device that would modify the signal from the mag pickup. If a modification is sensed in this

circuit an Alert will be set and the status LED will flash a Code 4. This Alert will continue to flash until

the ignition is kept turned On for 24 hours in order to reset. A 4000 rpm TCD Rev Limit is activated

until the 24 hour TCD timer is elapsed or reset by an NHRA official.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 7

INSTALLATION INSTRUCTIONS 7

STEP RETARDS

There are three step retards that are controlled through three corresponding activation wires or through

rpm. A minimum rpm can also be programmed that must be reached before a step becomes active.

A time based ramp can now be programmed to gradually bring the retard to its full On amount, or to

ramp the retard amount out (back to no retard) from its setting.

Step 1 - Pink Step 2 - Dark Brown Step 3 - Tan

Activation through Wiring: Each step is activated when 12 volts are applied to its corresponding

wire. When the steps are enabled at the same time the retard amounts are added together. The

maximum retard allowed by the Ignition is a total of 30° (including other retard amounts from a

launch, ICM or gear retard).

Activation through RPM: Each step retard can also be activated through rpm. In order to achieve

this, 12 volts must still be applied to the corresponding step retard, and an rpm value must be

selected from the Step RPM menu. When 12 volts are applied, the retard will not activate until

the rpm value is reached. Note that the retard will remain active above this rpm, even when other

stages are activated. It will deactivate when the rpm drops below the set amount.

Note: If you prefer to activate the step retards through the

activation wires and not rpm, then the rpm value in each

of the desired step menus must be set to 800 rpm.

Step Retard Off Delay: This feature will set a time based

delay to deactivate the step retards. This is designed to

keep the timing retarded to clear the engine of any nitrous

oxide prior to deactivating the retard. It is adjustable from

0 – 2.5 seconds and the default is 0.5 second.

Step Retard Ramp: Each retard step can be ramped to

and from its full retard amount over a time based program

(Figure 3). It is adjustable from 0-2.5 seconds in 0.01

second increments. Default is 0°.

RPM: The minimum engine rpm that must be

reached before a step retard is activated.

On: The amount of time it takes for the step retard

to reach its Retard Degree once activated. Allows a

gradual ramp On time to reach the Retard Degree.

User adjustable from 0.00 to 2.50 sec. (0.01 sec

increments).

Off: The amount of time it takes for the step to retard to

reach NO retard once deactivated. Allows a gradual

ramp Off time to reach NO Retard. User adjustable

from 0.00 to 2.50 sec. (0.01 sec increments).

Deg: The amount of retard.

Figure 3 Ramping the Step Retards.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 8

8 INSTALLATION INSTRUCTIONS

GEAR SELECT

The Three Step Retard wires, Pink (1), Violet (2) and Tan (3) can also be wired to indicate the first

three gear changes to the ignition control. When selected from the Step Wire menu, the ignition will

know that the car is in second gear when 12 volts are applied to the Pink wire, third for the Violet

and fourth when the Tan wire is applied to 12 volts. By using this feature, if you lift off the throttle and

get back on it, the ignition will not count it as a gear change.

Note: When selected, this feature overrides the RPM Drop Gear Select values.

This is a sequenced series meaning Tan (3) will not become active until it sees 12 volts on Pink (1),

and Violet (2). This way, 12 volts do not need to be removed from each wire before the following

gear is selected.

Note: Five and six speed transmissions will have to use the RPM Drop functions.

GEAR RETARDS

This program provides the ability to create a run curve for each gear. Up to six different curves can

be programmed from 800 – 12,500 rpm in 0.1° increments for every 100 rpm. You can program up

to 32 different points on each Gear Map. Also, all of these points are interpolated every millisecond

to create a smooth (no steps) curve.

The number of gears is adjustable under the SHIFT menu, as well as the amount of rpm drop the

ignition needs to see before knowing that a different gear has been selected. Up to six gears can

be programmed. You can also use the Step Retard wires as Gear Select Indicators for the first four

gears.

These retards are mapped out on the Gear Retard chart of the Graph View. In the chart, go to the

View pull down menu and select Trace Box. That will give you a small window to show the different

color gear traces so creating a different curve for each gear is easier.

If you want the same retard curve for all gears, compose the curve, select the Edit pull down menu

and copy the curve, then select Paste All.

ADVANCE

This is a Gear Shift Advance feature that is designed to advance the timing (or remove any retards)

during a shift to keep the combustion chamber temperatures consistent.

Gear: Select the number of gears.

DRpm: Program the rpm drop that indicates a gear change from 200-1,500 rpm.

Deg: The amount of timing that is advanced. This is determined by how much retard is active.

You cannot program more advance than the current amount of retard.

Sec: The amount of time that the advance is active. Adjustable in .01 second increments

from 0-1.5 seconds.

Note: The Step Wire Gear Select program overrides the RPM Drop value for shifts.

CYLINDER COUNT

CylCnt: This is the number of cylinders of the engine. Programmable for 4, 6, 8 and Odd fire

6-cylinders (90°/150° only). Once a change has been made, turn the ignition Off and On to

reset.

Tach Trigger: There are two choices for the output of the tach terminal on the end panel of

the ignition. The output is a 30° duration 12 volt signal that is compatible with most tachs and

data acquisition systems. The default is Trigger which provides the most accurate signal for

rpm sensing components. The Timing program should only be used when spark timing data

is required by an acquisition control or to fire another ignition.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 9

INSTALLATION INSTRUCTIONS 9

INDIVIDUAL CYLINDER TIMING

Each cylinder can be retarded up to 10° in 0.1° increments. Adjustments are made through the CylDeg

menu. Default for each cylinder is 0°. A Cam Sync signal for cylinder number one must be incorporated. The MSD Fiber Optic Pickup, PN 7555, is the easiest or a pickup kit could be fabricated on the

cam gear (MSD Kit PN 2346).

The spark sequence, or firing order needs to be considered when selecting the ICT. You can go

through the Cylinder Numbers and place them with the corresponding position, or go to the Sequence

window and select from the pre-programmed firing orders.

Spark Sequence Program the firing order of your engine.

Degree Program the amount of retard of each cylinder. These retard rates are

added to any other retards that are active. Max retard is 30°.

Sequence Select a firing order:

Program Order Application

1843 18436572 Most GM, Chrysler and AMC V8

1542 15426378 Most Ford V8

1372 13726548 Ford 341/400

1425 142536 Ford V6

1536 153624 Ford, Camaro, Chrysler, AMC V6

1654 165432 Most GM V6

1436 143625 Odd-fire 6-cylinder

RPM/TIME ACTIVATION SWITCH

This program lets you activate a circuit by supplying ground on the Brown/White wire (up to 3 Amps

continuous). This can be activated in two ways; RPM or Time.

RPM Window: Program an rpm value to activate and deactivate a circuit from 800 – 12,500

rpm in 100 rpm increments.

RPM On: Rpm that the circuit is activated

RPM Off: Rpm that the circuit is deactivated

RPM Hysterisis: Built in Hysterisis allows the deactivation point to be set lower than the

activation value.

Time Based: Program an activation point in 0.01 second increments after the launch. Up to 25 seconds of total time. The timer begins when the Dark Blue wire is removed from 12 volts and only if the

programmed Launch Rev Limit rpm has been acheived on the starting line.

OnDelay: The amount of time after launch (12 volts removed from the Dark Blue wire).

OnTime: The amount of time that the switch stays activated. This can be programmed from

0-25 seconds. It will always deactivate after 25 seconds.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 10

10 INSTALLATION INSTRUCTIONS

SHIFT LIGHT

This program lets you select the number of gears (Last Gear), program the shift light to come on

when the holeshot rpm is reached, set an rpm point for each gear and the rpm drop for the ignition

to recognize as a gear shift between each gear. When the correct rpm is reached the Yellow wire is

switched to ground to turn the shift light on.

LAUNCH LIGHT

This programs an rpm window that will illuminate the shift light when the correct rpm is reached for

the holeshot. When the rpm is in this window the light will be on solid. If the rpm goes high, the light

will flash. If the rpm goes low, the light turns off.

RpmHi: The high rpm for the launch light program.

RpmLo: The low rpm for the launch light program.

ShiftLight: Program the rpm point for each gear change.

(1)Rpm First gear rpm point to shift.

(2)Rpm Second gear rpm point to shift.

(3-5 gears)

ShiftGear: Program the rpm drop between each gear that the ignition must see to recognize

a shift. Programmable from 200-1500 rpm.

(1)DropRpm Rpm drop between first and second.

(2)DropRpm Rpm drop between second and third.

(3-5 gears)

Last Gear: The program lets you select the number of gears to use with the shift light from

2-6 gears. Default is five gears.

ALERTS

This is only used with the Hand Held Monitor, PN 7550. You can program an alert to interrupt the

screen on the monitor. You can select which alerts to show and how often. The alerts are No Cam

Sync, Low Battery, and Traction Control Detection (TCD).

Fault: Program the number of counts that occur for a Low Voltage alert.

BrownOut 0: This is the count of low voltage resets. This should always be set at 0.

WatchDog: The count of Watch Dog resets. This should always be set at 0.

TCD: When a traction control device is detected an alert is set and will flash a Code 4 (a 4

blink sequence) on the end panel LED. This alert will continue to flash until the ignition is kept

turned On for 24 hours in order to reset.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 11

INSTALLATION INSTRUCTIONS 11

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 12

12 INSTALLATION INSTRUCTIONS

DEFAULT MENU

Notes: 7530TV1. Uses menu 7530M01

MSD Digital Race Ignition.

Factory default data and menu.

7530T MO1

Monitor

Stats

Stat 1

RevLim

RevBurn

*Rpm 7000

RevMax

RevMax

*OutCAM

*Rpm 9500

*AdjOFF

RevLaun

RevLaunch

*Rpm 6200

TimeRev

TimeRev

Time 9.0

Rpm 2000

Retards

Start

StartRetard

* Deg10

Launch

LaunchRetard

* Deg .0

* Ramp .50

Step1

* Rpm 800

* On .00

* Off .00

* Deg 2.0

Step2

* Rpm 800

* On .00

* Off .00

* Deg 3.0

Step 3

* Rpm 800

* On .00

* Off .00

* Deg 5.0

StepDly

Step Retards

* OffDelay .50Sec

Gear 1

Pt 1

Rpm 800

Gear1

Deg .0

Gear2

Pt 1

Rpm 800

Gear2

Deg .0

Gear3

Pt 1

Rpm 800

Gear3

Deg .0

Gear4

Pt 1

Rpm 800

Gear 4

Deg .0

Gear5

Pt 1

Rpm 800

Gear5

Deg .0

Gear6

Pt 1

Rpm 800

Gear6

Deg .0

Advance

Gear1

* (1) dRpm 600

* (2) dRpm 600

* (3) dRpm 600

* (4) dRpm 600

* (5) dRpm 600

* (1) Deg .0

* (2) Deg .0

* (3) Deg .0

* (4) Deg .0

* (5) Deg .0

* (1) Sec .00

* (2) Sec .00

* (3) Sec .00

* (4) Sec .00

* (5) Sec .00

CylCnt

*CylCnt 8

*TachTrigger

DylDeg

SparkSEQ1

* (1) Cyl1

* (2) Cyl2

* (3) Cyl3

* (4) Cyl4

* (5) Cyl5

* (6) Cyl6

* (7) Cyl7

* (8) Cyl8

* (1) Deg .0

* (2) Deg .0

* (3) Deg .0

* (4) Deg .0

* (5) Deg .0

* (6) Deg .0

* (7) Deg .0

* (8) Deg .0

* SeqUser

RpmTimeSw

* SwSel RPM

RpmSw

*RpmOn 2000

*RpmOff 6000

TimeSw

*OnDelay 1.00

*OnTime 2.00

Shift

LaunchLight

*RpmHi 3200

*RpmLo 2800

ShiftLights

ShiftLight1

* (1) Rpm12500

* (2) Rpm12300

* (3) Rpm 12100

* (4) Rpm11900

* (5) Rpm11700

Gears

ShiftGr

Gear1

* (1) DropRpm 600

* (2) DropRpm 600

* (3) DropRpm 600

* (4) DropRpm 600

* (5) DropRpm 600

LastGr

*LastGear5

SetGear

StepWire 123

*SetGearOFF

Alerts

Alert 1

(1) SCAN

(2) SCAN

Fault

*BrownOut 0

*WatchDog 0

AlertsPer

*Alerts/Scan 0

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 13

INSTALLATION INSTRUCTIONS 13

TECH NOTES

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 14

14 INSTALLATION INSTRUCTIONS

TECH NOTES

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 15

INSTALLATION INSTRUCTIONS 15

TECH NOTES

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 16

TECH NOTES

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

Service

In case of malfunction, this MSD component will be repaired free of charge according to the terms of the warranty.

When returning MSD components for warranty service, Proof of Purchase must be supplied for verification. After

the warranty period has expired, repair service is based on a minimum and maximum fee.

All returns must have a Return Material Authorization (RMA) number issued to them before

being returned. To obtain an RMA number please contact MSD Customer Service at 1 (888) MSD-7859 or visit

our website at www.msdperformance.com/rma to automatically obtain a number and shipping information.

When returning the unit for repair, leave all wires at the length in which you have them installed. Be sure to include

a detailed account of any problems experienced, and what components and accessories are installed on the vehicle.

The repaired unit will be returned as soon as possible using Ground shipping methods (ground shipping is covered

by warranty). For more information, call MSD at (915) 855-7123. MSD technicians are available from 7:00 a.m. to

5:00 p.m. Monday - Friday (mountain time).

Limited Warranty

M

SD warrants this product to be free from defects in material and workmanship under its intended normal use*,

when properly installed and purchased from an authorized MSD dealer, for a period of one year from the date of

the original purchase. This warranty is void for any products purchased through auction websites. If found to be

defective as mentioned above, it will be repaired or replaced at the option of MSD. Any item that is covered under

this warranty will be returned free of charge using Ground shipping methods.

This shall constitute the sole remedy of the purchaser and the sole liability of MSD. To the extent permitted by

law, the foregoing is exclusive and in lieu of all other warranties or representation whether expressed or implied,

including any implied warranty of merchantability or fitness. In no event shall MSD or its suppliers be liable for special

or consequential damages.

*Intended normal use means that this item is being used as was originally intended and for the original application

as sold by MSD. Any modifications to this item or if it is used on an application other than what MSD markets the

product, the warranty will be void. It is the sole responsibility of the customer to determine that this item will work for

the application they are intending. MSD will accept no liability for custom applications.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

© 2012 Autotr onic Co ntrols Corpor ation

FRM29417 Revised 01/12 Printed in U.S.A.

Loading...

Loading...