MSD DynaForce Starter

Jeep Inline-6, 232, 258, 4.0L, PN 5094

ONLINE PRODUCT REGISTRATION: Register your MSD product online. Registering your product will help

if there is ever a warranty issue with your product and helps the MSD R&D team create new products that

you ask for! Go to www.msdperformance.com/registration.

IMPORTANT: Proper installation of the DynaForce Starter is important to the overall operation. Correct alignment

of the starter pinion with the ring gear is needed to achieve the best operation and longevity from

your starter. Please read the instructions before attempting the installation.

Parts Included:

1 - Starter 1 - Shim Ring 1 - Outer Shim

WARNING: Before installing the DynaForce Starter disconnect the battery cables. When disconnecting

the battery cables, always remove the Negative (-) cable first and install it last.

Thank you for purchasing the DynaForce Starter from MSD. Please be sure to read, understand, and

follow the instructions prior to installation so that everything goes smoothly and the engine starts

reliably time after time.

INSTALLATION

1. Make sure the starter mounting surface is clean and smooth.

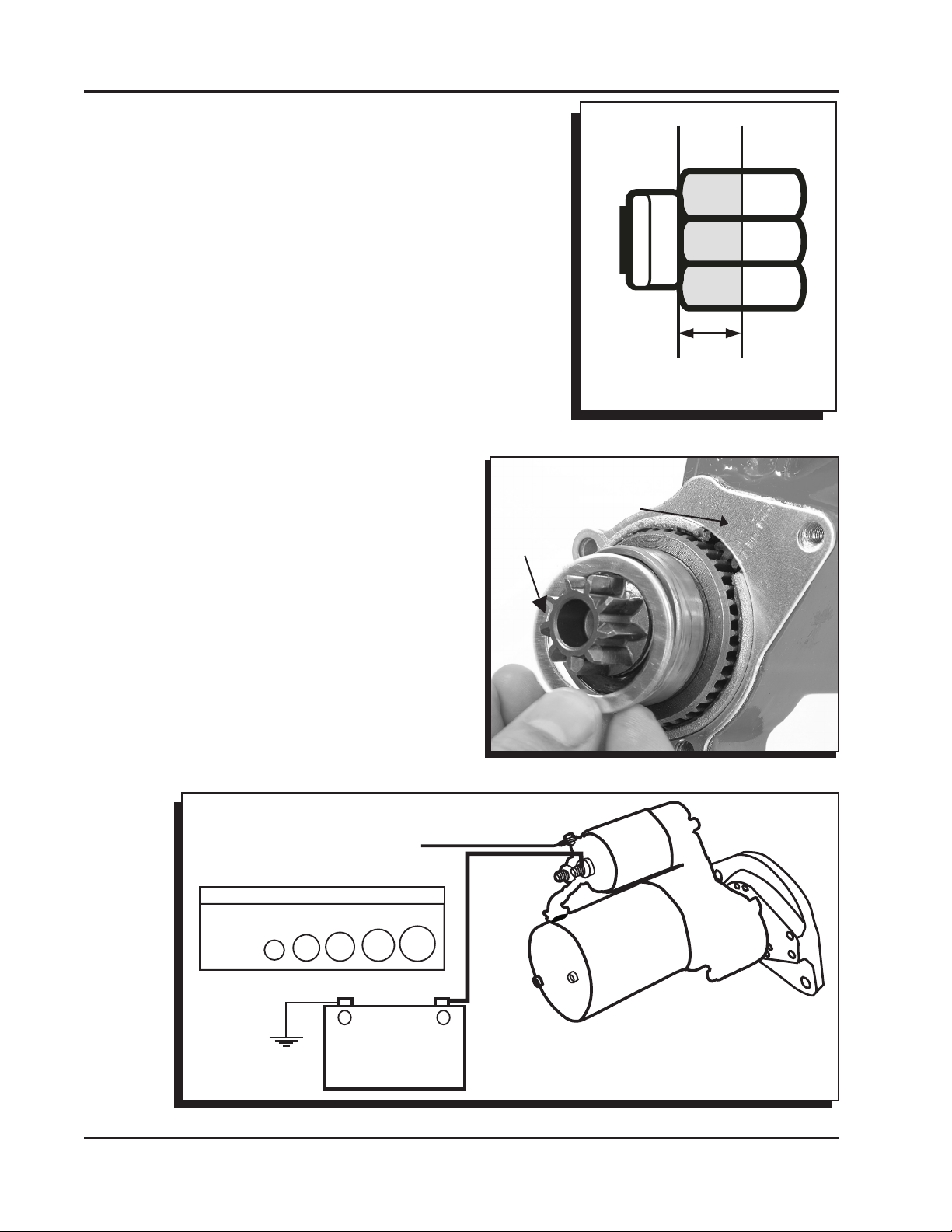

2. Mount the starter and check that the position of the solenoid is

away from direct heat sources and other components. If there

are clearance problems, the starter housing can be rotated to

move the location of the solenoid. This is done by removing

the three bolts on the mounting block and repositioning the

starter motor (Figure 1).

CLOCKING

LOCATIONS

Figure 1 Clocking the Starter

for Clearance.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

2 INSTALLATION INSTRUCTIONS

3. After confirming clearances and position of the solenoid, it is

time to check the pinion engagement to the ring gear. This

is done by gently prying out the pinion gear to the ring gear.

The pinion should engage by 1/4" minimum and 3/8" max on

to the ring gear (Figure 2).

• If there is not enough clearance, you will need to install the

supplied shim kit by removing the mounting block (Figure

3). If the pinion gear engages too far onto the ring gear,

there will be issues with disengagement. MSD supplies a

shim ring to move the pinion 0.060". Remove the mounting

block and place the small shim ring in the bearing bore and

install the outer shim on the support housing. Reinstall the

mounting block. This will move the pinion gear into the starter

approximately 0.060".

4. With the starter mounted and gear engagement confirmed,

THE CORRECT PINION DEPTH

SHOULD MEASURE 1/4” to 3/8”.

it is time to connect the wires. The switch wire that connects

to the solenoid should be at least 12-gauge (Figure 4). For

Figure 2 Pinion Gear Pattern.

alternative wiring to incorporate the factory remote

solenoid, See Figure 5.

5. Attach the battery cable. The gauge of the battery

cable depends on its length. Using the proper

gauge wire is important to the operation of the

starter. Both the positive and ground wires must

SHIM

RING

INSTALL OUTER

SHIM

be able to meet the demands of the starter. The

chart in Figure 5 shows the recommended sizes.

Be sure to route the wire away from the exhaust

and moving parts of the engine.

6. Connect the battery terminals and start the engine.

IMPORTANT: Never operate a starter for more than

30 seconds at a time without letting it

cool for at least two minutes.

Figure 3 Installing the Pinion Shim Spacers.

12-GAUGE MINIMUM

TO IGNITION

SWITCH

CABLE LENGTH VS. GAUGE

LENGTH

AWG

3’ 5’ 7’ 10’ +10’

00

0

1

2

4

-

BATTERY

+

Figure 4 Wiring the DynaForce High Speed Starter.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Loading...

Loading...