Page 1

MSD DynaForce Starter

FORD 289, 302, 351W

3/4" Depth, PN 5090, 3/8" Depth, PN 50901

ONLINE PRODUCT REGISTRATION: Register your MSD product online and you’ll be entered in our

monthly 8.5mm Super Conductor Spark Plug Wire give-away! Registering your product will help if there

is ever a warranty issue with your product and helps the MSD R&D team create new products that you

ask for! Go to www.msdperformance.com/registration.

IMPORTANT: Proper installation of the DynaForce Starter is important to the overall operation. Correct alignment

of the starter pinion with the ring gear is needed to achieve the best operation and longevity from

your starter. Please read the instructions before attempting the installation.

Parts Included:

1 - Starter 1 - Shim Ring 1 - Outer Shim

WARNING: Before installing the DynaForce Starter disconnect the battery cables. When disconnecting

the battery cables, always remove the Negative (-) cable first and install it last.

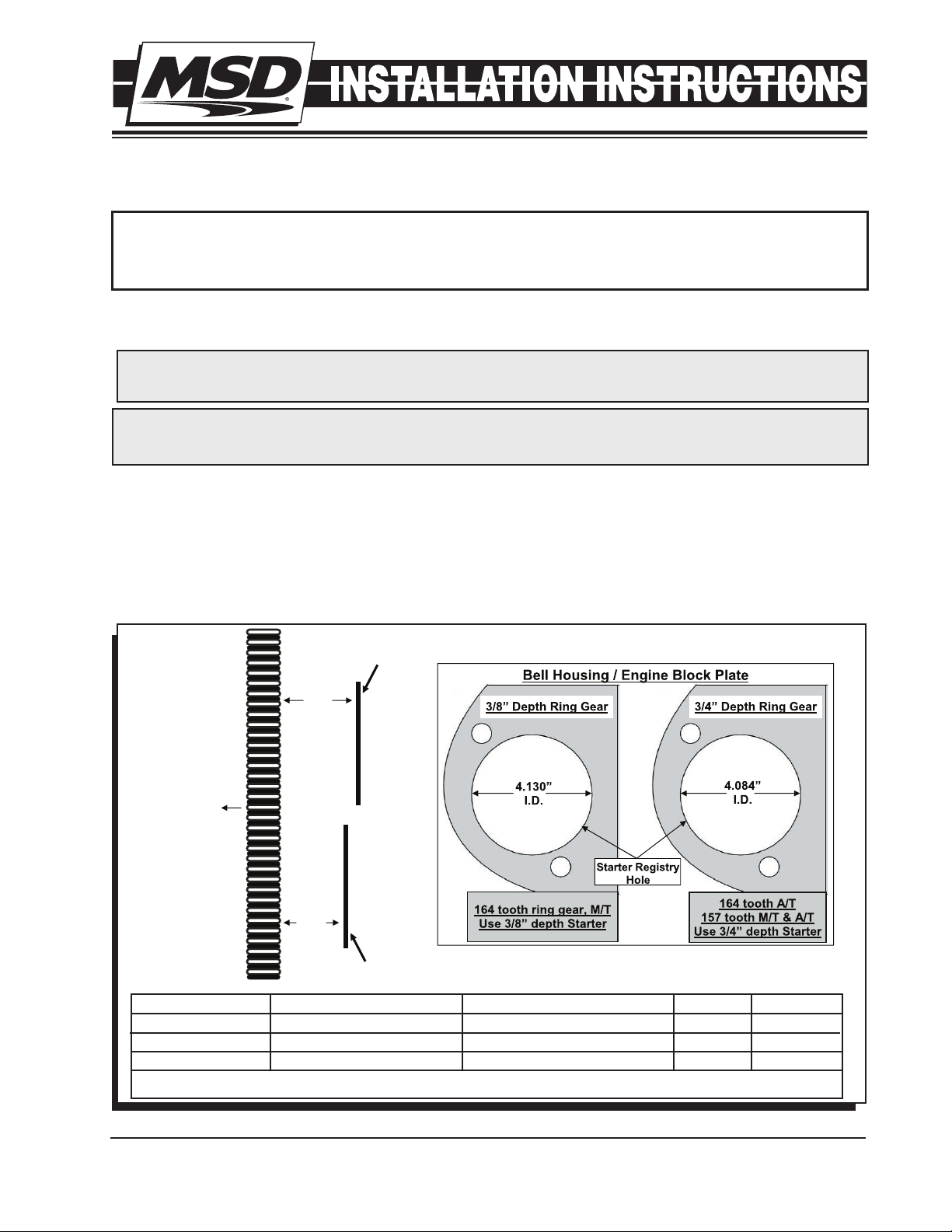

When selecting a starter for your Ford, our research has found that year, model and drivetrain

combination do not always dictate the correct starter. There are variations between the 164 tooth and

157 tooth flywheels and well as the inside diameter of the starter block plate (4.130” or 4.084”). MSD

offers two starters for the 289/302 and 351W engines; one with a 3/8th depth ring gear, one with a

¾” depth. Figure 1 shows the differences and applications.

When using OEM bell housings, it must be paired with the corresponding flywheel and ring gear.

Many aftermarket bellhousings feature a punch out to allow both to be used.

ENGINE BLOCK PLATE

3/4”

TRANSMISSION

3/8”

RING GEAR TEETH TRANSMISSION STARTER REGISTRY DIAMETER DEPTH STARTER

164 4-speed 4.130" 3/8" PN 50901

164 Automatic 4.084" 3/4" PN 5090

157 4-speed and Auto 4.084" 3/4" PN 5090

USE

PN 5090

USE

PN 50901

ENGINE BLOCK PLATE

Note that these are generally the applications, however there are variables.

Figure 1 Ring Gear Depth and Bell Housing/Engine Block Identification.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 2

2 INSTALLATION INSTRUCTIONS

INSTALLATION

CLOCKING

LOCATIONS

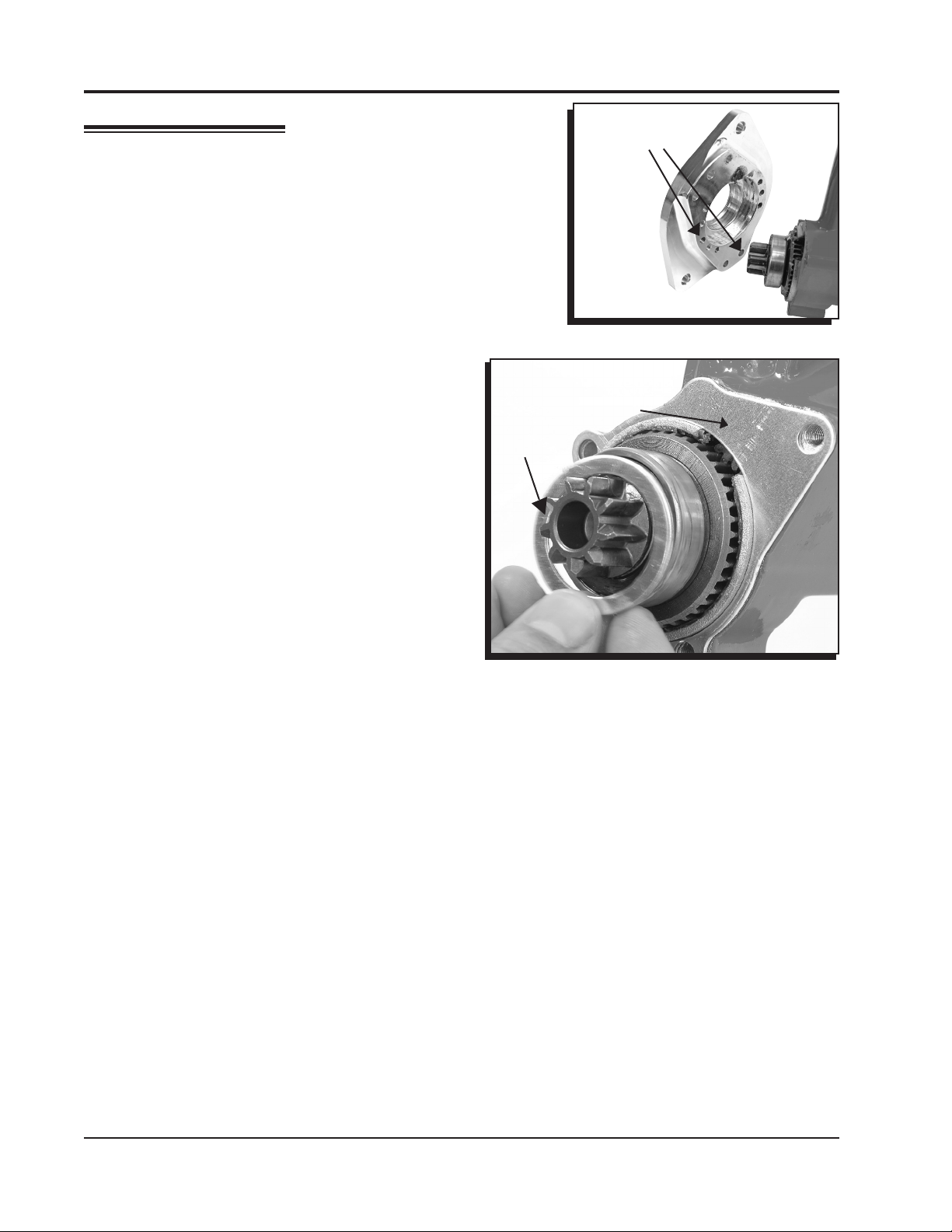

1. Make sure the starter mounting flange on the mid plate is

clean and smooth.

2. Before mounting the starter, measure the distance from the

front of the ring gear (engine side) to the starter mounting

surface (Figure 2).

• If there is not enough clearance, you will need to install

the supplied shim kit by removing the mounting block

(Figure 3). Place the small shim ring in the bearing bore

and install the outer shim on the support housing. Reinstall

the mounting block. This will move the pinion gear into the

Figure 2 Clocking the Starter for Clearance.

starter approximately 0.060".

3. Check that the position of the solenoid is away

from direct heat sources and other components.

If there are clearance problems, the starter

housing can be rotated to move the location of

the solenoid. This is done by removing the three

SHIM

RING

INSTALL OUTER

SHIM

bolts on the mounting block and repositioning the

starter motor (Figure 1).

4. After confirming clearances and positioning.

Mount the starter.

• If there is not enough clearance, you will need

to install the supplied shim kit by removing the

mounting block (Figure 3). Place the small shim

ring in the bearing bore and install the outer

shim on the support housing. Reinstall the

mounting block. This will move the pinion gear

into the starter approximately 0.060".

• The gear mesh is not adjustable on this

Figure 3 Installing the Pinion Shim Spacers.

application. Verify that all parts are correct for the application (flywheel, block plate, starter) and

verify starter is mounted correctly to engine plate.

5. The switch wire that connects to the solenoid should be at least 12-gauge (Figure 4). For alternative

wiring to incorporate the factory remote solenoid, See Figure 5.

Note: If your original starter had wire going to a second terminal, an ‘R’ terminal, this can generally

be bypassed. See the information on the last page of the instructions for more details.

6. Attach the battery cable. The gauge of the battery cable depends on its length. Using the proper

gauge wire is important to the operation of the starter. Both the positive and ground wires must be

able to meet the demands of the starter. The chart in Figure 5 shows the recommended sizes. Be

sure to route the wire away from the exhaust and moving parts of the engine.

7. Connect the battery terminals and start the engine.

IMPORTANT: Never operate a starter for more than 30 seconds at a time without letting it cool for at

least two minutes.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 3

INSTALLATION INSTRUCTIONS 3

12-GAUGE MINIMUM

TO IGNITION

SWITCH

CABLE LENGTH VS. GAUGE

LENGTH

AWG

3’ 5’ 7’ 10’ +10’

00

0

1

2

4

SWITCH

-

BATTERY

-

BATTERY

+

Figure 4 Wiring the Starter.

FACTORY REMOTE SOLENOID

10-12 GAUGETO IGNITION

+

Figure 5 Wiring to Incorporate Factory Solenoid.

INSTALLATION INFO

INSPECT PINION GEAR

After cranking the engine several times, you can inspect

the witness pattern on the pinion gear. The pattern should

show 1/4" to 3/8". If over, the internal shim is required.

SLOW CRANKING

The most common cause is due to low input voltage. The

battery should be checked, but also inspect the battery

wires, terminals, connections or switches.

THE CORRECT PINION DEPTH

SHOULD MEASURE 1/4” to 3/8”.

Figure 6 Pinion Gear Pattern.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 4

DISCONNECT SWITCHES

Most sanctioning bodies require an emergency disconnect switch. Be sure to use a heavy duty switch

that is capable of handling high current. Some starters may pull over 700 amps while cranking. Most

disconnect switches are rated at continuous and intermittent amps. Make sure to use a switch that

exceeds your starting and electrical system requirements.

R-TERMINAL

On older vehicles, mostly with breaker points, there was an extra terminal and wire on the original starter

(the MSD DynaForce Starter does not have this terminal). This extra terminal served as a ballast resistor

bypass. When the starter was cranking, 12 volts would be supplied on this terminal and directly to

the coil positive terminal for starting assistance.

Most ignition systems today do not need this terminal, however, if your ignition has no voltage when

cranking you can wire a system. Connect a 10A/250V diode in-line with the motor side of the solenoid.

The banded end of the diode goes away from the starter. This allows current to go to the ignition coil

during cranking and will not feed back to the starter while the engine is running.

Service

In case of malfunction, this MSD component will be repaired free of charge according to the terms of the warranty.

When returning MSD components for warranty service, Proof of Purchase must be supplied for verification. After

the warranty period has expired, repair service is based on a minimum and maximum fee.

All returns must have a Return Material Authorization (RMA) number issued to them before

being returned. To obtain an RMA number please contact MSD Customer Service at 1 (888) MSD-7859 or visit

our website at www.msdperformance.com/rma to automatically obtain a number and shipping information.

When returning the unit for repair, leave all wires at the length in which you have them installed. Be sure to include

a detailed account of any problems experienced, and what components and accessories are installed on the vehicle.

The repaired unit will be returned as soon as possible using Ground shipping methods (ground shipping is covered

by warranty). For more information, call MSD at (915) 855-7123. MSD technicians are available from 7:00 a.m. to

5:00 p.m. Monday - Friday (mountain time).

Limited Warranty

M

SD warrants this product to be free from defects in material and workmanship under its intended normal use*,

when properly installed and purchased from an authorized MSD dealer, for a period of one year from the date of

the original purchase. This warranty is void for any products purchased through auction websites. If found to be

defective as mentioned above, it will be repaired or replaced at the option of MSD. Any item that is covered under

this warranty will be returned free of charge using Ground shipping methods.

This shall constitute the sole remedy of the purchaser and the sole liability of MSD. To the extent permitted by

law, the foregoing is exclusive and in lieu of all other warranties or representation whether expressed or implied,

including any implied warranty of merchantability or fitness. In no event shall MSD or its suppliers be liable for special

or consequential damages.

*Intended normal use means that this item is being used as was originally intended and for the original application

as sold by MSD. Any modifications to this item or if it is used on an application other than what MSD markets the

product, the warranty will be void. It is the sole responsibility of the customer to determine that this item will work for

the application they are intending. MSD will accept no liability for custom applications.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

© 2012 Autotr onic Contr ols Corporation

FRM30960 Revised 06/12 Printed in U.S.A.

Loading...

Loading...