Page 1

Atomic EFI Return System

PN 2922

ONLINE PRODUCT REGISTRATION: Register your MSD product online. Registering your product

will help if there is ever a warranty issue with your product and helps the MSD R&D team create

new products that you ask for! Go to www.msdperformance.com/registration.

Thank you for selecting the Atomic Fuel Line Return kit. This kit is recommended for use with the

Atomic Throttle Body EFI and Atomic LS EFI systems.

Parts Included:

1 - Adjustable Regulator

1 - -6AN Port Plug

3 - -6AN Straight Port Fittings

2 - -6AN 90° Push-Lock Fittings

2 - -6AN Straight Push-Lock Fittings

15 Feet - High Pressure Fuel Hose

CAPABILITIES

The Atomic Adjustable Regulator is configured for a single -6AN inlet, and dual -6AN outlets (for

regulator-to-tank line routing flexibility). The recommended operating range is 0-90 psig (pounds

per square inch gauge). The maximum recommended flow rate is 500 liters/hour (2.2 GPM). The

vacuum/boost compensation ratio is 1:1.

1 - Regulator Parts Bag includes:

1 - Regulator Mounting Bracket

1 - Brass Hose Barb Fitting

1 - Stainless Steel Pipe Plug

2 - 10-32 x 0.375 Button Head Cap Screws

1 - High Pressure Fuel Hose Clamp

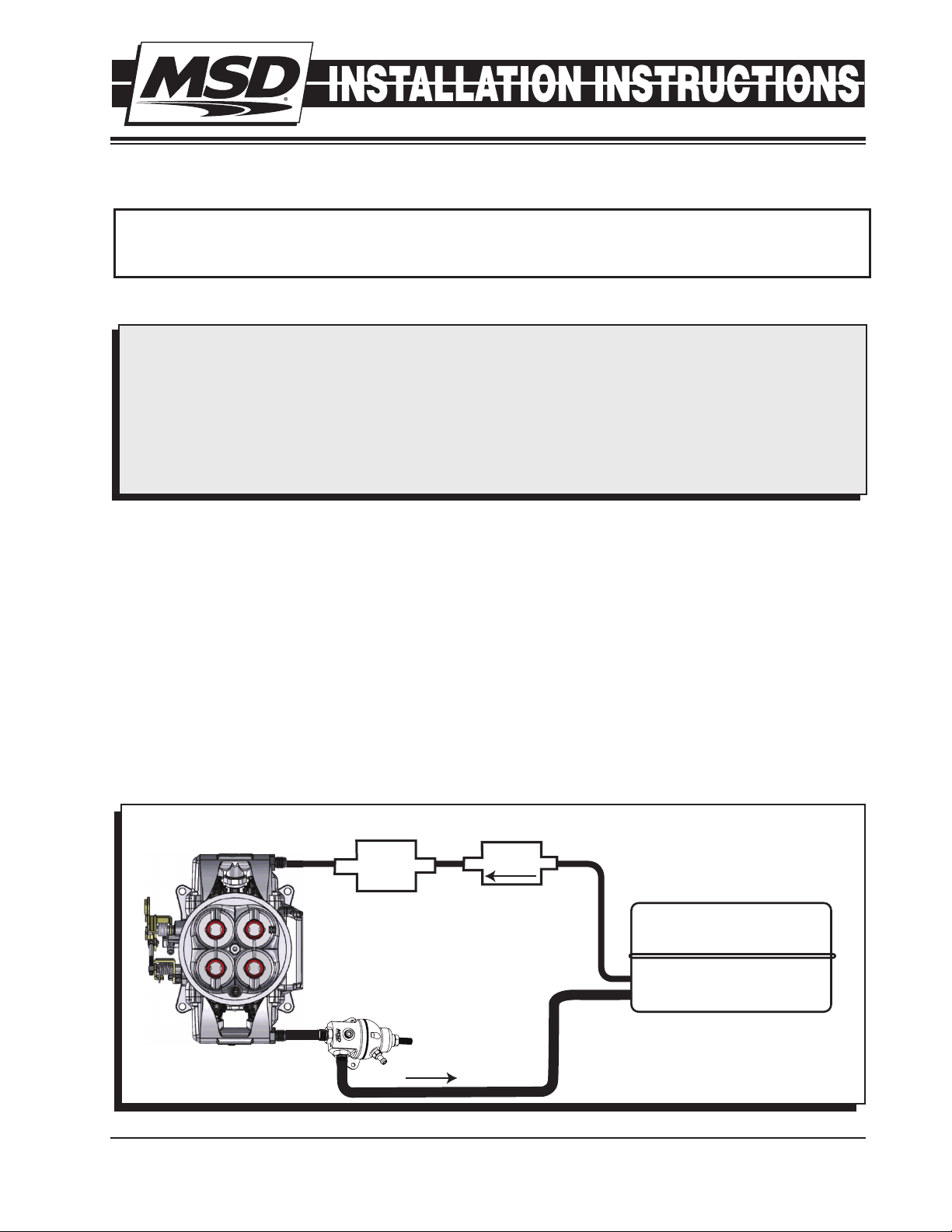

RECOMMENDED PLUMBING SCHEMATICS

Use the schematic below as a guide when installing the kit in conjunction with an Atomic throttle body

EFI system. There are two possible connection points on the throttle body unit, one of which will be

the fuel supply in an operational system. DO NOT “tee” into the supply line and leave the -6AN port

plug installed in the remaining throttle body port. Remove the -6AN port plug from the throttle body

and route fuel from that port to the regulator inlet port (using the supplied hose and fittings). The

hose length between the throttle body and regulator is not critical, but generally speaking, should be

kept to a minimum. Route and secure the hose as necessary to prevent chafing, stretching due to

engine movement, and heat-related damage.

CORRECT FOR RETURN STYLE FUEL SYSTEM.

FUEL

FILTER

MSD ADJUSTABLE

REGULATOR

FUEL

PUMP

FUEL TANK

Figure 1 Atomic TBI Return Fuel System.

MSD • WWW.ATOMICEFI.COM • (915) 857-5200 • FAX (915) 857-3344

Page 2

2 INSTALLATION INSTRUCTIONS

, MOUNT

ACCOMMODATES

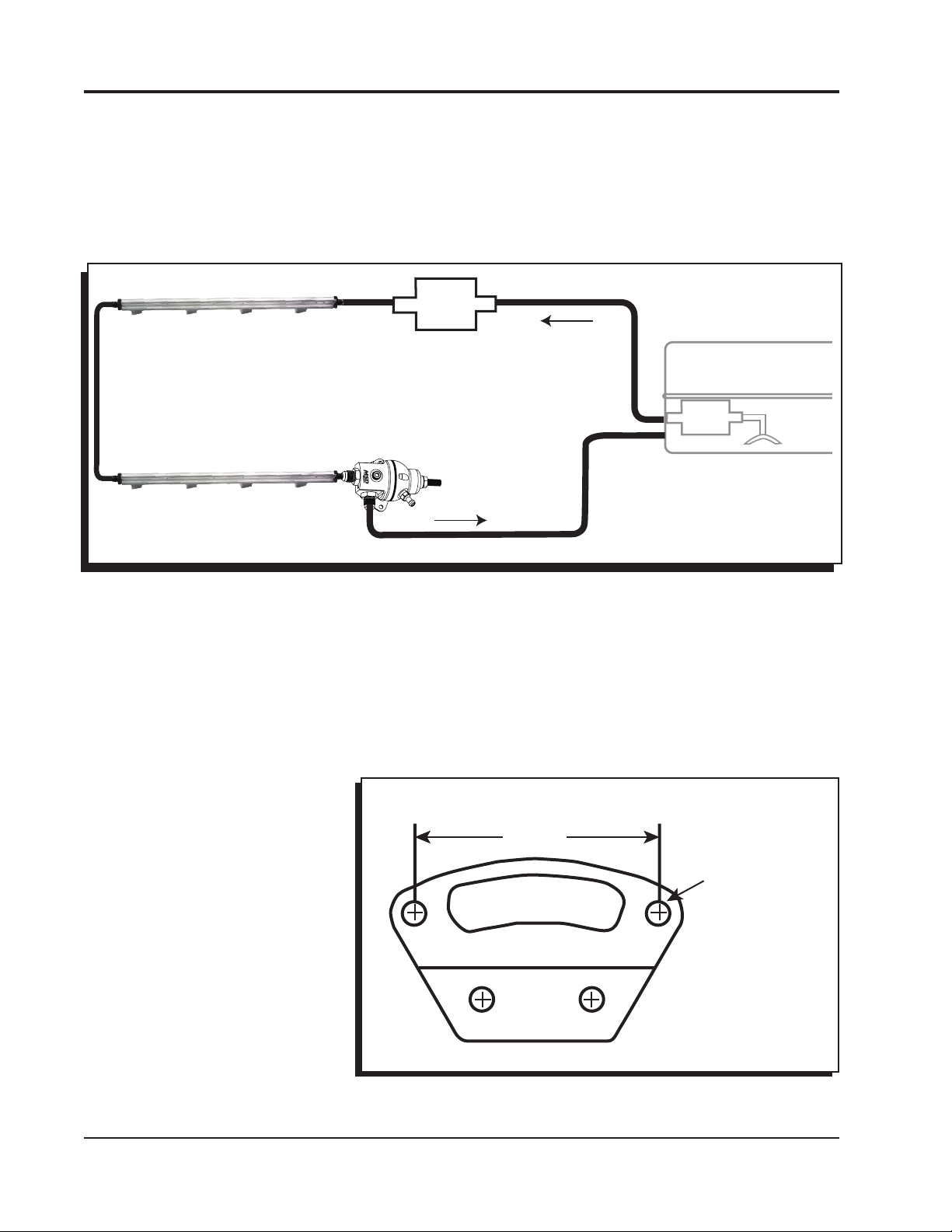

Use the schematic below as a guide when installing the kit in conjunction with an Atomic LS EFI system.

There are two possible connection points (one at the rear of each fuel rail assembly). One rail will be

connected to the fuel supply in an operational system. DO NOT “tee” into the supply line and leave

the opposing fuel rail plugged or capped. Fuel from the opposing rail should be routed to the regulator

inlet port (using the supplied hose and fittings). The hose length between the rail and regulator is not

critical, but generally speaking, should be kept to a minimum. Route and secure the hose as necessary

to prevent chafing, stretching due to engine movement, and heat-related damage.

FUEL RAIL

(UNDER COVER)

FUEL RAIL

FUEL RAIL

(UNDER COVER)

(UNDER COVER)

MSD ADJUSTABLE

REGULATOR

FUEL

FILTER

FUEL TANK

FUEL

PUMP

IT IS RECOMMENDED TO MOUNT

THE FUEL PUMP IN THE TANK

WHENEVER POSSIBLE. IF IT MUST

BE MOUNTED EXTERNALLY

THE PUMP WITHIN 2-FEET OF THE

FUEL TANK SENDING UNIT.

Figure 2 Atomic LS Return Fuel System.

The regulator-to-tank connection should be made using the supplied hose and fittings. Install the

supplied -6AN port plug in whichever regulator return port is not used. Depending on the configuration

of your fuel tank / fuel cell, the supplied high pressure fuel hose clamp may be used at the tank fitting

connection.

Use care when routing the hose from the regulator to the tank. Route and secure the hose as necessary

to prevent chafing, stretching due to engine movement, and heat-related damage.

REGULATOR MOUNTING

Using the two (2) supplied 10-32

x 0.375 Button Head Cap Screws

and a 1/8-inch hex key (Allen

wrench), attach the regulator

bracket to the regulator body. The

regulator may then be mounted

to the firewall, or other convenient

surface. Regulator orientation

is not critical, but be mindful of

adjustment screw access and hose

routing. Refer to Figure 3 for a

mounting bracket template.

2.200”

#10 SCREW

Figure 3 Regulator Mounting Bracket Template

MSD • WWW.MSDPERFORMANCE.COM • (915) 857-5200 • FAX (915) 857-3344

Page 3

INSTALLATION INSTRUCTIONS 3

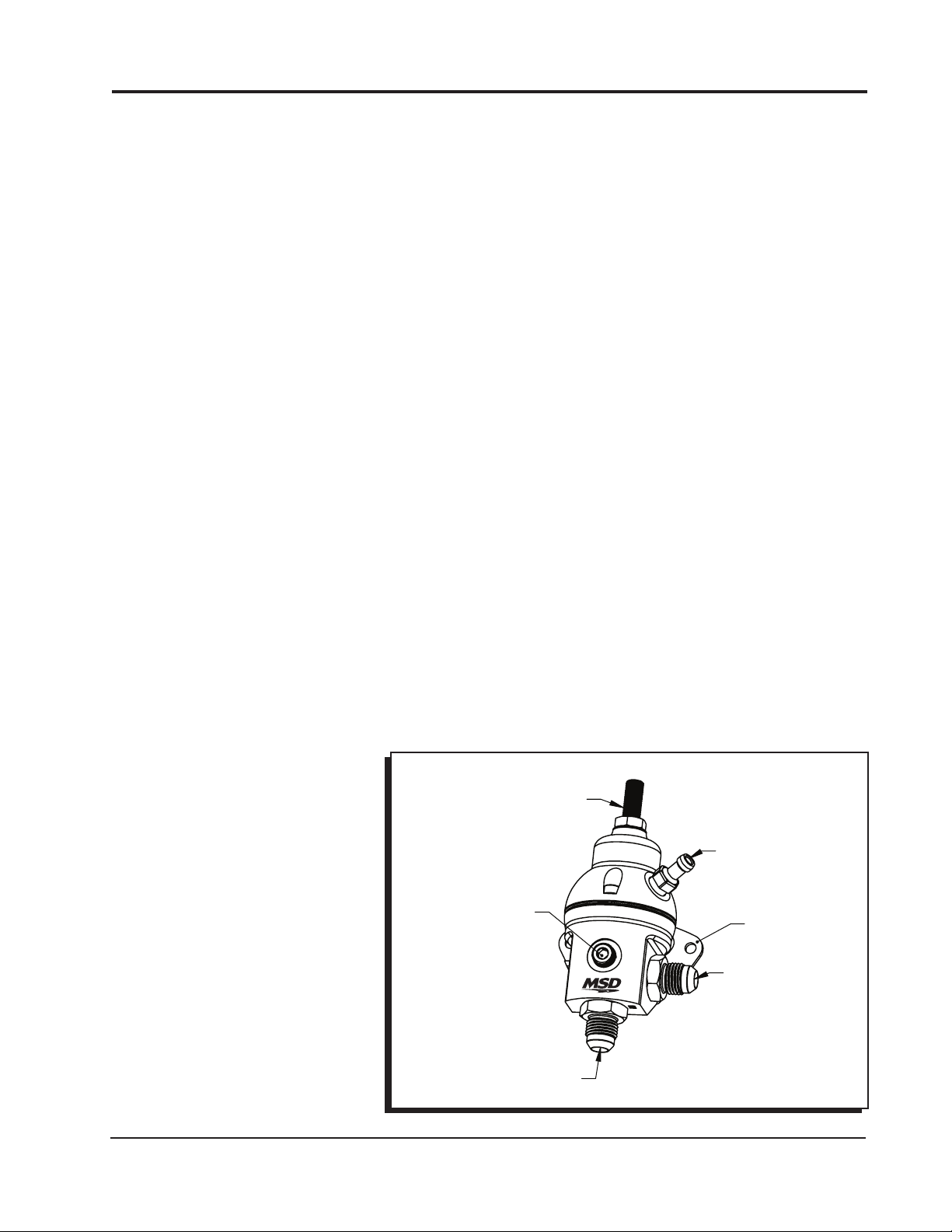

VACUUM / BOOST

ADJUSTMENT SCREW

INLET PORT

GAUGE PORT

REGULATOR CONNECTIONS AND ADJUSTMENT

The regulator inlet port is located on the bottom surface, and clearly marked with an identifier machined

in the housing (see Figure 4 below). Two (2) outlet ports are available, but typically only one (1) will

be used. Install the supplied -6AN port plug in the unused outlet port using a 5/16-inch hex key (Allen

wrench). The -6AN straight port fittings should be snugged with an 11/16-inch wrench or deep socket.

Install the supplied 1/8-27 NPT brass hose barb fitting in the upper regulator housing (see Figure 4

below) using a 7/16-inch wrench or deep socket. Thread sealer is not required on this fitting, but

can be used if desired. Connect an intake manifold vacuum / boost source to this fitting, or leave

it open to the atmosphere if manifold pressure compensation is not required. DO NOT plug this

opening. Ensure that contaminants (such as water and road spray) cannot enter the open fitting.

In the event that vacuum / boost reference is not required, a more cosmetically pleasing option is to

install a sintered metal exhaust muffler in this port (such as McMaster-Carr PN 4450K1-Bronze or PN

4402K51-Stainless Steel)

The 1/8-27 NPT port in the lower housing allows the installation of a fuel pressure gauge (direct or

remote-reading). If use of this port is not required, install the supplied stainless steel pipe plug using

a 3/16-inch hex key (Allen wrench). Use of a fuel compatible paste-type thread sealer is REQUIRED

on this plug. Thread sealing tape is also an option, but not recommended due to the potential for

particulate and debris generation.

Use a 5/32-inch hex key (Allen wrench) to adjust the regulator set point. Clockwise rotation (screw

advancing inward) increases the set point, and counter-clockwise rotation (screw advancing outward)

decreases the set point. When the desired set point has been reached, snug the jam nut using a

½-inch wrench.

Refer to the user installation instructions, supplied with the Atomic EFI kit, for regulator set point

recommendations.

Note: An overly lengthy and restrictive return line routing scheme may result in a non-negligible

pressure rise across the regulator-to-tank portion of the system. For this reason, the final

regulator adjustment should be made while monitoring the system fuel pressure (on the Atomic

hand-held Dash) with the engine at idle.

AND LOCK NUT

REFERENCE PORT

(1/8-27 NPT)

(1/8-27 NPT)

MOUNTING

BRACKET

OUTLET PORT

(1 OF 2)

MSD • WWW.ATOMICEFI.COM • (915) 857-5200 • FAX (915) 857-3344

Figure 4 - Regulator Feature Identification Guide

Page 4

4 INSTALLATION INSTRUCTIONS

STOP HERE

REVIEW YOUR INSTALLATION

Take a few extra minutes to check all aspects of your return fuel system installation at this point. Cycle

the key on and off several times to ensure a complete fuel system prime, and verify that all connections

and fittings are leak-tight. Don’t forget to make the final regulator adjustment with the engine idling.

REGULATOR SERVICE

The regulator diaphragm assembly is available as a service kit from MSD and considered a userserviceable item. Detailed instructions are available in the service kit, but for completeness, the

following guidelines must be observed if it is necessary to separate the regulator housings.

• Usea9/64-inchhexkey(Allenwrench)toremovethethree(3)8-32x0.375SocketHeadCap

Screws

• Usecarenottoloseanyinternalparts(particularlythe¼-inchballbeneaththeadjustmentscrew)

• Uponre-assembly,ensurethatnodebrisorparticulatesaretrappedbetweenthehousingmating

surfaces (these may cut or damage the diaphragm)

• Alignthediaphragmslotswiththethree(3)screwholesandstackthespringassemblypriorto

installing the upper housing

• Installthethree(3)8-32x0.375SHCStoastagednaltorqueof25-28*in-lb.

o Stage 1 Torque: 10 in-lb

o Stage 2 Torque: 20 in-lb

o Stage3(nal)Torque:25-28*in-lb.

*VerifytheStage3torqueafteratleastonehourhaselapsed(toallowfordiaphragmcompressionset)

Completing the installation of your MSD Atomic fuel return kit will require that several connections

be made using the supplied high-pressure hose and push-lock fittings. Use compressed air (or

equivalent) to ensure that all complete hose / fitting assemblies are clean prior to final installation.

To ensure that your connections are safe, durable, and cosmetically pleasing, we recommend that

you adhere to the guidelines in the following section:

MSD • WWW.MSDPERFORMANCE.COM • (915) 857-5200 • FAX (915) 857-3344

Page 5

INSTALLATION INSTRUCTIONS 5

PROPER INSTALLATION OF PUSH-LOCK AN FITTINGS

IN AEROQUIP AQP HOSE

Proper installation of push-lock fittings BEGINS with the first cut of the hose. The hose end must be

cut squarely and cleanly. If these two requirements are not met, the connection is compromised from

the start. See Figure 5 and 6 for additional information on achieving a proper cut.

Apply a light coating of fresh motor

oil to the fitting barbs. More is

NOT better – too much oil results

in a slippery mess which makes it

impossible to get a tight grip on the

hose.

To the extent possible, make sure

the push-lok fitting is well anchored

– whether it is in a vise, connected to

another stationary fitting, or against

a hard surface. You WILL NOT get

good results by trying to hold the

fitting in one hand, and the hose in

the other. Likewise, you WILL NOT

get good results if you cannot apply

sufficient force to fully engage the

fitting barbs in one smooth motion.

Having to stop and twist, and then

resume pushing, typically results

in an inferior connection - requiring

that you cut the hose off the fitting

and start again. This means that

you should not try to push the hose

on the fitting when leaning over the

engine while standing on an old

milk crate.

NOTE: THERE IS MINIMAL DISTURBANCE

OF THE OUTER JACKET, BRAIDS,

AND INNER LINER. THIS TYPE

OF CUT IS ACHIEVED WITH A

HOSE CUTTER, NEW RAZOR

BLADE, OR EXTREMELY SHARP

(NON-SERRATED) KNIFE. THE

HOSE SHOULD BE SEVERED

COMPLETELY – REQUIRING NO

TEARING OF BRAIDS AND / OR

RUBBER MATERIAL WHEN THE

CUT IS COMPLETE. THE CUT

PLANE IS PERPENDICULAR TO THE

LONGITUDINAL HOSE AXIS.

Figure 5 Correct Clean, Square Cut

NOTE: THERE IS VISIBLE DAMAGE TO THE

OUTER JACKET, BRAIDS, INNER

LINER, OR ANY COMBINATION

THEREOF. THIS TYPE OF CUT

RESULTS FROM THE USE OF A

DULL KNIFE, SERRATED KNIFE,

“SAWING ACTION” WHILE

CUTTING, THE USE OF SIDECUTTING PLIERS THAT CRUSH

THE HOSE WHILE CUTTING, OR

ANY TYPE OF CUTTER THAT

UTILIZES SHEARING ACTION.

THE CUT PLANE IS GENERALLY

NOT PERPENDICULAR TO

LONGITUDINAL HOSE AXIS.

Figure 6 Incorrect Jagged, Rough Cut

MSD • WWW.ATOMICEFI.COM • (915) 857-5200 • FAX (915) 857-3344

Page 6

6 INSTALLATION INSTRUCTIONS

The depth to which the fitting is inserted into the hose is EXTREMELY IMPORTANT. Stopping too soon,

with the end of the hose positioned directly above the inboard hose barb, will result in excessive hoop

stresses in the braids and outer jacket. Pushing too far, such that the hose starts to ride up on the beauty

ring lead-in chamfer, will have the same result. In either case, the residual hoop stresses (in the braids

and outer jacket) will lead to the formation of splits in the outer jacket once the hose has been exposed

to under-hood temperatures. See Figure 7 for an example of an improperly installed fitting. See

Figure 8 for an example of an improperly installed fitting – which resulted in splits in the outer hose

jacket following heat exposure.

Use the thin edge of the beauty ring as a depth gauge for the end of the hose. STOP pushing when

the end of the hose is flush with the thin edge of the beauty ring. At this point, the end of the hose

should have “rolled over” the inboard barb and conformed snugly to the fitting neck. See Figure 9

for an example of a properly installed fitting.

NOTE: EXCESSIVE GAP BETWEEN END OF HOSE AND THIN EDGE OF BEAUTY

RING - RESULTING IN RESIDUAL HOOP STRESSES IN BRAIDS AND OUTER

JACKET. CONNECTION INTEGRITY HAS BEEN COMPROMISED, AND OUTER

JACKET WILL SPLIT WHEN EXPOSED TO HEAT.

Figure 7 Improperly Installing Push-Lock Fitting

MSD • WWW.MSDPERFORMANCE.COM • (915) 857-5200 • FAX (915) 857-3344

Page 7

INSTALLATION INSTRUCTIONS 7

SPLITS IN OUTER HOSE JACKET (BEAUTY RING REMOVED FOR CLARITY)

Figure 8 Improperly Installed Push-Lock Fitting

END OF HOSE IS FLUSH WITH THE THIN EDGE OF THE BEAUTY RING.

Figure 9 Properly Installed Push-Lock Fitting

MSD • WWW.ATOMICEFI.COM • (915) 857-5200 • FAX (915) 857-3344

Page 8

8 INSTALLATION INSTRUCTIONS

TECH NOTES

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

Service

In case of malfunction, this MSD component will be repaired free of charge according to the terms of the warranty.

When returning MSD components for warranty service, Proof of Purchase must be supplied for verification. After

the warranty period has expired, repair service is based on a minimum and maximum fee.

All returns must have a Return Material Authorization (RMA) number issued to them before

being returned. To obtain an RMA number please contact MSD Customer Service at 1 (888) MSD-7859 or visit

our website at www.msdperformance.com/rma to automatically obtain a number and shipping information.

When returning the unit for repair, leave all wires at the length in which you have them installed. Be sure to include

a detailed account of any problems experienced, and what components and accessories are installed on the vehicle.

The repaired unit will be returned as soon as possible using Ground shipping methods (ground shipping is covered

by warranty). For more information, call MSD at (915) 855-7123. MSD technicians are available from 7:00 a.m. to

5:00 p.m. Monday - Friday (mountain time).

Limited Warranty

M

SDwarrantsthisproducttobefreefromdefectsinmaterialandworkmanshipunderitsintendednormaluse*,

when properly installed and purchased from an authorized MSD dealer, for a period of one year from the date of

the original purchase. This warranty is void for any products purchased through auction websites. If found to be

defective as mentioned above, it will be repaired or replaced at the option of MSD. Any item that is covered under

this warranty will be returned free of charge using Ground shipping methods.

This shall constitute the sole remedy of the purchaser and the sole liability of MSD. To the extent permitted by

law, the foregoing is exclusive and in lieu of all other warranties or representation whether expressed or implied,

including any implied warranty of merchantability or fitness. In no event shall MSD or its suppliers be liable for special

or consequential damages.

*Intendednormalusemeansthatthisitemisbeingusedaswasoriginallyintendedandfortheoriginalapplication

as sold by MSD. Any modifications to this item or if it is used on an application other than what MSD markets the

product, the warranty will be void. It is the sole responsibility of the customer to determine that this item will work for

the application they are intending. MSD will accept no liability for custom applications.

MSD • WWW.MSDPERFORMANCE.COM • (915) 857-5200 • FAX (915) 857-3344

© 2013 Autotr onic Controls Corp oration

FRM31527 Revised 4/13 Printed in U.S.A.

Loading...

Loading...