Page 1

MTH800

TETRA Handportable

Terminal

380-430 MHz (PT911FR)

440-470 MHz (PT511FR 1)

Basic Service Manual

Part Number: 6866539D22-D

*6866539D22*

GCD-EMEA, Issue: 04.2008

Page 2

ii MTH800 TETRA Handportable Terminal / Basic Service Manual COPYRIGHT

COPYRIGHT

Copyrights

© 2008 Motorola Inc. All rights reserved.

No part of this manual may be reproduced, transmitted, stored in a retrieval

system, or translated into any language or computer language, in any form or by

any means, without the prior written permission of Motorola Inc.

Computer Software Copyrights

The Motorola products described in this manual may include copyrighted

Motorola computer programs stored in semiconductor memories or other media.

Laws in the United States and other countries preserve for Motorola certain

exclusive rights for copyrighted computer programs including, but not limited to,

the exclusive right to copy or reproduce in any form the copyrighted computer

program. Accordingly, any copyrighted Motorola computer programs contained in

the Motorola products described in this manual may not be copied, reproduced,

modified, reverse-engineered, or distributed in any manner without the express

written permission of Motorola. Furthermore, the purchase of Motorola products

shall not be deemed to grant either directly or by implication, estoppel, or

otherwise, any license under the copyrights, patents or patent applications of

Motorola, except for the normal non-exclusive royalty-free license to use that

arises by operation of law in the sale of a product.

Trademarks

MOTOROLA and the Stylized M Logo are registered in the U.S.Patent and

Trademark Office. All other product or service names are the property of their

respective owners.

© Motorola, Inc. 2008

Page 3

DOCUMENT HISTORY MTH800 TETRA Handportable Terminal / Basic Service Manual iii

DOCUMENT HISTORY

The following major changes have been implemented in this manual since the previous edition:

Edition Description Date

6866539D22-A Initial edition with enhanced frequency range from 440-470MHz

(based upon the predecessor service manual for 380-430 &

450-470MHz).

6866539D22-B UCM-M Module (Upgrade kit GMLN4561) has been added to

several chapters.

6866539D22-C Updated GPS description (pg. 3-3) and service tanapa (pg. A-6). Oct. 2007

6866539D22-D Chapter 6

- Updated components list (pp. 6-24 to 6-25).

- Updated replacement parts list (pg. 6-29).

Aug. 2006

Dec. 2006

Apr. 2008

Page 4

iv MTH800 TETRA Handportable Terminal / Basic Service Manual

Notes

Page 5

SAFETY MTH800 TETRA Handportable Terminal / Basic Service Manual v

SAFETY

Product Safety and RF Exposure for Portable Two-Way Radios

THIS CHAPTER IS AN EXTRACT OF THE MULTI LINGUAL PORTABLE SAFETY

BOOKLET PUBLICATION No. 6864117B25. FOR THE LATEST SAFETY

INFORMATION REFER TO THE SEPARATE SAFETY BOOKLET DELIVERED WITH

YOUR RADIO.

BEFORE USING THIS RADIO, READ THIS BOOKLET WHICH CONTAINS IMPORTANT OPERATING

INSTRUCTIONS FOR SAFE USAGE AND RF ENERGY AWARENESS AND CONTROL INFORMATION AND

OPERATIONAL INSTRUCTIONS FOR COMPLIANCE WITH RF ENERGY EXPOSURE LIMITS IN

APPLICABLE NATIONAL AND INTERNATIONAL STANDARDS. ALSO READ THE OPERATIONAL

INSTRUCTIONS FOR SAFE USAGE. FOR RADIOS THAT HAVE BEEN APPROVED AS INTRINSICALLY

SAFE, READ THE INSTRUCTIONS AND INFORMATION ON INTRINSIC SAFETY ON PAGE VII

.

RF Energy Exposure Awareness and Control Information and Operational Instructions for Occupational Use

NOTICE: This radio is intended for use in occupational/controlled conditions where users

have full knowledge of their exposure and can exercise control over their exposure

to meet the occupational limits in FCC/ICNIRP and International standards. This

radio device is NOT authorized for general population consumer use.

This two-way radio uses electromagnetic energy in the radio frequency (RF) spectrum to provide

communications between two or more users over a distance. It uses radio frequency (RF) energy or

radio waves to send and receive calls. RF energy is one form of electromagnetic energy. Other

forms include, but are not limited to, sunlight and x-rays. RF energy, however, should not be

confused with these other forms of electromagnetic energy, which when used improperly, can cause

biological damage. Very high levels of x-rays, for example, can damage tissues and genetic

material.

Experts in science, engineering, medicine, health, and industry work with organizations to develop

standards for safe exposure to RF energy. These standards provide recommended levels of RF

exposure for both workers and the general public. These recommended RF exposure levels include

substantial margins of protection.

All Motorola two-way radios are designed, manufactured, and tested to ensure they meet

government-established RF exposure levels. In addition, manufacturers also recommend specific

operating instructions to users of two-way radios. These instructions are important because they

inform users about RF energy exposure and provide simple procedures on how to control it.

Please refer to the following websites for more information on what RF energy exposure is and how

to control your exposure to assure compliance with established RF exposure limits:

http://www.fcc.gov/oet/rfsafety/rf-faqs.html

http://www.osha.gov/SLTC/radiofrequencyradiation/index.html

Page 6

vi MTH800 TETRA Handportable Terminal / Basic Service Manual SAFETY

Federal Communication Commission (FCC) Regulations (US markets only)

The FCC rules require manufacturers to comply with the FCC RF energy exposure limits for portable

two-way radios before they can be marketed in the U.S. When two-way radios are used as a

consequence of employment, the FCC requires users to be fully aware of and able to control their

exposure to meet occupational requirements. Exposure awareness can be facilitated by the use of a

product label directing users to specific user awareness information. Your Motorola two-way radio

has a RF Exposure Product Label. Do not remove this RF Exposure Label from the device. Also,

your Motorola user manual, or separate safety booklet includes information and operating

instructions required to control your RF exposure and to satisfy compliance requirements.

Compliance with RF Exposure Standards

Your Motorola two-way radio is designed and tested to comply with a number of national and

International standards and guidelines (listed below) for human exposure to radio frequency

electromagnetic energy. This radio complies with the IEEE (FCC) and ICNIRP exposure limits

for occupational/controlled RF exposure environments at operating duty factors of up to 50%

talk-50% listen and is authorized by the IEEE/ICNIRP for occupational use only.

In terms of measuring RF energy for compliance with these exposure guidelines, your radio

generates measurable RF energy only while it is transmitting (during talking), not when it is

receiving (listening) or in standby mode.

NOTE:The approved batteries, supplied with the portable radio, are rated for a 5-5-90 duty cycle

(5% talk–5% listen–90% standby), even though this radio complies with IEEE/ICNIRP

occupational exposure limits at usage factors of up to 50% talk.

Your Motorola two-way radio complies with the following RF energy exposure standards and

guidelines:

• United States Federal Communications Commission, Code of Federal Regulations; 47 CFR part

2 sub-part J

• American National Standards Institute (ANSI) / Institute of Electrical and Electronic Engineers

(IEEE) C95. 1-1992

• Institute of Electrical and Electronic Engineers (IEEE) C95.1-1999 Edition

• International Commission on Non-Ionizing Radiation Protection (ICNIRP) 1998

• Ministry of Health (Canada) Safety Code 6. Limits of Human Exposure to Radiofrequency

Electromagnetic Fields in the Frequency Range from 3 kHz to 300 GHz, 1999

• Australian Communications Authority Radiocommunications (Electromagnetic Radiation Human Exposure) Standard, 2003

• ANATEL ANNEX to Resolution No. 303 of July 2, 2002 "Regulation of limitation of exposure to

electrical, magnetic and electromagnetic fields in the radio frequency range between 9 KHz and

300 GHz" and "Attachment to resolution # 303 from July 2, 2002"

Page 7

SAFETY MTH800 TETRA Handportable Terminal / Basic Service Manual vii

RF Exposure Compliance and Control Guidelines and Operating Instructions

To control your exposure and ensure compliance with the occupational/controlled environment

exposure limits, always adhere to the following procedures:

Guidelines:

• User awareness instructions should accompany device when transferred to other users.

• Do not use this device if the operational requirements described herein are not met.

Operating Instructions:

• Transmit no more than the rated duty factor of 50% of the time. To transmit (talk), push the PushTo-Talk (PTT) button. To receive calls, release the PTT button. Transmitting 50% of the time, or

less, is important because this radio generates measurable RF energy exposure only when

transmitting (in terms of measuring for standards compliance).

• When worn on the body, always place the radio in a Motorola-approved clip, holder, holster,

case, or body harness for this product. Using approved body-worn accessories is important

because the use of non-Motorola-approved accessories may result in exposure levels, which

exceed the IEEE/ICNIRP occupational/controlled environment RF exposure limits.

• If you are not using a body-worn accessory and are not using the radio in the intended use

position, along side the head in the phone mode (TETRA only), in front of the face in the hand

held mode, then ensure the antenna and the radio are kept 2.5 cm (one inch) from the body

when transmitting. Keeping the radio at a proper distance is important because RF exposures

decrease with increasing distance from the antenna.

Hand-held Mode - Operating Instructions:

• Hold the radio in a vertical position in front of the face with the microphone (and

other parts of the radio including the antenna) at least 2.5 cm (one inch) away from

the nose or lips. Antenna should be kept away from the eye. Keeping the radio at a

proper distance is important since RF exposures decrease with increasing distance

from the antenna.

Phone Mode (TETRA only) - Operating Instructions:

• When placing or receiving a phone call, hold your radio product as you would a wireless

telephone. Speak directly into the microphone.

Approved Accessories

• Use only Motorola-approved supplied or replacement antennas, batteries, and accessories. Use

of non–Motorola - approved antennas, batteries and accessories may exceed IEEE/ICNIRP RF

exposure guidelines. For a list of Motorola-approved antennas, batteries, and other accessories

please see your dealer or local Motorola contact. Your nearest dealer can be found at the

following web site:

http://www.motorola.com/businessandgovernment/wemea/engb/public/functions/dealerlocator/dealerlocator.aspx

Page 8

viii MTH800 TETRA Handportable Terminal / Basic Service Manual SAFETY

Additional Information

For additional information on exposure requirements or other training information, visit

http://www.motorola.com/rfhealth.

Electromagnetic Interference/Compatibility

NOTE:Nearly every electronic device is susceptible to electromagnetic interference (EMI) if

inadequately shielded, designed, or otherwise configured for electromagnetic compatibility.

Facilities

To avoid electromagnetic interference and/or compatibility conflicts, turn off your radio in any facility

where posted notices instruct you to do so. Hospitals or health care facilities may be using

equipment that is sensitive to external RF energy.

Aircraft

When instructed to do so, turn off your radio when on board an aircraft. Any use of a radio must be

in accordance with applicable regulations per airline crew instructions.

Medical Devices

Pacemakers

The Advanced Medical Technology Association (AdvaMed) recommends that a minimum separation

of 15 centimeters (6 inches) be maintained between a handheld wireless radio and a pacemaker.

These recommendations are consistent with those of the U.S. Food and Drug Administration.

Persons with pacemakers should:

• ALWAYS keep the radio more than 15 centimeters from their pacemaker when the radio is turned

ON.

• Not carry the radio in the breast pocket.

• Use the ear opposite the pacemaker to minimize the potential for interference.

• Turn the radio OFF immediately if you have any reason to suspect that interference is taking

place.

Hearing Aids

Some digital wireless radios may interfere with some hearing aids. In the event of such interference,

you may want to consult your hearing aid manufacturer to discuss alternatives.

Other Medical Devices

If you use any other personal medical device, consult the manufacturer of your device to determine

if it is adequately shielded from RF energy. Your physician may be able to assist you in obtaining this

information.

Page 9

SAFETY MTH800 TETRA Handportable Terminal / Basic Service Manual ix

Use of Communication Devices While Driving

Always check the laws and regulations on the use of radios in the area where you drive.

• Give full attention to driving and to the road.

• Use hands-free operation, if available.

• Pull off the road and park before making or answering a call if driving conditions or regulations so

require.

Operational Warnings

For Vehicles With An Air Bag

Refer to vehicle manufacturer's manual prior to installation of electronic equipment to avoid

interference with air bag wiring.

Do not place a portable radio in the area over an air bag or in the air bag deployment area. Air bags

inflate with great force. If a portable radio is placed in the air bag deployment area and the air bag

inflates, the radio may be propelled with great force and cause serious injury to occupants of the

vehicle.

Potentially Explosive Atmospheres

(Explosive atmospheres refers to hazard classified locations that may contain hazardous

gas, vapors, or dusts.)

Turn off your radio prior to entering any area with a potentially explosive atmosphere, unless it is a

radio type especially qualified for use in such areas as "Intrinsically Safe" (for example, Factory

Mutual, CSA, UL, CENELEC or ATEX Approved). Do not remove, install, or charge batteries in such

areas. Sparks in a potentially explosive atmosphere can cause an explosion or fire resulting in

bodily injury or even death.

The areas with potentially explosive atmospheres referred to above include fuelling areas such as

below decks on boats, fuel or chemical transfer or storage facilities, areas where the air contains

chemicals or particles, such as grain, dust or metal powders. Areas with potentially explosive

atmospheres are often but not always posted.

Blasting Caps And Blasting Areas

To avoid possible interference with blasting operations, turn off your radio when you are near

electrical blasting caps, in a blasting area, or in areas posted:

"Turn off two-way radio". Obey all signs and instructions.

Operational Cautions

Antennas

Do not use any portable radio that has a damaged antenna. If a damaged antenna comes into contact

with your skin, a minor burn can result.

Batteries

All batteries can cause property damage and/or bodily injury such as burns if a conductive material

such as jewelry, keys, or beaded chains touch exposed terminals. The conductive material may

complete an electrical circuit (short circuit) and become quite hot. Exercise care in handling any

charged battery, particularly when placing it inside a pocket, purse, or other container with metal

objects.

Page 10

xMTH800 TETRA Handportable Terminal / Basic Service Manual SAFETY

Intrinsically Safe Radio Information

The Intrinsically safe approval unit refers to a product that has been approved as intrinsically safe by

an approval agency (for example FM Approvals, CSA, UL, CENELEC or ATEX) and certifies that a

particular product meets the Agency's applicable intrinsic safety standards for specific types of

hazardous classified locations. A portable radio that has been approved for intrinsic safety will have

Approval label attached to the radio to identify the unit as being Approved for specified hazardous

atmospheres. This label specifies the hazardous Class/Division/Group along with the part number of

the battery that must be used. The Intrinsically Safe Approval Label will be located on the portable

radio unit.

Operational Cautions for Intrinsic Safe Equipment

• Do not operate radio communications equipment in a hazardous atmosphere unless it is a type

especially qualified (for example, FM, UL, CSA, or CENELEC or ATEX approved). An explosion or

fire may result.

• Do not operate a radio unit that has been approved as intrinsically safe product in a hazardous

atmosphere if it has been physically damaged (for example, cracked housing). An explosion or fire

may result.

• Do not replace or charge batteries in a hazardous atmosphere. Contact sparking may occur while

installing or removing batteries and cause an explosion or fire.

Operational Cautions for Intrinsic Safe Equipment

Radios must ship from the Motorola manufacturing facility with the hazardous atmosphere capability

and the intrinsic safety approval labelling (FM, UL, CSA, CENELEC or ATEX). Radios will not be

upgraded to this capability and labeled once they have been shipped to the field.

A modification changes the unit’s hardware from its original design configuration. Modifications can

only be made by the original product manufacturer.

• Do not replace or change accessories in a hazardous atmosphere. Contact sparking may

occur while installing or removing accessories and cause an explosion or fire.

• Turn the radio off before removing or installing a battery or accessory.

• Do not disassemble an intrinsically safe product in any way that exposes the internal

circuits of the unit.

• Failure to use an intrinsically safe approved battery or Approved accessories specifically

approved for the radio unit may result in the dangerously unsafe condition of an

unapproved radio combination being used in a hazardous location.

• Unauthorized or incorrect modification of the intrinsically safe approved Product will

negate the approval rating of the product.

• Incorrect repair or relabeling of any intrinsically safe Agency-approved radio could

adversely affect the Approval rating of the unit.

• Use of a radio that is not intrinsically safe in a hazardous atmosphere could result in

serious injury or death.

Page 11

SAFETY MTH800 TETRA Handportable Terminal / Basic Service Manual xi

Repair

REPAIRS FOR MOTOROLA PRODUCTS WITH INTRINSICALLY SAFE APPROVAL ARE THE

RESPONSIBILITY OF THE USER.

• Repairs to a Motorola FM approved radio product should only be done at a location that

has been FM audited under the FM 3605 repairs and service standard.

• Contact Motorola for assistance regarding repairs and service of Motorola intrinsically

safe equipment.

A repair constitutes something done internally to the unit that would bring it back to its original

condition.

Items not considered as repairs are those in which an action is performed on a unit which does not

require the outer casing of the unit to be opened in a manner which exposes the internal electrical

circuits of the unit.

Do Not Substitute Options or Accessories

The Motorola communications equipment certified as intrinsically safe by the approving agency,

(FM, UL, CSA, CENELEC or ATEX) is tested as a complete system which consists of the listed

agency Approved portable, Approved battery, and Approved accessories or options, or both. This

Approved portable and battery combination must be strictly observed. There must be no substitution

of items, even if the substitute has been previously Approved with a different Motorola

communications equipment unit. Approved configurations are listed by the Approving Agency (FM,

UL, CSA, CENELEC or ATEX).

The Intrinsically Safe Approval Label affixed to radio refers to the intrinsically safe classification of

that radio product, and the approved batteries that can be used with that system.

The manual PN referenced on the Intrinsically Safe Approval Label identifies the approved

Accessories and or options that can be used with that portable radio unit.

Using a non Motorola intrinsically safe battery and or accessory with the Motorola approved radio

unit will void the intrinsically safe approval of that radio unit.

European Union Directives Conformance Statement

This product is in conformance with the TETRA (TErrestrial Trunked RAdio) standard.

This product is in conformance with the requirements of the applicable EU Council Directives.

Declarations of Conformance with the requirements are located at:

Motorola a/s

Sydvestvej 15

DK-2600 Glostrup

Denmark

Page 12

xii MTH800 TETRA Handportable Terminal / Basic Service Manual

Notes

Page 13

CONTENTS MTH800 TETRA Handportable Terminal / Basic Service Manual xiii

CONTENTS

COPYRIGHT....................................................................................................ii

DOCUMENT HISTORY................................................................................... iii

SAFETY ...........................................................................................................v

CONTENTS ......................................................................................xiii

CHAPTER 1 SCOPE & WARRANTY ....................................................... 1-1

Scope of this Manual ..................................................................................................................................... 1-1

Manual Revisions........................................................................................................................................... 1-1

Related Publications ...................................................................................................................................... 1-1

Warranty and Service Support....................................................................................................................... 1-2

After Warranty Period......................................................................................................................... 1-2

CHAPTER 2 MODEL INFORMATION...................................................... 2-1

MTH800 Model Information ........................................................................................................................... 2-1

MTH800 Model Specifications ....................................................................................................................... 2-2

CHAPTER 3 OVERVIEW ......................................................................... 3-1

Digital Modulation Technology ....................................................................................................................... 3-1

Voice Compression Technology..................................................................................................................... 3-1

Description .................................................................................................................................................... 3-2

Transceiver Description............................................................................................................................ 3-2

Digital Section Description ....................................................................................................................... 3-2

Transmitter Path Description.................................................................................................................... 3-2

Receiver Path Description........................................................................................................................ 3-3

Frequency Generating Section Description ............................................................................................. 3-3

Global Positioning System (GPS) Section Description ............................................................................ 3-3

CHAPTER 4.1 TEST SETUP & TESTING 380-430MHz.......................... 4-1

Typical Test Setup.......................................................................................................................................... 4-2

Alternative Test Setup .................................................................................................................................... 4-3

Test Check List............................................................................................................................................... 4-3

Transmitter Tests ................................................................................................................................ 4-4

Call Processing Tests ......................................................................................................................... 4-4

Duplex Test......................................................................................................................................... 4-5

How to Configure the IFR 2968 Setup ........................................................................................................... 4-5

How to Configure the IFR 2968 Manual Test Screen............................................................................... 4-7

RF Tests ......................................................................................................................................................... 4-8

Receiver Tests.......................................................................................................................................... 4-8

Page 14

xiv MTH800 TETRA Handportable Terminal / Basic Service Manual CONTENTS

Simulate Base Station (registration) ................................................................................................... 4-8

RSSI Test............................................................................................................................................ 4-8

Transmitter Tests ...................................................................................................................................... 4-9

Call Processing Test..................................................................................................................................... 4-10

Talk Back ................................................................................................................................................ 4-10

Call to Mobile.......................................................................................................................................... 4-10

Digital Duplex Test (Tx) ................................................................................................................................ 4-11

Manual Mode Testing ................................................................................................................................... 4-12

Preparation for Testing ........................................................................................................................... 4-12

Tests ....................................................................................................................................................... 4-12

Charger Recognition Test....................................................................................................................... 4-15

Service Flowchart......................................................................................................................................... 4-16

CHAPTER 4.2 TEST SETUP & TESTING 440-470MHz.......................... 4-1

Typical Test Setup .......................................................................................................................................... 4-2

Alternative Test Setup .................................................................................................................................... 4-3

Test Check List............................................................................................................................................... 4-3

Transmitter Tests ................................................................................................................................ 4-4

Call Processing Tests ......................................................................................................................... 4-4

Duplex Test ......................................................................................................................................... 4-5

How to Configure the IFR 2968 Setup ........................................................................................................... 4-5

How to Configure the IFR 2968 Manual Test Screen ............................................................................... 4-7

RF Tests ......................................................................................................................................................... 4-8

Receiver Tests .......................................................................................................................................... 4-8

Simulate Base Station (Registration).................................................................................................. 4-8

RSSI Test............................................................................................................................................ 4-8

Transmitter Tests ...................................................................................................................................... 4-9

Call Processing Test..................................................................................................................................... 4-10

Talk Back ................................................................................................................................................ 4-10

Call to Mobile.......................................................................................................................................... 4-10

Digital Duplex Test (Tx) ................................................................................................................................ 4-11

Manual Mode Testing ................................................................................................................................... 4-12

Preparation for Testing ........................................................................................................................... 4-12

Tests ....................................................................................................................................................... 4-12

Charger Recognition Test....................................................................................................................... 4-15

Service Flowchart......................................................................................................................................... 4-16

CHAPTER 5 PROGRAMMING THE TERMINAL ..................................... 5-1

CHAPTER 6 MAINTENANCE................................................................... 6-1

Preventive Maintenance................................................................................................................................. 6-1

Inspection ........................................................................................................................................... 6-1

Cleaning ............................................................................................................................................. 6-1

Cleaning External Plastic Surfaces .................................................................................................... 6-2

Cleaning Internal Circuit Boards and Components............................................................................. 6-2

Safe Handling of CMOS Devices ................................................................................................................... 6-2

Pre-baking of Integrated Circuits.................................................................................................................... 6-3

Baking Precautions for TETRA Power Amplifiers (PAs)........................................................................... 6-3

Level 1 and Level 2 Maintenance .................................................................................................................. 6-4

Page 15

CONTENTS MTH800 TETRA Handportable Terminal / Basic Service Manual xv

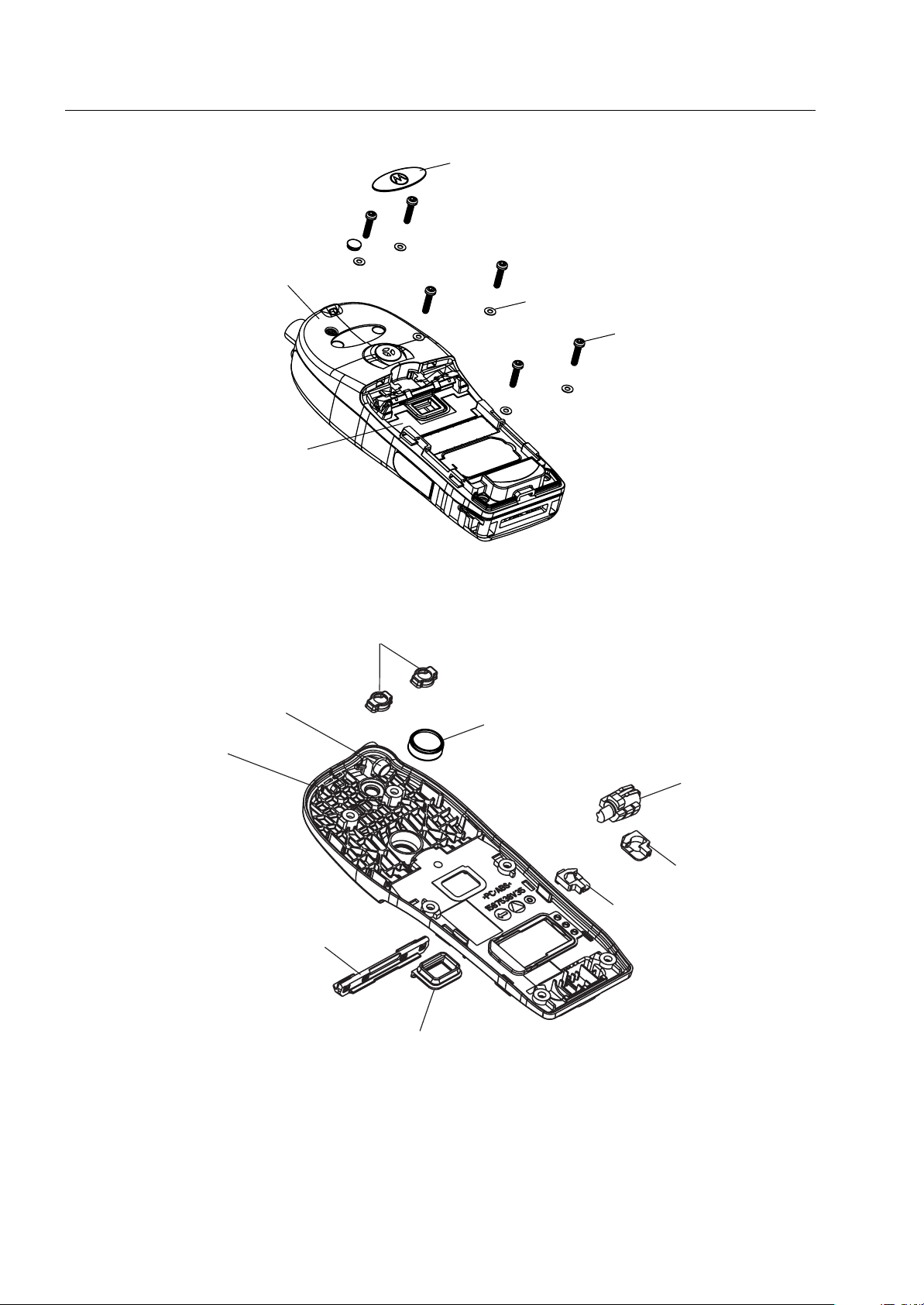

Disassembling and Reassembling the MTH800 Unit..................................................................................... 6-4

Protecting Static-Sensitive Devices.......................................................................................................... 6-4

To create a proper ground .................................................................................................................. 6-5

To store or transport a circuit board.................................................................................................... 6-5

Removing and Installing the Antenna ...................................................................................................... 6-5

To remove the antenna from the unit.................................................................................................. 6-5

To install the antenna in the unit ......................................................................................................... 6-6

Removing and Installing Battery Door and Battery .................................................................................. 6-6

To remove the battery door from the unit ........................................................................................... 6-6

To remove the battery......................................................................................................................... 6-6

To install the battery............................................................................................................................ 6-7

To install the battery door ................................................................................................................... 6-7

Removing and Installing the Audio Assembly Cap................................................................................... 6-8

To remove the audio assembly cap from the unit............................................................................... 6-8

To install the audio assembly cap onto the unit .................................................................................. 6-8

Removing and Installing the Back Housing.............................................................................................. 6-9

To remove the back housing from the unit ......................................................................................... 6-9

To install the back housing ................................................................................................................6-11

Removing and Installing the Vibrator ......................................................................................................6-11

To remove the vibrator.......................................................................................................................6-11

To install the vibrator..........................................................................................................................6-11

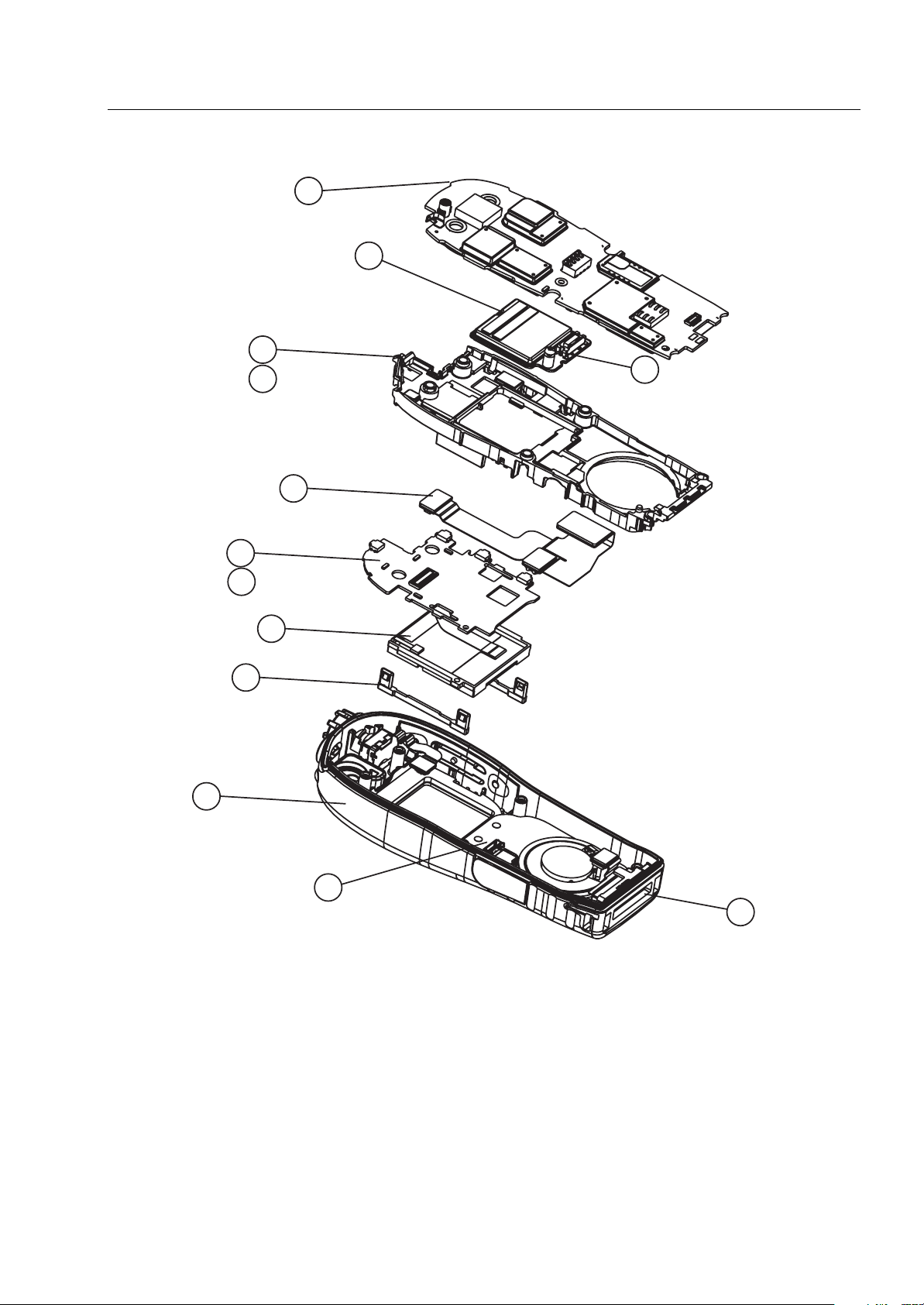

Removing and Installing the Main Board.................................................................................................6-11

To remove the main board from the unit............................................................................................6-11

To install the main board................................................................................................................... 6-12

Removing and installing the UCM Board ............................................................................................... 6-14

To remove the UCM board from the main board .............................................................................. 6-14

To install the UCM board on the main board .................................................................................... 6-15

Removing and installing the Display ...................................................................................................... 6-15

To remove the display from the unit ................................................................................................. 6-15

To install the display ......................................................................................................................... 6-17

Removing and Installing the Display Board............................................................................................ 6-17

To remove the display board from the unit .......................................................................................6-17

To install the display board ............................................................................................................... 6-18

Removing and Installing the Accessory Connector Assembly ............................................................... 6-18

To remove the accessory connector................................................................................................. 6-19

To install the accessory connector.................................................................................................... 6-19

Removing and Installing the Keypad...................................................................................................... 6-20

To remove the keypad ...................................................................................................................... 6-20

To install the keypad ......................................................................................................................... 6-21

Removing and Installing the Rotary Switch......................................................................................

...... 6-21

To remove the rotary switch.............................................................................................................. 6-21

To install the rotary switch ................................................................................................................ 6-21

Removing and Installing the Microphones ............................................................................................. 6-22

To remove the top microphone from the unit.................................................................................... 6-22

To install the top microphone............................................................................................................ 6-22

To remove the bottom microphone from the unit .............................................................................. 6-22

To install the bottom microphone...................................................................................................... 6-23

Removing and Installing the Earpiece.................................................................................................... 6-23

To remove the earpiece from the unit ............................................................................................... 6-23

To install the earpiece....................................................................................................................... 6-23

MTH800 Unit - Exploded View..................................................................................................................... 6-24

MTH800 Components List................................................................................................................ 6-24

Page 16

xvi MTH800 TETRA Handportable Terminal / Basic Service Manual CONTENTS

Torque List ........................................................................................................................................ 6-26

Replacement Parts....................................................................................................................................... 6-29

Terminal Replacement Parts List............................................................................................................ 6-29

Accessories Replacement Parts List...................................................................................................... 6-31

APPENDIX A SERVICE INFORMATION..................................................A-1

Replacement Parts.........................................................................................................................................A-1

Level 3 Maintenance......................................................................................................................................A-1

Service Information ........................................................................................................................................A-1

European Radio Support Centre (ERSC).................................................................................................A-1

EMEA Systems Support Centre (ESSC) ............................................................................................A-2

European Systems Component Centre (ESCC).................................................................................A-2

Parts Identification and Ordering ........................................................................................................A-2

EMEA Test Equipment Support ..........................................................................................................A-2

Asia, Pacific Region .................................................................................................................................A-3

Technical Support ...............................................................................................................................A-3

Further Assistance From Motorola .....................................................................................................A-3

Piece Parts .........................................................................................................................................A-3

Latin America Region ...............................................................................................................................A-4

Recommended Programming Equipment ......................................................................................................A-6

Service Replacement Kit Matrix .....................................................................................................................A-6

APPENDIX B CONNECTOR PIN FUNCTIONS .......................................B-1

CE Bottom Connector ....................................................................................................................................B-1

Mode Select (Option1 and Option2):........................................................................................................B-2

Accessory Connector Pin-Outs ................................................................................................................B-2

AUDIO Side Connector ..................................................................................................................................B-3

PHF/RSM Connector................................................................................................................................B-3

PHF/RSM Plug .........................................................................................................................................B-3

RSM Modes of Operation.........................................................................................................................B-4

Page 17

SCOPE & WARRANTY MTH800 TETRA Handportable Terminal / Basic Service Manual 1 - 1

CHAPTER 1

SCOPE & WARRANTY

Scope of this Manual

This manual contains information necessary to test and maintain the MTH800

TETRA Handportable Terminal at the module level. It also contains information

on radio assembling and disassembling. Accordingly, information in this manual

is divided into the following sections:

• Copyright

• Safety

• CHAPTER 1 Scope & Warranty

• CHAPTER 2 Model Information

• CHAPTER 3 Overview

• CHAPTER 4 Test Setup & Testing

• CHAPTER 5 Programming the Radio

• CHAPTER 6 Maintenance

• APPENDIX A Service Information

• APPENDIX B Connector Pin Functions

Manual Revisions

Changes which occur after this manual is printed are described in Manual

Revisions. These Manual Revisions provide complete information on changes

including pertinent parts listing data.

Related Publications

• 6802972C30 MTH800 Basic User Guide (EN, DE, FR, ES, NL)

• 6866537D97 MTH800 Basic User Guide (EN, SV, RU, IT, PL, DK, AR)

• 6802972C35 MTH800 Feature User Guide

• 6866539D22 MTH800 Basic Service Manual

• 6802972C45 MTH800 Detailed Service Manual 380-430MHz NON EPP

• 6866539D15 MTH800 Detailed Service Manual 380-430MHz EPP

• 6866539D23 MTH800 Detailed Service Manual 440-470MHz

• 6802974C10 CPS User’s Guide

• 6866539D26 Installation Manual for UCM-M Upgrade Kit GMLN4561

• IFR-Operational Manual Supplement 46882-324

• IFR-Operational Manual 46882-274T

Page 18

1 - 2 MTH800 TETRA Handportable Terminal / Basic Service Manual SCOPE & WARRANTY

Warranty and Service Support

Motorola offers long term support for its products. This support includes full exchange and/or repair

of the product during the warranty period, and service/ repair or spare parts support out of warranty.

Warranty Period and Return Instructions

The terms and conditions of warranty are defined fully in the Motorola Dealer or Distributor or

Reseller contract. These conditions may change from time to time and the following notes are for

guidance purposes only. In instances where the product is covered under a "return for replacement"

or "return for repair" warranty, a check of the product should be performed prior to shipping the unit

back to Motorola. This is to ensure that the product has been correctly programmed or has not been

subjected to damage outside the terms of the warranty.

Prior to shipping any radio back to the appropriate Motorola warranty depot, please contact

Customer Resources or your Motorola dealer, distributor or reseller. All returns must be

accompanied by a Warranty Claim Form, available from your Customer Service representative or

Motorola Online Extranet (MOL) or your Motorola dealer, distributor or reseller (refer to list in

Appendix A). Products should be shipped back in the original packaging, or correctly packaged to

ensure no damage occurs in transit.

After Warranty Period

After the Warranty period, Motorola continues to support its products in two ways.

• Motorola's Regional Radio Support Centers offer a repair service to both end

users and dealers at competitive prices.

• AAD supplies individual parts and modules that can be purchased by dealers

who are technically capable of performing fault analysis and repair.

Page 19

MTH800 Model Information MTH800 TETRA Handportable Terminal / Basic Service Manual 2 - 1

R

CHAPTER 2

MODEL INFORMATION

MTH800 Model Information

This manual applies to the following MTH800, 1 W, TETRA Handportable Terminal model:

H78PCN6TZ5AZ 380-430 MHz

H78RCN6TZ5AZ 440-470 MHz

Model Numbering System

Position:

Typical Model Number:

Position 1 - Type of Unit

H = Hand-Held Portable

M = Mobile Product

Positions 2 and 3 - Model Series

39=Motorola MTH650 Family

78=Motorola MTH800 Family

60=Motorola MTP850 Family

Position 4 - Frequency Band

P=380 to 400 MHz

Q=410 to 430 MHz

=438 to 482 MHz

*Values given represent range only;

they are not absolute.

Position 5 - Power Level

A=0 to 0.7 Watts

B=0.7 to 0.9 Watts

C=1.0 to 3.9 Watts

D=4.0 to 5.0 Watts

E=5.1 to 6.0 Watts

F=6.1 to 10.0 Watts

1

2 3

4 5 7

8 6

H 7 8 P C N 6 T Z 5 A Z

10 9

12

11

Position 10 - Feature Level

1=Basic

2=Limited Pkg

3=Limited Plus

4=Intermediate

5=Standard Pkg

Position 12 - Unique

Model Variations

N=Standard Package

R=Blue Housing

Z=Black Housing

Position 11 - Version

Version Letter (Alpha) Major Change

Version Letter (Beta)

Major Change

6=Standard Plus

7=Expanded Pkg

8=Expanded Plus

9=Full Feature/

Programmable

Position 6 - Physical Packages

F=Limited Keypad - With Display

H=Full Keypad - With Display

K=Limited Controls - Basic Display

N=Enhanced Controls - Enhanced Display

Position 7 - Channel Spacing

1=5 kHz

2=6.25 kHz

3=10 kHz

4=12.5 kHz

5=15 kHz

6=25 kHz

7=30 kHz

Position 9 - Primary System Type

R=iDEN Basic

S= iDen AFU

Z= Dimetra

Position 8 - Primary Operation

N=Digital Front

Q=Low Profile -Basic Display

R=Digital Multi-Service

T=TDMA Digital Dual Mode

Page 20

2 - 2 MTH800 TETRA Handportable Terminal / Basic Service Manual MTH800 Model Specifications

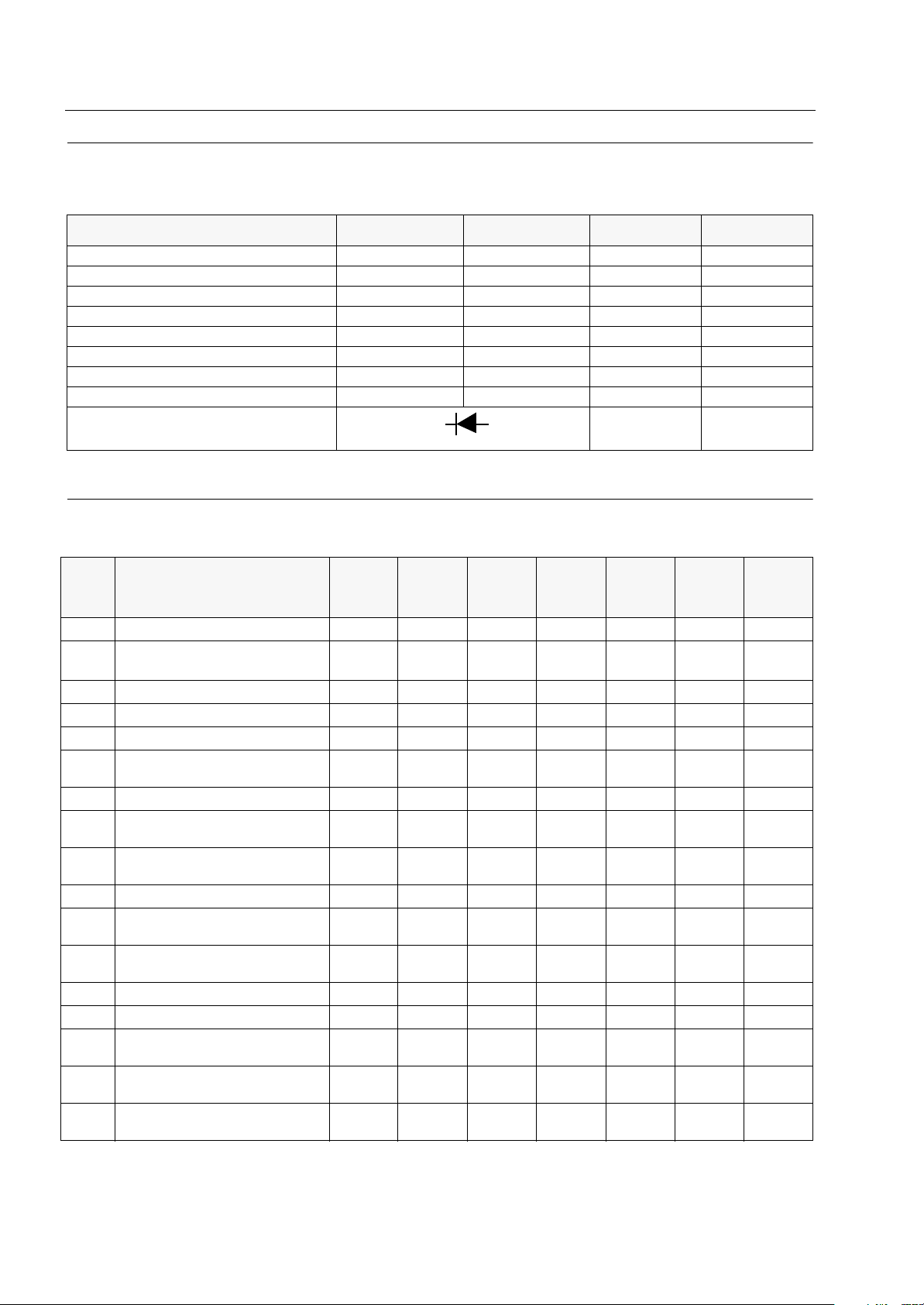

MTH800 Model Specifications

GENERAL RECEIVER TRANSMITTER

ETSI ETS 300 019-1-7 Receiver Type: Class A and B Modulation Type: π/ 4DQPSK

Type Number: 380-430 MHz

440-470 MHz

Temperature Range for Transceiver: Channel Spacing: 25 kHz RF Power: 1 Watt

Operating: -30°C to +60°C Sensitivity (4%) BER: -112 dBm

Storage: -40°C to +85°C Intermodulation:

Battery Types:

SNN5705 800 mAh (Li Ion)

NNTN4655 1500 mAh (Li lon)

Frequency Range: 380-430 MHz

Interfering Signal Level:

Selectivity Blocking:

(50-100 kHz

Interfering Signal Level:

440-470 MHz

(4%) BER

-47 dBm

(4%) BER

-40 dBm

Frequency Range: 380-430 MHz

Frequency Stability:

Locked to Base

Not Locked to Base

440-470 MHz

± 100 Hz

± 2 ppm

Battery Voltage:

Minimum:

Nominal:

Portable Dimensions HxWxD: 141x55x32 mmFrequency

Weight: 192 gr, without battery

3.4 Vdc

3.8 Vdc

Spurious

Rejection:

Interfering Signal

Level:

Stability:

Locked to Base:

Unlocked to Base: 2.0 ppm

Audio Rated: 1 W

Distortion at Rated Audio: 15% Max.

Specifications subject to change without notice.

(4%) BER

-45 dBm

100Hz

+

Spurious Emissions:

Conducted

30MHz-1GHz

1GHz-4GHz

Radiated

30MHz-1GHz

1GHz-4GHz

Adjacent Channel Power (at

55dBc

-36dBm

-30dBm

-36dBm

-30dBm

± 25kHz):

Page 21

Digital Modulation Technology MTH800 TETRA Handportable Terminal / Basic Service Manual 3 - 1

CHAPTER 3

OVERVIEW

To achieve a high spectrum efficiency, the MTH800 uses digital modulation

technology and sophisticated voice-compression algorithm. The voice of the

person speaking into the microphone is converted into a digital bit stream

consisting of zeros (0) and ones (1). This stream is then modulated into a radiofrequency (RF) signal, which is transmitted over the air to another terminal. The

process is called digital modulation.

Digital Modulation Technology

The MTH800 is a 380-430 or 440-470MHz TETRA Handportable Terminal that

can operate in dispatch and phone modes. The terminal can also operate in TMO

(Trunked Mode Operation) and DMO (Direct Mode Operation) modes. It uses two

digital technologies:

π/4 DQPSK and Time Division Multiple Access (TDMA).

π/4 DQPSK is a modulation technique that transmits information by altering the

phase of the radio frequency (RF) signal. Data is converted into complex

symbols, which alter the RF signal and transmit the information. When the signal

is received, the change in phase is converted back into symbols and then into the

original data.

The system can accommodate 4-voice channels in the standard 25 kHz channel

as used in the two-way terminal.

Time Division Multiple Access (TDMA) is used to allocate portions of the RF

signal by dividing time into four slots, one for each unit.

Time allocation enables each unit to transmit its voice information without

interference from other transmitting units. Transmission from a unit or base

station is accommodated in time-slot lengths of 15 milliseconds and frame

lengths of 60 milliseconds. The TDMA technique requires sophisticated

algorithms and a digital signal processor (DSP) to perform voice

compressions/decompressions and RF modulation/demodulation.

Voice Compression Technology

Voice is converted into a digital bit stream by sampling the voice at a high rate

and converting the samples into numbers, which are represented by bits.

Voice compression reduces the number of bits per second while maintaining the

voice at an acceptable quality level. The MTH800 uses a coding technique called

ACELP (Algebraic Code Excited Linear Prediction). The compressed voice-data

bits modulate the RF signal.

Page 22

3 - 2 MTH800 TETRA Handportable Terminal / Basic Service Manual Description

Description

Transceiver Description

All the terminal circuitry is contained in the Digital/RF Board and the keypad

board. The Digital/RF board is divided into the following sections: digital,

frequency generating, transmitter, and receiver.

Digital Section Description

The digital section includes the Patriot IC that consists of the Mcore risk machine

and the Digital Signal Processor (DSP).

The Mcore is the controller of the Digital/RF Board. It controls the operation of the

transmitter, receiver, audio, and synthesizer integrated circuits located in the RF

section. It communicates with the keypad and display.

The Digital Signal Processor (DSP) performs modulation and de-modulation

functions for the terminal. It also performs Forward Error Correction and other

correction algorithms for overcoming channel errors and ACELP speech coding.

It carries out linear 10-bit analog to digital conversions, audio filtering, and level

amplification for the microphone audio input and the received audio output.

The power and audio section is based on the GCAP III and includes power

supplies, 13-bit CODEC, audio routing, microphone and ear piece amplifiers. A

audio power amplifier is used for the loud speaker.

Transmitter Path Description

The transmitter circuitry includes a linear class AB Power Amplifier (PA) for the

linear modulation of the MTH800. It includes a cartesian feedback loop to

enhance its transmitter linearity and reduced splattering power into adjacent

channels.

The transmitter path consists of a cartesian feedback loop that contains the

forward and loop feedback paths.

The forward path includes the JAVELIN IC, BALUN, Attenuator, Power Amplifier

and Isolator.

The loop feedback path includes the directional coupler, attenuator, BALUN, and

JAVELIN IC.

Page 23

Description MTH800 TETRA Handportable Terminal / Basic Service Manual 3 - 3

The cartesian Feedback output power passes to the antenna through the

Isolator, Antenna Switch, Harmonic Filter and Duplexer.

Receiver Path Description

The receiver section in MTH800 is based on the novel DCR (Direct Conversion)

technology, the main concept of this technology is down converting of the RF

signal directly into a base band signal, skipping the intermediate stage of IF

signal.

The receiver path includes the Antenna Switch, Limiter, 10dB Step Attenuator,

Tunable Filter, LNA integrated with 28dB Step Attenuator and 40dB of AGC

continuous attenuation, Pre-selector Band Pass Filter, Balun, Half-Life Mixer, 1pole filter, and the Tomahawk IC which consists of all the base band receive

chain.

Frequency Generating Section Description

The frequency generating section provides description of the following main

components: Tomahawk IC fractional-N Synthesizer, Escort synthesizer,

Reference oscillator, Main VCO, Tx VCO and buffer.

Global Positioning System (GPS) Section Description

The GPS section includes the following main components: Duplexer, Front filter,

LNA, Post Filter, Instant GSCi-5000 IC, RTC, and TCXO.

The GPS in the MTH800 is based on the SIRF GSCi-5000 IC, which comprises a

standalone ROM-based multimode GPS receiver in a single chip BGA Package.

Page 24

3 - 4 MTH800 TETRA Handportable Terminal /Basic Service Manual

Notes

Page 25

TEST SETUP & TESTING 380-430MHz MTH800 TETRA Handportable Terminal / Basic Service Manual 4.1 - 1

CHAPTER 4.1

TEST SETUP & TESTING 380-430MHz

Any level 3 repairs can deeply affect the performance of the

MTH800 and may cause a new tuning procedure. This

tuning procedure can be applied by certain authorised

Motorola depots where the appropriate TEST & TUNE

EQUIPMENT is available.The appropriate TEST & TUNE

EQUIPMENT is a special automated test equipment which

is only available at some Motorola factories and Motorola

repair centers.

Do not use FLN9659 for testing MTH800

Page 26

4.1 - 2 MTH800 TETRA Handportable Terminal / Basic Service Manual TEST SETUP & TESTING 380-430MHz

Typical Test Setup

Note: Check with your Motorola local representative for the availability of Cradle

FTN6308 required for this type of testing, it is part of Digital Car Kit FTN6307.

Carry out the following instructions before testing:

• Check that you have a fully charged battery (not required when using Battery

Eliminator WALN4097).

• Install the MTH800 into the

• Connect RF cable 3086228J02

• Connect the other side of the RF cable to the cradle’s RF connector.

FTN6308 Digital Car Kit cradle.

to the N-type RF Connector of the IFR.

IFR 2968

BATTERY

ELIMINATOR

(WALN4097)

N-TYPE

RF CONNECTOR

MTH800

FTN6308 CRADLE

3086228J02

RF CABLE

3.8 V

POWER

SUPPLY

Figure 1. Typical Test Setup

Page 27

TEST SETUP & TESTING 380-430MHz MTH800 TETRA Handportable Terminal / Basic Service Manual 4.1 - 3

Alternative Test Setup

Cable adapter 2888482K04 enables connecting to the vehicle adapter connector

on a stand-alone main board. Thus, it allows testing of the main board in a

disassembled unit. One side, the cable adapter has a mating vehicle adapter

connector with mechanical grasping mechanism; on the other side the

connection is SMA male.

Test Check List

The following table summarises the required test setups.

No. Test Name Test Setup Terminal Setup Test

Conditions

1. Base Station

Registration

Control

Channel

Traffic Channel 422.0125 MHz 880 TETRA 410MS

Time Slot 3

Country Code 753

Network Code 2361

Base Color 1

Location Area 23

Min Rx Level -110dBm

Max Tx Level 30dBm

Access

Parameter

Mobile Power 30dBm

Burst Type Normal

422.0125 MHz 880 TETRA 410MS

-53dBm

Limits

2. Transmitter

Burst Power

RF Gen Level

Burst Power

Timing Error <=0.25 Symbols

Vector Error Max 10% RMS, 30%

Frequency

Error

-90dBm 28-32dBm

Peak

-/+ 100Hz

Page 28

4.1 - 4 MTH800 TETRA Handportable Terminal / Basic Service Manual TEST SETUP & TESTING 380-430MHz

No. Test Name Test Setup Terminal Setup Test

Conditions

3. Call

4. Call

Processing

Talk Back

Processing

Call to Mobile

1KHz Test

Signal

Group Mode

Private 4 digit random

number & “Send”

RF Gen Level

Burst Power

Timing Error <=0.25 Symbols

Vector Error Max 10% RMS, 30%

Frequency

Error

-50dBm

-90dBm 28-32dBm

Limits

28-32dBm

Peak

-/+ 100Hz

Transmitter Tests

1. Power Burst (Control Range)

2. Power Profiles

3. Tx Burst Timing Error

4. Vector Error RMS and Peak

5. Tx Frequency Error

Call Processing Tests

1. Talk Back

2. Call to Mobile

Page 29

TEST SETUP & TESTING 380-430MHz MTH800 TETRA Handportable Terminal / Basic Service Manual 4.1 - 5

Duplex Test

1. Digital Duplex Test (Tx)

Measurement Capabilities:

Bar charts (Tx Power, Freq. Err, Vector Rms.), Spectrum Analyser, Power

Analyser, Vector Analyser, Vector Diagrams

How to Configure the IFR 2968 Setup

Perform the following steps to configure the IFR 2968 with the terminal set:

1. Turn ON the IFR.

2. Press “Systems” Mode Key (wait until the digital system is initialised).

3. Press the “Tetra Mobile” softkey.

4. Press the “Setup” softkey and enter the System Parameters Screen.

5. Press the “Channel Plan” softkey.

6. Press “Tetra 410MS” softkey. The “Control Channel” automatically changes to

“800”; and “Traffic Channel” automatically changes to 900.

7. Press twice the “Traffic Channel” softkey and check that the marker goes to

Timeslot. Press Data key “3” followed by the “Traffic Channel” softkey, to

change to Timeslot “3”.

8. Press “Country Code” softkey. Enter “753” and “Country Code” softkey.

9. Press “Network Code” softkey. Thereafter, enter “2361” and press “Network

Code” softkey.

10. Press “Base Color” softkey. Thereafter, enter “1” and press “Base Color”

softkey.

11. Press “Location Area” softkey. Thereafter, enter “23” and press “Location

Area” softkey.

12. Press “More” softkey. Press “Min Rx Level” softkey. Thereafter, enter “110dBm” and press “Min Rx Level” softkey.

13. Press “Max Tx Level” softkey. Thereafter, enter “30dBm” and press “Max Tx

Level” softkey.

14. Press “Access Parameter” softkey. Thereafter, enter “-53dBm” and press

“Access Parameter” softkey.

15. Press “Base Service” softkey and “Supported” softkey

Page 30

4.1 - 6 MTH800 TETRA Handportable Terminal / Basic Service Manual TEST SETUP & TESTING 380-430MHz

Note: You are entering base services setup.

If the displayed values are different, please change the IFR setting to be similar

to the values below.

Power On Registration: required

Power Off Deregistration: required

Priority Cell: yes

Minimum Mode Service: never used

Migration: not supported

System Wide Services: normal mode

16. Press “More” softkey.

TETRA Voice Service: supported

Circuit Mode Data Service: not supported

(Reserved): not available

SNDCD Service: not available

Air Interface Encryption: not available

Advanced Link: not supported

17. Press the “Return” softkey.

18. Press the “Neighbr Cell” softkey.

19. Verify that the following NEIGHBOUR CELL INFO values are displayed:

Note: If the displayed values are different, please change the IFR setting to be

similar to the values below.

NEIGHBOUR CELL BROADCAST: SUPPORTED

BROADCAST INTERVAL: 10s

NEIGHBOUR CELL CHANNEL: 0000

NEIGHBOUR CELL LOCATION AREA: 00001

NEIGHBOUR CELL IDENTIFIER: 01

SLOW RE-SELECT THRESHOLD: 10dB

PRESS “MORE” softkey

Page 31

TEST SETUP & TESTING 380-430MHz MTH800 TETRA Handportable Terminal / Basic Service Manual 4.1 - 7

SLOW RE-SELECT HYSTERESIS: 10dB

FAST RE-SELECT THRESHOLD: 10dB

FAST RE-SELECT HYSTERESIS: 10dB

20. Press the “Return” softkey.

21. Press the “Trunk Type” softkey and “Tx Trunked” softkey (Transmission).

22. Press “More” Softkey.

Note:

The displayed values are factory defaults and should not be changed.

It is not required to configure “Call Types” “Call Times” and “Messages”.

23. Press “More” Softkey.

How to Configure the IFR 2968 Manual Test Screen

1. To enter “Manual test” screen, press “Manual” softkey.

2. Press “Control Channel” softkey. Thereafter, “880” and press “Control

Channel” softkey (IFR 880 = Rx 422.0125MHz).

3. Press “Traffic Channel” softkey. Enter “880” and press “Traffic Channel”

softkey. The marker goes to Timeslot. Enter “3” and press “Traffic Channel”

softkey. (Note that the Traffic Channel number changes automatically after

entering the Control Channel number).

4. Press "RF Gen Level" softkey. Thereafter, enter "-50" and press "dBm" data

keys.

5. Press "Mobile Power" softkey, press "+5dB step" or "-5dB step" softkey to

reach 30 dBm/1W. Make sure the "Mobile Power" either in "expected level" or

"close loop".

6. Press "return". Press “Burst Type” softkey and “Normal” softkey.

7. This completes the test equipment configuration setup.

Note: The System Setup Configuration Data is saved even after the power is

turned off. However, the Manual Test Setup is not saved.

Page 32

4.1 - 8 MTH800 TETRA Handportable Terminal / Basic Service Manual TEST SETUP & TESTING 380-430MHz

RF Tests

Receiver Tests

Simulate Base Station (registration)

NOTE: This test requires programming the terminal. Refer to 6802974C10

TETRA Customer Programming Software (CPS) for MTH800.

1. Via the Depot version CPS, enable the Test Page field in the terminal

codeplug and program the terminal.

2. Turn the terminal ON.

3. Check that registration and “GSSI:xxxxxx selected” is displayed on the IFR

“Manual Test” screen.

RSSI Test

Before carrying out the following steps, record the Insertion loss (dB) of the cable

loss value - (X) dB. Also, 0.5 dB, the maximum insertion loss of the Antenna

assembly adapter should be added to the total calculated insertion loss.

1. In the IFR Manual Test Mode, press the “RF Gen Level” softkey and enter

"-80dBm".

2. Before testing, the terminal should be configured to RSSI mode using the

following sequence. When performing steps 3 thru 6, make sure that you

press the handset keys sequentially (less than a second between every

consecutive press).

3. Press the “Star” Key.

4. Press the “#” Key.

5. Press the “Menu” Key.

6. Press the “Right Arrow” Key.

7. Scroll to “Cells Info”.

8. Press the “Select” softkey.

9. Press the “Right Arrow “Key.

10. Press the “Trace” softkey.

Page 33

TEST SETUP & TESTING 380-430MHz MTH800 TETRA Handportable Terminal / Basic Service Manual 4.1 - 9

Note:RSSI results will flash on the screen every few seconds.

The display shows: SERV: xx

RSSI: -81

SQE: xx

Disregard the “SERV” and “SQE” results.

The actual measured result should be:

{-80dBm (IFR RF Gen Level) -0.5dB(adapter)-XdB (cable)} +/-1 dB.

RSSI = {Radio RSSI Result – [Antenna assembly Adapter (dB) + Insertion loss

of the Cable (dB)]}.

To stop the “Trace” process, perform the following. When performing steps 11.

thru 14., make sure that you press the handset keys sequentially (less than a

second between every consecutive press):

11. Press the “Star” Key.

12. Press the “#” Key.

13. Press the “Menu” Key.

14. Press the “Right Arrow” Key.

15. Scroll to “Cells Info”

16. Press the “Select” softkey.

17. Press the “Stop” softkey.

Press twice the “Back” softkey.

Transmitter Tests

1. Verify that your terminal is in “Group Mode”.

2. Press the “RF Gen Level” softkey. Enter “-90dBm” by pressing the data keys

and “RF Gen Level” Key.

3. Press the “PTT” of the terminal and monitor the IFR “Manual Test” screen

which displays the Burst Power, Power Profile, Timing Error, Vector Error, and

Frequency Error.

Note: You have to hold the PTT in the pressed position long enough to enable

you to read the results.

- Burst Power Required Results: 28-32dbm.

- Power Profile: Passed.

- Timing Error: <

0.25 symbols.

Page 34

4.1 - 10 MTH800 TETRA Handportable Terminal / Basic Service Manual TEST SETUP & TESTING 380-430MHz

- Vector Error: Max 10% RMS, Max 30% Peak.

- Max 5% residual.

- Frequency Error: -/+ 100Hz.

4. Press the “Clear Down” softkey, to proceed with other tests.

Call Processing Test

Talk Back

Before you start this test, make sure that handset and test equipment are

configured the same as given in the Transmitter Test.

Call to Mobile

1. Press and hold the "PTT" then press "talk back" softkey and speak into the

mic of the terminal. Release the 'PTT" and you will hear your speech.

2. Press the "silence" softkey to stop the speech.

3. Press and hold the "PTT" then press the "Test Sound" softkey to provide the

1kHz signal to the terminal speaker.

4. Release the "PTT", you will hear a 1kHz tone from the terminal speaker

continuosly.

5. Press the "Silence" softkey to mute the 1kHz Audio Signal of the speaker.

6. Press the "Clear Down" softkey and check that the "Cleardown Complete"

status appear on the IFR "Manual Test" screen.

1. Press the “Call Mobile” softkey on the IFR.

Note: Select type of call.

2. Press "Private Call" softkey to select Private Call.

Note: You will hear beeps from the handset speaker.

3. Press “Abort Call” softkey. Duplex Test (Phone/Privet Mode)

Note: Repeat step 1 through 3 for "Phone Call" and "Emergency Call".

Page 35

TEST SETUP & TESTING 380-430MHz MTH800 TETRA Handportable Terminal / Basic Service Manual 4.1 - 11

Digital Duplex Test (Tx)

1. Perform the following test in “Phone” or “Private” mode.

2. Dial a random number “9359” using the Alphanumeric keys of the terminal

and press the “Send” Key.

The following results are displayed on the IFR “Manual Test” Screen.

- Burst Power Required Results: 28-32dbm

- Power Profile: Passed

- Timing Error: <0.25 Symbols.

- Vector Error: Max 10% RMS, Max 30% Peak.

- Max 5% residual.

- Frequency Error: -/+ 100Hz

3. Press the "talk back" softkey. Place the inernal earpiece close to your ear.

Speak into the handset microphone and hear your speech (after a short

delay) from the handset internal earpiece.

Note: If you need more details, press the “Duplex Test” mode key.

4. Press the "duplex test (Tx)" softkey.

The “Digital Duplex test” results will be displayed on the IFR screen providing

you with the following bar charts measurement capabilities:

- Power

- Vector RMS

- Frequency Error

For Power Analyser Graph:

5. Press “power ana” softkey.

6. Check that the power frame falls within the limits.

For Spectrum Analyser Graph:

7. Press “Spec ana” softkey.

8. Monitor the Tx frequency.

For Vector Analyser Diagram:

9. Press the “Vec Anal” softkey

10. Monitor the constellation diagram.

Page 36

4.1 - 12 MTH800 TETRA Handportable Terminal / Basic Service Manual TEST SETUP & TESTING 380-430MHz

11. Press the “Vector Diagram” softkey.

12. Press the “Rotated vector” to zoom in on the constellation.

13. Press the handset “End” key.

Manual Mode Testing

Preparation for Testing

1. Verify that the terminal is turned off.

2. Press the “4”, “5” and “6” keys together and then, press the On/Off key to turn

the terminal on.

3. The display shows “LCD Color test Press Any Key To Proceed”.

Tests

1. Press any key consecutively. The display shows horizontal red lines that

becomes thicker with every key press, until it becomes fully red.

2. Press any key again, the display shows four colored rectangles.

3. Press any key consecutively. The display shows vertical green lines that

becomes thicker with every key press, until it becomes fully green.

4. Press any key again. The display becomes fully blue and the message

"END LCD test !!!" appears.

5. Press any key again. The display shows "Battery Interface Test".

6. Press any key again. The display shows "Battery Interface Test PASS".

7. Press any key again. The display shows "Vibrator On", verify that the terminal

is vibrating.

8. Press any key again. The display shows "Red Led on" and the Red LED at

the top of the terminal is lit.

9. Press any key again. The display shows "Green Led on" and the Green LED

at the top of the terminal is lit.

10. Press any key. The display shows "Both Leds on" and the LED located on the

top of the terminal is blinking in amber (combination of red and green lights of

the two halves of the LED).

11. Press any key again. The display shows "Keypad Backlight On" and the

keypad backlight is On.

Page 37

TEST SETUP & TESTING 380-430MHz MTH800 TETRA Handportable Terminal / Basic Service Manual 4.1 - 13

12. Press any key again. The display shows "Display Backlight On" and the

display backlight is On.

Note: The following readings appears only when a Universal Crypto Module

(UCM) board is installed in the unit.

13. Press any key again. The display shows "UCM Detected".

14. Press any key again. The display shows "UCM Power up Success".

15. Press any key again. The display shows "UCM Wake Up Success".

16. Press any key again. The display shows "UCM Ping Success".

Note: The following reading appears only when a UCM board is not installed

in the unit.

17. Press any key again. The display shows "UCM Not Detected".

18. Press any key again. The display shows "Speaker Tone Test", a tone is heard

via the speaker.

19. Press any key again. The display shows "Internal Earpiece Tone Test", a tone

is heard via the internal earpiece.

20. Press any key again. The display shows "Connect PHF for the following

Tests". Insert a headset into the PHF connector and plug the PHF earpiece

into your ear.

21. Press any key again. The display shows "PHF Earpiece Tone Test". A tone is

heard via the PHF earpiece.

22. Press any key again. The display shows "Connect RSM-CE for the following

Tests". Connect the RSM to the CE connector.

23. Press any key again. The display shows "RSM-CE Connector Tone Test". A

tone is heard via the RSM speaker.

24. Press any key again. The display shows "INT MIC to INT EAR Loopback

Test". Place the internal earpiece close to your ear. Speak into the internal

MIC, and you will hear your voice via the internal earpiece.

25. Press any key again. The display shows "Connect PHF for the following

Tests". Insert a headset into the PHF connector and plug the PHF earpiece

into your ear.

26. Press any key again. The display shows "TOP Mic to PHF EAR Loopback

Test". Speak into the top microphone, and you will hear your voice via the

PHF earpiece.

27. Press any key again. The display shows "PHF Mic to PHF EAR Loopback

Test". Speak into the PHF microphone, and you will hear your voice via the

PHF earpiece.

28. Press any key again. The display shows "Connect RSM-CE for the following

Tests". Connect the RSM to the CE connector.

Page 38

4.1 - 14 MTH800 TETRA Handportable Terminal / Basic Service Manual TEST SETUP & TESTING 380-430MHz

29. Press any key again. The display shows "RSM-CE connector MIC to INT