Page 1

MTR2000

™

Base Station, Repeater and Receiver

For Analog Conventional,

and T runking Systems

Installation and Operation

Manual

68P81096E20-N

Page 2

COMPUTER SOFTWARE COPYRIGHTS

The Motorola products described in this instructions manual may include copyrighted Motorola computer programs stored in semiconductor

memories or other media. Laws in the United States and other countries preserve for Motorola certain exclusive rights for copyrighted computer programs. Including the exclusive right to copy or reproduce in any form the copyrighted computer program. Accordingly, any copyrighted Motorola computer programs contained in the Motorola products described in this Instruction manual may not be copied or reproduced in

any manner without the express written permission of Motorola. Furthermore, the purchase of Motorola products shall not be deemed to grant

either directly or by implication, estoppel or otherwise, any license under the copyrights, patents or patent applications of Motorola, except for

the normal nonexclusive, royalty free license to use that arises by operation of law in the sale of a product.

COMMERCIAL WARRANTY (U.S. Only)

Motorola radio commun ic ati ons p roduc ts are wa r ranti ed t o be fr ee fr om defe cts in m ateri al and wor k man ship for

a period of ONE (1) YEAR, (except for crystals and channel elements which are warrantied for a period of ten (10)

years from the date o f shipmen t. Parts, includ ing cry stals and cha nnel elem ents, will be repl aced and l abor will

be provided free of charge for the full warranty period, from the date of shipment. Thereafter purchaser must pay

for the labor involved in repairing the product and replacing the parts at the prevailing rates together with any transportation charges to or from the place where warranty service is provided. This express warranty is extended by

Motorola Communications and Electronics Inc., 1301 E. Algonquin Road, Schaumburg, Illinois 60196, to the original purchaser only, and only to those purchasing for purpose of leasing or solely for commercial, industrial, or government use.

THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED WHICH ARE

SPECIFICALL Y EXCLUDED, INCLUDING WARRANTIES OF MERCHANT ABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL MOTOROLA BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES TO THE FULL EXTENT SUCH MAY BE DISCLAIMED BY LAW.

In the event of a defect, malfunction or failure to conform to specifications established be seller, or if appropriate,

to specifications accepted by Seller in writing, during the period shown, Motorola, at its option, will either repair or

replace the product or refund the purchase price thereof, and such action on the part of Motorola shall be the full

extent of Motorola’s liability hereunder.

This warranty is void if:

a. the product is used in other than its normal and customary manner;

b. the product has been subject to misuse, accident, neglect or damage;

c. unauthorized alterations or repairs have been made, or unapproved parts used in the equipment.

This warranty extends only to individual products, batteries are excluded. Because each radio system is unique,

Motorola disclaims liability for range, coverage, or operation of the system as a whole under this warranty except

by a separate written agreement signed by an officer of Motorola.

LICENSED PROGRAMS -- Motorola software provided in connection with this order is warrantied to be free from

reproducible defects for a period of one (1) year. All material and labor to repair any such defects will be provided

free of charge for the full warranty period, and SUBJECT TO THE DISCLAIMER IN BOLD FACE TYPE.

Non-Motorola manufactur ed products are excluded from thi s warranty, but subject to the warra nty provided by

their manufacturers, a copy of which will be suppled to you on specific written request.

In order to obtain performance of thi s warranty, purchaser must contact its Motorola salesper son or Motorola at

the address shown in the second paragraph, attention Quality Assurance Department.

FCC INTERFERENCE WARNING

The FCC requires that manuals pertaining to Class A and Class B computing devices must contain warnings

about possible interference with local residential radio and TV reception. This warning reads as follows:

NOTE: The equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial or residential environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with its

instruction manual, may cause harmful interference to radio communication.

ELECTROMAGNETIC COMPATIBILITY

This product conforms with the protection requirements of Council Directive 89/336/EEC

of 3rd May 1989 (EM C) on the approx imati on of t he laws o f the Membe r States relating

to electromagnetic compatibility.

Page 3

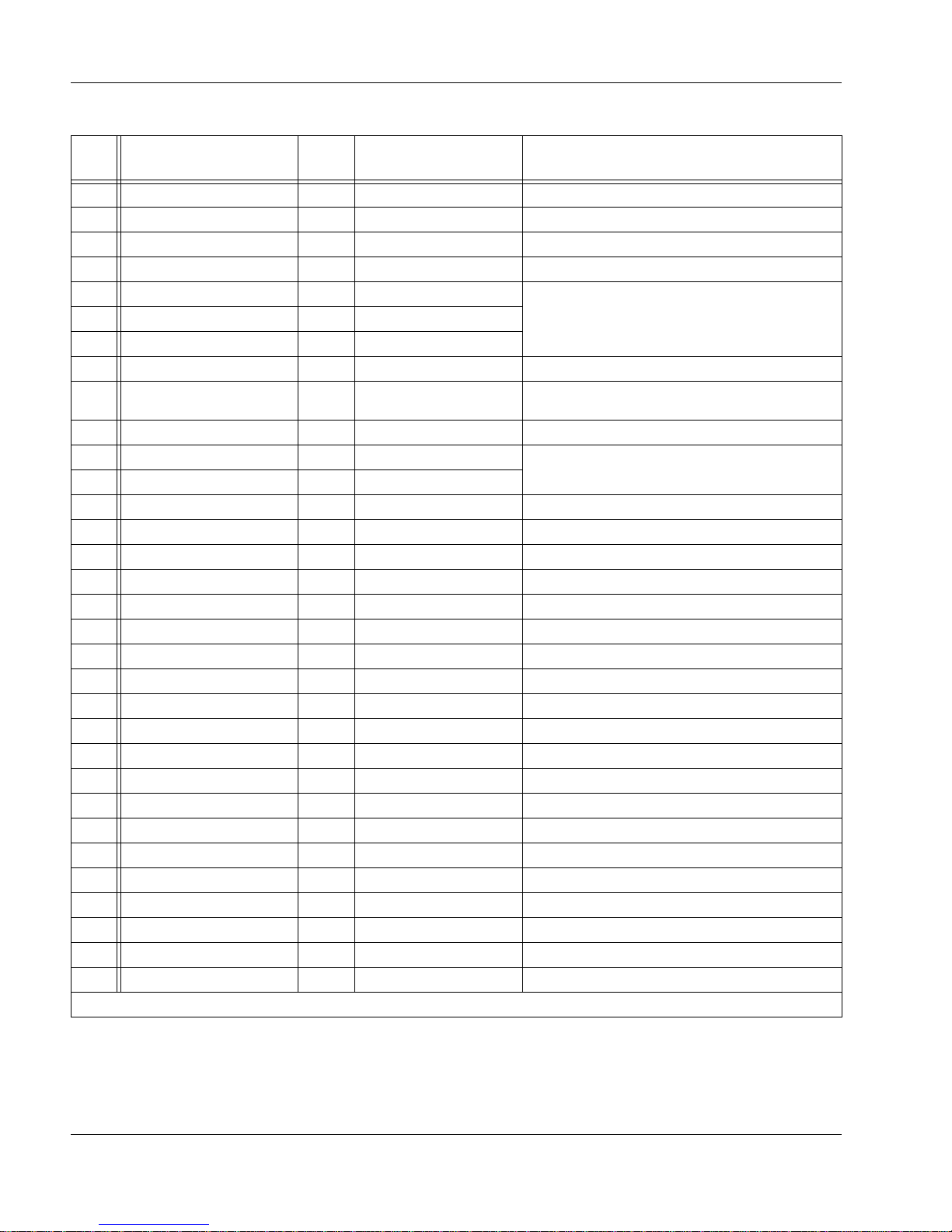

Material Content

ENVIRONMENTAL INFORMATION

The material content of the MTR2000 is 16% of the product it replaces.

The following table provides a rough estimate of the material content of

the station. The actual percentages vary in relation to the station configuration. The power supply is not included in the percentage of weights

since the end-of -life value is dependent on the model of supply used in

the station.

Most of the Material categories are self explanatory. Co pper bearing materials:

• include any material that contains copper.

• primarily consist of circuit boards.

• exclude cables (separate Material category).

Material % by weight

Features

Aluminum 92%

Steel 2%

Copper Bearing 4%

Cable 1%

Polycarbonate 1%

Beryllium Oxide has been used in the power amplifier. Beryllium Oxide

should not be subjected to any process which will generate dust.

Over 92% of the station is made of aluminum, one of the most recycled

materials commonly available today . In addition, the aluminum used in

the station consists of 90-95% recycled content.

Plastic use has been minimized since the market for recycled engineering plastics is limited. The plastic which has been used for the front panel is a relatively clean and pure resin.

06/28/05 68P81096E20-N i

Page 4

Disposal of your Electronic and Electric Equipment

Please do not dispose of Electronic and Electric Equipment or Electr onic and Electric

Accessor ies wi th your house hold wa ste. In some c ountr ies or re gions , col lect ion sys tems have been set up to handle waste of electrical and electronic equipment.

In European Union countries, please contact your local equipment supplier representative or service center for information about the waste collection system in your

country.

Disposal Guideline

The following symbol on a Motorola product indicates that the product should not

be disposed of with household waste.

ii 68P81096E20-N 06/28/05

Page 5

Scope of Manual

Note

CAUTION

!

STOP

WARNING

STOP

IMPORTANT

Documentation Conventions

FOREWORD

This manual is intended for use by experienced technicians familiar with

similar types of equipment.

It provides information which allows installation personnel to unpack,

mechanically install, el ectrically con nect, and verify operation of the station.

The information in this manual is current as of the printing date. Changes which occur after the printing date are incorporated by Manual Revisions (SMR). These SMRs are added to the manuals as the engineering

changes are incorporated into the equipment.

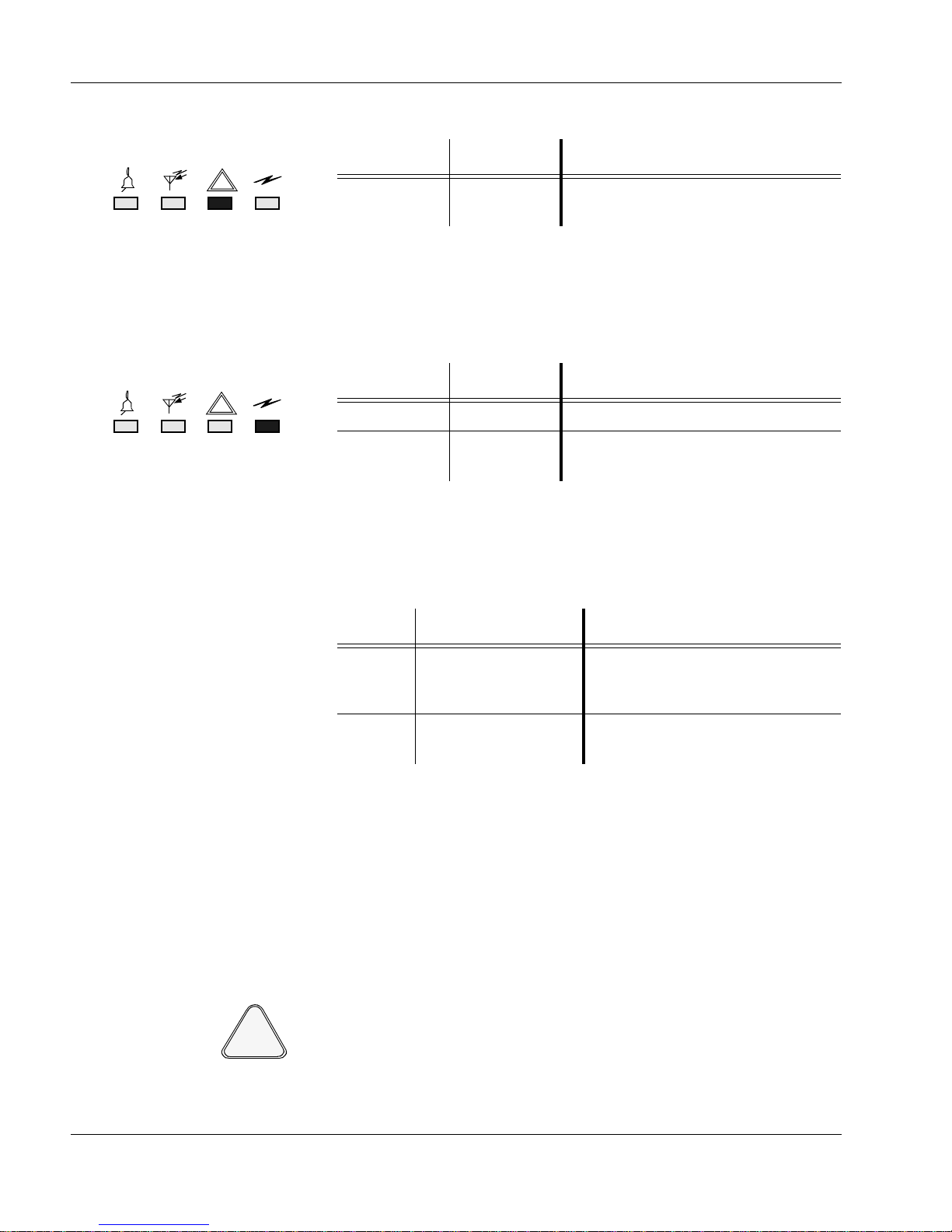

Documentation conventions are used in this manual to highlight certain

information.

The area to the left of the text column contains key words and graphic

symbols which allow the reader to quickly identify desired information.

The following text highlight sym b ols are used:

A note symbol indicates important inf ormation that helps improve the

described function.

A caution symbol indicates a potential problem, unle ss the prope r actions are taken. A caution also explains how to avoid the problem.

A WARNING symbol indicate s the pote ntial for personal injur y or serious system degradation unless the proper actions are taken. A

WARNING also explains how to avoid the problem.

An IMPOR TANT symbol indi cates the potenti al for damaging the station unless the proper actions are taken. An IMPORTANT note also

explains how to avoid the problem.

06/28/05 68P81096E20-N ix

Page 6

GENERAL SAFETY INFORMATION

The United States Department of Labor, through the provisions of the Occupational Safety and Health Act of 1970

(OSHA), has established an electromagnetic energy safety standard which applies to the use of this equipment.

Proper use of this radio will result in exposure below the OSHA limit. The following precautions are recommended:

• DO NOT operate the transmitter of a mobile radio when someone outside the vehicle is within two feet

(0.6 meter) of the antenna.

• DO NOT operate the transmitter of a fixed radio (base station, microwave and rural telephone rf equipment) or marine radio when someone is within two feet (0.6 meter) of the antenna.

• DO NOT operate the transmitter of any radio unless all rf connectors are secure and any open connectors

are properly terminated.

In addition:

• DO NOT operate this equipment near electrical blasting caps or in an explosive atmosphere.

• All equipment must be properly grounded according to Motorola installation instructions for safe operation.

• All equipment should be serviced only by a qualif ied technician.

• An operating license may be required to operate this station.

Refer to the appropriate section of the product service manual for additional pertinent safety information.

Some station components can become extremely hot during station operation. Turn off a ll power to the s tation, and wait until sufficiently coo l

before touching the station.

x 68P81096E 20-N 06/28/05

Page 7

DESCRIPTION

MTR2000

Station, Repeater and Receiver

For Analog Conventional,

and T runking Systems

Table of Contents

Scope of Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Documentation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

General Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .x

™

DESCRIPTION 68P81096E36

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Flexible Mechanical Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Electrical Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Trunking Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Summary of Operating Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

, MOTOROLA, MTR2000, Spectra-T AC, DigiTAC and Private Line are trademarks of Motorola Inc.

TORX is a trademark of Camcar Division of Textron Inc

Motorola Inc., 2005

All Rights Reserved

Printed in U. S.A.

Government & Enterprise Mobility Solutions

.

1301 E. Algonquin Road, Schaumburg, IL 60196

68P81096E20-N

06/28/05-UP

Page 8

STATION COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION

FUNCTIONAL THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Transmitter Circuitry Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Receiver Circuitry Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Station Control Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Wireline Interface Board Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Auxiliary I/O Board Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power Supply Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

INSTALLATION 68P81096E37

PRE-INSTALLATION CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Environmental Conditions at Intended Installation Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Equipment Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

AC Input Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Equipment Mounting Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Floor-mount Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Modular Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Site Grounding and Lightning Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Site Grounding Lightning Protection Recommendations . . . . . . . . . . . . . . . . . . . . . . . . 10

Equipment Grounding Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Recommended Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Equipment Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cabinet Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

iv 68P81096E20-N 06/28/05

Page 9

MECHANICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Unpacking Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Unpacking Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Front Panel – Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Unpacking Floor-mount Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Mounting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installing Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Mounting Floor-mount Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Transferring Equipment from Shipping Container to Rack or Cabinet . . . . . . . . . . . . . 16

Installing Slide Rail Assembly in a Motorola Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Installing Slide Rail Assembly in a Non-Motorola Cabinet . . . . . . . . . . . . . . . . . . . . . . . 19

BOARD CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4-Wire Wireline Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4-Wire Euro Wireline Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Auxiliary I/O Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

AC Input Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Ground Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DC Input Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Battery Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

RF Antenna Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

System Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Telephone Line Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Telephone Line Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Location of Telephone Line Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

System Type vs. Wireline Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Station Maintenance Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

POST INSTALLATION CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Verifying Proper Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Listening For Audible Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Exercising Radio Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

06/28/05 68P81096E20-N v

Page 10

OPTIMIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

STATION OPERATION

Optimizing Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Copying Station Codeplug Date To a PC-compatible Computer . . . . . . . . . . . . . . . . . . . . . . . . . 47

INSTALLING STATION HARDWARE OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

STATION OPERATION 68P81096E38

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

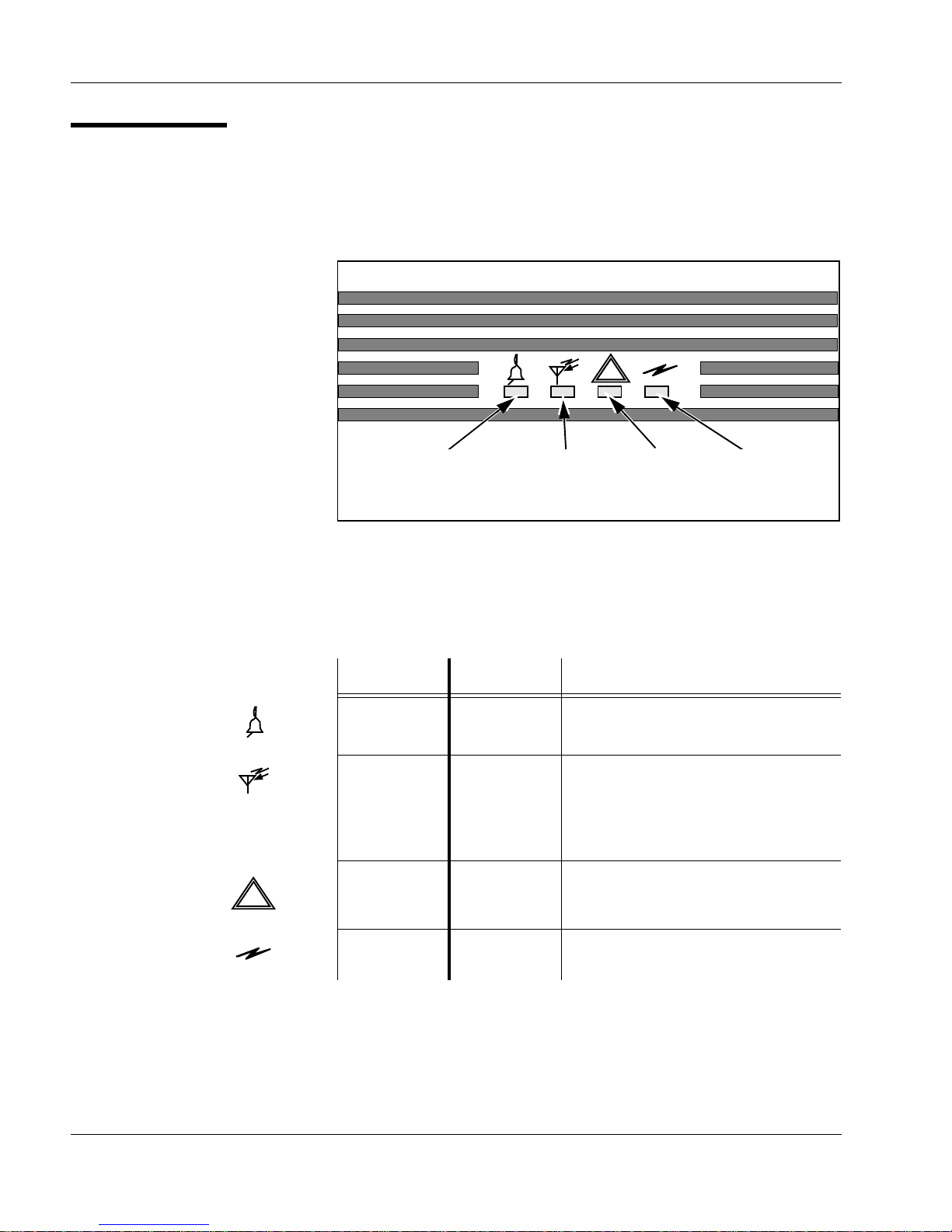

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

External Device Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

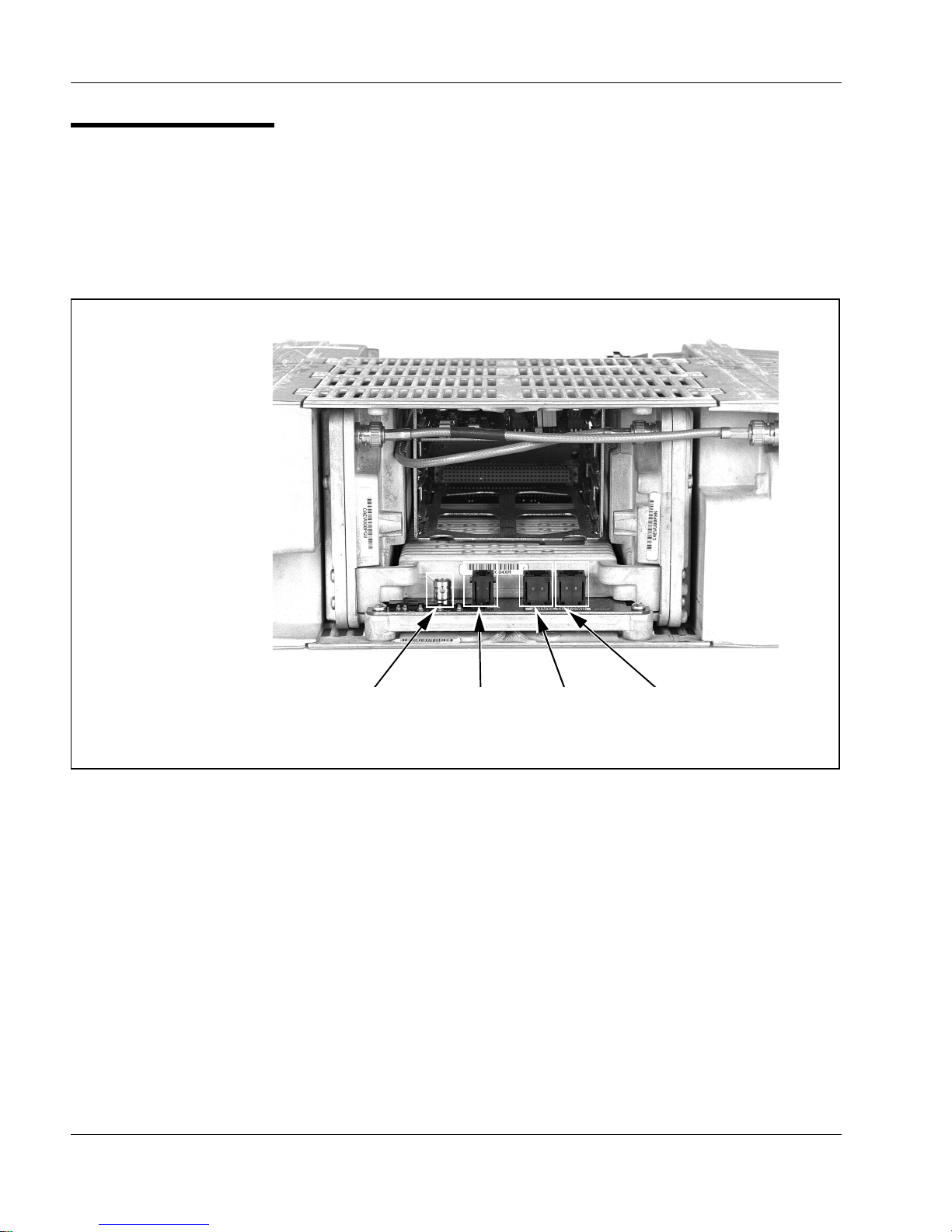

Service Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

vi 68P81096E20-N 06/28/05

Page 11

List of Figures

DESCRIPTION

INSTALLATION

STATION OPERATION

DESCRIPTION 68P81096E36

Figure 1. MTR2000 Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Figure 2. MTR2000 Station Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 3. MTR2000 Station Functional Block Diagram (Sheet 1 of 2) . . . . . . . . . . . . . . 14

Figure 3. MTR2000 Station Functional Block Diagram (Sheet 2 of 2) . . . . . . . . . . . . . . 15

INSTALLATION 68P81096E37

Figure 1. Floor-mount Cabinet – Dimensions and Clearances . . . . . . . . . . . . . . . . . . . . .7

Figure 2. Modular Rack – Dimensions and Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. Unpacking Procedures - Floor-mount Cabinets . . . . . . . . . . . . . . . . . . . . . . .14

Figure 5. Slide Rail Installation; Option X968AA (Left Side Shown) . . . . . . . . . . . . . .18

Figure 6. Slide Rail Installation; Option X346AB (Left Side Shown) . . . . . . . . . . . . . . . 20

Figure 7. CLN1203 Wireline Interface Board Jumper Settings . . . . . . . . . . . . . . . . . . . . 21

Figure 8. CLN1204 Wireline Interface Board Jumper Settings . . . . . . . . . . . . . . . . . . . . 22

Figure 9. CLN1206 Auxiliary I/O Board Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 10. Location of External Connectors at Rear of Station . . . . . . . . . . . . . . . . . . . . .27

Figure 11. Making Connections to Storage Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

STATION OPERATION 68P81096E38

Figure 1. Front Panel LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Figure 2. SCM Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

06/28/05 68P81096E20-N vii

Page 12

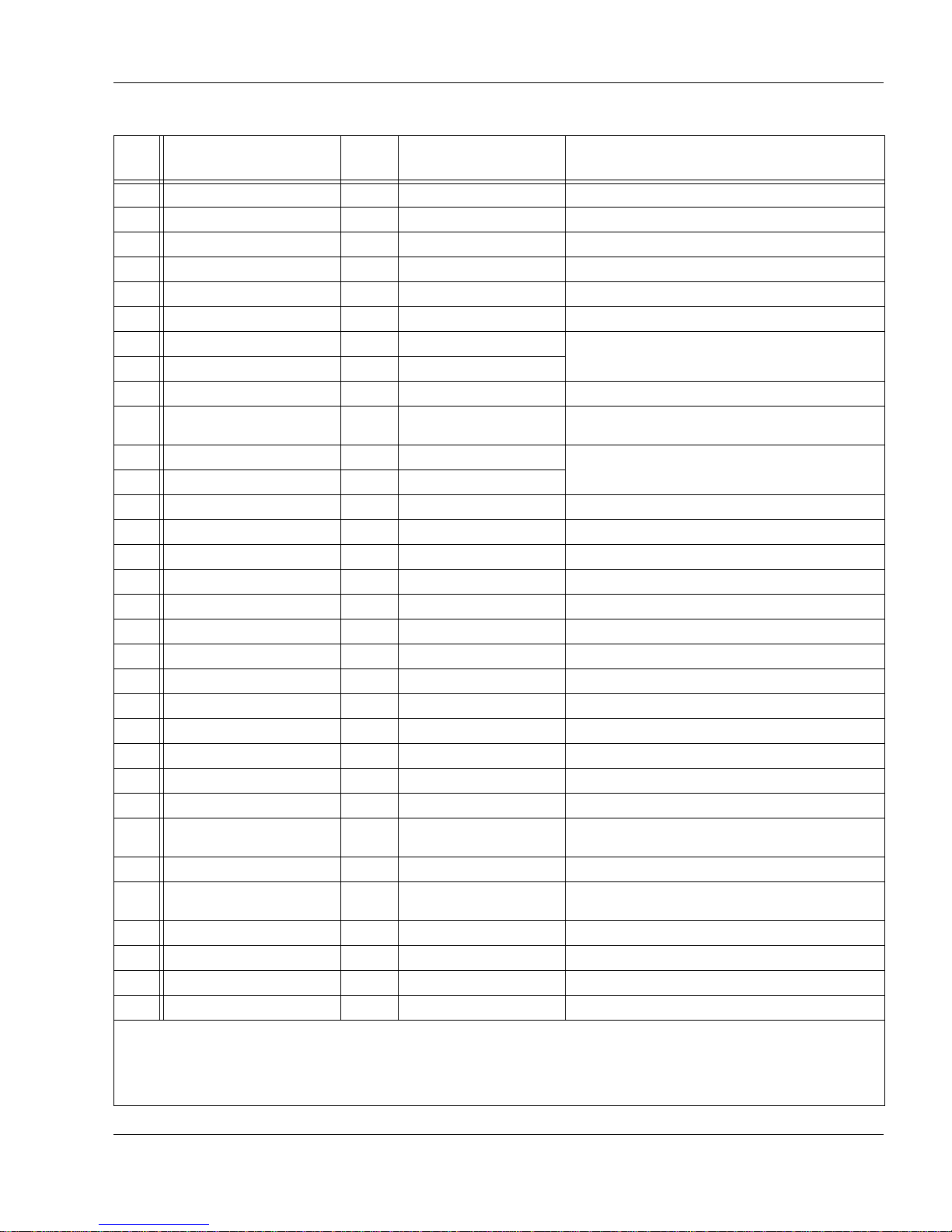

List of Tables

INSTALLATION

INSTALLATION 68P81096E37

Table 1. Configuring Input GPI_14 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 2. Configuring Output GPO_14 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 3. Configuring Output GPO_15 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 4. System Connector – Commonly Used Pins . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 5. Summary of Auxiliary Inputs/Outputs at the System Connector . . . . . . . . 34

Table 6. J5 SYSTEM CONNECTOR, Row A Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 7. J5 SYSTEM CONNECTOR, Row B Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 8. J5 SYSTEM CONNECTOR, Row C Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 9. Type 5 and “3002” Phone Line Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 10. Wireline Connector Line Pair Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 11. System Types vs. Wireline Circuit Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 12. Station Maintenance Connections on the SCM . . . . . . . . . . . . . . . . . . . . . . . . 42

viii 68P81096E20-N 06/28/05

Page 13

1 INTRODUCTION

Note

Figure 1. MTR2000 Station

DESCRIPTION

The Motorola MTR2000 Base Station/Repeater provides analog con v entional and trunking capabilities in a reliable, software-controlled design. An innovative modular design and microprocessor-controlled Station Control

Module (SCM) allows for superior station flexibility and simplified system upgrades.

All of the features described in this manual may not be currently supported

to the “Summary of Operatin g Features” section for a list of standard feat ures, optional features, and planned future features.

Flexible Mechanical Design

All elements of the station are designed for EIA 48.3cm (19") rack mounting, allowing the equipment to be mounted in standard telephone-style equipment racks, or

various sizes of Motorola cabinets. Figure 1 sho ws a typical 40W station.

. Refer

Motorola Inc., 2005

All Rights Reserved

Printed in U.S.A.

Government & Enterprise Mobility Solutions

1301 E. Algonquin Road, Schaumburg, IL 60196

68P81096E36-H

06/28/05-UP

Page 14

Description

Electrical Design

Transmitter Circuitry

The station transmitter circuitry is designed for continuous duty operation and may

be operated at full rated power. Output power is continually monitored by an internal directional coupler. The forward power voltage from the coupler feeds a power

control loop which continually adjusts and maintains the desired output power. All

adjustments are electronic, including deviation and output power.

Receiver Circuitry

The station receiver circuitry features multiple bandwidth (12.5kHz, 20kHz, 25kHz,

and 30kHz) capability. Injection signals for the first and second mixers are generated

by frequency synthesizer circuitry electronically controlled by the Station Control

Module. All receive signals (analog) are detected and digitized before being sent to

the Station Control Module, providing improved, consistent audio quality throughout the coverage area.

Trunking Capability

Station Control Module

The Station Control Module is microprocessor-based and features extensive use of

ASIC and digital signal processing technology. The module serves as the main controller for the station, providing signal processing and operational control for the station modules.

Wireline Circuitry

The station wireline circuitry options provide a wide variety of telephone interfaces

and control mechanisms such as Tone Control. Telephone line connections are easily

made to the wireline circuitry via connectors on the rear of the station.

When equipped for trunking capability, the station can operate in Motorola's Smartnet™ or the most advanced wide-area trunking system – SmartZone. The station can

operate as a remote voice channel or control channel repeater. The station interfaces

to a T runking Central Controller (TCC) which provides the call processing and channel assignment tasks.

2 68P81096E36-H

06/28/05

Page 15

Summary of Operating Features

Standard Features

The following are a few of the standard features:

• FRU maintenance philosophy (reducing down time).

• Easily programmed via Radio Service Software (RSS ).

• Extensive Self-Test Diagnostics and Alarm Reporting through RSS.

• Expansion and upgrades performed by module replaceme n t.

• Highly reliable and accurate continuous duty transmitter circuitry.

• Compatible (with appropriate options) with conventional analog signaling.

• Wide operating temperature range: -30°C to +60°C (-22°F to +140°F).

• Battery Backup Connector – allows connection to battery backup system which

automatically reverts to battery backup operation in the event of ac power failure.

•RA/RT

• Wide voltage supply range (AC or DC), with no setup configuration.

Description

Optional Features

The following are some of the leading optional features for the station:

• Double Circulator Option – provides additional isolation and intermodulation

protection for rf-congested transmitter sites (not available on 350MHz stations).

• Microprocessor Radio Telephone Interconnect (MRTI) – allows connection of

conventional station to the telepho ne network.

• Trunking – allows trunking repeater to operate as part of a Smartnet or Smart-

Zone system; through Auxiliary I/O board (CLN1206).

• Wildcard Input/Output; through Auxili ary I/O board (CLN1206).

• Main Standby; through Auxiliary I/O board (CLN1206).

• Multi-coded Squelch Interface; through Zetron Model 38 Repeater Panel.

• Console Priority Interface; through 8-Wire Wireline Interface Board (CLN1205).

• Auxiliary Input/Output for conventional operation; through Auxiliary I/ O

board (CLN1206).

Features Not Offered

Please disregard any references to the following items since they are not available

for the MTR2000:

• DC Remote control for the 4-wire Wireline Interface Board, CLN1203.

• Second Receiver configuration of the MTR2000.

68P81096E36-H 3

06/28/05

Page 16

Description

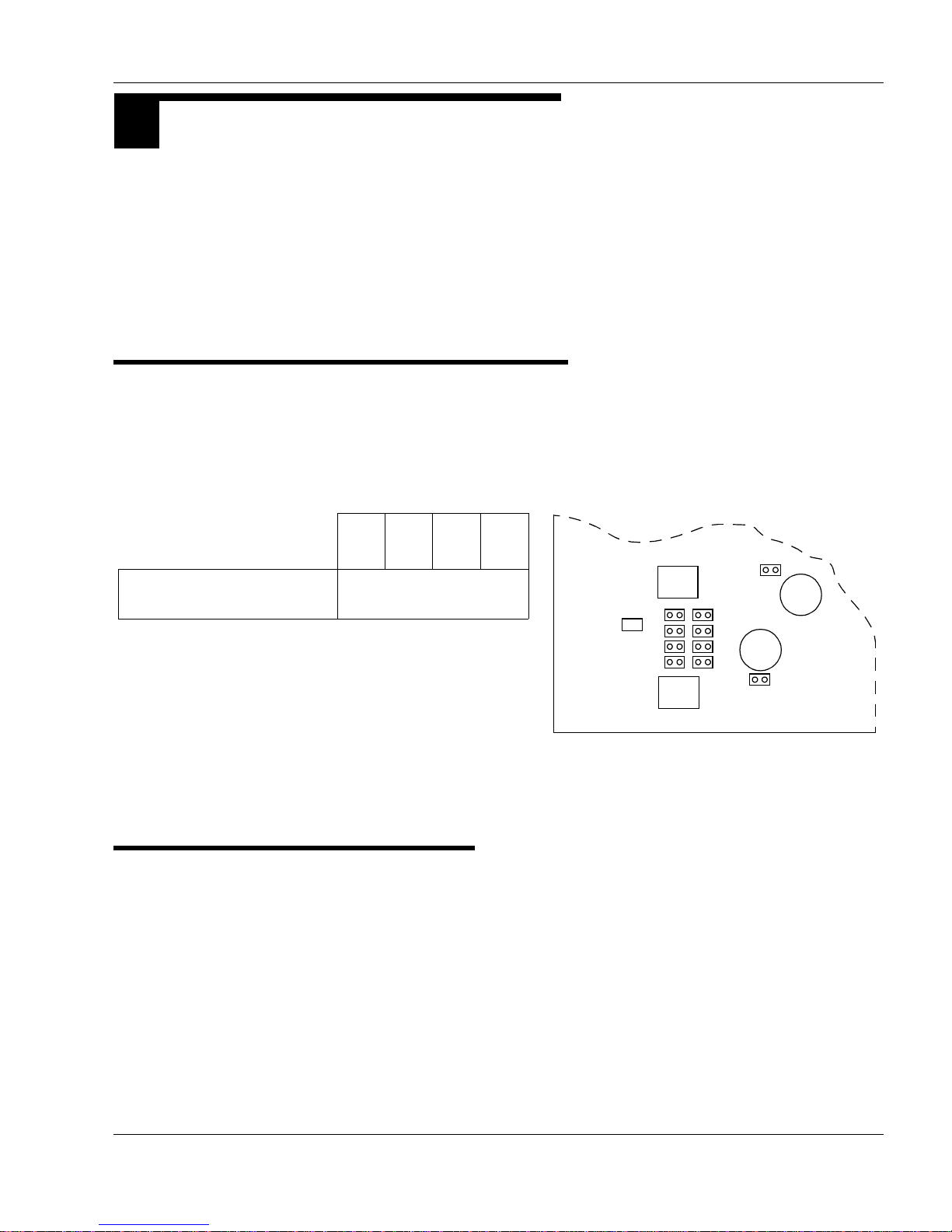

2 STATION COMPONENTS

Figure 2. MTR2000 Station Components

Power Supply

Module

Bottom Plate

Exciter Module

Receiver

Module

Sta tion Control M odule

Power Amplifier

Module

Front Cover

NOTE: Fans and fan covers

are only used on high power

Power Amplifier modules and

Power Supplies.

Backplane

NOTE: Fans and fan covers

are only used on high power

Power Amplifier modules and

Power Supplies.

Fan Cover

Auxiliary I/O

Board

Top Plate

Fan

Wireline

Interface Board

Figure 2 shows the modules and components that comprise a station.

4 68P81096E36-H

06/28/05

Page 17

Description

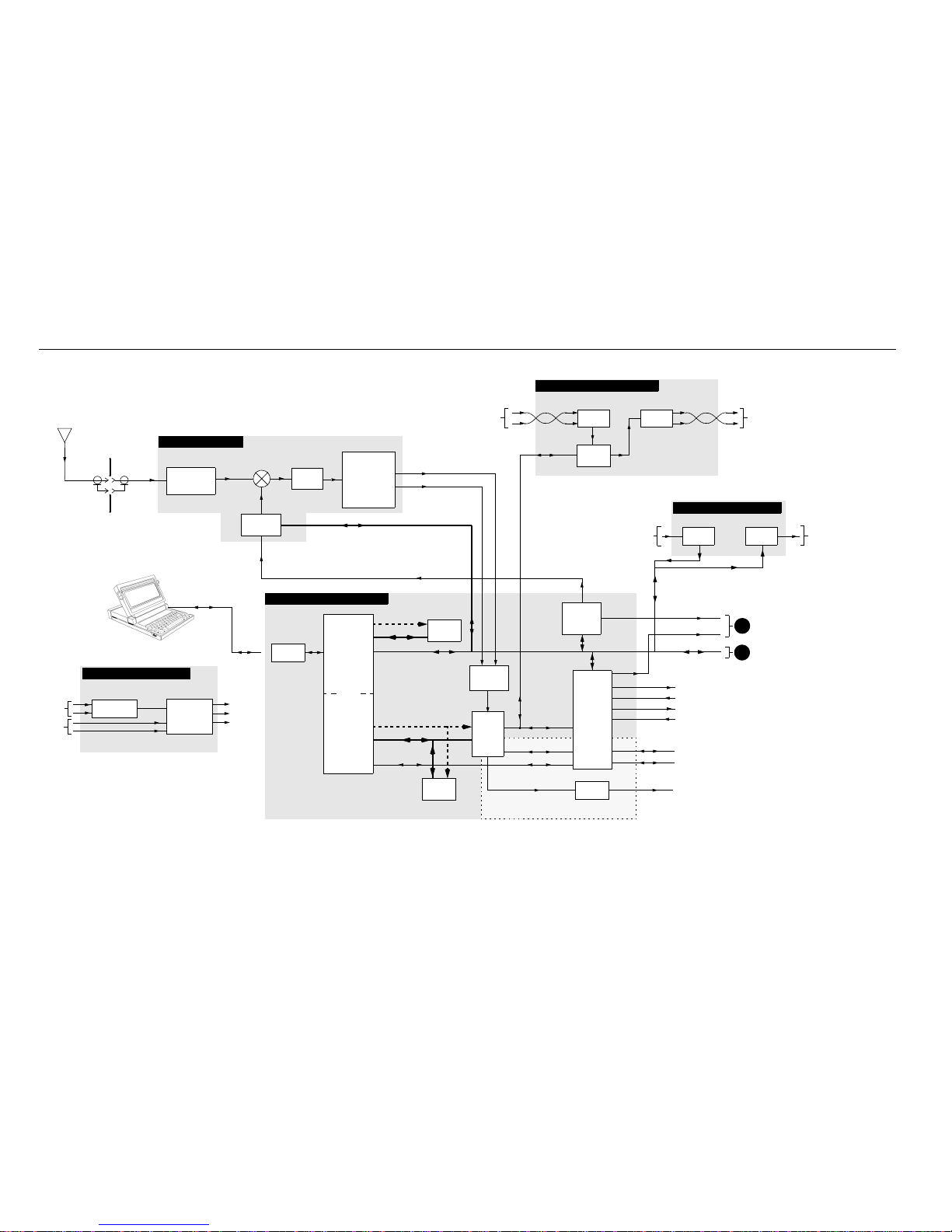

3 FUNCTIONAL THEORY OF OPERATION

The following functional theory of operation provides an overview of the station circuitry. For a more thorough

functional desc ription of a particular module , refer to the STATIO N MODULES section of the appropriate bandspecific Instruction Manual. The block diagram in Figure 3 supports the following functional theory of operation.

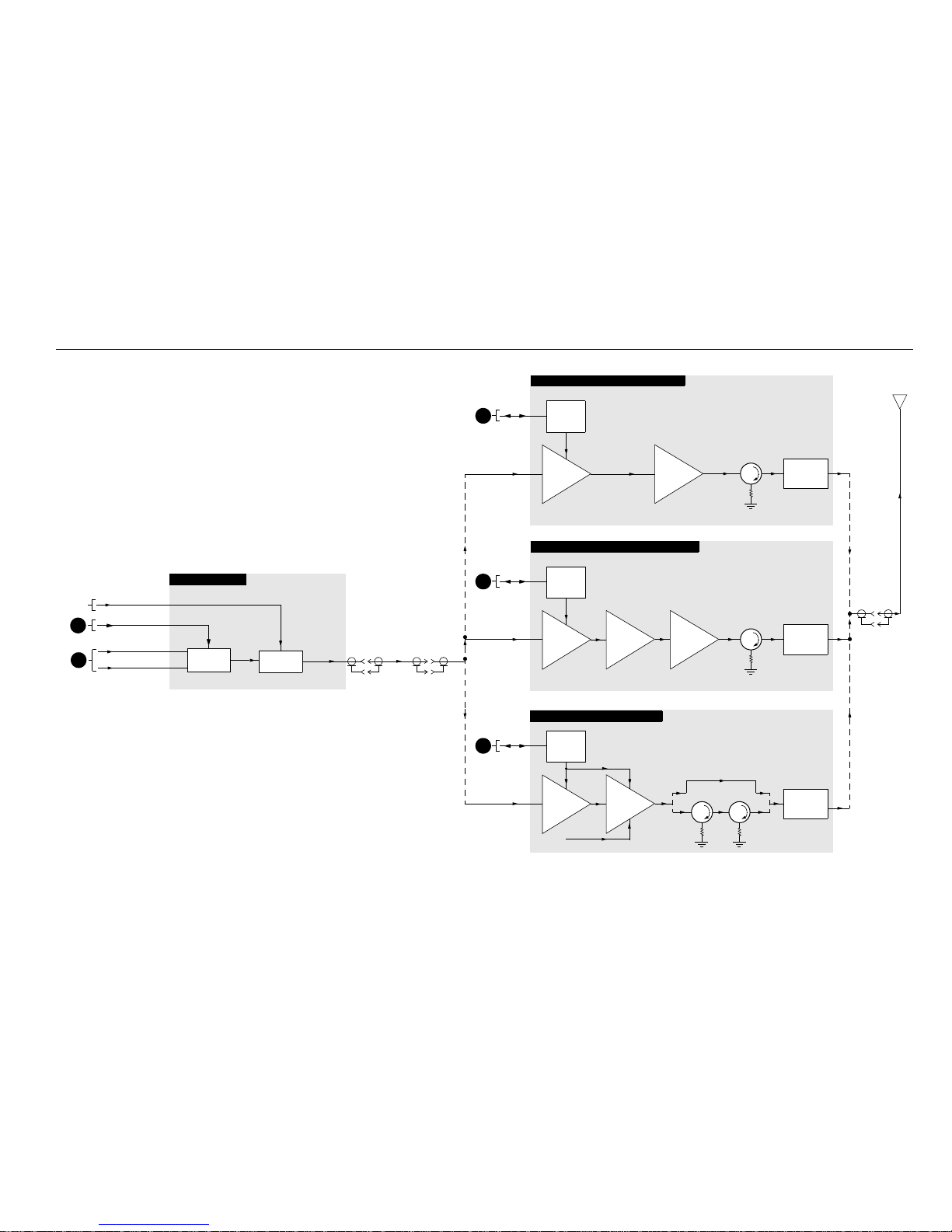

Transmitter Circuitry Operation

Introduction

The T ransmitter Circuitry comprises two modules, the Exciter Module and the Power Amplifier (PA) Module. These modules combine to generate, modulate, and amplify the rf signal which is transmitted via the site transmit antenna. Modulation

sensitivity and power output are adjusted electronically for each channel (through

the Radio Service Software), under the direct control of the Station Control Module

(SCM).

Exciter Module Operation

The Exciter Module, which interfaces directly to the SCM, generates a modulated rf

signal at the desired transmit frequency and sends this signal to the PA for amplification. The circuitry operates as follows.

The transmit synthesizer and VCO (voltage-controlled oscillator) circuitry on the Exciter Module accept frequency programming data from the SCM (via the SPI bus)

and generate an rf carrier at the specified frequency. The VCO is directly modulated

by transmit audio/data from the SCM. The resulting modulated rf signal (at a level

of approximately +12 dBm) is then fed to the PA.

Power Amplifier Module Operation

The PA modules are designed for continuous-duty operation across all bands and

power levels. The actual circuit stages employed in a PA depend on the specific frequency band, power output level and intermodulation requirements. All PA modules contain an Intermediate Power Amplifier (IPA) at the input, a low-pass

filter/directional coupler at the output, and diagnostic and power control circuitry.

High power (100 W) PA m odules employ a single int ernal circulator to protect the PA

from transmitter intermodulation and antenna mismatch (VSWR). The low power

30 W PA module employs two interna l cir cu lato rs. Al l PA stages and ci rc ulat ors ar e

broad-band devices and require no tuning to operate at the station site.

The modulated rf signal from the Exciter Module is input to the IPA in the PA Module, and amplified to within a range of 0 to 10 W (depending on power control signals

from the SCM). In P A Modules operating below 600MHz, the rf signal is fed to either

a Butterfly Module (30W/40W PA models) or a Dual Device Module (DDM – 100W

PA model s). In PA Modules operating above 600 MHz, a 15 W driver is introduced

68P81096E36-H 5

06/28/05

Page 18

Description

between the Pre-driver stage and the Final Module. The gain of the Pre-driver stage

is controlled by a power control voltage which is derived from power control signals

(from the SCM) and high VSWR/thermal protection circuitry on the PA output

board.

A combination of hardware and software controls are used to regulate the power output level. To set the powe r and current limits, the SCM provides software control

through a D/A converter connected to the SPI bus. This control relies on various

monitored PA signals which ar e fed ba ck to the SCM via an A/D convert er (also connected to the SPI bus).

The directional coupler is essentially a calibrated wattmeter which feeds a dc voltage

proportional to the output power to the power control circuitry to serve as the feedback signal in the power control loop. Under normal operating conditions, the power control circuitry compares this dc voltage from the directional coupler to a

reference voltage fr om the D/A converter which repr esents the desir ed output power . Based on the comparison, a power control voltage is generated to control the output power from the PA Module.

The modulated rf signal is amplified by the Driver/Final Module and is output to the

site transmit an tenna via a cir culator and a harmon ic filter/coupler . During excessive

output VSWR, the ratio of the forward and reflected voltages from the directional

coupler may be used to reduce, or turn off, the transmitter power. Additional circuitry is also provided to reduce output power during excessive curren t drain an d h igh

temperature conditions, and to control the fan used in high power PA Modules.

6 68P81096E36-H

06/28/05

Page 19

Receiver Circuitry Operation

Introduction

The Receiver Circuitry accepts receive rf signals from the site receive antenna, performs filtering and dual conversion, and outputs a digitized receive signal to the Station Control Module. The receiver module utilized may have either an internal

varactor-tuned preselector filter, or an external metal preselector filter.

Receiver Module Operation

The receive signal is input from the site receive antenna to the receiver module, or to

an external preselector filter (a separate assembly attached to the rear of the station

which provides highly selective bandpass filtering). The signal is fed through a lowpass filter , varactor-tuned pr eselector (if external preselector is not used), rf amplifier

and image filter to the rf input of the first mixer. The filtered signal is mixed with an

injection signal generated by the receive synthesizer/VCO, resulting in a first i-f (intermediate frequency) signal. The injection signal frequency is determined by frequency programming data from the Station Control Module via the SPI bus. The

specific frequency of the first i-f depends on the frequency band of the station.

Description

The first i-f signal is filtered and input to a custom receiver IC. This component contains

circuitry for generati ng the second injection sign al, mixing down the first i-f to 450 KHz,

amplification and A/D (analog-to-digital) conversion of the second i-f signal, resulting

in a digitized receive signal. This signal is fed as differential data to the Station Control

Module.

68P81096E36-H 7

06/28/05

Page 20

Description

Station Control Module Operation

Introduction

The Station Control Module (SCM) is the microprocessor -based controller for the station. Major components include an MC68356 microprocessor, which combines a

68302 Integrated Mul tiprotocol Pr ocessor (IMP) with a 56002 Digit al Signal Process or

(DSP), a DSP ASIC device, and several Codec filter devices.

Station Control Module Operation

The MC68356 forms the heart of the SCM. The 68302 portion is the Host Microprocessor (µP), which serves as the controller for the SCM and operates from station software stored in FLASH memory. This software determines the system capabilities of

the station. The Host µP communicates with the station modules and the SCM circuitry via address and data buses, three SCI (Serial Communication Interface) ports,

and an SPI bus.

The DSP portion of the MC68356, with the support of the DSP ASIC, perform the necessary digital processing for the station audio and data signals. The DSP circuitry interfaces with the Receiver Module (receive audio), the Exciter Module (VCO

modulation signal) , the Wir eline Interfac e Board (wireli ne audio), and external audio

devices (microphone and speaker).

The 2.1 MHz Reference Oscillator generates the reference signal used by the Receiver

and Exciter Modules.

8 68P81096E36-H

06/28/05

Page 21

Wireline Interface Board Operation

Note

Introduction

The Wir elin e Interface Boar d ( WIB) ser ves as the interface between the customer an alog telephone lines and the serial data signals of the station. WIBs are offered to

handle 2-wire, 4-wire and 8-wire configurations. In general, the WIB processes and

routes all wireline audio signals between the station and the landline equipment

(such as consoles, modems, etc.). Landline-to-station and station-to-landline audio

signals are connected to the WIB via copper pairs at the rear of the station.

Wireline Interface Board Operation

The WIB contains a PCM Codec-f ilter de vice to perfor m the audio di gitiz ation and r e construction, as well as the band-limiting and smoothing required by PCM syste ms.

Analog signals are routed as follows:

- Inbound analog signals are converted to digital signals and routed to the SCM

as wireline transmit data (WL TxD).

Description

- Outbound PCM data signals are converted to analog signals and routed to the

Line 2 output.

- A latch receives control signals from the SCM (via the SPI bus) to control the gating of the audio signals.

For a list of the actual features supported, refer to the “Summary of Operating Features” on page 3, or the MTR2000 System Planner.

68P81096E36-H 9

06/28/05

Page 22

Description

Note

Auxiliary I/O Board Operation

Introduction

The Auxiliary I/O Board serves as the interface between the customer auxiliary

equipment and the Station Control Module (SCM). In genera l, the Auxiliary I/O

Board routes all auxiliary equipment control signals between the SCM and the auxiliary equipment (e.g., a trunking controller).

Auxiliary I/O Board Operation

The Auxiliary I/O Board contains SPI Input Buffers and associa ted circuitry w hich

provides an input signal path from auxiliary equipment to the statio n S C M.

The input circuitry supports 16 general purpose inputs:

- 14 are transistor buffered inputs; 16V maximum, 10kΩ.

- 2 are opto isolated inputs; 60mA forward current, 3V dropout voltage, 2kV isolation.

The Auxiliary I/O Board contains SPI Output Latches and associated circuitry which

provides an output signal path from the station SCM to auxiliary equipment.

The output circuitry supports 16 general purpose outputs:

- 14 are open collector transistor outputs; maximum 40V, 100mA sink current

- 2 are dry contact outputs (relay); maximum 250V, 1A)

Not all inputs and outputs are supported, seeTable 4, on page 33 through

Table 8, on page 37.

10 68P81096E36-H

06/28/05

Page 23

Power Supply Module Operation

Power Supply Modules are offered to handle:

• ac or dc input power

• low power (250 W) or high power (500 W) station requirements

A high power Power Supply Module (500 W) is used in a station with a high power

Power Amplifier Module (e.g., rated at 100 W or 75 W output power).

A low power Power Supply Module (250 W) is used in a station with a low power

Power Amplifier Module (e.g., rated at 40 W output power), or if the station is configured as a Satellite Receiver.

ac Input Power The 250 W models generates the +5.1 V and +14.2 V operating voltages for the sta-

tion modules.

The 500 W models generates the +5.1 V, +14.2 V, and +28 V operating voltages for

the station modules.

These modules have power factor correction and include a connection for battery

backup.

Description

Model Supplied by

Stations with Low Power PA

DLN6624 ASTEC

Stations with High Power PA

DLN6622 ASTEC

Table 1. Power Supply Module Models

Input Voltage Range

85 to 264 Vac, 47 to

63 Hz

85 to 264 Vac, 47 to

63 Hz

Output

Voltages

+5.1 V and

+14.2 V

+5.1 V,

+14.2 V,

and +28 V

Power Factor Correction

Provided internally within

power supply module.

Provided internally within

power supply module.

68P81096E36-H 11

06/28/05

Page 24

Description

dc Input Power For dc-only operation the 250 W Power Supply Module (DLN6624) accepts a dc in-

put (+10.8 to +16 Vdc). The output voltages are:

- the input filtered voltage.

- a regulated +5.1 Vdc.

For dc-only operation the 500 W Powe r Suppl y Module (DLN6622) accepts a dc input (+21 to +32 Vdc).

The output voltages are:

- the input filtered voltage.

- a regulated +5.1 Vdc.

- a regulated +14.2 Vdc.

12 68P81096E36-H

06/28/05

Page 25

Description

THIS PAGE INTENTIONALLY LEFT BLANK

68P81096E36-H 13

06/28/05

Page 26

Description

14 68P81096E36-H

06/28/05

RECEIVER MODULE

LOW PASS FILTER/

PRESELECTOR/

IMAGE FILTER

1ST

MIXER

1ST I-F

CUSTOM

RECEIVER

IC

HOST

MEMORY

WIRELINE INTERFACE BOARD

2.1 MHz

REFERENCE

OSCILLATOR

RECEIVE

ANTENNA

RF INPUT/OUTPUT

CONNECTOR BRACKET

(REAR OF STATION)

BANDPASS

FILTERING

1ST LO INPUT

Figure 3. MTR2000 Station Functional Block

Diagram (Sheet 1 of 2)

(2ND INJECTION,

AMPLIFICATION,

A/D CONVERSION)

DIFFERENTIAL DATA

2.1 MHz REF

STATION CONTROL MODULE

HOST ADDRESS

HOST DATA BUS

SPI BUS

PCM CODEC BUS

RSSI DATA

RSSI

CIRCUITRY

CURRENT-TO-

VOLTAGE

CONVERTER

DSP

ASIC

EIA-232

INTERFACE

RSS TERMINAL

(IBM-PC LAPTOP

TYPICAL)

SPI BUS

TRUNKING AUDIO

MRTI AUDIO

RECEIVER SIGNAL

STRENGTH INDICATOR

(OPTION DEPENDENT)

AUXILIARY TX AUDIO

DISC AUDIO

MICROPHONE AUDIO

EXTERNAL SPEAKER

2.1 MHz REF

20 KHz CODEC BUS

24 KHz CODEC BUS

2.1 MHz REF

DSP

MEMORY

DSP ADDRESS BUS

DSP DAT A BUS

24 KHz CODEC BUS

DSP

HOST

MICROPROCESSOR

SSI

68356

SPI BUS

SPI BUS

LINE

RX

LINE

TX

(4-WIRE VERSION SHOWN)

LINE 1 IN

INBOUND

WIRELINE AUDIO

FROM

LANDLINE

TO

STATION

OUTBOUND

WIRELINE AUDIO

FROM

STATION

TO

LANDLINE

PCM CODEC BUS

LINE 2 OUT

SYNTHESIZER/

VCO

A

B

VCO & REF MOD AUDIO

SPI BUS

AUDIO

PROCESSING/

INTERFACE

CIRCUITRY

CODEC #3

(8 KHz PCM)

GENERAL

PURPOSE

OUTPUTS TO

AUXILIARY

EQUIPMENT

GENERAL

PURPOSE

INPUTS FROM

AUXILIARY

EQUIPMENT

AUXILIARY I / O BOARD

INPUT

BUFFERS

OUTPUT

LATCHES

POWER SUPPLY MODULE

AC

INPUT

TRANSFORMER

and PFC

REGULATOR

CIRCUITRY

+14.2 VDC

+5.1 VDC

+28.6 VDC

(HIGH POWER

PA ONLY)

AC/DC POWER SUPPLY with DC Backup Connecto r

DC

INPUT

Page 27

Description

68P81096E36-H 15

06/28/05

EXCITER MODULE

RF SWITCH

CIRCUITRY

TX ENABLE

MODULATED RF

2.1 MHz REF

A

B

SYNTHESIZER/

VCO

SPI BUS

VCO & REF MOD AUDIO

FROM

STATION

CONTROL

MODULE

MODULATED RF

CIRCULATOR

50 OHM

LOAD

1.5 W

PRE-DRIVER

15 W

DRIVER

LOW-PASS

FILTER/

DIRECTIONAL

COUPLER

FINAL

MODULE

TRANSMIT

ANTENNA

75 W POWER AMPLIFIER (800 & 900 MHz)

B

SPI BUS

POWER

CONTROL

CIRCUITRY

TWO CIRCULATORS

50 OHM

LOAD

15 W

INTERMEDIATE

POWER AMP

50 W

BUTTERFLY

MODULE

LOW-PASS

FILTER/

DIRECTIONAL

COUPLER

B

SPI BUS

POWER

CONTROL

CIRCUITRY

CIRCULATOR

50 OHM

LOAD

10 W

INTERMEDIATE

POWER AMP

LOW-PASS

FILTER/

DIRECTIONAL

COUPLER

DUAL

DEVICE

MODULE

100 W POWER AMPLIFIER (<600 MHz)

B

SPI BUS

POWER

CONTROL

CIRCUITRY

Figure 3. MTR2000 Station Functional Block

Diagram (Sheet 2 of 2)

50 OHM

LOAD

OR

OR

30 W & 40 W POWER AMPLIFIER

PA ENA BLE

Page 28

INSTALLATION

1 PRE-INSTALLATION CONSIDERATIONS

Proper installation ensures the best possible performance and reliability of the station equipment. Pre-installation

planning is required. This includes considering the mounting location of the equipment in relation to input power, antennas, and telephone interfaces. Also to be considered are site environment conditions, the particular

mounting method (several available), and required tools and equipment.

If this is the first time installing this type of equipment , it is hig hly recommended that the user read:

• this entire installation section before beginn ing the actual installation, an d

• the Motorola Quality Standards Fixed Network Equipment Installation manual, R56 (68P8108 9E50); specifically refer to the information on ground connection for lightning protection.

Installation Overview

The following information is an overview for installing the station and ancillary equipment. Step-by-step procedures for each of the major installation tasks are then provided beginning in Section 2, Mechanical

Installation.

• Plan the installation, paying particula r atten tion to environmental

conditions at the site, ventilation requirements, and grounding and

lightning protection.

• Unpack and inspect the equipment

• Mechanically install the equipment at the site

• If a Wireline Interface Board or an Auxiliary I/O Board is included

with the station, configure the board jumpers for required operation

• Make necessary electrical and cabling con nections, including the following:

- AC input cabling

- Coaxial cables to transmit and receive antennas

- Phone line con nections

-System cables

Motorola Inc., 2005

All Rights Reserved

Printed in U.S.A.

Government & Enterprise Mobility Solutions

1301 E. Algonquin Road, Schaumburg, IL 60196

68P81096E37-N

06/28/05-UP

Page 29

Installation

Note

STOP

IMPORTANT

• Perform a post-installation functional checkout test of the equipment

to verify proper installation

• Proceed to the Optimization procedures to customize the station parameters per customer specifications (e.g., operating frequency, PL,

codes, etc.)

Regulatory requirements may require the use of an optional high stability

reference for some modes of operation. It is recommended that the user

check current local regulations prior to operation.

Environmental Conditions at Intended Installation Site

If the station is to be installed in an environment which is unusually

dusty or dirty (and so does not meet the air quality requirements), the

air used to cool the station modules must be treated using appropriate

filtering devices. Dust or dirt accumulating on the internal circuit

boards and modules is not easily r emoved, a nd can cause such malf unctions as overheating and intermittent electrical connections.

Operating T emperature

Range

Humidity Not to exceed 95% relative humidity @ 50°C (122°F).

Air Quality For equipment operating in an environmentally controlled environment

The station may be installed in any location suitable for electronic communications equipment, provided that the environmental conditions do not

exceed the equipment specifications for temperature, humidity, and air

quality. These are:

–30°C (–22°F) to +60°C (+140°F)

This is the temperature measured in close proximity to the station. For example, if the station is mounted in a cabinet, the temperature within the

cabinet would be measured.

with the station(s) rack mounted, the airborne particulates level must not

exceed 25 µg/m

For equipment operating in an area which is not environmentally controlled (station(s) cabinet mounted), the airborne particulates level must

not exceed 90 µg/m

3

.

3

.

2 68P81096E37-N

06/28/05

Page 30

Equipment Ventilation

STOP

IMPORTANT

CAUTION

!

Installation

The high-power (100/75W) stations are equipped with cooling fans that

are used to provided forced convection cooling.

When planning the installation, observe the follo wing ventilation guidelines:

Mounting the MTR2000

in a Cabinet

• Customer-supplied cabinets must be equipped with ventilation slots

or openings in the front (for air entry) and back or side panels (for air

to exit). If several stations are installed in a single cabinet, be sure ventilation openings surround each station to allow for adequate cooling.

• All cabinets must have a least 15cm (6in) of open space between the

air vents and any wall or o ther cabinets. This all ows adequate air flow.

• When multiple cabinets (each equipped with several stations) are installed in an enclosed area, make sure the temperature within each

cabinet does not exceed the recommended / maximum operating temperature of +60°C (+140°F). It may be necessary to have air conditioning or other climate control equipment installed to satisfy the

environmental requiremen ts.

High Power Stations: The mounting o f only O NE STATION PER CABINET is recommended. More t han on e stati on per ca binet w ill result in

degradation of thermal specifications at high ambient temperatures.

Low Power Stations: In order to maintain thermal specifi cation of –30°C

(–22°F) to +60°C (+140°F), the low power stations must be mounted in a

cabinet with additional cool ing. A single low power stati on mounted in

a cabinet without additional cooling, will operate at thermal specification performance of –30°C (–22°F) to +54°C (+129°F).

Appropriate precautions should be taken to ensure that st ation ambient

temperature does not exceed +60°C (+140°F).

If multiple stations are required, AND THERMAL SPECIFICATION

DEGRADATION IS ACCEPTABLE, the following is recommended

when no cabinet fans are used. Up to three stations can be mounted in

a 76.2cm (30in) or larger cabi net with two rack units of spacing between

each station. This will result in t hermal specification perfo rmance of

–30°C (–22°F) to +40°C (+104°F).

Mounting the MTR2000

in a Rack

68P81096E37-N 3

06/28/05

When mounting multiple stations in a rack, ensure that the minimum

spacing between stations is:

• 3 rack units (13.3cm or 5.25in) for VHF and UHF low power stations,

and 350MHz stations.

• 1 rack unit (4.4cm or 1.75in) for VHF and UHF high power stations,

800MHz stations, and 900MHz stations.

This spacing needs to be complied with to ensur e that the thermal rating

of the station is not exceeded.

Page 31

Installation

CAUTION

!

AC Input Power Requirements

The station is equipped with a switching power supply, this assembly operates from 85 Vac

prong line cord is supplied to connect the power supply to the ac source.

It is recommended that a standard 3-wire grounded electrical outlet be

used as the ac source.

The ac socket-outlet must be instal led near the equipment and must be

easily accessible.

The outlet must be connected to an ac source capable of supplying a maximum of 1020 VA. For a nominal 110/120Vac input, the ac source must

supply 8.5A and should be protected by a circuit breaker rated at 15A. For

a nominal 220/24 0Vac input , the ac sour ce must suppl y 4.25A and should

be protected by a circuit breaker rated at 10A.

to 264 Vac at 47 to 63 Hz ac input power. A standard 3-

Requirement for

European Union (EU)

Countries

Beginning January 1, 2001, input harmonic current specifications were

changed for most electronic telecommunication equipment installed in EU

countries. Accordingly, power factor correction is necessary for MTR2000

stations.

Power Supply models DLN6 622 and DLN6624 h ave internal power fa ctor

correction.

4 68P81096E37-N

06/28/05

Page 32

Equipment Mounting Methods

Installation

The station equipment may be mounted in a rack or cabinet (available as

options).

The station can b e shi p pe d:

• …in an floor-mount indoor cabinet. Each floor-mount cabinet has

front and rear vented doors and has the capacity to hold a minimum

of a single station (see thermal limitations described under Equipment Ventilation), and required ancillary equipment. The larger cabinets provide additional room for supplementary peripheral

equipment.

• …in a rack. Open frame racks accept multiple stations and ancillary

equipment; EIA 48.3cm (19 in) rack configuration.

68P81096E37-N 5

06/28/05

Page 33

Installation

STOP

WARNING

Floor-mount Cabinet

The physical dimensions for all available floor-mount cabinets are shown

in Figure 2. All dimensions are common to all cabinets, except for cabinet

height. The cabinet options and associated he ight are:

Cabinet Option Height

X52AF 76.2cm (30in)

X308AD 1.168m (46in)

X180AC 1.524m (60in)

Minimum recommended clearances are 76.2cm (30in) front and 91.44 cm

(36in) rear for minimum installation access. Refer to Equipm ent Ventilation for recommended ventilation clearances.

For improved access to the unit, a tray slide is available; option X 968AA.

Ensure that the cabine t is securely anchored to the floor, thereby avoiding possible equipment tipping and personal injury. Refer to Mounting

Procedures – Mounting Flo or -mount Ca binets fo r details on pr oper ca binet installation.

6 68P81096E37-N

06/28/05

Page 34

Installation

5.1 cm

(2 in)

5.1 cm

(2 in)

5.1 cm

(2 in)

9.6 cm

(3.8 in)

5.1 cm

(2 in)

5.1 cm

(2 in)

Figure 1. Floor-mount Cabinet – Dimensions and Clearances

55.9 cm

(22 in)

46.5 cm

(18.3 in)

45.2 cm

(17.8 in)

55.9 cm

(22 in)

46.5 cm

(18.3 in)

FRONT

Mounting

Rails (4)

76.2 cm

(30 in)

0.64 cm

(0.25 in)

FRONT VIEW SIDE VIEW

BASE MOUNTING DETAIL

VIEWED FROM

TOP

5.1 cm

(2 in)

49 cm

(19.3 in)

5.1 cm

(2 in)

9.6 cm

(3.8 in)

5.1 cm

(2 in)

9.2 cm

(3.625 in)

holes (2)

1.575 cm

(0.62 in)

holes (4)

1.524m

(60 in)

1.168m

(46 in)

49 cm

(19.3 in)

Station

Support

Brackets (2)

68P81096E37-N 7

06/28/05

Page 35

Installation

Note

Modular Racks

The rack options, associated height and available number of racking units

are:

Rack Option Rack Height

Number of

Racking Units

X741AF 76.2cm (30in) 16

X742AF 1.143m (45in) 24

X743AF 1.32m (52 in) 27

The physical dimensions and clearances for all available modular racks are

shown in Figure 2. The top and bottom plates are identical. All dimensions and clearances are common to all racks, except for the 2 dimensions

identified below. The rack options and associated dimensions are:

Rack Option Dimension A Dimension B

X741AF 79.2cm (31.2in) 26.1cm (10.27in)

X742AF 1.147m (45in) 27.25 cm (10.73in)

X743AF 1.28m (52in) 31.15cm (12.26in)

Recommended clearance front and rear is 91.44cm (36in) minimum for

servicing access. Refer to Equipment Ventilation for recommended ventilation clearances.

FRU kit CLN6679A (MTR2000 Rack Mounting Hardware) is included

with each Rack Option. This allows proper installation of the MTR2000

station within the rack’s centre of gravity.

This kit includes two rack mount standoffs and eight mounting screws.

8 68P81096E37-N

06/28/05

Page 36

Installation

Figure 2. Modular Rack – Dimensions and Clearances

9.22cm

(3.63 in)

1.59cm

(0.625in)

20.58cm

(8.1in)

76.2cm

(3in)

Dimension BDimension B

17.78cm

(7in)

3.81cm

(1.5in)

17.78cm

(7in)

7.22cm

(2.85in)

38.74cm

(15.25in)

5cm

(2in)

15.9mm Diam

(0.625in)

9.4mm Diam

(0.37in)

52.7cm

(20.75in)

45.36cm

(17.86in)

48.77cm

(19.2in)

38.74cm

(15.25in)

13.45cm

(5.3in)

5cm

(2in)

9.4mm Diam

(0.37in)

Rack Center

SIDE VIEW

TOP / BOTTOM

VIEW

Dimension BDimension B

Dimension BDimension A

10.97cm

(4.375in)

13.21cm

(5.25in)

0784384T03

13.21cm

5.25in

Standoff

68P81096E37-N 9

06/28/05

Page 37

Installation

STOP

IMPORTANT

Note

Site Grounding and Lightning Protection

Site Grounding Lightning Protection Recommendations

Proper site grounding and lightning protection are vitally important

considerations. Failure to provide proper lightning protection may result in permanent damage to the radio equipment.

One of the most important considerations when designing a com munications site is the ground and lightning protection system. While proper

grounding techniques and ligh tning protection are closely related, the

general category of site grounding may be divided as follows:

Electrical Ground Ground wires carrying electrical current from circuitry or equipment at

the site is included in the category of electrical ground. Examples include

the ac or dc electrical power used to source equipment located at the site,

telephone lines, and wires or cables connected to alarms or sensors located

at the site.

RF Ground This type of ground is related to the transmission of radio frequency ener-

gy to earth ground. An example of rf grounding is the use of shielding to

prevent or at least minimize the leakage o f unwanted rf transmissions

from communications equipment and cables.

Lightning Ground Providing adequate lightning protection is critical to a s af e and reliable

communications site. Telephone lines, rf transmission cables, and ac and

dc power lines must all be protected to prevent lightning energy from entering the site building.

Although a comprehensive coverage of site grounding techniques and

lighting protection is not within the scope of this manual, there are several

excellent industry sources for rules and guidelines on ground and lightning protection at communications sites.

Motorola recommends the following reference source:

Motorola Quality Standards Fixed Network Equipment

Installation manual, R56. . . . . . . . . . . . . . . . . . . . . . . . . . . . .68P81089E50

Equipment Grounding Guidelines

10 68P81096E37-N

The station is equipped with a ground screw located on the rear of the station Power Supply module. This screw is used to connect the station to the

site ground point. It is assumed that all telephone lines, antenna cables,

and ac or dc power cabling has been properly grounded and lightning protected by following the rules and guidelines provided in the above reference.

06/28/05

Page 38

Recommended Tools and Equipment

Note

STOP

WARNING

In addition to the typical compliment of hand tool s, the following tools

and equipment are recommended for proper installation of the station

equipment.

• Tarpaulin or plastic drop cloth or cover surrounding equipment

while drilling concrete anchor holes (for in stallations where cabinet

or rack is being anchored to concrete).

• Vacuum cleaner for removing concrete dust caused by drilling.

Equipment Unpacking and Inspection

The station equipment may be shipped by either air freight or electronic

van (as specified by customer), except where noted.

Installation

Cabinet Unpacking

• If no cabinet or rack is desired, the station is shipped in a box; the station is positioned between pieces of cushioned corrugated cardboard.

• All available cabinets are shipped with the station(s) installed in the

cabinet, with the cabinet bolted to a wooden skid and covere d with a

cardboard box with corrugated interior corner braces.

• Stations to be used in open frame racks are shipped with the station

and ancillary equipment mounted in the rack and covered by an antistatic plastic bag. All rack shipments are electronic van only.

Thoroughly inspect the equipment as soon as possible a ft er delivery. If

any part of the equipment has been damaged in transit, immediately report the extent of the damage to the transportation company and to Motorola.

Antistatic plastic bags should be kept for future shipping/transporting of

station.

68P81096E37-N 11

06/28/05

When a station (mounted in a cabinet) is delivered from Motorola, it arrives in suitable packing materials. If the unpacked equipment is dam-

aged, return it to Motorola in its original packaging.

Equipment should be handled in its original pa ckaging unti l it is deliv -

ered to its final destination. If the equipment is damaged while being

moved without the original packaging, the warranty claim is not valid.

Page 39

Installation

2 MECHANICAL INSTALLATION

STOP

IMPORTANT

STOP

IMPORTANT

STOP

WARNING

This section describes the procedures to unpack and mechanically install the sta tion equipment. A variety of

mounting methods are possible, depending on whether a cabinet or rack (if any) has been selected to house the

station(s). Installation procedures are provided for each of the cabinet and rack types, as well as the slide rail.

Be sure to observe proper electrostatic discharge precautions if modules

must be removed from the station.

Unpacking Equipment

Introduction

Station equipment packing methods vary depending upon the type of optional rack or cabinet selected by the customer. Unpacking procedur es for

these various methods are provided in the following paragraphs.

The equipment must be immediately inspected for damage after unpacking, and a report of the ext ent of a ny damage made to the transportation company and to Motorola.

Unpacking Stations

The station is shipped in a carton, cushioned by four plastic inserts at the

corners of the carton.

Improper handling of the station may cause personal injury or damage

to the station. DO NOT pick up the station by holding the Preselector

(if so equipped). Use the handl es on the front of the sta tion, or the Power Supply and Power Amplifier casings when picking up the station.

Front Panel – Removal and Replacement

Remove station front panel by inserting a small flat-blade screwdriver into

one of two access holes at either end of the panel and, by carefully moving

the handle of the screwdriver away fro m the center , release the fr ont panel

locking clip from the chassis and pull away the panel

Replace station front panel by inserting one of the front panel locking clips

into corre sponding latc h on the station ho using, and car efully pre ssing the

panel on the opposite side until the second locking clip snaps into place.

.

12 68P81096E37-N

06/28/05

Page 40

Installation

Unpacking Floor-mount Cabinets

The floor-mount cabinets are shipped mounted to a wooden skid, secured

with corrugated corner braces held by a plastic strap, and covered with a

cardboard cover. Unpack the equipment as described in Figure 3.

68P81096E37-N 13

06/28/05

Page 41

Installation

Figure 3. Unpacking Procedures - Floor-mount Cabinets

1. Remove cardboard cover from station.

2. Cut band as shown.

3. Remove top packing spacer and

corrugated corner supports.

4. Remove antist at ic bag . Do not discard bag,

it will be reinstalled to protect equipment

during installation.

5. Depending on cabinet type, either open or

remove front and rear doors to gain access to

the four (4) bolts securing the station to the

wooden skid. Remove the bolts and nuts as

shown.

6. Use hoist to lift the station from the skid.

Remove skid and return station to floor.

7. Replace antistatic bag over station to

provide protection during installation.

Cardboard

Cover

Corrugated

Corner

Supports

Wooden

Skid

Cut This

Band

Top Packing

Spacer

Antistatic Bag

Wooden

Skid

Station

Cabinet

14 68P81096E37-N

06/28/05

Page 42

Mounting Procedures

Installation

Introduction

In most cases, stations are shipped in the selected cabinet or rack (i.e., the

station is mounted and cabled), and may be installed by following the procedures below. However, the following three scenarios require special

mounting procedures:

• Customer plans to mount equipment in customer-supplied rack or

cabinet, and orders equipment to ship from the factory without a rack

or cabinet.

• Customer orders two stations in a single rack.

• Customer requires slide rail assembly.

Installing Racks

In a typical installation, the rack is bolted to a concrete floor to provide stability.

The following procedure describes the steps necessary to bolt the rack to a

concrete floor . Be sure to check with local authorities to verify that the following procedure conforms to local building codes and regulations before

permanently installing the rack.

1. Carefully align the rack at the desired anchoring location.

2. Use the rack mounting foot as a template and mark the location of the

six 19mm (3/4in ) dia meter mounting holes. All six anchoring positions must be used.

3. Move the rack aside, drill holes in the concrete floor, and install the

mounting anchors (RAM RD-56 anchors recommended) per instructions provided with the anchors. Make sure that none of the anchors

comes in contact with the reinforcing wire mesh buried in the concrete; the rack must be electrically isolated fr om any other equipment

or materials at t he site.

4. Align the rack with the installed anchors and lightly secure the rack

to the floor using the proper mounting hardware. Do not tighten the

mounting hardware at this time.

5. Check the vertical plumb of the rack. Also check that the top is level.

Use shims (flat washers or flat aluminum plates) as necessa r y unde r

the rack mounting foot to achieve vertical plumb and horizontal

level.

68P81096E37-N 15

06/28/05

6. Tightly secure the rack to the floor anchors making sure that it remains vertically plumb and horizontally level.

7. After all debris is removed a nd cemen t dust is cleared away , remove

whatever protective covering has been placed on the equipment, including the antistatic bag.

Page 43

Installation

CAUTION

!

Note

Cement dust from concrete flooring is harmful to el ectronic equi pment

and wiring. Make sure that the rack and any collocated equipment are

protected prior to drilling holes in the concrete floor. Use a tarpaulin,

cloth, or plastic sheeting to cover exposed equipment. (The rack should

be already covered wit h an anti static bag; do not remove the bag at this

time.) Use a vacuum while drilling the holes to minimize th e spread o f

concrete dust. Carefully clean up any accumulated dust and debris from

the anchor installation before uncovering the equipment.

Mounting Floor-mount Cabinets

Each cabinet bottom is pre-drilled with four (4) mounti ng holes to allow

attachment to the site floor. If installing on a concrete floor, use the cabinet

as a template, mark the hole locations, and follow the procedures above for

anchoring equipment racks. If in stalling on a wooden floor, use lag bolts

and washers (customer supplied) to secure the cabinet to the floor.

Transferring Equipment from Shipping Container to Rack

or Cabinet

As mentioned under Equipment Unpa ckin g an d Ins pecti on, a s t ation can

be shipped in a box. Upon delivery , the equipment must be removed from

the container and transferred to a Motorola-supplied rack or cabinet, or to

a customer-supplied rack or cabinet.

Customer-supplied cabinets and racks must have mounting rails and hole

spacing compatible with EIA Universal 48.3cm (19in) specifications. Cabinets must provide adequate ventilation (as detailed under Equipment

Ventilat ion) and must meet the following criteria:

- 41.3cm (16.25in) deep

-48.3cm (19in) wide

- 13.4cm (5.25in) high

- Two mounting rails 5cm (2in ) from front of cabinet with front mounting holes 5.7 cm (2.25in) apart ( c enter to center).

Contact Motorola Engineering for specific questions regarding mounting

equipment in customer-supplied cabinets.

16 68P81096E37-N

06/28/05

Page 44

Installation

Note

Note

Installing Slide Rail Assembly in a Motorola Cabinet

Referring to Figure 4, perform the following procedure to install slide rail

option X968AA.

On a bench-top, working

on one side of the slide rail

assembly at a time…

1. Remove the Inner-Slide Rail from the slide assembly (left and right)

by depressing the Slide Locking Latch and sliding the Inner-Slide Rail

out from the slide assembly.

2. Install the Inner-Slide Rail (left) on the Power Supply side by:

- removing the 2 bottom screws from the station power supply

EMI cover, and

- in sta lling the Inner-Slide Rail (left) with the supplied screws.

3. Install the Inner-Slide Rail (right) on the PA side using the holes in the

PA casing .

4. Attach each Outer-Slide Rail to a Cabinet Bracket with supplied

screws.

The left and right Cabinet Brackets are identical.

The Locking Ta b of each Outer-Slide Rail must face towards the rear

of the cabinet.

Working in the cabinet… 5. The cabinet must have a set of vertical cabinet rails in the back as well

as the front. If there is no set in the back, these must be installed. The

back rail is installed the same as the front rail, with the supplied

screws.

6. Install each assembled Cabine t B r acket (with attached Outer-Slide

Rail) to the appropriate side of the cabinet.

The U-shaped cutout of the Cabinet Bracket must face up.

7. Slide the station (with an Inner-Slide Rails mounted on each side) into

the Outer-Slide Rails in the cabinet; an audible snap is heard. Continue sliding the station in until the station is fully seated.

8. Secure the station to the cabinet front rails with the supplied screws.

68P81096E37-N 17

06/28/05

Page 45

Bracket Screws;

6mm panhead (4)

Locking Tab

(towards back of

cabinet)

Outer-Slide Rail

Mounting Screws;

countersunk (2)

Inner-Slide Rail

Mounting Screws;

panhead (2),

station side

Inner-Slide Rail

Outer-Slide Rail

Cabinet

Bracket

Cabinet

Rail, front

Note

The left-side slide rail assembly is shown,

as viewed from the front of the cabinet.

The left side is a mirror image of the right

side.

Slide Locking

Latch

Cabinet

Rail, rear

Direction

That Station

Slides Out

L

E

F

T

Note: Middle-Slide Rail

not shown (for clarity).

Installation

Figure 4. Slide Rail Installation; Option X968AA (Left Side Shown)

18 68P81096E37-N

06/28/05

Page 46

Installation

Note

Installing Slide Rail Assembly in a Non-Motorola Cabinet

Referring to Figure 5, perform the following procedure to install slide rail

option X346AB .

On a bench-top, working

on one side of the slide rail

assembly at a time…

1. Remove the Inner-Slide Rail from the slide assembly (left and right)

by depressing the Slide Locking Latch and sliding the Inner-Slide Rail

out from the slide assembly.

2. Install the Inner-Slide Rail (left) on the Power Supply side by:

- removing the 2 bottom screws from the station power supply

EMI cover, and

- in sta lling the Inner-Slide Rail (left) with the supplied screws.

3. Install the Inner-Slide Rail (right) on the PA side using the holes in the

PA casing .

4. Attach each Outer-Slide Rail to the cabinet Brackets with supplied

screws. Only use the lower slot of each bracket. Leave the screws

loose; they will tightened when the brackets are mounted in the cabinet (step 7).

The left and right Cabinet Bracket sets are identical.

The Locking Ta b of each Outer-Slide Rail must face towards the rear

of the cabinet.

Working in the cabinet… 5. Install a cage nut in line with clearance hole in Threaded Strip prior

to fitting the Front Bracket to the front cabinet rail.

This nut is required for mounting the station (in step 9).

The cage nuts are provided with the cabinet.

6. Fit the Short Bracket and Long Bracket (with attached Outer-Slide

Rail) to the Front and Rear Cabinet Rails using the Bracket Mounting

Screws and Threaded Strips.

7. Tighten the Outer-Slide Rail hardware after positioning the OuterSlide Rail front side in line with the inner surface of the Front Cabinet

Rails.

8. Slide the station (with an Inner-Slide Rails mounted on each side) into

the Outer-Slide Rails in the cabinet; an audible snap is hea rd.

Continue sliding the station in until the station is fully seated.

9. Secure the station to the Front Cabinet Rails with the supplied Station

Mounting Screws.

68P81096E37-N 19

06/28/05

Page 47

Installation

Locking Ta b

(towards back

of cabinet)

Outer-Slide Rail

Mounting

Hardware sets; (4)

Inner-Slide Rail Mounting

Screws; panhead (2 ),

station side

Inner-Slide Rail

Outer-Slide

Rail

Note