Page 1

查询MPC7400EC供应商

Order Number: MPC7400EC/D

Rev. 1.1, 11/2000

Semiconductor Products Sector

™

Advance Information

MPC7400 RISC Microprocessor

Hardware Specifications

The MPC7400 is an implementation of the PowerPC™ family of reduced instruction set computing (RISC)

microprocessors. This document describes pertinent electrical and physical characteristics of the MPC7400.

For functional characteristics of the processor, refer to the MPC7400 RISC Microprocessor User’s Manual.

This document contains the following topics:

Topic Page

Section 1.1, “Overview” 2

Section 1.2, “Features” 4

Section 1.3, “General Parameters” 7

Section 1.4, “Electrical and Thermal Characteristics” 7

Section 1.5, “Pin Assignments” 25

Section 1.6, “Pinout Listings” 26

Section 1.7, “Package Description” 29

Section 1.8, “System Design Information” 31

Section 1.9, “Document Revision History” 43

Section 1.10, “Ordering Information” 43

To locate updates for this document, refer to the website at http://www.motorola.com/sps. For the most

current part errata document, please contact your Motorola Sales Office.

This document contains information on a new product under development by Motorola.

Motorola reserves the right to change or discontinue this product without notice.

© Motorola, Inc., 2000. All rights reserved.

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 2

Overview

1.1 Overview

The MPC7400 is the first implementation of the fourth generation (G4) of PowerPC microprocessors from

Motorola. The MPC7400 implements the full PowerPC 32-bit architecture and is targeted at both portable

and computing systems applications. Some comments on the MPC7400 (with respect to MPC750):

• The MPC7400 adds an implementation of the new AltiVec™ technology instruction set

• The MPC7400 includes significant improvements in memory subsystem (MSS) bandwidth and

offers an optional, high-bandwidth MPX bus interface

• The MPC7400 adds full hardware-based multiprocessing capability, including a 5-state cache

coherency protocol (4 MESI states plus a fifth state for shared intervention)

• The MPC7400 is implemented in a next generation process technology for core frequency

improvement

• The MPC7400 floating-point unit has been improved to make latency equal for double-precision

and single-precision operations involving multiplication

• The completion queue has been extended to 8 slots

• There are no other significant changes to scalar pipelines, decode/dispatch/completion mechanisms,

or the branch unit. The MPC750’s 4-stage pipeline model is unchanged (fetch, decode/dispatch,

execute, complete/writeback)

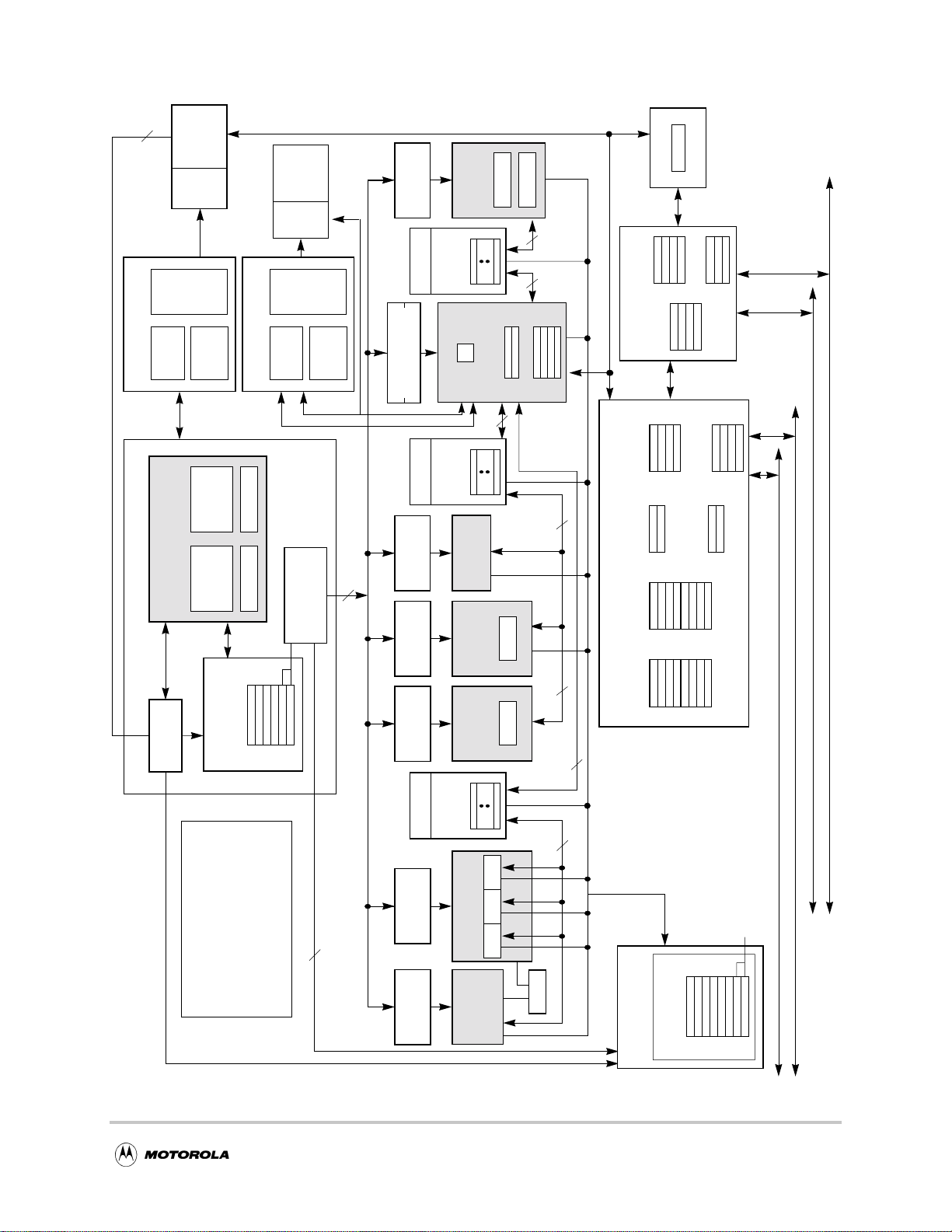

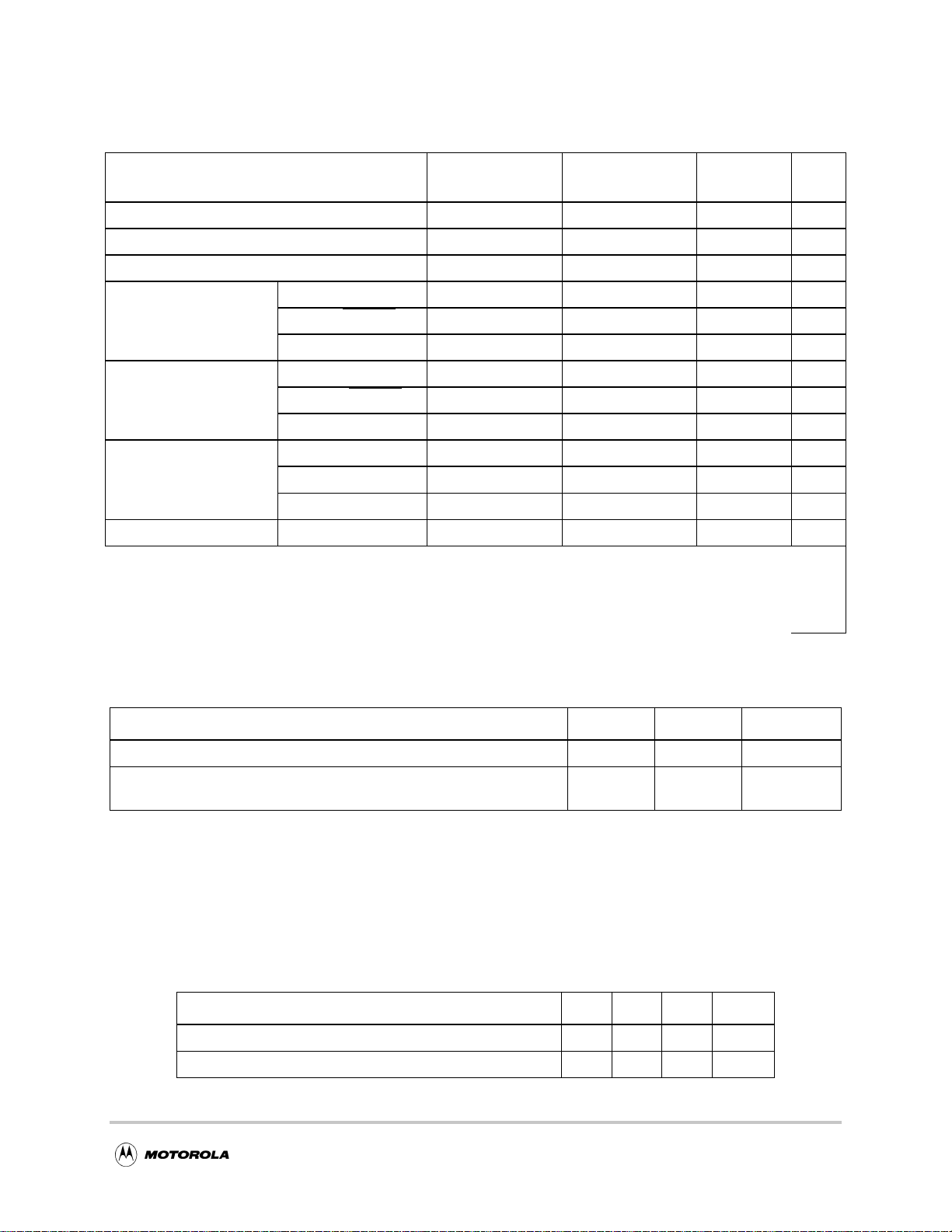

Figure 1 shows a block diagram of the MPC7400.

2

MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 3

Overview

128-Bit

(4 Instructions)

SRs

Instruction MMU

Branch Processing

Instruction Unit

i Cache

32-Kbyte

Tags

IBAT

Array

(Shadow)

128-Entry

BHT

Unit

BTIC

Data MMU

ITLB

CTRLR

(512 Entry)

(64 Entry)

32-Kbyte

SRs

(Original)

EA

D Cache

Tags

Array

DBAT

DTLB

128-Entry

PA

64-Bit (2 Instructions)

Dispatch Unit

Station

Station

Reservation

Reservation

Buffers

FPR File

6 Rename

Reservation

Station (2 Entry)

Load/Store Unit

Buffers

GPR File

6 Rename

Station

Reservation

Station

Reservation

FPSCR

+ x ÷

Floating-

Point Unit

+

Register UnitUnit 1 Unit 2

Integer

FPSCR

Finished Stores

(EA Calculation)

Completed Stores

32-Bit

+

64-Bit

64-Bit

32-Bit

L2CR

L2 Tags

L2 Controller

L2 MissL2 Data

L2 Bus Interface Unit

Queue

Load Fold

Instruction

Reload Queue

Bus Interface Unit

Queue

Data Reload

L2 Castout

Transaction

L1Operations

Instruction

Reload Table

Queue

64-/128-Bit L2 Data Bus

19-Bit L2 Address Bus

(6 Word)

Fetcher

Instruction Queue

Additional Features

• Time Base Counter/

Decrementer

2 Instructions

• Clock Multiplier

• JTAG/COP Interface

• Power Management

32-Bit

Station

Reservation

Buffers

VR File

6 Rename

Station

Reservation

Station

Reservation

+ x ÷

Integer System

128-Bit

128-Bit

VCIU

VSIU VFPU

Unit

Vector Vector ALU

Permute

VSCR

Figure 1. MPC7400 Block Diagram

Table

Data Reload

(8 Entry)

Reorder Buffer

Completion Unit

32-Bit 60x/MAX Address Bus

64-Bit 60x Data Bus/128-Bit MAX Data Bus

Ability to complete up

to two instructions per clock

MPC7400 RISC Microprocessor Hardware Specifications

3

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 4

Features

1.2 Features

This section summarizes features of the MPC7400’s implementation of the PowerPC architecture. Major

features of the MPC7400 are as follows:

• Branch processing unit

— Four instructions fetched per clock

— One branch processed per cycle (plus resolving 2 speculations)

— Up to 1 speculative stream in execution, 1 additional speculative stream in fetch

— 512-entry branch history table (BHT) for dynamic prediction

— 64-entry , 4-way set associative Branch Target Instruction Cache (BTIC) for eliminating branch

delay slots

• Dispatch unit

— Full hardware detection of dependencies (resolved in the execution units)

— Dispatch two instructions to eight independent units (system, branch, load/store, fixed-point

unit 1, fixed-point unit 2, floating-point, AltiV ec permute, AltiV ec ALU)

— Serialization control (predispatch, postdispatch, execution serialization)

• Decode

— Register file access

— Forwarding control

— Partial instruction decode

• Completion

— 8 entry completion buffer

— Instruction tracking and peak completion of two instructions per cycle

— Completion of instructions in program order while supporting out-of-order instruction

execution, completion serialization and all instruction flow changes

• Fixed-point units (FXUs) that share 32 GPRs for integer operands

— Fixed-point unit 1 (FXU1)—multiply, divide, shift, rotate, arithmetic, logical

— Fixed-point unit 2 (FXU2)—shift, rotate, arithmetic, logical

— Single-cycle arithmetic, shifts, rotates, logical

— Multiply and divide support (multi-cycle)

— Early out multiply

• Three-stage floating-point unit and a 32-entry FPR file

— Support for IEEE-754 standard single and double-precision floating-point arithmetic

— 3 cycle latency, 1 cycle throughput (single or double precision)

— Hardware support for divide

— Hardware support for denormalized numbers

— Time deterministic non-IEEE mode

• System unit

— Executes CR logical instructions and miscellaneous system instructions

— Special register transfer instructions

4

MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 5

Features

• AltiVec Unit

— Full 128-bit data paths

— Two dispatchable units: vector permute unit and vector ALU unit.

— Contains its own 32-entry 128-bit vector register file (VRF) with 6 renames

— The vector ALU unit is further sub-divided into the vector simple integer unit (VSIU), the

vector complex integer unit (VCIU), and the vector floating-point unit (VFPU).

— Fully pipelined

• Load/store unit

— One cycle load or store cache access (byte, half word, word, double-word)

— 2 cycle load latency with 1 cycle throughput

— Effective address generation

— Hits under misses (multiple outstanding misses)

— Single-cycle unaligned access within double word boundary

— Alignment, zero padding, sign extend for integer register file

— Floating-point internal format conversion (alignment, normalization)

— Sequencing for load/store multiples and string operations

— Store gathering

— Executes the cache and TLB instructions

— Big- and little-endian byte addressing supported

— Misaligned little-endian supported

— Supports FXU, FPU, and AltiVec load/store traffic

— Complete support for all 4 architecture AltiVec DST streams

• Level 1 (L1) cache structure

— 32K, 32-byte line, 8-way set associative instruction cache (iL1)

— 32K, 32-byte line, 8-way set associative data cache (dL1)

— Single-cycle cache access

— Pseudo least-recently-used (LRU) replacement

— Data cache supports AltiVec LRU and transient instructions algorithm

— Copy-back or write-through data cache (on a page per page basis)

— Supports all PowerPC memory coherency modes

— Non-blocking instruction and data cache

— Separate copy of data cache tags for efficient snooping

— No snooping of instruction cache except for ICBI instruction

• Level 2 (L2) cache interface

— Internal L2 cache controller and tags; external data SRAMs

— 512K, 1M, and 2Mbyte 2-way set associative L2 cache support

— Copyback or write-through data cache (on a page basis, or for all L2)

— 32 byte (512K), 64 byte (1M), or 128 byte (2M) sectored line size

— Supports pipelined (register-register) synchronous burst SRAMs and pipelined (register-

register) late-write synchronous burst SRAMs

— Core-to-L2 frequency divisors of ÷1, ÷1.5, ÷2, ÷2.5, ÷3, ÷3.5, and ÷4 supported

— 64 bit data bus

— Selectable interface voltages of 1.8, 2.5, and 3.3V.

MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

5

Page 6

• Memory management unit

— 128 entry, 2-way set associative instruction TLB

— 128 entry, 2-way set associative data TLB

— Hardware reload for TLBs

— 4 instruction BATs and 4 data BATs

— Virtual memory support for up to 4 exabytes (2

— Real memory support for up to 4 gigabytes (2

52

) of virtual memory

32

) of physical memory

— Snooped and invalidated for TLBI instructions

•Efficient data flow

— All data buses between VRF, load/store unit, dL1, iL1, L2, and the bus are 128-bits wide

— dL1 is fully pipelined to provide 128 bits/cycle to/from the VRF

— L2 is fully pipelined to provide 128 bits per L2 clock cycle to the L1s

— Up to 8 outstanding, out-of-order, cache misses between dL1 and L2/bus

— Up to 7 outstanding, out-of-order transactions on the bus

— Load folding to fold new dL1 misses into older, outstanding load and store misses to the same

line

— Store miss merging for multiple store misses to the same line. Only coherency action taken (i.e.,

address only) for store misses merged to all 32 bytes of a cache line (no data tenure needed).

— 2-entry finished store queue and 4-entry completed store queue between load/store unit and dL1

— Separate additional queues for efficient buffering of outbound data (castouts, write throughs,

etc.) from dL1 and L2

• Bus interface

— New MPX bus extension to 60X processor interface

— Mode-compatible with 60x processor interface

— 32-bit address bus

— 64 bit data bus

— Bus-to-core frequency multipliers of 2x, 2.5x, 3x, 3.5x, 4x, 4.5x, 5x, 5.5x, 6x, 6.5x, 7x, 7.5x,

8x supported

— Selectable interface voltages of 1.8 and 3.3V.

• Power management

— Low-power design with thermal requirements very similar to MPC740 and MPC750.

— 1.8 volt processor core

— Selectable interface voltages below 3.3V can reduce power in output buffers

— Three static power saving modes: doze, nap, and sleep

— Dynamic power management

• Testability

— LSSD scan design

— IEEE 1149.1 JTAG interface

— Array built-in self test (ABIST)—factory test only.

— Redundancy on L1 data arrays and L2 tag arrays

• Reliability and serviceability

— Parity checking on 60x and L2 cache buses

Features

6

MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 7

General Parameters

1.3 General Parameters

The following list provides a summary of the general parameters of the MPC7400:

Technology 0.20 µm CMOS, six-layer metal

Die size 7.86 mm x 10.58 mm (83 mm

2

)

Transistor count 10.5 million

Logic design Fully-static

Packages Surface mount 360 ceramic ball grid array (CBGA)

Core power supply: 1.8V ± 100 mV dc (nominal; see Table 3 for recommended operating

conditions)

I/O power supply 1.8V ± 100 mV dc or

2.5V ± 100 mV dc or

3.3V ± 5% (input thresholds are configuration pin selectable)

1.4 Electrical and Thermal Characteristics

This section provides the AC and DC electrical specifications and thermal characteristics for the MPC7400.

1.4.1 DC Electrical Characteristics

The tables in this section describe the MPC7400 DC electrical characteristics. T able 1 provides the absolute

maximum ratings.

Table 1. Absolute Maximum Ratings

Characteristic Symbol Maximum Value Unit Note

Core supply voltage Vdd –0.3 to 2.1 V 4

PLL supply voltage AVdd –0.3 to 2.1 V 4

L2 DLL supply voltage L2AVdd –0.3 to 2.1 V 4

Processor bus supply voltage OVdd –0.3 to 3.465 V 3

L2 bus supply voltage L2OVdd –0.3 to 3.465 V 3

Input voltage Processor bus V

L2 Bus V

JTAG Signals V

Storage temperature range T

Notes:

1. Functional and tested operating conditions are given in Table 3. Absolute maximum ratings are stress ratings only, and

functional operation at the maximums is not guaranteed. Stresses beyond those listed may affect device reliability or cause

permanent damage to the device.

2. Caution: Vin must not exceed OVdd or L2OVdd by more than 0.3V at any time including during power-on reset.

3. Caution: L2OVdd/OVdd must not exceed Vdd/AVdd/L2AVdd by more than 2.0V at any time including during power-on

reset.

in

in

in

stg

1

–0.3 to OVdd + 0.3V V 2,5

–0.3 to L2OVdd + 0.3V V 2,5

–0.3 to 3.6 V

–55 to 150 °C

MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

7

Page 8

Electrical and Thermal Characteristics

4. Caution: Vdd/AVdd/L2AVdd must not exceed L2OVdd/OVdd by more than 0.4V at any time including during power-on

reset. In addition, operation at nominal Vdd/AVdd/L2AVdd greater than nominal L2OVdd or OVdd in the 1.8V input

threshold select mode can cause erratic operation and AC timing values worse than described in this specification.

may overshoot/undershoot to a voltage and for a maximum duration as shown in Figure 2.

5. V

in

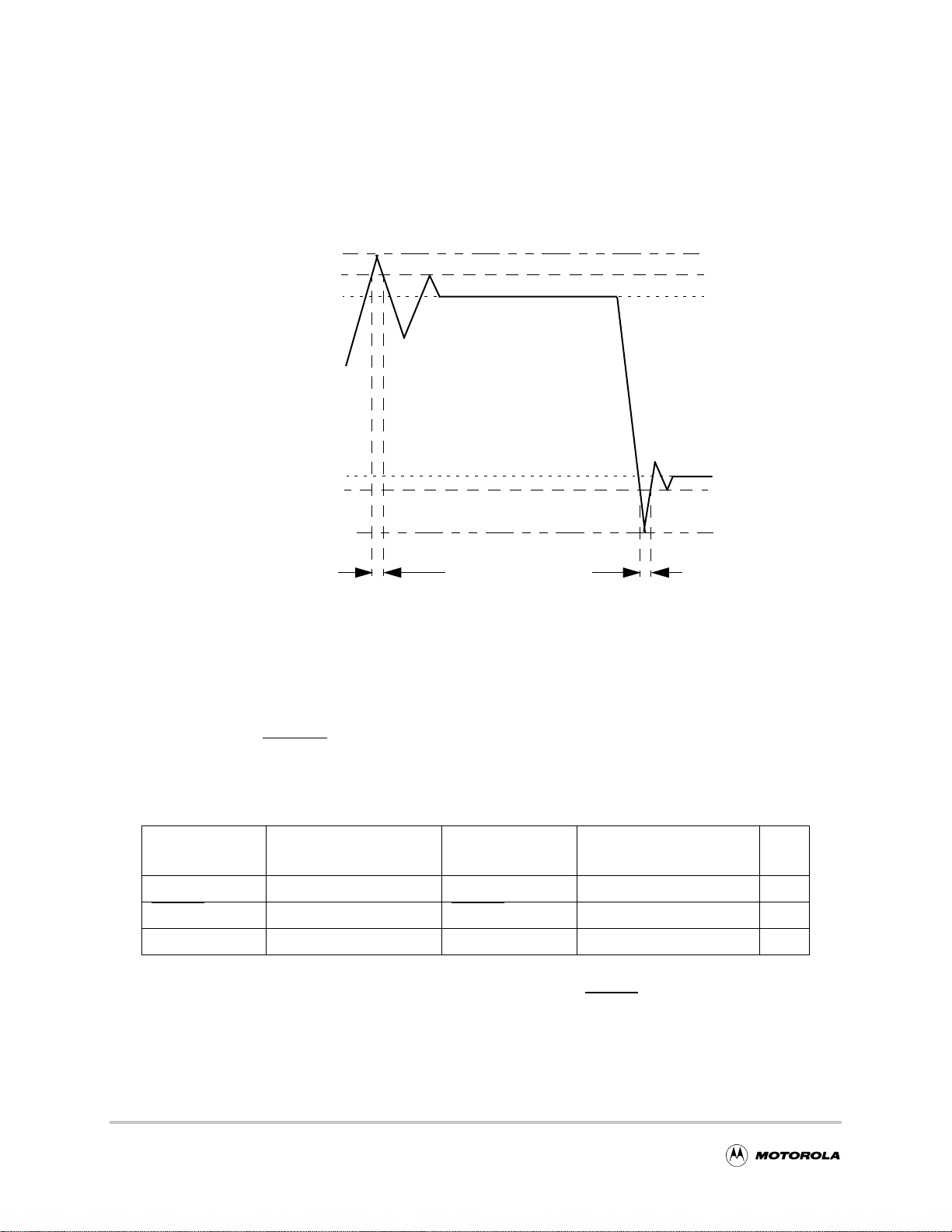

Figure 2 shows the undershoot and overshoot voltage on the MPC7400.

(L2)OVdd + 20%

(L2)OVdd + 5%

(L2)OVdd

V

IH

V

IL

Gnd

Gnd - .3V

Gnd - 0.7V

Not to exceed 10%

of t

SYSCLK

Figure 2. Overshoot/Undershoot Voltage

The MPC7400 provides several I/O voltages to support both compatibility with existing systems and

migration to future systems. The MPC7400 “core” voltage must always be provided at nominal 1.8V (see

Table 3 for actual recommended core voltage). Voltage to the L2 I/Os and processor interface I/Os are

provided through separate sets of supply pins and may be provided at the voltages shown in Table 2. The

input voltage threshold for each bus is selected by sampling the state of the voltage select pins at the

negation of the signal HRESET

. The output voltage will swing from GND to the maximum voltage applied

to the OVdd or L2OVdd power pins.

Table 2. Input Threshold Voltage Setting

BVSEL Signal

0 1.8V 0 1.8 1

HRESET

1 3.3V 1 3.3 1

Notes:

1. Caution: The input threshold selection must agree with the OVdd/L2OVdd voltages supplied.

2. To select the 2.5 volt threshold option, L2VSEL / BVSEL should be tied to HRESET

change state together.

Processor Bus Input

Threshold is Relative to:

2.5V HRESET 2.5 1,2

L2VSEL Signal

L2 Bus Input Threshold is

Relative to:

so that the two signals

Note

8

MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 9

Electrical and Thermal Characteristics

Table 3 provides the recommended operating conditions for the MPC7400.

Table 3. Recommended Operating Conditions

Characteristic Symbol

Core supply voltage Vdd 1.8v ± 100mv V 1

PLL supply voltage AVdd 1.8v ± 100mv V 1

L2 DLL supply voltage L2AVdd 1.8v ± 100mv V 1

Processor bus supply

voltage

L2 bus supply voltage L2VSEL = 0 L2OVdd 1.8v ± 100mv V 1

Input voltage Processor bus V

Die-junction temperature T

Note:

1. These are the recommended and tested operating conditions. Proper device operation outside of these

conditions is not guaranteed.

2. The extended temperature parts have die-junction temperature of -40 to 105 ˚C.

BVSEL = 0 OVdd 1.8v ± 100mv V 1

BVSEL = HRESET

BVSEL = 1 OVdd 3.3v ± 165mv V 1

L2VSEL = HRESET

L2VSEL = 1 L2OVdd 3.3v ± 165mv V 1

L2 Bus V

JTAG Signals V

OVdd 2.5v ± 100mv V 1

L2OVdd 2.5v ± 100mv V 1

in

in

in

j

Recommended

Value

GND to OVdd V 1

GND to L2OVdd V 1

GND to OVdd V 1

0 to 105 °C 2

Unit Note

Table 4 provides the package thermal characteristics for the MPC7400.

Table 4. Package Thermal Characteristics

Characteristic Symbol Value Rating

CBGA package thermal resistance, junction-to-case thermal resistance (typical)

CBGA package thermal resistance, die junction-to-lead thermal resistance

(typical)

Note: Refer to Section 1.8, “System Design Information,” for more details about thermal management.

θ

JC

θ

JB

0.03 °C/W

3.8 °C/W

The MPC7400 incorporates a thermal management assist unit (T AU) composed of a thermal sensor , digitalto-analog converter, comparator, control logic, and dedicated special-purpose registers (SPRs). See the

MPC7400 RISC Microprocessor User’s Manual for more information on the use of this feature.

Specifications for the thermal sensor portion of the TAU are found in Table 5.

Table 5. Thermal Sensor Specifications

At recommended operating conditions (See Table 3)

Characteristic Min Max Unit Notes

Temperature range 0 127

Comparator settling time 20 — µs 2

°C

1

MPC7400 RISC Microprocessor Hardware Specifications

9

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 10

Table 5. Thermal Sensor Specifications

At recommended operating conditions (See Table 3)

Characteristic Min Max Unit Notes

Electrical and Thermal Characteristics

Resolution 4 —

Accuracy -12 +12

°C

°C

3

Notes:

1. The temperature is the junction temperature of the die. The thermal assist unit’s raw output does not indicate an absolute

temperature, but it must be interpreted by software to derive the absolute junction temperature. For information about the

use and calibration of the TAU, see Motorola application note, “Programming the Thermal Assist Unit in the MPC750

Microprocessor,” (order #: AN1800/D).

2. The comparator settling time value must be converted into the number of CPU clocks that need to be written into the

THRM3 SPR.

3. Guaranteed by design and characterization.

Table 6 provides the DC electrical characteristics for the MPC7400.

Table 6. DC Electrical Specifications

At recommended operating conditions (See Table 3)

Nominal

Characteristic

Input high voltage (all inputs except

SYSCLK)

Input low voltage (all inputs except

SYSCLK)

SYSCLK input high voltage 1.8 CV

SYSCLK input low voltage 1.8 CV

Input leakage current, V

= L2OVdd/

in

OVdd

Bus

1

Voltage

1.8 V

2.5 V

3.3 V

1.8 V

2.5 V

3.3 V

3.3 CV

3.3 CV

I

in

Symbol Min Max Unit Notes

IH

0.65 *

(L2)OVdd + 0.3 V 2,3

(L2)OVdd

IH

IH

IL

IL

IL

IH

IH

IL

IL

1.7 (L2)OVdd + 0.3 V 2,3

2.0 (L2)OVdd + 0.3 V 2,3

-0.3 0.35 * OVdd V

-0.3 0.2 * (L2)OVdd V

-0.3 0.8 V

1.5 OVdd + 0.3 V 2

2.4 OVdd + 0.3 V 2

-0.3 0.2 V

-0.3 0.4 V

— 10 µA 2,3

Hi-Z (off-state) leakage current, V

L2OVdd/OVdd

Output high voltage, I

10

= -6 mA 1.8 V

OH

MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

=

in

2.5 V

3.3 V

I

TSI

OH

OH

OH

— 10 µA 2,3,5

(L2)OVdd–0.45 — V

1.7 — V

2.4 — V

Page 11

Electrical and Thermal Characteristics

Table 6. DC Electrical Specifications (Continued)

At recommended operating conditions (See Table 3)

Nominal

Characteristic

Output low voltage, I

Capacitance, V

=

in

6 mA 1.8 V

=

OL

0 V, f = 1 MHz C

Notes:

1. Nominal voltages; See Table 3 for recommended operating conditions.

2. For processor bus signals, the reference is OVdd

3. Excludes test signals (LSSD_MODE, L1_TSTCLK, L2_TSTCLK) and IEEE 1149.1 boundary scan (JTAG) signals.

Bus

Voltage

2.5 V

3.3 V

Symbol Min Max Unit Notes

1

OL —

OL —

OL —

in

— 7.5 pF 3,4

while L2OVdd is the reference for the L2 bus signals.

0.45 V

0.4 V

0.4 V

MPC7400 RISC Microprocessor Hardware Specifications

11

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 12

Electrical and Thermal Characteristics

4. Capacitance is periodically sampled rather than 100% tested.

5. The leakage is measured for nominal OVdd and Vdd, or both OVdd and Vdd must vary in the same direction (for example,

both OVdd and Vdd vary by either +5% or -5%).

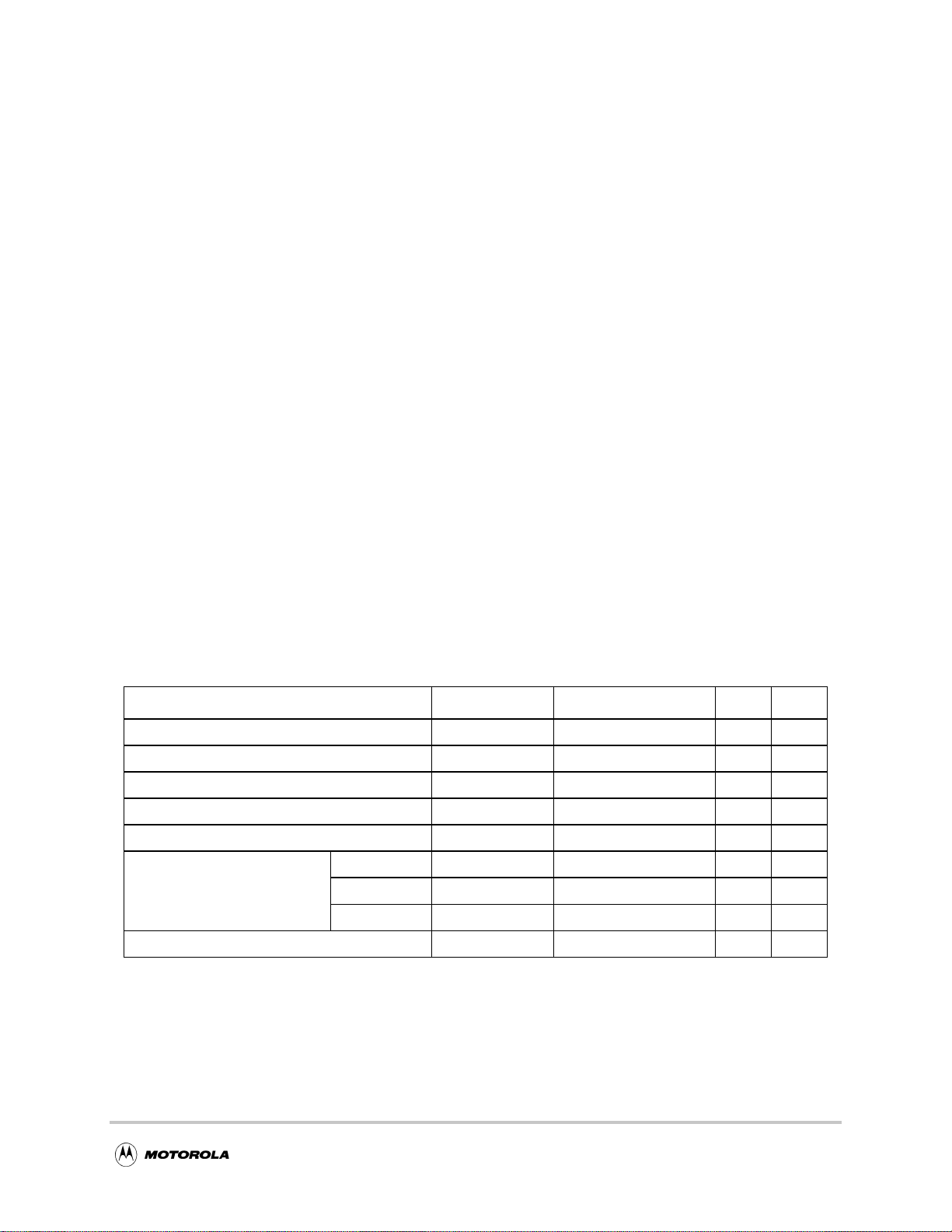

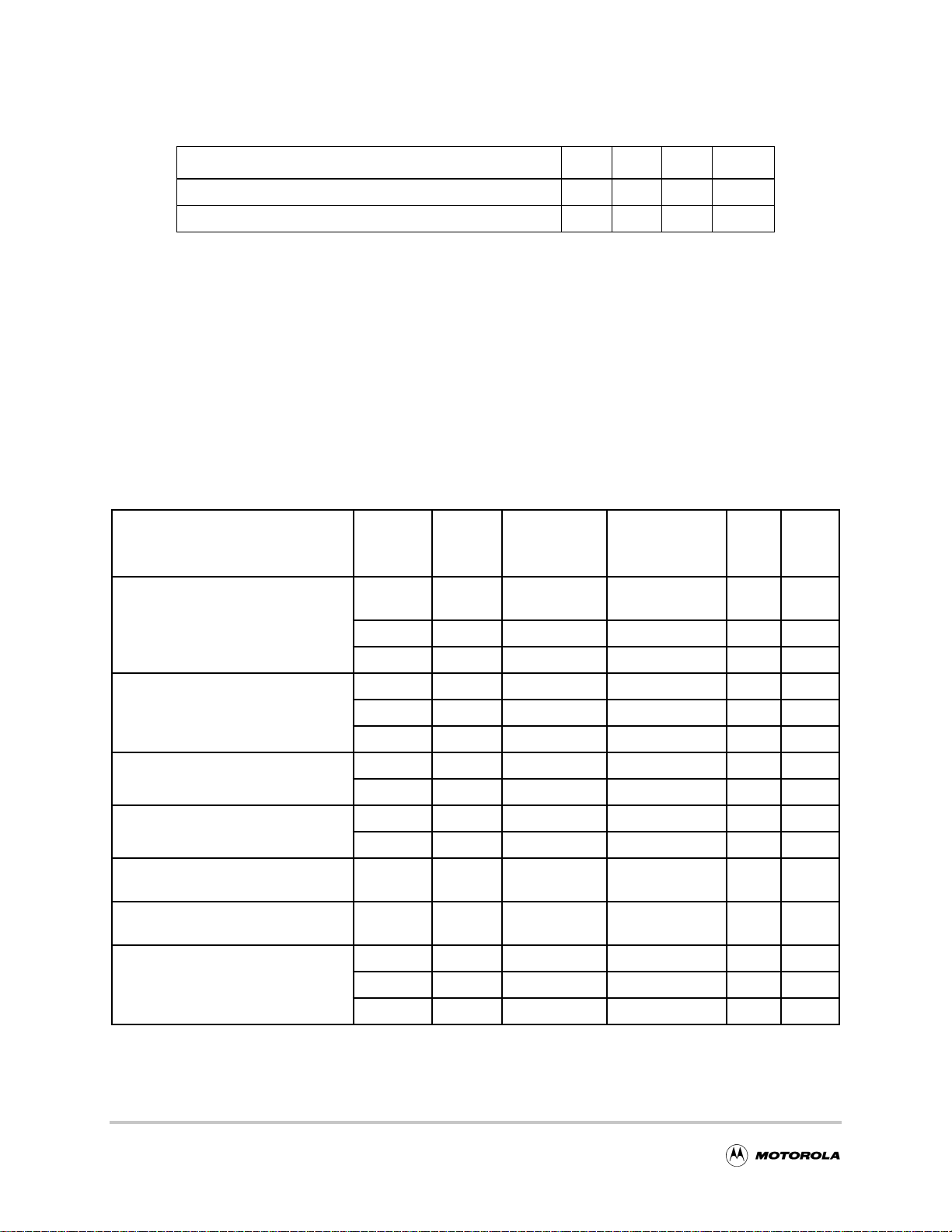

Table 7 provides the power consumption for the MPC7400.

Table 7. Power Consumption for MPC7400

Processor (CPU) Frequency

Unit Notes

350 MHz 400 MHz

Full-On Mode

Typical

Maximum

Doze Mode

Maximum 4.4 5.0 W 1, 2

Nap Mode

Maximum 1.75 2.0 W 1, 2

Sleep Mode

Maximum 1.75 2.0 W 1, 2

Sleep Mode—PLL and DLL Disabled

Typical 600 600 mW 1, 3

Maximum 1.0 1.0 W 1, 2

Notes:

1. These values apply for all valid processor bus and L2 bus ratios. The values do not include

I/O Supply Power (OVdd and L2OVdd) or PLL/DLL supply power (AVdd and

L2AVdd). OVdd and L2OVdd power is system dependent, but is typically <10% of Vdd

power. Worst case power consumption for AVdd = 15 mw and L2AVdd = 15 mW.

2. Maximum power is measured at Vdd = 1.9V while running an entirely cache-resident,

contrived sequence of instructions which keep the execution units, including AltiVec,

maximally busy.

3. Typical power is an average value measured at Vdd = AVdd = L2AVdd = 1.8V, OVdd =

L2OVdd = 3.3V in a system while running a codec application that is AltiVec intensive.

4. These values include the use of AltiVec. Without AltiVec operation, estimate a 25%

decrease.

4.6 5.3 W 1, 3

9.9 11.3 W 1, 2, 4

1.4.2 AC Electrical Characteristics

This section provides the AC electrical characteristics for the MPC7400. After fabrication, functional parts

are sorted by maximum processor core frequency as shown in Section 1.4.2.1, “Clock AC Specifications,”

and tested for conformance to the AC specifications for that frequency. The processor core frequency is

determined by the bus (SYSCLK) frequency and the settings of the PLL_CFG[0–3] signals. Parts are sold

by maximum processor core frequency; see Section 1.10, “Ordering Information.”

12

MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 13

Electrical and Thermal Characteristics

1.4.2.1 Clock AC Specifications

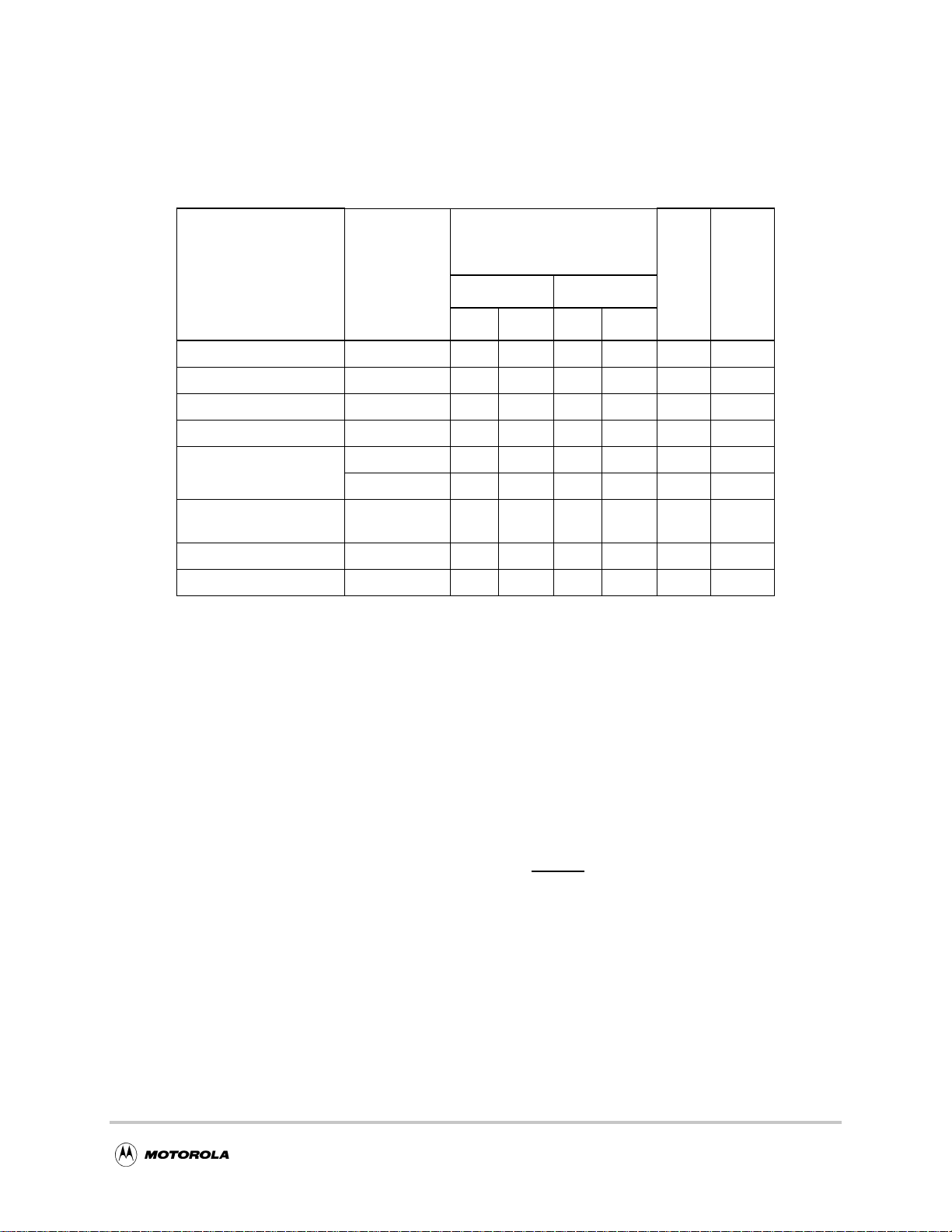

Table 8 provides the clock AC timing specifications as defined in Figure 3.

Table 8. Clock AC Timing Specifications

At recommended operating conditions (See Table 3)

Maximum Processor Core

Frequency

Characteristic Symbol

350 MHz 400 MHz

Min Max Min Max

Processor frequency f

VCO frequency f

SYSCLK frequency f

SYSCLK cycle time t

SYSCLK rise and fall time t

SYSCLK duty cycle

core

VCO

SYSCLK

SYSCLK

&

KR

&

t

KR

t

KHKL

t

KF

t

KF

/t

SYSCLK

measured at OVdd/2

SYSCLK jitter — ±150 — ±150 ps 5

300 350 300 400 MHz 1

600 700 600 800 MHz 1

25 100 25 100 MHz 1

10 40 7.5 40 ns

— 1.0 — 1.0 ns 2

— 0.5 — 0.5 ns 3

40 60 40 60 % 4

Unit Notes

Internal PLL relock time — 100 — 100

µ

s6

Notes:

1. Caution: The SYSCLK frequency and PLL_CFG[0–3] settings must be chosen such that the

resulting SYSCLK (bus) frequency, CPU (core) frequency, and PLL (VCO) frequency do not

exceed their respective maximum or minimum operating frequencies. Refer to the PLL_CFG[0–

3] signal description in Section 1.8.1, “PLL Configuration,” for valid PLL_CFG[0–3] settings

2. Rise and fall times for the SYSCLK input measured from 0.4V to 2.4V when OVdd = 3.3V

nominal.

3. Rise and fall times for the SYSCLK input measured from 0.4V to 1.4V when OVdd = 1.8V

nominal.

4. Timing is guaranteed by design and characterization.

5. This represents total input jitter—short term and long term combined—and is guaranteed by

design.

6. Relock timing is guaranteed by design and characterization. PLL-relock time is the maximum

amount of time required for PLL lock after a stable Vdd and SYSCLK are reached during the

power-on reset sequence. This specification also applies when the PLL has been disabled and

subsequently re-enabled during sleep mode. Also note that HRESET

must be held asserted for a

minimum of 255 bus clocks after the PLL-relock time during the power-on reset sequence.

MPC7400 RISC Microprocessor Hardware Specifications

13

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 14

Electrical and Thermal Characteristics

Figure 3 provides the SYSCLK input timing diagram.

CV

SYSCLK VMVMVM

t

KHKL

t

SYSCLK

CV

IL

IH

t

KR

t

KF

VM = Midpoint Voltage (OVDD/2)

Figure 3. SYSCLK Input Timing Diagram

1.4.2.2 Processor Bus AC Specifications

Table 9 provides the processor bus AC timing specifications for the MPC7400 as defined in Figure 4 and

Figure 5. Timing specifications for the L2 bus are provided in Section 1.4.2.3, “L2 Clock AC

Specifications.”y

Table 9. Processor Bus AC Timing Specifications

1

At Vdd=AVdd=1.8V±100mV; 0 ≤ Tj ≤ 105°C, OVdd = 3.3V±165mV or OVdd = 2.5V±100mV or OVdd=1.8V±100mV

350, 400 MHz

Unit Notes

Parameter Symbol

2

Min Max

Mode select input setup to HRESET

HRESET

to mode select input hold t

Setup Times:

Input Hold Times:

Valid Times:

Address/Transfer Attribute

Transfer Start (TS

Data/Data Parity

TRY/SHD0/SHD1

AR

All Other Inputs

Address/Transfer Attribute

Transfer Start (TS

Data/Data Parity

TRY/SHD0/SHD1

AR

All Other Inputs

Address/Transfer Attribute

, ABB, DBB

TS

Data

Data Parity

TRY/SHD0/SHD1

AR

All Other Outputs

t

MVRH

MXRH

t

AVKH

t

)

)

TSVKH

t

DVKH

t

ARVKH

t

IVKH

t

AXKH

t

TSXKH

t

DXKH

t

ARXKH

t

IXKH

t

KHAV

t

KHTSV

t

KHDV

t

KHDPV

t

KHARV

t

KHOV

8—t

sysclk

3,4,5,6

0 — ns 2,3,5

ns

1.6

1.6

1.6

1.6

1.6

—

—

—

—

—

7

—

8

—

9

ns

0

0

0

0

0

—

—

—

—

—

7

—

8

—

9

ns

—

—

—

—

—

—

3.2

3.4

3.5

3.5

2.5

3.2

7

—

8

8

—

10

14

MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 15

Electrical and Thermal Characteristics

Table 9. Processor Bus AC Timing Specifications1 (Continued)

At Vdd=AVdd=1.8V±100mV; 0 ≤ Tj ≤ 105°C, OVdd = 3.3V±165mV or OVdd = 2.5V±100mV or OVdd=1.8V±100mV

Parameter Symbol

Output Hold Times:

Address/Transfer Attribute

, ABB, DBB

TS

Data/Data Parity

TRY/SHD0/SHD1

AR

All Other Outputs

SYSCLK to Output Enable t

SYSCLK to Output High Impedance (all except TS

, ABB/

AMON(0), ARTRY/SHD, DBB/DMON(0) )

SYSCLK to TS

, ABB/AMON(0), DBB/DMON(0) High

Impedance after precharge

Maximum Delay to AR

SYSCLK to AR

TRY/SHD0/SHD1 Precharge t

TRY/SHD0/SHD1 High Impedance After

Precharge

t

KHAX

t

KHTSX

t

KHDX

t

KHARX

t

KHOX

KHOE

t

KHOZ

t

KHABPZ

KHARP

t

KHARPZ

2

350, 400 MHz

Min Max

0.75

0.75

0.6

0.75

0.75

—

—

—

—

—

0.5 — ns

— 4.0 ns

— 1.0 t

—1 t

—2 t

Unit Notes

ns

7

—

8

—

10

sysclk

sysclk

sysclk

5,11,13

5,12, 13

5,12, 13

MPC7400 RISC Microprocessor Hardware Specifications 15

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 16

Electrical and Thermal Characteristics

Table 9. Processor Bus AC Timing Specifications1 (Continued)

At Vdd=AVdd=1.8V±100mV; 0 ≤ Tj ≤ 105°C, OVdd = 3.3V±165mV or OVdd = 2.5V±100mV or OVdd=1.8V±100mV

350, 400 MHz

Unit Notes

Parameter Symbol

2

Min Max

Notes:

1. All input specifications are measured from the midpoint of the signal in question to the midpoint of the rising edge of the

input SYSCLK. All output specifications are measured from the midpoint of the rising edge of SYSCLK to the

midpoint of the signal in question. All output timings assume a purely resistive 50 ohm load (See Figure 4). Input and

output timings are measured at the pin;time-of-flight delays must be added for trace lengths, vias, and connectors in the

system.

2. The symbology used for timing specifications herein follows the pattern of t

t

(reference)(state)(signal)(state)

for outputs. For example, t

symbolizes the time input signals (I) reach the valid state (V)

IVKH

(signal)(state)(reference)(state)

relative to the SYSCLK reference (K) going to the high(H) state or input setup time. And t

KHOV

for inputs and

symbolizes the time

from SYSCLK(K) going high(H) until outputs (O) are valid (V) or output valid time. Input hold time can be read as the

time that the input signal (I) went invalid (X) with respect to the rising clock edge (KH) - note the position of the

reference and its state for inputs -and output hold time can be read as the time from the rising edge (KH) until the output

went invalid (OX). For additional explanation of AC timing specifications in Motorola PowerPC microprocessors, see

the application note “Understanding AC Timing Specifications for PowerPC Microprocessors.”

3. The setup and hold time is with respect to the rising edge of HRESET

4. This specification is for configuration mode select only. Also note that the HRESET

(see Figure 5).

must be held asserted for a

minimum of 255 bus clocks after the PLL re-lock time during the power-on reset sequence.

5. t

is the period of the external clock (SYSCLK) in nanoseconds (ns). The numbers given in the table must be

sysclk

multiplied by the period of SYSCLK to compute the actual time duration (in nanoseconds) of the parameter in question.

6. Mode select signals are BVSEL, EMODE, L2VSEL, PLL_CFG[0-3]

7. Address/Transfer Attribute signals are composed of the following—A[0–31], AP[0–3], TT[0–4], TBST

GBL

, WT , CI

, TSIZ[0–2],

8. Data signals are composed of the following—DH[0–31], DL[0–31]; Data Parity signals are composed of DP[0–7].

9. All other input signals are composed of the following— AACK

HRESET

, INT, MCP, QACK, SMI, SRESET, TA, TBEN, TEA, TLBISYNC.

10. All other output signals are composed of the following— BR

, BG, CKSTP_IN, DBG, DBWO/DTI[0], DTI[1-2],

, CKSTP_OUT, DRDY, HIT, QREQ, RSRV

11. According to the 60x bus protocol, TS, ABB and DBB are driven only by the currently active bus master. They are

asserted low then precharged high before returning to high-Z as shown in Figure 6. The nominal precharge width for

TS

, ABB or DBB is 0.5* t

TS

, ABB, or DBB on the following clock will not contend with the precharge. Output valid and output hold timing is

, i.e. less than the minimum t

SYSCLK

period, to ensure that another master asserting

SYSCLK

tested for the signal asserted. Output valid time is tested for precharge.The high-Z behavior is guaranteed by design.

12. According to the 60x bus protocol, AR

immediately following AACK

. Bus contention is not an issue since any master asserting ARTRY will be driving it low.

Any master asserting it low in the first clock following AACK

it high during the second cycle after the assertion of AACK

it should be high-Z as shown in Figure 6 before the first opportunity for another master to assert AR

TRY can be driven by multiple bus masters through the clock period

will then go to high-Z for one clock before precharging

. The nominal precharge width for ARTRY is 1.0 t

TRY. Output valid

sysclk

; i.e.

and output hold timing is tested for the signal asserted. Output valid time is tested for precharge.The high-Z behavior is

guaranteed by design.

13. Guaranteed by design and not tested.

16 MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 17

Electrical and Thermal Characteristics

Figure 4 provides the AC test load for the MPC7400.

OUTPUT

Z0 = 50Ω

RL = 50Ω

Figure 4. AC Test Load

Figure 5 provides the mode select input timing diagram for the MPC7400.

HRESET

MODE SIGNALS

t

MVRH

VM = Midpoint Voltage (OVDD/2)

Figure 5. Mode Input Timing Diagram

VM

t

MXRH

OVdd/2

MPC7400 RISC Microprocessor Hardware Specifications 17

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 18

Figure 6 provides the input/output timing diagram for the MPC7400.

Electrical and Thermal Characteristics

SYSCLK

ALL INPUTS

ALL OUTPUTS

(Except TS, ABB,

ARTRY, DBB)

ALL OUTPUTS

(Except TS, ABB,

ARTRY, DBB)

TS,

/AMON(0),

ABB

DBB

/DMON(0)

ARTRY,

SHD0,

SHD1

t

KHOE

VM

VM

t

AVKH

t

TSVKH

t

DVKH

t

ARVKH

t

IVKH

t

t

t

t

KHAV

KHDV

KHDPV

KHOV

t

KHTSV

t

t

t

t

t

t

t

t

KHTSV

t

KHARV

VM = Midpoint Voltage (OVDD/2)

AXKH

t

TSXKH

t

DXKH

ARXKH

IXKH

KHAX

KHDX

KHOX

t

KHOZ

t

KHABPZ

KHTSX

t

t

KHARP

t

KHARX

KHARV

VM

t

KHARPZ

Figure 6. Input/Output Timing Diagram

1.4.2.3 L2 Clock AC Specifications

The L2CLK frequency is programmed by the L2 Configuration Register (L2CR[4:6]) core-to-L2 divisor

ratio. See T able 15 for example core and L2 frequencies at various divisors. Table 10 provides the potential

range of L2CLK output AC timing specifications as defined in Figure 7.

The L2SYNC_OUT signal is intended to be routed halfway out to the SRAMs and then returned to the

L2SYNC_IN input of the MPC7400 to synchronize L2CLKOUT at the SRAM with the processor’s internal

clock. L2CLKOUT at the SRAM can be offset forward or backward in time by shortening or lengthening

the routing of L2SYNC_OUT to L2SYNC_IN. See Motorola Application Note AN179/D “PowerPC™

Backside L2 Timing Analysis for the PCB Design Engineer.”

18 MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 19

Electrical and Thermal Characteristics

The minimum L2CLK frequency of Table 10 is specified by the maximum delay of the internal DLL. The

variable-tap DLL introduces up to a full clock period delay in the L2CLKOUTA, L2CLKOUTB, and

L2SYNC_OUT signals so that the returning L2SYNC_IN signal is phase aligned with the next core clock

(divided by the L2 divisor ratio). Do not choose a core-to-L2 divisor which results in an L2 frequency below

this minimum, or the L2CLKOUT signals provided for SRAM clocking will not be phase aligned with the

MPC7400 core clock at the SRAMs.

The maximum L2CLK frequency shown in Table 10 is the core frequency divided by one. Very few L2

SRAM designs will be able to operate in this mode. Most designs will select a greater core-to-L2 divisor to

provide a longer L2CLK period for read and write access to the L2 SRAMs. The maximum L2CLK

frequency for any application of the MPC7400 will be a function of the AC timings of the MPC7400, the

AC timings for the SRAM, bus loading, and printed circuit board trace length.

Motorola is similarly limited by system constraints and cannot perform tests of the L2 interface on a

socketed part on a functional tester at the maximum frequencies of T able 10. Therefore functional operation

and AC timing information are tested at core-to-L2 divisors of 2 or greater.

L2 input and output signals are latched or enabled respectively by the internal L2CLK (which is SYSCLK

multiplied up to the core frequency and divided down to the L2CLK frequency). In other words, the AC

timings of T able 11 are entirely independent of L2SYNC_IN. In a closed loop system, where L2SYNC_IN

is driven through the board trace by L2SYNC_OUT, L2SYNC_IN only controls the output phase of

L2CLKOUTA and L2CLKOUTB which are used to latch or enable data at the SRAMs. However, since in

a closed loop system L2SYNC_IN is held in phase alignment with the internal L2CLK, the signals of T able

11 are referenced to this signal rather than the not-externally-visible internal L2CLK. During manufacturing

test, these times are actually measured relative to SYSCLK.

Table 10. L2CLK Output AC Timing Specifications

At recommended operating conditions (See Table 3)

350 MHz 400 MHz

Parameter Symbol

Min Max Min Max

L2CLK frequency f

L2CLK cycle time t

L2CLK duty cycle t

Internal DLL-relock time 640 — 640 — L2CLK 3

DLL capture window 0 10 0 10 ns 5

L2CLKOUT output-to-

output skew

L2CLKOUT output jitter ±150 ±150 ps 6

Notes:

1. L2CLK outputs are L2CLK_OUTA, L2CLK_OUTB, and L2SYNC_OUT pins. The L2CLK frequency to core frequency

settings must be chosen such that the resulting L2CLK frequency and core frequency do not exceed their respective

maximum or minimum operating frequencies. The maximum L2LCK frequency will be system dependent..

L2CLK_OUTA and L2CLK_OUTB must have equal loading.

2. The nominal duty cycle of the L2CLK is 50% measured at midpoint voltage.

3. The DLL re-lock time is specified in terms of L2CLKs. The number in the table must be multiplied by the period of

L2CLK to compute the actual time duration in nanoseconds. Re-lock timing is guaranteed by design and characterization.

4. The L2CR[L2SL] bit should be set for L2CLK frequencies less than 110 MHz. This adds more delay to each tap of the

DLL.

L2CLK

L2CLK

CHCL/tL2CLK

t

L2CSKW

100 350 133 400 MHz 1,4

2.86 10 2.5 7.5 ns

50 50 % 2

50 50 ps 6

Unit Notes

MPC7400 RISC Microprocessor Hardware Specifications 19

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 20

Electrical and Thermal Characteristics

5. Allowable skew between L2SYNC_OUT and L2SYNC_IN.

6. Guaranteed by design and not tested. This output jitter number represents the maximum delay of one tap forward or one tap

back from the current DLL tap as the phase comparator seeks to minimize the phase difference between L2SYNC_IN and

the internal L2CLK. This number must be comprehended in the L2 timing analysis. The input jitter on SYSCLK affects

L2CLKOUT and the L2 address/data/control signals equally and therefore is already comprehended in the AC timing and

does not have to be considered in the L2 timing analysis.

The L2CLK_OUT timing diagram is shown in Figure 7.

L2 Single-Ended Clock Mode

L2CLK_OUTA

VM

t

CHCL

t

L2CLK

VM

VM

t

L2CR

t

L2CF

L2CLK_OUTB

L2SYNC_OUT

VM

VM

VM

VM

VMVM

t

L2CSKW

VM

VM

L2 Differential Clock Mode

t

L2CLK

t

L2CLK_OUTB

L2CLK_OUTA

L2SYNC_OUT

CHCL

VM VM VM

VM VM VM

VM = Midpoint Voltage (L2OVdd/2)

Figure 7. L2CLK_OUT Output Timing Diagram

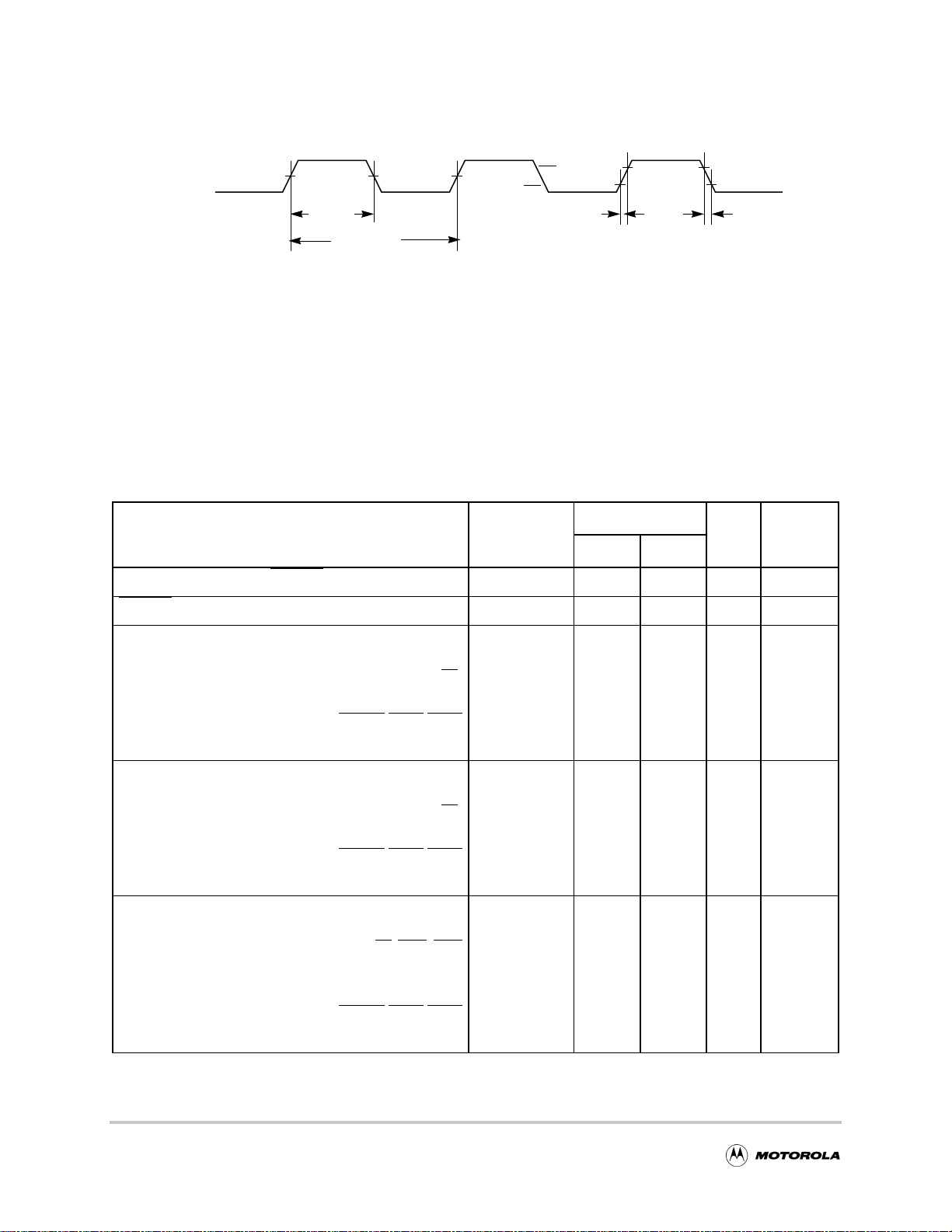

1.4.2.4 L2 Bus AC Specifications

T able 1 1 provides the L2 bus interface AC timing specifications for the MPC7400 as defined in Figure 8 and

Figure 9 for the loading conditions described in Figure 10.

Table 11. L2 Bus Interface AC Timing Specifications

At Vdd=AVdd=L2AVdd=1.8V±100mV; 0 ≤ Tj ≤ 105°C, L2OVdd = 3.3V±165mV or L2OVdd = 2.5V±100mV or L2OVdd=1.8V±100mV

350, 400 MHz

Parameter Symbol

Unit Notes

Min Max

L2SYNC_IN rise and fall time t

Setup Times:

Data and parity t

Input Hold Times:

Data and parity t

& t

L2CR

DVL2CH

DXL2CH

L2CF

— 1.0 ns 1

ns 2

1.5 —

ns 2

0.0 —

20 MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 21

Electrical and Thermal Characteristics

Table 11. L2 Bus Interface AC Timing Specifications (Continued)

At Vdd=AVdd=L2AVdd=1.8V±100mV; 0 ≤ Tj ≤ 105°C, L2OVdd = 3.3V±165mV or L2OVdd = 2.5V±100mV or L2OVdd=1.8V±100mV

Parameter Symbol

Unit Notes

Min Max

350, 400 MHz

Valid Times:

All outputs when L2CR[14-15] = 00

All outputs when L2CR[14-15] = 01

All outputs when L2CR[14-15] = 10

t

L2CHOV

2.5

-

3.0

-

3.5

-

4.0

-

ns 3,4

All outputs when L2CR[14-15] = 11

Output Hold Times

All outputs when L2CR[14-15] = 00

All outputs when L2CR[14-15] = 01

All outputs when L2CR[14-15] = 10

t

L2CHOX

0.4

1.0

1.4

1.8

ns 3

-

-

-

-

All outputs when L2CR[14-15] = 11

L2SYNC_IN to high impedance:

All outputs when L2CR[14-15] = 00

All outputs when L2CR[14-15] = 01

All outputs when L2CR[14-15] = 10

t

L2CHOZ

2.0

-

2.5

-

3.0

-

3.5

-

ns

All outputs when L2CR[14-15] = 11

Notes:

1. Rise and fall times for the L2SYNC_IN input are measured from 20% to 80% of L2OVdd.

2. All input specifications are measured from the midpoint of the signal in question to the

midpoint voltage of the rising edge of the input L2SYNC_IN (see Figure 8). Input timings

are measured at the pins.

3. All output specifications are measured from the midpoint voltage of the rising edge of

L2SYNC_IN to the midpoint of the signal in question. The output timings are measured at

the pins. All output timings assume a purely resistive 50 ohm load (See Figure 10).

4.The outputs are valid for both single-ended and differential L2CLK modes. For pipelined

registered synchronous burst RAMs, L2CR[14–15] = 00 is recommended. For pipelined

late-write synchronous burst SRAMs, L2CR[14–15] = 10 is recommended.

Figure 8 shows the L2 bus input timing diagrams for the MPC7400.

t

L2CR

L2SYNC_IN

L2 DATA AND DATA

PARITY INPUTS

t

DVL2CH

VM = Midpoint Voltage (L2OVDD/2)

Figure 8. L2 Bus Input Timing Diagrams

MPC7400 RISC Microprocessor Hardware Specifications 21

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

VM

t

DXL2CH

t

L2CF

Page 22

Figure 9 shows the L2 bus output timing diagrams for the MPC7400.

Electrical and Thermal Characteristics

L2SYNC_IN

ALL OUTPUTS

L2DATA BUS

VM

t

L2CHOV

VM = Midpoint Voltage (L2OVDD/2)

VM

t

L2CHOX

t

L2CHOZ

Figure 9. L2 Bus Output Timing Diagrams

Figure 10 provides the AC test load for L2 interface of the MPC7400.

OUTPUT

Z0 = 50Ω

R

= 50Ω

L

Figure 10. AC Test Load for the L2 Interface

L2OVdd/2

1.4.2.5 IEEE 1149.1 AC Timing Specifications

Table 12 provides the IEEE 1149.1 (JTAG) AC timing specifications as defined in Figure 12, Figure 13,

Figure 14, and Figure 15.

Table 12. JTAG AC Timing Specifications (Independent of SYSCLK)1

At recommended operating conditions (See Table 3)

Parameter Symbol Min Max Unit Notes

TCK frequency of operation f

TCK cycle time t

TCK clock pulse width measured at 1.4V t

TCK rise and fall times t

TRST assert time t

Input Setup Times:

Boundary-scan data

TMS, TDI

Input Hold Times:

Boundary-scan data

TMS, TDI

TCLK

TCLK

JHJL

JR

TRST

t

DVJH

t

IVJH

t

DXJH

t

IXJH

& t

JF

0 33.3 MHz

30—ns

15—ns

02ns

25—ns 2

ns

4

0

20

25

—

—

ns

—

—

3

3

22 MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 23

Electrical and Thermal Characteristics

Table 12. JTAG AC Timing Specifications (Independent of SYSCLK)1 (Continued)

At recommended operating conditions (See Table 3)

Parameter Symbol Min Max Unit Notes

Valid Times:

Boundary-scan data

TDO

t

JLDV

t

JLOV

4

4

20

25

ns

Output Hold Times:

Boundary-scan data

TCK to output high impedance:

Boundary-scan data

TDO

TDO

t

JLDX

t

JLOX

t

JLDZ

t

JLOZ

ns

3

3

19

9

Notes:

1. All outputs are measured from the midpoint voltage of the falling/rising edge of TCLK to the midpoint of the signal

in question. The output timings are measured at the pins. All output timings assume a purely resistive 50 ohm load

(See Figure 11). Time-of-flight delays must be added for trace lengths, vias, and connectors in the system.

2.

TRST is an asynchronous level sensitive signal. The setup time is for test purposes only.

3. Non-JTAG signal input timing with respect to TCK.

4. Non-JTAG signal output timing with respect to TCK.

5. Guaranteed by design and characterization.

Figure 11 provides the AC test load for TDO and the boundary-scan outputs of the MPC7400.

OUTPUT

Z0 = 50Ω

R

L

= 50Ω

OVdd/2

4

4,5

5

Figure 11. Alternate AC Test Load for the JTAG Interface

Figure 12 provides the JTAG clock input timing diagram.

TCLK VMVMVM

t

JHJL

t

TCLK

VM = Midpoint Voltage (OVDD/2)

Figure 12. JTAG Clock Input Timing Diagram

MPC7400 RISC Microprocessor Hardware Specifications 23

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

t

JR

t

JF

Page 24

Figure 13 provides the TRST timing diagram.

Electrical and Thermal Characteristics

TRST

VM VM

t

TRST

VM = Midpoint Voltage (OVDD/2)

Figure 13. TRST Timing Diagram

Figure 14 provides the boundary-scan timing diagram.

TCK

BOUNDARY

DATA INPUTS

BOUNDARY

DATA OUTPUTS

BOUNDARY

DATA OUTPUTS

VM

t

JLDX

t

OUTPUT DATA VALID

t

JLDV

JLDZ

t

DVJH

VM

INPUT

DATA VALID

OUTPUT DATA VALID

t

DXJH

VM = Midpoint Voltage (OVDD/2)

Figure 14. Boundary-Scan Timing Diagram

Figure 15 provides the test access port timing diagram.

TCK

TDI, TMS

TDO

TDO

VM

t

JLOX

t

JLOZ

OUTPUT DATA VALID

VM

= Midpoint Voltage (OVDD/2)

t

JLOV

t

IVJH

VM

INPUT

DATA VALID

OUTPUT DATA VALID

t

IXJH

Figure 15. Test Access Port Timing Diagram

24 MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 25

Pin Assignments

1.5 Pin Assignments

Figure 16 (in part A) shows the pinout of the MPC7400, 360 CBGA package as viewed from the top surface.

Part B shows the side profile of the CBGA package to indicate the direction of the top surface view.

Part A

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

17 18 19

Part B

U

V

W

Not to Scale

Substrate Assembly

Encapsulant

Figure 16. Pinout of the MPC7400, 360 CBGA Package as Viewed from the Top Surface

MPC7400 RISC Microprocessor Hardware Specifications 25

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

View

Die

Page 26

1.6 Pinout Listings

Table 13 provides the pinout listing for the MPC7400, 360 CBGA package.

Table 13. Pinout Listing for the MPC7400, 360 CBGA Package

Pinout Listings

I/F Voltages Supported

Signal Name Pin Number Active I/O 1.8v 2.5v 3.3v Notes

A[0–31] A13, D2, H11, C1, B13, F2, C13, E5,

D13, G7, F12, G3, G6, H2, E2, L3,

G5, L4, G4, J4, H7, E1, G2, F3, J7,

M3, H3, J2, J6, K3, K2, L2

AACK

ABB

AMON(0)

AP[0–3] C4, C5, C6, C7 High I/O √√ √

AR

TRY L6 Low I/O √√ √

AVDD A8 — Input 1.8V 1.8V 1.8V

BG

BR

BVSEL W1 High Input GND HRESET

CHK

CI

CKSTP_IN

CKSTP_OUT

CLK_OUT E3 High Output √√ √

DBB

DMON(0)

DBG

DH[0–31] W12, W11, V11, T9, W10, U9, U10,

DL[0-31] M6, P3, N4, N5, R3, M7, T2, N6, U2,

N3 Low Input √√ √

L7 Low Output √√ √12

H1 Low Input √√ √

E7 Low Output √√ √

K11 Low Input √√ √4, 8, 9

C2 Low I/O √√ √

B8 Low Input √√ √

D7 Low Output √√ √

K5 Low Output √√ √12

K1 Low Input √√ √

M11, M9, P8, W7, P9, W9, R10, W6,

V7, V6, U8, V9, T7, U7, R7, U6, W5,

U5, W4, P7, V5, V4, W3, U4, R5

N7, P11, V13, U12, P12, T13, W13,

U13, V10, W8, T11, U11, V12, V8,

T1, P1, V1, U1, N1, R2, V3, U3, W2

High I/O √√ √

High I/O √√ √

High I/O √√ √

1

3.3V 3, 8, 9

DP[0–7] L1, P2, M2, V2, M1, N2, T3, R1 High I/O √√ √

DRDY

DBWO

DTI[0]

DTI[1-2] H6, G1 High Input √√ √10, 13

EMODE

K9 Low Output √√ √6, 8, 13

D1 Low Input √√ √

A3 Low Input √√ √7, 10

26 MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 27

Pinout Listings

Table 13. Pinout Listing for the MPC7400, 360 CBGA Package (Continued)

I/F Voltages Supported

Signal Name Pin Number Active I/O 1.8v 2.5v 3.3v Notes

GBL B1 Low I/O √√ √

GND D10, D14, D16, D4, D6, E12, E8, F4,

F6, F10, F14, F16, G9, G11, H5, H8,

H10, H12, H15, J9, J11, K4, K6, K8,

K10, K12, K14, K16, L9, L11, M5,

M8, M10, M12, M15, N9, N11, P4,

P6, P10, P14, P16, R8, R12, T4, T6,

T10, T14, T16

HIT

HRESET

INT

L1_TSTCLK F8 High Input √√ √2

L2ADDR[0–16] L17, L18, L19, M19, K18, K17, K15,

L2ADDR[17] K19 High Output √√ √8

L2ASPARE W19 High Output √√ √ 8

L2AVDD L13 — Input 1.8V 1.8V 1.8V

L2CE

L2CLKOUTA N15 High Output √√ √

B5 Low Output √√ √6, 8

B6 Low Input √√ √

C11 Low Input √√ √

J19, J18, J17, J16, H18, H17, J14,

J13, H19, G18

P17 Low Output √√ √

— — GND GND GND

High Output √√ √

1

L2CLKOUTB L16 High Output √√ √

L2DATA[0–63] U14, R13, W14, W15, V15, U15,

W16, V16, W17, V17, U17, W18,

V18, U18, V19, U19, T18, T17, R19,

R18, R17, R15, P19, P18, P13, N14,

N13, N19, N17, M17, M13, M18,

H13, G19, G16, G15, G14, G13, F19,

F18, F13, E19, E18, E17, E15, D19,

D18, D17, C18, C17, B19, B18, B17,

A18, A17, A16, B16, C16, A14, A15,

C15, B14, C14, E13

L2DP[0–7] V14, U16, T19, N18, H14, F17, C19,

B15

L2OVDD D15, E14, E16, H16, J15, L15, M16,

K13, P15, R14, R16, T15, F15

L2SYNC_IN L14 High Input √√ √

L2SYNC_OUT M14 High Output √√ √

L2_TSTCLK F7 High Input √√ √2

L2VSEL A19 High Input GND HRESET

L2WE

L2ZZ G17 High Output √√ √

N16 Low Output √√ √

High I/O √√ √

High I/O √√ √

— — 1.8V 2.5V 3.3V 11

3.3V 1, 3, 8, 9

MPC7400 RISC Microprocessor Hardware Specifications 27

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 28

Table 13. Pinout Listing for the MPC7400, 360 CBGA Package (Continued)

Pinout Listings

I/F Voltages Supported

Signal Name Pin Number Active I/O 1.8v 2.5v 3.3v Notes

LSSD_MODE

MCP

OVDD D5, D8, D12, E4, E6, E9, E11, F5,

PLL_CFG[0–3] A4, A5, A6, A7 High Input √√ √

QACK

QREQ

V D3 Low Output √√ √

RSR

SHD0

SHD1

SMI

SRESET

SYSCLK H9 — Input √√ √

A F1 Low Input √√ √

T

TBEN A2 High Input √√ √

TBST

TCK B10 High Input √√ √

F9 Low Input √√ √2

B11 Low Input √√ √

— — 1.8V 2.5V 3.3V

H4, J5, L5, M4, P5, R4, R6, R9, R11,

T5, T8, T12

B2 Low Input √√ √

J3 Low Output √√ √

B3 Low I/O √√ √8

B4 Low I/O √√ √5, 8

A12 Low Input √√ √

E10 Low Input √√ √

A11 Low Output √√ √

1

TDI B7 High Input √√ √9

TDO D9 High Output √√ √

TEA

TMS C8 High Input √√ √9

TRST

TS

TSIZ[0–2] A9, B9, C9 High Output √√ √

TT[0–4] C10, D11, B12, C12, F11 High I/O √√ √

WT

VDD G8, G10, G12, J8, J10, J12, L8, L10,

Notes:

1. OVdd supplies power to the processor bus, JT AG, and all control signals except the L2 cache controls (L2CE

L2ZZ

); L2OVDD supplies power to the L2 cache interface (L2ADDR[0-16], L2ASPARE, L2DATA[0-63], L2DP[0-7]

and L2SYNC-OUT) and the L2 control signals; and Vdd supplies power to the processor core and the PLL and DLL (after

filtering to become AVDD and L2AVDD respectively). These columns serve as a reference for the nominal voltage

supported on a given signal as selected by the BVSEL/L2VSEL pin configurations of Table 2 and the voltage supplied.

For actual recommended value of Vin or supply voltages see Table 3.

2. These are test signals for factory use only and must be pulled up to OVdd for normal machine operation.

J1 Low Input √√ √

A10 Low Input √√ √9

K7 Low I/O √√ √

C3 Low I/O √√ √

— — 1.8V 1.8V 1.8V

L12, N8, N10, N12

, L2WE, and

28 MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 29

Package Description

3. To allow for future I/O voltage changes, provide the option to connect BVSEL and L2VSEL independently to either

OVDD (selects 3.3v), OGND (selects 1.8v), or to HRESET

options. (See Table 2. Input Threshold Voltage Setting)

4. Connect to HRESET

5. Ignored in 60x bus mode.

6. Unused output in 60x bus mode.

7. Deasserted (pulled high) at HRESET

8. Uses one of 9 existing no-connects in MPC750’s 360-BGA package.

9. Internal pull up on die.

10. Reuses MPC750’s DR

11. The VOLTDET pin position on the MPC750 360-CBGA package is now an L2OVDD pin on the MPC7400 360-CBGA

package.

12. Output only for MPC7400, was I/O for MPC750.

13. Enhanced mode only.

to trigger post power-on-reset (por) internal memory test.

for 60x bus mode.

TRY, DBDIS, and TLBISYNC pins (DTI1, DTI2, and EMODE respectively).

(selects 2.5v). The Processor bus and L2 bus support all 3

1.7 Package Description

The following sections provide the package parameters and mechanical dimensions for the MPC7400, 360

CBGA packages.

1.7.1 Package Parameters for the MPC7400

The package parameters are as provided in the following list. The package type is 25 x 25 mm, 360-lead

ceramic ball grid array (CBGA).

Package outline 25 x 25 mm

Interconnects 360 (19 x 19 ball array - 1)

Pitch 1.27 mm (50 mil)

Minimum module height 2.65 mm

Maximum module height 3.20 mm

Ball diameter 0.89 mm (35 mil)

MPC7400 RISC Microprocessor Hardware Specifications 29

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 30

Package Description

1.7.2 Mechanical Dimensions of the MPC7400

Figure 17 provides the mechanical dimensions and bottom surface nomenclature of the MPC7400, 360

CBGA package.

A1 CORNER

E2

E

2X

B

e

0.2

D

D2

D3

C5-1

C5-2

C4-1

C4-2

E3

12X

12X

J3

J1

C3-1

C3-2

12345678910111213141516

255X

0.15

2X

0.2

A

C6-2

C6-1

K2

K1

C1-1

C1-2

L2

C2-2

C2-1

12X

J2

L1

T

R

P

N

M

L

K

J

H

G

F

E

D

C

B

A

0.2 C

M

A3

A4

A

b

BC

A0.3

C

NOTES:

1. DIMENSIONING AND TOLERANCING

PER ASME Y14.5M, 1994.

2. DIMENSIONS IN MILLIMETERS.

3. TOP SIDE A1 CORNER INDEX IS A

C

METALIZED FEATURE WITH

VARIOUS SHAPES. BOTTOM SIDE A1

CORNER IS DESIGNATED WITH A

BALL MISSING FROM THE ARRAY.

Millimeters

DIM MIN MAX

A 2.65 3.20

A1 0.79 0.99

A2 1.10 1.30

A3 -- 0.6

A4 0.82 0.9

b 0.82 0.93

C1-1 L2OVDD

C1-2 GND

C2-1 L2OVDD

C2-2 GND

C3-1 VDD

C3-2 GND

C4-1 OVDD

A2

A1

C4-2 GND

C5-1 OVDD

C5-2 GND

C6-1 VDD

C6-2 GND

D 25.00 BSC

D2 9.6 typ.

D3 7.85

e 1.27 BSC

E 25.00 BSC

E2 12.3 typ.

E3 10.58

J1 0.89 BSC

J2 3.2 BSC

J3 0.68 BSC

K1 6.56

K2 8.13

L1 9.04

L2 7.47

M 2.00

Figure 17. Mechanical Dimensions and Bottom Surface Nomenclature of the MPC7400

30 MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 31

System Design Information

1.8 System Design Information

This section provides electrical and thermal design recommendations for successful application of the

MPC7400.

1.8.1 PLL Configuration

The MPC7400’s PLL is configured by the PLL_CFG[0–3] signals. For a given SYSCLK (bus) frequency,

the PLL configuration signals set the internal CPU and VCO frequency of operation. The PLL configuration

for the MPC7400 is shown in Table 14 for example frequencies.

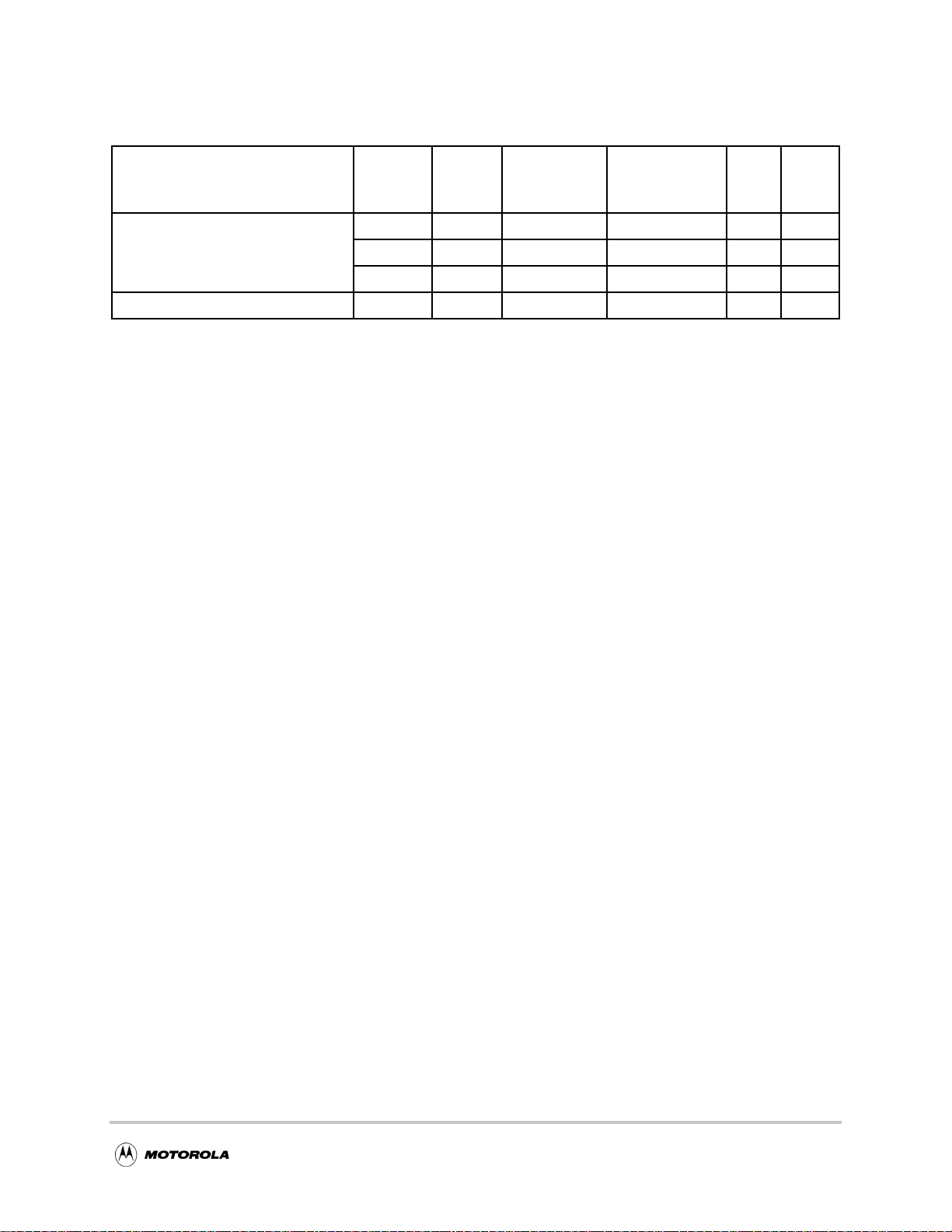

Table 14. MPC7400 Microprocessor PLL Configuration

Example Bus-to-Core Frequency in MHz (VCO Frequency in MHz)

PLL_CFG

[0–3]

0100 2x 2x

0110 2.5x 2x

1000 3x 2x 300 (600)

1110 3.5x 2x 350 (700)

1010 4x 2x 300 (600) 400

0111 4.5x 2x 300

1011 5x 2x 333

1001 5.5x 2x 366

1101 6x 2x 300 (600) 400

0101 6.5x 2x 325

0010 7x 2x 350 (700)

0001 7.5x 2x 375

1100 8x 2x 400

0000 9x 2x 300

0011 PLL off/bypass PLL off, SYSCLK clocks core circuitry directly, 1x bus-to-core

Bus-to-

Core

Multiplier

Core-to

VCO

Multiplier

Bus

25 MHz

Bus

33.3

MHz

(600)

Bus

50 MHz

(630)

(750)

(800)

450

(900)

(600)

(666)

(733)

(800)

433

(866)

implied

Bus

66.6

MHz

Bus

75 MHz

337 (675) 450 (900)

375 (750)

412

(825)

450 (900)

Bus

100 MHz

(800)

MPC7400 RISC Microprocessor Hardware Specifications 31

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 32

System Design Information

Table 14. MPC7400 Microprocessor PLL Configuration (Continued)

Example Bus-to-Core Frequency in MHz (VCO Frequency in MHz)

PLL_CFG

[0–3]

1111 PLL off PLL off, no core clocking occurs

Notes:

1. PLL_CFG[0–3] settings not listed are reserved.

2. The sample bus-to-core frequencies shown are for reference only. Some PLL configurations may select

bus, core, or VCO frequencies which are not useful, not supported, or not tested for by the MPC7400;

see Section 1.4.2.1, “Clock AC Specifications,” for valid SYSCLK, core, and VCO frequencies.

3. In PLL-bypass mode, the SYSCLK input signal clocks the internal processor directly, the PLL is

disabled, and the bus mode is set for 1:1 mode operation. This mode is intended for factory use only.

Note: The AC timing specifications given in this document do not apply in PLL-bypass mode.

4. In PLL-off mode, no clocking occurs inside the MPC7400 regardless of the SYSCLK input.

Bus-to-

Core

Multiplier

Core-to

VCO

Multiplier

Bus

25 MHz

Bus

33.3

MHz

Bus

50 MHz

Bus

66.6

MHz

Bus

75 MHz

Bus

100 MHz

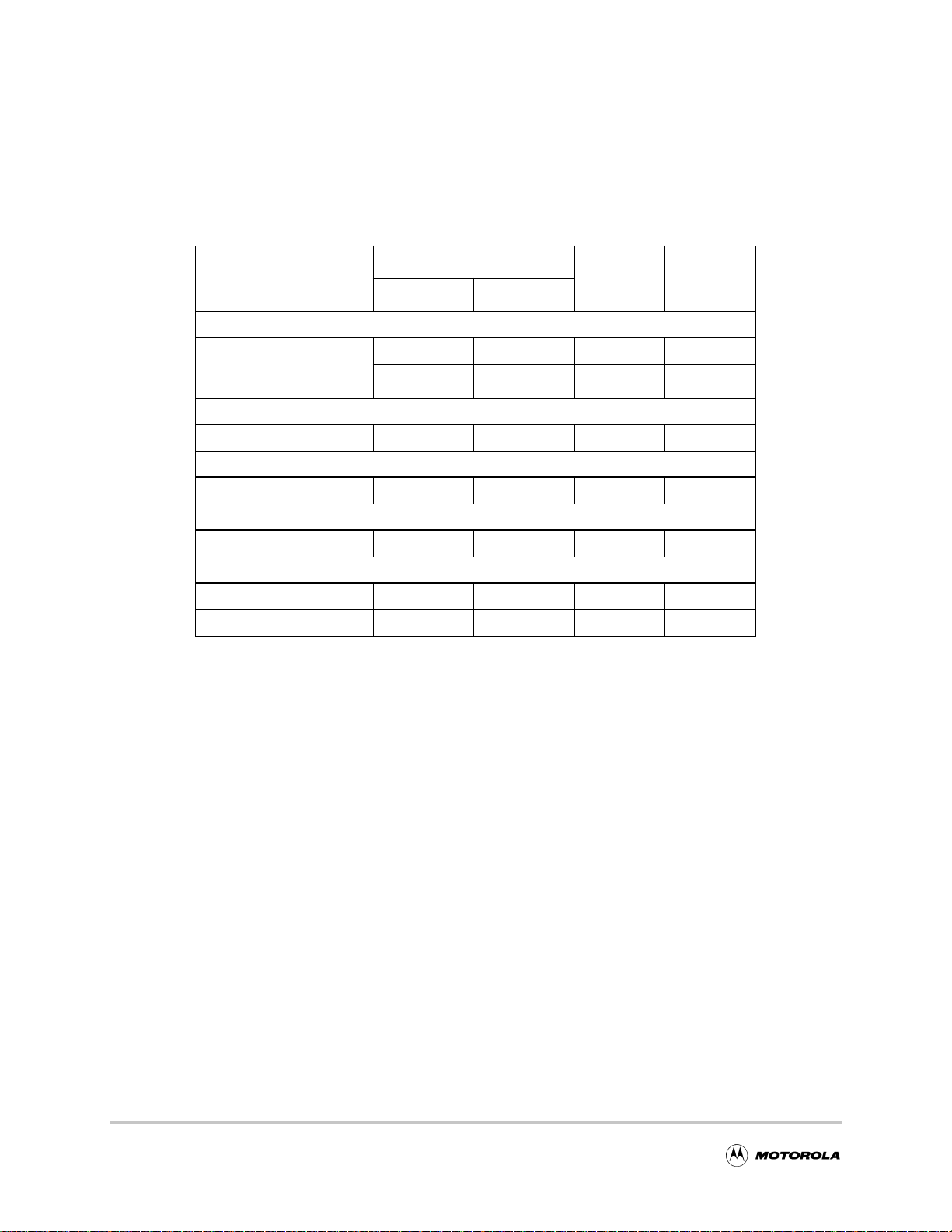

The MPC7400 generates the clock for the external L2 synchronous data SRAMs by dividing the core clock

frequency of the MPC7400. The divided-down clock is then phase-adjusted by an on-chip delay-lock-loop

(DLL) circuit and should be routed from the MPC7400 to the external RAMs. A separate clock output,

L2SYNC_OUT is sent out half the distance to the SRAMs and then returned as an input to the DLL on pin

L2SYNC_IN so that the rising-edge of the clock as seen at the external RAMs can be aligned to the clocking

of the internal latches in the L2 bus interface.

The core-to-L2 frequency divisor for the L2 PLL is selected through the L2CLK bits of the L2CR register.

Generally, the divisor must be chosen according to the frequency supported by the external RAMs, the

frequency of the MPC7400 core, and the phase adjustment range that the L2 DLL supports. Table 15 shows

various example L2 clock frequencies that can be obtained for a given set of core frequencies. The minimum

L2 frequency target is 100MHz.

Table 15. Sample Core-to-L2 Frequencies

Core Frequency in MHz ÷1 ÷1.5 ÷2 ÷2.5 ÷3 ÷3.5 ÷4

300 300 200 150 120 100 — —

333 333 222 166 133 111 — —

350 — — 175 140 117 100 —

366 — — 183 147 122 105 —

400 — — 200 160 133 114 100

Note:

1. The core and L2 frequencies are for reference only. Some examples may represent core or L2

frequencies which are not useful, not supported, or not tested for by the MPC7400; see

Section 1.4.2.3, “L2 Clock AC Specifications,” for valid L2CLK frequencies. The

L2CR[L2SL] bit should be set for L2CLK frequencies less than 110 MHz.

1.8.2 PLL Power Supply Filtering

The AVdd and L2AVdd power signals are provided on the MPC7400 to provide power to the clock

generation phase-locked loop and L2 cache delay-locked loop respectively. To ensure stability of the

internal clock, the power supplied to the AVdd input signal should be filtered of any noise in the 500kHz to

10MHz resonant frequency range of the PLL. A circuit similar to the one shown in Figure 18 using surface

mount capacitors with minimum Effective Series Inductance (ESL) is recommended.

32 MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 33

System Design Information

The circuit should be placed as close as possible to the AVdd pin to minimize noise coupled from nearby

circuits. An identical but separate circuit should be placed as close as possible to the L2AVdd pin. It is often

possible to route directly from the capacitors to the AVdd pin, which is on the periphery of the 360 CBGA

footprint, without the inductance of vias. The L2AVdd pin may be more difficult to route but is

proportionately less critical.

10 Ω

Vdd AVdd (or L2AVdd)

2.2 µF 2.2 µF

Low ESL surface mount capacitors

GND

Figure 18. PLL Power Supply Filter Circuit

1.8.3 Power Supply Voltage Sequencing

The notes in T able 1 contain cautions about the sequencing of the external bus voltages and core voltage of

the MPC7400 (when they are different). These cautions are necessary for the long term reliability of the part.

If they are violated, the ESD (Electrostatic Discharge) protection diodes will be forward biased and

excessive current can flow through these diodes. If the system power supply design does not control the

voltage sequencing, one or both of the circuits of Figure 19 can be added to meet these requirements. The

MUR420 Schottky diodes of Figure 19 control the maximum potential difference between the external bus

and core power supplies on power-up and the 1N5820 diodes regulate the maximum potential difference on

power-down.

3.3V 1.8V

MUR420

MUR420 MUR420

1N5820

1N5820

Figure 19. Example Voltage Sequencing Circuits

2.5V 1.8V

MUR420

MUR420

1N5820

1N5820

1.8.4 Decoupling Recommendations

Due to the MPC7400’s dynamic power management feature, large address and data buses, and high

operating frequencies, the MPC7400 can generate transient power surges and high frequency noise in its

power supply, especially while driving large capacitive loads. This noise must be prevented from reaching

other components in the MPC7400 system, and the MPC7400 itself requires a clean, tightly regulated source

of power. Therefore, it is recommended that the system designer place at least one decoupling capacitor at

each Vdd, OVdd, and L2OVdd pin of the MPC7400. It is also recommended that these decoupling

capacitors receive their power from separate Vdd, (L2)OVdd, and GND power planes in the PCB, utilizing

short traces to minimize inductance.

These capacitors should have a value of 0.01 µF or 0.1 µF. Only ceramic SMT (surface mount technology)

capacitors should be used to minimize lead inductance, preferably 0508 or 0603 orientations where

connections are made along the length of the part. Consistent with the recommendations of Dr. Howard

MPC7400 RISC Microprocessor Hardware Specifications 33

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 34

System Design Information

Johnson in High Speed Digital Design: A Handbook of Black Magic (Prentice Hall, 1993) and contrary to

previous recommendations for decoupling PowerPC microprocessors, multiple small capacitors of equal

value are recommended over using multiple values of capacitance.

In addition, it is recommended that there be several bulk storage capacitors distributed around the PCB,

feeding the Vdd, L2OVdd, and OVdd planes, to enable quick recharging of the smaller chip capacitors.

These bulk capacitors should have a low ESR (equivalent series resistance) rating to ensure the quick

response time necessary. They should also be connected to the power and ground planes through two vias

to minimize inductance. Suggested bulk capacitors—100-330 µF (AVX TPS tantalum or Sanyo OSCON).

1.8.5 Connection Recommendations

To ensure reliable operation, it is highly recommended to connect unused inputs to an appropriate signal

level. Unused active low inputs should be tied to OVdd. Unused active high inputs should be connected to

GND. All NC (no-connect) signals must remain unconnected.

Power and ground connections must be made to all external Vdd, OVdd, L2OVdd, and GND pins of the

MPC7400.

See Section 1.4.2.3, “L2 Clock AC Specifications” for a discussion of the L2SYNC_OUT and L2SYNC_IN

signals.

1.8.6 Output Buffer DC Impedance

The MPC7400 60x and L2 I/O drivers are characterized over process, voltage, and temperature. T o measure

Z

, an external resistor is connected from the chip pad to OVdd or GND. Then, the value of each resistor is

0

varied until the pad voltage is OVdd/2 (see Figure 20).

The output impedance is the average of two components, the resistances of the pull-up and pull-down

devices. When Data is held low, SW2 is closed (SW1 is open), and RN is trimmed until the voltage at the

pad equals OVdd/2. R

SW1 is closed (SW2 is open), and R

becomes the resistance of the pull-up devices. R

Then Z

= (RP + RN)/2.

0

then becomes the resistance of the pull-down devices. When Data is held high,

N

is trimmed until the voltage at the pad equals OVdd/2. RP then

P

Data

and RN are designed to be close to each other in value.

P

OVdd

R

N

SW2

Pad

SW1

R

P

OGND

Figure 20. Driver Impedance Measurement

34 MPC7400 RISC Microprocessor Hardware Specifications

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

Page 35

System Design Information

T able 16 summarizes the signal impedance results. The driver impedance values were characterized at 0°C,

65 °C, and 105 °C. The impedance increases with junction temperature and is relatively unaffected by bus

voltage.

Table 16. Impedance Characteristics

Vdd = 1.8V, OVdd = 3.3V, Tj = 0 - 105 °C

Impedance Processor bus L2 bus Symbol Unit

R

N

R

P

32-43 39-48 Z

36-48 41-50 Z

0

0

Ohms

Ohms

1.8.7 Pull-up Resistor Requirements

The MPC7400 requires high-resistive (weak: 10 KΩ) pull-up resistors on several control pins of the bus

interface to maintain the control signals in the negated state after they have been actively negated and

released by the MPC7400 or other bus masters. These pins are TS

In addition, the MPC7400 has one open-drain style output that requires a pull-up resistor (weak or stronger:

4.7 KΩ–10 KΩ) if it is used by the system. This pin is CKSTP_OUT

During inactive periods on the bus, the address and transfer attributes may not be driven by any master and

may therefore float in the high-impedance state for relatively long periods of time. Since the MPC7400 must

continually monitor these signals for snooping, this float condition may cause excessive power draw by the

input receivers on the MPC7400 or by other receivers in the system. It is recommended that these signals

be pulled up through weak (10 KΩ) pull-up resistors by the system, or that they may be otherwise driven by

the system during inactive periods of the bus. The snooped address and transfer attribute inputs are:

A[0:31], AP[0:3], TT[0:4], and GBL

.

The data bus input receivers are normally turned off when no read operation is in progress and therefore do

not require pull-up resistors on the bus. Other data bus receivers in the system, however, may require

pullups, or that those signals be otherwise driven by the system during inactive periods by the system. The

data bus signals are: D[0:63], DP[0:7]

, ARTRY, SHDO, and SHD1.

.

If address or data parity is not used by the system, and the respective parity checking is disabled through

HID0, the input receivers for those pins are disabled, and those pins do not require pull-up resistors and

should be left unconnected by the system. If all parity generation is disabled through HID0, then all parity

checking should also be disabled through HID0, and all parity pins may be left unconnected by the system.

The L2 interface does not normally require pull-up resistors.

1.8.8 JTAG Configuration Signals

Boundary scan testing is enabled through the JTAG interface signals. (BSDL descriptions of the MPC7400

are available on the internet at www.mot.com/PowerPC/teksupport.) The TRST

IEEE 1149.1 specification but is provided on all PowerPC implementations. While it is possible to force the

TAP controller to the reset state using only the TCK and TMS signals, more reliable power-on reset

performance will be obtained if the TRST

signal is asserted during power-on reset. Since the JT AG interface

is also used for accessing the common on-chip processor (COP) function of PowerPC processors, simply

tying TRST

to HRESET isn’t practical.

The common on-chip processor (COP) function of PowerPC processors allows a remote computer system

(typically a PC with dedicated hardware and debugging software) to access and control the internal

operations of the processor. The COP interface connects primarily through the JTAG port of the processor,

with some additional status monitoring signals. The COP port requires the ability to independently assert

MPC7400 RISC Microprocessor Hardware Specifications 35

PRELIMINARY—SUBJECT TO CHANGE WITHOUT NOTICE

signal is optional in the

Page 36

System Design Information

HRESET or TRST in order to fully control the processor. If the target system has independent reset sources,

such as voltage monitors, watchdog timers, power supply failures, or push-button switches, then the COP

reset signals must be merged into these signals with logic.

The arrangement shown in Figure 21 allows the COP to independently assert HRESET or TRST, while

insuring that the target can drive HRESET

as well. The pull-down resistor on TRST ensures that the JTAG

scan chain is initialized during power-on if a JTAG interface cable is not attached; if it is, it is responsible

for driving TRST

when needed.

From Tar get

Board

Sources

HRESET

QACK

2KΩ

2KΩ

COP Header

Figure 21. Suggested TRST connection

MPC7400

HRESET

QACK

TRST

The COP header shown in Figure 21 adds many benefits—breakpoints, watchpoints, register and memory

examination/modification and other standard debugger features are possible through this interface – and can

be as inexpensive as an unpopulated footprint for a header to be added when needed.