Page 1

Page 2

1

02/25/2015

Initial release.

2

04/24/2015

Updated Tools Required for Disassembly and Display Removal (With Display

Removal Fixture) sections with photos of current fixture.

3

05/21/2015

Added subheadings for Lens Removal Fixture Setup, Pre-Heat Method A,

Pre-Heat Method B, and Display Removal to Display Removal (With Display

Removal Fixture).

Revised Pre-Heat Method A steps to allow proper Hot Plate warm up time.

Added Pre-Heat Method B as an additional option for process time reduction.

Changed the Generic Lens Removal Fixture set temperature from 110 °C

(230 °F) to 100 °C (212°F).

Added instruction to hold the Styx Lens Removal Fixture down until the

Generic Lens Removal Fixture gauge reads 90 kPa.

Added note to Display Removal (Damaged Display Only) stating optional pre-

heat methods A and B can be used before removing a damaged Display

Lens.

Attached Generic Lens Removal Fixture user manual to end of manual.

Page 3

Page 4

Page 5

Page 6

The phone components may be damaged by electrostatic discharge (ESD). Always use an ESD mat and ground strap

when working with internal components.

Handle Battery with care. Ensure Battery edges and surfaces are not dented or deformed. If the Battery Pack is dropped

to the floor, it may be internally damaged and must be scrapped.

Ensure all surfaces, fixtures, and phone components contacting the Battery are smooth and clean.

Ensure Battery and its insulation are not damaged (e.g. scratched, dented, punctured) prior to and throughout

assembly.

Prior to assembly, ensure Battery edges and surfaces are not dented or deformed, and that fixtures and parts that

will contact the Battery are free of foreign material.

Ensure screws and screwdrivers do not contact the Battery.

Failure to adhere to Safety Critical Note(s) may increase risk of rupture, burning, or failure to function safely when

used by the customer.

Page 7

Page 8

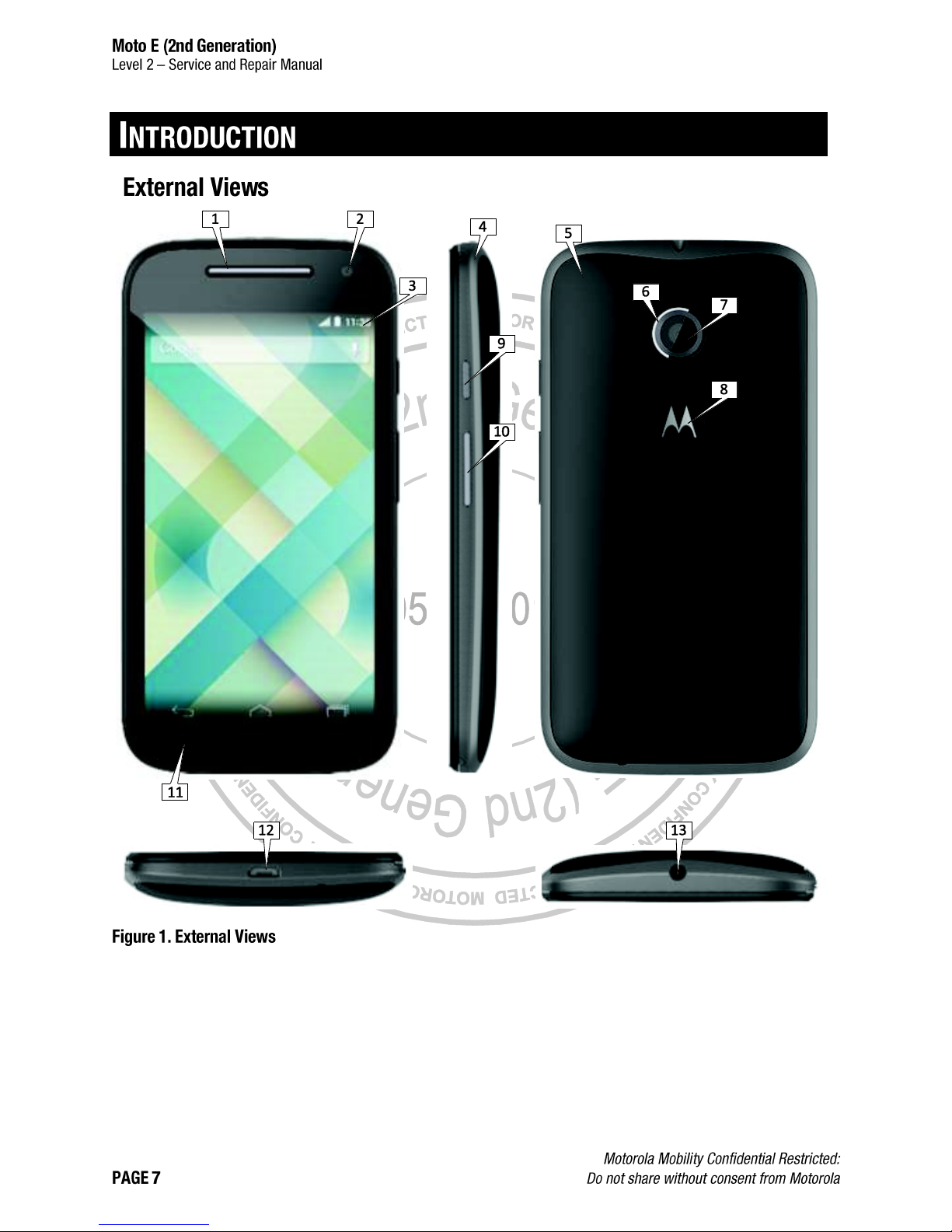

1

Earpiece

2

Front-Facing Imager

3

Main Display

4

Sideband

5

Housing

6

Rear-Facing Imager Deco Ring

7

Rear-Facing Imager

8

Motorola Logo

9

Power Key

10

Volume Key

11

Display Bezel

12

USB Port

13

Headset Jack

Page 9

All dimensions are in millimeters (mm). The following gaps are considered maximum allowable without further approval

from a supervisor. Measure gaps at an angle perpendicular to the surface/area being measured. Feeler Gauges must

not be used at an angle as they will give false-positive results.

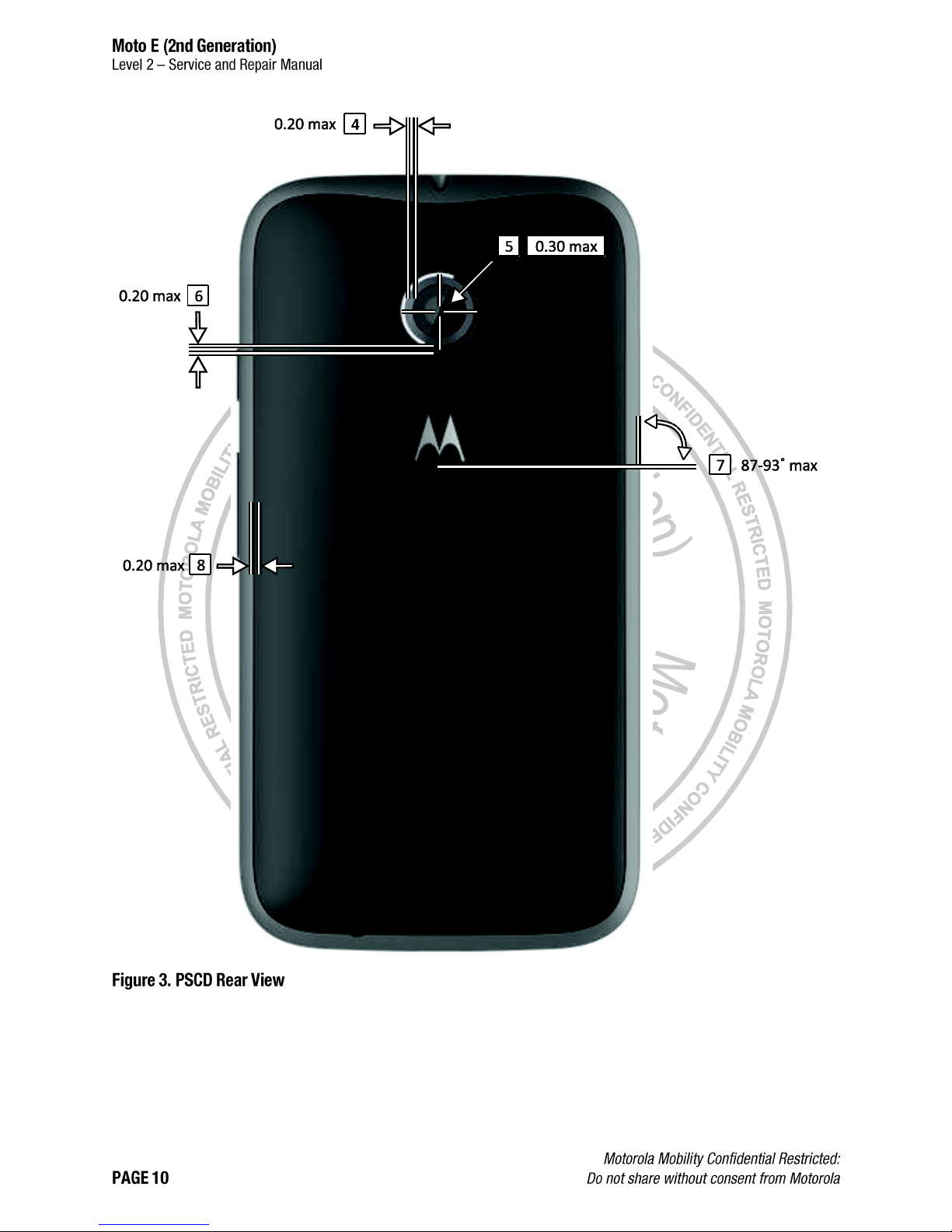

Page 10

Page 11

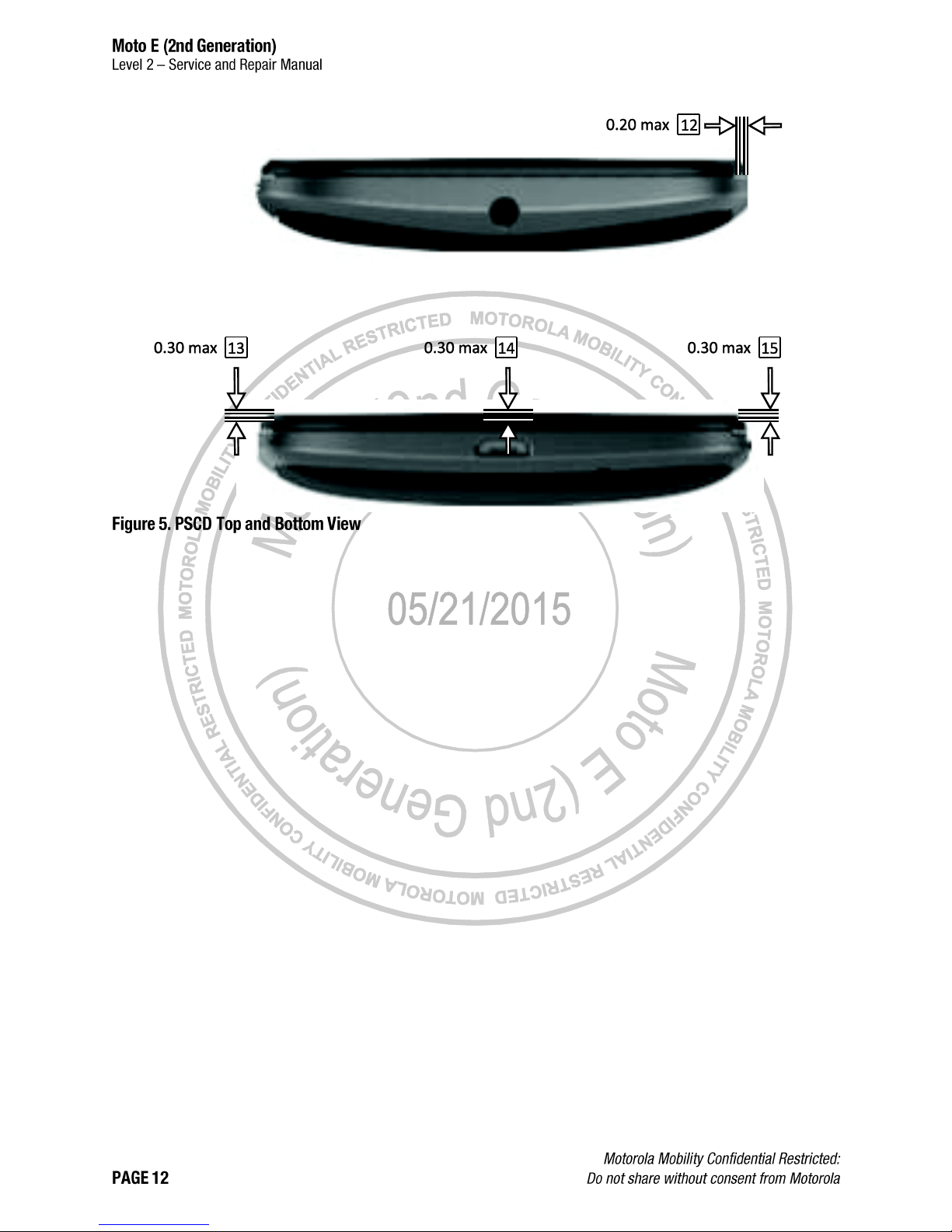

Page 12

Page 13

Page 14

1

Earpiece to Main Lens Perimeter

2

Front-Facing Imager to Main Lens Artwork Concentricity

3

Main Lens to Front Housing Perimeter

4

Rear-Facing Imager to Deco Ring Perimeter

5

Rear-Facing Imager to Lens Artwork Concentricity

6

Deco Ring to Housing Perimeter

7

Motorola Logo to Housing Side Rotation

8

Housing to Sideband Perimeter

9

Housing to Sideband Perimeter

10

Power Key to Sideband Perimeter

11

Volume Key to Sideband Perimeter

12

Housing to Sideband Step

13

Housing Protrusion over Lens Step (Left)

14

Housing Protrusion over Lens Step (Top and Bottom)

15

Housing Protrusion over Lens Step (Right)

16

Lens Viewing Area Alignment (Horizontal)

17

Lens Viewing Area Alignment (Vertical)

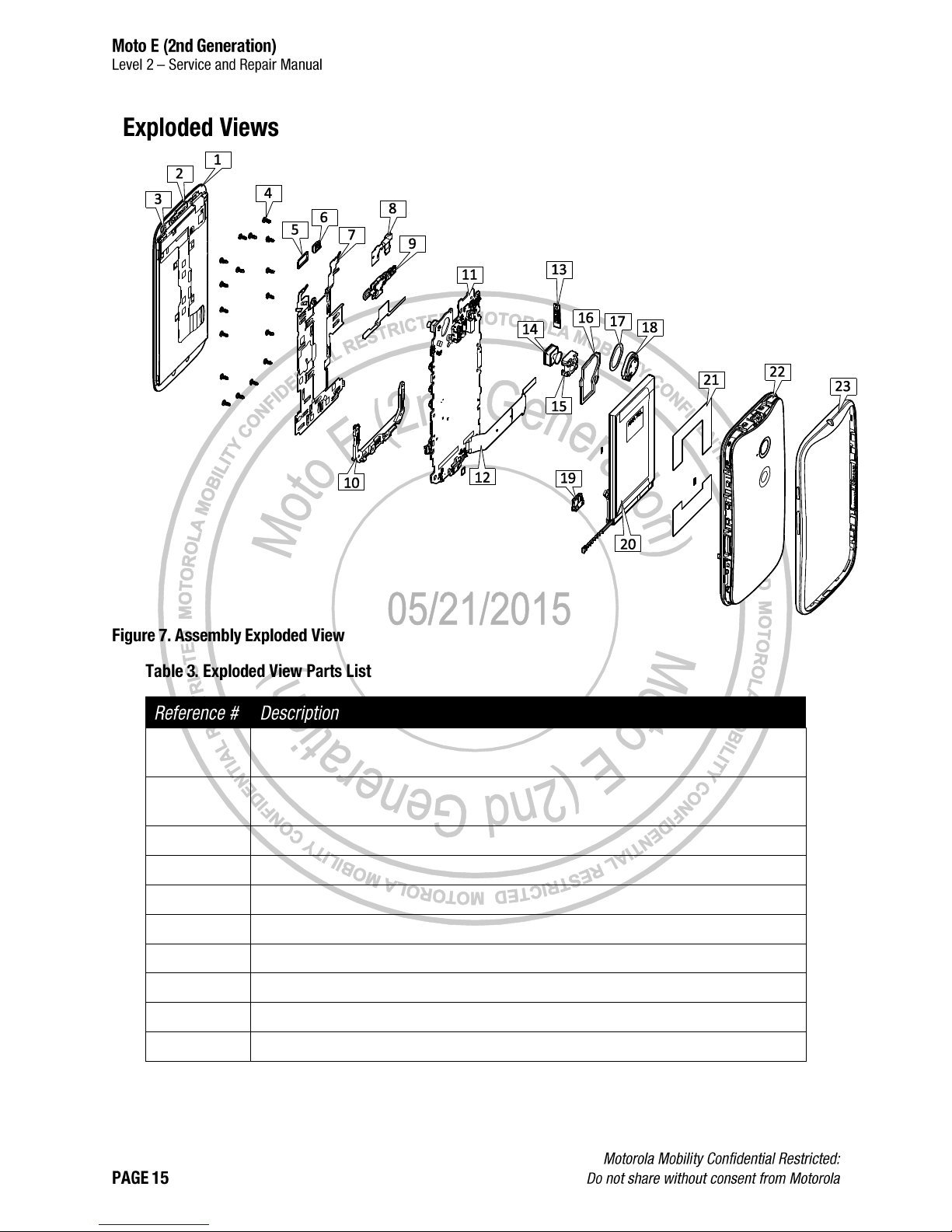

Page 15

1

ASSEMBLY,DISPLAY,4.5 Inches MDL ASSY,TFT,WITH LENS,INX,PROD,BLACK

ASSY,DISP,4.5 Inches MDL ASSY,TFT,WITH LENS,INX,PROD,WHITE

2

ASSEMBLY,EARPIECE,DECORATIVE

ASSY,EARPC,DECORATIVE,WHITE

3

GSKT,FF IMAGER,STYX

4

SCREW,4.0,UNIWAVE II,DVX

5

GROM,PROX,WITH ADHES

6

TRANSDUCER,SDRP0612HJ05-02-G AAC 6X12X2MM RCVR

7

CHAS,GND PLATE,STYX

8

FLEX,AUDIO

9

HSG,PCB FRAME,TOP,MOLDED,STYX

10

HSG,PCB FRAME,BOTTOM,MOLDED,STYX

Page 16

11

ASSY,PWA,XCVR,STYX 3G,1SIM

ASSY,PWA,XCVR,STYX 3G,AWS

ASSY,PWA,STYX,SPRINT/USC

ASSY,PWA,STYX,EUROPE

ASSY,PWA,STYX,LATAM SS

ASSY,PWA,STYX,NA

ASSY,PWA,STYX,VZW

ASSY,PWA,XCVR,PORT STYX 3G 2SIM

ASSY,PWA,STYX,LATAM DS

ASSY,PWA,STYX,LATAM DS DTV

ASSY,PWA,STYX,EUROPE

ASSY,PWA,XCVR,PORT STYX 3G 2SIM

12

LBL,MEID,STYX

13

CVR,SIM W/ ADHES

CVR,SIM W/ ADHESIVE, WHT

14

IMGR MDL,CMOS,5MP,8.5X8.5X4.55,MIPI,4P,1/5,LAND,2.8V

15

SHLD,TOP CVR CAMR SKT

16

PAD,GSKT LOUD ADHES

17

DIE CUT,ADHES,LOUD

18

TRANSDUCER,OTHR,2V,LOUDSPEAKER, 8OHM, 3.65 X 12 X 17MM, IP67, IN

19

GROM,UUSB,STYX

20

ASSY,BAT,FT40,LI POLYMER,SONY,TYP2390 MAH

21

DIE CUT,ADHES,BATTERY,STYX

22

ASSY,HSG,REAR,STYX,LICORICE

ASSY,HSG,REAR,STYX,WHITE

23

ASSY,HSG,BAND,LICORICE,STYX

ASSY,HSG,BAND,WHITE,STYX

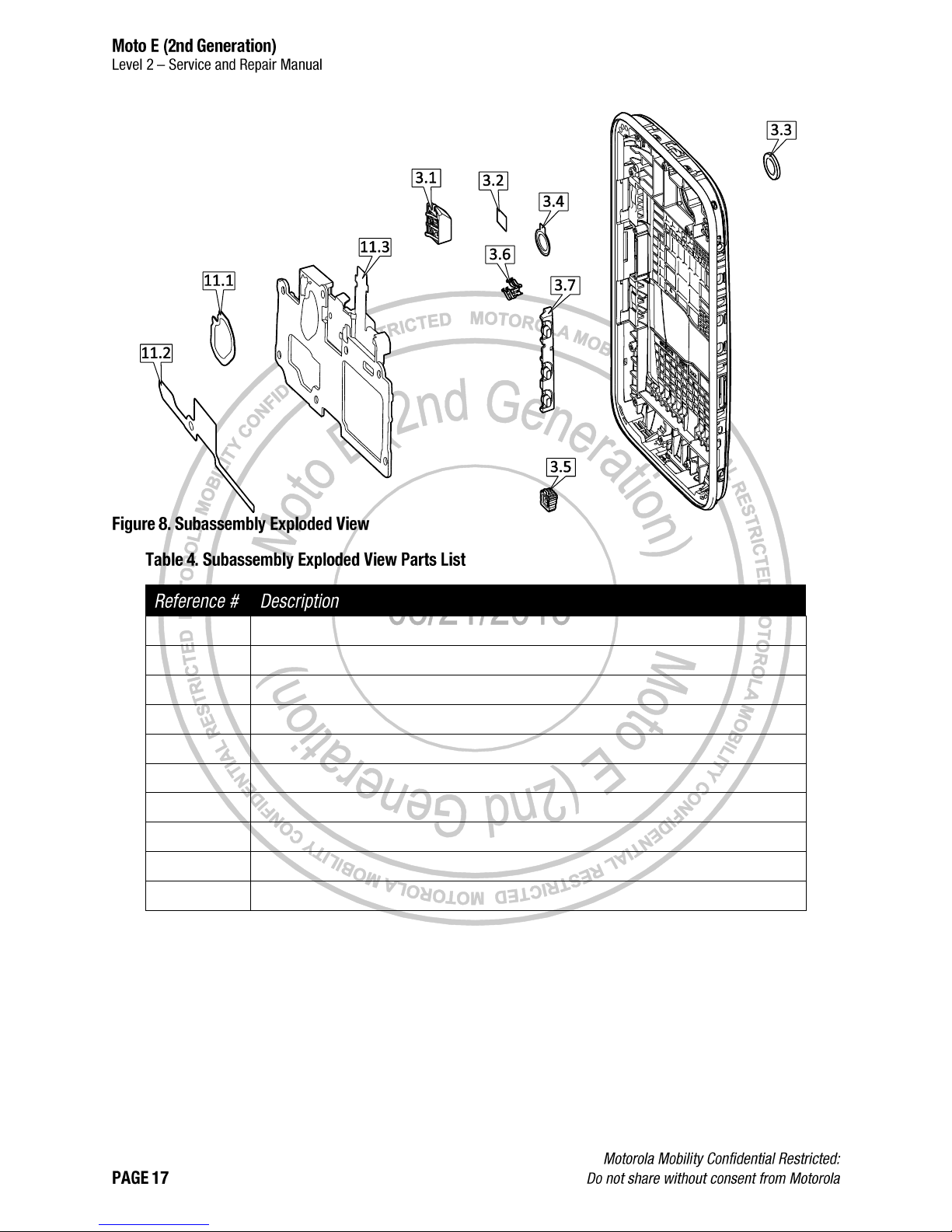

Page 17

3.1

CONN,JACK, HEADSET, 3.5 MM DIAMETER, 45 DEG SLOPED FRONT, SLVR

3.2

TAPE,ADHES,HEADSETJACK DVX

3.3

LENS,MN CAMR STYX

3.4

GSKT,REAR MN CAMR

3.5

COMP ASSY,GROM PRMRY MIC,STYX

3.6

CONT,SPKR

3.7

BTN,VOL,INNER,MOLDED W/ ADHESIVE,STYX

11.1

DIE CUT,ADHES,SPK PCB FRM

11.2

DIE CUT,ADHES,TOP FRAME,STYX

11.3

ASSEMBLY,FLEX CIRCUIT,HSJ

Page 18

Display

Sideband

Battery

Loudspeaker

Proximity

Grommet

Grounding

Plate

Bottom Spacer

Earpiece

Speaker

Headset Jack

USB Grommet

Rear-Facing

Imager Lens

Top Spacer

PCB

Side Key Pad

Main

Microphone

Grommet

Rear-Facing

Imager

Rear-Facing

Imager Gasket

Front-Facing

Imager Gasket

Earpiece Bezel

Loudspeaker

Gasket

Page 19

The following tools are required to disassemble the Moto E (2nd Generation) phone.

Generic Lens Removal Fixture*

4-00-X2-10000/

4-00-X7-10000

Lens Heating Nest

(optional – for use with Hot Plate if Oven is not

available)

4-00-X5-10000

Styx Lens Removal Fixture

4-00-X6-10000

“7x”7 Hot Plate

(optional – for reduction of process time if Oven is

not available)**

4-00-Z2-10000

(220V) /

4-00-Z3-10000

(110V)

Page 20

Oven

(optional - for reduction of process time if Hot Plate

and Lens Heating Nest are not available)

--

Blackstick

--

4IP Torx Bit

-Thin Plastic Spudger

0-00-00-40826

Tweezers (Plastic or Plastic-Tipped)

--

--

ESD Mat and Wrist Strap

--

--

Gloves or Finger Collets

--

--

Isopropyl (ISP) Alcohol

--

--

*Generic Lens Removal Fixtures 4-00-X2-10000 and 4-00-X7-10000 are identical tools. The only difference is the

voltage rating. Either the 4-00-X2-10000 or the 4-00-X7-10000 can be used with the Styx Lens Removal Fixture (4-00X6-10000).

**Hot Plates 4-00-Z2-10000 and 4-00-Z3-10000 are identical tools. The only difference is the voltage rating. Either the

220V 4-00-Z2-10000 or the 110V 4-00-Z3-10000 can be used with the Lens Heating Nest (4-00-X5-10000).

Page 21

1. Use a fingernail in the USB Port to unsnap the

bottom of the Sideband from the Housing.

2. Peel the Sideband away from the Housing to

disengage the snaps and remove the Sideband.

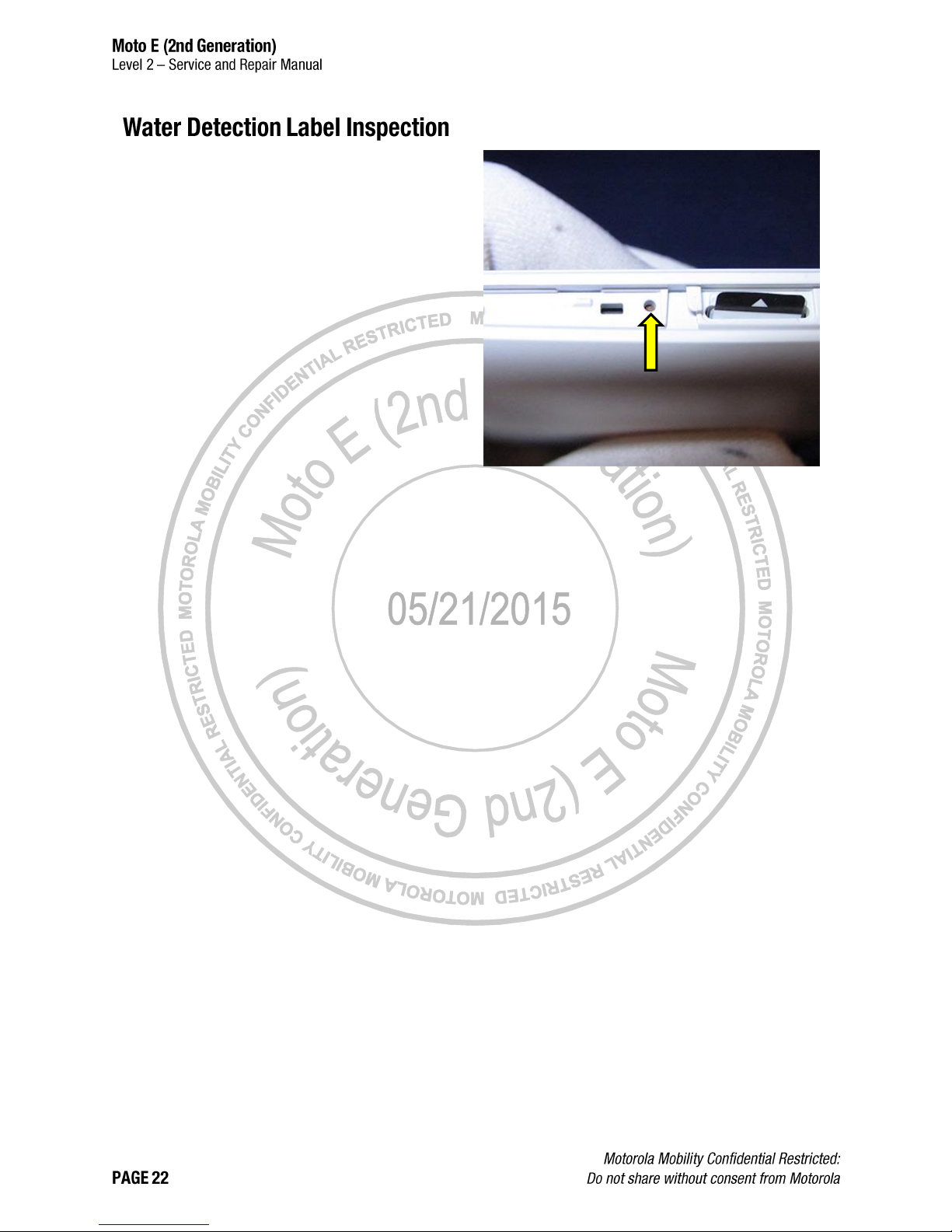

Page 22

Inspect the Water Detection Label (WDL) visible

through the opening next to the Label Tray, to

verify it is correctly placed and inspect it for signs

of activation.

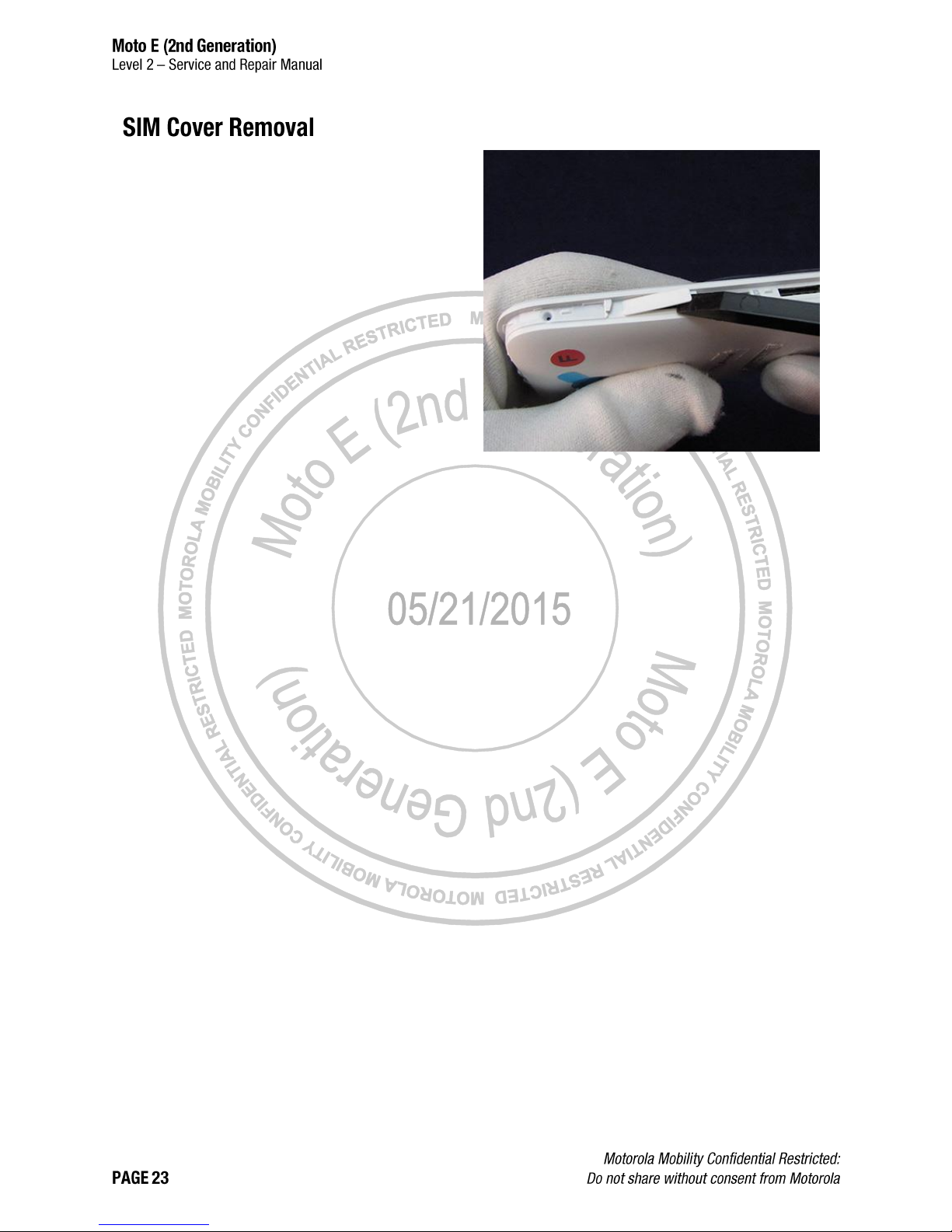

Page 23

Use the flat end of the Blackstick to unsnap the

SIM Cover from the Housing.

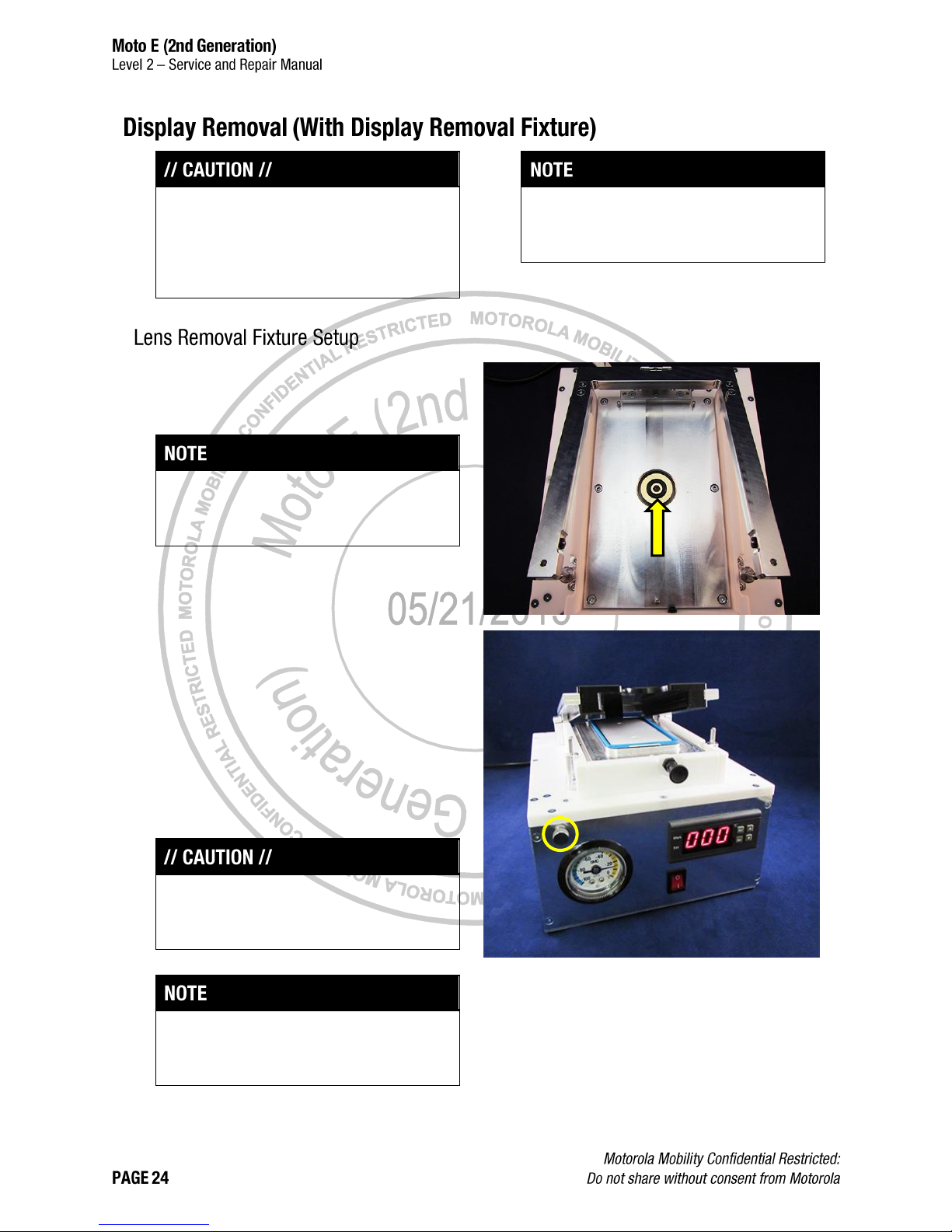

Page 24

If the controller on the Generic Lens Removal

Fixture must be adjusted, see the user manual on

page 126.

If the Display Lens is damaged, continue to

Display Removal (Damaged Display Lens Only)

on page 30. Do not use the Display Removal

(With Display Removal Fixture) procedure if the

Display Lens is damaged.

Pre-Heat Method A and Pre-Heat Method B are

optional procedures that may be used to reduce

the Display Removal process time.

1. Verify that the Vacuum O-ring is positioned in the

Generic Lens Removal Fixture (4-00-X210000/4-00-X7-10000) as shown.

The Generic Lens Removal Fixture vacuum will

not perform correctly if the Vacuum O-ring is not in

position.

2. Place the Styx Lens Removal Fixture (4-00-X6-

10000) into the Generic Lens Removal Fixture.

3. Press the black power switch (not shown) on the

back of the Generic Lens Removal Fixture to turn

the fixture ON.

4. Turn the vacuum knob (circled) clockwise until it

stops.

5. Wait 5-10 minutes for the Generic Lens Removal

Fixture to warm up to 100 °C (212°F).

Damage to the assembly may occur if the Generic

Lens Removal Fixture is not warmed up to

operating temperature before use.

Page 25

1. Place the Lens Heating Nest (4-00-X5-10000) on

the Hot Plate.

If the Lens Heating Nest and Hot Plate are not

available or not appropriate, use Pre-Heat Method

B on page 26 or skip to Display Removal on page

27.

2. Set the Hot Plate to 110 °C (230 °F).

Do not set the Hot Plate temperature higher than

110 °C (230 °F). Damage to the phone may

occur.

3. Wait 5-10 minutes for the Hot Plate to warm up.

4. Place the phone in the nest.

5. Wait 3 minutes for the Display to warm up.

6. Remove the phone from the nest.

Wear protective gloves when handling heated

phones.

7. Continue to Display Removal on page 27.

For phones with a damaged Display Lens,

continue to Display Removal (Damaged Display

Lens Only) on page 30.

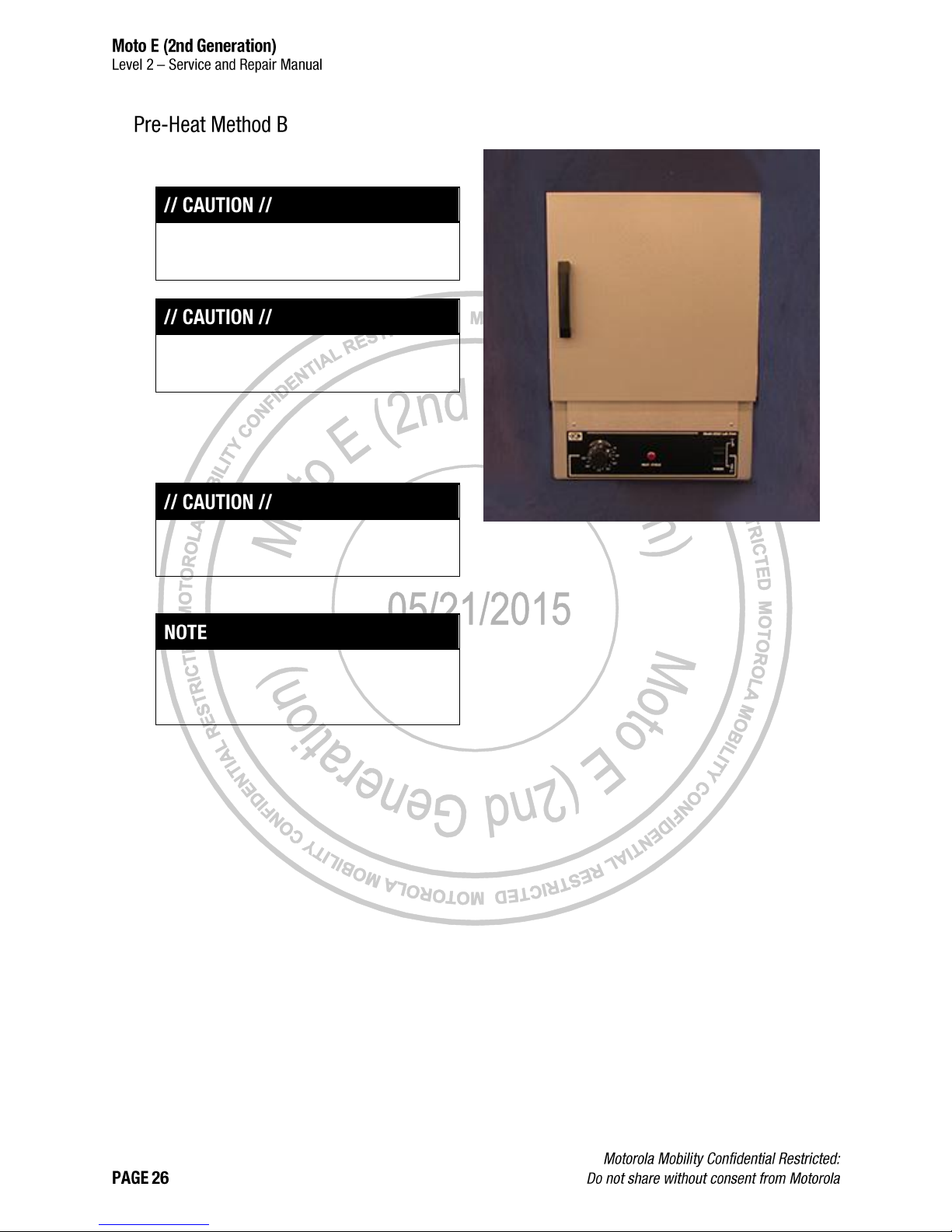

Page 26

1. Pre-heat the Oven to 70 °C (158 °F).

If the Oven is not available or not appropriate, skip

to Display Removal on page 27.

Do not set the Oven temperature higher than

70 °C (158 °F). Damage to the phone may occur.

2. Place the phone in the Oven.

3. Wait 25 minutes for the Display to warm up.

4. Remove the phone from the Oven.

Wear protective gloves when handling heated

phones.

5. Continue to Display Removal on page 27.

For phones with a damaged Display Lens,

continue to Display Removal (Damaged Display

Lens Only) on page 30.

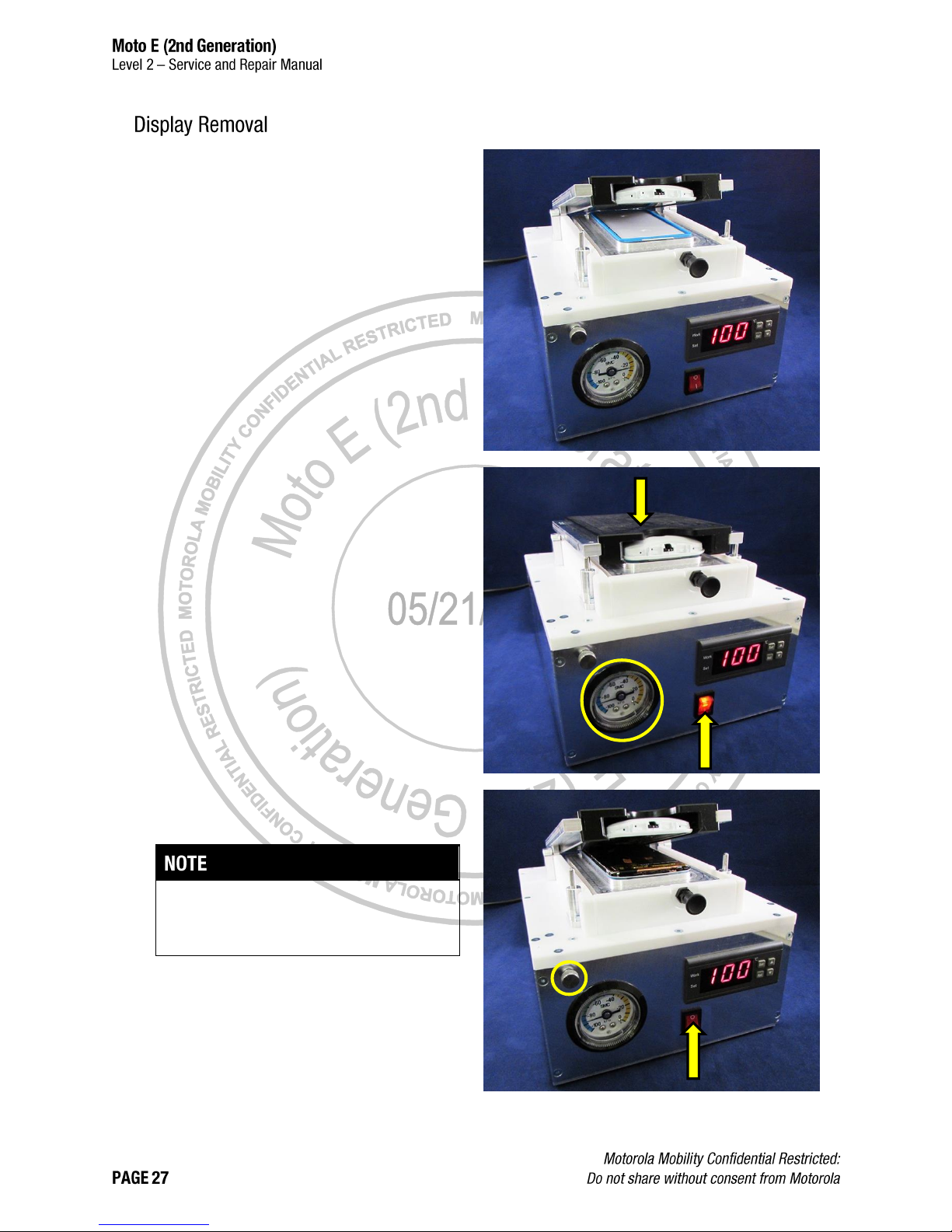

Page 27

1. Place the phone in the Styx Lens Removal

Fixture with the Display facing down and the

Headset Jack facing the front of the fixture.

2. Press down on the Styx Lens Removal Fixture

and press the red button to turn on the vacuum

pump.

3. Hold the Styx Lens Removal Fixture down until

the gauge (circled) reaches -90 kPa. When the

gauge reaches -90 kPa, remove your hand from

the Styx Lens Removal Fixture.

4. Wait for the Styx Lens Removal Fixture to spring

up.

The lid on the Generic Lens Removal Fixture is

spring loaded, and will automatically open when

the Display is separated from the Housing.

5. Press the red button to turn off the vacuum

pump.

6. Turn the vacuum knob (circled) counter-

clockwise to release the vacuum.

Page 28

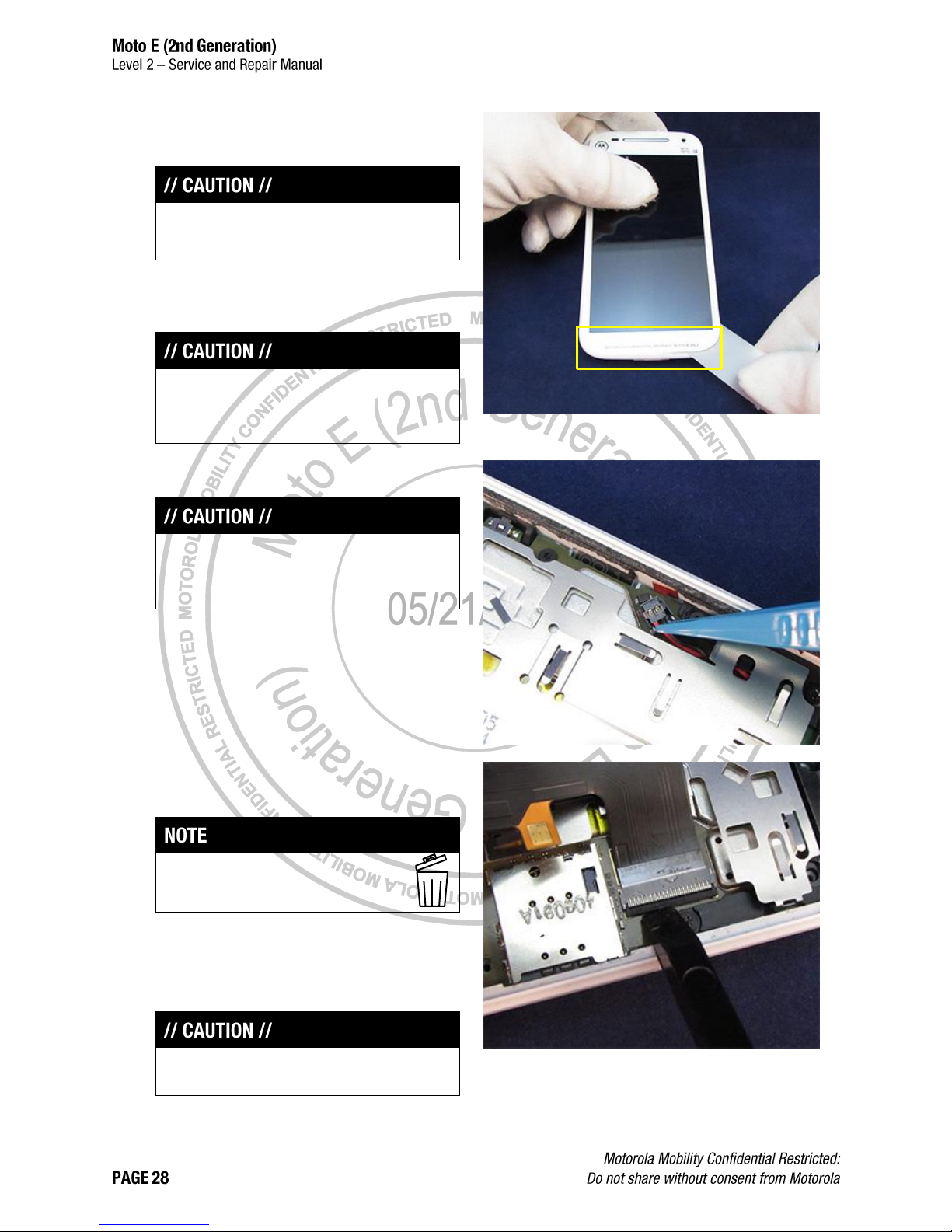

7. Remove the phone from the Styx Lens Removal

Fixture.

Wear protective gloves when handling heated

parts.

8. Use the Thin Plastic Spudger to separate the

remaining adhesive from the USB side of the

phone.

Do not insert the Thin Plastic Spudger farther than

necessary. The Lens may separate from the

Display.

9. Use the Tweezers to disconnect the Battery.

To avoid damage to the Display, the Battery must

be disconnected before disconnecting the Display

Flex.

10. Use the Tweezers to remove the Kapton® Tape

from the Display Flex ZIF Connector Door.

After you remove the Kapton Tape, you

cannot reuse it.

11. Use the Blackstick to open the Display Flex ZIF

Connector Door.

12. Slide the Display Flex free from the ZIF

Connector.

Do not damage the Display Flex.

Page 29

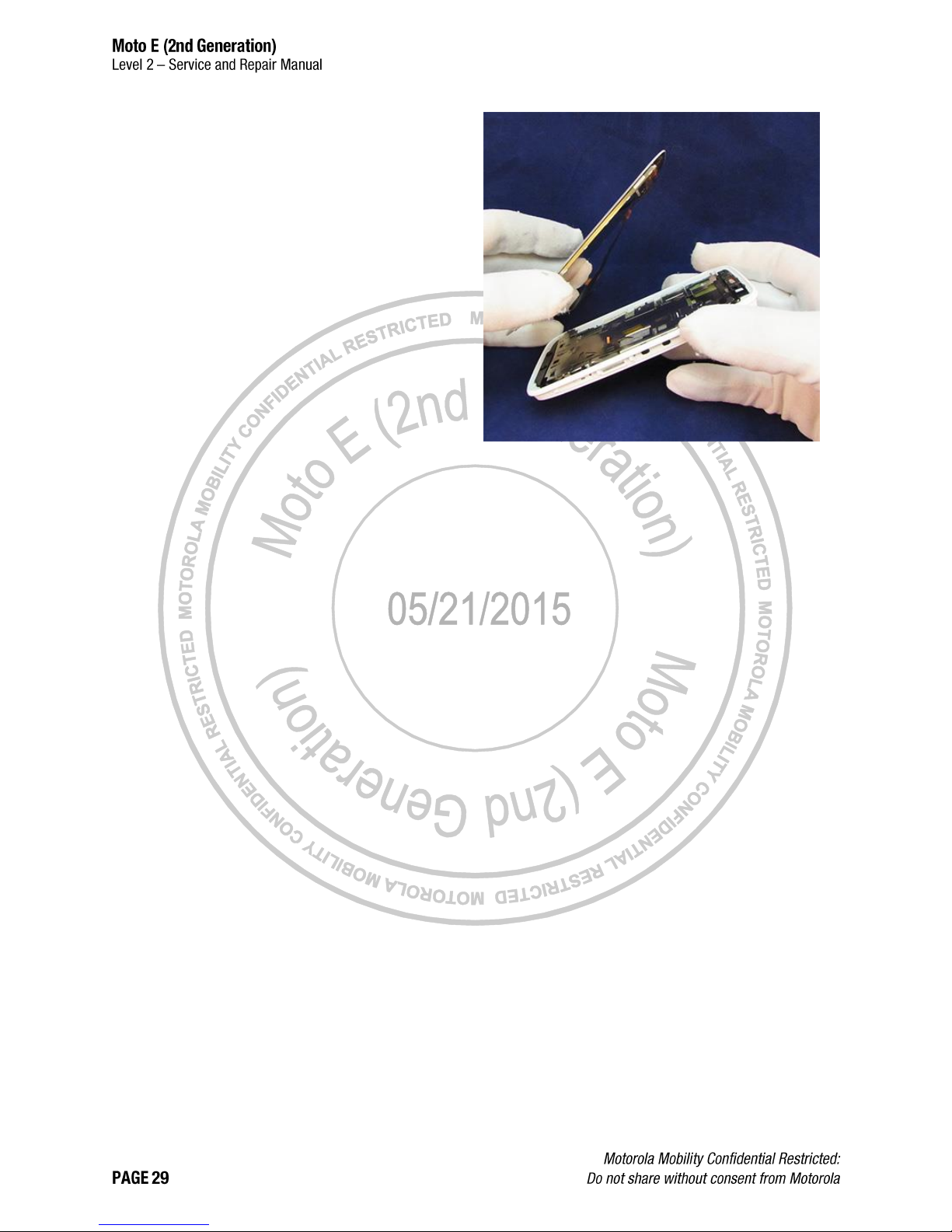

13. Verify that the Display Flex is disconnected and

that no other connection exists between the

Display and the phone assembly.

14. Lift the Display out of the Housing.

Page 30

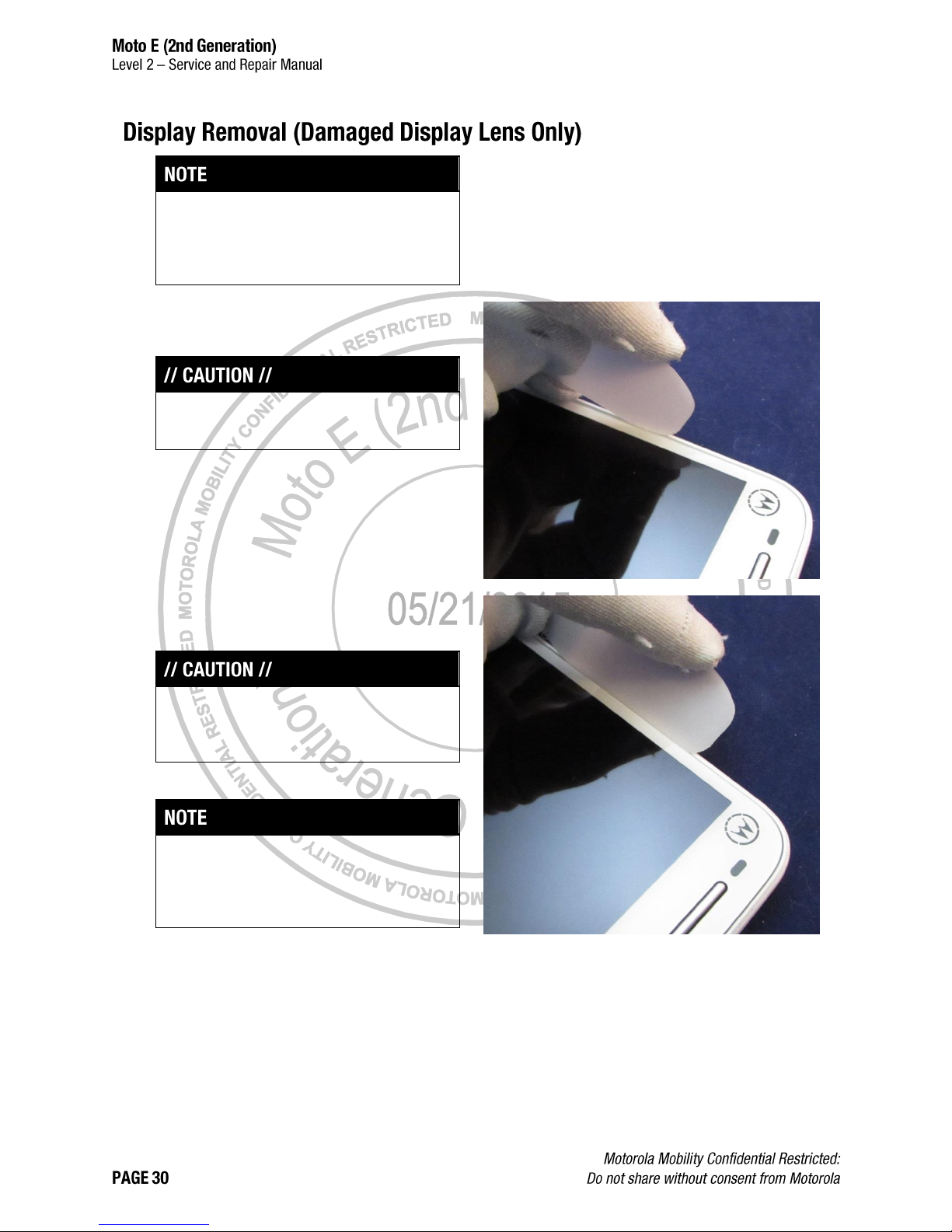

The phone may be pre-heated before Display

removal. See Pre-Heat Method A on page 25 and

Pre-Heat Method B on page 26 for pre-heating

instructions.

1. Slide the Thin Plastic Spudger into the gap

between the Display and the Housing.

This procedure should only be performed if the

Display Lens is damaged.

2. Move the Thin Plastic Spudger around the edge

of the Display to free the adhesive.

Do not insert the Thin Plastic Spudger deeper

than 1 mm. Deeper insertion may separate the

Display and Lens and cause damage.

While moving the Thin Plastic Spudger around the

Display, insert a shim or Thin Plastic Spudger

between the separated edges to prevent the

Display from re-adhering to the Housing.

Page 31

3. When the adhesive has been freed, slightly lift

the Display from the Housing.

To avoid damage to the Display Flex, do not lift

the Display any higher than necessary to

disconnect the Battery and Display Flex.

4. Use the Tweezers to disconnect the Battery.

To avoid damage to the Display, the Battery must

be disconnected before disconnecting the Display

Flex.

5. Use the Tweezers to remove the Kapton Tape

from the Display Flex ZIF Connector Door.

After you remove the Kapton Tape, you

cannot reuse it.

Page 32

6. Use the Blackstick to open the Display Flex ZIF

Connector Door.

7. Slide the Display Flex free from the ZIF

Connector.

Do not damage the Display Flex.

8. Verify that the Display Flex is disconnected and

that no other connection exists between the

Display and the phone assembly.

9. Lift the Display out of the Housing.

Page 33

Use the flat end of the Blackstick to push the Earpiece

Bezel out of the Display.

After you remove the Earpiece Bezel, you

cannot reuse it.

Page 34

Use the Plastic Tweezers to remove the Front-Facing

Imager Gasket from the Display.

After you remove the Front-Facing

Imager Gasket, you cannot reuse it.

Page 35

Use the Tweezers to remove the Proximity Grommet.

After you remove the Proximity Grommet,

you cannot reuse it.

Page 36

10. Use the Blackstick to push the Earpiece Speaker

towards the top edge of the phone. Verify that

the tab on the left side of the Earpiece Speaker

is clear of the retention feature.

11. Use the pointed end of the Blackstick on the

corner of the Earpiece Speaker to pry the

Earpiece Speaker out of the socket.

12. Use the Blackstick and ISP Alcohol to remove

the Earpiece Speaker Adhesive.

Remove the Earpiece Speaker Adhesive only if

the Earpiece Speaker will be reused. If the

Earpiece Speaker will be replaced, skip this step.

Page 37

1. Remove the 4IP Screw from the Grounding

Plate.

After you remove the 4IP Screw, you

cannot reuse it.

2. Slide the Grounding Plate to one side to

disengage one of the snap features, then to the

other side to free the other.

3. Slide the Grounding Plate upwards to disengage

the 2 top snap features.

Page 38

1. Remove the 6 4IP Screws from the Bottom

Spacer.

After you remove the 4IP Screws, you

cannot reuse them.

2. Use the flat end of the Blackstick on the 2

removal features of the Bottom Spacer to

disengage the Housing snaps.

Do not damage the Battery connector or Display

Flex ZIF Connector.

3. Slide the Blackstick under the Bottom Spacer to

remove it from the Housing.

Page 39

If the PCB will be replaced, record the Battery part

number (starts with “SNN”) and reprogram the

Battery part number in the PCB using MotoService

“Battery Link” use case after assembly.

1. Remove the 10 4IP Screws from the PCB.

After you remove the 4IP Screws, you

cannot reuse them.

2. Verify that all 4IP Screws are removed from the

PCB.

3. Use the pointed end of the Blackstick to

disengage the Top Spacer retaining tab.

4. Carefully pull on the right edge of the Housing to

disengage the PCB retaining tab.

Page 40

5. Insert the pointed end of the Blackstick on the

right edge of the PCB, near the Power Key

connector, and slowly pry up to release the PCB.

Verify that the Side Key Pad does not loosen from

the Housing when lifting the PCB.

6. Slide the PCB out of the Housing.

Page 41

1. Remove the Kapton Tape from the Audio ZIF

Connector.

After you remove the Kapton Tape, you

cannot reuse it.

2. Use the Blackstick to open the Audio ZIF

Connector Door.

3. Slide the Audio Flex free from the ZIF Connector.

4. Use the flat end of the Blackstick to disengage

the 2 snap features.

Page 42

5. Use the flat end of the Blackstick to pry the Top

Spacer off the PCB.

The Top Spacer uses a small amount of adhesive

to attach to the PCB. Do not damage the Top

Spacer when removing it from the PCB.

Page 43

1. Use the flat end of the Blackstick on the corners

of the Rear-Facing Imager Shield to raise it.

2. Remove the Rear Facing Imager Shield.

3. Use the pointed end of the Blackstick to free the

Rear-Facing Imager from the socket by pressing

on the retention tabs.

4. Use the Tweezers to remove the Rear-Facing

Imager from the socket.

Page 44

1. Use the flat end of the Blackstick to pry the

Loudspeaker from the PCB at the contact side of

the Loudspeaker.

2. Use the Blackstick and ISP Alcohol to remove

the Loudspeaker Adhesive.

Remove the Loudspeaker Adhesive only if the

Loudspeaker will be reused. If the Loudspeaker

will be replaced, skip this step.

Page 45

Use the flat end of the Blackstick to remove the USB

Grommet from the PCB.

Page 46

Failure to adhere to Safety Critical Note(s) may increase

risk of rupture, burning, or failure to function safely when

used by the customer. Refer to the Battery Safety

Guidelines.

Handle the Battery Pack with care. If dropped to the

floor, it may be internally damaged and must be

scrapped.

Ensure Battery and its insulation are not damaged (e.g.

scratched, dented, punctured) prior to and throughout

assembly.

Prior to assembly, ensure Battery edges and surfaces

are not dented or deformed, and that fixtures and parts

that will contact the Battery are free of foreign material.

Ensure screws and screwdrivers do not contact the

Battery.

1. With 2 hands, carefully twist the Housing

repeatedly to free the Battery Adhesive.

Do not twist the Housing more than necessary.

Only a slight amount of force is required to free

the Battery Adhesive.

If the Battery will be replaced, record the Battery

part number (starts with “SNN”) and reprogram the

Battery part number in the PCB using MotoService

“Battery Link” use case after assembly.

Page 47

1. From the inside of the Housing, pull the Label

Tray out of the Housing.

2. Remove the IMEI Label from the Label Tray.

Page 48

1. Insert the pointed end of the Blackstick into the

Headset Jack.

2. Use the Blackstick to pry the Headset Jack out

of the Housing.

3. Use the Blackstick and ISP Alcohol to remove

the Headset Jack Adhesive.

Remove the Headset Jack Adhesive only if the

Headset Jack will be reused. If the Headset Jack

will be replaced, skip this step.

Page 49

Use the Tweezers to remove the Main Microphone

Grommet from the Housing.

Page 50

Use the Tweezers to remove the Side Key Pad from

the Housing.

Page 51

From the inside of the Housing, use the pointed end

of the Blackstick to push the Rear-Facing Imager

Lens out.

Do not push the Lens free from the outside of the

Housing or remove the Rear-Facing Imager Deco

Ring. The Rear Facing Imager Deco Ring can not

be reassembled at this time.

Page 52

Use the Tweezers to remove the Rear-Facing Imager

Gasket.

Remove the Rear-Facing Imager Gasket only if it

is damaged. If the Rear-Facing Imager Gasket

can be reused, skip this step.

Page 53

The following tools are required for parts refresh of the Moto E (2nd Generation) phone.

PCB Process Fixture

4-00-W6-10000

Lens Assembly Process Fixture

4-00-W9-10000

Blackstick

-Tweezers (Plastic or Plastic-Tipped)

--

--

ESD Mat and Wrist Strap

--

--

Gloves or Finger Collets

--

--

Isopropyl (ISP) Alcohol

--

--

Page 54

1. Use the Blackstick and ISP Alcohol to remove

any remaining adhesive in the Battery pocket.

2. Use the Blackstick and ISP Alcohol to clean any

remaining adhesive from the Display ledge.

Page 55

1. Use the Blackstick and ISP Alcohol to remove

any remaining adhesive from where the Top

Carrier attaches to the PCB.

2. Use the Blackstick and ISP Alcohol to remove

any remaining adhesive from where the

Loudspeaker and Loudspeaker Gasket attaches

to the PCB.

3. Use the Tweezers to remove the PCB Kapton

Tape from the PCB Shields.

Page 56

4. Use the Tweezers to remove the Display ZIF

Connector pad.

Remove the Display ZIF Connector

pad only if it is damaged or if thermal

work will be performed on the PCB.

After you remove it, you cannot reuse

it.

5. Verify that the Display ZIF Connector Door is

open.

6. Use the Tweezers to remove the Audio ZIF

Connector pad.

Remove the Audio ZIF Connector

pad only if it is damaged or if thermal

work will be performed on the PCB.

After you remove it, you cannot reuse

it.

7. Verify that the Audio ZIF Connector Door is

open.

Page 57

Failure to adhere to Safety Critical Note(s) may increase

risk of rupture, burning, or failure to function safely when

used by the customer. Refer to the Battery Safety

Guidelines.

Handle the Battery Pack with care. If dropped to the

floor, it may be internally damaged and must be

scrapped.

Ensure Battery and its insulation are not damaged (e.g.

scratched, dented, punctured) prior to and throughout

assembly.

Prior to assembly, ensure Battery edges and surfaces

are not dented or deformed, and that fixtures and parts

that will contact the Battery are free of foreign material.

Ensure screws and screwdrivers do not contact the

Battery.

1. Use the Blackstick and ISP Alcohol to remove

any adhesive residue from the Battery.

To prevent damage, do not allow sharp tools or

screws to come in contact with the Battery.

2. Inspect the Battery to verify it is not creased,

crushed, or punctured.

3. If the Battery foil pack is wrinkled, slide the flat

edge of the Blackstick against the foil pack to

smooth out all wrinkles.

Page 58

1. Use the Blackstick and ISP Alcohol to remove

any remaining IMEI Label adhesive from the

Label Tray.

2. Inspect the Label Tray to verify it is not cracked,

creased, or otherwise damaged.

Page 59

1. Use the Blackstick and ISP Alcohol to remove

any remaining adhesive from the edge of the

Display.

Use care when cleaning the Display. Do not

separate the Display from the Lens or damage the

Display Flex.

2. Inspect the Display Flex to verify it is not torn,

creased, or otherwise damaged.

Page 60

ASSEMBLY,EARPIECE,DECORATIVE

ASSY,EARPC,DECORATIVE,WHITE

1

GSKT,FF IMAGER,STYX

2

ASSEMBLY,DISPLAY,4.5 Inches MDL ASSY,TFT,WITH LENS,INX,PROD,BLACK"

ASSY,DISP,4.5 Inches MDL ASSY,TFT,WITH LENS,INX,PROD,WHITE

3

Page 61

1. Place the Inlay in the Lens Assembly Process

Fixture (4-00-W9-10000) as shown.

2. Place the Display in the Lens Assembly Process

Fixture (4-00-W9-10000).

Page 62

3. Remove the Front-Facing Imager Gasket from

the carrier.

4. Place the Front-Facing Imager Gasket into the

fixture using the pins to align it.

5. Press down on the Front-Facing Imager Gasket

for 5 seconds to secure it to the Display.

6. Remove the adhesive liner from the Earpiece

Bezel.

7. Place the Earpiece Bezel into the fixture. The

bezel will align to the cutout in the fixture Inlay.

8. Press down on the Earpiece Bezel for 5 seconds

to secure it to the Display.

9. Remove the Display from the fixture.

10. Remove the liners from the Front-Facing Imager

Gasket and Earpiece Bezel.

Page 63

DIE CUT,ADHES,SPK PCB FRM

1

DIE CUT,ADHES,TOP FRAME,STYX

2

COMP ASSY,FRM FLX TOP,STYX

3

1. Use the Blackstick and ISP Alcohol to remove

the Top Spacer Adhesive and Loudspeaker-Side

Adhesive from the Top Spacer.

2. Place the Top Spacer in the PCB Process

Fixture (4-00-W6-10000).

Page 64

3. Remove the Loudspeaker-Side Adhesive from

the carrier.

4. Place the Loudspeaker-Side Adhesive in the

fixture over the Top Spacer. Align the adhesive

using the cutout in the fixture and the tab on the

adhesive liner.

5. Press down on the Loudspeaker-Side Adhesive

to secure it to the Top Spacer.

6. Remove the Top Spacer Adhesive from the

carrier.

7. Place the Top Spacer Adhesive in the fixture

over the Top Spacer. Align the adhesive using

the pin in the fixture and the rectangular cutout in

the Top Spacer.

8. Press down on the Top Spacer Adhesive to

secure it to the Top Spacer.

Page 65

Display

Labels

Loudspeaker

Gasket

Proximity

Grommet

Grounding

Plate

Bottom Spacer

Earpiece

Speaker

Headset Jack

USB Grommet

Rear-Facing

Imager Lens

Top Spacer

PCB

Side Key Pad

Main

Microphone

Grommet

Rear-Facing

Imager

Loudspeaker

Label Tray

Battery

Adhesive

Battery

ZIF Connector

Pads

Screws

Sideband

Housing

Rear-Facing

Imager Gasket

Display

Adhesive

Housing Prep

Page 66

The following tools are required to assemble the Moto E (2nd Generation) phone.

Loudspeaker Adhesive Alignment Fixture

4-00-W5-10000

PCB Process Fixture

4-00-W6-10000

Front Side Process Fixture

4-00-W8-10000

Lens Assembly Process Fixture

4-00-W9-10000

Cleaning Cover

--

Page 67

Press

19501980

Blackstick

--

3IP Torx Bit

--

Torque Driver (Adjustable)

-Tweezers (Plastic or Plastic-Tipped)

--

--

ESD Mat and Wrist Strap

--

--

Gloves or Finger Collets

--

--

Isopropyl (ISP) Alcohol

--

--

Cotton Swabs

--

--

3M AP-111 Adhesion Promoter

--

Page 68

ASSY,HSG,REAR,STYX,LICORICE

ASSY,HSG,REAR,STYX,WHITE

1

LENS,REAR

2

1. Remove the Rear-Facing Imager Lens from the

carrier.

2. Use the Tweezers to place the Rear-Facing

Imager Lens into the pocket of the Rear-Facing

Imager Deco Ring.

3. Press down on the Rear-Facing Imager Lens for

5 seconds to secure it to the Rear-Facing Imager

Deco Ring.

When securing the Rear-Facing Imager Lens, do

not push the Rear-Facing Imager Deco Ring free

of the Housing.

4. Verify the Rear-Facing Imager outer liner is in

position.

Page 69

ASSY,HSG,REAR,STYX,LICORICE

ASSY,HSG,REAR,STYX,WHITE

1

GSKT,REAR MN CAMR

2

1. Remove the Rear-Facing Imager Gasket from

the carrier.

2. Place the Rear-Facing Imager Gasket in the

Rear-Facing Imager Lens pocket.

3. Press down on the Rear-Facing Image Gasket to

secure it to the Lens pocket in the Housing.

4. Remove the liner from the Rear-Facing Imager

Gasket.

Page 70

ASSY,HSG,REAR,STYX,LICORICE

ASSY,HSG,REAR,STYX,WHITE

1

SIDE KEY CONNECTOR

2

1. Place the Side Key Pad into the pocket of the

Housing.

Page 71

2. Verify 3 points for correct alignment:

The Side Key Pad should fit around the 3

Housing posts.

The Side Key Pad should be even with or

below the inner ledge of the Housing.

The Side Key Pad should protrude slightly

from each of the 3 holes on the side of the

Housing.

Page 72

3. Test the Side Key Pad. Pressing the buttons on

the side of the Housing should cause the buttons

to flex inward. The buttons should spring back

immediately upon release.

Page 73

ASSY,HSG,REAR,STYX,LICORICE

ASSY,HSG,REAR,STYX,WHITE

1

GROM,MIC

2

1. Place the Main Microphone Grommet into the

pocket of the Housing. The orientation feature

points away from the Housing edge.

2. Press down on the Main Microphone Grommet

for 3 seconds to secure it in the Housing.

Page 74

ASSY,HSG,REAR,STYX,LICORICE

ASSY,HSG,REAR,STYX,WHITE

1

HSJ, STYX

2

1. Remove the Headset Jack Adhesive from the

carrier.

2. Apply the Headset Jack Adhesive to the Headset

Jack. The adhesive should not overhang the

lower edge of the Headset Jack.

3. Press down on the Headset Jack Adhesive to

secure it to the Headset Jack.

Page 75

4. Remove the Headset Jack Gasket from the

carrier.

5. Apply the Headset Jack Gasket to the Headset

Jack. The gasket should not overhang the edges

of the Headset Jack.

6. Remove the liner from the Headset Jack Gasket.

7. Remove the liner from the Headset Jack

Adhesive.

8. Place the Headset Jack into the pocket of the

Housing, angling the top of the jack into the

pocket first.

9. Press down on the Headset Jack to secure it in

the Housing.

Do not damage the Headset Jack contacts.

Page 76

ASSY,HSG,REAR,STYX,LICORICE

ASSY,HSG,REAR,STYX,WHITE

1

LBL,MEID,STYX

2

1. Route the Label Tray through the slots in the

Housing. The Label Tray fits under the bar inside

the Housing and out the slot on the side of the

Housing.

Page 77

2. Pull the Label Tray through the slot on the side of

the Housing until it stops.

Page 78

ASSY,BAT,FT40,LI POLYMER,SONY,TYP2390 MAH

ALTER SNN5955A for LG

1

DIE CUT,ADHES,BATTERY,STYX

2

Failure to adhere to Safety Critical Note(s) may increase

risk of rupture, burning, or failure to function safely when

used by the customer. Refer to the Battery Safety

Guidelines.

Handle the Battery Pack with care. If dropped to the

floor, it may be internally damaged and must be

scrapped.

Ensure Battery and its insulation are not damaged (e.g.

scratched, dented, punctured) prior to and throughout

assembly.

Prior to assembly, ensure Battery edges and surfaces

are not dented or deformed, and that fixtures and parts

that will contact the Battery are free of foreign material.

Ensure screws and screwdrivers do not contact the

Battery.

Page 79

1. Remove the Battery Adhesive from the carrier.

2. Place the Battery Adhesive in the PCB Process

Fixture (4-00-W6-10000) using the pins to align

it.

3. Place the alignment lid on the fixture.

Page 80

4. Place the Battery in the pocket. The Battery

Connector aligns to the cutout in the alignment

lid.

5. Press down on the Battery to secure the

adhesive.

Page 81

ASSY,HSG,REAR,STYX,LICORICE

ASSY,HSG,REAR,STYX,WHITE

1

ASSY,BAT,FT40,LI POLYMER,SONY,TYP2390 MAH

ALTER SNN5955A for LG

2

Failure to adhere to Safety Critical Note(s) may increase

risk of rupture, burning, or failure to function safely when

used by the customer. Refer to the Battery Safety

Guidelines.

Handle the Battery Pack with care. If dropped to the

floor, it may be internally damaged and must be

scrapped.

Ensure Battery and its insulation are not damaged (e.g.

scratched, dented, punctured) prior to and throughout

assembly.

Prior to assembly, ensure Battery edges and surfaces

are not dented or deformed, and that fixtures and parts

that will contact the Battery are free of foreign material.

Ensure screws and screwdrivers do not contact the

Battery.

Page 82

If a new Battery or PCB is used, record the Battery

part number (starts with “SNN”) and reprogram the

Battery part number in the PCB using MotoService

“Battery Link” use case after assembly.

1. Slide the Label Tray into the Housing,

underneath the Battery. Only a small portion of

the Label Tray remains visible.

2. Place the Housing in the Front Side Process

Fixture (4-00-W8-10000).

Page 83

3. Verify that the Label Tray is positioned in the

recess in the Housing.

4. Place the Battery in the Housing pocket. The

Battery Connector aligns to the cutout feature in

the pocket corner.

Page 84

5. Press down on the Battery to secure it in the

Housing.

6. Place the Front Side Process Fixture (4-00-W8-

10000) in the Press (19501980).

Page 85

7. Hold the Battery Connector out of the Housing

pocket.

Do not damage the Battery Connector.

Keep hands away form the press head during

operation. Injury and/or damage to equipment may

occur.

8. Press the Battery for 10 seconds to secure it to

the Housing.

Page 86

ASSY,PWA,XCVR,STYX 3G,1SIM

ASSY,PWA,XCVR,STYX 3G,AWS

ASSY,PWA,STYX,SPRINT/USC

ASSY,PWA,STYX,EUROPE

ASSY,PWA,STYX,LATAM SS

ASSY,PWA,STYX,NA

ASSY,PWA,STYX,VZW

1

IMGR MDL,CMOS,5MP,8.5X8.5X4.55,MIPI,4P,1/5,LAND,2.8V

2

SHLD,TOP CVR CAMR SKT

3

1. Place the Rear-Facing Imager into the PCB

socket. The dot on the Rear-Facing Imager

aligns with the hole in the socket.

2. Press the Rear-Facing Imager to secure it in the

socket.

Page 87

3. Remove the Rear-Facing Imager protective liner.

Do not discard the protective liner.

4. Place the Rear-Facing Imager Shield over the

Rear-Facing Imager. The slots on the sides of

the Shield align with the spring features on the

sides of the Imager socket.

5. Press the Rear-Facing Imager Shield to secure it

over the socket.

6. Apply the Rear-Facing Imager protective liner to

the Rear-Facing Imager.

Page 88

ASSY,PWA,XCVR,STYX 3G,1SIM

ASSY,PWA,XCVR,STYX 3G,AWS

ASSY,PWA,STYX,SPRINT/USC

ASSY,PWA,STYX,EUROPE

ASSY,PWA,STYX,LATAM SS

ASSY,PWA,STYX,NA

ASSY,PWA,STYX,VZW

1

PAD,GSKT LOUD ADHES

2

Page 89

1. Place the PCB in the PCB Process Fixture (4-00-

W6-10000).

2. Place the alignment tab in the fixture.

Page 90

3. Remove the Loudspeaker Gasket from the

carrier.

4. Place the Loudspeaker Gasket into the fixture

using the pins in the fixture and alignment tab to

align it.

5. Press down on the Loudspeaker Gasket to

secure it to the PCB.

Page 91

ASSY,PWA,XCVR,STYX 3G,1SIM

ASSY,PWA,XCVR,STYX 3G,AWS

ASSY,PWA,STYX,SPRINT/USC

ASSY,PWA,STYX,EUROPE

ASSY,PWA,STYX,LATAM SS

ASSY,PWA,STYX,NA

ASSY,PWA,STYX,VZW

1

DIE CUT,ADHES,LOUD

2

TRANSDUCER,OTHR,2V,LOUDSPEAKER, 8OHM, 3.65 X 12 X 17MM, IP67, IN"

3

Page 92

1. Remove the Loudspeaker Adhesive liner from

the Loudspeaker Adhesive carrier.

2. Place the Loudspeaker Adhesive carrier on the

Loudspeaker Adhesive Assembly Alignment

Fixture (4-00-W5-10000).

3. Place the alignment lid on the fixture.

Page 93

4. Place the Loudspeaker on the adhesive, aligning

the copper contacts to the cutout in the

alignment lid.

5. Press down on the Loudspeaker to secure the

adhesive.

6. Place the PCB into the PCB Processes Fixture

(4-00-W6-10000).

Page 94

7. Place the alignment lid on the fixture.

8. Place the Loudspeaker into the pocket of the

alignment lid.

9. Place the press tool over the pins in the

alignment lid.

10. Press the Loudspeaker for 5 seconds to secure it

to the PCB.

Page 95

ASSY,PWA,XCVR,STYX 3G,1SIM

ASSY,PWA,XCVR,STYX 3G,AWS

ASSY,PWA,STYX,SPRINT/USC

ASSY,PWA,STYX,EUROPE

ASSY,PWA,STYX,LATAM SS

ASSY,PWA,STYX,NA

ASSY,PWA,STYX,VZW

1

PAD,PROX HSJ FLX ZIF SPRT

2

PAD,MN DISP FLX ZIF SPRT

3

DIE CUT,LDL

N/A

1. Remove the Display ZIF Connector pad from the

carrier.

2. Place the Display ZIF Connector pad, aligning it

to the etched markings on the PCB.

Page 96

3. Remove the Audio ZIF Connector pad from the

carrier.

4. Place the Audio ZIF Connector pad, aligning it to

the etched markings on the PCB.

5. Remove the WDL from the carrier.

6. Place the WDL on the PCB as shown, aligning it

to the etched markings on the PCB.

Page 97

ASSY,PWA,XCVR,STYX 3G,1SIM

ASSY,PWA,XCVR,STYX 3G,AWS

ASSY,PWA,STYX,SPRINT/USC

ASSY,PWA,STYX,EUROPE

ASSY,PWA,STYX,LATAM SS

ASSY,PWA,STYX,NA

ASSY,PWA,STYX,VZW

1

GROM,UUSB,STYX

2

1. Remove the USB Grommet from the carrier.

2. Place the side of the USB Grommet without

adhesive over the shield side of the USB

Connector.

Page 98

3. Wrap the USB Grommet around the USB

Connector.

4. Press the USB Grommet to secure it to the USB

Connector.

5. Verify the USB Grommet is fully seated and does

not overlap the USB port.

Page 99

ASSY,PWA,XCVR,STYX 3G,1SIM

ASSY,PWA,XCVR,STYX 3G,AWS

ASSY,PWA,STYX,SPRINT/USC

ASSY,PWA,STYX,EUROPE

ASSY,PWA,STYX,LATAM SS

ASSY,PWA,STYX,NA

ASSY,PWA,STYX,VZW

1

COMP ASSY,FRM FLX TOP,STYX

2

1. Remove all protective and adhesive liners from

the Top Spacer.

2. Verify that the Audio Flex is extended from Top

Spacer.

3. Place the Top Spacer on the PCB, aligning it to

the pins and PCB features.

Page 100

4. Wrap the Audio Flex around top of PCB and

insert it into the Audio Flex ZIF Connector. Use

the white line as a guide for insertion depth.

5. Slide a fingertip across the Audio Flex ZIF

Connector Door to close it.

6. Apply Kapton Tape to the Audio Flex ZIF

Connector Door.

Loading...

Loading...