Page 1

M68HC11

REFERENCE MANUAL

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty, representation or guarantee regarding the suitability

of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and

all liability, including without limitation consequential or incidental damages. "Typical" parameters can and do vary in different applications. All operating parameters, including

"Typicals" must be validated for each customer application by customer's technical experts. Motorola does not convey any license under its patent rights nor the rights of others.

Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications intended to

support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury or death may occur. Should Buyer

purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola and its officers, employees, subsidiaries,

affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal

injury or death associated with such unintended or unauthorized use, even if such claim alleges that Motorola was negligent regarding the design or manufacture of the part.

MOTOROLA and the Motorola logo are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal Opportunity/Affirmative Action Employer.

REV 3

© MOTOROLA, INC. 1996

PREVIOUS EDITIONS © 1991

Page 2

Page 3

TABLE OF CONTENTS

Paragraph Title Page

SECTION 1GENERAL DESCRIPTION

1.1 General Description of the MC68HC11A8 ................................................1-1

1.2 Programmer’s Model .................................................................................1-2

1.3 Product Derivatives ...................................................................................1-4

SECTION 2 PINS AND CONNECTIONS

2.1 Packages And Pin Names .........................................................................2-1

2.1.1 MC68HC11A8 ...................................................................................2-1

2.1.2 MC68HC11D3/711D3 .......................................................................2-2

2.1.3 MC68HC11E9/711E9 ........................................................................ 2-3

2.1.4 MC68HC811E2 .................................................................................2-4

2.1.5 MC68HC11F1 ...................................................................................2-5

2.1.6 MC68HC24 Port Replacement Unit ..................................................2-6

2.2 Pin Descriptions ........................................................................................2-7

2.2.1 Power-Supply Pins (VDD and VSS) ..................................................2-7

2.2.2 Mode Select Pins (MODB/VSTBY and MODA/LIR) ..........................2-8

2.2.3 Crystal Oscillator and Clock Pins (EXTAL, XTAL, and E) ...............2-10

2.2.4 Crystal Oscillator Application Information ........................................2-15

2.2.4.1 Crystals for Parallel Resonance ..............................................2-15

2.2.4.2 Using Crystal Oscillator Outputs .............................................2-15

2.2.4.3 Using External Oscillator .........................................................2-15

2.2.4.4 AT-strip vs AT-cut Crystals .....................................................2-16

2.2.5 Reset Pin (RESET) .........................................................................2-16

2.2.6 Interrupt Pins (XIRQ, IRQ) ..............................................................2-17

2.2.7 A/D Reference and Port E Pins (VREFL, VREFH, PE[7:0]) ............2-18

2.2.8 Timer Port A Pins ............................................................................2-19

2.2.9 Serial Port D Pins ............................................................................2-19

2.2.10 Ports B and C, STRA, and STRB Pins ............................................2-20

2.3 Termination of Unused Pins ....................................................................2-21

2.4 Avoidance of Pin Damage .......................................................................2-23

2.4.1 Zap and Latchup .............................................................................2-24

2.4.2 Protective Interface Circuits ............................................................2-24

2.4.3 Internal Circuitry — Digital Input-Only Pin .......................................2-25

2.4.4 Internal Circuitry — Analog Input-Only Pin ......................................2-26

2.4.5 Internal Circuitry — Digital I/O Pin ...................................................2-28

2.4.6 Internal Circuitry — Input/Open-Drain-Output Pin ...........................2-29

2.4.7 Internal Circuitry — Digital Output-Only Pin ....................................2-29

2.4.8 Internal Circuitry — MODB/VSTBY Pin ...........................................2-30

2.4.9 Internal Circuitry — IRQ/VPPBULK Pin ..........................................2-31

2.5 Typical Single-Chip-Mode System Connections .....................................2-31

2.6 Typical Expanded-Mode-System Connections .......................................2-33

M68HC11 MOTOROLA

REFERENCE MANUAL iii

Page 4

TABLE OF CONTENTS

(Continued)

Paragraph Title Page

2.7 System Development and Debug Features ............................................2-37

2.7.1 Load Instruction Register (LIR) .......................................................2-37

2.7.2 Internal Read Visibility (IRV) ...........................................................2-37

2.7.3 MC68HC24 Port Replacement Unit ................................................2-38

SECTION 3 CONFIGURATION AND MODES OF OPERATION

3.1 Hardware Mode Selection .........................................................................3-1

3.1.1 Hardware Mode Select Pins ..............................................................3-2

3.1.2 Mode Control Bits in the HPRIO Register .........................................3-2

3.2 EEPROM-Based CONFIG Register ..........................................................3-3

3.2.1 Operation of CONFIG Mechanism ....................................................3-3

3.2.2 The CONFIG Register .......................................................................3-4

3.3 Protected Control Register Bits .................................................................3-6

3.3.1 RAM and I/O Mapping Register (INIT) ..............................................3-7

3.3.2 Protected Control Bits in the TMSK2 Register ..................................3-8

3.3.3 Protected Control Bits in the OPTION Register ................................3-9

3.4 Normal MCU Operating Modes ...............................................................3-10

3.4.1 Normal Single-Chip Mode ...............................................................3-10

3.4.2 Normal Expanded Mode ..................................................................3-10

3.5 Special MCU Operating Modes ...............................................................3-11

3.5.1 Testing Functions Control Register (TEST1) ..................................3-12

3.5.2 Test-Related Control Bits in the BAUD Register .............................3-14

3.5.3 Special Test Mode ...........................................................................3-14

3.5.4 Special Bootstrap Mode ..................................................................3-15

3.5.4.1 Loading Programs in Bootstrap Mode .....................................3-16

3.5.4.2 Executing User Programs in Bootstrap Mode .........................3-17

3.5.4.3 Using Interrupts in Bootstrap Mode .........................................3-17

3.5.4.4 Bootloader Firmware Options .................................................3-18

3.6 Test and Bootstrap Mode Applications ....................................................3-19

SECTION 4 ON-CHIP MEMORY

4.1 ROM .......................................................................................................... 4-1

4.2 RAM ..........................................................................................................4-2

4.2.1 Remapping Using the INIT Register ..................................................4-2

4.2.2 RAM Standby ....................................................................................4-3

4.3 EEPROM ................................................................................................... 4-4

4.3.1 Logical and Physical Organization ....................................................4-4

4.3.2 Basic Operation of the EEPROM ......................................................4-5

4.3.3 Systems Operating below 2-MHz Bus Speed (E Clock) ...................4-9

4.3.4 EEPROM Programming Register (PPROG) ...................................4-10

MOTOROLA M68HC11

iv REFERENCE MANUAL

Page 5

TABLE OF CONTENTS

(Continued)

Paragraph Title Page

4.3.5 Programming/Erasing Procedures ..................................................4-12

4.3.5.1 Programming ...........................................................................4-12

4.3.5.2 Bulk Erase ...............................................................................4-13

4.3.5.3 Row Erase ...............................................................................4-13

4.3.5.4 Byte Erase ...............................................................................4-13

4.3.5.5 CONFIG Register ....................................................................4-14

4.3.6 Optional EEPROM Security Mode ..................................................4-14

4.4 EEPROM Application Information ...........................................................4-16

4.4.1 Conditions and Practices to Avoid ...................................................4-16

4.4.2 Using EEPROM to Select Product Options .....................................4-18

4.4.3 Using EEPROM for Setpoint and Calibration Information ...............4-18

4.4.4 Using EEPROM during Product Development ................................4-19

4.4.5 Logging Data ...................................................................................4-19

4.4.6 Self-Adjusting Systems using EEPROM .........................................4-20

4.4.7 Software Methods to Extend Life Expectancy .................................4-21

SECTION 5 RESETS AND INTERRUPTS

5.1 Initial Conditions Established During Reset ..............................................5-1

5.1.1 System Initial Conditions ...................................................................5-2

5.1.1.1 CPU ...........................................................................................5-2

5.1.1.2 Memory Map .............................................................................5-2

5.1.1.3 Parallel I/O ................................................................................5-2

5.1.1.4 Timer ......................................................................................... 5-2

5.1.1.5 Real-Time Interrupt ...................................................................5-3

5.1.1.6 Pulse Accumulator ....................................................................5-3

5.1.1.7 COP Watchdog .........................................................................5-3

5.1.1.8 Serial Communications Interface (SCI) .....................................5-3

5.1.1.9 Serial Peripheral Interface (SPI) ...............................................5-3

5.1.1.10 Analog-to-Digital (A/D) Converter .............................................5-3

5.1.1.11 Other System Controls ..............................................................5-4

5.1.2 CONFIG Register Allows Flexible Configuration ...............................5-4

5.1.3 Mode of Operation Established .........................................................5-5

5.1.4 Program Counter Loaded with Reset Vector .....................................5-5

5.2 Causes Of Reset .......................................................................................5-5

5.2.1 Power-On Reset (POR) .....................................................................5-7

5.2.2 COP Watchdog Timer Reset .............................................................5-7

5.2.3 Clock Monitor Reset ..........................................................................5-9

5.2.4 External Reset .................................................................................5-10

5.3 Interrupt Process .....................................................................................5-11

5.3.1 Interrupt Recognition and Stacking Registers .................................5-12

5.3.2 Selecting Interrupt Vectors ..............................................................5-12

5.3.3 Return from Interrupt .......................................................................5-19

5.4 Non-Maskable Interrupts .........................................................................5-20

5.4.1 Non-Maskable Interrupt Request (XIRQ) ........................................5-20

M68HC11 MOTOROLA

REFERENCE MANUAL v

Page 6

TABLE OF CONTENTS

(Continued)

Paragraph Title Page

5.4.2 Illegal Opcode Fetch .......................................................................5-21

5.4.3 Software Interrupt ............................................................................5-22

5.5 Maskable Interrupts .................................................................................5-22

5.5.1 I Bit in the Condition Code Register ................................................5-22

5.5.2 Special Considerations for I-Bit-Related Instructions ......................5-23

5.6 Interrupt Request .....................................................................................5-24

5.6.1 Selecting Edge Triggering or Level Triggering ................................5-24

5.6.2 Sharing Vector with Handshake I/O Interrupts ................................5-25

5.7 Interrupts from Internal Peripheral Subsystems ......................................5-25

5.7.1 Inhibiting Individual Sources ............................................................5-26

5.7.2 Clearing Interrupt Status Flag Bits ..................................................5-26

5.7.3 Automatic Clearing Mechanisms on Some Flags ............................5-26

SECTION 6 CENTRAL PROCESSING UNIT

6.1 Programmer’s Model .................................................................................6-1

6.1.1 Accumulators (A, B, and D) ...............................................................6-1

6.1.2 Index Registers (X and Y) .................................................................6-2

6.1.3 Stack Pointer (SP) .............................................................................6-3

6.1.4 Program Counter (PC) ......................................................................6-4

6.1.5 Condition Code Register (CCR) ........................................................6-4

6.2 Addressing Modes .....................................................................................6-6

6.2.1 Immediate (IMM) ...............................................................................6-6

6.2.2 Extended (EXT) .................................................................................6-7

6.2.3 Direct (DIR) .......................................................................................6-8

6.2.4 Indexed (INDX, INDY) .......................................................................6-9

6.2.5 Inherent (INH) ..................................................................................6-10

6.2.6 Relative (REL) .................................................................................6-10

6.3 M68HC11 Instruction Set ........................................................................6-11

6.3.1 Accumulator and Memory Instructions ............................................6-11

6.3.1.1 Loads, Stores, And Transfers .................................................6-11

6.3.1.2 Arithmetic Operations ..............................................................6-12

6.3.1.3 Multiply and Divide ..................................................................6-13

6.3.1.4 Logical Operations ..................................................................6-13

6.3.1.5 Data Testing and Bit Manipulation ..........................................6-14

6.3.1.6 Shifts and Rotates ...................................................................6-14

6.3.2 Stack and Index Register Instructions .............................................6-15

6.3.3 Condition Code Register Instructions ..............................................6-16

6.3.4 Program Control Instructions ...........................................................6-17

6.3.4.1 Branches ................................................................................. 6-17

6.3.4.2 Jumps ......................................................................................6-18

6.3.4.3 Subroutine Calls And Returns (BSR, JSR, RTS) ....................6-18

MOTOROLA M68HC11

vi REFERENCE MANUAL

Page 7

TABLE OF CONTENTS

(Continued)

Paragraph Title Page

6.3.4.4 Interrupt Handling (RTI, SWI, WAI) .........................................6-18

6.3.4.5 Miscellaneous (NOP, STOP, TEST) .......................................6-18

SECTION 7 PARALLEL INPUT/OUTPUT

7.1 Parallel I/O Overview .................................................................................7-1

7.2 Parallel I/O Register And Control Bit Explanations ...................................7-3

7.2.1 Port Registers ....................................................................................7-4

7.2.2 Data Direction Registers ...................................................................7-5

7.3 Detailed I/O Pin Descriptions ....................................................................7-6

7.3.1 Port A ................................................................................................7-7

7.3.1.1 PA[2:0] (IC[3:1]) Pin Logic .........................................................7-7

7.3.1.2 PA[6:3] (OC[5:2]) Pin Logic .......................................................7-8

7.3.1.3 PA7 (OC1, PAI) Pin Logic .........................................................7-9

7.3.1.4 Port A Idealized Timing ...........................................................7-12

7.3.2 Port B ..............................................................................................7-12

7.3.2.1 Port B Pin Logic ......................................................................7-13

7.3.2.2 Port B Idealized Timing ...........................................................7-14

7.3.2.3 Special Considerations For Port B On MC68HC24 PRU ........7-15

7.3.3 R/W (STRB) Pin ..............................................................................7-15

7.3.3.1 R/W (STRB) Pin Logic ............................................................7-15

7.3.3.2 Special Considerations for STRB on MC68HC24 PRU ..........7-17

7.3.4 Port C ..............................................................................................7-17

7.3.4.1 Port C Pin Logic for Expanded Modes ....................................7-17

7.3.4.2 Summary of Port C Idealized Expanded-Mode Timing ...........7-18

7.3.4.3 Port C Single-Chip Mode Pin Logic .........................................7-19

7.3.4.4 Port C Idealized Single-Chip Mode Timing .............................7-23

7.3.4.5 Special Considerations for Port C on MC68HC24 PRU ..........7-24

7.3.5 AS (STRA) Pin ................................................................................7-24

7.3.5.1 AS (STRA) Pin Logic ...............................................................7-24

7.3.5.2 Special Considerations for STRA on MC68HC24 PRU ..........7-26

7.3.6 Port D ..............................................................................................7-26

7.3.6.1 PD0 (RxD) Pin Logic ...............................................................7-26

7.3.6.2 PD1 (TxD) Pin Logic ...............................................................7-28

7.3.6.3 PD2 (MISO) Pin Logic .............................................................7-30

7.3.6.4 PD3 (MOSI) Pin Logic .............................................................7-32

7.3.6.5 PD4 (SCK) Pin Logic ...............................................................7-34

7.3.6.6 PD5 (SS) Pin Logic .................................................................7-36

7.3.6.7 Idealized Port D Timing ...........................................................7-38

7.3.7 Port E ..............................................................................................7-40

7.3.7.1 Port E Pin Logic ......................................................................7-40

7.3.7.2 Idealized Port E Timing ...........................................................7-41

7.4 Handshake I/O Subsystem ......................................................................7-42

7.4.1 Simple Strobe Mode ........................................................................7-43

7.4.1.1 Port B Strobe Output. ..............................................................7-43

M68HC11 MOTOROLA

REFERENCE MANUAL vii

Page 8

TABLE OF CONTENTS

(Continued)

Paragraph Title Page

7.4.1.2 Port C Simple Latching Input ..................................................7-44

7.4.2 Full-input Handshake Mode ............................................................7-44

7.4.3 Full-Output Handshake Mode .........................................................7-45

7.4.3.1 Normal Output Handshake ......................................................7-46

7.4.3.2 Three-State Variation of Output Handshake ...........................7-46

7.4.4 Parallel I/O Control Register (PIOC) ...............................................7-47

7.4.5 Non-Handshake Uses of STRA and STRB Pins .............................7-49

SECTION 8 SYNCHRONOUS SERIAL PERIPHERAL INTERFACE

8.1 SPI Transfer Formats ................................................................................8-1

8.1.1 SPI Clock Phase and Polarity Controls .............................................8-1

8.1.2 CPHA Equals Zero Transfer Format .................................................8-2

8.1.3 CPHA Equals One Transfer Format ..................................................8-2

8.2 SPI Block Diagram ....................................................................................8-3

8.3 SPI Pin Signals ..........................................................................................8-4

8.4 SPI Registers ............................................................................................8-6

8.4.1 Port D Data Direction Control Register (DDRD) ................................8-6

8.4.2 SPI Control Register (SPCR) ............................................................8-7

8.4.3 SPI Status Register (SPSR) ..............................................................8-8

8.5 SPI System Errors .....................................................................................8-9

8.5.1 SPI Mode-Fault Error ........................................................................8-9

8.5.2 SPI Write-Collision Errors ................................................................8-10

8.6 Beginning and Ending SPI Transfers ......................................................8-10

8.6.1 Transfer Beginning Period (Initiation Delay) ....................................8-10

8.6.2 Transfer Ending Period ...................................................................8-12

8.7 Transfers to Peripherals with Odd Word Lengths ...................................8-14

8.7.1 Example 8–1: On-Chip SPI Driving an MC144110 D/A ..................8-16

8.7.2 Example 8–2: Software SPI Driving an MC144110 D/A ..................8-16

SECTION 9 ASYNCHRONOUS SERIAL COMMUNICATIONS INTERFACE

9.1 General Description ...................................................................................9-1

9.1.1 Transmitter Block Diagram ................................................................9-2

9.1.2 Receiver Block Diagram ....................................................................9-3

9.2 SCI Registers and Control Bits ..................................................................9-5

9.2.1 Port D Related Registers and Control Bits (PORTD, DDRD, SPCR) 9-6

9.2.2 Baud-Rate Control Register (BAUD) .................................................9-7

9.2.3 SCI Control Register 1 (SCCR1) .......................................................9-9

9.2.4 SCI Control Register 2 (SCCR2) .....................................................9-10

9.2.5 SCI Status Register (SCSR) ...........................................................9-11

9.2.6 SCI Data Register (SCDR) ..............................................................9-14

MOTOROLA M68HC11

viii REFERENCE MANUAL

Page 9

TABLE OF CONTENTS

(Continued)

Paragraph Title Page

9.3 SCI Transmitter .......................................................................................9-14

9.3.1 Eight- and Nine-Bit Data Modes ......................................................9-15

9.3.2 Interrupts and Status Flags .............................................................9-16

9.3.3 Send Break ......................................................................................9-16

9.3.4 Queued Idle Character ....................................................................9-17

9.3.5 Disabling the SCI Transmitter .........................................................9-18

9.3.6 TxD Pin Buffer Logic .......................................................................9-19

9.4 SCI Receiver ...........................................................................................9-20

9.4.1 Data Sampling Technique ...............................................................9-20

9.4.2 Worst-Case Baud-Rate Mismatch ...................................................9-26

9.4.3 Double-Buffered Operation .............................................................9-28

9.4.4 Receive Status Flags and Interrupts ...............................................9-28

9.4.5 Receiver Wake-Up Operation .........................................................9-29

9.4.5.1 Idle-Line Wake Up ...................................................................9-29

9.4.5.2 Address-Mark Wake Up ..........................................................9-29

9.5 Baud-Rate Generator ..............................................................................9-30

9.5.1 Timing Chain Block Diagram ...........................................................9-30

9.5.2 Baud Rates vs. Crystal Frequency ..................................................9-30

9.6 SCI Timing Details ...................................................................................9-30

9.6.1 Operation As Transmitter Is Enabled ..............................................9-31

9.6.2 TDRE and Transfers from SCDR to Transmit Shift Register ..........9-33

9.6.3 TC vs. Character Completion ..........................................................9-34

9.6.4 RDRF Flag Setting vs. End of a Received Character .....................9-35

SECTION 10 MAIN TIMER AND REAL-TIME INTERRUPT

10.1 General Description .................................................................................10-1

10.1.1 Overall Timer Block Diagram ..........................................................10-2

10.1.2 Input-Capture Concept ....................................................................10-2

10.1.3 Output-Compare Concept ...............................................................10-4

10.2 Free-Running Counter and Prescaler .....................................................10-5

10.2.1 Overall Clock Divider Structure .......................................................10-5

10.2.1.1 Prescaler ................................................................................. 10-7

10.2.1.2 Overflow ................................................................................ 10-10

10.2.1.3 Counter Bypass (Test Mode) ................................................10-11

10.2.2 Real-Time Interrupt (RTI) Function ...............................................10-11

10.2.3 COP Watchdog Function ...............................................................10-13

10.2.4 Tips for Clearing Timer Flags ........................................................10-14

10.3 Input-Capture Functions ........................................................................10-16

10.3.1 Programmable Options .................................................................10-17

10.3.2 Using Input Capture to Measure Period and Frequency ...............10-18

10.3.3 Using Input Capture to Measure Pulse Width ...............................10-20

10.3.4 Measuring Very Short Time Periods .............................................10-24

10.3.5 Measuring Long Time Periods with Input Capture and Overflow ..10-24

10.3.6 Establishing a Relationship between Software and an Event .......10-27

M68HC11 MOTOROLA

REFERENCE MANUAL ix

Page 10

TABLE OF CONTENTS

(Continued)

Paragraph Title Page

10.3.7 Other Uses for Input-Capture Pins ................................................10-28

10.4 Output-Compare Functions ...................................................................10-28

10.4.1 Normal I/O Pin Control Using OC[5:2] ...........................................10-32

10.4.2 Advanced I/O Pin Control Using OC1 ...........................................10-35

10.4.2.1 One Output Compare Controlling up to Five Pins .................10-35

10.4.2.2 Two Output Compares Controlling One Pin ..........................10-36

10.4.3 Forced Output Compares ..............................................................10-38

10.5 Timing Details For The Main Timer System ..........................................10-39

10.6 Listing of Timer Examples .....................................................................10-42

SECTION 11 PULSE ACCUMULATOR

11.1 General Description .................................................................................11-1

11.1.1 Pulse Accumulator Block Diagram ..................................................11-2

11.1.2 Pulse Accumulator Control and Status Registers ...........................11-3

11.2 Event Counting Mode ..............................................................................11-6

11.2.1 Interrupting after N Events ..............................................................11-6

11.2.2 Counting More Than 256 Events .....................................................11-6

11.3 Gated Time Accumulation Mode .............................................................11-8

11.3.1 Measuring Times Longer Than the Range of the 8-Bit Counter ......11-8

11.3.2 Configuring for Interrupt after a Specified Time ..............................11-9

11.4 Other Uses for the PAI Pin ......................................................................11-9

11.5 Timing Details for the Pulse Accumulator ...............................................11-9

SECTION 12 ANALOG-TO-DIGITAL CONVERTER SYSTEM

12.1 Charge-Redistribution A/D ......................................................................12-1

12.2 A/D Converter Implementation on MC68HC11A8 .................................12-10

12.2.1 MC68HC11A8 Successive-Approximation A/D Converter ............12-10

12.2.2 A/D Charge Pump and Resistor-Capacitor (RC) Oscillator ...........12-11

12.2.3 MC68HC11A8 A/D System Control Logic .....................................12-13

12.2.4 A/D Control/Status Register (ADCTL) ...........................................12-14

12.2.5 A/D Result Registers (ADR[4:1]) ...................................................12-15

12.3 A/D Pin Connection Considerations ......................................................12-16

APPENDIX A INSTRUCTION SET DETAILS

A.1 Introduction ............................................................................................... A-1

A.2 Nomenclature ........................................................................................... A-1

APPENDIX BBOOTLOADER LISTINGS

SUMMARY OF CHANGES

MOTOROLA M68HC11

x REFERENCE MANUAL

Page 11

LIST OF ILLUSTRATIONS

Figure Title Page

1-1 Block Diagram ................................................................................................1-3

1-2 M68HC11 Programmer’s Model ..................................................................... 1-4

1-3 Part Numbering .............................................................................................. 1-5

2-1 MC68HC11A8 Pin Assignments .................................................................... 2-2

2-2 MC68HC11D3/711D3 Pin Assignments .........................................................2-3

2-3 MC68HC11E9/711E9 Pin Assignments (52-Pin PLCC) .................................2-4

2-4 MC68HC811E2 Pin Assignments (48-Pin DIP) ..............................................2-5

2-5 MC68HC11F1 Pin Assignments (68-Pin PLCC) ............................................ 2-6

2-6 MC68HC24 Pin Assignments ......................................................................... 2-7

2-7 Reduced IDD MODA/LIR Connections .......................................................... 2-9

2-8 RAM Standby MODB/VSTBY Connections ..................................................2-10

2-9 High-Frequency Crystal Connections ...........................................................2-12

2-10 Low-Frequency Crystal Connections ........................................................... 2-12

2-11 Crystal Layout Example ............................................................................... 2-13

2-12 Reset Circuit Example .................................................................................. 2-17

2-13 Low-Pass Filter for A/D Reference Pins ....................................................... 2-19

2-14 CMOS Inverter ............................................................................................. 2-22

2-15 Internal Circuitry — Digital Input-Only Pin .................................................... 2-25

2-16 Internal Circuitry — Analog Input-Only Pin ...................................................2-27

2-17 Internal Circuitry — Digital I/O Pin ................................................................2-28

2-18 Internal Circuitry — Input/Open-Drain-Output Pin ........................................ 2-29

2-19 Internal Circuitry — Output-Only Pin ............................................................2-29

2-20 Internal Circuitry — MODB/VSTBY Pin ........................................................ 2-30

2-21 Internal Circuitry — IRQ/VPPBULK Pin ....................................................... 2-31

2-22 Basic Single-Chip-Mode Connections .......................................................... 2-32

2-23 Basic Expanded Mode Connections (Sheet 1 of 2) ......................................2-35

2–23 Basic Expanded Mode Connections (Sheet 2 of 2) ...................................... 2-36

3-1 Schematic for

3–1 Schematic for

3-2 Program to Check/Change CONFIG ............................................................ 3-23

4-1 Topological Arrangement of EEPROM Bytes (MC68HC11A8) ......................4-5

4-2 Topological Arrangement of Bits in an EEPROM Byte ...................................4-5

4-3 Condensed Schematic of EEPROM Array .....................................................4-6

4-4 EEPROM Cell Terminology ............................................................................ 4-7

4-5 Erasing an EEPROM Byte ............................................................................. 4-7

4-6 Programming an EEPROM Byte ....................................................................4-8

4-7 Reading an EEPROM Byte ............................................................................ 4-9

4-8 Erase-Before-Write Programming Method ...................................................4-24

4-9 Program-More-Zeros Programming Method ................................................ 4-24

4-10 Selective-Write Programming Method ..........................................................4-25

4-11 Composite Programming Method .................................................................4-26

5-1 Typical External Reset Circuit ...................................................................... 5-11

5-2 Processing Flow out of Resets (Sheet 1 of 2) ..............................................5-15

5–2 Processing Flow out of Resets (Sheet 2 of 2) .............................................. 5-16

Figure 3-2 (Sheet 1 of 2) ...................................................... 3-21

Figure 3-2 (Sheet 2 of 2) ...................................................... 3-22

M68HC11 MOTOROLA

REFERENCE MANUAL xi

Page 12

LIST OF ILLUSTRATIONS

(Continued)

Figure Title Page

5-3 Interrupt Priority Resolution (Sheet 1 of 2) ...................................................5-17

5–3 Interrupt Priority Resolution (Sheet 2 of 2) ................................................... 5-18

5-4 Interrupt Source Resolution within SCI ........................................................ 5-19

6-1 M68HC11 Programmer’s Model ..................................................................... 6-2

7-1 Parallel I/O Registers and Control Bits ........................................................... 7-3

7-2 Pin Logic Registers and Control Bits .............................................................. 7-4

7-3 Special Symbols used in Pin Logic Diagrams ................................................7-7

7-4 PA[2:0] (IC[3:1]) Pin Logic .............................................................................. 7-8

7-5 PA[6:3] (OC[5:2]) Pin Logic ..........................................................................7-10

7-6 PA7 (OC1, PAI) Pin Logic ............................................................................ 7-11

7-7 Idealized Port A Timing ................................................................................ 7-12

7-8 Port B Pin Logic ............................................................................................7-13

7-9 Idealized Port B Timing ................................................................................ 7-14

7-10 R/W (STRB) Pin Logic ..................................................................................7-16

7-11 Port C Expanded Mode Pin Logic ................................................................ 7-18

7-12 Summary of Idealized Port C Expanded-Mode Timing ................................ 7-20

7-13 Port C Single-Chip Mode Pin Logic .............................................................. 7-21

7-14 Idealized Port C Single-Chip Mode Timing .................................................. 7-23

7-15 AS (STRA) Pin Logic .................................................................................... 7-25

7-16 PD0 (RxD) Pin Logic .................................................................................... 7-27

7-17 PD1 (TxD) Pin Logic .....................................................................................7-29

7-18 PD2 (MISO) Pin Logic ..................................................................................7-31

7-19 PD3 (MOSI) Pin Logic ..................................................................................7-33

7-20 PD4 (SCK) Pin Logic .................................................................................... 7-35

7-21 PD5 (SS) Pin Logic ...................................................................................... 7-37

7-22 Idealized Port D Timing ................................................................................7-39

7-23 Port E Pin Logic ............................................................................................7-41

7-24 Idealized Port E Timing ................................................................................ 7-42

7-25 Idealized Timing for Simple Strobe Operations ............................................ 7-43

7-26 Idealized Timing for Full-Input Handshake ................................................... 7-45

7-27 Idealized Timing for Full-Output Handshake ................................................7-46

8-1 CPHA Equals Zero SPI Transfer Format ....................................................... 8-2

8-2 CPHA Equals One SPI Transfer Format ........................................................8-3

8-3 SPI System Block Diagram ............................................................................ 8-4

8-4 Delay from Write SPDR to Transfer Start (Master) ...................................... 8-12

8-5 Transfer Ending for an SPI Master ............................................................... 8-13

8-6 Transfer Ending for an SPI Slave ................................................................. 8-14

8-7 Hardware Hookup for Examples 8–1 and 8–2 ............................................. 8-15

8-8 Register Definitions and RAM Variables for Examples 8–1 and 8–2 ........... 8-16

8-9 Example 8–1 Software Listing (Sheet 1 of 2) ...............................................8-17

8–9 Example 8–1 Software Listing (Sheet 2 of 2) ............................................... 8-18

MOTOROLA M68HC11

xii REFERENCE MANUAL

Page 13

µ

µ

µ

µ

LIST OF ILLUSTRATIONS

(Continued)

Figure Title Page

8-10 Timing Analysis for Example 8–1 .................................................................8-19

8-11 Example 8–2 Software Listing ...................................................................... 8-20

(a) EN Low to SCK Start Delay (MC144110 Needs 5

(b) Data to SCK Setup (MC144110 Needs 1

s) ......................................... 8-21

8-12 Timing Analysis for Example 8–2 (Sheet 1 of 2) .......................................... 8-21

(c) Data Hold vs. SCK (MC144110 Needs 5

(d) SCK Low to EN Hold (MC144110 Needs 5

s) .......................................... 8-22

s) ...................................... 8-22

8–12 Timing Analysis for Example 8-2 (Sheet 2 of 2) ........................................... 8-22

9-1 SCI Transmitter Block Diagram ...................................................................... 9-2

9-2 SCI Receiver Block Diagram .......................................................................... 9-4

9-3 TxD Pin Logic Block Diagram .......................................................................9-19

9-4 Start Bit — Ideal Case .................................................................................. 9-22

9-5 Start Bit — Noise Case One .........................................................................9-22

9-6 Start Bit — Noise Case Two .........................................................................9-23

9-7 Start Bit — Noise Case Three ......................................................................9-24

9-8 Start Bit — Noise Case Four ........................................................................9-24

9-9 Start Bit — Noise Case Five .........................................................................9-25

9-10 Start Bit — Noise Case Six .......................................................................... 9-25

(a) Receive Data Slower Than Receiver Baud Rate .................................... 9-27

(b) Receive Data Faster Than Receiver Baud Rate .....................................9-27

9-11 Baud-Rate Frequency Tolerance ................................................................. 9-27

9-12 Baud-Rate Generator Block Diagram ...........................................................9-31

9-13 Transmitter Enable Timing Details ............................................................... 9-33

9-14 Write SCDR to Serial Data Start .................................................................. 9-34

9-15 Ending Details of Transmission .................................................................... 9-35

9-16 RDRF Flag-Setting Details ...........................................................................9-36

10-1 Main Timer System Block Diagram ..............................................................10-3

10-2 Timing Summary for Oscillator Divider Signals ............................................10-6

10-3 Major Clock Divider Chains in the MC68HC11A8 ........................................10-9

10-4 Measuring a Period with Input Capture ......................................................10-19

10-5 Timing Analysis for Example 10–1 .............................................................10-19

10-6 Measuring a Pulse Width with Input Capture ............................................. 10-22

10-6 (a) Leading Edge Latency .......................................................................... 10-23

10-6 (b) Process First Edge, Earliest Opportunity for Second Edge .................. 10-23

10-7 Timing Analysis for Example 10–2 .............................................................10-23

10-8 Measuring Long Periods with Input Capture and TOF (Sheet 1 of 2) ........ 10-26

10-8 Measuring Long Periods with Input Capture and TOF (Sheet 2 of 2) ........ 10-27

10-9 Simple Output-Compare Example ..............................................................10-31

10-10 Generating a Square Wave with Output Compare .....................................10-33

10-11 Timing Analysis for Example 10–5 ............................................................. 10-34

10-12 Producing Two PWM Outputs with OC1, OC2, and OC3 .......................... 10-37

s) ............................ 8-21

M68HC11 MOTOROLA

REFERENCE MANUAL xiii

Page 14

±

LIST OF ILLUSTRATIONS

(Continued)

Figure Title Page

10-13 Timer Counter as MCU Leaves Reset ....................................................... 10-40

10-14 Timer Counter Read — Cycle-by-Cycle Analysis ....................................... 10-40

10-15 Input-Capture Timing Details ...................................................................... 10-41

10-16 Output-Compare Timing Details .................................................................10-42

11-1 Pulse Accumulator Operating Modes ........................................................... 11-1

11-2 Block Diagram of Pulse Accumulator Subsystem ........................................ 11-3

11-3 Pulse Accumulator Control and Status Register Summary .......................... 11-4

11-4 PAI Pin Edge-Detection Timing .................................................................. 11-10

11-5 Pin Enable vs. Counting (Gated Accumulation Mode) ............................... 11-10

11-6 Timing Details for Pulse Accumulator Counter Overflow ........................... 11-11

(a) PACNT Read ........................................................................................ 11-12

(b) PACNT Write ........................................................................................ 11-12

11-7 PACNT Read and Write ............................................................................. 11-12

(a) Sample Mode ..........................................................................................12-2

(b) Hold Mode ............................................................................................... 12-2

(c) Approximation Mode ............................................................................... 12-2

12-1 Basic Charge-Redistribution A/D ..................................................................12-2

(a) Sample Mode ..........................................................................................12-8

(b) Hold Mode ............................................................................................... 12-8

(c) Approximation Mode ............................................................................... 12-8

12-2 Charge-Redistribution A/D with

12-3 MC68HC11A8 A/D in Sample Mode .......................................................... 12-11

12-4 Timing Diagram for a Sequence of Four A/D Conversions ........................ 12-14

12-5 Electrical Model of an A/D Input Pin (Sample Mode) ................................. 12-16

12-6 Graphic Estimation of Analog Sample Level (Case 2) ............................... 12-19

1/2 LSB Quantization Error ..................... 12-8

MOTOROLA M68HC11

xiv REFERENCE MANUAL

Page 15

LIST OF TABLES

Table Title Page

1-1 M68HC11 Family Members................................................................................... 1-6

2-1 Hardware Mode Select Summary..........................................................................2-9

2-2 Ports B and C, STRA, and STRB Pins................................................................2-21

3-1 Hardware Mode Select Summary..........................................................................3-2

3-2 Watchdog Rates vs. Crystal Frequency .............................................................. 3-10

3-3 Bootstrap Mode Pseudo-Vectors.........................................................................3-18

5-1 Hardware Mode Select Summary..........................................................................5-5

5-2 Reset Vector vs. Cause and MCU Mode...............................................................5-6

5-3 Watchdog Rates vs. Crystal Frequency ................................................................ 5-8

5-4 Highest Priority 1 Interrupt vs. PSEL[3:0]............................................................5-14

9-1 Baud-Rate Prescale Selects..................................................................................9-8

9-2 Baud-Rate Selects.................................................................................................9-9

9-3 Baud Rates by Crystal Frequency, SCP[1:0] and SCR[2:0]................................ 9-32

10-1 Crystal Frequency vs. PR1, PR0 Values......................................................... 10-10

10-2 RTI Rates vs. RTR1, RTR0 for Various Crystal Frequencies..........................10-13

10-3 COP Time-Out vs. CR1, CR0 Values.............................................................. 10-14

10-4 Instruction Sequences To Clear TOF..............................................................10-15

11-1 Pulse Accumulator Timing Periods vs. Crystal Rate .........................................11-2

12-1 A/D Channel Assignments...............................................................................12-15

M68HC11 MOTOROLA

REFERENCE MANUAL xv

Page 16

LIST OF TABLES

(Continued)

Table Title Page

MOTOROLA M68HC11

xvi REFERENCE MANUAL

Page 17

SECTION 1GENERAL DESCRIPTION

This reference manual will be a valuable aid in the development of M68HC11 applications. Detailed descriptions of all internal subsystems and functions have been developed and carefully checked against internal Motorola design documentation, making

this manual the most comprehensive reference available for the M68HC11 Family of

microcontroller units (MCUs).

Practical applications are included to demonstrate the operation of each subsystem.

These applications are treated as complete systems, including hardware/software interactions and trade-offs. Interfacing techniques to prevent component damage are

discussed to aid the hardware designer. For software programmers,

CENTRAL PROCESSING UNIT

contain examples demonstrating efficient use of the instruction set.

and APPENDIX A INSTRUCTION SET DETAILS

SECTION 6

This manual is intended to complement Motorola’s official data sheet, not replace it.

The information in the data sheet is current and is guaranteed by production testing.

Although the information in this manual was checked against parts and design documentation, the accuracy is not guaranteed like the data sheet is guaranteed. This manual assumes the reader has some basic knowledge of MCUs and assembly-language

programming; it may not be appropriate as an instruction manual for a first-time MCU

user.

The information in this manual is much more detailed than would usually be required

for normal use of the MCU, but a user who is familiar with the detailed operation of the

part is more likely to find a solution to an unexpected system problem. In many cases,

a trick based on software or on-chip resources can be used rather than building expensive external circuitry. Data sheets are geared toward customary, straightforward

use of the on-chip peripherals; whereas, an experienced MCU user often uses these

on-chip systems in very unexpected ways. The level of detail in this manual will help

the normal user to better understand the on-chip systems and will allow the more advanced user to make maximum use of the subtleties of these systems.

In addition to this manual, the data sheet(s) or technical summary is needed for the

specific version(s) of the M68HC11 being used. A pocket reference guide is another

beneficial source.

1

1.1 General Description of the MC68HC11A8

The HCMOS MC68HC11A8 is an advanced 8-bit MCU with highly sophisticated, onchip peripheral capabilities. New design techniques were used to achieve a nominal

bus speed of 2 MHz. In addition, the fully static design allows operation at frequencies

down to dc, further reducing power consumption.

The HCMOS technology used on the MC68HC11A8 combines smaller size and higher

speeds with the low power and high noise immunity of CMOS. On-chip memory sys-

M68HC11

REFERENCE MANUAL 1-1

GENERAL DESCRIPTION

MOTOROLA

Page 18

tems include 8 Kbytes of read-only memory (ROM), 512 bytes of electrically erasable

programmable ROM (EEPROM), and 256 bytes of random-access memory (RAM).

Major peripheral functions are provided on-chip. An eight-channel analog-to-digital (A/

D) converter is included with eight bits of resolution. An asynchronous serial communications interface (SCI) and a separate synchronous serial peripheral interface (SPI)

are included. The main 16-bit, free-running timer system has three input-capture lines,

five output-compare lines, and a real-time interrupt function. An 8-bit pulse accumulator subsystem can count external events or measure external periods.

Self-monitoring circuitry is included on-chip to protect against system errors. A computer operating properly (COP) watchdog system protects against software failures. A

clock monitor system generates a system reset in case the clock is lost or runs too

slow. An illegal opcode detection circuit provides a non-maskable interrupt if an illegal

opcode is detected.

Two software-controlled power-saving modes, WAIT and STOP, are available to conserve additional power. These modes make the M68HC11 Family especially attractive

for automotive and battery-driven applications.

1

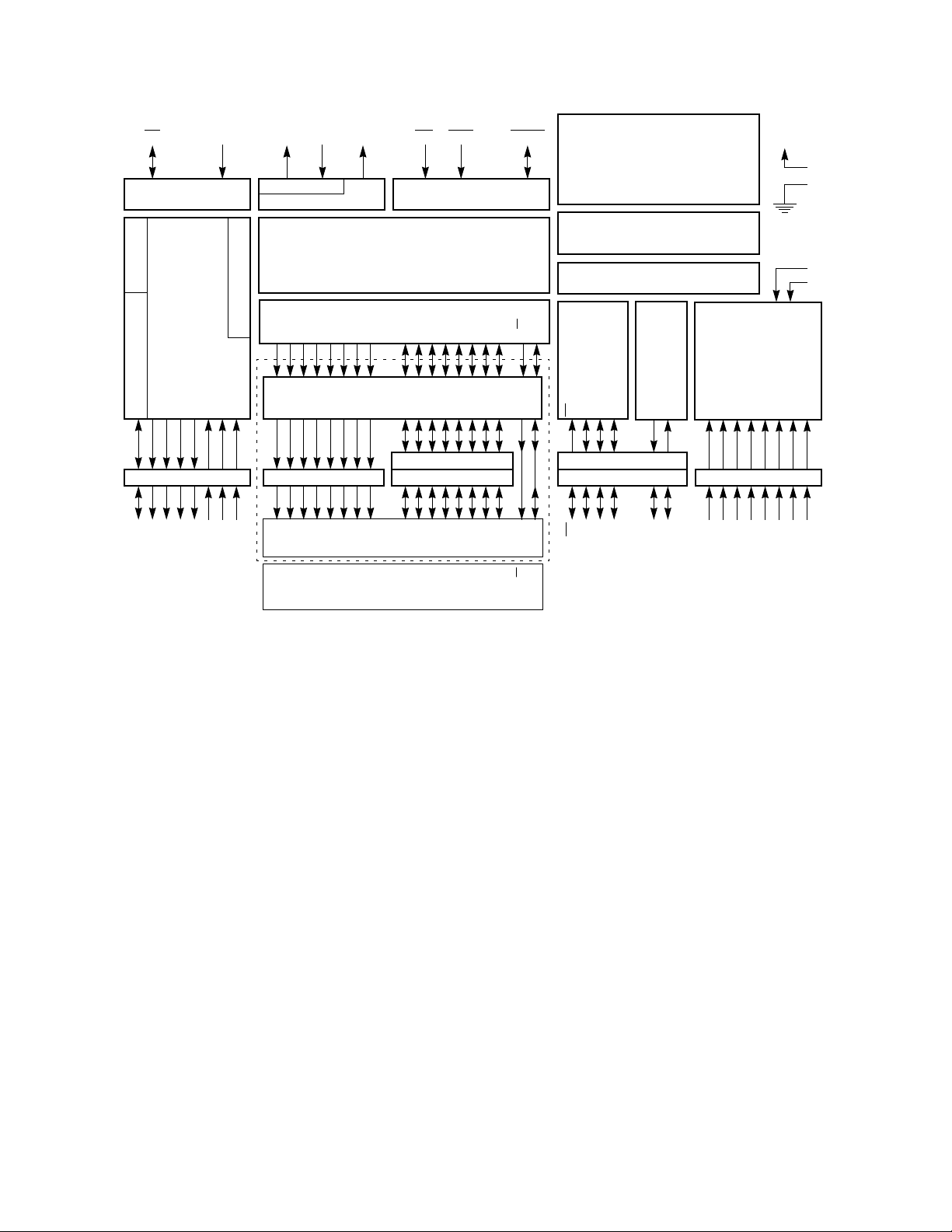

Figure 1-1 is a block diagram of the MC68HC11A8 MCU. This diagram shows the ma-

jor subsystems and how they relate to the pins of the MCU. In the lower right-hand corner of this diagram, the parallel I/O subsystem is shown inside a dashed box. The

functions of this subsystem are lost when the MCU is operated in expanded modes,

but the MC68HC24 port replacement unit can be used to regain the functions that were

lost. The functions are restored in such a way that the software programmer is unable

to tell any difference between a single-chip system or an expanded system containing

the MC68HC24. By using an expanded system containing an MC68HC24 and an external EPROM, the user can develop software intended for a single-chip application.

1.2 Programmer’s Model

In addition to executing all M6800 and M6801 instructions, the M68HC11 instruction

set includes 91 new opcodes. The nomenclature M68xx is used in conjunction with a

specific CPU architecture and instruction set as opposed to the MC68HC11xx nomenclature, which is a reference to a specific member of the M68HC11 Family of MCUs.

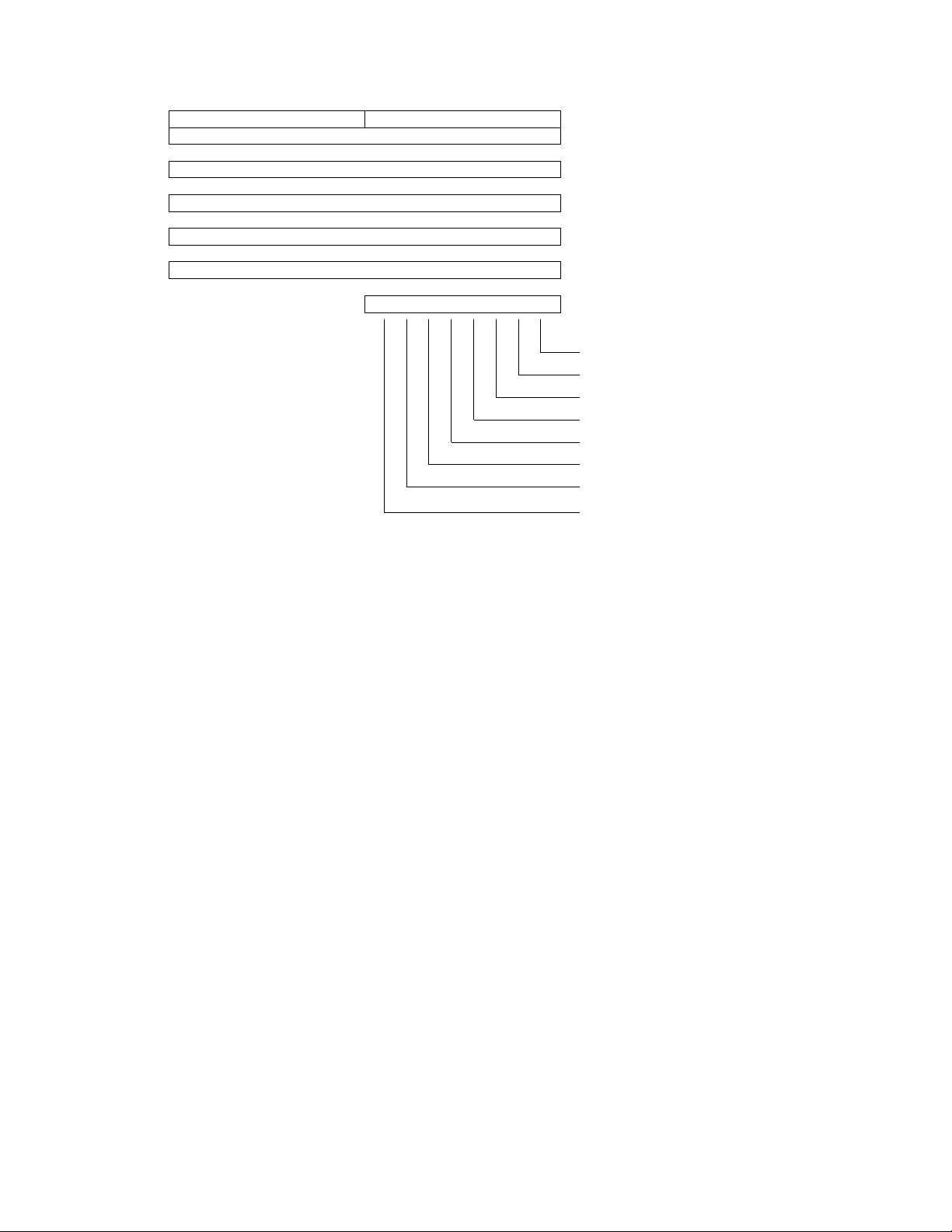

Figure 1-2 shows the seven CPU registers available to the programmer. The two 8-

bit accumulators (A and B) can be used by some instructions as a single 16-bit accumulator called the D register, which allows a set of 16-bit operations even though the

CPU is technically an 8-bit processor.

The largest group of instructions added involve the Y index register. Twelve bit manipulation instructions that can operate on any memory or register location were added.

The exchange D with X and exchange D with Y instructions can be used to quickly get

index values into the double accumulator (D) where 16-bit arithmetic can be used. Two

16-bit by 16-bit divide instructions are also included.

MOTOROLA

1-2 REFERENCE MANUAL

GENERAL DESCRIPTION

M68HC11

Page 19

MODA/

LIR

COPPULSE ACCUMULATOR

PA7/PAI/OC1

PA6/OC2/OC1

CIRCUITRY ENCLOSED BY DOTTED LINE IS EQUIVALENT TO MC68HC24.

MODB/

V

MODE

CONTROL

TIMER

SYSTEM

PORT A

PA5/OC3/OC1

PA4/OC4/OC1

PA3/OC5/OC1

STBY

OSCILLATOR

PERIODIC INTERRUPT

PA2/IC1

PA1/IC2

PA0/IC3

EXTALXTAL

CLOCK LOGIC

BUS EXPANSION

ADDRESS

STROBE AND HANDSHAKE

PORT B

PB7

PB6

PB5

PB4

PB3

PB2

A15

A14

A13

A12

A11

A10

E

CPU

PARALLEL I/O

PB1

PB0

SINGLE CHIP MODE

A9

EXPANDED MODE

PC7

A8

A7/D7

IRQ/

XIRQ

INTERRUPT LOGIC

ADDRESS/DATA

CONTROL

PORT C

PC6

PC5

PC4

PC3

A6/D6

A5/D5

A4/D4

A3/D3

PC2

PC1

A2/D2

A1/D1

RESET

PC0

A0/D0

R/W

AS

STRA

STRB

AS

R/W

8 KBYTES ROM

512 BYTES EEPROM

256 BYTES RAM

SPI A/D CONVERTERSCI

SS

SCK

MOSI

MISO

CONTROL

PORT D

PD5/SS

PD4/SCK

PD3/MOSI

PD2/MISO

TxD

RxD

PD1/TxD

PD0/RxD

PORT E

PE7/AN7

PE6/AN6

PE5/AN5

PE4/AN4

PE3/AN3

V

V

V

V

PE2/AN2

PE1/AN1

PE0/AN0

DD

SS

RH

RL

1

Figure 1-1 Block Diagram

M68HC11

GENERAL DESCRIPTION

MOTOROLA

REFERENCE MANUAL 1-3

Page 20

1

7070

15 0

AB

D

IX

IY

SP

PC

70

8-BIT ACCUMULATORS A & B

OR 16-BIT DOUBLE ACCUMULATOR D

INDEX REGISTER X

INDEX REGISTER Y

STACK POINTER

PROGRAM COUNTER

CONDITION CODES

CVZNIHXS

CARRY/BORROW FROM MSB

OVERFLOW

ZERO

NEGATIVE

I-INTERRUPT MASK

HALF CARRY (FROM BIT 3)

X-INTERRUPT MASK

STOP DISABLE

Figure 1-2 M68HC11 Programmer’s Model

1.3 Product Derivatives

The M68HC11 Family of MCUs is composed of several members (see Table 1-1 ), and

new members are being developed.

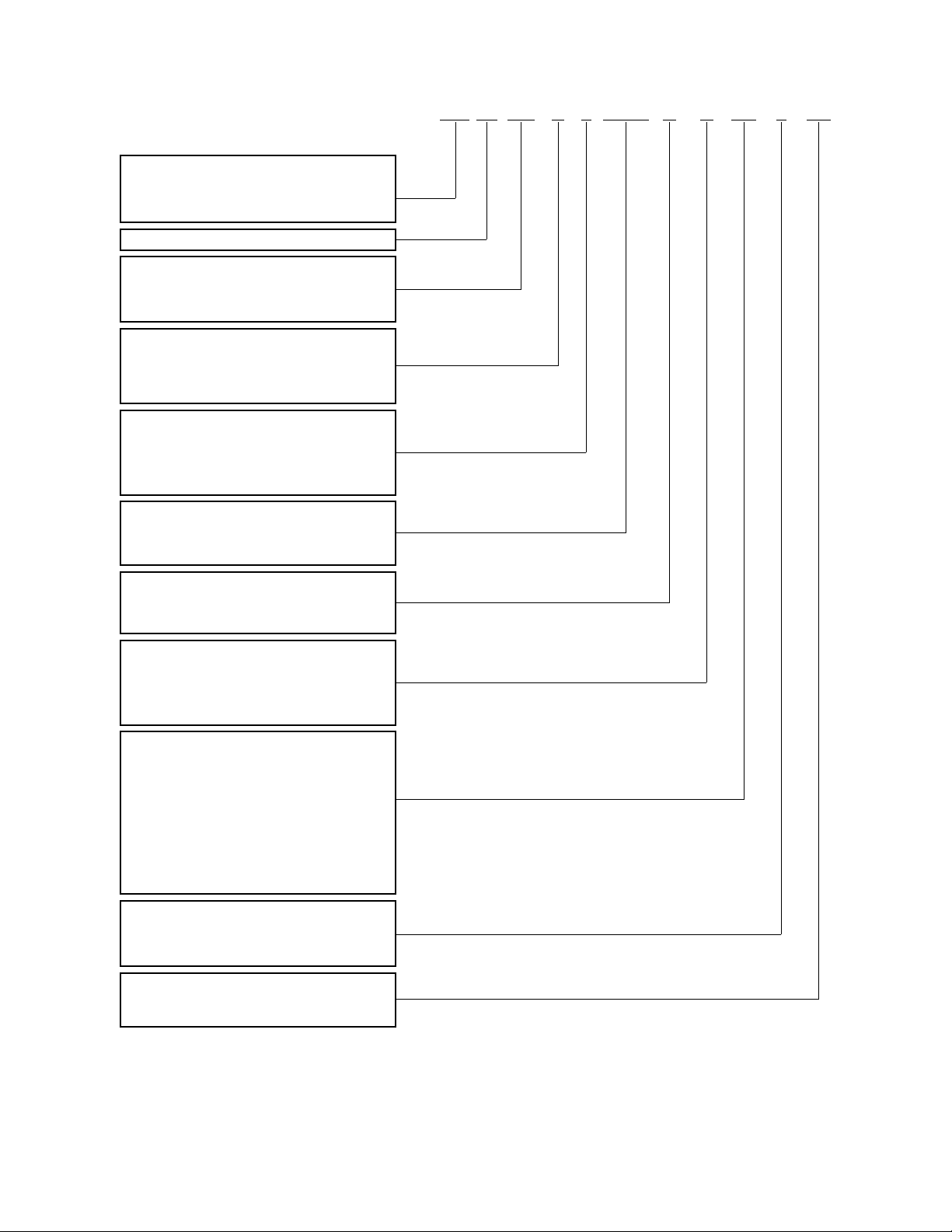

Figure 1-3 explains how the product part num-

bers are constructed.

MOTOROLA

1-4 REFERENCE MANUAL

GENERAL DESCRIPTION

M68HC11

Page 21

QUALIFICATION LEVEL

MC — FULLY SPECIFIED AND QUALIFIED

XC — PILOT PRODUCTION DEVICE

PC — ENGINEERING SAMPLE

NUMERIC DESIGNATOR (OPTIONAL)

OPERATING VOLTAGE RANGE

HC —

HCMOS (V

L —

HCMOS (V

COP OPTION (ONLY ON A-SERIES DEVICES)

NONE —

MEMORY TYPE

BLANK —

BASE PART NUMBER

11A8, 11D3, 11E9, 11K4, ETC.

COP DISABLED

P —

COP ENABLED

MASKED ROM OR NO ROM

7 —

EPROM/OTPROM

8 — EEPROM

= 5.0 VDC ±10%)

DD

= 3.0 VDC TO 5.5 VDC)

DD

MC 68 HC P 11XX B C FN 3 R2

7

1

MONITOR MASK

NONE —

TEMPERATURE RANGE

NONE —

PACKAGE TYPE

FN —

FS —

FU —

FB —

PV —

PU —

PB —

MAXIMUM SPECIFIED CLOCK SPEED

2 —

3 —

4 —

TAPE AND REEL OPTION

NONE —

BLANK

B —

BUFFALO

0°C TO 70°C

C —

– 40°C TO 85°C

V —

– 40°C TO 105°C

M —

– 40°C TO 125°C

44/52/68/84-PIN PLCC

44/52/68/84-PIN CLCC

64/80-PIN QFP

44-PIN QFP

112-PIN TQFP

80/100-PIN TQFP

52-PIN TQFP

P —

40/48-PIN DIP

S —

48-PIN SDIP

2.0 MHz

3.0 MHz

4.0 MHz

STANDARD PACKAGING

R2 —

TAPE AND REEL PACKAGING

HC11 PART NUMBERING

Figure 1-3 Part Numbering

M68HC11

REFERENCE MANUAL 1-5

GENERAL DESCRIPTION

MOTOROLA

Page 22

1

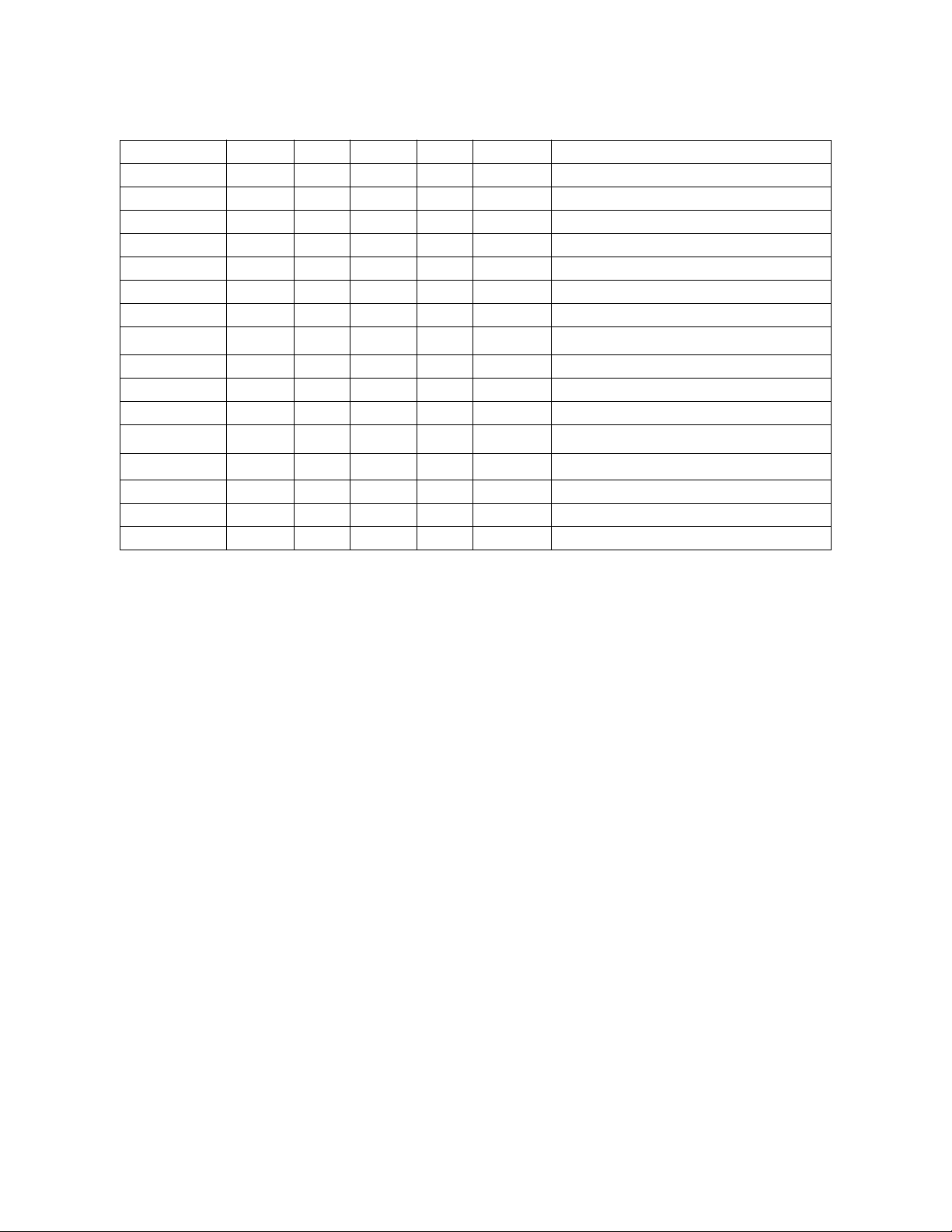

Table 1-1 M68HC11 Family Members

$FF

$FF

2

3

No ROM Part for Expanded Systems

3

High-Performance Non-Multiplexed 6B-Pin

Comments

, 84-Pin

S

Part Number EPROM ROM EEPROM RAM CONFIG

MC68HC11A8 — — 512 256 $0F Family Built Around This Device

MC68HC11A1 — — 512 256 $0D ’A8 with ROM Disabled

MC68HC11A0 — — — 256 $0C ’A8 with ROM and EEPROM Disabled

MC68HC811A8 — — 8K + 512 256 $0F EEPROM Emulator for ’A8

MC68HC11E9 — 12K 512 512 $0F Four Input Capture/Bigger RAM 12K ROM

MC68HC11E1 — — 512 512 $0D ’E9 with ROM Disabled

MC68HC11E0 — — — 512 $0C ’E9 with ROM and EEPROM Disabled

1

MC68HC811E2 — —

MC68HC711E9 12K — 512 512 $0F One-Time Programmable Version of ’E9

MC68HC11D3 — 4K — 192 N/A Low-Cost 40-Pin Version

MC68HC711D9 4K — — 192 N/A One-Time Programmable Version of ’D3

MC68HC11F1 — —

MC68HC11K4 — 24K 640 768 $FF > 1 Mbyte memory space, PWM, C

MC68HC711K4 24K — 640 768 $FF One-Time Programmable Version of ’K4

MC68HC11L6 — 16K 512 512 $0F Like ’E9 with more ROM and more I/O, 64/68

MC68HC711L6 16K — 512 512 $0F One-Time Programmable Version of ’L4

2K

512

256

1

1K

1. The EEPROM is relocatable to the top of any 4 Kbyte memory page. Relocation is done with the upper four bits of

the CONFIG register.

2. CONFIG register values in this table reflect the value programmed prior to shipment from Motorola.

3. At the time of this printing a change was being considered that would make this value $0F.

MOTOROLA

1-6 REFERENCE MANUAL

GENERAL DESCRIPTION

M68HC11

Page 23

SECTION 2 PINS AND CONNECTIONS

This section discusses the functions of each pin on the MC68HC11A8. Most pins on

this microcontroller unit (MCU) serve two or more functions. Information about the

practical use of each pin is presented in these pin descriptions. This section also includes information concerning pins that are exposed to illegal levels or conditions. The

most common source of illegal levels or conditions is transient noise; however, a designer may wish to take precautions against potential misapplication of a product or

failures of other system components such as power supplies. Consideration of these

factors can influence end-product reliability.

The basic connections for single-chip-mode and expanded-mode applications are presented in

panded-Mode-System Connections

starting point for any user application and can minimize the time required to achieve a

working prototype system. The explanation of these basic systems includes information concerning additions, such as additional memory on the expanded system.

2.5 Typical Single-Chip-Mode System Connections and 2.6 Typical Ex-

. These basic systems can be used as the

2

System noise generation and susceptibility primarily depend on each system and its

environment. The MC68HC11A8 is designed for higher bus speeds than earlier

MCUs; since it is high-density complementary metal-oxide semiconductor (HCMOS),

signals drive from rail to rail, unlike earlier N-channel metal-oxide semiconductor

(NMOS) processors. Since these factors can significantly affect noise issues, the system designer should consider these changes.

2.1 Packages And Pin Names

The following figures show pin assignments for several members of the M68HC11

MCU Family. The pin assignments for the MC68HC24 port replacement unit (PRU)

are also presented for reference although the PRU is not discussed in detail in this

manual.

Detailed mechanical data for packages may be found in the data sheets or technical

summaries. Ordering information, which relates part number suffixes to package types

and operating temperature range, are also found in the data sheets or technical summaries.

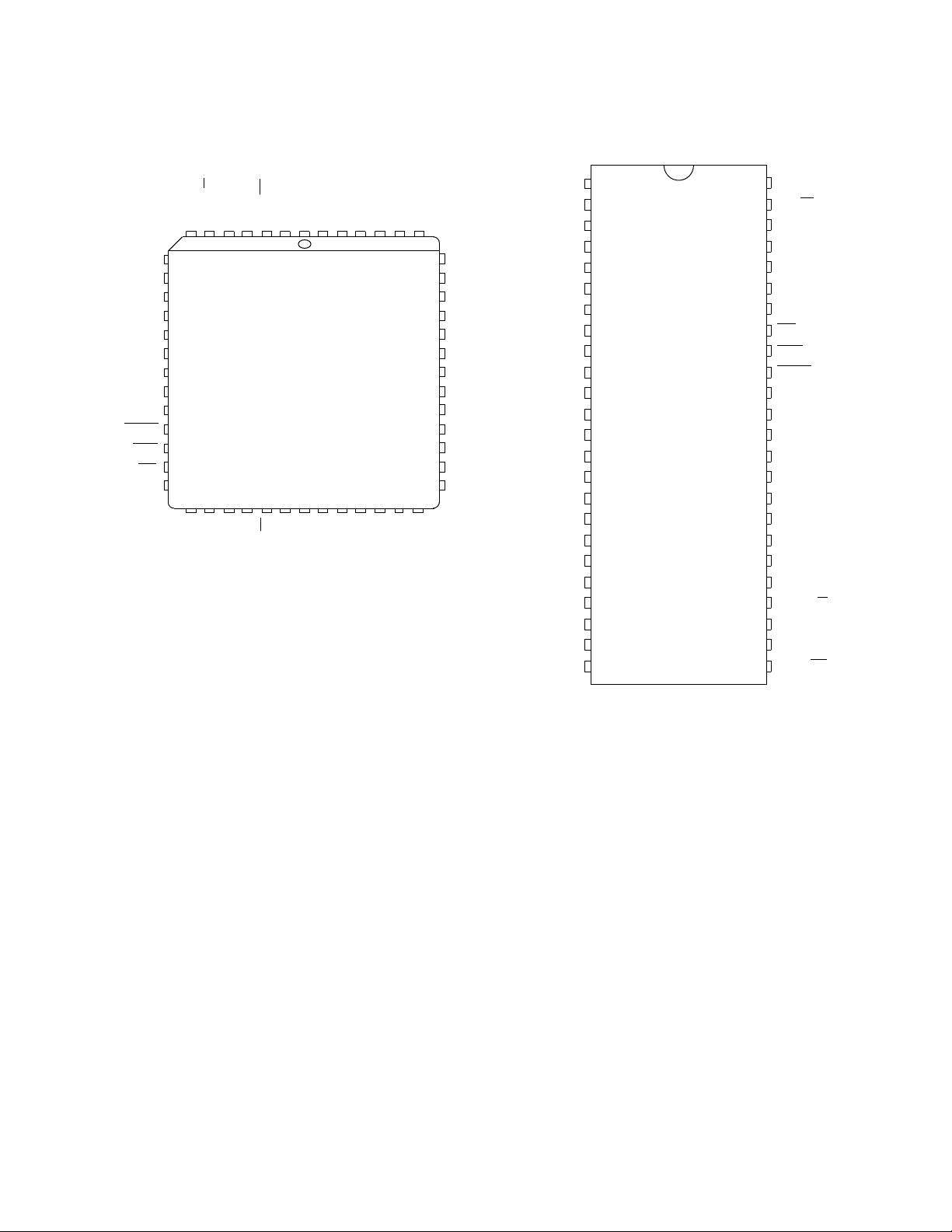

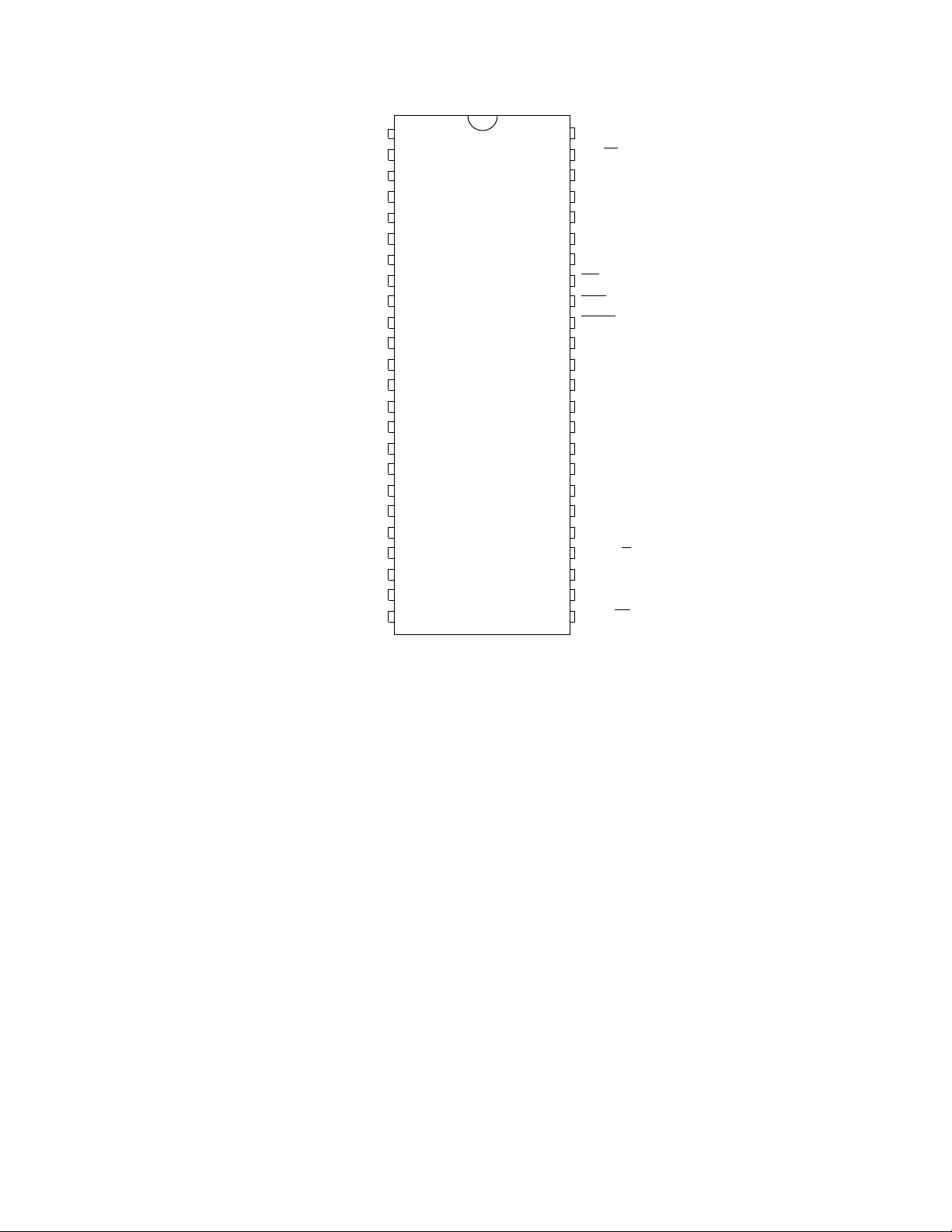

2.1.1 MC68HC11A8

The MC68HC11A8 is available in either a 52-pin plastic leaded chip carrier (PLCC)

package or a 48-pin dual-in-line package (DIP). The silicon die is identical for both

packages, but four of the analog-to-digital (A/D) converter inputs are not bonded out

to pins in the 48-pin DIP. The MC68HC11A1 and MC68HC11A0 devices also use the

same die as the MC68HC11A8, except that the contents of the nonvolatile CONFIG

register determine whether or not internal read-only memory (ROM) and/or electrically

erasable programmable ROM (EEPROM) are disabled. These downgraded device

versions have identical pin assignments as the MC68HC11A8.

M68HC11

REFERENCE MANUAL 2-1

PINS AND CONNECTIONS

MOTOROLA

Page 24

Figure 2-1 shows the pin assignments for the MC68HC11A8 in the 52-pin PLCC pack-

age and the 48-pin DIP package.

2

XTAL

PC0/A0/D0

PC1/A1/D1

PC2/A2/D2

PC3/A3/D3

PC4/A4/D4

PC5/A5/D5

PC6/A6/D6

PC7/A7/D7

RESET

XIRQ

IRQ

PD0/RxD

STBY

MODB/V

EXTAL

STRB/R/WESTRA/AS

765

8

9

10

11

12

13

14

15

16

17

18

19

20

2122232425262728293031

PD1/TxD

PD2/MISO

PD3/MOSI

4

PD4/SCK

VSSVRHV

MODA/LIR

312

525150

MC68HC11A8

DD

V

PD5/SS

PA7/PAI/OC1

PA6/OC2/OC1

RL

PE7/AN7

PE3/AN3

49

PA5/OC3/OC1

PA4/OC4/OC1

PA3/OC5/OC1

PE6/AN648

PE2/AN2

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

PA2/IC132PA1/IC2

PE5/AN5

PE1/AN1

PE4/AN4

PE0/AN0

PB0/A8

PB1/A9

PB2/A10

PB3/A11

PB4/A12

PB5/A13

PB6/A14

PB7/A15

PA0/IC3

PA7/PAI/OC1

PA6/OC2/OC1

PA5/OC3/OC1

PA4/OC4/OC1

PA3/OC5/OC1

PA2/IC1

PA1/IC2

PA0/IC3

PB7/A15

PB6/A14

PB5/A13

PB4/A12

PB3/A11

PB2/A10

PB1/A9

PB0/A8

PE0/AN0

PE1/AN1

PE2/AN2

PE3/AN3

V

V

RH

V

SS

MODB/V

STBY

V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

RL

22

23

24

MC68HC11A8

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

DD

PD5/SS

PD4/SCK

PD3/MOSI

PD2/MISO

PD1/TxD

PD0/RxD

IRQ

XIRQ

RESET

PC7/A7/D7

PC6/A6/D6

PC5/A5/D5

PC4/A4/D4

PC3/A3/D3

PC2/A2/D2

PC1/A1/D1

PC0/A0/D0

XTAL

EXTAL

STRB/R/W

E

STRA/AS

MODA/LIR

Figure 2-1 MC68HC11A8 Pin Assignments

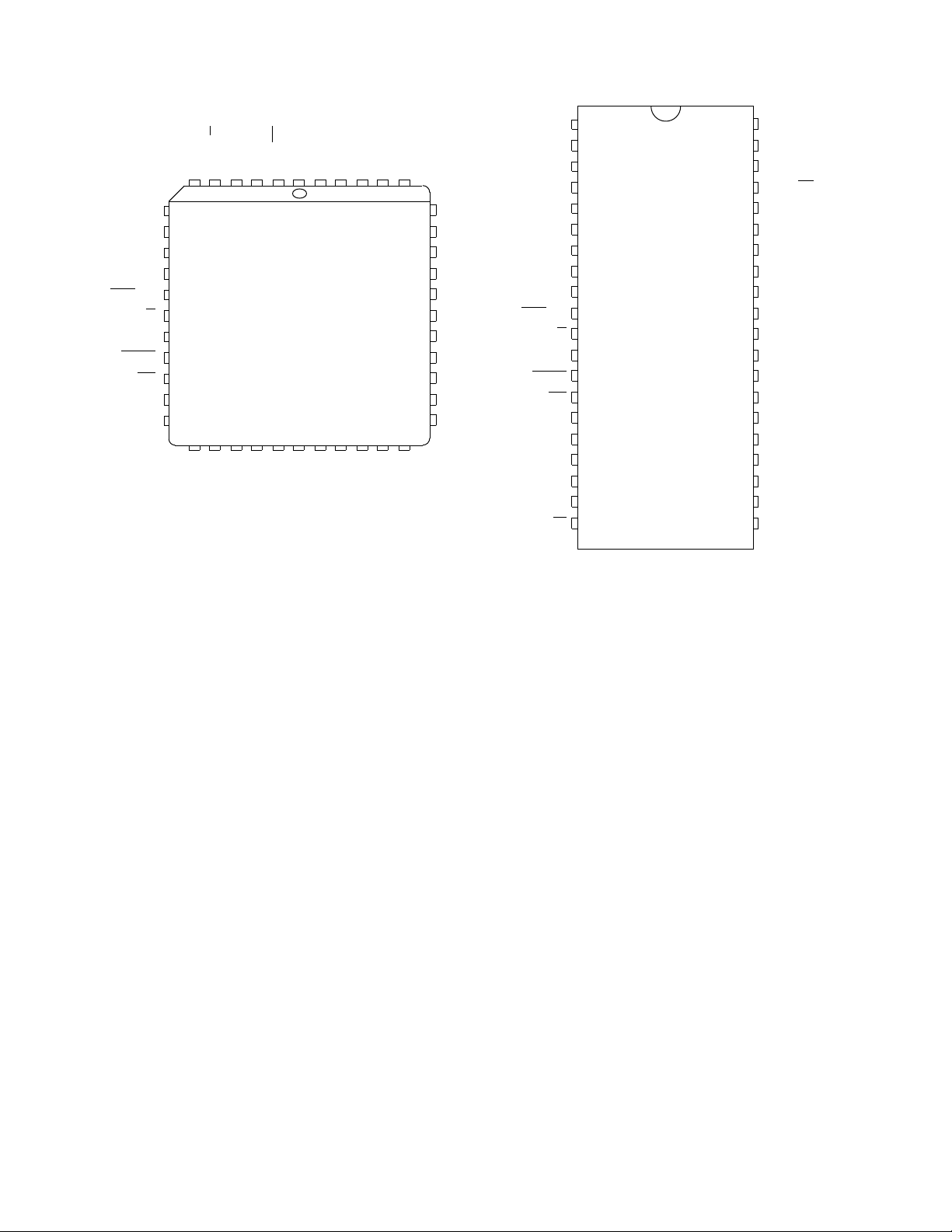

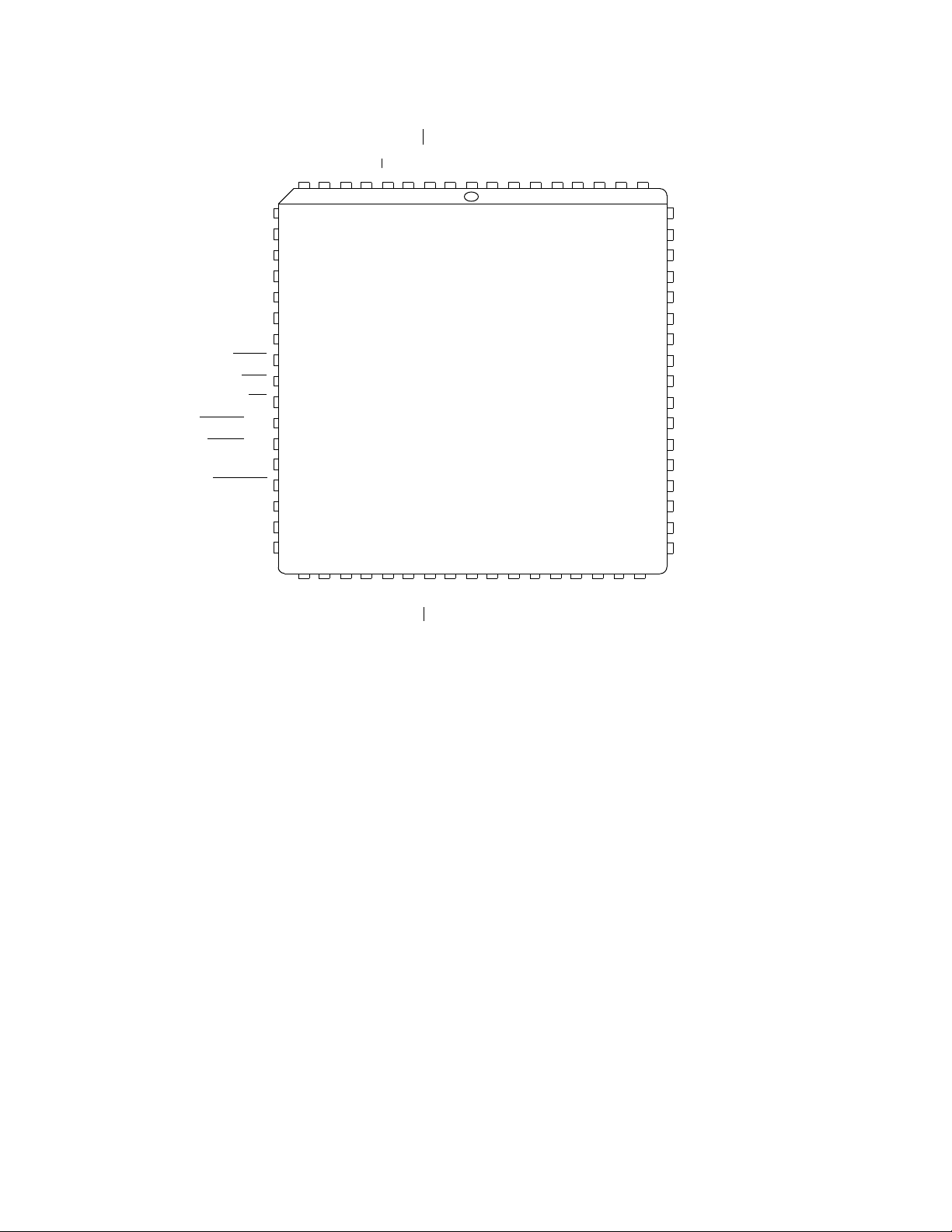

2.1.2 MC68HC11D3/711D3

The MC68HC11D3 is available in either a 44-pin PLCC package or a 40-pin DIP package. The silicon die is identical for both packages, but the PLCC version has two additional output compare pins bonded out and an extra V

pin named E

SS

VSS

. The

MC68HC711D3 is functionally equivalent to the MC68HC11D3 but has 4 Kbytes of

EPROM instead of mask programmed ROM. The MC68HC711D3 is available as a

one-time-programmable (OTP) MCU in an opaque plastic package or in a ceramic

windowed package for development applications.

Figure 2-2 shows the pin assignments for the MC68HC11D3/711D3 in the 44-pin

PLCC package and the 40-pin DIP package.

MOTOROLA

2-2 REFERENCE MANUAL

PINS AND CONNECTIONS

M68HC11

Page 25

PC4/ADDR4

PC5/ADDR5

PC6/ADDR6

PC7/ADDR7

XIRQ/V

PD7/R/W

PD6/AS

RESET

IRQ

PD0/RxD

PD1/TxD

V

1

STBY

EXTAL

STRB/R/WESTRA/AS

6

5

7

8

9

10

11

PP

12

13

14

15

16

17

1819202122

PD2/MISO

PD3/MOSI

MODA/LIR

4

3

2

MC68HC(7)11D3

DD

V

PD4/SCK

PA7/PAI/OC1

MODB/V

VSSVRHVRLPE7/AN7

44

434241

1

2324252627

PA6/OC3/OC1

PA5/OC3/OC1

PA5/OC3/OC1

PA4/OC4/OC1

PE3/AN3

40

39

PB0/ADDR8

PB1/ADDR9

38

37

PB2/ADDR10

36

PB3/ADDR11

35

PB4/ADDR12

PB5/ADDR13

34

33

PB6/ADDR14

PB7/ADDR15

32

NC

31

30

PA0/IC3

29

PA1/IC2

28

PA2/IC1

PA3/IC4/OC5/OC1

PC0/ADDR0

PC1/ADDR1

PC2/ADDR2

PC3/ADDR3

PC4/ADDR4

PC5/ADDR5

PC6/ADDR6

PC7/ADDR7

XIRQ

/V

PD7/R/W

PD6/AS

RESET

IRQ

PD0/RxD

PD1/TxD

PD2/MISO

PD3/MOSI

PD4/SCK

PD5/SS

SS

2

3

4

5

6

7

MC68HC(7)11D3

8

9

PP

10

11

12

13

14

15

16

17

18

19

20

XTAL

40

EXTAL

39

E

38

MODA/LIR

37

MODB/V

36

PB0/ADDR8

35

PB1/ADDR9

34

PB2/ADDR10

33

PB4/ADDR12

32

PB5/ADDR13

31

PB6/ADDR14

30

PB7/ADDR15

29

PA0/IC3

28

PA1/IC2

27

PA1/IC2

26

PA2/IC1

25

PA3/IC4/OC5/OC1

24

PA5/OC3/OC1

23

PA7/PAI/OC1

22

V

21

DD

STBY

2

Figure 2-2 MC68HC11D3/711D3 Pin Assignments

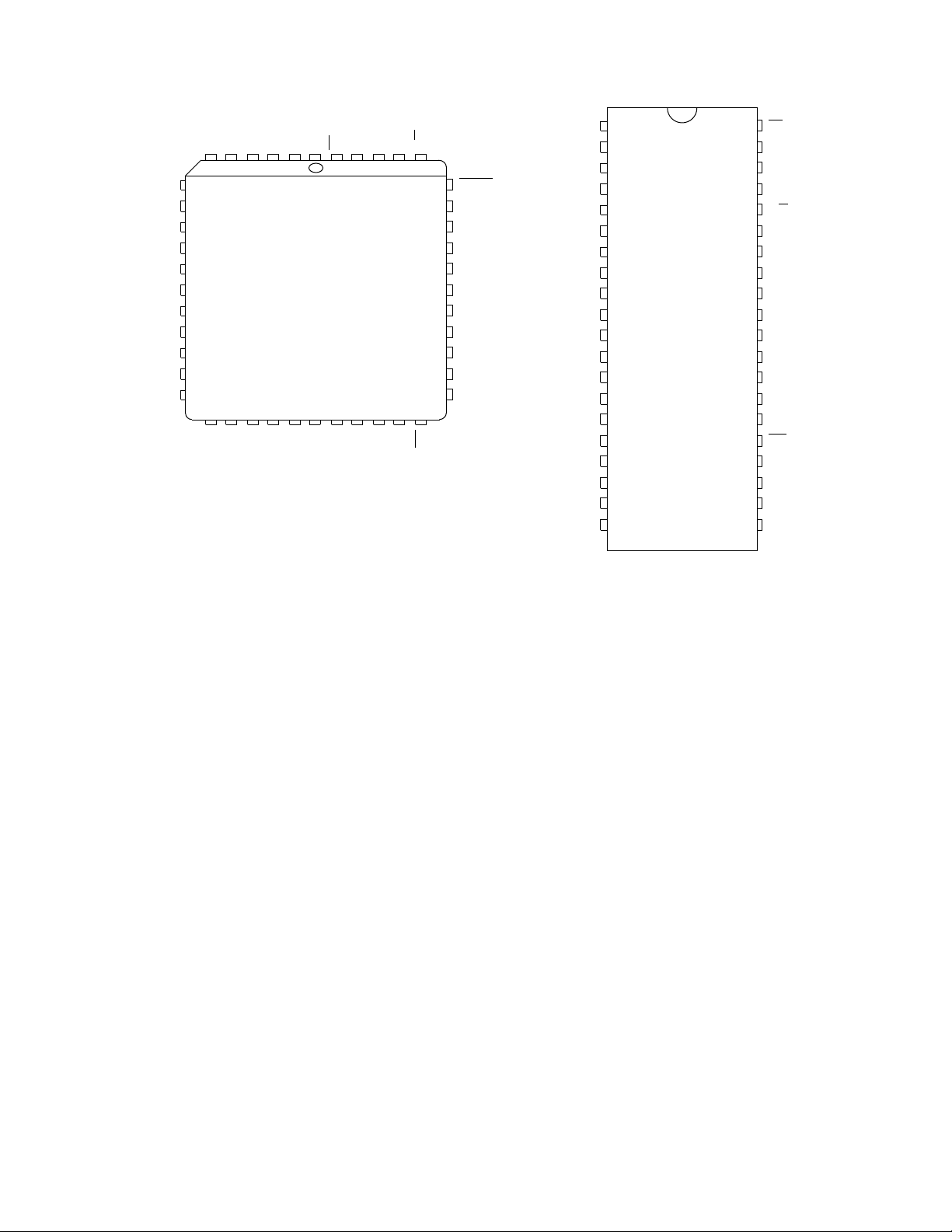

2.1.3 MC68HC11E9/711E9

The MC68HC11E9 is available in a 52-pin PLCC package only. The MC68HC11E1

and MC68HC11E0 devices also use the same die as the MC68HC11E9, except that

the contents of the nonvolatile CONFIG register determine whether or not internal

ROM and/or EEPROM are disabled. These downgraded device versions have identical pin assignments as the MC68HC11E9.

The MC68HC11E9 is an upgrade of the MC68HC11A8. The MC68HC11E9 has 12

Kbytes of mask ROM, 512 bytes of EEPROM, and 512 bytes of RAM. The timer system allows one output-compare channel to be reconfigured as a fourth input-capture

channel.

The MC68HC711E9 is functionally equivalent to the MC68HC11E9 but has 12 Kbytes

of EPROM instead of mask programmed ROM. The MC68HC711E9 is available as a

one-time programmable (OTP) MCU in an opaque plastic package or in a ceramic windowed package for development applications.

Figure 2-3 shows the pin assignments for the MC68HC11E9 in the 52-pin PLCC pack-

ages. These pin assignments are the same as the MC68HC11A8, except for the pin

name for the PA3/OC5/IC4/OC1 pin.

M68HC11

PINS AND CONNECTIONS

MOTOROLA

REFERENCE MANUAL 2-3

Page 26

STBY

2

RL

VSSVRHV

525150

PA7/PAI/OC1

PA6/OC2/OC1

PA5/OC3/OC1

PE7/AN7

PE3/AN3

PE6/AN648

49

PA2/IC132PA1/IC2

PA4/OC4/OC1

PA3/OC5/OC1

PE2/AN2

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

PE5/AN5

PE1/AN1

PE4/AN4

PE0/AN0

PB0/A8

PB1/A9

PB2/A10

PB3/A11

PB4/A12

PB5/A13

PB6/A14

PB7/A15

PA0/IC3

XTAL

PC0/A0/D0

PC1/A1/D1

PC2/A2/D2

PC3/A3/D3

PC4/A4/D4

PC5/A5/D5

PC6/A6/D6

PC7/A7/D7

RESET

XIRQ

IRQ

PD0/RxD

EXTAL

STRB/R/WESTRA/AS

765

8

9

10

11

12

13

14

15

16

17

18

19

20

2122232425262728293031

PD1/TxD

PD2/MISO

PD3/MOSI

MODB/V

MODA/LIR

4

312

MC68HC11E9

DD

V

PD5/SS

PD4/SCK

Figure 2-3 MC68HC11E9/711E9 Pin Assignments (52-Pin PLCC)

2.1.4 MC68HC811E2

The MC68HC811E2 is very similar to the MC68HC11E9 version, except in the on-chip

memory. The MC68HC811E2 includes 2 Kbytes of EEPROM, which can be remapped

to the upper half of any 4 Kbyte page in the 64 Kbyte map. There is no masked ROM

memory in the MC68HC811E2. The MC68HC811E2 is available in either a 52-pin

PLCC package or a 48-pin DIP. The silicon die used is the same for both packages,

but four of the A/D converter inputs are not bonded out to pins in the 48-pin package.

The MC68HC811E2 version replaces an earlier version called the MC68HC811A2.

The only significant difference between the MC68HC811E2 and MC68HC811A2 is

that the MC68HC811E2 has a slightly more flexible timer system, which allows one

output-compare channel to be reconfigured as a fourth input-capture channel.

The 52-pin PLCC package version of the MC68HC811E2 has identical pin assignments to the MC68HC11E9 pin assignments shown in

Figure 2-3 . Figure 2-4 illus-

trates the pin assignments for the MC68HC811E2 in the 48-pin DIP.

MOTOROLA

PINS AND CONNECTIONS

M68HC11

2-4 REFERENCE MANUAL

Page 27

PA7/PAI/OC1

PA6/OC2/OC1

PA5/OC3/OC1

PA4/OC4/OC1

PA3/OC5/OC1

PA2/IC1

PA1/IC2

PA0/IC3

PB7/A15

PB6/A14

PB5/A13

PB4/A12

PB3/A11

PB2/A10

PB1/A9

PB0/A8

PE0/AN0

PE1/AN1

PE2/AN2

PE3/AN3

V

RL

V

RH

V

SS

MODB/V

STBY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

MC68HC811E2

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

V

DD

PD5/SS

PD4/SCK

PD3/MOSI

PD2/MISO

PD1/TxD

PD0/RxD

IRQ

XIRQ