Page 1

Freescale Semiconductor, Inc.

Sensorless BLDC

Motor Control

nc...

I

Using the

cale Semiconductor,

Frees

M68HC08

Microcontrollers

MC68HC908MR32

Designer Reference

Manual

DRM028/D

Rev. 0, 03/2003

MOTOROLA.COM/SEMICONDUCTORS

For More Information On This Product,

Go to: www.freescale.com

Page 2

Freescale Semiconductor, Inc.

nc...

I

cale Semiconductor,

Frees

For More Information On This Product,

Go to: www.freescale.com

Page 3

Freescale Semiconductor, Inc.

Sensorless BLDC Motor

Control Using the

nc...

I

cale Semiconductor,

Frees

MC68HC908MR32

Designer Reference Manual — Rev 0

by: Libor Prokop

Motorola Czech System Laboratories

Roznov pod Radhostem, Czech Republic

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA 3

For More Information On This Product,

Go to: www.freescale.com

Page 4

Revision history

Freescale Semiconductor, Inc.

To provide the most up-to-date information, the revision of our

documents on the World Wide Web will be the most current. Your printed

copy may be an earlier revision. To verify you have the latest information

available, refer to:

http://www.motorola.com/semiconductors

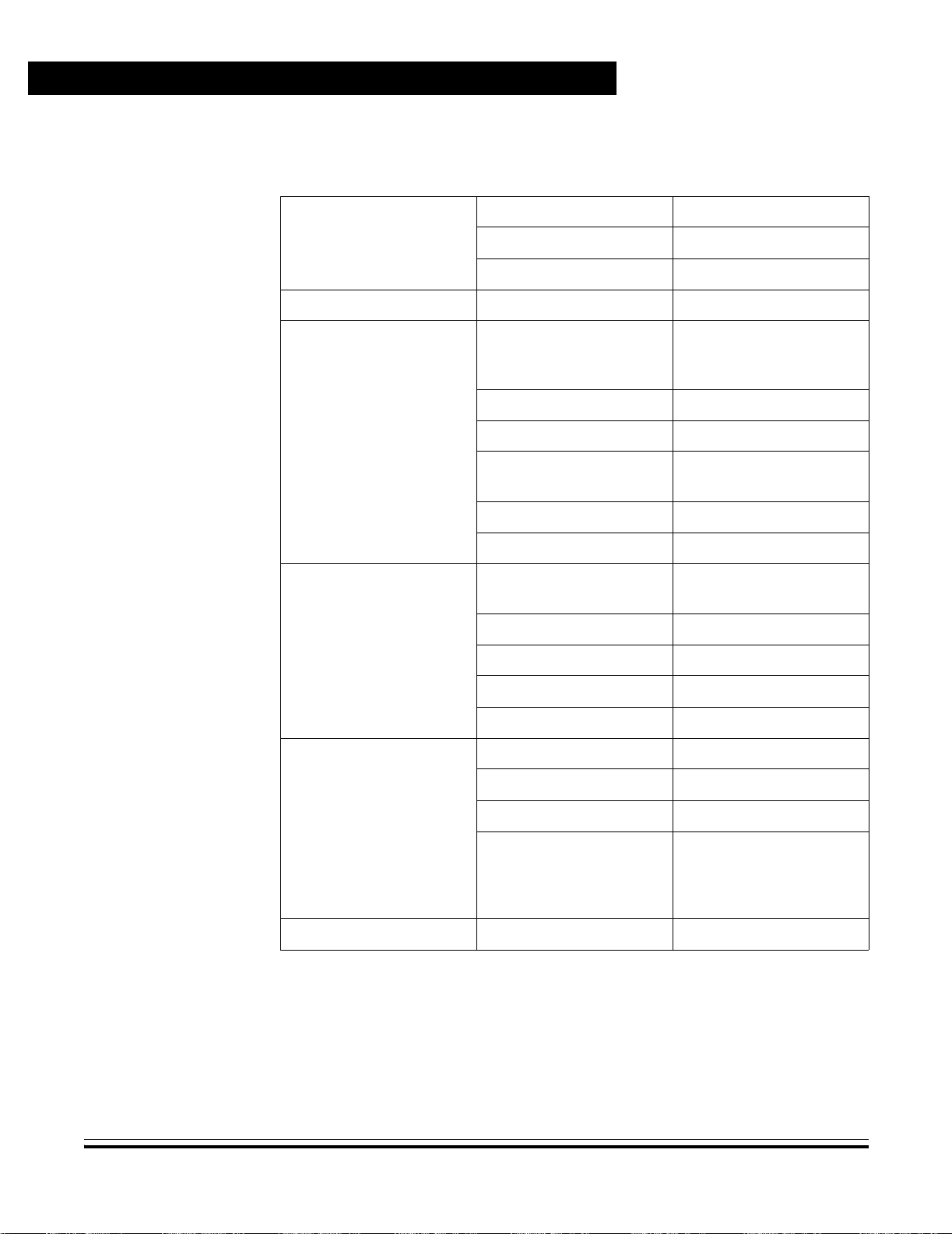

The following revision history table summarizes changes contained in

this document. For your convenience, the page number designators

have been linked to the appropriate location.

Revision history

nc...

I

cale Semiconductor,

Frees

Date

February,

2003

Revision

Level

1 Initial release N/A

Description

Page

Number(s)

Designer Reference Manual DRM028 — Rev 0

4 MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 5

Freescale Semiconductor, Inc.

Designer Reference Manual — Sensorless BLDC Motor Control

List of Sections

Section 1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Section 2. System Description. . . . . . . . . . . . . . . . . . . . . 15

Section 3. BLDC Motor Control . . . . . . . . . . . . . . . . . . . .23

nc...

I

cale Semiconductor,

Frees

Section 4. Hardware Design. . . . . . . . . . . . . . . . . . . . . . .57

Section 5. Software Design . . . . . . . . . . . . . . . . . . . . . . . 75

Section 6. User Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Appendix A. References. . . . . . . . . . . . . . . . . . . . . . . . .161

Appendix B. Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . .163

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA 5

For More Information On This Product,

Go to: www.freescale.com

Page 6

Freescale Semiconductor, Inc.

List of Sections

nc...

I

cale Semiconductor,

Frees

Designer Reference Manual DRM028 — Rev 0

6 MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 7

Freescale Semiconductor, Inc.

Designer Reference Manual — Sensorless BLDC Motor Control

Table of Contents

Section 1. Introduction

1.1 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

1.2 Application Functionality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

nc...

I

cale Semiconductor,

Frees

1.3 Benefits of the Solution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Section 2. System Description

2.1 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.2 System Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.3 System Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Section 3. BLDC Motor Control

3.1 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

3.2 Brushless DC Motor Control Theory. . . . . . . . . . . . . . . . . . . . .23

3.3 Used Control Technique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.4 Application Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Section 4. Hardware Design

4.1 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

4.2 System Configuration and Documentation . . . . . . . . . . . . . . . . 57

4.3 All HW Sets Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.4 High-Voltage Hardware Set Components. . . . . . . . . . . . . . . . .66

4.5 Low-Voltage Evaluation Motor Hardware Set Components . . .70

4.6 Low-Voltage Hardware Set Components . . . . . . . . . . . . . . . . .72

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA 7

For More Information On This Product,

Go to: www.freescale.com

Page 8

Table of Contents

Freescale Semiconductor, Inc.

Section 5. Software Design

5.1 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

5.2 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.3 Data Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

5.4 Main Software Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.5 State Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

5.6 Implementation Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

nc...

I

cale Semiconductor,

Frees

Section 6. User Guide

6.1 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

6.2 Application Suitability Guide . . . . . . . . . . . . . . . . . . . . . . . . . .109

6.3 Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

6.4 Application Hardware and Software Configuration . . . . . . . . .113

6.5 Tuning for Customer Motor. . . . . . . . . . . . . . . . . . . . . . . . . . .126

Appendix A. References

Appendix B. Glossary

Designer Reference Manual DRM028 — Rev 0

8 MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 9

nc...

I

cale Semiconductor,

Frees

Freescale Semiconductor, Inc.

Designer Reference Manual — Sensorless BLDC Motor Control

List of Figures

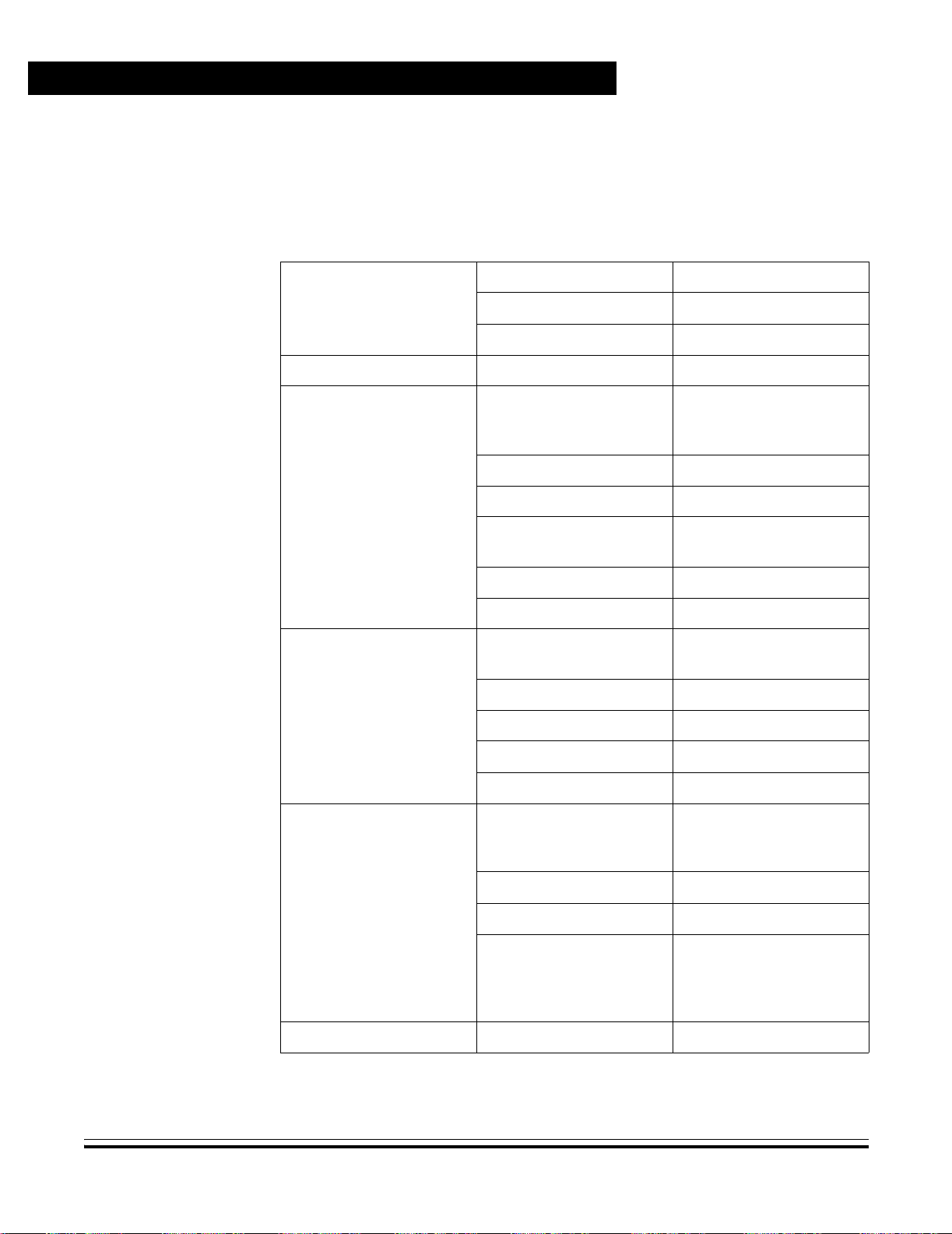

Figure Title Page

2-1 System Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3-1 BLDC Motor Cross Section. . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3-2 3-Phase Voltage System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-3 BLDC Motor Back EMF and Magnetic Flux . . . . . . . . . . . . . . .26

3-4 Classical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3-5 Power Stage — Motor Topology. . . . . . . . . . . . . . . . . . . . . . . .28

3-6 Phase Voltage Waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-7 Mutual Inductance Effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-8 Detail of Mutual Inductance Effect . . . . . . . . . . . . . . . . . . . . . . 33

3-9 Mutual Capacitance Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-10 Distributed Back-EMF by Unbalanced

Capacity Coupling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-11 Balanced Capacity Coupling. . . . . . . . . . . . . . . . . . . . . . . . . . .36

3-12 Back-EMF Sensing Circuit Diagram . . . . . . . . . . . . . . . . . . . . . 37

3-13 The Zero Crossing Detection . . . . . . . . . . . . . . . . . . . . . . . . . .38

3-14 Commutation Control Stages . . . . . . . . . . . . . . . . . . . . . . . . . .39

3-15 Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3-16 BLDC Commutation with Back-EMF

Zero Crossing Sensing Flowchart. . . . . . . . . . . . . . . . . . . . . . . 42

3-17 BLDC Commutation Time with Zero Crossing Sensing . . . . . .43

3-18 Vectors of Magnetic Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

3-19 Back-EMF at Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

3-20 Calculation of the Commutation Times During the Starting

(Back-EMF Acquisition) State. . . . . . . . . . . . . . . . . . . . . . . . . .49

4-1 High-Voltage Hardware System Configuration . . . . . . . . . . . . .59

4-2 Low-Voltage Evaluation Motor Hardware

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4-3 Low-Voltage Hardware System Configuration . . . . . . . . . . . . .63

4-4 MC68HC908MR32 Control Board . . . . . . . . . . . . . . . . . . . . . . 65

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA 9

For More Information On This Product,

Go to: www.freescale.com

Page 10

nc...

I

cale Semiconductor,

Frees

List of Figures

Freescale Semiconductor, Inc.

4-5 3-Phase AC High Voltage Power Stage . . . . . . . . . . . . . . . . . . 67

4-6 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

5-1 Main Data Flow — Part1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

5-2 Main Data Flow — Part 2: Alignment, Starting,

5-3 Closed Loop Control System . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5-4 Main Software Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5-5 Main Software Flowchart — Main Software Loop. . . . . . . . . . .86

5-6 Software Flowchart — Interrupts . . . . . . . . . . . . . . . . . . . . . . . 89

5-7 Application State Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5-8 Stand-by State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

5-9 Align State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

5-10 Back-EMF Acquisition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

5-11 Running State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

5-12 STOP State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

5-13 Fault State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

6-1 High-Voltage Hardware System Configuration . . . . . . . . . . . .114

6-2 Low-Voltage Evaluation Motor Hardware

6-3 Low-Voltage Hardware System Configuration . . . . . . . . . . . .116

6-4 Controller Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

6-5 Execute Make Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

6-6 PC Master Software Control Window . . . . . . . . . . . . . . . . . . . 124

6-7 Follow-up for Software Customizing to Customer Motor . . . . 128

6-8 Follow-up for Advanced Software Customizing . . . . . . . . . . .129

6-9 Follow-up for Software Customizing Trouble Shouting. . . . . .129

6-10 PC Master Software Parameters Tuning Control Window . . .130

6-11 PC Master Software Parameters Tuning Control Window . . .131

6-12 PC Master Software Current Parameters Tuning Window . . . 141

6-13 PC Master Software Start Parameters Tuning Window . . . . .149

6-14 PC Master Software Speed Parameters Tuning Window. . . .154

Running Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Designer Reference Manual DRM028 — Rev 0

10 MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 11

Freescale Semiconductor, Inc.

Designer Reference Manual — Sensorless BLDC Motor Control

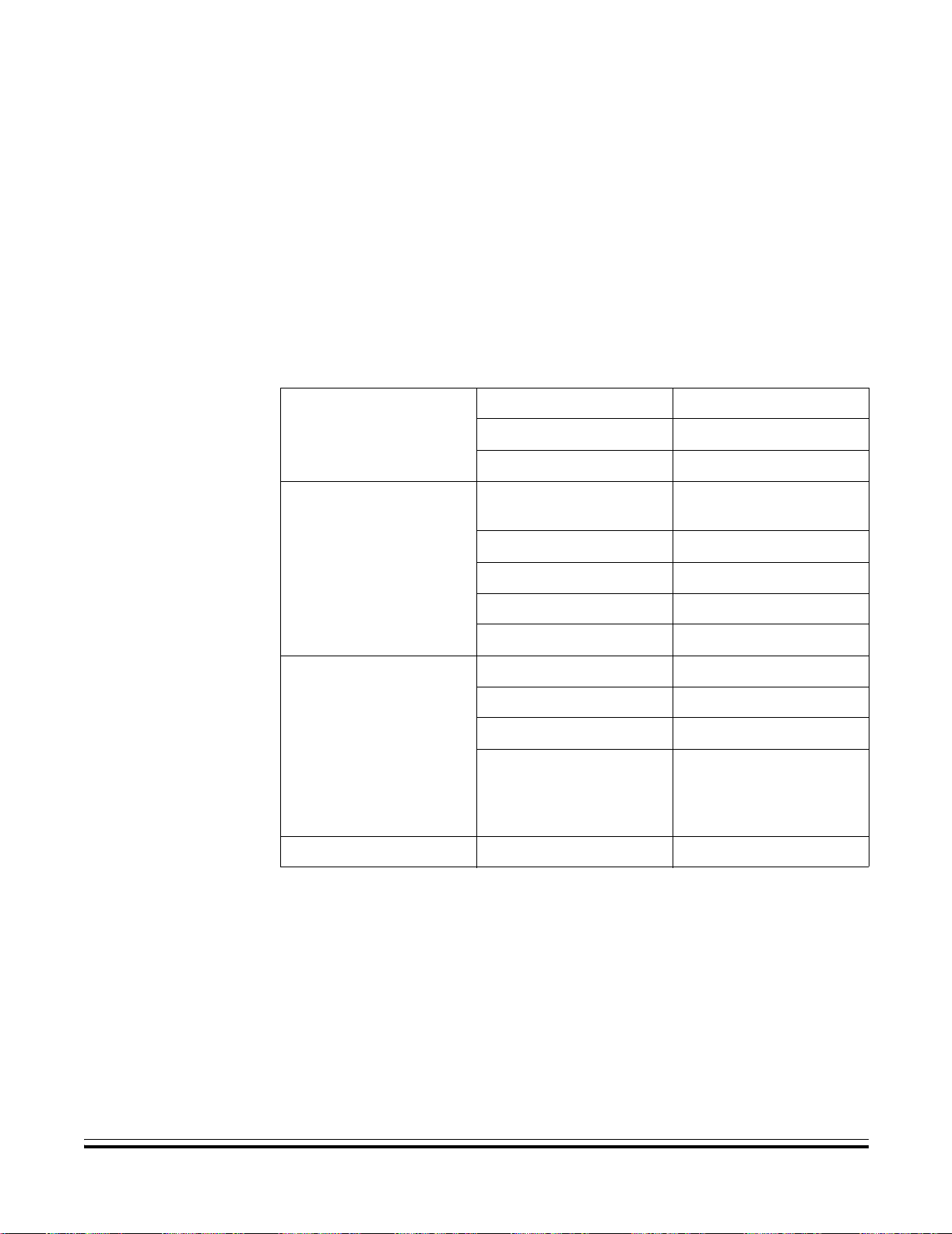

List of Tables

Table Title Page

2-1 Software Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2-2 High Voltage Hardware Set Specifications. . . . . . . . . . . . . . . . 20

2-3 Low Voltage Evaluation Hardware Set Specifications . . . . . . .21

nc...

I

cale Semiconductor,

2-4 Low Voltage Hardware Set Specifications . . . . . . . . . . . . . . . .22

3-1 PC Master Software Communication Commands . . . . . . . . . . 51

3-2 PC Master Software API Variables. . . . . . . . . . . . . . . . . . . . . .52

4-1 Electrical Characteristics of Control Board . . . . . . . . . . . . . . . . 66

4-2 Electrical Characteristics of Power Stage. . . . . . . . . . . . . . . . .68

4-3 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4-4 Electrical Characteristics of the EVM Motor Board. . . . . . . . . .71

4-5 Characteristics of the BLDC motor . . . . . . . . . . . . . . . . . . . . . . 71

4-6 Electrical Chatacteristics of the 3-Ph BLDC

Low Voltage Power Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

5-1 Software Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

6-1 Required Software Configuration

for Dedicated Hardware Platform . . . . . . . . . . . . . . . . . . . . . .118

6-2 Start-up Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

6-3 PWM Frequency Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

Frees

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA 11

For More Information On This Product,

Go to: www.freescale.com

Page 12

Freescale Semiconductor, Inc.

List of Tables

nc...

I

cale Semiconductor,

Frees

Designer Reference Manual DRM028 — Rev 0

12 MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 13

Freescale Semiconductor, Inc.

Designer Reference Manual — Sensorless BLDC Motor Control

Section 1. Introduction

1.1 Contents

1.2 Application Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.3 Benefits of the Solution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

nc...

I

1.2 Application Functionality

cale Semiconductor,

Frees

This Reference Design describes the design of a low-cost sensorless

3-phase brushless dc (BLDC) motor control with back-EMF

(electromotive force) zero-crossing sensing. It is based on Motorola’s

MC68HC908MR32 microcontroller which is dedicated for motor control

applications. The system is designed as a motor drive system for

medium power three phase BLDC motors and is targeted for

applications in automotive, industrial and appliance fields (e.g.

compressors, air conditioning units, pumps or simple industrial drives).

The reference design incorporates both hardware and software parts of

the system including hardware schematics.

1.3 Benefits of the Solution

The design of very low cost variable speed BLDC motor control drives

has become a prime focus point for the appliance designers and

semiconductor suppliers.

Today more and more variable speed drives are put in appliance or

automotive products to increase the whole system efficiency and the

product performance. Using of the control systems based on

semiconductor components and MCUs is mandatory to satisfy

requirements for high efficiency, performance and cost of the system.

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA Introduction 13

For More Information On This Product,

Go to: www.freescale.com

Page 14

Introduction

Freescale Semiconductor, Inc.

Once using the semiconductor components, it is opened to replace

classical universal and DC-motors with maintenance-free electrically

commutated BLDC motors. This brings many advantages of BLDC

motors when the system costs could be maintained equivalent.

The advantages of BLDC motor versus universal and DC-motors are:

• high efficiency

• reliability (no brushes)

• low noise

• easy to drive features

nc...

I

cale Semiconductor,

Frees

To control the BLDC motor, the rotor position must be known at certain

angles in order to align the applied voltage with the back-EMF, which is

induced in the stator winding due to the movement of the permanent

magnets on the rotor.

Although some BLDC drives uses sensors for position sensing, there is

a trend to use sensorless control. The position is then evaluated from

voltage or current going to the motor. One of the sensorless technique is

sensorless BLDC control with back-EMF (electromotive force)

zero-crossing sensing.

The advantages of this control are:

• Save cost of the position sensors & wiring

• Can be used where there is impossibility or expansive to make

additional connections between position sensors and the control

unit

• Low cost system (medium demand for control MCU power)

Designer Reference Manual DRM028 — Rev 0

14 Introduction MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 15

Freescale Semiconductor, Inc.

Designer Reference Manual — Sensorless BLDC Motor Control

Section 2. System Description

2.1 Contents

2.2 System Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.3 System Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

nc...

I

2.2 System Concept

cale Semiconductor,

Frees

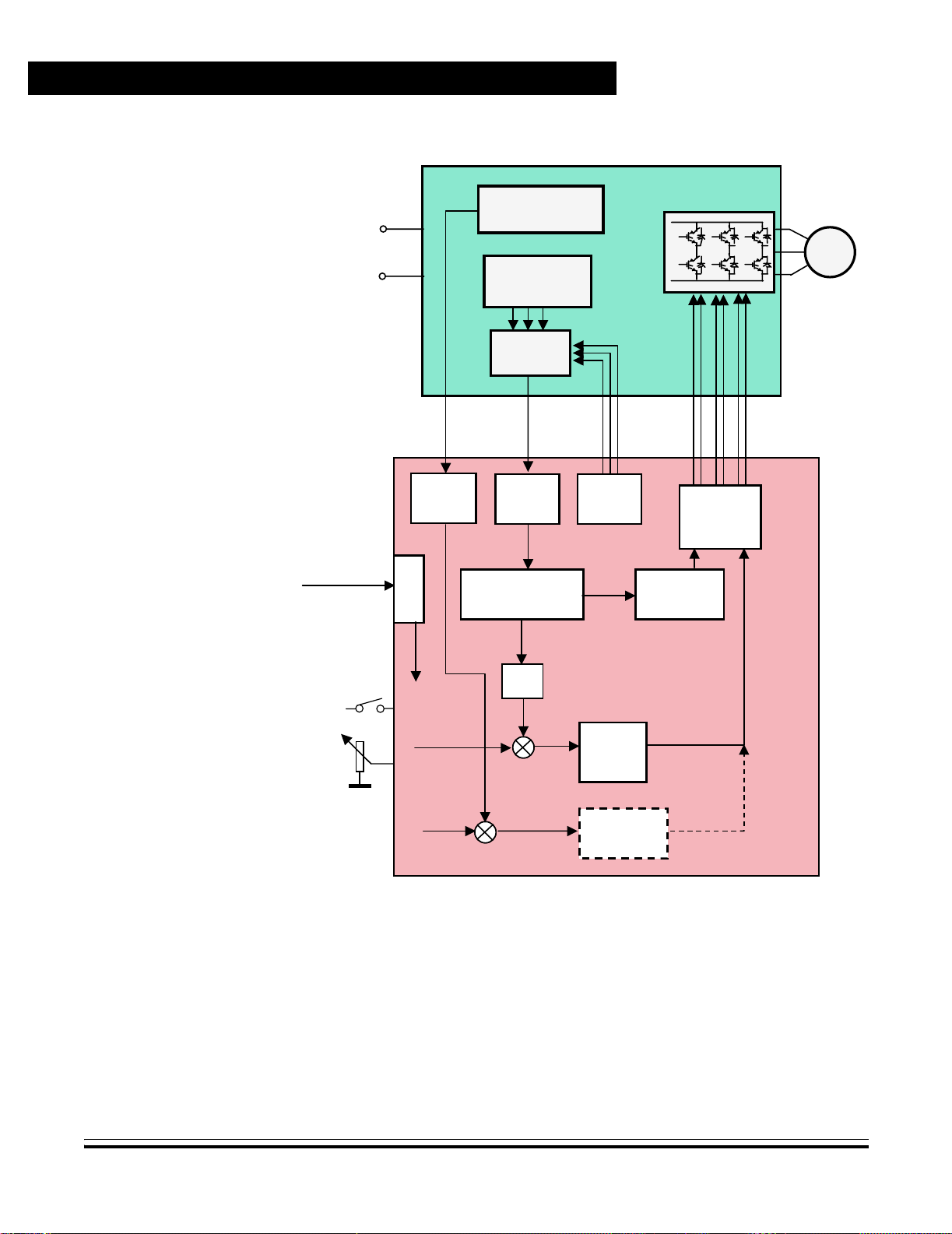

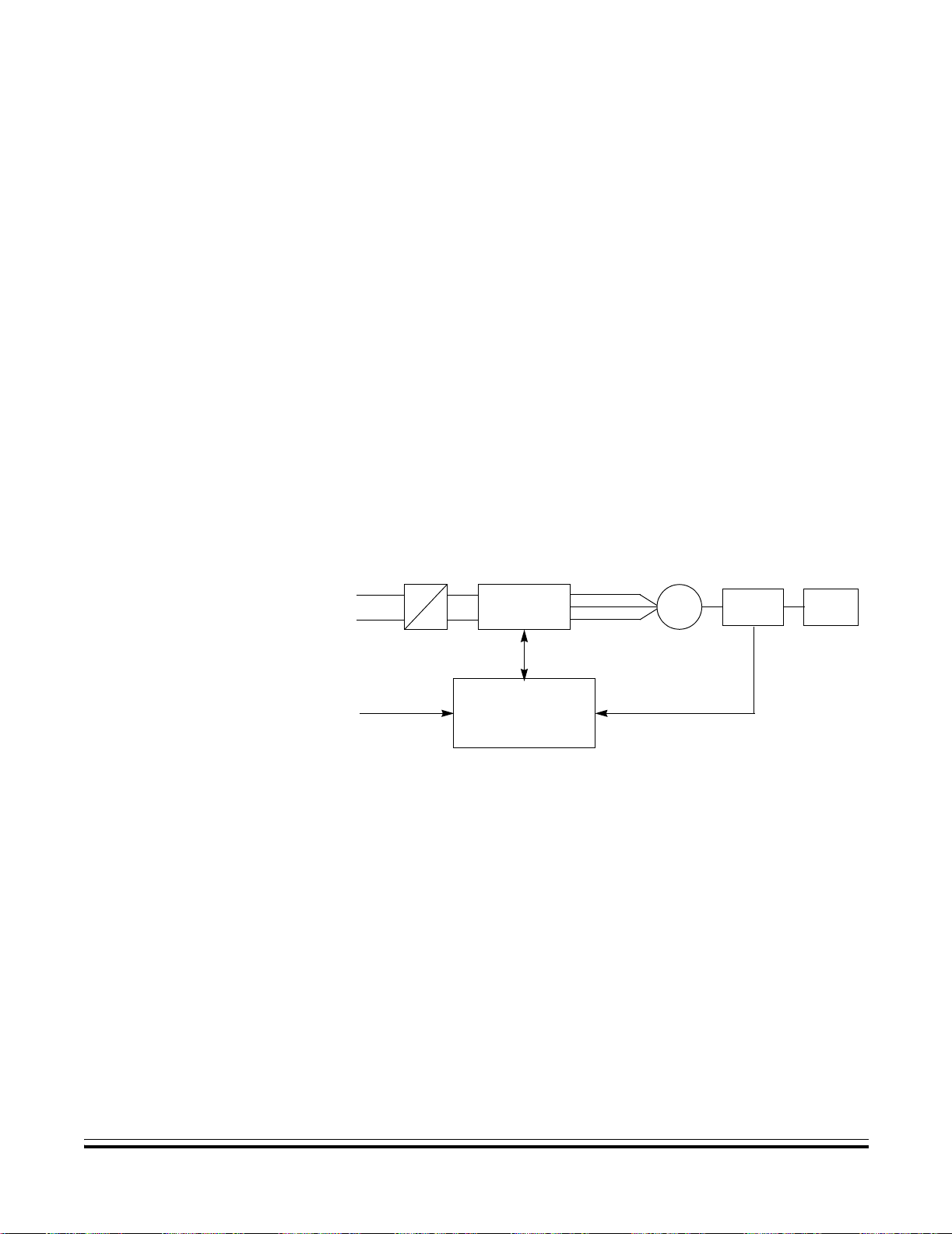

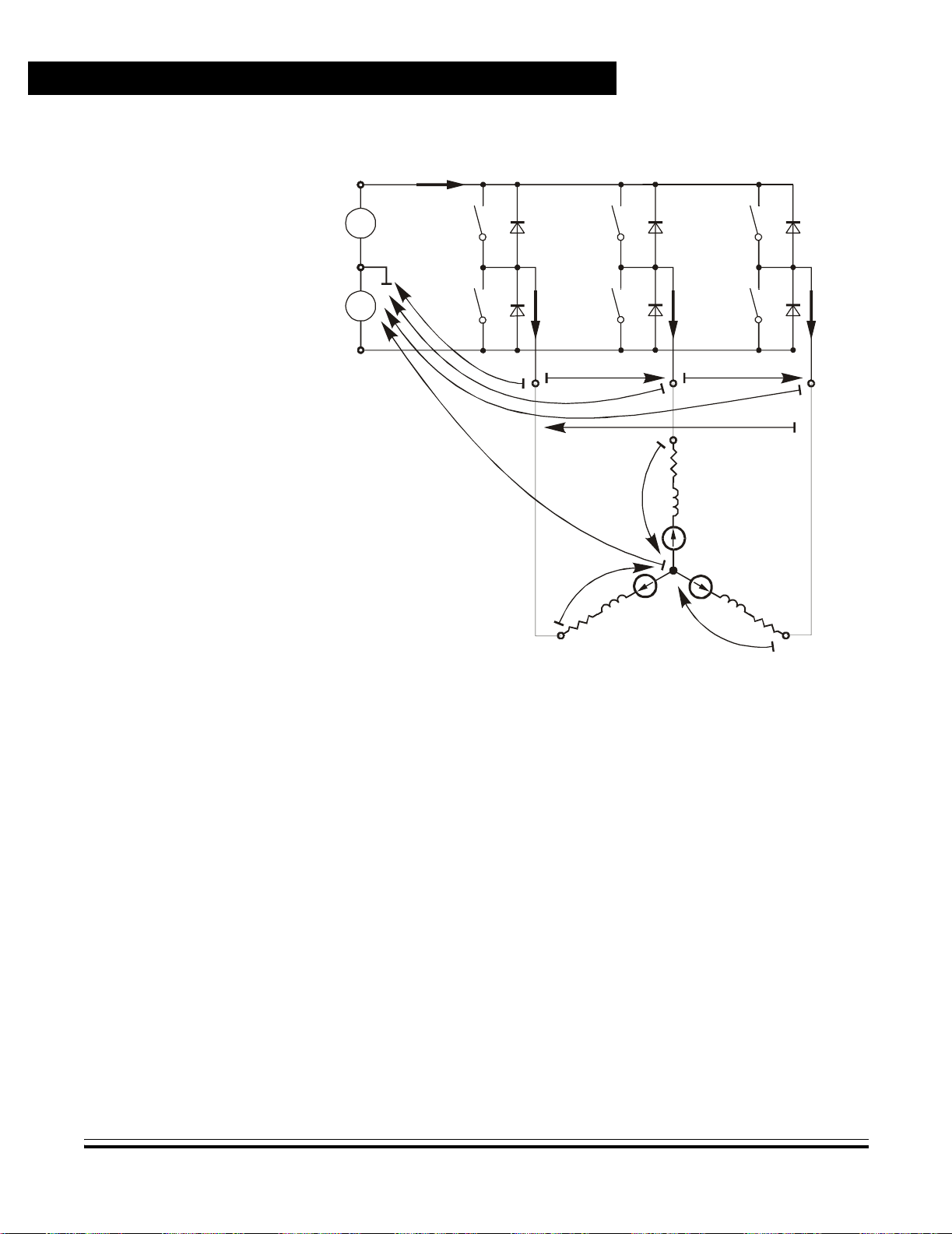

The application block diagram is shown in Figure 2-1. The sensorless

rotor position technique detects the zero crossing points of back-EMF

induced in the motor windings. The phase back-EMF zero crossing

points are sensed while one of the three phase windings is not powered.

The information obtained is processed in order to commutate the

energized phase pair and control the phase voltage, using pulse width

modulation.

The back-EMF zero crossing detection enables position recognition. The

resistor network is used to step down sensed voltages to a 0–3.3 V level.

Zero crossing detection is synchronized with the middle of center aligned

PWM signals by the software, in order to filter high voltage spikes

produced by switching the IGBTs (MOSFETs). The software selects by

MUX command the phase comparator output that corresponds to the

current commutation step. The multiplexer (MUX) circuit selects this

signal, which is then transferred to the MCU input.

The voltage drop resistor is used to measure the dc-bus current which is

chopped by the pulse-width modulator (PWM). The signal obtained is

rectified and amplified (0–3.3 V with 1.65 V offset). The internal MCU

analog-to-digital (A/D) converter and zero crossing detection are

synchronized with the PWM signal. This synchronization avoids spikes

when the IGBTs (or MOSFETs) are switched and simplifies the electric

circuit.

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA System Description 15

For More Information On This Product,

Go to: www.freescale.com

Page 16

System Description

Freescale Semiconductor, Inc.

nc...

I

cale Semiconductor,

Frees

MUX

Command

Commutation

Control

Three-Phase

Inverter

PWM

Generator

Dead Time

with

PWM

Duty

Cycle

HC08MR32

3-ph

BLDC

Motor

DC Bus Current &

DC Bus Voltage

Sensing

Power line

DC-Bus Voltage/

Current

Temperature

ADC

PC Master

START

STOP

SPEED

SCI

Required

Speed

Required

Alignment

Current

3 BEMF Voltage

Zero Crossing

Comparators

MUX

Digital

Inputs

Zero

Crossing

Zero Crossing

Period, Position

Recognition

1/T

Actual

Current

3 phase BLDC

Power Stage

BEMF Zero

Crossing

signal

Digital

Outputs

Zero Crossing

Time moment

Commutation

Period

Actual Speed

Speed PI

Regulator

Current PI

Regulator

(for Alignment)

Figure 2-1System Concept

During the rotor alignment state, the dc-bus current is controlled by the

current PI regulator. In the other states (motor running), the phase

voltage (PWM duty cycle) is controlled by the speed PI regulator.

Designer Reference Manual DRM028 — Rev 0

16 System Description MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 17

Freescale Semiconductor, Inc.

The A/D converter is also used to sense the dc-bus voltage and the drive

temperature. The dc-bus voltage is stepped down to a 3.3-V signal level

by a resistor network.

The six IGBTs (copack with built-in fly back diode), or MOSFETs, and

gate drivers create a compact power stage. The drivers provide the level

shifting that is required to drive the high side switch. The PWM technique

is used to control motor phase voltage.

2.3 System Specification

System Description

System Specification

nc...

I

cale Semiconductor,

Frees

The concept of the application is that of a speed-closed loop drive using

back-EMF zero crossing technique for position detection. It serves as an

example of a sensorless BLDC motor control system using Motorola’s

MC68HC908MR32 MCU. It also illustrates the usage of dedicated motor

control on-chip peripherals.

The system for BLDC motor control consists of hardware and software.

The application uses universal modular motion control development

hardware boards, which are provided by Motorola for customer

development support. For a description of these hardware boards refer

to Appendix A. References 3.,4.,5.,6.,7., and the World Wide Web at:

http://www.motorola.com

There are three board and motor hardware sets for the application:

1. High-Voltage Hardware Set — For variable line voltage 115–230

Vac and medium power (phase current < 2.93 A)

2. Low-Voltage Evaluation Motor Hardware Set — For automotive

voltage (12 V) and very low power (phase current < 4 A)

3. Low-Voltage Hardware Set — For automotive voltage (12 V or

possibly 42 V) and medium power (phase current < 50 A)

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA System Description 17

For More Information On This Product,

Go to: www.freescale.com

Page 18

Freescale Semiconductor, Inc.

System Description

2.3.1 Software Specification

The application software is practically the same for all three hardware

platforms. The only modification needed is to include one of three

constants that customize the hardware and motor parameter settings.

The software (written in C language) specifications are listed in

Table 2-1. A useful feature of the software is serial communication with

PC master software protocol via RS232. The PC master software is PC

computer software which allows reading and setting of all the system

variables, and can also run html script pages to control the application

from the PC. Another feature of the BLDC control software, is on-line

nc...

I

parameter modification with PC master software, which can be used for

software parameter tuning to a customer motor.

cale Semiconductor,

Frees

.

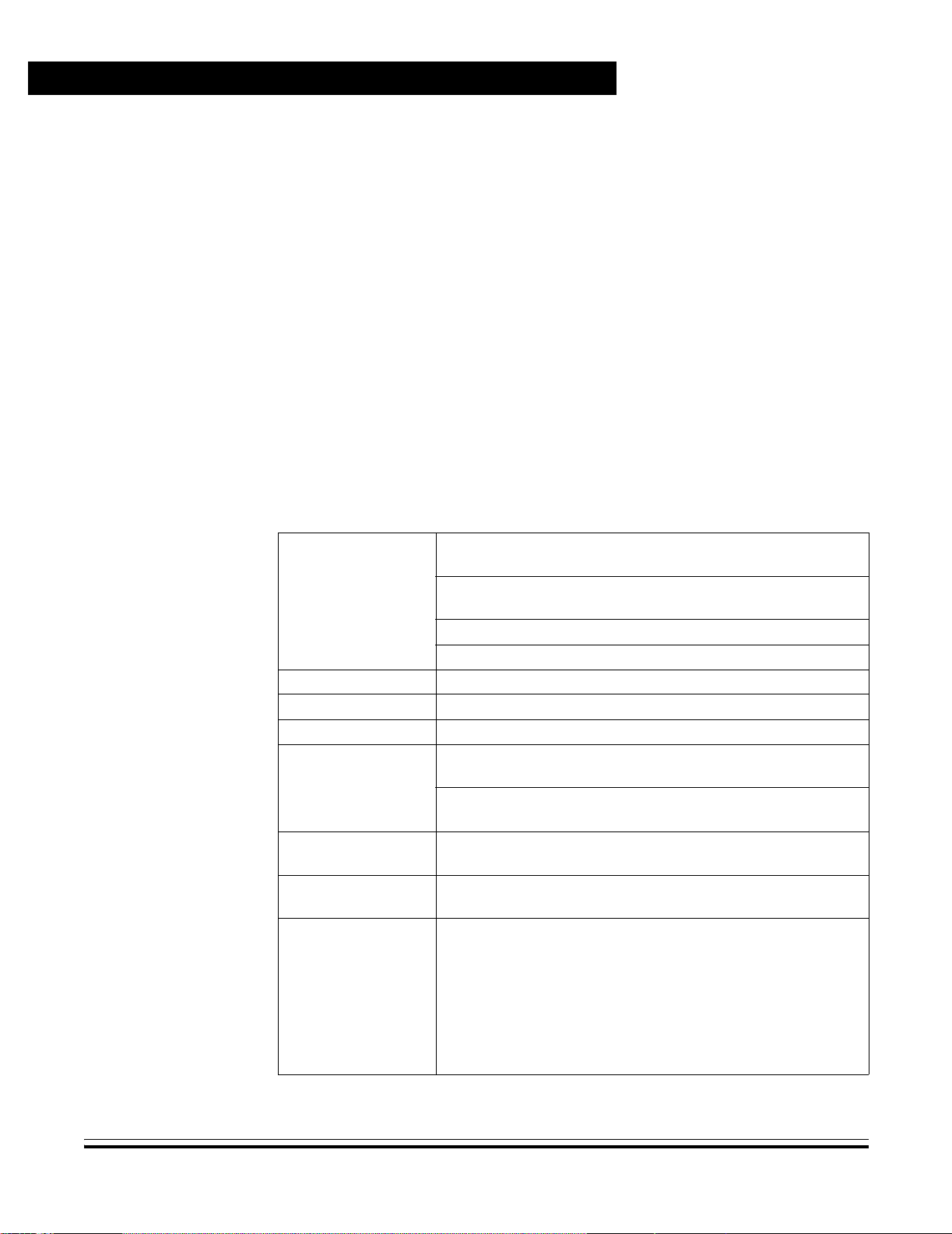

Table 2-1. Software Specifications

3-phase trapezoidal BLDC motor control star or delta!

connected

Control Algorithm

Target Processor MC68HC908MR32

Language C-language with some arithmetical functions in assembler

Compiler Metrowerks ANSI-C/cC++ Compiler for HC08

Application

Control

MCU Oscillator

Frequency

MCU Bus

Frequency

Minimal BLDC

Motor

Commutation

Period

(Without PC

Master

Software

Communication)

Sensorless, with back-EMF zero crossing commutation

control

Speed closed loop control

Motoring mode

Manual interface (start/stop switch, speed potentiometer

control, LED indication)

PC master software (remote) interface (via RS232 using PC

computer)

4 MHz (with default software setting)

8 MHz (with default software setting)

333 µs (with default software setting and COEF_HLFCMT =

0.450)

Designer Reference Manual DRM028 — Rev 0

18 System Description MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 19

nc...

I

cale Semiconductor,

Frees

Freescale Semiconductor, Inc.

Table 2-1. Software Specifications

Minimal BLDC

Motor

Commutation

Period (with PC

Master Software

Control)

Targeted

Hardware

Software

Configuration

and Parameters

Setting

2.3.2 Hardware and Drive Specifications

The other system specifications are determined by hardware boards and

motor characteristics. The boards and their connections are shown in

Section 4. Hardware Design. and Section 6. User Guide, 6.4.1

Hardware Configuration. The hardware set specifications are

discussed in the following subsections.

System Description

System Specification

520 µs (with default software setting and COEF_HLFCMT =

0.450)

Software is prepared to run on three optional board and

motor hardware sets:

• High-voltage hardware set at variable line voltage

115–230 Vac

(software customizing file const_cust_hv.h)

• Low-voltage evaluation motor hardware set

(software customizing file const_cust_evmm.h)

• Low-voltage hardware set (software customizing file

const_cust_lv.h)

Configuration to one of the three required hardware sets is

provided by inclusion of dedicated software customizing

files. The software pack contains the files const_cust_hv.h,

const_cust_lv.h, and const_cust_evm.h with predefined

parameter settings for running on one of the optional board

and motor hardware sets. The required hardware must be

selected in code_fun.c file by one of these files #include.

Where software is configuration for different customer

motors, the software configuration for any motor is

provided in the dedicated customizing file, according to the

hardware board used.

PWM frequency 15.626 kHz with default software setting,

possibly changeable in const.h file

2.3.2.1 High-Voltage Hardware Set Specification

This hardware set is dedicated for medium power (phase current <

2.93 A) and main voltage. The specifications for a high-voltage hardware

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA System Description 19

For More Information On This Product,

Go to: www.freescale.com

Page 20

Freescale Semiconductor, Inc.

System Description

and motor set are listed in Table 2-2. The hardware operates on both

230 Vac and 115 Vac mains.

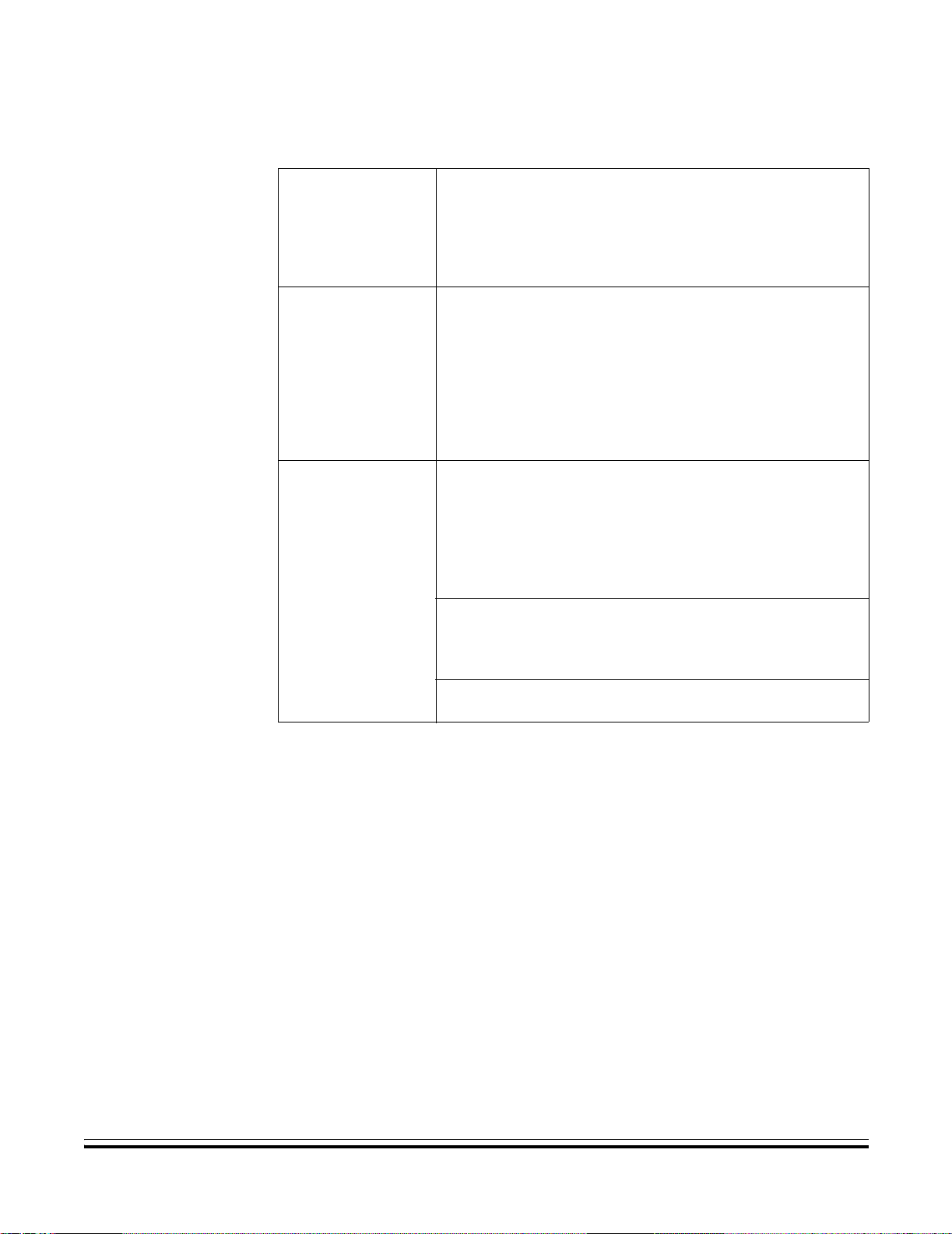

Table 2-2. High Voltage Hardware Set Specifications

Input voltage: 230 Vac or 115 Vac

Hardware Boards

Characteristics

Motor -Brake Set Manufactured EM Brno, Czech Republic

nc...

I

Maximum dc-bus voltage: 407 V

Maximal output current: 2.93A

EM Brno SM40V

Motor type:

Pole-Number: 6

3 phase, star connected

BLDC motor,

cale Semiconductor,

Frees

Motor Characteristics

Brake Characteristics

Maximum dc-bus voltage: 380 V

Drive Characteristics

Speed range: 2500 rpm (at 310 V)

Maximum electrical

power:

Phase voltage: 3*220 V

Phase current: 0.55 A

Brake Type:

Nominal Voltage: 3 x 27 V

Nominal Current: 2.6 A

Pole-Number: 6

Nominal Speed: 1500 rpm

Speed range:

Optoisolation: Required

Protection:

150 W

SG40N

3-Phase BLDC Motor

< 2500 rpm

(determined by motor

used)

Over-current,

over-voltage, and

under-voltage fault

protection

Load Characteristic Type: Varying

Designer Reference Manual DRM028 — Rev 0

20 System Description MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 21

Freescale Semiconductor, Inc.

System Description

System Specification

2.3.2.2 Low-Voltage Evaluation Hardware Set Specification

This hardware set is dedicated for 12 V voltage and very low power

(phase current < 4 A). The specifications for a low-voltage evaluation

hardware and motor set are listed in Table 2-3. It is targeted first of all to

software evaluation with small motors.

Table 2-3. Low Voltage Evaluation Hardware Set Specifications

Input voltage: 12 Vdc

nc...

I

Hardware Boards

Characteristics

Maximum dc-bus voltage: 16.0 V

Maximal output current: 4.0 A

cale Semiconductor,

Frees

Motor Characteristics

Drive Characteristics

Load Characteristic Type: Varying

2.3.2.3 Low-Voltage Hardware Set Specification

Motor type:

Speed range: < 5000 rpm (at 60 V)

Maximal line voltage: 60 V

Phase current: 2 A

Output torque: 0.140 Nm (at 2 A)

Speed range: < 1400 rpm

Input voltage: 12 Vdc

Maximum dc-bus voltage: 15.8 V

Protection:

4 poles, three phase, star

connected, BLDC motor

Over-current,

over-voltage, and

under-voltage fault

protection

This hardware set is dedicated for medium power (phase current < 50 A)

and automotive voltage. The specifications for a low-voltage hardware

and motor set are listed in Table 2-4. The hardware power stage board

is dedicated for 12 V, but can be simply configured to a 42 V supply

(described in documentation for the ECLOVACBLDC board). The

supplied motor is targeted for 12 V.

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA System Description 21

For More Information On This Product,

Go to: www.freescale.com

Page 22

System Description

Freescale Semiconductor, Inc.

Table 2-4. Low Voltage Hardware Set Specifications

Input voltage: 12 Vdc or 42 V

Hardware Boards

Characteristics

Motor -Brake Set Manufactured EM Brno, Czech Republic

Maximum dc-bus voltage: 16.0 V or 55.0 V

Maximal output current: 50.0 A

EM Brno SM40N

Motor type:

Pole-Number: 6

3 phase, star connected

BLDC motor,

nc...

I

cale Semiconductor,

Frees

Motor Characteristics

Brake Characteristics

Drive Characteristics

Maximum dc-bus voltage: 15.8 V

Speed range: 3000 rpm (at 12 V)

Maximum electrical

power:

Phase voltage: 3*6.5 V

Phase current: 17 A

Brake Type:

Nominal Voltage: 3 x 27 V

Nominal Current: 2.6 A

Pole-Number: 6

Nominal Speed: 1500 rpm

Speed range: < 2500 rpm

Input voltage: 12 Vdc

Protection:

150 W

SG40N

3-Phase BLDC Motor

Over-current,

over-voltage, and

under-voltage fault

protection

Load Characteristic Type: Varying

Designer Reference Manual DRM028 — Rev 0

22 System Description MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 23

Freescale Semiconductor, Inc.

Designer Reference Manual — Sensorless BLDC Motor Control

Section 3. BLDC Motor Control

3.1 Contents

3.2 Brushless DC Motor Control Theory. . . . . . . . . . . . . . . . . . . . .23

3.3 Used Control Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

nc...

I

cale Semiconductor,

Frees

3.4 Application Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

3.2 Brushless DC Motor Control Theory

3.2.1 BLDC Motor Targeted by This Application

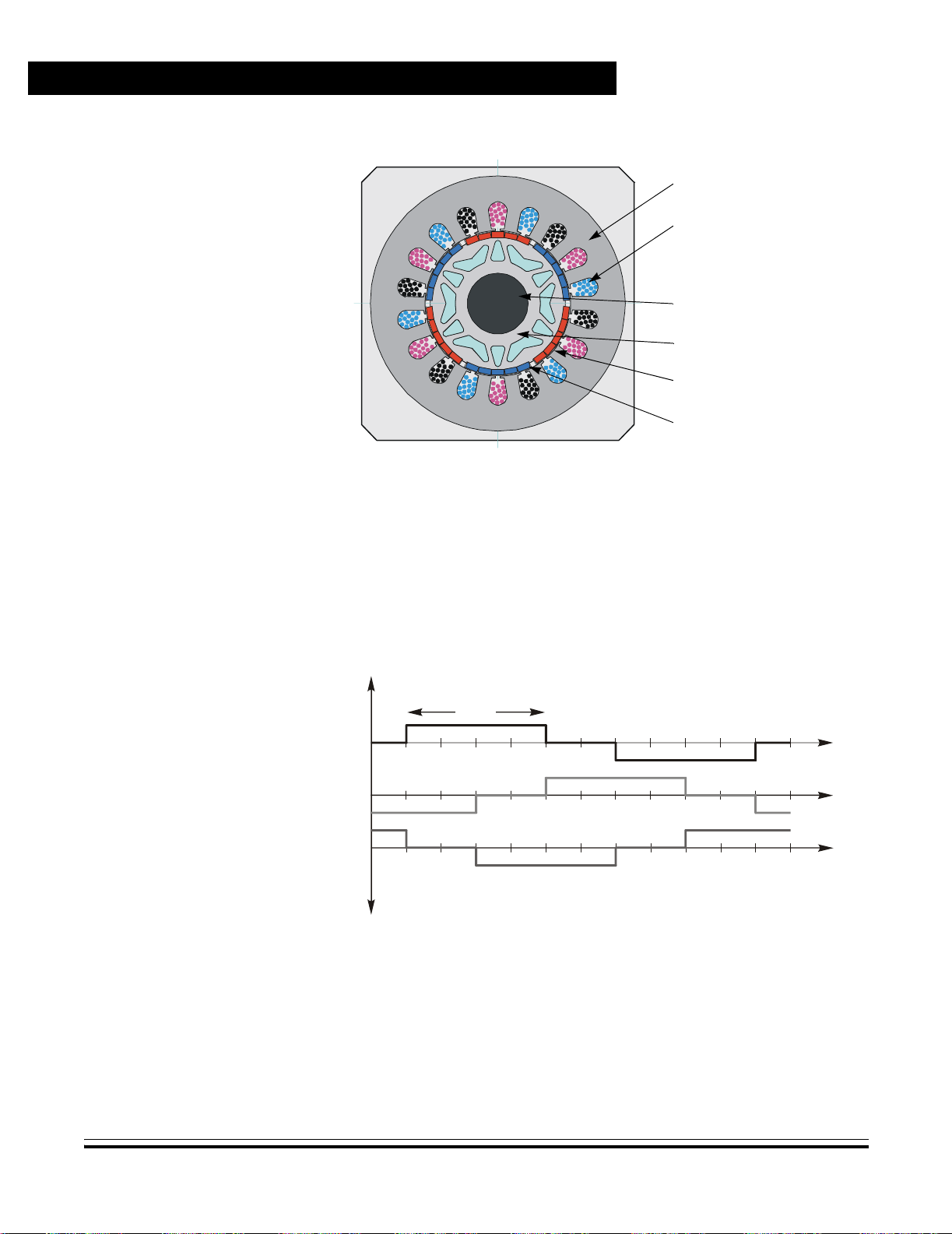

The brushless dc motor (BLDC motor) is also referred to as an

electronically commutated motor. There are no brushes on the rotor, and

commutation is performed electronically at certain rotor positions. The

stator magnetic circuit is usually made from magnetic steel sheets.

Stator phase windings are inserted in the slots (distributed winding) as

shown in Figure 3-1, or it can be wound as one coil on the magnetic

pole. Magnetization of the permanent magnets and their displacement

on the rotor are chosen in such a way that the back-EMF (the voltage

induced into the stator winding due to rotor movement) shape is

trapezoidal. This allows a rectangular shaped 3-phase voltage system

(see Figure 3-2) to be used to create a rotational field with low torque

ripples.

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA BLDC Motor Control 23

For More Information On This Product,

Go to: www.freescale.com

Page 24

BLDC Motor Control

Freescale Semiconductor, Inc.

STATOR

STATOR WINDING

(IN SLOTS)

SHAFT

ROTOR

AIR GAP

nc...

I

cale Semiconductor,

Frees

PERMANENT MAGNETS

Figure 3-1. BLDC Motor Cross Section

The motor can have more than just one pole-pair per phase. This defines

the ratio between the electrical revolution and the mechanical revolution.

The BLDC motor shown has three pole-pairs per phase, which represent

three electrical revolutions per one mechanical revolution.

Voltage

VOLTAGE

Phase A

PHASE A

Phase B

PHASE B

Phase C

PHASE C

30° 90° 150° 210° 270° 330°

30° 90° 150° 210° 270° 330°

120°

120°

ELECTRICAL

electrical

ANGLE

angle

Figure 3-2. 3-Phase Voltage System

The easy to create rectangular shape of applied voltage ensures the

simplicity of control and drive. But, the rotor position must be known at

certain angles in order to align the applied voltage with the back-EMF

(voltage induced due to movement of the PM). The alignment between

Designer Reference Manual DRM028 — Rev 0

24 BLDC Motor Control MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 25

Freescale Semiconductor, Inc.

back-EMF and commutation events is very important. In this condition,

the motor behaves as a dc motor and runs at the best working point.

Thus, simplicity of control and good performance make this motor a

natural choice for low-cost and high-efficiency applications.

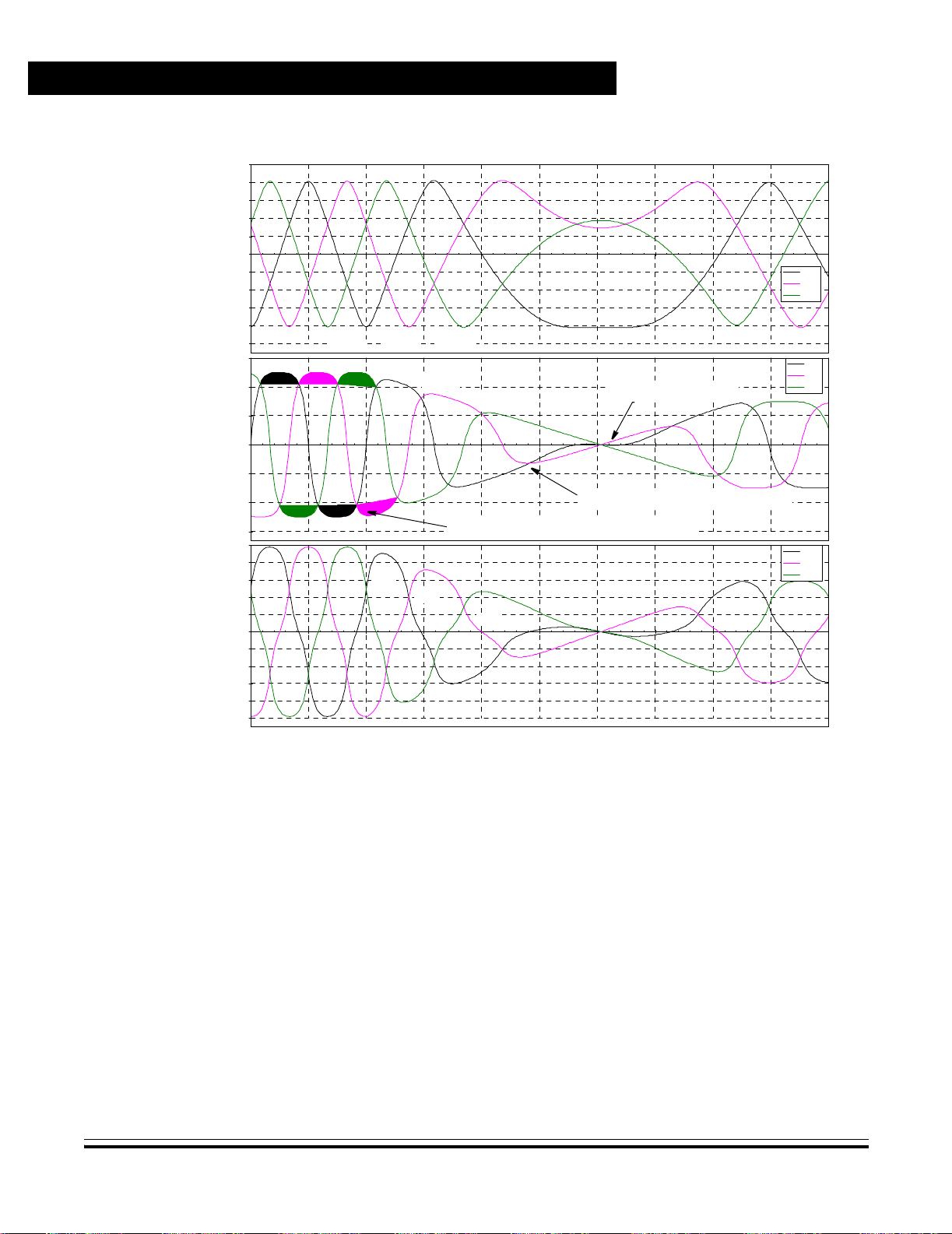

Figure 3-3 shows a number of waveforms:

• Magnetic flux linkage

• Phase back-EMF voltage

• Phase-to-phase back-EMF voltage

Magnetic flux linkage can be measured. However, in this case it was

nc...

I

calculated by integrating the phase back-EMF voltage (which was

measured on the non-fed motor terminals of the BLDC motor). As can

be seen, the shape of the back-EMF is approximately trapezoidal and

the amplitude is a function of the actual speed. During speed reversal,

the amplitude changes its sign and the phase sequence changes.

BLDC Motor Control

Brushless DC Motor Control Theory

cale Semiconductor,

Frees

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA BLDC Motor Control 25

For More Information On This Product,

Go to: www.freescale.com

Page 26

BLDC Motor Control

Phase Magnetic

Flux Linkage

Freescale Semiconductor, Inc.

Ps i_ A

Ps i_ B

Ps i_ C

nc...

I

cale Semiconductor,

Frees

PH. A

Phase Back EMF

Atop Btop Ctop

Cbot Abot Bbot

Phase-Phase

Back EMF

Figure 3-3. BLDC Motor Back EMF and Magnetic Flux

The filled areas in the tops of the phase back-EMF voltage waveforms

PH. A

A–B

PH. B

PH. C

PH. B

PH. C

“NATURAL” COMMUTATION POINT

“Natural” commutation point

ACTING POWER SWITCH IN THE POWER STAGE

B–C

C–A

SPEED REVERSAL

Speed reversal

Ui_A

Ui_B

Ui_C

Ui_A B

Ui_B C

Ui_CA

indicate the intervals where the particular phase power stage

commutations occur. The power switches are cyclically commutated

through the six steps; therefore, this technique is sometimes called six

step commutation control. The crossing points of the phase back-EMF

voltages represent the natural commutation points. In normal operation

the commutation is performed here. Some control techniques advance

the commutation by a defined angle in order to control the drive above

the pulse-width modulator (PWM) voltage control.

Designer Reference Manual DRM028 — Rev 0

26 BLDC Motor Control MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 27

Freescale Semiconductor, Inc.

BLDC Motor Control

Brushless DC Motor Control Theory

3.2.2 3-Phase BLDC Power Stage

The voltage for 3-phase BLDC motor is provided by a 3-phase power

stage controlled by digital signals. Its topology is the one as for the AC

induction motor (refer to Figure 3-5). The power stage is usually

controlled by a dedicated microcontroller with on-chip PWM module.

3.2.3 Why Sensorless Control?

As explained in the previous section, rotor position must be known in

order to drive a brushless dc motor. If any sensors are used to detect

rotor position, sensed information must be transferred to a control unit

nc...

I

(see Figure 3-4). Therefore, additional connections to the motor are

necessary. This may not be acceptable for some applications (see 1.3

Benefits of the Solution).

cale Semiconductor,

Frees

AC LINE VOLTAGE

SPEED

SETTING

–

=

CONTROL SIGNALS

3.2.4 Power Stage — Motor System Model

In order to explain and simulate the idea of back-EMF sensing

techniques a simplified mathematical model based on the basic circuit

topology has been created. See Figure 3-5.

POWER STAGE

CONTROL UNIT

MOTOR DRIVE

M

POSITION FEEDBACK

Figure 3-4. Classical System

POSITION

SENSORS

LOAD

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA BLDC Motor Control 27

For More Information On This Product,

Go to: www.freescale.com

Page 28

BLDC Motor Control

Freescale Semiconductor, Inc.

u

d

/2

u

d

/2

I

d0

+

S

=

-

+

=

-

At

S

Ab

S

Bt

I

S

Sa

Bb

S

Ct

I

S

Sb

Cb

I

Sc

u

VA

nc...

I

u

AB

u

VB

u

Sb

u

0

u

Sa

u

backEMF a

u

La

uu

Ra Rc

O

A

Figure 3-5. Power Stage — Motor Topology

The second goal of the model is to find how the motor characteristics

cale Semiconductor,

depend on the switching angle. The switching angle is the angular

difference between a real switching event and an ideal one (at the point

where the phase-to-phase back-EMF crosses zero).

u

VC

u

CA

B

u

Rb

u

Lb

u

backEMF b

u

u

Sc

u

BC

backEMF c

u

Lc

C

Frees

The motor-drive model consists of a normal 3-phase power stage plus a

brushless dc motor. Power for the system is provided by a voltage

source (U

). Six semiconductor switches (S

d

A/B/C t/b

), controlled

elsewhere, allow the rectangular voltage waveforms (see Figure 3-2) to

be applied.

The semiconductor switches and diodes are simulated as

ideal devices. The natural voltage level of the whole model is put at one

half of the dc-bus voltage. This simplifies the mathematical expressions.

Designer Reference Manual DRM028 — Rev 0

28 BLDC Motor Control MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 29

Freescale Semiconductor, Inc.

3.2.4.1 Stator Winding Equations

The BLDC motor is usually very symmetrical. All phase resistances,

phase and mutual inductances, flux-linkages can be thought of as equal

to, or as a function of the position θ with a 120° displacement.

The electrical BLDC motor model then consists of a set of the following

stator voltage equations (EQ 3-1.).

BLDC Motor Control

Brushless DC Motor Control Theory

nc...

I

cale Semiconductor,

Frees

The task of this section is to explain the background of the back-EMF

sensing and to demonstrate how the zero crossing events can be

detected. Parasitic effects that negatively influence the back-EMF

detection are discussed and their nature analyzed.

3.2.4.2 Indirect Back EMF Sensing

Let us assume a usual situation, where the BLDC motor is driven in

six-step commutation mode using PWM technique, where both top and

bottom switches in the diagonal are controlled using the same signal (so

called “hard switching PWM” technique). The motor phases A and B are

powered, and phase C is free, having no current. So the phase C can be

used to sense the back-EMF voltage. This is described by the following

conditions:

VB

Sc

Ψ

Sa

d

+=

Ψ

Sb

td

Ψ

Sc

1

=,

---± u

2

d–id==,

Sb

u

Sa

u

Sb

u

Sc

SAbSBt, PWM←

u

VA

i

iSb–i==i

Sa

u

backEMF aubackEMF bubackEMF c

++ 0=

i

Sa

R

i

S

Sb

i

Sc

1

−

=u

---u

+

d

2

di

Sa

0=i

Sc

d0=,

i

(EQ 3-1.)

d

(EQ 3-2.)

The branch voltage u

u

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA BLDC Motor Control 29

For More Information On This Product,

Go to: www.freescale.com

VC

u

Vc

1

---u

Sc

3

xa=

can be calculated using the above conditions,

c

∑

backEMF x

LacLbc–()

id

---- uVC–+–=

td

(EQ 3-3.)

Page 30

BLDC Motor Control

After evaluation the expression of the branch voltage uVc is as follows:

Freescale Semiconductor, Inc.

nc...

I

cale Semiconductor,

Frees

VC

3

---u

backEMF c

2

u

1

–()

---L

acLbc

2

id

(EQ 3-4.)

----–=

td

The same expressions can also be found for phase A and B:

3

VA

VB

---u

backEMF a

2

3

---u

backEMF b

2

u

u

1

–()

---L

baLca

2

1

–()

---L

cbLab

2

id

----–=

td

id

----–=

td

(EQ 3-5.)

(EQ 3-6.)

The first member in the equation (EQ 3-6.) demonstrates the possibility

to indirectly sense the back-EMF between the free (not powered) phase

terminal and the zero point, defined at half of the dc-bus voltage (see

Figure 3-5.). Simple comparison of these two levels can provide the

required zero crossing detection.

As shown in Figure 3-5, the branch voltage of phase B can be sensed

between the power stage output B and the zero voltage level. Thus,

back-EMF voltage is obtained and the zero crossing can be recognized.

When Lcb = Lab, this general expressions can also be found:

3

u

---u

Vx

backEMFx

2

where x A B C,,==

(EQ 3-7.)

There are two necessary conditions which must be met:

• Top and bottom switches (in diagonal) have to be driven with the

same PWM signal

• No current goes through the non-fed phase that is used to sense

the back-EMF

Figure 3-6 shows branch and motor phase winding voltages during a

0–360° electrical interval. Shaded rectangles designate the validity of

the equation (EQ 3-7.). In other words, the back-EMF voltage can be

sensed during designated intervals.

Designer Reference Manual DRM028 — Rev 0

30 BLDC Motor Control MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 31

Freescale Semiconductor, Inc.

0 30 60 90 120 150 180 210 240 270 300 330 360 390

BLDC Motor Control

Brushless DC Motor Control Theory

uVA

uSa

- Back-EMF can be sensed

Figure 3-6. Phase Voltage Waveform

nc...

I

However simple this solution looks, in reality it is more difficult, because

the sensed “branch” voltage also contains some ripples.

cale Semiconductor,

Frees

3.2.4.3 Effect of Mutual Inductance

As shown in previous equations (EQ 3-4.) through (EQ 3-6.), the mutual

inductances play an important role here. The difference of the mutual

inductances between the coils which carry the phase current, and the

coil used for back-EMF sensing, causes the PWM pulses to be

superimposed onto the detected back-EMF voltage. In fact, it is

produced by the high rate of change of phase current, transferred to the

free phase through the coupling of the mutual inductance.

Figure 3-7 shows the real measured “branch” voltage. The red curves

highlight the effect of the difference in the mutual inductances. This

difference is not constant.

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA BLDC Motor Control 31

For More Information On This Product,

Go to: www.freescale.com

Page 32

BLDC Motor Control

Freescale Semiconductor, Inc.

0 V

Figure 3-7. Mutual Inductance Effect

nc...

I

cale Semiconductor,

Frees

Due to the construction of the BLDC motor, both mutual inductances

vary. They are equal at the position that corresponds to the back-EMF

zero crossing detection.

The branch waveform detail is shown in Figure 3-8. Channel 1 in

Figure 3-8 shows the disturbed “branch” voltage. The superimposed

ripples clearly match the width of the PWM pulses, and thus prove the

conclusions from the theoretical analysis.

The effect of the mutual inductance corresponds well in observations

carried out on the five different BLDC motors. These observations were

made during the development of the sensorless technique.

NOTE: The BLDC motor with stator windings distributed in the slots has

technically higher mutual inductances than other types. Therefore, this

effect is more significant. On the other hand the BLDC motor with

windings wounded on separate poles, shows minor presence of the

effect of mutual inductance.

CAUTION: However noticeable this effect, it does not degrade the back-EMF zero

crossing detection because it is cancelled at the zero crossing point.

Simple additional filtering helps to reduce ripples further.

Designer Reference Manual DRM028 — Rev 0

32 BLDC Motor Control MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 33

Freescale Semiconductor, Inc.

nc...

I

BLDC Motor Control

Brushless DC Motor Control Theory

cale Semiconductor,

Frees

Figure 3-8. Detail of Mutual Inductance Effect

3.2.4.4 Effect of Mutual Phase Capacitance

The negative effect of mutual inductance is not the only one to disturb

the back-EMF sensing. So far, the mutual capacitance of the motor

phase windings was neglected in the motor model, since it affects

neither the phase currents nor the generated torque. Usually the mutual

capacitance is very small. Its influence is only significant during PWM

switching, when the system experiences very high du/dt.

The effect of the mutual capacitance can be studied using the model

shown in Figure 3-9.

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA BLDC Motor Control 33

For More Information On This Product,

Go to: www.freescale.com

Page 34

Freescale Semiconductor, Inc.

BLDC Motor Control

I

d0

+

u

d

/2

u

d

/2

S

=

-

+

=

-

At

S

Ab

S

Bt

u

VA

S

Bb

I

Sb

Figure 3-9. Mutual Capacitance Model

nc...

I

Let us focus on the situation when the motor phase A is switched from

negative dc-bus rail to positive, and the phase B is switched from

positive to negative. This is described by these conditions (EQ 3-8.):

A

i

C

R

C

i

Cab

u

Cba

C

B

u

VB

u

Cac

C

R

C

C

i

C

C

R

u

C

Ccb

u

VC Cap

cale Semiconductor,

Frees

SAbSBt, PWM←

1

1

–

u

VA

---u

→=u

---u

d

2

d

2

==

i

CaciCcbiC

The voltage that disturbs the back-EMF sensing, utilizing the free (not

powered) motor phase C, can be calculated based the equation:

u

VC Cap

1

++()u

---u

CcbuCac

2

2R

C

The final expression for disturbing voltage can be found as follows:

u

VC Cap

1

==

---

2

1

-------C

1

--------–

iCtd

∫

C

ac

cb

1

---u

VB

d

2

+()–

CcbRC

C

1

cbCac

---

----------------------

2

C

cbCac

1

–→=,

---u

d

2

1

---u

–()==

CacuCcb

2

–

⋅

td

i

C

∫

(EQ 3-8.)

(EQ 3-9.)

(EQ 3-10.)

NOTE: (EQ 3-10.) expresses the fact that only the unbalance of the mutual

capacitance (not the capacitance itself) disturbs the back-EMF sensing.

When both capacities are equal (they are balanced), the disturbances

disappear. This is demonstrated in Figure 3-10 and Figure 3-11.

Designer Reference Manual DRM028 — Rev 0

34 BLDC Motor Control MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 35

Freescale Semiconductor, Inc.

nc...

I

BLDC Motor Control

Brushless DC Motor Control Theory

cale Semiconductor,

Frees

Figure 3-10. Distributed Back-EMF by Unbalanced

Capacity Coupling

Channel 1 in Figure 3-11 shows the disturbed “branch” voltage, while

the other phase (channel 2) is not affected because it faces balanced

mutual capacitance. The unbalance was purposely made by adding a

small capacitor on the motor terminals, in order to better demonstrate

the effect. After the unbalance was removed the “branch” voltage is

clean, without any spikes.

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA BLDC Motor Control 35

For More Information On This Product,

Go to: www.freescale.com

Page 36

Freescale Semiconductor, Inc.

BLDC Motor Control

nc...

I

cale Semiconductor,

Frees

NOTE: The configuration of the phase windings end-turns has significant

impact; therefore, it needs to be properly managed to preserve the

balance in the mutual capacity. This is important, especially for prototype

motors that are usually hand-wound.

CAUTION: Failing to maintain balance in the mutual capacitance can easily

disqualify such a motor from using sensorless techniques based on the

back-EMF sensing. Usually, the BLDC motors with windings wound on

separate poles show minor presence of the mutual capacitance. Thus,

the disturbance is also insignificant.

3.2.5 Back-EMF Sensing Circuit

An example of the possible implementation of the back-EMF sensing

circuit is shown in Figure 3-12.

Figure 3-11. Balanced Capacity Coupling

Designer Reference Manual DRM028 — Rev 0

36 BLDC Motor Control MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 37

Freescale Semiconductor, Inc.

+DC_BUS PHASE A PHASE B PHASE C

BLDC Motor Control

Brushless DC Motor Control Theory

nc...

I

cale Semiconductor,

Frees

560k

560k

560k

2x27k

560k

560k

560k

2x27k 2x27k 2x27k

1n

560k

560k

560k

1n

+

–

1n

1n

+

–

+

–

MUX

ZERO

CROSSING

DETECTION

SIGNAL

MUX COMMAND

Figure 3-12. Back-EMF Sensing Circuit Diagram

As explained in the theoretical part of this designer reference manual,

the phase zero crossing event can be detected at the moment when the

branch voltage (of a free phase) crosses the half dc-bus voltage level.

The resistor network is used to step down sensed voltages down to a

0–15 V voltage level. The comparators sense the zero voltage difference

in the input signal. The multiple resistors reduce the voltage across each

resistor component to an acceptable level. A simple RC filter prevents

the comparators from being disturbed by high voltage spikes produced

by IGBT switching. The multiplexer (MUX) selects the phase comparator

output, which corresponds to the current commutation stage. This zero

crossing detection signal is transferred to the timer input pin.

The comparator control and zero crossing signals plus the voltage

waveforms are shown in Figure 3-13.

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA BLDC Motor Control 37

For More Information On This Product,

Go to: www.freescale.com

Page 38

Freescale Semiconductor, Inc.

BLDC Motor Control

Phase Selection

MUX Command

Phase Comparator

Output

(Zero crossing edge)

"Branch" Voltage

(Interval of phase

Back-EMF zero

crossing detection)

Reference Level

nc...

I

Commutation

Signal

Zero Crossing

Signal

90°

cale Semiconductor,

Frees

3.3 Used Control Technique

3.3.1 Sensorless Commutation Control

This section concentrates on sensorless BLDC motor commutation with

back-EMF zero crossing technique.

In order to start and run the BLDC motor, the control algorithm has to go

through the following states:

• Alignment

• Starting (Back-EMF Acquisition)

• Running

Figure 3-14 shows the transitions between the states. First the rotor is

aligned to a known position; then the rotation is started without the

position feedback. When the rotor moves, back-EMF is acquired so the

Figure 3-13. The Zero Crossing Detection

Designer Reference Manual DRM028 — Rev 0

38 BLDC Motor Control MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 39

Freescale Semiconductor, Inc.

BLDC Motor Control

Used Control Technique

position is known, and can be used to calculate the speed and

processing of the commutation in the running state.

START MOTOR

ALIGNMENT

nc...

I

cale Semiconductor,

Frees

3.3.1.1 Alignment

ALIGNMENT TIME

EXPIRED?

YES

STARTING

(BACK-EMF ACQUISITION)

MINIMAL CORRECT

COMMUTATIONS DONE?

YES

RUNNING

NO

NO

Figure 3-14. Commutation Control Stages

Before the motor starts, there is a short time (depending on the motor’s

electrical time constant) when the rotor position is stabilized by applying

PWM signals to only two motor phases (no commutation). The current

controller keeps current within predefined limits. This state is necessary

in order to create a high start-up torque. When the preset time-out

expires then this state is finished.

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA BLDC Motor Control 39

For More Information On This Product,

Go to: www.freescale.com

Page 40

Freescale Semiconductor, Inc.

BLDC Motor Control

The current controller subroutine, with PI regulator, is called to control

dc-bus current. It sets the correct PWM ratio for the required current. The

current PI controller works with constant execution (sampling) period.

This period should be a multiple of the PWM period, in order to

synchronize the current measurement with PWM:

Current controller period = n/PWM frequency

The BLDC motor rotor position with flux vectors during alignment is

shown in Figure 3-15.

nc...

I

cale Semiconductor,

Frees

3.3.1.2 Running

Figure 3-15. Alignment

The commutation process is a series of states which assure:

• The back-EMF zero crossing is successfully captured

• The new commutation time is calculated

• The commutation is performed

The following processes need to be provided:

Designer Reference Manual DRM028 — Rev 0

40 BLDC Motor Control MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 41

Freescale Semiconductor, Inc.

• BLDC motor commutation service

• Back-EMF zero crossing moment capture service

• Calculation of commutation time

• Interactions between these commutation processes

From diagrams an overview of how the commutation works can be

understood. After commuting the motor phases, there is a time interval

(Per_Toff[n]) when the shape of back-EMF must stabilized (after the

commutation the fly-back diodes are conducting the decaying phase

current; therefore, sensing of the back-EMF is not possible). Then the

new commutation time (T2[n]) is preset. The new commutation will be

nc...

I

performed at this time if the back-EMF zero crossing is not captured. If

the back-EMF zero crossing is captured before the preset commutation

time expires, then the exact calculation of the commutation time (T2*[n])

is made, based on the captured zero crossing time (T_ZCros[n]). The

new commutation is performed at this new time.

BLDC Motor Control

Used Control Technique

cale Semiconductor,

Frees

If for any reason the back-EMF feedback is lost within one commutation

period, corrective actions are taken in order to return to the regular

states.

The flowchart explaining the principle of BLDC commutation control with

back-EMF zero crossing sensing is shown in Figure 3-16.

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA BLDC Motor Control 41

For More Information On This Product,

Go to: www.freescale.com

Page 42

BLDC Motor Control

Freescale Semiconductor, Inc.

COMMUTATION DONE

nc...

I

cale Semiconductor,

Frees

BEMF ZERO CROSSING

DETECTED BETWEEN PREVIOUS

COMMUTATIONS?

YES

SERVICE OF COMMUTATION:

PRESET COMMUTATION

WAIT FOR PER_TOFF UNTIL PHASE

CURRENT DECAYS TO ZERO

BEMF ZERO CROSSING

MISSED?

BEMF ZERO CROSSING

NO

HAS COMMUTATION

NO

DETECTED?

NO

TIME EXPIRED?

YES

NO

YES

YES

MAKE MOTOR COMMUTATION

CORRECTIVE CALCULATION 1.

SERVICE OF RECEIVED BEMF

ZERO CROSSING:

CORRECTED SETTING

OF COMMUTATION TIME

HAS COMMUTATION

BEMF ZERO CROSSING MISSED

CORRECTIVE CALCULATION 2

CORRECTED SETTING

OF COMMUTATION TIME

TIME EXPIRED?

YES

NO

Figure 3-16. BLDC Commutation with Back-EMF

Zero Crossing Sensing Flowchart

3.3.1.3 Running — Commutation Time Calculation

Commutation time calculation is shown in Figure 3-17.

Designer Reference Manual DRM028 — Rev 0

42 BLDC Motor Control MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 43

Freescale Semiconductor, Inc.

BLDC Motor Control

Used Control Technique

nc...

I

cale Semiconductor,

Frees

T_Cmt[n-2]

T2[n-3] T2[n-2] T2[n-1] T2[n]

T_Cmt[n-1] T_Cmt[n]

n-2

ZERO CROSSING

DETECTION SIGNAL

Per_ZCros0[n] =

Per_ZCros[n-1]Per_ZCros[n-2]

n-1

ZERO CROSSING

DETECTION SIGNAL

T_ZCros[n-1]

Per_Toff[n]

ZERO CROSSING

DETECTION SIGNAL

2*Per_ZCrosFlt[n-1]

Per_ZCros[n]

Per_ZCros[n]

n

Per_ZCros[n]

Per_HlfCmt[n]

T_ZCros[n]

T_Cmt**[n+1]

Per_HlfCmt[n]

Figure 3-17. BLDC Commutation Time with Zero Crossing Sensing

The following calculations are made to calculate the commutation time

(T2[n]) during the Running state:

• Service of commutation — The commutation time (T2[n]) is

predicted:

T2[n] = T_Cmt[n] + 2*Per_ZCrosFlt[n-1]

If 2*Per_ZCrosFlt>Per_Cmt_Max

then result is limited at Per_Cmt_Max

COMMUTATION IS PRESET

COMMUTATED AT PRESET TIME NO

BACK-BMF FEEDBACK WAS RECEIVED

CORRECTIVE CALCULATION 1.

T_Cmt*[n+1]

BACK-EMF FEEDBACK

RECEIVED AND EVALUATED

COMMUTATED WHEN BACK-EMF

ZERO CROSSING IS MISSED

CORRECTION CALCULATION 2.

• Service of received back-EMF zero crossing — The

commutation time (T2*[n]) is evaluated from the captured

back-EMF zero crossing time (T_ZCros[n]):

Per_ZCros[n] = T_ZCros[n] - T_ZCros[n-1] = T_ZCros[n] - T_ZCros0

Per_ZCrosFlt[n] = (1/2*Per_ZCros[n]+1/2*Per_ZCros0)

HlfCmt[n] = 1/2*Per_ZCrosFlt[n]- Advance_angle =

= 1/2*Per_ZCrosFlt[n]- C_CMT_ADVANCE*Per_ZCrosFlt[n]=

Coef_HlfCmt*Per_ZCrosFlt[n]

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA BLDC Motor Control 43

For More Information On This Product,

Go to: www.freescale.com

Page 44

nc...

I

cale Semiconductor,

Frees

BLDC Motor Control

Freescale Semiconductor, Inc.

Per_Toff[n+1] = Per_ZCrosFlt*Coef_Toff and Per_Dis minimum

Per_ZCros0 <-- Per_ZCros[n]

T_ZCros0 <-- T_ZCros[n]

T2*[n] = T_ZCros[n] + HlfCmt[n]

The best commutation was get with Advance_angle:

60Deg*1/8 = 7.5Deg

which means Coef_HlfCmt = 0.375 at Running state

with default s/w setting

Coef_Toff = 0.375 at Running state, Per_Dis = 150

with default s/w setting

• If no back-EMF zero crossing was captured during preset

commutation period (T2P[n] then Corrective Calculation 1. is

made:

T_ZCros[n] <-- CmtT[n+1]

Per_ZCros[n] = T_ZCros[n] - T_ZCros[n-1] = T_ZCros[n] - T_ZCros0

Per_ZCrosFlt[n] = (1/2*Per_ZCros[n]+1/2*Per_ZCros0)

HlfCmt[n] = 1/2*Per_ZCrosFlt[n]-Advance_angle =

Coef_HlfCmt*Per_ZCrosFlt[n]

The best commutation was get with Advance_angle:

60Deg*1/8 = 7.5Deg

which means Coef_HlfCmt = 0.375 at Running state!

Per_Toff[n+1] = Per_ZCrosFlt*Coef_Toff and Per_Dis minimum

Per_ZCros0 <-- Per_ZCros[n]

T_ZCros0 <-- T_ZCros[n]

• If back-EMF zero crossing is missed then Corrective Calculation

2. is made:

T_ZCros[n] <-- CmtT[n]+Toff[n]

Per_ZCros[n] = T_ZCros[n] - T_ZCros[n-1] = T_ZCros[n] - T_ZCros0

Per_ZCrosFlt[n] = (1/2*T_ZCros[n]+1/2*T_ZCros0)

HlfCmt[n] = 1/2*Per_ZCrosFlt[n]-Advance_angle =

Coef_HlfCmt*Per_ZCrosFlt[n]

The best commutation was get with Advance_angle:

60Deg*1/8 = 7.5Deg

which means Coef_HlfCmt = 0.375 at Running state!

Per_ZCros0 <-- Per_ZCros[n]

T_ZCros0 <-- T_ZCros[n]

• Where:

T_Cmt = time of the last commutation

T2 = Time of the Timer 2 event (for Timer Setting)

T_ZCros = Time of the last zero crossing

T_ZCros0 = Time of the previous zero crossing

Per_Toff = Period of the zero crossing off

Per_ZCros = Period between zero crossings (estimates required

commutation period)

Per_ZCros0 = Pervious period between zero crossings

Per_ZCrosFlt = Estimated period of commutation filtered

Designer Reference Manual DRM028 — Rev 0

44 BLDC Motor Control MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 45

Freescale Semiconductor, Inc.

Per_HlfCmt = Period from zero crossing to commutation (half

commutation)

The required commutation timing is provided by setting commutation

constants Coef_HlfCmt, COEF_TOFF.

3.3.1.4 Starting (Back-EMF Acquisition)

The back-EMF sensing technique enables a sensorless detection of the

rotor position; however, the drive must be first started without this

feedback. This is due to the fact that the amplitude of the induced voltage

is proportional to the motor speed. Hence, the back-EMF cannot be

nc...

I

sensed at a very low speed and a special start-up algorithm must be

performed.

BLDC Motor Control

Used Control Technique

cale Semiconductor,

Frees

In order to start the BLDC motor, the adequate torque must be

generated. The motor torque is proportional to the multiplication of the

stator magnetic flux, the rotor magnetic flux, and the sine of the angle

between these magnetic fluxes.

It implies (for BLDC motors) the following:

1. The level of phase current must be high enough.

2. The angle between the stator and rotor magnetic fields must be

90°±30°.

The first condition is satisfied during the alignment state by maintaining

dc-bus current at a level sufficient to start the motor. In the starting

(back-EMF acquisition) state, the same value of PWM duty cycle is used

as the one which has stabilized the dc-bus current during the align state.

The second condition is more difficult to fulfill without any position

feedback information. After the alignment state, the stator and the rotor

magnetic fields are aligned (0° angle). Therefore, two fast commutations

(faster than the rotor can follow) must be applied to create an angular

difference in the magnetic fields (see Figure 3-18).

The commutation time is defined by the start commutation period

(Per_CmtStart). This allows starting the motor such that minimal

speed (defined by state when back-EMF can be sensed) and is achieved

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA BLDC Motor Control 45

For More Information On This Product,

Go to: www.freescale.com

Page 46

Freescale Semiconductor, Inc.

BLDC Motor Control

during several commutations, while producing the required torque. Until

the back-EMF feedback is locked, the commutation process (explained

in Running) assures that commutations are done in advance, so that

successive back-EMF zero crossing events are not missed.

After several successive back-EMF zero crossings:

• Exact commutation time can be calculated

• Commutation process is adjusted

• Control flow continues to the Running state

The BLDC motor is then running with regular feedback and the speed

nc...

I

controller can be used to control the motor speed by changing the PWM

duty cycle value.

cale Semiconductor,

Frees

Designer Reference Manual DRM028 — Rev 0

46 BLDC Motor Control MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 47

Freescale Semiconductor, Inc.

BLDC Motor Control

Used Control Technique

MOTOR IS RUNNING

AT STEADY-STATE CONDITION

WITH REGULAR BACK-EMF FEEDBACK

STATOR MAGNETIC FIELD

BORDER OF

STATOR POLE

ROTOR MOVEMENT

DURING ONE

COMMUTATION

nc...

I

ZERO CROSSING

EDGE INDICATOR

PHASE WINDING

ROTOR MAGNETIC

FIELD (CREATED BY PM)

DIRECTION OF

PHASE CURRENT

cale Semiconductor,

MOTOR IS STARTING

ALIGNMENT STATE

STARTING (BACK-EMF ACQUISITION)

The back-EMF feedback is tested.

When the back-EMF zero crossing

is recognized the time of new

commutation is evaluated. Until at

least two successive back-EMF

zero crossings are received the

exact commutation time can not be

calculated. Therefore, the

commutation is done in advance in

order to assure that successive

back-EMF zero crossing events

would not be missed.

The rotor position is stabilized by

applying PWM signals to only two

motor phases

The two fast (faster then the rotor

can move) commutations are

applied to create an angular

difference of the stator magnetic

field and rotor magnetic field.

Frees

RUNNING

After several back-EMF zero

crossing events the exact

commutation time is calculated. The

commutation process is adjusted.

Motor is running with regular

back-EMF feedback.

Figure 3-18. Vectors of Magnetic Fields

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA BLDC Motor Control 47

For More Information On This Product,

Go to: www.freescale.com

Page 48

BLDC Motor Control

Figure 3-19 demonstrates the back-EMF during the start up. The

amplitude of the back-EMF varies according to the rotor speed. During

the starting (back-EMF acquisition) state the commutation is done in

advance. In the running state the commutation is done at the right

moments.

PHASE BACK-EMFS

Freescale Semiconductor, Inc.

nc...

I

cale Semiconductor,

Frees

B

BOT

PHASE A

A

TOP

A

TOP

.................

B

TOP

C

BOT

B

TOP

C

BOT

C

TOP

A

BOT

C

TOP

A

BOT

PHASE C

BACK-EMF ZERO CROSSINGS

IDEAL COMMUTATION PATTERN WHEN POSITION IS KNOWN

B

TOP

C

BOT

REAL COMMUTATION PATTERN WHEN POSITION IS ESTIMATED

B

TOP

C

BOT

FIRST SECOND THIRD FOURTH

C

TOP

A

BOT

C

TOP

A

BOT

PHASE B

B

BOT

STARTING (BACK-EMF ACQUISITION)

RUNNINGALIGN

Figure 3-19. Back-EMF at Start Up

Figure 3-20 illustrates the sequence of the commutations during the

starting (back-EMF acquisition) state. The commutation times T2[1] and

T2[2] are calculated without any influence of back-EMF feedback. The

commutation time calculations are explained in the following section.

Designer Reference Manual DRM028 — Rev 0

48 BLDC Motor Control MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Page 49

Freescale Semiconductor, Inc.

BLDC Motor Control

Used Control Technique

nc...

I

cale Semiconductor,

Frees

T_Cmt[1]

T_ZCros[0]

T_Cmt[2] T_Cmt[3]

T2[1]

n=1

Per_CmtStart

n=2

2*Per_CmtStart

ZERO CROSSING

DETECTION SIGNAL

ZERO CROSSING

DETECTION SIGNAL

ZERO CROSSING

DETECTION SIGNAL

Per_Toff[n]

T2[2] T2[n]

n=3

2*Per_ZCrosFlt[n-1]

Per_HlfCmt[n]

Figure 3-20. Calculation of the Commutation Times During the Starting

(Back-EMF Acquisition) State

3.3.1.5 Starting — Commutation Time Calculation

Even the sub-states of the commutation process in the starting

(back-EMF acquisition) state remain the same as in the running state.

The required commutation timing depends on application state (starting

state, running state). So the commutation time calculation is the same as

that described in

Running — Commutation Time Calculation, but the following

computation coefficients are different:

COMMUTATION IS PRESET

Per_HlfCmt[n]

T_ZCros[n]

T2**[n]

COMMUTATED AT PRESENT TIME

NO BACK-EMF FEEDBACK WAS RECEIVED

CORRECTIVE CALCULATION 1

T2*[n]

COMMUTED WHEN CORRECT

BACK-EMF FEEDBACK

RECEIVED AND EVALUATED

COMMUTATED WHEN BACK-EMF

ZERO CROSSING IS MISSED

CORRECTIVE CALCULATION 2.

coefficient Coef_HlfCmt = 0.125 with advanced angle

Advance_angle: 60Deg*3/8 = 22.5Deg

at Starting state!

DRM028 — Rev 0 Designer Reference Manual

MOTOROLA BLDC Motor Control 49

For More Information On This Product,

Go to: www.freescale.com

Page 50

BLDC Motor Control

Coef_Toff = 0.5 at Running state, Per_Dis = 150 with default s/w

setting

3.3.2 Speed Control

The speed close loop control is provided by a well known PI regulator.

The required speed is calculated from speed input variable, as explained

in Process Desired Speed Setting. The actual speed is calculated from

the average of two back-EMF zero crossing periods (time intervals),

received from the sensorless commutation control block. The speed

regulator output is a PWM duty cycle.

Freescale Semiconductor, Inc.

nc...

I

cale Semiconductor,

Frees

3.4 Application Control

3.4.1 PC Master Software

The speed controller works with the constant execution (sampling)

period PER_T3_RUN_US. A detailed explanation is provided in

Processs Speed Control.

The application can be controlled in two basic modes:

• Manual mode

• PC master software mode

In manual mode, it is controlled by an on-board start/stop switch and

speed potentiometer. In PC master mode, it is controlled from a

computer using PC master software. In both modes, the individual

variables can be observed using the PC master software.

PC master software was designed to provide the debugging, diagnostic,

and demonstration tools for developing algorithms and applications. It

consists of components running on PCs and parts running on the target

MCU, connected by an RS232 serial port. A small program is resident in

the MCU that communicates with the PC master software to parse

commands, return status information, and process control information

1

from the PC. The PC master software uses Microsoft

as a user interface on the PC.

Designer Reference Manual DRM028 — Rev 0

50 BLDC Motor Control MOTOROLA

For More Information On This Product,

Go to: www.freescale.com

Internet Explorer

Page 51

Freescale Semiconductor, Inc.

3.4.1.1 Communication with PC Master Software Specifications

SCI communication protocol with a default of 9.6 Kbaud, is used for

communication as described in User’s Manual for PC Master Software,

Motorola 2000, found on the World Wide Web at:

http://e-www.motorola.com

PC master software controls and senses the status of the application

with:

• PC master software — BLDC demonstration suitcase

communication commands

BLDC Motor Control

Application Control

nc...

I

cale Semiconductor,

Frees

• PC master software — BLDC demonstration suitcase

communication bytes

After reset, the BLDC control MCU software is in manual mode. In order

to control the system from PC master software, it is necessary to set PC

master software mode, and then to provide the MCU software control

from PC master software via application interface variables.

3.4.1.2 PC Master Software, BLDC Control MCU Software API, Communication Commands

Commands defined for the BLDC control MCU software are listed in

Table 3-1. The commands are very simple. If the software executes the

command, it responds with OK byte 00. If it is unable to execute the

command, it responds with failed code 55. The commands “Set PC

master software mode”, “Set manual mode” can only be executed when