Page 1

Matsushita Electric Works, Ltd.GT10/GT30 Technical Manual ARCT1F340V1.1EN 5/2003

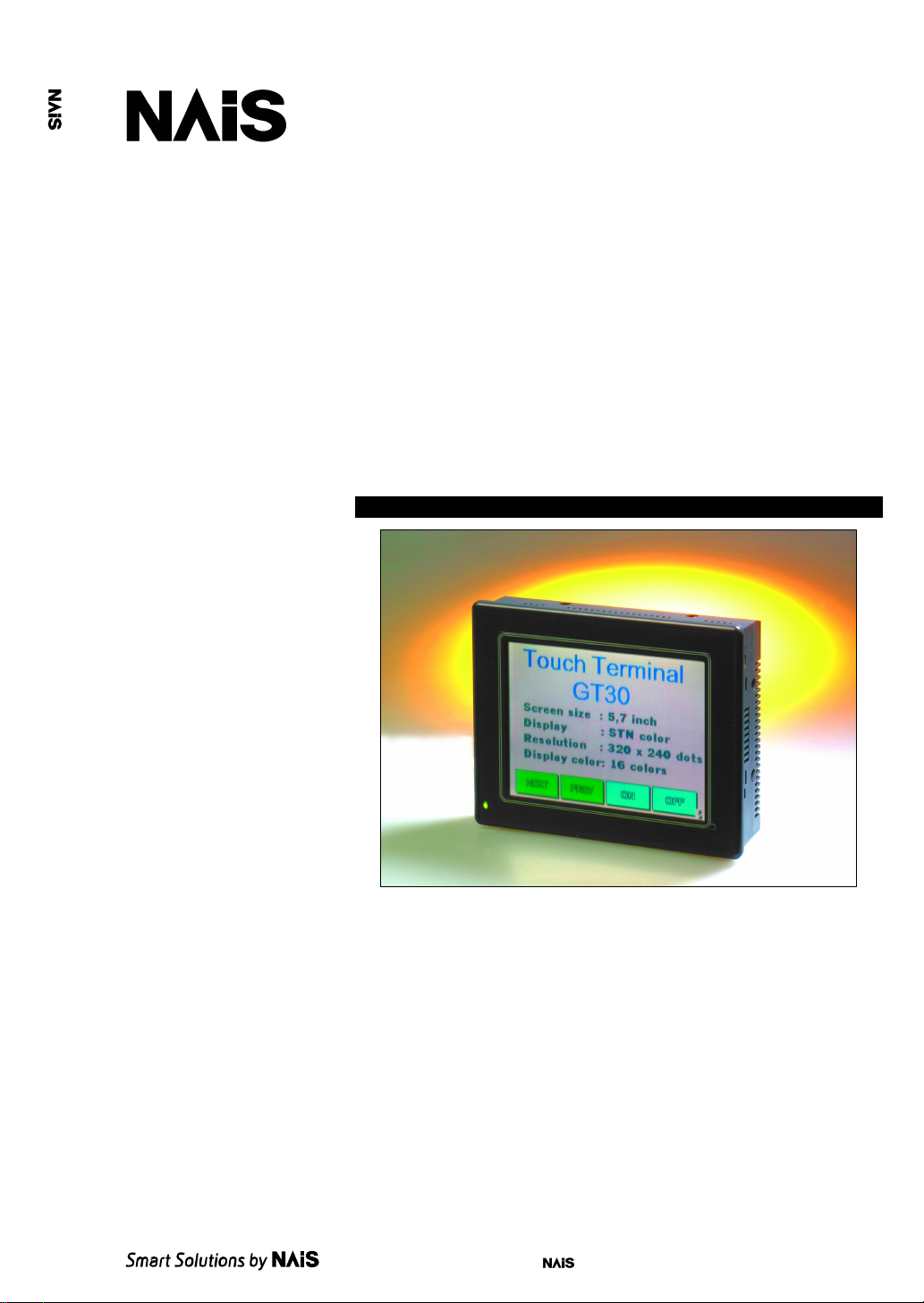

Programmable Display

GT10/GT30

Technical Manual

Includes installation guide for GTWIN screen

creation software.

Applicable Models

GT10 (Ver. 1/Ver. 2)

GT30

Dystrybutor w Polsce:

AUTOMATECH Sp.z o.o. www.automatech.pl e-mail: biuro.warszawa@automatech.pl

Tel.: +48 22 723 0606 Fax: +48 22 723 0662

is a global brand name of Matsushita Electric Works.

Page 2

SAFETY PRECAUTIONS

[ALWAYS OBSERVE THESE PRECAUTIONS]

Before installing, operating, servicing or inspecting this product, please make sure

you have read this manual and the explanations of how procedures are carried out,

and make sure the product is used correctly.

This manual uses two safety standard levels: “WARNING” and “CAUTION”.

WARNING

Erroneous handling of an item marked with this label can cause fatal or critical

injury to the user.

w If this product is used in applications where accidents involving bodily

injury and/or significant damage may be conceivable, measures should

be taken to ensure adequate safety, such as the use of duplicate safety

mechanisms.

w The functions of the GT main unit should not be used to design systems

which may pose a threat to human life or which may cause severe injury

or damage. Designs should include safety mechanisms for use in the

event that switch functions do not function correctly.

w Do not use this product in an environment where combustible gases are

present. This can cause explosion.

w Do not dispose of it by incineration. This can cause it to explode.

CAUTION

Erroneous handling of an item marked with this label can cause injury to the

user, or physical damage to property.

w This product should not be used outside of the stated specifications

ranges for ratings, service life, configuration factors and other

elements. This can cause abnormal generation of heat and smoke.

w The operational force of the touch panel should be kept to 0.98 N or

lower. Operating the touch panel at a higher force could cause damage.

w Never touch terminals while the power supply is on. This can cause

electric shock.

w Never disassemble or alter this product. This can cause electric shock

and smoke generation.

Page 3

How This Manual Is Configured

GT10/GT30 Main Unit

Before Using the GT series

This section describes items that should be confirmed and precautions that should

be observed before the GT series are used.

Chapter 1. Specifications

This chapter contains the names and specifications of the various parts of the GT series, as well as a table of functions, wiring diagrams, and dimensions.

Chapter 2. Installation and Wiring

This chapter explains how the GT series should be installed and how wiring should be

connected.

Chapter 3. Setup

This chapter describes the setup procedures necessary when using the GT series for

the first time.

Chapter 4. Connecting and Communicating with the PLC

This chapter explains how to connect the GT series to the PLC and the FP series by

Matsushita, and how to set up communications between the units.

Chapter 5. GT10 Configuration Settings

This chapter describes the configuration settings for the GT10, and how they should

be entered.

Chapter 6. GT30 Configuration Settings

This chapter describes the configuration settings for the GT30, and how they should

be entered.

Chapter 7. How the Various Functions Are Used

Functions such as switching GT series screens, backlighting, and buzzer control are

explained here.

Chapter 8. Servicing and Maintenance

This chapter describes servicing and maintenance procedures for the GT series, as

well as how optional items are handled.

Chapter 9. Troubleshooting

This explains what to do if there appears to be something wrong with the GT series,

or an error occurs.

Screen Creation Tool Terminal GTWIN

Before Using Terminal GTWIN

This section contains special precautions that should be read if you are using GTWIN.

Chapter 10. Preparing GTWIN

This section explains how to install GTWIN in the personal computer, how to boot it,

and how to exit it.

ii

Page 4

Table of Contents

How This Manual Is Configured ii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part I GT10, GT30 Main Unit

Before Using the GT10/GT30 x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GT10/GT30 Usage Procedures xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Confirming the Package Contents xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GT Series System Configuration xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Products for the GT Series xix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Precautions xx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1 Specifications

1.1 GT10/GT30 Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 General Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Display 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.3 Functions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.4 Touch Key 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.5 Memory (1) 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.6 Memory (2) 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.7 Interface 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 GT10 Names and Functions of Parts 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 GT10 (front) 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 GT10 (rear) 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Names and Functions of Parts 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 GT30 Names and Functions of Parts 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 GT30 (front) 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 GT30 (rear) 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Names and Functions of Parts 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Internal Wiring Connections for Ports 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 COM. Port 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 TOOL Port 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3 Power Supply Terminals 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Dimensions 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.1 GT10 Dimensions 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.2 GT10 Panel Cutout Dimensions 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.3 GT30 Dimensions 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.4 GT30 Panel Cutout Dimensions 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 5

GT10/GT30

Table of Contents

Chapter 2 Installation and Wiring

2.1 Installation 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Installation Environment 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 GT10 Installation Method 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 GT30 Installation Method 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Wiring the Power Supply 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Wiring the COM. Port 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Wiring Method 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Precautions Concerning Wiring 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Setup

3.1 Setup Procedure for the GT10 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Setting the Basic Communication Area, GT10 and PLC 29. . . . . . . . . . . . . . . .

3.2.1 What is the Basic Communication Area? 29. . . . . . . . . . . . . . . . . . . . .

3.2.2 GT10 Basic Communication Area Map 30. . . . . . . . . . . . . . . . . . . . . . .

3.3 Setup Procedure for the GT30 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Setting the Basic Communication Area, GT30 and PLC 37. . . . . . . . . . . . . . . .

3.4.1 What is the Basic Communication Area? 37. . . . . . . . . . . . . . . . . . . . .

3.4.2 GT30 Basic Communication Area Map 38. . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Connecting and Communicating with the PLC

4.1 Connecting the FP–Sigma 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 Connecting to the COM. Port 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 Connecting to the TOOL Port 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Connecting the FP0 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Connecting to the COM. Port 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Connecting to the TOOL Port 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Connecting the FP1 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Connecting to the COM. Port 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Connecting the FP2/FP2SH 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Connecting to the COM. Port 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Connecting to the TOOL Port 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Connecting the FP2/FP2SH CCU 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Connecting the FP10SH 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.1 Connecting to the COM. Port 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.2 Connecting to the TOOL Port 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Connecting the FP10SH/FP3 CCU 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

Page 6

GT10/GT30

4.8 Connecting the FP–M 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.1 Connecting to the COM. Port 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.2 Connecting to the TOOL Port 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 Automatic Communication Settings Function 58. . . . . . . . . . . . . . . . . . . . . . . . .

4.10 Through Function 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11 Connecting with a PLC by Mitsubishi Electric Corp. 62. . . . . . . . . . . . . . . . . . . .

4.11.1 FX Series 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.12 Connecting with a PLC by Omron Corp. 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.12.1 SYSMAC C Series, a Series, CV Series, and CS1 Series 64. . . . . .

Table of Contents

Chapter 5 GT10 Configuration Settings

5.1 GT10 Configuration Settings 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Two Types of GT10 Configuration Settings 72. . . . . . . . . . . . . . . . . . .

5.2 Entering Configuration Settings with GTWIN 73. . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Opening the GT Configuration Settings 73. . . . . . . . . . . . . . . . . . . . . .

5.2.2 GT Configuration Settings: “Basic Setup” 73. . . . . . . . . . . . . . . . . . . . .

5.2.3 GT Configuration Settings: “Communication Parameters” 75. . . . . . .

5.2.4 GT Configuration Settings: “Auto–Paging” 77. . . . . . . . . . . . . . . . . . . .

5.2.5 GT Configuration Settings: “Startup Screen Settings” 79. . . . . . . . . .

5.2.6 GT Configuration Settings: “Setup” 80. . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.7 GT Configuration Settings: “Hold PLC Device” 82. . . . . . . . . . . . . . . .

5.2.8 GT Configuration Settings: “GT Internal Device Hold” 83. . . . . . . . . .

5.3 Entering Configuration Settings from the GT10 85. . . . . . . . . . . . . . . . . . . . . . .

5.3.1 What is the System Menu? 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Bringing Up the System Menu 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Setting Mode: “Communication Parameters”

(COM. Port / TOOL Port) 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.4 Setting Mode: “Liquid Crystal Display Contrast Adjustment”

(Contrast) 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.5 Setting Mode: “Clock Settings” (Clock) 88. . . . . . . . . . . . . . . . . . . . . . .

5.3.6 Setting Mode: “Memory Initialization” (Clear Memory) 89. . . . . . . . . .

5.3.7 Test Mode: “Self–Diagnosis” 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.8 Inhibiting the System Menu Display 91. . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 GT30 Configuration Settings

6.1 GT30 Configuration Settings 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Two Types of GT30 Configuration Settings 94. . . . . . . . . . . . . . . . . . .

6.2 Entering Configuration Settings with GTWIN 95. . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Opening the GT Configuration Settings 95. . . . . . . . . . . . . . . . . . . . . .

6.2.2 GT Configuration Settings: “Basic Setup” 95. . . . . . . . . . . . . . . . . . . . .

v

Page 7

GT10/GT30

6.2.3 GT Configuration Settings: “Communication Parameters” 97. . . . . . .

6.2.4 GT Configuration Settings: “Auto–Paging” 99. . . . . . . . . . . . . . . . . . . .

6.2.5 GT Configuration Settings: “Startup Screen Settings” 101. . . . . . . . . .

6.2.6 GT Configuration Settings: “Setup” 102. . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.7 GT Configuration Settings: “Hold PLC Device” 104. . . . . . . . . . . . . . . .

6.2.8 GT Configuration Setting: “GT Internal Device Hold” 105. . . . . . . . . . .

6.3 Entering Configuration Settings from the GT30 108. . . . . . . . . . . . . . . . . . . . . . .

6.3.1 What is the System Menu? 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Bringing Up the System Menu 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.3 Setting Mode: “Liquid Crystal Display Contrast Adjustment” 108. . . . .

6.3.4 Setting Mode: “Clock Settings” (Clock) 109. . . . . . . . . . . . . . . . . . . . . . .

6.3.5 Setting Mode: “Communication Parameters”

(TOOL Port / COM. Port) 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.6 Setting Mode: “Memory Initialization” (Clear Memory) 112. . . . . . . . . .

6.3.7 Test Mode: “Self–Diagnosis” 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.8 Inhibiting the System Menu Display 114. . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Chapter 7 How the Various Functions Are Used

7.1 Switching Screens 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Switching the Screen from the PLC 116. . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Switching the Screen with the GT Main Unit 117. . . . . . . . . . . . . . . . . .

7.2 GT10 Bit Device Functions 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 GT30 Bit Device Functions 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8 Servicing and Maintenance

8.1 The Internal Secondary Battery (GT10) 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Battery (GT30) 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Replacing the Front Panel Protective Sheet 131. . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Replacing the Waterproof Packing 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Replacing the Backlight (GT30 Only) 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 9 Troubleshooting

9.1 What to Do If Something Unusual Occurs (GT10) 136. . . . . . . . . . . . . . . . . . . . .

9.2 What to Do If Something Unusual Occurs (GT30) 139. . . . . . . . . . . . . . . . . . . . .

9.3 Error Codes and How to Handle Them 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.1 GT Series Error Codes 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.2 PLC Error Codes 144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Page 8

GT10/GT30

9.4 GT10 Screen Messages 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 GT30 Screen Messages 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Part II Screen Creation Tool Terminal GTWIN

Usage Environment and GT Main Unit Models that are Supported 149. . . . . . . . . . . .

Important Note About Saving Screen Data Files 150. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 10 Preparing GTWIN

10.1 Installing GTWIN 152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Booting GTWIN 158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.1 Selecting the Working Menu 158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.2 Selecting the Model 158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.3 Entering Settings for the Basic Communication Area to PLC 159. . . .

10.3 Exiting GTWIN 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 Procedures for Using GTWIN 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A Code Tables

A.1 BIN/HEX/BCD Code Correspondence Table 166. . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 ASCII Code Table 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index

Record of Changes

vii

Page 9

GT10/GT30

Table of Contents

viii

Page 10

Part I

GT10, GT30 Main Unit

ix

Page 11

GT10/GT30

Before Using the GT10/GT30

This section describes items that should be confirmed and precautions that should be

observed before the GT10/GT30 is used. Make sure you read this section before using

the GT10/GT30.

x

Page 12

GT10/GT30

GT10/GT30 Usage Procedures

GT10/GT30 Usage Procedures

If you are using the GT10/GT30 for the first time, please follow the procedure outlined

below.

Procedure For Using the GT10/GT30

1. Confirm the items included with the product. page xiii

Please confirm that all of the items have been included with the product you have

purchased. Products are carefully checked before being shipped, but if you do find

anything missing, please contact your dealer.

2. Confirm the items listed under “Safety Precautions”.

Before using your product, please make sure you read the items listed under “Safety

Precautions”, in order to make sure your product is used safely. After reading the

precautions, please make sure the product is used correctly.

3. Install and wire the main unit.

Install the main unit, and connect the power supply, PLC connection cable and other

wiring. When installing and wiring the product, carefully read the explanation on pages

16 to 19 concerning the installation environment, and make sure the product is installed

correctly, in an appropriate environment. For information on connecting the product to

the FP series PLC, and on entering communications settings, please see page 42 and

subsequent pages.

4. Set up the main unit.

When the product is shipped from the factory, it is set up with specifications that enable

connection to the FP series PLC. If you plan to use the product without changing these

settings, no setup is required, but if you plan to change the settings, you will need to follow

the setup procedure outlined on page 26, 34 and subsequent pages. Particularly with

regard to the basic communication area to the PLC and other devices, please confirm

the settings carefully and change only those that are necessary.

Main cases in which setup is necessary

page xx

page 16

page 26, 34

· When the device being connected is a general–purpose serial device (such as

a computer or microcomputer board)

· When the basic communication area for the device is different from that

set when the product is shipped

5. Check communication with the external device (PLC, etc.).

Check the connections and communication with the external device. Connections and

communication with devices in the FP series PLC vary depending on the device, so

check the information on page 45 and subsequent pages.

6. Enter the operating environment settings.

In addition to the setup described at step 4, various detailed settings can be entered for

the GT10/GT30 operating environment. Enter any necessary operating environment

settings, referring to page 72 and subsequent pages.

page 45

page 72

xi

Page 13

GT10/GT30

GT10/GT30 Usage Procedures

7. Install the screen creation tool. page 149

Install the Terminal GTWIN screen creation tool in the personal computer. Follow the

instructions on page 149 and subsequent pages to install the software.

8. Create the screen contents.

Create the screen contents using the Terminal GTWIN screen creation tool, and send

the screen to the GT main unit. For information on creating screens and on operating

GTWIN, please refer to the Help function that comes with GTWIN.

9. Test the operation.

Connect the GT main unit containing the screen data to an external device (PLC or

general–purpose serial device), and check the operation contents.

xii

Page 14

GT10/GT30

Confirming the Package Contents

Confirming the Package Contents

Check to make sure the necessary items have been included with the product you have

purchased.

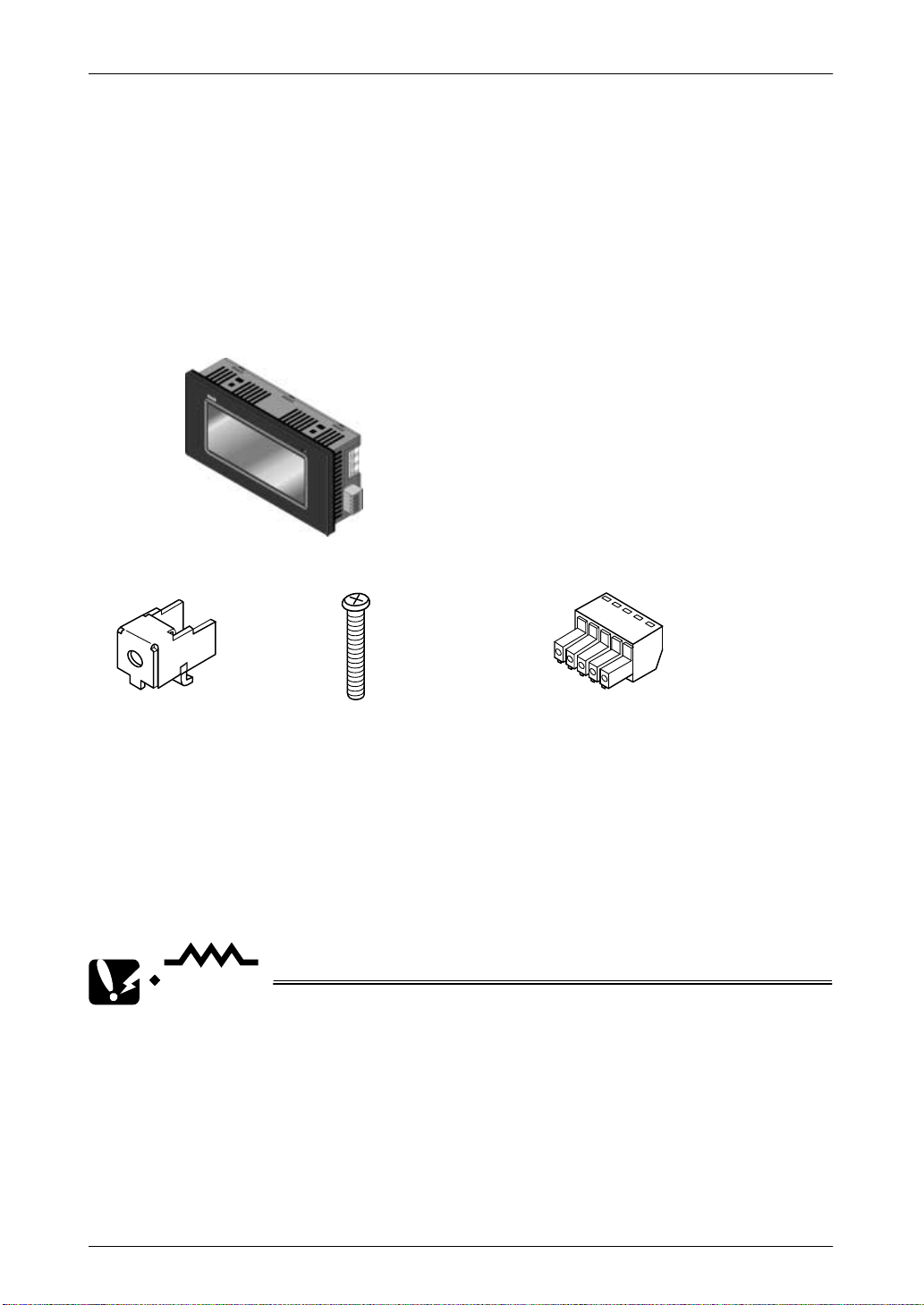

Items Included with the GT10 (AIGT1000B)

Main unit

Set of attachment fittings

Attachment fittings x 4 Attachment screws x 4

Front panel protective sheet

There is a front panel protective sheet,

available as an optional product, attached

to the front panel of the unit.

Installation instructions

Please read these instructions carefully before using the product.

CAUTION

Communication connector

Waterproof packing

One piece of waterproof packing

has been attached to unit.

• There is a film over the front panel protective sheet. Remove this film

when using the unit. For instructions on removing the film, see page

131.

• Front panel protective sheets for replacement are available as a

separate purchase (AIGT180). Please see page xix.

• Waterproof packings for replacement are available as a separate

purchase (AIGT181). Please see page xix.

xiii

Page 15

GT10/GT30

Confirming the Package Contents

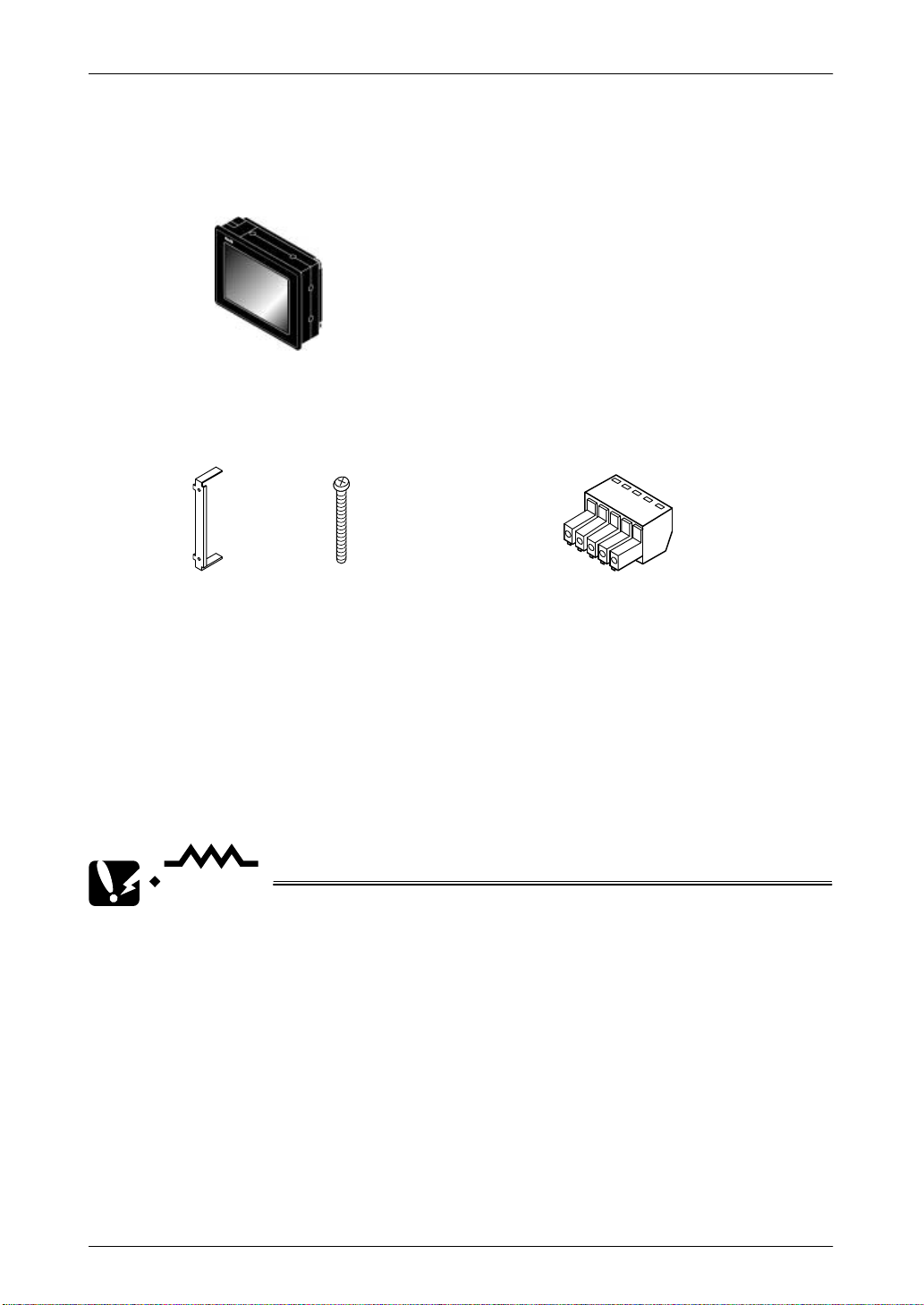

Items Included with the GT30 (AIGT3100B/AIGT3300B)

Main unit

STN monochrome liquid crystal display type: AIGT3100B

STN color liquid crystal display type: AIGT3300B

Set of attachment fittings

Fittings x 2 Screws x 4

Front panel protective sheet

There is a front panel protective sheet,

available as an optional product, attached

to the front panel of the unit.

Installation instructions

Please read these instructions carefully before using the product.

CAUTION

Communication connector

Waterproof packing

One piece of waterproof packing

has been attached to unit.

• There is a film over the front panel protective sheet. Remove this film

when using the unit. For instructions on removing the film, see page

131.

• Front panel protective sheets for replacement are available as a

separate purchase (AIGT380). Please see page xix.

• Waterproof packings for replacement are available as a separate

purchase (AIGT381). Please see page xix.

• A replacement backlight (AIGT382) is available, sold separately.

Please see page xix for details.

• The commercially available CR2032 should be used for battery

replacement.

xiv

Page 16

GT10/GT30

Confirming the Package Contents

Items Included with the Terminal GTWIN English–language version

(AIGT8001V2)

Terminal GTWIN CD–ROM

Software usage license agreement and user card

Read the “Software usage license agreement” carefully, and fill in the user card. Please

return the user card to Matsushita.

GT10/GT30 Technical Manual

This is the manual you are currently reading. It contains instructions on installing and

booting GTWIN. Please read it carefully before using your product.

CAUTION

About the software usage license agreement and user card

• Before using GTWIN, read the “Software usage license agreement”

carefully.

• The license agreement comes as a set with the user card. Fill in the

user card, and return it to Matsushita. The user card is necessary in

order to obtain support services such as future version upgrades and

technical support. Don’t forget to return the card in order to be

eligible for such services.

• The serial number needed in order to install GTWIN is found on the

user card. Please make a copy of it before returning the card, and

keep it in a safe place.

xv

Page 17

GT10/GT30

Confirming the Package Contents

Items Included With the PLC Connection Cable (AIGT8192 / AIP81842D)

Cable

One of the following two cables has been included with the product you have purchased.

AIP81842D

(2m)

AIGT8192

(2m)

Wiring diagram

The package includes a diagram that shows the internal wiring of the cables pictured

above.

REFERENCE

For information on connecting and wiring the cables shown above and

the PLC, please refer to page 41, Chapter 4, “Connecting and

Communicating with the PLC”.

Items Included with the Front Panel Protective Sheet (AIGT180/AIGT380)

Front panel protective sheet

In order to protect the touch panel on the GT series and keep it clean, one front panel

protective sheet is included when the unit is shipped. If this front panel protective sheet

is dirty or has become worn, it should be replaced. Replacement sheets are sold

separately, in packages of ten.

Installation instructions

Please read these instructions carefully before installing the product.

REFERENCE

For information on replacing the front panel protective sheet, please

refer to page 131.

xvi

Page 18

GT10/GT30

,

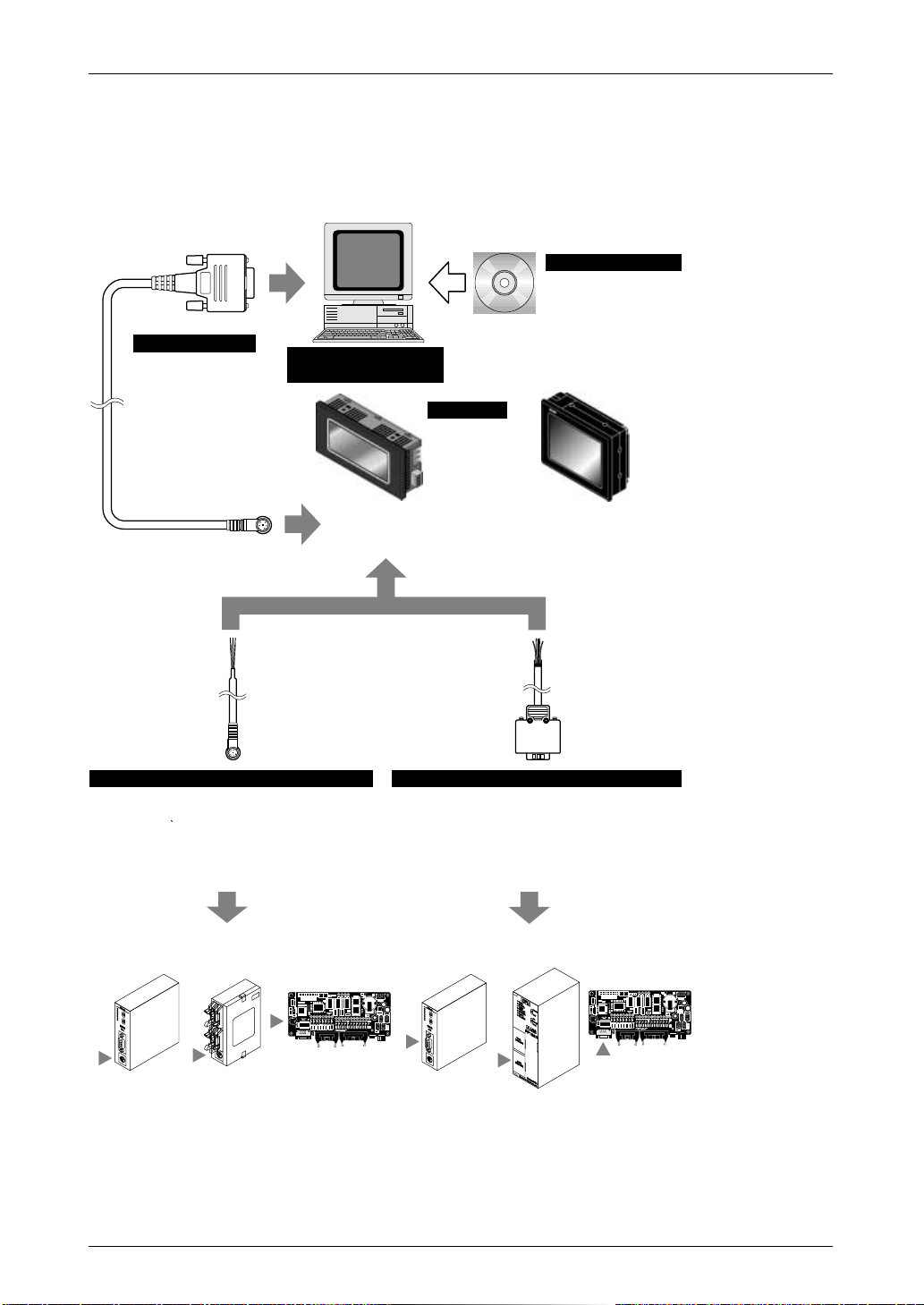

GT Series System Configuration

GT Series System Configuration

The following devices are necessary in order to use the GT series.

Screen creation tool

Terminal GTWIN

English–language version

Windows 95/98/2000/NT supported

Connecting cable

Screen transfer cable

D–sub 9–pin –

mini–DIN 5–pin

(3 m/9.84 ft)

Product No.: AFC8513

Commercially available

personal computer

Main unit

GTWIN CD–ROM

GT10 Technical Manual included as

accessory

Product No.: AIGT8001V2

GT10

STN monochrome liquid

crystal display

Product No.: AIGT1000B

Communication cable

PLC connecting cable (1)

For connection to TOOL port of FP0 / FP2 /

FP2SH / FP–M

Mini–DIN 5–pin loose–wire cable

(2 m/6.56 ft)

Product No.: AIGT8192

Connecting to the TOOL port of the FP0 /

FP2 / FP2SH / FP–M

GT30

STN monochrome liquid

crystal display

Product No.: AIGT3100B

Communication cable

PLC connecting cable (2)

For connection to COM. port of FP1 / FP2 / FP2SH / FP–M /

FP10SH, TOOL port of FP10SH, and computer communication unit

of FP2 / FP3

D–sub 9–pin loose–wire cable (2 m/6.56 ft)

Product No.: AIP81842D

Connecting to the COM. port of FP1 / FP2 / FP2SH / FP–M / FP10SH

TOOL port of FP10SH, and computer communication unit of FP2/FP3

GT30

STN color liquid crystal

display

Product No.: AIGT3300B

xvii

Page 19

GT10/GT30

Connecting to the COM. port of the FP0

Because connecting the unit to the COM. port of the FPΣ/FP0 requires a

loose–wire connection, this cable is not available. For more detailed

information, please see “Connecting the FPΣ” on page 42 or

“Connecting the FP0” on page 45.

GT Series System Configuration

CAUTION

xviii

Page 20

GT10/GT30

GT30 main uni

W

f

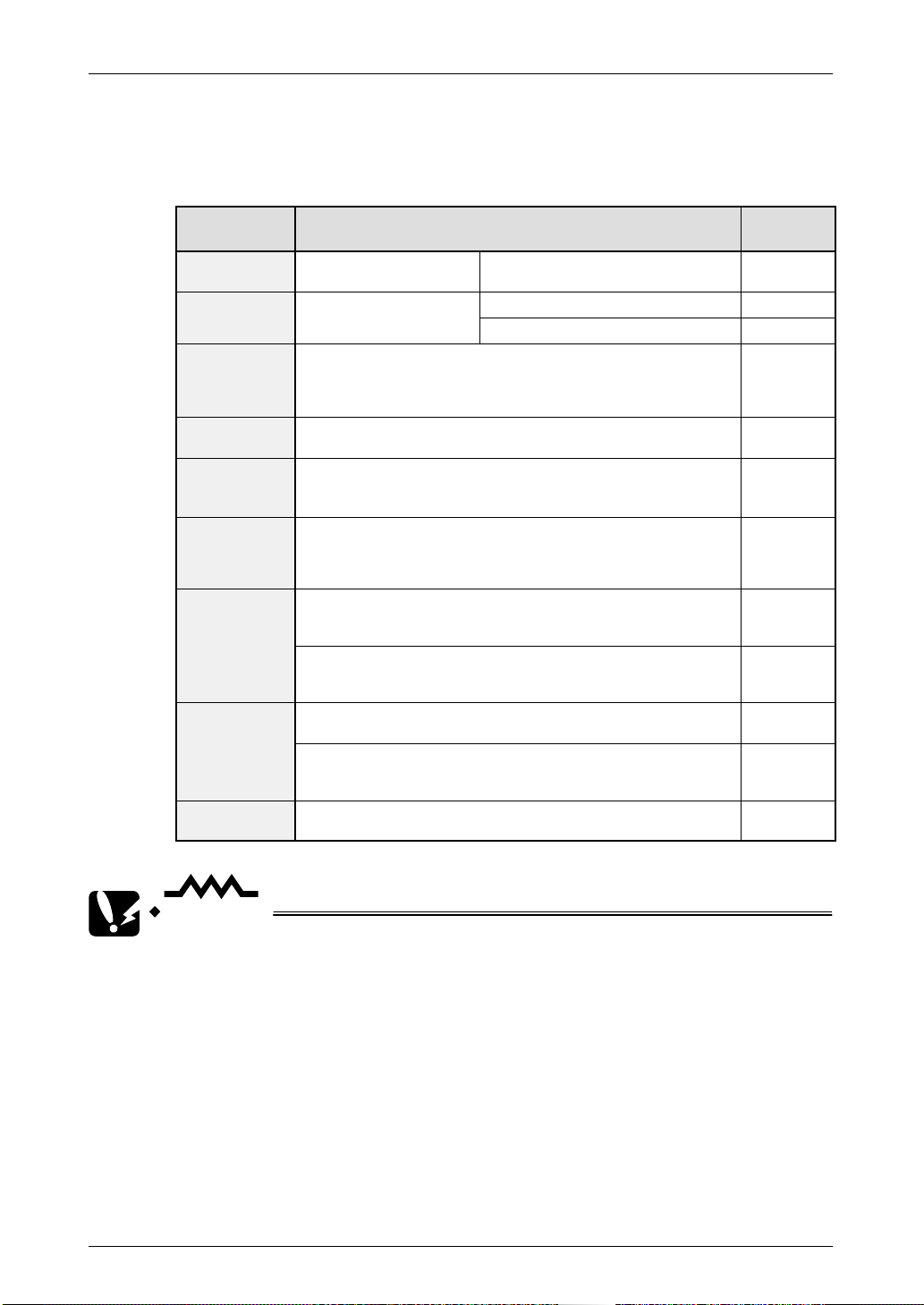

Products for the GT Series

Products types

Item Name Contents

GT10 main unit

Terminal

GTWIN

English–langua

ge version

Screen transfer

cable

PLC

connecting

cable (1)

PLC

connecting

cable (2)

Front panel

protective

sheet

aterproo

packing

Replacement

backlight

Programmable display unit

GT10 main unit

Programmable display unit

t

GT30 main unit

– “Terminal GTWIN” English–language screen creation tool

(CD–ROM)

– Set of GT10 Technical manuals (English)

Cable for transferring data between GTWIN and GT10

(3m/)

For connection to TOOL port of FP0 / FP2 / FP2SH / FP–M

Mini–DIN 5–pin loose–wire cable (2m)

For connection to COM. port of FP1 / FP2 / FP2SH / FP–M /

FP10SH, TOOL port of FP10SH, and computer communication unit

of FP2 / FP3

D–sub 9–pin loose–wire cable (2m)

Front panel protective sheet for GT10 (for replacement).

Ten i n se t .

* 1 sheet included with GT10 when shipped.

Front panel protective sheet for GT30 (for replacement).

Ten in set.

* 1 sheet included with GT30 when shipped.

Waterproof packing for GT10 (for replacement). Ten in set.

* 1 piece included with GT10 when shipped.

Waterproof packing for GT30 (for replacement).

Ten i n se t .

* 1 sheet included with GT30 when shipped.

This is the replacement backlight for the GT30 color/monochrome

liquid crystal display.

STN monochrome

liquid crystal display

STN monochrome liquid crystal display AIGT3100B

STN color liquid crystal display AIGT3300B

Products for the GT Series

Product

No.

AIGT1000B

AIGT8001V2

AFC8513

AIGT8192

AIP81842D

AIGT180

AIGT380

AIGT181

AIGT381

AIGT382

CAUTION

• Connecting to the COM. port of the FP0

Because connecting the unit to the COM. port of the FPΣ/FP0 requires

a loose–wire connection, this cable is not available. For more detailed

information, please see “Connecting the FPΣ” on page 42 or

“Connecting the FP0” on page 45.

• About the manual packed with the Terminal GTWIN English–language

version

The manual you are currently reading is included as an accessory

with the Terminal GTWIN English–language version. This manual

contains information only on procedures such as installing GTWIN.

For detailed information on operating GTWIN, please refer to the Help

function in the software.

xix

Page 21

GT10/GT30

Safety Precautions

Safety Precautions

Before installing, operating, servicing or inspecting this product, please make sure you

have read this manual and the installation instructions, and make sure the product is

used correctly.

This manual uses two safety standard levels: “WARNING” and “CAUTION”.

WARNING

Erroneous handling of an item marked with this label can cause fatal or critical injury to

the user.

• If this product is used in applications where accidents involving

bodily injury and/or significant damage may be conceivable,

measures should be taken to ensure adequate safety, such as the

use of duplicate safety mechanisms.

• The functions of the GT series should not be used to design

systems which may pose a threat to human life or which may cause

severe injury or damage. Designs should include safety

mechanisms for use in the event that switch functions malfunction.

• Do not use this product in an environment where combustible gases

are present. (This can cause explosion.)

• Do not dispose of it by incineration. (This can cause it to explode.)

CAUTION

Erroneous handling of an item marked with this label can cause injury to the user, or

physical damage to property.

• This product should not be used outside of the stated specifications

ranges for ratings, service life, configuration factors and other

elements. (This can cause abnormal generation of heat and

smoke.)

• The operational force of the touch panel should be kept to 0.98 N or

lower. Operating the touch panel at a higher force could cause

damage.

• Never touch terminals while the power supply is on. (This can cause

electric shock.)

• Never disassemble or alter this product. (This can cause electric

shock and smoke generation.)

xx

Page 22

GT10/GT30

Safety Precautions

Special Items

Maximum attention has been given to quality control of this product; however:

(1) In order to prevent, as much as possible, unexpected situations not covered by these

specifications, please consult us regarding your product’s specifications and demands,

as well as this unit’s operating conditions and installation details.

(2) To avoid the unlikely event of a situation attributed to inferior quality of the unit which

has serious adverse affects on persons or property, the numeric values for guaranteed

characteristics and performance noted in this specifications manual should be

considered the minimum necessary values. As the manufacturer of this unit, we

recommend incorporating additional safety measures such as duplicate circuits

wherever possible.

(3) The quality of this product is guaranteed for one year after purchase, and this

guarantee is limited to the range of items stated in these specifications. In the case of

a defect in the product which is clearly Matsushita’s responsibility, we will offer a

replacement unit or replacement of the defective part(s) of the unit and we will repair the

unit promptly at the place of purchase. The following are not included in the warranty:

1. Other damage resulting from damage to or defects in the supplied product.

2. Problems caused by conditions other than those noted in these specifications

involving use, storage, or shipment (transport) after product delivery.

3. Developments which were unforeseeable given the technology in practical use prior

to product delivery.

4. Earthquake, flood, fire, war, and damage due to other naturally occurring events or

human disasters for which Matsushita bears no responsibility.

xxi

Page 23

GT10/GT30

Safety Precautions

xxii

Page 24

Chapter 1

Specifications

Page 25

GT10/GT30 1.1 GT10/GT30 Specifications

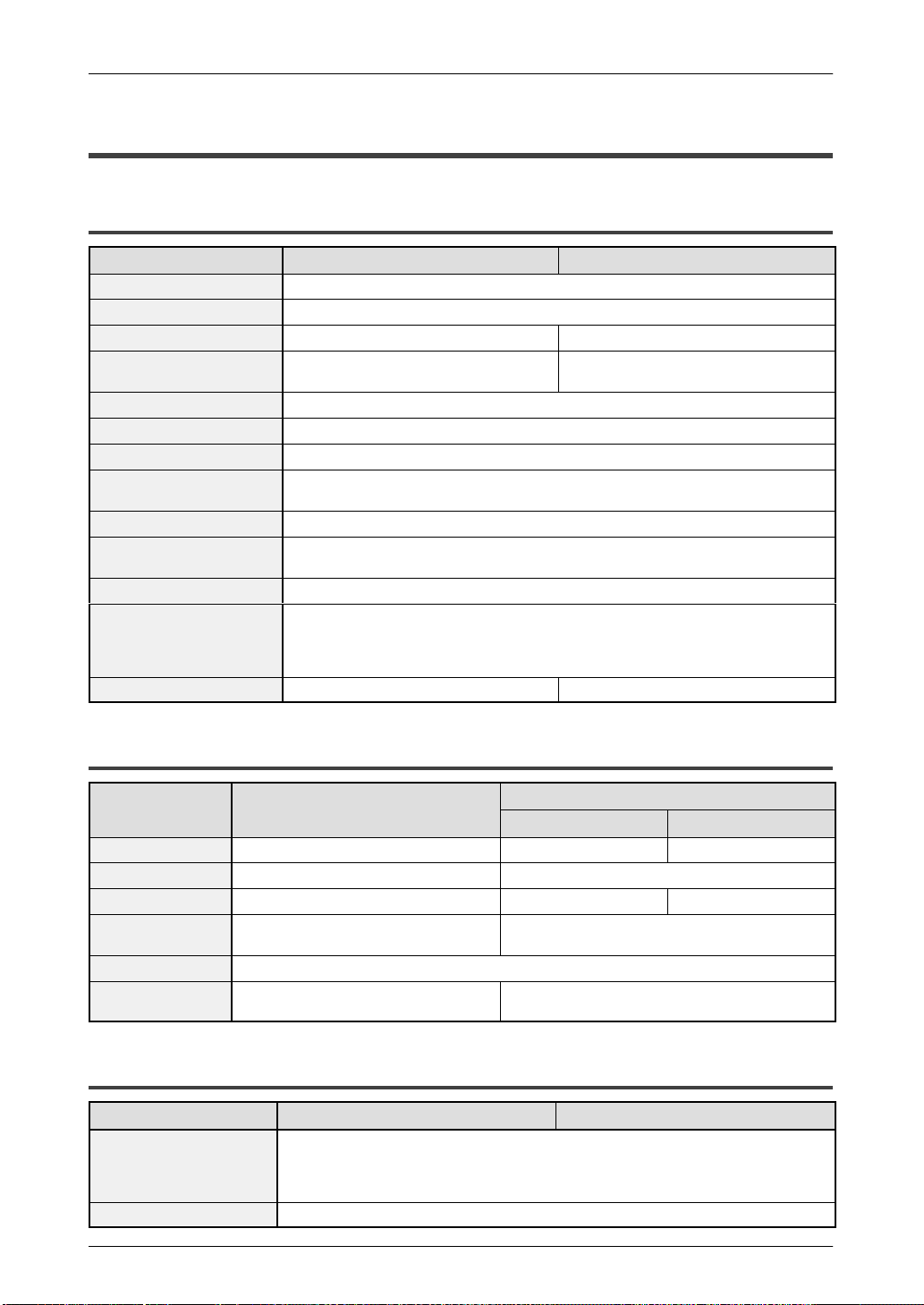

ItemGT10

ificati

1.1 GT10/GT30 Specifications

1.1.1 General Specifications

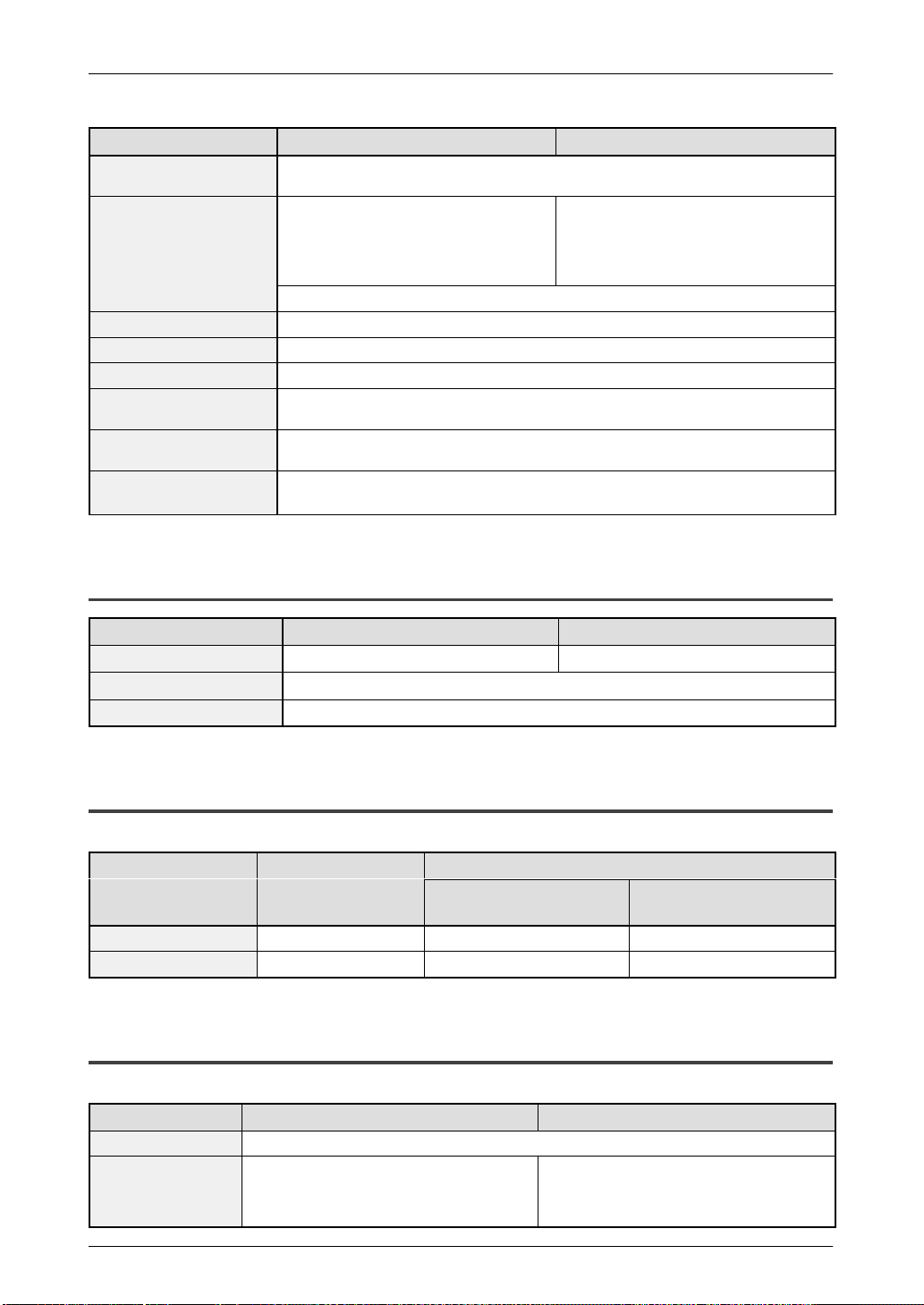

Item GT10 specifications GT30 specifications

Rated voltage 24 V DC

Operating voltage range 21.6 to 26.4 V DC

Power consumption 5 W max. 10 W max.

Ambient temperature

Ambient humidity 20% RH to 85% RH (non condensing)

Storage temperature –20°C to 60°C/–4°F to 140°F

Storage humidity 10% RH to 85% RH (non condensing)

Vibration resistance

Shock resistance 98 m/s2 min., 4 times on 3 axes

Noise immunity

Static noise resistance 5,000 V min. (panel display)

Protective construction

Mass Approx. 260 g/9.171 oz Approx. 440 g/15.519 oz

0°C to 40°C/32°F to 104°F

(25 V DC max. if installed horizontally)

10Hz to 55 Hz (1–minute cycle)

Amplitude: 0.75 mm, 10 min on 3 axes

1,000 V [p–p] min., pulse width 50 ns, 1 µs between power supply terminals (based

on noise simulator)

IP65 (in initial status)

Dustproof and drip–proof from front panel only (packing used on panel contact surface)

* When reattaching, replace waterproof packing.

0°C to 50°C/ 32°F to 122°F

(25 V DC max. if installed horizontally)

1.1.2 Display

spec

Display STN monochrome LCD STN monochrome LCD STN color LCD

Resolution 160 (W) x 64 (H) dots 320 (W) x 240 (H) dots

Display color 2 colors (black/white) 2 colors (blue/white) 16 colors

Displayable area

LCD life Average: 50,000 hours (at normal temperature of 25°C)

Backlight

92.8 (W) x 37.1 (H) mm

3.65(W) inch x 1.46 (H) inch

3–color LED backlight (green, red,

orange) * No replacement necessary

ons

GT30 specifications

AIGT3100B AIGT3300B

118.18 (W) x 89.38 (H) mm

4.65 (W) inch x 3.52 (H) inch

CFL * Average backlight service life: 50,000 hours

(25°C)

1.1.3 Functions

Item GT10 specifications GT30 specifications

Fixed fonts: 1/4 width (8 x 8), half width (16 x 8), full width (16 x 16)

Displayable fonts

Character types Alphanumeric characters

Half width and full width characters can be displayed at same width, doubled width, or

quadrupled width

True Type fonts

2

Page 26

GT10/GT30 1.1 GT10/GT30 Specifications

GT30 specificationsGT10 specificationsItem

Graphics

Number of screens

Part functions Messages, lamps, switches, data, bar graphs, clocks, keyboard

Clock functions Clock built into main unit (can also be displayed with reference to PLC clock)

Contrast adjustment Contrast can be adjusted using touch panel operation

Automatic

communication settings

Debugging functions

Screen creation

Straight lines, continuous straight lines, squares, circles, ovals, arcs, elliptic arcs, fan

shapes, elliptic fan shapes, beveled squares, bitmaps

Approx. 160 screens

Screen numbers that can be set: Base

screens No. 00 to FF (HEX)

Number of screens that can be registered varies depending on registered contents.

Settings for communication between dedicated software and PLC set automatically by

connecting cable

Through function (PLC can be debugged from personal computer by connecting computer to TOOL port and PLC to COM. port)

Approx. 220 screens (monochrome LCD

type)

Approx. 160 screens (color LCD type)

Screen numbers that can be set: Base

screens No. 00 to 3FF

Dedicated software Terminal GTWIN used.

Applicable OS: Windows 95/98/2000/NT (Ver. 4.0 or later )

1.1.4 Touch Key

Item GT10 specifications GT30 specifications

Touch key resolution

Touch key operation

Touch key life

20 (W) x 8 (H)

0.98 N max.

6

Min. 10

16 (W) x 12 (H)

1.1.5 Memory (1)

Screen data and GTWIN Configuration Settings data

GT30 specifications

Item GT10 specifications

Memory type F–ROM F–ROM F–ROM

Memory capacity

384 kbytes

AIGT3100B

(monochrome LCD type)

1.5 Mbytes 3.25 Mbytes

AIGT 3300B

(color LCD type)

1.1.6 Memory (2)

Clock data and PLC device storage data (24 words max.)

Item GT10 specifications GT30 specifications

Memory SRAM

Memory backup

Backed up by internal secondary battery

(charged when power is on)

(Note) When using, set operation mode

switch on back of main unit to “ON” position.

Lithium battery (replaceable type)

CR2032 (commercially available)

3

Page 27

GT10/GT30 1.1 GT10/GT30 Specifications

Conditions for

1.1.7 Interface

Item GT10 specifications GT30 specifications

Communications ratings Conforms to RS232C

COM.

Port

TOOL

port

Baud rate: 9600, 19200, 38400,

Conditions for

communications with

external devices

Protocol FP series supported/general–purpose RS232C supported

Connector Connector terminal base (5–pin)

Communications ratings Conforms to RS232C

Conditions for

communications with

external devices

Protocol Dedicated protocol

Connector

57600, 76800, 115200 bits/s

Data bits: 7 or 8 bits

Parity: None, Odd, Even

Stop bits: 1 bit

Baud rate: 9600, 19200, 115200 bits/s

Data bits: 8 bits

Parity: None, Odd, Even

Stop bits: 1 bit

Mini–DIN (5–pin)

Baud rate: 9600, 19200, 38400,

57600, 115200 bits/s

4

Page 28

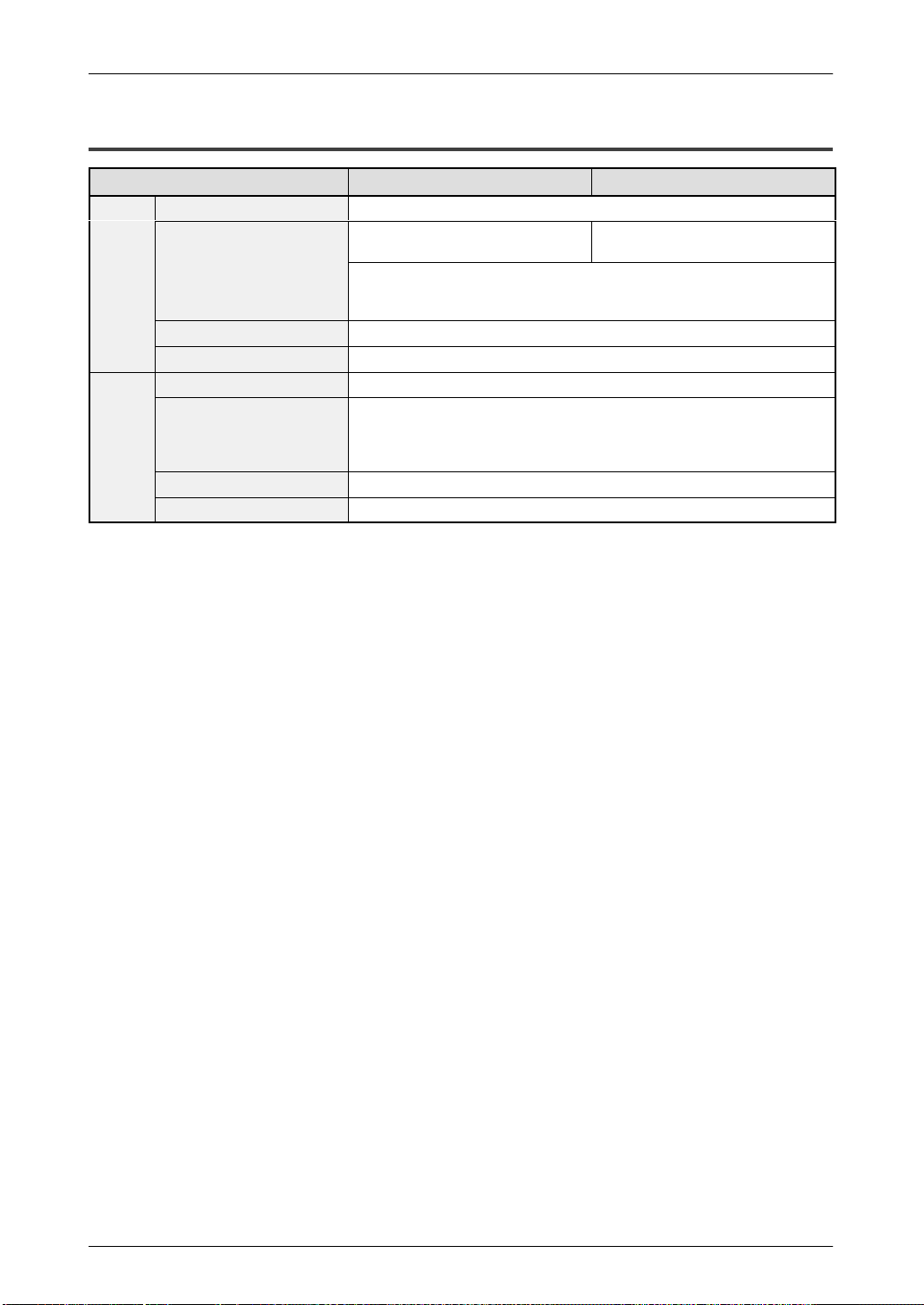

GT10/GT30 1.2 GT10 Names and Functions of Parts

1.2 GT10 Names and Functions of Parts

1.2.1 GT10 (front)

Liquid crystal display panel

1

(touch panel)

2

Front panel protective sheet

(one sheet is attached to unit

when unit is shipped)

1.2.2 GT10 (rear)

3

Power supply terminal

4

5

Operation mode setting switches

6

COM. port (PLC/external device connection

port) (1 communication connector provided as

accessory when when unit is shipped)

TOOL port (connection port for GTWIN

screen creation tool)

7

Waterproof packing

(1 piece is attached to unit when

unit is shipped)

1.2.3 Names and Functions of Parts

(1) Liquid crystal display panel / touch panel

Various screens are displayed here. A touch panel is provided on the liquid crystal

display panel, and switches can be operated and data entered simply by touching the

panel.

5

Page 29

GT10/GT30 1.2 GT10 Names and Functions of Parts

(2) Front panel protective sheet

This protects the touch panel and keeps it clean. One sheet is attached to the panel when

the unit is shipped.

(3) Power supply terminal

The operation power supply is connected here.

(4) COM. port (PLC/external device connection port)

A device such as a PLC, a higher–order computer, or a microcomputer board can be

connected to this RS232C port. (One communication connector is provided as an

accessory when the unit is shipped.)

(5) TOOL port (GTWIN connection port)

This port is used to connect a personal computer in which the screen creation tool

GTWIN has been installed, using a dedicated cable (AFC8513).

(6) Operation mode setting switches

With the GT10, screen data and configuration settings data are stored in an internal

F–ROM, so no battery backup is needed. However, data such as clock data and the Hold

PLC Device Data is stored in the internal SRAM, and is backed up by the internal

secondary battery, which is charged when the power supply is turned on.

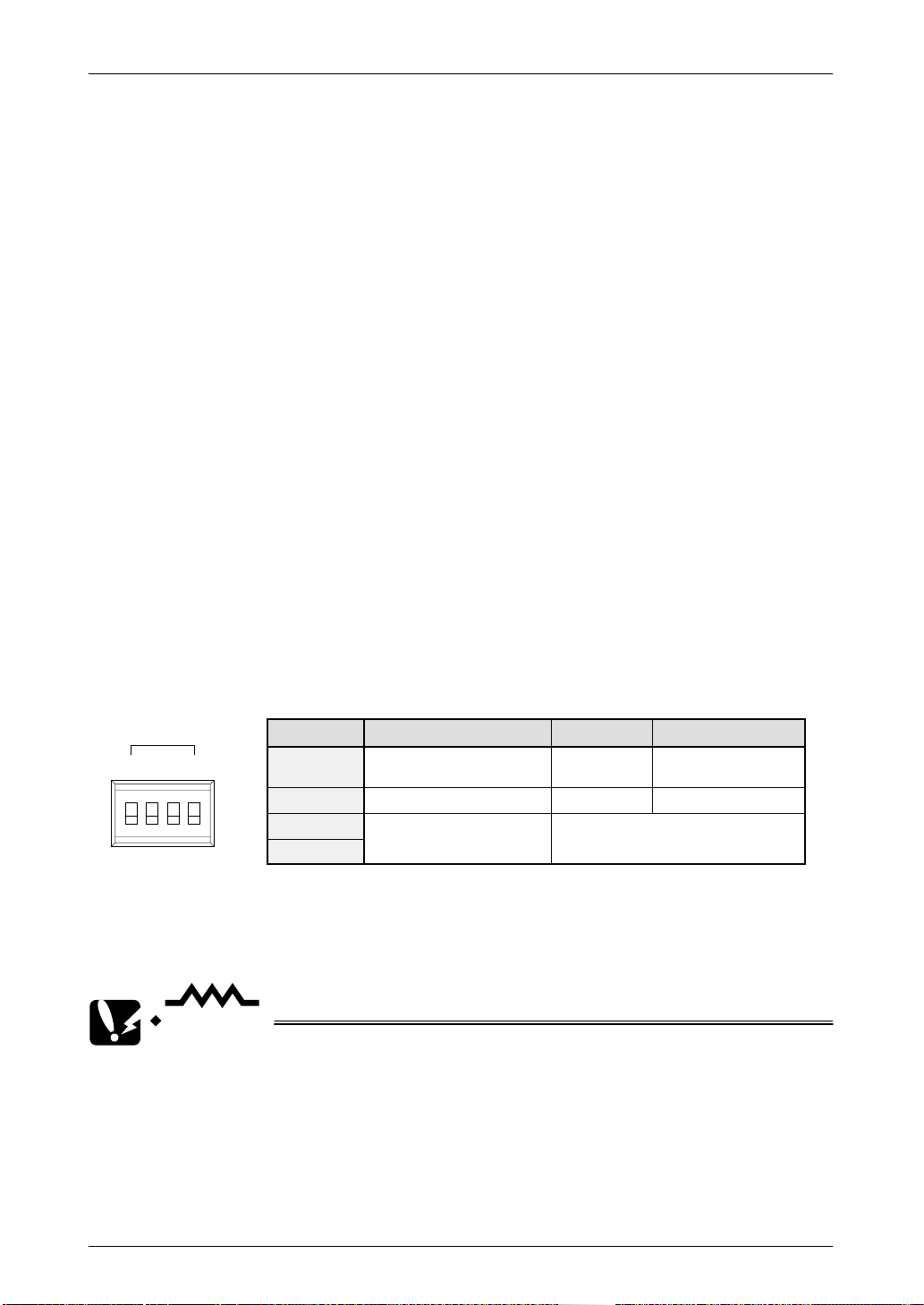

The operation mode setting switches control the ON/OFF settings for the secondary

battery backup function, the ability to shift to the system menu, and other functions.

Operation mode setting

switches

MODE

12

(settings when shipped)

43

Switch no. Function OFF ON

1

ON

2 Inhibits system menu shift Shift possible Shift inhibited

3 Usage inhibited Should always be in the OFF position

OFF

4

SRAM backup using

secondary battery

No Ye s

when unit is used

(7) Waterproof packing

This assures that the front panel is waterproof. One piece is provided as an accessory

when the unit is shipped.

CAUTION

SRAM backup by the secondary battery

When the unit is shipped, the No. 1 operation mode setting switch is

set to the “OFF” psosition, in order to prevent excessive discharging

of the secondary battery. Before using the unit, turn on the No. 1

operation mode setting switch on the back of the main unit, to turn on

the SRAM backup function of the secondary battery. For detailed

information on the secondary battery, please see page 128, “What the

Internal Secondary Battery Does”.

6

Page 30

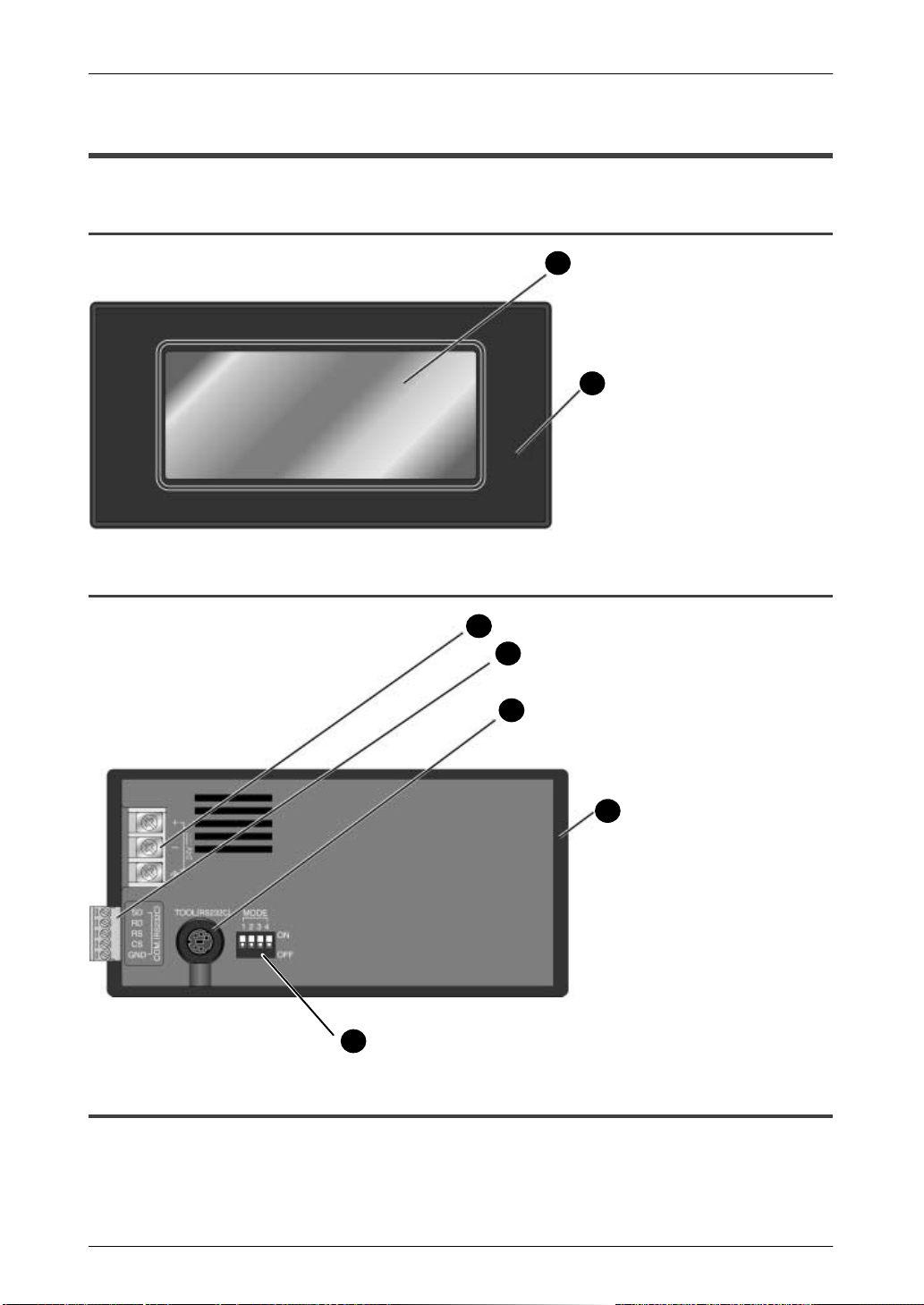

GT10/GT30 1.3 GT30 Names and Functions of Parts

1.3 GT30 Names and Functions of Parts

1.3.1 GT30 (front)

Liquid crystal display panel

1

(touch panel)

Front panel protective sheet

2

(one sheet is attached to unit

when unit is shipped)

1.3.2 GT30 (rear)

Waterprrof packing (1 piece is attached to unit

7

when unit is shipped)

Tool port (connection port for GTWIN screen

5

creation tool)

6

Operation mode setting switches

COM. port (PLC/external device connection port)

4

(1 communication connector provided as

accessory when unit is shipped)

Power supply terminal

3

1.3.3 Names and Functions of Parts

(1) Liquid crystal display panel / touch panel

Various screens are displayed here. A touch panel is provided on the liquid crystal

display panel, and switches can be operated and data entered simply by touching the

panel.

(2) Front panel protective sheet

This protects the touch panel and keeps it clean. One sheet is attached to the panel when

the unit is shipped.

7

Page 31

GT10/GT30 1.3 GT30 Names and Functions of Parts

(3) Power supply terminal

The operation power supply is connected here.

(4) COM. port (PLC/external device connection port)

A device such as a PLC, a higher–order computer, or a microcomputer board can be

connected to this RS232C port. (One communication connector is provided as an

accessory when the unit is shipped.)

(5) TOOL port (GTWIN connection port)

This port is used to connect a personal computer in which the screen creation tool

GTWIN has been installed, using a dedicated cable (AFC8513).

(6) Operation mode setting switches

The operation mode setting switches control the ability to shift to the system menu, and

other functions.

Operation mode setting

switches

MODE

12

(settings when shipped)

43

Switch no. Function OFF ON

1

ON

2 Inhibits system menu shift Shift possible Shift inhibited

3 Usage inhibited Should always be in the OFF position

OFF

4

Usage inhibited Should always be in the OFF position

when unit is used

when unit is used

(7) Waterproof packing

This assures that the front panel is waterproof. One piece is provided as an accessory

when the unit is shipped.

CAUTION

With the GT30, screen data and configuration settings are stored in the

internal F–ROM. Clock data and PLC device hold data are stored in the

internal SRAM, however, and can be backed up by the lithium battery (a

replaceable battery). When replacing the lithium battery, be sure to

insert the new battery within 20 seconds of removing the old one, to

avoid losing the data.

8

Page 32

GT10/GT30 1.4 Internal Wiring Connections for Ports

1.4 Internal Wiring Connections for Ports

1.4.1 COM. Port

When connecting the unit to the FP series, there is

no need to wire both the RS and CS.

Wiring and cables should be laid out in such a way

that cables are not affected by external noise. Also,

shielded wiring should be used for cables.

1.4.2 TOOL Port

2

4

5

1

3

Pin No. Contents

1 SG

2 SD

3 RD

4 N.C.

5 (+5 V)

The +5 V of Pin 5 is reserved for the FP

Programmer II. It should not be used for

any other application.

9

Page 33

GT10/GT30 1.4 Internal Wiring Connections for Ports

JST Mfg

e

1.4.3 Power Supply Terminals

Applicable crimp terminals

– The terminal screws are M3 screws. We recommend using crimp terminals for

wiring to terminals.

+24 V

0 V

Open–tip terminals

6.0 mm

max.

Round terminals

6.0 mm

max.

F.E.

(D–type

ground)

Maker Shape

Round 1.25–MS3 0.25 mm2 to 1.65 mm20.5 N m

JST Mfg.

Co., Ltd.

Front–opening 1.25–B3A

.

Round 2–MS3 1.04 mm

Front–opening 2–N3A

Model Applicable wiring Tightening

torque

2 to

2.63 mm

The tightening torque for terminal base screws should be

between 0.5 and 0.6 N

force could cause damage.

If crimp terminals are not being used, wire with a diameter

of 0.5 mm

In keeping with the European EMC Directive (EMC Directive 89/336/EEC), the GT10 conforms to European Standards (EN50081–2:1993, EN50082–2:1995). As a condition of compatible, a ferrite core should be installed when

wiring to the terminal base (Seiwa Electric Mfg. Co., Ltd.

E04RC281613 or equivalent).

When installing make sure that the connection and power

cables are not stressed, as this could result in broken connections.

2

to 1.25 mm2 should be used for power cables.

Ferrite core

.

m, or less. Operating at a higher

2

The GT30 conform to European EMC directives (EMC Directive 89/336/EEC) and meet European EMC standards

(EN50081–2, EN6100–6–2). A ferrite core (E04SR211132

by Seiwa Electric Mfg. Co., Ltd. or an equivalent product)

should be installed when wiring connections to the terminal

base, as shown below, in order to meet these requirements.

When installing make sure that the connection and power

cables are not stressed, as this could result in broken connections.

Ferrite cor

Ferrite core

10

Page 34

GT10/GT30 1.5 Dimensions

1.5 Dimensions

1.5.1 GT10 Dimensions

8.5/0.33

(7/0.28)

144/5.67

97/3.82

138.0/5.43

80/3.15

(Display unit)

4/0.16

72/2.83

40/1.57

(Display unit)

65.8/2.59

32/1.26

2/0.08

(Packing)

(7/0.28)

9.6/0.38

60/2.36

(Unit: mm/inch)

11

Page 35

GT10/GT30 1.5 Dimensions

1.5.2 GT10 Panel Cutout Dimensions

The panel cutout dimensions of the GT10 are as shown below.

1

+

0

139

Applicable panel thickness: 1.0 to 6.0/0.002 to 0.236

1.5.3 GT30 Dimensions

177/6.97

126.8/4.99

0.04

+

0

/5.47

(Display unit)

+

+

0.04

1

0

/2.64

0

67

(Unit: mm/inch)

118.8/4.68

88/3.46 (Display unit)

158.2/6.23

150.2/5.91

4.4/0.17

(8/0.31)

Attachment fitting

(Unit: mm/inch)

38.0/1.50

3.1/0.12

12

Page 36

GT10/GT30 1.5 Dimensions

1.5.4 GT30 Panel Cutout Dimensions

The panel cutout dimensions of the GT30 are as shown below.

1

+

0

150.5

Applicable panel thickness: 1.0 to 5.0/0.039 to 0.197

/5.93

0.04

+

0

0.04

+

0

/4.69

1

+

0

119

(Unit: mm/inch)

13

Page 37

GT10/GT30 1.5 Dimensions

14

Page 38

Chapter 2

Installation and Wiring

Page 39

GT10/GT30 2.1 Installation

2.1 Installation

2.1.1 Installation Environment

When installing and using the GT series, always make sure the following conditions are

observed.

Usage Conditions

When installing the product, make sure it is used within the range of the general

specifications. Do not use in the following environments:

– Areas where the unit may come in contact with water (the unit is warranted by

IP65 for the installed panel, but this applies to initial values and operation cannot

be guaranteed in areas where the unit is constantly subjected to water or to

extreme temperatures or humidity).

– Areas where the ambient temperature exceeds the range 0°C to 40°C/32°F to

104°F (0°C to 50°C/32°F to 122°F for the GT30).

– Areas where the ambient humidity exceeds 20% RH to 85% RH.

– If the control panel and other parts are installed in an environment where the air

tends to be poorly ventilated, forced cooling should be used to keep the ambient

temperature of the from going over 40°C/104°F (50°C/122°F for the GT30). This

prevents the temperature of the GT display unit from rising.

– Locations where condensation may form because of sudden fluctuations in

temperature.

– Locations where flammable or corrosive gases are present.

– Locations where there are high concentrations of dust or iron filings.

– Locations where substances such as organic solvents (thinner, benzene, etc.) or

strong alkali substances (ammonia, caustic soda, etc.) might adhere to the

product.

– Locations where the product is subject to extreme vibration and/or impact.

– Avoid installing the product near high–voltage lines, high–voltage devices, power

lines, power devices, amateur radio sets and other transmitters, and devices that

generate strong current surges.

– Avoid locations where the display unit is subject to direct sunlight.

Safety Precautions

– The switch functions of the programmable display unit should not be used to

design systems which may pose a threat to human life or which may cause

severe injury or damage. Designs should include safety mechanisms for use in

the event that switch functions do not function correctly.

Power Supply Wiring

– For the power supply, use twisted wire (strand wire).

– There is sufficient noise resistance to offset power line noise, but we recommend

reducing noise by measures such as installing an insulated transformer.

16

Page 40

GT10/GT30 2.1 Installation

– Separate wiring systems should be used for the power supply unit and the

operating unit.

Static Electricity/Noise

– Keep the GT10/GT30 main unit, PLC connecting cable, and other wiring as far

away as possible from machines which are likely to produce noise (welding

equipment, power lines, inverters, motors, etc.).

– For use in environments where the frequent occurrence of static electricity,

radiation, or induced noise can be expected, the use of shielded cable on all

wiring and grounding of shield (1–point ground) is recommended. When wiring

the equipment, shielded wires should be electrically insulated to signal lines and

signal grounds.

– If excessive static electricity is applied to the panel surface, the LCD display unit

may be damaged.

Battery Service Life

– The service life of the internal battery will be radically shortened if used

continually in ambient operating temperatures of more than 40°C/104°F

(50°C/122°F for the GT30) or when the operating voltage exceeds 25V DC. Use

caution when using the clock and device hold area functions.

Other Precautions

– Do not leave the GT10 connected to the TOOL port of the FP Programmer II.

– Always operate the touch panel with your fingers. Excessive load (about 98

2

N/cm

) or impact (operating with tools, etc.) will cause damage. Touch panel

operation must be within the standard operating power range. Uniform pressure

should be used to avoid abnormal wear of electrodes which may disable

operation. Operate the unit only by touch.

– Never dismantle, re–assemble, or alter the unit. Performance cannot be

warranted if this precaution is disregarded.

2.1.2 GT10 Installation Method

Secure the GT10 to the installation panel using the four fittings and four screws

provided with the unit.

(1) Place the GT10 main unit in the installation panel.

17

Page 41

GT10/GT30 2.1 Installation

(2) Insert the fittings into the grooves provided in the GT10 main unit, and tighten

the screws to secure the GT10 main unit to the installation panel.

Four fittings and four screws provided

with the unit

Enlarged view

CAUTION

Screw tightening torque

The screw tightening torque should be 0.1 N m to 0.25 N m.

Applicable panel thickness

A panel with a thickness of 1.0 mm to 6.0 mm should be used.

Installation angle

If the installation angle is between 60 degrees and 0 degrees

(horizontal), the operating voltage should be set to 25V DC or lower.

Installation angle

Clearance when the GT10 is installed

When installing the GT10, if other parts are being installed to the

panel or cables are being wired to it, we recommend providing a

clearance of 30 mm to 50 mm/1.18 inch to 1.97 inch around the

GT10. This prevents cables from being damaged, and facilitates the

installation work. Also, make sure that the slits in the main unit are

never obstructed.

18

Page 42

GT10/GT30 2.1 Installation

2.1.3 GT30 Installation Method

Secure the GT30 to the installation panel using the two fittings and four screws provided

with the unit.

(1) Place the GT30 main unit in the installation panel.

(2) Insert the fittings into the grooves provided in the GT30 main unit, and tighten

the screws to secure the GT30 main unit to the installation panel.

Slits (located all the way around the periphery)

Attachment screws

Installation panel

CAUTION

Attachment fittings

Screw tightening torque

The screw tightening torque should be 0.1 N m to 0.25 N m.

Tightening the screws too hard can cause deformation of the front

panel , so that the switch will not function properly. Make sure

screws are tightened to the appropriate degree.

Applicable panel thickness

A panel with a thickness of 1.0 mm to 5.0 mm should be used.

Installation angle and ambient temperature range for usage

If the unit is being installed in a horizontal orientation and the

Matsushita Programmer II and C–NET adaptor are being connected

to the Tool port, please be aware that the ambient usage

temperature should not exceed 40°C/104°F.

Liquid display panel side

Installation panel

(Horizontal installation)

Clearance when the GT30 s installed

When installing the GT30, if other parts are being installed to the

panel or cables are being wired to it, we recommend providing a

19

Page 43

GT10/GT30 2.1 Installation

clearance of 30 mm to 50 mm/1.18 inch to 1.97 inch around the

GT30. This prevents cables from being damaged, and facilitates the

installation work. Also, make sure that the slits in the main unit are

never obstructed.

20

Page 44

GT10/GT30 2.2 Wiring the Power Supply

2.2 Wiring the Power Supply

The power supply should be wired by securely connecting the terminal on the rear of

the main unit to the terminal. Always use crimp terminals for wiring.

+24 V

+24 V

0 V

(D–type ground)

F. E.

+24 V

0 V

F. E.

(D–type

ground)

Use twisted wiring for the power supply

In order to minimize influence from noise, the wiring for the power supply should be

twisted.

Insulate the power supply inside a protective circuit

– In order to protect the unit against abnormal voltage from the power supply line, the

power supply should be an insulated type, and should be enclosed within a protective

circuit.

– A non–insulated regulator is used with the GT series.

– If a power supply device without an internal protective circuit is being used, power

should always be supplied to the GT series through a fuse or a similar protective device.

Keep the power supply voltage within the operating voltage range

Operating voltage range 21.6 to 26.4V DC

Use M3 crimp terminals

– The terminal screws are M3 screws. We recommend using crimp terminals for wiring

to terminals.

Open–tip terminals Round terminals

6.0 mm

max.

Maker Shape Model

Round 1.25–MS3 0.25 mm2 to 0.5 N·m

JST Mfg.

JST Mfg.

Co., Ltd.

Front–opening 1.25–B3A

Round 2–MS3 1.04 mm2 to

Front–opening 2–N3A

6.0 mm

max.

Applicable

wiring

1.65 mm

2.63 mm

Tightening

torque

2

2

The tightening torque for terminal

base screws should be between 0.5

and 0.6 N·m, or less. Operating at a

higher force could cause damage.

If crimp terminals are not being

used, wire with a diameter of 0.5

mm2 to 1.25 mm2 should be used

for power cables.

For precautions concerning conformance to European EMC directives, please see “Power

Supply Terminals” on page 10.

21

Page 45

GT10/GT30 2.2 Wiring the Power Supply

Keep the power supply wiring separate

– Wiring to the GT series, PLC, and other power equipment should have separate wiring

systems.

Breaker

Power

equipment

PLC

GT series

Insulated DC

power supply

22

Page 46

GT10/GT30 2.3 Wiring the COM. Port

2.3 Wiring the COM. Port

Accessory communication connector/applicable wiring

The communication connector used for the COM. port (provided as an accessory with

the main unit) has a screw–tightening type of terminal base. The wiring shown below

should be used.

Accessory communication connector

The communication connector is made by Fenics Contact Co., Ltd.

No. of pins

5–pin MC1, 5/5 –ST–3,5 1840396

Fenics Model No.

Model No. Product No.

Applicable wiring (twisted wiring)

Size Conductor Cross–Section Surface Area

AGW#28 to 1 6 0.08 mm2 to 1.25 mm

2

Applicable stick–type terminals with insulated sleeves

If stick–type terminals are used, the models listed below are marketed by Fenics

Contact Co., Ltd.

Maker Cross–Section Surface Size Fenics Co. Model

2

2

2

2

AGW#24 AI 0,25 to 6 YE

AGW#20 AI 0,50 to 6 WH

AGW#18 AI 0,75 to 6 GY

AGW#18 AI 1 to 6 RD

Fenics Contact

Fenics Contact

Co., Ltd.

0.25 mm

0.50 mm

0.75 mm

1.00 mm

Crimp tools for stick–type terminals

Maker

Fenics Contact Co., Ltd. CRIMPFOX UD6 1204436

Fenics Model No.

Model No. Product No.

Use a special tool to tighten the terminal base of the communication connector

Tightening of terminals should be done using a screwdriver made by Fenics Contact

Co., Ltd. (Fenics mfg. no. 1205037, blade width 0.4 x 2.5, model no. SZS 0.4 x 2.5), or

a screwdriver made by Matsushita Electric Works Co., Ltd. (Product number AFP0806).

The tightening torque should be 0.22 N·m to 0.25 N·m or less.

23

Page 47

GT10/GT30 2.3 Wiring the COM. Port

2.3.1 Wiring Method

(1) Remove the sheath from the wire.

7 mm/0.28 inch

(2) Insert the wire all the way into the terminal base, and tighten the screw in the

clockwise direction to secure it.

2.3.2 Precautions Concerning Wiring

The following precautions should be observed, to avoid broken or disconnected wires.

– When removing the sheath, be careful not to scratch the core wire.

– Wire the terminal without twisting the core wire.

– The core wire should be connected without soldering it. Vibration can sometimes

cause soldered connections to break loose.

– After connecting the wiring, avoid subjecting the cable to stress.

– Because of the construction of the terminal, tightening the wire in the

counterclockwise direction will cause a faulty connection. If this happens,

disconnect the wire, check the terminal hole, and connect the wire again.

CounterclockwiseClockwise

REFERENCE

For information on connecting the COM. port of the GT series with

various PLC units, please see Chapter 4, “Connecting and

Communicating with the PLC”, on page 41.

24

Page 48

Chapter 3

Setup

Page 49

GT10/GT30 3.1 Setup Procedure for the GT10

3.1 Setup Procedure for the GT10

The GT10 should be set up using the procedure outlined below.

(1) Setting the “Configuration File” with GTWIN

The GT10 has an internal file called the “Configuration file”, which is used to determine

various operating environment parameters. When the GT10 is shipped from the factory,

the settings listed below are set for the parameters in the configuration settings file. If

changes are made to these settings, they are made from GTWIN screen creation tool.

(For detailed information on changing settings, see page 73 and subsequent pages.)

If the GT10 is being used without changing the factory settings, the following setup

procedure is not necessary.

Contents of configuration settings for GT10 when shipped from the factory

Classification Item Setting contents

Basic Setup

Communication

parameter

parameter

settings

Auto paging Automatic paging No

Startup screen

Startup screen

settings

Other settings

Other settings

Hold PLC Device Holds a PLC device Not held

GT internal

device hold

Area for basic

communication

with PLC

COM. port

TOOL port

Startup screen No. 00

Rise delay time 0 seconds

Clock GT main unit clock / external transmission: No

Backlight control Not turned of f automatically

Touch operation

sounds

GT internal device

hold

Mode : GT10 mode

Word area: DT0 to DT2

Bit area : WR0 to WR2

Communication speed: 19200 bits/s, data length: 8 bits, stop bit: 1 bit, parity: odd

<Communication error temporary processing> Retries: 3, error code displayed

(not held)

Communication speed: 19200 bits/s, data length: 8 bits, stop bit: 1 bit, parity: odd

<Through function local setting> None

Valid

Not held

Always confirm “Basic communication area to PLC” under “Basic Setup”

This is an internal device area that comes already provided in the GT10 for the purpose

of communicating with a PLC. If the factory settings are to be changed, the setup

procedure must be carried out. For detailed information, please see page 29.

(2) Connect the GT10 and the personal computer.

After the settings have been entered with GTWIN, connect the computer and the GT10,

using the screen transfer cable.

GTWIN

Screen transfer

cable (AFC8513D)

GT10

26

Page 50

GT10/GT30 3.1 Setup Procedure for the GT10

(3) Transfer the GT10 Configuration file from GTWIN.

After connections have been completed, use the following procedure to transfer the

GT10 Configuration file from GTWIN.

Boot GTWIN, and select “Transfer” on the “File” menu.

When the transfer function is selected, a dialog box for file transfer is displayed.

At this point, specify the type of data to be transferred, and the direction of

transfer.

Transfer data: “GT10 Configuration”

Transfer direction: “GTWIN → GT main unit”

Enter the above conditions and click on the “OK” button. The system files are

transferred to the GT10.

27

Page 51

GT10/GT30 3.1 Setup Procedure for the GT10

When the menu operation as shown at the left page is carried out, the configuration file

is sent to the GT10. During the transfer, a screen like that shown below is displayed.

GTWIN

GT10 Configuration

file being transferred

Screen transfer cable

(AFC8513D)

Transferring

PC→GT

GT10

(4) Setup is completed.

If the transfer has been completed without any problems, the setup is completed.

CAUTION

Backup of the GT10 Configuration file

The GT10 Configuration file is stored in the user memory (F–ROM) of

the GT10. This file is deleted if the memory is initialized using the

command on the system menu of the GT10 main unit (see page 89),

and will have to be transferred again.

28

Page 52

GT10/GT30 3.2 Setting the Basic Communication Area, GT10 and PLC

3.2 Setting the Basic Communication Area, GT10 and PLC

3.2.1 What is the Basic Communication Area?

Communication between the GT10 and PLC is carried out as shown below.

Basic communication area

For screen switching settings and system

control

Ongoing

Communication

GT10

As shown in the illustration, communication is carried out on an ongoing basis between

the GT10 and internal devices in the PLC. Internal PLC devices are divided into the

following two devices:

Basic communication area

This area is for system control, such as screen switching settings. PLC devices belong

to this area on a fixed basis, and communication is constantly being carried out.

Breakdown of the basic communication area

Word devices (DT, FL, etc.)

(word device / bit device: 3 words each)

Part reference / output device

For part functions

(free device specification)

Internal PLC devices

Bit devices (WR, etc.)

PLC

3 consecutive words

3 consecutive words

– Word devices ––– For reading devices handled in word units (3 consecutive words)

– Bit devices ––– For reading devices handled in bit units (3 consecutive words)

References and output devices for parts

These are devices that are used in parts functions, and can be freely specified by the

user. Communication is carried out on an ongoing basis only for those that are currently

displayed on the screen and pertain to devices currently in use.

With the GT10, before GTWIN screen creation tool is used to specify the devices for

parts functions, the “basic communication area” must be determined.

DT0 to DT2 and WR0 to WR2 are set as the default values for the basic communication

area, but the initial address can be changed using the following procedure.

CAUTION

The basic communication area should be used in the PLC ladder

program to control the GT main unit.

Settings in GTWIN

Select “Configuration” under “File” on the menu bar, and then select the sub–menu

called “GT Configuration”. This displays the dialog box for the GT10 Basic Setup, as

29

Page 53

GT10/GT30 3.2 Setting the Basic Communication Area, GT10 and PLC

shown below.

Clicking on the

button in “Basic Communication Area to PLC” displays the device

settings dialog box shown below, where the initial addresses for the word area and bit

area can be changed.

GT10 Configuration Basic Setup dialog box

EXPLANATION

Key operation in the Device Settings dialog box

Click on the

button to display a pull–down menu, and then select

the device for which settings are to be entered. Use the ten–keys to

enter the address.

The

address, and the

button acts as a backspace key when entering an

button functions as a Clear key.

3.2.2 GT10 Basic Communication Area Map

In order for communication to be carried out between the GT10 and PLC, an internal

device area like that shown below is provided in the PLC. This should be used to control

the GT main unit through the PLC ladder program actually being run.

The starting address “N” of the field shown below is specified in the GT10 configuration

settings of GTWIN screen creation tool, and is then sent to the GT main unit.

30

Page 54

GT10/GT30 3.2 Setting the Basic Communication Area, GT10 and PLC

Word devices

Word position F E D C B A 9 8 7 6 5 4 3 2 1 0

N+0 Screen no. specified by PLC (area read by GT10 from PLC)

N+1 Usage prohibited

N+2 No. of currently displayed screen (area in which data is written from GT10 to PLC)

Explanation of system area

Screen no. specified by PLC ––– The screen number displayed on the GT10 is

specified from the PLC in hexadecimal format.

No. of currently displayed screen ––– The number of the screen currently

displayed on the GT10 is written to the PLC in hexadecimal format.

Bit devices

Word

position

N+0 BZ

N+1 Usage prohibited

N+2 BAT

F E D C B A 9 8 7 6 5 4 3 2 1 0

Forced–

display flag

Explanation of system areas

Backlight

Valid flag

Backlight

Flashing

Backlight

Color

Data Input In

Progress flag

BZ ––– This turns on the buzzer.

Forced–Display flag ––– At the rise when the bit is turned on, the screen specified by

the PLC is forcibly displayed. (This is executed only when at the rise of the bit.)

Backlight Valid flag ––– When the bit is turned on, the backlight flashing/backlight

color control becomes effective.

Backlight Flashing ––– 0: Lighted (normal), 1: Flashing

Backlight Color ––– 00: Off, 01: Green, 10: Red, 11: Orange

BAT ––– This goes on if clock data and Hold PLC Device data held in the SRAM are

not being backed up normally. (This bit also goes on if the SRAM is not backed up by

the internal secondary battery.)

Data Input In Progress flag ––– This is 1 while data is being input, and 0 when data

input has been completed.

EXPLANATION

“IOP01” mode

The GT10 is equipped with an IOP01 mode for users with

conventional models (I.O.P. B01C / M01L / D01TL series).Using this

function enables compatibility with earlier models, so that

communication is possible between the GT10 and PLC, except for

one part of the basic communication area.

Entering settings for the IOP01 mode

Click on the “File” menu in GTWIN, and then select “Configuration”

from the displayed menu. Next, select “GT Configuration” from the

31

Page 55

GT10/GT30 3.2 Setting the Basic Communication Area, GT10 and PLC

sub–menu. Turn on the radio button for “IOP01 Mode” in the

displayed dialog box.

For information on the displayed dialog box, please see “Basic

Setup” under “GT10 Configuration Settings” on page 73.

Map of the basic communication area for conventional models

(conventional name: system area)

If the IOP01 mode is set, the basic communication area map for the

GT10 is as follows.

Reference data area

Address

n BZ PC Screen no.

n+1

n+2

n+3

•

•

•

•

Bit configuration

F E D C B A 9 8 7 6 5 4 3 2 1 0

Tag bit field * Note 1

(Used to turn tag display on/off, display status screen segments, and display settings)