Page 1

`

Consumer Solutions & Support

US Competency Center

600 North US Highway 45

Libertyville, Illinois 60048

Website: gs.mot.com

NOTE: This FSB will expire on Aug 18, 2004 or until replacement battery

connectors become available. A revised FSB will be issued at that time.

FSB Number: LVCCFSB2003-115 Rev C

Author: Max Dekirmandjian

Date: June 23, 2004

Total No. of Pages: 9

Subject: C33x Battery Metering Inaccurate

Model Affected: C330, C331, C332, & C333 GSM

Level of Repair: 3 & 4

Problem

Service has been made aware of an issue with the battery level indicator on

C33x GSM phones. When a call is placed, the battery level indicated on the

phone’s display will initially show three bars (with a fully charged battery), then

drops one bar within minutes. Therefore the end user perceives this as “Short

Battery Life”, or “Battery Not Holding Charge” This false indication is particularly

evident when a test call is made using a call simulator such as a CMU200 or

HP8922 when the TX Power Level is set at maximum power. Within 15 minutes,

the indicator can drop one bar.

Solution

Battery/Charging failures have been determined to be the result of one or any

combination of the following root causes:

1) Phone software-versions prior to TA02_06.04.2FR have a lower A to D

sampling rate;

2) MIWA sideband(C333 only)-a conductive coating on the front housing

sideband leads to degradation of the RF signal which results in the phone

transmitting at a higher power level, thus shortening battery life;

3) Faulty phone battery

4) Hirose Battery connector (assy P/N 0189727L01) and/or PCB connector

(P/N 2809180T01)-Oxidation/plating issues on contact pin(s) increasing

the pin’s resistance.

In addition, it has also been determined that changing the SEEM elements in the

unit’s flex results in a more accurate battery level reading.

Field Service Action

Customer Returns:

Perform the following procedure on all C33x returns:

1. Verify that the phone’s software version is TA02_06.04.2FR or later.

Reflash if necessary.

MOTOROLA INTERNAL USE ONLY Page 1

Page 2

`

Consumer Solutions & Support

US Competency Center

600 North US Highway 45

Libertyville, Illinois 60048

2. Replace Miwa sideband if necessary (C333 only). Refer to Field Service

Bulletin LVFSB2003-49 Rev A for details.

3. For US Band products-Re-flex with flex version 171.

4. For Euro Band products-Re-flex with flex version 173

Perform the following Battery Connector rework using the procedure below only

on units returned for battery or charging related complaints such as:

1) Battery Life Short

2) Battery Not Holding Charge

3) Battery Meter Inaccurate

4) Battery Charging Too Slow

5) Battery Does Not Charge

Website: gs.mot.com

Battery Connector Rework Procedure:

CAUTION: The rework process involves working with exposed

battery wires. Extreme care must be taken throughout the

rework process to avoid shorting of these wires to each other or

with PCB components. If a short does occur, then the wires will

quickly become extremely hot, possibly resulting in a burn. The

procedure MUST be followed step by step as described

1) Disassemble the unit to gain access to the battery.

2) Remove the battery from the PCB battery connector

3) Using a flatblade jeweler’s screwdriver, break off the of the PCB battery

connector negative (-) pin by moving the pin back and forth several times

until it breaks at the connector’s base. Refer to Photos 1 thru 4 below.

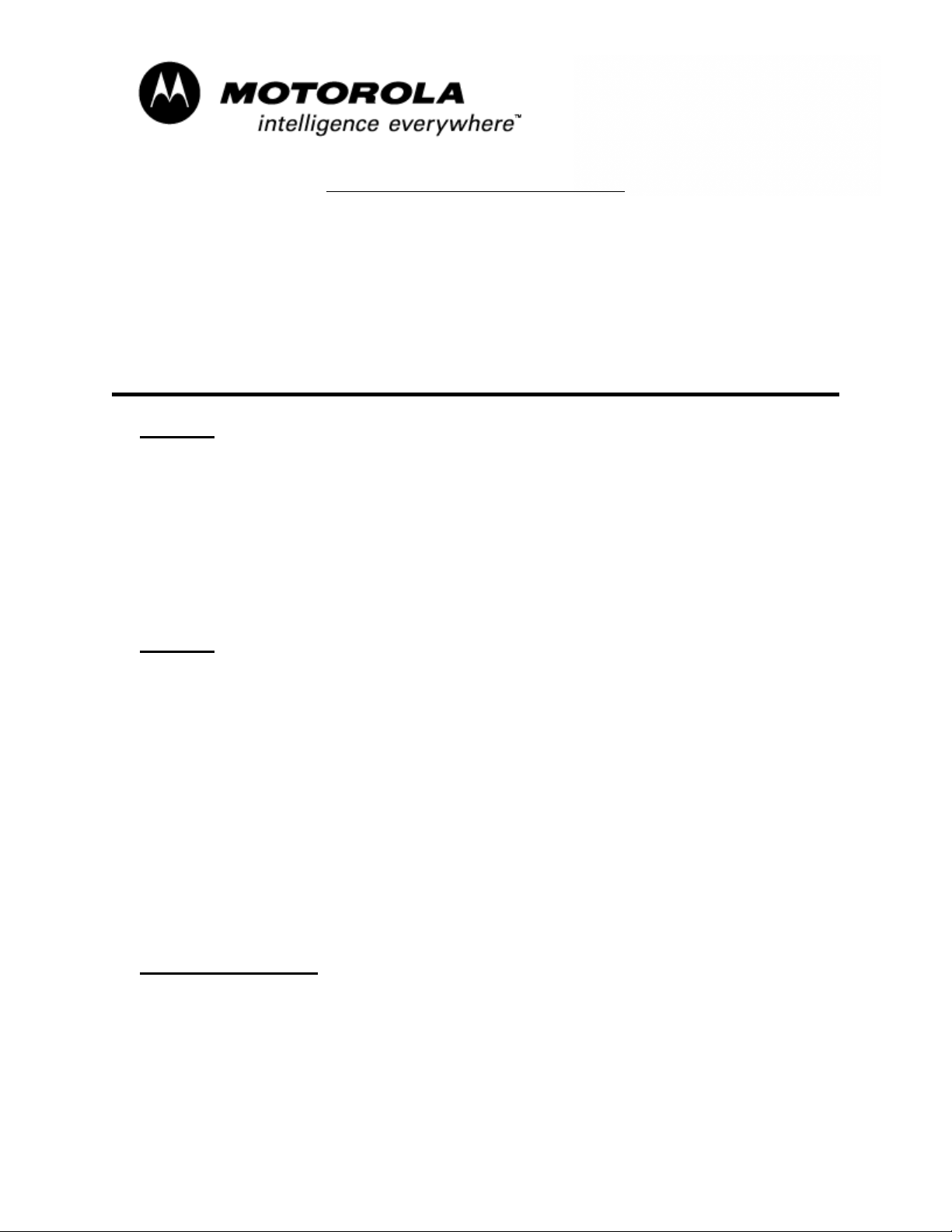

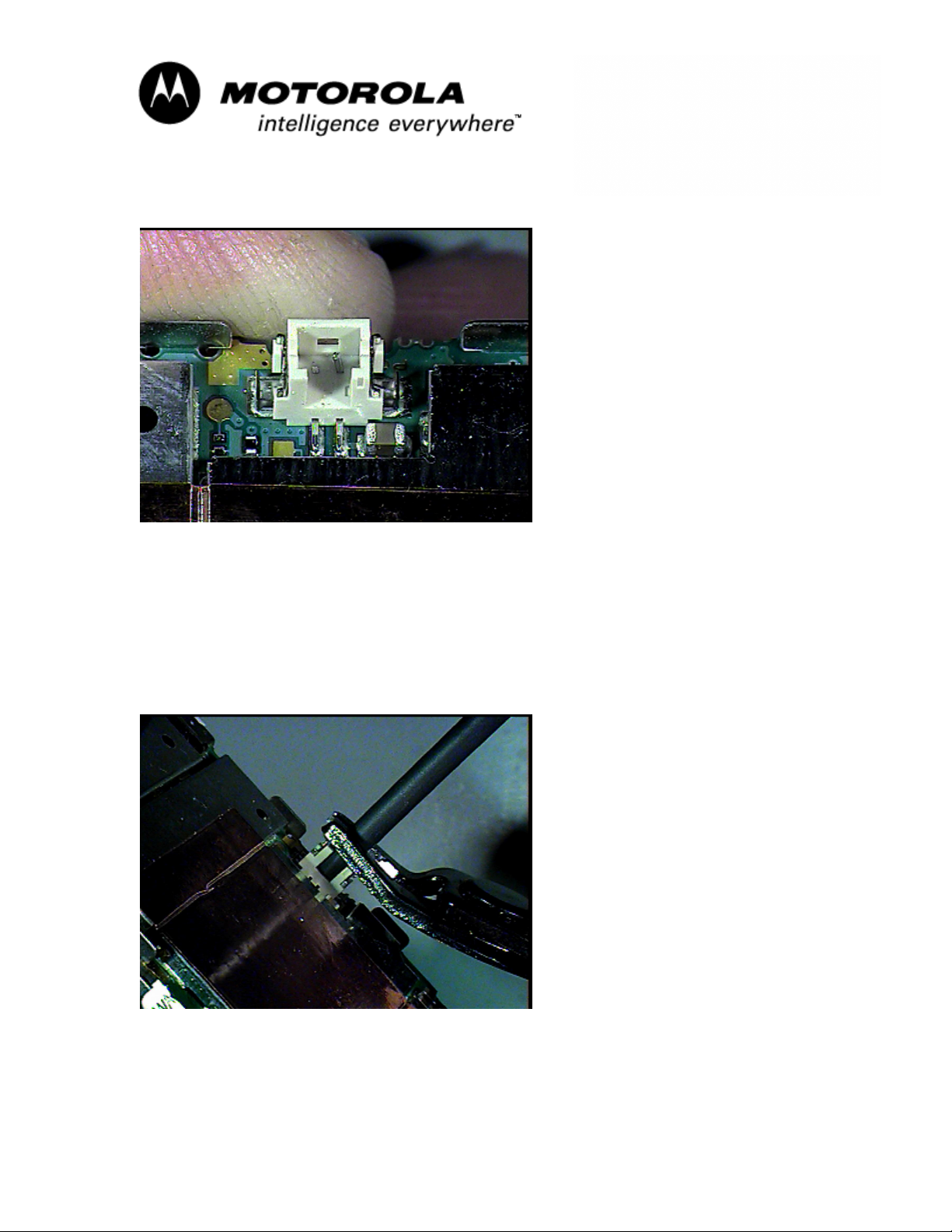

Photo #1-Original PCB Batt Connector

.

MOTOROLA INTERNAL USE ONLY Page 2

Page 3

`

Consumer Solutions & Support

US Competency Center

600 North US Highway 45

Libertyville, Illinois 60048

Website: gs.mot.com

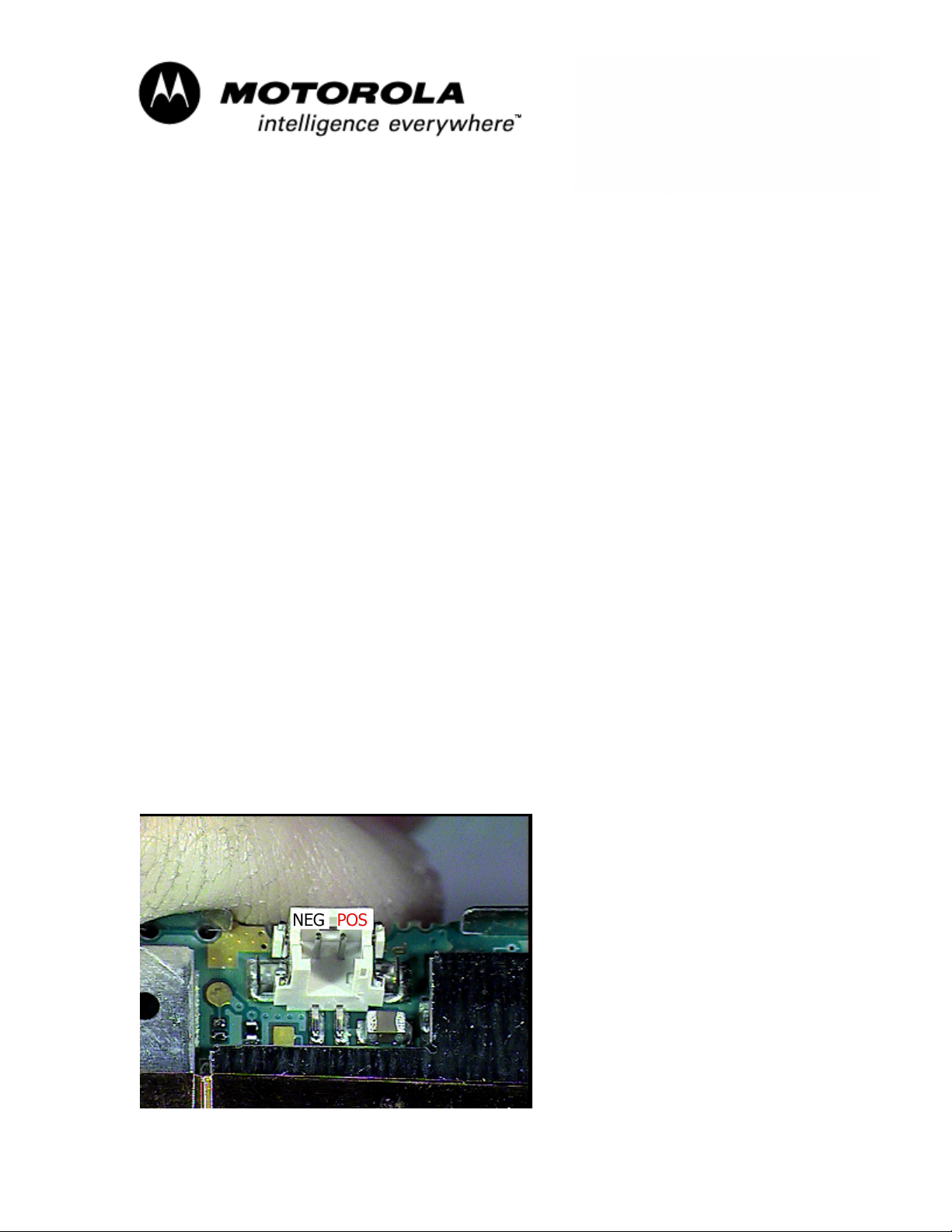

Photo #2-Bending PCB Batt Connector Negative Pin

Photo #3-PCB Batt Connector Negative Pin Broken Off

MOTOROLA INTERNAL USE ONLY Page 3

Page 4

`

Consumer Solutions & Support

US Competency Center

600 North US Highway 45

Libertyville, Illinois 60048

Website: gs.mot.com

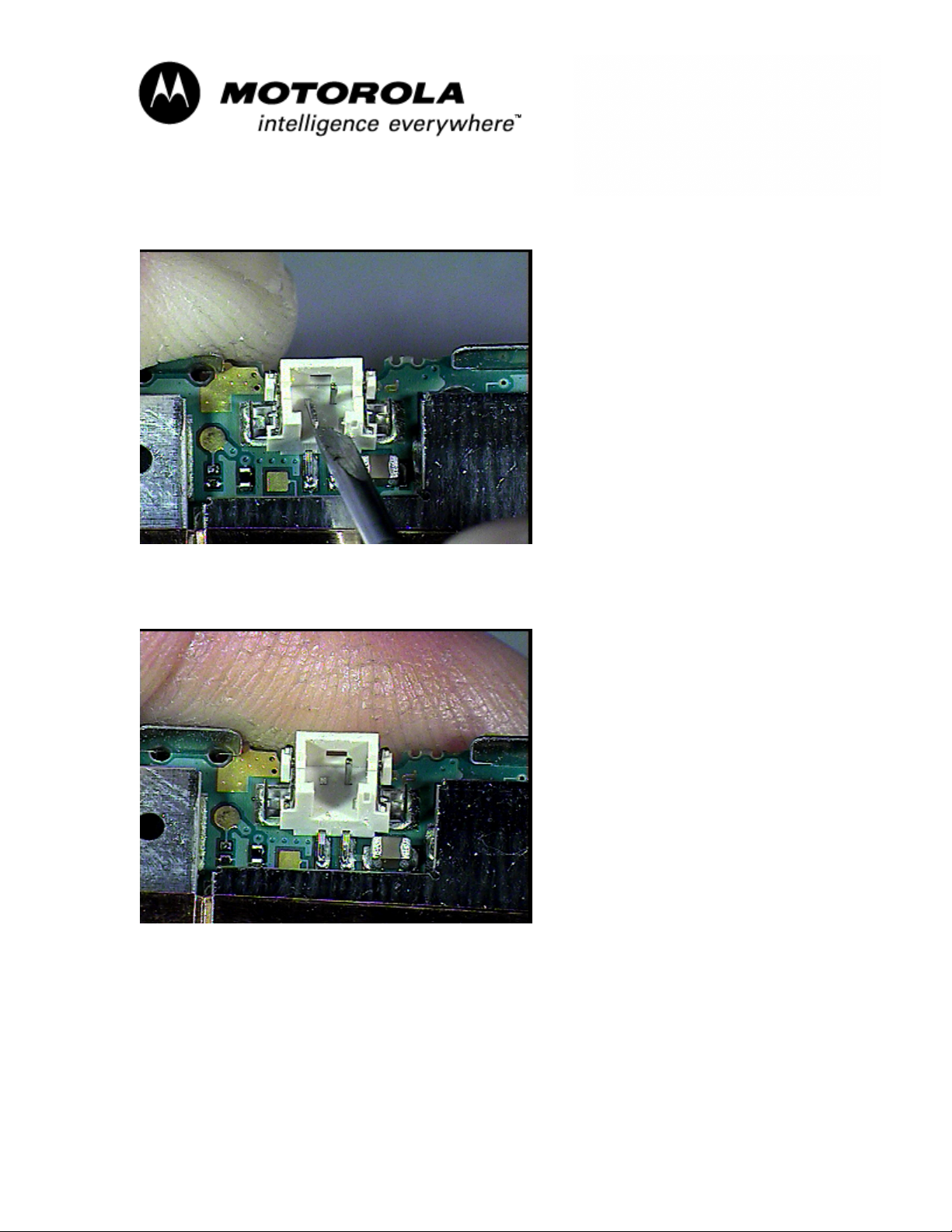

Photo #4-Side View Of PCB Batt Connector Without Negative Pin

4) Using the flatblade jeweler’s screwdriver, bend the PCB Battery Connector

positive (+) pin approximately 20 degrees towards the center of the

connector. This is to allow clearance between the heat shrink tubing

(installed later in this procedure) & the PCB connector body. Refer to

Photos #5 & #6.

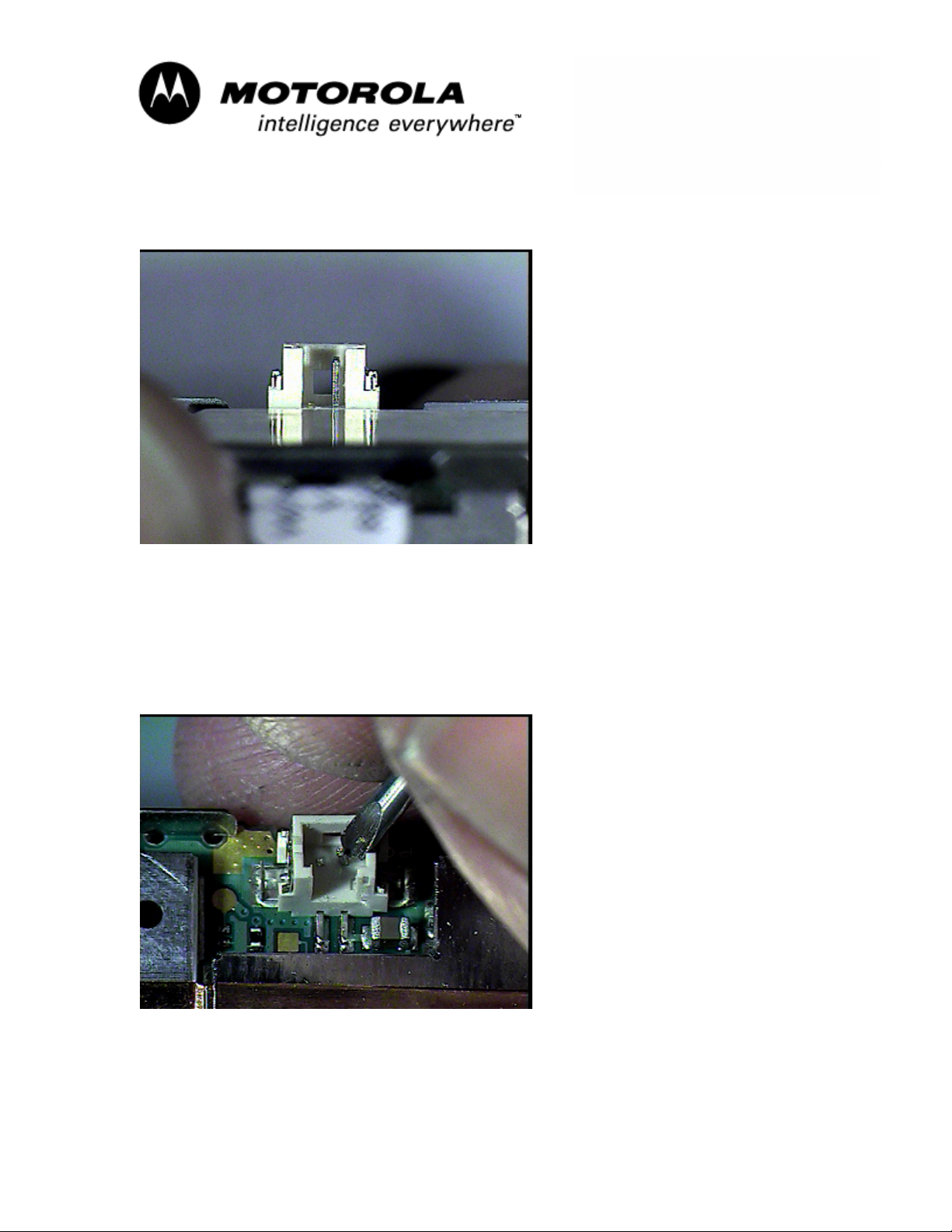

Photo #5-Bending Positive Pin

MOTOROLA INTERNAL USE ONLY Page 4

Page 5

`

Consumer Solutions & Support

US Competency Center

600 North US Highway 45

Libertyville, Illinois 60048

Website: gs.mot.com

Photo #6-Positive Pin Bent Toward Center Of Connector

In Steps 5 & 6, the height of the PCB battery connector is being used as a gauge

to cut the heat shrink to the correct length:

5) Insert a 3/32 diameter heat shrink tubing (3M Part # FP-301) until it fully

seats into the PCB battery connector.

6) Using a diagonal wire cutter, cut the heat shrink flush to the top of the

connector. The cut length must not exceed 4mm. Refer to Photo #7

Photo #7-Using PCB Batt Connector To Cut Heat Shrink to Proper Length

7) Remove the heat shrink from the connector.

MOTOROLA INTERNAL USE ONLY Page 5

Page 6

`

Consumer Solutions & Support

US Competency Center

600 North US Highway 45

Libertyville, Illinois 60048

Website: gs.mot.com

NOTE: If a short condition occurs while performing the following steps, cut

any ONE of the battery leads immediately to break the circuit. DO NOT CUT

BOTH BATTERY LEADS SIMULTANEOUSLY. Welding of the leads can

occur and the battery leads will quickly become extremely hot due to the

high current condition, possibly resulting in a burn.

8) Using the diagonal wire cutter, cut the side of the battery connector

housing which is closest to the red lead in order to remove the lead from

the battery connector. Use caution to avoid damaging the battery wire or

contact pin. Refer to Photo #8.

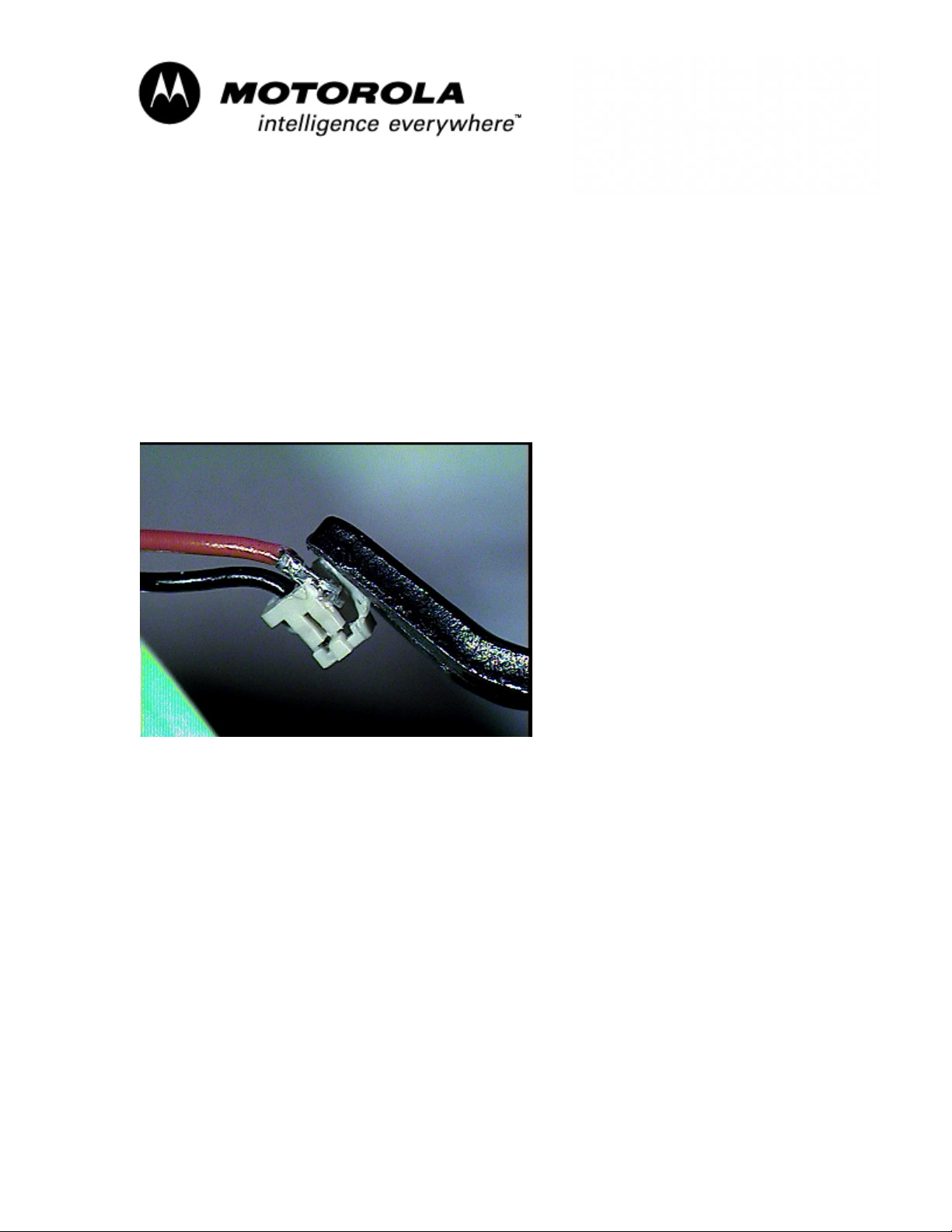

Photo #8-Cutting Batt Connector Housing

9) Remove the red lead from the battery connector housing. DO NOT

REMOVE THE BLACK LEAD AT THIS TIME.

10) Install the heat shrink tubing that was cut in the previous steps over the

red battery lead.

11) Apply a drop of liquid flux to the battery red lead contact pin.

12) Add solder to the soldering iron tip. Avoid using excess solder.

13) Position the the red battery lead pin so it’s tabs are facing toward the

opening of the PCB batt connector. The tabs must not face the neg

side of the batt connector. Refer to Photo #9.

MOTOROLA INTERNAL USE ONLY Page 6

Page 7

`

Consumer Solutions & Support

US Competency Center

600 North US Highway 45

Libertyville, Illinois 60048

Website: gs.mot.com

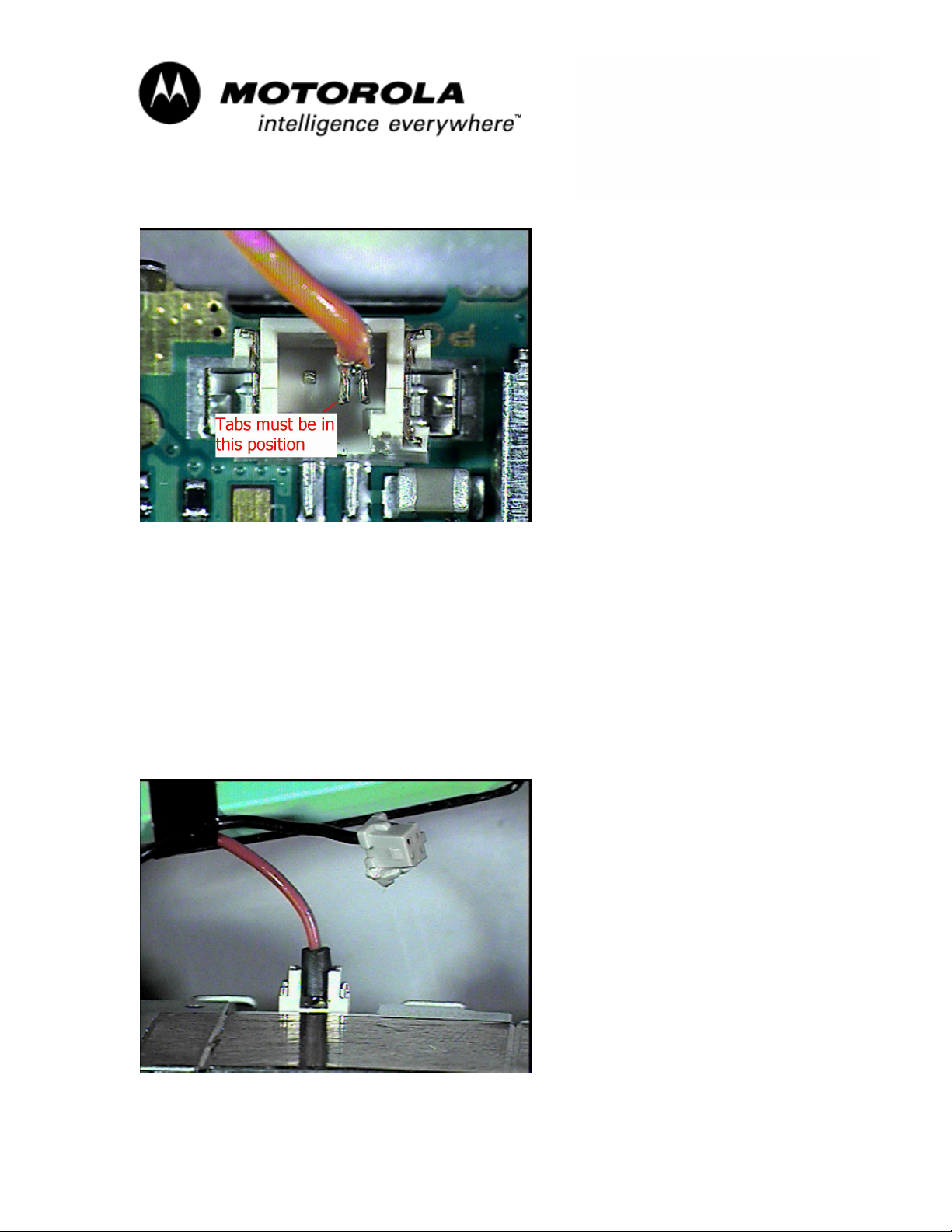

Photo #9-Batt (+) Lead Tab Position

14) Attach the battery lead pin to the PCB battery connector positive pin and

touch the soldering iron tip to the connection. Use care to avoid excessive

heat.

15) Verify proper soldering adhesion has taken place by gently pulling on the

red lead. If the lead disengages from the PCB connector pin, repeat Steps

11 thru 14.

16) Slip the heat shrink tubing over the soldered connection until it fully seats

into the PCB battery connector.

17) Using a heat gun, apply heat to the tubing. Refer to Photo #10.

Photo #10-Positive Lead Complete

18) Repeat Steps 8 & 9 with the black battery lead.

MOTOROLA INTERNAL USE ONLY Page 7

Page 8

`

Consumer Solutions & Support

US Competency Center

600 North US Highway 45

Libertyville, Illinois 60048

Website: gs.mot.com

19) Squeeze the black battery lead pin tabs together using needle nose

pliers. Refer to Photo #11,

Photo #11-Black Battery Lead Pin Tabs

20) Tin the lead’s contact pin with solder. Avoid excessive heat.

21) Add a drop of flux to the pin.

22) Insert the pin into the PCB battery connector’s metal ground tab which is

located on the side of the connector near C840. Ensure the pin is seated

fully into the metal tab. Refer to Photo #12

Photo #12-Battery Black Lead to PCB Connection

23) Solder the black battery lead pin to the connector’s ground tab as shown

in Photo #12 above.

MOTOROLA INTERNAL USE ONLY Page 8

Page 9

`

Consumer Solutions & Support

US Competency Center

600 North US Highway 45

Libertyville, Illinois 60048

Website: gs.mot.com

24) Dress the battery leads so they do not exceed the battery height. Refer

to Photo #13.

Photo #13-Dressing Battery Leads

25) Reassemble the unit.

26) Verify battery charger is functional and unit is able to power on.

Service Inventory:

1) For US Band products only-Re-flex all units with flex version 171

2) For Euro Band products only-Re-flex all units with flex version 173

Service Entry Codes

Please ensure that repairs of this type are logged on to the applicable database

as follows:

ServiceLink-

Customer Complaint: BAT02 Battery Life Short

Problem Found: BAT05 Battery Meter Inaccurate

Reference Designator: J Connector

Repair: RBT10 Replace Battery-Mech Fault Contacts

PRC E-service Entry Codes

Complaint Code: 4002 Short Battery Life

4005 Battery Meter Inaccurate

Root Cause Code: 1006 Mechanical Parts Oxidation

MOTOROLA INTERNAL USE ONLY Page 9

Loading...

Loading...