RACK MAGAZINE TOUCH PANEL

OPERATION MANUAL

Applicable Model

NH4000 DCG

NH5000 DCG

NH6300 DCG

NH8000 DCG

NMH6300 DCG

Applicable Function

60-tool Magazine

140-tool Magazine

180-tool Magazine

240-tool Magazine

300-tool Magazine

Applicable NC Unit

MSX-701 MSX-701III

MSX-711 MSX-711III

Before starting operation, maintenance, or programming, carefully read the

manuals supplied by Mori Seiki, the NC unit manufacturer, and equipment

manufacturers so that you fully understand the information they contain.

Keep the manuals carefully so that they will not be lost.

OM-NHRACKTP-A0E

• The contents of this manual are subject to change without notice due to

improvements to the machine or in order to improve the manual.

Consequently, please bear in mind that there may be slight discrepancies

between the contents of the manual and the actual machine. Changes to

the instruction manual are made in revised editions which are

distinguished from each other by updating the instruction manual number.

• Should you discover any discrepancies between the contents of the

manual and the actual machine, or if any part of the manual is unclear,

please contact Mori Seiki and clarify these points before using the

machine. Mori Seiki will not be liable for any damages occurring as a

direct or indirect consequence of using the machine without clarifying

these points.

• All rights reserved: reproduction of this instruction manual in any form, in

whole or in part, is not permitted without the written consent of Mori Seiki.

The product shipped to you (the machine and accessory

equipment) has been manufactured in accordance with the laws

and standards that prevail in the relevant country or region.

Consequently it cannot be exported, sold, or relocated, to a

destination in a country with different laws or standards.

The export of this product is subject to an authorization from the

government of the exporting country.

Check with the government agency for authorization.

990730

SIGNAL WORD DEFINITION

A variety of symbols are used to indicate different types of warning information and advice.

Learn the meanings of these symbols and carefully read the explanation to ensure safe operation

while using this manual.

<Symbols related with warning>

The warning information is classified into three categories, DANGER, WARNING, and CAUTION.

The following symbols are used to indicate the level of danger.

DANGER

WARNING

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury or damages to the machine.

The information described following the caution symbol must be strictly observed.

<Other symbols>

Indicates the items that must be taken into consideration.

NOTE

Indicates useful guidance relating to operations.

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

The information described in the DANGER frame must be strictly

observed.

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

The information described in the WARNING frame must be strictly

observed.

Indicates the page number or manual to be referred to.

The number in ( ) indicates the section number.

CONTENTS

1 RACK MAGAZINE TOUCH PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

1-1 Transition of Touch Panel Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

1-2 Tool Pot Layout Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

1-2-1 300-tool Magazine for NH4000 DCG . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

1-2-2 180-tool Magazine for NH5000/40 DCG . . . . . . . . . . . . . . . . . . . . . . . . . P-6

1-2-3 240-tool Magazine for NH5000/40 DCG . . . . . . . . . . . . . . . . . . . . . . . . . P-7

1-2-4 300-tool Magazine for NH5000/40 DCG . . . . . . . . . . . . . . . . . . . . . . . . . P-8

1-2-5 140-tool Magazine for NH5000/50 DCG . . . . . . . . . . . . . . . . . . . . . . . . . P-9

1-2-6 180-tool Magazine for NH5000/50 DCG . . . . . . . . . . . . . . . . . . . . . . . . P-10

1-2-7 60-tool Magazine for NH6300 DCG

60-tool Magazine for NH8000 DCG . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-11

1-2-8 140-tool Magazine for NH6300 DCG

140-tool Magazine for NH8000 DCG . . . . . . . . . . . . . . . . . . . . . . . . . . . P-12

1-2-9 180-tool Magazine for NH6300 DCG

180-tool Magazine for NH8000 DCG . . . . . . . . . . . . . . . . . . . . . . . . . . . P-13

1-2-10 60-tool Magazine for NMH6300 DCG . . . . . . . . . . . . . . . . . . . . . . . . . . P-14

1-2-11 140-tool Magazine for NMH6300 DCG . . . . . . . . . . . . . . . . . . . . . . . . . P-15

1-2-12 180-tool Magazine for NMH6300 DCG . . . . . . . . . . . . . . . . . . . . . . . . . P-16

1-3 Magazine Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-17

1-3-1 Magazine Mode Selection Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-17

1-3-2 Magazine Indexing Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-18

1-3-3 Emergency Stop Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-18

1-4 Selecting the Operation Mode (Only in Maintenance Operations) . . . . . . . . . . . P-19

2 OPERATION OF TOUCH PANEL SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-22

2-1 Magazine Index Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-23

2-2 Setting-Up of Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-24

2-3 Self-Diagnosis of the Magazine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-28

2-4 Indexing the Magazine Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-29

2-5 Manual Rack Magazine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-30

2-6 Recovering Rack Magazine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-32

3 SETTING LIGHT TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-34

3-1 Setting the Use-Inhibited Pots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-35

1 RACK MAGAZINE TOUCH PANEL

A rack magazine touch panel provided at the left side of the machine (rack magazine side) is used

to operate the rack magazine.

The switches on the rack magazine touch panel is used for mounting tools in the magazine and

removing tools from it.

P-1

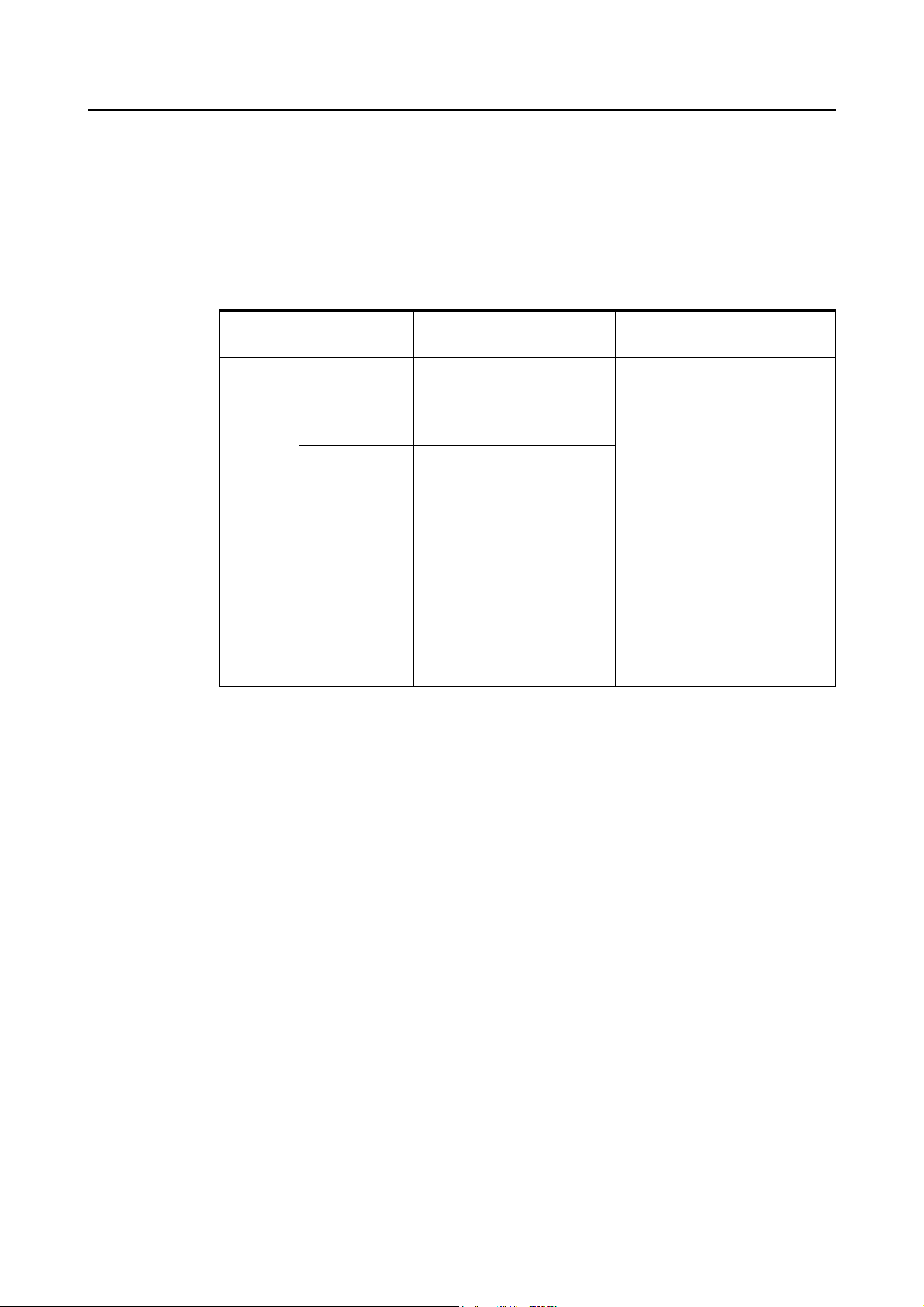

Type

Type 5

Applicable

Magazines

No. 40 taper

tool magazine

No. 50 taper

tool magazine

Magazine Specifications Tool Transfer Method

NH4000 DCG 300 tools

NH5000/40 DCG 180 tools

240 tools

300 tools

NH5000/50 DCG 140 tools

180 tools

NH6300 DCG 60 tools

140 tools

180 tools

NH8000 DCG 60 tools

140 tools

180 tools

NMH6300 DCG 60 tools

140 tools

180 tools

Pot transfer

(without turnover mechanism)

P-2

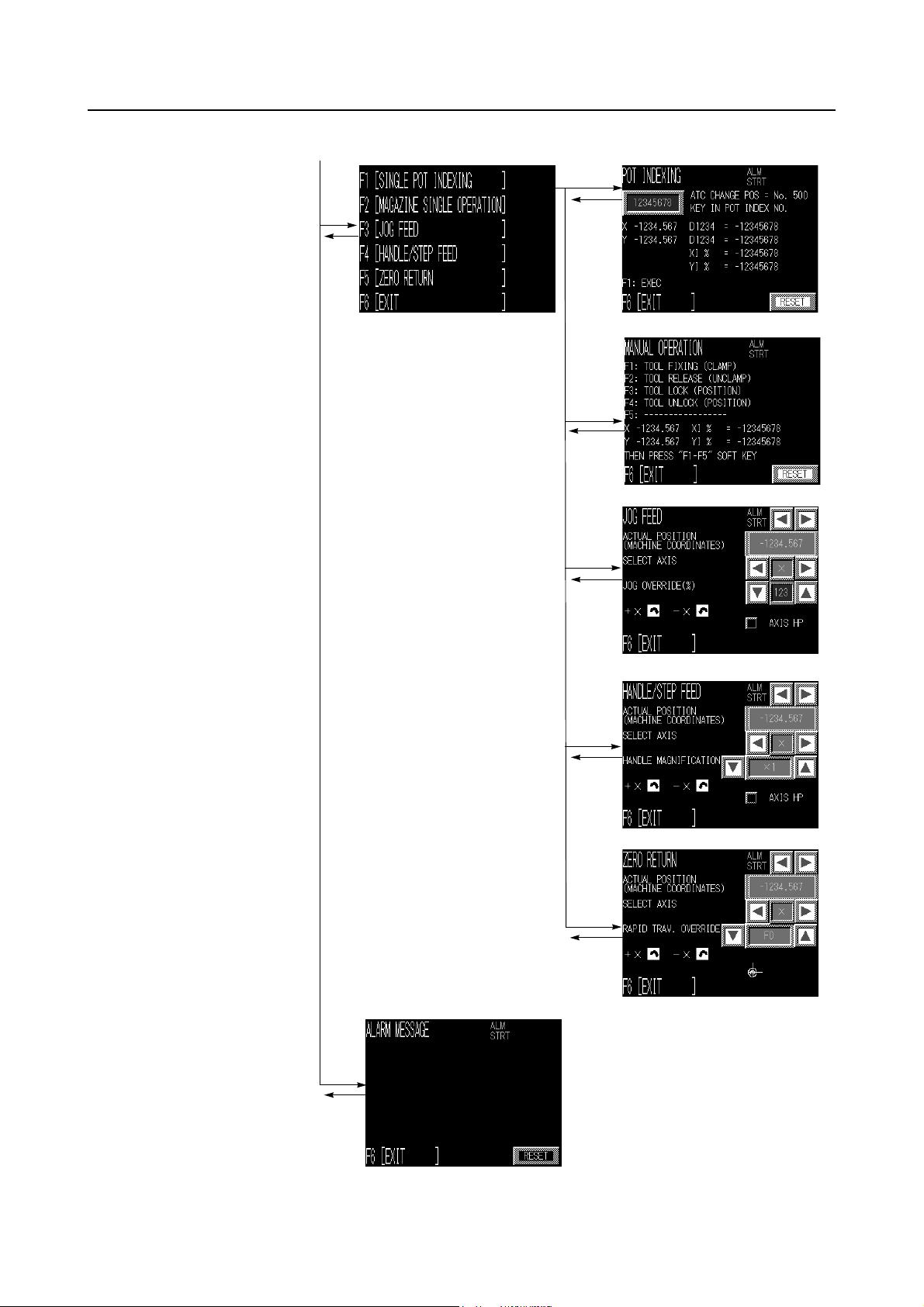

1-1 Transition of Touch Panel Screens

The screens displayed on the touch panel change as follows:

By pressing the [EXIT] (F6) soft-key on the start-up screen displayed immediately after turning the

power ON, the main menu screen is displayed.

By pressing the [TOOL SETUP] (F1) soft-key on the main menu screen, the TOOL RETURN/

CALL screen (the same as the start-up screen displayed immediately after turning the power ON)

is displayed.

Any required screen can be called by pressing the relevant soft-key on the main menu screen.

Main menu screen

Start-up screen displayed immediately

after turning the power ON

F1

F6

[ ]

F6

F4

F6

F1

P-3

F2

F6

F6

F2

F6

F3

F6

F4

F6

P-4

F1

F3

F6

F6

F2

F6

F3

F6

F4

F6

F4

F6

F5

F6

1-2 Tool Pot Layout Diagrams

1-2-1 300-tool Magazine for NH4000 DCG

P-5

(H61582A01)

P-6

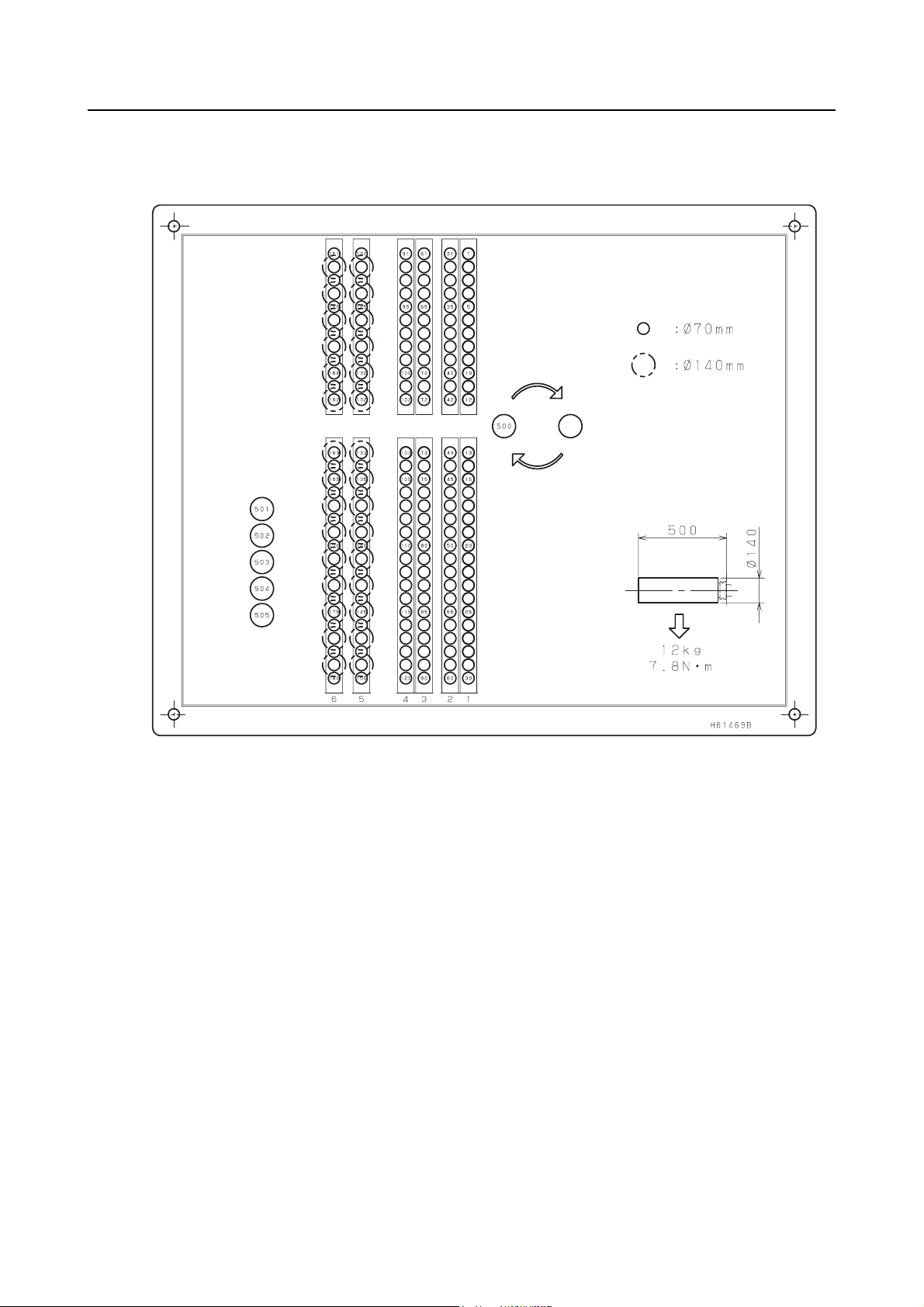

1-2-2 180-tool Magazine for NH5000/40 DCG

(H61469B01)

1-2-3 240-tool Magazine for NH5000/40 DCG

P-7

(H61470B01)

P-8

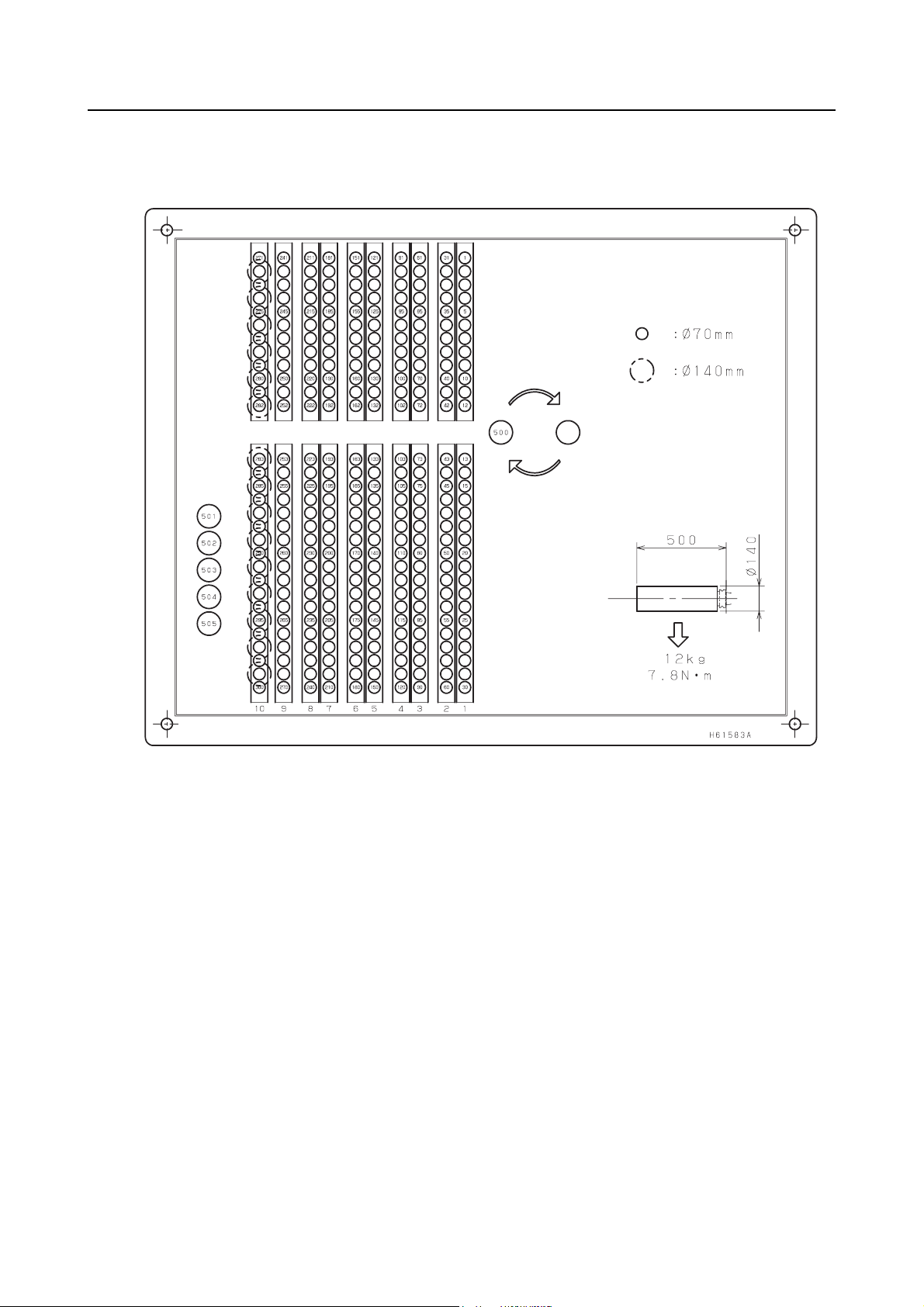

1-2-4 300-tool Magazine for NH5000/40 DCG

(H61583A02)

1-2-5 140-tool Magazine for NH5000/50 DCG

P-9

(H61514A01)

P-10

1-2-6 180-tool Magazine for NH5000/50 DCG

(H61515A01)

1-2-7 60-tool Magazine for NH6300 DCG

60-tool Magazine for NH8000 DCG

P-11

(H61386A04)

P-12

1-2-8 140-tool Magazine for NH6300 DCG

140-tool Magazine for NH8000 DCG

(H61389A04)

1-2-9 180-tool Magazine for NH6300 DCG

180-tool Magazine for NH8000 DCG

P-13

(H61388A03)

P-14

1-2-10 60-tool Magazine for NMH6300 DCG

(H61455A01)

1-2-11 140-tool Magazine for NMH6300 DCG

P-15

(H61456A01)

P-16

1-2-12 180-tool Magazine for NMH6300 DCG

(H61457A01)

1-3 Magazine Operation Panel

1-3-1 "Magazine Mode

Selection Button"

1-3-2 "Magazine Indexing Switches"

1-3-3 "Emergency Stop Button"

P-17

The magazine operation panel is provided on the manual

tool change unit.

The switches on the magazine operation panel is used for

mounting tools in the magazine and removing tools from it.

1-3-1 Magazine Mode Selection Button

The magazine mode selection button is used to determine

whether the magazine is rotated by T commands

(automatic operation) or by manual operation.

Magazine Mode Function

On

Magazine rotation by manual operation is enabled. The button will not light even if it

is pressed during automatic operation.

The magazine can be operated by T commands (in automatic operation). With rack

Unlit

magazine type 5 for No. 50 taper tools, the fixing pin engages in the tool setup

station. The tool setup station can be fixed in position even when it is pulled out for a

tool change operation. Change tools in this status.

P-18

1-3-2 Magazine Indexing Switches

Switch Function

The X- or Y- axis is moved in the negative direction.

The X- or Y- axis is moved in the positive direction.

The magazine indexing switches are used to move the

X- and Y-axes of the magazine.

NOTE

2. The magazine door can be opened during automatic operation. However, if a

T command is read with the magazine door open, automatic operation is stopped by

the magazine door interlock function.

3. The magazine cannot be rotated manually during automatic operation.

1. Close the magazine door before moving the magazine axes.

CAUTION

Be aware that the magazine will start rotating if the magazine indexing switch

(counterclockwise) or (clockwise) is pressed by mistake while the JOG,

STEP or ZRN mode is selected. Take care not to press the magazine indexing switch

(counterclockwise) or (clockwise) by mistake. If you do this, you could be

caught by the magazine.

1-3-3 Emergency Stop Button

The EMERGENCY STOP button has the same function

as that available with the EMERGENCY STOP button on

the machine operation panel.

Pressing the EMERGENCY STOP button on the

magazine operation panel turns off the power to the

circuits that control the axis movements and spindle

rotation, stopping the machine as well as magazine

operation.

The operator must be able to press this button any time at

any place while operating the machine.

P-19

The status display lights at the touch panel indicate the rack magazine status as indicated below.

Status Display Lights Status

ALARM Lights (red) if an alarm occurs.

STOP Lights (red) in the feed hold state.

START Lights after cycle start.

MANUAL Lights when the manual mode is selected for the rack magazine.

HP Lights when all axes are at the home position.

AXIS HP

Lights when the X- and Y-axes of the magazine are in the specified

operation enabled range.

"X" and "Y" are displayed when the X- and Y-axes are at the zero

point.

1-4 Selecting the Operation Mode (Only in Maintenance Operations)

When operating the rack magazine, first press the axis selection switches and

simultaneously to change the NC screen to path system 2. Display the OPERATOR'S PANEL

screen and select the operation mode of the rack magazine.

Select the operation mode of the rack magazine by following the steps below.

1) Press the function selection key (SETTING).

SETTING

2) Press the menu selection key .

3) Press the [OPERAT PANEL] soft-key.

The mode selection items are displayed at the screen.

4) Select the operation mode using the cursor control keys.

P-20

Operation Mode Explanation

To input parameters MDI To input the parameters, set "VALID" for "PARAMETER WRITE" on

the SETTING screen.

If the PS100 alarm occurs, press the (RESET) key while

holding down the (CAN) key. The alarm will be cleared.

To output parameters MDI

To move an axis in

handle feed operation

STEP <Operation procedure>

1) Select the manual mode for magazine operation

(the indicator will light).

2) Display the "HANDLE/STEP FEED" screen on the touch

panel.

The operation mode is automatically selected as the touch

panel screen changes.

3) Set the axis to be moved and the feed amount using "AXIS"

and "HANDLE MULT." on the screen.

Horizontal axis direction: Select the X-axis.

Vertical axis direction: Select the Y-axis.

4) Press the magazine indexing switch to move the axis.

+ direction: Magazine indexing switch

(counterclockwise)

− direction: Magazine indexing switch (clockwise)

5) After moving axes, press the [EXIT] soft-key (F6) to exit the

screen.

1. Unless the screen is exited, the mode stays as it is

NOTE

(STEP).

2. Use this function only for return operations. Please

note that no interlock is imposed.

Operation Mode Explanation

To move an axis in

JOG feed operation

To return an axis to

the zero point

JOG or ZRN

Before moving an axis in JOG feed operation or returning

NOTE

an axis to the zero point, make sure that the conditions

below are satisfied.

1. The manual mode is selected for magazine

operation.

2. The magazine is not operating.

<Operation procedure>

1) Display the "JOG FEED" or "ZERO RETURN" screen on the

touch panel.

The operation mode is automatically selected as the touch

panel screen changes.

P-21

2) Select the axis to be moved and press the button for the

direction in which the axis is to be moved.

Horizontal axis direction: Select the X-axis.

Vertical axis direction: Select the Y-axis.

3) Press the magazine indexing switch to move the axis.

+ direction: Magazine indexing switch

(counterclockwise)

− direction: Magazine indexing switch (clockwise)

4) After moving axes, press the [EXIT] soft-key (F6) to exit the

screen.

1. Unless the screen is exited, the mode stays as it is

NOTE

(JOG or ZRN).

2. Use this function only for return operations. Please

note that no interlock is imposed.

Change pages within the "HANDLE/STEP FEED", "JOG FEED" or "ZERO RETURN"

NOTE

screen using the page selection keys and .

P-22

2 OPERATION OF TOUCH PANEL SCREEN

By pressing the [EXIT] (F6) soft-key on the start-up screen displayed immediately after turning the

power ON, the main menu screen, shown below, is displayed.

If the tool transfer arm is positioned at the standby position, the arm moves from the standby

position to the magazine side position when the manual mode is selected. If the arm is holding a

tool, it returns this tool to the magazine temporarily. The arm moves to receive the temporarily

returned tool when the manual mode is turned OFF. The arm does not receive a tool if an

emergency stop or an alarm has occurred during the manual mode of magazine operation.

F1: TOOL SETUP

This function calls the specified tool from the pot to the tool setup position or returns the tool

from the tool setup position to the specified pot. Usually, this screen opens when the power

is switched ON.

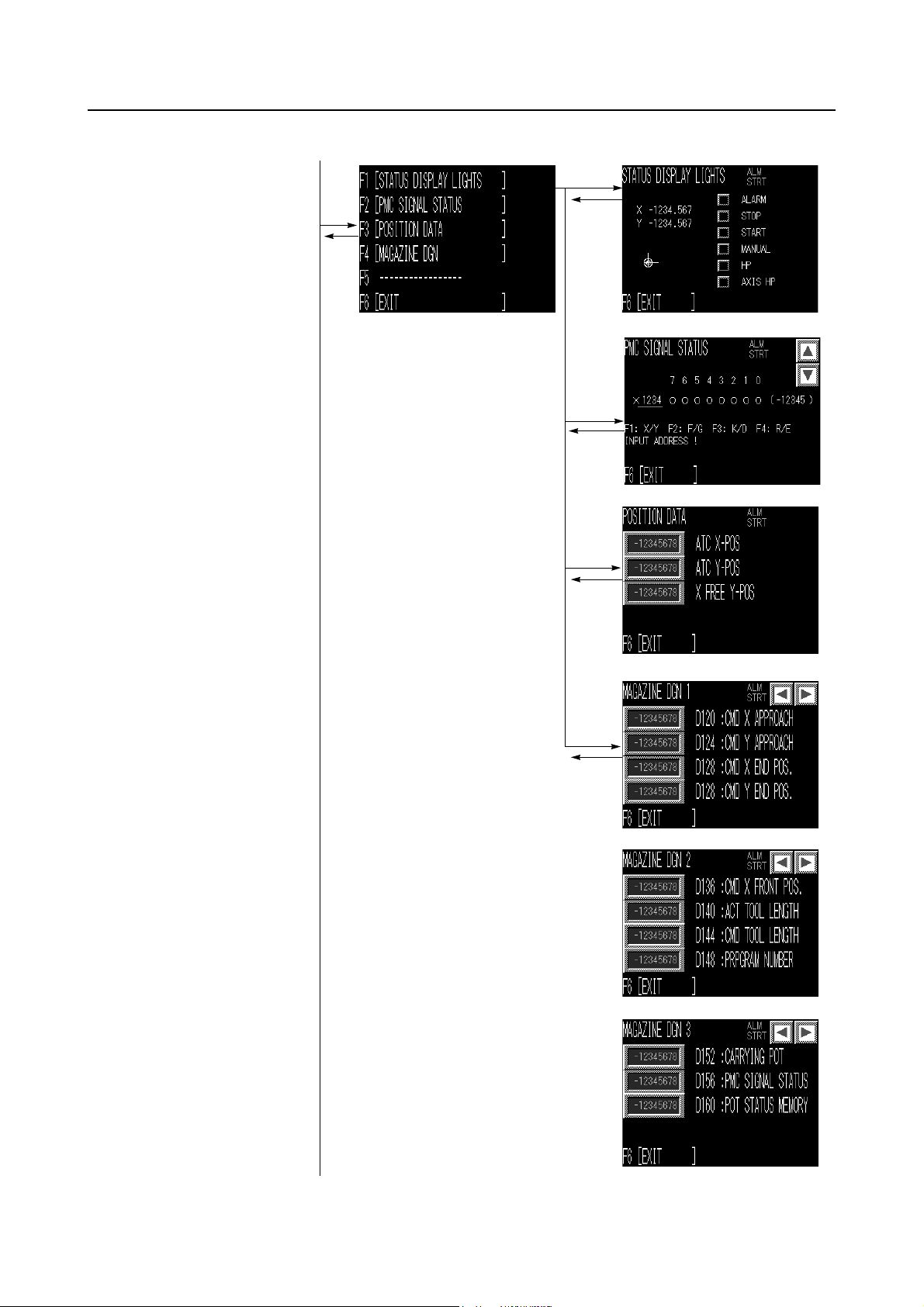

F2: DIAGNOSTIC

This function displays the internal status of the magazine, PMCDGN, and some other data

set in the machine.

For example, the screen allows you to check information like the pot number of the tool

being transferred if the magazine has stopped due to an emergency stop.

F3: MANUAL OPERATION

Used for recovering magazine operation. This function allows manual pot indexing, manual

magazine operation, JOG/STEP feed operation, and so on.

F4: ALARM MESSAGE

Displays PMC alarm messages.

F5: -----

Not used.

2-1 Magazine Index Operation

When the magazine index command is executed, the rack magazine operates in the sequence

shown below.

Start (ATC standby position)

Positioning of X- and Y-axes (Positioning at the return pot)

Tool release (The tool is unlocked) (Pot released)

Positioning of X- and Y-axes (Positioning at the specified pot)

Tool fixing (The tool is locked) (Pot clamped)

Positioning of X- and Y-axes

(Positioning at the ATC standby position)

P-23

Completion (ATC standby position)

P-24

2-2 Setting-Up of Tools

On machines equipped with a rack magazine, the tool setup pot (tool change position) is located

at the lower right of the rack magazine.

The setup pot is used for storing and removing tools at the rack magazine. When storing a tool in

the rack magazine, mount a new tool in the setup pot; it will be transported to the specified pot.

When removing a tool from the rack magazine, specify the pot number of the tool to be removed to

call it to the setup pot.

Storing a Tool

Calling a Tool

Pot No.

501

502

503

504

505

*

*

*

*

NOTE

*

Five tool setup positions, Nos. 501 to 505, are provided with NH4000 DCG and

NH5000/40 DCG machines that are equipped with a 300-tool magazine.

P-25

1) Select the magazine manual operation mode by

pressing the magazine mode selection button.

The magazine mode selection button lights.

When there is a tool at ATC standby position, the

tool is returned to the magazine.

By selecting automatic mode after finishing the

setup operation, the returned tool is loaded again

and then the operation mode changes to automatic

mode.

2) Display the main menu screen on the touch panel.

TOOL RETURN/CALL Screen

3) Press the [TOOL SETUP] (F1) soft-key on the

screen.

The TOOL RETURN/CALL screen is displayed.

4) There are two ways of selecting a pot number.

• Press the area where a pot number

is displayed. The keyboard will then be

displayed on the touch panel screen for input

of a pot number. Input the pot number of the

tool to be mounted or removed and press the

[ENT] key. The set pot number is displayed.

• Press [POT NO.]. A screen for selecting a pot

number will be displayed. Press inside the

frame of the required tool number. The pot

number of the selected tool is displayed.

• [+] increases the pot number by one and [−]

decreases the pot number by one.

P-26

Pot No. entry keyboard screen

Pot No. selection screen

NOTE

machines equipped with a 300-tool

magazine, tool Nos. 501 to 505 can be

selected on the TOOL RETURN/CALL

screen using the page selection keys

and .

2. When a pot number is input for POT NO.,

the tool number registered for the pot at the

TOOL REGISTRATION screen is displayed

at TOOL NO. To change the displayed tool

number, follow the steps below.

a) Press the area of the tool

number to be changed and input the

desired tool number.

b) Press the [WRITE] soft-key (F3).

If a new tool number can be assigned, the tool

number registered at the TOOL REGISTRATION

screen is changed accordingly. If the tool number

cannot be changed, it returns to the previously

displayed number.

1. With NH4000 DCG and NH5000/40 DCG

The following symbols displayed on the

screen denote meanings as below.

TB: Broken tools

∗: Tools used to the preset life

#: Skip tools

: Help key

Pressing this key displays the

description of the TB, ∗ and #.

The description is cleared by

pressing the key again.

: Page selection key

5) To store a tool in the rack magazine, press the

[RETURN] soft-key (F1). To call a tool from the rack

magazine, press the [CALL] soft-key (F2).

1. When the tool is stored, the set value of the

NOTE

pot number becomes "0".

2. With NH4000 DCG and NH5000/40 DCG

machines equipped with a 300-tool

magazine, pressing the [RETURN] or

[CALL] soft-key will return the tools to/call

the tools from all five tool set up pots.

6) Open the magazine door.

7) Mount/remove the tool.

With rack magazine type 5 for No. 50 taper tools,

turn the magazine manual operation mode OFF to

engage the fixing pin before removing or mounting a

tool.

P-27

NOTE

1. Even if no tool is stored in the magazine pot,

always specify the return operation after

calling a tool.

On completion of calling, "CALL FIN. (0/1) =

1" is displayed on the screen. In this state,

the pot number cannot be changed.

After the completion of the tool return

operation, "CALL FIN. (0/1) = 0" is displayed

on the screen. In this state, the return

command cannot be executed.

2. To set tools in the magazine consecutively, it

is necessary to perform repeated tool return

operations. To make this possible, "CALL

COMPLETE (0/1)" has to be set to "0" after

setting the pot number.

To change the setting of "CALL COMPLETE

(0/1)", press the [CALL COMPLETE (0/1)]

(F4) soft-key. Perform this operation with

due care because interference will occur if

there is a tool in the pot to which the tool is

to be returned.

3. If the tool number is specified with the pot

number set to "0", a search will be

conducted for the appropriate tool pot and

the specified tool number will be set for that

tool pot.

<Example>

Pot No.

000

Pot No.

Search

Pot No.

123

Initial

conditions

Automatically

set

Too l N o .

0000

Too l N o .

1001

Too l N o .

1001

If an appropriate tool pot is not found, the tool

number is set and the pot number is left as "0".

Specify a

number

P-28

2-3 Self-Diagnosis of the Magazine

The MAGAZINE DGN screens display the internal status of the magazine. These screens are not

used in normal operation.

For example, one of the screens allows you to check information like the pot number of the tool

being transferred if the magazine has stopped due to an emergency stop.

The pot number of the tool being transferred is displayed at "CARRYING POT".

• When a tool is in the spindle

When the next tool is called, the pot for the spindle tool at the standby position is temporarily

returned to the empty pot storage position*, and "D160 :POT STATUS MEMORY" is turned

to "1". When "D160 :POT STATUS MEMORY" is already set to "1", an alarm "EX3211 POT

FOR SPINDLE TOOLS AVAILABLE." is displayed. When a pot is in the empty pot storage

position*, remove the pot and set "D160 :POT STATUS MEMORY" to "0".

• When tools are in the spindle and in the standby position

When the next tool at the standby position is returned to the magazine by T0, the pot for the

spindle tool - which has been temporarily returned to the empty pot storage position* - is

called to the standby position again, and "D160 :POT STATUS MEMORY" is turned to "0".

When "D160 :POT STATUS MEMORY" is already set to "0", an alarm "EX3210 NO POT

FOR SPINDLE TOOLS." is displayed. When no pot is in the empty pot storage position*,

mount a pot on the empty pot storage position* and set "D160 :POT STATUS MEMORY" to

"1". If mounting a pot is difficult, remove the spindle tool, delete the spindle tool data on the

TOOL REGISTRATION screen, and set "D160 :POT STATUS MEMORY" to "0".

*

NOTE

The empty pot storage position is as follows.

60-tool specifications: No. 60

140-tool specifications: No. 140

180-tool specifications: No. 180

240-tool specifications: No. 240

300-tool specifications: No. 300

2-4 Indexing the Magazine Manually

The POT INDEXING screen displayed at the touch panel is used to index the magazine manually.

P-29

NOTE

move axes in JOG or STEP feed operation.

2. Use the manual magazine indexing function only for recovery operations.

3. Take care when performing a recovery operation using JOG feed because the

interference check function will not be operating.

"Pot index" means the operation to positioning the X- and Y-axes in front of the specified pot

number.

1) Select the magazine manual operation mode by

pressing the magazine mode selection button.

The magazine mode selection button lights.

2) Display the main menu screen on the touch panel.

3) Display the POT INDEXING screen. Press the

[MANUAL OPERATION] (F3) and [SINGLE POT

INDEXING] (F1) soft-keys in this order.

1. The magazine indexing switches (clockwise and counterclockwise) are used to

4) Press the area where a pot number is

displayed. The keyboard will then be displayed on

the touch panel screen for input of a pot number.

Input the pot number to be indexed.

5) Press the [ENT] key.

The pot number is set and the tool number currently

set for that pot number is displayed.

6) Press the [EXEC] soft-key (F1).

The axes are positioned at the set pot number position.

Positioning is performed in different ways

NOTE

depending on whether or not there is a tool at the

next tool position.

1. The existence of a tool at the next tool

position is judged by the tool status (tool

fixed or tool released).

2. The tool change position for the ATC is pot

No. 500. For tool change operation, the tool

change position is the same as position of

the input pot No.

7) After completing pot indexing operation, press the

[EXIT] soft-key (F6).

P-30

2-5 Manual Rack Magazine Operation

To operate the rack magazine manually, use the rack magazine touch panel at the rack magazine

side.

NOTE

ZRN) after pot indexing. (When the MANUAL OPERATION screen is displayed, the

operation mode automatically switches to STEP mode.)

2. Perform manual rack magazine operation for the purposes of a recovery operation

only.

3. Take care when performing a recovery operation using JOG feed because the

interference check function will not be operating.

The manual magazine operation procedure is described below.

<Example: No. 50 taper tool (type 5)>

Rack side

1. Perform single rack magazine operations in a manual operation mode (STEP, JOG,

TOOL UNLOCK

TOOL LOCK

TOOL FIXING

(CLAMP)

TOOL RELEASE

(UNCLAMP)

1) Carry out pot indexing.

P-29 page (2-4)

2) Press the [EXIT] soft-key (F6).

3) Press the [MAGAZINE SINGLE OPERATION] soft-

key (F2).

The MANUAL OPERATION screen is displayed.

4) Press the soft-key (F1 to F5) for the required

operation.

The rack magazine performs the selected

procedure.

5) Press the [EXIT] soft-key (F6) after the manual

operation is completed.

<Rack magazine operating conditions (interlocks) for manual operation>

In order to avoid interference, the following operating conditions (interlocks) are provided for each

manual operation of the rack magazine

Please take care during the return operation because the following interlocks may be

NOTE

bypassed in some cases to enable the operation.

P-31

<Type 5>

No. Operation

1 TOOL FIXING Tool transport device clamps pot

Without operating conditions (interlocks)

2 TOOL RELEASE

Tool transport device unclamps pot

Tool transport device in tool lock position

3 TOOL LOCK

Tool transport device moves from pot indexing position to rack side

Tool transport device in tool indexing position

4 TOOL UNLOCK

Tool transport device moves from rack side to pot indexing position

Tool transport device in the tool lock position

*

NOTE

The interlock can be bypassed by canceling the ATC interlock at the ATC MANUAL

screen displayed on the NC operation panel.

Explanation

Interlock

*

*

*

P-32

2-6 Recovering Rack Magazine Operation

If the rack magazine stops part way through, follow the procedure below to recover the magazine

operation (tool transfer axis, sensor axis).

Check that the JOG or HND/STEP mode is selected on the touch panel, and perform a recovery

operation first using STEP feed operation. After the completion of the recovery operation, the

"AXIS HP" (magazine X-/Y-axes in the operation enabled range) lights on the screen.

If the tool transport device is holding a tool, display the POT INDEXING screen for the rack

magazine and execute the SINGLE POT INDEX operation. After that, display the MANUAL

OPERATION screen for the rack magazine, and carry out the recovery procedure.

CAUTION

After recovering the rack magazine operation, always check the tool data of the tool in

the spindle and the standby tool on the TOOL REGISTRATION screen. If the tool data

on the screen does not agree with the actual tools, the tool could fall or strike the

workpiece or other trouble could occur.

Note in particular that if the screen displays "no standby tool" although there is a

standby tool present, the tool will fall.

<Recovery operation using STEP feed operation (tool transfer axis)>

If the tool transfer axis motion fails part way through, recover the operation using a STEP feed

operation.

When using JOG feed operation for the recovery operation, set the feedrate override at

NOTE

the lowest setting.

After the completion of the recovery operation, the "AXIS HP" (magazine X/Y-axes in the operation

enabled range) lights on the screen.

Usually, the axes enter the operation enabled range when the X-axis is moved to the center

between the magazine columns.

1) Display the main menu screen on the touch panel.

2) Display the HANDLE/STEP FEED screen.

Press the [MANUAL OPERATION] (F3) and

[HANDLE/STEP FEED] (F4) soft-keys in this order.

3) Check that the coordinate value changes in

response to one-pulse input. Then, select a larger

magnification ratio with the axis feed amount

selection switch and feed the X-axis.

The X-axis has reached the operation recovery

position when the "AXIS HP" (magazine X/Y-axes in

the operation enabled range) lights on the screen.

4) Display the MANUAL OPERATION screen and

carry out the remaining steps necessary for the

recovery operation.

P-33

NOTE

1. If a pot indexing operation is necessary,

specify the pot indexing data and execute

"MAGAZINE SINGLE OPERATION".

2. The magazine door cannot be opened in the

STEP mode (pulse handle mode).

3. JOG feed operation can be used for a

recovery operation in which long axis

movements are made. In such a case, set

the feedrate override at the lowest setting.

P-34

3 SETTING LIGHT TOOLS

Tools classified as "light" can be set at the TOOL REGISTRATION screen displayed on the NC

operation panel.

1) Press the function selection key (OFFSET).

OFFSET

2) Press the [TOOL REGIST.] soft-key.

The TOOL REGISTRATION screen will be displayed.

3) Using the cursor control keys, move the cursor to the tool number of the tool to be set as a

light tool.

The setting is necessary for every tool number of the light tools.

NOTE

4) Press the [TOOL DETAIL] soft-key.

The TOOL DETAILS field is displayed.

5) Select "LIGHT TOOL" using the [DETAIL UP] or [DETAIL DOWN] soft-key.

6) Press the [SET] soft-key.

"VALID" is highlighted and the tool specified on the screen of the TOOL REGISTRATION

screen is registered as a light tool.

The setting items on the TOOL REGISTRATION screen are described below.

NOTE

Item Explanation

LIGHT TOOL

Set "VALID" for the light tools for which high-speed ATC

operation is possible.

FACE CONTACT This item is used only for two-face constrained tools.

"VALID" is displayed when the tool is called to the tool setup

SETUP TOOL

position.

"INVALID" is displayed when the tool is returned to the

magazine pot from the tool setup position.

"VALID" is displayed if the tool is judged to be broken at the

BREAKAGE TOOL

rack magazine. "INVALID" is displayed when the tool is called

to the tool setup position.

(Tool breakage detection specifications)

If the tool in the setup state (SETUP TOOL: "VALID") is specified using a T code,

the following alarm occurs.

"EX0201 IMPROPER T-CODE SPECIFIED"

If a tool judged to be broken (BREAKAGE TOOL: "VALID") is specified using a T code,

the following alarm occurs (tool breakage detection specifications).

"EX0201 IMPROPER T-CODE SPECIFIED"

7) After completing the setting for light tools, press the [RETURN] soft-key.

The screen returns to the screen of the TOOL REGISTRATION screen.

The pot numbers of the tools for which "VALID" is selected in the TOOL DETAILS field are

highlighted in green.

If both the spindle tool and the next tool are light tools, the ATC operates at a high speed.

NOTE

In other cases, the ATC operates at a low speed.

3-1 Setting the Use-Inhibited Pots

With the rack magazine specification, the pots next to the one where a large diameter tool is

stored must be left empty. To avoid returning a tool to such pots accidentally, use-inhibited pots

can be set. Make this setting using the function keys on the NC operation panel.

1) Set the machine in the emergency stop state.

P-35

2) Press the function selection key (SETTING).

SETTING

3) Set "VALID" for "PARAMETER WRITE" on the SETTING screen.

4) After pressing the function selection key (SYSTEM), press the menu selection key

SYSTEM

several times to display the [PMC MAINTE] soft-key.

5) Press the [PMC MAINTE] soft-key.

6) Press the [(OPRT)] soft-key to display the [SWITCH PMC] soft-key.

7) Press the [SWITCH PMC] soft-key to switch the screen to "2ND PMC "

8) Press the [ZOOM] soft-key.

9) After pressing the data input key , press the [G-SRCH] soft-key.

7

A

The screen displays the data from D2800 onward.

P-36

10) Using the page selection keys and the cursor control keys, display the data for D (2800 + pot

number).

11) Make the necessary pot settings.

Use-inhibited pots: Set "0".

<Example>

To set pot No. 6 as a use-inhibited pot

D2806 = 0

12) Set the machine in the emergency stop state again.

13) Press the function selection key (SETTING).

SETTING

14) Set "INVALID" for "PARAMETER WRITE" on the SETTING screen.

15) Turn off the power and then turn it on again.

This completes the pot setting.

On shipping, a number other than 0 is set for all pot data. To set a pot as a use-inhibited

NOTE

pot, "0" must be explicitly set as the pot data.

Comment Form

To improve this manual, we invite you to make comments on any insufficient description or errors in this

manual. We want to know how you think we can make this manual better. Please restrict your comments to

those concerning this manual only. Comments can also be submitted using the company website at

http://www.moriseiki.com.

Name of Manual RACK MAGAZINE TOUCH PANEL OPERATION MANUAL

Number of Revisions OM-NHRACKTP-A0E (2006.12)

Name Company

Department Telephone

Address

Chapter Page Line Comments/Requests

Date:

For Mori Seiki's Use - Do not write below this line.

Description Reception No. Received by

http://www.moriseiki.com

MORI SEIKI CO., LTD.

Nagoya Head Office

Nara Campus

Iga Campus

Chiba Campus

2-35-16 Meieki, Nakamura-ku, Nagoya City, Aichi 450-0002, Japan

Phone: (052) 587-1811 Fax.: (052) 587-1818

362 Idono-cho, Yamato-Koriyama City, Nara 639-1183, Japan

Phone: (0743) 53-1121

106 Kita Koriyama-cho, Yamato-Koriyama City, Nara 639-1160, Japan

Phone: (0743) 53-1125

201 Midai, Iga City, Mie 519-1414, Japan

Phone: (0595) 45-4151

488-19 Suzumi-cho, Funabashi City, Chiba 274-0052, Japan

Phone: (047) 410-8800

MORI SEIKI U.S.A., INC.

Head Office

Administrative Department

Technical Centers

Representative Office

5655 Meadowbrook Drive, Rolling Meadows, Illinois 60008

Phone: (1)-847-593-5400 Fax.: (1)-847-593-5433

2100 Golf Road Suite 300, Rolling Meadows, Illinois 60008

Phone: (1)-847-290-8535 Fax.: (1)-847-290-5500

Chicago, Dallas, Los Angeles, Detroit, Cincinnati, Boston, New Jersey

Charlotte, San Francisco

MORI SEIKI MEXICO, S.A. DE C.V.

Head Office & Technical Center

Montecito 38 Piso 12-38 Col. Napoles 03810 México D.F.

Phone: (52)-55-9000-3276 Fax.: (52)- 55-9000-3279

MORI SEIKI BRASIL LTDA.

Head Office & Technical Center

Rua República do Iraque, 1432 2 and, Campo Belo 04611-002 São Paulo - SP, Brasil

Phone: (55)-11-5543-1762 Fax.: (55)-11-5543-1948

MORI SEIKI ESPAÑA S.A.

Head Office & Technical Center

Calle de la Electrónica, Bloque B, Nave 9 Poligono Industrial "La Ferreria" 08110

Montcada I Reixac (Barcelona), Spain

Phone: (34)-935-75-36-46 Fax.: (34)-935-75-08-47

MORI SEIKI SINGAPORE PTE LTD

Head Office & Technical Center

Technical Center

3 Toh Guan Road East, Singapore 608835

Phone: (65)-6560-5011 Fax.: (65)-6567-6234

MALAYSIA BRANCH

MORI SEIKI (THAILAND) CO., LTD.

Head Office & Technical Center

119/2 Moo 8, Bangnathani Building 1st Floor A1, Bangna-Trad KM.3 Road Kwaeng

Bangna, Khet Bangna, Bangkok 10260, Thailand

Phone: (66)-2-361-3700-5 Fax.: (66)-2-361-3706

MORI SEIKI (TAIWAN) CO., LTD.

Head Office & Technical Center

No. 8, Kong 8th Road, Linkou No. 2 Industrial District, Linkou Hsiang, Taipei Hsien,

Taiwan, R.O.C.

Phone: (886)-2-2603-1701 Fax.: (886)-2-2603-1706

MORI SEIKI HONG KONG LIMITED

Head Office & Technical Center

Unit 02, 8/F., Vicwood Plaza, 199 Des Voeux Road, Central, Hong Kong

Phone: (852)-2757-8910 Fax.: (852)-2757-7839

MORI SEIKI (SHANGHAI) CO., LTD.

Head Office

Technical Center

Room 4301, 4307, Maxdo Center, No.8 Xing Yi Rd., HongQiao Development Zone,

Shanghai 200336, China

Phone: (86)-21-5208-0270 Fax.: (86)-21-5208-0273

Shanghai, Beijing, Tianjin, Dalian, Shenzhen, Chongqing, Guangzhou

MORI SEIKI GmbH

Head Office

Technical Centers

Antoniusstrasse 14, 73249 Wernau, Germany

Phone: (49)-7153-934-0 Fax.: (49)-7153-934-220

Stuttgart, Istanbul, Prague, München, Hamburg, Düsseldorf

MORI SEIKI (UK) LTD.

Head Office

Technical Centers

Representative Office

202 Bedford Avenue, Slough SL1 4RY, England

Phone: (44)-1753 526518 Fax.: (44)-1753 524695

London, Birmingham

Leicester

MORI SEIKI FRANCE S.A.S.

Head Office & Technical Center

Technical Centers

Parc du Moulin, 1 Rue du Noyer BP 19326 Roissy en France 95705 Roissy CDG

Cedex, France

Phone: (33)-1-39-94-68-00 Fax.: (33)-1-39-94-68-59

Toulouse, MS SYFRAMO S.A.S.

MORI SEIKI ITALIANA S.R.L.

Head Office & Technical Center

Via Riccardo Lombardi N. 10, 20153 Milano, Italy

Phone: (39)-02-4894921 Fax.: (39)-02-48914448

MORI SEIKI KOREA CO., LTD.

Head Office & Technical Center

A-101, 2 SK TWIN TECH TOWER, 345-9 Kasan-dong, Kumcheon-Ku, Seoul,

Korea

Phone: (82)-2-862-0925 Fax.: (82)-2-862-0928

PT. MORI SEIKI INDONESIA

Head Office & Technical Center

Komplek Gading Bukit Indah Blok M/01 J1. Bukit Gading Raya, Kalapa Gading,

Jakarta Utara, 14240 Indonesia

Phone: (62)-21-453-1199 Fax.: (62)-21-4585-7414

MORI SEIKI CO., LTD. India Branch

Head Office & Technical Center

India Branch: 404 A World Trade Centre, Babar Rd. Connaught Place,

Phone: (91)-11-4152-8520 Fax.: (91)-11-4152-8530

New Delhi - 110001, India

MORI SEIKI AUSTRALIA PTY LTD

Head Office

Technical Centers

6/6 Garden Road Clayton VIC 3168, Australia

Phone: (61)-3-8545-0900 Fax.: (61)-3-9561-4999

Melbourne, Sydney

The export of this product is subject to an authorization from the government of the exporting country.

Check with the government agency for authorization.

Printed in Japan

06 1110

Loading...

Loading...