Morii-Seiiki NL1500, NL2000, NL2500, NL3000 User Manual

NL SERIES

NL SERIES

NL SERIES

R i g i d a n d P r e c i s e C N C L a t h e s

NL1500/NL2000/NL2500/NL3000

Rigid & Precise

We have created a lathe that will change the world.

Ever since our first machine tool rolled off the production line in 1968, we here at Mori Seiki have continued to make CNC lathes that are praised by customers everywhere. Over those 35 years, we have released around 100 models.

We can say with confidence that we believe every single one was an improvement on its predecessor. Today, we are on the threshold of a new beginning in the field of CNC lathes, and we are determined once again to create a lathe that will lead the industry in innovation. After reworking our designs, and incorporating data received from confronting heat related problems and thousands of customer comments, we have improved our products even more. Our uncompromising development stance has made it possible to deliver unprecedented rigidity, precision, and reliability. Our efforts have created our newest line, the NL Series. These new machines are high-rigidity, highprecision CNC lathes and set the new standard in “common sense” machining for a new age.

Turret with a built-in milling motor |

P.4 7 |

Turning performance/Rigidity |

P.8 11 |

|

|

Thermal isolation |

P.12 13 |

|

|

Machining power |

P.14 15 |

|

|

Productivity |

P.16 17 |

|

|

Digital tailstock/Convenience |

P.18 19 |

|

|

Maintenance |

P.20 21 |

|

|

Automatic operation support |

P.22 23 |

|

|

Eco-friendly design |

P.24 |

|

|

Peripheral equipment |

P.25 |

|

|

MAPPS (a new high-performance operating system) P.26 27

Variation |

P.28 29 |

Package |

P.30 |

|

|

Installation drawing |

P.31 35 |

|

|

Standard & optional features |

P.36 37 |

|

|

NC unit specifications (MSX-850) |

P.38 |

|

|

Machine specifications |

P.39 43 |

|

|

Service support |

P.44 |

|

|

MAPPS: Mori Advanced Programming Production System

● Figures in inches were converted from metric measurements.

2

NL SERIES

R i g i d a n d P r e c i s e C N C L a t h e s

NL1500/NL2000/NL2500/NL3000

3

4

Rigid & Precise

NL SERIES

Innovative turret design

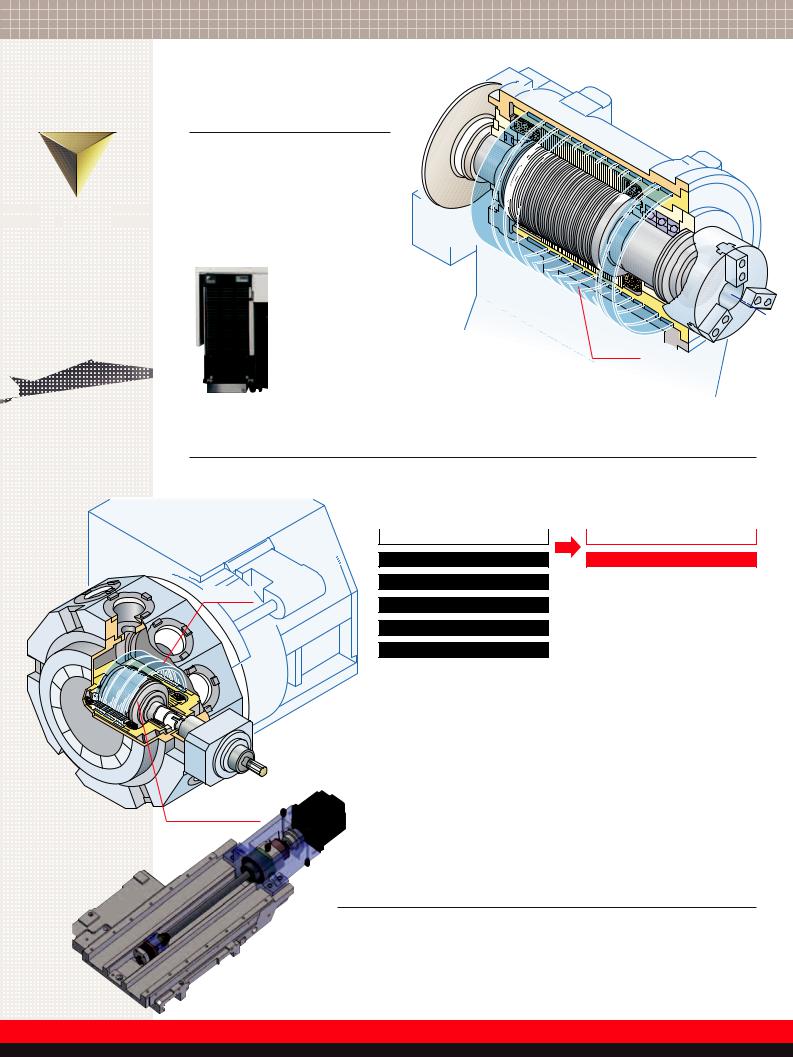

Turret with a built-in milling motor

The milling mechanism on conventional lathes generates a great deal of heat and vibration due to the large number of parts involved, including the motor and gear belt. The NL Series, however, features the industry's first turret with a built-in milling motor. This revolutionary design minimizes heat generation and vibration while eliminating transmission losses. The new design increases both machining accuracy and cutting performance.

NL2500

Face mill

φ80 mm

(φ3.1 in.)

Tapping capacity M20

The NL Series was designed to create a CNC lathe with true milling capability. For example, the NL2500 can accommodate face mills of up to φ80 mm (φ3.1 in). NL Series machines boast milling performance approaching that of No. 40 taper machining centers.

Actual size

5

Extremely rigid turret

In order to enhance the milling function, it is essential to increase the rigidity of the rotary-tool holders. The NL Series rotary-tool holders have a broader grip as compared to conventional lathes. By raising attachment precision we have vastly improved rigidity.

■ Super-rigid rotary-tool holders

Taking a hint from couplings, which are praised for their high repeatability, we developed a very rigid rotary-tool holder.

■ Comparison of rotary-tool holder rigidity

Conventional lathes leave chatter marks when the depth of cut is made deeper, but with the NL Series,

it is now possible to cut to a depth equal to the tool diameter. This is attributed to the tool holders that have been designed to be more rigid.

Previous model |

|

|

|

NL2500 |

||||||||||

Tool diameter and depth of cut |

|

|

Tool diameter and depth of |

|||||||||||

|

|

|

|

|

|

|

Rotary-tool holder rigidity |

|

|

|

|

|

|

|

|

|

10 15 mm |

|

180 % Greater |

|

|

|

|

20 mm |

|||||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

(0.4 0.6 in.) |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

(0.8 in.) |

||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

φ |

|

|

|

|

|

|

|

φ |

|

|

|

|

||

20 mm |

|

|

||||||||||||

|

|

|

20 mm |

|||||||||||

(φ0.8 in.) |

|

|

|

(φ0.8 in.) |

||||||||||

■ Coupling diameter

Previous model |

NL2500 |

|

|

|

Greater coupling diameter than before. |

||

φ210 mm |

φ250 mm |

Coupling diameter |

|

(φ9.8 in.) |

19 % Greater |

||

(φ8.3 in.) |

|||

|

|

||

Tool diameter Depth of cut

20 mm (0.8 in.)

6

■ High-performance rotary tool spindle

A DDS motor that has no gear belt is used for the rotary tool spindle, delivering high-speed, high-efficiency machining.

Max. rotary tool spindle speed

Rigid & Precise |

Previous model |

NL SERIES |

|||

4,000 min-1 |

6,000 min-1 |

||||

NL SERIES |

|||||

|

|

|

|

||

|

|

50 % |

|

|

|

|

|

Greater |

|

|

|

|

Rotary tool spindle acceleration time |

|

|||

|

Previous model |

|

NL2500 |

||

|

0→4,000 min-1 |

|

0→4,000 min-1 |

||

|

Reduced |

0.11 sec. |

|||

|

0.35 sec. approximately |

||||

|

70 % |

|

|

||

0→6,000 min-1

0.23 sec.

Maximum rotary tool spindle torque

NL1500 24 N·m (17.7 ft·lbf) <3 min>

NL2000 29 N·m (21.4 ft·lbf) <3 min>

NL2500NL3000 40 N·m (29.5 ft·lbf) <3 min>

DDS: Direct Drive Spindle

Y-axis specification construction

We also independently developed a powerful platform for maximizing performance in the Y-axis specifications. This has achieved rigidity between the spindle and the tool tip that exceeds that of conventional two-axis lathes.

NL2500 NL2500Y

A solid construction that can hold its own with the NL Series two-axis models.

Y-axis travel (Y-type)

NL1500/NL2000/NL2500 |

NL3000 |

I50 mm |

I60 mm |

(I2.0 in.) |

(I2.4 in.) |

7

The ultimate in turning

Improved tool tip rigidity

Our goal was to minimize tool tip vibration, thus reducing the need to grind after cutting as well as extending tool life. The NL Series achieves this with its increased rigidity between the spindle and tool tip.

8

Rigid & Precise

NL SERIES

Handles large-diameter workpieces

Although the NL Series machines remain rock solid during heavy-duty cutting, their design incorporates the largest spindle through hole in its class <φ91 mm (φ3.6 in.) for NL2500>.

NL2500

NL2500

Through

Through spindle

spindle

hole

hole diameter

diameter

Through spindle hole diameter (headstock 1 spindle)

NL1500 |

NL2500 |

61 mm |

91 mm |

(2.4 in.) |

(3.6 in.) |

NL2000 |

NL3000 |

73 mm |

105 mm |

(2.9 in.) |

(4.1 in.) |

91

mm

mm

(3.6

(3.6

in.)

in.)

● See Automatic Operation Support (p23) for details on bar work capacity.

● See Automatic Operation Support (p23) for details on bar work capacity.

Thanks to high rigidity, machining no longer requires additional grinding.

Increasing the rigidity between the spindle and the tool tip has made it possible to achieve high quality machined surfaces through turning alone.

■End face finishing accuracy

Conventional machines create a pattern on material due to the amount of vibration the tool tip generates. With the NL Series, there is no pattern on the material, thus eliminating the need for grinding.

Tool |

WTKNR2525M-16N |

Inserts |

TNMG160408-PF (4015) |

Material <JIS> S45C <A 150×150 mm (A 5.9×5.9 in.)> |

|

Cutting speed |

380 m/min (1,246.8 fpm) |

Feedrate |

0.12 mm/rev (0.005 ipr) |

Depth of cut |

0.1 mm (0.004 in.) |

SL-253BMC |

|

NL2500 |

|

Patterns caused by large |

|

|

|

Patterns caused by small |

|

|

vibration during machining |

|

|

|

vibration during machining |

|

■ Roundness

(turning) |

90° |

|

|

Filter: 1 50 |

|

180° 0.4

μm 0°

μm 0°

|

10 μm |

|

|

270° |

|

Machine type |

NL2500MC/700 |

|

Tool |

Diamond tool |

|

<Nose radius 0.5 mm (0.020 in.)> |

||

|

||

Material |

Brass |

|

Outer diameter |

40 mm (1.6 in.) |

|

Spindle speed |

4,000 min-1 |

|

Feedrate |

0.05 mm/rev (0.0020 ipr) |

Carbon steel |

● The cutting test results indicated in this catalog are provides as an example. The results indicated in this catalog |

JIS: Japanese Industrial Standard |

may not be obtained due to differences in cutting conditions and environmental conditions during measurement. |

9

Ultra-high

We have a new design for the This new design ensures consistent has not been seen before, with

Torsionally rigid

100

Greater

<comparison to conventional

■ Bed torsion rigidity

Dramatically better bed torsion rigidity compared to conventional machines has been achieved through static analysis. |

NL2500Y/700 |

Torsion displacement graph

Torsionally rigid

100 % Greater

NL2500

Top rail

Bottom rail

|

2 |

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

| <![if ! IE]> <![endif]>(μm) |

-2 |

|

|

|

|

|

|

|

|

|

|

-4 |

|

|

|

|

|

|

|

|

|

|

|

-6 |

|

|

|

|

|

|

|

|

|

|

|

| <![if ! IE]> <![endif]>Displacement |

|

|

|

|

|

|

|

|

|

|

|

-8 |

|

|

|

|

|

|

|

|

|

|

|

-10 |

|

|

|

|

|

|

|

|

|

|

|

-12 |

|

|

|

|

|

|

|

|

|

|

|

-14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-16 |

|

|

|

|

|

|

|

|

|

|

|

-18 |

|

|

|

|

|

|

|

|

|

|

|

-2,000 |

-1,800 |

-1,600 |

-1,400 |

-1,200 |

-1,000 |

-800 |

-600 |

-400 |

-200 |

0 |

Distance along rail (mm)

NL2500 |

|

|

|

|

|||

|

|

|

Top rail |

|

|

|

Bottom rail |

|

|

|

|

||||

Previous model |

|

|

|

|

|||

|

|

|

Top rail |

|

|

|

Bottom rail |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

■ Broader guideways

The slideways are 30 % wider than those of conventional machines and are the largest in the class. We have achieved an unknown level of stability not only in turning work but also in milling work.

Guideway 30

width %Greater

<comparisoni to conventionali l machines>i

NL2500

model A

model B

10

Highly rigid spindle

Rigid &

Rigid & Precise

Precise

NL

NL SERIES

SERIES

The axis rigidity of the headstock and its mounting have been improved by changing the shape of the headstock and increasing the thickness of its parts. The diameter of the bearings has been increased. This allows better spindle rigidity while enlarging the through-hole diameter.

Axis rigidity 20 % Greater

Headstock attachment rigidity

30 % Greater

Rigidityofthespindleitself 50

%Greater

<comparison to conventional machines>

■ Improved acceleration/deceleration time and torque specs

Raising the rigidity has endowed the NL Series with performance equal to that of spindle motors one class above.

Acceleration/deceleration time |

|

Maximum spindle torque (standard) |

Previous model |

NL2500 |

Spindle acceleration time |

Spindle acceleration time |

(0→4,000 min-1) |

(0→4,000 min-1) |

Reduced |

3.4 sec. |

4.9 sec. approximately 31 % |

|

Spindle deceleration time |

Spindle deceleration time |

(4,000→0 min-1) |

(4,000→0 min-1) |

Reduced |

3.6 sec. |

4.2 sec. approximately 14 % |

NL1500 200 N·m (147.5 ft·lbf) <50 %ED>

NL2000 349 N·m (257.4 ft·lbf) <50 %ED>

NL2500 599 N·m (441.8 ft·lbf) <25 %ED>

NL3000

1,025 N·m (756.0 ft·lbf) <30 min>

When mounted with chuck

■Headstock 2 spindle (S-, SMC-, SY-types)

The No. 2 spindle also delivers powerful turning.

Maximum headstock 2 spindle torque

NL SERIES

77.8 N·m

(57.4 ft·lbf) <25 %ED>

11

Thermal isolation

Designed to eliminate all heat

The most prominent feature of the NL Series is said to be the elimination of the adverse effects of heat. In order to raise the continuous machining precision of lathes, 95 % of which is said to be taken up by cutting time, we at Mori Seiki have come up with the concept of total heat elimination.

■ Heat elimination layout

Previous model

It is common to find the oil cooler – a major source of heat – located right next to the spindle in conventional machines. As a result, the headstock is affected adversely by that heat.

Large heat displacement

NL SERIES |

Oil cooler |

|

Placing the oil cooler behind the machine removes that heat source from the headstock. The machine is designed so that the exhaust from the oil cooler doesn’t come in direct contact with the machine.

Oil cooler

Low heat displacement

Oil cooler exhaust vent

The oil cooler’s exhaust heat is blown out of the cover in the direction of the machine’s side.

Spindle thermal displacement

|

0.003 |

|

|

|

|

|

|

|

|

|

|

0.001 |

|

3.1 μm |

|

|

|

|

|

|

|

| <![if ! IE]> <![endif]>) |

-0.001 |

|

|

|

|

|

|

|

|

|

| <![if ! IE]> <![endif]>(mm |

-0.003 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| <![if ! IE]> <![endif]>Displacement |

-0.005 |

|

|

|

|

|

|

|

|

|

-0.007 |

|

12.7 μm |

|

|

|

|

|

|

|

|

-0.009 |

|

|

|

|

|

|

|

|

|

|

-0.011 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-0.013 |

|

|

|

|

|

|

|

|

|

|

-0.015 |

|

|

|

|

|

|

|

|

|

|

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

Time (hour)

NL2500 |

|

|

||

|

|

Oil cooler/Rear side, exhaust blocked (X-axis tip) |

|

Oil cooler/Rear side, exhaust blocked (X-axis base) |

|

|

|

||

Previous model |

|

|

||

|

|

Oil cooler/Left side surface layout (X-axis tip) |

|

Oil cooler/Left side surface layout (X-axis base) |

|

|

|

||

|

|

|

|

|

■ Fully-covered bed

Covering the bed with a cover makes it difficult for the heat from chips to be transmitted to the bed.

12

Rigid &

Rigid & Precise

Precise

NL

NL SERIES

SERIES

Spindle Cooling

We have redesigned the spindle, which is the greatest source of heat, to employ a uniform-heat construction that maintains an equal temperature all around the spindle. The main spindle unit is protected from rises in temperature by the spiraling oil jacket located all the way to the back side.

Inverter-controlled oil cooler |

Oil jacket |

|

An inverter-controlled oil cooler with |

||

|

||

very accurate temperature regulation |

|

|

has been used. |

|

Milling turret with a heat-suppressing design

NL SERIES

Internal design of the turret

Oil jacket

Built-in milling motor

The industry’s first turret with a built-in milling motor minimizes heat.

Previous model |

|

NL SERIES |

|

|

|

Motor |

|

Built-in milling motor |

+ |

+ |

|

Timing belt 1

+

Timing belt 2

+

Involuted spline

+

Bevel gear

+

Keyed shaft

Keyed shaft

The built-in milling motor design has eliminated the transmission mechanism. Therefore, sources of heat are eliminated and jacket cooling is performed. This is only achieved with a built-in milling motor.

The transmission with all its gear, belts, and more, generates a substantial amount of heat and can adversely affect machining precision.

Rising turret 1/10 temperatures

or less

Ball screw shaft cooling (option)

Shaft cooling is used on ball screws to control heat during feed.

X-axis only.

13

Rigid & Precise

NL SERIES |

Machining power |

|

By employing a super-rigid construction for the NL Series and equipping it with a turret with a built-in milling motor, it is able to deliver cutting equal to that of machines one class above. This contributes to productivity.

Turning performance

Heavy-duty cutting <O.D.> |

|

Throw-away drill |

Machine type |

NL2500MC/700 |

Material <JIS> |

S45C |

Spindle speed |

764 min-1 |

Depth of cut |

10 mm (0.4 in.) |

Cutting speed |

120 m/min (393.7 fpm) |

Feedrate |

0.4 mm/rev (0.016 ipr) |

As you can see, wide cutting can be done in outer diameter heavy cutting.

Actual size

<![endif]>

A 58 mm (A 2.3 in.)

A 58 mm (A 2.3 in.)

Machining rate per minute

435.2 mL/min

(26.5 in3./min)

|

|

Machine type |

NL2500MC/700 |

Machining rate per minute |

|

Material <JIS> |

S45C |

576.0 mL/min |

|

Spindle speed |

549 min-1 |

|

Drill diameter |

58 mm (2.3 in.) |

|

(35.1 in3./min) |

|

Cutting speed |

100 m/min (328.1 fpm) |

|

Feedrate |

0.3 mm/rev (0.012 in.) |

Milling capacity (material <JIS> S45C )

End mill <B 20 mm (B 0.8 in.) High speed steel> |

|

Drill <B 23 mm (B 0.9 in.) High speed steel> |

|

Tap |

20 mm (0.8 in.) |

|

20 mm (0.8 in.) |

|

A 23 mm (A 0.9 in.) |

|

|

||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Machining rate per minute |

|

Machining rate per minute |

|

|

|

Tool |

||

25.6 mL/min (1.6 in3./min) |

|

43.0 mL/min (2.6 in3./min) |

|

|

M20×P2.5 |

|||

Machine type |

NL2500MC/700 |

|

Machine type |

NL2500MC/700 |

|

Machine type |

NL2500MC/700 |

|

Rotary tool spindle speed |

320 min-1 |

|

Rotary tool spindle speed |

345 min-1 |

|

Rotary tool spindle speed |

160 min-1 |

|

Depth of cut |

20 mm (0.8 in.) |

|

Cutting speed |

25 m/min (82.0 fpm) |

|

Cutting speed |

10 m/min (32.8 fpm) |

|

Cutting speed |

20 m/min (65.6 fpm) |

|

Feedrate |

103.5 mm/min (4.1 ipm) |

|

Feedrate |

400 mm/min (15.7 ipm) |

|

Feedrate |

64 mm/min (2.5 ipm) |

|

|

|

|

|

|

|

JIS: Japanese Industrial Standard Carbon steel

● The cutting test results indicated in this catalog are provides as an example. The results indicated in this catalog may not be obtained due to differences in cutting conditions and environmental conditions during measurement.

14

Loading...

Loading...