Moog MSD Servo Drive single axis system, MSD Servo Drive Compact, MSD Servo Drive multi axis system User Manual

Page 1

MSD Servo Drive

User Manual

moog

Single Axis System

Multi Axis System

Compact

Page 2

moog

This document details the functionality of the following equipment

MSD Servo Drive single axis system

MSD Servo Drive multi axis system

MSD Servo Drive Compact

MSD Servo Drive User Manual CANopen/EtherCAT

CANopen/EtherCAT for MSD Servo Drive User Manual

ID no.: CA65647-001, Rev. 1.0

Status: 03/2012

We reserve the right to make technical changes.

Technical alterations reserved.

The contents of our documentation have been compiled with greatest care and in

compliance with our present status of information.

Nevertheless we would like to point out that this document cannot always be updated

parallel to the technical further development of our products.

Information and specifications may be changed at any time. For information on the

latest version please refer to drives-support@moog.com.

Page 3

How to use the document

Dear User,

This manual is intended for project engineers, commissioning engineers or programmers

of drive and automation solutions on the CANopen and EtherCAT fieldbus.

It is assumed that you are already familiar with these fieldbus systems through appropriate training and from reading the relevant literature. We assume that your drive is

already in operation – if not, you should first consult the Operation Manual.

NOTE: This manual applies to the MSD Servo Drive family.

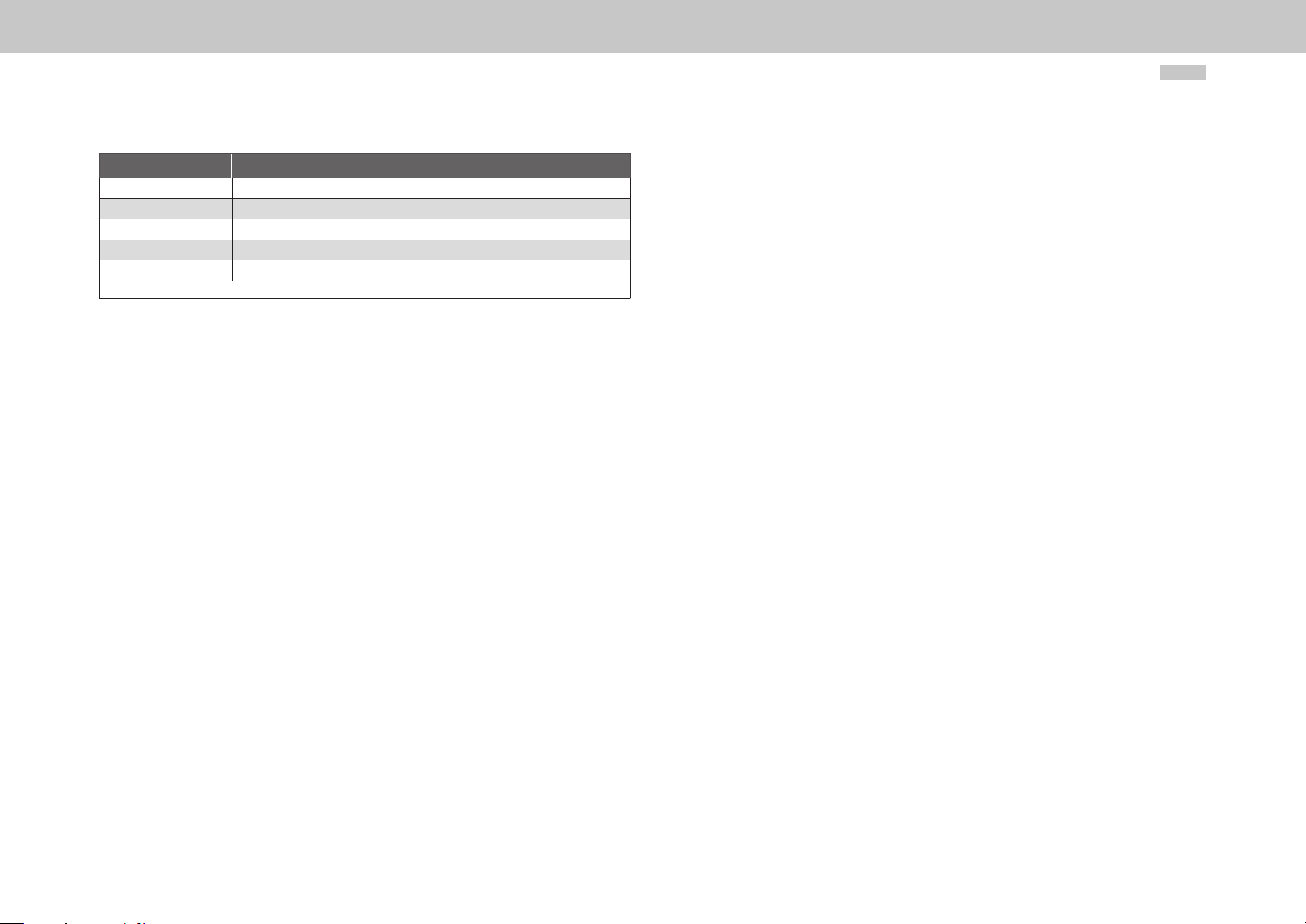

General introduction

Mounting and connection of CANopen

Mounting and Connection of EtherCAT

Commissioning and Configuration CANop.

Setting the Device Parameters for CANopen

Setting the Device Parameters for EtherCAT

Implemented CiA402 functionality

Operation modes CiA402

Emergency objects

Technology functions

EDS file, object directory, parameter list

Bibliography

Appendix: Glossary

11

22

33

44

55

66

77

88

99

1010

1111

1212

1313

moog

MSD Servo Drive User Manual CANopen/EtherCAT

3

Page 4

moog

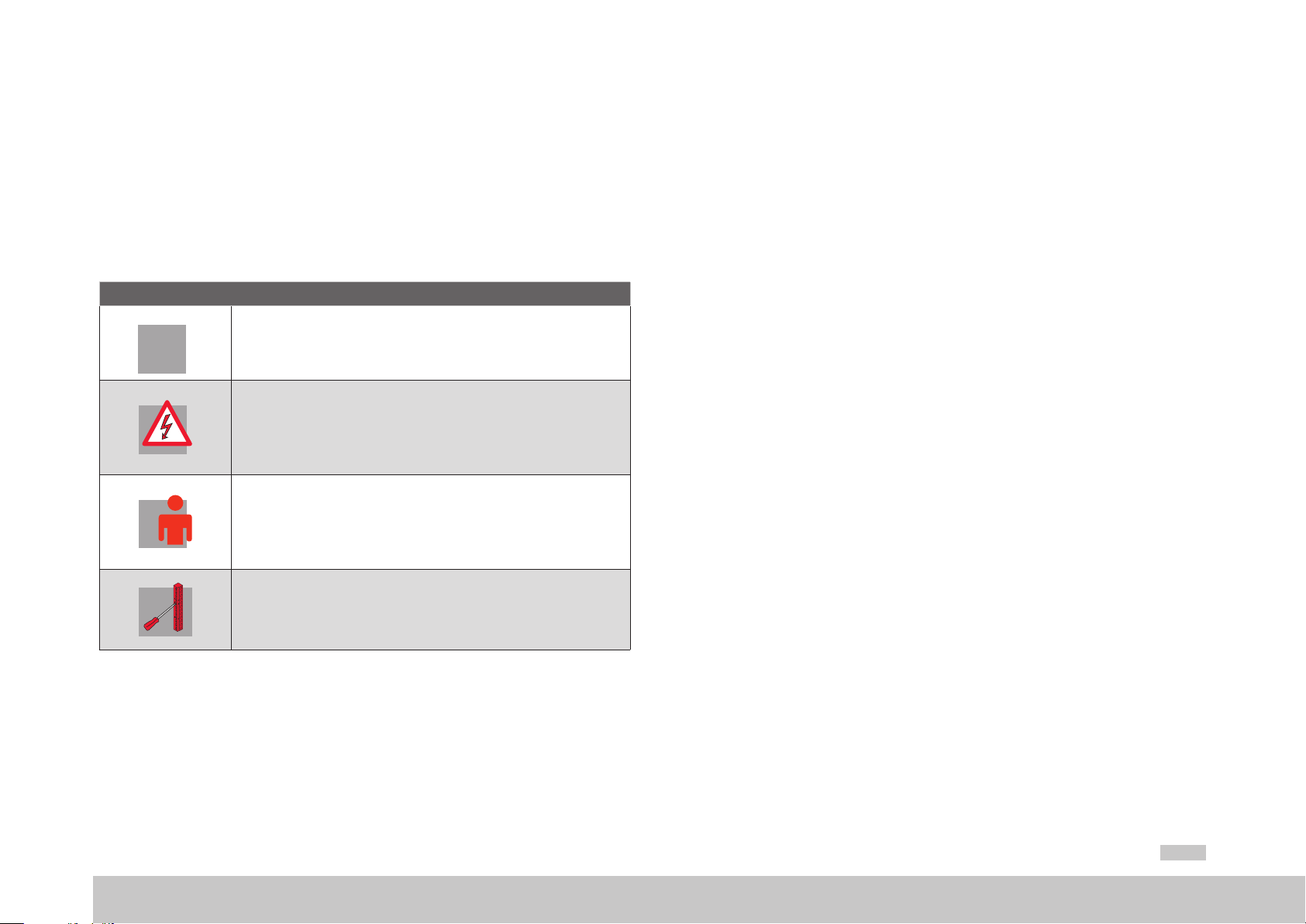

Pictograms

MSD Servo Drive User Manual CANopen/EtherCAT

4

!

Important! Misoperation may result in damage to the drive or malfunctions.

Danger from electrical voltage! Improper behaviour may endanger human life.

Danger from rotating parts! Drive may start up automatically.

Note: Useful information.

Page 5

Table of Contents

Drive ADmi nistr Ator

1 General Introduction ................................................................ 7

1.1 Measures for your safety .........................................................................................7

1.2 Introduction to CANopen .......................................................................................7

1.3 Introduction to EtherCAT ........................................................................................8

1.4 System requirements ...............................................................................................8

1.5 Further documentation ........................................................................................... 8

2 Mounting and Connection of CANopen ................................... 9

2.1 Setting the address .................................................................................................9

2.2 Meanings of LEDs ...................................................................................................10

2.3 Installation ..............................................................................................................11

2.4 Transmission speeds ................................................................................................12

2.5 Display of operating states via 7-segment display ....................................................13

2.6 Hardware enable ....................................................................................................13

3 Mounting and Connection of EtherCAT ................................. 15

3.1 Installation and cabling ...........................................................................................15

3.2 Pin assignment of the RJ45 socket ..........................................................................16

3.3 Meanings of LEDs ...................................................................................................16

3.4 Display of operating statuses via 7-segment display ................................................17

3.5 Hardware enable ....................................................................................................18

4 Commissioning and Configuration of CANopen ..................... 19

4.1 General commissioning of CANopen/EtherCAT ......................................................19

4.1.1 Commissioning ............................................................................................19

4.1.2 Commissioning sequence ............................................................................19

4.1.3 Commissioning via Moog

4.1.4 Operation mode selection (modes of operation) ..........................................20

4.1.5 Functionality of operation modes ................................................................20

4.1.6 Setting the timing parameters .....................................................................21

4.2 CAN-specific configuration .....................................................................................21

4.2.1 Setting the software address and baud rate ................................................21

4.2.2 Commissioning instructions .........................................................................21

4.2.3 Testing the higher-order drive ......................................................................22

4.2.4 Data handling ..............................................................................................22

4.2.5 Control functions .........................................................................................22

4.3 Commissioning and Configuration of EtherCAT ......................................................23

................................................20

5 Setting the Device Parameters for CANopen .......................... 25

5.1 Implemented CiA301 functionality .........................................................................25

5.1.1 Communication objects ...............................................................................25

5.1.2 Object directory of CiA301 ..........................................................................25

5.2 Parameter channel (Ser vice Data Objects) ...............................................................26

5.2.1 Data types ...................................................................................................27

5.2.2 Representation of data types in the control protocol ...................................27

5.2.3 Access to device parameters ........................................................................27

5.3 Examples of SDO handling ......................................................................................28

5.3.1 Parameter set download ..............................................................................31

5.4 PDO transmission types ........................................................................................... 32

5.5 Event-controlled TxPDO transmission...........................................................32

moog

MSD Servo Drive User Manual CANopen/EtherCAT

5

Page 6

moog

MSD Servo Drive User Manual CANopen/EtherCAT

6

5.6 PDO mapping .........................................................................................................33

5.6.1 Mapping – general ......................................................................................33

5.6.2 Mapping notes ............................................................................................33

5.7 Heartbeat function .................................................................................................34

5.8 Monitoring of telegram failure ................................................................................35

6 Setting the Device Parameters for EtherCAT ........................... 37

6.1 Supported EtherCAT functionality ...........................................................................37

6.2 Configuration for operation in a drive .....................................................................40

7 Implemented CiA402 functionality ......................................... 41

7.1 Device control and state machine ...........................................................................41

7.1.1 General information ....................................................................................41

7.1.2 State machine ..............................................................................................41

7.1.3 Device states ................................................................................................42

7.2 Option codes ..........................................................................................................44

7.3 Device control objects ............................................................................................. 44

7.4 Units and scalings, factor group .............................................................................. 45

7.5 I/O map ...................................................................................................................47

7.5.1 Object 60FDh – digital inputs ......................................................................47

7.5.2 Object 2079h – MPRO_ INPUT_STATE ..........................................................47

7.5.3 Object 208Fh – MRPO_OUTPUT_STATE.......................................................47

7.5.4 Setting digital outputs via fieldbus ...............................................................48

7.5.5 Object 60FE, digital outputs: .......................................................................48

8 Operation modes CiA402 ...................................................... 49

8.1 CiA402 compatible operation modes ......................................................................49

8.1.1 Configuring MSD Servo Drive for activation via CiA402 ...............................49

8.1.2 Control word CiA402 ..................................................................................49

8.1.3 Status word CiA402 ....................................................................................51

8.2 Operation modes with profile generation in drive ...................................................52

8.2.1 Profile velocity mode ...................................................................................52

8.2.2 Homing mode .............................................................................................54

8.2.3 Profile position mode ...................................................................................55

8.2.4 Velocity mode (V/F mode) ............................................................................57

8.3 Cyclical operation modes, profile generation in the drive ........................................58

8.3.1 Interpolated position mode .........................................................................58

8.3.2 Cyclic Synchronous Position mode (EtherCAT only) ......................................59

8.3.3 Cyclic Synchronous Velocity mode (EtherCAT only) ......................................60

8.3.4 Cyclic Synchronous Torque mode (EtherCAT only)........................................61

8.3.5 External pre-control of speed/torque ...........................................................61

9 Emergency objects ................................................................. 63

9.1 Error acknowledgement, general ............................................................................63

9.2 Error acknowledgement via bus system ..................................................................63

10 Technology functions ............................................................. 65

10.1 Touch probe ............................................................................................................65

10.1.1 Description of manufacturer-specific implementation ..................................65

10.1.2 Control-led homing .....................................................................................66

10.2 Indexing table function ...........................................................................................66

11 EDS file, object directory, parameter list.................................. 69

11.1 EDS file, object directory .........................................................................................69

12 Bibliography........................................................................... 71

Page 7

1 General Introduction

1.

1.1 Measures for your safety

1.2 Introduction to CANopen

CANopen is an interconnection concept based on the CAN (Controller Area Network)

serial bus system. CAN has many specific advantages, in particular multi-master capability, real-time capability, resistant response to electromagnetic interference, a high level

of availability and the low cost of drive chips. These advantages have resulted in CAN

being introduced into widespread use in automation too.

The MSD Servo Drives quick and safe to handle. For your own safety and for the safe

functioning of your device, please be sure to observe the following points:

Read the operation manual first!

• Follow the safety instructions!

Electric drives are dangerous:

• Electrical voltages > 230 V/460 V:

Dangerously high voltages may still be present 10 minutes after the power

is cut, so always make sure the system is no longer live.

• Rotating parts.

• Hot surfaces.

Your qualification:

• In order to prevent personal injury and damage to property, only qualified

electrical engineers may work on the device.

• Knowledge of national accident prevention regulations (e.g. VBG4 in

Germany).

• Knowledge of layout and interconnection with the CAN bus fieldbus.

U

U

V

V

N

N

L+

L+

RB

RB

L-

L-

L3

L3

L2

L2

L1

L1

During installation observe the following instructions:

• Always comply with the connection conditions and technical specifications.

• Electrical installation standards, e.g. for cable cross-section, shielding etc.

• Do not touch electronic components and contacts (elec trostatic discharge

may destroy components).

Simplified cross-manufacturer communication

The integration of any number of devices in a manufacturer-specific network involves

substantial expense. CANopen was developed to solve this problem. In CANopen the

use of CAN identifiers (message addresses), the time response on the bus, the network

management (e.g. system start and user monitoring) and the coding of the data contents is specified in a uniform way. CANopen makes it possible for devices from different

manufacturers to communicate in a network at minimal cost. CANopen uses a subset

of the communication services offered by CAL to define an open interface. The selected

CAL services are summarised in a kind of "user guide". This guide is called the CANopen

Communication Profile.

CANopen functionality of MSD Servo Drive

The CANopen Communication Profile is documented in CiA301 and regulates the way

communication is executed. It distinguishes between process data objects (PDOs) and

service data objects (SDOs). The Communication Profile additionally defines a simplified

network management system.

The device profile for CiA402 (Rev. 2.0) variable-speed drives was compiled on the basis

of the CiA301 (Rev. 4.01) communication services. It describes the operation modes and

device parameters supported.

The following sections will provide you with an overview of the CANopen functionality

integrated in MSD Servo Drive, followed by the information necessary for commissioning.

[ Section 1 ]

moog

MSD Servo Drive User Manual CANopen/EtherCAT

7

Page 8

moog

MSD Servo Drive User Manual CANopen/EtherCAT

8

1.3 Introduction to EtherCAT

As far as real-time Ethernet systems are concerned, EtherCAT has become well established in the area of automation. The decisive factor here is not only the IEEE 802.3/

100BaseTX Ethernet physics known in the home office area, but also the excellent

value for money with regard to implementation in the master and slave modules.

Interconnection can be executed as required in a star, ring or line structure using standard patch or crossover cables and is therefore easily adapted to the machine infrastructure.

To reduce the amount of training required, familiar communication and device profiles

were used as of the application layer. In this way, users familiar with CANopen profiles

such as CiA301 or CiA402 can change over to this new fieldbus technology with minimal training.

In MSD Servo Drive we have combined all our past experience in the CANopen area with

this new fieldbus technology and achieved maximum compatibility and functionality.

1.4 System requirements

It is assumed you have a standard CANopen setup program and a CANopen interface

dr iver.

For the precise protocol definitions, please refer to the CAL specification.

With the aid of these objects it is possible to configure the actual CANopen communication very flexibly and adapt it to the specific needs of the user.

• EtherCAT Communication Specification Version 1.0 2004

• EtherCAT Indicator Specification Proposal V0.91 2005

• IEC 61158-2-12 to IEC 61158-6-12

1.5 Further documentation

• Operation manual, for commissioning of the drive unit

• Application manual, for additional parameter setting to adapt to the application.

• CiA301 (Rev. 4.0): Application Layer and Communication Profile

• CiA402 (Rev. 2.0): Device Profile Drives and Motion Control

Page 9

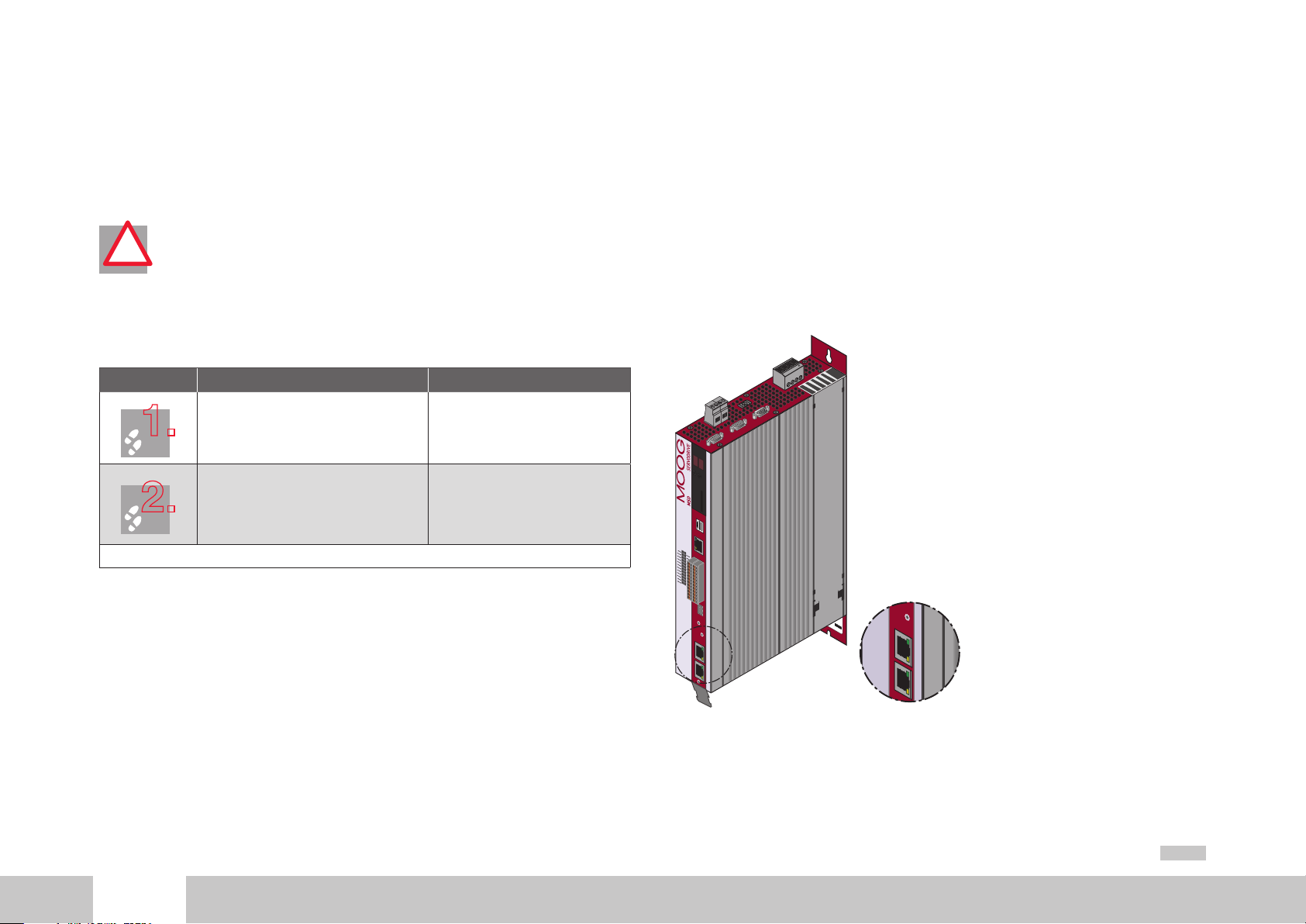

2 Mounting and Connection

1.

2.

ACHTUNG

WARNING

Kondensatorenent-

ladezeit > 3 min.

Betriebsanleitung

beachten!

Capacitor discharge

time > 3 min.

Pay attention to the

operation manual!

X

15

X

16

H

1

of CANopen

ATTENTION: Do NOT insert or remove the CANopen connector during

operation.

!

2.1 Setting the address

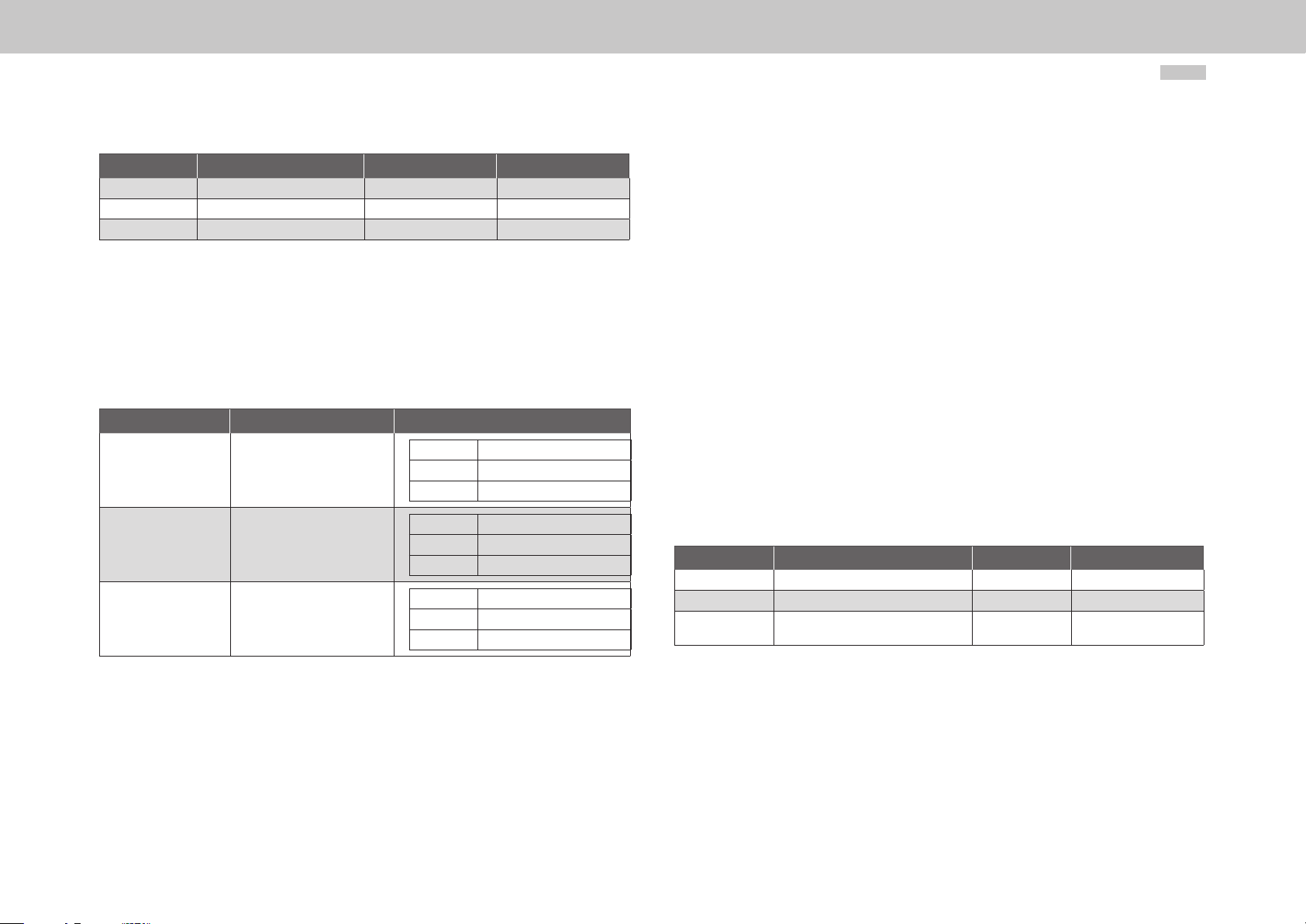

Step Action Note

Find out which address is assigned to the

device you are installing.

Select the mode of addressing:

• by bus address parameter

• by DIP switch (S4)

• by bus address parameter and DIP

switch (S4)

Address setting finished; for further procedure see Installation.

Ask your project engineer.

See below

Three possible methods of address allocation

1. Only using bus address parameter P 2005-COM_CAN_Adr: You will find parameter

P 2005-COM_CAN_Adr (factory setting 1) in the "fieldbus" subject area under

CANopen.

2. Only using DIP switch S4

3. Combination of bus address parameter and DIP switch S4 CAN address = hardware address (S4) + parameter P 2005-COM_CAN_Adr. This option is advanta-

geous if, for example, you intend always to use the same parameter set with up to

15 drives, but the lowest address is 30. Parameter P 2005-COM_CAN_Adr is then

set to 30. The device address is then defined using the coding switch, which

ranges from 0-15.

L3

L2

L1

11

X

J+

J-

J+

J-

J+

J-

J+

J-

10

REL

REL

ISDSH

ISD06

ISD05

ISD04

ISD03

ISD02

ISD01

ISD00

+24 V

DGND

ACHTUNG

Kondensatorenent-

Betriebsanleitung

WARNING

Capacitor discharge

Pay attention to the

operation manual!

X

X

9

5

6

1

X

2

X

3

X

24

12

RSH

23

11

RSH

22

10

4

X

ENPO

21

9

OSD02

20

8

OSD01

19

7

OSD00

18

6

17

ISA1-

5

ISA1+

16

4

15

ISA0-

3

14

ISA0+

2

13

+24 V

1

DGND

5

X

1

H

15

X

ladezeit > 3 min.

beachten!

time > 3 min.

16

X

X

8

X

7

X

6

356

33 Lah

www.l

Type:

M

u

nau

ad

s

t

SOA84.006.0

-

e

te

i

n

c

German

.

d

e

In:

C

y

000.00

US

LISTED

Out:

Ind. Co

00.0

19BB

nt. Eq.

SN.:

Fig. 2.1

moog

Position of CAN connection on MSD Servo Drive

MSD Servo Drive User Manual CANopen/EtherCAT

9

[ Section 2 ]

Page 10

moog

MSD Servo Drive User Manual CANopen/EtherCAT

10

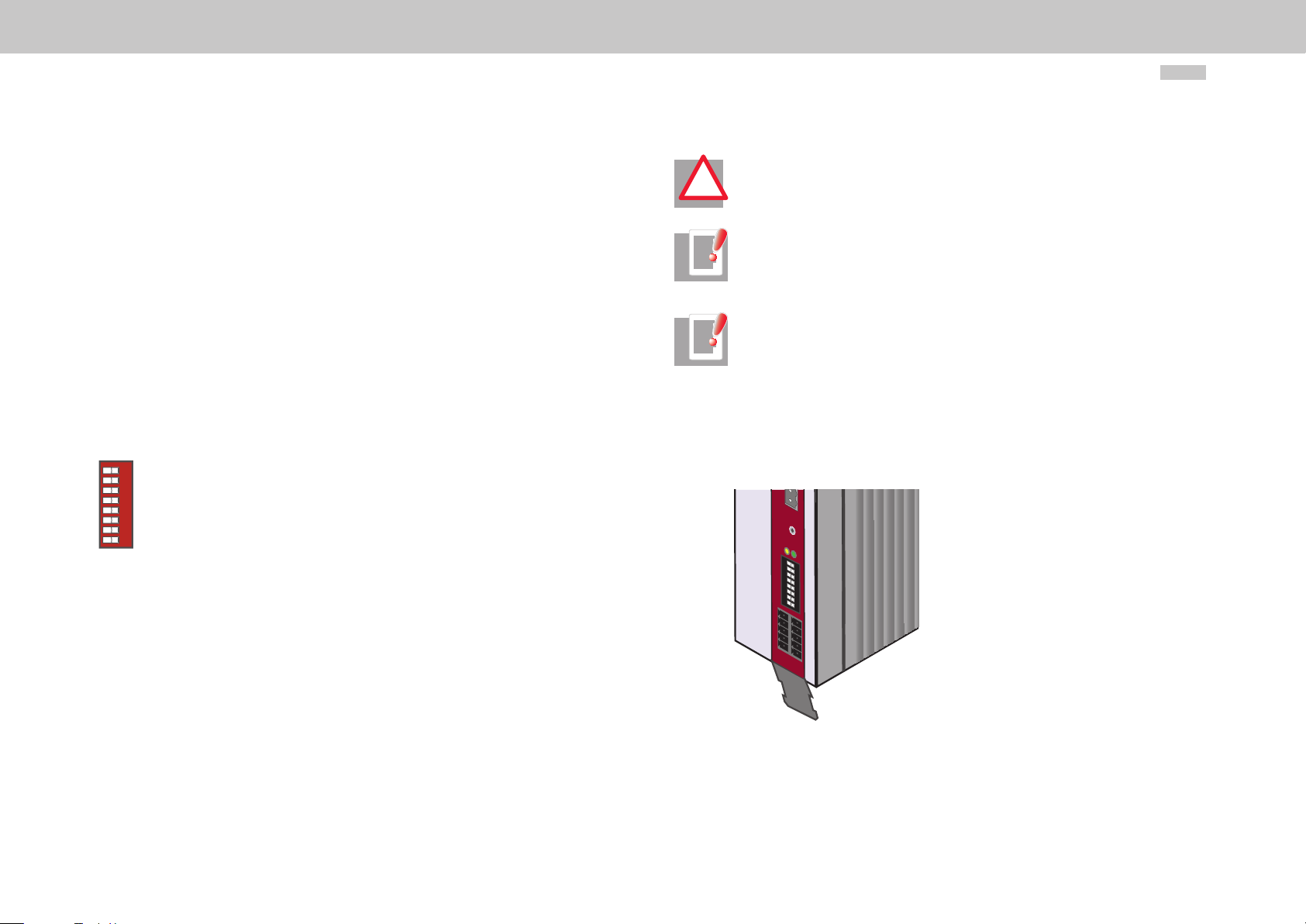

Address setting using DIP switch

An address between 0 and 127 can be selected decimally using DIP switch S4 on the

position drive.

The DIP switch is assigned as follows: Positions 1-7 are reserved for the address setting,

position 8 for the activation/deactivation of the 120 Ohm bus termination in the device.

Function/assignment:

DIP switch 1 significance 20 = 1

DIP switch 2 significance 2

DIP switch 3 significance 2

1

= 2

2

= 4

...

DIP switch 7 significance 2

6

= 64

DIP switch 8 = bus termination ON/OFF

12345678

Fig. 2.2

Device with CANopen Option

Example of use of the DIP switches:

Setting address "3" using the DIP switches:

- Set switch 1 and switch 2 to ON

0

- 2

+ 21 = 3

- Resulting device address = 3

- (If the software address = 0 is set)

IMPORTANT: Switch 8 = bus termination!

!

Note: Changes to the CAN address are applied on a

- Reset node command

- Restart (device power-up).

Note: The active bus address can be found in the boot-up message.

2.2 Meanings of LEDs

The CAN option of MSD Servo Drive has two diagnostic LEDs (H14, H15).

14

H

15

H

4

S

ACHTUNG

Kondensatorenent-

ladezeit >3 min.

Betriebsanleitung

beachten!

WARNING

Capacitordischarge

Pay attentionto the

time> 3 min.

operation m

Fig. 2.3 Device with CANopen Option

1 2 3 4 5 6 7 8

anual!

32

X

Page 11

The LEDs have the following function:

1.

2.

3.

LED Function Meaning

The LED displays the current network status.

• NMT STOPPED

H14 (yellow LED)

CANopen

network status

• NMT PRE-OPERATIONAL

• NMT OPERATIONAL

H15 (green LED)

Voltage supply

CAN option

Permanently lit if the 24 V supply is

powering the CAN option via the CAN bus.

Table 2.1 Meanings of LEDs

2.3 Installation

Step Action Note

flashing with 800 ms cycle

flashing with 1600 ms cycle

permanently lit.

24 VDC

N

L1

L-

CAN-Bus

L+

SPS/PLC

X

5

6

1

X

2

X

3

X

REL

24

REL

1

2

R

23

S

H

IS

1

DS

1

R

22

H

S

IS

H

1

4

D

0

06

X

ENPO

21

ISD

9

05

OSD02

20

ISD

8

04

OSD01

19

IS

7

D

03

OSD00

18

IS

D02

6

17

IS

A

IS

1-

5

D01

ISA

16

IS

1+

D00

4

15

IS

+24

A

0-

3

V

14

ISA

D

0+

G

2

N

D

13

+

2

4

1

V

D

G

ND

5

X

14

H

1

5

H

4

S

8

7

6

ACHTUNG

5

Kon

d

4

e

n

satore

lad

3

Bet

eze

n

r

i

e

t

iebsa

n

>

2

t3

m

n

i

leitun

n

1

.

be

ach

WARNING

g

C

ten!

a

pacit

o

r

disch

P

a

y

t

im

atte

arg

e

op

>

nti

e

3

e

m

rat

on

i

n.

ion

to

t

m

h

e

an

ual

!

3

2

X

12345678910

1234

5678910

1112 1314

1112 1314 15 16 17 18 1920

1516 17 18 1920

L

3

L

3

L

2

L

1

11

X

J+

J-

J+

J-

J+

J-

J+

J

10

X

X

8

9

X

7

X

6

REL

24

REL

1

23

IS

1

DS

22

H

ISD

1

06

21

ISD

05

20

ISD

04

19

ISD

03

18

IS

D02

17

IS

D01

16

IS

D00

15

+24

V

14

D

G

N

D

13

3

5

6

3

www

3

L

T

a

y

hna

.

M

l

u

pe

ad

st-

u

SO

e i

t

:

ec.

n

A8

G

d

er

e

4

ma

.

00

In

n

C

y

:

6.

0

00

U

LI

0.

S

S

000

Ou

T

I

nd

E

0.0

t

D

.

C

:

o

1

n

t.

9B

E

q

.

B

S

N.:

ACHTUNG

Kond

en

satore

lad

Bet

eze

r

i

ie

bsa

be

WARNING

C

a

pacit

o

r

disch

P

a

y

t

im

atte

op

nti

e

rat

io

n

L

2

L

1

11

X

J+

J-

J+

J-

J+

J-

J+

J

10

X

X

8

X

9

X

7

X

6

5

6

1

X

2

X

3

X

2

R

S

H

1

R

S

H

4

0

X

ENPO

9

OSD02

8

OSD01

7

OSD00

6

IS

A

1-

5

ISA

1+

4

IS

A

0-

3

ISA

0+

2

+

2

4

1

V

D

G

ND

5

X

14

H

1

5

H

4

S

8

7

6

5

4

3

n

e

t

n

2

>

t 3

m

n

i

le

n

1

.

itun

ach

g

ten

!

arg

e

>

3

e

m

on

i

n

to

.

t

m

h

e

an

ual

!

3

2

X

3

5

6

3

www

3

L

T

a

y

hna

.

M

l

u

pe

a

s

d

t

u

SO

-

e i

t

:

ec

n

A8

G

.

d

er

e

4

ma

.

00

n

In

C

y

:

6.

0

00

U

LI

0.

S

S

000

Ou

T

I

nd

E

0.0

t

D

.

Co

:

1

n

t.

9B

E

q

.

B

S

N.:

Make sure the hardware enable is wired on

MSD Servo Drive (X4).

Wire the CAN connection using connector X32

• Connection of CAN signal cables

• Connection of interface power supply

• Activation of the internal bus terminating resistor

on the final servo drive

• See Operation

Manual

See Specification of

CAN bus connection

table and A ssignment

of connection X19 table

Switch on the drive device.

Electrical installation is finished; for how to proceed further, refer to section 4 "Commissioning and

configuration".

The CANopen interface is integrated in MSD Servo Drive. The connection is made via

connector X32. The interface is isolated from the servo drive electronics. The supply to

the isolated secondary side is provided by the customer via connector X32.

moog

[ Section 2 ]

Fig. 2.4

System connection

Connection Spring-type terminal

Wave terminating resistor

- Bus termination -

Max. input frequency 1 MHz

Ext. voltage supply

Voltage ripple Max. 3 Vss

Power consumption Max. 50 mA per user

Cable type 4-wire, surge impedance 120 W

• 120 W (internal)

• Activation of the bus termination in the device via

switch 8 on the CAN option

+24 V +25%, 50 mA

(isolated from servo drive)

Table 2.2 Specification of CAN bus connection

MSD Servo Drive User Manual CANopen/EtherCAT

11

Page 12

moog

MSD Servo Drive User Manual CANopen/EtherCAT

12

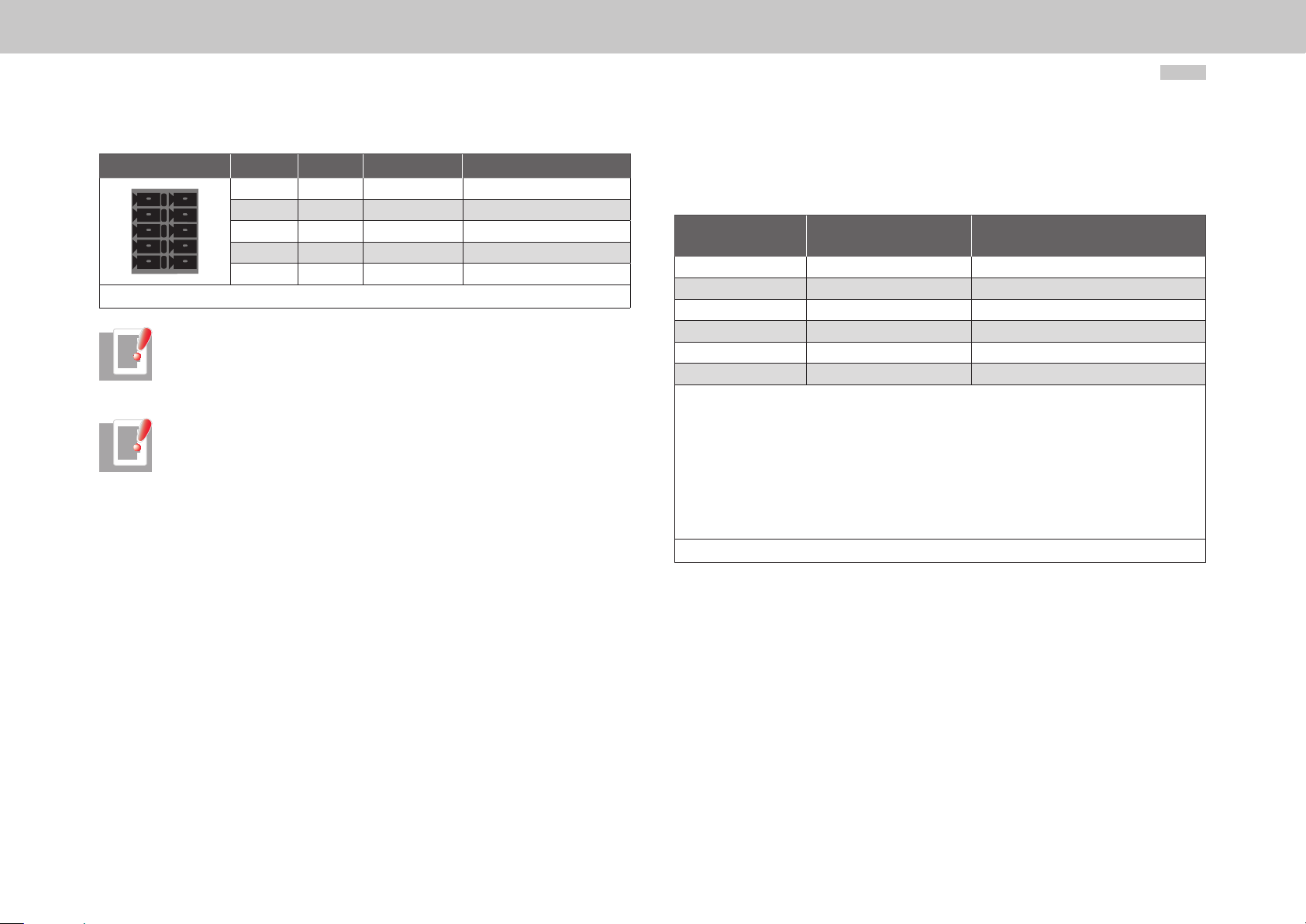

Terminal X32 PIN PIN Function Description

10 5 CAN_+24 V External 24 V supply

9 4 CAN_H CAN High

8 3 CAN_SHLD CAN Shield (optional)

7 2 CAN_L CAN Low

6 1 CAN_GND CAN Ground (0V)

Table 2.3 Assignment of connection X19

NOTE: Both connectors on terminal X32 are connected to each other in

the device.

NOTE: The external 24 V supply for the option board is essential. It is not

powered by the device.

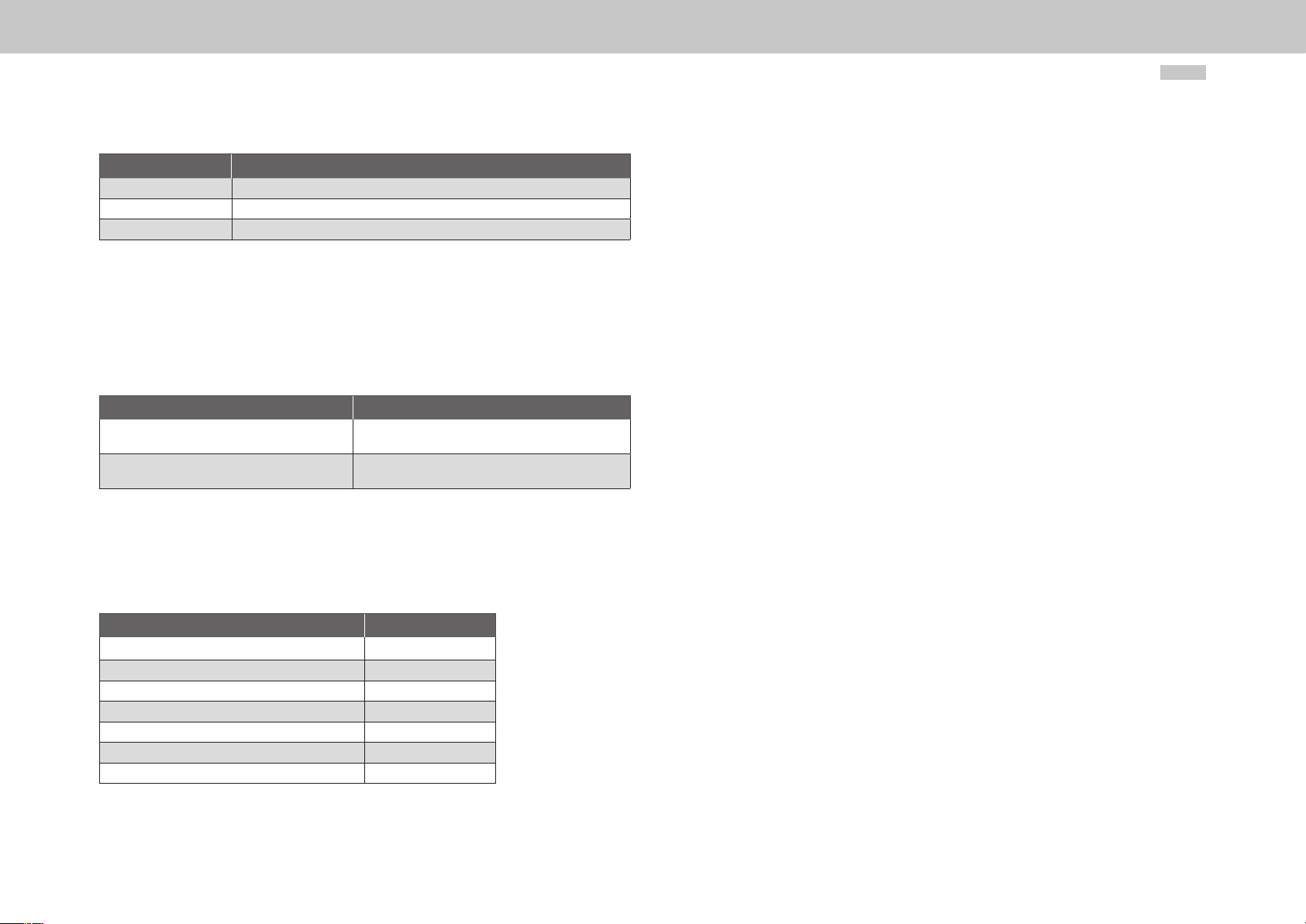

2.4 Transmission speeds

The CAN bus can be operated at the following baud rates:

Transmission speed

1000 kBaud 25 m • Factory setting

500 kBaud 100 m

250 kBaud

125 kBaud

50 kBaud

20 kBaud

1) Rounde d bus length estimation (worst case) on basis 5 ns /m propagation delay and a t otal effe ctive device interna l in-out

delay as follows:

1M–800 kbit/s: 210 ns

500–250 kbit/s: 3 00 ns (includes 2 * 40 ns for optocouplers)

125 kbit/s: 450 ns (includes 2 * 100 ns for optocouple rs)

50–10 kbit/s: Effective delay = delay recessive to dominant plus dominant to recessi ve divided by two.

2) For a bus length gre ater than abo ut 200 m, the us e of optocouplers is recommende d. If optocouplers ar e placed between

the CAN Co ntroller and the transce iver this af fects the maximum bus length d epending upon the propagation delay of the

optocouplers, i.e. - 4 m per 10 ns prop agation de lay of employed optocoupler typ e.

3) For a bus length gre ater than abo ut 1 km, bridge or repeater device s may be need ed.

2)

2)

3)

3)

Table 2.4 Transmission speeds

When selecting the transmission rate it should, however, be ensured that the line length

does not exceed the permissible line length for the transmission rate in question.

Maximum line length

over the entire network

250 m

500 m

1000 m

2500 m

1)

Page 13

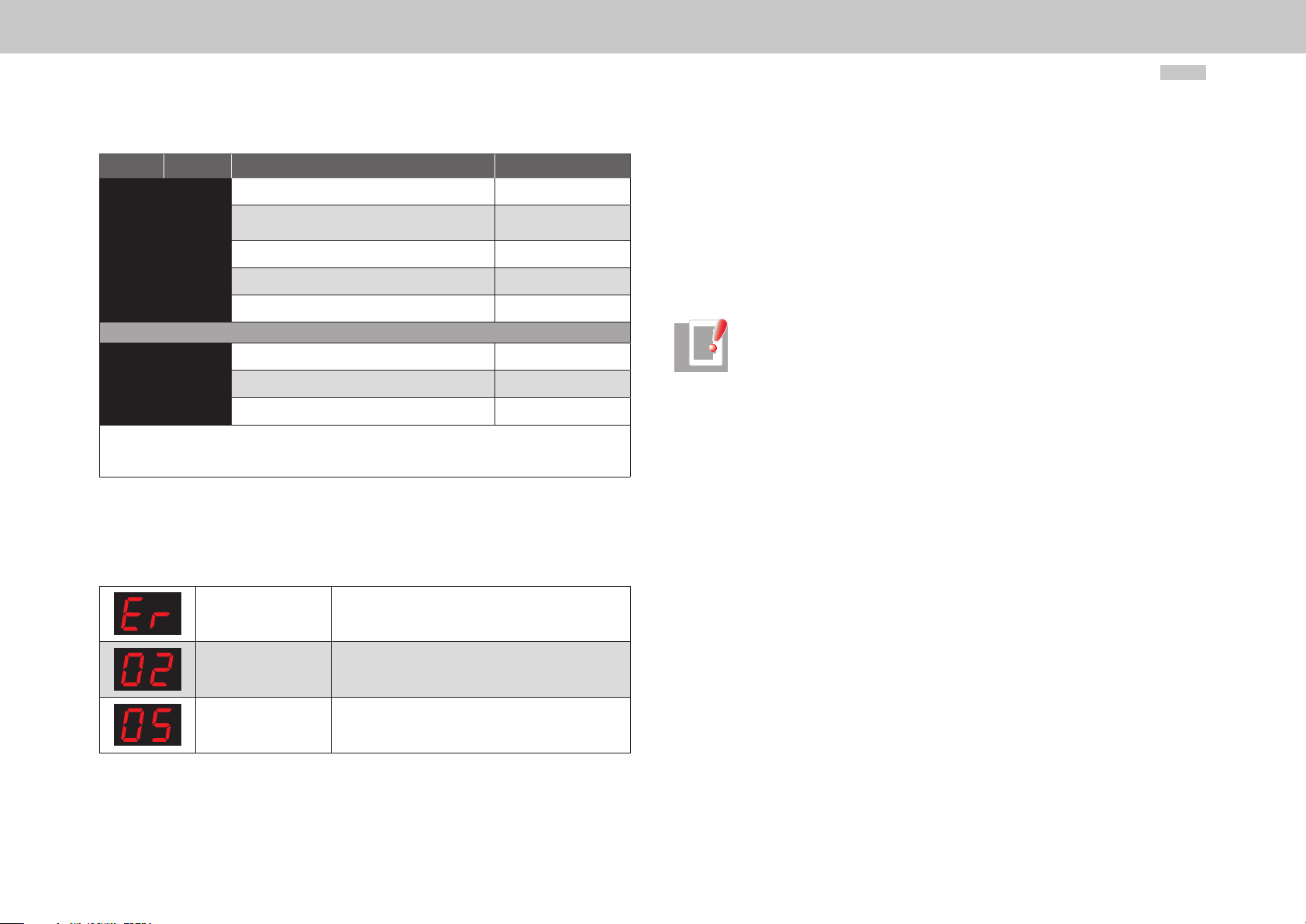

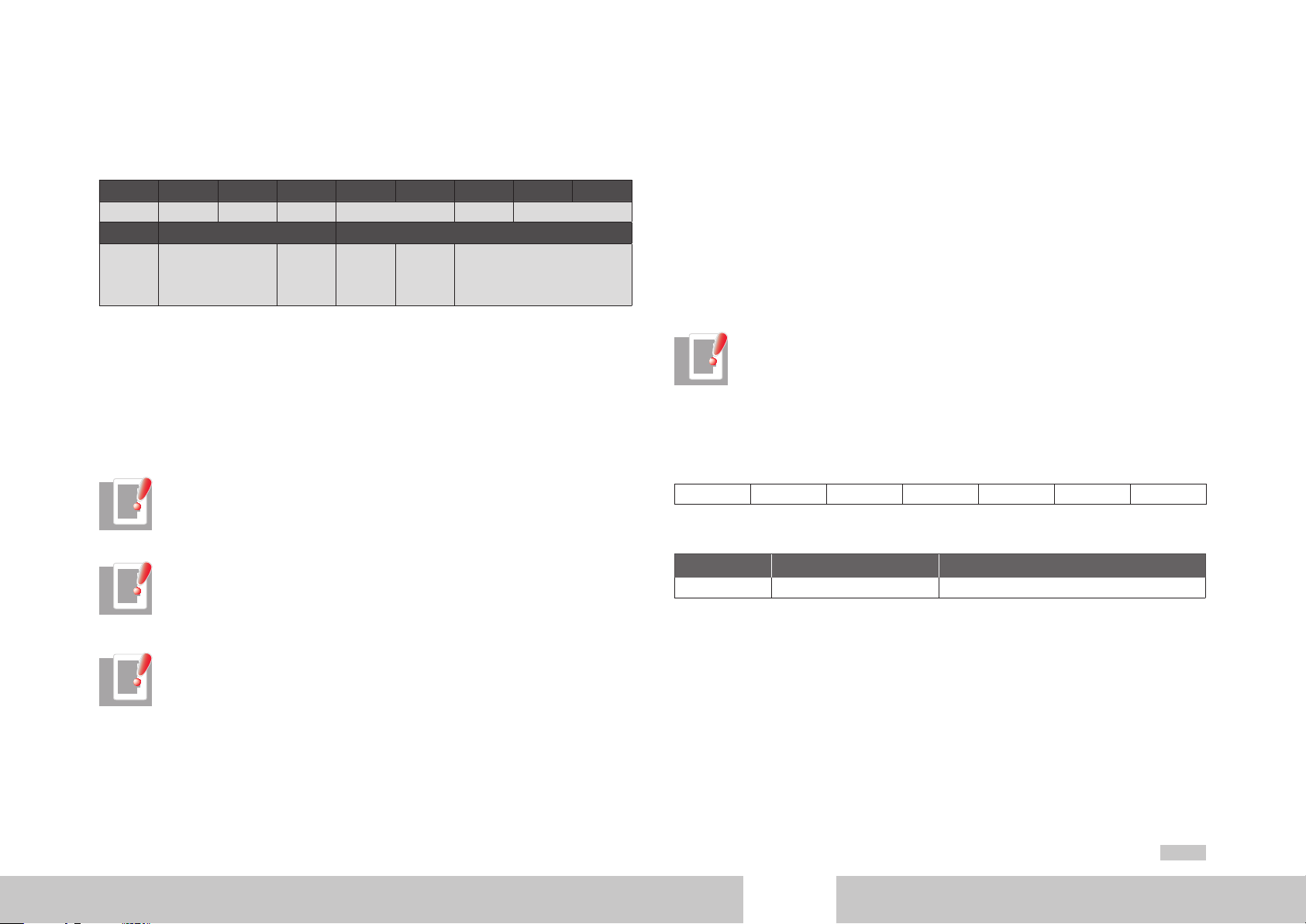

2.5 Display of operating states via 7-segment display

Example of the flash sequence:

ER > 02 > 05 * ER > 02 > 05 ...

D1 D2 Meaning Parameter

System statuses

8.

8.

0.

S.*) 1.

S.*) 2.

3.

4.

5.

6.

7.

E R

The following appear alternately in the event of error

E R.

X X

Y Y

1) S. flashes if t he STO (Safe Torqu e Off) functio n is active; the display is not lit if the func tion is not ac tive.

*) This is not a "safe display" under the terms of EN 61800-5-2.

2) The point flashes if the power stage is active.

Device in reset status

Auto-initialisation on device startup (Start)

1) Not ready to switch on (no DC link voltage) (NotReadyToSwitchOn)

1) Starting lockout (DC link is OK, power stage not

ready)

Ready to switch on (power stage is ready) (ReadyToSwitchOn)

On (power is connected to the device)

Drive ready (current applied to drive and drive ready

for input of setpoint)

Quick stop

Fault response active

Fault (see below) (Fault)

Display for errors or non-acknowledgeable errors

Error number (decimal)

Error localisation (decimal)

2)

2)

2)

2)

(SwitchOnDisabled)

(SwitchedOn)

(OperationEnable)

(QuickStopActive)

(FaultReactionActive)

Error: ER = "Fault"

Error name: 02 = "Error in the parameter list"

Description of error: 05 = "Function for checking current parameter list"

2.6 Hardware enable

MSD Servo Drive has a control input for ENPO hardware enable on the control terminal.

This input must be configured to operate the power stage at 24 V.

The device also provides the function "STO (Safe Torque Off)" (see Operation Manual

or Application Manual MSD Servo Drive), category 3, control terminal ISDSH. For these

devices the relevant function logic must be implemented by way of the higher-order

drive as per the Application Manual.

NOTE: When the inputs ENPO and ISDSH are not configured, the device stays

in status 1 = "Not Ready to Switch On" or 2 = "Switch On Disabled".

Only after correct configuration can the status be exited by a "Shutdown"

command via bus.

moog

[ Section 2 ]

MSD Servo Drive User Manual CANopen/EtherCAT

13

Page 14

moog

MSD Servo Drive User Manual CANopen/EtherCAT

14

Page 15

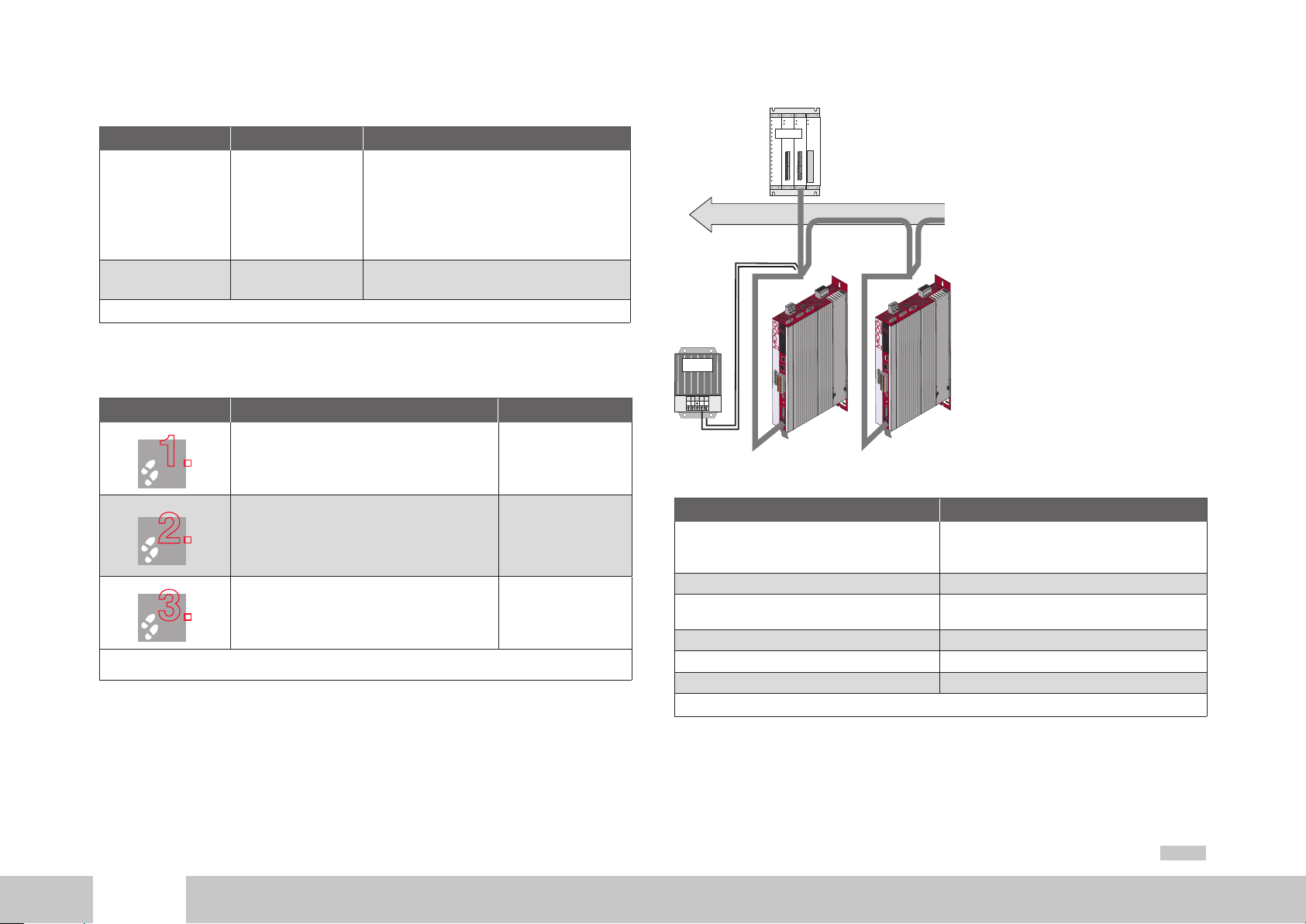

3 Mounting and Connection

ACHTUNG

WARNING

Kondensatorenent-

ladezeit > 3 min.

Betriebsanleitung

beachten!

Capacitor discharge

time > 3 min.

Pay attention to the

operation manual!

X

15

X

16

H

1

of EtherCAT

3.1 Installation and cabling

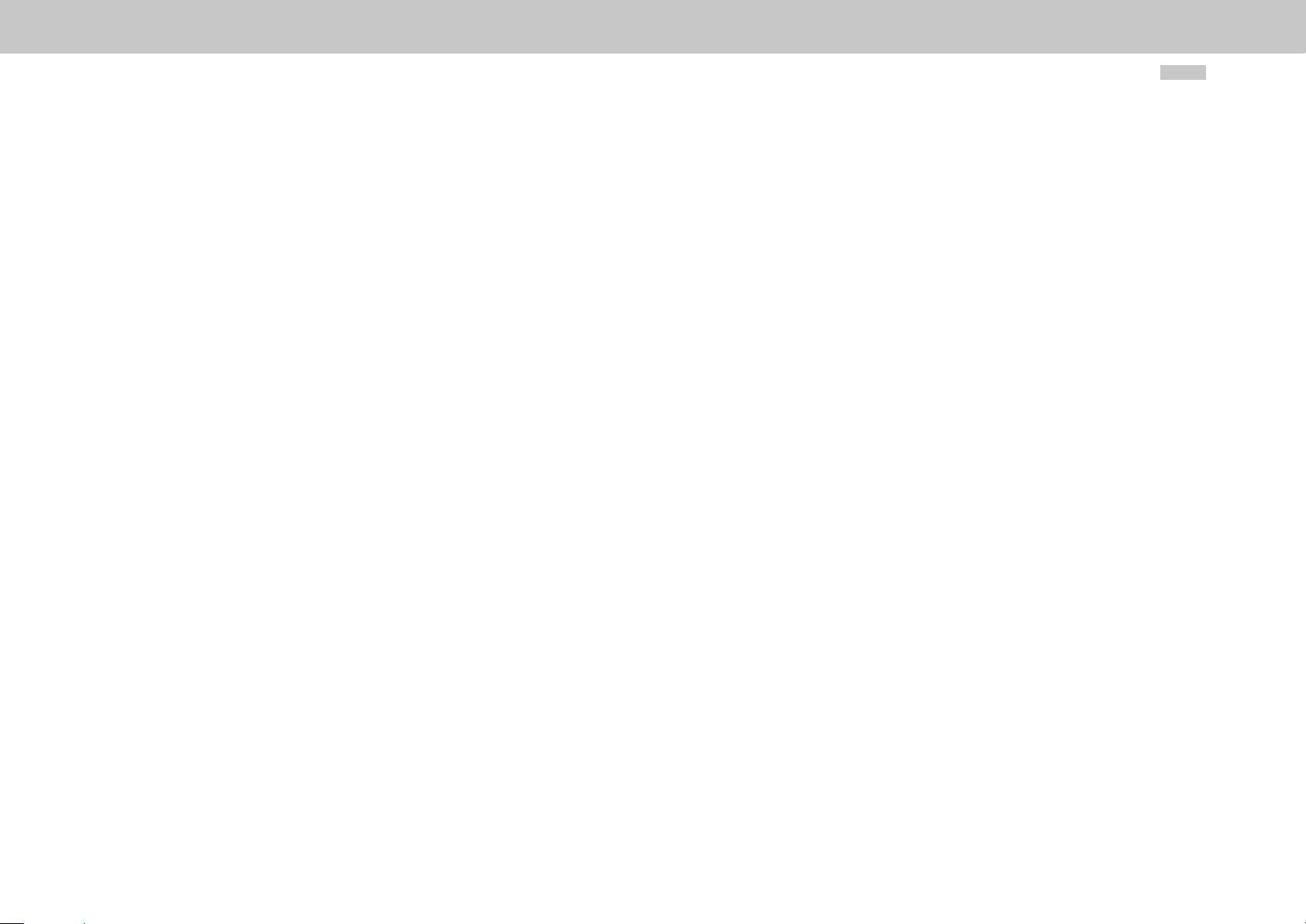

Setup of the EtherCAT network

In an EtherCAT network there is always one EtherCAT master (e.g. an industrial PC) and

a variable number of slaves (e.g. servo drive, bus terminals etc). Each EtherCAT slave has

two Ethernet ports. Slave to slave cabling is thus possible. All EtherCAT users are generally connected in a line with the master at the beginning of the circuit. On the last slave

in the line the second Ethernet port remains open.

IPC

56

1

X

2

X

3

X

4

X

5

X

4

1

H

15

12345678

4

S

19

X

16

1

X

2

X

3

X

4

X

REL

RSH

24

12

23

11

RSH

REL

22

10

ENPO

ISDSH

21

9

OSD02

ISD06

20

8

ISD05

OSD01

19

7

OSD00

ISD04

18

6

ISA1-

ISD03

17

5

ISA1+

ISD02

16

4

ISA0-

ISD01

15

3

ISD00

ISA0+

14

2

+24 V

+24 V

13

1

DGND

DGND

5

X

4

X

1

H

15

12345678

X

4

S

19

ACHTUNG

X

Kondensatorenent-

ladezeit > 3 min.

Betriebsanleitung

beachten!

WARNING

Capacitor discharge

time > 3 min.

Pay attention to the

operation manual!

16

X

Fig. 3.1

EtherCAT connection

56

REL

RSH

24

12

23

11

RSH

REL

22

10

ENPO

ISDSH

21

9

OSD02

ISD06

20

8

ISD05

OSD01

19

7

OSD00

ISD04

18

6

ISA1-

ISD03

17

5

ISA1+

ISD02

16

4

ISA0-

ISD01

15

3

ISD00

ISA0+

14

2

+24 V

+24 V

13

1

DGND

DGND

X

X

ACHTUNG

Kondensatorenent-

ladezeit > 3 min.

Betriebsanleitung

beachten!

WARNING

Capacitor discharge

time > 3 min.

Pay attention to the

operation manual!

X

56

1

X

2

X

3

X

4

X

REL

RSH

24

12

23

11

RSH

REL

22

10

ENPO

ISDSH

21

9

OSD02

ISD06

20

8

ISD05

OSD01

19

7

OSD00

ISD04

18

6

ISA1-

ISD03

17

5

ISA1+

ISD02

16

4

ISA0-

ISD01

15

3

ISD00

ISA0+

14

2

+24 V

+24 V

13

1

DGND

DGND

5

X

4

X

1

H

15

12345678

X

4

S

19

ACHTUNG

X

Kondensatorenent-

ladezeit > 3 min.

Betriebsanleitung

beachten!

WARNING

Capacitor discharge

time > 3 min.

Pay attention to the

operation manual!

16

X

IN and OUT socket (RJ45 input/output)

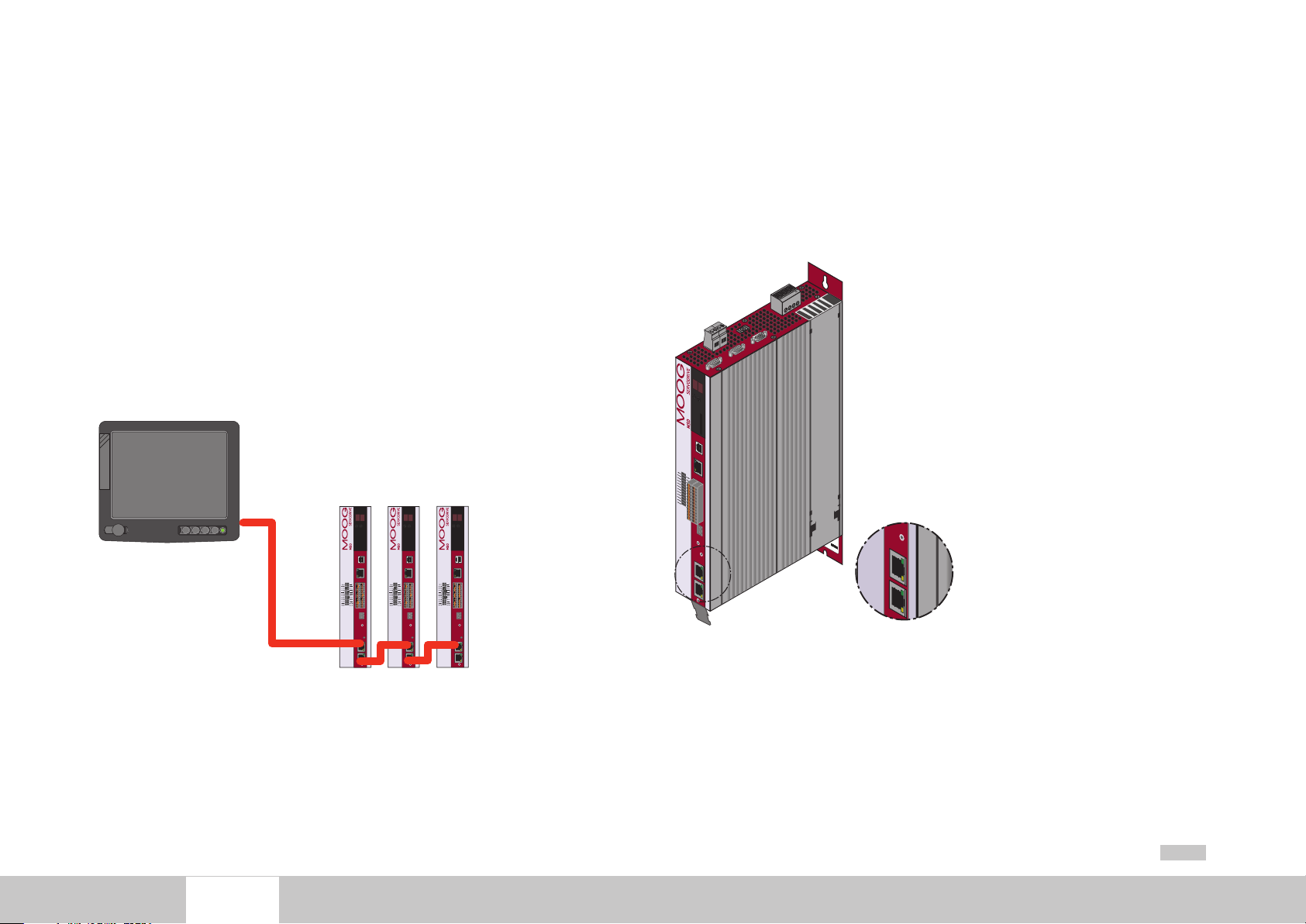

Each EtherCAT slave has two RJ45 sockets. The upper port (X15) is the input (IN) and the

lower port (X16) is the output (OUT) of the slave. The incoming cable (from the direction

of the master) is connected using the IN port, and the outgoing cable is connected to

the next slave using the OUT port. The OUT port remains blank for the last slave in the

series. An open output on a slave leads internally to a logical short circuit of the transmit

(Tx) and receive (Rx) cables. For this reason every EtherCAT network can be regarded as

a logical ring in terms of its topology.

L3

L2

L1

11

X

J+

J-

J+

J-

J+

J-

J+

J-

10

X

X

9

5

6

1

X

2

X

3

X

REL

24

REL

12

RSH

23

ISDSH

11

RSH

22

ISD06

10

4

X

ENPO

21

ISD05

9

OSD02

20

ISD04

8

OSD01

19

ISD03

7

OSD00

18

ISD02

6

17

ISA1-

ISD01

5

ISA1+

16

ISD00

4

15

ISA0-

+24 V

3

14

ISA0+

DGND

2

13

+24 V

1

DGND

5

X

1

H

15

X

ACHTUNG

Kondensatorenent-

ladezeit > 3 min.

Betriebsanleitung

beachten!

WARNING

Capacitor discharge

Pay attention to the

time > 3 min.

operation manual!

16

X

Fig. 3.2

Upper RJ45 port = input

Lower RJ45 port = output

X

8

X

7

X

6

EtherCAT option

356

33 Lah

www.l

Type:

Made

u

nau

s

t

SOA84.00

-

te

i

n

c

German

.

d

e

In:

C

y

6.0

000.00

US

LISTED

Out:

Ind. Co

00.0

19BB

nt. Eq.

SN.:

moog

MSD Servo Drive User Manual CANopen/EtherCAT

15

[ Section 3 ]

Page 16

moog

Pair #

MSD Servo Drive User Manual CANopen/EtherCAT

16

IMPORTANT: Errors in cabling (incorrect connection of input and output)

can lead to faulty addressing by the master.

Connecting cables

Ethernet patch cables or crossover cables are suitable connection cables as per the

CAT5e specification. Cables lengths of 0.3 m to a max. 100 m are permissible.

IMPORTANT: Never use EtherCAT and standard Ethernet together in one

physical network.

This can lead to impairments including communication outages!

To avoid confusion, always use different colours for EtherCAT and Ethernet

cables.

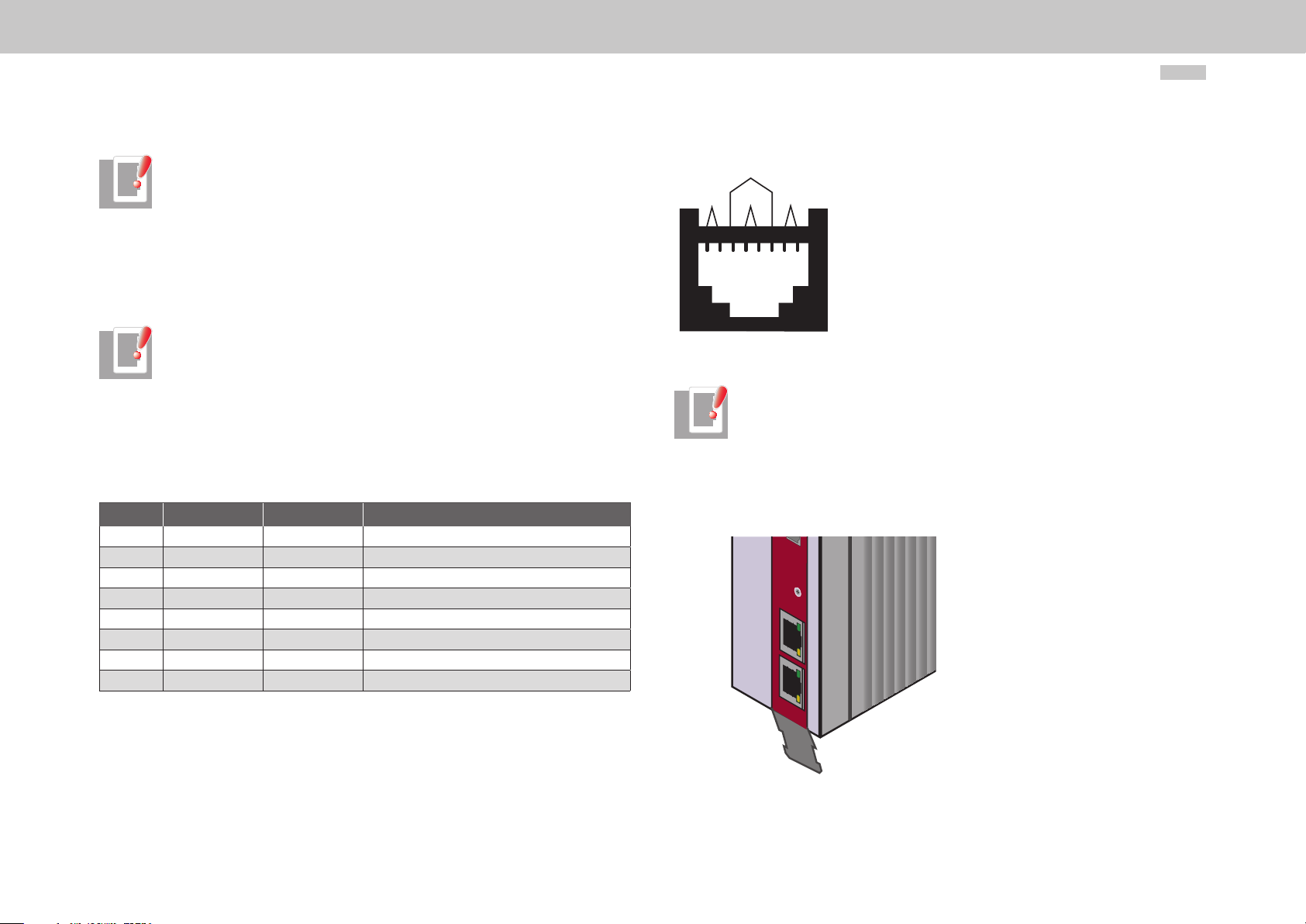

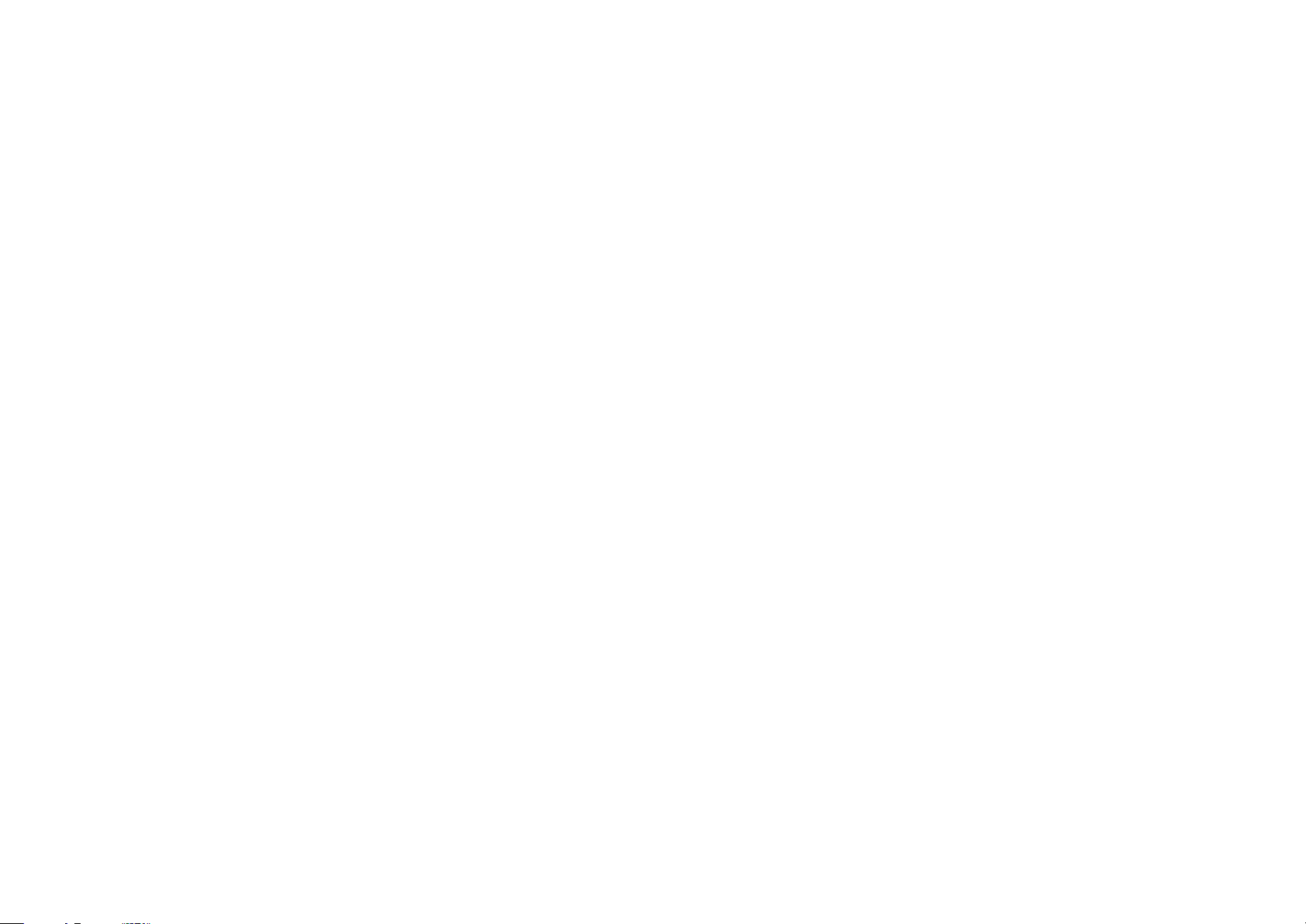

3.2 Pin assignment of the RJ45 socket

The two LEDs on the RJ45 socket mean the following:

PIN Colour Cable wire pairs Function

1 White/orange 2 TxData +

2 Orange 2 TxData -

3 White/green 3 RecvData +

4 Blue 1 Unused

5 White/ blue 1 Unused

6 Green 3 RecvData -

7 White/brown 4 Unused

8 Brown 4 Unused

Table 3.1 Meaning of LEDs without additional status/error LED

3

4

1

2

1234 5678

Fig. 3.3

RJ45 socket

NOTE: Ethernet cables are available in various lengths in the IT specialist

trade. Use CAT5e cable or better.

3.3 Meanings of LEDs

There are 2 LEDs on each RJ45 socket.

1

H

15

X

ACHTUNG

Kondensatorenent-

ladezeit> 3 min.

Betriebsanleitung

beachten!

WARNING

Capacitor discharge

Payattention to the

time > 3 min.

operationmanual!

16

X

Fig. 3.4

Device with EtherCAT option

Page 17

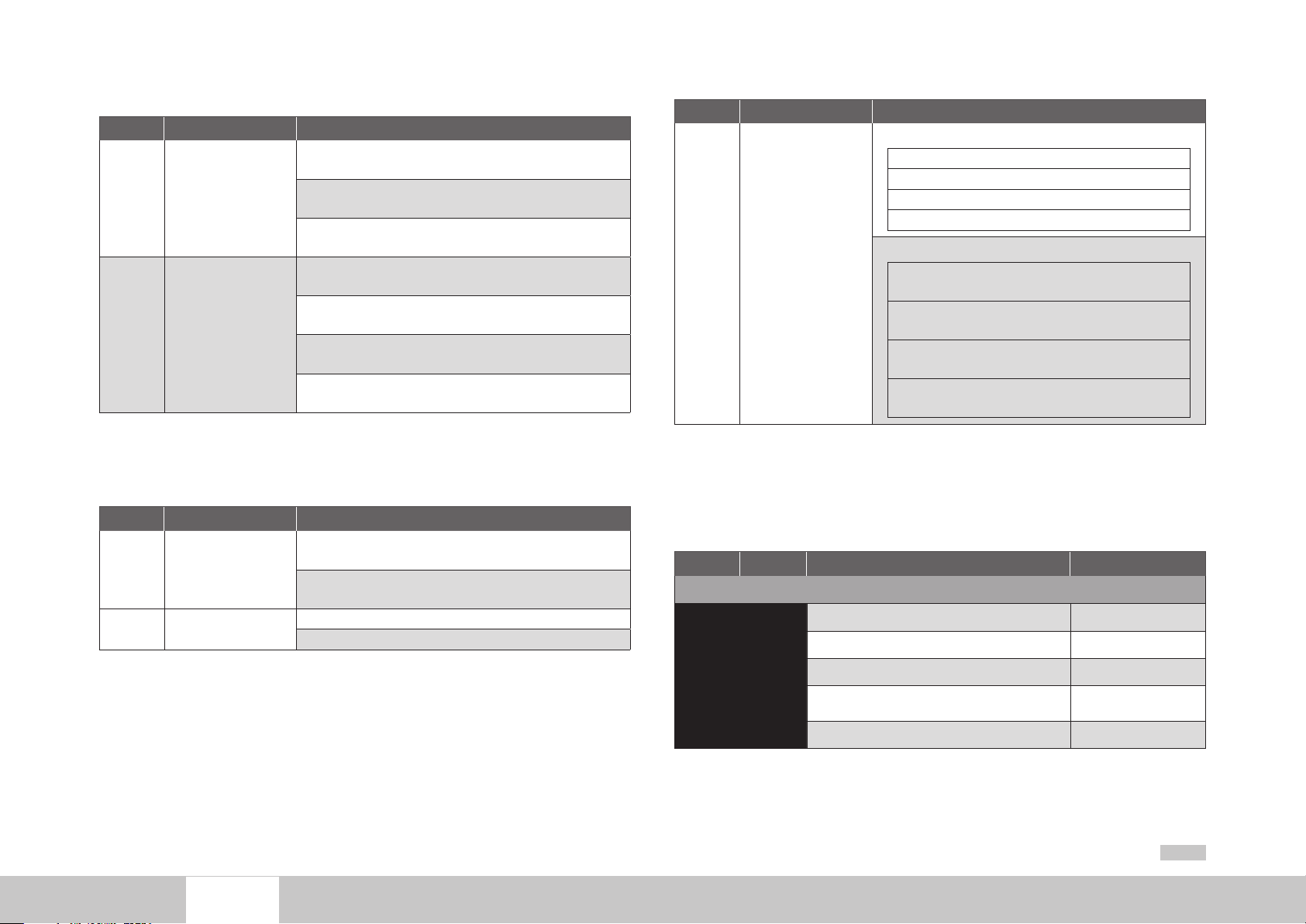

The two LEDs on the RJ45 socket mean the following:

LED Function Meaning

Off = no link

No connection with another user

Upper LED Link/activity

RUN

Lower

LED

(only active on

the lower port

if another user is

connected here)

On = link

Connection with another user exists, no data exchange

Flashing = activity

Data exchange active

Off = initialisation

Device is in initialisation state

Flashing = pre-operational

Device is in "pre-operational" state

Single flash = safe-operational

Device is in "safe-operational" state

On = operational

Device ready to start

Table 3.2 Meaning of LEDs without additional status/error LED

Depending on the device's hardware status, an additional status/error LED may be present in addition to the two LEDs on the two RJ45 sockets. In this case, the meaning of

the LEDs is as shown in the table below.

LED Function Meaning

Off = no link

Upper LED Link/activity

Lower LED Link (PHY)

Table 3.3 Meaning of LEDs with additional status/error LED

No connection with another user

On = link

Connection with another user exists, no data exchange

On = link

Off = no link

LED Function Meaning

Red = error

Off = no error

Flashing = invalid configuration

Single flash = local error

Double flash = watchdog timeout

Status LED

(RUN/

error)

Status/error

Green = RUN

Off = initialisation

Device is in initialisation state

Flashing = pre-operational

Device is in "pre-operational" state

Single flash = safe-operational

Device is in "safe-operational" state

On = operational

Device ready to start

Table 3.3 Meaning of LEDs with additional status/error LED

3.4 Display of operating statuses via 7-segment display

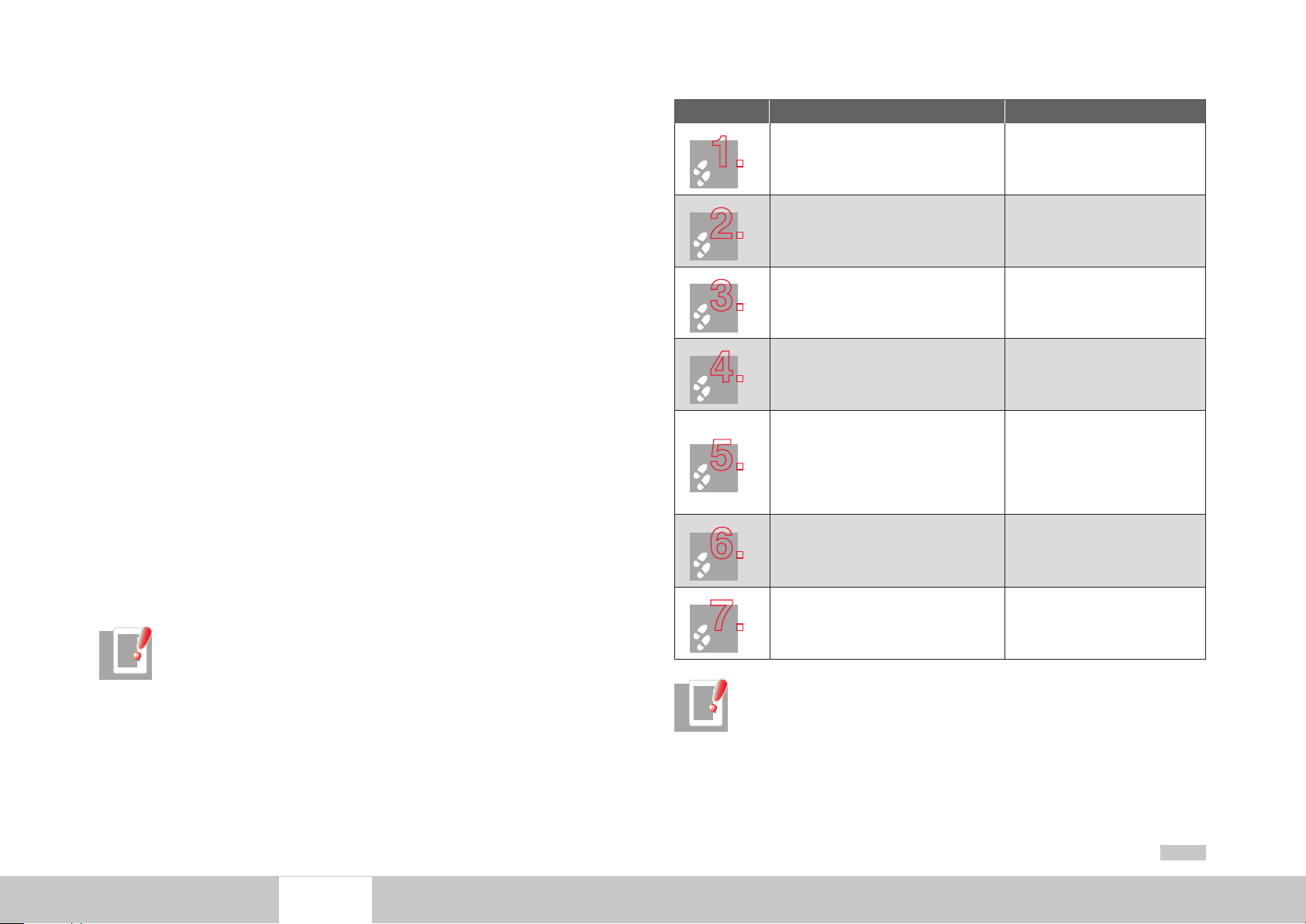

D1 D2 Meaning Parameter

System statuses

8.

8.

0.

S.*) 1.

S.*) 2.

3.

Device in reset status

Auto-initialisation on device startup (Start)

1) Not ready to switch on (no DC link voltage) (NotReadyToSwitchOn)

1) Starting lockout (DC link is OK, power stage not

ready)

Ready to switch on (power stage is ready) (ReadyToSwitchOn)

(SwitchOnDisabled)

moog

[ Section 3 ]

MSD Servo Drive User Manual CANopen/EtherCAT

17

Page 18

moog

MSD Servo Drive User Manual CANopen/EtherCAT

18

D1 D2 Meaning Parameter

4.

5.

6.

7.

E R

The following appear alternately in the event of error

E R.

X Y

X Y

1) S. flashes if t he STO (Safe Torqu e Off) functio n is active; the display is not lit if the func tion is not ac tive.

*) This is not a "safe display" under the terms of EN 61800-5-2.

2) The point flashes if the power stage is active.

On (power is connected to the device)

Drive ready (current applied to drive and drive ready

for input of setpoint)

Quick stop

Fault response active

Fault (see below) (Fault)

Display for errors or non-acknowledgeable errors

Error number (decimal)

Error localisation (decimal)

2)

2)

2)

2)

(SwitchedOn)

(OperationEnable)

(QuickStopActive)

(FaultReactionActive)

Example of the flash sequence:

ER > 02 > 05 * ER > 02 > 05 ...

Error: ER = "Fault"

3.5 Hardware enable

MSD Servo Drive has a control input for ENPO hardware enable on the control terminal.

This input must be configured to operate the power stage at 24 V.

The device also provides the function "STO (Safe Torque Off)" (see Operation Manual

or Application Manual MSD Servo Drive), category 3, control terminal ISDSH. For these

devices the relevant function logic must be implemented by way of the higher-order

drive as per the Application Manual.

Note: When the inputs ENPO and ISDSH are not configured, the device

stays in status 1 = "Not Ready to Switch On" or 2 = "Switch On Disabled".

Only after correct configuration can the status be exited by a "Shutdown

command" via bus.

Error name: 02 = "Error in the parameter list"

Description of error: 05 = "Function for checking current parameter list"

Page 19

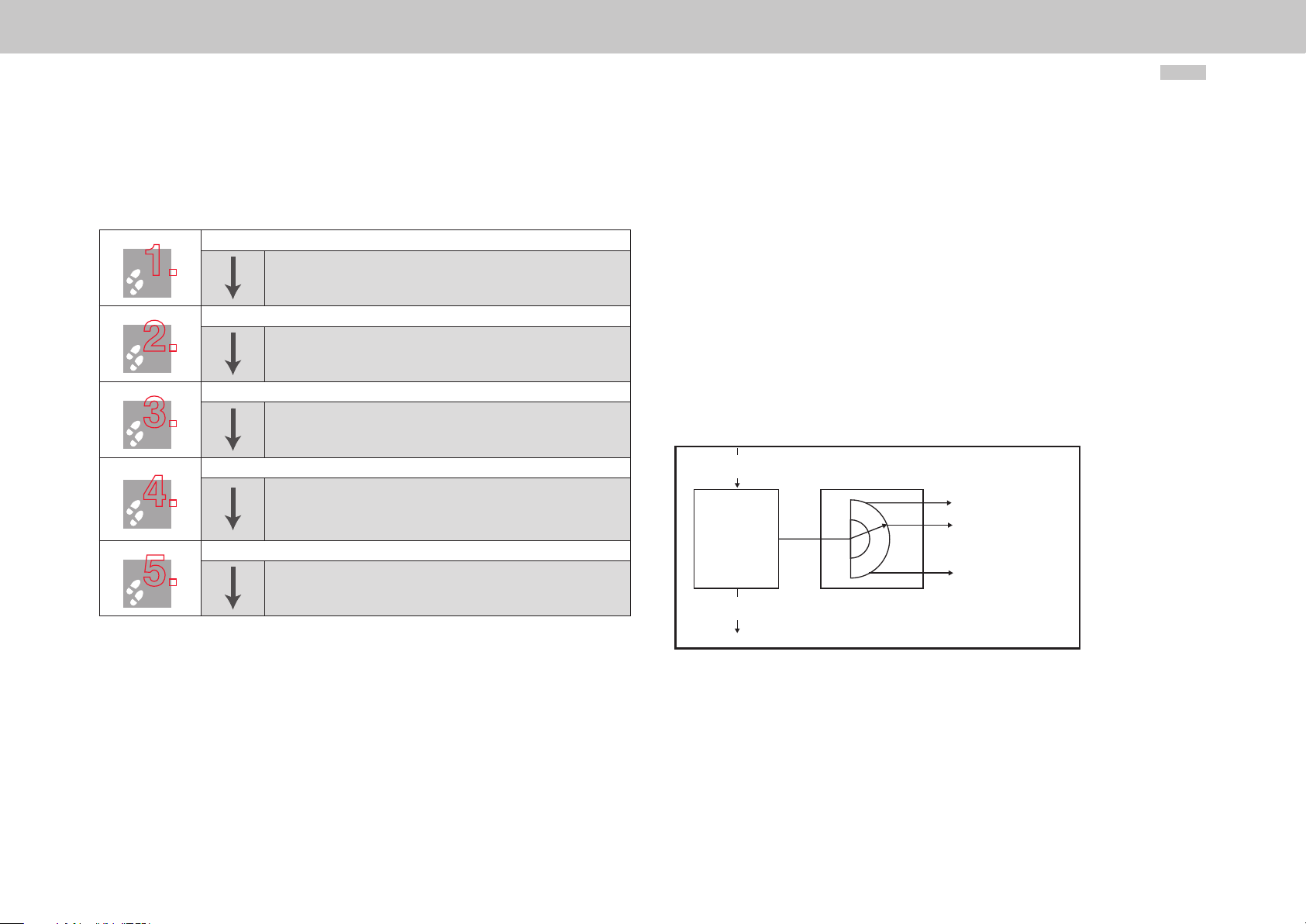

4 Commissioning and Configu-

Drive ADmin istrAtor

Drive ADmin istrAtor

1.

2.

3.

4.

5.

6.

7.

Step Action Note

ration of CANopen

4.1 General commissioning of CANopen/Ether-

CAT

4.1.1 Commissioning

The Moog

drive system. The Moog

access to a motor database for servo motors and enables general device configuration.

First commissioning is a separate subject regarding operation via the user interface and

is described in detail in the device's application manual.

4.1.2 Commissioning sequence

Preconditions:

• The drive device is wired as specified in the operation manual and first commis-

sioning is completed. (To test CAN communication, it is sufficient to connect

the voltage supply of the CAN option and the control voltage).

• If current is to be applied to the motor, the hardware enable (ENPO) and the

"STO (Safe Torque Off)" must also be correctly configured.

NOTE: For more detailed information on optimisation of the software func-

tions and control circuits, refer to the device application manual.

user interface is used for general commissioning of the

includes tools to identify motor data, provides

Check the wiring. Make sure the ENPO

hardware enable (X4) is not connected.

Switch on the mains power and the 24 V

supply to the CAN interface.

Configure the drive device using the

application manual.

Test the control quality and optimise

the drive settings as necessar y using the

operation manual.

Set the parameters for the CAN communication. The baud rate and the device

address are required. The address can be

selected using software and hardware.

The mapping must also be completed and

the active operation mode selected as per

CiA301/402.

Test the drive on the higher-order drive –

see section 3.4.

Finally, save the setting.

(Inputs/outputs, software functions

etc.)

Software and hardware address

are added...

Save device setting

Non-volatile in device

moog

[ Section 4 ]

NOTE: For more information on the subject of "Units and scalings", please

refer to section 7.4.

MSD Servo Drive User Manual CANopen/EtherCAT

19

Page 20

moog

DriveADministrAtor

1.

2.

3.

4.

5.

Drive ADminis trAtor

MSD Servo Drive User Manual CANopen/EtherCAT

20

4.1.3 Commissioning via Moog

Procedure for commissioning with the aid of the application manual

First commissioning based on operation manual

A precondition for this is first commissioning with the aid of the operation manual.

The user manual only covers adjustment of the soft ware functions.

Commissioning as per application manual

Setting the servo drive parameters using the application manual.

This includes, for example, the configuration of technology functions.

Commissioning based on CA Nopen user manual

Configuration of fieldbus-specific settings (e.g. baud rate) using this

document.

Checking the set application solution

To preserve the safety of personnel and machiner y, the application

solution should only be checked at low speed. Make sure the direction

of rotation is correct. In case of emergency the drive power stage can

be disabled, and the drive stopped, by removing the ENPO signal.

Completing commissioning

When you have successfully completed commissioning, save your

settings (using Moog

device.

) and store the data set in the

– Interpolated Position mode

– Cyclic Synchronous Position mode (EtherCAT only)

– Cyclic Synchronous Velocity mode (EtherCAT only)

– Cyclic Synchronous Torque mode (EtherCAT only)

In the course of first commissioning the user implements the drive settings using motor

data, control settings, I/O configuration etc.

A relevant control mode is also directly connected with the respective operation mode.

By switching modes of operation via CANopen/EtherCAT, it is possible to switch directly

between position control, speed control and torque control.

The drive is thus in speed control for Profile Velocity mode and in position control for

Profile Position mode.

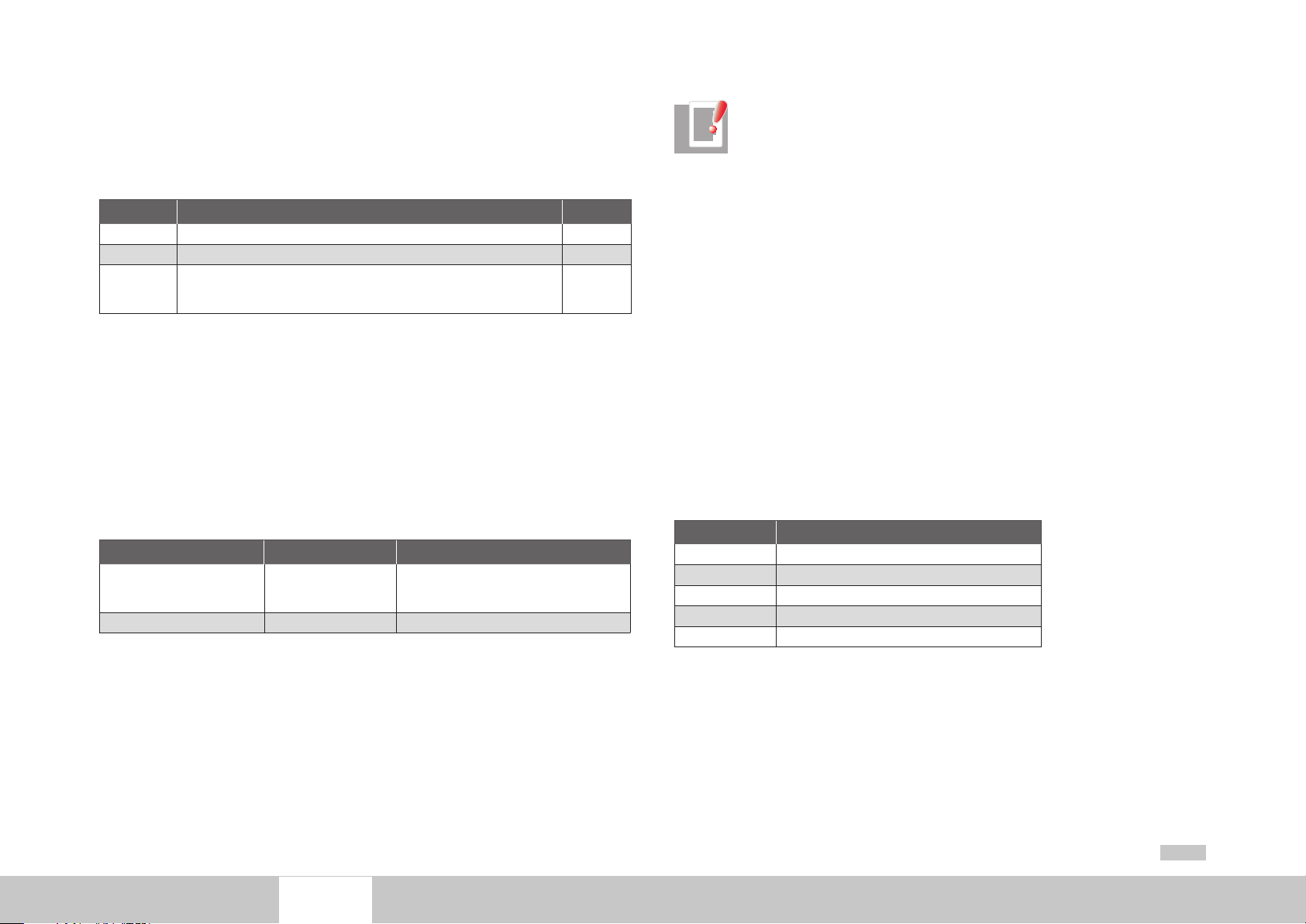

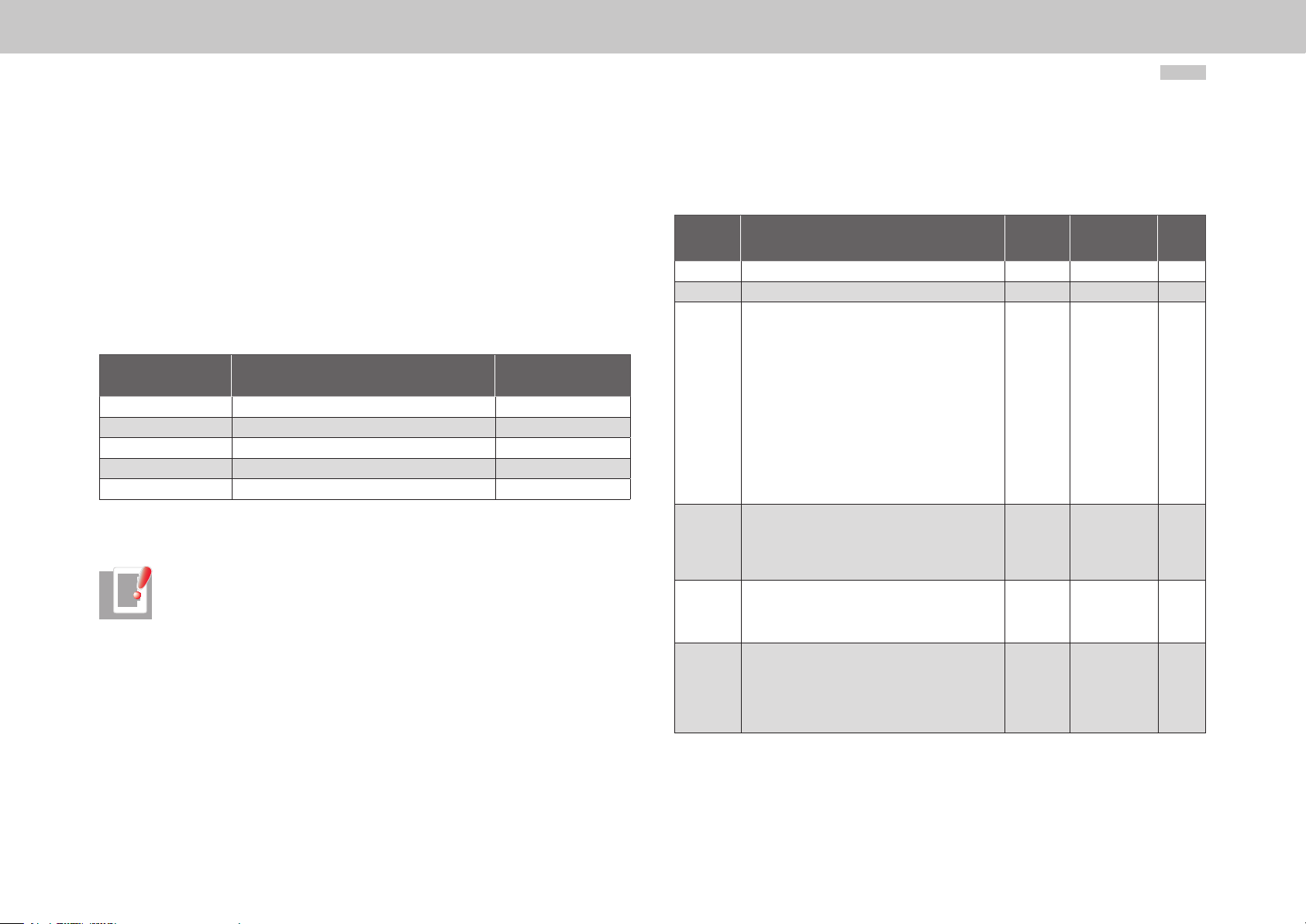

4.1.5 Functionality of operation modes

modes_of_operation

(6060h)

Profile Position Mode

Operation

Mode

Function

modes_of_operation_display

(6061h)

Profile Velocity Mode

Homing Mode

4.1.4 Operation mode selection (modes of operation)

There are different control modes for operation of the devices via CANopen. The active

operation mode is always selected via CiA402 object 6060h (Modes of Operation).

MSD Servo Drive supports the operation modes as per the CiA402:

– Profile Position mode

– Profile Velocity mode

– Homing mode

Fig. 4.1

Users can switch between the various operation modes, as long as these are supported

by the device.

The status word contains bits, the meaning of which depends on the operation mode.

For monitoring, it is necessary for the bits to change their meaning when switching

operation modes; see also Chapter 6.

Changing functionality of operation modes in the display

Page 21

4.1.6 Setting the timing parameters

Drive ADmin istrAtor

To ensure correct communication with the drive, three timing parameters have to be set

on MSD Servo Drive. As a rule, these should all be set to the same value. It should be

borne in mind that different units have to be used when setting the three parameters

(see table).

Para ID Name/object Unit

P 0306 Internal interpolator cycle time ms

P 2015 Communication cycle period/0x1006 µs

P 2266

Index 0

Index 1

Table 4.1 Setting the timing parameters

0x60C2

Interpolation time base

Interpolation time exponent

s

-

For EtherCAT, parameter P 2266 MPRO_402_IntTimePeriod (object 0x60C2) must be set

to the cycle time for the setpoints (or the telegrams).

4.2 CAN-specific configuration

4.2.1 Setting the software address and baud rate

The software address and baud rate can be set using the following device parameters via

Moog

Parameter Function Description

P 2005-COM_CAN_Adr CANopen address Address assignment via parameter. For

P 2006-COM_CAN_Baudrate Baud rate Permissible baud rates – see section 2.3

Table 4.2 Parameters on the Bus Systems function screen

:

more information on setting the address,

see section 2.1

NOTE: MSD Servo Drive has a default baud rate of 1 Mbit.

The actual address is calculated by adding the software and hardware

address and is displayed using parameter P 2058 COM_CAN_Adr_Act.

Any change to the baud rate in parameter P 2006 COM_CAN_Baudrate only takes effect once MSD Servo Drive has been restarted. The current baud rate is displayed using

parameter P 2059 COM_CAN_Baudrate_act.

4.2.2 Commissioning instructions

A drive device may not respond to a telegram for a variety of reasons:

• There is no reply if the scope of telegram (baud rate, data length) on the master

computer is not correct.

• There is no reply if a drive device is addressed with the wrong bus address.

• There is no reply if the serial connection between the master computer and the

drive device is not correctly set up.

• There is no reply if the 24 V supply to the CAN connection is missing or the cabling

is faulty.

• There is no valid reply if several devices with the same device address are con-

nected to the bus.

• There is no reply if the device has certain network statuses. The current network

status can be checked using parameter P 2060 COM_CAN_NMT_State.

Parameter 2060 Description

0 Boot- up

1 Init

4 Stopped /safe OP

5 Operational

127 Pre-Operational

Table 4.3 Parameter P 2060

moog

[ Section 4 ]

MSD Servo Drive User Manual CANopen/EtherCAT

21

Page 22

moog

Drive ADmin istrAtor

Drive ADmin istrAtor

Drive ADmin istrAtor

Drive ADmin istrAtor

MSD Servo Drive User Manual CANopen/EtherCAT

22

4.2.3 Testing the higher-order drive

To activate changed settings the device must be switched off and back on again. When

the power is connected, after an initialisation period of a few seconds the device must

transmit a one-off boot-up message (ID 700h + node ID = 701h for device address 1).

If this happens, the communication is OK.

NOTE: When transferring data to the device via SDO telegrams the number

of data bytes transferred should be taken into account. For this the correct

length information must be transferred in the control byte.

Alternatively, however, an SDO transfer without specification of the data

length is also possible. The correct operation of the control byte in the SDO

telegram should also be observed.

4.2.4 Data handling

Saving the settings

All configuration data can be backed up by the Moog

NOTE: Please note, however, that some objects are RAM variables, which

must be correctly operated and initialised by the drive. This includes, for example, object 6060h: Modes of Operation.

.

Restoring factory defaults

There are two possible ways of restoring the devices' default factory settings:

Via fieldbus

• Write value 1 to subindex 3 of object 200BH-PARA _SetCmd. The factory settings

are then applied to the whole device.

NOTE: Please note that this also affects the settings for the baud rate/device

address. The changes take effect after a "Reset node" command or device

restart.

Via Moog

Object 200BH-PARA_SetCmd Subindex 1 is automatically set to 0 by the device after

the save operation. This process can be used for timeout monitoring of the function.

• First select the relevant MSD Servo Drive in the Moog

ture. The right mouse button opens a context menu from which you can select the

"Reset Device Setting" entry.

NOTE: In both cases it takes approx. 10 seconds for the device to signal that

it is ready for operation again. During this time the device performs a self-test

and changes all its settings to the factory setting. However, this setting is only

retained if the data is backed up in the device. Data backup is initiated via the

Moog

SetCmd Subindex 1 = 1 via the bus system. The save operation can also be

executed using object 1010 hex.

ATTENTION: Data backup takes a few hundred ms. During that time the

device must not be switched off, otherwise the settings will be lost.

!

user interface or by writing to object 200BH-PARA_

tree struc-

4.2.5 Control functions

Control functions can be optimally adapted to the relevant application. Consequently,

several control formats are offered. The appropriate formats can be selected by the master during the setup phase via the bus, or by adjusting the relevant device parameters.

The drive devices' state machine has a cycle time of 1 ms.

All control commands and setpoints are processed within that cycle time by the drive

device.

NOTE: Control PDOs are processed in a minimum cycle time of 1 ms. If

protocols arrive at the device faster, the telegram that arrived most recently

overwrites the previous one. An error message is not generated if telegrams

are overwritten as a result of insufficient cycle time.

Page 23

4.3 Commissioning and Configuration of

EtherCAT

Commissioning via EtherCAT is possible using the XML file supplied on your drive. All

further commissioning and configuration steps depend on the drive used. For notes on

this, please refer to the documentation provided by your drive manufacturer.

moog

[ Section 4 ]

MSD Servo Drive User Manual CANopen/EtherCAT

23

Page 24

moog

MSD Servo Drive User Manual CANopen/EtherCAT

24

Page 25

5 Setting the Device Parameters

for CANopen

5.1 Implemented CiA301 functionality

5.1.2 Object directory of CiA301

For a full overview of the supported CAN objects of MSD Servo Drive, please refer to the

EDS file.

Here you can refer both to the CANopen objects of CiA301 and CiA402, and to the

manufacturer-specific objects of the device.

The following list shows an extract of the object directories with important CiA301

objects. For these objects the transmission types or mapping, for example, are explained

below.

5.1.1 Communication objects

• Boot-up to CiA301 V4.01 (guarding boot-up via identifier 700h)

• Four variably mappable TxPDOs (transmission type 1 to 240, 254 and 255 dec

possible)

• Four variably mappable RxPDOs (transmission type 1 to 240, 254 and 255 dec

possible)

• One SDO server – pay attention to definition of time conditions (typical processing

time in device approx. 5 ms, depending on capacity utilisation)

• One emergency object error code to CiA402 plus manufacturer-specific error loca-

tion and number, operating hours of the device

• One Sync object

• NMT state machine to CiA301

• Node guarding and heartbeat (see below)

• Processing cycle:

PDO protocols can be processed in a minimum cycle time of 1 ms. If protocols

arrive faster, the previous protocols are overwritten.

• SDO protocols and NMT services are processed acyclically. Typical processing times

lie between 1 and 5 ms.

• Initialisation values of the COB IDs based on Predefined Connection Set

• Access to device parameters 2000h–5FFFh (expedited/non-expedited)

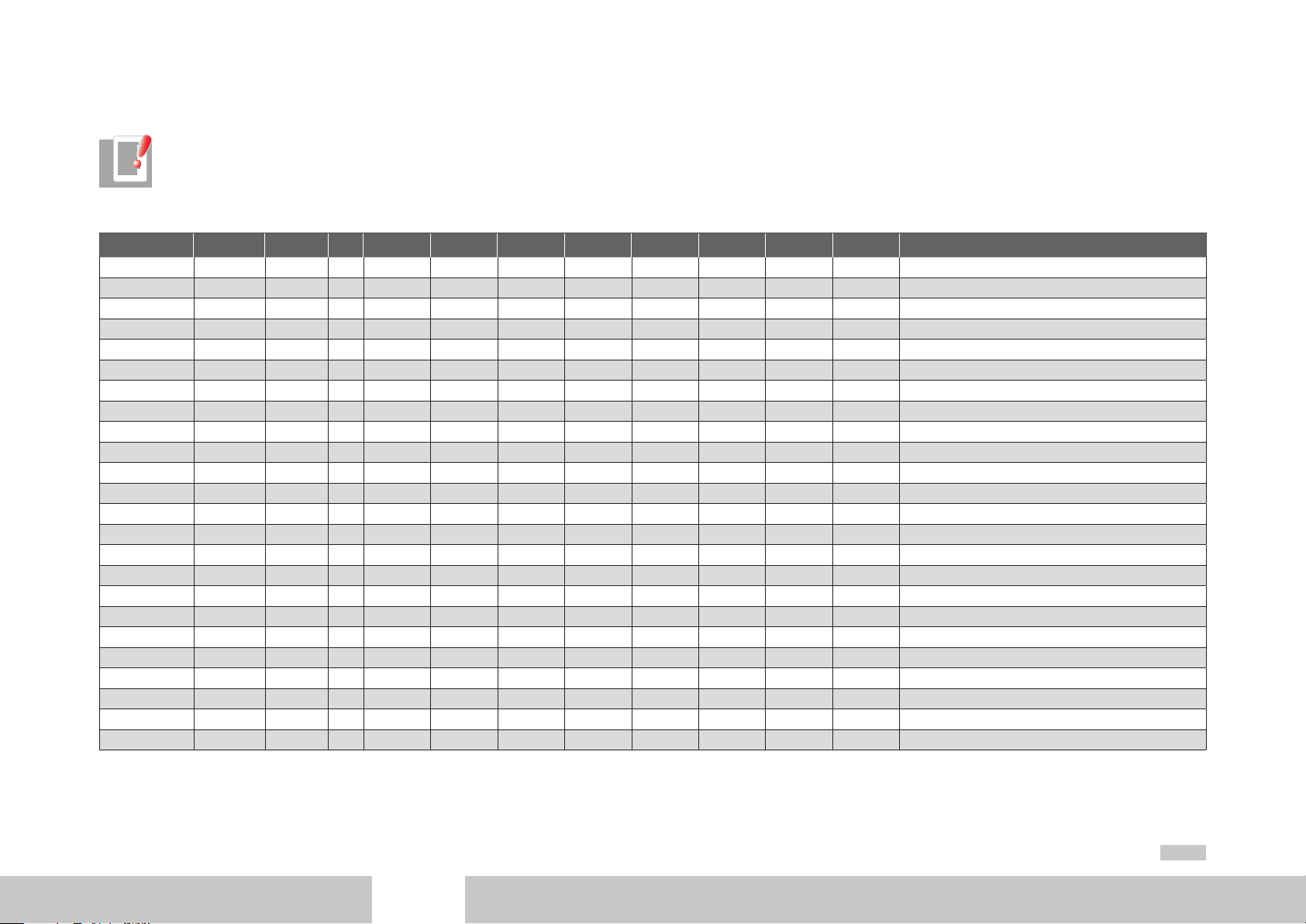

Object

no.

0x1000 Device_Type VAR Unsigned32 ro

0x1001 Error_ Register VAR Unsigned8 ro

0x1003 Pre-Defined_Error_Field One

0x1005 COB-ID_SYNC VAR Unsigned32 rw

0x1006 Communication_Cycle_Period VAR Unsigned32 rw

0x1007 Synchronous_Window_Length VAR Unsigned32 rw

0x1008 Manufacturer device name String

0x1009 Manufacturer hardware version String

0x100A Manufacturer software version String

0x100C Guard_Time VA R Unsigned16

0x100D Life_Time_Factor VAR Unsigned8

0x1010 Store parameters AR R AY Unsigned32 rw

0x1011 Restore default parameters AR R AY Unsigned32 rw

0x1014 COD - ID _EMCY VAR Unsigned32

0x1017 Producer_Heartbeat_Time VAR Unsigned16 rw

0x1018 Identity_Object: support all 4

0x14 00 1st_ Receive_ PDO_Parameter RECORD PDO CommPar rw

0x14 01 2nd_Receive_ PDO_Parameter R ECORD PDO CommPar rw

0x14 02 3rd_Receive_PDO_ Parameter RECO RD PDO CommPar rw

Table 5.1 Object directory

Object name

subentry

entries (serial number etc.)

Object

code

AR R AY Unsigned32 ro

RECORD Identity (23h) ro

Typ e At tr.

moog

[ Section 5 ]

MSD Servo Drive User Manual CANopen/EtherCAT

25

Page 26

moog

MSD Servo Drive User Manual CANopen/EtherCAT

26

Object

no.

0x14 03 4th_ Receive_ PDO_ Parameter RECO RD PDO CommPar rw

0x1600 1st_Receive_ PDO_Mapping

0x1601 2nd_Receive_PDO_Mapping

0x1602 3rd_Receive_ PDO_Mapping

0x1603 4th_Receive_ PDO_Mapping

max. 8

objects

0x1800 1st_Transmit_PDO_Parameter RE COR D PDO CommPar (20h) rw

0x1801 2nd_Transmit_PDO_Parameter RECORD PDO CommPar (20h) rw

0x1802 3rd_Transmit_PDO_Parameter RECORD PDO CommPar rw

0x1803 4th_Transmit_PDO_Parameter RECORD PDO CommPar rw

0x1A00 1st_Transmit_PDO_Mapping

max. 8

objects

0x1A01 2nd_Transmit_PDO_ Mapping

max. 8

objects

0x1A02 3rd_Transmit_PDO_Mapping

max. 8

objects

0x1A03 4th_Transmit_PDO_Mapping

max. 8

objects

Object name

max. 8 objects

max. 8 objects

max. 8 objects

Object

code

RECORD PDO Mapping (21h) rw

RECORD PDO Mapping rw

RECORD PDO Mapping rw

RECORD PDO Mapping rw

RECORD PDO Mapping rw

RECORD PDO Mapping rw

RECORD PDO Mapping rw

RECORD PDO Mapping rw

Typ e At tr.

Table 5.1 Object directory

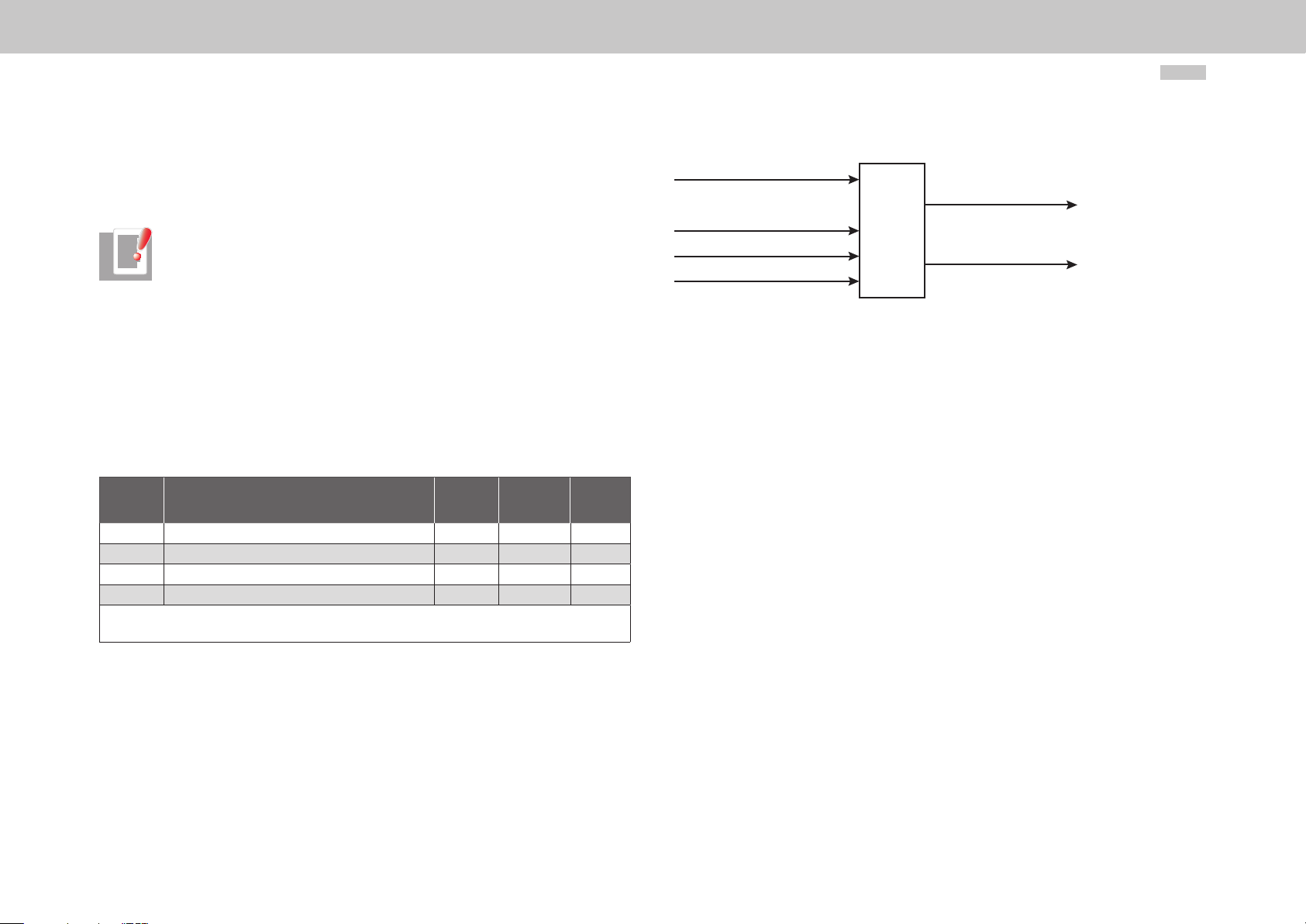

5.2 Parameter channel (Service Data Objects)

The Service Data Object (SDO) permits write and read access to the object directory.

This SDO is implemented according to the CAL specification by the Multiplexed Domain

CMS object. The protocol is designed for the transfer of data of any length. An SDO

server is integrated into the device for SDO transfer. Communication is by way of two

reserved identifiers.

Receive SDO: 600 h

Transmit SDO: 580 h

SDO client

600H + node-ID Byte 0 1 2 3 4 5 6 7

580H + node-ID Byte 0 1 2 3 4 5 6 7

Fig. 5.1

Example of an SDO data transfer in Expedited mode

Data

Subindex

Index

Control field

Subindex

Index

Control field

The CAL specification makes a basic distinction between three protocol services:

• Download protocol (Write)

• Upload protocol (Read)

• Abort protocol (Error)

The upload and download protocols also differentiate between:

• Expedited Multiplexed Domain protocol, for access to objects with a data length

of up to 4 bytes (shown above) and

• Multiplexed Domain protocol, for access to objects of any length

SDO server

Object

directory

Servo

drive

Page 27

The entries in the "Control field" are generated by the CANopen driver. They are only

Drive ADmin istrAtor

Drive ADmin istrAtor

Drive ADmin istrAtor

included to fully document the examples cited. The entries are dependent on the transferred data.

The control field is described in the CiA301 profile.

5.2.1 Data types

NOTE: The Moog

settings in the form of value substitution texts.

Example: Parameter 45 0-MOT_Type = PSM

When writing and reading via the fieldbus the corresponding numerical values for these

value substitution texts must be used. These values are displayed in brackets ( ) when the

parameter is opened in Moog

Example:

Parameter 45 0-MOT_Type = PSM (1)

The drive units support the following parameter data formats:

user interface displays many parameter

.

5.2.2 Representation of data types in the control protocol

All data types are represented as 32-bit variables in Intel format, and with the correct

preceding sign.

Data bytes in the

control protocol

USIGN8/INT8*

USI GN16 / IN T16*

USIGN32/INT 32

FLOAT32 IEEE format

STRING See examples

* filled up with the appropriate preceding sign (00H or FFH)

Table 5.3 Assignment of data types in the data field

3 4 5 6

Low Word

Low Byte

Low Word High

Byte

High Word Low

Byte

High Word

High Byte

5.2.3 Access to device parameters

Where can I find the device parameters?

Data type Value range Function

USIGN8 0...255

UnsignedUSI GN16 0...65535

USIGN32 0...4294967295

INT8 -128 ...127

Integer, signedINT8 -32768 ...32767

INT32 -21474836 48 ...2147483647

FLOAT32 see IEEE

STRING

Table 5.2 Data types

32-bit floating point number in IEEE

format

ASCII characters, max. 100 bytes in

bus mode incl. zero terminator

moog

[ Section 5 ]

All device parameters are addressed by way of a parameter number.

In addition to the standard objects, the CANopen profile also provides an area for

manufacturer-specific entries. This area lies between 2000 h and 5FFF h. If you then

want to read or write parameter 455-MOT_FNOM (rated motor frequency) of the device,

the object index is generated from 2000 h + parameter number (hex).

In our example: Index = 2000 h + 1C7 H

NOTE: Profile-specific parameters are visible in Moog

, but

only in the 1000H... (CiA301 objects)/6000H... (CiA402 objects) writeable/

readable range. This means parameters stored both as device parameters

(2xxxH range) and as profile parameters (CiA301/CiA402) can only be read

and written to via their object number (CiA301/CiA402 profile).

MSD Servo Drive User Manual CANopen/EtherCAT

27

Page 28

moog

Example:

The object 1000h Device Type exists both in the CiA301 profile and also as a device

parameter with parameter number 2011. Simultaneous two-way access would therefore

be possible via CANopen or EtherCAT. In order to uniquely configure the access, the

read/write access for this object is only possible via profile-specific object number 1000h

(as per CiA301).

5.3 Examples of SDO handling

The CANopen objects and the servo drive parameters can be accessed via the Receive

SDO (COB IDs: 600 h + node ID).

In a data transfer protocol a maximum of 4 data bytes can be transferred in Expedited

mode. This means all device parameters, apart from String parameters, can be written

to with a single transfer protocol.

String parameters can be written to using the Multiplexed Domain protocol.

MSD Servo Drive User Manual CANopen/EtherCAT

28

Page 29

Example of read access to string parameters (parameter 3 DV_DeviceAliasName)

Note:

- All numeric values are hexadecimal

- The string "X-axis" is to be transferred

- This text is entered in MSD Servo Drive parameter 3 DV_DeviceAliasName

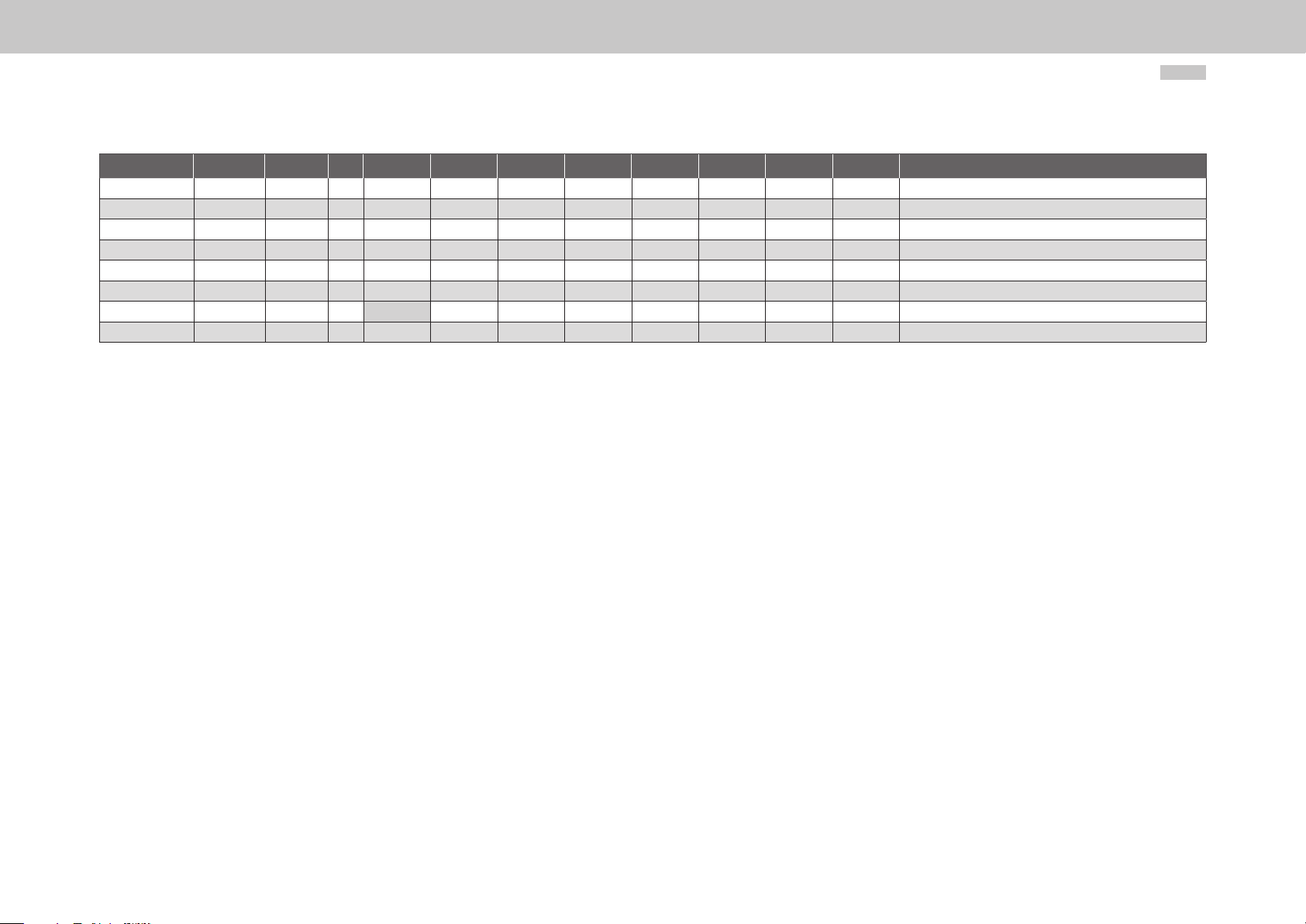

TIME ID Direction DLC Byte 0 Byte 1 Byte 2 Byte 3 By te 4 Byte 5 Byte 6 Byte 7 Comments

18.992445 Tx 6 01 8 40 03 20 00 00 00 00 00 Read object 2003h (= parameter 3)

18.992972 Rx 581 8 41 03 20 00 64 00 00 00 Reply: 64h --> 100 bytes are to be transferred

35.514341 Tx 601 8 60 00 00 00 00 00 00 00 Requirement: segment 1

35.514 59 4 Rx 581 8 00 58 2d 41 78 69 73 00 Reply: segment 1 – contains "X-axis"

36.269620 Tx 601 8 70 00 00 00 00 00 00 00 Requirement: segment 2

36 .270175 Rx 581 8 10 00 00 00 00 00 00 00 Reply: segment 2

36.982385 Tx 601 8 60 00 00 00 00 00 00 00 Requirement: segment 3

36.982664 Rx 581 8 00 00 00 00 00 00 00 00 Reply: segment 3

37.686447 Tx 601 8 70 00 00 00 00 00 00 00 Requirement: segment 4

37.686706 Rx 581 8 10 00 00 00 00 00 00 00 Reply: segment 4

38 .4213 44 Tx 601 8 60 00 00 00 00 00 00 00 Requirement: segment 5

38.4216 04 Rx 581 8 00 00 00 00 00 00 00 00 Reply: segment 5

39.053526 Tx 601 8 70 00 00 00 00 00 00 00 Requirement: segment 6

39.053787 Rx 581 8 10 00 00 00 00 00 00 00 Reply: segment 6

39.749 0 81 Tx 6 01 8 60 00 00 00 00 00 00 00 Requirement: segment 7

39.749347 Rx 581 8 00 00 00 00 00 00 00 00 Reply: segment 7

40.428981 Tx 601 8 70 00 00 00 00 00 00 00 Requirement: segment 8

40.429249 Rx 581 8 10 00 00 00 00 00 00 00 Reply: segment 8

41.0 85 839 Tx 601 8 60 00 00 00 00 00 00 00 Requirement: segment 9

41.086198 Rx 581 8 00 00 00 00 00 00 00 00 Reply: segment 9

41.74075 5 Tx 601 8 70 00 00 00 00 00 00 00 Requirement: segment 10

41.741148 Rx 581 8 10 00 00 00 00 00 00 00 Reply: segment 10

42.514 034 Tx 601 8 60 00 00 00 00 00 00 00 Requirement: segment 11

42.514294 Rx 581 8 00 00 00 00 00 00 00 00 Reply: segment 11

moog

[ Section 5 ]

MSD Servo Drive User Manual CANopen/EtherCAT

29

Page 30

moog

TIME ID Direction DLC Byte 0 Byte 1 Byte 2 Byte 3 By te 4 Byte 5 Byte 6 Byte 7 Comments

43.172512 Tx 601 8 70 00 00 00 00 00 00 00 Requirement: segment 12

43.172787 Rx 581 8 10 00 00 00 00 00 00 00 Reply: segment 12

43.908571 Tx 601 8 60 00 00 00 00 00 00 00 Requirement: segment 13

43.908831 Rx 581 8 00 00 00 00 00 00 00 00 Reply: segment 13

44.668466 Tx 601 8 70 00 00 00 00 00 00 00 Requirement: segment 14

44.66 874 0 Rx 581 8 10 00 00 00 00 00 00 00 Reply: segment 14

53.884 044 Tx 601 8 60 00 00 00 00 00 00 00 Requirement: segment 15

53. 8 84414 Rx 581 8 0b 00 00 00 00 00 00 00 Reply: segment 15 – No further segments

MSD Servo Drive User Manual CANopen/EtherCAT

Transmission of transferred values (ASCII):

At 6 bytes, the string "X-axis" is so short that it can be fully transferred in the first

segment.

The following segments (of 100 bytes of the parameter) therefore only include zeroes...

Transmitted bytes (HEX) 58 2d 41 78 69 73

Interpretation (ASCII) X - a x i s

30

Page 31

5.3.1 Parameter set download

Drive ADmin istrAtor

The following data can be transferred to MSD Servo Drive via the CANopen interface:

• Parameter set

• A parameter data set can be downloaded by SDO transfer or via the

Moog

ic device parameters are also accessible via objects 2000h–5FFFh

If a unified valid data set (i.e. not just individual parameters) needs to be transferred from

the CAN master to the device, the following points must be considered:

On every transfer of an individual parameter the servo drive checks whether the parameter matches its existing data set. The check of the new parameter value sometimes

refers to existing parameter values. This means it is possible that the servo drive may

reject a parameter, even though it originates from a valid parameter data set, because

the parameter set is not yet complete in the device.

Since a simple error reset may not eliminate the cause of the error, it may be necessary

to reset to the factory defaults.

user interface version 5 or higher. All manufacturer-specif-

Remedy:

The parameter data set is transferred to the servo drive without a logic check. At the

end of the download, the logic check is reactivated and the servo drive checks the

transferred parameters for plausibility. During this check parameter settings that do not

functionally match are reported as errors.

Download procedure for a completed parameter data set:

1. Reporting a download without logic check

To deactivate the logic check and to report the download of a data set, the value 1

is written to parameter 11 subindex 4.

3. Completing download and activating plausibility check

Once all parameter data has been transferred to the servo drive, parameter 11

subindex 4 is reset to the value 0. Then a logic check of the device parameters is

carried out. In case of error the user receives an emergency message.

NOTE: The download of a complete parameter data set is only possible when

the system is at a standstill. Make sure the servo drive is not switched on for

the duration of the download.

2. Downloading the parameter data to the servo drive

In this step the individual parameters of the data set are sequentially transferred

to the drive. Despite the deactivated logic check, basic checking mechanisms are

still active. These monitor, for example, the maintenance of parameter limits and

become active if these are infringed. Therefore, if a value range limit is infringed

by the download of a parameter, this SDO protocol is directly rejected (Abort message).

moog

[ Section 5 ]

MSD Servo Drive User Manual CANopen/EtherCAT

31

Page 32

moog

MSD Servo Drive User Manual CANopen/EtherCAT

32

5.4 PDO transmission types

In connection with the PDO transfer, various transmission types are defined in CANopen

profile CiA301. The transmission type and event control can be set separately for all supported RxPDOs and TxPDOs. The servo drive supports the following transmission types:

Acyclic synchronous type no. 0 h

Meaning: RxPDOs are evaluated once a device-specific event has been triggered and

the next SYNC object has been received; the TxPDO is then transmitted (from firmware

version 2.15-00).

Cyclic synchronous types no. 1–F0 h

Meaning: The difference between this and the acyclic synchronous transmission type is

that RxPDOs are only evaluated after receipt of 1–F0 h Sync objects and TxPDOs are only

transmitted every 1–F0 h Sync objects.

Asynchronous types no. FE h and FF h

Meaning: RxPDOs are evaluated immediately on receipt; TxPDOs are transmitted by

a device-specific event. The Sync object is irrelevant to this mode of transfer. Special

feature of type FF h:

For this the event is defined in the associated device profile.

NOTE: The desired transmission types are set by way of the corresponding

CANopen objects 1400h for RxPDOs and 1800h for TxPDOs.

5.5 Event-controlled TxPDO transmission

Note: Event control is only active when the relevant "transmission type" is set

to asynchronous (FEh or FFh).

Function of event control:

Any bit changes within the TxPDO can serve as an event for the transmission of a TxPDO.

This means that only the mapped contents of this TxPDO can be used as an event for

transmission of a TxPDO. Accordingly it is not possible to send a TxPDO dependent on

the changes in content of another TxPDO.

Example:

The status word 6041h is mapped in TxPDO1. TxPDO2 contains the current actual position. A change in the status word in TxPDO1 can therefore not be used as an event

for transmission of the TxPDO2. If this is required, the status word 6041h can also be

mapped in TxPDO2 however.

Selecting events:

In MSD Servo Drive every bit (or any change to it) in a TxPDO can be defined as an event.

By default all bits (max. 64bit = 8byte) are monitored for changes and are evaluated as

events. Individual bits can be displayed using screens, however, and therefore are no

longer used for event generation.