Mitsubishi X3U-4AD-PT-ADP, FX3U-4AD-ADP, FX3U-4AD-TC-ADP, FX3U-485ADP-MB, FX3U-232ADP-MB User Manual

...

JY997D33401F(ENGLISH)

FX3G SERIES PROGRAMMABLE

CONTROLLERS

HARDWARE MANUAL

Manual Number JY997D33401

Revision F

Date December 2009

This manual describes the part names, dimensions, mounting,

cabling and specifications for the product. This manual is extracted

from FX3G Series User's Manual - Hardware Edition. Refer to FX3G

Series User's Manual - Hardware Edition for more details. Before

use, read this manual and manuals of relevant products fully to

acquire proficiency in the handling and operating the product. Make

sure to learn all the product information, safety information, and

precautions.

And, store this manual in a safe place so that you can take it out and

read it whenever necessary. Always forward it to the end user.

Registration

The company name and the product name to be described in this

manual are the registered trademarks or trade marks of each

company.

Effective December 2009

Specifications are subject to change without notice.

© 2008 Mitsubishi Electric Corporation

Safety Precaution (Read these precautions before use.)

This manual classifies the safety precautions into two categories:

and .

Indicates that incorrect handling may cause

hazardous conditions, resulting in death or

severe injury.

Indicates that incorrect handling may cause

hazardous conditions, resulting in medium or

slight personal injury or physical damage.

Depending on the circumstances, procedures indicated by

may also cause severe injury.

It is important to follow all precautions for personal safety.

STARTUP AND

MAINTENANCE

PRECAUTIONS

• Do not touch any terminal while the PLC's power is on.

Doing so may cause electric shock or malfunctions.

• Before cleaning or retightening terminals externally cut off all

phases of the power supply.

Failure to do so may cause electric shock.

.

STARTUP AND

MAINTENANCE

PRECAUTIONS

• Use the battery for memory backup correctly in FX3G Series

User's Manual - Hardware Edition.

- Use the battery only for the specified purpose.

- Connect the battery correctly.

- Do not charge, disassemble, heat, put in fire, short-circuit,

connect reversely, weld, swallow or burn the battery, or apply

excessive forces (vibration, impact, drop, etc.) to the battery.

- Do not store or use the battery at high temperatures or

expose to direct sunlight.

- Do not expose to water, bring near fire or touch liquid

leakage or other contents directly.

- Incorrect handling of the battery may cause heat excessive

generation, bursting, ignition, liquid leakage or deformation,

and lead to injury, fire or failures and malfunctions of facilities

and other equipment.

• Before modifying or disrupting the program in operation or

running the PLC, carefully read through this manual and the

associated manuals and ensure the safety of the operation.

An operation error may damage the machinery or cause accidents.

STARTUP AND

MAINTENANCE

PRECAUTIONS

• Turn off the power to the PLC before attaching or detaching the

memory cassette. If the memory cassette is attached or

detached while the PLC's power is on, the data in the memory

may be destroyed, or the memory cassette may be damaged.

• Do not disassemble or modify the PLC.

Doing so may cause fire, equipment failures, or malfunctions.

For repair, contact your local Mitsubishi Electric distributor.

•

Turn off the power to the PLC before connecting or disconnecting

any extension cable.

Failure to do so may cause equipment failures or malfunctions.

• Turn off the power to the PLC before attaching or detaching the

following devices.

Failure to do so may cause equipment failures or malfunctions.

- Peripheral devices, Display module, expansion boards, and

special adapters

- Connector conversion adapter, extension blocks, and FX

Series terminal blocks

- Battery and memory cassette

DISPOSAL

PRECAUTIONS

• Please contact a certified electronic waste disposal company

for the environmentally safe recycling and disposal of your

device.

When disposing of batteries, separate them from other waste

according to local regulations.

(For details of the Battery Directive in EU countries, refer to

FX3G Series User's Manual - Hardware Edition.)

TRANSPORT AND

STORAGE

PRECAUTIONS

• When transporting the FX3G Series PLC incorporating the

optional battery, turn on the PLC before shipment, confirm that

the battery mode is set using a parameter and the ALM LED is

OFF, and check the battery life.

If the PLC is transported with the ALM LED on or the battery

exhausted, the battery-backed data may be unstable during

transportation.

• The PLC is a precision instrument. During transportation, avoid

impacts larger than those specified in Section 2.1. Failure to do

so may cause failures in the PLC.

After transportation, verify the operations of the PLC.

• When transporting lithium batteries, follow required

transportation regulations.

(For details of the regulated products, refer to FX3G Series

User's Manual - Hardware Edition.)

Compliance with EC directive(CE Marking )

This document does not guarantee that a mechanical system

including this product will comply with the following standards.

Compliance to EMC directive and LVD directive of the entire

mechanical system should be checked by the user / manufacturer.

For more details please contact the local Mitsubishi Electric sales

site.

Requirement for Compliance with EMC directive

The following products have shown compliance through direct

testing (of the identified standards below) and design analysis

(through the creation of a technical construction file) to the European

Directive for Electromagnetic Compatibility (2004/108/EC) when

used as directed by the appropriate documentation.

Attention

• This product is designed for use in indu strial applications.

• Manufactured by:

Mitsubishi Electric Corporation

2-7-3 Marunouchi, Chiyoda-ku, Tokyo, 100-8310 Japan

• Manufactured at:

Mitsubishi Electric Corporation Himeji Works

840 Chiyoda-machi, Himeji, Hyogo, 670-8677 Japan

• Authorized Representative in the European Community:

Mitsubishi Electric Europe B.V.

Gothaer Str. 8, 40880 Ratingen, Germany.

Type : Programmable Controller (Open Type Equipment)

Models : MELSEC FX

from June 1st, 2005 FX3U-232ADP FX3U-485ADP

from April 1st, 2007 FX3U-232ADP-MB FX3U-485ADP-MB

from December 1st, 2007 FX3U-4AD-PTW-ADP

from November 1st, 2008 FX3G-ËËMT/ES(-A)

from December 1st, 2008 FX3G-ËËMR/ES(-A)

from March 1st, 2009 FX3G-ËËMT/ESS

from June 1st, 2009 FX

from December 1st, 2009 FX

Standard Remark

EN61131-2:2003

Programmable controllers

-Equipment

requirements and tests

3G series manufactured

FX3U-4AD-ADP FX3U-4DA-ADP

FX3U-4AD-PT-ADP FX3U-4AD-TC-ADP

FX3U-4AD-PNK-ADP

Where ËË indicates:14,24,40,60

3G-232-BD FX3G-422-BD

FX

FX3G-485-BD

FX

3G-EEPROM-32L

3G-CNV-ADP

FX

FX3G-2AD-BD FX3G-1DA-BD

FX

3G-8AV-BD FX3G-5DM

Where ËË indicates:14,24,40,60

Where ËË indicates:14,24,40,60

3U-3A-ADP

3G-ËËMR/DS FX3G-ËËMT/DS

3G-ËËMT/DSS

FX

Where ËË indicates:14,24,40,60

Compliance with all relevant aspects

of the standard.

EMI

• Radiated Emissions

• Conducted Emissions

EMS

• Radiated electromagnetic field

• Fast transient burst

• Electrostatic discharge

• High-energy surge

• Voltage drops and interruptions

• Conducted RF

• Power frequency magnetic field

Models : MELSEC FX2N series manufactured

from July 1st, 1997 FX2N-ËËER-ES/UL FX2N-ËËET-ESS/UL

from April 1st, 1998 FX2N-48ER-DS FX2N-48ET-DSS

from August 1st, 1998 FX2N-48ER-UA1/UL

from August 1st, 2005 FX2N-8ER-ES/UL FX2N-8EX-ES/UL

Where ËË indicates:32,48

FX2N-16EX-ES/UL FX2N-16EYR-ES/UL

FX2N-16EYT-ESS/UL

FX2N-8EYR-ES/UL FX2N-8EYT-ESS/UL

For the products above, PLCs manufactured

before March 31st, 2002 are compliant with EN50081-2 (EN610006-4) and EN50082-2

from April 1st, 2002 to April 30th, 2006 are compliant with EN500812 (EN61000-6-4) and EN61131-2:1994+A11:1996+A12:2000

after May 1st, 2006 are compliant with EN61131-2:2003

Standard Remark

EN61000-6-4:2007

- Generic emission

standard

Industrial environment

EN50081-2:1993

Electromagnetic

compatibility

EN50082-2:1995

Electromagnetic

compatibility

- Generic immunity

standard

Industrial environment

EN61131-2:1994

/A11:1996

/A12:2000

Programmable controllers

-Equipment

requirements and t ests

EN61131-2:2003

Programmable controllers

-Equipment

requirements and t ests

Compliance with all relevant aspects

of the standard.

• Radiated Emissions

• Mains Terminal Voltage Emissions

Compliance with all relevant aspects

of the standard.

• RF immunity

• Fast Transients

• ESD

• Conducted

• Power magnetic fields

Compliance with all relevant aspects

of the standard.

• RF Immunity

• Fast Transients

• ESD

• Damped oscillatory wave

Compliance with all relevant aspects

of the standard.

EMI

• Radiated Emissions

• Conducted Emissions

EMS

• Radiated electromagnetic field

• Fast transient burst

• Electrostatic discharge

• High-energy surge

• Voltage drops and interruptions

• Conducted RF

• Power frequency magnetic field

Requirement for Compliance with LVD directive

The following products have shown compliance through direct

testing (of the identified standards below) and design analysis

(through the creation of a technical construction file) to the European

Directive for Low Voltage (2006/95/EC) when used as directed by

the appropriate documentation.

Type : Programmable Controller (Open Type Equipment)

Models : MELSEC FX3G series manufactured

from November 1st, 2008 FX

from December 1st, 2008 FX

from March 1st, 2009 FX3G-ËËMT/ESS

from December 1st, 2009 FX

Standard Remark

EN61131-2:2003

Programmable controllers

- Equipment

requirements and tests

Models :MELSEC FX

from July 1st, 1997 FX

from April 1st, 1998 FX2N-48ER-DS

from August 1st, 1998 FX2N-48ER-UA1/UL

from August 1st, 2005 FX2N-8ER-ES/UL FX2N-8EYR-ES/UL

For the products above, PLCs manufactured

before March 31st, 2002 are compliant with IEC1010-1

from April 1st, 2002 to April 30th, 2006 are compliant with EN611312:1994+A11:1996+A12:2000

after May 1st, 2006 are compliant with EN61131-2:2003

Standard Remark

IEC1010-1:1990

/A1:1992

Safety requirements for

electrical equipment for

measurement, control, and

laboratory use

- General requirements

EN61131-2:1994

/A11:1996

/A12:2000

Programmable controllers

- Equipment

requirements and tests

EN61131-2:2003

Programmable controllers

- Equipment

requirements and tests

3G-ËËMT/ES(-A)

Where ËË indicates:14,24,40,60

3G-ËËMR/ES(-A)

Where ËË indicates:14,24,40,60

Where ËË indicates:14,24,40,60

3G-ËËMR/DS

Where ËË indicates:14,24,40,60

The equipment has been assessed

as a component for fitting in a

suitable enclosure which meets the

requirements of EN61131-2:2003

2N series manufactured

2N-ËËER-ES/UL FX2N -ËËET-ESS/UL

Where ËË indicates:32,48

FX2N-16EYR-ES/UL

The equipment has been assessed

as a component for fitting in a

suitable enclosure which meets the

requirements of IEC 1010-1:

1990+A1:1992

The equipment has been assessed

as a component for fitting in a

suitable enclosure which meets the

requirements of EN61131-2:

1994+A11:1996+A12:2000

The equipment has been assessed

as a component for fitting in a

suitable enclosure which meets the

requirements of EN61131-2:2003

Caution for compliance with EC Directive

Installation in Enclosure

Programmable logic controllers are open-type devices that must be

installed and used within conductive control boxes. Please use the

FX

3G Series programmable logic controllers while installed in

conductive shielded control boxes. Please secure the control box lid

to the control box (for conduction). Installation within a control box

greatly affects the safety of the system and aids in shielding noise

from the programmable logic controller.

Associated manuals

FX3G Series PLC (main unit) comes with this document (hardware

manual).

For a detailed explanation of th e FX3G Series hardware and

information on instructions for PLC programming and special

extension unit/block, refer to the relevant documents.

Manual name Manual No. Description

FX3G Series

User's Manual

- Hardware

Edition

FX3G/FX3U/

FX3UC Series

Programming

Manual

- Basic & Applied

Instruction Edition

FX Series User’s

Manual - Data

Communication

Edition

FX

3G/FX3U/

FX3UC Series

User's Manual

- Analog Control

Edition

FX3G/FX3U/

3UC Series

FX

User's Manual

- Positioning

Control Edition

JY997D31301

MODEL CODE:

09R521

JY997D16601

MODEL CODE:

09R517

JY997D16901

MODEL CODE:

09R715

JY997D16701

MODEL CODE:

09R619

JY997D16801

MODEL CODE:

09R620

How to obtain manuals

For the necessary product manuals or documents, consult with the

Mitsubishi Electric dealer from where you purchase your product.

Explains FX3G Series PLC

specification details for I/O,

wiring, installation, and

maintenance.

Describes PLC

programming for basic/

applied instructions STL/

SFC programming and

devices.

Explains N:N link, parallel

link, computer link, no

protocol communication by

RS instructions/FX

232IF.

Describes specifications for

analog control and

programming methods for

FX3G/FX3U/FX3UC Series

PLC.

Explains the specifications

for positioning control of

FX3G/FX3U/FX3UC Series

and programming

procedures

2N-

Incorporated Items

Check if the following product and items are included in the package:

Included Items

Main units

Product 1 unit

3G-14M~

FX

FX3G-60M

Dust proof protection sheet 1 sheet

Manuals [Japanese version*1,

English version]

1 manual

each

Input/output extension units

FX2N-32E

FX2N-48E

,

Product 1 unit

Extension cable 1 cable

Input/output number label 1 sheet

Input/output extension blocks

FX2N-8E

FX2N-16E

Product 1 unit

Input/output number label 1 sheet

*1 The FX3G-M/ES-A becomes Chinese version.

1. Outline

For the input/output extension units/blocks, refer to the following

manual.

→ Refer to FX3G Series User's Manual - Hardware Edition.

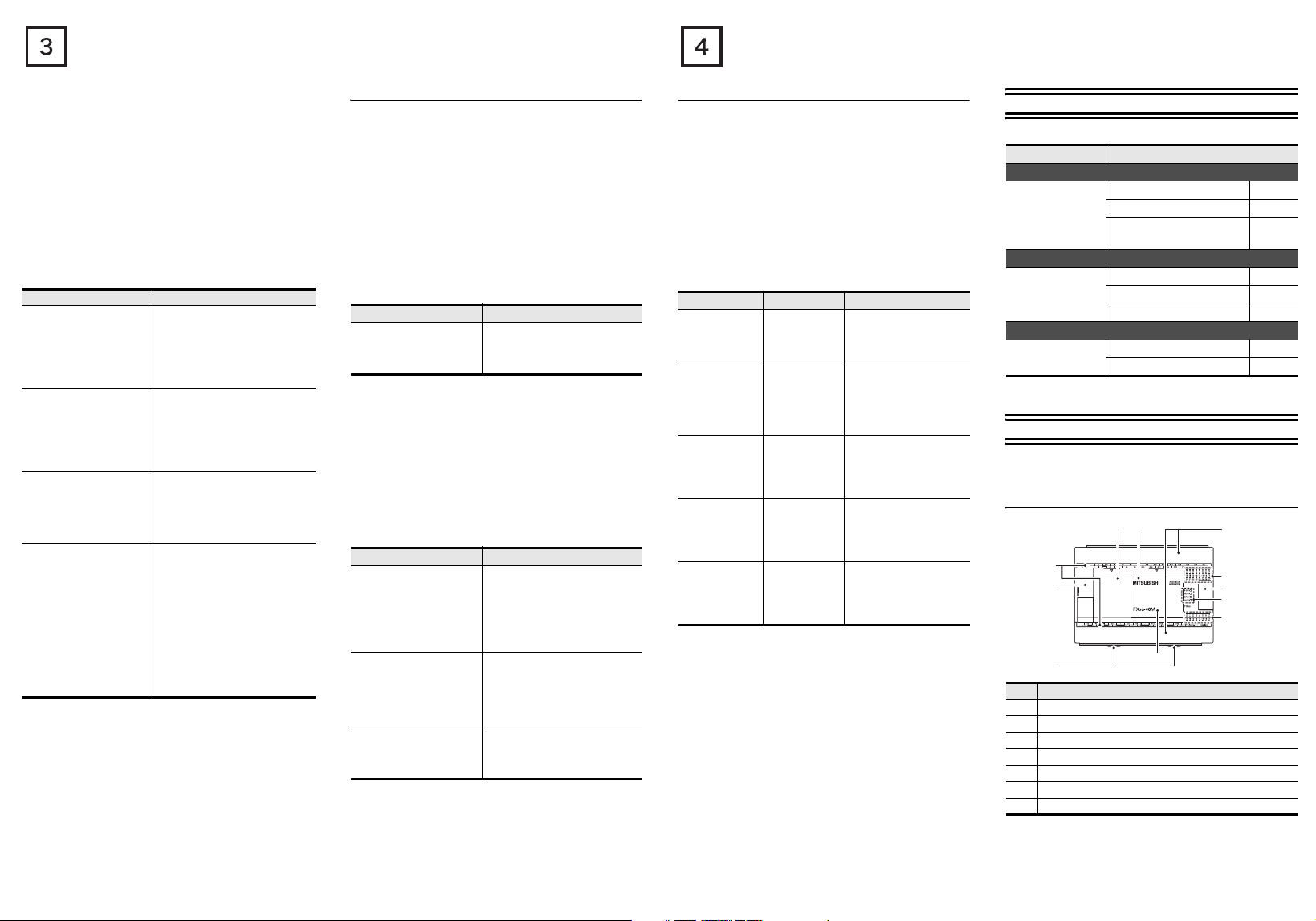

1.1 Part names

[3]

[4]

[2]

[1]

[11]

[10]

No. Name

[1] Peripheral device connecting connector cover

[2] Terminal names

[3] Top cover(S) (40points, 60points type only)

[4] Top cover

[5] Terminal block covers

[6] Input display LEDs (red)

[7] Extension device connecting connector cover

[5]

[6]

[7]

[8]

[9]

No. Name

Operation status display LEDs

POW Green On while power is on the PLC.

RUN Green On while the PLC is running.

[8]

ERR

ALM Red

Red Flashing when a program error occurs.

Red Lights when a CPU error occurs.

Lights when the battery voltage drops.

(When the optional battery is used)

[9] Output display LEDs (red)

[10] Model name (abbreviation)

[11] DIN rail mounting hooks

With terminal cover open

[6] [7] [8]

[5]

[4]

[3]

[2]

[1]

[5]

[14] [13]

[7]

No. Name

[1] Peripheral device connecting connector (USB)

[2] Peripheral device connecting connector (RS-422)

[3] R UN/STOP switch

Variable analog potentiometers

[4]

Upper side : VR1, Lower side : VR2

[5] Terminal block mounting screws

[6] Optional equipment connector1

[7] Terminal cover (FX3G-M/ES-A is excluded)

Optional equipment connector2

[8]

(40points, 60points type only)

[9] Power supply terminal, Input (X) terminals

[10] Battery connector

[11] Battery holder

[12] Power supply terminal, Output (Y) terminals

Optional equipment connecting screw holes2

[13]

(40points, 60points type only)

[14] Optional equipment connecting screw holes1

[9]

[10]

[11]

[12]

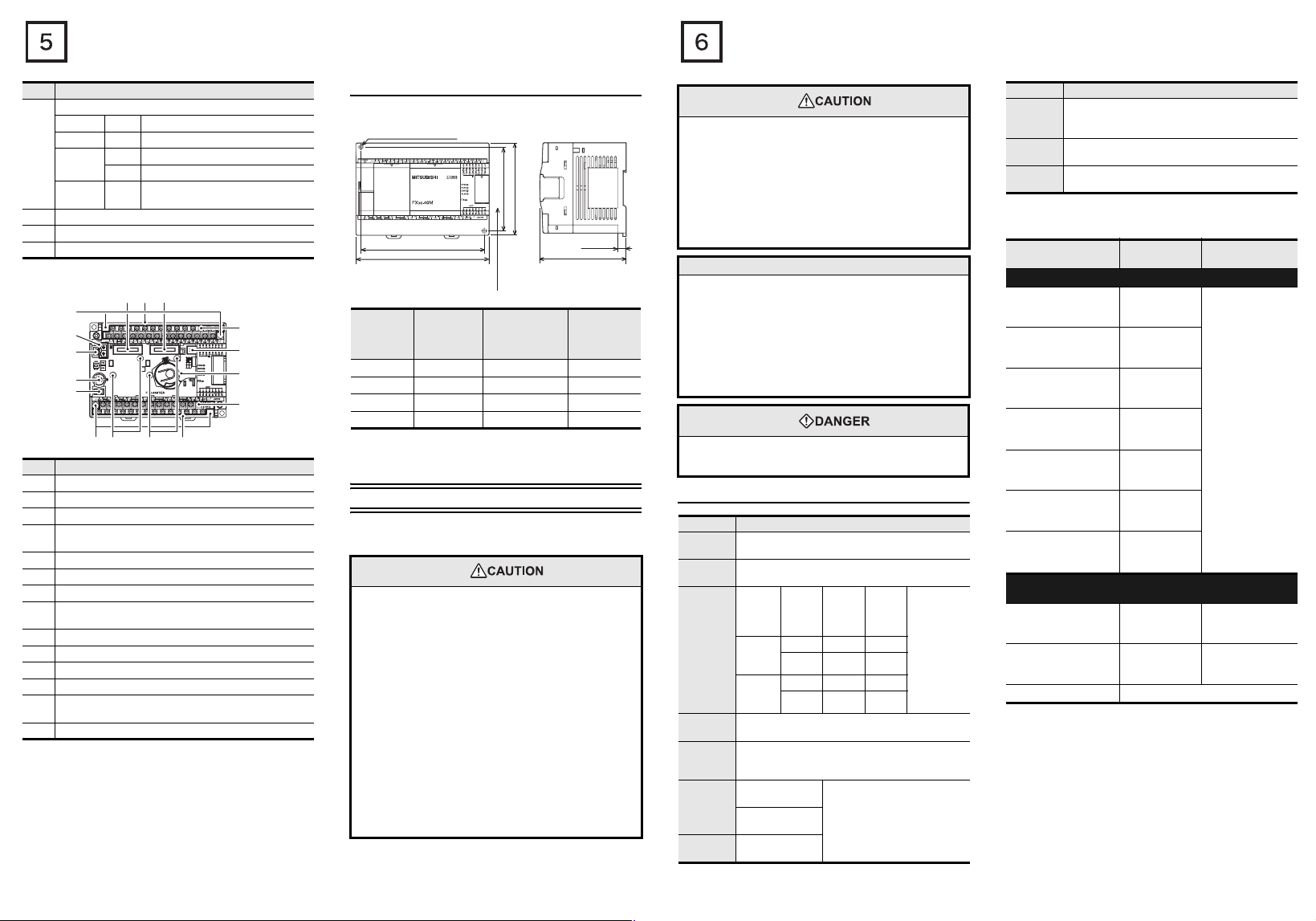

1.2 External dimensions and weight

→ For the input/output extension units/blocks,

refer to FX3G Series User's Manual - Hardware Edition.

2-φ4.5 mounting holes

Model name

W1

W

W:

mm (inches)

82(3.23")

Mounting hole pitches

mm (inches)

Direct mounting

hole pitches

90(3.55")

W1:

Unit: mm(inches)

8(0.32")

86(3.39")

MASS (Weight)

kg (lbs)

FX3G-14M 90 (3.55”) 82 (3.23”) 0.50 (1.10lbs)

FX3G-24M 90 (3.55”) 82 (3.23”) 0.55 (1.21lbs)

3G-40M 130 (5.12”) 122 (4.81”) 0.70 (1.54lbs)

FX

FX3G-60M 175 (6.89”) 167 (6.58”) 0.85 (1.87lbs)

Installation

• 35-mm-wide DIN rail or Direct (screw) mounting (M4)

2. Installation (general specifications)

As for installation of the input/output extension units/blocks, special

adapters and expansion boards, refer to the following manual.

→ Refer to FX3G Series User's Manual - Hardware Edition.

INSTALLATION

PRECAUTIONS

• Use the product within the generic environment specifications

described in section 2.1 of this manual.

Never use the product in areas with excessive dust, oily smoke,

conductive dusts, corrosive gas (salt air, Cl2, H2S, SO2 or

NO

2), flammable gas, vibration or impacts, or exposed to high

temperature, condensation, or rain and wind.

If the product is used in such conditions, electric shock, fire,

malfunctions, deterioration or damage may occur.

•

Do not touch the conductive parts of the product directly to avoid

failure or malfunctions.

• Install the product securely using a DIN rail or mounting screws.

• Install the product on a flat surface.

If the mounting surface is rough, undue force will be applied to

the PC board, thereby causing nonconformities.

• When drilling screw holes or wiring, make sure cutting or wire

debris does not enter the ventilation slits.

Failure to do so may cause fire, equipment failures or

malfunctions.

• Be sure to remove the dust proof sheet from the PLC's

ventilation port when installation work is completed. Failure to

do so may cause fire, equipment failures or malfunctions.

INSTALLATION

PRECAUTIONS

• Connect the extension cables, peripheral device cables, input/

output cables and battery connecting cable securely to their

designated connectors.

Unsecured connection may cause malfunctions.

• Turn off the power before attaching or detaching the following

devices.

Failure to do so may cause device failures or malfunctions.

- Peripheral devices, display modules, expansion boards and

special adapters

- Extension units/blocks and the FX Series terminal block

- Battery and memory cassette

• When a dust proof sheet is supplied with an extension unit/

block, keep the sheet applied to the ventilation slits during

installation and wiring work.

:

• To prevent temperature rise, do not install the PLC on a floor, a

ceiling or a vertical surface.

Install it horizontally on a wall as shown in section 2.2.

• Keep a space of 50mm (1.97”) or more between the unit main

body and another device or structure (part A). Install the unit as

far away as possible from high-voltage lines, high-voltage

devices and power equipment.

WIRING

PRECAUTIONS

• Cut off all phases of the power supply externally before

installation or wiring work in order to avoid damage to the

product or electric shock.

2.1 Generic specifications

Item Specification

Ambient

temperature

Ambient

humidity

Vibration

*1

resistance

Shock

*1

resistance

Noise

resistance

Dielectric

withstand

*2

voltage

Insulation

*2

resistance

Notes

0 to 55°C (32 to 131°F) when operating and -25 to

75°C (-13 to 167°F) when stored

5 to 95%RH (no condensation) when operating

ration

2

(m/s

)

4.9 -

9.8 -

Half

ampli-

tude

(mm)

Sweep Count

for X, Y, Z: 10

times

(80 min in

each

direction)

*2

and

Accele-

Fre-

quency

(Hz)

When

10 to 57 - 0.035

installed

57 to 150

on DIN rail

When

10 to 57 - 0.075

installed

57 to 150

directly

147m/s2 Acceleration, Action time: 11ms, 3 times by

half-sine pulse in each direction X, Y, and Z

By noise simulator at noise voltage of 1,000Vp-p,

noise width of 1μs, rise time of 1ns and period of 30 to

100Hz

1.5kV AC for one

minute

500V AC for one

minute

5MΩ or more by

500V DC megger

Between each terminals

ground terminal

Item Specification

Class D grounding (grounding resistance: 100Ω or

Grounding

Working

atmosphere

Working

altitude

less) <Common grounding with a heavy electrical

system is not allowed.>

Free from corrosive or flammable gas and excessive

conductive dusts

*4

<2000m

*3

*1 The criterion is shown in IEC61131-2.

*2 Dielectric withstand voltage and insulation resistance are

shown in the following table.

Terminal

Dielectric

strength

Insulation

resistance

Main units, Input/output extension units/blocks

Between power supply

terminal (AC power) and

ground terminal

Between power supply

terminal (DC power) and

ground terminal

Between input terminal

(24V DC) and ground

terminal

Between input terminal

(100V AC) and ground

*5

terminal

Between output terminal

(relay) and ground

terminal

Between output terminal

(transistor) and ground

terminal

Between output terminal

(triac) and ground

*5

terminal

Expansion boards, Special function adapters, Special function

blocks

Between terminal of

expansion board and

ground terminal

Between terminal of

special adapter and

ground terminal

1.5 kV AC for

one minute

500V AC for

one minute

500V AC for

one minute

1.5 kV AC for

one minute

1.5 kV AC for

one minute

500V AC for

one minute

1.5 kV AC for

one minute

5MΩ or more by

500V DC megger

Not allowed Not allowed

500V AC for

1min

5MΩ or more by

500V DC megger

Special function block Each manual

For dielectric with stand voltage test and insulation resistance test of

each product, refer to the following manual.

→ Refer to FX

3G Series User's Manual - Hardware Edition.

*3 For common grounding, refer to section 3.3.

*4 The PLC cannot be used at a pressure higher than the

atmospheric pressure to avoid damage.

*5 Input/output extension units/blocks only

Loading...

Loading...