Page 1

Air-Conditioners

SLZ-KA25, KA35, KA50VAQ3

KA25, KA35, KA50VAL3

INSTALLATION MANUAL

For safe and correct use, please read this manual and the outdoor unit installation manual thoroughly before installing the air-conditioner unit.

INSTALLATIONSHANDBUCH

Aus Sicherheitsgründen und zur richtigen Anwendung vor Installation der Klimaanlage die vorliegende Bedienungsanleitung und das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Avant d’installer le climatiseur, lire attentivement ce manuel, ainsi que le manuel d’installation de l’appareil extérieur

pour une utilisation sûre et correct.

INSTALLATIEHANDLEIDING

Lees deze handleiding en de installatiehandleiding van het buitenapparaat zorgvuldig door voordat u met het installeren van de airconditioner begint.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire

acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, prima di installare il condizionatore d’aria leggere attentamente il presente manuale ed

il manuale d’installazione dell’unità esterna.

EΓΧEIPIΔIO OΔHΓIΩN EΓKATAΣTAΣHΣ

Για σωστή και ασφαλή χρήση, διαβάστε προσεκτικά αυτό το εγχειρίδιο, καθώς και το εγχειρίδιο εγκατάστασης της

εξωτερικής μονάδας, πριν από την εγκατάσταση της μονάδας κλιματιστικού.

MANUAL DE INSTALAÇÃO

Para uma utilização segura e correcta, leia atentamente este manual e o manual de instalação da unidade exterior

antes de instalar o aparelho de ar condicionado.

INSTALLATIONSMANUAL

Läs bruksanvisningen och utomhusenhetens installationshandbok noga innan luftkonditioneringen installeras så att

den används på ett säkert och korrekt sätt.

MONTAJ ELKİTABI

Emniyetli ve doğru kullanım için, klima cihazını monte etmeden önce bu kılavuzu ve dış ünite montaj kılavuzunu

tamamıyla okuyun.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для обеспечения безопасной и надлежащей эксплуатации внимательно прочтите данное руководство и руководство по установке наружного прибора перед установкой кондиционера.

FOR INSTALLER

FÜR INSTALLATEURE

POUR L’INSTALLATEUR

VOOR DE INSTALLATEUR

PARA EL INSTALADOR

PER L’INSTALLATORE

ΓΙΑ ΑΥΤΟΝ ΠΟΥ ΚΑΝΕΙ ΤΗΝ ΕΓΚΑΤΑΣΤΑΣΗ

PARA O INSTALADOR

FÖR INSTALLATÖREN

MONTÖR İÇİN

ДЛЯ УСТАНОВИТЕЛЯ

English

Deutsch

Français

Nederlands

Español

Italiano

Eλληνικά

Português

Svenska

Türkçe

Русский

Page 2

Contents

1. Safety precautions .....................................................................................2

2. Selecting the installation location ..............................................................2

3. Installation diagram ...................................................................................3

4. Installing the indoor unit ............................................................................3

5. Refrigerant piping work .............................................................................5

Note:

The phrase “Wired remote controller” in this installation manual refers only to the PAR-32MAA. If you need any information for the other remote controller,

please refer to either the installation manual or initial setting manual which are included in these boxes.

6. Drainage piping work .................................................................................6

7. Electrical work ...........................................................................................7

8. Installing the grille ....................................................................................10

9. Test run ....................................................................................................12

1. Safety precautions

• Be sure to read “Safety precautions” before installing the air conditioner.

• Be sure to observe the cautions specifi ed here as they include important

items related to safety.

• The indications and meanings are as follows.

Warning:

Could lead to death, serious injury, etc.

Caution:

Could lead to serious injury in particular environments when operated incorrectly.

Warning:

• Do not install it by yourself (customer).

Incomplete installation could cause injury due to fi re, electric shock, the unit

falling or leakage of water. Consult the dealer from whom you purchased the

unit or special installer.

• Install the unit securely in a place which can bear the weight of the unit.

When installed in an insuffi cient strong place, the unit could fall causing

injured.

• Use the specifi ed wires to connect the indoor and outdoor units securely and

attach the wires fi rmly to the terminal board connecting sections so the stress

of the wires is not applied to the sections.

Incomplete connecting and fi xing could cause fi re.

• Do not use intermediate connection of the power cord or the extension cord

and do not connect many devices to one AC outlet.

It could cause a fi re or an electric shock due to defective contact, defective

insulation, exceeding the permissible current, etc.

• Check that the refrigerant gas does not leak after installation has completed.

• Perform the installation securely referring to the installation manual.

Incomplete installation could cause a personal injury due to fi re, electric

shock, the unit falling or leakage of water.

• Perform electrical work according to the installation manual and be sure to

use an exclusive circuit.

If the capacity of the power circuit is insuffi cient or there is incomplete electri-

cal work, it could result in a fi re or an electric shock.

• The user should never attempt to repair the unit or transfer it to another loca-

tion.

Caution:

• Perform grounding.

Do not connect the ground wire to a gas pipe, water pipe arrester or telephone

ground wire. Defective grounding could cause an electric shock.

• Do not install the unit in a place where an infl ammable gas leaks.

If gas leaks and accumulates in the area surrounding the unit, it could cause

an explosion.

• Install a ground leakage breaker depending on the installation place (where

it is humid).

If a ground leakage breaker is not installed, it could cause an electric

shock.

• After reading this manual, be sure to keep it together with the instruction

manual in a handy place on the customer’s site.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels affi xed to the main unit.

• The appliance shall be installed in accordance with national wiring regula-

tions.

• If the supply cord is damaged, it must be replaced by the manufacturer, its

service agent or similarly qualifi ed persons in order to avoid a hazard.

• Attach the electrical part cover to the indoor unit and the service panel to the

outdoor unit securely.

If the electrical part cover in the indoor unit and/or the service panel in the

outdoor unit are not attached securely, it could result in a fi re or an electric

shock due to dust, water, etc.

• Be sure to use the part provided or specifi ed parts for the installation work.

The use of defective parts could cause an injury or leakage of water due to a

fi re, an electric shock, the unit falling, etc.

• Ventilate the room if refrigerant leaks during operation.

If the refrigerant comes in contact with a fl ame, poisonous gases will be

released.

• When installing or relocating, or servicing the air conditioner, use only the

specifi ed refrigerant (R410A) to charge the refrigerant lines. Do not mix it with

any other refrigerant and do not allow air to remain in the lines.

If air is mixed with the refrigerant, then it can be the cause of abnormal high

pressure in the refrigerant line, and may result in an explosion and other

hazards.

The use of any refrigerant other than that specifi ed for the system will cause

mechanical failure or system malfunction or unit breakdown. In the worst

case, this could lead to a serious impediment to securing product safety.

• Perform the drainage/piping work securely according to the installation

manual.

If there is a defect in the drainage/piping work, water could drop from the unit

and household goods could be wet and damaged.

• Fasten a fl are nut with a torque wrench as specifi ed in this manual.

When fastened too tight, a fl are nut may broken after a long period and cause

a leakage of refrigerant.

• If the unit is run for long hours when the air above the ceiling is at high tem-

perature/high humidity (dew point above 26 ºC), dew condensation may be

produced in the indoor unit or the ceiling materials. When operating the units

in this condition, add insulation material (10-20 mm) to the entire surface of

the unit and ceiling materials to avoid dew condensation.

2. Selecting the installation location

2.1. Indoor unit

• Where airfl ow is not blocked.

• Where cool air spreads over the entire room.

• Where it is not exposed to direct sunshine.

• At a distance 1 m or more away from your TV and radio (to prevent picture from

being distorted or noise from being generated).

2.2. Wireless remote controller mounting

(For SLZ-KA·VAL3)

• Place of mounting

• Where it is easy to operate and easily visible.

• Where children can not touch.

• Mounting

Select a position about 1.2 m above the fl oor, check that signals from the remote

controller are surely received by the indoor unit from that position (‘beep’ or ‘beepbeep’ receiving tone sounds). After that, attach remote controller holder to a pillar

or wall and set the wireless remote controller.

2

• In a place as far away as possible from fl uorescent and incandescent lights (so the

infrared remote control can operate the air conditioner normally).

• Where the air fi lter can be removed and replaced easily.

Warning:

Mount the indoor unit into a ceiling strong enough to withstand the weight of

the unit.

In rooms where inverter type fl uorescent lamps are used, the signal from the

wireless remote controller may not be received.

Page 3

3. Installation diagram

23520

650

650

Fig. 3-1

4. Installing the indoor unit

1

3

6

0

7

A

2

4

8

(mm)

3.1. Indoor unit (Fig. 3-1)

A Ceiling

B Grille

C Obstacle

D Min. 1000 mm

E Min. 500 mm (Entire periphery)

If setting the maintenance space for E, be sure to leave is a minimum of 700 mm.

Warning:

Mount the indoor unit on a ceiling strong enough to withstand the weight of

the unit.

3.2. Outdoor unit

Refer to the outdoor unit installation manual.

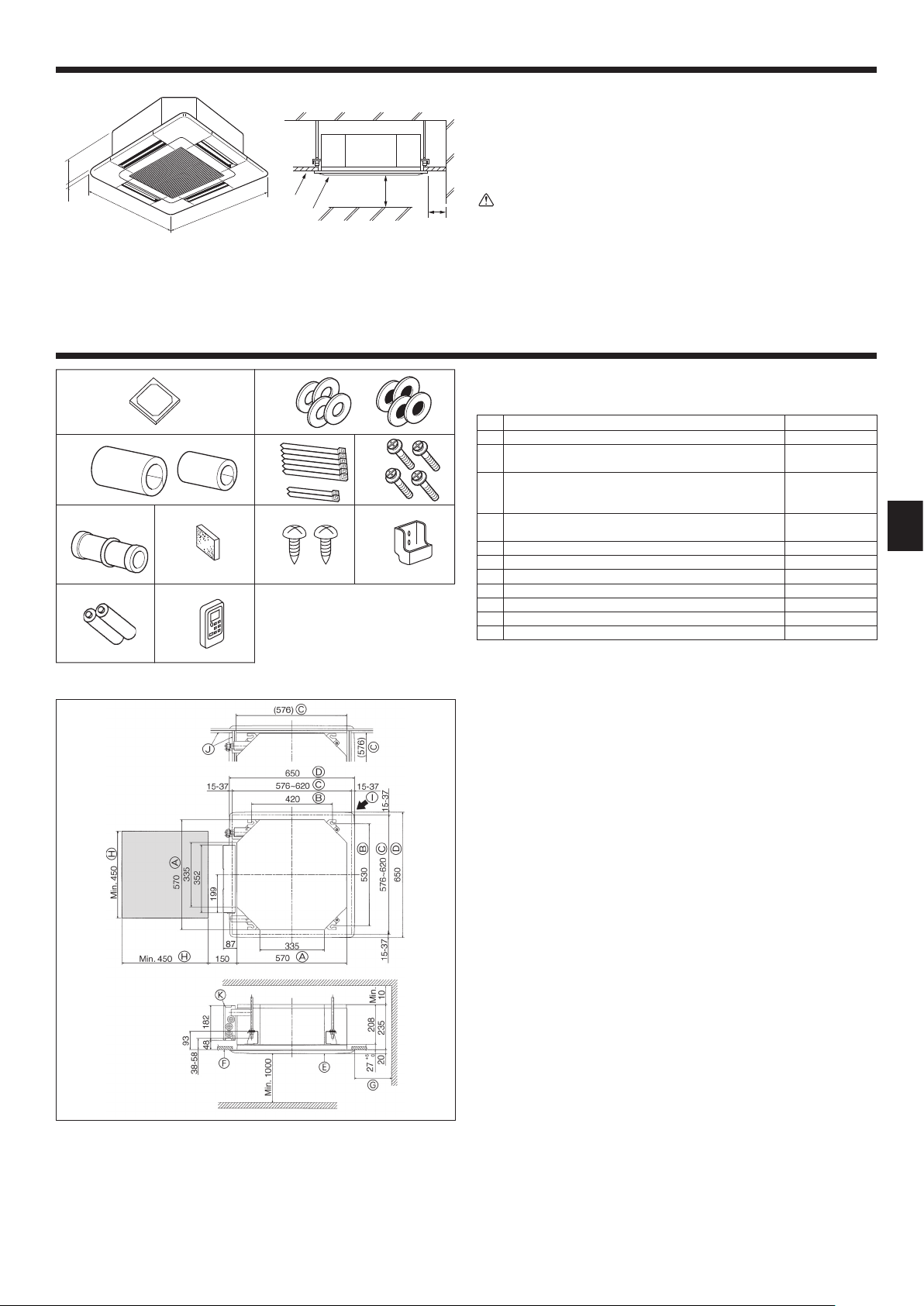

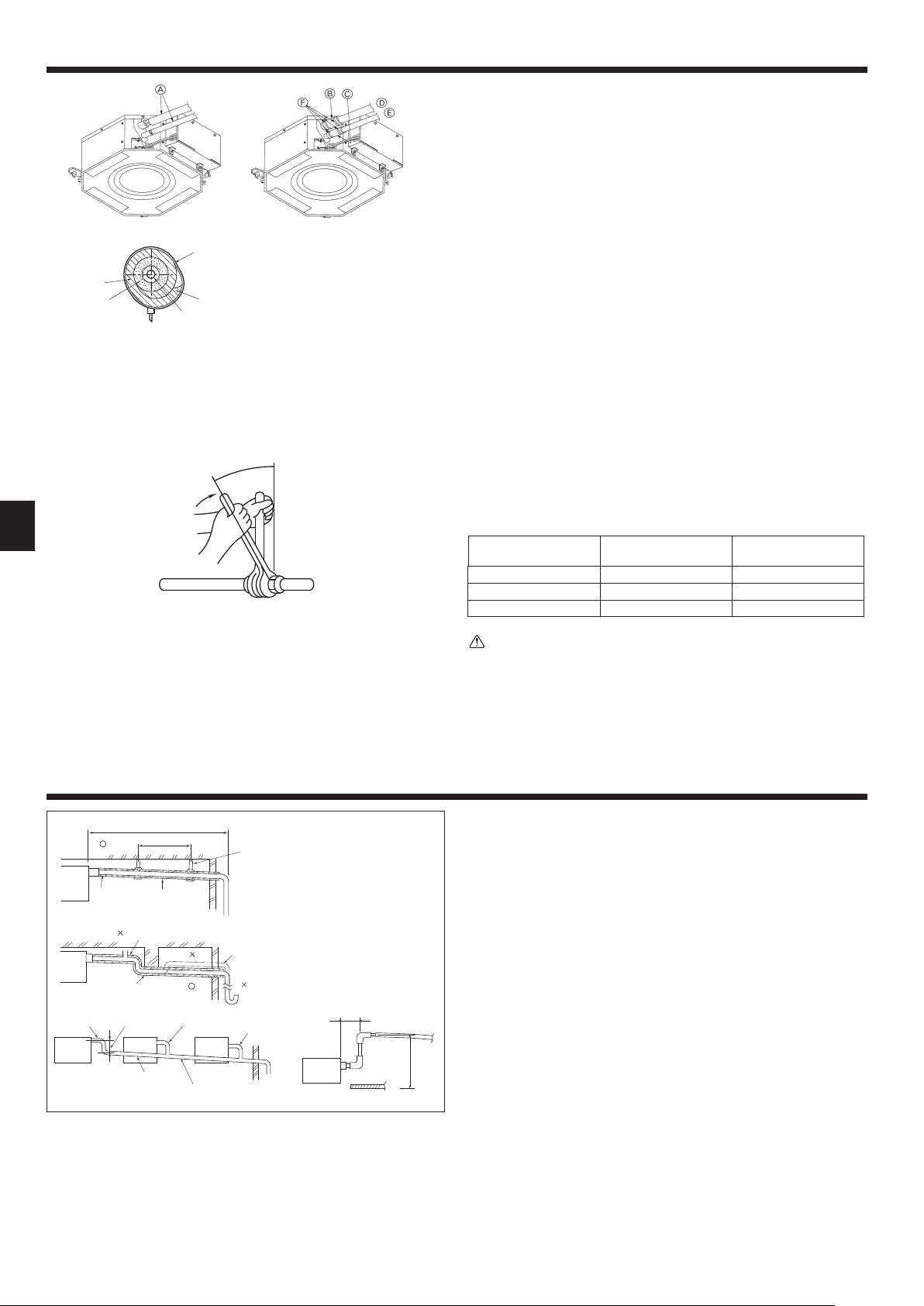

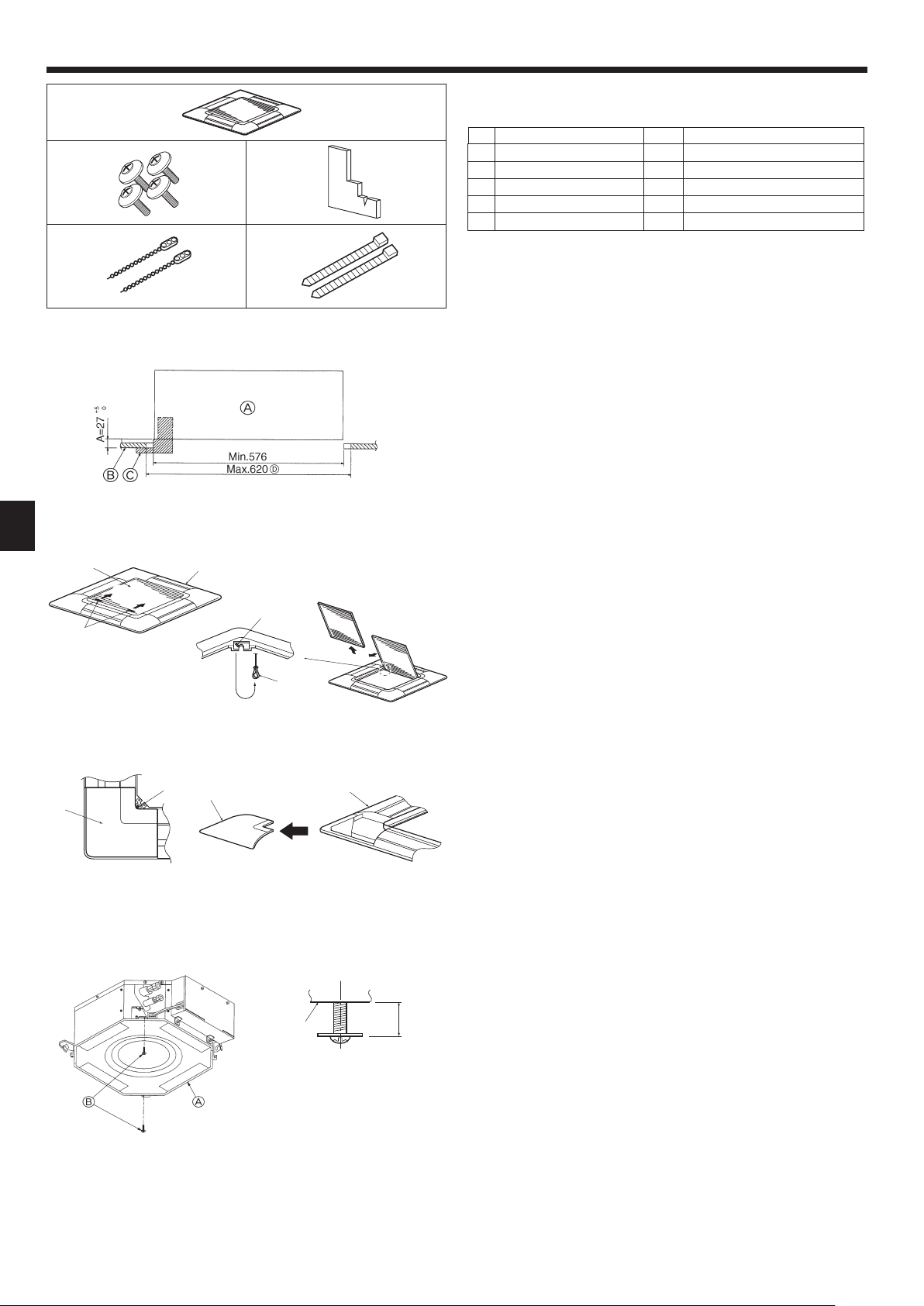

4.1. Check the indoor unit accessories (Fig. 4-1)

The indoor unit should be supplied with the following accessories.

Installation template 1

5

9

1

Washers (with insulation)

2

Washers (without insulation)

Pipe cover (for refrigerant piping joint)

small diameter (liquid)

3

large diameter (gas)

Band (large)

4

Band (small)

Screw with washer (M5 25) for mounting grille 4

5

Drain socket 1

6

Insulation 1

7

8 Fixing screw for 9 3.5 16 (Black) (for SLZ-KA·VAL3)

Remote controller holder (for SLZ-KA·VAL3) 1

9

Battery (AAA) (for SLZ-KA·VAL3) 2

0

Wireless remote controller (for SLZ-KA·VAL3) 1

1

Accessory name Q’ty

4

4

1

1

6

2

2

Fig. 4-1

(mm)

4.2. Ceiling openings and suspension bolt installation

locations (Fig. 4-2)

• Using the installation template (top of the package) and the gauge (supplied as an

accessory with the grille), make an opening in the ceiling so that the main unit can

be installed as shown in the diagram. (The method for using the template and the

gauge are shown.)

* Before using, check the dimensions of template and gauge, because they

change due to fl uctuations of temperature and humidity.

* The dimensions of ceiling opening can be regulated within the range shown in

following diagram; so center the main unit against the opening of ceiling, ensuring that the respective opposite sides on all sides of the clearance between

them becomes identical.

• Use M10 (3/8") suspension bolts.

* Suspension bolts are to be procured at the fi eld.

• Install securely, ensuring that there is no clearance between the ceiling panel &

grille, and between the main unit & grille.

A Outer side of main unit

B Bolt pitch

C Ceiling opening

D Outer side of Grille

E Grille

F Ceiling

* Note that the space between ceiling panel of the unit and ceiling slab, etc., must be 10 to 15

mm to be left.

* Leave the maintenance space at the electric component box end.

G Min. 500 mm (Entire periphery)

If setting the maintenance space for G, be

sure to leave is a minimum of 700 mm.

H Maintenance space

I Fresh air intake

J Angle

K Electric component box

Fig. 4-2

3

Page 4

4. Installing the indoor unit

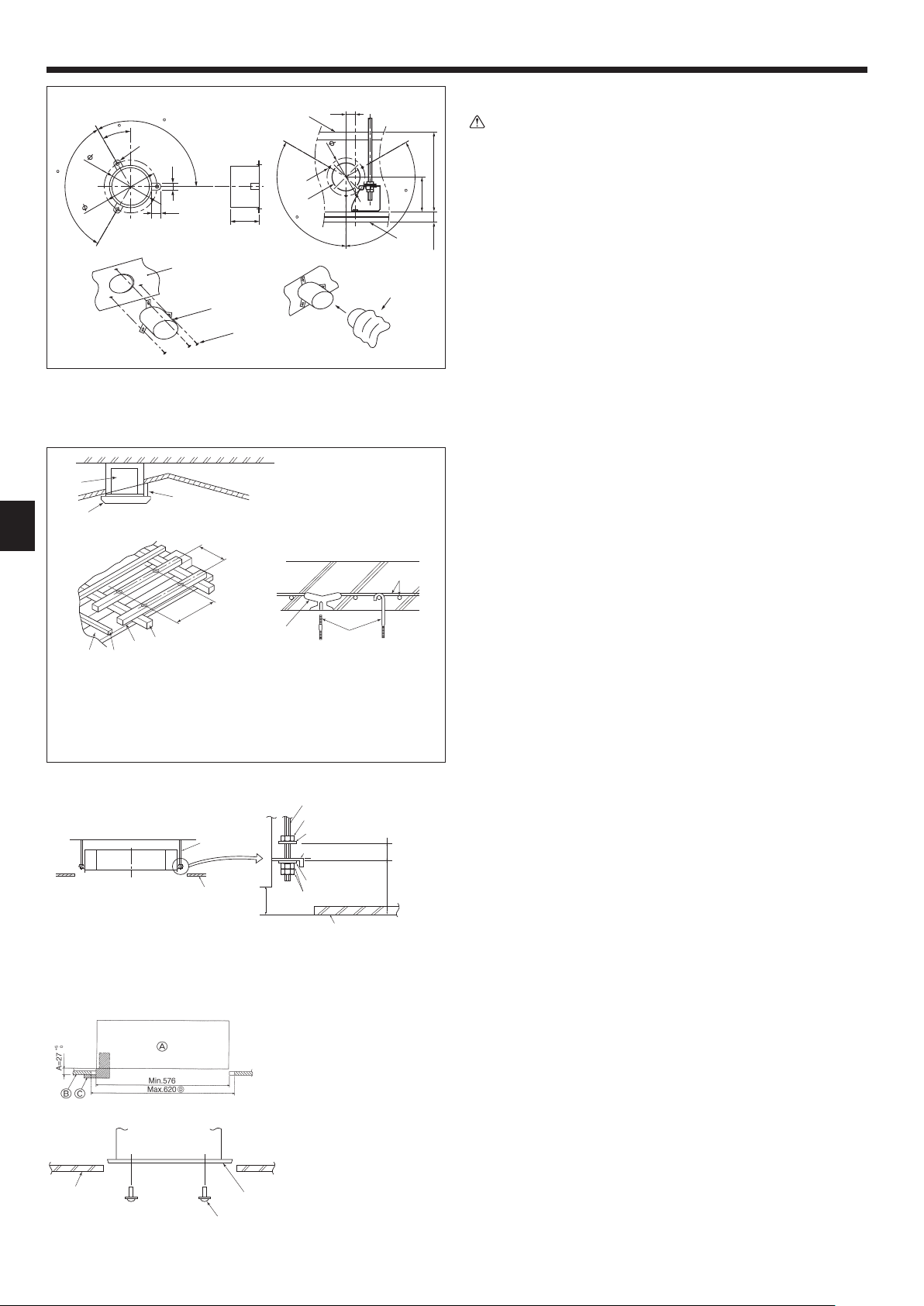

4.3. Installation of duct (in case of fresh air intake)

(Fig. 4-3)

Linkage of duct fan and air conditioner

ln case that a duct fan is used, be sure to make it linked with the air conditioner

when outside air is taken.

208

Do not run the duct fan only. It can cause dew drop.

Making a duct fl ange (prepared locally)

• The shape of duct fl ange shown left is recommended.

Installation of duct fl ange

0

• Cut out the cutout hole. Do not knock it out.

+5

27

• Install a duct fl ange to the cutout hole of the indoor unit with three 4 10 tapping

Installation of duct (should be prepared locally)

• Prepare a duct of which inner diameter fi ts into the outer diameter of the duct

• In case that the environment above the ceiling is high temperature and high humidity,

120

(mm)

92

AC

120

30

75

120

100

15

20

120

70

25

100

Fig. 4-3

4.4. Suspension structure (Give site of suspension

• The ceiling work differs according to the construction of the building. Building con-

(1) Extent of ceiling removal: The ceiling must be kept completely horizontal and the

(2) Cut and remove the ceiling foundation.

(3) Reinforce the ends of the ceiling foundation where it has been cut and add ceiling

(4) When installing the unit on a slanting ceiling, interlock a pillow between the ceiling

1 Wooden structures

• Use tie beams (single-story houses) or second fl oor beams (two story houses) as

• Wooden beams for suspending air conditioners must be sturdy and their sides must

2 Ferroconcrete structures

Secure the suspension bolts using the method shown, or use steel or wooden hangers, etc. to install the suspension bolts.

4.5. Unit suspension procedures (Fig. 4-5)

Suspend the main unit as shown in the diagram.

1. In advance, set the parts onto the suspension bolts in the order of the washers

• Fit the washer with cushion so that the insulation faces downward.

• In case of using upper washers to suspend the main unit, the lower washers (with

2. Lift the unit to the proper height of the suspension bolts to insert the mounting

3. When the main unit can not be aligned against the mounting hole on the ceiling,

• Make sure that step A is performed within 27-32 mm. Damage could result by

4.6. Confi rming the position of main unit and tightening

• Using the gauge attached to the grille, ensure that the bottom of the main unit is

• Confi rm that the main unit is horizontally levelled, using a level or a vinyl tube fi lled

• After checking the position of the main unit, tighten the nuts of the suspension bolts

• The installation template can be used as a protective sheet to prevent dust from

* As for the details of fi tting, refer to the instructions given on the Installation template.

1

*B

D Ceiling

E Rafter

F Beam

G Roof beam

A Suspension bolt (Procure locally)

B Ceiling

C Nut (Procure locally)

D Washer (with insulation) (Accessory)

A Unit

B Grille

C Pillow

*B

2

H Use inserts rated at 100-150 kg

each (procure locally)

I Suspension bolts M10 (3/8") (procure

locally)

J Steel reinforcing rod

*B: Suspension bolt pitch (see Fig. 4-2 B for details)

Fig. 4-4

+5

0

27

Min. 30

93

E Mounting plate

F Washer (without insulation) (Accessory)

G Check using the Installation gauge

Fig. 4-5

A Main unit

B Ceiling

C Gauge (Grille accessory)

D Ceiling opening dimensions

Fig. 4-6

A Main unit

B Ceiling

C Installation template (Accessory)

D Screw with washer (Accessory)

Fig. 4-7

Caution:

screws which should be prepared locally.

fl ange.

wrap the duct in a heat insulate to avoid causing dew drop on the wall.

A Duct fl ange recommended shape

(Thickness:0.8 or more)

B 3-ø5 hole

C Detail drawing of fresh air intake

D Indoor unit

E Ceiling surface

F 3-ø2.8 Burring hole

G ø73.4 cutout hole

H Duct fl ange (Prepared locally)

I 4 10 Tapping screw (Prepared locally)

J Duct

strong structure) (Fig. 4-4)

structors and interior decorators should be consulted for details.

ceiling foundation (framework: wooden slats and slat holders) must be reinforced

in order to protect the ceiling from vibration.

foundation for securing the ends of the ceiling board.

and the grille and set so that the unit is installed horizontally.

reinforcing members.

be at least 6 cm long if the beams are separated by not more than 90 cm and their

sides must be at least 9 cm long if the beams are separated by as much as 180

cm. The size of the suspension bolts should be ø10 (3/8

"). (The bolts do not come

with the unit.)

(with insulation), washers (without insulation) and nuts (double).

insulation) and nuts (double) are to be set later.

plate between washers and then fasten it securely.

it is adjustable owing to a slot provided on the mounting plate. (Fig. 4-6)

failing to adhere to this range.

the suspension bolts (Fig. 4-7)

properly aligned with the opening of the ceiling. Be sure to confi rm this, otherwise

condensation may form and drip due to air leakage etc.

with water.

securely to fasten the main unit.

entering the main unit when the grilles are left unattached for a while or when the

ceiling materials are to be lined after installation of the unit is fi nished.

4

Page 5

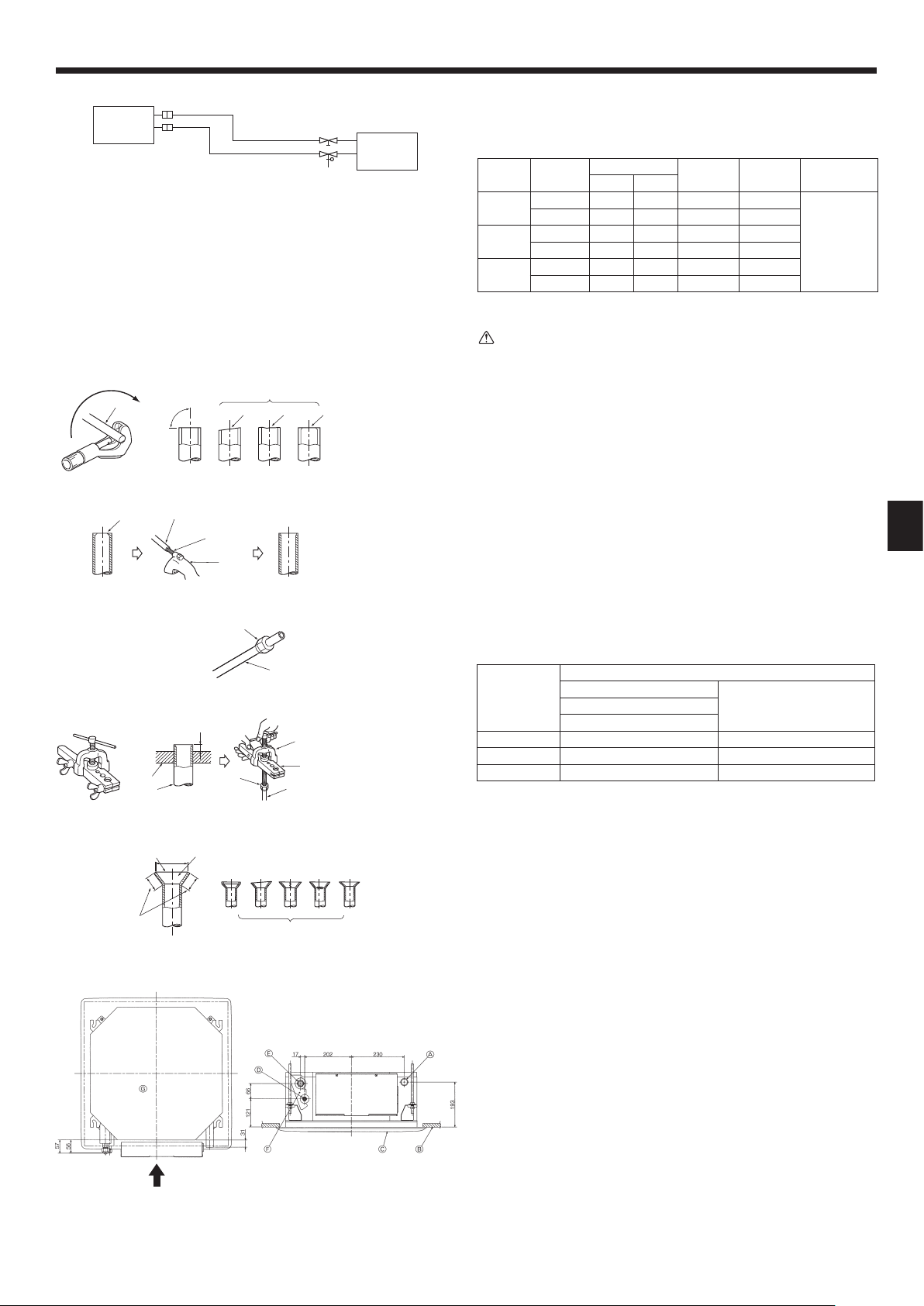

5. Refrigerant piping work

SLZ-KA25, KA35: ø9.52

SLZ-KA50: ø12.7

/

/

/

0

1

A Indoor unit

ø6.35

B Outdoor unit

Fig. 5-1

a Copper tubes

90

21034

b Good

c No good

d Tilted

e Uneven

f Burred

5.1. Refrigerant pipe (Fig. 5-1)

Piping preparation

• Refrigerant pipes of 3, 5, 7, 10 and 15 m are available as optional items.

(1) Table below shows the specifi cations of pipes commercially available.

Model Pipe

SLZ-KA25

SLZ-KA35

SLZ-KA50

(2) Ensure that the 2 refrigerant pipes are well insulated to prevent condensation.

(3) Refrigerant pipe bending radius must be 100 mm or more.

Using careful insulation of specifi ed thickness. Excessive thickness prevents

storage behind the indoor unit and smaller thickness causes dew drippage.

For liquid 6.35 1/4 0.8 mm 8 mm

For gas 9.52 3/8 0.8 mm 8 mm

For liquid 6.35 1/4 0.8 mm 8 mm

For gas 9.52 3/8 0.8 mm 8 mm

For liquid 6.35 1/4 0.8 mm 8 mm

For gas 12.7 1/2 0.8 mm 8 mm

Caution:

Outside diameter

mm inch

Min. wall

thickness

Insulation

thickness

Insulation

material

Heat resist-

ing foam

plastic 0.045

specifi c

gravity

5.2. Flaring work

• Main cause of gas leakage is defect in fl aring work.

Carry out correct fl aring work in the following procedure.

5.2.1. Pipe cutting (Fig. 5-2)

• Using a pipe cutter cut the copper tube correctly.

Fig. 5-2

0

1

2

a Burr

b Copper tube/pipe

c Spare reamer

d Pipe cutter

Fig. 5-3

/

0

a Flare nut

b Copper tube

Fig. 5-4

A

3

2

0

1

a Flaring tool

b Die

c Copper tube

d Flare nut

e Yoke

5.2.2. Burrs removal (Fig. 5-3)

• Completely remove all burrs from the cut cross section of pipe/tube.

• Put the end of the copper tube/pipe to downward direction as you remove burrs in

order to avoid burrs drop in the tubing.

5.2.3. Putting nut on (Fig. 5-4)

• Remove fl are nuts attached to indoor and outdoor unit, then put them on pipe/tube

having completed burr removal.

(not possible to put them on after fl aring work)

5.2.4. Flaring work (Fig. 5-5)

• Carry out fl aring work using fl aring tool as shown at the right.

Dimension

Pipe diameter

(mm)

6.35 0 - 0.5 9.1

9.52 0 - 0.5 13.2

12.7 0 - 0.5 16.6

Firmly hold copper tube in a die in the dimension shown in the table at above.

When the tool for R410A is used

A (mm)

Clutch type

+0

B

(mm)

-0.4

Fig. 5-5

0

/

B

23456

1

7

Fig. 5-6

5.2.5. Check (Fig. 5-6)

• Compare the fl ared work with a fi gure in right side hand.

• If fl are is noted to be defective, cut off the fl ared section and do fl aring work

again.

a Smooth all around

b Inside is shining without any scratches

c Even length all around

d Too much

e Tilted

f Scratch on fl ared plane

g Cracked

h Uneven

i Bad examples

5.3. Refrigerant and drainage piping locations (Fig.5-7)

A Drain pipe

B Ceiling

C Grille

D Refrigerant pipe (liquid)

E Refrigerant pipe (gas)

F Water supply inlet

G Main unit

A

As viewed from A

Fig. 5-7

5

Page 6

5. Refrigerant piping work

,

A Refrigerant pipe and insulating material

B Pipe cover (large) (Accessory)

C Pipe cover (small) (Accessory)

D Refrigerant pipe (gas)

E Refrigerant pipe (liquid)

F Band (Accessory)

G Cross-sectional view of connection

H Refrigerant pipe

I Insulating material

J Squeeze

Fig. 5-8

(Procure locally)

5.4. Pipe connection (Fig. 5-8)

Indoor unit

1) When using commercially available copper pipes:

• Apply thin layer of refrigerant oil to pipe and joint seating surface before tightening

fl are nut.

• Use two wrenches to tighten piping connections.

• Air-purge the refrigerant piping using your own refrigerant gas (don’t air-purge the

refrigerant charged in the outdoor unit).

• Use leak detector or soapy water to check for gas leaks after connections are

completed.

• Use refrigerant piping insulation provided to insulate indoor unit connections. Insulate

carefully following shown below.

2) Heat insulation for refrigerant pipes:

1 Wrap the enclosed large-sized pipe cover around the gas pipe, making sure that

the end of the pipe cover touches the side of the unit.

2 Wrap the enclosed small-sized pipe cover around the liquid pipe, making sure that

the end of the pipe cover touches the side of the unit.

3 Secure both ends of each pipe cover with the enclosed bands. (Attach the bands

20 mm from the ends of the pipe cover.)

See that stop valve on outdoor unit is fully shut (unit is shipped with valve shut).

After all piping connections between indoor and outdoor unit have been completed,

vacuum-purge air from system through the service port for the stop valve on the

outdoor unit.

After completing procedures above, open outdoor unit stop valves stem fully. This

completes connection of refrigerant circuit between indoor and outdoor units. Stop

valve instructions are marked on outdoor unit.

• Apply a thin coat of refrigeration oil on the seat surface of pipe. (Fig. 5-9)

• For connection fi rst align the center, then tighten the fi rst 3 to 4 turns of fl are nut.

• Use tightening torque table below as a guideline for indoor unit side union joint

section, and tighten using two wrenches. Excessive tightening damages the fl are

section.

Fig. 5-9

6. Drainage piping work

1

2

Max. 20 m

1.5–2 m

Copper pipe O.D.

(mm)

Flare nut O.D.

(mm)

Tightening torque

(N·m)

ø6.35 17 14 - 18

ø9.52 22 34 - 42

ø12.7 26 49 - 61

Warning:

Be careful of fl ying fl are nut! (Internally pressurized)

Remove the fl are nut as follows:

1. Loosen the nut until you hear a hissing noise.

2. Do not remove the nut until the gas has been completely released (i.e., hiss-

ing noise stops).

3. Check that the gas has been completely released, and then remove the

nut.

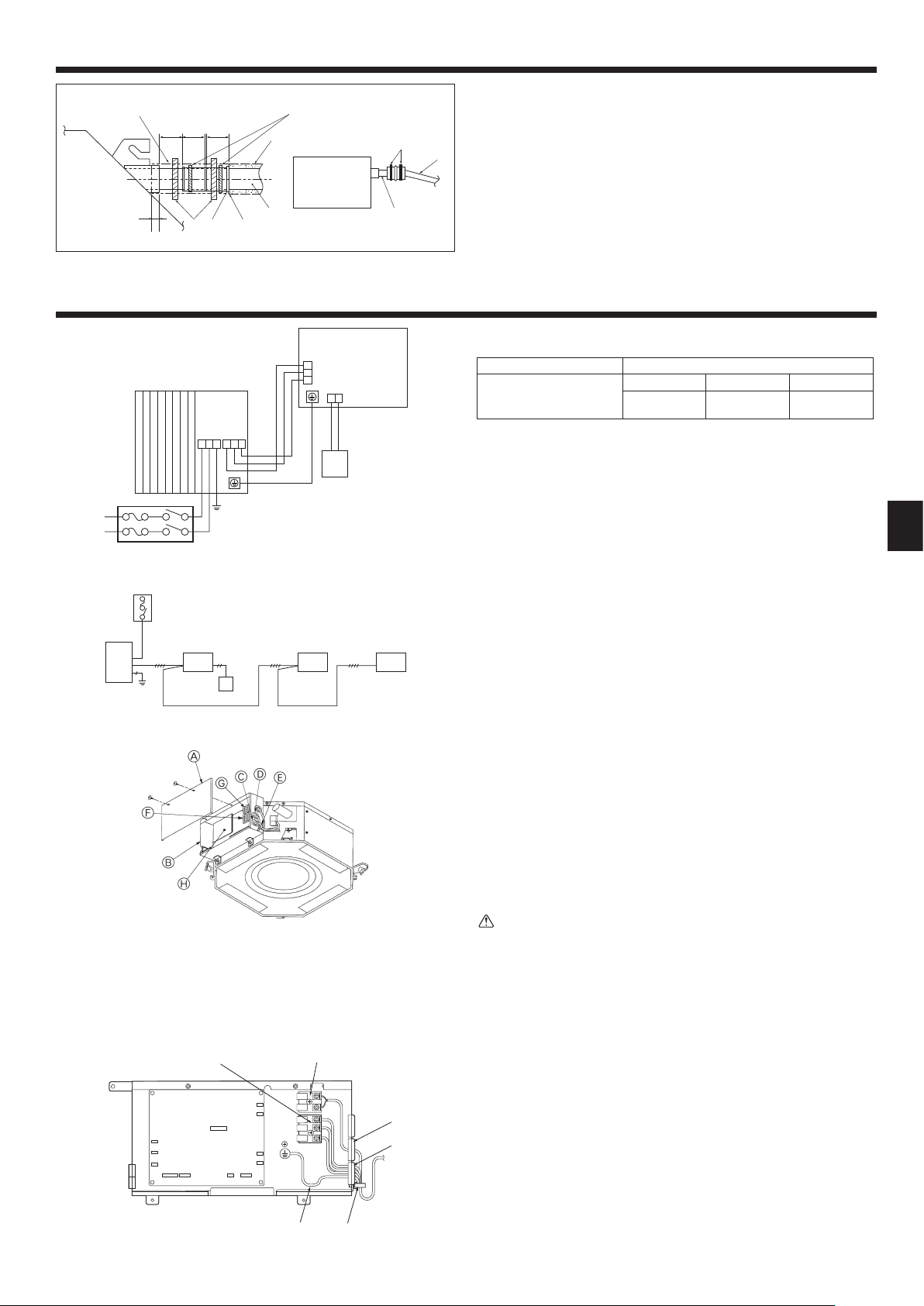

6.1. Drainage piping work (Fig. 6-1)

• Use VP25 (O. D. ø32 PVC TUBE) for drain piping and provide 1/100 or more

downward slope.

• Be sure to connect the piping joints using a polyvinyl type adhesive.

• Observe the fi gure for piping work.

• Use the included drain hose to change the extraction direction.

1 Correct piping

2 Wrong piping

A Insulation (9 mm or more)

B Downward slope (1/100 or more)

Grouped piping

D O. D. ø32 PVC TUBE

E Make it as large as possible

Max. 150 mm

F Indoor unit

G Make the piping size large for grouped piping.

H Downward slope (1/100 or more)

I O. D. ø38 PVC TUBE for grouped piping.

(9 mm or more insulation)

J Up to 500 mm

C Support metal

K Air bleeder

L Raised

M Odor trap

Fig. 6-1

6

Page 7

6. Drainage piping work

30 30

11

7. Electrical work

For Power supply

30

Fig. 6-2

S3

S2S1

A Indoor unit

B Outdoor unit

C Wired remote controller

D Wired main switch/fuse

E Grounding

(mm)

,

1. Connect the drain socket (supplied with the unit) to the drain port. (Fig. 6-2)

(Affi x the tube using PVC adhesive then secure it with a band.)

2. Install a locally purchased drain pipe (PVC pipe, O.D. ø32).

(Affi x the pipe using PVC adhesive then secure it with a band.)

3. Insulate the tube and pipe. (PVC pipe, O.D. ø32 and socket)

4. Check that drain fl ows smoothly.

5. Insulate the drain port with insulating material, then secure the material with a

band. (Both insulating material and band are supplied with the unit.)

A Main unit

B Insulating material

C Band (large)

D Drain port (transparent)

E Insertion margin

F Matching

G Drain pipe (O.D. ø32 PVC TUBE)

H Insulating material (purchased locally)

I Transparent PVC pipe

J O.D. ø32 PVC TUBE (Slope 1/100 or more)

K Band (small)

L Drain socket

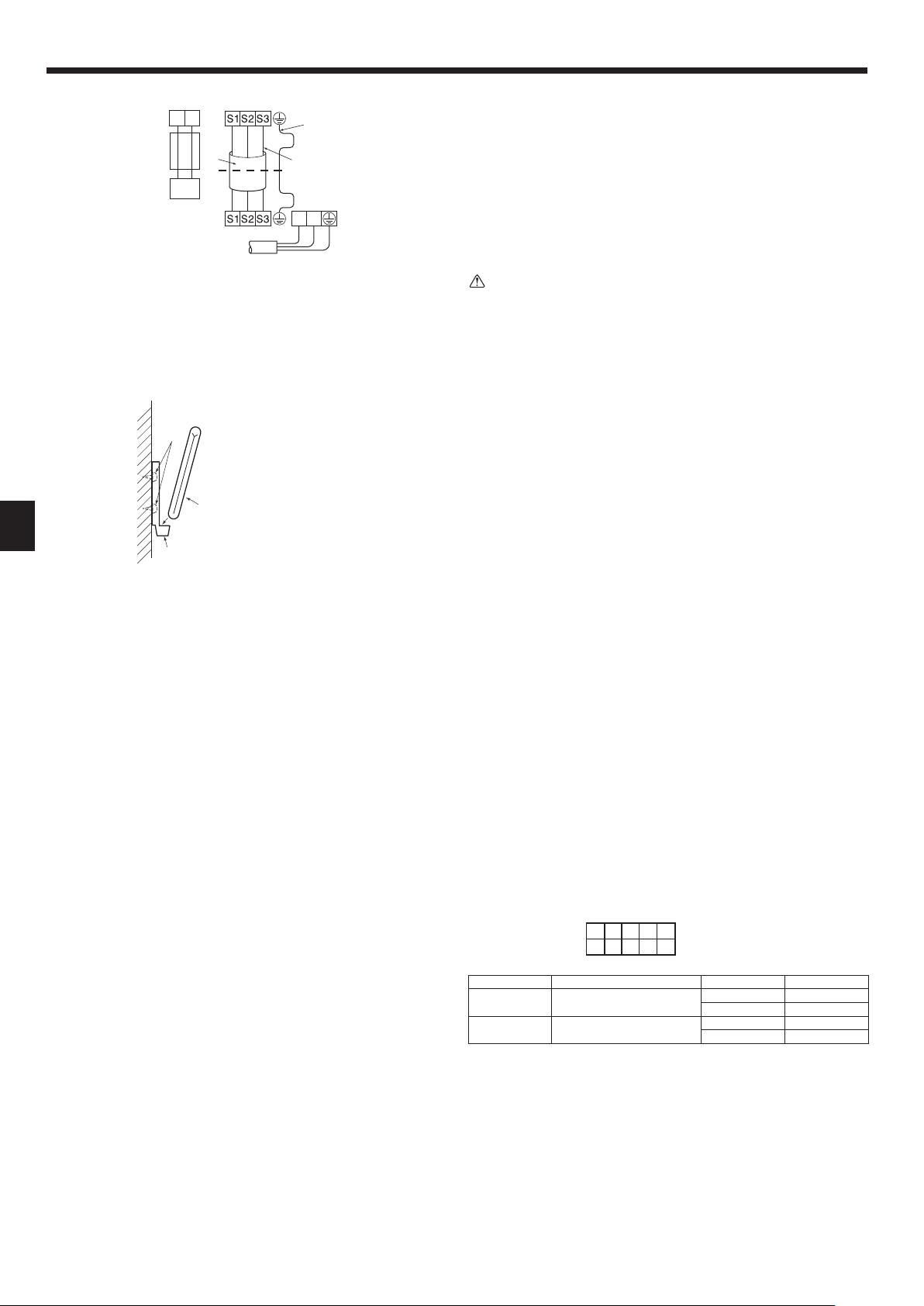

7.1. Precautions (Fig. 7-1)

S1

S2

S3

21

Electrical specifi cation Input capacity Main Switch/Fuse (A)

Power supply

(1 phase ~/N, 230V,

50Hz)

• The compressor will not operate unless the power supply phase connection is cor-

rect.

• Grounding protection with a no-fuse breaker (earth leakage breaker [ELB]) is usually

installed for D.

• The connection wiring between the outdoor and indoor units can be extended up

to a maximum of 50 meters, and the total extension including the crossover wiring

between rooms is a maximum of 80 m.

A switch with at least 3.5 mm contact separation in each pole shall be provided by

the air conditioner installation.

* Label each breaker according to purpose (heater, unit etc.).

SLZ-KA25 SLZ-KA35 SLZ-KA50

10 10 20

For Power

supply

Fig. 7-1

A Electric component cover

B Electric component box

C Entry for Indoor-Outdoor connecting cable

D Entry for wired remote controller cable

E Cable clamp

Fig. 7-2

F Indoor/Outdoor unit connecting terminal

G Wired remote controller terminal

(For SLZ-KA·VAQ3)

H Indoor controller

I Earth cable

7.2. Indoor unit (Fig. 7-2) (Fig. 7-3)

Work procedure

1. Remove 2 screws to detach the electric component cover.

2. Route each cable through the wiring intake into the electric component box. (Procure

power supply cable and indoor/outdoor connecting cable locally.)

3. Securely connect the power supply cable and the indoor/outdoor connecting cable

to the terminal blocks.

4. Secure the cables with clamps outside the electric component box.

5. Attach the electric component cover as it was.

• Fix power supply cable and indoor/outdoor connecting cable to electric component

box by using buffer bushing for tensile force. (PG connection or the like.)

Warning:

• Attach the electric component cover securely. If it is attached incorrectly, it

could result in a fi re, electric shock due to dust, water, etc.

• Use the specifi ed indoor/outdoor unit connecting cable to connect the indoor

and outdoor units and fi x the cable to the terminal block securely so that no

stress is applied to the connecting section of the terminal block. Incomplete

connection or fi xing of the cable could result in a fi re.

Fig. 7-3

S1S2 S3 1 2

7

Page 8

7. Electrical work

• Perform wiring as shown in the diagram to the lower left. (Procure the cable locally).

(Fig. 7-4)

Make sure to use cables of the correct polarity only.

1 Connecting cable

Cable 3-core 1.5 mm2, in conformity with Design 245 IEC 57.

2 Indoor terminal block

3 Outdoor terminal block

4 Always install an earth wire (1-core 1.5 mm2) longer than other cables

5 Remote controller cable (non-polar)

Cable 2-core 0.3 mm

The 10 m wire is attached in the remote controller accessory. Max. 500 m

6 Wired remote controller

7 Power supply cord

Caution:

• Use care not to make miswiring.

• Firmly tighten the terminal screws to prevent them from loosening.

• After tightening, pull the wires lightly to confi rm that they do not move.

• Wiring for remote controller cable shall be apart (5 cm or more) from power

source wiring so that it is not infl uenced by electric noise from power source

wiring.

2

12

Indoor terminal block

Outdoor terminal block

Power supply cord

Fig. 7-4

Earth wire (green/yellow)

Indoor/outdoor unit

connecting wire

3-core 1.5 mm

L

N

2

or more

7.3. Remote controller

A Wireless remote controller (Accessory)

B Wall

C Remote controller holder (Accessory)

D Fixing screw (Accessory)

Fig. 7-5

7.3.1. Wireless remote controller (Fig. 7-5)

1) Installation area

• Area in which the remote controller is not exposed to direct sunshine.

• Area in which there is no nearby heating source.

• Area in which the remote controller is not exposed to cold (or hot) winds.

• Area in which the remote controller can be operated easily.

• Area in which the remote controller is beyond the reach of children.

2) Installation method

1 Attach the remote controller holder to the desired location using two tapping screws.

2 Place the lower end of the controller into the holder.

• The signal can travel up to approximately 7 meters (in a straight line) within 45

degrees to both right and left of the center line of the receiver.

In addition, the signal may not be received if there is interference of light of fl uores-

cent lights or strong sunlight.

7.3.2. Wired remote controller

1) Installing procedures

Refer to the installation manual that comes with each remote controller for details.

2) Function selection of remote controller

If two remote controllers are connected, set one to “Main” and the other to “Sub”. For

setting procedures, refer to “Function selection of remote controller” in the operation

manual for the indoor unit.

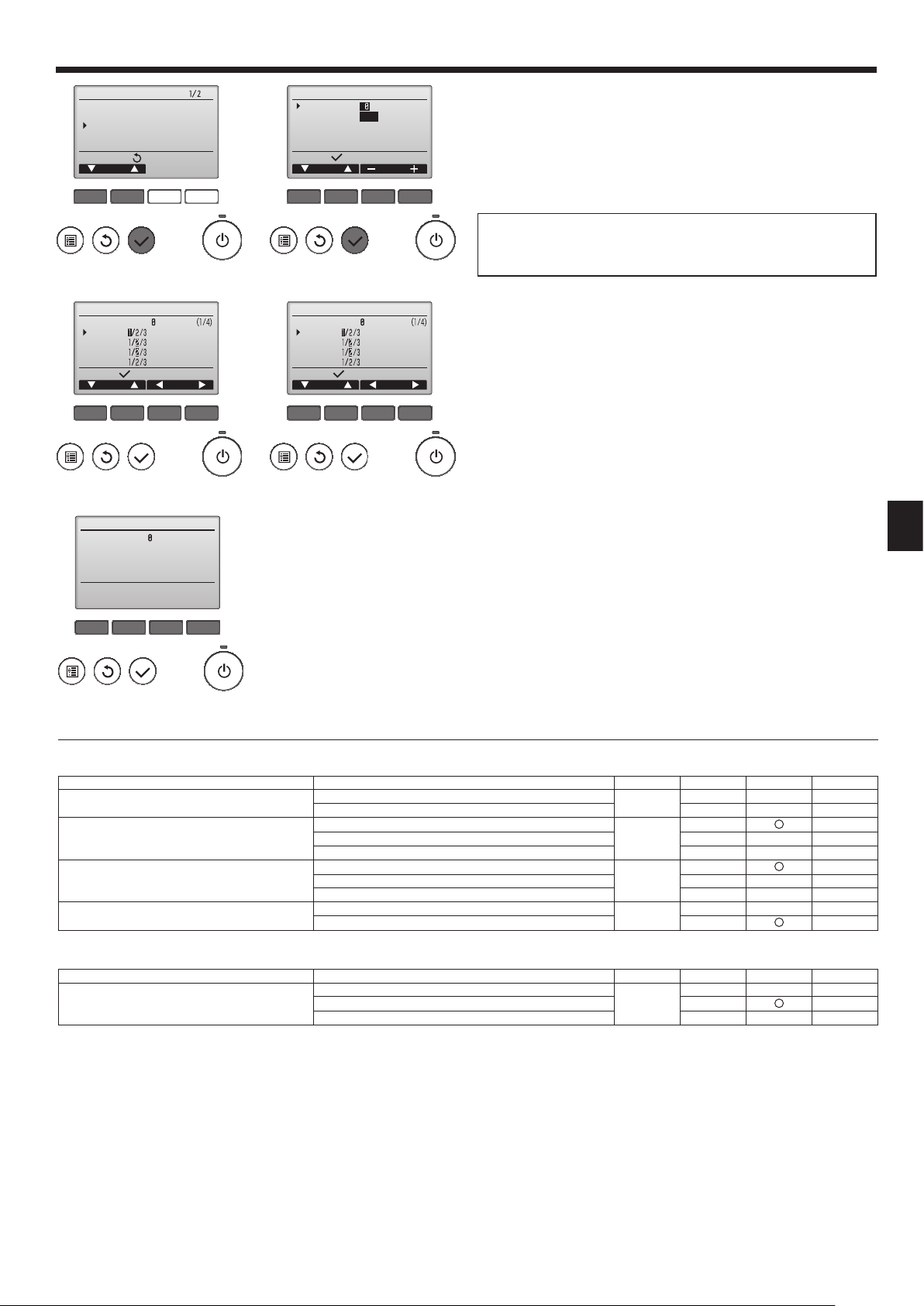

7.4. Function settings

7.4.1 Function setting on the unit (Selecting the unit functions)

1) FUNCTION

Indoor controller board

This model is equipped with the FUNCTION.

(the DIP switch on the indoor controller board)

When the indoor unit is controlled with the remote controller, the operation mode, set

temperature, and the fan speed are memorized by the indoor controller board.

Factory default setting

Switch Function Switch setting Setting

SW3-1

SW3-3

Power failure automatic recovery

Fan speed when the heating

thermostat is OFF

SW3

15

2

34

ON

OFF

ON Available

OFF Not available

ON Stop

OFF Extra low

8

Page 9

7. Electrical work

Service menu

Test run

Input maintenance info.

Function setting

Check

Self check

Main menu:

Cursor

F1 F2 F3 F4

Fig. 7-6 Fig. 7-7

Function setting

Ref. address

Mode 1

Mode 2

Mode 3

Mode 4

Request:

Cursor Cursor

F1 F2 F3 F4

Grp.

Fig. 7-8 Fig. 7-9

Function setting

Ref. address

Grp.

Sending data

Function setting

Ref. address

Unit No.

Monitor:

Cursor Address

Grp./1/2/3/4/All

F1 F2 F3 F4

Function setting

Ref. address

Mode 7

Mode 8

Mode 9

Mode 10

Request:

Cursor Cursor

Unit # 1

F1 F2 F3 F4

For wired remote controller only

(Fig. 7-6)

1

• Select “Service” from the Main menu, and press the [SELECT] button.

• Select “Function settings” with the [F1] or [F2] button, and press the [SELECT]

button.

(Fig. 7-7)

2

• Set the indoor unit refrigerant addresses and unit numbers with the [F1]

through [F4] buttons, and then press the [SELECT] button to confi rm the cur-

rent setting.

<Checking the Indoor unit No.>

When the [SELECT] button is pressed, the target indoor unit will start fan

operation. If the unit is common or when running all units, all indoor units for the

selected refrigerant address will start fan operation.

(Fig. 7-8)

3

• When data collection from the indoor units is completed, the current settings

appears highlighted. Non-highlighted items indicate that no function settings

are made. Screen appearance varies depending on the “Unit No.” setting.

(Fig. 7-9)

4

• Use the [F1] or [F2] button to move the cursor to select the mode number, and

change the setting number with the [F3] or [F4] button.

(Fig. 7-10)

5

• When the settings are completed, press the [SELECT] button to send the setting data from the remote controller to the indoor units.

• When the transmission is successfully completed, the screen will return to the

Function setting screen.

Note:

• Make the above settings on Mr. Slim units as necessary.

• Table 1 summarizes the setting options for each mode number. Refer to the

indoor unit Installation Manual for the detailed information about initial settings, mode numbers, and setting numbers for the indoor units.

• Be sure to write down the settings for all functions if any of the initial settings has been changed after the completion of installation work.

F1 F2 F3 F4

Fig. 7-10

Function table

Select unit number 00

Mode Settings Mode no. Setting no.

Power failure automatic recovery *1

(AUTO RESTART FUNCTION)

Indoor temperature detecting

LOSSNAY connectivity

Power voltage 240 V

Select unit numbers 01 to 03 or all units (AL)

Mode Settings Mode no. Setting no.

Filter sign 100 Hr

*1 For this model, mode no. 1 cannot be set using the remote controller. Set this mode using DIP switch SW3-1 of the indoor controller board.

Not available

Available 2*1

01

Indoor unit operating average

Set by indoor unit’s remote controller 2

02

1*1

1

Remote controller’s internal sensor 3

Not Supported

Supported (indoor unit is not equipped with outdoor-air intake) 2

03

1

Supported (indoor unit is equipped with outdoor-air intake) 3

220 V, 230 V 2

04

1

1

2500 Hr 2

07

No fi lter sign indicator 3

Initial setting

Initial setting

Setting

Setting

9

Page 10

8. Installing the grille

1

23

45

Fig. 8-1

Fig. 8-2

8.1. Check the grille accessories (Fig. 8-1)

• The grille should be supplied with the following accessories.

Accessory name Q’ty Remark

Grille 1 650 × 650 (mm)

1

Screw with washer 4 M5 × 0.8 × 25 (mm)

2

Gauge 1

3

Fastener 2

4

Band 2

5

8.2. Preparing to attach the grille (Fig. 8-2)

• With the gauge supplied with this kit, adjust and check the positioning of the unit

relative to the ceiling. If the unit is not properly positioned in the ceiling, there may

be air leaks, condensation may form, or the up/down vanes may not operate correctly.

• Make sure that the opening in the ceiling is within the following tolerances:

576 576 - 620 620

• Make sure that step A is performed within 27-32 mm. Damage could result by failing

to adhere to this range.

A Main unit

B Ceiling

C Gauge (Accessory)

D Ceiling opening dimensions

8.2.1. Removing the intake grille (Fig. 8-3)

• Slide the levers in the direction indicated by the arrow 1 to open the intake grille.

• Unlatch the hook that secures the grille.

* Do not unlatch the hook for the intake grille.

• With the intake grille in the “open” position, remove the hinge of the intake grille

from the grille as indicated by the arrow 2.

Fig. 8-3

8.2.2. Removing the corner panel (Fig. 8-4)

Fig. 8-4

(mm)

• Remove the screw from the corner of the corner panel. Slide the corner panel as

indicated by the arrow 1 to remove the corner panel.

A Intake grille

B Grille

C Intake grille levers

D Grille hook

E Hole for the grille’s hook

F Corner panel

G Screw

8.3. Installing the grille

• Please pay attention because there is a restriction in the attachment position of the

grille.

10

Fig. 8-5

15~20

8.3.1. Preparations (Fig. 8-5)

• Install the two enclosed screws with washer in the main unit (at the corner refrigerant

pipe area and at the opposite corner) as shown in the diagram.

A Main unit

B Detailed diagram of installed screw with washer (accessory).

Page 11

8. Installing the grille

Fig. 8-6

Fig. 8-8

8.3.2. Temporary installation of the grille (Fig. 8-6)

• Align the electric component box of the main unit and the receiver of the grille, and

then temporarily secure the grille using the bell shaped holes.

* Make sure that the lead wiring of the grille does not get pinched between the

grille and the main unit.

A Main unit

B Electric component box

C Screw with washer (for temporary use)

D Screw with washer (Accessory)

E Grille

F Bell shaped hole

G Receiver (For SLZ-KA·VAL3)

8.3.3. Securing the grille (Fig. 8-7)

• Secure the grille to the main unit by tightening the previously installed two screws

(with captive washer) as well as the two remaining screws (with captive washer).

* Make sure that there are no gaps between the main unit and the grille or the

grille and the ceiling.

Caution:

When tightening the screw with captive washer 2, tighten it at a torque of 4.8

N•m or less. Never use an impact screwdriver.

• It may result in parts damage.

A Ceiling

B Main unit

C Grille

D Make sure that there are no gaps.

Fig. 8-7

8.3.4. Wire connection (Fig. 8-8)

• Be sure to connect the unit to the connector (white:10-pole/red:9-pole). Next, at-

tach the white glass tube that comes with the main unit so that the tube covers the

connector. Close the opening of the glass tube with the band.

• Make sure that there is no slack in the each lead wire at the fastener on the

grille.

A Fastener (Accessory)

B White glass tube

C Connector of the main unit

D Connector of the grille

E Band (Accessory)

F Receiver (For SLZ-KA·VAL3)

A Button

B Vane motor

C Up/down vanes

D Connector

Fig. 8-9

E Measurement standard

position of grille

F Up/down vanes

A

8.4. Locking the up/down airfl ow direction (Fig. 8-9)

The vanes of the unit can be set and locked in on up or down orientation depending

upon the environment of use.

• Set according to the preference of the customer.

The operation of the fi xed up/down vanes and all automatic controls cannot be

performed using the remote controller. In addition, the actual position of the vanes

may differ from the position indicated on the remote controller.

1 Turn off the main power switch.

Injuries and or an electrical shock may occur while the fan of the unit is rotating.

2 Disconnect the connector for the vane motor of the vent that you want to lock.

(While pressing the button, remove the connector in the direction indicated by

the arrow as shown in the diagram.) After removing the connector, insulate it with

tape.

3 To adjust the desired airfl ow direction, slowly move the up/down vanes within the

specifi ed range. (Fig. 8-10)

Specifi ed range

Up/down airfl ow

direction

A (mm) 21 25 28 30

• The vanes can be set between 21 and 30 mm.

Caution:

Do not set the up/down vanes passed the specifi ed range. Condensation could

form on and drop from the ceiling, or the unit could malfunction.

Horizontal 30° Downward 45° Downward 55° Downward 70°

Fig. 8-10

11

Page 12

8. Installing the grille

9. Test run

SLP-2ALW (For SLZ-KA·VAL3)

Fig. 8-11

8.5. Installing the intake grille (Fig. 8-11)

• Perform the procedure that is described in “8.2. Preparing to attach the grille” in

reverse order to install the intake grille and the corner panel.

A Refrigerant piping of the main unit

B Drain piping of the main unit

C Corner panel

* Installation in any position is possible.

D Position of the levers on the intake grille when sent from the factory.

* Although the clips can be installed in any of four positions.

E Receiver (For SLZ-KA·VAL3)

8.6. Check

• Make sure that there is no gap between the unit and the grille, or between the grille

and the surface of the ceiling. If there is any gap between the unit and the grille, or

between the grille and the surface of the ceiling, it may cause dew to collect.

• Make sure that the wires have been securely connected.

A Emergency operation switch (heating)

B Emergency operation switch (cooling)

C Operation lamp

SLP-2ALW (For SLZ-KA·VAL3)

Fig. 9-1

9.1. Before test run

► After installation of indoor and outdoor units, and piping and electric wiring

work, recheck that the unit is free from leaks of refrigerant, loosened connections, and incorrect polarity.

► Measure an impedance between the power supply terminal block (L, N,

on the units and the ground with a 500 V Megger and check that it is equal

to or greater than 1.0 M.

9.2. Test run

9.2.1. For wireless remote controller (Fig. 9-1)

Measure an impedance between the power supply terminal block on the outdoor unit and

the ground with a 500 V Megger and check that it is equal to or greater than 1.0 M.

• Before performing the test run, recheck for any wrong wiring.

Wrong wiring prevents normal operation or results in blown fuse disabling opera-

tion.

• Perform test run in the following procedure.

Procedure

1 Press the

If the operation lamp C blinks every 0.5 seconds, inspect the indoor/outdoor

connecting wire for miswiring.

• Check that the vanes operate properly when cool air is blown out.

2 Press it once more, and the operation stops.

3 Press the

Check that warm air blows out.

• In starting the heating operation, indoor unit fan may not operate to prevent blowing

cool air. Please wait for a few minutes until the temperature of heat exchanger rises

and warm air blows out.

4 Press it once more, and the operation stops.

Checking the remote (infrared) signal reception

Press the ON/OFF button on the remote controller and check that an electronic sound

is heard from the indoor unit. Press the ON/OFF button again to turn the air conditioner

off.

Emergency operation (when wireless remote controller is lost)

The emergency operation can be started by pressing the button B/A (cooling/heating). When the button is once pressed, the unit will start the emergency operation at

a fi xed temperature setting of 24°C in cooling mode or heating mode.

Note:

• Emergency operation does not stop automatically.

• Although the thermostat is forcibly set to on during the test run, the temperature is

set to 24°C during emergency operation and the thermostat operates according to

the room temperature.

If the indoor unit is operated with the remote controller, both the test run and the

emergency operation are released by commands from the remote controller.

Once the compressor stops, the restart preventive device operates so the compressor

will not operate for three minutes to protect the air conditioner.

button B for more than 3 seconds to start the cooling operation.

button A for more than 3 seconds to start the heating operation.

)

12

Page 13

9. Test run

9.2.2. Wired remote controller

■ Make sure to read operation manual before test run. (Especially items to secure safety)

Step 1 Turn on the power.

● Remote controller: The system will go into startup mode, and the remote controller power lamp (green) and “PLEASE WAIT” will blink. While the lamp and message

are blinking, the remote controller cannot be operated. Wait until “PLEASE WAIT” is not displayed before operating the remote controller. After the power is turned on,

“PLEASE WAIT” will be displayed for approximately 2 minutes.

● Indoor controller board: LED 1 will be lit up, LED 2 will be lit up (if the address is 0) or off (if the address is not 0), and LED 3 will blink.

● Outdoor controller board: LED 1 (green) and LED 2 (red) will be lit up. (After the startup mode of the system fi nishes, LED 2 will be turned off.) If the outdoor controller

board uses a digital display, [- ] and [ -] will be displayed alternately every second.

If the operations do not function correctly after the procedures in step 2 and thereafter are performed, the following causes should be considered and eliminated if they

are found.

(The symptoms below occur during the test run mode. “Startup” in the table means the LED display written above.)

Symptoms in test run mode

Remote Controller Display

Remote controller displays “PLEASE WAIT”,

and cannot be operated.

After power is turned on, “PLEASE WAIT” is

displayed for 3 minutes, then error code is

displayed.

No display appears even when remote controller

operation switch is turned on. (Operation lamp

does not light up.)

Display appears but soon disappears even

when remote controller is operated.

OUTDOOR BOARD LED Display

< > indicates digital display.

After “startup” is displayed, only green lights up.

<00>

After “startup” is displayed, green(once) and

red(once) blink alternately. <F1>

After “startup” is displayed, green(once) and

red(twice) blink alternately. <F3, F5, F9>

After “startup” is displayed, green(twice) and

red(once) blink alternately. <EA. Eb>

After “startup” is displayed, only green lights up.

<00>

After “startup” is displayed, only green lights up.

<00>

• After power is turned on, “PLEASE WAIT” is displayed for 2

minutes during system startup. (Normal)

• Incorrect connection of outdoor terminal block (R, S, T and S

2

S

, S3.)

• Outdoor unit’s protection devise connector is open.

• Incorrect wiring between the indoor and outdoor unit (Polarity

is wrong for S

• Remote controller transmission wire short.

• There is no outdoor unit of address 0. (Address is other than 0.)

• Remote controller transmission wire open.

• After canceling function selection, operation is not possible for

about 30 seconds. (Normal)

1

, S2, S3.)

Cause

1

,

Step 2 Switch the remote controller to “Test run”.

Select “Test run” from the Service menu, and press the [SELECT] button. (Fig. 9-2)

1

Select “Test run” from the Test run menu, and press the [SELECT] button. (Fig. 9-3)

2

The test run operation starts, and the Test run operation screen is displayed.

3

Step 3 Perform the test run and check the airfl ow temperature and auto vane.

Press the [F1] button to change the operation mode. (Fig. 9-4)

1

Cooling mode: Check that cool air blows from the unit.

Heating mode: Check that warm air blows from the unit.

Press the [SELECT] button to display the Vane operation screen, and then press

2

the [F1] and [F2] buttons to check the auto vane. (Fig. 9-5)

Press the [RETURN] button to return to the Test run operation screen.

Test run

Input maintenance info.

Function setting

Check

Self check

unem ecivreS

:unem niaM

rosruC

F1 F2 F3 F4

Fig. 9-2

RemainTest run

Pipe

Cool

Switch disp.

Mode Fan

F1 F2 F3 F4

Auto

Test run menu

Test run

Drain pump test run

Service menu:

Cursor

F1 F2 F3 F4

Fig. 9-3

Remain

Van e

F1 F2 F3 F4

Fig. 9-4

Fig. 9-5

13

Page 14

9. Test run

Step 4 Confi rm the operation of the outdoor unit fan.

The speed of the outdoor unit fan is controlled in order to control the performance of the unit. Depending on the ambient air, the fan will rotate at a slow speed and will keep

rotating at that speed unless the performance is insuffi cient. Therefore, the outdoor wind may cause the fan to stop rotating or to rotate in the opposite direction, but this is

not a problem.

Step 5 Stop the test run.

Press the [ON/OFF] button to stop the test run. (The Test run menu will appear.)

1

Note: If an error is displayed on the remote controller, see the table below.

LCD Description of malfunction LCD Description of malfunction LCD Description of malfunction

P1 Intake sensor error P9 Pipe sensor error (dual-wall pipe)

P2 Pipe sensor error (liquid pipe) PA Leakage error (refrigerant system)

Drain fl oat switch connector disconnected

P4

(CN4F)

PL Refrigerant circuit abnormal

E0 ~ E5

P5 Drain overfl ow protection operation FB Indoor controller board error

Freezing/overheating protection

P6

operation

P8 Pipe temperature error

U*, F*

(* indicates an

alphanumeric

character

excluding FB.)

Outdoor unit malfunction

Refer to the wiring diagram for the

outdoor unit.

E6 ~ EF

See the table below for the details of the LED display (LED 1, 2, and 3) on the indoor controller board.

LED1 (microcomputer power supply) Indicates whether control power is supplied. Make sure that this LED is always lit.

LED2 (remote controller power supply)

Indicates whether power is supplied to the wired remote controller. The LED is lit only for the indoor unit that is

connected to the outdoor unit that has an address of 0.

LED3 (indoor/outdoor unit communication) Indicates whether the indoor and outdoor units are communicating. Make sure that this LED is always blinking.

Communication error between the

remote controller and the indoor unit

Communication error between the

indoor unit and the outdoor unit

TOO

COOL

TOO

SELECT

FAN

TIME

AUTO COOL

VANE

DRY

HEAT

RESET

h

ON/OFF

TOO

TOO

WARM

COOL

The OPERATION INDICATOR

lamp comes on regardless of

the remote controller display.

Fig. 9-6

OPERATION INDICATOR lamp

9.3. Self-check

9.3.1. Wired remote controller

■

Refer to the installation manual that comes with each remote controller for de-

tails.

9.3.2. Wireless remote controller [SLZ-KA·VAL3 only] (Fig. 9-6)

1 Turn ON the power.

2 While pressing both the MODE SELECT button and TOO COOL button on the

remote controller at the same time, press the RESET button.

3 Release the RESET button.

4 Release the other two buttons. After three seconds, all items in the LCD are

displayed.

5 Transmit the signal of remote controller by pressing the OPERATE/STOP (ON/

OFF) button on the remote controller.

(The above procedure allows OPERATION INDICATOR lamp to indicate the

failure-mode.)

6 Transmit the signal of remote controller by pressing the OPERATE/STOP (ON/

OFF) button to stop the self-check.

14

Page 15

9. Test run

• Refer to the following tables for details on the check codes.

[Output pattern A]

Beeper sounds

OPERATION

INDICATOR

lamp fl ash

pattern

[Output pattern B]

Beeper sounds

OPERATION

INDICATOR

lamp fl ash

pattern

[Output pattern A] Errors detected by indoor unit

Wireless remote controller

Beeper sounds/OPERATION

INDICATOR lamp fl ashes

(Number of times)

[Output pattern B] Errors detected by unit other than indoor unit (outdoor unit, etc.)

Wireless remote controller

Beeper sounds/OPERATION

INDICATOR lamp fl ashes

(Number of times)

*1 If the beeper does not sound again after the initial two beeps to confi rm the self-check start signal was received and the OPERATION INDICATOR lamp does not come

on, there are no error records.

*2 If the beeper sounds three times continuously “beep, beep, beep (0.4 + 0.4 + 0.4 sec.)” after the initial two beeps to confi rm the self-check start signal was received, the

specifi ed refrigerant address is incorrect.

Beep Beep Beep Beep Beep Beep Beep

1st2nd3

Off

Self-check

starts

(Start signal

received)

Self-check

starts

(Start signal

received)

Approx. 2.5 sec.On0.5 sec.On0.5 sec.On0.5 sec.

Number of fl ashes/beeps in pattern indicates the check

code in the following table (i.e., n=5 for “P5”)

Beep Beep Beep Beep Beep Beep Beep

Off

Approx. 2.5 sec.OnApprox. 3 sec.On0.5 sec.On0.5 sec.On0.5 sec.

rd

Number of fl ashes/beeps in pattern indicates the check

code in the following table (i.e., n=5 for “U2”)

th

n

On

0.5 sec.

1st2nd3

nd

1st2

Off

Approx. 2.5 sec.On0.5 sec.On0.5 sec.

Number of fl ashes/beeps in pattern indicates

the check code in the following table

rd

th

n

On

0.5 sec.

Approx. 2.5 sec.OnApprox. 3 sec.On0.5 sec.On0.5 sec.

· · · Repeated

Off

st

1

Number of fl ashes/beeps in pattern indicates

the check code in the following table

Wired remote

controller

Symptom Remark

Check code

1 P1 Intake sensor error

2

P2 Pipe (TH2) sensor error

P9 Pipe (TH5) sensor error

3 E6, E7 Indoor/outdoor unit communication error

4 P4 Drain sensor error

5

P5 Drain pump error

PA Forced compressor error

6 P6 Freezing/Overheating safeguard operation

7 EE Communication error between indoor and outdoor units

8 P8 Pipe temperature error

9 E4 Remote controller signal receiving error

10 — —

11 — —

12 Fb Indoor unit control system error (memory error, etc.)

14

PL Refrigerant circuit abnormal

Wired remote

controller

Symptom Remark

Check code

1 E9 Indoor/outdoor unit communication error (Transmitting error) (Outdoor unit)

2 UP Compressor overcurrent interruption

3 U3, U4 Open/short of outdoor unit thermistors

4 UF Compressor overcurrent interruption (When compressor locked)

5 U2 Abnormal high discharging temperature/49C worked/insuffi cient refrigerant

6 U1, Ud Abnormal high pressure (63H worked)/Overheating safeguard operation

7 U5 Abnormal temperature of heat sink

8 U8 Outdoor unit fan safeguard stop

For details, check the LED display

of the outdoor controller board.

9 U6 Compressor overcurrent interruption/Abnormal of power module

10 U7 Abnormality of super heat due to low discharge temperature

11 U9, UH

Abnormality such as overvoltage or voltage shortage and abnormal synchronous

signal to main circuit/Current sensor error

12 — —

13 — —

14 Others Other errors (Refer to the technical manual for the outdoor unit.)

nd

· · · Repeated

2

15

Page 16

9. Test run

• On wireless remote controller

The continuous buzzer sounds from receiving section of indoor unit.

Blink of operation lamp

• On wired remote controller

Check code displayed in the LCD.

• If the unit cannot be operated properly after the above test run has been performed, refer to the following table to remove the cause.

Symptom

Wired remote controller

PLEASE WAIT

PLEASE WAIT Error code

Display messages do not appear even

when operation switch is turned ON

(operation lamp does not light up).

On the wireless remote controller with condition above, following phenomena takes place.

• No signals from the remote controller are accepted.

• OPE lamp is blinking.

• The buzzer makes a short piping sound.

Note:

Operation is not possible for about 30 seconds after cancellation of function selection. (Correct operation)

For description of each LED (LED1, 2, 3) provided on the indoor controller, refer to the following table.

LED1 (power for microcomputer) Indicates whether control power is supplied. Make sure that this LED is always lit.

LED2 (power for wired remote controller) Indicates whether power is supplied to the wired remote controller.

LED3 (communication between indoor and outdoor units) Indicates state of communication between the indoor and outdoor units. Make sure that this LED is

For about 2 minutes

following power-on

After about 2 minutes has expired

following power-on

• For about 2 minutes following power-on, operation of the

remote controller is not possible due to system start-up.

(Correct operation)

• Connector for the outdoor unit’s protection device is not

connected.

• Reverse or open phase wiring for the outdoor unit’s power

terminal block

• Incorrect wiring between indoor and outdoor units (incorrect polarity of S1, S2, S3)

• Remote controller wire short

always blinking.

Cause

SLP-2ALW (For SLZ-KA·VAL3)

Fig. 9-7

9.4. Check drainage

9.4.1. For wireless remote controller (Fig. 9-7)

• During the test run, ensure the water is being properly drained out and that no water

is leaking from joints.

• Always check this during installation even if the unit is not required to provide cooling/drying at that time.

• Similarly, check the drainage before fi nishing ceiling installation in a new premis-

es.

(1) Remove the cover of the water supply inlet and add about 1000 cc of water using

a water supply pump etc. During this process, be careful not to spray water into

the drain pump mechanism.

(2) Switching on emergency operation switch (cooling) on the grille.

(3) Confi rm that water is being drained out through the drainage outlet.

(4) After checking the drainage, ensure that the cover is replaced and the power

supply is isolated.

(5) After confi rming the drainage system is functioning, replace the drain plug.

A Insert the pump end 3 to 5 cm

B Cover of water supply inlet

C About 1000 cc

9.4.2. For wired remote controller

(1) Remove the cover of the water supply inlet and add about 1000 cc of water using

a water supply pump etc. During this process, be careful not to spray water into

the drain pump mechanism.

(2) Confi rm that water is being drained out through the drainage outlet, after switching

over from remote control mode to test run mode (cooling mode).

(3) After checking the drainage, ensure that the cover is replaced and the power

supply is isolated.

(4) After confi rming the drainage system is functioning, replace the drain plug.

D Water

E Drain plug

F Emergency operation switch (cooling)

16

Page 17

Содержание

1. Меры предосторожности.....................................................................152

2. Выбор места установки .......................................................................152

3. Диаграмма установки ..........................................................................153

4. Установка внутреннего прибора .........................................................153

5. Подготовка

Примечание:

В этом руководстве по использованию аппарата фраза “проводной пульт дистанционного управления” относится к пульту дистанционного

управления PAR-32 MA A.

Сведения о других пультах дистанционного управления приводятся в руководстве по установке или руководстве по начальным настройкам,

находящемся в этих коробках.

трубопровода охладителя ...............................................155

6. Дренажные трубы ................................................................................ 156

7. Электромонтажные работы ................................................................157

8. Установка вентиляционной решетки .................................................. 160

9. Выполнение испытания.......................................................................162

1. Меры предосторожности

• Обязательно прочтите раздел “Меры предосторожности” до установки

кондиционера.

• Обязательно соблюдайте меры предосторожности, изложенные ниже,

поскольку в них содержатся важные с точки зрения безопасности

положения.

• Символика, используемая в данном руководстве, имеет следующие

значения.

Предупреждение:

Невыполнение данного требования может привести к смертельному

исходу, тяжелой травме и т.д.

Осторожно:

Неправильное выполнение данной инструкции в определенных условиях

может привести к тяжелой травме.

Предупреждение:

• Самостоятельная установка данного прибора (клиентом) запрещается.

Незавершенная установка может привести к травме вследствие пожара, поражения

электрическим током, падения прибора или утечки воды. Обратитесь к специалисту

по установке или к дилеру, у которого вы приобрели данный прибор.

• Надежно устанавливайте прибор в месте, способном выдержать его вес.

Установка прибора в месте недостаточной прочности может привести к

падению прибора и получению травм.

• Используйте провода указанных параметров для надежного соединения

внутреннего и наружного приборов. Надежно закрепите провода в

секторах соединений выводного щитка, чтобы натяжение провода не

передавалось в секторы

Незавершенные соединения и крепление проводов могут привести к пожару.

• Не используйте промежуточные соединения в шнуре питания или

удлинитель шнура питания, и не подсоединяйте несколько приборов к

одной розетке переменного тока.

Это может привести к пожару или поражению электрическим током

вследствие дефекта контакта, дефекта изоляции, превышения

допустимого тока в сети и т.д.

•

Убедитесь в отсутствии утечки газа хладагента после завершения установки.

• Выполняйте установку с соблюдением правил безопасности, используя

руководство по установке в качестве справочника.

Незавершенная установка может привести к личной травме вследствие пожара,

поражения электрическим током, падения прибора или утечки воды.

• Выполняйте электромонтажные работы в соответствии с руководством

по установке и обязательно используйте отдельный контур питания.

При недостаточной мощности контура питания или в случае незавершенных

электромонтажных работ возможен пожар или поражение электрическим током.

• Запрещается самостоятельный ремонт или перемещение прибора.

Осторожно:

• Выполните заземление.

Запрещается подключать провод заземления к стопорным механизмам

газовых и водопроводных труб, а также проводу телефонного заземления.

Дефект заземления может привести к поражению электрическим током.

•

Запрещается устанавливать прибор в местах утечки воспламеняющихся газов.

При утечке и скоплении газа рядом с прибором возможен взрыв.

• Уст ановите прерыватель утечки тока на землю с учетом конкретного места

установки (во влажных местах).

Если прерыватель утечки тока на землю не установлен, возможно

поражение электрическим током.

соединений.

• После прочтения данного руководства обязательно храните его вместе

с руководством по эксплуатации в легкодоступном месте в помещении,

где данное оборудование эксплуатируется клиентом.

: Указывает, что данная часть должна быть заземлена.

Предупреждение:

Внимательно прочтите тек ст на этикетках главног о прибора.

• Уст ановк у необходимо выполнять в соответствии с действующими

правилами электробезопасности.

• Поврежденный кабель из комплекта поставки должен быть заменен в

целях безопасности производителем, сервисным агентом или лицами,

обладающими необходимой квалификацией.

• Надежно прикрепите крышку электрического компонента к внутреннему

прибору, а сервисную панель – к наружному прибору.

Если крышка электрического компонента и сервисная панель ненадежно

прикреплены соответственно к внутреннему и наружному приборам, это

может привести к пожару или поражению электрическим током вследствие

попадания пыли, воды и т.д. внутрь приборов.

• При выполнении работ по установке обязательно используйте детали,

входящие в комплект поставки, или детали, характеристики которых

приводятся

Использование дефектных деталей может привести к травме или утечке воды

вследствие пожара, поражения электрическим током, падения прибора и т.д.

•

В случае утечки охладителя во время выполнения работ проветрите комнату.

Если охладитель вступит в контакт с огнем, то при этом образуется токсичный газ.

• При монтаже или перемещении, а также при обслуживании кондиционера

используйте только указанный хладагент (R410A) для заполнения

трубопроводов хладагента. Не смешивайте его ни с каким другим

хладагентом и не допускайте наличия воздуха в трубопроводах.

Наличие воздуха в трубопроводах

результате которых может произойти взрыв или другие повреждения.

Использование любого хладагента, отличного от указанного для этой

системы, вызовет механическое повреждение, сбои в работе системы,

или выход устройства из строя. В наихудшем случае, это может послужить

серьезной преградой к обеспечению безопасной работы этого изделия.

• Надежно выполняйте соединения дренажных труб/трубных соединений

в соответствии с требованиями руководства по

В случае дефекта соединений дренажных труб/трубных соединений

возможно капание воды из прибора и повреждение имущества в помещении

вследствие намокания.

• Затягивайте конусную гайку с помощью тарированного ключа с крутящим

моментом, указанным в данном руководстве.

Слишком сильная затяжка конусной гайки может привести к поломке гайки

через некоторое время, результатом

•

Если прибор работает длительное время и выше потолка присутствует

воздух высокой температуры/высокой влажности (выше точки росы 26 °С),

во внутреннем приборе или на потолочных материалах может возникать

конденсация росы. При эксплуатации приборов в таких условиях, на

всю поверхность прибора и потолочных материалов следует добавлять

изоляционный материал (10–2 0 мм), чтобы предотвратить конденсацию росы

в данном руководстве.

может вызывать скачки давления, в

установке.

чего станет утечка хладагента.

2. Выбор места установки

.

2.1. Внутренний прибор

• Где нет преград на пути движения воздушного потока.

• Где прохладный воздух распространяется по всем уголкам помещения.

• Где прибор не подвержен воздействию прямых солнечных лучей.

• На расстоянии по меньшей мере 1 м от телевизора и радиоприемника. (во

избежание помех изображения или создания дополнительного шума).

• Как можно дальше от люминесцентных ламп

можно было использовать пульт дистанционного управления для нормальной

работы с прибором).

и ламп накаливания ( с тем, чтобы

2.2. Установка беспроводного пульта дистанционного

управления (Для SLZ-KA·VAL3)

• Место крепления

• Где им легко пользоваться, и где его хорошо видно.

• В недоступном для детей месте.

• Крепление

Выберите место на высоте около 1,2 м от уровня пола и убедитесь в том, что с этой позиции

сигналы с пульта дистанционного управления безошибочно принимаются внутренним

прибором (при приеме сигнала слышен одиночный или двукратный тональный гудок).

Затем прикрепите держатель пульта дистанционного управления к колонне или стене

и установите в него беспроводной пульт

дистанционного управления.

152

• Где можно легко снимать и устанавливать на место воздушный фильтр.

Предупреждение:

Устанавливайте внутренний прибор на потолок, достаточно прочный,

чтобы выдержать вес прибора.

В помещениях, где используются люминесцентные лампы инверторного

типа, сигналы с беспроводного пульта дистанционного управления могут

не приниматься прибором.

Page 18

3. Диаграмма установки

23520

650

650

Fig. 3-1

4. Установка внутреннего прибора

(мм)

3.1. Внутренний прибор (Fig. 3-1)

A Потолок

B Решетка

C Препятствие

D Мин. 1000 мм

E Мин. 500 мм (Весь периметр)

При необходимости обеспечить пространство для технического обслуживания в E,

оставьте не менее 700 мм.

Предупреждение:

Устанавливайте внутренний прибор на потолок, достаточно прочный,

чтобы выдержать вес прибора.

3.2. Наружный прибор

Обратитесь к руководству по установке наружного прибора.

1

2

4.1. Проверьте наличие дополнительных прина-

длежностей к внутреннему прибору (Fig. 4-1)

Внутренний прибор должен поставляться в комплекте со следующими дополнительными принадлежностями:

3

6

0

7

A

4

8

5

9

Fig. 4-1

(

мм)

Название приспособления Количество

Установочный шаблон 1

1

Прокладка (с изоляцией)

2

Прокладка (без изоляции)

Изоляция для труб (для соединения труб хладагента)

малого диаметра (жидкости)

3

большого диаметра (газа)

Лента (большая)

4

Лента (малая)

Винт с прокладкой (М5 × 25) для установки решетки 4

5

Соединительная муфта для дренажа 1

6

Изоляция 1

7

Шуруп крепления для 9 3,5 16 (черный)

8

(для SLZ-KA·VAL3)

Держатель пульта дистанционного управления

9

(для SLZ-KA·VAL3)

Батарейка (AAA) (для SLZ-KA·VAL3) 2

0

Беспроводной пульт дистанционного управления

1

(для SLZ-KA·VAL3)

4

4

1

1

6

2

2

1

1

4.2. Расположение отверстия в потолке и навесных

болтов (Fig. 4-2)

• С помощью установочного шаблона ( верх упаковки) и калибра (поставляется в

комплекте дополнительных принадлежностей к решетке) проделайте отверстие

в потолке таким образом, чтобы главный прибор можно было установить, как

показано на диаграмме. (Метод использования шаблона и калибра указан.)

* Прежде, чем использовать шаблон и калибр, проверьте их размеры, пос-

кольку они меняются

* Размеры отверстия в потолке можно регулировать в диапазоне, указанном

на схеме; поэтому расположите главный прибор напротив отверстия в

потолке, убедившись, что соответствующие противоположные стороны

на всех сторонах зазора между ними одинаковы.

• Используйте навесные болты М10 (3/8").

Мин.

Мин.

Мин.

Мин.

* Навесные болты приобретаются на месте.

• Выполните установку,

а также между главным прибором и решеткой нет зазора.

A Внешняя сторона главного прибора

B Шаг болта

C Потолочное отверстие

D Внешние стороны решетки

E Решетка

F Потолок

G Мин. 500 мм (Весь периметр)

При необходимости обеспечить про-

странство для технического обслуживания в G, оставьте не менее 700 мм.

* Заметьте, что между потолочной панелью прибора и потолочной плитой и т.д. следует

оставить расстояние от 10 до 15 мм слева.

* Оставьте пространство для технического обслуживания в конце коробки электрических

компонентов.

из-за перепадов температур и влажности.

убедившись, что между потолочной панелью и решеткой,

H Пространство для технического обслу-

живания

I Впуск свежего воздуха

J Угол

K Коробка электрических компонентов

Fig. 4-2

153

Page 19

4. Установка внутреннего прибора

AC

120

30

75

120

100

15

20

120

70

25

100

(мм)

208

92

120

0

+5

27

Fig. 4-3

A Прибор

B Решетка

C Вкладыш

1

*B

2

*B

D Потолок

E Стропило

F Балка

G Балка крыши

*B: Шаг подвесного болта (см. Fig. 4-2 B для получения подробной информации)

H Используйте вставки с рейтингом

100-150 кг каждая (приобретают-

ся на месте)

I Навесные болты М10 (3/8")

(приобретаются на месте)

J Стальной стержень для укрепле-

ния

Fig. 4-4

Мин.30

+5

0

27

Min. 30

93

A Навесной болт (Приобретается на месте)

B Потолок

C Га йка (Приобретается на месте)

D Прокладка (с изоляцией)

(Дополнительная принадлежность)

E Плита для навешивания

F Прокладка (без изоляции)

(Дополнительная принадлежность)

G Проверьте с помощью установочного калибра

Fig. 4-5

A Главный прибор

B Потолок

C Шаблон (Дополнительное

устройство с решеткой)

Мин.576

Макс.620

D Габариты потолочного

отверстия

Fig. 4-6

A Главный прибор

B Потолок

C Установочный шаблон (Допол-

нительная

D Винт с прокладкой (Дополни-

тельная принадлежность)

принадлежность)

Fig. 4-7

4.3. Установка короба (в случае использования

впуска свежего воздуха) (Fig. 4-3)

Осторожно:

Соединение канального вентилятора и кондиционера

Если используется канальный вентилятор, убедитесь, что при заборе

наружного воздуха он соединен с кондиционером.