Page 1

MELSEC iQ-R Simple Motion Module

User's Manual (Network)

-RD77GF4

-RD77GF8

-RD77GF16

-RD77GF32

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention to safety to handle

the product correctly.

The precautions given in this manual are concerned with this product only. Refer to the MELSEC iQ-R Module Configuration

Manual for a description of the PLC system safety precautions.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to serious

consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be configured

external to the programmable controller.

(2) When the programmable controller detects an abnormal condition, it stops the operation and all

outputs are:

• Turned off if the overcurrent or overvoltage protection of the power supply module is activated.

• Held or turned off according to the parameter setting if the self-diagnostic function of the CPU

module detects an error such as a watchdog timer error.

(3) All outputs may be turned on if an error occurs in a part, such as an I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to "General Safety Requirements" in the MELSEC iQ-R Module Configuration

Manual.

(4) Outputs may remain on or off due to a failure of a component such as a relay and transistor in an

output circuit. Configure an external circuit for monitoring output signals that could cause a

serious accident.

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

● For the operating status of each station after a communication failure, refer to manuals relevant to the

network. Incorrect output or malfunction due to a communication failure may result in an accident.

1

Page 4

[Design Precautions]

WARNING

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not write any data to the "system area" and "write-protect area" of the buffer memory in the

module. Also, do not use any "use prohibited" signals as an output signal from the CPU module to

each module. Doing so may cause malfunction of the programmable controller system. For the

"system area", "write-protect area", and the "use prohibited" signals, refer to the user's manual for the

module used.

● If a communication cable is disconnected, the network may be unstable, resulting in a communication

failure of multiple stations. Configure an interlock circuit in the program to ensure that the entire

system will always operate safely even if communications fail. Failure to do so may result in an

accident due to an incorrect output or malfunction.

● To maintain the safety of the programmable controller system against unauthorized access from

external devices via the network, take appropriate measures. To maintain the safety against

unauthorized access via the Internet, take measures such as installing a firewall.

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Machine home position return is controlled by two kinds of data: a home position return direction

and a home position return speed. Deceleration starts when the proximity dog signal turns on. If

an incorrect home position return direction is set, motion control may continue without

deceleration. To prevent machine damage caused by this, configure an interlock circuit external to

the programmable controller.

(2) When the module detects an error, the motion slows down and stops or the motion rapidly stops,

depending on the stop group setting in parameter. Set the parameter to meet the specifications of

a positioning control system. In addition, set the home position return parameter and positioning

data within the specified setting range.

(3) Outputs may remain on or off, or become undefined due to a failure of a component such as an

insulation element and transistor in an output circuit, where the module cannot detect any error. In

a system that the incorrect output could cause a serious accident, configure an external circuit for

monitoring output signals.

● If safety standards (ex., robot safety rules, etc.,) apply to the system using the module, servo amplifier

and servomotor, make sure that the safety standards are satisfied.

● Construct a safety circuit externally of the module or servo amplifier if the abnormal operation of the

module or servo amplifier differs from the safety directive operation in the system.

2

Page 5

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100 mm or more between them. Failure to do so may result in malfunction

due to noise.

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned from off to on.

Therefore, use a module that has a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design circuits so

that the entire system will always operate safely, regardless of the time.

● Do not power off the programmable controller or reset the CPU module while the settings are being

written. Doing so will make the data in the flash ROM and SD memory card undefined. The values

need to be set in the buffer memory and written to the flash ROM and SD memory card again. Doing

so also may cause malfunction or failure of the module.

● When changing the operating status of the CPU module from external devices (such as the remote

RUN/STOP functions), select "Do Not Open by Program" for "Opening Method" of "Module

Parameter". If "Open by Program" is selected, an execution of the remote STOP function causes the

communication line to close. Consequently, the CPU module cannot reopen the line, and external

devices cannot execute the remote RUN function.

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

3

Page 6

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the Safety

Guidelines included with the base unit. Failure to do so may result in electric shock, fire, malfunction,

or damage to or deterioration of the product.

● To mount a module, place the concave part(s) located at the bottom onto the guide(s) of the base unit,

and push in the module until the hook(s) located at the top snaps into place. Incorrect interconnection

may cause malfunction, failure, or drop of the module.

● To mount a module with no module fixing hook, place the concave part(s) located at the bottom onto

the guide(s) of the base unit, push in the module, and fix it with screw(s). Incorrect interconnection

may cause malfunction, failure, or drop of the module.

● When using the programmable controller in an environment of frequent vibrations, fix the module with

a screw.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the screw,

short circuit, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, or malfunction.

● When using an extension cable, connect it to the extension cable connector of the base unit securely.

Check the connection for looseness. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the SD memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● Securely insert an extended SRAM cassette into the cassette connector of the CPU module. After

insertion, close the cassette cover and check that the cassette is inserted completely. Poor contact

may cause malfunction.

● Do not directly touch any conductive parts and electronic components of the module, SD memory

card, extended SRAM cassette, or connector. Doing so can cause malfunction or failure of the

module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach a blank cover module (RG60) to each empty slot and an included

extension connector protective cover to the unused extension cable connector before powering on the

system for operation. Failure to do so may result in electric shock.

4

Page 7

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less. Failure to do so may result in electric shock or malfunction.

● Use a solderless terminal with an insulation sleeve for terminal block wiring. Note that up to two

solderless terminals can be connected per terminal block.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when the terminal screw comes loose, resulting in

failure.

● Check the rated voltage and signal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause fire

or failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit, fire, or

malfunction.

● Securely connect the connector to the module. Poor contact may cause malfunction.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100 mm or more between them. Failure to do so may result in malfunction

due to noise.

● When an overcurrent caused by an error of an external device or a failure of a module flows for a long

time, it may cause smoke and fire. To prevent this, configure an external safety circuit, such as a fuse.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in damage to the module or cables or malfunction due to poor contact. Do not clamp the

extension cables with the jacket stripped. Doing so may change the characteristics of the cables,

resulting in malfunction.

● When disconnecting the communication cable or power cable from the module, do not pull the cable

by the cable part. For the cable connected to the terminal block, loosen the terminal screws. Pulling

the cable connected to the module may result in malfunction or damage to the module or cable.

● Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable to an

incorrect interface) may cause failure of the module and external device.

● Tighten the terminal screws or connector screws within the specified torque range. Undertightening

can cause drop of the screw, short circuit, fire, or malfunction. Overtightening can damage the screw

and/or module, resulting in drop, short circuit, fire, or malfunction.

● Tighten the terminal block mounting screws, terminal screws, and module fixing screws within each

specified torque range. Undertightening of the terminal block mounting screws and terminal screws

can cause short circuit, fire, or malfunction. Overtightening of them can damage the screw and/or

module, resulting in drop, short circuit, or malfunction. Undertightening of the module fixing screws

can cause drop of the screw. Overtightening of them can damage the screw and/or module, resulting

in drop.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable. For the cable connected to the terminal block,

loosen the terminal screw. Pulling the cable connected to the module may result in malfunction or

damage to the module or cable.

5

Page 8

[Wiring Precautions]

CAUTION

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

● Programmable controllers must be installed in control panels. Connect the main power supply to the

power supply module in the control panel through a relay terminal block. Wiring and replacement of a

power supply module must be performed by qualified maintenance personnel with knowledge of

protection against electric shock. For wiring, refer to the MELSEC iQ-R Module Configuration Manual.

● For Ethernet cables to be used in the system, select the ones that meet the specifications in the user's

manual for the module used. If not, normal data transmission is not guaranteed.

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire. Also, do not expose it to liquid or strong shock. Doing so will cause the

battery to produce heat, explode, ignite, or leak, resulting in injury and fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws, connector screws, or module fixing screws. Failure to do so may

result in electric shock.

6

Page 9

[Startup and Maintenance Precautions]

CAUTION

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25 cm away in all directions from the programmable controller. Failure to do so

may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the

component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or module,

resulting in drop, short circuit, or malfunction.

● After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module, and do not insert/remove the extended SRAM cassette to/from the

CPU module more than 50 times (IEC 61131-2 compliant) respectively. Exceeding the limit may cause

malfunction.

● After the first use of the product, do not insert/remove the SD memory card to/from the CPU module

more than 500 times. Exceeding the limit may cause malfunction.

● Do not touch the metal terminals on the back side of the SD memory card. Doing so may cause

malfunction or failure of the module.

● Do not touch the integrated circuits on the circuit board of an extended SRAM cassette. Doing so may

cause malfunction or failure of the module.

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage the

battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any shock is

applied to it, dispose of it without using.

● Startup and maintenance of a control panel must be performed by qualified maintenance personnel

with knowledge of protection against electric shock. Lock the control panel so that only qualified

maintenance personnel can operate it.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

● Before testing the operation, set a low speed value for the speed limit parameter so that the operation

can be stopped immediately upon occurrence of a hazardous condition.

● Confirm and adjust the program and each parameter before operation. Unpredictable movements

may occur depending on the machine.

● When using the absolute position system function, on starting up, and when the module or absolute

position motor has been replaced, always perform a home position return.

7

Page 10

[Startup and Maintenance Precautions]

CAUTION

● Before starting the operation, confirm the brake function.

● Do not perform a megger test (insulation resistance measurement) during inspection.

● After maintenance and inspections are completed, confirm that the position detection of the absolute

position detection function is correct.

● Lock the control panel and prevent access to those who are not certified to handle or install electric

equipment.

[Operating Precautions]

CAUTION

● When changing data and operating status, and modifying program of the running programmable

controller from an external device such as a personal computer connected to an intelligent function

module, read relevant manuals carefully and ensure the safety before operation. Incorrect change or

modification may cause system malfunction, damage to the machines, or accidents.

● Do not power off the programmable controller or reset the CPU module while the setting values in the

buffer memory are being written to the flash ROM in the module. Doing so will make the data in the

flash ROM and SD memory card undefined. The values need to be set in the buffer memory and

written to the flash ROM and SD memory card again. Doing so also may cause malfunction or failure

of the module.

● Note that when the reference axis speed is specified for interpolation operation, the speed of the

partner axis (2nd, 3rd, or 4th axis) may exceed the speed limit value.

● Do not go near the machine during test operations or during operations such as teaching. Doing so

may lead to injuries.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

● When disposing of batteries, separate them from other wastes according to the local regulations. For

details on battery regulations in EU member states, refer to the MELSEC iQ-R Module Configuration

Manual.

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. For details on the regulated

models, refer to the MELSEC iQ-R Module Configuration Manual.

● The halogens (such as fluorine, chlorine, bromine, and iodine), which are contained in a fumigant

used for disinfection and pest control of wood packaging materials, may cause failure of the product.

Prevent the entry of fumigant residues into the product or consider other methods (such as heat

treatment) instead of fumigation. The disinfection and pest control measures must be applied to

unprocessed raw wood.

8

Page 11

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

9

Page 12

INTRODUCTION

Thank you for purchasing the Mitsubishi Electric MELSEC iQ-R series programmable controllers.

This manual describes the functions, programming, and troubleshooting of the relevant products listed below. Before using

this product, please read this manual and the relevant manuals carefully and develop familiarity with the functions and

performance of the MELSEC iQ-R series programmable controller to handle the product correctly.

When applying the program examples provided in this manual to an actual system, ensure the applicability and confirm that it

will not cause system control problems.

Please make sure that the end users read this manual.

Relevant products

RD77GF4, RD77GF8, RD77GF16, RD77GF32

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES

Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage Directives when incorporated into other

machinery or equipment, certain measures may be necessary. Please refer to one of the following manuals.

MELSEC iQ-R Module Configuration Manual

Safety Guidelines (This manual is included with the base unit.)

The CE mark on the side of the programmable controller indicates compliance with EMC and Low Voltage Directives.

Additional measures

To ensure that this product maintains EMC and Low Voltage Directives, please refer to one of the following manuals.

MELSEC iQ-R Module Configuration Manual

Safety Guidelines (This manual is included with the base unit.)

10

Page 13

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

CHAPTER 1 FUNCTIONS 17

1.1 Fixed Cycle Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2 CC-Link IE Field Network Synchronous Communication Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.3 Cyclic Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Data flow and link device assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Link refresh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Direct access to link devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Cyclic data integrity assurance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Interlink transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Input and output status settings when failure occurs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Output status setting for CPU STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Cyclic transmission stop and restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

1.4 Transient Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Communications within the same network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Communications with different networks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

1.5 IP Packet Transfer Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

System configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

IP communication test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Access range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Relay using CC-Link IE Controller Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Example of communications using the IP packet transfer function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1.6 Safety Communication Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Communications with safety stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Safety station interlock function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

CONTENTS

CHAPTER 2 PARAMETER SETTINGS 64

2.1 Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

2.2 Required Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Station Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Network No.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Station No.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Parameter Setting Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.3 Basic Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Network Configuration Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Refresh Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Network Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

2.4 Application Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Supplementary Cyclic Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

11

Page 14

Communication Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Parameter Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Dynamic Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Event Reception from Other Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Module Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Interlink Transmission Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Safety Communication Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

CHAPTER 3 PROGRAMMING 84

3.1 Precautions for Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.2 Communication Example of Safety Communication Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

System configuration example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Setting in the master station and remote device station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Setting in the local station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Checking the network status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Program examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

CHAPTER 4 TROUBLESHOOTING 100

4.1 Checking with LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

4.2 Checking the Module Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

4.3 Checking the Network Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

4.4 Troubleshooting by Symptom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

4.5 List of Parameter Nos. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

4.6 Event List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

APPENDICES 133

Appendix 1 Module Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Appendix 2 Buffer Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

List of buffer memory addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Details of buffer memory addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Appendix 3 List of Link Special Relay (SB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Appendix 4 List of Link Special Register (SW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Appendix 5 Dedicated Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

Precautions for dedicated instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Appendix 6 Processing Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

Link scan time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Cyclic transmission delay time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Interlink transmission time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Transmission delay time of safety communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Appendix 7 Differences in Cyclic Transmission Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

INDEX 178

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

12

Page 15

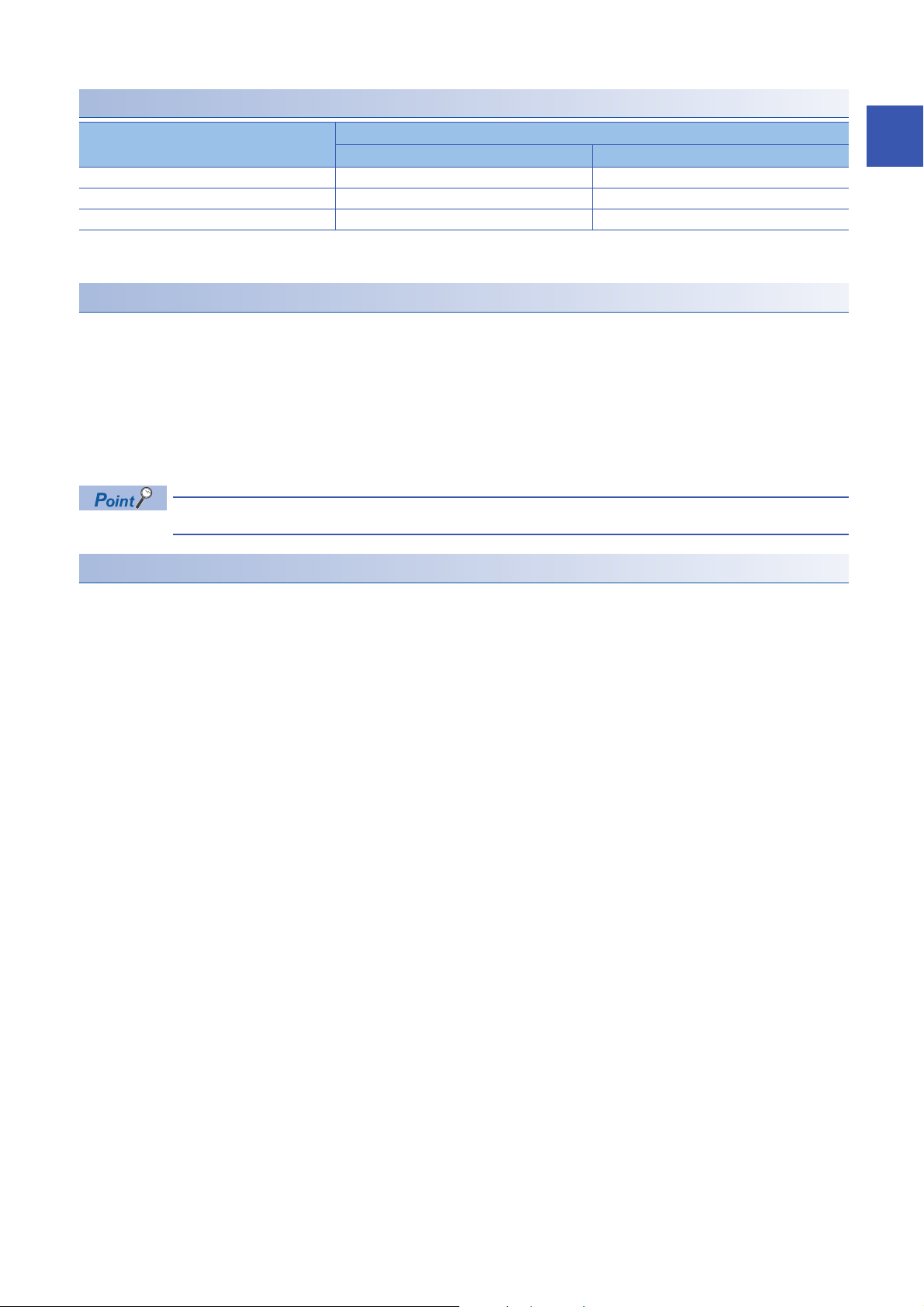

RELEVANT MANUALS

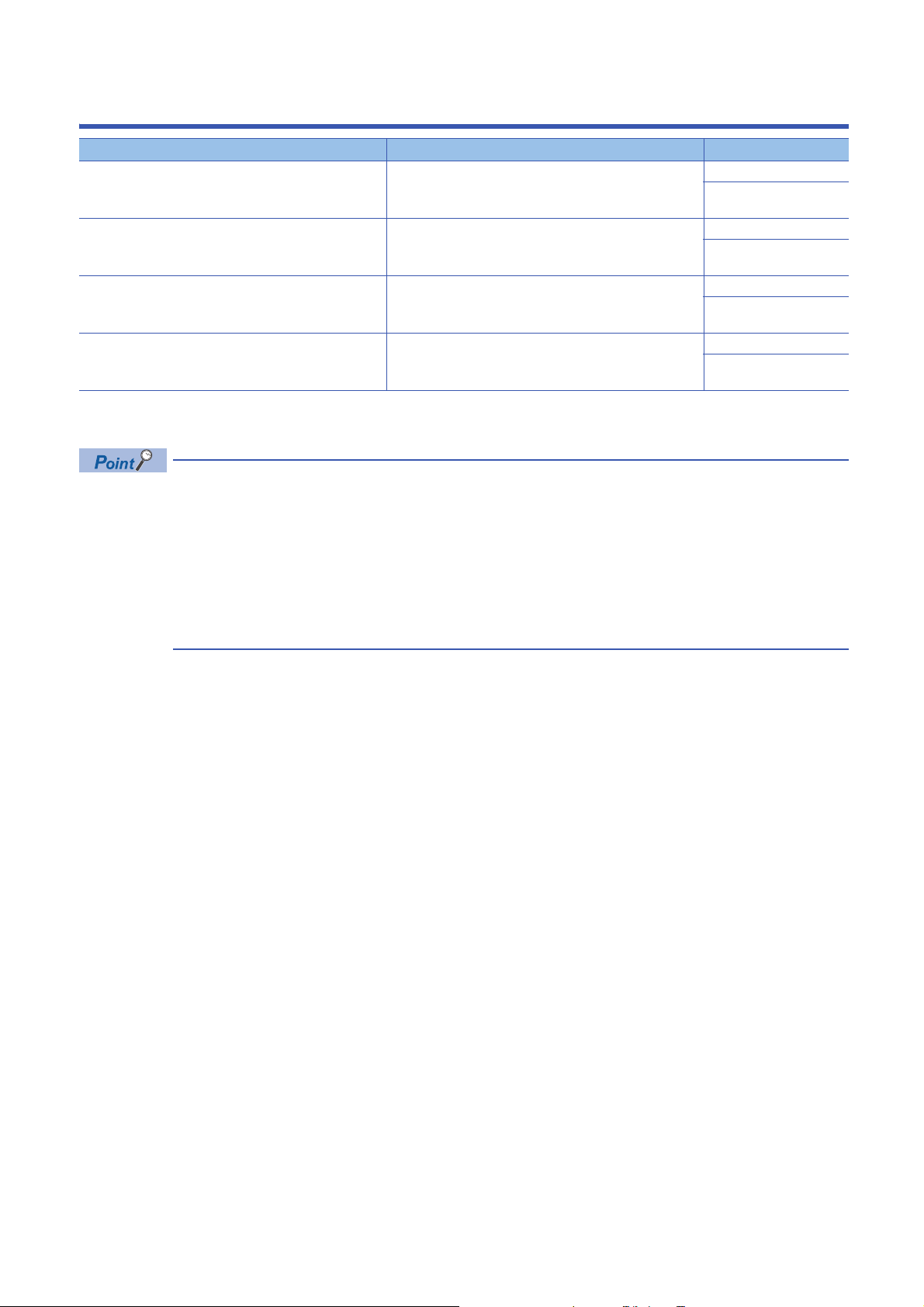

Manual name [manual number] Description Available form

MELSEC iQ-R Simple Motion Module User's Manual

(Network)

[IB-0300307ENG] (This manual)

MELSEC iQ-R Simple Motion Module User's Manual

(Startup)

[IB-0300245ENG]

MELSEC iQ-R Simple Motion Module User's Manual

(Application)

[IB-0300247ENG]

MELSEC iQ-R Simple Motion Module User's Manual

(Advanced Synchronous Control)

[IB-0300249ENG]

This manual does not include information on the module function blocks.

For details, refer to the Function Block Reference for the module used.

e-Manual refers to the Mitsubishi Electric FA electronic book manuals that can be browsed using a dedicated

tool.

e-Manual has the following features:

• Required information can be cross-searched in multiple manuals.

• Other manuals can be accessed from the links in the manual.

• The hardware specifications of each part can be found from the product figures.

• Pages that users often browse can be bookmarked.

• Sample programs can be copied to an engineering tool.

Functions, parameter settings, troubleshooting, and buffer

memory of CC-Link IE Field Network

Specifications, procedures before operation, system

configuration, wiring, and operation examples of the Simple

Motion module

Functions, input/output signals, buffer memory, parameter

settings, programming, and troubleshooting of the Simple

Motion module

Functions and programming for the synchronous control of the

Simple Motion module

Print book

e-Manual

PDF

Print book

e-Manual

PDF

Print book

e-Manual

PDF

Print book

e-Manual

PDF

13

Page 16

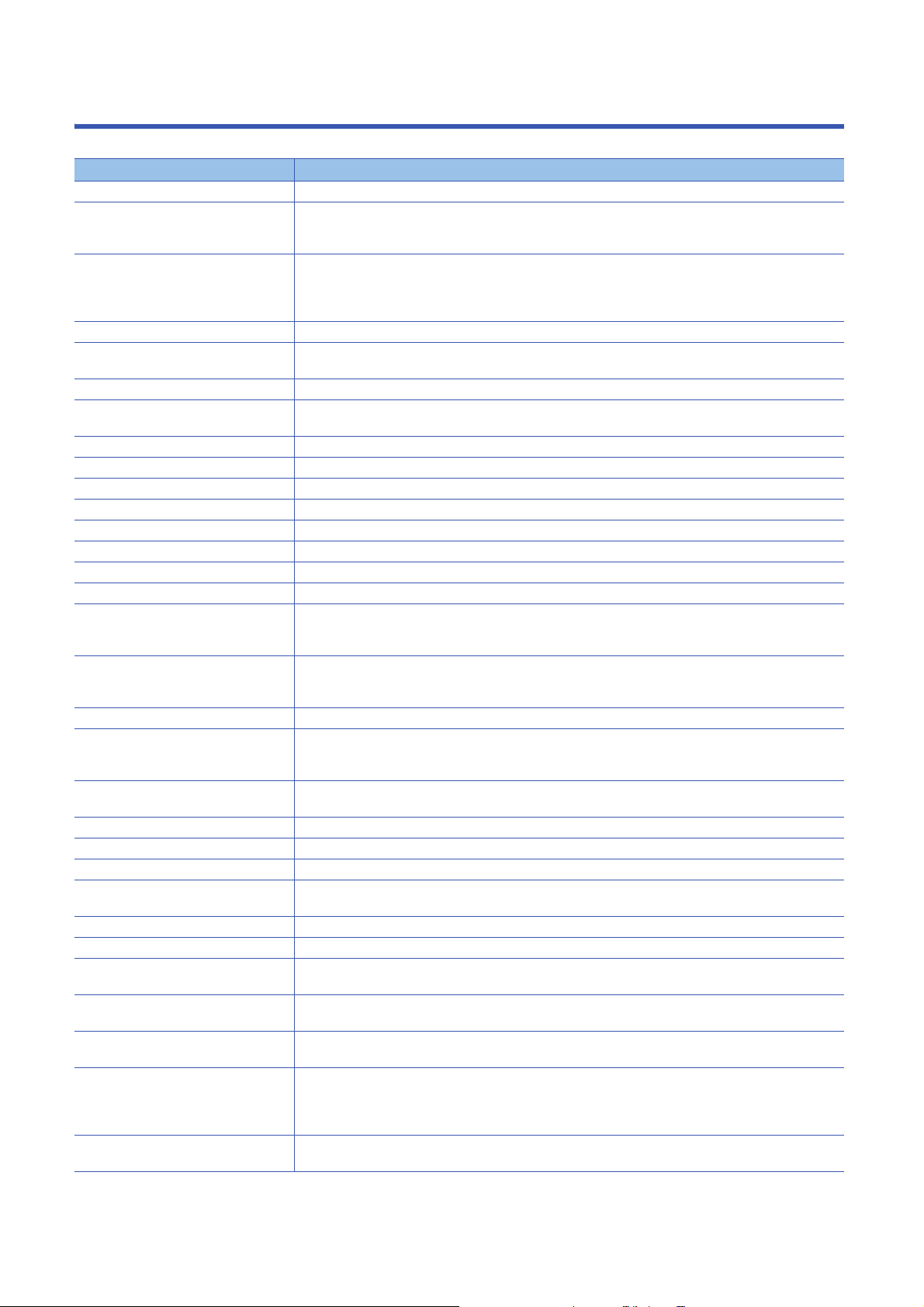

TERMS

Unless otherwise specified, this manual uses the following terms.

Term Description

Baton pass A token to send data over a network

Buffer memory A memory in an intelligent function module, where data (such as setting values and monitoring values) are

stored. When using the CPU module, the memory is indicated for storing data (such as setting values and

monitored values) of the Ethernet function and data used for data communication of the multiple CPU function.

CC-Link IE Controller Network-equipped

module

CC-Link IE Field Network A high-speed and large-capacity open field network that is based on Ethernet (1000BASE-T)

Control CPU A CPU module that controls connected I/O modules and intelligent function modules. In a multiple CPU system,

CPU module The abbreviation for the MELSEC iQ-R series CPU module

CPU module (built-in Ethernet port part) A built-in Ethernet port part of the CPU module (CPU part for the RnENCPU) ( MELSEC iQ-R Ethernet/CC-

Cyclic transmission A function by which data are periodically exchanged among stations on the network using link devices

Data link A generic term for cyclic transmission and transient transmission

Dedicated instruction An instruction for using functions of the module

Device A device (X, Y, M, D, or others) in a CPU module

Disconnection A process of stopping data link if a data link error occurs

Engineering tool A generic term for GX Works3 and MR Configurator2

Ethernet adapter module The abbreviation for the NZ2GF-ETB CC-Link IE Field Network Ethernet adapter module

Ethernet device A generic term for the devices supporting IP communication (such as personal computers)

Ethernet-equipped module A generic term for the following modules when the Ethernet function is used

Global label A label that is enabled for all program data when creating multiple program data in the project. There are two

Head module The abbreviation for the LJ72GF15-T2 CC-Link IE Field Network head module

Intelligent device station A station that exchanges I/O signals (bit data) and I/O data (word data) with another station by cyclic

Intelligent function module A MELSEC iQ-R series module that has functions other than input and output, such as an A/D converter module

Label A label that represents a device in a given character string

Link device A device (RX, RY, RWr, or RWw) in a module on CC-Link IE Field Network

Link refresh Automatic data transfer between a link device of the Simple Motion module and a device in a CPU module

Link scan (link scan time) Time required for all the stations on the network to transmit data. The link scan time depends on data volume and

Link special register (SW) Word data that indicates the operating status and data link status of a module on CC-Link IE Field Network

Link special relay (SB) Bit data that indicates the operating status and data link status of a module on CC-Link IE Field Network

Local station A station that performs cyclic transmission and transient transmission with the master station and other local

Master operating station A station that controls the entire network in the network where a master station and submaster station are

Master station A station that controls the entire network. This station can perform cyclic transmission and transient transmission

Master/local module A generic term for the RJ71GF11-T2 CC-Link IE Field Network master/local module and the following modules

Module label A label that represents one of memory areas (I/O signals and buffer memory areas) specific to each module in a

A generic term for the RJ71GP21-SX CC-Link IE Controller Network module and the following modules when the

CC-Link IE Controller Network function is used:

• RJ71EN71

• RnENCPU

there are multiple CPU modules and each connected module can be controlled by a different CPU module.

Link IE User's Manual (Startup))

• RJ71EN71

• CPU module

types of global labels: module label that is automatically generated by GX Works3 and label that can be created

for the any of the specified devices.

transmission. This station responds to a transient transmission request from another station and also issues a

transient transmission request to another station.

and D/A converter module

the number of transient transmission requests.

stations

connected. Only one master station can be used in a network.

with all stations. Only one master station can be used in a network.

when the CC-Link IE Field Network function is used:

• RJ71EN71

• RnENCPU

given character string. GX Works3 automatically generates this label, which can be used as a global label.

14

Page 17

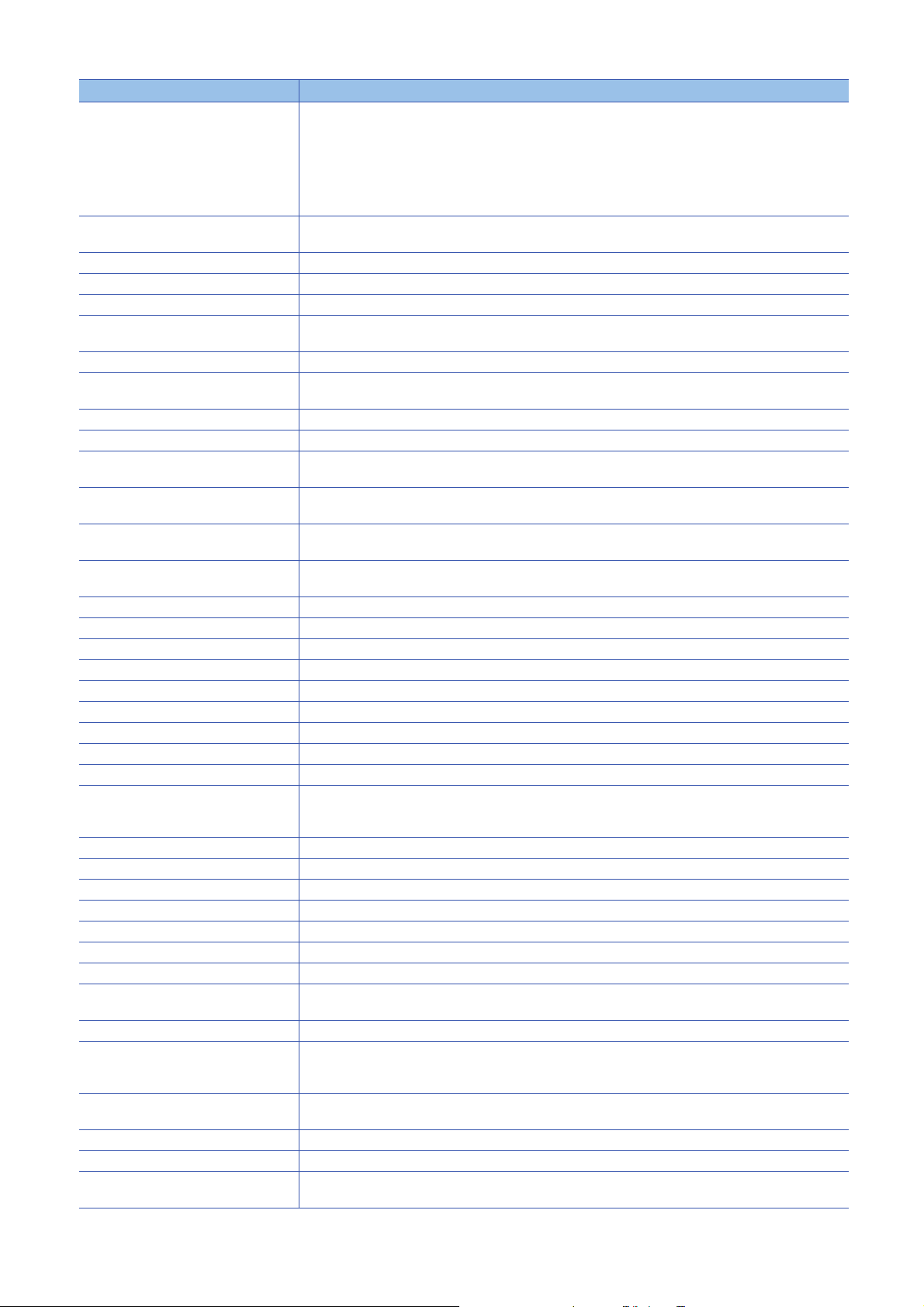

Ter m Description

Network module A generic term for the following modules:

RAS The abbreviation for Reliability, Availability, and Serviceability. This term refers to usability of automated

READ A generic term for the JP.READ and GP.READ

RECV A generic term for the JP.RECV and GP.RECV

RECVS A generic term for the G.RECVS and Z.RECVS

Relay station A station that includes two or more network modules. Data are passed through this station to stations on other

REMFR A generic term for the JP.REMFR and ZP.REMFR

Remote device station A station that exchanges I/O signals (bit data) and I/O data (word data) with another station by cyclic

Remote head module The abbreviation for the RJ72GF15-T2 CC-Link IE Field Network remote head module

Remote I/O station A station that exchanges I/O signals (bit data) with the master station by cyclic transmission

Remote input (RX) Bit data input from a slave station to the master station (For some areas in a local station, data are input in the

Remote output (RY) Bit data output from the master station to a slave station (For some areas in a local station, data are output in the

Remote register (RWr) Word data input from a slave station to the master station (For some areas in a local station, data are input in the

Remote register (RWw) Word data output from the master station to a slave station (For some areas in a local station, data are output in

REMTO A generic term for the JP.REMTO and ZP.REMTO

REQ A generic term for the J.REQ, JP.REQ, G.REQ, and GP.REQ

Reserved station A station reserved for future use. This station is not actually connected, but counted as a connected station.

Return A process of restarting data link when a station recovers from an error

RIRD A generic term for the J.RIRD, JP.RIRD, G.RIRD, and GP.RIRD

RIWT A generic term for the J.RIWT, JP.RIWT, G.RIWT, and GP.RIWT

RnENCPU A generic term for the R04ENCPU, R08ENCPU, R16ENCPU, R32ENCPU, and R120ENCPU

RnENCPU (CPU part) The left side (CPU part) of the RnENCPU (MELSEC iQ-R Ethernet/CC-Link IE User's Manual (Startup))

RnENCPU (network part) The right side (network part) of the RnENCPU (MELSEC iQ-R Ethernet/CC-Link IE User's Manual (Startup))

Routing A process of selecting paths for communication with other networks. There are two types of routing: dynamic

Safety communications A function to exchange safety data between safety stations on the same network

Safety connection A connection established for safety communications

Safety CPU A generic term for the R08SFCPU, R16SFCPU, R32SFCPU, and R120SFCPU

Safety data Data exchanged through safety communications

Safety device A device that can be used in safety programs

Safety function module Another term for the R6SFM

Safety station A generic term for a station that performs safety communications and standard communications

Seamless communication Communication that allows users to access a different kind of networks without having to consider the

SEND A generic term for the JP.SEND and GP.SEND

Servo amplifier A generic term for a drive unit

Simple Motion module The abbreviation for the MELSEC iQ-R series Simple Motion module (compatible with CC-Link IE Field Network)

Slave station A generic term for a local station, remote I/O station, remote device station, and intelligent device station

SREAD A generic term for the JP.SREAD and GP.SREAD

Submaster operating station A station that monitors the status of a master operating station in the network where a master station and

• Ethernet interface module

• CC-Link IE Controller Network module

• Module on CC-Link IE Field Network

• MELSECNET/H network module

• MELSECNET/10 network module

• RnENCPU (network part)

equipment.

networks

transmission. This station responds to a transient transmission request from another station.

opposite direction.)

opposite direction.)

opposite direction.)

the opposite direction.)

routing that auto-selects the communication routes, and static routing where communication routes are arbitrarily

set.

differences as if data were exchanged within one single network

Unless specified in particular, indicates the motor driver unit of the sequential command method which is

controlled by the Simple Motion module (belonging to own station).

• RD77GF

submaster station are connected. Only one master station can be used in a network.

15

Page 18

Term Description

Submaster station A station that serves as a master station to control the entire network if the master station is disconnected. Only

SWRITE A generic term for the JP.SWRITE and GP.SWRITE

System switching A function which switches the systems between the control system and the standby system to continue operation

Transient transmission A function of communication with another station, which is used when requested by a dedicated instruction or the

WRITE A generic term for the JP.WRITE and GP.WRITE

one master station can be used in a network.

of the redundant system when a failure or an error occurs in the control system

engineering tool

16

Page 19

1 FUNCTIONS

1.1 Fixed Cycle Communication

The communication cycle of the Simple Motion module is fixed cycle. The communication is performed with slave modules in

a cycle set in the inter-module synchronization cycle setting.

Refer to the following for details.

MELSEC iQ-R Inter-Module Synchronization Function Reference Manual

1.2 CC-Link IE Field Network Synchronous

Communication Function

A slave module which supports the CC-Link IE Field Network synchronous communication function operates synchronously

with the inter-module synchronization cycle of the Simple Motion module (the communication cycle of CC-Link IE Field

Network). Therefore, the operation timing between the Simple Motion module and each slave module can be synchronized.

A slave module which does not support the CC-Link IE Field Network synchronous communication function is also

connectable. However, the operation is not synchronized with the inter-module synchronization cycle of the Simple Motion

module. Therefore, the operation timing of the slave module is not synchronized with the Simple Motion module.

Refer to the following for details.

MELSEC iQ-R Inter-Module Synchronization Function Reference Manual

1

1 FUNCTIONS

1.1 Fixed Cycle Communication

17

Page 20

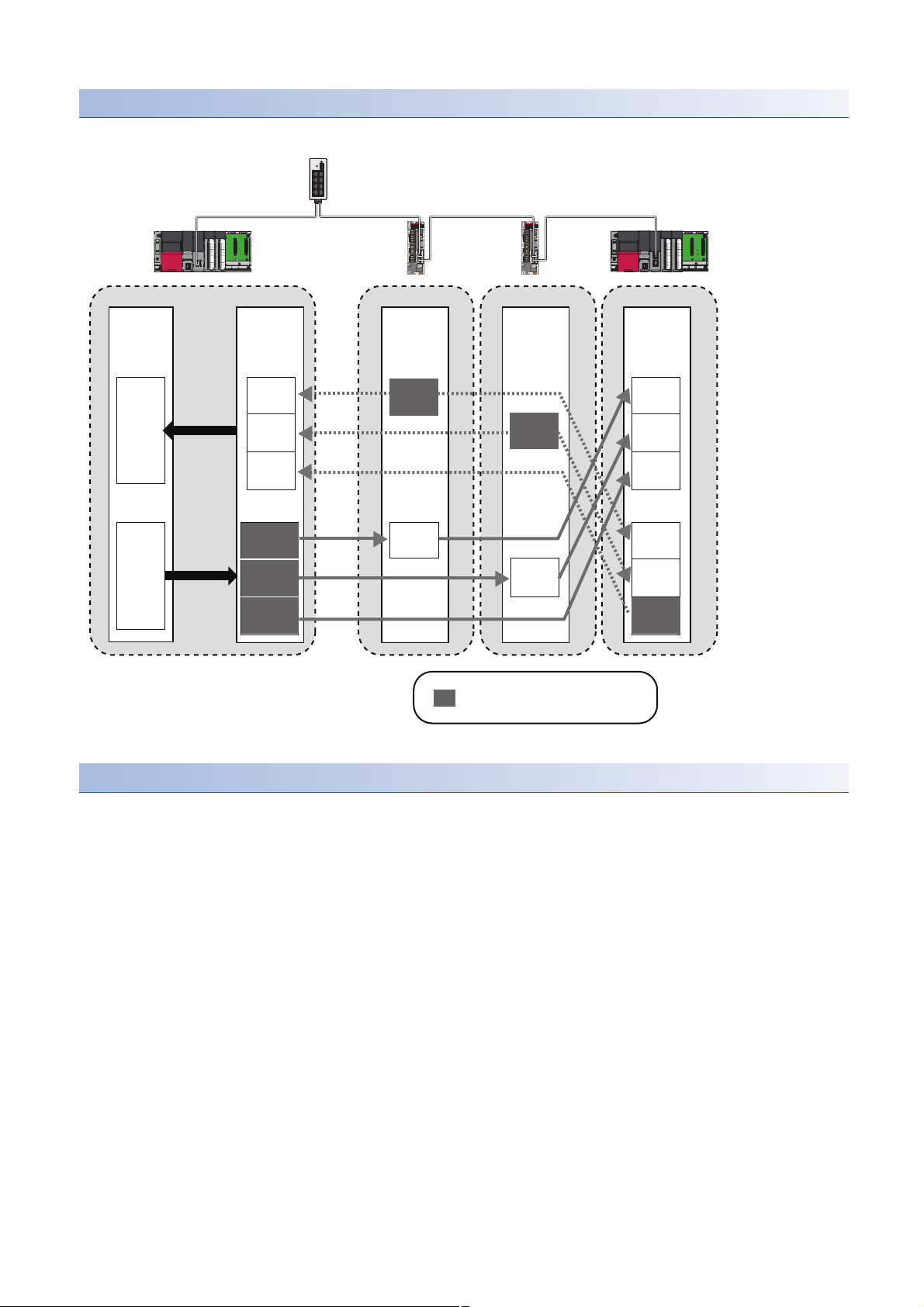

1.3 Cyclic Transmission

RX, RWr

*1

RX, RWr

*1

RX, RWr

END

RY, RWw

*1

RY, RWw

*1

RY, RWw

END

RX, RWr

M0

Y

Ò

Ó

Ø

×

×

×

Ô

Ô

Ô

Ö

Õ

Slave station

Station No.1

Slave station

Station No.2

Slave station

Station No.3

Station

No.1

Station

No.2

Station

No.3

External device

External device

CPU module

Device

Device

Station No.1

Station No.2

Station No.3

Station No.0

Area where data is sent to

other stations

Station

No.1

Station

No.2

Station

No.3

Station No.1

Station No.2

Station No.3

Link

refresh

Link

refresh

Link

scan

Inter-module

synchronization

cycle

Inter-module

synchronization

cycle

Master station

(Simple

Motion

module)

RY, RWw

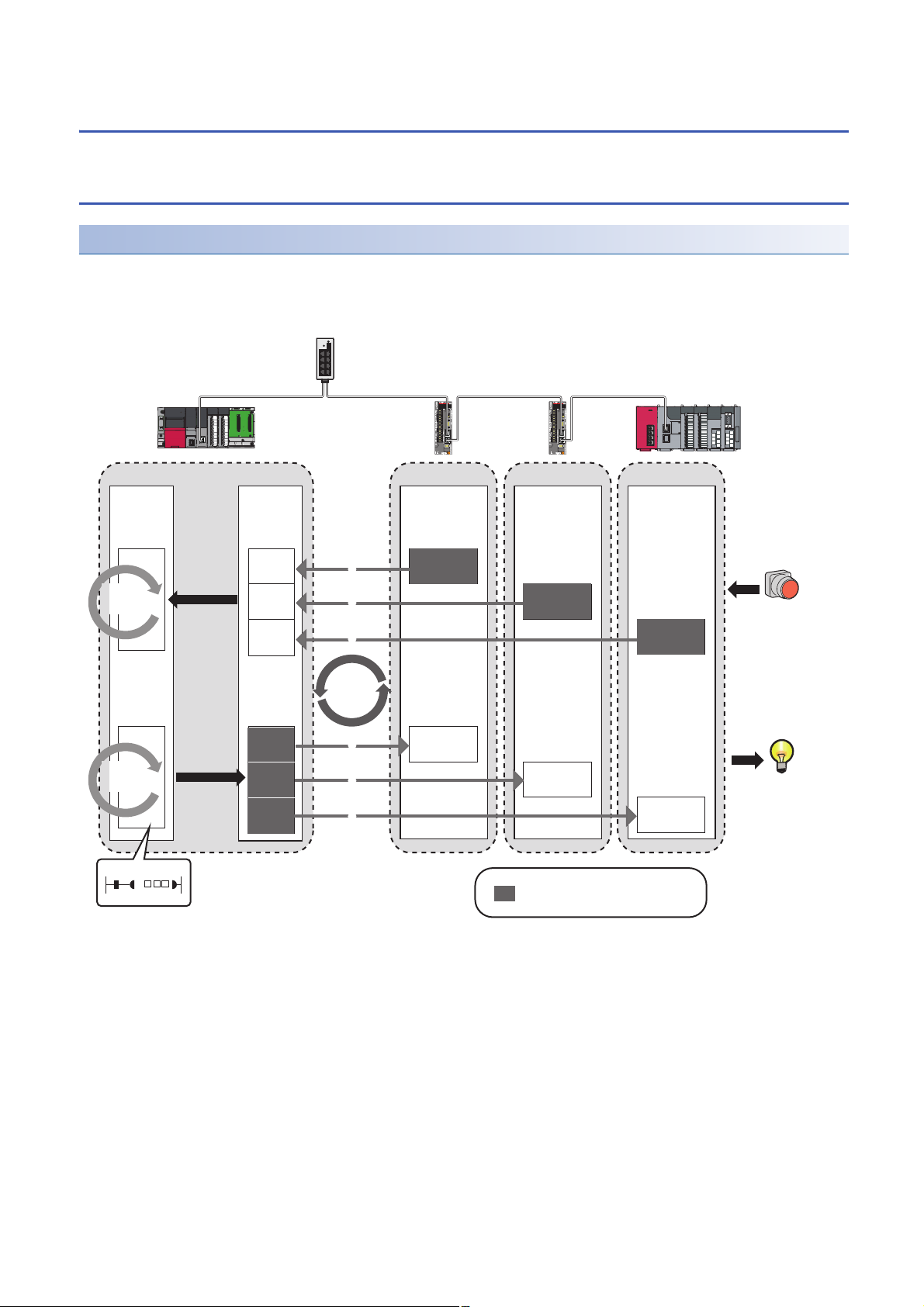

This function allows data to be periodically exchanged among stations on the same network using link devices.

Data flow and link device assignment

Master station and slave stations (except for local stations)

One-to-one communication is possible between the master and slave stations. The status data of the link devices (RY, RWw)

of the master station is output to the external device of the slave station, and the input status information from the external

device of the slave station is stored in the link devices (RX, RWr) of the master station.

18

*1 There is no RX or RY depending on the slave module.

• Output from the master station

The device of the CPU module turns on.

The status data of the device of the CPU module are stored in the link devices (RY, RWw) of the master station by link refresh.

The status data of the link devices (RY, RWw) of the master station are stored in the link devices (RY, RWw) of each slave station by link scan.

The status data of the link devices (RY, RWw) of the slave station are output to the external device.

• Input from the slave station

The status data of the external device are stored in the link devices (RX, RWr) of the slave station.

The status data of the link devices (RX, RWr) of the slave station are stored in the link devices (RX, RWr) of the master station by link scan.

The status data of the link devices (RX, RWr) of the master station are stored in the devices of the CPU module by link refresh.

1 FUNCTIONS

1.3 Cyclic Transmission

Page 21

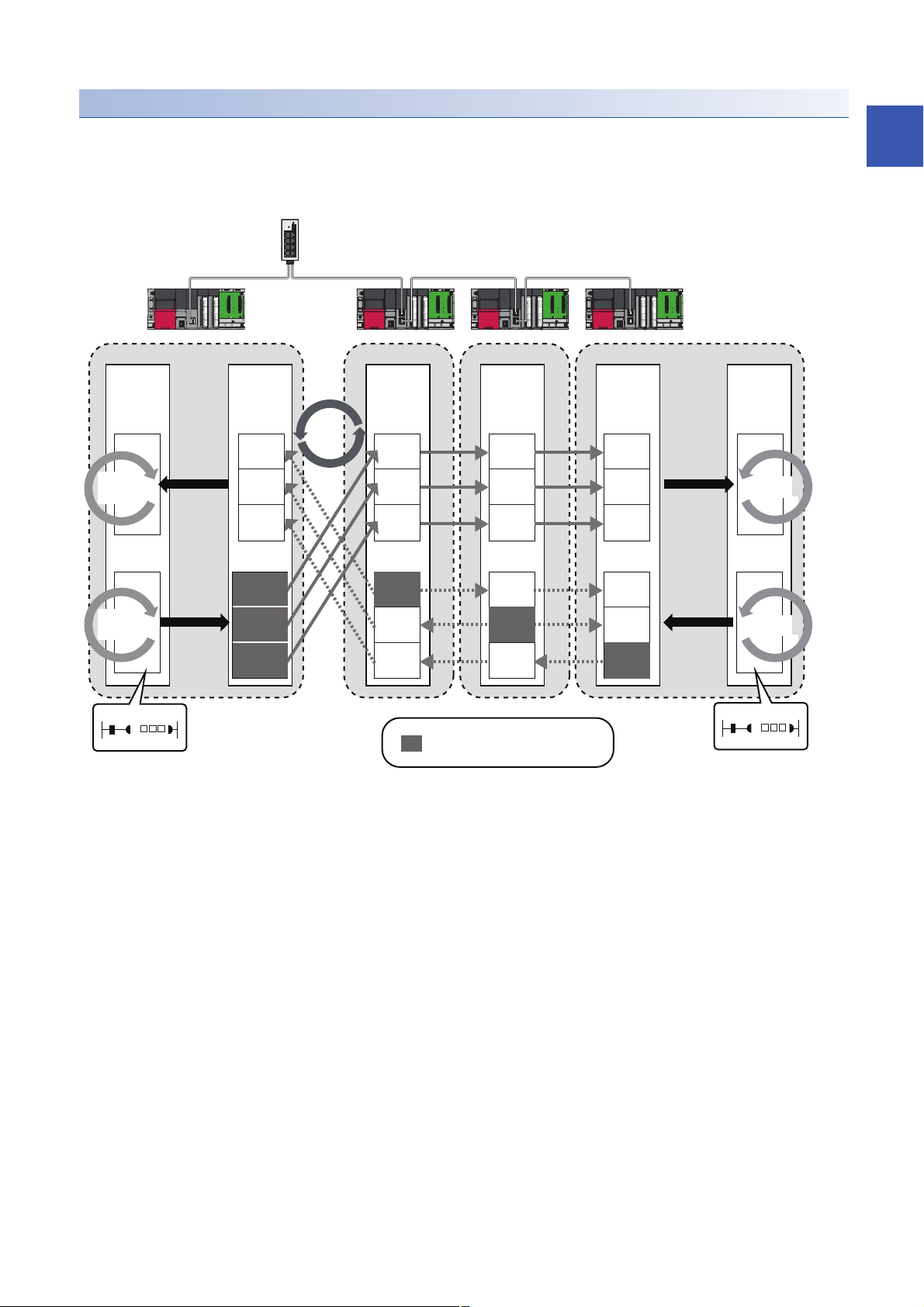

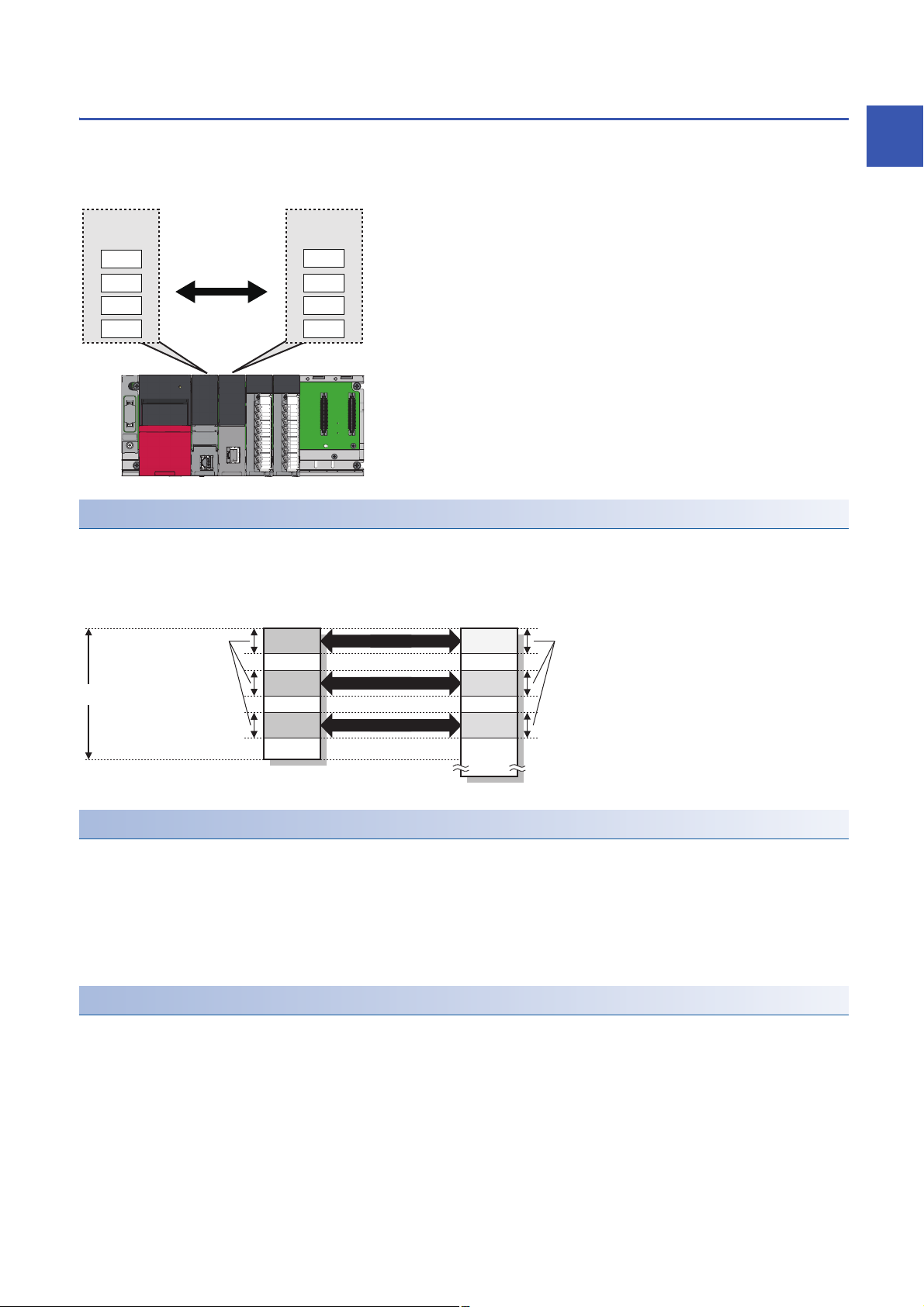

Master station and local stations

M0

END

END

M0

END

END

Ò

Ó

Ô

Õ

×

Ö

Ù

Ø

Y

Y

RX, RWr

RY, RWw

RX, RWr

RY, RWw

RX, RWr

RY, RWw

RX, RWr

RY, RWw

Inter-module

synchronization

cycle

Inter-module

synchronization

cycle

Local station

Station No.1

Local station

Station No.2

Local station

Station No.3Station No.0

Area where data is sent to

other stations

Range of the

station No.1

sending data

Range of the

station No.2

sending data

Range of the

station No.3

sending data

Range of the

sending data to

the station No.1

Range of the

sending data to

the station No.2

Range of the

sending data to

the station No.3

Sequence

scan

Sequence

scan

Station

No.1

Station

No.2

Station

No.3

Station

No.1

Station

No.2

Station

No.3

Station

No.2

Station

No.3

Station

No.1

Station

No.2

Station

No.3

Station

No.1

Station

No.3

Station

No.1

Station

No.2

Station

No.1

Station

No.2

Station

No.3

CPU module CPU module

Device

Device

Device

Device

Link

refresh

Link

refresh

Link

refresh

Link

refresh

Link

scan

Master

station

(Simple

Motion

module)

Data can be written into the send range of the link devices (RY, RWw) of each station and can be sent to any station on the

same network. The status data of the link devices (RY, RWw) of the master station are stored in the link devices (RX, RWr) of

each local station. The status data of the link devices (RY, RWw) of local stations are stored in the link devices (RX, RWr) of

the master station and the link devices (RY, RWw) of other local stations.

1

• Output from the master station

The device of the CPU module turns on.

The status data of the device of the CPU module are stored in the link devices (RY, RWw) of the master station by link refresh.

The status data of the link devices (RY, RWw) of the master station are stored in the link devices (RX, RWr) of the local station by link scan.

The status data of the link devices (RX, RWr) of the local station are stored in the devices of the CPU module.

• Input from the local station

The device of the CPU module turns on.

The device status data of the CPU module are stored in the own station send range of the link devices (RY, RWw).

The status data of the link devices (RY, RWw) of the local station are stored in the link devices (RX, RWr) of the master station by link scan.

The status data of the link devices (RX, RWr) of the master station are stored in the devices of the CPU module by link refresh.

1.3 Cyclic Transmission

1 FUNCTIONS

19

Page 22

Coexistence of local stations and the other slave stations (other than local stations)

RX, RWr

RY, RWw

*1

RX, RWr

*1

RY, RWw

*1

RX, RWr

RY, RWw

RX, RWr

RY, RWw

Master

station

(Simple

Motion

module)

Slave station

Station No.1

Slave station

Station No.2 Station No.3Station No.0

Local station

Area where data is sent to

other stations

Range of the

station No.1

sending data

Range of the

station No.2

sending data

Range of the

sending data to

the station No.1

Range of the

sending data to

the station No.2

Range of the

sending data to

the station No.3

CPU module

Station

No.1

Station

No.2

Station

No.1

Station

No.2

Station

No.1

Station

No.2

Station

No.3

Station

No.1

Station

No.2

Station

No.3

Device

Device

*1

Range of the

station No.3

sending data

The data of all slave stations are also stored in the local stations in the same way as the master station.

*1 There is no RX or RY depending on the slave module.

Setting method

The link devices can be assigned in "Network Configuration Settings" under "Basic Settings". (Page 67 Network

Configuration Settings)

The link refresh is assigned in "Refresh Settings" under "Basic Settings". (Page 70 Refresh Settings)

20

1 FUNCTIONS

1.3 Cyclic Transmission

Page 23

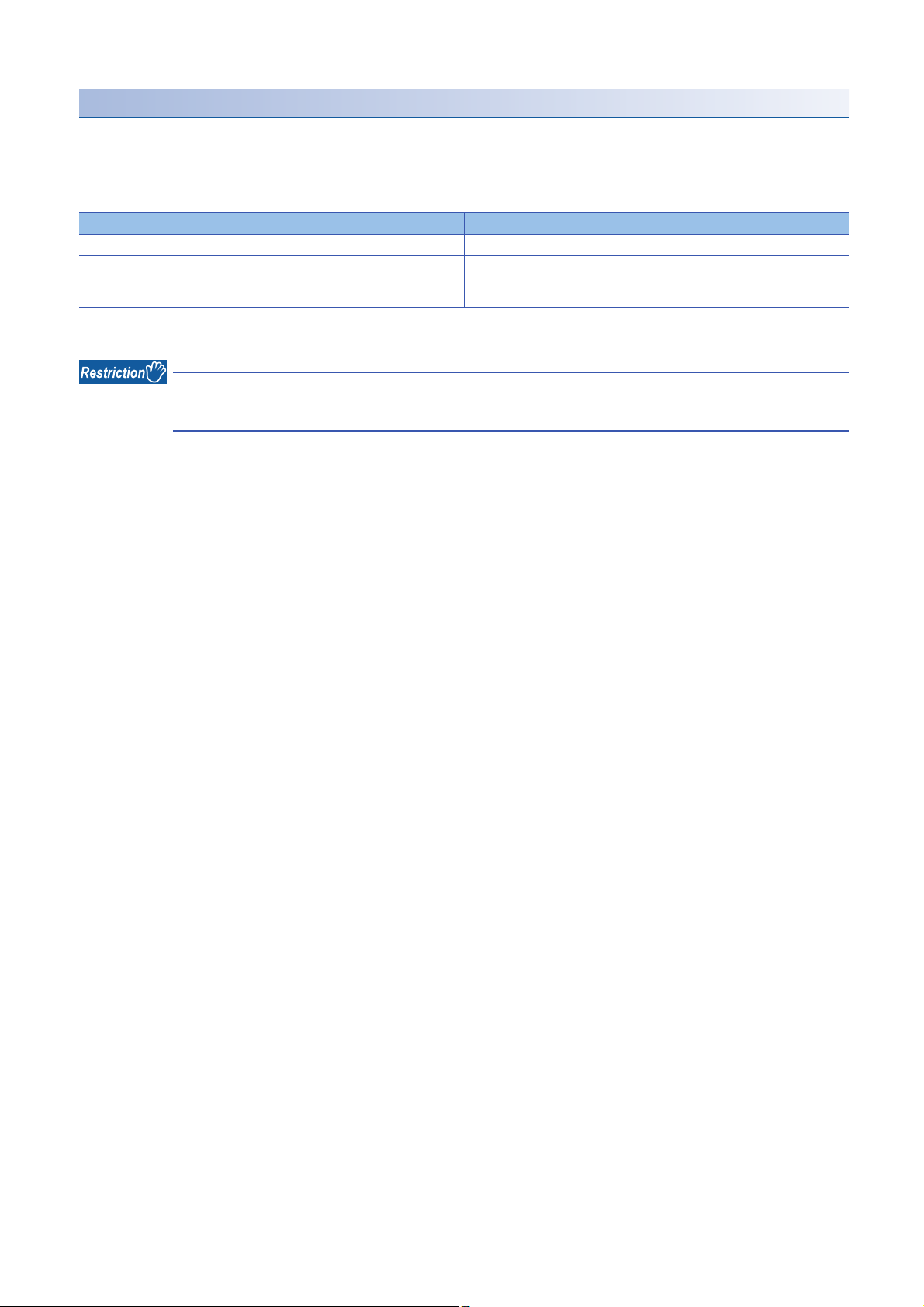

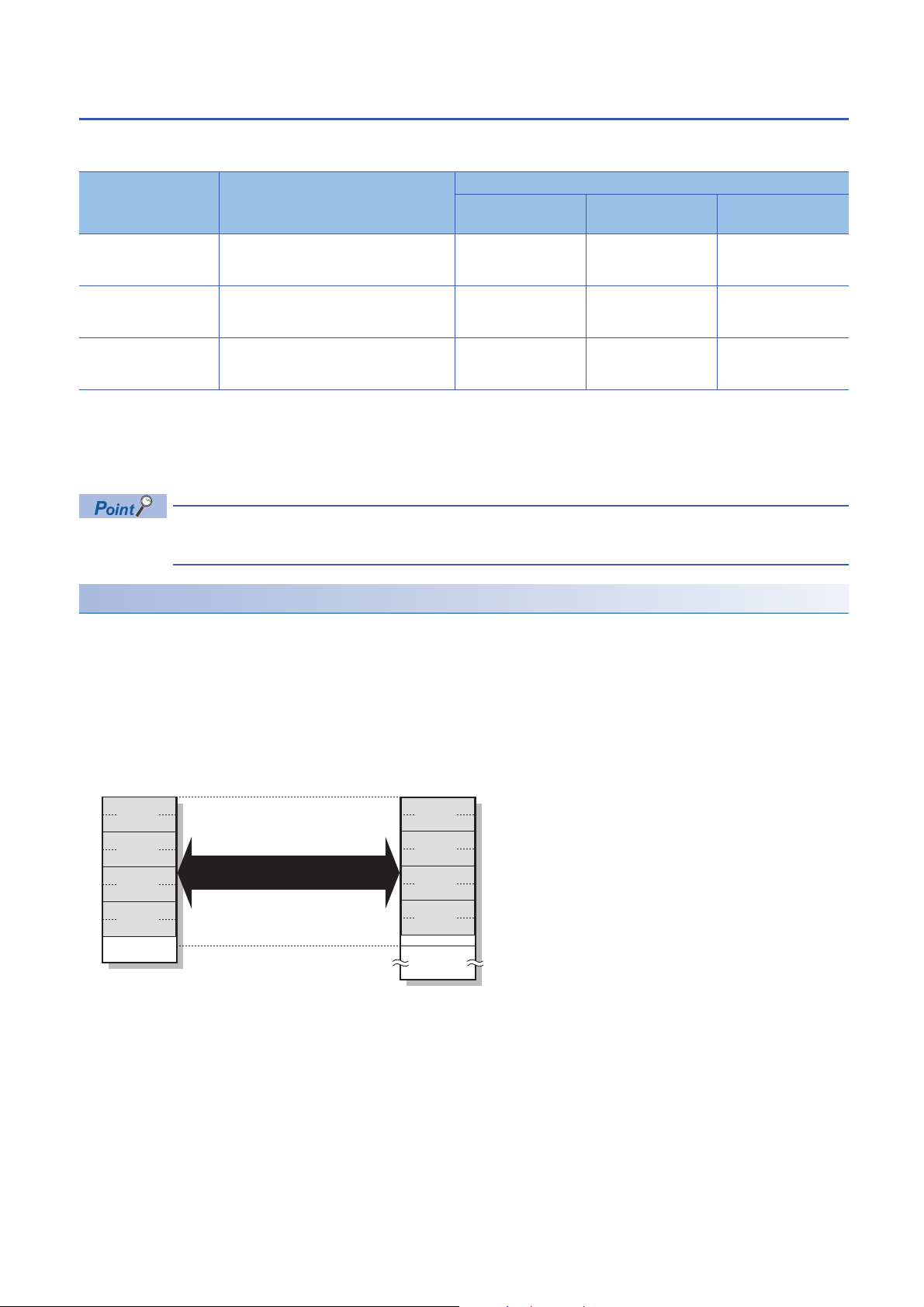

Link refresh

RX

RY

RWr

RWw

CPU module

Device

Link refresh

Simple Motion module

Link device

(1)

(2) (3)

CPU module

Device

Simple Motion

module

Link device

Link refresh

Link refresh

Link refresh

Empty

Empty

This function automatically transfers data between the link devices of the Simple Motion module and the devices of the CPU

module.

Concept of the link refresh range (number of points)

The link refresh is performed to the area set in "Refresh Settings" under "Basic Settings" and also specified in "Network

Configuration Settings" under "Basic Settings".

(1) Range set in "Refresh Settings" under "Basic

Settings"

(2) Actual link refresh range

(3) Range set in "Network Configuration Settings"

under "Basic Settings"

1

Shortening the link refresh time and transmission delay time

The link refresh time and transmission delay time can be shortened by reducing the number of link refresh points to the CPU

module. The following methods can be used to reduce the number of the link refresh points.

• In "Refresh Settings" under "Basic Settings", set only the link devices used in the CPU module as the link refresh range.

(Page 70 Refresh Settings)

• Directly access infrequently used link devices from the program, and remove the corresponding settings from the link

refresh range. (Page 23 Direct access to link devices)

Setting method

The link refresh is assigned in "Refresh Settings" under "Basic Settings". (Page 70 Refresh Settings)

1 FUNCTIONS

1.3 Cyclic Transmission

21

Page 24

Precautions

■Latched devices of the CPU module

If data in latched devices of the CPU module are cleared to zero on a program when the CPU module is powered off and on

or reset, the data may be output without being cleared to zero, depending on the timing of the link scan and link refresh. Take

the following actions not to output the data in the latched devices of the CPU module.

CPU module device How to disable the device data

Latch relay (L), file register (R, ZR) Use the initial device value of the CPU module to clear the device to zero.

CPU module device within the latch range Delete all the latch range settings specified in "Latch Interval Operation

Setting" under "Device Latch Interval Setting" in "Memory/Device Setting" of

"CPU Parameter".

*1 For the initial device value setting of the CPU module, refer to the following.

GX Works3 Operating Manual

When the inter-module synchronization setting is set to "Not Use", the link device (RX/RY/RWr/RWw) of the

station whose network synchronous communication is set to "Synchronous" is not refreshed.

*1

22

1 FUNCTIONS

1.3 Cyclic Transmission

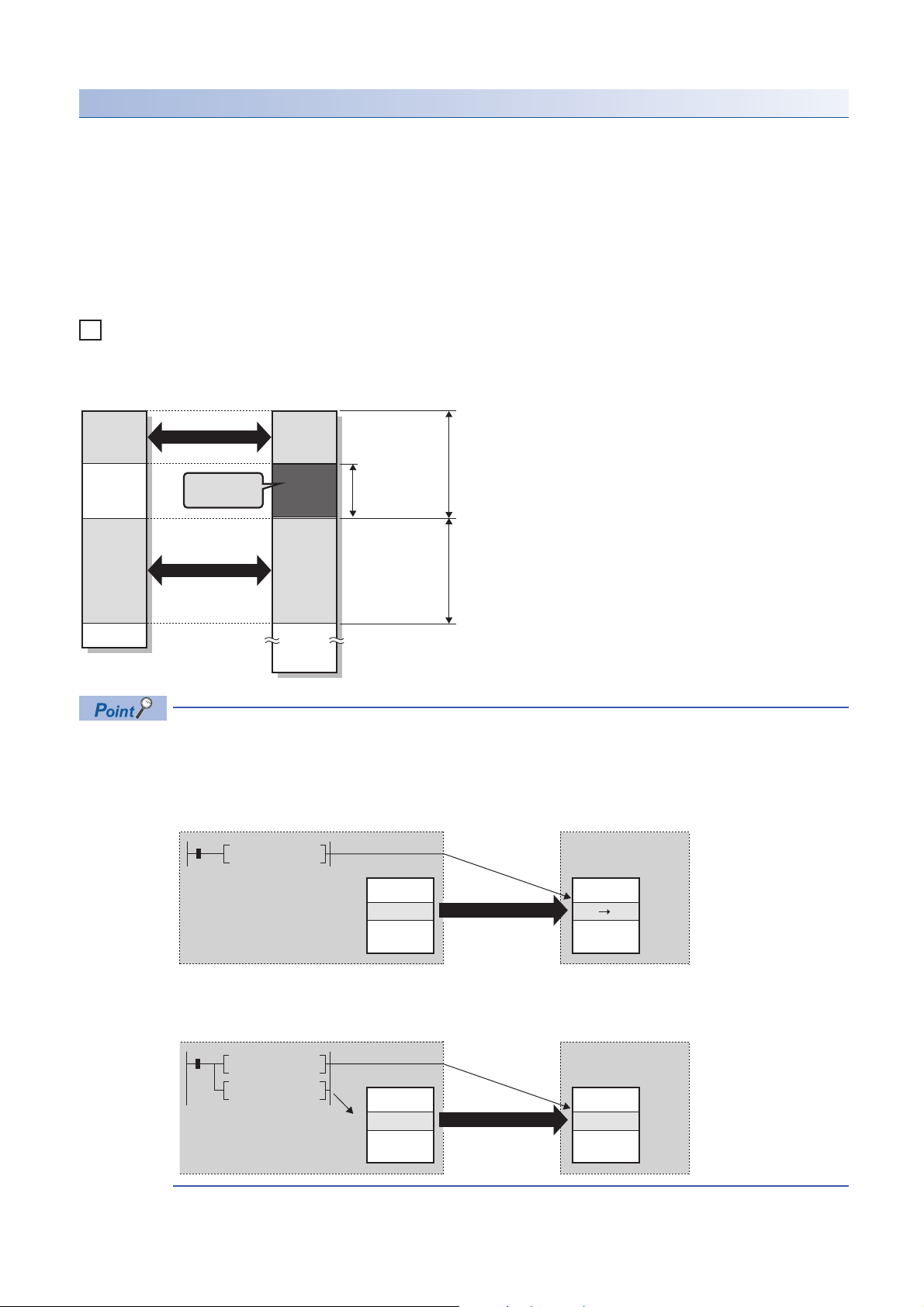

Page 25

Direct access to link devices

Ex.

J

(1) (2)

__

\

RWw100 RWw100

RWr100 RWr100

RY1000

RY1000

RX1100RX1100

XYWRX

RWr RWw

RY RX RY

RWr RWw

Master station Slave station

Network No.1

Simple Motion

module

Send

request

CPU module Slave station

Cyclic transmission

MOV K20 J1\W100

= J1\W2100 K300

J1\X1100

J1\Y1000

Actual I/O

This function directly accesses the link devices (RX, RY, RWr, RWw, SB, or SW) of the Simple Motion module from the

program. Specify a link device as the link direct device (J_\_) for direct access.

Specification method

Specify the network No. and the link device of the Simple Motion module for reading or writing.

(1) Network No.: 1 to 239

(2) Remote input (RX): X0 to X3FFF

Remote output (RY): Y0 to Y3FFF

Remote register (RWw): W0 to W1FFF

Remote register (RWr): W2000 to W3FFF

Link special relay (SB): SB0 to SB1FF

Link special register (SW): SW0 to SW1FF

1

1 FUNCTIONS

1.3 Cyclic Transmission

23

Page 26

Readable and writable range

Ex.

(2)

(1)

(3)

Y

RY

CPU module Simple Motion module

This area is

writable.

Link refresh

Link refresh

RWw

20 RWw100

W

W100

20

Simple Motion moduleCPU module

MOV K20 J1\W100

Link refresh

MOV K20 W100

Data can be read or written between the Simple Motion module and CPU module mounted on the same base unit.

■Read

All link devices of the Simple Motion module can be specified. (Page 23 Specification method)

■Write

The range that satisfies all of the following conditions can be specified.

• Area where data is sent to other stations and outside the link refresh range (Page 18 Data flow and link device

assignment)

• Within the link device range of the Simple Motion module (Page 23 Specification method)

The following shows the example.

(1) Out of the link refresh range

(2) Area where data is sent to other stations

(3) Area for receiving the data from other stations

When writing data to the area in the link refresh range, directly access the link device and write the same data

in the device of the CPU module.

• Bad example (Only direct access to the link refresh target)

Link refresh overwrites the value.

MOV K20 J1\W100

• Good example (In addition to direct access, writing the same data to the CPU module device)

The value written by direct access is reflected.

Simple Motion moduleCPU module

W

300W100

Link refresh

RWw

20 300 RWw100

24

1 FUNCTIONS

1.3 Cyclic Transmission

Page 27

Differences from link refresh

Item Access method

Link refresh Direct access

Number of steps 1 step 2 steps

Processing speed

Cyclic data integrity assurance Available Not available

*1 For actual values, refer to the following.

MELSEC iQ-R Programming Manual (CPU Module Instructions, Standard Functions/Function Blocks)

*1

High speed Low speed

Shortening the link refresh time and transmission delay time

■Shortening the link refresh time

Remove infrequently used link devices from the link refresh range, and directly read or write the corresponding data using link

direct devices. This reduces the number of the link refresh points to the CPU module, resulting in a shorter link refresh time.

(Page 21 Link refresh)

■Shortening the transmission delay time

Because the link direct device allows direct reading or writing of data to the link devices of the Simple Motion module at the

time of the instruction execution, the transmission delay time can be shortened.

Link refresh is executed in END processing of the sequence scan of the CPU module.

Precautions

1

■Cyclic data integrity assurance

Direct access to link devices does not provide station-based block data assurance. Use 32-bit data assurance, or if cyclic data

of more than 32 bits needs to be assured, use interlock programs. (Page 26 Cyclic data integrity assurance)

■Mounting multiple modules of the same network No.

When multiple Simple Motion modules of the same network No. are mounted, the target of direct access is the module which

has the smallest slot No. in the base unit.

■Link direct device in a multiple CPU system

In a multiple CPU system, link direct devices cannot be used for the CC-Link IE Controller Network-equipped module

controlled by another CPU module.

1 FUNCTIONS

1.3 Cyclic Transmission

25

Page 28

Cyclic data integrity assurance

0H

1H

2H

3H

4H

5H

6H

7H

RWr, RWw

2 words

(32 bits)

Simple Motion module

Device

CPU module

Link refresh

2 words

(32 bits)

2 words

(32 bits)

2 words

(32 bits)

2 words

(32 bits)

2 words

(32 bits)

2 words

(32 bits)

2 words

(32 bits)

This function assures the cyclic data integrity in units of 32 bits or station-based units.

: Assured, : Not assured

Method Description Availability

Link refresh Direct access to

link devices

32-bit data assurance Assures data in 32-bit units.

Station-based block data

assurance

Interlock program Assures data of more than 32 bits.

*1

Data is automatically assured by satisfying

assignment conditions of link devices.

Assures data in station-based units.

Data is assured by enabling the station-based

block data assurance in the parameter setting.

Data is assured by configuring interlocks on

programs.

*1 When the software version of the Simple Motion module is "Ver.01":

The set parameter is ignored in the Simple Motion module and operate as "Disable". Assure data using interlock programs as required.

When the software version of the Simple Motion module is "Ver.02" or later:

To enable data assurance in an asynchronous station, read/write data by direct access in the inter-module synchronous interrupt

program (I44) without using a link refresh.

When there is a remote device station in the network, use station-based block data assurance. If it is disabled,

the functions of the remote device station cannot be assured.

Access to buffer

memory

32-bit data assurance

The RWr and RWw data can be assured in 32-bit units.

■Data assurance at the time of direct access to link devices

When link refresh target devices are accessed, the integrity of 32-bit data can be assured by satisfying the following

conditions.

• The start device No. of RWr, RWw is multiples of 2.

• The number of points assigned to RWr, RWw is multiples of 2.

26

1 FUNCTIONS

1.3 Cyclic Transmission

Page 29

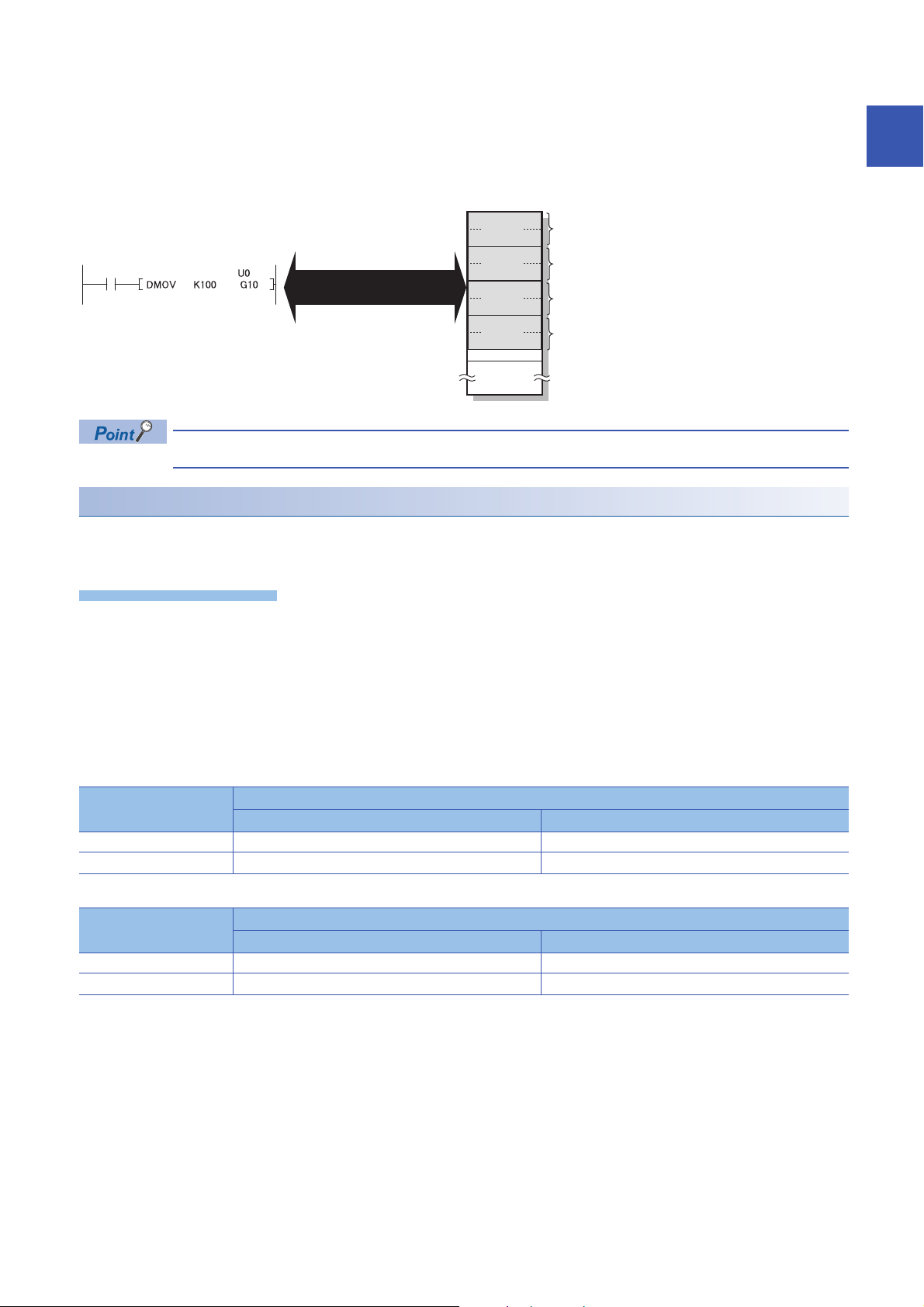

■Data integrity assurance at the time of access to buffer memory

Precautions

0H

1H

2H

3H

4H

5H

6H

7H

2 words

(32 bits)

Buffer memory

Simple Motion module

2 words

(32 bits)

2 words

(32 bits)

2 words

(32 bits)

DMOV instruction

\

The integrity of 32-bit data can be assured by satisfying the following conditions.

• Access using the DMOV instruction

• The start address of the buffer memory is multiples of 2.

For data assurance of more than 32 bits, use station-based block data assurance or interlock programs.

Station-based block data assurance

Integrity of the cyclic data is assured for each station by handshake between the CPU module and Simple Motion module for

a link refresh.

1

• When the software version of the Simple Motion module is "Ver.01":

The set parameter is ignored in the Simple Motion module and operate as "Disable". Assure data using interlock programs

as required.

• When the software version of the Simple Motion module is "Ver.02" or later:

To enable data assurance in an asynchronous station, read/write data by direct access in the inter-module synchronous

interrupt program (I44) without using a link refresh. There are restrictions on the operation by the inter-module

synchronization setting, operation mode, and network synchronous communication.

<Inter-module synchronization valid>

Operation mode Network communication setting

Synchronous Asynchronous

High-speed Enable Disable

Normal Enable Enable

<Inter-module synchronization invalid>

Operation mode Network communication setting

Synchronous Asynchronous

High-speed Disable Disable

Normal Disable Enable

■Setting

Set station-based block data assurance under "Supplementary Cyclic Settings" in "Application Settings" of the master station.

(Page 74 Application Settings)

Once this setting is enabled on the master station, integrity of the data for all stations is assured for each station.

1 FUNCTIONS

1.3 Cyclic Transmission

27

Page 30

■Access to link devices

Station

No.1

Station

No.2

Station

No.3

Station

No.4

Data

assurance

Data

assurance

Data

assurance

Data

assurance

Data

assurance

Data

assurance

Data

assurance

Data

assurance

Station

No.1

Station

No.2

Station

No.3

Station

No.4

Link device

Simple Motion module

Device

CPU module

Link refresh

Simple Motion module

Master/local module

Receiving stationSending station

Master station

(station No.0)

Local station

(station No.1)

SET Y1000

X1000

Y1000

RX0

RY0RY0

RWw0

RWr0

RWw0

RWr0

RX0

Y1000

W0

W1000

W0

W1000

X1000

X1000

Send

request

Send data (W)

CPU

module

Master

station

CPU

module

Local

station

Cyclic transmission

Link refresh

Receive data (W)

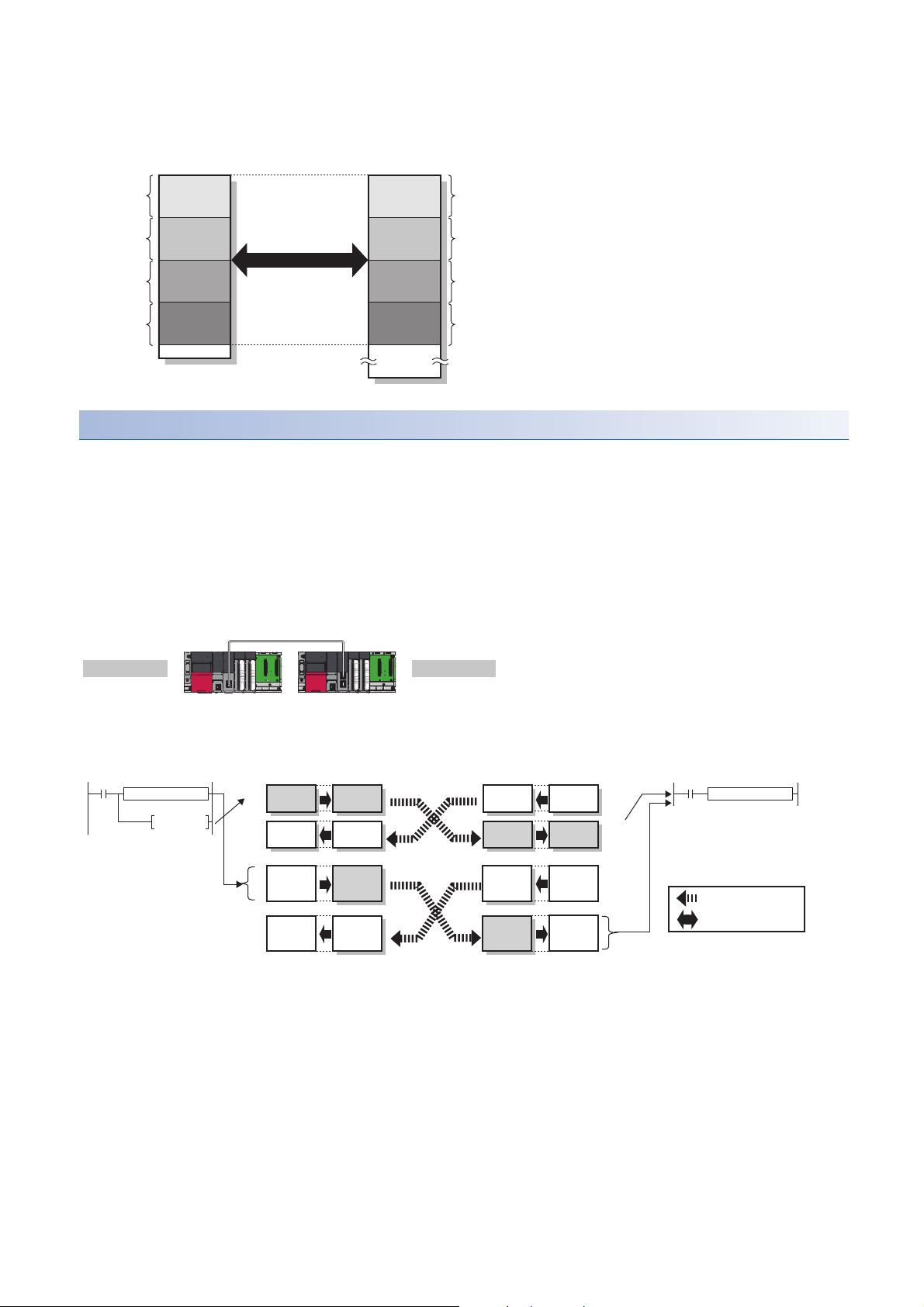

During a link refresh, data are assured for each station as shown below.

Interlock program

Data of more than 32 bits can be assured with the station-based block data assurance setting disabled. Use either of the

following methods.

• Interlock using X and Y

• Interlock using devices other than X and Y (when X, Y cannot be used as an interlock device)

■Example of interlock using X and Y

An example of sending data in W0 to W3 of the master station (station No.0) to W1000 to W1003 of the local station (station

No.1) is shown below. (X1000 and Y1000 are used for a handshake to the CPU module.)

• Data flow

28

1 FUNCTIONS

1.3 Cyclic Transmission

Page 31

•Program

Program example

Sending station: Master station (station No.0)

Classification Description

Label to be defined Define global labels as shown below:

Receiving station: Local station (station No.1)

Classification Description

Label to be defined Define global labels as shown below:

1

• Program flow

Sending station (0) "bStartDirection" (M0) is turned on.

Sending station (0) The contents of "uTransferFrom" (D0 to D3) are stored in W0 to W3.

Sending station (0) Upon completion of storage in W0 to W3, turn on Y1000 of the sending station for a handshake.

Receiving station (0) Cyclic transmission sends RWw followed by RY, and X1000 of the receiving station turns on.

Receiving station (0) The contents of W1000 to W1003 are stored in "uTransferTo" (D0 to D3).

Receiving station (0) Upon completion of storage in "uTransferTo" (D0 to D3), turn on Y1000 of the receiving station for a handshake.

Sending station (23) When X1000 of the sending station turns on, turn off Y1000 of the sending station.

Receiving station (23) When X1000 of the receiving station turns off, turn off Y1000 of the receiving station.

1 FUNCTIONS

1.3 Cyclic Transmission

29

Page 32

■Example of interlock using devices other than X and Y

Program example

Simple Motion module

Master/local module

Receiving stationSending station

Master station

(station No.0)

Local station

(station No.1)

SET B0

RWw0

RWr0

RWr3F0

RWw0

RWr0

RWr3F0

RWw3F0 RWw3F0

W0

B0

B1000

W1000

W0

B0

B1000

W1000

B1000

Cyclic transmission

Link refresh

Send

request

CPU

module