Page 1

MELSEC iQ-R C Intelligent Function Module

User's Manual (Application)

-RD55UP06-V

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully, and pay full attention to safety to

handle the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions for the programmable

controller system, refer to the user's manual for the CPU module used.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to serious

consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future reference.

1

Page 4

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be configured

external to the programmable controller.

(2) When the programmable controller detects an abnormal condition, it stops the operation and all

outputs are:

• Turned OFF if the overcurrent or overvoltage protection of the power supply module is

activated.

• Held or turned OFF according to the parameter setting if the self-diagnostic function of the CPU

module detects an error such as a watchdog timer error.

(3) All outputs may be turned on if an error occurs in a part, such as an I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to "General Safety Requirements" in MELSEC iQ-R Module Configuration Manual.

(4) Outputs may remain ON or OFF due to a failure of a component such as a relay and transistor in

an output circuit. Configure an external circuit for monitoring output signals that could cause a

serious accident.

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

● For the operating status of each station after a communication failure, refer to manuals relevant to the

network. Incorrect output or malfunction due to a communication failure may result in an accident.

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

2

Page 5

[Design Precautions]

WARNING

● Do not write any data to the "system area" and "write-protect area" of the buffer memory in the

module. Also, do not use any "use prohibited" signals as an output signal from the CPU module to

each module. Doing so may cause malfunction of the programmable controller system. For the

"system area", "write-protect area", and the "use prohibited" signals, refer to the user's manual for the

module used.

● If a communication cable is disconnected, the network may be unstable, resulting in a communication

failure of multiple stations. Configure an interlock circuit in the program to ensure that the entire

system will always operate safely even if communications fail. Incorrect output or malfunction due to a

communication failure may result in an accident.

● To maintain the safety of the programmable controller system against unauthorized access from

external devices via the network, take appropriate measures. To maintain the safety against

unauthorized access via the Internet, take measures such as installing a firewall.

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100 mm or more between them. Failure to do so may result in malfunction

due to noise.

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned OFF and ON.

Therefore, use a module that has a sufficient current rating.

● After the power is turned OFF and ON or the CPU module is reset, the time taken to enter the RUN

status varies depending on the system configuration, parameter settings, and/or program size. Design

circuits so that the entire system will always operate safely, regardless of the time.

● Do not turn the power OFF or reset the CPU module while the settings are being written. Doing so will

make the data in the flash ROM or SD memory card undefined. The values need to be set in the buffer

memory and written to the flash ROM or the SD memory card again. Doing so may cause malfunction

or failure of the module.

● When changing the operating status of the CPU module from external devices (such as remote RUN/

STOP functions), select "Do Not Open in Program" for "Open Method Setting" in the module

parameters. If "Open in Program" is selected, an execution of remote STOP causes the

communication line to close. Consequently, the CPU module cannot reopen the communication line,

and the external device cannot execute the remote RUN.

3

Page 6

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets general specifications written in Safety

Guidelines included in the base unit. Failure to do so may result in electric shock, fire, malfunction, or

damage to or deterioration of the product.

● To mount a module, place the concave part(s) located at the bottom onto the guide(s) of the base unit,

and push in the module, and make sure to fix the module with screws since this module has no

module fixing hook. Incorrect interconnection may cause malfunction, failure, or drop of the module.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the screw,

short circuit, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, or malfunction.

● When using an extension cable, connect it to the extension cable connector of the base unit securely.

Check the connection for looseness. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● Securely insert an extended SRAM cassette into the cassette connector of a CPU module. After

insertion, close the cassette cover and check that the cassette is inserted completely. Poor contact

may cause malfunction.

● Do not directly touch any conductive parts and electronic components of the module, SD memory

card, extended SRAM cassette, or connector. Doing so may cause malfunction or failure of the

module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach the included terminal cover to the module before turning it on for

operation. Failure to do so may result in electric shock.

4

Page 7

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less. Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when the terminal screw comes loose, resulting in

failure.

● Check the rated voltage and signal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause fire

or failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit, fire, or

malfunction.

● Securely connect the connector to the module. Poor contact may cause malfunction.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100 mm or more between them. Failure to do so may result in malfunction

due to noise.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in damage to the module or cables or malfunction due to poor contact. Do not clamp the

extension cables with the jacket stripped. Doing so may change the characteristics of the cables,

resulting in malfunction.

● Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable to an

incorrect interface) may cause failure of the module and external device.

● Tighten the terminal screws or connector screws within the specified torque range. Undertightening

can cause drop of the screw, short circuit, fire, or malfunction. Overtightening can damage the screw

and/or module, resulting in drop, short circuit, fire, or malfunction.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable. For the cable connected to the terminal block,

loosen the terminal screw. Pulling the cable connected to the module may result in malfunction or

damage to the module or cable.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

5

Page 8

[Wiring Precautions]

CAUTION

● Programmable controllers must be installed in control panels. Connect the main power supply to the

power supply module in the control panel through a relay terminal block. Wiring and replacement of a

power supply module must be performed by qualified maintenance personnel with knowledge of

protection against electric shock. For wiring, refer to MELSEC iQ-R Module Configuration Manual.

● For Ethernet cables to be used in the system, select the ones that meet the specifications in the user's

manual for the module used. If not, normal data transmission is not guaranteed.

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire. Also, do not expose it to liquid or strong shock. Doing so will cause the

battery to produce heat, explode, ignite, or leak, resulting in injury or fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws, connector screws, or module fixing screws. Failure to do so may

result in electric shock.

6

Page 9

[Startup and Maintenance Precautions]

CAUTION

● When connecting an external device with a CPU module or intelligent function module to modify data

of a running programmable controller, configure an interlock circuit in the program to ensure that the

entire system will always operate safely. For other forms of control (such as program modification,

parameter change, forced output, or operating status change) of a running programmable controller,

read the relevant manuals carefully and ensure that the operation is safe before proceeding. Improper

operation may damage machines or cause accidents.

● Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure. To prevent this, configure an interlock circuit in the program, and determine corrective actions

to be taken between the external device and CPU module in case of a communication failure.

● Do not disassemble or modify the modules. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm away in all directions from the programmable controller. Failure to do so

may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the screws within the specified torque range. Undertightening can cause drop of the

component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or module,

resulting in drop, short circuit, or malfunction.

● After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module, and do not insert/remove the extended SRAM cassette to/from the

CPU module more than 50 times (IEC 61131-2 compliant) respectively. Exceeding the limit may cause

malfunction.

● After the first use of the product, do not insert/remove the SD memory card to/from the CPU module

more than 500 times. Exceeding the limit may cause malfunction.

● Do not touch the metal terminals on the back side of the SD memory card. Doing so may cause

malfunction or failure of the module.

● Do not touch the integrated circuits on the circuit board of an extended SRAM cassette. Doing so may

cause malfunction or failure of the module.

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage the

battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any shock is

applied to it, dispose of it without using.

● Startup and maintenance of a control panel must be performed by qualified maintenance personnel

with knowledge of protection against electric shock. Lock the control panel so that only qualified

maintenance personnel can operate it.

7

Page 10

[Startup and Maintenance Precautions]

CAUTION

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

[Operating Precautions]

CAUTION

● When changing data and operating status, and modifying program of the running programmable

controller from an external device such as a personal computer connected to an intelligent function

module, read relevant manuals carefully and ensure the safety before operation. Incorrect change or

modification may cause system malfunction, damage to the machines, or accidents.

● Do not turn the power OFF or reset the CPU module while the setting values in the buffer memory are

being written to the flash ROM in the module. Doing so will make the data in the flash ROM undefined.

The values need to be set in the buffer memory and written to the flash ROM again. Doing so can

cause malfunction or failure of the module.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

● When disposing of batteries, separate them from other wastes according to the local regulations. For

details on battery regulations in EU member states, refer to MELSEC iQ-R Module Configuration

Manual.

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. For details on the regulated

models, refer to MELSEC iQ-R Module Configuration Manual.

● The halogens (such as fluorine, chlorine, bromine, and iodine), which are contained in a fumigant

used for disinfection and pest control of wood packaging materials, may cause failure of the product.

Prevent the entry of fumigant residues into the product or consider other methods (such as heat

treatment) instead of fumigation. The disinfection and pest control measures must be applied to

unprocessed raw wood.

8

Page 11

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

9

Page 12

CONSIDERATIONS FOR USE

Considerations for the Wind River Systems product

C intelligent function modules have an embedded real-time operating system, VxWorks, manufactured by Wind River

Systems, Inc. in the United States. We, Mitsubishi, make no warranty for the Wind River Systems product and will not be liable

for any problems and damages caused by the Wind River Systems product during use of a C intelligent function module.

For the problems or specifications of the Wind River Systems product, refer to the corresponding manual or consult Wind

River Systems, Inc.

Contact information is available on the following website.

• Wind River Systems, Inc.: www.windriver.com

Considerations for the sampling function

The data sampling in each sequence scan of the sampling function is not supported by CPU modules on other stations via a

network.

INTRODUCTION

Thank you for purchasing the Mitsubishi MELSEC iQ-R series programmable controllers.

This manual describes the performance specifications, procedure before operation, wiring, and operation examples to use the

module listed below.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

performance of the MELSEC iQ-R series programmable controller to handle the product correctly.

When applying the program examples provided in this manual to an actual system, ensure the applicability and confirm that it

will not cause system control problems.

Please make sure that the end users read this manual.

Relevant product

RD55UP06-V

10

Page 13

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CONSIDERATIONS FOR USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

CHAPTER 1 FUNCTION 15

1.1 Program Related Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Device access function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Label communication function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

User program execution function from CPU module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Interrupt function to a CPU module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Interrupt function to a C intelligent function module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Data analysis function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Data analysis or statistical analysis using a CPU module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.2 Ethernet Communication Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

FTP function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Telnet function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.3 RAS Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Program Monitoring (WDT) Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Error history function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Event history function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Self-diagnostic function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Initialization function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.4 Security Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Individual identification information read function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

File access restriction function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Service/account setting function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

IP filter function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1.5 Time Synchronization Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1.6 Sampling Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

CONTENTS

CHAPTER 2 PARAMETER SETTING 44

2.1 Parameter Setting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.2 Basic Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.3 Application Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2.4 Interrupt Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2.5 Refresh Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

CHAPTER 3 TROUBLESHOOTING 51

3.1 Checking Method for Error Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.2 Error Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.3 Checking Module Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Error information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Module information list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.4 Self-Diagnostics Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.5 Troubleshooting by Symptom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

11

Page 14

RUN LED does not turn ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

RUN LED continues flashing (low-speed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Ethernet communication cannot be established between personal computer and C intelligent function module57

File access fails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Connection with peripherals fails. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

File read (download) fails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

An error occurs during user program execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Communication cannot be established with an Ethernet device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

An error occurs in communication processing on other modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

A C intelligent function module dedicated instruction is not executed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

3.6 Error Code List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3.7 Event List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

APPENDIX 71

Appendix 1 Module Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Appendix 2 Input/Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Input/Output signals list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Input signal details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Output signal details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Appendix 3 Buffer Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Buffer memory list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Buffer memory details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Appendix 4 Dedicated Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Dedicated instruction list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Appendix 5 VxWorks Component List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Appendix 6 Added and Changed Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

INDEX 96

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

12

Page 15

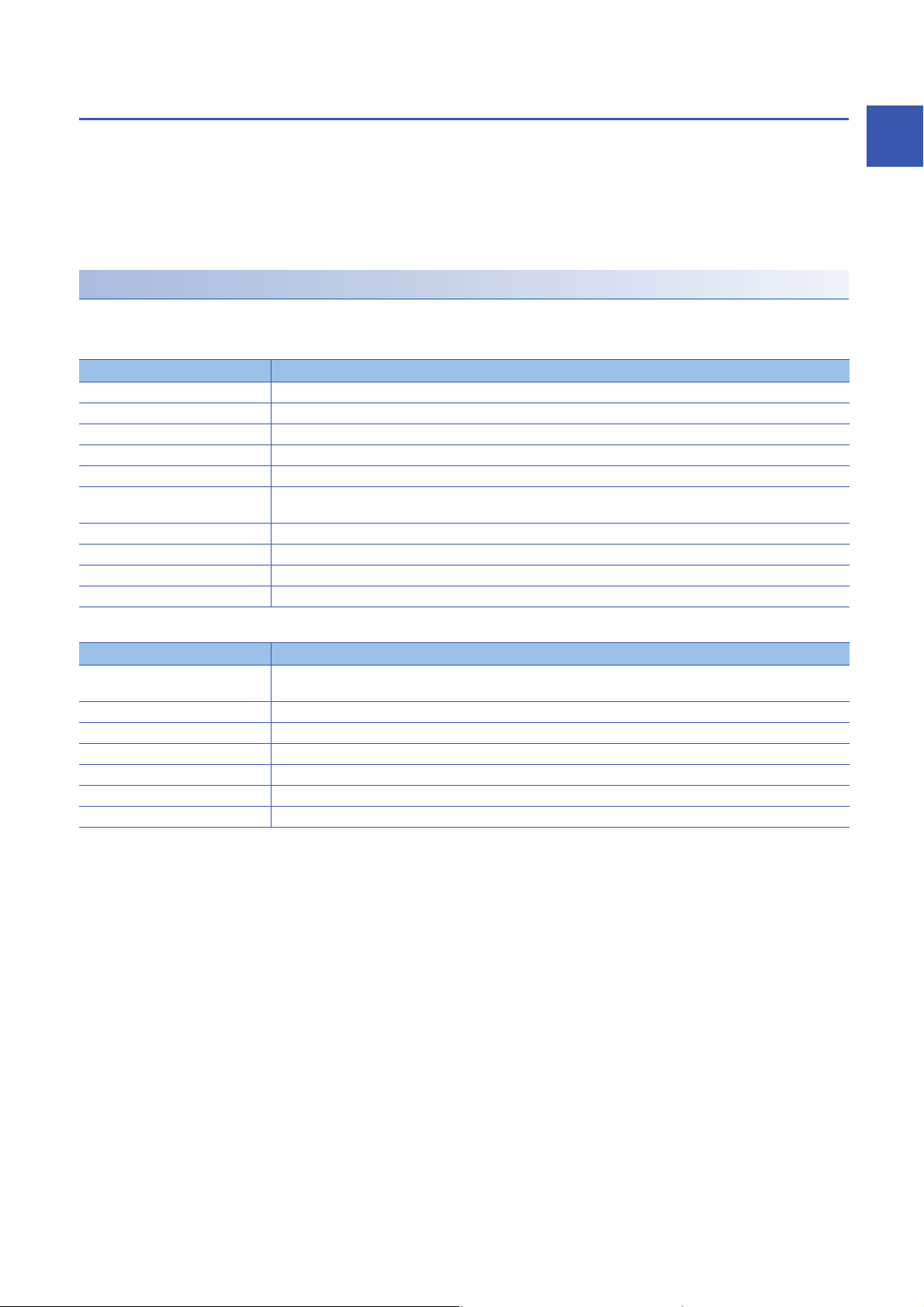

RELEVANT MANUALS

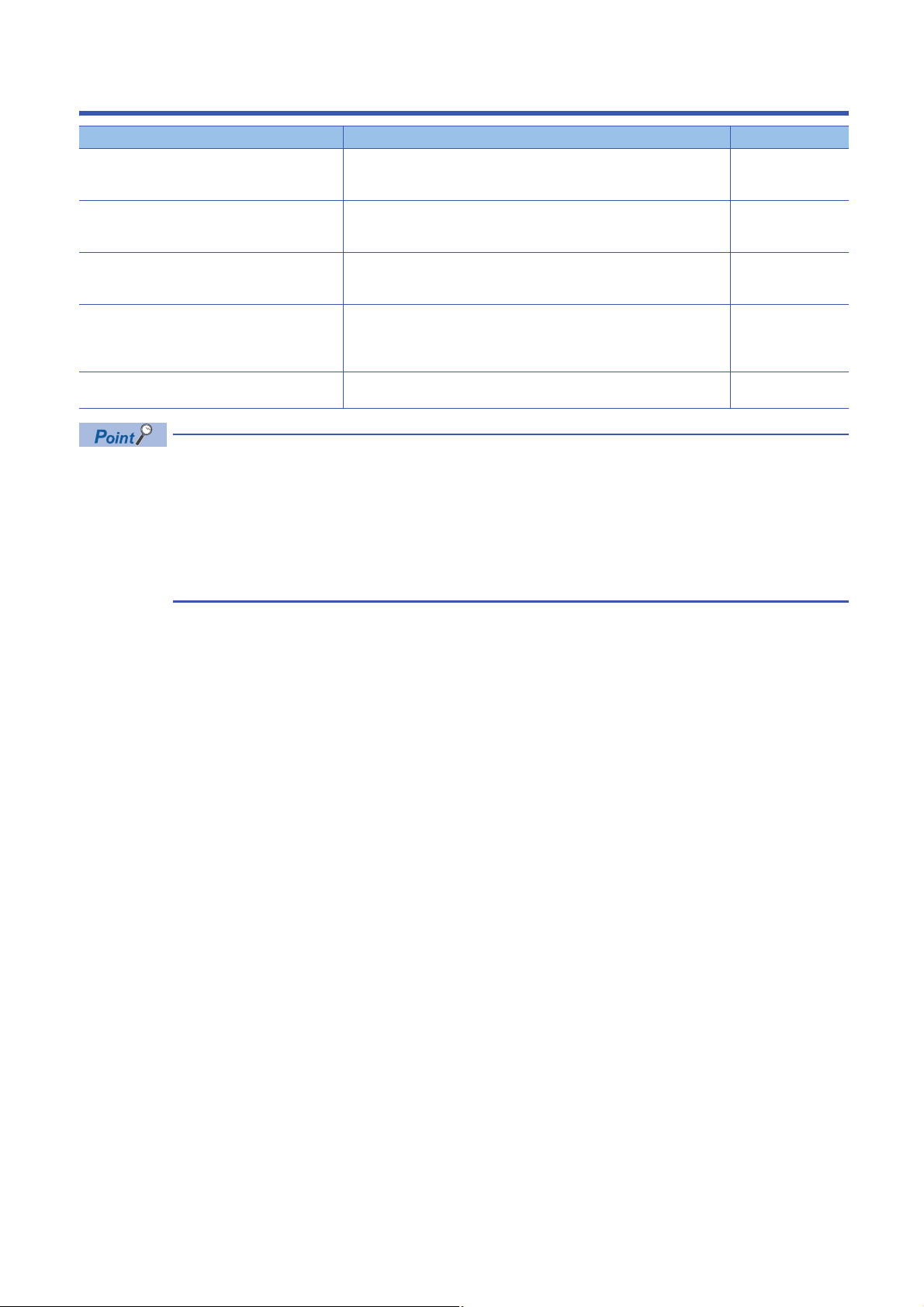

Manual name [manual number] Description Available form

MELSEC iQ-R C Intelligent Function Module User's

Manual (Application)

[SH-081567ENG] (this manual)

MELSEC iQ-R C Intelligent Function Module User's

Manual (Startup)

[SH-081566ENG]

MELSEC iQ-R C Intelligent Function Module

Programming Manual

[SH-081568ENG]

MELSEC iQ-R C Controller Module/C Intelligent

Function Module Programming Manual (Data

Analysis)

[SH-081756ENG]

CW Workbench/CW-Sim Operating Manual

[SH-081373ENG]

e-Manual refers to the Mitsubishi Electric FA electronic book manuals that can be browsed using a dedicated

tool.

e-Manual has the following features:

• Required information can be cross-searched in multiple manuals.

• Other manuals can be accessed from the links in the manual.

• Hardware specifications of each part can be found from the product figures.

• Pages that users often browse can be bookmarked.

Explains the functions, input/output signals, buffer memory, parameter setting,

and troubleshooting of a C intelligent function module.

Explains the specifications, procedure before operation, wiring, and operation

examples of a C intelligent function module.

Explains the programming specifications and dedicated function library of a C

intelligent function module.

Explains the programming specifications and dedicated function library for

analyzing the data of a C Controller module and a C intelligent function

module.

Explains the system configuration, specifications, functions, and

troubleshooting of CW Workbench/CW-Sim.

Print book

e-Manual

PDF

Print book

e-Manual

PDF

e-Manual

PDF

e-Manual

PDF

e-Manual

PDF

13

Page 16

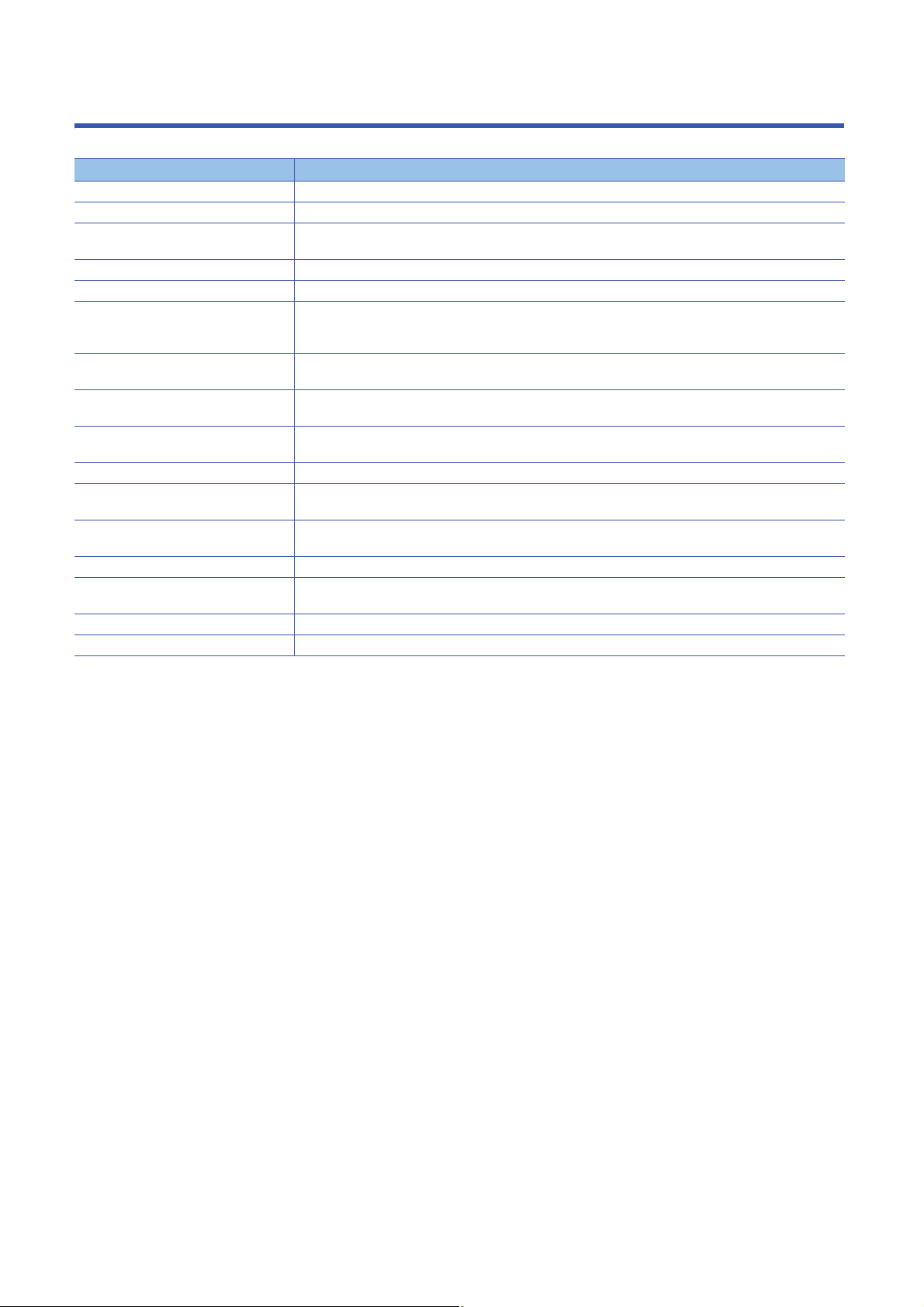

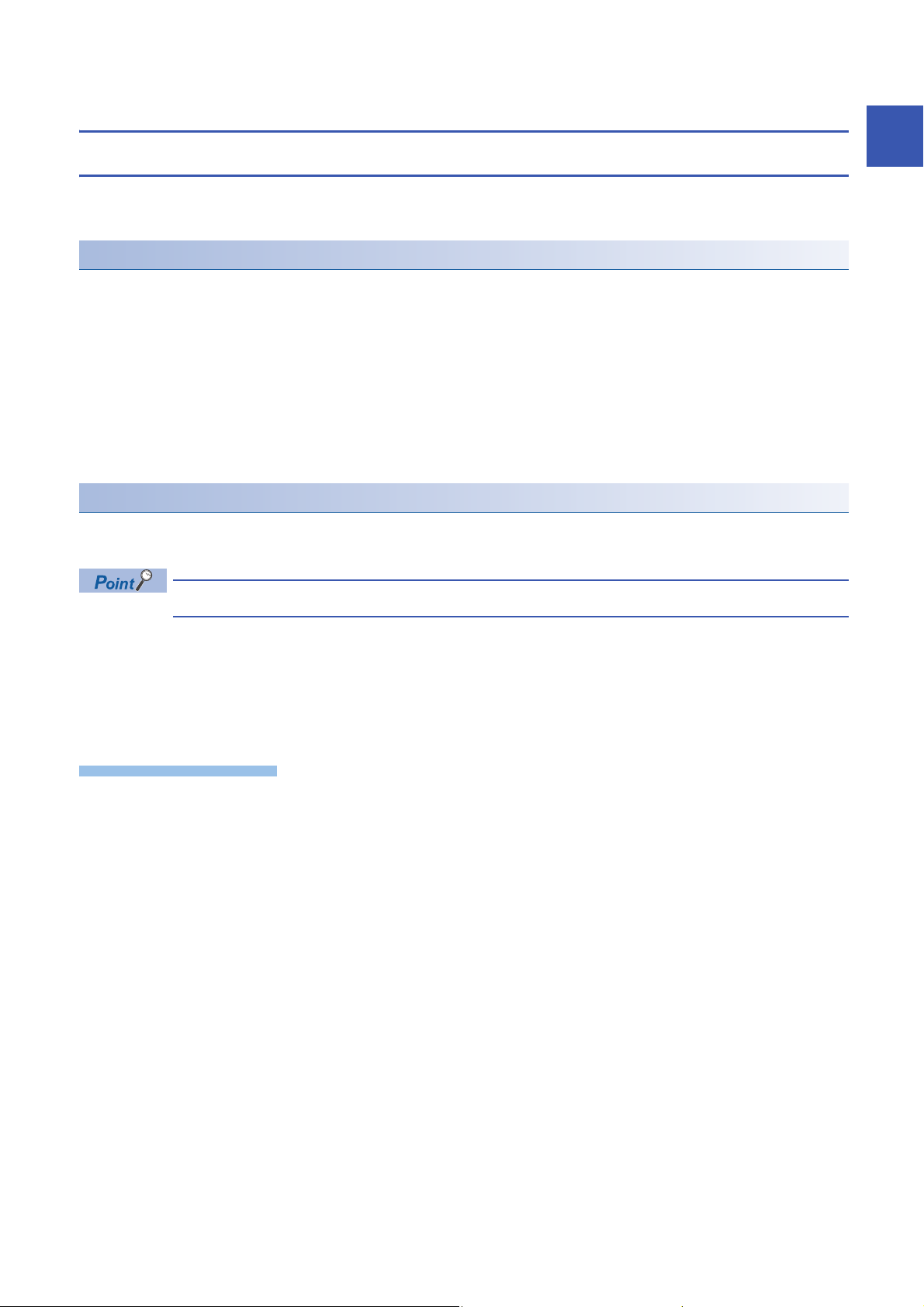

TERMS

Unless otherwise specified, this manual uses the following terms.

Ter ms Description

C Controller module A generic term for MELSEC iQ-R series C Controller modules.

C intelligent function module A generic term for MELSEC iQ-R series C intelligent function modules.

C intelligent function module dedicated

function

CW Configurator A generic product name for SWnDND-RCCPU ('n' indicates its version.)

CW Workbench An abbreviation for a C Controller module and C intelligent function module engineering tool, CW Workbench.

CW-Sim An abbreviation for VxWorks simulator that can operate and debug the C Controller module and C intelligent

Data analysis function A dedicated function library offered by a C Controller module and a C intelligent function module.

Dedicated function library A generic term for C intelligent function module dedicated functions, MELSEC iQ-R series data link functions,

Engineering tool Another term of the software package for MELSEC programmable controllers.

GX Works3 A generic product name for SWnDND-GXW3. ('n' indicates its version.)

Intelligent function module A module which has functions other than input and output, such as an A/D converter module or a D/A converter

MELSEC iQ-R series data link function A dedicated function library offered by a C intelligent function module.

RD55UP06-V An abbreviation for RD55UP06-V C intelligent function modules.

Statistical analysis function A dedicated function library offered by a C Controller module and a C intelligent function module.

Target device A personal computer or another CPU module to connect for data communication.

VxWorks A product name for a real-time operating system manufactured by Wind River Systems, Inc..

A dedicated function library offered by a C intelligent function module.

It is used to control a C intelligent function module.

function module programs on a personal computer with CW Workbench installed, without connecting to an actual

device (target).

It is used for data analysis processing.

data analysis functions, and statistical analysis functions.

It indicates GX Works3 and CW Configurator in this manual.

module.

It is used to access an own station or modules on the network.

It is used for statistical analysis processing.

14

Page 17

1 FUNCTION

This chapter shows the details of the functions of a C intelligent function module.

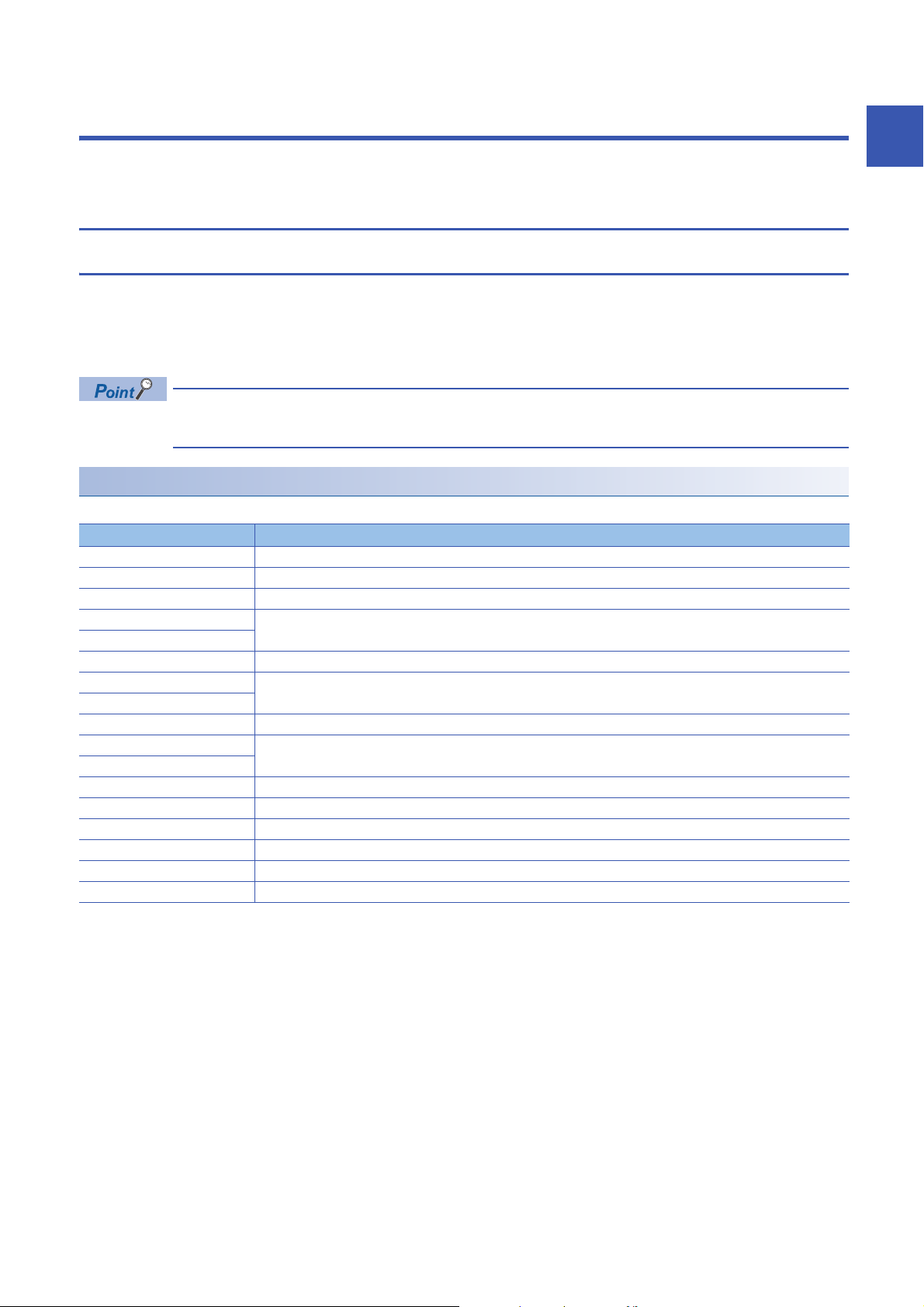

1.1 Program Related Function

Device access function

Data can be read from/written to devices and buffer memory of a C intelligent function module or a CPU module by using a

dedicated function library.

For accessible modules and routes, refer to the following manual.

MELSEC iQ-R C Intelligent Function Module Programming Manual

Data can be read from/written to devices and buffer memory of a C intelligent function module by using a

peripheral device (engineering tool).

Function list

The following table shows the functions used for accessing devices.

Function name Description

CITL_FromBuf To read data from the buffer memory of a C intelligent function module.

CITL_ToBuf To write data to the buffer memory of a C intelligent function module.

CITL_X_In_Bit To read an input signal (X) in bit (1-point) units.

CITL_X_In_Word To read an input signal (X) in word (16-point) units.

CITL_X_In_Word_ISR

CITL_X_Out_Bit To write to an input signal (X) in bit (1-point) units.

CITL_X_Out_Word To write to an input signal (X) in word (16-point) units.

CITL_X_Out_Word_ISR

CITL_Y_In_Bit To read an output signal (Y) in bit (1-point) units.

CITL_Y_In_Word To read an output signal (Y) in word (16-point) units.

CITL_Y_In_Word_ISR

mdrDevRst To reset (turns OFF) bit devices.

mdrDevSet To set (turns ON) bit devices.

mdrRandR To read devices randomly.

mdrRandW To write devices randomly.

mdrReceive To read devices in batch.

mdrSend To write devices in batch.

*1

*1

*1

*1

1

*1 CPU buffer memory cannot be accessed.

1 FUNCTION

1.1 Program Related Function

15

Page 18

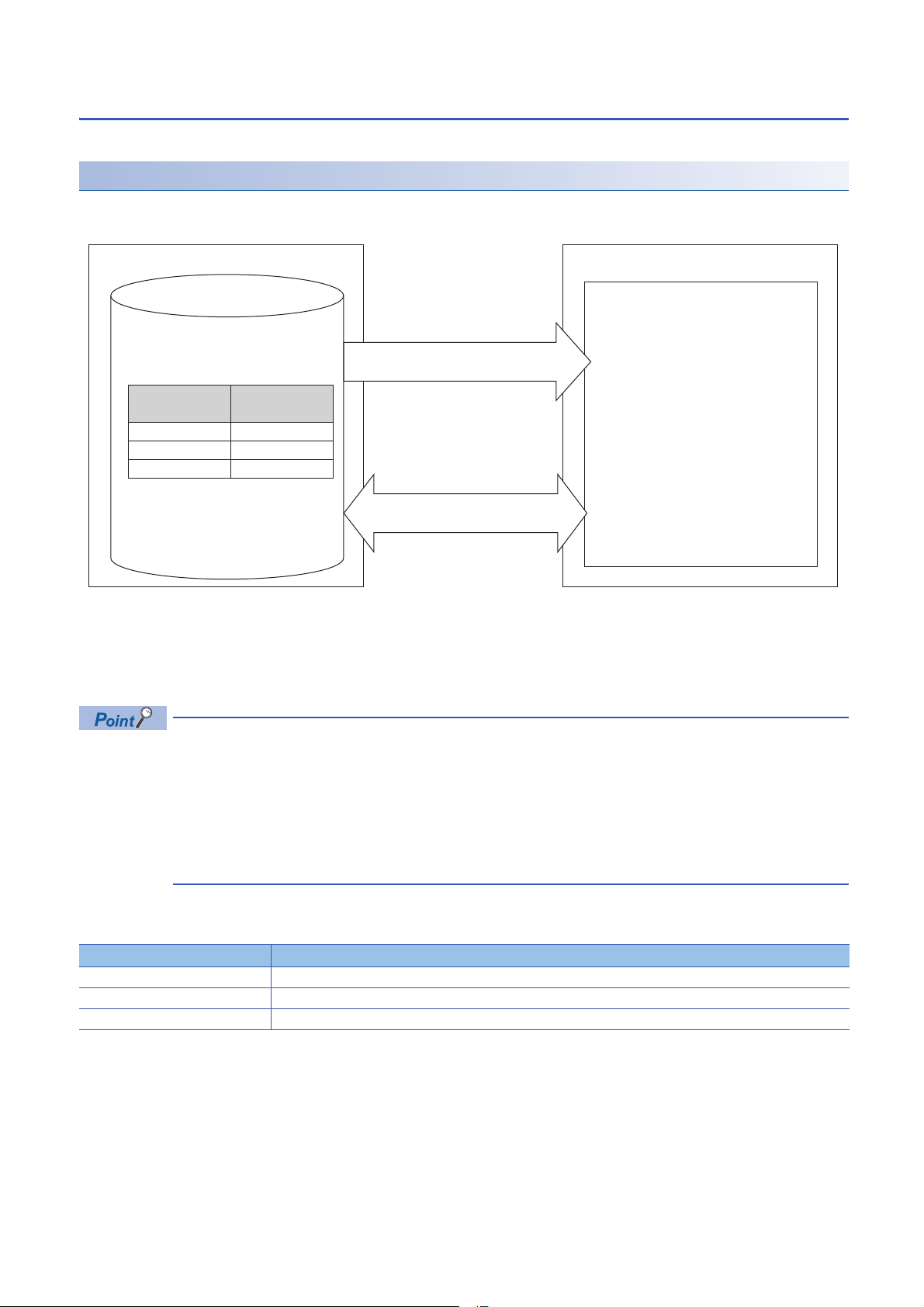

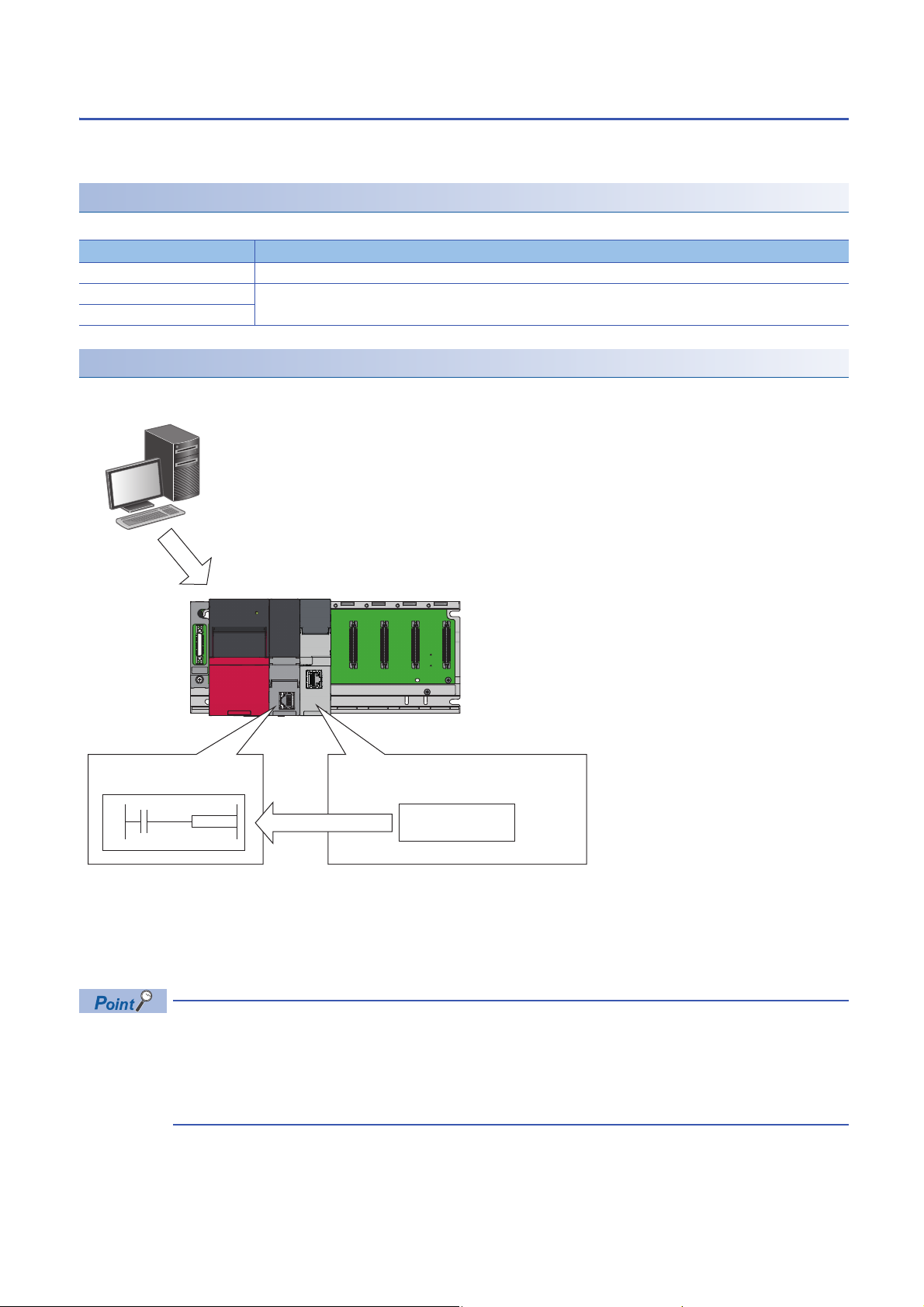

Label communication function

Label1

Label2

Label3

D0

D1

X0

C intelligent function module

(reference side)

CPU module

(Label definition side)

User program

Obtain an information of the corresponding

devices using specified label (Label1, Label2).

1. Execute the mdrGetLabelInfo function.

Label assignment information

Assignment target

(Device name)

Label name

Execute Reading/Writing for the device

corresponding to the label.

2. Execute the

mdrRandRLabel/mdrRandWLabel function.

Data can be read from/written to labels stored in a CPU module.

Label communication flow

1. Acquire label assignment information (device information) of the specified label with the MELSEC iQ-R series data link

function (mdrGetLabelInfo).

2. Read/write data from/to a device based on the acquired label assignment information (device information) by using each

MELSEC iQ-R series data link function (mdrRandRLabel/mdrRandWLabel).

• In the label communication, a CPU module can be accessed without changing a user program by acquiring

label assignment information again even if the label assignment information of the CPU module is changed.

• The label assignment information (device information) acquired by using the MELSEC iQ-R series data link

function (mdrGetLabelInfo) does not need to be acquired for each MELSEC iQ-R series data link function

(mdrRandRLabel/mdrRandWLabel) execution. However, if the label assignment information (device

information) stored in a CPU module is changed, acquire it again by using the MELSEC iQ-R series data

link function (mdrGetLabelInfo). (Otherwise, an error response is returned.)

■Function list

The following table shows the functions used for label communication.

Function name Description

mdrGetLabelInfo To acquire device information corresponding to label names.

mdrRandRLabel To read devices corresponding to labels randomly.

mdrRandWLabel To write devices corresponding to labels randomly.

16

1 FUNCTION

1.1 Program Related Function

Page 19

Accessible CPU modules

The following table shows the accessible CPU modules.

Product name Model name

Programmable controller CPU R00CPU, R01CPU, R02CPU, R04CPU, R08CPU, R16CPU, R32CPU, R120CPU

Process CPU R08PCPU, R16PCPU, R32PCPU, R120PCPU

Label types which can be referred to

The following table shows the label types that can be referred to from a C intelligent function module.

: Applicable, : Not applicable, : Not available

Label type "Access from External Device" is selected or not selected. Availability

Global label Selected

Unselected

Local label

System label

*1 The availability of the label differs depending on the device type assigned to the label.

For device type, refer to the following manual.

MELSEC iQ-R C Intelligent Function Module Programming Manual

For referring to a label, select "Access from External Device" in GX Works3.

(GX Works3 Operating Manual)

1

*1

User program execution function from CPU module

A routine(user program), which is registered by C intelligent function module dedicated instruction

(CITL_EntryDedicatedInstFunc), can be executed on the CPU module using (G(P).CEXECUTE) dedicated instruction.

Function list

The following table shows the function used for executing a routine (user program) from a CPU module.

Function name Description

CITL_EntryDedicatedInstFunc To register a routine to be executed using the dedicated instruction (G(P).CEXECUTE).

■Execution procedure

This section explains the procedure for executing the user program.

1. Register a routine (user program) to be executed by C intelligent function module dedicated function

(CITL_EntryDedicatedInstFunc).

2. Execute the dedicated function (G(P).CEXECUTE) on the CPU module.

3. A registered routine (user program) is executed.

Dedicated instructions

For dedicated instructions, refer to the following section.

Page 85 Dedicated Instructions

1 FUNCTION

1.1 Program Related Function

17

Page 20

Interrupt function to a CPU module

I0

X10: ON = I0

1. Setting interrupt conditions

3. Interrupt program starts

2. Execute the

CITL_X_Out_Bit/CITL_X_Out_Word function

Module Parameter

Interrupt conditions

Interrupt request

When the interrupt condition set to an input signal (X) is satisfied, a C intelligent function module issues an interrupt request

for a CPU module. An interrupt program of the CPU module can be activated by the interrupt request.

Function list

The following table shows the functions used for interrupting a CPU module.

Function name Description

CITL_X_Out_Bit To write to an input signal (X) in bit (1-point) units.

CITL_X_Out_Word To write to an input signal (X) in word (16-point) units.

CITL_X_Out_Word_ISR

Interrupt procedure

Interrupt requests to the CPU module are executed by interrupt conditions set in the unit parameter.

1. Set interrupt conditions in the C intelligent function module using an engineering tool. (Page 49 Interrupt Setting)

2. When an interrupt condition is set at the time of C intelligent function module dedicated function execution

(CITL_X_Out_Bit/CITL_X_Out_Word), an interrupt request for the CPU module is executed.

3. Interrupt program of the CPU module is started by the interrupt request.

18

1 FUNCTION

1.1 Program Related Function

When "Leading Edge/Trailing Edge" is set in the "Interrupt Condition Setting", the first interrupt factor which

occurs during an interrupt program execution is recorded and the second or later ones are ignored. When

'trailing edge → leading edge' occurs during an interrupt program execution by leading edge, the second or

later interrupt programs are not executed. Therefore, ensure a sufficient interval between input ON and OFF.

(Same for 'trailing edge → leading edge → trailing edge)

Page 21

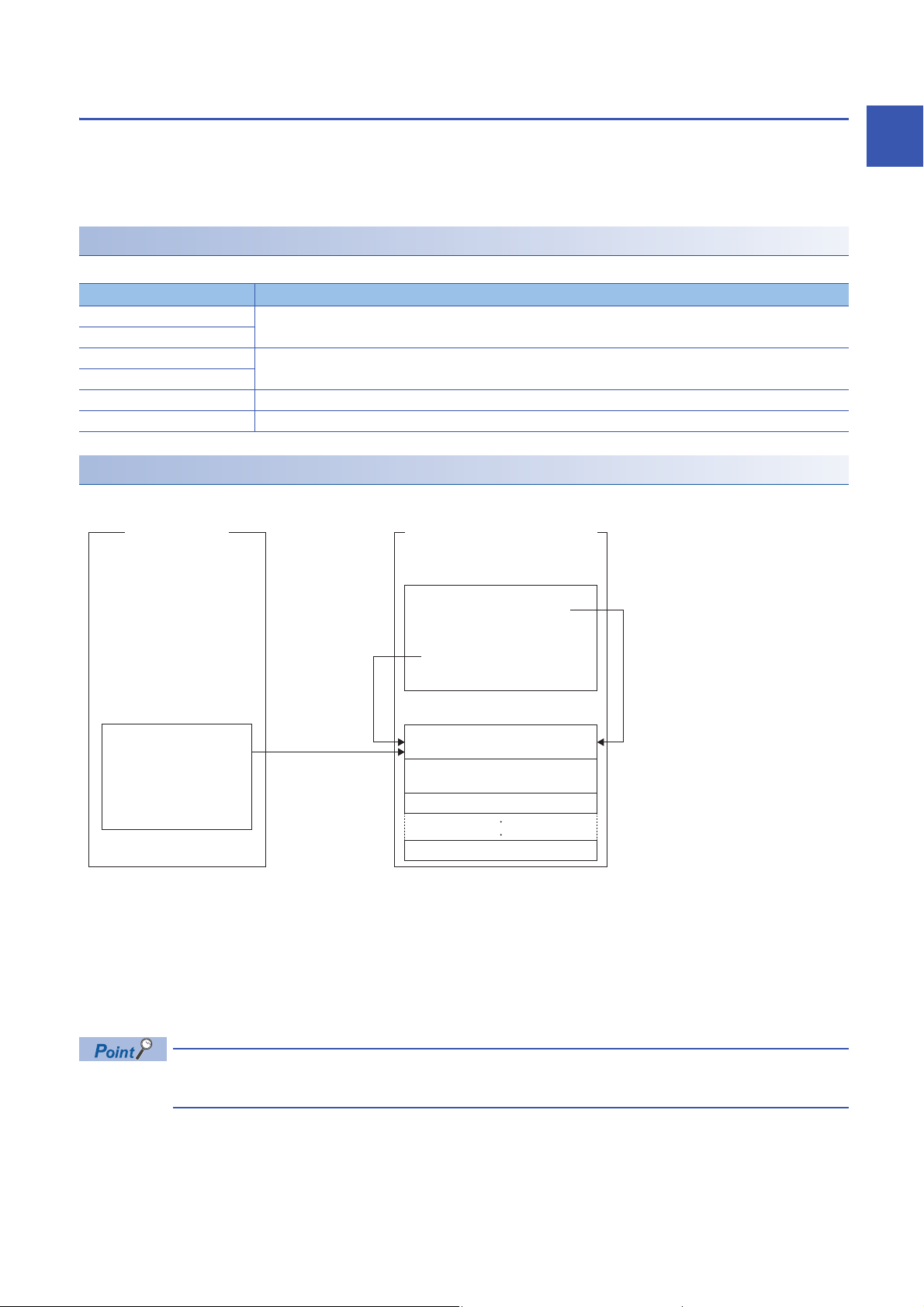

Interrupt function to a C intelligent function module

C intelligent function module

CPU module

User program

1. Execute the CITL_EntryYInt function

2. Execute the CITL_EnableYInt function

Register a

routine.

Enable a

routine.

User Interrupt Processing Table

Sequence program

Interrupt routine 1

(Interrupt program)

3. Output signal (Y) is

turned ON.

Interrupt routine 2

(Interrupt program)

(Empty)

(Empty)

When the output signal (Y) of the C intelligent function module is ON, the routine (user program) registered with the C

intelligent function module dedicated function (CITL_EntryYInt) can be executed as an interrupt routine (interrupt program).

A user program in a state of waiting for an output signal (Y) interrupt event notification can be restarted by using the C

intelligent function module dedicated function (CITL_WaitYEvent).

Function list

The following table shows the functions used for interrupting a C intelligent function module.

Function name Description

CITL_DisableYInt To disable the routine registered with the CITL_EntryYInt function.

CITL_DisableYInt_ISR

CITL_EnableYInt To enable the routine registered with the CITL_EntryYInt function.

CITL_EnableYInt_ISR

CITL_EntryYInt To register a routine to be called when an output signal (Y) interrupt occurs.

CITL_WaitYEvent To wait for the output signal (Y) interrupt event notification.

Interrupt procedure

■Executing interrupt routines

1

1. By using the C intelligent function module dedicated function (CITL_EntryYInt), register a routine (user program) to be

called as an interrupt routine (interrupt program) when an output signal (Y) of a C intelligent function module turns ON.

2. Enable the registered interrupt routine (interrupt program) by using the C intelligent function module dedicated function

(CITL_EnableYInt). If it is disabled, the interrupt routine (interrupt program) will not be executed.

3. When the output signal (Y) of a C intelligent function module turns ON, the interrupt routine (interrupt program) is

executed.

When an interrupt request is issued to the routine disabled with the C intelligent function module dedicated

function (CITL_DisableYInt), the interrupt request is ignored.

1 FUNCTION

1.1 Program Related Function

19

Page 22

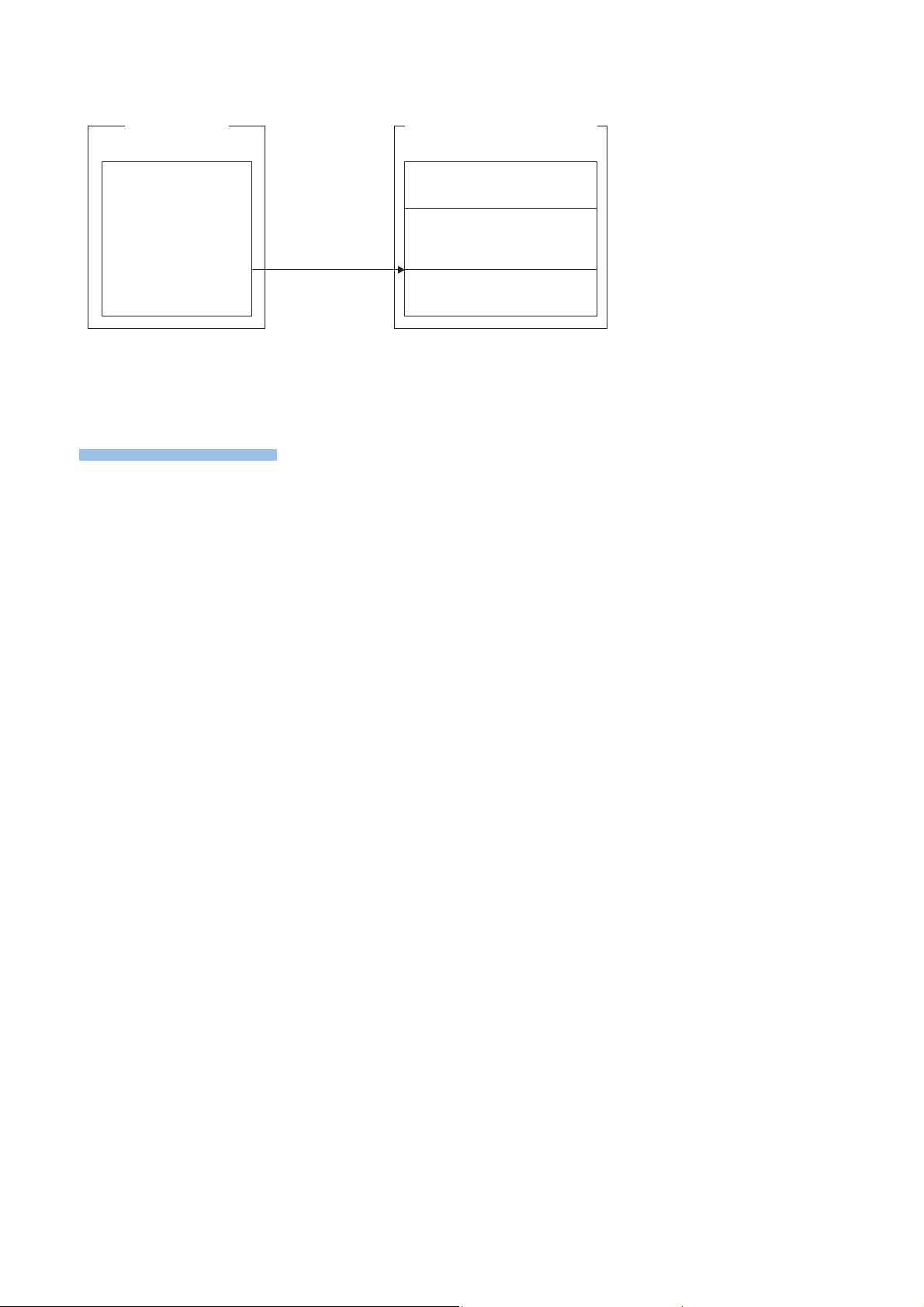

■Restarting user programs

Precautions

C intelligent function module

CPU module

Sequence program User program

1. Execute the

CITL_WaitYEvent function

2. Interrupt event wait state

3. Output signal (Y) is

turned ON.

Restart

1. Execute the C intelligent function module dedicated function (CITL_WaitYEvent) while executing a user program.

2. The user program is placed into a state of waiting for an output signal (Y) interrupt event notification.

3. When the output signal (Y) of a C intelligent function module is turned ON, the user program is restarted.

The following shows the considerations when using C intelligent function module dedicated function (CITL_WaitYEvent).

■When an interrupt event has already been notified

When an interrupt event has already been notified at the time of executing the C intelligent function module dedicated function

(CITL_WaitYEvent), a user program restarts from a state of waiting for an interrupt event at the same time as the execution of

the function.

In addition, when multiple interrupt events have been notified to the same interrupt event number at the time of executing the

C intelligent function module dedicated function (CITL_WaitYEvent), a user program performs processing as a single interrupt

event notification.

■When using the function in multiple user programs

Do not specify a same interrupt event (output signal (Y) number) in multiple user programs.

Otherwise, a user program to which a specified interrupt event (output signal (Y) number) is notified will be undefined.

20

1 FUNCTION

1.1 Program Related Function

Page 23

Data analysis function

This function performs data analysis processing such as fast Fourier transform, digital filter operation, calculation of a cross

point between a wave and a specified value, and calculation of a standard deviation.

This function enables the detection of machining errors by monitoring current wave and the preventive maintenance of

devices by analyzing vibrations.

For data analysis functions and statistical analysis functions, refer to the following manual.

MELSEC iQ-R C Controller Module/C Intelligent Function Module Programming Manual (Data Analysis)

Function list

The following table shows the functions used for the data analysis function.

■Data analysis function

Function name Description

DANL_SetOpCondition To set operating conditions for data analysis.

DANL_GetOpCondition To acquire operating conditions for data analysis.

DANL_DigitalFilter To perform digital filter operation for the specified wave.

DANL_EnvelopeCalculation To calculate the envelope of the specified wave.

DANL_FFTSpectrum To perform spectrum calculation using fast Fourier transform (FFT) for the specified wave.

DANL_FindCrossPoint To calculate the number of cross points of the specified wave and a reference value for the number of cross points

specified to the maximum number of cross points.

DANL_Peak To calculate the peak values (maximum and minimum) of the specified wave.

DANL_RMS To calculate an RMS (root mean square) of the specified wave.

DANL_BoundCompareTest To compare the specified wave and a check value to check an upper/lower limit.

DANL_AryBoundCompareTest To compare the specified wave and a check value to check an upper/lower limit of the wave.

1

■Statistical analysis function

Function name Description

DANL_LeastSquare To calculate a coefficient and a constant of a polynomial, and a multiple correlation coefficient by using a least-squares

method for the specified array.

DANL_MovingAverage To calculate a moving average of the specified array.

DANL_StandardDeviation To calculate a standard deviation of the specified array.

DANL_Variance To calculate a variance of the specified array.

DANL_MTUnit To determine a unit space that is used in the MT method based on the specified normal data.

DANL_MTMahalanobisDistance To calculate a Mahalanobis distance of the specified input data.

DANL_MultipleRegression To calculate a coefficient, constant, and regression statistics for multiple regression analysis.

1 FUNCTION

1.1 Program Related Function

21

Page 24

Data analysis or statistical analysis using a CPU module

Using a dedicated instruction or a module FB, analysis processing can be performed on a C intelligent function module.

Dedicated instructions

For dedicated instructions, refer to the following section.

Page 85 Dedicated Instructions

Module FBs

For module FBs, refer to the following manual.

MELSEC iQ-R C Intelligent Function Module Function Block Reference

Processing flow for analyzing data

The following shows the processing flow for analyzing data when a dedicated instruction or a module FB is executed on a

CPU module.

1. A dedicated instruction or a module FB is executed on a CPU module.

2. An analysis processing is performed on the C intelligent function module.

3. After the completion of the process, the C intelligent function module returns the result to the CPU module.

22

1 FUNCTION

1.1 Program Related Function

Page 25

1.2 Ethernet Communication Function

Precautions

FTP function

The server function of FTP(File Transfer Protocol), which is a protocol used to transfer files with target devices, is supported.

The target device with FTP client function can access the files in the C intelligent function module.

File operation

The following operations can be performed for a file in a C intelligent function module from a target device with the FTP client

function.

■Reading file (Download)

Use this when storing a file in a C intelligent function module on the target device side.

■Writing files (Upload)

Use this when registering a file stored on the target device side to a C intelligent function module.

■Browsing and deleting files and folders

Use this when browsing and deleting a file and folder in a C intelligent function module from the target device side.

Using FTP function

For using the FTP function, the service/account needs to be set.

Page 33 Service/account setting function

1

Users for file transfer function can be restricted by using user information (account settings).

■Account setting

This shows account settings set prior to the shipment (Initial settings).

• Login name: target

• Password: password

To prevent unauthorized access, change the password when using the FTP function.

■Specifications of FTP client

For the specifications of the FTP client installed on the target device, refer to the manual of the target device.

■Operation while accessing file

Do not perform any of the following operations while accessing the file. The file may get damaged.

• Reset the CPU module, or turn the power OFF.

• Insert/remove an SD memory card.

■Reconnection after timeout

If a timeout error occurred during file transfer, the TCP connection will be closed (disconnected).

Log in to the C intelligent function module again with the FTP client before restarting the file transfer.

■File transmission time

The file transfer processing time will differ depending on the following causes.

• Load rate of Ethernet line (line congestion)

• Number of connections to be used simultaneously (processing of other connections)

• System Configuration

1 FUNCTION

1.2 Ethernet Communication Function

23

Page 26

■Number of simultaneous connections

• Up to 10 target devices (FTP client) can log in to a C intelligent function module. If connecting from the 11th FTP client in

the state where 10 target devices have logged in, an error will occur without establishing the connection.

• If UDP communication is performed during file transfer with FTP, an error such as timeout may occur. Either communicate

after the file transfer or communicate with TCP.

■Writing files

• Files with the read-only attribute and files that are locked from other devices/functions cannot be written. Doing so may

cause a write error.

• The write files cannot be transferred if the SD memory card is write-protected. Doing so may cause a write error.

■Deleting files

Determine the timing for deleting the files for the entire system including the C intelligent function module and peripheral

devices.

■If the password has been forgotten

Initialize the C intelligent function module. Password before the shipment (Initial settings) will be changed. (Page 29

Initialization function)

24

1 FUNCTION

1.2 Ethernet Communication Function

Page 27

Telnet function

Precautions

This function executes the Shell command with a Telnet tool in a personal computer without using CW Workbench for a TCP/

IP network. This allows simple remote debugging (such as task information display and memory dumping) of a C intelligent

function module.

Using Telnet function

For using the Telnet function, the service/account needs to be set.

Page 33 Service/account setting function

■Account setting

This shows account settings set prior to the shipment (Initial settings).

• Login name: target

• Password: password

To prevent unauthorized access, change the password when using the Telnet function.

■Available Shell commands

Shell commands of CW Workbench can be used. For details on the shell commands, refer to the manual of VxWorks.

■Number of connections

The same C intelligent function module cannot be connected by using multiple Telnet tools. Connect a Telnet tool to a C

intelligent function module on a 1:1 basis. When connecting another Telnet tool, make sure to close (disconnect) the Telnet

tool being connected.

1

■Shell command

Shell commands entered from the Telnet tool operate on task of priority 1.

Note the following when executing the command. System errors/stop (such as watchdog timer error) may occur in a C

intelligent function module.

• Make sure to check the command specifications before executing commands which occupy the CPU processing.

• For rebooting VxWorks, reset the CPU module, or turn the power OFF and ON. Do not reboot VxWorks by executing the

command (reboot) of VxWorks or pressing + .

• Before executing a command in which arguments are included, make sure to check the command specifications/argument

specifications. (When executed without specifying those arguments, with the result that 0 is specified to an argument.) Do

not execute the close command with no argument specified. By doing so, a resource that is reserved in the VxWorks

system will be closed. When a command that shows the status of the module, such as the show command, is executed, the

module will be in the interrupt-disabled state for a long period of time, and any processing called from an interrupt routine is

not executed. As a result, an interrupt which occurs at the fixed interval may be delayed.

■Message display on Shell

A message issued by VxWorks during Telnet connection may be displayed on Shell. For the message of VxWorks, refer to the

manual and help of VxWorks.

1 FUNCTION

1.2 Ethernet Communication Function

25

Page 28

■Timeout

When the line is disconnected during Telnet connection, it will take 30 seconds before Telnet connection (TCP) times out on

the C intelligent function module side. Telnet cannot be reconnected until it times out.

Timeout time can be changed by the command provided by VxWorks.

ipcom_sysvar_set("iptcp.KeepIdle","XX",1);

ipcom_sysvar_set("iptcp.KeepIntvl","YY",1);

ipcom_sysvar_set("iptcp.KeepCnt","ZZ",1);

ipcom_ipd_kill("iptelnets");

ipcom_ipd_start("iptelnets")

Timeout time = iptcp.KeepIdle value + (iptcp.KeepIntvl value × iptcp.KeepCnt value)

• iptcp.KeepIdle: Time from when the line is disconnected to the first retry

• iptcp.KeepIntvl: Interval between retries

• iptcp.KeepCnt: Number of retries

• XX, YY: Specify the time (in seconds). (When '0' is specified, no timeout will occur.)

• ZZ: Specify the number of retries.

The following shows the procedure to change the timeout time of a C intelligent function module in operation.

1. Establish a Telnet connection to a C intelligent function module with a Telnet tool.

2. Execute the commands given above from the Shell command of the Telnet tool and change the timeout time.

3. Reboot the Telnet server.

4. Close (disconnect) the Telnet connection.

5. Establish a Telnet connection to a C intelligent function module with a Telnet tool again.

To change the Telnet connection (TCP) timeout time while starting the C intelligent function module, follow the procedure

below.

1. Describe the commands given above in the script file (STARTUP.CMD).

2. Turn the power of the CPU module ON.

■If the Telnet password has been forgotten

Initialize the C intelligent function module. Password before the shipment (Initial settings) will be changed. (Page 29

Initialization function)

26

1 FUNCTION

1.2 Ethernet Communication Function

Page 29

1.3 RAS Function

Precautions

Program Monitoring (WDT) Function

This function monitors and detects errors on hardware and a user program by using the watchdog timer (WDT), an internal

timer of a C intelligent function module.

Program monitoring (WDT) type

■System watchdog timer

A timer to monitor the system of a C intelligent function module.

Use this to detect an error in hardware and system software.

■User watchdog timer

A timer to monitor a user program.

Use this to detect an error in a user program.

Monitoring time setting and reset

■System watchdog timer

The monitoring time of the system watchdog timer is 2000 ms (fixed value).

The system of a C intelligent function module resets it every cycle (2000 ms).

■User watchdog timer

Set a monitoring time for the user watchdog timer within the range of 100 ms to 10000 ms (in 10 ms units) by using the C

intelligent function module dedicated function (CITL_StartWDT).

Monitoring starts by executing the C intelligent function module dedicated function (CITL_StartWDT), and the monitoring time

is reset by executing the C intelligent function module dedicated function (CITL_ResetWDT).

1

Timeout of watchdog timer

When the watchdog timer times out, an error indicating that the monitoring time set in the watchdog timer setting has been

exceeded (watchdog timer error) occurs. If a system watchdog timer error occurs, the RUN LED turns OFF and the ERR LED

turns ON. If a user watchdog timer error occurs, the ERR LED starts flashing.

■System watchdog timer

In case of failure of a C intelligent function module hardware and interrupt program execution, timeout will occur as the system

processing has been suspended for a long time.

■User watchdog timer

If a user program cannot complete processing within the time specified by using the C intelligent function module dedicated

function (CITL_StartWDT), and also cannot reset by using the C intelligent function module dedicated function

(CITL_ResetWDT), a timeout will occur.

When using the following functions, a user watchdog timer error occurs easily since the CPU utilization by a system task with

high priority increases.

• Shell command

• Connection with CW Workbench and Wind River Workbench

• Mounting and unmounting an SD memory card

• File access

• Ethernet communication

• NFS server communication

1 FUNCTION

1.3 RAS Function

27

Page 30

Error history function

Errors occurred in a C intelligent function module are stored in maximum 16 buffer memory as a history. If a major/moderate

error occurs, even if new errors have occurred, the history is not updated.

Event history function

The errors occurred in a C intelligent function module and operations executed are sampled in the CPU module as an event

information.

Event information occurred in a C intelligent function module is sampled and held in the data memory or an SD memory card

in a CPU module.

An event information sampled by CPU module can be displayed by an engineering tool and the occurrence history can be

checked chronologically.

Setting method

Event history function can be set from the event history setting screen of an engineering tool.

For the setting method, refer to the following section.

MELSEC iQ-R CPU Module User's Manual (Application)

■Checking an event history

Can be checked from an engineering tool.

For details on the operating procedures and how to read the displayed information, refer to the following manual.

GX Works3 Operating Manual

Self-diagnostic function

Self-diagnostics test is performed to check the hardware of a C intelligent function module.

Self-diagnostics test is as follows.

• Automatic Hardware Test (Page 54 Automatic hardware test)

• Hardware test for LED check (Page 55 Hardware test for LED check)

28

1 FUNCTION

1.3 RAS Function

Page 31

Initialization function

Initialization and script of the C intelligent function module can be stopped.

When the initialization is in progress, the value of buffer memory cannot be checked by an engineering tool.

Types of initialization

■Stop script setting

Execution of a script file (STARTUP.CMD), which is registered in standard ROM, is stopped.

*1 Registration will be cancelled by renaming the script file name with "STARTUP.BAK".

■Module initialization setting

Service/account settings are initialized (factory default status) by initializing the standard ROM.

*1

Initialization

1. Change to "Stop Script File Setting" or "Module Initialization Setting" in [Basic Settings] [Various Operations Settings]

[Mode Settings] in the module parameter of the C intelligent function module in the parameter setting of an

engineering tool. (Page 45 Basic Setting).

2. Set the CPU module to the STOP state, and write the parameters.

3. Reset the CPU module.

4. After resetting the CPU module, initialization is automatically executed.

Status RUN LED status ERR LED status

Initialization in progress Flashing (low-speed) OFF

Initialization complete Normal completion ON OFF

Abnormal completion ON ON

1

5. When the initialization completed normally, select "Online" in [Basic Settings] [Various Operations Settings] [Mode

Settings] in the module parameter of the C intelligent function module in the parameter setting of an engineering tool to

reset the CPU module.

6. At an abnormal completion, check whether measures are taken to reduce noise of the programmable controller system

and execute the automatic hardware test again. If the process is completed abnormally again, there may be a hardware

failure in the C intelligent function module. Please consult your local Mitsubishi representative. While removing the

module, do not use an electric screwdriver. Remove the module when the module fixing screws are in fully loosened

state.

1 FUNCTION

1.3 RAS Function

29

Page 32

1.4 Security Function

This function prevents assets stored in a C intelligent function module from being stolen, falsified, operated incorrectly, and

executed improperly due to unauthorized access from a third party.

The security function is one of the methods for preventing unauthorized access (such as program or data

corruption) from an external device. However, this function does not prevent unauthorized access completely.

Incorporate measures other than this function if the programmable controller system's safety must be

maintained against unauthorized access from an external device. Mitsubishi Electric Corporation cannot be

held responsible for any system problems that may occur from unauthorized access.

Examples of measures for unauthorized access are shown below.

• Install a firewall.

• Install a personal computer as a relay station, and control the relay of send/receive data with an application

program.

• Install an external device for which the access rights can be controlled as a relay station. (For details on the

external devices for which access rights can be controlled, consult the network provider or equipment

dealer.)

Individual identification information read function

The individual identification information of a C intelligent function module can be read with the C intelligent function module

dedicated function (CITL_GetIDInfo). By implementing an activation function with a user program, a user program, which

does not run in C intelligent function modules with other individual identification information, can be created.

For C intelligent function module dedicated functions, refer to the following manual.

MELSEC iQ-R C Intelligent Function Module Programming Manual

30

1 FUNCTION

1.4 Security Function

Page 33

File access restriction function

S R H

S

R

H

Indicates the hidden file attribute is specified.

Indicates the hidden file attribute is not specified.

Indicates the system file attribute is specified.

Indicates the system file attribute is not specified.

Indicates the read-only attribute is specified.

Indicates the read-only attribute is not specified.

Blank

Blank

Blank

A file attribute can be set for the files stored in the following types of memory. By setting a file attribute, access to a target file

can be restricted, and falsification by an unauthorized user and data leakage to outside can be prevented.

• Standard ROM

• SD memory card

• When an SD memory card is inserted to a peripheral device other than a C intelligent function module (such

as a personal computer), files to which the access restriction is set can be operated. If the access restriction

is set for the file in the SD memory card, take appropriate measures so that the SD memory card cannot be

removed from the C intelligent function module at will.

• Access restrictions cannot be set for the folder.

File access restriction function setting

Change a file attribute handled in a C intelligent function module by using the attrib() command. A security password is

required to change a file attribute.

For details on the attrib() command, refer to the manual of VxWorks.

■Setting file attribute

Set a file attribute to a file to be restricted by using the attrib() command.

The file attributes that can be handled in a C intelligent function module are as follows.

Attribute Description

S System file attribute File attributions can be prohibited.

R Read-only attribute

H Hidden file attribute

*1

*2

File deletion and data write can be prohibited.

A file is not listed by using the ls command and it is not displayed at FTP connection.

1

*1 This attribute is not supported by the file access restriction function. However, if it is set, file deletion and file write can be prohibited.

*2 When the file is opened by specifying the file name, file operations can be performed. In order to prohibit the file operations, ensure to

set the system file attribute.

■Checking file attribute

A file attribute which is set can be checked by using the attrib() command.

1 FUNCTION

1.4 Security Function

31

Page 34

Checking file access restriction status

Precautions

File access restriction status can be checked by executing the Shell command or the C intelligent function module dedicated

function (CITL_GetFileSecurity).

File access restriction status cannot be checked by using the script file (STARTUP.CMD).

Canceling/re-setting file access restriction

Change the file access restriction status by using the Shell command, the script file (STARTUP.CMD), or a user program. The

security password set with an engineering tool is required.

■Changing system file attribute

For operating a file with a system file attribute attached, cancel the file access restriction temporarily with the C intelligent

function module dedicated function (CITL_ChangeFileSecurity). The canceled setting can be set again by setting the file

access restriction with the C intelligent function module dedicated function (CITL_ChangeFileSecurity) or resetting the C

intelligent function module.

• When accessing a file to which a system file attribute is attached in the script file "STARTUP.CMD", cancel

the access restriction in the script file (STARTUP.CMD). Again, add the system file attribute to the script file

(STARTUP.CMD) in order to prevent the leakage of the password.

• Do not use the files with the system file attribute attached in the script file (STARTUP.CMD) in an SD

memory card in order to prevent the leakage of password.

■When maintaining the safety against unauthorized access from external parties

To maintain the safety of a programmable controller system against unauthorized access from external parties, take

appropriate measures. Note the following when setting a security password to prevent the leakage of the security password.

• Avoid settings with only simple alphanumeric characters.

• Set a complex password with symbols.

■Settable characters for a security password

Characters that can be set are single byte alphanumeric characters and symbols. (Security password is case-sensitive.)

■If the security password has been forgotten

Initialize the C intelligent function module. (Page 29 Initialization function)

32

1 FUNCTION

1.4 Security Function

Page 35

Service/account setting function

Window

Displayed items

Set the services, account, and security password for a C intelligent function module.

By restricting the services and setting an account, unauthorized access from other users can be prevented.

Security password is required to change the service and account settings.

[Tool] [Module Tool List] [Information Module] [Service/account setting]

1

Item Description Setting Range

Service Settings Telnet A service to use a Telnet. • Enable

FTP A service to use an FTP.

WDB A service to connect CW Workbench.

DHCP A service to use a function which assigns the network

settings automatically.

MELSEC iQ-R series data link

function

Memory card access A service to access the memory card.

Memory card script execution A service to use the script file stored in the memory card.

Security password

settings

Account setting Login Name Set the account log in name. 1 to 12 characters (single byte

*1 If the password setting is not entered (blank), it does not change from the current password.

Password Setting

Password Setting

*1

*1

A service to use MELSEC iQ-R series data link functions.

Set a security password. 8 to 16 characters

Set the account password. 8 to 32 characters

• Disable

(Default: Enable)

(Default: password)

alphanumeric characters)

(Default: target)

(Default: password)

Usable character string for password setting

The following table shows the usable characters in the password setting.

Item Description

Character ASCII character string (Alphanumeric characters and special characters)

Usable special characters for password setting is as follows.

• `, ~, !, @, #, $, %, ^, &, *, (, ), _, +, -, =, {, }, |, \, :, ", ;, ', <, >, ?, ,, ., /, [, ], space

*2

*1

*1 The password is case-sensitive.

*2 Special characters (|, ,, space) cannot be used in the password setting of the account settings.

1 FUNCTION

1.4 Security Function

33

Page 36

IP filter function

Precautions