C

MIT

SUBIS

C

HI ELECTRI

MELSEC System Q

Programmable Logic Controllers

User’s Manual

Art. no.: 130027

05 02 2003

SH (NA)-080036-E

Version E

High-Speed Counter Module

QD62, QD62E, QD62D,

GX Configurator-CT

(SW0D5C-QCTU-E)

MITSUBISHI ELECTRI

INDUSTRIAL AUTOMATION

SAFETY PRECAUTIONS

•

(Always read before starting use.)

Before using this product, please read this manual introduced in this manual carefully and pay full

attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. For the safety instructions of the

programmable controller system, please read the User's Manual for the CPU module to use.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

•

DANGER

!

CAUTION

!

Note that the !CAUTION level may lead to a serious consequence according to t he circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please store this manual in a safe place and make it accessible when required. Alway s forward it to the

end user.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight personal injury or physical damage.

[DESIGN PRECAUTIONS]

!

DANGER

Do not write data into the "system area" of the buffer memory of intelligent function modules.

•

Writing data into the "system area" may cause a PLC system malfunction.

Depending on the malfunction of the external output transistor, there may be cases where the

•

output is ON or OFF status. Install external monitoring circuitry for output signals that may lead

to major accidents.

!

CAUTION

Do not bunch the control wires or communication cables with the main circuit or power wires, or

•

install them close to each other.

They should be installed 150 mm(5.9 inch) or more from each other.

Not doing so could result in noise that may cause malfunction.

A - 1 A - 1

[INSTALLATION PRECAUTIONS]

!

CAUTION

Use the PLC in an environment that meets the general specifications contained in the CP U

•

User's Manual.

Using this PLC in an environment outside the range of the general specificat ions may cause

electric shock, fire, malfunction, and damage to or deterioration of the product.

When installing the module, securely insert the module fixing tabs into the mountin g holes of the

•

base module while pressing the installation lever located at the bottom of the module downward.

Improper installation may result in malfunction, breakdown or the module co ming loose and

dropping. Securely fix the module with screws if it is subject to vibration during use.

Tighten the screws within the range of specified torque.

•

If the screws are loose, it may cause the module to fallout, short circuits, or malfunction.

If the screws are tightened too much, it may cause damage to the screw and/or the module,

resulting in fallout, short circuits or malfunction.

Switch all phases of the external power supply off when mounting or removing the module.

•

Not ding so may cause electric shock or damage to the module.

Do not directly touch the conductive area or electronic components of the module.

•

Doing so may cause malfunction or failure in the module.

[WIRING PRECAUTIONS]

!

CAUTION

Perform correct pressure-displacement, crimp-contact or soldering for connector wire

•

connections using the tools specified by the manufactures.

Attach connectors to the module securely.

Be careful not to let foreign matters such as sawdust or wire chips get inside the module.

•

They may cause fires, failure or malfunction.

The top surface of the module is covered with protective film to prevent foreign objects such as

•

cable offcuts from entering the module when wiring.

Do not remove this film until the wiring is complete.

Before operating the system, be sure to remove the film to provide adequate heat ventilation.

Be sure to fix communication cables or power supply cables leading from the module by placing

•

them in the duct or clamping them.

Cables not placed in the duct or without clamping may hang or shift, allow ing them to be

accidentally pulled, which may cause a module malfunctio n and cable da mage.

When removing the communication cable from the module, do not pull the cable. When

•

removing the cable with a connector, hold the connector on the side that is connected to the

modules.

Pulling the cable that is still connected to t he module may cause malfunctio n or damage t o the

module or cable.

A - 2 A - 2

[WIRING PRECAUTIONS]

!

CAUTION

Always ground the shielded cable on the encoder side (relay box).

•

Otherwise, malfunction may occur.

When wiring, be sure to verify the rated voltage of the product as well as the terminal layout. Fire

•

or failure may result if incorrect voltage is input or incorrect wiring is performed.

Connecting terminals with incorrect voltage may result in malfunction or mechanical failure.

•

[STARTUP/MAINTENANCE PRECAUTIONS]

!

CAUTION

Do not disassemble or modify the module.

•

Doing so could cause failure, malfunction, injury or fire.

Switch all phases of the external power supply off when mounting or removing the module.

•

Not doing so may cause failure or malfunction of the module.

Do not touch the connector while the power is on.

•

Doing so may cause malfunction.

Switch all phases of the external power supply off when cleaning or retightening the terminal

•

screws and module installation screws.

Not doing so may cause failure or malfunction of the module.

If the screws are loose, it may cause the module to fallout, short circuits, or malfunction.

If the screws are tightened too much, it may cause damages to the screws and/or the module,

resulting in the module falling out, short circuits or malfunct ion.

Always make sure to touch the grounded metal to discharge the electricity charged in the body,

•

etc., before touching the module.

Failure to do so may cause a failure or malfunctions of the module.

[DISPOSAL PRECAUTIONS]

!

CAUTION

When disposing of the product, handle it as industrial waste.

•

A - 3 A - 3

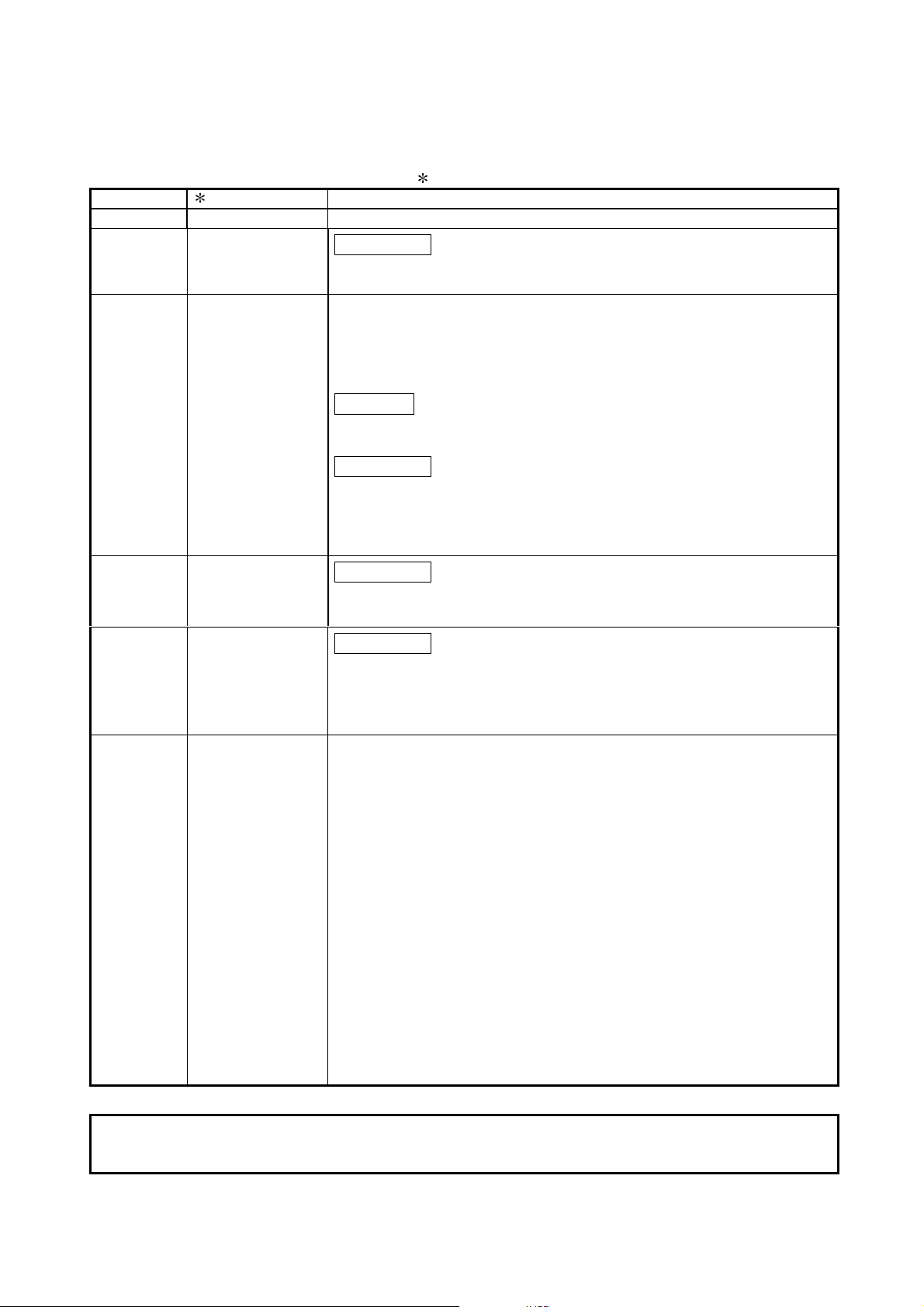

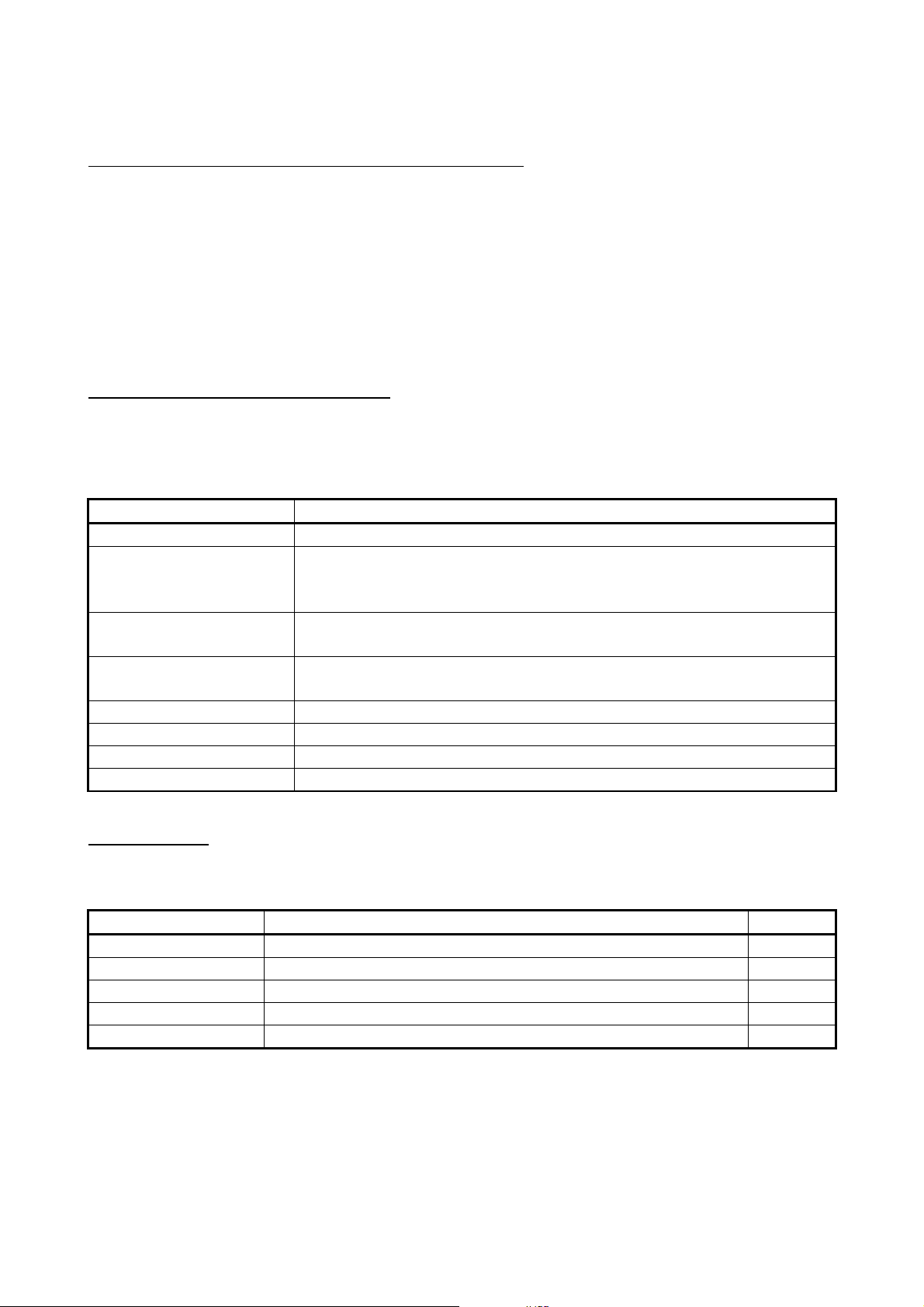

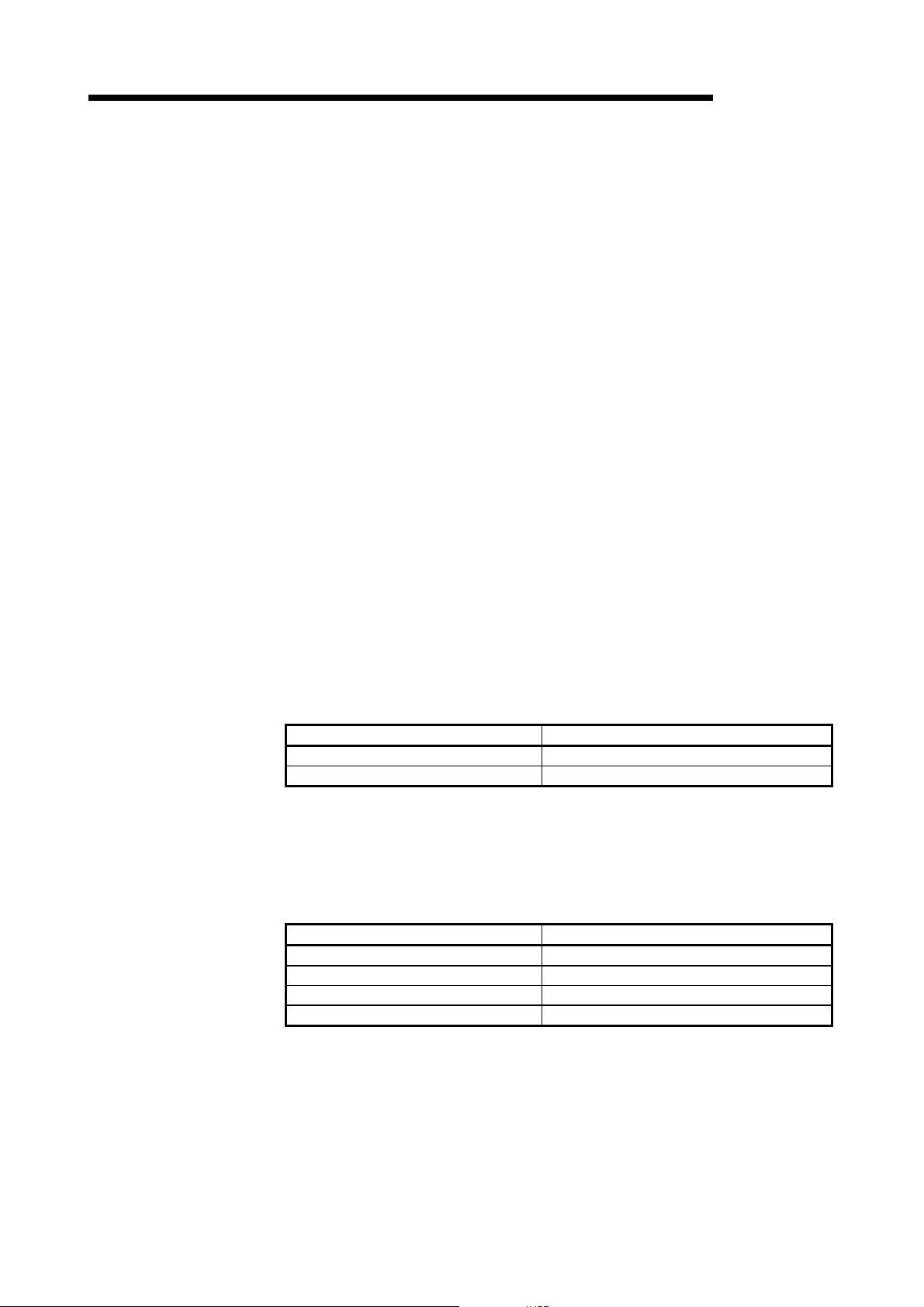

REVISIONS

The manual number is given on the bottom left of the back cover.

Print Date Manual Number Revision

Dec., 1999 SH(NA)-080036-A First edition

Oct., 2000 SH(NA)-080036-B

Correction

About the Generic Terms and Abbreviation, Section 2.1, Section 7.2.2,

7.3.3, 7.6.1

Jun., 2001 SH(NA)-080036-C

Standardize the name from software package (GPP function) to

Product name (GX Developer).

Standardize the name from utility package (QCTU) to Product name

(GX Configurator-CT).

Addition

Section 2.2, 2.3

Correction

Safety Precautions, Conformation to the EMC Directive and Low

Voltage Instruction, About the Generic Terms and Abbreviations,

Product Structure, Section 2.1, Section 3.2, 3.5, Section 6.2, Section

7.2, 7.2.1, 7.2.2, 7.3.3

Feb., 2002 SH(NA)-080036-D

Correction

About the Generic Terms and Abbreviation, Section 2.1, Section 7.2.1,

7.2.2

Feb., 2003 SH(NA)-080036-E

Correction

SAFETY PRECAUTIONS, INTRODUCTION, CONTENTS, About the

Generic Terms and Abbreviations, Section 2.1, Section 3.5, Section

4.3, Section 5.4, Section 7.2.2, Sect ion 7.3. 2, Sec ti on 7.3. 3, Sec tio n 7.4

to Section 7.6, Section 8.1.1, INDEX

Japanese Manual Version SH-080035-H

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

1999 MITSUBISHI ELECTRIC CORPORATION

A - 4 A - 4

INTRODUCTION

Thank you for purchasing the MELSEC-Q series PLC.

Before using the equipment, please read this manual carefully to develop full familiarity with the functions

and performance of the Q series PLC you have purchased, so as to ensure correct use.

CONTENTS

SAFETY PRECAUTIONS..............................................................................................................................A- 1

REVISIONS...................................................................................................................... ..............................A- 4

INTRODUCTION............................................................................................................................................A- 5

CONTENTS....................................................................................................................................................A- 5

Conformation to the EMC Directive and Low Voltage Instruction ................................................................A- 8

About the Generic Terms and Abbreviations ................................................................................................A- 8

Product Structure ...........................................................................................................................................A- 8

1 OVERVIEW 1- 1 to 1- 3

1.1 Features ..................................................................................................................................................1- 2

2 SYSTEM CONFIGURATIONS 2- 1 to 2- 4

2.1 Applicable System ..................................................................................................................................2- 1

2.2 How to Check Software Version............................................................................................................. 2- 3

2.3 About Use of the QD62 (E/D) with the Q00J/Q00/Q01CPU .................................................................2- 4

3 SPECIFICATION S 3- 1 to 3-14

3.1 Performance Specifications....................................................................................................................3- 1

3.2 Function List............................................................................................................................................3- 4

3.3 I/O Signals for the PLC CPU ..................................................................................................................3- 5

3.3.1 List of I/O signals..............................................................................................................................3- 5

3.3.2 Functions of I/O signals....................................................................................................................3- 6

3.4 Buffer Memory Assignments ..................................................................................................................3- 8

3.5 Interface with External Devices ..............................................................................................................3-11

3.6 Encoders that can be Connected...........................................................................................................3-14

4 SETUP AND PROCEDURE BEFORE STARTING THE OPERATION 4- 1 to 4-16

4.1 Handling Precautions..............................................................................................................................4- 1

4.2 Procedure Before Starting the Operation............................................................................................... 4- 2

4.3 Part Identification Nomenclature ............................................................................................................4- 3

4.4 Wiring.......................................................................................................................................................4- 5

4.4.1 Wiring precautions ...............................................................................................................................4- 5

4.4.2 Wiring example of a module and a pulse generator.......................................................................4- 6

4.4.3 Wiring example of a controller and an external input terminal........................................................ 4- 8

4.4.4 Wiring example with an external output ..........................................................................................4-11

4.4.5 Using the connector/terminal block converter module.................................................................... 4-12

4.5 Switch Settings for the Intelligent Function Module...............................................................................4-14

A - 5 A - 5

5 BASIC USAGE 5- 1 to 5-11

5.1 Understanding the Pulse Input and Counting Method...........................................................................5- 1

5.1.1 Types of pulse input methods..........................................................................................................5- 1

5.1.2 Setting the count method................................................................................................................. 5- 3

5.1.3 Reading the present values.............................................................................................................5- 3

5.2 Selecting the Counter Format.................................................................................................................5- 4

5.2.1 Selecting the linear counter .............................................................................................................5- 4

5.2.2 Selecting the ring counter ................................................................................................................5- 5

5.3 Using the Coincidence Output Function................................................................................................. 5- 7

5.4 Using the Preset Function ......................................................................................................................5-10

6 CONVENIEN T US A GE 6- 1 to 6- 8

6.1 Selecting the Counter Function..............................................................................................................6- 1

6.1.1 Reading the counter function selection count value .......................................................................6- 2

6.1.2 Count error........................................................................................................................................6- 3

6.2 Using the Disable Count Function..........................................................................................................6- 4

6.3 Using the Latch Counter Function..........................................................................................................6- 5

6.4 Using the Sampling Counter Function ...................................................................................................6- 6

6.5 Using the Periodic Pulse Counter Function........................................................................................... 6- 7

7 UTILITY PACKAGE (GX Configurator-CT) 7- 1 to 7-17

7.1 Utility Package Functions........................................................................................................................7- 1

7.2 Installing and Uninstalling the Utility Package........................................................................................7- 2

7.2.1 User precautions ..............................................................................................................................7- 2

7.2.2 Operating environment.....................................................................................................................7- 4

7.3 Explanation of Utility Package Operations.............................................................................................7- 5

7.3.1 How to perform common utility package operations.......................................................................7- 5

7.3.2 Operation overview ..........................................................................................................................7- 7

7.3.3 Starting the intelligent function utility ...............................................................................................7- 9

7.4 Initial Settings..........................................................................................................................................7-11

7.5 Auto Refresh ...........................................................................................................................................7-13

7.6 Monitor/Test ............................................................................................................................................7-15

7.6.1 Monitor/Test......................................................................................................................................7-15

8 PROGRAMMING 8- 1 to 8- 9

8.1 Program Example When GX Configurator-CT is Used .........................................................................8- 2

8.1.1 Operating GX Configurator-CT........................................................................................................8- 2

8.1.2 Program example.............................................................................................................................8- 4

8.2 Program Example when GX Configurator-CT is not Used....................................................................8- 6

8.3 Example of a Program Using the Coincidence Detection Interrupt Function .......................................8- 9

A - 6 A - 6

9 TROUBLESHOOTING 9- 1 to 9- 2

9.1 Error Information .....................................................................................................................................9- 1

9.2 The Count Operation is not Working......................................................................................................9- 2

9.3 The Count Value is not Normal ..............................................................................................................9- 2

APPENDIX App- 1 to App- 2

Appendix 1 External Dimension Diagram ................................................................................................App- 1

Appendix 2 Difference Between A1SD62, A1SD62E and A1SD62D (S1).............................................App- 2

INDEX Index- 1 to Index- 2

A - 7 A - 7

Conformation to the EMC Directive and Low Voltage Instruction

For details on making Mitsubishi PLC conform to the EMC directive and low voltage

instruction when installin g it in your pro duct, ple as e see Cha pter 3, "EM C Dir ec tive

and Low Voltage Instruction" of the User's Manual (Hardware) of the PLC CPU to

use.

The CE logo is printed on the rating plate on the main body of the PLC that conforms

to the EMC directive and low voltage instruction.

By making this product conform to the EMC directive and low voltage instruction, it is

not necessary to make those steps individually.

About the Generic Terms and Abbreviations

Unless otherwise specified, this manual uses the following generic terms and

abbreviations to describe the Type QD62, QD62D and QD62E high-speed counter

module.

Generic Term/Abbreviation Description of the abbreviation/general terms

DOS/V personal computer DOS/V-compatible personal computer of IBM PC/AT® and its compatible

Generic product name of the product types SWnD5C-GPPW-E, SWnD5C-GPPW-EA,

GX Developer

QCPU (Qmode)

GX Configurator-CT

QD62 Abbreviation of the Type QD62 high-speed counter module

QD62E Abbreviation of the Type QD62E high-speed counter module

QD62D Abbreviation of the Type QD62D high-speed counter module

QD62(E/D) Generic term of QD62, QD62E and QD62D

SWnD5C-GPPW-EV and SWnD5C-GPPW-EVA.

"n" in the model name is 4 or greater.

Generic term of Q00JCPU, Q00CPU, Q01CPU, Q02CPU, Q02HCPU, Q06HCPU,

Q12HCPU, Q25HCPU, Q12PHCPU, Q25PHCPU

Generic term of counter module setting/monitor tool GX Configurator-CT (SW0D5CQCTU-E)

Product Structure

The product structure of this product is given in the table below.

Model Name Product Name Quantity

QD62 Type QD62 high-speed counter module 1

QD62E Type QD62E high-speed counter module 1

QD62D Type QD62D high-speed counter module 1

SW0D5C-QCTU-E GX Configurator-CT Version 1 (1-license product) (CD-ROM) 1

SW0D5C-QCTU-EA GX Configurator-CT Version 1 (Multiple-license product) (CD-ROM) 1

A - 8 A - 8

1 OVERVIEW

1 OVERVIEW

MELSEC-Q

This User's Manual describes the specifications, handling and programming method

for the QD62, QD62E and QD62D high-speed counter modules (QD62 (E/D)) used

together with the MELSEC-Q series CPUs.

The QD62(E/D) modules are available with the following I/O types, maximum counting

speeds and number of channels.

Item QD62 QD62E QD62D

I/O type

Maximum counting

speed

DC input sinking

output

200 kPPS 500 kPPS

DC input sourcing

output

Differential input

sinking output

Number of channels 2 channels

The QD62(E/D) modules have the following input methods for 1 phase/2 phase pulse input:

• Phase 1 pulse input multiple of 1 • Phase 1 pulse input multiple of 2 • CW/CCW

• Phase 2 pulse input multiple of 1 • Phase 2 pulse input multiple of 2

• Phase 2 pulse input multiple of 4

See Section 5.1 for details on the input methods.

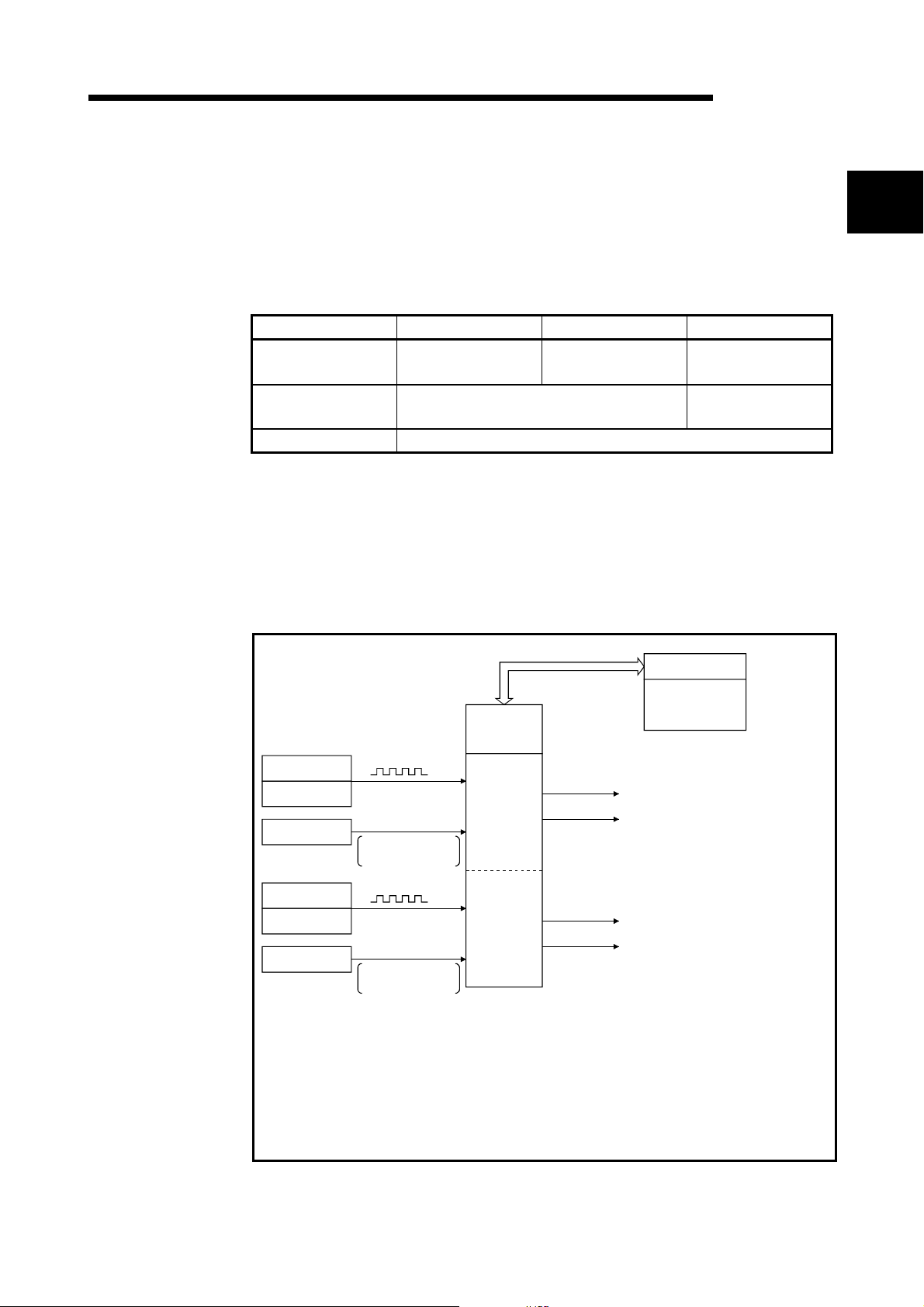

An overview of QD62 (E/ D ) ope rat ion is shown in the figure below.

4) I/O signal

Buffer memory

read/write

QD62(E/D)

PLC CPU

QCPU (Q mode)

1

Pulse generator

Encoder

Controller

Pulse generator

Encoder

Controller

Pulse

External

control signal

Preset counter

function selection

Pulse

External

control signal

Preset counter

function selection

1)

CH1

2)

3)

CH2

4)

3) Coincidence signal output (2 points)

3) Coincidence signal output (2 points)

1) Counts the pulses to be input to the QD62 (E/D).

2) Preset or counter function can be selected with an external control signal.

3) The present count value and the coincidence output point setting value can be

compared to output a coincidence signal.

4) Using the sequence program, the I/O signal and buffer memory status of the

QD62 (E/D) can be verified.

Also, count start/stop, preset, and counter function can be selected.

1 - 1 1 - 1

1 OVERVIEW

1.1 Features

MELSEC-Q

1

The features of the QD62(ED) are as follows:

(1) Counting can be performed in a wide range (The count value can be

expressed within the range between –2147483648 and 2147483647)

The count values are stored as 2-channel 32-bit signed binary codes.

(2) The maximum counting speed can be ch ang ed

The maximum speed of the QD62D can be changed by selecting from among

500 k, 200 k, 100 k and 10 k, while that of the QD62 and QD62E can be selected

from among 200k, 100k and 10k. This allows an error-free count even with

gradual rise/fall pulses.

(3) Pulse input can be selected

The pulse input can be selected from 1 phase multiple of 1, 1 phase multiple of 2,

2 phase multiple of 1, 2 phase multiple of 2, 2 phase multiple of 4, CW and CCW.

(4) Counter format can be selected

Either one of the following counter formats can be selected.

(a) Linear counter format

A count from –2147483648 to 2147483647 is possible and if the count

exceeds the range , an ov er flow will be detected.

(b) Ring counter format

Counting is performed repeatedly between the ring counter maximum value

and minimum value.

(5) Coincidence output is possible

Any channel coincidence out put point can be preset to co mpare with the present

counter value to output the ON/OFF signal out put, o r to start an int errupt pr ogram.

(6) Selection can be made from four counter functi ons

One of the following four functions can be selected.

(a) Latch counter function

This function latches the present value of the counter when the signal was

input.

(b) Sampling counter function

This function counts the pulses that were input within the preset time period

from the sign al inpu t .

(c) Periodic pulse counter function

This function stores the present and previous values of the counter at each

preset time interval while the signal is being input.

(d) Disable count function

This function i nput s a sig na l whil e e xec u ti ng the cou nt e nabl e command to

stop pulse counting.

1 - 2 1 - 2

1 OVERVIEW

MELSEC-Q

(7) The preset function/counter selection function can be executed

using an external control signal

By applying voltage to the preset terminal/function start terminal of an external

terminal, preset function/counter function selection can be executed.

(8) Easy settings using the utility package

A utility package is sold separately (GX Configurator-CT).

The utility package is not a required item. However, it can be used to set initial

settings and automatic refresh settings onscreen, reduce sequence programs,

and check settings and operating status.

(9) A blown fuse in the external output section can be de tected

A blown fuse in th e e xte r nal ou tput se ctio n can be de te ct ed ; i t is no tified by the

input signal X and the LED display on the module.

1 - 3 1 - 3

2 SYSTEM CONFIGURATIONS

2 SYSTEM CONFIGURATIONS

This chapter explains the system configuration of the QD62 (E/D).

2.1 Applicable System

MELSEC-Q

2

This section explains the applicable system.

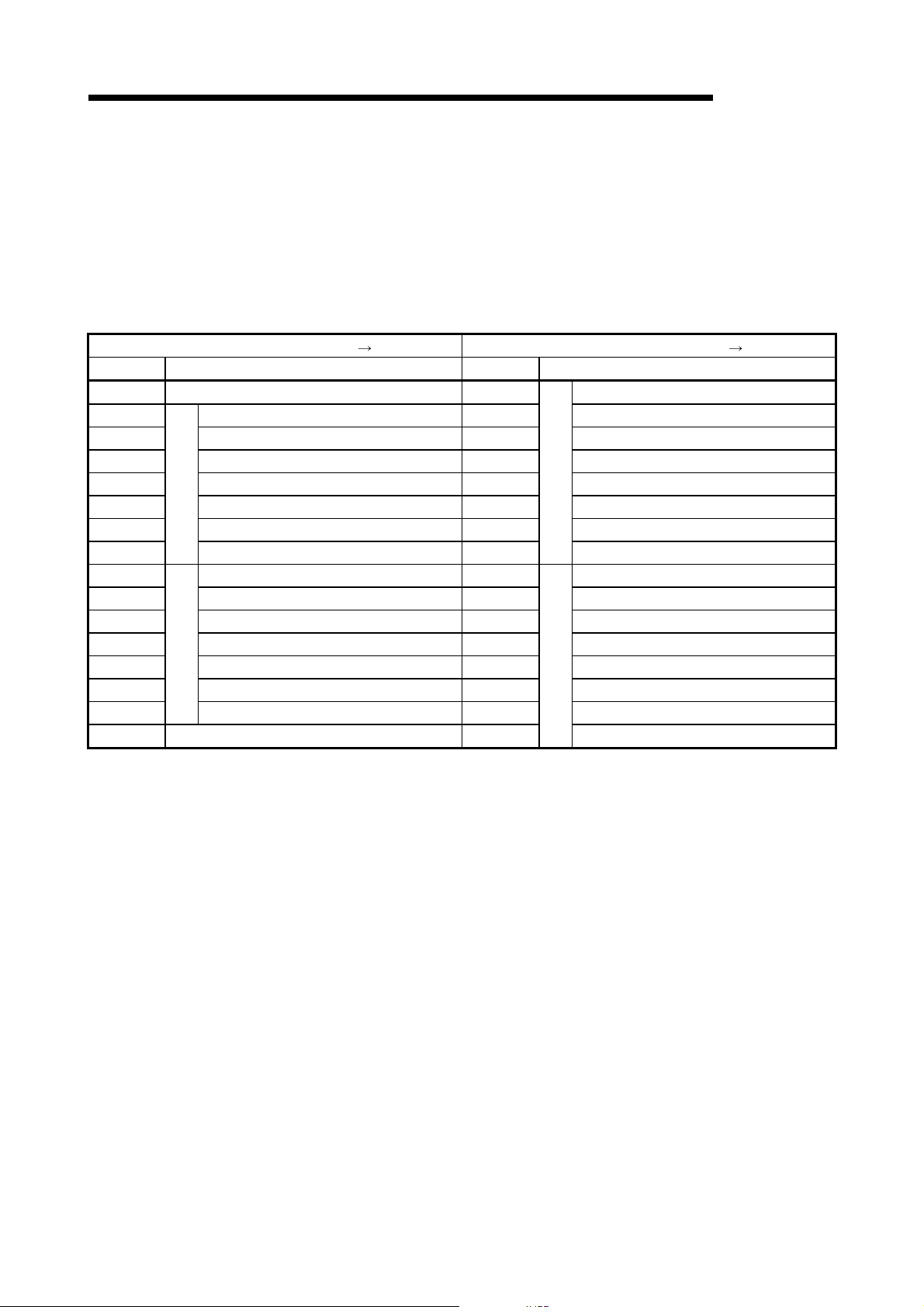

(1) Applicable CPU and number o f modul es that can be m ounte d

The CPU module and network module (for remote I/O station) that can have the

QD62 (E/D) and the number of modules that can be mounted are listed below.

CPU module

Network module

1 See User's Manual (Function Explanation, Program Fundamentals) for the CPU module to use.

2 See Q Corresponding MELSECNET/H Network System Reference Manual (Remote I/O

network).

Applicable module

Q12PHCPU

Q25PHCPU

QJ72LP25-25

QJ72LP25G

QJ71LP25GE

Number of modules that

can be installed

Q00JCPU Maximum 16

Q00CPU

Q01CPU

Q02CPU

Q02HCPU

Q06HCPU

Q12HCPU

Q25HCPU

QJ72BR15

Maximum 24

Maximum 64

Maximum 64

Maximum 64

Can be installed in Q mode only

1

(

MELSECNET/H Remote I/O

station (

Remarks

1

(

)

)

1

(

)

2

)

(2) Mountable base unit

QD62 (E/D) can be mounted on any of the base unit’s I/O slots ( 3). However,

depending on combinations with other mounted modules and the number of

mountings, there may be cases where the power capacity is insufficient. Be sure

to consider the power capacity when mounting the module.

3 Must be inside the point number range of 1 CPU unit and network module

(for remote I/O station).

(3) Compatibility with a multiple PLC system

First read the QCPU (Q mode) User's Manual (Function Explanation, Program

Fundamentals) if the QD62 (E/D) is used with a multiple PLC system.

(a) Compatible QD62 (E/D)

In case of using the QD62 (E/D) with the multiple PLC system, there is no

restriction by the version.

(b) Intelligent function module parameters

Perform PLC write of the intelligent function module parameters to the

control PLC of the QD62 (E/D) only.

2 - 1 2 - 1

2 SYSTEM CONFIGURATIONS

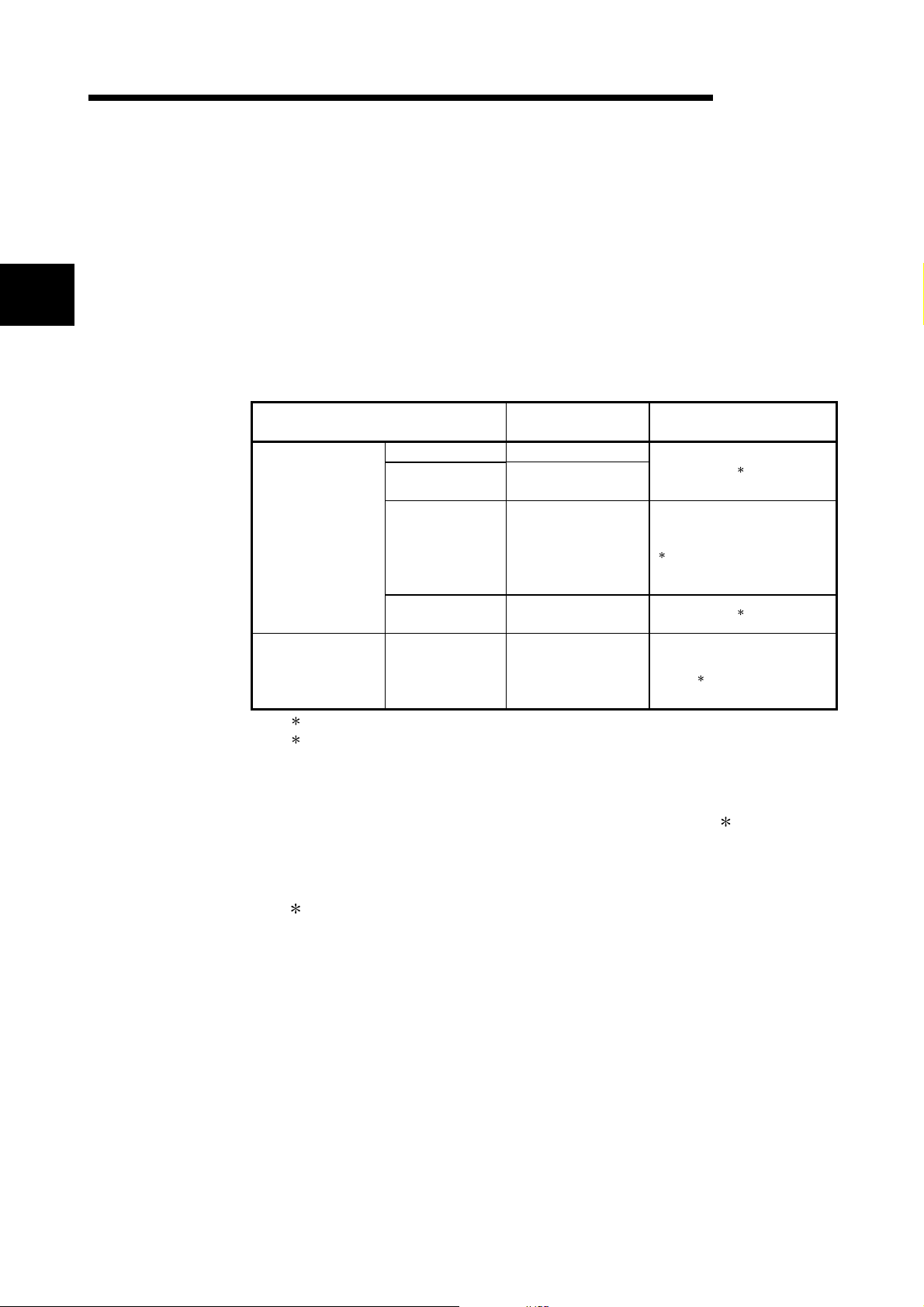

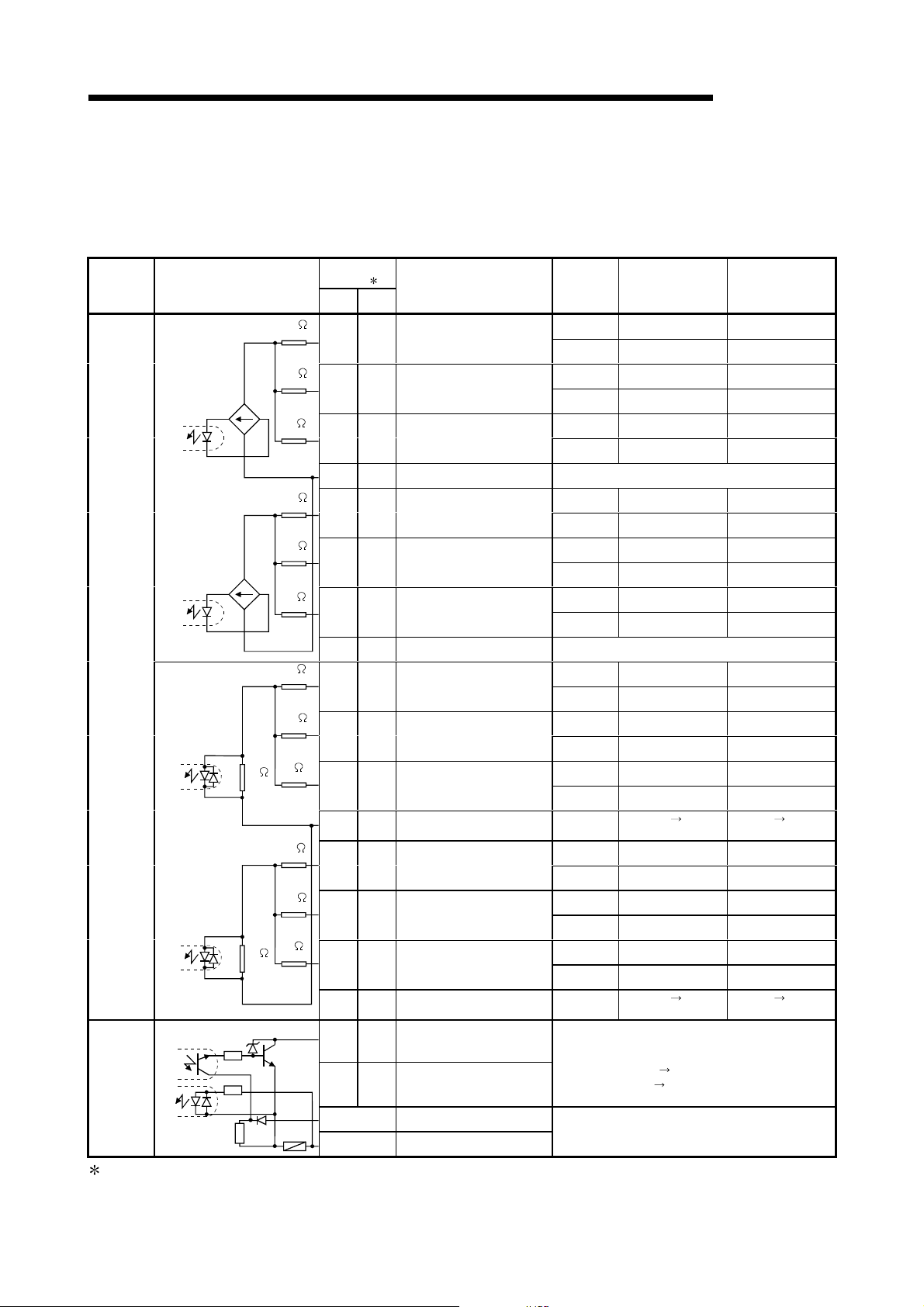

(4) Software packages supported

Correspondence between systems which use QD62 (E/D) and software

packages are as shown below.

The GX Developer is necessary when using a QD62 (E/D).

Q00J/Q00/Q01CPU

Q02/Q02H/Q06H/

Q12H/Q25HCPU

Q12PH/Q25PHCPU

If installed in a MELSECNET/H

remote I/O station

Single PLC

system

Multiple PLC

system

Single PLC

system

Multiple PLC

system

Single PLC

system

Multiple PLC

system

MELSEC-Q

Software Version

GX Developer GX Configurator-CT

Version 7 or later

Version 8 or later

Version 4 or later

Version 6 or later

Version 7.10L or later

Version 6 or later

Version 1.10L or later

(cannot be used with the

SW0D5C-QCTU-E 50F or

earlier versions)

SW0D5C-QCTU-E 00A or

later

SW0D5C-QCTU-E 50F or

later

Version 1.13P or later

(cannot be used with the

SW0D5C-QCTU-E 50F or

earlier versions)

SW0D5C-QCTU-E 50F or

later

2

(5) Connector

For the QD62(D/E), the connector is sold separately.

See Section 4.3 and make separate arrangements for the connector.

2 - 2 2 - 2

2 SYSTEM CONFIGURATIONS

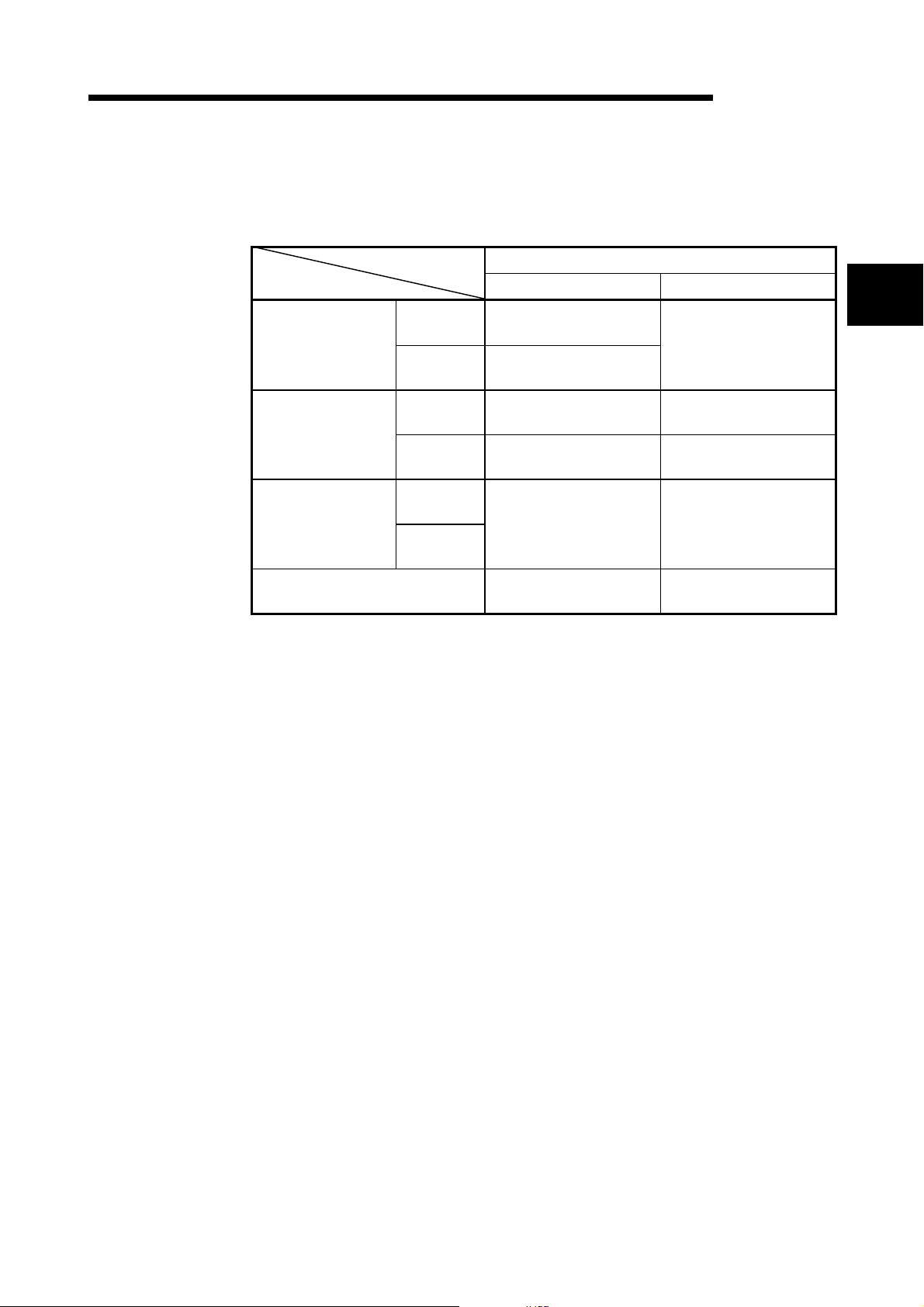

2.2 How to Check Software Version

This section describes how to check the GX Configurator-CT software version.

(1) How to check the GX Configurator-C T software version

The GX Configurator-CT software version can be checked in GX Developer's

"Product information" screen.

[Startup procedure]

GX Developer "Help" Product information

MELSEC-Q

Software version

(In the case of GX Developer Version 7)

REMARK

The version indi cat io n for th e GX Confi gu r ato r -C T has b een chan ge d as show n

below from the SW0D5C-QCTU-E 50F upgrade product.

Previous product Upgrade and subsequent versions

SW0D5C-QCTU-E 50F

GX Configurator-CT Version 1.10L

2 - 3 2 - 3

2 SYSTEM CONFIGURATIONS

2.3 About Use of the QD62 (E/D) with the Q00J/Q00/Q01C PU

Here, use of the QD62 (E/D) with the Q00J/Q00/Q01CPU is explained.

(1) Number of QD62 (E/D) that can be installed when the

Q00J/Q00/Q01CPU is used

See Section 2.1 concerning the number of QD62 (E/D) that can be installed

when the Q00J/Q00/Q01CPU is used.

(2) Limitations when using the Q00J/Q00/Q01CPU

(a) The coincidence detection interrupt function cannot be used.

MELSEC-Q

2 - 4 2 - 4

3 SPECIFICATIONS

3 SPECIFICATIONS

The following describes the performance specifications, I/O signals for the PLC CPU

and buffer memory specifications of the QD62(E/D).

For the general specifications of the QD62(E/D), see the User's Manual (hardware) for

the CPU module use d.

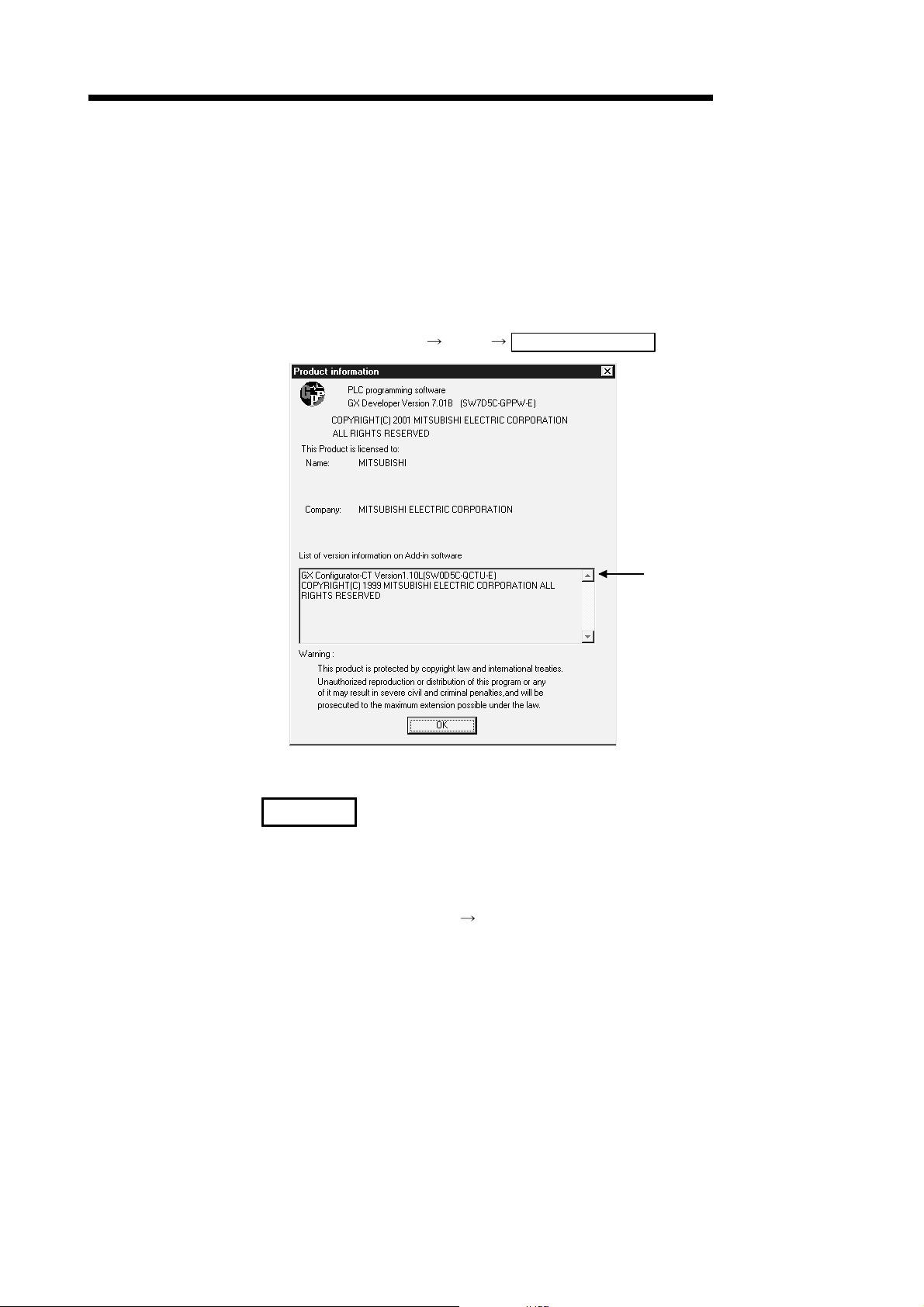

3.1 Performance Specifications

The following describes the performance specifications of the QD62(E/D):

MELSEC-Q

3

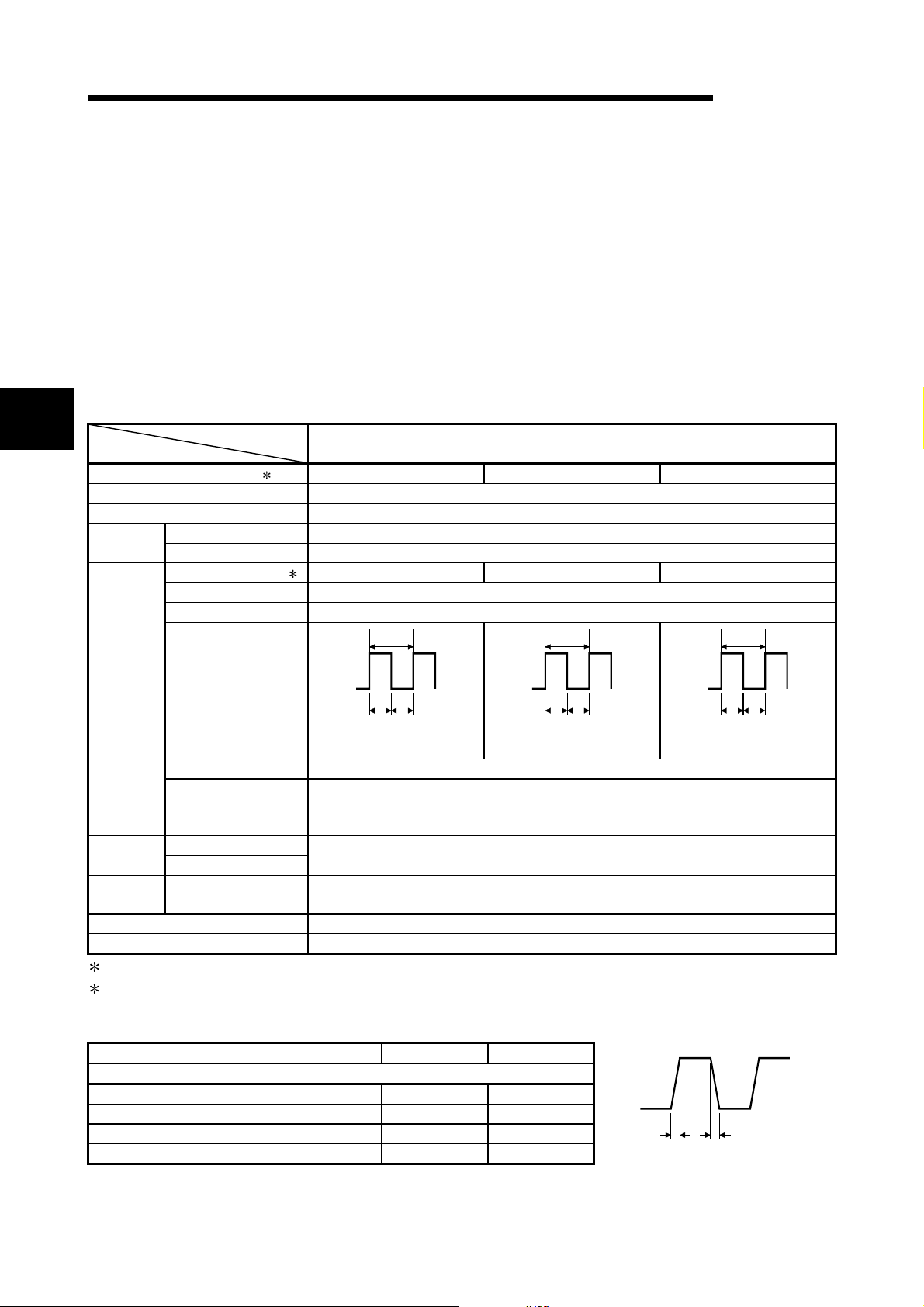

(1) QD62 (DC input sinking output type) performance specifications

Model name

Item

Counting speed switch settings 1 200 k (100 k to 200 kPPS) 100 k (10 k to 100 kPPS) 10 k (10 kPPS or less)

I/O occupied points 16 points (I/O assignment: Intelligent 16 points)

Number of channels 2 channels

Count input

signal

Counter

Coincidence

output

External

input

External

output

5V DC internal current consumption (A) 0.30

Weight (kg) 0.11

Phase 1-phase input, 2-phase input

A,

Signal level (

Counting sp eed ( max) 2 200 kPPS 100 kPPS 10 kPPS

Counting range 32-bit signed binary values (–2147483648 to 2147483647)

Model UP/DOWN Preset counter + Ring counter function

Minimum count pulse

width (µ s)

(Duty ratio 50 %)

Comparison range 32-bit signed binary values

Comparison result

Preset

Function start

Coincidence output

B) 5/12/24 V DC 2 to 5 mA

φ

φ

5

2.5 2.5

(Min. phase differential for

2-phase input: 1.25 µ s)

2 points/channel 12/24 V DC 0.5 A/1 point 2 A/1 common

(Min. phase differential for

Set value < Count value

Set value = Count value

Set value > Count value

Transistor (sinking type) output

1: The counting speed switching can be set using the intelligent function module switch.

2: Counting speed is affected by pulse rise and fall time. Possible counting speeds are shown in the following

table. Note that if a pulse that has a large rise and/or fall time is counted, a miscount may occur.

QD62

10

5 5

2-phase input: 2.5 µ s)

5/12/24 V DC

2 to 5 mA

(Min. phase differential for

2-phase input: 25 µ s)

100

50 50

Counting speed switch settings 200 k 100 k 10 k

Rise/fall time Both 1 and 2 phase input

t = 1.25 µ s or less 200 kPPS 100 kPPS 10 kPPS

t = 2.5 µ s or less 100 kPPS 100 kPPS 10 kPPS

t = 25 µ s or less

t = 500 µ s

—

——

10 kPPS 10 kPPS

500 PPS

tt

3 - 1 3 - 1

3 SPECIFICATIONS

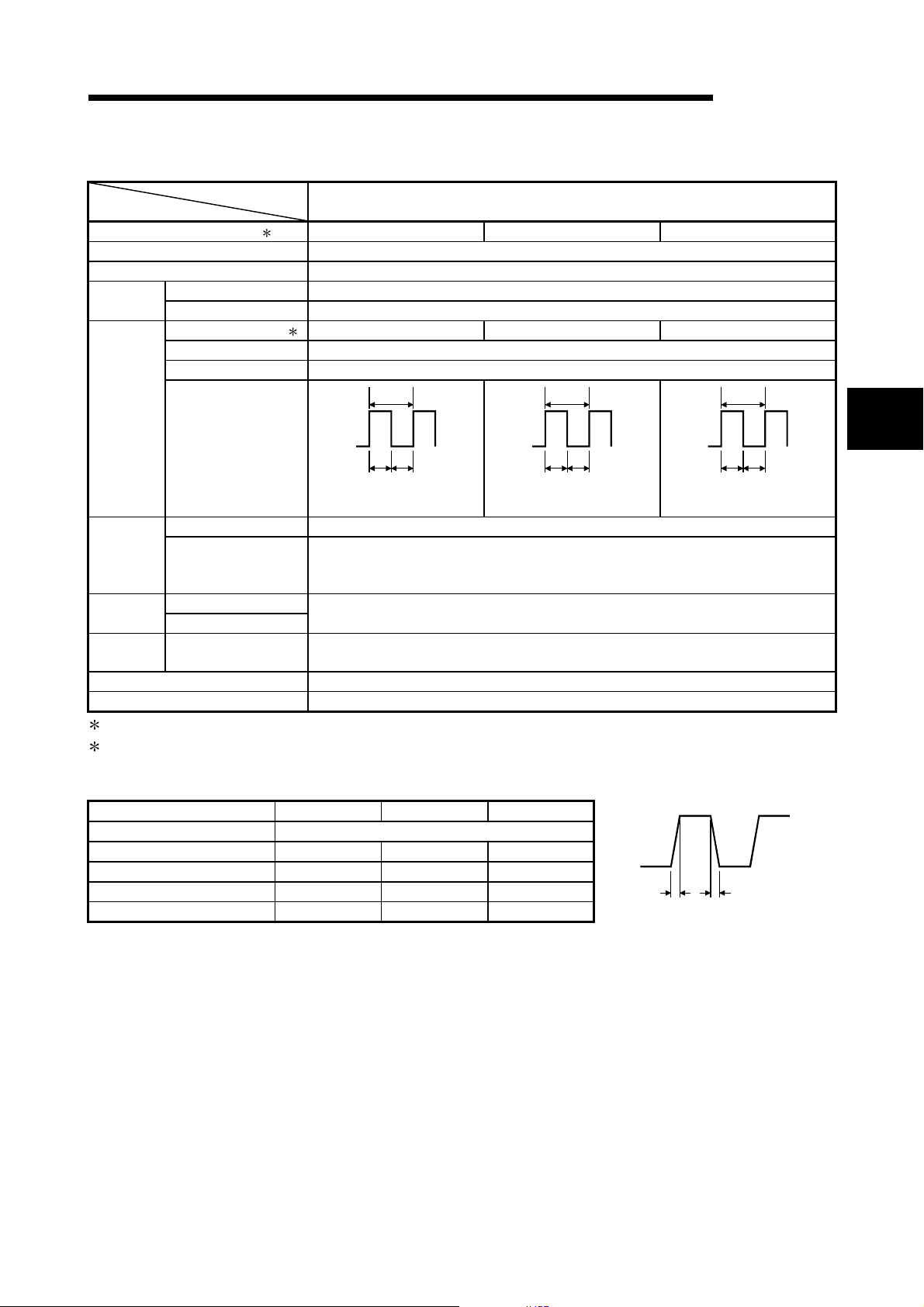

(2) QD62E (DC input sourcing output type) per formance speci fications

MELSEC-Q

Model name

Item

Counting speed switch settings 1 200 k (100 k to 200 kPPS) 100 k (10 k to 100 kPPS) 10 k (10 kPPS or less)

I/O occupied points 16 points (I/O assignment: Intelligent 16 points)

Number of channels 2 channels

Count input

signal

Counter

Coincidence

output

External

input

External

output

5V DC internal current consumption (A) 0.33

Weight (kg) 0.11

Phase 1-phase input, 2-phase input

A,

Signal level (

Counting sp eed ( max) 2 200 kPPS 100 kPPS 10 kPPS

Counting range 32-bit signed binary values (–2147483648 to 2147483647)

Model UP/DOWN Preset counter + Ring counter function

Minimum count pulse

width (µ s)

(Duty ratio 50 %)

Comparison range 32-bit signed binary values

Comparison result

Preset

Function start

Coincidence output

B) 5/12/24 V DC 2 to 5 mA

φ

φ

5

2.5 2.5

(Min. phase differential for

2-phase input: 1.25 µ s)

Transistor (sourcing type) output : 2 points/channel

12/24 V DC 0.1 A/1 point 0.4 A/1 common

(Min. phase differential for

QD62E

10

5 5

2-phase input: 2.5 µ s)

Set value < Count value

Set value = Count value

Set value > Count value

5/12/24 V DC

2 to 5 mA

100

50 50

(Min. phase differential for

2-phase input: 25 µ s)

1: The counting spee d sw it chi ng can be se t u si ng th e in t elli ge nt fu nc tion modu le swi t ch.

2: Counting speed is affected by pulse rise and fall time. Possible counting speeds are shown in the following

table. Note that if a pulse that has a large rise and/or fall time is counted, a miscount may occur.

3

Counting speed switch settings 200 k 100 k 10 k

Rise/fall time Both 1 and 2 phase input

t = 1.25 µ s or less 200 kPPS 100 kPPS 10 kPPS

t = 2.5 µ s or less 100 kPPS 100 kPPS 10 kPPS

t = 25 µ s or less

t = 500 µ s

—

——

10 kPPS 10 kPPS

500 PPS

tt

3 - 2 3 - 2

3 SPECIFICATIONS

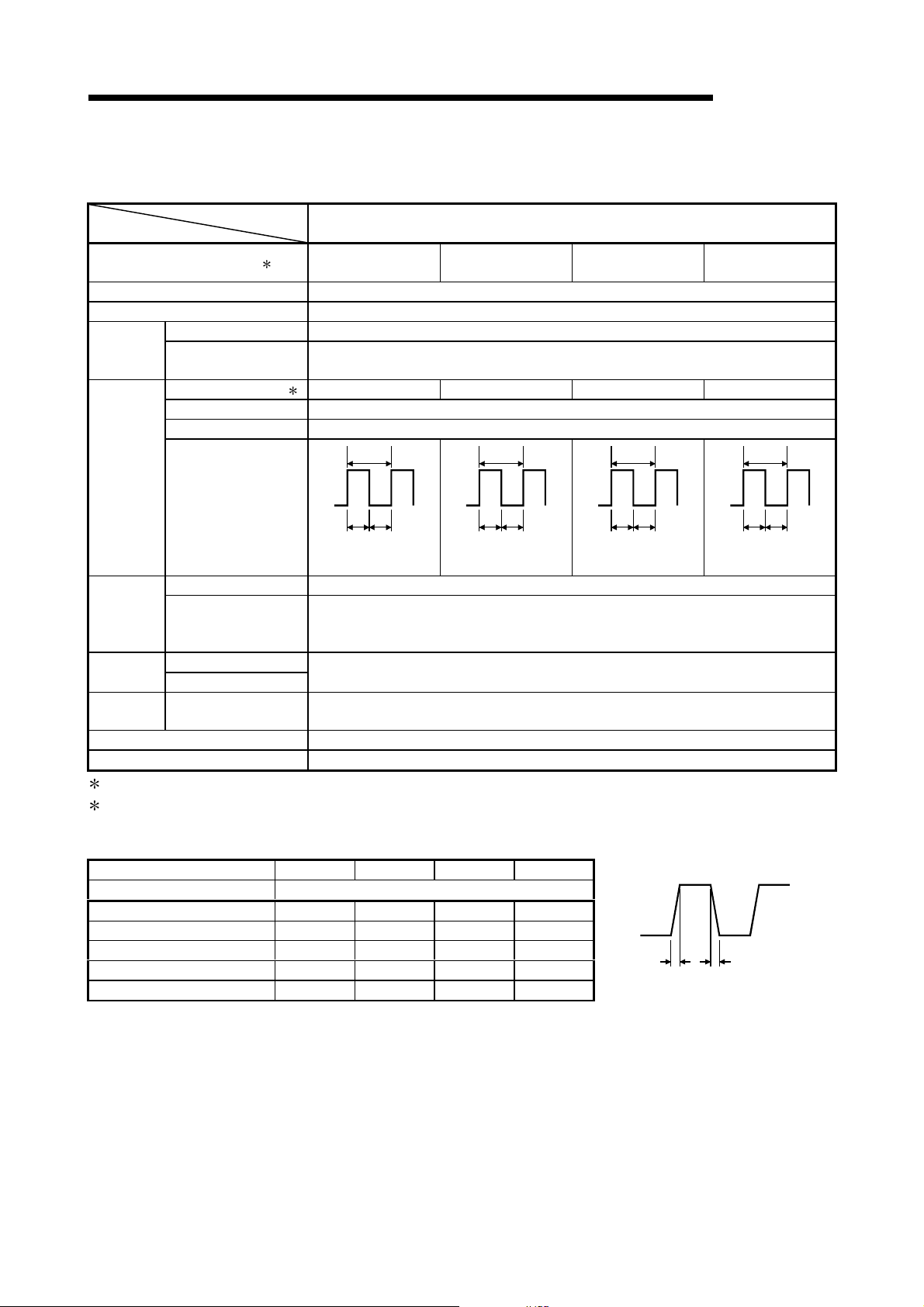

(3) QD62D (differential input sinking output ty pe) per formance

MELSEC-Q

specifications

Model name

Item

Counting speed switch settings 1

I/O occupied points 16 points (I/O assignment: Intelligent 16 points)

Number of channels 2 channels

Count input

signal

Counter

Coincidence

output

External

input

External

output

5 V DC internal current consumption (A) 0.38

Weight (kg) 0.12

Phase 1-phase input, 2-phase input

A,

Signal level (

Counting sp eed ( max) 2 500 kPPS 200 kPPS 100 kPPS 10 kPPS

Counting range 32-bit signed binary values (–2147483648 to 2147483647)

Model UP/DOWN Preset counter + Ring counter function

Minimum count pulse

width (µ s)

(Duty ratio 50 %)

Comparison range 32-bit signed binary values

Comparison result

Preset

Function start

Coincidence output

B)

φ

φ

(Min. phase differential for

500 k

(200 k to 500 kPPS)

Differential line driver level (Am26LS31 [manufactured by Texas Instruments] or equivalent)

2

1 1

(Min. phase differential for

2-phase input: 0.5 µ s)

(EIA Standard RS-422-A Differential Line Driver may be connected)

Transistor (sinking type) output 2 points/channel

200 k

(100 k to 200 kPPS)

5

2.5 2.5

2-phase input: 1.25 µ s)

5/12/24 V DC 2 to 5 mA

12/24 V DC 0.5 A/1 point 2 A/1 common

QD62D

100 k

(10 k to 100 kPPS)

EIA Standard RS-422-A

5 5

(Min. phase differential for

2-phase input: 2.5 µ s)

Set value < Count value

Set value = Count value

Set value > Count value

10

10 k

(10 kPPS or less)

100

50 50

(Min. phase differential for

2-phase input: 25 µ s)

1: The counting speed switching can be set using the intelligent function module switch.

2: Counting speed is affected by pulse rise and fall time. Possible counting speeds are shown in the following

table. Note that if a pulse that has a large rise and/or fall time is counted, a miscount may occur.

Counting speed switch settings 500 k 200 k 100 k 10 k

Rise/fall time Both 1 and 2 phase input

t = 0.5 µ s or less 500 kPPS 200 kPPS 100 kPPS 10 kPPS

t = 1.25 µ s or less 200 kPPS 200 kPPS 100 kPPS 10 kPPS

t = 2.5 µ s or less

t = 25 µ s or less

t = 500 µ s

—

——

———

100 kPPS 100 kPPS 10 kPPS

10 kPPS 10 kPPS

500 PPS

tt

3 - 3 3 - 3

3 SPECIFICATIONS

MELSEC-Q

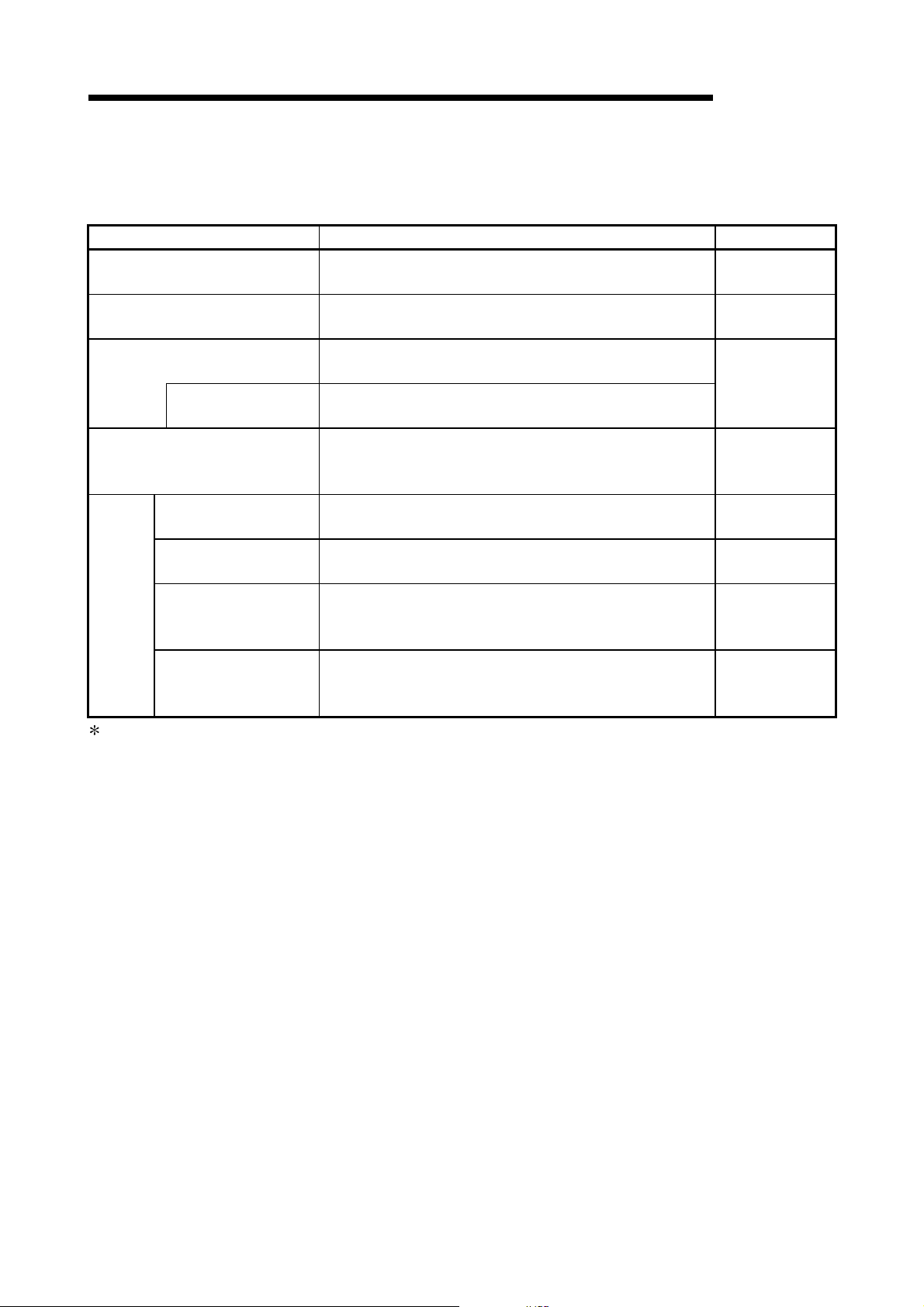

3.2 Function List

The QD62(E/D) func ti on s a re li st ed below.

Name Function Reference section

Linear counter function

Ring counter function

Coincidence output function

Coincidence detection

interrupt function

Preset function

Disable count function

Latch counter function

Counter

function

selection

Sampling counter function

Periodic pulse counter

function

The functions can be used in combination. However, only either one of the linear counter function or ring

counter function can be used, and only one of the four counter functions can be selected.

Values from –2147483648 to 2147483647 can be counted. If the

count exceeds the range, this function detects an overflow.

Repeatedly executes counting between the ring counter

maximum and minimum values.

Compares the coincidence output point of any preset channel

with the present counter value, and outputs the ON/OFF signal.

Generates an interrupt signal to the PLC CPU when coincidence

is detected, and starts the interrupt program.

Rewrites the present counter value to any numeric value.

Performs preset using the sequence program or external preset

input.

Stops the pulse count while the count enable command is being

executed.

Stores the present counter value at the time the counter function

selection start command signal is input in the buffer me mory .

Counts the pulses that are input during the preset sampling time

period from the time the counter function selection start

command is input, and stores the count in the buffer memory.

While the counter function selection start command sign al is

being input, stores the present value in the buffer memory at

preset interval.

Section 5.2.1

Section 5.2.2

Section 5.3

Section 5.4

Section 6.2

Section 6.3

Section 6.4

Section 6.5

3 - 4 3 - 4

3 SPECIFICATIONS

MELSEC-Q

3.3 I/O Signals for the PLC CPU

3.3.1 List of I/O signals

The I/O signals for the QD62(E/D) PLC CPU are listed in the table below.

For the I/O numbers (X/Y) and I/O addresses indicated in this and succeeding

sections, it is assumed that the QD62(E/D) is mounted into I/O slot 0 of the standard

base module.

Input signal (Signal direction QD62(E/D) PLC CPU) Output signal (Signal direction PLC CPU QD62(E/D))

Device No. Signal name Device No. Signal name

X00 Module ready Y00 Coincidence signal No. 1 reset command

X01 Counter value large (point No. 1) Y01 Preset command

X02 Counter value coincidence (point No. 1) Y02 Coincidence signal enable command

X03 Counter v alue small (point N o. 1) Y03 Down count command

X04 External preset request detection Y04 Count enable command

X05 Counter value large (point No. 2) Y05 External preset detection reset command

X06 Counter value coincidence (point No. 2) Y06 Counter function selection start command

X07

X08 Counter value large (point No. 1) Y08 Coincidence signal No. 1 reset command

X09 Counter value coincidence (point No. 1) Y09 Preset command

X0A Counter value small (point No. 1) Y0A Coincidence signal enable command

X0B External preset request detection Y0B Down count command

X0C Counter value large (point No. 2) Y0C C ount enable co mmand

X0D Counter value coincidence (point No. 2) Y0D External preset detection reset command

X0E

X0F Fuse broken detection flag Y0F

CH1

Counter value small (point No. 2) Y07

CH2

Counter value small (point No. 2) Y0E Counter function selection start command

CH1

Coincidence signal No. 2 reset command

CH2

Coincidence signal No. 2 reset command

3 - 5 3 - 5

3 SPECIFICATIONS

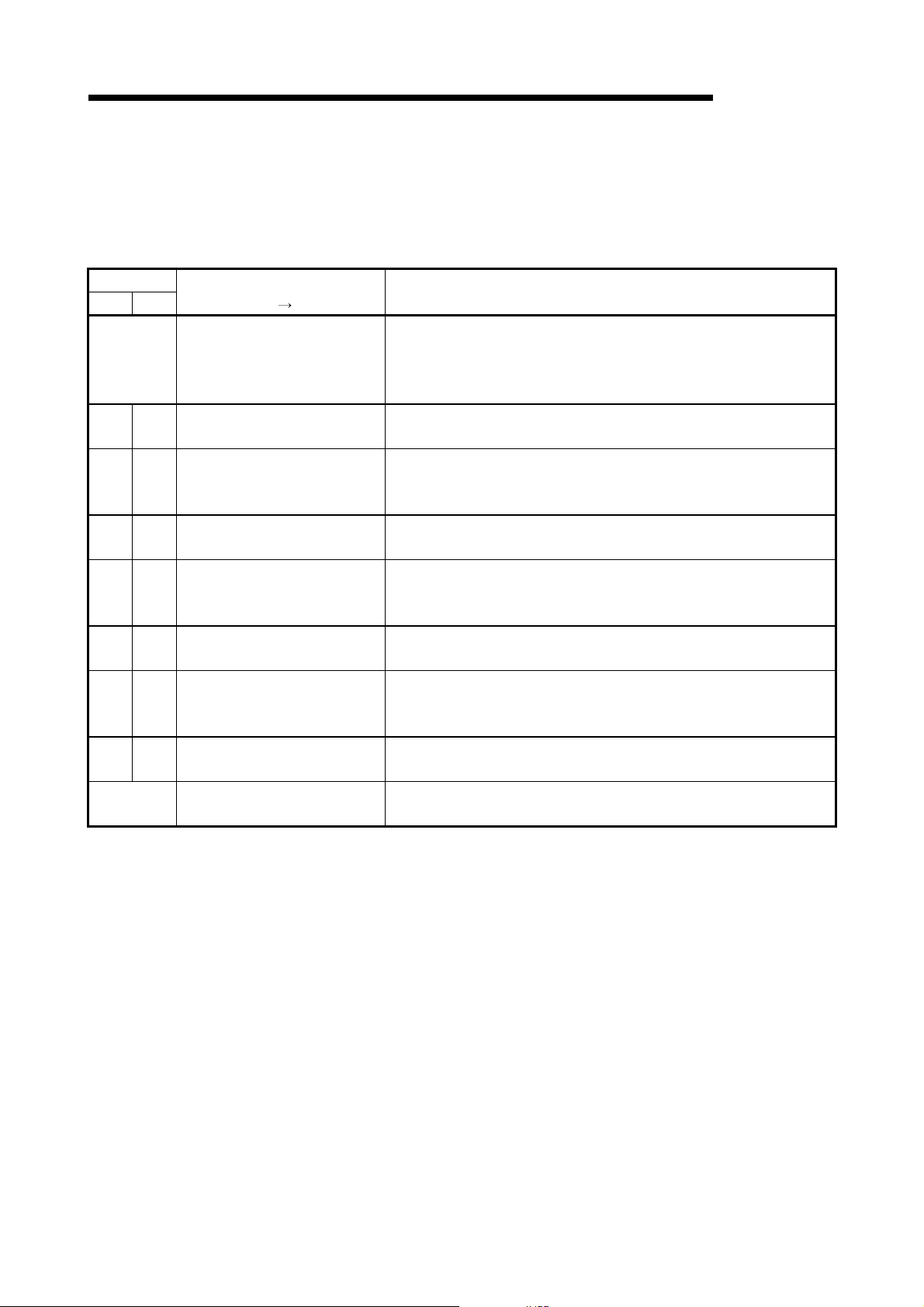

3.3.2 Functions of I/O signals

The details of the I/O signals for the QD62(E/D) are listed in the table below.

(1) Input signals

MELSEC-Q

Device No.

CH1 CH2

X00 Module ready

X01 X08

X02 X09

X03 X0A

X04 X0B External preset request detection

X05 X0C

X06 X0D

X07 X0E

X0F Fuse broken detection flag

Counter value large

(point No. 1)

Counter value coincidence

(point No. 1)

Counter value small

(point No. 1)

Counter value large

(point No. 2)

Counter value coincidence

(point No. 2)

Counter value small

(point No. 2)

Signal name

QD62(E/D) PLC CPU

Description

Turns ON when the count preparation for QD62(E/D) is completed at the

time of PLC CPU power on or reset operation, and count processing is

performed.

When Module ready (X00) is OFF, count processing is not performed.

H

Turns ON when the present value (CH1: 2

coincidence output point No. 1 setting (CH1: 4H to 5H, CH2: 24H to 25H).

Turns ON when the present value = coincidence output point No. 1

setting and the present value is latched.

Turns OFF with the coincidence signal No. 1 reset command (Y 00/Y 08).

Turns ON when the present value < coincidence output point No. 1

setting.

Turns ON with a preset command signal from the external input termina l,

and the request is latched.

Turns OFF with the external preset detection reset signal (Y05/Y 0D).

Turns ON when the present value > coincidence output point No. 2

H

setting (CH1: 6

Turns ON when the present value = coincidence output point No. 2

setting and the present value is latched.

Turns OFF with the coincidence signal No. 2 reset command (Y 07/Y 0F).

Turns ON when the present value < coincidence output point No. 2

setting.

Fuse broken detection flag (X0F) turns ON when a fuse in the

coincidence signal output section is blow n.

to 7H, CH2: 26H to 27H).

to 3H, CH2: 22H to 23H) >

3 - 6 3 - 6

3 SPECIFICATIONS

(2) Output signals

MELSEC-Q

Device No.

CH1 CH2

Y00 Y08

Y01 Y09 Preset command Turns ON when the preset function is executed.

Y02 Y0A

Y03 Y0B Down count command

Y04 Y0C C ount enable co mmand Turns ON when the count operation is performed.

Y05 Y0D

Y06 Y0E

Y07 Y0F

Coincidence signal No. 1 reset

command

Coincidence signal enable

command

External preset detection reset

command

Counter function selection start

command

Coincidence signal No. 2 reset

command

Signal name

PLC CPU

QD62 (E/D)

Operation timing Description

Turns ON when the counter value coincidence (point

No. 1) signal (X02/X09) is reset.

Turns ON when the counter value coincidence signal

(X02/X09, X06/X0D) is output to the external terminal.

Turns ON when a subtraction count is executed in the

1 phase pulse input mode.

Turns ON when the external preset request detection

signal (X04/X0B) is reset.

Turns ON when counter function selection is

executed.

• Latch counter function

• Sampling counter function

• Count disable function

• Periodic pulse counter function

Turns ON when the counter value coincidence (point

No. 2) signal (X06/X0D) is reset.

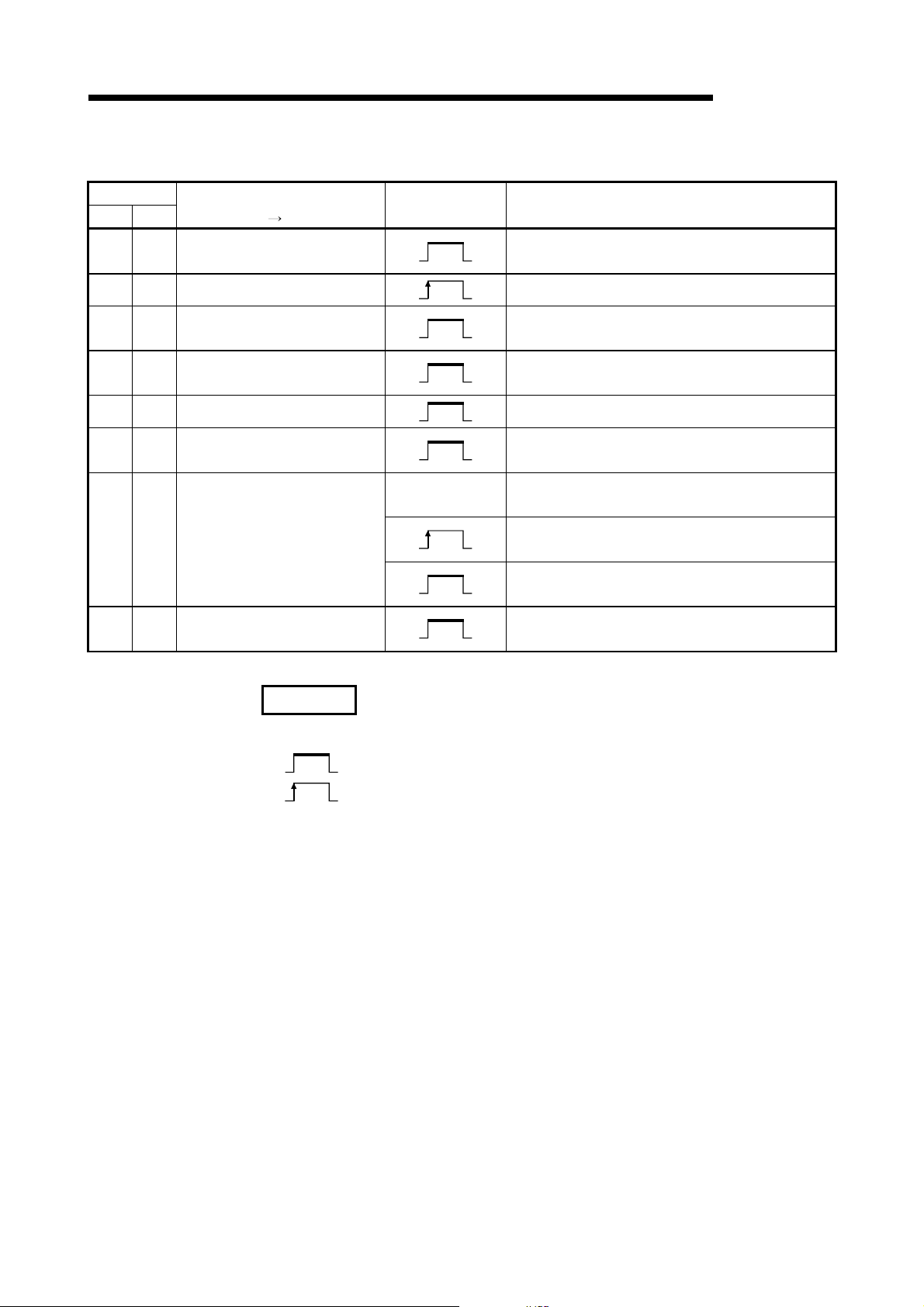

REMARK

The symbols used in the operation timing column signify the following:

………

•

•

Enabled while the signal is in ON status.

………

Enabled at signal ri se (fro m OFF to ON).

3 - 7 3 - 7

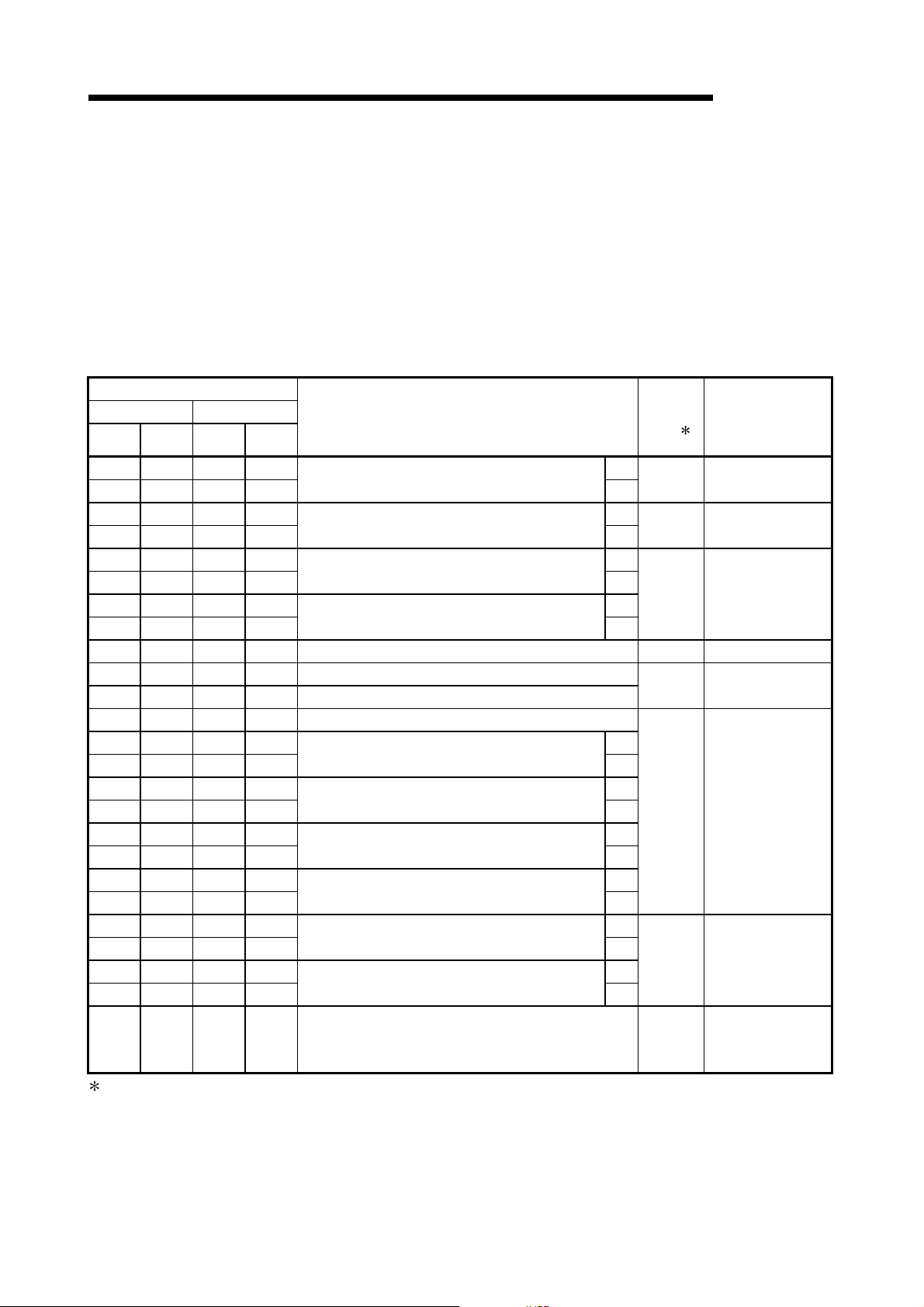

3 SPECIFICATIONS

3.4 Buffer Memory Assignments (1) Buffer memory assignment list

Buffer memory assignments (without battery backup) for the QD62 (E/D) are

listed in the table below.

The initial values are set for the buffer memory when the power is turned on or

the PLC CPU is re s e t.

The contents of the buffer memory can be read/written using the FROM/TO

commands in the sequence program or the automatic refresh function of the PLC

CPU.

Address

CH1 CH2

Hexade-

cimal

H

0

H

1

H

2

H

3

H

4

H

5

H

6

H

7

H

8

H

9

H

A

H

B

H

C

H

D

H

E

H

F

H

10

H

11

H

12

H

13

H

14

H

15

H

16

H

17

H

18

to

H

1F

Decimal

Hexade-

020H32 (L)

121H33

222H34 (L)

323H35

424H36 (L)

525H37

626H38 (L)

727H39

cimal

Decimal

Preset value setting

Present value

Coincidence output point set No. 1

Coincidence output point set No. 2

828H40 Overflow detection flag 0 Read only

929H41 Counter function selection setting

38

3F

H

42 Sampling/periodic setting

H

43 Sampling/periodic counter flag

H

44 (L)

H

H

H

H

H

H

H

H

H

H

H

H

to

H

Latch count value

45

46 (L)

Sampling count value

47

48 (L)

Periodic pulse count previous value

49

50 (L)

Periodic pulse count present value

51

52 (L)

Ring counter minimum value

53

54 (L)

Ring counter maximum value

55

56

System area — —

to

63

10 2A

11 2B

12 2C

13 2D

14 2E

15 2F

16 30

17 31

18 32

19 33

20 34

21 35

22 36

23 37

24

to

31

1: The initial v alu es are set w hen th e powe r is tu rned on or th e PLC CPU is reset.

Set data

(H)

(H)

(H)

(H)

(H)

(H)

(H)

(H)

(H)

(H)

MELSEC-Q

Initial

value

0 Read/w r ite enabled

0 R ead only

0 Read/w r ite enabled

0 Read/w r ite enabled

0 R ead only

0 Read/w r ite enabled

1

Read/write

3 - 8 3 - 8

3 SPECIFICATIONS

(2) Preset value setting (Buffer memory addr esses CH 1: 0H to1 H,

MELSEC-Q

CH2: 20H to 21H)

• This area is used to set the values that are preset in the counter.

• The setting range is from –2147483648 to 2147483647 (32-bit signed binary

values).

(3) Present value (Buffer memory addresses C H 1: 2H to 3H, CH2: 22

to 23H)

• The present values for the counter are stored.

• The range of the values that are read is from –2147483648 to 2147483647

(32-bit signed binary values).

(4) Coincidence output point set No. 1 and No. 2

(Buffer memory addresses CH1: 4H to 7H, CH2: 24H to 27H)

• This area is used to write the setting values of the coincidence output points to

be compared with the present counter value.

• No. 1 and No.2 coincidence output points can be set for each channel.

• The setting range is from –2147483648 to 2147483647 (32-bit signed binary

value).

(5) Overflow detec tio n fl ag (Bu ffer mem ory add ress es CH1 : 8H, CH2:

28H)

• A counter overflow occurrence status is stored when the counter format is

linear counter.

• The following values corresponding to the overflow occurrence status are

stored in this area.

Condition Buffer memory content

No overflow detection 0

Overflow occurred 1

H

(6) Counter function selection setting (Buffer memory addresses CH1:

9H, CH2: 29H)

• This area is used to set the data for which a counter function is selected.

• The relationships between the selected counter function and set value are

shown below.

Counter function selection Set value

Count disable function 0

Latch counter function 1

Sampling counter function 2

Periodic pulse counter function 3

3 - 9 3 - 9

3 SPECIFICATIONS

(7) Sampling/periodic setting (Buffer memory addresses CH1: AH,

(8) Sampling/periodic counter flag (Buffer memory addresses CH1: BH,

MELSEC-Q

CH2: 2AH)

• This area is used to write the time setting values of the sampling counter

function and periodic pulse counter function during counter function selection.

• The setting range is from 1 to 65535 (16-bit binary values) and the time unit is

10[ms].

Example) When 420 is set for the sampling/periodic setting in the buffer

memory

420

10= 4200 [ms]

CH2: 2BH)

• This area is used to store the function operating status while the sampling

counter function and periodic pulse counter function are being executed during

counter function selection.

• One of the values cor re sp ondi ng to the fu n ctio n ope rat i o n st at us show n in th e

table below is stored in this area.

Operating status Buffer memory content

Idling function 0

Executing function 1

(9) Latch count value (Buffer memory addr esses CH 1: CH to DH,

CH2: 2CH to 2DH)

• This area is used to store the latch count values when the latch counter

function is executed.

• The range of the values to be read is from –2147483648 to 2147483647 (32-bit

signed binary value s) .

(10) Sampling count value (Buffer memory addresses CH1: EH to FH,

CH2: 2EH to 2FH)

• This area is used to store the sampling count values when the sampling

counter function is executed.

• The range of the values to be read is from –2147483648 to 2147483647 (32-bit

signed binary value s) .

(11) Periodic pulse count previous and present value

(Buffer memory addresses CH1: 10H to 13H, CH2: 30H to 33H)

• This area is used to store the present and previous values for the periodic

pulse count when the periodic pulse counter function is executed.

• The range of the values to be read is from –2147483648 to 2147483647 (32-bit

signed binary value s) .

(12) Ring counter minimum and maximum value

(Buffer memory addresses CH1: 14

• This area is used to set the count range when the counter format is ring counter.

• The setting range is from –2147483648 to 2147483647 (32-bit signed binary

values).

3 - 10 3 - 10

to 17H, CH2: 34H to 37H)

H

3 SPECIFICATIONS

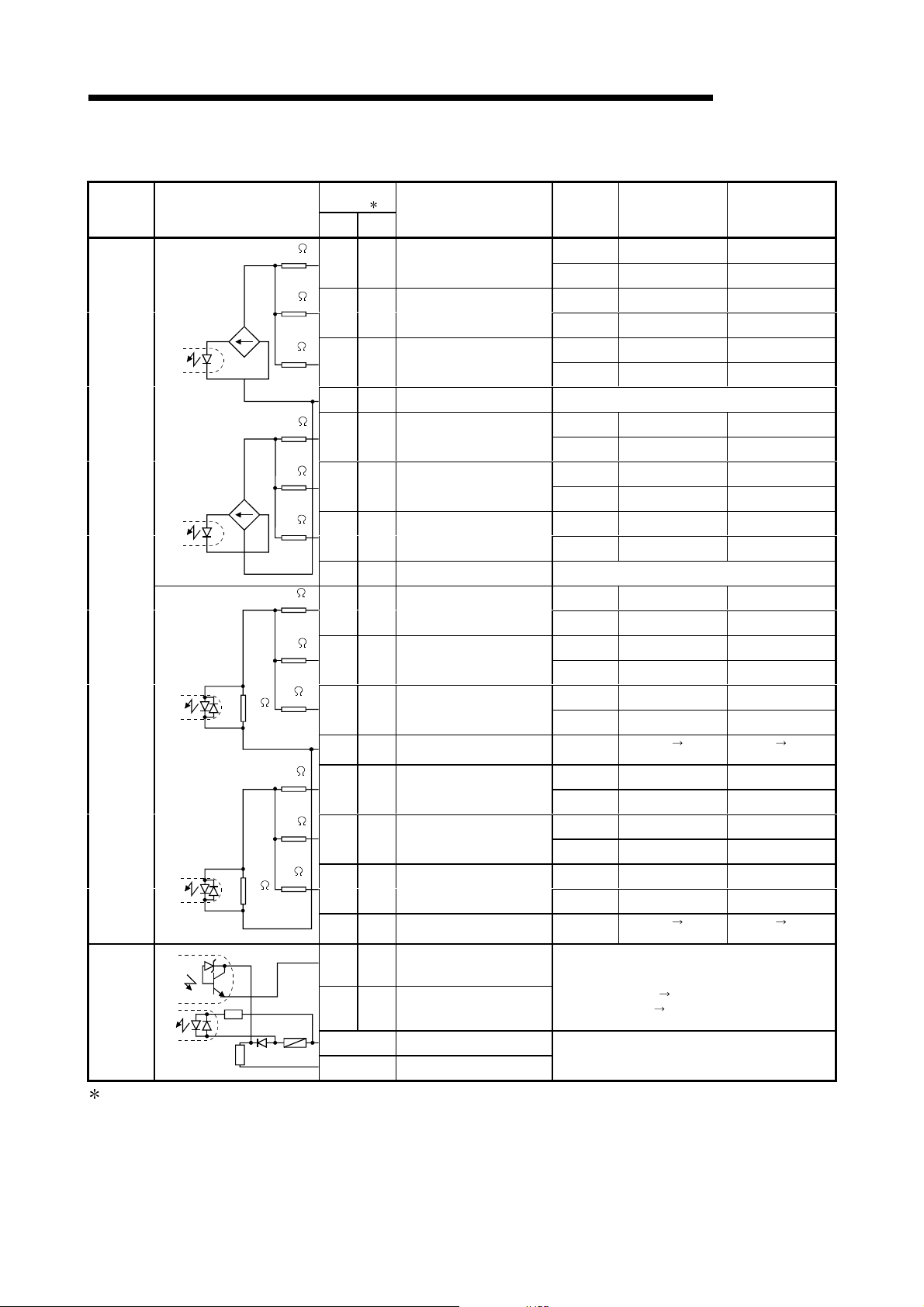

3.5 Interface with External Devices

The table below lists the external device interface for the QD62(E/D).

(1) QD62 (DC input sinking output type)

I/O

classification

Input

Output

Internal circuit

To the fuse

broken detection

circuit

1k

1/10W

1k

1/10W

4.7k

1/3W

3.3k

1/10W

470

1/16W

4.7k

1/3W

3.3k

1/10W

470

1/16W

10k

1/3W

5.6k

1/10W

2k

1/10W

10k

1/3W

5.6k

1/10W

2k

1/10W

FUSE

1: Terminal nu mbe rs A0 3, A04 , B03 an d B0 4 a re no t u sed .

Terminal

number

CH1 CH2

A20 A13 Phase A pulse input 24 V

B20 B13 Phase A pulse input 12 V

A19 A12 Phase A pulse input 5 V

B19 B12 ABCOM —

A18 A11 Phase B pulse input 24 V

B18 B11 Phase B pulse input 12 V

A17 A10 Phase B pulse input 5 V

—— — —

B17 B10 Preset input 24 V

A16 A09 Preset input 12 V

B16 B09 Preset input 5 V

A15 B08 CTRLCOM

B15 B08 Function start input 24 V

A14 A07 Function start input 12 V

B14 B07 Function start input 5 V

—— —

A06 A05

B06 B05

1

EQU1

(Coincidenc e ou tput poi nt No. 1)

EQU2

(Coincidenc e ou tput poi nt No. 2)

B02, B01 12/24 V

A02, A01 0 V

Signal name Operation

MELSEC-Q

Input voltage

(guaranteed va lu e)

When ON 21.6 to 26.4 V 2 to 5 mA

When OFF 5 V or less 0.1 mA or less

When ON 10.8 to 13.2 V 2 to 5 mA

When OFF 4 V or less 0.1 mA or less

When ON 4.5 to 5.5 V 2 to 5 mA

When OFF 2 V or less 0.1 mA or less

When ON 21.6 to 26.4 V 2 to 5 mA

When OFF 5 V or less 0.1 mA or less

When ON 10.8 to 13.2 V 2 to 5 mA

When OFF 4 V or less 0.1 mA or less

When ON 4.5 to 5.5 V 2 to 5 mA

When OFF 2 V or less 0.1 mA or less

When ON 21.6 to 26.4 V 2 to 5 mA

When OFF 5 V or less 0.1 mA or less

When ON 10.8 to 13.2 V 2 to 5 mA

When OFF 4 V or less 0.1 mA or less

When ON 4.5 to 5.5 V 2 to 5 mA

When OFF 2 V or less 0.1 mA or less

Response

time

When ON 21.6 to 26.4 V 2 to 5 mA

When OFF 5 V or less 0.1 mA or less

When ON 10.8 to 13.2 V 2 to 5 mA

When OFF 4 V or less 0.1 mA or less

When ON 4.5 to 5.5 V 2 to 5 mA

When OFF 2 V or less 0.1 mA or less

Response

time

Operating voltage 10.2 to 30 V

Maximum load current 0.5 A/point, 2 A/1 common

Maximum voltage drop when ON 1.5 V

Response ti me OFF

ON

Input voltage 10.2 to 30 V

Current consumption 8 mA (TYP 24 V DC)

ON

OFF

0.5 ms or less

ON

OFF

0.5 ms or less

ON 0.1 ms or less

OFF 0.1 ms or less (rated loa d,

Operating current

(guaranteed va lu e)

ON OFF

1 ms or less

ON OFF

1 ms or less

resistive load)

3 - 11 3 - 11

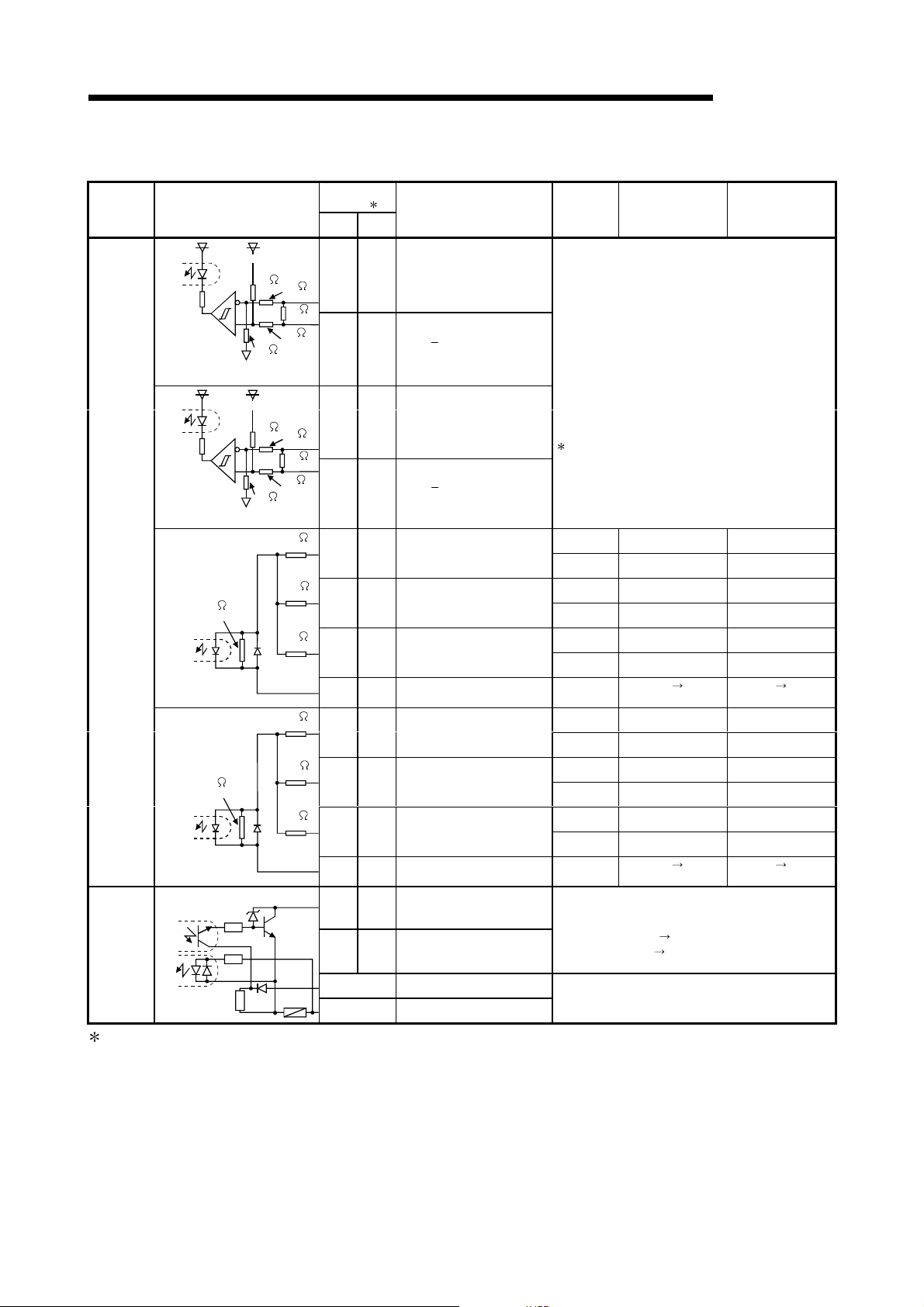

3 SPECIFICATIONS

(2) QD62E (DC input sourcing output type)

I/O

classification

Input

Internal circuit

1k

1/10W

1k

1/10W

4.7k

1/3W

3.3k

1/10W

470

1/16W

4.7k

1/3W

3.3k

1/10W

470

1/16W

10k

1/3W

5.6k

1/10W

2k

1/10W

10k

1/3W

5.6k

1/10W

2k

1/10W

Output

To the fuse

broken detection

circuit

FUSE

1: Terminal nu mbe rs A0 3, A04 , B03 an d B0 4 a re no t u sed .

Terminal

number

1

Signal name Operation

CH1 CH2

A20 A13 Phase A pulse input 24 V

B20 B13 Phase A pulse input 12 V

A19 A12 Phase A pulse input 5 V

B19 B12 ABCOM —

A18 A11 Phase B pulse input 24 V

B18 B11 Phase B pulse input 12 V

A17 A10 Phase B pulse input 5 V

—— — —

B17 B10 Preset input 24 V

A16 A09 Preset input 12 V

B16 B09 Preset input 5 V

A15 B08 CTRLCOM

B15 B08 Function start input 24 V

A14 A07 Function start input 12 V

B14 B07 Function start input 5 V

—— —

A06 A05

B06 B05

EQU1

(Coincidenc e ou tput poi nt No. 1)

EQU2

(Coincidenc e ou tput poi nt No. 2)

B02, B01 12/24 V

A02, A01 0 V

MELSEC-Q

Input voltage

(guaranteed va lu e)

When ON 21.6 to 26.4 V 2 to 5 mA

When OFF 5 V or less 0.1 mA or less

When ON 10.8 to 13.2 V 2 to 5 mA

When OFF 4 V or less 0.1 mA or less

When ON 4.5 to 5.5 V 2 to 5 mA

When OFF 2 V or less 0.1 mA or less

When ON 21.6 to 26.4 V 2 to 5 mA

When OFF 5 V or less 0.1 mA or less

When ON 10.8 to 13.2 V 2 to 5 mA

When OFF 4 V or less 0.1 mA or less

When ON 4.5 to 5.5 V 2 to 5 mA

When OFF 2 V or less 0.1 mA or less

When ON 21.6 to 26.4 V 2 to 5 mA

When OFF 5 V or less 0.1 mA or less

When ON 10.8 to 13.2 V 2 to 5 mA

When OFF 4 V or less 0.1 mA or less

When ON 4.5 to 5.5 V 2 to 5 mA

When OFF 2 V or less 0.1 mA or less

Response

time

ON

OFF

0.5 ms or less

When ON 21.6 to 26.4 V 2 to 5 mA

When OFF 5 V or less 0.1 mA or less

When ON 10.8 to 13.2 V 2 to 5 mA

When OFF 4 V or less 0.1 mA or less

When ON 4.5 to 5.5 V 2 to 5 mA

When OFF 2 V or less 0.1 mA or less

Response

time

ON

OFF

0.5 ms or less

Operating voltage 10.2 to 30 V

Maximum load current 0.1 A/point, 0.4 A/1 common

Maximum voltage drop when ON 1.5 V

Response ti me OFF

ON 0.3 ms or less

ON

OFF 0.3 ms or less (rated loa d,

Input voltage 10.2 to 30 V

Current consumption 8 mA (TYP 24 V DC)

Operating current

(guaranteed va lu e)

ON OFF

1 ms or less

ON OFF

1 ms or less

resistive load)

3 - 12 3 - 12

3 SPECIFICATIONS

(3) QD62D (Differential input sinking output type)

I/O

classification

Internal circuit

+ 5V

(DC/DC converter)

Line

receiver

1/16W

+ 5V

(DC/DC converter)

Line

receiver

1/16W

27k

1/16W

27k

27k

1/16W

27k

Terminal

number

1

CH1 CH2

A20 A14 Phase A pulse input

4.7k

1/16W

100

1/2W

4.7k

1/16W

B20 B14 Phase A pulse input

A19 A13 Phase B pulse input

4.7k

1/16W

100

1/2W

4.7k

1/16W

A19 B13 Phase B pulse input

Signal name Operation

Line driver lev e l (A m26L S31 [ manu fa c tur ed by Texa s

Instruments ] or equ iva le nt ) th at co nf or ms to RS- 422 - A in

EIA Standard

EIA standard R S-42 2- A line dri ver l ev e l

Equivalent to Am26LS31 (made by Japan Texas

Instruments, Inc.)

V

Hysteresis (VT+ - VT-) 60 mV

hys

V

"H" level enable in put vo l ta ge : 2 V or high er

IH(E)

V

"L" level enable input voltage: 0.8 V or lower

IL(E)

A current type li ne drive r ca nn ot be us e d.

Input voltage

(guaranteed va lu e)

MELSEC-Q

Operating current

(guaranteed va lu e)

Input

Output

1k

1/10W

1k

1/10W

To the fuse

broken detection

circuit

10k

1/3W

A18 A12 Preset input 24 V

5.6k

1/10W

B18 B12 Preset input 12 V

680

1/10W

A17 A11 Preset input 5 V

B17 B11 PRSTCOM

10k

1/3W

A16 A10 Function start input 24 V

5.6k

1/10W

B16 B10 Function start input 12 V

680

1/10W

A15 A09 Function start input 5 V

B15 B09 FUNCCOM

A06 A05

B06 B05

EQU1

(Coincidenc e ou tput poi nt No. 1)

EQU2

(Coincidenc e ou tput poi nt No. 2)

B02, B01 12/24 V

FUSE

A02, A01 0 V

When ON 21.6 to 26.4 V 2 to 5 mA

When OFF 5 V or less 0.1 mA or less

When ON 10.8 to 13.2 V 2 to 5 mA

When OFF 4 V or less 0.1 mA or less

When ON 2.5 to 5.5 V 2 to 5 mA

When OFF 1 V or less 0.1 mA or less

Response

time

ON

OFF

0.5 ms or less

ON OFF

1 ms or less

When ON 21.6 to 26.4 V 2 to 5 mA

When OFF 5 V or less 0.1 mA or less

When ON 10.8 to 13.2 V 2 to 5 mA

When OFF 4 V or less 0.1 mA or less

When ON 2.5 to 5.5 V 2 to 5 mA

When OFF 1 V or less 0.1 mA or less

Response

time

ON

OFF

0.5 ms or less

ON OFF

1 ms or less

Operating voltage 10.2 to 30 V

Maximum load current 0.5 A/point, 2 A/1 common

Maximum voltage drop when ON 1.5 V

Response ti me OFF

ON 0.1 ms or less

OFF 0.1 ms or less (rated loa d,

ON

resistive load)

Input voltage 10.2 to 30 V

Current consumption 8 mA (TYP 24 V DC)

1: Terminal numbers A08, A07, A03, A04, B08, B07, B04 and B03 are not used.

3 - 13 3 - 13

3 SPECIFICATIONS

3.6 Encoders that can be Connected

The encoders that can be connected to the QD62(E/D) are described below.

(1) Encoders that can be connected to the QD62 and QD 62E

• Open collector ou tp ut ty pe en co de rs

• CMOS level voltage output type encoders

(Verify that the encoder output voltage meets the specifications for the QD62

and QD62E.)

(2) Encoders that can be connected to the QD62D

• Line driver output type encoders

(Verify that the encoder output voltage meets the specifications for the

QD62D.)

POINT

The following encoders cannot be used with the QD62(E/D).

• TTL level voltage output type encoders

MELSEC-Q

3 - 14 3 - 14

Loading...

Loading...