Page 1

Outdoor unit

SPLIT-TYPE, AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

Outdoor unit

[Model names] [Service Ref.]

PU-2NJA PU-2NJA.TH

PU-2.5NJA PU-2.5NJA.TH

PU-3NJA PU-3NJA.TH

PU-4TJSA PU-4TJSA.TH

PU-5TJSA PU-5TJSA.TH

PU-5XJSA PU-5XJSA.TH

August 2005

No.OC353

PU-6TJSA PU-6TJSA.TH

PU-6XJSA PU-6XJSA.TH

CONTENTS

1.

COMBINATION OF INDOOR AND OUTDOOR UNITS

2. PART NAMES AND FUNCTIONS ··················2

3. DATA ·······························································3

4. OUTLINES AND DIMENSIONS······················5

5. WIRING DIAGRAM·········································9

6. REFRIGERANT SYSTEM DIAGRAM···········11

7. TROUBLESHOOTING ··································12

8. DISASSEMBLY PROCEDURE ·····················16

Model name

indication

9. PARTS LIST··················································18

10. OPTIONAL PARTS ·······································27

···2

Page 2

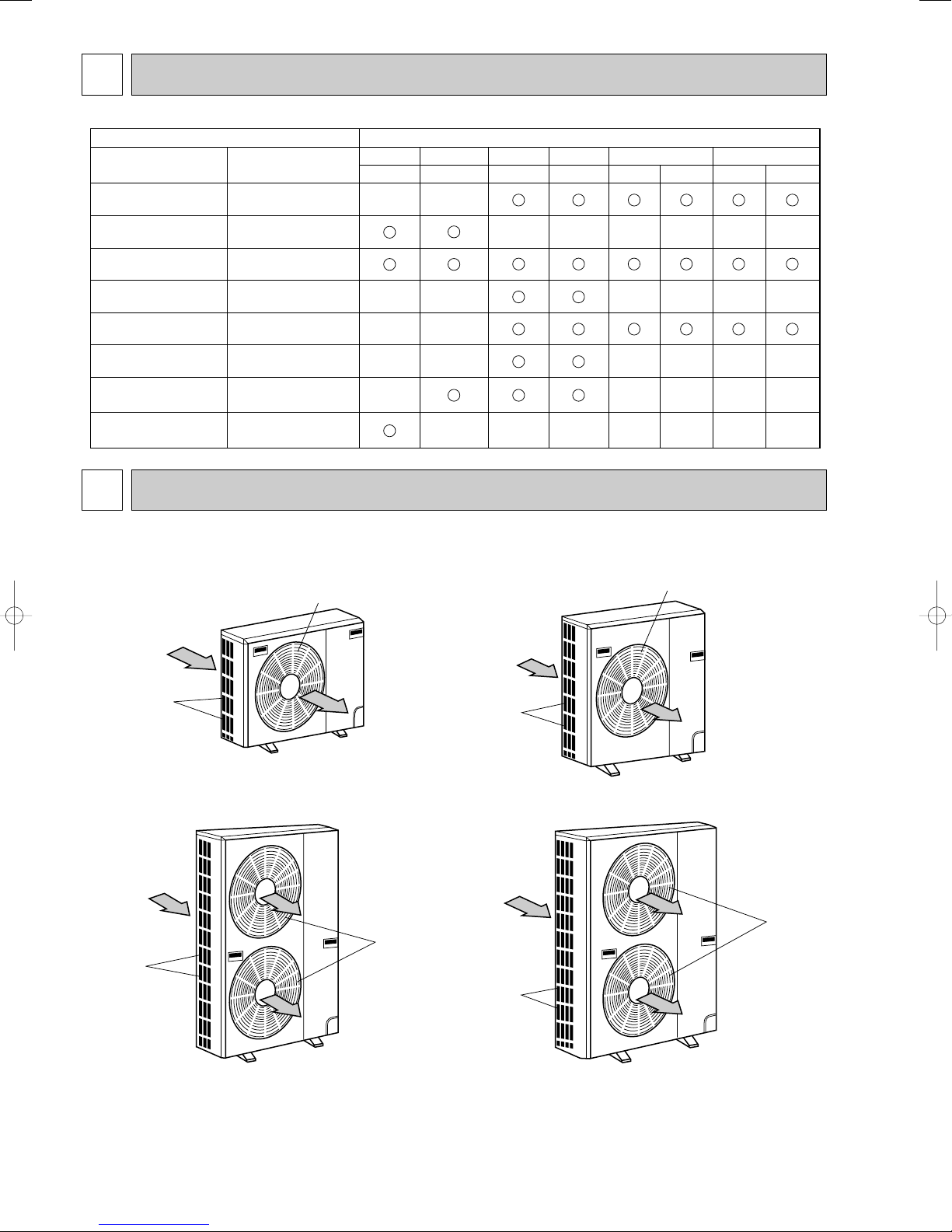

1 COMBINATION OF INDOOR AND OUTDOOR UNITS

Air intake

Air outlet

(Expels warm air during cooling)

Air intake

Air outlet

Air intake

Air outlet

Air intake

Air outlet

Indoor unit Outdoor unit

Model Service

Manual No.

PL-AK(S)C

PL-AK(S)D

PL-KJD OC233

PC-GJ(S)D OC215

OC227

PU-2.TH PU-2.5.TH PU-3.TH PU-4.TH PU-5.TH PU-6.TH

NJA NJA NJA TJSA TJSA XJSA TJSA XJSA

——

——————

PE-EJH(S)A OC131

PE-EJ(S)A OC155

PS-GJ(S

PK-FL(S)D OC232

PK-2GKLD OC228

)

OC143

—— ————

——

—— ————

—————

———————

2 PART NAMES AND FUNCTIONS

●Outdoor Unit

PU-2NJA.TH

PU-2.5NJA.TH

PU-3NJA.TH

wUnit of pressure is based on ISO (International Standardization Organization)

[kgf/cm

2

]➝[MPa] (1MPa=10.2kgf/cm2)

PU-4TJSA.TH

PU-5XJSA.TH

PU-5TJSA.TH

PU-6XJSA.TH

PU-6TJSA.TH

2

Page 3

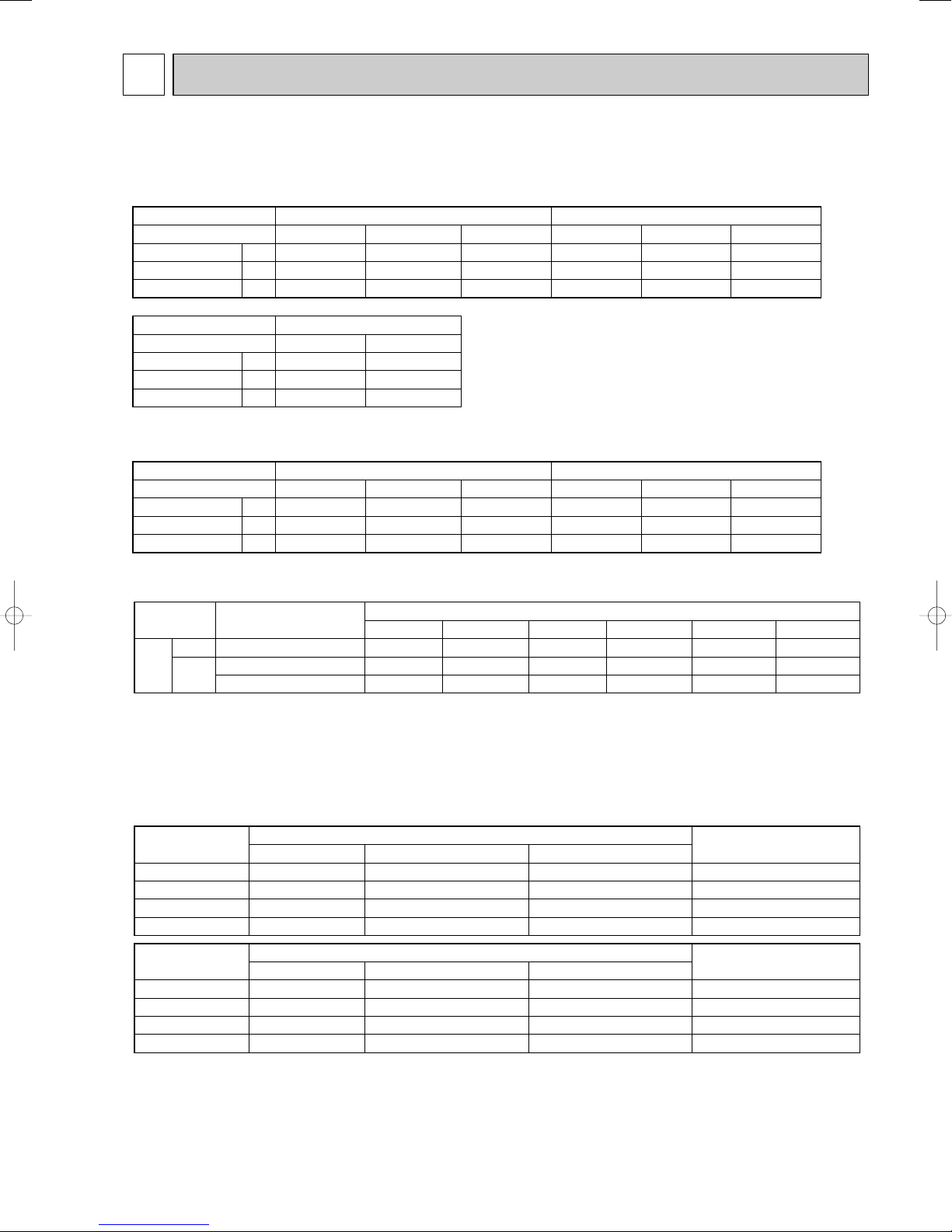

3 DATA

●JIS B8616

Indoor 27:(80°F)D.B.,19:(66°F)W.B.

Outdoor 35:(115°F)D.B.,24:(75°F)W.B.

Power supply N:220V(1phase) 60Hz T:220V(3phase) 60Hz

Service Ref PU-2NJA.TH PU-2.5NJA.TH PU-3NJA.TH PU-4TJSA.TH PU-5TJSA.TH PU-6TJSA.TH

Current A 11.4 13.4 17.6 12.2 16.83 18.7

Input kW 2.45 2.91 3.44 4.27 5.63 6.15

Starting current A 54 58 80 69 135 140

Power supply X:380V(3phase) 60Hz

Service Ref PU-5XJSA.TH PU-6XJSA.TH

Current A 8.69 9.35

Input kW 5.12 5.71

Starting current A 64 70

●SSA 385,386

Indoor 29:(84°F)D.B.,19:(66°F)W.B

Outdoor 46:(115°F)D.B.,24:(75°F)W.B.

Power supply N:220V(1phase) 60Hz T:220V(3phase) 60Hz

Service Ref PU-2NJA.TH PU-2.5NJA.TH PU-3NJA.TH PU-4TJSA.TH PU-5TJSA.TH PU-6TJSA.TH

Current A 13.6 15.8 20.9 14.0 19.61 21.45

Input kW 2.97 3.44 4.09 4.97 6.68 7.28

Starting current A 54 58 80 69 135 140

Power supply Service Ref.(inddor unit

)

Model name (Outdoor unit)/Service Ref.

PU-2 PU-2.5 PU-3 PU-4 PU-5 PU-6

60Hz

1ph 220V

PU-2NJA.TH

PU-2.5NJA.TH PU-3NJA.TH — — —

3ph

220V — — — PU-4TJSA.TH PU-5TJSA.TH PU-6TJSA.TH

380/220V — — — — PU-5XJSA.TH PU-6XJSA.TH

Notes:1.Powert supply key

N····1ph, 220V, 60Hz

T···· 3ph, 220V, 60Hz

X···· 3ph, 380/220V, 60Hz, 4 wires

Compressor

Winding resistance

(")

at20:Outdoor unit

R-C/U-V S-C/V-W W-U Service Ref.

NHJ33NBDT 0.92 1.93 — PU-2NJA.TH

NHJ38NBDT 0.83 1.83 — PU-2.5NJA.TH

NHJ47NADT 0.55 1.24 — PU-3NJA.TH

NHJ56TKAT 0.87 0.87 0.87 PU-4TJSA.TH

Compressor

Winding resistance

(")

at20:Outdoor unit

T1-T2 T2-T3 T3-T1 Service Ref.

ZR-61KC-TF5

0.628-0.722 0.628-0.722 0.628-0.722 PU-5TJSA.TH

ZR-61KC-TF7

2.23 2.23 2.23 PU-5XJSA.TH

ZR-68KC-TF5

0.517 0.517 0.517 PU-6TJSA.TH

ZR-68KC-TF7

1.92 1.92 1.92 PU-6XJSA.TH

1. ELECTRICAL SPECIFICATIONS

(1) Rating conditions

2.POWER SUPPLY & MODEL NAMES

3.COMPRESSOR TECHNICAL DATA

3

Page 4

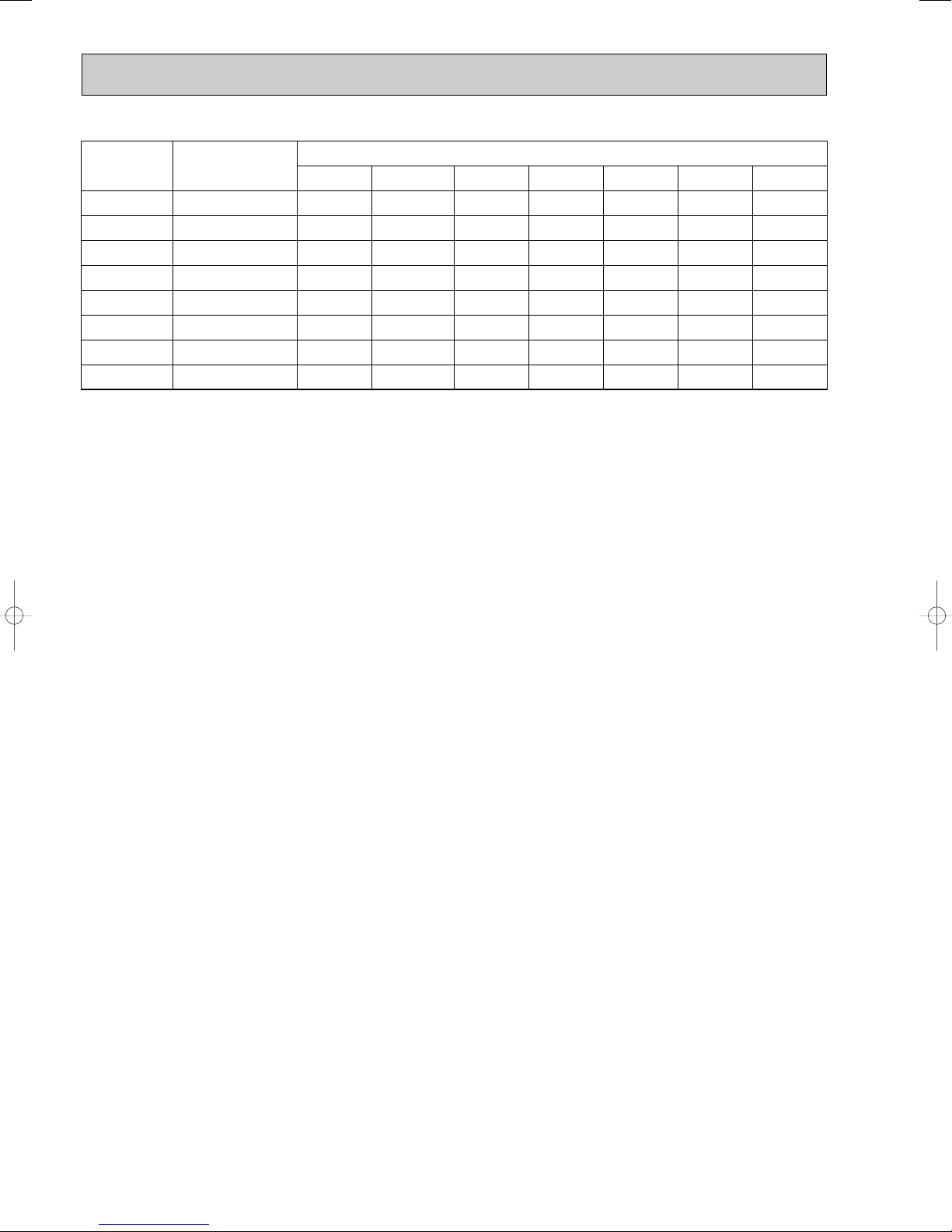

4. ADDITIONAL REFRIGERANT CHARGE (R-22

Outdoor unit

precharged (kg)

(up to 20m)

Service Ref.

Refrigerant piping length (one way)

PU-2NJA.TH

PU-2.5NJA.TH

PU-3NJA.TH

PU-4TJSA.TH

1.9

2.4

3.5

4.6

20m (66ft) 25m (82ft) 30m (98ft) 35m (115ft) 40m (131ft)

0

0

0

0

0.06 (0.13)

0.06 (0.13)

0.06 (0.13)

0.15 (0.33)

––

––

––

0.45 (0.99) 0.6 (1.32)

45m (148ft)

–

–

–

–

50m (164ft)

–

–

–

–

0.12 (0.26)

0.12 (0.26)

0.12 (0.26)

0.30 (0.66)

PU-5XJSA.TH

5.1

0 0.15 (0.33) 0.45 (0.99) 0.6 (1.32) 0.75 (1.65) 0.9 (1.98)0.30 (0.66)

PU-5TJSA.TH

5.1

0 0.15 (0.33) 0.45 (0.99) 0.6 (1.32) 0.75 (1.65) 0.9 (1.98)0.30 (0.66)

PU-6XJSA.TH

5.7

0 0.15 (0.33) 0.45 (0.99) 0.6 (1.32) 0.75 (1.65) 0.9 (1.98)0.30 (0.66)

PU-6TJSA.TH

5.7

0 0.15 (0.33) 0.45 (0.99) 0.6 (1.32) 0.75 (1.65) 0.9 (1.98)0.30 (0.66)

……

kg (lbs))

4

Page 5

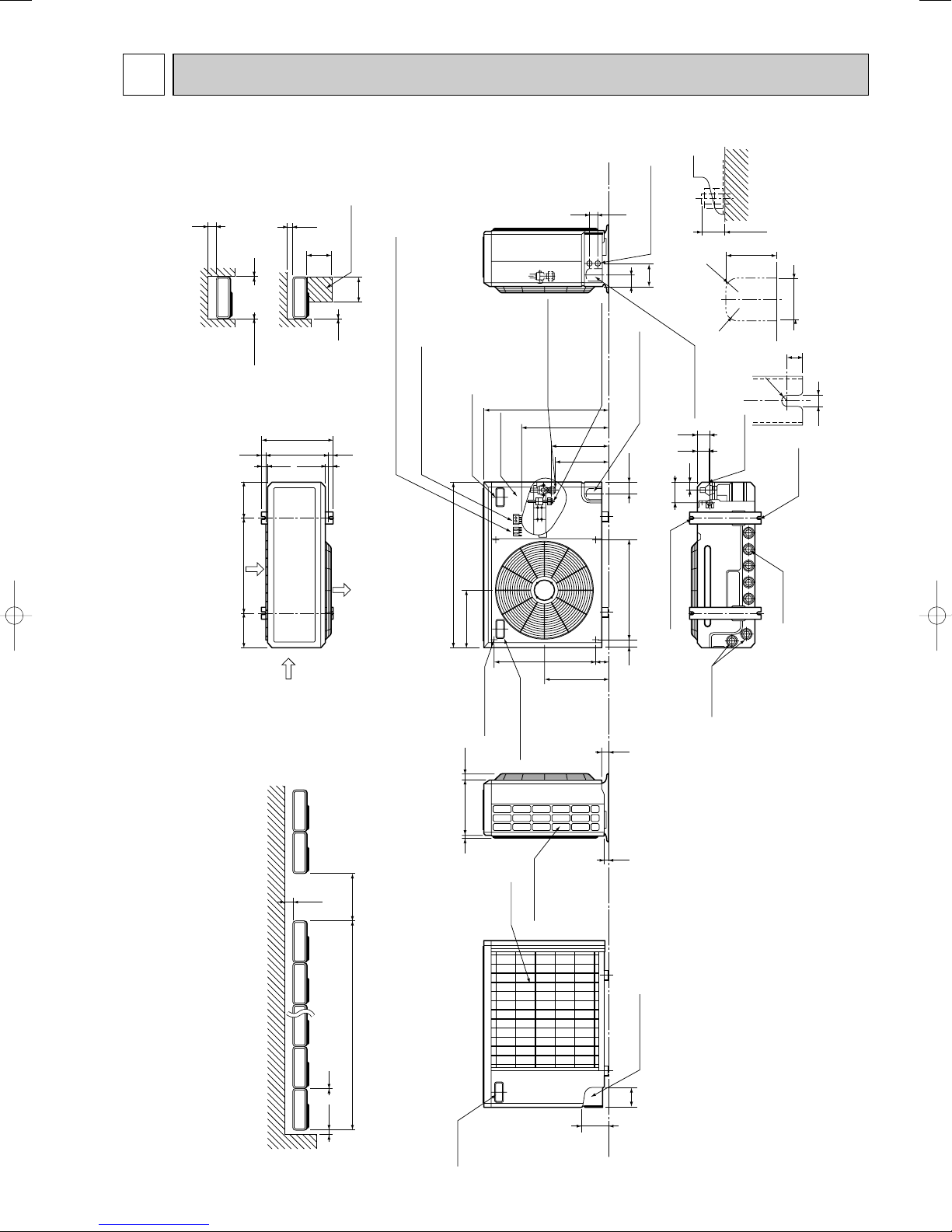

4 OUTLINES AND DIMENSIONS

100 10

1000For 10 units or less

200

Outdoor Unit-necessary surrounding clearance

(Concentrated installation)

The upper side must be open.

Outdoor Unit-necessary surrounding clearance

200

10

10

10

Note:Allow adequate

upper clearance

150

500

500

Service space

Front opening

Handle

for moving

138

95

Rear piping hole

23

33

Rear fresh

air intake

Side air intake

7 24(1)295(11-5/8)

Outlet guide

installation hole

302

Air intake

Air intake

Air outlet

870(34-1/4)

185

(7-9/32)

185

(7-9/32)

500(19-11/16)

330(13)

362(14-1/4)

1715

39.5 27.5

Terminal block for indoor and outdoor unit connection

Terminal block for power line

Handle for moving

77

524

339

282

297

444

650 (25-5/8)

40 60524

Service panel

(Ground terminal)

Refrigerant-pipe flared

connection

[15.88 3/8F

Refrigerant-pipe flared

connection

[9.52 3/8F

Knock out hole

for front piping

(refrigerant,drainage

and wiring)

Knock out hole

for front piping

(refrigerant,drainage

and wiring)

R

20

R20

60

120

4553

25 max.

Knock out holes for

power line 2-[27

Standard bolt length

65

Front right piping holes-

detail figures

80

17

42

45

12

R6

104

33

Bottom

piping hole

2-U-shaped

notched

holes

Drain hole

Drain hole

2-12o23 Oval holes

(standard bolt M10)

Handle for moving

PU-2NJA.TH

Unit : mm (inch)

5

Page 6

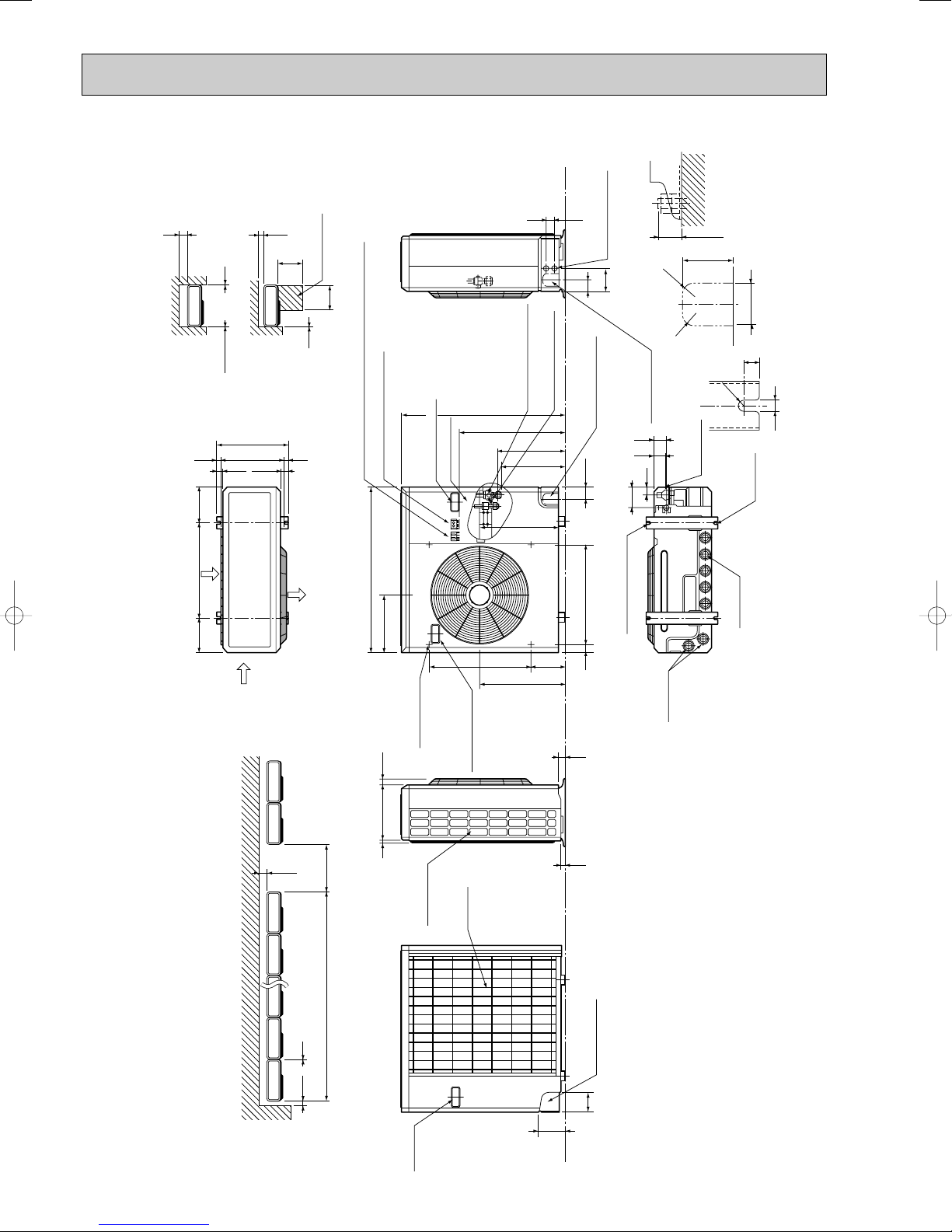

PU-2.5NJA.TH

100 10

1000For 10 units or less

200

Outdoor Unit-necessary surrounding clearance

(Concentrated installation)

The upper side must be open.

Outdoor Unit-necessary surrounding clearance

200

10

10

10

Note:Allow adequate

upper clearance

150

500

500

Service space

Front opening

Handle

for moving

138

95

Rear piping hole

23

33

Rear fresh

air intake

Side air intake

7 24(1)295(11-5/8)

Outlet guide

installation hole

302

Air intake

Air intake

Air outlet

870(34-1/4)

185

(7-9/32)

185

(7-9/32)

500(19-11/16)

330(13)

362(14-1/4)

1715

39.5 27.5

Terminal block for indoor and outdoor unit connection

Terminal block for power line

Handle for moving

179 524

441

337

352

403

553

850(33-7/16)

40 60524

Service panel

(Ground terminal)

Refrigerant-pipe flared

connection [15.88 5/8F

Refrigerant-pipe flared

connection [9.52 3/8F

Knock out hole

for front piping

(refrigerant,drainage

and wiring)

Knock out hole

for front piping

(refrigerant,drainage

and wiring)

R

20

R20

60

120

4553

25 max.

Knock out holes for

power line 2-[27

Standard bolt length

65

Front right piping holes-

detail figures

80

17

42

45

12

R6

104

33

Bottom

piping hole

2-U-shaped

notched

holes

Drain hole

Drain hole

2-12o23 Oval holes

(standard bolt M10)

Handle for moving

PU-3NJA.TH

Unit : mm (inch)

6

Page 7

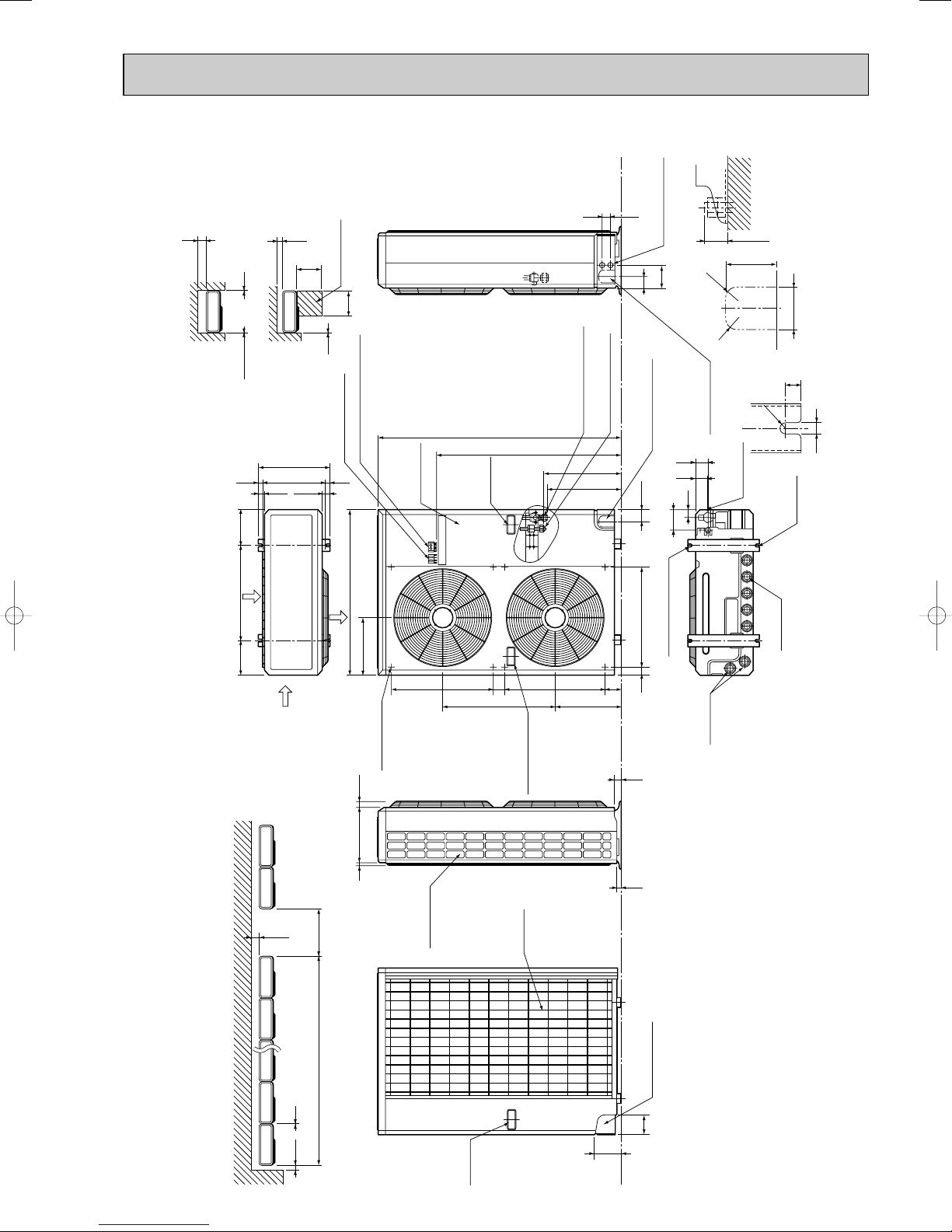

PU-4TJSA.TH

300

Outdoor Unit-necessary surrounding clearance

Note:Allow adequate

upper clearance

10

Front opening

10

1715

185

(7-9/32)

150

500

Service space

500

10

Terminal block for

indoor and outdoor

unit connection

362(14-1/4)

330(13)

39.5 27.5

(Ground terminal)

Terminal block for power line

Service panel

Handle

for moving

Refrigerant-pipe flared

1258(49-1/2)

959

4553

Knock out holes for

60

connection [19.05 3/4F

Refrigerant-pipe flared

connection [9.52 3/8F

Knock out hole

for front piping

403

382

power line 2-[27

120

(refrigerant,drainage

104

Knock out hole

for front piping

and wiring)

57

52

39

R20

R20

(refrigerant,

Bottom

Unit : mm (inch)

Standard bolt length

25 max.

80

65

Front right piping holes-

17

R6

drainage and wiring)

piping hole

2-U-shaped

notched

holes

detail figures

12

Air intake

500(19-11/16)

185

(7-9/32)

Air intake

300

1000For 10 units or less

The upper side must be open.

870(34-1/4)

302

Air outlet

Outlet guide

7 24(1)295(11-5/8)

installation hole

Side air intake

52461

585

Handle for moving

Rear fresh

air intake

345

2-12o23 Oval holes

(standard bolt M10)

83 524

40 60524

Drain hole

33

23

Drain hole

Outdoor Unit-necessary surrounding clearance

(Concentrated installation)

150 10

Handle

for moving

7

Rear piping hole

95

138

Page 8

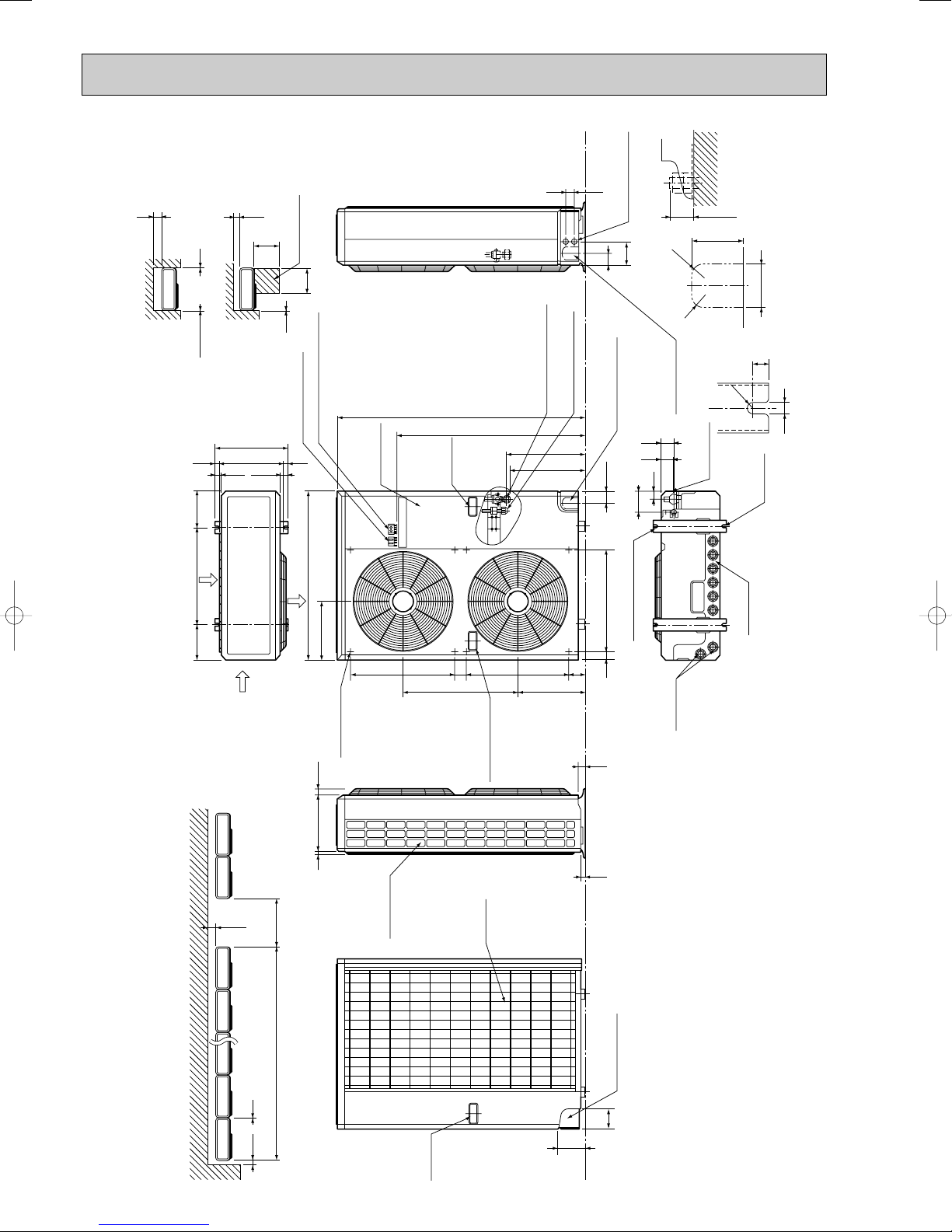

PU-5TJSA.TH PU-6TJSA.TH

150 10

1000For 10 units or less

300

Outdoor Unit-Necessary surrounding clearance

(Concentrated installation)

Outdoor Unit-Necessary surrounding clearance

The upper side must be open.

Handle

for moving

138

95

Rear piping hole

23

33

Rear fresh

air intake

Side air intake

7 24(1)345(13-9/16)

Outlet guide

installation hole

352

Air intake

Air intake

Air outlet

970(38-3/16)

185

(7-9/32)

185

(7-9/32)

600(23-5/8)

380(14-31/32)

412(16-1/4)

1715

39.5 27.5

Terminal block for

indoor and outdoor

unit connection

Terminal block for power line

300

10

10

10

Note:Allow adequate

upper clearance

150

500

500

Service space

Handle for moving

52461

585

83 524

345

382

403

959

1258(49-1/2)

90 60524

Service panel

(Ground terminal)

Handle

for moving

Refrigerant-pipe flared

connection [19.05 3/4F

Refrigerant-pipe flared

connection [9.52 3/8F

Knock out hole

for front piping

(refrigerant,drainage

and wiring)

Knock out hole

for right piping

(refrigerant,

drainage and wiring)

R

20

R20

60

120

4553

25 max.

Knock out holes for

power line 2-[27

Standard bolt length

65

Front right piping holes-

detail figures

80

17

52

57

12

R6

104

39

Bottom

piping hole

2-U-shaped

notched

holes

Drain hole

Drain hole

2-12o23 Oval holes

(standard bolt M10)

Front opening

PU-5XJSA.TH PU-6XJSA.TH

Unit : mm (inch)

8

Page 9

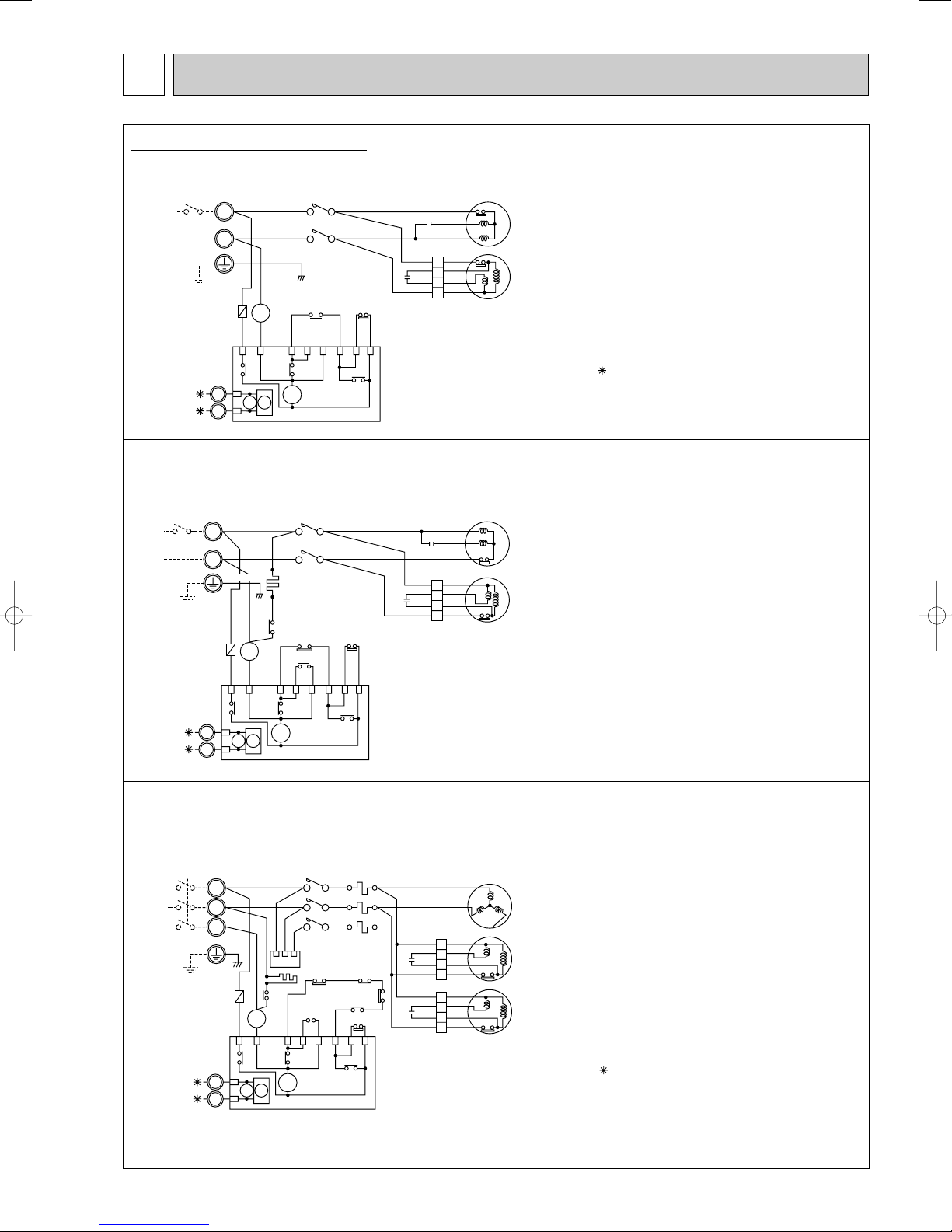

5 WIRING DIAGRAM

WHT

BLU

BRN

YLW

WHT

49F4

MF4

MF3

MC

BLU

RED

ORN

4

2

1

3

WHT

YLW

YLW

GRY

GRY

C

HC

9695

47

51C

52C

13

32

31

14

63L

26C

63H

A1

A2

A

WHT

REDTB3

1

1

2

2

BP1 P3P3

X17

X6

X6

X17X14

X14

CP

P2

52C 52C

52C

52

C

F3

(5A)

WHT

WHT

BRN

VLT

VLT

GRY

GRY

RED

ORN

YLW

WHT

BLU

RED

ORN

WHT

BLU

BLU

C3

C4

RED

WHT

BLK

GRY

RED

WHT

BLU

RED

TB1

TB1

26C

47

49F3,4

51C

52C

63H

63L

CP

C3,4

F3

HC

MC

MF3,4

POWER SUPPLY TERMINAL BLOCK

LINE TERMINAL BLOCK

TB3 INDOOR/OUTDOOR CONNECTING

THERMAL SWITCH

ANTI-PHASE PROTECTOR

FAN MOTOR INTERNAL THERMOSTAT

THERMAL RELAY

COMPRESSOR CONTACTOR

HIGH PRESSURE SWITCH

LOW PRESSURE SWITCH

COMPRESSOR PROTECTOR

FAN MOTOR CAPACITOR

FUSE(5A)

CRANKCASE HEATER

COMPRESSOR

FAN MOTOR

NOTES:1.THE DOTTED LINES SHOW FIELD WIRING.

2. TO INDOOR UNIT TERMINAL BLOCK.

POWER SUPPLY

3~

220V 60Hz

L1

L2

L3

GRN/

YLW

T3/6

T2/4

T1/2

L3/5

RST

47

L2/3

L1/1

51C

52C

WHT

49F3

BLU

RED

ORN

4

U

2

1

3

V

W

A

PU-2NJA.TH PU-2.5NJA.TH

POWER

SUPPLY

~/N

220V 60z

PU-3NJA.TH

TB3

POWER

SUPPLY

~/N

220V 60Hz

TB3

TB1

RED

1

2

WHT

N

L

(5A)

RED

1

2

WHT

F3

TB1

L

N

F3

(5A)

GRN/YLW

RED

YLW

A

1

2

GRY

P1

P1

X6

L1/1

L3/5

HC

22

21

13 14

GRY

52C

X6

X6

52C

L1/1

T1/2

WHT

P3 P3

T1/2

T3/6

GRY

BLUT3/6

C3

63L

WHT

WHT

GRY

P2

X17

CP

BLU

WHT

C3

63L

WHT

WHT

P2

CP

X17

L3/5

63H

GRY

52C

52C

X6

52C

63H

52C

VLT

VLT

52C

P3 P3

RED

BLU

GRN/YLW

BLU

RED

A1

52

C

A2

YLW

ORN

A

B

X14

1

X17X14

2

WHT

BLU

BLU

GRY

52C

A1

52

C

A2

ORN

B

X14

X17X14

WHT

ORN

BLU

BLU

RED

WHT

49C

C

C

S

RED

R

BLU

WHT

3

ORN

1

REDRED

2

BLU

4

BLU

C

RED

BLU

4

RED

2

ORNORN

1

3

WHT

S

C

49C

49F3

R

MC

MF3

MC

MF3

49F3

C

COMPRESSOR RUN CAPACITOR

CP

COMPRESSOR PROTECTOR

C3

FAN MOTOR CAPACITOR

F3

FUSE(5A)

MC

COMPRESSOR

MF3

FAN MOTOR

TB1

POWER SUPPLY TERMINAL BLOCK

TB3

INDOOR/OUTDOOR CONNECTING LINE TERMINAL BLOCK

49C

COMPRESSOR INTERNAL THERMOSTAT

49F3

FAN MOTOR INTERNAL THERMOSTAT

52C

COMPRESSOR CONTACTOR

63H

HIGH PRESSURE SWITCH

63L

LOW PRESSURE SWITCH

NOTES:1.THE DOTTED LINES SHOW FIELD WIRING.

2. TO INDOOR UNIT TERMINAL BLOCK.

C

COMPRESSOR RUN CAPACITOR

CP

COMPRESSOR PROTECTOR

C3

FAN MOTOR CAPACITOR

F3

FUSE(5A)

HC

CRANKCASE HEATER

MC

COMPRESSOR

MF3

FAN MOTOR

TB1

POWER SUPPLY TERMINAL BLOCK

TB3

INDOOR/OUTDOOR CONNECTING LINE TERMINAL BLOCK

49C

COMPRESSOR INTERNAL THERMOSTAT

49F3

FAN MOTOR INTERNAL THERMOSTAT

52C

COMPRESSOR CONTACTOR

63H

HIGH PRESSURE SWITCH

63L LOW PRESSURE SWITCH

NOTES:1.THE DOTTED LINES SHOW FIELD WIRING.

2. TO INDOOR UNIT TERMINAL BLOCK.

PU-4TJSA.TH

9

Page 10

PU-5TJSA.TH PU-6TJSA.TH

96

95

51C

A

C

47

51C

T1/2

T2/4

T3/6

TB1

26C

63H

GRY

63L

GRY

BLK

WHT

CIRCUIT

BREAKER

BLU

49C

49C

49C

GRN/YLW

N

POWER SUPPLY

3N~ (3PHASE 4WIRES)

380V 60Hz

L1

L2

L3

BLK

WHT

RED

F3

(5A)

BLU

RED

A1

A2

14

13

52C

GRY

RED

WHT

GRY

RED

BLK

YLW

47

RTS

RED

WHT

BLK

L3/5

L2/3

L1/1

52C

52

C

T3

T2

T1

BLK

WHT

RED

MF4

49F4

WHT

ORN

RED

BLU

WHT

ORN

RED

BLU

MC

MF3

49F3

C4

C3

WHT

ORN

RED

BLU

BLU

RED

ORN

WHT

3

1

2

4

3

1

2

4

CP

X17

X6

X14

P2P3P3

52C

52C

P1

BA

WHT

RED

TB3

X6

2

1

1

2

X17

X14

THERMAL RELAY51C

LOW PRESSURE SWITCH63L

PHASE PROTECTOR47

INTERNAL THERMOSTAT FOR MC49C

NOTES: 1.THE DOTTED LINES SHOW FIELD WIRING.

2. TO INDOOR UNIT TERMINAL BLOCK.

TERMINAL BLOCK (CONNECTING WIRES INDOOR/OUTDOOR)

CP

TERMINAL BLOCK (POWER SUPPLY)

COMPRESSOR

FAN MOTOR

FUSE (5A)

FAN MOTOR CAPACITOR

HIGH PRESSURE SWITCH

COMPRESSOR CONTACTOR

INTERNAL THERMOSTAT FOR MF3,4

THERMAL SWITCH

COMPRESSOR PROTECTOR

63H

52C

49F3,4

26C

TB3

TB1

MF3,4

MC

F3

C3,4

POWER SUPPLY

3~ (3PHASE)

220V 60Hz

CIRCUIT

BREAKER

TB3

TB1

RED

L1

L2

L3

F3

(5A)

RED

1

*

2

*

WHT

1

2

RED

YLW

X14

A1

52

A2

WHT

BLK

GRN/YLW

WHT

C

GRY

X17X14

RED

RTS

51C

52C

RED

BLK

52C

P1BA

X6

X6

52C

95

96

L1/1

L2/3

L3/5

WHT

63L

1413

BLK

GRY

RED

52C

47

GRY

26C

63H

X17

WHT

P2P3P3

51C

47

T1/2

T2/4

T3/6

BLK

GRY

RED

WHT

T2

49C

BLK

BLU

BLU BLU

WHT

RED

C3

ORN

A

C

WHT

BLU

RED

C4

ORN

WHT

CP

C3,4

CP

F3

T3

4

RED

2

ORN

1

WHT

3

BLU

4

RED

2

ORN

1

WHT

3

COMPRESSOR PROTECTOR

FAN MOTOR CAPACITOR

FUSE(5A)

T1

MC

49C

49C

MF3

49F3

MF4

49F4

PHASE PROTECTOR47

MC

MF3,4

TB1

TB3

26C

COMPRESSOR

FAN MOTOR

TERMINAL BLOCK(POWER SUPPLY)

TERMINAL BLOCK

(CONNECTING WIRES INDOOR/OUTDOOR)

THERMAL SWITCH

INTERNAL THERMOSTAT FOR MC49C

49F3,4

52C

63H

INTERNAL THERMOSTAT FOR MF3,4

COMPRESSOR CONTACTOR

HIGH PRESSURE SWITCH

LOW PRESSURE SWITCH63L

THERMAL RELAY51C

NOTES: 1.THE DOTTED LINES SHOW FIELD WIRING.

2.* TO INDOOR UNIT TERMINAL BLOCK.

PU-5XJSA.TH PU-6XJSA.TH

10

Page 11

6 REFRIGERANT SYSTEM DIAGRAM

Low pressure

switch

Charge

plug

Ball

valve

[15.88

(5/8)

Ball valve

(with service port)

Accumulator

[9.52

(3/8)

O.D.3.2oI.D.2.0-L430

Check

plug

Compressor

Capillary tube

O.D.3.2oI.D.1.2

-L1000

Capillary tube

for injection

Strainer

#100

Outdoor heat

exchanger

High pressure

switch

flow of refrigerant

Charge

plug

Ball

valve

Ball valve

(with service port)

Accumulator

[9.52

(3/8)

Compressor

Capillary tube for

injection

#100

Strainer

Outdoor heat

exchanger

Check

plug

flow of refrigerant

Low pressure

switch

High pressure

switch

[15.88

(5/8)

w

Capillary

tube

PU-2.5

(O.D.3.2oI.D.1.6

-L760)o2pcs

PU-3

(

O.D.3.2oI.D.1.8

-

L800)o2pcs

PU-2.5 (O.D.3.2oI.D.1.2-L1000)

PU-3 (O.D.3.2oI.D.1.6-

L500

)

Charge

plug

Ball

valve

[19.05

(3/4)

Ball valve

(with service port)

Accumulator

[9.52

(3/8)

Compressor

Capillary tube for

injection

Strainer

#100

Outdoor heat

exchanger

Check

plug

flow of refrigerant

Low pressure

switch

High pressure

switch

w

Capillary

tube

O.D.3.2oI.D.2.0

-L840o2pcs

O.D.3.2oI.D.1.2-L500

Outdoor heat

exchanger

Ball

valve

Ball valve

(with service port)

High pressure

switch

Compressor

Accumulator

DPR

Capillary tube

PU-5 (O.D. 4.0 oI.D. 2.4 oL400)

PU-6 (O.D. 4.0 oI.D. 2.4 oL200)

Capillary tube

PU-5

(O.D. 4.0 oI.D. 2.4 oL840)o2pcs

PU-6

(O.D. 4.0 oI.D. 2.4 oL740)o2pcs

[9.52

(3/8)

[19.05

(3/4)

Check plug

Charge

plug

: flow of refrigerant

Strainer #100

Low pressure

switch

Strainer

#50

DPR : Discharge pressure

regulator

PU-2NJA.TH

PU-2.5NJA.TH

PU-3NJA.TH

PU-4TJSA.TH

PU-5TJSA.TH PU-6TJSA.TH

PU-5XJSA.TH PU-6XJSA.TH

11

Page 12

7

TROUBLE SHOOTING

7-1. SELF-DIAGNOSTIC FUNCTION

7-1-1. Wired remote controller (1)

! When trouble occurs during operation, the unit stops and enters the self-diagnostic mode, and displays the trouble loca-

tion with the timer lamps on the remote controller. All the other lamps are OFF.

@ To activate the self-diagnostic function for service, press the UP and DOWN buttons simultaneously for more than two

TEMP.

seconds during operation with lamp ON.

# The timer lamps show the latest trouble. Trouble data is memorized until the next trouble occurs, even when the breaker

turns OFF. To clear the memory, press the UP and DOWN buttons simultaneously for more than two seconds during the

test run.

$ All buttons except the POWER ON/OFF button are unavailable during the self-diagnostic mode.

% To release the self-diagnostic mode, press the POWER ON/OFF button.

Unit

Transmission error

Unit

No.1

Unit

No.2

Unit

No.1

Unit

No.2

Unit

No.1

Unit

No.2

Unit

No.1

Unit

No.2

Unit

No.1

Unit

No.2

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

TIMER

▲

TEMP.

29

29

28

28

27

27

26

26

25

25

24

24

23

23

22

22

21

21

20

20

19

19

18

18

▲

▲

Trouble location

in twin control

Outdoor unit

Room

temperature

thermistor

(RT1)

Indoor coil

thermistor

(RT2)

Drain sensor

(DS)

Drain

overflow

protection

Coil frost

or overheat

prevention

Cause

●Wrong wiring between No. 1

and No. 2 units

●Poor connector contact

●Wrong wiring between

indoor/outdoor units

●Outdoor unit abnormality

detection

●Malfunction of outdoor coil

thermistor

●Reversed phase detected

●Poor connector contact

●Thermistor malfunction

●Poor connector contact

●Thermistor malfunction

●Poor connector contact

●Thermistor malfunction

●Drain pump malfunction

●Drain sensor improperly

mounted

●Air passage short cycle

●Air filter clogged

●Indoor fan malfunction

Measures

●Check dip switch setting

●Check wiring

●Check wiring

●Check outdoor unit

●Check outdoor coil thermistor

●Check connector

●Check thermistor

➔ No trouble ➔ replace indoor

●Check connector

●Check thermistor

➔ No trouble ➔ replace indoor

●Check connector

●Check thermistor

➔ No trouble ➔ replace indoor

●Check drain pump

●Check drain sensor

➔ No trouble ➔ replace indoor

●Remove blockage

●Check air filter

●Check indoor fan

}

controller

board.

}

controller

board.

}

controller

board.

}

controller

board.

(Indicates that the unit is in self-diagnostic mode)

12

Page 13

7-1-2. WIRED REMOTE CONTROLLER(2)

1) When malfunction occurs during operation

When a malfunction occurs, the indoor and outdoor units stop and the malfunction is displayed on the LCD of the remote

controller.

(1) ON the set temperature display part, “CHECK” appears, and the unit

address and the check code are displayed alternately at one-second

intervals. (Check mode)

Example

CHECK mode

Check

code

Unit

address

(2) When one remote controller controls several units in the group con-

trol, the LCD shows the unit address and check code of the first malfunctioning unit.

(3) To cancel the check mode, press the ON/OFF button. In remote

ON/OFF control, press the remote ON/OFF switch. In centralized

control, turn OFF the ON/OFF button of centralized controller.

Check button

NOTE: The latest check code is memorized, even if the check mode is cancelled by the way mentioned above. It takes

60 seconds maximum to display the memorized check code.

2) How to use the self diagnostic function for service

A. For normal control with one unit and one remote controller

(1) Pressing the CHECK button on the remote controller twice starts the self diagnostic function.

(2) During the self diagnostic function, “CHECK MODE” appears at two positions on the remote controller display. Then, at

least 10 seconds later, the unit address and the check code is alternately displayed at one-second intervals.

(3) Check and repair the unit according to the check code.

B. For group control using one remote controller

(1) Pressing the CHECK button on the remote controller twice starts the self diagnostic function.

(2) Press the TEMP. button or TEMP. button on the remote controller to advance or go back to the unit address.

Each time TEMP. button is pressed, the unit address advances by one. Each time TEMP. button is pressed,

▲

▲ ▼

▼

the unit address goes back by one.

The check code and the unit address, appear alternately.

(3) The check code “U8” means no malfunction has occurred since installation.

The check code “EO” means the following conditions:

● The unit address displayed on the remote controller does not apply to any unit.

● power is not supplied to the unit.

● Signal transmitting/receiving circuit is abnormal.

(4) Check and repair the unit according to the check code.

13

Page 14

Check

code

(P1)

(P2)

Diagnosis of malfunction Cause Check points

Abnormality of room temperature thermistor (RT1)

Abnormality of indoor coil

thermistor (RT2)

1) Bad contact of thermistor

2) Damaged thermistor

1) Check the thermistor.

2) Measure the resistance of the thermistor.

Normal resistance should be as follows.

0°C···15kΩ 30°C····4.3kΩ

10°C·····9.6kΩ 40°C·····3.0kΩ

20°C·····6.3kΩ

If the resistance is normal, replace the indoor

controller board.

(P4) Abnormality of drain sensor 1) Bad contact of transmission

(P5) Malfunction of drain pump 1) Malfunction of drain pump

(P6) Coil frost protection is work-

ing.

(P8) Abnormality in outdoor unit 1) Wrong wiring of indoor/outdoor

wire

2) Damaged thermistor

2) Damaged drain sensor

1) Short cycle of air cycle

2) Dirty air filter

3) Damaged fan

4) Abnormal refrigerant

connecting wire

2) Reversed phase

3) Protection device is working

4) Damaged outdoor coil thermistor

1) Check the connector.

2) Measure the resistance of the thermistor 4 ~

5.

As for the normal resistance, refer to the case

of P1.

If the resistance is normal, replace the indoor controller board.

1) Check the drain pump.

2) ● Check the drain sensor.

● Check the drain sensor heater. Normal resistance should be 82Ω.

If the resistance is normal, replace the indoor controller board.

1) Clear obstructions from the air cycle.

2) Clean the air filter

3) Check the fan.

4) Check the refrigerant temperature.

1) Check the indoor/outdoor connecting wire.

2) Change the connection of electric wiring.

3) Check the protection device.

4) Measure the resistance of the outdoor coil thermistor. If the resistance is normal, replace the

outdoor controller board.

14

Page 15

7-2. HOW TO CHECK THE PARTS

Check points

FAN MOTOR

Parts name

Measure the resistance between the terminals using a tester.

(

MF3,MF4

)

(Surrounding temperature

20:

)

Motor lead wire

Normal

Abnormal

2,2.5,3N 4T 5,6T,X

White-Blue 68.8" 74.6" 91.3"

Open or short

Blue-Red(Brown

)

88.4" 122.0" 96.0"

Protector

OPEN:145I8:

CLOSE:90I15:

CRANK CASE

Measure the resistance between the terminals using a tester.

HEATER(HC

)

Normal

Abnormal

3N 4T

1274" 1274" Open or short

COMPRESSOR 1Winding resistance

(")

(MC)

Measure the resistance between the terminals using a tester.

(

Surrounding temperature20:

)

Terminals

Normal

Abnormal

2N 2.5N 3N 4T

R-C(U-V

)

0.92" 0.83" 0.55" 0.87"

Open or short

S-C(V-W

)

1.933" 1.83" 1.24" 0.87"

W-U — — — 0.87"

Terminals

Normal

Abnormal

5T 5X 6T 6X

T1-T2 0.628-0.722" 2.23" 0.517" 1.92"

Open or short

T2-T3 0.628-0.722" 2.23" 0.517" 1.92"

T3-T1 0.628-0.722" 2.23" 0.517" 1.92"

2

Internal thermostat motor protection (49C)

Internal

thermostat

motor protection

PU-4T PU-5T PU-5X PU-6T PU-6X

NH56TKAT

TF5

ZR-61KC-

TF7

ZR-61KC-

TF5

ZR-68KC-F7ZR-68KC-T

Opening temp. 125I5: 120I5: 120I5: 120I5: 120I5:

Closing temp. 90I7: 90I15: 90I15: 90I15: 90I15:

PU-2NJA.TH

PU-2.5NJA.TH

PU-3NJA.TH

PU-4TJSA.TH

PU-5TJSA.TH PU-5XJSA.TH

PU-6TJSA.TH PU-6XJSA.TH

15

Page 16

8 DISASSEMBLY PROCEDURE

OUTDOOR UNIT PU-3NJA.TH

OPERATING PROCEDURE PHOTOS

1. Removing the electrical parts

(1)

Remove the 5 screws and the top panel. (3 screws in

front and 2 screws in rear

(2)

Remove the screw of the cover panel. To remove the

cover panel, pull it toward you and unhook the catches from the side panel.

(3)

Remove the screw of the service panel. To remove the

service panel, pull it down toward you and unhook the

catches on the both sides.

)

Photo 1

Photo 2

Screws

Front panel

Compressor

protector

Top panel

Service panel

Panel cover

Capacitor

Contactor

2. Removing the fan motor

(1)

Remove the 3 screws of the front panel. Open the

front panel to a 45-degree angle. Then lift it and

unhook the 3 catches to remove.

(2)

Remove the propeller nut and the propeller.

(3)

Remove the 3 screws and the fan motor.

Disconnect the lead connectors.

Photo 3

Propeller

16

Terminal blockScrews

Motor support

Propeller nut Crankcase heater

Separator support plate

High-pressure control

Lead

connectors

Valve bed

switch

Page 17

OPERATING PROCEDURE PHOTOS

3. Removing the heat exchanger and the compressor

(1)

Remove the rear panel (2 screws in front, 1 screw on

the side, 3 screws in the rear). Remove the valve bed,

and open the rear panel to the rear to remove.

NOTE :

All panels are fixed by catches, and must be removed by

shifting up and down.

(2)

Remove the 4 screws of the right side panel and

remove it.

(3)

Remove the 3 screws of the rear guard and remove

the rear guard.

(4)

Remove the 4 screws of the separator support plate

and remove the separator support plate .

(5)

Remove the 2 screws of the motor support and

remove the motor support.

(6)

Remove the 5 screws of the valve bed.

The valve bed is fixed by the catches on the right and

left sides.

Lift it to remove.

(7)

Remove the electrical parts box.

Disconnect the connectors from the high pressure

switch, crank case heater, shell thermo, and fan motor

lead.

(8)

Remove the 2 screws of the separator and remove the

separator.

(9)

Remove the 2 screws of the heat exchanger and

remove the heat exchanger.

Detach the welded point of pipe.

)

(

Remove the 3 nuts of the compressor and remove the

10

compressor.

Detach the welded points of the compressor suction

pipe and discharge pipe.

Photo 4

Screws

Screws

Photo 5

Heat exchanger

Accumulator

Photo 6

Charge plug

Ball valve

Compressor

17

Page 18

9 PARTS LIST

1

2

3

4

5

6

7

8

9

10

11

12

13

Part No. Part Name

SpecificationNo.

Q,ty/set

Wiring

Diagram

Symbol

Recom-

mended

Q,ty

Price

Unit

Amount

SCREW

LEFT SIDE PANEL

HANDLE

FRONT PANEL

FAN GUARD

MOTOR SUPPORT

BASE

SERVICE PANEL

PANEL COVER

REAR PANEL

LABEL

REAR GUARD

TOP PANEL

13

1

3

1

1

1

1

1

1

1

1

1

1

Remarks

(BG00N264G06)

(JG79C180H02)

(5o10)

NJA.TH

PU-2

—

E07 001 249

E07 001 009

E07 001 232

E07 001 521

—

E07 003 290

E07 001 245

E07 001 006

E07 001 522

—

E07 001 523

E02 214 297

(Z004M203H10)

13Pcs/set

STRUCTURAL PARTS

PU-2NJA.TH

13 12

11 103

1

2

3

4

5

7689

18

Page 19

STRUCTURAL PARTS

1

2

3

4

5

6

7

8

9

10

11

12

13

Part No. Part Name

SpecificationNo.

Wiring

Diagram

Symbol

Recom-

mended

Q,ty

Price

Unit

Amount

SCREW

LEFT SIDE PANEL

FRONT PANEL

HANDLE

FAN GUARD

BASE

MOTOR SUPPORT

SERVICE PANEL

PANEL COVER

REAR PANEL

LABEL

REAR GUARD

TOP PANEL

13

1

1

3

1

1

1

1

1

1

1

1

1

Remarks

(5o10)

NJA.TH

PU-2.5, 3

—

E02 214 249

E07 003 232

E07 001 009

E02 527 521

E07 003 290

—

E07 003 245

E07 001 006

E07 003 522

—

E07 003 523

E02 214 297

(SU02Y704G04)

(JG79C180H02)

(Z004M203H10)

13Pcs/set

Q,ty/set

PU-2.5NJA.TH

PU-3NJA.TH

13 12

11104

1

2

3

4

5

67 89

19

Page 20

STRUCTURAL PARTS

Part No. Part Name

SpecificationNo.

Q,ty/set

Wiring

Diagram

Symbol

Recom-

mended

Q,ty

Price

Unit

Amount

SCREW

LEFT SIDE PANEL

FAN GUARD

FRONT PANEL

HANDLE

BASE

SERVICE PANEL

PANEL COVER

REAR PANEL

LABEL

REAR GUARD

TOP PANEL

MOTOR SUPPORT

1

2

3

4

5

6

7

8

9

10

11

12

13

13

1

2

1

3

1

1

1

1

1

1

1

1

Remarks

(5o10)

TJSA.TH

PU-4

—

E07 005 249

E02 527 521

E07 005 232

E07 001 009

E07 005 290

E07 005 245

E07 001 006

E07 005 522

—

E07 005 523

E02 214 297

—

(JG79C180H02)

(BG00N264G08)

(Z004M203H10)

13Pcs/set

PU-4TJSA.TH

12 1113

10 9

1

2

3

4

5

3

5

67

20

8

Page 21

STRUCTURAL PARTS

1

2

3

4

5

6

7

8

9

10

11

12

13

(JG79C180H02)

(BG00N264G08)

Part No. Part Name

SpecificationNo.

Q,ty/set

Wiring

Diagram

Symbol

Recommended

Q,ty

Price

Unit

Amount

Remarks

(Drawing No.)

(5o10)

TJSA.TH

XJSA.TH

PU-5, 6

1

2

3

1

1

1

1

1

1

1

1

13

1

(Z004M203H10)

13Pcs/set

E07 016 232

E02 527 521

E07 001 009

E07 016 290

E07 016 006

E07 016 522

E07 016 245

—

E07 016 523

E07 016 297

—

—

E07 016 249

FRONT PANEL

FAN GUARD

HANDLE

BASE

PANEL COVER

REAR PANEL

SERVICE PANEL

LABEL

REAR GUARD

TOP PANEL

MOTOR SUPPORT

SCREW

LEFT SIDE PANEL

PU-5TJSA.TH PU-6TJSA.TH

PU-5XJSA.TH PU-6XJSA.TH

1

13

12

11

10

9

7

8

6

2

3

5

34

21

Page 22

FUNCTIONAL PARTS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

FUSE HOLDER

FUSE

COMPRESSOR PROTECTOR

FAN MOTOR

HEAT EXCHANGER

PROPELLER FAN

NUT

CHARGE PLUG

COMPRESSOR

BALL VALVE

BALL VALVE

LOW PRESSURE SWITCH

ACCUMULATOR

HIGH PRESSURE SWITCH

TERMINAL BLOCK

TERMINAL BLOCK

CONTACTOR

FAN MOTOR CAPACITOR

COMPRESSOR CAPACITOR

CAPILLARY TUBE

CAPILLARY TUBE

STRAINER

Part No. Part Name Specification

No.

Q,ty/set

PU-2

NJA.TH

Price

Unit

Amount

250V 5A

230V

PK6V85-UA

M8

NHJ33NBDT

3/8˝ (LIQ)

5/8˝ (GAS)

CUT 0.05MPa

CUT 3.3MPa

3P(L,N,;)

2P(1,2)

S-N20 200VAC

2.5+ 440V

50+ 440V

{3.2o{1.2o1000

{3.2o{2.0o430

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Remarks

F3

CP

MF3

MC

63L

63H

TB1

TB3

52C

C3

C

E07 001 241

E07 001 382

E07 197 330

E07 011 301

E07 002 630

E07 001 501

E07 070 508

E07 001 641

E07 190 900

E02 010 662

E07 001 661

E07 001 647

E07 002 932

E07 001 646

E07 006 375

E07 002 374

E02 177 342

E02 063 351

E02 946 353

E07 003 937

E07 002 936

E07 002 933

Wiring

Diagram

Symbol

Recommended

Q,ty

PU-2NJA.TH

1

2

3

4

5

6

7

Part numbers that are circled are not shown in the figure.

19

18

98

17

16

15

14

13

12

8

11

10

22

Page 23

FUNCTIONAL PARTS

Part No. Part Name Specification

No.

Q,ty/set

NJA.TH

PU-2.5 PU-3

NJA.TH

Wiring

Diagram

Symbol

Recommended

Q,ty

Price

Unit

Amount

Remarks

(Drawing No.)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

TB1

TB3

MF3

MC

MC

HC

63L

63H

52C

C3

CP

C

F3

E07 001 241

E07 006 375

E07 002 374

E07 003 630

E07 004 630

E07 001 501

E07 070 508

E07 011 301

E07 001 641

E07 191 900

E07 192 900

E07 199 240

E02 010 661

E02 010 662

E07 003 932

E07 001 647

E07 001 646

E02 177 342

E02 138 351

E07 197 330

E02 177 353

E07 001 382

E07 198 933

E07 003 936

E07 070 936

E07 003 937

E07 199 936

FUSE HOLDER

TEAMINAL BLOCK

TEAMINAL BLOCK

HEAT EXCHANGER

HEAT EXCHANGER

PROPELLER FAN

NUT

FAN MOTOR

CHARGE PLUG

COMPRESSOR

COMPRESSOR

CRANKCASE HEATER

BALL VALVE

BALL VALVE

ACCUMULATOR

LOW PRESSURE SWITCH

HIGH PRESSURE SWITCH

CONTACTOR

FAN MOTOR CAPACITOR

COMPRESSOR PROTECTOR

COMP.RUN CAPACITOR

FUSE

STRAINER

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

3P(L,N,

;)

2P(1,2)

M8

PK6V85-UA

NHJ38NBDT

NHJ47NADT

240V 38W

5/8"(Gas)

3/8"(Liquid)

S-N25EX

3.0µF/440VAC

60µF/440VAC

250V 5A

[3.2O[1.6-L760

[3.2O[1.8-L800

[3.2O[1.2-L1000

[3.2O[1.6-L500

PU-2.5NJA.TH

PU-3NJA.TH

1

2

20

19

18

17

16

15

3

4

5

6

Part numbers that are circled are not shown in the figure.

87

9

23

14

13

8

12

11

10

Page 24

FUNCTIONAL PARTS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

TERMINAL BLOCK

TERMINAL BLOCK

FAN MOTOR

HEAT EXCHANGER

PROPELLER FAN

NUT

HIGH PRESSURE SWITCH

CHARGE PLUG

THERMAL SWITCH

COMPRESSOR

CRANKCASE HEATER

BALL VALVE

BALL VALVE

CAPILLARY TUBE

LOW PRESSURE SWITCH

ACCUMULATOR

COMPRESSOR CONTACTOR

ANTI-PHASE PROTECTOR

COMPRESSOR PROTECTOR

FAN MOTOR CAPACITOR

FUSE

FUSE HOLDER

CAPILLARY TUBE

STRAINER

Part No. Part Name Specification

No.

TJSA.TH

Price

Unit

Amount

3P(L,N,;)

2P(1,2)

PK6N60-UA

M8

CUT 3.3MPa

NHJ56TKAT

240V 38W

3/4˝ (GAS)

3/8˝ (LIQ)

{3.2o{2.0o840mm

CUT 0.05MPa

MSO-N25KF 230V AC

230V

4+ 440V AC

250V 5A

{3.2o{1.2o500mm

1

1

2

2

2

2

1

2

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

1

Remarks

TB1

TB3

MF3,4

63H

26C

MC

HC

63L

51C,52C

47

CP

C3, C4

F3

E07 193 374

E07 002 374

E07 005 301

E07 005 630

E07 001 501

E07 070 508

E07 001 646

E07 001 641

E07 005 308

E07 193 900

E07 200 240

E07 005 661

E02 010 662

E07 005 936

E07 001 647

E07 005 932

E07 193 340

E07 200 344

E07 197 330

E02 064 351

E07 001 382

E07 001 241

E07 005 937

E07 200 933

Wiring

Diagram

Symbol

Recommended

Q,ty

Q,ty/set

PU-4

PU-4TJSA.TH

2122

1

1920

18

17

2

3

4

5

6

Part numbers that are circled are not shown in the figure.

16

15

14

13

12

11

7

8

9

10

24

Page 25

FUNCTIONAL PARTS

Part No. Part Name Specification

No.

Q,ty/set

TJSA.TH

PU-5

PU-6

Wiring

Diagram

Symbol

Recom-

mended

Q,ty

Price

Unit

Amount

Remarks

(Drawing No.)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

2

2

2

2

1

1

1

1

1

2

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

2

2

2

1

1

1

1

1

2

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

MF3,4

63H

MC

MC

26C

51C,52C

C3,C4

47

TB1

CP

F3

TB3

63L

FAN MOTOR

HEAT EXCHANGER

HEAT EXCHANGER

PROPELLER FAN

NUT

HIGH PRESSURE SWITCH

COMPRESSOR

COMPRESSOR

BALL VALVE

BALL VALVE

THERMAL SWITCH

CHARGE PLUG

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

ACCUMULATOR

CONTACTOR

FAN MOTOR CAPACITOR

ANTI-PHASE PROTECTOR

TERMINAL BLOCK

COMPRESSOR PROTECTOR

FUSE

TERMINAL BLOCK

FUSE HOLDER

LOW PRESSURE SWITCH

STRAINER

STRAINER

DIS PRESSURE REGULATOR

E07 194 301

E07 035 630

E07 037 630

E07 001 501

E07 070 508

E07 001 646

E07 194 900

E07 195 900

E07 005 661

E02 010 662

E07 035 308

E07 001 641

E07 016 936

E07 195 936

E07 035 937

E07 037 937

E07 016 932

E07 194 340

E02 064 351

E07 200 344

E07 193 374

E07 197 330

E07 001 382

E07 002 374

E07 001 241

E07 201 647

E07 037 933

E07 015 933

E02 069 644

PK6N65-UA

M8

ZR61KCTF5

ZR68KCTF5

5/8"(GAS)

3/8"(LIQ)

[4.0O[2.4-L840

[4.0O[2.4-L740

[4.0O[2.4-L400

[4.0O[2.4-L200

MSO-N25KF

4.0µ F/440VAC

5P (L1,L2,L3,N,;)

250V 5A

2P (1,2)

PU-5TJSA.TH

PU-6TJSA.TH

19

20

21

1

18

17

16

15

14

13

2

3

1

Part numbers that are circled are not shown in the figure.

2

3

12

11

10

9

4

5

25

6

8

7

Page 26

FUNCTIONAL PARTS

Part No. Part Name Specification

No.

Q,ty/set

XJSA.TH

PU-5

PU-6

Wiring

Diagram

Symbol

Recommended

Q,ty

Price

Unit

Amount

Remarks

(Drawing No.)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

2

2

2

2

1

1

1

1

1

2

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

2

2

2

1

1

1

1

1

2

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

MF3,4

63H

MC

MC

26C

52C

C3,C4

47

TB1

CP

F3

TB3

63L

FAN MOTOR

HEAT EXCHANGER

HEAT EXCHANGER

PROPELLER FAN

NUT

HIGH PRESSURE SWITCH

COMPRESSOR

COMPRESSOR

BALL VALVE

BALL VALVE

THERMAL SWITCH

CHARGE PLUG

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

CAPILLARY TUBE

ACCUMULATOR

CONTACTOR

FAN MOTOR CAPACITOR

ANTI-PHASE PROTECTOR

TERMINAL BLOCK

COMPRESSOR PROTECTOR

FUSE

TERMINAL BLOCK

FUSE HOLDER

LOW PRESSURE SWITCH

STRAINER

STRAINER

DIS PRESSURE REGULATOR

E07 194 301

E07 035 630

E07 037 630

E07 001 501

E07 070 508

E07 001 646

E07 204 900

E07 205 900

E07 005 661

E02 010 662

E07 035 308

E07 001 641

E07 016 936

E07 195 936

E07 035 937

E07 037 937

E07 016 932

E07 204 340

E02 064 351

E07 005 344

E07 005 374

E07 197 330

E07 001 382

E07 002 374

E07 001 241

E07 201 647

E07 037 933

E07 015 933

E02 069 644

PK6N65-UA

M8

ZR61KCTF7

ZR68KCTF7

5/8"(GAS)

3/8"(LIQ)

[4.0O[2.4-L840

[4.0O[2.4-L740

[4.0O[2.4-L400

[4.0O[2.4-L200

MSO-N20KF

4.0µ F/440VAC

5P (L1,L2,L3,N,;)

250V 5A

2P (1,2)

PU-5XJSA.TH

PU-6XJSA.TH

19

20

21

1

18

17

16

15

14

13

2

3

1

Part numbers that are circled are not shown in the figure.

2

3

4

12

11

10

9

5

26

6

7

8

Page 27

10 OPTIONAL PARTS

538

537

5247

524

72

7

4O{6 hole

7

7

AIR OUTLET GUIDE

This guide is needed for changing the direction of the outdoor unit’s air discharge upward or downward. For PU-4~6, 2 pcs

of PAC-292SG are needed.

Part No. PAC-292SG

Unit : mm

27

Page 28

TM

HEAD OFFICE : MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

CCopyright 2005 MITSUBISHI ELECTRIC ENGINEERING CO., LTD.

Issued in Aug. 2005. No. OC353 PDF 8

Made in Japan.

New publication, effective Aug. 2005

Specifications subject to change without notice.

Loading...

Loading...