Page 1

MITSUBISHI

ADVANCED

AND

EVER

ADVANONG

MnSUBISHI

ELECTRIC

Industrial Sewing

INSTRUCTION

Machine

MANUAL

Data input System for Electronic Pattern Sewing

Machine

Model

PTN-A10

A180E228P01

Page 2

*

All

right of this manual

without

our

previous approval.

* The specifications

without previous notice.

are

and

contents of

reserved

and

should not

the

manual may

* Yourquestion or inquiry about any part of this manual is accepted by us.

*

COPYRIGHT01991

MITSUBISHI

ELECTRIC

CORPORATION

be

cited partly or totally

be

subjecttochange

Page 3

Thank you for your

purchase

Sewing Machine. Before

carefully

instructions

and

install,

written

operate

here.

of Mitsubishi Data Input System for Electronic Pattern

use

of your Data Input System,

and

maintain your

system

please

in

accordance

read this manual

vyith

the

PTN-AIO is a

Electronic Sewing Machines

• Maximum

• Stitch length

resolution

• For stitch

• Maximum 150 stitching

floppy disk.

Maximum 16 stitching patterns

• Smooth curve

plural

• Data of circle or

specifying the stitch length

8000

of

pattem

points

data

0.1

on

input

stitches

can

mm.

data

data

the

arc

system

can

be

set

storage,

patterns

can

be createdautomatically by specifyingthe stitch length

cunre.

can

used

and

be

within

to

create

has

the

following features:

storedinthe

the

range

floppy disks

and

a total 360000 stitches

and

a total 8000 stitches

be

made automatically

and

3 points on a circle or an arc.

sewing

dataofeach

data

from 0.1 mm

and

PROM

can

can

and

in a specified

for Mitsubishi Industrial

stitching pattern.

to

12.7 mm with

be

used.

can

be

stored in a PROM.

be

stored

sequence

• Zigzag data between 2 points can be made automatically by specifying the

and

pitch of zigzag,

and

2 points.

the

in a

and

by

width

• Function selecting menu, operation procedures and various

displayed

• Pattem

•

If

the system is connected

modified

• Pattem dataon a floppy disk can be read,

the

data

•

If

the system is connected with an electronic sewing machine, pattem

communicated

on

the

data

can

and

added.

onaPROM.

between

screen.

be

enlarged, reduced, tumed around

with

an electronicsewing machine, pattem data can be

written

them.

and

modified.

or deleted. The same applies to

messages

data

can

are

be

Page 4

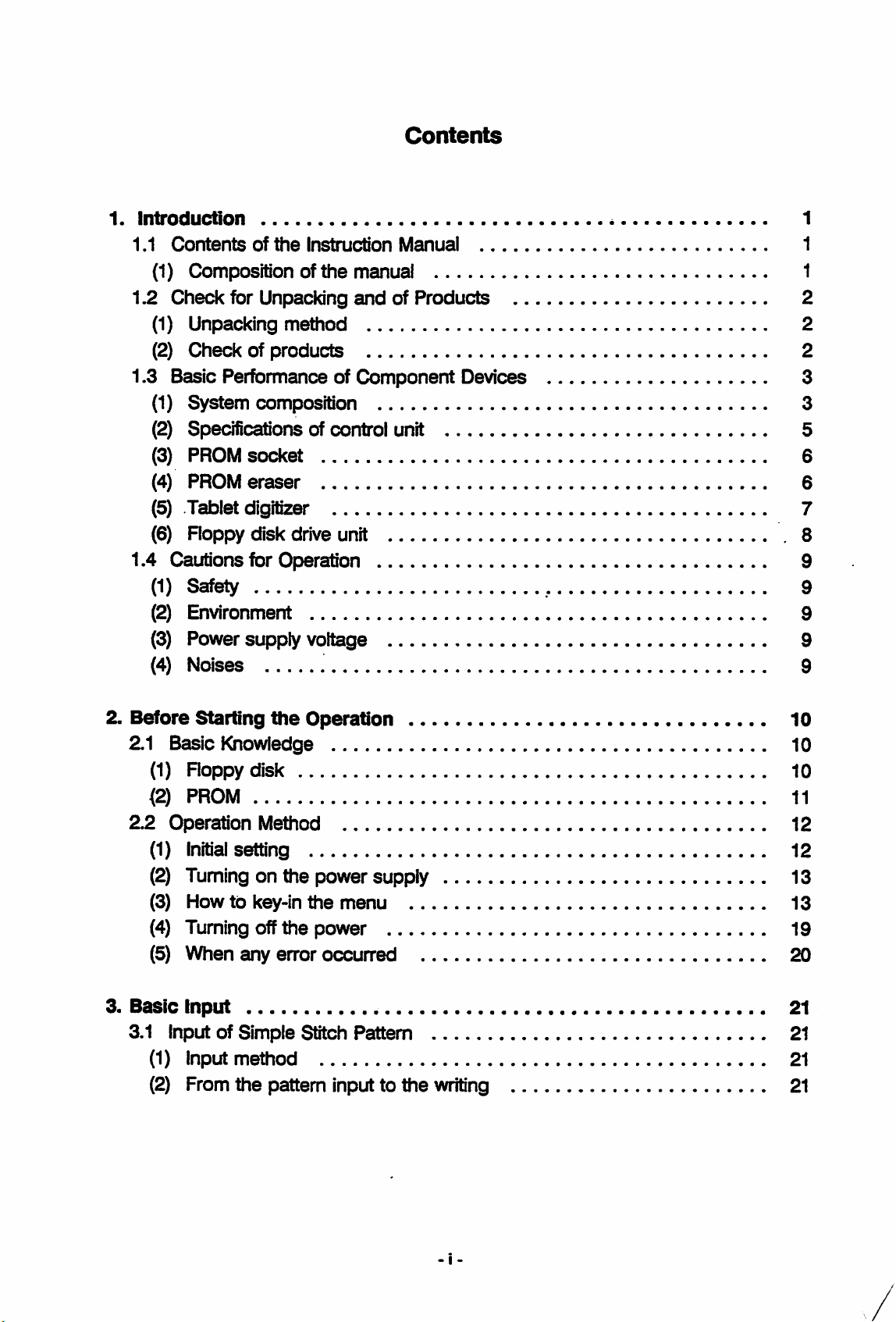

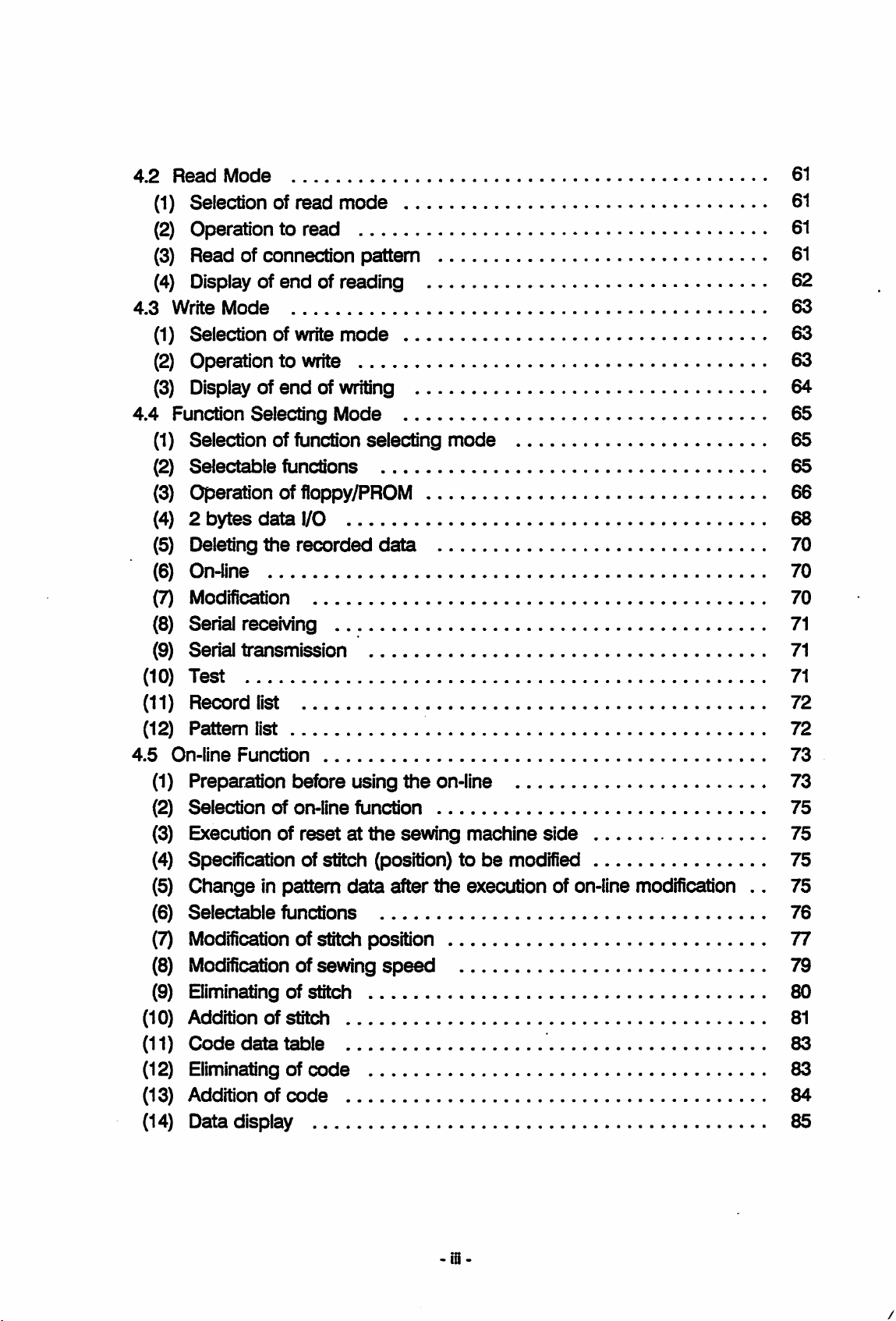

1.

Introduction

1.1

Contents

of

the

Instruction

Contents

Manual

1

1

(1) Composition of

1.2 Check for Unpacking

the

manual 1

and

of Products 2

(1) Unpacking method 2

(2)

Check

of products 2

1.3 Basic Performance of Component Devices 3

(1) System composition 3

(2) Specifications of control unit 5

(3) PROM

(4) PROM

socket

eraser

(5) Tablet digitizer 7

(6)

Roppy

disk drive unit 8

1.4 Cautions for Operation 9

(1) Safety 9

(2) Environment 9

(3) Power supply voltage 9

(4)

Noises

2. Before Starting

the

Operation

2.1 Basic Knowledge 10

6

6

9

10

(1)

Roppy

disk 10

(2) PROM 11

2.2

Operation Method 12

(1)

Initial

setting 12

(2) Tuming on the power supply 13

(3) Howtokey-in

the

menu

(4) Tuming offthe power 19

(5) When

3.

Basic

Input

3.1 Input of Simple Stitch

any

error occurred

Pattem

(1) Input method 21

(2)

From the pattem input to the writing 21

13

20

21

21

-1

Page 5

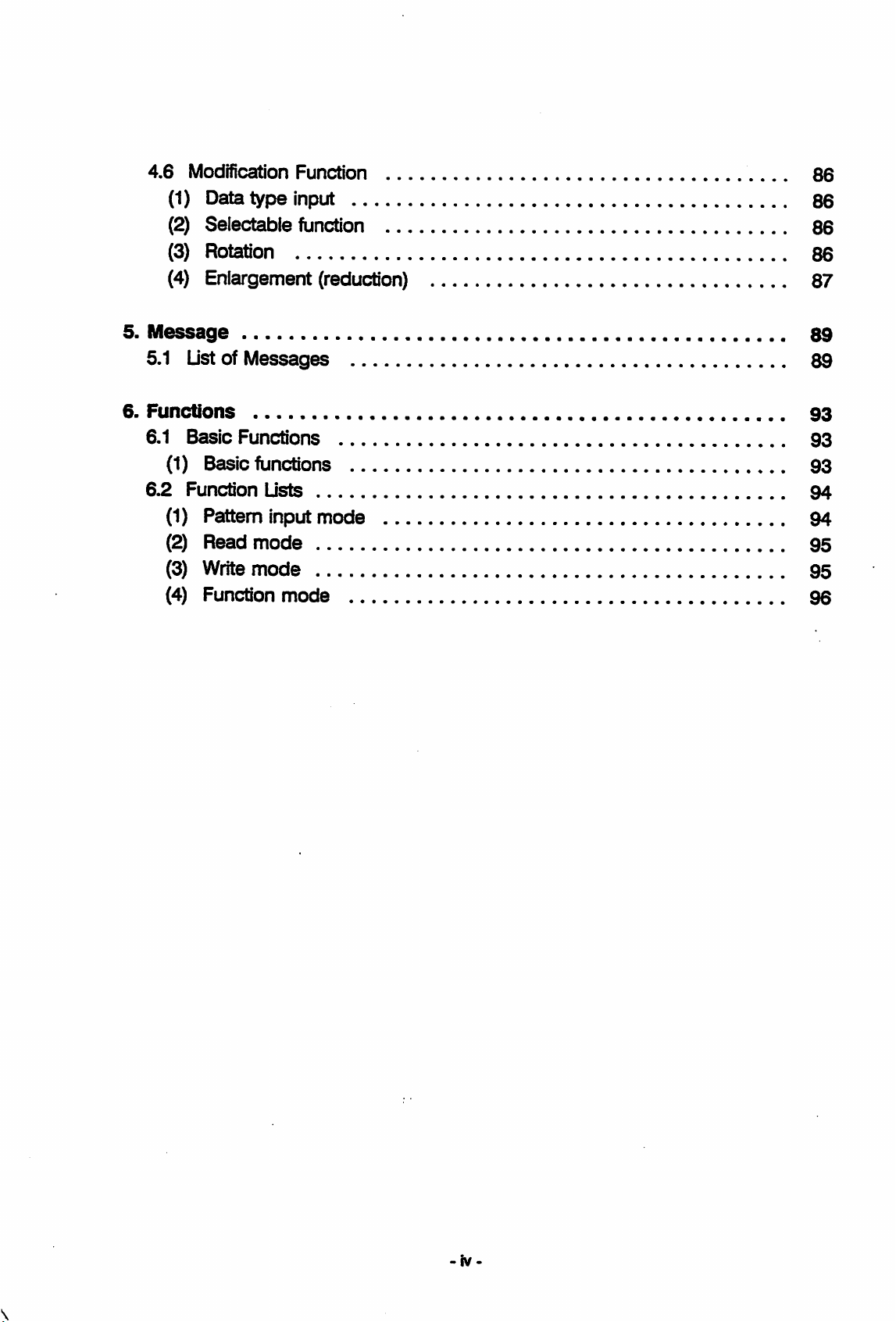

4.

Reference

4.1 Pattern Input

Mode

36

36

(1) Pattern input

(2) Setting

(3) Input operation

the

mode

input conditions

selection

36

36

38

(4) Start of pattem input 38

(5)

Selectable

(6)

Record

(7) Recall :

(8) Clear of

(9) Deleting

(10) On-line

(11) Modification

(12) Serial transmission

(13)

(14) Curve (SPUNE) 43

(15)

(16) Input

(17)

(18)

Change

Sewing

Stitchlessfeed (FED-*) 46

Second origin

functions

pattem

the

of input conditions 43

speed

method

data

recorded

data

change ! 44

change

(GRIG)

38

39

40

41

41

42

42

42

45

47

(19)

Stop (STOP) 47

(20) Reverse

(21)

Xsymmetry

(22)

Ysymmetry

(23)

Point symmetry

(24)

Circle (CIR-*) 49

(25)

Arc

(ARC-

(26)

(27)

(28)

(29)

(30)

(31)

(32)

(33)

(34)

Zigzag

Thread trimming

Origin retum

End

(END)

Straight line clear

1 stitch clear

Function code

Record list (RC US) 58

Pattem

(REVER)

(X-INV)

(Y-INV)

*)

(ZIGZA)

(RTN)

(1-CLR)

list

(FT

(XY-INV)

(TRIM)

(L-CLR)

(FUNCT)

US)

47

47

48

48

49

50

56

56

56

56

56

57

59

-H

Page 6

4.2

Read

(1)

Mode

Selection of read mode

(2) Operation to read 61

(3) Read of connection pattem 61

(4) Display of

4.3

Write

Mode

(1) Selection of write

end

of reading 62

mode

(2) Operationtowrite 63

61

61

63

63

(3) Display of

4.4

Function Selecting

(1) Selection of function selecting

(2)

Selectable

end

of writing 64

Mode

mode

functions

(3) Operation of floppy/PROM 66

(4) 2

(5) Deleting

bytes

data

the

I/O

recorded

data

(6) On-line 70

(7) Modification

(8) Serial receiving 71

(9) Serial transmission 71

(10)

Test

(11)

Record

(12)

Pattem

4.5

On-line

(1) Preparation before using

(2)

Selection

(3) Execution of

(4) Specification of stitch (position)tobe

list

list

Function

of on-line function

resetatthe

the

on-line

sewing

machine

side

modified 75

65

65

65

68

70

70

71

72

72

73

73

75

75

(5)

Change

in pattem

data

after

the

execution of on-line modification

(6) Selectable functions

(7) Modification of stitch position 77

(8)

Modification of sewing

speed

(9) Eliminating of stitch 80

(10) Addition of stitch 81

(11)

Code

(12) Eliminating of

(13) Addition of

data

table

code

code

(14) Data display 85

..

75

76

79

83

83

84

Page 7

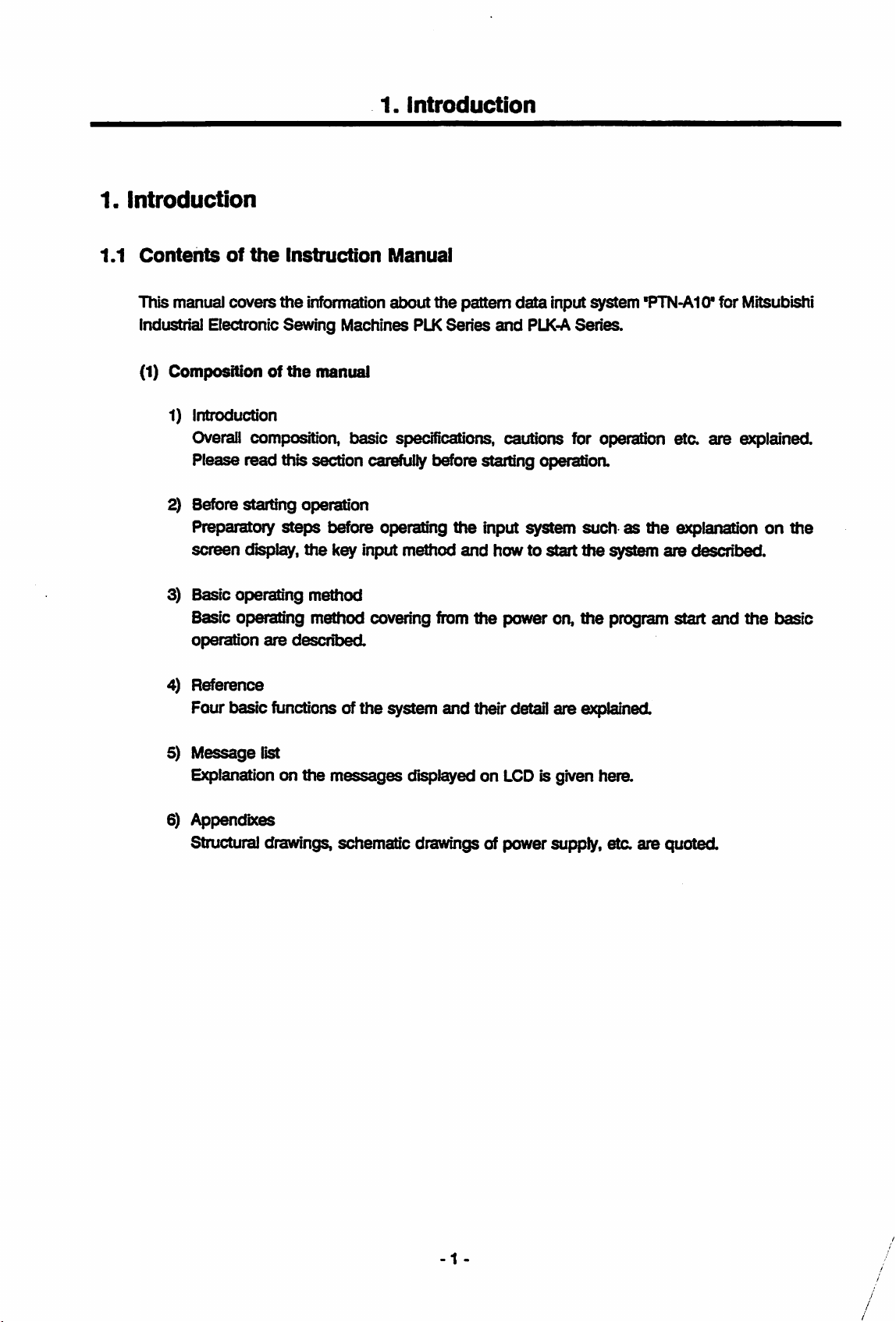

4.6

Modffication Function

(1) Data

type

86

input 86

(2) Selectabie function

(3) Rotation

(4)

Enlargement (reduction) 87

5.

Message

5.1 Listof

6-

Functions

6.1 Basic Functions

(1) Basic functions

6.2

Function Lists

Messages

(1) Pattem input mode

(2)

Read

(3) Write

(4) Function

mode

mode

mode

86

86

89

89

93

93

93

94

94

95

95

96

-IV

Page 8

1.

Introduction

1.1

Contents

of

the

Instruction

1.

Introduction

Manual

This manual covers

the

information aisout

industrial Electronic Sewing Machines

(1)

Compositionofthe

1) Introduction

manual

Overall composition, basic specifications, cautions for operation etc.

Please

read

this section carefully t)efore staiUng

2) Before starting operation

Preparatory

screen

steps

display,

before operating

the

key input method

3) Basic operating method

Basic operating method covering from

operation

4)

Reference

Four basic functions of

5)

Message

Explanation on

are

list

described.

the

messages

the

system

the

pattern

PLK

Series

the

input system

and

the

and

their detail are explained.

displayed on

data

input system

and

PLK-A

operatioa

how to start

power on,

LCD

is given here.

Series.

suchasthe

the

system

the

program start

'PTN-A10*

explanation

are

described.

for Mitsubishi

are

explained.

on

and

the

basic

the

6) Appendixes

Structural drawings, schematic drawings of power supply, etc. are quoted.

-1

-

Page 9

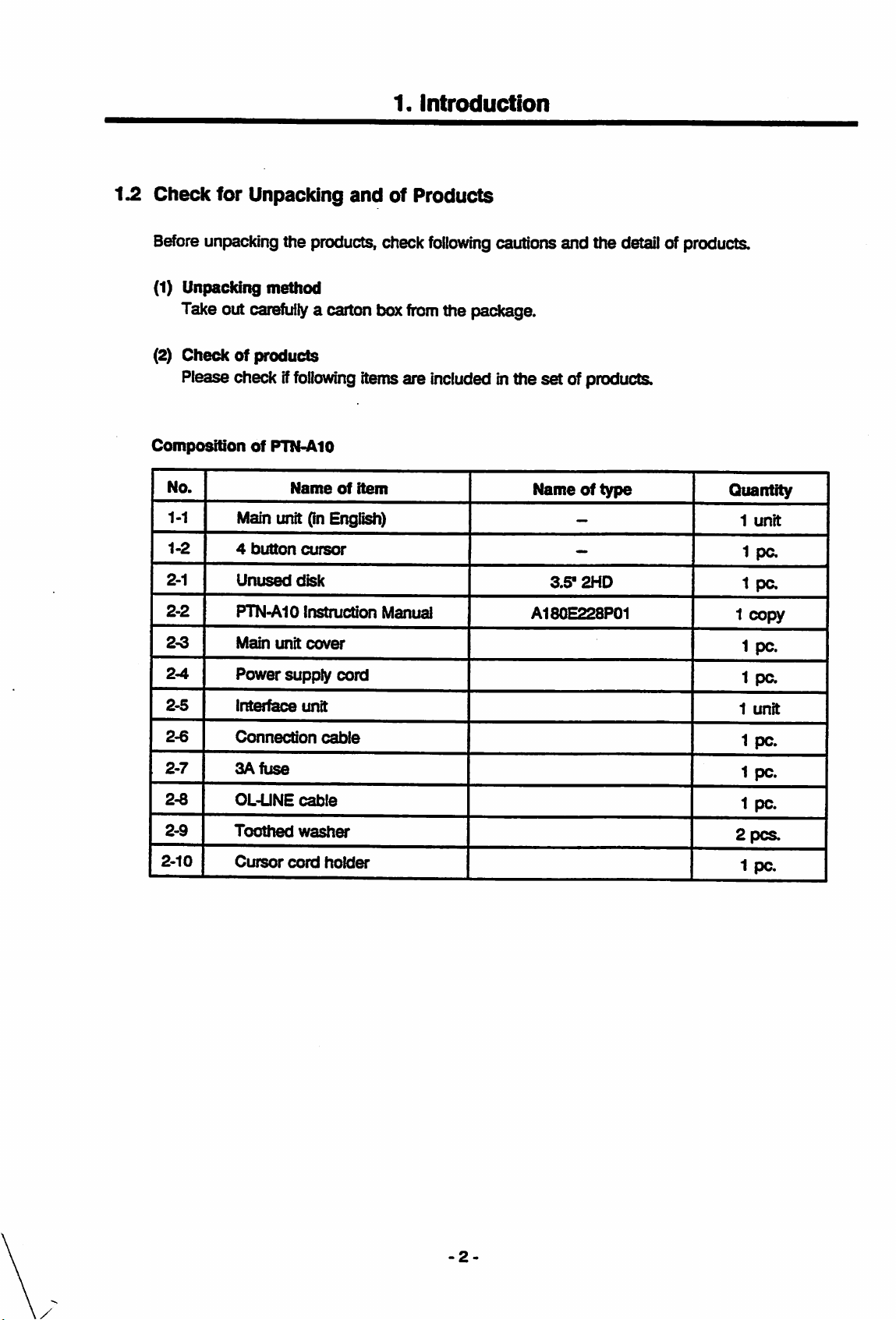

1.2

Check

for Unpacking

and

1.

Introduction

of

Products

Before

unpackingthe products, check

(1) Unpacking method

Take out

(2)

Checkofproducts

Please check if

carefully

foilowing

a carton box

CompositionofPTN-AIO

No.

1-1

1-2

2-1

2-2

2-3

2-4

Main unit (In English)

4

Unused

PTN-AIO

Main

Power

button

unit

Name

cursor

disk

Instruction

cover

supply

foilowing

from

the package.

cautions and the detailof products.

itemsare includedInthe set ofproducts.

of

item

Manual

cord

Nameoftype

—

—

3.5-

2HD

A180E228P01

Quantity

1

unit

1

pa

1

pa

1

copy

1

pc.

1

pa

2-5

2-6

2-7

2-8

2-9

2-10

Interim

Connection

3A

fuse

OL-UNE

Toothed

Cursor

cord

unit

cable

cable

washer

holder

1

unit

1

pc.

1

pc.

1

pc.

2 PCS.

1

pc.

-2-

Page 10

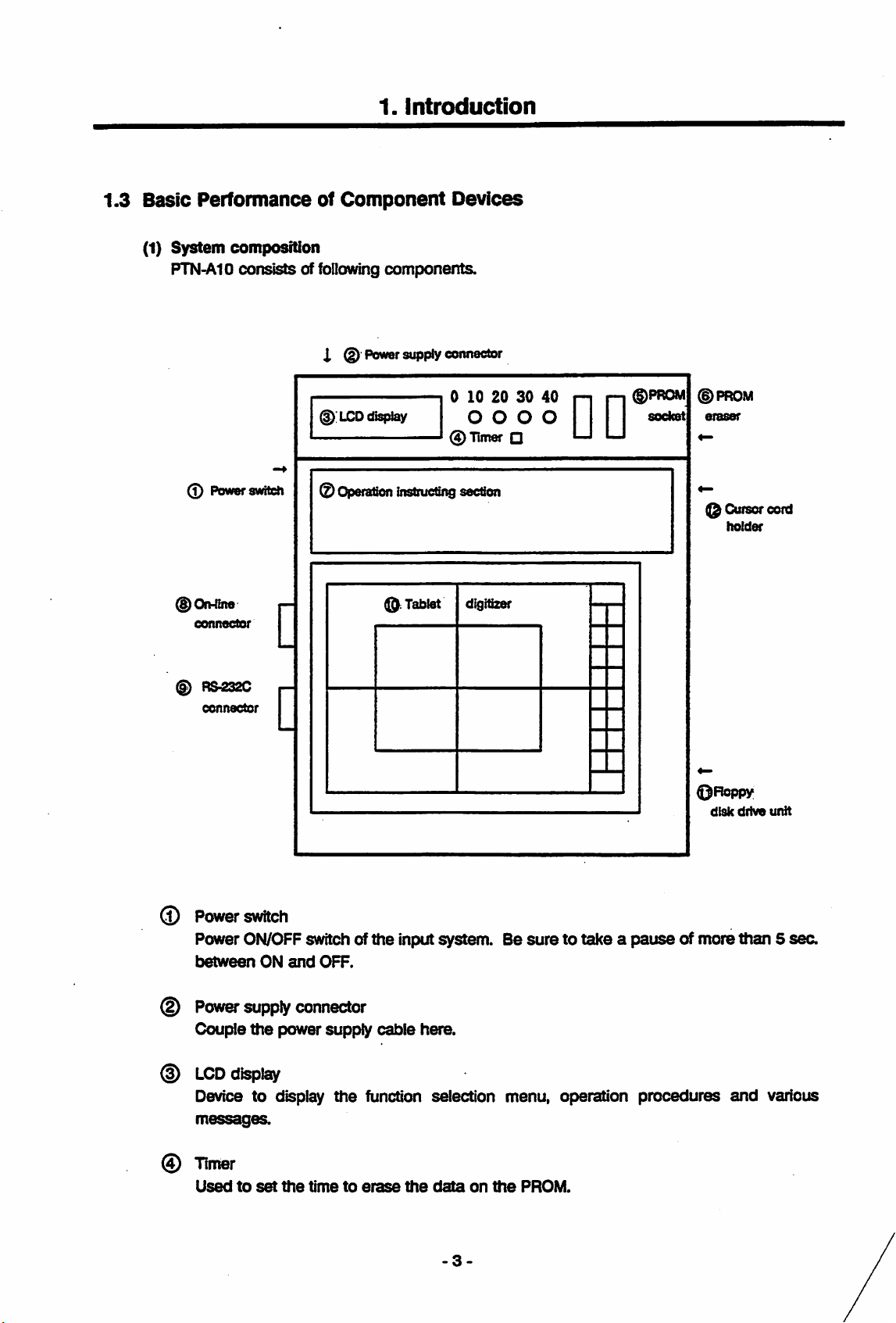

1.3

Basic

(1)

System

PTN-A10

1.

introduction

PerformanceofComponent

composition

consists

of fcllawing

X ®

Power

components.

supply

Devices

connector

0

Powerswiteh

(§)On-nne

connector

(§)

RS232C

connector

d);

LCD

®

Operatton

display

Instructing

©Tablet

010203040

O O O O socket

0

Timer

• LJ LJ

n n

section

digitizer

©PROM

eraser

©Cursorcord

holder

0Roppy

disk

drive

unit

©

Power

Power

between

(f)

Power

Couple

(D

LCD

Device to display

®

Timer

Usedtoset

switch

ON/OFF

ON

supply

the

display

switch of

and

OFF.

connector

power supply

the

the

timetoerase

the

input system. Be

cable

here.

suretotakeapause

function selection menu, operation

the

data

on

the

FROM.

3-

of more than 5

procedures

and

sec.

various

Page 11

(f)

PROM

Device to write in

©

PROM

Usedtoerase

©

Operation

Brief

explanation on the operating method,

©

On-fine

On-fine

©

RS-232C

RS-232C

@

Tablet

Patters

socket

and

eraser

the

data

instructing

connector

cableisconnected

connector

interface

cableisconnected

digitizer

and

menus

are

1.

Introduction

read

fronn

savedinthe

section

hera

k^edinhera

the

PROM

PROM.

hera

which

code

saves

No.,

the

eta

is displayed.

pattern

data

O

Floppy

Unitto write in or read from

Cursor

It

retains

disk

cord

the

drive

holder

cursor

unit

cord

the

holder.

floppy disk which

saves

the

pattern

data

-4

Page 12

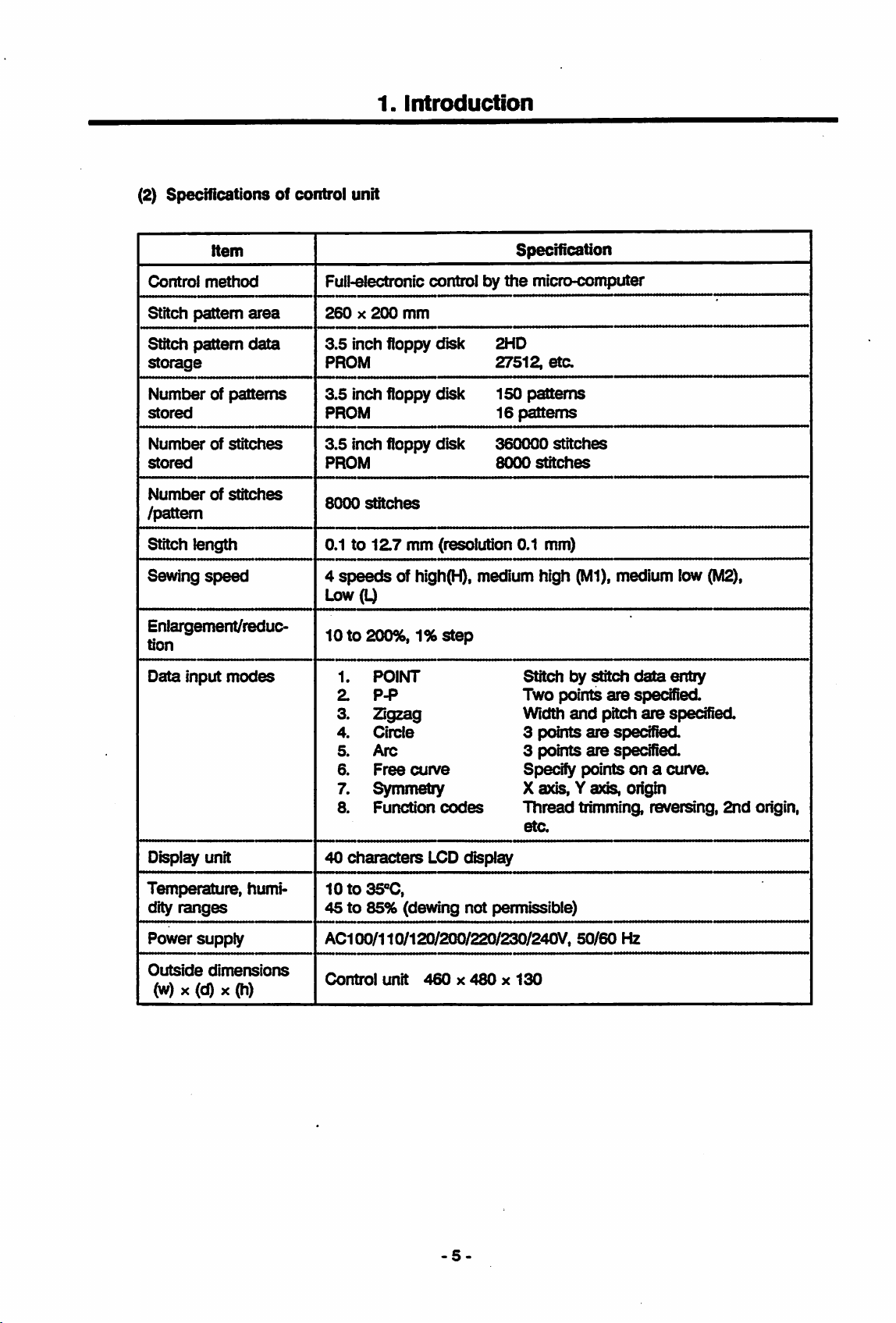

(2) Specifications of control unit

1.

Introduction

Item

Control

Stitch

Stitch

storage

method

pattem

pattem

area

data

Numberofpatterns

stored

Number

stored

Number

of

of

stitches

stitches

/pattern

Stitch length

Sewing

speed

Enlargement/reduc

tion

Data

input

modes

Specification

FuMectronlc

260X200

3.5

inch floppy

PROM

3.5

inch floppy

PROM

3.5

inch floppy disk

PROM

8000

stitches

control by

mm

disk

disk

the

micro-computer

2HD

27512,

150

16

360000

8000

etc.

patterns

patterns

stitches

stitches

0.1to12.7 mm (resolution 0.1 mm)

4

speeds

of high(H), medium high (Ml), medium low

Low (L)

10to200%,

1.

3.

4.

5.

6.

7.

8.

1%step

POINT

P-P

Zigzag

Circle

Arc

Free

curve

Stitchbystitch

Two points

Width

3

points

3 points

Specify pointsona cunre.

Symmetry X axis, Y axis, origin

Function

codes

Thread

etc.

data

entry

are

specified.

and

pitch

are

specified

are

specified

are

specified

trimming, reversing,

(M2),

2nd

origin.

Display unit

Temperature, humi

dity

ranges

Power

Outside

supply

dimensions

(w) XW X (h)

40

characters

LCD

dispiay

10to35«C,

45 to 85% (dewing not permissible)

AC100/110/120/200/220/230/240V,

Control

unit

460x480x130

50/60

Hz

Page 13

1.

Introduction

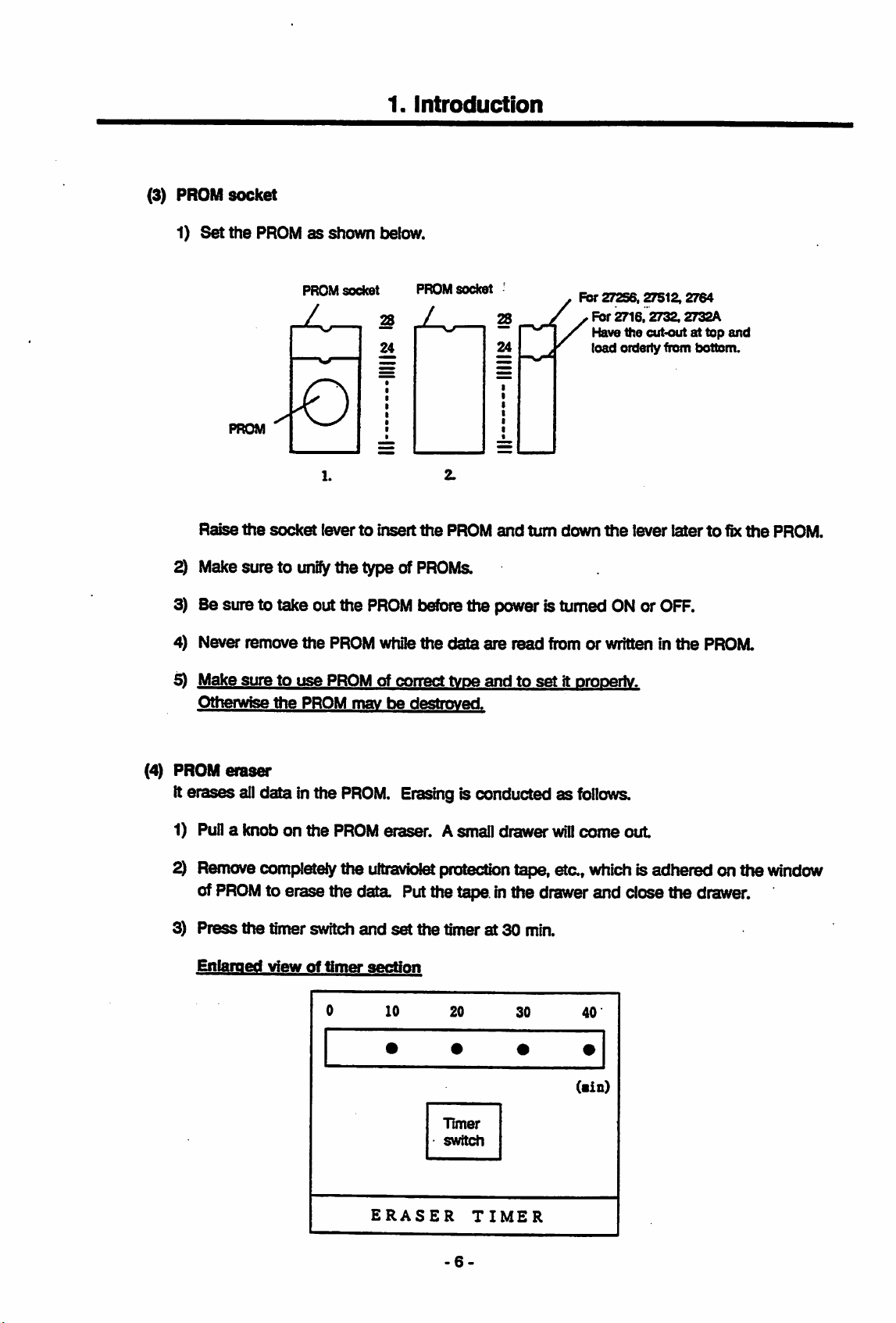

(3) PROM

1)

Set

Raise

socket

the

PROMasshown below.

PROM

the

socket

2) Makesure to

3) Be sure to take outthe

4) Never remove

PROM

socket

1.

levertoinsert

unify

the type of

the

PROM while

28

24

PROM

PROM

y

the

socket

PROM

28

24

and

turn

For

down

PROMs.

beforethe power is turned

the

data

are

read

fromorwritten In

27256,27512.2764

Fbr

2716,2732.2732A

Have

the

cut<outattop

load

orderlyfrom

the

lever

ONorOFF.

and

bottom.

latertofix

the

PROM.

the

PROM.

^ Make

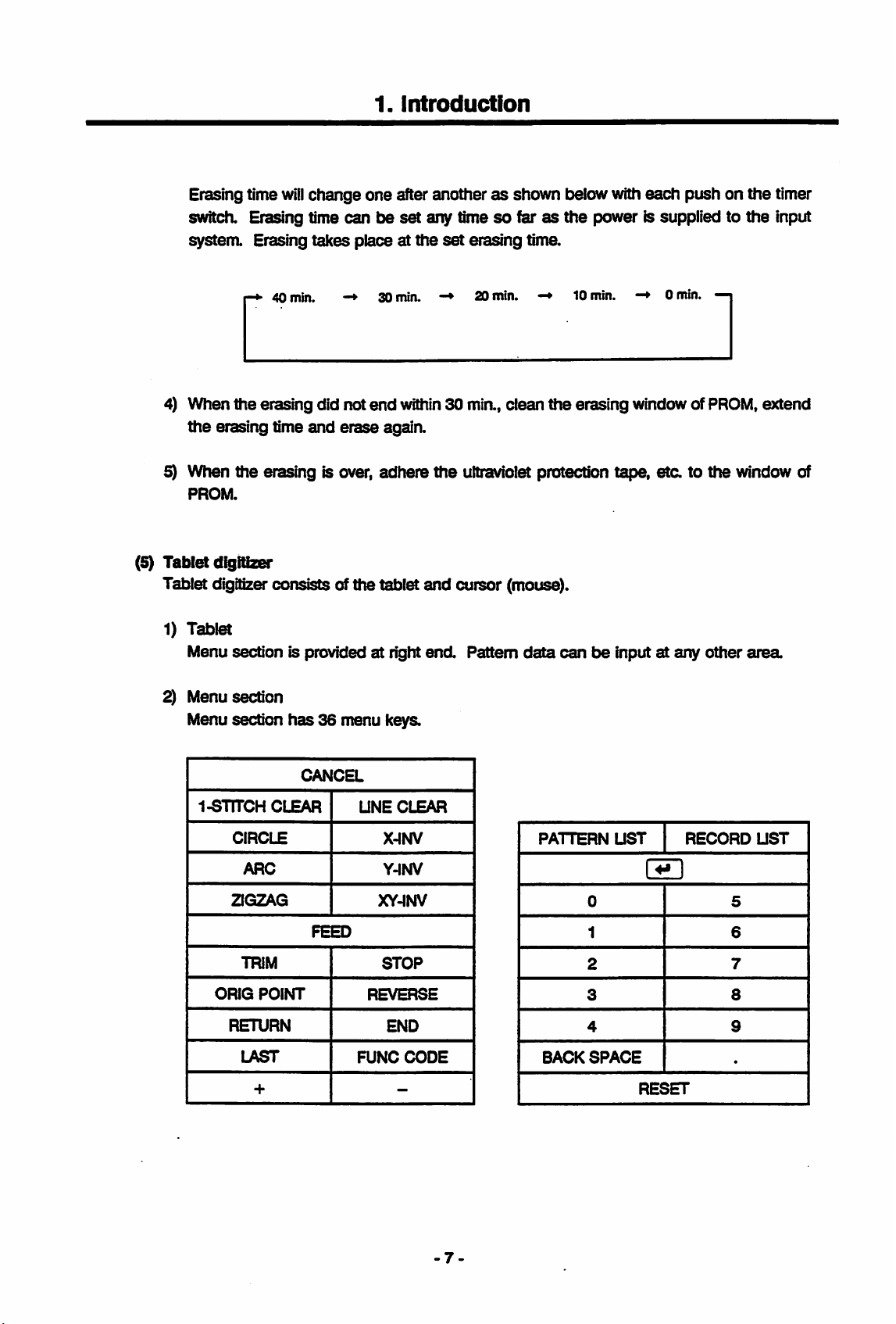

(4) PROM

suretouse

Otherwise

eraser

Iterases alldata inthe

1) Pull a

2)

3)

knobonthe

Remove

of

PROM

Press

the

Enlarged

completely the ultraviol^ protection tape,

the

PROM

PROM

of correct tvoe

mavbedestroved.

PROM.

Erasingis conductedasfollows.

PROM eraser. Asmall

andtoset

drawer

it oropeilv.

will

come

eta,

whichis adhered on the

to erase the data. Putttie tape inthe drawer and

timer

switch

viewoftimer

and

section

set

the

timerat30

Timer

switch

min.

out

dose

window

the drawer.

ERASER

TIMER

-6-

Page 14

1.

Introduction

Erasing time

switch. Erasing time

system. Erasing

4) When the erasing did not

the

erasing

5) When the erasing is over, adhere

PROM.

r*'

will

change one after anotherasshown

40min.

time

takes

and

canbeset

place at

30

end

erase

any timesofarasthe

the

set

erasing

min.

within

30 min., clean

again.

the

ultraviolet protection tape,

20

min.

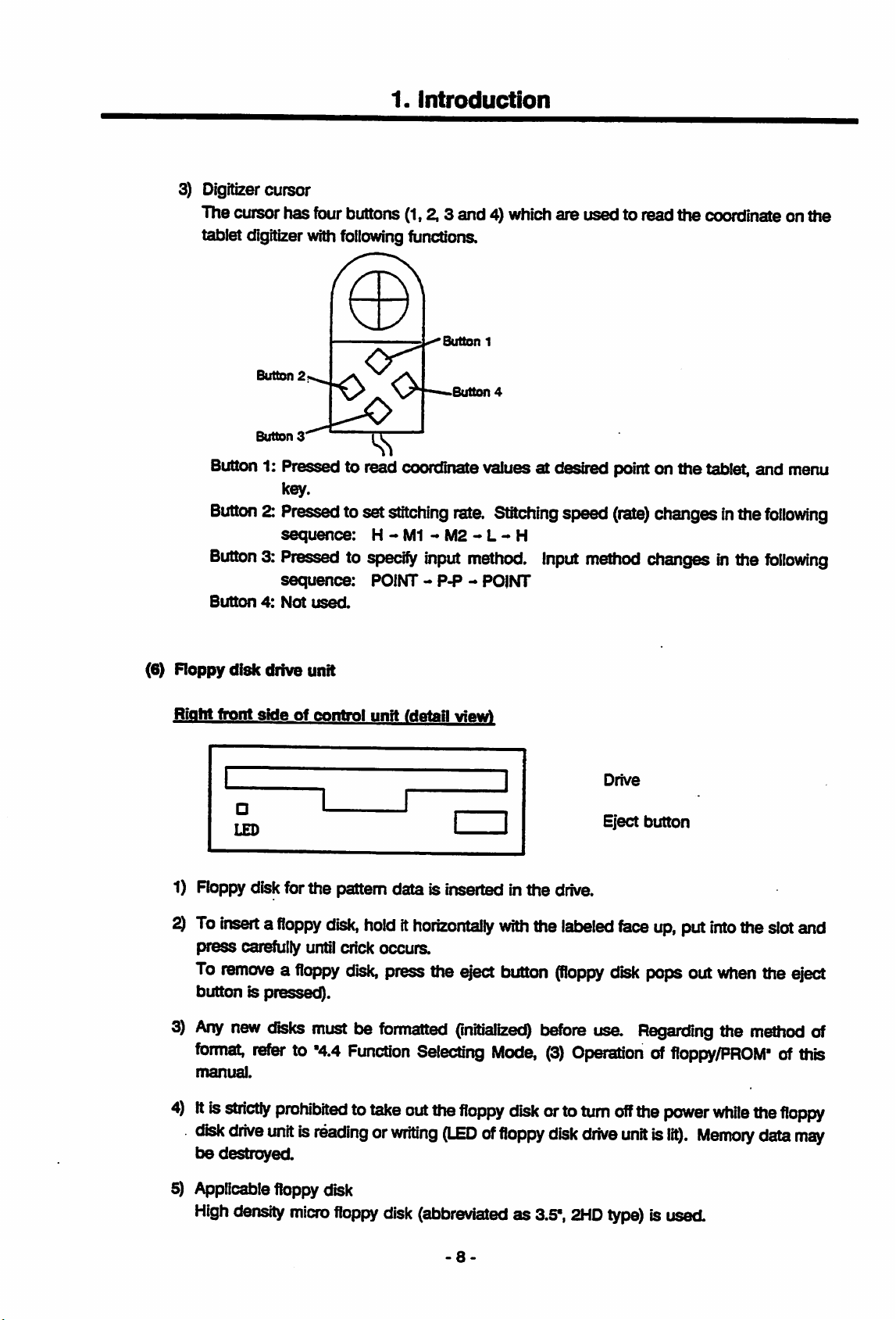

(5) Tablet digitizer

Tablet digitizer consists of the tablet and cursor (mouse).

1) Tablet

Menu section is provided at right

end.

Pattern

t>elow

with

power is supplied to

time.

10

min.

the

erasingwindow of

data

canbeinputatany

each

push on

0

min.

etatothe

—1

PROM,

window of

other

the

the

extend

area

timer

input

2) Menu section

Menu section

l-STITCH

CIRCLE

ARC

ZIGZAG

TRIM

ORIG

POINT

RETURN

LAST

+

has36menu keys.

CANCEL

CLEAR

FEED

UNE

REVERSE

FUNC

CLEAR

X-INV

Y-INV

XY-INV

STOP

END

CODE

-

PATTERN

0 5

1 6

2

3

4 9

BACKSPACE

UST

RESET

RECORD

7

8

UST

.

-7

Page 15

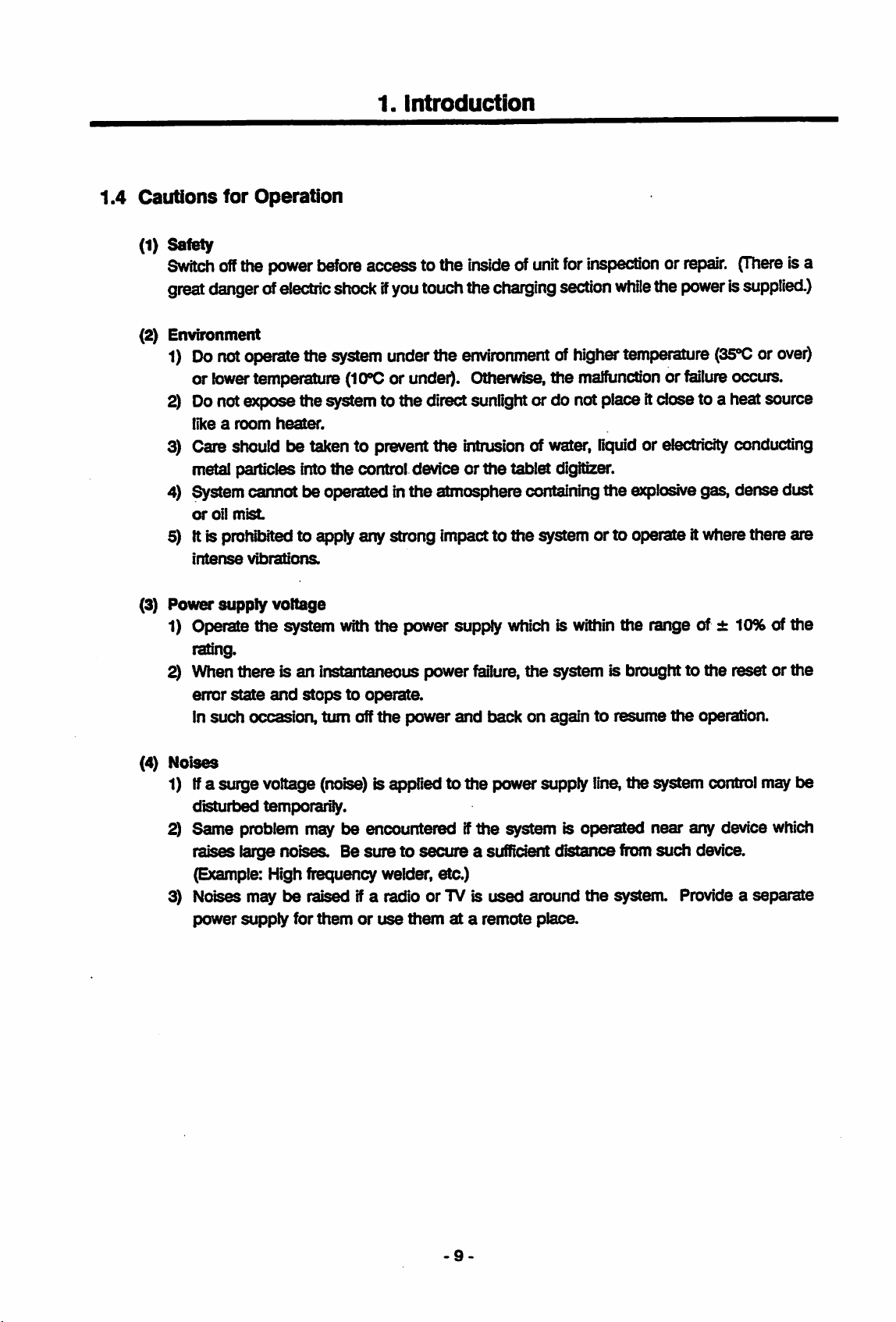

3) Digitizer cursor

The cufsor has fourbuttons

tablet digitizerwith

Button

Button

following

2

3

1.

Introduction

(1,2.3

functions.

Button

Button

and4}whichare used to read thecoordinate on the

1

4

Button

Button2:Pressed

Button3:Pressedtospecify

Button4:Not

(6)

Roppy

Right

1) Roppy diskforthe pattern data is inserted inthe

1: Pressed to read coordinate values at desired pointon thetablet, and menu

key.

toset

disk

front

sideofcontrol

sequence:

sequence:

used.

drive unit

stitching

H-M1

POINT -

unit

fdctail

rate.

-M2-L-H

input

method.

P-P-POINT

viewA

Stitching

Input

speed

drive.

(rate)

method

Drive

Eject

changesinthe

changesinthe

button

following

following

^

To

insertafloppy

press

carefully until crick occurs.

To

removeafloppy

button is pressed).

3)

Any

new

disks

format,

manual.

4)Itis

disk

be

5) Applicable

High

referto"4.4

stn'cUy

drive

unitisreadingorwriting

destroyed.

density

prohibitedtotake

floppy

disk,

holdithorizontally

disk,

press

mustbeformatted

Function

disk

micro

floppy

disk

with

the

eyect

button

(initialized)

Selecting

out

the

Mode,

floppy

disk

(LEDoffloppy

(abbreviatedas3.5",

-8

the

labeled

(floppy

before

(3)

orto

disk

face

up,

put

into

the

slot

and

disk

pops

out

when

the

eject

use.

Regarding

the

method

Operationoffloppy/PROM"ofthis

turn

off

the

drive

2HD

unitislit).

type)

isused.

power

while

the

Memory

data

floppy

may

of

Page 16

1.4

Cautions

(1)

Safety

Switch

great

(2) Environment

1)

2) Do not expose the system to the direct sunlight or do not place it

3) Care should be taken to prevent

4)

5) Itis prohibited to apply any strong impact to

for

Operation

off

the

power

dangerofelectric

Do

notoperatethe

or

lower

temperature

likearoom

metal particles into

^stem

or

oil

intense

heater.

cannot be operated inthe atmospherecontaining the

met

vibrations.

1.

t>6fore

access to the

shockifyou

system

(ICTC

the

control device or

introduction

insideofunit

touch

the

charging

underthe

or under). Otherwise, the

environmentofhigher

the

intrusionof water,

the

tablet digitizer.

the

system or to operate itwhere there are

for

inspectionorrepair.

section

while

the

temperature

matfunction

dose

liquid

or etectridty conducting

explosive

(There

powerissupplied.)

(35°Corover)

or falure occurs.

to a heat source

gas, dense dust

is a

(3)

Power

1) Operate the system

2) When there isaninstantaneous powerfailure,

(4)

Noises

1) Ifa

2)

3) Noises mayberaised if a radio or TV is

supply

rating.

error

Insuch occasion, turn off

surge

disturbed

Same

raises large noises. Be

(Example: High frequency welder, etc.)

power

voltage

with

the power supply which is

state

and

stopstooperate.

the

power

voltage (noise) is appliedtotfie power supply line,

temporarily.

problem may be encountered if

suretosecure

supply

for

themoruse

themata

within

the

system is broughttothe reset or

and

tsack on again to resume

the

system is operated near any device which

a sufficient distance from

used

remote

around

place.

the

the range of ± 10% of the

the

operation.

the

system control may

such

device.

system. Provide a

separate

the

be

9-

Page 17

2.

Before

2.1

Basic

(1)

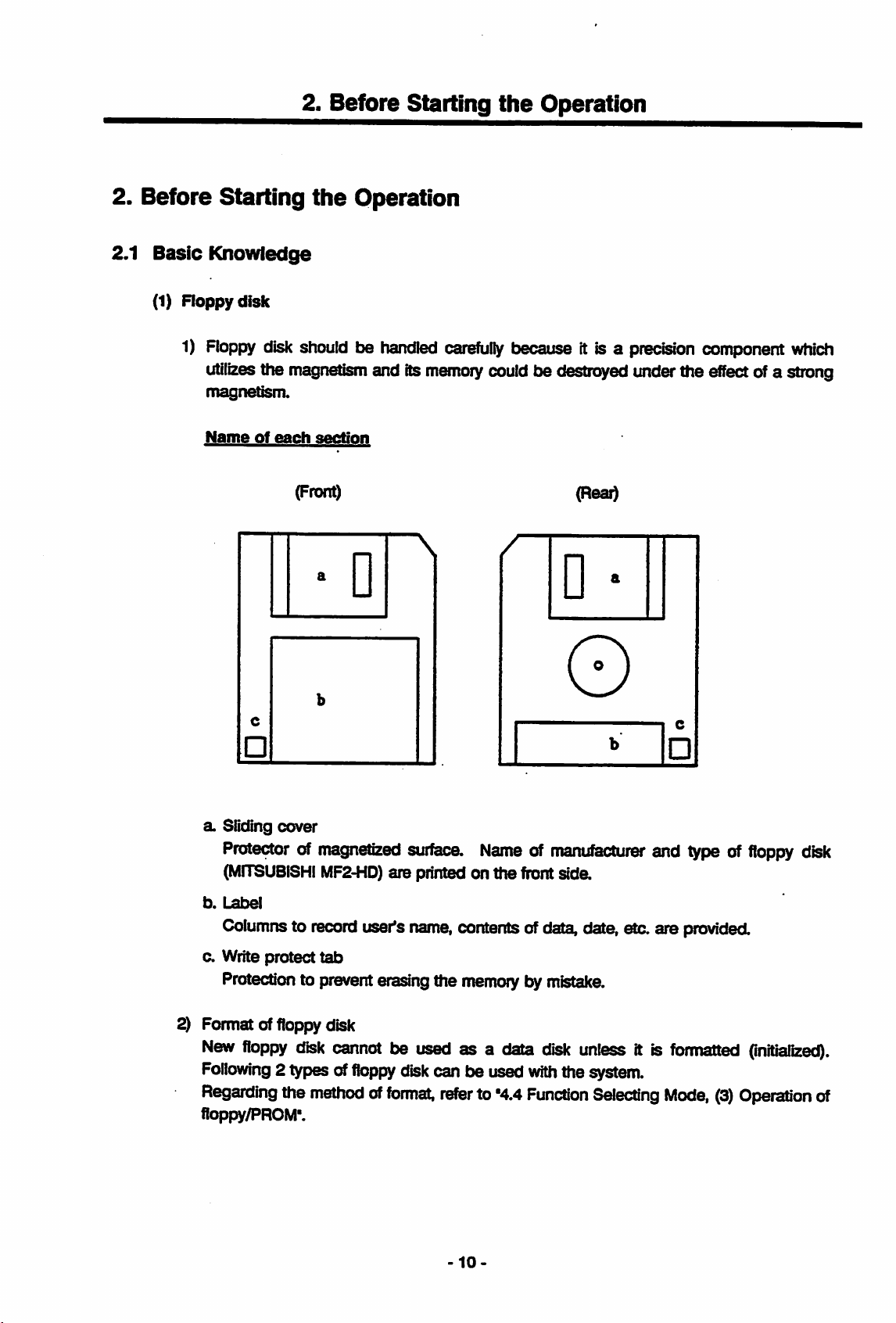

Roppydisk

1)

Starting

Knowledge

Floppy

utilizes

magnetism.

disk

the magnetism and its

2. Before Starting

the

Operation

should

be

handled

memory

carefully

the

Operation

because it is a

couldbe destroyedunder the effectof a strong

precision

component

which

Name

a. Sliding cover

of

each

section

(Front)

Protectorofmagnetized

(MITSUBISHI

MF2-HD)

D n

surf^.

are printed on the front

Nameofmanufacturer

sida

(Rear)

and type of

floppy

disk

b.

Label

Columnstorecord

a Write protect

Protection to preventerasingthe

2) Format of

New

Following

Regarding

floppy/PROM'.

floppy

floppy

2 types of

disk

the

methodofformat,

tab

disk

cannot

user's

name,

be used as a data

floppy

disk

can be used

refer

-10-

contentsofdata,

memorybymistake.

disk

with

the system.

to'4.4

Function

data

etc. are

unless

Selecting

it is

provided.

formatted

Mode,

(3)

(initialized).

Operation

of

Page 18

2.

Before

Starting

the

Operation

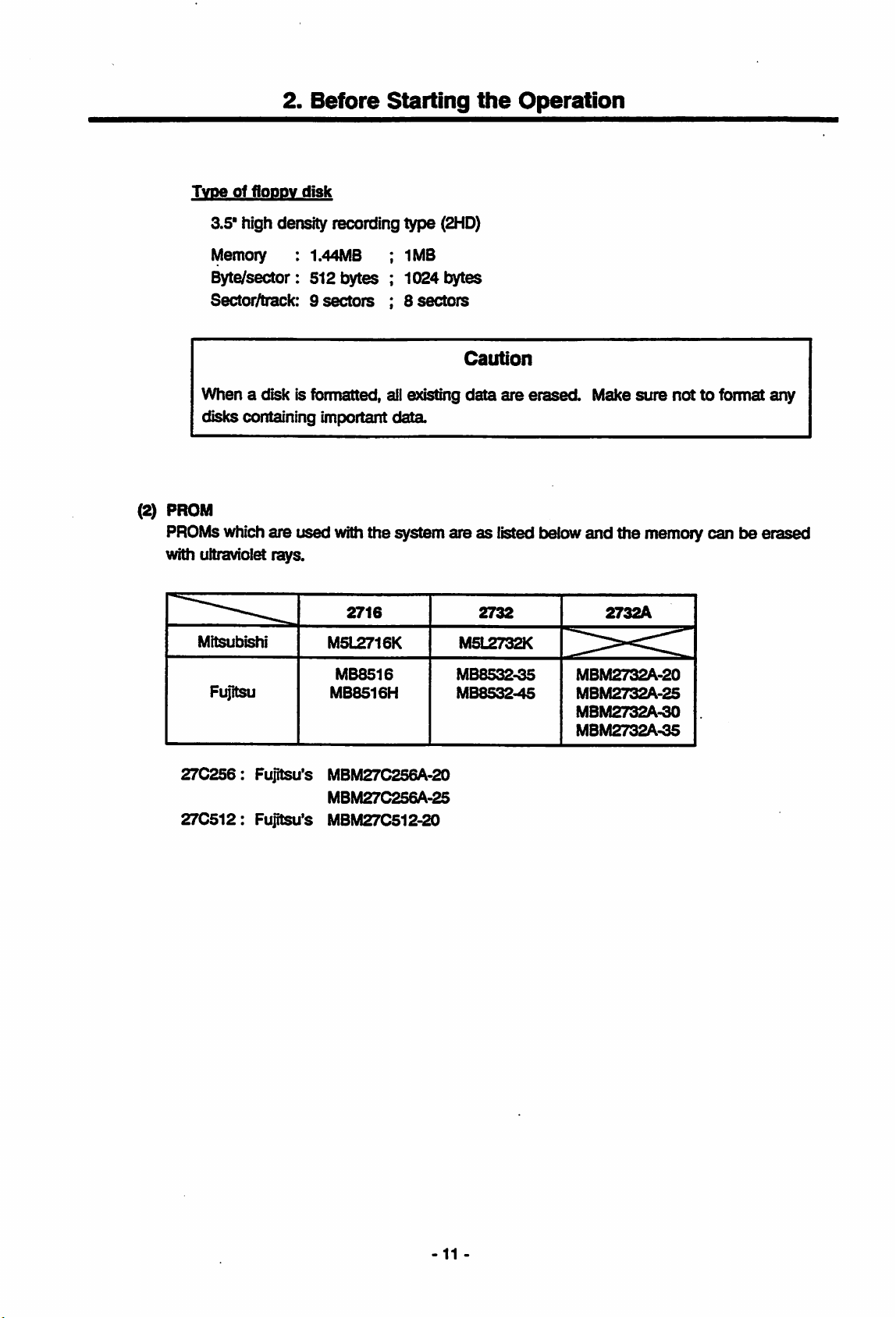

TypeoffloDDv

(2) PROM

PROMs

with ultraviolet

Mitsubishi

disk

3.5*

high density recording type

Memoiy : 1.44MB ; 1MB

Byte/sector:

Sector/track: 9

512bytes;1024bytes

sectors

; 8

When a disk is formatted, ail existing

disks containing important

data

(2HD)

sectors

Caution

data

are

erased.

Make

sure

nottoformat

whichare used withthe system are as listed below and the memory can

rsys.

2716

M5L2716K

2732

M5L2732K

2732A

any

be

Fujitsu

27C256:

27C512:

MB8516

MB8516H

Fujitsu's MBM27C256A-20

MBM27C256A-25

Fujitsu's MBM27C512-20

MB85^-35

MB8532-45

MBM2732A-20

MBM2732A-25

MBM2732A-30

MBM2732A-35

11

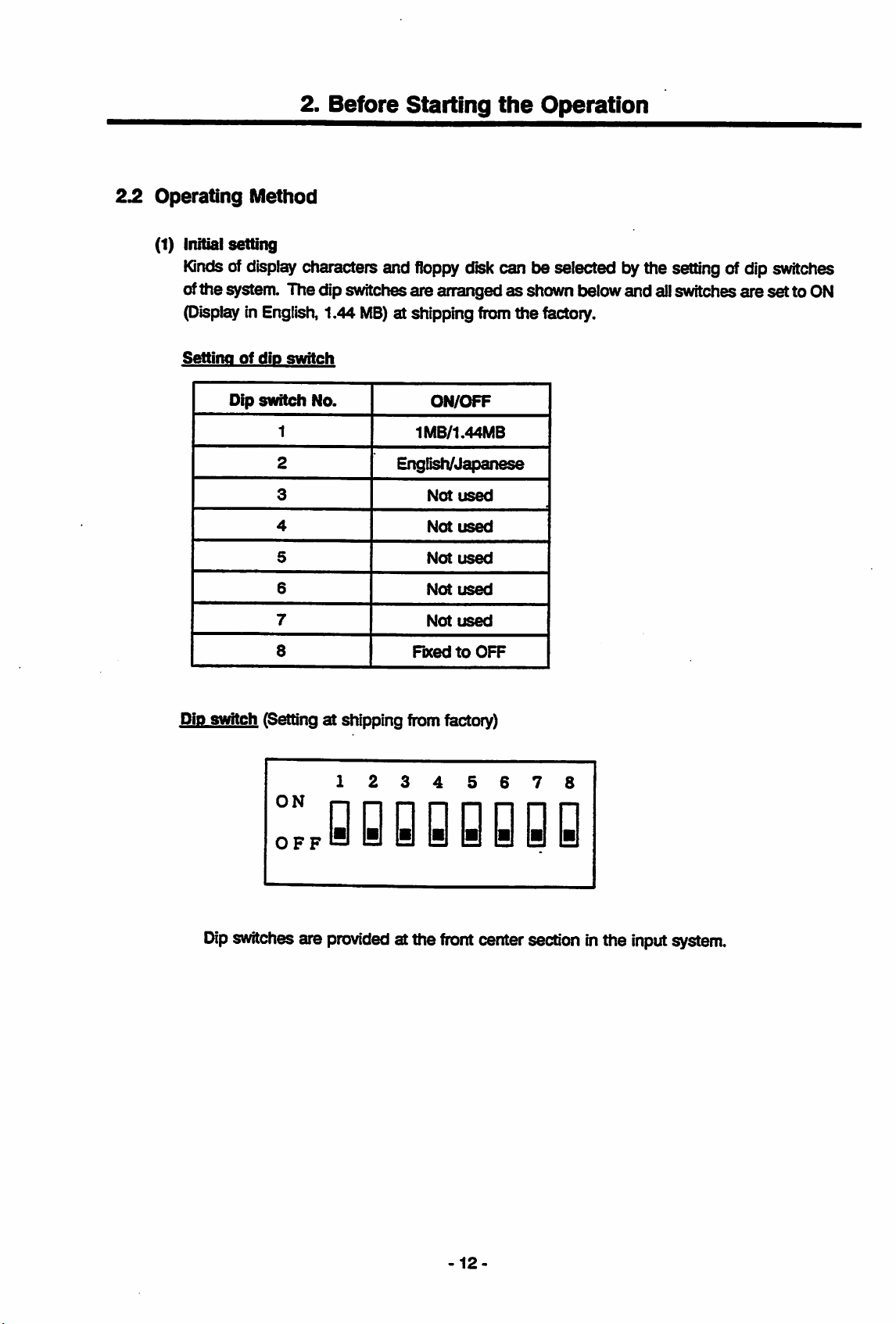

Page 19

22

Operating

(1) Initial setting

Kindsofdisplay

ofthe system. The dip switches are arrangedasshown below and allswitches are

P'isplay in English, 1.44

2.

Method

characters and

Before

MB)

Starting

floppy

the

Operation

diskcan be selected by the settingof dip switches

at shipping fromthe factory.

set

to ON

Setting

Dip

of

dip

switch

switch

1

2

3

4

5

6

7

8

No.

ON/OFF

1MB/1.44MB

English/Japanese

Not

used

Not

used

Not

used

Not

used

Not

used

FixedtoOFF

Dip switch (Setting at shipping from factory)

Dip

switches are

OFF

yyyyyyyB

provided

at the

front

centersectionin the inputsystem.

12

Page 20

2.

Before

Starting

the

Operation

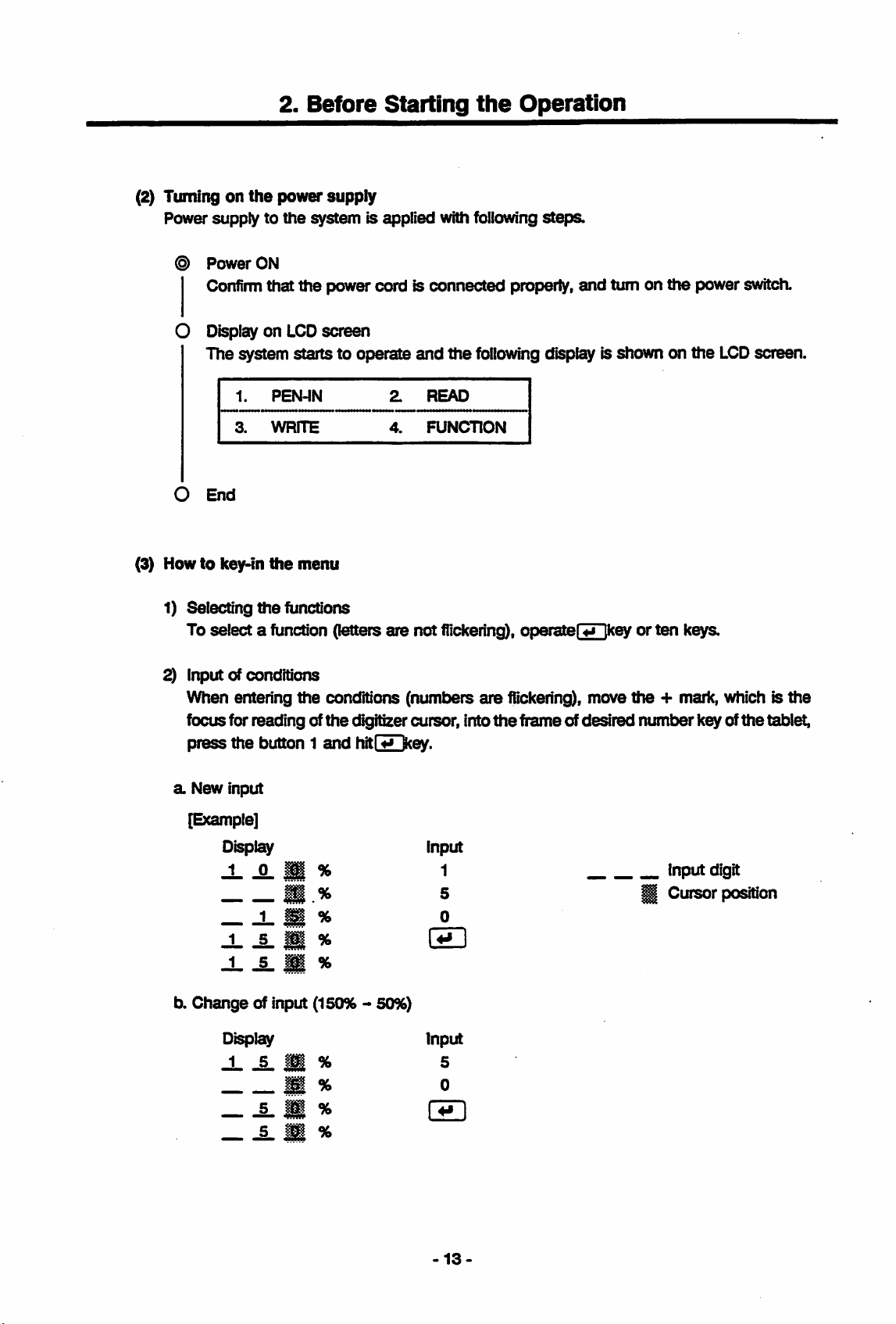

(2) Turningonthe

Power supply to

©

Power

ON

Confirmthat

O Displayon

The system startsto operate

1.

3.

O

End

(3) Howtokey-in

1) Selecting

select

To

the

a function (letters

power

supply

the

system is appHed with following

the

power cord is connected properly,

LCD

screen

and

PEN-IN

WRITE

the

menu

functions

2.

4.

are

READ

FUNCTION

not

flickering),

steps.

and

turn on

the

following display is shown on

operater^key

or

the

power switch.

the

ten

keys.

LCD

screen.

2) Input of conditions

When enten'ng

focusfor reading of

press

the

a New input

[Example]

Display Input

J_

the

button1and

^ M * 1

® % 5 ^

tx

Change

of input (150% 50%)

Display

-L

^

li

M % 0

conditions (numt>ers

the

digitizer cursor, into

hitM

kev.

0

% S

%

Input

% 5

are

flickering), move

the

frameof

desired

the

+ mark, which is

number

key of

Inputdigit

Cursor

the

tabl^

position

the

5.

H %

-13-

Page 21

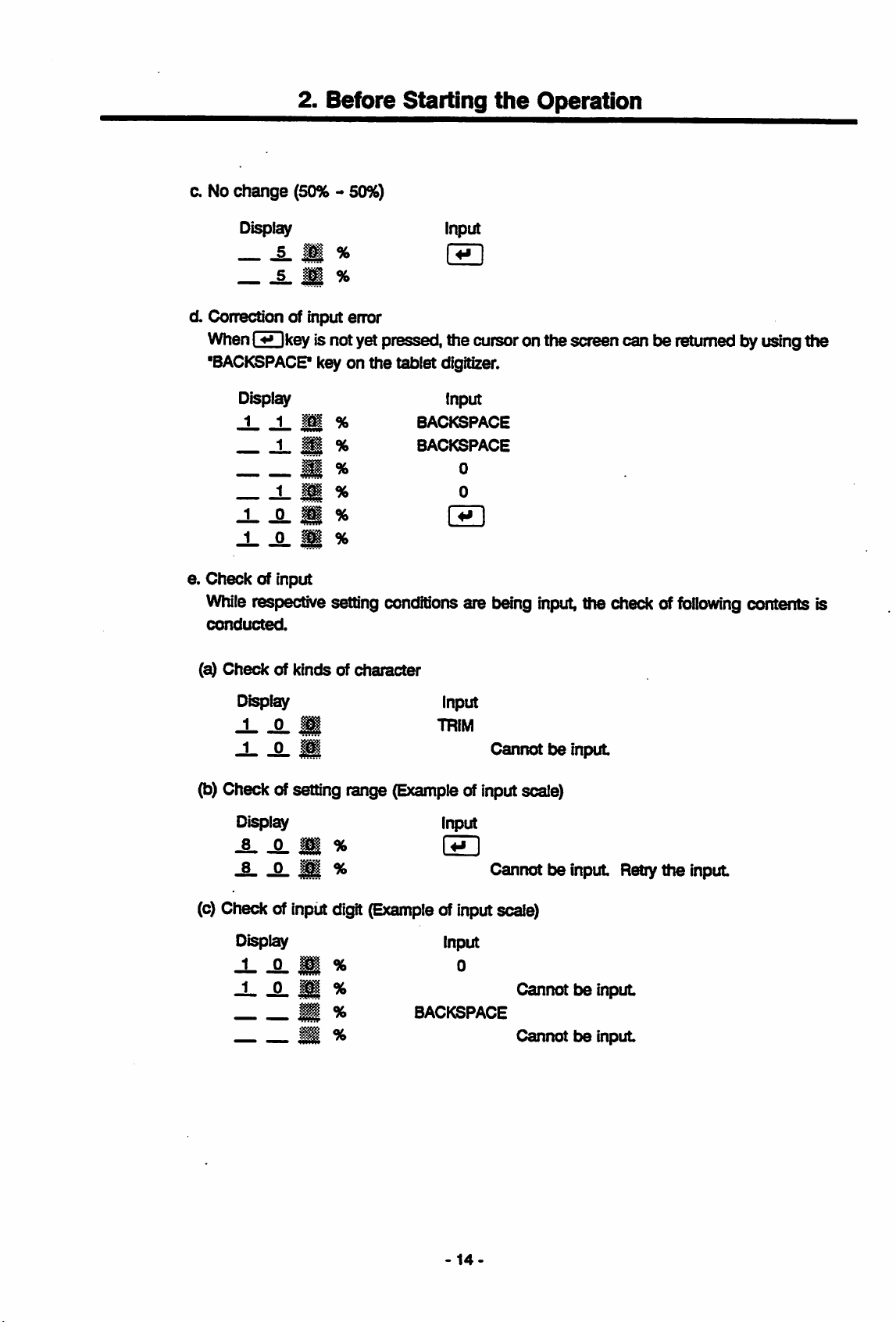

c. No

2. Before

change

Display input

(50% 50%)

Starting

§. s % ®

i.

%

the

Operation

d. Correction of input

When\4*ikev

"BACKSPACP key on the tablet digitizer.

Display

1 1 1m %

1.

1

1

1 i

J-

-Q. 1

J-

J2-

i

e.

Check

While

conducted.

(a)

of input

respective setting

Check

of kinds of character

Display Input

J-

-0. S

J

Q.

^

ener

isnotyet pressed, the cursoron the screen can

BACKSPACE

^ %

BACKSPACE

M %

M %

'& %

M %

conditions

TRIM

Input

0

0

are

being

Cannot

input,

tse

input

t>e

the checkof

returnedby usingttie

following

contents is

(b)Check ofsetting range

Display Input

-8.

^ ®

JL

^ S ^

(c)

Checkofinput

Display Input

-L

A M * 0

digit

(Exampleofinput

J ^ X %

® %

S % Cannot

(Example

ofinputscale)

BACKSPACE

Cannotbeinput

scale)

Cannotbeinput

t}e

Retiy

input

theinput

-14-

Page 22

2.

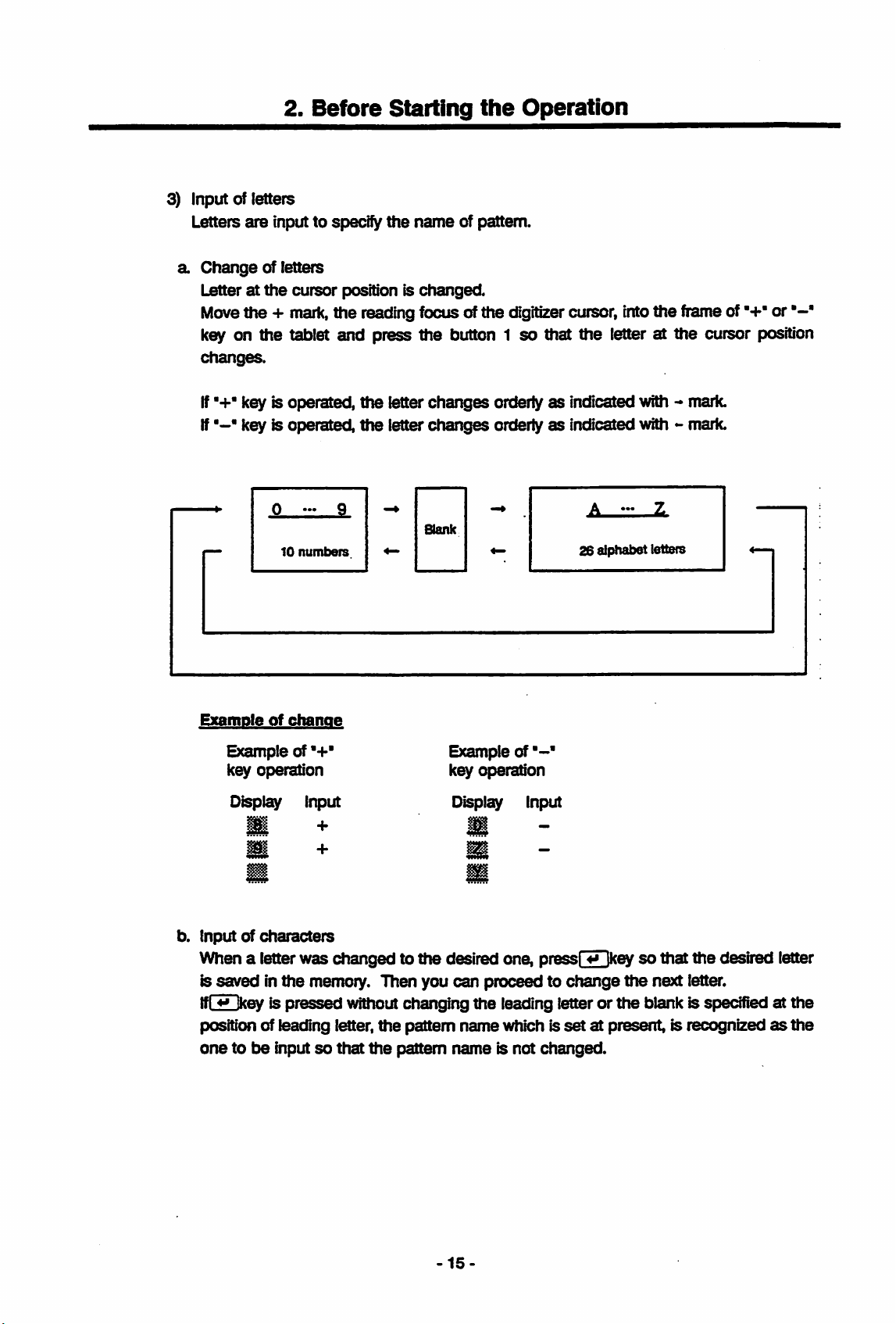

3) Input of letters

Letters

a

are

input to specify

Change

Letteratthe

Move

of letters

the +

Before

cursor

mark,

position is

the reading focus ofthe digitizer cursor, intotheframe of

Starting

the

name

changed.

key on the tablet and press the button 1

changes.

the

of pattern.

Operation

•+"

so

that the letter at the cursor position

or

If'+* key is operated,

If key is operated,

10

numbers

Example

of

ctMrnoe

Example of

key

operation

Display Input

•+•

the

the

letter

letter

changes

changes

Blank

orderlyasindicated with mark.

orderlyasindicated with mark.

Example of

key operation

Display Input

26 alphabet letters

b. Input of

When a letter

is

IfLilJkey is

position of leading letter,

onetobe

characters

savedinthe

pressed

inputsothat

was

changedtothe

memory. Then you

without changing

the

pattern

the

pattem

desired one, press! Ikeysothat

can

-15

the

name

name

proceed to

leading letter or

which is

is not

change

setatpresent, is recognizedasthe

changed.

the

the

next letter.

the

blank is specified at

desired letter

the

Page 23

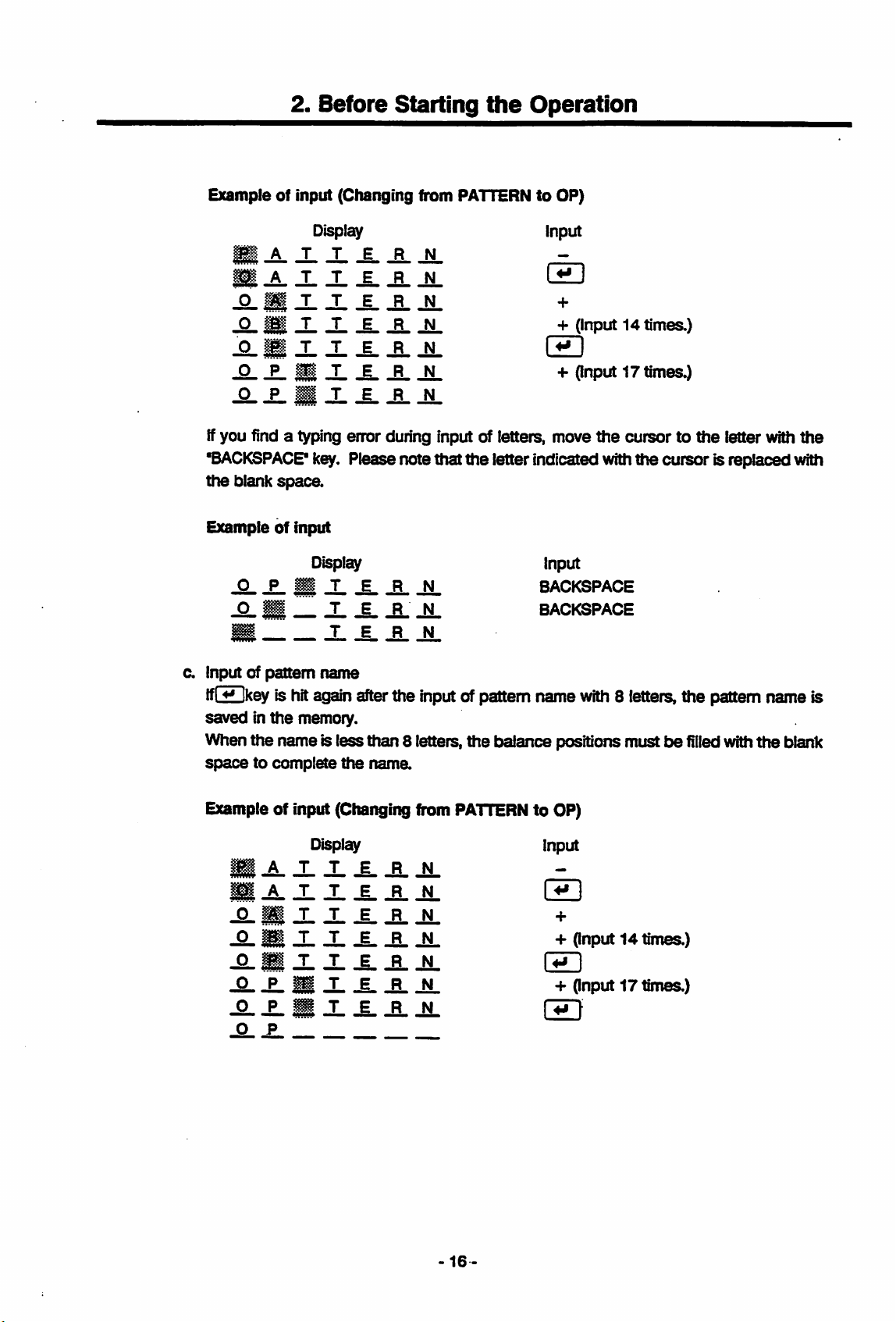

2. Before

Example of Input (Changing from PATTERNtoOP)

Display Input

Starting

the

Operation

•-L-L-S-JL

+

-S-

S

-I- -I-

-Q-B

X

-Q- -E- S X X -B-

O P ^ T E R N

-S- -B-

JL-i--R.

-M-

+

JL I^D

JL

+

(Input

(Input

14times.)

17times.)

Ifyou find a typing error during input of letters, move

'BACKSPACP

the

blank

Exampleofinput

-Q- X B X X -B-

-O. • _ X X X

•

c. Input of

Ifl**Ikev

savedinthe

When

the

spacetocomplete

Example of input (Changing from

k^.

Pleasenote that the letter indicated withthe cursoris replaced with

space.

Display Input

JL

JL

TERN

pattem

is hitagain afterthe inputof pattem name

name

memory.

name is lessthan 8 letters,

the

name.

Display Input

the

balance positions mustbefiiled

PATTERN

BXXXXXX

S

J-J.

^-B.

JL

X S X X X X X +

X®XXXXX

X X B X X X X +

XX

^ P

X X X X

the

BACKSPACE

BACKSPACE

with

8 letters,the pattem name is

to OP)

CH]

+

(Input14times.)

(Input

17times.)

cursor to

the

with

letter with

the

blank

the

16-

Page 24

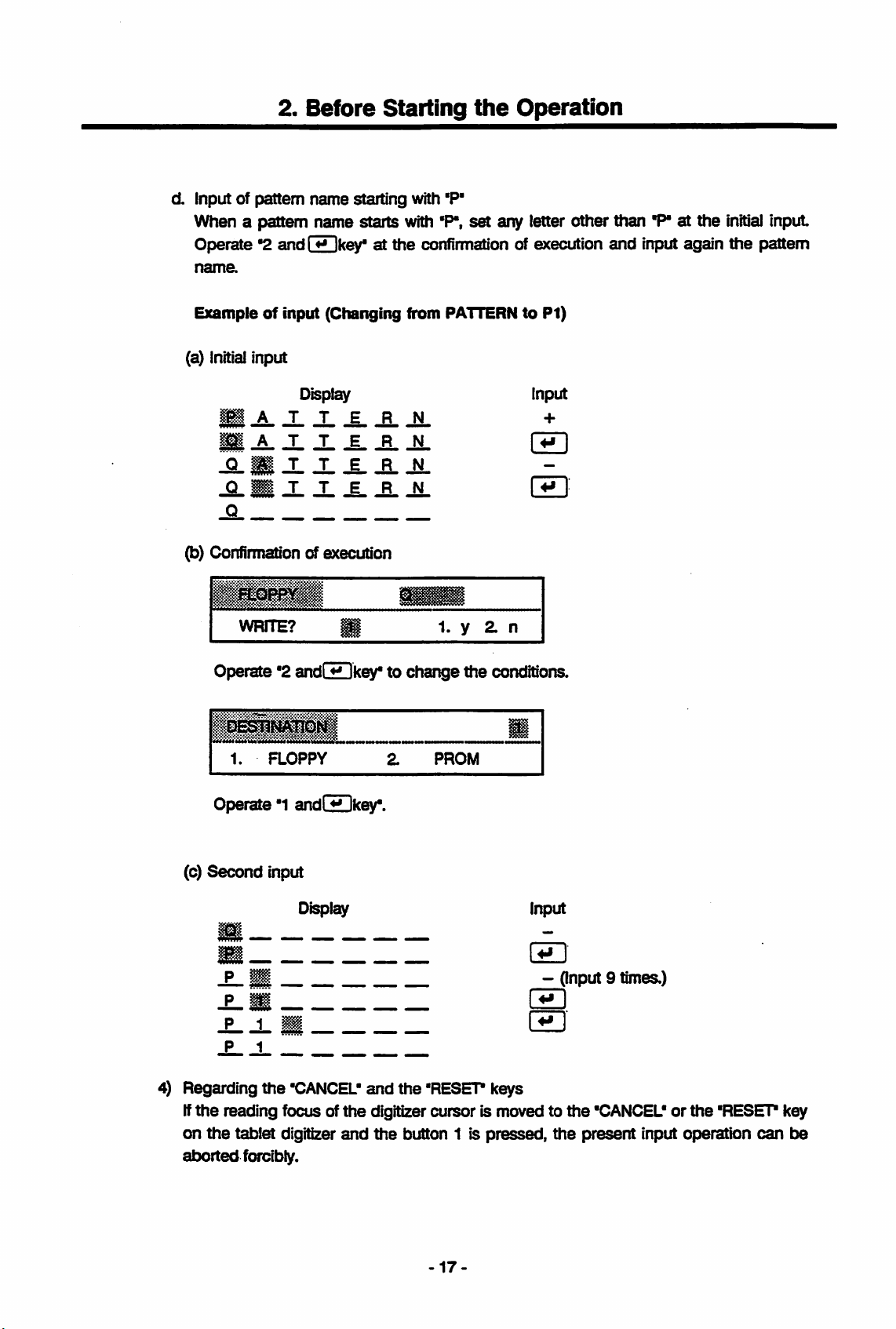

2.

Before

Starting

the

Operation

d. Input of pattern

When a pattern name starts with 'P*.

Operate*2andi^key*

nama

Exampleofinput (Changing from

(a)

Initial

input

M A T T E R N

M A T T E R N

JSL

M X

Q T T E R N

.0

(b) Confirmation of execution

WRITE?

name

Display

JL

starting with

at the

-i-

-E- -N

P

1 1. y 2. n

'P'

set

any letter other than

confirmation

PATTERNtoPI)

"P"atthe

initial

input

of execution and inputagain the isattem

Input

Operate '2 andC^key*to changethe

1.

Operate '1 andLUJkey'.

(c)

Second

aZZZZZZ

P U -

i_L«

P 1

4) Regarding

If

the

reading focus of

on

the

tablet digitizer

aborted

forcibly.

FLOPPY

input

Display Input

the

"CANCEL"

Z

and

the

digitizer cursor is moved to

and

the

PROM

the

"RESET"

button 1 is

conditions.

m

E

®

E

keys

pressed,

(Input9times.)

the

"CANCEL"orthe

the

present

"RESET key

input operation

can

be

17-

Page 25

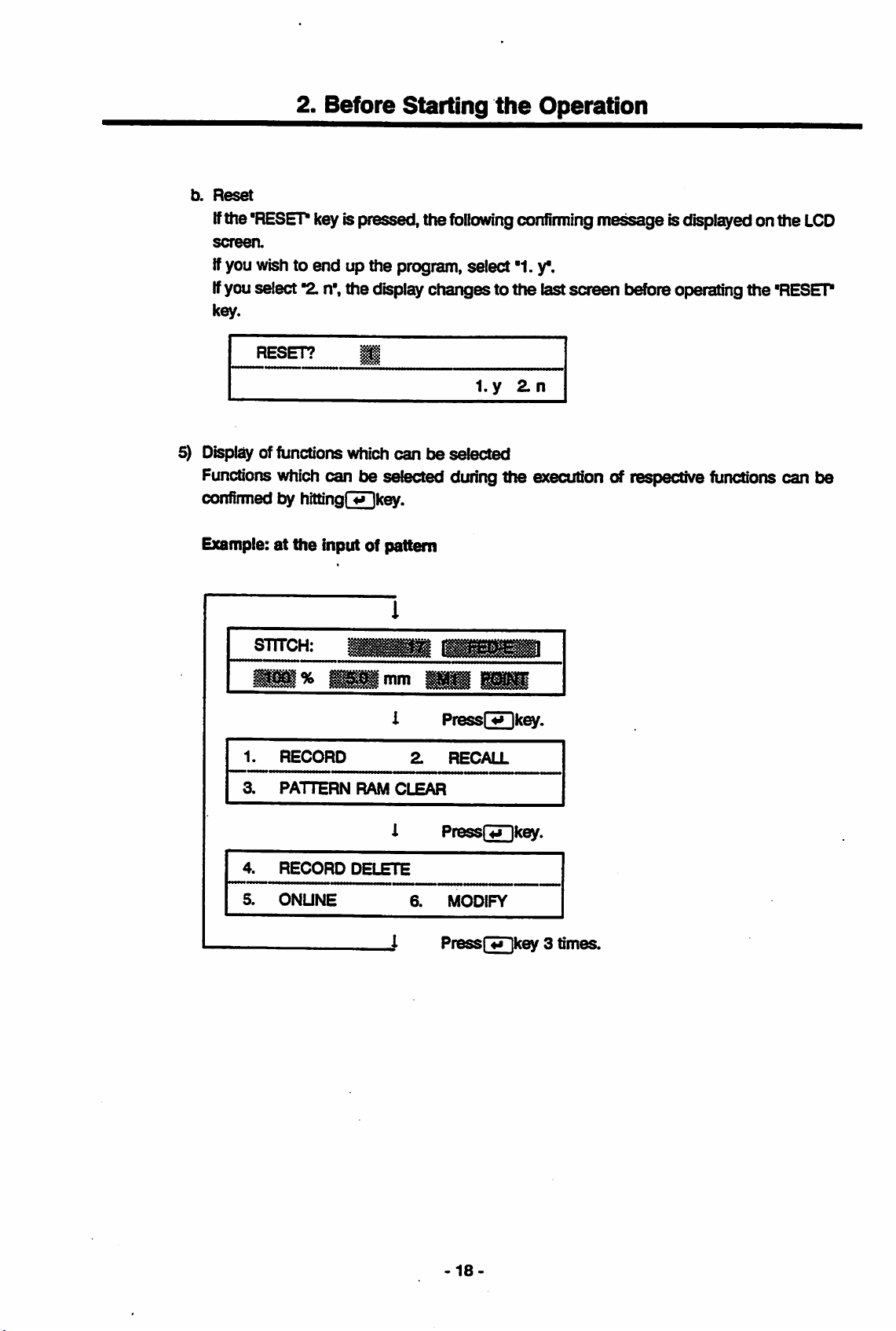

2. Before

b.

Reset

ifthe'RESEP keyispressed, the

screen.

If

you

wish

to end up the program, select

If

youselect

key.

"2.

n', the display changes to the lastscreen

Starting

fbllowirtg

the

Operation

corrfirming

"1.

y*.

me^ge

tsefore

isdisplayedonthe

LCD

operating the 'RESET

RESET?

1

5) Displayof functions which

Functions

confirmed by

Example:atthe

STITCH:

1.

3.

which

can be selected duringthe execution of respective functions can be

hittinqr^kev.

input of pattern

%

RECORD

PATTERN

RAM

l.y

canbeselected

mm

Press!

Z

RECALL

CLEAR

4*

Zn

ikev.

4.

5.

RECORD

ONUNE

DELETE

PressHSHkey.

6.

MODIFY

Press

-18

fTTikey3times.

Page 26

2.

Before

Starting

the

Operation

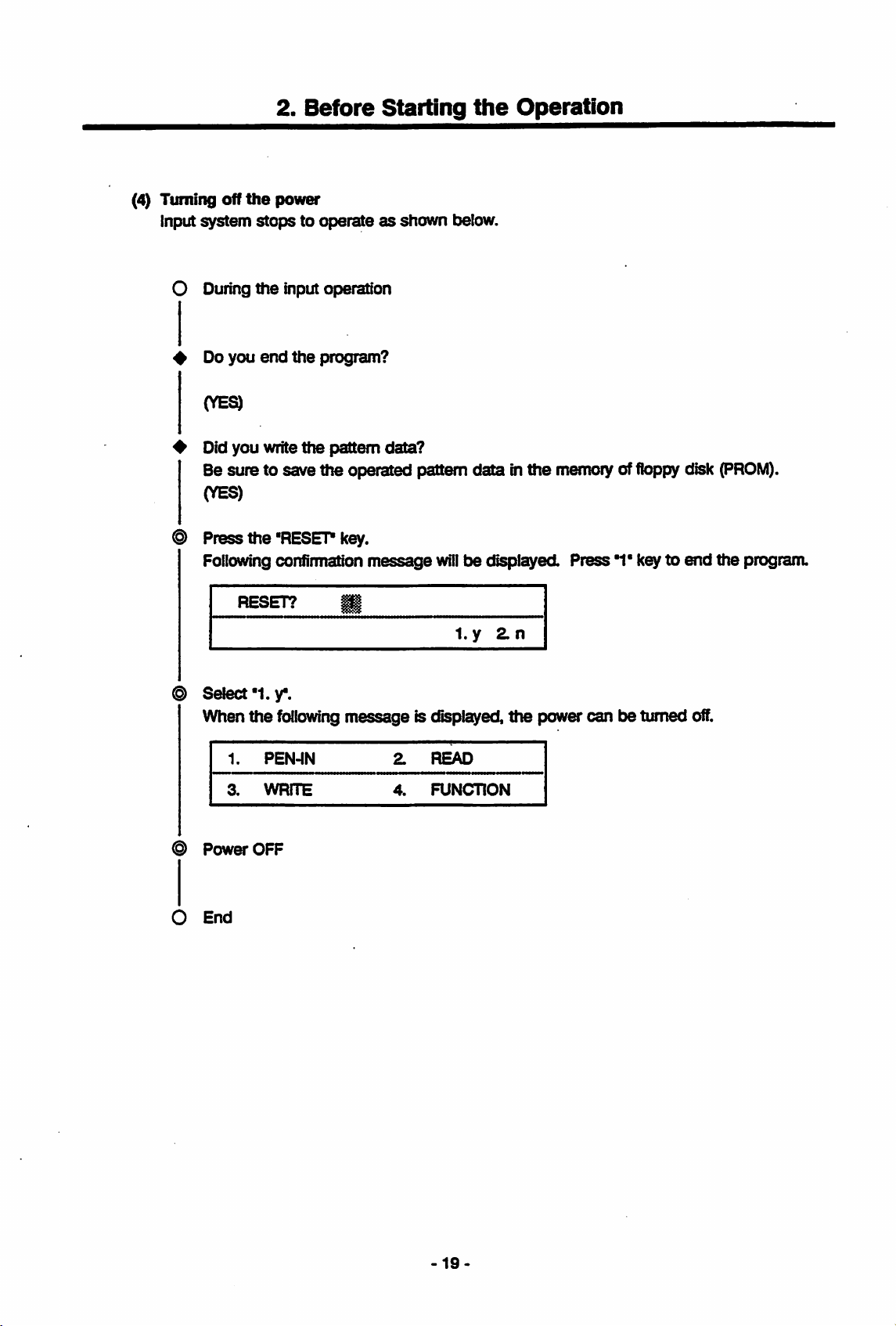

(4) Turning off

Input

system

the

power

stopstooperateasshown

O Duringthe input operation

4 Do

you

(YE^

end

the

# Didyou write

Be sure to save the operated pattern data in

(YES)

® Press the 'RESET

Followingconfimriatlon

RESET?

program?

the

pattern data?

key.

message

t}e!ow.

the

willbedisplayed.

1. y

2.

n

memoryof

floppy

Press1*key to

disk

end

(PROM).

the

program.

Select

When

Power

O

End

*1.

y.

the

following

1.

PEN-IN

3.

WRITE

OFF

message is displayed,

2.

READ

4.

FUNCTION

the

power can be turned

off.

-19.

Page 27

2.

Before Starting

the

Operation

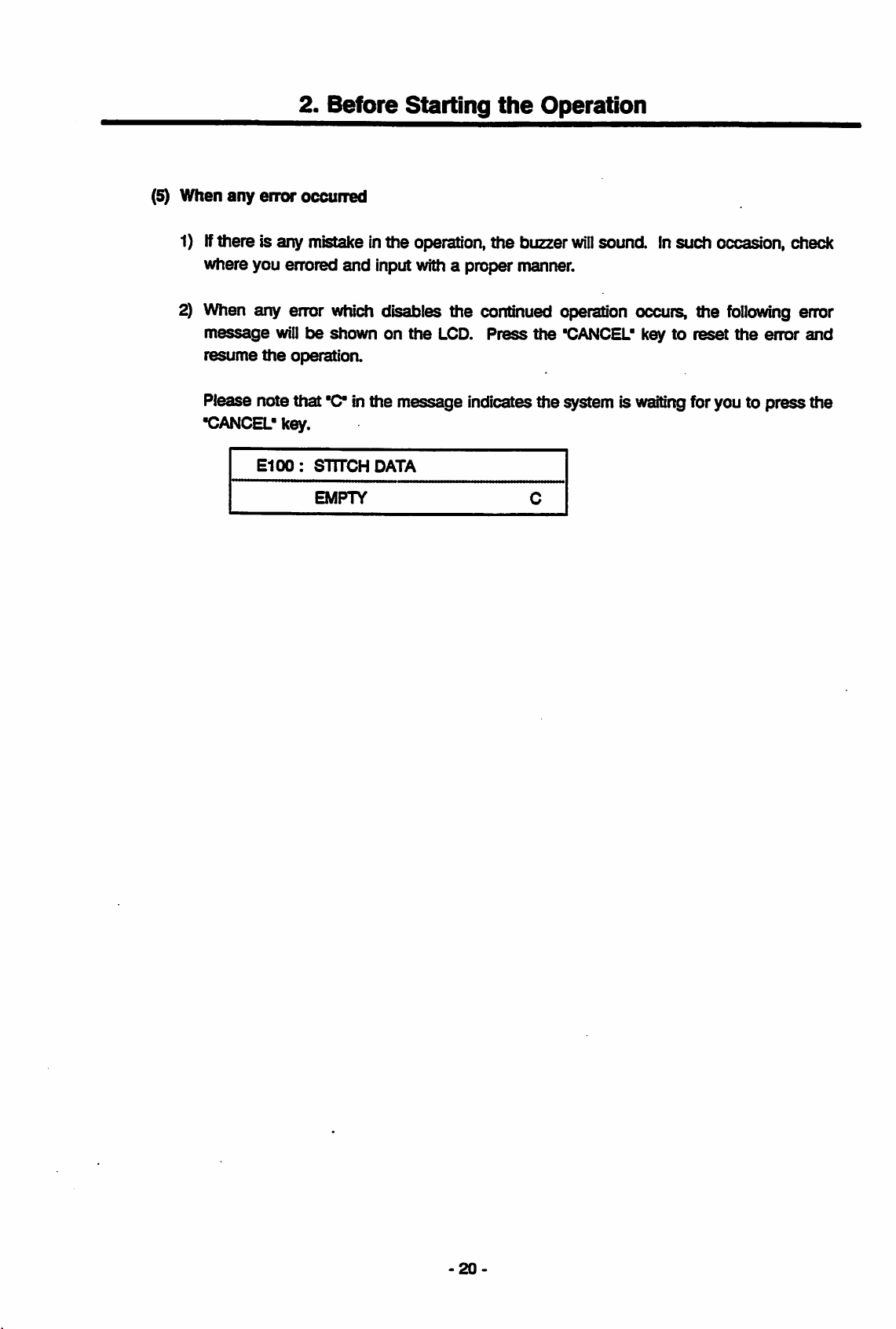

(5) When

any

error

occuired

1)Ifthere is any mistake inthe operation,the buzzer

where you errored

2) When any error

message

resume

will

the

operation.

Please note that

•CANCEL'

key.

E100:

and

input with a proper manner.

which

t>e

shownonthe

'C

inthe message indicates the system is

STTTCHDATA

EMPTY

disables the continued operation occurs, the

LCD.

Press

win

sound. Insuch occasion, check

the

"CANCEL' keytoreset

waiting

following

the

error

error

and

foryou to pressthe

-20

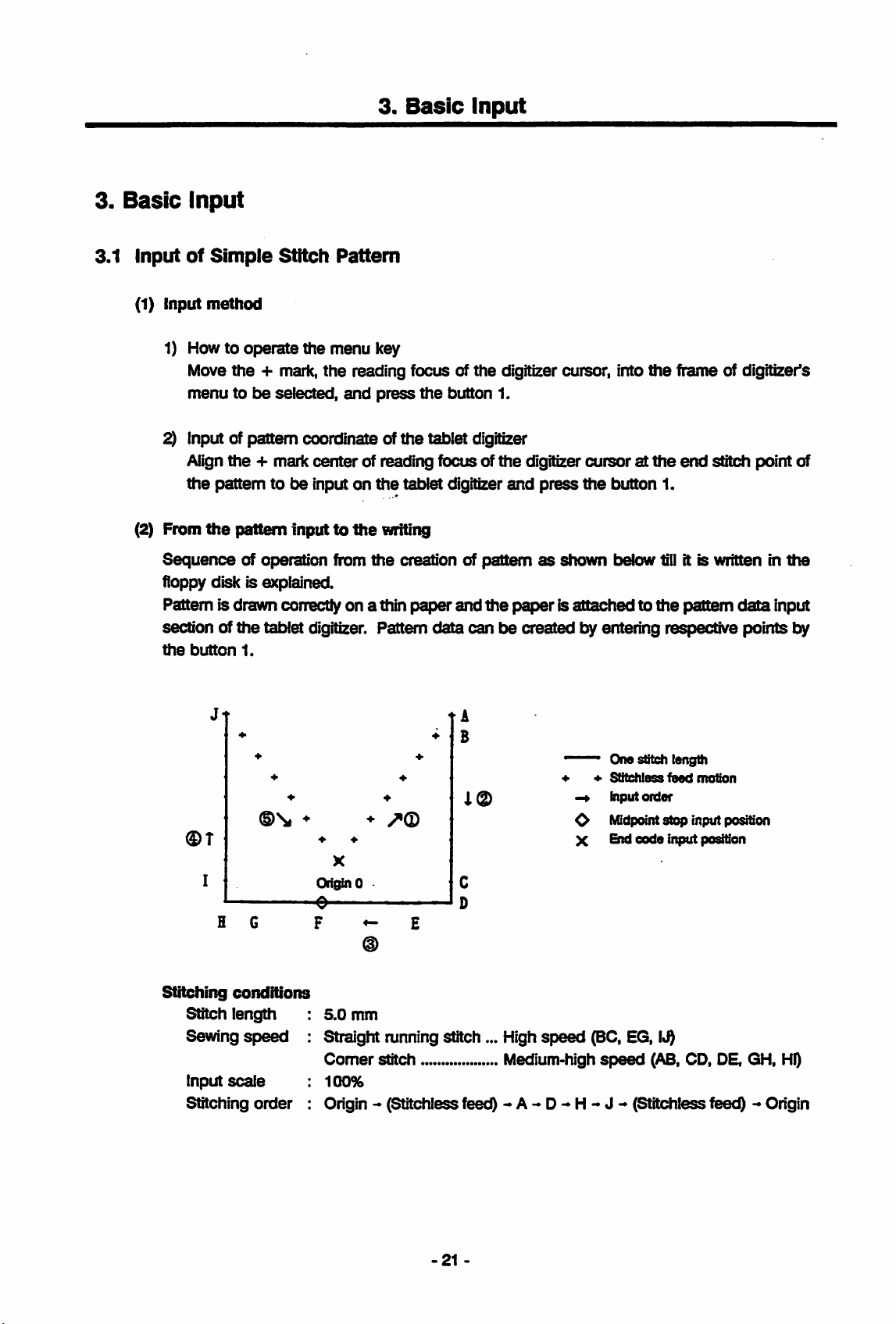

Page 28

3.

Basic

input

3.

Basic

Input

3.1 InputofSimple

(1) Input

(2) From

method

1) Howtooperate

Move

the

menutobe

2) Input of pattem coordinate of

Align

the

+ mark

the

pattemtobe

the

pattem

Sequence

of operation from

floppy disk is explained.

Pattem is drawn correctly

section of

the

button

the

1.

Stitch

+ mark,

selected,

the

Pattern

menu

key

the

reading focus of

and

press

the

center

inputonthe

Inputtothe

of reading focus of

tatjiet digitizer

writing

the

creation of

on

a thin

paper

tablet digitizer. Pattem

the

the

button

1.

tablet digitizer

the

pattemasshown

and

the

data

canbecreated

digitizer cursor, into

digitizer

and

press

cursoratthe

the

button 1.

below till it is written in

paperisattachedtothe

lay

entering respective points

the

frame of digitizer's

end

stitch point of

pattem

data

the

input

t>y

Jt

0r

I

Stitching

Stitch length

Sewing

Input

Stitching

©Si

H G

conditions

speed

scale

order

t A

B

i©

♦

♦

OriginO

0

F ^ E

:

5.0

♦

^(D

♦

X

mm

: Straight running stitch... High

Comer

:

100%

: Origin - (Stitehlessfeed) -

stitch Medium-high

A-

speed

D-

One Stitch length

Stitehless

input

Midpcrint

O

End

X

(BC, EG,

speed

H-

J-

feed

motion

order

stop

input position

code

input position

i«0

(AB,

CD, DE, GH,

HQ

(Stitehlessfeet^ -»Origin

-21

Page 29

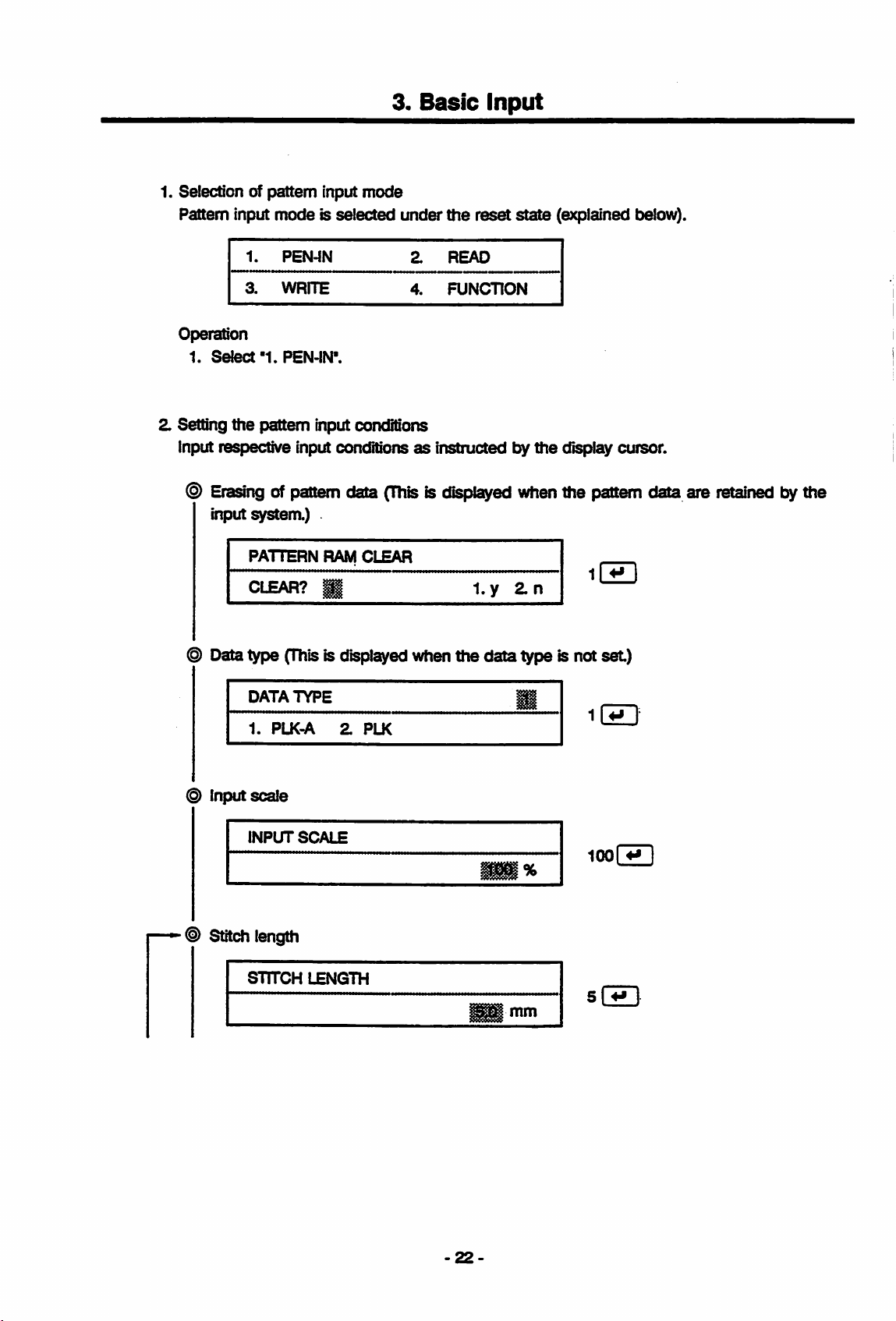

1. Selection of pattern input mode

Pattern input

Operation

1.

Select

modeisselected

1.

PEN-IN

3.

WRITE

"1.

PEN-IN'.

3.

under

2.

4.

Basic

the

READ

FUNCTION

input

reset

state

(explained tselow).

2. Setting

the

pattern input conditions

Input respective input conditions

®

Erasingofpattern

input system.)

PATTERN

CLEAR?

@ Datatype

DATATYPE

1.

PLK^

(This

data

RAM

g

1

is displayed whenthe data type is not

2.

® input scale

INPUT

SCALE

as

instructed

(Thisisdisplayed

CLEAR

PLK

l.y

t>y

the

when

2.n

display cursor.

the

p)attem

data are

set)

100

retained

bythe

—Stitch

length

STITCH

LENGTH

mm

-22-

sS

Page 30

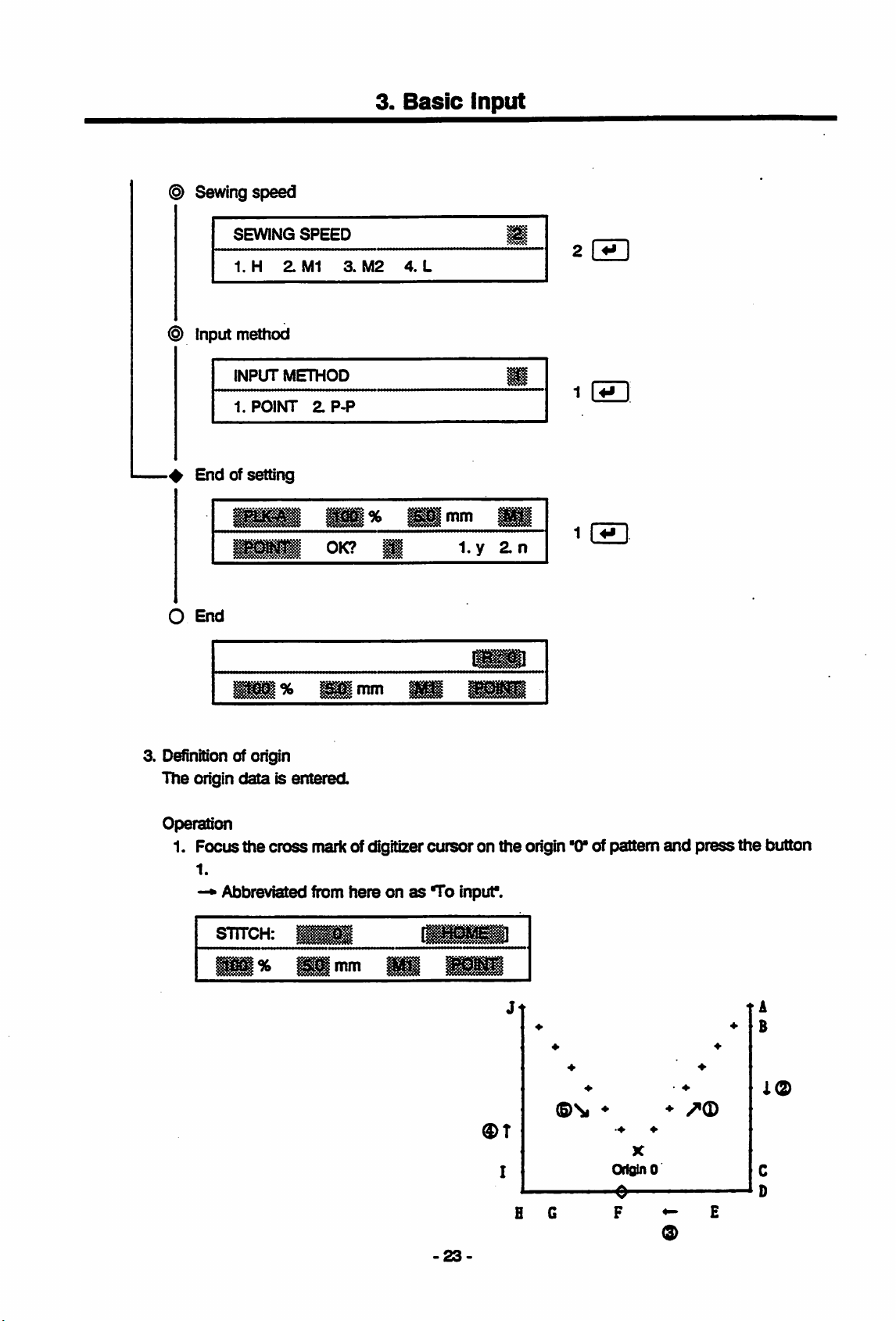

© Sewing speed

3.

Basic

input

SEWING

1.

H

© Input method

INPUT

1.

POINT

End

of setting

O

End

SPEED

Zm

METHOD

ZP-P

pii%

OK?

3.

2 [HD

M2

4.

L

1

mm

l.y

\

i

2.n

1CZ3

3.

D^nition

The

Operation

1. Focus

of origin

origin

data

is entered.

the

cross

1.

—•

Abbreviated from

STTTCH:

%

%

HH

mm

markof digitizercursoron

hereonas

illimm

To

-23-

inpur.

©T

the

Jt

I

origin

B G

*0*

®\i

of pattern

♦

X

OrklinO

0

*

and

♦

O

press

E

the

t A

button

B

i(2>

Page 31

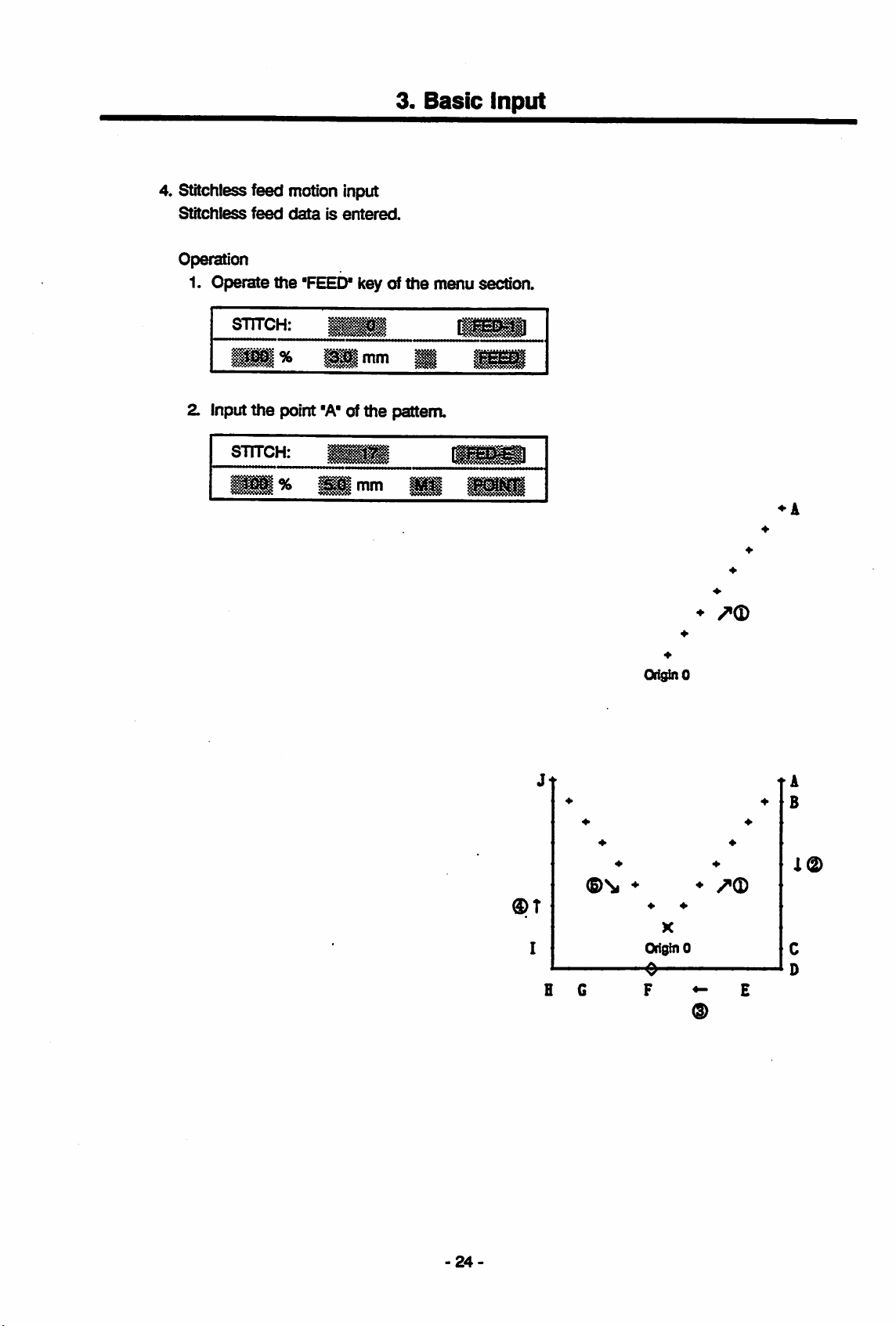

4. Stitchless feed motion input

Stitchless

feed

dataisentered.

Operation

1. Operate

the

'FEED*

key of

3.

Basic

the

menu section.

Input

STTTCH:

•1%

2. Input

STITCH:

Hi

the

point

"A"ofthe

% H

••

1

pattern.

mm

1

•">"

Ml

HH

♦A

♦

♦

Ori^O

0T

Jt

I

H G

<5)\

♦

♦

Origin0

0

F E

♦

♦

X

tA

B

i(2)

24-

Page 32

5. Point input

One-sdtch

Operation

1. Input

dataisentered.

the

point'B'of

the

3.

Basic

pattern.

Input

snrcH:

SB

SHl

V

♦

IB

Ol^O;

Jt

(S>\

♦ ♦

X

I

Origin 0

^(D

ti

B

i(2)

H G

-25

F E

Page 33

3.

Basic

input

6. Change of sewing

Sewing

Operation

1. Press

speed is changed

the

button of digitizercursor 2 or 3 times.

Eachpress onthe button 2 change the speedstep bystep,

- Lxw - High -

STITGH:

STITCH:

STITCH:

1%

speed

Medium

|

••

®

•

^ M

mm

1

^^nim

from

high

medium

—.

m

highspeed

BB

enBi

IHH

mmmm

(Ml)

to highspeed

Medium

(H).

high-

Medium

low

7. Input method change

Input

mode is changed

Operation

from

point

1. Press the button3 of digitizer cursor.

With

each

press

onthe

line-—.

snrcH:

%

button

mm

(POINT)

to straight line

3, itchanges

from

Point-Straight

Jt

®T

I

AG

(P-P).

One-Point-Straight

tA

B

♦ ♦

X

Origin 0

e

F E

(3>

26

Page 34

8. Straight line (P-P)data input

Straight line (P-P) is entered.

Operation

1. Input

the

point'Cofthe

3.

Basic

pattern.

input

snrcH:

\%

1

SI

t A

B

/>0

Oi^O

t A

B

X<2>

®T

Jt

I

E G

♦

♦

(§>S<

♦ ♦

X

O^inO

-e

F E

-27-

Page 35

3.

Basic

Input

9. Bend

Sewing

(POINT)

Operation

1. Press

2.

data

input

spe^ischangedtomedium

and

bend

dataisinput

the

button 2 of mouse (digitizer cursor) to

medium high).

STITCH:

Press

STTTCH:

%

the

button 3 of

%

mm

mousetochange

^Bnrun

high

wmm

speed

the

(Ml),

input

modeischangedtopoint

change

input method (straight line - point).

Jt

ttie sewing

speed

(high -

ti

I®

®T

I

H G

♦ ♦

X

OriginO

0

F ^ E

-28-

Page 36

3.

Basic

input

3. Input

4. Input

the

point'0'of

the

point

the

"E*ofthe

pattern.

pattern.

t A

B

i®

^(D

*

♦

Ori^O

Jt

t A

B

0T

I

H 6

®\

♦

♦

♦ ♦

OriginO

0

♦

i®

♦

X

E

-29

Page 37

3.

Basic

input

10. Bend and straight

Sewing

input fine

Operation

1. Pressthe

2. Pressttie

3. Input

speed Isset to

data

button

button

the

point'Pof the pattern.

One

data input

2 of

3 of

high

mouse

mouse

speed

(H)

to changethe

to changethe

and

input

mode

sewing

input

ischangedto

speed

method

(medium

(point

♦

Or^nO

F

straight

high-high).

- straight

line

fine).

t A

B

(P-P)

to

€)T

Jt

I

H G

(§)\i

♦

♦

Origin 0

0

F ^

tA

B

♦

♦

X

(D

-30-

Page 38

3.

Basic

Input

11. Midpoint

Midpoint

Operation

1.

Operate

stop

(STOP)

stop

(STOP)

the

"STOP*ofthe

STITCH;

IK

^ S

code input

code

is input

menu.

H i

IB

t A

B

i®

+

•f

Origin 0

-e—

®T

Jt

1

H G

♦

♦

X

Origin 0

9

t A

B

+

+

I®

31

-

Page 39

12. Input of remaining pattem

Input

the

remaining

pattem

Operation

the

point

1. Input

Z

Press

3.

Press

4. Input

5. Input

6. Press

7.

Press

8. Input

the

the

the

the

the

the

the

'G'ofthe

button 2 of

button 3 of

point

'H'ofthe

point

*1"ofthe

button 2 of mousetochange

button3of

point

'J'ofthe

3.

Basic

Input

in compliance with

pattem.

mousetochange

mousetochange

pattem.

pattem.

mousetochange

pattem.

the

fore-going procedures.

the

sewing

the

input method (straight line - point).

the

sewing

the

input

speed

speed

method

(high medium high).

(medium high•*high).

(^int

straight

line).

t A

B

1(g)

®T

®T

+

+

I

H

Jt

I

H

Origin 0

-e—

♦

X

Origin 0

(D

t A

B

•f

*

+

♦

A®

32

Page 40

3.

Basic

Input

13. Origin return

Origin

Operation

return data is entered.

1. Operate

snrcH:

data

the

'RETURN'

input

!

aimm

key of the menu section.

Jt

®T

I

Jt

®T

I

+

♦

©Si

♦

♦

Origin 0

e

H G F ^ E

♦

♦

/•©

*

©

+ +

+ +

+

♦ +

©\

HQ

* *

♦

X

Origin 0

e

F E

/^Q

©

i®

i®

33-

Page 41

3.

Basic

input

14. End

End

Operation

1.

(END)

(END)

Operate

1.

3.

code

code

the

PEN-IN

WRITE

input

is entered.

"END*

key of

the

2.

4.

menu

section.

READ

FUNCTION

®T

Jt

+

©Si

*

X

I

H

Origin 0

-6

t A

B

X©

15.

"WRITE"

"WRITE"

Operation

1.

3.

1. Input

mode

selection

modeisselected

PEN-IN

WRITE

"3"

key of

the

under

menu

reset

Z.

READ

4.

FUNCTION

section.

condition.

34

Page 42

16. Write condition setting

input

the

write conditions using the cursor.

Operation

3.

Basic

Input

^ Write

© Pattern

4 Confirmation of executing of writing

destination

Selection of write to

DESTINATION

1.

FLOPPY

name

Set

'PATTERN'asthe

PATTERN

Execution of writing

WRITE?

selection

input

NAME

the

floppy disk.

pattern

Z

name.

PROM

1B

[Z3

il53

O

End

17.

Endofpattern

Following

Number

message

FLOPPY

NAME:

and

name of

data

writing

willbedisplayedonthe

the

written pattern

LCDasthe

and

numberofstitches

35

writing is completed.

willbedisplayed on

the

LCD.

Page 43

4.

Reference

4.1

Pattern

Patterns

(1)

(2)

4.

Reference

Input

are

Pattern

Select

Setting

Set

respective pattern Input conditions before starting

created

input

"1.

the

Mode

mode

PEN-IN"

Input

or

edited.

selection

under

conditions

the

reset

state.

the

pattern Input

1) Confirmation of erasing of pattern

the

pattern

Select whether to

a new pattern

When

data,

When

data)

data

the

pattem

if It

exists.Iserased

PATTERN

CLEAR?

the

pattern

erase

the

or to

add

data

addition "Z n' Isselected,

automatically.

RAM

CLEAR

data

is newly input:

data

pattern

data

new pattern

1.y

1 (ZD

When

the

dataIsadded

to

the

one

whichIscreated

2[Z]or(ZDonly

2) Data type Input (This Is displayed when

Select

A Series machine or

Please

number

the

typeofdatatobe

note

that. If

which

canbeInput,

Input

depending

the

conventional electronic sewing

the

data

type

is Input,

are

changedasshown

(This Is displayed

which

are

retained In

data

the

"END

Zn

or

the

data

type Is

on whether

the

stitch

length

below.

when

code" at

which

not

yet

the

sewing

machine

and

the

Input system retains

the

was

system,

the

written:

and

end

set)

machine Is

(PLK

Series, etc.).

the

limitation of stitch

to Input

of a pattern

the

PLK-

Length

and

Data

PLK-A

PLK

DATATYPE

1.

PLK-A

In

caseofPLK-A

Any

other

number

type

cases

of

stitches

Max.

series: 11 ^ |

: 2

which

PLK

stitch

1Z7

6.2

36

can

mm

mm

be

Input

length

Max.

number

8000

4000

of

stitches

stitches

stitches

Page 44

3) Input ofthe input scale

Ratio

ofsize ofthe

input in

Range

If

of input is 10to200%.

lOOCHDis

material

of

sewing

the

unit of %.

input,

and

the

patternand stitches reduced to 1/2

actual

the

patternonthe

ratio

4.

Reference

sewing

becomes

tablet

material

100%

digitizer

againstthe pattern on the tablet

which

means

arethe

the size ofthe

same.If50(5I3is

actual

input,

(50%).

digitizer

sewing

the

is

size

INPUT

4) Input of stitch length

Length

the

method

It

canbeset

STITCH

5) Sewing

Speed

•1.H"isforthe highspeed,

speed

SCALE

ofone

to sew

and

stitchisinput

explained later.

within

LENGTH

speed

selection

the

*4.

L' for the low

inthe

unitofmm

the

range

of 0.1to12.7 mm.

pattern is specified.

*2.

Ml•forthe

speed.

1^^

medium

Scale

whenthe straight

mm

highspeed,

Please notethat the sewing speed can be changed at anytime

mouse.

SEWING

1.H

^M1

SPEED

1

3.

M2

4.

L

I ^ I

Ipriflth f ^ 1

^4

line

input

•3.M2"

forthe medium

with

the button 2 ofthe

I

isspecified by

low

6) Selection of input

Input method of pattern

method

data

is specified.

Whenthe pointinputis selected, the stitch length can be specifiedfor each stitch and it

is possibleto

explained

input

anystitchesunder 12.7

previously.

mm

regardless ofthe stitch length, whichwas

Onthe other hand,ifthe straight lineinputmethod isspecified and

2 points are defined, the data of stitch of specified length for the straight line between

these

2 points

are

created

automatically.

The input method can be changed at any time by the button 3 of mouse.

INPUT

When it is input one stitch after another;

When two points are specified first

in between are created automatically :

METHOD

POINT

37

and

11

then

21

^

the

^ I

stitches

Page 45

4.

Reference

7) Confirmation of

Confirm

If

the

If

the

the

end

reset

the

end

setting value.

of setting M.y'is

'2.n'is selected,

1

To

end

the

setting: 11 j

To

reset

After

the

input system is started,

saved

(3)

input

Refer to '3. Basic input* regarding

not

changed,

operation

in memory

just

and

press

of setting

selected,

the

:2|^ {

the

stateisdisplayedonthe

keysothat

the

input

canberepeated

the

setting of conditions on

1

the

pattem

pattem

input is Initiated.

screen.

the

cursor

movestothe

input method, etc.

from

the

stitch length.

and

after

When

the

next setting item.

2nd

set

conditions

setting

are

are

(4)

Startofpattem

As

the

Input

(5)

Selectable

Input

pattem input is started,

Number

STITCH:

IS

of input

i

mm

the

stitches

following

T . T T T

scale Stitch length

functions

1.

RECORD

3.

PATTERN

4.

RECORD

5.

ONUNE

7.

SERIAL

TRANSMIT

Sewing

RAM

DELETE

speed Inputmethod

2.

RECALL

CLEAR

6.

MODIFY

message

Nameofselected

the number of patterns registered in

(when "R:"is displayed)

i

willbeshown on

function (abbreviation) or,

RAM.

the

LCD.

8.

CHANGE

9.

SPUNE

38-

Page 46

Menu

1.

RECORD

Z

RECALL

3.

PATTERN

4.

RECORD

5.

ONUNE

6.

MODIFY

7.

SERIAL

8.

CHANGE

9.

SPUNE

4.

RAM

CLEAR

DELETE

TRANSMIT

Reference

'1'

•3'

•5"

•e-

•a-

'9'

Digitizer

10. Sewing

11. Input

Tablet

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

cursor

Stitchless

2nd

Stop

Reverse

X-INV

Y-INV

X

Y-INV

Circle

Arc

Zigzag

Trim

Origin

End

Line

1

stitch

Function

Record

Pattern

(mouse)

speed

method

origin

return

clear

clear

list

list

feed

code

change

change

input

•Button

•Button

•FEED'

•ORIG

"STOP"

•REVERSE"

•X-INV

•Y-INV

"X Y-INV"

"CIRCLE"

"ARC"

"ZIGZAG"

TRIM"

•RETURN"

"END"

"UNE

•1-STITCH

"FUNC

"RECORD

•PATTERN

2"

3'

POINT

CLEAR-

CODE"

CLEAR"

UST

UST

(6)

Record

Pattern data held by the control unit is down-loaded to record memory or floppy disk.

Maximum

339), up to 4000 stitches,

Available record No. is

Please

memory

20 patterns (record No.400 to 419)and

can

be stored in record memory and floppy disk respectively.

note

that,ifthe

willbecleared.

assigned

powerofthe

automatically to

control

39

maximum

each

unitistumed

pattem in incremental order.

40 patterns (record No.300 to

off,

the

data

storedinthe

record

Page 47

1)

Selectionofthe

DESTINATION

1.

REC

record

RAM

4.

Reference

destination

2.

FLOPPY

1

oraCy

Select

RAM"

2) Confirmation of execution of recording

To record under the specified conditions, select "1.y*andtochange

select

the

address

or,

when

RECORD?

"2.

n".

to record. When it is

saving on

the

floppy disk,

savedinthe

select

1. y 2. n

"2.

FLOPPY".

record memory,

1

or2

I I

select

the

conditions,

If'1. y" is selected, recording starts.Ifit is recorded in a floppy disk,besuretoset

floppy

3) Display of

a When saving in

diskinthe

end

REC

RAM

disk drive.

of recording

the

record memory.

No.

®i®IlL®^4000)

:

c

Number which has been given by recording, the number of pattern

been recorded, and the total number ofstitches ofthe

are

displayedonthe

LCD

screen.

data

saved in

data

which have

the

record memory

*1. REO

a

b. Recordingona floppy disk

FLOPPY

Numberwhichhas been givenbyrecording and the number ofstitches of pattern data

(7)

which

Recall

has

been

Datasaved on the record

are

now

input.

1) Input of record No.

RECORD

R:

400-419

No.

:

recorded are displayed on

No.

memory

F:

300-339

orthe

floppy

40

|)

C

the

LCD

screen.

diskcan be added to the pattern data

which

Page 48

4.

Reference

(8)

Record

Record

2)

Confirmation

To

•2.

No. of

No.

ofthe record

ofexecution of

No.

RECALL?

recall

under the specifiedconditions, select

n'.

Since the recall starts

beforehand in

Evenifthe

in

executed.

Please

Clear

recorded

of pattern

note,

data

data

however,

data

datatobe

recalled is

memory

entered.

is 400 - 419 and itis 300 - 339 forthe

recall

1

or2

1.y

2. n

*1.

y or,to changethe conditions, select

as

soon

as

'1. y is selected,

the

disk drive ifyou wish to recall from

be

the

floppy disk.

suretoset

type of pattem which is retained in the input system

are

different

that

the

when

stitch

the

recall

lenothisnot

has

checked.

been

selected,

floppy

1

disk.

a floppy disk

and

the

data

type

the

recall

can

be

Pattem data which is created presently can be cleared and it

can

be brought to

the

inputstart state.Insuch occasion, anydata otherthan the pattern data are not accepted.

1) Confirmation of execution of clearing

PATTERN

CLEAR?

Select '1.y"to clear the pattern data or '2.n*unless

(9) Deleting

The

the

data

recordedinthe

Inthis occasion, any data other than the specified recorded

1) Input of record No.

RECORD

R:

400-419

RAM

recorded

No.

CLEAR

1. y 2. n

data

record memory or floppy disk

F:

300-339

1 or 2 I 1

the

data

are cleared.

are

deleted.

data

are not accepted.

pattem

Input the record No. of pattem to be deleted.

-41

-

Page 49

4.

Reference

2) Confirmation of execution of deleting

No.

DELETE?

^

1. y Z n

1

or2

I I

When it is recorded under

conditions,

select

'2.

n".

the

specified condition, select

Sincedeleting startsassoonas'1. y isselected,besuretoset

drive

when

the

data

of floppy disk is deleted.

(10) On-line

Pattern

machine.

For

data

further

retained in

details, referto'4.

the

input system are corrected by connecting with

5 On-line Function".

(11) Modification

Pattem data retained in the inputsystem are

machineinthis

For further details, referto"4. 6 Modification Function"

case.)

modified

*1.y*or, to

a floppy disk on

(it

is not connected

change

the

with

the sewing

the

disk

sewing

the

(12) Serial

transmission

Pattem data for 1 pattern is transmitted to an external device (electronic sewing machine,

etc.) via

Connect

unit of

1) Confirmation of execution of transmission

the

RS-232C

one

endofRS-232C

the

input system

SERIAL

TRANSMIT?

serial

and

TRANSMIT

interface.

serial

the

other

interfacetoRS-232C

endtothe

1. y Z n

external device.

connectoratthe

1 or 2 I I

Whenthe pattem data is transmittedto an extemal device,select

end

the

mode,

"2. n".

left

sideofmain

"1.

y or,ifnot and to

Since the transmission by the system takes place as soonas"1.y"is selected, be sure

to

set

beforehand the external device ready for

data

communication.

42-

Page 50

2)

Display

Whenthe datatransmission is completed, the number ofstitches oftransmitted pattern

data

(13)

Changeofinput

Pattern

Conditions

speed

Regarding

of result of transmission

TRANSMIT STITCH: •

is displayed.

conditions

input

conditions

which

which can be changed

and

the

input method.

the settingofthese

4.

Reference

CANCEL

havealready been set can be changed.

with

this

conditions,

function

referto"(2)

are 3 items of the stitch length, the

Setting the

input

conditions'.

(14) Curve (SPUNE)

Dataof a smooth

is selected and the

However,

produced.

1) Example of curve

when the

Input

the points Aand Bto drawa straight line before

state to input a curvedata.

will

t>easshown

cun/e,

points

point

data

above.

which

passes overthe last

position

specified before this

largerthan 1 and less than 127being set

which

is specified next is

only

one, the data of straight

inputting

And

then specify

orderly

the pointC - D

next,

can be created.

'9'

keyto putItat the

-...

- J. The result

function

line

is

43-

Page 51

4.

Reference

2) input of a curve

Following

are

being

STITCH

data

message

inputted.

: 1

will

be shownon the

mm

Input

respective pointson a curveunderthe abovestate. The numberofinputpointsis

displayedonthe

3) Erasing the input point(s)

If

the

"1-STITCH

4) Creation of curve

Input

every

numberofstitches)

Whenacurve

data

canbeinput.

5) Ending

Pressthe

input

the

"CANCEL"

state.

LCD.

CLEAR"

data

point

on a

and

data is

input of curve

completed,

key

^

keyIsinput,

desired

then

curve

inputC^key.

the

data

sothatthe

LCD

screen

1

SPUN

the last

(the

input

processing

numberofinput

curve

data

input

while

respectivepointsof a curve

point

Iserased.

time

varies

point

turnsto 1 andthe nextcunre

isendedandit

depending on the

returns

tothe

pattern

(15) Sewing

speed

Thisisusedtochange

been

established.

Sewing

speedIsIncrementedasshown

High

speed

r

Result of

change

STITCH

change

the

sewing

(H)-Medium

is displayed on

: r

Pimm

speedinthe

below

high

(Ml)-Medium

the

LCDasshown below.

iiB

npi

TStitching speed

pattern

with

input

each push on the

low

(M2)-Low

conditions

button

which

is set presently.

which

(L)

]

have

2.

already

-44

Page 52

4.

Reference

(16) Input method

Thisisusedtochange

have already

Pattern

p-POINT

Resultof change is displayed on the

data

snXCH

change

the

been

established.

input

methodischangedasshown

(poirrt

input)-P-P

:

•i

Hmm

Cautionsatthe

1) Regarding

Although

inputofcurve.

If

you

specify

inputofcurve

the

stitch length at

the

normal

more

than

pattern

data

• •

the

stitch

lengthis0.1to12.7

12.1

mm,

input

methodinthe

below

(line

input)—

LCD

as shown

TInput method which is

input of curve

mm,

a correct

stitch

with

below.

itis

data

pattern

each

input

push

set

limitedto0.1

may

notbe obtained.

conditions

onthe

presently.

to12.0

button

mm

with

which

3.

the

:d

2)

When

youcreatea data

at the pointKtemporarily and proceed to inputthe furtherdata of curve.

like

the one

whichisshown

below,

complete

the

inputofcurve

45

Page 53

4.

Reference

3) Whena curveinput data is created, a more precise data

many pointsaspossibie. Do not hesitateto specify many pointsto obtain a more

and

smooth

Example

Whena circleor any data cioseiy resembies an arc, input more than 3 points with90"

shown

data

1

below.

.u..

Example

With

sure

2

a curveasshown

to inputasmany pointsaspossible.

below,

whichturns abruptly

wiil

be obtained by inputting

90*

from

a section ofsmooth curve,make

as

faithful

as

(17)

Stitchless feed

If

this function is seiected, a straight line stitchless feed

position

When

when

If

the

numberofinput

before

the

last

the

basting,

—X—

—X—X"*

(FED-

the

function

data is a

the

points

*)

are scarce, a desired curvemaynot be obtained.

isselectedandthe

stitch

data,

basting

codeandthe

the

thread

thread

position

trimming

trimming

X

t

\

data

is inserted between the iast

specified next

code is

automatically

codeareadded

(3.0

mm

unit)

added,

and

automatically.

46

Page 54

4.

Reference

(18)

Second

This

start point of stitching cycle.

ThisIsused when the start point ofstitching cycleis

zero

pattern data

(19)

Stop

origin

function

point

(STOP)

(ORIG)

makes the last positionspecifiedjust beforethe selectionofthis

ofthe sewing machine. Please notethat

due

to the character of this function.

functionasthe

set

at a pointotherthanthe mechanical

only

one 2nd

originIsallowed

Sewing machine operation (stitching) stops at previouslyspecified point withthe needle at

up

position.

If

the

start switch of

stitched.

When

the

'STOP'

data

after

canbeinput

the

sewing machine is

the

stop

codeisthe

several

timesIneach

turned

stitching data,

pattern

data

on,

the

the

subsequent

start

codeIsadded

pattern

automatically.

Ineach

can

be

(20) Reverse

When this function is selected,

specified before

•REVER'

the

(21) X

symmetry

Ifthis function Is selected,

position specified before selecting this function.

(REVER)

the

selection of this function.

canbeInput several times In

input of

odd

number

(X-INV)

and

the

the

released

previous

1) Example of Xsymmetry

reverse

each

with

data

presser

pattern

the

Input of

Is Inverted

is driven at

data

The

even

around

the

last position which

reverse

number.

presser

Yaxis which

Isstartedwith

passes

the

was

last

Input A - B - C

is

created.

and

press

the

'X-INV keysothat

47

the

symmetrical pattern of C - D - E

Page 55

4.

Reference

(22) Y symmetry

If

this function is selected,

(Y-INV)

the

previous

positionspecified before selectingthis function.

1) Example of Ysymmetry

data

is inverted around Xaxis which

passes

the

last

Input A - B - C

is

created.

(23) Point

symmetry

If

this

function is

the

last position before selecting this function.

1) Example of point symmetry

(XY-INV)

selected,

and

press

the

the

"Y-INV

previous

A

31

D .

keysothat

data

is inverted at

c

the

symmetrical pattern of C - D - E

the

point

symmetry

position

around

\

E

Input A - B - C

created.

and

press

the

"XY-INV"sothat

48

a symmetrical

pattern

of C - D - E is

Page 56

4.

Reference

(24) Circle

If

(CIR-*).

the

function is selected, a

specified before selecting this function

1) Example of circle

data

Inputthe points A•*Bto draw a straight lineand press the

circle

data

input state. Then input

C - D -

B.

data

of circle which

passes

ahd

2 points specified next, is created.

a total 3 points, i.e.

'CIRCLE*

the

points C•*D

and

complete

the

last position

keyto bringitto the

the

data of A - B -

If

itis specified

A-B-D-C-Bis

In either

cases,

the

points D C after

created.

the

end

stitch point

the

operation of 'CIRCLE' key,

does

not coincide with

the

(25) Arc (ARC-*)

Ifthis function is selected,anarc

data

which

passes

a total 3 points, i.e.

specified before selecting the function and 2 points specified next, is created.

1) Example 1 of

arc

data

. »

the

pattem

point C or D.

the

data

last position

of

Inputthe points A - Bto draw a straight line and operate the 'ARC key to bring itto the

arc data input state.

B - C -

Point C

D.

does

not necessarily coincide with

Next,

specifythe points C - Dto complete the pattern data ofA -

the

end

stitch

-49-

point

Page 57

4.

Reference

2) Example 2 of

If

the points D - C are specified afterthe inputofthe

B - D - Ciscreated.

Point D

(26) Zigzag

If

the function to the position specified next is created.

(ZIGZA)

this

functionisselected,azigzag

arc

data

does

not necessarily coincide withthe end stitch point

data

connecting

from

"ARC

the

key,

the pattern data ofA

last

position

before

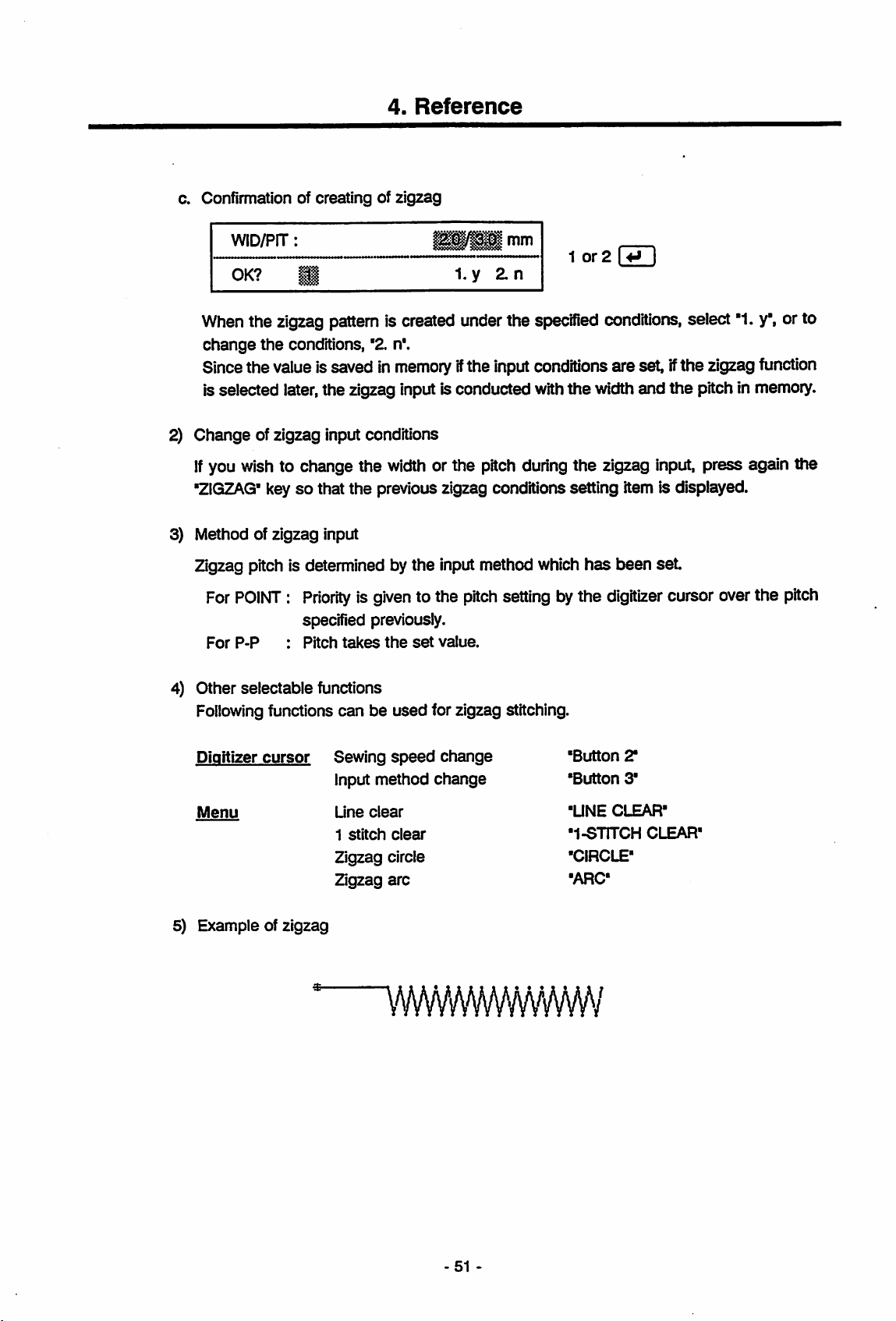

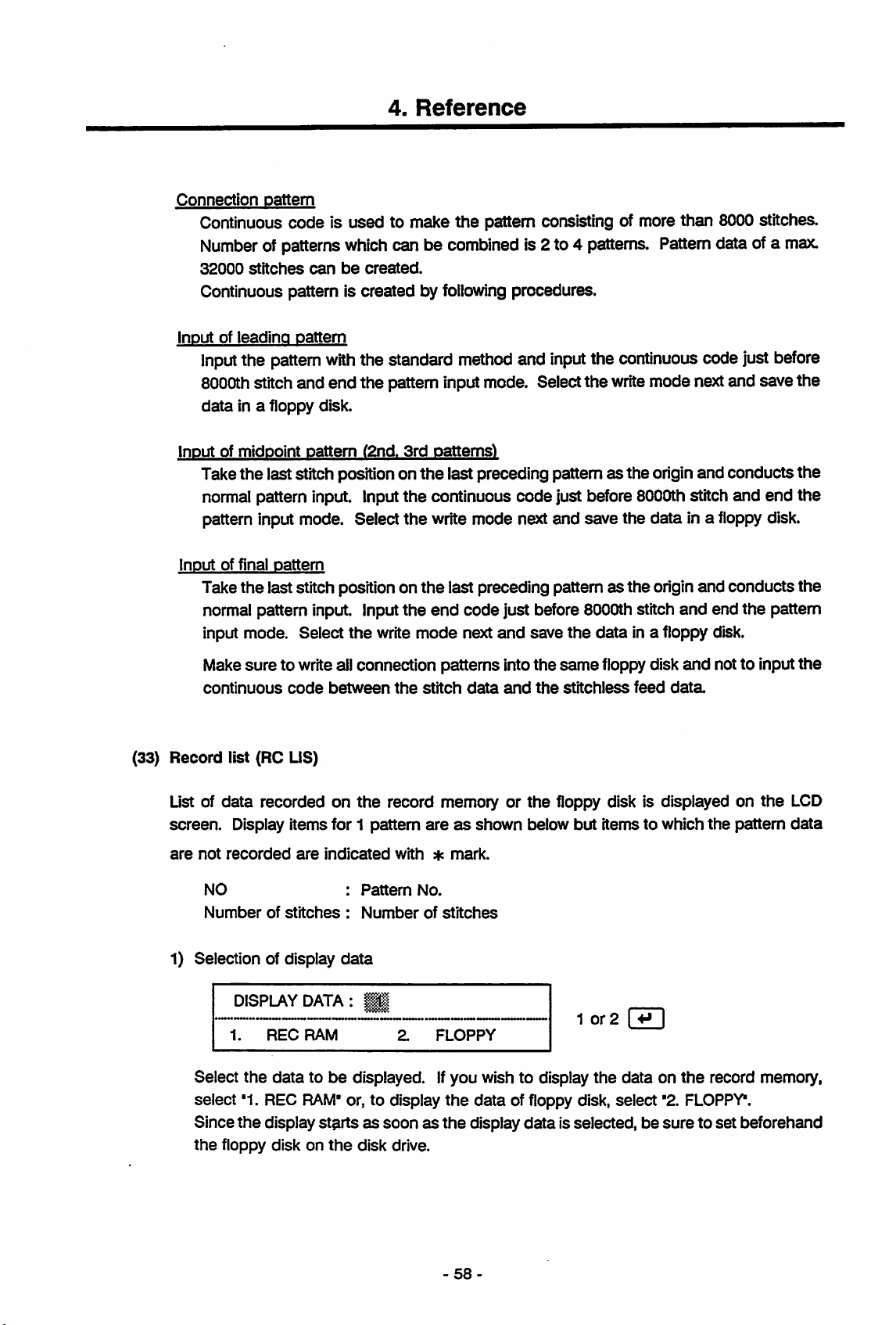

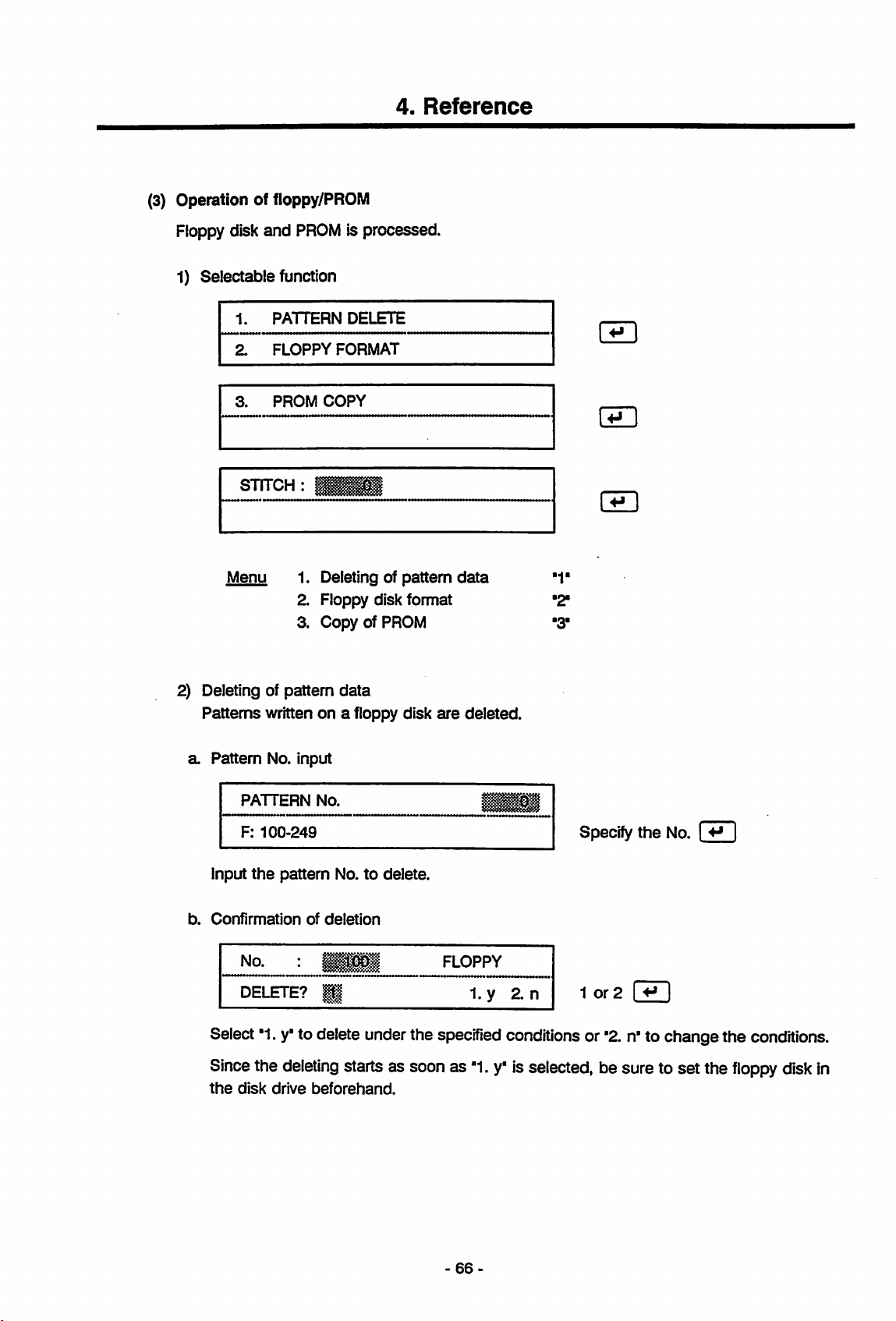

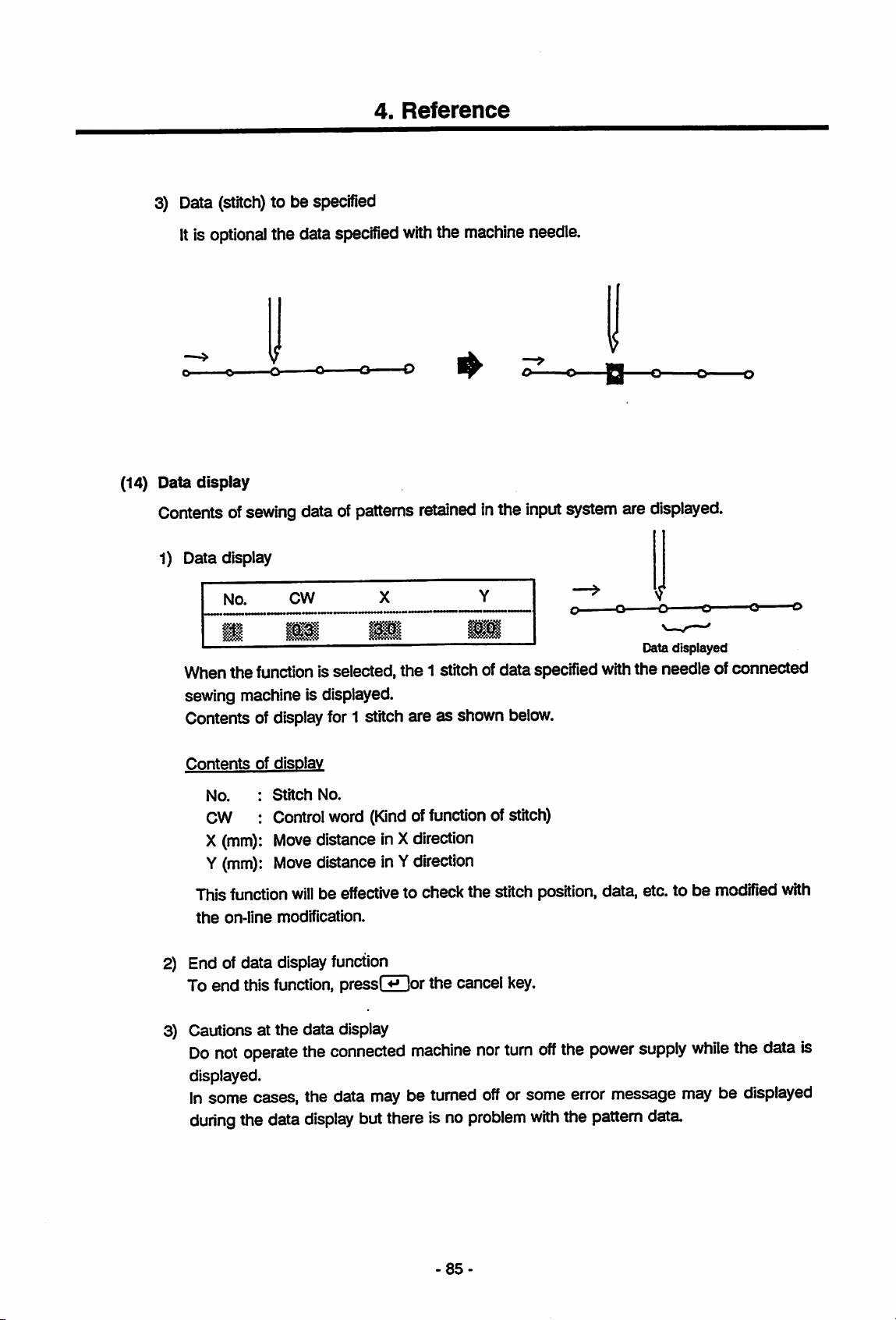

selecting