Page 1

<Dual-In-Line Package Intelligent Power Module >

DIPIPM+ Series APPLICATION NOTE

PSSxxMC1Fx, PSSxxNC1Fx

Table of contents

CHAPTER 1 : INTRODUCTI ON ............................................................................................................................... 2

1.1 Feature of DIPIPM+ ..................................................................................................................................................................................... 2

1.2 Functions ..................................................................................................................................................................................................... 3

1.3 Applications ................................................................................................................................................................................................. 3

1.4 Line-up ........................................................................................................................................................................................................ 4

CHAPTER 2 : SPE CI FICATIONS and CHARACTERISTICS ................................................................................. 5

2.1 Specification of DIPIPM+ ............................................................................................................................................................................. 5

2.1.1 Maximum ratings ........................................................................................................................................................................................................................... 5

2.1.2 Thermal Resistance ...................................................................................................................................................................................................................... 8

2.1.3 Electric Characteristics and Recommended Conditions ............................................................................................................................................................... 9

2.1.4 Mechanical characteristics and speci fications ............................................................................................................................................................................13

2.2 Protection functions and operating sequence ............................................................................................................................................ 14

2.2.1 Short circ uit pr otection.................................................................................................................................................................................................................14

2.2.2 Control Supply UV Protection .....................................................................................................................................................................................................16

2.2.3 Temperature output function VOT ................................................................................................................................................................................................19

2.3 Package outline of DIPIPM+ ...................................................................................................................................................................... 21

2.3.1 Package outline ...........................................................................................................................................................................................................................21

2.3.2 Marking ........................................................................................................................................................................................................................................22

2.3.3 Terminal Description ...................................................................................................................................................................................................................23

2.4 Mounting Method ....................................................................................................................................................................................... 26

2.4.1 Electric Spacing of DIPIPM+ .......................................................................................................................................................................................................26

2.4.2 Mounting Method and Precautions .............................................................................................................................................................................................26

2.4.3 Soldering Conditions ...................................................................................................................................................................................................................28

CHAPTER 3 : SYSTEM APPL ICATION G UIDANCE ............................................................................................ 29

3.1 Application guidance ................................................................................................................................................................................. 29

3.1.1 System connection ......................................................................................................................................................................................................................29

3.1.2 Interface Circuit (Direct Coupling Interface example for using one shunt resistor) ....................................................................................................................30

3.1.3 Interface circuit (example of opto-coupler isolated interface) .....................................................................................................................................................32

3.1.4 External SC protection circuit with using three shunt resistors...................................................................................................................................................33

3.1.5 Circuits of Signal Input Terminals and Fo Terminal ....................................................................................................................................................................33

3.1.6 Snubber circuit ............................................................................................................................................................................................................................35

3.1.7 Recommen de d wiri ng me tho d a rou nd s hu nt resistor .................................................................................................................................................................36

3.1.8 SOA of DIPIPM+ at switching state ............................................................................................................................................................................................38

3.1.9 SCSOA ........................................................................................................................................................................................................................................39

3.1.10 Power Life Cycles ......................................................................................................................................................................................................................40

3.2 Power loss and thermal dissipation calculation .......................................................................................................................................... 41

3.2.1 Power loss calculation .................................................................................................................................................................................................................41

3.2.2 DIPIPM+ performance according to carreir frequency ...............................................................................................................................................................43

3.3 Noise and ESD withstand capability........................................................................................................................................................... 45

3.3.1 Evaluation circuit of noise withstand capability ...........................................................................................................................................................................45

3.3.2 Countermeasures and precautions .............................................................................................................................................................................................46

3.3.3 Static electricity withstand capability ...........................................................................................................................................................................................47

CHAPTER 4 : Bootstrap Circuit O peration ......................................................................................................... 48

4.1 Bootstrap Circuit Operation ........................................................................................................................................................................ 48

4.2 Bootstrap supply circuit current at switching state ...................................................................................................................................... 49

4.3 Note for designing the bootstrap circuit ...................................................................................................................................................... 51

4.4 Initi a l charging in bootstrap circuit .............................................................................................................................................................. 52

CHAPTER 5 : PACKAGE HANDLING .................................................................................................................. 53

5.1 Packaging Specification ............................................................................................................................................................................. 53

5.2 Handling Precautions................................................................................................................................................................................. 54

Publication Date: September 2016

1

Page 2

< Dual-In-Line Package Intelligent Power Module >

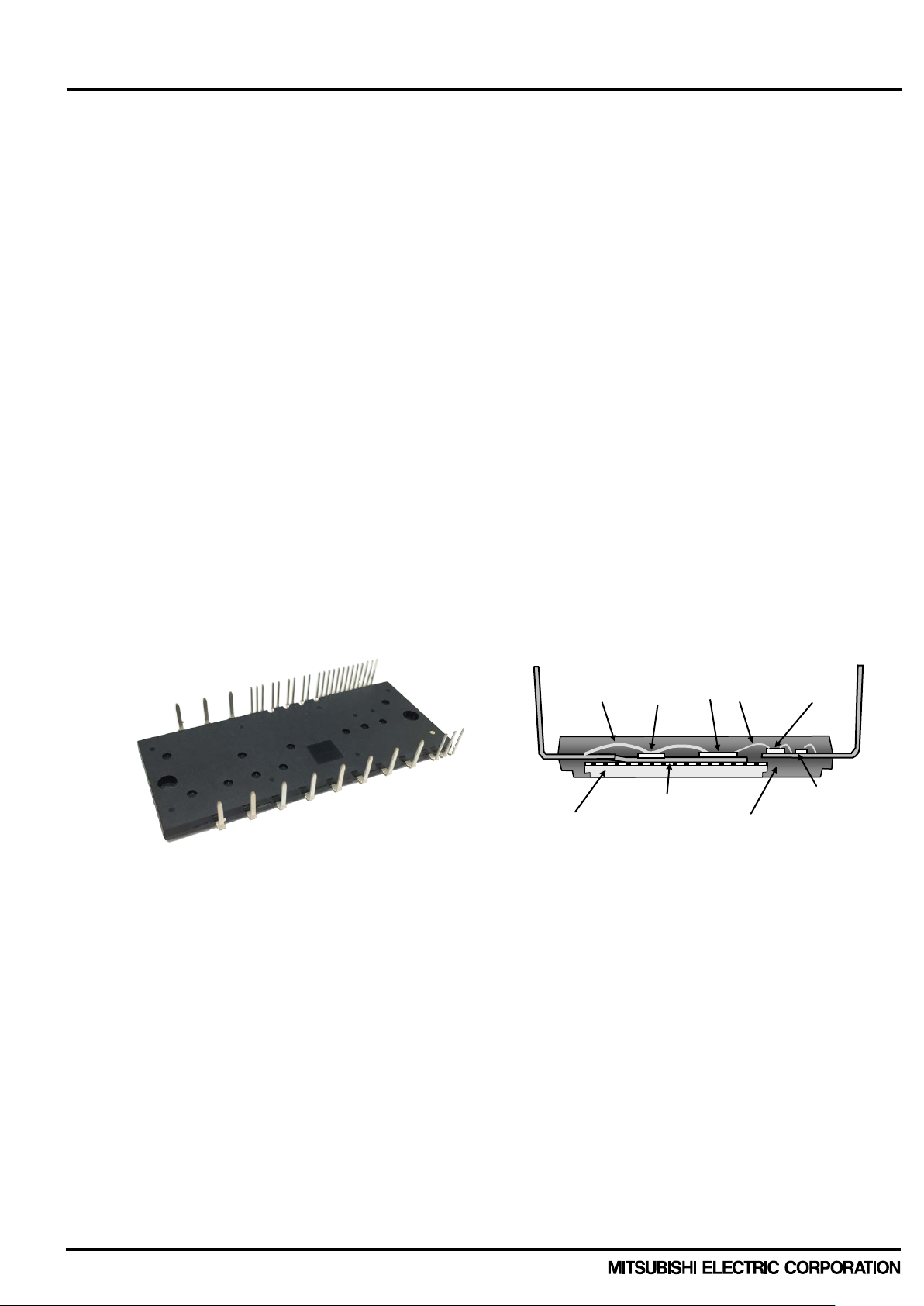

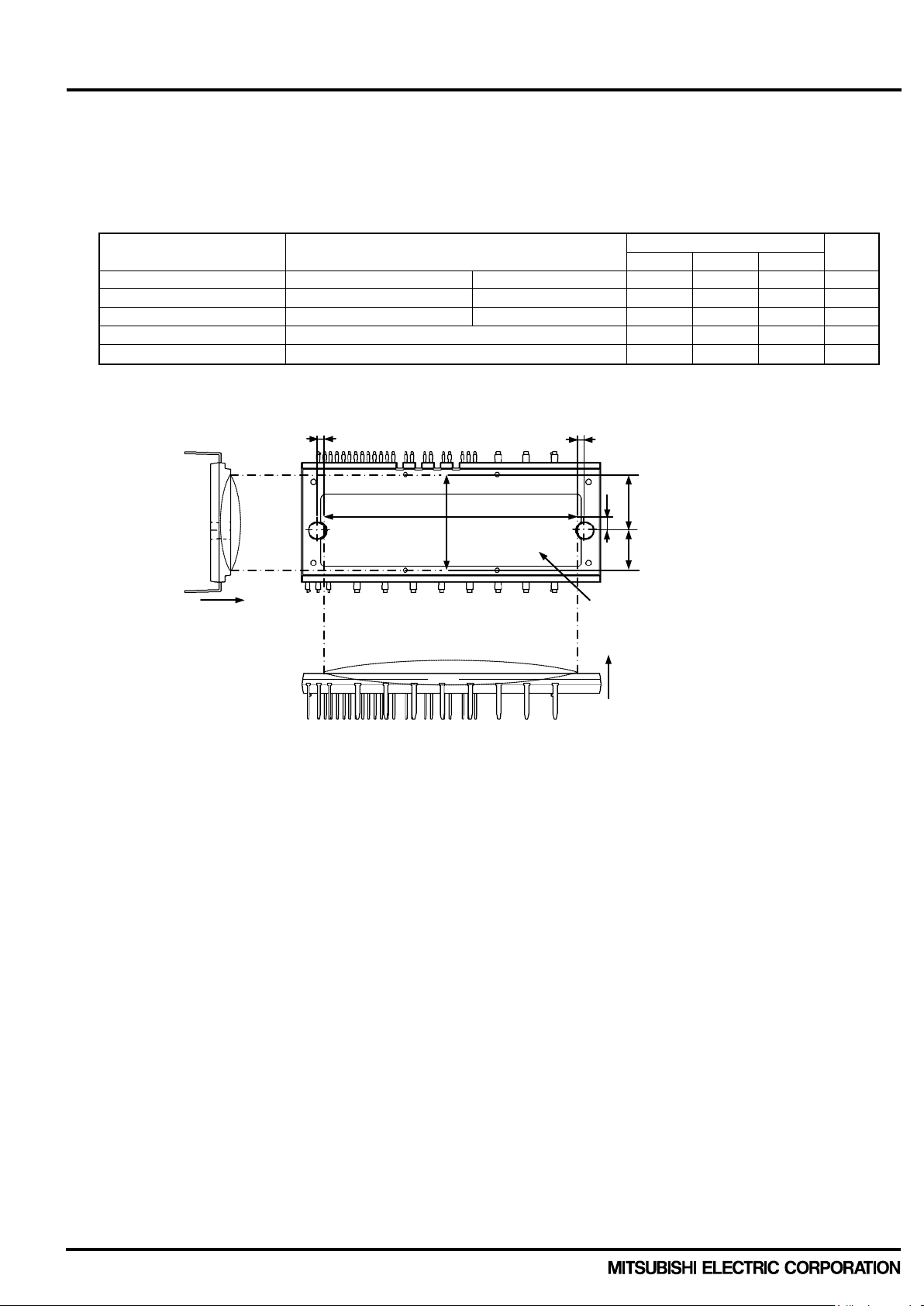

Fig.1-1. Package photograph

1-2 Cross-sectional structure

Molding resin

Aluminum heatsink

Insulation sheet

IGBT

IC

FWDi

Aluminum wire

Gold wire

Copper frame

BSD

DIPIPM+ Series Application note

CHAPTER 1 : INTRODUCTION

1.1 Feature of DIPIPM+ DIPIPM+ series is our latest transfer molding CIB type IPM(CIB: Converter Inverter Brake, IPM: Intelligent

Power Module). It in tegrates the inverter, c onverter and brake parts to make up a compact inverter systems for

commercial and industria l inverter application lik e com m ercial air c ondi tioner, ser vo an d gener al purpose inverter.

We also offers DIPIPM+ without brake type.

General DIPIPM integrates a inverter part only, but recent market demand requires highly integrated IPM

products including more functions and peripheral circuits. So we realized this All-in-One DIPIPM, “DIPIPM+”.

DIPIPM+ series is well designed transfer molding package from our long term histroy as the pioneer.

DIPIPM+ integrates m ain compornents f or inverter circuit a nd it will contribute to reduce total cos t by smaller

mounting area for inverter circuit, shorter designing time and more reasonable assembly cost. It employs

low-voltage (LV) and high voltage (HV) control ICs a nd their correspon ding bootstrap circ uit for IGBT driving and

protection, as same as general DIPIPM series. So DIPIPM+ series enable same system design for its inverter part

like general DIPIPM series.

By adopting same s tructur e of heat r adiation as Lar ge DIPIPM ser ies which h as h igh th erm al conduc tivit y, it is

possible to design system with high reliability.

Main features of this series are described as follows;

・

Newly optimized CSTBT are integrated for improving performance

・

1200V series covers from 5A to 35A and 600V has 50A rating product, DIPIPM+ has wide lineup

・

Easy to design a PCB pattern wiring by smart terminal layout.

・

Incorporating bootstrap diode(BSD) with current limiting resistor for P-side gate driving supply

・

Easy to use temperature output function of the sensor integrated on control IC

Fig.1-1 shows package photograph and Fig.1-2 shows the cross-sectional structure.

Publication Date: September 2016

図

2

Page 3

< Dual-In-Line Package Intelligent Power Module >

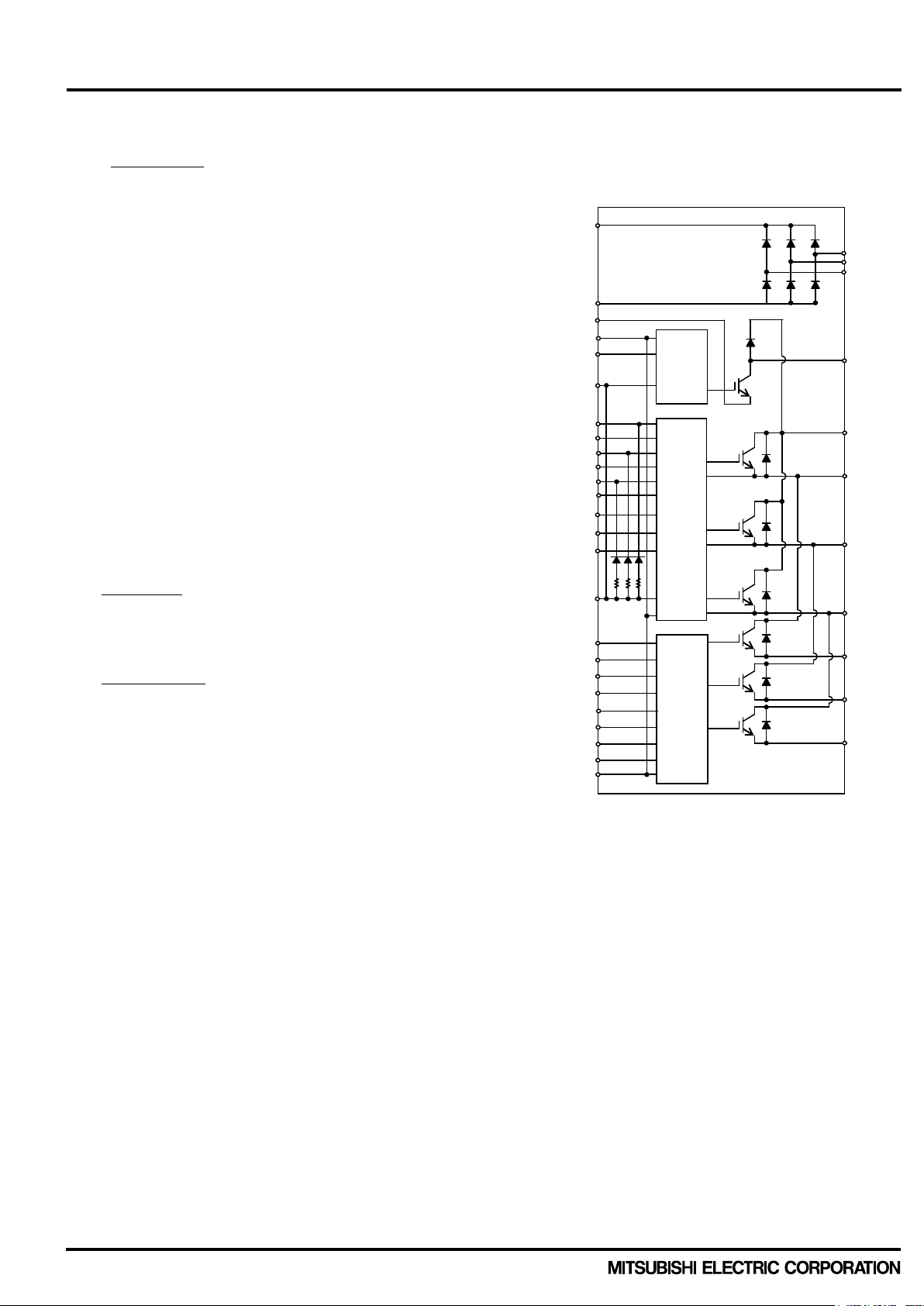

Inverter block

Fig. 1-3 Internal circuit block diagram for

DIPIPM+ with Brake circuit

UN

VN

WN

Fo

VN1

V

VFB

VP

V

WFB

WP

UP

VNC

CIN P U

V W NW

VP1

LVIC

V

UFB

NV

NU

VOT

HVIC

P1 R S

T

N1

B

N(B)

AIN

VNC

LVIC

VP1

V

V

VFS

V

WFS

CFo

DIPIPM+ Series Application note

1.2 Functions

Brake block

Common items

●For P-side IGBT

- Drive circuit

- High voltage level shift circuit

- Control supply under voltage (UV)

lockout circuit (without fault signal output)

- Built-in bootstrap diode (BSD)

with current limiting resistor

●For N-side IGBTs:

- Drive circuit;

- Short circuit (SC) protection circuit

- Control supply under voltage (UV)

lockout circuit (with fault signal output)

- Outputting LVIC temperature by analog signal

(No self over temperature protection)

(note) about SC protection

By detecting voltage of external shunt resistor,

DIPIPM+ works to protect.

●Fault signal output

- Corresponding to N-side IGBT SC protection

and N-side UV protection.

●For IGBT

- Drive circuit

- UV protection circuit without fault signal

●IGBT drive supply

- Single DC15V power supply

●Control input supply

- High active logic with 5V

●UL recognized

- UL1557 File E323585

UFS

1.3 Applications

Motor drives for low power industrial equipment and commercial equipment such as air conditioners

Publication Date: September 2016

3

Page 4

< Dual-In-Line Package Intelligent Power Module >

Type name

Rated current

Rated voltage

Motor ratings

(note1)

Brake

Isolation voltage

PSS05MC1FT

5A

0.75kW/440VAC

PSS10MC1FT

10A

1.5kW/440VAC

PSS15MC1FT

15A

2.2kW/440VAC

PSS25MC1FT

25A

3.7kW/440VAC

PSS35MC1FT

35A

5.5kW/440VAC

PSS50MC1F6

50A

600V

3.7kW/220VAC

Type name

Rated current

Rated voltage

Motor ratings

(note1)

Brake

Isolation voltage

PSS05NC1FT

5A

0.75kW/440VAC

PSS10NC1FT

10A

1.5kW/440VAC

PSS15NC1FT

15A

2.2kW/440VAC

PSS25NC1FT

25A

3.7kW/440VAC

PSS35NC1FT

35A

5.5kW/440VAC

PSS50NC1F6

50A

600V

3.7kW/220VAC

DIPIPM+ Series Application note

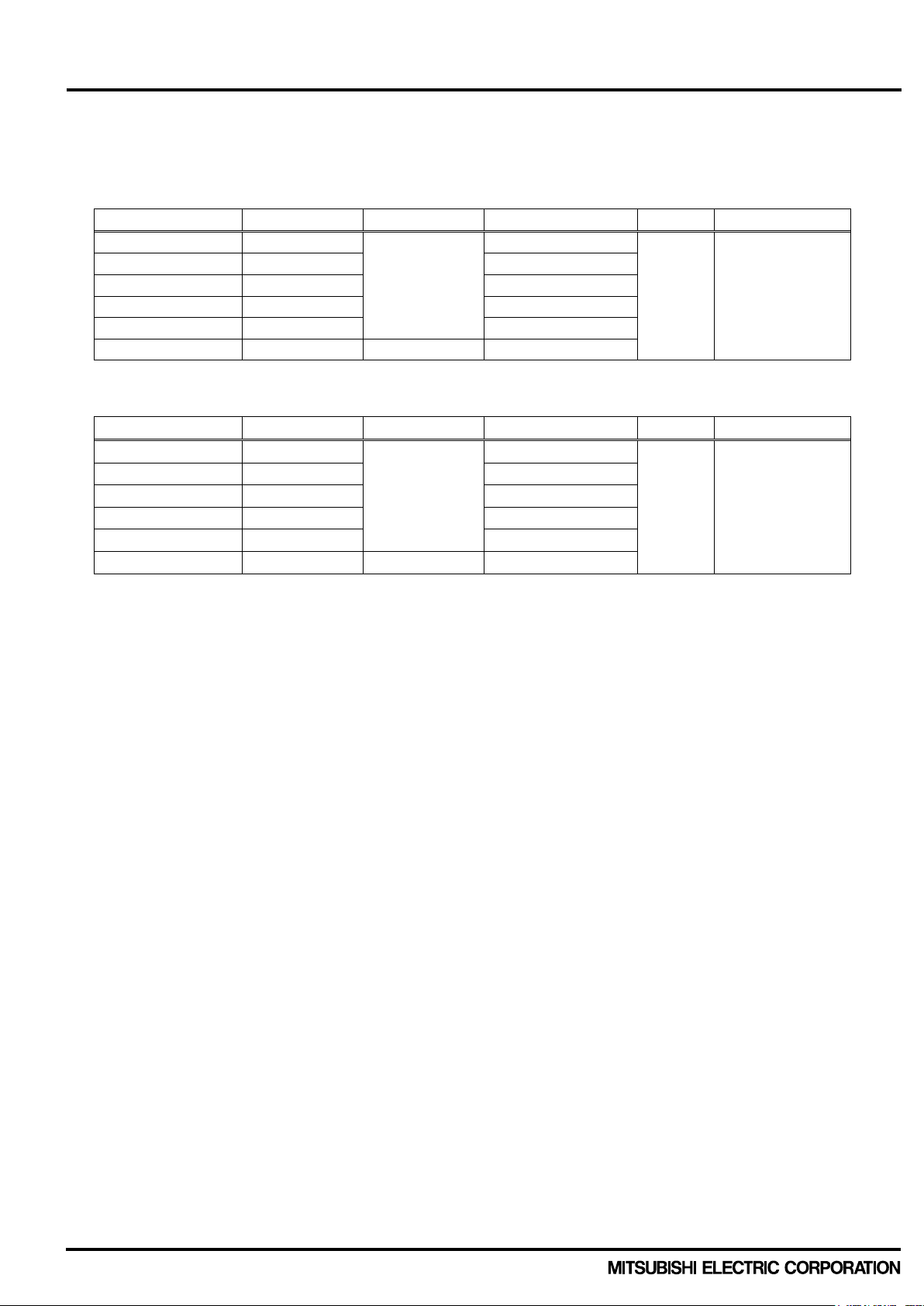

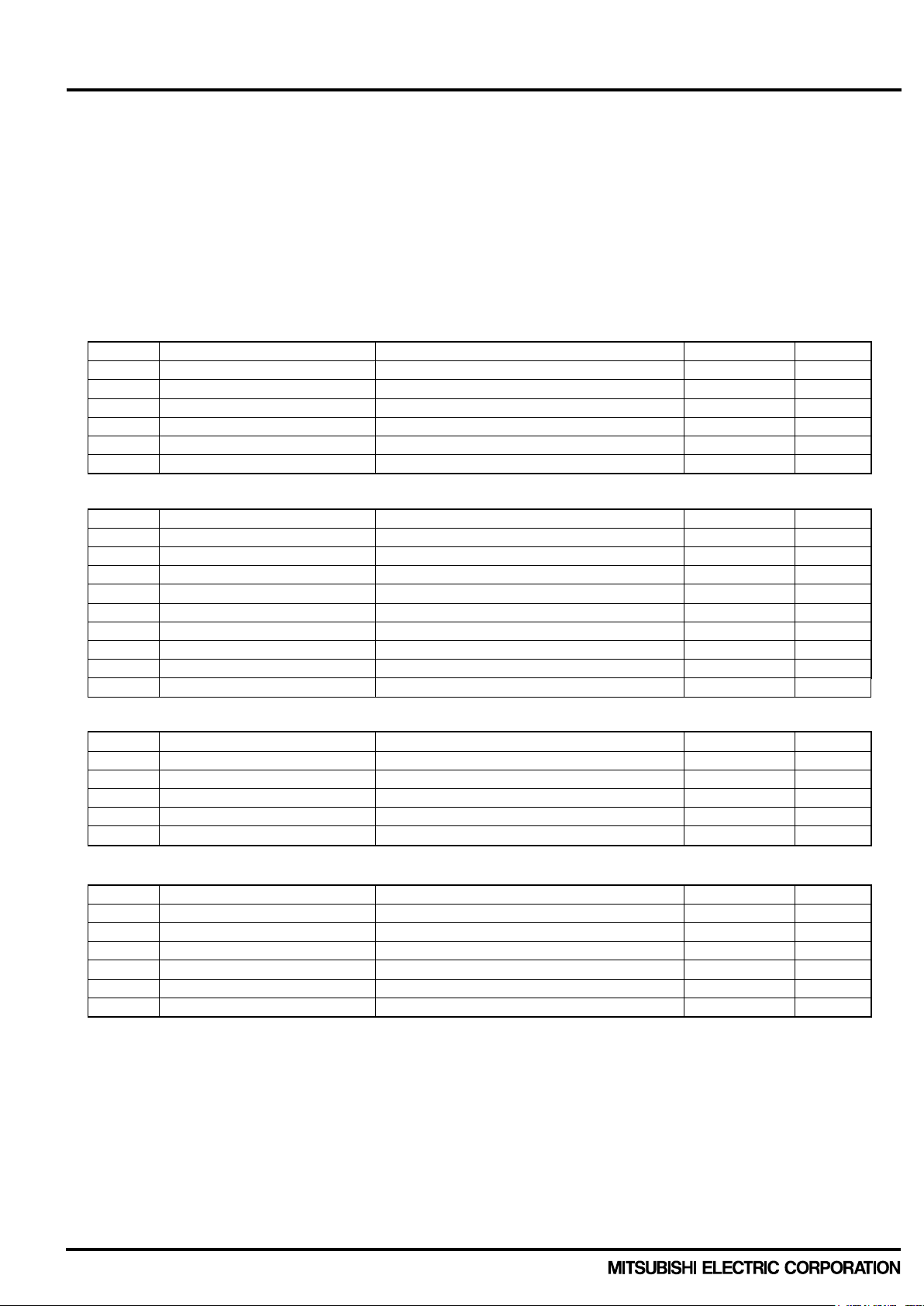

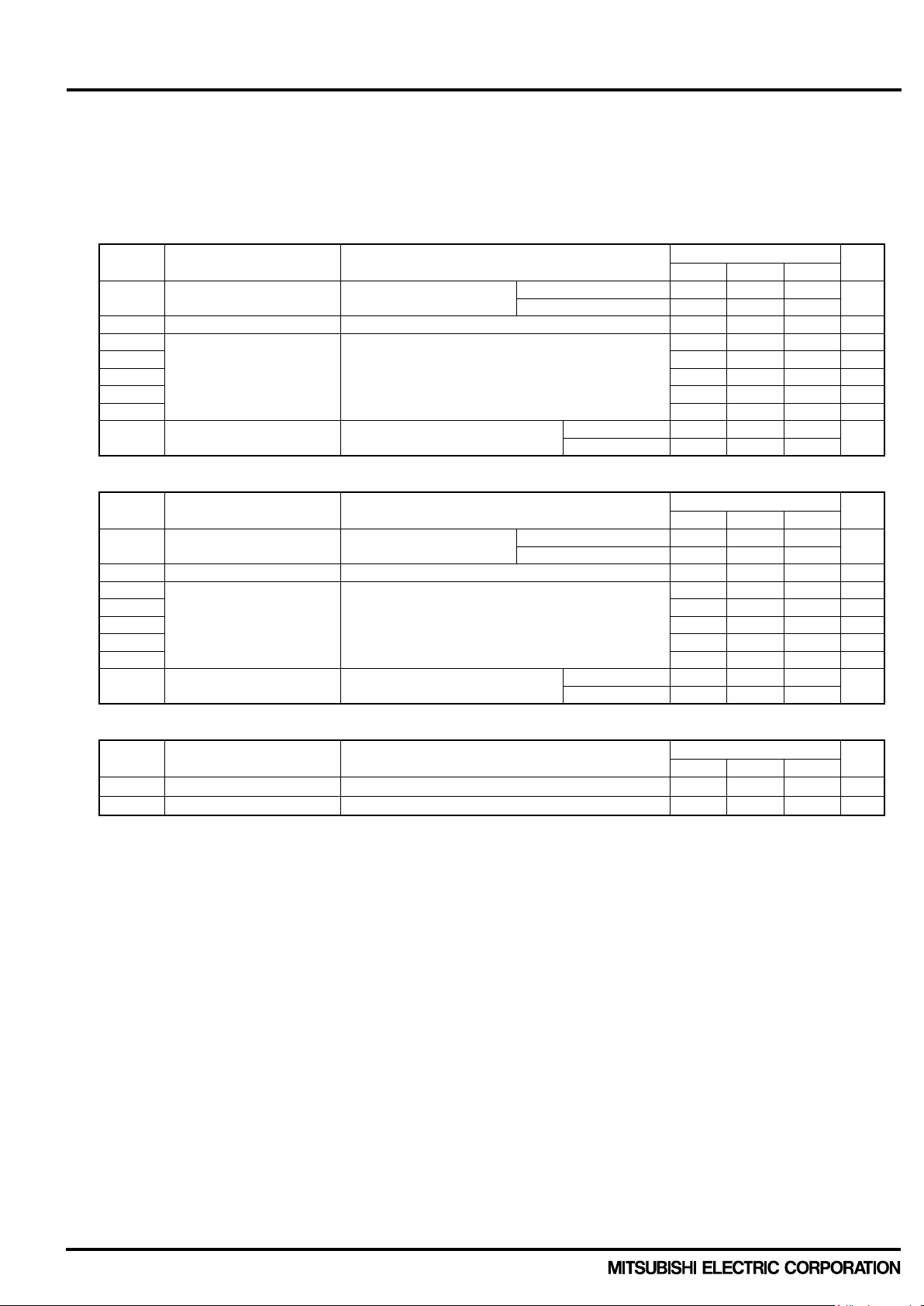

1.4 Line-up

Line-ups are described as following table 1-1. and 1-2.

Table 1-1. DIPIPM+ with Brake circuit

1200V

Yes 2500Vrms

Table 1-1. DIPIPM+ without Brake circuit

1200V

No 2500Vrms

(note 1)

The motor ratings are described for industrial and general motor capability, and actual ratings are different

with application condition.

(note 2)

Isolation voltage is tested under the condition of which all terminals are connected with conductive

material and DIPIPM+ is applied 60Hz sinusoidal voltage between the terminals and heatsink for 1minute.

(note2)

(note2)

Publication Date: September 2016

4

Page 5

< Dual-In-Line Package Intelligent Power Module >

INVERTER PART

Symbol Parameter Condition

Ratings

Unit

V

CC

Supply voltage

Applied between P-NU,NV,NW

900

V

V

CC(surge)

Supply voltage (surge)

Applied between P-NU,NV,NW

1000

V

V

CES

Collector-emitter voltage

1200

V

±IC

Each IGBT collector current

TC= 25°C

(Note 1)

25

A

±ICP

Each IGBT collector current (peak)

TC= 25°C, less than 1ms

50

A

Tj

Junction temperature

-30~+150

°C

BRAKE PART

Symbol Parameter Condition

Ratings

Unit

V

Supply voltage

Applied between P-N(B)

900

V

V

CC(surge)

Supply voltage (surge)

Applied between P-N(B)

1000

V

V

CES

Collector-emitter voltage

1200

V

IC

Each IGBT collector current

TC= 25°C

15

A

ICP

Each IGBT collector current (peak)

TC= 25°C, less than 1ms

30

A

V

RRM

Repetitive peak reverse voltage

1200

V

IF

Forward current

TC= 25°C

15

A

CONVERTER PART

Symbol Parameter Condition

Ratings

Unit

Repetitive peak reverse voltage

Io

DC output current

3-phase full wave rectification

25

A

I

FSM

Surge forward current

Peak value of half cycle at 60Hz, Non-repetitive

315

A

I2t

I2t capability

Value for 1 cycle of surge current

416

A2s

Tj

Junction temperature

-30~+150

°C

CONTROL (PROTECTION) PART

Symbol Parameter Condition

Ratings

Unit

VD

Control supply voltage

Applied between

VP1-VNC, VN1-VNC

20

V

VDB

Control supply voltage

Applied between

V

, V

, V

20

V

VIN

Input voltage

Applied between

UP,VP,WP,UN, VN, WN, AIN-VNC

-0.5~VD+0.5

V

F

VSC

Current sensing input voltage

Applied between CIN-VNC

-0.5~VD+0.5

V

(1)

(2)

(3)

(4)

(5)

(5)

(5)

DIPIPM+ Series Application note

CHAPTER 2 : SPECIFICATIONS and CHARACTERISTICS

2.1 Specification of DIPIPM+ It is representatively described as follows with PSS25MC1FT (25A/1200V,CIB type). For the other products, please refer each data sheets in details.

2.1.1 Maximum ratings Maximum ratings are described as following table 2-1-1. (T

Table 2-1-1 Maximum rating of PSS25MC1FT (25A/1200V,CIB type)

MAXIMUM RATINGS (T

= 25°C, unless otherwise noted)

j

= 25°C, unless otherwise noted)

j

CC

IFP Forward current (peak) 30 A

Tj Junction temperature -30~+150 °C

V

RRM

1600 V

(Note 1)

VFO Fault output supply voltage Applied between

IFO Fault output current Sink current at FO terminal 5 mA

Note1: Pulse width and period are limited due to junction temperature.

Publication Date: September 2016

UFB-VUFS

O-VNC

5

VFB-VVFS

-0.5~VD+0.5 V

WFB-VWFS

Page 6

< Dual-In-Line Package Intelligent Power Module >

TOTAL SYSTEM

Symbol Parameter Condition

Ratings

Unit

Self protection supply voltage limit

(Short circuit protection capability)

VD = 13.5~16.5V, Inverter Part

Tj = 125°C, non-repetitive, less than 2μs

TC

Module case operation temperature

-30~+110

°C

T

stg

Storage temperature

-40~+125

°C

60Hz, Sinusoidal, AC 1min, between connected all

pins and heat sink plate

No.

Symbol

Description

brake circuit is necessary if P-N voltage exceeds this value.

The maximum P-N surge voltage in switching status. If P-N voltage exceeds this voltage, a

snubber circuit is necessary to absorb the surge under this voltage.

(3)

V

CES

The maximum sustained collector-emitter voltage of built-in IGBT and FWDi.

are limited due to junction temperature.

The maximum junction temperature rating is 150°C. But for safe operation, it is recommended

for safety design.

The maximum supply voltage for turning off IGBT s afely in the case of an SC or OC faults.

higher than this specif ic atio n.

Isolation voltage is the withstanding voltage between all terminals connected with conductive

material and heatsink of heat radiation.

information. Due to the control schemes such different control between P and

is necessary to change the measuring point to that under the highest power chip.

Tc point

IGBT chip

Heat radiation

6.4mm

19.6mm

Control terminals

Power terminals

(7)

(6)

DIPIPM+ Series Application note

V

CC(PROT)

V

Isolation voltage

iso

Note2: Measurement point of Tc is described in below figure. (8)

(Note 2)

800 V

2500 V

rms

surface

(1) VCC

(2) V

CC(surge)

(4) +/- IC

(5) Tj

(6) V

CC(PROT)

(7) Viso

(8) Tc position

The maximum voltage can be biased between P-N. A voltage suppressing circuit such as a

The allowable cont inuous current flowing at collect electrode (Tc=25°C) Pulse width and period

to limit the average junction temperature up to 125°C (at Tc is less than 100℃). Repetitive

temperature variation ΔTj affects the life time of power cycle, so please refer life time curves

The power chip might not be protected and break down in the case that the supply voltage is

Tc (case temperature) is defined to be the temperature just beneath the specified power chip.

Please mount a thermocouple on the heat sink surface at the defined position to get accurate

temperature

N-side, there is the possibility that highest Tc point is different from above point. In such cases, it

Publication Date: September 2016

6

Page 7

< Dual-In-Line Package Intelligent Power Module >

INV-IGBT x 6

INV-Di x 6

Br UP VP WP UN VN WN

Br-Di

CONV-Di x 3

CONV-Di x 3

RP SP TP

RN SN TN

Tc position

Br-IGBT

Reference point of

location

DIPIPM+ Series Application note

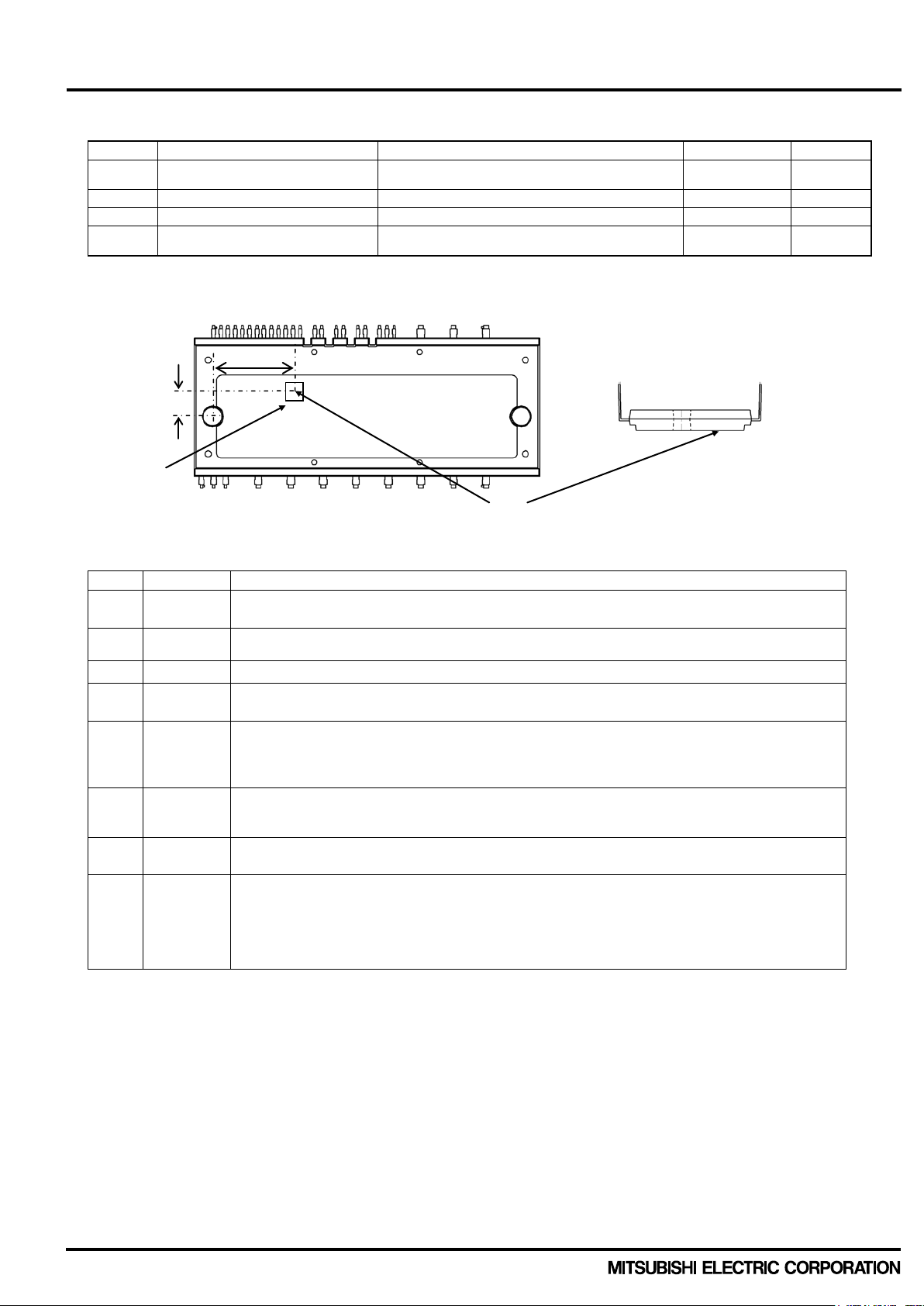

Power chips layout

Fig.2-1-1 indicates the position of the each power chips. (This figure is the view from laser marked side.)

In case of PSSxxNC1Fx, Br-IGBT and Br-Di are not built-in.

Fig. 2-1-1 Power chips layout (Unit : mm)

Publication Date: September 2016

7

Page 8

< Dual-In-Line Package Intelligent Power Module >

Limits

Min.

Typ.

Max.

R

Inverter IGBT part (per 1/6 module)

- - 1.15

R

th(j-c)F

Inverter FWD part (per 1/6 module)

- - 1.65

R

th(j-c)Q

Brake IGBT part (per 1module)

- - 1.45

R

Brake Di part (per 1module)

- - 1.65

R

Converter part (per 1/6module)

- - 1.10

0.01

0.10

1.00

0.001 0.01 0.1 1

Normalized transient

thermal impedance Zth(j-c)*

DIPIPM+ Series Application note

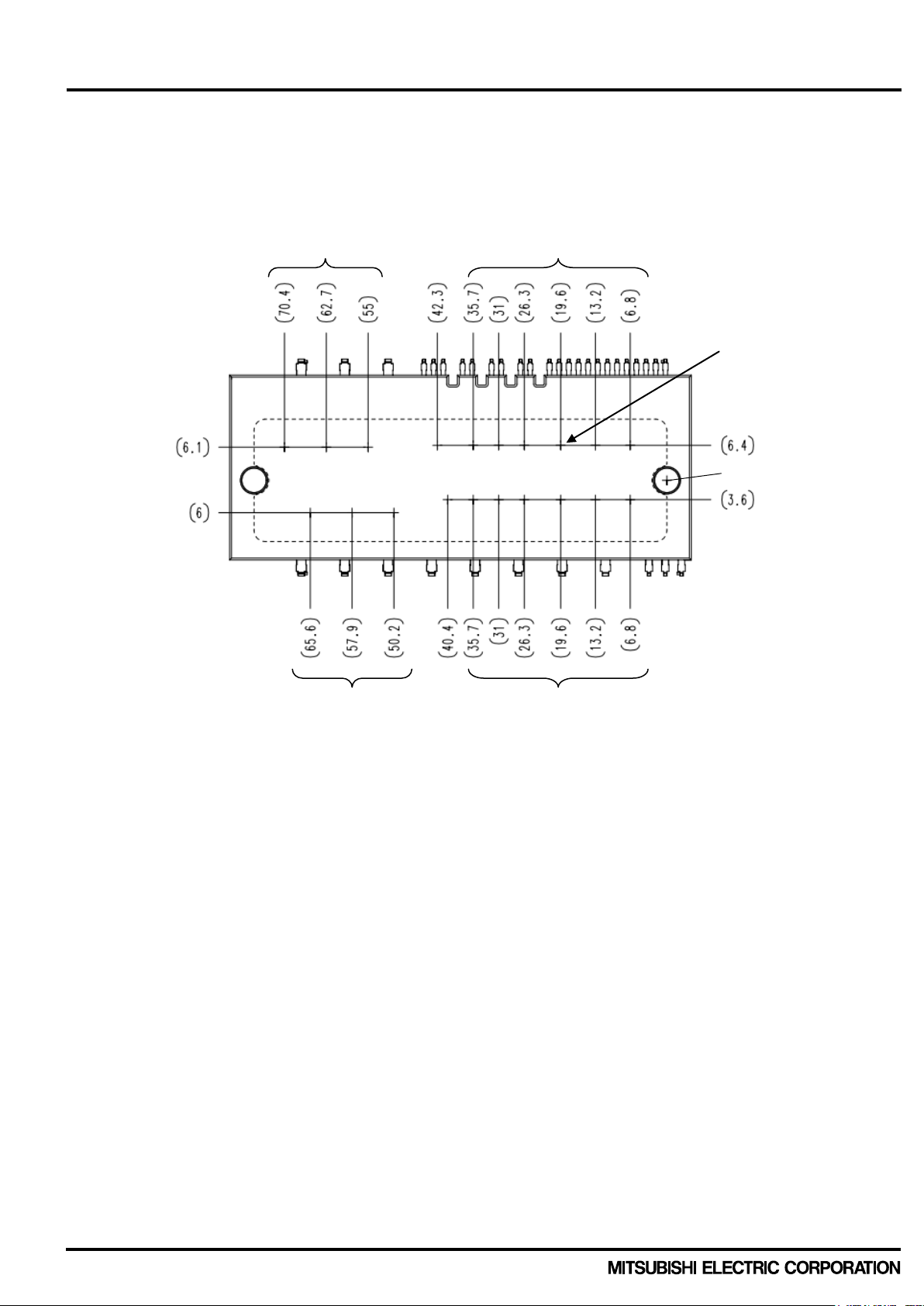

2.1.2 Thermal Resistance Table 2-1-2 shows the thermal resistance between its chip junction and case.

Table 2-1-2. Thermal resistance of PSS25MC1FT (25A/1200V, CIB type)

Symbol Parameter Condition

th(j-c)Q

Junction to case thermal

th(j-c)F

resistance

th(j-c)R

(Note 3)

Unit

K/W

Note 3: Grease with good thermal conductivity and long-term endurance should be applied evenly with about +100μm~

+200μm on the contacting surface of DIPIPM and heat sink. The contacting thermal resistance between DIPIPM

case and heat sink Rth(c-f) is determined by the thickness and the thermal conductivity of the applied grease.

For reference, Rth(c-f) is about 0.25K/ W (per 1chip, grease thickness: 20μm, thermal conductivity: 1.0W/m•K).

The above data shows static state ther m al resis tance. T he ther m al resistanc e goes into sat uratio n in about 10

seconds. The unsaturated thermal resistance is called as transient thermal impedance which is shown in

Fig.2-1-2. Zth(j-c)* is the normalized transient thermal impedance and formulation is described as Zth(j-c)*=

Zth(j-c) / Rth(j-c)max. For example, the IGBT transient thermal impedance at 0.2s is 1.15×0.7=0.81K/W. The

transient thermal im pedance isn’t used for constantly current, but f or short period current as millisecond order.

(e.g. motor starting, motor lock・・・e.t.c)

Publication Date: September 2016

Fig. 2-1-2. Normalized transient thermal impedance

8

Page 9

< Dual-In-Line Package Intelligent Power Module >

INVERTER PART

IC= 25A, Tj= 25°C

-

1.50

2.20

IC= 25A, Tj= 125°C

-

1.80

2.45

VEC

FWDi forward voltage

VIN= 0V, -IC= 25A

-

2.40

3.10

V

ton

1.10

1.90

2.60

μs

t

C(on)

- 0.60

0.90

μs

t

off

- 2.80

3.80

μs t

C(off)

- 0.50

0.90

μs

trr - 0.60 - μs

Tj= 25°C

- - 1

Tj= 125°C

- - 10

BRAKE PART

IC= 15A, Tj= 25°C

-

1.50

2.20

IC= 15A, Tj= 125°C

-

1.80

2.45

VF

Di forward voltage

VIN= 0V, IF= 15A

-

2.20

2.80

V

ton

1.10

1.90

2.60

μs t

C(on)

- 0.65

1.00

μs t

off

- 2.60

3.60

μs

t

C(off)

- 0.40

0.95

μs

trr - 0.65 - μs

Tj= 25°C

- - 1

Tj= 125°C

- - 10

CONVERTER PART

Limits

Repetitive reverse current

−

Forward voltage drop

DIPIPM+ Series Application note

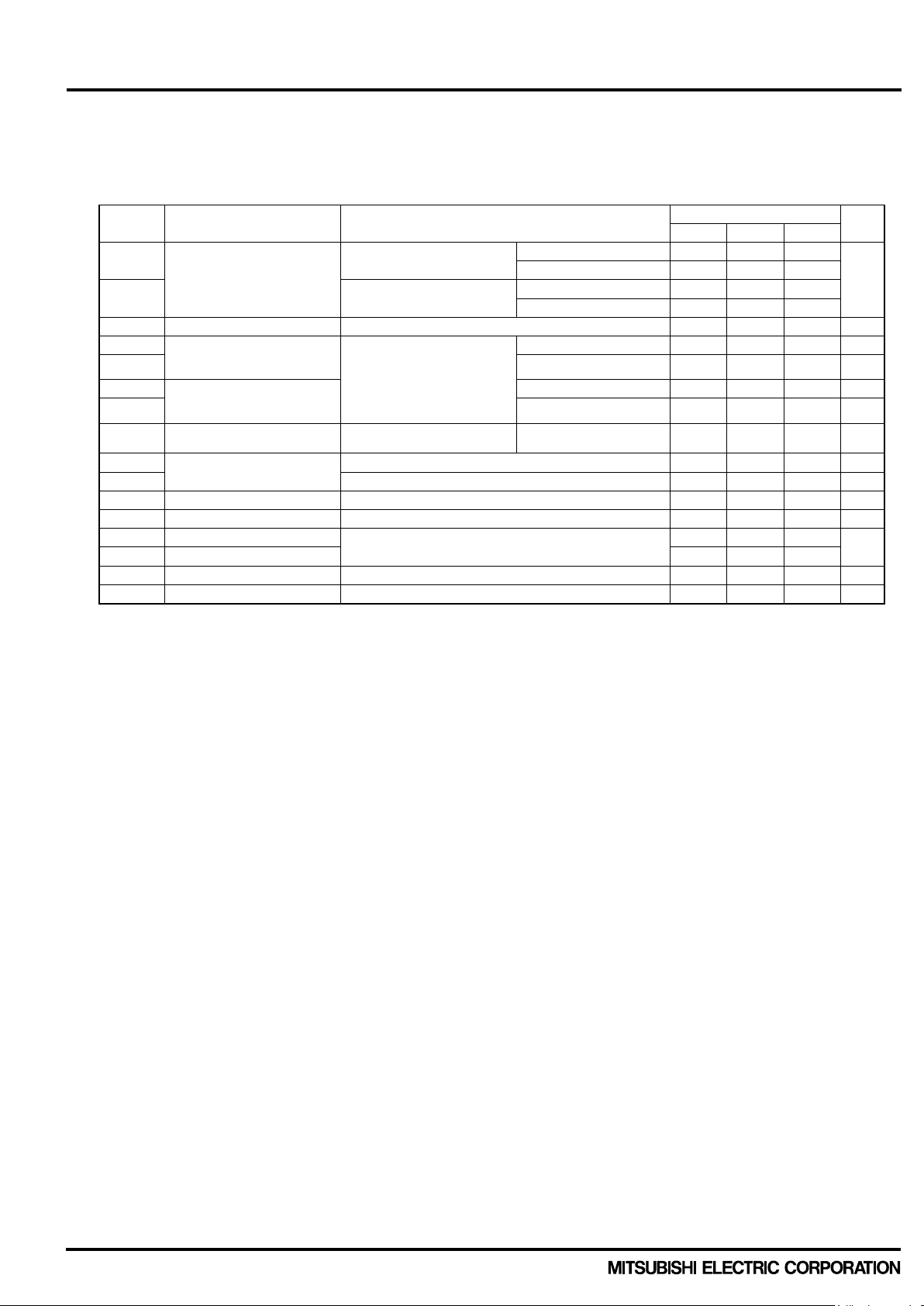

2.1.3 Electric Characteristics and Recommended Conditions Table 2-1-3 shows the typical static characteristics and switching characteristics. (T

Table 2-1-3 Static characteristics and switching characteristics of PSS25MC1FT(25A/1200V, CIB type)

ELECTRICAL CHARACTERISTICS (T

= 25°C, unless otherwise noted)

j

= 25°C, unless otherwise noted)

j

Symbol Parameter Condition

V

CE(sat)

Collector-emitter saturation

voltage

Switching times

VD=VDB = 15V, VIN= 5V

V

= 600V, VD= VDB= 15V

CC

= 25A, Tj= 125°C, VIN= 0↔ 5V

I

C

Inductive Load (upper-lower arm)

I

CES

Collector-emitter cut-off

current

VCE=V

CES

Symbol Parameter Condition

V

I

CES

CE(sat)

Collector-emitter saturation

voltage

Switching times

Collector-emitter cut-off

current

VD=VDB = 15V, VIN= 5V

V

= 600V, VD= VDB= 15V

CC

= 15A, Tj= 125°C, VIN= 0↔ 5V, Inductive Load

I

C

VCE=V

CES

Limits

Min. Typ. Max.

Limits

Min. Typ. Max.

Unit

V

mA

Unit

V

mA

Symbol Parameter Condition

I

RRM

VF

VR=V

IF=25A

, Tj=125°C

RRM

Min. Typ. Max.

−

−

1.1 1.4

7.0

Unit

mA

V

Publication Date: September 2016

9

Page 10

< Dual-In-Line Package Intelligent Power Module >

trr

Irr

tc(on)

10%

10%

10%

10%

90%

90%

td(on)

tc(off)

td(off)

tf

tr

( ton=td(on)+tr )

( toff=td(off)+tf )

Ic

VCE

V

CIN

P-side SW

Input signal

N-side SW

Input signal

VIN(5V⇔0V)

VD

VCC

IN GND CIN

LO

VCC

IN

VB

S

HO

UP,VP,WP

UN,VN,WN

VNC

V

UFB,VVFB,VWFB

VN1

CIN

COM

VP1 P U,V,W

Ic

VCC

N-side

P-side

VDB

NU,NV,

NW

V

UFS,VVFS,VWFS

L load

L load

time:500nsec/div.

VCE:200V/div.

Ic:10A/div.

time:500nsec/div.

VCE:200V/div.

Ic:10A/div.

DIPIPM+ Series Application note

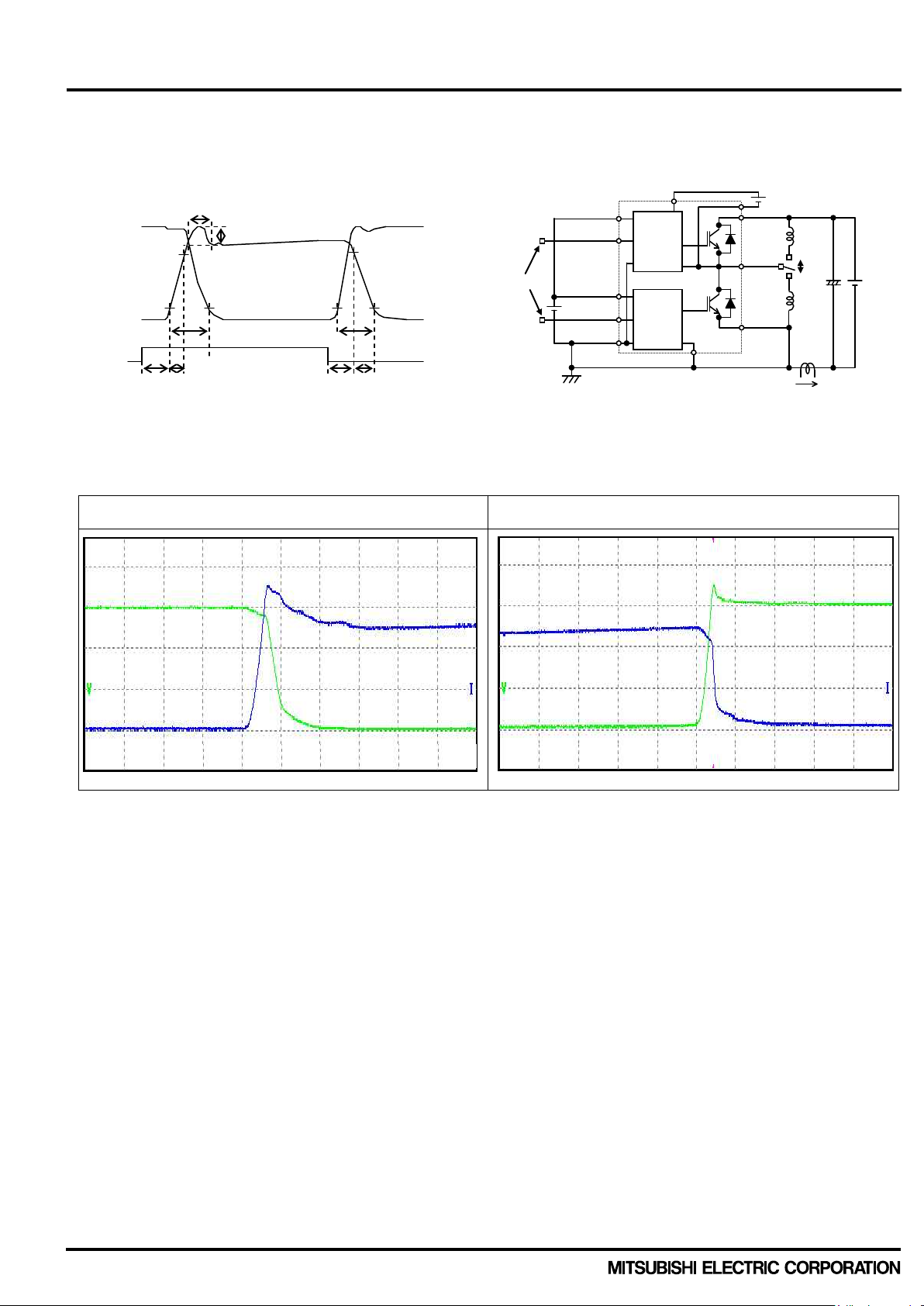

Definition of switching time and performance test topology are shown in Fig.2-1-3 and 2-1-4.

Switching characteristics are measured b y half bridge c irc uit with ind uct ance loa d.

Fig. 2-1-3 Switching time definition Fig. 2-1-4 Evaluation circuit (inductive load)

V

TURN OFF TURN ON

Fig. 2-1-5 Typical switching waveform for PSS25MC1FT (25A/1200V) inverter part

Condition: V

=600V, VD=VDB=15V, Ic=25A, Tj=125°C, inductive load half bridge circuit

CC

Publication Date: September 2016

10

Page 11

< Dual-In-Line Package Intelligent Power Module >

CONTROL (PROTECTION) PART

Min.

Typ.

Max.

VD=15V, VIN=0V

- - 5.70

VD=15V, VIN=5V

- - 5.70

V

SC(ref)

Short circuit trip level

VD = 15V

0.455

0.480

0.505

V

UV

DBt

Control supply under-voltage

inverter part

Trip level

10.0 - 12.0

V

UVDt

Control supply under-voltage

inverter part and brake part

Trip level

10.3 - 12.5

V

LVIC

Temperature=100°C

tFO

Fault output pulse width

In case of CFo=22nF

1.6

2.4

ms

IIN

Input current

VIN = 5V

0.70

1.00

1.50

mA

V

th(on)

ON threshold voltage

-

3.5

V

th(off)

OFF threshold voltage

0.8

-

VF

Bootstrap Di forward voltage

IF=10mA including voltage drop by limiting resistor

0.9

1.3

V R Built-in limiting resistance

Included in bootstrap Di

16

20

24

Ω

DIPIPM+ Series Application note

Table 2-1-4 shows the typical control part characteristics. (T

Table 2-1-4. Typical control part characteristics of PSS25MC1FT(25A/1200V, CIB type)

= 25°C, unless otherwise noted)

j

Symbol Parameter Condition

ID

Circuit current

IDB

UV

UVDr Reset level 10.8 - 13.0 V

VOT Temperature Output Pull down R=5.1kΩ (Note 5)

V

FOH

V

FOL

protection(UV) for P-side of

Reset level 10.5 - 12.5 V

DBr

protection(UV) for N-side of

Fault output voltage

VSC = 1V, IFO = 1mA - - 0.95 V

Total of VP1-VNC, VN1-VNC

=15V, VIN=0V - - 0.55

V

Each part of V

V

VSC = 0V, FO terminal pulled up to 5V by 10kΩ 4.9 - - V

Applied between UP,VP,WP,UN, VN, WN, AIN-VNC

VFB-VVFS

, V

WFB-VWFS

UFB-VUFS

,

D=VDB

VD=VDB=15V, VIN=5V - - 0.55

(Note 4)

2.89 3.02 3.14 V

(Note 6,7)

-

Limits

-

-

Note 4 : SC protection works only for N-side IGBT in inverter part. Please select the external shunt resistance such that

the SC trip-level is less than 1.7 times of the current rating.

5 : DIPIPM don't shutdown IGBTs and output fault signal automatically when temperature rises excessively. When

temperature exceeds the protective level that user defined, controller (MCU) should stop the DIPIPM.

Temperature of LVIC vs. VOT output characteristics is described in Section 2.2.3.

6 : Fault signal Fo outputs when SC or UV protection works for N-side IGBT in inverter part. The fault output

pulse-width t

is depended on the capacitance value of CFO (CFO = tFO × 9.1 × 10-6 [F]).

FO

7 : UV protection also works for P-side IGBT in inverter part or brake part without fault signal Fo.

Unit

mA

V

Publication Date: September 2016

11

Page 12

< Dual-In-Line Package Intelligent Power Module >

RECOMMENDED OPERATION CONDITIONS

Limits

Min.

Typ.

Max.

VCC

Supply voltage

Applied between P-NU,NV,NW

0

600

800

V

VD

Control supply voltage

Applied between VP1-VNC,VN1-VNC

13.5

15.0

16.5

V

t

dead

Arm shoot-through blocking time

For each input signal

3.0 - -

μs

f

PWM

PWM input frequency

T

C

100°C, T

j

125°C

- - 20

kHz

PWIN(on)

1.5 - -

Less than

rated current

From rated

current

VNC

VNC variation

Between VNC- NU、NV、NW (including surge)

-5.0 - +5.0

V

Tj

Junction temperature

-20 - 125

°C

P Side Control Input

Internal IGBT Gate

Output Current Ic

t1

t2

Real line…off pulse width>PWIN(off); turn on time t1

Broken line

DIPIPM+ Series Application note

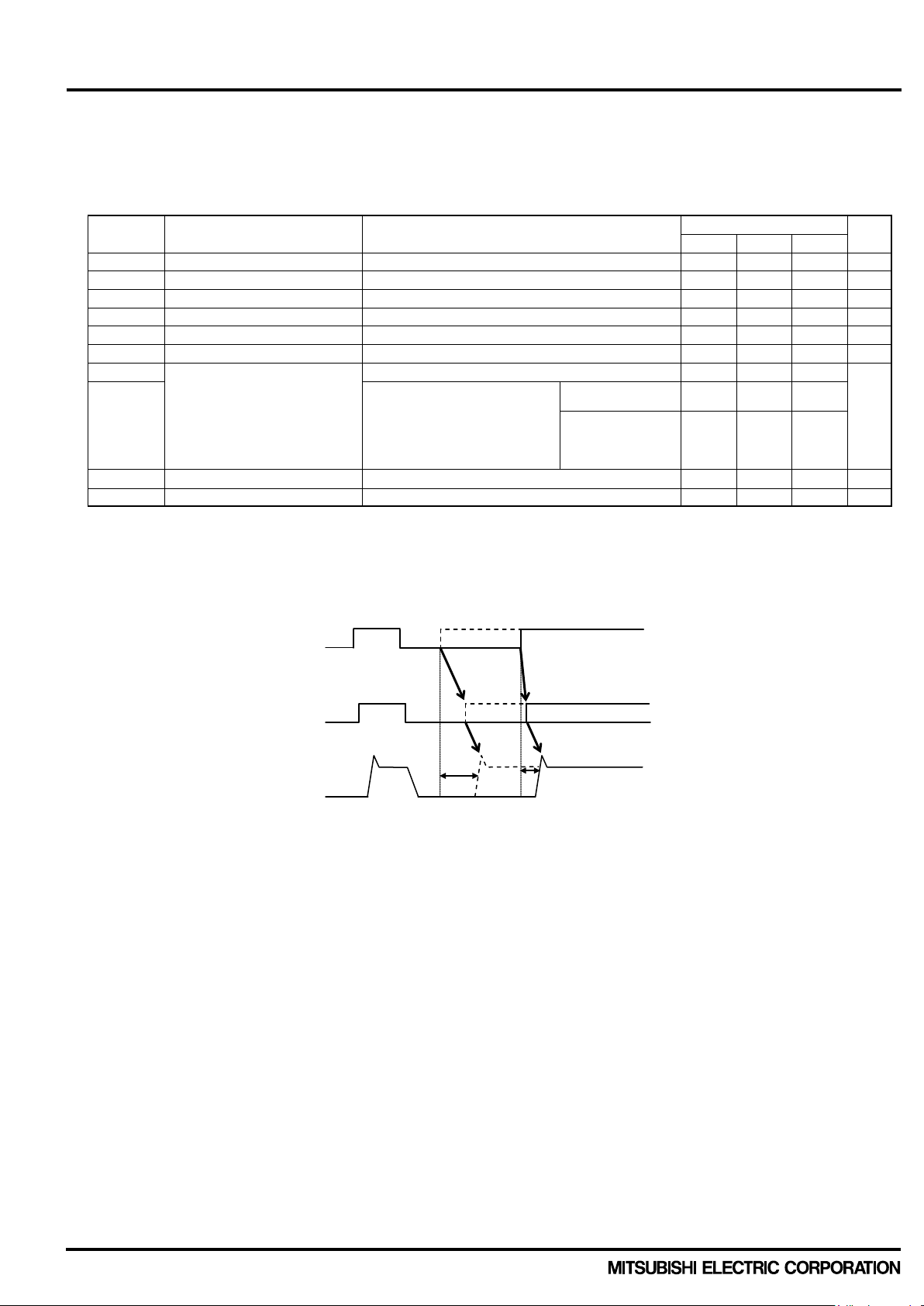

Table 2-1-5 shows recommended operation conditions. Please apply and use under the recommended conditions

to operate DIPIPM+ series safely. (T

Table 2-1-5. Recommended operation conditions of PSS25MC1FT (25A/1200V, CIB type)

= 25°C, unless otherwise noted)

j

Symbol Parameter Condition

VDB Control supply voltage Applied between V

ΔVD, ΔVDB Control supply variation -1 - 1 V/μs

≤

I

≤1.7 times of rated current (Note 8)

C

≤800V, 13.5≤VD≤16.5V,

0≤V

PWIN(off)

Note 8: DIPIPM might not make response if the input signal pulse width is less than PWIN(on).

Minimum input pulse width

CC

13.0≤V

N line wiring inductance

less than 10nH

≤18.5V, -20≤TC≤100°C,

DB

UFB-VUFS,VVFB-VVFS,VWFB-VWFS

≤

(Note 9)

current to 1.7

times of rated

13.0 15.0 18.5 V

3.0 - -

3.5 - -

9: DIPIPM might make no response or delayed response (P-side IGBT only) for the input signal with off pulse width

less than PWIN(off). Please refer below figure about delayed response.

About Delayed Response Against Shorter Input Off Signal Than PWIN(off) (P side only)

…off pulse width<PWIN(off); turn on time t2

[note] About control supply variation

If high frequency noise superimposed to the control supply line, IC malfunction might happen and cause DIPIPM erroneous

operation. To avoid such problem, line ripple voltage should meet the following specifications:

dV/dt ≤ +/-1V/μs, Vripple≤2Vp-p

Unit

μs

Publication Date: September 2016

12

Page 13

< Dual-In-Line Package Intelligent Power Module >

MECHANICAL CHARACTERISTICS AND RATINGS

Limits

Terminal pulling strength

20N load

JEITA-ED-4701

10

-

s

Terminal bending strength

90deg bending with 10N load

JEITA-ED-4701

2

-

times

Weight

40

g

Heat radiation part flatness

-50 -

+100

μm

3.5

15.5

11.5

2

2

Aluminum heatsink

Heatsink side

Heatsink side

Measurement position (X)

Measurement

position (Y)

+

+

-

DIPIPM+ Series Application note

2.1.4 Mechanical characteristics and specifications Table 2-1-6 shows mechanical characteristics and specifications. Please also refer section 2.4 for mounting instruction of DIPIPM+.

Table 2-1-6. Mechanical characteristics and specifications of PSS25MC1FT (25A/1200V, CIB type)

Parameter Condition

Mounting torque Mounting screw : M4 (Note 10) Recommended 1.18N·m 0.98 1.18 1.47 N·m

(Note 11)

Min. Typ. Max.

-

-

-

Note 10: Plain washers (ISO 7089~7094) are recommended.

Note 11: Measurement positions of heat radiati on part flatness are as below.

Unit

-

Publication Date: September 2016

13

Page 14

< Dual-In-Line Package Intelligent Power Module >

V

N1

N

C

Shunt resistor

P V U W N-side IGBTs

P-side IGBTs

Drive circuit

SC protection circuit

CIN

DIPIPM

R

External parts

Lower-side control

input

Protection circuit state

Internal IGBT gate

Output current Ic

Sense voltage of

the

Error output Fo

SC trip current level

a2

SET

RESET

SC reference voltage

a1

a3

a6

a7

a4

a8

a5

Delay by RC filtering

SC protection level

Collector current Ic

Input pulse width tw (μs)

2

0

Collector

waveform

DIPIPM+ Series Application note

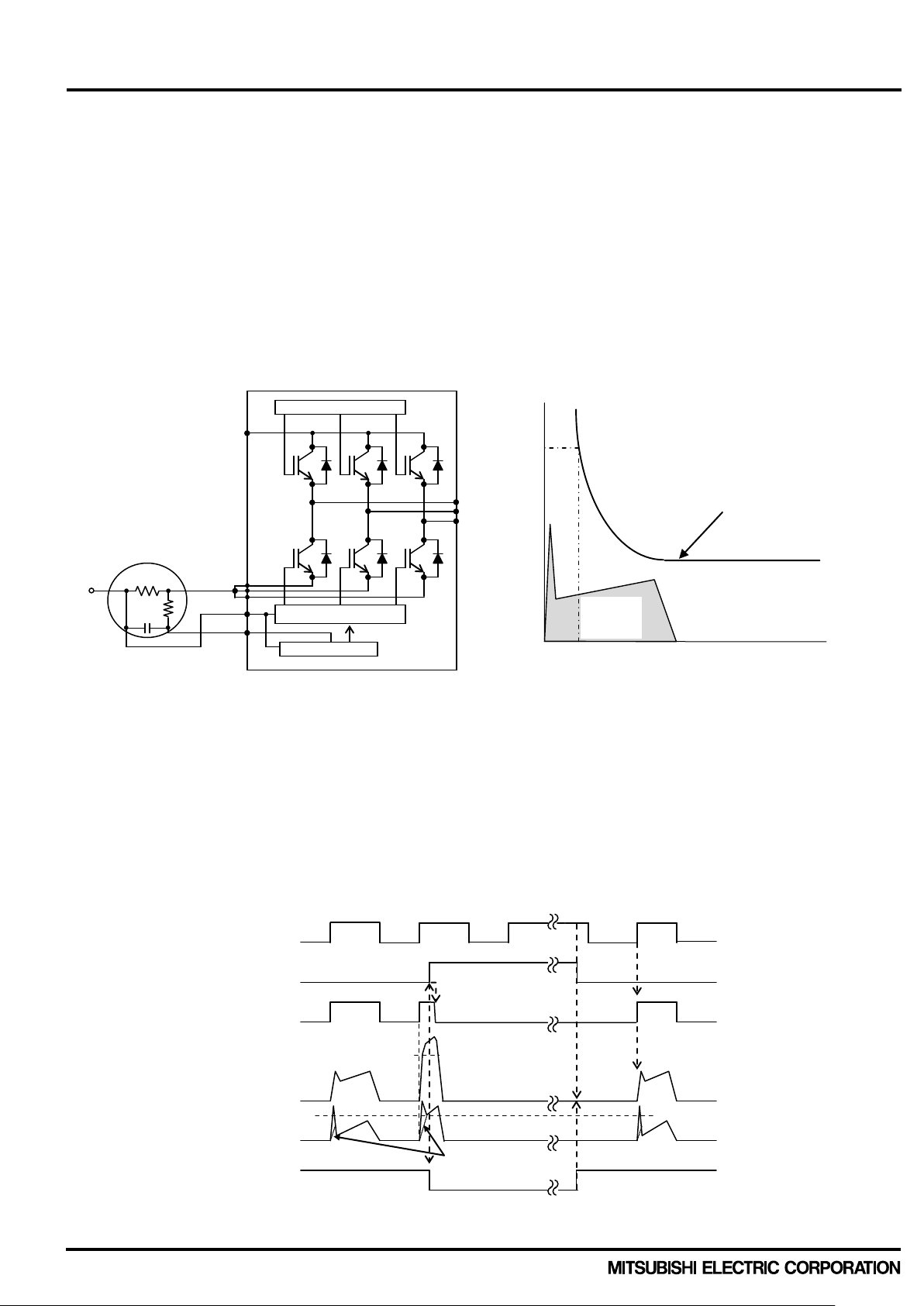

2.2 Protection functions a nd operating sequence DIPIPM+ has two protec t io n f unc tions of s hort c irc uit ( SC ) an d u nder vo lta ge of c ontrol s upp ly (UV). And i t has

also temperature output function of LVIC (VOT). The operating principle and sequence are described as follows.

2.2.1 Short circuit protection (1) Outline

DIPIPM+ uses ex ternal shunt resistor for the current detec tion as shown in F ig.2-2-1. The intern al protection

circuit inside the IC ca ptures the excessive large curr ent by comparing the CIN voltage ge nerated at the shunt

resistor with the ref erenced SC tr ip voltage , and perf orm protec tion autom aticall y. The thres hold voltage tr ip leve l

of the SC protection Vsc(ref) is 0.48V typical.

In case of SC protec tion works, all the gates of N-side thr ee phase IGBTs will be interrupted t ogether with a

fault signal output. To prevent DIPIPM+ erroneous protection due to normal switching noise and/or recovery

current, it is necessar y to set an RC f ilter (tim e constant: 1.5μ ~ 2μs) to the CIN t erminal input (Fi g.2-2-1, 2-2-2).

Also, please make the pattern wiring around the shunt resistor as short as possible.

NC

Fig.2-2-1 SC protection circuit Fig.2-2-2 Filtering time constant setting

Drive circuit

Current

(2) SC protection sequence for only low-side with external shunt resistor and RC filter

a1. Normal operation: IGBT ON and outputs current.

a2. Short circuit current detection (SC trigger)

(It is recommended to set RC time constant 1.5~2.0μs so that IGBT shut down within 2.0μs when SC.)

a3. All N-side IGBT's gates are hard interrupted.

a4. All N-side IGBTs turn OFF.

a5. LVIC starts outputting fault signal (fault signal output time is controlled by external capacitor C

a6. Input = “L”: IGBT OFF

a7. Fo finishes output, but IGBTs don't turn on until inputting next ON signal (LH).

(IGBT of each phase can return to normal state by inputting ON signal to each phase.)

a8. Normal operation: IGBT ON and outputs current.

shunt resistor

Fig.2-2-3 SC protection timing chart

FO

)

Publication Date: September 2016

14

Page 15

< Dual-In-Line Package Intelligent Power Module >

Symbol

Condition

Min

Typ

Max

Unit

V

SC(ref)

Tj=25°C, VD=15V

0.455

0.480

0.505

V

Condition

min.

typ.

max.

Unit

Tj=25°C, VD=15V

34.7

38.4

42.5

A

)1ln(1

)1(

1

cshunt

SC

t

cshuntSC

IR

V

t

IRV

⋅

−⋅−=

−⋅⋅=

−

τ

ε

τ

Item

Min

typ

max

Unit

IC transfer delay time

-

-

1.0

μs

DIPIPM+ Series Application note

(3) Calculation of shunt resistance

The value of current sensing shunt resistance for current sensing is calculated by the following formulation:

= V

R

Shunt

The maximum SC trip level SC(max) should be set less than the IGBT minimum saturation current which is 1.7

times as large as th e rated current. F or example, t he SC(max) of PSS25MC1FT s hould be set to 25x 1.7=42.5A.

The parameters ( V

of DIPIPM+ series is +/-0.025V in the specification of V

Table 2-2-1 Specification for V

Therefore, the rang e of SC trip level can be c alculated b y the following d escriptions w ith +/-5% disp ersion of

shunt resistor :

R

Shunt(min)=VSC(ref) max

where SC(max) is 1.7 times of rated current, and so 0.95 is due to -5% dispersion of shunt resistor that

R

Shunt(typ)

Therefore, SC(typ) = V

R

Shunt(max)

Therefore, SC(min)= V

In this case, SC trip level is 42.5A,

R

Shunt(min)

When the both of SC tr ip level and s hunt resis tor will be m aximum, t ypical and m inimum, these will be des cribed

as follows;

SC(max)= 42.5 A (setting), SC (typ) = 0.480 / 12.5 = 38.4 A, SC(min) = 0.455 / 13.1 = 34.7 A

From the above, the SC trip level range is described as Table 2-2-2.

Table 2-2-2 Operative SC Range

/SC where V

SC(ref)

SC(ref)

, R

) dispersion s hould be c onsid ered w hen d esignin g the SC tr ip le vel. The dispersion

Shunt

SC(ref)

SC(ref)

/SC(max)

= R

= R

Shunt(min)

Shunt(typ)

/ 0.95

SC(ref) typ

/ R

Shunt(typ)

x 1.05* *1.05 is due to +5% dispersion of shunt resistor

SC(ref) min

/ R

Shunt(max)

= 0.505V / 42.5A = 11.9 mΩ, R

is the SC trip voltage.

as shown in Table 2-2-1.

SC(ref)

.

= 11.9mΩ / 0.95 = 12.5 mΩ, R

Shunt(typ)

Shunt(max)

= 12.5 x 1.05 = 13.1mΩ

There is the possibility that the actual SC protection level becomes less than the calculated value. This is

considered due to the resonant signals caused mainly by parasitic inductance and parasitic capacitance. It is

recommended to make a confirmation of the resistance by prototype experiment.

(4) RC filter time constant

It is necessar y to s e t a n R C f ilter i n the S C s e ns ing ci r c uit in or der to prevent m al f unc tion of SC protection due

to noise interferenc e. The RC time cons tant is determined dep ending on the appl ying time of noise interf erence

and the SCSOA of the DIPIPM.

When the voltage dro p on the external shunt resisto r exceeds the SC trip level, The tim e (t1) that the CIN

terminal voltage rises to the referenced SC trip level can be calculated by the following expression:

Where Vsc is the CIN terminal input voltage, Ic is the peak current, τ is the RC time constant.

On the other hand, t he typical t ime dela y t2 (from Vs c voltage reaches Vsc(ref ) to IGBT ga te shutdown) of IC

is shown in Table 2-2-3.

Table 2-2-3 Internal time delay of IC

Therefore, the total delay time from an SC level current happened to the IGBT gate shutdown becomes:

Publication Date: September 2016

t

TOTAL

=t1+t2

15

Page 16

< Dual-In-Line Package Intelligent Power Module >

Control supply voltage

(VD, VDB)

In this voltage range, built-in control IC may not work properly. Normal

xternal noise may cause DIPIPM

starts-up.

UV function becomes active and output Fo (N-side only).

Even if control signals are applied, IGBT does not work.

UVDt (N)-13.5V

UV

DBt

(P)-13.0V

IGBT can work. However, conducting loss and switching loss will increase, and

result extra temperature rise at this state,.

13.5-16.5V (N)

13.0-18.5V (P)

16.5-20.0V (N)

18.5-20.0V (P)

IGBT works. However, switching speed becomes fast and saturation current

becomes large at this state, increasing SC broken risk.

20.0V- (P, N)

The control circuit might be destroyed.

DIPIPM+ Series Application note

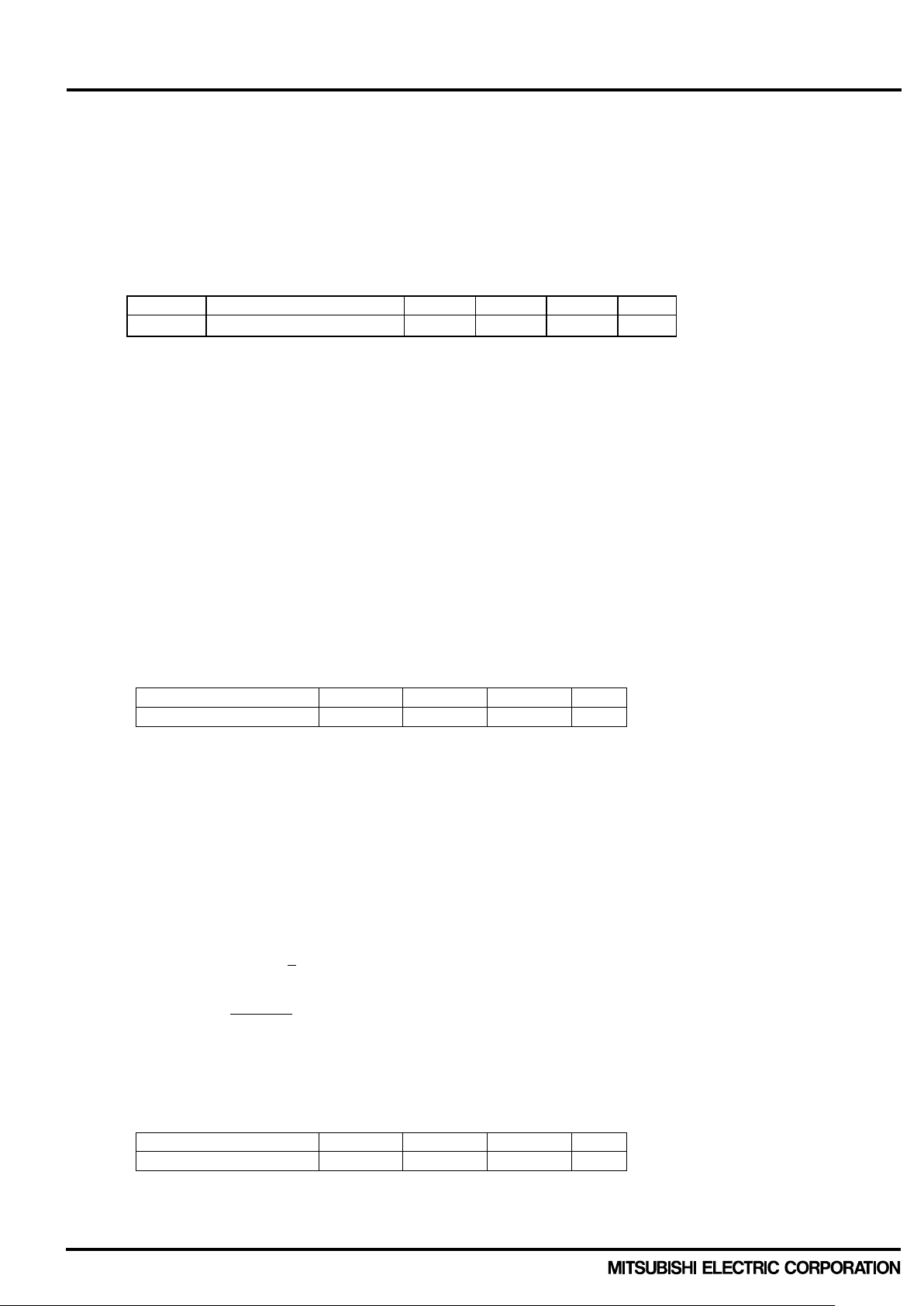

2.2.2 Control Supply UV Protect ion The UV prot ection is designed to prevent u nexpected operating behavior as described in Table 2-2-4. Both P-side, N-side of inverter part and Brak e part have UV protecting functi on. However fault s ignal(Fo) output only corresponds to N-side UV protection. Fo output continuously during UV state. In addition, there is a no ise filter (typ. 10μs) integr at ed i n t he UV protection circ uit t o pr e vent insta ntan eous UV erroneous trip. Therefore, the control signals are still transferred in the initial 10μs after UV happened.

Table 2-2-4 DIPIPM operating behavior versus control supply voltage

Operating behavior

operating of each protection function (UV, Fo output etc.) is not also assured.

0-4.0V (P, N)

Normally IGBT does not work. But e

malfunction (turns ON) , so DC-link voltage need t o s ta r t up af ter contr ol supply

4.0-UVDt (N), UV

(note) Ripple Voltage Limitation of Control Supply

If high frequency noise superimpos ed to the control supp ly line, IC m alfunction might happ en and cause

DIPIPM erroneous operation. To avoid such problem happens, line ripple voltage should meet the

following specifications:

dV/dt

(P)

DBt

Recommended conditions.

≤ +/-1V/μs, Vripple ≤ 2Vp-p

Publication Date: September 2016

16

Page 17

< Dual-In-Line Package Intelligent Power Module >

UVDr

RESET

SET

RESET

UVDt

a1

a2

a3

a4

a6

a7

a5

Control input

Protection circuit state

Control supply voltage VD

Output current Ic

Error output Fo

Control input

Protection circuit state

Control supply voltage VDB

Output current Ic

Error output Fo

UV

RESET

SET

RESET

UV

Keep High-level (no fault output)

a1

a2

a3

a4

a5

a6

DIPIPM+ Series Application note

(1) N-side UV Protection Sequence

a1. Control supp ly voltage V

ON signal (LH).

(IGBT of each phase can return to normal state by inputting ON signal to each phase.)

a2. Normal operation: IGBT ON and carrying current.

level dips to under v olta ge tr ip le vel . (UVDt).

a3. V

D

a4. All N-side IGBTs turn OFF in spite of contr ol input c ondit io n.

a5. Fo outputs for the period set by the capacitance C

level reaches UVDr.

a6. V

D

a7. Normal operation: IGBT ON and outputs current.

Fig.2-2-4 Timing Chart of N-side UV protection

(2) P-side UV Protection Sequence

a1. Control supply voltage V

IGBT turns on by next ON signal (LH).

a2. Normal operation: IGBT ON and outputs current.

a3. V

level drops to under voltage trip level (UV

DB

a4. IGBT of the corresponding phase only turns OFF in spite of control input signal level,

but there is no F

a5. V

level reaches UV

DB

signal output.

O

a6. Normal operation: IGBT ON and outputs current.

Fig.2-2-5 Timing Chart of P-side UV protection

exceeds under voltage reset level (UVDr), but IGBT turns ON by next

D

but output is extended during VD keeps below UVDr.

FO,

rises. After the voltage r eac hes under voltage reset level UV

DB

).

DBt

.

DBr

DBr

DBt

DBr

,

Publication Date: September 2016

17

Page 18

< Dual-In-Line Package Intelligent Power Module >

Control input

Protection circuit state

Control supply voltage VD

Output current Ic

Error output Fo

UV

RESET

SET

RESET

UVDt

Keep High-level (no fault output)

a1

a2

a3

a4

a5

a6

DIPIPM+ Series Application note

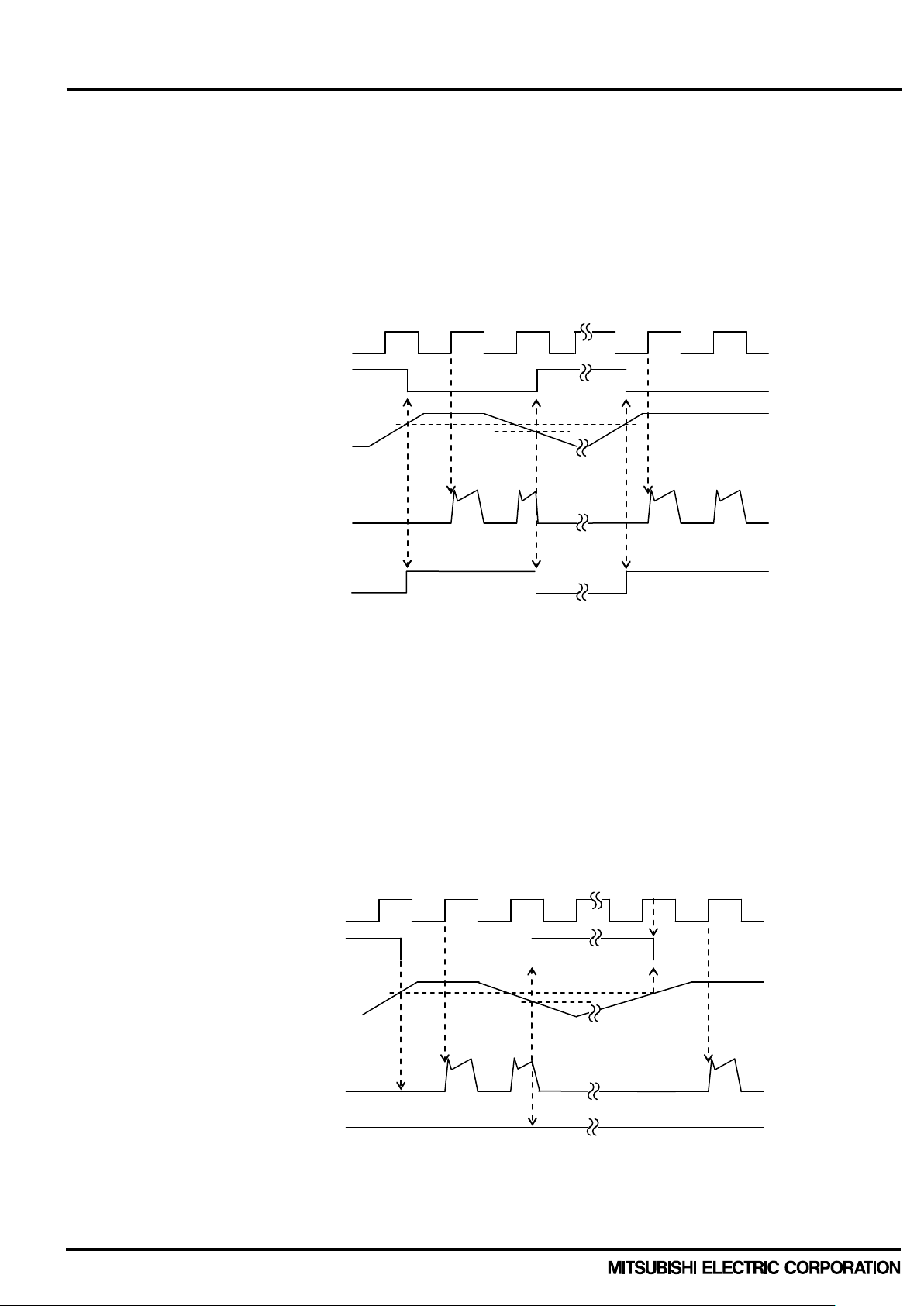

(3) Brake UV Protection Sequence ( with Brake product only : PSSxxMC1Fx)

a1. Control supply voltage V

IGBT turns on by next ON signal (LH).

a2. Normal operation: IGBT ON and collector current.

level drops to under vo ltag e trip level (UVDt).

a3. V

D

a4. IGBT of the corresponding phase only turns OFF in spite of control input signal level,

but there is no F

level reaches UVDr.

a5. V

D

signal output.

O

a6. Normal operation: IGBT ON and outputs current.

Fig.2-2-6 Timing Chart of brake circuit UV protect ion

rises. After the voltage reaches under voltage reset level UVDr,

D

Dr

Publication Date: September 2016

18

Page 19

< Dual-In-Line Package Intelligent Power Module >

min.

Source

1.7mA

Sink

0.1mA

Ref

VOT

Temperature

signal

VNC

Inside LVIC

of

5V

MCU

Ref

VOT

Temperature

signal

VNC

Inside LVIC

of

5.1kΩ

LVIC

Power chip area

Heatsink

IGBT

LVIC

FWDi

Temperature of

DIPIPM+ Series Application note

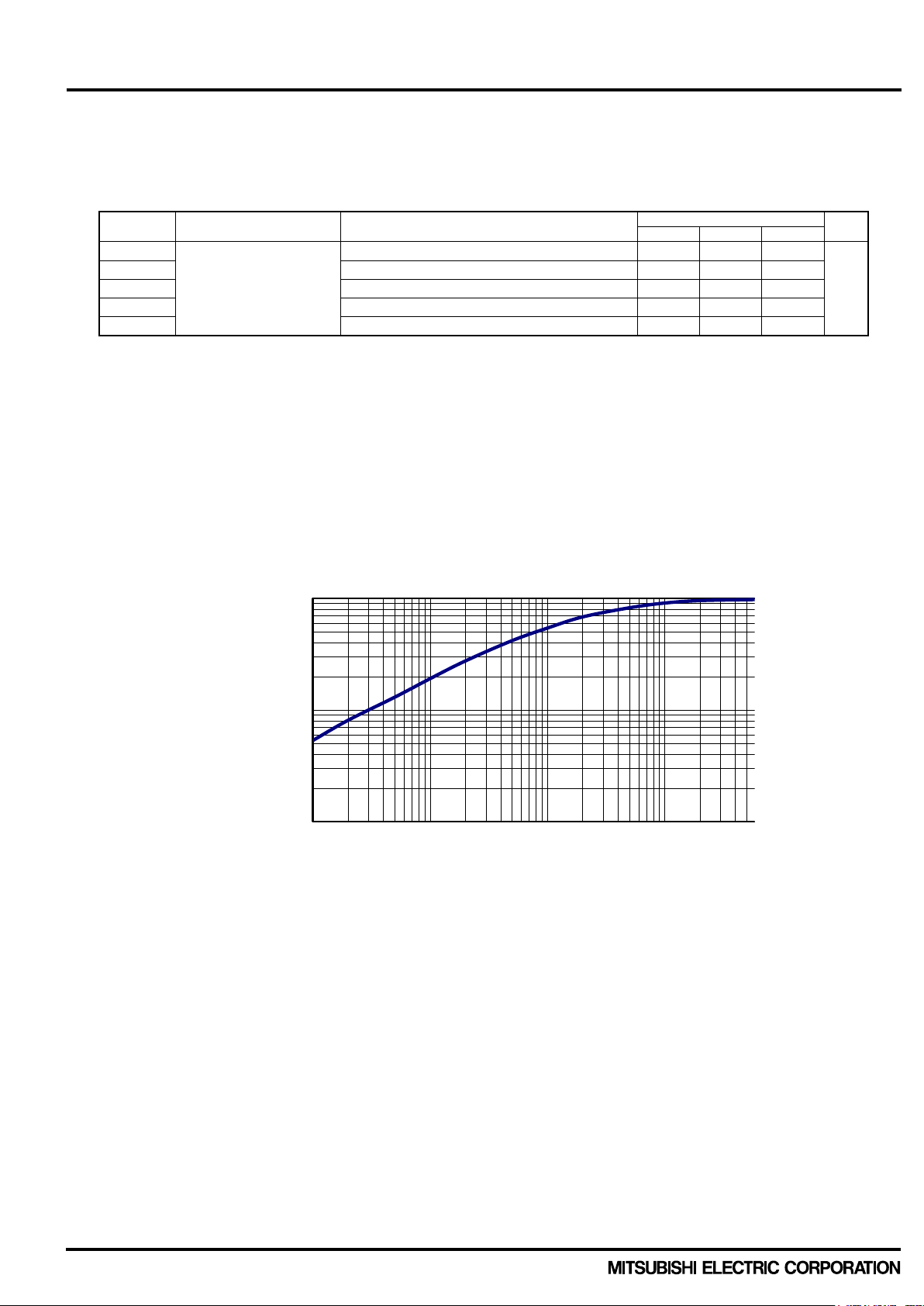

2.2.3 Temperature output function V

(1) Usage of this function

This function measures the temperature of control LVIC by built in temperature sensor on LVIC.

The heat generated at IGBT and FWDi transfers to LVIC through molding resi n of pac k age and outer heat sink.

So LVIC temperature cannot respo nd to rapid tem perature r ise of those p ower chips effectivel y. (e.g. motor lock,

short circuit). It is recom mended to use this f unction for protectin g from slow exces sive temperature rise by such

cooling system down and continuance of overload operation. (Replacement from the thermistor which was

mounted on outer heat sink currently)

(note)

In this function, DIPIPM cannot shutdown IGBT and output fau lt signal by itself when temperature rises

excessively. W hen temperature exceeds the defined protection level, controller (MCU) should s top the

DIPIPM.

(Detecting point)

Fig.2-2-7 Temperature detecting point Fig.2-2-8 Thermal conducting from power chips

(2) VOT characteristics

VOT output circuit, which is des cribed in Fig.2-2-9, is the o utput of OP am plifier circuit. The c urrent capabilit y

of VOT output is described as Table 2-2-5. The characteristics of VOT output vs. LVIC temperature is linear

characteristics described in Fig.2-2-11. There are some cautions for using this function as follows.

Table 2-2-5 Output capability

(Tc=-20°C ~100°C)

OT

LVIC is affected

from heatsink.

DIPIPM

Publication Date: September 2016

Source: Current flow from V

Sink : Current flow from outside to V

to outside.

OT

.

OT

Fig.2-2-9 VOT output circuit

(note) In the case of detecting lower temperature than room temperature

It is recommended to insert 5.1kΩ pull down resistor for getting linear output characteristics at lower

temperature than room temperature . W hen the pull do wn resis tor is inser ted bet ween V

GND), the extra current calculated by V

current continuously. In the case of only using V

output voltage / pull down resistance flows as LVIC circuit

OT

for detecting higher temperature than room

OT

and VNC(control

OT

temperature, it isn't necessary to insert the pull down resistor.

Fig.2-2-10 V

output circuit in the case of detecting low temperature

OT

DIPIPM

MCU

19

Page 20

< Dual-In-Line Package Intelligent Power Module >

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

2.2

2.4

2.6

2.8

3

3.2

3.4

3.6

3.8

4

-30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130

VOT out put [V]

LVIC temperature [degC]

3.14

3.02

2.89

Max. Min. Typ.

Output range without 5.1kΩ pull down resistor

Output range with 5.1kΩ pull down resistor

DIPIPM+ Series Application note

←

(Output might saturated under this level)

←

(Output might saturated under this level)

Fig.2-2-11 V

output vs. LVIC temperature

OT

Publication Date: September 2016

20

Page 21

< Dual-In-Line Package Intelligent Power Module >

with brake type

without brake type

DIPIPM+ Series Application note

2.3 Package outline of DIPIPM+

2.3.1 Package outline

Fig. 2-3-1 Package outline drawing (Dimension in mm)

Publication Date: September 2016

21

Page 22

< Dual-In-Line Package Intelligent Power Module >

Country of origin

DIPIPM+ Series Application note

2.3.2 Marking

The laser marking specifications of DIPIPM+ are described in Fig.2-3-2. Company name, Country of origin,

Type name, Lot number, and 2D code are marked on the surface of module.

Fig.2-3-2 Laser marking view PSSxxxC1Fx (Dimension in mm)

The Lot number indicates production year, month, running number and country of origin.

The detailed is described as below.

(Example)

6 9 AA1

Running number

Product month (however O: October, N: November, D: Decem ber)

Last figure of Product year (e.g. This case describes the year 2016.)

Publication Date: September 2016

22

Page 23

< Dual-In-Line Package Intelligent Power Module >

PSSxxMC1Fx

PSSxxNC1Fx

With Brake

Without Brake

1

P1

Output terminal for converter (+)

2

N1

Output terminal for converter (-)

3

N(B)

(NC)

IGBT emitter terminal for brake

4

V

NC

*1)

Control supply GND terminal (Brake part)

5

AlN

(NC)

Brake part control input terminal

6

V

P1

*2)

Control supply positive terminal (+)

7

V

UFB

U-phase P-side drive supply positive terminal

8

V

UFS

U-phase P-side drive supply GND terminal

9

V

VFB

V-phase P-side drive supply positive terminal

10

V

VFS

V-phase P-side drive supply GND terminal

11

V

WFB

W-phase P-side drive supply positive terminal

12

V

WFS

W-phase P-side drive supply GND terminal

13

UP

U-phase P-side control input terminal

14

VP

V-phase P-side control input terminal

15

WP

W-phase P-side control input terminal

16

V

P1

*2)

Control supply positive terminal (+)

17

UN

U-phase N-side control input terminal

18

VN

V-phase N-side control input terminal

19

WN

W-phase N-side control input terminal

20

Fo

Fault signal output terminal

21

VOT

Temperature output terminal

22

CIN

SC current trip voltage detecting terminal

23

CFo

Fault pulse output width setting terminal

24

VN1

N-side control supply positive terminal (+)

25

V

NC

*1)

GND terminal for brake control supply

26

NW

WN-phase IGBT emitter terminal

27

NV

VN-phase IGBT emitter terminal

28

NU

UN-phase IGBT emitter terminal

29

W

W-phase output terminal

30

V

V-phase output terminal

31

U

U-phase output terminal

32

P

Inverter DC-link positive terminal

33 B (NC)

Brake terminal

34

T

AC input terminal

35

S

AC input terminal

36

R

AC input terminal

DIPIPM+ Series Application note

2.3.3 Terminal Description

Table 2-3-1 Terminal Description

(note)

1) Two V

connect either terminal to GND and make the other terminal leave no connection.

2) Two V

other terminal leave no connection.

terminals (GND ter minal for control supply) ar e connected mutually inside of DIPIPM+, pleas e

NC

term inals are connected mutually inside, please c onnect either ter minal to suppl y and m ake the

P1

Description

NC: No connection

Publication Date: September 2016

23

Page 24

< Dual-In-Line Package Intelligent Power Module >

Item

Symbol

Description

P-side drive

V

- V

Drive supply terminals for P-side IGBTs.

terminals is helpful to prevent control IC from surge destruction.

P-side control

V

Control supply terminals for the built-in HVIC and LVIC.

control supply terminals to prevent surge destruction.

N-side control

VNC

Control ground terminal for the built-in HVIC and LVIC.

through this terminal in order to avoid noise influences.

Control input

UP,VP,WP

Control signal input terminals. This is Voltage input type.

resistor.

Short-circuit trip

terminal

CIN

For short circuit protection, input the potential of external shuint res istor to

The time constant of RC filter is recommended to be up to 2μs.

Fault signal

FO

Fault signal output terminal for N-side abnormal state(SC or UV).

increasing I

FO.

)

Fault pulse output

CFO

The terminal is for setting the fault pulse output width.

2.4ms. Because of CFO = t

FO

x 9.1 x 10-6 (F)

Temperature

VOT

LVIC temperature is ouput by analog signal. It is ouput of OP amplifer

necessary under room temperature.

Inverter DC-link

P

DC-link positive power supply terminal.

characteristics for snubber.

DIPIPM+ Series Application note

Table 2-3-2 Detailed description of input and output terminals

supply

positive terminal

P-side drive

supply

GND terminal

supply terminal

N-side control

supply terminal

GND terminal

terminal

UFB

V

- V

VFB

- V

V

WFB

P1

V

N1

UN,VN,W

AlN

UFS

VFS

WFS

•

• By mounting bootstrap ca pacitor, individ ual isolated p ower supplies are not

needed for the P-s ide IGBT drive. Each bootstrap capacitor is charged b y

the N-side V

• Abnormal operation might happen if the V

supply when potential of output terminal is almost GND level.

D

supply is not aptly stabilized or

D

has insufficient current capability due to ripple or surge. In order to prevent

malfunction, a bypass capacitor with favorable frequency and temperature

characteristics should be mounted very closely to each pair of these

terminals.

• Inserting a Zener diode (24V/1W) between each pair of control supply

•

• V

, and VN1 should be connected externall y on PCB. In order to prevent

P1

malfunction caused by noise and ripple in the supply voltage, a bypass

capacitor with go od f r eque ncy characteristics shou ld be m ounted ver y close

to these terminals.

• Please design the supply carefully so that the voltage ripple caused by

operation keep within the specification. (dV/dt ≤ +/-1V/μs, Vripple≤2Vp-p)

• It is recommended to insert a Z ener diode (24V/1W) between eac h pair of

•

• Please make sure that line current of the power circuit does not flow

•

N

• These terminals are internally connecte d to Schmitt trigger circuit and pulled

down by min 3.3kΩ resistor internally

• The wiring of each input should be as short as possible to protect the

DIPIPM from noise interference.

• Please use RC coupling in case of signal oscillation. Pay attention to

threshold voltage of input terminal, because input circuit has pull down

•

voltage detecting

output terminal

CIN terminal through RC filter (for the noise immunity).

•

•

• This output is open drain t ype. I t is r ecom mended to pull up F

the 5V supply by 10kΩ when Fo signal is input to MCU directly (Check

whether the V

resistance).

• In the case of directl y driving opto coupler b y Fo output it is needed to set

the pull-up resistance so that I

And pulled up to 15V suppl y is recommended.(V

•

width setting

terminal

output terminal

positive terminal

• An external capacitor should be connected between this terminal and V

When 22nF capacitor is connected, then the Fo pulse width becomes

•

internally.

• It is recommended to con nect 5.1kΩ pulldo wn resistor if output linearl ity is

•

• Internally connected to the collectors of all P-side IGBTs.

• To suppress surge voltage caused by DC-link wiring or PCB pattern

inductance, smoothing capacitor should be inserted very closely to the P

terminal. It is also eff ective to add small film capacitor with good frequenc y

signal lin e to

O

satisies t he thresh old le vel of inpu t of MCU when s electing

FO

becomes under 5mA(maximum rating).

FO

increases in propo tion to

FO

NC

.

Publication Date: September 2016

24

Page 25

< Dual-In-Line Package Intelligent Power Module >

Item

Symbol

Description

Inverter DC-link

NU, NV, NW

Emitter terminal of each N-side IGBT

terminals together at the point as close from the package as possible.

Inverter power

U, V, W

Inverter output terminals for connection to inverter load (e.g. AC motor).

corresponding IGBT half bridge arm.

AC power supply

input terminal

R, S, T

AC power supply input terminal

Converter positive

output terminal

P1

Converter positive output terminal

Converter GND

terminal

N1

Converter GND terminal

DIPIPM+ Series Application note

(Continue)

•

negative terminal

output terminal

(note)

Use oscilloscope to check voltage waveform of each po wer supply terminals and P and N term inals, the

time division of OSC should be set to about 1μs/div. Please ensure the voltage (including surge) not

exceed the specified limitation.

If there is a surge more than threshold of ratings or superimposed noise, it is necessary to take some

counter noise m easurements; revising pattern, rep lacing capacitor, apply zener diode, enh ancing filtering

and so on.

• Usually, these terminals are connected to the power GND through individual

shunt resistor.

• If common emitter circuit (one shunt control) is applied, connect these

•

• Each terminal is internally connected to the intermidiate point of the

•

•

•

Publication Date: September 2016

25

Page 26

< Dual-In-Line Package Intelligent Power Module >

Clearance(mm)

Creepage(mm)

Between power terminals

5.8

Between power terminals

6.0

Between control terminals

2.5

Between control terminals

6.4

Between terminals and heat sink

2.5

Between terminals and heat sink

4.3

(1)

(2)

DIPIPM+ Series Application note

2.4 Mounting Method This section are describe d the electric spacing and mounting precautions of DIPIPM+.

2.4.1 Electric Spacing of DIPIPM + The electric spacing specification of DIPIPM+ is shown in Table 2-4-1.

Table 2-4-1 Minimum insulation distance(minimum value)

2.4.2 Mounting Method and Precautions When installing the modul e to the heat sink , excessive or uneven fasten ing force m ight apply stress to inside chips. Then it will lead to a broken or degradation of the c hips or insu lat ion s truc tu r e. T he r ec ommended fastening procedure is shown in Fig.2-4-1. When f astening, it is necessary to use the torque wrenc h and fasten up to th e specified torque. And pay attention not to have any foreign par ticle on the contact sur face between the modu le and the heat sink. Even if the f ixing of heatsi nk was d one b y proper proc edure a nd condition, there is a pos s ibilit y of damaging the pac kage bec ause of tightening by unexpected excessive torque or tuck ing partic le. For ens uring safety it is recom mended to conduct the confirm ation test (e.g. insulation inspection) on the f inal product after fixing the DIPIPM with the heatsink.

Fig.2-4-1 Recommended screw fastening order

Temporary fastening

(1)→(2)

Permanent fastening

(1)→(2)

Note: Generally, the temporary fastening torque is set to

20-30% of the maximum torque rating.

Not care the order of fastening (1) or (2), but need to

fasten alternately.

Publication Date: September 2016

26

Page 27

< Dual-In-Line Package Intelligent Power Module >

Item

Condition

Min.

Typ.

Max.

Unit

Mounting torque

Screw : M4

0.98 -

1.47

N・m

Flatness of outer heat sink

Refer Fig.2-4-2

-50 -

+100

μm

+

+

Measurement position

Outer heatsink

Measurement position

Aluminum Heatsink

DIPIPM+ Series Application note

Table 2-4-2 Mounting torque and heat sink flatness specifications

(note): Recommend to use plain washer (ISO7089-7094) in fastening the screws.

Fig.2-4-2 Measurement positions of heat radiation part flatness

In order to get effective heat d issipation, it is necessary to enlarge t he contact area as much as pos sible to

minimize the contact t hermal resistance. Regarding the he at sink flatness (war p/concavity and con vexity) on the

module installation surface, the surface finishing-treatment should be within Rz12.

Evenly apply thermally-conductive grease with 100μ-200μm thickness over the contact surface between a

module and a heat sink, whic h is also useful for preventing corrosion. Furtherm ore, the grease should be with

stable quality and long-term endurance within wide operating temperature range. The contacting thermal

resistance between DIPIPM case and heat sink Rth(c-f) is determined by the thickness and the thermal

conductivity of the applied grease. For referenc e, Rth(c-f) is about 0.25K/W (per chip, grease thickness: 20μm,

thermal conductivity: 1.0W/m·k). W hen applying grease and fixing heat sink, pay attention not to take air into

grease. It might lead to make contact thermal resistance worse or loosen fixing in operation.

-

Publication Date: September 2016

27

Page 28

< Dual-In-Line Package Intelligent Power Module >

Item

Condition

DIPIPM+ Series Application note

2.4.3 Soldering Conditions The recommended soldering condition is mentioned as below. (Note: The reflow soldering cannot be recommended for DIPIPM.)

(1) Flow (wave) Soldering

DIPIPM is tested on the condition described in Table 2-4-3 about the soldering thermostability, so the

recommended conditions for flow (wave) soldering are soldering temperature is up to 265°C and the

immersion time is within 11s.

The actual cond ition might need som e adjustment based on its flow condition of solder, the speed of the

conveyer, the la nd pat ter n and the t hr oug h ho le s h ape on th e PC B, etc. It is necessary to confirm whether it is

appropriate or not for your real PCB finally..

Table 2-4-3 Reliability test specification

Soldering thermostability 260±5°C, 10±1s

(2) Hand soldering

Since the temperature impressed upon the DIPIPM may changes based on the soldering iron types

(wattages, shape of soldering tip, etc.) and the land pattern on PCB, the unambiguous hand soldering

condition cannot be decided.

As a general requirem ent of the temperatur e profile for hand s oldering, the temper ature of the root of the

DIPIPM terminal should be kept less than 150°C for considering glass transition temperature (Tg) of the

package molding resin and the thermal withstand capability of internal chips. Therefore, it is necessary to

check the DIPIPM terminal root temperature, solderability and so on in your real PCB, when configure the

soldering temperature profile. (It is recommended to set the soldering time as short as possible.)

Publication Date: September 2016

28

Page 29

< Dual-In-Line Package Intelligent Power Module >

C1: Electrolytic type with good temperature and frequency characteristics

Z : Surge absorber

C : AC filter(ceramic capacitor 2.2n

Drive circuit

UV lockout

circuit

Level shift

Input signal

conditioning

Drive circuit

Level shift

Input signal

conditioning

Drive circuit

Level shift

Input signal

conditioning

Drive circuit

UV lockout

circuit

Fo Logic

Input signal

conditioning

P-side input

Fo

Fo output

V

N1

N CIN

V

NC

V

D

(15V line)

C1

C2

N-side input

Inrush

P V U W

M

AC output

N-side IGBTs

P-side IGBTs

AC line input

DIPIPM+

(CIB type)

Protection

D1

C3

C1

C2

D1

UV lockout

circuit

UV lockout

circuit

CFo

Drive circuit

UV lockout

circuit

Brake input

Temp. output

VOT

B

Input signal

conditioning

Braking

resistor

N(B)

Brake IGBT

Brake Di

Z

C

P

N1

R S T

DIPIPM+ Series Application note

CHAPTER 3 : SYSTEM APPLICATION GUIDANCE

3.1 Application guidance This chapter states the DIPIPM+ application method and interface circuit design hints.

3.1.1 System connection

(note) The capacitance also depends on the PWM

control strategy of the application system

C2: 0.01μ-2μF ceramic capacitor with good temperature,

frequency and DC bias characteristics

C3: 0.1μ-0.22μF Film capacitor (for snubber)

D1: Zener diode 24V/1W for surge absorber

(Common-mode noise filter)

-6.5nF)

limiting circuit

NC

Fig.3-1-1 System block diagram (Example)

circuit (SC)

Publication Date: September 2016

29

Page 30

< Dual-In-Line Package Intelligent Power Module >

Long GND wiring might generate noise to input signal

and cause IGBT malfunction

M

MCU

C2

15V

VD

C4

R1

Shunt resistor

N1

C

5V

+

C1

D

D1

C3

+

R2

5.1kΩ

C2 + C1 D1 C2

C5

R3

C5

R3

Brake

Resistor

Prevention circuit

for

P (32)

U (31)

V (30)

W (29)

NW (26)

LVIC

NV (27)

NU (28)

HVIC

S (35)

T (34)

B (33)

LVIC

Power GND patterning

Control GND patterning

C5

R3

C5

R3

C5

R3

C5

R3

C5

R3

+

+

A

B

UN (17)

VN (18)

WN (19)

Fo (20)

V

(9)

VP (14)

V

(11)

WP (15)

UP (13)

V

(25)

V

(16)

V

(7)

V

(21)

P1(1)

N1 (2)

N(B) (3)

AIN (5)

V

NC

(4)

V

(6)

V

(8)

V

VFS

(10)

V

(12)

R (36)

V

(24)

CIN (22)

CFo (23)

X

Y

X

Y

Long wiring might cause short

AC input

Long wiring might cause SC level fluctuation

DIPIPM+ Series Application note

3.1.2 Interface Circuit (Direct Coupling Interface example for using one shunt resistor) Fig.3-1-2 shows a t ypical a pplicati on circui t of inter fac e schem atic , in which co ntrol sig nals are transf erred di rect ly input from a controller (e.g. MCU).

inrush current

P1

UFB

UFS

VFB

WFB

WFS

P1

OT

N1

NC

Fig.3-1-2 Interface circuit example in the case of using with one shunt resistor

and malfunction

circuit failure

Publication Date: September 2016

30

Page 31

< Dual-In-Line Package Intelligent Power Module >

DIPIPM+ Series Application note

Note for the previous application circuit:

(1) If control GND is connected with power GND by common broad pattern, it may cause malfunction by power GND fluctuation. It

is recommended to connect control GND and power GND at only a point N1 (near the terminal of shunt resistor).

(2) It is recommended to insert a Zener diode D1(24V/1W) between each pair of control supply terminals to prevent surge

destruction.

(3) To prevent surge destruction, the wiring between the smoothing capacitor and the P, N1 terminals should be as short as

possible. Generally a 0.1-0.22μF snubber capacitor C3 between the P-N1 terminals is recommended.

(4) R1, C4 of RC filter for preventing protection circuit malfunction is recommended to select tight tolerance, temp-compensated

type. The time constant R1C4 should be set so that SC current is shut down within 2μs. (1.5μs~2μs is recommended

generally.) SC interrupting time might vary with the wiring pattern, so the enough evaluation on the real system is necessary.

(5) To prevent malfunction, the wiring of A, B, C should be as short as possible.

(6) The point D at which the wiring to CIN filter is divided should be near the terminal of shunt resistor. NU, NV, NW terminals

should be connected each other at near those three terminals when it is used by one shunt operation. Low inductance SMD

type with tight tolerance, tem p-compensated type is recommended for shunt resistor.

(7) All capacitors should be mounted as close to the terminals as possible. (C1: good temperature, frequency characteristic

electrolytic type and C2:0.01μ-2μF, good temperature, frequency and DC bias characteristic ceramic type are recommended.)

(8) Input logic is High-active. There is a 3.3kΩ(min.) pull-down resistor in the input circuit of IC. To prevent malfunction, the input

wiring should be as short as possible. When using RC coupling, make the input signal level meet the turn-on and turn-off

threshold voltage.

(9) Fo output is open drain type. Fo output will be max 0.95V(@I

supply (e.g. 5V,15V) by a resistor that makes I

up to 1mA. (In the case of pulled up to 5V, 10kΩ is recommended.) About

FO

driving opto coupler by Fo output, please refer the application note of this series.

(10) Fo pulse width can be set by the capacitor connected to CFO terminal. C

(11) If high frequency noise superimposed to the control supply line, IC malfunction might happen and cause DIPIPM erroneous

operation. To avoid such problem, line ripple voltage should meet dV/dt ≤+/-1V/μs, Vripple ≤ 2Vp-p.

(12) For DIPIPM, it isn't recommended to drive same load by parallel connection with other phase IGBT or other DIPIPM.

(13) No.4 and No.25 V

No.16 V

terminals are connected mutually inside, please connect either No.4 or No.25 terminal to GND and also connect

P1

terminals (GND terminal for control supply) are connected mutually inside of DIPIPM+ and also No.6 and

NC

either No.6 or No.16 terminal to supply and make the unused terminal leave no connection.

=1mA,25°C), so it should be pulled up to MCU or control power

FO

(F) = 9.1 x 10-6 x tFO (Required Fo pulse width).

FO

Publication Date: September 2016

31

Page 32

< Dual-In-Line Package Intelligent Power Module >

Long GND wiring might

generate noise to input signal

and cause IGBT malfunction

M

C2

15V

VD

C4

R1

Shunt resistor

N1

C

+

C1

D

D1

C3

+

5.1kΩ

C2

+

C1 D1 C2

C5

R3

C5

R3

Brake

Resistor

Prevention circuit

for

P (32)

U (31)

V (30)

W (29)

NW (26)

LVIC

NV (27)

NU (28)

HVIC

S (35)

T (34)

B (33)

LVIC

Power GND patterning

Control GND patterning

C5

R3

C5