Mitsubishi Electric PSA-RP71GA, PSA-RP140GA, PSA-RP125GA, PSH-P71GAH, PSH-P100GAH Service Manual

...Page 1

SERVICE MANUAL

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

SPLIT-TYPE, AIR CONDITIONERS

No. OC332

REVISED EDITION-B

CONTENTS

1. TECHNICAL CHANGES

..................................

2

2. REFERENCE MANUAL

..............................................

2

3. SAFETY PRECAUTION

...................................

3

4. PART NAMES AND FUNCTIONS

....................

7

5. SPECIFICATIONS

............................................

9

6. NOISE CRITERION CURVES

........................

12

7. OUTLINES AND DIMENSIONS

.....................

14

8.

WIRING DIAGRAM

.................................................

16

9.

REFRIGERANT SYSTEM DIAGRAM

....................

17

10. TROUBLESHOOTING

....................................

18

11. SPECIAL FUNCTION

.....................................

29

12. DISASSEMBLY PROCEDURE

......................

32

13. PARTS LIST

...................................................

35

14. RoHS PARTS LIST

.........................................

39

Indoor unit

[Model names] [Service Ref.]

PSA-RP71GA PSA-RP71GA

PSA-RP71GA#1

PSA-RP100GA PSA-RP100GA

PSA-RP100GA#1

PSA-RP125GA PSA-RP125GA

PSA-RP125GA#1

PSA-RP140GA PSA-RP140GA

PSA-RP140GA#1

PSH-P71GAH PSH-P71GAH

PSH-P100GAH PSH-P100GAH

PSH-P125GAH PSH-P125GAH

PSH-P140GAH PSH-P140GAH

May 2008

Note:

• This manual describes only

service data of the indoor

units.

• RoHS compliant products have

<G> mark on the spec name

plate.

• For servicing of RoHS compliant

products, refer to the RoHS Parts

List.

Revision:

• PSA-RP71~140GA#1 are added

in REVISED EDITION-B.

• Some descriptions have been

modified.

• Please void OC332

REVISED EDITION-A.

Page 2

2

PSA-RP71GA PSA-RP71GA#1

PSA-RP100GA PSA-RP100GA#1

PSA-RP125GA PSA-RP125GA#1

PSA-RP140GA PSA-RP140GA#1

INDOOR CONTROLLER BOARD(I.B.) has been changed.

2

REFERENCE MANUAL

2-1. OUTDOOR UNIT’S SERVICE MANUAL

2-2. TECHNICAL DATA BOOK

TECHNICAL CHANGES

1

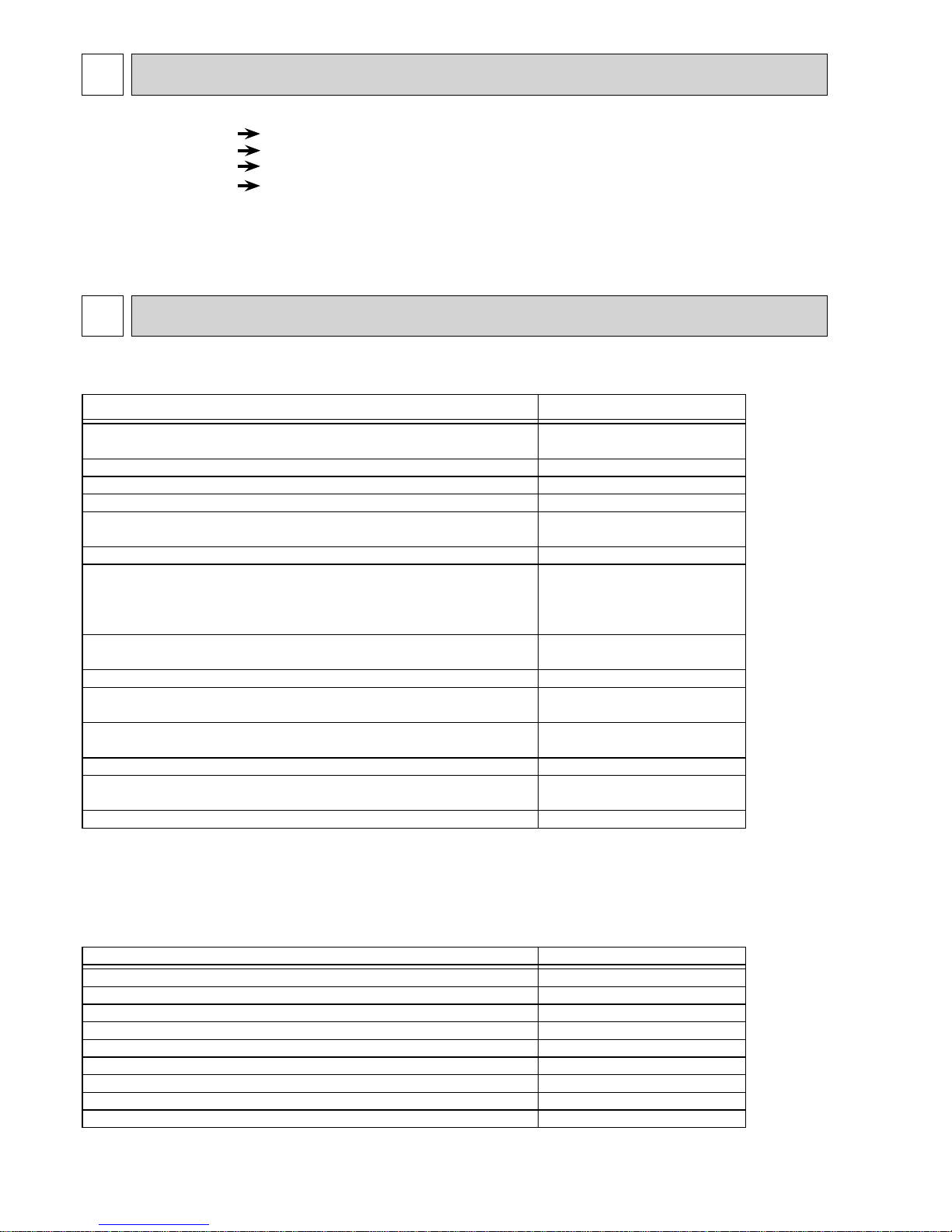

Service Ref. Service Manual No.

PUHZ-RP71/100/125/140VHA

(1)

PUHZ-RP100/125/140YHA

OC334

PUHZ-RP71/100/125/140VHA

(1)

-A OC337

PUHZ-RP200/250YHA

(1)(2)

OC338

PUHZ-RP200/250YHA

(1)

-A OC339

PU(H)-P • VGAA.UK

PU(H)-P • YGAA.UK

OC336

PUHZ-P100/125/140VHA.UK OC359

PUHZ-RP71/100/125/140VHA2

(1)

PUHZ-RP100/125/140YHA2

(1)

PUHZ-RP71/100VHA3

PUHZ-RP100YHA3

OC374

PU(H)-P71/100VHA

(1)

.UK

PU(H)-P100/125/140YHA

(1)

.UK

OC379

PUHZ-P100/125/140VHA2

(1)

.UK OCH415 / OCB415

PUHZ-RP71/100/125/140VHA2-A

PUHZ-RP100/125/140YHA2-A

OCH422 / OCB422

PUHZ-BP100/125/140VHA-A

PUHZ-BP200/250YHA-A

OCH423 / OCB423

PUHZ-P200/250YHA2 OCH424 / OCB424

PUHZ-HRP71/100VHA

PUHZ-HRP100/125YHA

OCH425 / OCB425

PUHZ-RP200/250YHA2 OCH428 / OCB428

Series (Outdoor unit) Manual No.

PUHZ-RP • HA(-A) OCS01

PU(H)-P • GAA.UK OCS02

PUHZ-RP • HA2 OCS05

PUHZ-P • HA OCS06

PU(H)-P • HA OCS07

PUHZ-P • VHA2, PUHZ-P • YHA OCS08

PUHZ-RP • HA2-A OCS09

PUHZ-BP • HA OCS10

PUHZ-HRP • HA OCS11

Page 3

3

SAFETY PRECAUTION

3

Cautions for units utilising refrigerant R407C

3-2. CAUTIONS RELATED TO NEW REFRIGERANT

Do not use the existing refrigerant piping.

The old refrigerant and lubricant in the existing piping

contains a large amount of chlorine which may cause the

lubricant deterioration of the new unit.

Use “low residual oil piping”

If there is a large amount of residual oil (hydraulic oil, etc.)

inside the piping and joints, deterioration of the lubricant

will result.

Use ESTER , ETHER or HAB as the lubricant to

coat flares and flange connection parts.

If large amount of mineral oil enter, that can cause

deterioration of refrigerant oil etc.

Use liquid refrigerant to charge the system.

If gas refrigerant is used to seal the system, the composition

of the refrigerant in the cylinder will change and performance

may drop.

Do not use a refrigerant other than R407C.

If another refrigerant (R22, etc.) is used, the chlorine in the

refrigerant may cause the lubricant deterioration.

Use a vacuum pump with a reverse flow check valve.

The vacuum pump oil may flow back into the refrigerant

cycle and cause the lubricant deterioration.

Store the piping to be used during installation

indoors with keep both ends sealed until just

before brazing.

(Store elbows and other joints in a plastic bag.)

If dust, dirt, or water enters the refrigerant cycle,

deterioration of the oil and compressor trouble may result.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

3-1. ALWAYS OBSERVE FOR SAFETY

Before obtaining access to terminal, all supply

circuits must be disconnected.

Page 4

4

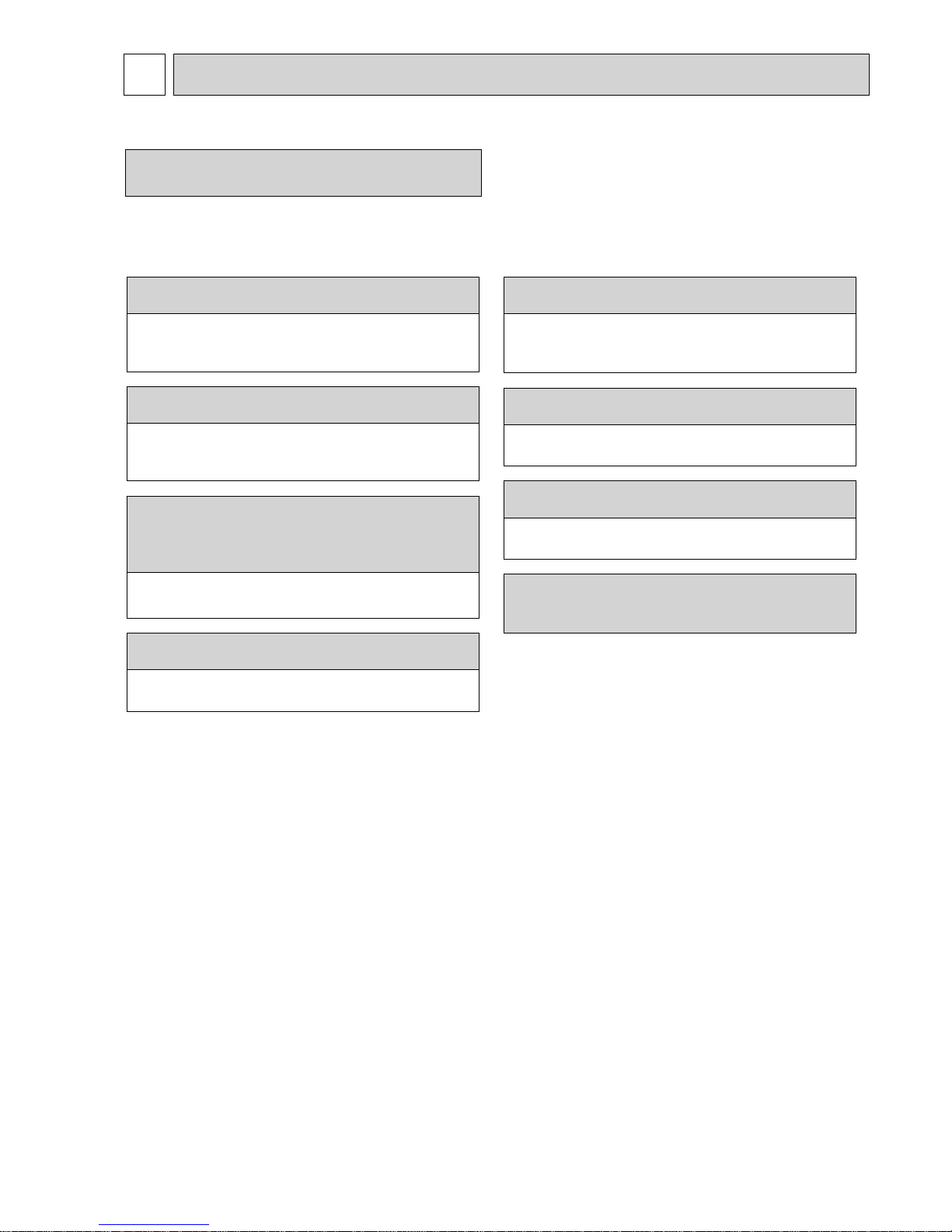

[3] Service tools

Use the below service tools as exclusive tools for R407C refrigerant.

No. Tool name Specifications

1 Gauge manifold ·Only for R407C.

·Use the existing fitting SPECIFICATIONS. (UNF7/16)

·Use high-tension side pressure of 3.43MPa·G or over.

2 Charge hose ·Only for R407C.

·Use pressure performance of 5.10MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a or R407C.

5 Adapter for reverse flow check. ·Attach on vacuum pump.

6 Refrigerant charge base.

7 Refrigerant cylinder. ·For R407C ·Top of cylinder (Brown)

·Cylinder with syphon

8 Refrigerant recovery equipment.

[2] Refrigerant recharging

(1) Refrigerant recharging process

1Direct charging from the cylinder.

·R407C cylinder are available on the market has a syphon pipe.

·Leave the syphon pipe cylinder standing and recharge it.

(By liquid refrigerant)

(2) Recharge in refrigerant leakage case

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release the refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

[1] Cautions for service

·After recovering the all refrigerant in the unit, proceed to working.

·Do not release refrigerant in the air.

·After completing the repair service, recharge the cycle with the specified amount of

liquid refrigerant.

Gravimeter

Unit

Page 5

5

Cautions for units utilising refrigerant R410A

CAUTIONS RELATED TO NEW REFRIGERANT

Use new refrigerant pipes.

Make sure that the inside and outside of refrigerant piping is clean and it has no contamination

such as sulfur hazardous for use, oxides, dirt,

shaving particles, etc.

In addition, use pipes with specified thickness.

Store the piping to be used during installation

indoors and keep both ends of the piping sealed

until just before brazing. (Leave elbow joints, etc.

in their packaging.)

Use ester oil, ether oil or alkylbenzene oil (small

amount) as the refrigerant oil applied to flares

and flange connections.

In case of using the existing pipes for R22, be careful with

the followings.

· For RP71VHA3 and RP100, 125 and 140, be sure to

perform replacement operation before test run.

· Change flare nut to the one provided with this product.

Use a newly flared pipe.

· Avoid using thin pipes.

Charge refrigerant from liquid phase of gas

cylinder.

If the refrigerant is charged from gas phase, composition

change may occur in refrigerant and the efficiency will be

lowered.

Do not use refrigerant other than R410A.

If other refrigerant (R22 etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil etc.

Use a vacuum pump with a reverse flow check

valve.

Vacuum pump oil may flow back into refrigerant cycle and

that can cause deterioration of refrigerant oil etc.

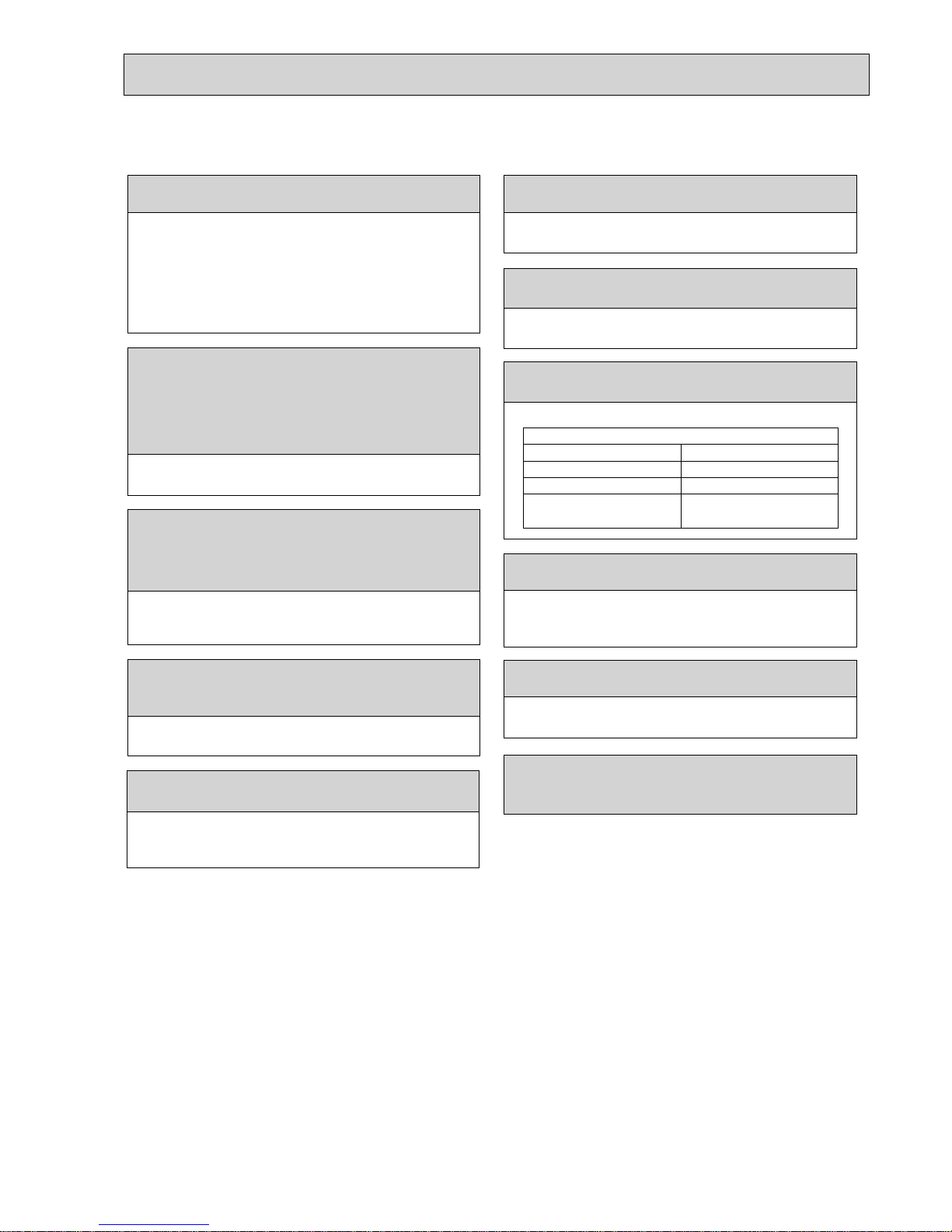

Use the following tools specifically designed for

use with R410A refrigerant.

The following tools are necessary to use R410A refrigerant.

Keep the tools with care.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Do not use a charging cylinder.

If a charging cylinder is used, the composition of refrigerant will change and the efficiency will be lowered.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R410A

Contamination inside refrigerant piping can cause deterioration of refrigerant oil etc.

If dirt, dust or moisture enter into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

If large amount of mineral oil enter, that can cause deterioration of refrigerant oil etc.

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

[1] Cautions for service

(1) Perform service after collecting the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

[2] Additional refrigerant charge

When charging directly from cylinder

· Check that cylinder for R410A on the market is syphon type.

· Charging should be performed with the cylinder of syphon stood vertically. (Refrigerant is charged from liquid phase.)

Page 6

6

Gravimeter

Unit

[3] Service tools

Use the below service tools as exclusive tools for R410A refrigerant.

No. Tool name Specifications

1 Gauge manifold ·Only for R410A

·Use the existing fitting

specifications

. (UNF1/2)

·Use high-tension side pressure of 5.3MPa·G or over.

2 Charge hose ·Only for R410A

·Use pressure performance of 5.09MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R134a, R407C or R410A.

5 Adaptor for reverse flow check ·Attach on vacuum pump.

6 Refrigerant charge base

7 Refrigerant cylinder ·Only for R410A Top of cylinder (Pink)

Cylinder with syphon

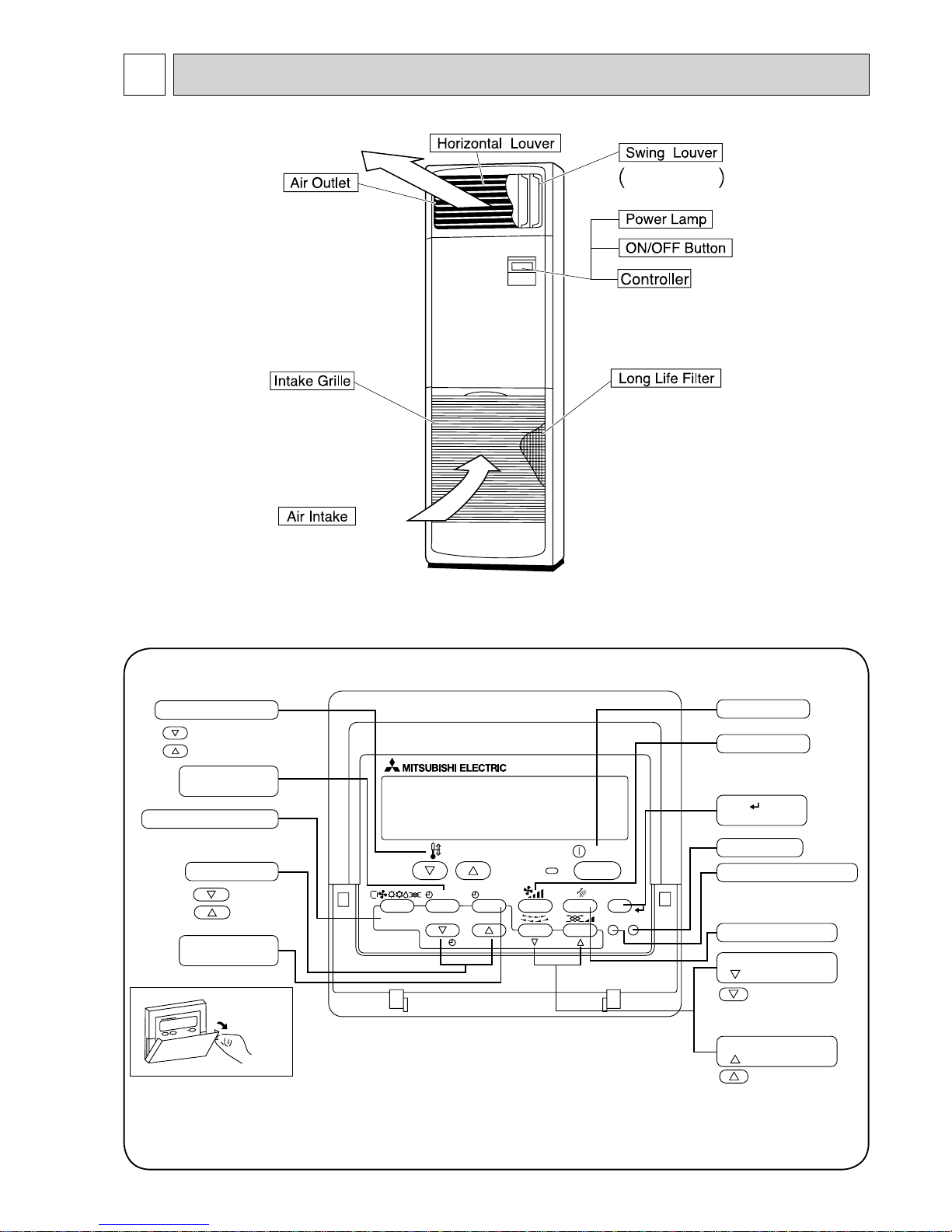

8 Refrigerant recovery equipment

Page 7

77

Disperses air

up and down

Disperses air left

and right.

Removes dust and pollutants from intake air.

(Intakes air from room.)

PART NAMES AND FUNCTIONS

4

•

Controller

Once the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button.

•

Indoor Unit

•

Operation buttons

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK DAY

MONITOR/SET

CLOCK

ON/OFF

Set T emperature buttons

Down

Up

Timer Menu button

(Monitor/Set button)

Mode button (Return button)

Set Time buttons

Back

Ahead

Timer On/Off button

(Set Day button)

Opening the

door.

ON/OFF button

Fan Speed button

Filter button

(<Enter> button)

Test Run button

Check button (Clear button)

Airflow Up/Down button

Louver button

( Operation button)

To preceding operation

number.

Ventilation button

(

Operation button)

T o next operation number.

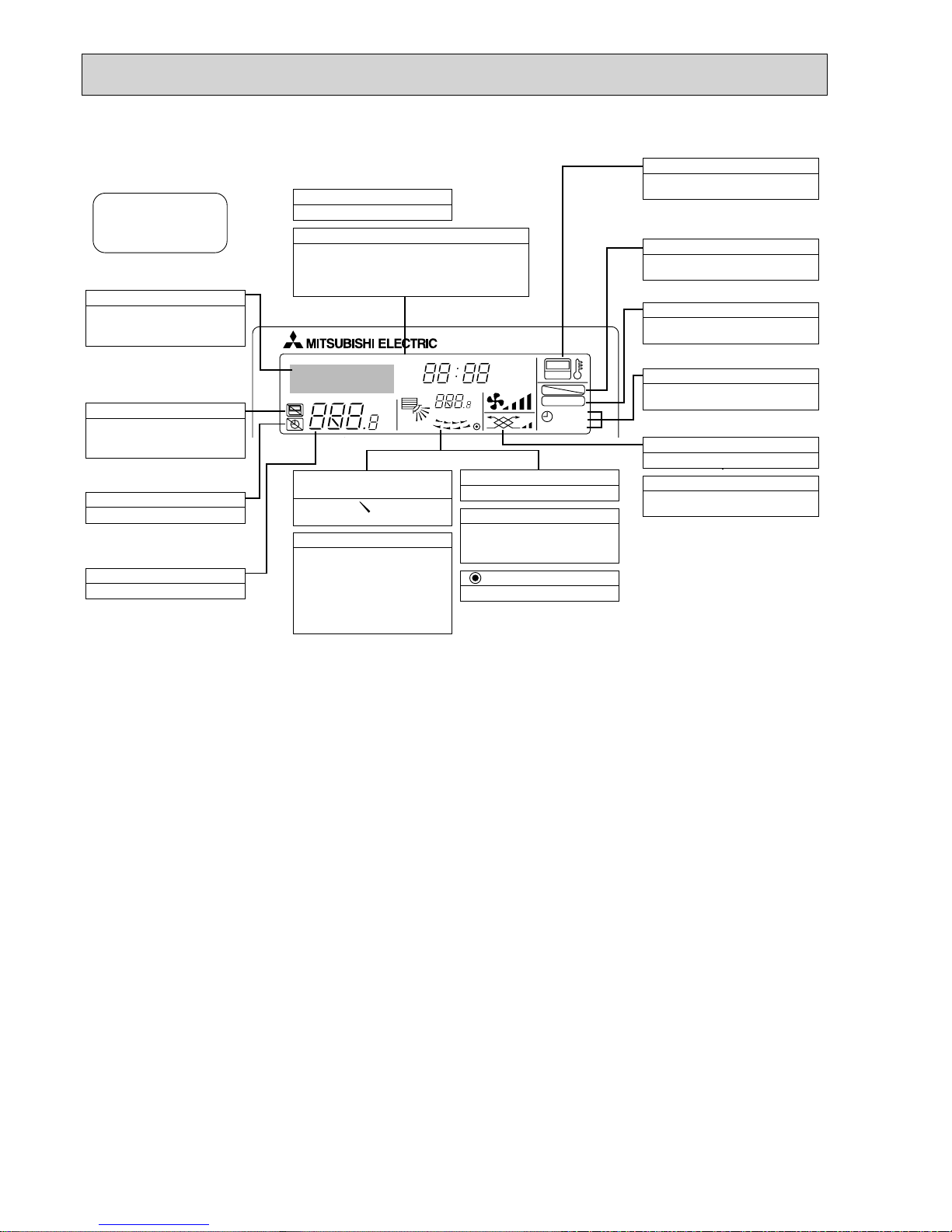

Page 8

8

For purposes of this explanation,

all parts of the display are shown

as lit. During actual operation, only

the relevant items will be lit.

°F°C

°F°C

ERROR CODE

AFTER

TIMER

TIME SUN MON TUE WED THU FRI SAT

ON

OFF

Hr

AFTER

FILTER

FUNCTION

ONLY1Hr.

WEEKLY

SIMPLE

AUTO OFF

Identifies the current operation

Shows the operating mode, etc.

* Multilanguage display is sup-

ported.

“Centrally Controlled” indicator

Indicates that operation of the remote controller has been prohibited by a master controller.

“Timer Is Off” indicator

Indicates that the timer is off.

Temperature Setting

Shows the target temperature.

Day-of-Week

Shows the current day of the week.

Time/Timer Display

Shows the current time, unless the simple or Auto Off

timer is set.

If the simple or Auto Off timer is set, shows the time

remaining.

“Sensor” indication

Displayed when the remote controller

sensor is used.

“Locked” indicator

Indicates that remote controller buttons have been locked.

“Clean The Filter” indicator

Comes on when it is time to clean the

filter.

Timer indicators

The indicator comes on if the corresponding timer is set.

Up/Down Air Direction indicator

The indicator shows the direction of the outcoming airflow.

“One Hour Only” indicator

Displayed if the airflow is set to

weak and downward during COOL

or DRY mode. (Operation varies

according to model.)

The indicator goes off after one

hour, at which time the airflow direction also changes.

Room Temperature display

Shows the room temperature.

Louver display

Indicates the action of the swing

louver. Does not appear if the

louver is stationary.

(Power On indicator)

Indicates that the power is on.

Fan Speed indicator

Shows the selected fan speed.

Ventilation indicator

Appears when the unit is running in

Ventilation mode.

Caution

Only the Power on indicator lights when the unit is stopped and power supplied to the unit.

If you press a button for a feature that is not installed at the indoor unit, the remote controller will display the “Not Available”

message.

If you are using the remote controller to drive multiple indoor units, this message will appear only if he feature is not

present at the parent unit.

When power is turned ON for the first time, it is normal that “PLEASE WAIT” is displayed on the room temperature indication

(For max. 2minutes). Please wait until this “PLEASE WAIT” indication disappear then start the operation.

•

Display

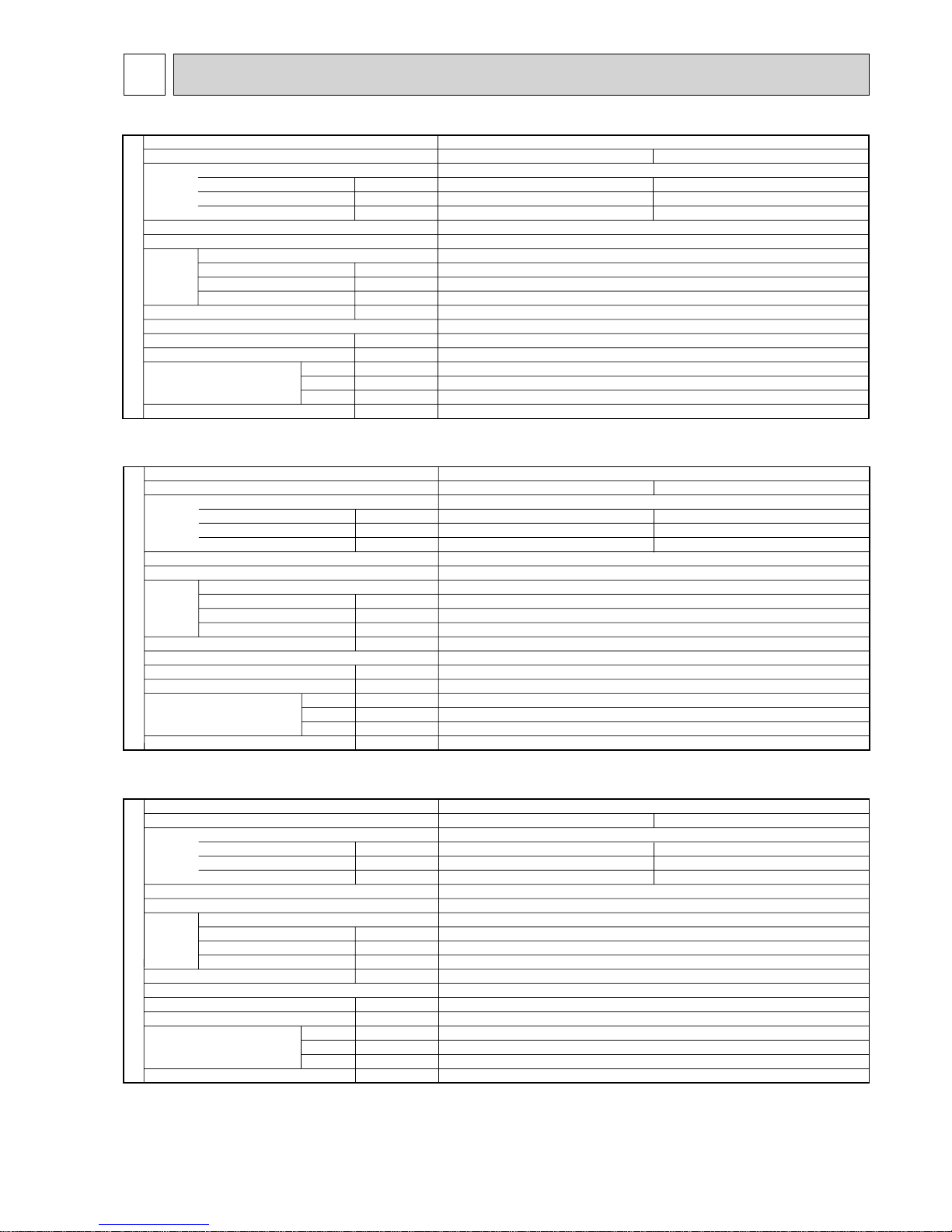

Page 9

99

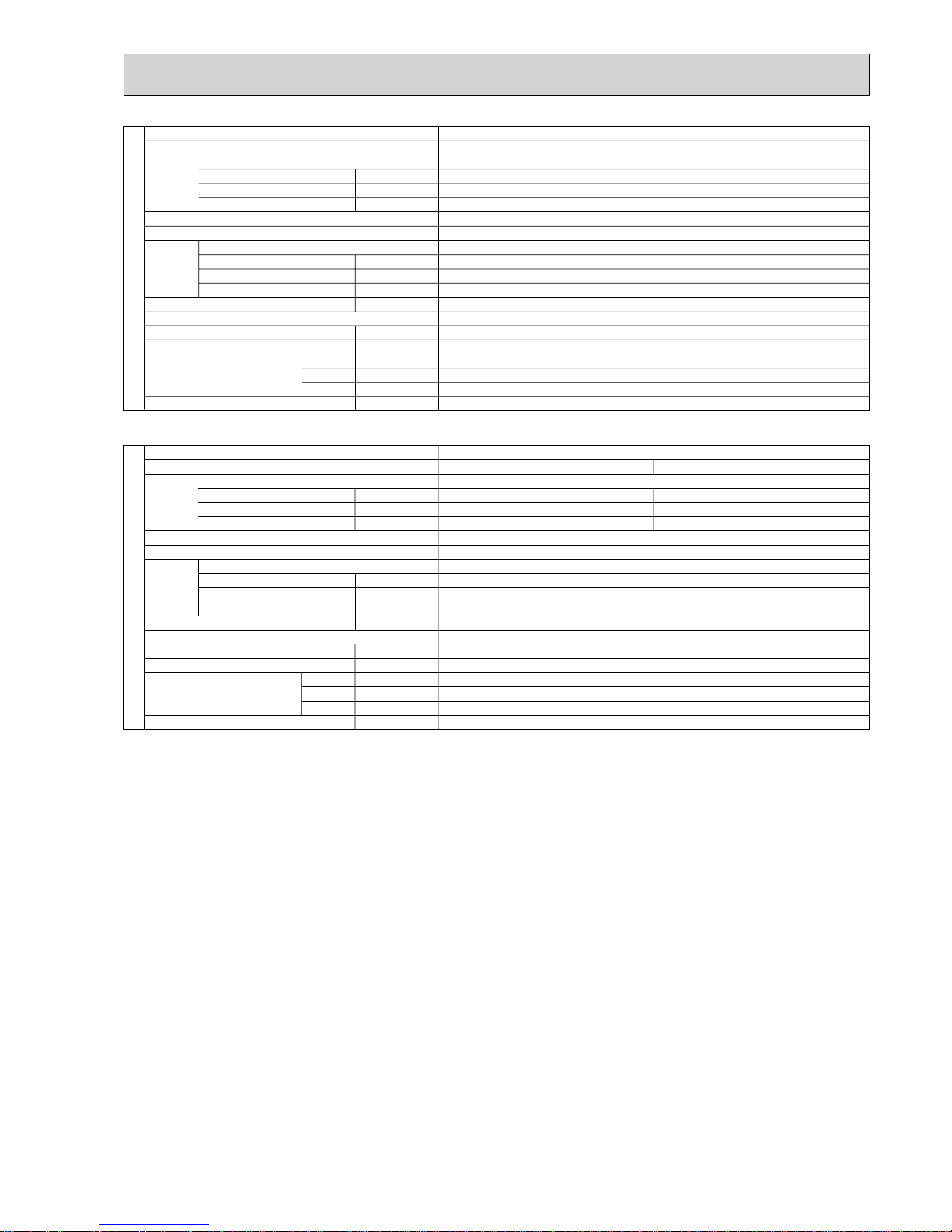

SPECIFICATIONS

5

kW

A

A

kW

*/min(CFM)

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Service Ref.

Mode

Power supply(phase, cycle, voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan Fan(drive) % No.

Fan motor output

Airflow(Low-High)

External static pressure

Booster heater

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

W

D

H

INDOOR UNIT

PSA-RP100GA, PSA-RP100GA#1

Cooling

0.24

1.06

1.50

Heating

0.24

1.06

1.50

Single phase, 50Hz, 230V

Munsell 0.70Y 8.59/0.97

Plate fin coil

Centrifugal (direct) % 1

0.070

24-31(850-1,060)

0(direct blow)

Ñ

Remote controller & built-in

44-49

20(13/16)

600(23-5/8)

350(13-3/4)

1,900(74-13/16)

51(112)

Cooling

0.15

0.66

0.80

Heating

0.15

0.66

0.80

Single phase, 50Hz, 230V

Munsell 0.70Y 8.59/0.97

Plate fin coil

Centrifugal (direct) % 1

0.03

15-18(530-635)

0(direct blow)

Ñ

Remote controller & built-in

40-45

20(13/16)

600(23-5/8)

270(10-5/8)

1,900(74-13/16)

43(98)

PSA-RP71GA, PSA-RP71GA#1

kW

A

A

kW

*/min(CFM)

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Service Ref.

Mode

Power supply(phase, cycle, voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan Fan(drive) % No.

Fan motor output

Airflow(Low-High)

External static pressure

Booster heater

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

W

D

H

INDOOR UNIT

Cooling

0.28

1.23

1.50

Heating

0.28

1.23

1.50

Single phase, 50Hz, 230V

Munsell 0.70Y 8.59/0.97

Plate fin coil

Centrifugal (direct) % 1

0.11

26-33(920-1,165)

0(direct blow)

Ñ

Remote controller & built-in

46-51

20(13/16)

600(23-5/8)

350(13-3/4)

1,900(74-13/16)

51(112)

PSA-RP125GA, PSA-RP125GA#1

kW

A

A

kW

*/min(CFM)

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Service Ref.

Mode

Power supply(phase, cycle, voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan Fan(drive) % No.

Fan motor output

Airflow(Low-High)

External static pressure

Booster heater

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

W

D

H

INDOOR UNIT

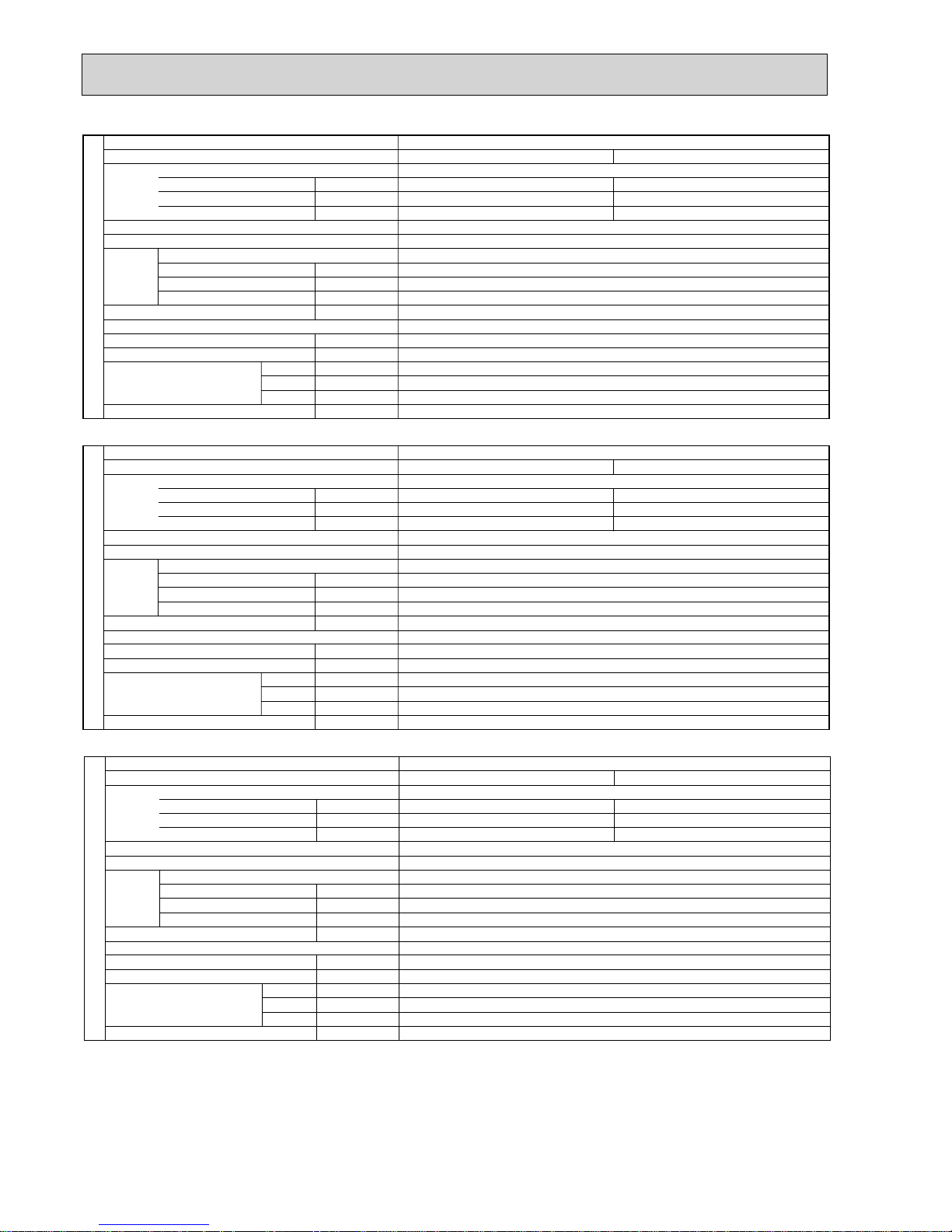

Page 10

10

kW

A

A

kW

*/min(CFM)

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Service Ref.

Mode

Power supply(phase, cycle, voltage)

Input

Running current

Starting current

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Booster heater

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

W

D

H

INDOOR UNIT

PSA-RP140GA, PSA-RP140GA#1

Cooling

0.36

1.59

2.10

Heating

0.36

1.59

2.10

Single phase, 50Hz, 230V

Munsell 0.70Y 8.59/0.97

Plate fin coil

Centrifugal (direct) % 1

0.11

27-35(955-1,240)

0(direct blow)

Ñ

Remote controller & built-in

47-52

20(13/16)

600(23-5/8)

350(13-3/4)

1,900(74-13/16)

53(117)

kW

A

A

kW

*/min(CFM)

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Service Ref.

Mode

Power supply(phase, cycle, voltage)

Input +1

Running current +1

Starting current +1

External finish

Heat exchanger

Fan Fan(drive) % No.

Fan motor output

Airflow(Low-High)

External static pressure

Booster heater +1

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

W

D

H

INDOOR UNIT

Cooling

0.15

0.66

0.80

Heating

0.15<1.93>

0.66<8.39>

0.80<8.39>

Single phase, 50Hz, 230V

Munsell 0.70Y 8.59/0.97

Plate fin coil

Centrifugal (direct) % 1

0.03

15-18(530-635)

0(direct blow)

<1.93>

Remote controller & built-in

40-45

20(13/16)

600(23-5/8)

270(10-5/8)

1,900(74-13/16)

45(99)

PSH-P71GAH

+1 : < > Shows the only booster heater rating.

Cooling

0.24

1.06

1.50

Heating

0.24<2.48>

1.06<10.78>

1.50<10.78>

Single phase, 50Hz, 230V

Munsell 0.70Y

8.59/0.97

Plate fin coil

Centrifugal (direct) % 1

0.07

24-31(850-1,060)

0(direct blow)

<2.48>

Remote controller & built-in

44-49

20(13/16)

600(23-5/8)

350(13-3/4)

1,900(74-13/16)

53(117)

kW

A

A

kW

*/min(CFM)

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

W

D

H

INDOOR UNIT

PSH-P100GAH

Service Ref.

Mode

Power supply(phase, cycle, voltage)

Input +1

Running current +1

Starting current +1

External finish

Heat exchanger

Fan Fan(drive) % No.

Fan motor output

Airflow(Low-High)

External static pressure

Booster heater +1

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

Page 11

11

Cooling

0.28

1.23

1.50

Heating

0.28<2.76>

1.23<12.00>

1.50<12.00>

Single phase, 50Hz, 230V

Munsell 0.70Y 8.59/0.97

Plate fin coil

Centrifugal (direct) % 1

0.11

26-33(920-1,165)

0(direct blow)

<2.76>

Remote controller & built-in

46-51

20(13/16)

600(23-5/8)

350(13-3/4)

1,900(74-13/16)

53(117)

kW

A

A

kW

*/min(CFM)

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Service Ref.

Mode

Power supply(phase, cycle, voltage)

Input +1

Running current +1

Starting current +1

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Booster heater +1

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

W

D

H

INDOOR UNIT

PSH-P125GAH

Cooling

0.36

1.59

2.10

Heating

0.36<2.76>

1.59<12.00>

2.10<12.00>

Single phase, 50Hz, 230V

Munsell 0.70Y 8.59/0.97

Plate fin coil

Centrifugal (direct) % 1

0.11

27-35(955-1,240)

0(direct blow)

<2.76>

Remote controller & built-in

47-52

20(13/16)

600(23-5/8)

350(13-3/4)

1,900(74-13/16)

55(121)

kW

A

A

kW

*/min(CFM)

Pa(mmAq)

kW

dB

mm(in.)

mm(in.)

mm(in.)

mm(in.)

kg(lbs)

W

D

H

INDOOR UNIT

PSH-P140GAH

Service Ref.

Mode

Power supply(phase, cycle, voltage)

Input +1

Running current +1

Starting current +1

External finish

Heat exchanger

Fan Fan(drive) x No.

Fan motor output

Airflow(Low-High)

External static pressure

Booster heater +1

Operation control & Thermostat

Noise level(Low-High)

Unit drain pipe O.D.

Dimensions

Weight

+1 : < > Shows the only booster heater rating.

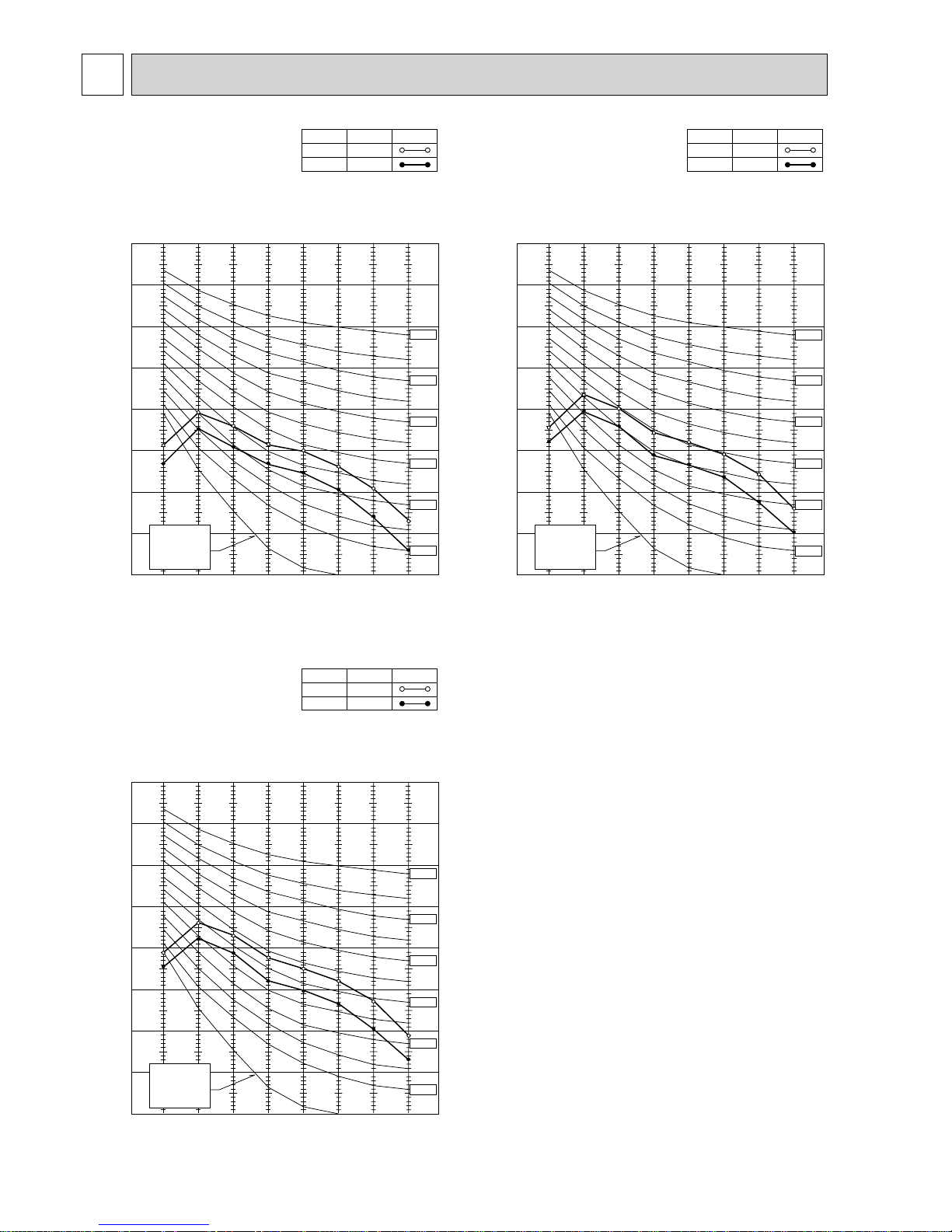

Page 12

12

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

REARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB ( 0dB = 0.0002 μbar )

BAND CENTER FREQUENCIES, Hz

PSA-RP71GA

PSA-RP71GA#1

PSH-P71GAH

NOTCH

High

Low

SPL(dB)

45

40

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

REARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB ( 0dB = 0.0002 μbar )

BAND CENTER FREQUENCIES, Hz

PSA-RP100GA

PSA-RP100GA#1

PSH-P100GAH

NOTCH

High

Low

SPL(dB)

49

44

LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

REARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB ( 0dB = 0.0002 μbar )

BAND CENTER FREQUENCIES, Hz

PSA-RP125GA

PSA-RP125GA#1

PSH-P125GAH

NOTCH

High

Low

SPL(dB)

51

46

LINE

NOISE CRITERION CURVES

6

Page 13

1313

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

APPROXIMATE

THRESHOLD OF

REARING FOR

CONTINUOUS

NOISE

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB ( 0dB = 0.0002 μbar )

BAND CENTER FREQUENCIES, Hz

PSA-RP140GA

PSA-RP140GA#1

PSH-P140GAH

NOTCH

High

Low

SPL(dB)

52

47

LINE

1m

1m

unit

about 1.4m

MICROPHONE

floor

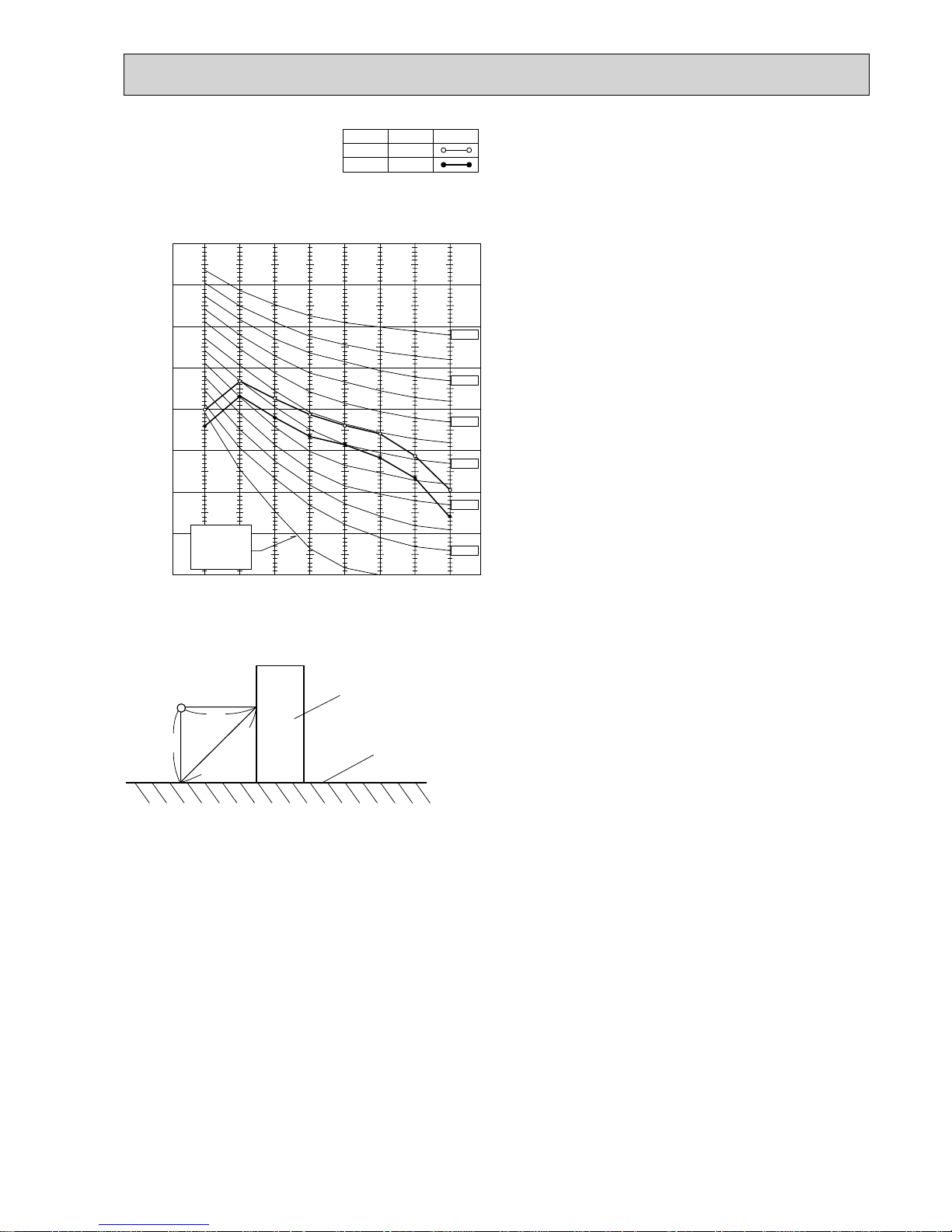

Page 14

14

125

240

Front side

Metal fixture

against overturning

controller

Rear side

Knockout hole

for branch duct

100

10

3838

50260

130130

766

1900

608

50

115

714 123

767

110

480

590

216

40

82730

2010

130

132

VIEW "A"

A

340

370

520

260

240

130 71

530

600

270

250

70

180

235

Knockout hole for

wiring.:27

(Provided on both sides)

Knockout hole for refrigerant and drainage.

90 60 oval (Provided on both sides)

Knockout hole for piping and wiring

(140 80 oval)

20

105

Terminal block for

indoor/outdoor

connection.

Electrical parts box

Liquid pipe :9.52(3/8F)

1. Service access allows for

insertion of screw driver.

2. Adjustable

Gas pipe :15.88(5/8F)

Drain pipe

Terminal block for

heater power supply

(Only PSH-P¥GAH)

95

46122

47

Front side

Rear side

Knockout hole

for bottom fixing

Knockout hole

for under-piping

Knockout hole for

under-piping(120 70 oval)

277

160

20

218

175

90

55 143

100

95

40 66

186

100 or more 100 or more

2

5 or more

1

300 or more

Front 1,000 or more

10

PSA-RP71GA

PSA-RP71GA#1

PSH-P71GAH

Unit : mm

OUTLINES AND DIMENTIONS

7

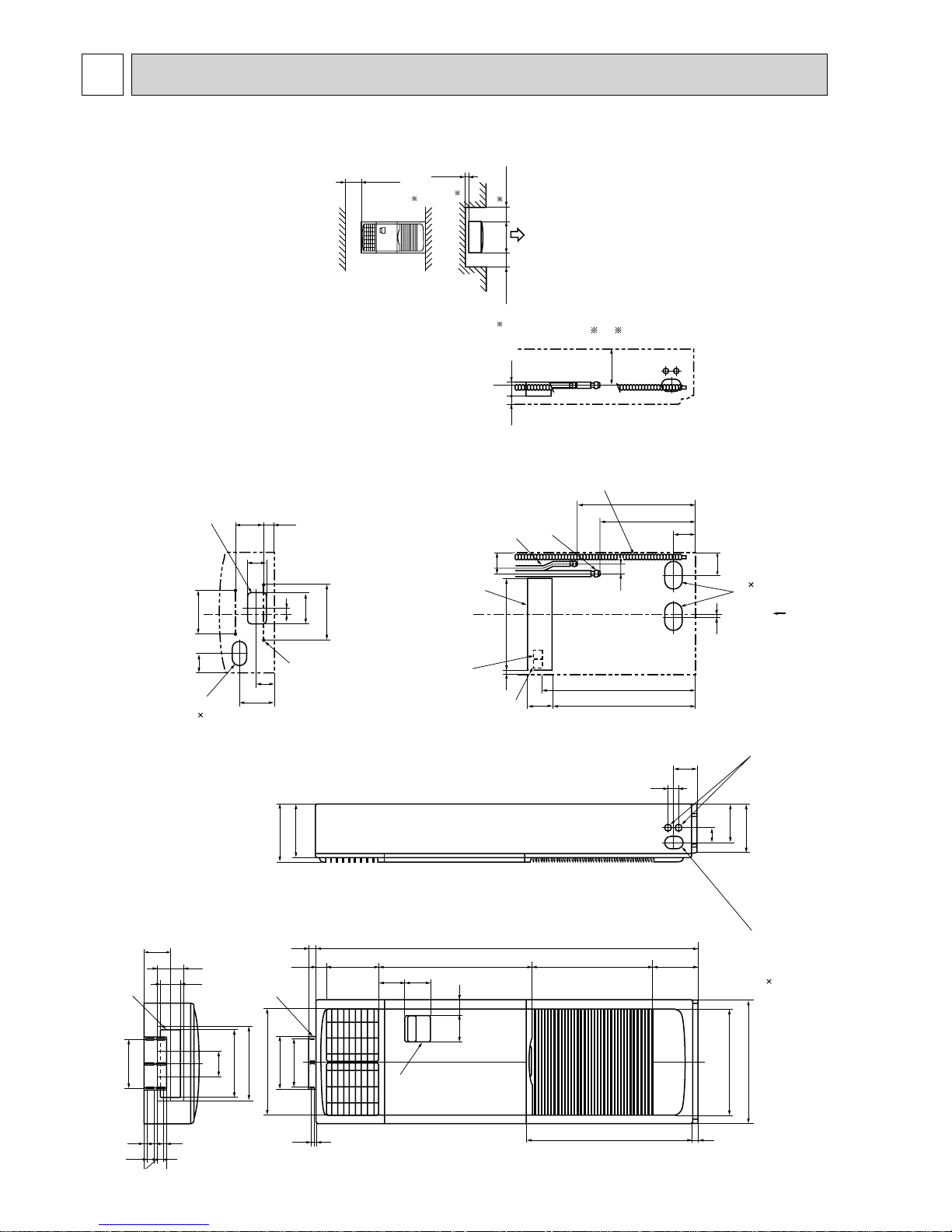

Page 15

1515

125

240

Front side

Metal fixture

against overturning

controller

Rear side

Knockout hole

for branch duct

100

10

3838

50260

130130

766

1900

608

50

115

714 123

767

110

480

590

216

40

82730

2010

130

132

340

370

520

260

240

130 71

530

600

350

330

70

260

315

Knockout hole for

wiring.:27 (Provided on both sides)

Knockout hole for refrigerant and drainage.

90 60 oval (Provided on both sides)

Knockout hole for piping and wiring

(140 80 oval)

20

105

Electrical parts box

Liquid pipe :9.52(3/8F)

1. Service access allows for

insertion of screw driver.

2. Adjustable

Gas pipe :15.88(5/8F)

:19.05(3/4F)

Drain pipe

95

46122

47

Front side

Rear side

Knockout hole

for bottom fixing

Knockout hole

for under-piping

Knockout hole for

under-piping(120 70 oval)

277

120

20

218

255

140

77

201

120

95

40 66

261

100 or more 100 or more

2

5 or more

1

300 or more

Front 1,000 or more

10

VIEW "A"

A

Terminal block for

indoor/outdoor

connection.

Terminal block for

heater power supply

(Only PSH-P·GAH)

: 9.52

RP100,125,140

: 15.88

: 19.05

Use the current nuts meeting the pipe size

of the outdoor unit.

Available pipe size

LIQUID SIDE

GAS SIDE

: 9.52

P100,125,140—: 19.05

: Initial flare nut size

PSA-RP100GA

PSA-RP100GA#1

PSH-P100GAH

PSA-RP125GA

PSA-RP125GA#1

PSH-P125GAH

PSA-RP140GA

PSA-RP140GA#1

PSH-P140GAH

Unit : mm

Page 16

16

PSA-RP71GA PSA-RP100GA PSA-RP125GA PSA-RP140GA

PSA-RP71GA#1 PSA-RP100GA#1 PSA-RP125GA#1 PSA-RP140GA#1

PSH-P71GAH PSH-P100GAH PSH-P125GAH PSH-P140GAH

1357

MF

ORN

C

RED

BLK

BLU

YLW

13 13 13 12

1

2

2

1

3

13

ML

YLW

YLW

BLK

ORN

YLW

YLW

ORNS1S2

S3

WHT

WHT

WHT

BRN

ORN

RED

I.B

FAN

(WHT)

LOUVER

CNL

(YLW)

X4X5X6

X6

X5 X4

X2

ZNR

FUSE

X2

LED3 LED2 LED1

SWE

ON

OFF

POWER

CNDK

(RED)

POWER

CND

(ORN)

POWER

CN2D

(WHT)

WIRELESS

CN90

(WHT)

2

1

REMOCON

CN22

(BLU)

CN32

CN2L

2

1

TB6

2

2

1

1

2

1

LIQUID

CN21

(WHT)

INTAKE

CN20

(RED)

PIPE

CN29

(BLK)

CN24 CN41

CN51

R.B

TRANSMISSION

WIRES DC12V

BLU

BLU

TH1

TH2

TH5

SW1SW2

TB4

REDRED

WHT

RED

BLU

GRN/YLW

88H

FS1FS2

H

53

1

2

L

N

TB2

POWER SUPPLY

~(1 PHASE)

230V 50Hz

2

1

6

5

RED

RED

YLW

26H

88H

YLW

YLW

16

HEATER

CN24

(YLW)

I.B

PSH -P.GAH

models only

INDOOR UNIT

Please set the voltage using the

remote controller.

For the setting method, please refer to

the indoor unit Installation Manual.

INDOOR/OUTDOOR

COMMUNICATION

CN3C

(BLU)

Refer to tables 1

and 2 for service PCB.

P.B

CNSK

(RED)

CN2S

(WHT)

DC13.1V

TO

OUTDOOR

UNIT

3131

POWER

CND

(ORN)

INDOOR/OUTDOOR

COMMUNICATION

CN3C

(BLU)

TB2

TB4

POWER SUPPLY

~(1PHASE)

230V 50Hz

RED

BLU

GRY/YLW

RED

BLU

TO

OUTDOOR

UNIT

L

S1

S2

S3

N

I.B

YLW

ORN

ORN

BRN

1 (Fig.1)

Service board

SW2

Table 2

1 2 3 4 5

MODELS

PSA-RP71GA

PSH-P71GAH

PSA-RP100GA

PSH-P100GAH

PSA-RP125GA

PSH-P125GAH

PSA-RP140GA

PSH-P140GAH

ON

OFF

1 2 3 4 5

ON

OFF

1 2 3 4 5

ON

OFF

1 2 3 4 5

ON

OFF

Service board

SW2

Table 1

1 2 3 4 5

MODELS

PSA-RP.GA

PSH-P.GAH

ON

OFF

P.B

INDOOR POWER BOARD

SYMBOL NAME SYMBOL NAME SYMBOL NAME

I.B

I.B

INDOOR CONTROLLER BOARD

FUSE FUSE (T6.3AL250V)

ZNR VARISTOR

CN2L CONNECTOR (LOSSNAY)

CN32 CONNECTOR (REMOTE SWITCH)

CN41 CONNECTOR (HA TERMINAL-A)

CN51 CONNECTOR (CENTRALLY CONTROL)

SW1

SWITCH (MODEL SELECTION) See Table 1.

SW2

SWITCH (CAPACITY CODE) See Table 2.

SWE SWITCH (EMERGENCY OPERATION)

X4 RELAY (FAN MOTOR)

X5 RELAY (FAN MOTOR)

X6 RELAY (FAN MOTOR)

X2

RELAY (LOUVER)

POWER SUPPLY (R.B)

LED1 POWER SUPPLY (I.B)

LED2

TRANSMISSION (INDOOR-OUTDOOR)LED3

WIRED REMOTE CONTROLLER BOARD

TERMINAL BLOCK (REMOTE CONTROLLER

TRANSMISSION LINE)

R.B

TB6

HEATER

HEATER

THERMAL FUSE (110°C16A)

H

FS1,2

HEATER THERMAL SWITCH

26H

HEATER CONTACTOR

88H

C CAPACITOR (FAN MOTOR)

FAN MOTOR

MF

LOUVER MOTOR

ML

TB2

TERMINAL BLOCK

(INDOOR/OUTDOOR CONNECTING LINE)

TB4

TERMINAL BLOCK (HEATER) PSH-P.GAH

models only or option for PSA-RP.GA models.

ROOM TEMP.THERMISTOR

(0°C/15k, 25°C/5.4k DETECT)

PIPE TEMP.THERMISTOR/LIQUID

(0°C/15k, 25°C/5.4k DETECT)

COND./EVA.TEMP.THERMISTOR

(0°C/15k, 25°C/5.4k DETECT)

TH1

TH2

TH5

[NOTES]

1.Symbols used in wiring diagram above are, : Connector, : Terminal (block).

2.Indoor and outdoor connecting wires are made with polarities, make wiring

matching terminal numbers (S1,S2,S3).

3.Since the outdoor side electric wiring may change be sure to check the outdoor

unit electric wiring for servicing.

4.This diagram shows the wiring of Indoor and Outdoor connecting wires

(specification of 230V), adopting superimposed system of power and signal.

1 ; When work to supply power separately to Indoor and Outdoor unit

was applied, refer to Fig1.

2 ; For power supply system of this unit, refer to the caution label

located near this diagram.

WIRING DIAGRAM

8

Page 17

17

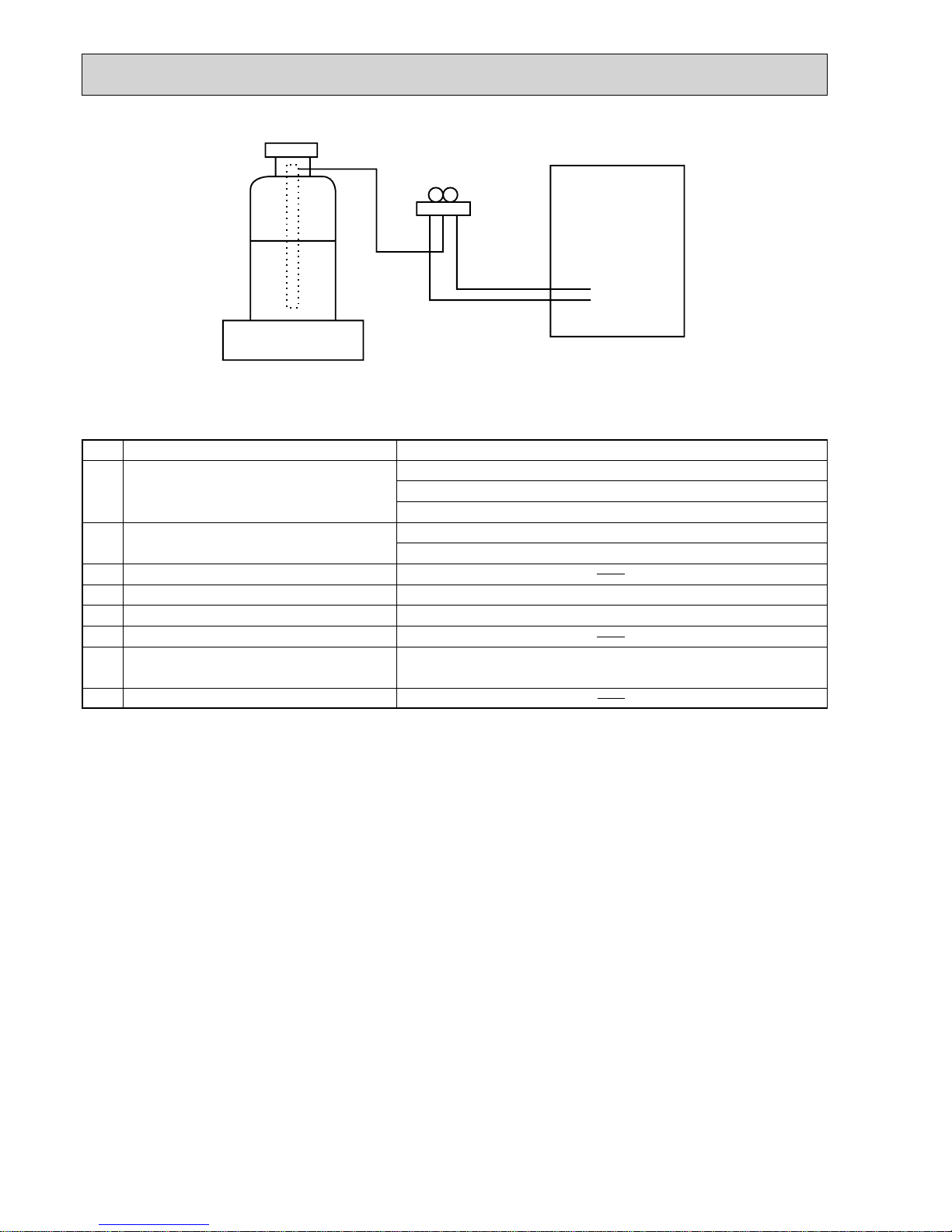

PSA-RP71GA PSA-RP100GA PSA-RP125GA PSA-RP140GA

PSA-RP71GA#1 PSA-RP100GA#1 PSA-RP125GA#1 PSA-RP140GA#1

PSH-P71GAH PSH-P100GAH PSH-P125GAH PSH-P140GAH

Pipe temperature

thermistor/liquid

(TH2)

Distributor

with strainer

#50

Condenser/evaporator

temperature thermistor

(TH5)

Room temperature

thermistor (TH1)

Refrigerant flow in cooling

Refrigerant flow in heating

Strainer

#50

Strainer

#50

Heat exchanger

Refrigerant GAS pipe connection

(Flare)

Refrigerant LIQUID pipe connection

(Flare)

REFRIGERANT SYSTEM DIAGRAM

9

Page 18

18

TROUBLESHOOTING

10

<Error code display by self-diagnosis and actions to be taken for service (summary)>

Present and past error codes are logged and displayed on the wired remote controller or controller board of outdoor unit.

Actions to be taken for service and the trouble reoccurrence at field are summarized in the table below. Check the contents

below before investigating details.

10-1. TROUBLESHOOTING

Unit conditions at service

Error code

Actions to be taken for service (summary)

The trouble is reoccurring.

Displayed

Not displayed

Judge what is wrong and take a corrective action

according to “SELF-DIAGNOSIS ACTION TABLE” (10-2).

Conduct troubleshooting and ascertain the cause of the

trouble according to “TROUBLESHOOTING

BY INFERIOR PHENOMENA ” (10-3).

The trouble is not reoccurring.

Logged

Not logged

Consider the temporary defects such as the work of

protection devices in the refrigerant circuit including

compressor, poor connection of wiring, noise and etc.

Re-check the symptom, and check the installation

environment, refrigerant amount, weather when the

trouble occurred, and wiring related.

Reset error code logs and restart the unit after finishing

service.

There is no abnormality in electrical components,

controller boards, and remote controller.

Recheck the abnormal symptom.

Identify the cause of the trouble and take a corrective

action according to “TROUBLESHOOTING

BY INFERIOR PHENOMENA ” (10-3).

Continue to operate unit for the time being if the cause

is not ascertained.

There is no abnormality in electrical components,

controller boards, remote controller etc.

Page 19

1919

10-2. SELF-DIAGNOSIS ACTION TABLE

Note: Refer to the manual of outdoor unit for the details of display

such as F, U, and other E.

Error Code

Abnormal point and detection method

Cause

Countermeasure

P1

P2

P4

Drain sensor (DS)

1 Suspensive abnormality, if short/open

of thermistor is detected for 30 seconds

continuously.Compressor and indoor fan

will be turned off

2 Short/open is detected for 30 seconds

continuously during suspensive

abnormality.

(The unit returns to normal operation,

if it has normally reset.)

3 Detect the following condition.

• During cooling and drying operation.

• In case that pipe <liquid> temperature room temperature <-10deg

(Except defrosting)

• When pipe <liquid> temperature or

room temperature is short/open

temperature.

• During drain pomp operation.

1 Defective thermistor

characteristics

2 Contact failure of connector

(CN31) on the indoor controller

board. (Insert failure).

3 Breaking of wire or contact

failure of drain sensor wiring.

4 Defective indoor controller board.

1–3 Check resistance value of thermistor.

0:

......

6.0k"

10:

....

3.9k"

20:

....

2.6k"

30:

....

1.8k"

40:

....

1.3k"

2 Check contact failure of connector (CN31)

on the indoor controller board. Refer to 10-6.

Turn the power on again and check restart

after inserting connector again.

4 Replace indoor controller board if drain

pump operates with the line of drain sensor

connector CN31-1 and 2 is short-circuited,

and abnormality reappears.

Turn the power off, and on again to operate

after check.

P5

Malfunction of drain pump (DP)

1 Suspensive abnormality, if thermistor

of drain sensor is let heat itself and

temperature rises slightly. Compressor

and indoor fan will be turned off.

2 Drain pomp is abnormal if the condition

above is detected during suspensive

abnormality.

3 Constantly detected during drain pump

operation.

1 Malfunction of drain pump

2 Defective drain

Clogged drain pump

Clogged drain pipe

3 Attached drop of water at the

drain sensor

•

Drops of drain trickles from

lead wire.

• Clogged filter is causing

wave of drain.

4 Defective indoor controller board.

1 Check if drain-up machine works.

2 Check drain function.

3 Check the setting of lead wire of drain sensor

and check clogs of the filter.

4 Replace indoor controller board if drain

pump operates with the line of drain sensor

connector CN31-1 and 2 is short-circuited

and abnormality reappears.

Refer to 10-6.

Turn the power off, and on again to operate

after check.

Room temperature thermistor (TH1)

1 The unit is in 3-minute resume

prevention mode if short/open of

thermistor is detected. Abnormal if the

unit does not reset normally after 3 minutes. (The unit returns to normal opera-

tion, if it has been reset normally.)

2 Constantly detected during cooling,

drying, and heating operation.

Short: -90: or more

Open: -40: or less

1 Defective thermistor

characteristics

2 Contact failure of connector

(CN20) on the indoor controller

board (Insert failure)

3 Breaking of wire or contact

failure of thermistor wiring

4 Defective indoor controller

board

1–3 Check resistance value of thermistor.

0:

....

15.0k"

10:

....

9.6k"

20:

....

6.3k"

30:

....

4.3k"

40:

....

3.0k"

If you put force on (draw or bend) the lead wire

with measuring resistance value of thermistor, breaking of wire or contact failure can be

detected.

2 Check contact failure of connector (CN20)

on the indoor controller board. Refer to 10-6.

Turn the power on again and check restart

after inserting connector again.

4 Check room temperature display on remote

controller.

Replace indoor controller board if there is

abnormal difference with actual room

temperature.

Turn the power off, and on again to operate

after check.

Pipe temperature thermistor/Liquid

(TH2)

1 The unit is in 3-minute resume

prevention mode if short/open of

thermistor is detected. Abnormal if the

unit does not reset normally after 3 minutes. (The unit returns to normal opera-

tion, if it has been reset normally.)

2 Constantly detected during cooling,

drying, and heating (except defrosting)

operation

Short: 90: or more

Open: -40: or less

1 Defective thermistor

characteristics

2 Contact failure of connector

(CN44) on the indoor control-

ler board (Insert failure)

3 Breaking of wire or contact

failure of thermistor wiring

4 Defective refrigerant circuit is

causing thermistor tempera-

ture of 90: or more or -40:

or less.

5 Defective indoor controller

board

1–3 Check resistance value of thermistor.

For characteristics, refer to (P1) above.

2 Check contact failure of connector (CN44)

on the indoor controller board. Refer to 10-6.

Turn the power on and check restart after

inserting connector again.

4 Check pipe <liquid> temperature with remote

controller in test run mode. If pipe <liquid>

temperature is extremely low (in cooling

mode) or high (in heating mode), refrigerant

circuit may have defective.

5 Check pipe <liquid> temperature with

remote controller in test run mode. If there is

extremely difference with actual pipe <liquid>

temperature, replace indoor controller board.

Turn the power off, and on again to operate

after check.

Page 20

20

Error Code

Abnormal point and detection method

Cause

Countermeasure

P6

Freezing/overheating protection is working

1 Freezing protection (Cooling mode)

The unit is in 6-minute resume prevention mode if pipe <liquid or condenser/

evaporator> temperature stays under

-15: for 3 minutes, 3 minutes after the

compressor started. Abnormal if it stays

under -15: for 3 minutes again within

16 minutes after 6-minute resume prevention mode.

2 Overheating protection (Heating mode)

The units is in 6 minute resume

prevention mode if pipe <condenser /

evaporator> temperature is detected as

over 70: after the compressor started.

Abnormal if the temperature of over

70: is detected again within 30 minutes

after 6 minute resume prevention mode.

P8

1 Slight temperature difference

between indoor room

temperature and pipe <liquid

or condenser / evaporator>

temperature thermistor

• Shortage of refrigerant

• Disconnected holder of pipe

<liquid or condenser /

evaporator> thermistor

• Defective refrigerant circuit

2 Converse connection of

extension pipe (on plural units

connection)

3 Converse wiring of indoor/

outdoor unit connecting wire

(on plural units connection)

4 Defective detection of indoor

room temperature and pipe

<condenser / evaporator>

temperature thermistor

5 Stop valve is not opened

completely.

(Cooling or drying mode)

1 Clogged filter (reduced airflow)

2 Short cycle of air path

3 Low-load (low temperature)

operation out of the tolerance

range

4 Defective indoor fan motor

• Fan motor is defective.

• Indoor controller board is defective.

5 Defective outdoor fan control

6 Overcharge of refrigerant

7 Defective refrigerant circuit

(clogs)

(Heating mode)

1 Clogged filter (reduced airflow)

2 Short cycle of air path

3 Over-load (high temperature)

operation out of the tolerance

range

4 Defective indoor fan motor

• Fan motor is defective.

• Indoor controller board is defective.

5 Defective outdoor fan control

6 Overcharge of refrigerant

7 Defective refrigerant circuit

(clogs)

8 Bypass circuit of outdoor unit

is defective.

(Cooling or drying mode)

1 Check clogs of the filter.

2 Remove shields.

4 Refer to 10-6.

5 Check outdoor fan motor

.

67 Check operating condition of refrigerant

circuit.

(Heating mode)

1 Check clogs of the filter.

2 Remove shields.

4 Refer to 10-6.

5 Check outdoor fan motor.

6~8Check operating condition of refrigerant

circuit.

Pipe temperature

<Cooling mode>

Detected as abnormal when the pipe temperature is not in the cooling range 3 minutes after compressor start and 6 minutes

after the liquid or condenser/evaporator

pipe is out of cooling range.

Note 1) It takes at least 9 minutes to

detect.

Note 2) Abnormality P8 is not detected in

drying mode.

Cooling range : -3 °C ] (TH-TH1)

TH: Lower temperature between: liquid

pipe temperature (TH2) and condenser/evaporator temperature (TH5)

TH1: Intake temperature

<Heating mode>

When 10 seconds have passed after the

compressor starts operation and the hot

adjustment mode has finished, the unit is

detected as abnormal when condenser/

evaporator pipe temperature is not in heating range within 20 minutes.

Note 3) It takes at least 27 minutes to

detect abnormality.

Note 4) It excludes the period of defrosting.

(Detection restarts when defrosting

mode is over.)

Heating range : 3 °C [ (TH5-TH1)

1~4 Check pipe <liquid or condenser / evapo-

rator> temperature with room temperature display on remote controller and

outdoor controller circuit board.

Pipe <liquid or condenser / evaporator>

temperature display is indicated by setting SW2 of outdoor controller circuit

board as follows.

23Check converse connection of extension

pipe or converse wiring of indoor/outdoor

unit connecting wire.

Conduct temperature check with outdoor

controller circuit board after connecting

‘A-Control Service Tool(PAC-SK52ST)’.

(

)

Page 21

21

Error Code

Abnormal point and detection method

Cause

Countermeasure

P9

Pipe temperature thermistor /

Condenser-Evaporator (TH5)

1 The unit is in 3-minute resume protec-

tion mode if short/open of thermistor is

detected. Abnormal if the unit does not

get back to normal within 3 minutes. (The

unit returns to normal operation, if it has

been reset normally.)

2 Constantly detected during cooling,

drying, and heating operation (except

defrosting)

Short: 90: or more

Open: -40: or less

1 Defective thermistor

characteristics

2 Contact failure of connector

(CN44) on the indoor controller

board (Insert failure)

3 Breaking of wire or contact

failure of thermistor wiring

4 Temperature of thermistor is

90: or more or -40: or less

caused by defective refrigerant

circuit.

5 Defective indoor controller

board

1–3 Check resistance value of thermistor.

For characteristics, refer to (P1) above.

2 Check contact failure of connector (CN44)

on the indoor controller board.

Refer to 10-7.

Turn the power on and check restart after

inserting connector again.

4 Operate in test run mode and check pipe

<condenser / evaporator> temperature with

outdoor controller circuit board. If pipe

<condenser / evaporator> temperature is

extremely low (in cooling mode) or high (in

heating mode), refrigerant circuit may have

defect.

5 Operate in test run mode and check pipe

<condenser / evaporator> temperature with

outdoor control circuit board. If there is

extreme difference with actual pipe

<condenser / evaporator> temperature,

replace indoor controller board.

There is no abnormality if none of above

comes within the unit.

Turn the power off and on again to operate.

E0

or

E4

Remote controller transmission

error(E0)/signal receiving error(E4)

1 Abnormal if main or sub remote con-

troller cannot receive any transmission

normally from indoor unit of refrigerant

address “0” for 3 minutes.

(Error code : E0)

2 Abnormal if sub remote controller could

not receive any signal for 2 minutes.

(Error code: E0)

1 Abnormal if indoor controller board can

not receive any data normally from

remote controller board or from other

indoor controller board for 3 minutes.

(Error code: E4)

2 Indoor controller board cannot receive

any signal from remote controller for 2

minutes. (Error code: E4)

1 Check disconnection or looseness of indoor

unit or transmission wire of remote controller.

2 Set one of the remote controllers “main”

if there is no problem with the action above.

3 Check wiring of remote controller.

• Total wiring length: max. 500m

(Do not use cable x 3 or more.)

• The number of connecting indoor units:

max. 16 units

• The number of connecting remote controller: max. 2 units

When it is not the above-mentioned problem of

1~3

4

Diagnose remote controllers.

a) When “RC OK” is displayed,

Remote controllers have no problem.

Turn the power off, and on again to check.

If abnormality generates again, replace

indoor controller board.

b) When “RC NG” is displayed,

Replace remote controller.

c)When “RC E3” or “ERC 00-66” is dis-

played, noise may be causing abnormality.

* If the unit is not normal after replacing

indoor controller board in group control,

indoor controller board of address “0” may

be abnormal.

E3

or

E5

Remote controller transmission

error(E3)/signal receiving error(E5)

1 Abnormal if remote controller could not

find blank of transmission path for 6 seconds and could not transmit.

(Error code: E3)

2 Remote controller receives transmitted

data at the same time and compares the

received and transmitted data. Abnormal

if these data are judged to be different

30 continuous times. (Error code: E3)

1 Abnormal if indoor controller board could

not find blank of transmission path.

(Error code: E5)

2 Indoor controller board receives trans-

mitted data at the same time and compares the received and transmitted data.

Abnormal if these data are judged to

be different 30 continuous times. (Error

code: E5)

1 Set a remote controller to main, and the

other to sub.

2 Remote controller is connected with only one

indoor unit.

3 The address changes to a separate setting.

4~6 Diagnose remote controller.

a) When “RC OK” is displayed, remote con-

trollers have no problem.

Turn the power off,and on again to check.

When becoming abnormal again, replace

indoor controller board.

b)When “RC NG” is displayed, replace

remote controller.

c)When “RC E3” or “ERC 00-66” is dis-

played, noise may be causing abnormal-

ity.

1 Contact failure at transmission

wire of remote controller

2 All remote controllers are set

as “sub” remote controller.

In this case, E0 is displayed

on remote controller, and E4

is displayed at LED (LED1,

LED2) on the outdoor controller

circuit board.

3 Miswiring of remote controller

4 Defective transmitting receiving

circuit of remote controller

5 Defective transmitting receiving

circuit of indoor controller board

of refrigerant addresses “0”.

6 Noise has entered into the

transmission wire of remote

controller.

1 2 remote controllers are set as

“main.”

(In case of 2 remote con trollers)

2 Remote controller is connected

with 2 indoor units or more.

3 Repetition of refrigerant

address

4 Defective transmitting receiving

circuit of remote controller

5 Defective transmitting receiving

circuit of indoor controller board

6 Noise has entered into trans-

mission wire of remote control-

ler.

In case of checking pipe temperature

with outdoor controller circuit board,

be sure to connect A-control service

tool (PAC-SK52ST).

(

)

Page 22

22

E6

E7

Error Code

Abnornal point and detection method

Cause

Countermeasure

Fb

E1

or

E2

PA

Forced compressor stop

(due to water leakage abnormality)

1 When the intake temperature subtracted

with liquid pipe temperature is less than

-10:, drain sensor is detected whether

it is soaked in the water or not at the interval

of 90 seconds. (Drain pump will start operating

when the drain sensor is detected to be

soaked in the water.)

2 The unit has a water leakage abnormality

when the following conditions, a and b, are

satisfied while the above-mentioned detection

is performed.

a) The drain sensor is detected to be

soaked in the water 10 times in a row.

b) The intake temperature subtracted with

liquid pipe temperature is detected to be

less than -10: for a total of 30 minutes.

(When the drain sensor is detected to

be NOT soaked in the water, the detection

record of a and b will be cleared.)

3 The drain sensor detection is performed

in operations other than cooling. (When

the unit stops operating, during heating

or fan operation, when the unit stops

because of some abnormality)

*Once the water leakage abnormality is

detected, abnormality state will not be

released until the main power is reset.

1 Drain pump trouble

2 Drain defective

· Drain pump clogging

· Drain pipe clogging

3 Open circuit of drain sensor

side heater

4 Contact failure of drain sensor

connector

5 Dew condensation on drain

sensor

· Drain water descends along

lead wire.

· Drain water waving due to filter

clogging.

6 Extension piping connection

difference at twin, triple,

quadruple system.

7 Mis-wiring of indoor/ outdoor

connecting at twin, triple,

quadruple system.

8 Room temperature thermistor /

liquid pipe temperature thermis tor detection is defective.

1 Check the drain pump.

2 Please confirm whether water can be

drained.

3 Confirm the resistance of the drain sensor.

4 Check the connector contact failure.

5 Check the drain sensor leadwire mounted.

Check the filter clogging

6 Check the piping connection.

7 Check the indoor/ outdoor connecting wires.

8 Check the room temperature display of

remote controller.

Check the indoor liquid pipe temperature

display of outdoor controller board.

1 Contact failure, short circuit or,

miswiring (converse wiring) of

indoor/outdoor unit connecting

wire

2 Defective transmitting receiving

circuit of indoor controller board

3 Defective transmitting receiving

circuit of indoor controller board

4 Noise has entered into indoor/

outdoor unit connecting wire.

* Check LED display on the outdoor control

circuit board. (Connect A-control service

tool, PAC-SK52ST.)

Refer to outdoor unit service manual.

1 Check disconnection or looseness of indoor/

outdoor unit connecting wire of indoor unit or

outdoor unit.

Check all the units in case of twin triple

indoor unit system.

2-4 Turn the power off, and on again to check.

If abnormality generates again, replace

indoor controller board or outdoor

controller circuit board.

* Other indoor controller board may have

defect in case of twin triple indoor unit

system.

Indoor/outdoor unit communication

error (Transmitting error)

Abnormal if “1” receiving is detected 30

times continuously though indoor controller

board has transmitted “0”.

1 Defective transmitting receiving

circuit of indoor controller board

2 Noise has entered into power

supply.

3 Noise has entered into outdoor

control wire.

1-3 Turn the power off, and on again to check.

If abnormality generates again, replace

indoor controller board.

Indoor/outdoor unit communication

error (Signal receiving error)

1

Abnormal if indoor controller board

cannot receive any signal normally for 6

minutes after turning the power on.

2 Abnormal if indoor controller board

cannot receive any signal normally for 3

minutes.

3 Consider the unit abnormal under the fol-

lowing condition: When 2 or more indoor

units are connected to an

outdoor unit, indoor controller board

cannot receive a signal for 3 minutes

from outdoor controller circuit board, a

signal which allows outdoor controller

circuit board to transmit signals.

Indoor controller board

Abnormal if data cannot be read normally

from the nonvolatile memory of the indoor

controller board.

1 Defective indoor controller

board

1 Replace indoor controller board.

Remote controller control board

1 Abnormal if data cannot be read nor-

mally from the nonvolatile memory of the

remote controller control board.

(Error code: E1)

2 Abnormal if the clock function of remote

controller cannot be operated normally.

(Error code: E2)

1 Defective remote controller 1 Replace remote controller.

Page 23

23

(For the separate indoor/outdoor unit power sup-

ply system)

1 Power supply of 220~240V AC is not supplied to

indoor unit.

2 The connectors of the optional replacement kit are

not used.

3 Defective indoor controller board.

4 Defective indoor power board.

10-3. TROUBLESHOOTING BY INFERIOR PHENOMENA

Note: Refer to the manual of outdoor unit for the detail of remote

controller.

Phenomena

Cause

Countermeasure

(1)LED2 on indoor controller board

is off.

• When LED1 on indoor controller board is also off.

1 Power supply of rated voltage is not supplied to out-

door unit.

2 Defective outdoor controller circuit board.

3 Power supply of 220~240V is not supplied to indoor

unit.

4 Defective indoor power board.

5 Defective indoor controller board.

1 Check the voltage of outdoor power

supply terminal block (L, N) or (L3, N).

• When AC 220~240V is not detected.

Check the power wiring to outdoor unit

and the breaker.

• When AC 220~240V is detected.

—Check 2 (below).

2 Check the voltage between outdoor

terminal block S1 and S2.

• When AC 220~240V is not detected.

Check the fuse on outdoor controller cir-

cuit board.

Check the wiring connection.

• When AC 220~240V is detected.

—Check 3 (below).

3 Check the voltage between indoor terminal

block S1 and S2.

• When AC 220~240V is not detected.

Check indoor/outdoor unit connecting

wire for mis-wiring.

• When AC 220~240V is detected.

—Check 4 (below).

4 Check voltage output from CN2S on indoor

power board (DC13.1V). Refer to 10-6-1.

• When no voltage is output.

Check the wiring connection.

• When output voltage is between DC12.5V

and DC13.7V.

—Check 5 (below).

5 Check the wiring connection between indoor

controller board and indoor power board.

Check the fuse on indoor controller board.

If no problems are found, indoor controller

board is defective.

• When LED1 on indoor controller board is lit.

1 Mis-setting of refrigerant address for outdoor unit

(There is no unit corresponding to refrigerant

address “0”.)

1 Reconfirm the setting of refrigerant address

for outdoor unit

Set the refrigerant address to “0”.

(For grouping control system under

which 2 or more outdoor units are

connected, set one of the units to “0”.)

Set refrigerant address using SW1 (3-6)

on outdoor controller circuit board.

1 Check the voltage of indoor power supply

terminal block (L,N).

• When AC220~240V is not detected.

Check the power supply wiring.

• When AC220~240V is detected.

-Check 2 (below).

2 Check that there is no problem in the meth-

od of connecting the connectors.

• When there are problems in the method of

connecting the connectors.

Connect the connector correctly referring

to installation manual of an optional kit.

• When there is no problem in the method

of connecting the connectors.

-Check 3 (below).

3 Check voltage output from CNDK on indoor

controller board.

• When AC220~240V is not detected.

Check the fuse on indoor controller board.

Check the wiring connection between

indoor power supply terminal block and

CND on indoor controller board.

• When AC220~240V is detected.

-Check 4 (below).

4 Check voltage output from CN2S on indoor

power board.

• When no voltage output.

Check the wiring connection between

CNDK on indoor controller board and

CNSK on indoor power board.

If no problem are found,indoor power

board is defective.

• When DC12.5~13.7V is detected.

Check the wiring connection between

CN2S on indoor power board and

CN2D on indoor power board.

If no problem are found,indoor controller

board is defective.

Page 24

24

Note: Refer to the manual of outdoor unit for the detail of remote

controller.

(3)Upward/downward vane

performance failure

1 The vane is not downward during defrosting and heat

preparation and when the thermostat is OFF in HEAT

mode. (Working of COOL protection function)

2 Vane motor does not rotate.

• Defective vane motor

• Breaking of wire or connection failure of connector

• Up/down vane setting is “No vanes”.

3 Upward/downward vane does not work.

• The vane is set to fixed position.

1 Normal operation (The vane is set to

horizontal regardless of remote control.)

2 Check 2 (left).

• Check the vane motor. (Refer to “How

to check the parts”.)

• Check for breaking of wire or connection failure of connector.

• Check “Up/down vane setting”. (Unit

function selection by remote controller).

3 Normal operation (Each connector on

vane motor side is disconnected.)

Phenomena

Cause

Countermeasure

(2)LED2 on indoor controller board

is blinking.

• When LED1 on indoor controller board is also blinking.

Connection failure of indoor/outdoor unit connecting

wire

• When LED1 is lit.

1 Mis-wiring of remote controller wires

Under twin triple indoor unit system, 2 or more indoor

units are wired together.

2 Refrigerant address for outdoor unit is wrong or not

set.

Under grouping control system, there are some units

whose refrigerant address is 0.

3 Short-cut of remote controller wires

4 Defective remote controller

Check indoor/outdoor unit connecting wire

for connection failure.

1 Check the connection of remote con troller wires in case of twin triple indoor

unit system. When 2 or more indoor units

are wired in one refrigerant system,

connect remote controller wires to one of

those units.

2 Check the setting of refrigerant address

in case of grouping control system.

If there are some units whose refrigerant

addresses are 0 in one group, set one of

the units to 0 using SW1 (3-6) on outdoor

controller circuit board.

34 Remove remote controller wires and

check LED2 on indoor controller board.

• When LED2 is blinking, check the shortcut of remote controller wires.

• When LED2 is lit, connect remote

controller wires again and:

if LED2 is blinking, remote controller

is defective; if LED2 is lit, connection

failure of remote controller terminal

block etc. has returned to normal.

(4)Receiver for wireless remote

controller

1 Weak batteries of wireless remote controller.

2 Contact failure of connector (CNB) on wireless

remote controller board.

(Insert failure)

3 Contact failure of connector (CN90) on indoor con-

troller board.(Insert failure)

4 Contact failure of connector between wireless remote

controller board and indoor controller board.

1 Replace batteries of wireless remote con-

troller.

2~4

Check contact failure of each connector.

If no problems are found of connector,

replace indoor controller board.

When the same trouble occurs even if

indoor controller board is replaced,

replace wireless remote controller

board.

Page 25

25

White

Orage

Red

Black

Blue

Yellow

White

Orage

Red

Blue

Black

Brown

Yellow

Measure the resistance of each heater element by using a tester.

Heater(H)

(Only PSH)

Normal

Abnormal

71

18.9

0.7kW 80V

100

14.7

0.9kW 80V

125, 140

13.2

1kW 80V

Open or short

Parts name Check points

Disconnect the connector then measure the resistance using a tester

.

(Surrounding temperature 10~30)

(Refer to the <Thermistor Characteristic graph> for a detail.)

Room temperature

thermistor (TH1)

Pipe temperature

thermistor (TH2)

Condenser/evaporator

temperature thermistor

(TH5)

Normal

4.3k~9.6k

Abnormal

Open or short

Fan motor(MF)

71, 100

125, 140

Measure the resistance between the terminals using a tester.

(Winding temperature 20)

Abnormal

Open or short

White–Black

Black–Blue

Blue–Yellow

Black–Red

Motor terminal

or

Relay connector

71

112.1

22.1

41.0

178.5

100

91.5

18.0

29.6

174.9

Normal

Abnormal

Open or short

White–Brown

Brown–Black

Black–Blue

Blue–Yellow

Yellow–Red

Motor terminal

or

Relay connector

125

28.0

6.9

13.3

8.4

53.6

140

21.7

7.8

14.3

7.7

54.4

Normal

Measure the resistance between the terminals using a tester.

(Surrounding temperature 25)

Louver motor(ML)

Normal

11000~13000

Abnormal

Open or short

0

10

20

30

40

50

-20-100 1020304050

< Thermistor for lower temperature >

Temperature ()

Resistance (K)

<Thermistor Characteristic graph>

Room temperature thermistor(TH1)

Pipe temperature thermistor(TH2)

Condenser/evaporator temperature

thermistor(TH5)

Thermistor R0=15k" ± 3%

Fixed number of B=3480 ± 2%

Rt=15exp { 3480( ) }

0: 15k"

10: 9.6k"

20: 6.3k"

25: 5.4k"

30: 4.3k"

40: 3.0k"

Thermistor for

lower temperature

1

273+t

1

273

10-5. HOW TO CHECK THE PARTS

PSA-RP71GA PSA-RP100GA PSA-RP125GA PSA-RP140GA

PSA-RP71GA#1 PSA-RP100GA#1 PSA-RP125GA#1 PSA-RP140GA#1

PSH-P71GAH PSH-P100GAH PSH-P125GAH PSH-P140GAH

Page 26

26

10-6. TEST POINT DIAGRAM

10-6-1. Power board

PSA-RP71GA PSA-RP100GA PSA-RP125GA PSA-RP140GA

PSA-RP71GA#1 PSA-RP100GA#1 PSA-RP125GA#1 PSA-RP140GA#1

PSH-P71GAH PSH-P100GAH PSH-P125GAH PSH-P140GAH

CNSK

Connect to the indoor controller board

(CNDK)

Between 1 to 3 220-240V AC

CN2S

Connect to the indoor controller board (CN2D)

Between 1 to 3 12.6-13.7V DC (Pin1 (+))

Page 27

27

10-6-2. Indoor controller board

PSA-RP71GA PSA-RP100GA PSA-RP125GA PSA-RP140GA

PSA-RP71GA#1 PSA-RP100GA#1 PSA-RP125GA#1 PSA-RP140GA#1

PSH-P71GAH PSH-P100GAH PSH-P125GAH PSH-P140GAH

FAN

Fan motor output

CNP

Drain-pump output

(DP)

(220~240V AC)

CNC

Dew prevention

heater (H2)

(220~240V AC)

CNDK

Connect to the indoor

power board (CNSK)

(220~240V AC)

FUSE

(6.3A 250V)

CND

Power

supply input

(220~240V AC)

SWE

Emergency operation

SW2

Capacity setting

SW1

Model setting

CN2L

Connector

(LOSSNAY)

CN51

Centrally control

CN6V

Vane motor output

(MV)

CN90

Connect to the

wireless remote

controller board

(CNB)

CN31

Drain sensor (DS)

CN29

Condenser/evaporator

temperature thermistor

(TH5)

CN21

Pipe temperature

thermistor/Liquid

(TH2)

CN20

Room temperature

thermistor (TH1)

CN22

Remote controller

connecting wire

(10.4~14.6V DC)

LED3

Transmission

(Indoor/outdoor)

LED2

Power supply

(R.B)

LED1

Power supply

(I.B)

CN2D

Connector to the indoor

power board (CN2S)

(12.5~13.7V DC)

CN3C

Transmission

(Indoor/outdoor)

(0~24V DC)

}

}

Non polarity

+

–

+

–

CN41

Connector

(HA terminal-A)

CNL

Louver motor output

(220~240V AC)

Page 28

28

SW1

Setting by the dip switch and jumper wire

Functions

Jumper wire

Model

settings

Capacity

settings

Pair number

setting with

wireless

remote

controller

For service board

Remarks

SW2

J41

J42

Unit type

setting

JP1

Indoor

controller

board type

setting

JP3

0

1

2

3 ~ 9

Wireless remote

controller setting

Control PCB setting

J41 J42

<Initial setting>

Wireless remote controller: 0

Control PCB: (for both J41 and J42)

Four pair number settings are supported.

The pair number settings of the wireless remote

controller and indoor control PCB (J41/J42) are

given in the table on the left.

(' ' in the table indicates the jumper line is disconnected.)

There is no jumper (JP1) because these models

have the cond./eva. temperature thermistor (TH5).

(Marks in the table below) Jumper wire ( : Short : Open)

Without TH5

With TH5

Model

JP1

For product

Service parts

Indoor controller board type

JP3

12345

ON

OFF

Service board

MODELS

1 2 3 4 5

1 2 3 4 5

PSA-RP71GA

PSH-P71GAH

1 2 3 4 5

ON

OFF

PSA-RP100GA

PSH-P100GAH

ON

OFF

PSA-RP125GA

PSH-P125GAH

1 2 3 4 5

ON

OFF

PSA-RP140GA

PSH-P140GAH

ON

OFF

10-7. FUNCTIONS OF DIP SWITCH AND JUMPER WIRE

Each function is controlled by the dip switch and the jumper wire on control P.C. board.

SW1 and SW2 are equipped only for service parts.

Model setting and capacity setting are memorized in the nonvolatile memory of the control P.C. board of

the unit.

Page 29

2929

SPECIAL FUNCTION

11

Note:

· When the uint is restarted to operate after turning off the power or OFF operation, the unit which was operating will start

operation.

· To operate the main unit, refer to the 11-1-2. and set the requet code No. which is not the same as the current one, and set

again the former request code No.

(2) 2nd stage cut-in function

• Outline of functions

· Number of operating units is determined according to the room temperature and set point.

· When room temperature becomes higher than set point, standby unit starts.(2 units operation)

· When room temperature falls below set point -4:, standby unit stops.(1 unit operation)

• System constraint

· This function is available only in rotation operation and back-up function in

cooling mode.

[2nd stage cut-in function]··· Request code number "322~324"

Start operation Sub unit start operation

Room temp. Set point

Sub unit stop

Run

Stop StopRun

Main

unit

IC-1

Sub

unit

IC-2

Room temp. < Set point -4

11-1. ROTATION FUNCTION(AND BACK-UP FUNCTION, 2ND STAGE CUT-IN FUNCTION)

For PSA-RP71/100/125/140GA#1

11-1-1. Operation

(1) Rotation function (and Back-up function)

• Outline of functions

· Main and sub unit operate alternately according to the interval of rotation setting.

w Main and sub unit should be set by refrigerant address.(Outdoor Dip switch setting)

Refrigerant address"00" Main unit

Refrigerant address"01" Sub unit

· When error occurrs to one unit, another unit will start operation.(Back-up function)

• System constraint

· This function is available only by the grouping control system(INDOOR UNIT : OUTDOOR UNIT=1:1) of 2 refrigerant

groups.(Refer to Fig. 1)

· Main indoor unit should be connected for wired remote controller and the transmission line(TB5) for main and sub unit

should also be connected. (Refer to Fig. 1)

(This function cannot be set by wireless remote controller.)

· Set refrigerant address of each unit.(Dip switch on the outdoor unit···Refrigerant address 00/01)

Operation pattern

OC-1

OC-2

IC-1

IC-2

3(2)

3(2)

2

RC

2

Main

unit

Sub

unit

Refrigerant address

"01"

Refrigerant address

"00"

Fig. 1

[Back-up function only]··· Request code number "312"

[Rotation function] & [Back-up function]··· Request code number "313~318"

(Ex:When the request code number is "313", each unit operates alternately in daily cycle.)

Error occurs on main unit.

Start operation

Run

Abnormal condition

Stop

Run

Main

unit

IC-1

Sub

unit

IC-2

Error occurs on main unit.

Start operation

1~28 days 1~28 days

Run

Abnormal condition

Stop

Stop

Run

Run

Stop Run

Main

unit

IC-1

Sub

unit

IC-2

Main Sub