Page 1

USER’S MANUAL

ORIGINAL INSTRUCTIONS

MITSUBISHI HEAVY INDUSTRIES LTD. PACKAGED AIR CONDITIONER

Ceiling cassette −4 way− (FDT)

Ceiling cassette −4 way Compact (600×600mm)− (FDTC)

Duct connected −High static pressure− (FDU, FDUS)

Duct connected −Middle static pressure− (FDUM)

Ceiling Suspended (FDE)

Floor Standing (FDF)

РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ

MANUEL DE L’UTILISATEUR

MANUAL DEL PROPIETARIO

GEBRUIKERSHANDLEIDING

MANUAL DO UTILIZADOR

USER’S MANUAL

ANWENDERHANDBUCH

ISTRUZIONI PER L’USO

О∆НГІЕΣ ХРНΣНΣ

KULLANIM KILAVUZU

ENGLISH

FRANÇAIS

DEUTSCH

ITALIANO

ESPAÑOL

NEDERLANDS

PORTUGUÊS

ЕΛΛΗNIKA

РУССКИЙ

TÜRKÇE

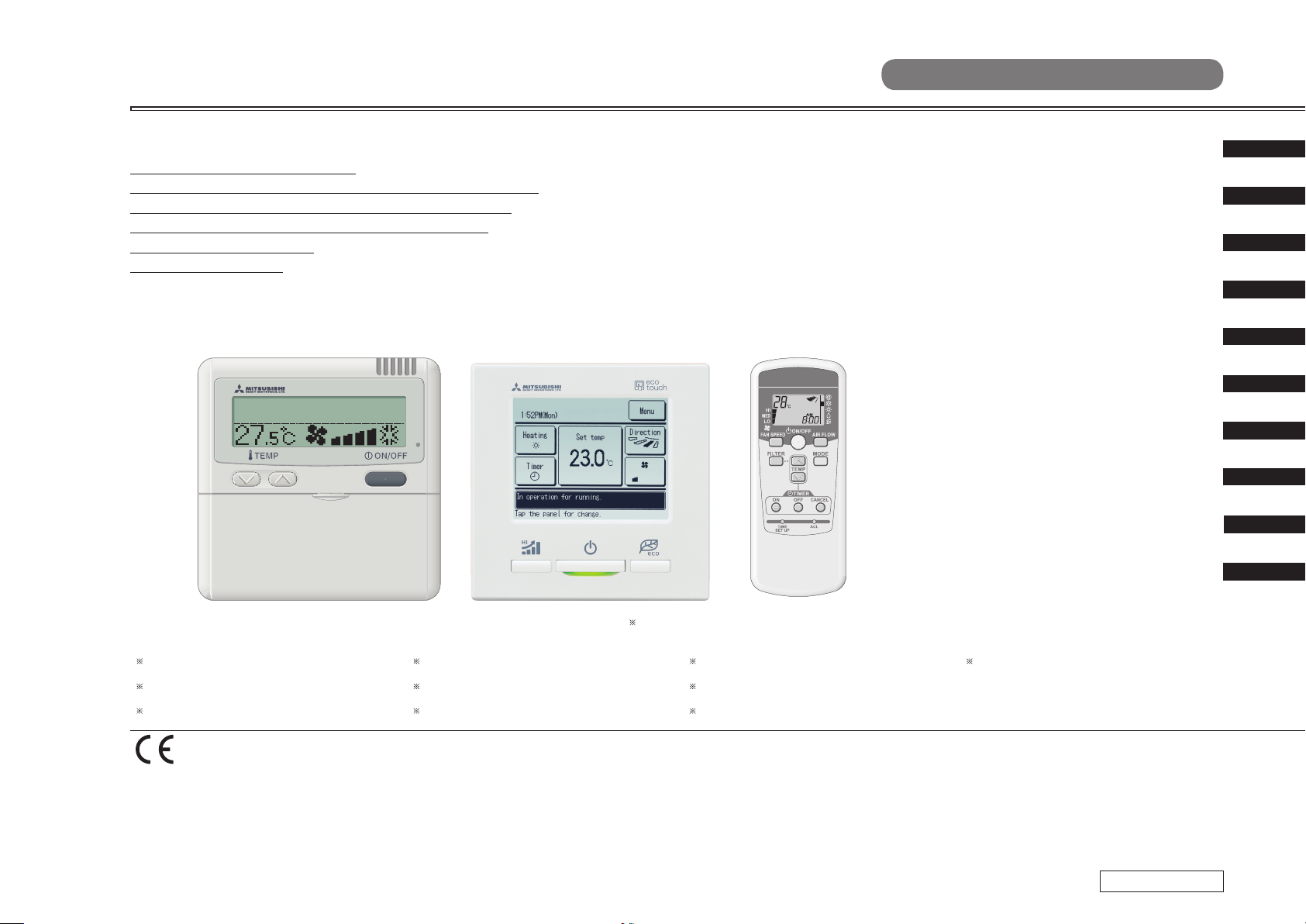

<WIRED REMOTE CONTROL>

Please refer to the manual provided with eco touch REMOTE

CONTROL

S'il vous plaît se référer à la documentation fournie avec la

eco touch télécommande

Bitte beachten Sie die Dokumentation, die mit der eco touch

Fernbedienung kam

This air conditioner complies with EMC Directive 2004/108/EC,

LV Directive 2006/95/EC.

CE marking is applicable to the area of 50 Hz power supply.

Ce climatiseur est conforme à la Directive EMC: 2004/108/EC,

LV Directive 2006/95/EC.

La marque CE s’applique aux régions alimentées en courant

de 50 Hz.

RC-E5

<eco touch REMOTE CONTROL>

Si prega di fare riferimento alla documentazione fornita con il

eco touch telecomando

Por favor, consulte la documentación que viene con el eco

touch mando a distancia

Raadpleeg de documentatie die bij de eco touch afstandsbediening

Dieses Kimagerä t erfü llt die EMC Direktiven 2004/108/EC, LV

Direktiven 2006/95/EC.

Die CE-Marke gilt für Bereiche mit einer Netzstromversorgung

von 50 Hz.

Questo condizionatore d’aria è conforme alla Direttiva EMC:

2004/108/EC, LV Direttiva 2006/95/EC.

Il marchio CE è applicabile alla fascia di alimentazione 50 Hz.

RC-EX series

<WIRELESS REMOTE CONTROL>

Por favor, consulte a documentação que veio com o eco

touch controle remoto

Ανατρέξτε στην τεκμηρίωση που συνόδευε το eco touch

τηλεχειριστήριο

Пожалуйста, обратитесь к документации, поставляемой

с eco touch дистанционным управлением

Este acondicionador de aire cumple con la directiva EMC:

2004/108/EC, LV Directiva 2006/95/EC.

La indicación CE sólo corresponde al área de suministro

eléctrico de 50 Hz.

Deze airconditioner voldoet aan EMC Directive 2004/108/EC,

LV Directive 2006/95/EC.

CE-markering is van toepassing op het gebied met een netstroom van 50 Hz.

eco touch uzaktan kumanda ile birlikte gelen belgelere bakın

Este aparelho de ar condicionado está em conformidade com a

Directiva EMC 2004/108/EC, a Directiva LV 2006/95/EC.

A marca CE aplica-se à zona de fornecimento de energia a

50 Hz.

Το κλιματιστικό συμμορφώνεται προς την οδηγία 2004/108/ΕΚ

περί ηλεκτρομαγνητικής συμβατότητας (EMC) και την οδηγία LV

2006/95/ΕΚ.

Tο οήμα CE ισχύει μόνον σε περιοχές όπου η τροφοδοσία είναι

50 Hz.

PSA012B790

Page 2

Thank you very much for your purchase of this packaged air conditioning system

produced by Mitsubishi Heavy Industries. Please read through this manual before

using the product and use the product appropriately according to the instructions in

the manual. After you have read the manual, store it with the warranty certificate in a

safe place. It will help you when you have questions or problems.

Do not vent R410A into the atmosphere: R410A is a fluorinated greenhouse gas

specified in the Kyoto Protocol and its Global Warming Potential (GWP) is 1975.

The emission sound pressure level from each Indoor and Outdoor unit is under

70 dB(A).

TABLE OF CONTENTS

J SAFETY PRECAUTIONS ...................................................................................................................................................1

J HOW TO USE

< WIRED REMOTE CONTROL >

NAMES AND FUNCTIONS OF REMOTE CONTROL BUTTONS

“WIRED REMOTE CONTROL” ...........................................................................................................................................4

HOW TO OPERATE ........................................................................................................................................................... 5

HOW TO PERFORM THE TIMER OPERATION ................................................................................................................5

THE SELECTION OF TIMER MODE ...............................................................................................................................5

SETTING THE TIME ........................................................................................................................................................6

SLEEP TIMER MODE ...................................................................................................................................................... 6

OFF TIMER MODE ..........................................................................................................................................................6

ON TIMER MODE ............................................................................................................................................................7

WEEKLY TIMER MODE ...................................................................................................................................................7

TIMER CANCELLATION MODE ....................................................................................................................................10

HOW TO OPERATE IN SILENT MODE ...........................................................................................................................10

HOW TO ADJUST THE LOUVER ....................................................................................................................................11

HOW TO SET THE AIRFLOW DIRECTION ..................................................................................................................... 11

HOW TO OPERATE VENTILATION ................................................................................................................................12

FOR COMFORTABLE USE ..............................................................................................................................................12

INSPECTION DISPLAY, FILTER SIGN, AIR CONDITIONER NUMBER, STANDBY AND ROOM TEMPERATURE

DISPLAY ...........................................................................................................................................................................13

< WIRELESS REMOTE CONTROL >

NAMES AND FUNCTIONS OF REMOTE CONTROL BUTTONS

WIRELESS REMOTE CONTROL ....................................................................................................................................13

HOW TO OPERATE ......................................................................................................................................................... 14

CURRENT TIME SETTING PROCEDURE ......................................................................................................................14

ON – TIMER OPERATION ...............................................................................................................................................14

OFF – TIMER OPERATION .............................................................................................................................................14

PROGRAM TIMER OPERATION .....................................................................................................................................14

HOW TO ADJUST THE LOUVER ...................................................................................................................................15

FOR COMFORTABLE USE ..............................................................................................................................................15

CHECK INDICATION, FILTER SIGN ...............................................................................................................................15

BACKUP BUTTON ...........................................................................................................................................................16

J FOR SMART USE

HOW TO MAINTAIN ......................................................................................................................................................... 16

J TROUBLE SHOOTING ....................................................................................................................................................17

J NOTICE

PREPARATION OF HEATING .........................................................................................................................................18

AUTO RESTART ..............................................................................................................................................................18

SETTING TO DISABLE BUTTON OPERATION ..............................................................................................................18

INSTALLATION, RELOCATION, AND INSPECTION MAINTENANCE ...........................................................................18

OPERATION RANGE ....................................................................................................................................................... 18

MAINTENANCE AND INSPECTION GUIDELINE OF MAIN PARTS OF PACKAGED AIR CONDITIONER ...................19

SAFETY PRECAUTIONS

J

Please read these

“SAFETY PRECAUTIONS”

before starting to use

this product and use the

product appropriately

according to the

instructions.

J

The precautions provided

here are classified into

“

DANGER” and

“

CAUTION”. The

“

DANGER” sections

describe potentially

hazardous situations

that may lead to serious

outcomes such as death

and serious injuries if the

product is mishandled.

Note, however, that

depending on the

situation, the items listed

in the “

CAUTION”

sections do also have

the potential of causing

serious outcomes. Both

warnings and cautions

provide you important

information related to

safety ; please make sure

to observe them.

J

The symbols used

throughout the main text

of this manual have the

following meaning.

marks mean danger,

alarm, and caution. The

specified prohibited

item is described in the

triangle. The left mark

means “Shock hazard

alarm”.

marks mean

prohibited items. The

specified prohibited

item is described in the

circle or in the vicinage.

marks mean

compulsory action

or instruction. The

specified prohibited

item is described in

the circle. The left

mark means “Earth is

needed”.

J

After you have read the

manual, always store it

where other users can

refer to at any time. If a

new owner takes over the

system, make sure to pass

this manual.

INSTALLATION PRECAUTIONS

DANGER

Make sure to have the

installation done by your

dealer or a specialist.

If you install by yourself and the

unit is not properly installed,

water leakage, electric shock,

fire and injuries caused by the

drop of the unit may occur.

ENGLISH

1

Page 3

The preventive measures

that the density of leaked

refrigerant does not exceed

the limit is necessary in case

of installing the unit in a

small room.

The leakage of refrigerant

may cause oxygen deficiency

accident. Consult your dealer

for the measures.

CAUTION

Make sure to perform

grounding work.

Do not connect grounding wire

to any gas pipe, water pipe,

conductor rods or telephones.

Incomplete grounding may

cause electric shock through

leakage of electricity.

Make sure to mount a

leakage breaker.

Otherwise electric shock may

occur. Please consult your

dealer or a specialist for the

mounting.

Do not mount where

flammable gas leakage

can happen.

If leaked gas stagnates in the

unit, the gas may cause fire.

Make sure to layout the

drain pipe so that the

water is completely drained.

Otherwise, water may leak and

wet household goods.

OPERATION PRECAUTIONS

DANGER

This appliance can be

used by children aged

from 8 years and above

and persons with reduced

physical, sensory or mental

capabilities or lack of

experience and knowledge

if they have been given

supervision or instruction

concerning use of the

appliance in a safe way and

understand the hazards

involved.

Children shall not play

with the appliance.

Cleaning and user

maintenance shall not be

made by children without

supervision.

Do not expose yourself

directly to cooled air flow

for a long time or cool too

much.

It may be cause of

deconditioning or health

disorder.

Do not insert fingers or

sticks into the air inlet or

outlet grilles.

It may cause injuries because

of the fan rotating at high

speed.

If the unit has been

submerged under water

due to a natural disaster

such as flood or typhoon,

consult your dealer before

using it again.

If you use it as it stands, it may

lead to failure, electric shock or

fire.

If any abnormal symptom

(scorched flavor etc.) is

found, cut off the power and

stop the operation.

Then consult your dealer.

If you use it as it stands, it may

lead to failure, electric shock or

fire.

One of the causes of poor

cooling or poor heating

may be refrigerant leakage.

Please consult your dealer.

If the repair requires additional

refrigerant, determine the

service with the service

staff. The refrigerant of air

conditioner is not toxic.

Normally the refrigerant

does not leak. But if it leaks

and contacts fire such as

fan heater, space heater or

cooking heater, it may produce

toxic chemicals.

Do not insert fingers or

sticks even if air blower

does not operate.

It may suddenly operate and

cause injuries.

CAUTION

Do not use for particular

purpose such as the

storage of food, animals and

plants, precision apparatus

and arts etc.

Storage goods may degrade.

Do not operate the button

with wet hand.

It may cause electric shock.

When a burning appliance

is used together with the

unit, ventilate frequently.

If ventilation is not sufficient, it

may cause oxygen deficiency

accident.

Do not place a burning

appliance where the

airflow from the unit is

directly blown.

It may cause the imperfect

combustion of the equipment.

Make sure that the unit

installation foundation is

not damaged due to longterm use.

If it is left to stand, the unit may

fall down causing injury.

Do not wash the unit with

water, nor place a vase

with water on the unit.

It may cause electric shock or

ignition.

2

Page 4

Do not install the unit

where the airflow is

directly blown to animals and

plants.

They may suffer from adverse

effect.

Before cleaning, make

sure to stop operation

and cut off the power.

The fan inside rotates at high

speeds.

Make sure to use proper

size of fuse.

Using steel wire or copper wire

may lead to failure or fire.

Do not store a flammable

spray etc. near the unit,

nor blow directly to the unit.

It may lead to fire.

Before maintenance,

make sure to stop

operation and cut off the

power.

The fan inside rotates at high

speeds.

When the unit isn’t used

for a long-term, cut off the

power.

The accumulation of dirt may

lead to heat generation or fire.

But, before resuming the

operation, turn on the unit for

six hours beforehand to save

harmless.

Do not place any other

electric appliances or

household goods below or

around the air conditioner.

Dripping from the unit may lead

to failure or contamination.

Do not touch the

aluminum fin.

Otherwise it may lead to

injuries.

Do not clean the inside

of the indoor unit by

yourself. Make sure to

consult your dealer or user

inquiry counter specified by

our company.

If you select incorrect detergent

or improper method, resin

parts may be damaged and

lead to water leakage. If the

detergent is dropped on the

electric component or motor, it

may lead to failure, smoking or

ignition.

Do not place objects on

the outdoor unit, nor

mount on it.

It may lead to injuries resulting

from dropping or falling.

During the operation or

maintenance, do not use

an unstable footrest.

It may lead to injuries resulting

from falling.

Be careful so that the

dust does not get into

your eyes when removing

the air filter.

Do not operate the air

conditioner while the air

filter is removed.

Piled up dust may lead to

malfunction.

During thunderstorm,

stop the operation and

turn off the switch.

A lightning strike may lead to

failure.

After several seasons of

operating, inspections

and maintenances are

required except routine care

and cleaning.

Accumulated dirt or dust inside

the indoor unit may cause odor,

water leakage through the

clogging of water discharging

pipe for dehumidification.

Specialized information

and skills are required for

inspections and maintenances.

Therefore contact your dealer.

Do not place any object

around the outdoor unit,

nor allow fallen leaves to pile

up.

Fallen leaves may induce

insects and worms in them,

and they may lead to failure,

ignition or smoking by touching

electric components.

Do not use with inlet/

outlet grilles or other

panel removed.

Otherwise, it may lead to

injuries.

Do not operate or stop the

unit by using the power

supply switch.

It may lead to fire or water

leakage.

If auto restart is set effectively,

the fan may rotate suddenly

causing injuries.

Do not touch blowout port

when the swing louver

moves.

Otherwise, it may lead to

injuries.

Do not strain the remote

control cord.

A part of core wire may be cut

off causing electric leakage.

Do not use water heater

etc. near the indoor unit

or remote control.

If a Vapor-generating appliance

is used near them, it may lead

to water drop causing electric

leakage or short circuit.

Do not use the unit where

powder or fiber is floating.

Fine powder or fiber passing

through the air filter may

stagnate inside the unit and

lead to electric leak or short

circuit.

Do not place objects

under the unit which

must avoid being exposed to

water.

Over 80 percent humidity or

the clogging of drain pipe may

damage them through dew

dropping.

3

Page 5

PRECAUTIONS FOR RELOCATION

OR REPAIRING

CAUTION

Neverperformany

modification.Contact

yourdealerforrepairing.

Improper repairing may lead to

water leakage, electric shock

or fire. Normally the refrigerant

does not leak. But if it leaks

and contacts fire such as

fan heater, space heater or

cooking heater, it may produce

toxic chemicals. When repairing

refrigerant leakage, determine

the service with the service

staff that the repair has been

finished without fault.

Ifitisrequiredto

relocationandreinstall

theunit,consultyourdealer

oraspecialist.

Improper installation of air

conditioning unit may cause

water leakage, electric shock

and/or fire.

Beforerepairingor

checkingindoorunit,be

suretoturnoff“Indoorunit

powersupplybreaker”.

It can result in electric shock or

injury due to rotation of indoor

unit fan if you perform check

or repair with the “Indoor unit

power supply breaker” turned

on.

Placethepanelsremoved

forrepairingorchecking

onthestablespot.

Otherwise, dropping or falling

may lead to injury.

HOW TO USE< WIRED REMOTE CONTROL >

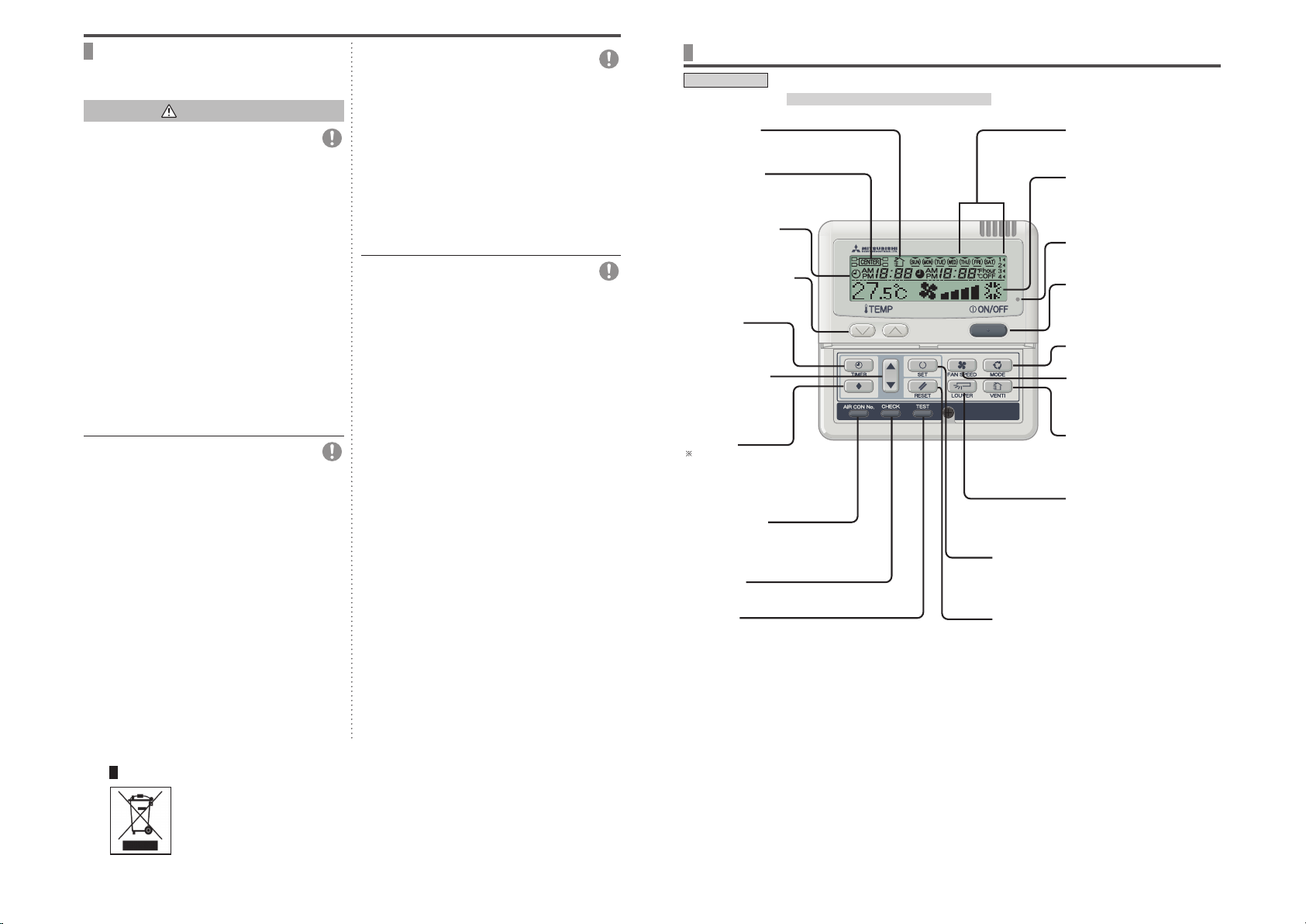

NAMES AND FUNCTIONS OF REMOTE CONTROL BUTTONS (WIRED REMOTE CONTROL)

Wired remote control

Ventilation display

Displayed during ventilation operation

☞ See page 12

Central control display

Displayed when the air conditioning system is

controlled by centralized remote control.

Timer operation display

Displays the timer operation setting.

Temperature setting buttons

These buttons are used to set the

temperature of the room.

Timer button

This button is used to set

the timer mode.

☞ See page 5

Timer setting buttons

These buttons are used to set

the timer mode and the time.

☞ See page 5 to 12

E.S.P. button

This button is only used by service

engineers for installation purposes.

AIR CON No. button

•Display the indoor unit number connected to this

remote control.

•This button is used for indoor unit address setting.

CHECK button

This button is only used by service engineers

for installation purposes.

TEST button

This button is used during test operation.

• Thefigurebelowshowstheremotecontrolwiththecoveropened.Notethattheitemsintheliquid

crystaldisplay(LCD)areaareshownforexplanationpurpose.

Pull the cover downwards to open.

Weekly timer display

Displays the settings of the

weekly timer.

Operation setting display area

Displays setting temperature, airflow

volume, operation mode and operation

message.

Operation/check indicator light

During operation: Lit in green

In case of error: Flashing in red

Operation/stop button

This button is used to operate and stop

the air conditioning system.

Press the button once to operate

the system and press it twice

to stop the system.

MODE button

This button is used to change the

operation mode.

FAN SPEED button

This button is used to set the airflow

volume.

VENT button

This button is used to operate external

ventilator. ☞ See page 12

LOUVER button

This button is used to operate/stop the

swing louver. ☞ See page 11

SET button

•This button is used to fix the setting.

•This button is used to set the silent mode.

☞ See page 5 to 12

RESET button

•If you press this button while making settings,

you can go back to the previous operation. ☞ See page 5 to 12

•This button is also used to reset the “FILTER CLEANING” display.

(Press it after cleaning the air filter)

PRECAUTIONS FOR WASTE DISPOSAL

Your Air Conditioning product may be marked with this symbol. It means that waste electrical and

electronic equipment (WEEE as in directive 2012/19/EU) should not be mixed with general household

waste. Air conditioners should be treated at an authorized treatment facility for re-use, recycling and

recovery and not be disposed of in the municipal waste stream. Please contact the installer or local

authority for more information.

4

Page 6

3

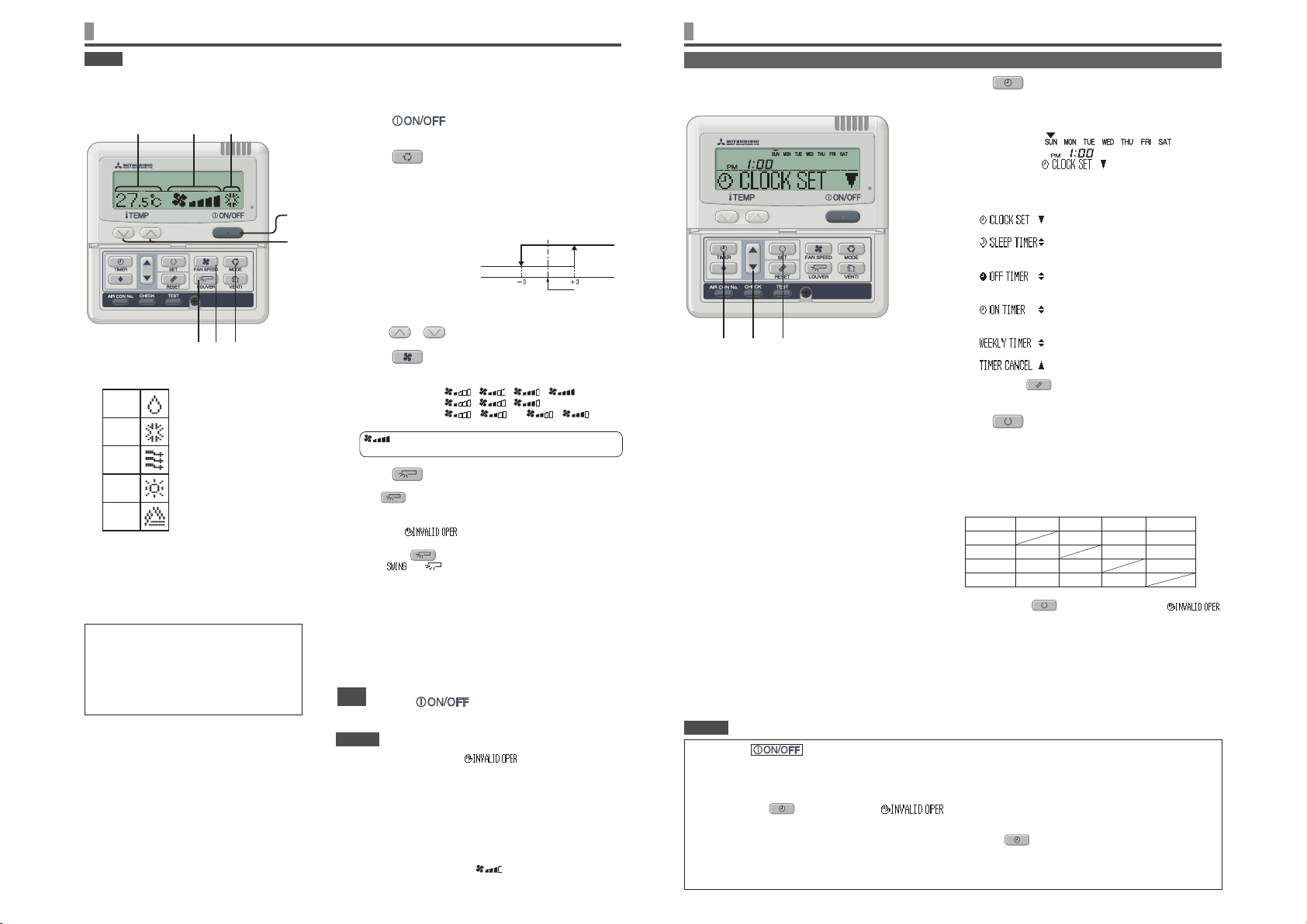

HOW TO OPERATE < WIRED REMOTE CONTROL >

• In order to protect both indoor/outdoor air conditioners, keep the power supply on for six hours before initial operation. (The

ATTENTION

Guideline for room temperature setting

crank case heater is energized in order to heat up the compressor.) Do not turn off the power supply. (Power is distributed to

the crankcase heater, even if the compressor is stopped. This keeps the compressor warm, and prevents failures caused by

accumulation of liquid refrigerant.)

Setting

temperature

Operation mode

Fan speed

DRY

COOL

FAN

HEAT

AUTO

COOL ...............26 to 28°C

DRY .................. 21 to 24°C

HEAT ................22 to 24°C

FAN ...................Setting unnecessary

• The settings of operation change, temperature

and air flow volume adjustment can be changed

even when the air conditioner is stopped. When a

button is pressed while the operation is stopped,

the corresponding display is turned on and you

can change the setting. The display lights for three

seconds after changing the setting, and then turns

off automatically.

mode

Operation

mode

2 4 5

1 Press button.

The unit starts operating.

2 Press MODE button.

The range of operation mode is displayed according to the model

of indoor unit.

Every time the button is pressed, the display changes in the

following order: dry cool fan heat auto.

1

3

(EXAMPLE display for auto-operation enabled)

With auto operation,

•

heating and cooling is

automatically changed

depending on difference

between the setting

temperature and sucking

room air temperature.

3 Press TEMP button.

Press or button to set the room temperature.

4 Press FAN SPEED button.

The range of fan speed modes is displayed according to the model

of indoor unit.

At 4-speed ............. “ ↔ ↔ ↔ ”

At 3-speed ............. “ ↔ ↔ ”

At 2-speed ............. “

At 1-speed ............. The operation is invalid

at 4-speed

The unit operates with the maximum fan speed.

5 Press LOUVER button.

If the indoor unit is equipped with the auto swing function, press

the LOUVER button once and current louver status is

displayed.

If the indoor unit is not equipped with the auto swing function, the

message “ ” is displayed.

For the louver operation •

1 Press LOUVER button, and change the display to

For the louver stopping •

1 Press once while the louver is operating to display stop

positions in order.

2 Press the button once more at the preferred stop position to

stop the louver at that position.

Effective stop position

For automatic operation: ...............................middle

For cooling/dehumidifying operation: ............Hor izontal

For heating operation: ................................... downwards

Stop

Press button

NOTICE

There may be a case that “• ” is displayed when any

button mentioned in the above is pressed, but it is not a malfunction.

In that case, the operation of the button is prohibited.

When you start to operate the unit for the first time after turning the •

power supply on, the default settings are listed below. You can change

them as you like.

Central control ...................... Turned off

Operation changeover .......... With auto mode : auto cooling

Set temperature ...................23°C

Fan speed ............................

Louver position ..................... Horizontal

heating

operation

↔ ” or “ ↔ ”

See page 11 to 12

☞

See page 11 to 12

☞

See page 11 to 12

☞

Without auto mode : cooling

cooling operation

room setting

temperature

HOW TO PERFORM THE TIMER OPERATION

< WIRED REMOTE CONTROL >

THE SELECTION OF TIMER MODE

1 Press TIMER button.

The mode changes to timer mode.

“Current day of the week” and “Current time ” are displayed.

[EXAMPLE] Sunday : 1 o’clock in the afternoon

Display area : [

2 Press ▲ or ▼ button.

By pressing ▼ or ▲ button, it is possible to choose the item to set.

[

[

[

[

2 1

Functions of each timer operation

Sleep timer•

When the specified period of time elapses, operation

stops.

10 settings are available, from “an hour later OFF” to “10

hours later OFF”.

The unit will stop when the setting time is reached.

OFF timer•

The unit stops operating at the setting time.

It will operate one time per setting.

ON timer•

The unit starts to operate at the setting time. The

temperature can be set together. It will operate one time

per setting.

Weekly timer•

You can set up to four ON/OFF timers per day.

Once Weekly timer is set, it repeats every week.

NOTICE

• If you press button while timer mode is under setting, timer mode is canceled and the display will return

to the original one. Note that the setting which has not completed is canceled.

• If you have set the ON timer mode and either the OFF timer or Sleep timer mode at the same time, the OFF timer

(or Sleep timer) precedes the ON timer.

• If you press the

button operation is disabled. If you want to make the button effective , consult your dealer.

• If you do not press any button for several minutes after pressing the

display returns to the original one.

• When the weekly timer setting recovers from power failures, the setting data (four settings per day) remain stored,

but holiday settings will automatically override the settings for each day.

Timer button and “ ” is displayed, the button can not be operated because the

[

[

If you press the

to original status.

3 Press SET button.

The selected timer mode is set.

For setting of each timer mode, see the following pages.

The possible combination of the timer function is mentioned in the

following table.

Combination of modes that can be set together

(: possible ×: impossible)

Sleep timer

OFF timer

ON timer

Weekly timer

• If you select a combination of modes that cannot be set together

and press the

(invalid operation)” is displayed for 3 seconds and then the

display returns to the one selected in step 2.

[ ]

[ ] (lights)

] (set to current time)

] (Every operation stops after a certain period

of time has elapsed.)

] (The unit stops operating at the setting

time.)

] (The unit starts operating at the setting

time.)

] (Timer set for each day of the week)

] (Cancel the timer setting)

RESET button, timer mode ends and return

Sleep timer

OFF timer

ON timer

×

×

×

SET button, the message “

Timer button, Timer mode ends and the

×

×

]

Weekly timer

×

×

×

5

Page 7

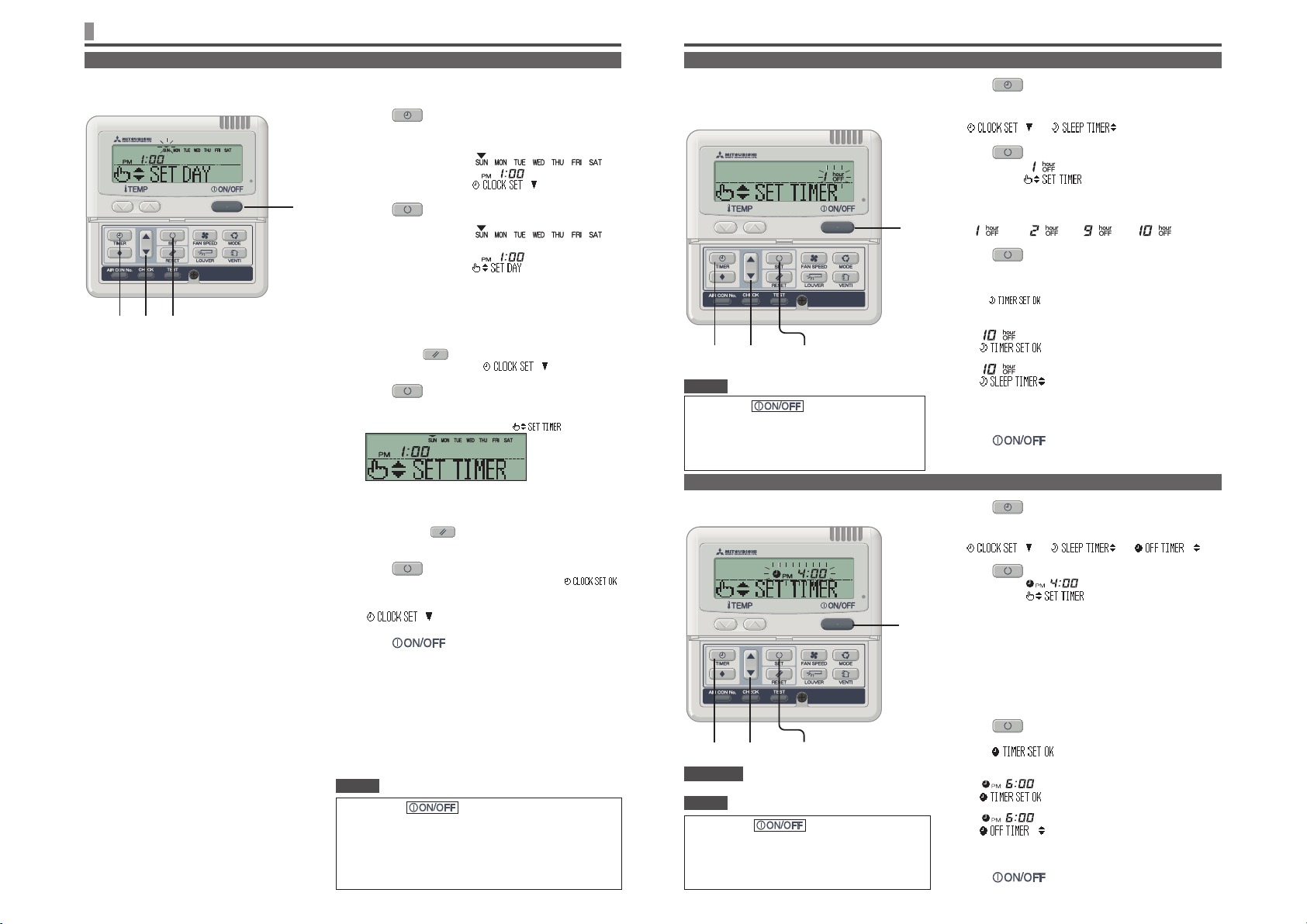

HOW TO PERFORM THE TIMER OPERATION < WIRED REMOTE CONTROL >

SETTING THE TIME

Timer operation is performed based on the time of the clock which is set by the following steps. Make sure to

set the time to the current time correctly.

1 Press TIMER button.

The mode changes to timer mode.

“Current day of the week” and “Current time” are displayed.

Display area : [

2 Press SET button.

7

The display area shows : [ ]

3 Press ▲ or ▼ button.

Place the “▼” mark above the day of the week to the current

2 3 1

• •

4 5

•

6

6

day.

Press ▲ and ▼ mark to move to the right and the left respectively.

If you press the RESET button, the remote control will return to

the previous screen and display “ ”.

4 Press SET button.

The day of the week is fixed, and the flashing of ▼ mark stops

and lights.

The “current time” value flashes, and “ ” is displayed.

5 Press ▲ or ▼ button.

Set to the current time.

If you press the

the one in step

6 Press SET button.

The flashing for time display stops and lights, and “ ”

is displayed to show that the current time is set.

Two seconds later, the display in step 1 returns, and

“ ” is displayed.

7 Press button.

The timer mode is finished.

NOTICE

•

If you press button while timer mode is under

setting, timer mode is canceled and the display will return

to the original one. Note that the setting which has not been

completed is canceled.

•

If you do not press any button for several minutes after

entering the timer mode, the timer mode ends and the

display returns to the original one.

[ ]

[ ]

(▼ flashes)

[

[

RESET button, the display is returned to

1.

] (current time)

]

]

SLEEP TIMER MODE

After a certain period of time has elapsed, operation

stops.

• Sleep timer

The unit stops after the set time elapses.

3•5 2•4 1

NOTICE

• If you press button while timer mode

is under setting, timer mode is canceled and the

display will return to the original one.

If you do not press any button for several minutes

•

after entering the timer mode, the timer mode

ends and the display returns to the original one.

OFF TIMER MODE

The unit stops operating at the setting time.

This setting is effective for only once.

6

3•5 2•4 1

ATTENTION

NOTICE

• If you press button while timer mode

is under setting, timer mode is canceled and the

display will return to the original one.

• If you do not press any button for several minutes

after entering the timer mode, the timer mode

ends and the display returns to the original one.

Once the OFF timer is set, it is not possible to

start operation. If you would like to operate the

air conditioner, press ON/OFF button before

hand to turn on.

1 Press TIMER button.

2 Press ▼ button once.

“ ” “ ”

3 Press SET button.

[EXAMPLE] “ ” flashes,

4 Press ▲ or ▼ button.

The display changes as below. Set as you like.

6

“ ” “ ” ~ “ ” “ ”

5 Press SET button.

Sleep timer has been set.

The air conditioner will turn on if a sleep timer is set while it is

turned off.

After “

in step 2 returns.

<When “Ten hours later OFF” is set >

The remaining time is displayed, and changes in an hourly basis.

When the setting time elapses, the unit stops operating.

Every operation stops after a certain period of time has elapsed.

“ ” lights.

” is displayed in the display area, the display

“ ” (lights)

“ ” (lights for two seconds)

“ ” (lights)

“

” (lights)

6 Press button. The timer mode is finished.

1 Press TIMER button.

2 Press ▼ button twice.

[ ] [ ] [ ]

3 Press SET button.

[EXAMPLE] “ ” flashes,

4 Press ▲ or ▼ button.

Set the time at which you want to stop the operation.

Set “Hour”•

If you press ▲ or ▼ button for a while, “Hour” display is changed

by one hour, and stops when you stop pressing.

Set “Minute”•

If you press ▲ or ▼ button, the number in the display becomes

larger or smaller by ten minutes.

5 Press SET button.

OFF timer has been set.

After “ ” is displayed in the display area, the

display in step 2 returns.

<If set to 6:00 PM >

“ ” lights.

“

“

“ ”(lights)

“ ” (lights)

The unit stops operating at 6:00 PM.

The time display is also turned off.

” (lights)

” (lights for two seconds)

↓

6 Press button. The timer mode is finished.

Page 8

3•5

HOW TO PERFORM THE TIMER OPERATION < WIRED REMOTE CONTROL >

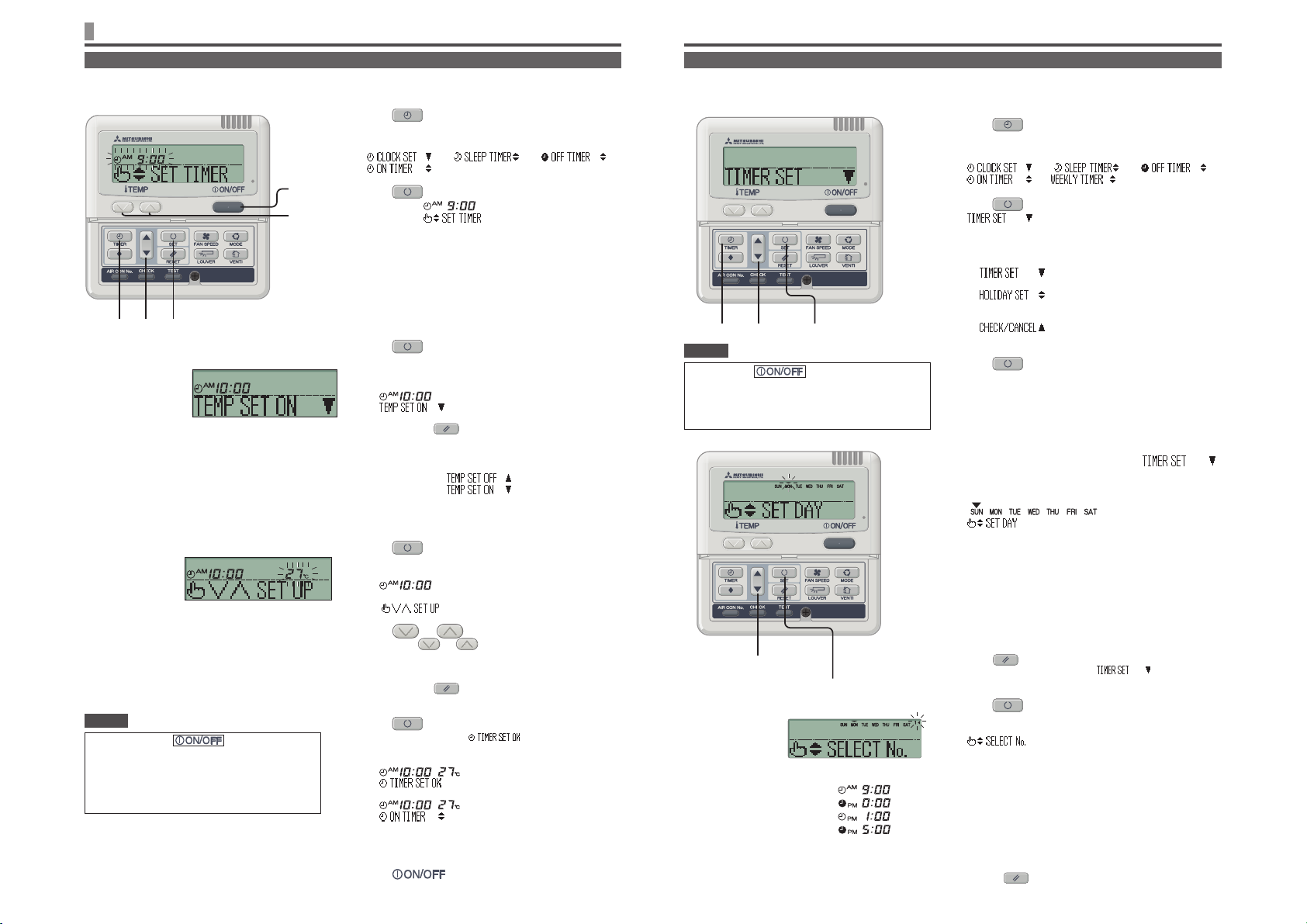

ON TIMER MODE

The unit starts to operate at the set time. It is possible to set temperature at which you want to start the operation.

Only one setting is applicable to each operation.

1 Press TIMER button.

2 Press ▼ button for three times.

[ ] [ ] [ ]

10

8

3 2 1

• •

5 4

•

•

7 6

•

9

NOTICE

• If you press the button while timer

mode is under setting, timer mode is canceled

and the display will return to the original one.

• If you do not press any button for several

minutes after entering the timer mode, the

timer mode ends and the display returns to the

original one.

•

ON timer and either Sleep timer or OFF timer are

set together, the temperature of ON timer is not

displayed.

• ON timer and either Sleep timer or OFF timer are

set together, OFF timer (or Sleep timer) precedes.

[

3 Press SET button.

[EXAMPLE] “ ” flashes,

4 Press ▲ or ▼ button.

Set the preferred time to start the operation

Set “Hour”•

If you press ▲ or ▼ button for a while, “Hour” display is changed

by one hour, and stops when you stop pressing.

Set “Minute”•

If you press ▲ or ▼ button, the number in the display becomes

larger or smaller by ten minutes.

5 Press SET button.

ON timer has been set.

The left image is displayed in the display area.

<If set to 10:00 AM >

“

“ ” (lights)

If you press the RESET button, the remote control will

return to the previous screen.

6 Press ▲ or ▼ button.

Press ▼ button and “ ” is displayed

Press ▲ button and “ ” is displayed

Select either of the above two.

Go to step •

Go to step •

7 Press SET button.

The left image is displayed in the display area.

<If set to 10:00 AM >

“

“27°C” (The current set temperature is displayed flashing)

“ ” (lights)

8 Press or button to set temperature.

If you press or button, the number in the display

becomes larger or smaller by 1°C.

Set temperature at which you want to start the operation.

If you press the RESET button, the remote control will

return to the previous screen.

9 Press SET button.

ON timer is set, and after “ ” is displayed, the display

in step 2 returns.

<If set to 10:00 AM >

“

“ ” (lights)

“ ” (lights)

“

Set temperature is displayed only in case it is set.

The unit starts to operate at setting time with set temperature.

The time display is turned off.

10

Press button.

The timer mode is finished.

]

“

” (lights)

7 if temperature is set.

9 if temperature is not set.

”(lights)

” lights.

” (lights)

” (lights)

WEEKLY TIMER MODE

Selection of Weekly timer mode

You can set up to four ON/OFF timers per day.

Note : Set time every month in Weekly timer mode.

2•4 1

NOTICE

• If you press button while timer mode

is under setting, timer mode is canceled and the

display will return to the original one.

• If you do not press any button for several minutes

after entering the timer mode, the timer mode

ends and the display returns to the original one.

WEEKLY TIMER SETTING

2•4•6•8•10

3•5•7•9•11•13

<In case Monday is set>

[EXAMPLE]

Number 1 :

Number 2 :

Number 3 :

Number 4 :

* Four operations can be set

with only ON timer or only OFF

timer.

1 Press TIMER button.

2 Press ▼ button for four times.

[ ] [ ] [ ]

[

3 Press SET button.

“ ”is displayed in the display area.

4 Press ▲ or ▼ button.

By pressing ▲ or ▼ button, it is possible to choose the item to set.

“

“ ” (for setting the selected day of the week to

“ ” (for checking the timer setting and canceling

5 Press SET button.

The selected mode is fixed.

] [ ]

” (for setting the timer)

↕

holiday)

↕

individual settings)

1 In the Weekly timer mode, select “ ”

and press SET button to confirm.

☞

See step 1 to 5 in “Selection of Weekly timer mode” above

“ ” (▼ is flashing)

“

2 Press ▲ or ▼ button.

Set the ▼ mark above the day of the week to the day to be set

for timer setting. Press ▲ and ▼ to move to the right and left

respectively, ▲ and ▼ will move flashing.

If you press the ▲ button, the day (“SUN” to “SAT”) indicated with

the flashing “▼” mark will change one day at a time. If you press

the ▲ button when the “▼” mark is indicating “SAT”, multiple “▼”

marks will appear and flash above “MON” to “FRI”. Press the ▲

button again, and multiple “▼” marks will appear and flash above

“SUN” to “SAT” (every day). The same schedule can be applied to

all the days indicated with the “▼” marks by using this function.

Press

timer mode screen”, and “ ” is displayed.

3 Press SET button.

The “▼” mark above the day stops flashing and lights, which

indicates that the setting is fixed.

“ ” is displayed as the left image.

4 Press ▲ or ▼ button.

Up to four schedules can be set for each day. Select the timer

schedule number you want to set. Set either ON timer or OFF

timer for each single operation. (See the left EXAMPLE ).

Press ▼ button to make the ◄ mark next to the number flash and

move downwards.

Press the ▲ button to move the mark upwards.

Press the

” is displayed in the display area.

RESET button to return to “selecting Weekly

☞

1◄

2

3

4

RESET button to return to the display in step 1.

See the above step 3.

7

Page 9

HOW TO PERFORM THE TIMER OPERATION < WIRED REMOTE CONTROL >

5 Press SET button.

◄ mark next to a number lights.

“ ” or “ ” is displayed.

The settings so far are effective and the display changes as shown

on the left.

6 Press ▲ or ▼ button.

Press ▼ button and “ ” is displayed.

Press ▲ button and “ ” is displayed.

Select either of the above two.

<When “ ” is selected>

Press the

7 Press SET button.

“ ” is displayed

8 Press ▲ or ▼ button.

Set the time.

Press the

9 Press SET button.

When time display lights, the time is fixed.

In case of OFF timer setting, setting process is completed on

this step.

A “_” mark lights (

you set and the display appears as the left image.

Proceed to “Next setting and Exiting Weekly timer Mode” on the

right page.

In case of ON timer setting, “

proceed to step

10

Press ▲ or ▼ button.

Select either “ ” or “ ”.

RESET button to return to the display in step 3.

RESET button to return to the display in step 5.

) under the day of the week which

10.

” is displayed,

Next setting and exiting Weekly timer mode

After “ ” is displayed, “ ” is displayed.

1 Press ▲ or ▼ button.

2 Press SET button.

2 1

By pressing ▲ or ▼ button, it is possible to choose the item to set.

“

“ ” (select the next day)

“ ” (Timer mode ends)

If “ ” is selected, “ ” is displayed.

Repeat step 3 and the subsequent steps of Weekly timer setting

on page 7.

If “

Repeat step 1 and the subsequent steps of Weekly timer setting

on page 7.

If “

” (select the next timer operation number

within the same day)

↕

↕

” is selected, “ ” is displayed.

” is selected, timer mode ends.

11

Press SET button.

In case “ ” has been selected, ON timer setting

process is completed.

A “_” mark lights (

you set and the display appears as the left image.

Proceed to “Next setting and Exiting Weekly timer Mode” on the

right page.

In case “

is displayed; Proceed to step 12.

12

Press the temperature setting buttons or

.

Press the or the button to increase or decrease by

1°C.

Set the temperature at the start of operation.

Press the reset button to return to the display “ ”.

13

Press SET button.

ON timer setting with start-up temperature has been

completed.

The value of the temperature stops flashing and lights.

A “_” mark lights (

you set and the display appears as the left image.

Proceed to “Next setting and exiting Weekly timer mode” on the

right page.

8

) under the day of the week which

” has been selected, “ ”

) under the day of the week which

NOTICE

• If you press

mode is under setting, timer mode is canceled

and the display will return to the original one.

• If you do not press any button for several

minutes after entering the timer mode, the

timer mode ends and the display returns to

the original one.

• If you select a day of the week for which setting

have already been made, all the timer numbers

that have been set are displayed. And the details

of the timer setting for the number which has “◄”

mark is displayed. You can modify the selected

setting by overwriting it.

•

If you set ON timer and OFF timer operating at

the same time, OFF timer will precede.

• If the same two times are set for ON timer on the

same day, the lower number precedes.

button while timer

Display after Weekly timer modes setting

• The day of the week set is underlined.

• The ▼ mark is displayed above the current day of the week.

• The display of all the timer operation numbers set for the

current day is turned on. The ◄ mark indicates the next

setting number to be activated, and the set time is displayed.

• The timer operations are executed in order, and the number

and time display are turned off when all the timer operations

for the current day are completed.

Page 10

3

5

4

HOW TO PERFORM THE TIMER OPERATION < WIRED REMOTE CONTROL >

JWeekly timer Holiday Setting

It is possible to temporarily disable each day’s timer setting by using the Holiday Setting. When the Holiday

Setting is cancelled, the timer setting is enabled again.

1 In the Weekly timer mode, select and set

”.

See “Selection of Weekly timer mode” step 1 to 5 on page 7.

” is displayed.

”(lights)

” is displayed for two seconds and the display returns

(▼ is flashing)

] (lights)

”.

” (lights for two seconds)

” (lights)

] (lights)

] (lights)

3 2

JCanceling Holiday Setting

NOTICE

• If you press button while timer mode

is under setting, timer mode is canceled and the

display will return to the original one.

• If you do not press any button for several

minutes after entering the timer mode, the

timer mode ends and the display returns to the

original one.

“

☞

“ ” is displayed in the display area

“

2 Press ▲ or ▼ button.

Move the “▼” mark displayed above the days of week to the

day which you want to set as Holiday.

Press ▲ and ▼ to move to the right and left respectively.

If you press the ▲ button, the day (“SUN” to “SAT”) indicated with

the flashing “▼” mark will change one day at a time. If you press the

▲ button when the “▼” mark is indicating “SAT”, multiple “▼” marks

will appear and flash above “MON” to “FRI”. Press the ▲ button

again, and multiple “▼” marks will appear and flash above “SUN” to

“SAT” (every day). The same schedule can be applied to all the days

indicated with the “▼” marks by using this function. This can be used

in case you would like to apply Holiday setting to these days.

In case press the RESET button, the remote control will

return to the previous screen and display “ ”.

3 Press SET button.

The “▼” mark above the day stops flashing and lights, and the day set as

a holiday also lights enclosed with ( ). Then, the following is displayed.

[ ] (lights)

“ ” (lights for two seconds)

[

“

After the holiday setting has been completed, the display of the

remote control returns to that of step 1. Repeat step 2 and 3 to

continue setting further holidays.

NOTICE

If you set a day of the week for which no timer operation is set,

“

to the one shown in step 1.

4 Press button.

Timer mode ends.

1 In the Weekly timer mode, select and set

“

See “Selection of Weekly timer mode” step 1 to 5 on page 7.

☞

2 Press ▲ or ▼ button.

Move the “▼” mark displayed above the day of week to the

day on which you want to cancel Holiday setting.

Select the day of the week that has been set as holiday.

3 Press SET button.

( ) display is turned off and the following is displayed.

[

“

[

“

After the holiday setting has been completed, the display of the

remote control returns to that of step 1. Repeat step 2 and 3 to

continue canceling further holiday settings.

4 Press button.

Timer mode ends.

JWeekly timer Checking

1 In the Weekly timer mode, select and set

“

See “Selection of Weekly timer mode” step 1 to 5 on page 7.

☞

The display shows the detailed timer operation setting information

of the smallest timer operation number on the day of the week as

shown on the left. (But if not set, “

2 Press ▲ or ▼ button.

Detailed timer operation settings are displayed in accordance with

the timer operation you have selected.

Press ▼ button to display from Sunday and the lowest timer

operation number.

Press ▲ button to display the settings in the reverse order.

3 Press button.

2

JWeekly timer mode Setting Canceling

It is possible to cancel Weekly timer mode settings of each day of the week, as well as individual timer operation number.

See “Timer Operation Cancellation Mode” on page 10 to cancel settings of all days of week.

Timer mode ends.

”.

” is displayed.)

1 In the Weekly timer mode, select and set

”.

RESET button, the remote control will

RESET button, the remote control will

” is displayed again.

3

2

•

4

NOTICE

• Ifyoupress button while timer mode

is under setting, timer mode is canceled and the

display will return to the original one.

• If you do not press any button for several

minutes after entering the timer mode, the

timer mode ends and the display returns to the

original one.

“

☞ See “Selection of Weekly timer mode” step 1 to 5 on page 7.

The display shows the detailed timer operation setting information

of the smallest timer operation number on the day of the week as

shown on the left.

2 Press ▲ or ▼ button.

Detailed timer operation settings are displayed in accordance with

the timer operation you have selected.

Press ▼ button to display from Sunday and the lowest timer

operation number.

Press ▲ button to display the settings in the reverse order.

Select the timer operation number on a day of the week you

want to cancel.

If you press the

return to the previous screen, and display “ ”.

3 Press SET button.

“ ” is displayed.

If you press the

return to the previous screen, and display “ ”.

4 Press SET button.

“ ” is displayed, and the displayed detail timer operation

setting disappears and is canceled.

“

Repeat step 2 to 4 to continue canceling other settings.

5 Press button.

Timer mode ends.

9

Page 11

8

HOW TO PERFORM THE TIMER OPERATION < WIRED REMOTE CONTROL >

TIMER CANCELLATION MODE

1 Press TIMER button.

Timer mode begins.

The current “The day of the week” and “the current time” are

displayed.

7

1

3•5•6

2•4

In case “ ” , “ ” or “ ” was

selected.

5 Press SET button.

The detailed setting of selected timer mode is displayed as

shown below.

(But if not set, “ ” is displayed)

<Display EXAMPLE when “

” is selected>

[

“ ”

“ ”

2 Press ▼ button for five times.

“ ”

“

“

“

“

“

3 Press SET button.

Timer Cancellation Mode begins.

4 Press ▲ or ▼ button.

By pressing ▲ or ▼ button, it is possible to choose the item to cancel.

“ ”

“

“

“

If you press the RESET button, the remote control will

return to the previous screen, and display “ ”.

(step 2 above)

In case “ ” was selected.

All the Weekly timer setting will be canceled if you proceed the

following steps.

To cancel a part of the timer setting, please see “Canceling

Weekly timer Mode Setting” on page 9.

5 Press SET button.

The settings are displayed as shown below.

(But if not set, “

” (▼ first press)

” (▼ second press)

” (▼ third press)

” (▼ fourth press)

” (▼ fifth press)

↕

”

↕

”

↕

” (canceling all days of the week)

]

” is displayed)

HOW TO OPERATE IN SILENT MODE

< WIRED REMOTE CONTROL >

SILENT MODE

When the silent mode is set, the unit operates more silently reducing noise from the outdoor unit.

The system applies the silent operation mode at the starting time to be set, and finish it after a certain period of

time has passed.

Once the system is set to operate with the silent mode, the setting is applied everyday until it is canceled.

Silent Mode Setting

3

•

5

•

7

2

•

4

•

6

1

•

Canceling Silent Mode (Setting)

Select “ ” in step 2, press

SET button and silent setting is canceled

ending the silent mode.

“

” is displayed.

1

In the timer mode, set the current day of the week

and current time.

See page 6 step 1 to 7

☞

2

Press SET button for three seconds or more.

The remote control goes into silent mode setting and the following

is displayed.

“

3 Press ▲ or ▼ button.

If ▼ button is pressed, “ ” is displayed.

If ▲ button is pressed, “ ” is displayed.

Select “ ”.

If you press the

the original screen.

4 Press SET button.

The following setting is displayed.

“

“ ” (lights)

5 Press ▲ or ▼ button.

Set the “ON TIME”.

Set “Hour”•

If you hold ▲ or ▼, the number in “Hour” display changes, and

if you release it, the number stops changing.

Set “Minute”•

If you press ▲ or ▼ button, the number in the display becomes

larger or smaller by ten minutes.

If you press the

the “

6 Press SET button.

The ON TIME is set and the following is displayed.

“

“ ” (lights for two seconds)

“ ” (flashing)

“ ” (lights)

” or “ ” (lights)

RESET button, the remote control return to

” (flashing)

RESET button, the remote control return to

” display.

” (flashing)

If you would like to quit cancellation, press the RESET

button to return to the “

6 Press SET button.

The display of the detailed timer setting is turned off, and

after the message “ ” is displayed for two seconds,

“ ” is displayed again. (step 4 above)

Repeat steps 4 to 6 to continue canceling timer mode settings.

NOTICE

• If you press button while timer mode

is under setting, timer mode is canceled and the

display will return to the original one.

• If you do not press any button for several minutes

after entering the timer mode, the timer mode ends

and the display returns to the original one.

10

” display. (step 4 above)

If you would like to quit cancellation, press the RESET

button to return to the “

6 Press SET button to confirm.

The day of the week display area turns off, and after the

message “ ” is displayed for two seconds, the

display returns to “ ”. (step 4 above)

These operation settings cancel all days of the week.

7 Press ON/OFF button.

Timer mode ends.

” display. (step 4 above)

NOTICE

• The remote control has main-sub units, silent setting

cannot be operated with sub unit .

• After the silent mode is set, the following is displayed

for 3 seconds at the set time and the unit returns to

the original display.

At the ON time : “ ”

At the OFF time : “

• If you select “

silent mode until it is canceled. At the first ON time,

the display shows “ ” for three seconds

and returns to original display.

• If you press button while

timer mode is under setting, timer mode is

canceled and the display will return to the

original one. Note that the setting which has

not been completed is canceled.

”

”, you can continue the

7 Press ▲ or ▼ button to set the duration.

Select OFF time.

When you press ▲ button, and the duration is increased by two

hours as below, “

“

When you press ▼ button, and the duration is decreased by two

hours.

If you press

returns.

8 Press SET button.

The setting is fixed and displayed.

“ ” is displayed, and the silent mode setting ends.

The setting display turns off, and returns to original display.

”

” “ ” “ ”

RESET button, the “ON TIME SET” display

Page 12

3•5

(

)

HOW TO ADJUST THE LOUVER

ADJUSTING WITH LOUVER BUTTON (Indoor unit with auto swing function)

Press LOUVER button once, and the current status of louver is displayed.

(IN CASE OF FDT, FDTC, FDE) < WIRED REMOTE CONTROL >

The display during

auto swing

Press

The display with the

louver position fixed

When you operate the swing louver

1. Press LOUVER button, and change the display

to “

”.

Press

The function of the swing louver

horizontal position

during the heating preparation,

heating/defrost

“ ” or “Heating/Defrost” is

displayed, the position of the swing louver is

automatically switched to horizontal.

When the operation is switched to normal after “The heating

preparation” or “Heating/Defrost” ends, the position of swing louver

returns to the last setting.

CAUTION

• Do not move the swing louver forcibly by hands for fear that it may be damaged.

• Do not blow downwards during cooling operation for a long time for fear that dew condensation may be formed at the side panel.

case of FDE)

HOW TO ADJUST THE LOUVER

ADJUSTING WITH LOUVER BUTTON (Indoor unit with auto swing function)

Press LOUVER button once, and the current status of louver is displayed.

Press

When the position of the swing louver is fixed

1. Press LOUVER button once while the louver

is swinging, and 4 stop positions are displayed every

one second in order.

“ ” ↔

“ ” ↔ “ ”

2. Press LOUVER button once when the display

of the louver comes to the position you desire.

The display is switched to stop, and the position of louver is fixed.

Recommended louver fixed position

COOL•DRY

HEAT

“

” ↔

(IN CASE OF FDF CONTROL)

The display during

auto swing

The display during

stop

(In

HOW TO SET THE AIRFLOW DIRECTION

It is possible to change the movable range of the louver on the air outlet from the wired remote control. Once the top and bottom positions

are set, the louver will swing within the range between the top and the bottom positions when swing operation is chosen.

With Ceiling cassette −4 way − FDT and FDTC, it is also possible to apply different setting to each louver.

2•4•6•8 1

•7•9

NOTICE

• For FDT and FDTC type, in case the

louver No. to be set is uncertain, set

any louver temporarily. The louver

will swing once when the setting

is completed and it is possible to

confirm the louver No. and the

position.

After that, choose the correct louver

No. and set the top and bottom

positions.

•

For FDE type, set louver No. 1.

Other settings selected have no

effect.

Control box

No. 2

No. 1

Piping side

Louver No.

[for FDT]

No. 2

No. 1

Drain hose side

Louver No.

[for FDTC]

No. 4

Control box

(IN CASE OF FDT, FDTC, FDE) <WIRED REMOTE CONTROL>

1

Stop the air conditioner and press SET

button and

for three seconds or more.

The following is displayed if the number of the indoor units

connected to the remote control is one. Go to step 4.

“

10

No. 3

No. 4

Drain

hose side

No. 3

Piping

side

“ ”

The following is displayed if the number of the indoor units

connected to the remote control are more than one

“

“ ”

2 Press ▲ or ▼ button.(selection of indoor unit)

Select the indoor unit of which the louver is set.

[EXAMPLE]

“ ”“ ”“ ”

“ ”

3 Press

4 Press ▲ or ▼ button. (selection of louver No.)

5 Press

indoor unit)

Selected indoor unit is fixed.

[EXAMPLE]

“ ” (lights for two seconds)

“ ”

“ ”

Select the louver No. to be set according to the left figure.

[EXAMPLE]

“ ” “ ” “ ”

“ ”

Note : For FDE, select “

have no effect.

louver No.)

The louver No. to be set is confirmed and the display shows the

upper limit of the movable range.

[EXAMPLE] If No.1 louver is selected,

“

LOUVER button simultaneously

”

”

SET button. (determination of

”. Other louver No. settings

SET button. (Determination of

” ←current upper limit position

6 Press ▲ or ▼ button. (selection of upper limit

position)

(horizontal)

downwards

the position of the louver

Select the upper limit of louver movable range.

“position 1” is the most horizontal, and “position 6” is the most

downwards.

“position --” is to return to the factory setting. If you need to

change the setting to the factory setting, use “position --”.

“

“

“

“

“

“

“

” (The most horizontal)

”

”

”

”

” (The most downward)

” (Return to the position of shipment)

11

Page 13

HOW TO SET THE AIR FLOW DIRECTION

< WIRED REMOTE CONTROL >

7 Press SET button (Fixing of the upper

limit position)

The upper limit position is fixed and the setting position is

displayed for two seconds. Then proceed to lower limit position

selection display.

[EXAMPLE]

“

“ ” (shows current setting)

” (lights for two seconds)

8 Press ▲ or ▼ button (Selection of lower limit

position)

(horizontal)

(downwards)

the position of the louver

Select the lower limit position of louver.

“position 1” is the most horizontal, and “position 6” is the most

downwards.

“position --” is to return to the factory setting. If you need to

change the setting to the factory setting, use “position --”.

“

“

“

“

“

“

“

” (the most horizontal)

”

”

”

”

” (the most downwards)

” (return to the position of shipment)

9 Press SET button (Fixing of the lower limit

position)

[EXAMPLE] For Upper position 2, Lower position 6

Upper

position

Movable

range

Lower

Note : If the upper limit position number and the lower limit

position number are set to the same position, the louver

is fixed at that position. And auto swing does not function.

NOTICE

• If you press RESET button during settings, the display will return to previous display. If you press

button during settings, the mode will end and the original display will return, and the settings that have not been

completed will become invalid.

• When plural remote controllers are connected, louver position setting cannot be set by slave remote control.

position

The upper limit position and lower limit position are fixed, the set

positions lights for two seconds, and then the setting is completed.

• After the setting is completed, the louver which was set

moves from the original position to the lower limit position,

and goes back to the original position again. (This operation

is not performed if the indoor unit and/or indoor unit fan is in

operation.)

[Example]

“

“ ”

“

10

Press button.

Louver adjusting mode ends and returns to the original display.

” (lights for two seconds)

HOW TO OPERATE VENTILATION (WHEN A VENTILATOR IS INSTALLED) < WIRED REMOTE CONTROL >

When the ventilator is set to “NO VENTI LINK”, the ventilator can be turned on and off independently regardless

of the operation of the air conditioner.

When the ventilator is set to “VENTI LINK”, the ventilator operation will be interlocked with the air conditioner

operation.

VENTILATION OPERATION NOT LINKED WITH UNIT’S

OPERATION

1 Press VENTI button.

“ ” is displayed, and the ventilation operation begins.

Stop

Press VENTI button again.

NOTICE

• If no ventilator is connected, no operation can be performed by

pressing the ventilation button. (“ ” is displayed).

VENTILATION OPERATION LINKED WITH UNIT’S OPERATION

1 Press button.

1

If a ventilator is connected, ventilation will operate automatically.

“ ” is displayed.

Stop

Press button again.

NOTICE

• No operation can be performed by pressing the ventilation button.

(“ ” is displayed).

FOR COMFORTABLE USE

Clean the filter frequently

If the filter is clogged…

• The cooling/heating capacity will get reduced. Moreover it leads

to waste of electricity and larger operation noise.

• It may cause failure.

• Dew may form and drop during cooling.

See page 16

☞

The filter should be cleaned when

the “Filter cleaning” message

is displayed, and at the ends of

cooling and heating seasons.

Do not block the inlet and outlet grilles of the

indoor and outdoor units.

Excessive load to the unit may cause failure.

Keep moderate room temperature

Too much cooling or heating is not good for your health. It will also

waste the electricity.

Block direct sunlight and prevent draft

Block direct sunlight with blinds and curtains during cooling. Close

the windows and doors except when ventilation is necessary.

Adjust the airflow properly

Do not expose yourself directly to the airflow for too long time. For

small animals and plants, it is harmful as well.

If you feel cold underneath your feet during heating

If the ceiling is so high that the warm airflow does not circulate

underneath your feet, it is recommended to use a circulator.

Consult your dealer for more detail.

Stop the operation and turn the power supply

off if there are any possibility of lightning

strikes during a thunderstorm.

Lightning strikes may lead to the failure of air-conditioning system.

12

Page 14

INSPECTION DISPLAY, FILTER SIGN, AIR CONDITIONER NUMBER, STANDBY AND ROOM TEMPERATURE DISPLAY

< WIRED REMOTE CONTROL >

WHEN THE CHECK INDICATOR LIGHT (RED) FLASHES

Error code

Air conditioner No.

ERROR display when multiple indoor units are connected

J

If errors have occurred for all the connected air conditioning units.

Initially, the error display shows the formation of the air

conditioning unit whose number is the lowest.

Errors of other air conditioning unit can be checked with the

following procedure.

1 2

J If errors have occurred for some of the connected AIR CON

units.

Only the units for which errors have occurred stop operating.

The remote control shows the operating units.

1 2

NOTICE

• If button is pressed once while errors are displayed,

the errors display is turned off, and the stop mode returns.

If

J The air conditioner stops in the event

any trouble occurs.

At the same time, the check indicator

light flashes in red and the error code is

displayed in the ON timer display area and

the following is displayed in the display area.

“ ” ⇔ “ ”

(Air conditioner number)

(lights for 2 seconds by turns)

1

Press AIR CON No. button.

Enter AIR CON No. display mode.

2 Press ▲ button.

AIR CON No. and error codes are

displayed in order from the lowest.

Press ▼ button to display in the

reverse order.

3 Press button.

Return to the AIR CON of the lowest

number.

1

Press AIR CON No. button.

AIR CON No. display mode appears.

2 Press ▲ button.

AIR CON No. are displayed in order

from the lowest. And error codes are

displayed on the unit in trouble.

Press ▼ button to display in the

reverse order.

3 Press button.

Return to the AIR CON of the lowest

number.

button is pressed again, the errors are displayed.

ROOM TEMPERATURE DISPLAY

If room temperature display setting is activated, room temperature is

displayed on the remote control display. Then airflow display turns off,

but airflow adjusting button is operative. Consult your dealer for settings.

The room temperature display

WHEN THE FILTER CLEANING MESSAGE IS DISPLAYED

The “ ” is displayed

when the cumulative operation time

reaches to the predetermined number

of hours in order to notify the time for

cleaning.

JClean the air filter.

“FILTER CLEANING” is displayed in the

display area. It is displayed for one second

1

HOW TO DISPLAY AIR CON NO.

By operating AIR CON No. button, the number of the connected AIR CON

unit and error codes of the units which have the record are displayed.

1 2

NOTICE

• The AIR CON No. can be displayed without relation to its modes of

operation, stop, forcible stop due to an error.

• Buttons other than “AIR CON No.” “▲” “▼” “ON/OFF” cannot be

operated.

every five seconds while the unit is running.

It stays lit while the system stopped.

After cleaning

1 Press RESET button.

The cumulative operation hours are

reset and the “FILTER CLEANING”

message turns off.

1

Press AIR CON No. button.

AIR CON No. display mode appears

and the AIR CON of the lowest number

is displayed. Other displays all turn off.

2 Press ▲ button.

AIR CON No. are displayed in order

from the lowest. In addition, if any

errors have occurred to the unit in

the past, error codes can be found

here too.

Press ▼ button to display in the

reverse order.

3 Press button.

Return to the original display.

STANDBY DISPLAY

During the first operation after breaker power supply input or the

recovery from power failure, “

the remote control for max 30 minutes.

The refrigerant oil protection control is activated to protect the

compressor and this isn’t a failure. Please wait till the display turns

off.

” can be displayed on

See page 16

☞

NAMES AND FUNCTIONS OF REMOTE CONTROL BUTTONS

•

WIRELESS REMOTE CONTROL

ROOM TEMP display

Indicates set temperature.

FAN SPEED display

Indicates the selected airflow volume

ON-TIMER display

Indicates when ON-TIMER is set. ☞See page 14

ON TIMER setting time display

Indicates the ON-TIMER setting time.

Nothing displayed when ON-TIMER is not set.

☞See page 14

Transmitter

Sends signal to the air conditioner.

FAN SPEED button

Every time this button is pressed, the mode is switched

as below.

FILTER button

Used to reset (turn off) the filter sign.

Press the button only after completing the filter cleaning.

ON TIMER button

Operation section Display section

Sets ON TIMER operation. ☞See page 14

OFF TIMER button

Sets OFF TIMER operation. ☞See page 14

TIME SET UP switch

Sets current time. ☞See page 14

NOTICE

HI MED LO

If the display of remote control has troubles, press

WIRELESS REMOTE CONTROL HANDLING PROCEDURE

REPLACING THE BATTERIES

If the following occurs, the batteries are exhausted. Replace them with new ones.

• When the signal is transmitted, the AIR CON does not display reception.

• The display fades away or does not show anything.

1 Pull out the cover.

2 Replace the old

batteries with

new ones.

(R03×2)

3 Close cover.

4 Adjust the current time.

JWhen any error occurs on the

display,

Press

ACL

switch with

a ballpoint

etc.

See page 14

☞

NOTICE

If the remote control is set as “Radio

Interference Prevention Setting”, it

returns to default when the batteries

are removed. It is necessary to

perform the next procedures again.

When the batteries are inserted, each operation mode

is set as the right figure. Adjust the current time referring

to page 14. (The figure is for operation, and only the

current time is displayed for stopping)

In order to explain the displays in the liquid crystal display, all of them are shown in the figure below.

switch.

ACL

J How to set Radio Interference

Pay attention

to the and

marks

Prevention Setting

It is possible to be sent in two ways.

ACL

Press

button kept pressing or insert the

batteries with

kept pressing.

switch with

AIR FLOW

AIR FLOW

button

ATTENTION

• Do not use old and new batteries

mixed.

• Remove the batteries when the

remote control is not used for a long

time.

•

The recommendable effective period

of a battery is about 6 to 12 months.

(It depends on the usage.)

• The recommendable effective

period is printed on the battery.

This may be shorter due to

manufacturing time of the unit.

• However the battery may be still

working in order after expiry date.

<WIRELESS REMOTE CONTROL>

AIR FLOW display

Indicates the status of swing louver. ☞See page 15

OPERATION MODE display

Indicates selected operation with .

FILTER display

Indicates for two seconds

when FILTER button is pressed.

OFF-TIMER display

Indicates when OFF-TIMER is set. ☞See page 14

OFF-TIMER setting time display

Indicates OFF-TIMER setting time. Indicates the

current time when the OFF-TIMER is not set. ☞See page 14

ON/OFF button

When this is pressed once, the AIR CON starts to

operate and when this is pressed once again, it stops

operating.

AIR FLOW button

Used to swing the louver. ☞See page 15

OPERATION MODE select button

Every time this button is pressed, displays switch as below

(AUTO) (COOL) (HEAT)

(FAN) (DRY)

ROOM TEMP/TIME SETTING button

Sets room temperature by pressing or button.

Sets time when setting the time.

TIMER CANCEL button

Used to cancel the TIMER SETTINGS.

ACL switch

Used to reset the microcomputer.