Page 1

GROUP 00

GENERAL

CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00

GENERAL <ELECTRICAL> . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00E

00-1

Page 2

NOTES

Page 3

GROUP 00

GENERAL

CONTENTS

00-1

VEHICLE IDENTIFICATION . . . . . . . 00-2

MODELS. . . . . . . . . . . . . . . . . . . . . . . . . . . 00-2

VEHICLE IDENTIFICATION NUMBER

(CHASSIS NUMBER) . . . . . . . . . . . . . . . . . 00-3

GENERAL DATA AND

SPECIFICATIONS . . . . . . . . . . . . . . . 00-4

PRECAUTIONS BEFORE

SERVICE. . . . . . . . . . . . . . . . . . . . . . . 00-8

CODING LIST . . . . . . . . . . . . . . . . . . . . . . . 00-8

Page 4

00-2

GENERAL

VEHICLE IDENTIFICATION

VEHICLE IDENTIFICATION

MODELS

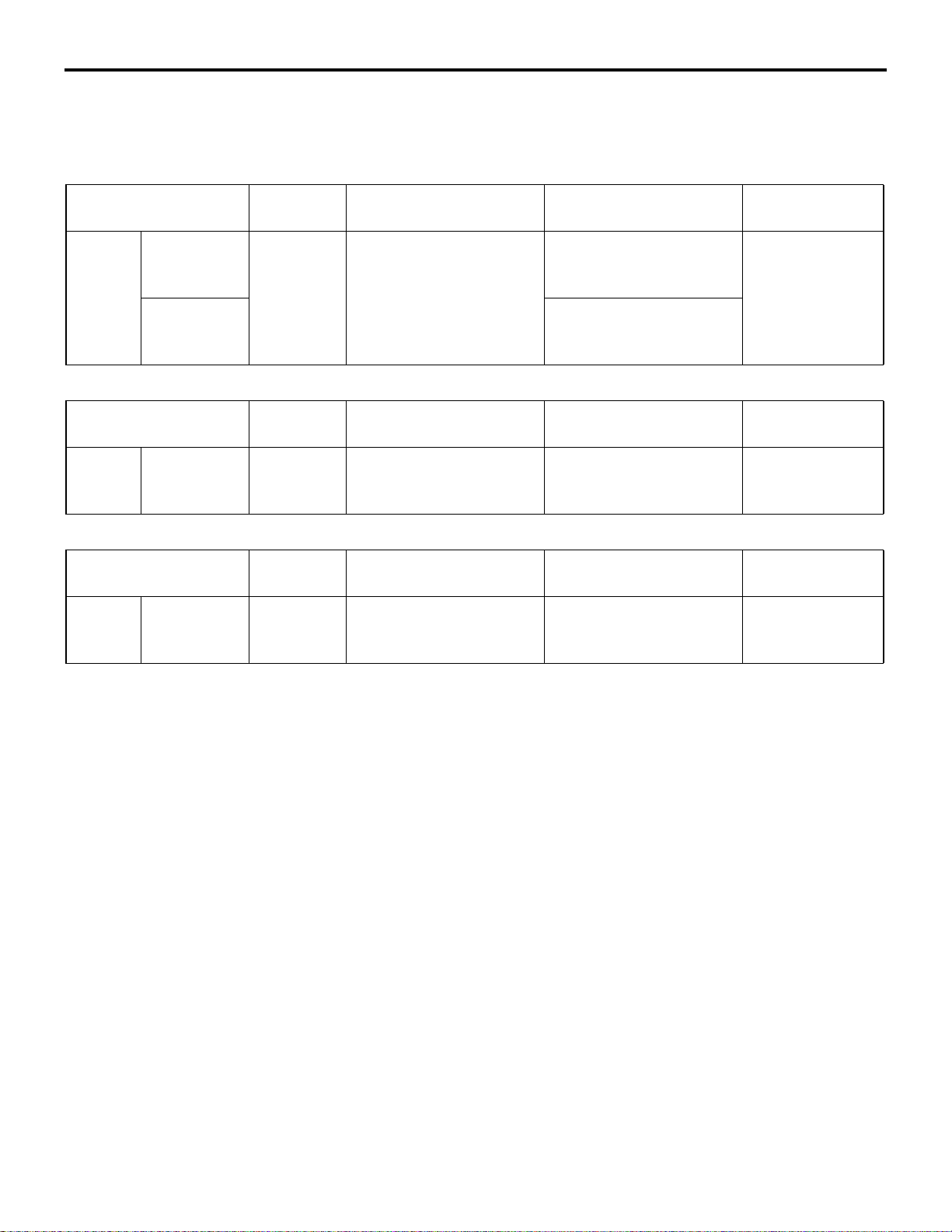

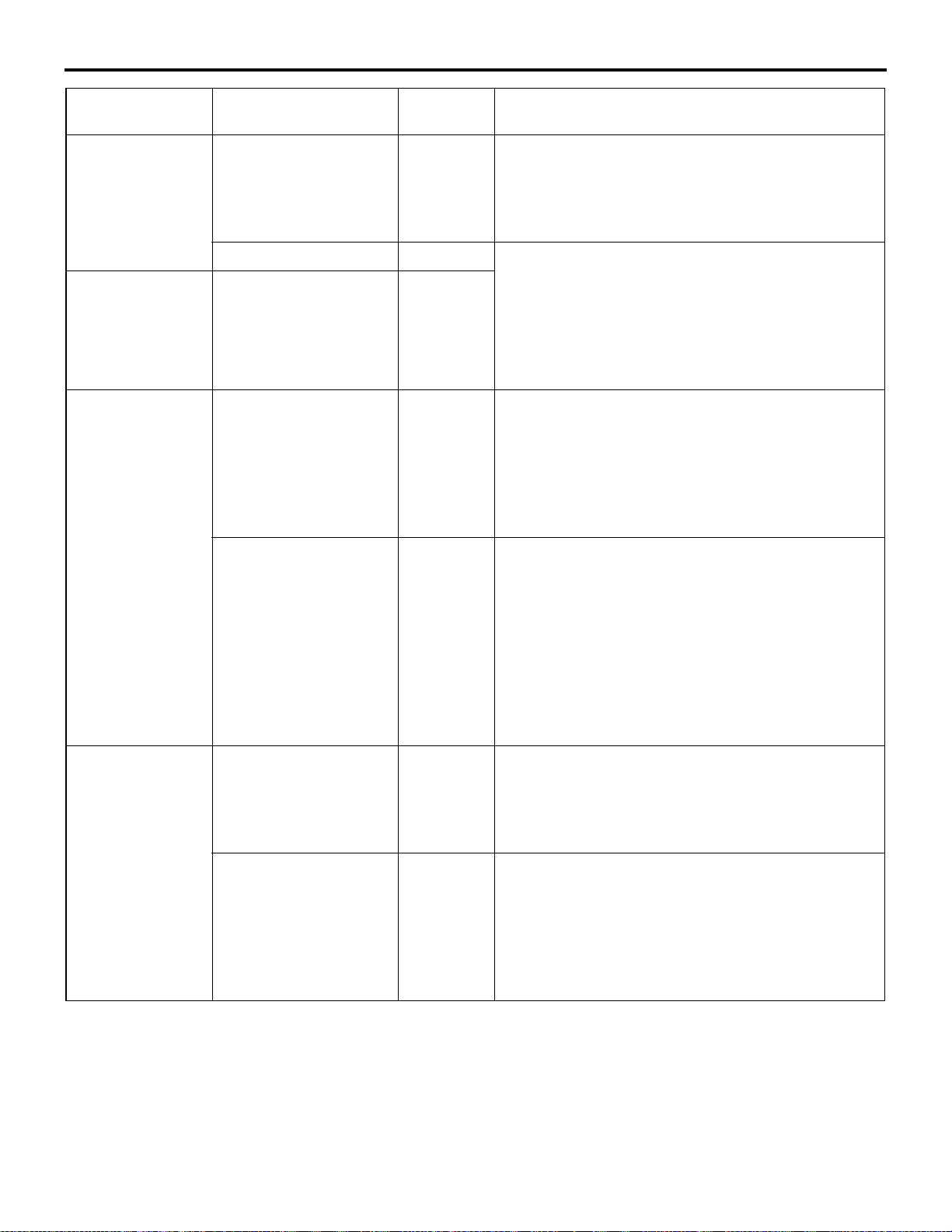

<2000>

Model code Seating

capacity

GF2W XTSHLAZ 5-persons 4B11 (1,998 mL) DOHC

XTSHZLAZ W1CJC (Electronic

<2400>

Model code Seating

capacity

GF3W XTHHZLAZ 5-persons 4B12 (2,360 mL) DOHC

<3000>

Model code Seating

capacity

GF4W XLHYZLAZ 5-persons 6B31 (2,998 mL)

Engine model Transm ission model Fuel supply

MIVEC petrol engine

Engine model Transm ission model Fuel supply

MIVEC petrol engine

Engine model Transm ission model Fuel supply

SOHC MIVEC petrol

engine

F1CJC (Front wheel

drive 2WD, INVECS-III

CVT with sport mode)

control 4WD, INVECS-III

CVT with sport mode)

W1CJC (Electronic

control 4WD, INVECS-III

CVT with sport mode)

W6AJA (Electronic

control 4WD, INVECS-II

6A/T with sport mode)

M1001000308668

system

MPI

system

MPI

system

MPI

Page 5

GENERAL

12345678910

ACD04356

AB

LLHYZ AZ4

ACC03409

AB

Cowl top panel

VEHICLE IDENTIFICATION

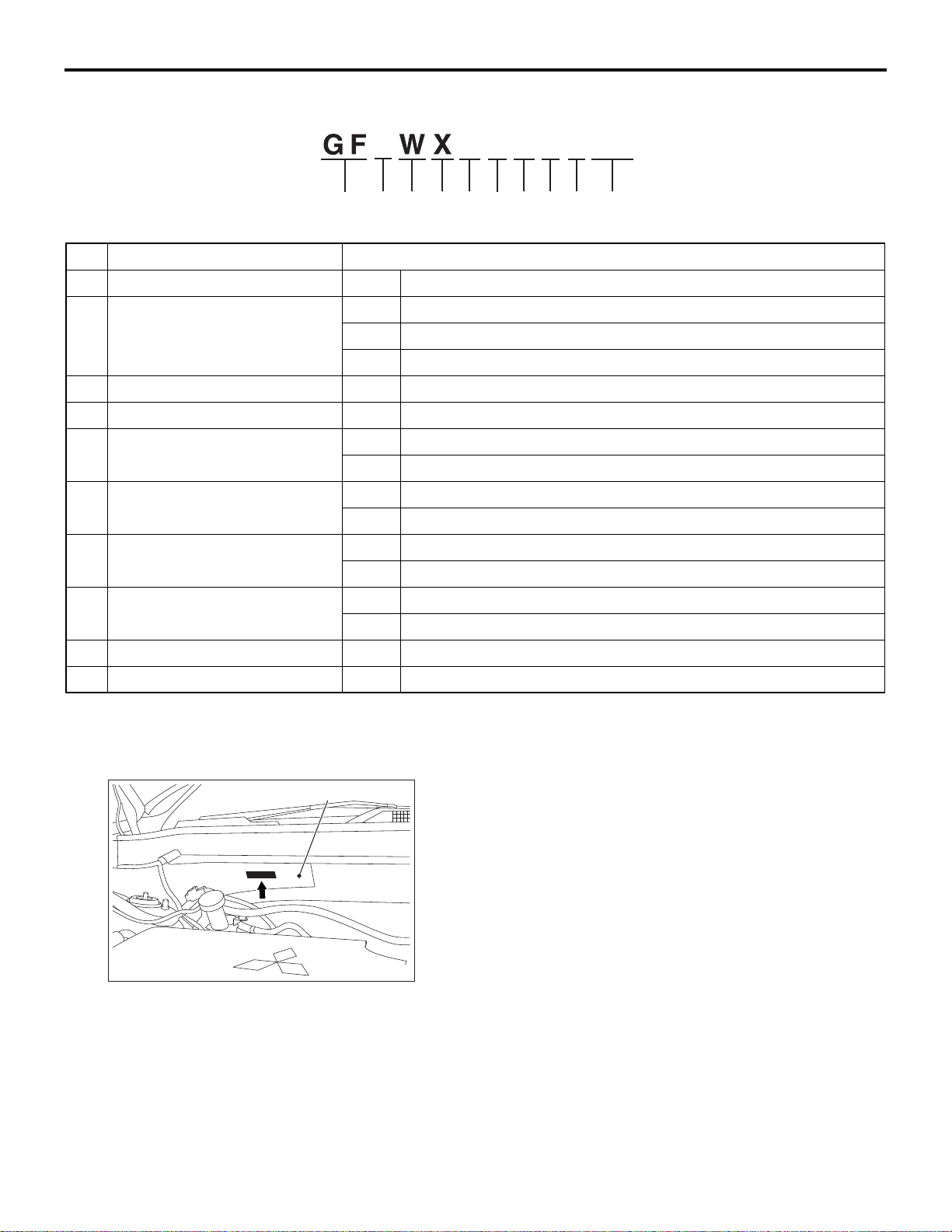

MODEL CODE

No. Item Content

1 Development GF OUTLANDER

2 Engine type 2 2.0L MPI (4B11) MIVEC

3 2.4L MPI (4B12) MIVEC

4 3.0L MPI (6B31) MIVEC

3 Vehicle type W Station wagon

4 Body style X 4-door with tailgate

5 Transmission type L 6A/T

T CVT

6 Trim level (Price class) H INTENSE <2400>, INSTYLE <3000>

S INFORM, INVITE

00-3

7 Engine specification H MIVEC (DOHC)

Y MIVEC (SOHC)

8 Special feature None 2WD

Z 4WD

9 Steering wheel location L Left-hand Drive

10 Destination AZ Vehicles for Russia

VEHICLE IDENTIFICATION NUMBER (CHASSIS NUMBER)

M1001005603960

The vehicle identification number (chassis number)

is stamped on the cowl top panel inside the engine

compartment.

Page 6

00-4

ACD04362

1234 678 95

XWMGF

LG4

AD

ACE03172

AB

1

2

345

6

7

8

9

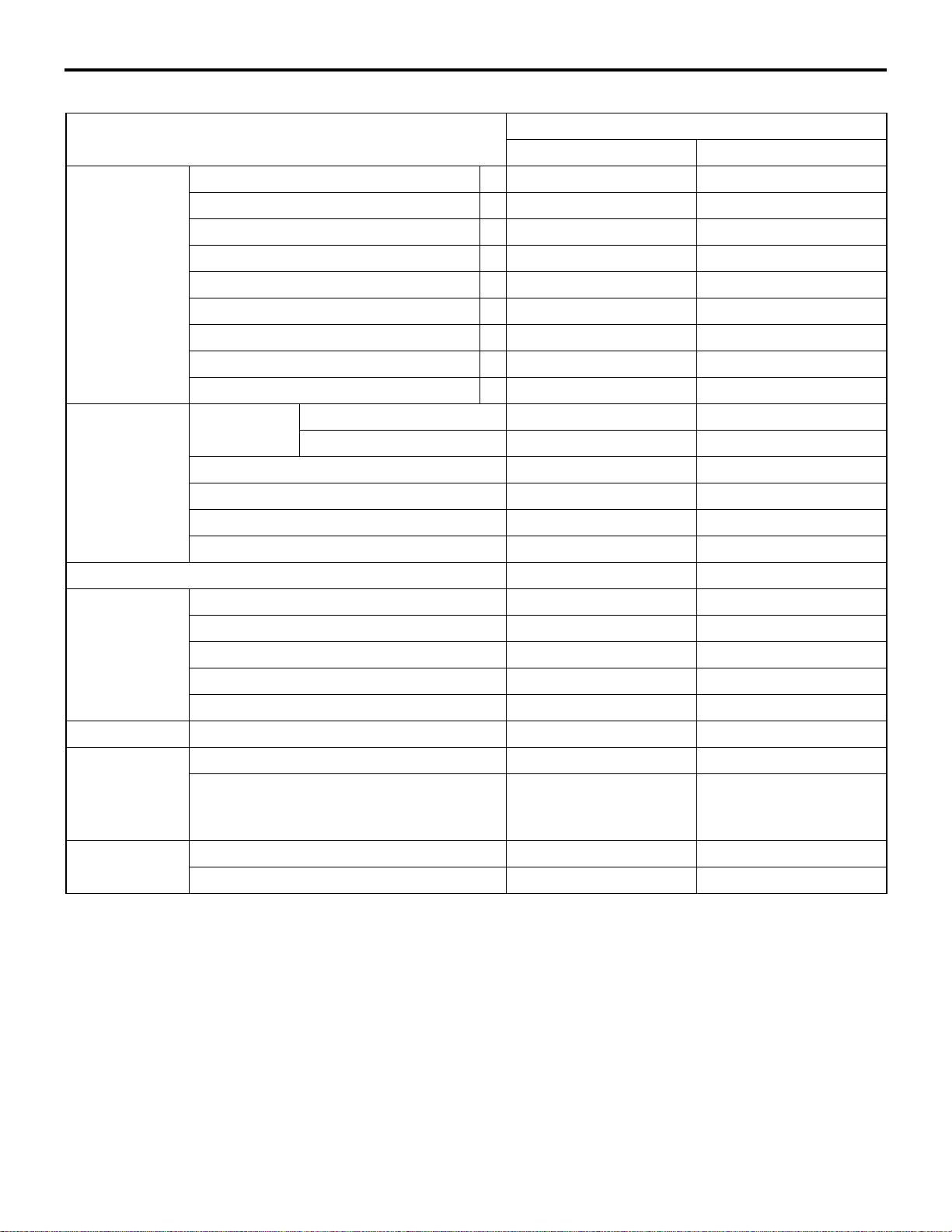

GENERAL DATA AND SPECIFICATIONS

GENERAL

CODE CHART

No. Item Content

1 World Manufacturer Identifier (WMI) Z8T PCMA-rus

2 Body type X 4-door with tailgate

3 Transmission L 6A/T

T CVT

4 Development order GF OUTLANDER

5 Engine type 2 2.0L MPI (4B11) MIVEC

3 2.4L MPI (4B12) MIVEC

4 3.0L MPI (6B31) MIVEC

6 Vehicle type W Station wagon

7 Model year G 2016 year

8 Assembly plant M Kaluga (PCMA-rus)

9 Serial number 900001 to 940000

GENERAL DATA AND SPECIFICATIONS

M1001000909083

Page 7

GENERAL

GENERAL DATA AND SPECIFICATIONS

<2000>

Item GF2W

XTSHLAZ XTSHZLAZ

Vehicle

dimension mm

Vehicle weight kgKerb weight Without full optional parts 1,425 1,490

Front track 1 1,540 1,540

Overall width 2 1,810 1,810

Front overhang 3 990 990

Wheelbase 4 2,670 2,670

Rear overhang 5 1,035 1,035

Overall length 6 4,695 4,695

Ground clearance (unladen) 7 215 215

Overall height (unladen) 8 1,680 1,680

Rear track 9 1,540 1,540

With full optional parts 1,507 1,582

Gross vehicle weight 1,985 1,985

Gross axle weight rating-front 1,150 1,150

00-5

Gross axle weight rating-rear 1,250 1,250

Gross combination weight 3,665 3,665

Seating capacity 5 5

Engine Model No. 4B11 4B11

Type DOHC MIVEC DOHC MIVEC

Total displacement mL 1,998 1,998

Max. output <EEC> kW/rpm 107/6,000 107/6,000

Max. torque <EEC> N⋅m/rpm 196/4,200 196/4,200

Fuel system Fuel supply system MPI MPI

Transmission Model code F1CJC W1CJC

Type Front wheel drive 2WD,

INVECS-III CVT with

sport mode

Turning radius mBody 5.73 5.73

Wheel 5.3 5.3

Electronic control 4WD,

INVECS-III CVT with

sport mode

Page 8

00-6

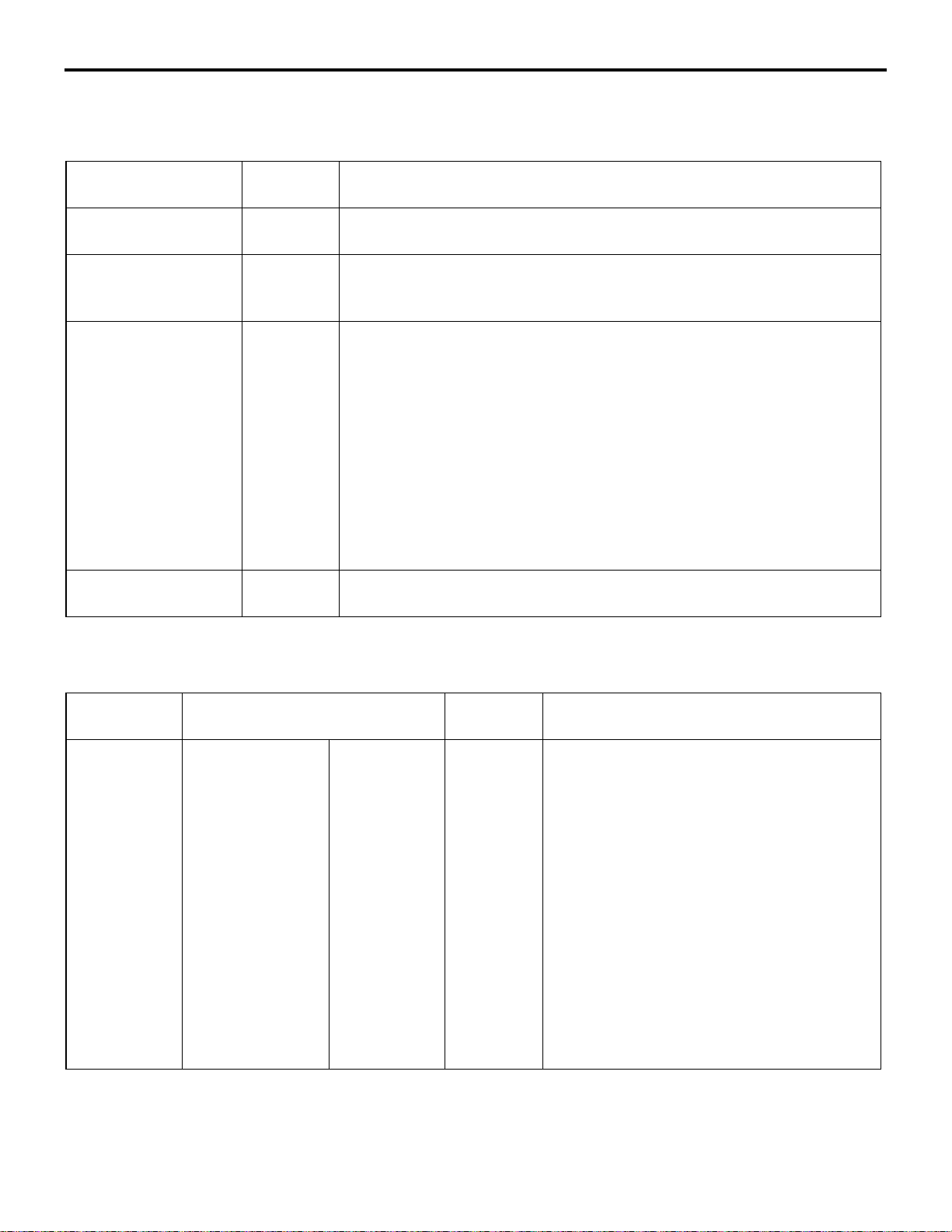

<2400>

Item GF3W

Vehicle

dimension mm

Vehicle weight kgKerb weight Without full optional parts 1,505

Front track 1 1,540

Overall width 2 1,810

Front overhang 3 990

Wheelbase 4 2,670

Rear overhang 5 1,035

Overall length 6 4,695

Ground clearance (unladen) 7 215

Overall height (unladen) 8 1,680

Rear track 9 1,540

With full optional parts 1,592

Gross vehicle weight 2,210

Gross axle weight rating-front 1,150

GENERAL DATA AND SPECIFICATIONS

GENERAL

XTHHZLAZ

Gross axle weight rating-rear 1,250

Gross combination weight 3,890

Seating capacity 5

Engine Model No. 4B12

Type DOHC MIVEC

Total displacement mL 2,360

Max. output <EEC> kW/rpm 123/6,000

Max. torque <EEC> N⋅m/rpm 222/4,100

Fuel system Fuel supply system MPI

Transmission Model code W1CJC

Type Electronic control 4WD,

INVECS-III CVT with

sport mode

Turning radius mBody 5.73

Wheel 5.3

Page 9

GENERAL

GENERAL DATA AND SPECIFICATIONS

<3000>

Item GF4W

XLHYZLAZ

Vehicle

dimension mm

Vehicle weight kgKerb weight Without full optional parts 1,580

Front track 1 1,540

Overall width 2 1,810

Front overhang 3 990

Wheelbase 4 2,670

Rear overhang 5 1,035

Overall length 6 4,695

Ground clearance (unladen) 7 215

Overall height (unladen) 8 1,680

Rear track 9 1,540

With full optional parts 1,646

Gross vehicle weight 2,270

Gross axle weight rating-front 1,150

00-7

Gross axle weight rating-rear 1,250

Gross combination weight 3,950

Seating capacity 5

Engine Model No. 6B31

Type SOHC MIVEC

Total displacement mL 2,998

Max. output <EEC> kW/rpm 169/6,250

Max. torque <EEC> N⋅m/rpm 292/3,750

Fuel system Fuel supply system MPI

Transmission Model code W6AJA

Type Electronic control 4WD,

INVECS-II 6A/T with

sport mode

Turning radius mBody 5.73

Wheel 5.3

Page 10

00-8

GENERAL

PRECAUTIONS BEFORE SERVICE

PRECAUTIONS BEFORE SERVICE

CODING LIST

M1001015003174

The coding data of engine-ECU and ETACS-ECU

has been changed.

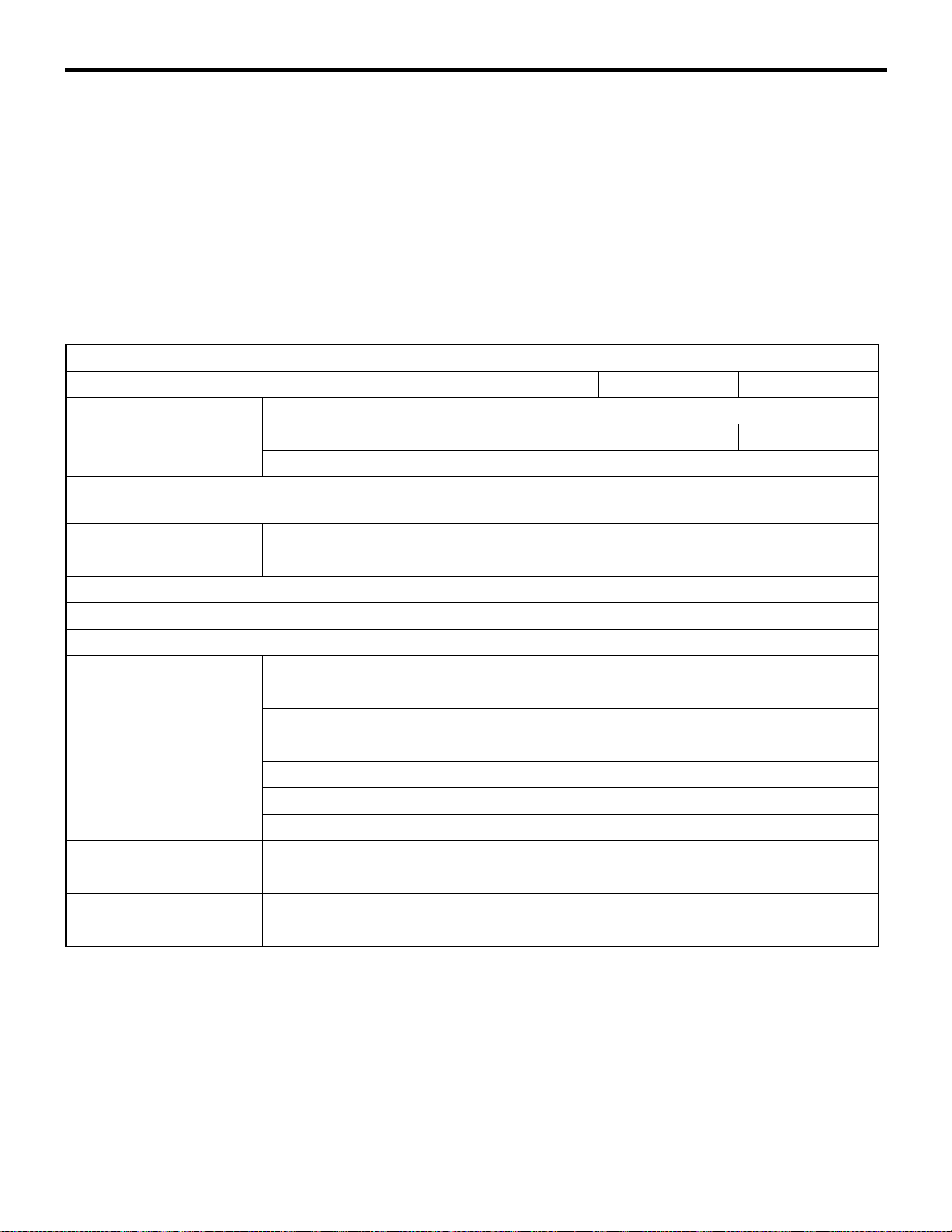

ENGINE ECU CODING DATA LIST

NOTE: The items to be displayed may differ depending on the version of the M.U.T.-III.

Item name Initial value

Final gear ratio 6.026 <4B1>

3.360 <6B3>

Adaptive cruise control Not present or Present

ETACS-ECU CODING DATA LIST

NOTE: The items to be displayed may differ depending on the version of the M.U.T.-III.

Item name Initial value

Corner sensor control unit Not present

FCM function Not present or Present

FCM type Undefined or Type 1

ACC type Undefined or Type 5

ACC Not present or Present

ACC function Not present or Present

DRL*1 type

DRL function

Head Lamp Leveling system type OUTLANDER LED

T/M oil cooler Present (B)

EPS type Type 4 or Type 5 or Type 11

TCL Type Not present or Type 7 or Type 11 or Type 12

ACC Type for A.S.C. Not present or Type 9

FCM Type for A.S.C. Not present or Type 2

Battery heater type Not present

NOTE: .

*1

•

: TPMS is an abbreviation of Tyre Pressure

Monitoring System, DRL of Daytime Running

Lamp.

*2

•

: The setting can be changed by the option

coding.

*2

Independent DRL

Present/Chg Ng

Page 11

GROUP 00E

GENERAL

<ELECTRICAL>

CONTENTS

00E-1

OUTLINE OF CHANGE . . . . . . . . . . . 00E-2

COMPONENT LOCATIONS. . . . . . . . . . . . 00E-2

CONFIGURATION DIAGRAMS . . . . . . . . . 00E-2

CIRCUIT DIAGRAMS . . . . . . . . . . . . . . . . . 00E-4

Page 12

00E-2

GENERAL <ELECTRICAL>

OUTLINE OF CHANGE

OUTLINE OF CHANGE

COMPONENT LOCATIONS

Location of changes Reference

page

RELAY

ECU

SENSOR

FUSIBLE LINK AND

FUSE

P.70-2

P.70-3

P.70-4

P.70-5

M1001016000543

Description of changes

• A daytime running lamp relay has been added. <6B3>

• Heated windshield relays 1 and 2 have been added.

• The EPS-ECU has been relocated as the EPS-ECU and the EPS

motor have been integrated as one unit.

• A LED headlamp control unit has been added.

• The sensors below have been added due to the introduction of

automatic anti-dazzling mirrors.

• Front lamp sensor

• Rear lamp sensor

• The sensors below have been changed or added due to the

introduction of a new CVT.

• The installation position of the primary pulley speed sensor has

been changed.

• The installation position of the secondary pulley speed sensor

has been changed.

• The installation position of the turbine speed sensor has been

added.

• Due to the introduction of a heated windshield, fusible link Nos. 6 to

12 have been added.

CONFIGURATION DIAGRAMS

Connector

symbol

A ENGINE

Name Reference

4B1

COMPARTMENT

page

P.80-2

M1001016100722

Description of change

• Due to the change in the headlamp

assembly, the number of the headlamp

assembly (LH, RH) (A-27, 37) connector

terminals has been reduced from 6 to 8.

• The number of the front wiring harness

and fog lamp wiring harness

combination connector (A-33) terminals

has been changed from 4 to 2.

• Due to the adoption of a heated

windshield, the following connectors

have been added.

• Heated windshield relay 2 (A-60X)

• Heated windshield relay 1 (A-61X)

• Heated windshield (A-147)

• The CVT control relay (A-07X) has been

discontinued.

Page 13

GENERAL <ELECTRICAL>

OUTLINE OF CHANGE

00E-3

Connector

symbol

A ENGINE

B ENGINE AND

C INSTRUMENT PANEL

Name Reference

6B3

COMPARTMENT

4B1

TRANSMISSION

page

P.80-4

P.80-6

P.80-8

Description of change

• Due to the addition of vehicles with

daytime running lamp, daytime running

lamp relay connector (A-10X) has been

added.

• Due to the change in the headlamp

assembly, the number of the headlamp

assembly (LH, RH) (A-27, 37) connector

terminals has been reduced from 6 to 8.

• The number of the front wiring harness

and fog lamp wiring harness

combination connector (A-33) terminals

has been changed from 4 to 2.

• Due to the adoption of a heated

windshield, the following connectors

have been added.

• Heated windshield relay 2 (A-60X)

• Heated windshield relay 1 (A-61X)

• Heated windshield (A-147)

• Due to the adoption of an adaptive

cruise control system (ACC) and forward

collision mitigation (FCM), the following

connectors have been added.

• J/C (CAN2) (integrated in relay box)

<Vehicles with ACC> (A-123)

• ACC/FCM -ECU (A-125)

• Due to the change of the CVT assembly,

turbine speed sensor (B-149) has been

added.

• The number of J/C (CAN3, CAN1)

(C-27, 29) connector terminals and the

connector colour have been changed

from "22-GR" to "18".

• Due to the introduction of forward

collision mitigation (FCM), FCM ON/OFF

switch (C-132) has been added.

• Due to the introduction of heated

windshield, heated windshield switch

(C-152) has been added.

• Due to the adoption of the EPS-ECU

integrated with the motor, the following

connectors have been changed or

added.

• The terminal numbers of EPS-ECU

(C-218) connector has been changed

from 4 to 8.

• Front wiring harness and EPS sub

wiring harness combination (C-246,

247) has been added.

Page 14

00E-4

GENERAL <ELECTRICAL>

OUTLINE OF CHANGE

Connector

symbol

D FLOOR

E ROOF

G TAILGATE

Name Reference

page

P.80-13

P.80-15

P.80-16

Description of change

• The terminal number and colour of floor

wiring harness and tailgate wiring

harness (LH) combination connector

<Vehicles with electric tailgate> (D-112)

have been changed from "15-L" to "14".

• No connection (D-138, 139) has been

added.

• Inside rear view mirror assembly

connector (E-19) has been added due to

the introduction of automatic

anti-dazzling mirrors.

• The colour of back-up lamp (RH)

connector (G-25) has been changed

from "B" to "GR."

• Tail lamps (RH and LH) (G-26 and 28)

have been added.

• The pin number and colour of the rear

end wiring harness-to-rear bumper

wiring harness combination connector

has been changed from "13-GR" to "6."

Due to this, this connector identification

has been changed from "G-18" to

"G-27."

CIRCUIT DIAGRAMS

Main title Sub title Reference

page

J/C

CENTRALIZED

JUNCTION

POWER

DISTRIBUTION

SYSTEM

− P.90-4

− P.90-7

− P.90-16

M1001008400944

Description of changes

• The J/C has been changed as the following

equipment and model have been added.

• A new CVT

• Tail lamps mounted on the tailgate

• Heated windshield

• Due to the introduction of a heated windshield,

fusible link Nos. 6 to 12 (in engine

compartment) and heated windshield relays 1

and 2 have been added.

• Due to the introduction of a heated windshield,

the circuit has been changed.

Page 15

GENERAL <ELECTRICAL>

OUTLINE OF CHANGE

00E-5

Main title Sub title Reference

page

IGNITION

SYSTEM

CHARGING

SYSTEM

ENGINE

CONTROL

SYSTEM

COOLING

SYSTEM

4B1

6B3

− P.90-24

4B1

6B3

4B1

6B3

P.90-20

P.90-22

P.90-26

P.90-29

P.90-33

P.90-35

Description of changes

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The adaptive cruise control system (ACC)

has been added.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The CVT-ECU has been changed due to the

introduction of a new CVT.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• A circuit between engine-ECU (B-07)

terminal No. 82 and J/C (6) (C-28) terminal

No. 7 has been added.

• The heated windshield has been introduced.

• The adaptive cruise control system (ACC)

has been added.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The adaptive cruise control system (ACC)

has been added.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

Page 16

00E-6

GENERAL <ELECTRICAL>

OUTLINE OF CHANGE

Main title Sub title Reference

page

SHIFT LOCK

MECHANISM

CVT

A/T

HEADLAMP

TAIL LAMP,

POSITION LAMP,

LICENCE PLATE

LAMP AND

LAMP

REMINDER

BUZZER

− P.90-37

− P.90-38

− P.90-41

− P.90-44

− P.90-47

Description of changes

• Due to the introduction of a heated windshield,

the circuit diagram has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• A new CVT adopted

• The heated windshield has been introduced.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The adaptive cruise control system (ACC)

has been added.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• A LED headlamp has been introduced.

• A halogen headlamp assembly has been

changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN3) connector

terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The headlamp assembly has been changed

in conjunction with the introduction of a LED

position lamp.

• Tail lamps have been added on the tailgate.

• The heated windshield has been introduced.

• The number of the J/C (CAN3) connector

terminals has been changed.

HEADLAMP

MANUAL

LEVELLING

SYSTEM

HEADLAMP

AUTOMATIC

LEVELLING

SYSTEM

− P.90-50

− P.90-51

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• Headlamp assembly has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• Headlamp assembly has been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

Page 17

GENERAL <ELECTRICAL>

OUTLINE OF CHANGE

00E-7

Main title Sub title Reference

page

DAYTIME

RUNNING LAMP

(DRL)

FRONT FOG

LAMP

REAR FOG

LAMP

ROOM LAMP,

LUGGAGE

COMPARTMENT

LAMP AND

IGNITION KEY

CYLINDER

ILLUMINATION

LAMP

V ANITY MIRROR

LAMP

GLOVE BOX

LAMP

TURN-SIGNAL

LAMP AND

HAZARD

WARNING LAMP

STOP LAMP

− P.90-53

− P.90-55

− P.90-57

− P.90-59

− P.90-62

− P.90-63

− P.90-64

− P.90-66

Description of changes

• Due to the following change, the circuit

diagrams have been changed.

• Integrated in the headlamp assembly.

• The heated windshield has been introduced.

• The adaptive cruise control system (ACC)

has been added.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the front wiring harness and

fog lamp wiring harness combination (A-33)

connector terminals has been changed.

• The number of the J/C (CAN3) connector

terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The rear end wiring harness and rear bumper

wiring harness combination connector has

been reassigned from "G-18" to "G-27" .

• The number of the J/C (CAN3) connector

terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN3) connector

terminals has been changed.

• Due to the adoption of a heated windshield, the

circuit diagram has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• Headlamp assembly has been changed.

• The number of the J/C (CAN3) connector

terminals has been changed.

• Due to the introduction of a heated windshield,

the circuit diagram has been changed.

Page 18

00E-8

GENERAL <ELECTRICAL>

OUTLINE OF CHANGE

Main title Sub title Reference

page

BACK-UP LAMP

HORN

METER AND

GAUGE

FUEL WARNING

LAMP, OIL

PRESSURE

WARNING LAMP

AND BRAKE

WARNING LAMP

POWER

WINDOWS

− P.90-67

− P.90-68

− P.90-69

− P.90-71

− P.90-73

Description of changes

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The rear end wiring harness and rear bumper

wiring harness combination connector has

been reassigned from "G-18" to "G-27" .

• The back-up lamp (LH, RH) connectors

(G-09, 25) have been reshaped.

• Due to the introduction of a heated windshield,

the circuit diagram has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN3) connector

terminals has been changed.

CENTRAL DOOR

LOCKING

SYSTEM

ELECTRIC

TAILGATE

AIR

CONDITIONER

WINDSHIELD

WIPER AND

WASHER

VEHICLES WITHOUT

KOS

VEHICLES WITH KOS

− P.90-82

− P.90-85

− P.90-88

P.90-75

P.90-78

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The CVT-ECU has been changed due to the

introduction of a new CVT.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The CVT-ECU has been changed due to the

introduction of a new CVT.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• The number of the floor wiring harness and

tailgate wiring harness (LH) combination

(D-112) connector has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

Page 19

GENERAL <ELECTRICAL>

OUTLINE OF CHANGE

00E-9

Main title Sub title Reference

page

REAR WIPER

AND WASHER

HEADLAMP

WASHER

REAR WINDOW

DEFOGGER

WIPER DEICER

HEATED

WINDSHIELD

HEATED DOOR

MIRROR

REMOTE

CONTROLLED

MIRROR

− P.90-90

− P.90-92

− P.90-93

− P.90-94

− P.90-96

− P.90-98

− P.90-100

Description of changes

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN3) connector

terminals has been changed.

• Due to the change in the J/C (CAN3) connector,

the circuit has been changed.

• Due to the introduction of a heated windshield,

a new circuit diagram has been established.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN3) connector

terminals has been changed.

• Due to the introduction of a heated windshield,

the circuit diagram has been changed.

ELECTRIC

RETRACTABLE

REMOTE

CONTROLLED

MIRROR

AUTOMATIC

ANTI-DAZZLING

MIRROR

AUDIO SYSTEM

MMCS

− P.90-102

− P.90-105

− P.90-106

− P.90-109

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• This circuit diagram has been added due to the

introduction of automatic anti-dazzling mirrors.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The power supply circuit to the radio and CD

player has been changed.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The power supply circuits to the multivision

display and the CAN box unit have been

changed.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

Page 20

00E-10

GENERAL <ELECTRICAL>

OUTLINE OF CHANGE

Main title Sub title Reference

page

HANDS-FREE

INTERFACE

SYSTEM

SPARE

CONNECTOR

(FOR AUDIO)

ACCESSORY

SOCKET AND

CIGARETTE

LIGHTER

IMMOBILIZER

SYSTEM

KEY INTERLOCK VEHICLES WITHOUT

ONE-TOUCH

START SYSTEM

(OSS)

CRUISE

CONTROL

SYSTEM

VEHICLES WITHOUT

MMCS

VEHICLES WITH

MMCS

− P.90-116

− P.90-118

VEHICLES WITHOUT

KOS

KOS

− P.90-121

− P.90-124

P.90-112

P.90-114

P.90-119

P.90-120

Description of changes

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The power supply circuit to the

handsfree-ECU has been changed.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The power supply circuit to the spare

connector (for audio) has been changed.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the introduction of a heated windshield,

the circuit diagram has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the introduction of a heated windshield,

the circuit diagram has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• A circuit between engine-ECU (B-07)

terminal No. 82 and J/C (6) (C-28) terminal

No. 7 has been added <6B3>.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• The CVT-ECU has been changed due to the

introduction of a new CVT.

Page 21

GENERAL <ELECTRICAL>

OUTLINE OF CHANGE

00E-11

Main title Sub title Reference

page

ADAPTIVE

CRUISE

CONTROL

SYSTEM (ACC)

AND FORWARD

COLLISION

MITIGATION

(FCM)

ANTI-SKID

BRAKING

SYSTEM (ABS)

ACTIVE

STABILITY

CONTROL (ASC)

AND HILL ST ART

ASSIST (HSA)

− P.90-126

− P.90-131

− P.90-133

Description of changes

• New circuits have been added as an adaptive

cruise control system (ACC) and forward

collision mitigation (FCM) have been introduced

on vehicles with 6B3 engine.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The CVT-ECU has been changed due to the

introduction of a new CVT.

• The adaptive cruise control system (ACC)

has been added.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

ELECTRONICAL

LY

CONTROLLED

4WD

SUPER ALL

WHEEL

CONTROL

(S-AWC)

SUNROOF

SUPPLEMENTAL

RESTRAINT

SYSTEM (SRS)

− P.90-136

− P.90-138

− P.90-140

− P.90-142

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The EPS-ECU has been changed.

• The adaptive cruise control system (ACC)

has been added.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN3) connector

terminals has been changed.

Page 22

00E-12

GENERAL <ELECTRICAL>

OUTLINE OF CHANGE

Main title Sub title Reference

page

ELECTRIC

POWER

STEERING

SYSTEM

HEATED SEAT

POWER SEAT

REAR VIEW

CAMERA

DOOR AJAR

WARNING

BUZZER

SEAT BELT

WARNING

PARKING

BRAKE

REMINDER

BUZZER

− P.90-145

− P.90-147

− P.90-149

VEHICLES WITH

DISPLAY AUDIO

− P.90-151

− P.90-153

− P.90-155

P.90-150

Description of changes

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The EPS-ECU and the EPS motor have been

integrated as one unit.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• Due to the introduction of a heated windshield,

the circuit diagram has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN3) connector

terminals has been changed.

• Due to the following change, the circuit

diagrams have been changed.

• The heated windshield has been introduced.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

CAN

SPARE

CONNECTOR

(FOR TRAILER

LAMPS)

− P.90-157

− P.90-159

• Due to the following change, the circuit

diagrams have been changed.

• The number of the J/C (CAN1, CAN3)

connector terminals has been changed.

• The heated windshield has been introduced.

• The CVT-ECU has been changed due to the

introduction of a new CVT.

• The EPS-ECU has been changed.

• The adaptive cruise control system (ACC)

has been added.

• Due to the introduction of a heated windshield,

the circuit diagram has been changed.

Page 23

GROUP 13

FUEL

CONTENTS

MULTIPOINT FUEL INJECTION (MPI) <4B1> . . . . . . . . . . . . . 13A

MULTIPOINT FUEL INJECTION (MPI) <6B3> . . . . . . . . . . . . . 13F

13-1

Page 24

NOTES

Page 25

GROUP 13A

MULTIPOINT FUEL

INJECTION (MPI)

<4B1>

CONTENTS

13A-1

GENERAL INFORMATION . . . . . . . . 13A-2

Page 26

13A-2

MULTIPOINT FUEL INJECTION (MPI) <4B1>

GENERAL INFORMATION

GENERAL INFORMATION

OUTLINE OF CHANGES

• The engine-ECU has been changed.

• Due to the change of the engine-ECU, diagnosis

code No. P0125 has been discontinued.

GENERAL SPECIFICATIONS

Items Specifications

Engine-ECU Identification

No.

Vehicles without heated windshield E6T79775 <4B11 - Euro4>

Vehicles with heated windshield E6T79777 <4B11 - Euro4>

The other service procedures are the same as the

conventional ones.

E6T79874 <4B12 - Euro4>

E6T79876 <4B12 - Euro4>

M1131000107638

Page 27

GROUP 13F

MULTIPOINT FUEL

INJECTION (MPI)

<6B3>

CONTENTS

13F-1

GENERAL INFORMATION . . . . . . . . 13F-2

Page 28

13F-2

MULTIPOINT FUEL INJECTION (MPI) <6B3>

GENERAL INFORMATION

GENERAL INFORMATION

OUTLINE OF CHANGES

The engine-ECU has been changed. The other service procedures are the same as the conventional

ones.

GENERAL SPECIFICATIONS

Items Specifications

Engine-ECU Identification

No.

Vehicles without heated windshield E6T80379 <Euro4>

Vehicles with heated windshield E6T80384 <Euro4>

M1130500100059

Page 29

GROUP 14

ENGINE COOLING

CONTENTS

GENERAL INFORMATION . . . . . . . . 14-2

14-1

Page 30

14-2

ENGINE COOLING

GENERAL INFORMATION

GENERAL INFORMATION

OUTLINE OF CHANGE

The following components have been changed or

discontinued <4B1>.

The other service procedures are the same as

before.

M1141000102827

• Radiator lower hose reshaped.

• Radiator hose support discontinued.

Page 31

GROUP 15

INTAKE AND

EXHAUST

CONTENTS

GENERAL INFORMATION . . . . . . . . 15-2 EXHAUST PIPE AND MAIN

MUFFLER . . . . . . . . . . . . . . . . . . . . . . 15-2

REMOVAL AND INSTALLATION . . . . . . . . 15-2

15-1

Page 32

15-2

ACE03974

13 ± 2 N·m

Exhaust pipe damper

AB

GENERAL INFORMATION

OUTLINE OF CHANGE

The service procedure has been revised as an

exhaust pipe damper has been added on the

exhaust centre pipe <2WD>.

The other service procedures are the same as

before.

EXHAUST PIPE AND MAIN MUFFLER

REMOVAL AND INSTALLATION

<2WD>

INTAKE AND EXHAUST

GENERAL INFORMATION

M1151000102549

M1151008703946

Page 33

GROUP 17

ENGINE AND

EMISSION

CONTROL

CONTENTS

17-1

ADAPTIVE CRUISE CONTROL

SYSTEM (ACC) . . . . . . . . . . . . . . . . . 17-2

GENERAL INFORMATION. . . . . . . . . . . . . 17-2

CHECK CHART FOR

DIAGNOSIS CODES . . . . . . . . . . . . . . . . . 17-2

DIAGNOSIS CODE PROCEDURES. . . . . . 17-2

CHECK CHART FOR TROUBLE

SYMPTOMS . . . . . . . . . . . . . . . . . . . . . . . . 17-5

SYMPTOM PROCEDURES . . . . . . . . . . . . 17-5

Page 34

17-2

CAUTION

ENGINE AND EMISSION CONTROL

ADAPTIVE CRUISE CONTROL SYSTEM (ACC)

ADAPTIVE CRUISE CONTROL SYSTEM (ACC)

GENERAL INFORMATION

M1172000102083

OUTLINE OF CHANGE

Due to the addition of vehicles with adaptive cruise

control system (ACC), the service procedure has

been established. <6B3>

CHECK CHART FOR DIAGNOSIS CODES

Code No. Diagnosis item Reference page

C1776 Received ACC failure from engine-ECU

C1786 Received limp home from T/M-ECU

U0100 Engine CAN timeout

U0101 T/M CAN timeout

P.17-2

P.17-3

P.17-3

P.17-4

DIAGNOSIS CODE PROCEDURES

Code No. C1776: Received ACC Failure from Engine-ECU

M1172002202019

• If there is any problem in the CAN bus lines,

an incorrect diagnosis code may be set. Prior

to this diagnosis, diagnose the CAN bus

lines.

• Whenever the ECU is replaced, ensure that

the CAN bus lines are normal.

OPERATION

ACC/FCM-ECU communicates with the engine-ECU

via the CAN bus lines.

DIAGNOSIS CODE SET CONDITION

This diagnosis code is set when the abnormality

below is detected:

• A signal, which indicates a defective engine control system, is received from the engine-ECU.

PROBABLE CAUSES

• Malfunction of the CAN bus line

• Malfunction of engine-ECU

• Malfunction of ACC/FCM-ECU

DIAGNOSIS PROCEDURE

STEP 1. M.U.T.-III CAN bus diagnostics.

Use M.U.T.-III to perform the CAN bus diagnosis.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair the CAN bus lines (Refer to GROUP

− Troubleshooting P.54C-2).

54C

STEP 2. M.U.T.-III other system diagnosis code.

Check the engine diagnosis code (Refer to GROUP

−Troubleshooting).

13F

Q: Is the diagnosis code set?

YES : Perform the relevant troubleshooting.

NO : Go to Step 3.

STEP 3. Check whether the diagnosis code is set

again.

Q: Is diagnosis code No.C1776 set?

YES : Replace the ACC/FCM-ECU.

NO : Intermittent malfunction (Refer to GROUP

− How to Cope with Intermittent

00

Malfunction).

Page 35

ENGINE AND EMISSION CONTROL

CAUTION

CAUTION

ADAPTIVE CRUISE CONTROL SYSTEM (ACC)

Code No. C1786: Received limp Home from T/M-ECU

• If there is any problem in the CAN bus lines,

an incorrect diagnosis code may be set. Prior

to this diagnosis, diagnose the CAN bus

lines.

• Whenever the ECU is replaced, ensure that

the CAN bus lines are normal.

OPERATION

ACC/FCM-ECU communicates with the A/T-ECU via

the CAN bus lines.

DIAGNOSIS CODE SET CONDITION

This diagnosis code is set when the abnormality

below is detected:

• A signal, which indicates an abnormal transmission system, is received from the A/T-ECU.

17-3

STEP 2. Use M.U.T.-III to confirm a diagnosis

code of other systems.

Check the automatic transmission (FF) diagnosis

code (Refer to GROUP 23C

Q: Is the diagnosis code set?

YES : Perform the relevant troubleshooting.

NO : Go to Step 3.

STEP 3. Check the data list.

Using M.U.T.-III, check the data list (Refer to data list

reference table).

• Item 56: transmission fail switch

Q: Is the check result normal?

YES : Go to Step 4.

NO : Go to Step 4.

−Troubleshooting).

PROBABLE CAUSES

• Malfunction of the CAN bus line

• Malfunction of A/T-ECU

• Malfunction of ACC/FCM-ECU

DIAGNOSIS PROCEDURE

STEP 1. Using M.U.T.-III, diagnose the CAN bus

line.

Use M.U.T.-III to perform the CAN bus diagnosis.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair the CAN bus lines (Refer to GROUP

54C

− Troubleshooting P.54C-2).

Code No. U0100: Engine CAN Timeout

• If there is any problem in the CAN bus lines,

an incorrect diagnosis code may be set. Prior

to this diagnosis, diagnose the CAN bus

lines.

• Whenever the ECU is replaced, ensure that

the CAN bus lines are normal.

OPERATION

ACC/FCM-ECU communicates with the engine-ECU

via the CAN bus lines.

STEP 4. Check whether the diagnosis code is set

again.

Q: Is diagnosis code No.C1786 set?

YES : Replace the ACC/FCM-ECU.

NO : Intermittent malfunction (Refer to GROUP

− How to Cope with Intermittent

00

Malfunction).

DIAGNOSIS CODE SET CONDITION

This diagnosis code is set when the abnormality

below is detected:

• The signal sent from the engine-ECU cannot be

received for a certain period.

PROBABLE CAUSES

• Malfunction of the CAN bus line

• Malfunction of engine-ECU

• Malfunction of ACC/FCM-ECU

Page 36

17-4

CAUTION

ENGINE AND EMISSION CONTROL

ADAPTIVE CRUISE CONTROL SYSTEM (ACC)

DIAGNOSIS PROCEDURE

STEP 1. M.U.T.-III CAN bus diagnostics.

Use M.U.T.-III to perform the CAN bus diagnosis.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair the CAN bus lines (Refer to GROUP

− Troubleshooting P.54C-2).

54C

STEP 2. M.U.T.-III other system diagnosis code.

Check the engine diagnosis code (Refer to GROUP

13F

−Troubleshooting).

Q: Is the diagnosis code set?

YES : Perform the relevant troubleshooting.

NO : Go to Step 3.

Code No. U0101: T/M CAN Timeout

• If there is any problem in the CAN bus lines,

an incorrect diagnosis code may be set. Prior

to this diagnosis, diagnose the CAN bus

lines.

• Whenever the ECU is replaced, ensure that

the CAN bus lines are normal.

STEP 3. M.U.T.-III other system diagnosis code.

Check if diagnosis code No. U0100 is set in other

ECU.

Q: Is the diagnosis code set?

YES : Replace the engine-ECU (Refer to GROUP

13F

− Engine-ECU).

NO : Go to Step 4.

STEP 4. Check whether the diagnosis code is set

again.

Q: Is diagnosis code No.U0100 set?

YES : Replace the ACC/FCM-ECU.

NO : Intermittent malfunction (Refer to GROUP

− How to Cope with Intermittent

00

Malfunction).

STEP 2. M.U.T.-III other system diagnosis code.

Check the automatic transmission (FF) diagnosis

code (Refer to GROUP 23C

Q: Is the diagnosis code set?

YES : Perform the relevant troubleshooting.

NO : Go to Step 3.

−Troubleshooting).

OPERATION

ACC/FCM-ECU communicates with the A/T-ECU via

the CAN bus lines.

DIAGNOSIS CODE SET CONDITION

This diagnosis code is set when the abnormality

below is detected:

• The signal sent from the A/T-ECU cannot be

received for a certain period.

PROBABLE CAUSES

• Malfunction of the CAN bus line

• Malfunction of A/T-ECU

• Malfunction of ACC/FCM-ECU

DIAGNOSIS PROCEDURE

STEP 1. M.U.T.-III CAN bus diagnostics.

Use M.U.T.-III to perform the CAN bus diagnosis.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair the CAN bus lines (Refer to GROUP

− Troubleshooting P.54C-2).

54C

STEP 3. M.U.T.-III other system diagnosis code.

Check if diagnosis code No. U0101 is set in other

ECU.

Q: Is the diagnosis code set?

YES : Replace the A/T-ECU (Refer to GROUP

− A/T-ECU).

23C

NO : Go to Step 4.

STEP 4. Check whether the diagnosis code is set

again.

Q: Is diagnosis code No.U0101 set?

YES : Replace the ACC/FCM-ECU.

NO : Intermittent malfunction (Refer to GROUP

00

− How to Cope with Intermittent

Malfunction).

Page 37

ENGINE AND EMISSION CONTROL

CAUTION

ADAPTIVE CRUISE CONTROL SYSTEM (ACC)

CHECK CHART FOR TROUBLE SYMPTOMS

Trouble symptom Inspection

procedure No.

17-5

M1172002302469

Reference page

Cruise control cannot be set (No response SET − switch is

2

P.17-5

pressed).

The cruise control is cancelled although the switch is not

3

P.17-6

operated during the ACC operation.

SYMPTOM PROCEDURES

Inspection Procedure 2: Cruise Control cannot be Set (No Response SET − Switch is Pressed).

COMMENTS ON TROUBLE SYMPTOM

The conditions for initiating the adaptive cruise control system (ACC) may not be satisfied.

PROBABLE CAUSES

• Malfunction of CAN bus system.

• Damaged harness or connector.

• Malfunction of the clock spring.

• Malfunction of the cruise control switch.

• Malfunction of the stop lamp switch.

• Malfunction of the inhibitor switch <A/T>.

• Malfunction of the parking brake switch.

• Malfunction of the engine system.

• Malfunction of the ASC system.

• Malfunction of the A/T system.

• Malfunction of the ACC/FCM−ECU.

DIAGNOSIS PROCEDURE

STEP 2. Check whether the diagnosis code is set

again.

Q: Is diagnosis code set?

YES : Repair the adaptive cruise control system

(ACC) (Refer to

NO : Go to Step 3.

P.17-2).

STEP 3. Check the other system diagnosis code.

Using M.U.T.-III, perform MPI system diagnosis code

(Refer to GROUP 13F

− Troubleshooting, Diagnosis

Function).

Q: Is any diagnosis code set?

YES : Repair the MPI system (Refer to GROUP

− Troubleshooting, Inspection Chart for

13F

Diagnosis Code).

NO : Go to Step 4.

• If there is any problem in the CAN bus lines,

an incorrect diagnosis code may be set. Prior

to this diagnosis, diagnose the CAN bus

lines.

• Before replacing the ECU, ensure that the

CAN bus lines is normal.

STEP 1. Check the CAN bus system diagnosis.

Using M.U.T.-III, perform CAN bus diagnosis (Refer

to GROUP 54C

− Explanation About The M.U.T.-III

Can Bus Diagnostics).

Q: Is the check result satisfactory?

YES : Go to Step 2.

NO : Repair the CAN bus lines (Refer to GROUP

54C

− Troubleshooting, Can Bu s Diagnostic

P.54C-2). Then go to Step 2.

Table

STEP 4. Check the other system diagnosis code.

Using M.U.T.-III, perform ASC system diagnosis

code (Refer to GROUP 35C

− Troubleshooting,

Diagnosis Function).

Q: Is the diagnosis code set?

YES : Repair the ASC system (Refer to GROUP

35C

− Troubleshooting, Inspection Chart for

Diagnosis Code

NO : Go to Step 5.

P.35C-2).

STEP 5. Check the other system diagnosis code.

Using M.U.T.-III, perform A/T system diagnosis code

(Refer to GROUP 23C

− Troubleshooting, Diag nosis

Function).

Q: Is any diagnosis code set?

YES : Repair the A/T system (Refer to GROUP

23C

−Troubleshooting, Inspection Chart for

Diagnosis Code).

NO : Go to Step 6.

Page 38

17-6

CAUTION

ENGINE AND EMISSION CONTROL

ADAPTIVE CRUISE CONTROL SYSTEM (ACC)

STEP 6. Check the other symptom.

The system should be turned on when the cruise

control switch is operated.

Q: Is the system turned on by operating the cruise

control switch?

YES : Go to Step 7.

NO : Refer to "When the cruise control switch is

operated, the system is not turned on."

STEP 8. Check the cruise control switch.

Check the cruise control switch.

Q: Is the check result normal?

YES : Replace the engine-ECU (Refer to GROUP

− Engine-ECU).

13F

NO : Replace the cruise control switch.

STEP 9. Check the symptom.

(1) Drive the vehicle for approx. three minutes.

STEP 7. Check the data list.

Using M.U.T.-III, check the data list of MPI system

(Refer to data list reference table).

• Item 75: CANCEL switch

• Item 92: SET − switch

Q: Is the check result normal?

YES : Go to Step 9.

NO : Go to Step 8.

Q: Can cruise control be set?

YES : It can be assumed that this malfunction is

intermittent (Refer to GROUP 00

− How to

Use Troubleshooting/Inspection Service

Points, How to Cope with Intermittent

Malfunction).

NO : Replace the ACC/FCM-ECU.

Inspection Procedure 3: The Cruise Control is Cancelled Although The Switch is not Operated During

The ACC Operation.

COMMENTS ON TROUBLE SYMPTOM

A malfunction is detected while the adaptive cruise

control system (ACC) is activated.

PROBABLE CAUSES

• Malfunction of CAN bus system.

• Damaged harness or connector.

• Malfunction of the engine system.

• Malfunction of the ASC system.

• Malfunction of the ACC/FCM−ECU.

DIAGNOSIS PROCEDURE

• If there is any problem in the CAN bus lines,

an incorrect diagnosis code may be set. Prior

to this diagnosis, diagnose the CAN bus

lines.

• Before replacing the ECU, ensure that the

CAN bus lines is normal.

STEP 1. Check the CAN bus system diagnosis.

Using M.U.T.-III, perform CAN bus diagnosis (Refer

to GROUP 54C

Can Bus Diagnostics).

− Explanation About The M.U.T.-III

STEP 2. Check whether the diagnosis code is set

again.

Q: Is diagnosis code set?

YES : Repair the adaptive cruise control system

(ACC) (Refer to

NO : Go to Step 3.

P.17-2).

STEP 3. Check the other system diagnosis code.

• Using M.U.T.-III, perform MPI system diagnosis

code (Refer to GROUP 13F

− Troubleshooting,

Diagnosis Function).

• Using M.U.T.-III, perform cruise control system

diagnosis code (Refer to

Q: Is any diagnosis code set?

YES <MPI system> : Repair the MPI system (Refer

to GROUP 13F

P.17-2>.

− Troubleshooting,

Inspection Chart for Diagnosis Code).

YES <Cruise control system> : Repair the cruise

control system (Refer to

NO : Go to Step 4.

P.17-2).

Q: Is the check result satisfactory?

YES : Go to Step 2.

NO : Repair the CAN bus lines (Refer to GROUP

54C

− Troubleshooting, Can Bu s Diagnostic

P.54C-2). Then go to Step 2.

Table

Page 39

ENGINE AND EMISSION CONTROL

ADAPTIVE CRUISE CONTROL SYSTEM (ACC)

17-7

STEP 4. Check the other system diagnosis code.

Using M.U.T.-III, perform ASC system diagnosis

code (Refer to GROUP 35C

− Troubleshooting,

Diagnosis Function).

Q: Is the diagnosis code set?

YES : Repair the ASC system (Refer to GROUP

− Troubleshooting, Inspection Chart for

35C

Diagnosis Code

NO : Go to Step 5.

P.35C-2).

STEP 5. Check the other symptom.

The system should be turned on when the cruise

control switch is operated.

Q: Is the system turned on by operating the cruise

control switch?

YES : Go to Step 6.

NO : Refer to "When the cruise control switch is

operated, the system is not turned on."

STEP 6. Check the cruise control switch.

Check the cruise control switch.

Q: Is the check result normal?

YES : Go to Step 7.

NO : Replace the cruise control switch.

STEP 7. Check the symptom.

(1) Drive the vehicle for approx. three minutes.

Q: Is the cruise control cancelled?

YES : Replace the ACC/FCM-ECU.

NO : It can be assumed that this malfunction is

intermittent (Refer to GROUP 00

− How to

Use Troubleshooting/Inspection Service

Points, How to Cope with Intermittent

Malfunction).

Page 40

NOTES

Page 41

GROUP 23

AUTOMATIC

TRANSMISSION

CONTENTS

CVT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23A

23-1

CONTINUOUSLY VARIABLE

TRANSMISSION OVERHAUL . . . . . . . . . . . . . . . . . . . . . . . . . . 23B

Page 42

NOTES

Page 43

GROUP 23A

CVT

CONTENTS

23A-1

GENERAL INFORMATION . . . . . . . . 23A-2

SERVICE SPECIFICATIONS. . . . . . . 23A-14

LUBRICANTS . . . . . . . . . . . . . . . . . . 23A-14

SPECIAL TOOLS. . . . . . . . . . . . . . . . 23A-15

TROUBLESHOOTING. . . . . . . . . . . . 23A-18

INITIALISATION PROCEDURE

FOR CVT LEARNED VALUE . . . . . . . . . . . 23A-18

LEARNING PROCEDURE . . . . . . . . . . . . . 23A-18

FLUID DETERIORATION LEVEL

ERASING PROCEDURE . . . . . . . . . . . . . . 23A-23

DIAGNOSTIC FUNCTION . . . . . . . . . . . . . 23A-23

ROAD TEST . . . . . . . . . . . . . . . . . . . . . . . . 23A-24

RATIO PATTERN . . . . . . . . . . . . . . . . . . . . 23A-28

DAMPER CLUTCH OPERATION ZONE . . 23A-29

DIAGNOSIS CODE CHART . . . . . . . . . . . . 23A-30

DIAGNOSIS CODE PROCEDURES . . . . . 23A-31

TROUBLE SYMPTOM DIAGNOSIS

CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23A-64

DATA LIST REFERENCE TABLE . . . . . . . 23A-66

CVT-ECU TERMINAL

VOLTAGE TABLE. . . . . . . . . . . . . . . . . . . . 23A-72

OSCILLOSCOPE INSPECTION

PROCEDURES. . . . . . . . . . . . . . . . . . . . . . 23A-74

HYDRAULIC PRESSURE TEST. . . . . . . . . 23A-83

SELECTOR LEVER OPERATION

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23A-85

SHIFT LOCK MECHANISM CHECK. . . . . . 23A-86

OIL SEAL . . . . . . . . . . . . . . . . . . . . . . 23A-87

REMOVAL AND INSTALLATION . . . . . . . . 23A-87

OIL FILTER. . . . . . . . . . . . . . . . . . . . . 23A-89

REMOVAL AND INSTALLATION . . . . . . . . 23A-89

OIL PAN AND VALVE BODY

ASSEMBLY. . . . . . . . . . . . . . . . . . . . . 23A-90

REMOVAL AND INSTALLATION . . . . . . . . 23A-90

INHIBITOR SWITCH. . . . . . . . . . . . . . 23A-93

REMOVAL AND INSTALLATION . . . . . . . . 23A-93

SENSORS. . . . . . . . . . . . . . . . . . . . . . 23A-94

REMOVAL AND INSTALLATION . . . . . . . . 23A-94

TRANSMISSION ASSEMBLY . . . . . . 23A-94

REMOVAL AND INSTALLATION . . . . . . . . 23A-94

TRANSFER ASSEMBLY <4WD>. . . . 23A-99

REMOVAL AND INSTALLATION . . . . . . . . 23A-99

ON-VEHICLE SERVICE. . . . . . . . . . . 23A-76

ESSENTIAL SERVICE . . . . . . . . . . . . . . . . 23A-76

CONTROL SYSTEM COMPONENT

PART CONFIGURATION DIAGRAM . . . . . 23A-79

CVT CONTROL COMPONENT CHECK . . 23A-79

TORQUE CONVERTER STALL TEST. . . . 23A-83

CVT-ECU. . . . . . . . . . . . . . . . . . . . . . . 23A-100

REMOVAL AND INSTALLATION . . . . . . . . 23A-100

CVT FLUID COOLER AND

COOLER LINE . . . . . . . . . . . . . . . . . . 23A-100

REMOVAL AND INSTALLATION . . . . . . . . 23A-100

Page 44

23A-2

GENERAL INFORMATION

CVT

GENERAL INFORMATION

M1231200101103

CVT

Newly developed F1CJC type CVT and W1CJC type

CVT have been adopted.

They are basically the same as conventional CVT.

However, they have the following features:

• Shift feeling and fuel efficiency have been

improved due to a wider range of pulley ratio.

SPECIFICATIONS

Item Specifications

Transmission model F1CJC W1CJC-1 W1CJC-2

Torque converter Model 3-element, 1-stage, 2-phase

Stall torque ratio 1.995 1.826

Lock-up Present

Transmission type Forward automatic CVT (steel belt-driven), reverse 1

• Fuel efficiency has been improved as a compact

oil pump has been used, resistance in stirred oil

has been reduced and a belt running efficiency

has been improved.

speed

Pulley ratio Forward 2.631 − 0.378

Reverse 1.960

Final reduction gear ratio 6.026

Shift position P-R-N-D+6-speed sport mode (with the paddle shift)

Control type Electronically-controlled

Function Shift control Present

Line pressure control Present

Select control Present

Lock-up control Present

Self-diagnosis function Present

Fail-safe function Present

Slip control at start Present

Oil pump Model Vane-type pump

Drive type Driven by the engine, sprocket, and chain

CVT fluid Brand name MITSUBISHI MOTORS GENUINE CVTF-J4

Capacity (L) 6.9

Page 45

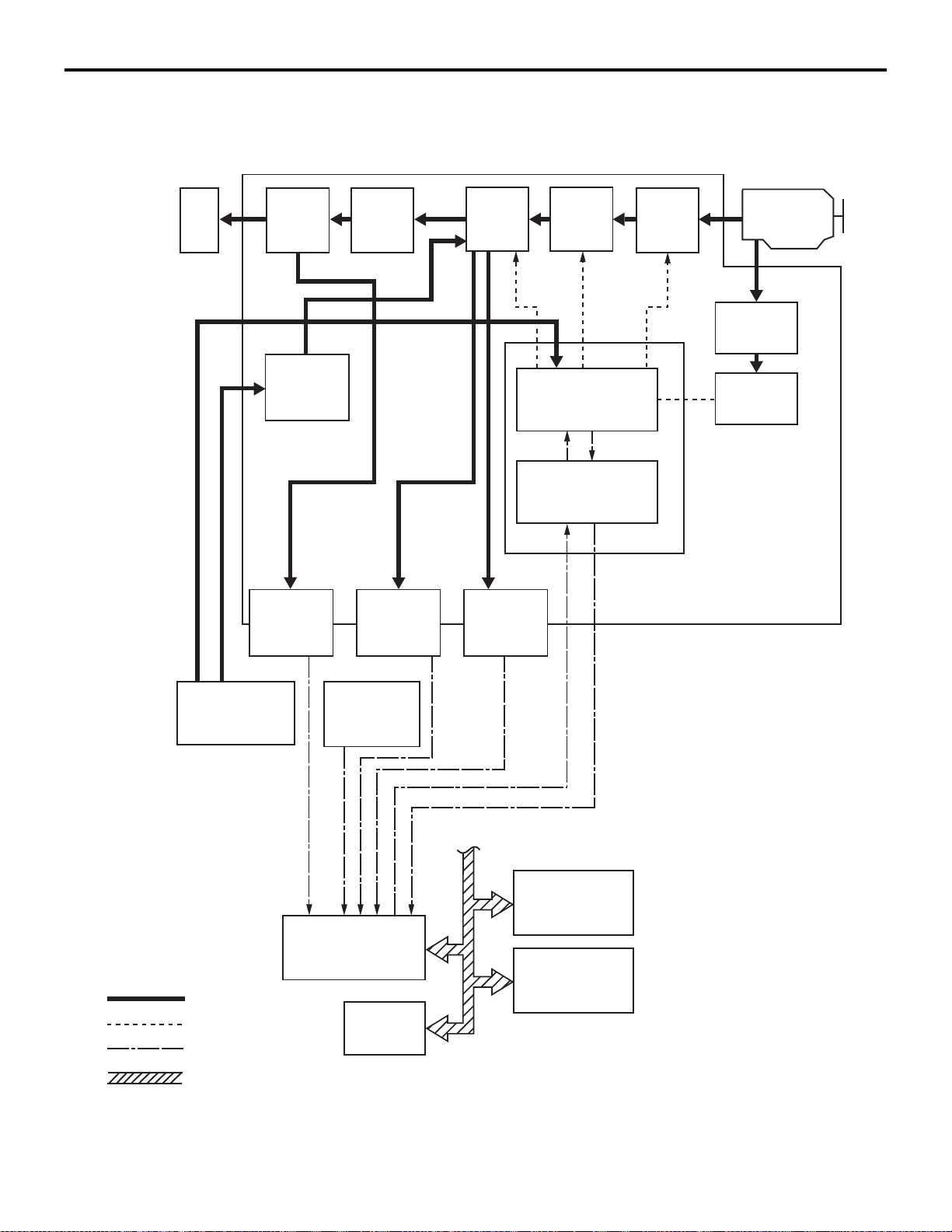

SYSTEM CONFIGURATION

ACD03944

Belt &

pulley

AB

Wheel

Reduction

gear

Engine

Forward/

reverse

switching

mechanism

Torque

converter

Sprocket & chain

Oil pump

Hydraulic control

system

Turbine

speed

sensor

Control device Inhibitor switch

CVT-ECU

ABS/ASC-ECU

Engine-ECU

Parking

mechanism

<In transmission>

<In valve body>

: Mechanical system

: CAN communication

ETACSECU

Differential

gear

Electronic control

system

Secondary

pulley speed

sensor

: Oil pressure system

: Electrical system

Primary

pulley speed

sensor

CVT

GENERAL INFORMATION

23A-3

Page 46

23A-4

ACD03886

CVT fluid

cooler

Inhibitor switch

AB

Secondary pulley

speed sensor

Primary pulley

speed sensor

CVT fluid filter

Turbine speed

sensor

OVERVIEW

CVT

GENERAL INFORMATION

Page 47

CVT

ACD03942

AB

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

GENERAL INFORMATION

DESCRIPTION OF STRUCTURE AND OPERATION

SECTIONAL VIEW

23A-5

1. Converter housing

2. Driven sprocket

3. Chain

4. Reverse brake

5. Oil pump

6. Forward clutch

7. Planet carrier

8. Primary pulley

9. Sun gear

10. Steel belt

11. Side cover

12. Internal gear

13. Parking gear

14. Secondary pulley

15. Final ge ar

16. Differential case

Page 48

23A-6

ACD03885

AB

CVTECU

Primary pulley

speed

CVT fluid

temperature

Lubricating and

cooling systems

Torque

converter

engage

Oil pump

Primary pulley

Secondary pulley

Forward clutch

Reverse brake

Manual valve

Primary reducing

valve

Valve body

Mechanical system

Oil pressure system

Electrical system

Pressure

regulator valve

Torque converter

regulator valve

Lock-up

control valve

Lock-up

solenoid valve

Inhibitor

switch

Engine

speed

Secondary

pulley speed

Throttle

opening

Secondary pressure

solenoid valve

Primary pressure

solenoid valve

Pilot valve A

Input signals

Secondary

pressure

Torque

converter

release

Primary

pressure

Turbine

speed

Line pressure

solenoid valve

Select solenoid valve

Pilot valve B

Secondary

reducing valve

GENERAL INFORMATION

17. Idler ge ar

18. Reduction gear

19. Taper roller bearing

20. Output gear

21. Drive sprocket

22. Input shaft

23. Torque converter

HYDRAULIC CONTROL SYSTEM

CONTROL DESCRIPTION

The hydraulic control mechanism is comprised of the

vane-type oil pump driven by the engine via the oil

pump drive chain, the hydraulic control valve which

controls the line pressure and shift change, and the

input signal system.

CVT

Page 49

CVT

GENERAL INFORMATION

23A-7

GENERAL INFORMATION REGARDING THE MAIN COMPONENTS

Component Function

Manual valve Distributes the clutch operating pressure to each circuit,

depending on each selector lever position.

Lock-up control valve Regulates the engagement pressure and disengagement

pressure of the torque converter.

Torque converter regulator valve Regulates the supply pressure to the torque converter to the

optimal pressure for the driving conditions.

Pressure regulator valve Regulates the discharge pressure from the oil pump to the

optimal pressure (line pressure) for the driving conditions.

Secondary reducing valve Reduces the line pressure to regulate the secondary pressure.

Primary reducing valve Reduces the line pressure to regulate the primary pressure.

Pilot valve A Reduces the line pressure to regulate the operation pressures

of the solenoid valves below:

• Primary pressure solenoid valve

• Secondary pressure solenoid valve

• Line pressure solenoid val ve

• Select solenoid valve

Pilot valve B Reduces fluid pressure delivered from pilot valve A to regulate

the operation pressure of the lock-up solenoid valve.

Line pressure solenoid valve Controls the pressure regulator valve.

Primary pressure solenoid valve Controls the primary reducing valve.

Secondary pressure solenoid valve Controls the secondary reducing valve.

Lock-up solenoid valve Controls the lock-up control valve.

Select solenoid valve Regulates the forward clutch pressure and reverse brake

pressure.

Page 50

23A-8

ACD03887

AB

Line pressure

Primary pulley

Secondary pulley

Primary reducing

valve

Secondary

reducing valve

SHIFT MECHANISM

Pulley ratio

CVT

GENERAL INFORMATION

The system applies the primary pressure, which is

regulated by the primary reducing valve, to the pri

mary pulley and the secondary pressure, which is

regulated by the secondary reducing valve, to the

secondary pulley, respectively. Pulley ratio depends

on these pressures.

-

Page 51

CVT

ACD03888

Line pressure

solenoid valve

: Electrical system

: CAN communication

Line pressure

control

Inhibitor switch signal

Turbine speed sensor

CVT fluid temperature

sensor

Secondary pulley

speed sensor

Primary pulley speed

Primary pulley

speed sensor

CVT fluid temperature

Secondary pulley speed

Secondary pressure

sensor

Secondary hydraulic pressure

Turbine speed

CVT-ECU

·

Accelerator opening angle

signal

·

Engine speed signal

·

Engine torque signal

·

Stop lamp switch signal

·

Sport mode signal

AB

: Oil pressure system

Pressure

regulator valve

Secondary

pressure

control

Secondary pressure

solenoid valve

Secondary

reducing valve

Primary pressure

sensor

Primary hydraulic pressure

GENERAL INFORMATION

LINE PRESSURE CONTROL AND SECONDARY PRESSURE CONTROL

23A-9

The high-precision line pressure control and secondary pressure control have reduced the friction for better fuel economy.

Page 52

23A-10

ACD03889

Lock-up

solenoid valve

: Electrical system

: CAN communication

Lock-up

control

Inhibitor switch signal

Turbine speed sensor

CVT fluid temperature

sensor

Secondary pulley

speed sensor

Primary pulley speed

Primary pulley

speed sensor

CVT fluid temperature

Secondary pulley speed

Secondary pressure

sensor

Secondary hydraulic pressure

Turbine speed

CVT-ECU

AB

: Oil pressure system

Lock-up pressure

control valve

·

Accelerator opening angle

signal

·

Engine speed signal

·

Engine torque signal

·

Stop lamp switch signal

·

Sport mode signal

Primary pressure

sensor

Primary hydraulic pressure

LOCK-UP CONTROL

CVT

GENERAL INFORMATION

• The system engages the lock-up clutch in the

torque converter to eliminate slips in the torque

converter. This improves the transmission effi

ciency. The slip in the lock-up clutch is controlled

optimally, thus allowing a comfortable driving.

-

• The lock up control valve is controlled by the

lock-up pressure solenoid valve, and the lock-up

solenoid valve is controlled by the signal from the

CVT-ECU. The lock up control valve sets the

lock-up clutch into a state of engagement, or dis

engagement.

• It inhibits lock-up operation when the fluid temperature is low.

-

Page 53

SELECT CONTROL

ACD03890

Line pressure

solenoid valve

: Electrical system

: CAN communication

Select

control

Inhibitor switch signal

Turbine speed sensor

CVT fluid temperature

sensor

Secondary pulley

speed sensor

Primary pulley speed

Primary pulley

speed sensor

CVT fluid temperature

Secondary pulley speed

Secondary pressure

sensor

Secondary hydraulic pressure

Turbine speed

CVT-ECU

AB

Select solenoid valve

·

Accelerator opening angle

signal

·

Engine speed signal

·

Engine torque signal

·

Stop lamp switch signal

Primary pressure

sensor

Primary hydraulic pressure

CVT

GENERAL INFORMATION

23A-11

When an operation of N → D or P → R range is performed, the optimal operating pressure is set based

on the accelerator angle, engine speed, primary pul

ley speed, secondary pulley speed and turbine

speed to reduce the shock caused by shifting.

-

Page 54

23A-12

GENERAL INFORMATION

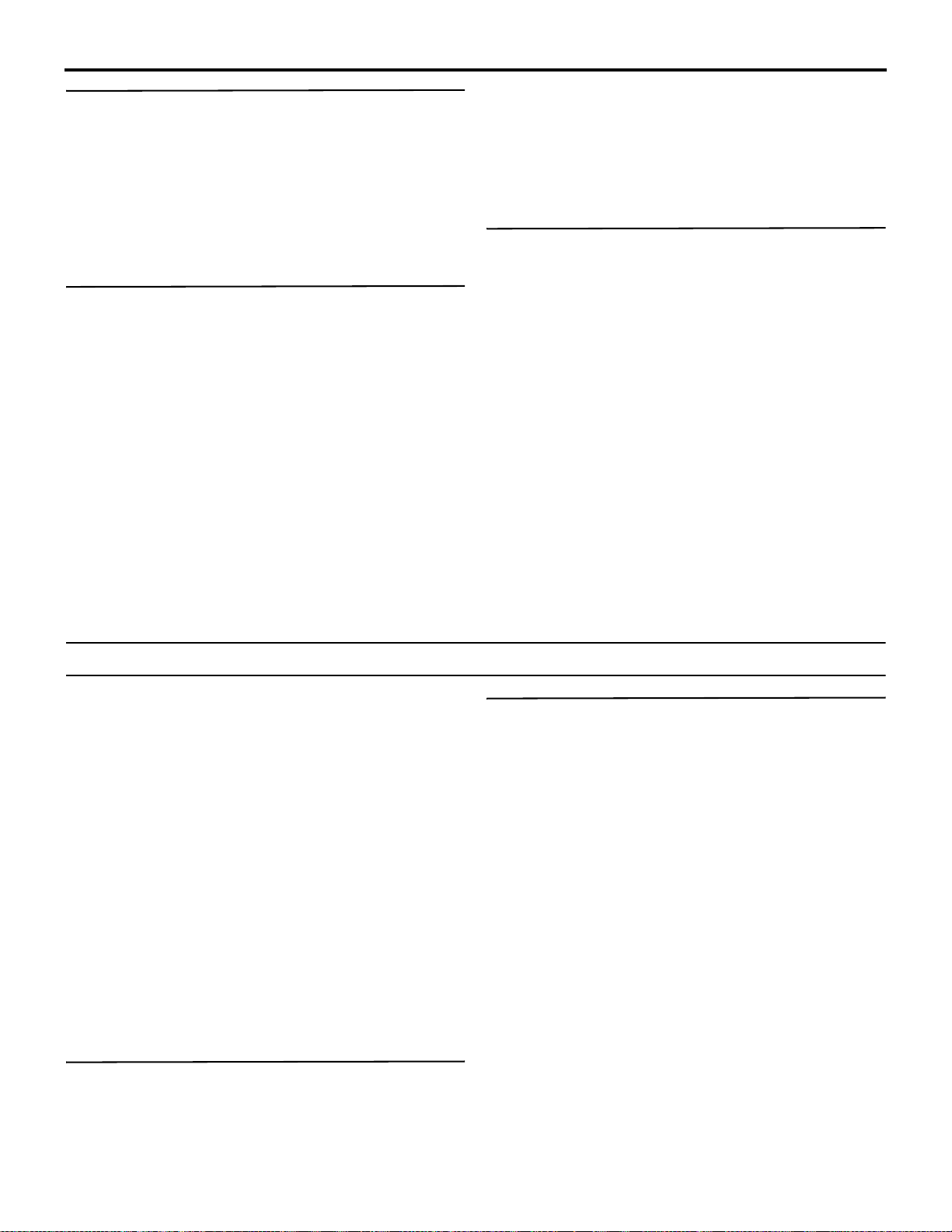

CONTROL ELEMENTS AND INPUT/OUTPUT

Item Input/output signal Control

Shift

control

CVT

Line

pressure

control

Select

control

Lock-up

control

Fail-safe

function*

Input Engine torque signal

Engine speed signal

Throttle position signal

Idle signal

Stop lamp switch signal

Primary pressure sensor

Secondary pressure sensor

CVT fluid temperature sensor

Turbine speed sensor

Primary pulley speed sensor

Secondary pulley speed sensor

Inhibitor switch

Shift switch assembly

Output Line pressure solenoid valve

Primary pressure solenoid valve

Lock-up solenoid valve

Secondary pressure solenoid valve

× × × × ×

× × × × ×

× × × × −

× × − × −

× × × × −

− × − − ×

× × − − ×

× × × × ×

× × × × ×

× × × × ×

× × − × ×

× × × × ×

× × − × −

× × × − ×

× × − − ×

− − − × ×

× × − − ×

Select solenoid valve

Selector lever position display

NOTE: *: If an abnormal input/output signal is generated, the CVT-ECU will trigger a fail-safe function.

× − × − ×

− − × − −

Page 55

CVT

GENERAL INFORMATION

23A-13

FAIL-SAFE FUNCTION

If abnormality occurs in signals from various sensors,

switches, or solenoids, this function allows control

ling them with the minimum adverse effect to the

driving performance.

-

PROTECTION CONTROL

General

• If the CVT-ECU or the transmission may be damaged or deteriorated, the CVT-ECU will be protected temporarily for safety. If a safety can be obtained again, the system will resume normal operation.

• The CVT-ECU has the protection functions as below:

Control during wheel spinning

Item Contents

Control content When the system detects a wheel spinning, it will restrict engine performance and

pulley ratio to increase line pressure. The clutch pressure is also increased.

Vehicle behaviour

during control

Resume condition The system resumes normal operation when wheel spinning is eliminated.

The engine speed and the vehicle speed will not be increased although the driver

continues to depress the accelerator pedal during a wheel spinning.

Control at high oil temperature

Item Contents

Control content When the CVT fluid temperature rises, the system will decrease the maximum

permissible shifting speed and torque to avoid overheat.

Vehicle behaviour

during control

Resume condition Resumes normal operation when the CVT fluid temperature drops.

Torque reduction when the vehicle is reversing

Item Contents

Control content The system restricts the engine performance in accordance with vehicle speed when

Vehicle behaviour

during control

Resume condition Resumes normal operation when the selector lever is moved from R range to

Reversing prevention

Item Contents

Control content The system will deactivate the reverse brake when the selector lever is moved to R

Vehicle behaviour

during control

Resume condition Resumes normal operation when the vehicle is driven at lower speed. (The system

Note that driving performance may be deteriorated.

the vehicle is reversing.

Driving performance may be deteriorated.

another.

range while driving forwards at a certain speed.

The transmission will remain at neutral range although the driver moves the selector

lever to R range while the vehicle is driven forwards.

engages the reverse brake)

Page 56

23A-14

SERVICE SPECIFICATIONS

CVT

SERVICE SPECIFICATIONS

M1231200300740

Item Standard value

CVT fluid temperature sensor resistance kΩ at 20°C 6.29 − 6.83

at 50°C 2.10 − 2.25

at 80°C 0.85 − 0.90

Line pressure solenoid valve coil resistance Ω • 5.5 − 7.0 (fluid temperature:

20

Primary pressure solenoid valve coil resistance Ω

Secondary pressure solenoid valve coil resistance Ω

Select solenoid valve coil resistance Ω

Lock-up solenoid valve coil resistance Ω

Engine stall speed r/min D range 2,400 − 2,900

R range 2,400 − 2,900

°C)

• 6.0 − 8.0 (fluid temperature:

°C)

50

• 6.5 − 8.5 (fluid temperature:

°C)

80

LUBRICANTS

Item Brand name Capacity L

CVT fluid MITSUBISHI MOTORS GENUINE CVTF-J4 6.9

M1231200400907

Page 57

CVT

ACB05421

MB992745

MB992746

MB992744

MB992747

MB992748

a

b

c

d

e

DO NOT USE

AB

SPECIAL TOOLS

SPECIAL TOOLS

Tool Number Name Use

a.MB992744

b.MB992745

c. MB992746

d.MB992747

e.MB992748

a.Vehicle

communication

interface-Lite

(V.C.I.-Lite)

b.V.C.I.-Lite main

harness A (for

vehicles with

CAN

communication)

c. V.C.I.-Lite main

harness B (for

vehicles without

CAN

communication)

d.V.C.I.-Lite USB

cable short

e.V.C.I.-Lite USB

cable long

CVT check (M.U.T.-III diagnosis

code display and service data

display)

23A-15

M1231200600752

Page 58

23A-16

CAUTION

MB991910

MB991826

MB991955

MB991911

MB991824

MB991827

MB991825

a

b

c

d

e

f

DO NOT USE

MB992006

AC103525

A

a

CVT

SPECIAL TOOLS

Tool Number Name Use

MB991955

a: MB991824

b: MB991827

c: MB991910

d: MB991911

e: MB991825

f: MB991826

M.U.T.-III

sub-assembly

a: Vehicle

communication

interface (V.C.I.)

b: USB cable

c: M.U.T.-III main

harness A

(applicable to

vehicles with

CAN

communication)

For vehicles with CAN

communication, use the M.U.T .-III

main harness A to send the

simulated vehicle speed. If you

connect the M.U.T.-III main

harness B instead, the CAN

communication does not

function correctly.

CVT check (M.U.T.-III diagnosis

code display and service data

display)

d: M.U.T.-III main

harness B

(applicable to

vehicles without

CAN

communication)

e: Measurement

adapter

f: Trigger harness

MB992006 Extra fine probe Continuity check and voltage

measurement at harness wire or

connector

MD998330

a: MD998331

Oil pressure gauge

(3.0 MPa)

Hydraulic pressure measurement

a: Joint

MB992127 Joint

Page 59

CVT

B991454

B991527

MB992906

Z203830

B992853

SPECIAL TOOLS

Tool Number Name Use

MB992075 Handle Use with oil seal installer

MB992140 Oil seal installer Installation of side oil seal

MB992206 Oil seal installer Installation of side oil seal <2WD>

23A-17

MB991454 Engine hanger

balancer

MB991527 Engine hanger

MB992906 Engine hanger

attachment

MB991895 Engine hanger

Engine assembly support during

automatic transmission assembly

removal and installation {For the

engine hanger balancer

(MB991454), use chains only.}

NOTE: Engine hanger balancer

(MB991454) is a part of the engine

hanger assembly (MB991453).

MB992853 Engine hanger plate

Page 60

23A-18

ACD04025

1XG3C

Y13317653

Serial number (A)

1XG3C Y317653

Serial number (M.U.T.-III Display)

Part number

Factory code

Year

Month

Number

Part number

Factory code

Number

Month

AB

A

CVT

TROUBLESHOOTING

TROUBLESHOOTING

INITIALISATION PROCEDURE FOR CVT LEARNED VALUE

M1231202400419

PURPOSE

After the CVT assembly and the valve body assembly are replaced, their serial number and learned

value must be initialised. The initialisation procedure

is as below.

INITIALISATION PROCEDURE

1. Move the selector lever to the P range and turn

the ignition switch to the "LOCK" (OFF) position.

Then, connect M.U.T.-III to the diagnosis

connector.

2. Turn the ignition switch to the "ON" position, and

then move the selector lever to the R range.

3. Depress the accelerator pedal while depressing

the brake pedal. (Engine stops.) Use the M.U.T.-III

special function to execute "Reset (item No.1:

Control learning value)" while holding them in

applied position.

4. Set the selector lever to the P range.

5. Turn the ignition switch to the "LOCK" (OFF)

position, and then wait for ten seconds.

6. Turn the ignition switch to the "ON" position.

Execute the special function "CVT oil degradation

level (item No.1: Clear CVT oil degradation level)"

on the M.U.T.-III to delete a CVT fluid

deterioration level.

WHEN REPLACING THE CVT-ECU

1. Turn the ignition switch to the "LOCK" (OFF)

position. Then, connect M.U.T.-III to the diagnosis

connector.

2. Turn the ignition switch to the "ON" position.

3. Execute the special function "Write calibration

value (Calibration value Read&save)" on the

M.U.T.-III to read a serial number which is stored

in the CVT-ECU.

LEARNING PROCEDURE

When the CVT-ECU, the CVT assembly or the valve

body assembly is replaced, adopt the system by

using the M.U.T.-III.

M1231224400019

4. Make sure that the read serial number

corresponds with the one stamped on the CVT

assembly (see illustration).

NOTE: If it does not correspond, observe the following procedure.

.

Page 61

a.

ACD04026

1XG3C Y317653

Serial number (M.U.T.-III Display)

Part number

Factory code

Number

Y317653 - 13

Serial number (B)

Factory code

Year

Month

Number

Month

1XG3C

Serial number (A)

Part number

AB

B

A

a. Remove the oil pan (refer to P.23A-90), and

check the serial number of the valve body

assembly shown in the illustration.

b. If no serial number is stamped on the valve

body assembly, import data from the server to

the M.U.T.-III according to the serial number

on the CVT assembly.

c. If a serial number is stamped on the valve

body assembly , ma ke sure that the read serial

number corresponds with the one stamped on

the valve body assembly (see illustration).