Mitsubishi PKFY-P-NHMU-E2 Installation Manual

Air-Conditioners For Building Application

INDOOR UNIT

PKFY-P·NHMU-E2

For use with the R410A & R22

A utiliser avec le R410A et le R22

Para utilizar con el R410A y el R22

INSTALLATION MANUAL

For safe and correct use, read this manual and the outdoor unit installation manual thoroughly before installing

the air-conditioner unit.

MANUEL D’INSTALLATION

Avant d’installer le climatiseur, lire attentivement ce manuel, ainsi que le manuel d’installation de l’appareil

extérieur pour une utilisation sûre et correct.

MANUAL DE INSTALACIÓN

Para un uso correcto y seguro, lea detalladamente este manual y el manual de instalación de la unidad exterior

antes de instalar la unidad de aire acondicionado.

FOR INSTALLER

English

POUR L’INSTALLATEUR

Français

PARA EL INSTALADOR

Español

Contents

1. Safety precautions .............................................................................................2

2. Installation location ............................................................................................3

3. Installing the indoor unit ....................................................................................3

4. Installing the refrigerant piping ..........................................................................6

Note:

The phrase “Wired remote controller” in this installation manual refers to the PAR-21MAA.

If you need any information for the other remote controller, please refer to either the installation manual or initial setting manual which are included in these

box.

5. Drainage piping work .........................................................................................7

6. Electrical work ...................................................................................................8

7. Test run (Fig. 7-1) ............................................................................................10

1. Safety precautions

X Before installing the unit, make sure you read all the “Safety

precautions”.

X Please report to your supply authority or obtain their consent before

connecting this equipment to the power supply system.

Warning:

Describes precautions that must be observed to prevent danger of injury or

death to the user.

Caution:

Describes precautions that must be observed to prevent damage to the unit.

After installation work has been completed, explain the “Safety Precautions,” use,

and maintenance of the unit to the customer according to the information in the

Operation Manual and perform the test run to ensure normal operation. Both the

Installation Manual and Operation Manual must be given to the user for keeping.

These manuals must be passed on to subsequent users.

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

• Install the unit at a place that can withstand its weight.

• Use the specified cables for wiring.

• Use only accessories authorized by Mitsubishi Electric and ask the dealer

or an authorized technician to install them.

• Do not touch the heat exchanger fins.

• Install the air conditioner according to this Installation Manual.

• Have all electric work done by a licensed electrician according to local

regulations.

• If the air conditioner is installed in a small room, measures must be taken

to prevent the refrigerant concentration from exceeding the safety limit

even if the refrigerant should leak.

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts.

: Indicates that the main power switch must be turned off before servicing.

: Beware of electric shock.

: Beware of hot surface.

: At servicing, please shut down the power supply for both the Indoor and

ELV

Outdoor Unit.

Warning:

Carefully read the labels affixed to the main unit.

• The cut face punched parts may cause injury by cut, etc. The installers are

requested to wear protective equipement such as gloves, etc.

• When installing or relocating, or servicing the air conditioner, use only the

specified refrigerant (R410A) to charge the refrigerant lines. Do not mix it

with any other refrigerant and do not allow air to remain in the lines.

If air is mixed with the refrigerant, then it can be the cause of abnormal

high pressure in the refrigerant line, and may result in an explosion and

other hazards.

The use of any refrigerant other than that specified for the system will

cause mechanical failure or system malfunction or unit breakdown. In the

worst case, this could lead to a serious impediment to securing product

safety.

Caution:

• Do not use the existing refrigerant piping, when use R410A refrigerant.

• Use ester oil, either oil or alkylbenzene (small amount) as the refrigerator

oil to coat flares and flange connections, when use R410A refrigerant.

• Do not use the air conditioner where food, pets, plants, precision

instruments, or artwork are kept.

• Do not use the air conditioner in special environments.

• Ground the unit.

• Install an leak molded case circuit braker, as required.

• Use power line cables of sufficient current carrying capacity and rating.

• Use only a molded case circuit braker and fuse of the specified capacity.

• Do not touch the switches with wet fingers.

• Do not touch the refrigerant pipes during and immediately after operation.

• Do not operate the air conditioner with the panels and guards removed.

• Do not turn off the power immediately after stopping operation.

2

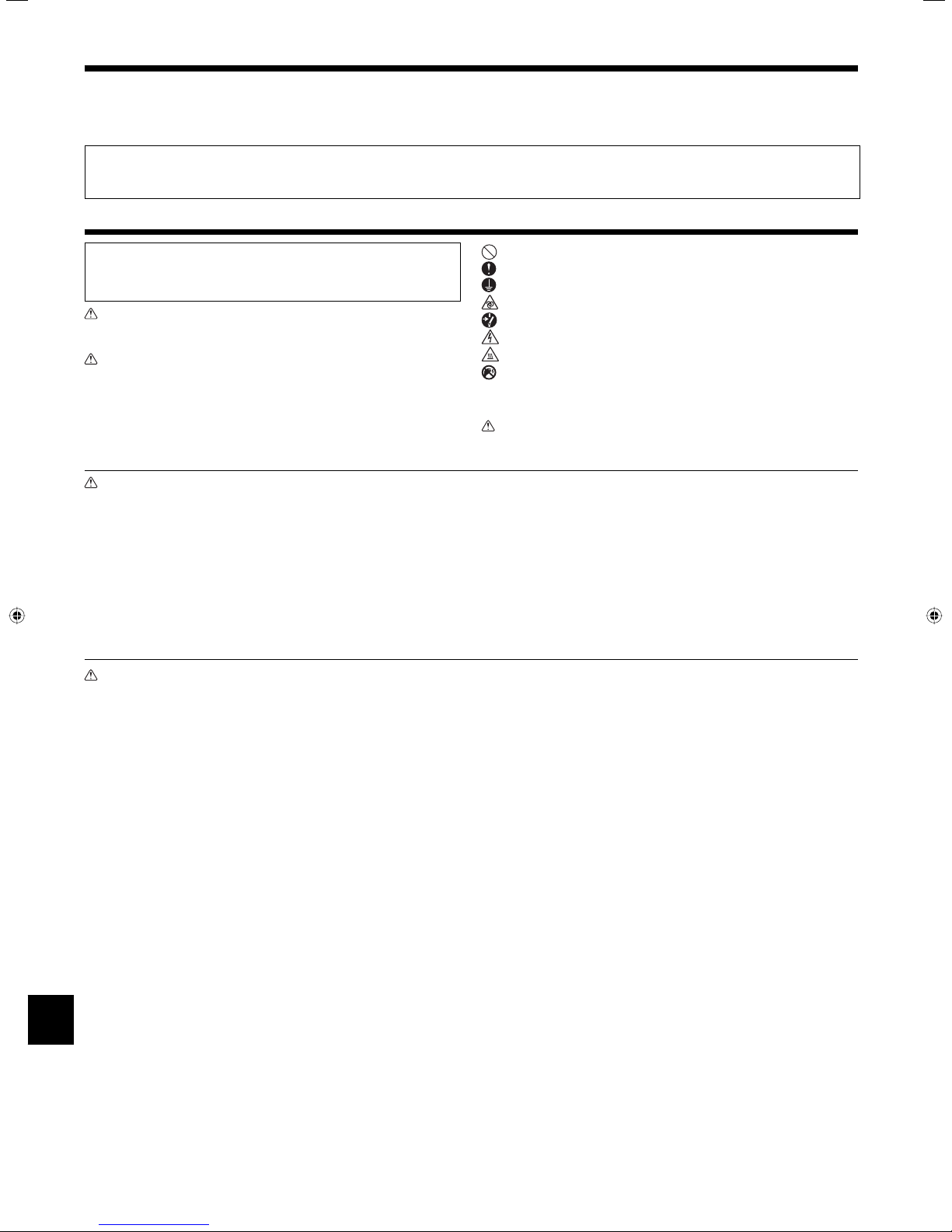

2. Installation location

G

PKFY-P·NHMU-E2

L

M

B

F

898

35-23/64

Fig. 2-1

3. Installing the indoor unit

1

4 5

2 3

2.1. Outline dimensions (Indoor unit) (Fig. 2-1)

A

249

9-51/64

E

*

(mm)

(inch)

C

K

295

11-39/64

D

J

H

I

Select a proper position allowing the following clearances for installation and

maintenance.

PKFY-P·NHMU-E2

(mm, inch)

ABCDE

Min. 150 Min. 50 Min. 50 Min. 250 Min. 220

Min. 5-29/32 Min. 1-31/32 Min. 1-31/32 Min. 9-27/32 Min. 8-21/32

F

Air outlet: Do not place an obstacle within 1500 mm, 59-1/16 inch of the air outlet.

G Floor surface

H Furnishing

I When the projection dimension of a curtain rail or the like from the wall exceeds 60 mm,

2-23/64 inch extra distance should be taken because the fan air current may create a short

cycle.

J 1800 mm, 70-7/8 inch or greater from the floor surface (for high location mounting)

K 55 mm, 2-11/64 inch or greater with left or rear left piping and optional drain pump

installation

L 550 mm, 21-21/32 inch or greater with optional drain pump installation

M Minimum 7 mm, 9/32 inch: 250 mm, 9-27/32 inch or greater with optional drain pump

installation

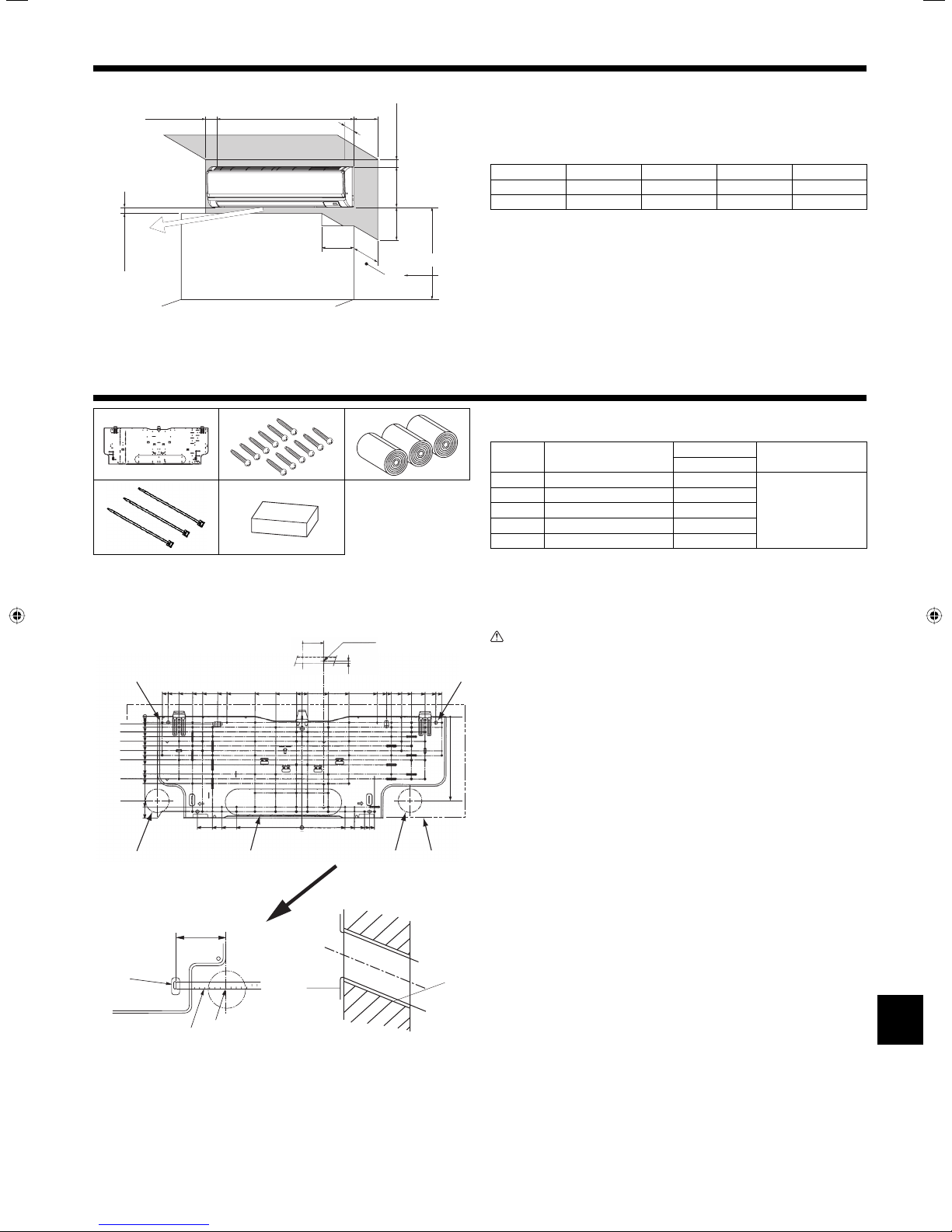

3.1. Check the indoor unit accessories (Fig. 3-1)

The indoor unit should be supplied with the following accessories.

PART

NUMBER

1

2

3

4

5

ACCESSORY

Mount board 1

Tapping screw 4 × 35

Felt tape 3

Band 3

Block of cushion 1

QUANTITY

P08, P12, P15, P18

12

LOCATION OF

SETTING

Fix at the back of

the unit

Fig. 3-1

PKFY-P·NHMU-E2

G

2-9/32

H

14-21/32

14-1/32

12-57/64

11-15/32

10-7/16

8-55/64

7-7/8

4-59/64

2-3/4

19/32

5/8

25/32

1-1/8

1-39/64

2-7/64

2-19/32

3-3/32

3-37/64

4-5/64

4-9/16

5-1/16

6-3/64

6-17/32

7-1/32

9-5/32

9-31/64

9-63/64

9-3/8

8-25/64

6-27/32

3-15/16

J

10-61/64

A

I

CE B

A

K

Fig. 3-2

19/32

C

5/64

2-3/4

4-17/32

4-59/64

7-7/8

8-55/64

7-5/8

7-3/32

5-33/64

6-37/64

D

Fig. 3-3

9-3/8

10-7/16

11-15/32

E

(inch)

12-57/64

14-1/32

14-21/32

9-7/64

D

B

3.2. Installing the wall mounting fixture (Fig. 3-2)

3.2.1. Setting the wall mounting fixture and piping positions

X Using the wall mounting fixture, determine the unit’s installation position

and the locations of the piping holes to be drilled.

Warning:

Before drilling a hole in the wall, you must consult the building contractor.

F

PKFY-P·NHMU-E2

A Mount board 1

B

Indoor unit

C Bottom left rear pipe hole (ø65 mm, 2-9/16 inch)

D Bottom right rear pipe hole (ø65 mm, 2-9/16 inch)

E Knockout hole for left rear hole (70 mm, 2-3/4 inch × 310 mm, 12-13/14 inch)

F Bolt hole (4-ø9 mm, 23/64 inch hole)

G Center measurement hole (ø2.5 mm, 3/32 inch hole)

H Tapping hole (77-ø5.1 mm, 13/64 inch hole)

I Hole centre

J Align the scale with the line.

K Insert scale.

3.2.2. Drilling the piping hole (Fig. 3-3)

X Use a core drill to make a hole of 65-80 mm, 2-9/16-3-5/32 inch diameter in

the wall in the piping direction, at the position shown in the diagram to the

left.

X The hole should incline so that the outside opening is lower than the

inside opening.

X Insert a sleeve (with 65-80 mm, 2-9/16-3-5/32 inch diameter and purchased

locally) through the hole.

A

Sleeve

B Hole

C (Indoors)

D Wall

E (Outdoors)

Note:

The purpose of the hole’s inclination is to promote drain flow.

3

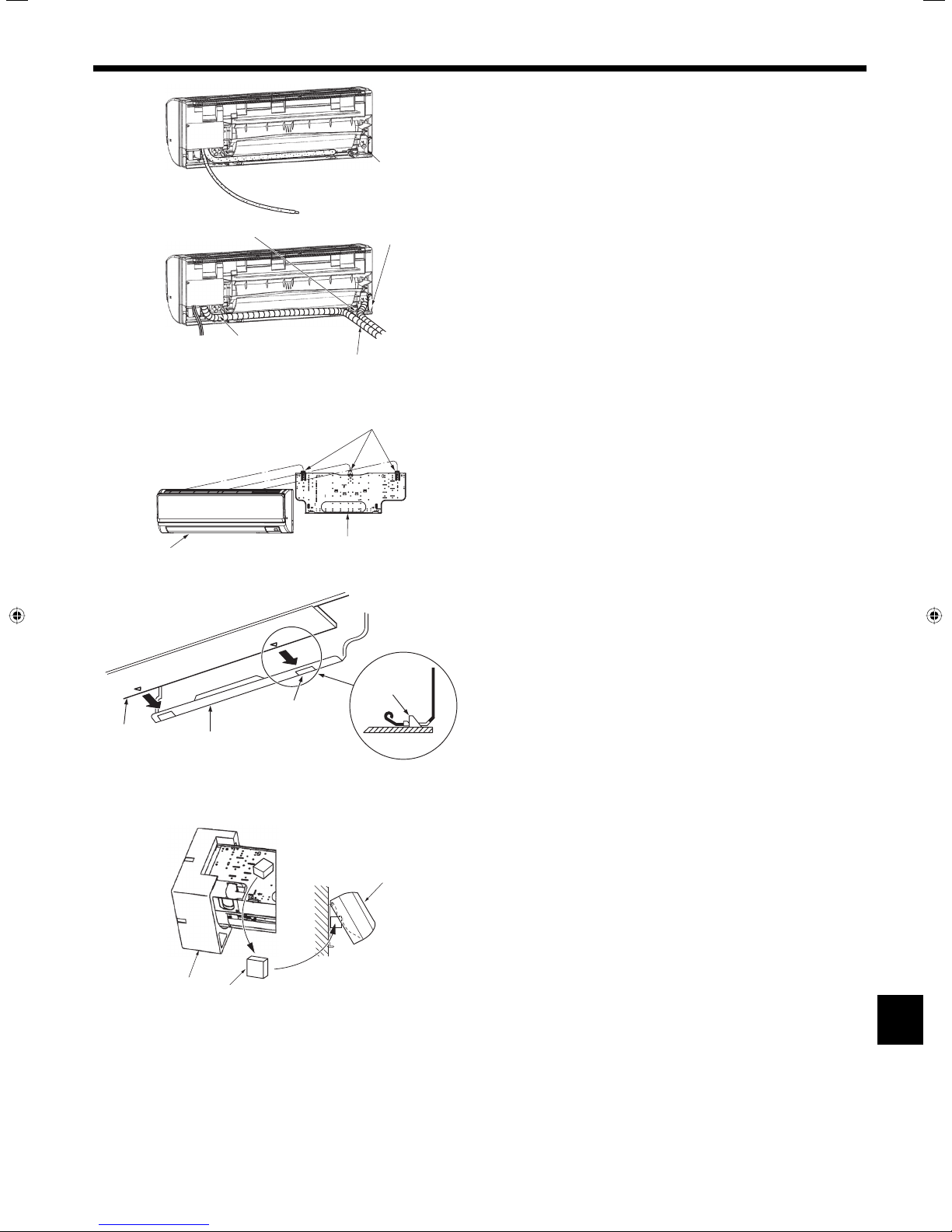

3. Installing the indoor unit

E

D

B

PKFY-P·NHMU-E2

F

A

D

C

E

I

H

Fig. 3-4

B

Fig. 3-5

C

D

Fig. 3-6

)

1

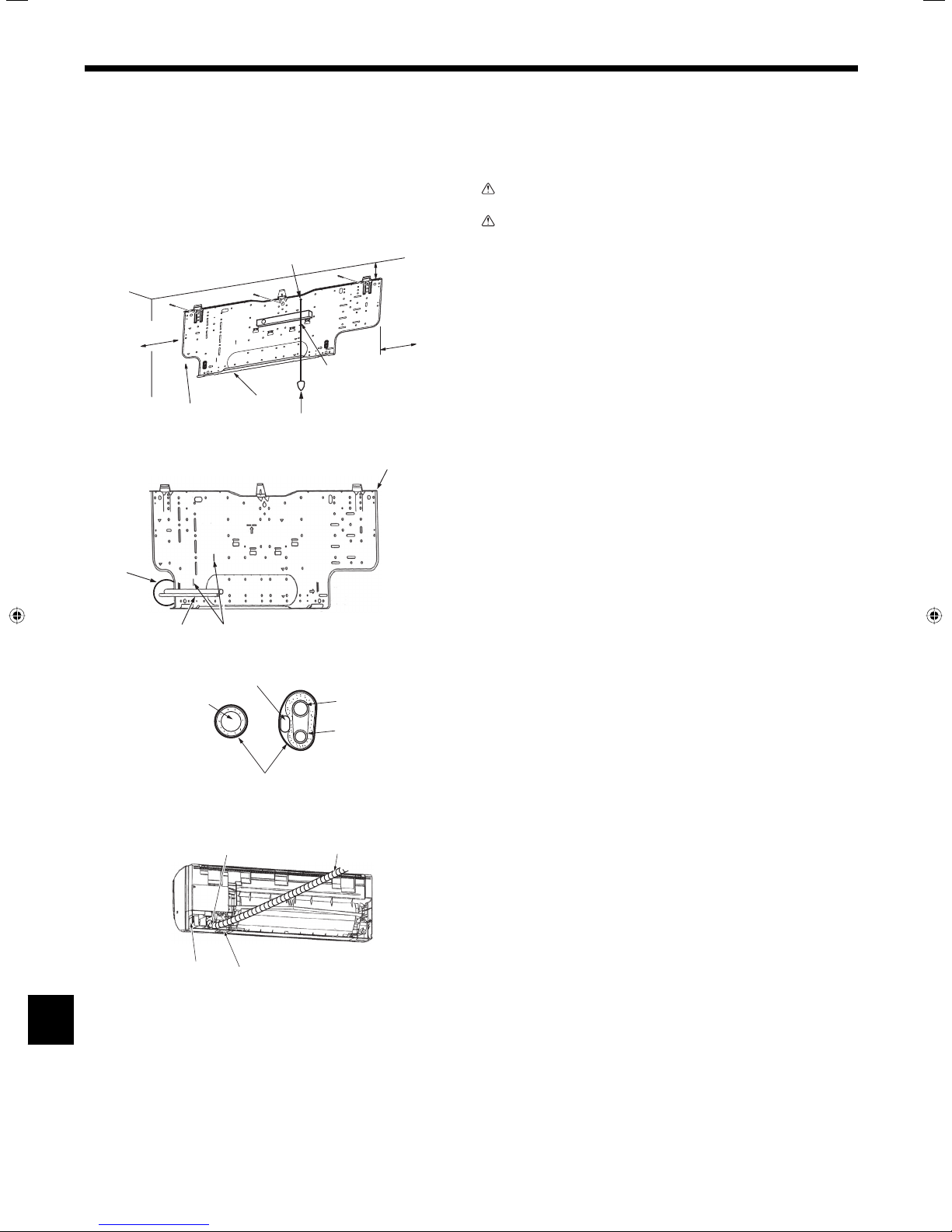

3.2.3. Installing the wall mounting fixture

X Since the indoor unit weighs near 13 kg, 29lbs, selection of the mounting

location requires thorough consideration. If the wall does not seem to be

strong enough, reinforce it with boards or beams before installation.

X The mounting fixture must be secured at both ends and at the centre, if

possible. Never fix it at a single spot or in any nonsymetrical way.

(If possible, secure the fixture at all the positions marked with a bold

arrow.)

Warning:

If possible, secure the fixture at all positions indicated with a bold arrow.

Caution:

• The unit body must be mounted horizontally.

• Fasten at the holes marked with S as shown by the arrows.

C

B

G

PKFY-P·NHMU-E2 (Fig. 3-4)

A Min. 90 mm, 3-35/64 inch (617.6 mm, 24-5/16 inch or greater with optional drain pump

installation)

B Min. 200 mm, 7-7/8 inch

C Min. 72 mm, 2-53/64 inch (142.5 mm, 5-39/64 inch or greater with left, rear left, or lower

left piping, and optional drain pump installation)

D Fixing screws (4 × 35 mm, 1-3/8 inch) 2

E

Level

F Fasten a thread to the hole.

G

Place the level against the horizontal reference line of the mount board and mount so that it is

level. Hang a weight from the thread and align with

H Weight

I Mount board 1

V

EPK of the mount board to permit leveling.

3.3. When embedding pipes into the wall (Fig. 3-5)

A

• The pipes are on the bottom left.

• When the cooling pipe, drain pipes internal/external connection lines etc are to

be embedded into the wall in advance, the extruding pipes etc, may have to be

bent and have their length modified to suit the unit.

• Use marking on the mount board as a reference when adjusting the length of the

embedded cooling pipe.

• During construction, give the length of the extruding pipes etc some leeway.

A

Mount board 1

Reference marking for flare connection

B

C Through hole

D On-site piping

3.4. Preparing the indoor unit

* Check beforehand because the preparatory work will differ depending on the

exiting direction of the piping.

* When bending the piping, bend gradually while maintaining the base of the

piping exiting portion. (Abrupt bending will cause misshaping of the piping.)

Extraction and processing of the piping and wiring (Fig. 3-6)

B

A

)

2

1. Connection of indoor/outdoor wiring See page. 8.

2. Wrap the felt tape 3 in the range of the refrigerant piping and drain hose which

will be housed within the piping space of the indoor unit.

• Wrap the felt tape 3 securely from the base for each of the refrigerant piping

and the drain hose.

• Overlap the felt tape 3 at one-half of the tape width.

• Fasten the end portion of the wrapping with vinyl tape.

A

Liquid pipe

B Gas pipe

C Indoor/outdoor connection cable

D Drain hose

E Felt tape 3

3. Be careful that the drain hose is not raised, and that contact is not made with the

indoor unit box body.

Do not pull the drain hose forcefully because it might come out.

A

Fig. 3-7

4

Rear, right and lower piping (Fig. 3-7)

1) Be careful that the drain hose is not raised, and that contact is not made with

the indoor unit box body.

Arrange the drain hose at the underside of the piping and wrap it with felt

tape 3.

2) Securely wrap the felt tape 3 starting from the base. (Overlap the felt tape at

one-half of the tape width.)

A

Cut off for right piping.

B Cut off for lower piping.

3. Installing the indoor unit

B

)

1

)

2

Fig. 3-8

Left and left rear piping (Fig. 3-8)

4. Drain hose replacement See 7. Drainage piping work

Be sure to replace the drain hose and the drain cap for the left and rear left

piping. Dripping may occur if you forget to install or fail to replace these parts.

C

Drain cap

1) Be careful that the drain hose is not raised, and that contact is not made with

C

the indoor unit box body.

2) Securely wrap the felt tape 3 starting from the base. (Overlap the felt tape at

one-half of the tape width.)

3) Fasten the end portion of the felt tape 3 with vinyl tape.

D

Cut off for left piping.

D

)

3

B

PKFY-P·NHMU-E2

A

Fig. 3-9

D

Fig. 3-10

A

C

C

A

3.5. Mounting the indoor unit

1. Affix the mount board 1 to the wall.

2. Hang the indoor unit on the hook positioned on the upper part of the mount

board.

Rear, right and lower piping (Fig. 3-9)

3. While inserting the refrigerant piping and drain hose into the wall penetration

hole (penetration sleeve), hang the top of the indoor unit to the mount board 1.

4. Move the indoor unit to the left and right, and verify that the indoor unit is hung

securely.

5. Fasten by pushing the bottom part of the indoor unit onto the mount board 1.

(Fig. 3-10)

* Check that the knobs on the bottom of the indoor unit are securely hooked into

the mount board 1.

6. After installation, be sure to check that the indoor unit is installed level.

A

Mount board 1

Indoor unit

B

C Hook

D square hole

Left and left rear piping (Fig. 3-11)

3. While inserting the drain hose into the wall penetration hole (penetration sleeve),

hang the top of the indoor unit to the mount board 1.

Giving consideration to the piping storage, move the unit all the way to the left

side, then cut part of the packaging carton and wrap into a cylindrical form as

illustrated in the diagram. Hook this to the rear surface rib as a spacer, and raise

the indoor unit.

4. Connect the refrigerant piping with the site-side refrigerant piping.

5. Fasten by pushing the bottom part of the indoor unit onto the mount board 1.

* Check that the knobs on the bottom of the indoor unit are securely hooked into

the mount board 1.

6. After installation, be sure to check that the indoor unit is installed level.

A

Indoor unit

B Packaging cushion

C Block of cushion 5

B

C

Fig. 3-11

5

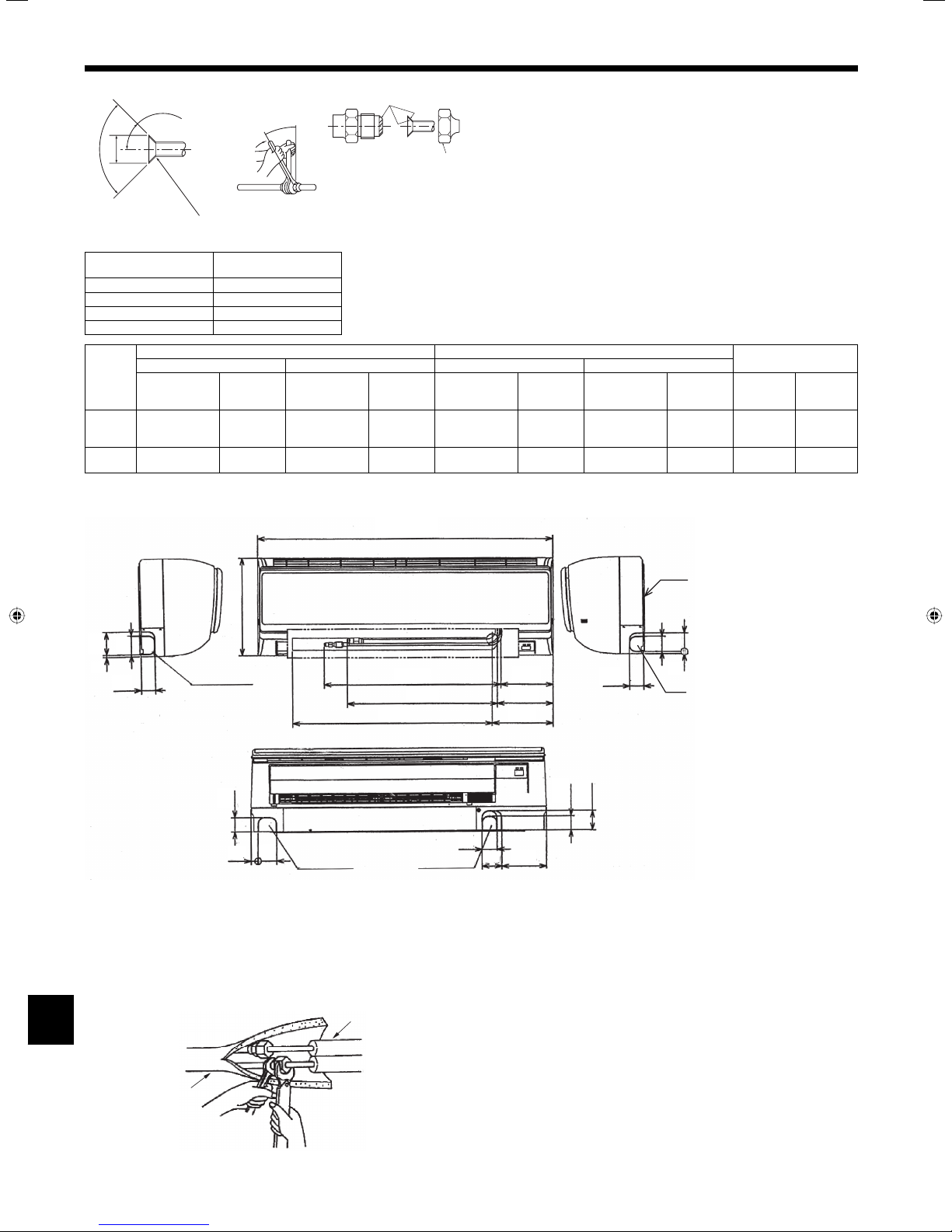

4. Installing the refrigerant piping

A

90°±0.5°

øA

45°±2°

R1/64 to R1/32

B

(inch)

C

Fig. 4-1

A Flare cutting dimensions

Copper pipe O.D.

(mm, inch)

ø6.35, 1/4” 8.7 - 9.1, 11/32 - 23/64

ø9.52, 3/8” 12.8 - 13.2, 1/2 - 33/64

ø12.7, 1/2” 16.2 - 16.6, 41/64 - 21/32

ø15.88, 5/8” 19.3 - 19.7, 49/64 - 25/32

Liquid pipe Gas pipe Liquid pipe Gas pipe

Pipe size O.D.

(mm, inch)

P08,

P12,

P15

P18

* Connect the joint with the following pipes: Liquid and gas pipes of P18.

E Apply refrigerating machine oil over the entire flare seat surface.

PKFY-P·NHMU-E2 (inch)

ODø6.35

1/4”

ODø9.52

3/8”

Flare dimensions

øA dimensions (mm, inch)

R22 R410A

Tightening

torque.

(N·m, ft·lbs)

14 - 18

10 - 13

14 - 18*

10 - 13

Pipe size O.D.

(mm, inch)

ODø12.7

1/2”

ODø15.88

5/8”

Tightening

torque.

(N·m, ft·lbs)

49 - 61

35 - 44

49 - 61*

35 - 44

4.1. Connecting pipes (Fig. 4-1)

• When commercially available copper pipes are used, wrap liquid and gas pipes

with commercially available insulation materials (heat-resistant to 100 °C, 212 °F

or more, thickness of 12 mm, 1/2 inch or more).

• The indoor parts of the drain pipe should be wrapped with polyethylene foam

insulation materials (specific gravity of 0.03, thickness of 9 mm, 23/64 inch or

D

more).

• Apply thin layer of refrigerant oil to pipe and joint seating surface before

tightening flare nut.

• Use two wrenches to tighten piping connections.

• Use refrigerant piping insulation provided to insulate indoor unit connections.

Insulate carefully.

B Refrigerant pipe sizes & Flare nut tightening torque

C Do not apply refrigerating machine oil to the screw portions.

(This will make the flare nuts more apt to loosen.)

D Be certain to use the flare nuts that are attached to the main unit.

(Use of commercially-available products may result in cracking.)

Pipe size O.D.

(mm, inch)

ODø6.35

1/4”

ODø6.35

1/4”

Tightening

torque.

(N·m, ft·lbs)

14 - 18

10 - 13

14 - 18

10 - 13

Pipe size O.D.

(mm, inch)

ODø12.7

1/2”

ODø12.7

1/2”

Tightening

torque.

(N·m, ft·lbs)

49 - 61

35 - 44

49 - 61

35 - 44

35-23/64

Flare nut O.D.

Liquid pipe

(mm, inch)

17

43/64

17

43/64

Gas pipe

(mm, inch)

26

1-1/16

26

1-1/16

2-23/32

15/64

1-11/16

2-13/64

G

1-27/32

E

2-13/64

15/64

25/32

11-39/64

D

1-11/16

2-13/64

(B)

21-7/32

17-63/64

24-1/64

(A)

(C)

1-27/32

FF

2-23/64

6-7/32

6-21/32

7-7/32

5-5/16

1-11/16

1-11/16

2-21/64

Fig. 4-2

4.2. Positioning refrigerant and drain piping (Fig. 4-2)

PKFY-P·NHMU-E2

A Gas pipe * Indicates the condition with accessories mounted.

B Liquid pipe

C Drain hose

D Left-side piping knockout hole

E Right-side piping knockout hole

F Lower piping knockout hole

A

G Mount board 1

4.3. Refrigerant piping (Fig. 4-3)

Indoor unit

1. Remove the flare nut and cap of the indoor unit.

2. Make a flare for the liquid pipe and gas pipe and apply refrigerating machine oil

B

Fig. 4-3

(available from your local supplier) to the flare sheet surface.

3. Quickly connect the on site cooling pipes to the unit.

4. Wrap the pipe cover that is attached to the gas pipe and make sure that the

connection join is not visible.

5. Wrap the pipe cover of the unit’s liquid pipe and make sure that it covers the

insulation material of the on site liquid pipe.

6. The portion where the insulation material is joined is sealed by taping.

A

Site-side refrigerant piping

B Unit side refrigerant piping

6

4. Installing the refrigerant piping

E

PKFY-P·NHMU-E2

C

Fig. 4-4

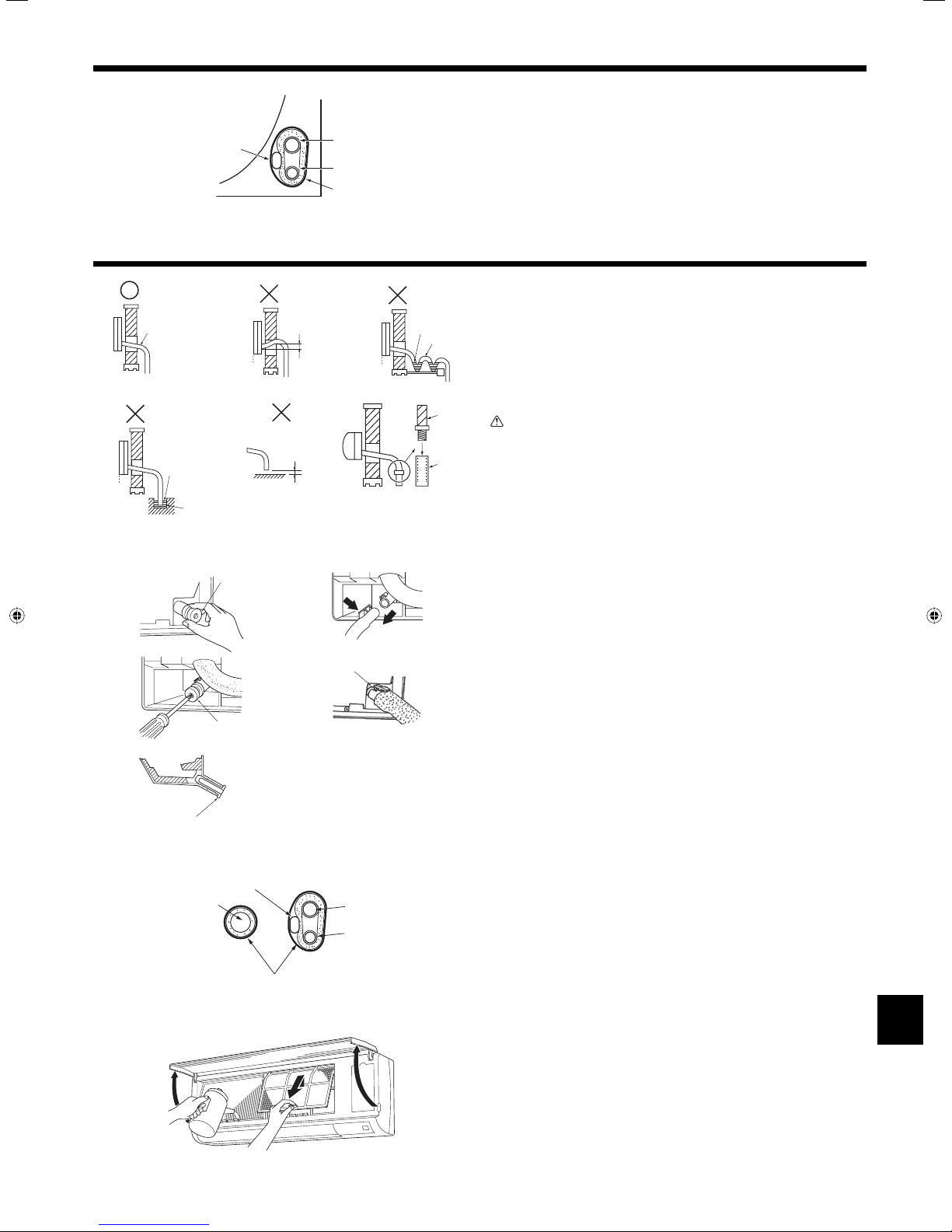

5. Drainage piping work

A

C

G

C

H

Fig. 5-1

1

3

A

I

B

2

4

4.3.1. Storing in the piping space of the unit (Fig. 4-4)

1. Wrap the supplied felt tape in the range of the refrigerant piping which will be

housed within the piping space of the unit to prevent dripping.

2. Overlap the felt tape at one-half of the tape width.

A

B

D

3. Fasten the end portion of the wrapping with vinyl tape, etc.

A

Gas pipe

B Liquid pipe

C Indoor/outdoor connection cable

D Felt tape 3

5.1. Drainage piping work (Fig. 5-1)

• Drain pipes should have an inclination of 1/100 or more.

• For extension of the drain pipe, use a soft hose (inner dia. 15 mm, 19/32 inch)

available on the market or hard vinyl chloride pipe (VP-16/O.D. ø22 mm,

ø55/64 inch PVC TUBE). Make sure that there is no water leakage from the

connections.

• Do not put the drain piping directly in a drainage ditch where sulphuric gas may

be generated.

• When piping has been completed, check that water flows from the end of the

drain pipe.

Caution:

The drain pipe should be installed according to this Installation Manual to

ensure correct drainage. Thermal insulation of the drain pipes is necessary

to prevent condensation. If the drain pipes are not properly installed and

insulated, condensation may drip on the ceiling, floor or other possessions.

A

Inclined downwards

B Must be lower than outlet point

C Water leakage

D Trapped drainage

E Air

F Wavy

G The end of drain pipe is under water.

H Drainage ditch

I 5 cm, 1-31/32 inch or less between the end of drain pipe and the ground.

J Drain hose

K Soft PVC hose (Inside diameter 15 mm, 19/32 inch)

or

Hard PVC pipe (VP-16)

* Bond with PVC type adhesive

B

D

E

C

F

J

K

a

b

A

Preparing left and left rear piping (Fig. 5-2)

1 Remove the drain cap.

A

Fig. 5-2

D

C

A

B

Fig. 5-3

• Remove the drain cap by holding the bit that sticks out at the end of the pipe and

pulling.

Drain cap

A

2 Remove the drain hose.

• Remove the drain hose by holding on to the base of the hose a (shown by

arrow) and pulling towards yourself b.

3 Insert the drain cap.

• Insert a screwdriver etc into the hole at the end of the pipe and be sure to push

to the base of the drain cap.

4 Insert the drain hose.

• Push the drain hose until it is at the base of the drain box connection outlet.

• Please make sure the drain hose hook is fastened properly over the extruding

drain box connection outlet.

B

Hooks

¡ Storing in the piping space of the indoor unit (Fig. 5-3)

* When the drain hose will be routed indoors, be sure to wrap it with commercially

available insulation.

* Gather the drain hose and the refrigerant piping together and wrap them with the

supplied felt tape 3.

* Overlap the felt tape 3 at one-half of the tape width.

* Fasten the end portion of the wrapping with vinyl tape, etc.

A

Gas pipe

B Liquid pipe

C Drain hose

D Indoor/outdoor connection wiring

E Felt tape 3

¡ Check of drainage (Fig. 5-4)

1. Open the front grille and remove the filter.

2. Facing the fins of the heat exchanger, slowly fill with water.

3. After the drainage check, attach the filter and close the grille.

Fig. 5-4

7

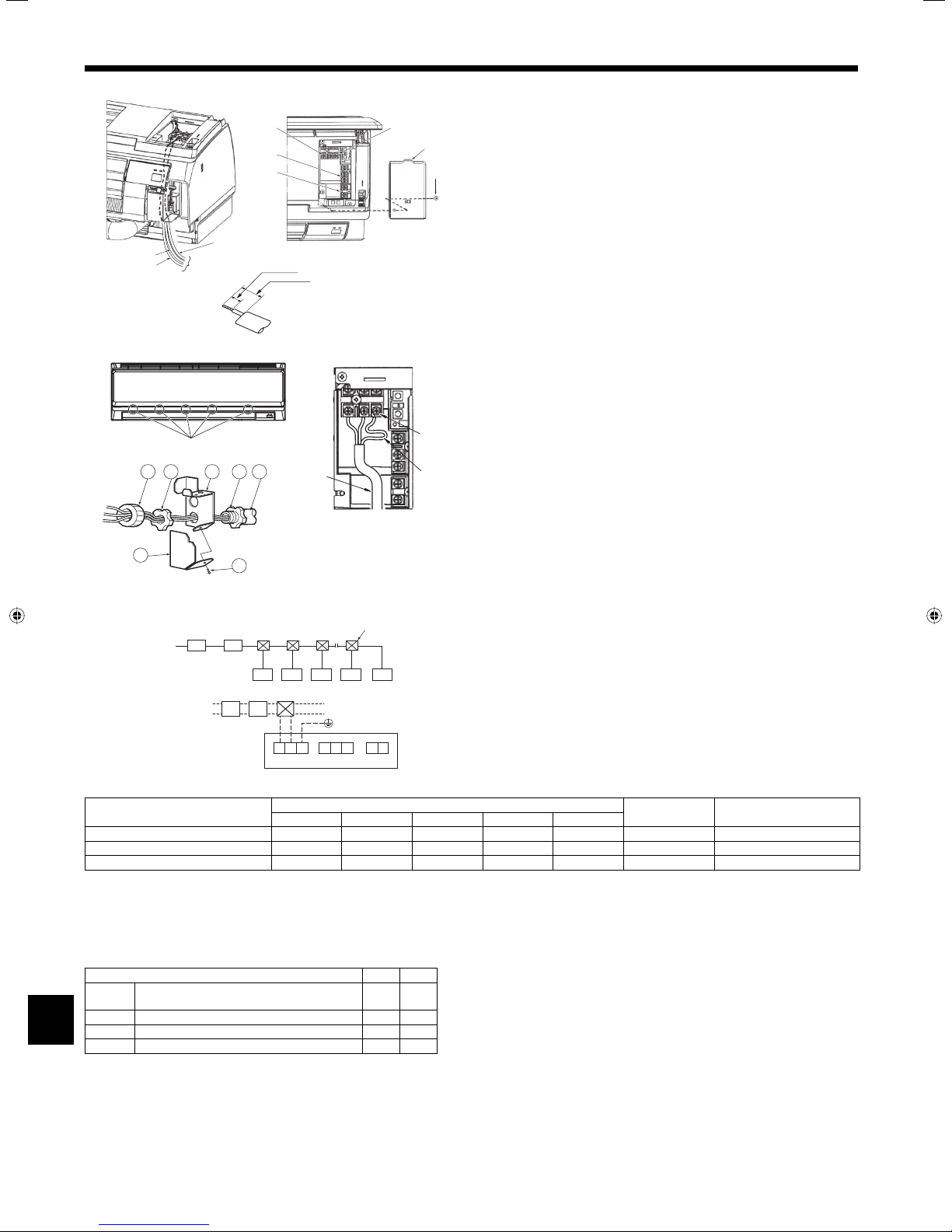

6. Electrical work

M

PKFY-P·NHMU-E2

L

J

6.1. Electric wiring

PKFY-P·NHMU-E2 (Fig. 6-1)

F

E

D

K

G

JKL

15/32 inch

2-11/64 inch

C

A

B

L1

L2

GR

C

RQNO P

L

I

Connection can be made without removing the front panel.

1. Open the front grille, remove the screw (1 piece), and remove the electrical

parts cover.

* Electrical work can be conducted more effectively with the panel removed.

When attaching the panel, check that the hooks M at five locations on the air

outlet side are connected securely.

2. Securely connect each wire to the terminal board.

* In consideration of servicing, provide extra length for each of the wires.

* Take care when using strand wires, because beards may cause the wiring to

short out.

3. Install the parts that were removed back to their original condition.

4. Fasten each of the wires with the clamp under the electrical parts box.

A

Electrical box cover

B Fixing screw (Electrical box cover)

C Ground wire connection portion

D MA remote control terminal board: (1, 2) do not have polarity

E Transmission terminal board: (M1, M2, S) do not have polarity

F Power supply terminal board (L1, L2, GR).

G Lead

I Ground wire: Connect the ground wire in the direction illustrated in the diagram.

J MA remote controller

K Transmission cable

L Power supply cable

M Hook

N Conduit plate

O Bush (purchased locally)

P Lock nut (purchased locally)

Q Connector (purchased locally)

R Conduit (purchased locally)

S Conduit cover

T Fixing screw (Conduit cover)

S

~230V

AB

AB

~230V

T

Fig. 6-1

CCCCC

D

L1L2GR

C

TB2 TB5 TB15

M1

M2

D

S12

6.2. Power supply wiring

• Install an earth line longer than other cables.

• Power supply codes of appliance shall not be lighter than design 245IEC57 or

227IEC57, 245 IEC 53 or 227 IEC 53.

• A switch with at least 3 mm, 1/8 inch contact separation in each pole shall be

provided by the air conditioner installation.

[Fig. 6-2]

A

Ground-fault interrupter

B Local switch/Wiring breaker

C Indoor unit

D Pull box

Fig. 6-2

Total operating current of the indoor unit

F0 = 15A or less *2 2.1/14 2.1/14 2.1/14 15 15 15 15A current sensitivity *3

F0 = 20A or less *2 3.3/12 3.3/12 3.3/12 20 20 20 20A current sensitivity *3

F0 = 30A or less *2 5.3/10 5.3/10 5.3/10 30 30 30 30A current sensitivity *3

Apply to IEC61000-3-3 about max. permissive system impedance.

*1 The Ground-fault interrupter should support inverter circuit.

The Ground-fault interrupter should combine using of local switch or wiring breaker.

*2 Please take the larger of F1 or F2 as the value for F0.

F1 = Total operating maximum current of the indoor units × 1.2

F2 = {V1 × (Quantity of Type1)/C} + {V1 × (Quantity of Type2)/C} + {V1 × (Quantity of Type3)/C} + {V1 × (Quantity of Others)/C}

Indoor unit V1 V2

Type 1 PLFY-NBMU, PMFY-NBMU, PEFY-NMSU,

PCFY-NKMU, PKFY-NHMU, PKFY-NKMU

Type 2 PEFY-NMAU 38 1.6

Type 3 PEFY-NMHSU 13.8 4.8

Others Other indoor unit 0 0

C : Multiple of tripping current at tripping time 0.01s

Please pick up "C" from the tripping characteristic of the breaker.

Main cable Branch Ground Capacity Fuse

Minimum wire thickness (mm²/AWG) Breaker for wiring

(NFB)

18.6 2.4

Ground-fault interrupter *1

8

6. Electrical work

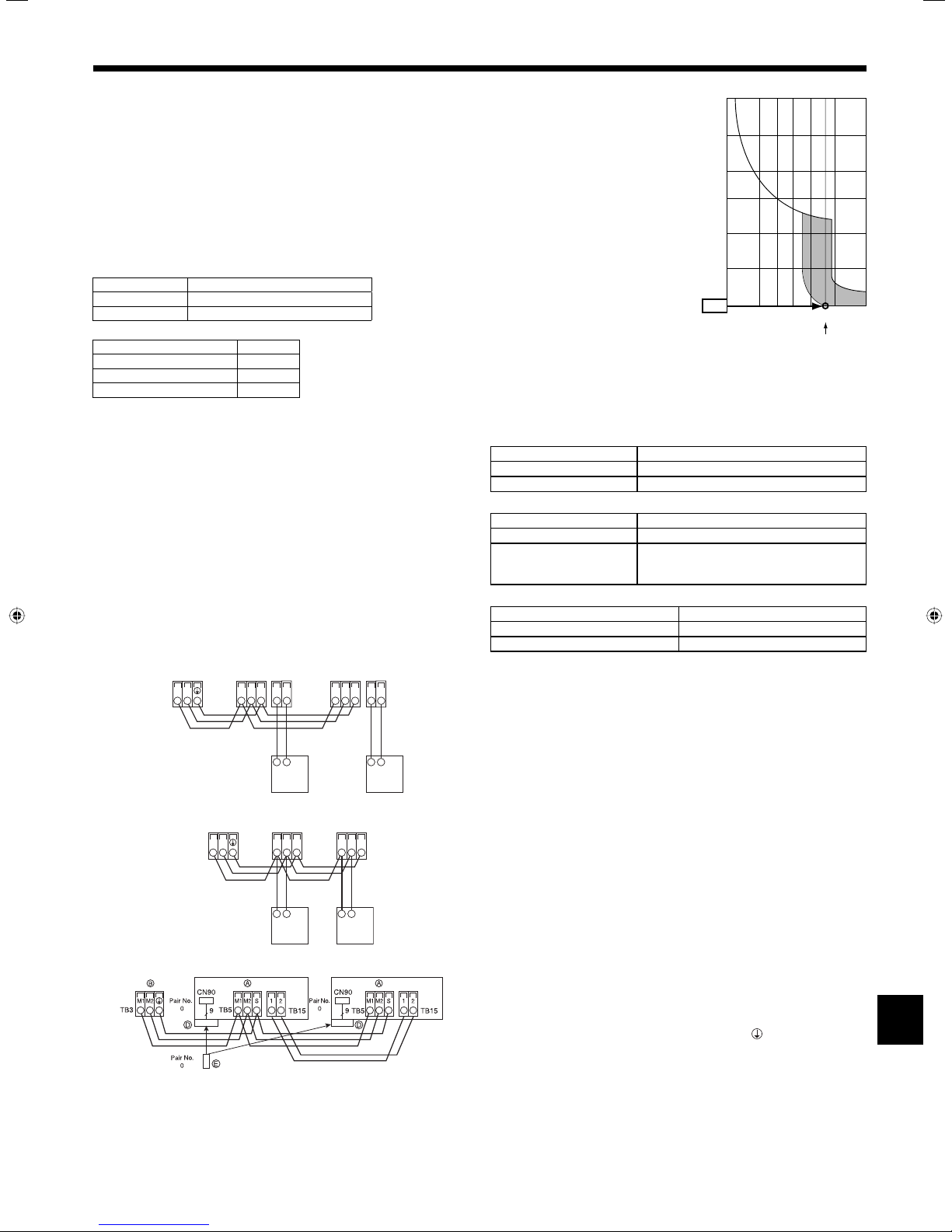

Sample chart

6000

<Example of "F2" calculation>

*Condition PEFY-NMSU × 4 + PEFY-NMAU × 1, C = 8 (refer to right sample chart)

F2 = 18.6 × 4/8 + 38 × 1/8

= 14.05

→ 16A breaker (Tripping current = 8 × 16A at 0.01s)

*3 Current sensitivity is calculated using the following formula.

G1 = V2 × (Quantity of Type1) + V2 × (Quantity of Type2) + V2 × (Quantity of Type3) + V2 × (Quantity of Others)

+ V3 × (Wire length[km])

G1 Current sensitivity

30 or less 30 mA 0.1sec or less

100 or less 100 mA 0.1sec or less

Wire thickness (mm2/AWG) V3

2.1/14 48

3.3/12 56

5.3/10 66

6.3. Types of control cables

1. Wiring transmission cables

Types of transmission cable Shielding wire CVVS or CPEVS

Cable diameter More than 1.25 mm

Length Less than 200m, 219 yard

2. M-NET Remote control cables

Types of remote control cable

Cable diameter More than 0.5 (AWG20) to 1.25 mm

Length Add any portion in excess of 10m, 33 ft to

3. MA Remote control cables

Types of remote control cable 2-core cable (unshielded)

Cable diameter 0.3 (AWG22) to 1.25 mm

Length Less than 200m, 219 yard

600

60

10

Tripping Time [s]

1

0.1

0.01

12

Shielding wire MVVS

Rated Tripping current (x)

2

(AWG16)

SAMPLE

34 68C10 20

2

(AWG16)

within the longest allowable transmission cable

length 200m, 219 yard.

2

(AWG16)

1

B

M1M2 21

TB3

AA

SM1 M2 SM1 M2

TB5 TB15 TB5 TB15

21

6.4. Connecting remote controller, indoor and

outdoor transmission cables (Fig. 6-3)

• Connect indoor unit TB5 and outdoor unit TB3. (Non-polarized 2-wire) The “S”

on indoor unit TB5 is a shielding wire connection. For specifications about the

connecting cables, refer to the outdoor unit installation manual.

• Install a remote controller following the manual supplied with the remote

controller.

• Connect the remote controller’s transmission cable within 10 m, 33 ft using a

C

2

TB3

B

M1M2

AA

SM1 M2 SM1M2

TB5 TB5

C

1 MA Remote controller

• Connect the “1” and “2” on indoor unit TB15 to a MA remote controller. (Non-

• DC 9 to 13 V between 1 and 2 (MA remote controller)

2 M-NET Remote controller

2

0.75 mm

(AWG22) core cable. If the distance is more than 10 m, 33 ft, use a

2

1.25 mm

(AWG16) junction cable.

polarized 2-wire)

• Connect the “M1” and “M2” on indoor unit TB5 to a M-NET remote controller.

(Nonpolarized 2-wire)

• DC 24 to 30 V between M1 and M2 (M-NET remote controller)

3 Wireless remote controller(When installing wireless signal receiver)

• Connect the wire of wireless signal receiver (9-pole cable) to CN90 of indoor

C

C

3

con-troller board.

• When more than two units are run under group control using wireless remote

controller, connect TB15 each with the same number.

• To change Pair No. setting, refer to installation manual attached to wireless re-

mote controller. (In the default setting of indoor unit and wireless remote controller, Pair No. is 0.)

A

Terminal block for indoor transmission cable

B Terminal block for outdoor transmission cable(M1(A), M2(B), (S))

C Remote controller

D Wireless signal receiver

Fig. 6-3

E Wireless remote controller

9

6. Electrical work

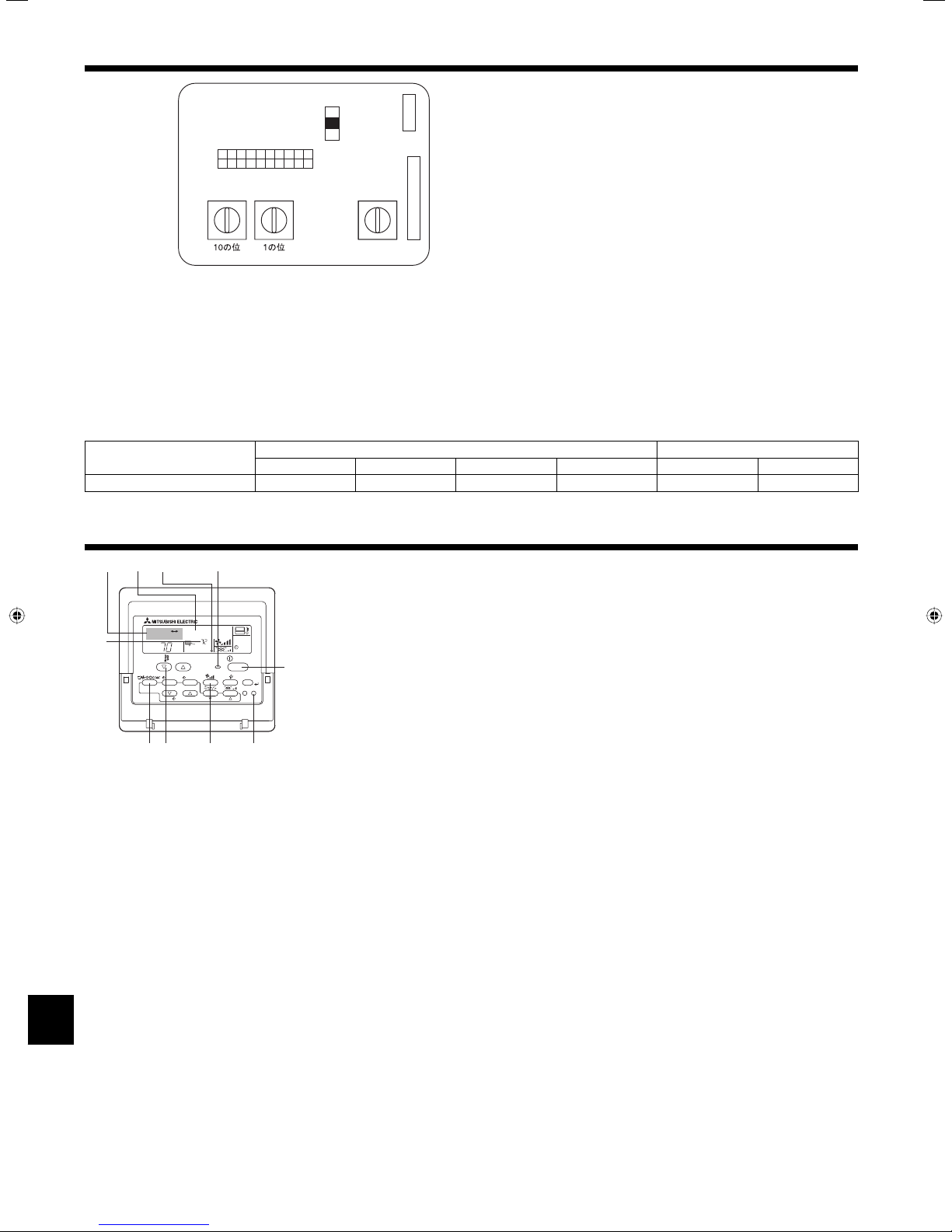

A

ON

OFF

SW1

12345678910

SW12 SW11

9

8

7

6

0

0

1

9

2

8

3

7

4

6

5

㧔U&+)+6㧔VJU&+)+6

Fig. 6-4

6.7. Electrical characteristics

Model

PKFY-P08, P12, P15, P18 NHMU-E2

7. Test run (Fig. 7-1)

SWA

3

ࠕ࠼ࠬ

2

1

1

2

3

4

5

CN43

ࠕ࠼ࠬ

CN82

SW14

0

1

F

2

E

3

D

4

C

5

B

6

A

7

9

8

ಽጘญ0Qࡍࠕ0Q

㧔$4#0%*0Q

(Be sure to operate with the main power turned OFF.)

• There are two types of rotary switch setting available: setting addresses 1 to 9

and over 10, and setting branch numbers.

1 How to set addresses

Example: If Address is “3”, remain SW12 (for over 10) at “0”, and match SW11

(for 1 to 9) with “3”.

2 How to set branch numbers SW14 (Series R2 only)

Match the indoor unit’s refrigerant pipe with the BC controller’s end connection

number.

Remain other than series R2 at “0”.

• The rotary switches are all set to “0” when shipped from the factory. These

switches can be used to set unit addresses and branch numbers at will.

• The determination of indoor unit addresses varies with the system at site. Set

them referring to the Data Book.

6.6. Sensing room temperature with the built-in

sensor in a remote controller (Fig. 6-4)

If you want to sense room temperature with the built-in sensor in a remote

controller, set SW1-1 on the control board to “ON”. The setting of SW1-7 and

SW1-8 as necessary also makes it possible to adjust the air flow at a time when

the heating thermometer is OFF.

6.5. Setting addresses (Fig. 6-4)

Symbols: MCA: Max. Circuit Amps (= 1.25×FLA) FLA: Full Load Amps

Power supply IFM

Hz Volts Voltage range MCA (A) Output (kW) FLA (A)

60Hz 208 / 230V 198 to 253V 0.38 / 0.38 0.030 / 0.030 0.30 / 0.30

IFM: Indoor Fan Motor Output: Fan motor rated output

FCED

B

TEST RUN

COOL, HEAT

°F

TEMP.

MENU

ON/OFF

BACK DAY

MONITOR/SET

PAR-21MAA

CLOCK

°F

OPERATION

SIMPLE

ON/OFF

FILTER

CHECK

TEST

CLEAR

MIHG

Fig. 7-1

A

A ON/OFF button

B Test run display

C Indoor temperature liquid

line temperature display

D ON/OFF lamp

E Power display

F Error code display

Test run remaining time

display

G Set temperature button

H Mode selection button

I Fan speed button

M TEST button

1 Turn on the power at least 12 hours before the test run.

2 Press the [TEST] button twice. “TEST RUN” liquid crystal display

3 Press the [Mode selection] button. Make sure that wind is blown out.

4 Press the [Mode selection] button and switch to the cooling (or heating) mode.

Make sure that cold (or warm) wind is blown out.

5 Press the [Fan speed] button. Make sure that the wind speed is switched.

6 Check operation of the outdoor unit fan.

7 Release test run by pressing the [ON/OFF] button. Stop

8 Register a telephone number.

The telephone number of the repair shop, sales office, etc., to contact if an

error occurs can be registered in the remote controller. The telephone number

will be displayed when an error occurs. For registration procedures, refer to the

operation manual for the indoor unit.

10

Loading...

Loading...