Mitsubishi MXZ-2F53VF, MXZ-2F33VF, MXZ-2F42VF-ET1, MXZ-2F42VF-E1, MXZ-2F53VF-E1 Service Manual

...

Models

MXZ-2F33VF

-

E1,

ET1

MXZ-2F42VF

-

E1,

ET1

MXZ-2F53VF

-

E1,

ET1

MXZ-2F53VFH

-

E1

MXZ-3F54VF

-

E1,

ET1

MXZ-3F68VF

-

E1,

ET1

MXZ-4F72VF

-

E1,

ET1

HFC

utilized

R32

SERVICE MANUAL

No. OBH790

OUTDOOR UNIT

NOTE:

RoHS compliant products have <G> mark

on the spec name plate.

PARTS CATALOG (OBB790)

Indoor unit service manual

MSZ-LN•VG Series (OBH766)

MSZ-EF•VG Series (OBH589)

MSZ-AP•VF Series (OBH799)

MSZ-AP•VG Series (OBH788)

MLZ-KP•VF Series (OBH801)

SLZ-M•FA Series

SEZ-M•DA Series

PCA-M•KA Series (OCH659)

PEAD-M•JA(L) Series (HWE16130)

CONTENTS

1. TECHNICAL CHANGES ···································3

2. SAFETY PRECAUTION ···································· 3

3. PART NAMES AND FUNCTIONS ··················· 13

4. SPECIFICATION ·············································· 14

5. NOISE CRITERIA CURVES ···························· 20

6. OUTLINES AND DIMENSIONS ······················ 22

7. WIRING DIAGRAM ·········································· 25

8. REFRIGERANT SYSTEM DIAGRAM ·············29

9. PERFORMANCE CURVES ····························· 35

10. ACTUATOR CONTROL ··································· 56

11. SERVICE FUNCTIONS ···································· 57

12. TROUBLESHOOTING ····································· 61

13. DISASSEMBLY INSTRUCTIONS ···················· 86

MXZ-2F33VF

MXZ-2F42VF

MXZ-2F53VF MXZ-2F53VFH

2

<Preparation before the repair service>

Prepare the proper tools.

Prepare the proper protectors.

Provide adequate ventilation.

After stopping the operation of the air conditioner, turn off the power-supply breaker and remove the power plug.

Discharge the capacitor before the work involving the electric parts.

<Precautions during the repair service>

Do not perform the work involving the electric parts with wet hands.

Do not pour water into the electric parts.

Do not touch the refrigerant.

Do not touch the hot or cold areas in the refrigeration cycle.

When the repair or the inspection of the circuit needs to be done without turning off the power, exercise great caution not to

touch the live parts.

Use the specifi ed refrigerant only

Never use any refrigerant other than that specified.

Doing so may cause a burst, an explosion, or fire when the unit is being used, serviced, or disposed of.

Correct refrigerant is specified in the manuals and on the spec labels provided with our products.

We will not be held responsible for mechanical failure, system malfunction, unit breakdown or accidents caused by

failure to follow the instructions.

OBH790

3

TECHNICAL CHANGES

1

MXZ-2F33VF -E1,

ET1

MXZ-2F42VF -E1,

ET1

MXZ-2F53VF -E1,

ET1

MXZ-2F53VFH -

E1

MXZ-3F54VF -E1,

ET1

MXZ-3F68VF -E1,

ET1

MXZ-4F72VF -E1,

ET1

1. New model

2-1. ALWAYS OBSERVE FOR SAFETY

Before obtaining access to terminal, all supply circuits must be disconnected.

2

SAFETY PRECAUTION

2-2. CAUTIONS RELATED TO NEW REFRIGERANT

Cautions for units utilizing refrigerant R32

Preparation before the repair service.

3UHSDUHWKHSURSHUWRROV

3UHSDUHWKHSURSHUSURWHFWRUV

3URYLGHDGHTXDWHYHQWLODWLRQ

$IWHUVWRSSLQJWKHRSHUDWLRQRIWKHDLUFRQGLWLRQHUWXUQRII

WKHSRZHUVXSSO\EUHDNHU

'LVFKDUJHWKHFRQGHQVHUEHIRUHWKHZRUNLQYROYLQJWKH

HOHFWULFSDUWV

Precautions during the repair service.

'RQRWSHUIRUPWKHZRUNLQYROYLQJWKHHOHFWULFSDUWV

ZLWKZHWKDQGV

'RQRWSRXUZDWHULQWRWKHHOHFWULFSDUWV

'RQRWWRXFKWKHUHIULJHUDQW

'RQRWWRXFKWKHKRWRUFROGDUHDVLQWKHUHIULJHUDWLQJF\FOH

:KHQWKHUHSDLURUWKHLQVSHFWLRQRIWKHFLUFXLWQHHGVWREH

GRQHZLWKRXWWXUQLQJRIIWKHSRZHUH[HUFLVHJUHDWFDXWLRQ

QRWWRWRXFKWKHOLYHSDUWV

Use new refrigerant pipes.

,QFDVHRIXVLQJWKHH[LVWLQJSLSHVIRU5EHFDUHIXOZLWK

WKHIROORZLQJ

Â%HVXUHWRFOHDQWKHSLSHVDQGPDNHVXUHWKDWWKHLQVLGHV

RIWKHSLSHVDUHFOHDQ

Â&KDQJHIODUHQXWWRWKHRQHSURYLGHGZLWKWKLVSURGXFW

8VHDQHZO\IODUHGSLSH

Â$YRLGXVLQJWKLQSLSHV

Use a vacuum pump with a reverse flow check

valve.

9DFXXPSXPSRLOPD\IORZEDFNLQWRUHIULJHUDQWF\FOHDQG

WKDWFDQFDXVHGHWHULRUDWLRQRIUHIULJHUDQWRLOHWF

MEANINGS OF SYMBOLS DISPLAYED ON THE UNIT

WARNING

This mark is for R32 refrigerant only. Refrigerant type is written on nameplate of outdoor unit.

Read the OPERATION MANUAL carefully before operation.

Service personnel are required to carefully read the OPERATION MANUAL and INSTALLATION MANUAL before operation.

Further information is available in the OPERATION MANUAL, INSTALLATION MANUAL, and the like.

OBH790

4

Make sure that the inside and outside of refrigerant piping is clean and it has no contaminants

such as sulfur, oxides, dirt, shaving particles, etc,

which are hazard to refrigerant cycle.

In addition, use pipes with specified thickness.

Contamination inside refrigerant piping can cause deterioration of refrigerant oil, etc.

Store the piping indoors, and both ends of the

piping sealed until just before brazing.

(Leave elbow joints, etc. in their packaging.)

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

The refrigerant oil applied to flare and flange

connections must be ester oil, ether oil or

alkylbenzene oil in a small amount.

If large amount of mineral oil enters, that can cause deterioration of refrigerant oil, etc.

Do not use refrigerant other than R32.

If other refrigerant (R22, etc.) is used, chlorine in refrigerant can cause deterioration of refrigerant oil, etc.

Handle tools with care.

If dirt, dust or moisture enters into refrigerant cycle, that can

cause deterioration of refrigerant oil or malfunction of compressor.

Use the following tools specifically designed for

use with R32 refrigerant.

The following tools are necessary to use R32 refrigerant.

Flare tool

Electronic refrigerant

charging scale

Vacuum pump adaptor

Size adjustment gauge

Gauge manifold

Torque wrench

Gas leak detector

Charge hose

Tools for R32

Ventilate the room if refrigerant leaks during

operation. If refrigerant comes into contact with

a flame, poisonous gases will be released.

Never use any refrigerant other than that specified.

Doing so may cause a burst, an explosion, or fire when the

unit is being used, serviced, or disposed of.

Correct refrigerant is specified in the manuals and on the

spec labels provided with our products.

We will not be held responsible for mechanical failure,

system malfunction, unit breakdown or accidents caused

by failure to follow the instructions.

Use the specified refrigerant only.

OBH790

5

[1] Warning for service

(1) Do not alter the unit.

(2) For installation and relocation work, follow the instructions in the Installation Manual and use tools and pipe components

specifically made for use with refrigerant specified in the outdoor unit installation manual.

(3) Ask a dealer or an authorized technician to install, relocate and repair the unit.

For appliances not accessible to the general public.

(4) Refrigerant pipes connection shall be accessible for maintenance purposes.

(5)

If the air conditioner is installed in a small room or closed room, measures must be taken to prevent the refrigerant concentra-

tion in the room from exceeding the safety limit in the event of refrigerant leakage. Should the refrigerant leak and cause the

concentration limit to be exceeded, hazards due to lack of oxygen in the room may result.

(6) Keep gas-burning appliances, electric heaters, and other fire sources (ignition sources) away from the location where

installation, repair, and other air conditioner work will be performed.

If refrigerant comes into contact with a flame, poisonous gases will be released.

(7) When installing or relocating, or servicing the air conditioner, use only the specified refrigerant (R32) to charge the refrig-

erant lines.

Do not mix it with any other refrigerant and do not allow air to remain in the lines.

If air is mixed with the refrigerant, then it can be the cause of abnormal high pressure in the refrigerant line, and may

result in an explosion and other hazards.

(8) After installation has been completed, check for refrigerant leaks. If refrigerant leaks into the room and comes into contact

with the flame of a heater or portable cooking range, poisonous gases will be released.

(9) Do not use low temperature solder alloy in case of brazing the refrigerant pipes.

(10)

When performing brazing work, be sure to ventilate the room sufficiently. Make sure that there are no hazardous or flam-

mable materials nearby.

When performing the work in a closed room, small room, or similar location, make sure that there are no refrigerant leaks

before performing the work.

If refrigerant leaks and accumulates, it may ignite or poisonous gases may be released.

(11) Do not install the unit in places where refrigerant may build-up or places with poor ventilation such as a semi-basement or a

sunken place in outdoor: Refrigerant is heavier than air, and inclined to fall away from the leak source.

(12)

Do not use means to accelerate the defrosting process or to clean, other than those recommended by the manufacturer.

(13)

The appliance shall be stored in a room without continuously operating ignition sources (for example: open flames, an

operating gas appliance or an operating electric heater).

(14)

Do not pierce or burn.

(15)

Be aware that refrigerants may not contain an odour.

(16)

Pipe-work shall be protected from physical damage.

(17)

The installation of pipe-work shall be kept to a minimum.

(18)

Compliance with national gas regulations shall be observed.

(19)

Keep any required ventilation openings clear of obstruction.

(20)

Servicing shall be performed only as recommended by the manufacturer.

(21)

The appliance shall be stored in a well-ventilated area where the room size corresponds to the room area as specified

for operation.

(22) Maintenance, service and repair operations shall be performed by authorized technician with required qualification.

(23)

Be sure to have appropriate ventilation in order to prevent ignition. Furthermore, be sure to carry out fire prevention

measures that there are no dangerous or flammable objects in the surrounding area.

[2] Cautions for service

(1) Perform service after recovering the refrigerant left in unit completely.

(2) Do not release refrigerant in the air.

(3) After completing service, charge the cycle with specified amount of refrigerant.

(4) When performing service, install a filter drier simultaneously.

Be sure to use a filter drier for new refrigerant.

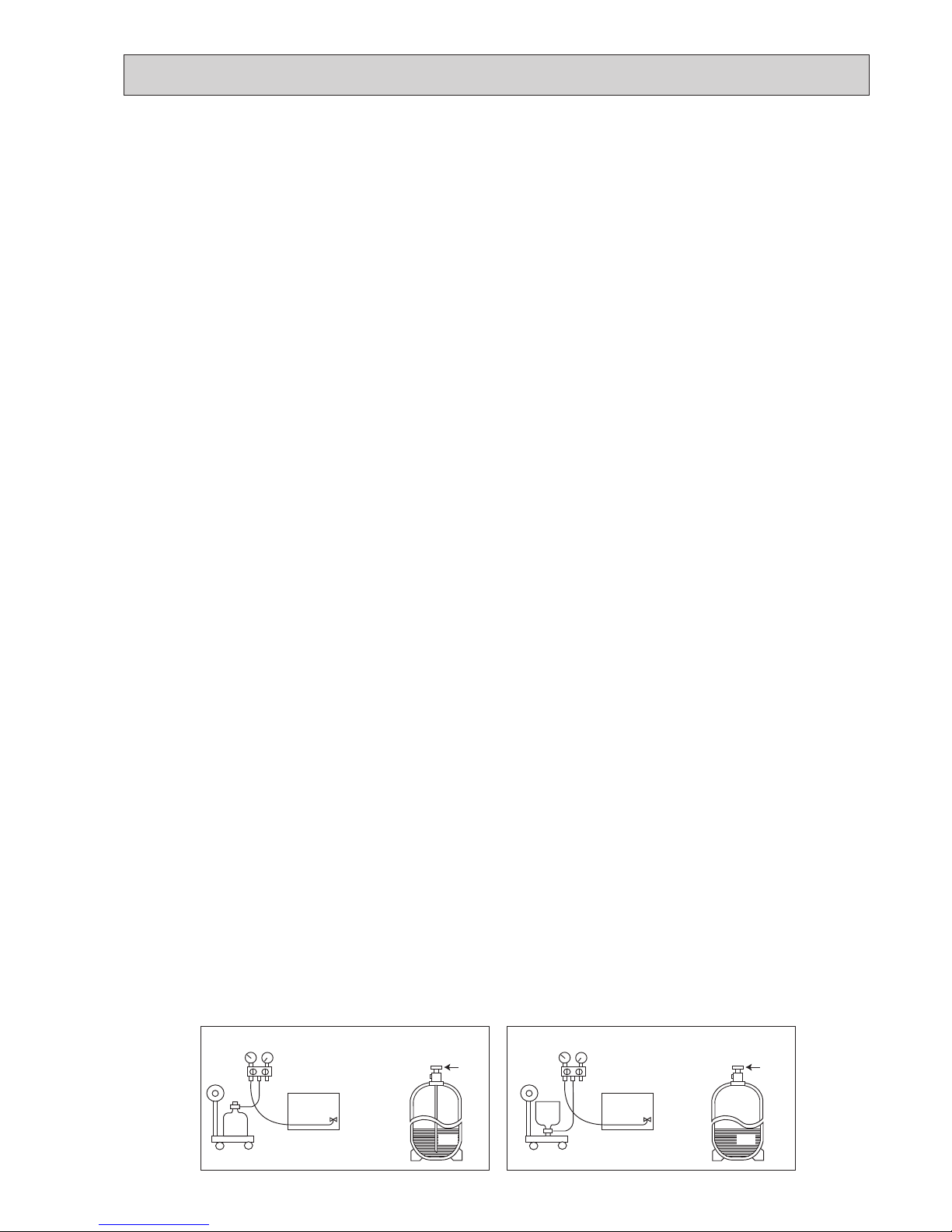

[3] Additional refrigerant charge

When charging directly from cylinder

R32 is a single refrigerant and its composition does not change. Therefore, both liquid charging and gas charging are

possible. Liquid charging of refrigerant all at once from the low-pressure side may cause the compressor malfunction.

Accordingly, make sure that charging is gradual.

< Cylinder without a siphon tube >< Cylinder with a siphon tube >

Charging liquid refrigerant

Cylinder

Cylinder

Liquid

Valve

Liquid

Valve

OBH790

6

[4] Cautions for unit using R32 refrigerant

Basic work procedures are the same as those for conventional units using refrigerant R410A. However, pay careful

attention to the following points.

(1) Information on servicing

(1-1) Checks on the Area

Prior to beginning work on systems containing flammable refrigerants, safety checks are necessary to ensure that the

risk of ignition is minimized.

For repair to the refrigerating systems, (1-3) to (1-7) shall be completed prior to conducting work on the systems.

(1-2) Work Procedure

Work shall be undertaken under a controlled procedure so as to minimize the risk of a flammable gas or vapor being

present while the work is being performed.

(1-3) General Work Area

All maintenance staff and others working in the local area shall be instructed on the nature of work being carried out.

Work in confined spaces shall be avoided. The area around the workspace shall be sectioned off. Ensure that the conditions within the area have been made safe by control of flammable material.

(1-4) Checking for Presence of Refrigerant

The area shall be checked with an appropriate refrigerant detector prior to and during work, to ensure the technician is

aware of potentially toxic or flammable atmospheres. Ensure that the leak detection equipment being used is suitable

for use with all applicable refrigerants, i.e. non-sparking, adequately sealed or intrinsically safe.

(1-5) Presence of Fire Extinguisher

If any hot work is to be conducted on the refrigeration equipment or any associated parts, appropriate fire extinguishing

equipment shall be available to hand.

Have a dry powder or CO2 fire extinguisher adjacent to the charging area.

(1-6) No Ignition Sources

No person carrying out work in relation to a refrigeration system which involves exposing any pipe work shall use any

sources of ignition in such a manner that it may lead to the risk of fire or explosion. All possible ignition sources, including cigarette smoking, should be kept sufficiently far away from the site of installation, repairing, removing and disposal,

during which refrigerant can possibly be released to the surrounding space. Prior to work taking place, the area around

the equipment is to be surveyed to make sure that there are no flammable hazards or ignition risks. “No Smoking” signs

shall be displayed.

(1-7) Ventilated Area

Ensure that the area is in the open or that it is adequately ventilated before breaking into the system or conducting any

hot work. A degree of ventilation shall continue during the period that the work is carried out. The ventilation should

safely disperse any released refrigerant and preferably expel it externally into the atmosphere.

(1-8) Checks on the Refrigeration Equipment

Where electrical components are being changed, they shall be fit for the purpose and to the correct specification. At all

times the manufacturer’s maintenance and service guidelines shall be followed. If in doubt, consult the manufacturer’s

technical department for assistance.

The following checks shall be applied to installations using flammable refrigerants:

•

The charge size is in accordance with the room size within which the refrigerant containing parts are installed.

•

The ventilation machinery and outlets are operating adequately and are not obstructed.

•

Marking to the equipment continues to be visible and legible. Markings and signs that are illegible shall be corrected.

•

Refrigeration pipe or components are installed in a position where they are unlikely to be exposed to any substance

which may corrode refrigerant containing components, unless the components are constructed of materials which are

inherently resistant to being corroded or are suitably protected against being corroded.

(1-9) Checks on Electrical Devices

Repair and maintenance to electrical components shall include initial safety checks and component inspection procedures. If a fault exists that could compromise safety, then no electrical supply shall be connected to the circuit until it is

satisfactorily dealt with. If the fault cannot be corrected immediately but it is necessary to continue operation, an adequate temporary solution shall be used. This shall be reported to the owner of the equipment so all parties are advised.

Initial safety checks shall include that:

•

capacitors are discharged: this shall be done in a safe manner to avoid possibility of sparking;

•

no live electrical components and wiring are exposed while charging, recovering or purging the system;

•

there is continuity of earth bonding

(2) Repairs to Sealed Components

(2-1) During repairs to sealed components, all electrical supplies shall be disconnected from the equipment being worked

upon prior to any removal of sealed covers, etc. If it is absolutely necessary to have an electrical supply to equipment

during servicing, then a permanently operating form of leak detection shall be located at the most critical point to warn

of a potentially hazardous situation.

(2-2) Particular attention shall be paid to the following to ensure that by working on electrical components, the casing is not

altered in such a way that the level of protection is affected. This shall include damage to cables, excessive number of

connections, terminals not made to original specification, damage to seals, incorrect fitting of glands, etc.

Ensure that the apparatus is mounted securely.

Ensure that seals or sealing materials have not degraded to the point that they no longer serve the purpose of preventing the ingress of flammable atmospheres.

Replacement parts shall be in accordance with the manufacturer’s specifications.

OBH790

7

(3) Repair to intrinsically Safe Components

Do not apply any permanent inductive or capacitance loads to the circuit without ensuring that this will not exceed the

permissible voltage and current permitted for the equipment in use.

Intrinsically safe components are the only types that can be worked on while live in the presence of a flammable atmosphere. The test apparatus shall be at the correct rating.

Replace components only with parts specified by the manufacturer. Other parts may result in the ignition of refrigerant in

the atmosphere from a leak.

(4) Cabling

Check that cabling will not be subject to wear, corrosion, excessive pressure, vibration, sharp edges or any other adverse

environmental effects. The check shall also take into account the effects of aging or continual vibration from sources such

as compressors or fans.

(5) Detection of Flammable Refrigerants

Under no circumstances shall potential sources of ignition be used in the searching for or detection of refrigerant leaks.

A halide torch (or any other detector using a naked flame) shall not be used.

(6) Leak Detection Methods

Electronic leak detectors may be used to detect refrigerant leaks but, in the case of flammable refrigerants, the sensitivity

may not be adequate, or may need re-calibration. (Detection equipment shall be calibrated in a refrigerant-free area.)

Ensure that the detector is not a potential source of ignition and is suitable for the refrigerant used. Leak detection equipment shall be set at a percentage of the LFL of the refrigerant and shall be calibrated to the refrigerant employed, and the

appropriate percentage of gas (25% maximum) is confirmed.

Leak detection fluids are suitable for use with most refrigerants but the use of detergents containing chlorine shall be

avoided as the chlorine may react with the refrigerant and corrode the copper pipe-work.

If a leak is suspected, all naked flames shall be removed/extinguished.

If a leakage of refrigerant is found which requires brazing, all of the refrigerant shall be recovered from the system, or

isolated (by means of shut off valves) in a part of the system remote from the leak. For appliances containing flammable

refrigerants, oxygen free nitrogen (OFN) shall then be purged through the system both before and during the brazing process.

(7) Removal and Evacuation

When breaking into the refrigerant circuit to make repairs – or for any other purpose conventional procedures shall be

used. However, for flammable refrigerants it is important that best practice is followed since flammability is a consideration. The following procedure shall be adhered to:

• remove refrigerant

• purge the circuit with inert gas

• evacuate

• purge again with inert gas

• open the circuit by cutting or brazing.

The refrigerant charge shall be recovered into the correct recovery cylinders. For appliances containing flammable refrigerants, the system shall be “flushed” with OFN to render the unit safe. This process may need to be repeated several

times.

Compressed air or oxygen shall not be used for purging refrigerant systems.

For appliances containing flammable refrigerants, flushing shall be achieved by breaking the vacuum in the system with

OFN and continuing to fill until the working pressure is achieved, then venting to atmosphere, and finally pulling down to

a vacuum. This process shall be repeated until no refrigerant is within the system. When the final OFN charge is used,

the system shall be vented down to atmospheric pressure to enable work to take place. This operation is absolutely vital

if brazing operations on the pipe-work are to take place.

Ensure that the outlet for the vacuum pump is not close to any ignition sources and that ventilation is available.

(8) Charging Procedures

In addition to conventional charging procedures, the following requirements shall be followed:

•

Ensure that contamination of different refrigerants does not occur when using charging equipment. Hoses or lines

shall be as short as possible to minimize the amount of refrigerant contained in them.

•

Cylinders shall be kept upright.

•

Ensure that the refrigeration system is earthed prior to charging the system with refrigerant.

•

Label the system when charging is complete (if not already).

•

Extreme care shall be taken not to overfill the refrigeration system.

Prior to recharging the system, it shall be pressure-tested with the appropriate purging gas. The system shall be leaktested on completion of charging but prior to commissioning. A follow up leak test shall be carried out prior to leaving the

site.

(9) Decommissioning

Before carrying out this procedure, it is essential that the technician is completely familiar with the equipment and all its

detail. It is recommended good practice that all refrigerants are recovered safely. Prior to the task being carried out, an

oil and refrigerant sample shall be taken in case analysis is required prior to re-use of reclaimed refrigerant. It is essential

that electrical power is available before the task is commenced.

a) Become familiar with the equipment and its operation.

OBH790

8

b) Isolate system electrically.

c) Before attempting the procedure, ensure that:

• mechanical handling equipment is available, if required, for handling refrigerant cylinders;

• all personal protective equipment is available and being used correctly;

• the recovery process is supervised at all times by a competent person;

• recovery equipment and cylinders conform to the appropriate standards.

d) Pump down refrigerant system, if possible.

e) If a vacuum is not possible, make a manifold so that refrigerant can be removed from various parts of the system.

f) Make sure that cylinder is situated on the scales before recovery takes place.

g) Start the recovery machine and operate in accordance with manufacturer ’s instructions.

h) Do not overfill cylinders. (No more than 80 % volume liquid charge).

i) Do not exceed the maximum working pressure of the cylinder, even temporarily.

j) When the cylinders have been filled correctly and the process completed, make sure that the cylinders and the equip-

ment are removed from site promptly and all isolation valves on the equipment are closed off.

k) Recovered refrigerant shall not be charged into another refrigeration system unless it has been cleaned and checked.

(10) Labelling

Equipment shall be labelled stating that it has been de-commissioned and emptied of refrigerant. The label shall be

dated and signed. For appliances containing flammable refrigerants, ensure that there are labels on the equipment stating the equipment contains flammable refrigerant.

(11) Recovery

When removing refrigerant from a system, either for servicing or decommissioning, it is recommended good practice

that all refrigerants are removed safely. When transferring refrigerant into cylinders, ensure that only appropriate refrigerant recovery cylinders are employed. Ensure that the correct number of cylinders for holding the total system charge

are available. All cylinders to be used are designated for the recovered refrigerant and labelled for that refrigerant (i.e.

special cylinders for the recovery of refrigerant). Cylinders shall be complete with pressure-relief valve and associated

shut-off valves in good working order. Empty recovery cylinders are evacuated and, if possible, cooled before recovery

occurs.

The recovery equipment shall be in good working order with a set of instructions concerning the equipment that is at

hand and shall be suitable for the recovery of all appropriate refrigerants including, when applicable, flammable refrigerants. In addition, a set of calibrated weighing scales shall be available and in good working order. Hoses shall be complete with leak-free disconnect couplings and in good condition. Before using the recovery machine, check that it is in

satisfactory working order, has been properly maintained and that any associated electrical components are sealed to

prevent ignition in the event of a refrigerant release. Consult manufacturer if in doubt.

The recovered refrigerant shall be returned to the refrigerant supplier in the correct recovery cylinder, and the relevant

waste transfer note arranged. Do not mix refrigerants in recovery units and especially not in cylinders. If compressors or

compressor oils are to be removed, ensure that they have been evacuated to an acceptable level to make certain that

flammable refrigerant does not remain within the lubricant. The evacuation process shall be carried out prior to returning

the compressor to the suppliers. Only electric heating to the compressor body shall be employed to accelerate this process. When oil is drained from a system, it shall be carried out safely.

OBH790

9

2-3. PRECAUTIONS WHEN REUSING EXISTING R22/R410a REFRIGERANT PIPES

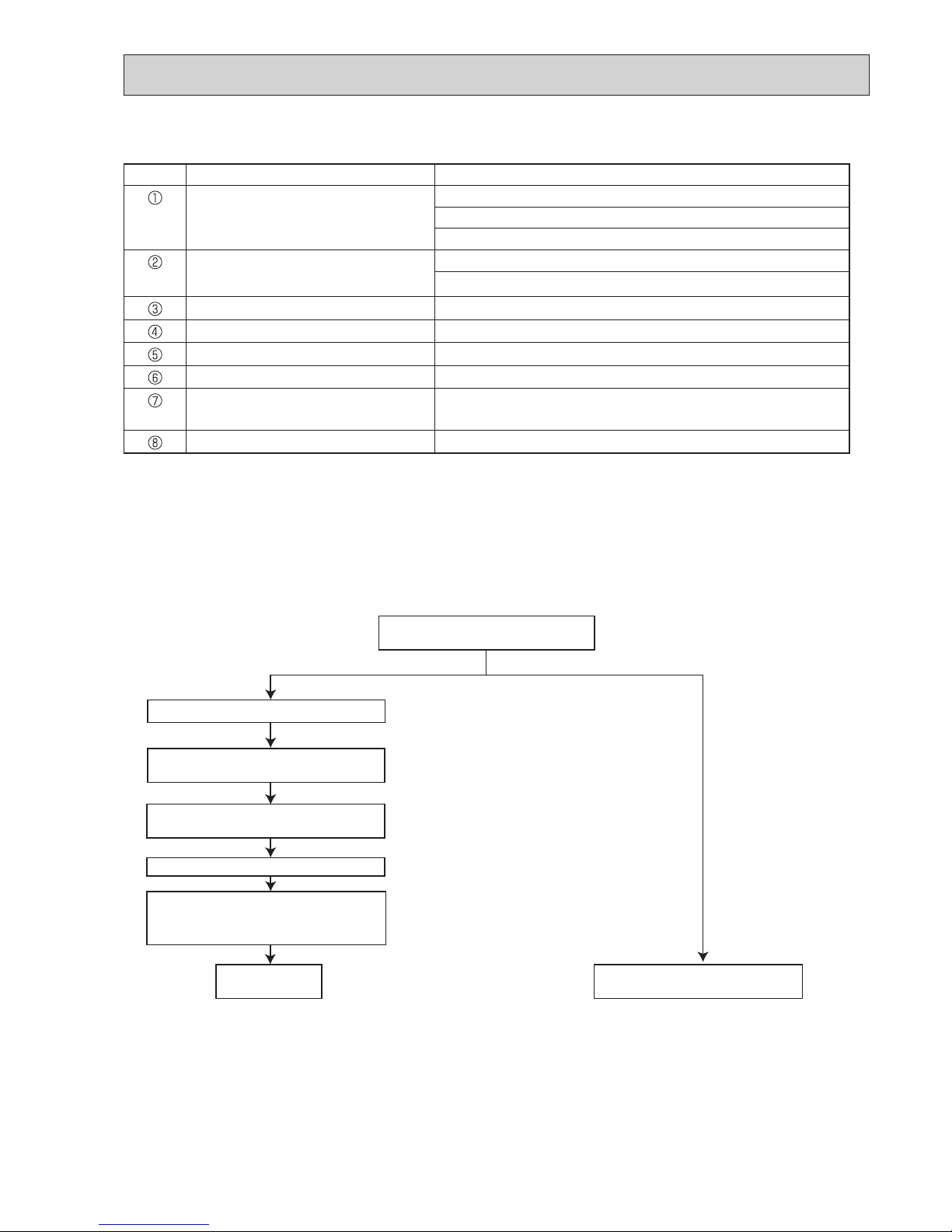

(1) Flowchart

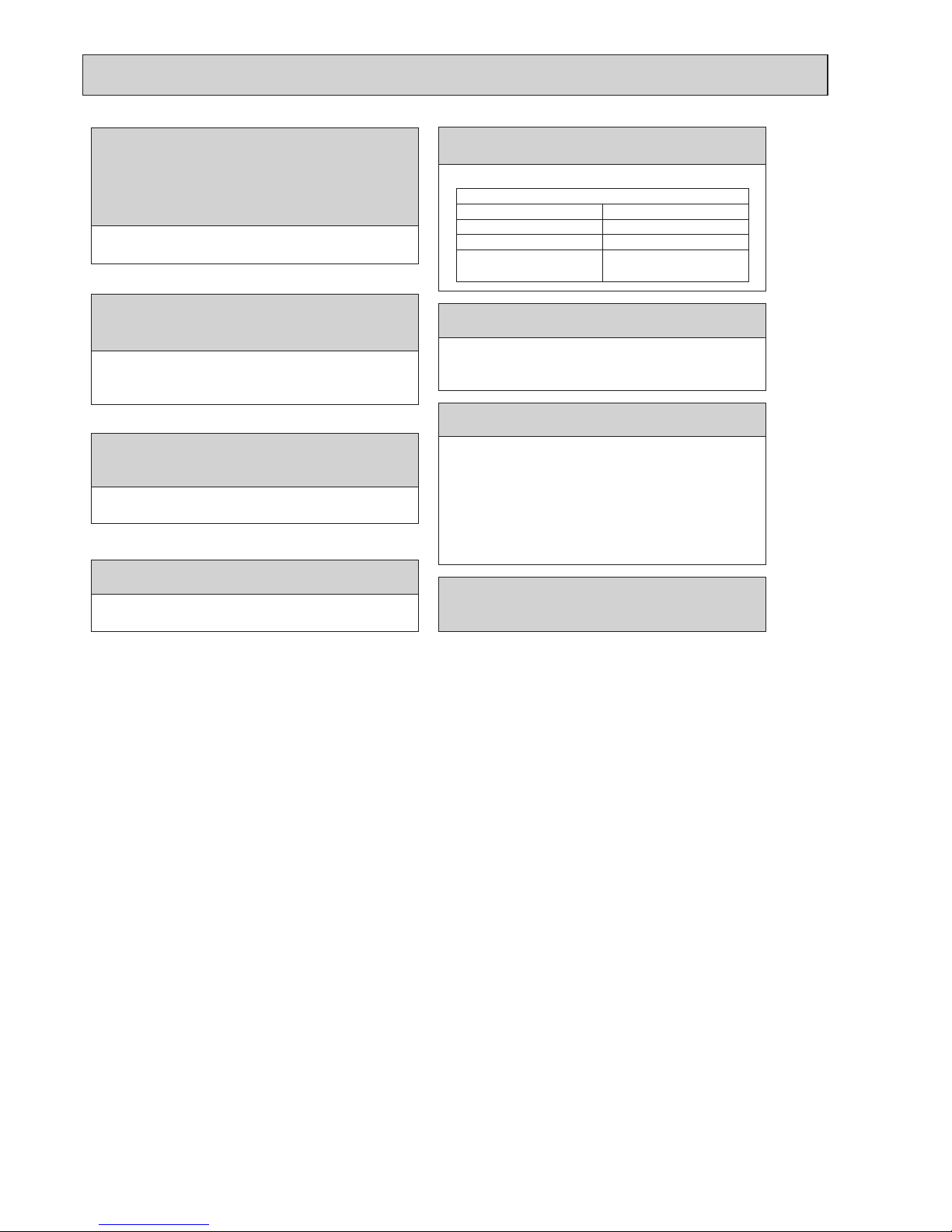

[5] Service tools

Use the below service tools as exclusive tools for R32 refrigerant.

No. Tool name Specifications

Gauge manifold · Only for R32

· Use the existing fitting

specifications

. (UNF1/2)

· Use high-tension side pressure of 5.3MPa·G or over.

Charge hose · Only for R32

· Use pressure performance of 5.09MPa·G or over.

Electronic scale

—

Gas leak detector

· Use the detector for R134a, R407C, R410a or R32.

Adaptor for reverse flow check

· Attach on vacuum pump.

Refrigerant charge base

—

Refrigerant cylinder · Only for R32

· Cylinder with syphon

Refrigerant recovery equipment

—

• Refer to the fl owchart below to determine if the existing pipes can be used and if it is necessary to use a fi lter dryer.

• If the diameter of the existing pipes is different from the specifi ed diameter, refer to technological data materials to confi rm if

the pipes can be used.

Perform the airtight test, vacuum air purging,

additional refrigerant charging (if necessary),

and gas leak check.

Measure the existing pipe thickness and

check for damage.

The existing pipe thickness meets specifi ca-

tions and the pipes are not damaged.

Check if the existing air conditioner can operate.

After operating the cooling system for about 30

minutes, perform pump down work.

Disconnect the existing air conditioner from the

pipes.

Connect the new air conditioner.

Test run

The existing pipes cannot be reused.

Use new pipes.

Note:

If the existing air conditioner cannot operate, use a

refrigerant recovery device to collect the refrigerant.

Use new pipes for MXZ-3F/4F models.

The existing pipe thickness does not meet

specifi cations or the pipes are damaged.

OBH790

10

(2) Cautions for refrigerant piping work

New refrigerant R32 is adopted for replacement inverter series. Although the refrigerant piping work for R32 is same as for

R22, exclusive tools are necessary so as not to mix with different kind of refrigerant. Furthermore as the working pressure

of R32 is 1.6 times higher than that of R22, their sizes of flared sections and flare nuts are different.

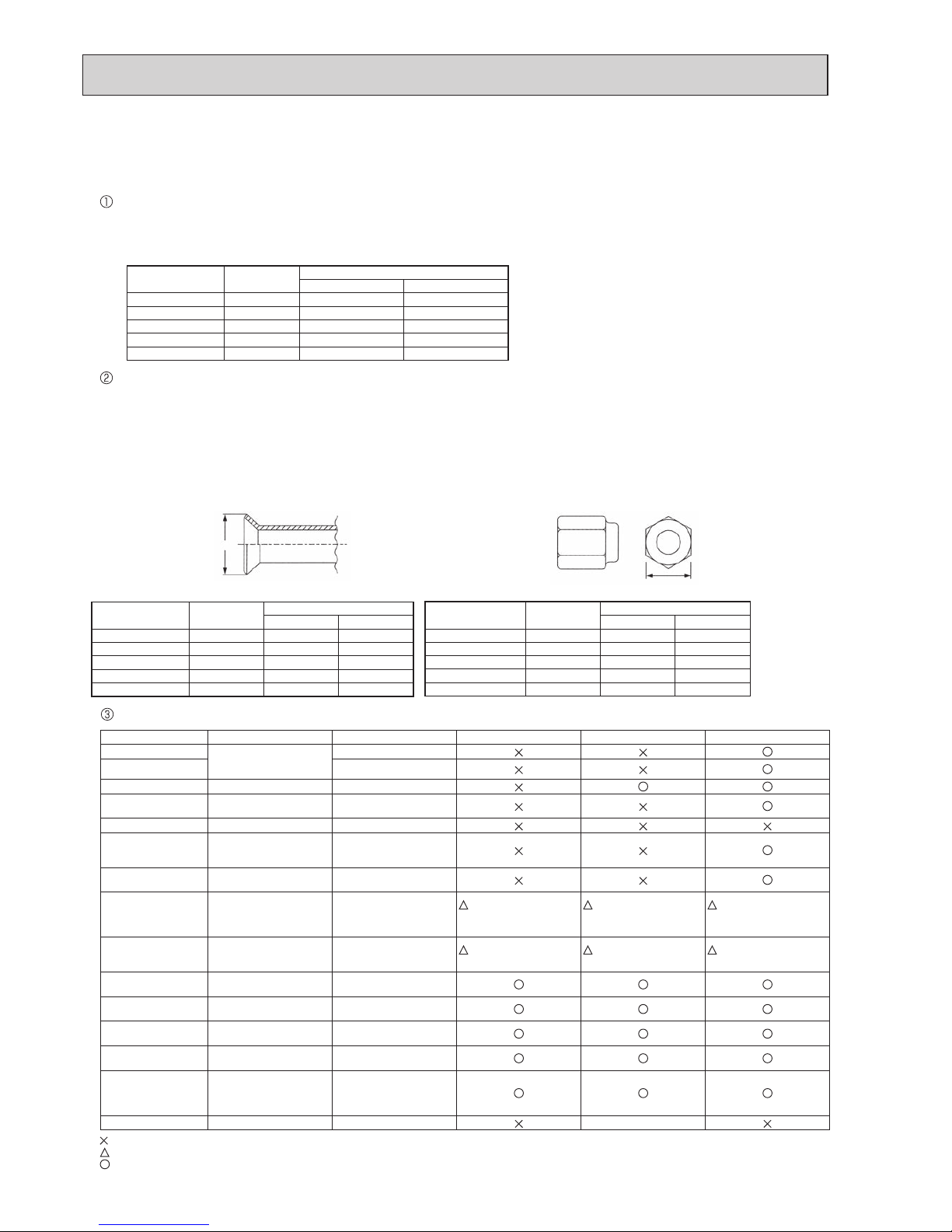

Thickness of pipes

Because the working pressure of R32 is higher compared to R22, be sure to use refrigerant piping with thickness shown

below. (Never use pipes of 0.7 mm or below.)

Dimensions of flare cutting and flare nut

The component molecules in HFC refrigerant are smaller compared to conventional refrigerants. In addition to that, R32

is a refrigerant, which has higher risk of leakage because its working pressure is higher than that of other refrigerants.

Therefore, to enhance airtightness and strength, flare cutting dimension of copper pipe for R32 has been specified separately from the dimensions for other refrigerants as shown below. The dimension B of flare nut for R32 also has partly

been changed to increase strength as shown below. Set copper pipe correctly referring to copper pipe flaring dimensions

for R32 below. For 1/2 and 5/8 inch pipes, the dimension B changes.

Use torque wrench corresponding to each dimension.

Tools for R32 (The following table shows whether conventional tools can be used or not.)

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

0.8

0.8

0.8

1.0

—

0.8

0.8

0.8

1.0

1.0

Nominal

dimensions(inch)

Diagram below: Piping diameter and thickness

Outside

diameter

(mm)

Thickness

(mm)

R32/R410a R22

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

9.1

13.2

16.6

19.7

—

9.0

13.0

16.2

19.4

23.3

Nominal

dimensions(inch)

Flare cutting dimensions

Outside

diameter(mm)

R32/R410a R22

Dimension A

( )

+0

-0.4

(mm)

1/4

3/8

1/2

5/8

3/4

6.35

9.52

12.70

15.88

19.05

17.0

22.0

26.0

29.0 *

—

17.0

22.0

24.0

27.0

36.0

Nominal

dimensions(inch)

Flare nut dimensions

Outside

diameter(mm)

Dimension B

R32/R410a

* 36.0mm for

indoor unit

of RP100,

125 and 140

R22

(mm)

Dimension A

Dimension B

Tools and materials Use R32 tools Can R22 tools be used?

Can R407C tools be used?

Can R410a tools be used?

Gauge manifold Air purge, refrigerant

charge and operation

check

Tool exclusive for R32

Charge hose

Tool exclusive for R32

Gas leak detector Gas leak check Tool for HFC refrigerant

Refrigerant recovery

equipment

Refrigerant recovery Tool exclusive for R32

Refrigerant cylinder Refrigerant charge Tool exclusive for R32

Safety charger

Prevent compressor malfunction

when charging refrigerant by

spraying liquid refrigerant

Tool exclusive for R32

Charge valve

Prevent gas from blowing out

when detaching charge hose

Tool exclusive for R32

Vacuum pump

Vacuum drying and air

purge

Tools for other refrigerants

can be used if equipped

with adapter for reverse

fl ow check

(Usable if equipped with

adapter for reverse

fl ow)

(Usable if equipped with

adapter for reverse

fl ow)

(Usable if equipped with

adapter for reverse

fl ow)

Flare tool

Flaring work of piping

Tools for other refrigerants

can be used by adjusting

fl aring dimension

(Usable by adjusting

fl aring dimension)

(Usable by adjusting

fl aring dimension)

(Usable by adjusting

fl aring dimension)

Bender

Bend the pipes

Tools for other refrigerants

can be used

Pipe cutter

Cut the pipes

Tools for other refrigerants

can be used

Welder and nitrogen

gas cylinder

Weld the pipes

Tools for other refrigerants

can be used

Refrigerant charging

scale

Refrigerant charge

Tools for other refrigerants

can be used

Vacuum gauge or

thermistor vacuum

gauge and vacuum

valve

Check the degree of vacuum.

(Vacuum valve prevents back

fl ow of oil and refrigerant to

thermistor vacuum gauge)

Tools for other refrigerants

can be used

Charging cylinder Refrigerant charge Tool exclusive for R32 –

: Prepare a new tool. (Use the new tool as the tool exclusive for R32.)

: Tools for other refrigerants can be used under certain conditions.

: Tools for other refrigerants can be used.

OBH790

11

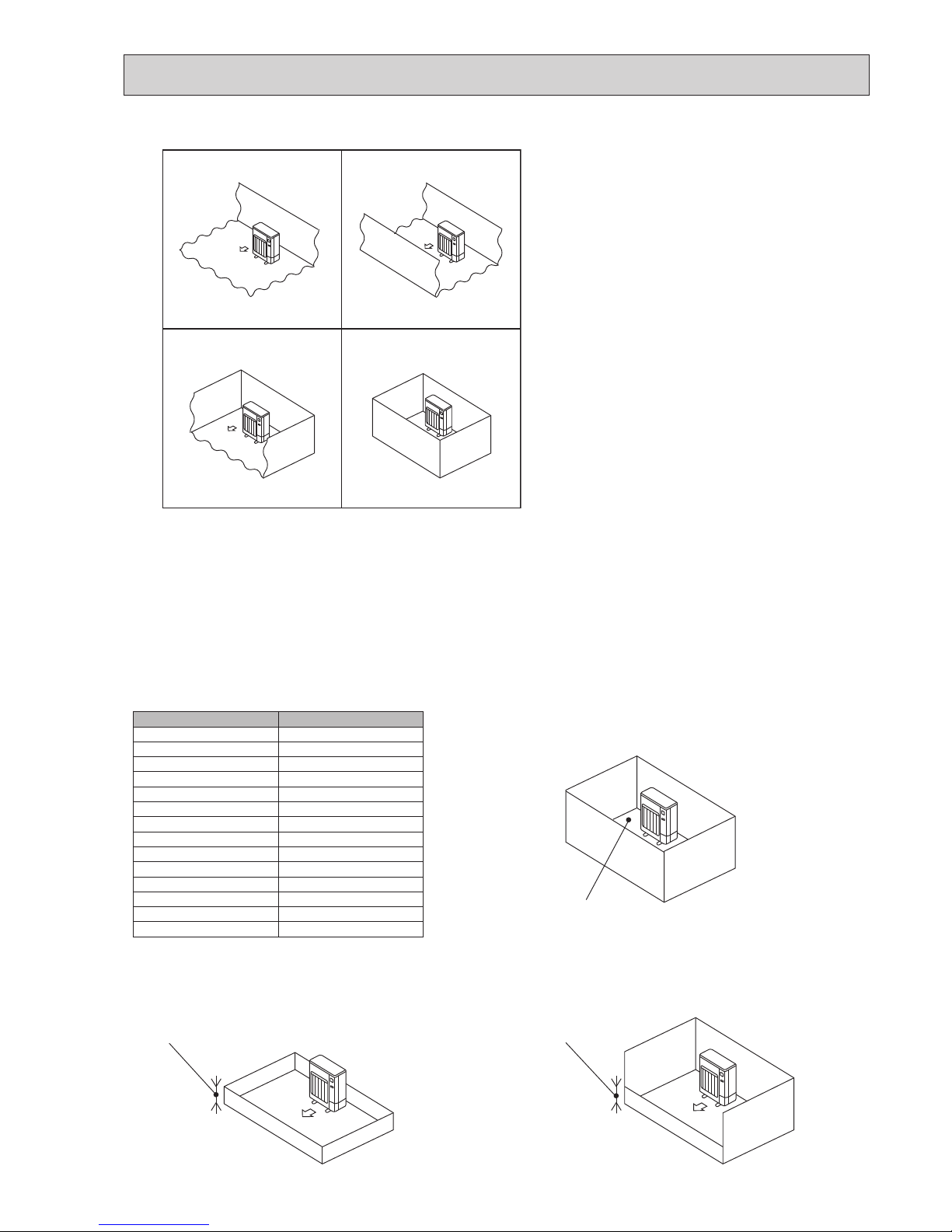

2-4. CHOOSING THE OUTDOOR UNIT INSTALLATION LOCATION

R32 is heavier than air—as well as other refrigerants—

so tends to accumulate at the base (in the vicinity of the

floor). If R32 accumulates around base, it may reach a

flammable concentration in case room is small. To avoid

ignition, maintaining a safe work environment is required

by ensuring appropriate ventilation. If a refrigerant leak is

confirmed in a room or an area where there is insufficient

ventilation, refrain from using of flames until the work

environment can be improved by ensuring appropriate

ventilation.

Install outdoor units in a place where at least one of the

four sides is open, and in a sufficiently large space without depressions.

2-5. MINIMUM INSTALLATION AREA

If you unavoidably install a unit in a space where all four sides are blocked or there are depressions, confirm that one of

these situations (A, B or C) is satisfied.

Note: These countermeasures are for keeping safety not for specification guarantee.

A) Secure sufficient installation space (minimum installation area Amin).

Install in a space with an installation area of Amin or more, corresponding to refrigerant quantity M (factory-charged

refrigerant + locally added refrigerant).

B) Install in a space with a depression height of 0.125 [m] or less.

OK OK

OK NG

Amin

Height from the bottom of

0.125 [m] or less

Height from the bottom of

0.125 [m] or less

M [kg] Amin [m²]

1.0 12

1.5 17

2.0 23

2.5 28

3.0 34

3.5 39

4.0 45

4.5 50

5.0 56

5.5 62

6.0 67

6.5 73

7.0 78

7.5 84

OBH790

12

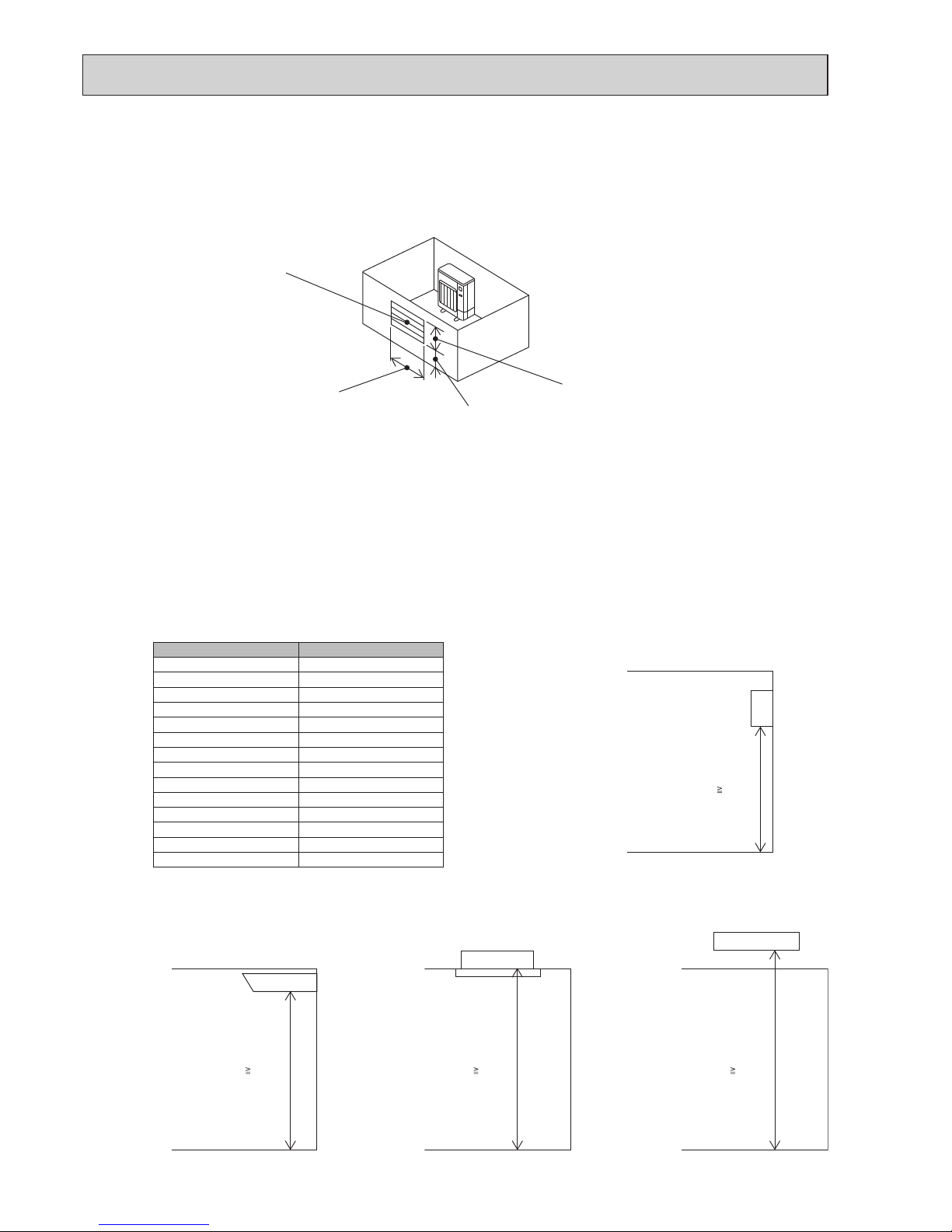

C) Create an appropriate ventilation open area.

Make sure that the width of the open area is 0.9 [m] or more and the height of the open area is 0.15 [m] or more.

However, the height from the bottom of the installation space to the bottom edge of the open area should be 0.125 [m]

or less.

Open area should be 75% or more opening.

■ Indoor units

Install in a room with a floor area of Amin or more, corresponding to refrigerant quantity M (factory-charged refrigerant + locally added refrigerant).

* For the factory-charged refrigerant amount, refer to the spec nameplate or installation manual.

For the amount to be added locally, refer to the installation manual.

Install the indoor unit so that the height from the floor to the bottom of the indoor unit is h0;

for wall mounted: 1.8 m or more;

for ceiling suspended, cassette and ceiling concealed: 2.2 m or more.

* There are restrictions in installation height for each model, so read the installation manual for the particular unit.

75% or more opening

Width W 0.9 [m] or more

Height from the bottom

0.125 [m] or less

Height H 0.15 [m] or more

M [kg] Amin [m²]

1.0 3

1.5 4.5

2.0 6

2.5 7.5

3.0 9

3.5 12

4.0 15.5

4.5 20

5.0 24

5.5 29

6.0 35

6.5 41

7.0 47

7.5 54

Wall mounted

h0

1.8 [m]

Ceiling concealedCassetteCeiling suspended

h0 2.2 [m]h0 2.2 [m]h0 2.2 [m]

OBH790

13

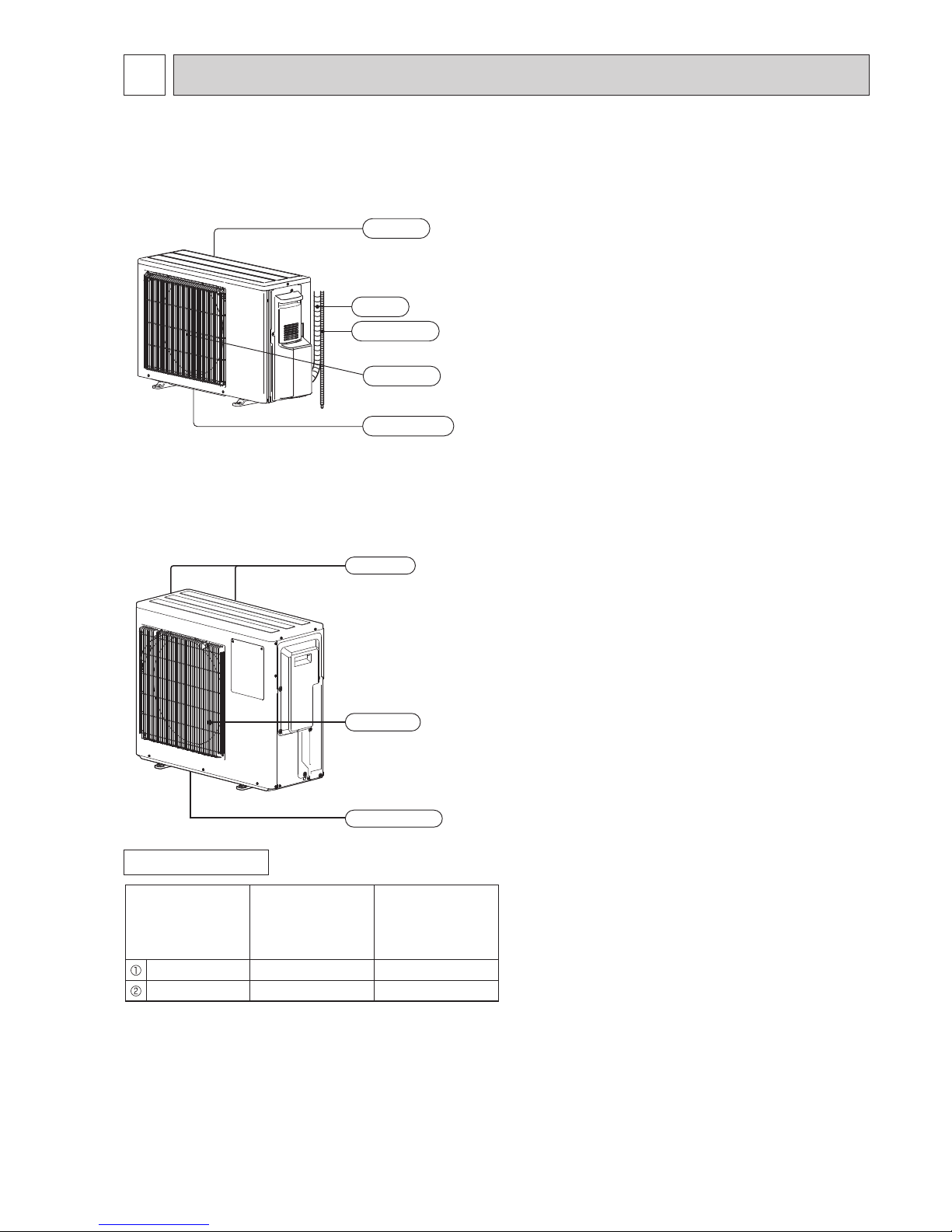

PART NAMES AND FUNCTIONS

3

ACCESSORIES

Model

MXZ-2F33VF

MXZ-2F42VF

MXZ-2F53VF

MXZ-3F54VF

MXZ-3F68VF

MXZ-4F72VF

Drain socket 1 1

Drain cap - 2

Air outlet

Drain outlet

Air inlet

(Back and side)

MXZ-3F54VF

MXZ-3F68VF

MXZ-4F72VF

MXZ-2F33VF

MXZ-2F42VF

MXZ-2F53VF

MXZ-2F53VFH

Air inlet

Air outlet

Drain outlet

Piping

Drain hose

(Back and side)

OBH790

14

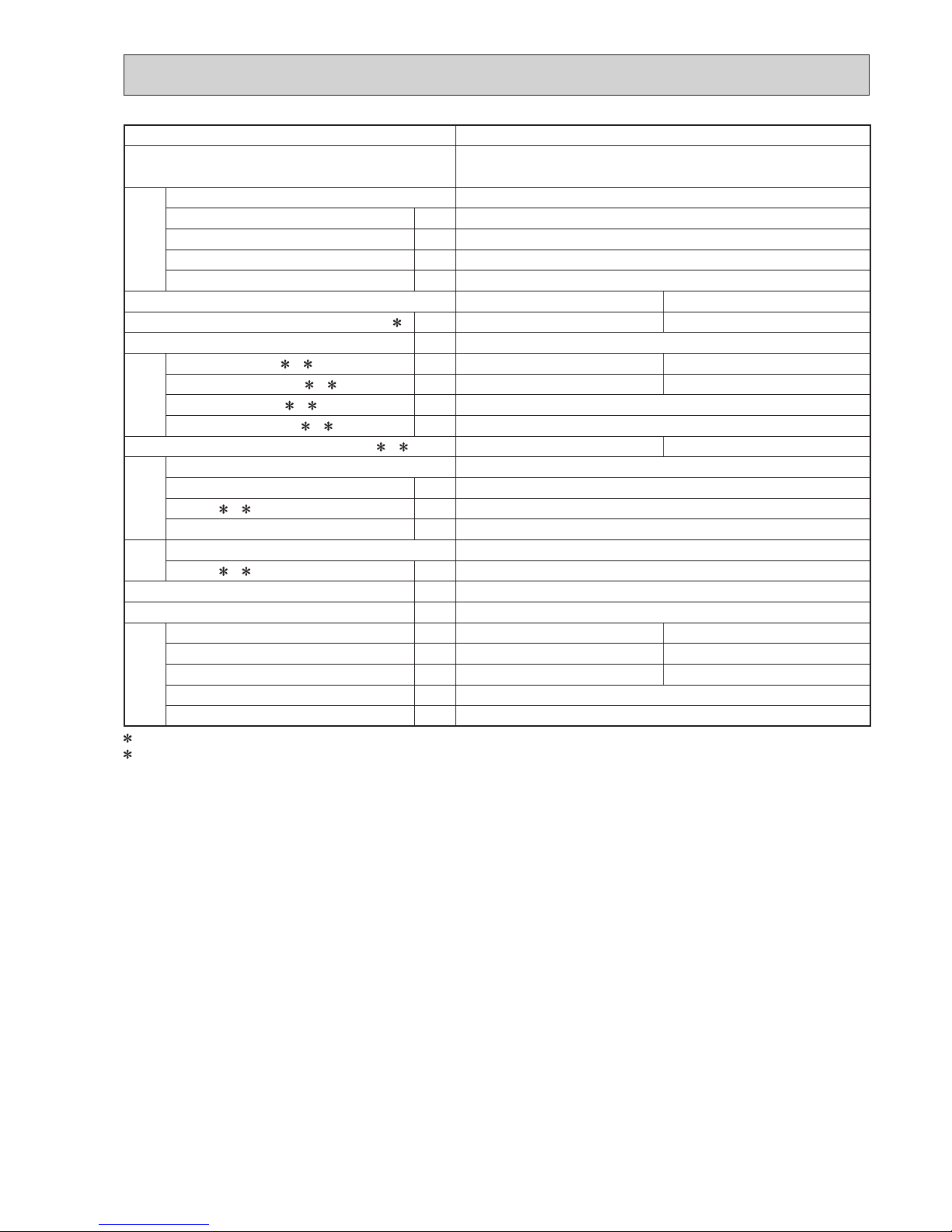

SPECIFICATION

4

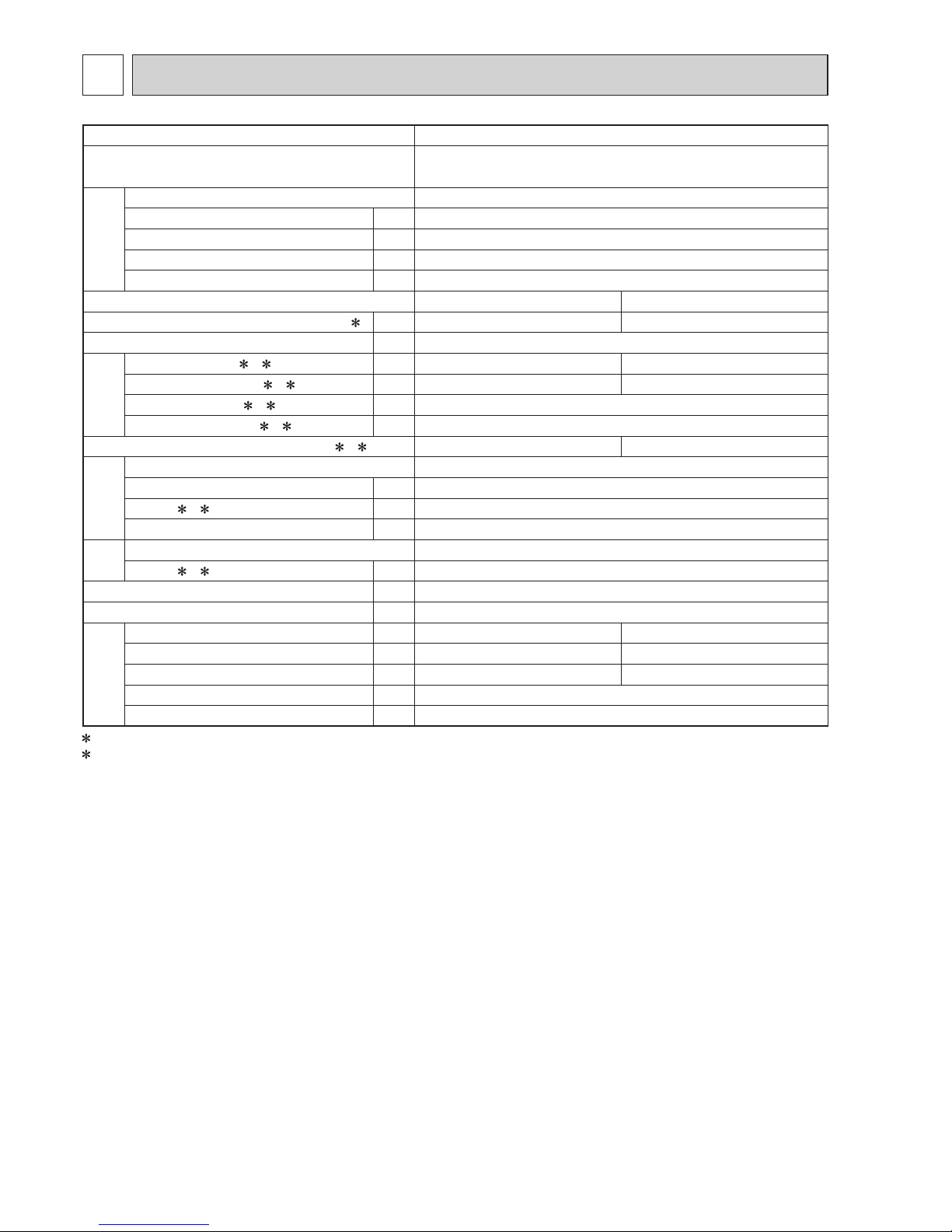

Outdoor model MXZ-2F33VF

Outdoor unit power supply

Single phase

220 - 230 - 240 V, 50 Hz

System

Indoor units number 2

Piping total length m Max. 20

Connecting pipe length m Max. 15

Height difference (Indoor ~ Outdoor) m Refer to 8 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 8 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 3.3 (1.1 - 3.8) 4.0 (1.0 - 4.1)

Breaker capacity A 15

Electrical

data

Power input (Total) 1, 2 W 850 910

Running current (Total)

1, 2 A 4.3 - 4.1 - 3.9 4.6 - 4.4 - 4.2

Power factor (Total)

1, 2% 90

Starting current (Total)

1, 2 A 4.6

Coeffi cient of performance (C.O.P) (Total)

1, 2 3.88 4.40

Compressor

Model KVB073FYXMC

Output W 470

Current

1, 2 A 3.8

Refrigeration oil (Model) L 0.27 (FW68S)

Fan

motor

Model RC0J50-FA

Current

1, 2 A 0.35

Dimensions W x H x D mm 800 x 550 x 285

Weight kg 33

Special

remarks

Air fl ow (Rated) m3 /h 1,890 1,938

Sound level (Rated) dB(A) 49 50

Fan speed (Rated) rpm 860 880

Pre-charged refrigerant quantity (R32) kg 1.0

Max refrigerant quantity (R32) kg 1.0

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-AP15VF + MSZ-LN18VG

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH790

15

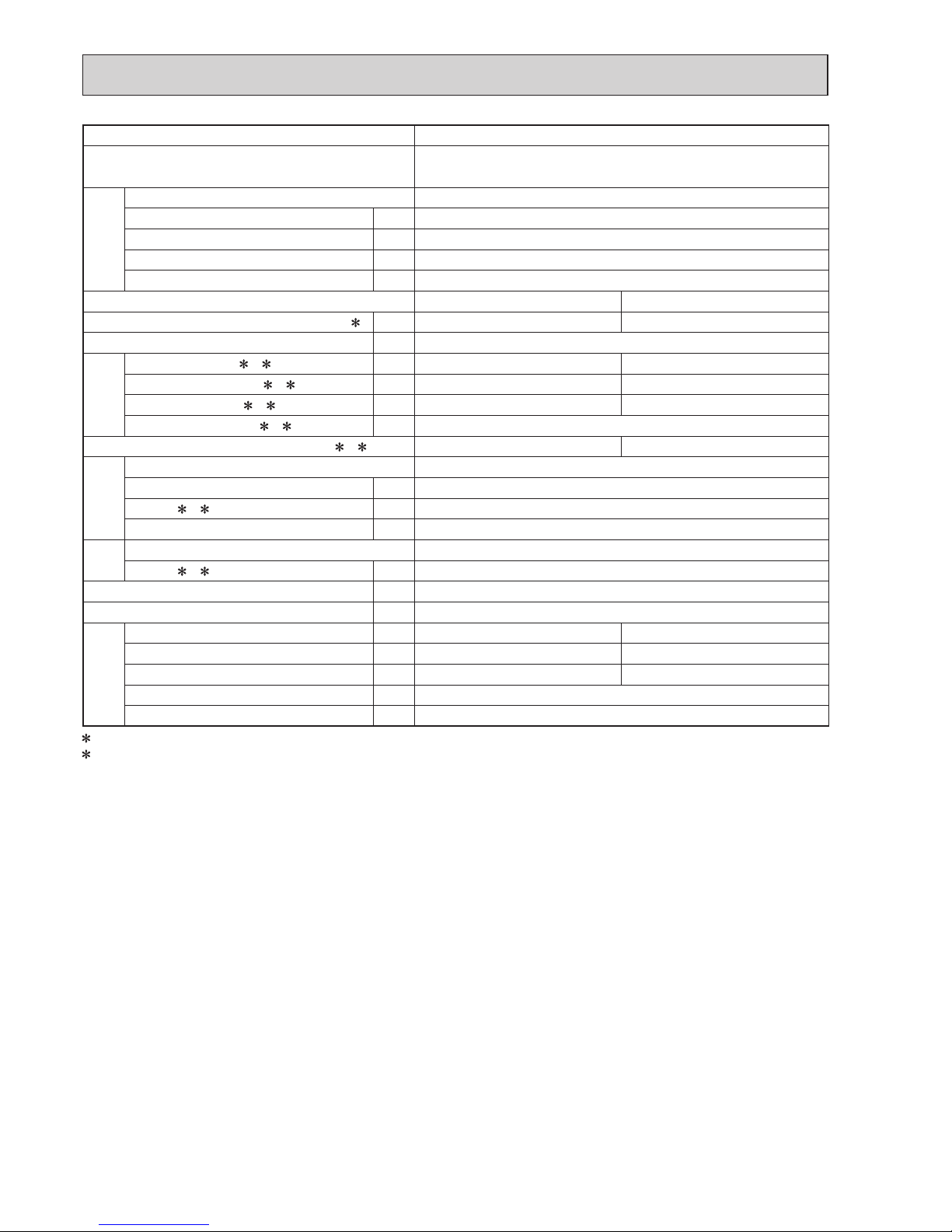

Outdoor model MXZ-2F42VF

Outdoor unit power supply

Single phase

220 - 230 - 240 V, 50 Hz

System

Indoor units number 2

Piping total length m Max. 30

Connecting pipe length m Max. 20

Height difference (Indoor ~ Outdoor) m Refer to 8 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 8 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 4.2 (1.1 - 4.4) 4.5 (1.0 - 4.8)

Breaker capacity A 15

Electrical

data

Power input (Total) 1, 2 W 980 880

Running current (Total)

1, 2 A 4.9 - 4.7 - 4.5 4.4 - 4.3 - 4.1

Power factor (Total)

1, 2% 90

Starting current (Total)

1, 2 A 7.6

Coeffi cient of performance (C.O.P) (Total)

1, 2 4.29 5.11

Compressor

Model SVB130FBBMT

Output W 1,100

Current

1, 2 A 3.99

Refrigeration oil (Model) L 0.35 (FW68S)

Fan

motor

Model RC0J50-FA

Current

1, 2 A 0.35

Dimensions W x H x D mm 800 x 550 x 285

Weight kg 37

Special

remarks

Air fl ow (Rated) m3 /h 1,704 2,010

Sound level (Rated) dB(A) 44 50

Fan speed (Rated) rpm 780 910

Pre-charged refrigerant quantity (R32) kg 1.2

Max refrigerant quantity (R32) kg 1.2

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-LN18VG + MSZ-LN25VG

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH790

16

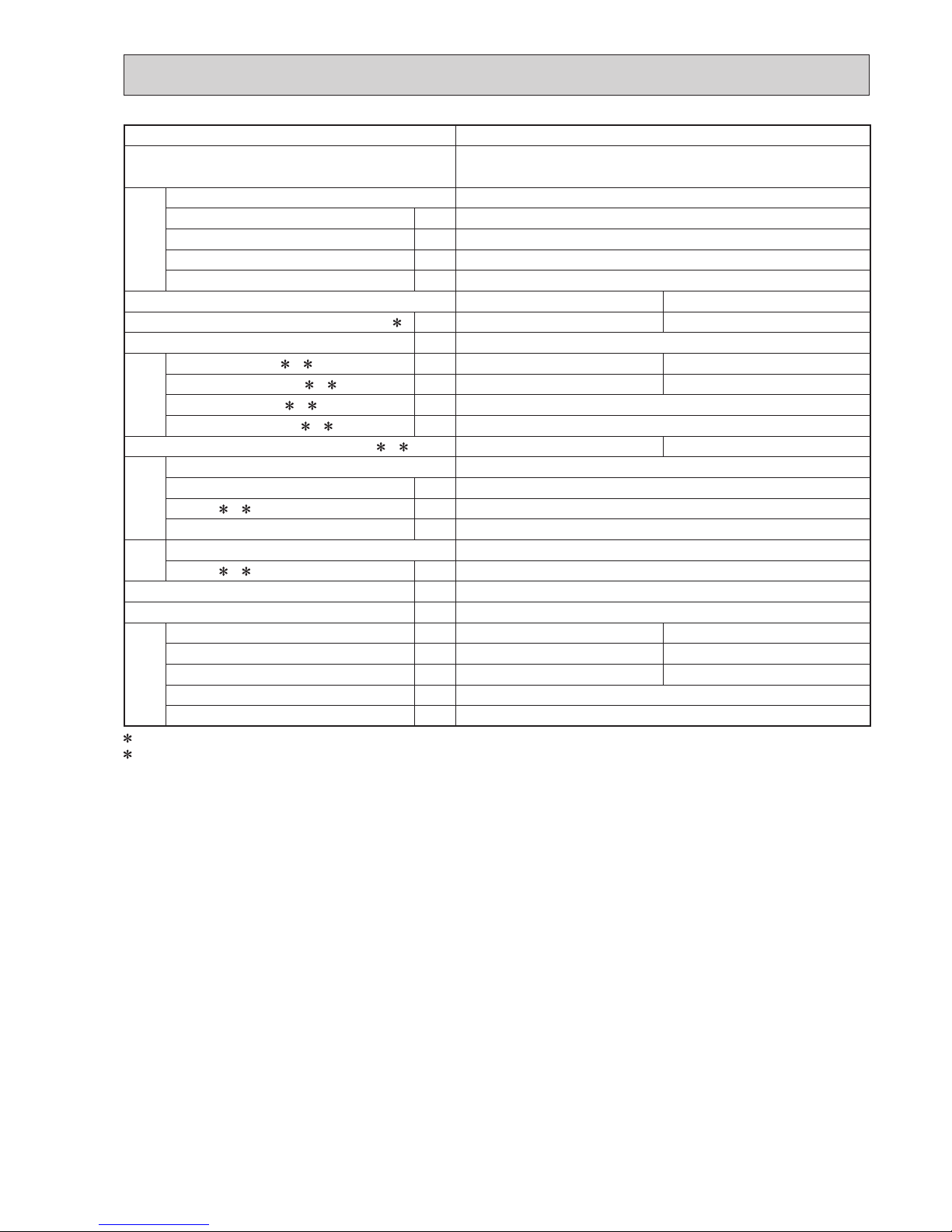

Outdoor model MXZ-2F53VF MXZ-2F53VFH

Outdoor unit power supply

Single phase

220 - 230 - 240 V, 50 Hz

System

Indoor units number 2

Piping total length m Max. 30

Connecting pipe length m Max. 20

Height difference (Indoor ~ Outdoor) m Refer to 8 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 8 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 5.3 (1.1 - 5.6) 6.4 (1.0 - 7.0)

Breaker capacity A 15

Electrical

data

Power input (Total) 1, 2 W 1,400 1,560

Running current (Total)

1, 2 A 6.5 - 6.2 - 6.0 7.5 - 7.1 - 6.8

Power factor (Total)

1, 2 % 97.5 95

Starting current (Total)

1, 2 A 7.6

Coeffi cient of performance (C.O.P) (Total)

1, 2 3.79 4.10

Compressor

Model SVB130FBBMT

Output W 1,400

Current

1, 2 A 6.59

Refrigeration oil (Model) L 0.35 (FW68S)

Fan

motor

Model RC0J50-FA

Current

1, 2 A 0.35

Dimensions W x H x D mm 800 x 550 x 285

Weight kg MXZ-2F53VF: 37 MXZ-2F53VFH: 38

Special

remarks

Air fl ow (Rated) m3 /h 1,962 2,082

Sound level (Rated) dB(A) 46 51

Fan speed (Rated) rpm 890 940

Pre-charged refrigerant quantity (R32) kg 1.2

Max refrigerant quantity (R32) kg 1.2

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-LN18VG + MSZ-LN35VG

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH790

17

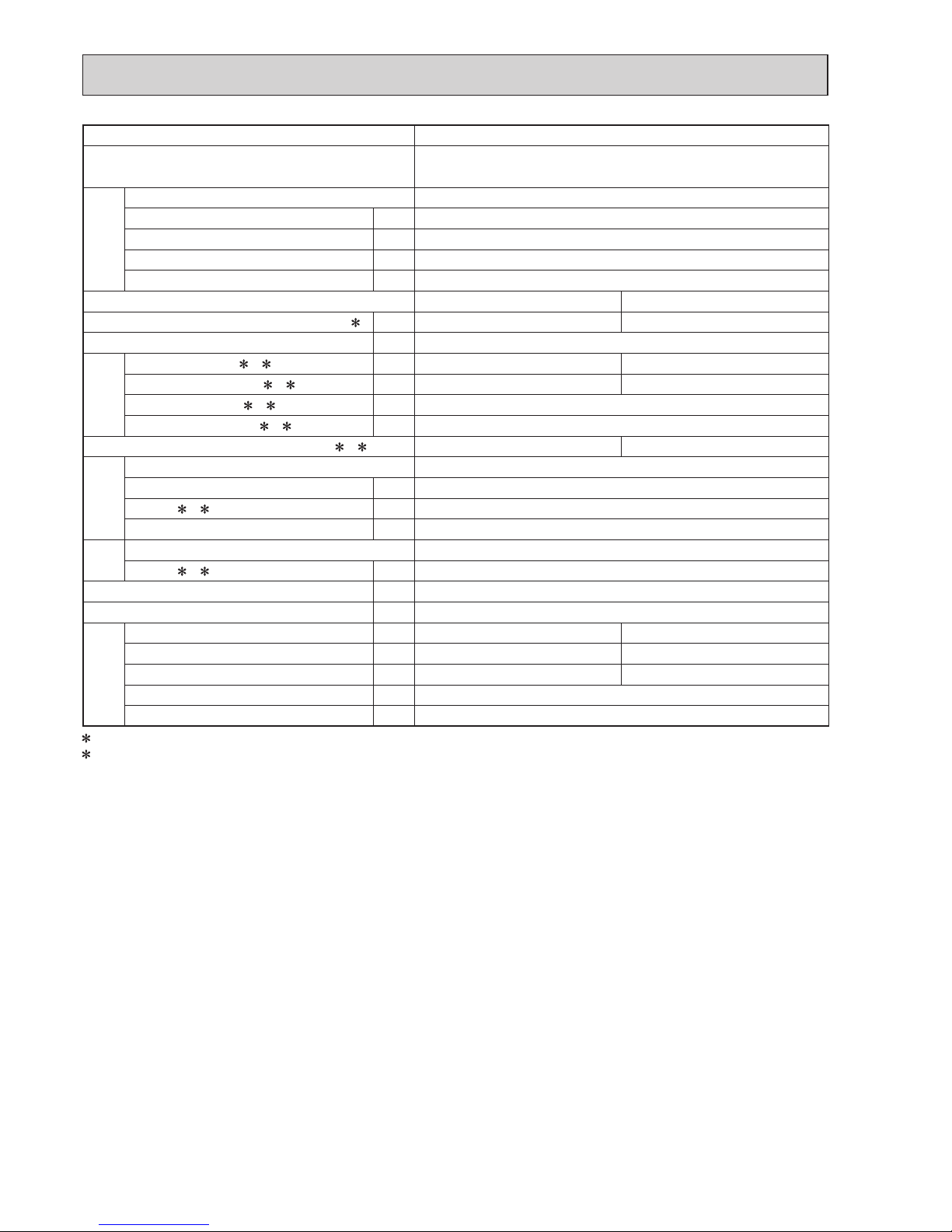

Outdoor model MXZ-3F54VF

Outdoor unit power supply

Single phase

220 - 230 - 240 V, 50 Hz

System

Indoor units number 2 to 3

Piping total length m Max. 50

Connecting pipe length m Max. 25

Height difference (Indoor ~ Outdoor) m Refer to 8 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 8 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 5.4 (2.9 - 6.8) 7.0 (2.6 - 9.0)

Breaker capacity A 25

Electrical

data

Power input (Total) 1, 2 W 1,320 1,400

Running current (Total)

1, 2 A 6.0 - 5.7 - 5.5 6.4 - 6.1 - 5.9

Power factor (Total)

1, 2% 99

Starting current (Total)

1, 2 A 6.7

Coeffi cient of performance (C.O.P) (Total)

1, 2 4.09 5.00

Compressor

Model SVB130FBBM1T

Output W 1,400

Current

1, 2 A 5.06

Refrigeration oil (Model) L 0.6 (FW68S)

Fan

motor

Model SIC-82FX-F764-1

Current

1, 2 A 0.5

Dimensions W x H x D mm 840 x 710 x 330

Weight kg 57

Special

remarks

Air fl ow (Rated) m3 /h 1,860 1,632

Sound level (Rated) dB(A) 46 50

Fan speed (Rated) rpm 600 560

Pre-charged refrigerant quantity (R32) kg 1.4

Max refrigerant quantity (R32) kg 2.4

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-LN18VG + MSZ-LN18VG + MSZ-LN18VG

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH790

18

Outdoor model MXZ-3F68VF

Outdoor unit power supply

Single phase

220 - 230 - 240 V, 50 Hz

System

Indoor units number 2 to 3

Piping total length m Max. 60

Connecting pipe length m Max. 25

Height difference (Indoor ~ Outdoor) m Refer to 8 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 8 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 6.8 (2.9 - 8.4) 8.6 (2.6 - 10.6)

Breaker capacity A 25

Electrical

data

Power input (Total) 1, 2 W 1,840 1,910

Running current (Total)

1, 2 A 8.4 - 8.0 - 7.7 8.8 - 8.4 - 8.0

Power factor (Total)

1, 2% 99

Starting current (Total)

1, 2 A 10.1

Coeffi cient of performance (C.O.P) (Total)

1, 2 3.70 4.50

Compressor

Model SVB172FCKM1T

Output W 1,800

Current

1, 2 A 8.58

Refrigeration oil (Model) L 0.6 (FW68S)

Fan

motor

Model SIC-82FX-F764-1

Current

1, 2 A 0.5

Dimensions W x H x D mm 840 x 710 x 330

Weight kg 57

Special

remarks

Air fl ow (Rated) m3 /h 2,124 2,376

Sound level (Rated) dB(A) 48 53

Fan speed (Rated) rpm 650 700

Pre-charged refrigerant quantity (R32) kg 1.4

Max refrigerant quantity (R32) kg 2.4

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-LN18VG + MSZ-LN25VG + MSZ-LN25VG

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH790

19

Outdoor model MXZ-4F72VF

Outdoor unit power supply

Single phase

220 - 230 - 240 V, 50 Hz

System

Indoor units number 2 to 4

Piping total length m Max. 60

Connecting pipe length m Max. 25

Height difference (Indoor ~ Outdoor) m Refer to 8 REFRIGERANT SYSTEM DIAGRAM.

Height difference (Indoor ~ Indoor) m Refer to 8 REFRIGERANT SYSTEM DIAGRAM.

Function Cooling Heating

Capacity Rated frequency (Min.-Max.)

2 kW 7.2 (3.7 - 8.8) 8.6 (3.4 - 10.7)

Breaker capacity A 25

Electrical

data

Power input (Total) 1, 2 W 1,850 1,870

Running current (Total)

1, 2 A 8.5 - 8.1 - 7.8 8.6 - 8.2 - 7.9

Power factor (Total)

1, 2% 99

Starting current (Total)

1, 2 A 10.1

Coeffi cient of performance (C.O.P) (Total)

1, 2 3.89 4.60

Compressor

Model SVB172FCKM1T

Output W 2,000

Current

1, 2 A 6.98

Refrigeration oil (Model) L 0.6 (FW68S)

Fan

motor

Model SIC-82FX-F764-1

Current

1, 2 A 0.5

Dimensions W x H x D mm 840 x 710 x 330

Weight kg 58

Special

remarks

Air fl ow (Rated) m3 /h 2,124 2,562

Sound level (Rated) dB(A) 48 54

Fan speed (Rated) rpm 650 740

Pre-charged refrigerant quantity (R32) kg 1.4

Max refrigerant quantity (R32) kg 2.4

1 Measured under rated operating frequency.

2 When connected with indoor units below.

MSZ-LN18VG + MSZ-LN18VG + MSZ-LN18VG + MSZ-LN18VG

NOTE: Test conditions are based on ISO 5151. (Refrigerant piping length (one way): 5 m)

COOLING INDOOR Dry-bulb temperature 27.0 °C Wet-bulb temperature 19.0 °C

OUTDOOR Dry-bulb temperature 35.0 °C Wet-bulb temperature 24.0 °C

HEATING INDOOR Dry-bulb temperature 20.0 °C

OUTDOOR Dry-bulb temperature 7.0 °C Wet-bulb temperature 6.0 °C

OBH790

20

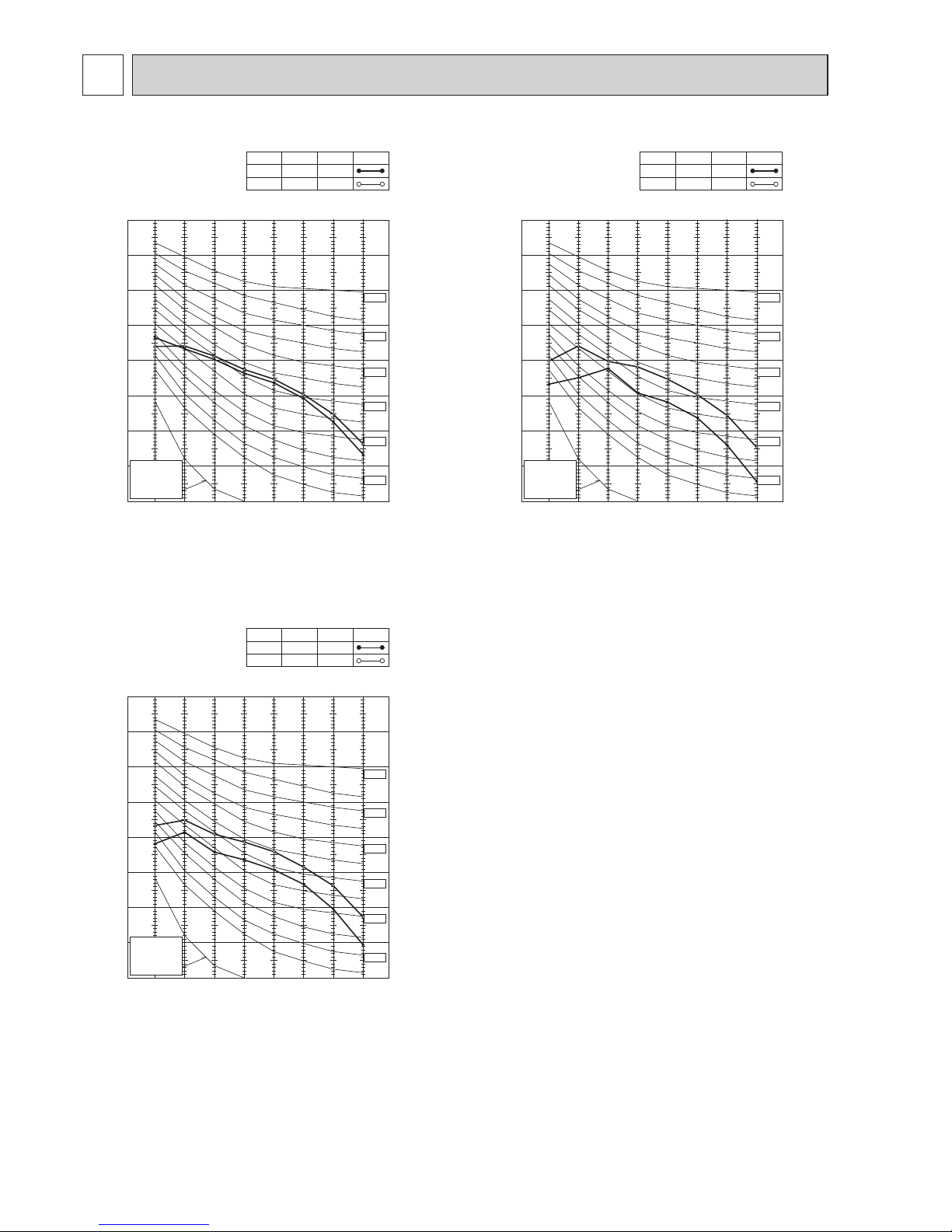

NOISE CRITERIA CURVES

5

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

44

SPL(dB(A))50LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

49

SPL(dB(A))50LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

46

SPL(dB(A))51LINE

MXZ-2F53VF

MXZ-2F53VFH

MXZ-2F33VF MXZ-2F42VF

OBH790

21

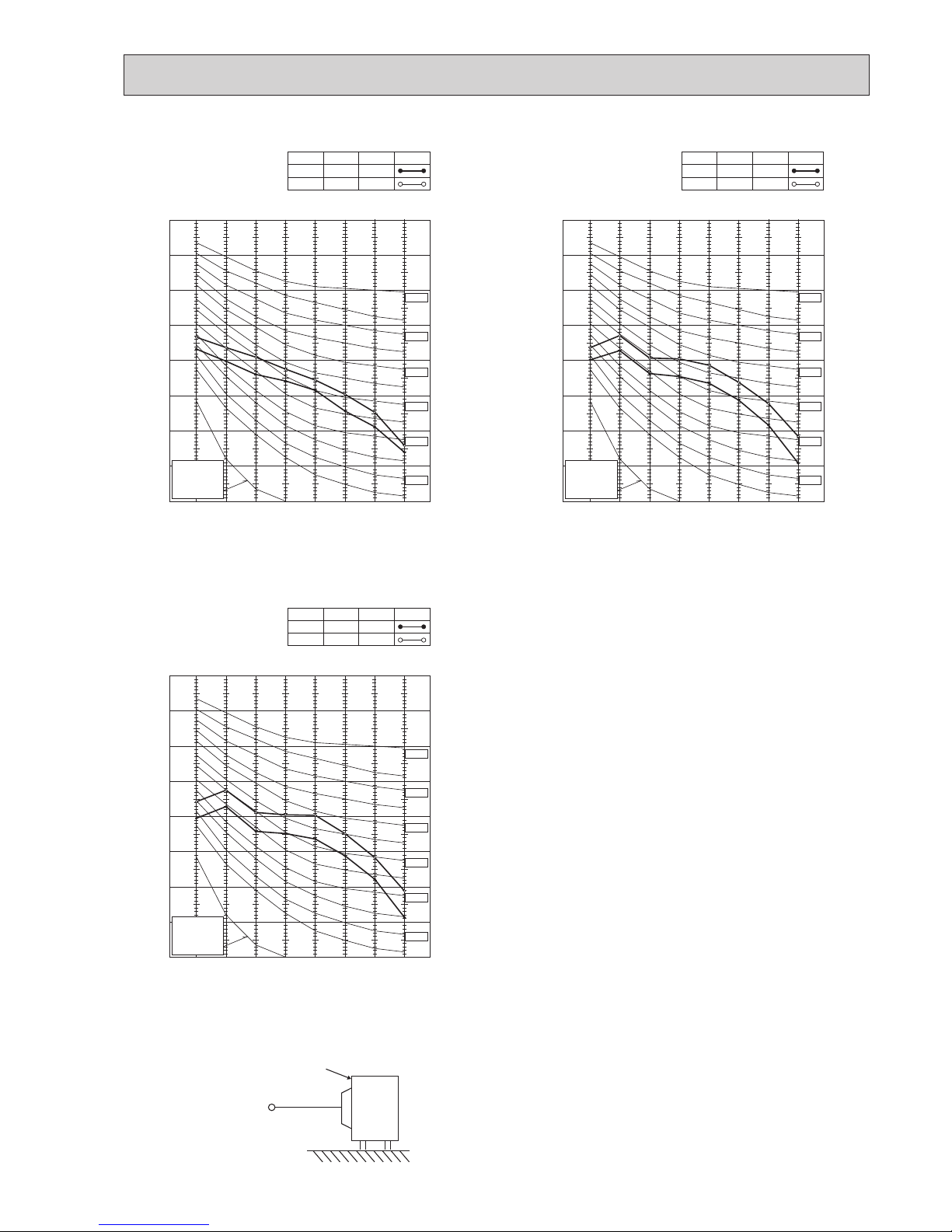

OUTDOOR UNIT

MICROPHONE

1m

Test conditions

Cooling :Dry-bulb temperature 35.0°C Wet-bulb temperature 24.0°C

Heating :Dry-bulb temperature 7.0°C Wet-bulb temperature 6.0°C

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

46

SPL(dB(A))50LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

48

SPL(dB(A))53LINE

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

NC-60

NC-50

NC-40

NC-30

NC-20

NC-70

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

CoolingHigh

FUNCTION

FAN SPEED

HeatingHigh

48

SPL(dB(A))54LINE

MXZ-3F54VF MXZ-3F68VF

MXZ-4F72VF

OBH790

22

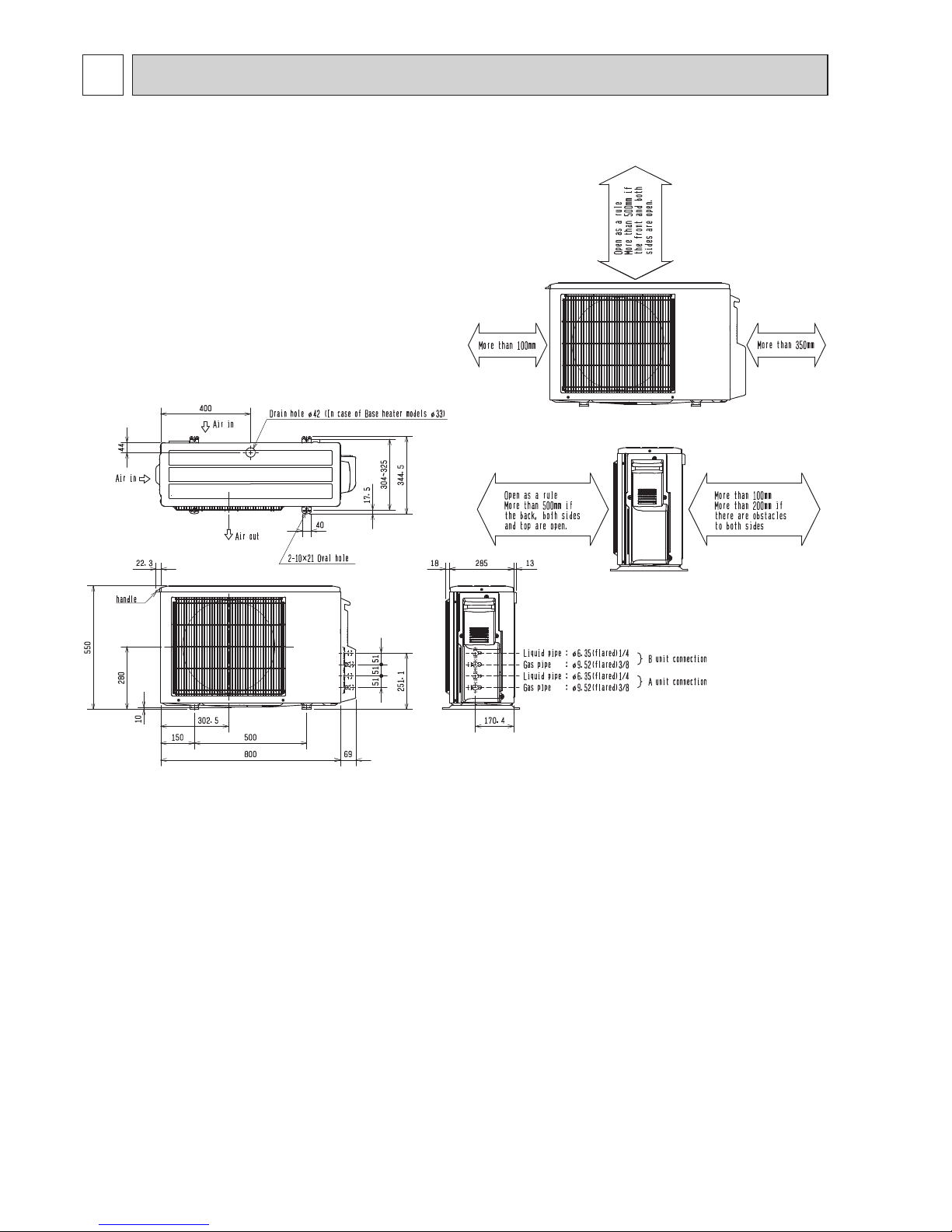

OUTLINES AND DIMENSIONS

6

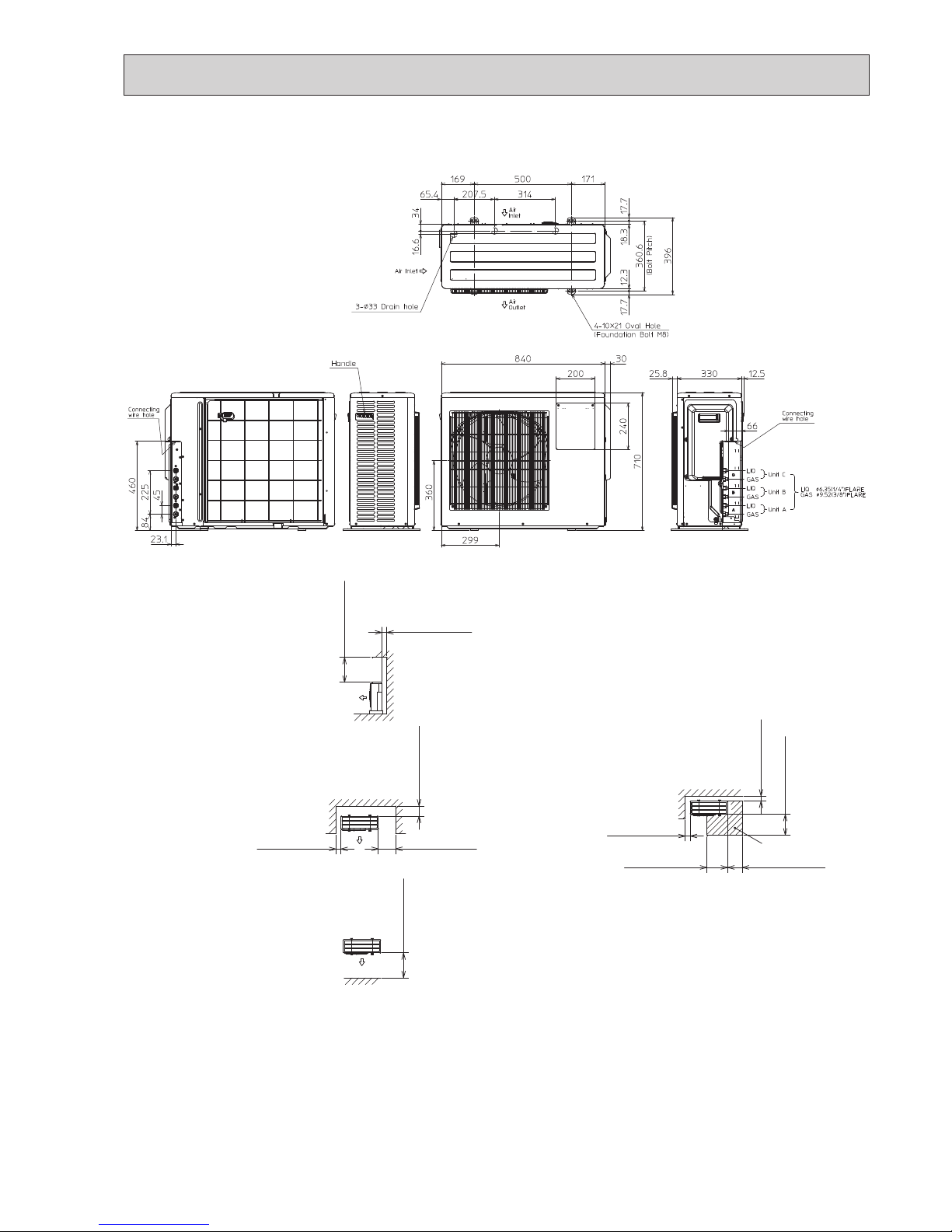

MXZ-2F33VF MXZ-2F42VF MXZ-2F53VF MXZ-2F53VFH

Unit: mm

OBH790

23

1.Installation space

Note : Leave front and both sides

free of obstruction.

Note : Leave rear, overhead and

both sides free of obstruction.

500 or more

100 or more

Note : Leave front and overhead

free of obstruction.

100 or more

350 or more

200 or more

500 or more

2.Service space

100 or more

500 or more

350 or more

350 or more

100 or more

Service space

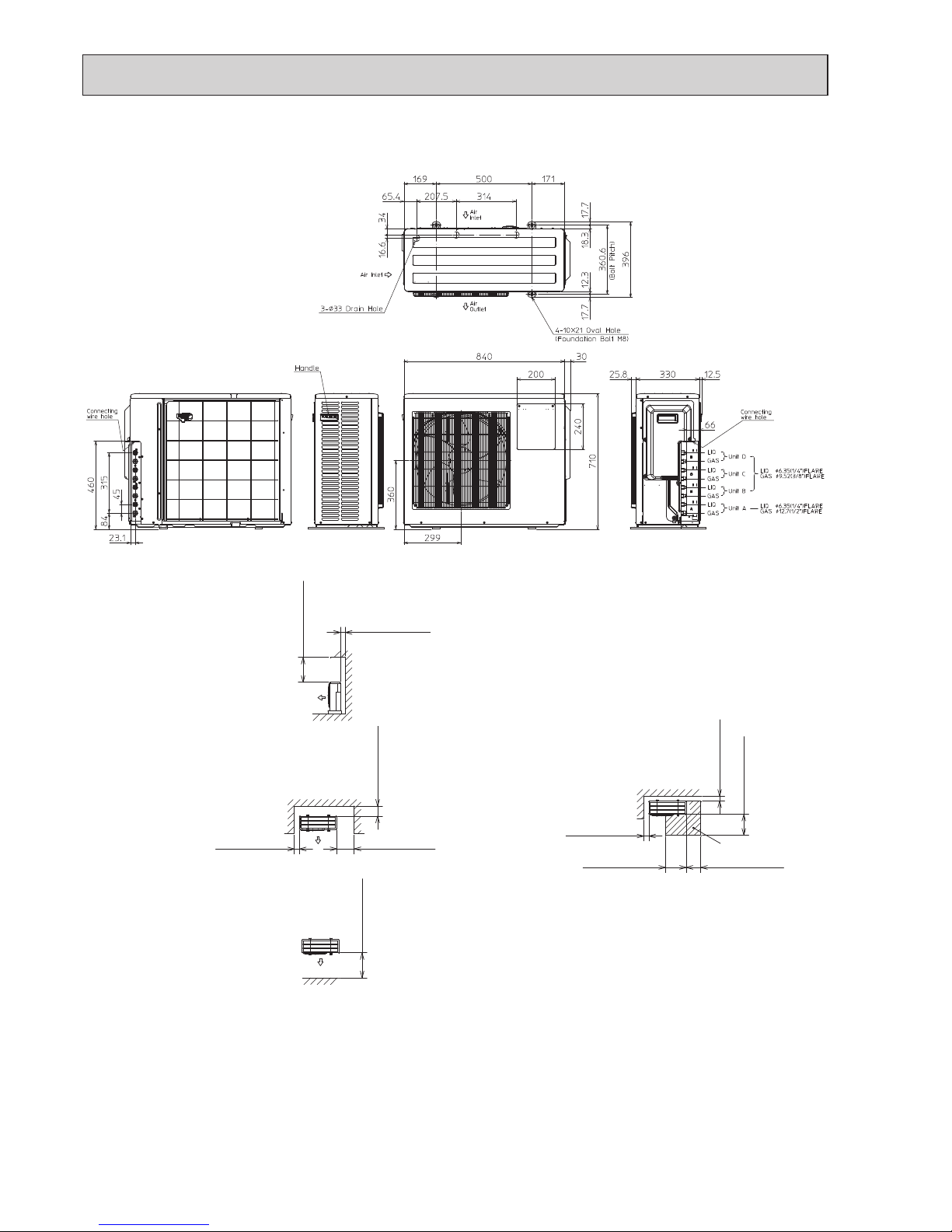

MXZ-3F54VF MXZ-3F68VF

Unit: mm

OBH790

24

1.Installation space

Note : Leave front and both sides

free of obstruction.

Note : Leave rear, overhead and

both sides free of obstruction.

500 or more

100 or more

Note : Leave front and overhead

free of obstruction.

100 or more

350 or more

200 or more

500 or more

2.Service space

100 or more

500 or more

350 or more

350 or more

100 or more

Service space

MXZ-4F72VF

Unit: mm

OBH790

25

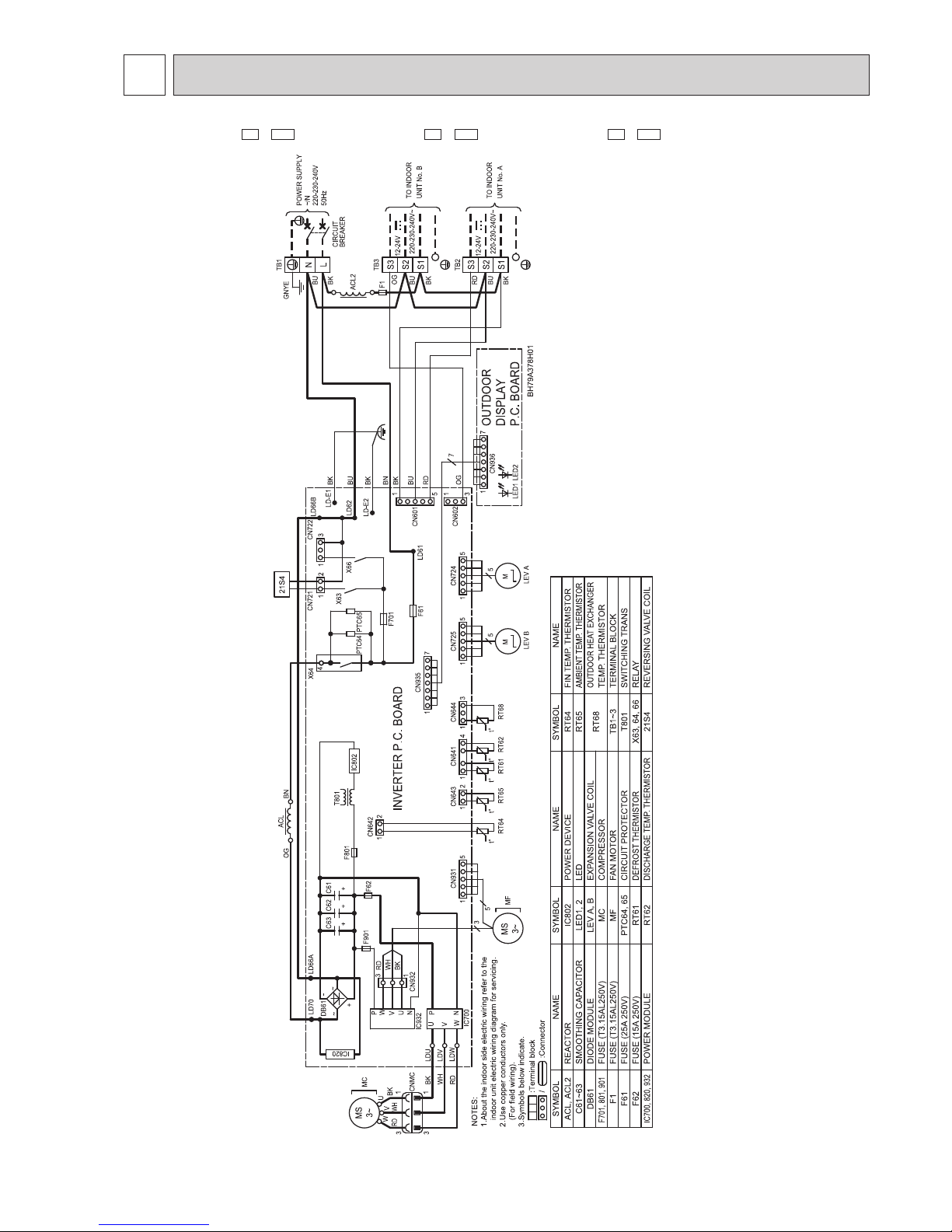

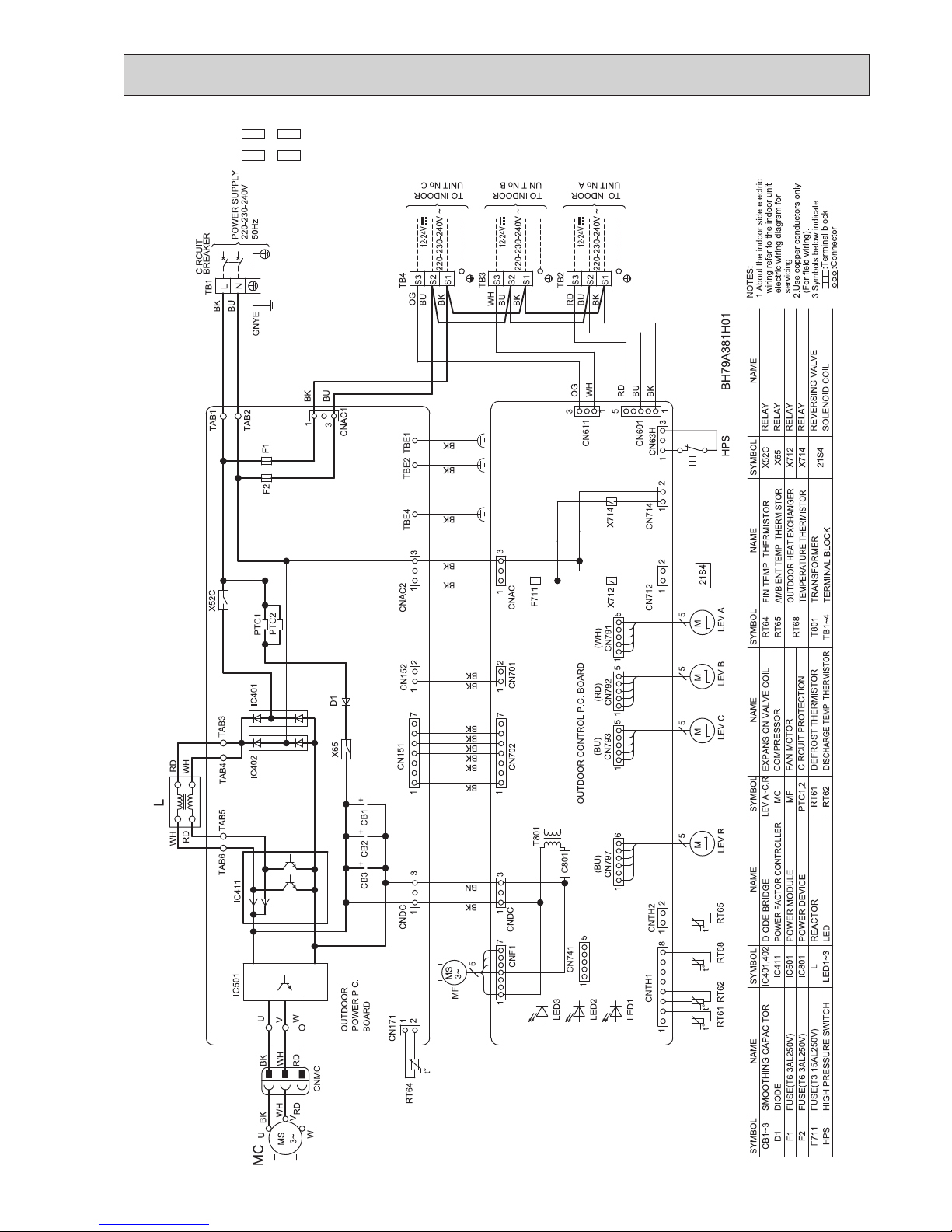

WIRING DIAGRAM

7

MXZ-2F33VF -

E1

,

ET1

MXZ-2F42VF -E1,

ET1

MXZ-2F53VF -

E1, ET1

OBH790

26

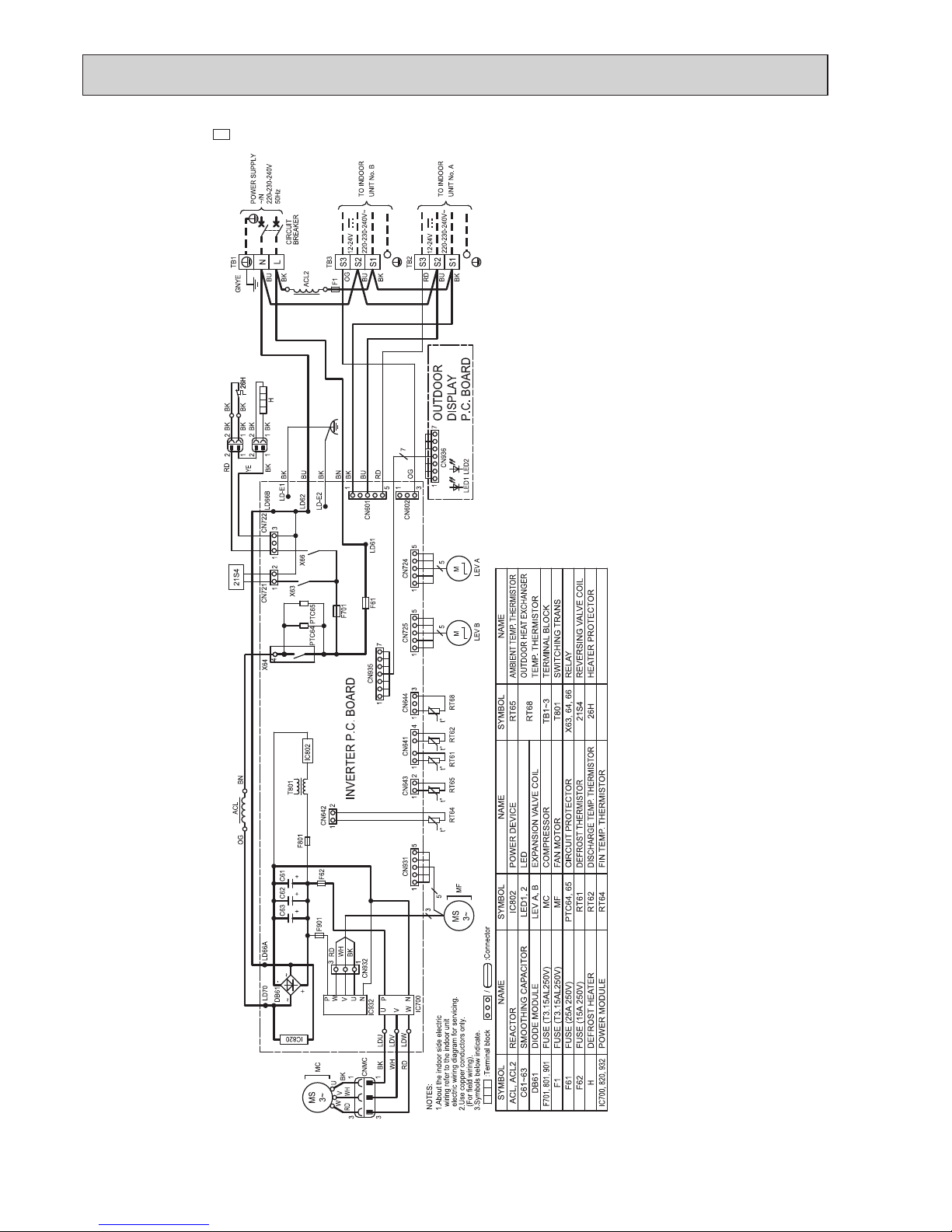

MXZ-2F53VFH -

E1

OBH790

27

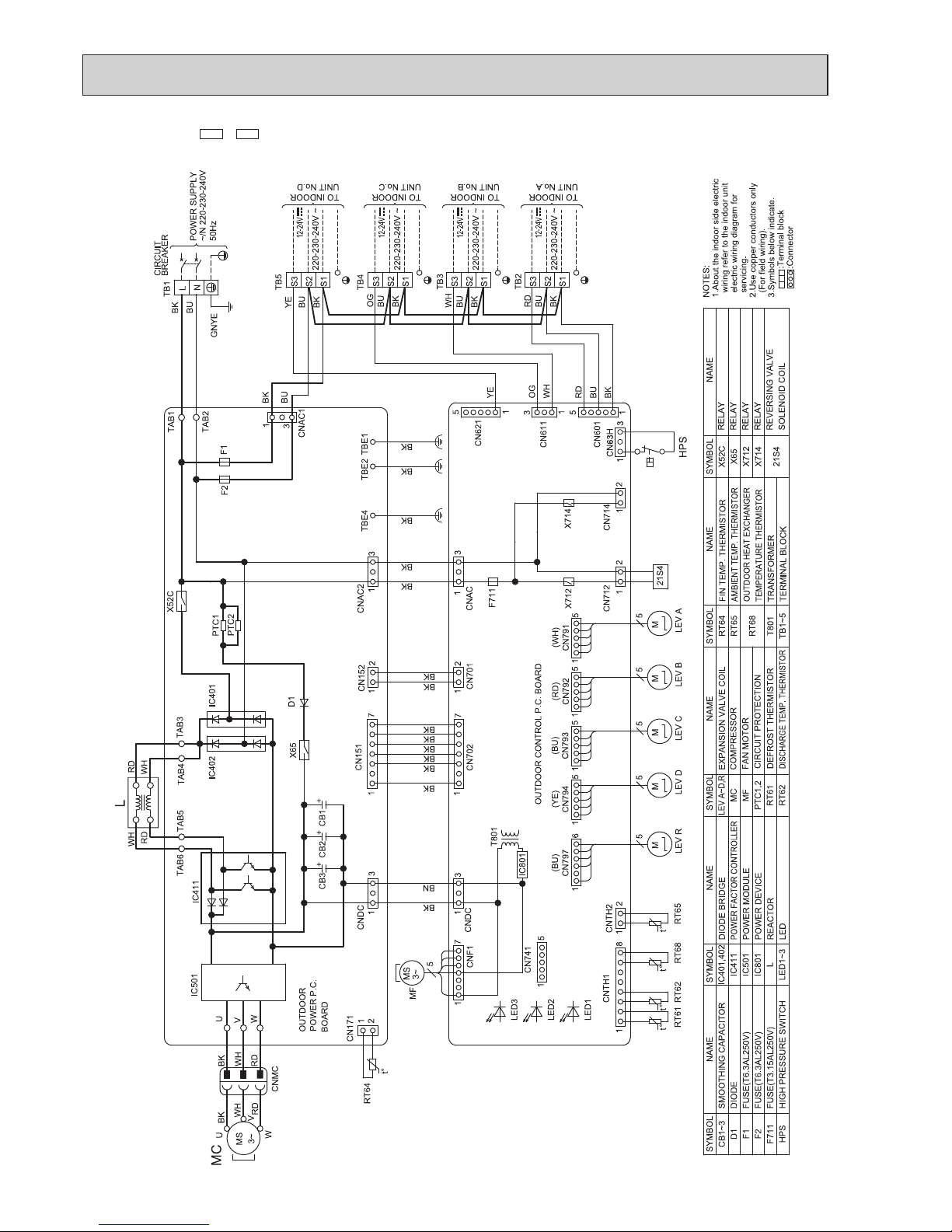

MXZ-3F54VF -E1,

ET1

MXZ-3F68VF -E1,

ET1

OBH790

28

MXZ-4F72VF -E1,

ET1

OBH790

29

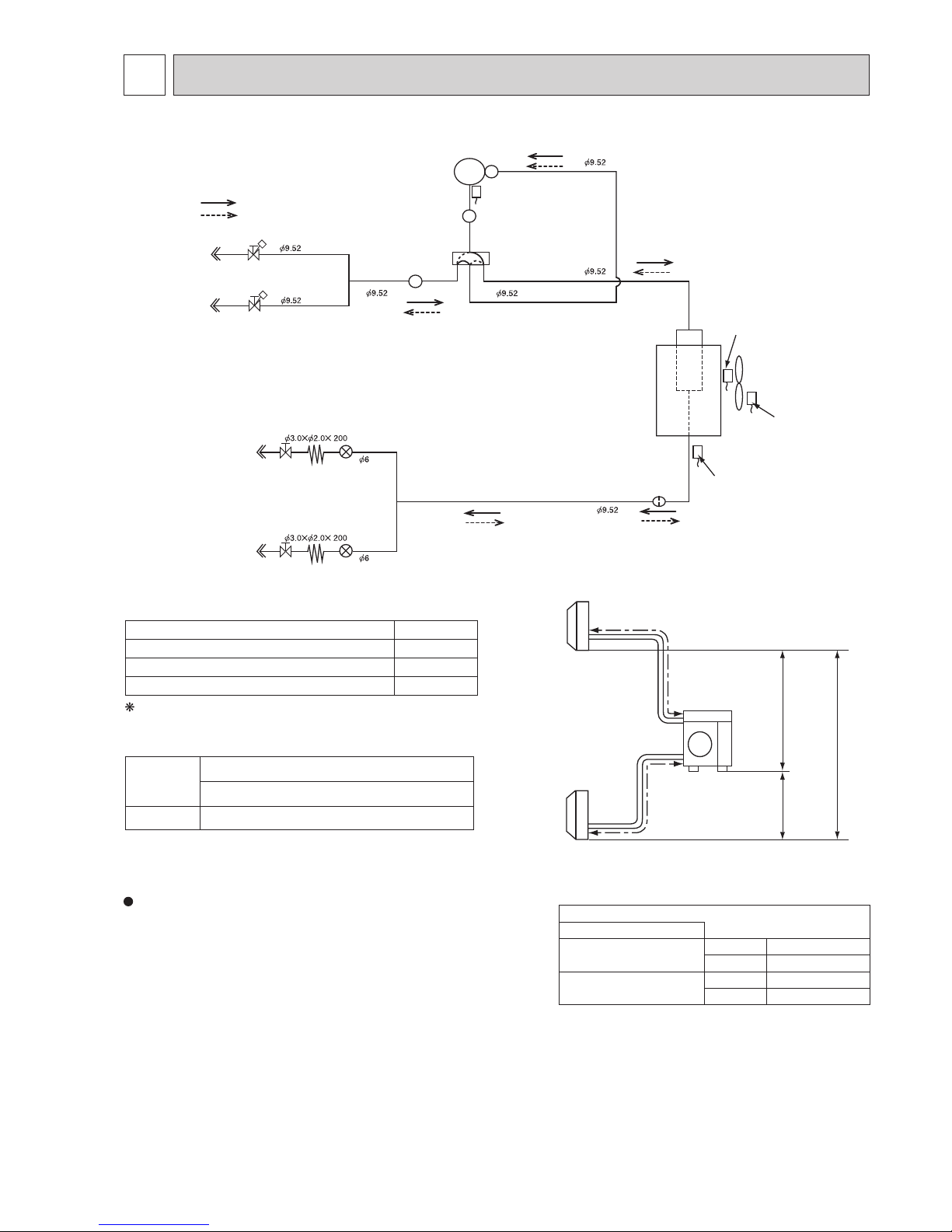

REFRIGERANT SYSTEM DIAGRAM

8

a

b

Outdoor

unit

Indoor

units

10 m

10 m

10 m

Max.

Height

difference

Stop valve

(with strainer #100)

LEV A

LEV B

Compressor

Defrost

thermistor

RT61

Muffler

4-way valve

Indoor unit

A

Indoor unit

B

Indoor unit

A

Indoor unit

B

Capillary tube

Capillary tube

Strainer

#100

Stop valve

(with strainer #100)

R.V. coil

OFF

ON

Refrigerant flow in cooling

Refrigerant flow in heating

Ambient

temperature

thermistor

RT65

Outdoor heat

exchanger

temperature

thermistor

RT68

FAN-OUT

HEX-OUT

Discharge

temperature

thermistor RT62

Stop valve

(with service port)

Stop valve

(with service port)

Sub muffler

UNIT: mm

MXZ-2F33VF

UNIT: mm (inch)

Outdoor unit union diameter

For

Indoor unit A

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit B

Liquid 6.35(1/4)

Gas 9.52(3/8)

MAX REFRIGERANT PIPING LENGTH

Piping length each indoor unit (a, b) 15 m

Total piping length (a+b) 20 m

Bending point for each unit 15

Total bending point 20

It is irrelevant which unit is higher.

ADDITIONAL REFRIGERANT CHARGE

Outdoor unit

precharged

(g)

Refrigerant piping length (one way, 2 unit total)

20 m

1,000 0

Refrigerant pipe diameter is different according to indoor unit to be

connected. When using extension pipes, refer to the right table. .

OBH790

30

Stop valve

(with strainer #100)

LEV A

LEV B

Compressor

Defrost

thermistor RT61

Distributor

Muffler

4-way valve

Indoor unit

A

Indoor unit

B

Indoor unit

A

Indoor unit

B

Capillary tube

Capillary tube

Capillary tube

Strainer

#100

Stop valve

(with strainer #100)

R.V. coil

OFF

ON

Refrigerant flow in cooling

Refrigerant flow in heating

Ambient

temperature

thermistor

RT65

Outdoor heat

exchanger

temperature

thermistor RT68

FAN-OUT

HEX-OUT

Discharge

temperature

thermistor RT62

Stop valve

(with service port)

Stop valve

(with service port)

Sub muffler

UNIT: mm

MXZ-2F42VF MXZ-2F53VF MXZ-2F53VFH

MAX REFRIGERANT PIPING LENGTH

Piping length each indoor unit (a, b) 20 m

Total piping length (a+b) 30 m

Bending point for each unit 30

Total bending point 20

It is irrelevant which unit is higher.

a

b

Outdoor

unit

Indoor

units

15 m

10 m

15 m

Max.

Height

dif

ference

UNIT: mm (inch)

Outdoor unit union diameter

For

Indoor unit A

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit B

Liquid 6.35(1/4)

Gas 9.52(3/8)

ADDITIONAL REFRIGERANT CHARGE

Outdoor unit

precharged

(g)

Refrigerant piping length (one way, 2 unit total)

30 m

1,200 0

Refrigerant pipe diameter is different according to indoor unit to be

connected. When using extension pipes, refer to the right table.

For MXZ-2F53VF and MXZ-2F53VFH, when diameter of refriger-

ant pipe is different from that of outdoor unit union, use optional

Different-diameter pipe.

For further information on Different-diameter pipe, refer to "PARTS

CATALOG"

OBH790

31

Strainer

#100

Power

receiver

LEV A

LEV B

LEV C

Oil separator

Compressor

Defrost

thermistor RT61

Distributor

Muffler

4-way

valve

LEV E

Indoor unit

A

Indoor unit

B

Indoor unit

C

Indoor unit

A

Indoor unit

B

Indoor unit

C

Capillary tube

Capillary tube

Charge pipe

Capillary tube

Capillary tube

Capillary tube

Discharge

temperature

thermistor RT62

Strainer

#100

Strainer

#100

Strainer

#100

R.V. coil

OFF

ON

Refrigerant flow in cooling

Refrigerant flow in heating

Ambient

temperature

thermistor

RT65

Outdoor heat

exchanger

temperature

thermistor

RT68

FAN-OUT

HEX-OUT

Strainer

#100

Stop valve with

service port

Stop valve

High-pressure switch

UNIT: mm (inch)

UNIT: mm

MXZ-3F54VF

Outdoor unit union diameter

For

Indoor unit A

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit B

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit C

Liquid 6.35(1/4)

Gas 9.52(3/8)

a

b

c

Outdoor

unit

Indoor

units

15 m

10 m

15 m

Max.

Height

difference

MAX REFRIGERANT PIPING LENGTH

Piping length each indoor unit (a, b, c) 25 m

Total piping length (a+b+c) 50 m

Bending point for each unit 25

Total bending point 50

It is irrelevant which unit is higher.

Refrigerant pipe diameter is different according to indoor unit to be

connected. When using extension pipes, refer to the right table.

When diameter of refrigerant pipe is different from that of outdoor

unit union, use optional Different-diameter pipe.

For further information on Different-diameter pipe, refer to "PARTS

CATALOG".

ADDITIONAL REFRIGERANT CHARGE

Refer to "Method of charging refrigerant".

Outdoor unit

precharged

(g)

Refrigerant piping length (one way, 3 unit total)

50 m

1,400 0

OBH790

32

Strainer

#100

Power

receiver

LEV A

LEV B

LEV C

Oil separator

Compressor

Defrost

thermistor RT61

Distributor

Muffler

4-way

valve

LEV E

Indoor unit

A

Indoor unit

B

Indoor unit

C

Indoor unit

A

Indoor unit

B

Indoor unit

C

Capillary tube

Capillary tube

Capillary tube

Capillary tube

Capillary tube

Discharge

temperature

thermistor RT62

Strainer

#100

Strainer

#100

Strainer

#100

R.V. coil

OFF

ON

Refrigerant flow in cooling

Refrigerant flow in heating

Ambient

temperature

thermistor

RT65

Outdoor heat

exchanger

temperature

thermistor

RT68

FAN-OUT

HEX-OUT

Strainer

#100

Stop valve with

service port

Stop valve

High-pressure switch

Charge pipe

UNIT: mm

MXZ-3F68VF

a

b

c

Outdoor

unit

Indoor

units

15 m

10 m

15 m

Max.

Height

difference

MAX REFRIGERANT PIPING LENGTH

Piping length each indoor unit (a, b, c) 25 m

Total piping length (a+b+c) 60 m

Bending point for each unit 25

Total bending point 60

It is irrelevant which unit is higher.

ADDITIONAL REFRIGERANT CHARGE

Refer to "Method of charging refrigerant".

Outdoor unit

precharged

(g)

Refrigerant piping length (one way, 3 unit total)

60 m

1,400 0

UNIT: mm (inch)

Outdoor unit union diameter

For

Indoor unit A

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit B

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit C

Liquid 6.35(1/4)

Gas 9.52(3/8)

Refrigerant pipe diameter is different according to indoor unit to be

connected. When using extension pipes, refer to the right table.

When diameter of refrigerant pipe is different from that of outdoor

unit union, use optional Different-diameter pipe.

For further information on Different-diameter pipe, refer to "PARTS

CATALOG".

OBH790

33

MXZ-4F72VF

Indoor unit

A

Power

receiver

LEV A

LEV B

LEV C

LEV D

Oil separator

Compressor

Muffler

4-way

valve

LEV E

Indoor unit

B

Indoor unit

C

Indoor unit

D

Indoor unit

A

Indoor unit

B

Indoor unit

C

Indoor unit

D

Capillary tube

Capillary tube

Discharge

temperature

thermistor RT62

Strainer

#100

Strainer

#100

Strainer

#100

Strainer

#100

Strainer

#100

R.V. coil

OFF

ON

Refrigerant flow in cooling

Refrigerant flow in heating

Distributor

HEX-OUT

Outdoor heat

exchanger

temperature

thermistor

RT68

Defrost

thermistor RT61

Capillary tube

Ambient

temperature

thermistor

RT65

FAN-OUT

Strainer

#100

Stop valve with

service port

Stop valve

High-pressure

switch

Charge pipe

UNIT: mm

a

b

c

d

Outdoor

unit

Indoor

units

15 m

10 m

15 m

Max.

Height

difference

UNIT: mm (inch)

Outdoor unit union diameter

For

Indoor unit A

Liquid 6.35(1/4)

Gas 12.7(1/2)

Indoor unit B

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit C

Liquid 6.35(1/4)

Gas 9.52(3/8)

Indoor unit D

Liquid 6.35(1/4)

Gas 9.52(3/8)

Refrigerant pipe diameter is different according to indoor unit to be

connected. When using extension pipes, refer to the right table.

When diameter of refrigerant pipe is different from that of outdoor

unit union, use optional Different-diameter pipe.

For further information on Different-diameter pipe, refer to "PARTS

CATALOG".

MAX REFRIGERANT PIPING LENGTH

Piping length each indoor unit (a, b, c, d) 25 m

Total piping length (a+b+c+d)

60 m

Bending point for each unit 25

Total bending point 60

It is irrelevant which unit is higher.

ADDITIONAL REFRIGERANT CHARGE

Refer to "Method of charging refrigerant".

Outdoor unit

precharged

(g)

Refrigerant piping length (one way, 4 unit total)

60 m

1,400 0

OBH790

34

When relocating or disposing of the air conditioner, pump down the system following the procedure below so that no refrigerant is

released into the atmosphere.

1) Turn off the breaker.

2) Connect the gauge manifold valve to the service port of the stop valve on the gas pipe side of the outdoor unit.

3) Fully close the stop valve on the liquid pipe side of the outdoor unit.

4) Turn on the breaker.

5) Start the emergency COOL operation on all the indoor units.

6) When the pressure gauge shows 0.05 to 0 MPa [Gauge] (approximately 0.5 to 0 kgf/cm²), fully close the stop valve on the gas

pipe side of the outdoor unit and stop the operation. (Refer to the indoor unit installation manual about the method for stopping

the operation.)

* If too much refrigerant has been added to the air conditioner system, the pressure may not drop to

0.05 to 0 MPa [Gauge] (ap-

proximately 0.5 to 0 kgf/cm²)

, or the protection function may operate due to the pressure increase in the high pressure refrigerant circuit. If this occurs, use a refrigerant collecting device to collect all of the refrigerant in the system, and then recharge the

system with the correct amount of refrigerant after the indoor and outdoor units have been relocated.

7) Turn off the breaker. Remove the pressure gauge and the refrigerant piping.

Method of Charging refrigerant

ŶMXZ-3F54VF/3F68VF/4F72VF

PipingConnectionIndoor unit

+=

number *1

+

of speci¿c I/U *2

+

length

0.0 kg

k g______k g______1.4 kggk______

ŶMXZ-2F42VF/2F53VF/2F53VFH

Piping

+

=

length

1.2 kg1.2 kg

0.0 kg

ŶMXZ-2F33VF

Piping

+

=

length

1.0 kg1.0 kg

0.0 kg

*1:If you connect indoor unit number 3 or 4 units, please add to charge refrigetrant amount 0.5kg

*2:If you connect specific indoor unit(s), please add to charge refrigetrant amount 0.17kg per 1unit

Specific indoor unit is following: MSZ-LN18/25/35VG MLZ-KP25/35/50VF

SEZ-M50DA(L) PCA-M50/60KA

PEAD-M50JA(L)Q

*3: In case total refrigerant amount exceed 2.4kg depending on combination, please charge only 1.0kg for maximum.

Pre charge

Total

refrigerant

Total

refrigerant *3

Pre charge

Total

refrigerant

Pre charge

When pumping down the refrigerant, stop the compressor before disconnecting the refrigerant pipes.

The compressor may burst and cause injury if any foreign substance, such as air, enters the pipes.

WARNING

PUMPING DOWN

OBH790

35

PERFORMANCE CURVES

9

The standard specifications apply only to the operation of the air conditioner under normal conditions.

Since operating conditions vary according to the areas where these units are installed, the following information has been pro-

vided to clarify the operating characteristics of the air conditioner under the conditions indicated by the performance curve.

(1) GUARANTEED VOLTAGE

198 - 264 V 50 Hz

(2) AIR FLOW

Air flow should be set at MAX.

(3) MAIN READINGS

(1) Indoor intake air wet-bulb temperature: °CWB

(2) Indoor outlet air wet-bulb temperature: °CWB

(3) Outdoor intake air dry-bulb temperature: °CDB

(4) Total input: W

(5) Indoor intake air dry-bulb temperature: °CDB

(6) Outdoor intake air wet-bulb temperature: °CWB

(7) Total input: W

Indoor air wet and dry bulb temperature difference on the left side of the following chart shows the difference between the

indoor intake air wet and dry bulb temperature and the indoor outlet air wet and dry bulb temperature for your reference at

service.

How to measure the indoor air wet and dry bulb temperature difference

1. Attach at least 2 sets of wet and dry bulb thermometers to the indoor air intake as shown in the figure, and at least 2 sets

of wet and dry bulb thermometers to the indoor air outlet. The thermometers must be attached to the position where air

speed is high.

2. Attach at least 2 sets of wet and dry bulb thermometers to the outdoor air intake.

Cover the thermometers to prevent direct rays of the sun.

3. Check that the air filter is cleaned.

4. Open windows and doors of room.

5. Press the EMERGENCY OPERATION switch once (twice) to start the EMERGENCY COOL (HEAT) MODE.

6. When system stabilizes after more than 15 minutes, measure temperature and take an average temperature.

7. 10 minutes later, measure temperature again and check that the temperature does not change.

INDOOR UNIT

OUTDOOR UNIT

}

}

Cooling

Heating

Wet and dry bulb

thermometers

BACK VIEW

Wet and dry bulb

thermometers

FRONT VIEW

MXZ-2F33VF MXZ-2F42VF MXZ-2F53VF MXZ-2F53VFH

MXZ-3F54VF MXZ-3F68VF MXZ-4F72VF

OBH790

36

9-1. CAPACITY AND THE INPUT CURVES

MXZ-2F33VF MXZ-2F42VF MXZ-2F53VF MXZ-2F53VFH

Cooling capacity

Capacity correction factors

1.4

0.9

1.0

1.1

1.2

1.3

-10 0 15 30 45

Outdoor intake air Dry - bulb temperature (ºC)

22

20

18

46-5 5 10 20 25 35 40

-10 0 15 30 45

Outdoor intake air Dry - bulb temperature (ºC)

46-5 5 10 20 25 35 40

Total input (Cooling)

Input correction factors

1.4

0.9

0.8

0.8

0.7

0.7

1.0

1.1

1.2

1.3

22

20

18

26

24

26

24

22 class

5.2

4.8

4.4

4.0

3.6

3.2

2.8

2.4

5.8

5.4

4.9

4.5

4.0

3.6

3.2

2.8

5.9

5.5

5.0

4.6

4.1

3.7

3.2

2.8

4.1

3.8

3.5

3.2

2.9

2.6

2.3

2.0

8.7

8.0

7.3

6.6

5.9

5.3

4.6

4.0

35 class

11.1

10.2

9.3

8.3

7.5

6.6

5.8

5.0

42 class

12.8

11.6

10.5

9.5

8.5

7.5

6.6

5.6

50 class

25 class

15 class

18 class

7.4

6.8

6.2

5.7

5.1

4.5

4.0

3.5

20 class

(MXZ-2F53)

(MXZ-2F42/53)

(

MXZ-2F53)

Indoor air Wet-bulb temperature

difference (°C)

Indoor intake air Wet-bulb temperature (°C)

Indoor intake air Wet-bulb temperature (°C)

-16 -8 -4 4 12 16

Capacity correction factors

Outdoor intake air Wet

-

bulb temperature (

ºC

)

15

20

26

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

0.5

0.4

Outdoor intake air Wet

-

Heating capacity

1.4

-12 0 8 18

-16 -8 -4 4 12 16

Outdoor intake air Wet

-

bulb temperature (

ºC

)

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

0.5

0.4

Outdoor intake air Wet

-

1.4

-12 0 8 18

26

20

15

Input correction factors

Total input (Heating)

26

20

15

Indoor intake air Dry-bulb temperature (°C)

Indoor intake air Dry-bulb temperature (°C)

22 class

25 class

35 class

42 class

(MXZ-2F53)

(MXZ-2F42/53)

50 class

(

MXZ-2F53)

15 class

18 class

20 class

Indoor air Dry-bulb temperature

difference (°C)

17.6

16.3

15.1

13.8

12.6

11.3

10.1

8.8

7.5

6.3

5.0

19.5

18.1

16.7

15.3

13.9

12.6

11.2

9.8

8.4

7.0

5.6

21.2

19.7

18.2

16.7

15.2

13.6

12.1

10.6

9.1

7.6

6.1

19.5

18.1

16.7

15.3

13.9

12.6

11.2

9.8

8.4

7.0

5.6

21.3

19.8

18.3

16.7

15.2

13.7

12.2

10.7

9.1

7.6

6.1

22.2

20.6

19.0

17.4

15.8

14.3

12.7

11.1

9.5

7.9

6.3

26.6

24.7

22.8

20.9

19.0

17.1

15.2

13.3

11.4

9.5

7.6

26.7

24.8

22.9

21.0

19.1

17.1

15.2

13.3

11.4

9.5

7.6

OBH790

37

0.9

1.0

1.1

1.2

1.3

1.4

0.8

-10 0 15

30

45 46

Capacity correction factors

Outdoor intake air Dry

- bulb temperature (

)

Cooling capacity

ºC

0.7

-5 5 10 20 25 35 40

-10 0 15

30

45 46

Outdoor intake air Dry

- bulb temperature (

)

ºC

-5 5 10 20 25 35 40

Input correction factors

Total input (Cooling)

0.9

1.0

1.1

1.2

1.3

1.4

0.8

0.7

0.6

0.5

0.4

18

16

19

22

20

24

26

18

16

19

22

20

24

26

Indoor air Wet-bulb temperature

difference (°C)

22 class

5.8

5.4

4.9

4.5

4.0

3.6

3.2

2.8

4.1

3.8

3.5

3.2

2.9

2.6

2.3

2.0

7.4

6.8

6.2

5.7

5.1

4.5

4.0

3.5

5.2

4.8

4.4

4.0

3.6

3.2

2.8

2.4

5.9

5.5

5.0

4.6

4.1

3.7

3.2

2.8

8.7

8.0

7.3

6.6

5.9

5.3

4.6

4.0

11.1

10.2

9.3

8.3

7.5

6.6

5.8

5.0

12.8

11.6

10.5

9.5

8.5

7.5

6.6

5.6

8.7

8.0

7.3

6.6

5.9

5.3

4.6

4.0

60 class

50 class

35 class

42 class

25 class

15 class

18 class

20 class

Indoor intake air Wet-bulb temperature (°C)

Indoor intake air Wet-bulb temperature (°C)

MXZ-3F54VF MXZ-3F68VF MXZ-4F72VF

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

-16 -8 -4 4 12 18

Capacity correction factors

Outdoor intake air Wet

-

bulb temperature (

ºC

)

Heating capacity

15

20

26

1.4

0.5

0.4

-12 0 8 16

-16 -8 -4 4 12 18-12 0 8 16

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

0.5

0.4

Input correction factors

Total input (Heating)

26

20

15

Outdoor intake air Wet

-

bulb temperature (

ºC

)

22 class

25 class

60 class

35 class

50 class

42 class

15 class

18 class

20 class

17.6

16.3

15.1

13.8

12.6

11.3

10.1

8.8

7.5

6.3

5.0

19.5

18.1

16.7

15.3

13.9

12.6

11.2

9.8

8.4

7.0

5.6

21.2

19.7

18.2

16.7

15.2

13.6

12.1

10.6

9.1

7.6

6.1

19.5

18.1

16.7

15.3

13.9

12.6

11.2

9.8

8.4

7.0

5.6

21.3

19.8

18.3

16.7

15.2

13.7

12.2

10.7

9.1

7.6

6.1

22.2

20.6

19.0

17.4

15.8

14.3

12.7

11.1

9.5

7.9

6.3

29.9

27.8

25.7

23.5

21.4

19.2

17.1

15.0

12.8

10.7

8.6

38.4

35.7

32.9

30.2

27.4

24.7

21.9

19.2

16.5

13.7

11.0

30.9

28.7

26.5

24.3

22.1

19.9

17.7

15.5